Powder sending and laying device for quickly shaping device

A technology of forming equipment and powder spreading device, which is applied in the field of components of rapid prototyping equipment, can solve problems such as adverse effects on forming quality, affecting the quality of formed parts, and affecting work reliability, etc., to achieve improved powder utilization, simple control, and reliability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

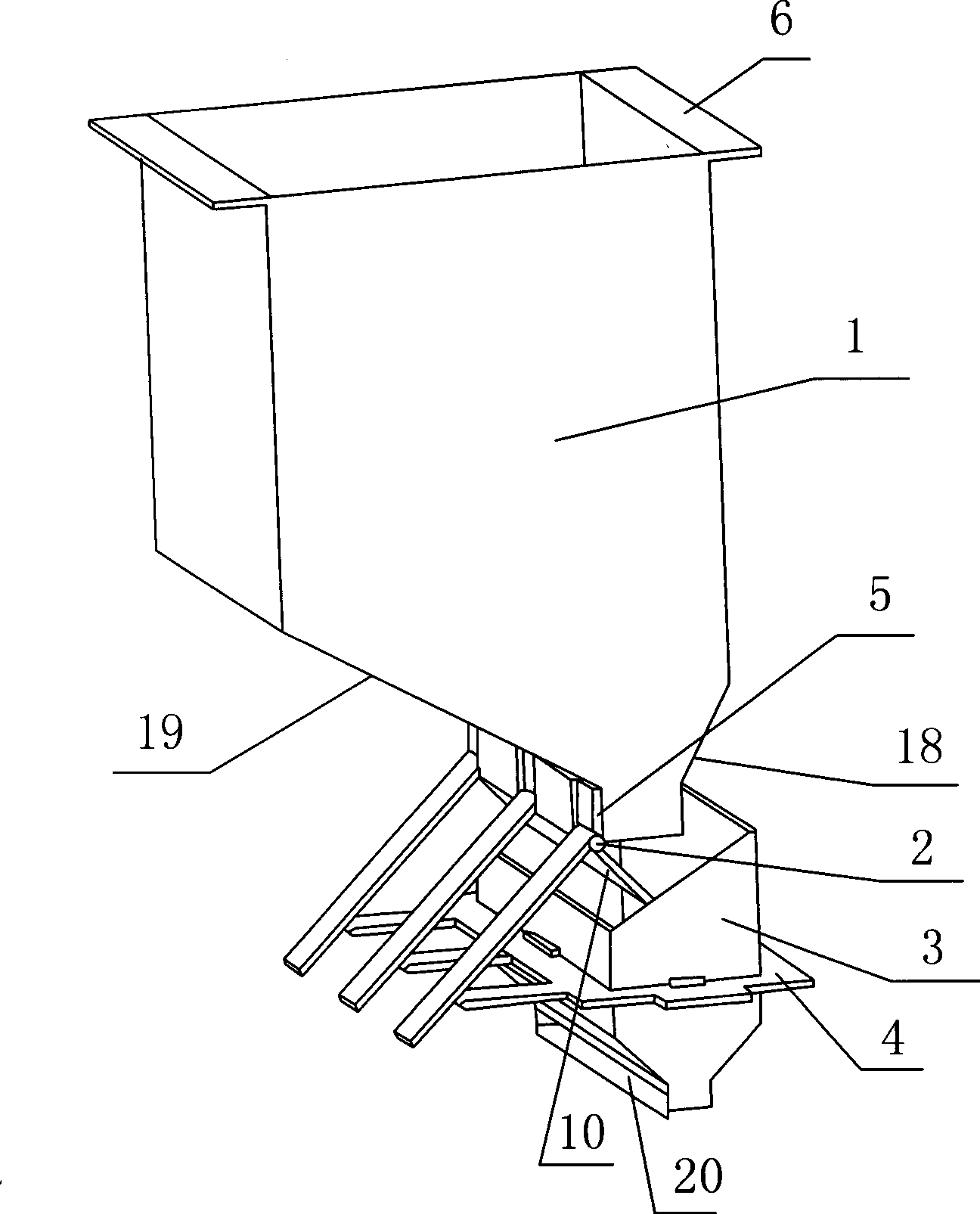

[0030] Such as figure 1 As shown, the present invention includes a powder storage box 1 and a mobile hopper 3, wherein the powder storage box 1 is an upper-mounted powder storage box located above the mobile hopper 3 and having a powder lowering port at the bottom. Moreover, the position of the powder storage box 1 is fixed, and the powder storage box 1 is provided with two left and right installation platform structures 6 which are fixed on the upper part of the forming space of the rapid prototyping equipment. The powder storage box 1 is a rectangular box with an upper opening, and the bottom of the rectangular box is composed of two inclined box bottoms on the left and right and two vertical box bottoms on the front and back. The two inclined box bottoms are both downward and inwardly inclined. The inclination angles are different, and the powder lowering port is a rectangular powder lowering port correspondingly arranged at the bottom of the box bottom. In this embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com