Patents

Literature

251 results about "Fuel quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for developing a unified quality assessment and providing an automated fault diagnostic tool for turbine machine systems and the like

InactiveUS20050267702A1Accurate analysisAccurate assessmentVibration measurement in solidsMachine part testingFuel qualityFailure diagnosis

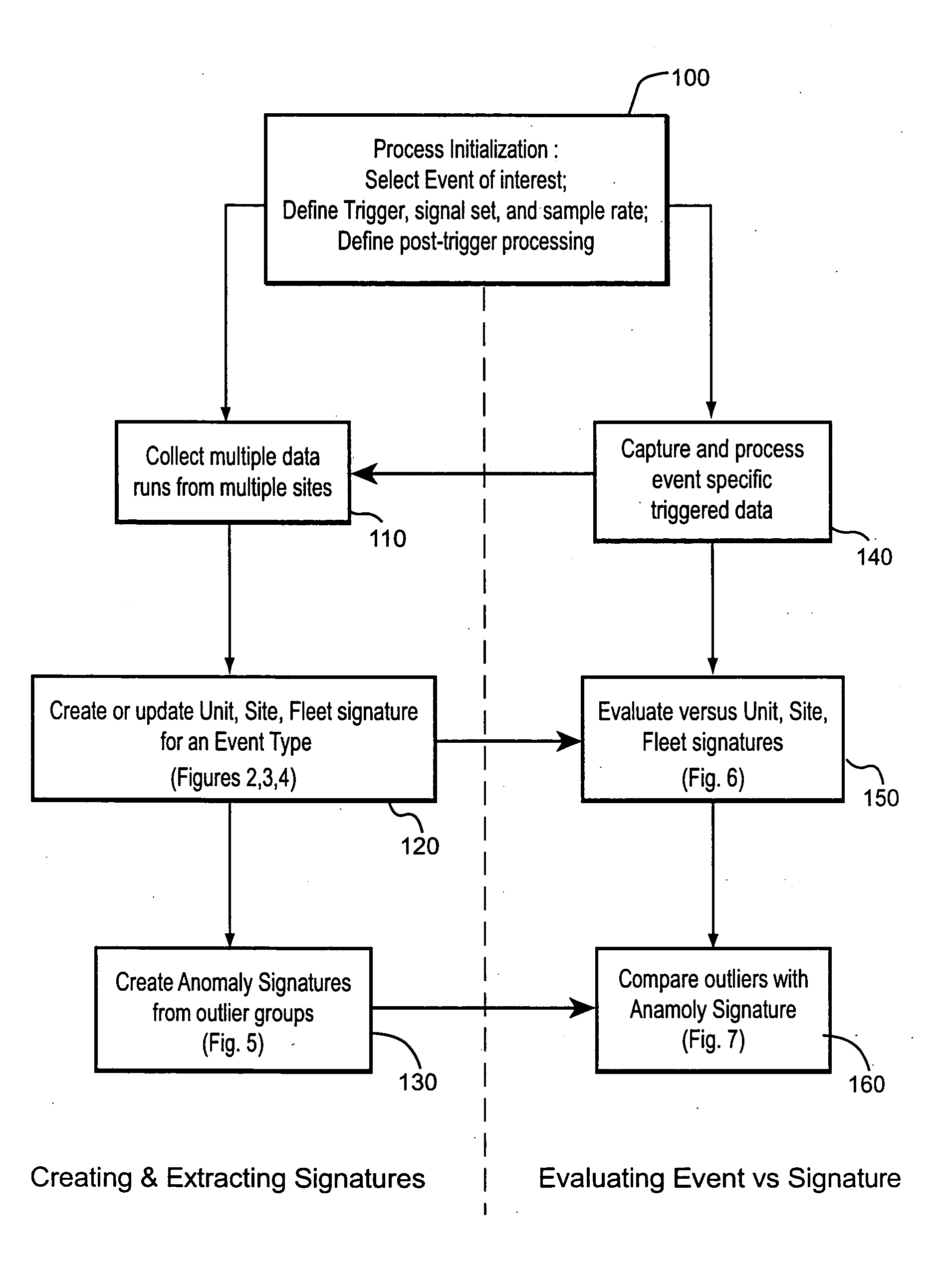

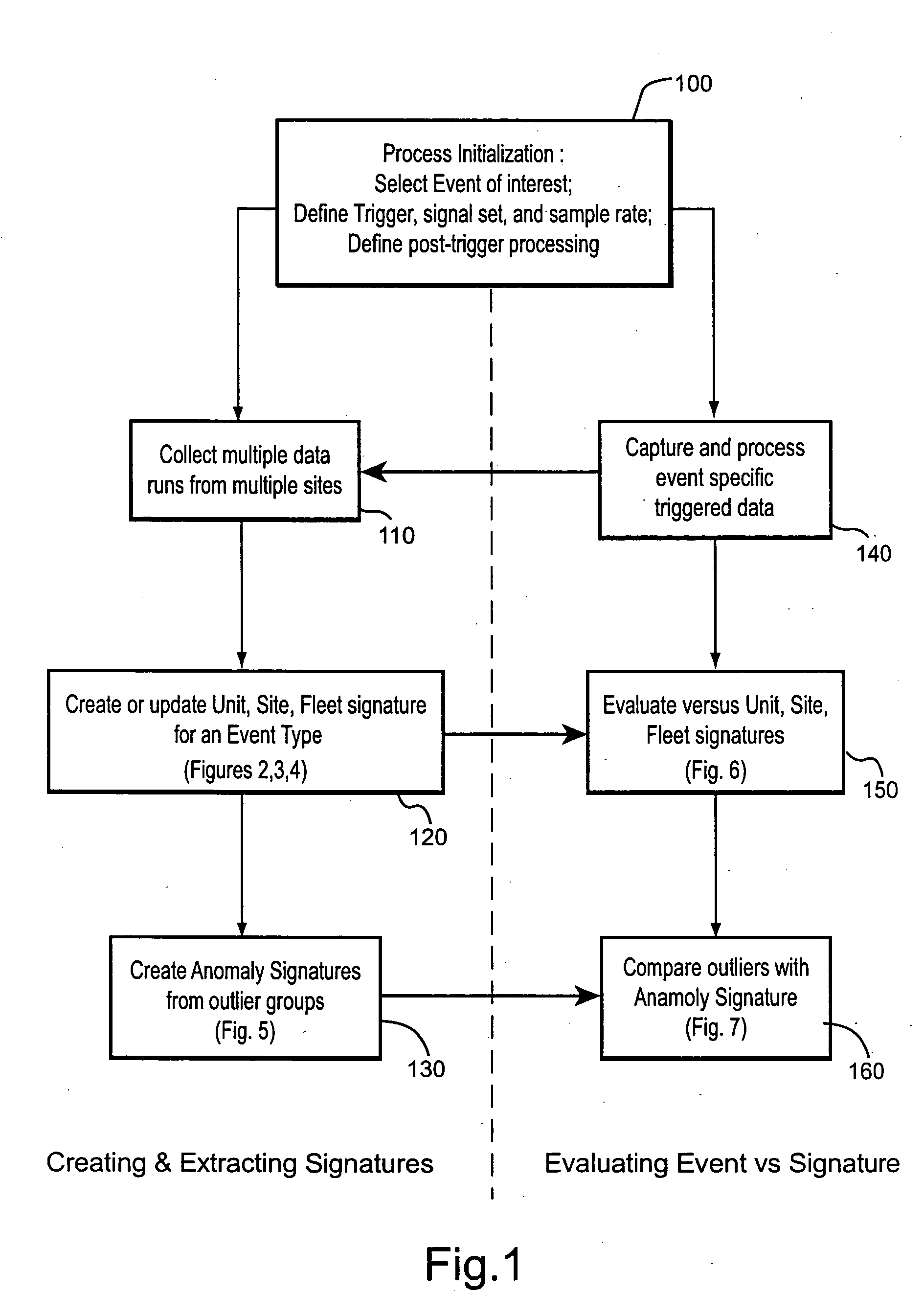

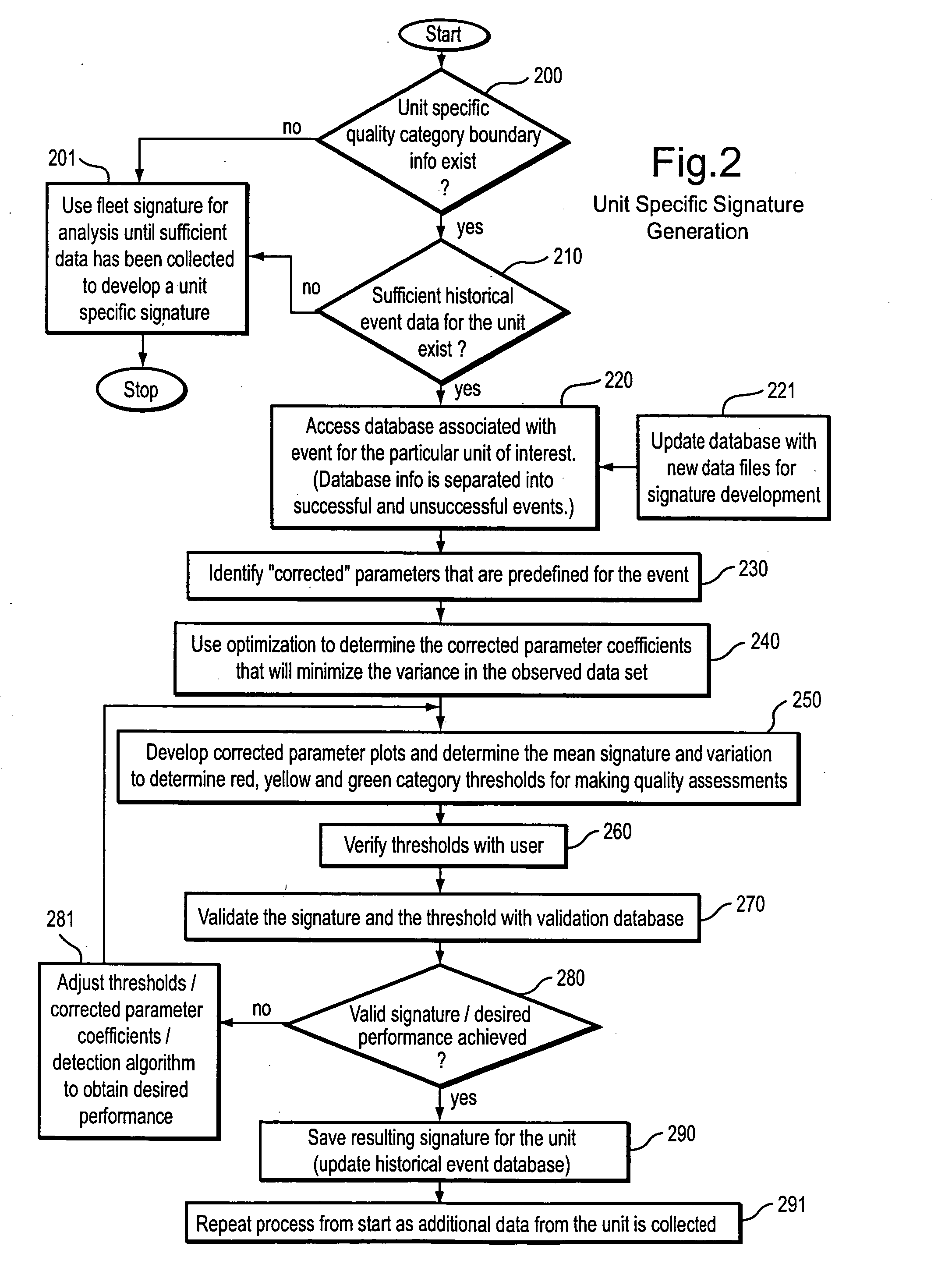

A computer implemented process is provided for assessing and characterizing the degree of success or failure of an operational event of a machine system such as a fluid compressor machine or turbine machine or the like on a continuous numerical scale. The computer implemented process develops and tracks machine unit signatures, machine site signatures and machine fleet signatures to evaluate various operational events and provide fault detection. At least some sensor data acquired from the machine system during an operational event is transformed to correct or at least reduce variabilities in the data caused by ambient conditions and fuel quality. The transformed data is then analyzed using statistical methods to determine how closely the operational event conforms to an expected normal behavior and the information is used to develop a single comprehensive quality assessment of the event. By saving, tracking and updating operational event assessments over time, machine / component degradation may be recognized at any early stage and corrective action may be initiated in advance of a catastrophic failure.

Owner:GENERAL ELECTRIC CO

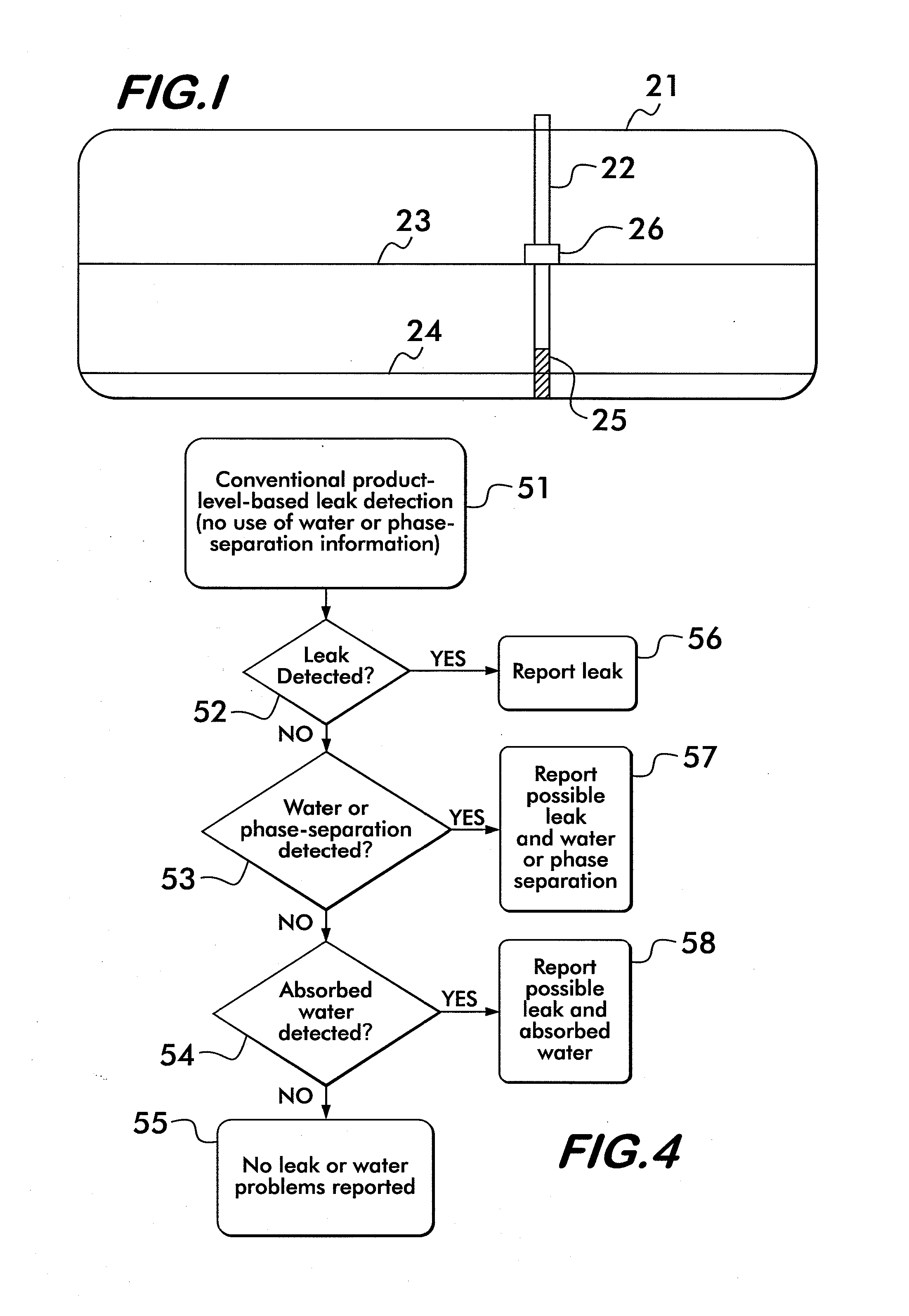

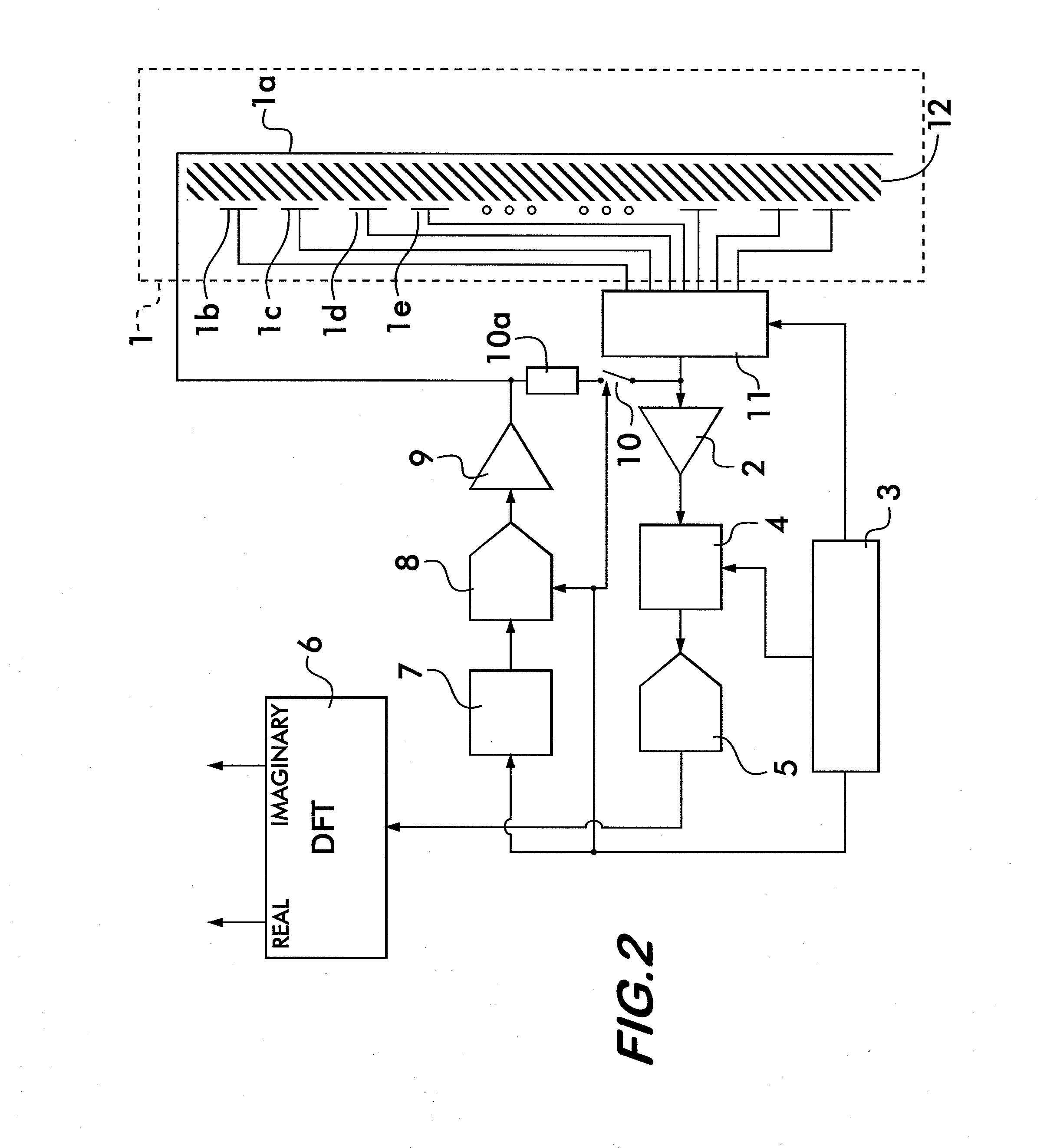

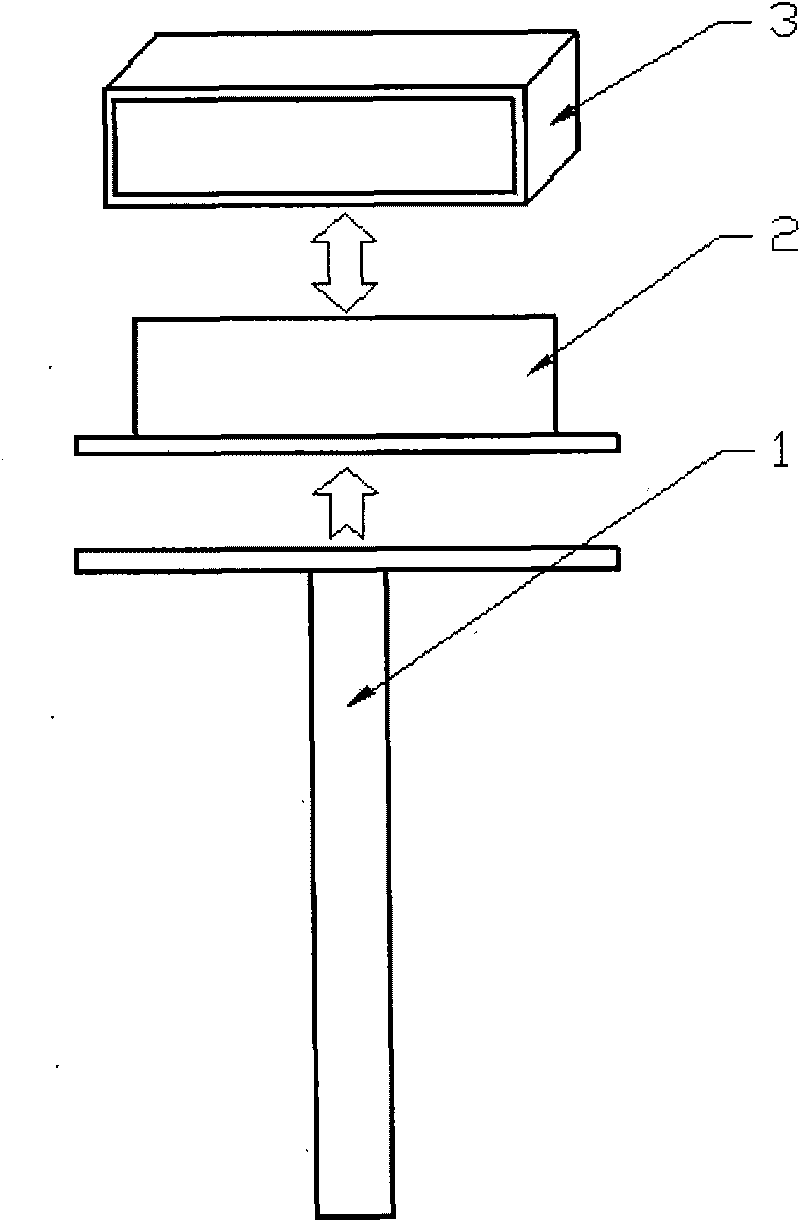

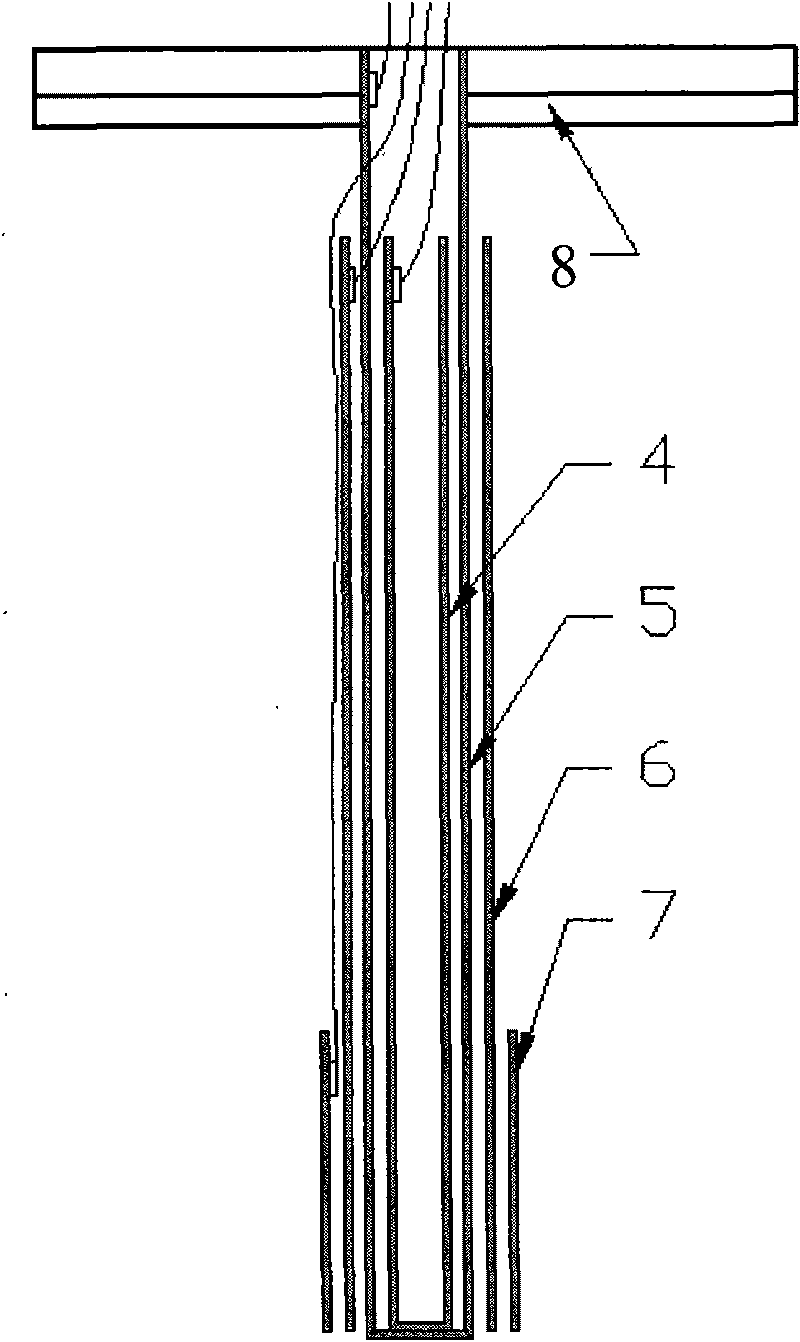

Automated phase separation and fuel quality sensor

InactiveUS20100295565A1Not easy to make mistakesMinimize attractionVolume measurement apparatus/methodsResistance/reactance/impedenceFuel qualityEngineering

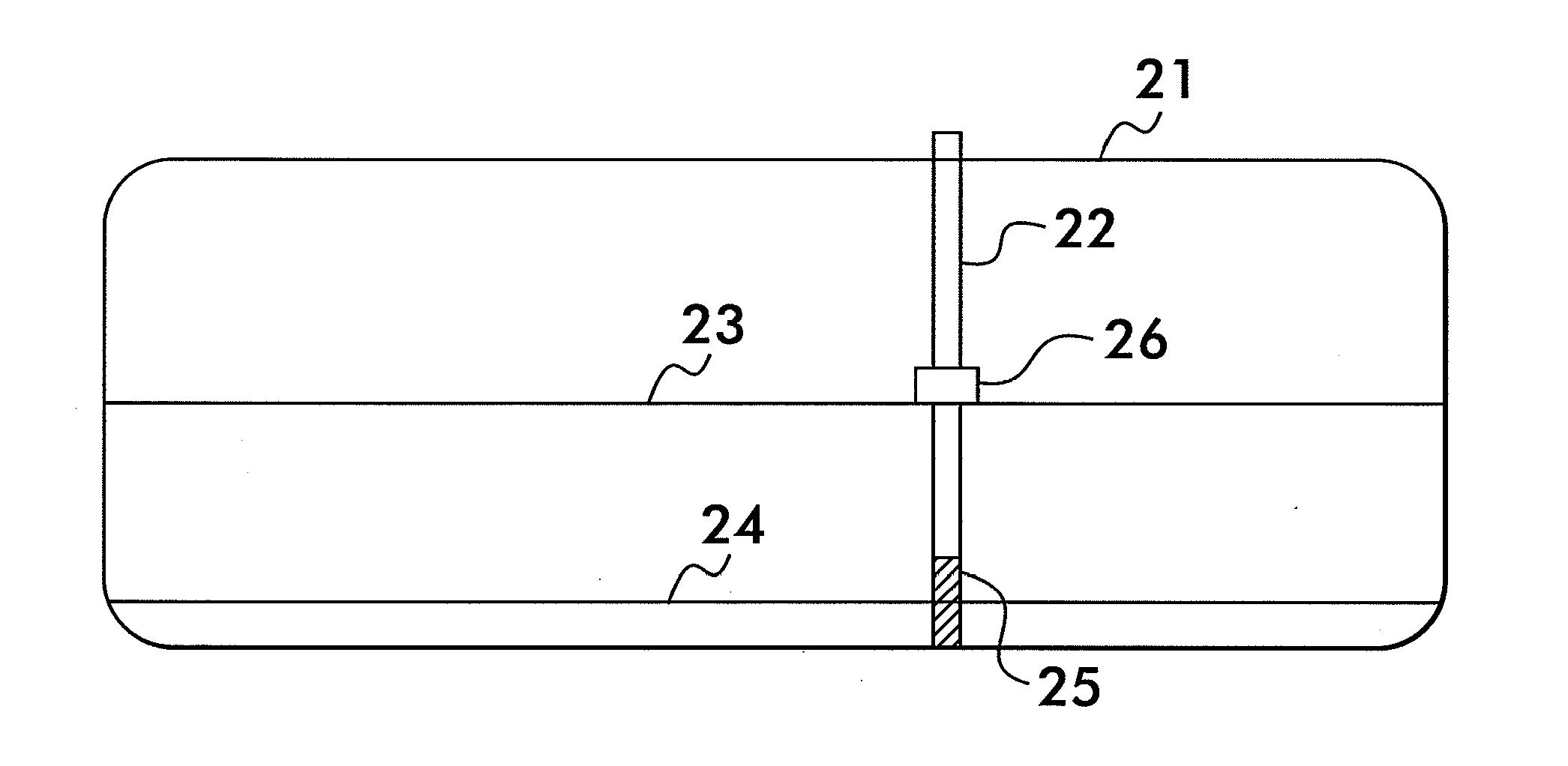

A fluid characterization sensor comprising a plurality of sensor segments is disclosed. Each segment comprises two electrodes, spaced apart so the fluid in the corresponding interval of depth for that segment is positioned between them. Complex current or impedance is measured by exciting one electrode with an AC signal, and measuring the amplitude and phase of the current in the other electrode. After automatically measuring and accounting for pre-determined gain, offset, temperature, and other parasitic influences on the raw sensor signal, the complex electrical impedance of the fluid between the electrodes is calculated from the measured phase / amplitude and / or real / imaginary components of the received electrical current signal and / or the variation of the measured response with variation in excitation frequency. Comparison of measured results with results taken using known fluids identifies fluid properties. Alternatively, measured results are compared to predicted results using forward models describing expected results for different fluids or contaminants.

