Patents

Literature

137results about How to "Guaranteed flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

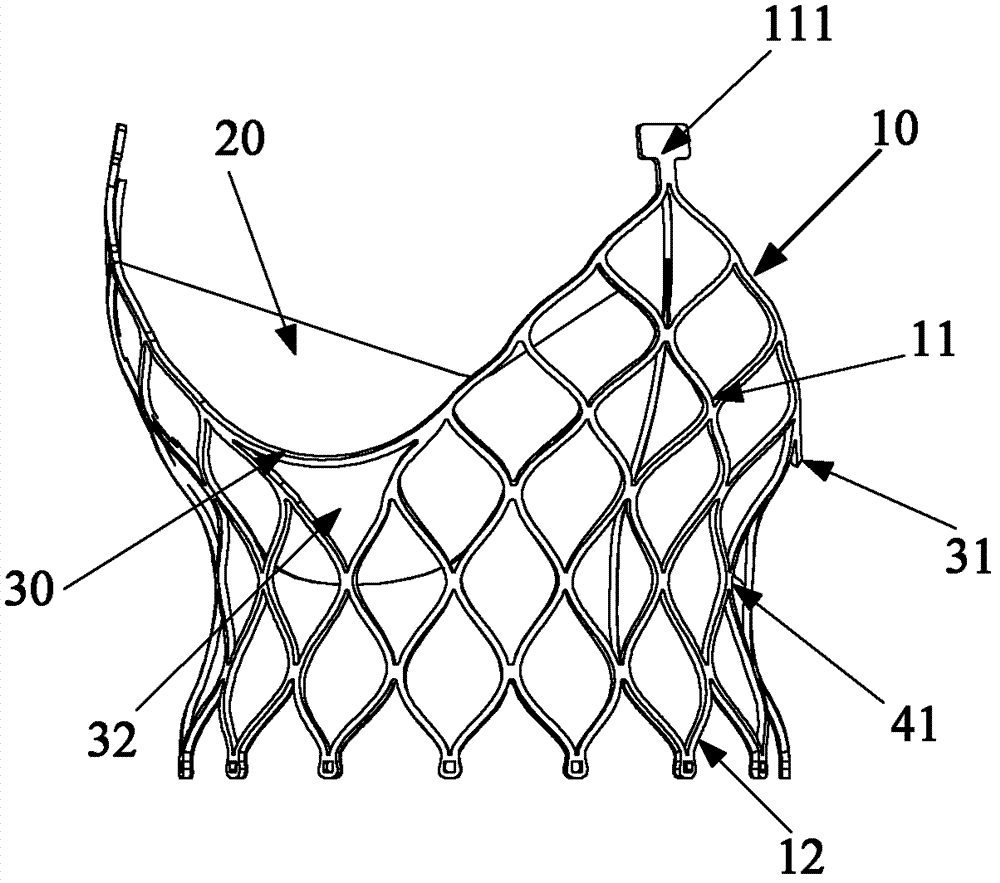

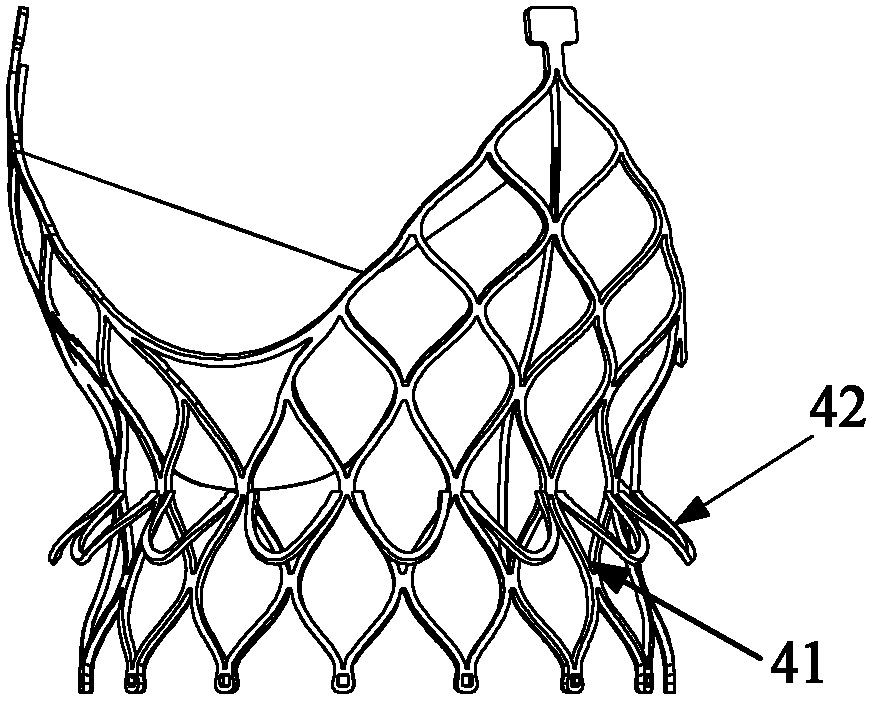

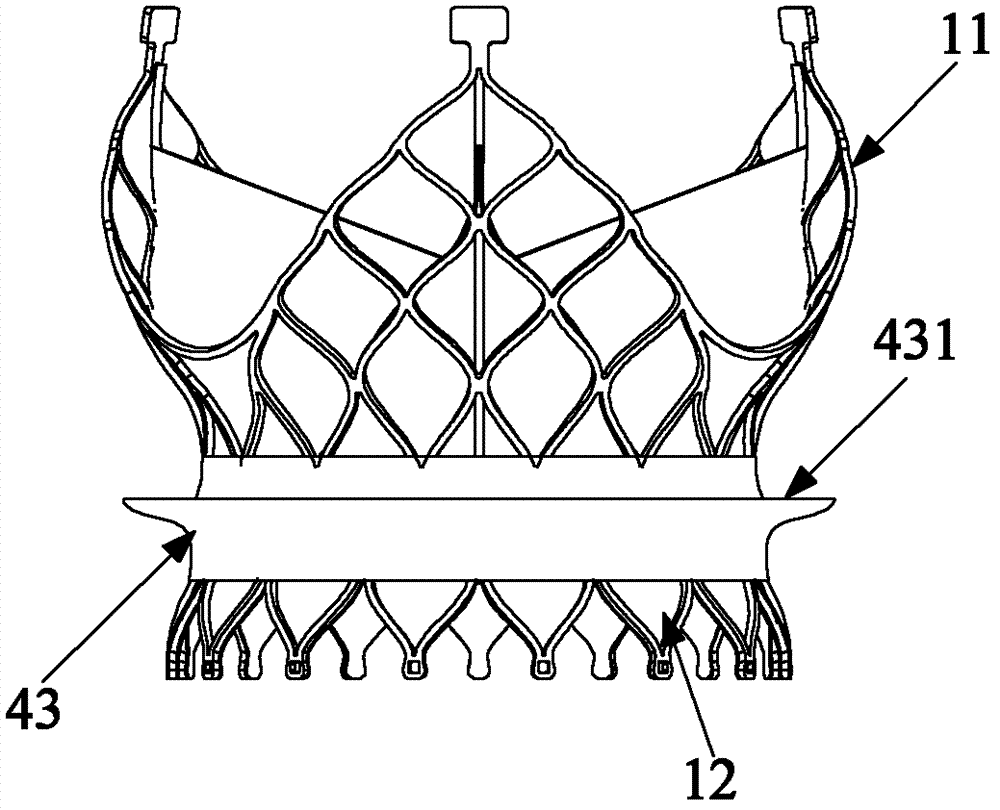

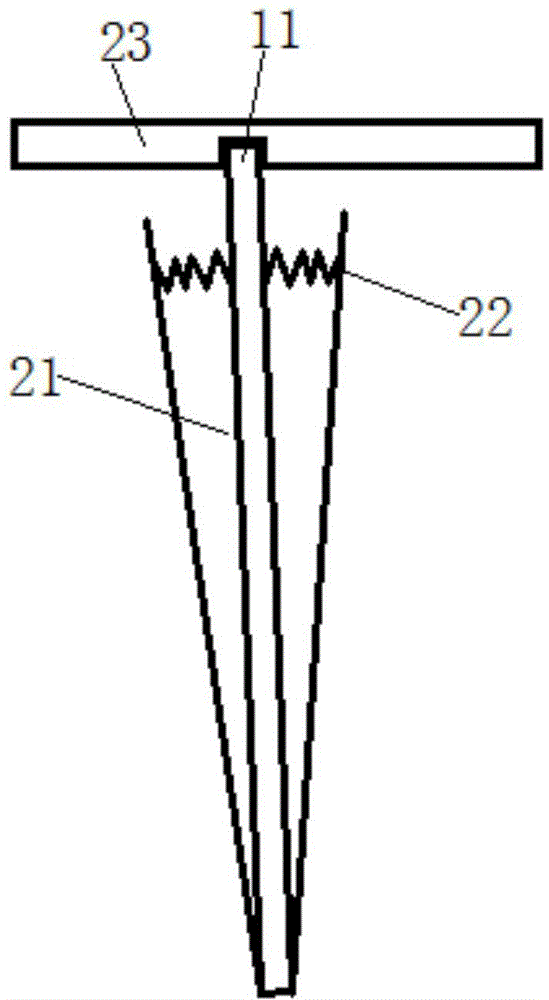

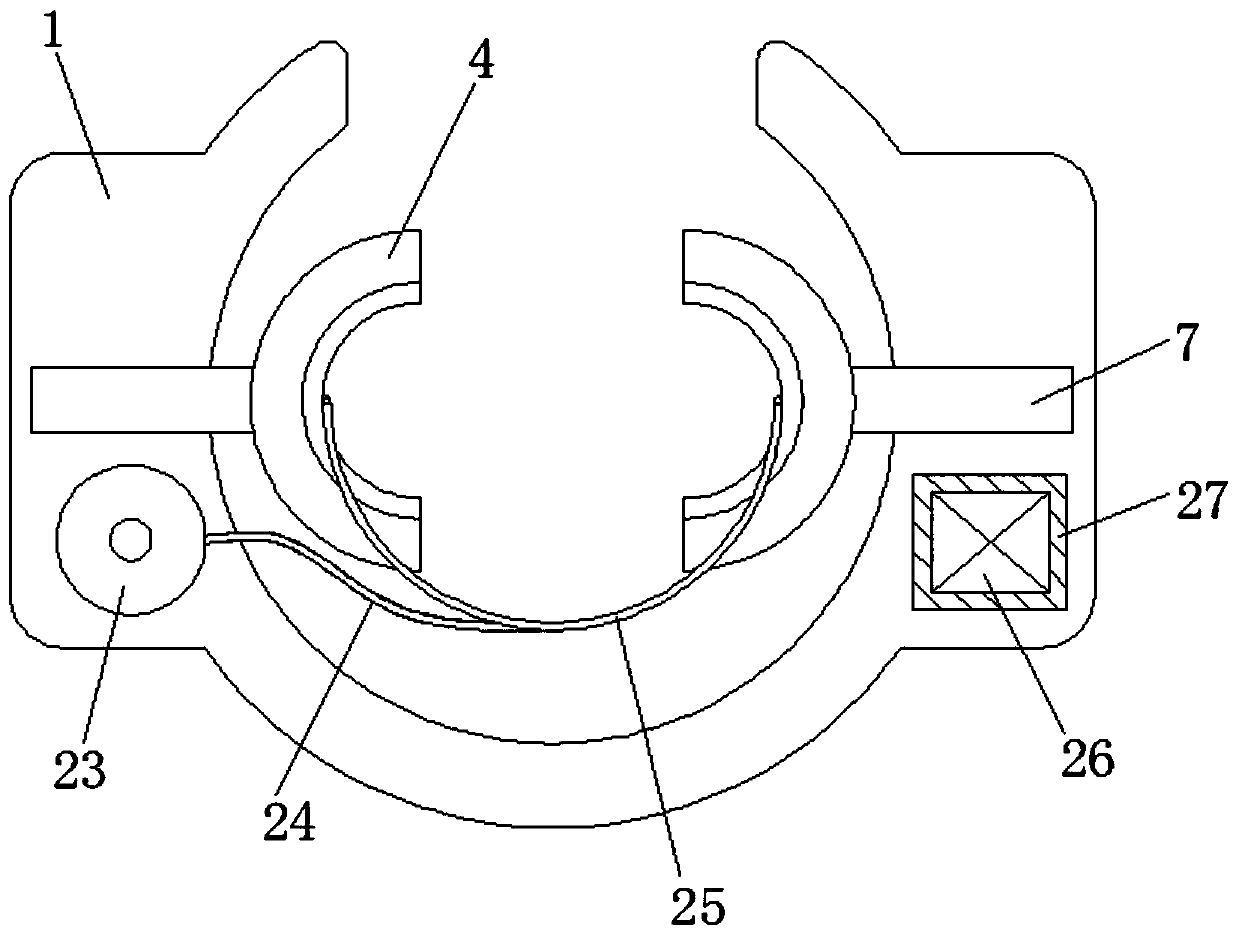

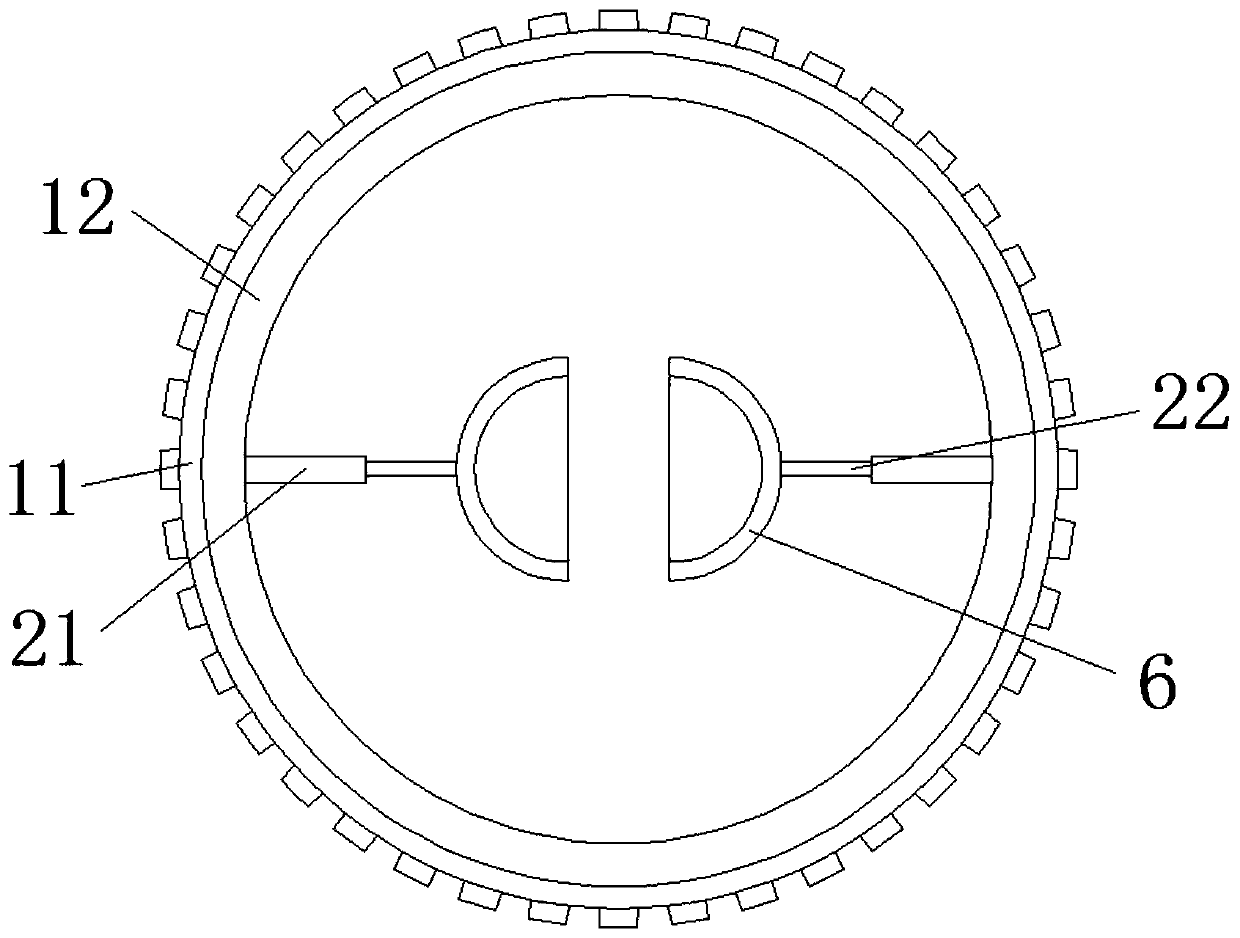

Artificial cardiac valve and valve bracket for same

The invention discloses an artificial cardiac valve and a valve bracket for the same. The valve bracket is an elastic bracket which can be axially contracted, and is hollowed. U-shaped openings are formed in a manner opposite to valve leaflets in the valve bracket. By the hollowed valve bracket with the U-shaped openings, integral metal structures of the cardiac valve are greatly reduced to facilitate the loading and recovery of intervention and implantation and reduce the repellence of a human body to an implantable appliance.

