Patents

Literature

168 results about "Coalbed methane extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coalbed methane extraction (CBM extraction) is a method for extracting methane from a coal deposit.

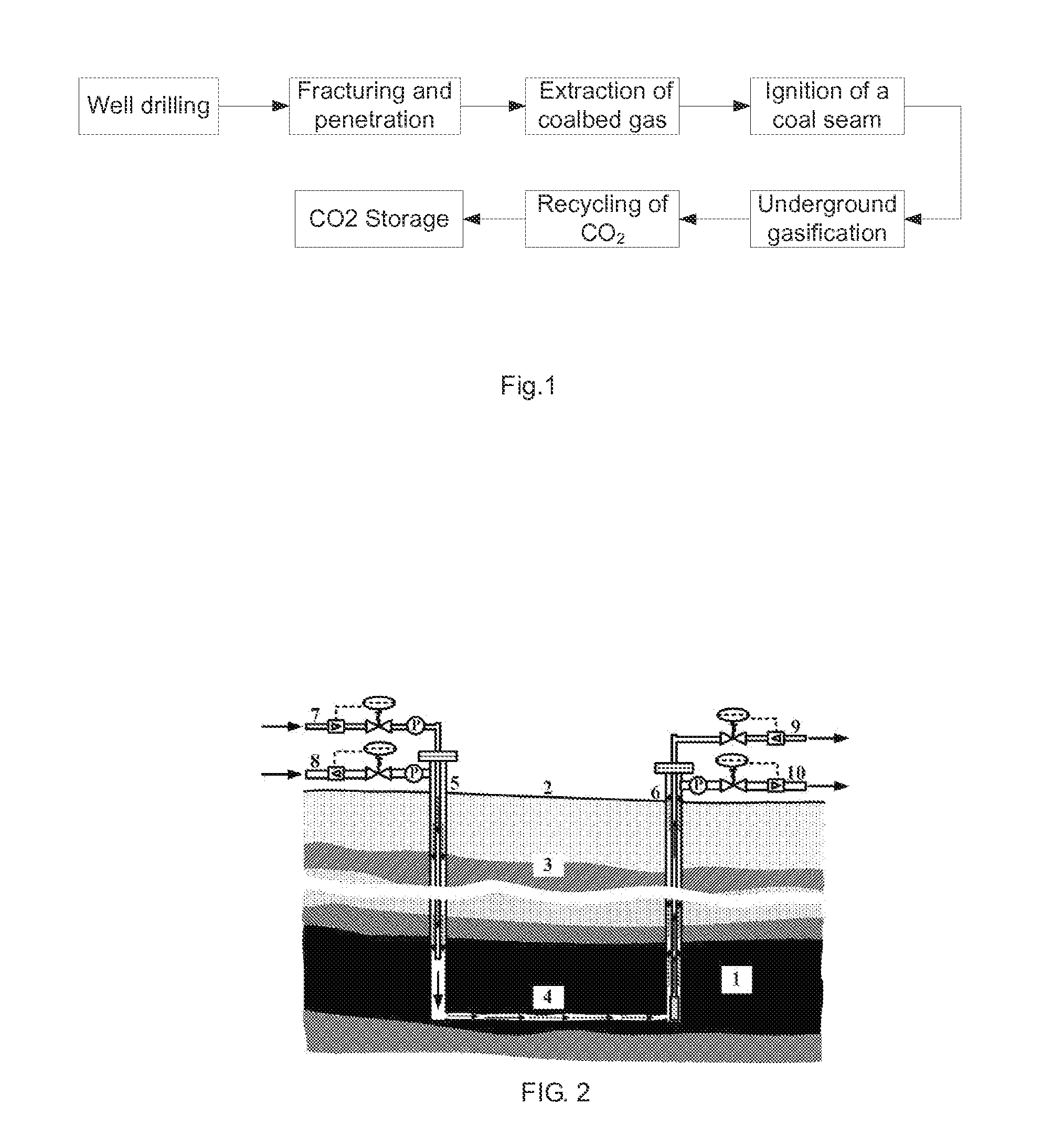

Method for joint-mining of coalbed gas and coal

InactiveUS20150247385A1Increase ratingsImprove breathabilityArtificial islandsFluid removalWell drillingProcess engineering

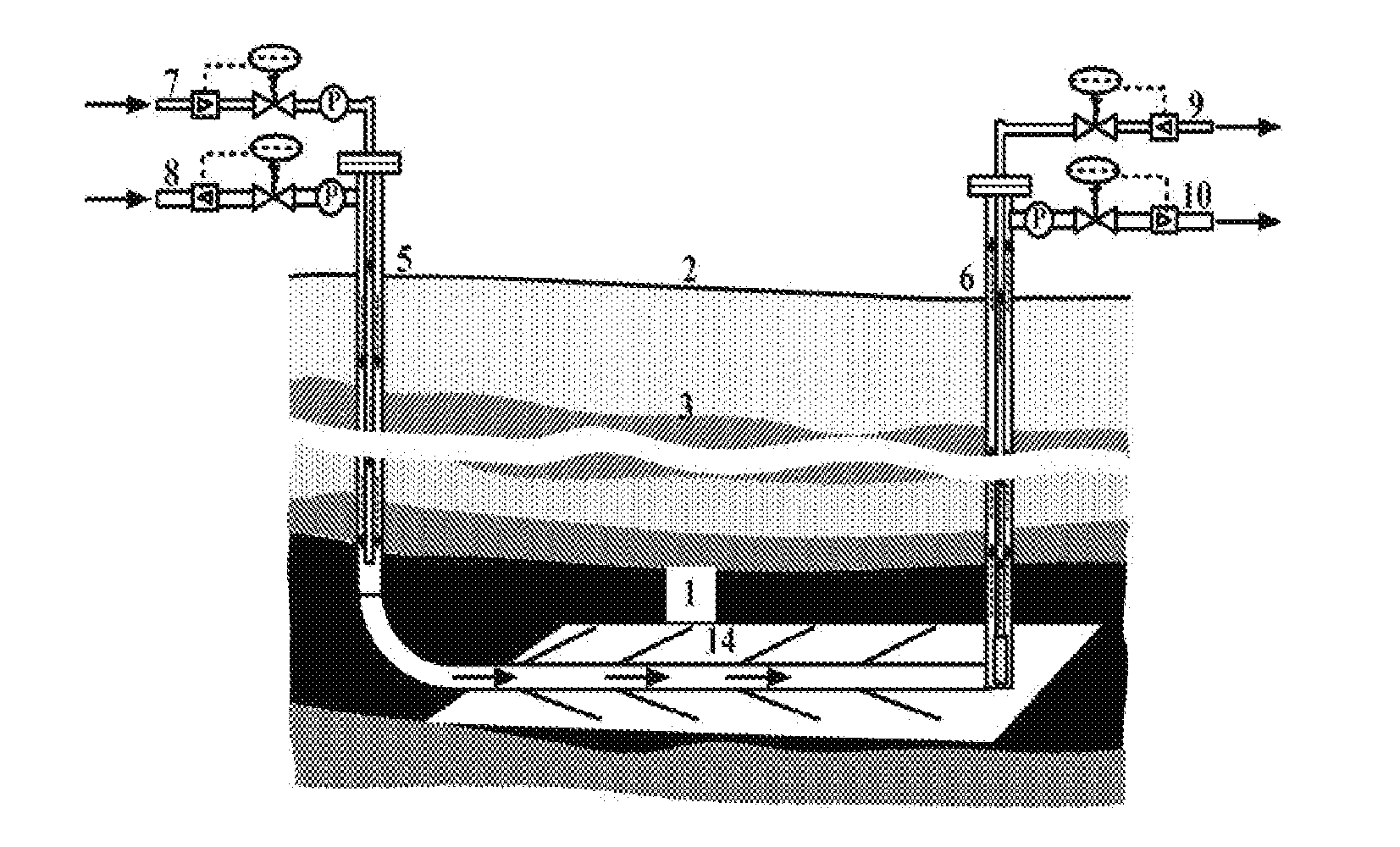

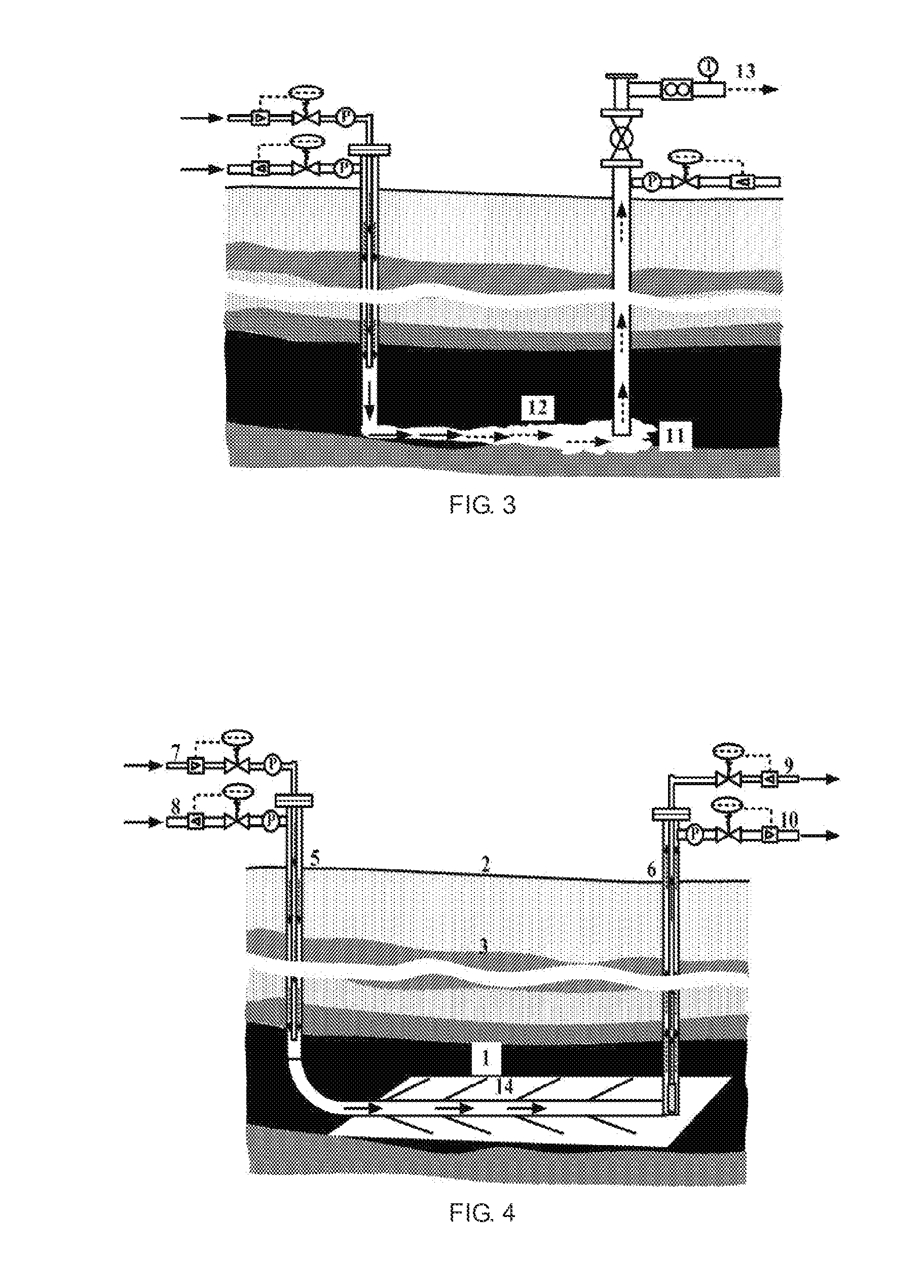

Provided is a method for joint-mining of coalbed gas and coal. The method comprises: a well-drilling step; a fracturing and penetration step; a coalbed gas extraction step: an ignition step, and an underground gasification step. The method combines an underground coal gasification technology and a coalbed gas extraction technology, not only allows for utilization of the high temperature of underground gasification to heat a coalbed. thus increasing the permeability of a coal seam. and increasing the recovery rate of the coalbed gas, but also allows for utilization of the coalbed gas to perform the drilling and the fracturing and penetration processes, thus increasing the efficiency of underground coal gasification for mining.

Owner:ENN COAL GASIFICATION MINING

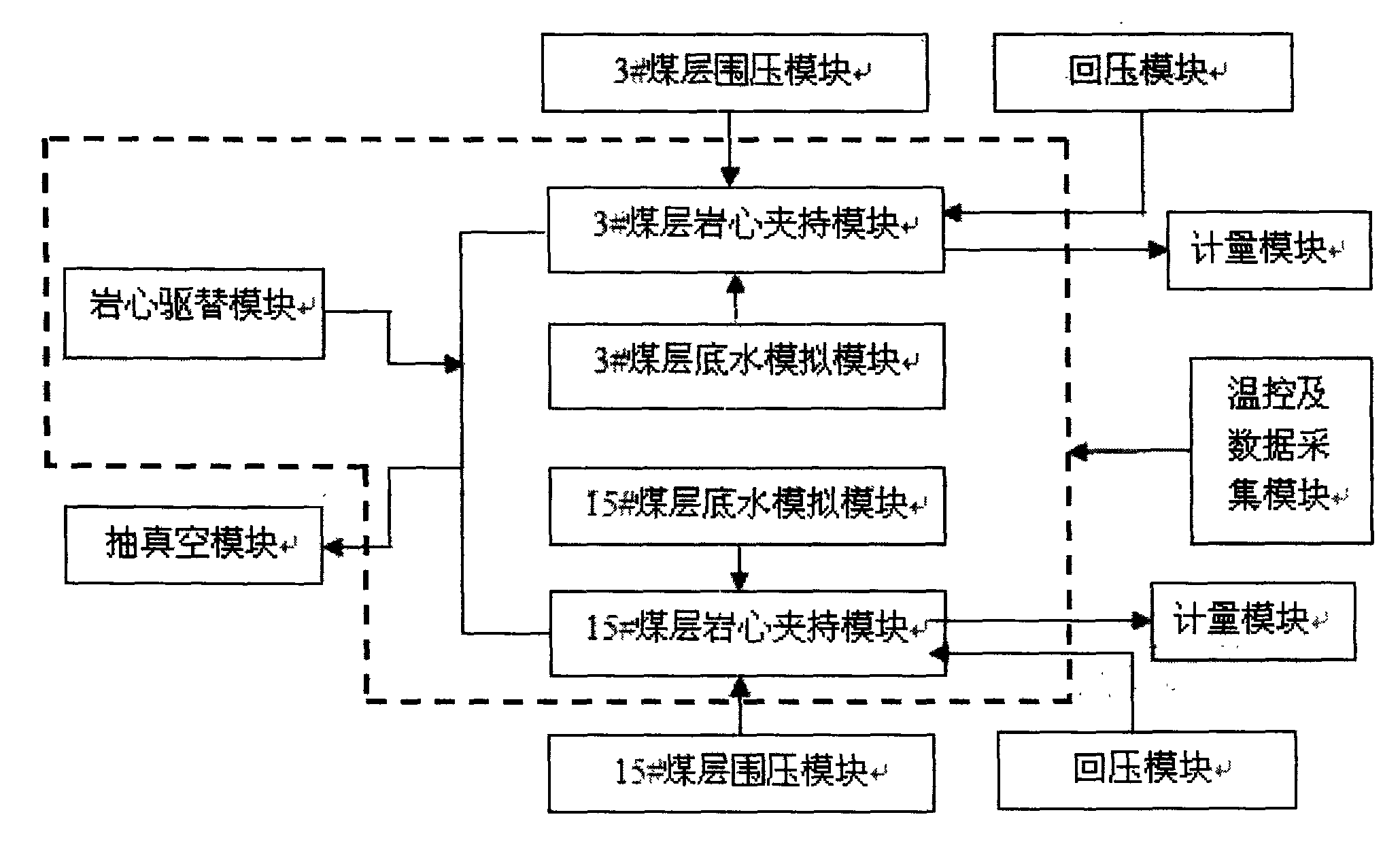

Coal bed gas reservoir layering co-mining high temperature and high pressure discharging mining dynamic evaluation instrument

InactiveCN103174412ARealize fully automatic recordingEnhanced overall recoverySurveyBottom waterVacuum pump

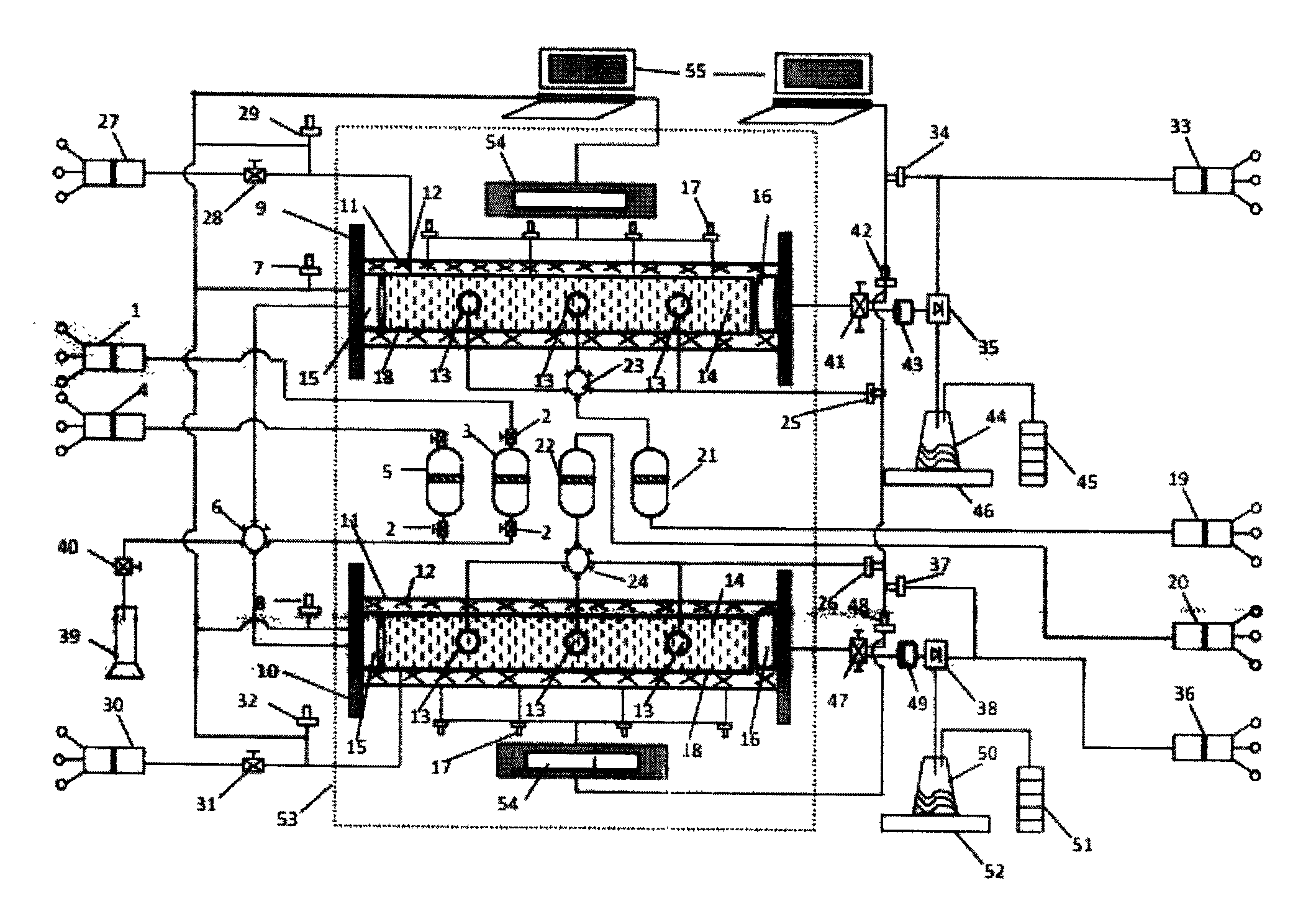

The invention discloses a coal bed gas reservoir layering co-mining high temperature and high pressure discharging mining dynamic evaluation instrument. The coal bed gas reservoir layering co-mining high temperature and high pressure discharging mining dynamic evaluation instrument comprises a displacement module, a core clamping module, a bottom water analog module, a surround pressure module, a return pressure module, a vacuum pumping module, a measuring module and a temperature control and data collecting module. The coal bed gas reservoir layering co-mining high temperature and high pressure discharging mining dynamic evaluation instrument is particularly used for evaluating influence of critical desorption pressure, reservoir differential pressure, permeability differences and feed liquid capacity differences I respective reservoir on discharging mining parameters in coal bed gas layering co-mining, explores an optimal discharging mining system in layering co-mining technology to improve using degrees of all layering, increases gas output per well, eliminates influence of interference between layers on production, achieves reasonable, long and efficient development, improves recovery efficiency of coal bed gas, and promotes development of mining technology of the coal bed gas.

Owner:SOUTHWEST PETROLEUM UNIV

Ultrasonic cavitation and hydrofracture combined stimulation coalbed methane extraction method

ActiveCN105971660ASave construction timeGreat practicabilityFluid removalGas removalUltrasonic cavitationHydraulic fracturing

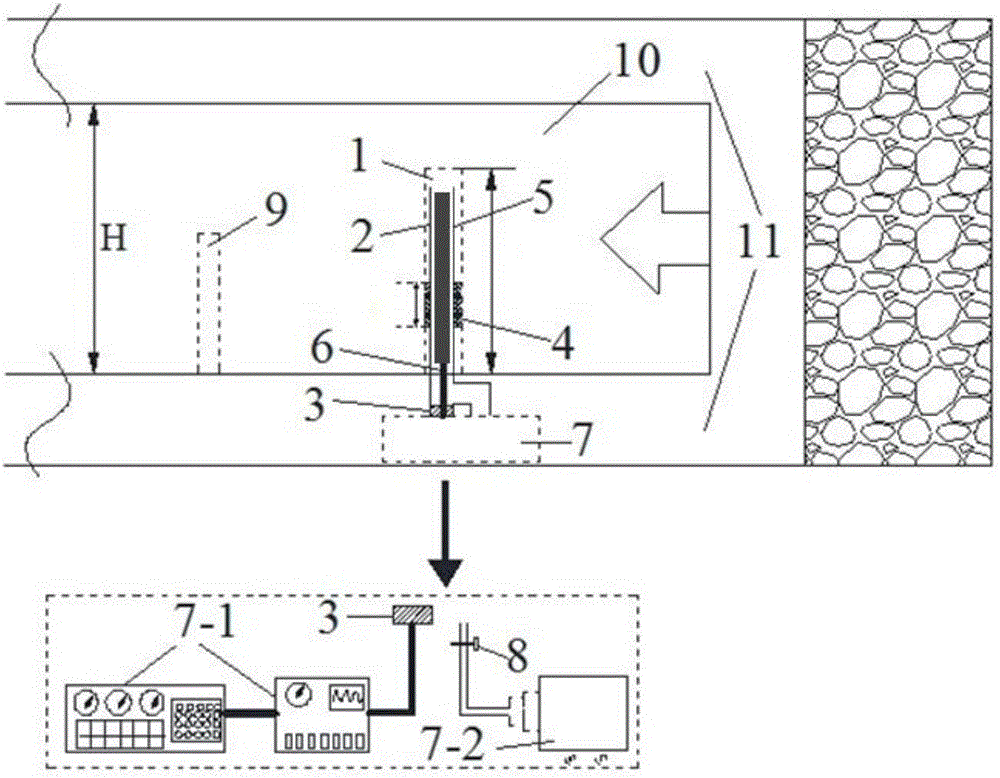

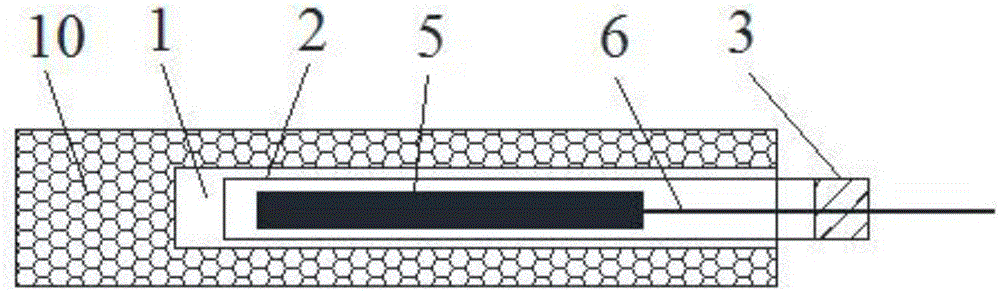

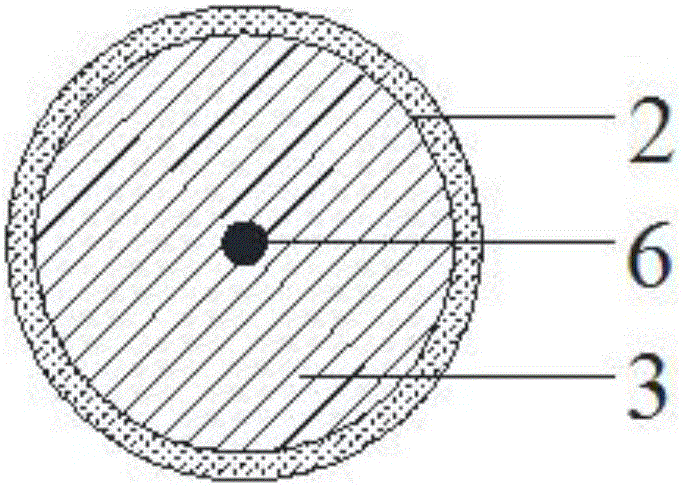

The invention discloses an ultrasonic cavitation and hydrofracture combined stimulation coalbed methane extraction method. A main drill hole and a monitoring drill hole are constructed in an air inlet way or an air return way of the working face at first, a steel pipe of a built-in ultrasonic transducer is sent into the main drill hole after a drill bit in the main drill hole reaches a coalbed preset target position, the main drill hole is subjected to high-pressure-resistant hole sealing through a conventional grouting method, and an ultrasonic generator is turned on to continuously emit low-frequency ultrasonic waves with the frequency being 20-25 kHz to the coalbed after hole sealing is completed; hydrofracture equipment is started in 1-2 h to conduct hydrofracture operation on the main drill hole; the power of the ultrasonic waves is kept unchanged while coalbed hydrofracture is conducted, and the frequency of the ultrasonic waves is adjusted to 30-35 kHz; and hydrofracture is stopped when water flows out of the monitoring drill hole or pressure of a water injection pump decreases suddenly, the frequency and power of the ultrasonic waves are kept unchanged at the time, ultrasonic waves are emitted to the coalbed continuously, and the ultrasonic generator is turned off in 30 min. The coalbed permeability-increase method is free of pollution, low in cost and good in effect.

