Patents

Literature

125 results about "Ultra-low-sulfur diesel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra-low-sulfur diesel (ULSD) is diesel fuel with substantially lowered sulfur content. Since 2006, almost all of the petroleum-based diesel fuel available in Europe and North America has been of a ULSD type.

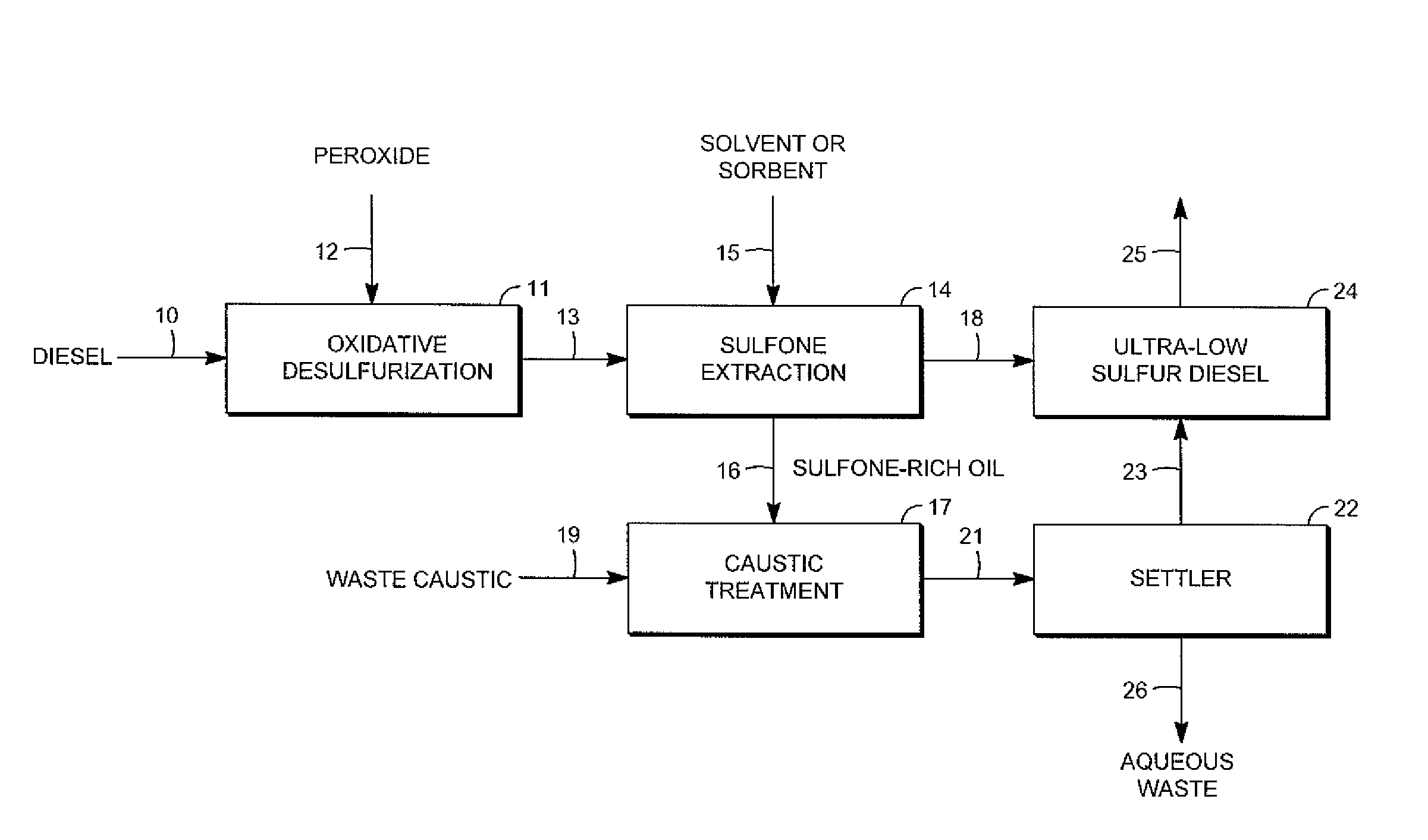

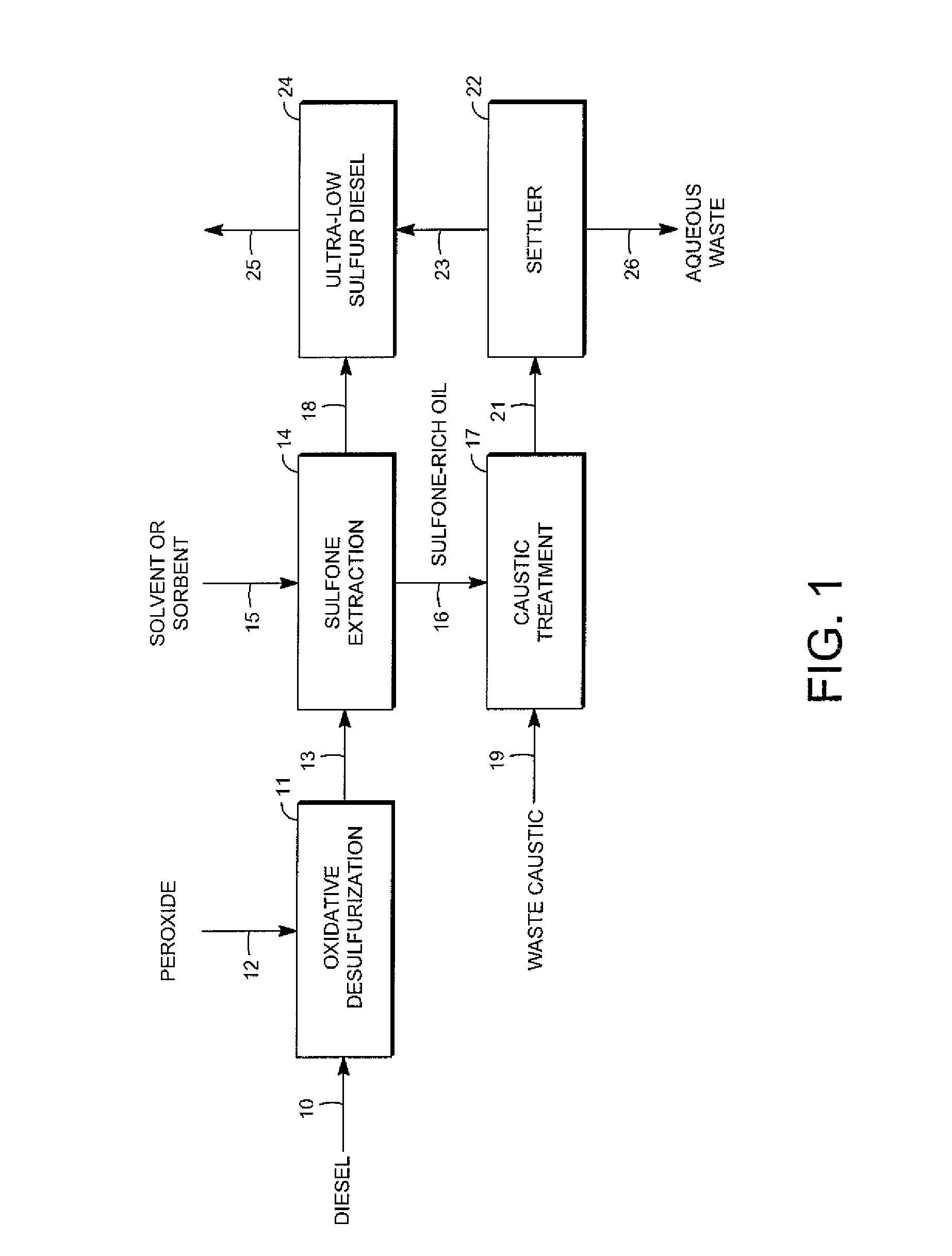

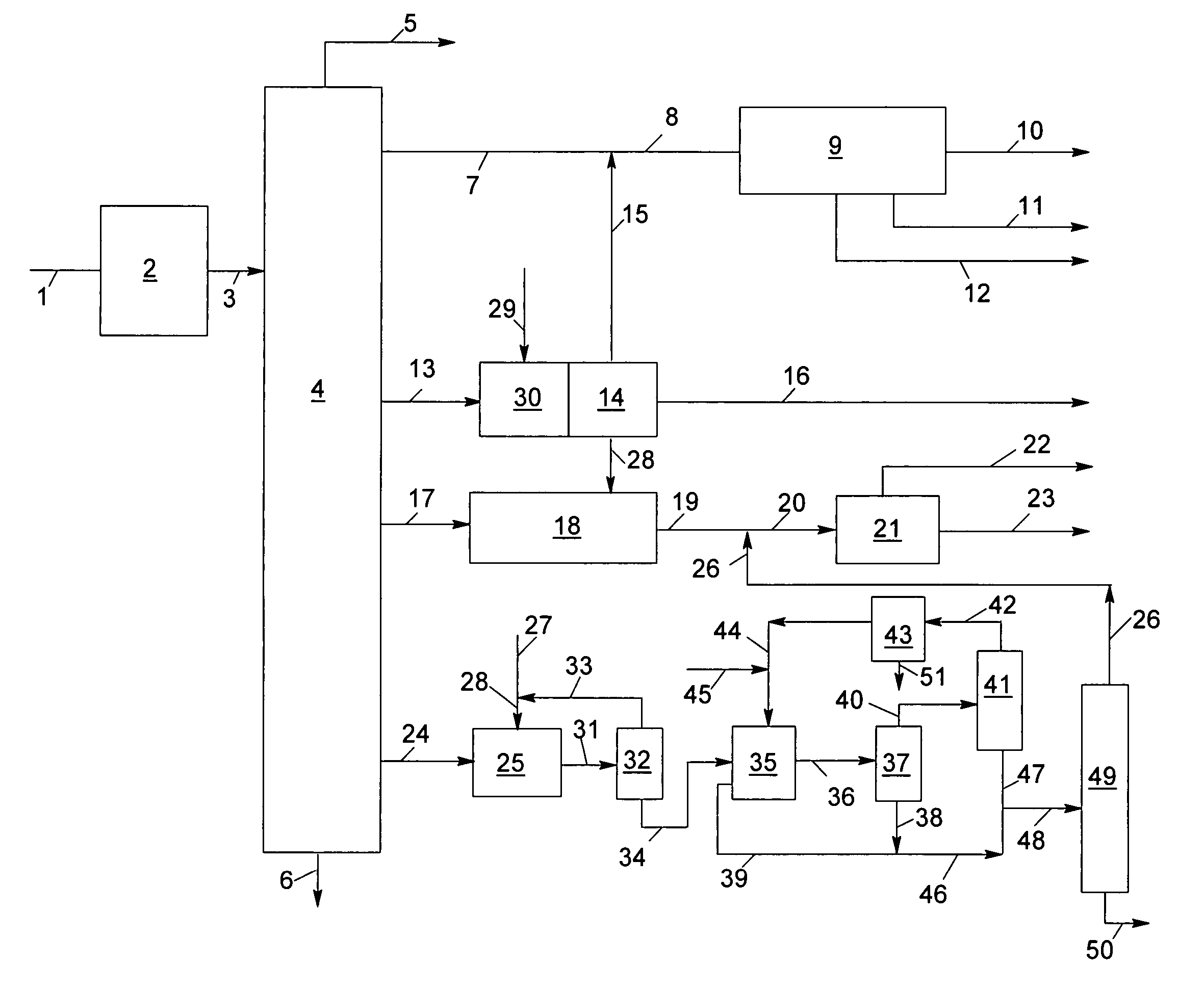

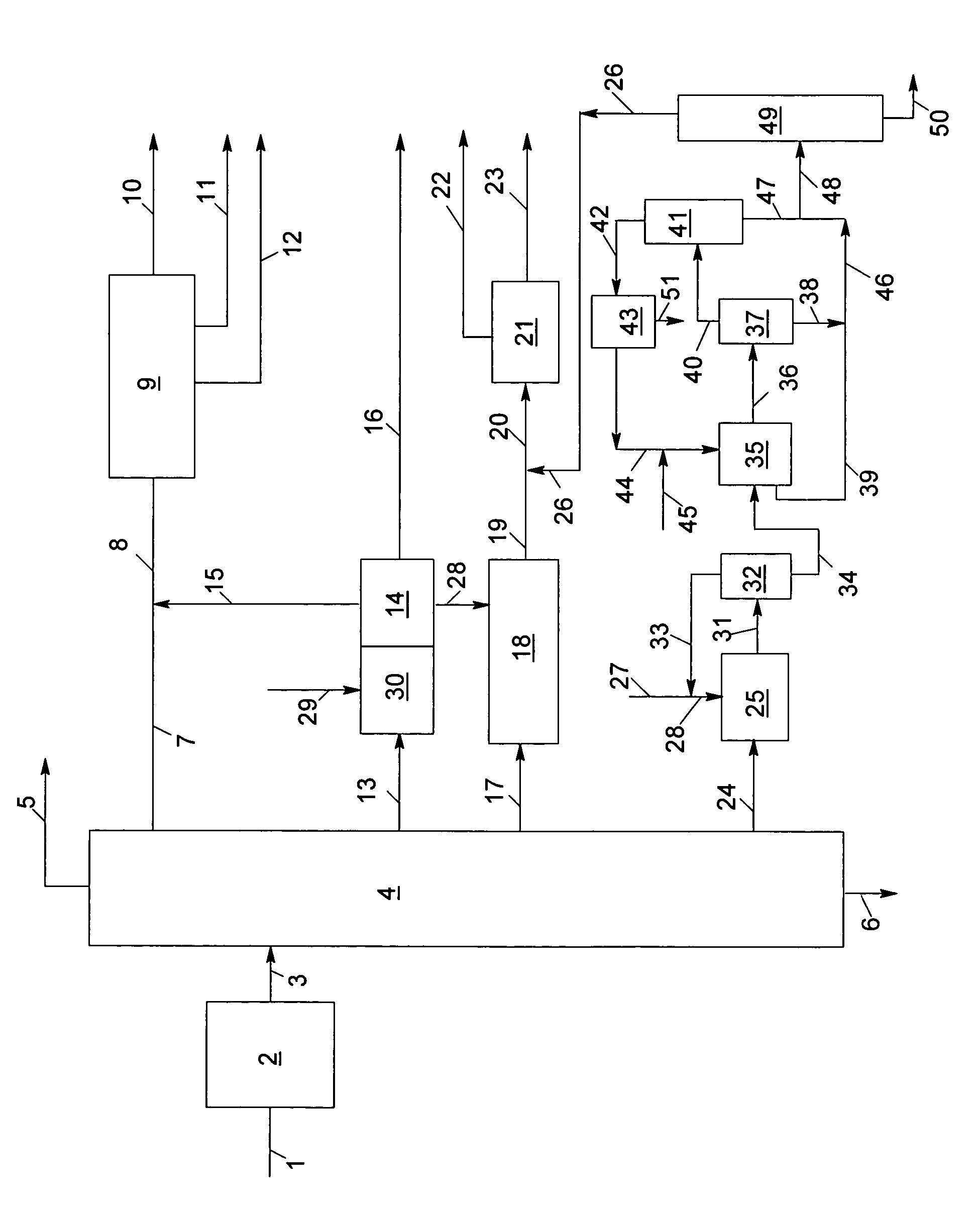

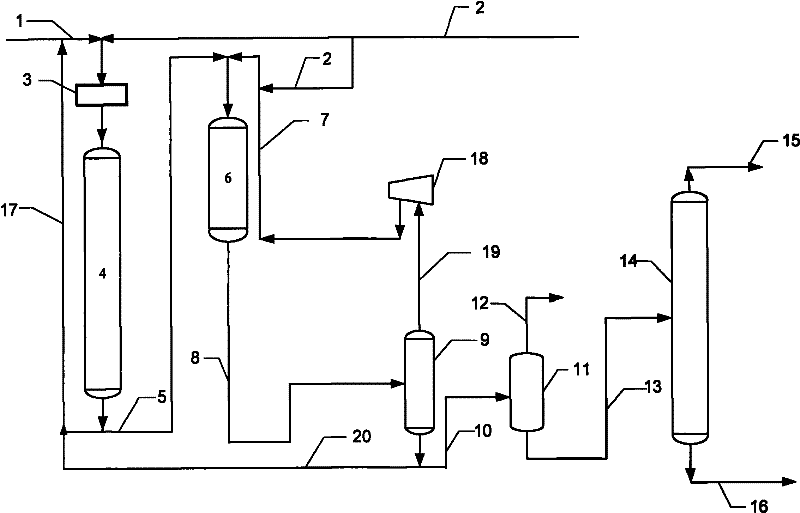

Removal of sulfur-containing compounds from liquid hydrocarbon streams

InactiveUS20090065399A1Easy to separateEasy extractionRefining with oxygen compoundsTreatment with plural serial refining stagesLiquid hydrocarbonsImproved method

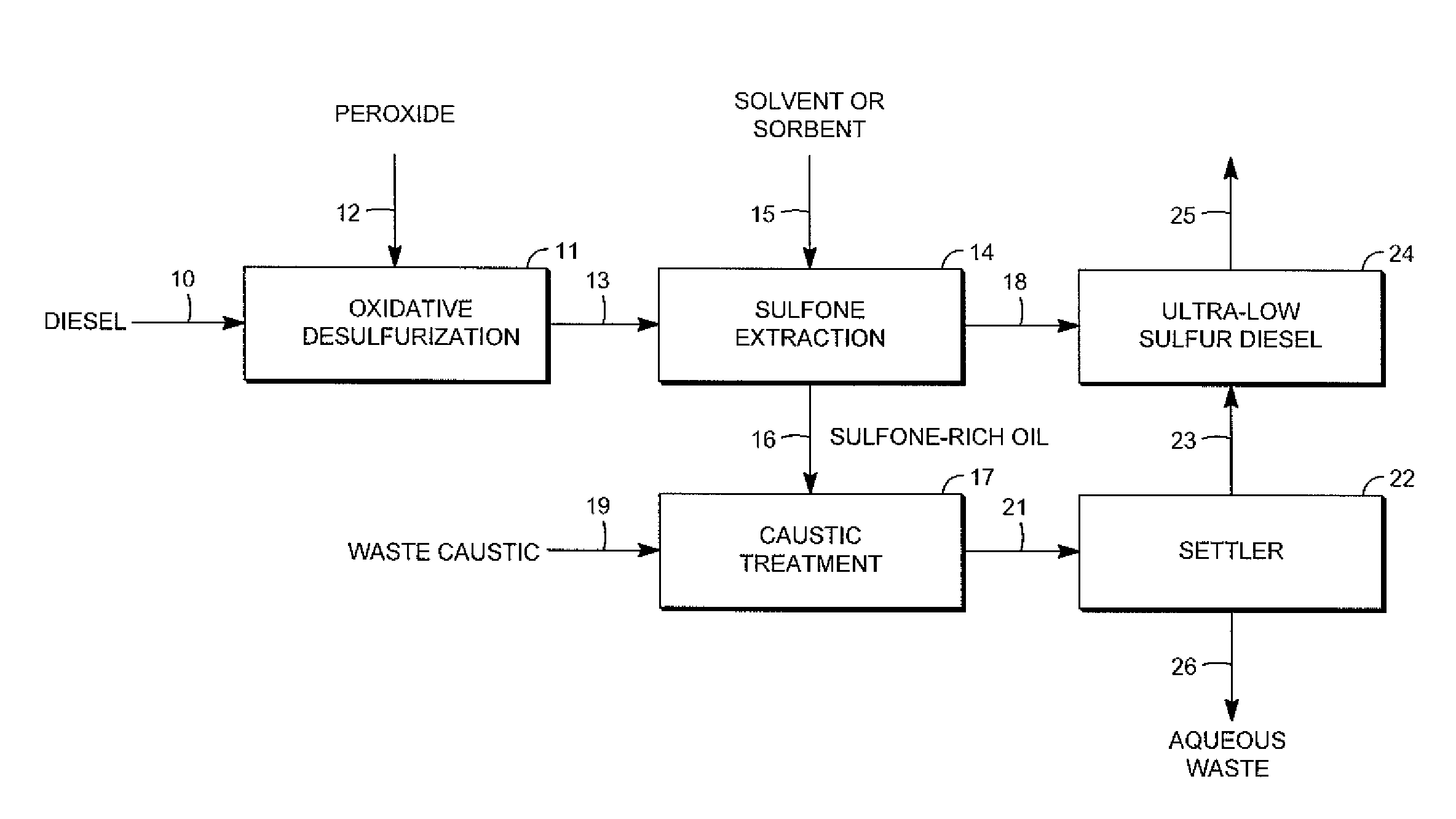

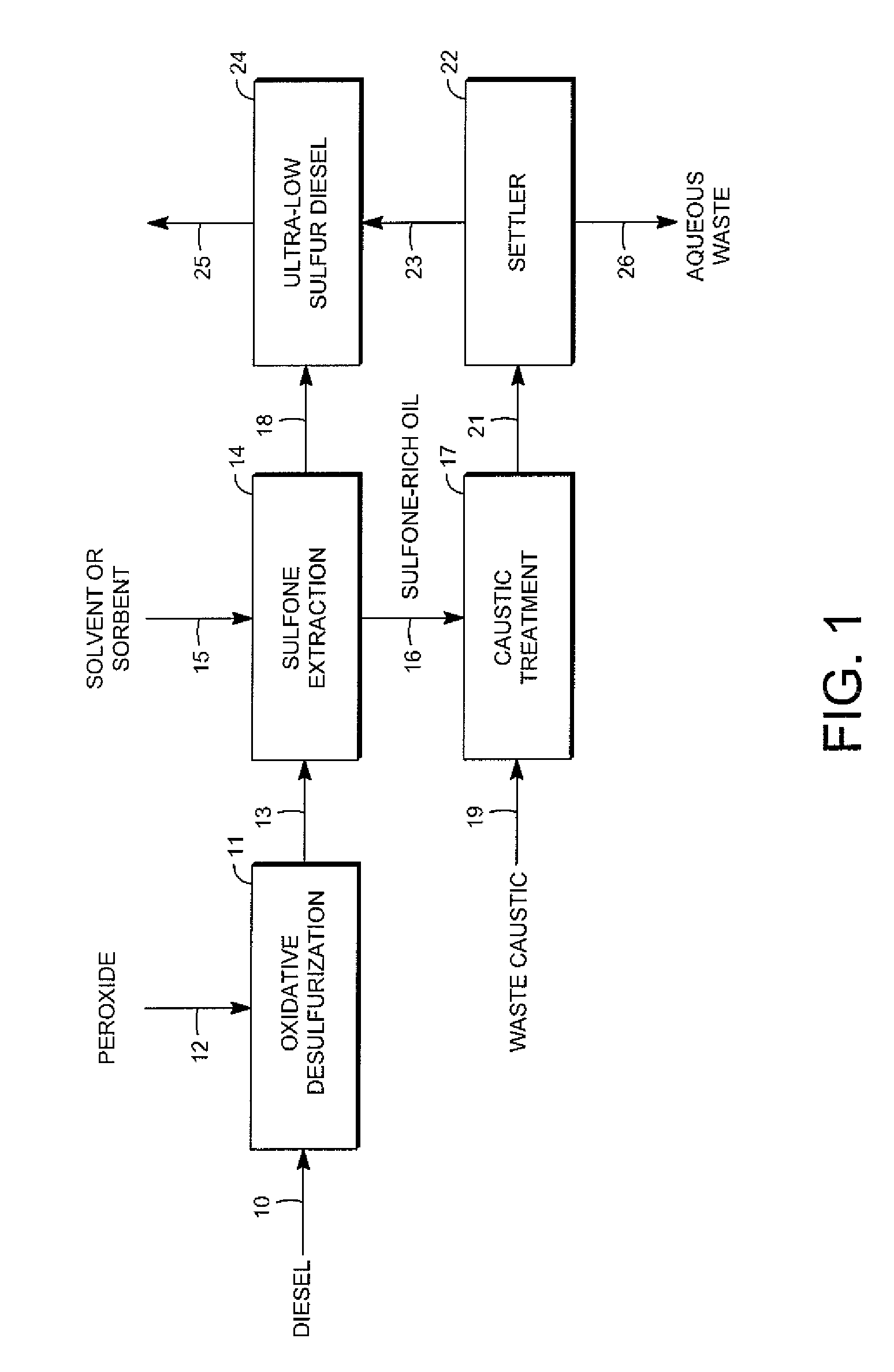

An improved method for desulfurizing a fuel stream such as a diesel stream is disclosed which includes generation of a sulfone oil, the desulfurization of the sulfone oil and the recycling of the resulting biphenyl-rich stream and ultra-low sulfur diesel streams. The method includes combining a thiophene-rich diesel stream with an oxidant to oxidize the thiophenes to sulfones to provide a sulfone-rich diesel stream. Sulfone oil is extracted from the sulfone-rich diesel stream to provide sulfone oil and a first low-sulfur diesel stream The low-sulfur diesel stream is recycled. The sulfone-rich oil stream is combined with an aqueous oxidant-containing stream, such as caustic stream, which oxidizes the sulfones to biphenyls and forms sulfite to provide a second low-sulfur diesel stream