Owner:DIRACTION

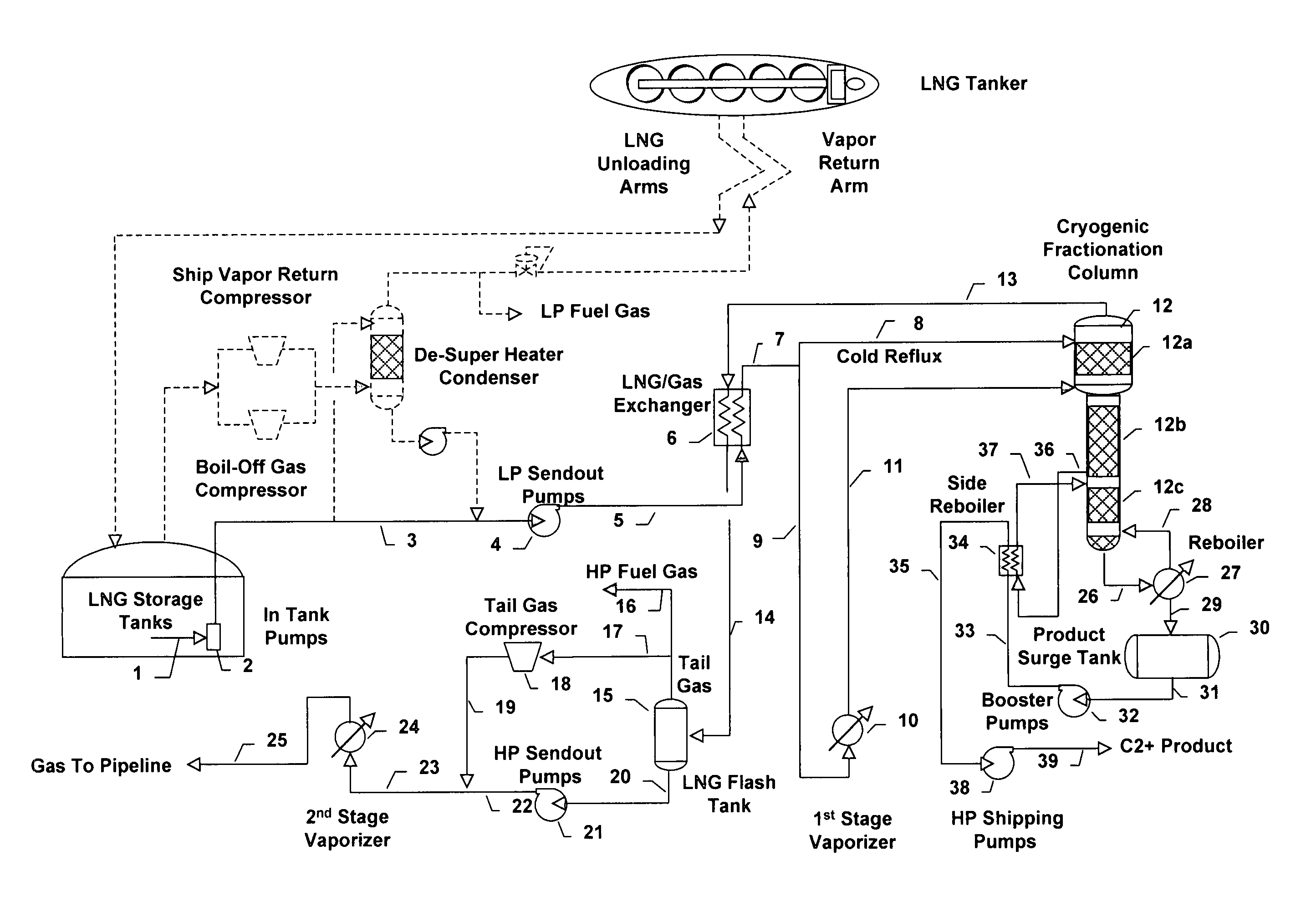

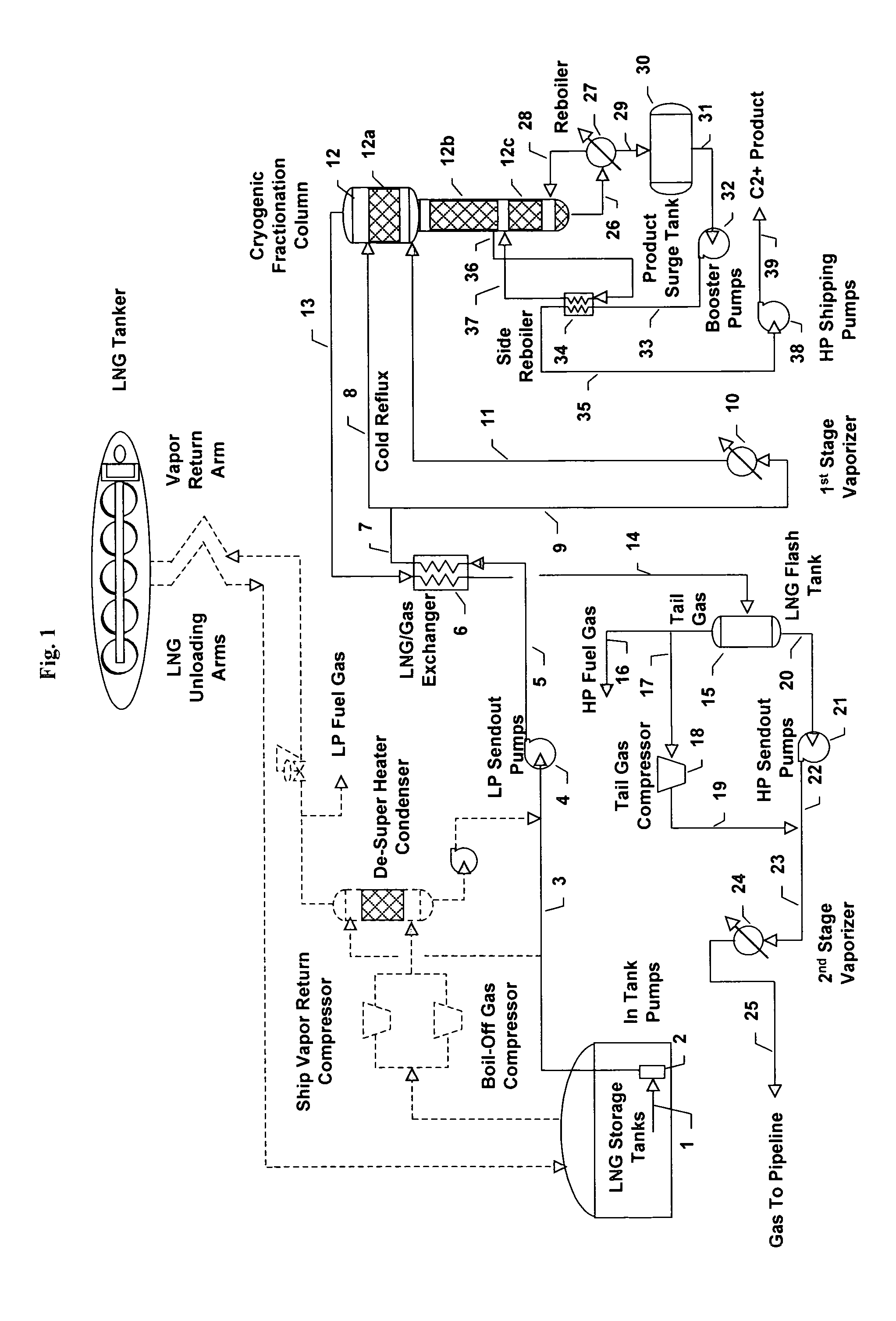

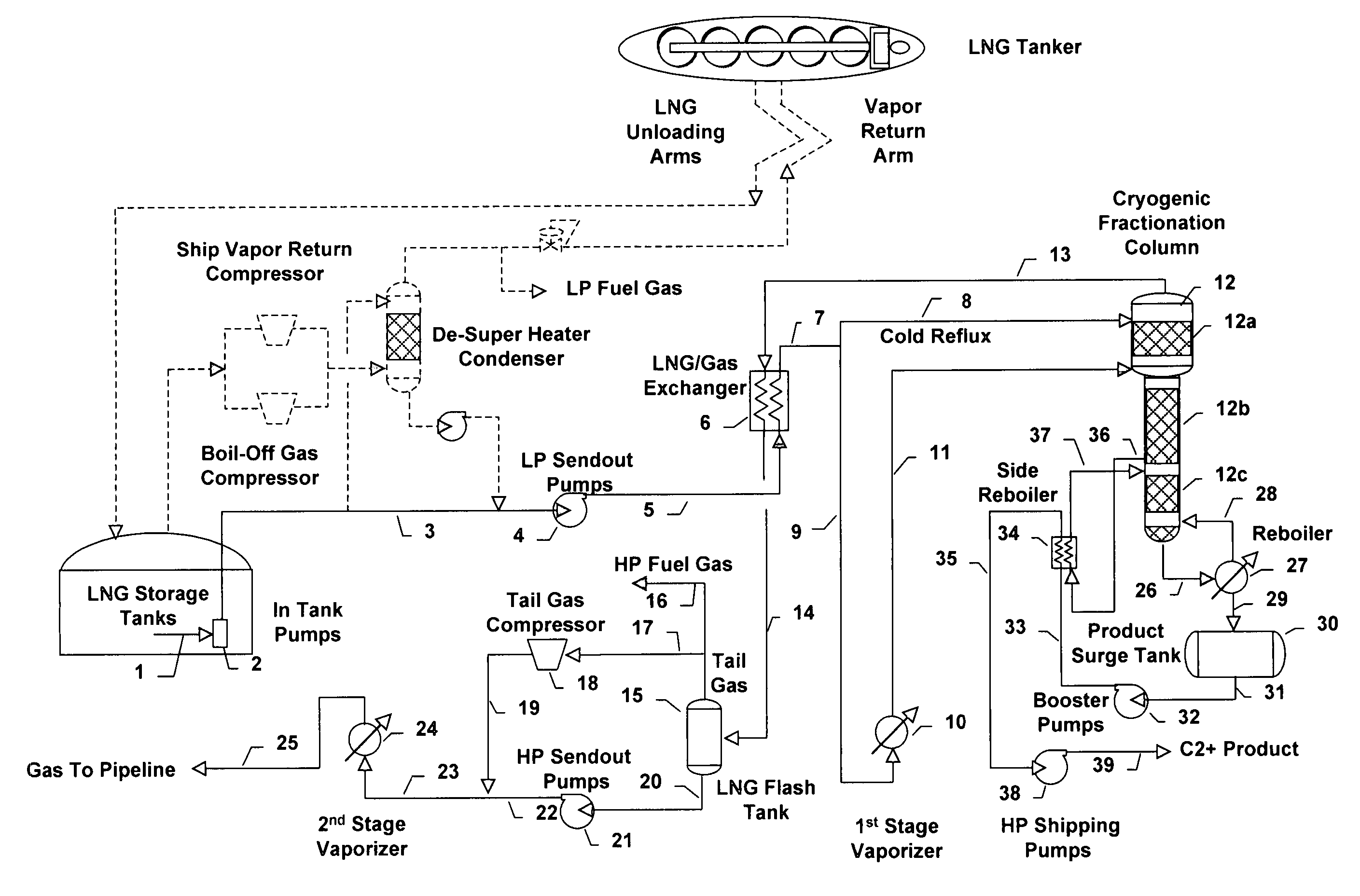

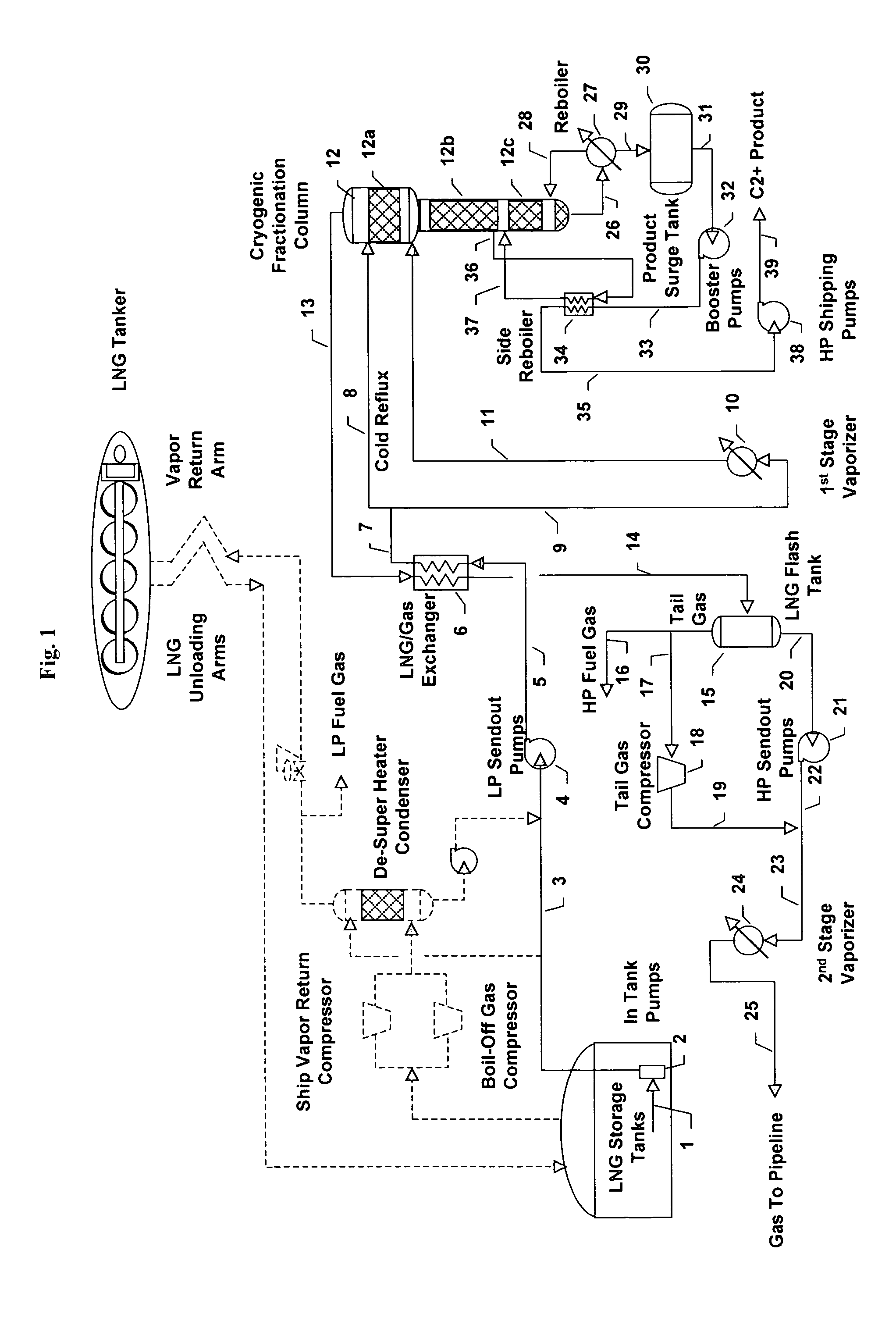

Process for extracting ethane and heavier hydrocarbons from LNG

ActiveUS7165423B2Efficiently extracting NGL productsAdvanced technologySolidificationLiquefactionFuel qualityFractionation

A process for the extraction and recovery of ethane and heavier hydrocarbons (C2+) from LNG. The process covered by this patent maximizes the utilization of the beneficial cryogenic thermal properties of the LNG to extract and recover C2+ form the LNG using a unique arrangement of heat exchange equipment, a cryogenic fractionation column and processing parameters that essentially eliminates (or greatly reduces) the need for gas compression equipment minimizing capital cost, fuel consumption and electrical power requirements.This invention may be used for one or more of the following purposes:to condition LNG so that send-out gas delivered from an LNG receiving and regasification terminal meets commercial natural gas quality specifications;to condition LNG to make Lean LNG that meets fuel quality specifications and standards required by LNG powered vehicles and other LNG fueled equipment;to condition LNG to make Lean LNG so that it can be used to make CNG meeting specifications and standards for commercial CNG fuel;to recover ethane, propane and / or other hydrocarbons heavier then methane from LNG for revenue enhancement, profit or other commercial reasons.

Owner:PI TECH ASSOC INC

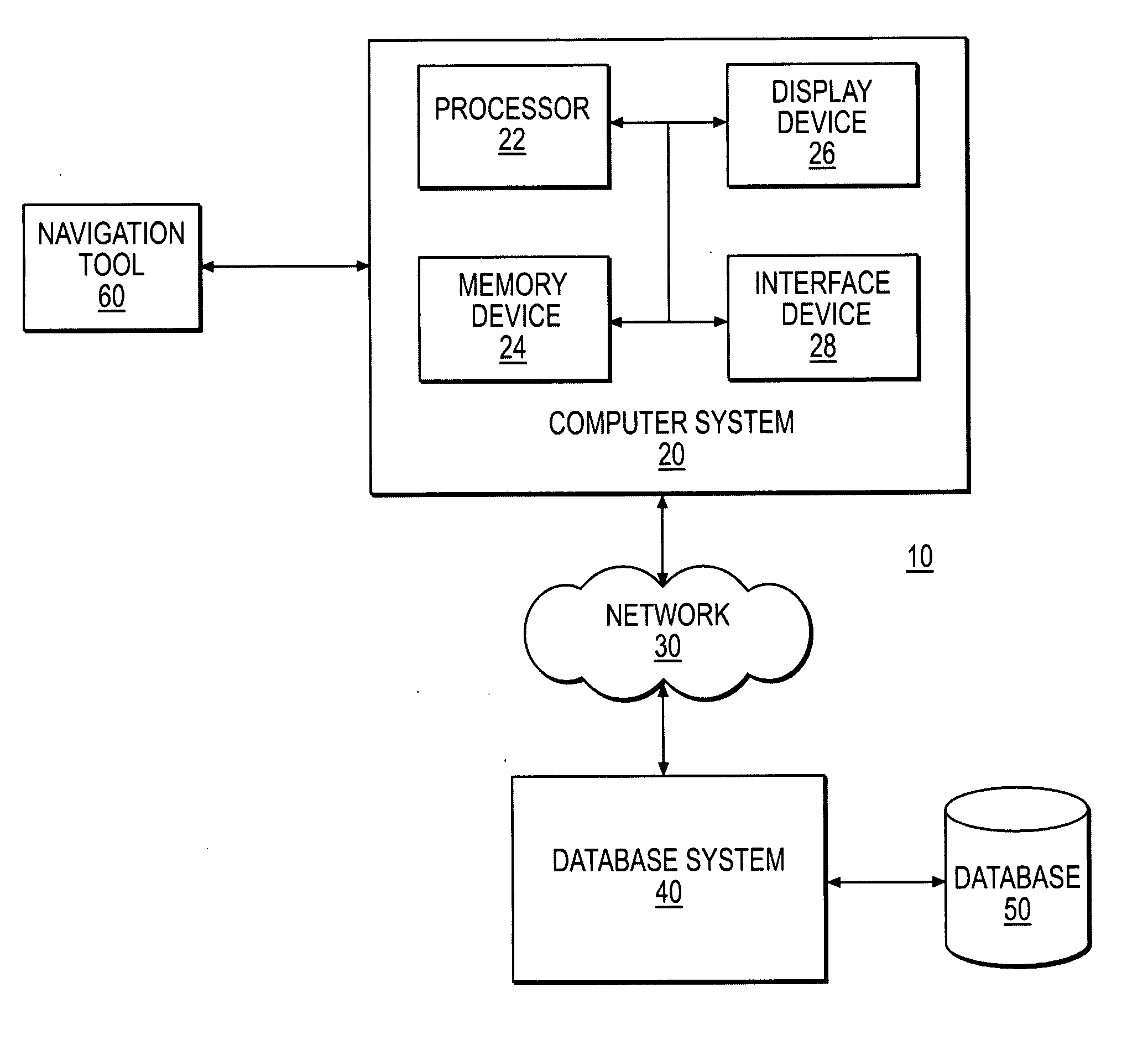

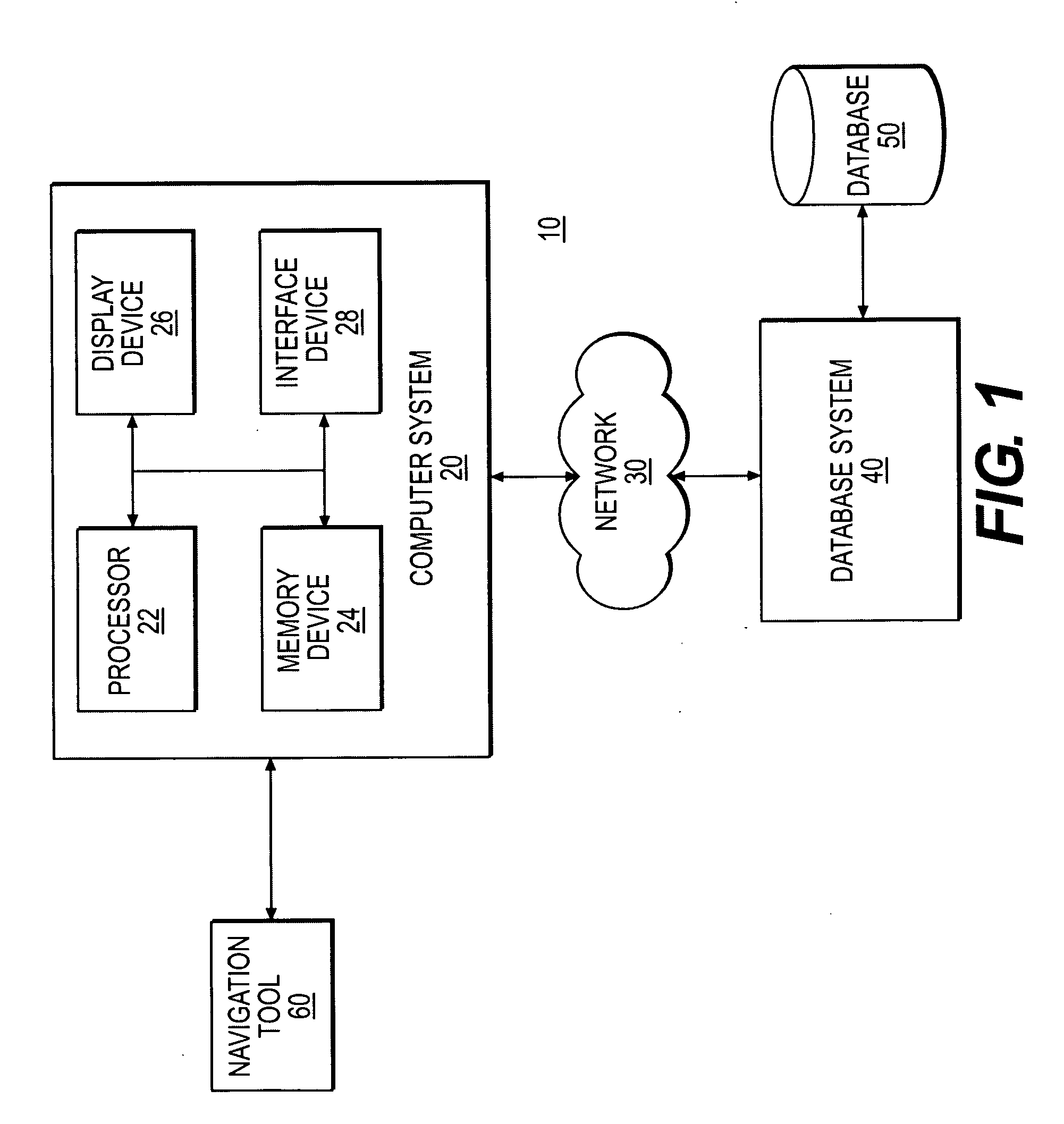

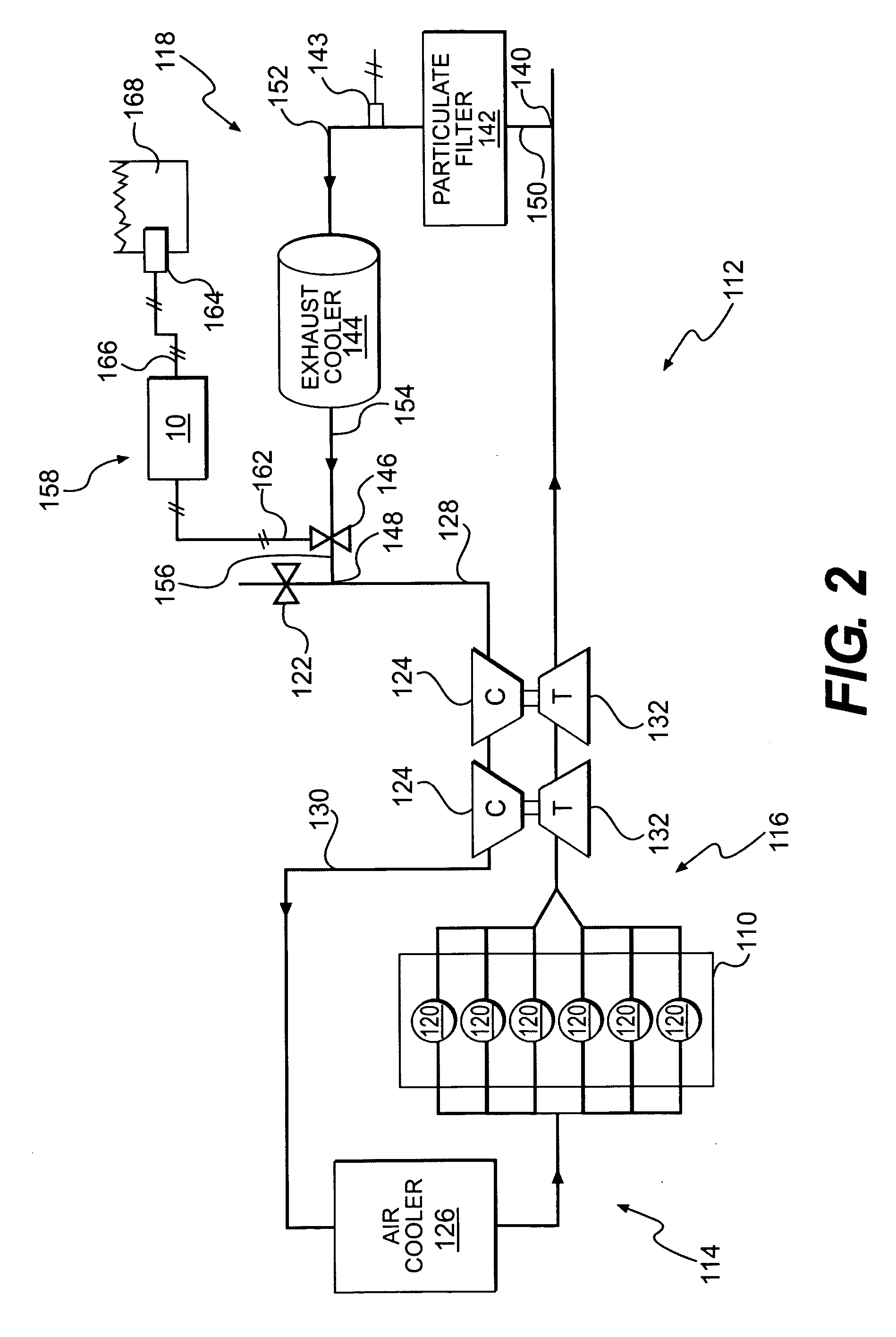

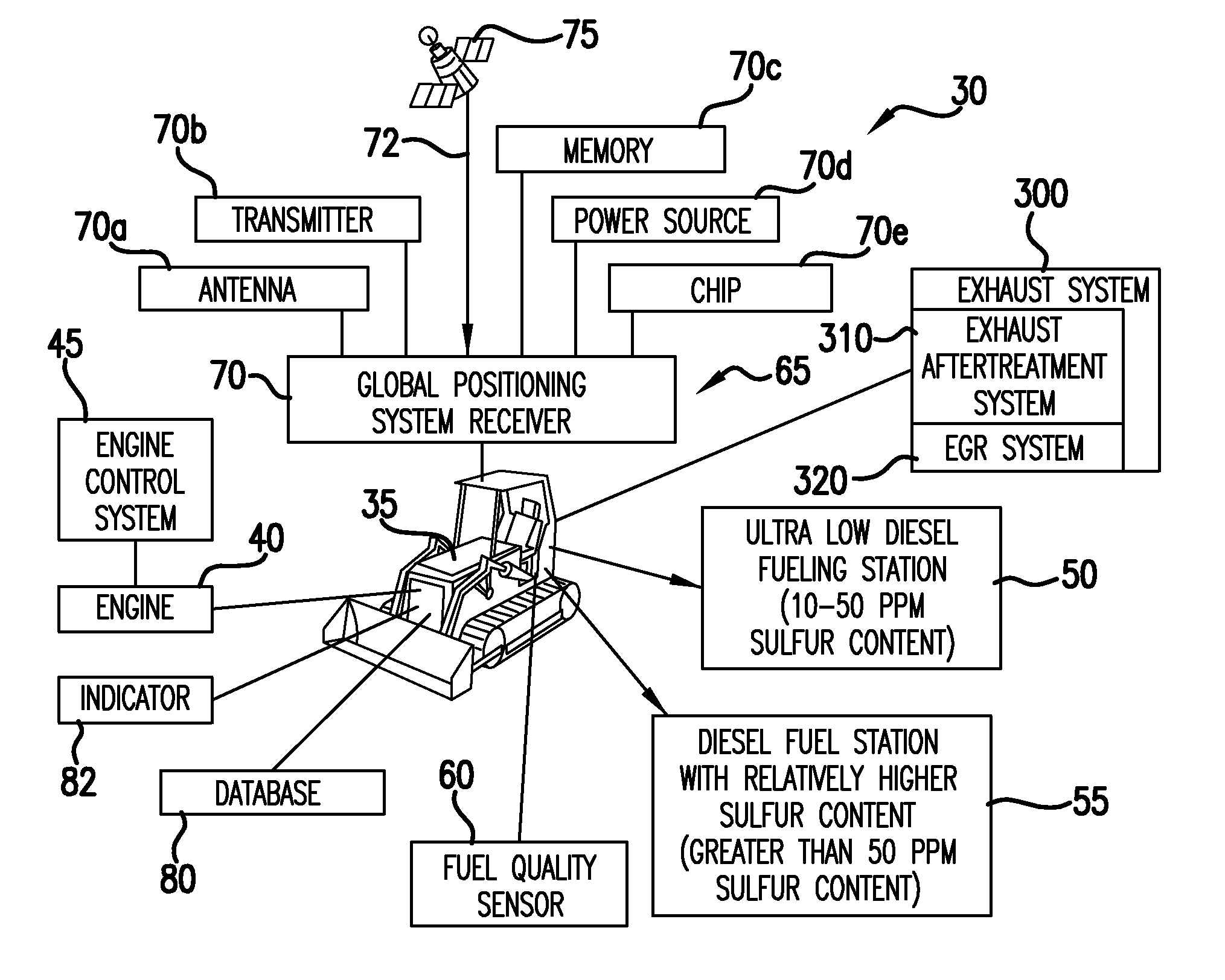

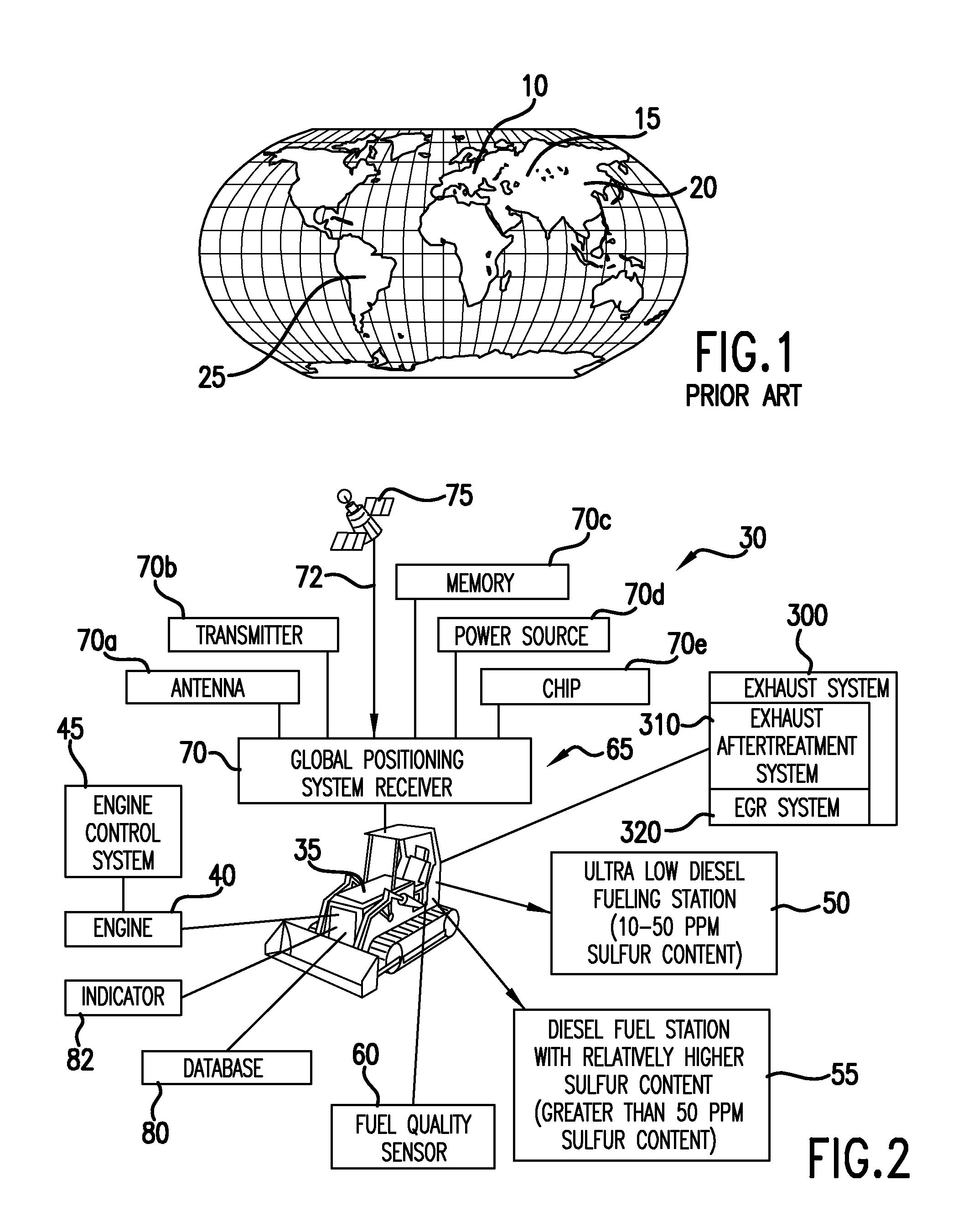

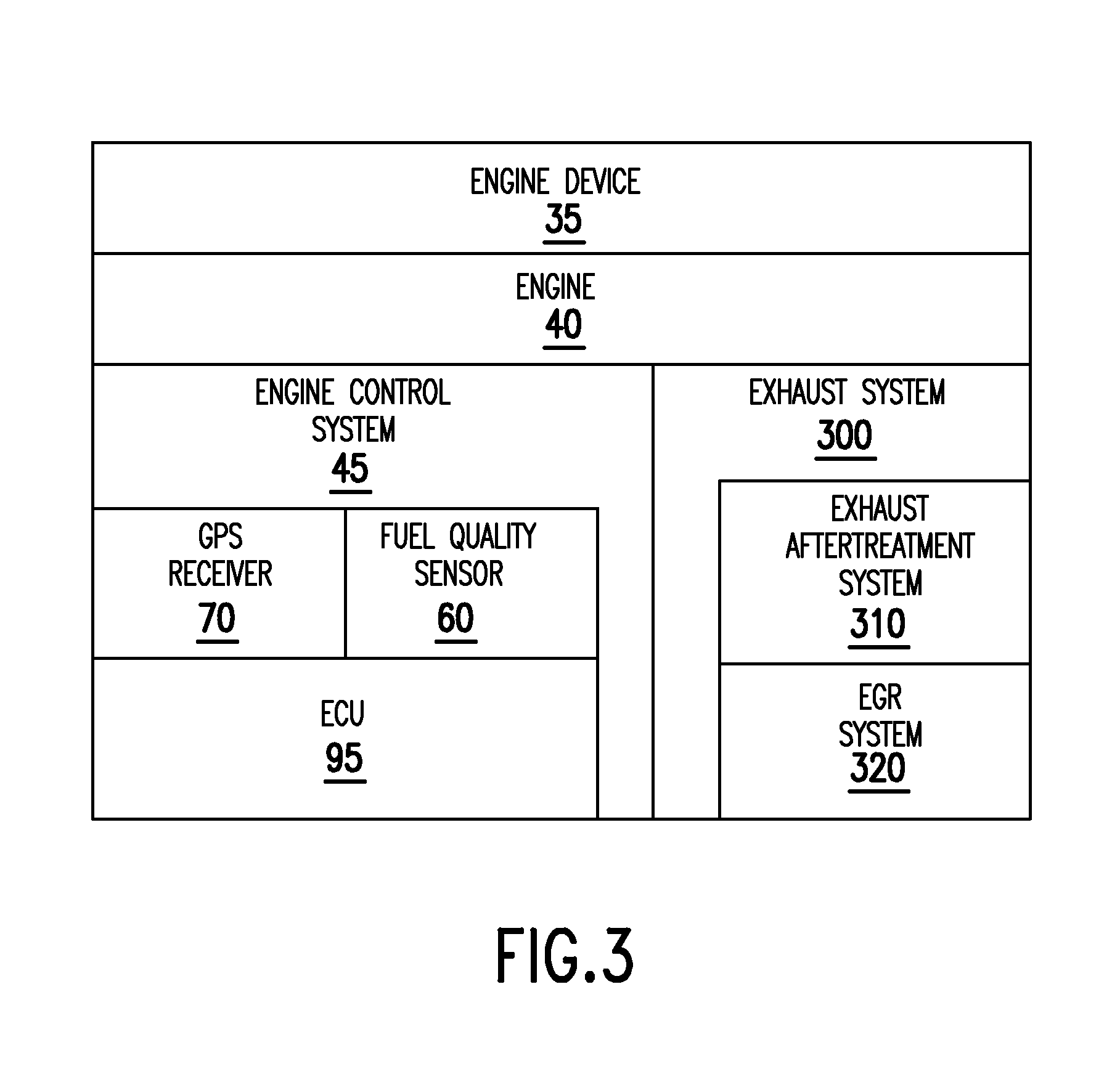

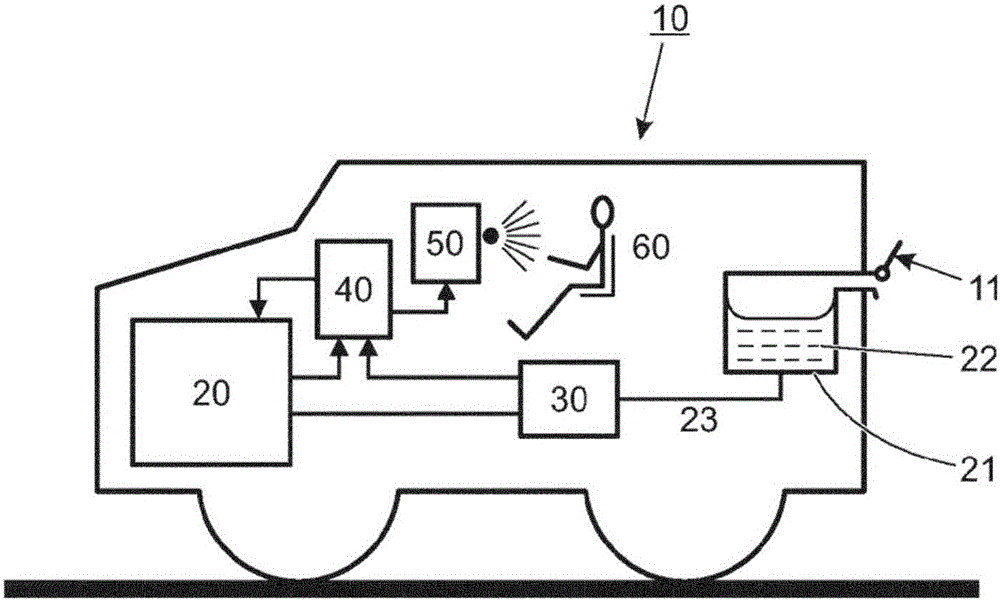

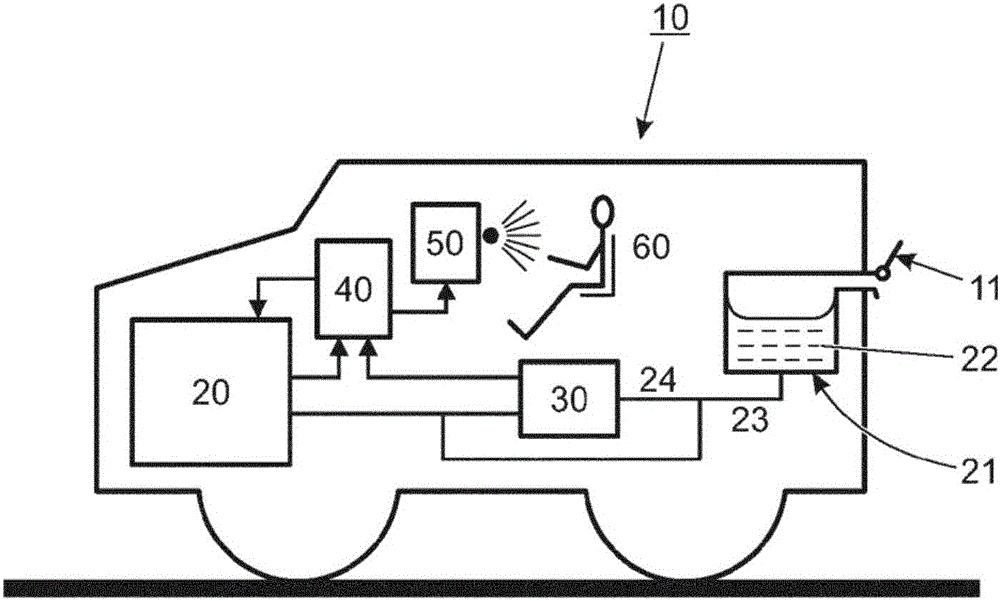

Exhaust control system implementing fuel quality detection

An exhaust control system for a power source is disclosed. The exhaust control system includes a navigation tool and a processor. The navigation tool is configured to detect a geographical location of a power source. The processor is configured to compare the geographical location of the power source with fuel-location data stored in a database. The exhaust control system is configured to modify, activate, or deactivate at least one engine control system, or activate or deactivate at least one power source warning system, based on a result of comparing the geographical location of the power source with the fuel-location data.