Owner:CHINA UNIV OF MINING & TECH

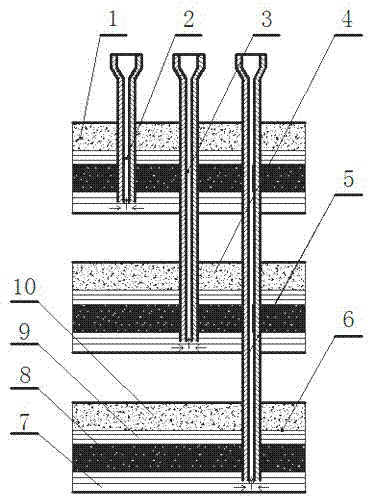

Method for designing exploiting wells of multi-layer stacking coal bed gas system

The invention relates to a method for designing exploiting wells of a multi-layer stacking coal bed gas system. The designing method includes the steps of (1) ranking reservoirs with the same reservoir pressure into the same gas contained system reservoir; (2) selecting the coal seam with the high capacity for serving as a main target reservoir of coal bed gas exploiting; (3) according to the number of the reservoirs of a multi-seam region gas-contained system, determining the number of the vertically-drilled wells needing to be drilled by a drilling platform, and accordingly determining perforation reservoir positions and non-perforation reservoir positions of the vertically-drilled wells. By means of the method for designing the exploiting wells of the multi-layer stacking coal bed gas system, advantages of the vertical wells and advantages of the cluster wells are combined, and novel cluster well type design is proposed; that is, on the same drilling platform, the coal bed gas vertical wells are drilled in the reservoirs of the gas contained system respectively and are not interfered, coal bed gas in a region is exploited to the maximum degree accordingly, and the effect of increasing the capacity of the coal bed gas wells is achieved.

Owner:CHINA UNIV OF MINING & TECH

Multi-round compressed air deblocking method for coal bed gas well fracturing and blocking

ActiveCN108729891AEnsure construction safetyEasy to get materialsConstructionsFluid removalFast releaseProcess engineering

The invention relates to a deblocking method for coal bed gas well fracturing and powder blocking in the field of coal bed gas exploitation. The method includes adopting an air compressor to slowly inject compressed air from the ground into a shaft of a blocked coal bed gas well to form certain high pressure in the shaft and a coal bed, then opening a well opening discharge valve to quickly release high pressure gas in the shaft, so that blocking coal powder and sand in a fracturing crack will be loosened and move to the shaft with the compressed air and then return to the ground through a delocking pipe column. The process is repeated for multiple rounds to eliminate the well fracturing and coal powder blocking phenomenon, and the gas production will be restored. More importantly, the coal bed is not damaged, and high application value is achieved.

Owner:北京方圆天地油气技术有限责任公司

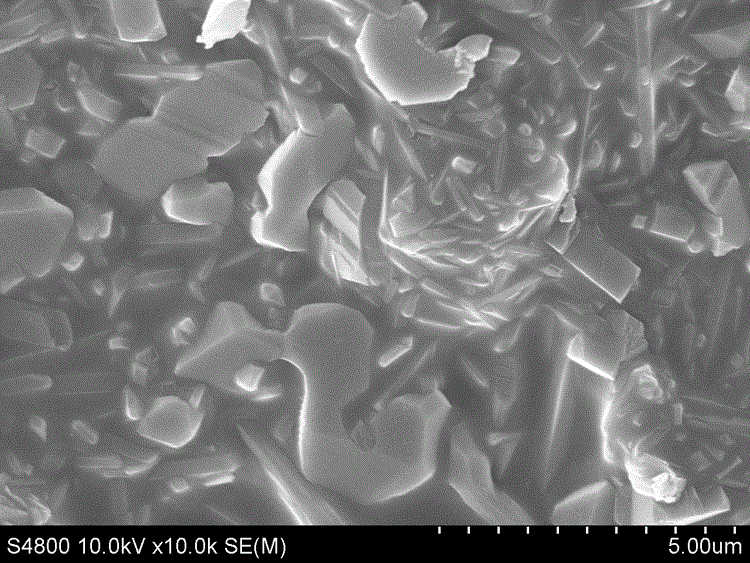

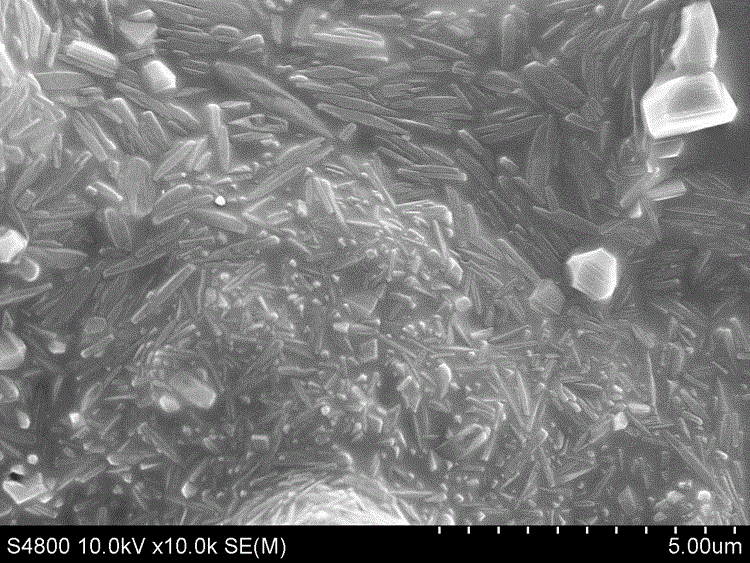

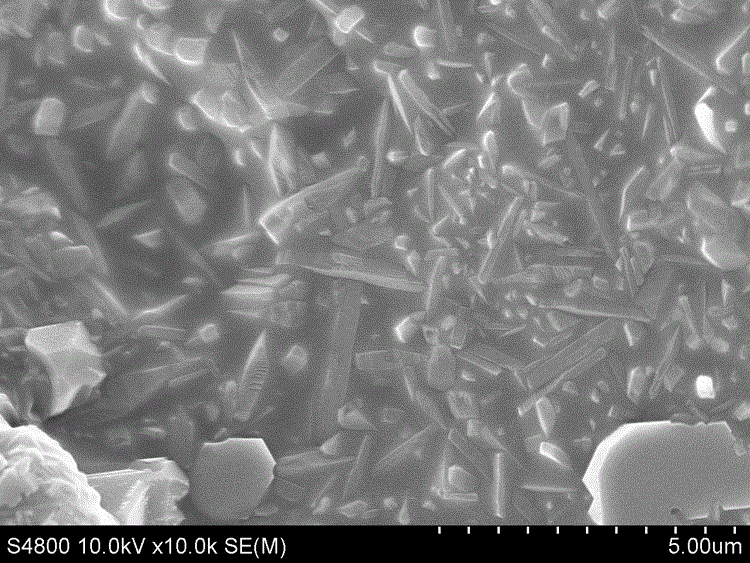

Ceramsite proppant for well producing coalbed methane from coal gangue and preparation method thereof

InactiveCN105885820AMeet the use requirementsRealize resource utilizationFluid removalDrilling compositionExpanded clay aggregateProcess engineering

A ceramsite proppant for a well producing coalbed methane from coal gangue and a preparation method thereof belong to the technical field of ceramic materials and proppants for coalbed methane fracturing construction propping. The proppant comprises coal gangue and bauxite and is characterized by comprising according to percent by weight: 80-90% of coal gangue and 10-20% of bauxite; and the ceramsite proppant 20-40 mesh in particle size is obtained by: grinding the coal gangue and the bauxite respectively to target mesh size less than 325 mesh in particle size so as to obtain starting powder; mixing well the starting powder to obtain mixed powder; adding a temporary binder to the mixed powder, and granulating in a granulator; drying spherical granule blanks, and screening sequentially with a 18-mesh screen and a 40-mesh screen to obtain spherical granule blanks; sintering the screened blanks, cooling with the furnace to room temperature, and screening the blanks sequentially with a 20-mesh screen and a 40-mesh screen. The ceramsite proppant prepared herein enables reduced exploitation cost of coalbed methane, resourceful utilization of coal gangue waste and reduced solid waste accumulation and environmental pollution.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

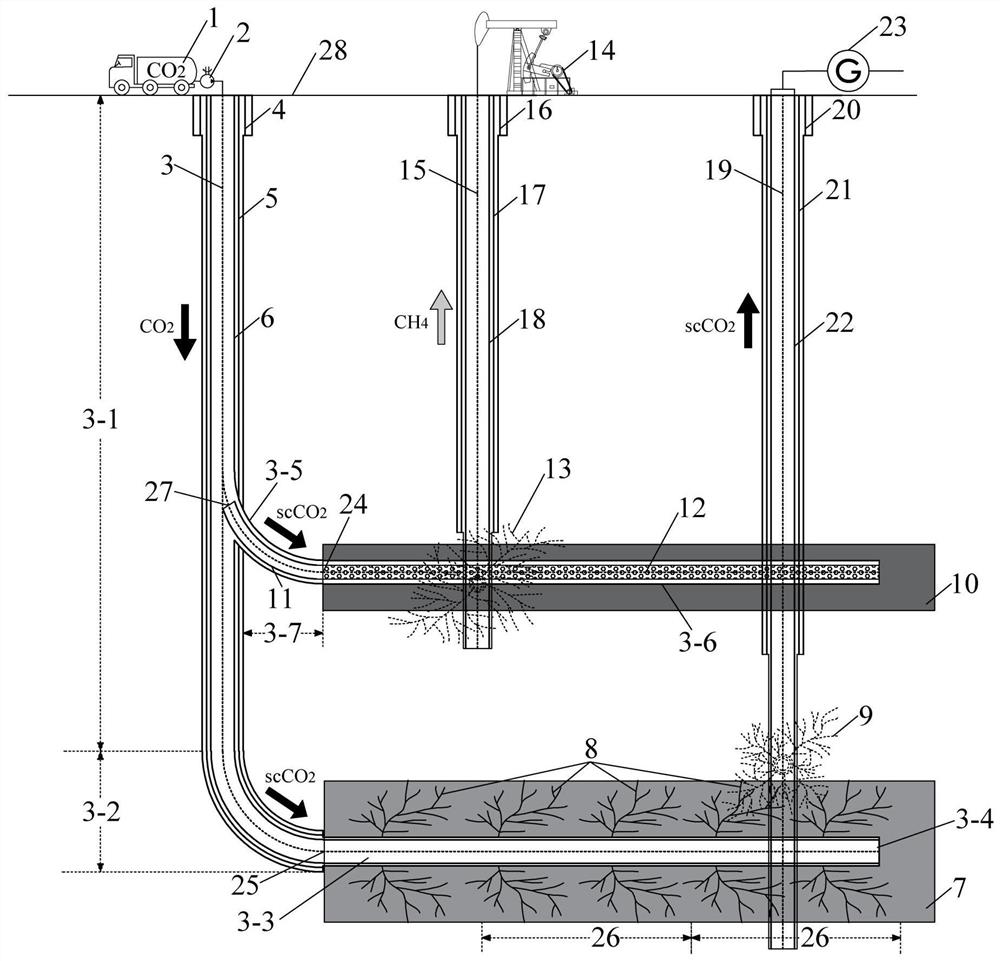

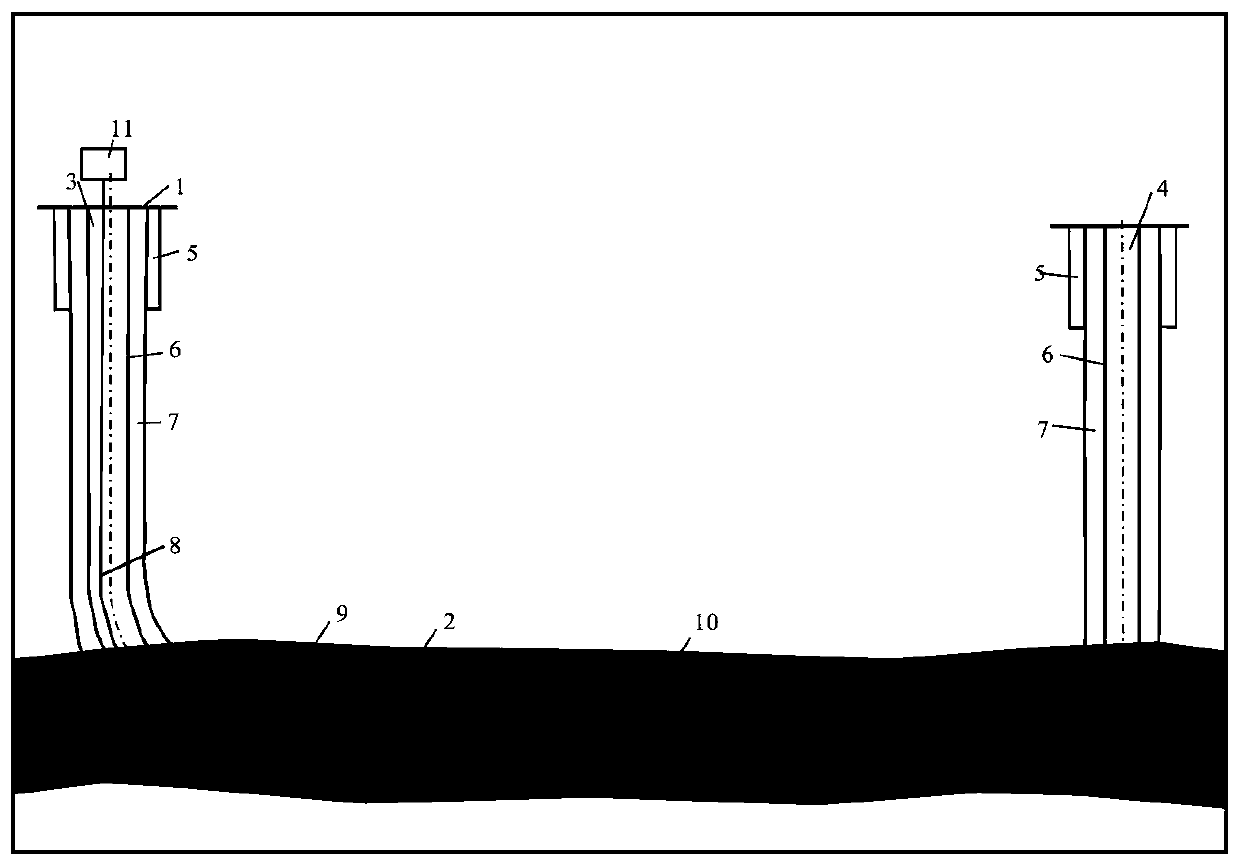

Deep coal bed gas and dry hot rock type terrestrial heat combined mining method

InactiveCN113738317AImproved resource recoveryRealize joint miningOther gas emission reduction technologiesGeothermal energy generationThermodynamicsHorizontal wells

The invention discloses a deep coal bed gas and dry hot rock type terrestrial heat combined mining method, and belongs to the technical field of geological new energy development. A CO2 injection well is a single-branch horizontal well, a horizontal well section is located in a hot dry rock geothermal reservoir, and 8-10 geothermal exploitation vertical wells are constructed on the ground on the two sides of the horizontal well section; and the CO2 injection well horizontal well section is subjected to staged fracturing and is synchronously fractured with the geothermal exploitation vertical well, so that an artificial fracture channel is formed between the CO2 injection well and the geothermal exploitation well. Lateral drilling of a branch horizontal well is carried out on a straight well section of the CO2 injection well, the lateral drilling horizontal well section is located in the deep coal reservoir, and after drilling is completed, a screen pipe is put down for well completion; and 8-10 coalbed methane mining vertical wells are constructed on the ground on the two sides of the lateral drilling horizontal well section, and a deep coal reservoir is transformed in a fracturing mode after perforation well completion. CO2 is injected into a well for continuous gas injection, the recovery ratio of deep coal bed gas is increased through the replacement and displacement effects of CO2 on CH4, meanwhile, the geothermal energy in the hot dry rock is extracted with supercritical CO2 as a circulating working medium, and the geothermal energy is converted into electric energy through a supercritical CO2 generator.