Owner:UOP LLC

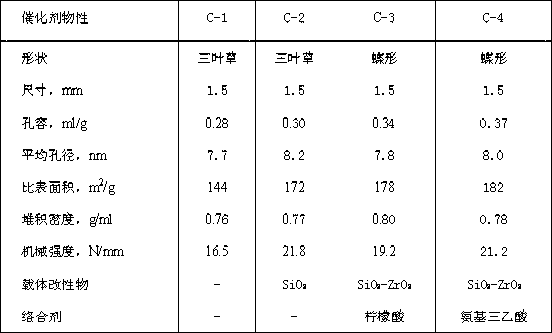

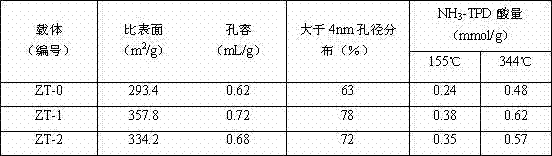

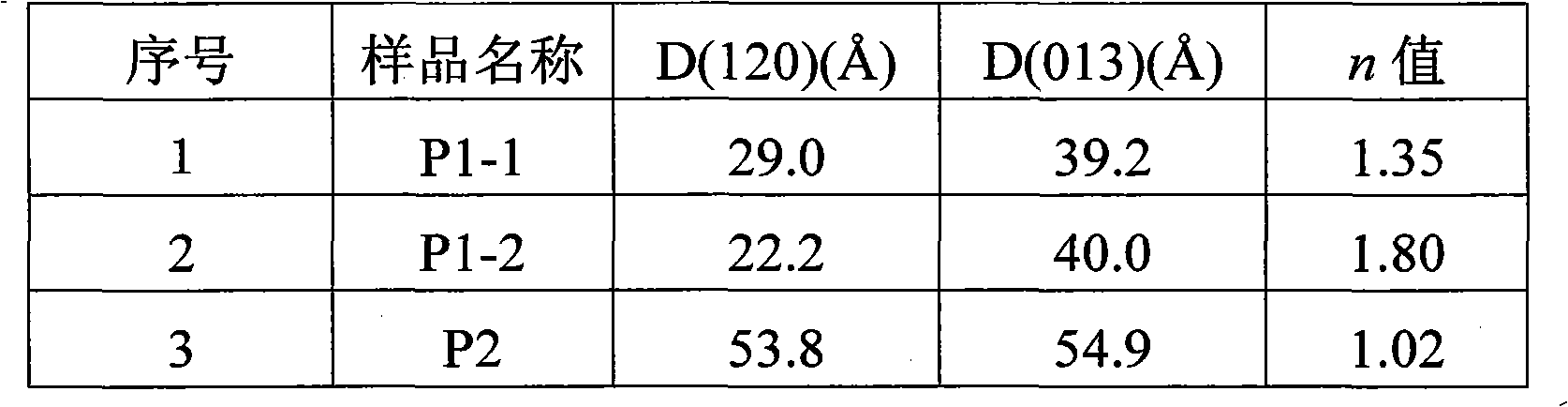

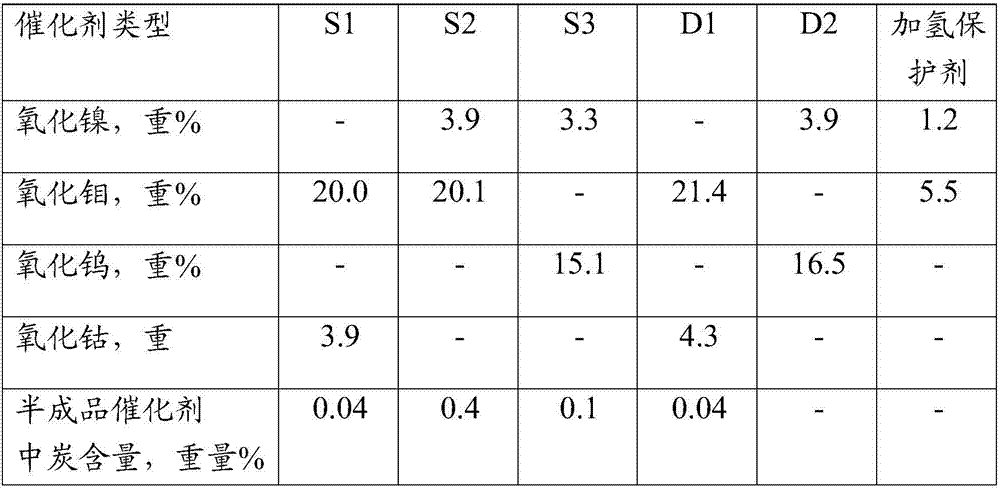

Preparation method of catalyst by ultralow-sulfur hydrofining

InactiveCN102909027ALarge specific surface areaLarge hole volumeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsDispersityReduction Activity

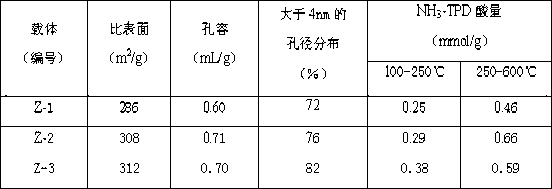

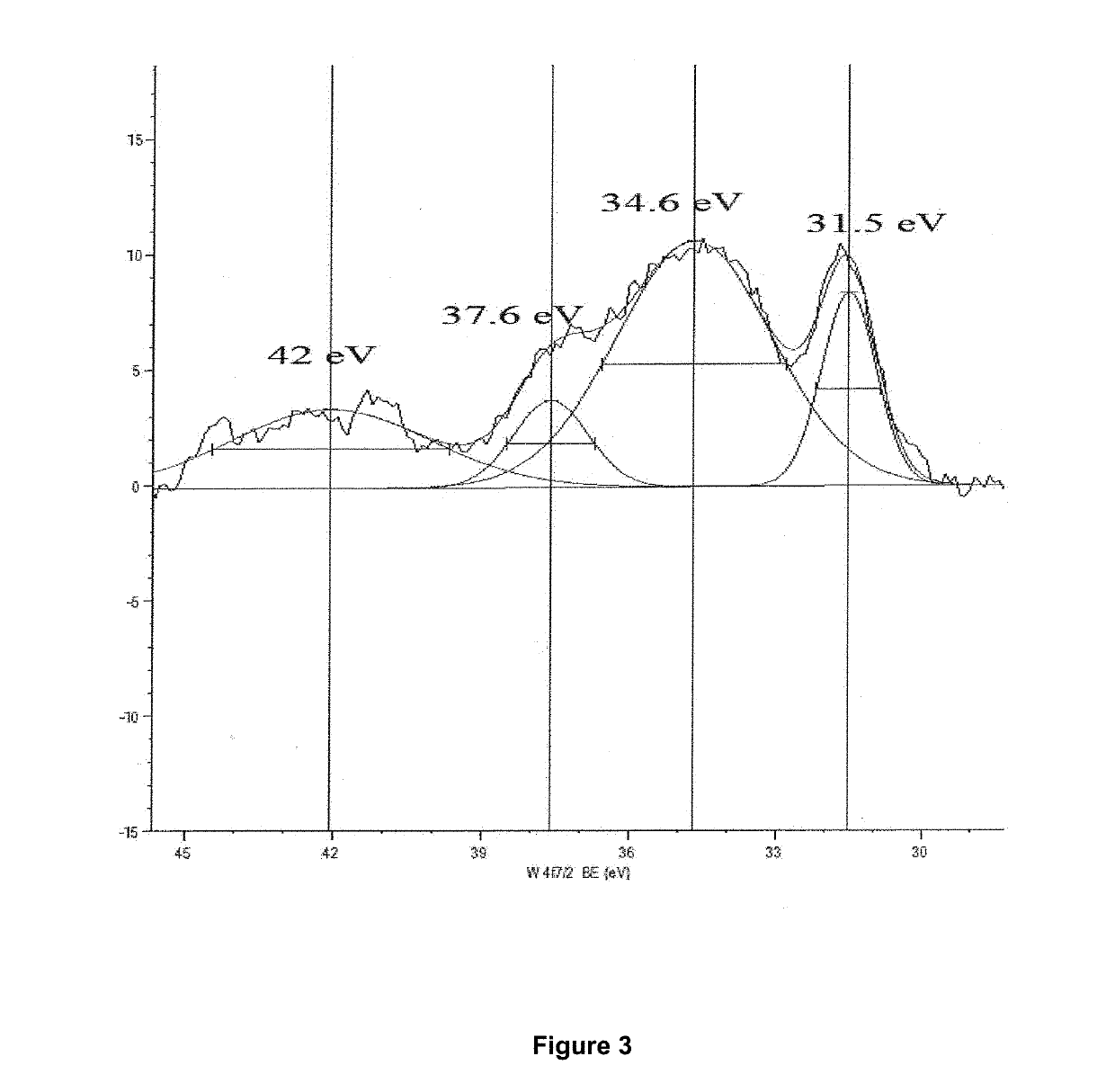

The invention relates to a preparation method of catalyst by ultralow-sulfur hydrofining. Al2O3-SiO2-ZrO2 tertiary compound oxide as a carrier, W-Mo-Ni-Co quaternary elements as active metal components and P as aid are used to prepare the catalyst which is butterfly-shaped. The preparation method is characterized by introducing SiO2 to Al2O3 to modulate surface acidity of the carrier and increasing specific surface area and pore volume of the carrier; introducing ZrO2 to increase low-temperature reactivity of the catalyst; preparing metallic co-impregnated solution by complexing process, and loading W-Mo-Ni-Co quaternary active metal components and the aid P by means of stepwise saturated impregnation to increase dispersity and utilization rate of active metals. The catalyst has the advantages of large specific surface, large pore volume, moderate surface acidity, high metal reduction activity and high low-temperature reactivity. Compared with like catalysts, the catalyst can be used to produce ultralow-sulfur diesel with lower than 10microgram / g sulfur content under low reaction severity.

Owner:CHINA NAT OFFSHORE OIL CORP +2

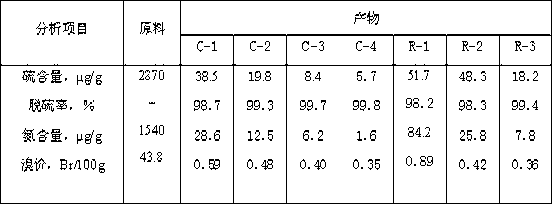

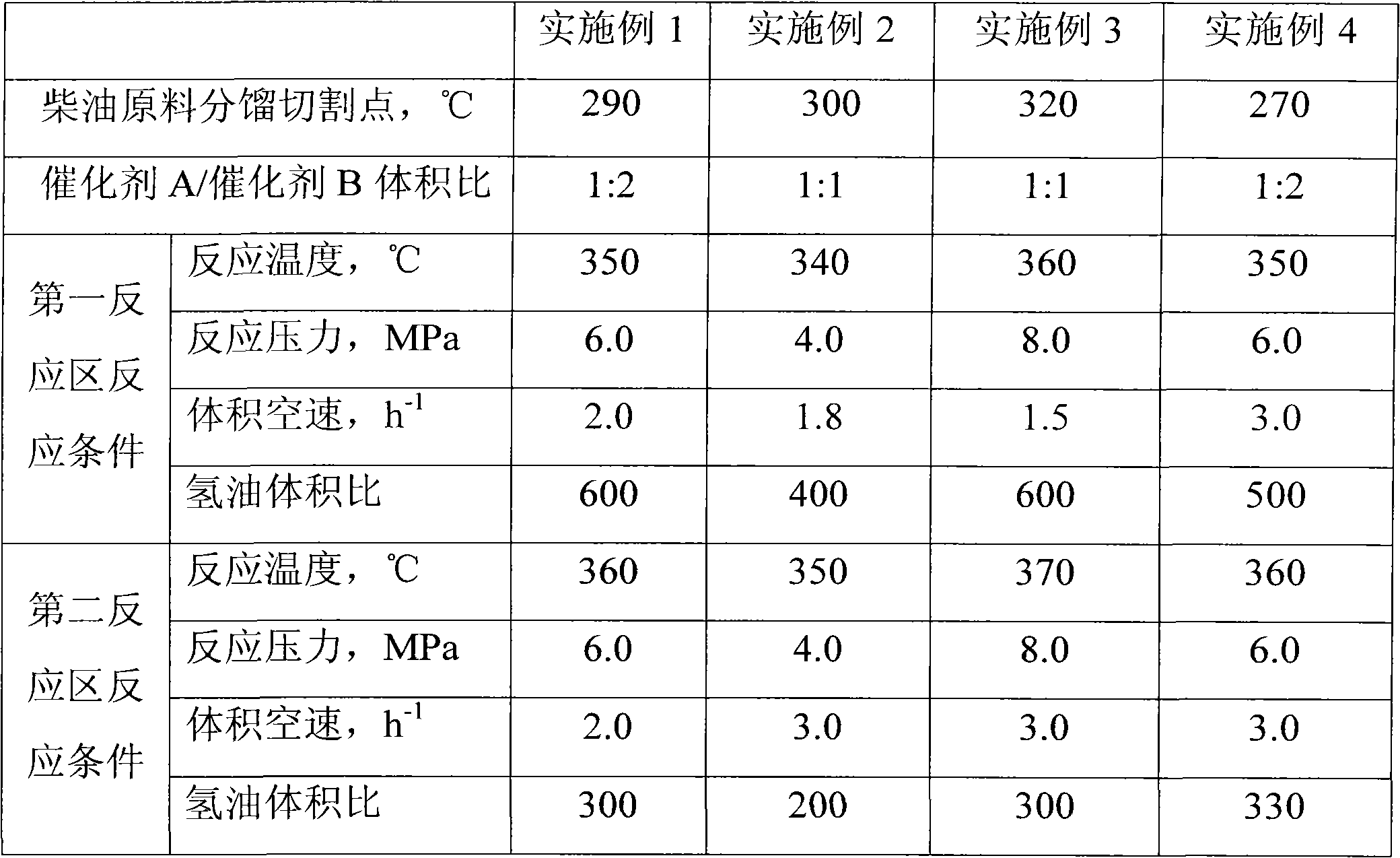

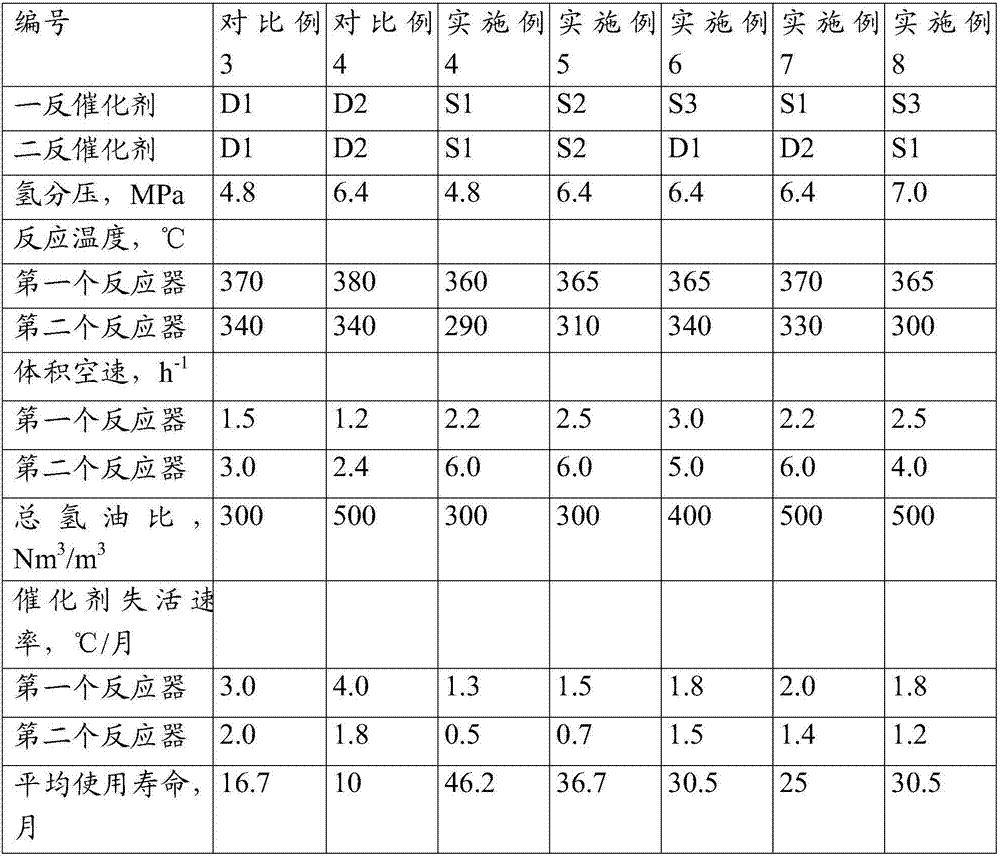

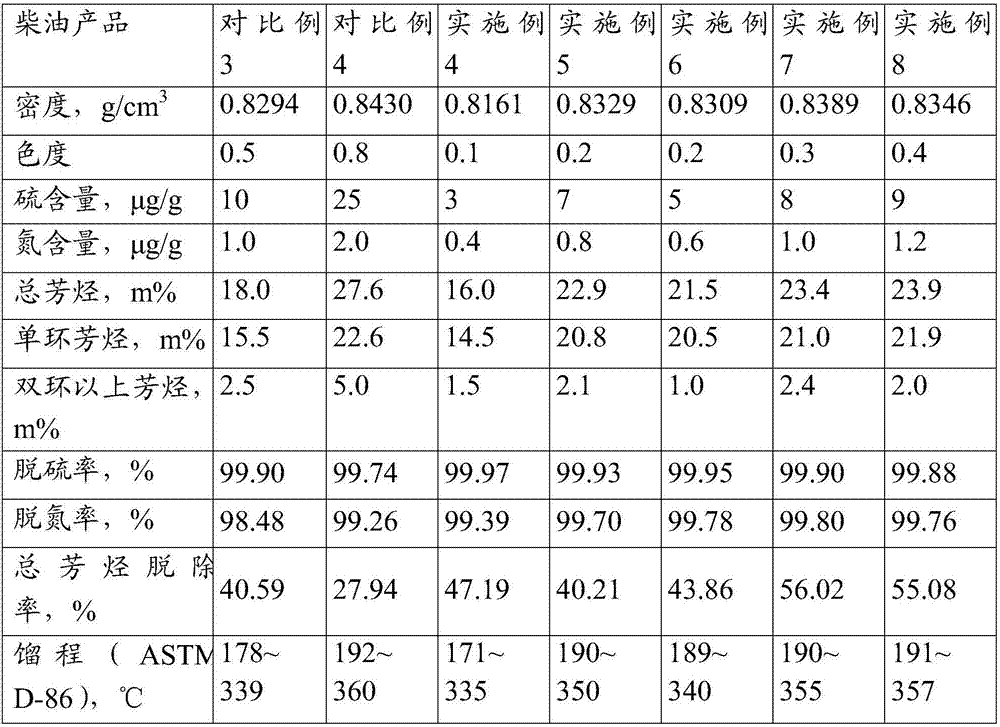

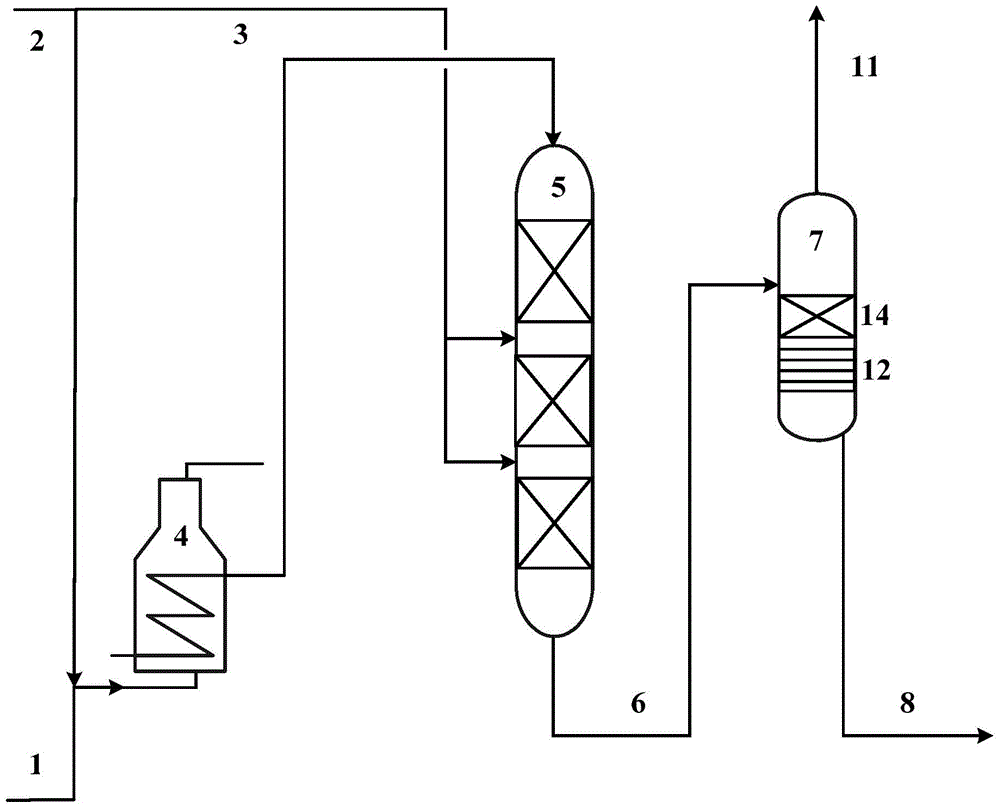

Grading method of catalyst of deep hydrodesulfurization of diesel oil

ActiveCN101591566AHigh activityReduce dosageTreatment with hydrotreatment processesRefining to eliminate hetero atomsLiquid productHydrodesulfurization