Owner:CATERPILLAR INC

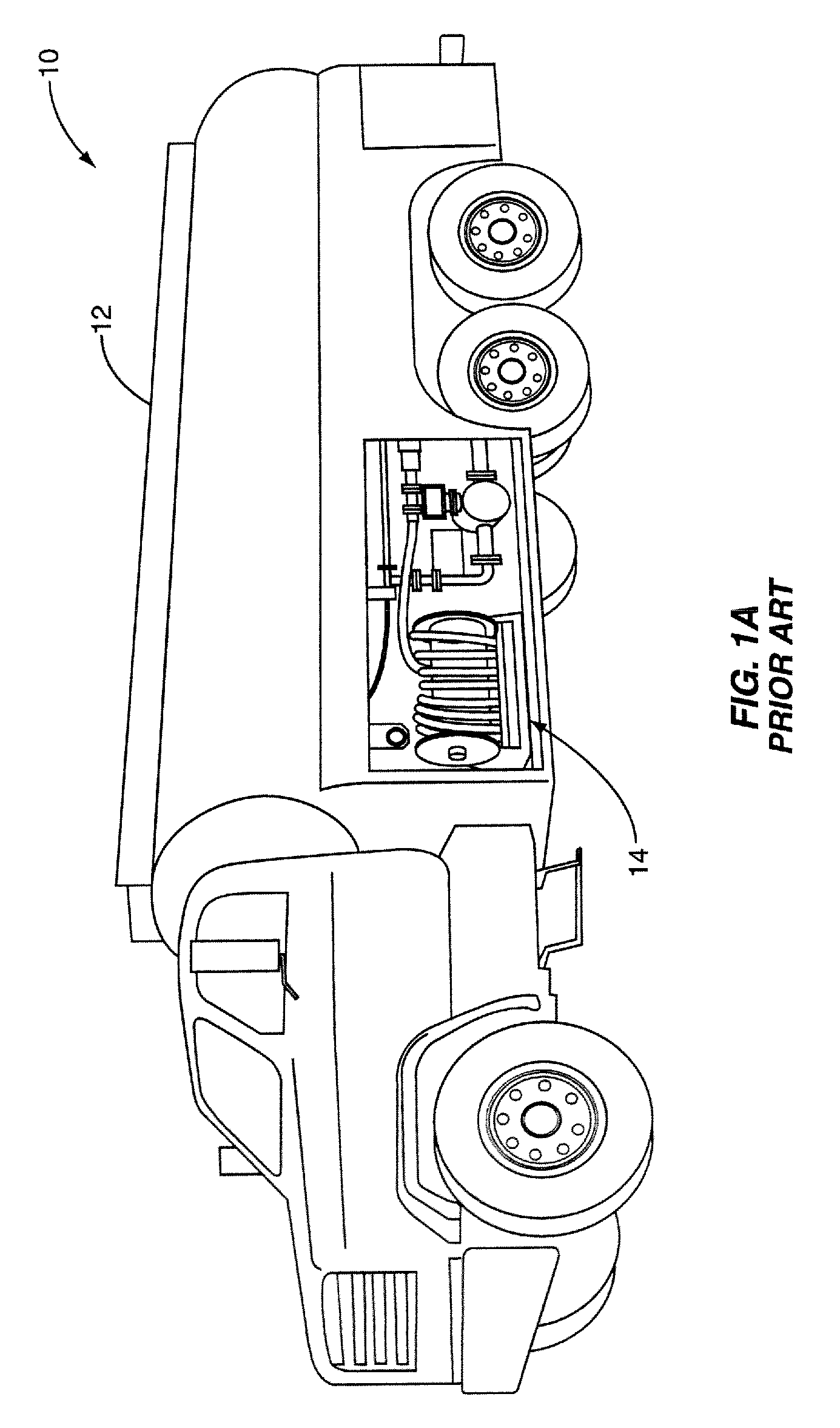

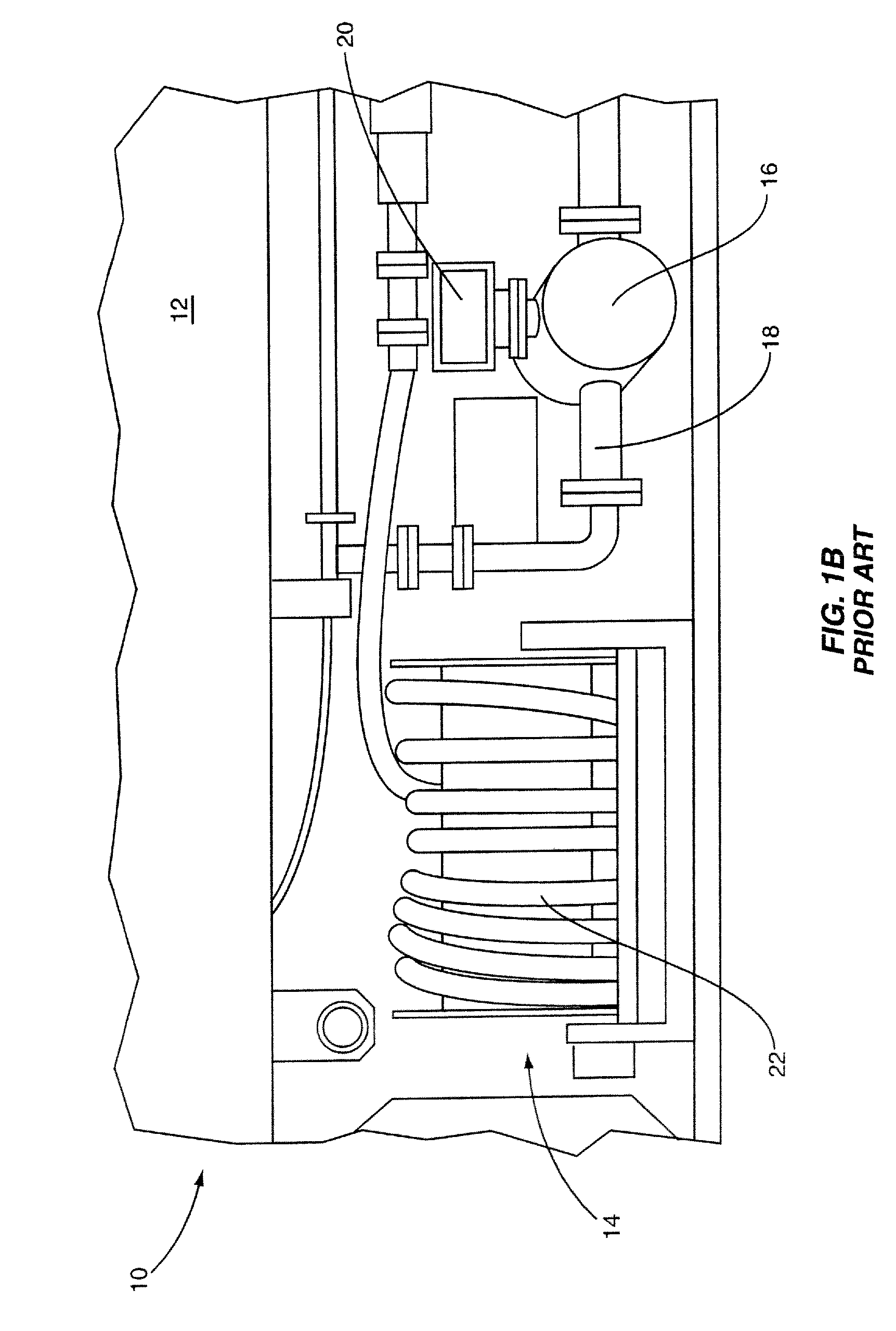

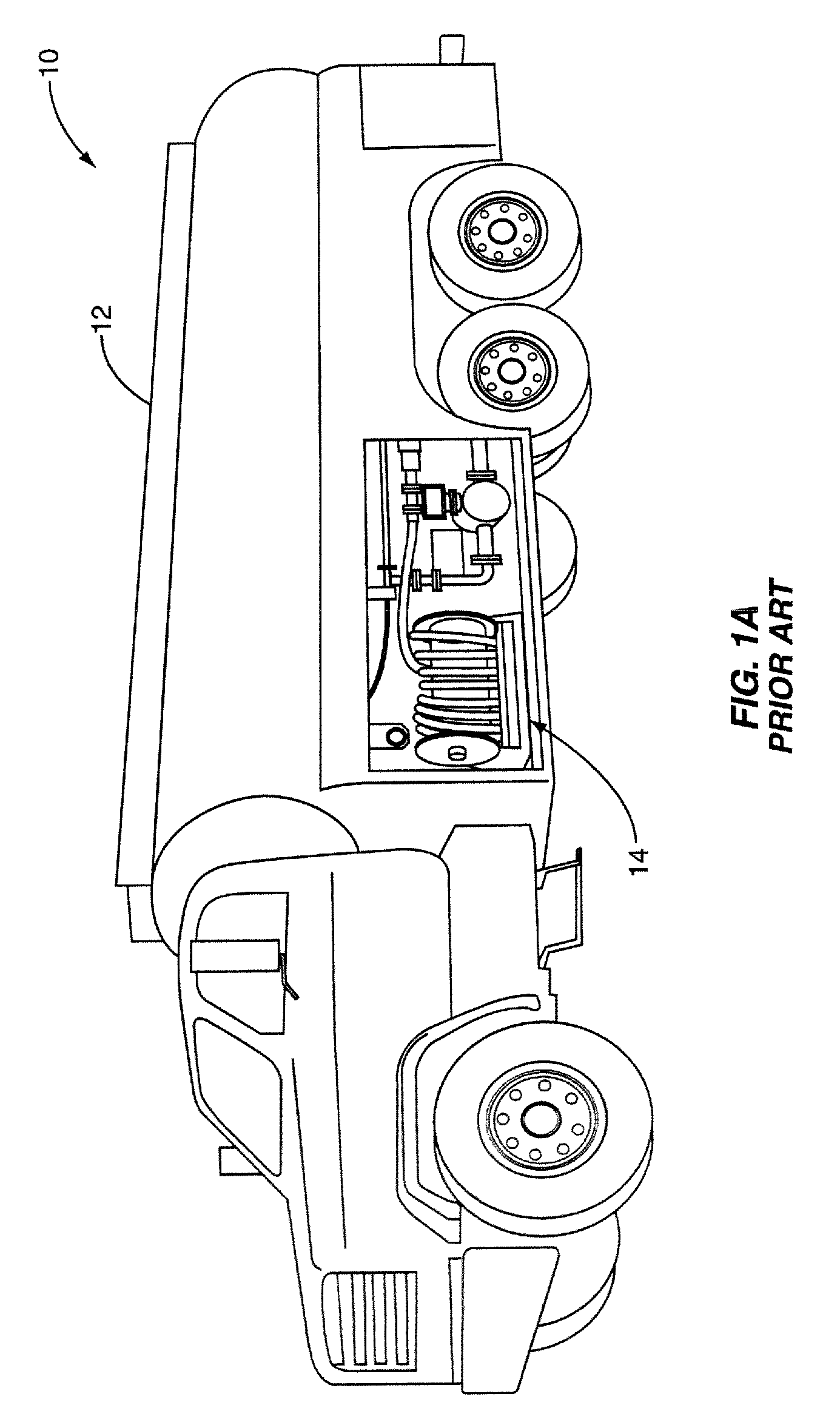

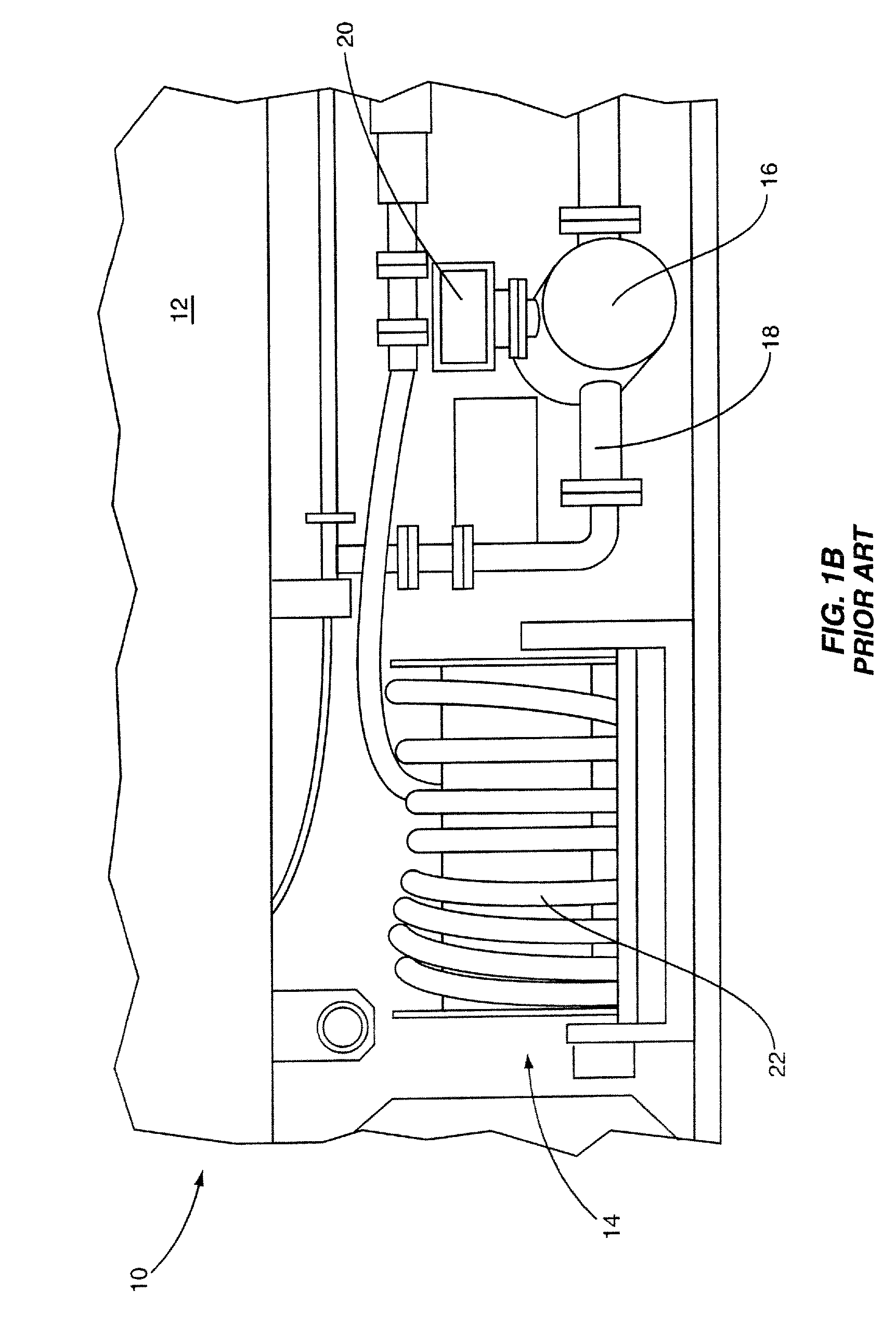

Automated Fuel Quality Detection and Dispenser Control System and Method, Particularly for Aviation Fueling Applications

ActiveUS20080230146A1Reduce riskAvoid refuelingLiquid handling installationsLevel indicatorsWater detectorAviation

A fuel quality monitoring system and method to automatically and / or continuously monitor quality of fuel dispensed and control the operation of the fuel dispenser. The control system monitors fuel quality to prevent unsafe refuelings when the fuel quality is unacceptable. In one embodiment, a combination of a differential pressure sensor, a water detector, and / or a particle monitor is employed inline the fuel flow path of a fuel dispenser, and in particular an aviation refueling truck, to monitor the quality of the fuel. If fuel quality is at an acceptable level although not ideal, the control system can allow fueling with the generation of reports and alarms. If the fuel quality is unacceptable, fuel flow can be stopped. If the differential pressure across the filter indicates a high degree of debris and / or water retention, the control system can automatically lower the flow rate to reduce the risk of filter breakdown without completely preventing fueling until the filter can be replaced.

Owner:FUEL GUARD SYST +1

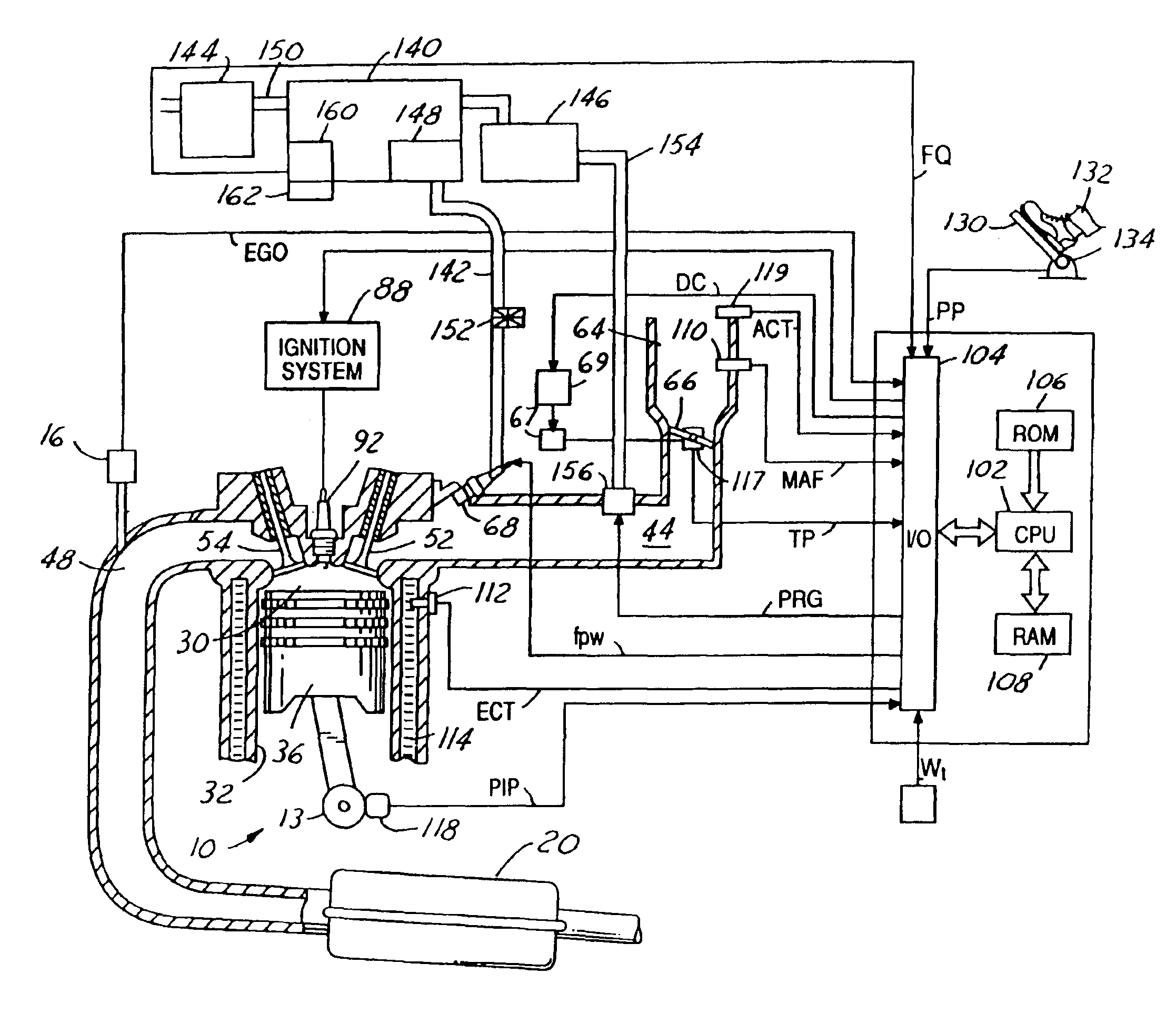

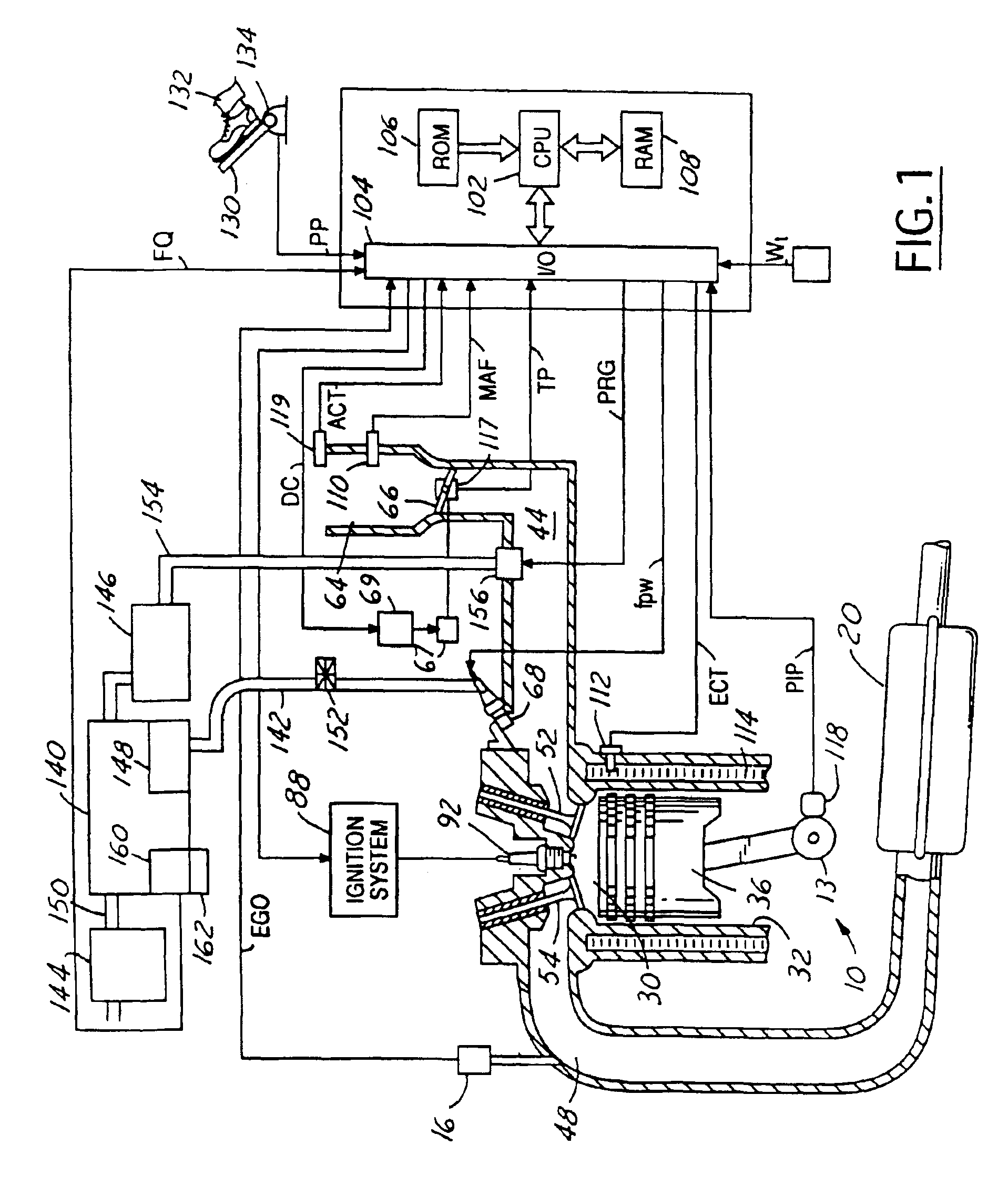

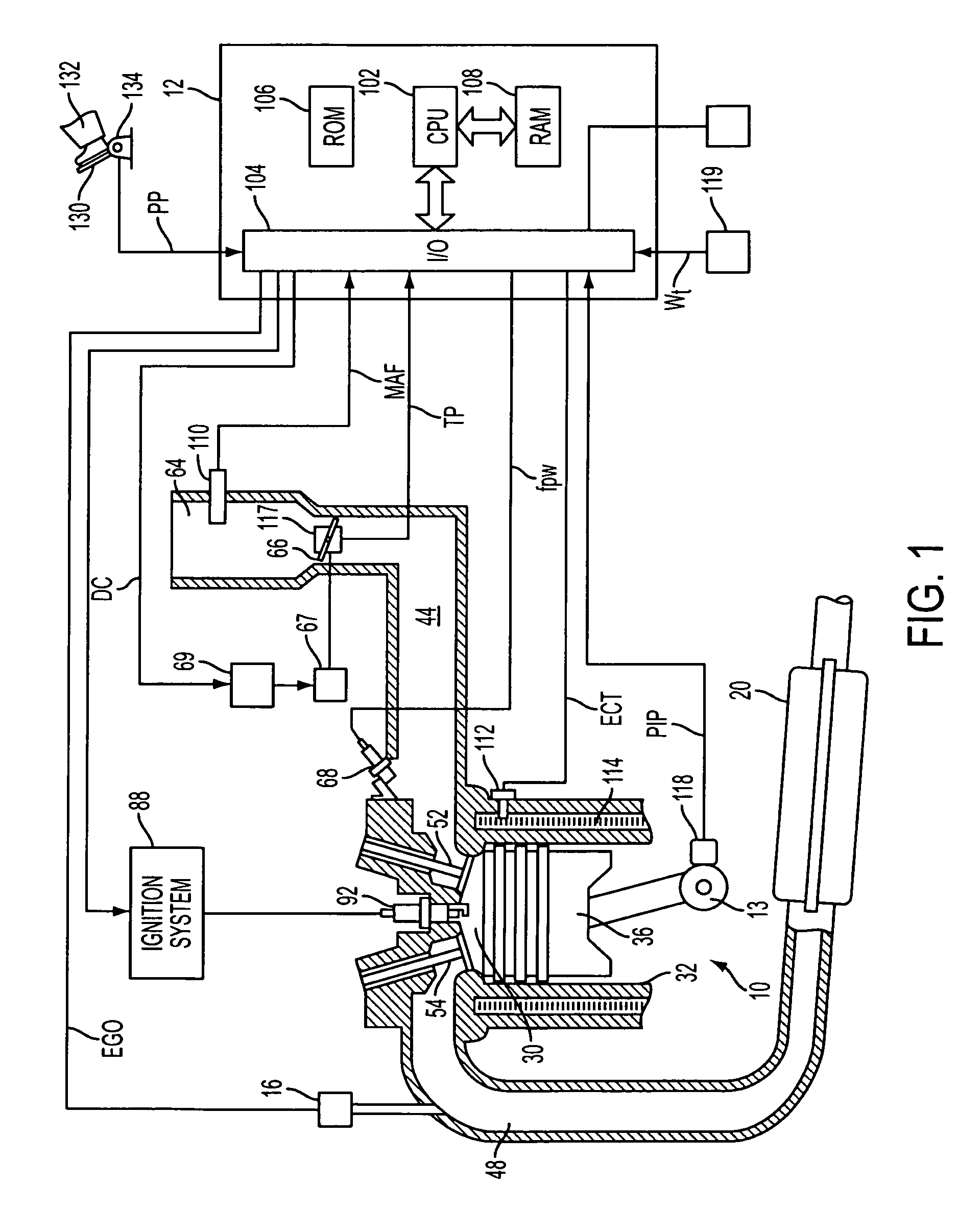

Engine control with fuel quality sensor

InactiveUS6935311B2Improved cold-start emissionImprove driveabilityElectrical controlInternal combustion piston enginesGasoline fuelFuel quality

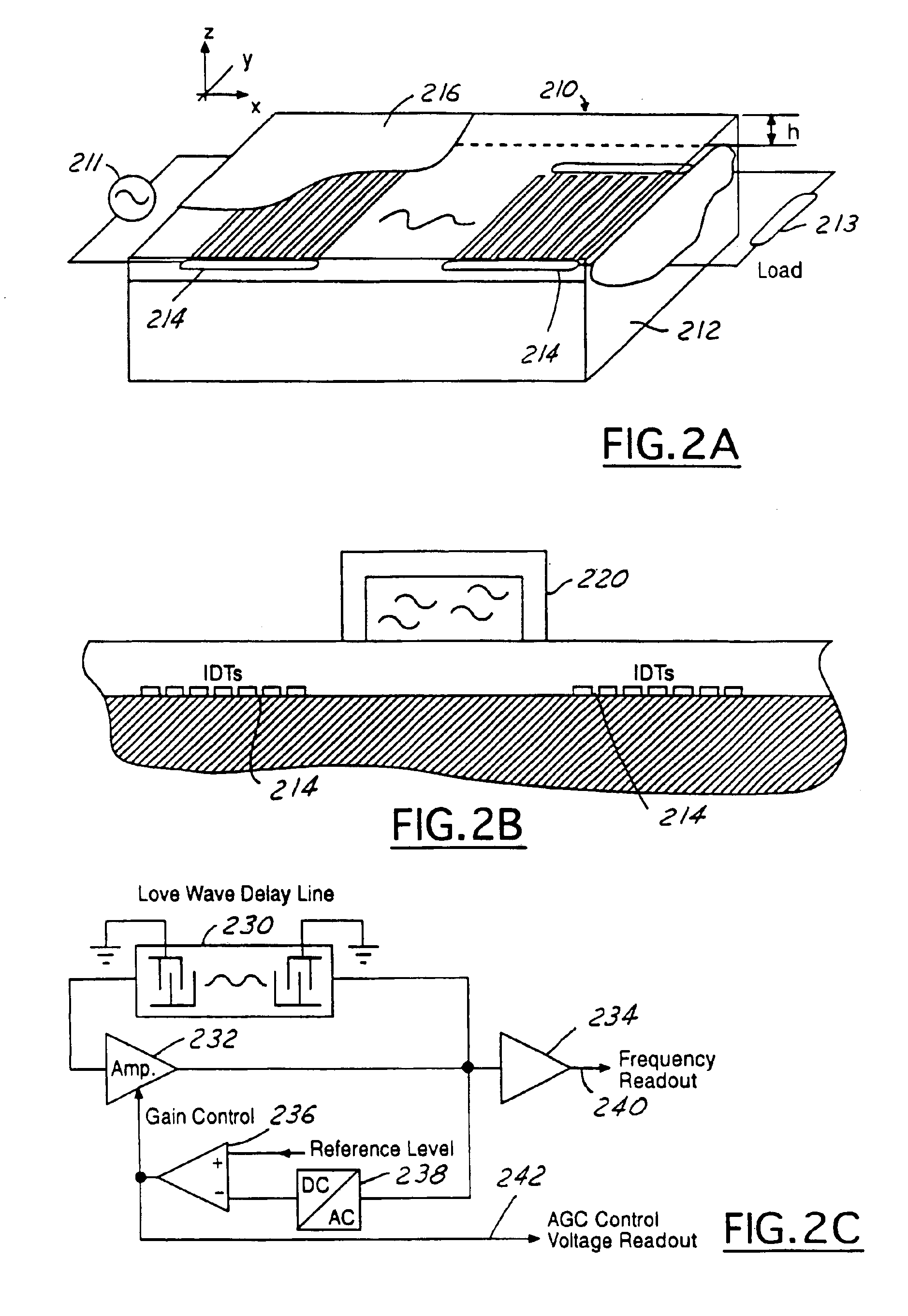

A system is described using a fuel quality sensor for controlling various aspects of engine operation. In particular, an acoustic wave sensor is utilized to measure viscosity and density of gasoline fuels. This measurement is utilized to predict engine combustion quality during an engine start. Based on the prediction, the method adjusts engine operating parameters (such as fuel injection amount and ignition timing) to achieve improved vehicle driveability and engine combustion.

