Patents

Literature

1671results about "Volume measurement apparatus/methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

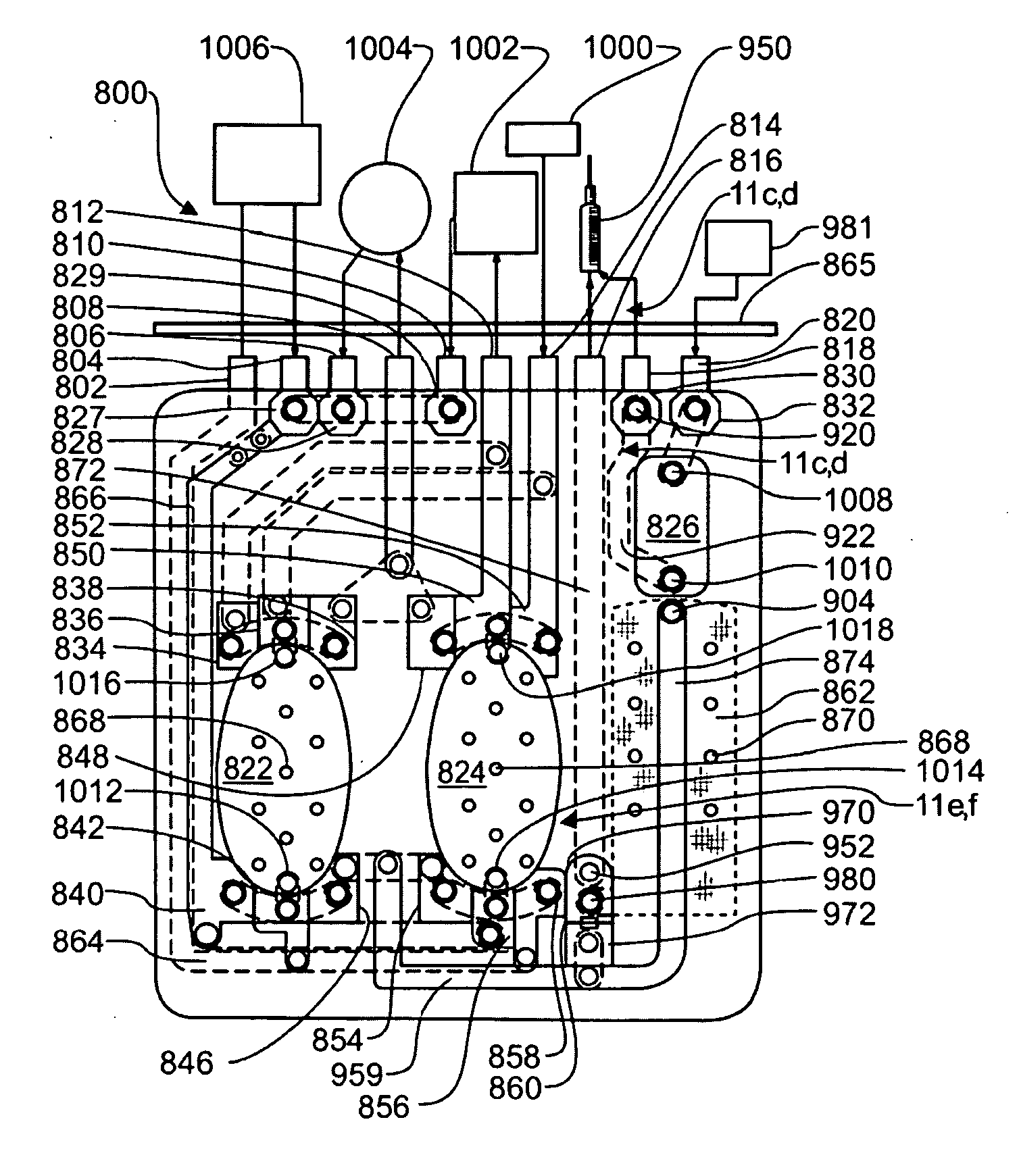

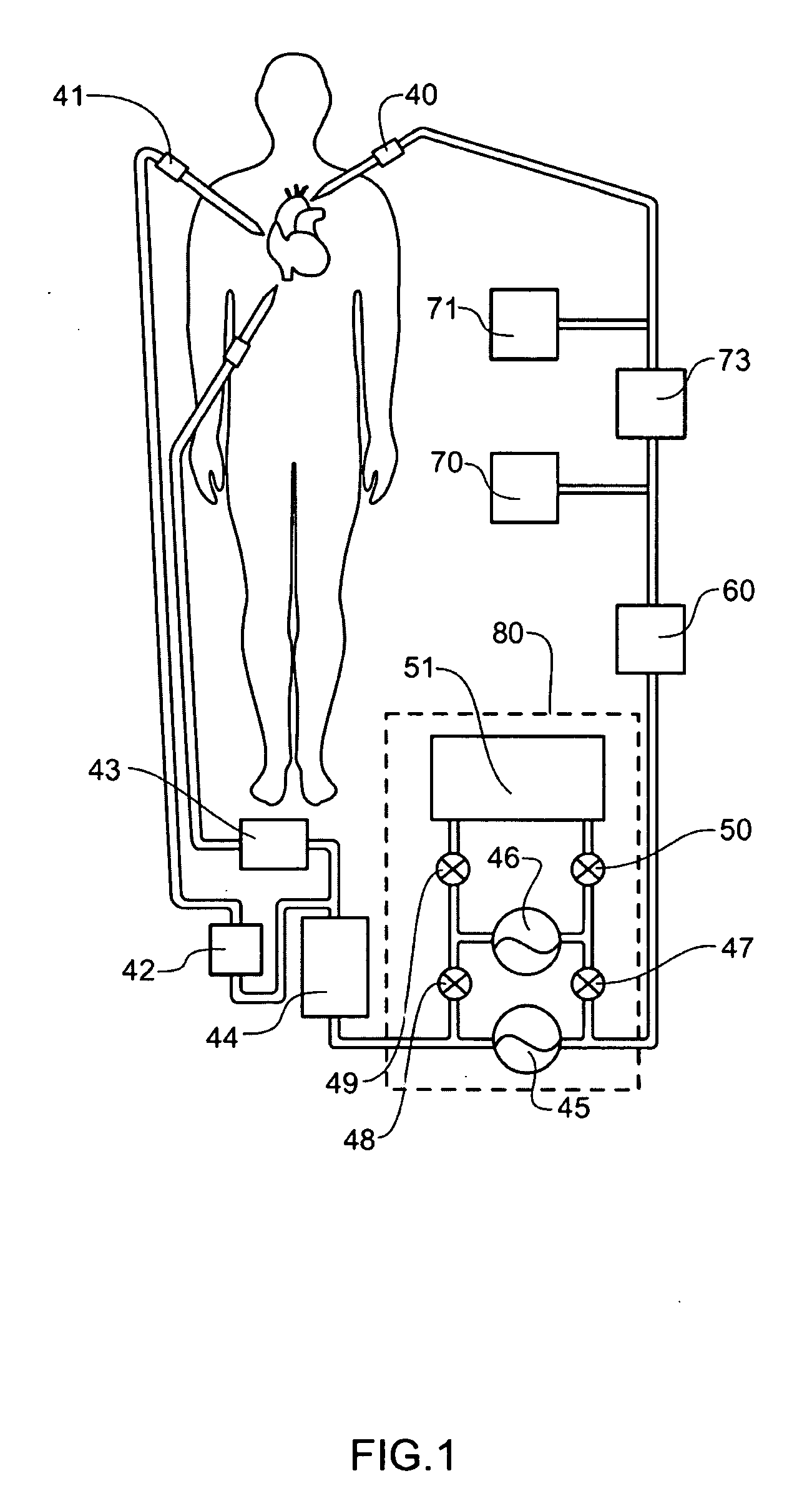

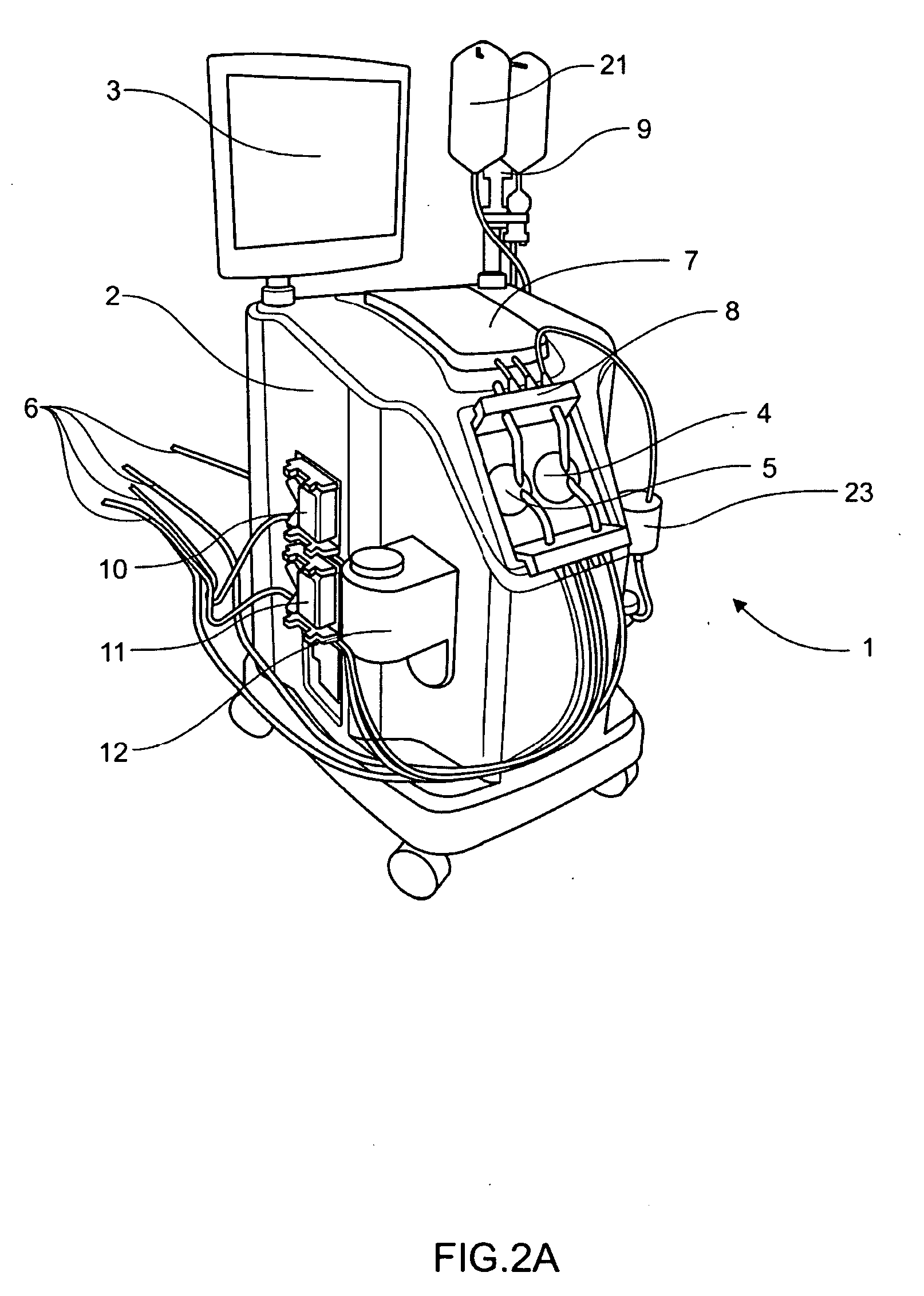

Systems, Devices and Methods for Cardiopulmonary Treatment and Procedures

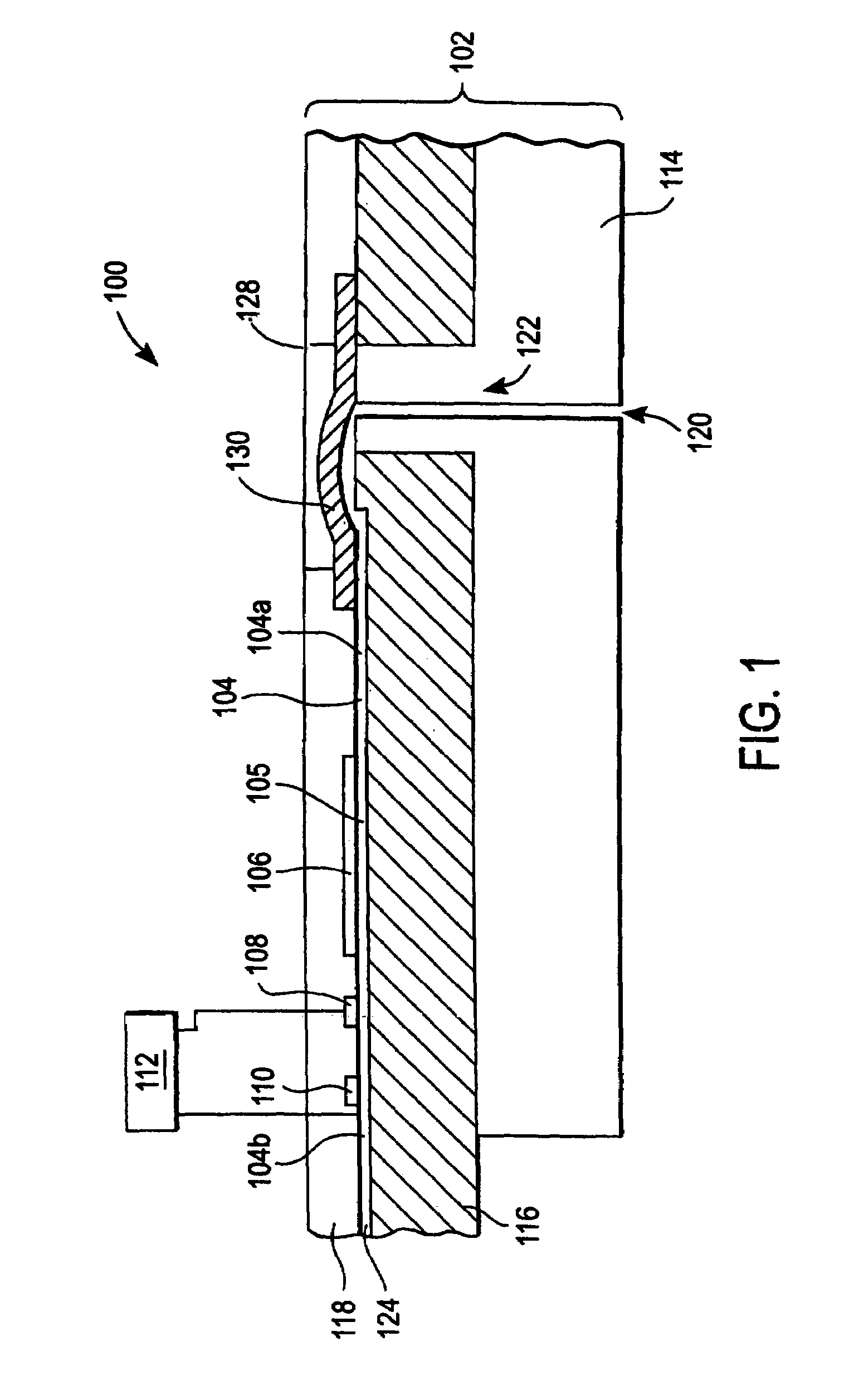

ActiveUS20090099498A1Reduces hard snappingReduce shear forceVolume measurement apparatus/methodsControl devicesBlood pumpControl room

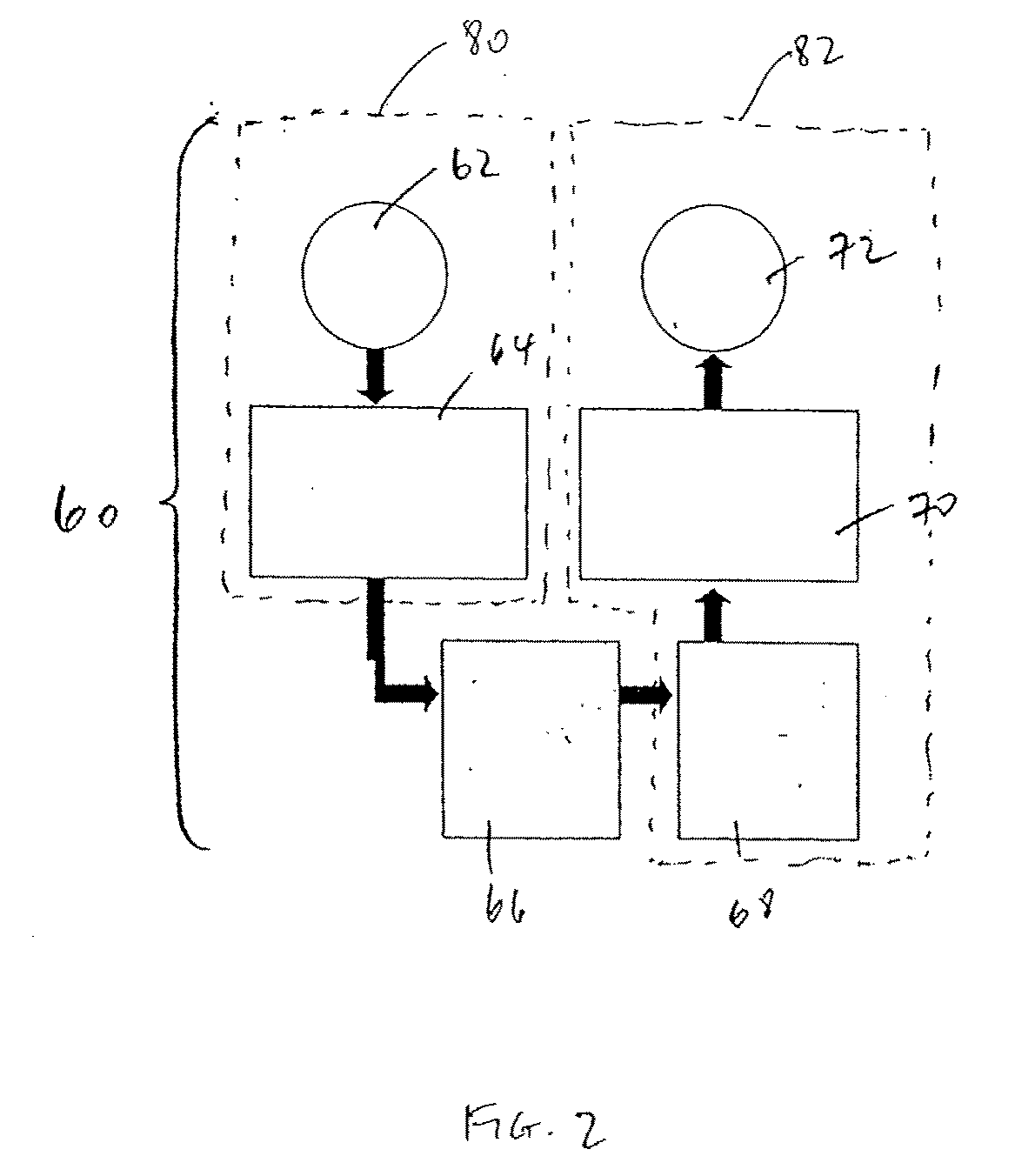

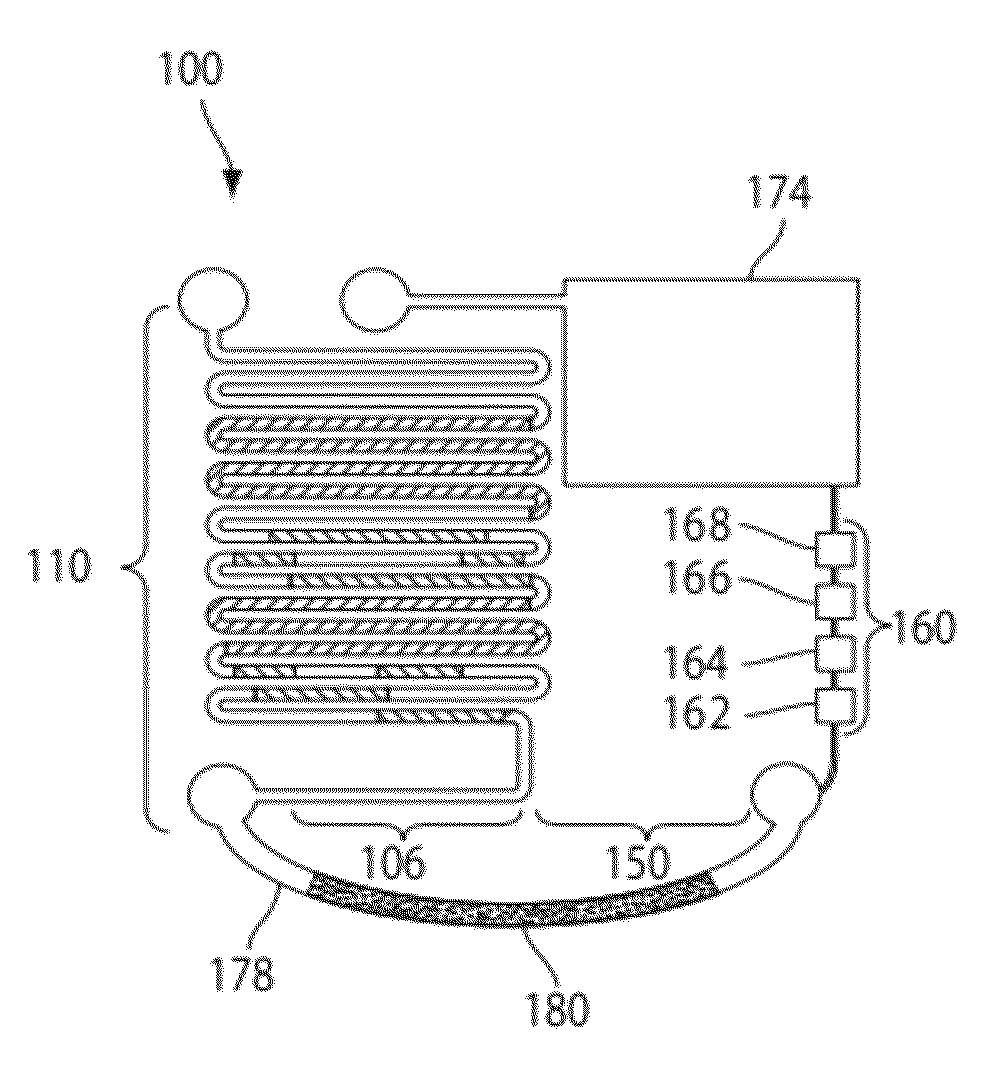

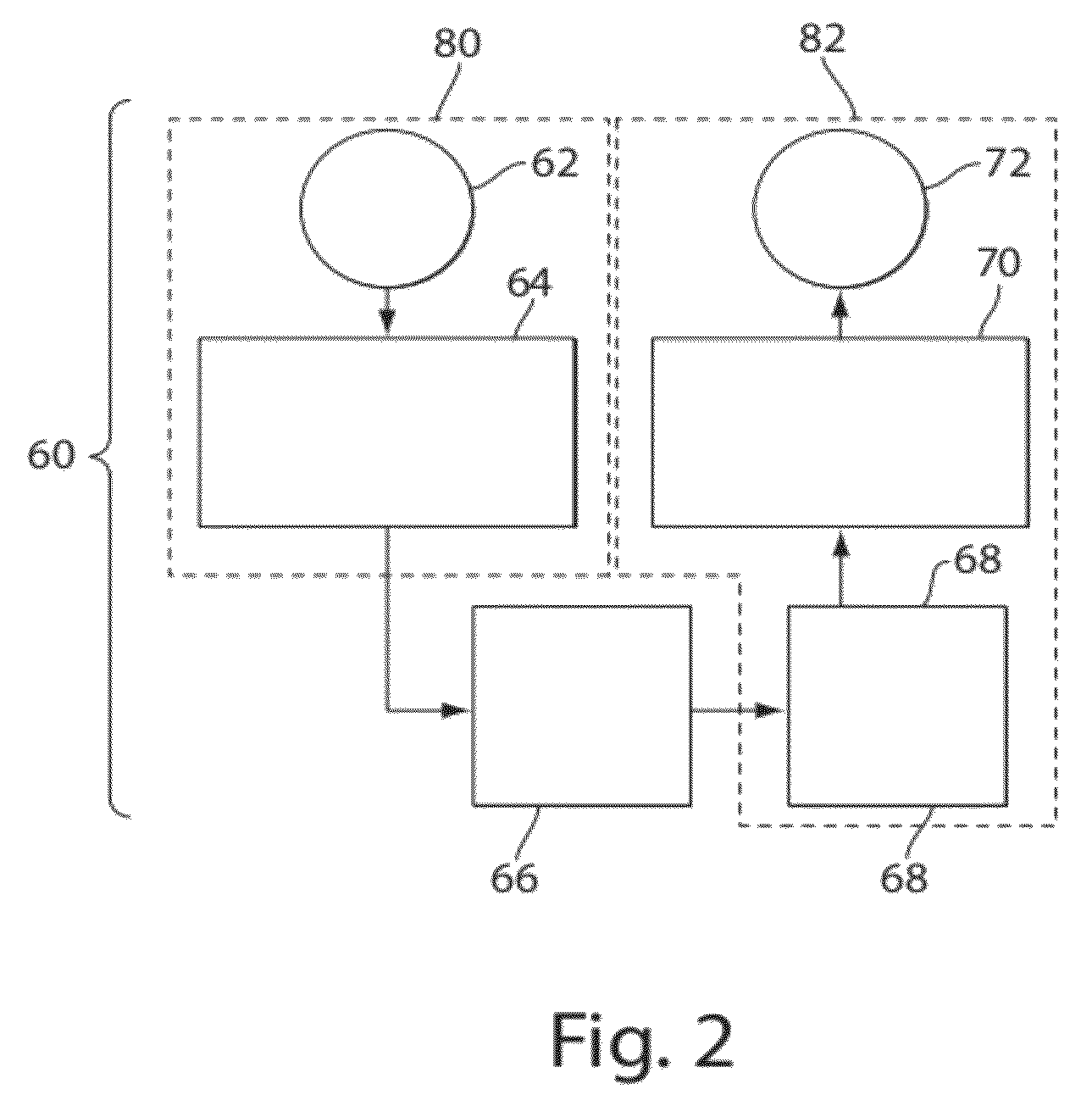

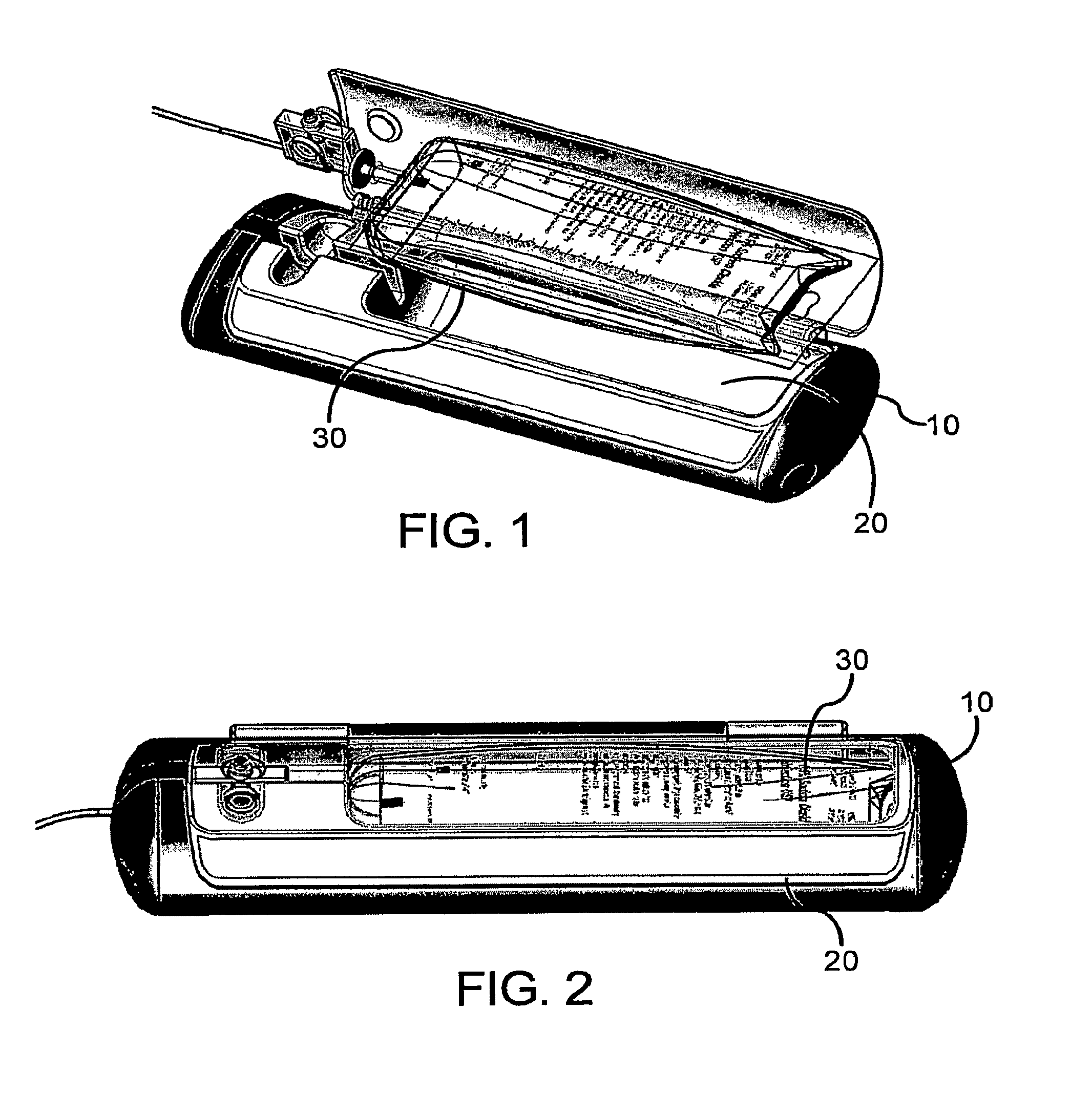

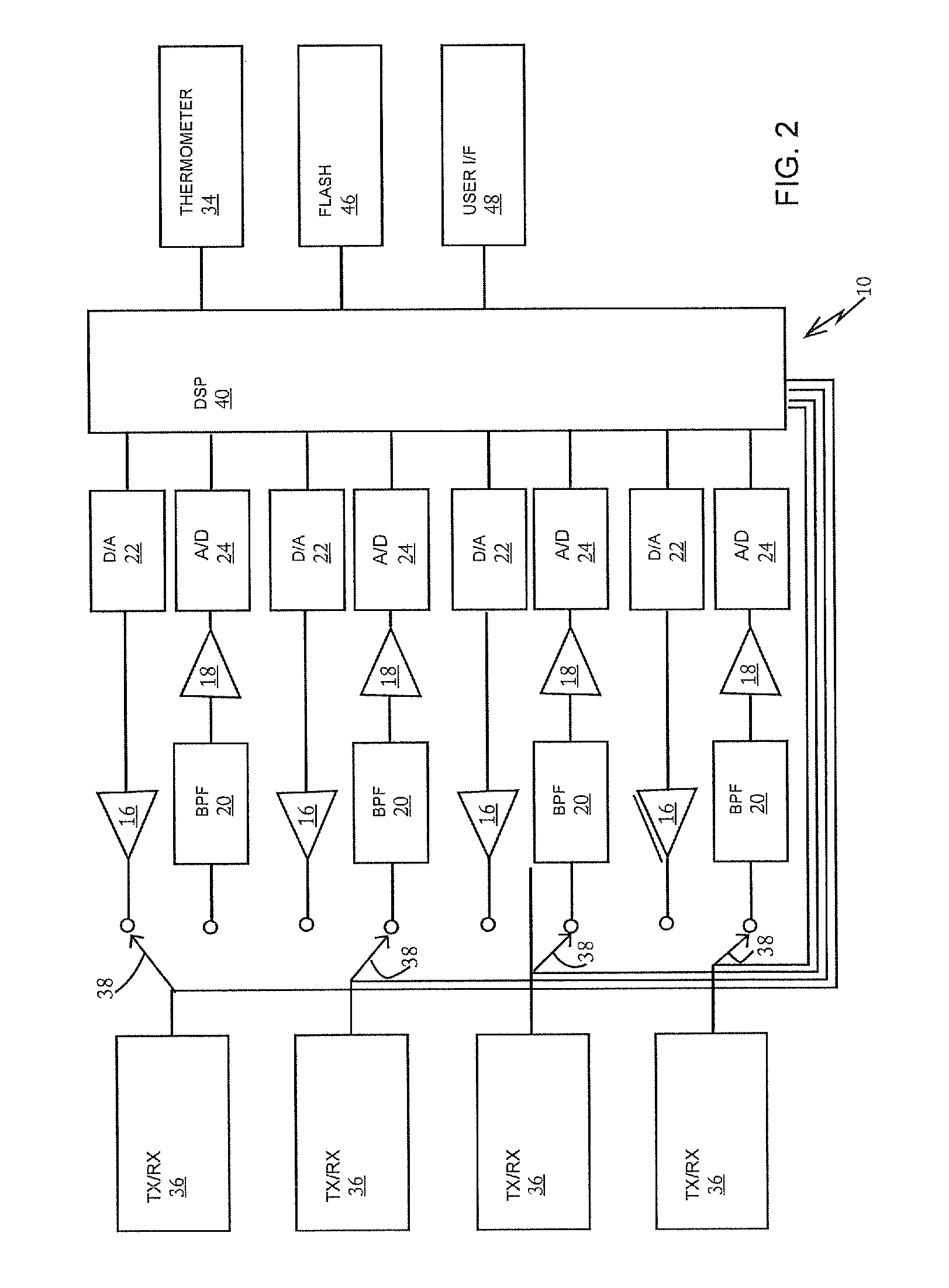

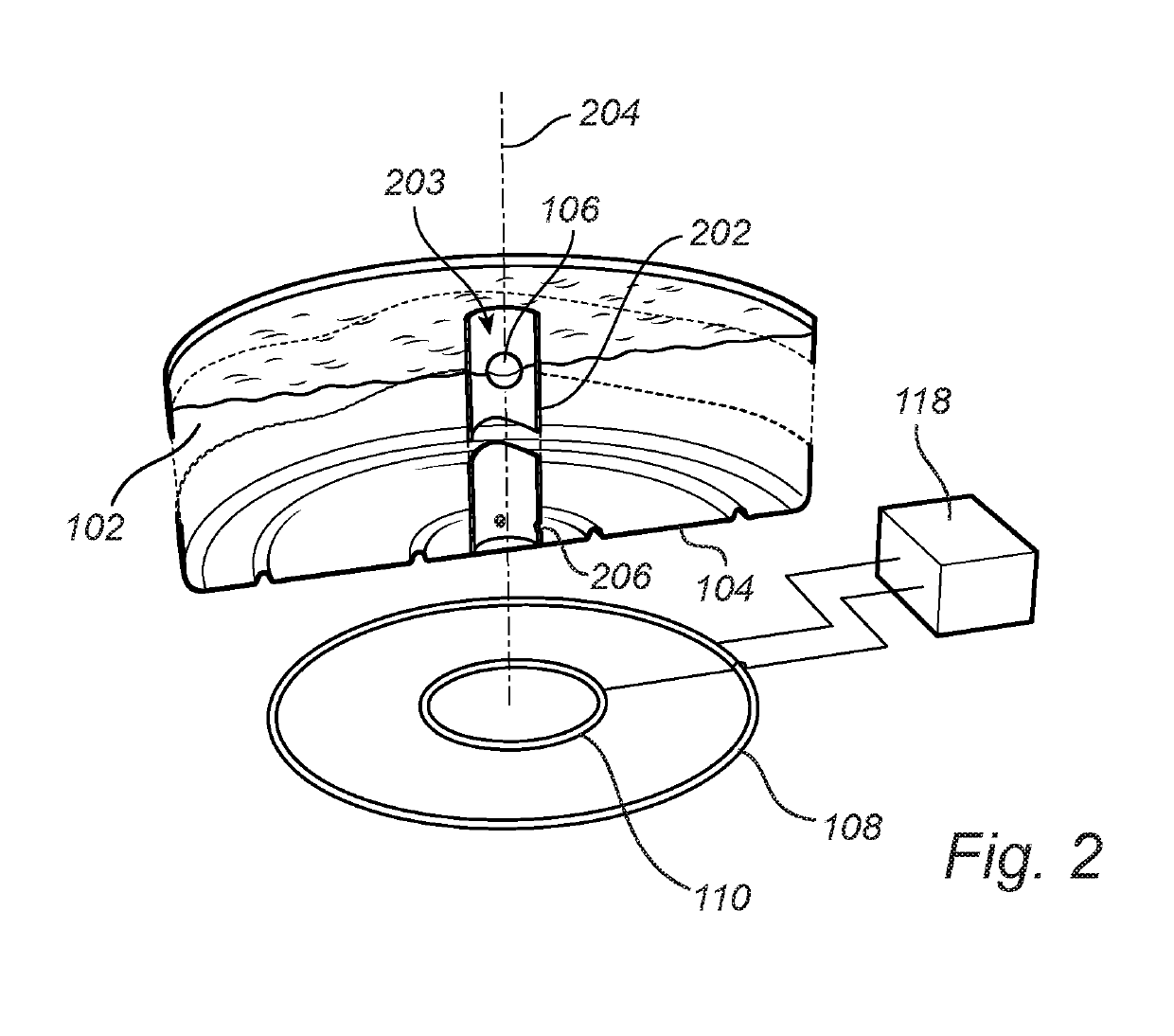

A cardiopulmonary bypass system utilizing membrane-based reciprocating positive displacement blood pumps (“pod pumps”). In one aspect, the pod pumps are constructed to provide reduced shear forces on the blood being pumped. In another aspect blood flow through the pod pumps can be controlled by a controller using information from pressure sensors in the control chamber of the pod pumps. In another aspect, the pod pumps are included on a disposable unit that can be received and held by a receptacle means on a base unit, the base unit also providing pressurized control fluid to the pod pumps on the disposable unit through the receptacle means.