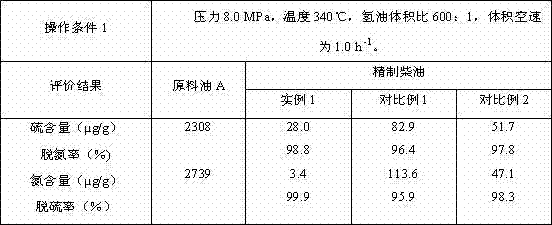

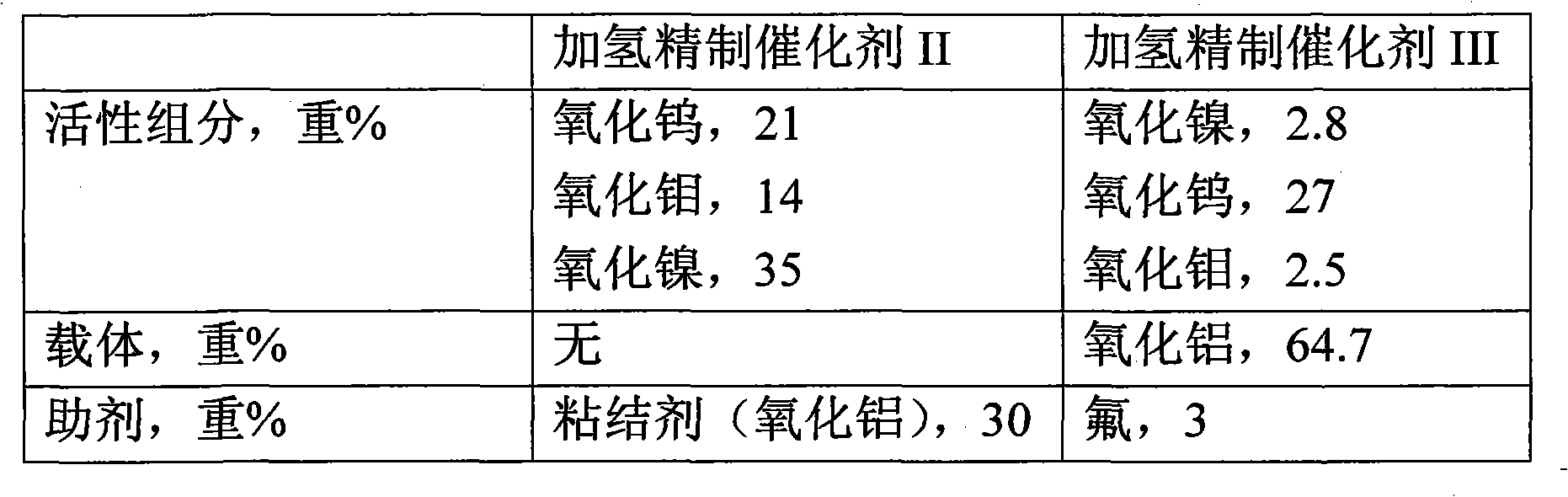

The invention discloses a grading method of catalyst of deep hydrodesulfurization of diesel oil, comprising the following steps: base oil and hydrogen are mixed, then the mixture is led into a hydrogenation reactor to carry out hydrogenation reaction; reaction effluent is cooled and separated to obtain hydrogen-rich gas and liquid product; the hydrogenation reactor sequentially comprises four hydrogenation reaction zones, wherein, the first hydrogenation reaction zone is filled with hydrogenation protective agent, the second hydrogenation reaction zone is filled with hyrorefining catalyst (1)containing active metal cobalt-molybdenum, the third hydrogenation reaction zone is filled with the mixture of the hyrorefining catalyst (1) and hyrorefining catalyst (2), and the fourth hydrogenation reaction zone is filled with the hyrorefining catalyst (2) containing active metal nickel-tungsten. The invention carries out reasonable grading on catalyst of different systems, gives full play to the advantages of each catalyst in different desulphurizing states, improves whole catalyst activity by synergy of each catalyst, and can obtain ultra low sulfur diesel oil, sulfur content of which satisfies Euro IV standard under moderate operation condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

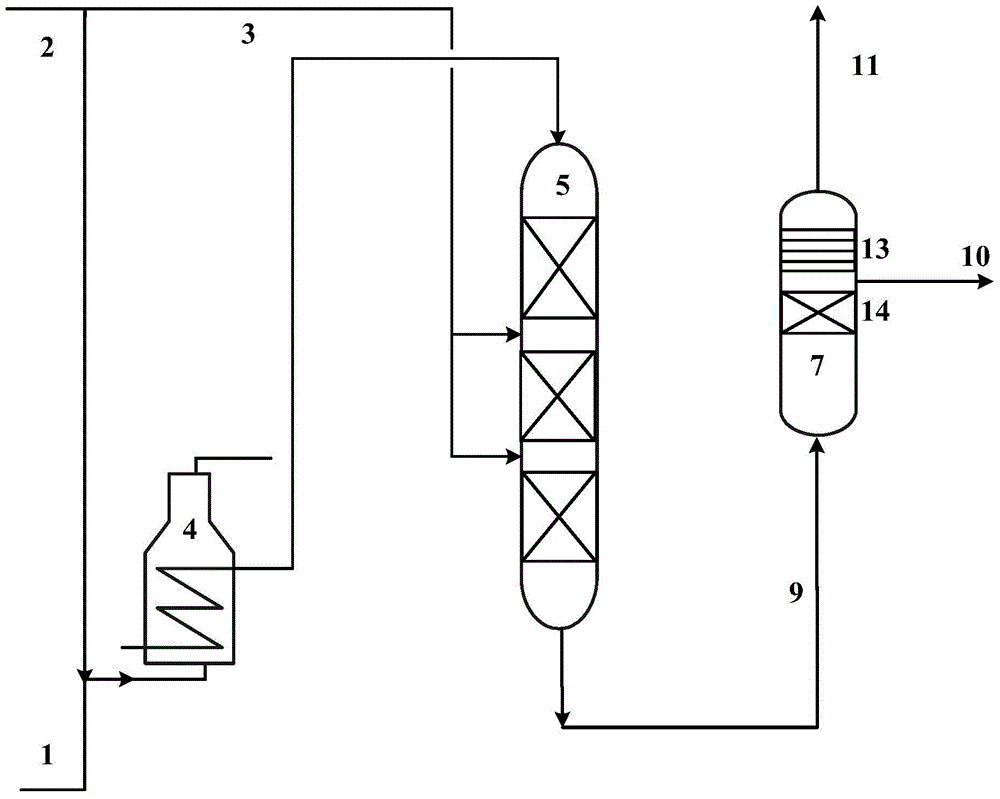

Inferior diesel oil hydrodesulfurization method

ActiveCN102876374AReduce sulfur contentImprove operational flexibilityTreatment with hydrotreatment processesLiquid productHydrogen

The invention discloses an inferior diesel oil hydrodesulfurization method. Under the hydrofinishing condition, raw materials diesel oil and hydrogen are mixed and pass through four reaction zones in order; reaction products are cooled and enter a separation system so as to obtain a liquid product and a hydrogen-rich gas. A first catalyst is filled in a first reaction zone; a mixture of the first catalyst and a second catalyst are filled in a second reaction zone; the second catalyst is filled in a third reaction zone; and the first catalyst is filled in a fourth reaction zone, wherein the first catalyst is an Mo-Co catalyst and the second catalyst is a W-Mo-Ni catalyst or W-Ni catalyst. According to the invention, catalysts of different types and different hydrogenation activities are subjected to reasonable grading, and advantages of each catalyst at different desulphurization stages are fully performed. Through synergism of the catalysts, the whole catalyst activity is raised; and under a mild operational condition, ultra-low sulfur diesel oil, the sulfur content of which meets the European IV standard, can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Removal of sulfur-containing compounds from liquid hydrocarbon streams

InactiveUS7790021B2Easy to separateEasy extractionRefining with oxygen compoundsTreatment with plural serial refining stagesLiquid hydrocarbonsSulfite

An improved method for desulfurizing a fuel stream such as a diesel stream is disclosed which includes generation of a sulfone oil, the desulfurization of the sulfone oil and the recycling of the resulting biphenyl-rich stream and ultra-low sulfur diesel streams. The method includes combining a thiophene-rich diesel stream with an oxidant to oxidize the thiophenes to sulfones to provide a sulfone-rich diesel stream. Sulfone oil is extracted from the sulfone-rich diesel stream to provide sulfone oil and a first low-sulfur diesel stream The low-sulfur diesel stream is recycled. The sulfone-rich oil stream is combined with an aqueous oxidant-containing stream, such as caustic stream, which oxidizes the sulfones to biphenyls and forms sulfite to provide a second low-sulfur diesel stream.

Owner:UOP LLC

Purification of ultralow sulfur diesel fuel

InactiveUS20100155302A1Decreased color body contentReduce colorTreatment with hydrotreatment processesHydrocarbon oils treatment productsActivated carbonCoal

The invention is a method of purifying an ultralow sulfur diesel fuel which contains polycyclic aromatic color bodies. The method comprises contacting the ULSD fuel in the liquid phase with a coal-based activated carbon adsorbent having a surface area ranging from 800 to 1500 m2 / g and containing pores having pore size greater than 20 Å, and recovering a purified diesel product having a decreased color bodies content.

Owner:LYONDELL CHEM TECH LP

Preparation method of super low sulfur diesel oil

InactiveCN1534082AHigh catalytic activityStrong catalytic selectivityTreatment with plural serial refining stagesOrganic sulfide compoundSorbent

A process for preparing ultralow-sulfur diesel oil includes mixing refined low-sulfur diesel oil with phase-transfer catalyst and aqueous solution of hydrogen peroxide, stirring, reaction for converting the organic sulfide to sulfone and / or sulfoxide, recovering phase-transfer catalyst, removing excessive hydrogen peroxide, selectively removing sulfone and / or sulfoxide by polar solvent, and adsorption. The final sulfur content is lower than 10 ppm (even up to 0 ppm).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for producing ultralow sulfur diesel fuels

ActiveCN101311252AReduce sulfur contentReduce PAH contentTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonNaphtha

The invention relates to a production method for ultra-low sulfur diesel oil; wherein, after mixed with hydrogen, straight-run atmosphere 3rd side cut distillate and (or) diesel oil heavy distillate enter(s) a first hydrogenation reaction zone and reacts under the action of hydro-upgrading catalyst and hydrofining catalyst; after mixed with the reaction effluent of the first hydrogenation reaction zone, straight-run atmosphere 2nd side cut distillate and (or) diesel oil light distillate enter(s) a second hydrogenation reaction zone and reacts under the action of the hydrofining catalyst; the reaction effluent of the second hydrogenation reaction zone is cooled, separated and distilled to obtain naphtha fraction and diesel products. The method provided by the invention can treat the diesel distillate with high sulfur, high nitrogen and high final boiling point, and under mild operating conditions, obtain clear diesel products with low content of sulfur and polycyclic aromatic hydrocarbons as well as high cetane number; meanwhile, the product quality can reach the indexes of the IV European emission standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

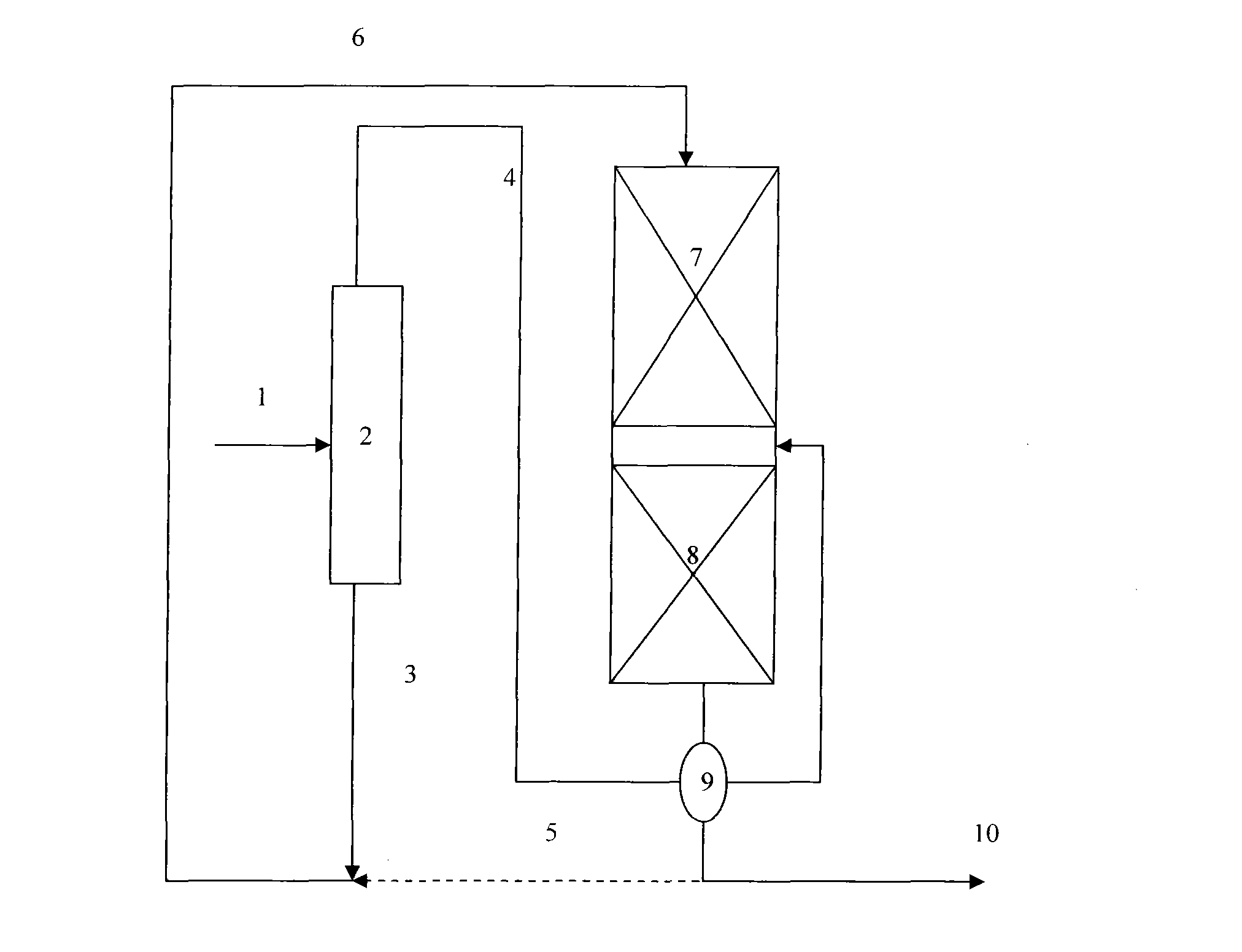

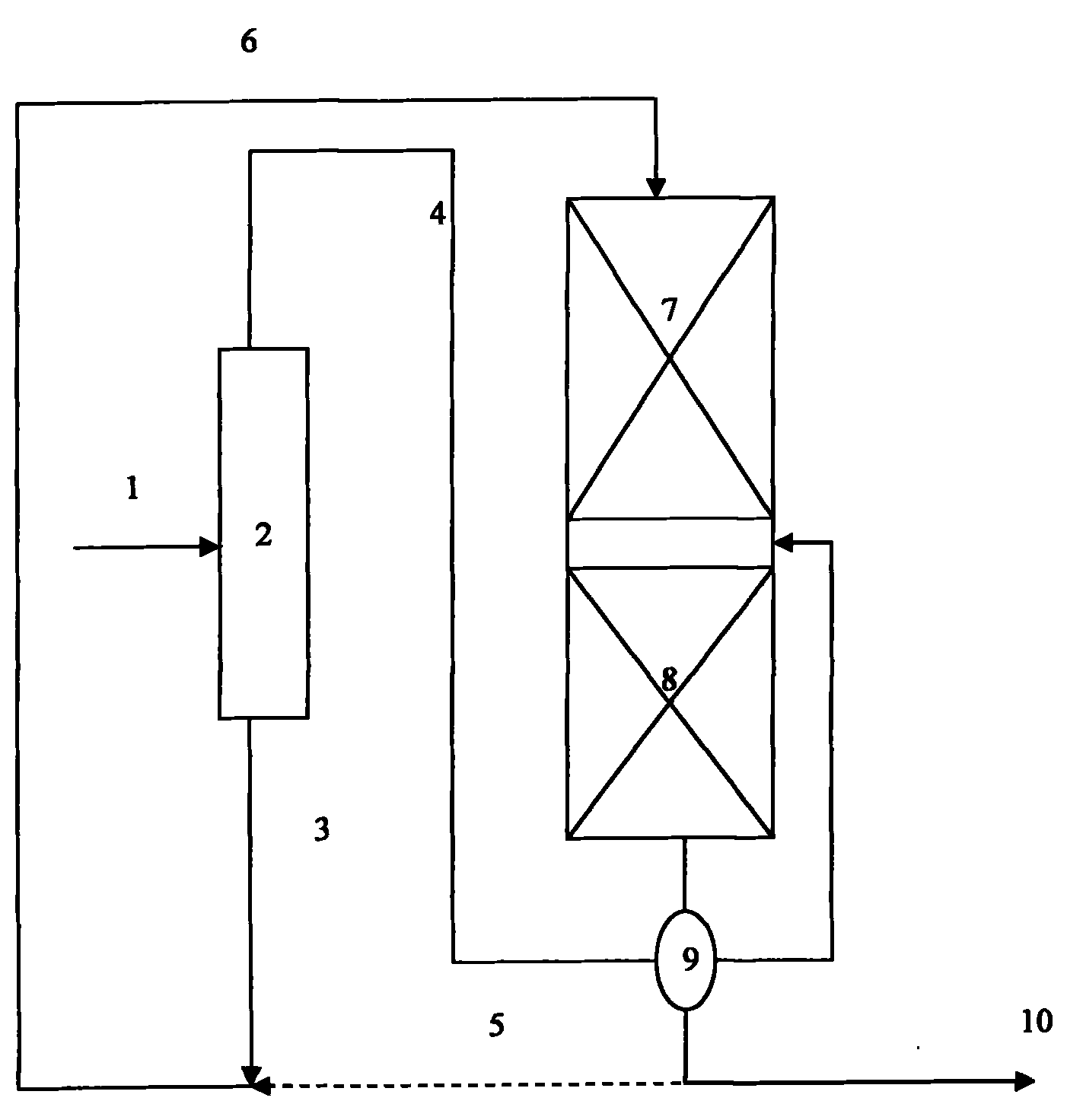

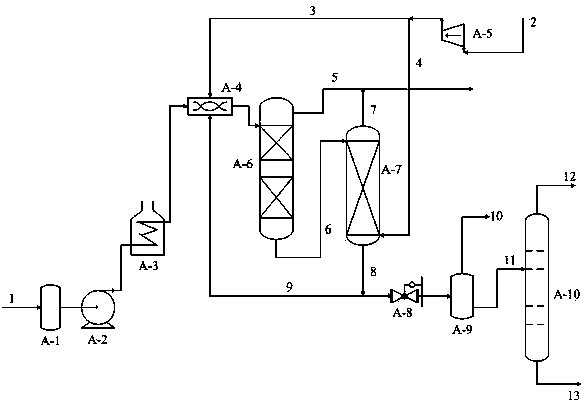

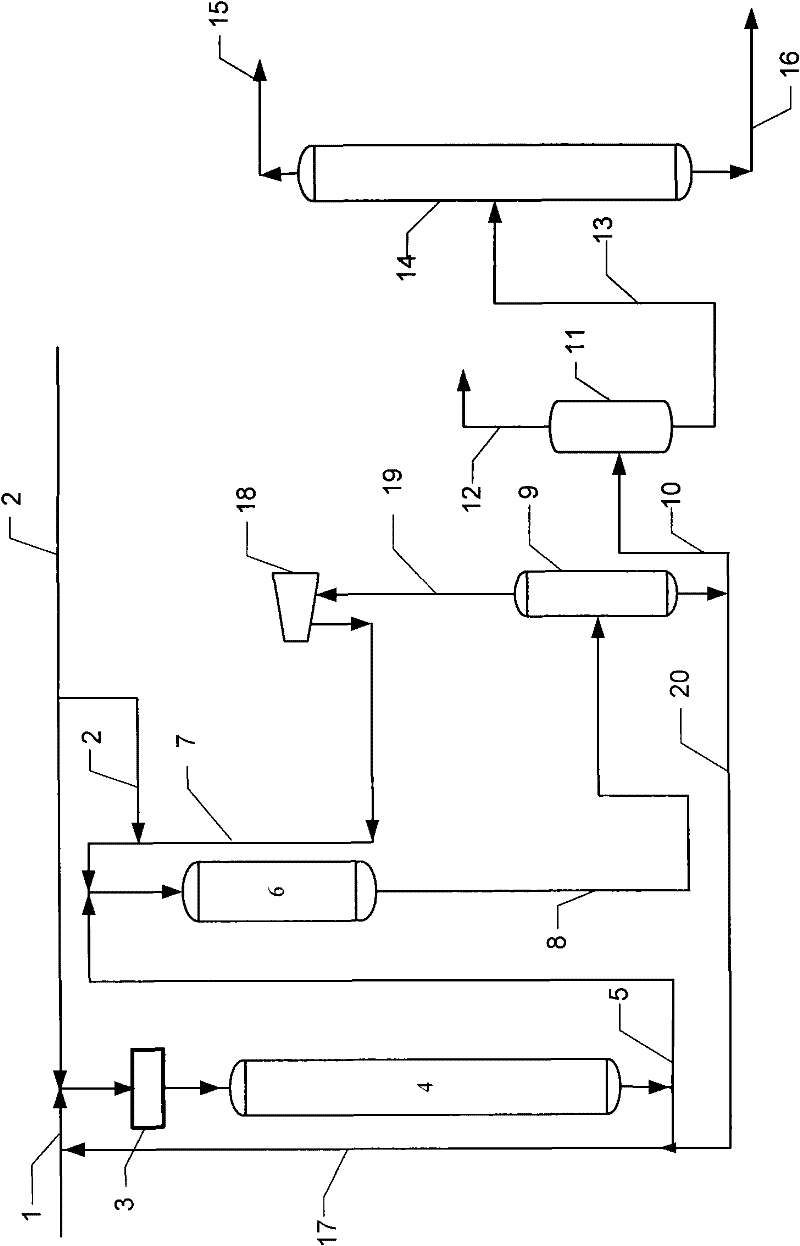

Hydrogenation technology for diesel

ActiveCN102041071AUniform temperature distributionExtended service lifeTreatment with hydrotreatment processesHydrogenNitrogen