Owner:FORD GLOBAL TECH LLC

Method for developing a unified quality assessment and providing an automated fault diagnostic tool for turbine machine systems and the like

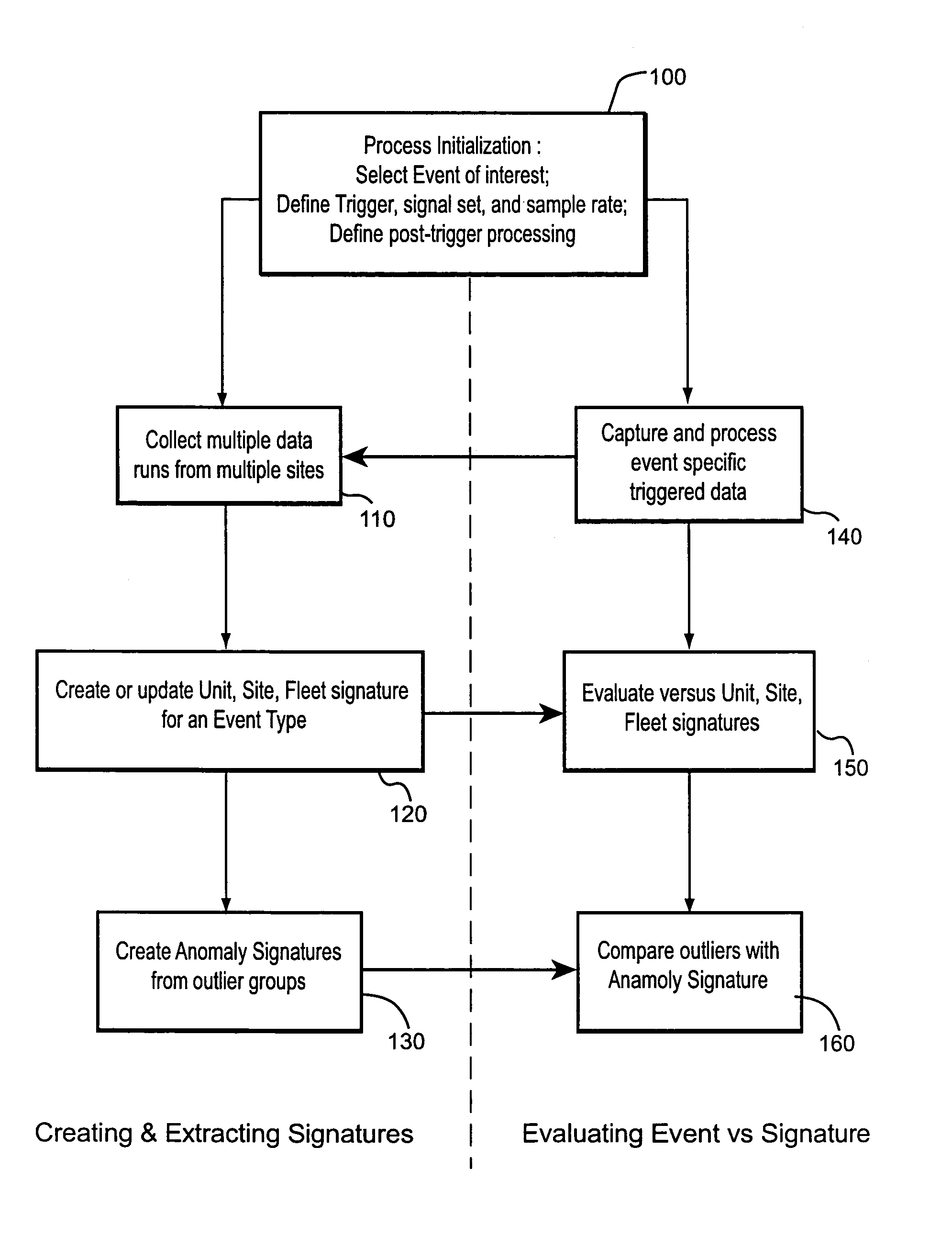

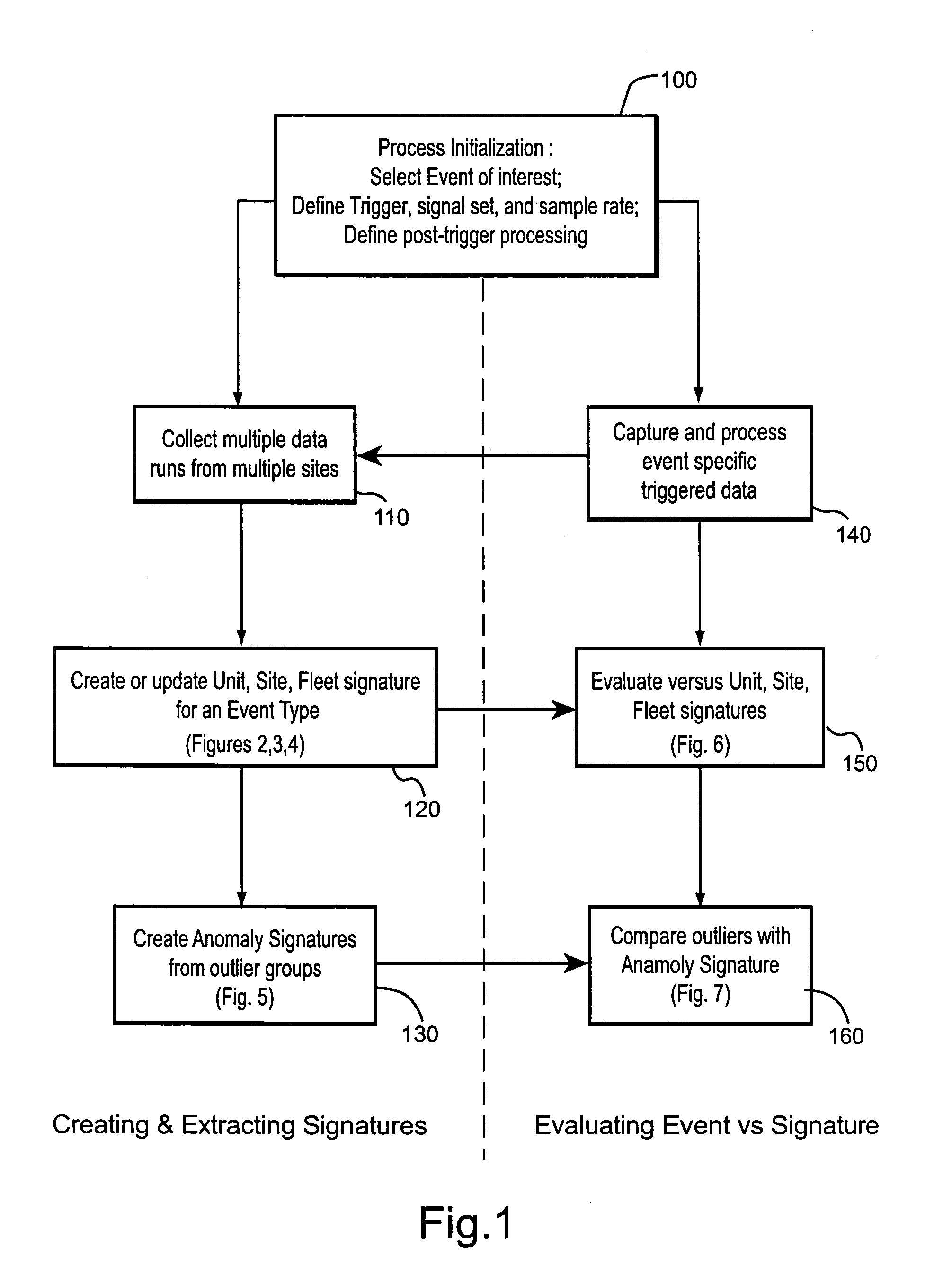

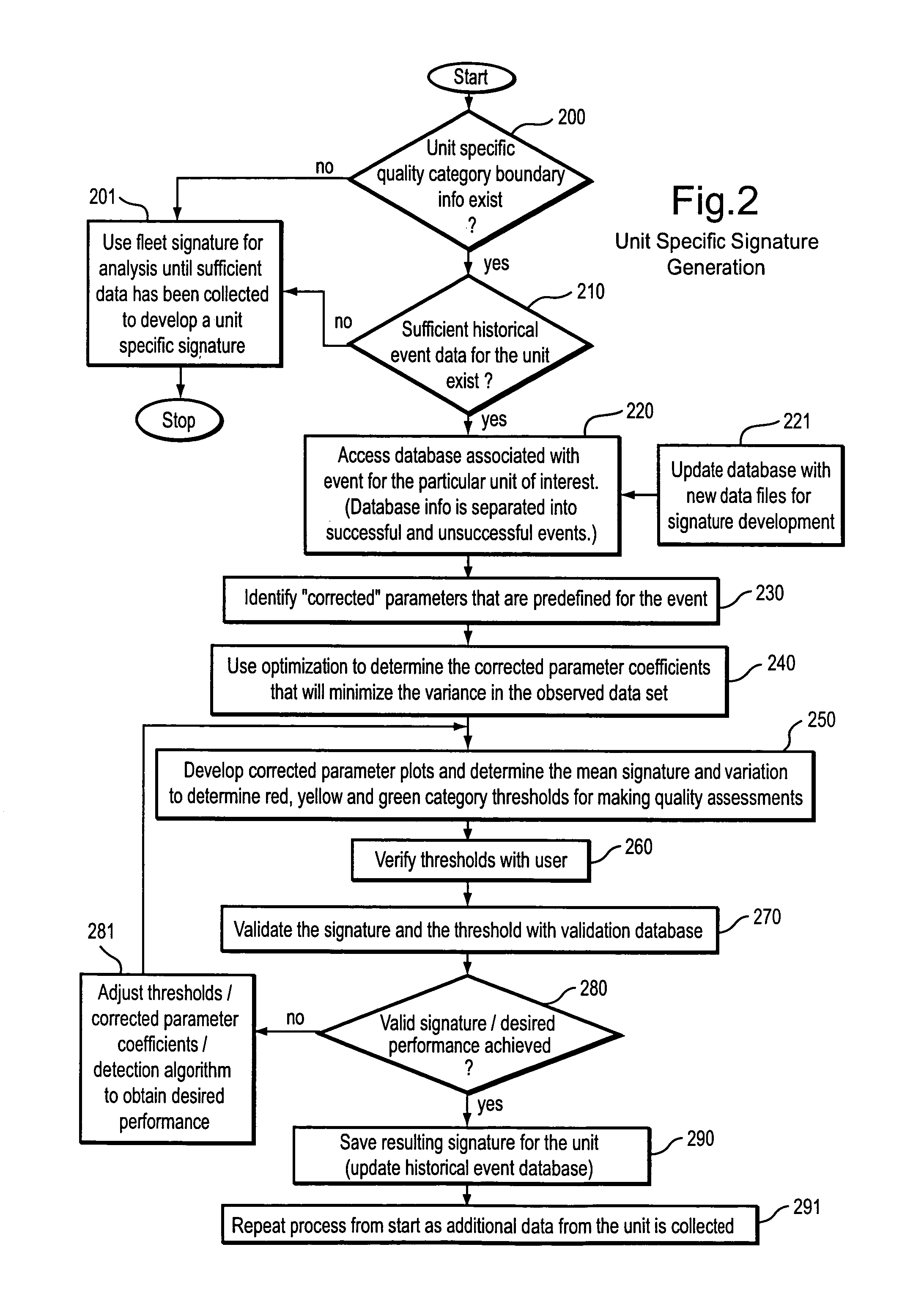

InactiveUS6973396B1Accurate analysisAccurate assessmentVibration measurement in solidsMachine part testingFuel qualityMachining system

A computer implemented process is provided for assessing and characterizing the degree of success or failure of an operational event of a machine system such as a fluid compressor machine or turbine machine or the like on a continuous numerical scale. The computer implemented process develops and tracks machine unit signatures, machine site signatures and machine fleet signatures to evaluate various operational events and provide fault detection. At least some sensor data acquired from the machine system during an operational event is transformed to correct or at least reduce variabilities in the data caused by ambient conditions and fuel quality. The transformed data is then analyzed using statistical methods to determine how closely the operational event conforms to an expected normal behavior and the information is used to develop a single comprehensive quality assessment of the event. By saving, tracking and updating operational event assessments over time, machine / component degradation may be recognized at any early stage and corrective action may be initiated in advance of a catastrophic failure.

Owner:GENERAL ELECTRIC CO

Process for extracting ethane and heavier hydrocarbons from LNG

ActiveUS20060042312A1Advanced technologyEfficiently extracting NGL productsSolidificationLiquefactionFuel qualityFractionation

A process for the extraction and recovery of ethane and heavier hydrocarbons (C2+) from LNG. The process covered by this patent maximizes the utilization of the beneficial cryogenic thermal properties of the LNG to extract and recover C2+ form the LNG using a unique arrangement of heat exchange equipment, a cryogenic fractionation column and processing parameters that essentially eliminates (or greatly reduces) the need for gas compression equipment minimizing capital cost, fuel consumption and electrical power requirements. This invention may be used for one or more of the following purposes: to condition LNG so that send-out gas delivered from an LNG receiving and regasification terminal meets commercial natural gas quality specifications; to condition LNG to make Lean LNG that meets fuel quality specifications and standards required by LNG powered vehicles and other LNG fueled equipment; to condition LNG to make Lean LNG so that it can be used to make CNG meeting specifications and standards for commercial CNG fuel; to recover ethane, propane and / or other hydrocarbons heavier then methane from LNG for revenue enhancement, profit or other commercial reasons.

Owner:PI TECH ASSOC INC

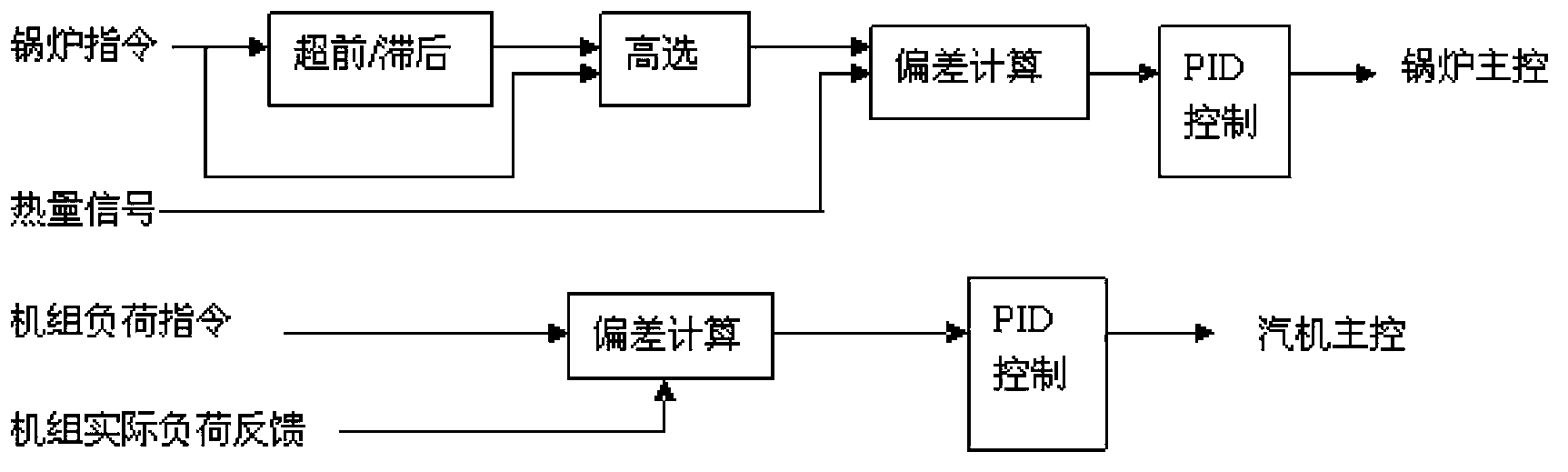

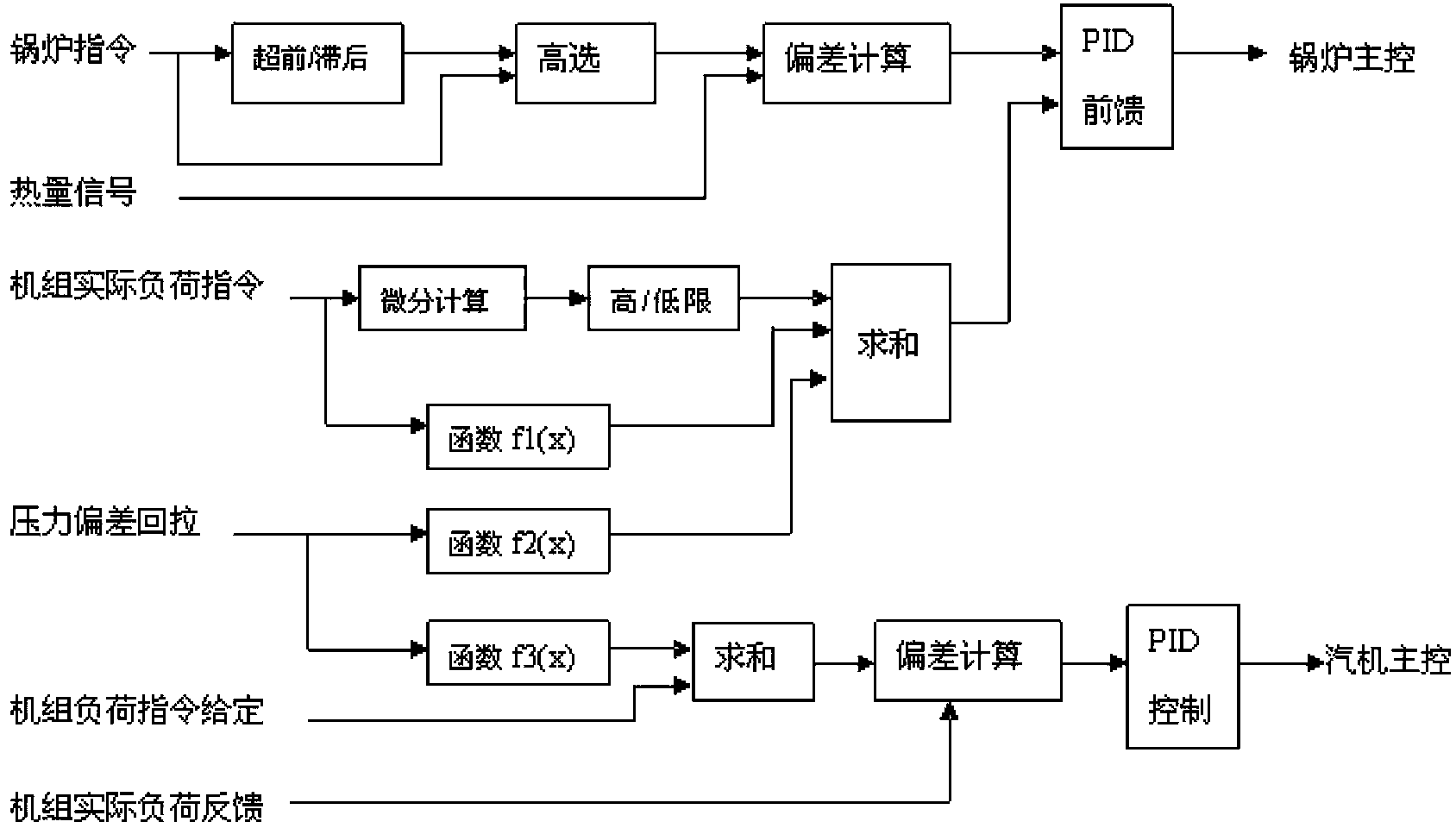

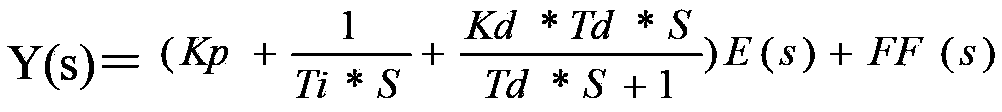

Method for effectively improving quick response on external load change for generator set

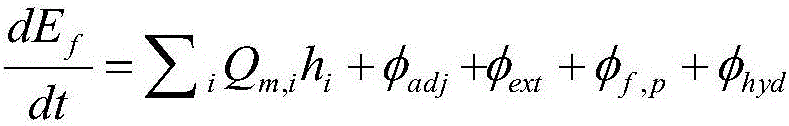

ActiveCN103437838ACompensation for changes in heat storageCompensation for non-linear characteristicsBoiler controlSteam engine plantsFuel qualityEngineering

The invention relates to a method for effectively improving quick response on external load change for a generator set. The method comprises the following steps of (1) quickly estimating rough fuel quantity required by a generator set under a practical load command via a function f1(x) by a generator set load control loop; (2) according to the specific mode of a boiler powder preparing system, properly regulating the function f1(x); (3) adding a differential module into the generator set load control loop, and regulating the differential action intensity and the differential action time of the practical load command; (4) leading the deviation signal of machine front pressure into the master-control feedforward loop of the boiler and the master-control loop of a steam turbine, and meanwhile, changing the fuel quality of the boiler and the capacity of a steam turbine generator set. According to the method disclosed by the invention, the change of boiler heat storage quantity in the generator set load change process is effectively compensated, the nolinear characteristic of the coal-fired boiler is compensated, and the capability of the generator set for quickly adapting to the external load is improved.

Owner:STATE GRID CORP OF CHINA +1

Apparatuses and methods for providing visual indication of dynamic process fuel quality delivery conditions with use of multiple colored indicator lights

InactiveUS20140202580A1Quick fixLiquid fillingLiquid transferring devicesFuel qualityVisual perception

Embodiments of the present disclosure include a fuel dispensing apparatus for delivering fuel from a fuel source, and related components, systems, and methods. As fuel is delivered from the fuel source, fuel quality is monitored using one or more fuel quality sensor devices, which detect one or more corresponding fuel quality characteristics. In response to the detected fuel quality characteristics, a visual indication of fuel quality is provided at a visual indication device. The visual indication includes a unique combination of a color component and a frequency component, thereby allowing a user of the fuel dispensing apparatus to quickly determine fuel quality status as the fuel is delivered from the fuel source.

Owner:FUEL GUARD SYST

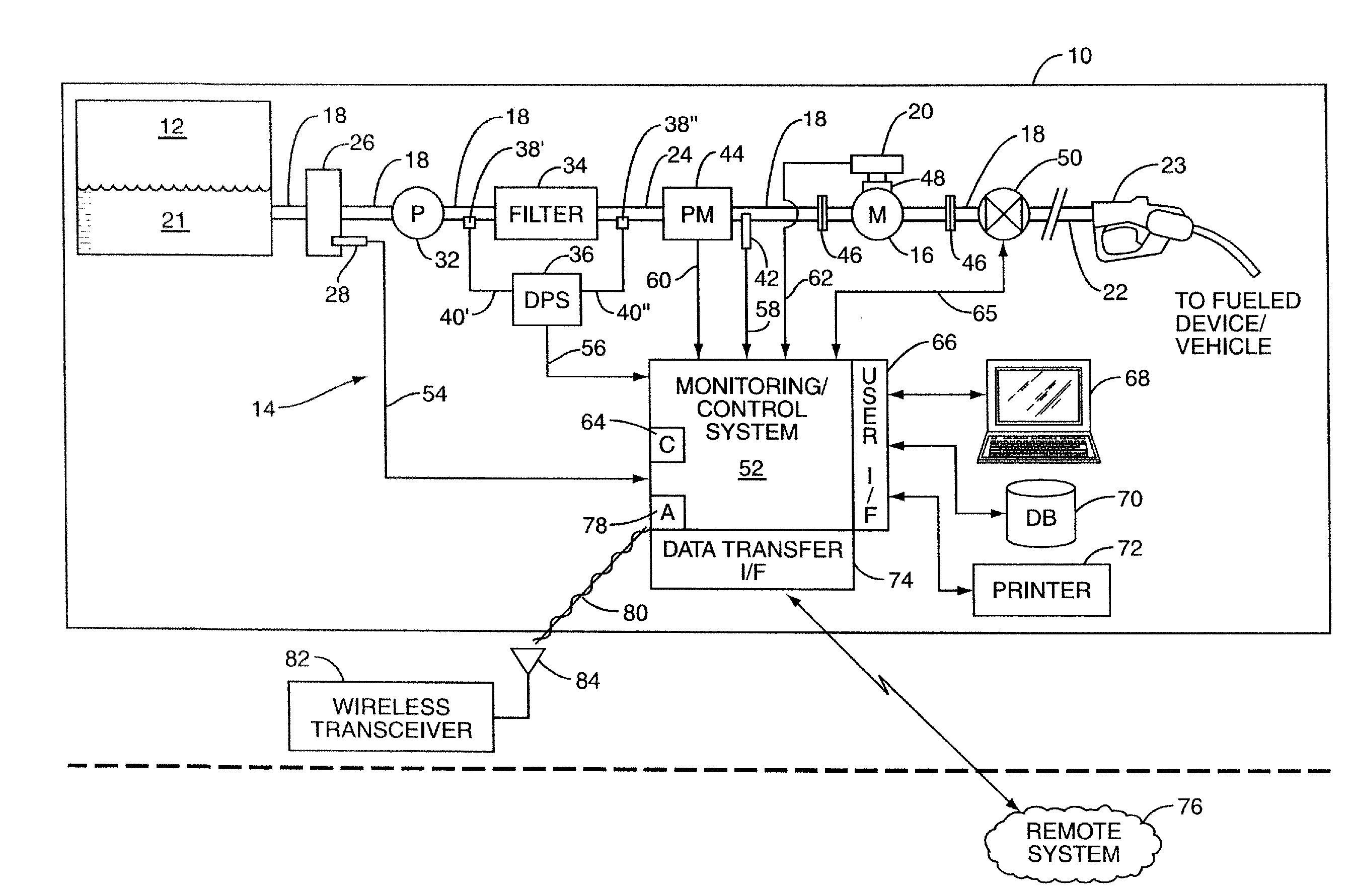

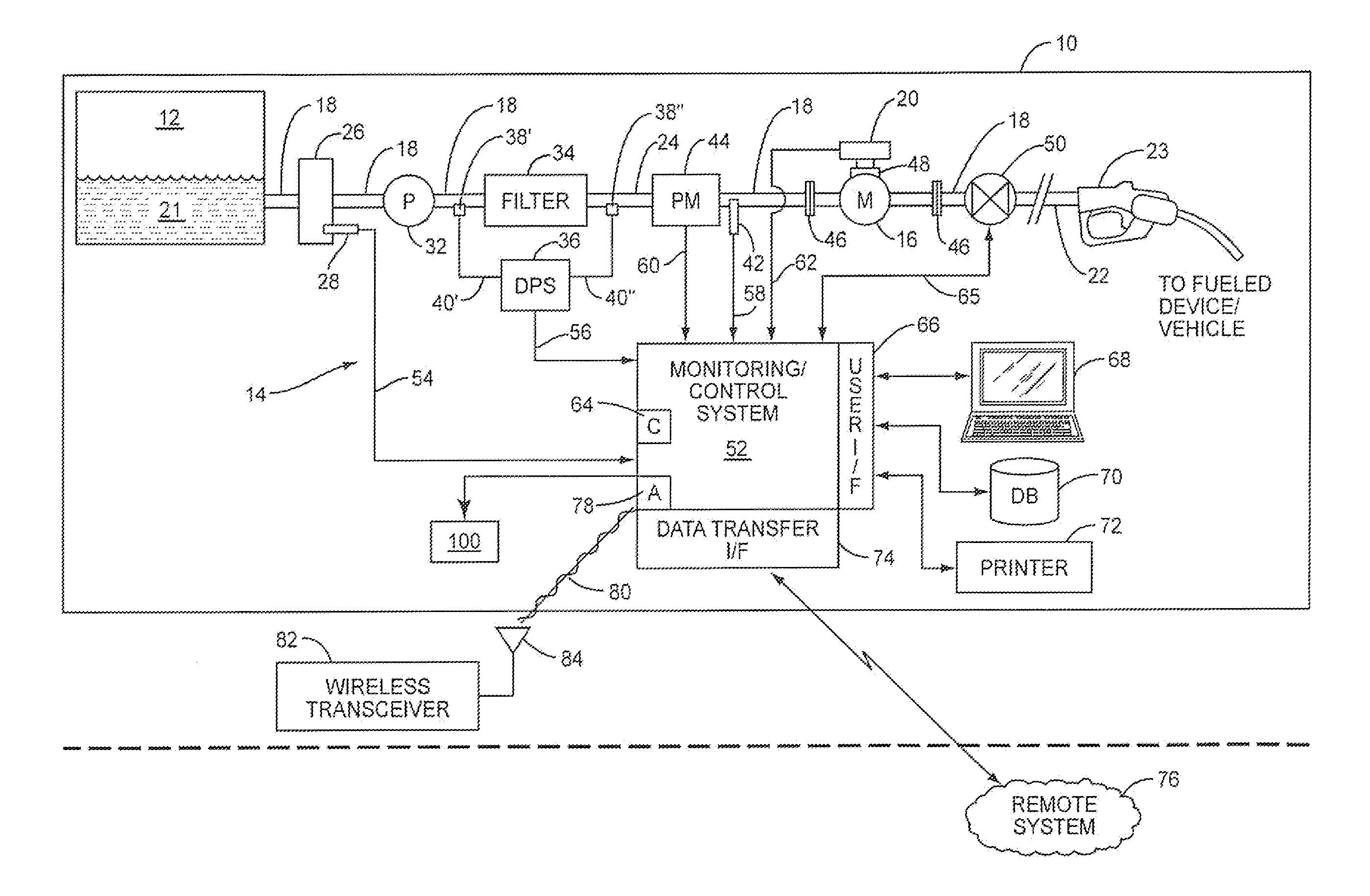

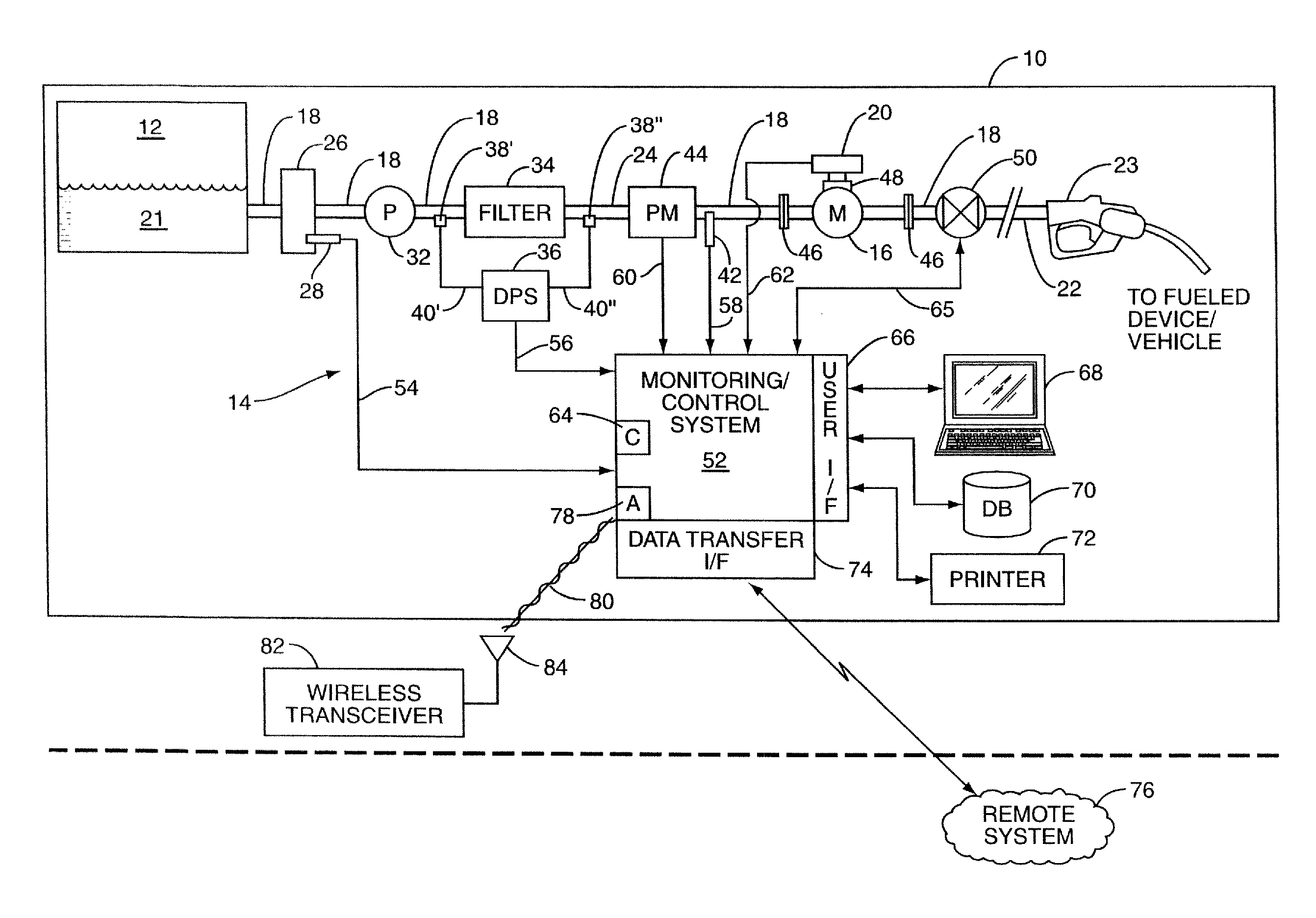

Fuel Quality Traceable and Remote System

ActiveUS20110130882A1Quality improvementPromote generationLiquid handling installationsEnergy efficient operational measuresRemote systemFuel quality

A fuel quality traceable and remote system for monitoring and controlling fuel characteristics during transport from a fuel supply to a supplied device is provided. The system includes one or more subsystems that include at least one sensor monitoring the characteristics of the fuel. The sensor operably sends the data relating to the characteristics to a data register-transmitter which sends the data to a base station that uploads the data to a remote server. The remote server is remotely accessible by a user. The system can also generate warning messages to warn a user when the characteristics are outside a tolerable range. Further, the system can automatically or manually interrupt fuel transport when the characteristics are outside a tolerable range.

Owner:PECOFACET OKLAHOMA

Engine control system and method based on fuel quality

An engine control system and method includes sensing the quality of fuel in the engine relative to emissions, by for example sensing the level of an emission related constituent, such as sulfur. A fuel quality sensor detects a fuel quality of a fuel, such as the sulfur level in the fuel, and provides a signal in response to the fuel quality. The engine control system also includes a navigation device to determine whether an engine is located in a regulated or non-regulated region. The engine control system receives the signal and controls engine operation by, for example, enabling or disabling one or more engine algorithms to improve performance of the engine based on the fuel quality signal or, in other embodiments, the combination of the fuel quality and the location of the engine.

