Method for production of ultralow-sulfur diesel oil

A technology for ultra-low-sulfur diesel and diesel oil, which is applied in the field of hydrogenation for the production of ultra-low-sulfur clean diesel, and can solve the problems of increasing equipment investment and operating costs, high reaction pressure, and low space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

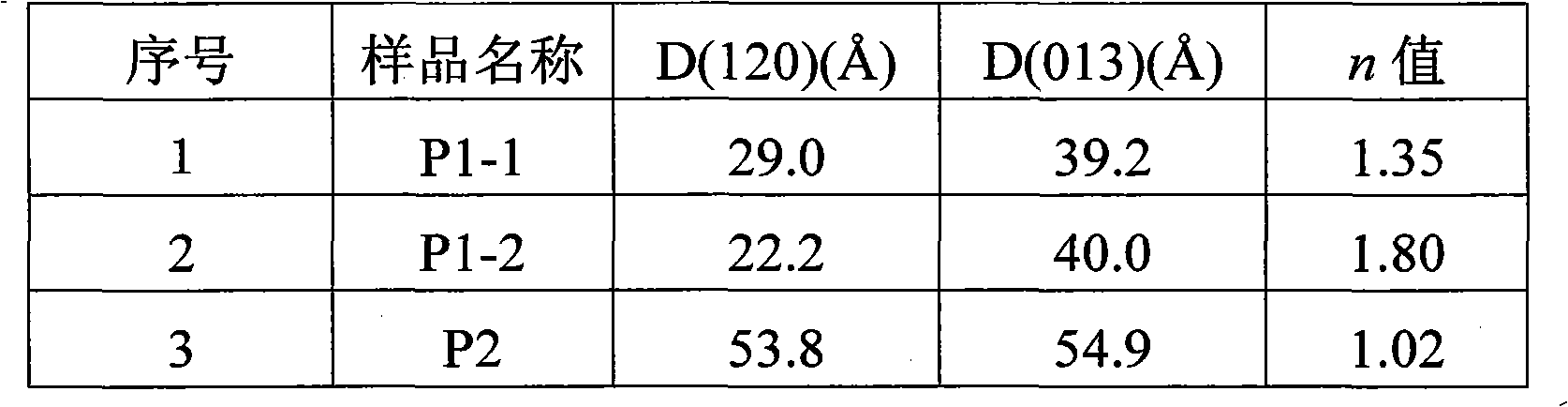

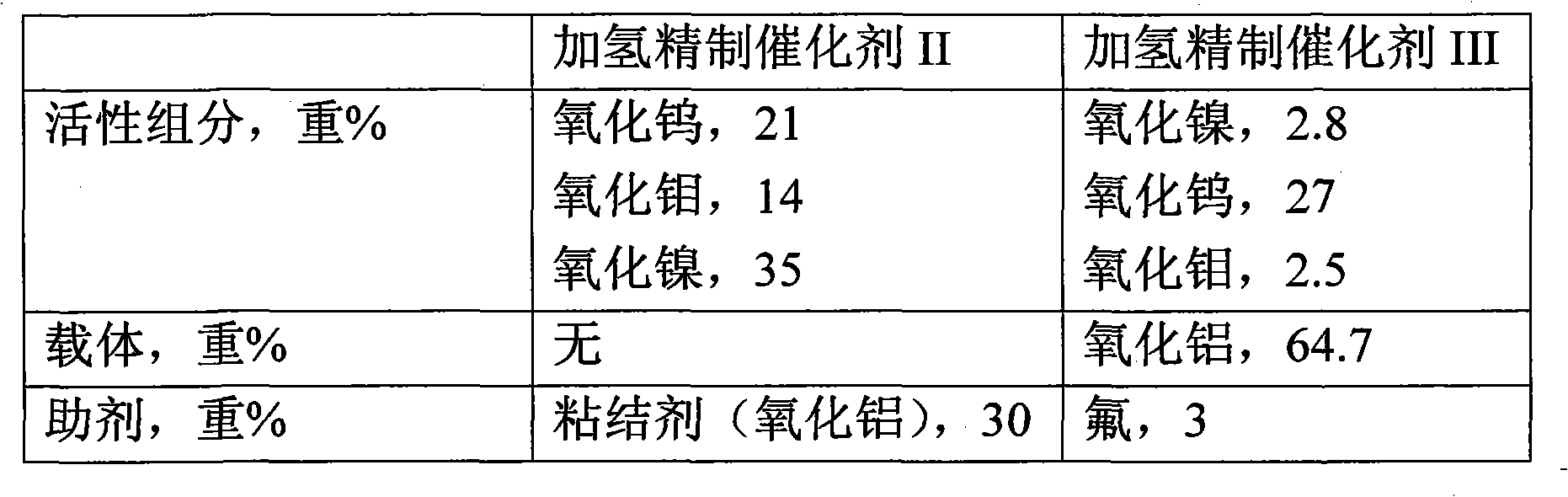

Embodiment 1

[0083] A high-sulfur straight-run diesel fraction from the Middle East is raw material A, and its properties are shown in Table 3. Raw material A enters the reactor equipped with two hydrorefining catalysts from the top, and the supplementary hydrogen and recycled hydrogen are mixed and then enter the reactor from the bottom. The reactor is divided into two catalyst beds. The upper part of the reactor is filled with hydrofinishing catalyst I-catalyst C1, and the lower part of the reactor is filled with hydrofinishing catalyst II. The filling ratio of the two hydrofinishing catalysts is 6:4 (volume ratio) . Raw material A and mixed hydrogen are subjected to deep hydrodesulfurization reaction under the action of two hydrorefining catalysts in the countercurrent contact mode. The reaction conditions are: reaction temperature 355 ° C, reaction hydrogen partial pressure 6.4 MPa, liquid hourly volume space velocity 2.4 h -1 , hydrogen oil volume ratio 300Nm 3 / m 3 . After the r...

Embodiment 2

[0090] A middle-east high-sulfur straight-run diesel fraction was mixed with a domestic catalytic cracking diesel fraction at a weight ratio of 5:3, and the obtained mixed diesel fraction was raw material B, and its properties are shown in Table 3. Raw material B enters the reactor