Dust cover for coal mine conveyor belt

A conveyor belt and dustproof cover technology, which is applied in the field of windproof equipment for coal mine conveyor belts, can solve the problems of increasing the concentration of windy coal dust, failing to achieve dust prevention, and deteriorating the working environment, so as to reduce friction and improve windproof and dustproof effects , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

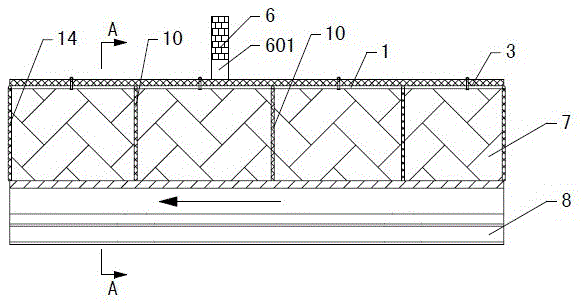

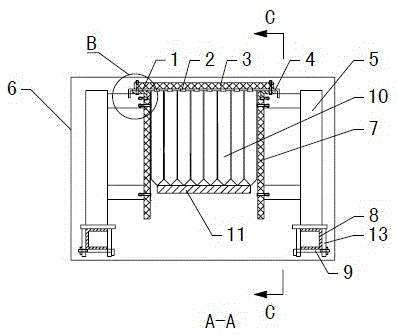

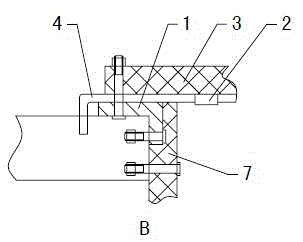

[0026] refer to Figure 1~2 , the dust cover of the coal mine conveyor belt, including the adjustment wall 6 and the conveyor belt 11, the conveyor belt 11 passes through the belt hole 601 of the adjustment wall 6, and the conveyor belt 11 on both sides of the adjustment wall 6 is fixed with a horizontal upper baffle 3, Both sides are fixed with side baffle 7, and the front end opening of upper baffle 3 and side baffle 7 is fixed with windshield 14, and the back side of windshield 14 is also fixed with a plurality of dust catch baffles 10, and windshield 14 and The dust-catching baffles 10 are made of flexible materials, and are vertically fixed on the upper side of the conveyor belt 11. The direction of the arrow in the figure is the transmission direction of the conveyor belt 11. Wind speed can become bigger, and wind deflector 14 blocks high-speed wind flow, but because wind speed is very fast, still can be blown in the space that upper baffle plate 3 and side baffle 7 form...

Embodiment 2

[0033] refer to Figure 5 , the difference between this embodiment and Embodiment 1 is that the dust catch baffle 10 is an integral flexible material, and the bottom is wave-shaped. Deformation, so that large coals pass through the wavy depressions, prevent the formation of gaps, and improve the windproof effect of the dust-catching baffle 10. The windshield 14 can be a whole flexible material, or it can be made of multiple strips of rubber belts. Arrangement composition. Other structures are with embodiment 1.

Embodiment 3

[0035] refer to Image 6 , the upper baffle 3 and the side baffle 7 are made of hard materials, can adopt planks or iron plates, the side baffles 7 are directly fixed on both sides of the conveyor belt 11, and the upper baffle 3 is fixed on the top of the side baffles 7, The windshield 14 and the dust catch baffle 10 are made of flexible material, and the upper end is fixed on the upper baffle 3 . The upper baffle plate 3 and the side baffle plate 7 can be longitudinal splicing structures respectively, and the length can be adjusted to meet the needs of different mines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com