Owner:CUMMINS INTPROP INC

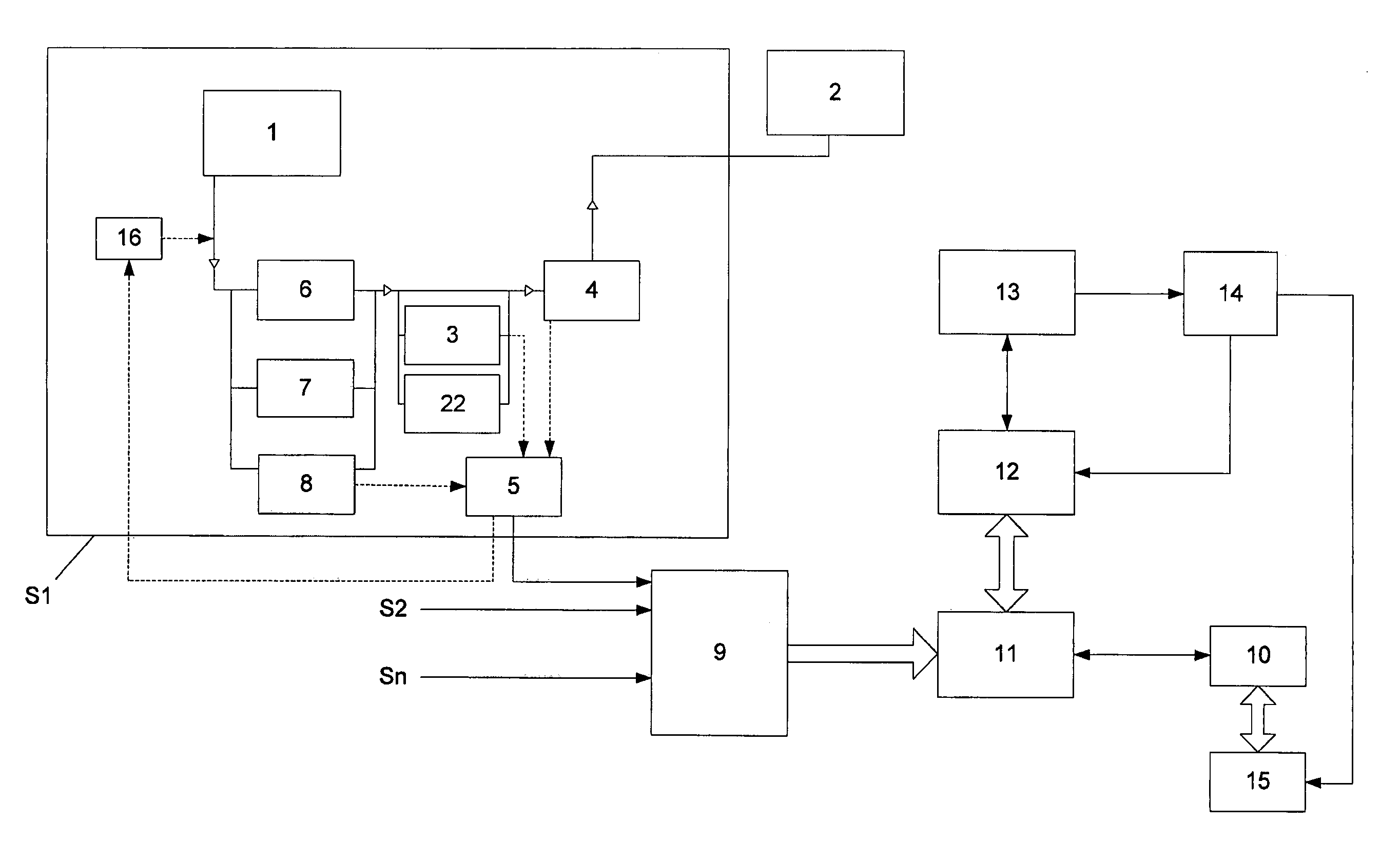

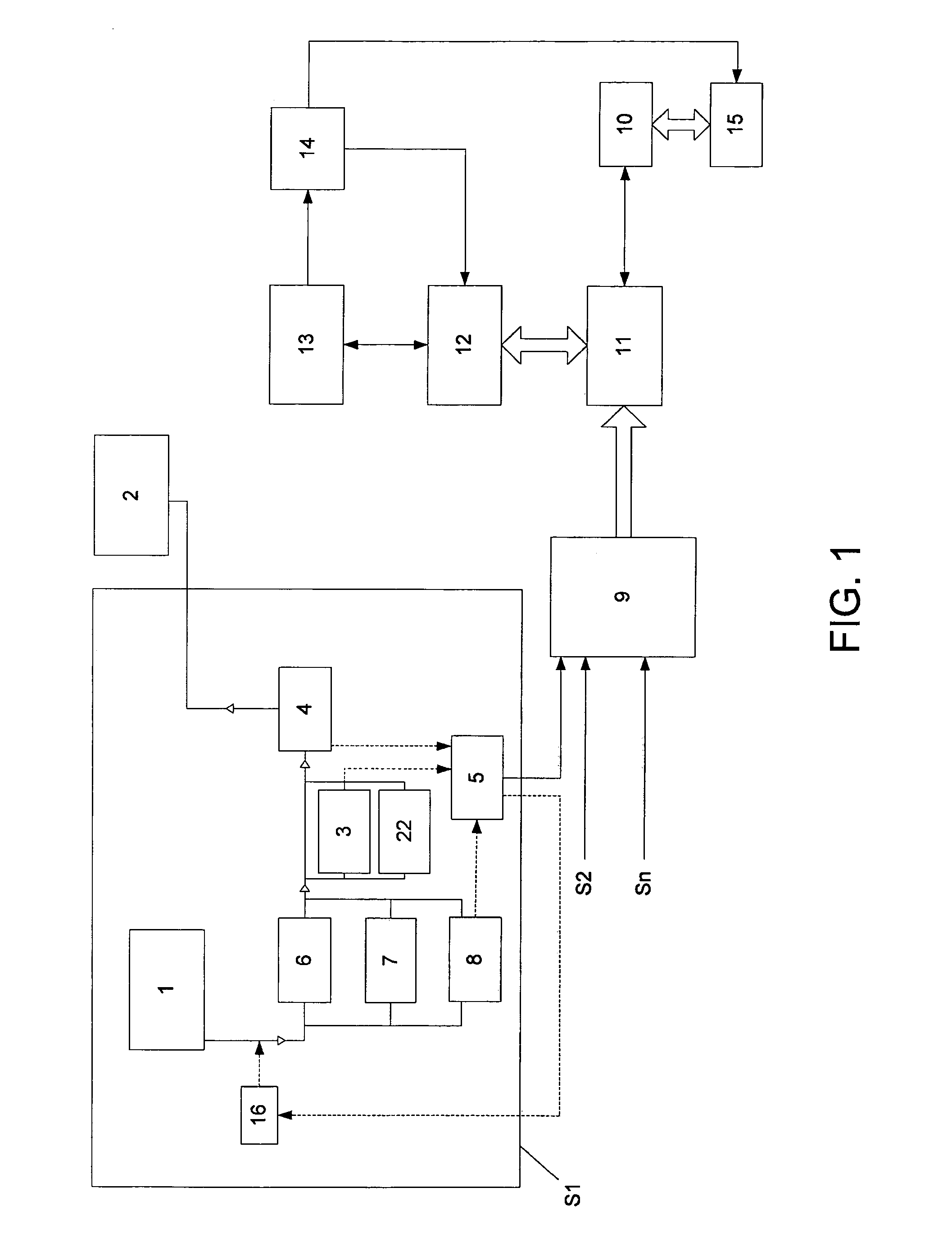

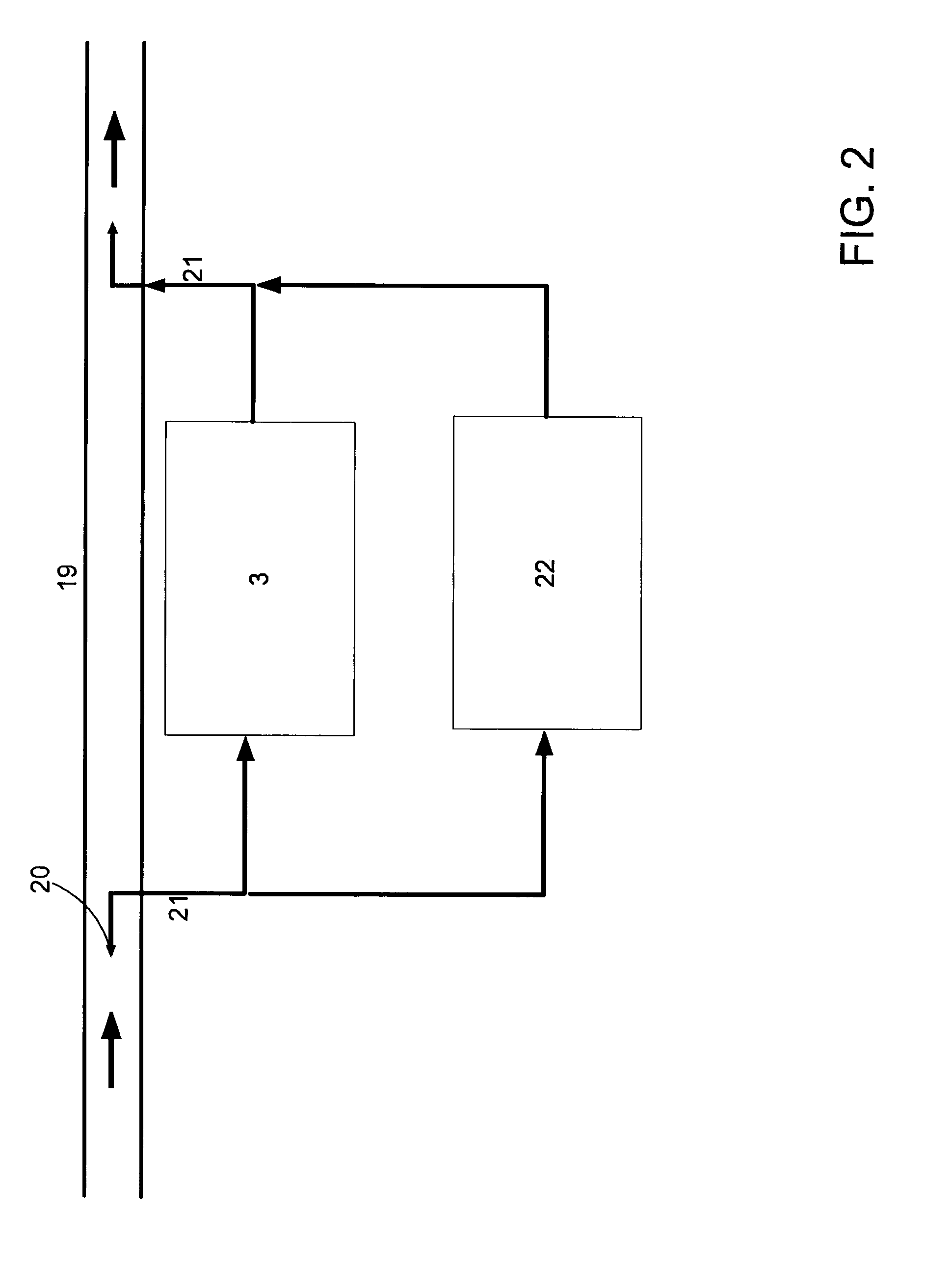

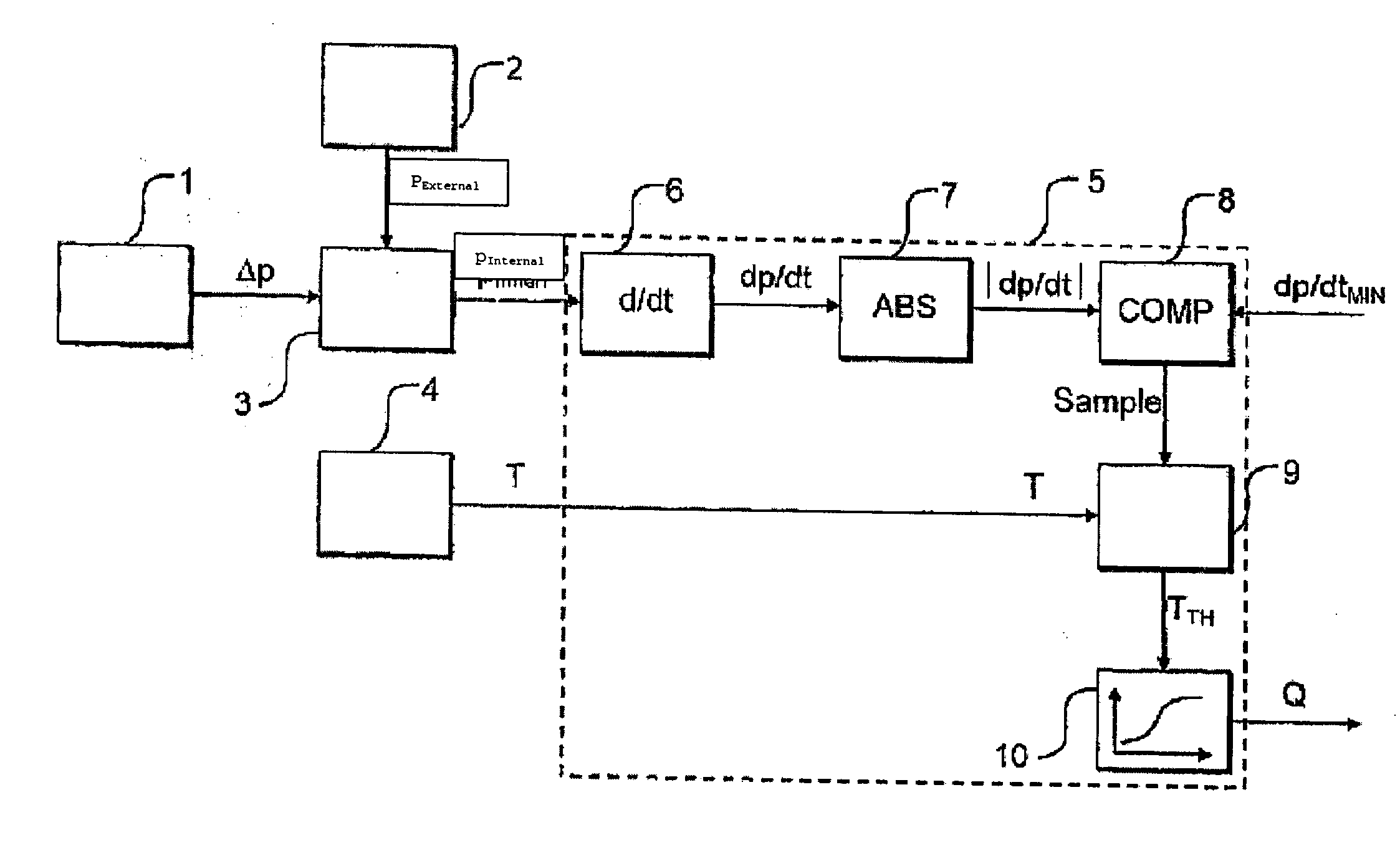

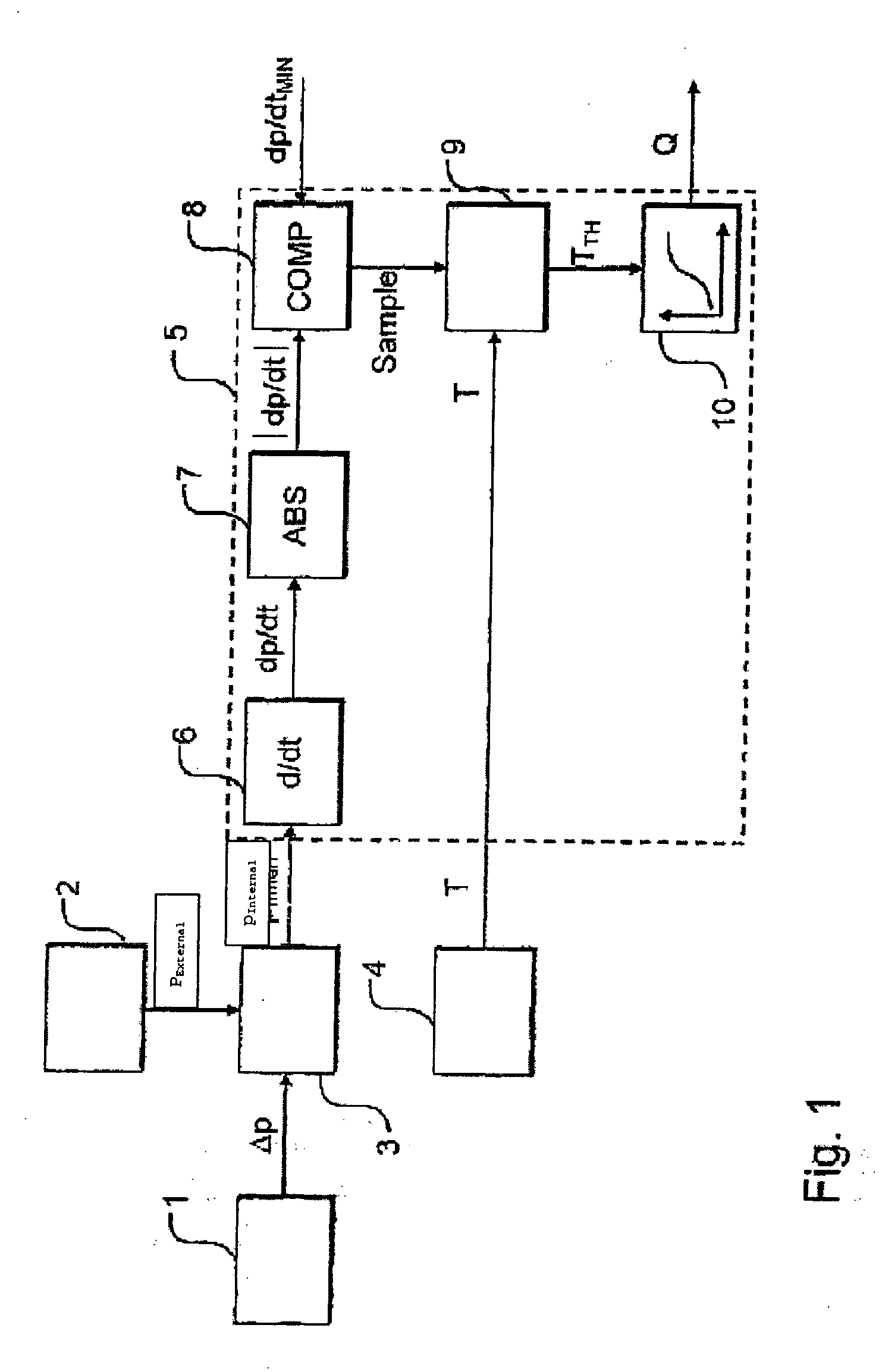

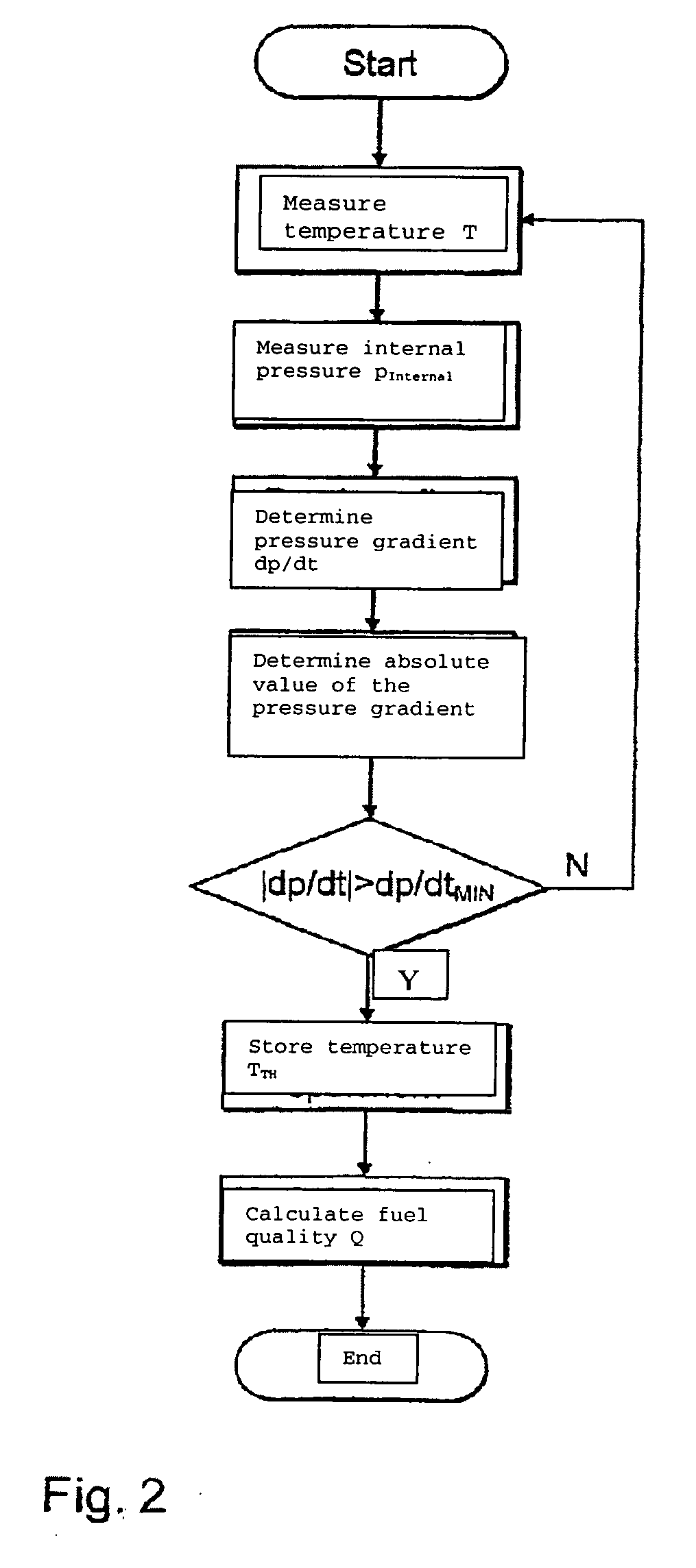

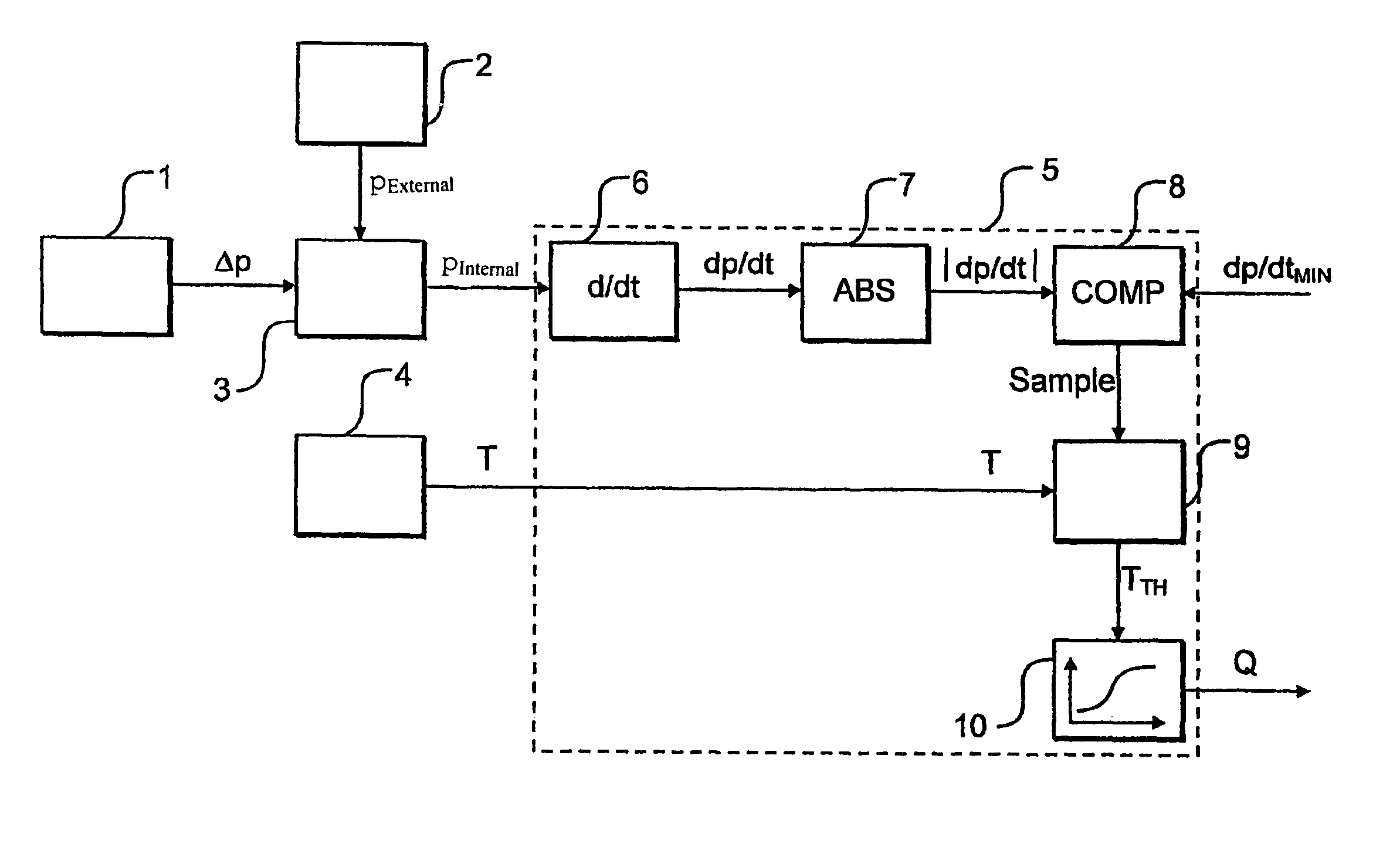

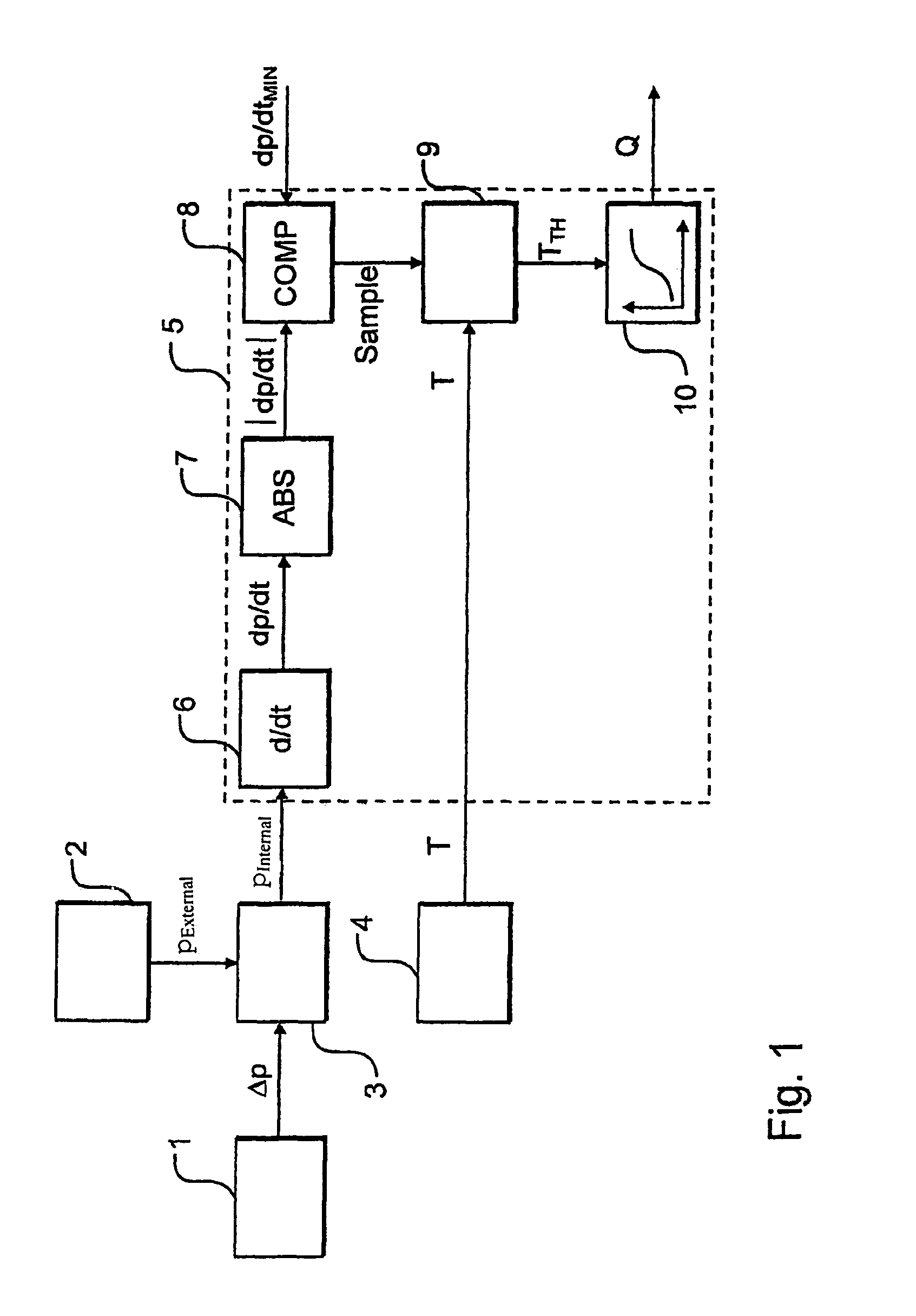

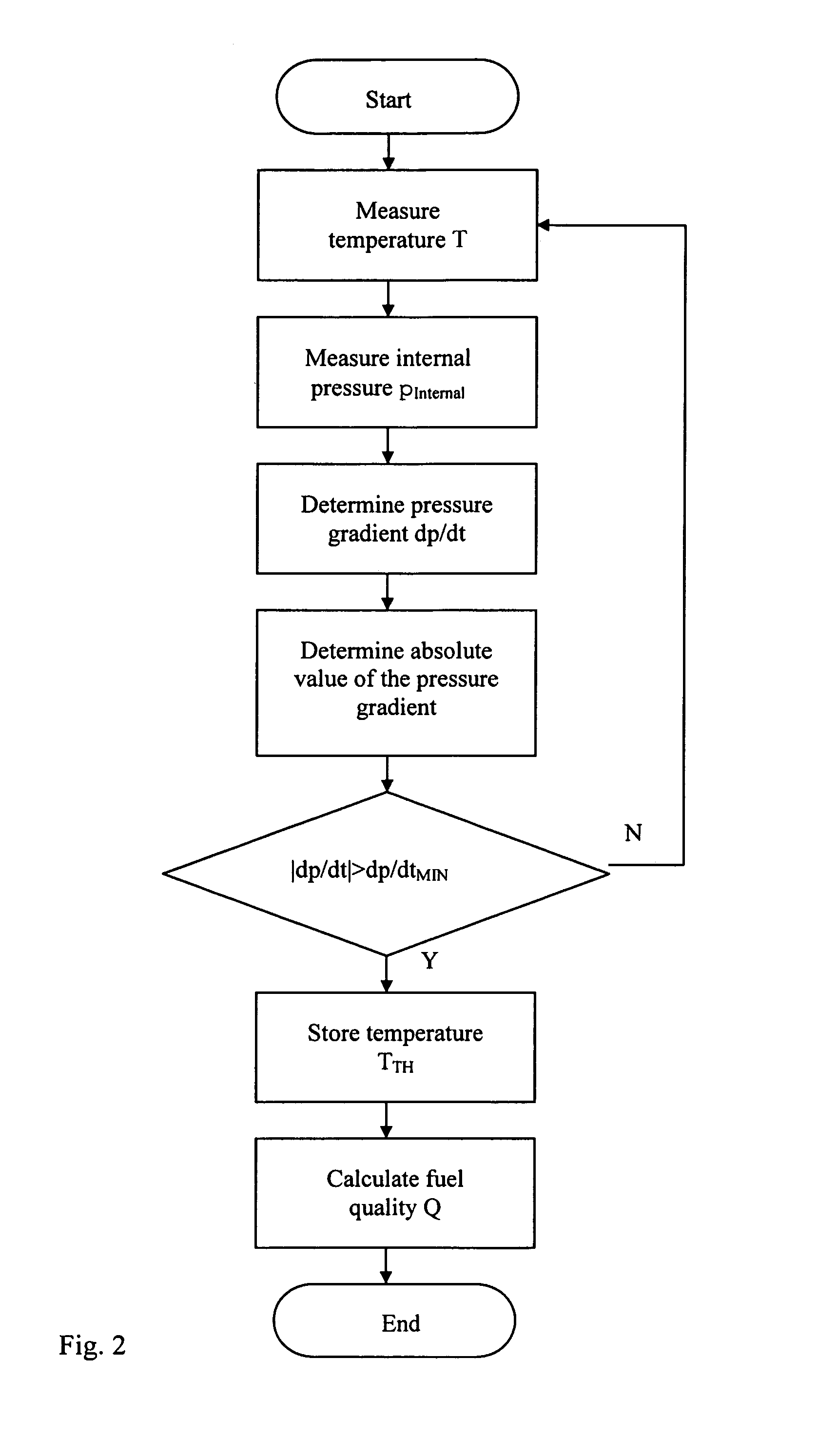

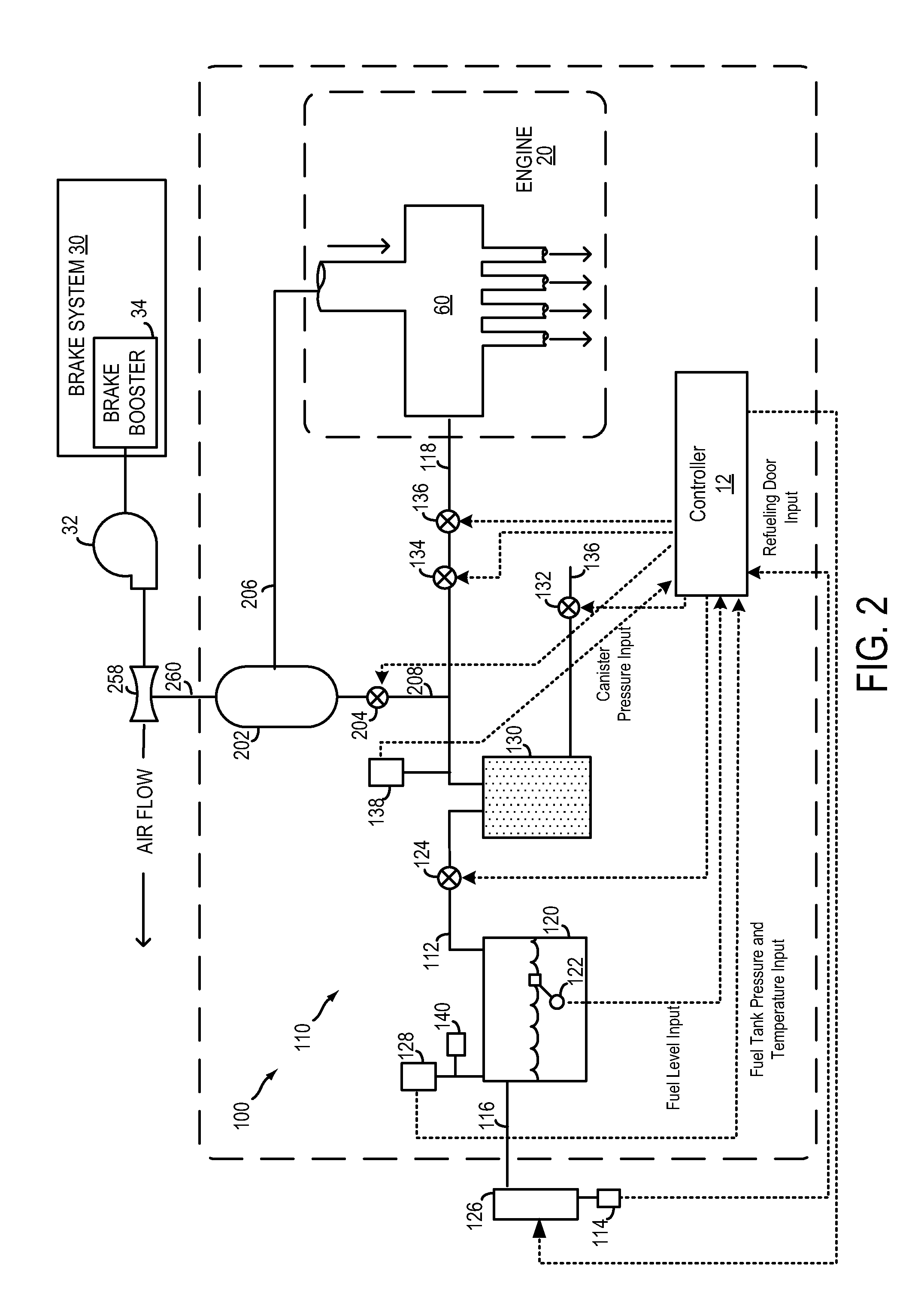

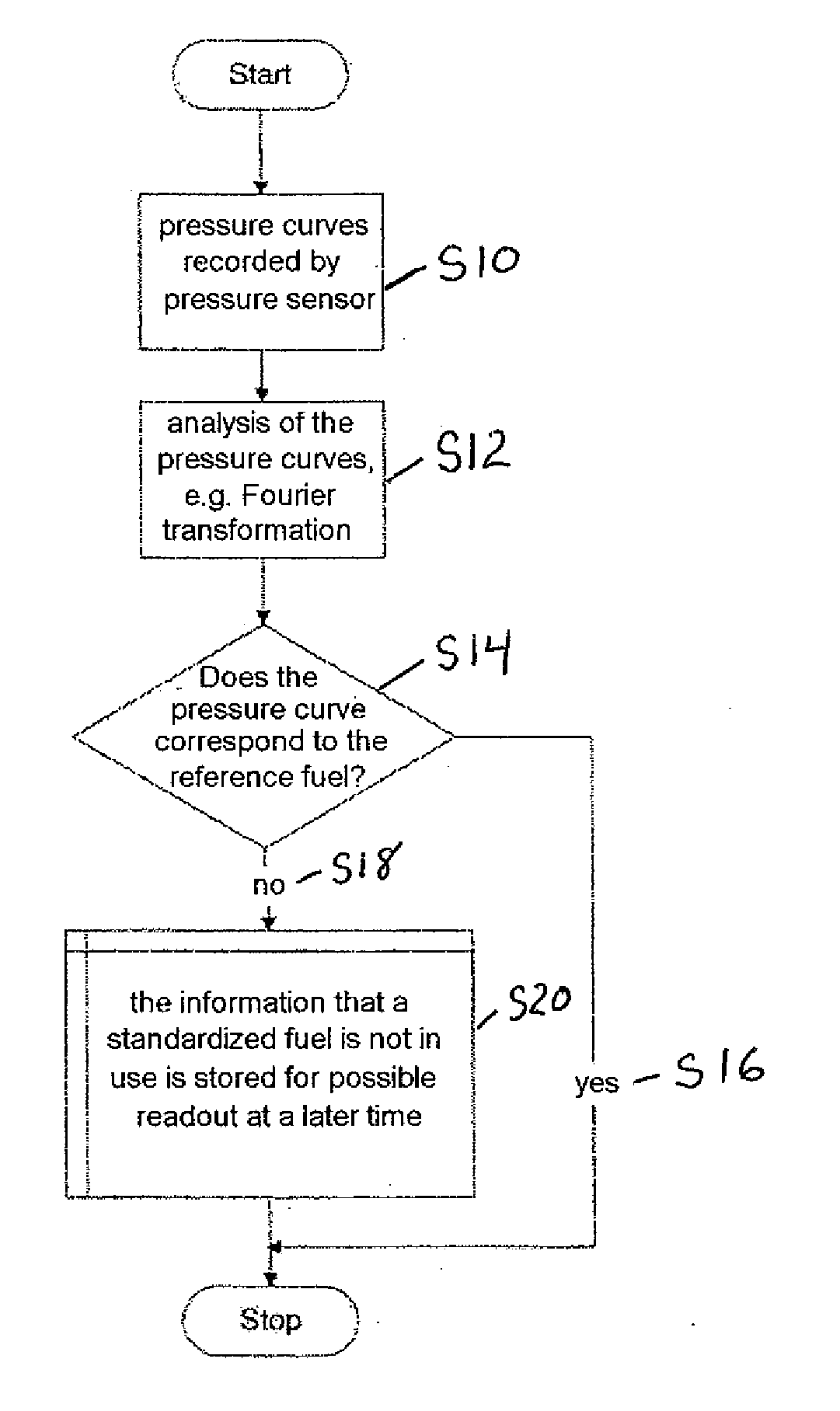

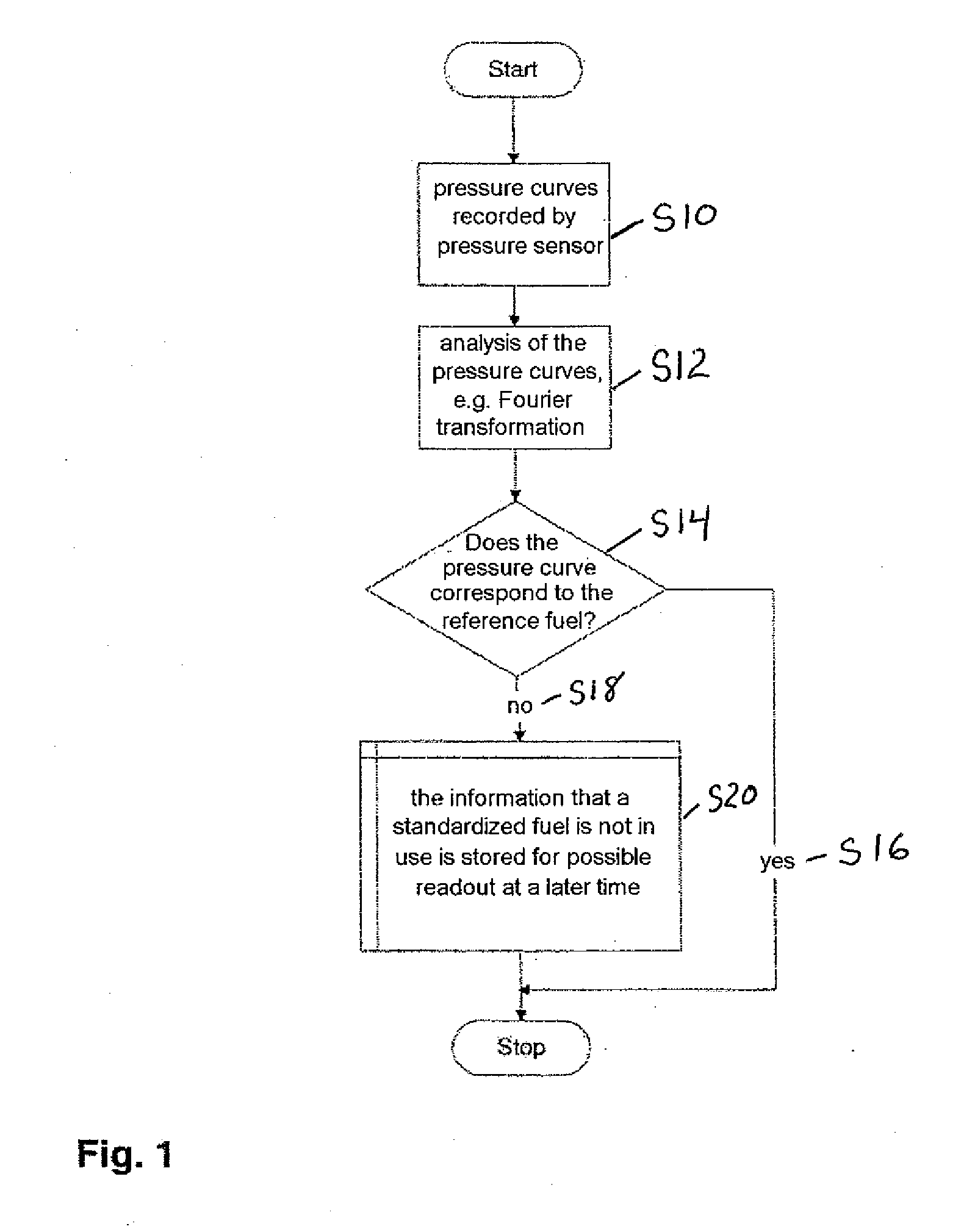

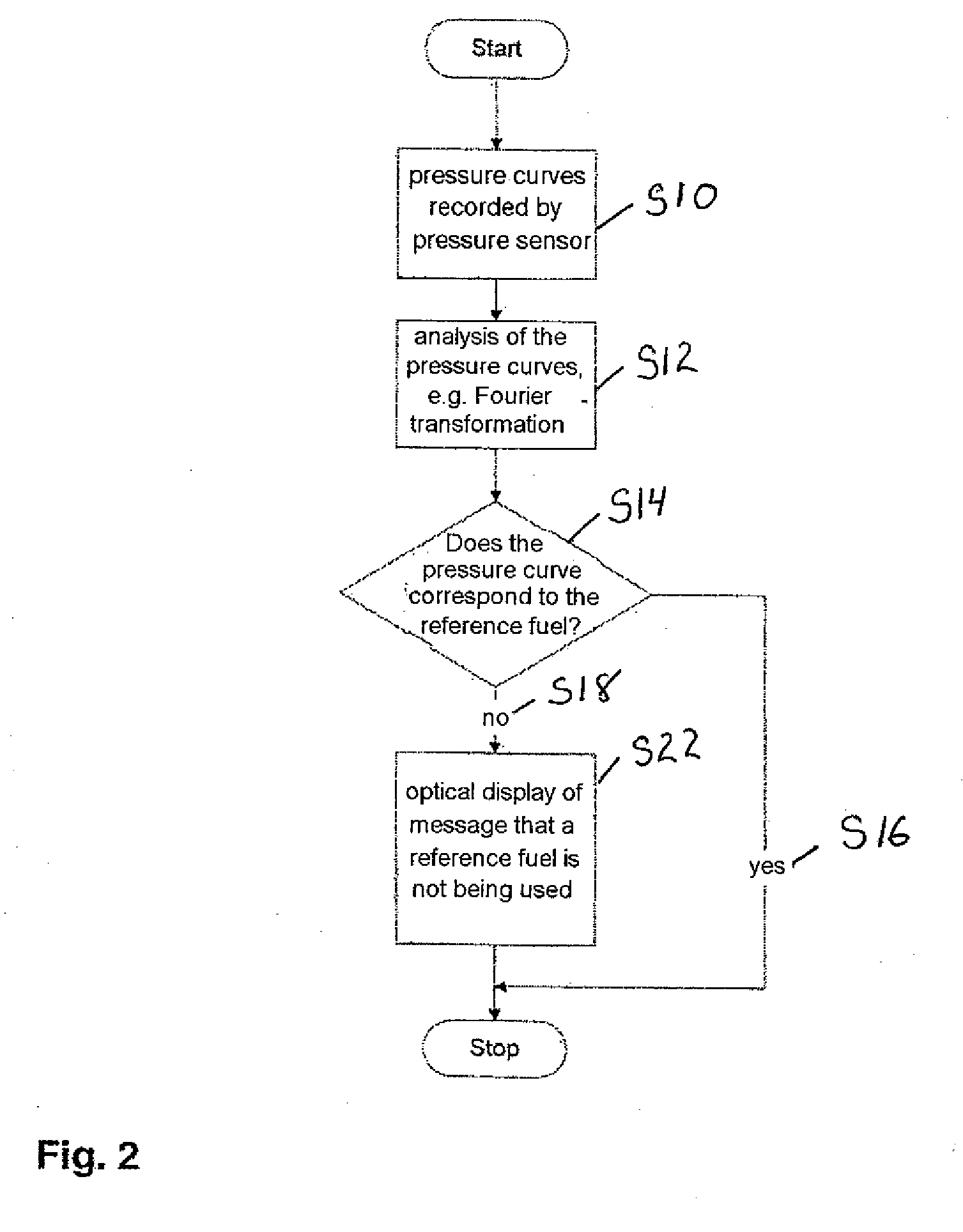

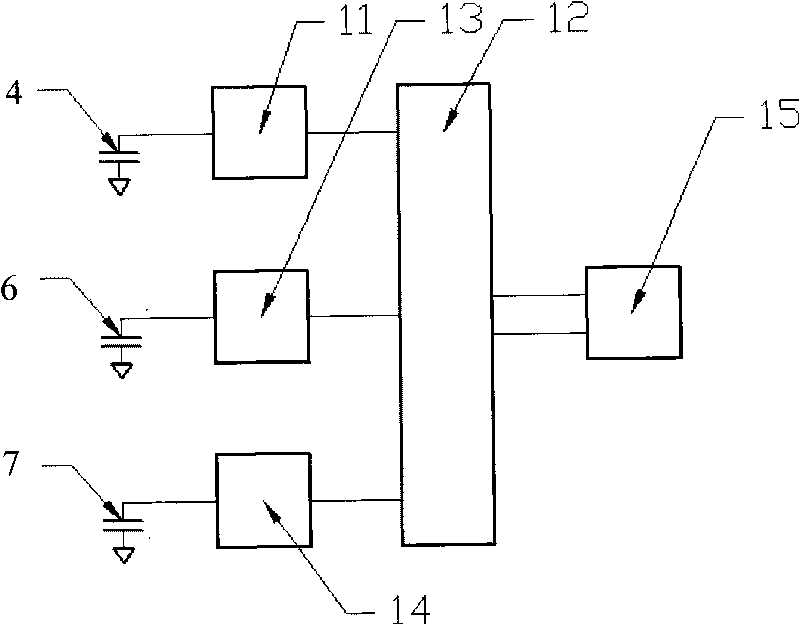

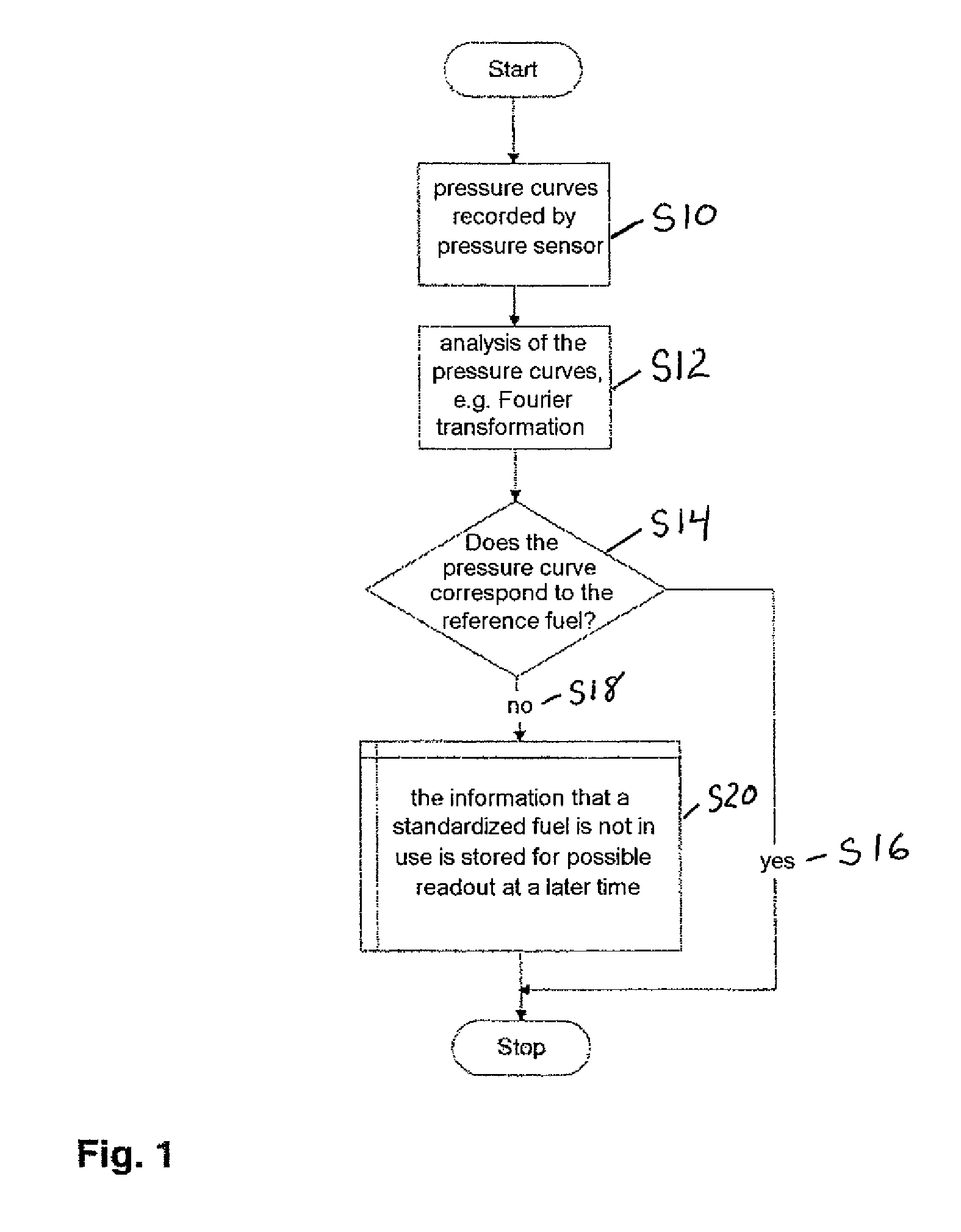

Device for determining fuel quality and corresponding method

InactiveUS20050224055A1Low costElectrical controlNon-fuel substance addition to fuelFuel qualityFuel tank

The invention relates to a device for determining the quality of fuel for an internal combustion engine, comprising a pressure sensor (1) for determining the pressure (p) inside a fuel tank and / or comprising a temperature sensor (4) for determining the temperature (T) inside a fuel tank. According to the invention, an evaluation unit (5) is provided for determining a quality value (Q), which depicts die quality of the fuel, based on the temperature (T) and / or the pressure (p) inside the fuel tank. Said evaluation unit is connected on the input side to the pressure sensor (1) and / or to the temperature sensor (4).

Owner:VITESCO TECH GMBH

Device for determining fuel quality and corresponding method

InactiveUS7128057B2Low costElectrical controlInternal combustion piston enginesFuel qualityFuel tank

The invention relates to a device for determining the quality of fuel for an internal combustion engine, comprising a pressure sensor (1) for determining the pressure (p) inside a fuel tank and / or comprising a temperature sensor (4) for determining the temperature (T) inside a fuel tank. According to the invention, an evaluation unit (5) is provided for determining a quality value (Q), which depicts die quality of the fuel, based on the temperature (T) and / or the pressure (p) inside the fuel tank. Said evaluation unit is connected on the input side to the pressure sensor (1) and / or to the temperature sensor (4).