Owner:VENUS MEDTECH (HANGZHOU) INC

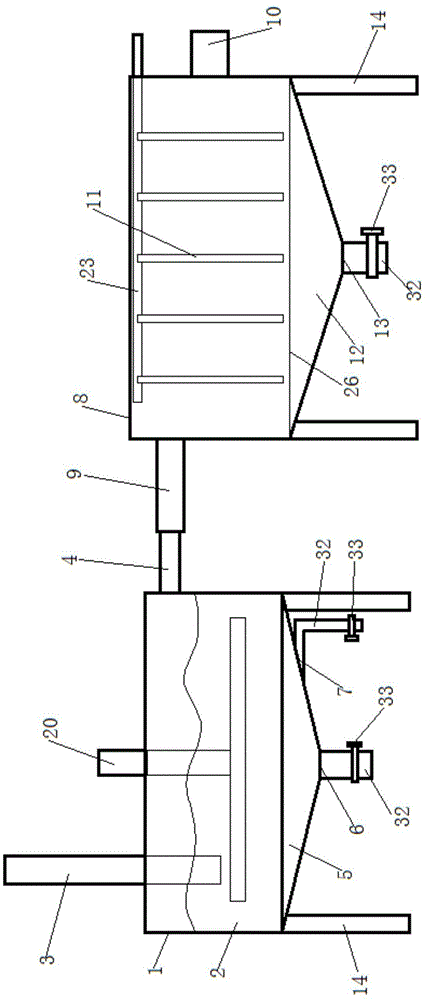

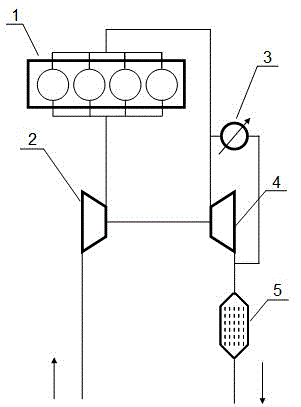

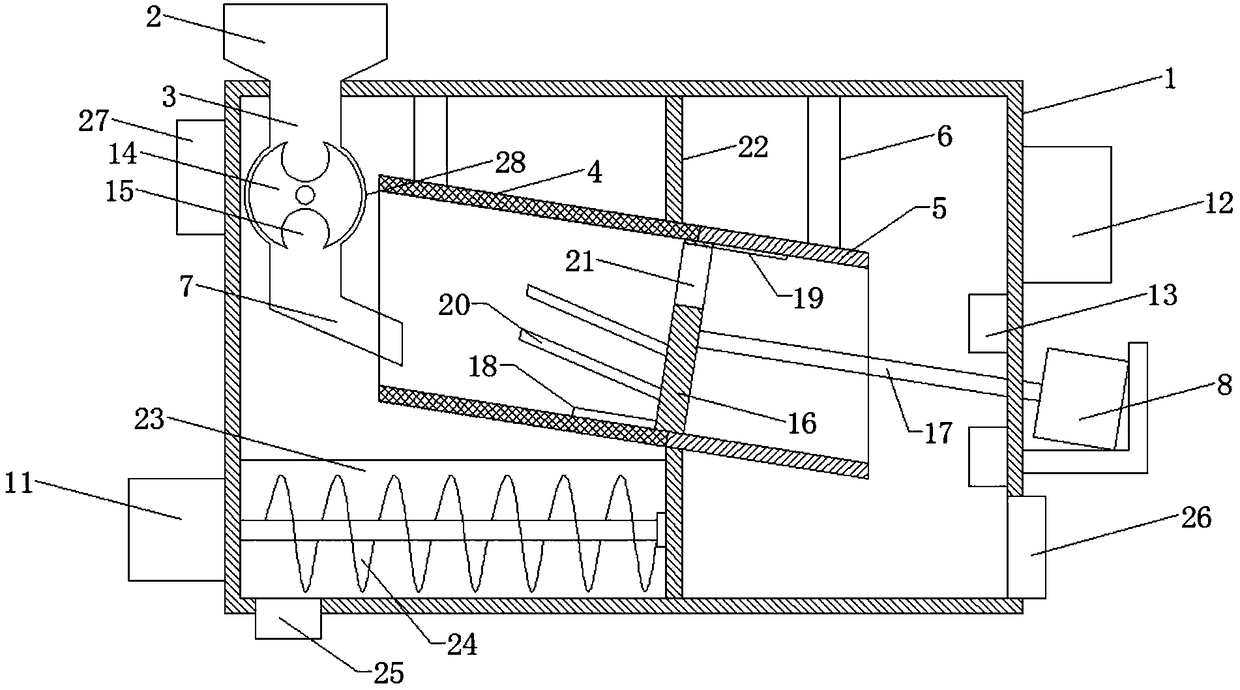

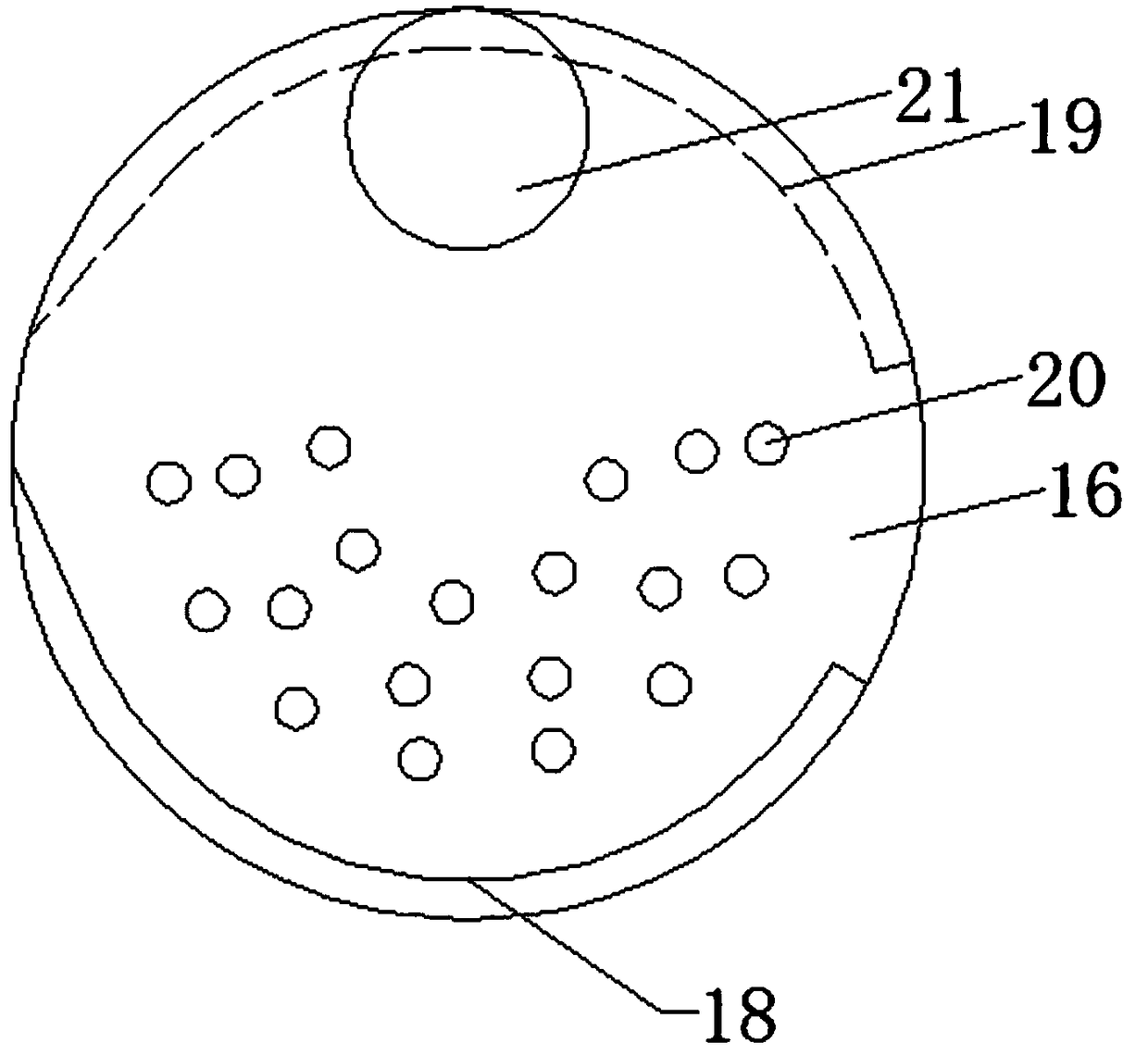

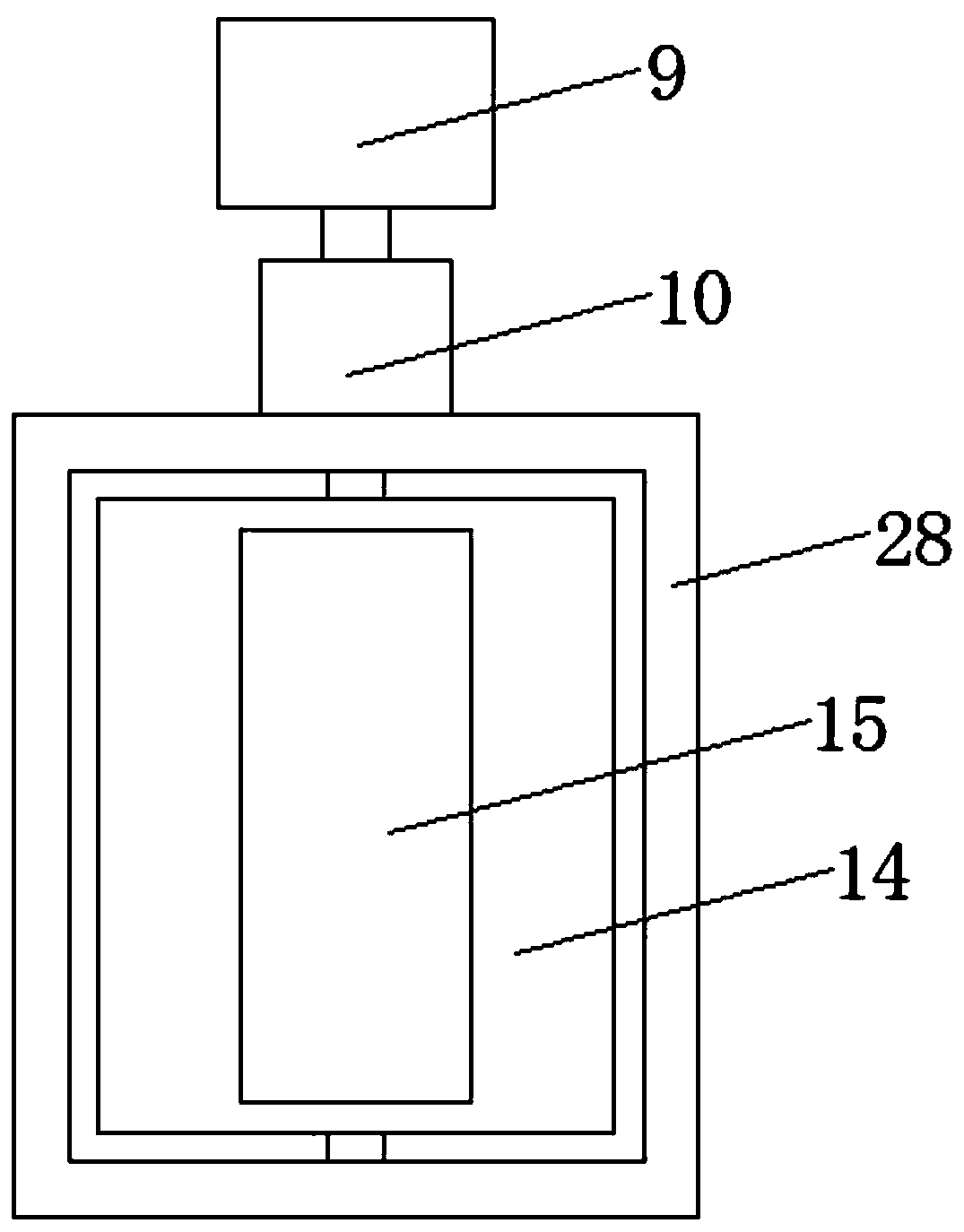

Workshop waste gas dust removal device

ActiveCN104587783AAvoid the impact of dust removalQuality assuranceCombination devicesExhaust fumesEngineering

The invention discloses a workshop waste gas dust removal device and belongs to the field of air purification devices. The dust removal device comprises a liquid dust removal device and a solid dust removal device, wherein the liquid dust removal device comprises a liquid dust removal box; water is contained in the liquid dust removal box; a first gas inlet pipe is arranged at the top of the liquid dust removal box in the vertical direction; a first gas outlet pipe is arranged on the side wall, far away from the first gas inlet pipe, above the liquid dust removal box; the solid dust removal device comprises a solid dust removal box; a second gas inlet pipe and a second gas outlet pipe are respectively arranged on opposite side walls of the solid dust removal box; a filter screen is arranged on the solid dust removal box in the axis direction of the second gas inlet pipe and the second gas outlet pipe; the liquid dust removal device and the solid dust removal device are respectively arranged on a support frame. According to the workshop waste gas dust removal device, a dry-type dust remover and a wet-type dust remover are combined so that the air dust removal efficiency and quality are greatly improved.