Owner:DEKA PROD LLP

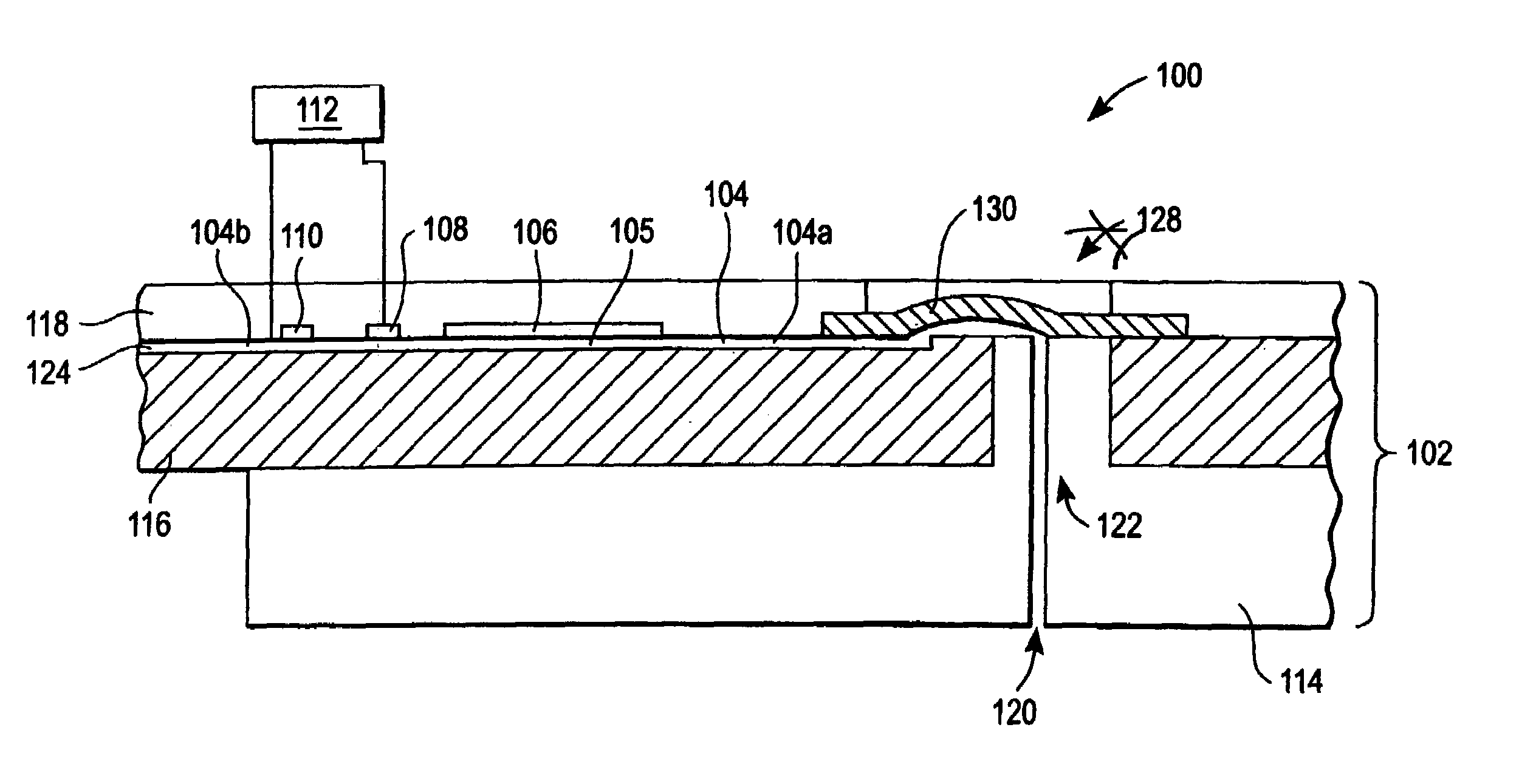

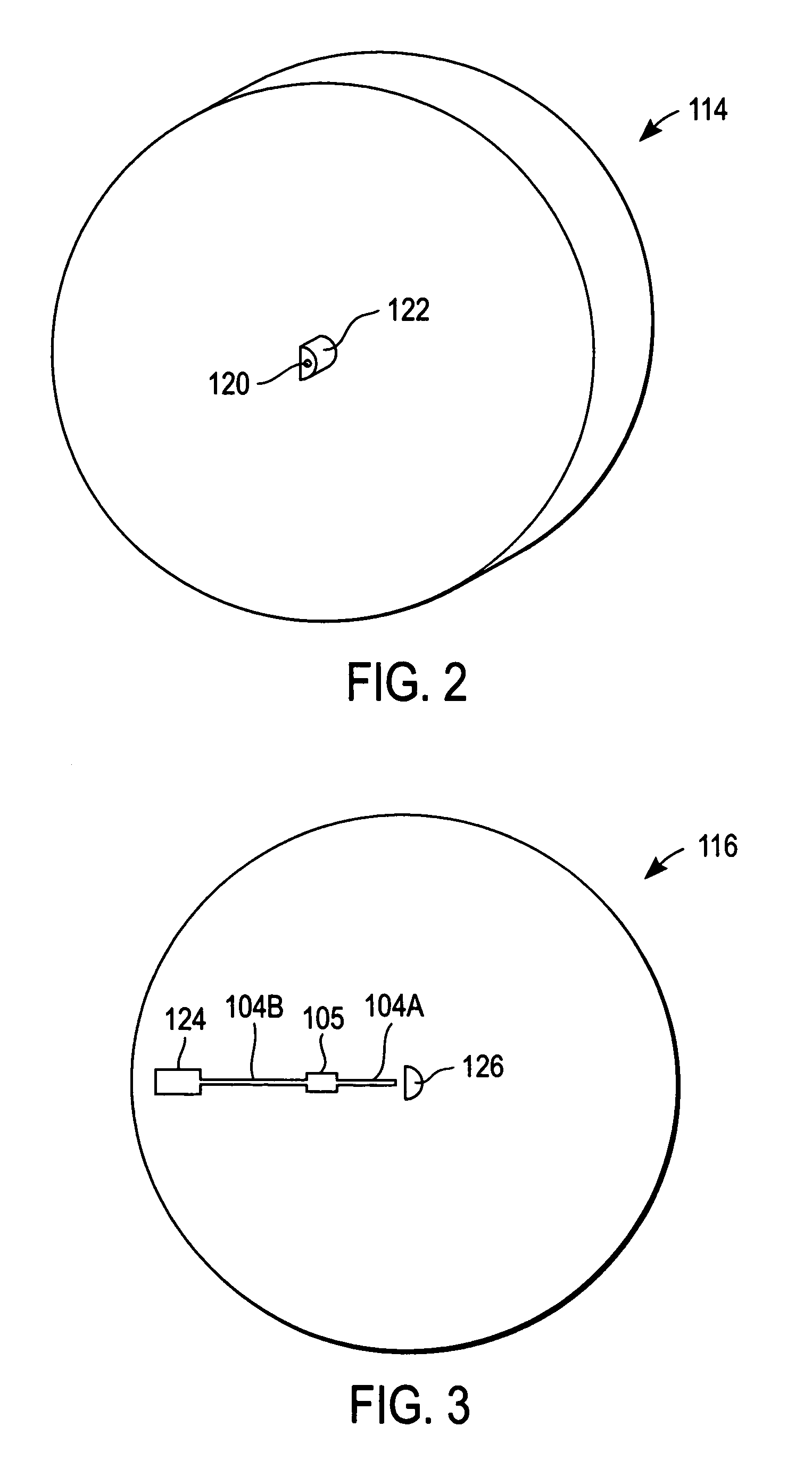

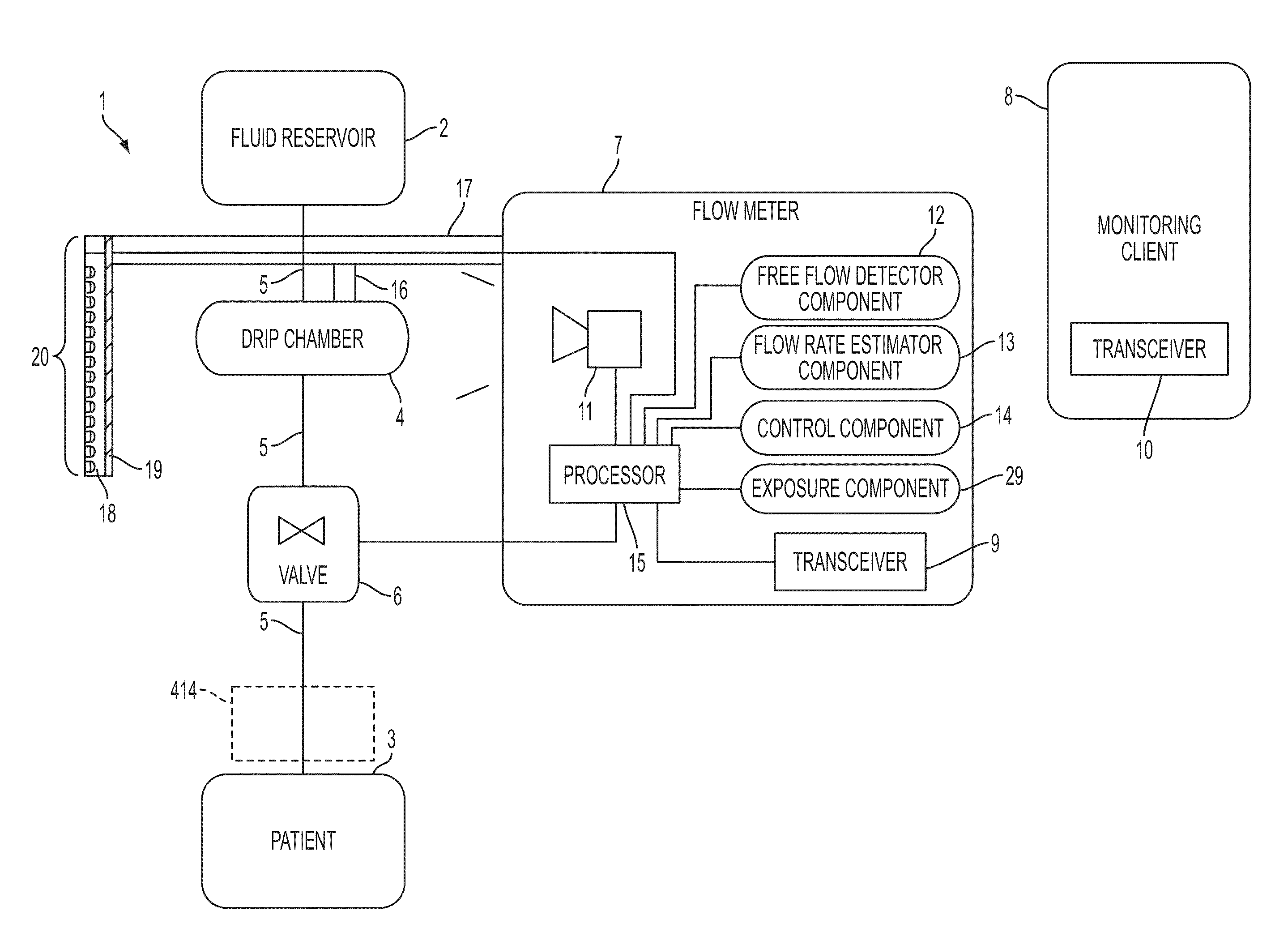

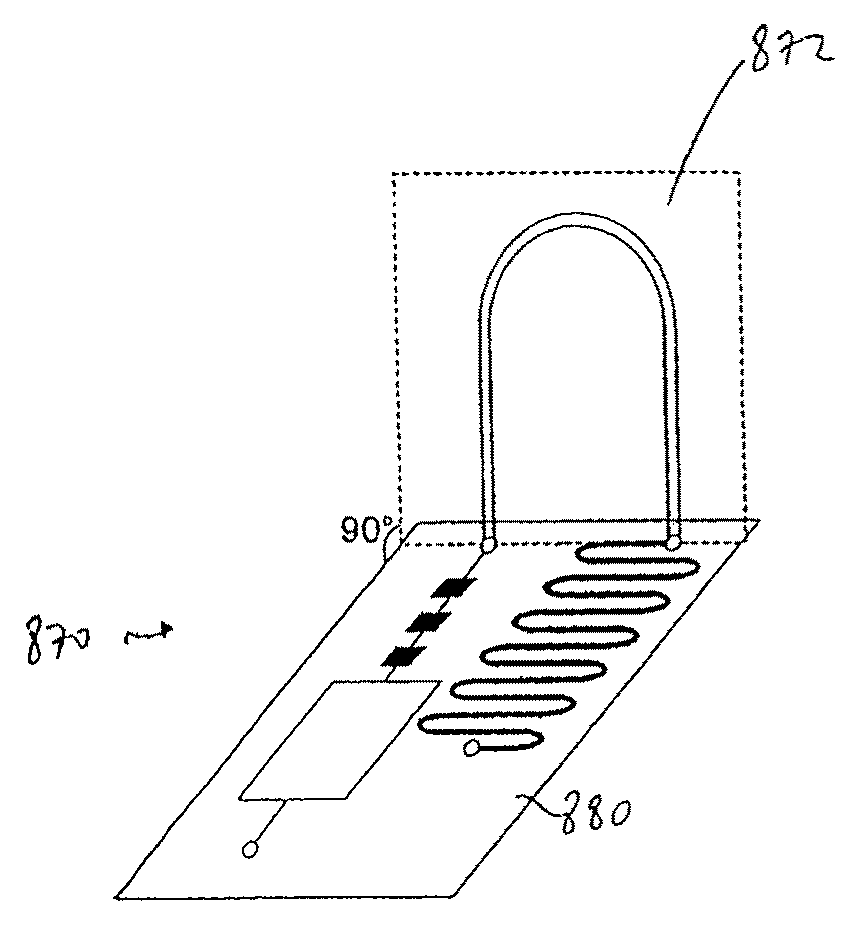

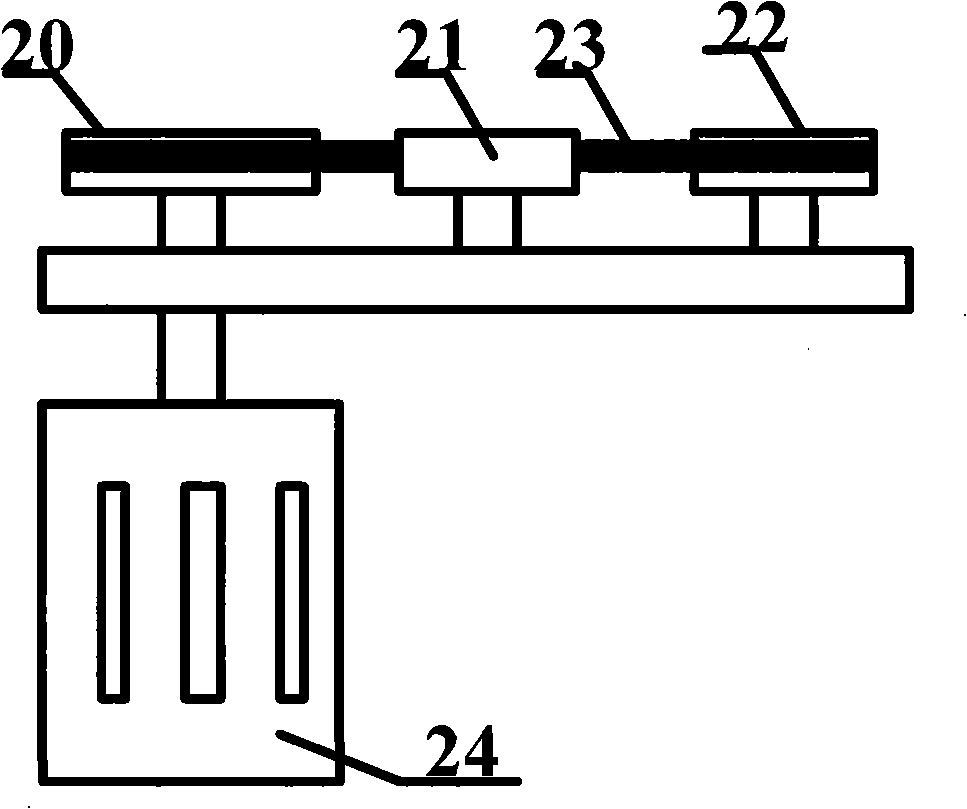

Microfluidic analytical system with position electrodes

ActiveUS6990849B2Bioreactor/fermenter combinationsBiological substance pretreatmentsElectricityElectrical resistance and conductance

A microfluidic analytical system for monitoring an analyte (for example, glucose) in a liquid sample (e.g., ISF) includes an analysis module with at least one micro-channel for receiving and transporting a liquid sample, at least one analyte sensor for measuring an analyte in the liquid sample and at least one position electrode. The analyte sensor(s) and position electrode(s) are in operative communication with the micro-channel. The microfluidic system also includes a meter configured for measuring an electrical characteristic (such as impedance or resistance) of the position electrode(s). Moreover, the measured electrical characteristic is dependent on the position of the liquid sample in the micro-channel that is in operative communication with the position electrode for which an electrical characteristic is measured.