The invention discloses a hydrogenation technology for diesel, comprising the following steps: distilling a diesel raw material into light components and heavy components; under the hydrogenation refined condition, carrying out hydrorefining reaction on the heavy components in a first reaction region; mixing effluents at the first reaction region with the light components to enter a second reaction region for the hydrorefining reaction; and carrying out separation treatment on the effluents in the second reaction region. Compared with the prior art, by the technology in the invention, released reaction heat is effectively utilized in the hydrorefining process of the diesel raw material, a great amount of cold hydrogen is not used, and the negative influence of nitrogenous compounds and nuclei aromatics in the heavy components on deep desulfuration reaction of the diesel is overcome; and simultaneously, the technology is simple, energy consumption is reduced, and ultra low sulfur diesel products can be manufactured by using the technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

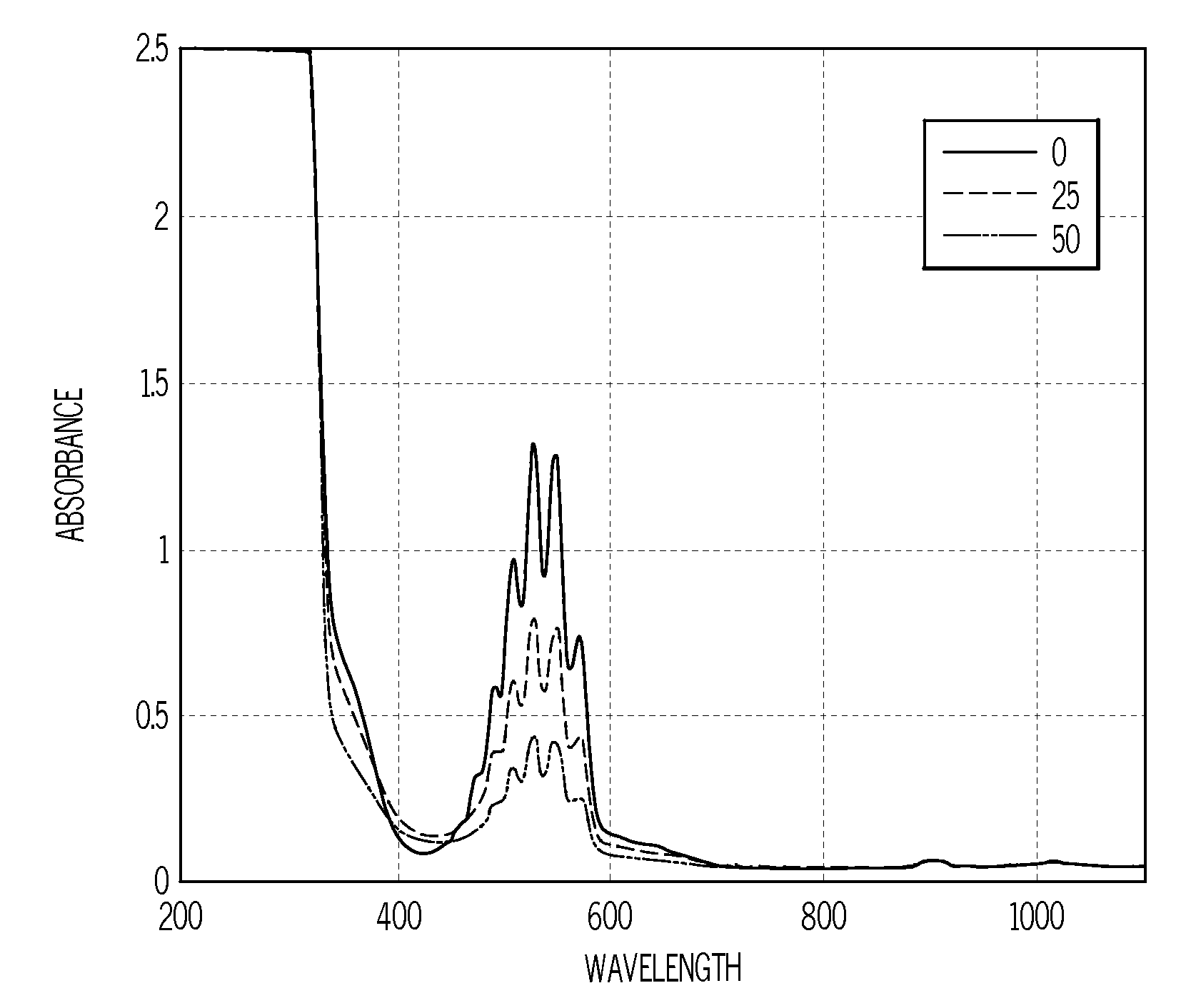

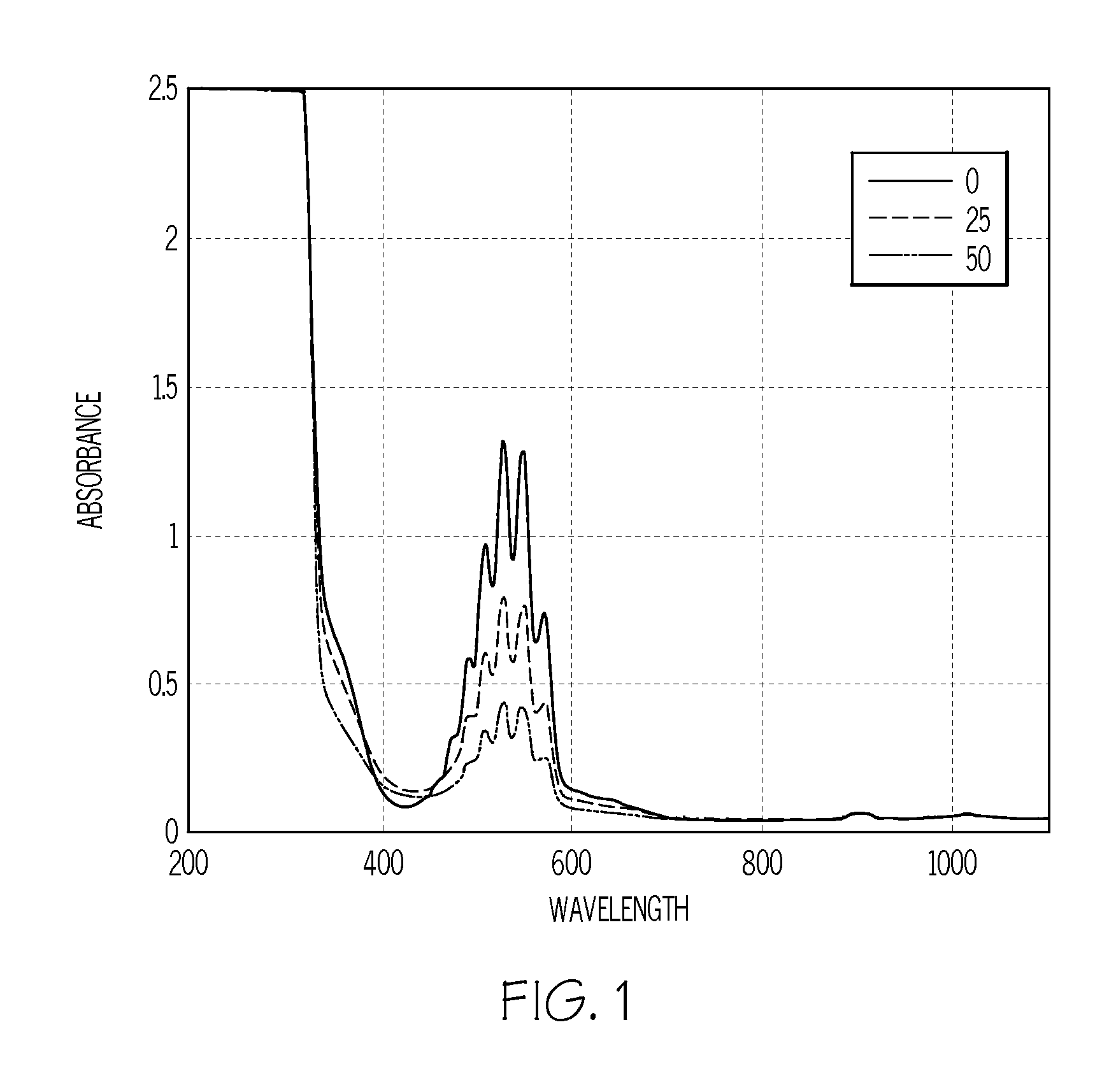

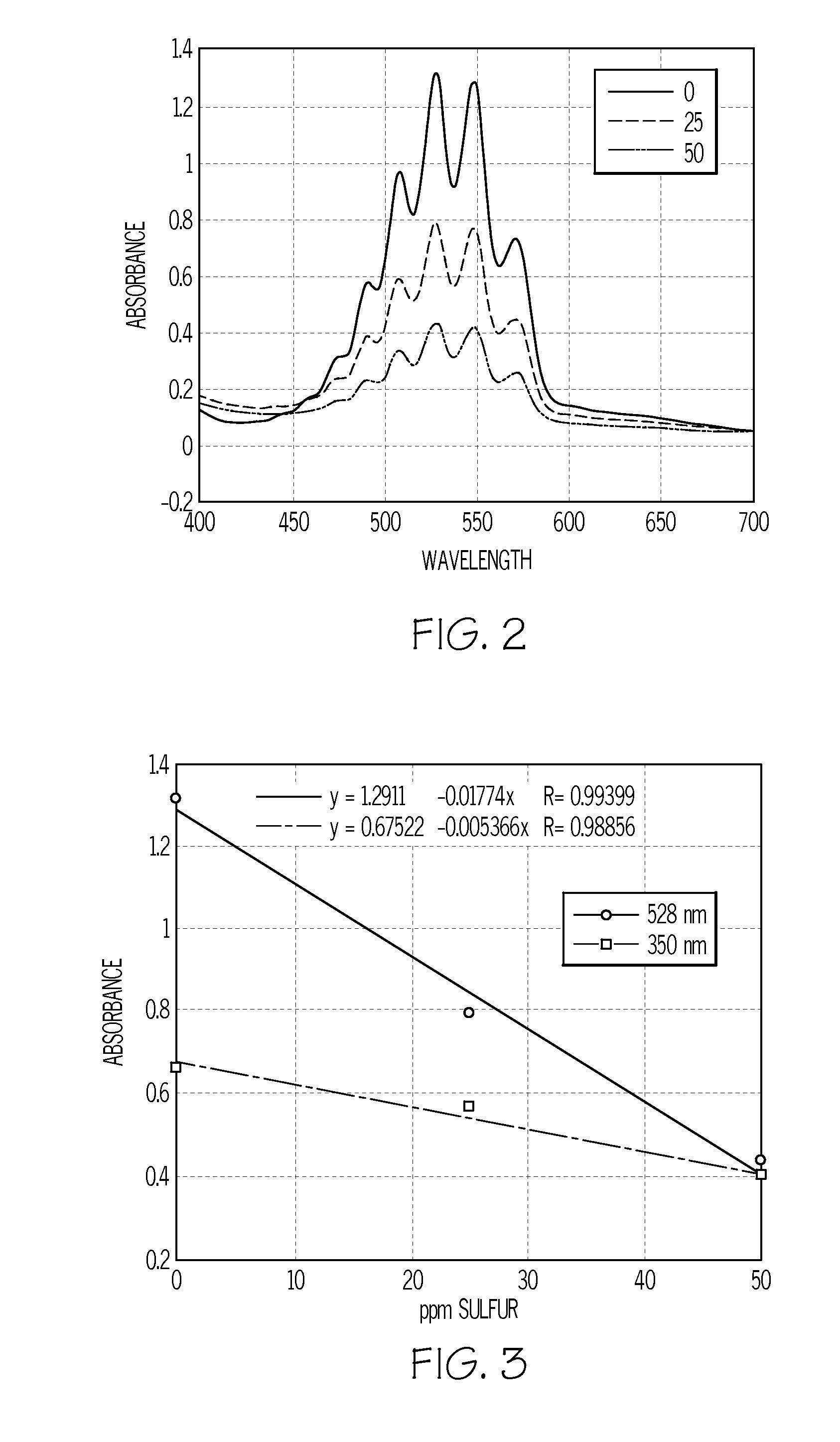

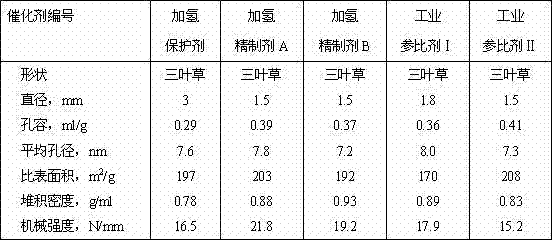

Method of analyzing sulfur content in fuels

InactiveUS20080165361A1Radiation pyrometryAnalysis using chemical indicatorsSolventColorimetric analysis

A method of detecting the amount of sulfur compounds in fuels such as ultra low sulfur diesel (ULSD) fuels is provided in which a fuel sample is reacted with a solvent and an oxidizing agent to produce a reaction product which may be analyzed by visual observation and / or in combination with spectrophotometric or colorimetric analysis. The oxidizing agent may be selected from potassium permanganate, sodium dichromate, nitric acid, hydrogen peroxide, cumene hydroperoxide, and sodium hypochlorite, and may be used in combination with an acid.

Owner:UNIV OF DAYTON

Method for grading catalysts for hydrofining of inferior distillate oil

ActiveCN102876365AHigh activityGive full play to the adsorption effectTreatment with hydrotreatment processesNitrogenHigh surface

The invention relates to a method for grading catalysts for hydrofining of inferior distillate oil. A hydrogenation reactor is divided into three sections of reaction regions sequentially from top to bottom, wherein a hydrogenating protective agent is filled in the first section of reaction region; a hydrofining agent A is filled in the second section of reaction region and is characterized in that the catalyst adopts Al2O3-TiO2-SiO2-ZrO2 quaternary composite oxide as a carrier, W-Mo-Ni ternary metal as an active metal component and P as an aid; and a hydrofining agent B is filled in the third section of reaction and is characterized in that the catalyst adopts Al2O3-SiO2-ZrO2 ternary composite oxide as a carrier, W-Mo-Ni ternary metal as an active metal component and P and F as aids. The method is used for grading different systems of catalysts reasonably, wherein due to combination of the hydrofining agent A with large pore volume, large specific surface area and high surface acid quantity and the ternary metal component with high activity, certain desulfuration and deep denitrogenation effects are achieved, and the influence of azacyclo compounds on the desulfurization activity of the catalyst in the next step is reduced; and due to the hydrofining agent B and the deep desulfurization performance of the catalyst, ultralow sulfur diesel oil with the sulfur content meeting the European IV standard is obtained finally.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