Owner:CHINA UNIV OF MINING & TECH +1

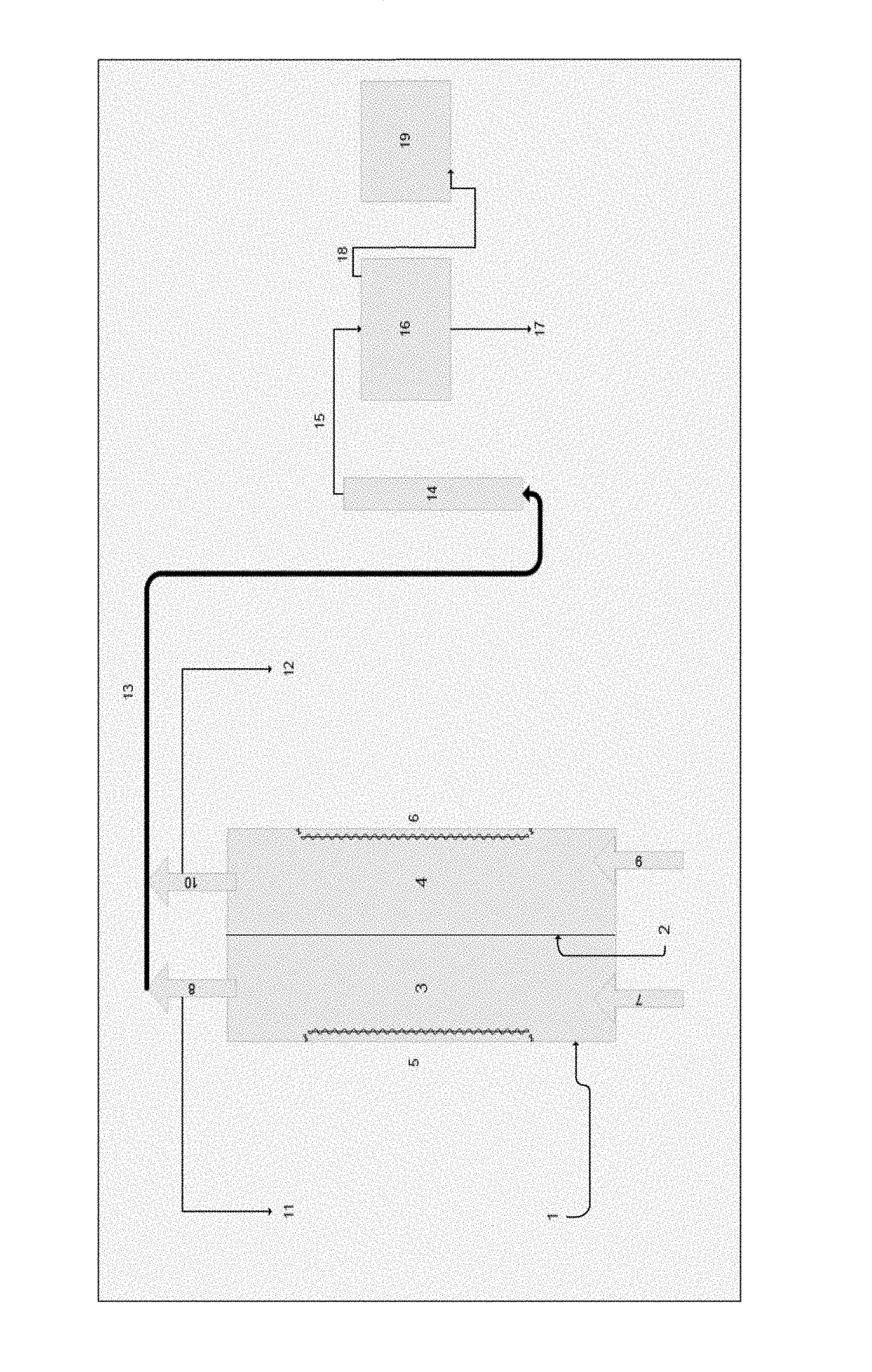

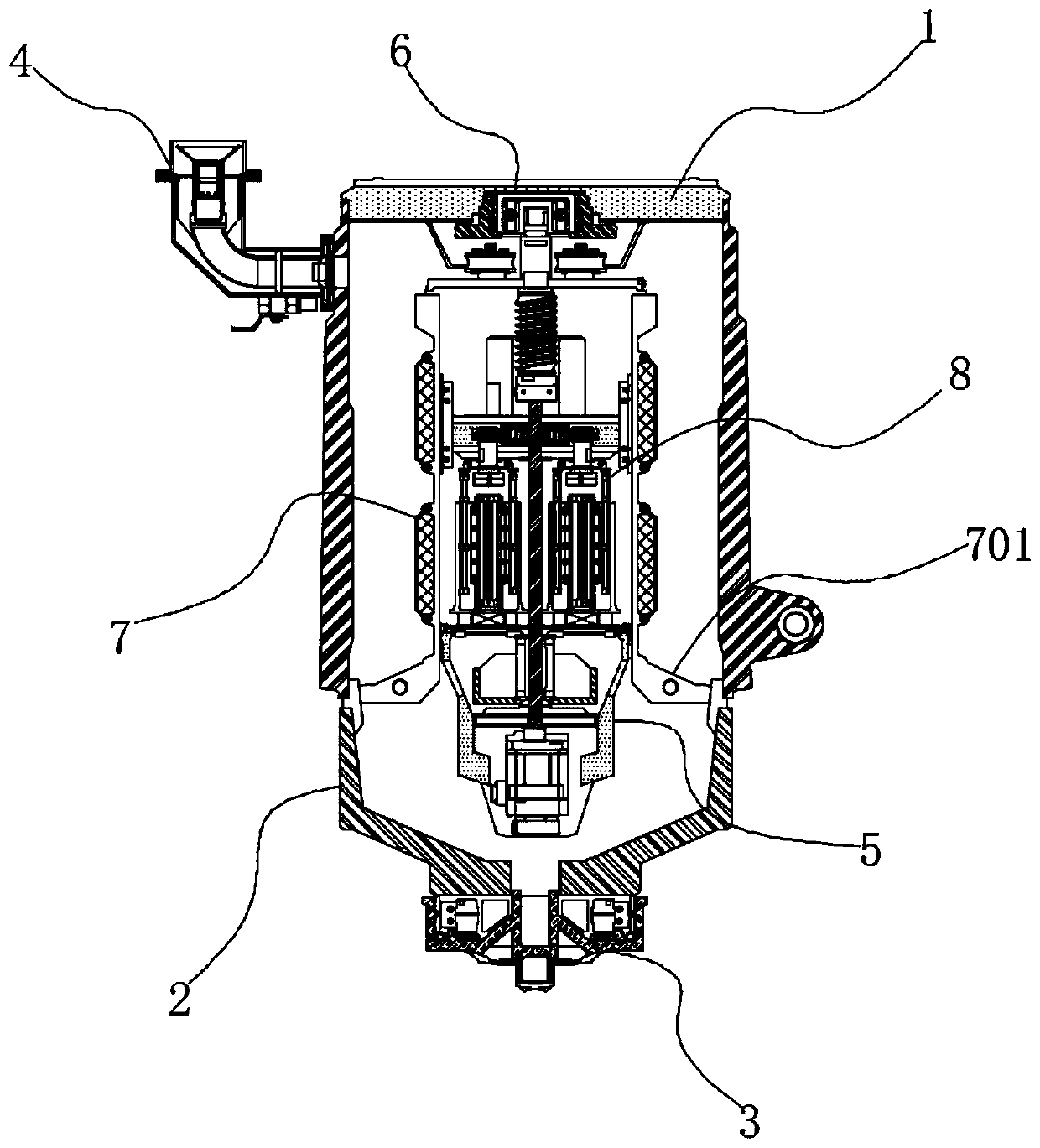

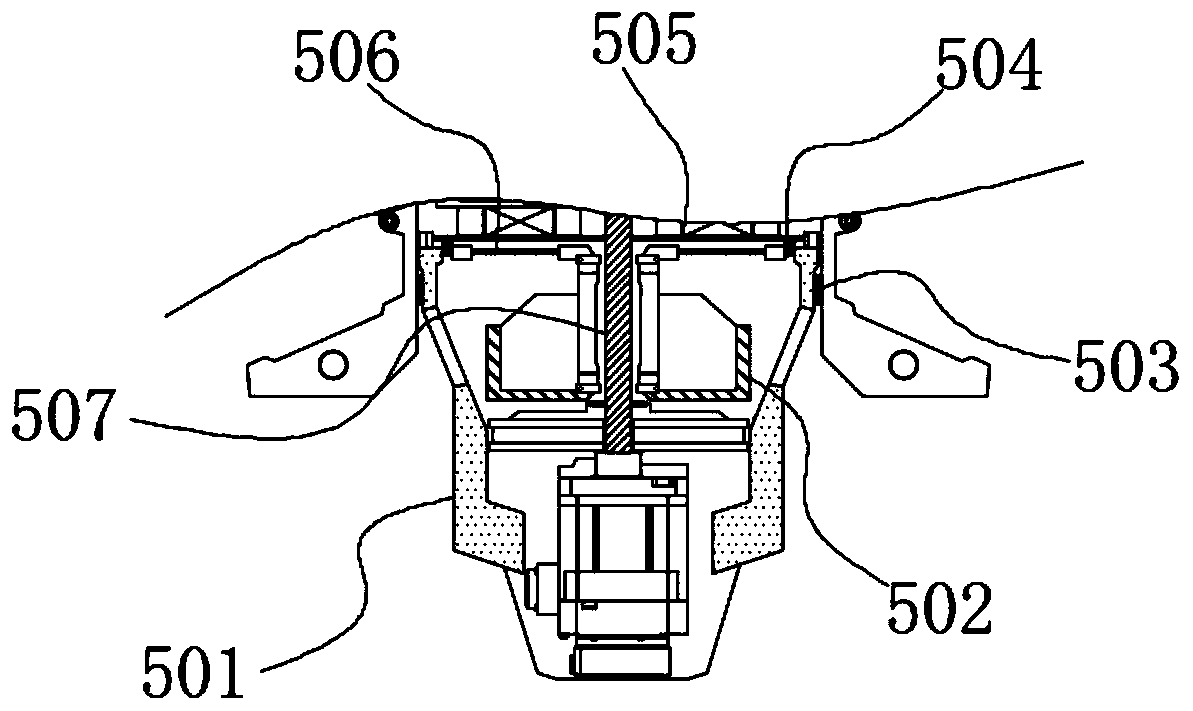

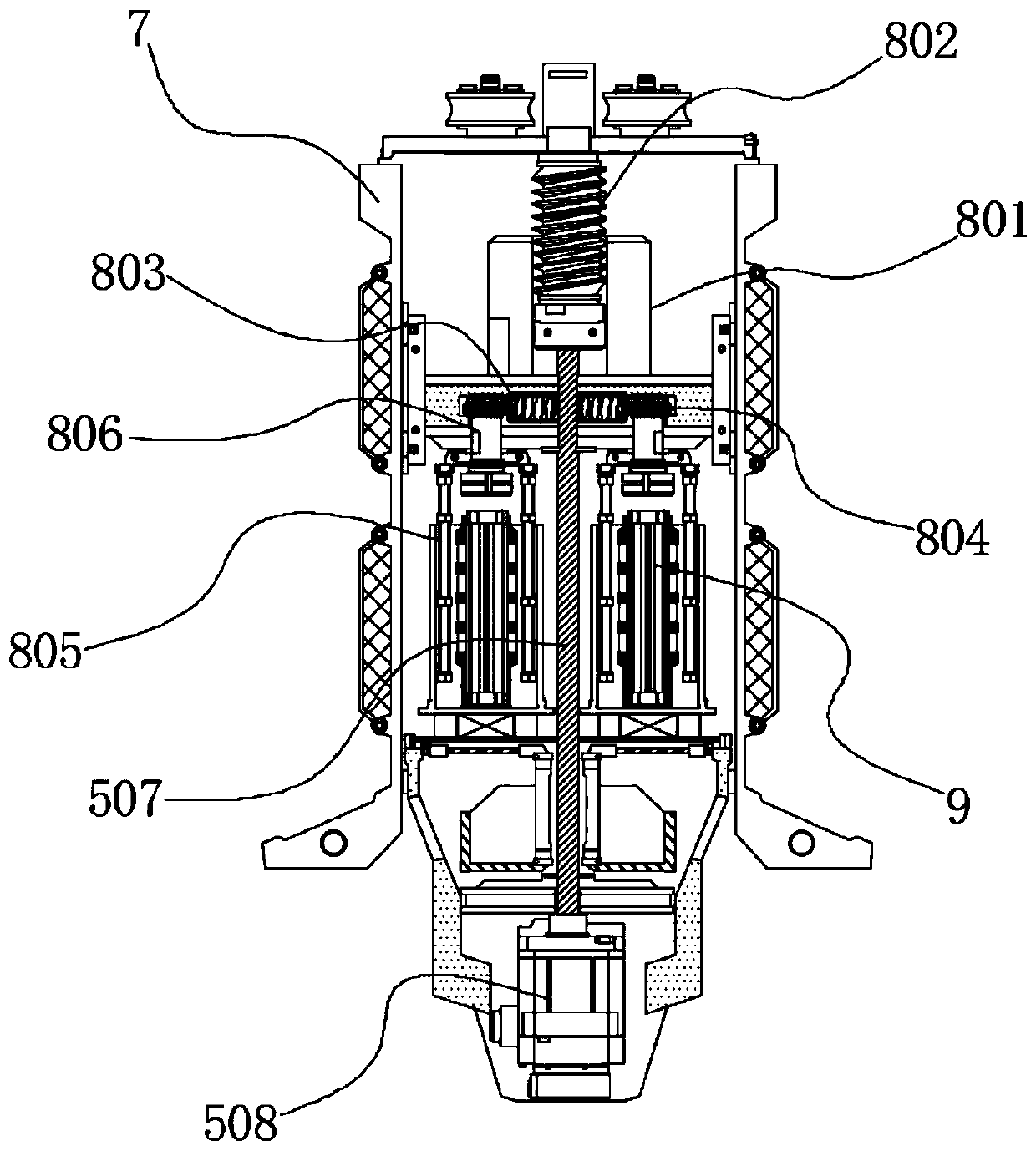

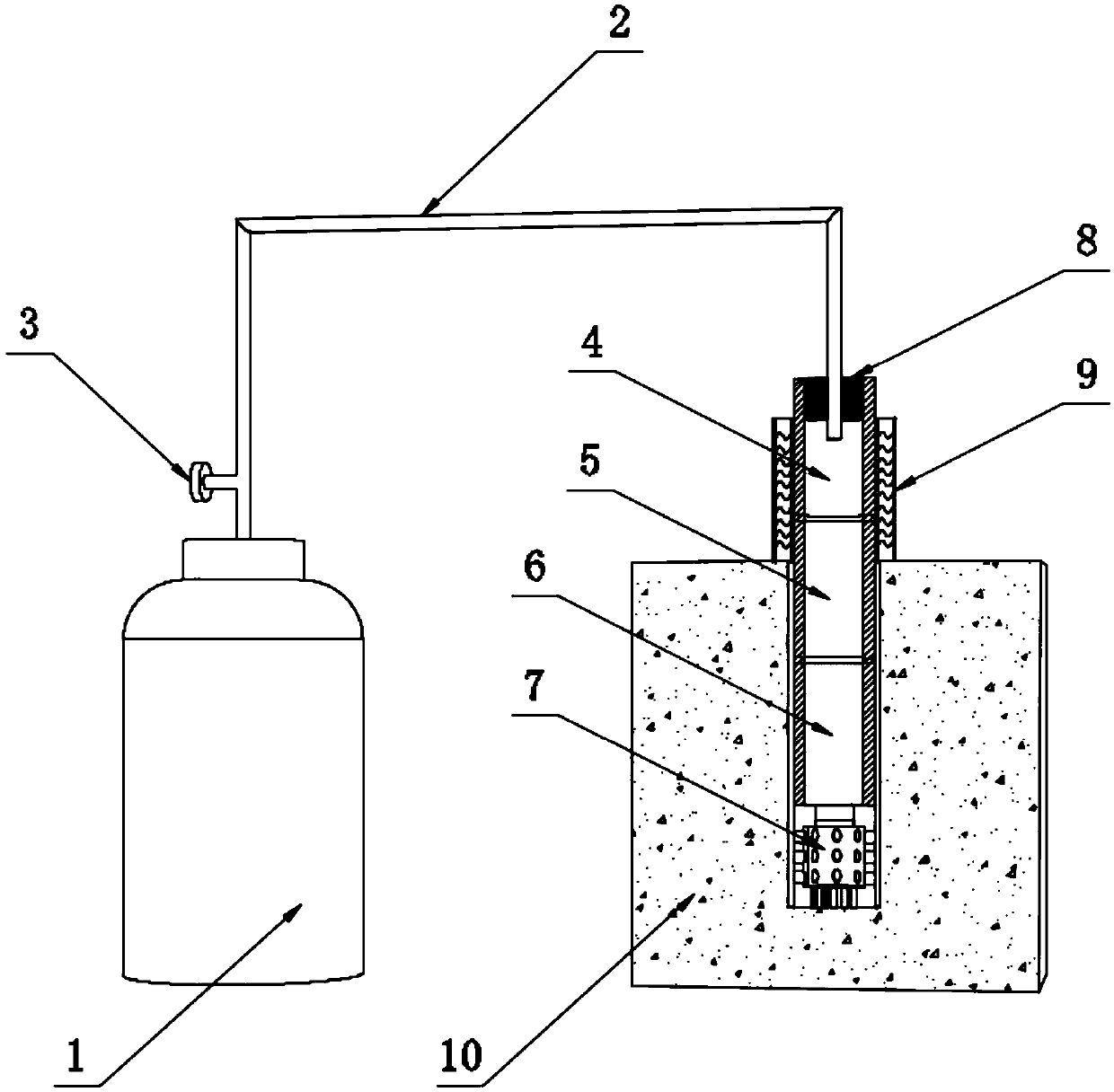

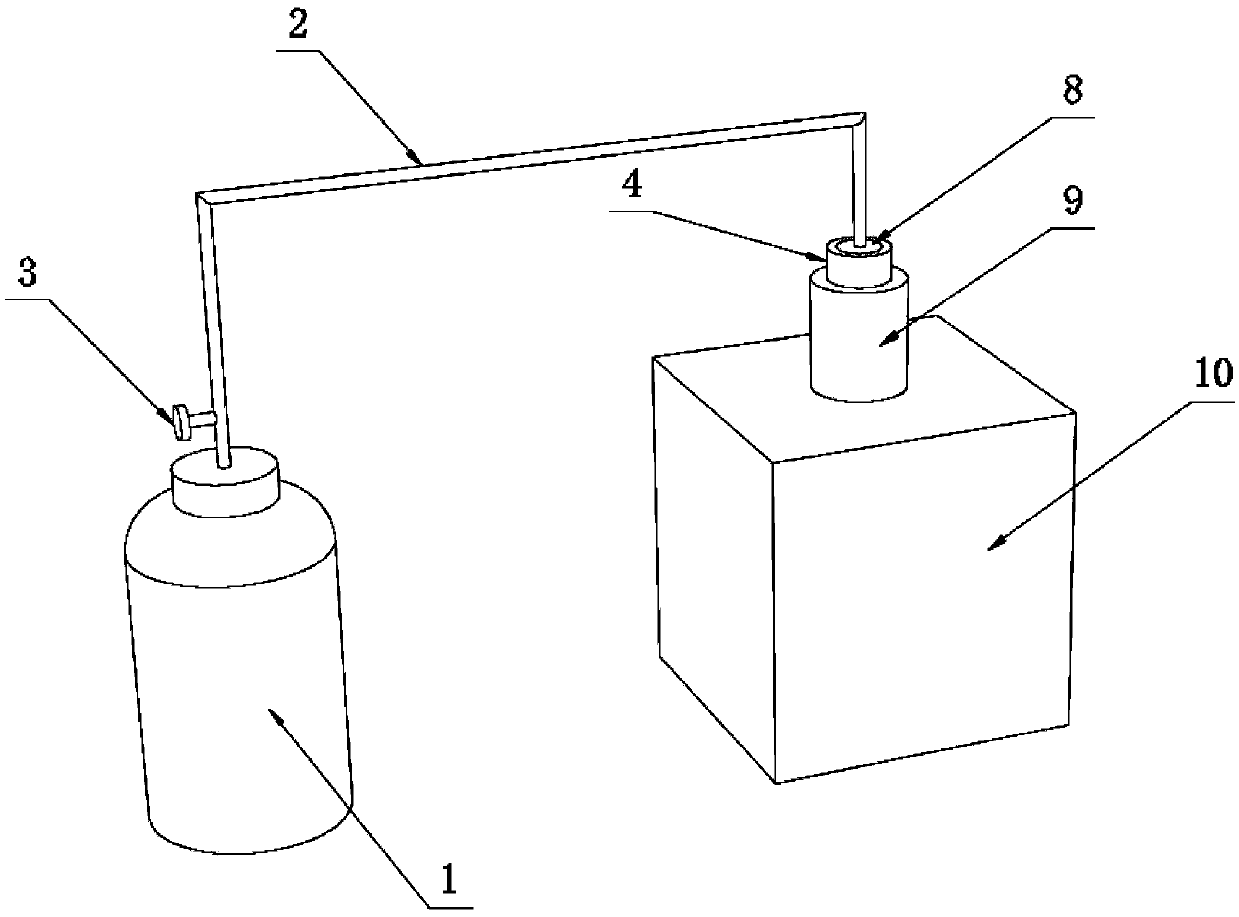

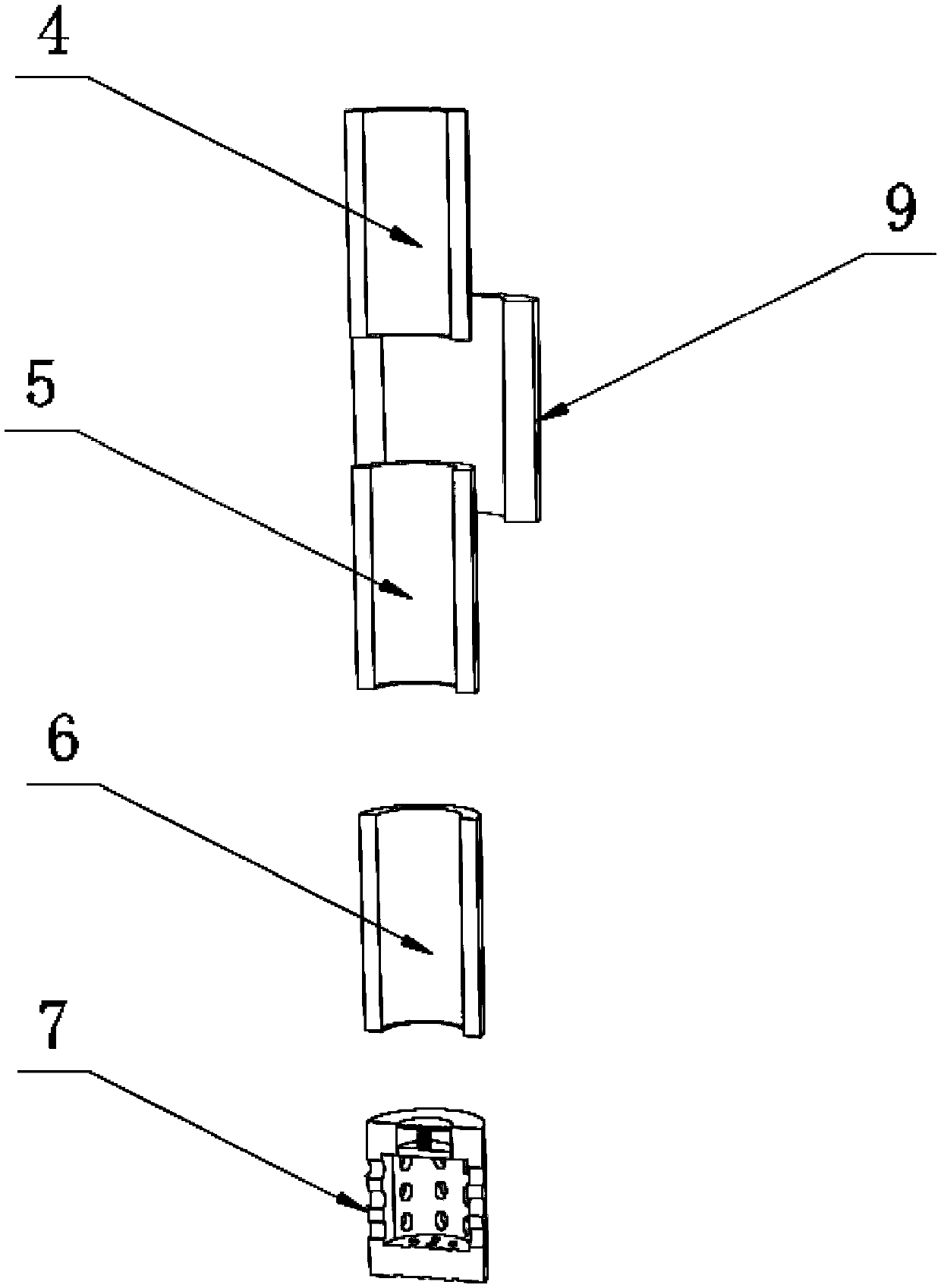

Fast and efficient gas-water separating apparatus at well mouth of coalbed methane extraction well

InactiveCN103352686AEfficient separationEasy to separateFluid removalSeparation technologyWater flow

The invention discloses a fast and efficient gas-water separating apparatus at the well mouth of a coalbed methane extraction well. The fast and efficient gas-water separating apparatus comprises a water tank (1), a gas-water separating system is arranged in the water tank (1), a water inlet pipe (2) which stretches into the water tank (1) is arranged on the upper portion of the water tank (1), a negative pressure pumping system is arranged on the top of the water tank (1), an automatic drainage system is arranged on the lower portion of the water tank (1), and a sealing system is arranged on the outer side of the gas-water separating system. By means of the fast and efficient gas-water separating apparatus, columnar water is changed into plate-shaped water, processes of impact and smashing are combined with negative pressure pumping and secondary separation technologies, gas and water are separated from each other quickly and efficiently, and the problem of resource waste due to the fact that the gas and the water are difficult to separate is solved. A plurality of wells can share one set of negative pressure pumping system, and thus cost input is saved. Further, the fast and efficient gas-water separating apparatus at the well mouth of the coalbed methane extraction well is small in occupation area, simple to operate, cheap, good in gas-water separating effect and wide in application range.