Owner:广州尚洁环保科技股份有限公司

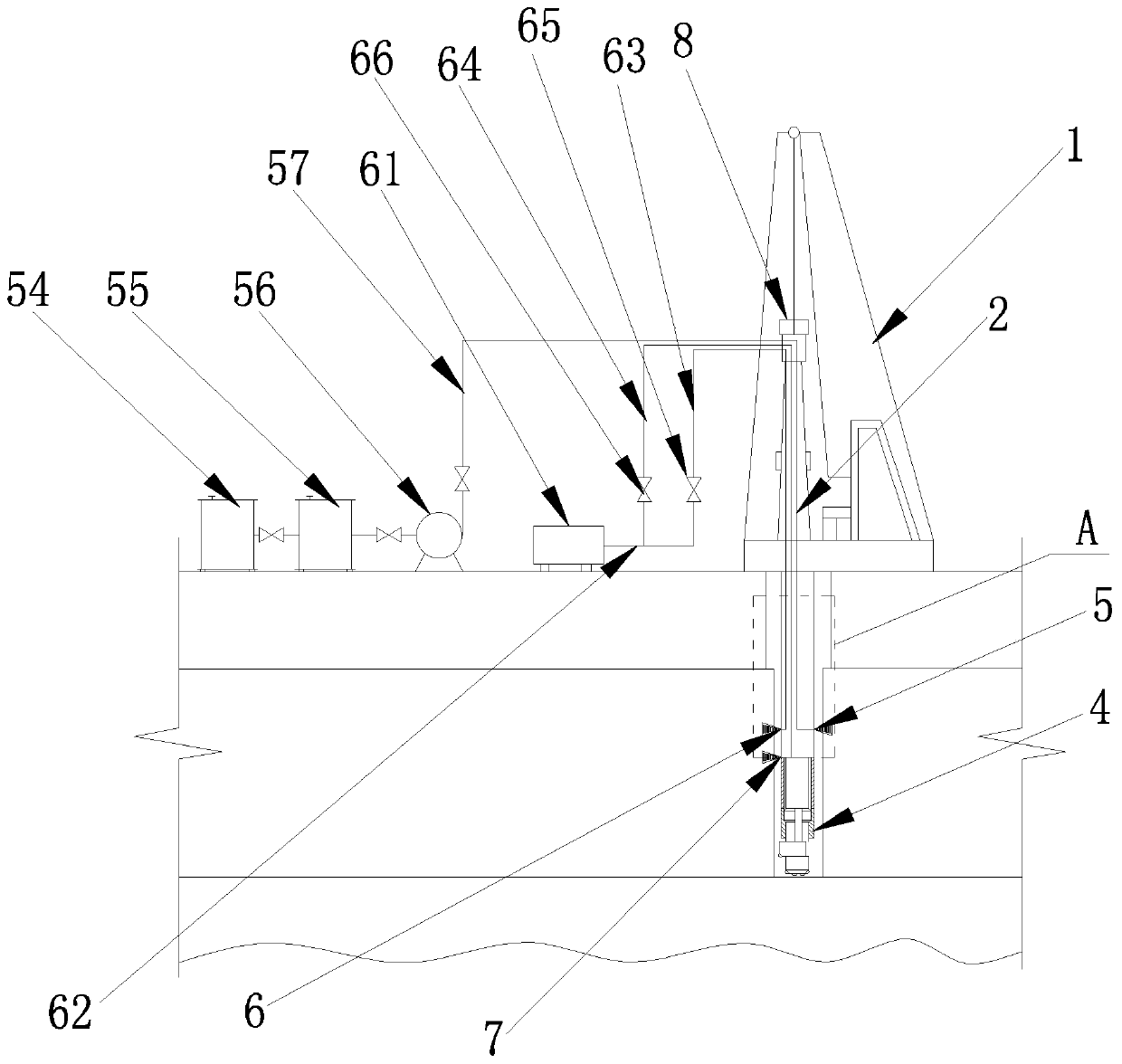

High-pressure jet grouting pile hole leading construction integrated device and construction method thereof

PendingCN111577136ASimple structureHigh pile strengthDirectional drillingBorehole drivesPipeUltimate tensile strength

The invention relates to a high-pressure jet grouting pile hole leading construction integrated device and a construction method thereof. The high-pressure jet grouting pile hole leading constructionintegrated device comprises a jet grouting drilling machine, a high-pressure jet grouting drill rod and a triple pipe, wherein the triple pipe is fixedly arranged at the bottom of the high-pressure jet grouting drill rod, and a down-the-hole hammer is fixedly arranged at the bottom of the triple pipe; and the triple pipe comprises a grout outlet ejector, an inner air outlet ejector and an outer air outlet ejector which are sequentially arranged from inside to outside. The high-pressure jet grouting pile hole leading construction integrated device is simple in structure, convenient to use and practical, the construction technology of combining the triple pipe and the down-the-hole hammer is adopted for the environment of a complex geological layer, and by optimizing construction technical parameters, an obtained pile body is high in strength and good in construction quality. Compared with a traditional high-pressure jet grouting pile construction method, the input mechanical materials are few, the cost is low, construction is safe, and construction is rapid.