equipped with two hydrorefining catalysts from the top, and the supplementary hydrogen and recycled hydrogen are mixed and then enter the reactor from the bottom. The reactor is divided into two catalyst beds. The upper part of the reactor is filled with hydrofinishing catalyst I—catalyst C1, and the lower part of the reactor is filled with hydrofinishing catalyst II. The filling ratio of the two hydrofinishing catalysts is 1:1 (volume ratio) . Raw material B undergoes deep hydrodesulfurization reaction under the action of two hydrorefining catalysts. The reaction conditions are: reaction temperature 355°C, reaction hydrogen partial pressure 7.0MPa, liquid hourly volume space velocity 1.5h -1 , hyd...

Embodiment 3

[0097] A secondary processing catalytic cracking diesel oil fraction is raw material C, its main properties are shown in Table 3, raw material C enters the reactor equipped with two kinds of hydrofining catalysts from the top, supplements hydrogen and circulates hydrogen and mixes it from the bottom into the above reactor. The reactor is divided into two catalyst beds. The upper part of the reactor is filled with hydrofinishing catalyst I-catalyst C2, and the lower part of the reactor is filled with hydrofinishing catalyst II. The filling ratio of the two hydrogenation catalysts is 3:7 (volume ratio) . Raw material C undergoes deep hydrodesulfurization reaction under the action of two hydrorefining catalysts. The reaction conditions are: reaction temperature 360°C, reaction hydrogen partial pressure 7.0MPa, liquid hourly volume space velocity 2.0h -1 , hydrogen oil volume ratio 350Nm 3 / m 3 . After the reaction product is cooled and separated, the obtained hydrogen-rich ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com