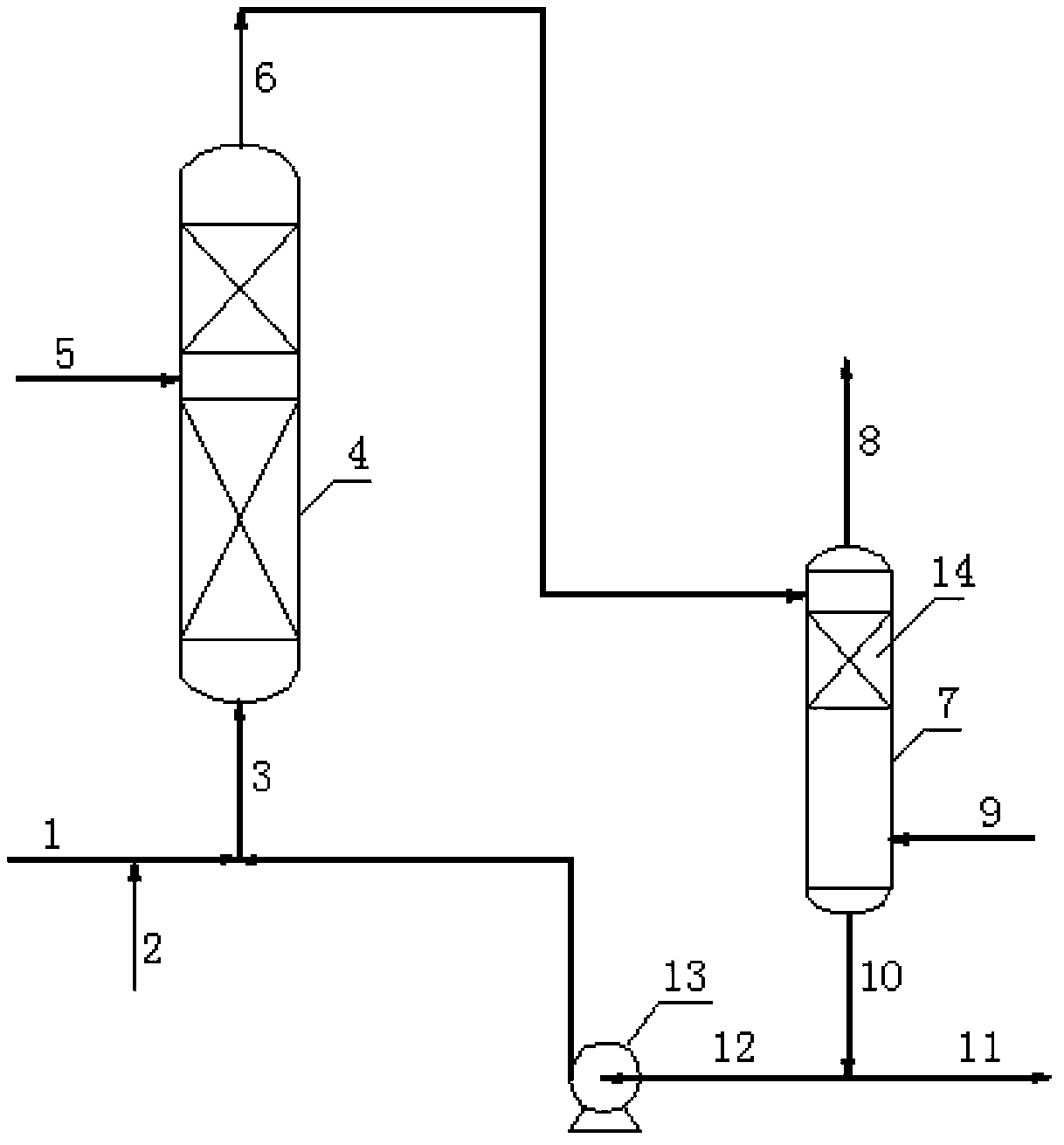

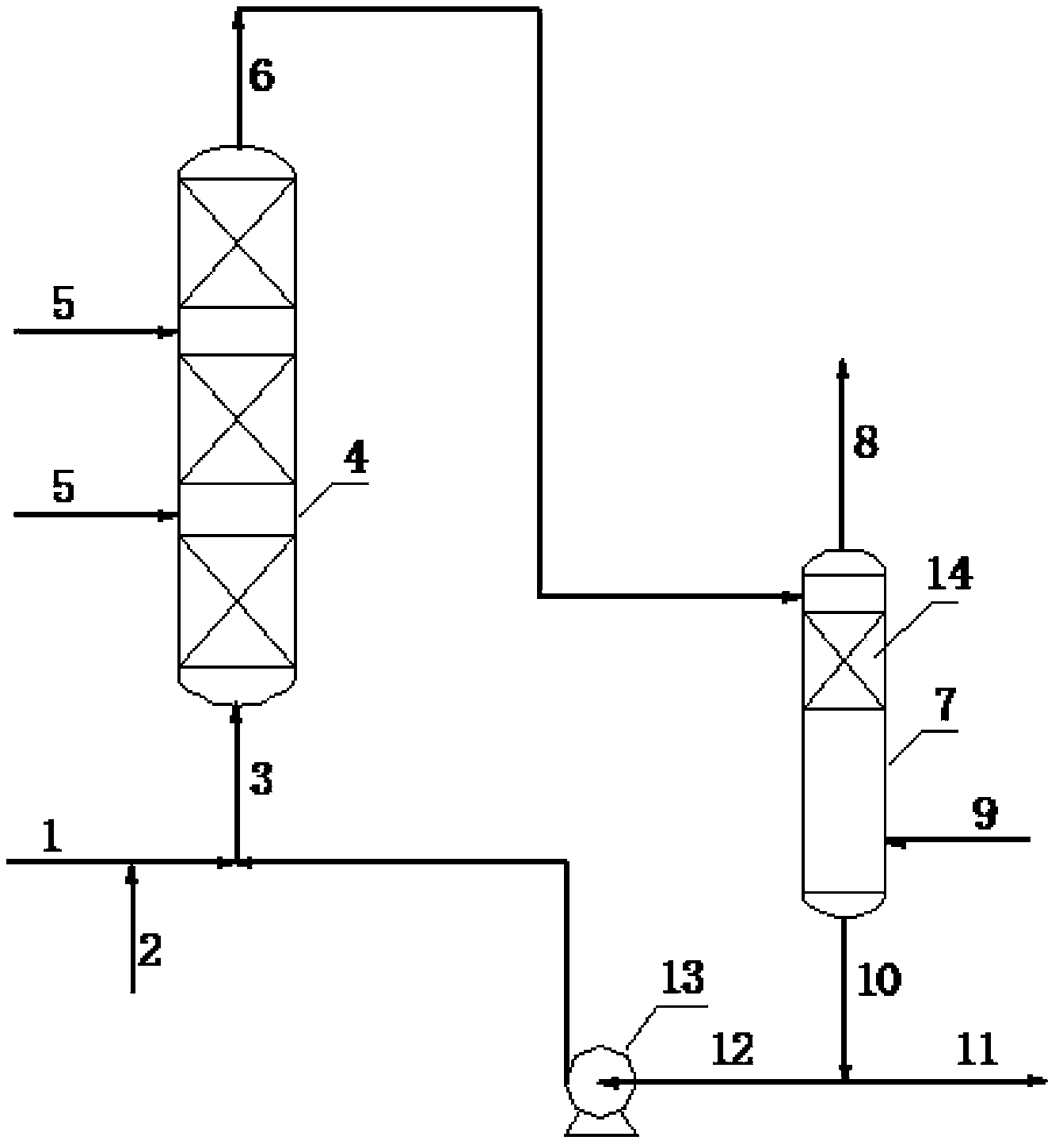

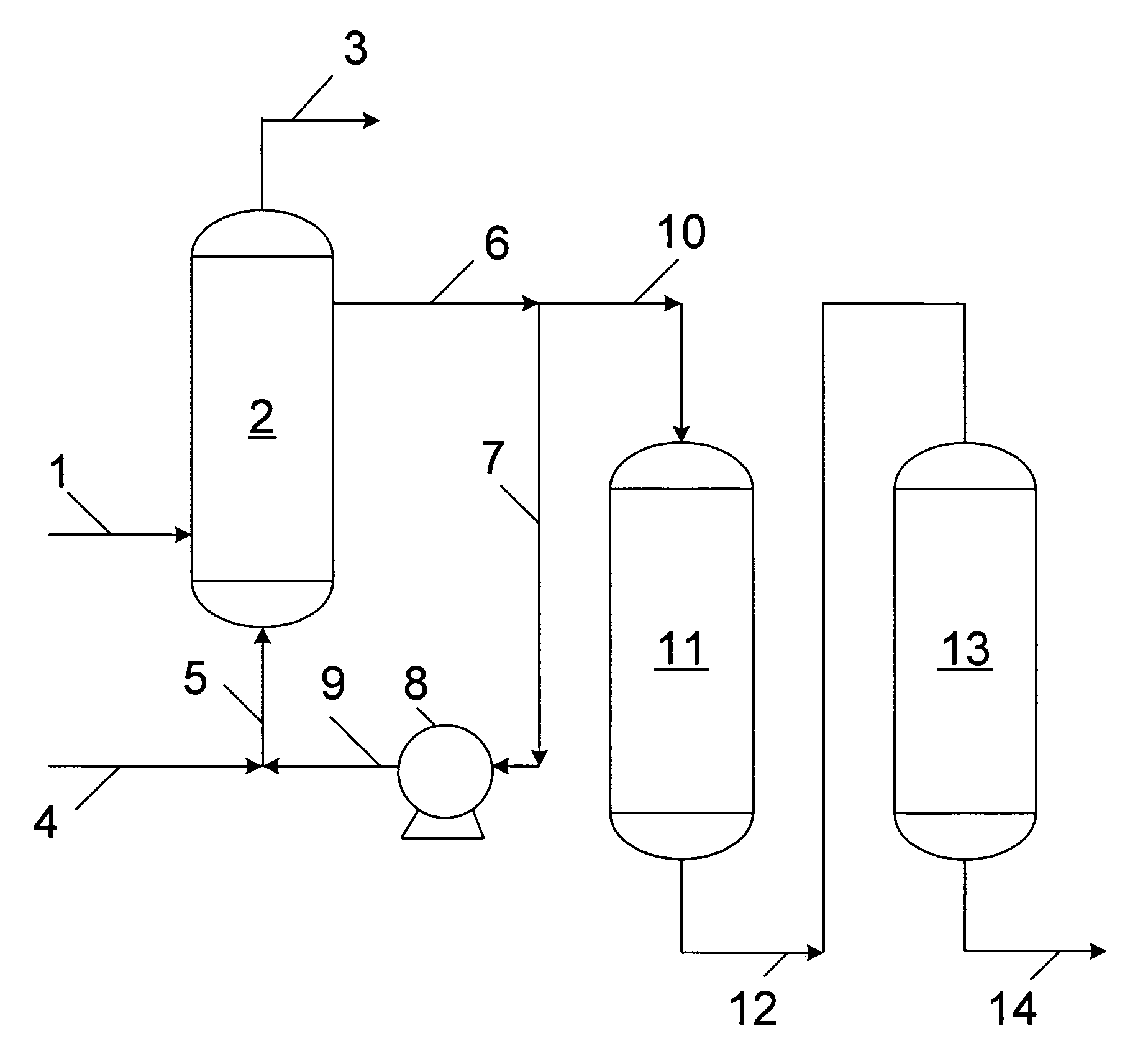

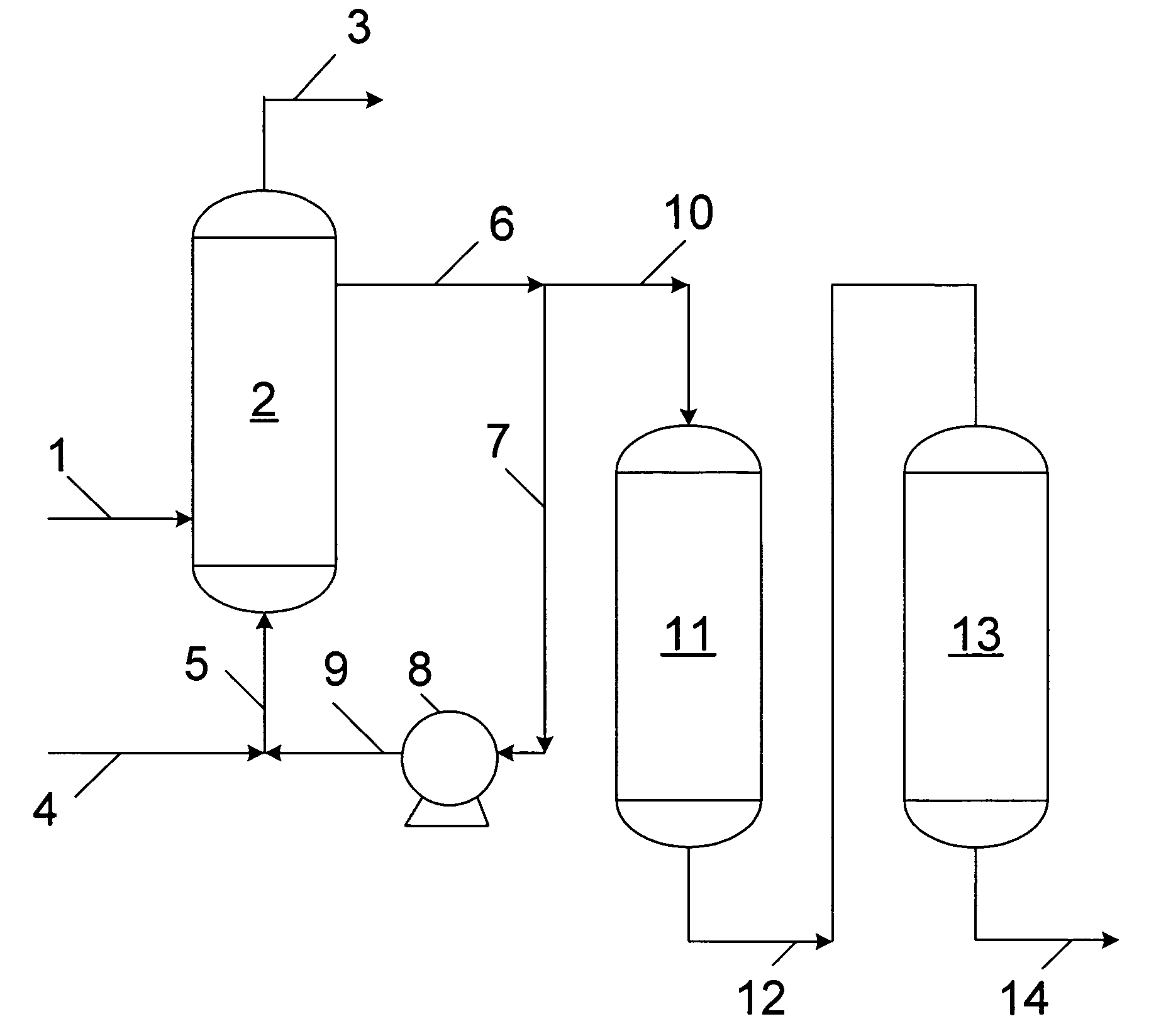

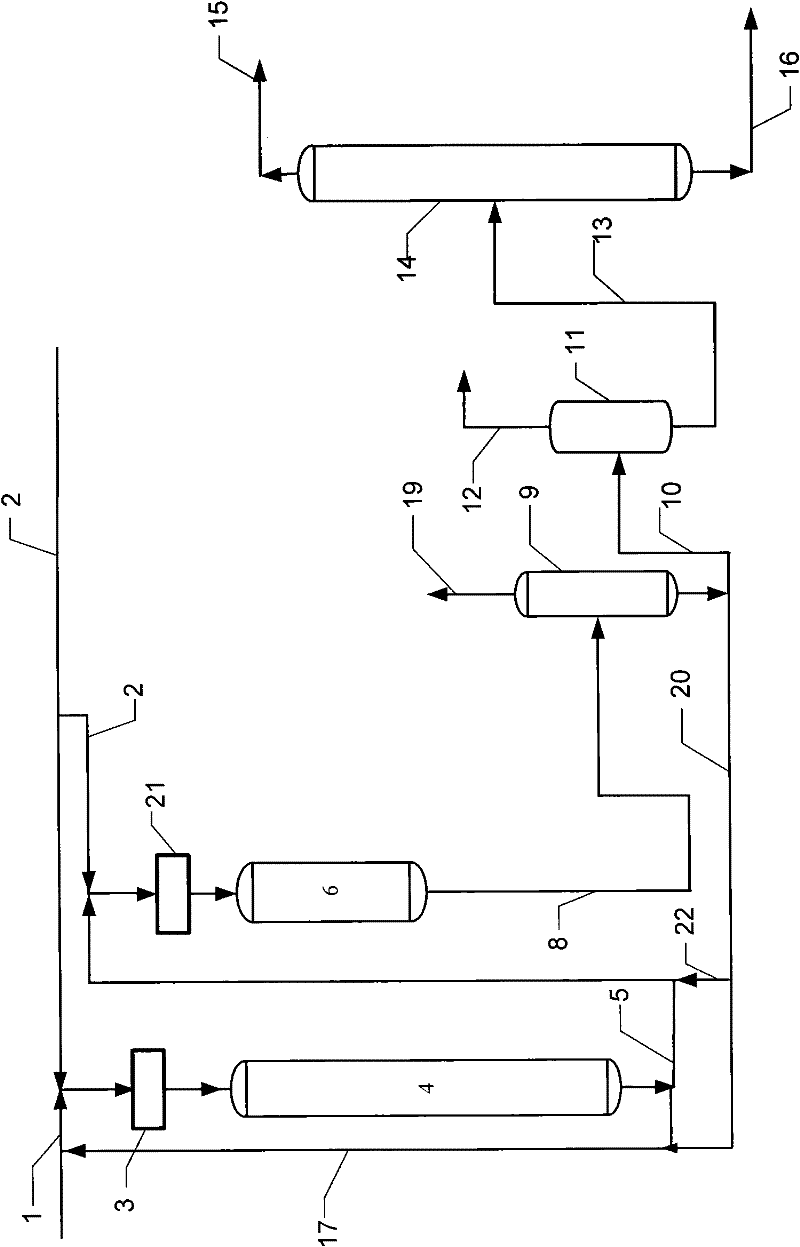

Hydrogenation system for producing ultralow-sulfur diesel oil, and method thereof

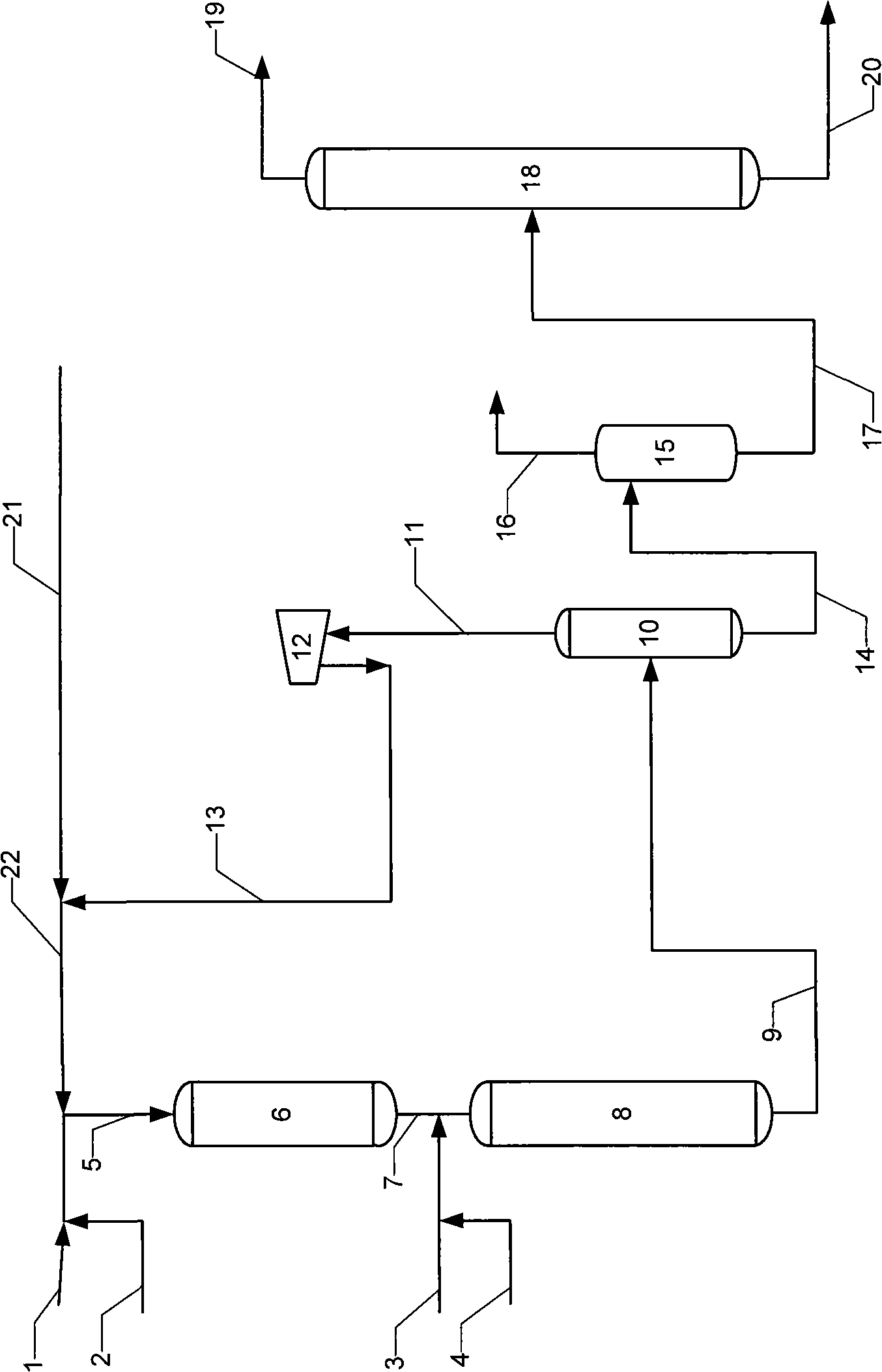

ActiveCN103509598ALarge heat capacityReduce temperature riseTreatment with hydrotreatment processesHydrodesulfurizationGas phase

The invention relates to a hydrogenation system for producing ultralow-sulfur diesel oil, and a method thereof. The system comprises a first-segment hydrogenation reaction zone a second-segment hydrogenation reaction zone; the first-segment hydrogenation reaction zone is an upflow fixed bed reactor; the second-segment hydrogenation reaction zone is an active hydrogenation catalyst layer filled in an upper portion of a thermal high stripping reactor; a reaction raw material enters from the bottom of the upflow fixed bed reactor, and a reaction product flows out through the top of the upflow fixed bed reactor and directly enters the thermal high stripping reactor from a position over the second-segment hydrogenation reaction zone; a liquid phase in the upflow fixed bed reactor is a continuous phase, and a gas phase in the upflow fixed bed reactor is a disperse phase; and stripped hydrogen is introduced to the thermal high stripping reactor from a position below the second-segment hydrogenation reaction zone, and the above first-segment hydrogenation reaction product has a countercurrent contact with the stripped hydrogen for a super-deep hydrodesulfurization reaction and product stripping. The above finally-obtained reaction product is partially returned to an inlet of the first-segment hydrogenation reactor as circulation oil. The hydrogenation system for producing ultralow-sulfur diesel oil, and the method are economic and efficient.