Owner:浙江岩科建设有限公司

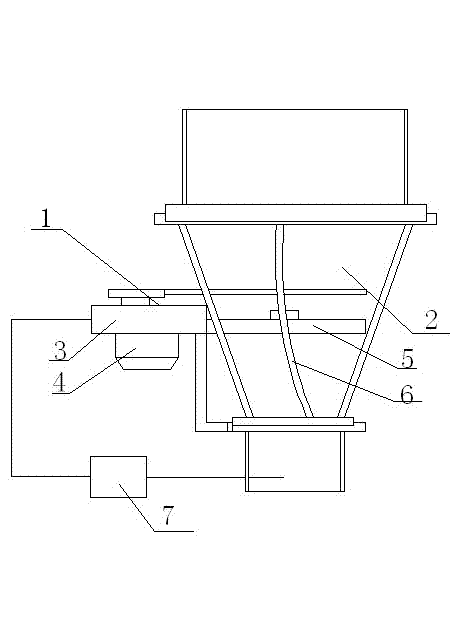

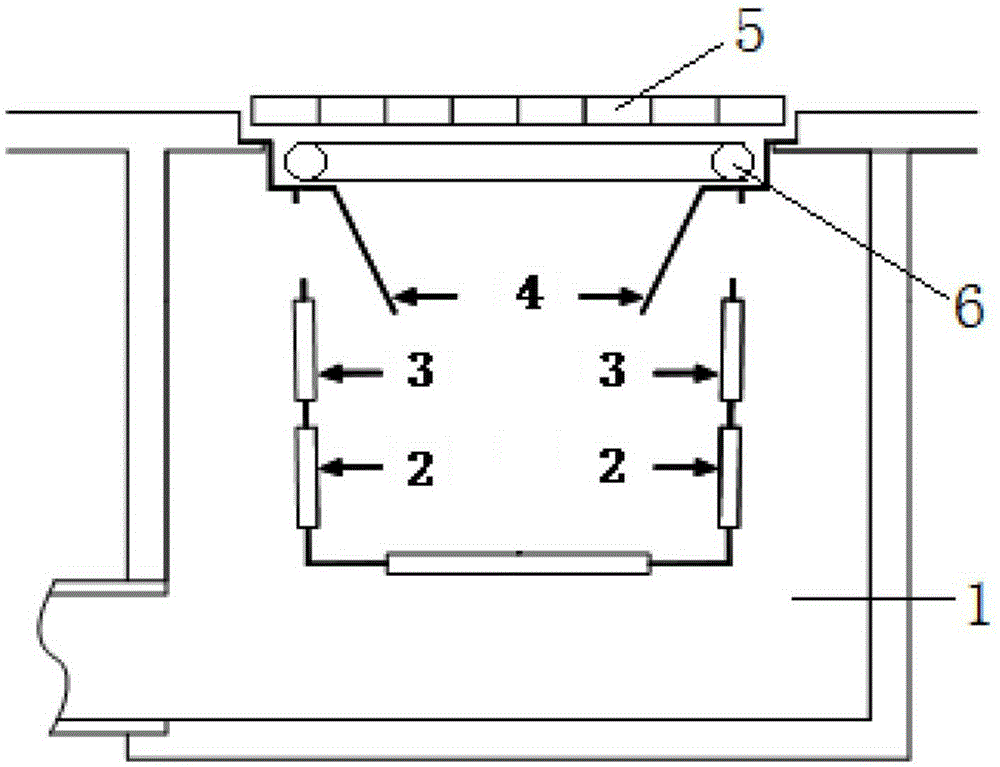

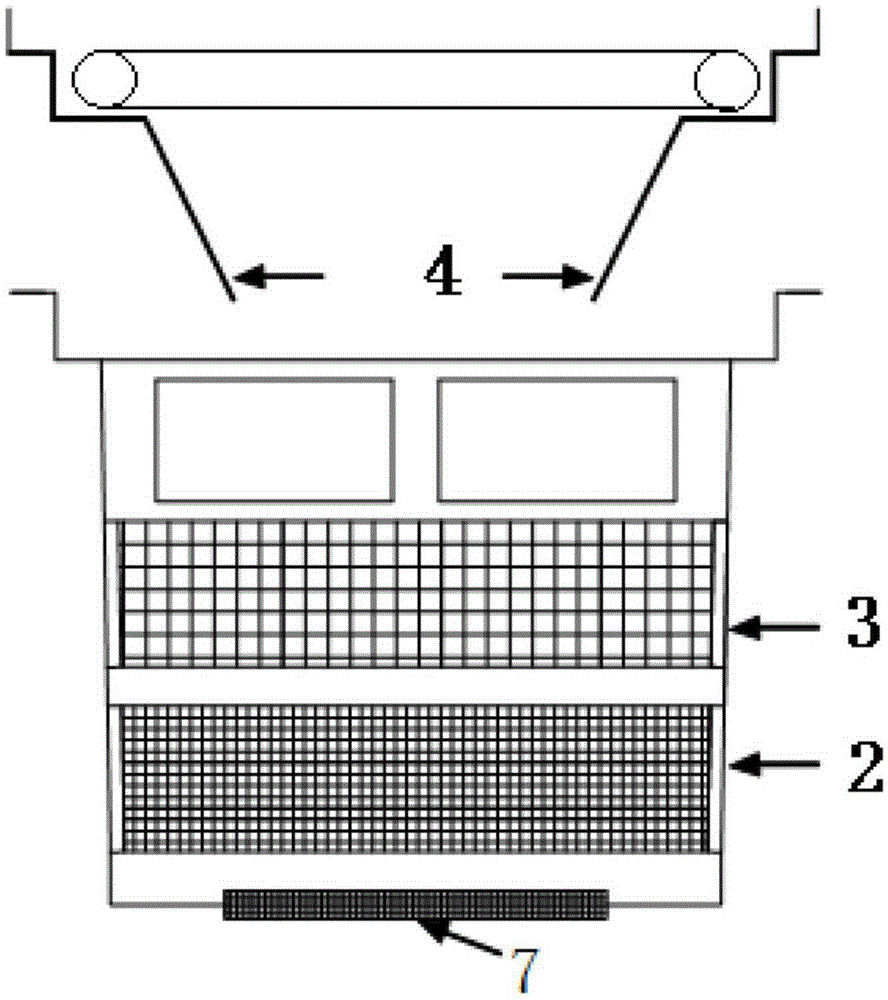

Storage bin automatic detection blockage clearing device

The invention relates to a storage bin automatic detection blockage clearing device. The storage bin automatic detection blockage clearing device consists of a storage bin blockage clearing device and an automatic control system which is connected with the storage bin blockage clearing device, wherein the storage bin blockage clearing device is arranged on a lower storage bin section. The storage bin automatic detection blockage clearing device can solve the problems of bulk material bridging and arched blockage of the lower part of a bin body of a conical storage bin or a hyperbolic storage bin, the blockage clearing area is large, coagulated arched blockage, bridging blockage, freezing, funnel flow and groove-like flow are absolutely cleared, and automatic detection blockage clearing can be realized.

Owner:山东天元节能环保工程有限公司

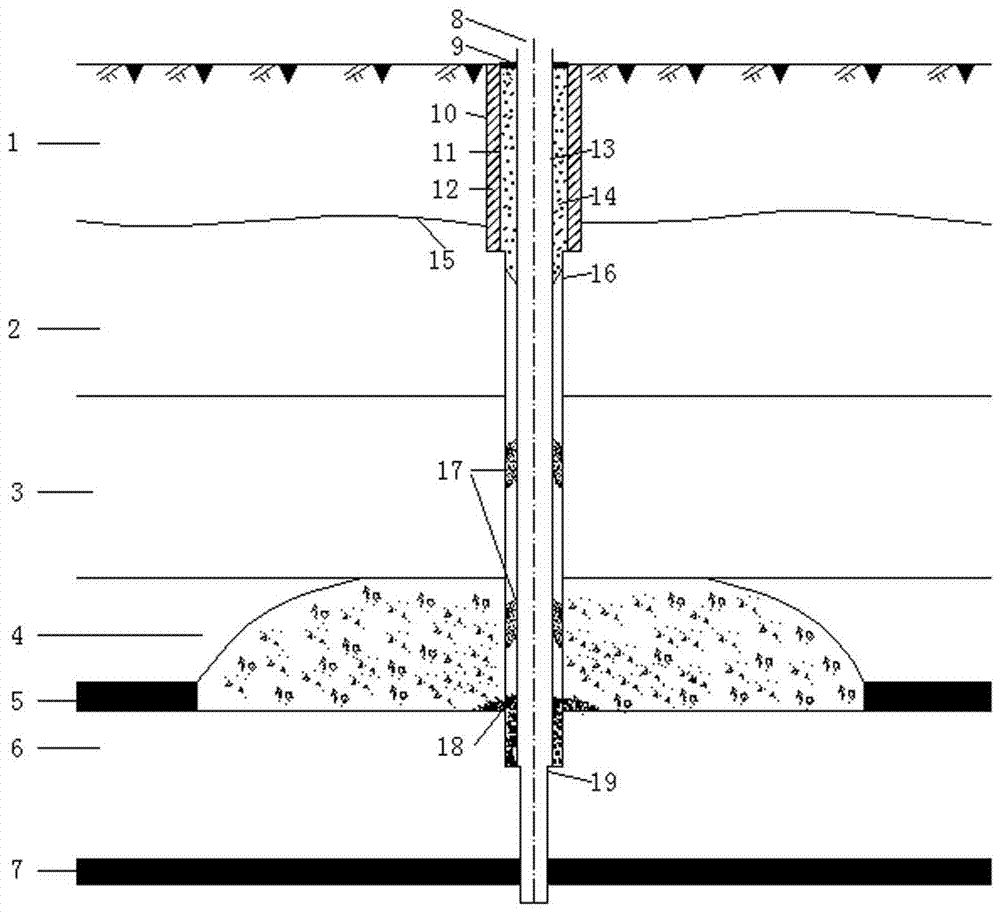

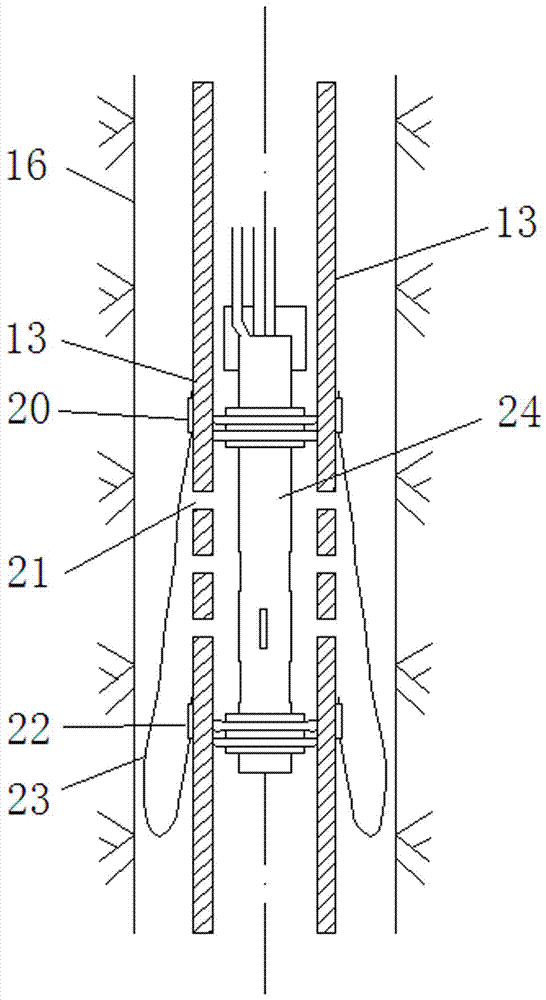

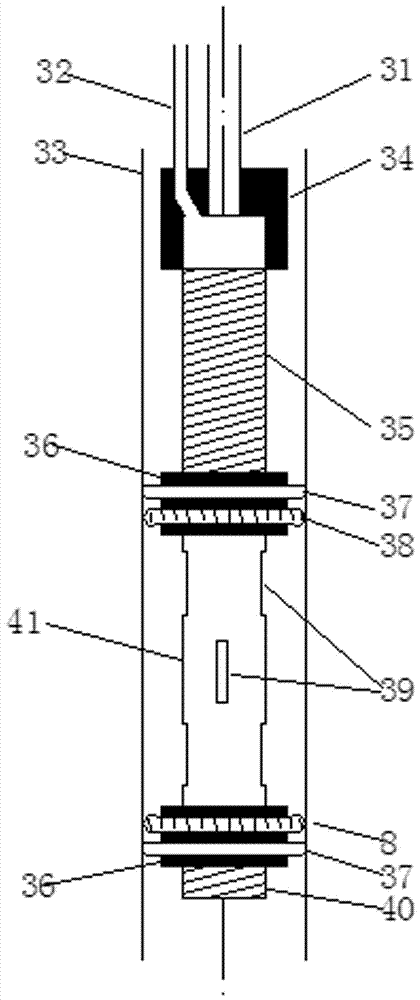

Multi-joint intensive grouting well-reinforcing method for reinforcing coal-bed gas well penetrating through goaf