Owner:LIFESCAN IP HLDG LLC +2

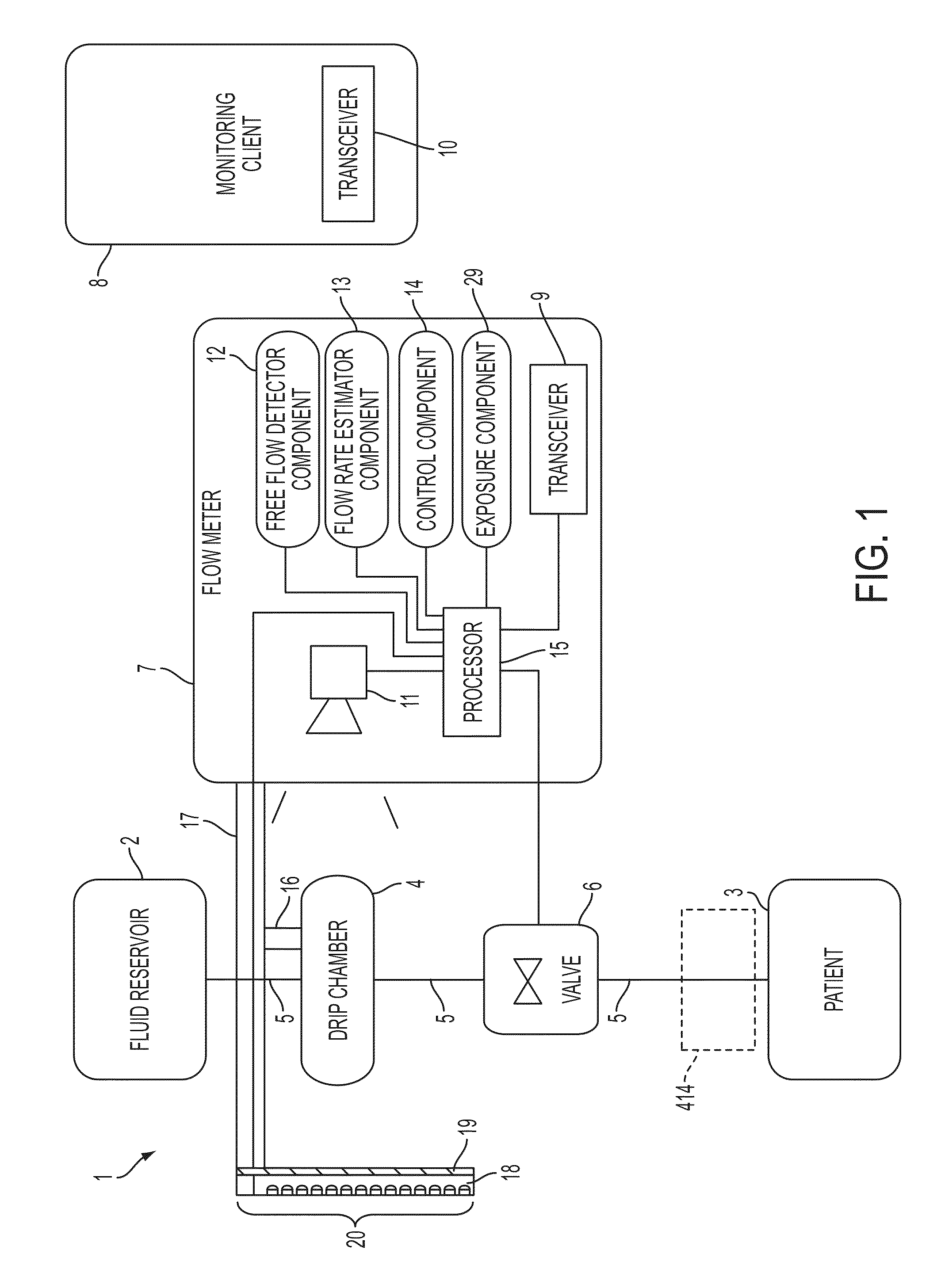

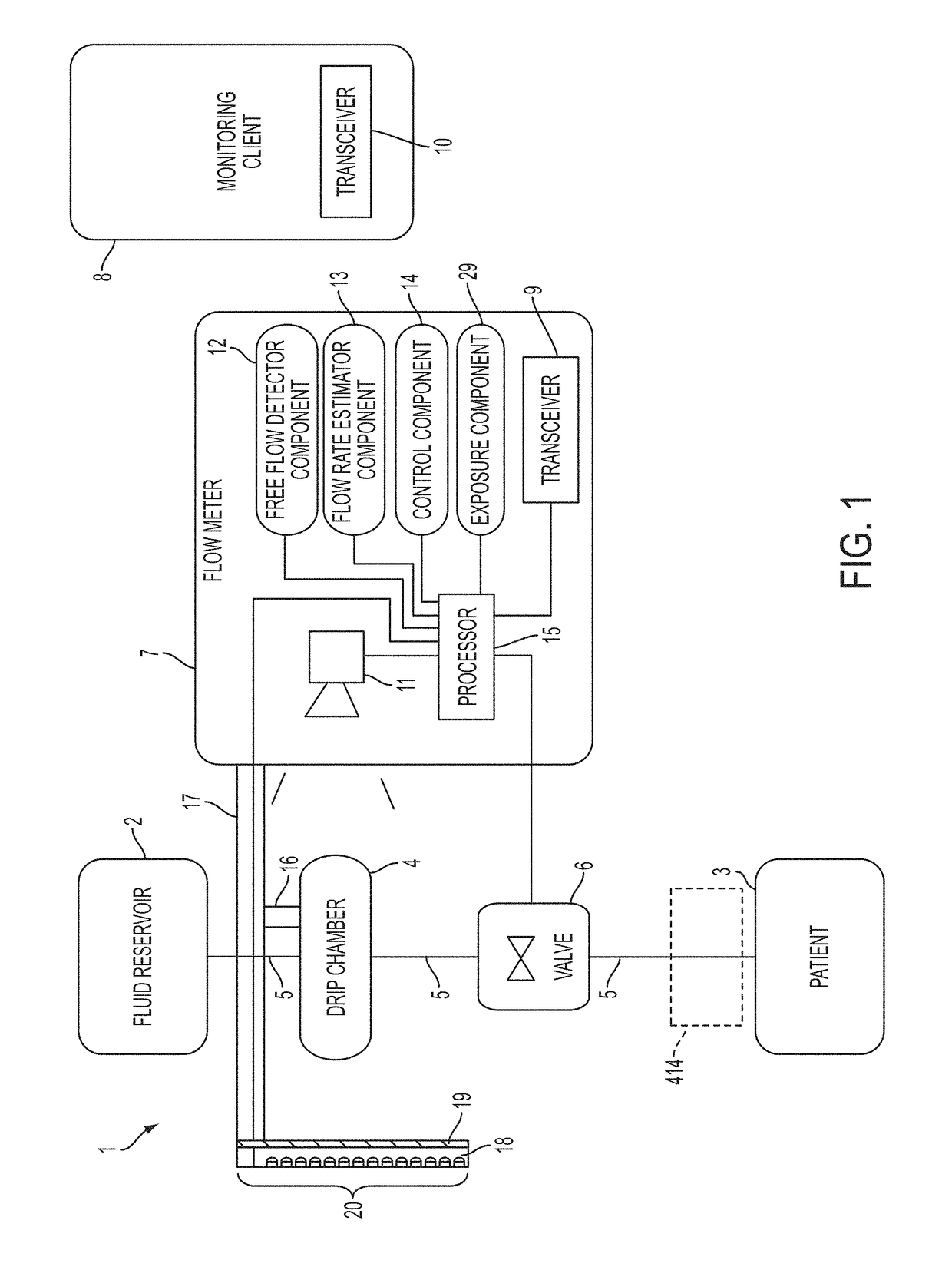

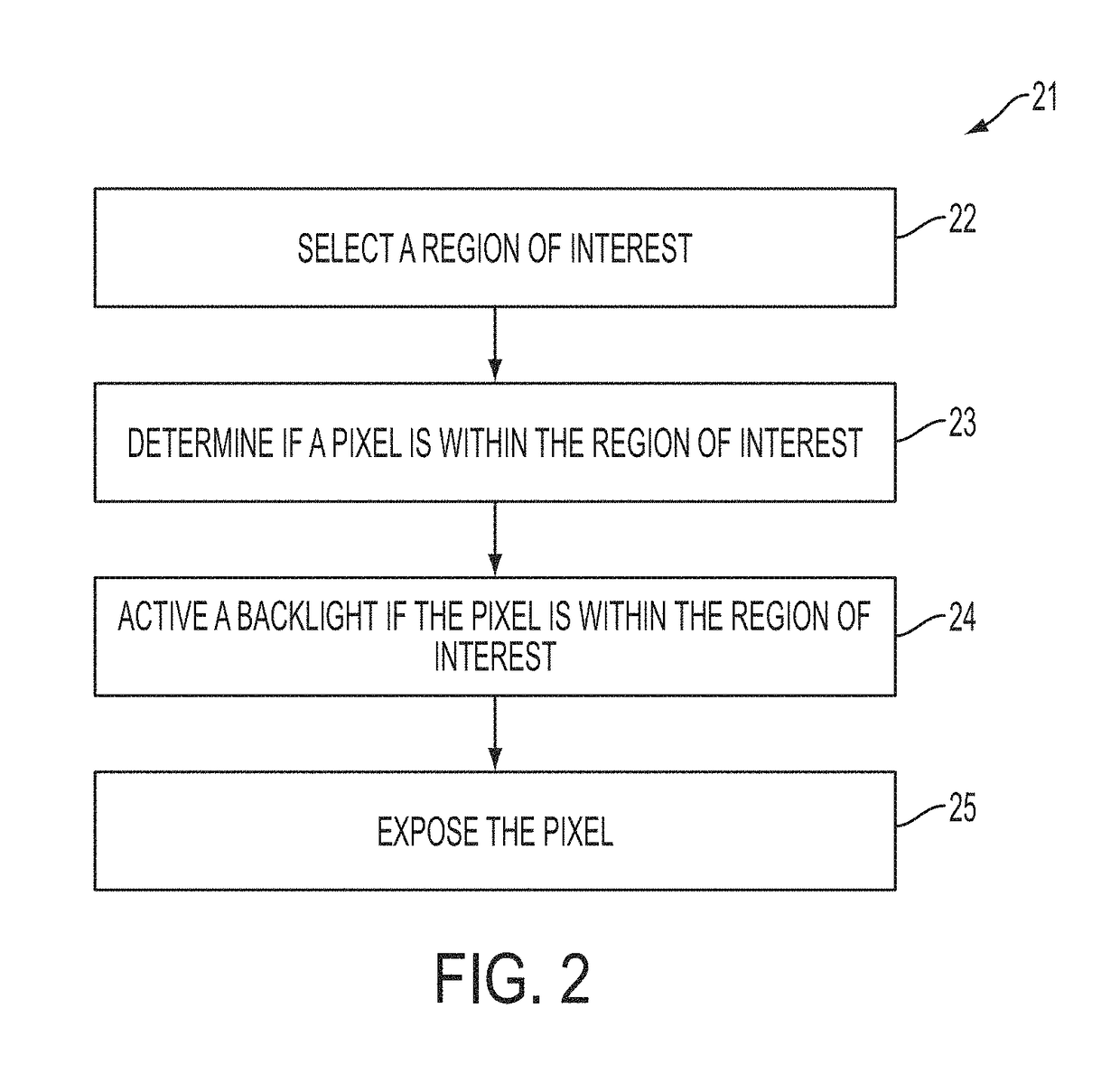

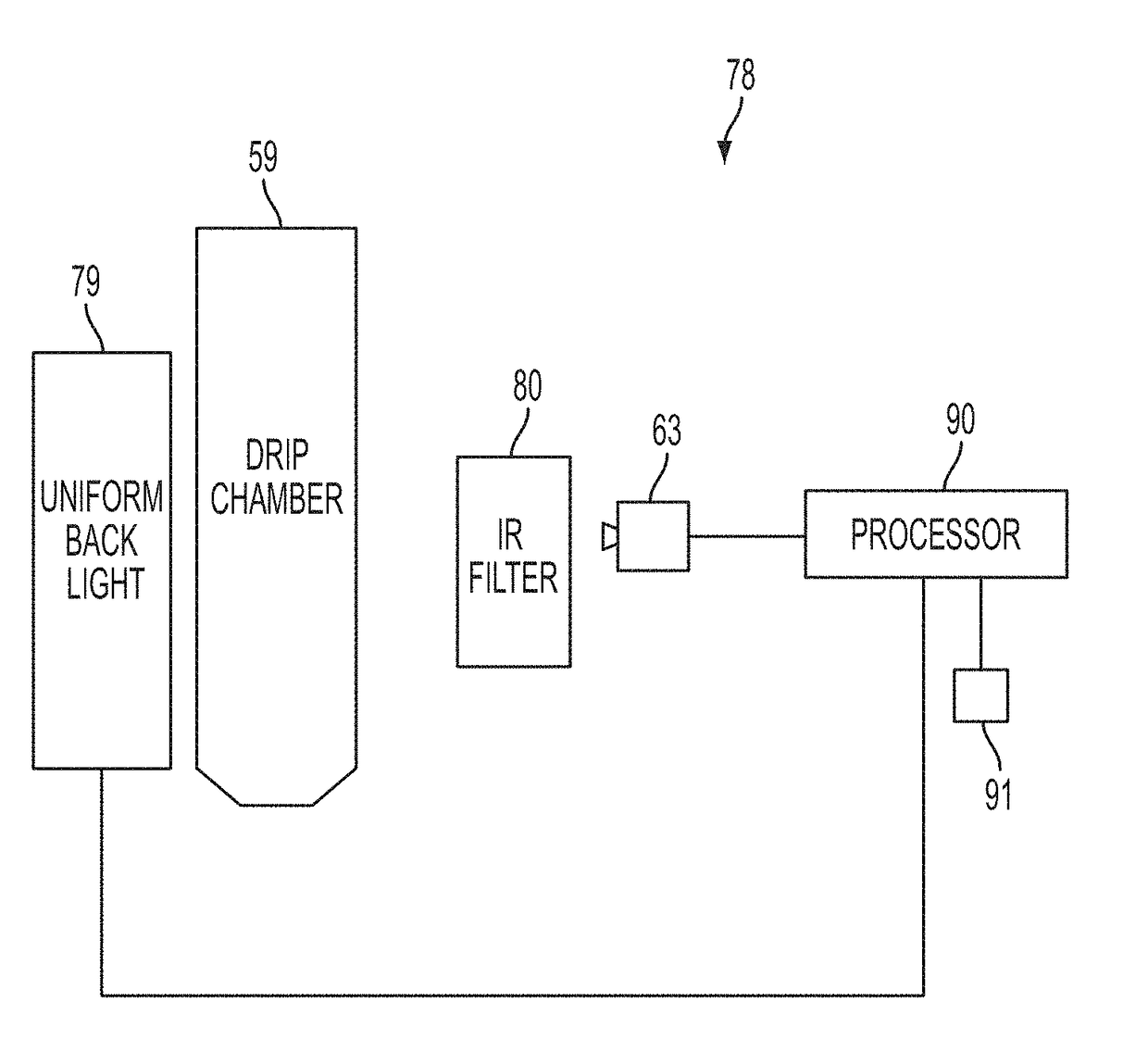

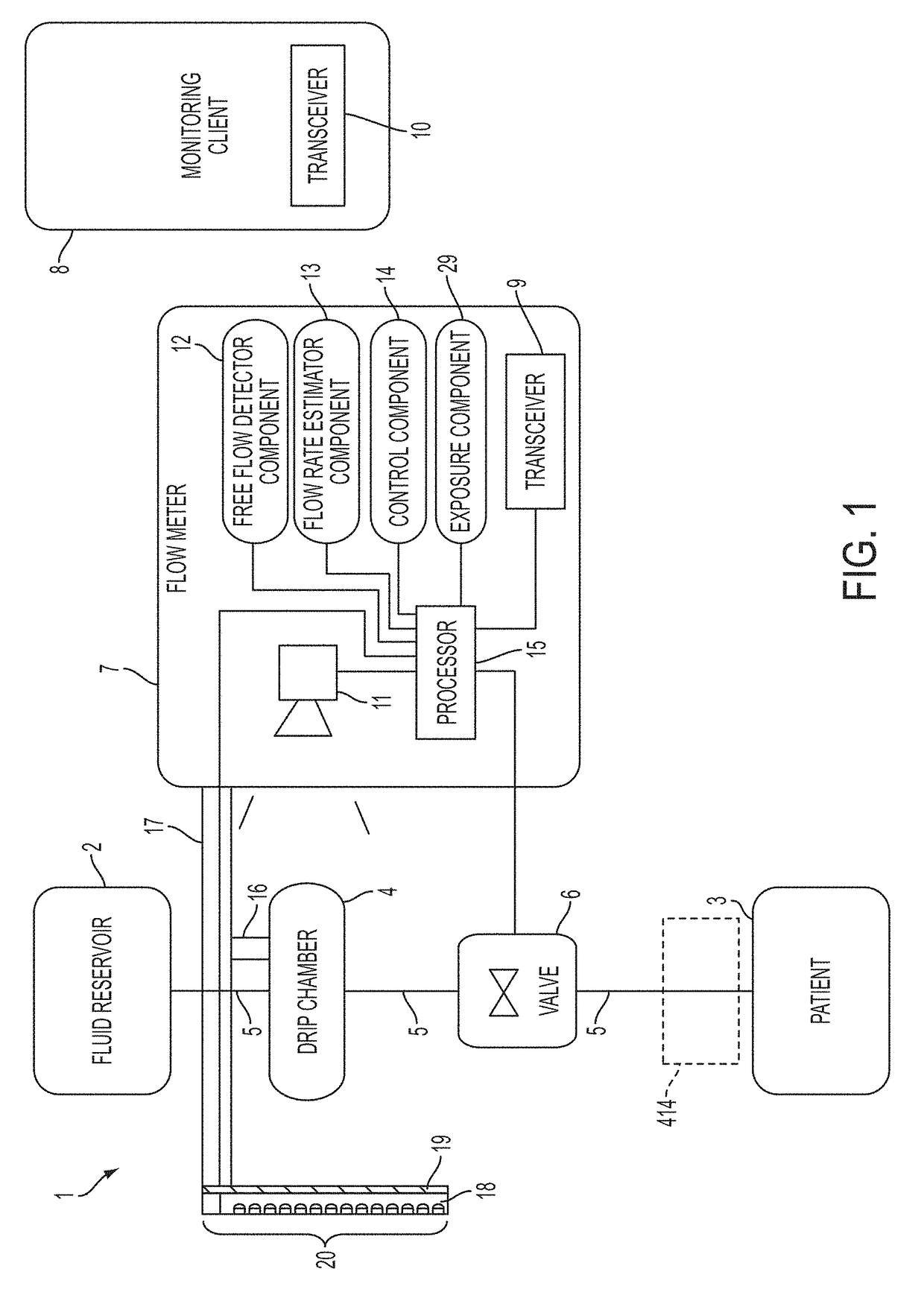

Flow meter

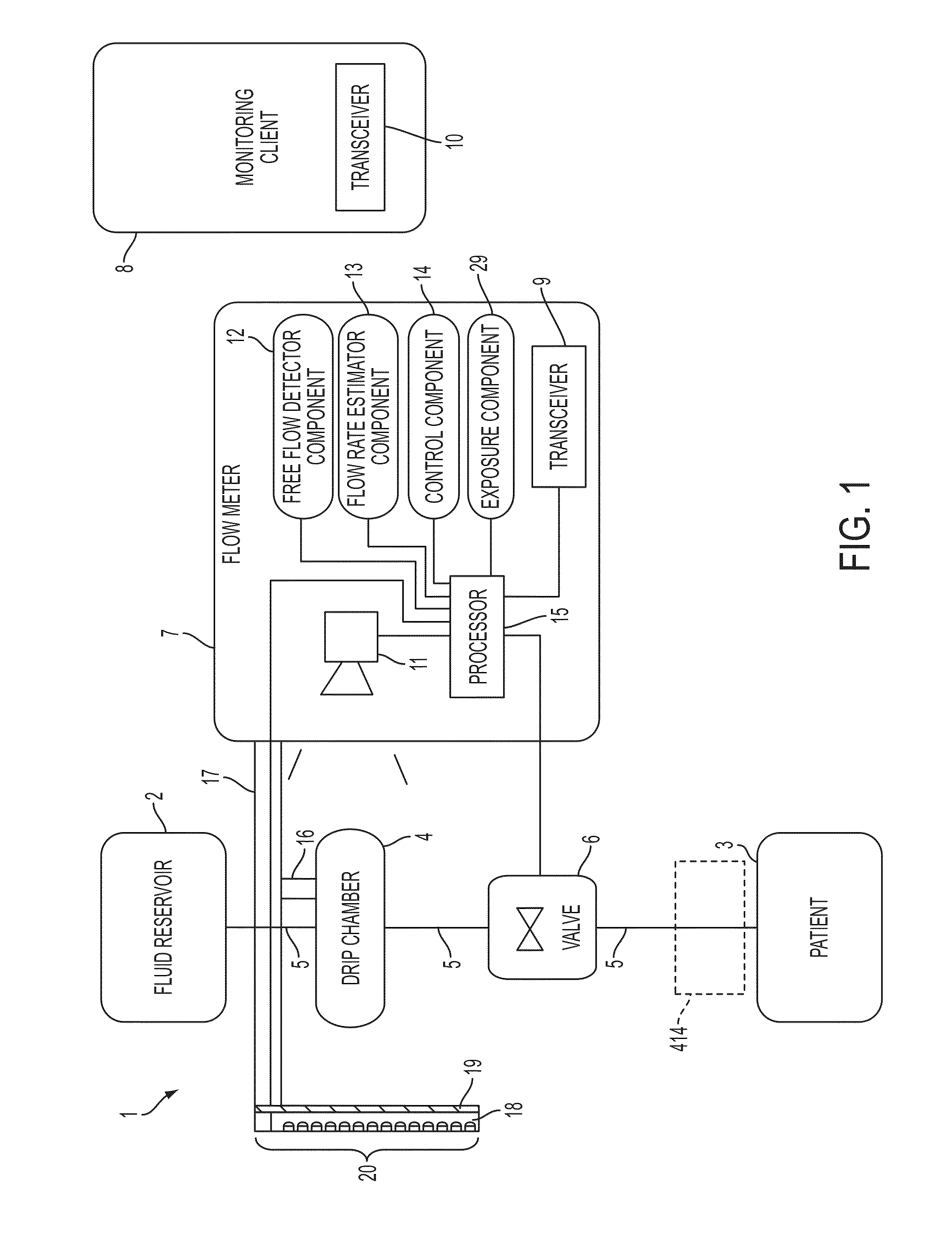

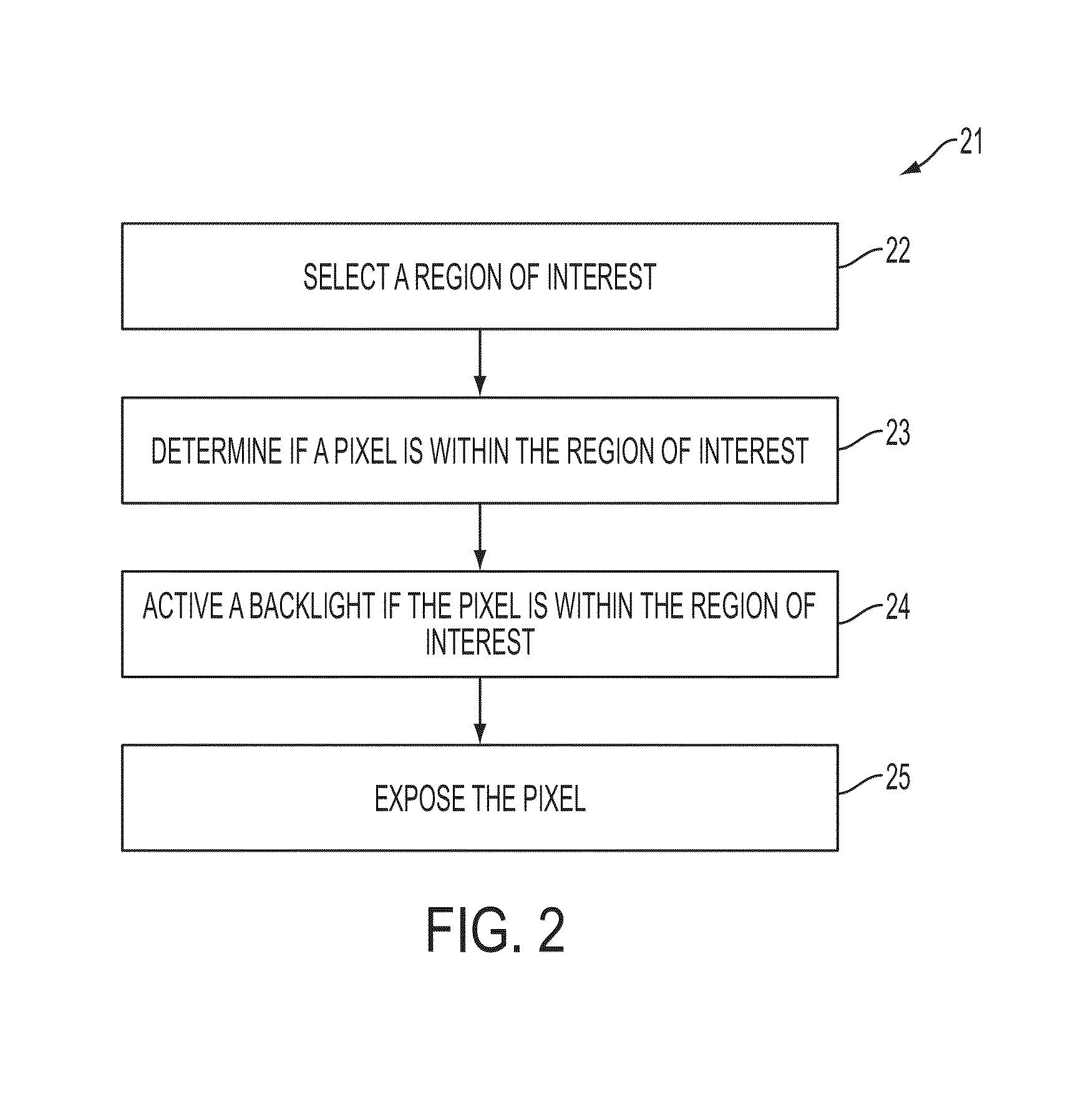

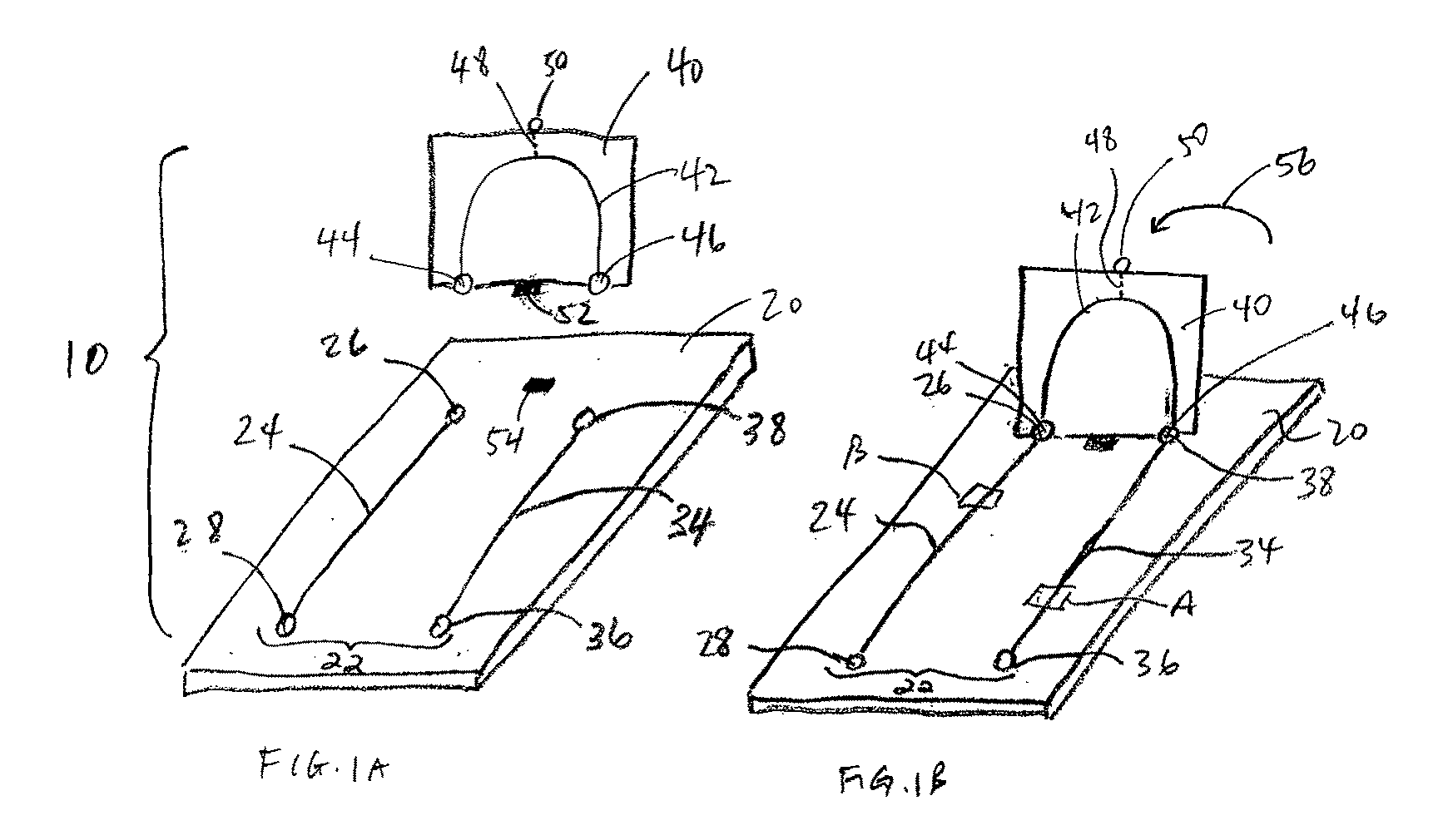

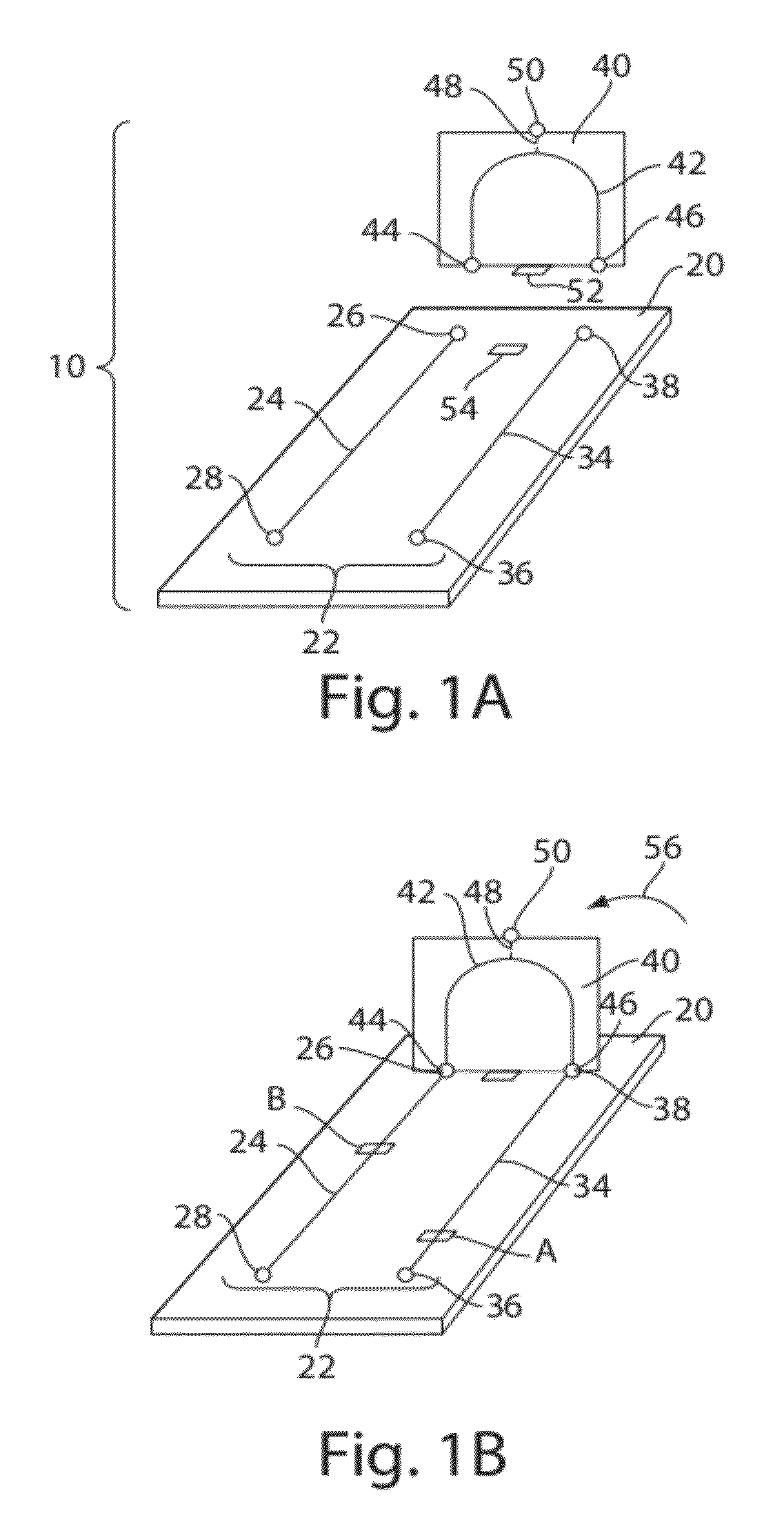

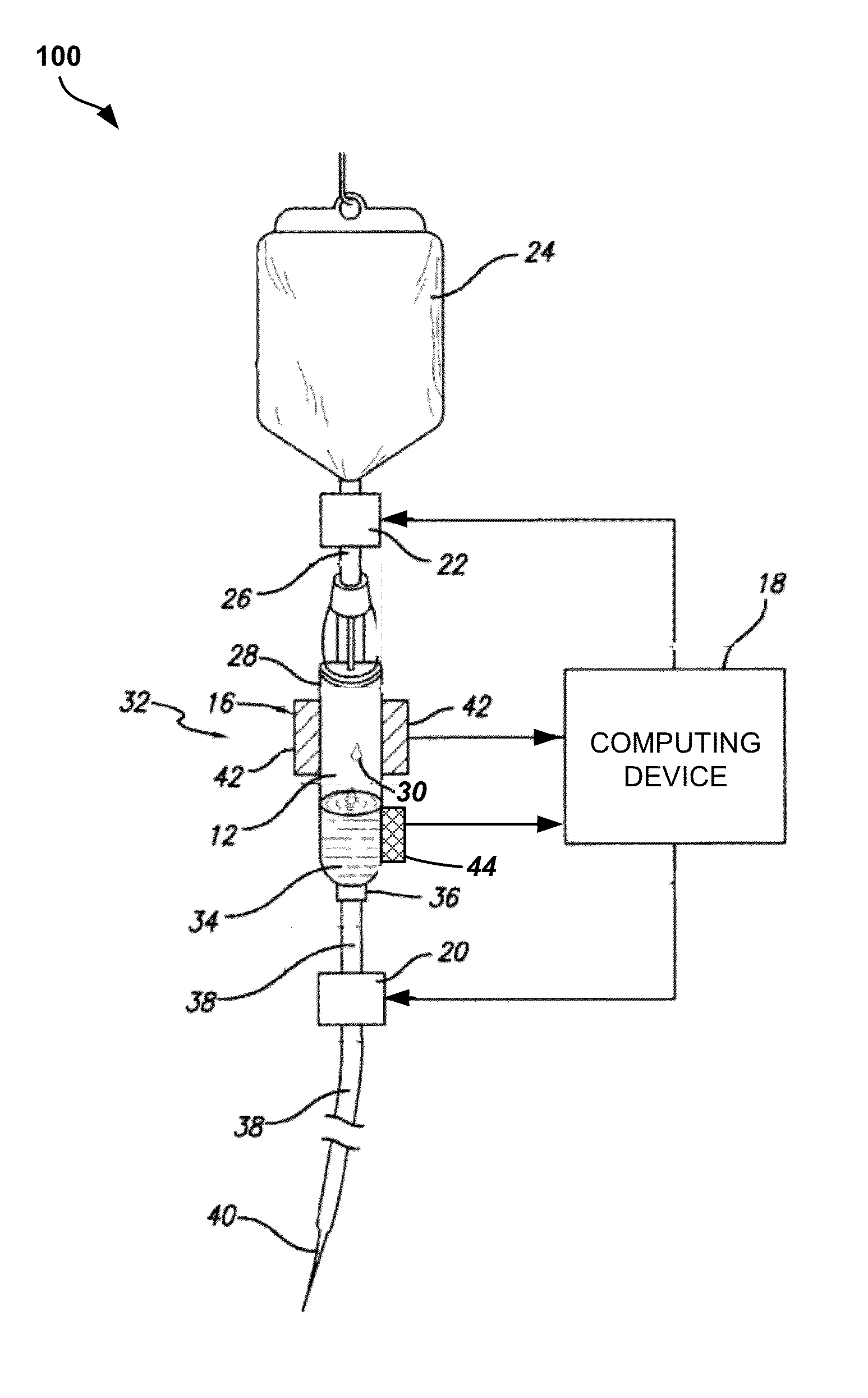

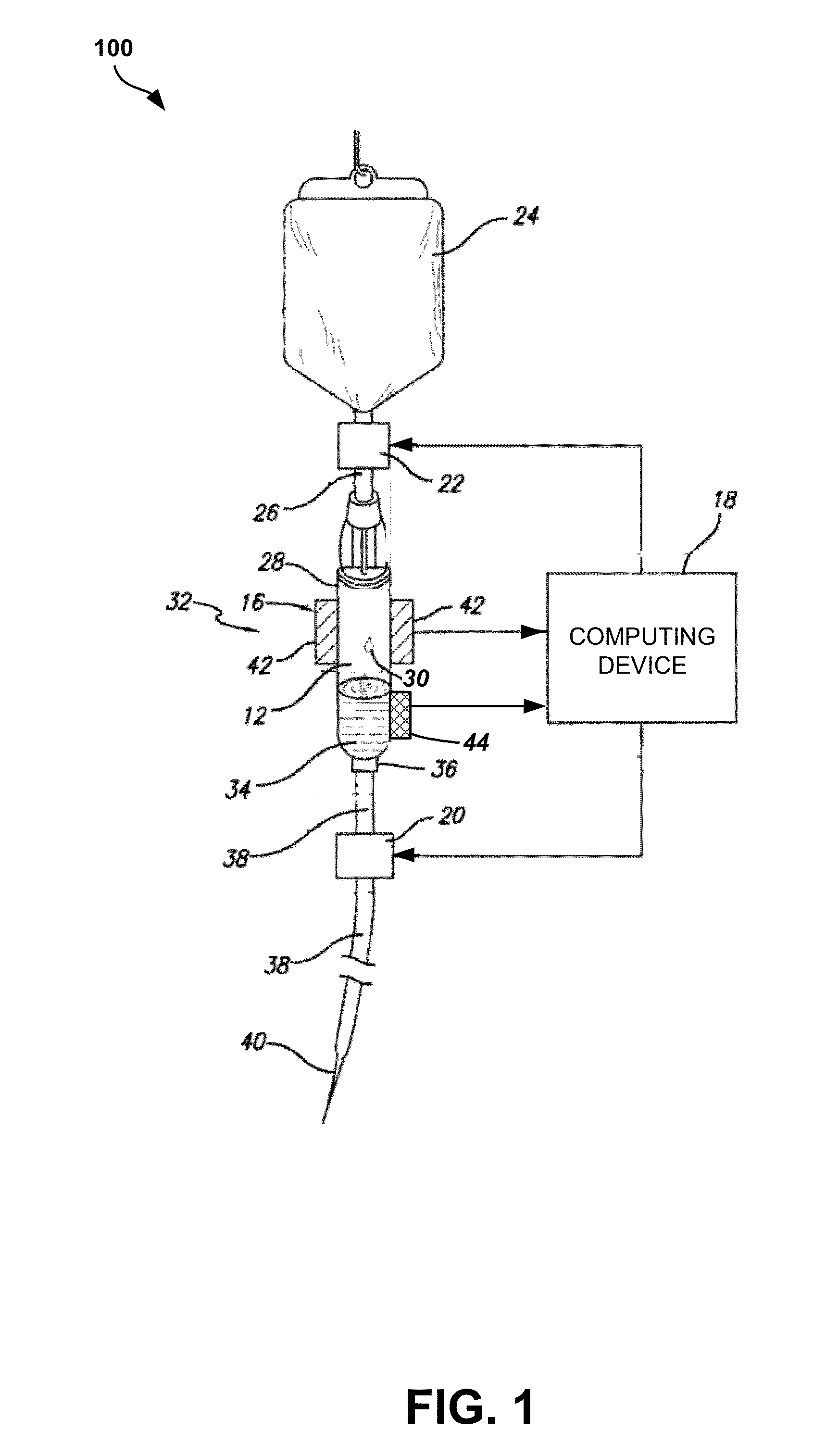

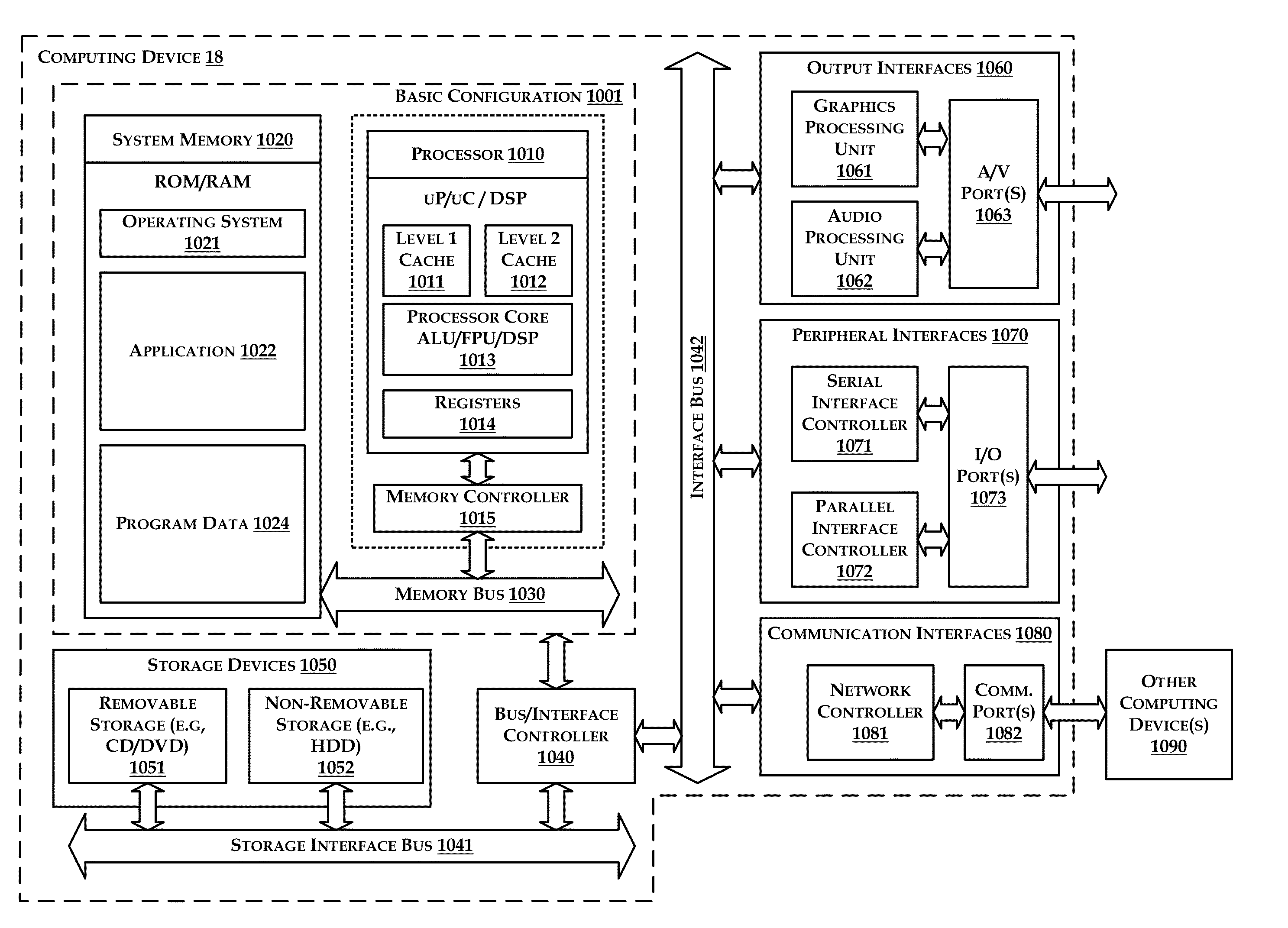

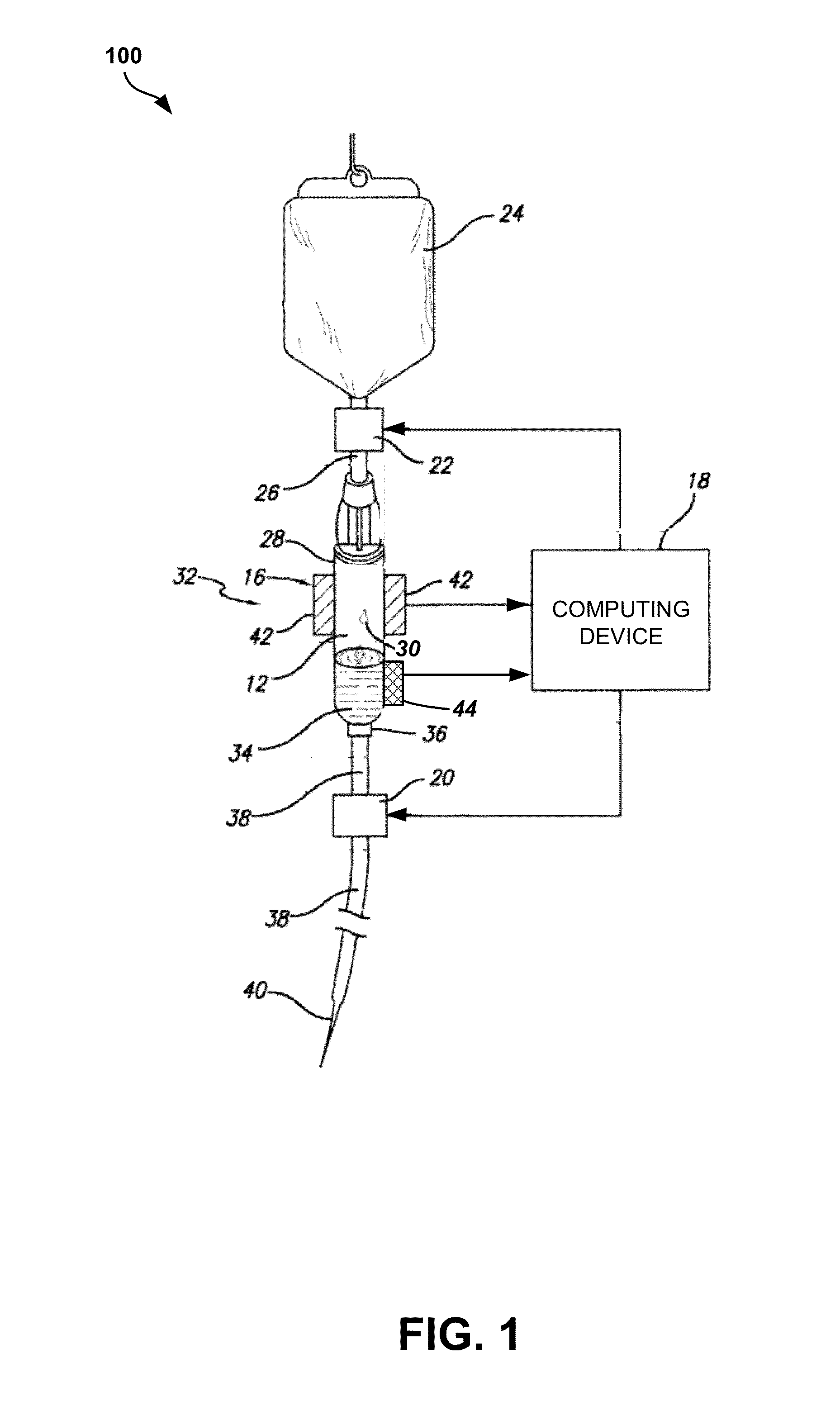

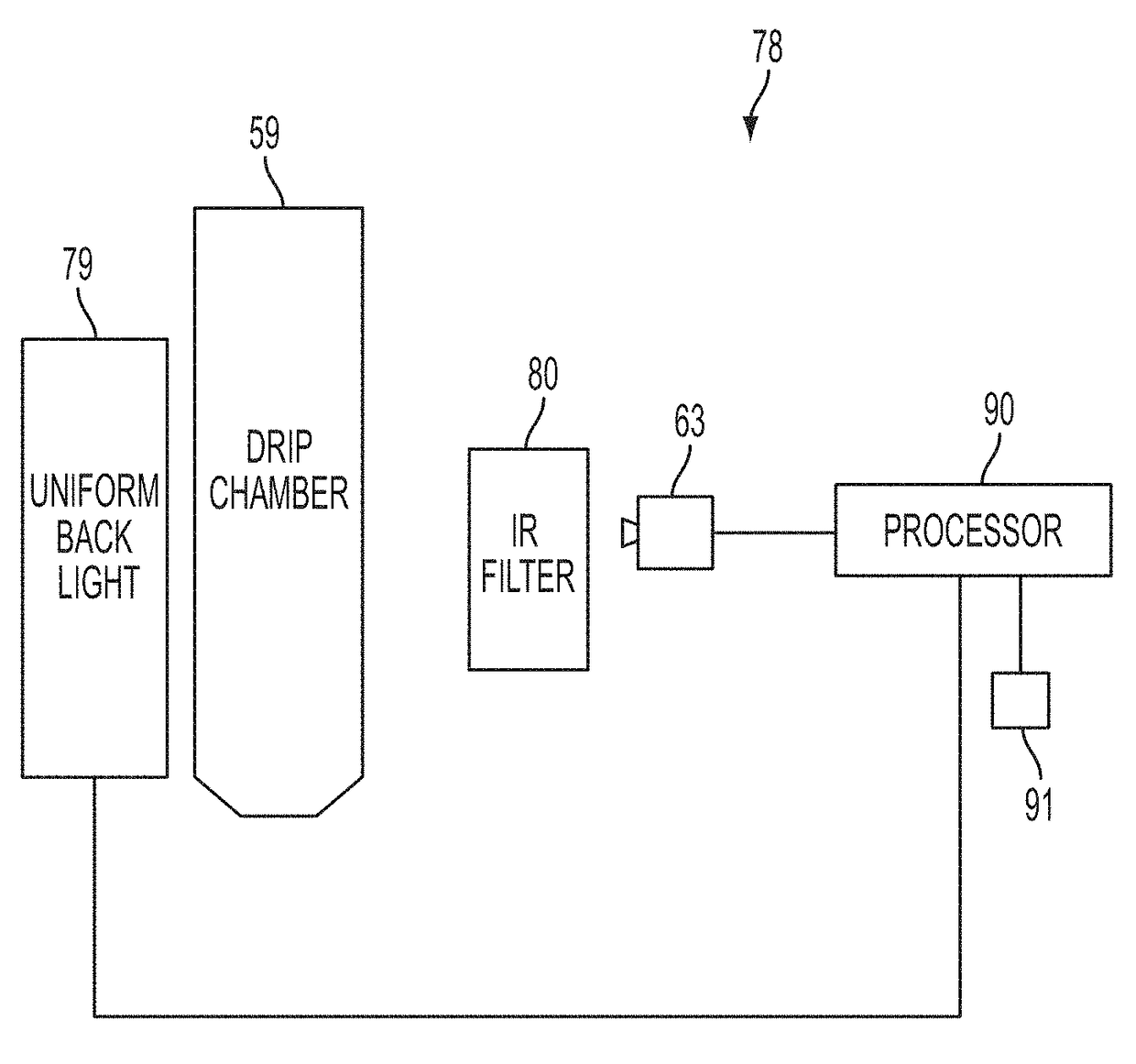

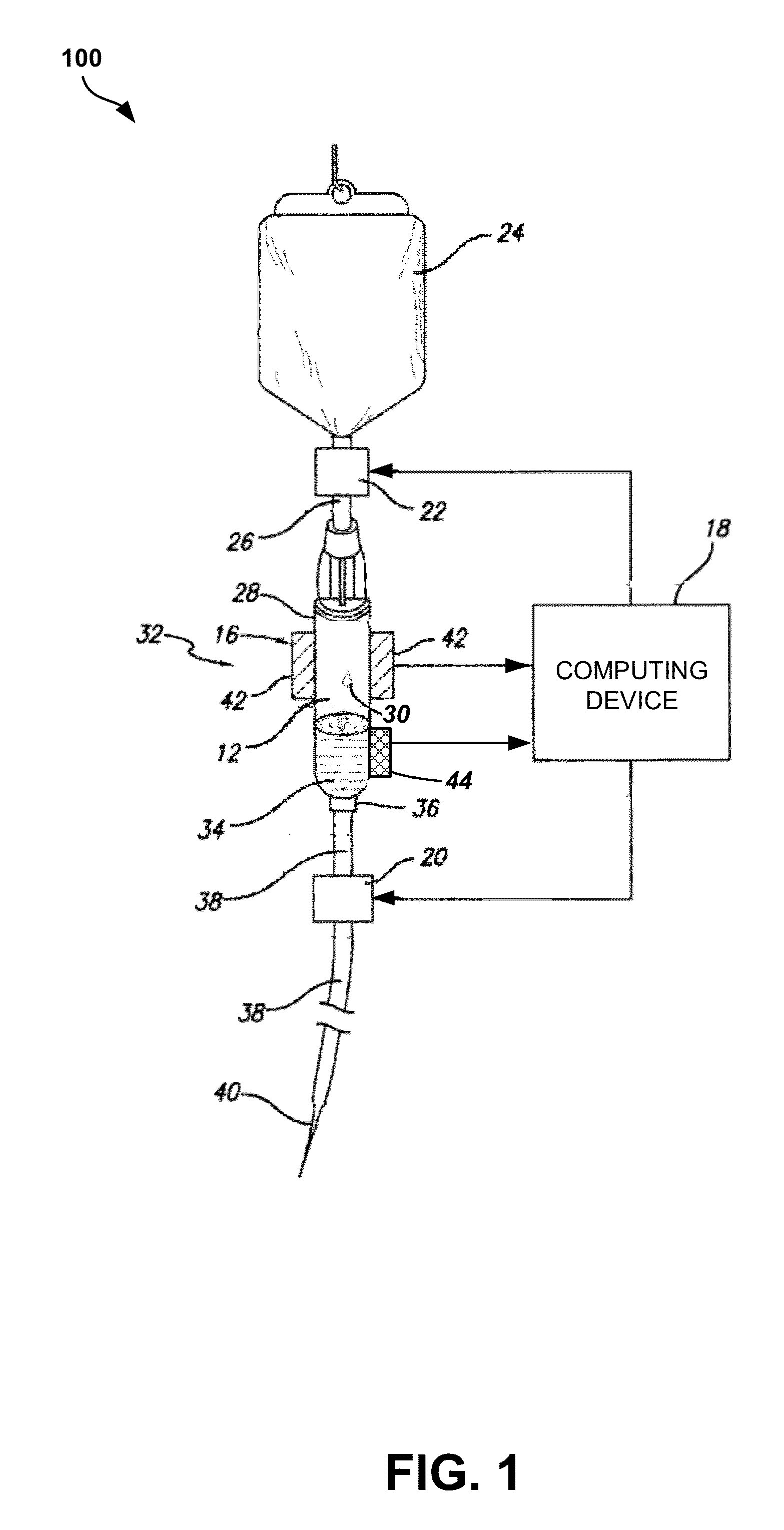

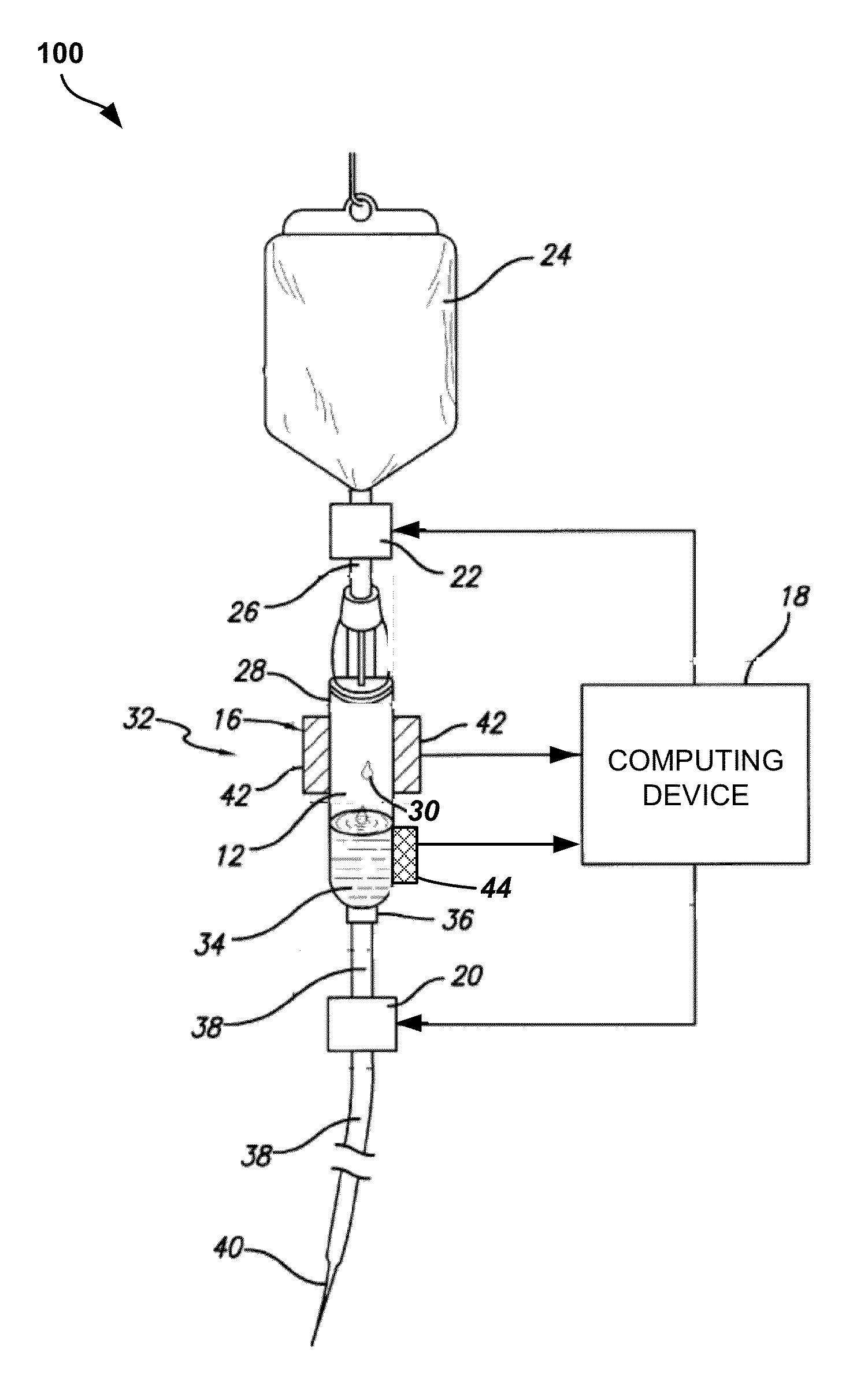

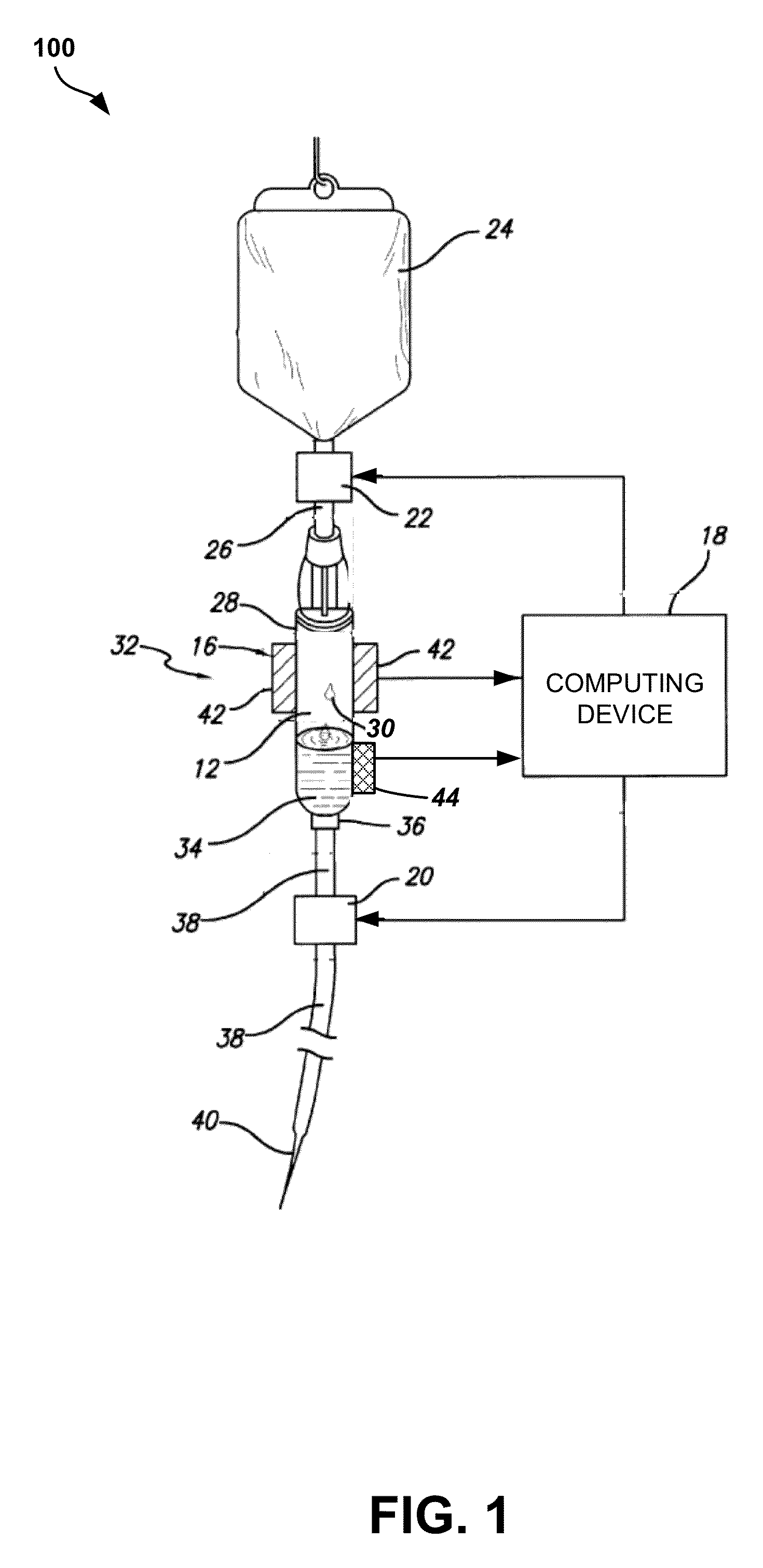

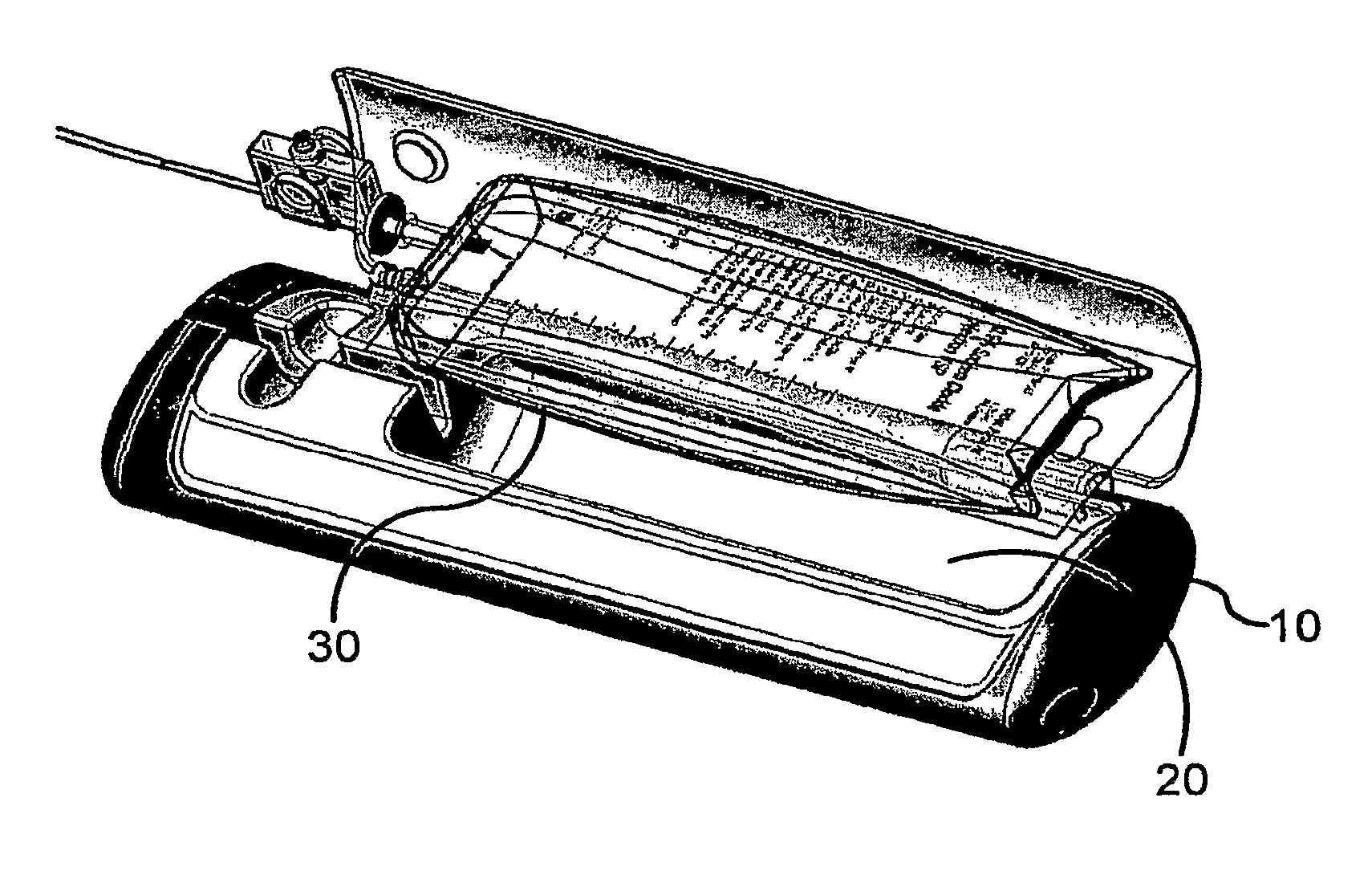

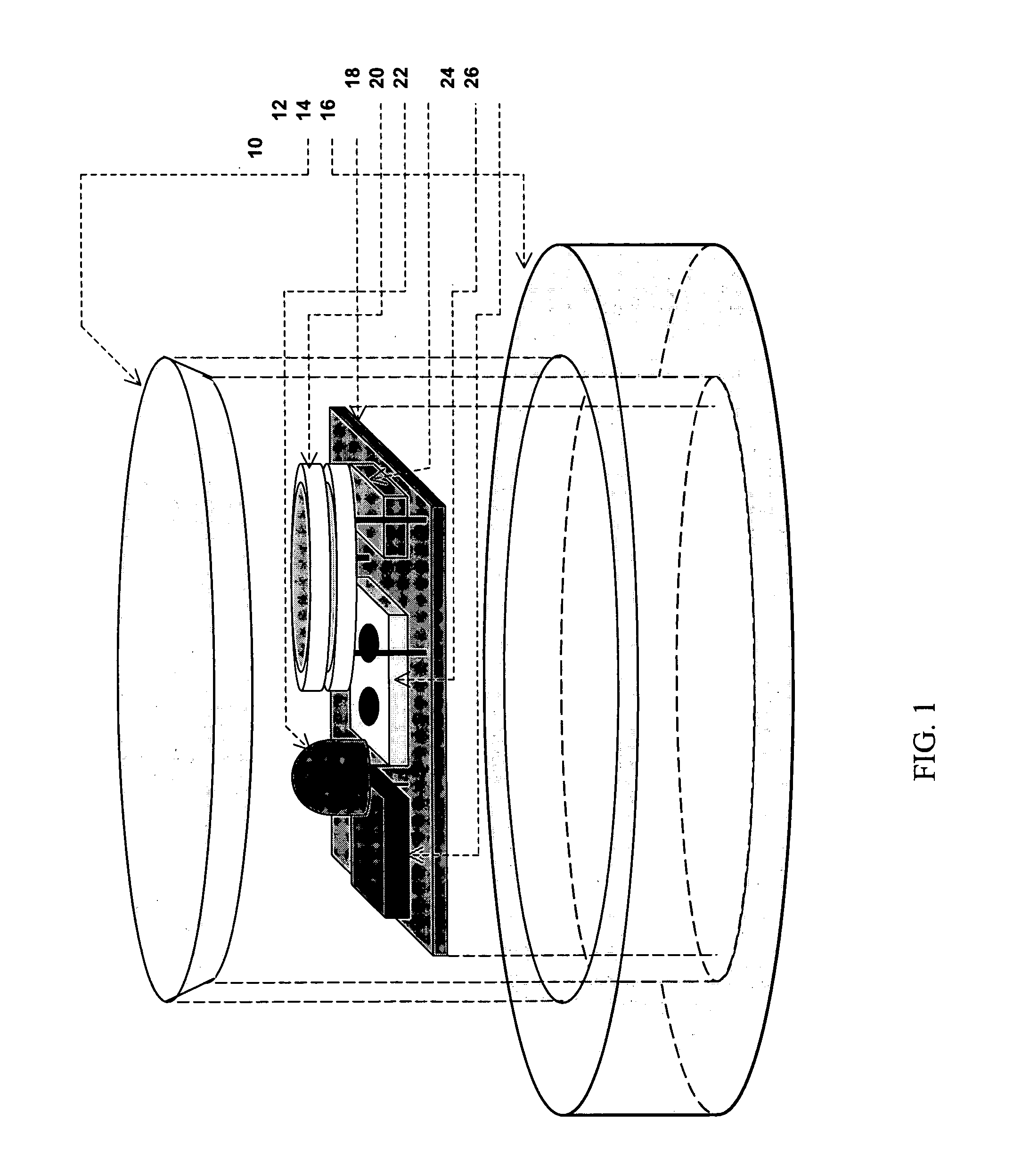

ActiveUS20150002667A1Reduce liquid volumeAmount being removedImage enhancementImage analysisOptical distortionField of view