Owner:CHINA PETROCHEMICAL CORP +1

Method for production of ultralow-sulfur diesel oil

ActiveCN102851070AReduce partial pressureReduce inhibitionTreatment with hydrotreatment processesHydrogenTungsten

Disclosed is a method for production of ultralow-sulfur diesel oil. Raw oil of diesel oil fraction enters a reactor from the top, make-up hydrogen and circulating hydrogen are mixed and then enter the reactor from the bottom, the raw oil of diesel oil fraction sequentially contacts a hydrofining catalyst I and a hydrofining catalyst II for reaction under the hydrofining reaction conditions, and the reaction products are separated and fractionated to obtain diesel oil product. The hydrofining catalyst I is a loaded hydrofining catalyst using nickel-molybdenum or nickel-molybdenum-tungsten as active metal component, and the hydrofining catalyst II is a bulk hydrofining catalyst. The invention can solve the problems of harsh operating conditions and low space velocity in prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

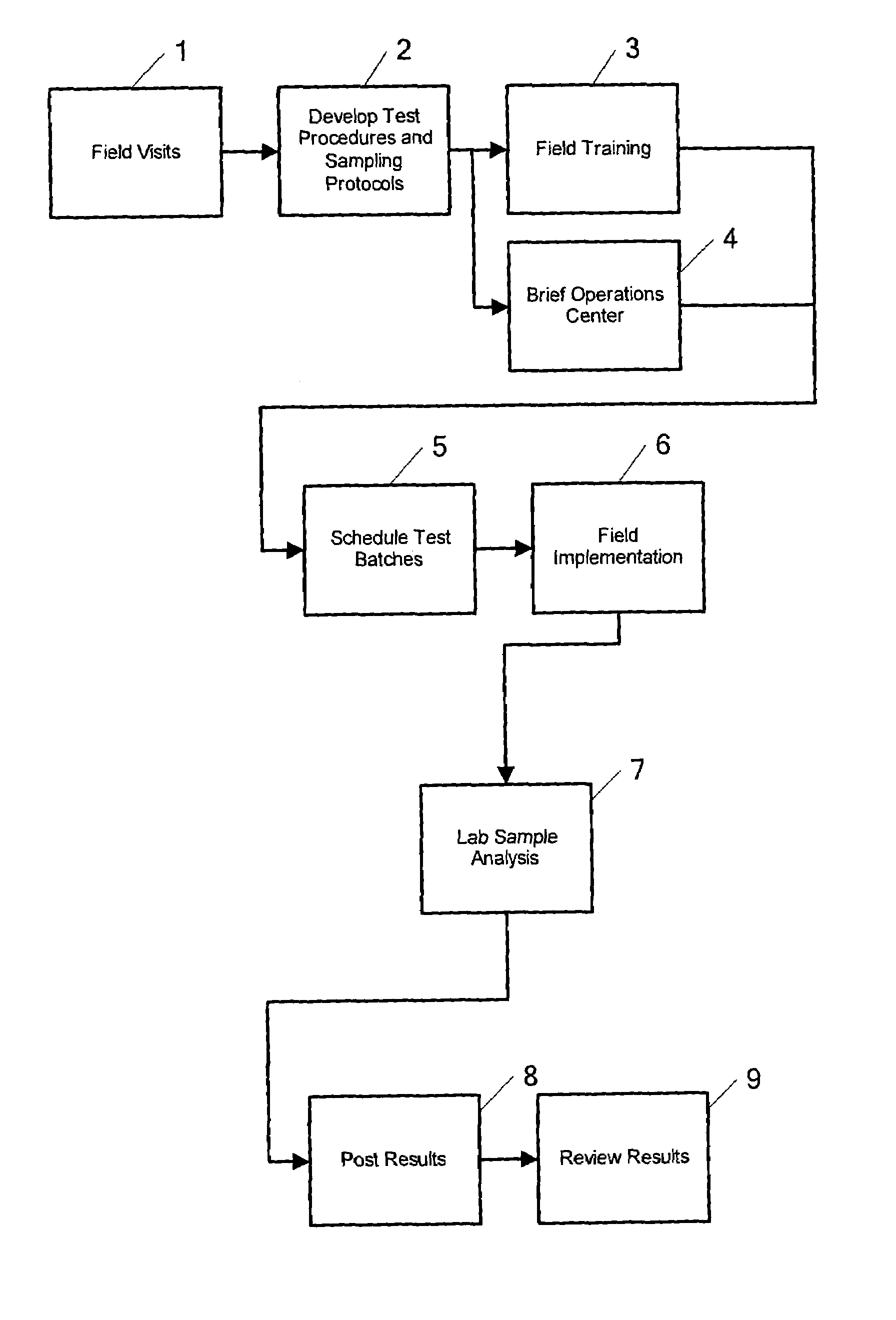

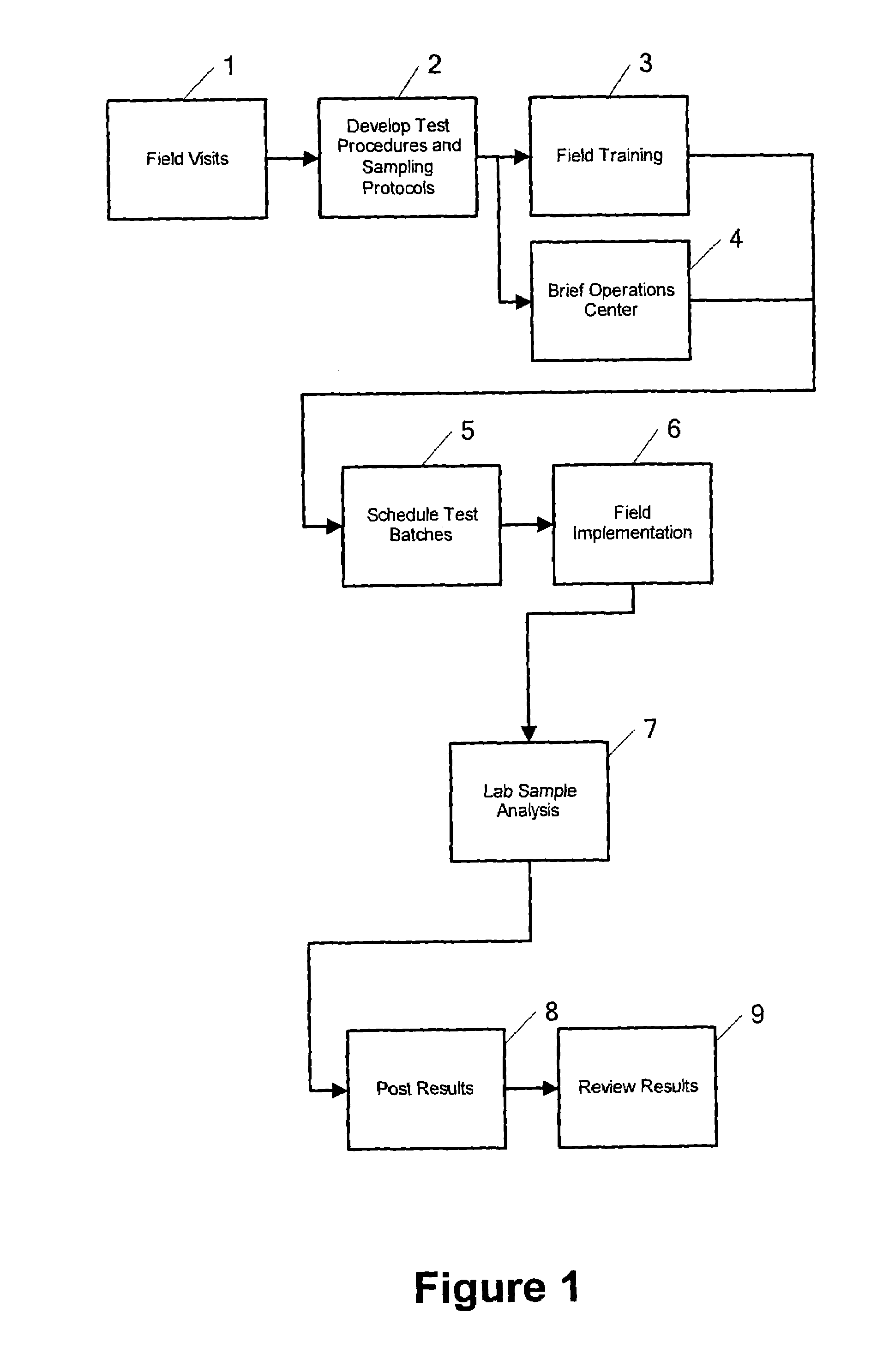

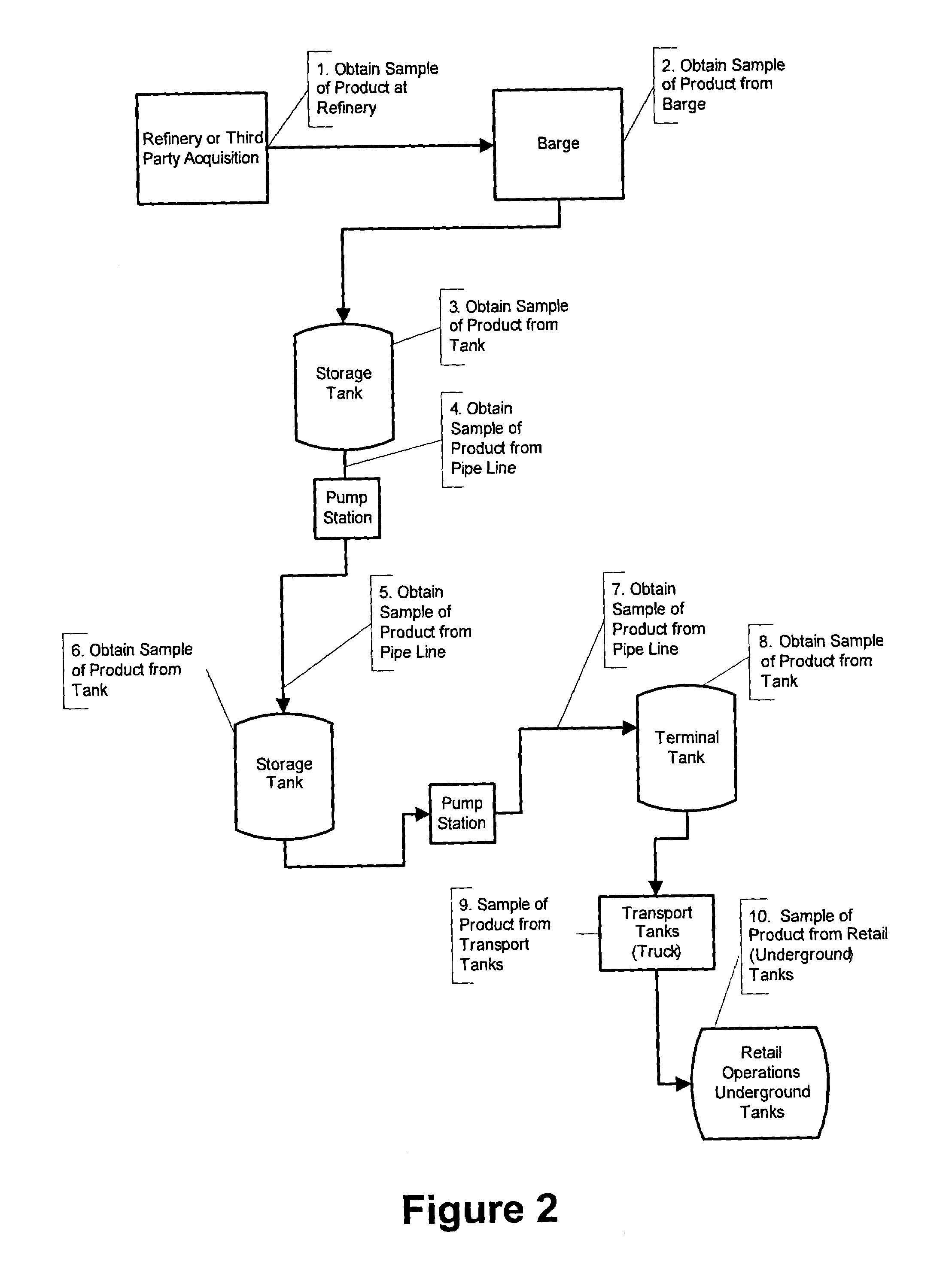

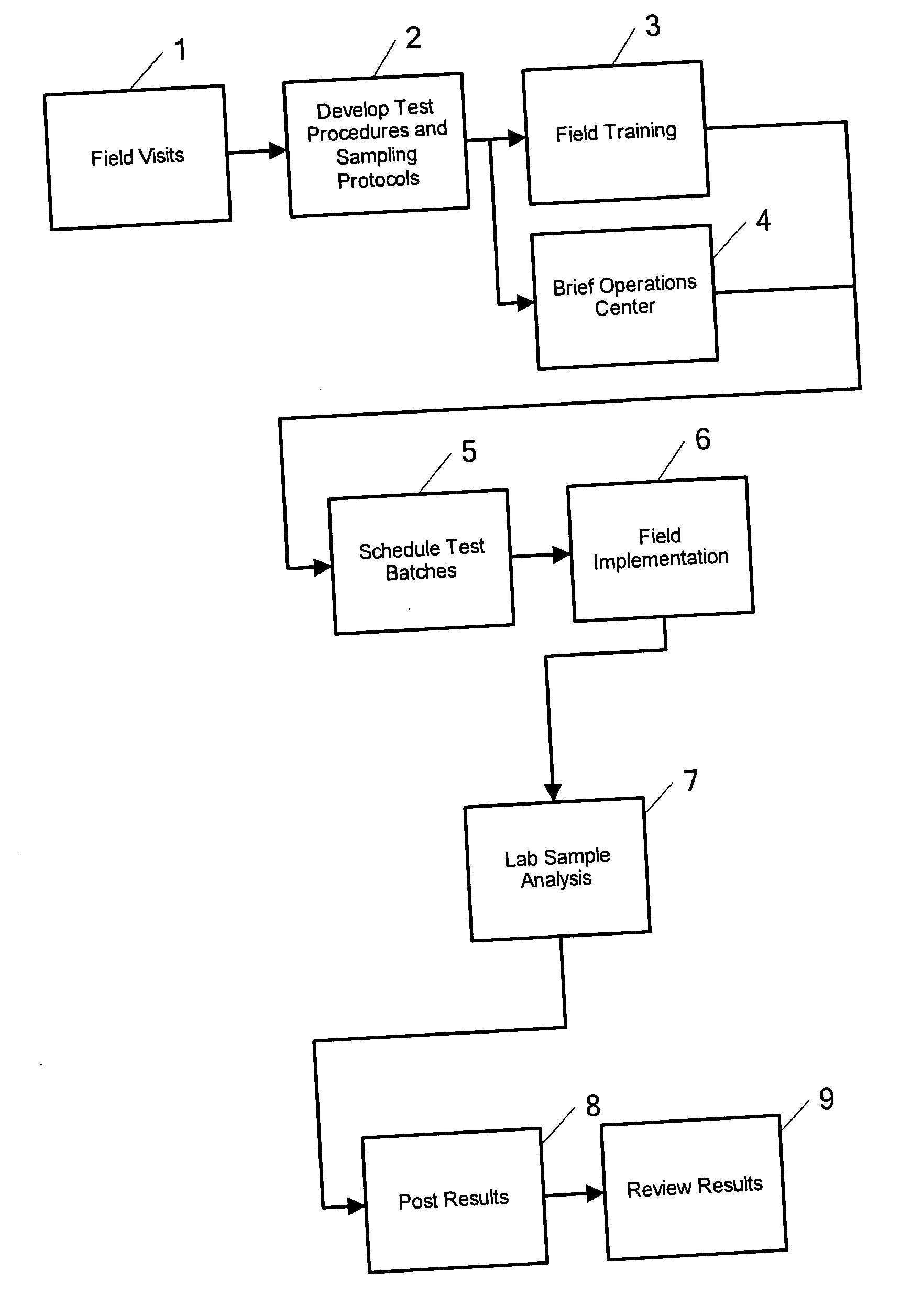

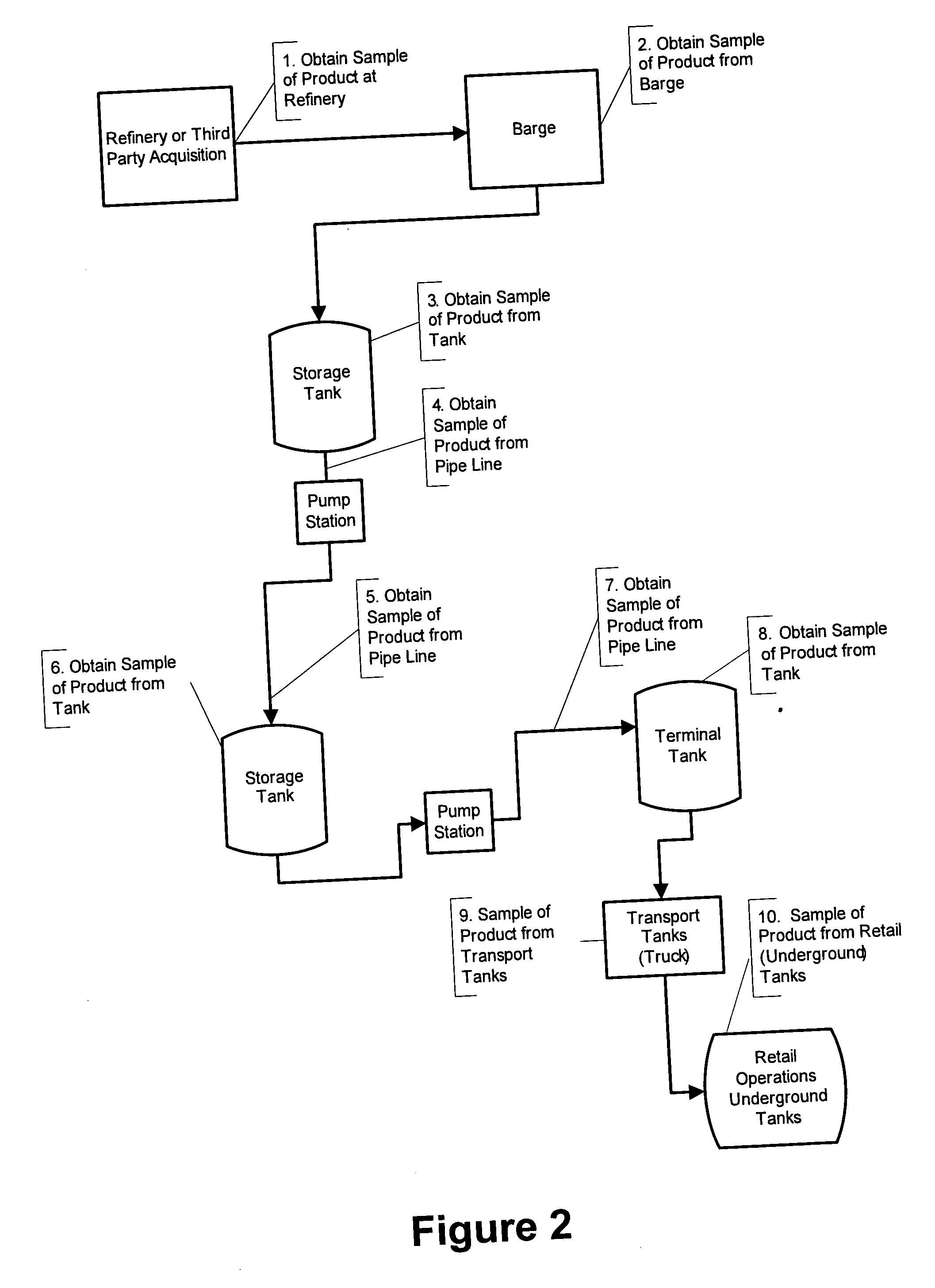

Method for transporting and testing ultra low sulfur diesel

InactiveUS7228250B2Data processing applicationsStructural/machines measurementPetroleum productPipeline transport

A method for determining the variations in the sulfur content of ultra-low sulfur diesel fuel when it is transported through a petroleum transportation system includes sampling fuels at various points during barge transport, pipeline transport and in terminaling operations. New procedures and special handling regiments are developed in view of how the sulfur content of ultra-low sulfur fuel may change when transported through the system in sequence and stored with other petroleum products.

Owner:MARATHON PETROLEUM

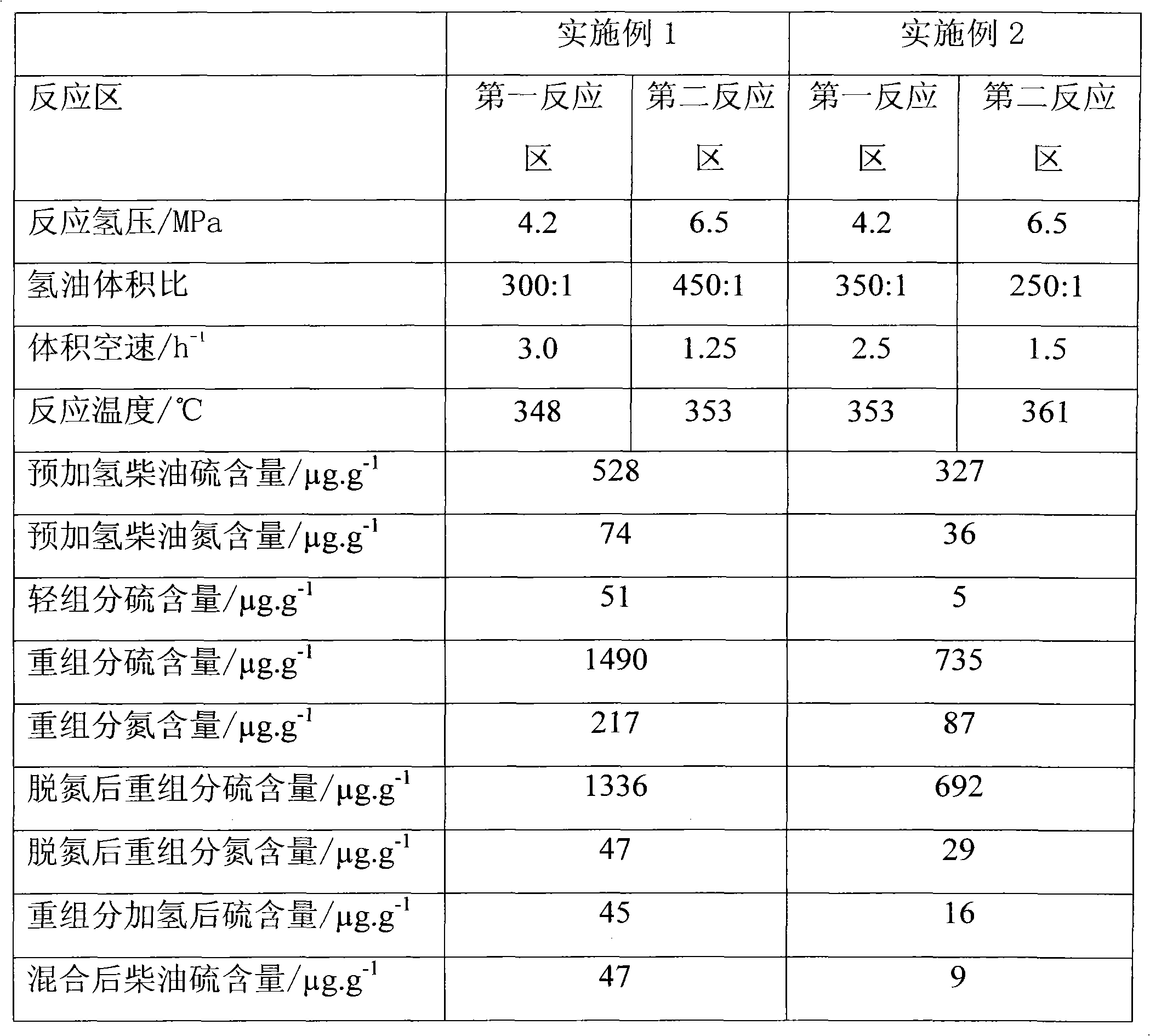

Method for producing ultra-low-sulfur diesel in long period

ActiveCN107446621AHigh activityExtended service lifeCatalyst activation/preparationTreatment with hydrotreatment processesHydrogenNitrogen