ActiveCN107313745AImprove long-term stabilityGuaranteed flowSealing/packingWell drillingWell cementing

The invention belongs to the technical field of coal-bed gas exploitation and provides a multi-joint intensive grouting well-reinforcing method for reinforcing a coal-bed gas well penetrating through a goaf. According to the method, the problems that during passing-through of the goaf, the third spud-in well-drilling construction process is complex, and the stability of a third spud-in well body structure is poor are solved. The third spud-in drilling construction process is adopted; a well body of the coal-bed gas well is composed of a first spud-in drilled hole, a surface casing, a second spud-in drilled hole, an intermediate casing and a third spud-in drilled hole; when third spud-in drilling is constructed, multi-joint grouting reinforcing is conducted on well wall surrounding rock outside the intermediate casing, so that the strength of the well wall surrounding rock is improved, long-term stability of the coal-bed gas well is guaranteed, and the stabilized intermediate casing is directly used as the production casing of the coal-bed gas well. A multi-joint cement paste wrapped body supporting structure is formed between the intermediate casing and the well wall surrounding rock, the long-term stability of the well wall surrounding rock of the coal-bed gas well and the well body structure can be strengthened greatly.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +2

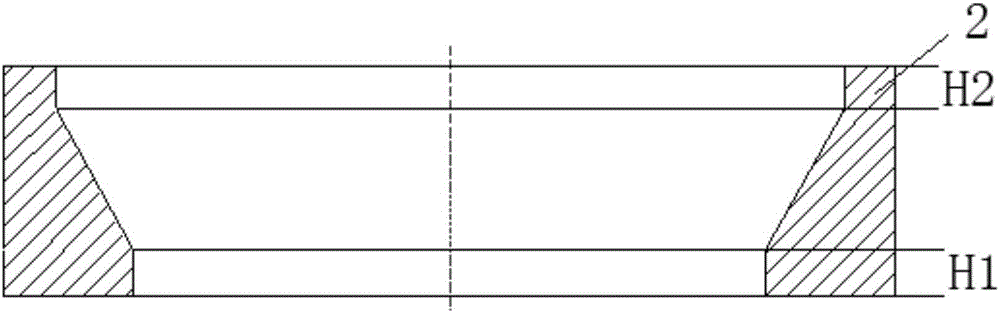

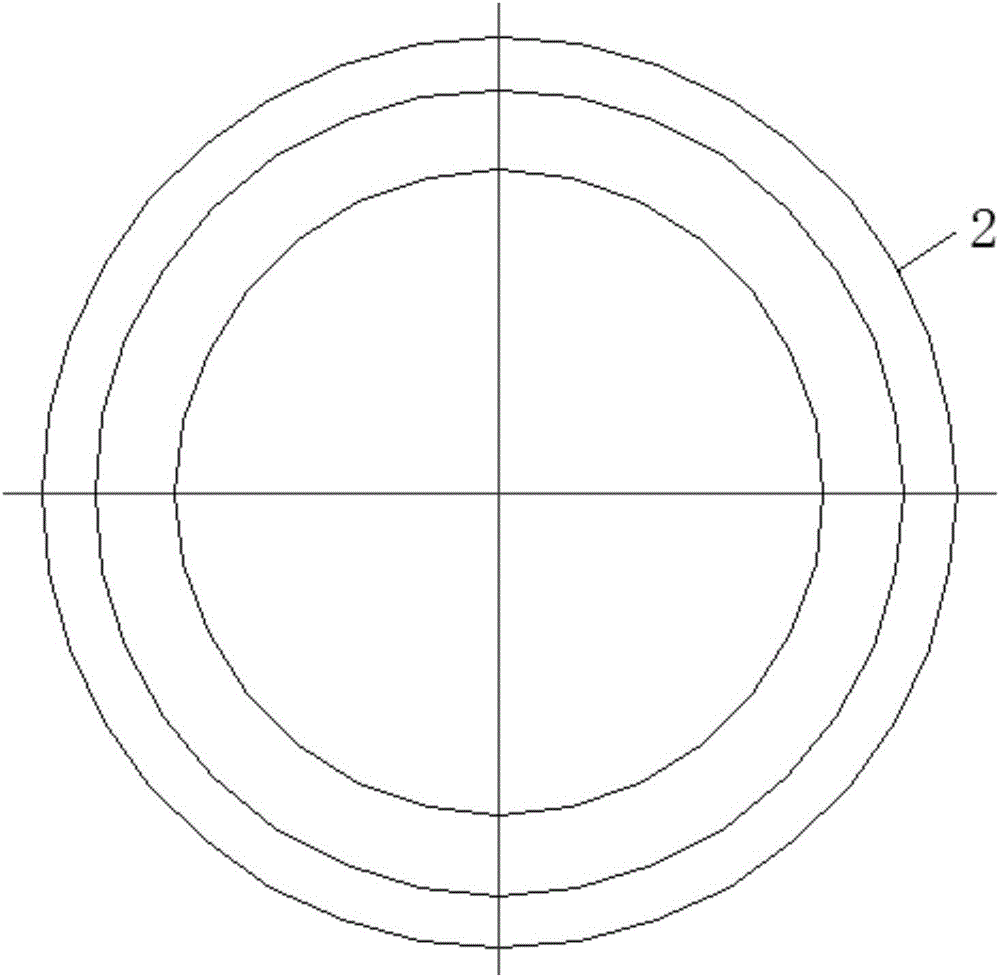

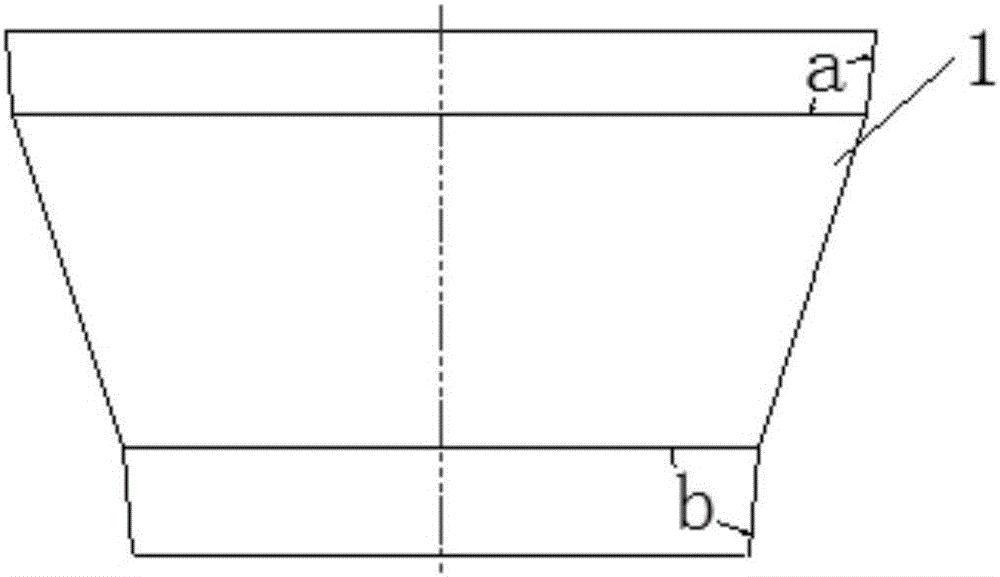

Free forging method for conical inner hole ring type forge piece

ActiveCN106583612AGuaranteed internal flowExtended service lifeMetal-working apparatusRing typeForging

The invention discloses a free forging method for a conical inner hole ring type forge piece. The free forging method includes the steps that firstly, a blank is manufactured, secondly, an inner hole is expanded, wherein a cylindrical saddle is used for broaching the blank to the required size, then an expanded punch is used for expanding the inner hole, and a blank with the initial early form is obtained; thirdly, broaching is conducted, wherein a conical saddle horizontally penetrates the inner hole of the blank, a flat anvil is used for downwards pressing the outer circle of the blank, the conical saddle is used for expanding the inner hole of the blank, the blank is rotated by 12 degrees to 15 degrees after each time of downward pressing, circulation is conducted in order, and the inner hole of the blank is preliminarily formed; and fourthly, the inner hole is subjected to secondary finishing, wherein the conical saddle is used for conducting broaching again to reach the required size of the finished forge piece, the end face is flattened, final forming is achieved after finishing, the rotating angle is reduced properly in the finishing stage, the blank is rotated by 8 degrees to 10 degrees after each time of downward pressing, and the finished forge piece is obtained. According to the method, the equipment and the technology are simple, and the product quality is reliable.