Owner:VITESCO TECH GERMANY GMBH

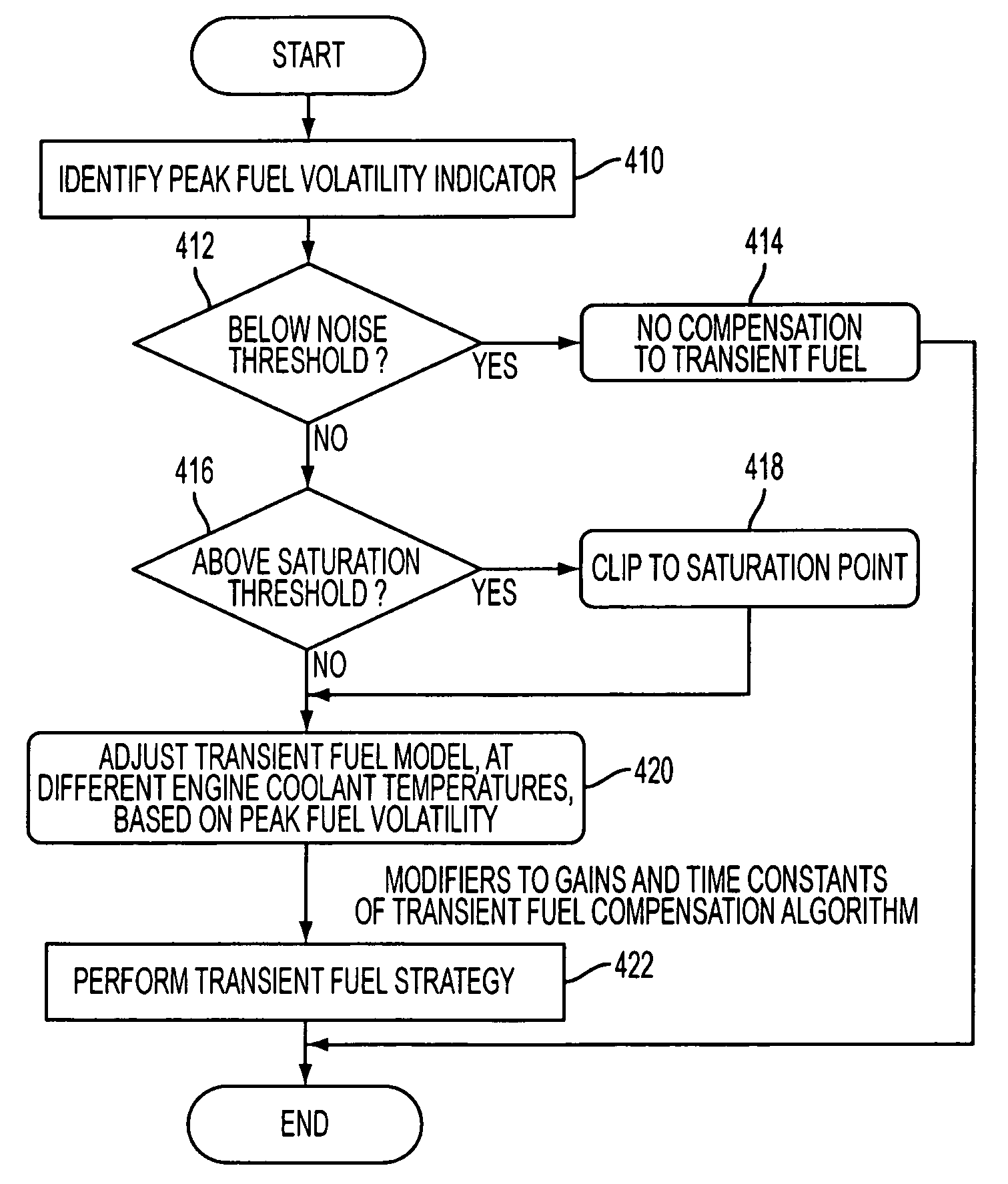

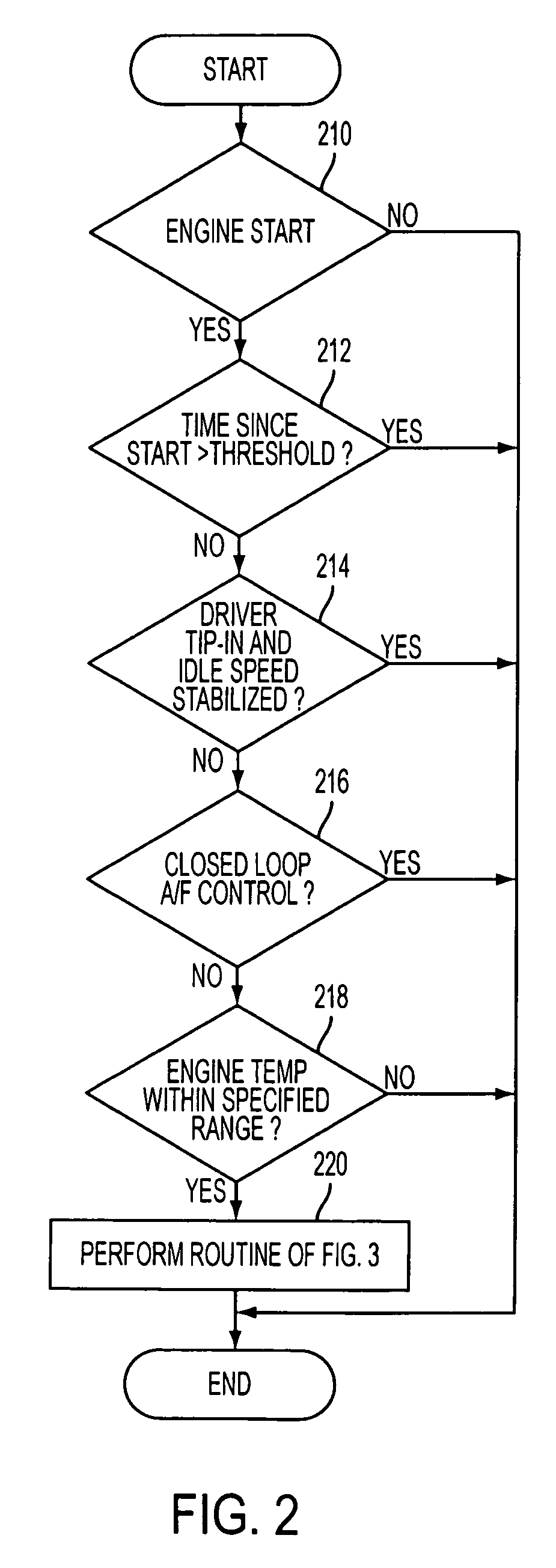

Fuel injection system and method

ActiveUS7163002B1Improve engine performanceAccurate air-fuel ratio controlElectrical controlDigital data processing detailsFuel qualityFuel supply

A method for adjusting fuel injection, the method comprising during an engine start from a non-warmed-up condition, identifying a fuel quality of fuel supplied to the engine during said start based on a performance of said start, and after said start is completed and during a transient fueling condition, adjusting a fuel injection amount based on said identified fuel quality from said start.

Owner:FORD GLOBAL TECH LLC

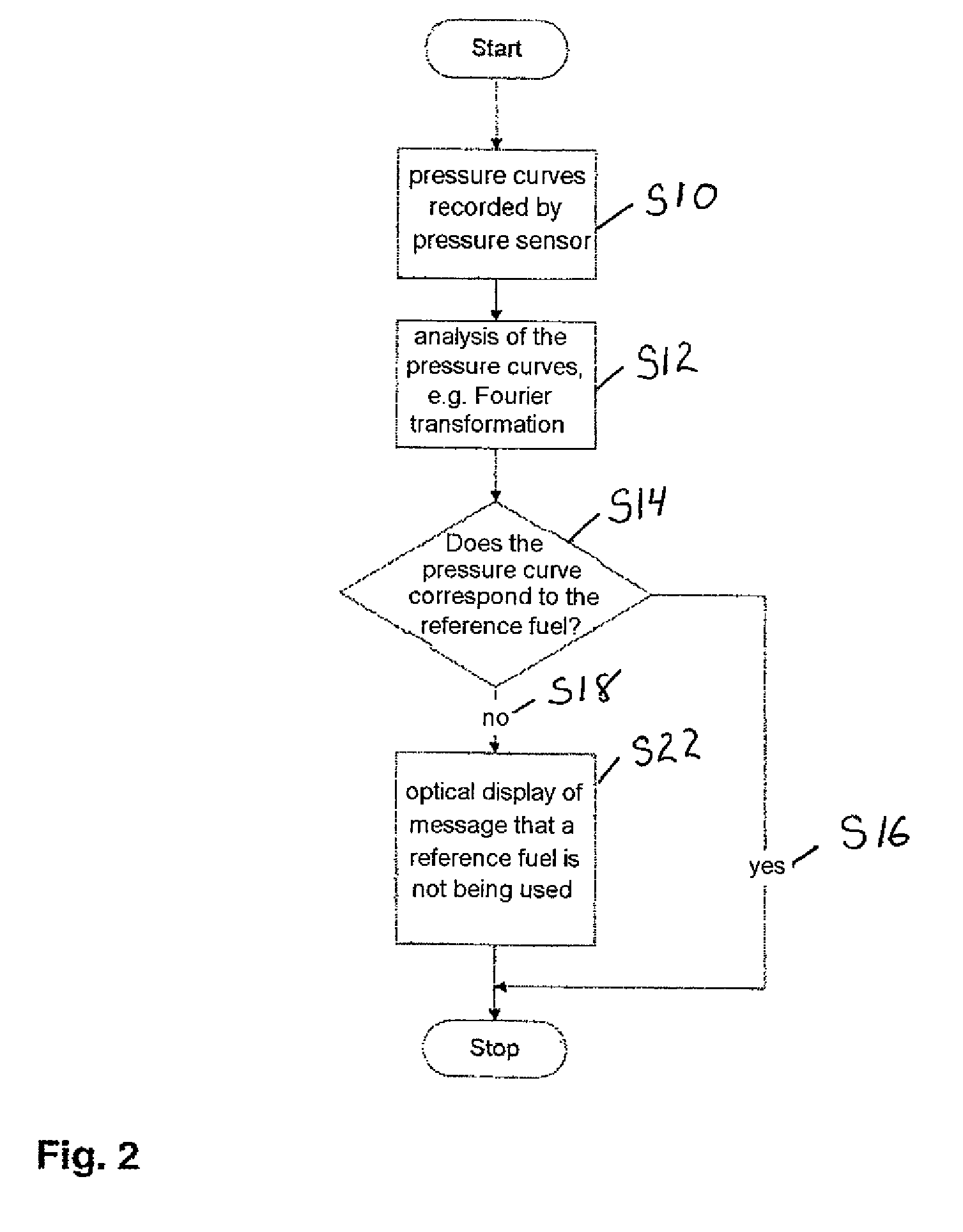

Method for ascertaining a quality characteristics of a diesel fuel

InactiveUS20080308067A1Good reproducibilityImprove accuracyElectrical controlInternal combustion piston enginesFuel qualityInternal combustion engine

A method for ascertaining a quality characteristic of a Diesel fuel for a Diesel internal combustion engine, having a device for determining the cylinder pressure curve of at least one cylinder, a process variable of the combustion being ascertained from the cylinder pressure curve, which characterizes the fuel quality.

Owner:ROBERT BOSCH GMBH

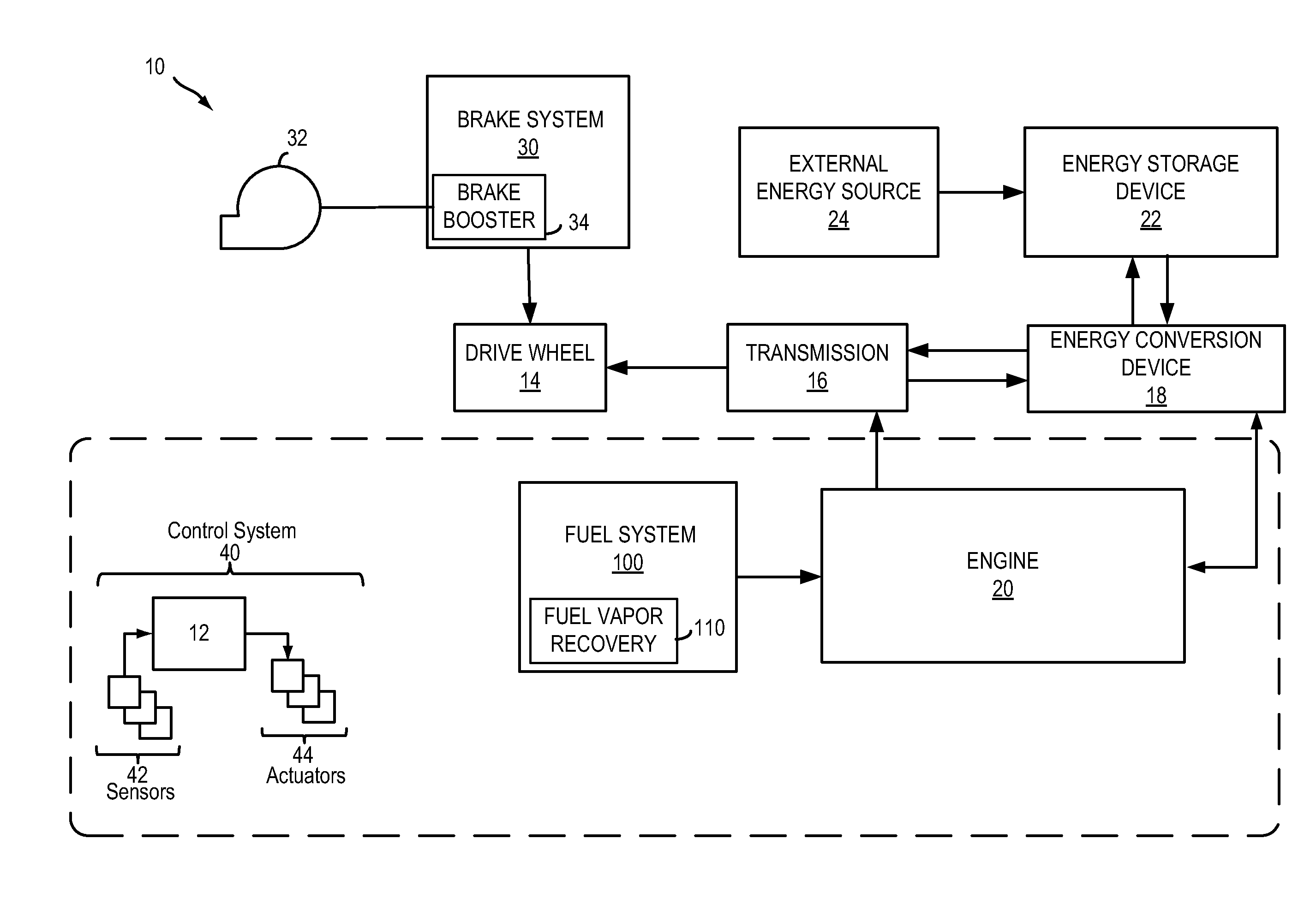

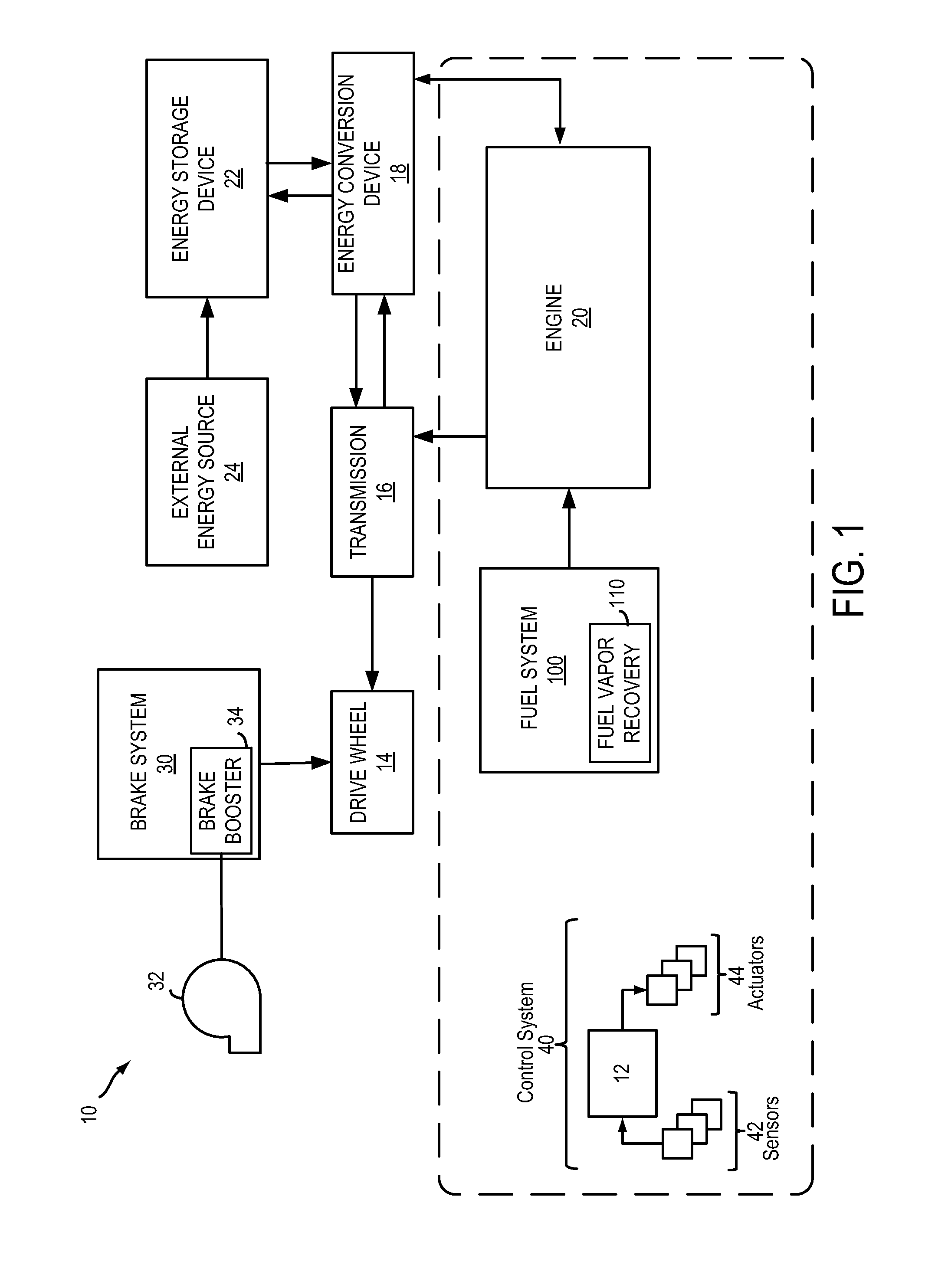

Fuel oxidation reduction for hybrid vehicles

ActiveUS20150083089A1Reduce carbon emissionsShorten operation timeNon-fuel substance addition to fuelMachines/enginesFuel qualityOn board

Systems and methods to control fuel tank pressure to reduce fuel oxidation in plug-in hybrid electric vehicles are disclosed. A method comprises routing vapors from a fuel system canister to the fuel tank to maintain the fuel tank pressure at a desired pressure. In this way, the engine may be maintained off for greater durations while still retaining fuel quality of fuel stored on-board the vehicle.