The invention discloses a method for producing ultra-low-sulfur diesel in a long period. The method comprises the following steps: enabling a diesel raw material and hydrogen to contact a hydrofining catalyst I in a first reaction zone to implement a reaction, feeding a reaction effluent of the first reaction zone into a second reaction zone without separation, contacting a hydrofining catalyst II to implement a reaction, cooling an effluent of the second reaction zone, separating, and distilling, thereby obtaining a diesel product, wherein the content of sulfur of a liquid-phase effluent in the reaction effluent of the first reaction zone is 20-200mu g / g, and the content of nitrogen is 0-50mu g / g. By adopting the method, not only is a diesel fraction with high sulfur converted into a diesel product of which the sulfur content is less than 10mu g / g, but also the operation period of a device is effectively prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

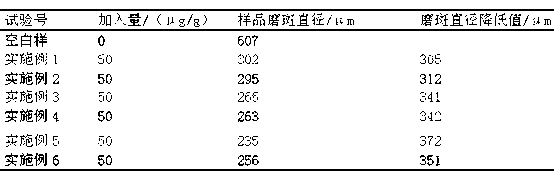

Ultra-low-sulfur diesel lubricating property improver and preparation method thereof

InactiveCN103173254AImprove conversion rateReduce lubricationLiquid carbonaceous fuelsFuel additivesBiodieselMonoglyceride

The invention relates to an ultra-low-sulfur diesel lubricating property improver and a preparation method thereof. The improver is a mixture of monoglyceride, fatty acid and low-molecular-weight alcohol. The improver has acid value being lower than 30.0mgKOH / g and a condensation point being lower than -1 DEG C. according to the preparation method, biodiesel co-product glycerin and low-molecular-weight alcohols serving as the raw materials have esterification reaction with the fatty acid in the presence of an ionic liquid catalyst to generate the mixture of monoglyceride, fatty acid and low-molecular-weight alcohols, namely the ultra-low-sulfur diesel lubricating property improver, wherein the addition of the improver relative to low-sulfur diesel is 50mu g / g, the temperature is 100-170 DEG C, the pressure is 0.1-0.2MPa and the time is 1-2 hours. The detailed preparation method refers to the specification. The low-sulfur diesel lubricating property improver has low acid value and high lubrication improvement property, can be directly used without use of antioxidants and cleaning agents; production cost is low, the production process is clean and the production flow is short.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Method for preparing desulfurized diesel oil

InactiveCN101003744AEfficient removalHigh catalytic activityRefining with oxygen compoundsOrganic sulfide compoundSulfide

This invention discloses a method for preparing low-sulfur diesel oil (sulfur content is less than 50 ppm). The method comprises: (1) stirring hydrogenated or unhydrogenated diesel oil and a mixture of Q+[MWxOy]- emulsion catalyst and H2O2 aqueous solution, and reacting under mild conditions to convert organic sulfide in diesel oil into sulfone and / or sulfoxide to obtain oxidized diesel oil; (2) separating the catalyst from oxidized diesel oil, and recovering; (3) washing oxidized diesel oil with distilled water, and removing most of sulfone and / or sulfoxide with a polar solvent to obtain low-sulfur diesel oil (sulfur content is less than 50 ppm).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

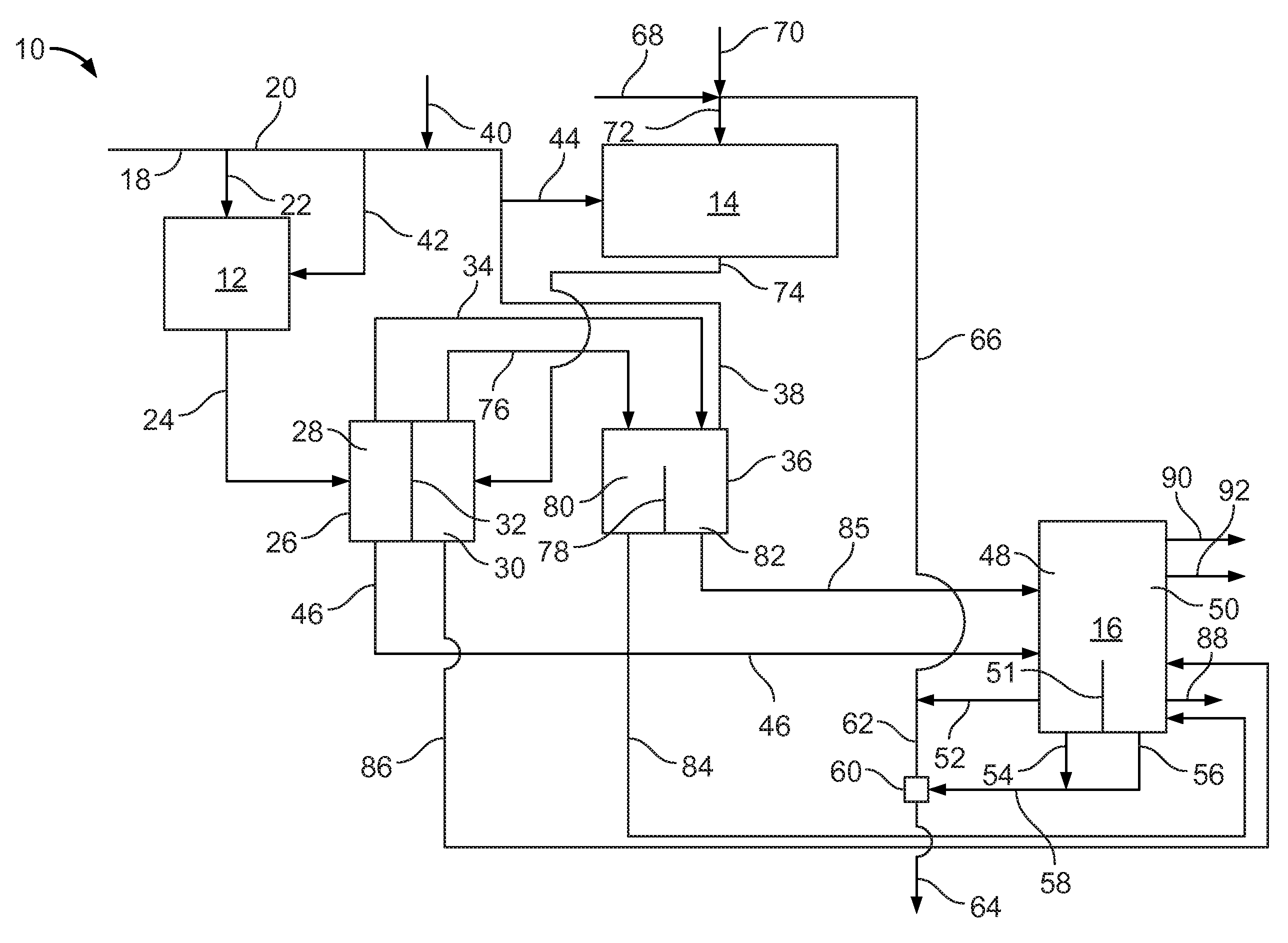

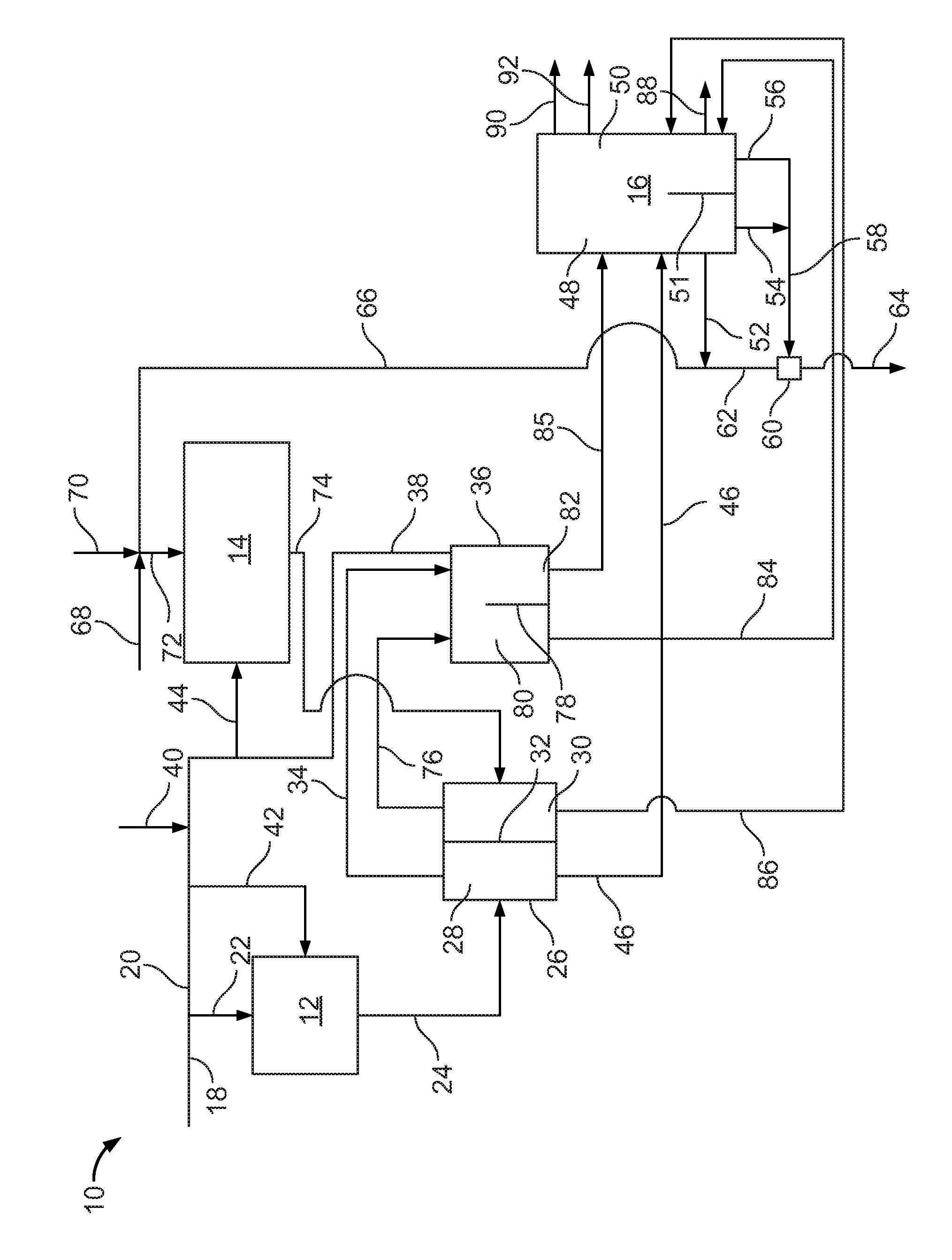

Integrated fluid catalytic cracking process

InactiveUS7601254B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyBoiling pointAlkene

A process for the conversion of a hydrocarbon feedstock to produce olefins, aromatic compounds and ultra low sulfur diesel wherein the hydrocarbon feedstock is reacted in a fluid catalytic cracking (FCC) zone to produce olefins and light cycle oil. The effluent from the FCC is preferably separated to produce a stream comprising ethylene and propylene, a stream comprising higher boiling olefins and light cycle oil (LCO). The stream containing the higher boiling olefins is cracked to provide additional ethylene and propylene. The LCO is selectively hydrocracked to produce aromatic compounds and ultra low sulfur diesel.

Owner:UOP LLC

Hydrocarbon conversion process

InactiveUS7951290B2Thermal non-catalytic crackingHydrocarbon oil cracking processUltimate tensile strengthUltra-low-sulfur diesel

Owner:UOP LLC

Process for producing hydroperoxides

A process for the autocatalytic production of organic hydroperoxides and ultra low sulfur diesel boiling range hydrocarbons is disclosed. The organic hydroperoxides react with sulfur compounds to produce sulfones, and the sulfones can be removed from the diesel boiling range hydrocarbons to provide ultra low sulfur diesel.

Owner:UOP LLC

Grading method of catalyst of deep hydrodesulfurization of diesel oil

ActiveCN101591566BHigh activityReduce dosageTreatment with hydrotreatment processesRefining to eliminate hetero atomsLiquid productHydrodesulfurization

The invention discloses a grading method of catalyst of deep hydrodesulfurization of diesel oil, comprising the following steps: base oil and hydrogen are mixed, then the mixture is led into a hydrogenation reactor to carry out hydrogenation reaction; reaction effluent is cooled and separated to obtain hydrogen-rich gas and liquid product; the hydrogenation reactor sequentially comprises four hydrogenation reaction zones, wherein, the first hydrogenation reaction zone is filled with hydrogenation protective agent, the second hydrogenation reaction zone is filled with hyrorefining catalyst (1)containing active metal cobalt-molybdenum, the third hydrogenation reaction zone is filled with the mixture of the hyrorefining catalyst (1) and hyrorefining catalyst (2), and the fourth hydrogenation reaction zone is filled with the hyrorefining catalyst (2) containing active metal nickel-tungsten. The invention carries out reasonable grading on catalyst of different systems, gives full play to the advantages of each catalyst in different desulphurizing states, improves whole catalyst activity by synergy of each catalyst, and can obtain ultra low sulfur diesel oil, sulfur content of which satisfies Euro IV standard under moderate operation condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

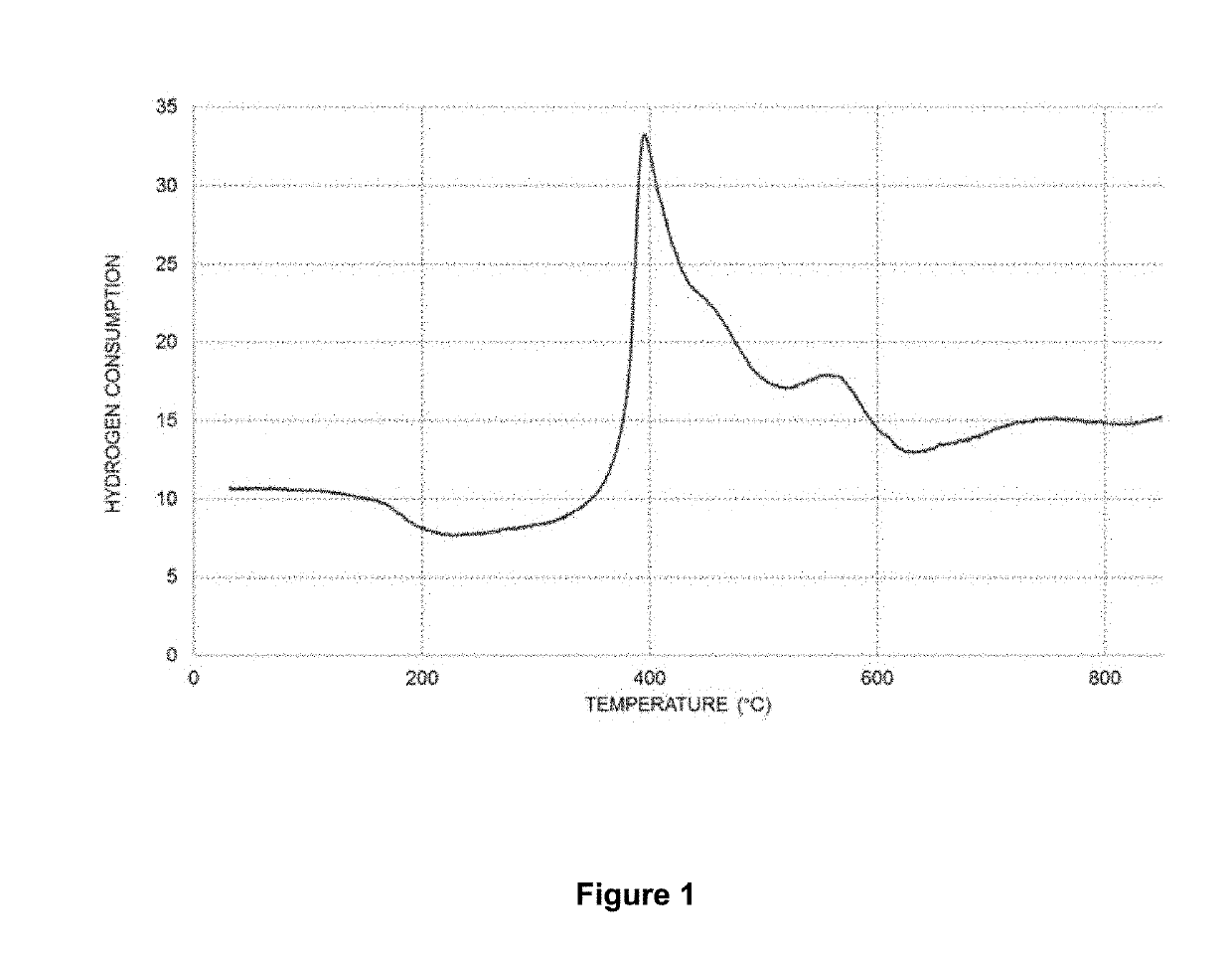

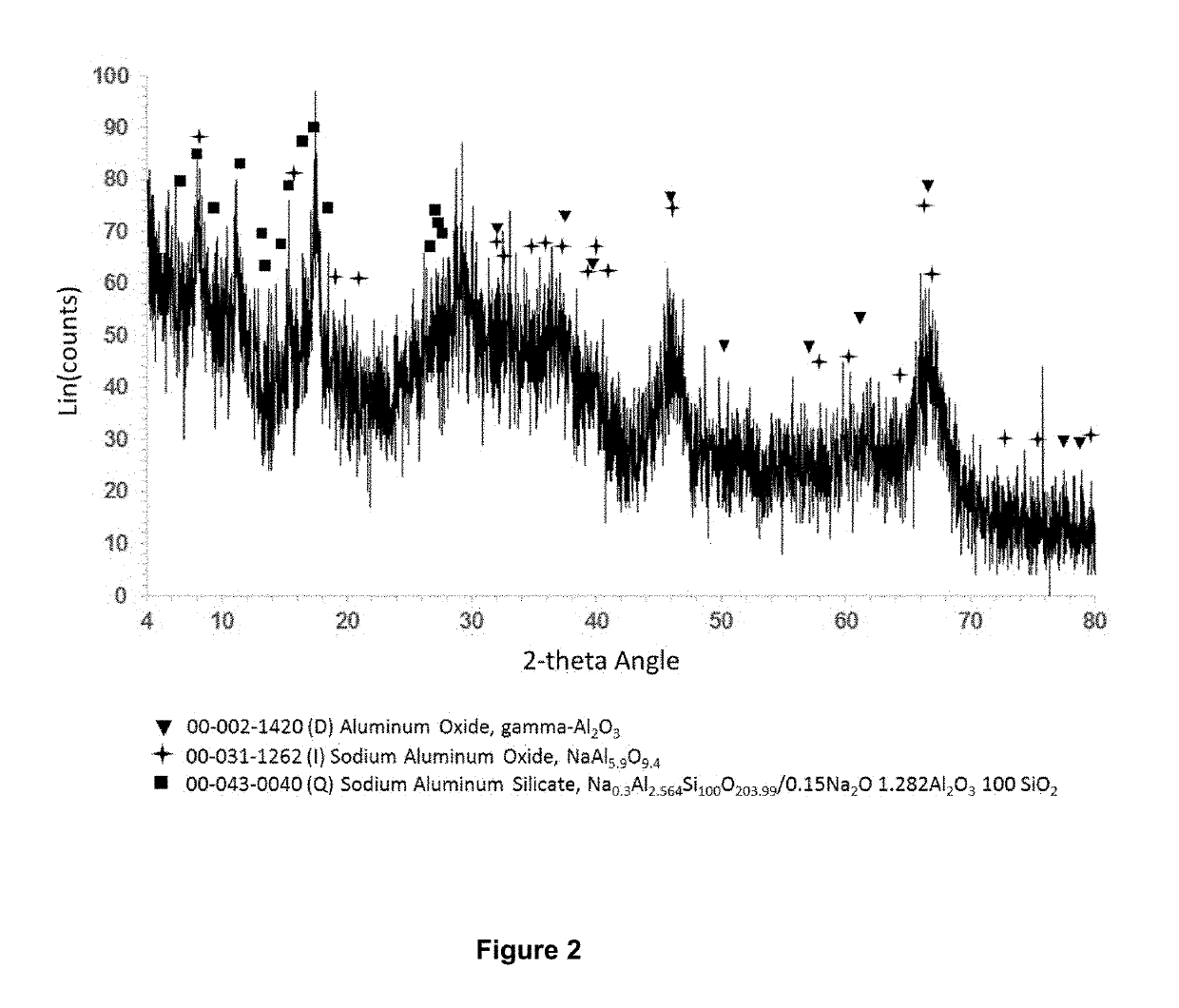

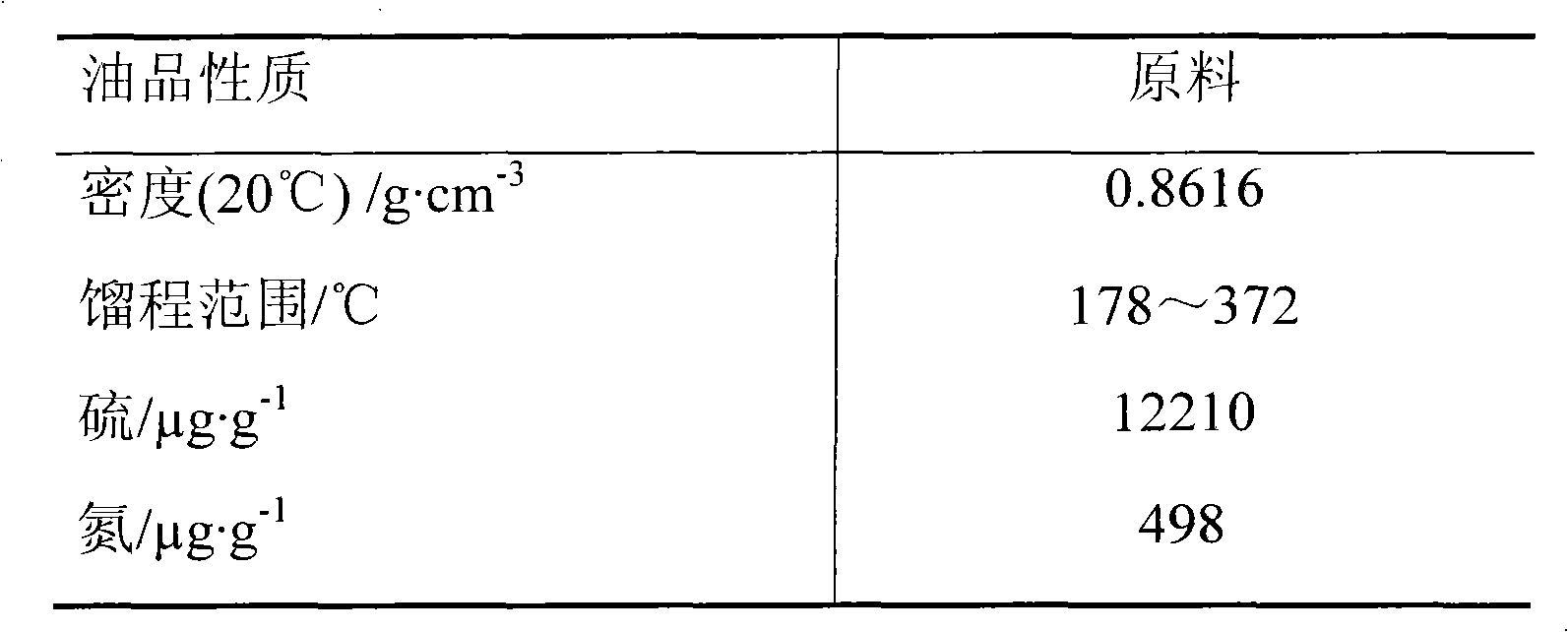

Procedure to prepare a supported trimetallic catalyst for production of ultra low sulfur diesel and its application

ActiveUS20190126254A1Heterogenous catalyst chemical elementsCatalyst activation/preparationHydrodesulfurizationMetallic sulfide

According to this invention, a Ni—Mo—W trimetallic catalyst supported on porous alumina is obtained that shows very high activity for hydrotreating (HDT) of gasoils, particularly deep hydrodesulfurization (HDS) and hydrodesnitrogenation (HDN) of straight run gasoil in conditions of moderate pressure.When the catalyst is applied to HDT of diesel, the NiMoW catalyst exhibits high catalytic activity. The content of sulfur and nitrogen in the resulting diesel can be reduced from 13,200 to 10 ppm and nitrogen from 360 ppm to less than 1 ppm, under moderate pressure, temperature and space-velocity (LHSV) similar to those of an industrial unit.The catalytic composition, of trimetallic type, is prepared from an alumina support of high surface area to which a solution containing a metal precursor of an element of group VIB is added, followed by other solution that contains one of the precursors of the active metallic phase, a solution containing another of the precursors of the active metallic phase from group VIB, a metal promoter of group VIII and an additive promoter of acidity from group VB, and finally another solution containing a metal of group VIB, a metal of Group VIII and an organic compound, the used route promotes the preferential formation of well dispersed structures of the used metals on the support of porous alumina, less refractory to sulfidation, with high stacking and short lengths of metal sulfides formed in the resulting hydrodesulfurization catalyst. In the formulation, at least a percentage, but not all the Mo is replaced by W, in a Mo / W molar ratio of 0.6 to 2.0.