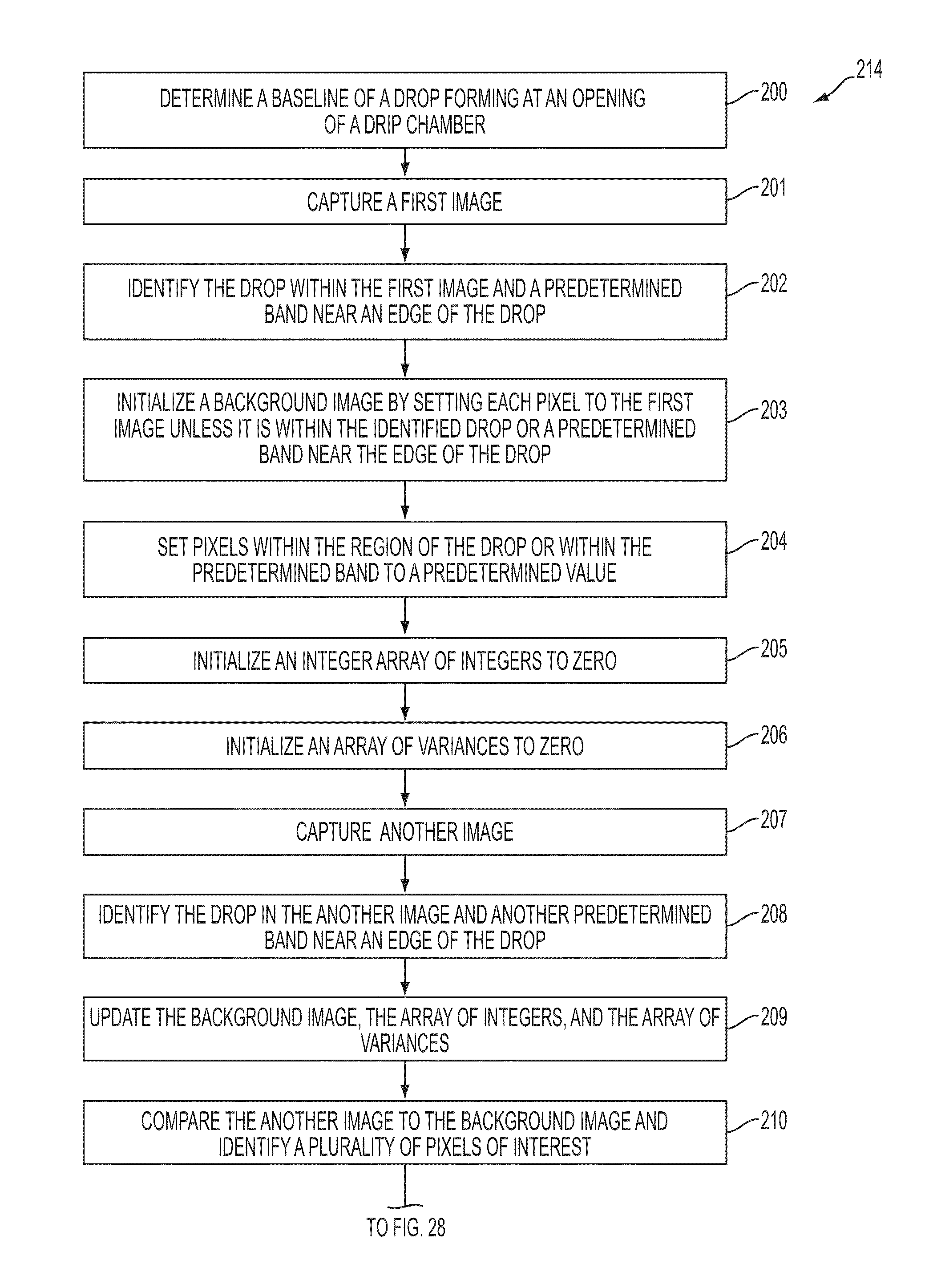

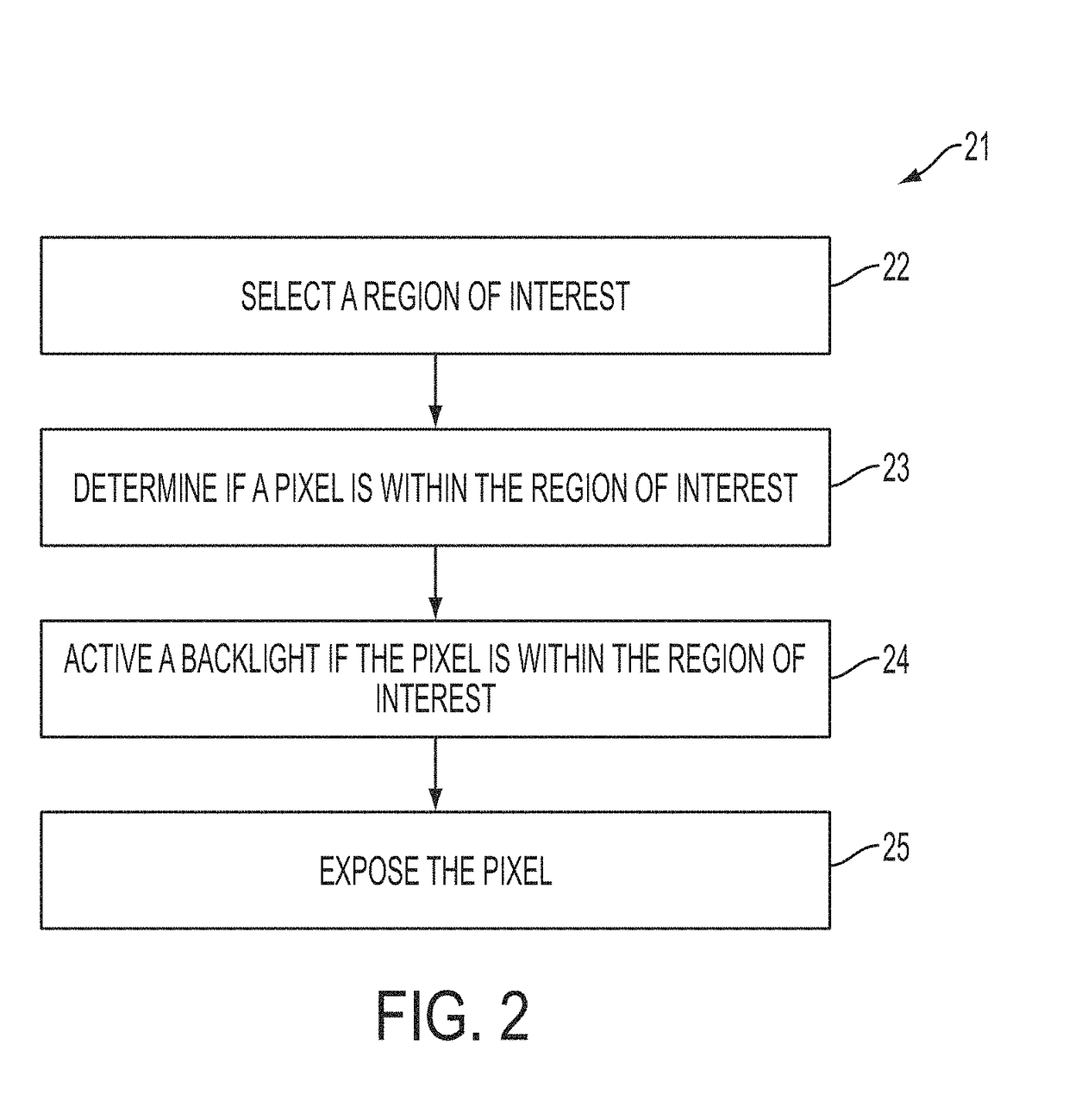

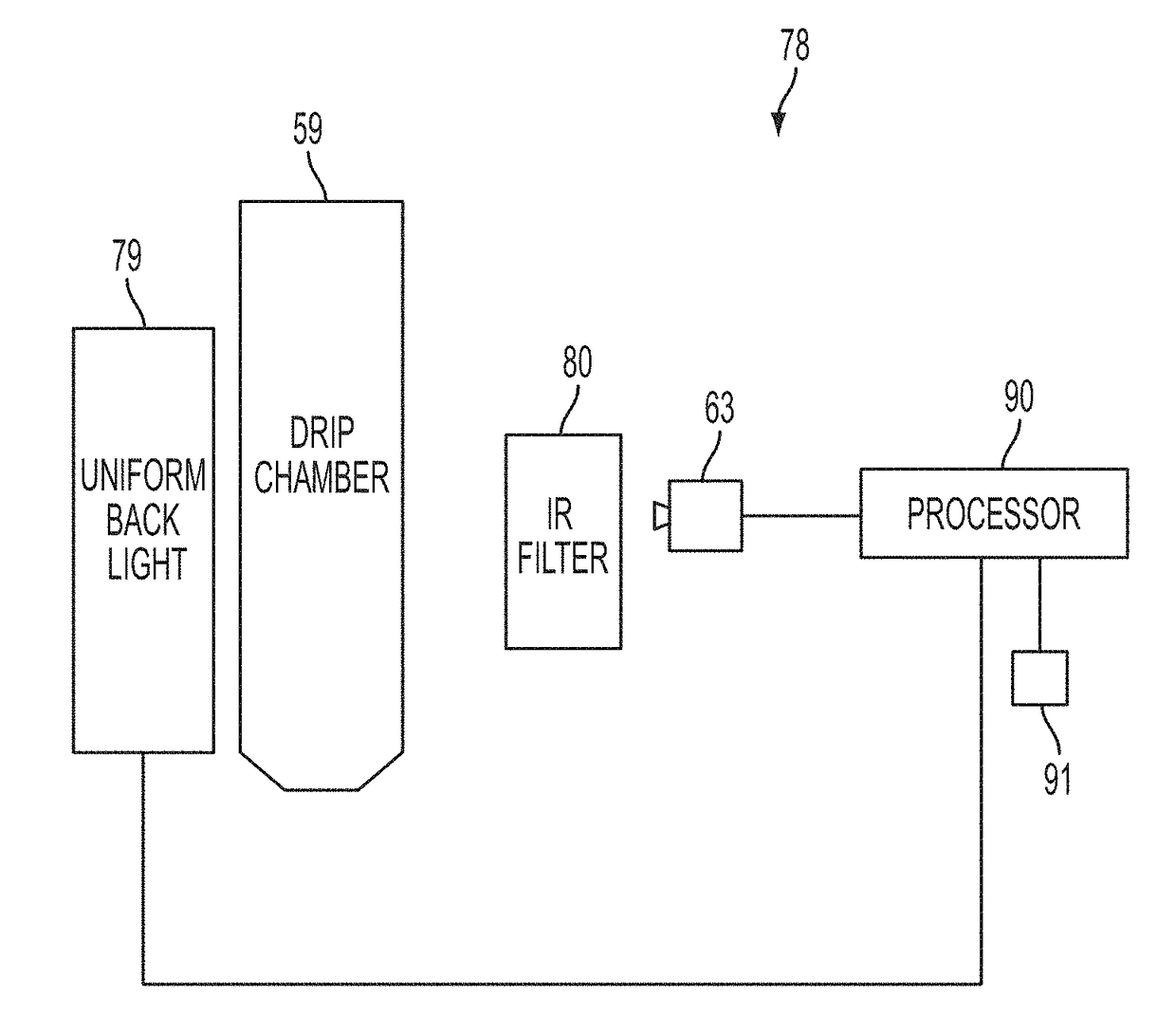

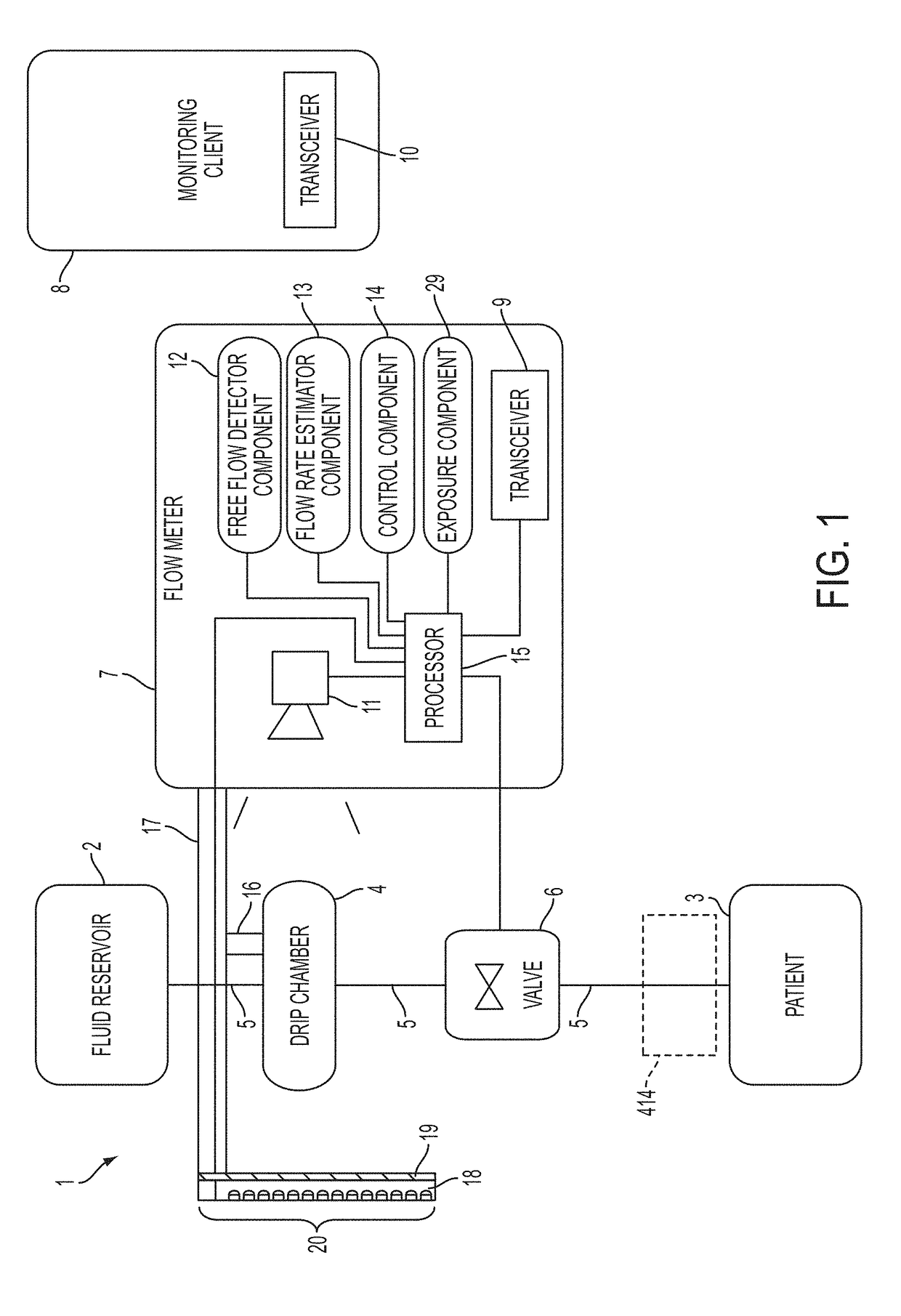

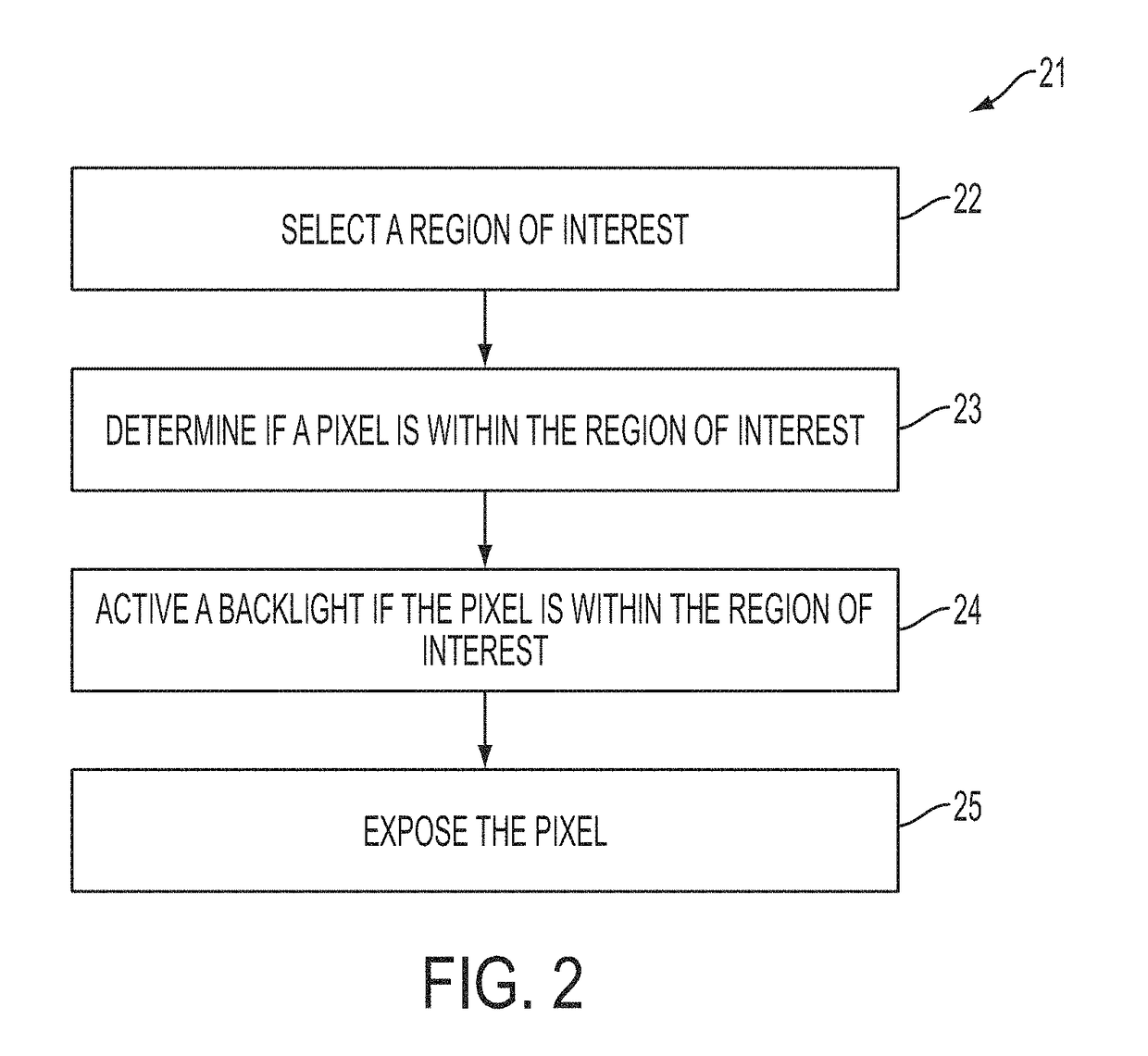

An flow meter includes a coupler, a support member, an image sensor, and one or more processors. The coupler is adapted to couple to a drip chamber. The support member is operatively coupled to the coupler. The image sensor has a field of view and is operatively coupled to the support member. The image sensor is positioned to view the drip chamber within its field of view. The one or more processors are operatively coupled to the image sensor to receive data thereform. The one or more processors (1) receive image data from the image sensor, and (2) determine an existence of a free flow condition by identifying an optical distortion of an area behind the free flow condition within the drip chamber using the received image data.

Owner:DEKA PROD LLP

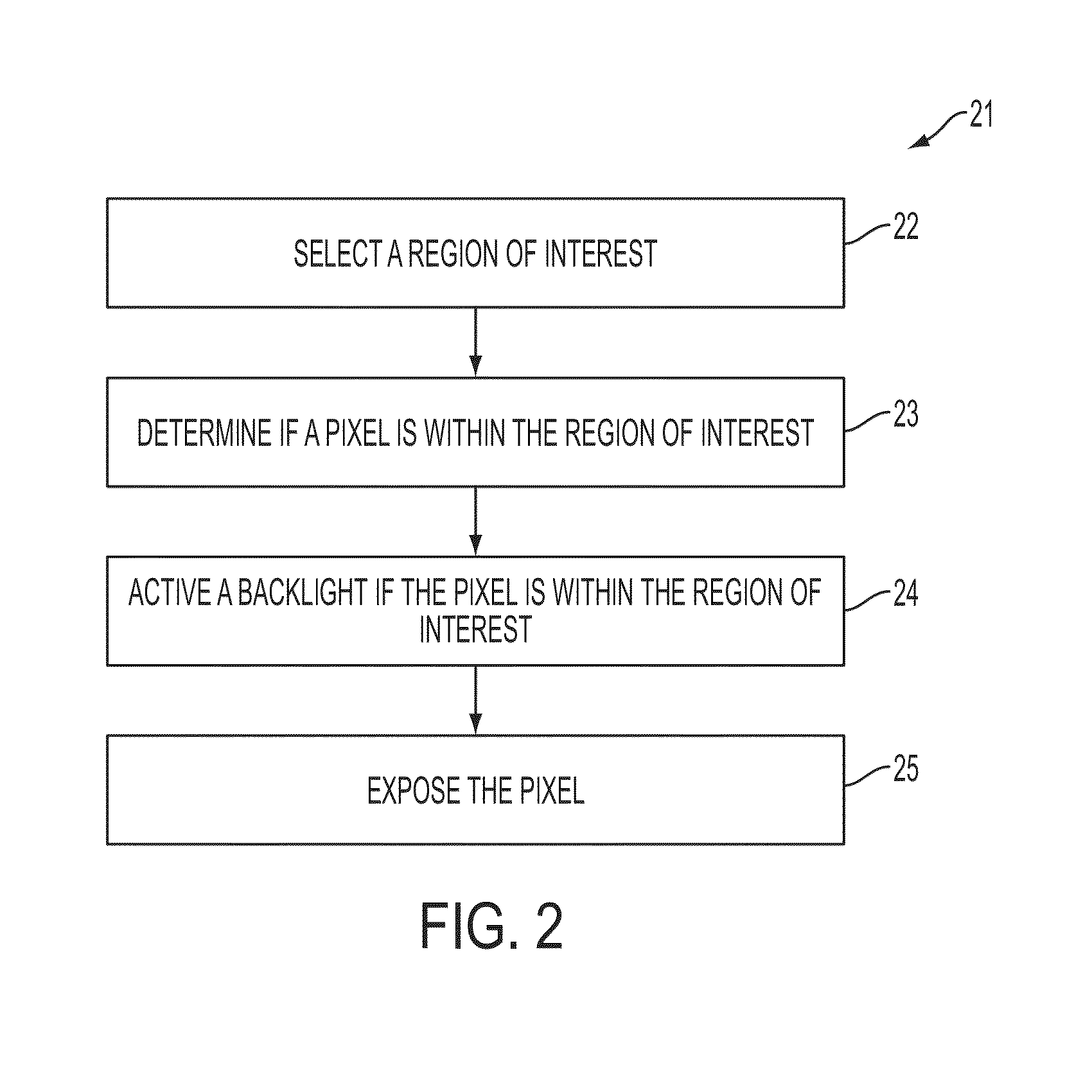

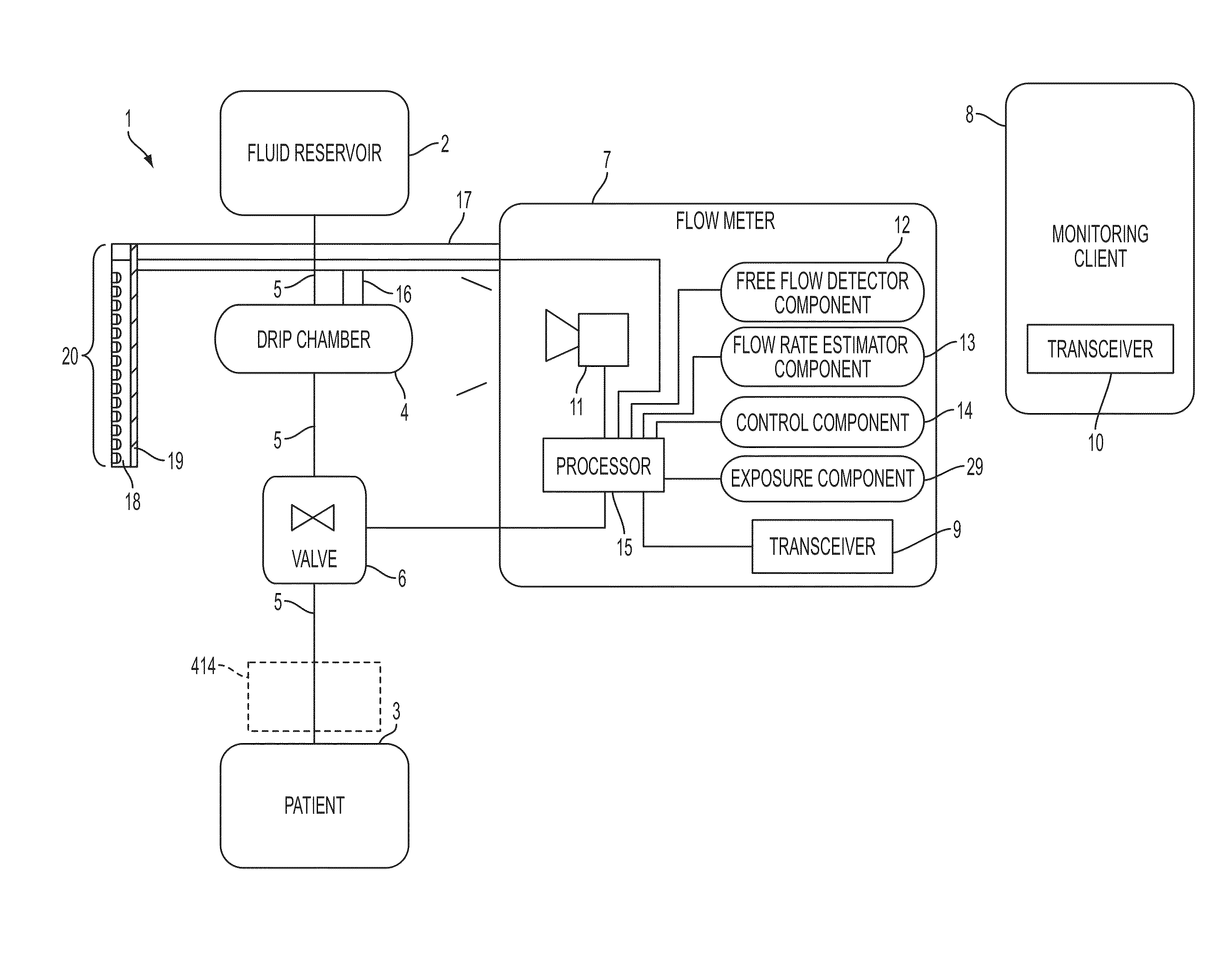

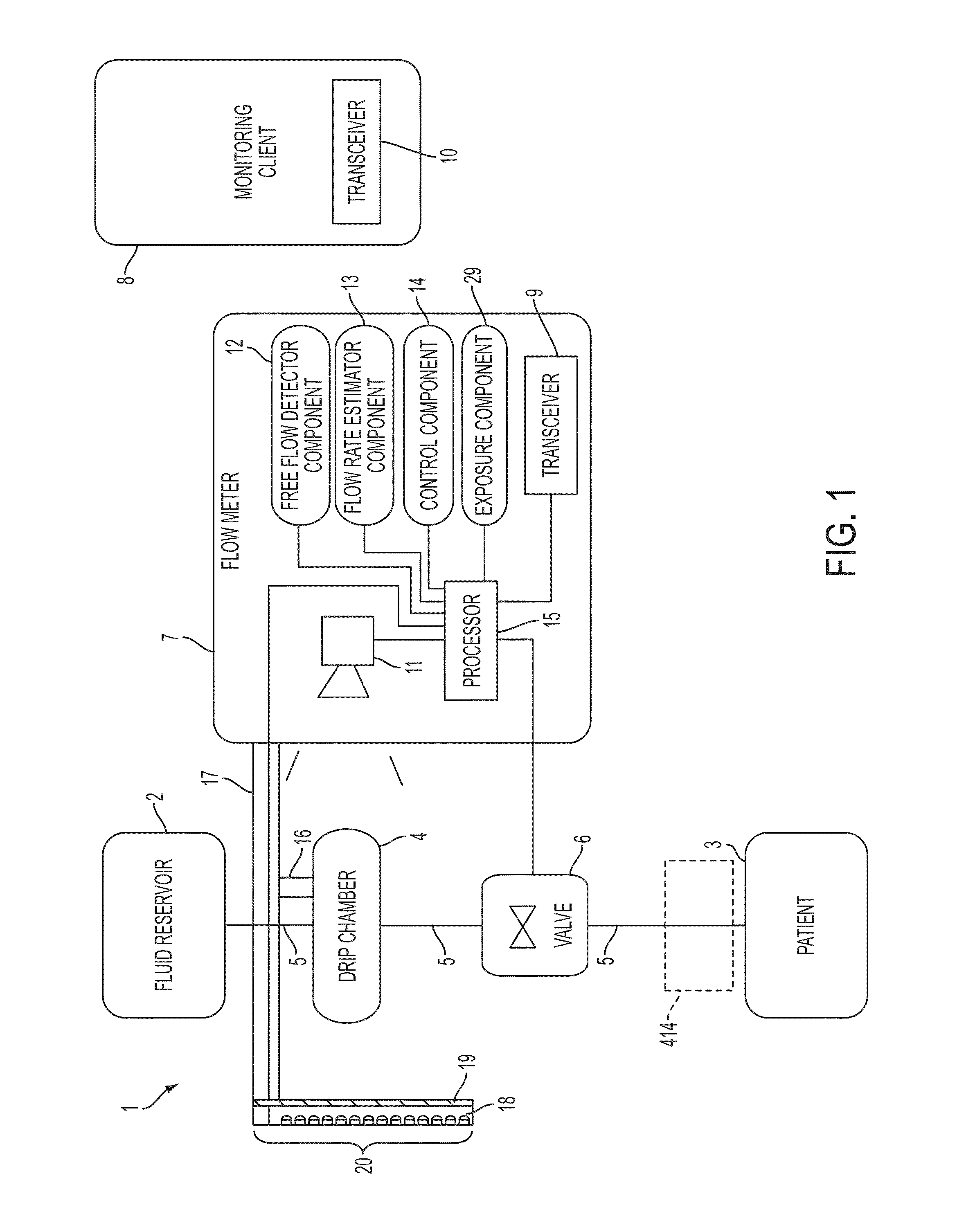

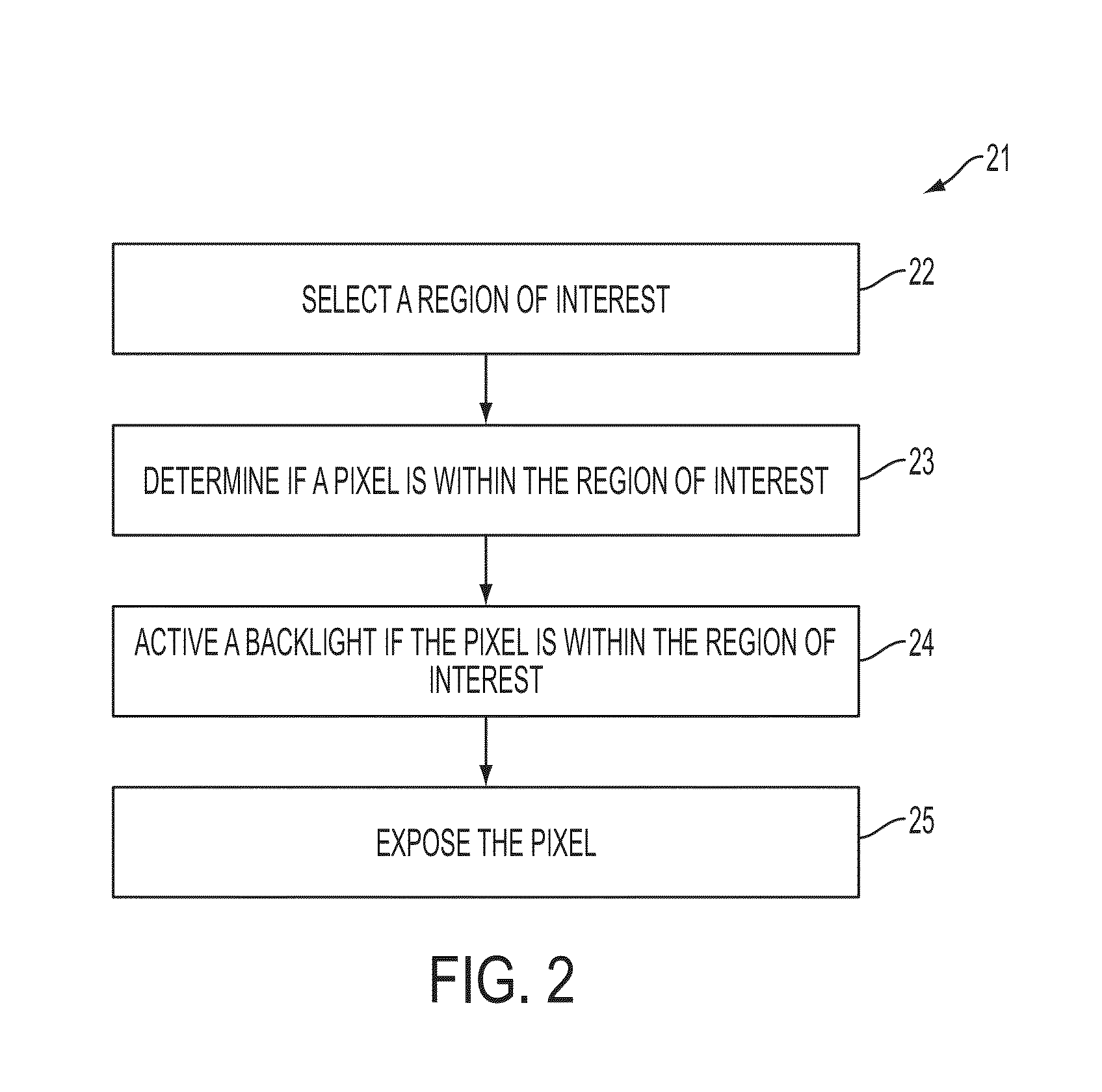

Flow Meter

ActiveUS20150002668A1Reduce liquid volumeImage enhancementImage analysisOptical distortionField of view

An flow meter includes a coupler, a support member, an image sensor, and one or more processors. The coupler is adapted to couple to a drip chamber. The support member is operatively coupled to the coupler. The image sensor has a field of view and is operatively coupled to the support member. The image sensor is positioned to view the drip chamber within its field of view. The one or more processors are operatively coupled to the image sensor to receive data thereform. The one or more processors (1) receive image data from the image sensor, and (2) determine an existence of a free flow condition by identifying an optical distortion of an area behind the free flow condition within the drip chamber using the received image data.

Owner:DEKA PROD LLP

Flow Meter

ActiveUS20150002677A1Reduce liquid volumeImage enhancementImage analysisOptical distortionField of view

An flow meter includes a coupler, a support member, an image sensor, and one or more processors. The coupler is adapted to couple to a drip chamber. The support member is operatively coupled to the coupler. The image sensor has a field of view and is operatively coupled to the support member. The image sensor is positioned to view the drip chamber within its field of view. The one or more processors are operatively coupled to the image sensor to receive data thereform. The one or more processors (1) receive image data from the image sensor, and (2) determine an existence of a free flow condition by identifying an optical distortion of an area behind the free flow condition within the drip chamber using the received image data.

Owner:DEKA PROD LLP

Fluidic connectors and microfluidic systems

Fluidic connectors, methods, and devices for performing analyses (e.g., immunoassays) in microfluidic systems are provided. In some embodiments, a fluidic connector having a fluid path is used to connect two independent channels formed in a substrate so as to allow fluid communication between the two independent channels. One or both of the independent channels may be pre-filled with reagents (e.g., antibody solutions, washing buffers and amplification reagents), which can be used to perform the analysis. These reagents may be stored in the channels of the substrate for long periods amounts of time (e.g., 1 year) prior to use. Prior to connection of the fluid connector and the substrate, the fluid path may be filled with a sample (e.g., blood). The sample may be obtained, for example, by pricking a finger of a user until blood is drawn from the finger into the fluid path (e.g., by capillary forces). Upon connection of the fluidic connector and the channels of the substrate, the sample can pass through a reaction area within the first channel of the substrate. This process can allow components of the sample to interact with components disposed in the reaction area. Afterwards, reagents from the second channel can flow to the reaction area via the fluid path, allowing components in the reaction area to be processed (e.g., amplified to produce detectable signal). Components in the reaction area can then be determined using various methods of detection.

Owner:OPKO DIAGNOSTICS

Fluidic connectors and microfluidic systems

Fluidic connectors, methods, and devices for performing analyses (e.g., immunoassays) in microfluidic systems are provided. In some embodiments, a fluidic connector having a fluid path is used to connect two independent channels formed in a substrate so as to allow fluid communication between the two independent channels. One or both of the independent channels may be pre-filled with reagents (e.g., antibody solutions, washing buffers and amplification reagents), which can be used to perform the analysis. These reagents may be stored in the channels of the substrate for long periods amounts of time (e.g., 1 year) prior to use. Prior to connection of the fluid connector and the substrate, the fluid path may be filled with a sample (e.g., blood). The sample may be obtained, for example, by pricking a finger of a user until blood is drawn from the finger into the fluid path (e.g., by capillary forces). Upon connection of the fluidic connector and the channels of the substrate, the sample can pass through a reaction area within the first channel of the substrate. This process can allow components of the sample to interact with components disposed in the reaction area. Afterwards, reagents from the second channel can flow to the reaction area via the fluid path, allowing components in the reaction area to be processed (e.g., amplified to produce detectable signal). Components in the reaction area can then be determined using various methods of detection.

Owner:OPKO DIAGNOSTICS

Intravenous Flow Rate Controller

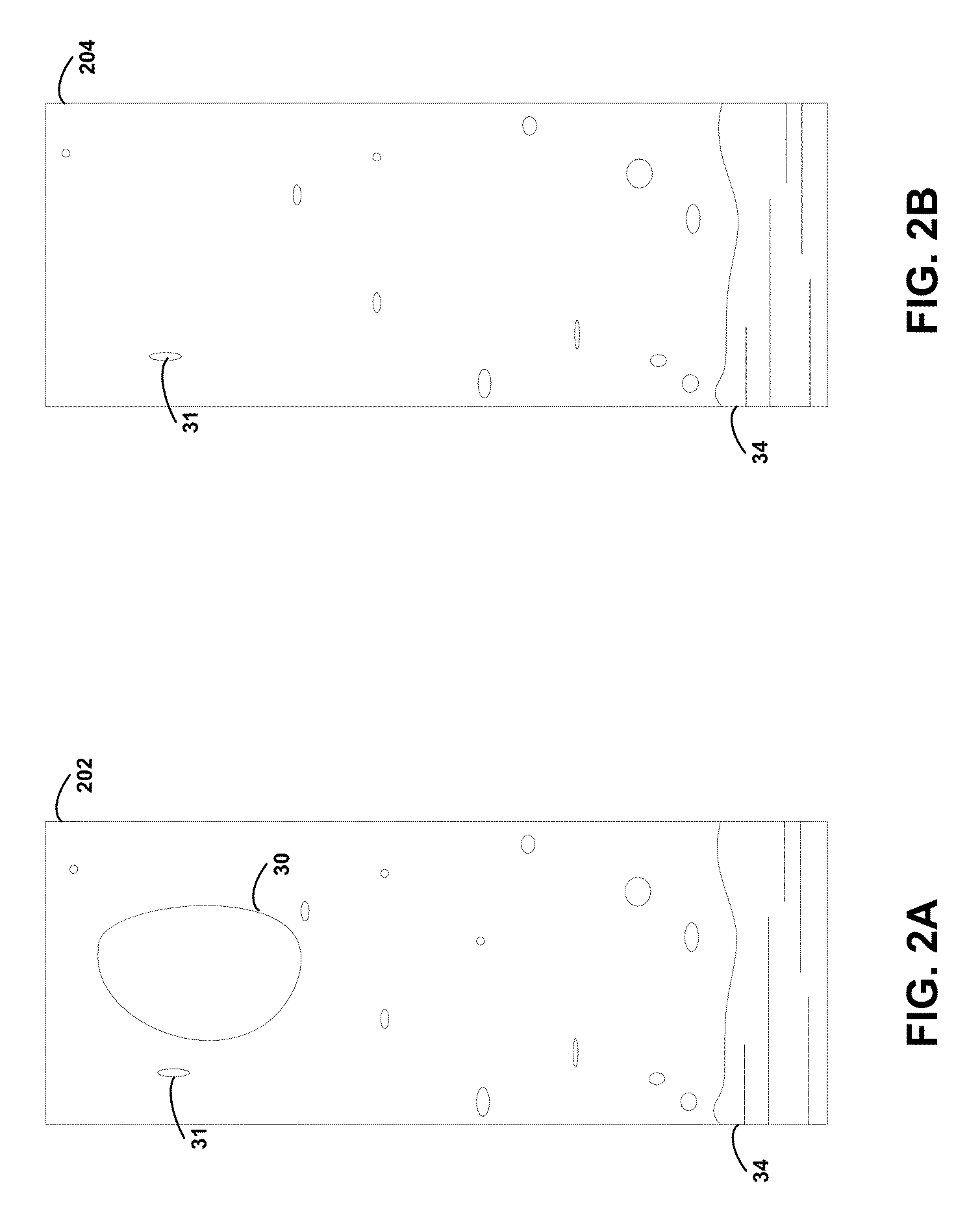

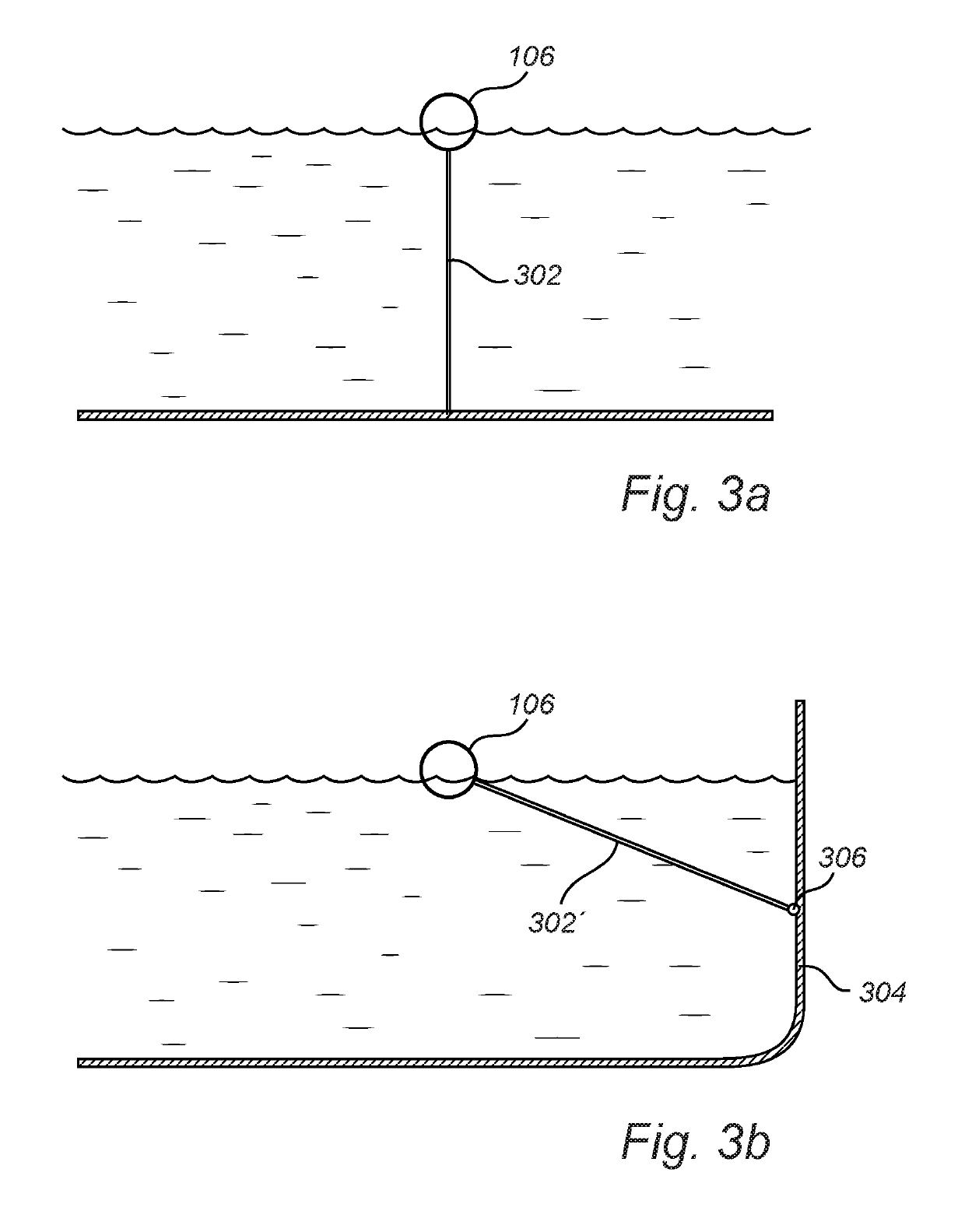

Tilting of a drip chamber from its vertical axis during fluid administration can have negative effects upon the accuracy of systems configured for drop counting and / or for volumetric measurement of individual drops passing through the drip chamber. To address these negative effects, in accordance with one embodiment of the present disclosure, a fluid delivery system engages in a fluid control process that comprises determining an error parameter, based at least in part on a tilt signal, generating an error condition, and either holding the fluid flow at the present rate or stopping the flow.