Owner:FORD GLOBAL TECH LLC

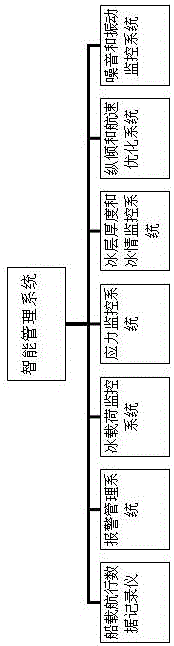

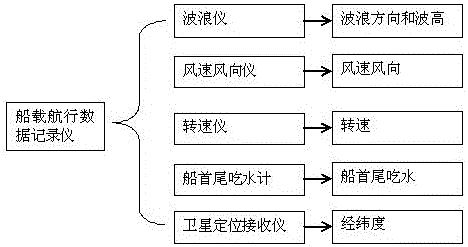

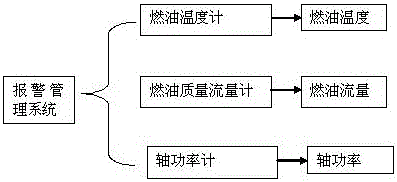

Intelligent ship for arctic navigation

ActiveCN106327610AEnsure safetyGuaranteed efficiencyWaterborne vesselsMeasurement devicesEngineeringNavigation safety

The invention discloses an intelligent ship for arctic navigation. The intelligent ship comprises a voyage data recorder, an alarm management system, an ice load monitoring system, a stress monitoring system, an ice layer thickness and ice condition monitoring system, a longitudinal inclination optimization and navigational speed optimization system, a storage system, a noise and vibration monitoring system and an intelligent management system, wherein the voyage data recorder comprises a wave gauge, an anemorumbometer, a rotational speed meter, a fore-and-aft draft gauge and a satellite positioning receiver, and the alarm management system comprises a fuel thermometer, a fuel mass flow meter and a shaft power meter detection alarm system. A mariner adjusts the floatation condition, navigational speed and course of a ship according to data and information provided by the intelligent systems, so as to avoid icebergs or dangerous sea areas where ice layers are thick during arctic navigation, and then navigation safety is guaranteed; navigation resistance is reduced in ice-free or little-ice sea areas, and then oil consumption is reduced. Meanwhile, the maintenance and repair plan of equipment including a main engine and an auxiliary engine can be adjusted in time according to the monitored operation condition of machinery equipment.

Owner:NANTONG COSCO KHI SHIP ENG

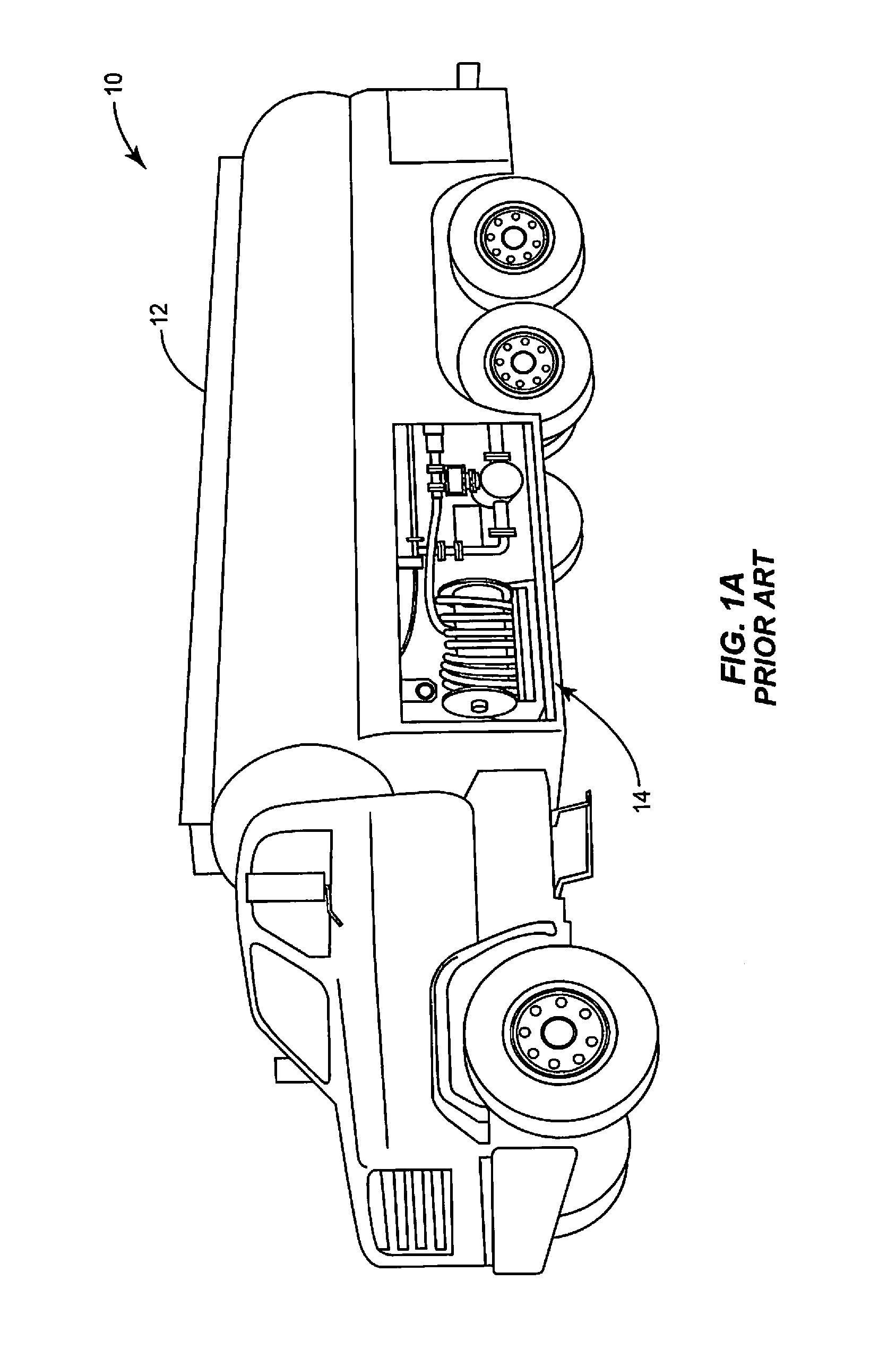

Automated fuel quality detection and dispenser control system and method, particularly for aviation fueling applications

ActiveUS8720499B2Reduce riskAvoid refuelingLiquid handling installationsLevel indicatorsWater detectorAviation

A fuel quality monitoring system and method to automatically and / or continuously monitor quality of fuel dispensed and control the operation of the fuel dispenser. The control system monitors fuel quality to prevent unsafe refuelings when the fuel quality is unacceptable. In one embodiment, a combination of a differential pressure sensor, a water detector, and / or a particle monitor is employed inline the fuel flow path of a fuel dispenser, and in particular an aviation refueling truck, to monitor the quality of the fuel. If fuel quality is at an acceptable level although not ideal, the control system can allow fueling with the generation of reports and alarms. If the fuel quality is unacceptable, fuel flow can be stopped. If the differential pressure across the filter indicates a high degree of debris and / or water retention, the control system can automatically lower the flow rate to reduce the risk of filter breakdown without completely preventing fueling until the filter can be replaced.

Owner:FUEL GUARD SYST +1

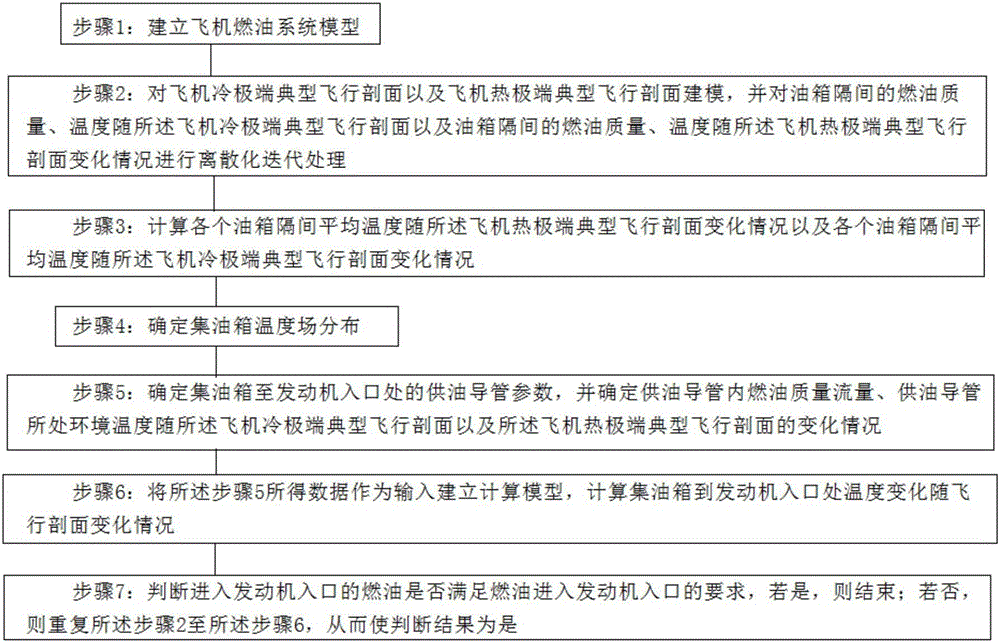

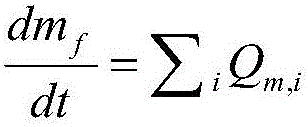

Design method for airplane fuel system

ActiveCN106446325ASolve the accuracy problemSolve environmental problemsGeometric CADDesign optimisation/simulationAircraft fuel systemFuel quality

The invention discloses a design method for an airplane fuel system. The design method for the airplane fuel system comprises the following steps of 1: building fuel flow models of fuel tanks of an airplane; 2: performing discretized iterative processing on fuel quality of fuel tank compartments and change of temperature along with typical flight profiles of cold and hot extremes of the airplane; 3: calculating change of average temperature of the fuel tank compartments along with the typical flight profiles of the cold and hot extremes of the airplane; 4: determining temperature field distribution of a fuel collection tank; 5: determining fuel mass flow in a fuel supply guide pipe and change of temperature of an environment, in which the fuel supply guide pipe is located, along with the typical flight profiles of the cold and hot extremes of the airplane; 6: calculating change of temperature from the fuel collection tank to an engine inlet along with the flight profiles; and 7: judging whether fuel entering the engine inlet meets a requirement of entering the engine inlet by the fuel or not. According to the design method for the airplane fuel system, the problem of low calculation precision in a conventional method is solved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

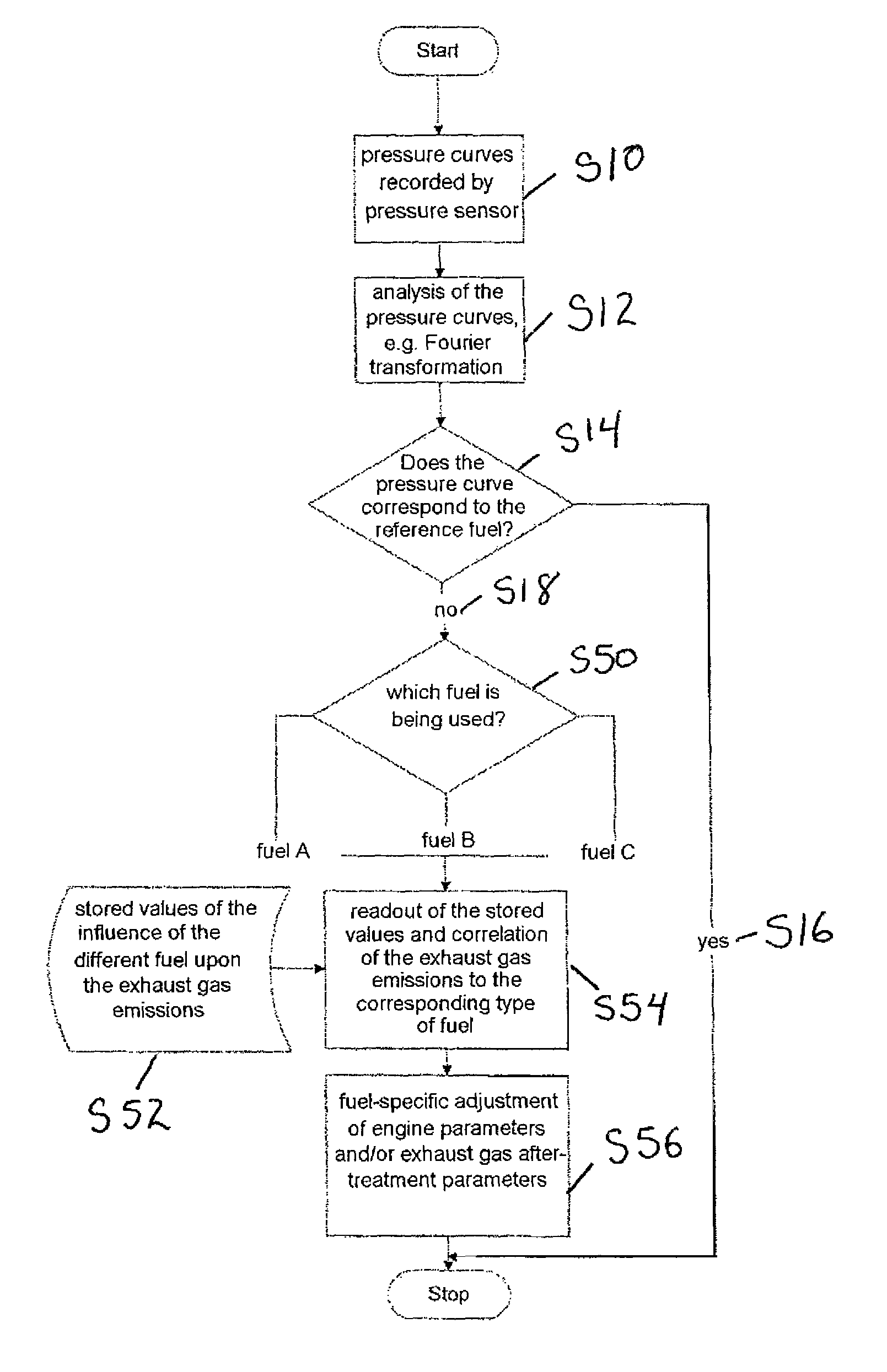

Determination of fuel characteristics and their influence on exhaust gas emissions during operation of an internal combustion engine

ActiveUS20100132435A1Good effectSimple and inexpensive possibilityInternal-combustion engine testingElectrical controlFuel qualityExhaust fumes

A method for determining a deviation of a fuel quality from a reference quality and for determining a change in exhaust gas emissions caused by this deviation by evaluating pressure waves in a fuel system of an internal combustion engine outfitted with one of a discontinuous fuel delivery and a fuel take-off. The method includes detecting pressure oscillations in the fuel system during operation by at least one sensor; determining at least one of a fuel type and the deviation from a reference fuel quality by analyzing the detected pressure oscillations in an electronic monitoring unit; and at least one of changing behavior of an exhaust gas aftertreatment system downstream of the internal combustion engine based at least in part on deviations of the untreated emissions of the internal combustion engine from the untreated emissions occurring when using the reference fuel, changing service intervals when a deviation from the reference fuel quality is determined, changing engine oil change intervals are changed when a deviation from the reference fuel quality is determined displaying information about use of a fuel deviating from the reference fuel is, displaying the changed service interval, changing operating parameters of the internal combustion engine, and changing operating parameters of the exhaust gas aftertreatment system downstream of the internal combustion engine.

Owner:MAN NUTZFAHRZEUGE AG

Capacitance sensing type fuel meter

InactiveCN101738240AAccurate measurementHigh precisionMaterial capacitanceLevel indicators by physical variable measurementFuel qualityFuel tank

The invention relates to a type fuel metering device, in particular to a capacitance sensing type fuel meter. The meter comprises a comparison capacitance sensor group, a capacitance measuring transducer circuit board and a signal processing, calculating and displaying instrument circuit board, wherein the comparison capacitance sensor group is inserted in an oil tank, the capacitance of the sensor group changes with the dielectric constant of a medium between polar plates so that the oil quantity in the oil tank can be obtained by measuring the capacitance value of the measured capacitor. Compared with the existing fuel needle indicator, the meter of the invention has the following beneficial effects: the meter has high precision, sensitivity and reliability, the oil quantity and fuelingcharge of the vehicle-mounted oil tank can be accurately measured, the fueling charge and the fuel quality can be monitored simultaneously; and no mechanical movement is generated and the shock resistant performance is good.

Owner:苟阳明

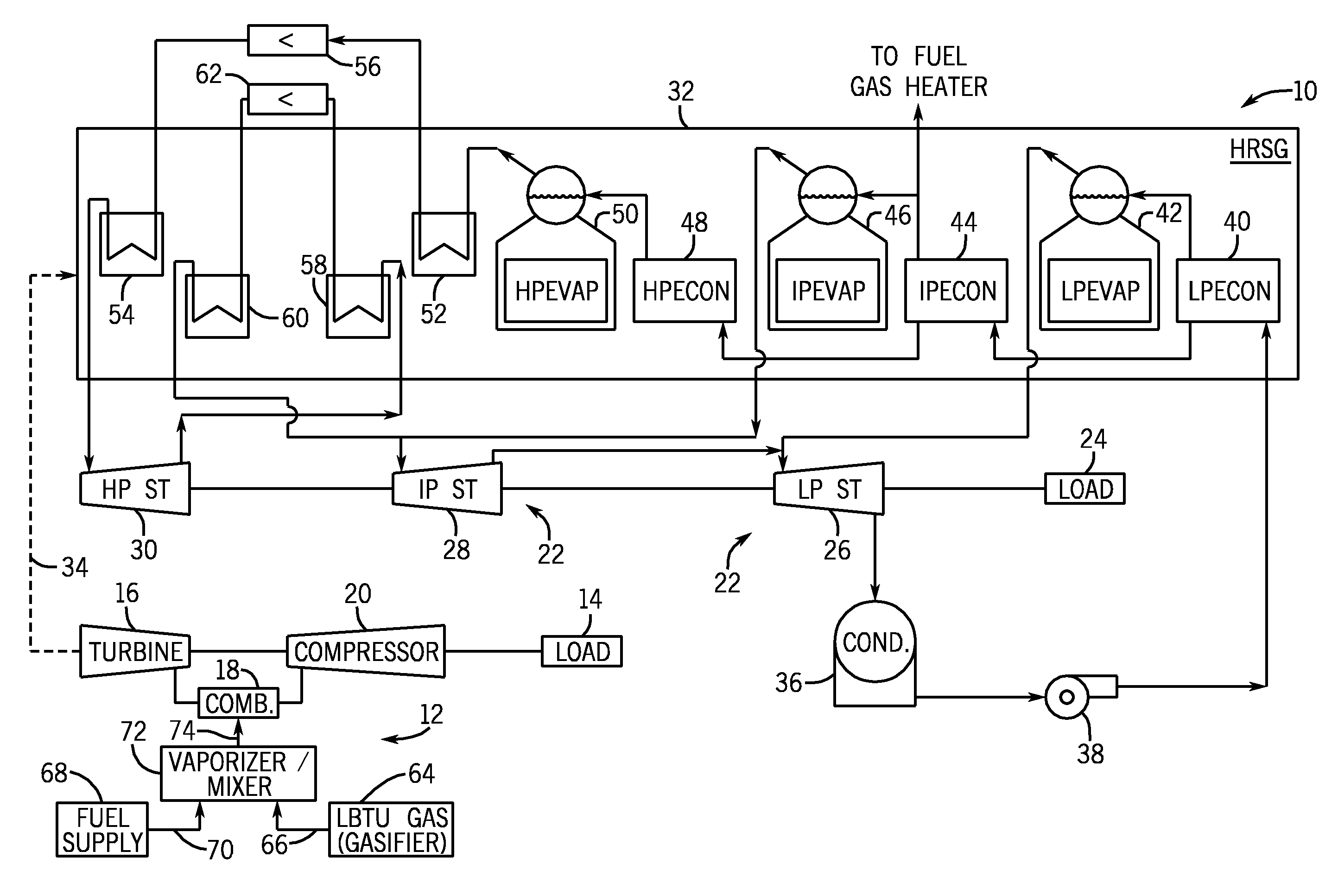

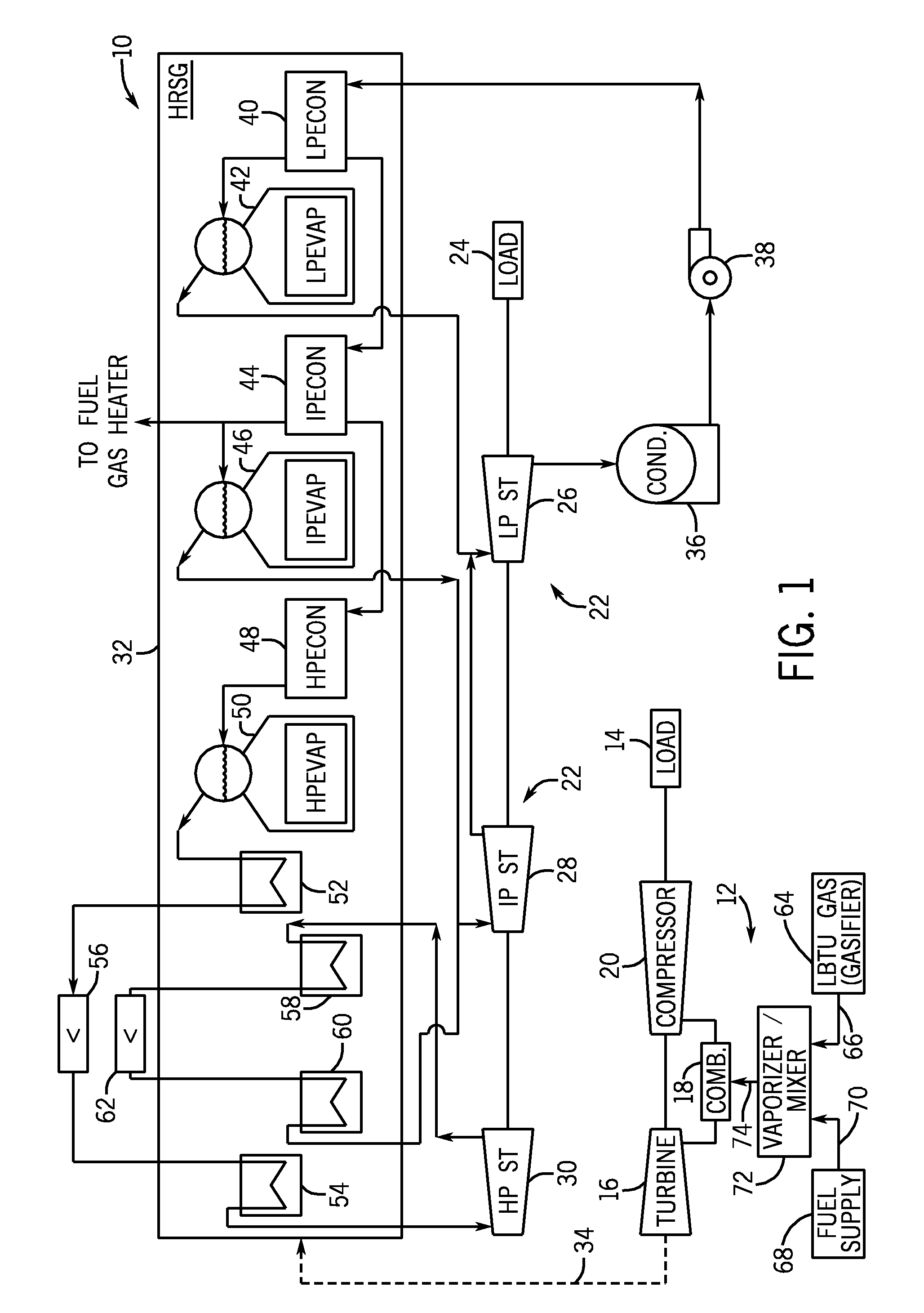

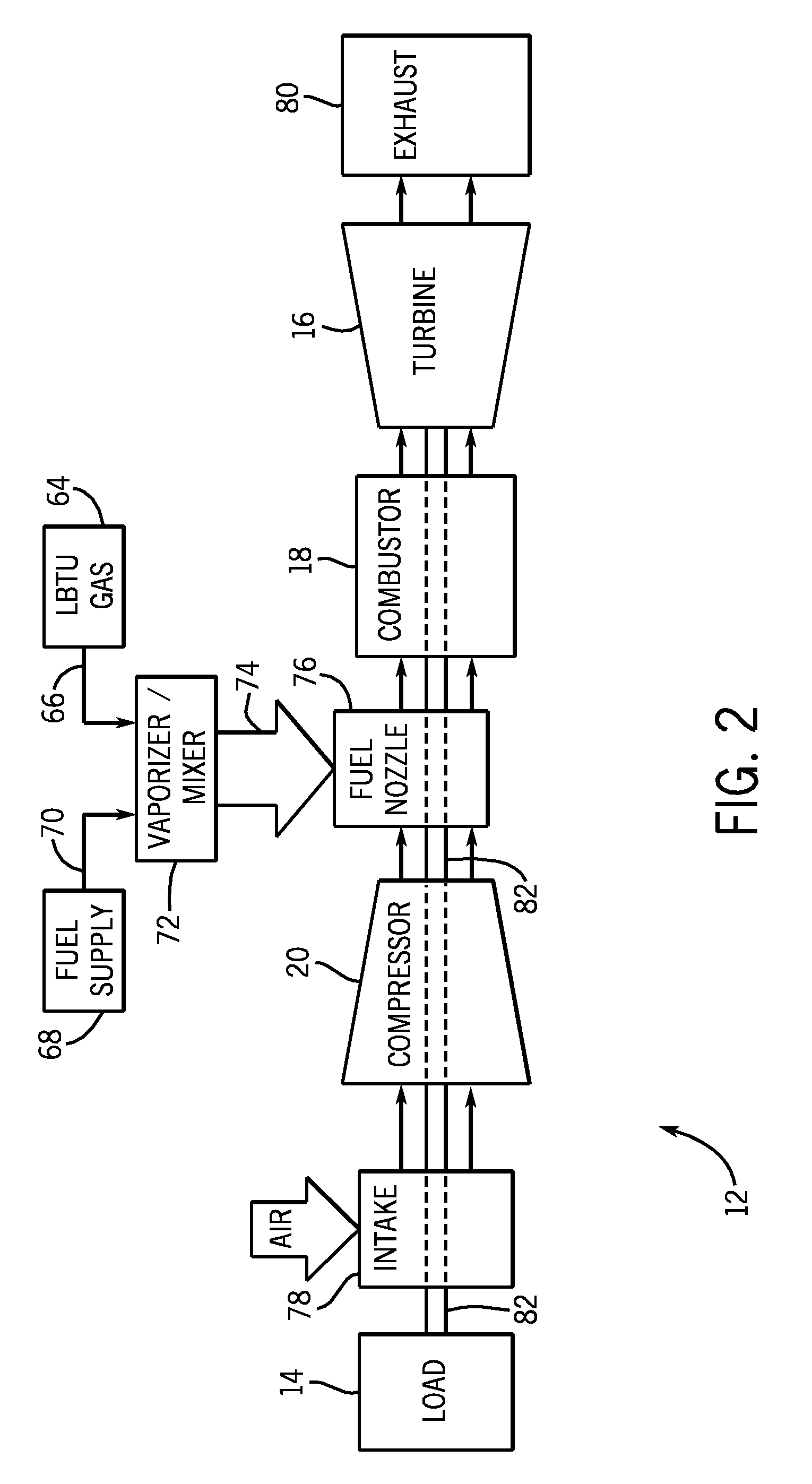

Method and apparatus for controlling a heating value of a low energy fuel

ActiveUS20100170266A1Turbine/propulsion engine ignitionTurbine/propulsion engine startersQuality levelFuel quality

In an embodiment, a method includes determining a first heating value of a low BTU fuel, determining a target fuel quality level based on a state of a turbine system, controlling a second heating value of a high BTU fuel, and injecting the high BTU fuel into the low BTU fuel to achieve the target fuel quality level.

Owner:GENERAL ELECTRIC CO

Determination of fuel characteristics and their influence on exhaust gas emissions during operation of an internal combustion engine

ActiveUS8191412B2Simple and inexpensive possibilityImprove performanceInternal-combustion engine testingElectrical controlFuel qualityFuel type

A method for determining a deviation of a fuel quality from a reference quality and for determining a change in exhaust gas emissions caused by this deviation by evaluating pressure waves in a fuel system of an internal combustion engine outfitted with one of a discontinuous fuel delivery and a fuel take-off. The method includes detecting pressure oscillations in the fuel system during operation by at least one sensor; determining at least one of a fuel type and the deviation from a reference fuel quality by analyzing the detected pressure oscillations in an electronic monitoring unit; and at least one of changing behavior of an exhaust gas aftertreatment system downstream of the internal combustion engine based at least in part on deviations of the untreated emissions of the internal combustion engine from the untreated emissions occurring when using the reference fuel, changing service intervals when a deviation from the reference fuel quality is determined, changing engine oil change intervals are changed when a deviation from the reference fuel quality is determined displaying information about use of a fuel deviating from the reference fuel is, displaying the changed service interval, changing operating parameters of the internal combustion engine, and changing operating parameters of the exhaust gas aftertreatment system downstream of the internal combustion engine.

Owner:MAN TRUCK & BUS AG

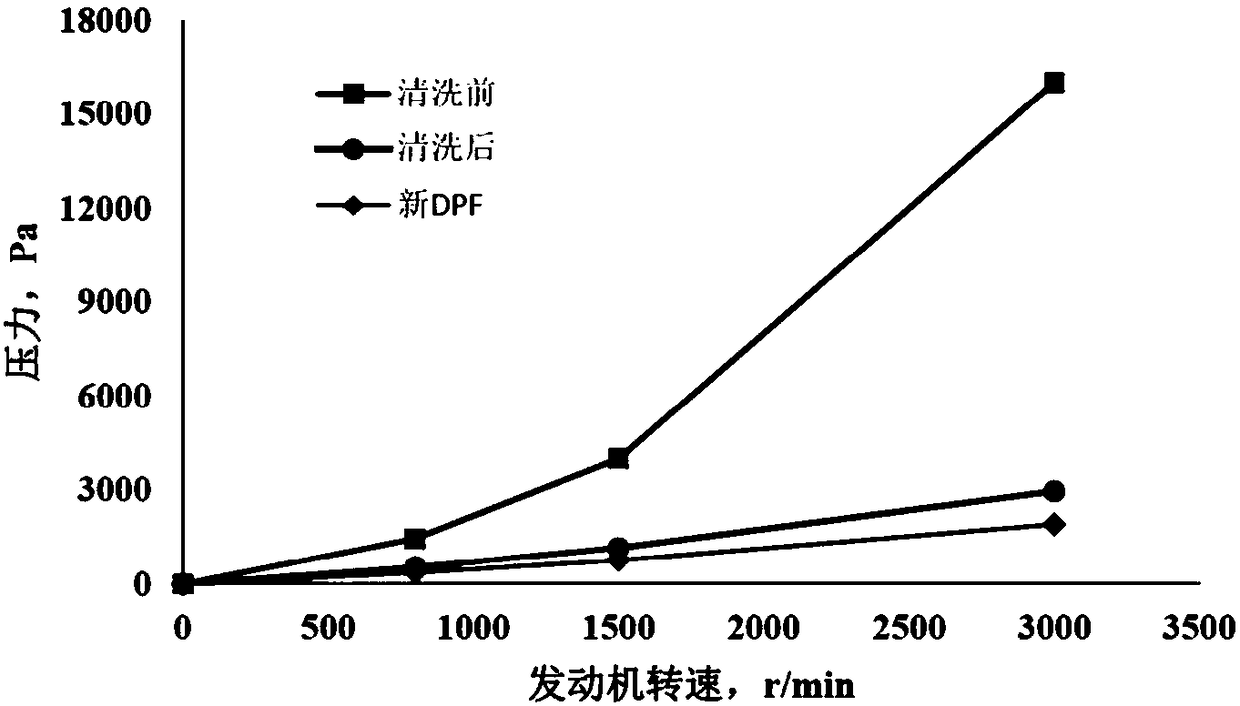

Diesel DPF cleaning regenerating agent and application thereof

ActiveCN108085169AEasy to cleanNo pollution in the processNon-ionic surface-active compoundsOrganic detergent compounding agentsOil sludgeCarbon deposit

The invention discloses a diesel DPF cleaning regenerating agent and application thereof. The diesel DPF cleaning regenerating agent comprises a solubilizer, sodium lignosulphonate, sodium salicylate,a carbon deposit dissolving agent, a dispersing agent, a wetting agent, a surfactant, rust inhibitor and water; the diesel DPF cleaning regenerating agent is applied to the regenerating process of acarbon deposit-blocked DPF system. The diesel DPF cleaning regenerating agent has the advantages as follows: the diesel DPF cleaning regenerating agent not only has an extremely good cleaning effect,but also is safe, environment-friendly and pollution-free; when the diesel DPF cleaning regenerating agent is applied to the regenerating process of the diesel DPF system failing due to carbon depositblockage caused by poor fuel quality and incomplete combustion, carbon deposit, soot, colloid, oil sludge and other blocking substances in DPF pore passages can be safely and efficiently dissolved, dispersed and cleaned, so that the maintenance or replacement cost of the blocked DPF is reduced, the fuel consumption of a diesel is reduced, the engine power thereof is restored and the DPF tail gaspurifying effect is improved.