Owner:HENAN POLYTECHNIC UNIV

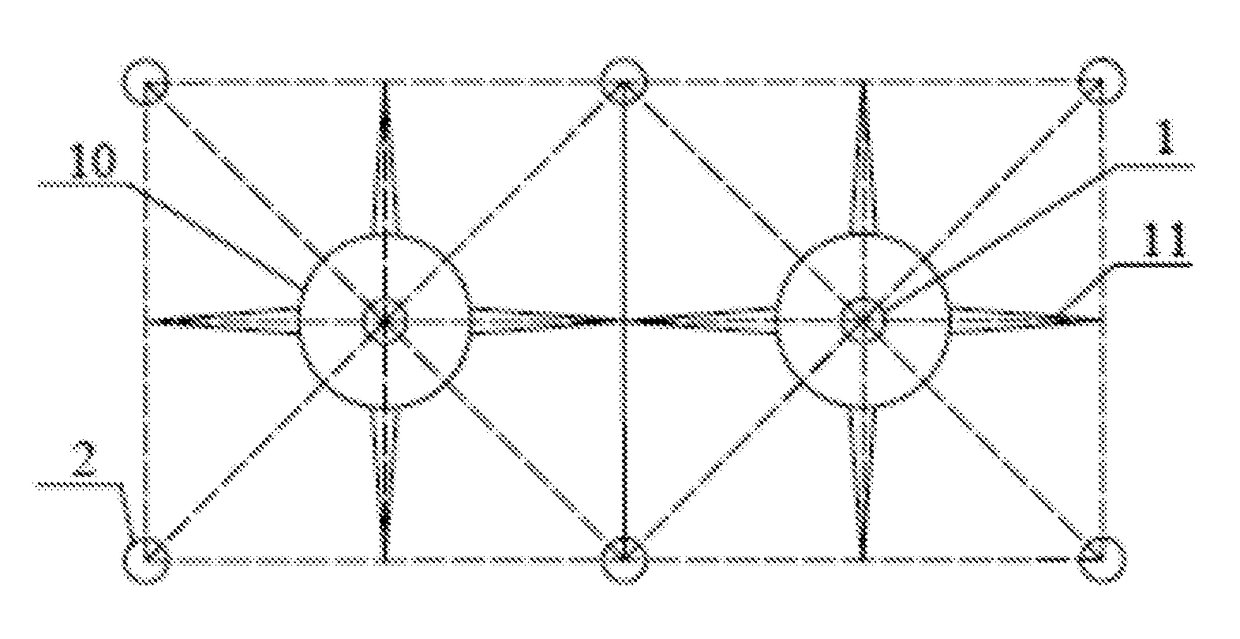

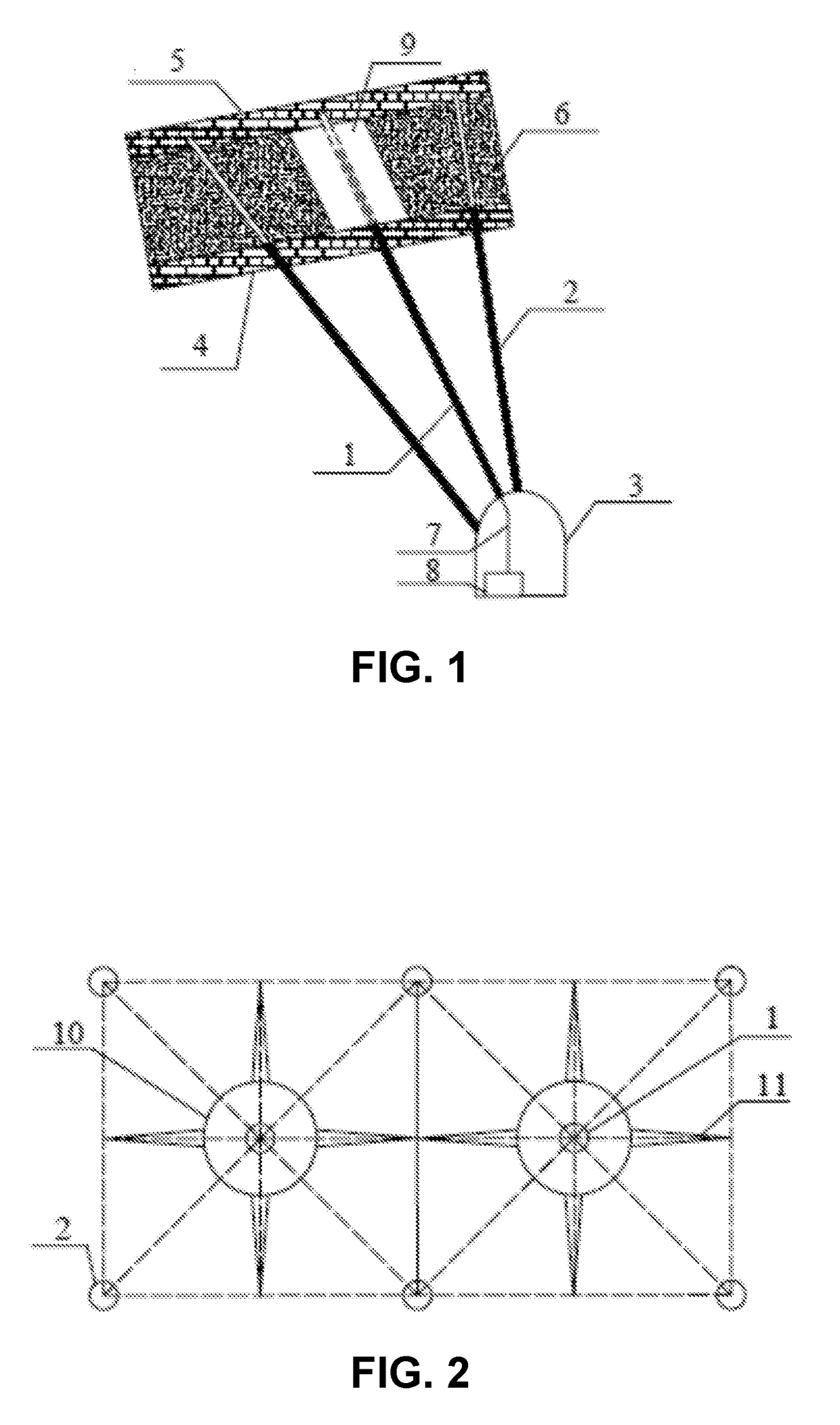

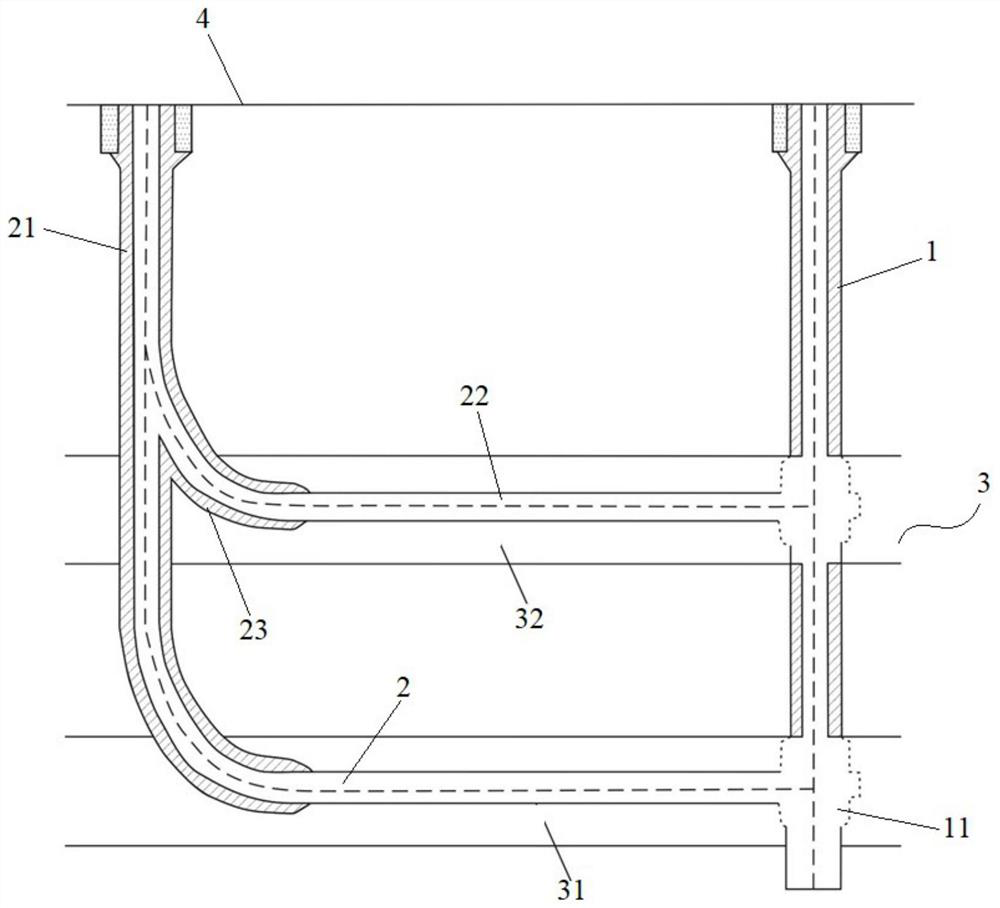

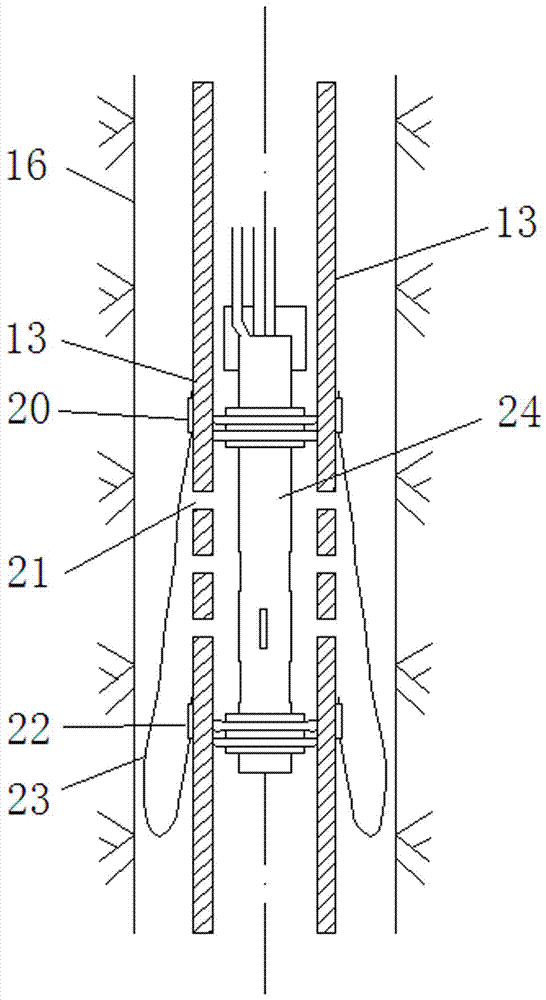

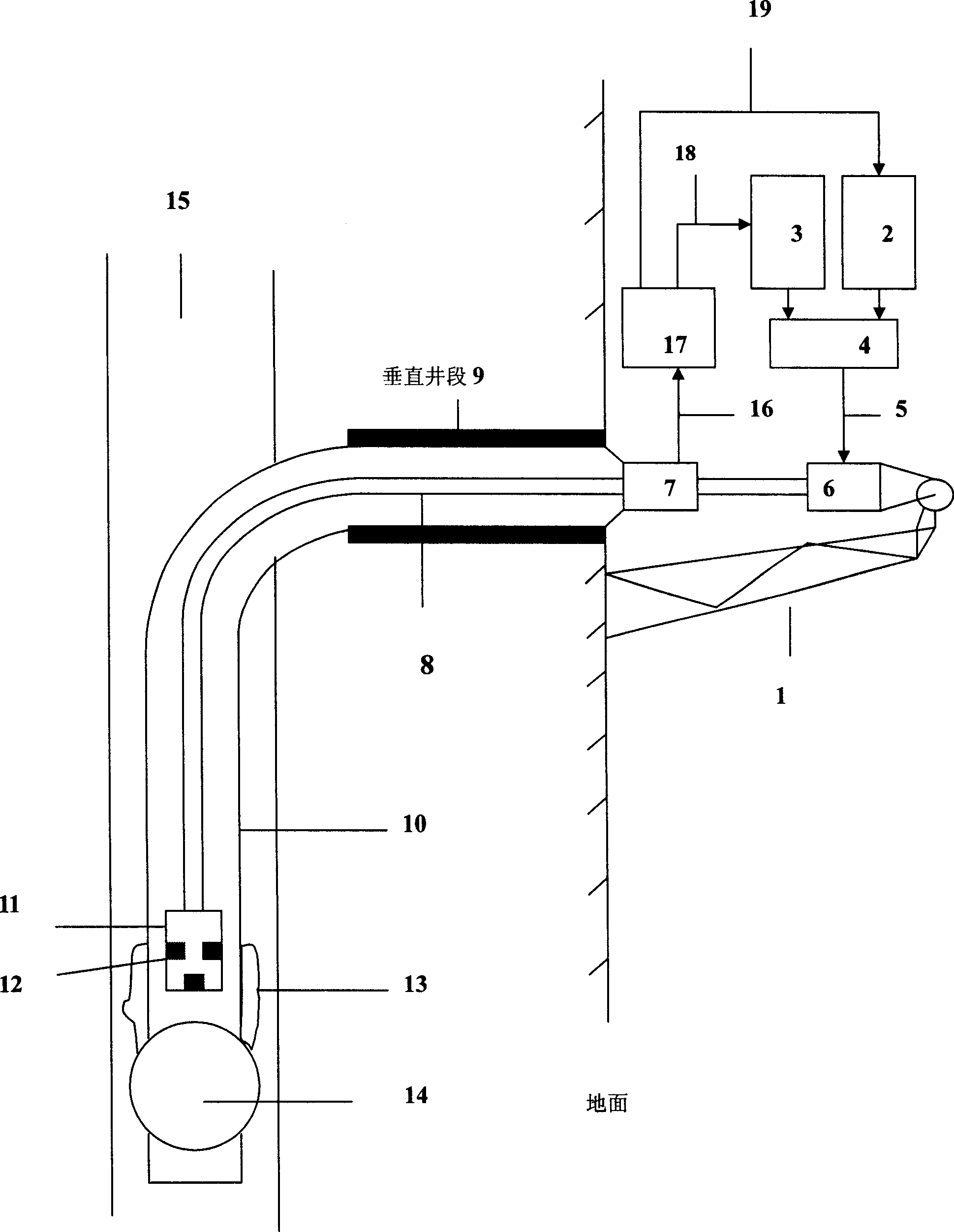

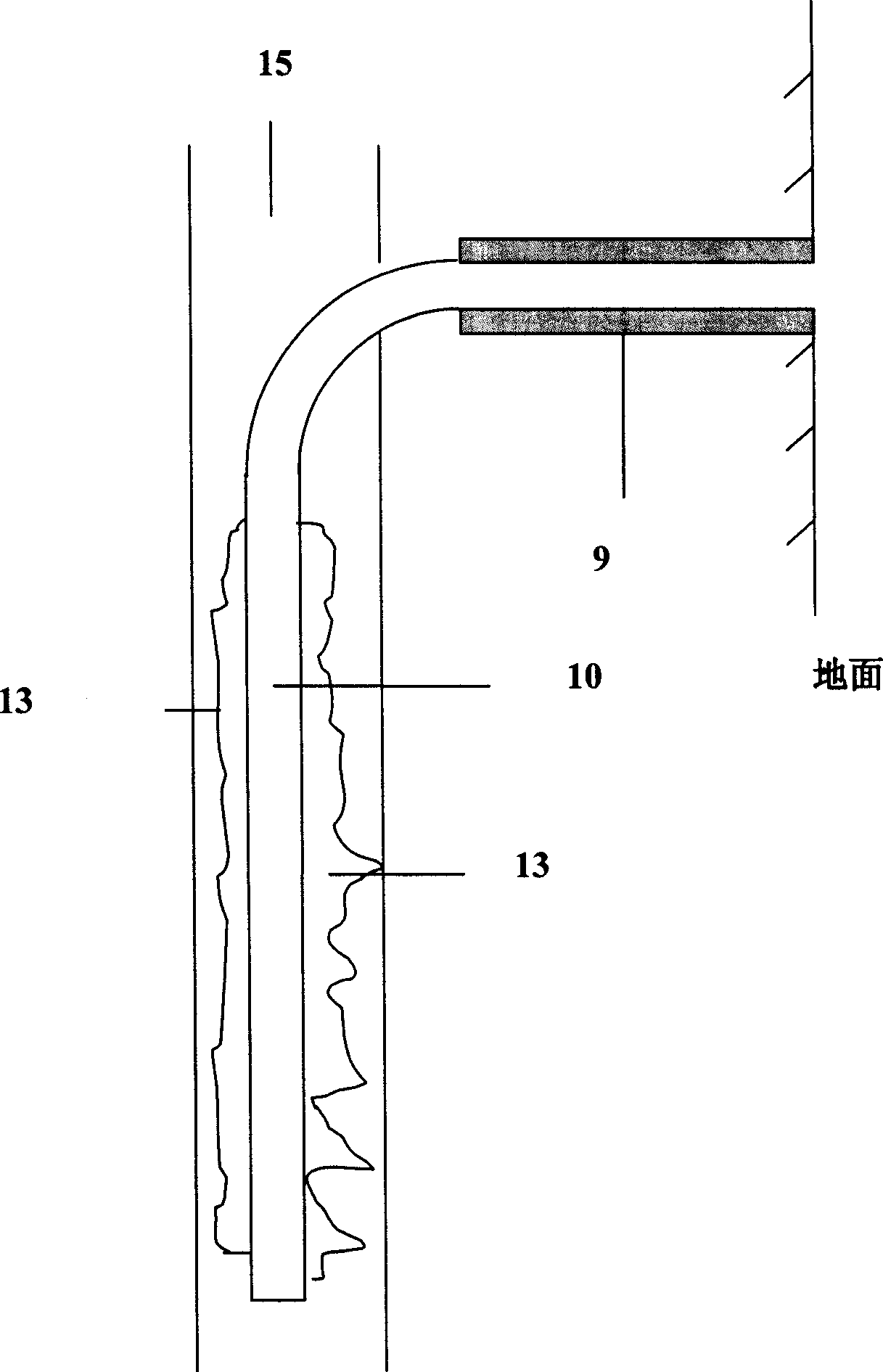

U-shaped well system and drilling method thereof

InactiveCN105134162AIncrease contact areaGood drainageFluid removalDirectional drillingControl areaCoalbed methane extraction

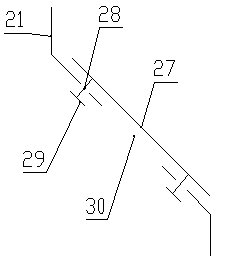

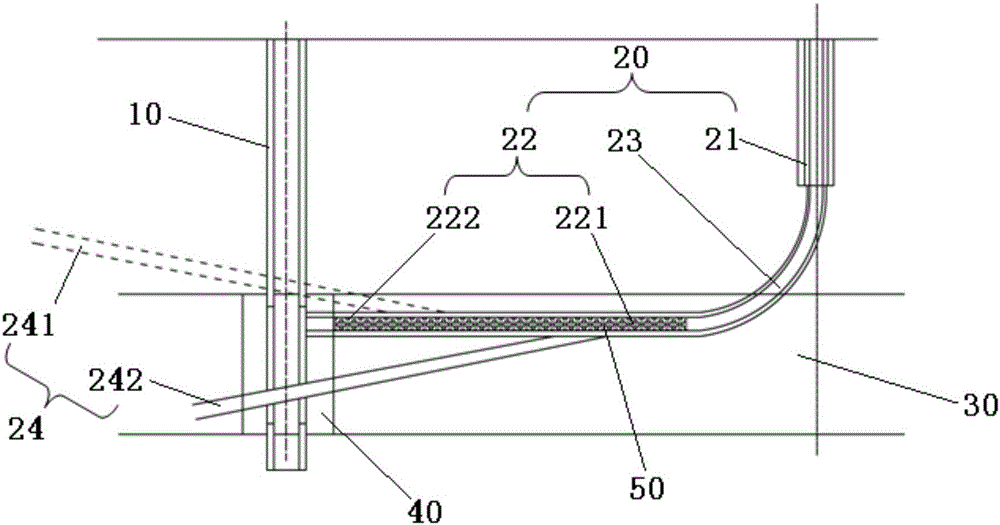

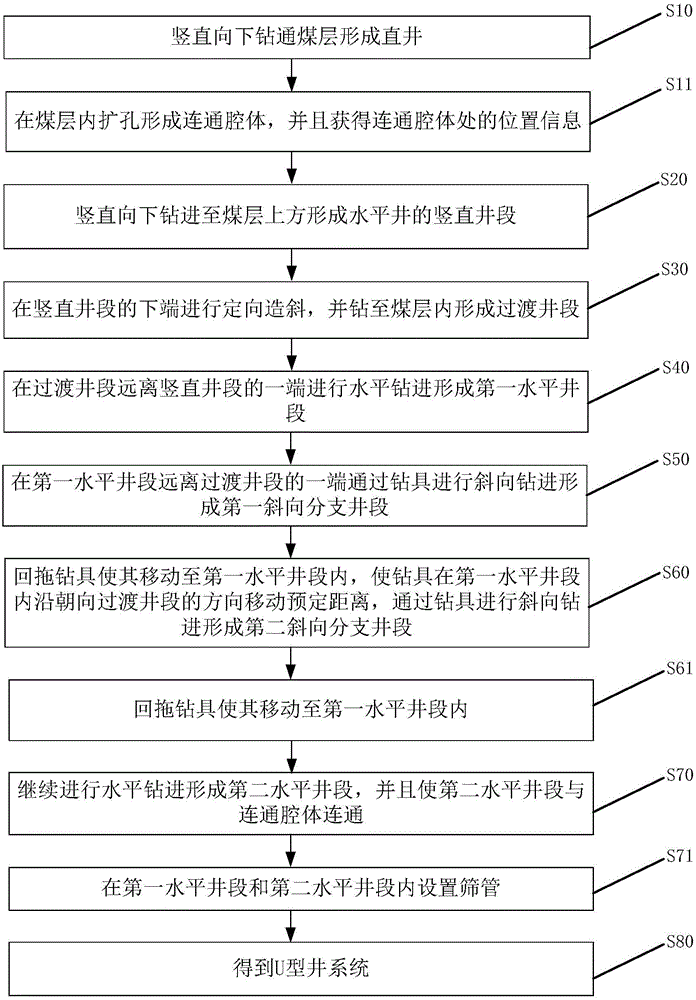

The invention provides a U-shaped well system and a drilling method thereof. The U-shaped well system comprises a straight well (10) and a horizontal well (20). The horizontal well (20) comprises a vertical well section (21), a horizontal well section (22) and a transition well section (23) connected between the vertical well section (21) and the horizontal well section (22). The end, away from the transition well section (23), of the horizontal well section (22) is communicated with the straight well (10). The horizontal well (20) further comprises an inclined branch well section (24), and one end of the inclined branch well section (24) is connected to the horizontal well section (22). According to the technical scheme, the problems that in the prior art, the control area of coalbed methane extraction is limited, and the extraction amount can be hardly improved can be effectively solved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

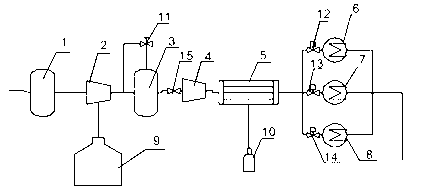

Three-axis permeability testing method

ActiveCN108414418AEasy connectionGuarantee system securityPermeability/surface area analysisPetrologyTest efficiency

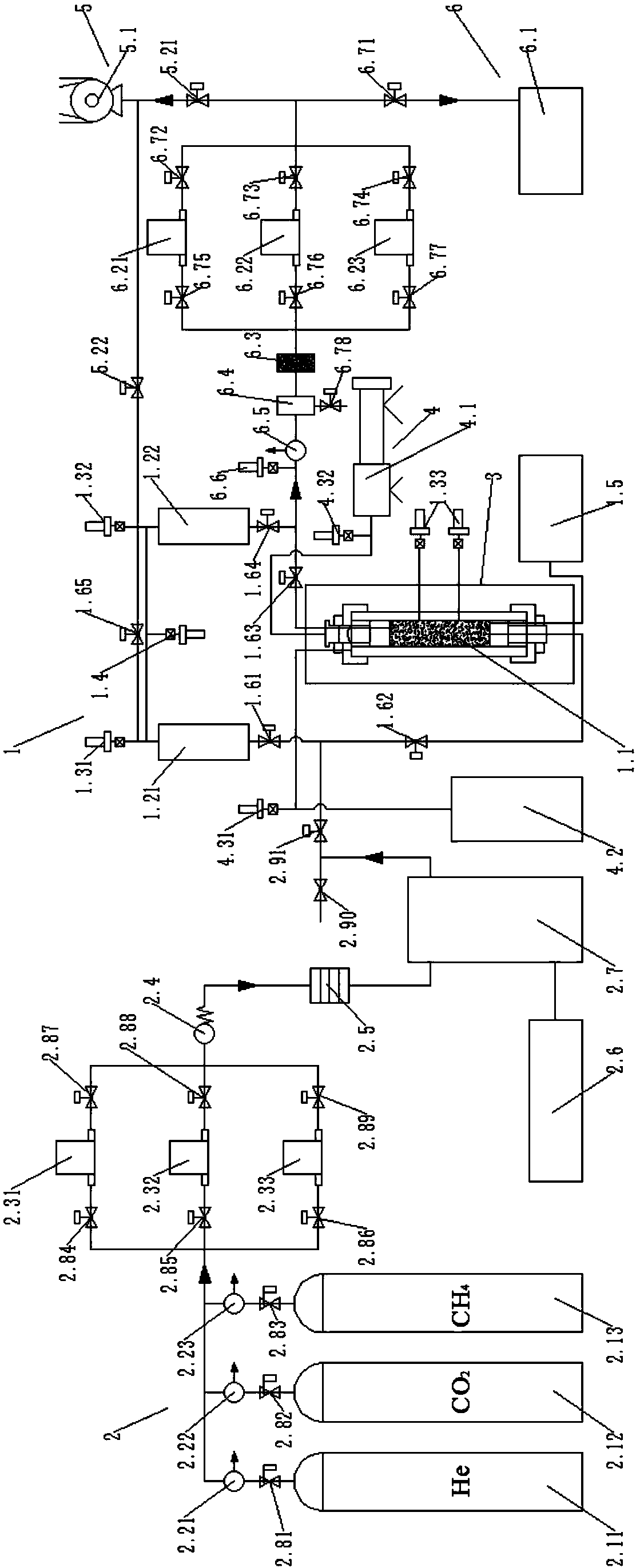

The invention discloses a three-axis permeability testing method, and belongs to the field of coal bed gas exploitation. A rock sample is placed in a model system (1), then pressure pulse is applied on the rock sample; a gas control system (2) supplies test gas to the model system (1); a temperature control system (3) controls the temperature of the model system (1); a three-axis loading system (4) applies confining pressure and axial pressure on the rock core clamper of the model system (1); a vacuumizing system (5) vacuumizes the test device; a gas sample collecting system (6) detects the gas components after the test; and an electrical controlling and monitoring system monitors the test process. The method comprises following steps: filling a sample into a tank, checking the airtightness, carrying out a permeability test, and cleaning the test system. The provided method can simulate a high temperature and high pressure environment of a deep stratum in a lab; pressure pulse is applied on the inlet end of a rock sample, the attenuation data of pressure pulse can be obtained, and then the rock sample permeability is calculated based on the attenuation data. The test efficiency ishigh, the external interference is little, and the test result is more accurate.