Owner:INST MEXICANO DEL GASOLINEEO

Low-cost combined hydrofinishing method

ActiveCN103805240AImprove reaction efficiencyImprove hydrogen mixing effectTreatment with hydrotreatment processesLiquid productDirect production

The invention discloses a low-cost combined hydrofinishing method of oil products. The low-cost combined hydrofinishing method comprises following steps: firstly, hydrogen is mixed with a liquid phase material; the liquid phase material with dissolved hydrogen is delivered into a liquid phase hydrogenation reactor for reaction; an obtained material is delivered into a counter current reactor through the upper part of the counter current reactor, and is further reacted with a small amount of fresh hydrogen which is delivered into the counter current reactor through the bottom of the counter current reactor; and a part of an obtain liquid product is recycled into the liquid phase hydrogenation reactor, and the rest is taken as a hydrogenation products. Compared with existing liquid phase hydrogenation method, the low-cost combined hydrofinishing method is capable of preparing ultra-low-sulfur diesel oil with sulfur content less than 10<mu>g / g directly, and reducing equipment investment and operation cost greatly; and operation is flexible, and raw material adaptability is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

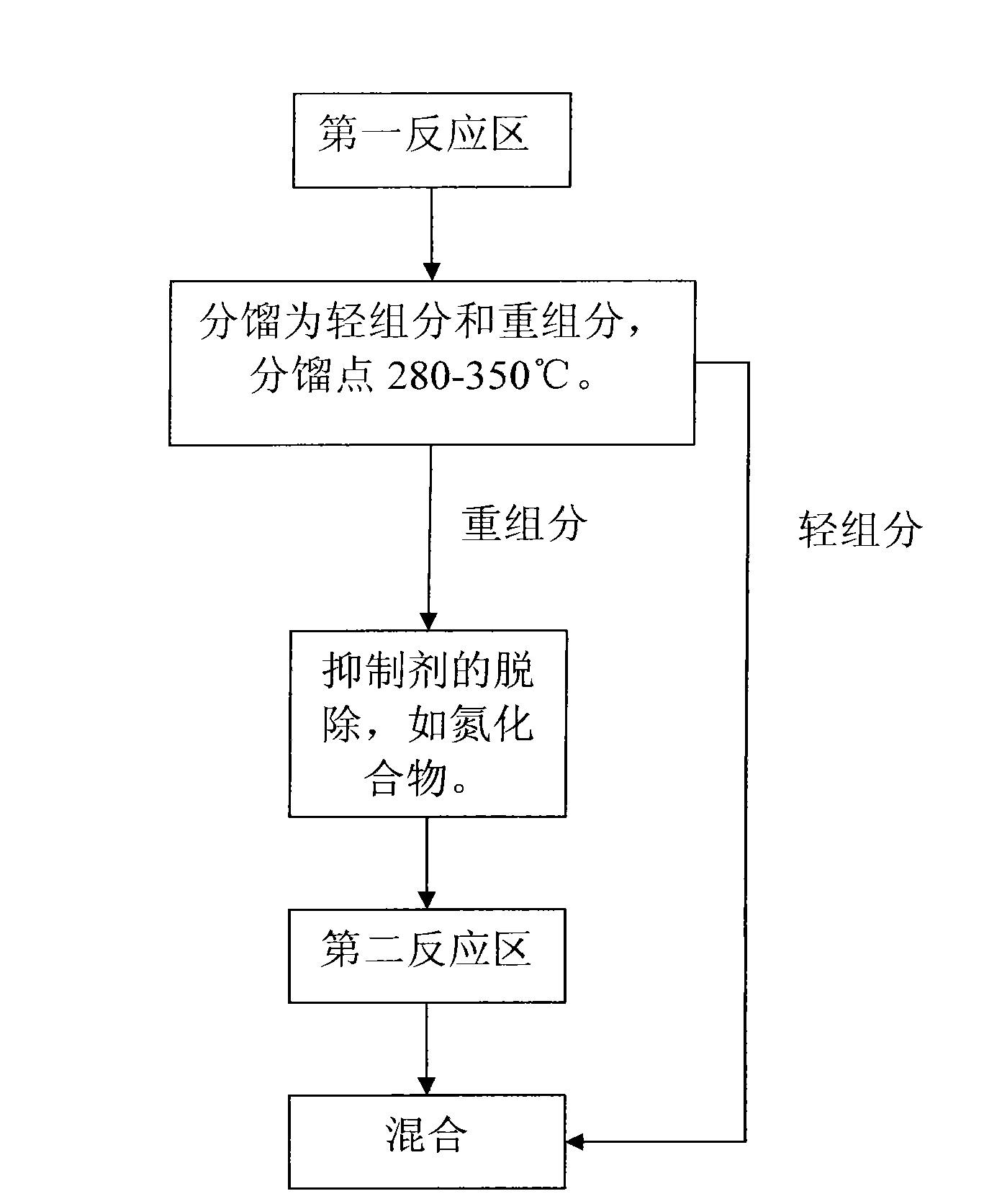

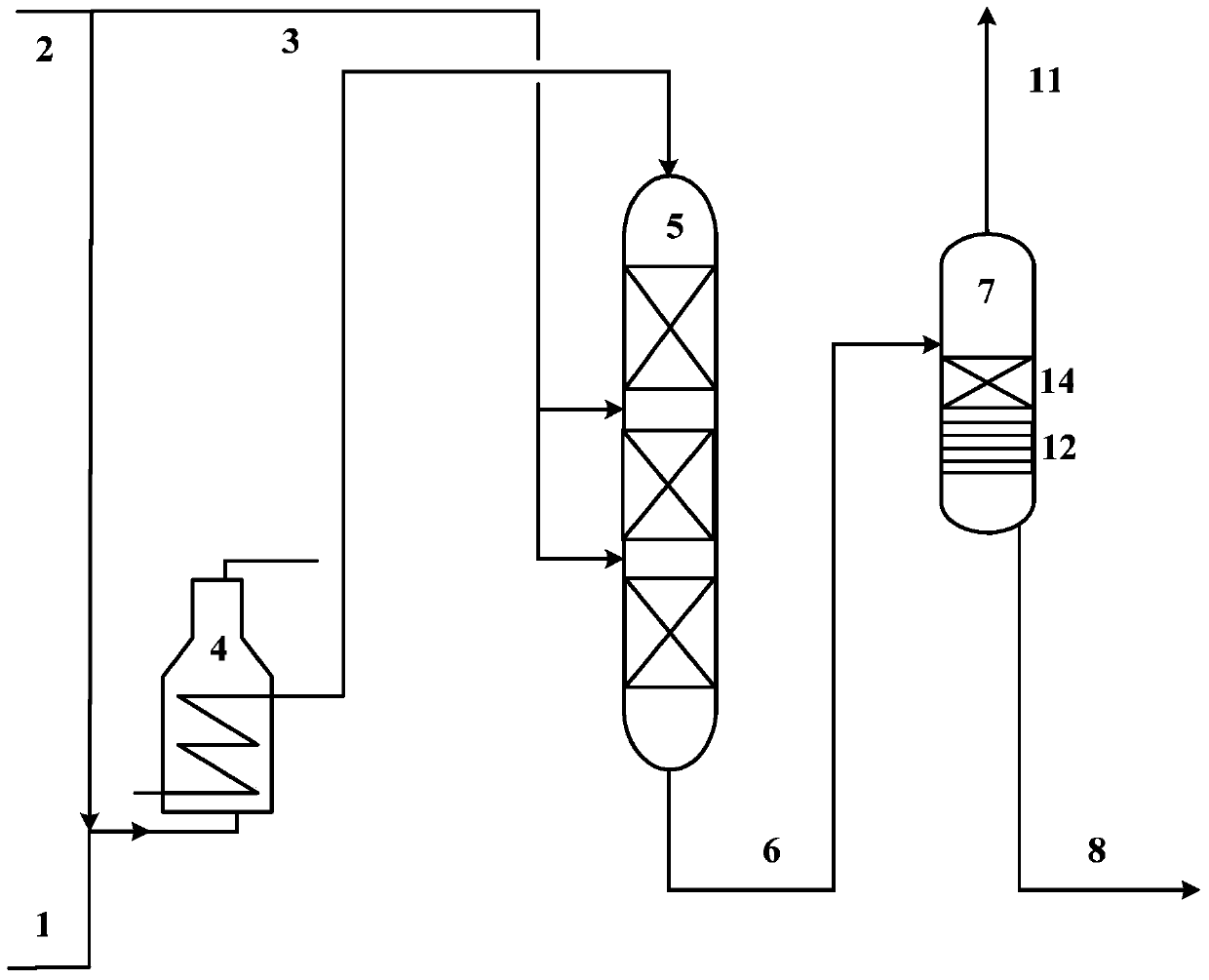

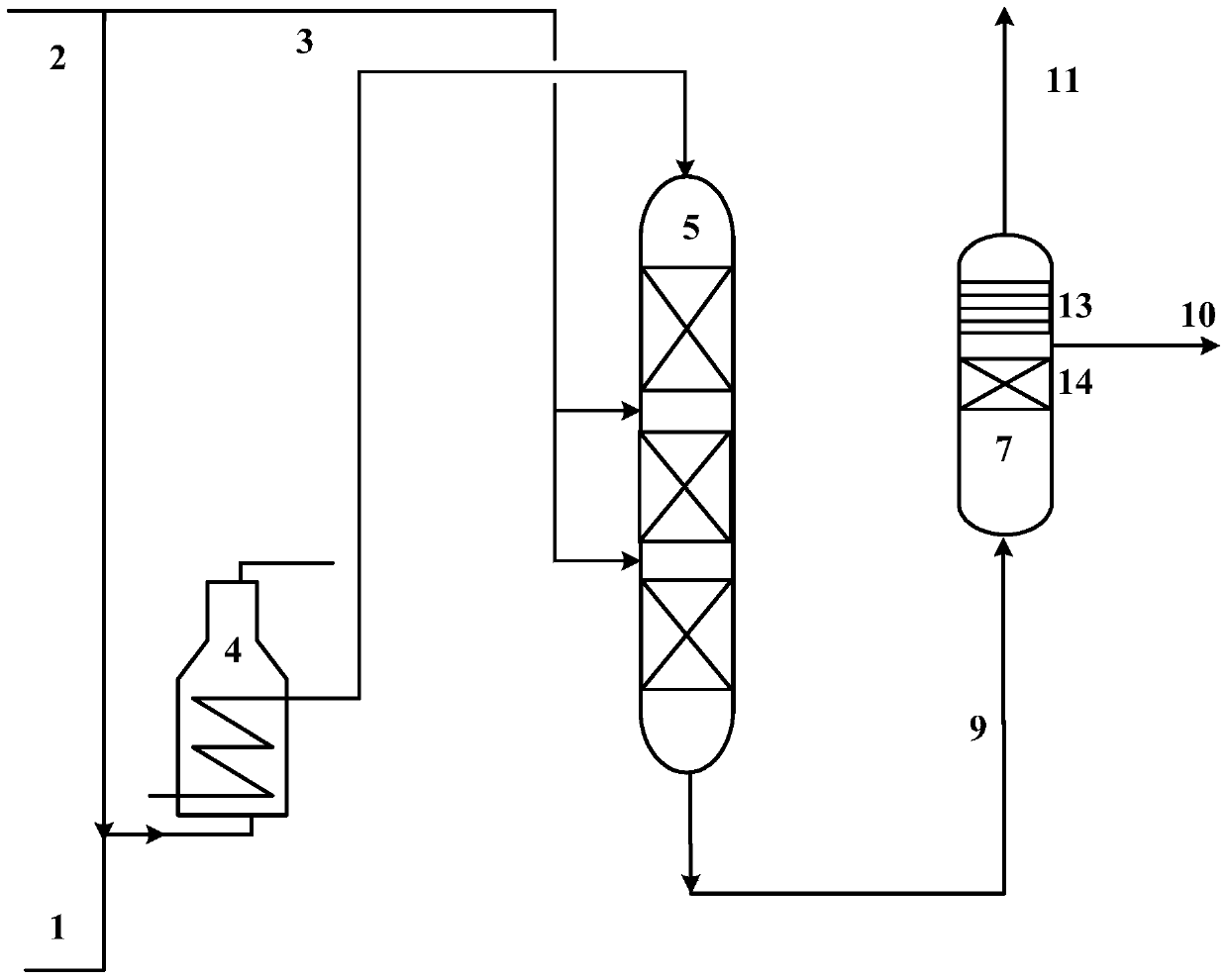

Hydrotreating method for producing low-sulphur and ultra-low sulphur diesel oil

InactiveCN102041089ARealization of deep desulfurizationReduce processingTreatment with hydrotreatment processesHydrogenation reactionHydrodesulfurization

The invention provides a hydrotreating method for producing low-sulphur and ultra-low sulphur diesel oil, which comprises the following steps of: subjecting raw oil into pre-hydrogenation reaction in the first reaction region, then fractionating the diesel oil into a light fraction and a heavy fraction after implementing pre-hydrogenation, and then absorbing or extracting the heavy fraction to remove the organic nitrogen-containing compound which has an inhibition effect to deep desulfurization; infusing the heavy fraction into the second reaction region to implement deep hydrodesulfurization after removing the organic nitrogen-containing compound; and mixing the light fraction and the heavy fraction to obtain producing low-sulphur or ultra-low sulphur diesel oil. Compared with conventional refining process of diesel oil, the hydrotreating method for producing low-sulphur and ultra-low sulphur diesel oil provided by the invention has the advantages that the purpose for deep or ultra-deep hydrodesulfurization of diesel oil can be realized in the condition that the whole operation conditions are relatively mild due to the point that the negative factor which can influence the deep hydrodesulfurization of diesel oil is removed, and the hydrogen consumption of the method is relatively low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxidation sweetening method of hydrogenated diesel oil

The invention disclosed an oxygenized desulphuring method of hydrogenated diesel oil distillate. The invention only treats the heavy distillate rather than the light distillate. The processing procedure comprises the following steps: dividing the hydrogenated diesel oil into light distillate and heavy distillate; adding the oxidant (the mole ratio of oxidant to sulphur is 2-10); adding the acid assistant (the mole ratio of the oxidant to the acid assistant is 0.5-3) to oxidize the sulphide into the sulfone; using extracting separation or adsorbing separation to remove the sulfone or sulfoxide substances in the diesel oil; mixing the heavy distillate with the light distillate to get the diesel oil with supra-low content of sulphur. The invention is especially applicable to the hydrogenated diesel oil distillate which contains less than 500500 mug / g sulphur. It can remove the dibenzothiophene substance effectively, the sulphur content of the product is less than 1010 mug / g while the oil vecovery rate is 5wt%-15wt% higher than the regular ways without fractional distillating process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for Ultra-Deep Desulfurization of Diesel via Oxidative Distillation, Its Preparation and Desulfurization Method

InactiveUS20100181230A1Avoid easy removalReduce sulfur contentOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsQuaternary ammonium cationDistillation

A catalyst for ultra-deep desulfurization of diesel via oxidative distillation is an amphiphilic oxidative catalyst, which is expressed as Qm[XMnOq], wherein 1≦m≦12; 9≦n≦18; 34≦q≦62; Q is a quaternary ammonium cation; X is P, Si, As or B; and M is Mo) or W. A desulfurization method comprises a) mixing well a diesel, the amphiphilic catalyst, and hydrogen peroxide, reacting for 10-300 minutes at ambient temperature and normal pressure, transforming the sulfur-containing compounds in the diesel into sulfone to obtain an oxidized diesel; b) distilling the oxidized diesel obtained in step a) under reduced pressure to obtain the ultra-low sulfur diesel having a sulfur content of less than 10 ppm; and c) separating and recovering the catalyst and sulfone.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A method for ultra-deep hydrodesulfurization of diesel oil

ActiveCN105273754BReduce usageGood chromaTreatment with hydrotreatment processesHydrodesulfurizationHydrogenation reaction

A method for ultra-deep hydrodesulfurization of diesel oil. Diesel feedstock oil and hydrogen enter the reactor together, and hydrogenation reaction is carried out under the action of hydrogenation catalyst I. The middle part of the separator is filled with hydrogenation catalyst II, and the liquid phase stream separated by the hot high-pressure separator is cooled and fractionated to obtain hydrogenated gasoline and hydrogenated diesel oil. The invention can process straight-run diesel oil or low-quality secondary processed diesel oil to produce ultra-low-sulfur diesel oil with a sulfur content of less than 10ppm, and can complete the hydrodecolorization reaction without an independent hydrodecolorization reactor, making the product ASTMD1500 chromaticity less than 1.0.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-processing method for producing ultra-low sulfur diesel

ActiveCN102443429AEasy and flexible operationIncrease local temperatureTreatment with hydrotreatment processesHydrogenReaction temperature

A hydro-processing method for producing ultra-low sulfur diesel comprises the following steps: completely dissolving the hydrogen I in diesel fraction raw oil to enter into a first hydro-processing reaction zone to be contacted with hydro-processing catalyst under pure liquid phase; reacting under the temperature of 340 to 400 DEG C; mixing the effluent of the first hydro-processing reactor with the hydrogen II to enter into a second hydro-processing reaction zone to be contacted with the hydro-processing catalyst under the state of pure liquid phase or low hydrogen-oil ratio; reacting under the reaction temperature of 240-320 DEG C, and cooling and separating the effluent of the second hydro-processing reaction zone to obtain diesel product. The method of the invention can be used for translating the diesel fraction with high sulfur content into ultra-low sulfur diesel product with good color, wherein the sulfur content can meet the Euro IV and Euro V discharge standard requirement and simultaneously, the chromaticity is less than 0.5.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for transporting and testing ultra low sulfur diesel

InactiveUS20060047446A1Data processing applicationsStructural/machines measurementPetroleum productPipeline transport

A method for determining the variations in the sulfur content of ultra-low sulfur diesel fuel when it is transported through a petroleum transportation system includes sampling fuels at various points during barge transport, pipeline transport and in terminaling operations. New procedures and special handling regiments are developed in view of how the sulfur content of ultra-low sulfur fuel may change when transported through the system in sequence and stored with other petroleum products.

Owner:MARATHON PETROLEUM

Diesel oil deep hydrodesulfurization method

ActiveCN105273754AReduce usageGood chromaTreatment with hydrotreatment processesHydrodesulfurizationFractionation

The invention relates to a diesel oil deep hydrodesulfurization method, which comprises that diesel oil raw material oil and hydrogen enter a reactor and are subjected to a hydrogenation reaction under the effect of a hydrogenation catalyst I, the reactor effluent is subjected to heat exchange, the obtained material enters a hot high pressure separator, a hydrogenation catalyst II is filled on the middle portion of the hot high pressure separator, and the liquid-phase stream separated by the hot high pressure separator is subjected to cooling and fractionation to obtain the hydrogenation gasoline and the hydrogenation diesel oil. According to the present invention, the straight-run diesel oil or poor-quality secondary processing diesel oil can be treated, the ultra-low sulfur diesel oil with the sulfur content of less than 10 ppm can be produced, the hydrogenation decolorization reaction can be separately completed without the separate hydrogenation decolorization reactor, and the product ASTMD1500 chrominance is less than 1.0.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com