Multi-joint intensive grouting well-reinforcing method for reinforcing coal-bed gas well penetrating through goaf

A coalbed methane well and grouting reinforcement technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of poor structural stability of the three-cut well body and complicated construction process of the third-cut well, and achieve Improve the quality of grouting and its controllability, save the amount of casing, and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

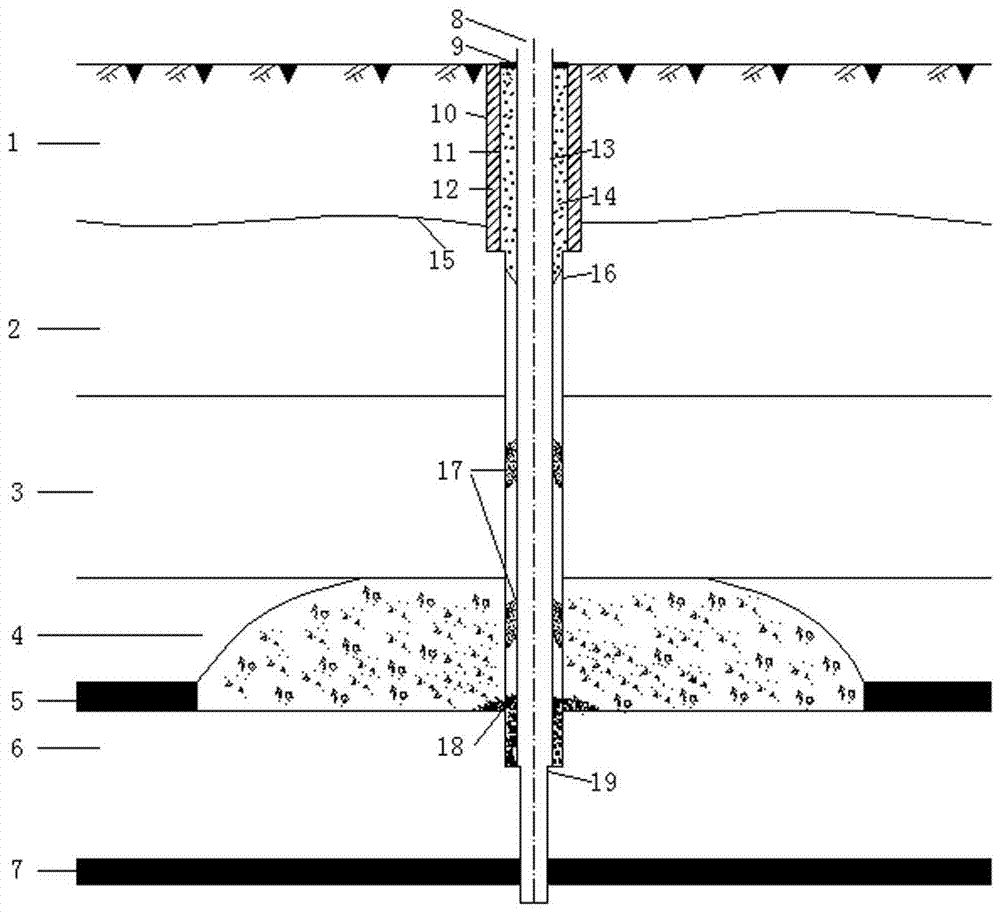

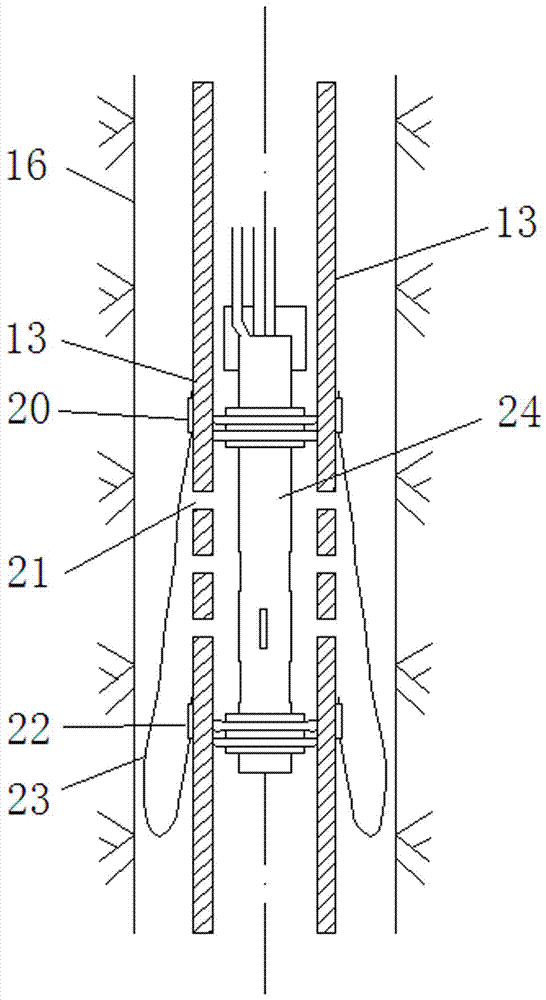

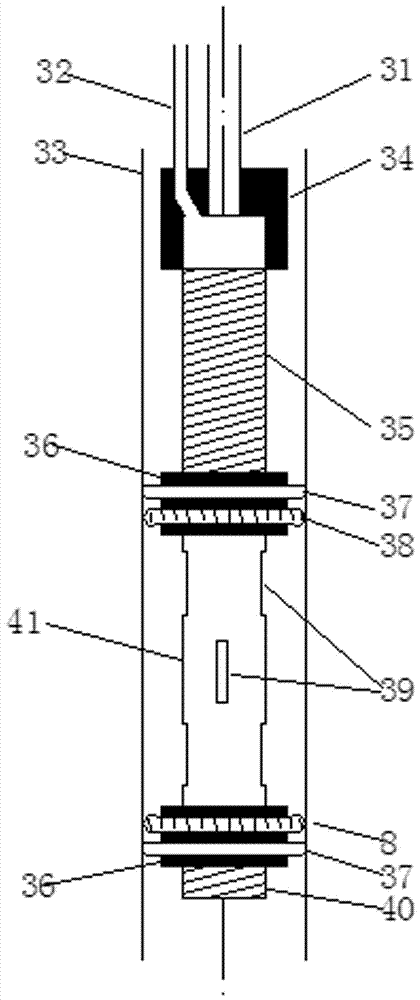

[0043]Shanxi Jincheng Anthracite Coal Mining Group Co., Ltd. State Key Laboratory of Coal and Coalbed Methane Co-mining analyzed the shortcomings of the current Sankai shaft structure and the difficulties in the construction process, and then proposed the multi-node intensification of the goaf The cementing method of grouting to strengthen coalbed methane wells mainly adopts the pipe skirt technology, and multi-node grouting inclusions (reinforcement bodies) are formed between the second drill hole 16 and the technical casing 13, which not only increases the well wall circumference At the same time, there is a good coupling and stable support between the technical casing 13 and the well wall, which can ensure the long-term stability of the coalbed methane well. Simultaneously, after the three-drilled borehole 19 is formed, the production casing is no longer installed, and the stable technical casing 13 is directly used as the production casing of the coalbed methane well. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com