Owner:CHINA UNIV OF MINING & TECH

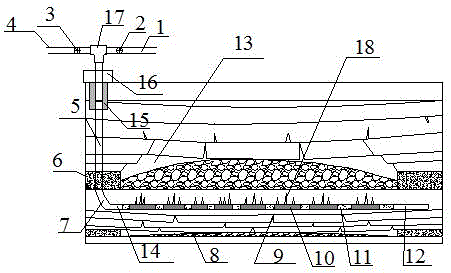

Method for integrated drilling, flushing, slotting and thermal injection for coalbed gas extraction

ActiveUS20170145794A1Speed up the extraction processEasy to operateFluid removalGas removalDesorptionEngineering

A method for combining integrated drilling, flushing and slotting with thermal injection to enhance coalbed gas extraction, applicable to managing gas extraction from microporous, low-permeability, high-adsorption coalbed areas. A gas extraction borehole is drilled within a certain distance of a predetermined drilling, flushing and slotting borehole, and, once sealed, is used for gas extraction. An integrated drilling, flushing and slotting drill bit is used to sink the borehole, which is then sealed. Concentration variation in the gas extraction borehole is monitored in real time, and when concentration is below 30%, borehole is opened and high-temperature steam is injected by means of a steam generator, after which the borehole is again closed. Drilling a drilling, flushing and slotting borehole increases pressure relief space and the surface of exposed coal, relieves stress on the coal body, and increases gas permeability of the coalbed, while the injection of high-temperature steam promotes gas desorption in the coal body, promotes crack propagation around the borehole, and increases channels for gas flow, thus achieving highly efficient extraction of gas from the coalbed.

Owner:CHINA UNIV OF MINING & TECH

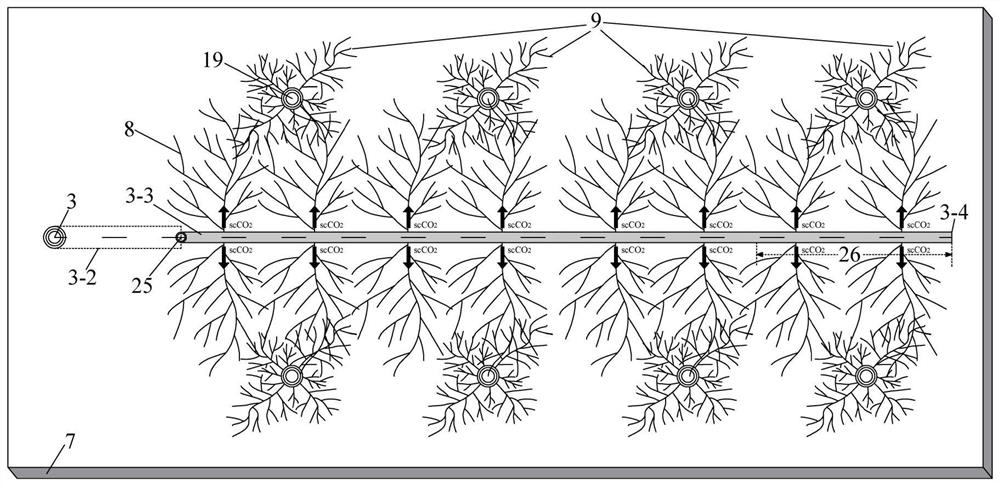

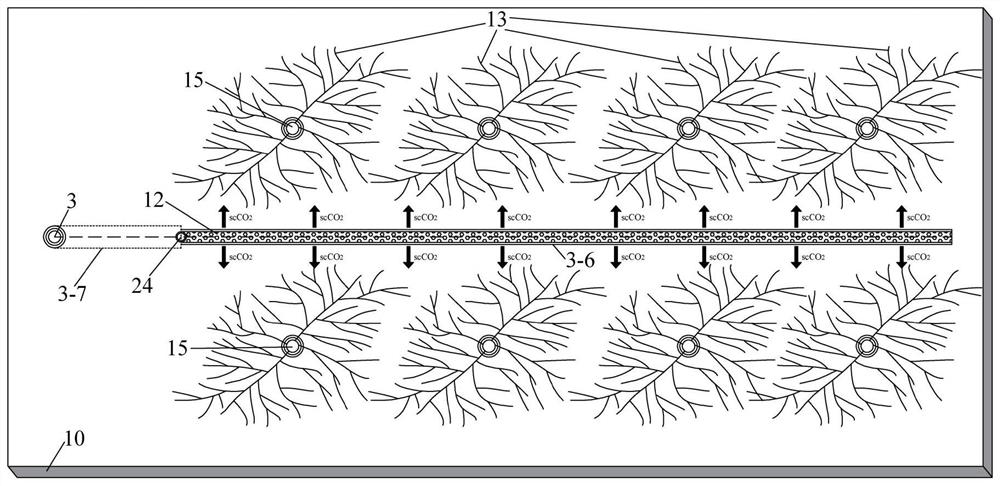

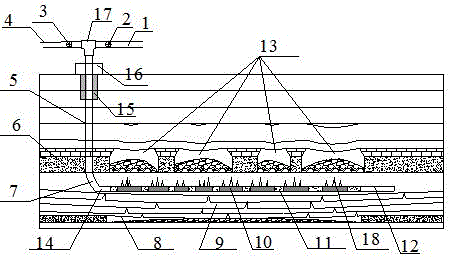

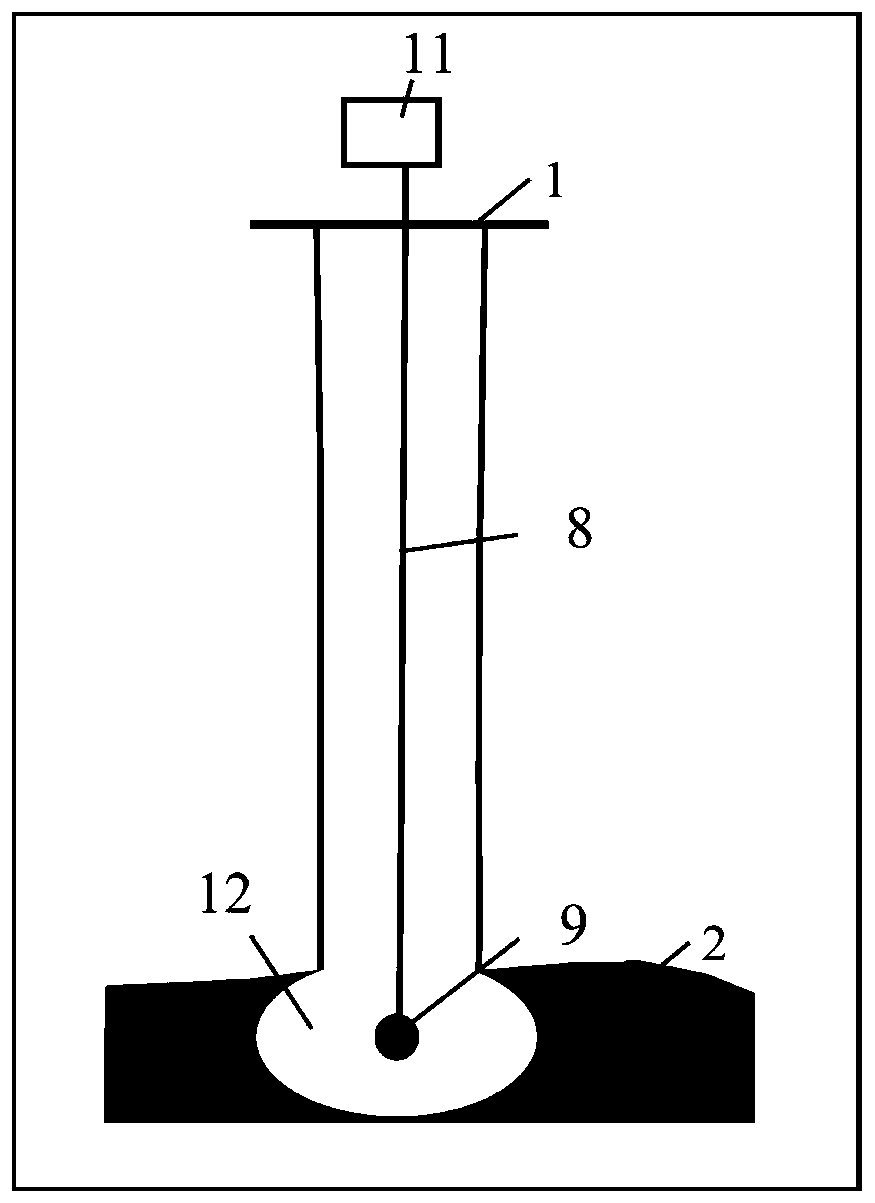

Coal underground gasification and coalbed methane collaborative mining method and structure and construction method

PendingCN112081558ADraining is safe and efficientGuarantee safe miningConstructionsFluid removalCoalbed methane extractionPetroleum engineering

The invention relates to the technical field of coal mining, in particular to a coal underground gasification and coalbed methane collaborative mining method and structure and a construction method. The coal underground gasification and coalbed methane collaborative mining method comprises the following steps that in a target coalbed, coal underground gasification is carried out on a lower coalbed, and coalbed methane extraction is carried out on an upper coalbed at the same time, wherein the lower coalbed is adjacent to the upper coalbed, and the lower coalbed is located below the upper coalbed. The method aims to combine coal underground gasification with coalbed methane exploitation, fully exploit coal underground gasification for complex difficult-to-exploit coalbeds, fully utilize heat generated by coal underground gasification, further assist in extraction of coalbed gas in the upper coalbed, further reduce the content of coalbed gas in the coalbeds and guarantee safe and efficient extraction of coal.

Owner:XIAN UNIV OF SCI & TECH +1

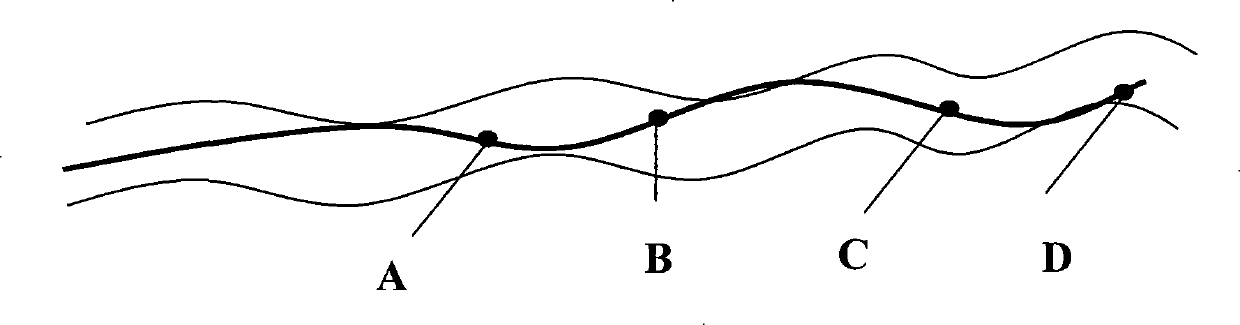

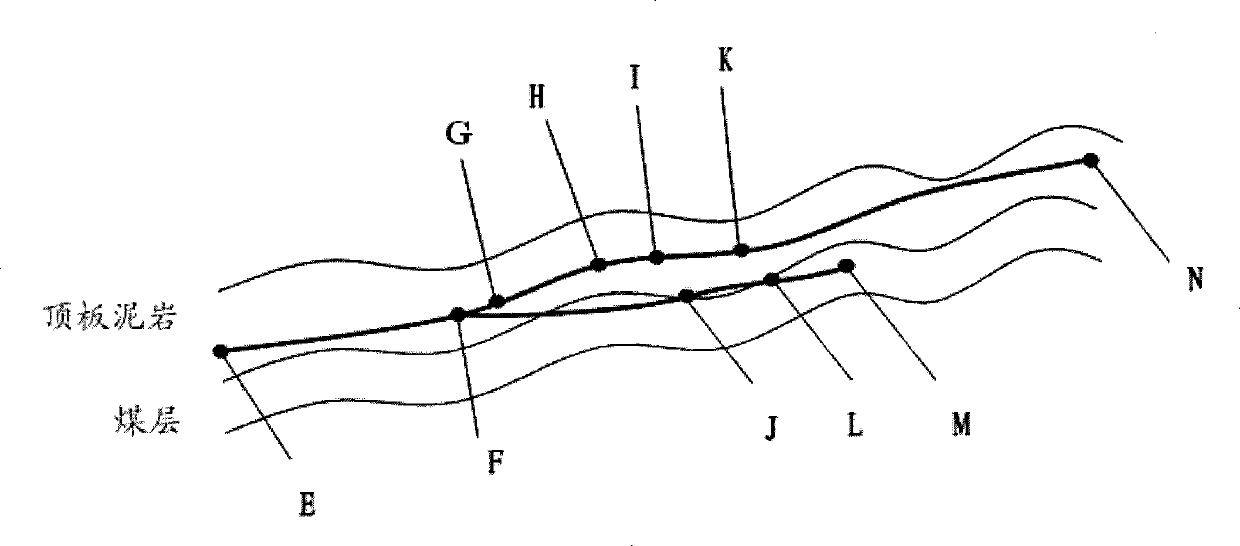

Coal bed gas horizontal well track control method

InactiveCN103867180AConducive to drainage and gas recoverySolve the \"water blockage\"Fluid removalThermodynamicsWell logging

The invention provides a coal bed gas horizontal well track control method, which belongs to the field of coal bed gas exploitation. According to earthquake data and drilled logging well logging data, the coal bed top surface depth and the coal bed occurrence are determined, and a single-inclination region is selected for well position deployment; the initial end of a multi-branch horizontal well hole track is designed to be positioned at a lower position of the structure, the tail end of the multi-branch horizontal well hole track is positioned at the higher position of the structure, a main branch well hole is positioned at a coal bed top layer rock layer, and a branch well hole is positioned at the coal bed; main and branch well hole track control target points are determined according to the coal bed top surface depth and the coal bed occurrence, geometric orientation is used as the main measure for controlling the well hole tracks in the top plate rock layer, the well hole and the coal bed top maintain a proper vertical distance, meanwhile, and the well inclination angle is maintained to be always greater than 90.5 degrees; the coal bed gas multi-branch horizontal well branch well hole track is completed by adopting a dropping lateral extending mode. The method provided by the invention effectively solves the problems that the coal bed drilling encountering rate is excessively pursued, the well hole tracks are in wave-shaped fluctuation along with the coal bed local inclination angle change, and the water blockage and ash blockage are caused in the later-stage discharge and exploitation process.

Owner:华北石油管理局有限公司

Multi-joint intensive grouting well-reinforcing method for reinforcing coal-bed gas well penetrating through goaf

ActiveCN107313745AImprove long-term stabilityGuaranteed flowSealing/packingWell drillingWell cementing

The invention belongs to the technical field of coal-bed gas exploitation and provides a multi-joint intensive grouting well-reinforcing method for reinforcing a coal-bed gas well penetrating through a goaf. According to the method, the problems that during passing-through of the goaf, the third spud-in well-drilling construction process is complex, and the stability of a third spud-in well body structure is poor are solved. The third spud-in drilling construction process is adopted; a well body of the coal-bed gas well is composed of a first spud-in drilled hole, a surface casing, a second spud-in drilled hole, an intermediate casing and a third spud-in drilled hole; when third spud-in drilling is constructed, multi-joint grouting reinforcing is conducted on well wall surrounding rock outside the intermediate casing, so that the strength of the well wall surrounding rock is improved, long-term stability of the coal-bed gas well is guaranteed, and the stabilized intermediate casing is directly used as the production casing of the coal-bed gas well. A multi-joint cement paste wrapped body supporting structure is formed between the intermediate casing and the well wall surrounding rock, the long-term stability of the well wall surrounding rock of the coal-bed gas well and the well body structure can be strengthened greatly.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +2

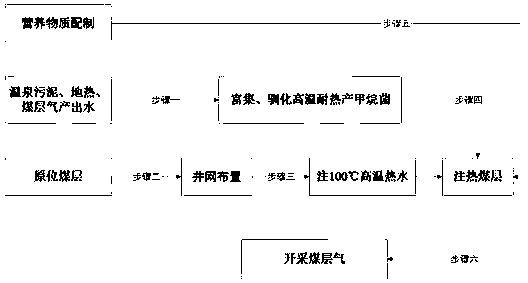

Method for production increasing of coal-bed gas through combination of heat injection decomposition and microbial degradation

ActiveCN110242255AConducive to mining and utilizationImprove permeabilityFluid removalDecompositionOrganic matter

The invention discloses a method for production increasing of coal-bed gas through combination of heat injection decomposition and microbial degradation, and belongs to the technical field of coal-bed gas mining. The method comprises the three steps of high-temperature heat-resistant methanogen enrichment culture, heat injection decomposition and microbial degradation for production increasing of the coal-bed gas, coal structure decomposition at the high temperature is realized through heat injection, and thus microbial degradation of coal is promoted so as to increase the recovery ratio of the coal-bed gas. Through heat injection, on the one hand, the coal structure is changed, organic matter in the coal is dissolved, microbial degradation is facilitated, and the speed of biological reaction is increased; and on the other hand, the permeability of a coal seam is improved, an channel is opened for a coal seam injection bacterium group, a methane flow channel is unblocked, the coal-bed gas and the bacterium group are transported in the coal seam advantageously, and the recovery ratio of the coal-bed gas is increased.

Owner:TAIYUAN UNIV OF TECH

Process and apparatus for generating or recovering hydrochloric acid from metal salt solutions

The present invention relates to an electrochemical process for generating or recovering hydrochloric acid from metal salt solutions such as acidic metal salt solutions and saline solutions. The process is useful for treating acidic salt solutions that are waste products from mineral processing or other industrial processes such as metal finishing, water softening, water treatment, reverse osmosis, electrodialysis, coal seam gas extraction, shale gas extraction and shale oil extraction, to generate high purity hydrochloric acid, metal salts and recycled water that may be re-used in the industrial process. An apparatus for performing the electrochemical process is also described.

Owner:AUSTRALIAN BIOREFINING

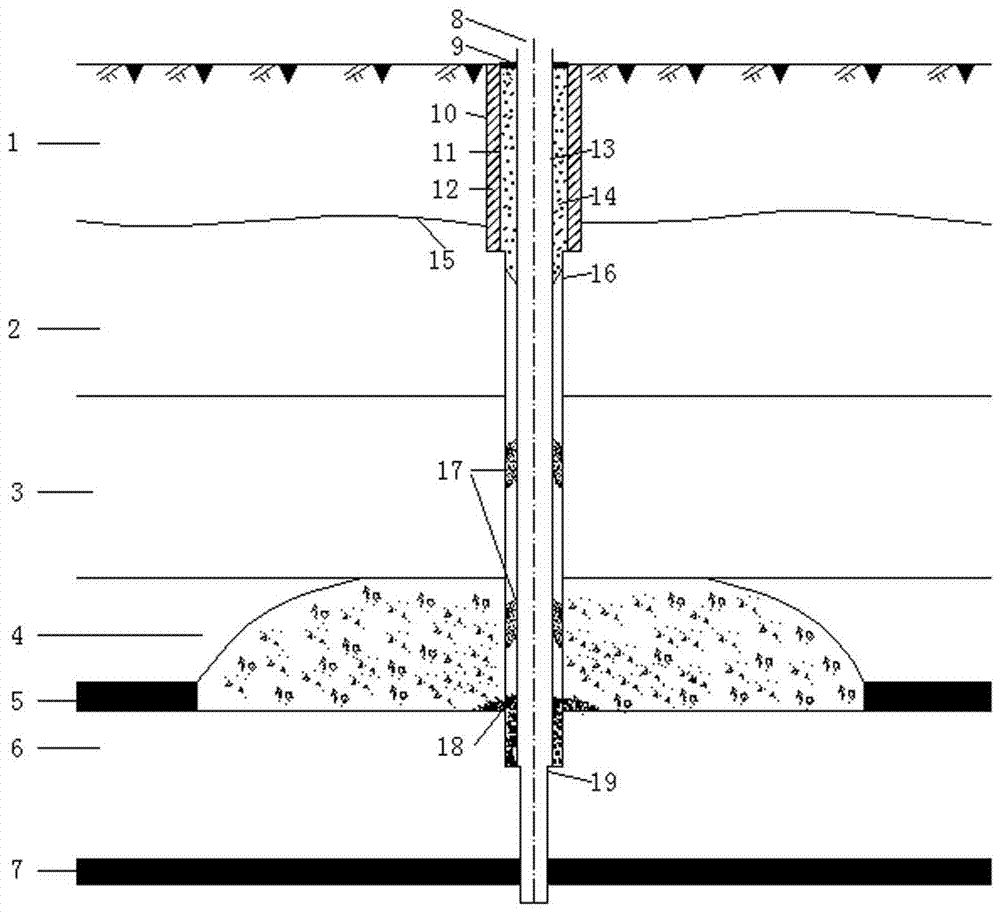

Extraction method for mining formed composite goaf coalbed methane through lower caving method

The invention discloses an extraction method for mining formed composite old mined-out area coalbed methane through a lower caving method. The method includes the steps that coalbed methane extraction is conducted by constructing a horizontal well at the position 1-5 meters above a lower goaf fissure zone; when the extraction amount of the coalbed methane is dropped to 10-20% of Q, segmented crushing is conducted, extraction is conducted on the goaf coalbed methane again, and when the extraction amount of the coalbed methane is dropped to 10-20% of Q again, supercritical carbon dioxide is injected to drive and replace the coalbed methane; extraction is conducted again till the extraction amount is dropped to 6 m<3> / min, and extraction is stopped. By means of the method, the problems that when a ground vertical drilling well is separately used to conduct extraction on a goaf originally, the effective contact area between the extraction drilling well and a goaf reservoir is small, and the extraction range is limited are solved; while the coalbed methane of the goaf on the lower layer is extracted, the coalbed methane resource close to the upper portion of the goaf is also extracted, and cost is saved; meanwhile, the horizontal well is located in the rock stratum, and therefore shaft collapse and blocking of the drilling well in a coal seam are avoided.