Owner:ICU MEDICAL INC

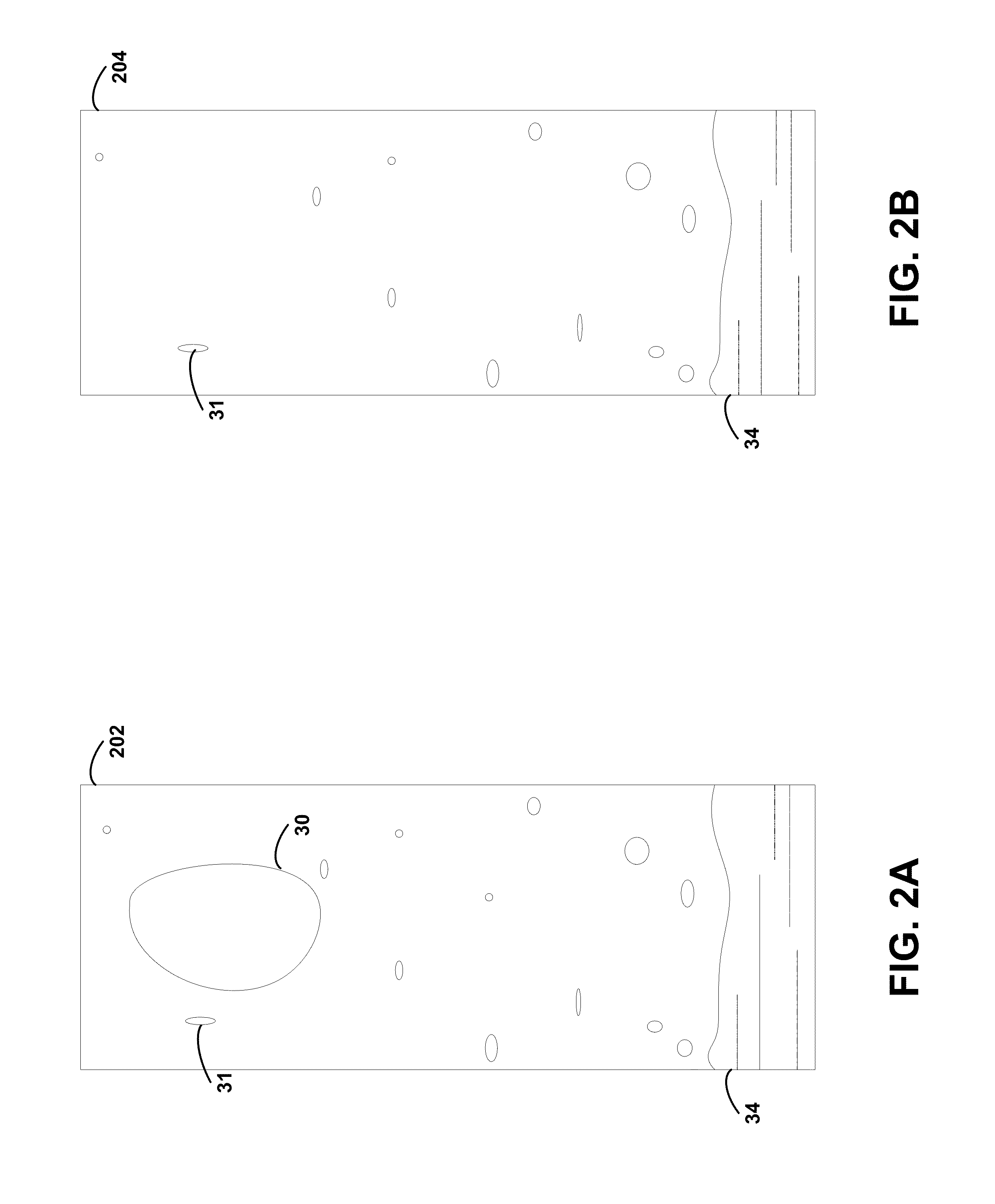

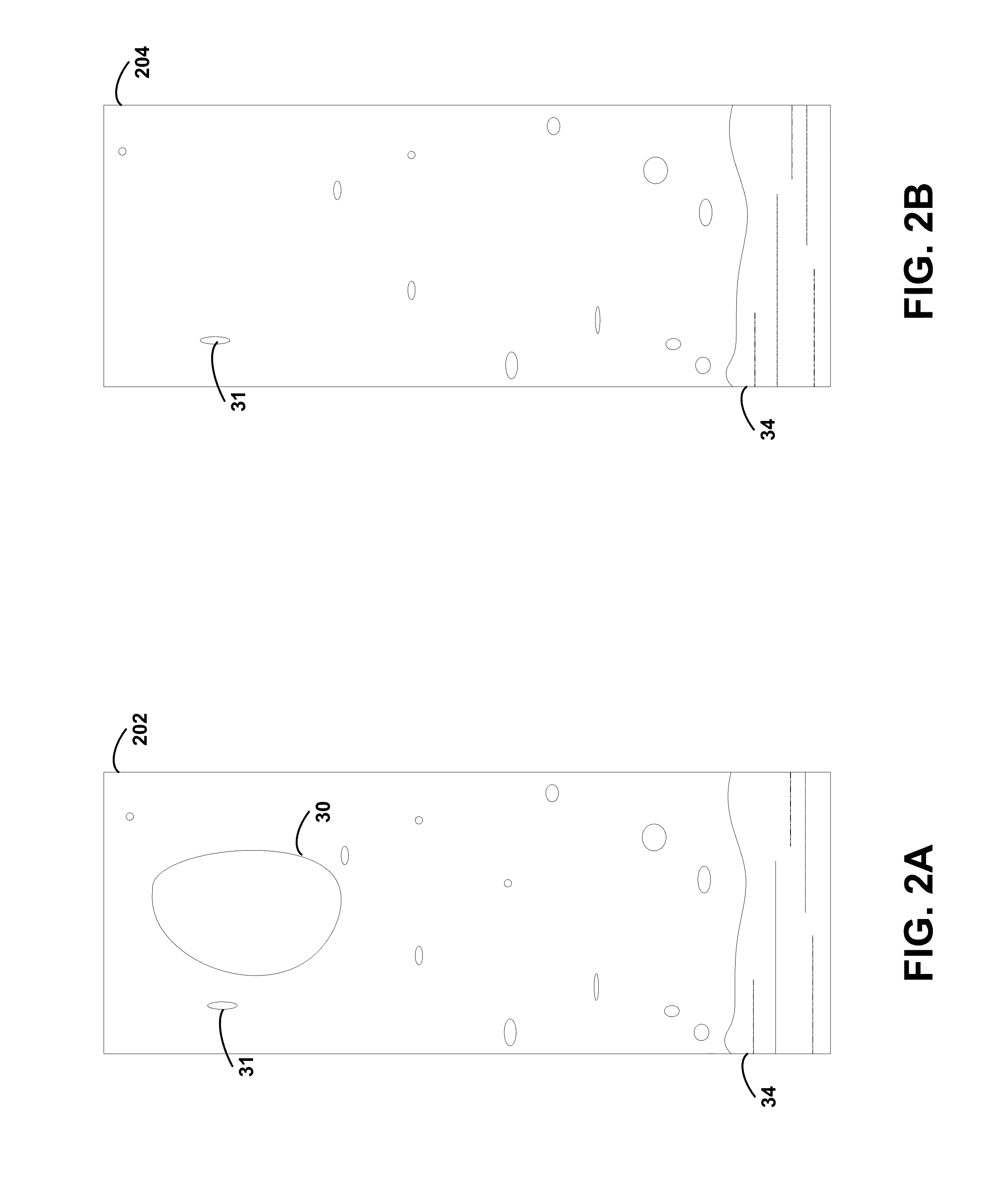

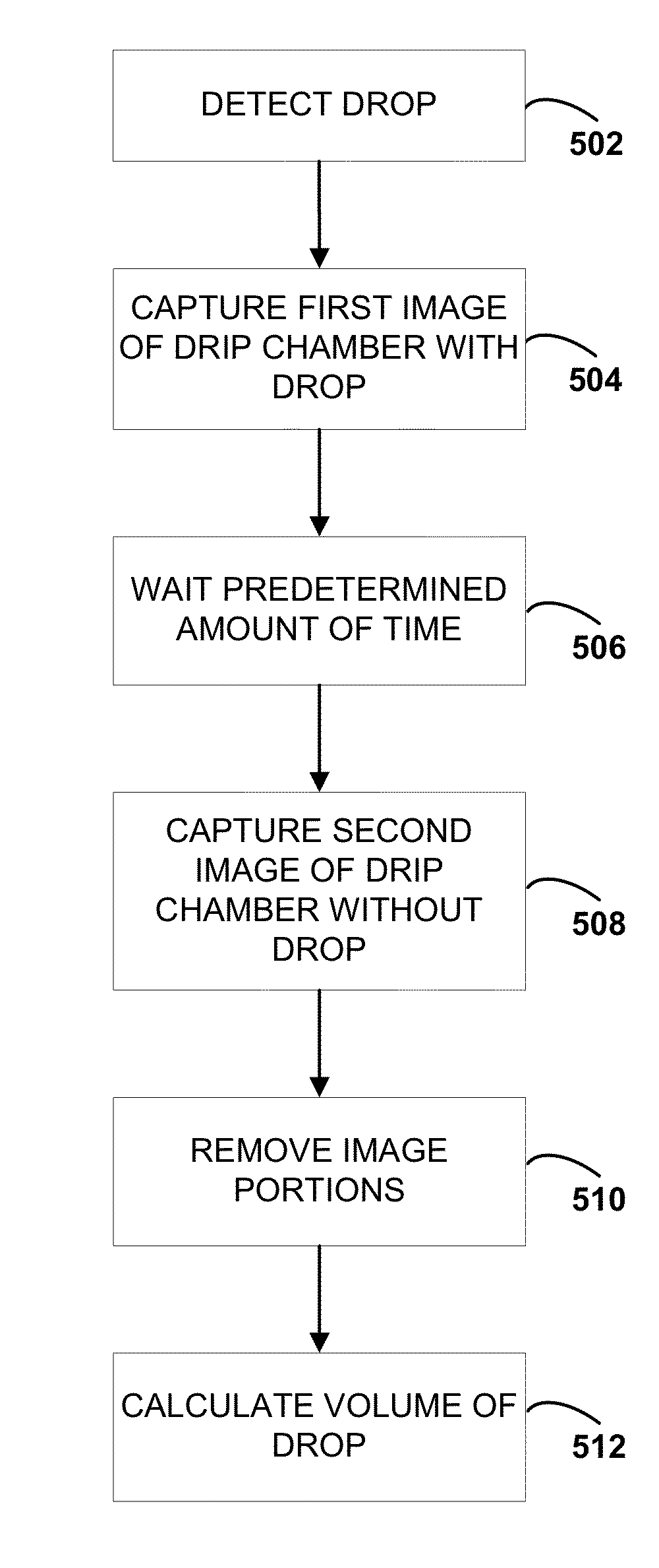

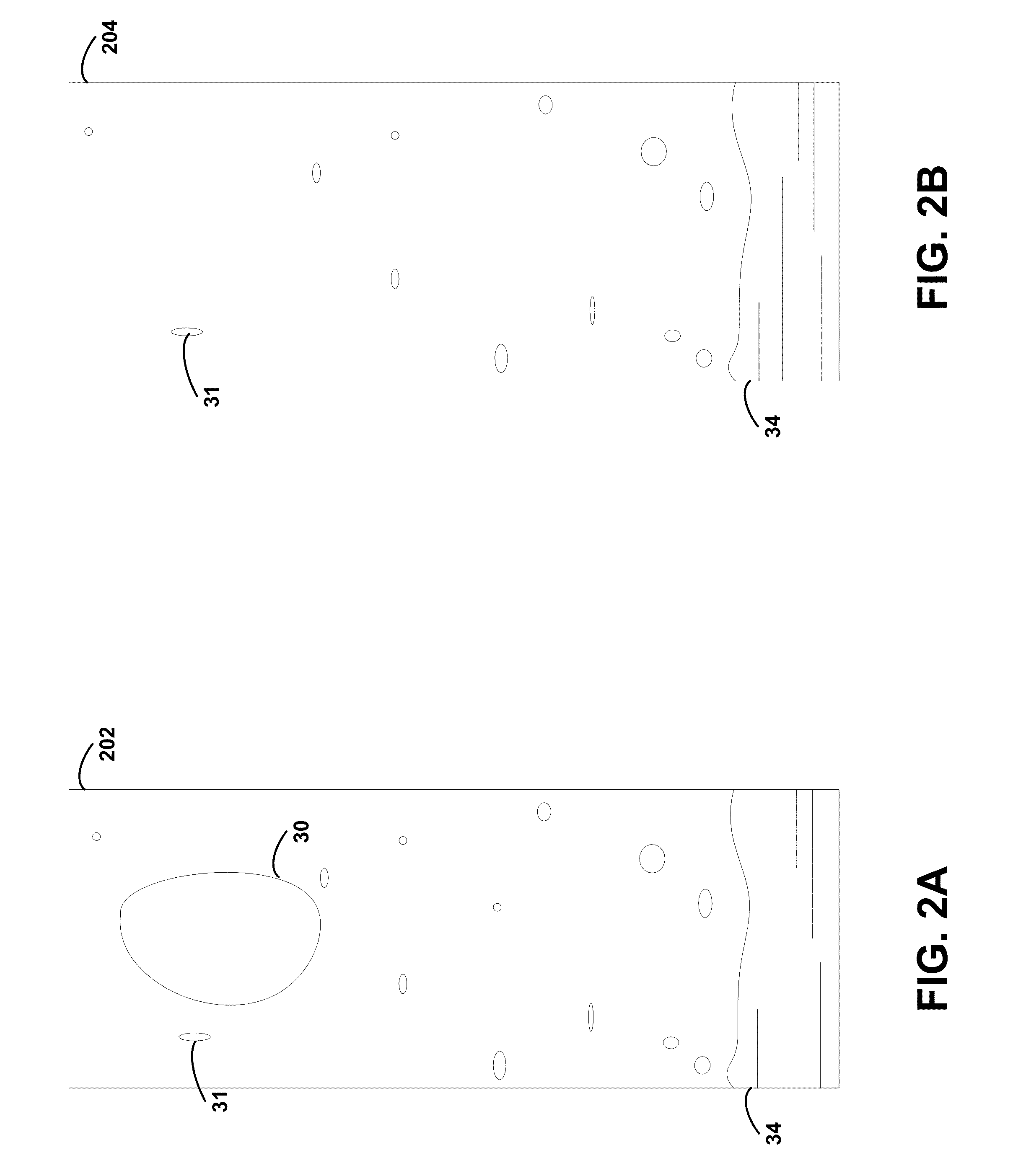

Intravenous Flow Rate Controller

Tilting of a drip chamber from its vertical axis during fluid administration can have negative effects upon the accuracy of systems configured for drop counting and / or for volumetric measurement of individual drops passing through the drip chamber. To address these negative effects, in accordance with one embodiment of the present disclosure, a fluid delivery system that measures the flow volume of a fluid delivery system is disclosed, which includes an imaging apparatus that captures a first image of a drip chamber while a drop is falling therein and a second image of the drip chamber with no drop. Portions of each image that are in substantially the same position in each image are subtracted.

Owner:ICU MEDICAL INC

Flow meter

An flow meter includes a coupler, a support member, an image sensor, and one or more processors. The coupler is adapted to couple to a drip chamber. The support member is operatively coupled to the coupler. The image sensor has a field of view and is operatively coupled to the support member. The image sensor is positioned to view the drip chamber within its field of view. The one or more processors are operatively coupled to the image sensor to receive data thereform. The one or more processors (1) receive image data from the image sensor, and (2) determine an existence of a free flow condition by identifying an optical distortion of an area behind the free flow condition within the drip chamber using the received image data.

Owner:DEKA PROD LLP

Flow meter

ActiveUS9724465B2Amount being removedImage enhancementImage analysisOptical distortionComputer science

Owner:DEKA PROD LLP

Flow meter

An flow meter includes a coupler, a support member, an image sensor, and one or more processors. The coupler is adapted to couple to a drip chamber. The support member is operatively coupled to the coupler. The image sensor has a field of view and is operatively coupled to the support member. The image sensor is positioned to view the drip chamber within its field of view. The one or more processors are operatively coupled to the image sensor to receive data thereform. The one or more processors (1) receive image data from the image sensor, and (2) determine an existence of a free flow condition by identifying an optical distortion of an area behind the free flow condition within the drip chamber using the received image data.

Owner:DEKA PROD LLP

Intravenous flow rate controller

Tilting of a drip chamber from its vertical axis during fluid administration can have negative effects upon the accuracy of systems configured for drop counting and / or for volumetric measurement of individual drops passing through the drip chamber. To address these negative effects, in accordance with one embodiment of the present disclosure, a fluid delivery system that measures the flow volume of a fluid delivery system is disclosed, which includes an imaging apparatus that captures a first image of a drip chamber while a drop is falling therein and a second image of the drip chamber with no drop. Portions of each image that are in substantially the same position in each image are subtracted.

Owner:ICU MEDICAL INC

Intravenous flow rate controller

Tilting of a drip chamber from its vertical axis during fluid administration can have negative effects upon the accuracy of systems configured for drop counting and / or for volumetric measurement of individual drops passing through the drip chamber. To address these negative effects, in accordance with one embodiment of the present disclosure, a fluid delivery system engages in a fluid control process that comprises determining an error parameter, based at least in part on a tilt signal, generating an error condition, and either holding the fluid flow at the present rate or stopping the flow.

Owner:ICU MEDICAL INC

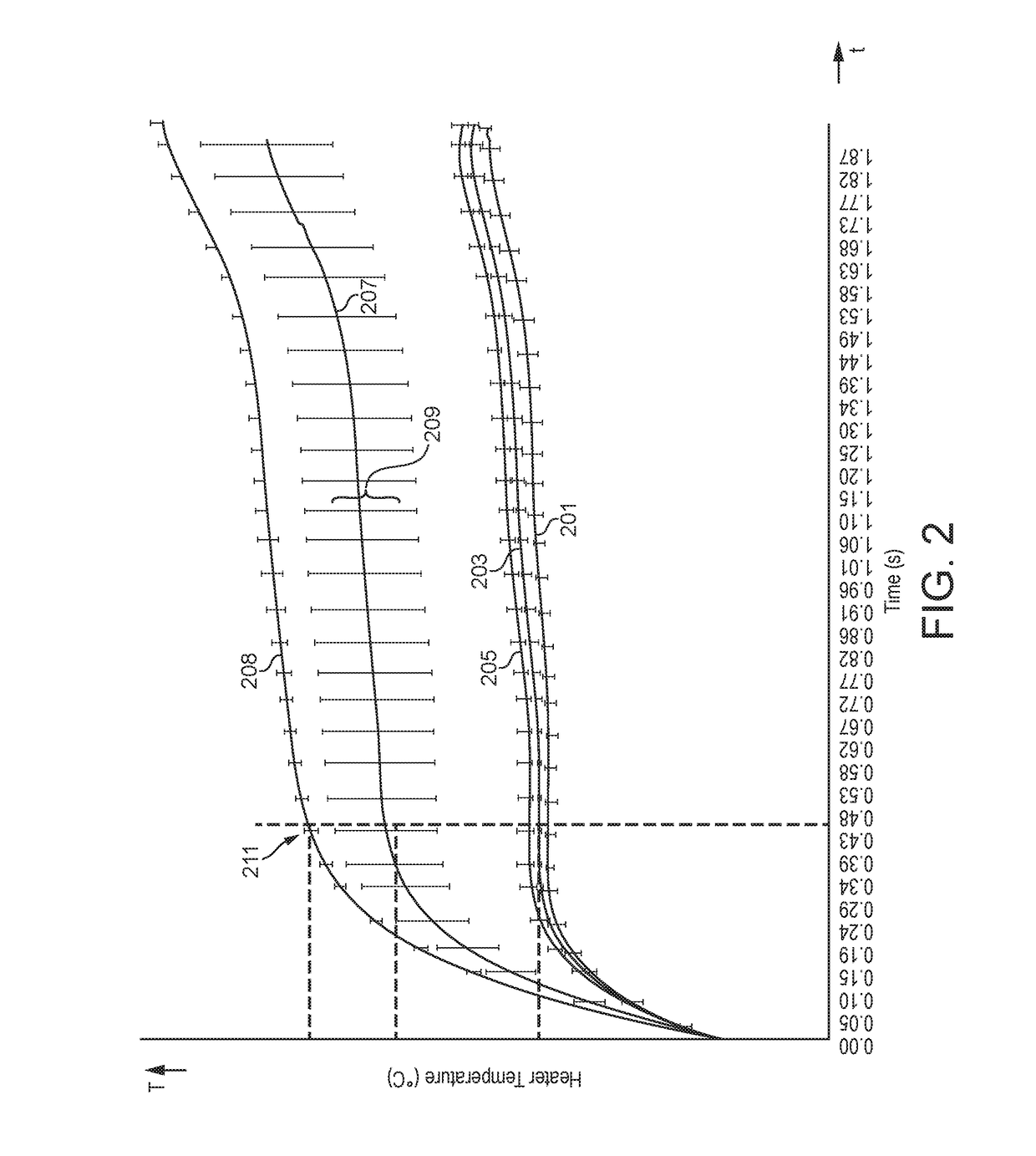

Aerosol-generating systems with liquid level determination and methods of determining liquid level in aerosol-generating systems

An electrically operated aerosol-generating system may include a liquid storage portion configured to store a liquid from which aerosol may be generated, an electric heater, a capillary wick extending between the liquid storage portion and the electric heater and configured to convey liquid from the liquid storage portion to the electric heater and electric circuitry connected to the electric heater. The electric circuitry may be configured to: activate the electric heater for a first heating time period in response to an input to vaporize liquid in the capillary wick, activate the electric heater for a second heating time period upon the elapse of a first cooling time period after the first heating time period, record a temperature measurement of the electric heater during the second heating time period, and determine an amount of liquid in the liquid storage portion based on the temperature measurement.

Owner:AKRIA CLIENT SERVICES LLC

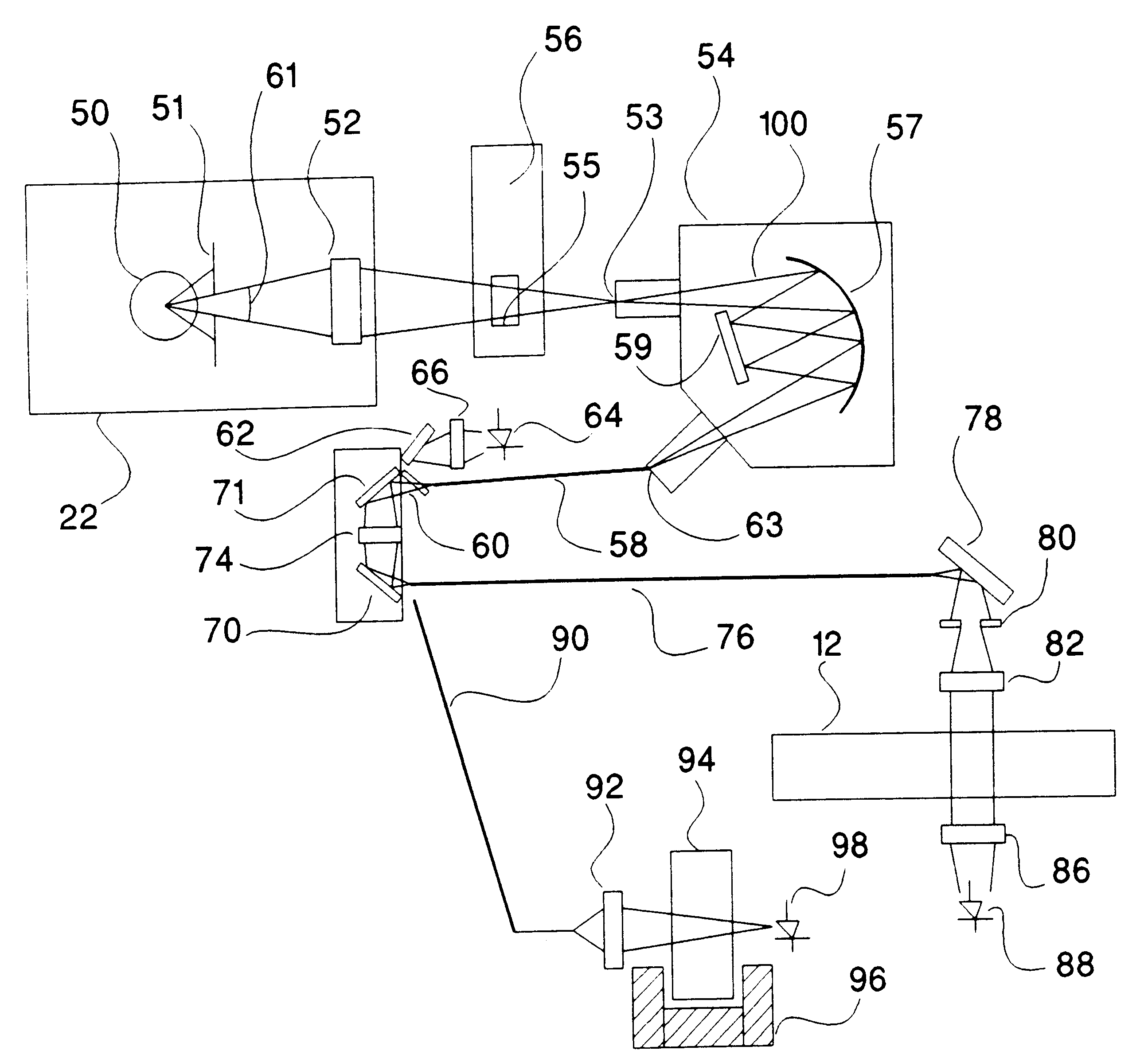

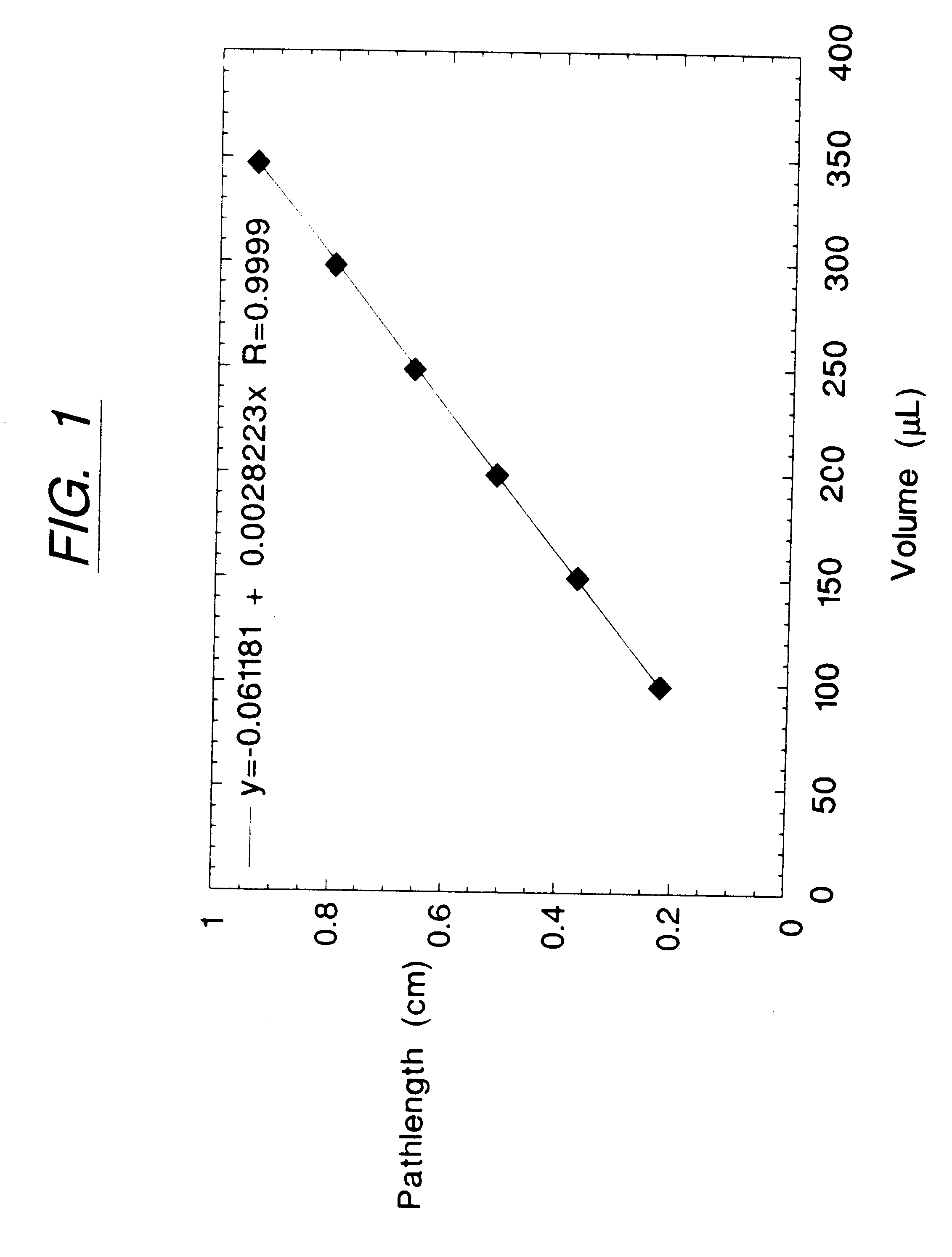

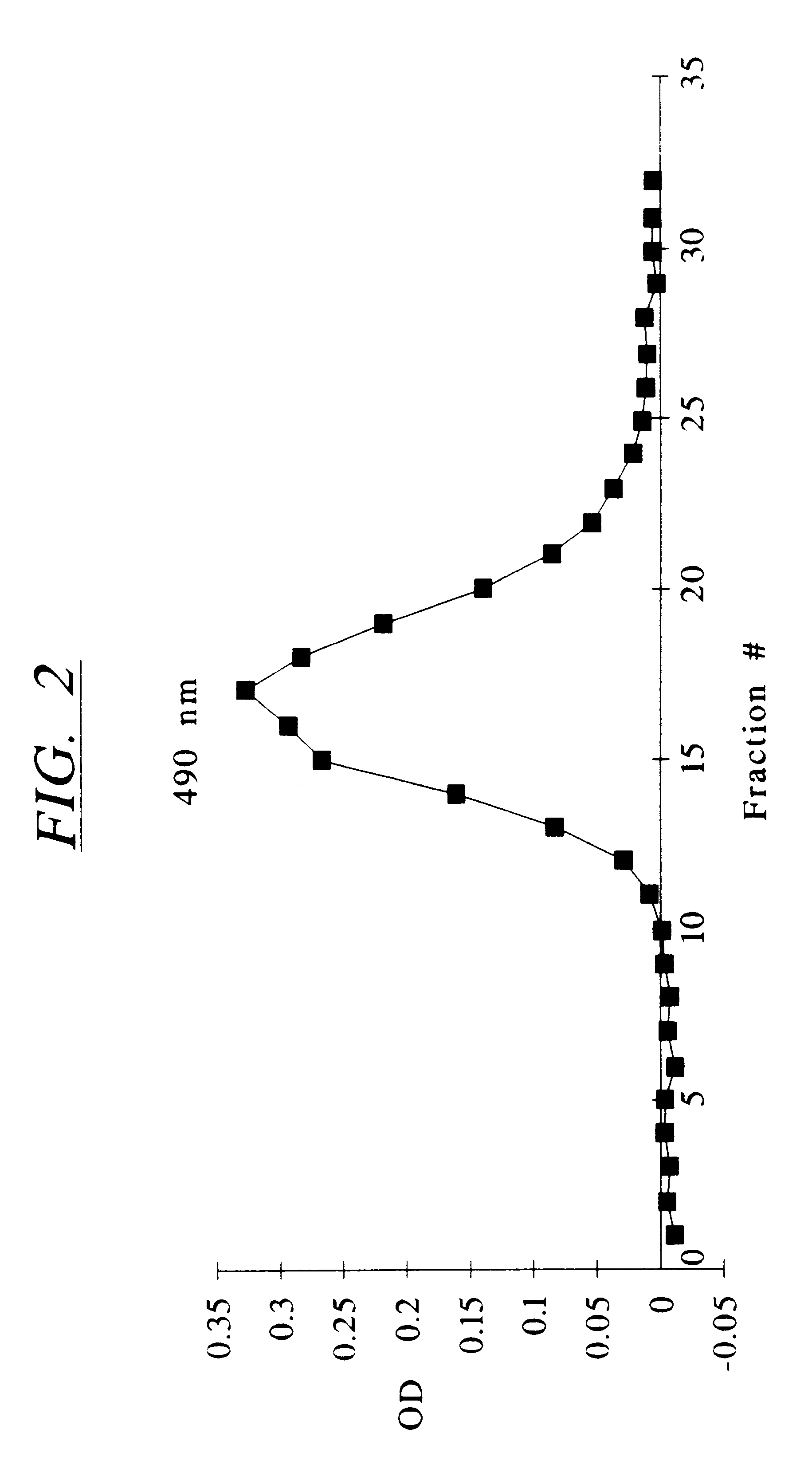

Determination of light absorption pathlength in a vertical-beam photometer

InactiveUS6188476B1Volume measurement apparatus/methodsColor/spectral properties measurementsAnalyteLight beam

Disclosed are photometric methods and devices for determining optical pathlength of liquid samples containing analytes dissolved or suspended in a solvent. The methods and devices rely on determining a relationship between the light absorption properties of the solvent and the optical pathlength of liquid samples containing the solvent. This relationship is used to establish the optical pathlength for samples containing an unknown concentration of analyte but having similar solvent composition. Further disclosed are methods and devices for determining the concentration of analyte in such samples where both the optical pathlength and the concentration of analyte are unknown. The methods and devices rely on separately determining, at different wavelengths of light, light absorption by the solvent and light absorption by the analyte. Light absorption by the analyte, together with the optical pathlength so determined, is used to calculate the concentration of the analyte. Devices for carrying out the methods particularly advantageously include vertical-beam photometers containing samples disposed within the wells of multi-assay plates, wherein the photometer is able to monitor light absorption of each sample at multiple wavelengths, including in the visible or UV-visible region of the spectrum, as well as in the near-infrared region of the electromagnetic spectrum. Novel photometer devices are described which automatically determine the concentration of analytes in such multi-assay plates directly without employing a standard curve.

