Rotary furnace low-order powdered coal pyrolysis upgrading method with coal gas circulation

A technology of pyrolysis upgrading and rotary furnace, which is applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of lack of energy integration and optimization in drying, pyrolysis, and cooling processes, so as to improve the yield of coal tar, Effect of Coal Dust Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

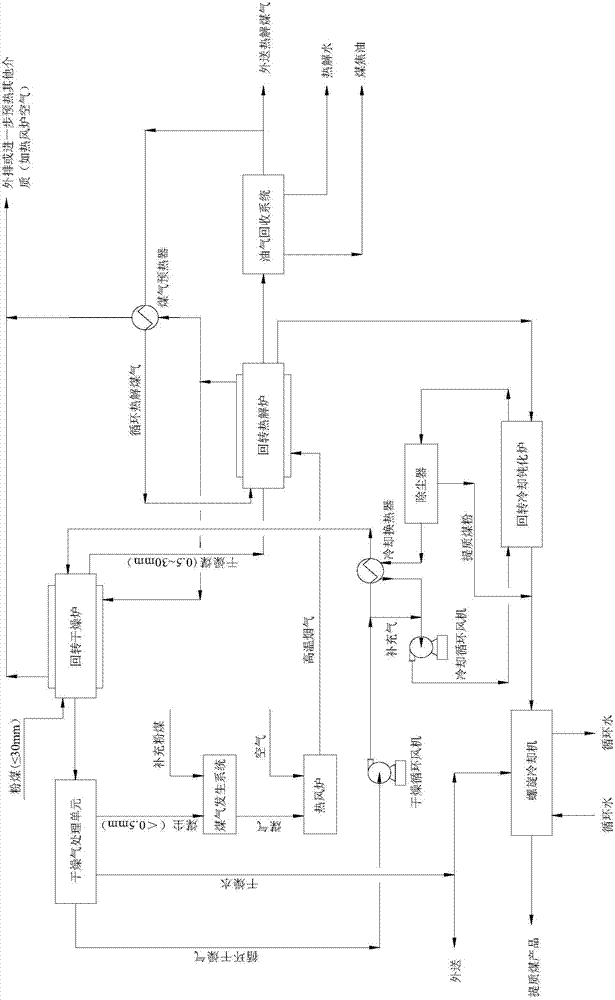

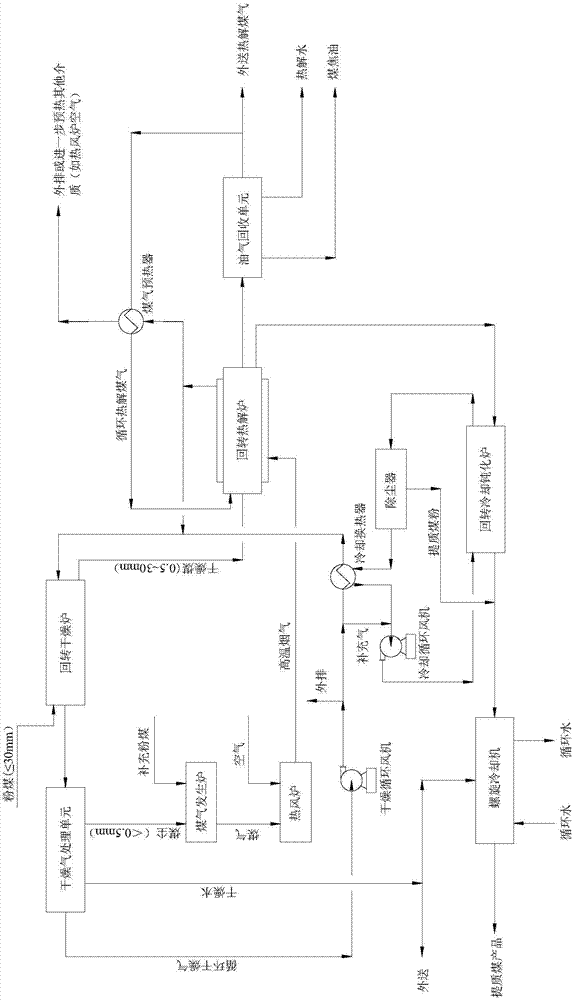

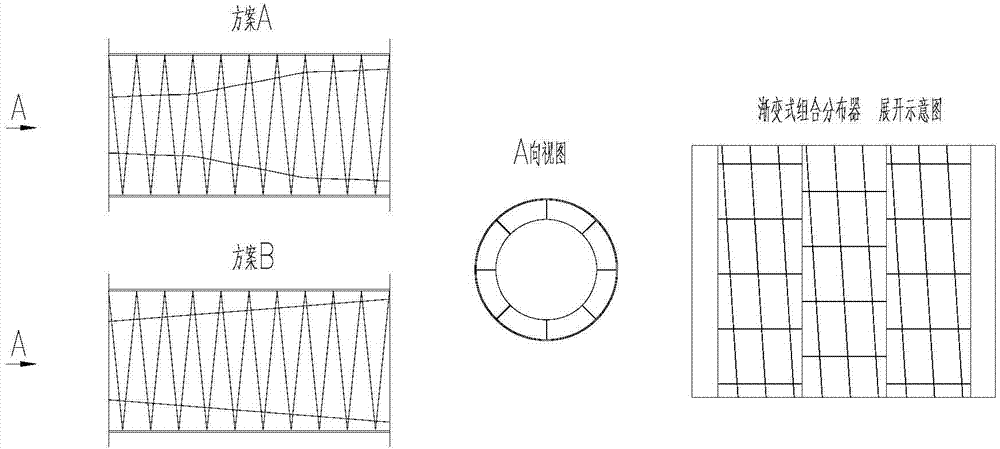

[0049] 2 tons of Shenfu pulverized coal (0-30mm) are continuously sent to the direct and indirect combined rotary drying furnace, and the flue gas from the 600 ℃ rotary pyrolysis furnace is passed through the jacket as a heat source, and the coal is heated and dried to 250 ℃, The water content is reduced to 0wt%; meanwhile, circulating drying gas at 300°C is introduced into the rotary drying furnace, and under the action of the gradient combined distributor, the coal dust with a particle size of less than 0.5mm and more than 85% in the pulverized coal is removed.

[0050] The drying gas discharged from the rotary drying furnace is entrained with coal dust and water vapor, and enters the drying gas processing unit to separate coal dust, cool down and recycle drying water. The furnace forms a closed-circuit circulation of circulating drying gas.

[0051] The dry coal of 0.5-30mm from the rotary drying furnace enters the rotary pyrolysis furnace. At the same time, the circulating...

Embodiment 2

[0055] 6 tons of Shenfu pulverized coal (0-30mm) are continuously sent to the direct heating rotary drying furnace, and the clean flue gas (O 2 content of 2vol%) as a drying heat source, the coal is heated and dried to 250 ℃, and the water content is reduced to 0wt%; at the same time, under the action of the gradient combined distributor, the coal dust that is less than 0.5mm and more than 85% in the pulverized coal is removed. remove.

[0056] The drying gas discharged from the rotary drying furnace is entrained with coal dust and water vapor, and enters the drying gas processing unit for separation of coal dust, cooling and recycling of drying water. The high-temperature flue gas at the outlet of the furnace jacket is returned to the rotary drying furnace to form a closed-circuit circulation of circulating drying gas.

[0057] The dry coal of 0.5-30mm from the rotary drying furnace enters the rotary pyrolysis furnace. At the same time, the circulating pyrolysis gas from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com