Owner:TAIYUAN UNIV OF TECH

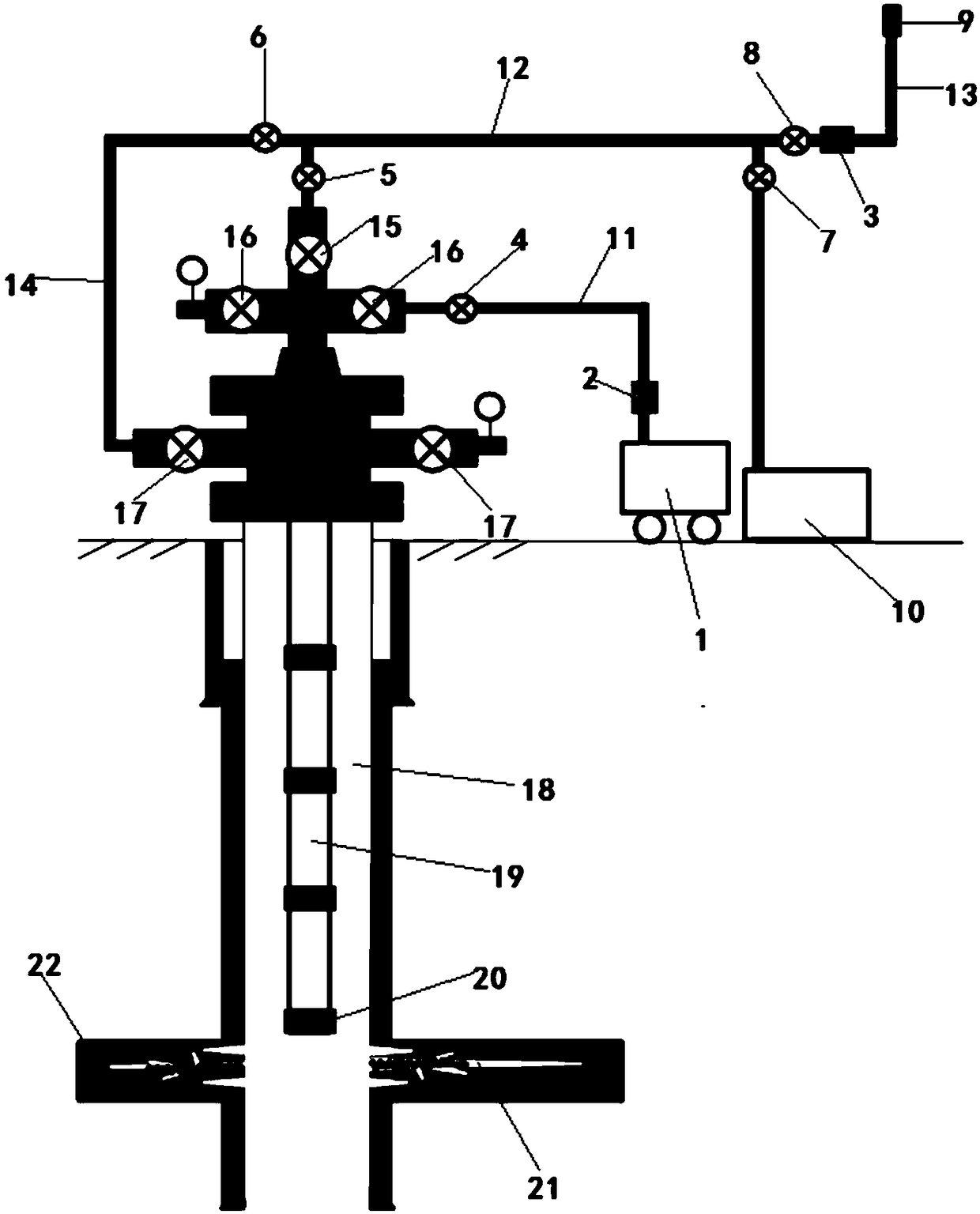

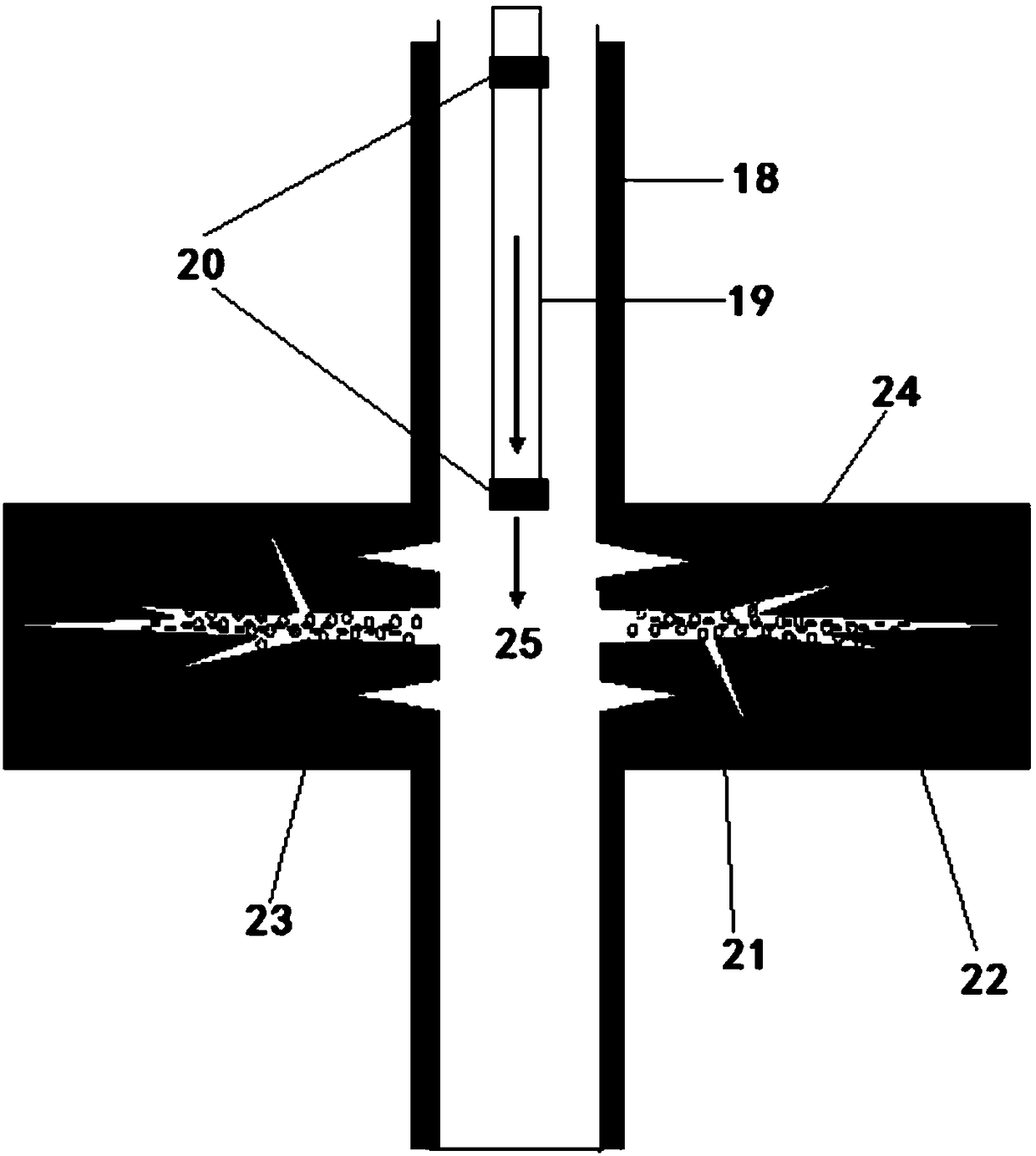

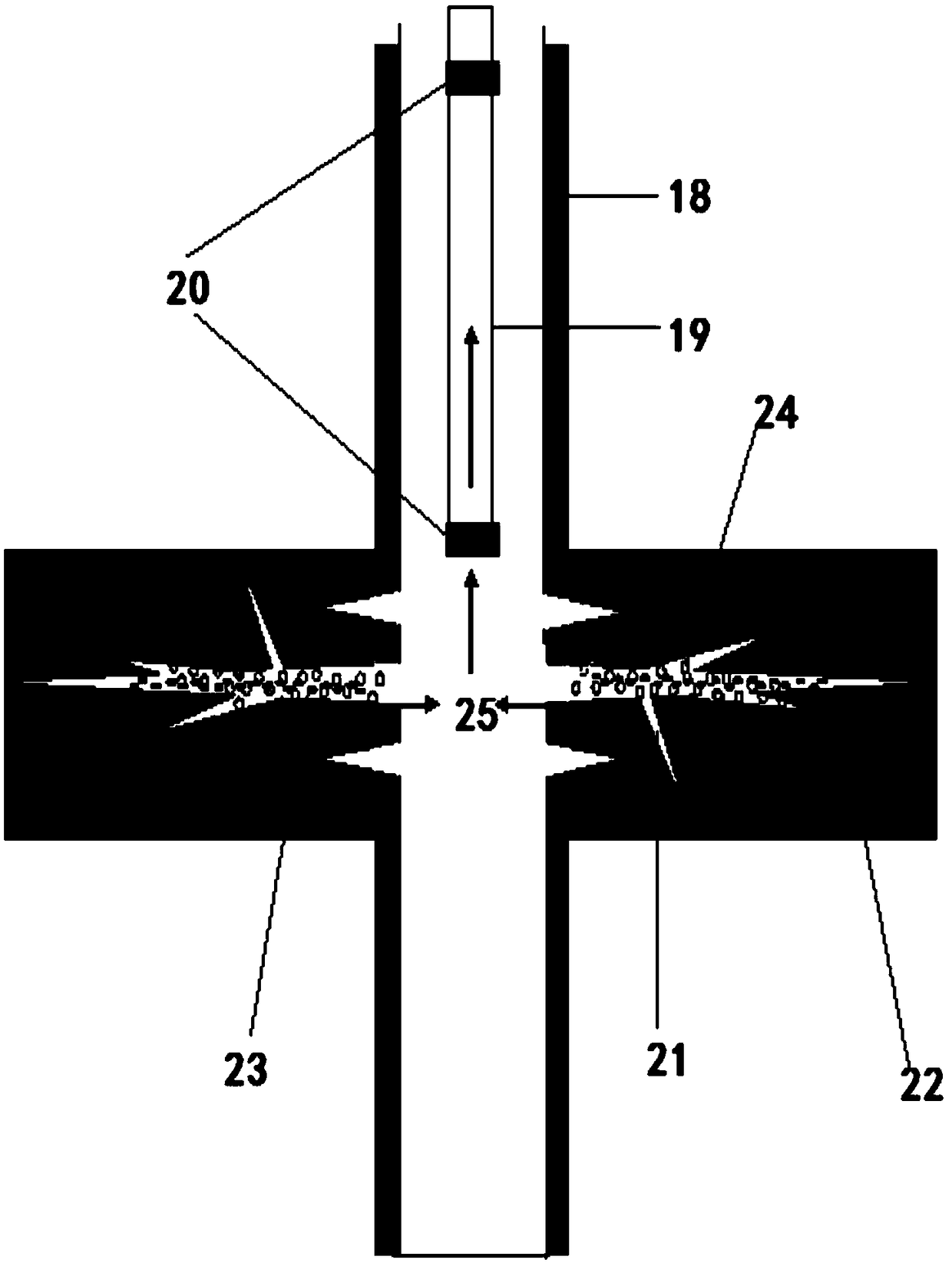

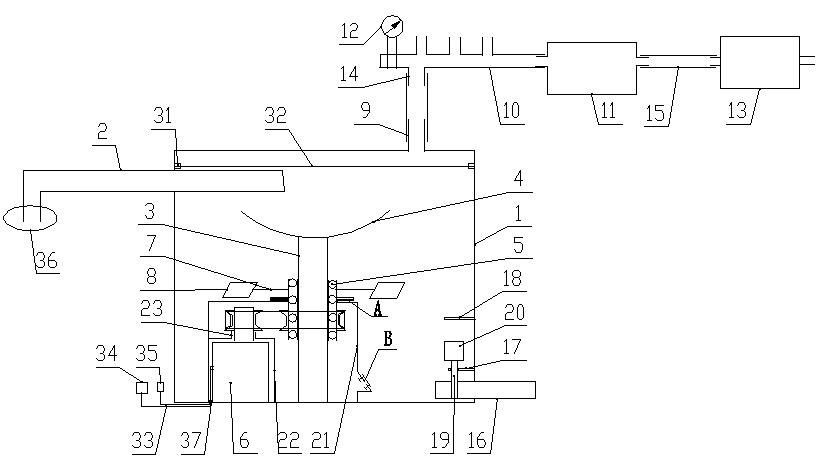

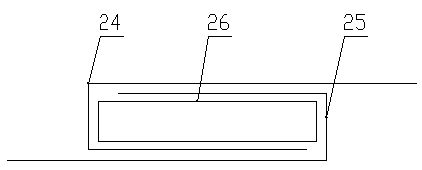

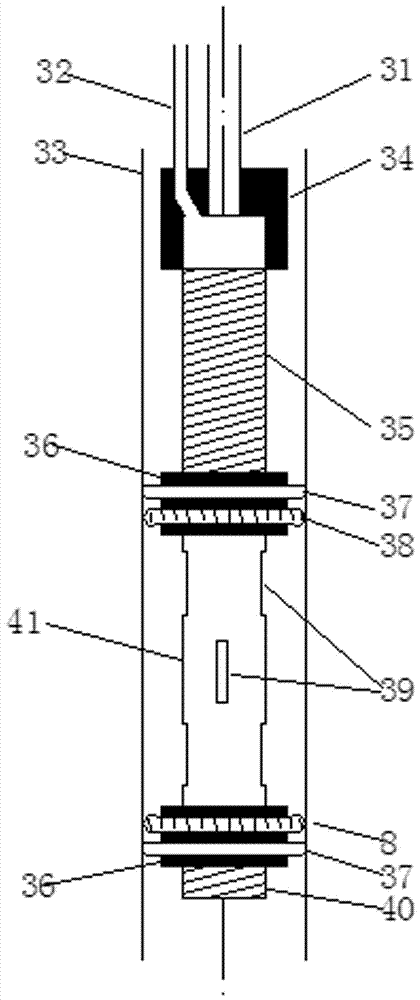

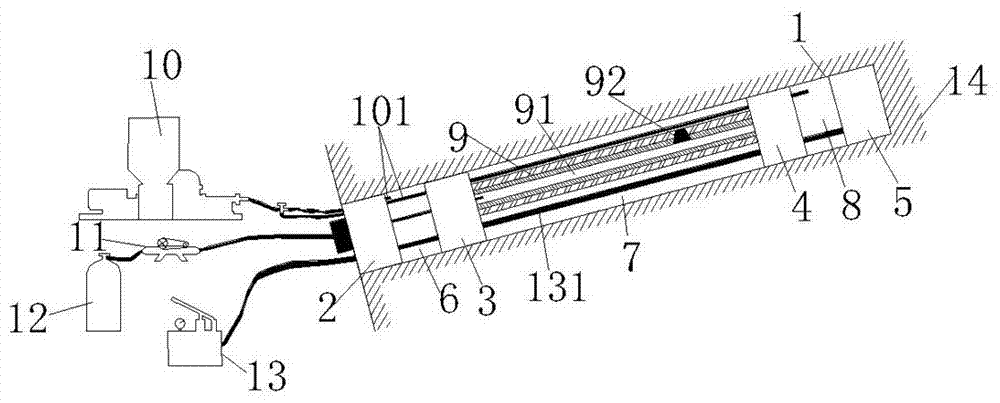

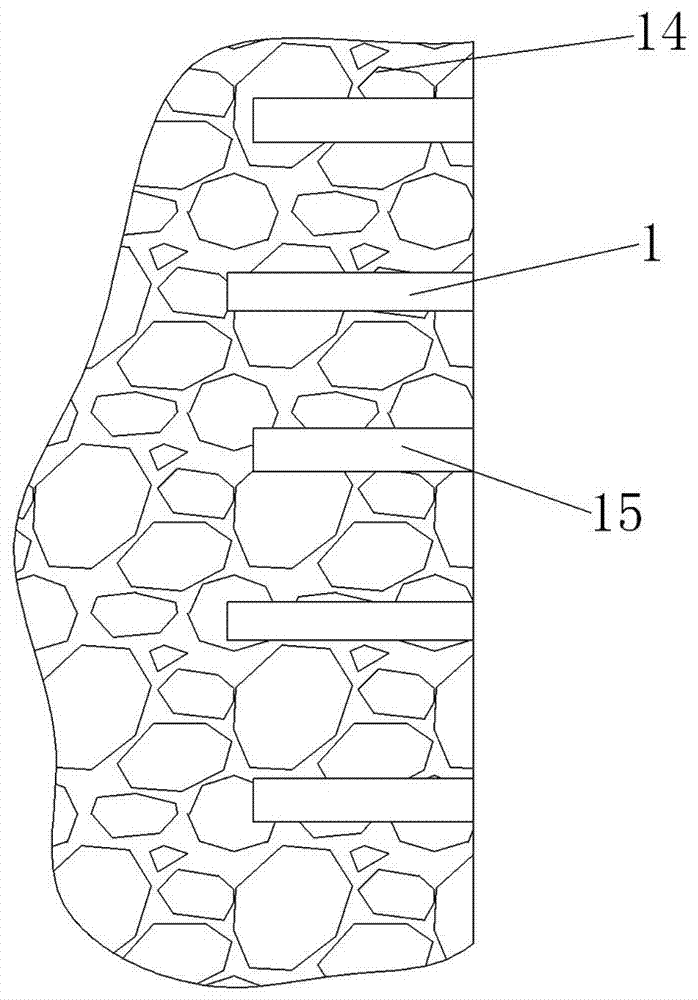

Method and device for displacement of coal seam gas with supercritical carbon dioxide

ActiveCN106894799AAvoid lostGuarantee statusOther gas emission reduction technologiesFluid removalThermodynamicsProcess engineering

The invention belongs to the technical field of coal seam gas exploitation and discloses a method and a device for displacement of coal seam gas with supercritical carbon dioxide. The device comprises a coal seam gas displacement device body which comprises an upper capsule group and a lower capsule group. The upper capsule group is internally provided with a grouting area I, the lower capsule group is internally provided with a grouting area II, and a supercritical carbon dioxide radiation area is formed between the upper capsule group and the lower capsule group. The method and the device have advantages that supercritical carbon dioxide energy loss can be avoided, and states of the supercritical carbon dioxide injected into coal seams finally are guaranteed; structural simplicity, convenience in use, easiness in construction, low cost, safety, high efficiency and applicability to large-scale industrial application of the supercritical carbon dioxide to coal seam gas exploitation are realized, coal seam permeability is improved, and coal seam gas exploitation rate is increased.

Owner:NORTH CHINA INST OF SCI & TECH

Mobile coalbed methane extraction device

The invention discloses a mobile coalbed methane extraction device. The mobile coalbed methane extraction device comprises a particulate matter filter, a first compressor, a second compressor, a carbon dioxide filtering tower, a heat exchanger, a heating device, a first control valve and a second control valve. The gas outlet end of the particulate matter filter is connected with the gas inlet end of the first compressor, the gas outlet end of the first compressor is connected with the gas inlet end of the carbon dioxide filtering tower, the first end of the first control valve is communicated with the top of the carbon dioxide filtering tower, the other end of the first control valve is connected with the gas outlet end of the first compressor and the gas inlet end of the carbon dioxide filtering tower respectively, the gas outlet end of the carbon dioxide filtering tower is connected with one end of the second control valve, and the other end of the second valve is connected with the heat exchanger. The mobile coalbed methane extraction device is simple in structure and convenient to use and can extract coalbed methane without using any explosives or dangerous gas, thereby being high in extraction speed and efficiency and effective in resource utilization and achieving the green and environment-friendly production of resources.

Owner:徐毅

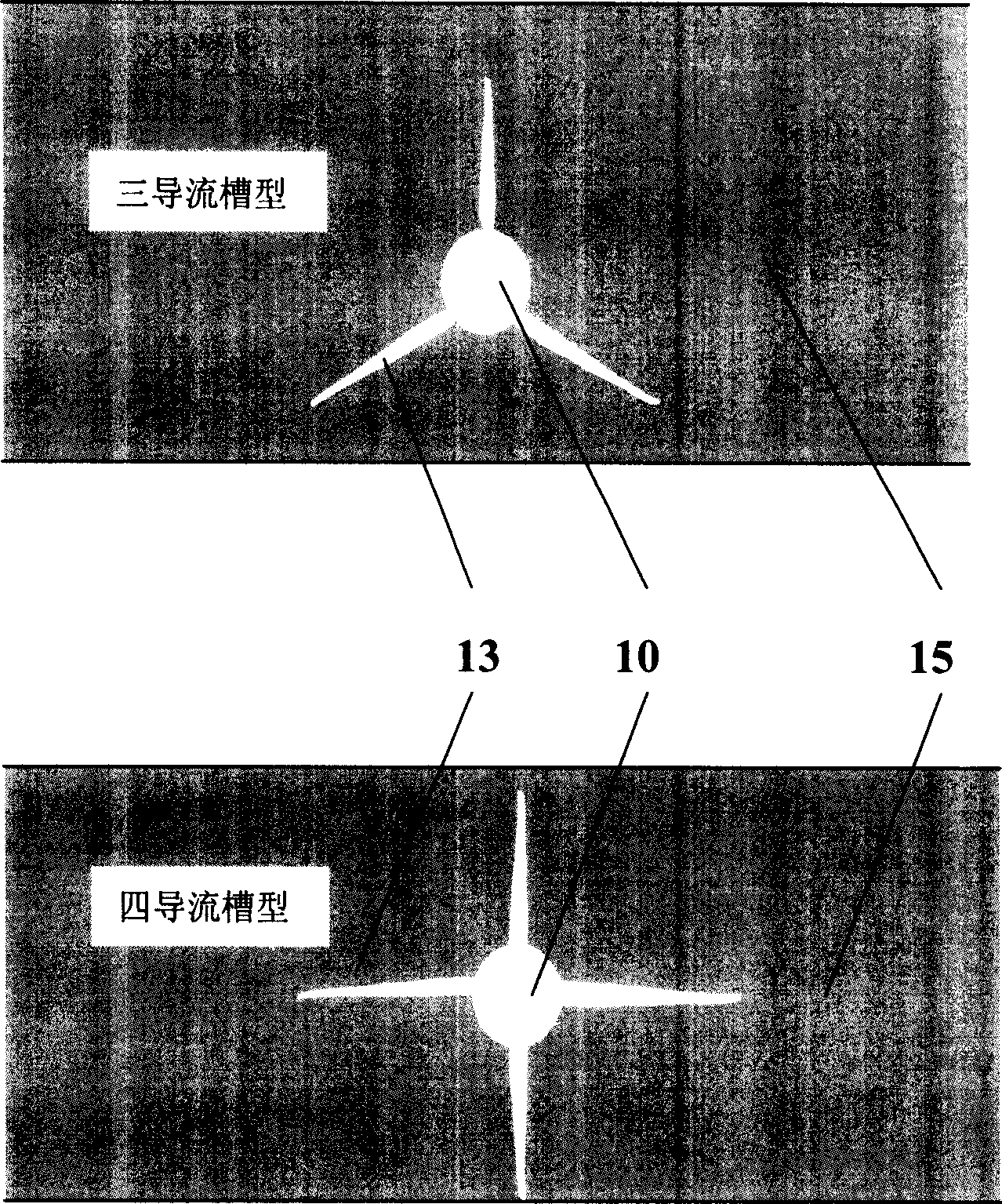

Horizontal bare hole flow guiding slot well and method for mining coal bed gas of sugarcoated haw well

The present invention discloses a method for exploiting coal-bed methane in a horizontal open-hole diversion trench well and a cavity string well. In a coal-bed horizontal open-hole well section, a fluid cutter adopts high-pressure air-liquid mixture fluid to cut a group of diversion trenches with a certain depth and a certain phase angle in a coal bed neighboring a borehole until the diversion trench well is formed, and, in a coal-bed horizontal well section, alternately cut diversion trenches and a string of cavities with a certain interval and a certain diameter until the cavity string well, in which the borehole is communicated with the diversion trenches, is formed.