Owner:KELAS ENVIRONMENTAL PROTECTION TECH CO LTD

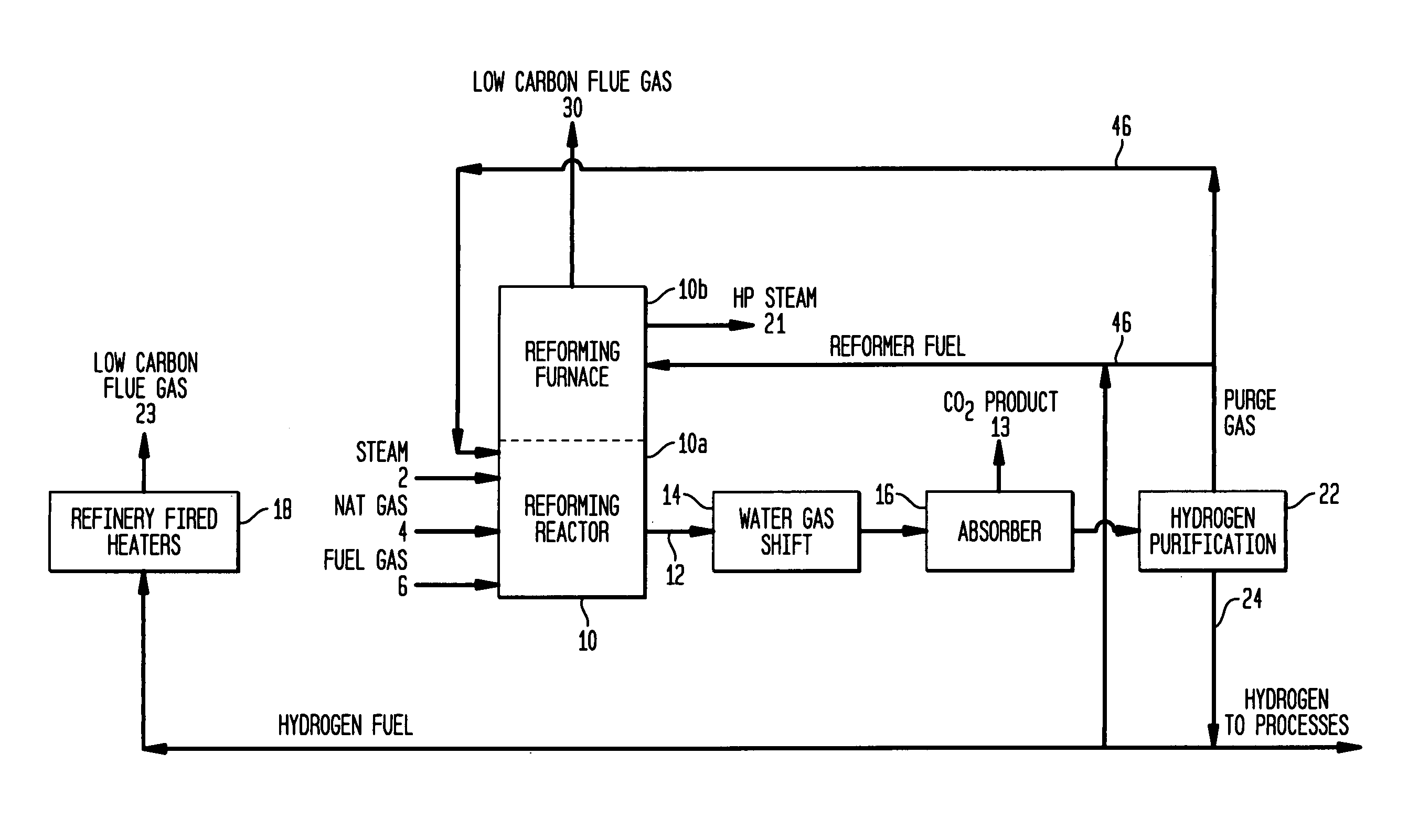

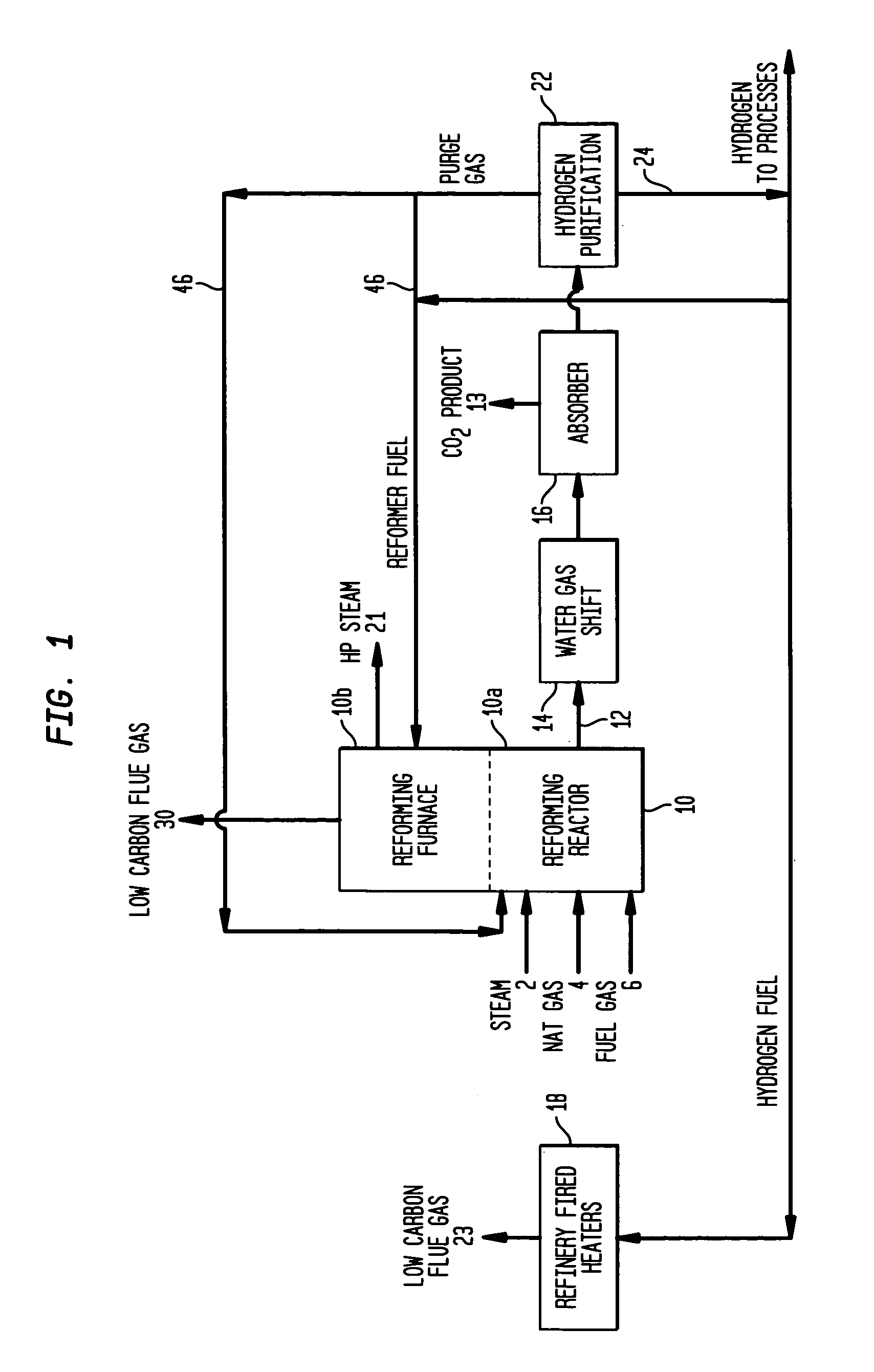

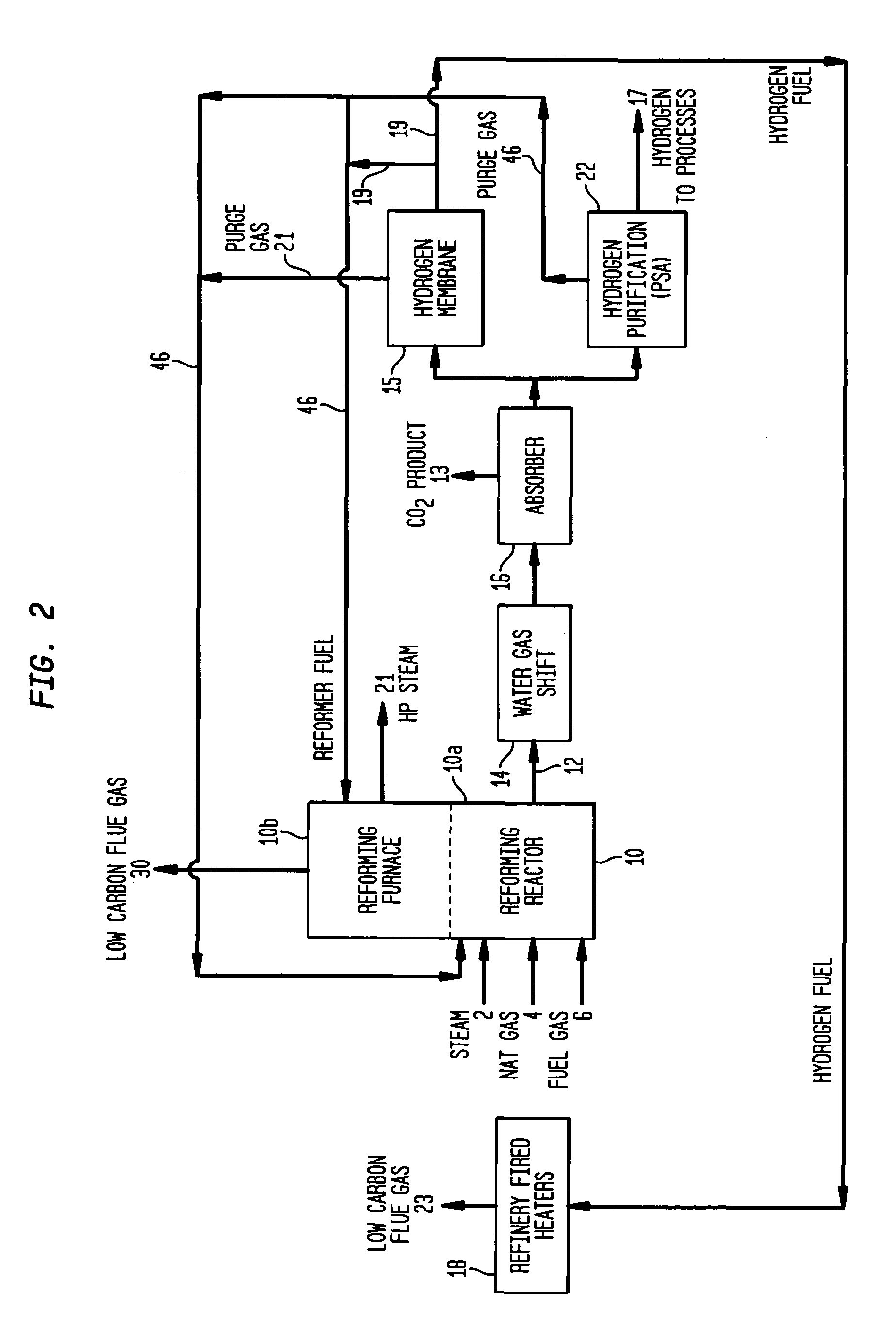

Reduction of greenhouse gas emission from petroleum refineries

The invention described herein relates to a novel process that eliminates the need for post combustion CO2 capture from fired heaters (at atmospheric pressure and in dilute phase) in a petroleum refinery to achieve environmental targets by capturing CO2 in a centralized facility and providing fuel gas low in carbon to the fired heaters. It combines the pre-combustion capture of carbon dioxide with production of a hydrogen fuel source within a refinery to drastically reduce the carbon dioxide emissions of the plant. The hydrogen fuel is utilized for the process fired heaters and the fuel quality (carbon content) can be set to meet the refinery's emissions objectives. Moreover, the carbon dioxide captured can be sequestered and / or utilized for enhanced oil recovery (EOR).

Owner:INST FR DU PETROLE

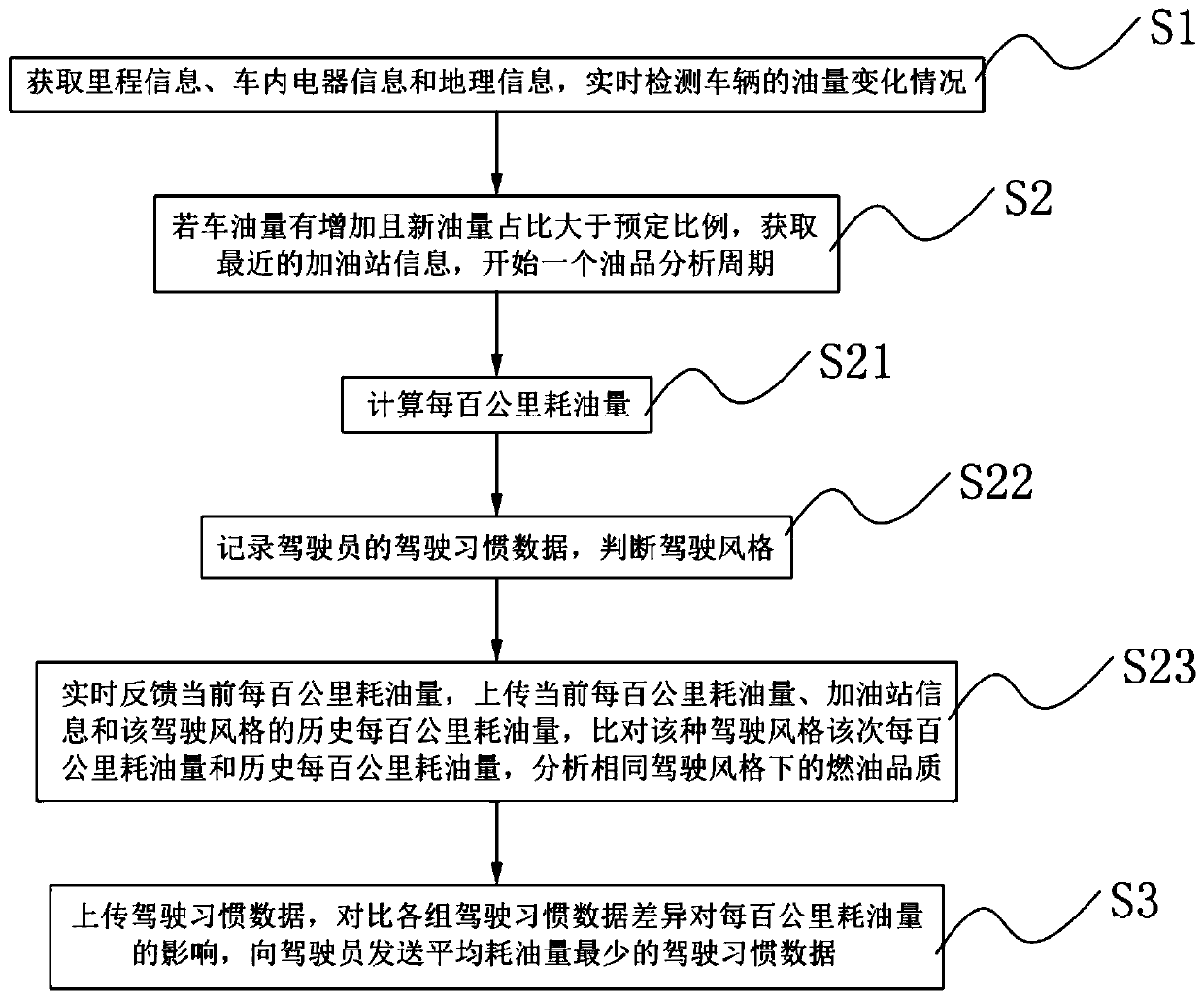

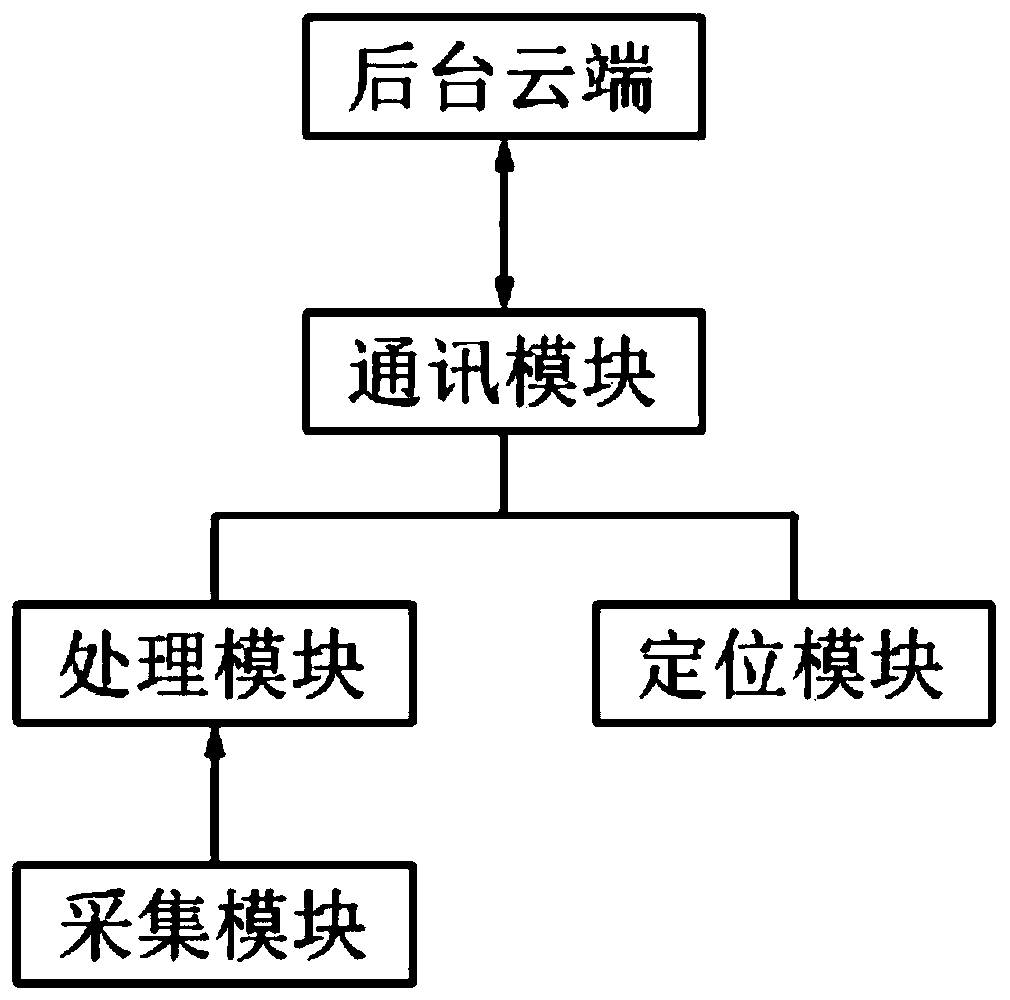

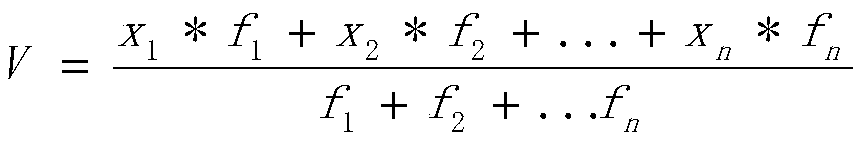

Gas station oil product analysis method and system

PendingCN110414860AReduce adverse effectsAvoid financial expenditureRegistering/indicating working of vehiclesResourcesFuel qualityIn vehicle

The invention relates to the technical field of oil product analysis, in particular to a gas station oil product analysis method and a gas station oil product analysis system. The gas station oil product analysis method comprises the steps S1, obtaining mileage information, in-vehicle electric appliance information and geographic information of a vehicle, and detecting the oil quantity change condition of the vehicle in real time; S2, if the proportion of the new oil is greater than a preset proportion, obtaining the nearest gas station information, and starting an oil product analysis period;S21, calculating the oil consumption per hundred kilometers; S22, recording current driving habit data, and analyzing a driving style; S23, judging the influence of the driving style on the fuel consumption, and analyzing the current fuel quality under the same driving style. The gas station oil product analysis system comprises an acquisition module, a processing module, a positioning module, abackground cloud and a communication module. According to the method, driving style analysis and fuel consumption after refueling are combined. The quantitative scoring is carried out on the fuel. Theobjective fuel reference is provided for a vehicle owner, and adverse effects of bad fuel on economic expenditure of the vehicle owner and the vehicle are avoided.

Owner:广东好帮手安与科技有限公司

Methods and system for determining fuel quality in vehicle

Disclosed is a method to determine whether fuel quality falls below a predetermined quality threshold during or after a vehicle refuelling event. The method comprises determining that a novel fuel has been introduced into a vehicle; undertaking at least one measurement of the novel fuel in order to determine at least one parameter of the novel fuel, wherein the parameter is associated with a property of the fuel; comparing the at least one parameter of the novel fuel with a threshold reference parameter in order to determine whether fuel quality falls below a predetermined quality threshold; and providing an alert to the operator of the vehicle to indicate whether the fuel quality of the novel fuel falls below the predetermined quality threshold.

Owner:JAGUAR LAND ROVER LTD

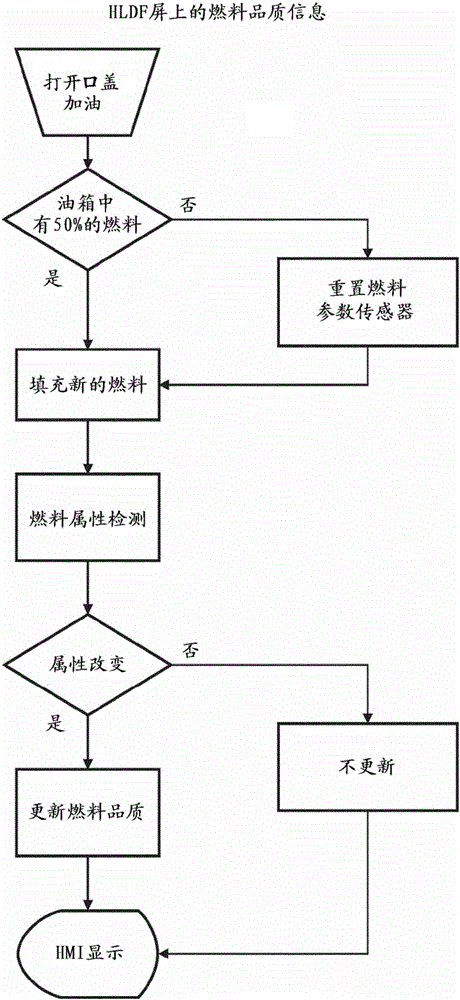

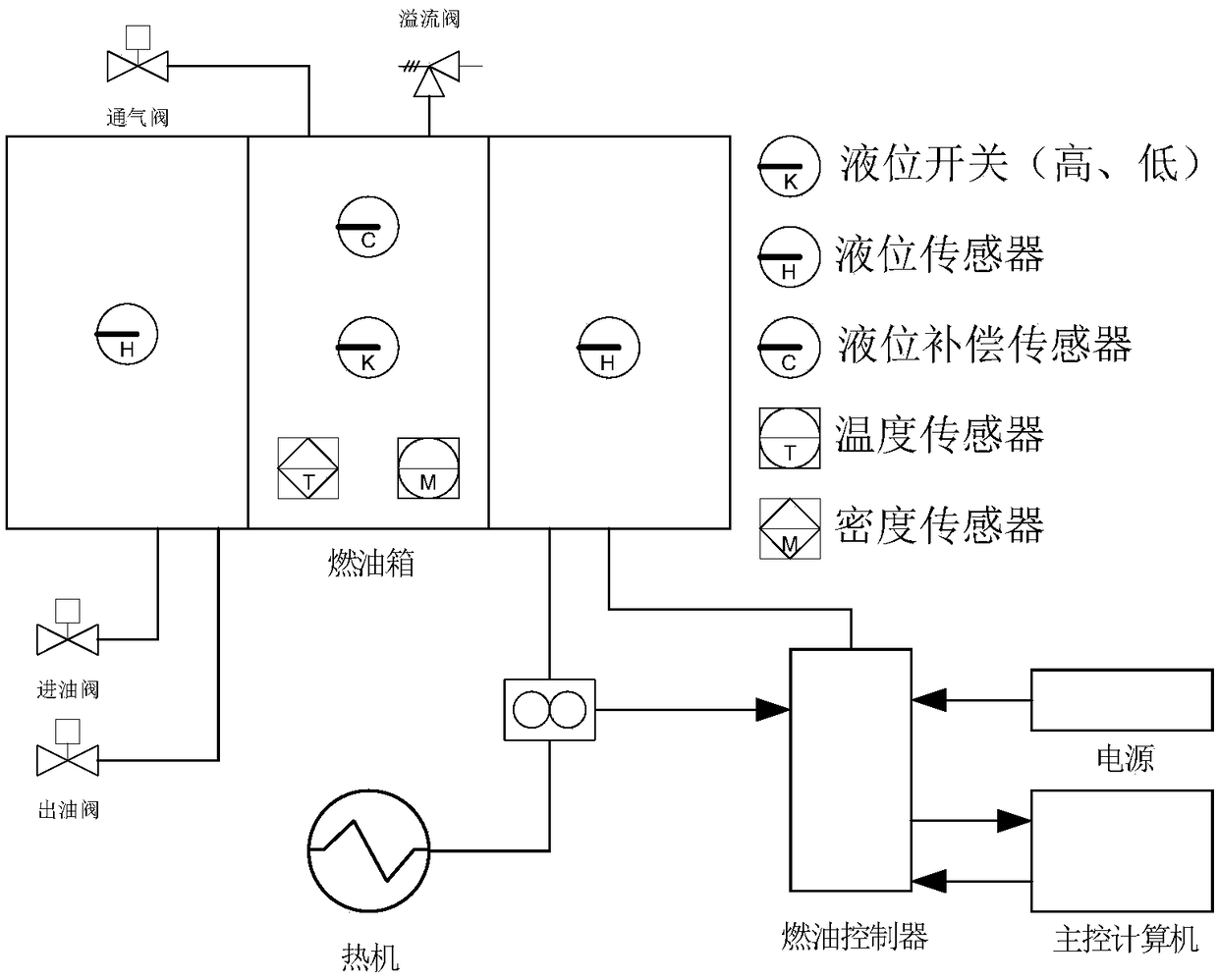

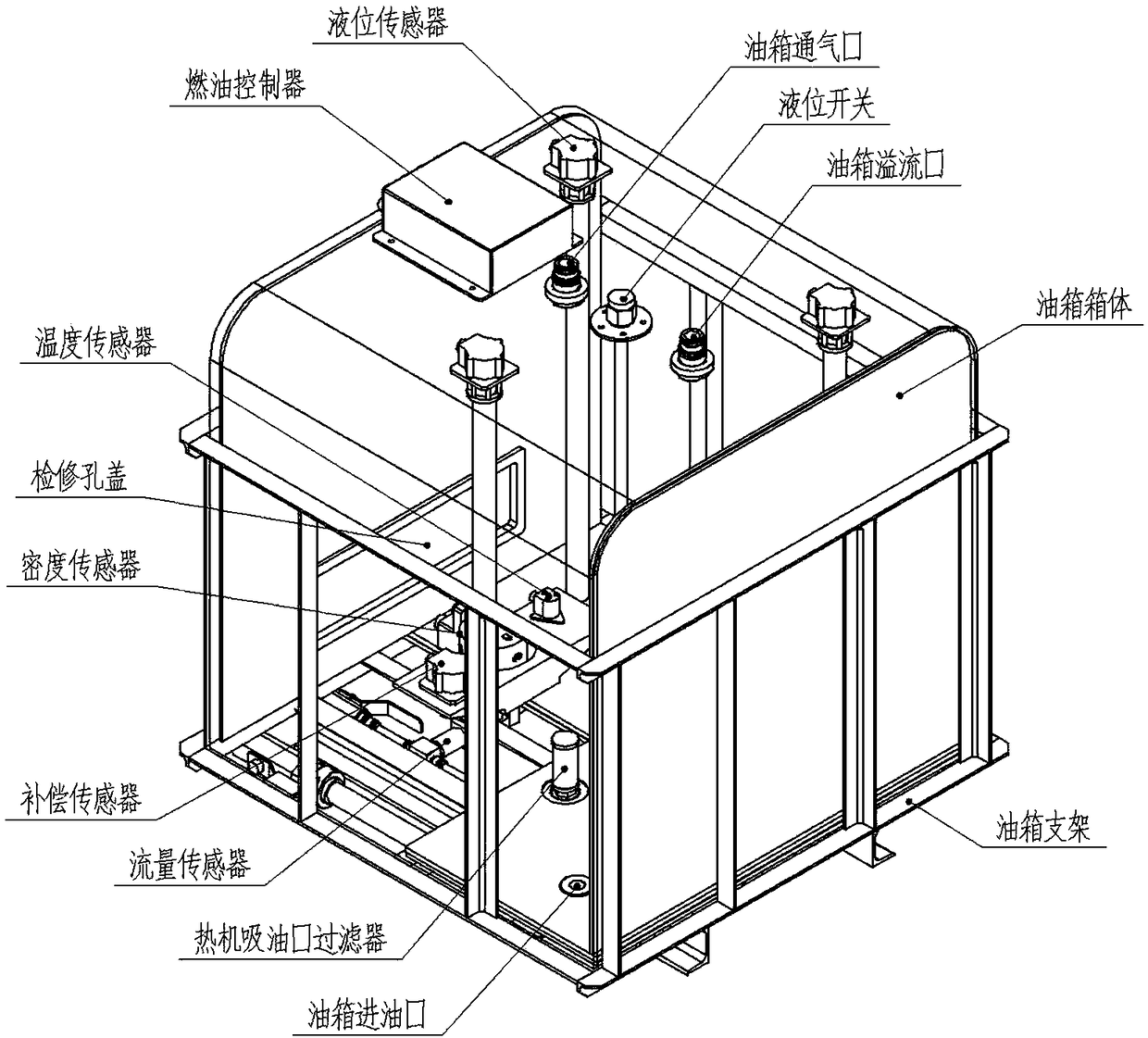

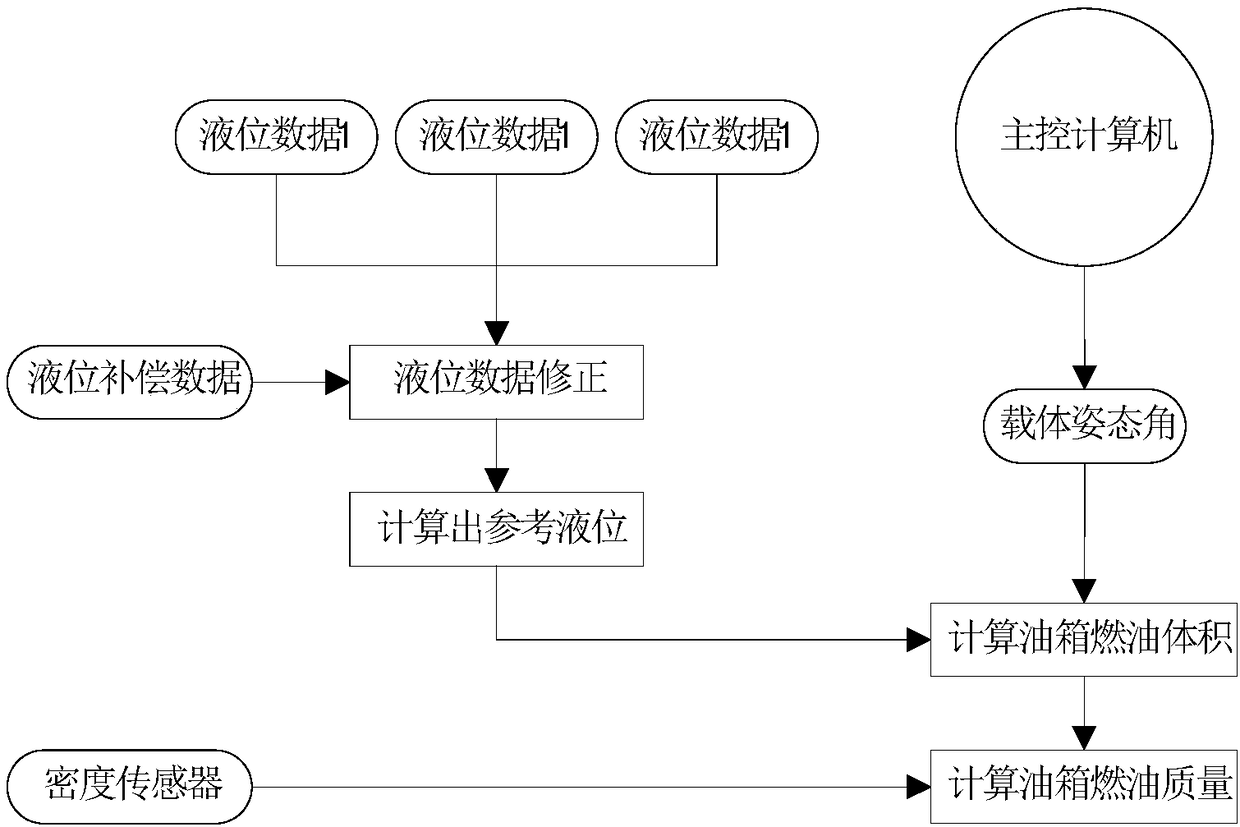

Device and method for measuring fuel capacity of fuel tank for maritime robot

InactiveCN108120485AThe influence of carrier attitude changes is smallAvoid influenceLevel indicators by physical variable measurementFuel qualityMultiple sensor

The invention relates to a device and method for measuring fuel capacity of a fuel tank for a maritime robot. The device includes a fuel controller, the fuel tank, a liquid level sensor, a temperaturesensor, a density sensor, a liquid level compensation sensor, a liquid level switch and a flow sensor. The liquid level sensor is used for obtaining liquid level information; the temperature sensor,the density sensor and the liquid level compensation sensor are used for obtaining property parameters of fuel; the flow sensor measures the consumption rate of the fuel; the fuel controller processessensor signals. The method includes the steps that the fuel controller corrects the liquid level to figure out a reference liquid level according to a received liquid level of the fuel and a receiveddielectric constant of the fuel, figures out the volume of the fuel in the fuel tank according to a carrier attitude angle and finally figures out the mass of the fuel in the fuel tank according to received fuel density. By using the independent fuel controller and multiple sensors to achieve combined measurement, an influence caused by environmental factors and the mass of the fuel on a measurement result is avoided, the remaining fuel capacity of the fuel tank is measured in real time, and the device and method are also applicable to measurement of the mass and volume of a liquid in an underwater sealing cabin.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

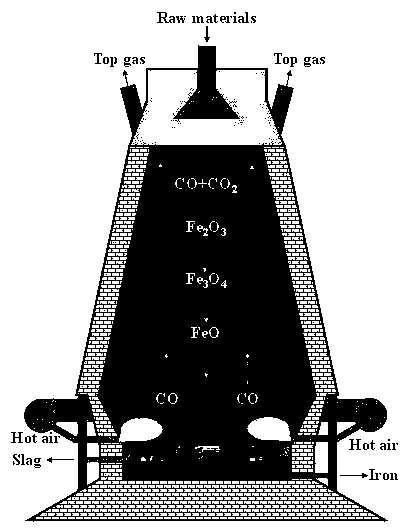

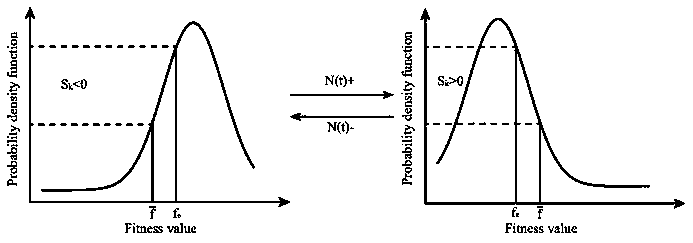

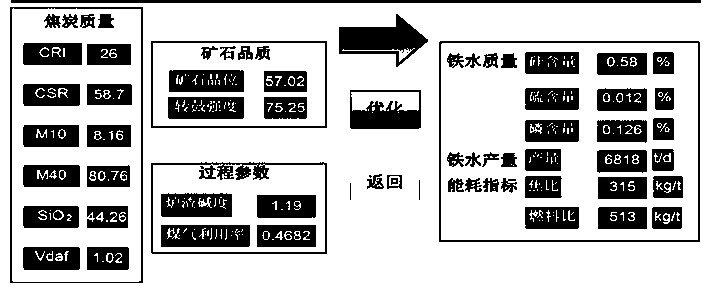

Blast furnace ironmaking multi-objective intelligent optimization method based on adaptive genetic algorithm

InactiveCN110400009ABest search performanceSolving Objective Optimization ProblemsForecastingNeural architecturesFuel qualityCoupling

The invention discloses a blast furnace ironmaking multi-objective intelligent optimization method based on an adaptive genetic algorithm. According to the self-adaptive genetic algorithm, the population fitness skewness coefficient is continuously calculated in the iteration process. The population scale is automatically updated according to the change trend of the population fitness skewness coefficient so as to obtain the optimal search performance. The method is applied to blast furnace ironmaking process index multi-objective optimization. Aiming at different crude fuel qualities, production conditions and market conditions, a factory has different requirements on various indexes of the blast furnace. The fitness function of the genetic algorithm is solved by setting the weight of each index through the furnace length. The population size is automatically updated according to the positive and negative change trend of the fitness function in the evolution process so as to ensure that the algorithm has the optimal optimization performance. By applying the self-adaptive genetic algorithm to the ironmaking process, the problem of multi-target optimization of mutual coupling of blast furnaces can be effectively solved. Compared with a traditional optimization algorithm, the method has the advantages that local extremum can be effectively avoided, and a globally optimal solutioncan be efficiently and accurately solved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com