Engine control system and method based on fuel quality

a technology of engine control and fuel quality, applied in the direction of electric control, ignition automatic control, instruments, etc., can solve the problem of engine operating in compliance with more restrictive emissions standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

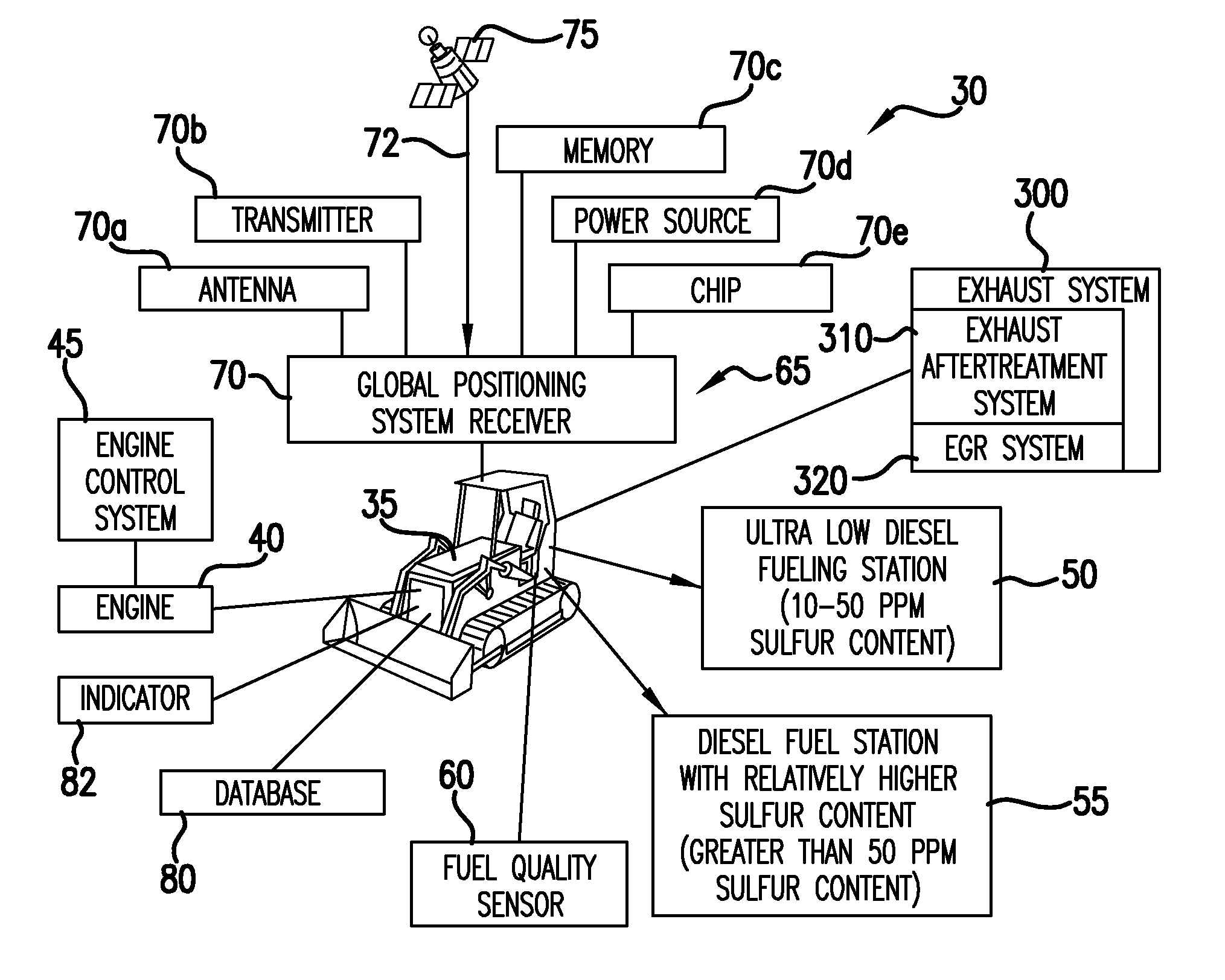

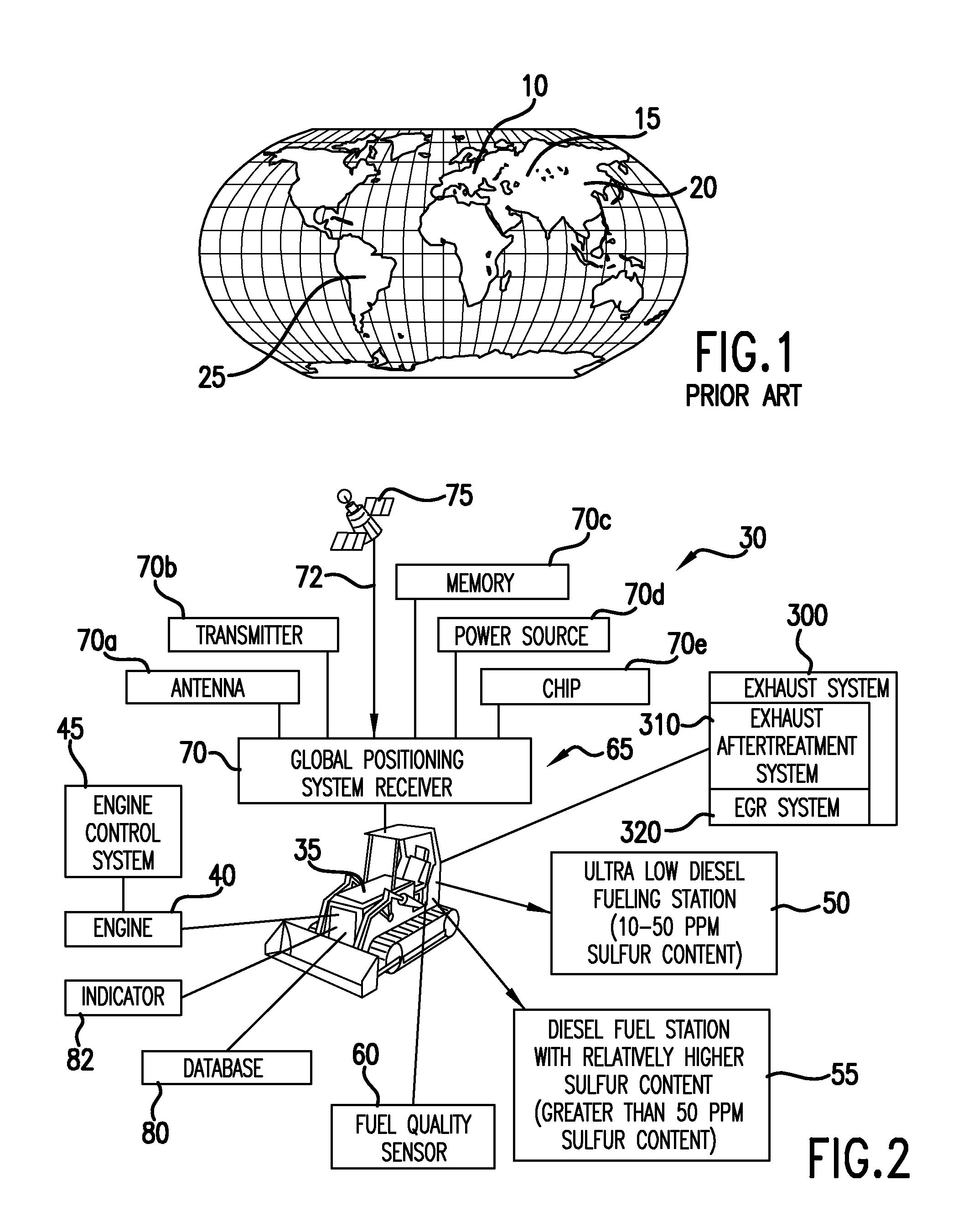

[0014]There exist multiple geographical jurisdictions having different and varying emissions standards. Turning now to FIG. 1, there is shown a geographical map illustrating different areas or regions potentially having different diesel fuel emissions standards. The map of FIG. 1 is illustrative and forms no limitations to the present disclosure, and the present disclosure is not limited to any particular number of emissions standards. It should be noted that a particular country may even have more than two different standards. For example, in the European Union shown as reference numeral 10, the Euro 4 standard has applied since 2005, which specifies a maximum of 50 parts per million “ppm” of sulfur in diesel fuel for most highway vehicles. In 2005, ultra-low sulfur diesel with a maximum of 10 ppm of sulfur also became available. In 2009, the European Union 10 defined the Euro 5 fuel standard as diesel fuel with no more than 10 ppm of sulfur. Diesel fuel for most non-highway applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com