Owner:王建生

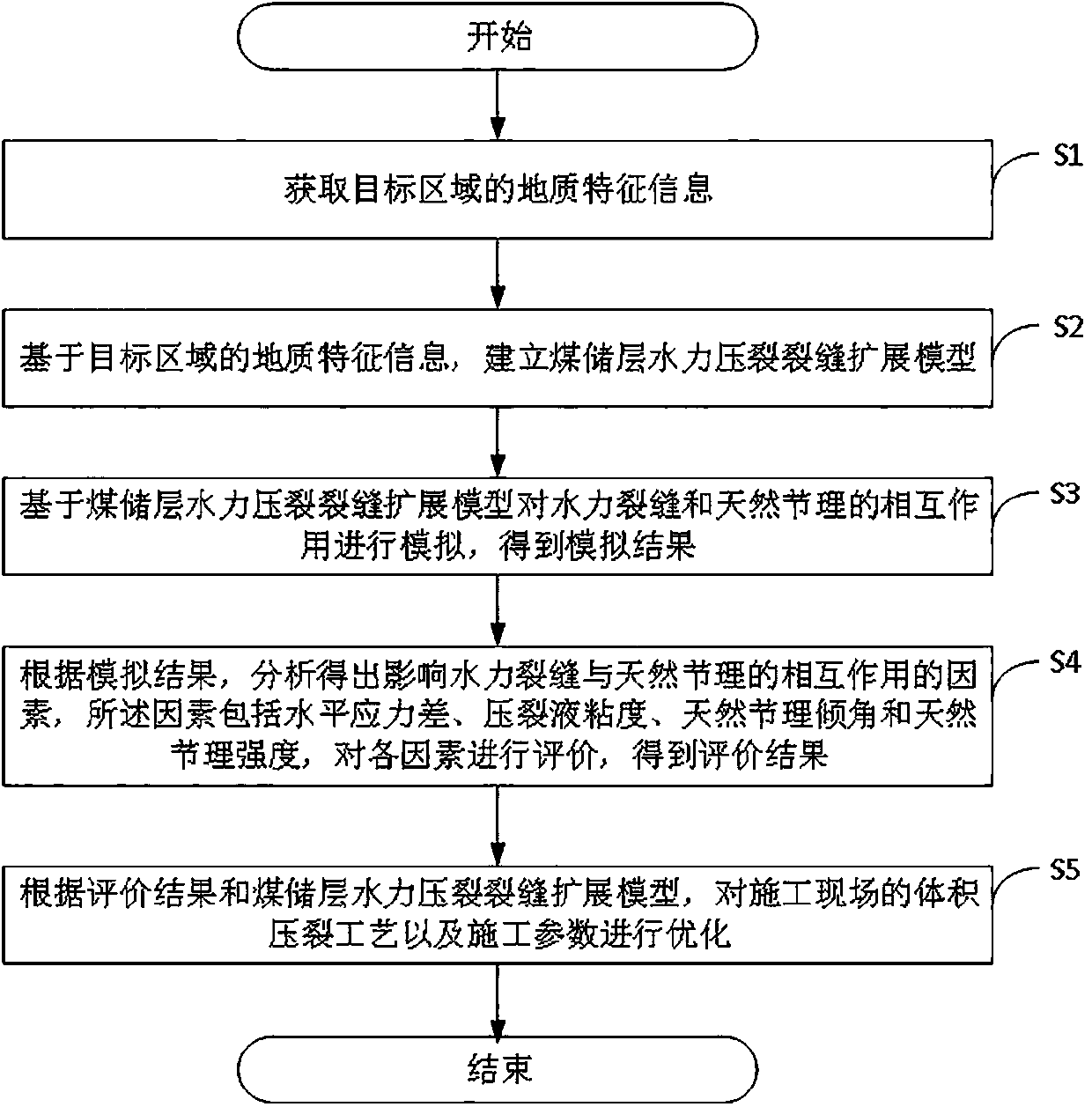

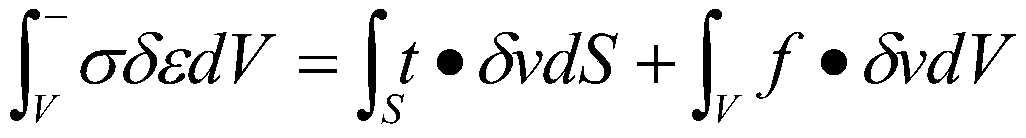

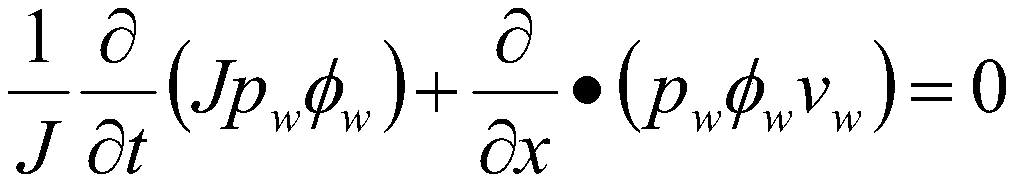

Volume fracturing treatment method for coal layer

InactiveCN111042788AImprove development efficiencyFluid removalEvaluation resultHydraulic fracturing

The invention relates to the technical field of coal bed gas exploitation, in particular to a volume fracturing treatment method for a coal layer. The method includes the steps that geological featureinformation of a target area is acquired, and a coal reservoir hydraulic fracturing fracture propagation model is established on the basis of destination geological feature information; the interaction of hydraulic fractures and natural joints is simulated based on the coal reservoir hydraulic fracturing fracture propagation model, and a simulation result is obtained; factors influencing the interaction of hydraulic fractures and natural joints are analyzed according to the simulation result, various factors are evaluated, and an evaluation result is obtained; and the volume fracturing process and construction parameters of a construction site are optimized according to the evaluation result and the coal reservoir hydraulic fracturing fracture propagation model. In this way, the efficiency of coal bed gas exploitation is improved by optimizing the volume fracturing process and the construction parameters.

Owner:SOUTHWEST PETROLEUM UNIV

Coalbed methane exploitation filtering treatment equipment

ActiveCN111389132AEffective preliminary collection and processingAffect mining efficiencyDispersed particle filtrationFiltrationCoal dust

The invention discloses coalbed methane exploitation filtering treatment equipment. The equipment comprises a treatment box body, a lower end cover, a sealed cover body, an exhaust device and an innerfilter cylinder. The sealed cover body is fixed to a lower end surface of the treatment box body through bolts, the lower end cover is mounted at an air inlet of the sealed cover body, and fed air issealed through the lower end cover, the inner filter cylinder is mounted in the treatment box body in the vertical direction, the inner filter cylinder is fixed with the treatment box body through connecting brackets on two sides outside the inner filter cylinder, also the treatment box body is externally communicated with the exhaust device, the filtered coalbed methane is effectively absorbed and discharged, a primary dust collection assembly, an extraction assembly and a fine filtration assembly are arranged in the inner filter cylinder, wherein the primary dust collecting assembly is usedfor primarily filtering and collecting large-particle coal dust mixed in coalbed methane, the fine filtration assembly is sleeved with the extraction assembly, and the extraction assembly is used forextracting the coalbed methane subjected to dust removal from the fine filtration assembly in time, so that the filtering treatment of the fine filtration assembly on the coalbed methane is accelerated.

Owner:CHINA UNITED COALBED METHANE NAT ENGRES CENT

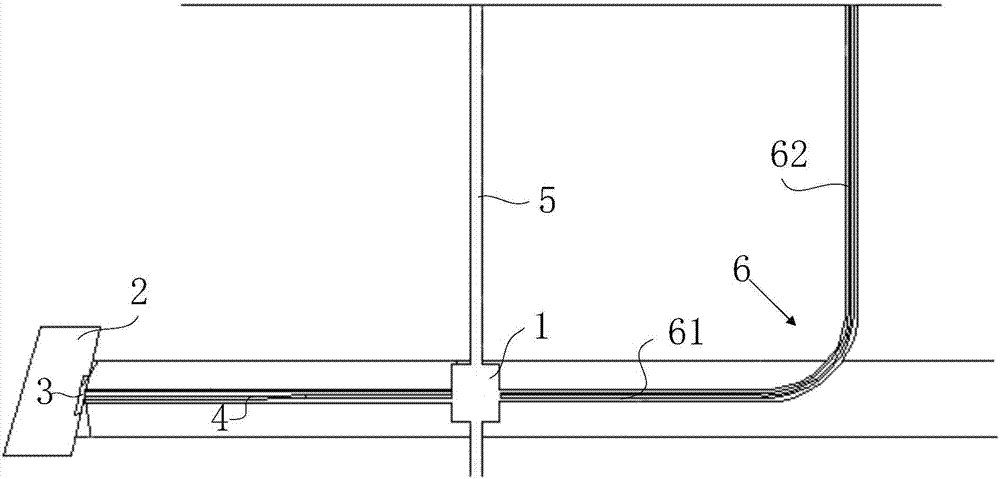

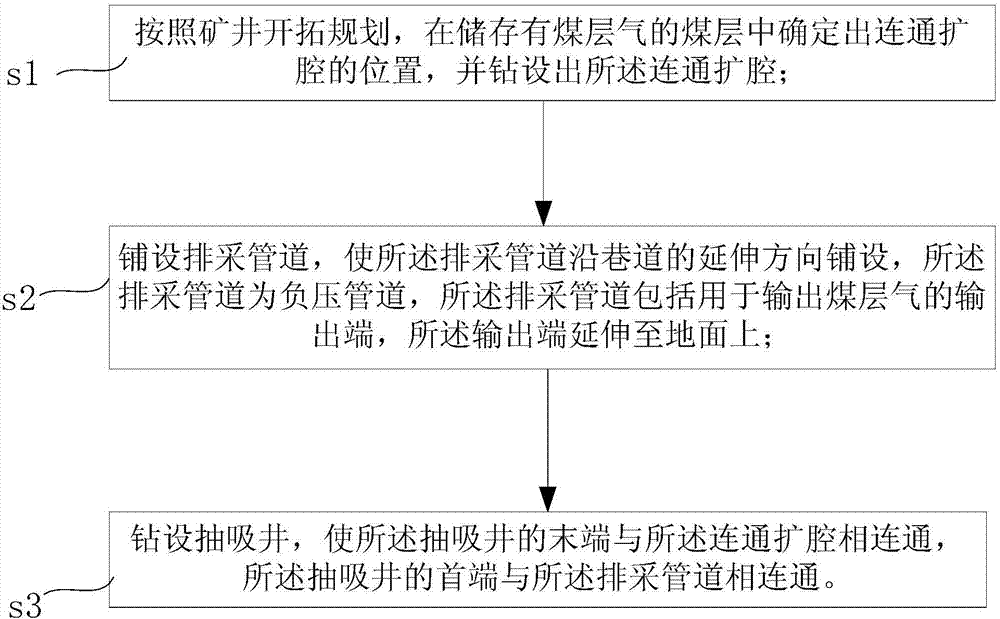

Coalbed methane extraction system and construction method

InactiveCN107152261AReduce manufacturing costReduce energy consumptionFluid removalWell drillingEnergy consumption

The invention discloses a coalbed methane extraction system and a construction method. The coalbed methane extraction system comprises a communicating expansion cavity, a discharge and mining pipeline and a pumping well, wherein the communicating expansion cavity is used for collecting coalbed methane from a coalbed and is arranged in the coalbed; the discharge and mining pipeline is paved along the extending direction of a roadway, is a negative pressure pipeline and comprises an output end used for outputting the coalbed methane, the output end extends to the ground surface, the tail end of the pumping well is communicated with the communicating expansion cavity, and the head end of the pumping well is communicated with the discharge and mining pipeline. The invention further provides the construction method of the coalbed methane extraction system to construct the coalbed methane extraction system. According to the provided coalbed methane extraction system and the construction method, the energy consumption is reduced, the extraction cost of the coalbed methane is lowered, the cost for ground construction is lowered, and the operation cost for a drilling well is lowered.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Coal powder removal method in coal seam gas exploitation pipeline

ActiveCN111097764ADoes not affect normal mining workAvoid enteringHollow article cleaningCleaning apparatusThermodynamicsProcess engineering

The invention provides a coal powder removal method in a coal seam gas exploitation pipeline. The coal powder removal method includes the following steps that firstly, a pipeline robot is placed intothe coal seam gas exploitation pipeline and a walking mechanism is started to move forwards along the inner wall of the pipeline; secondly, while the pipeline robot moves along the inner wall of the pipeline, the pipeline robot is controlled to carry out the rotary removal operation, and the coal powder attached to the inner wall of the pipeline is removed; thirdly, the pipeline robot is controlled to collect and store the removed coal powder; fourthly, the stored coal powder is compressed and water is squeezed out; and fifthly, when the coal powder is full, the rotary removal, the coal powdercollection and compression operation of the pipeline robot is turned off, the walking mechanism of the pipeline robot is controlled to move backwards and the pipeline robot exits from the pipeline. According to the coal powder removal method, the normal exploitation work of coal seam gas cannot be affected when the coal powder removal operation is carried out. After the plugging of the inner wallof the pipeline is removed, the removed coal powder is stored, the operation is convenient, the automation degree is high, and the reliability is high.

Owner:NORTHEAST GASOLINEEUM UNIV

Coal bed gas thermal production increasing method

InactiveCN110821463AReduce mining costsIncrease productionSurveyFluid removalThermodynamicsWell drilling

The invention relates to a coal bed gas thermal production increasing method. The coal bed gas thermal production increasing method comprises the following steps that a drilling hole or a drilling shaft is obtained and drilled to a target coal bed; a coil pipe is arranged in the drilling hole or the drilling shaft, the bottom end of the coil pipe stretches into the target coal bed, a movable spraynozzle and an igniter are arranged at the bottom end of the coil pipe, and the movable spraying nozzle and the igniter face an area to be ignited of the coal bed; and a gasifying agent is sprayed tothe area to be ignited through the movable spray nozzle, the gasifying agent of the area to be ignited is ignited by the igniter, and a coked area or a coked cavity with a certain diameter is formed in the coal bed. By means of the coal bed gas thermal production increasing method, generation of a large amount of coal dust can be avoided, the problems that the permeability of a coal reservoir is low and coal dust blocks a coal bed gas channel are solved, the well yield of coal bed gas is improved, abandoned wells are reduced to the maximum extent, or the abandoned wells can be enabled again ina production increase mode, and the exploitation cost of coal bed gas is reduced.

Owner:CHINA COAL GEOLOGY GRP CO LTD

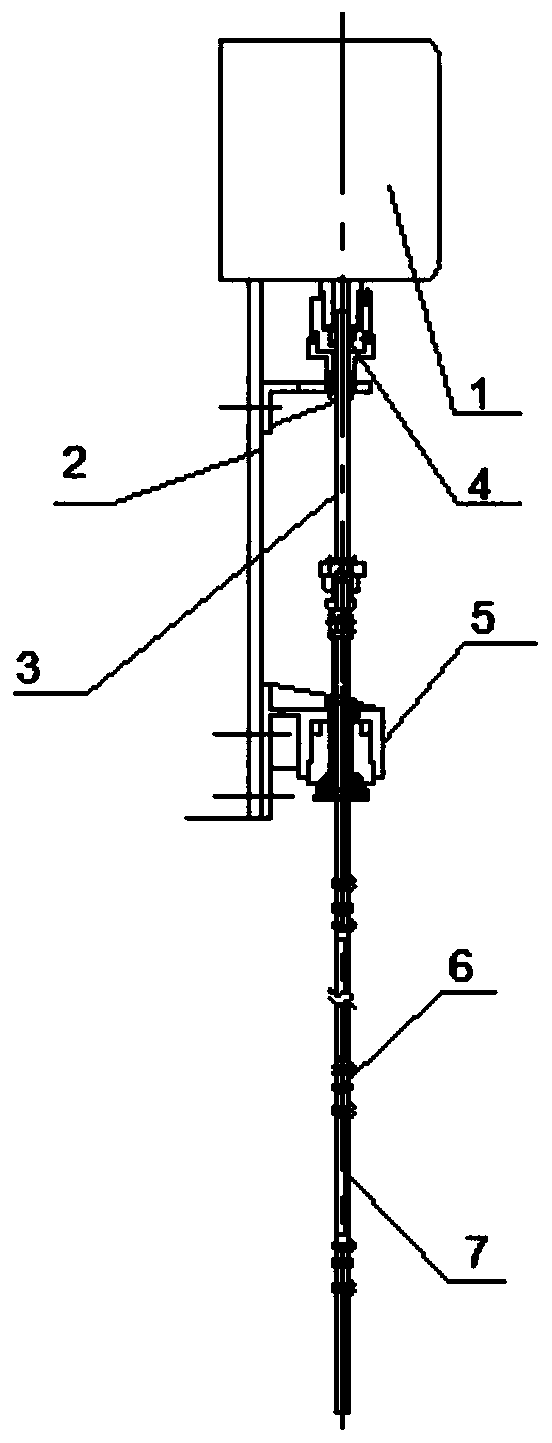

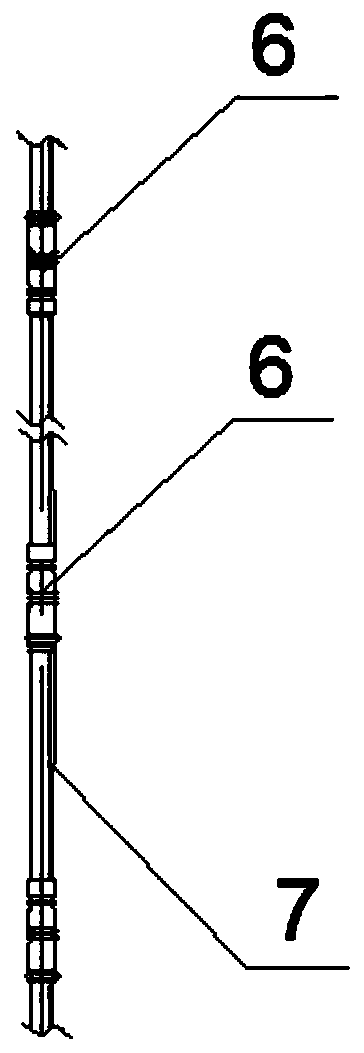

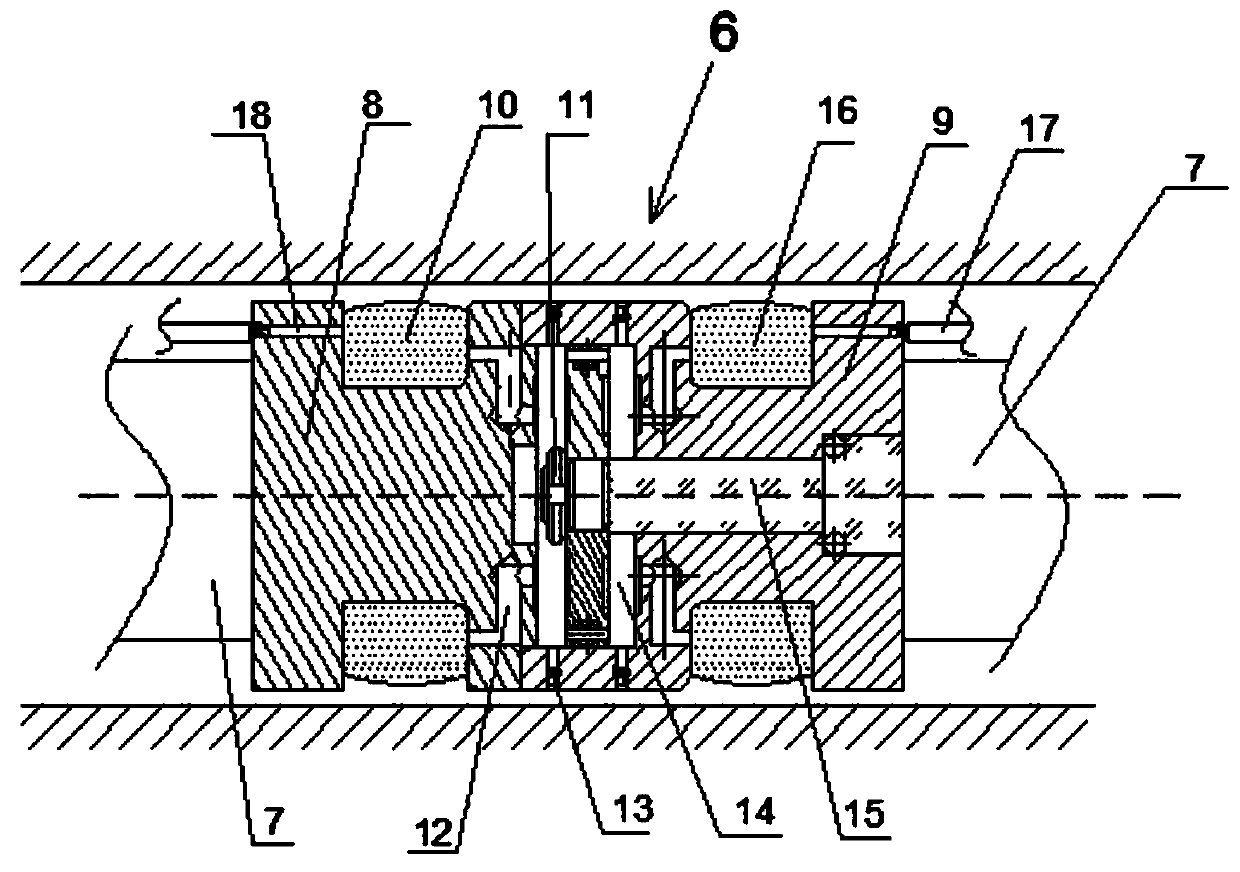

Fracturing device for exploitation of coal bed methane in low-permeability zone

ActiveCN110905473AImprove uniformityImprove thoroughnessFluid removalSealing/packingMechanical engineeringCoalbed methane extraction

The invention discloses a fracturing device for exploitation of coal bed methane in a low-permeability zone. According to the device, a fracturing controller is used for controlling the fracturing condition of a fracturing pipe and the hole sealing condition of a segmented hole sealing mechanism for fracturing respectively, and the fracturing condition in a fracturing hole can be effectively controlled. The segmented hole sealing mechanism for fracturing of the device can separate all segments of the fracturing pipe in the fracturing hole in a separated sealed manner, and segmented fracturingoperation is realized by utilizing each segment of the fracturing pipe, so that the uniformity and completeness of fracturing are effectively improved, and the fracturing capacity is ensured. When hole sealing operation is carried out on each section, the hole sealing effect of each section can be ensured, the hole sealing efficiency is ensured, the fracturing capacity of each section of fracturing is improved, and the fracturing effect is guaranteed.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

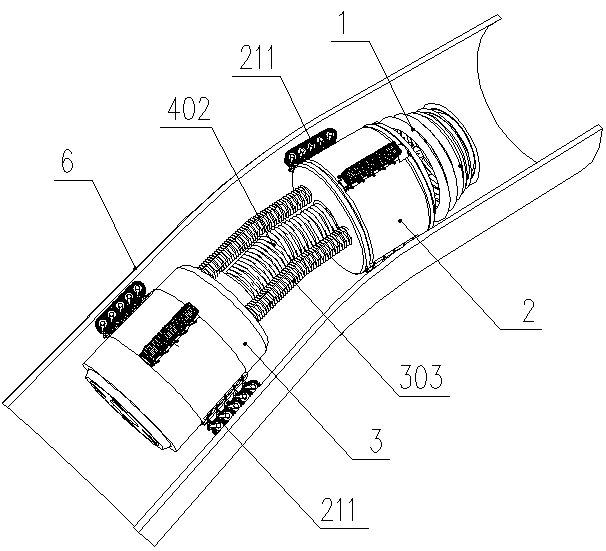

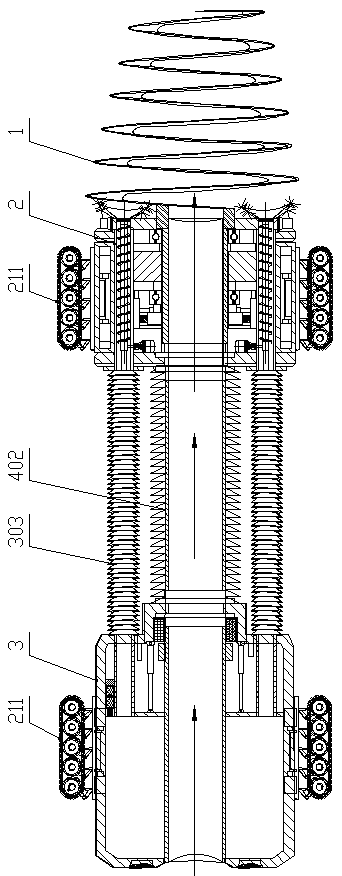

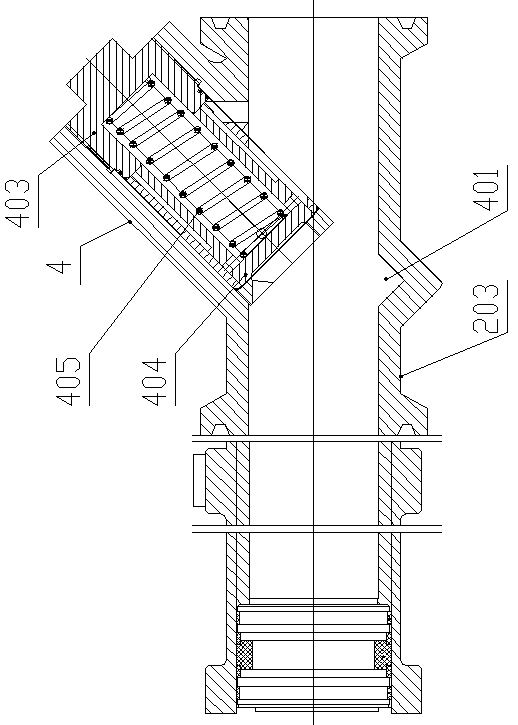

Carbon dioxide fracturing anti-reflection device for coalbed methane extraction

InactiveCN109611057ADetonation achievedIncrease detonation rateFluid removalGas removalDetonationCombined use

The invention discloses a carbon dioxide fracturing anti-reflection device for coal bed gas extraction. According to the invention, a detonating cavity is arranged between a detonating assembly and ananti-reflection liquid storage assembly; a low-melting-point molten liquid metal can be injected into the detonation cavity so that detonation of liquid carbon dioxide in the anti-reflection liquid storage assembly can be achieved through energy released by the low-melting-point molten liquid metal, the detonation speed can be greatly increased, instant strong detonation expansion impact force can be achieved, and the anti-reflection effect can be guaranteed. Through the combined use of a first liquid storage pipe, a second liquid storage pipe and a third liquid storage pipe, the quantity ofsections of liquid storage pipes can be selected and used according to the depth of a coalbed, so that the working efficiency is improved. Through the combined use of an energy relief head main body,a support frame, a spring, a sealing gasket and an exhaust pressure relief hole, carbon dioxide can be uniformly diffused into a coalbed, so that the fracturing and anti-reflection effects are better.