Owner:MOLECULAR DEVICES

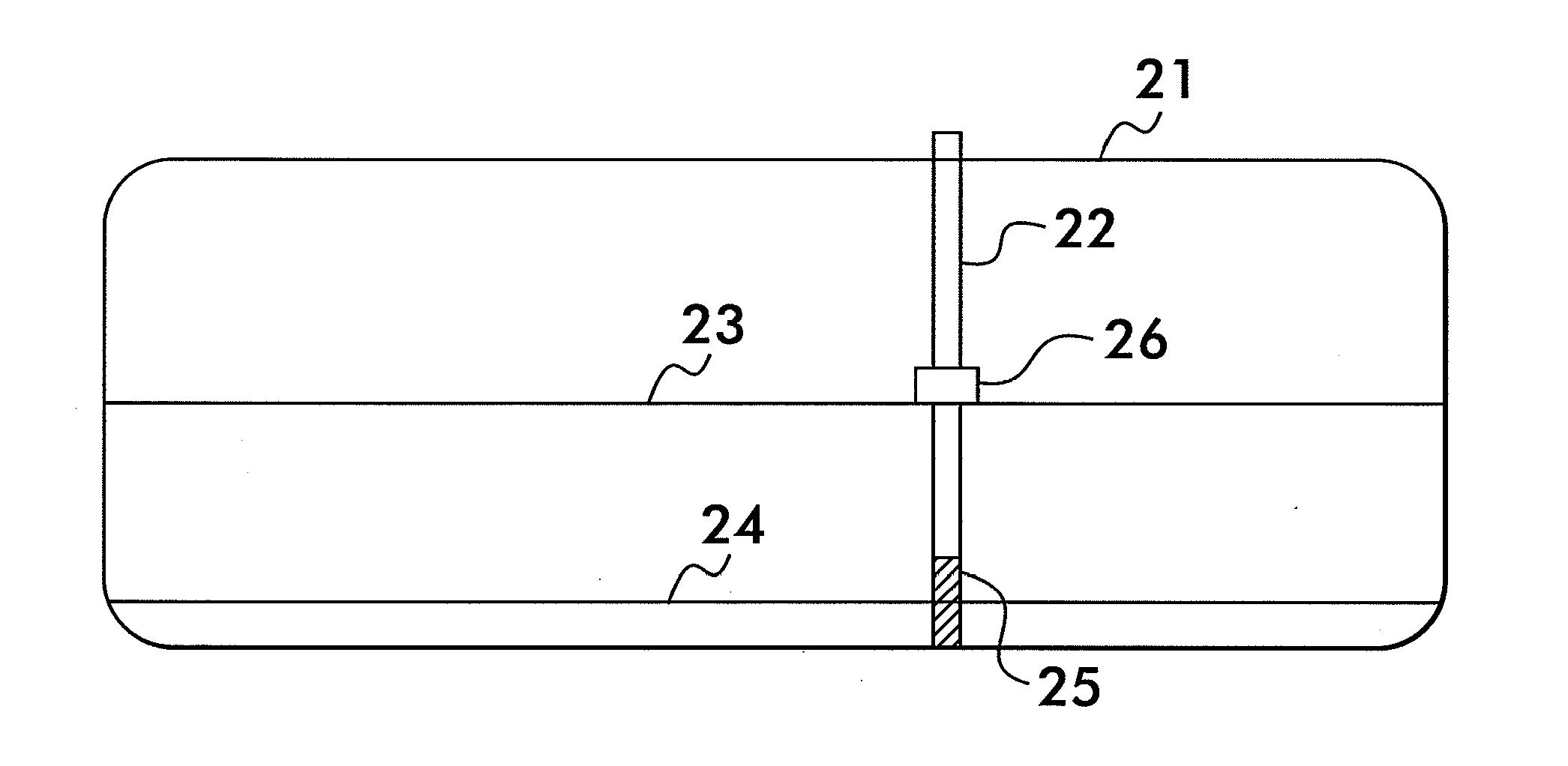

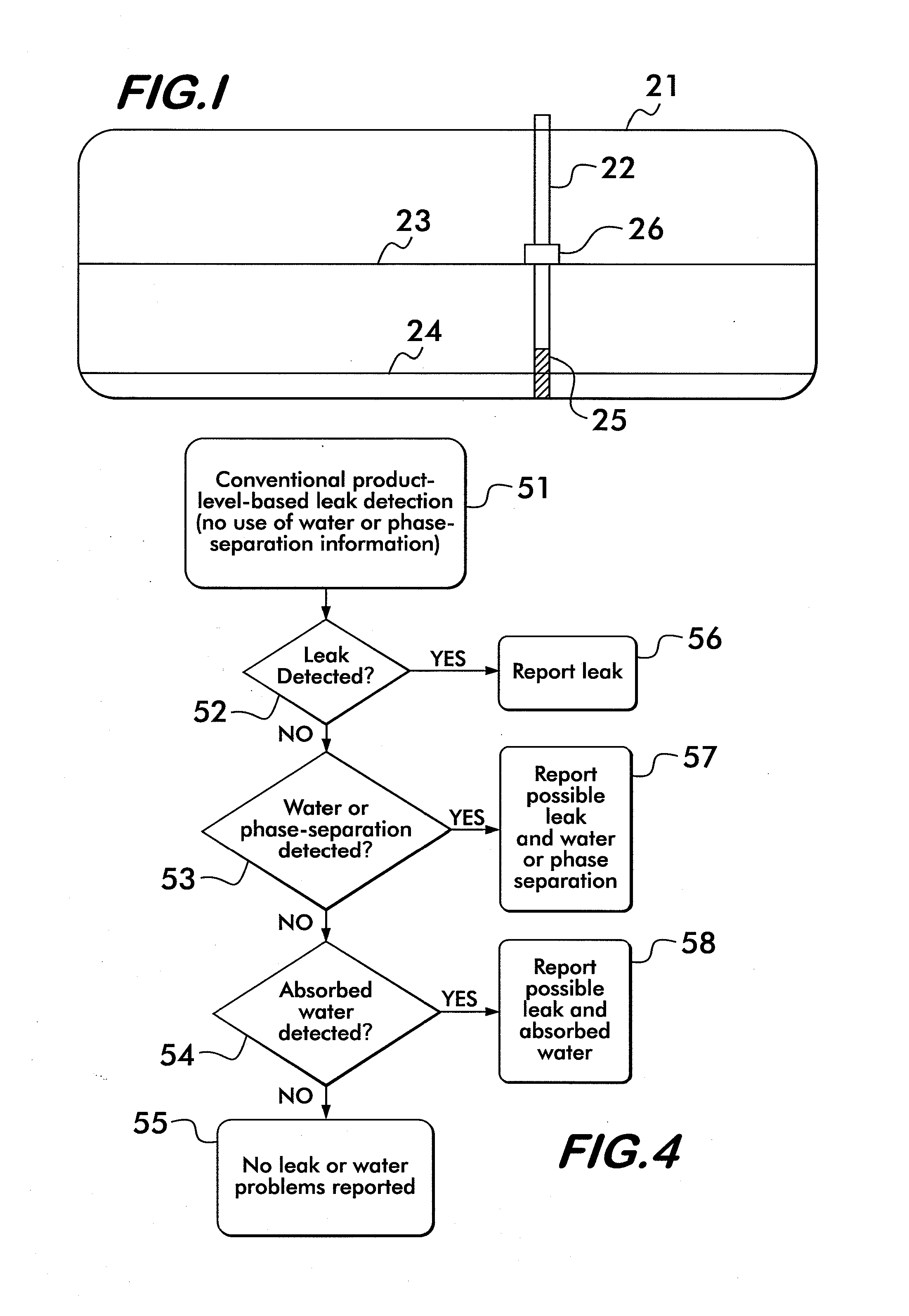

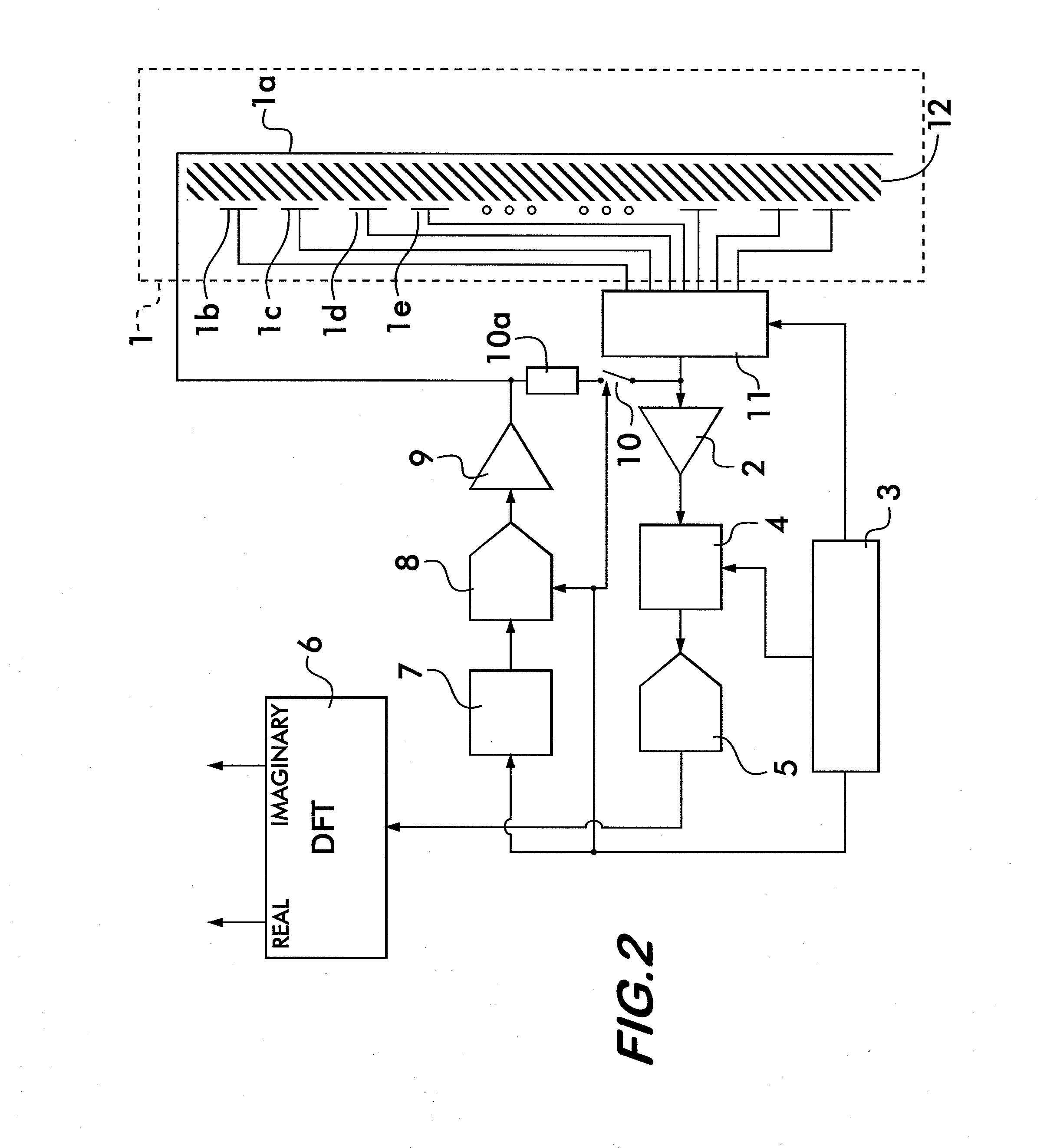

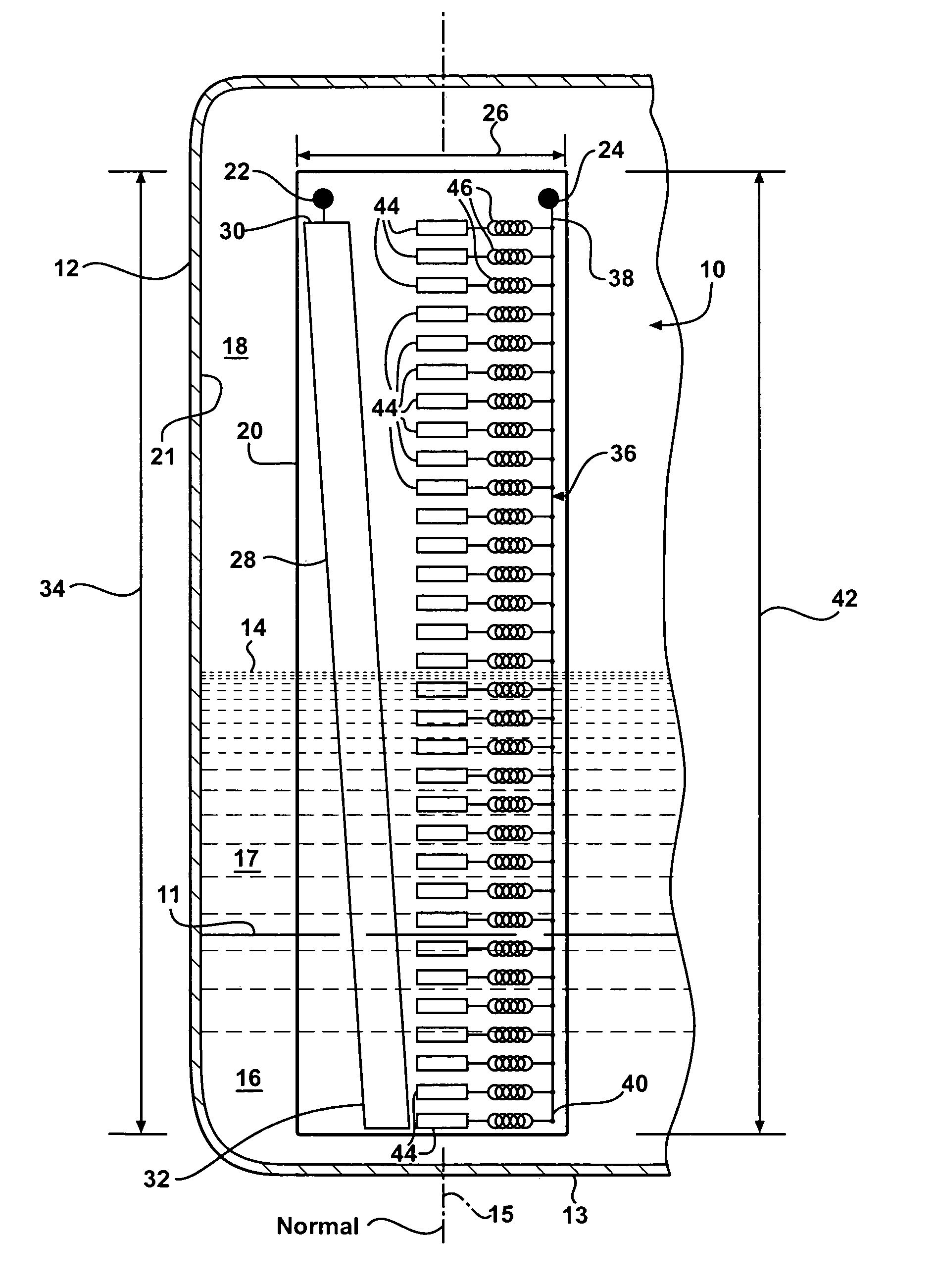

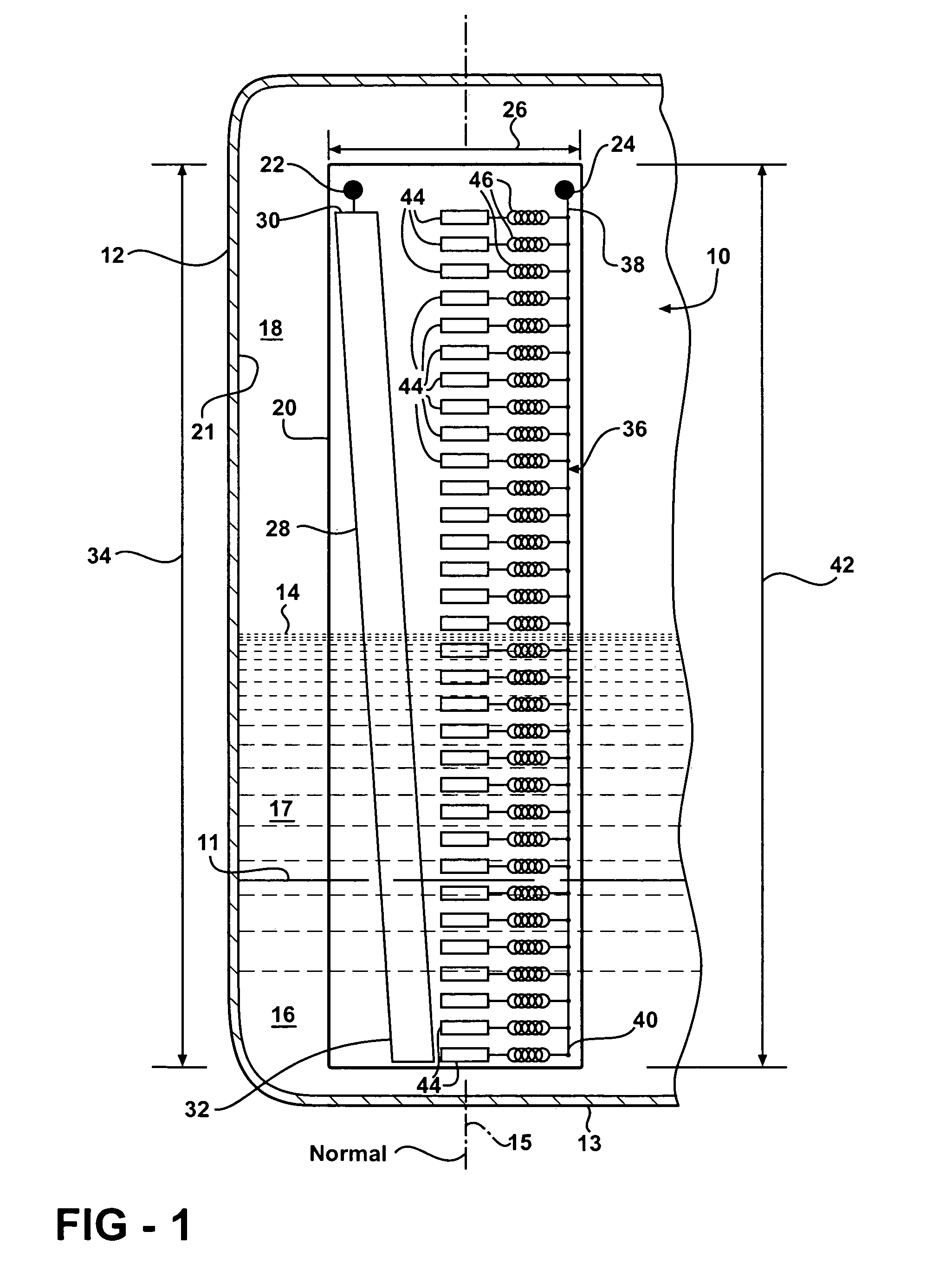

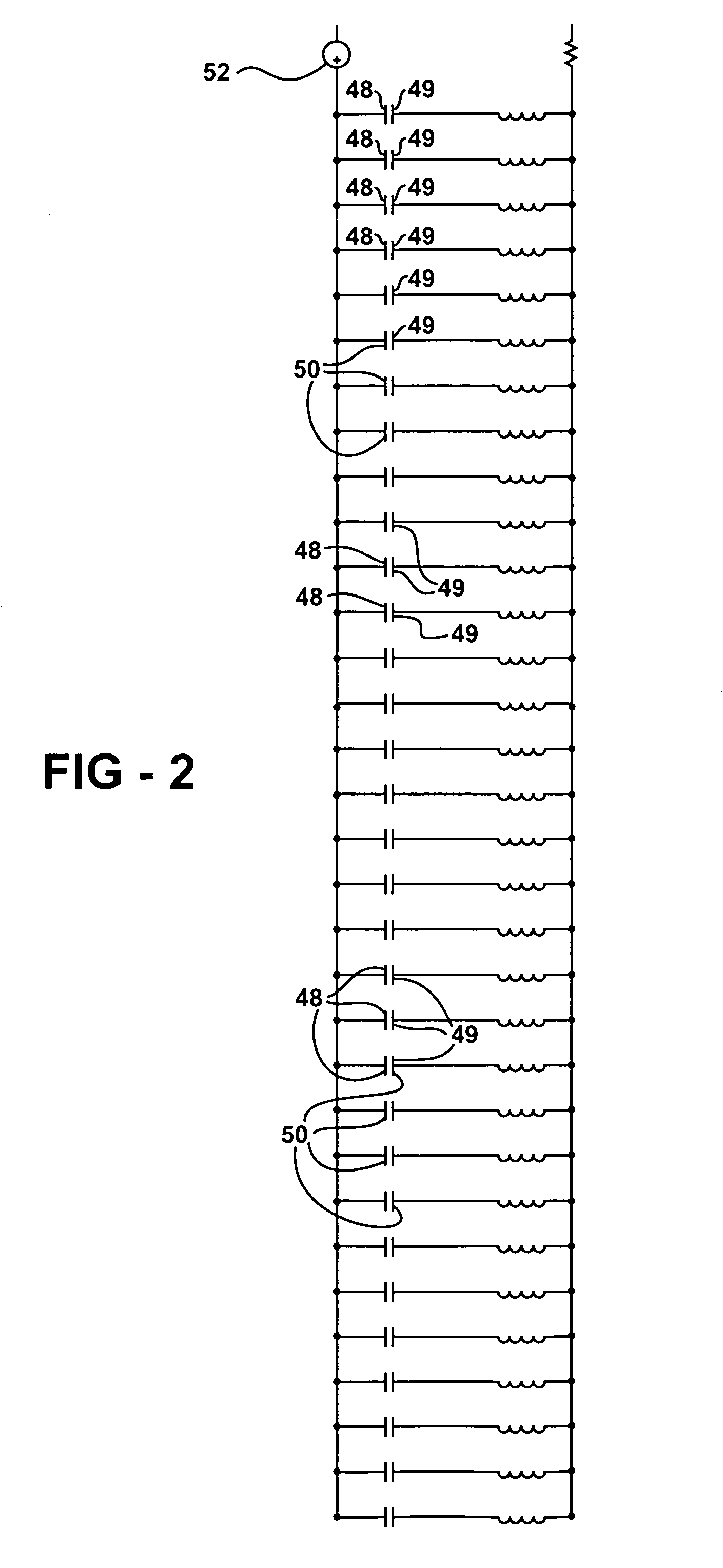

Automated phase separation and fuel quality sensor

InactiveUS20100295565A1Not easy to make mistakesMinimize attractionVolume measurement apparatus/methodsResistance/reactance/impedenceFuel qualityEngineering

A fluid characterization sensor comprising a plurality of sensor segments is disclosed. Each segment comprises two electrodes, spaced apart so the fluid in the corresponding interval of depth for that segment is positioned between them. Complex current or impedance is measured by exciting one electrode with an AC signal, and measuring the amplitude and phase of the current in the other electrode. After automatically measuring and accounting for pre-determined gain, offset, temperature, and other parasitic influences on the raw sensor signal, the complex electrical impedance of the fluid between the electrodes is calculated from the measured phase / amplitude and / or real / imaginary components of the received electrical current signal and / or the variation of the measured response with variation in excitation frequency. Comparison of measured results with results taken using known fluids identifies fluid properties. Alternatively, measured results are compared to predicted results using forward models describing expected results for different fluids or contaminants.

Owner:DIRACTION

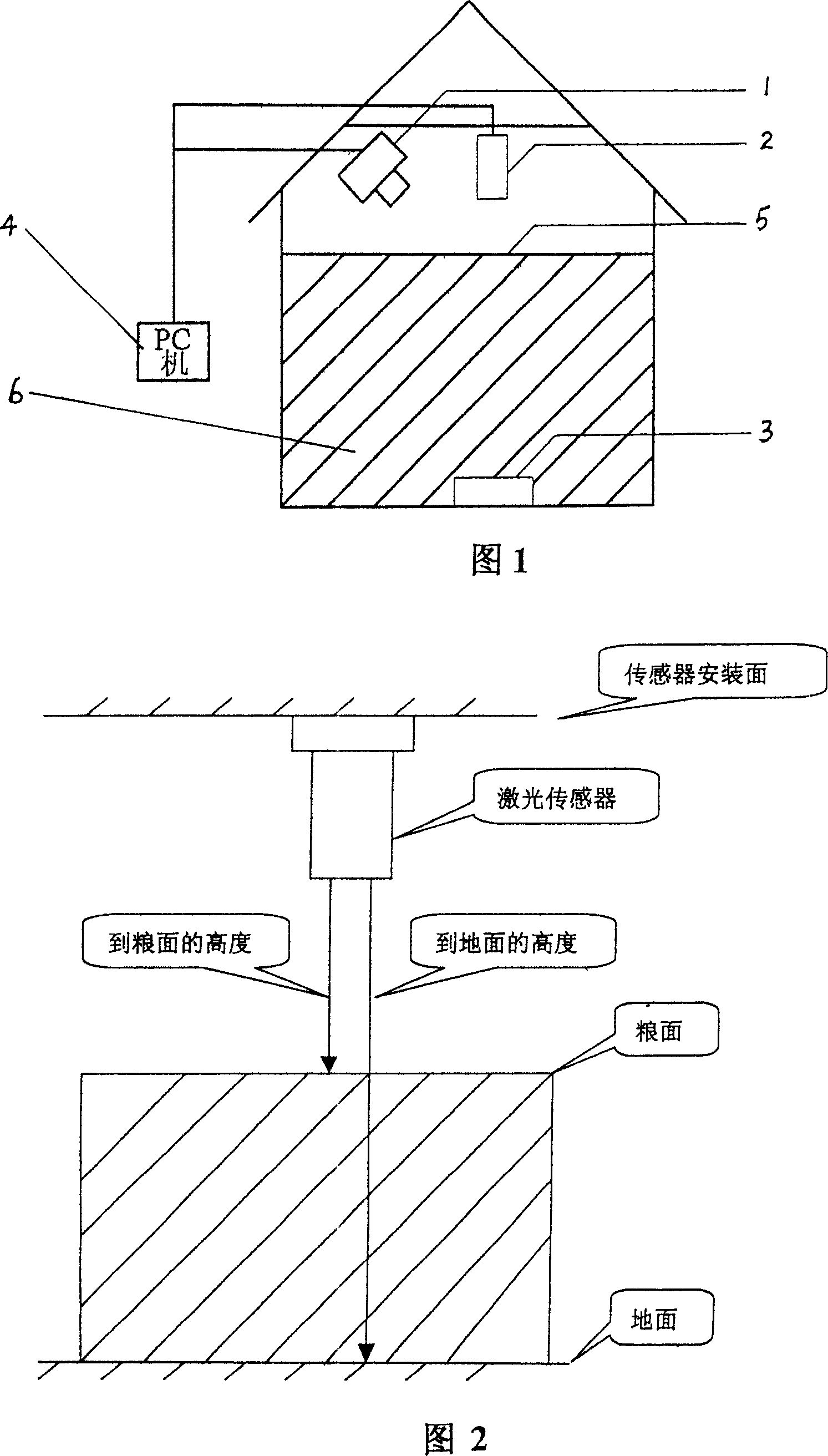

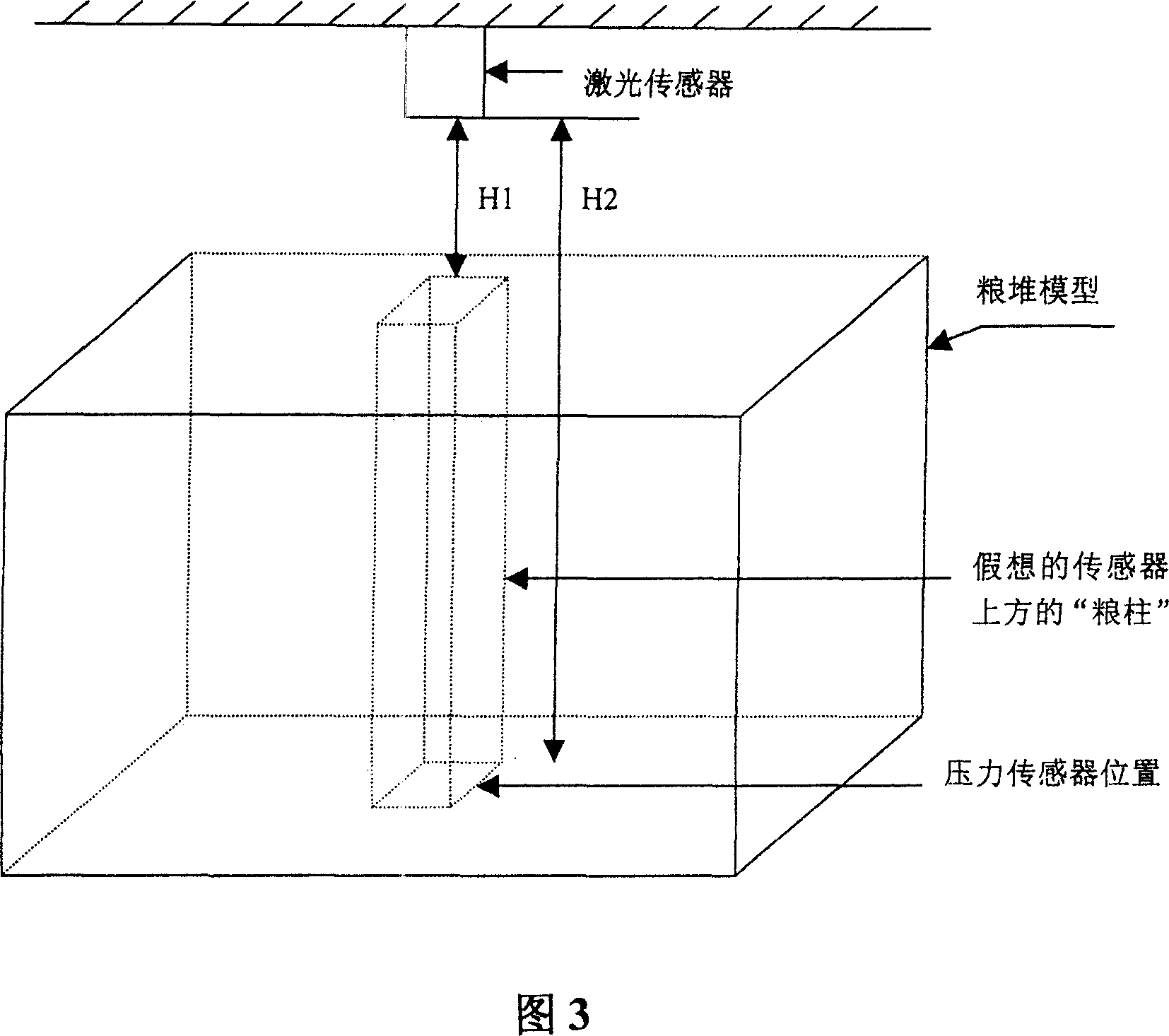

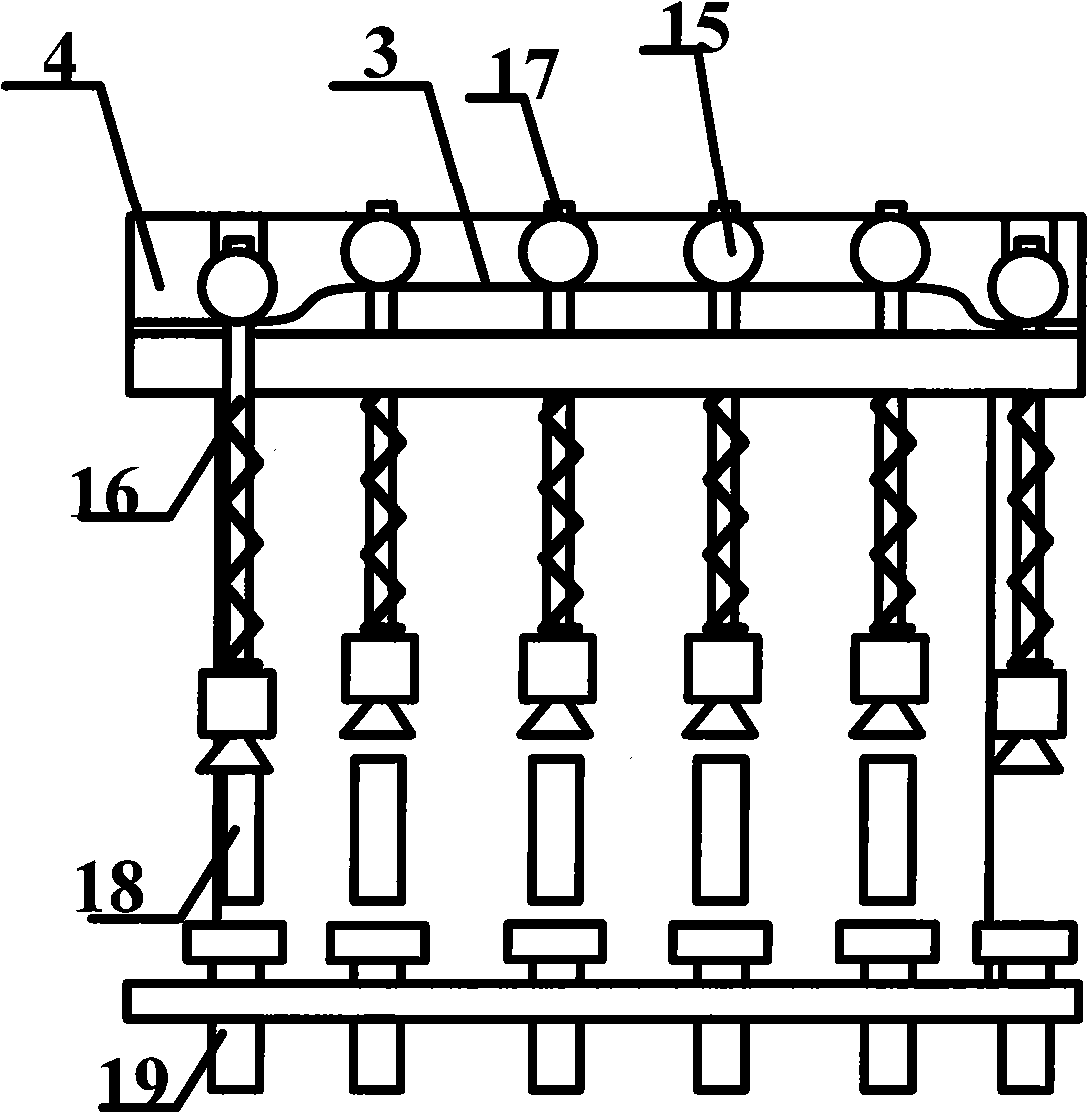

Measuring method for amount of grain reserve in grain depot

InactiveCN1963377AThe measurements are trueAccurate measurementElectric signal transmission systemsVolume measurement apparatus/methodsVolume measurementsStorage management

This invention relates to one food storage volume measurement method, which comprises the following steps: using laser sensor to measure its volume and starting cameral head for shot stored into PC database; correcting according to the volume by laser sensor; measuring food storage intensity by use of pressure sensor to weight sensor above column weight and measuring sensor food column height through laser sensor; computing food column intensity according to the weight, height and pressure area; computing food storage total weight according to the intensity and volume.

Owner:朱阳明

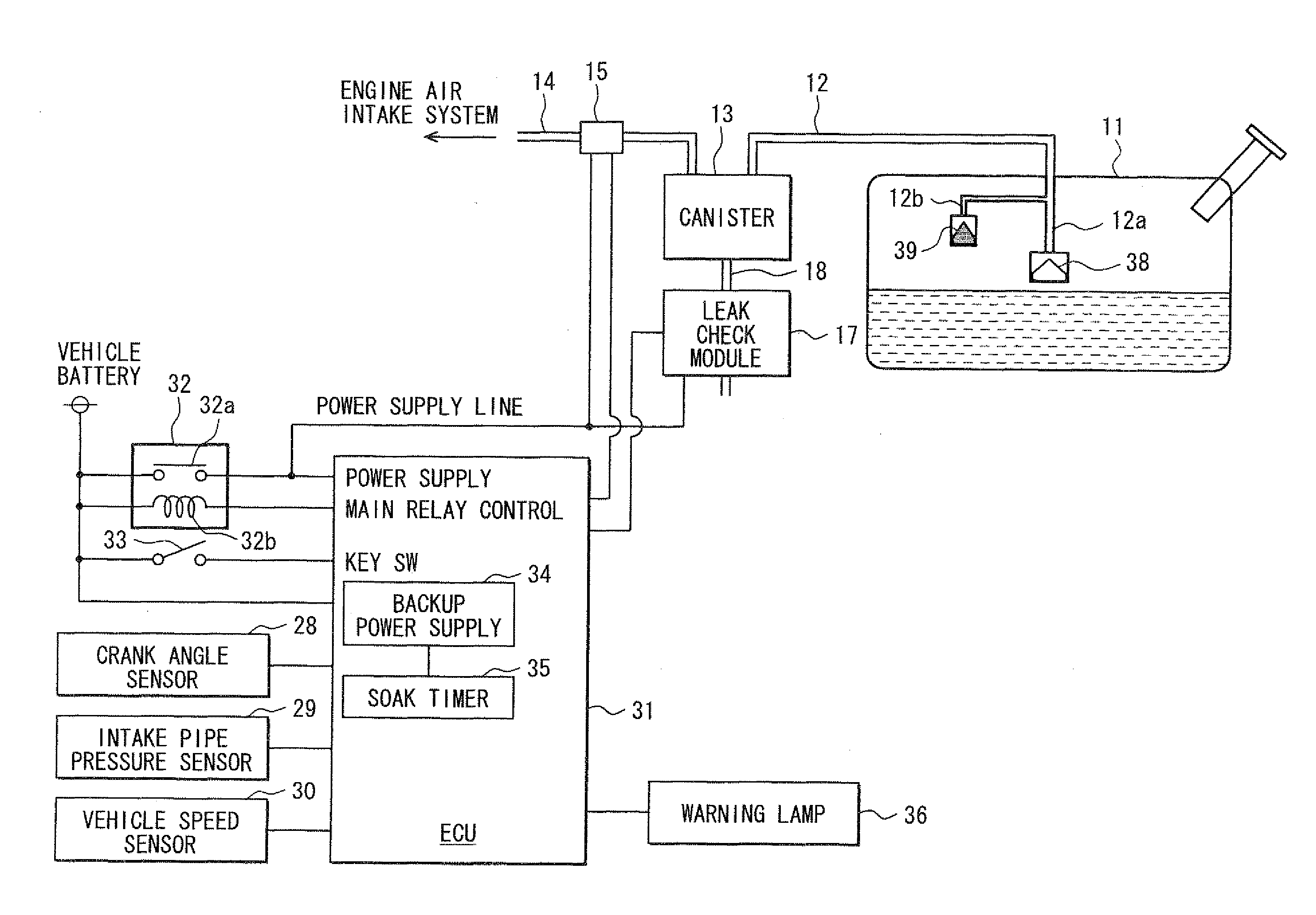

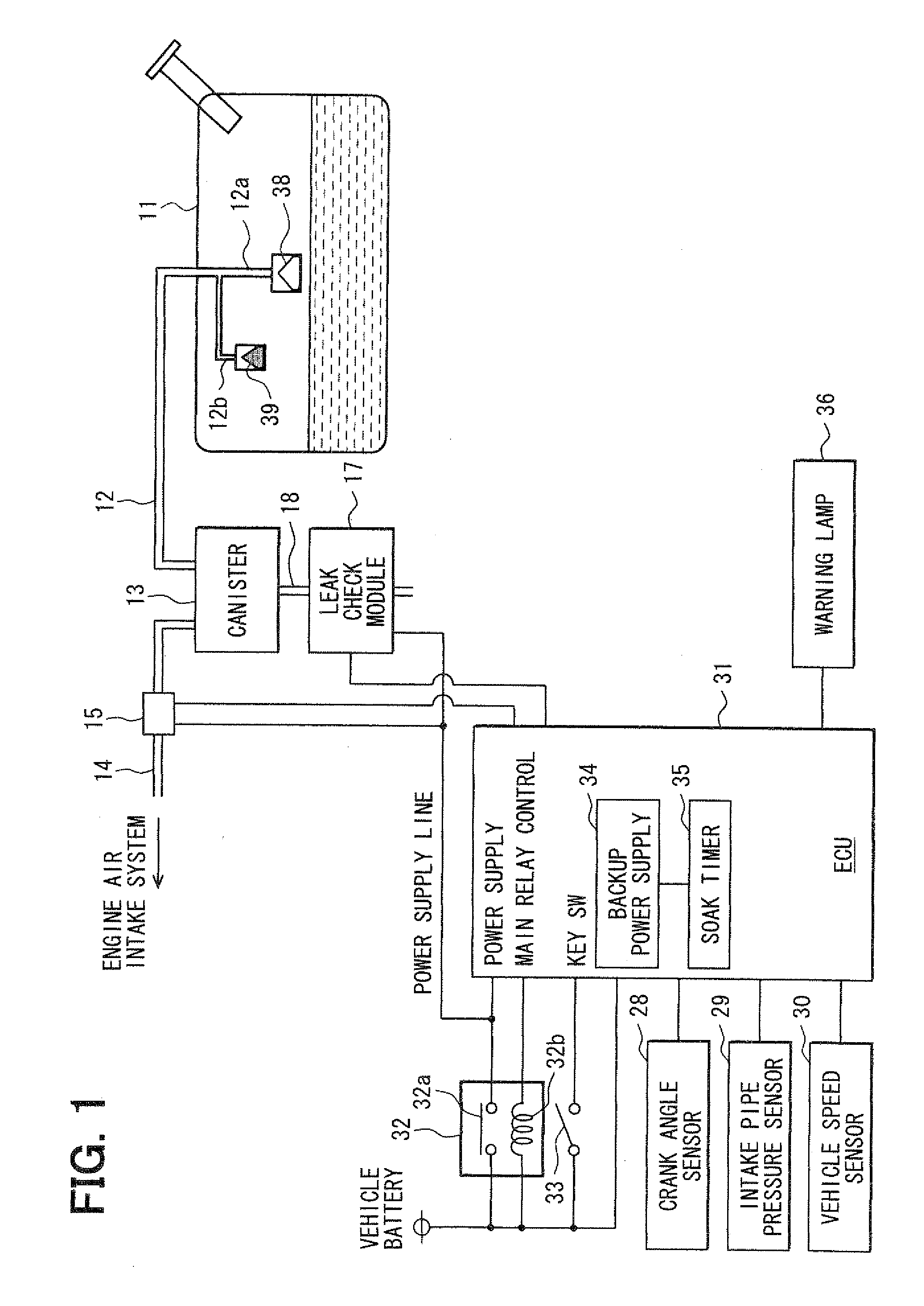

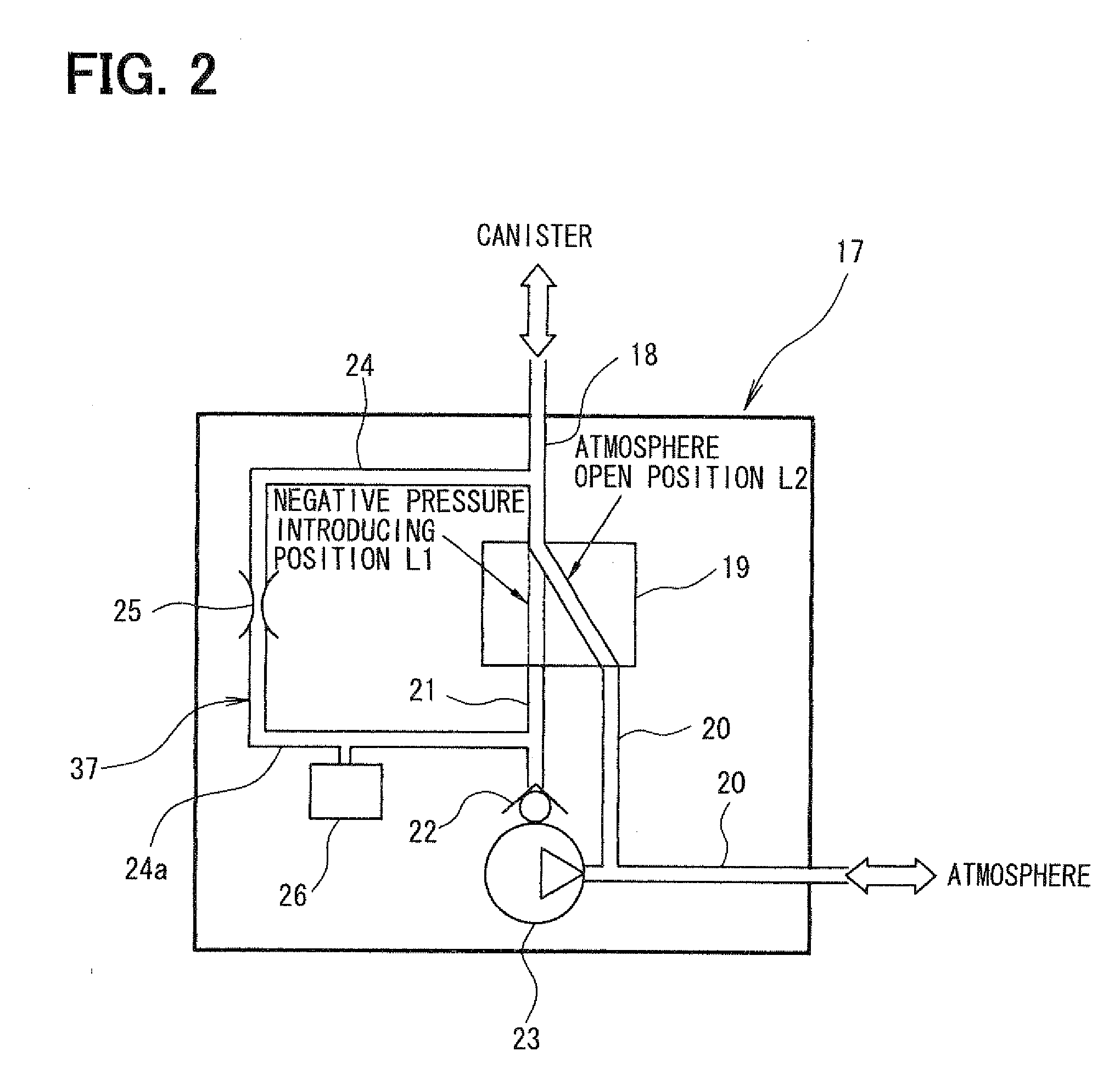

Flow diagnosis apparatus for fuel vapor purge system

InactiveUS20090266147A1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateFuel vaporPressure sensor

A pressure sensor senses a pressure of a fuel vapor system at a fuel vapor passage. An electronic control unit executes a post-depressurization period flow diagnosis to determine whether the fuel vapor passage is clogged based on a behavior of the pressure in the fuel vapor system, which is sensed with the pressure sensor in a sealed state of the fuel vapor system after introduction of a negative pressure into the fuel vapor system.