Owner:MCC SFRE HEAVY IND EQUIP

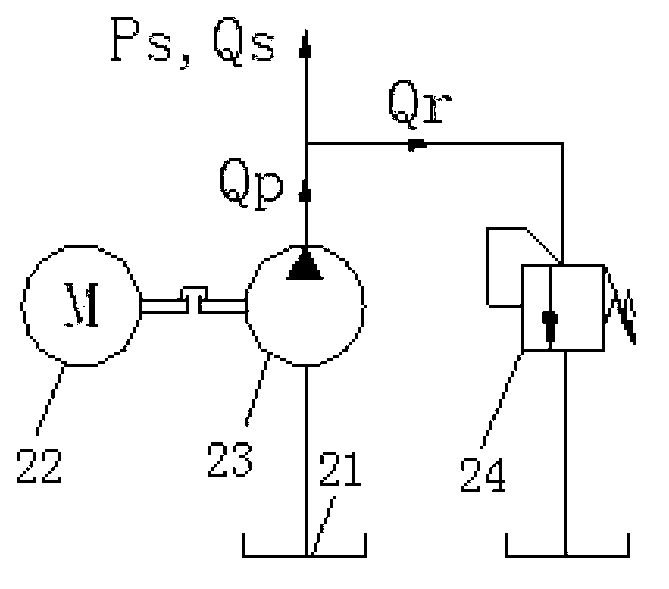

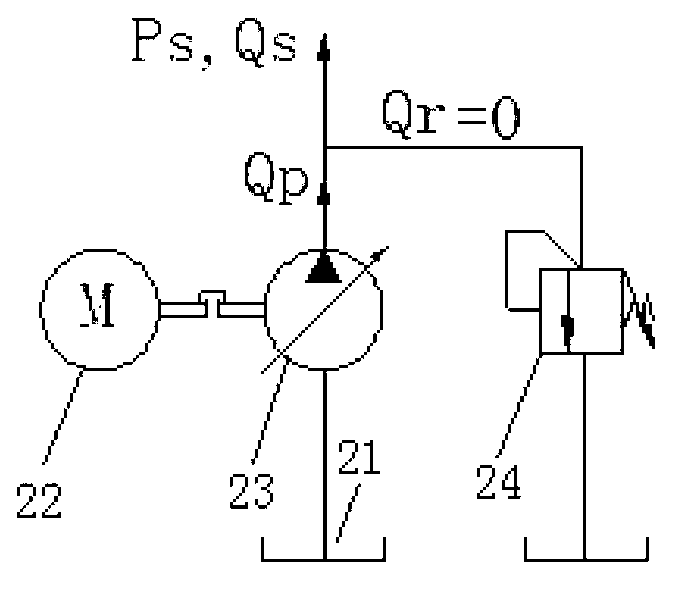

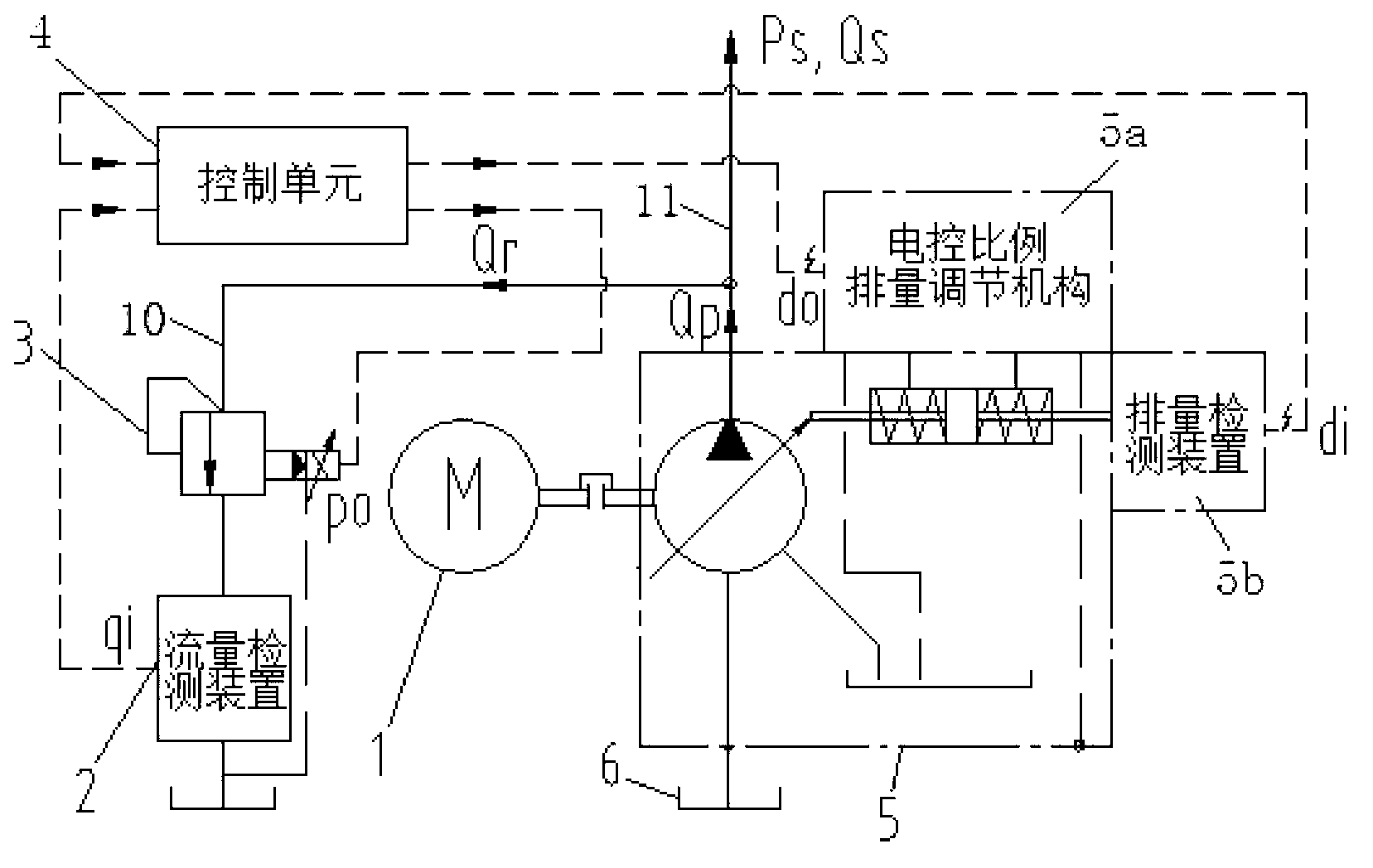

Hydraulic oil supply unit, hydraulic power unit and oil supply control method of hydraulic oil supply unit

ActiveCN103016466AHigh pressure regulation accuracyGuaranteed flowFluid-pressure actuator componentsElectricityHydraulic pump

The invention relates to a hydraulic oil supply unit which comprises an oil flow regulating device, an oil pressure regulating device, a control unit (4) and an oil supply control oil way (10), wherein the oil supply control oil way (10) is provided with a flow detection device (2); one of the oil flow regulating device and the oil pressure regulating device is arranged on the oil supply control oil way (10), and the other one is used for controlling a hydraulic pump; the oil flow regulating device and the oil pressure regulating device are respectively and electrically connected with the control unit (4), so as to regulate the oil flow (Qs) and the oil pressure (Ps) of the hydraulic oil supply unit through the control of the control unit; and the flow detection device (2) is electrically connected with the control unit. In addition, the invention further provides an oil supply control method and a hydraulic power unit of the hydraulic oil supply unit. In the aspects of constant pressure oil supply control, constant-current source oil supply control and the like, the hydraulic oil supply unit, the hydraulic power unit and the oil supply control method have the advantages of higher control flexibility, wider applicability and better energy saving, and the control precision is obviously increased.