Owner:LULIANG UNIV

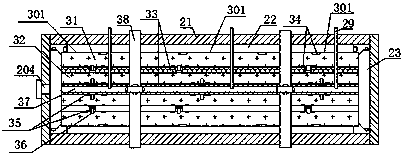

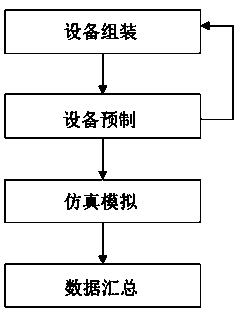

Coalbed methane staged fracturing horizontal well productivity simulation test device and method

ActiveCN111594099AAccurate measurementImprove work efficiencyFluid removalHorizontal wellsData acquisition

The invention discloses a coalbed methane staged fracturing horizontal well productivity simulation test device. The device comprises a bearing platform, a power loading mechanism, a coal reservoir simulation mechanism, a gas recovery mechanism and a data acquisition device; the bearing platform comprises a bearing frame, a working platform and a control console; the coal reservoir simulation mechanism is connected with the working platform; and the power loading mechanism, the gas recovery mechanism and the data acquisition device are all connected with the bearing frame, and are connected with the coal reservoir simulation mechanism. The specific test method comprises four steps: equipment assembly, equipment prefabrication, simulation and data collection. The device and the method can effectively simulate different geological structures, thereby effectively realizing the test accuracy of accurately measuring the gas production after fracturing operation, and at the same time effectively improving the working efficiency of the detection test operation, providing the relatively actual reference basis for productivity prediction under similar coal reservoir conditions, and effectively improving the accuracy and reliability of coalbed methane mining area design, mining technology and mining activities.

Owner:HENAN POLYTECHNIC UNIV +1

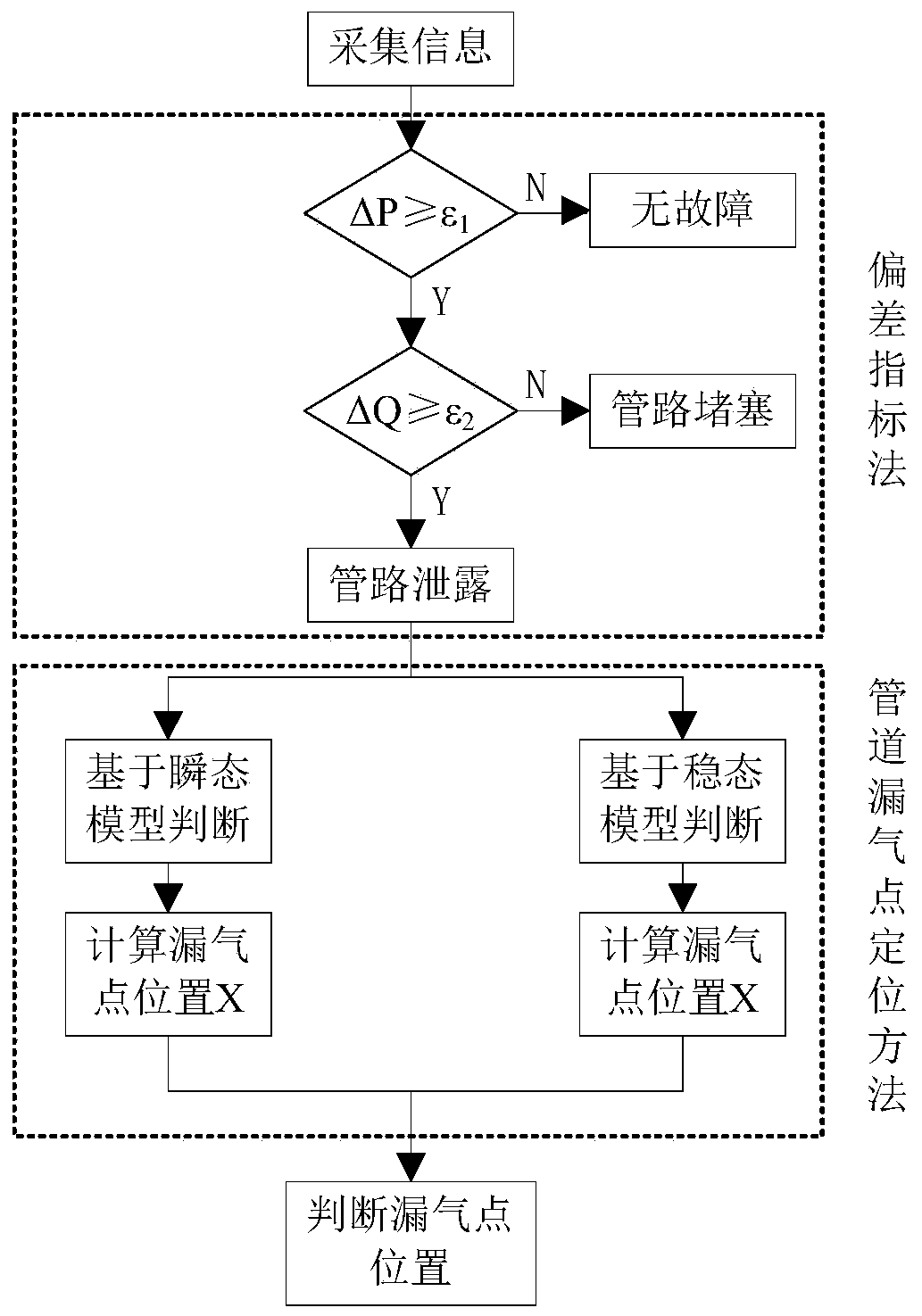

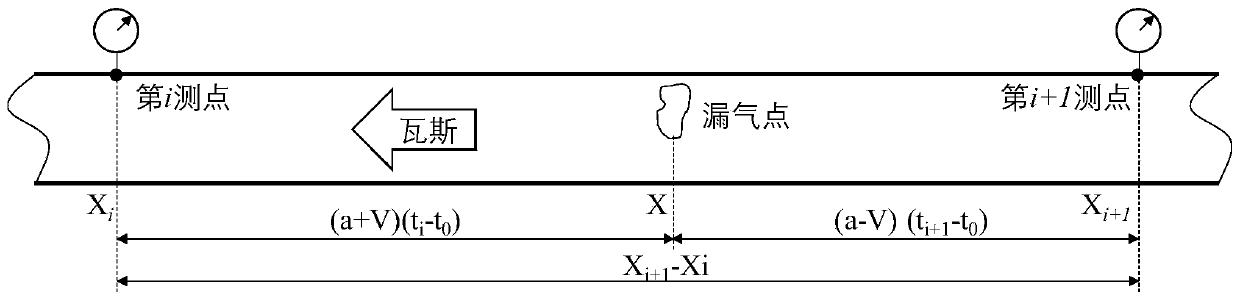

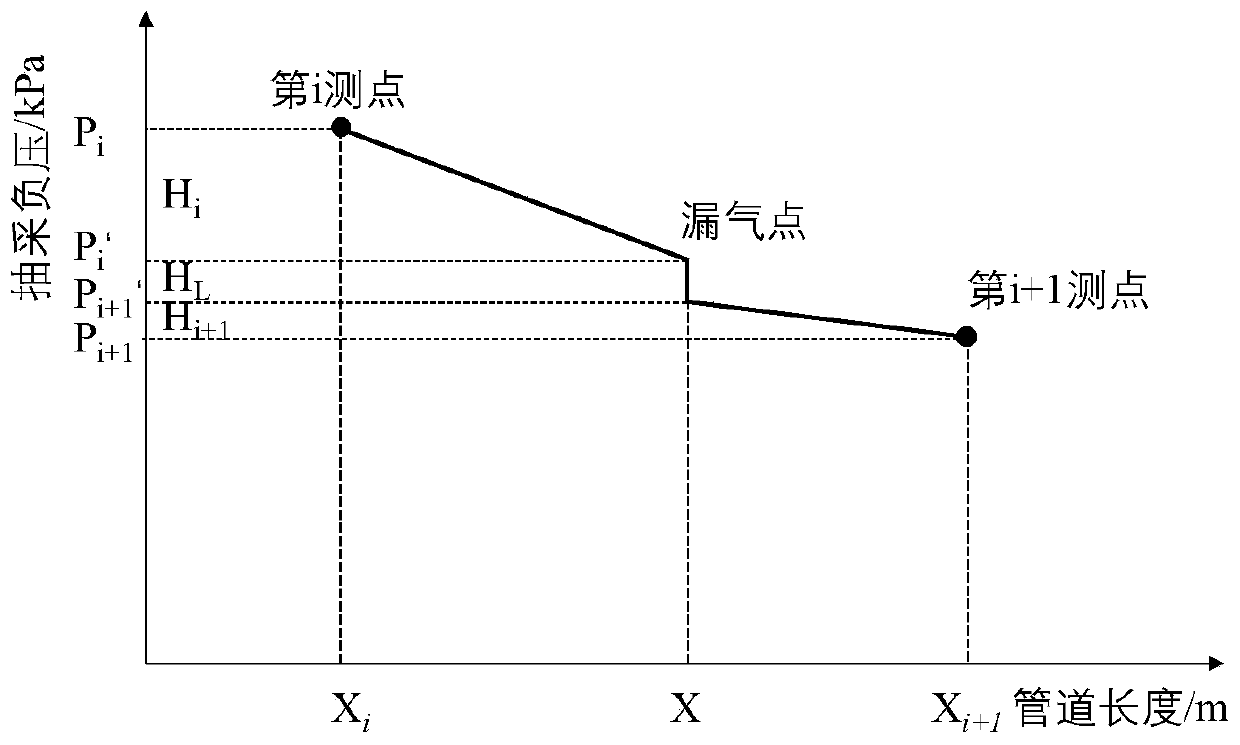

Coal mine underground coalbed methane extraction pipeline fault automatic diagnosis method

ActiveCN111578147ASolve the problem of low efficiency of manual fault detectionRapid positioningPipeline systemsMixed flowStream flow

The invention discloses a coal mine underground coalbed methane extraction pipeline fault automatic diagnosis method. The coal mine underground coalbed methane extraction pipeline fault automatic diagnosis method comprises the following steps of 1, collecting extraction negative pressure and mixed flow values of each measuring point of an extraction pipeline, numbering the extraction negative pressure and the mixed flow values of the ith measuring point according to the distance from the measuring point to an extraction pump station from near to far, and recording the extraction negative pressure and the mixed flow values of the ith measuring point as Pi and Qi correspondingly; 2, analyzing whether a fault exists between the ith measuring point and the (i + 1) th measuring point of the extraction pipeline or not by adopting a deviation index method, judging the fault type, if the fault type is pipeline leakage, executing the step 3, and otherwise, directly executing the step 4; 3, judging the position of an air leakage point between the ith measuring point and the (i + 1) th measuring point of the extraction pipeline by adopting a pipeline air leakage point positioning method; and4, replacing i with i + 1, and returning to the step 2 to judge the fault type of the next position until i is equal to the number of the last measuring point. The method can effectively solve the problem of low manual detection efficiency of the fault of the underground extraction pipeline of the coal mine, and provides a technical guarantee for the construction of an extraction pipe network intelligent management and control platform.

Owner:CCTEG CHINA COAL RES INST

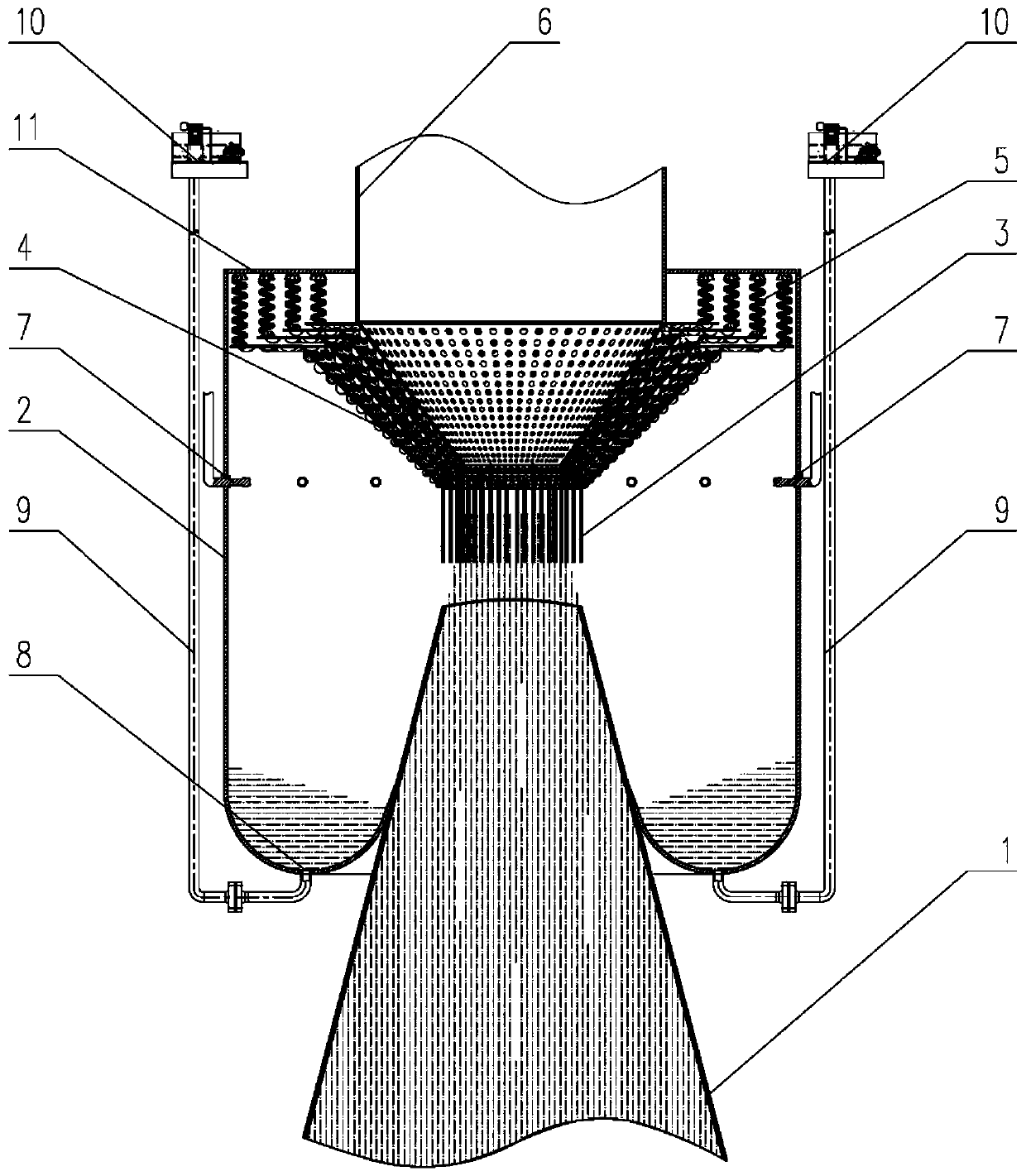

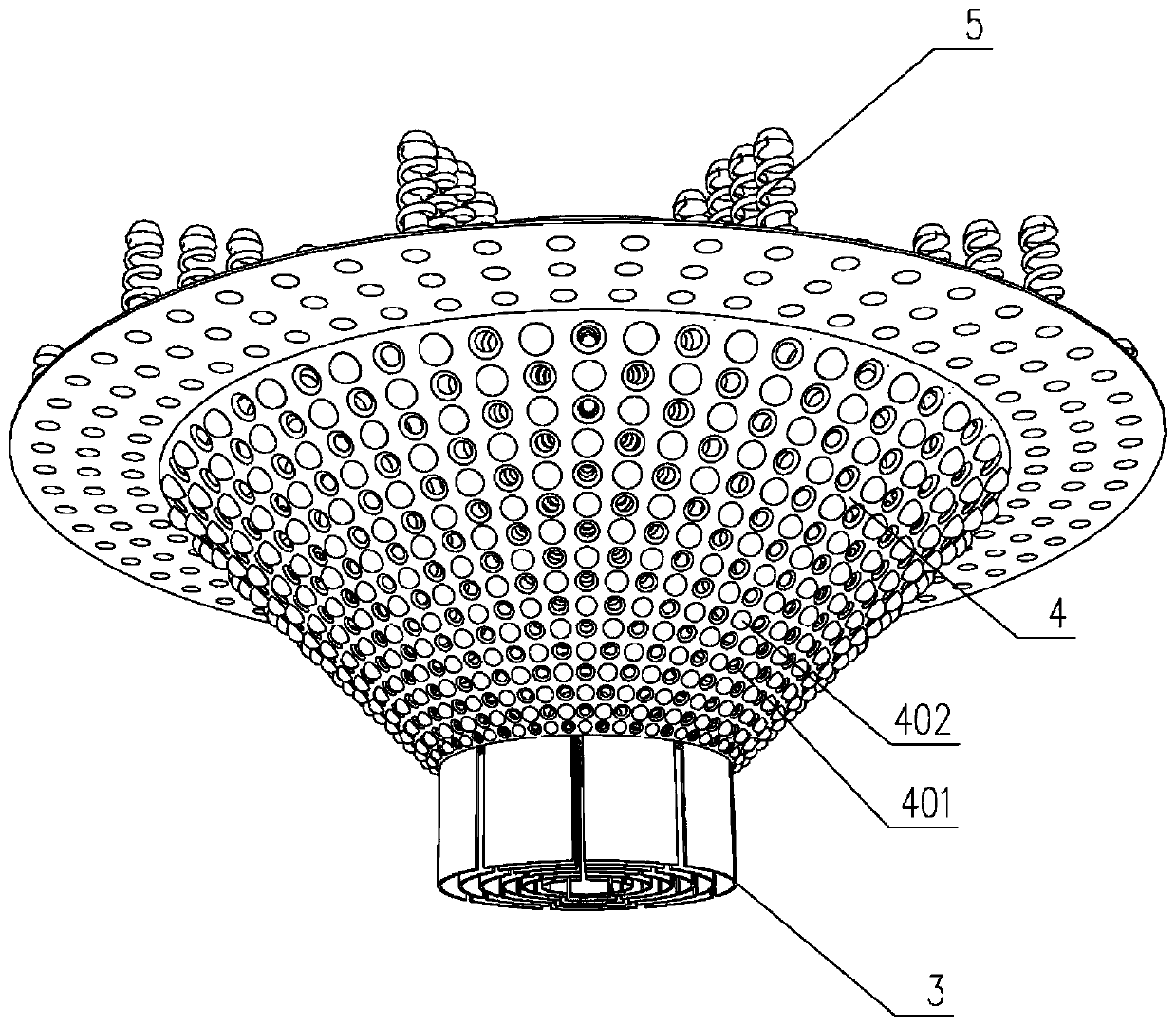

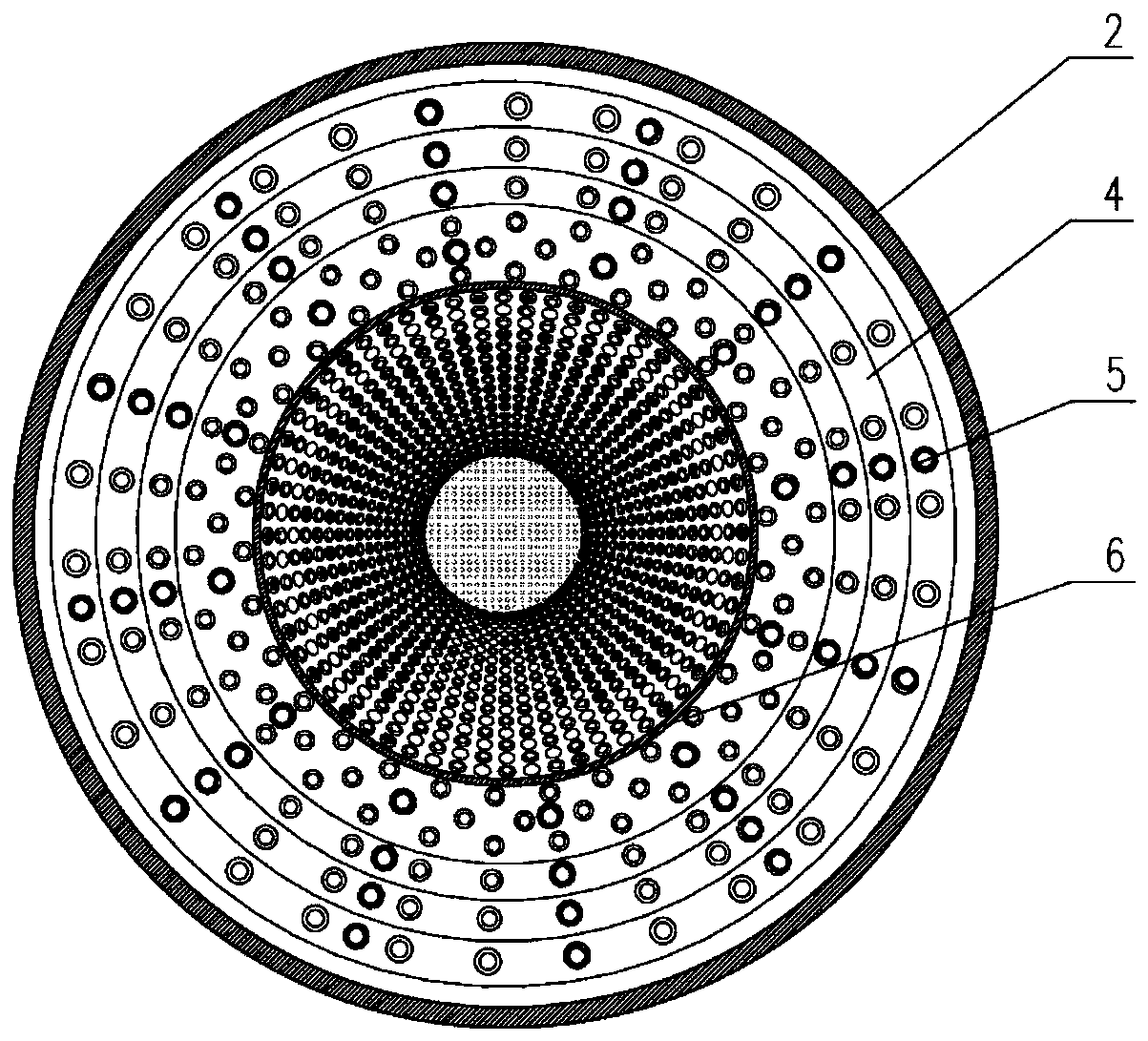

Self-oscillation coal powder filtering system used in process of coalbed methane mining

The invention discloses a self-oscillation coal powder filtering system used in a process of coalbed methane mining. The self-oscillation coal powder filtering system comprises an external cylinder seat, an end cover, a spring assembly, a filter screen assembly, an oscillation piece, a water inlet pipe, a water outlet pipe and a sand pump; the external cylinder seat is a cylinder body internally provided with a cavity, and a hole is formed in the bottom center of the external cylinder seat; an upper pipe orifice of the water inlet pipe extends upward from the hole in the bottom of the externalcylinder seat into the inner cavity of the external cylinder seat; a lower pipe orifice of the water inlet pipe is connected with a coalbed methane mining well downward; the end cover covers the upper end of the external cylinder seat in a sealing mode; a gas outlet communicating with an external coalbed methane mining pipeline is formed in the center of the end cover; the end cover, the spring assembly, the filter screen assembly and the oscillation piece are sequentially connected from top to bottom; the gas outlet is surrounded by the filter screen assembly; the oscillation piece is hung over the pipe orifice of the water inlet pipe; a water outlet is formed in the bottom of the external cylinder seat; and the sand pump communicates with the water outlet through the water outlet pipe.According to the self-oscillation coal powder filtering system, coalbed methane and coal powder are effectively separated, the coalbed methane and the coal powder are correspondingly collected, and the extraction efficiency is improved.

Owner:CNOOC ENERGY TECH & SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com