Owner:DENSO CORP

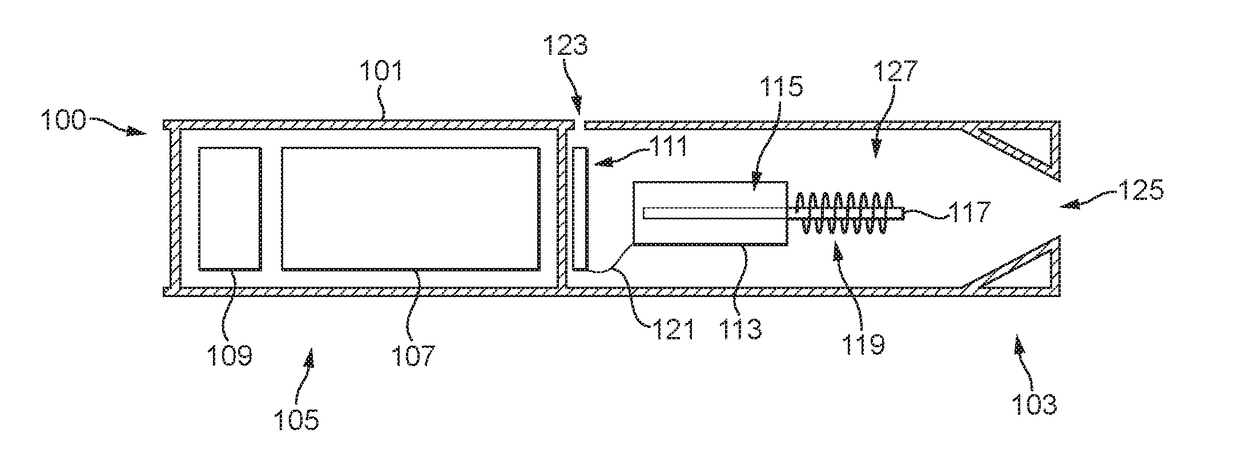

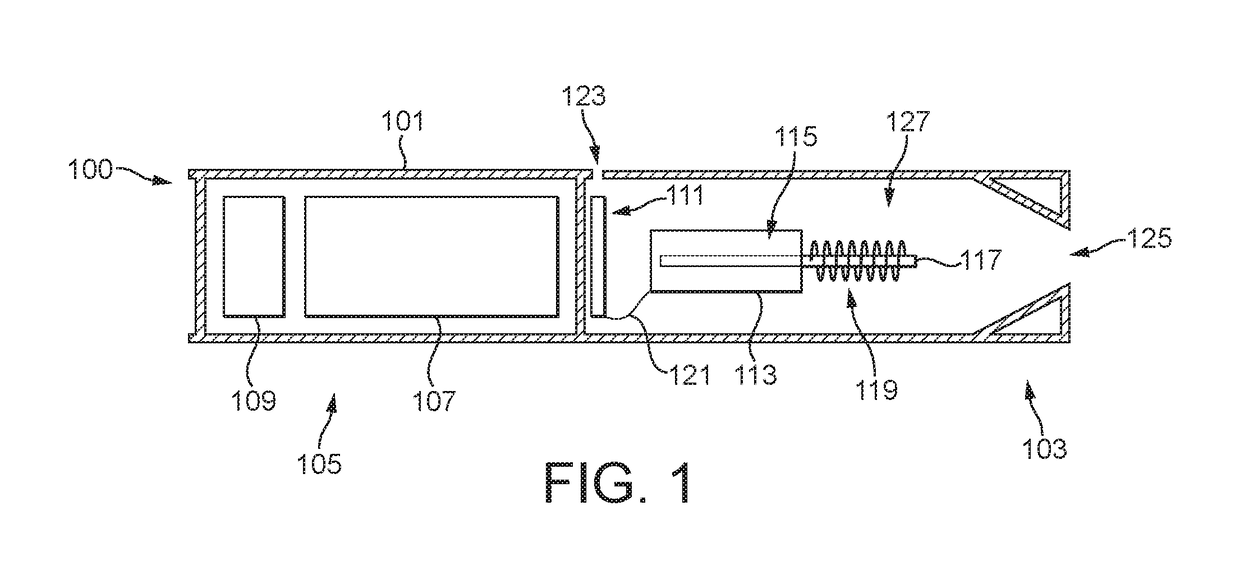

Flow Sensor Calibrated by Volume Changes

InactiveUS20100063765A1High precisionIncrease opportunitiesVolume measurement apparatus/methodsTesting/calibration apparatusVolume variationInfusion pump

An infusion pump and method are provided which combine flow rate measurements calibrated by accurate volume measurements over time.

Owner:IVENIX

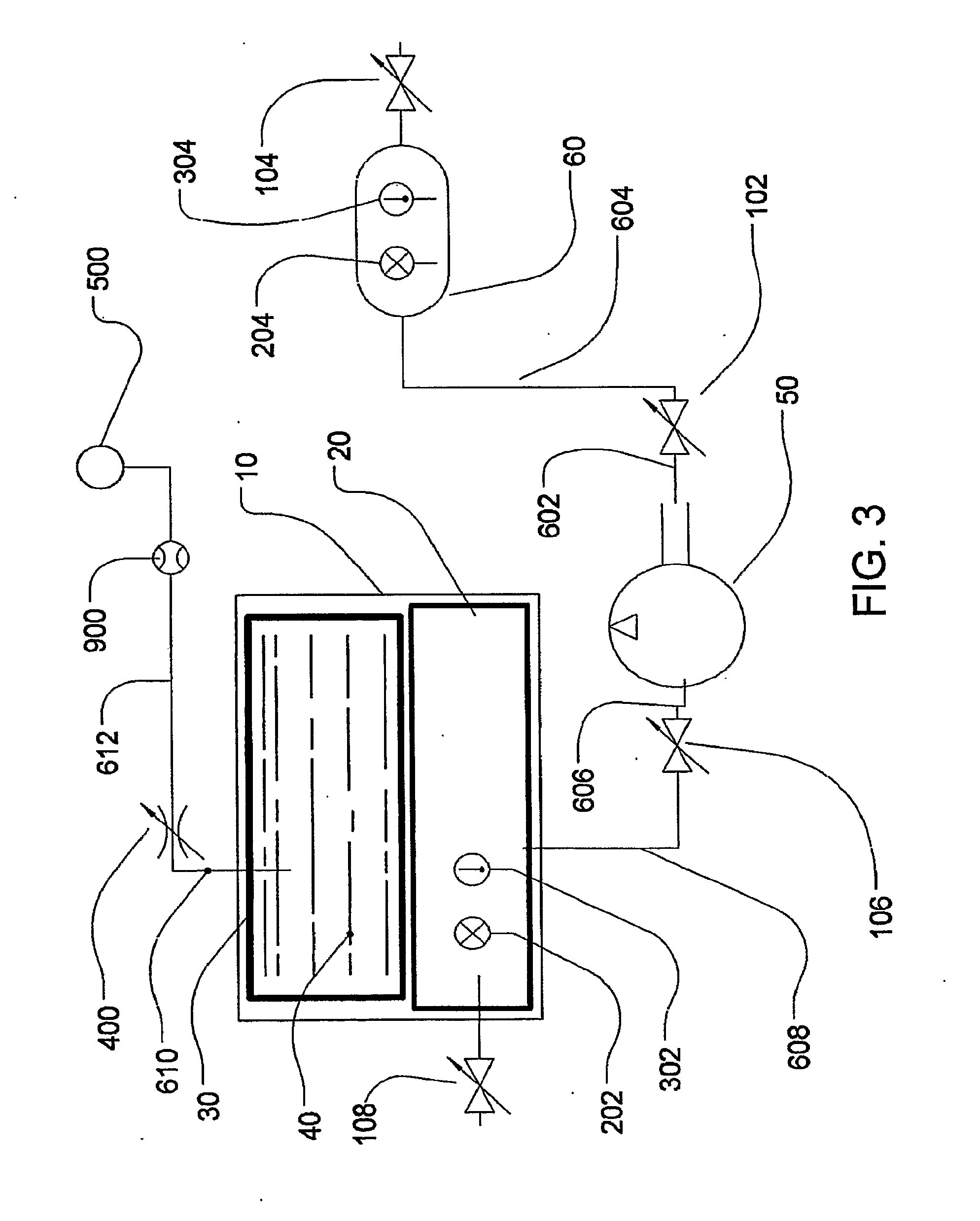

Full-automatic bottling liquor inspection machine

InactiveCN101403706AVolume measurement apparatus/methodsOptically investigating flaws/contaminationForeign matterImaging processing

The invention relates to a completely automatic bottled liquor testing machine, belonging to the field of medicine quality detection and control. The whole structure of the testing machine consists of a bottle feeding system, a detection system, a bottle outlet sorting system and a transmission system; medicine bottles to be tested are sequentially sent to a medicine clamp in the detection system by the bottle feeding system; the clamp drives the medicine bottles to rotate at high speed and stop suddenly; the medicine bottles stop rotating but the liquor continues rotating at high speed; a machine visible imaging and image processing system is used for obtaining the image and processing of the rotating liquor; and the unqualified medicine bottles are removed by the bottle outlet sorting system. The testing machine can check and sort various visible foreign matters in the bottled liquor of various specifications, the capacity of the liquor and the cracks of the bottle body by replacing the manpower, can be widely applied to bottled liquor checking link of medicine production enterprises and can be used for checking the foreign matters in various nutritional oral liquid, beverage and wine.

Owner:TSINGHUA UNIV

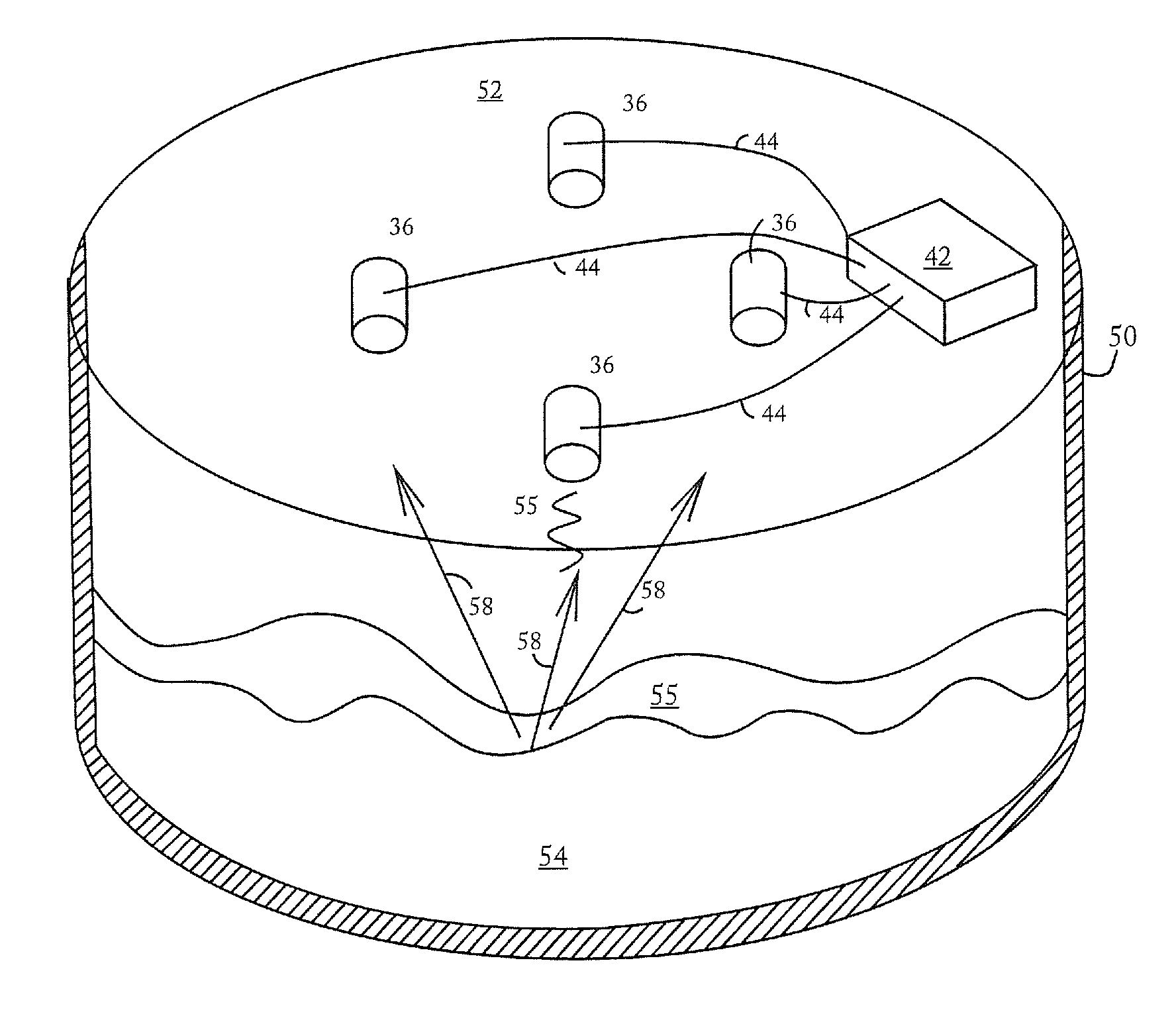

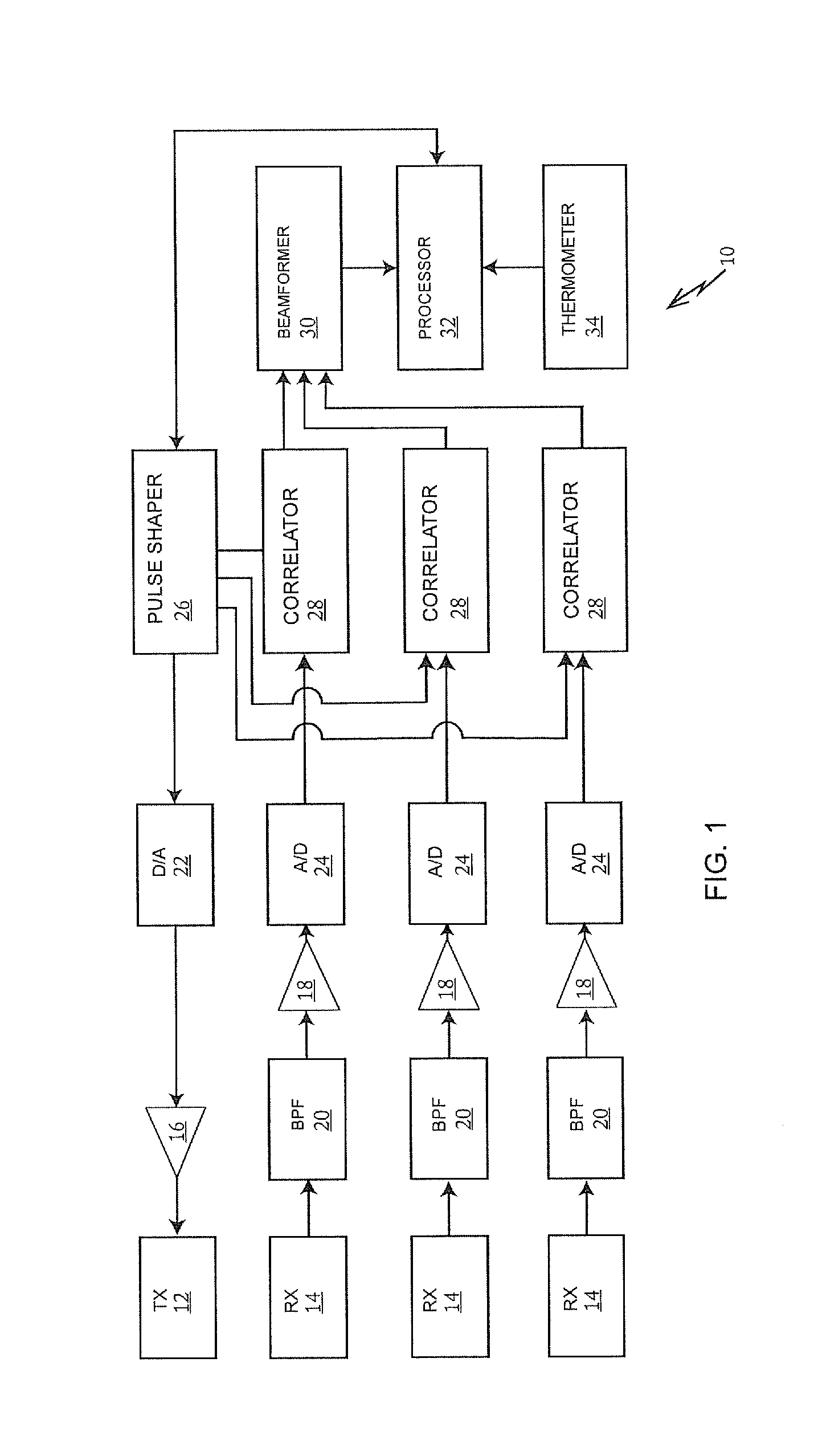

Surface mapping by virtual array processing via separate transmissions

ActiveUS20140208845A1Volume measurement apparatus/methodsMachines/enginesEngineeringSignal correlation

A system for measuring the height of bin contents includes transmitters for transmitting pulses of wave energy towards the upper surface of the contents and receivers for receiving echoes of the pulses and producing corresponding signals. The transmitters and receivers are distributed aerially above the contents. The system also includes a processing apparatus, for using the received signals to map the upper surface, that includes correlators that correlate pulse waveforms with the signals, and a beamformer. In one embodiment, the beamformer computes, from the signals considered as corresponding to echoes, of pulses from fewer synthetic transmitters, received at a synthetic receiver array, respective directions of arrival of the signals. In another embodiment, the beamformer computes respective directions of transmission and arrival of the signals, and the processing apparatus also includes a processor that selects, according to the computed transmission and arrival directions, which signals to use for the mapping.

Owner:ROSEMOUNT TANK RADAR

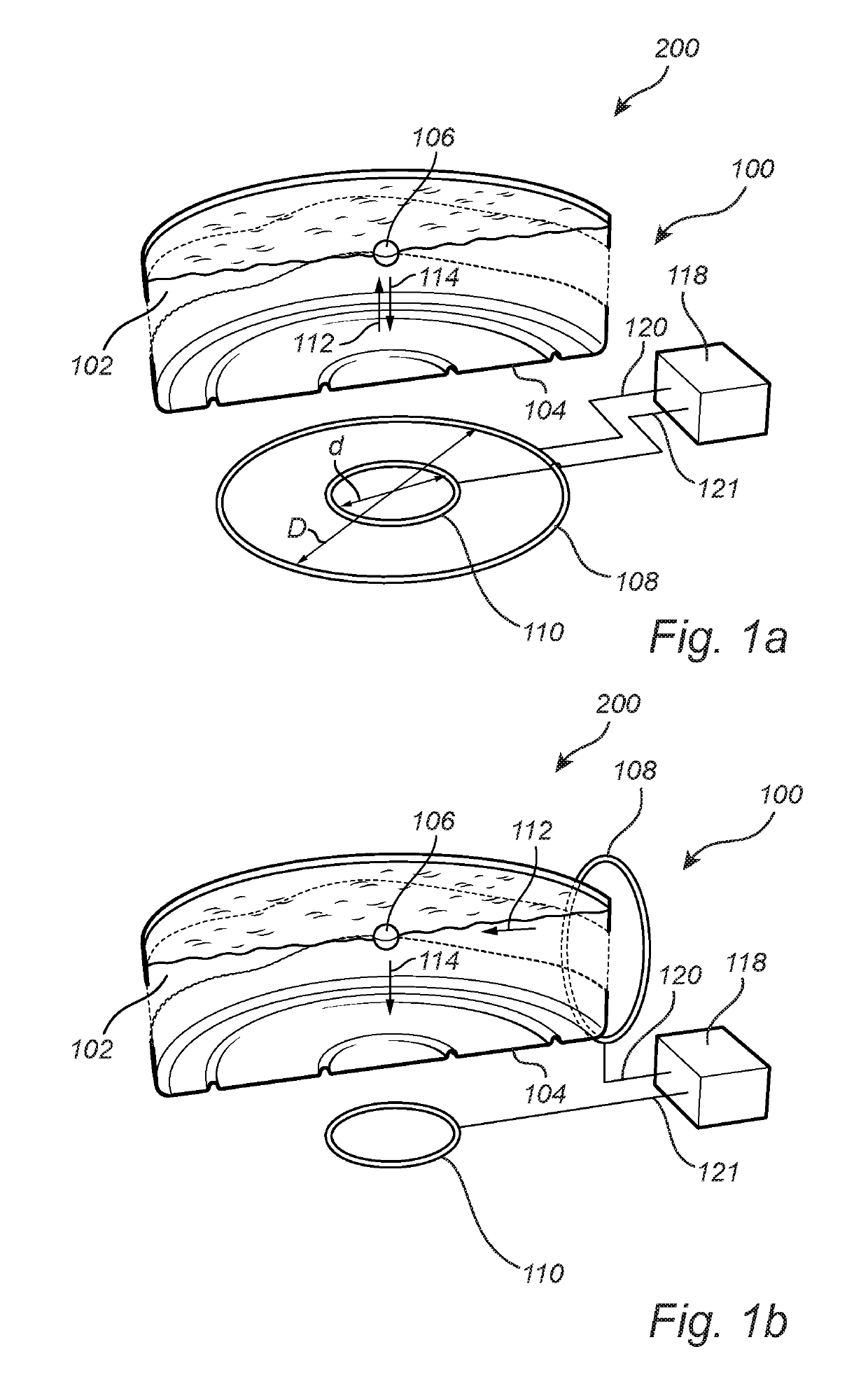

Method of measuring fluid phases in a reservoir

A method identifies a level of each of a plurality of liquids in a reservoir. The method includes using a sensing assembly having first and second electrodes extending along a side of the reservoir, wherein the first and second electrodes combine to form a plurality of capacitors each having a unique capacitance. The method includes the steps of applying an input AC signal voltage to the first electrode. An output AC signal voltage is then measured across the second electrode. The method continues by locating clusters of frequency variations. The method then associates a level identification for each of the plurality of liquids with each of the clusters of frequency variations.

Owner:DELPHI TECH INC

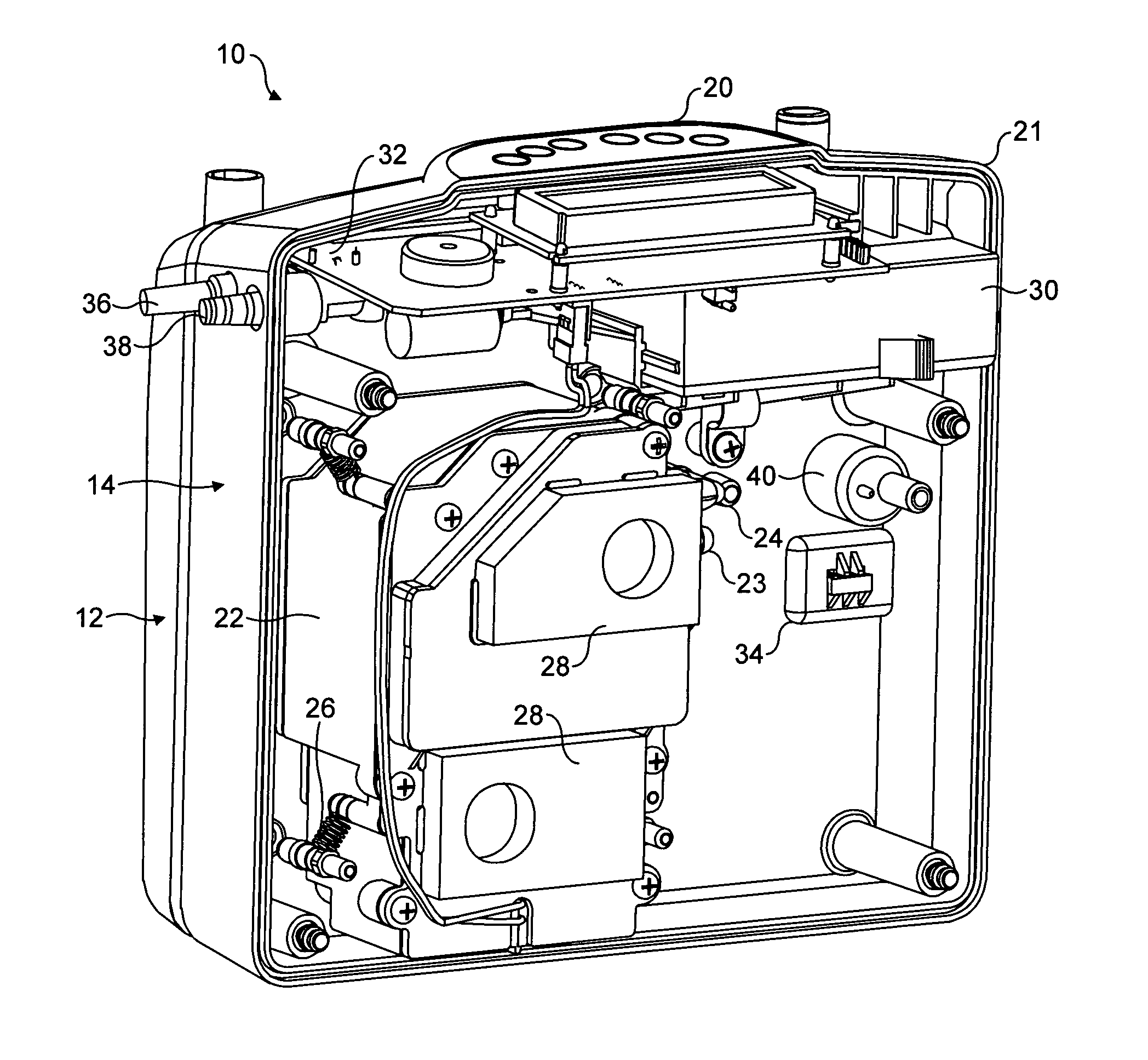

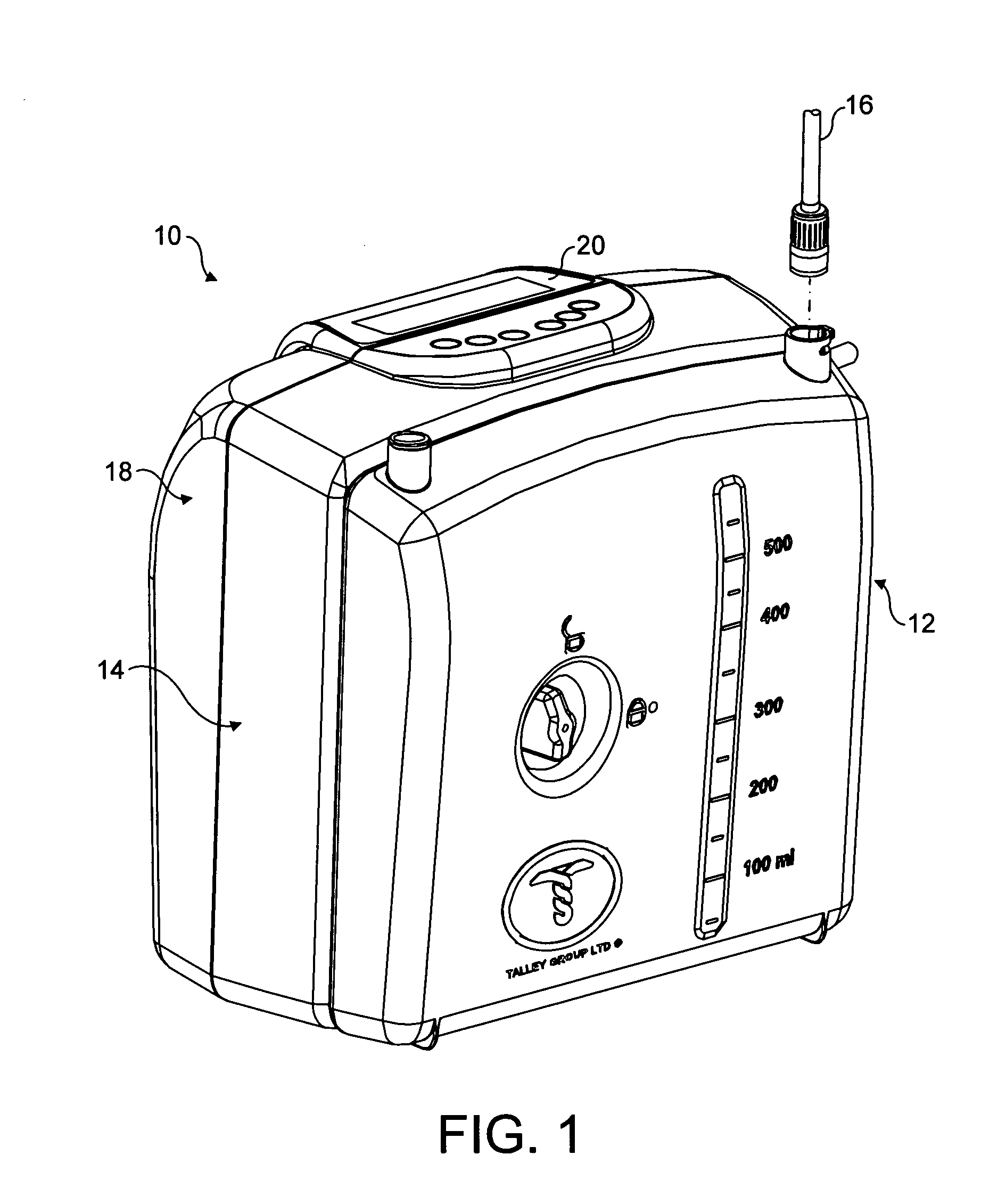

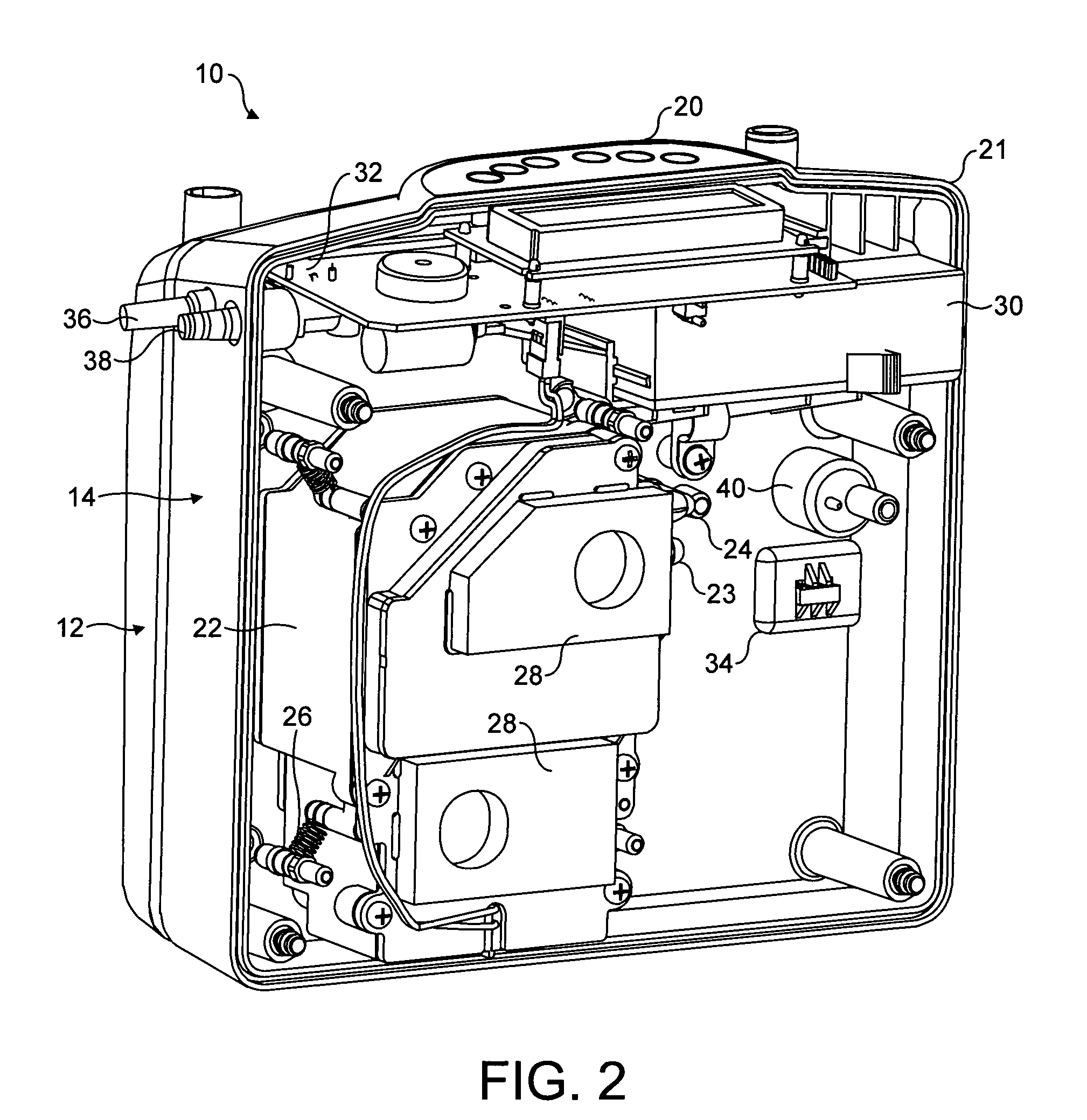

Medical apparatus for collecting fluid

ActiveUS20100191199A1Relieve stressVolume measurement apparatus/methodsVolume/mass flow measurementInlet flowMedical device

Owner:TALLEY GRP

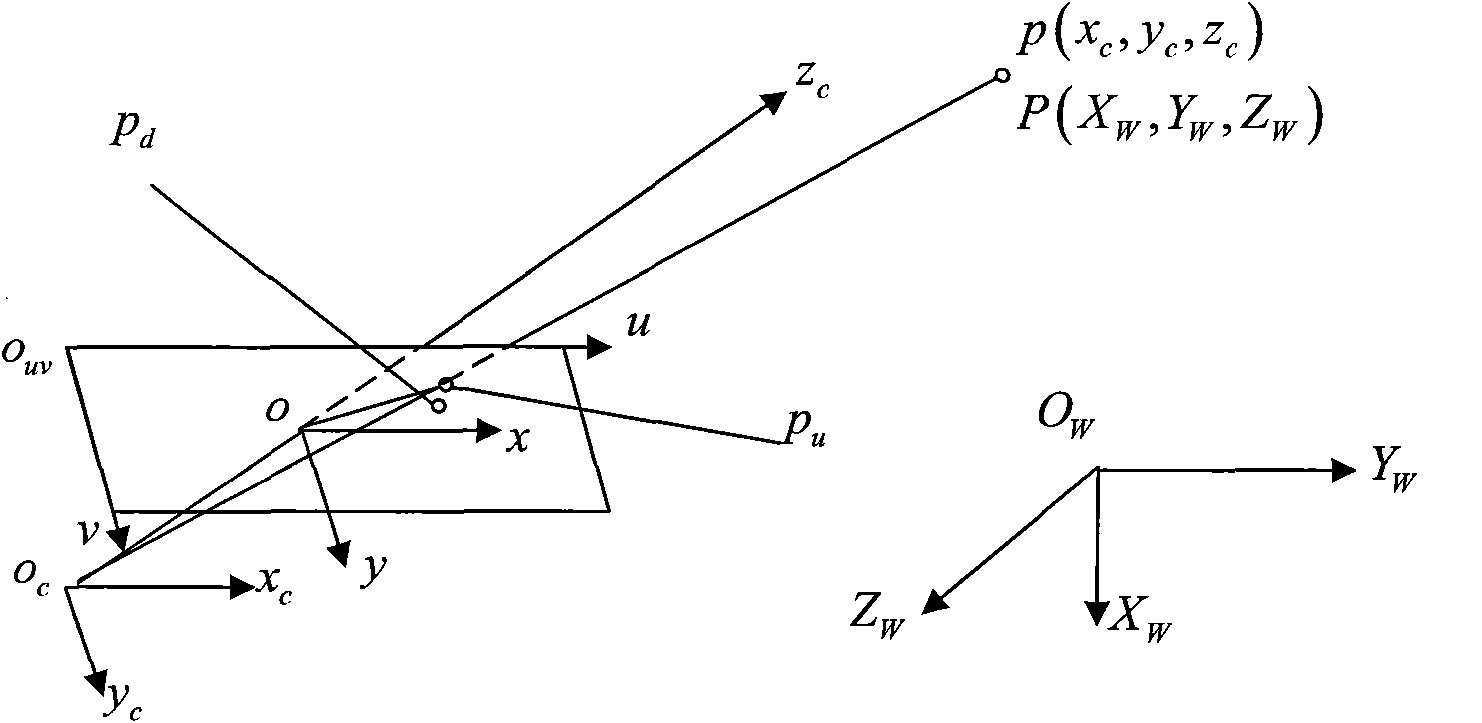

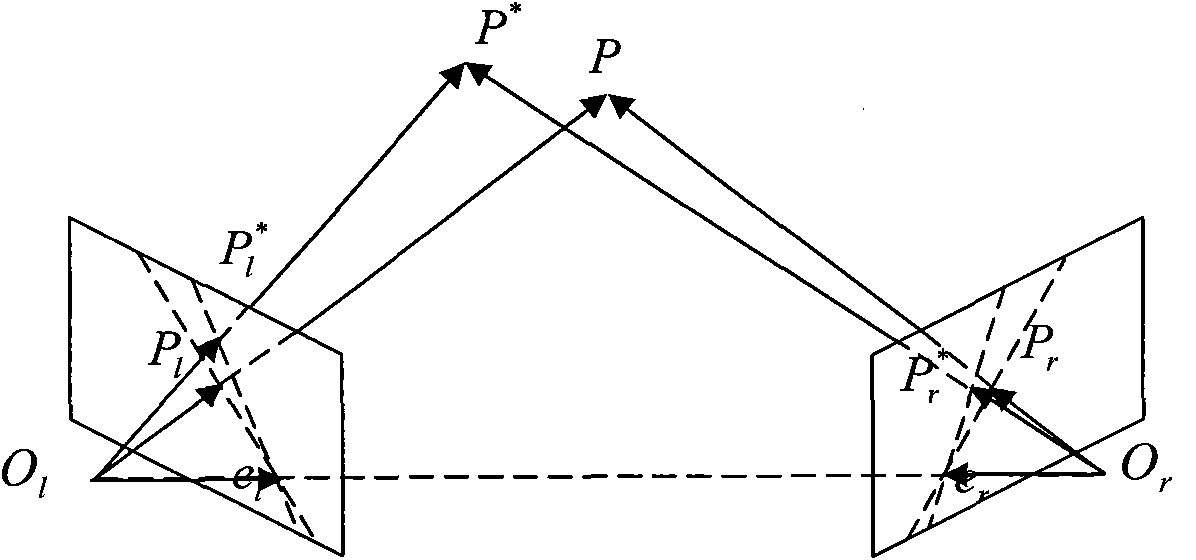

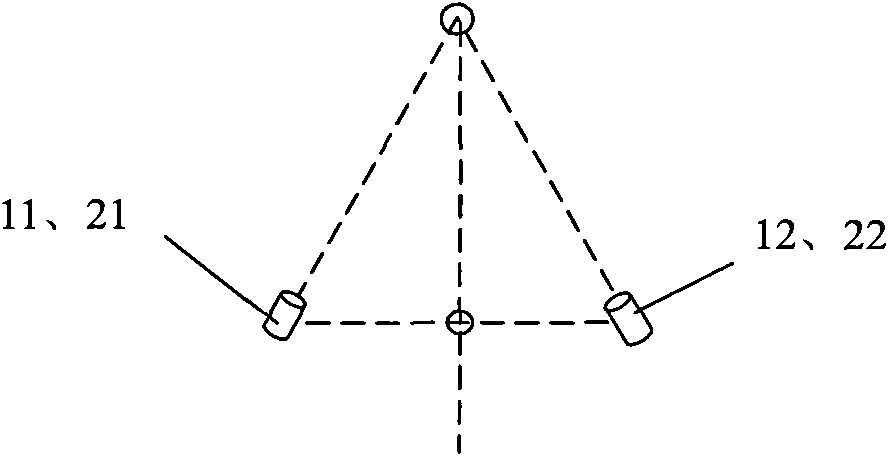

Visual measuring method of stockpile in large-scale stock ground

The invention relates to a non-contact measuring method, in particular to visual measuring method of a stockpile in a large-scale stock ground. The method comprises the following steps of: (1) constructing a visual measuring system of stock ground; (2) mounting a binocular vision subsystem; (3) establishing a geometric model of a CCD (Charge Coupled Device) camera; (4) calibrating the parameters of the CCD camera; (5) collecting images; (6) processing the images; (7) searching and matching angular points; (8) confirming the three-dimensional coordinate values of an object point; and (9) interpolating a curve and establishing a height map in a world coordinate system; and (10) measuring the volume. The visual measuring method of the invention automatically eliminates the image distortion caused by a wide-angle lens, can automatically and accurately match the angular points of a left view and a right view, automatically generates the three-dimensional space coordinates of the object point by utilizing an image data conversion relation, optimizes the three-dimensional angular point distribution and constructs the height map of the world coordinate system so that the volume a geometrical irregular stockpile can be simply, intuitively and accurately calculate.

Owner:BAOSHAN IRON & STEEL CO LTD +1

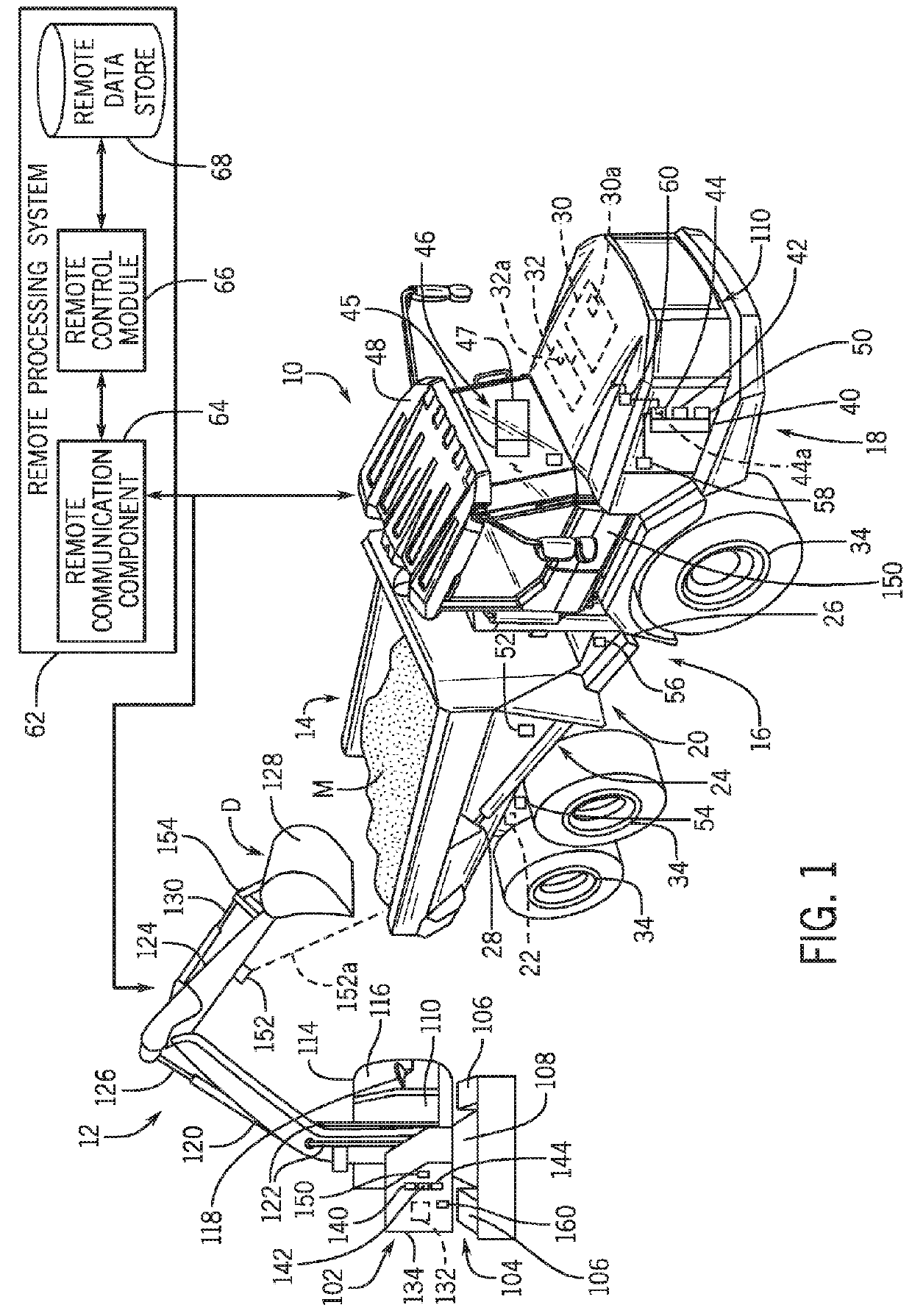

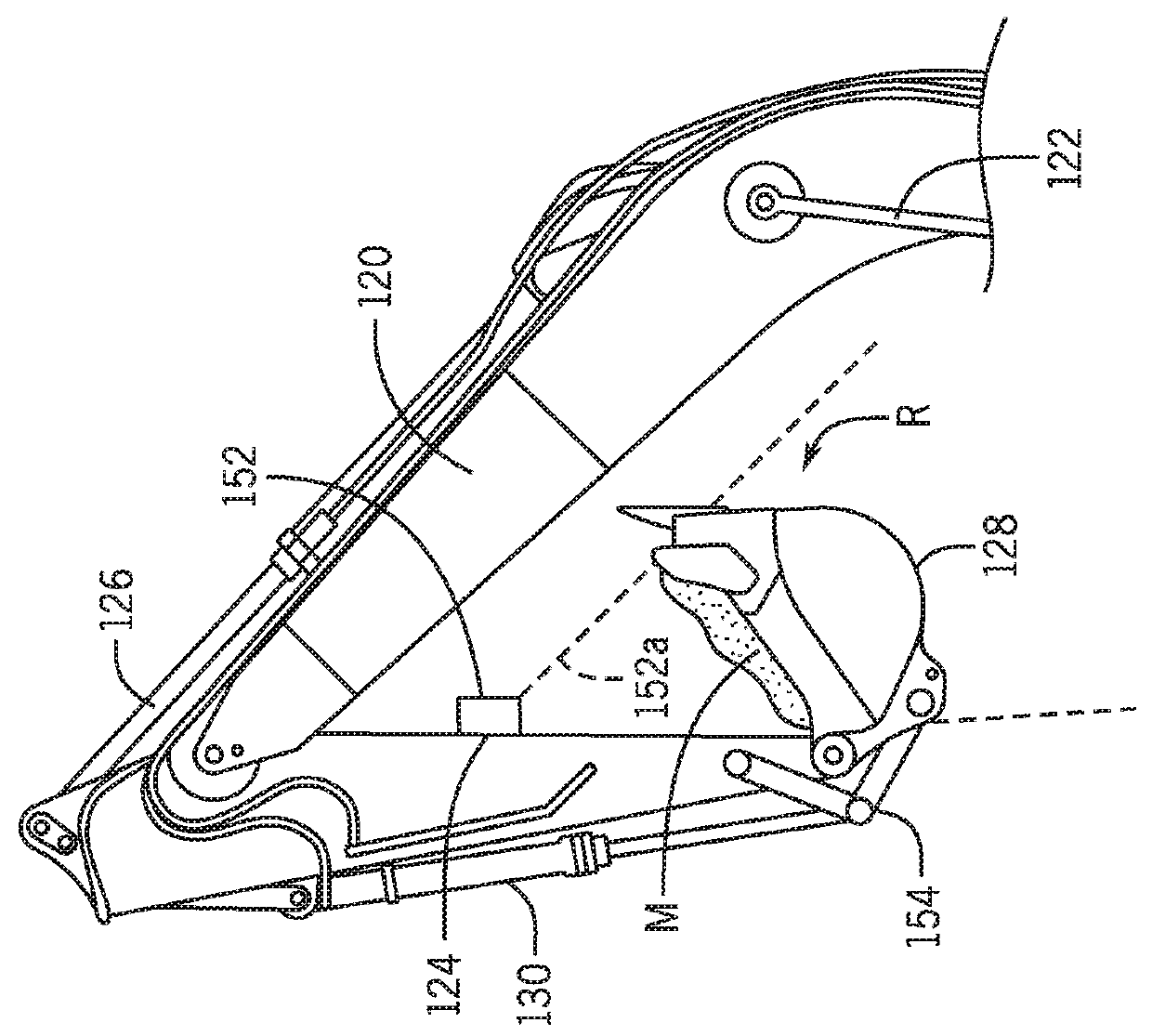

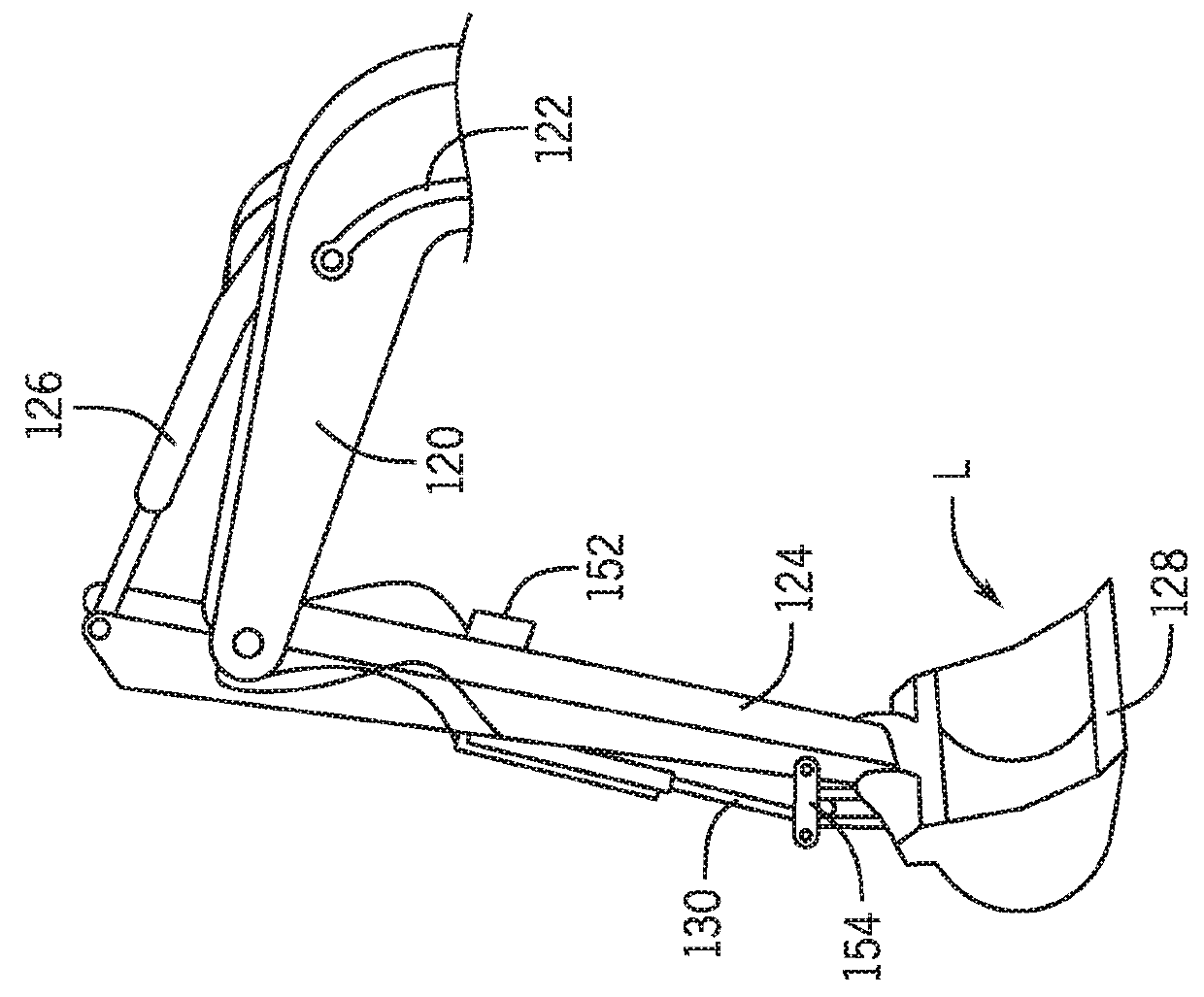

System and method for load evaluation

ActiveUS20180106709A1Volume measurement apparatus/methodsRegistering/indicating working of vehiclesData signalVerification system

A load verification system and method may be used to assess the loading of material from a loading work vehicle having a load bucket to a haulage work vehicle having a load bin. The system includes at least one volume sensor coupled to the loading work vehicle that observes a volume of material in at least one of the load bucket and the load bin and generates a corresponding volume data signal. The system also includes a first controller onboard the loading work vehicle and a second controller onboard the haulage work vehicle. At least one of the first and second controllers: receives the volume data signal from the at least one volume sensor; receives a unique haulage work vehicle identifier; associates volume data of the corresponding volume data signal with the unique haulage work vehicle identifier; and stores in memory the associated volume data and haulage work vehicle identifier.

Owner:DEERE & CO

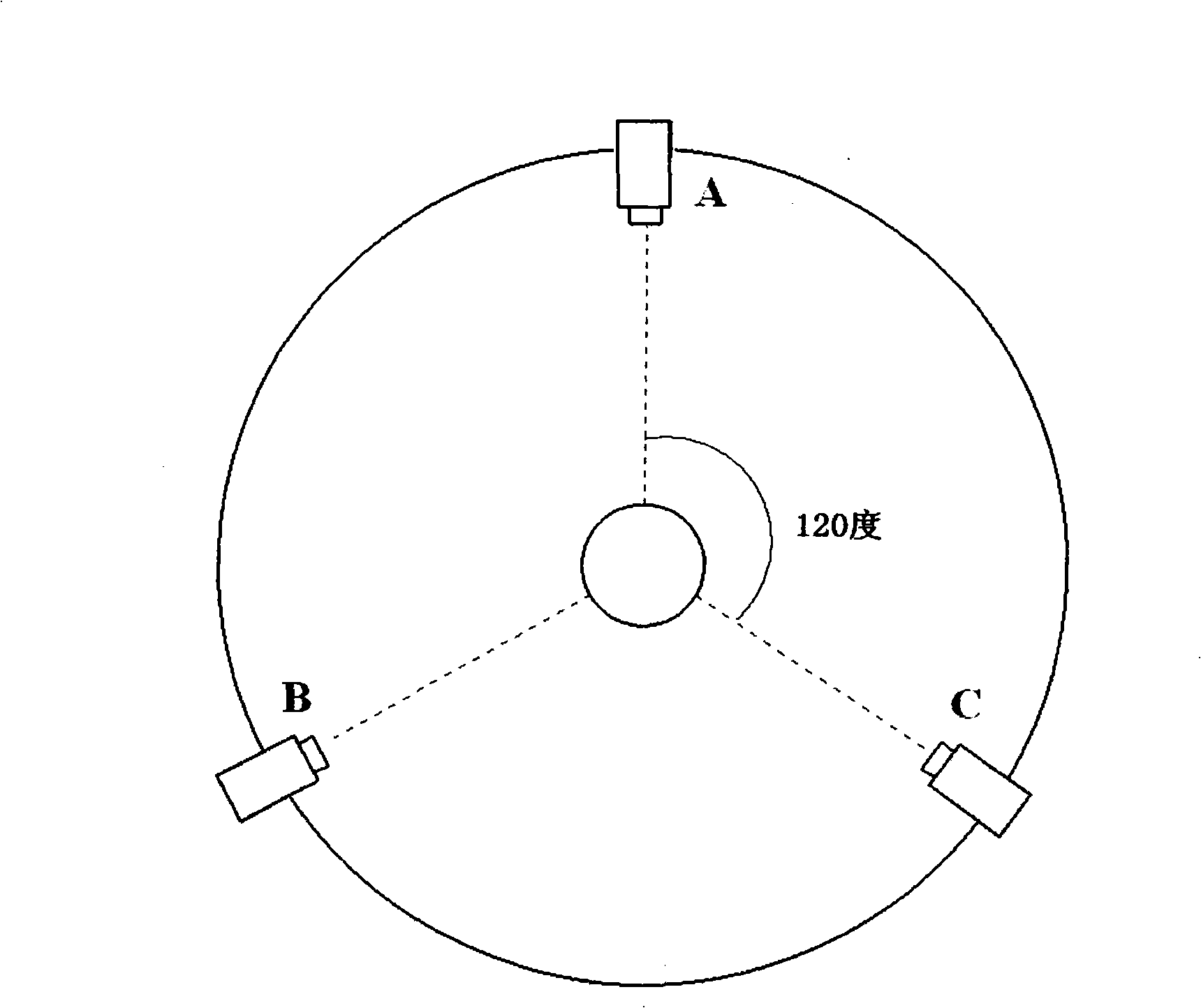

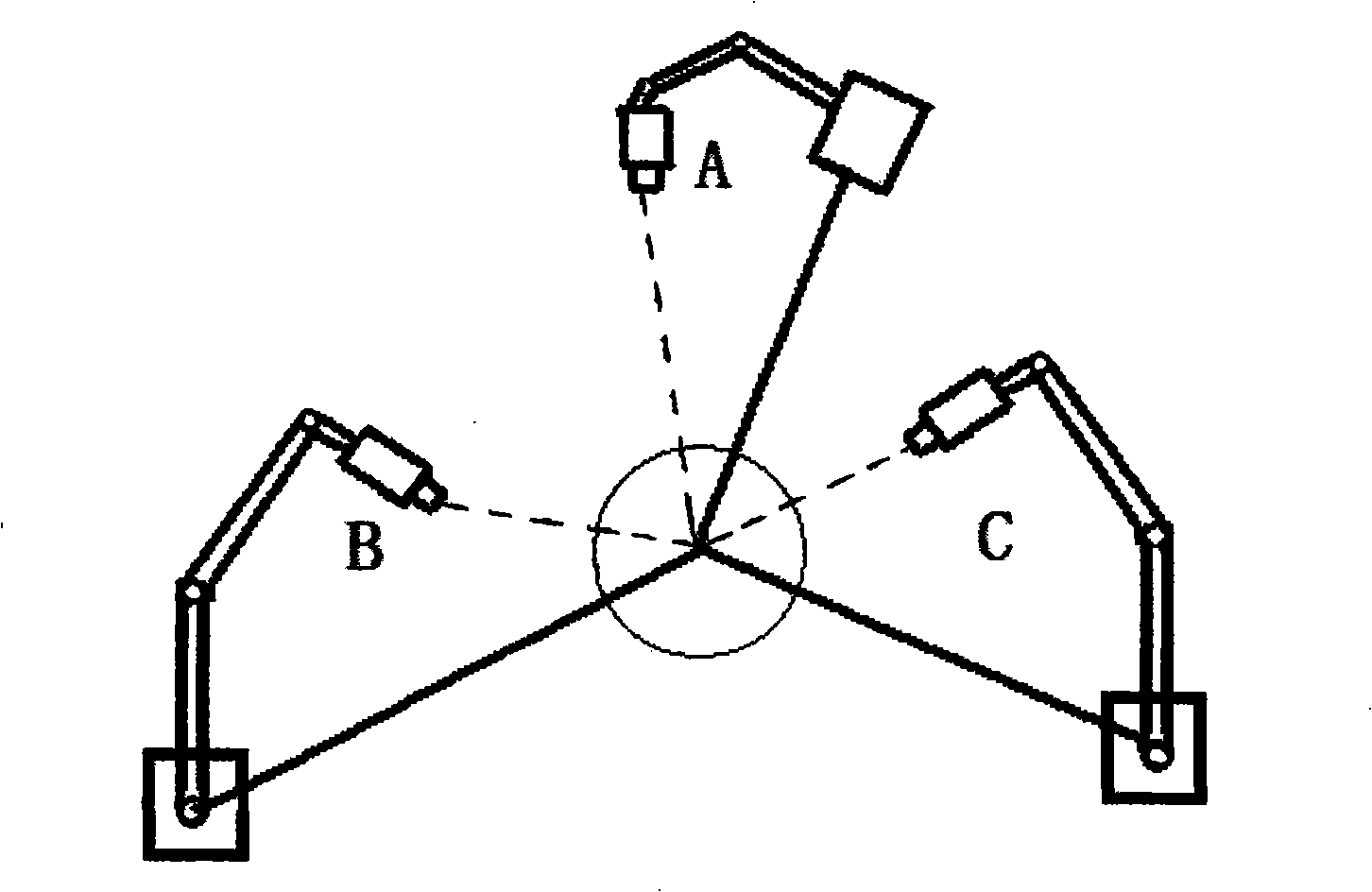

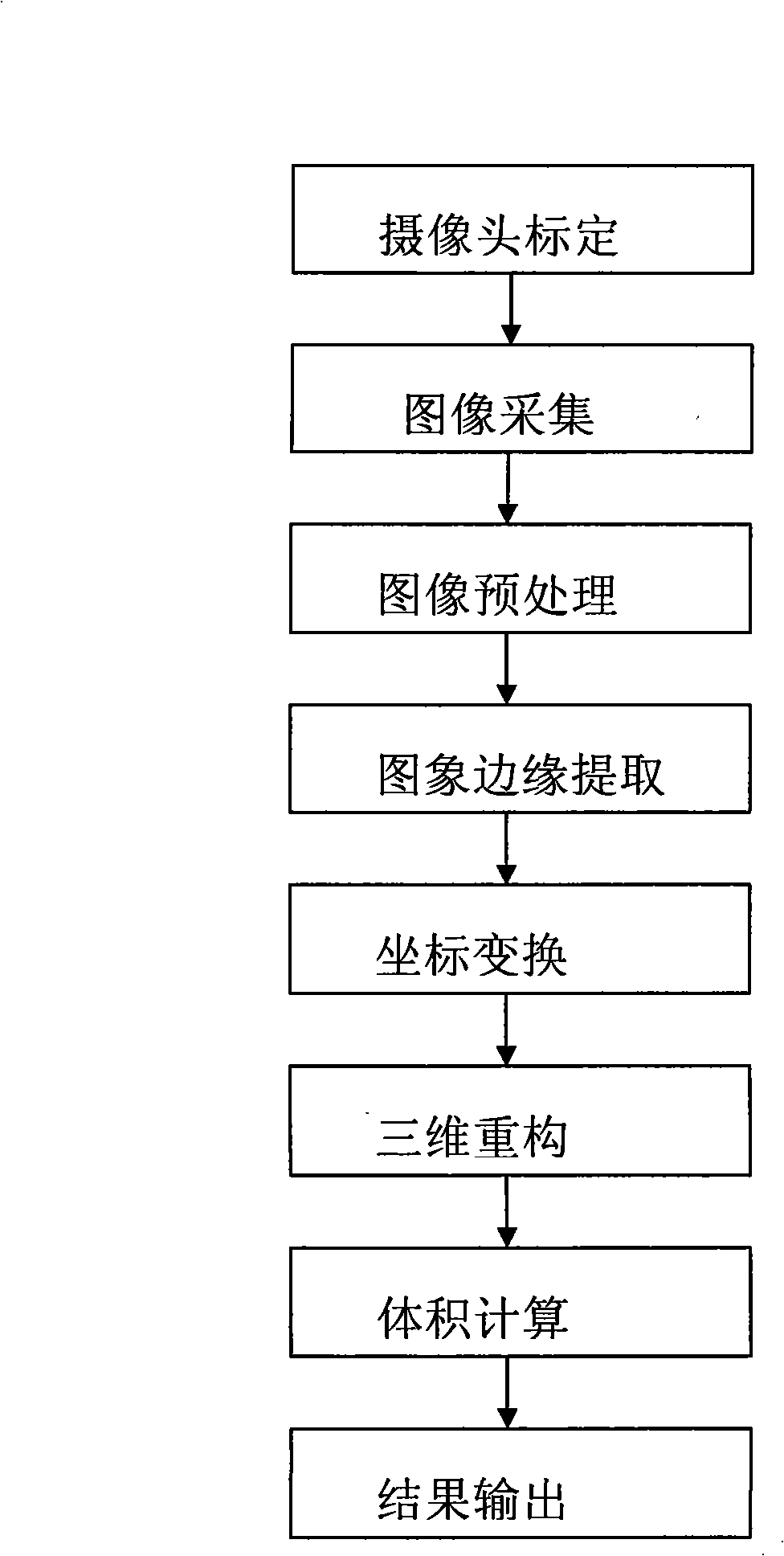

Volume measurement device based on image and its measurement method

InactiveCN101266131ALow costEasy to operateVolume measurement apparatus/methodsImage analysisChemical industryMeasurement device

This invention relates to the field of object volume survey, which discloses a method based on the image volume metering and the measuring technique. This metering equipment comprises the image gathering installment and the computer. The image collecting installment comprises objective table, as well as three cameras established symmetrically on objective table; Take the above metering equipment as the foundation, this measuring technique including the camera demarcation, image gathering, the image pretreatment, the picture edge extraction, the coordinate transformation, the three dimensional restructuring step, finally counts all three dimensional spots on the measured object, then obtain the actual volume of objects. This invention may be widely applied in areas such as medicine, chemical industry, food, environmental protection, water treatment, building materials, grain micro powdery, the granulated material continual quota throws in Canadian, ingredient craft domains dried noodles batch feeding and so on.

Owner:CHANGAN UNIV

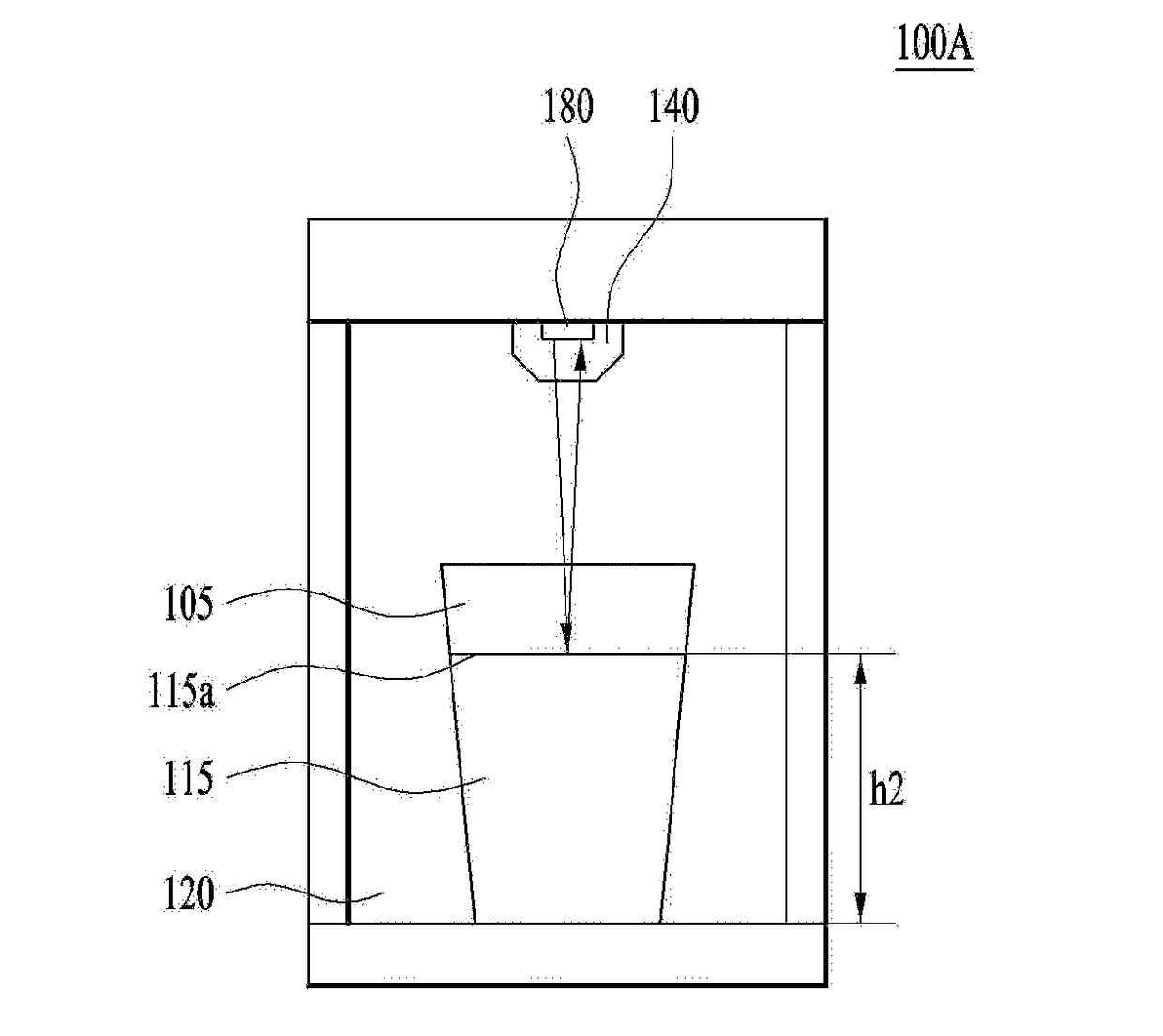

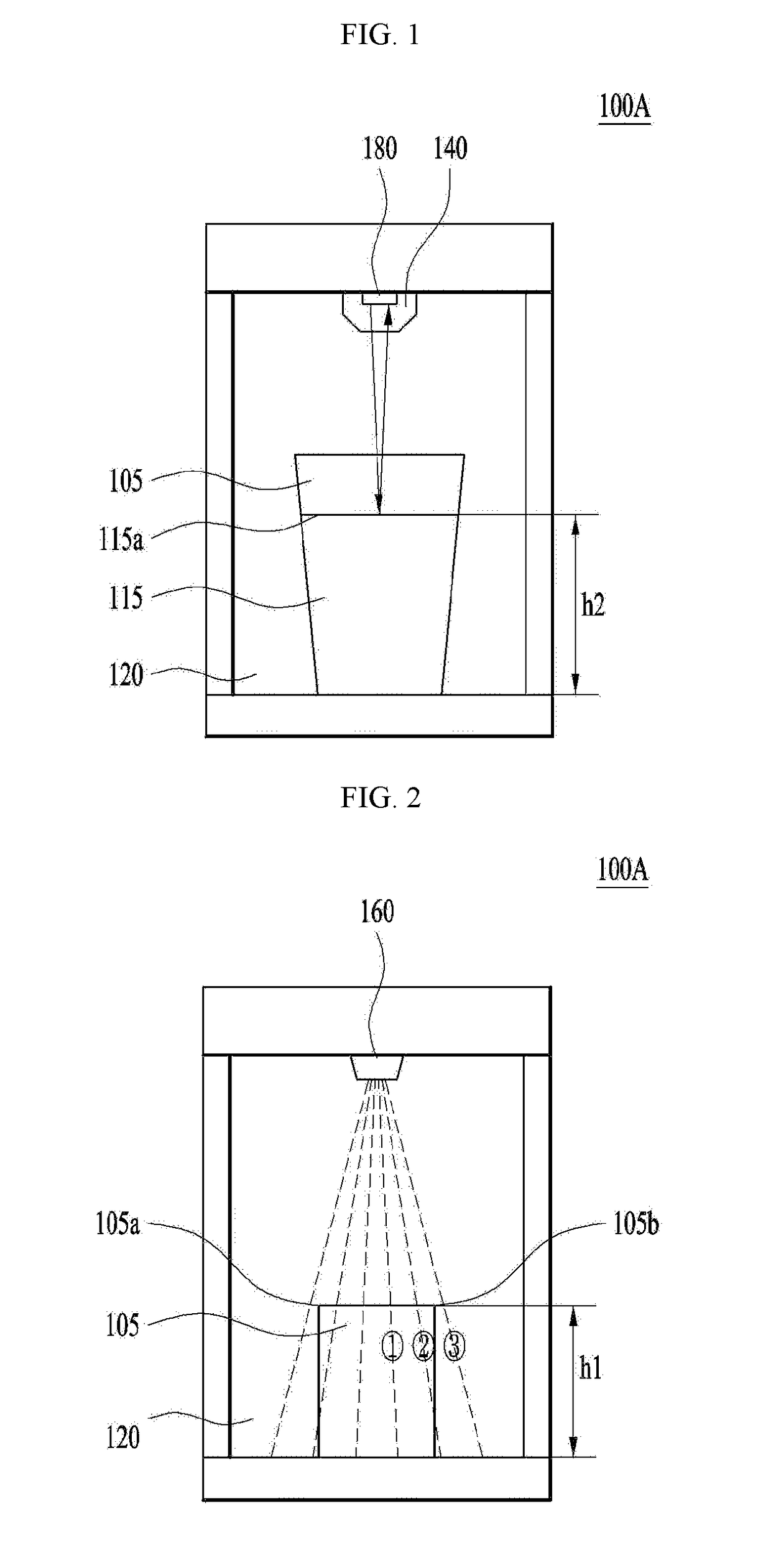

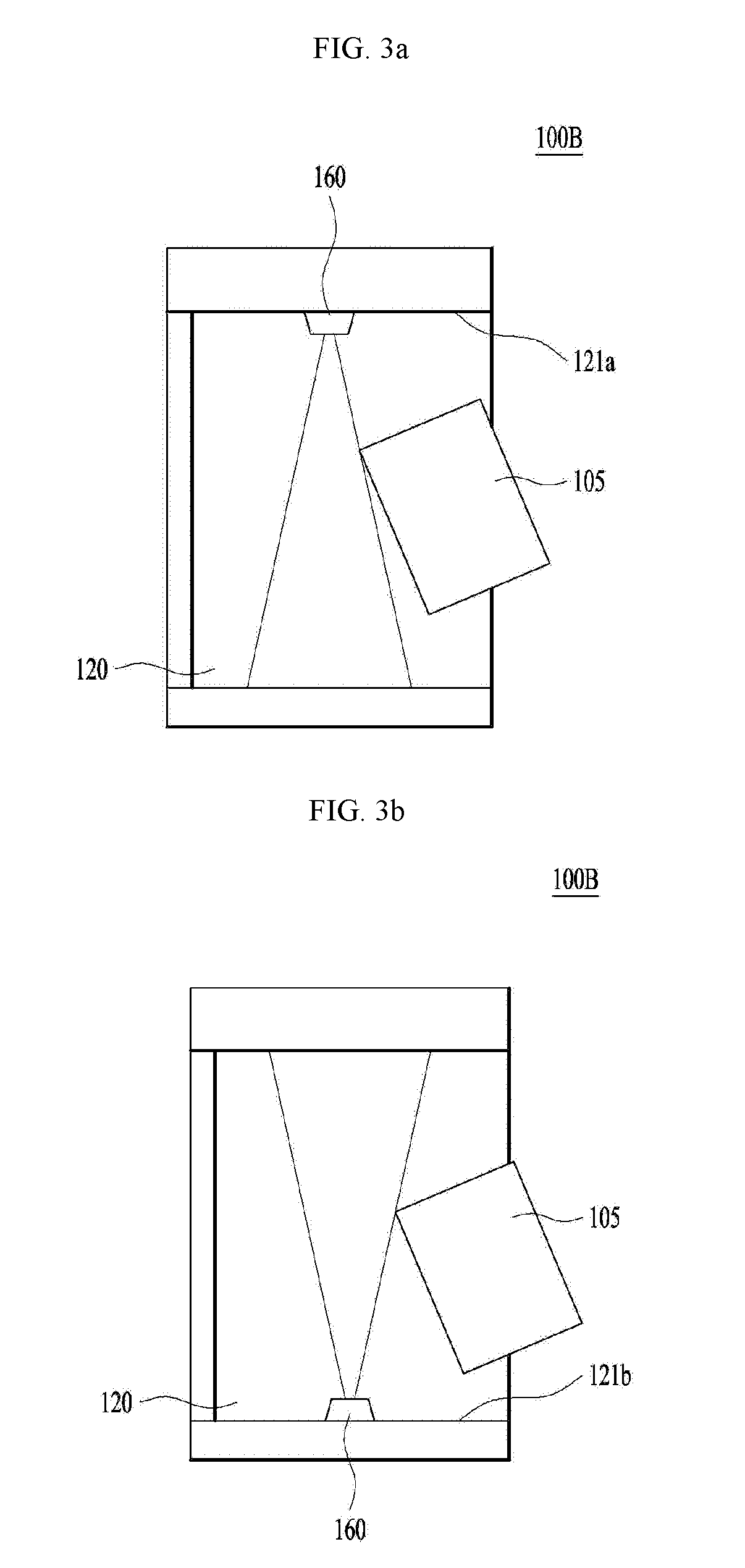

Automatic Water Supply Device

An embodiment relates to an automatic water supply device comprising: a container seating portion, one side of which is open such that a container is placed; a water intake member arranged on the upper portion of the container seating portion so as to supply the container with a liquid; a container height measuring unit and a water level measuring unit arranged to be adjacent to the water intake member, respectively; and a control unit for comparing the height of the container, which is measured by the container height measuring unit, and the water level, which is measuring by the water level measuring unit, thereby checking whether the water level inside the container reaches a preset height or not, and adjusting the water level inside the container using the result of the checking, wherein the container height measuring unit comprises a plurality of first optical sensors for sensing both ends of the upper end of the container, and can measure the height of the container in response to the result of sensing by the first optical sensors.

Owner:LG INNOTEK CO LTD

Device for determining liquid level in a container

ActiveUS10408665B2High leveling accuracyImprove accuracyVolume measurement apparatus/methodsUnderstructuresElectricityEngineering

The present invention relates to a level indicator for determining the level of liquid in a container, the level indicator comprising: a floating device comprising a metal; a transmitter arranged to transmit an electromagnetic signal towards the floating device; and a receiver arranged to receive a response signal from the floating device. The floating device is moveable relative to the receiver so that a distance from the floating device to the receiver is altered in response to an altered level of liquid in the container, and wherein the electrical signal is a function of at least said distance. The receiver is electrically connectable to a control unit configurable to determine a position of the floating device relative to the receiver based on the electrical signal. The invention also relates to a system and a tank comprising the level indicator.

Owner:VOLVO CAR CORP

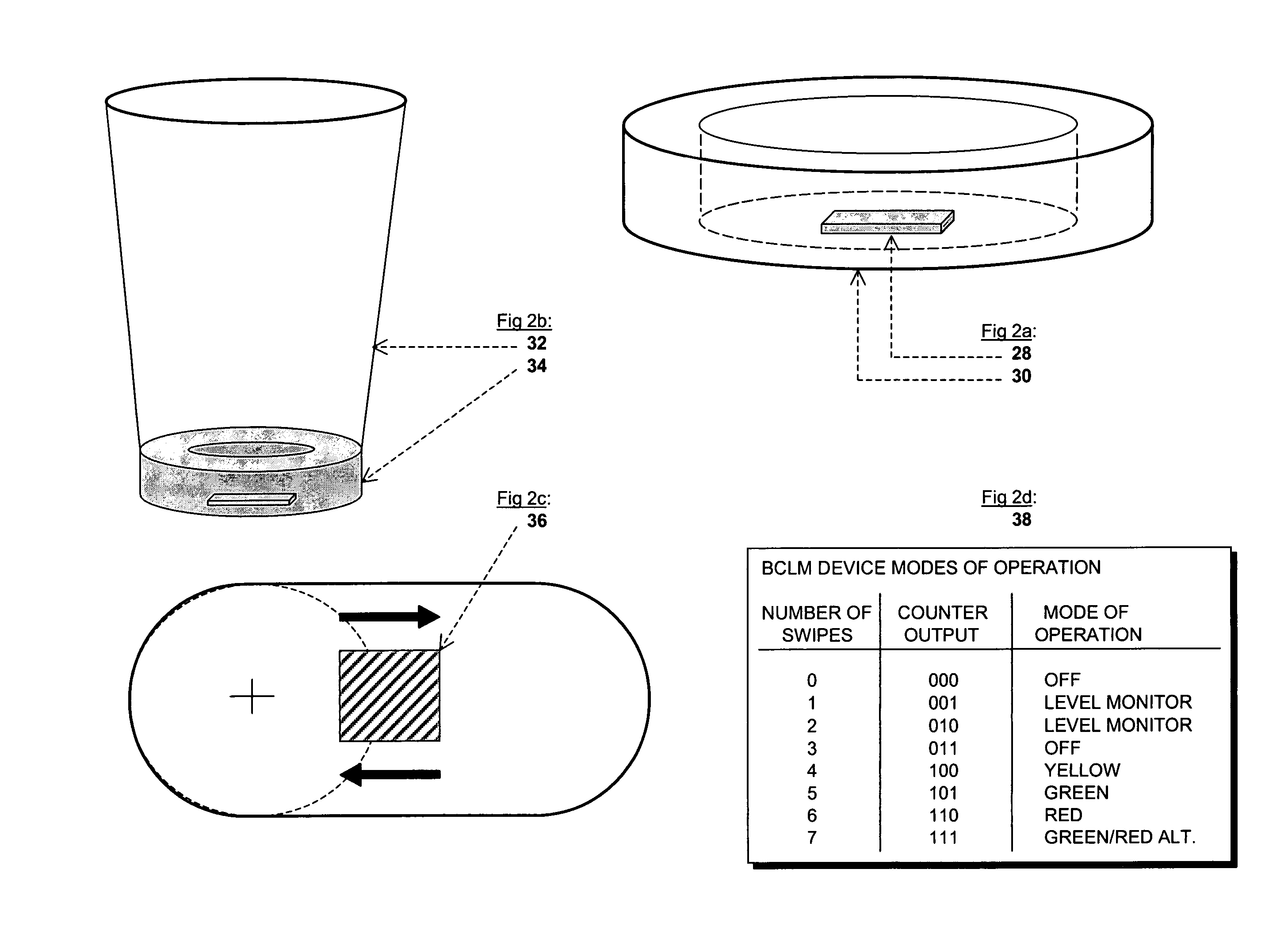

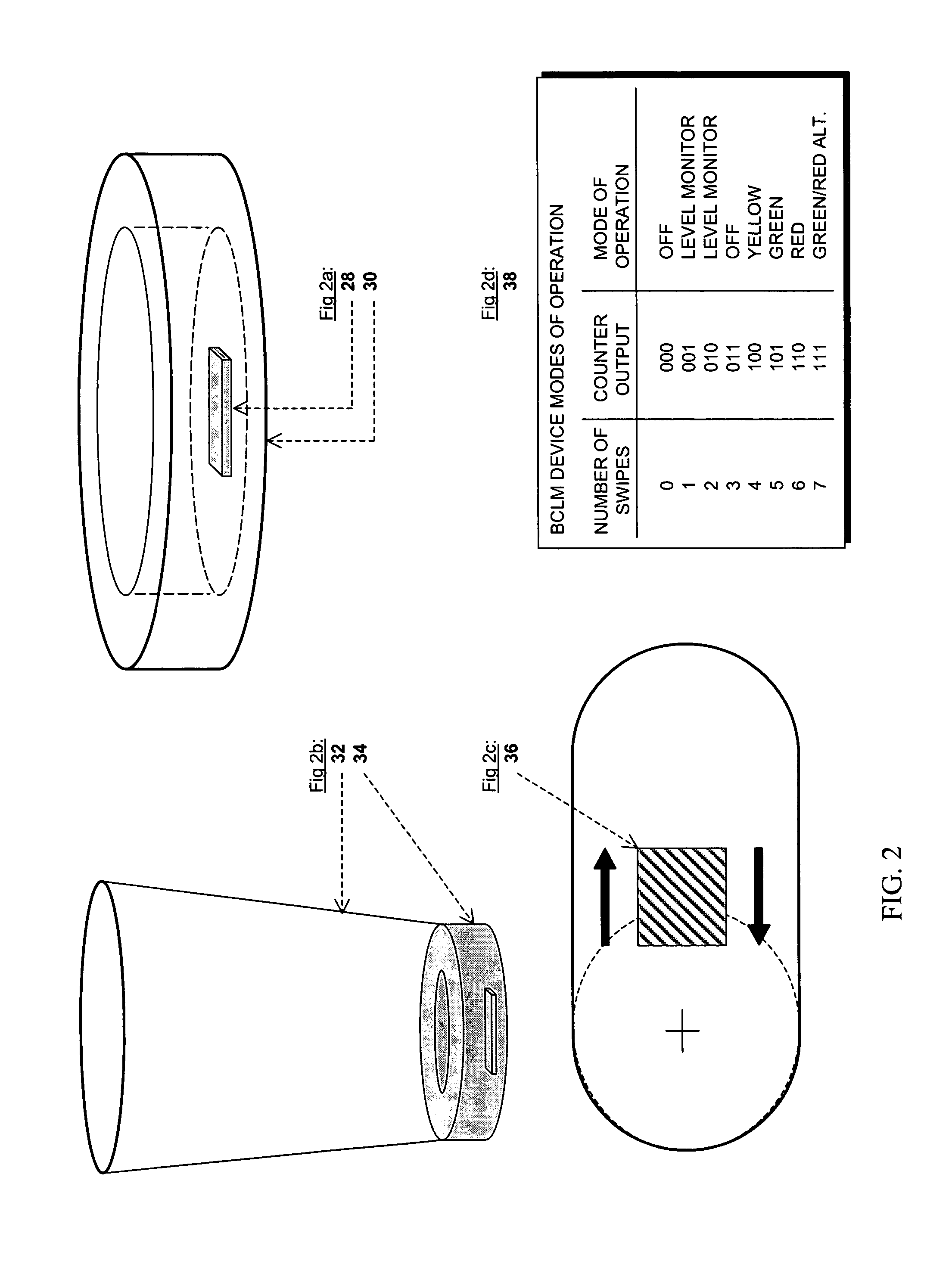

Device for monitoring a beverage consumption level

ActiveUS20060000277A1Modulate behaviorIncreasing beverage saleVolume measurement apparatus/methodsLiquid flow controllersEngineeringBeverage consumption

A device which detects or senses liquid level in a beverage containment vessel, and produces either light, audio or a data output based on the liquid level being equal to or less than a predetermined level. The device, in practice, preferably retains the shape of the beverage containment vessel (e.g., cylindrical), and have an outer housing of opaque or semi-translucent material. The device is either integrated into a new beverage containment vessel, or retrofitted to existing vessels. The device is powered by battery, and can be switched on, off, or into various operating modes by internal switching mechanism.

Owner:COLGATE PALMOLIVE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com