Owner:ZOOMLION HEAVY IND CO LTD

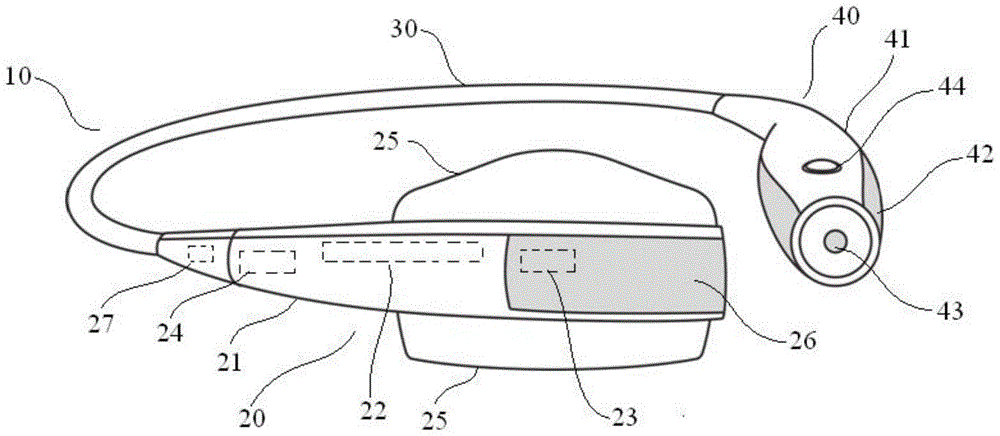

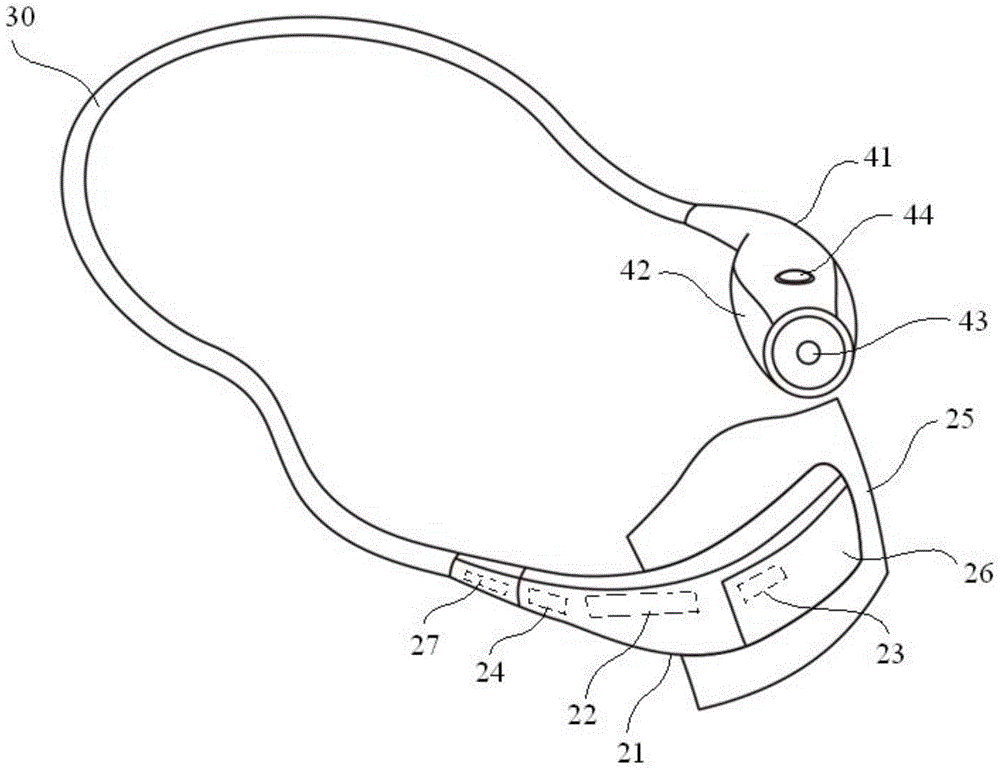

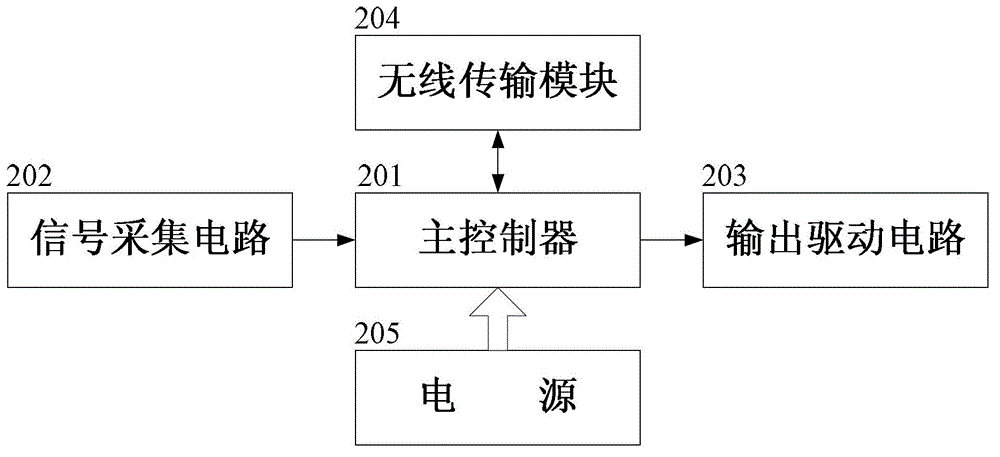

Wearable intelligent atomization inhalation device

The invention relates to a wearable intelligent atomization inhalation device which comprises a bendable fixing support. The bendable fixing support is of a three-section type structure and comprises a fog outlet unit section, a connecting section and a fog outlet control section which are connected in sequence. The fog outlet control section comprises a first support shell, a PCB control board, an expiration and inspiration signal sensing assembly and a power source, wherein the PCB control board, the expiration and inspiration signal sensing assembly and the power source are arranged in the first support shell. The PCB control board is connected with the expiration and inspiration signal sensing assembly, the power source and the fog outlet unit section. The PCB control board obtains the breathing state of a user through the expiration and inspiration signal sensing assembly, when the breathing state of the user is in the inspiration state, the fog outlet unit section is controlled to discharge fog, and when the breathing state of the user is the expiration state, the fog outlet unit section is controlled to stop atomizing. Compared with the prior art, the wearable intelligent atomization inhalation device has the advantages of being capable of preventing liquid medicine from being wasted and air from being polluted, convenient to use and the like.

Owner:苏州雾联医疗科技有限公司

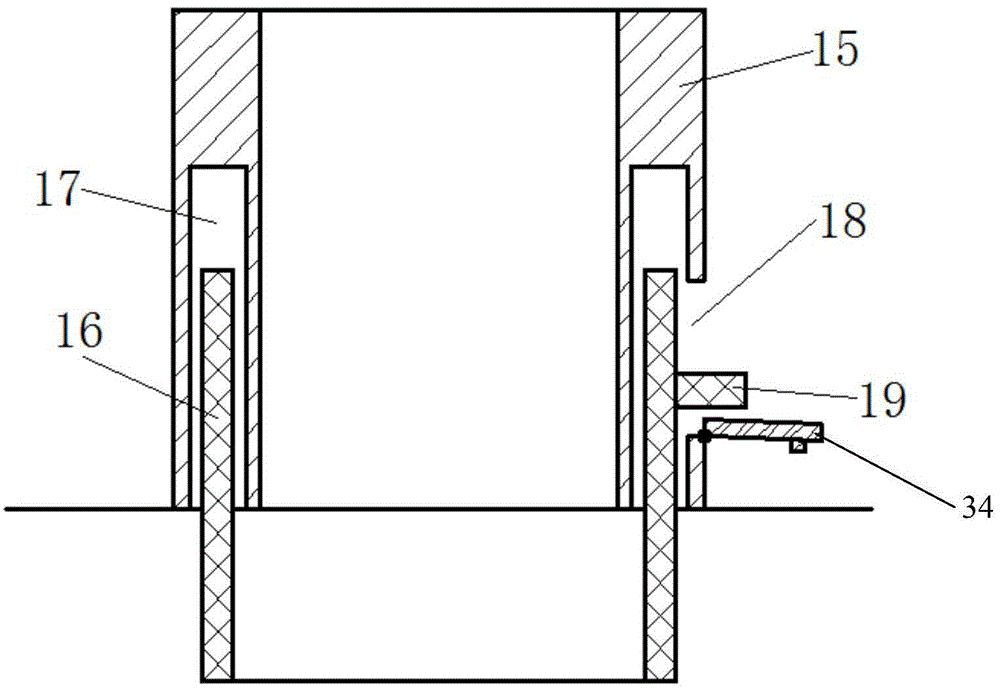

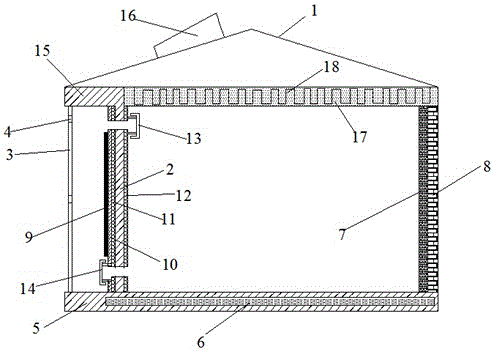

Solar heat accumulation type passive solar house

ActiveCN106545096AHigh yieldIncrease storage capacitySolar heating energySolar heat devicesIsolation layerSolar water

The invention discloses a solar heat accumulation type passive solar house. A solar water heater communicates with a roof warming assembly. A passive ventilation heat exchange wall is arranged on the inner side of a glass seal plate. An upper ventilation assembly is arranged on the upper portion of the passive ventilation heat exchange wall. A lower ventilation assembly is arranged on the upper portion of the passive ventilation heat exchange wall. By means of the upper ventilation assembly, gas flow is made to flow to the indoor portion from a cavity; and by means of the lower ventilation assembly, the gas flow is made to flow to the cavity from the indoor portion. By arranging the passive ventilation heat exchange wall, by means of an outer honeycomb structure heat conduction layer, an inner honeycomb structure heat conduction layer and a honeycomb porous structure, the absorption rate and storage amount of solar energy are increased, and heat in a phase change heat storage box can be slowly released to the indoor portion; the loss of energy consumed by the underground portion is reduced through a water isolation layer according to the property that the specific heat capacity of water is large; and by means of the upper ventilation assembly and the lower ventilation assembly, the flow direction of the gas flow can be ensured, circulation of the indoor gas flow is achieved, and the effect that hot gas inflows from the upper portion and cold gas outflows from the lower portion is ensured.

Owner:HUITONG ROAD & BRIDGE CONSTR GROUP

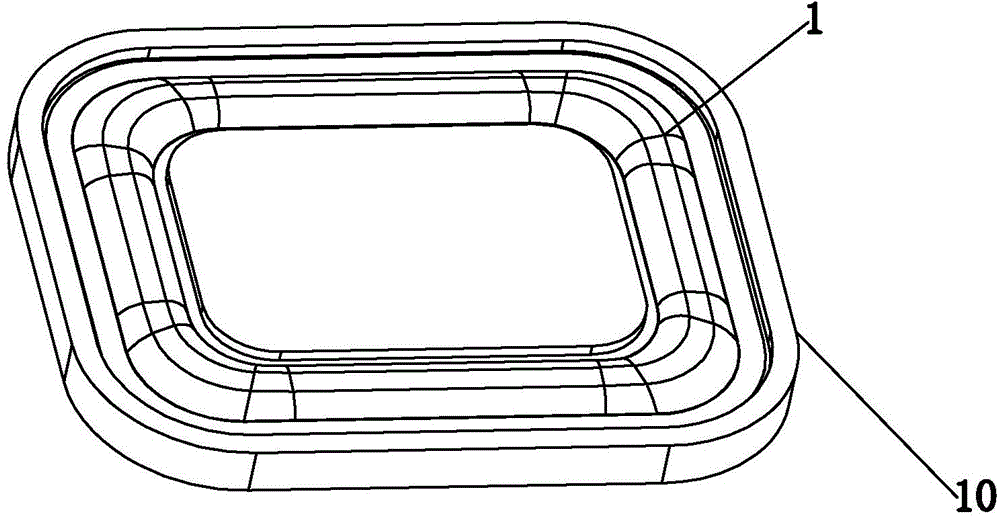

Micro loudspeaker

The invention discloses a micro loudspeaker which comprises a vibrating diaphragm and a housing, wherein the vibrating diaphragm comprises a ball top and a folding ring part, and is supported and fixed through the housing; a combined part is arranged at the part, connected with the housing, of the edge of the vibrating diaphragm; the combined part of the vibrating diaphragm is adhered and fixed to the housing through an adhesive layer; the combined part of the vibrating diaphragm is combined with a bonding surface of the upper surface of the housing; an excessive glue groove used for accommodating excessive glue is formed in the edge of the outer side of the bonding surface and is covered with the edge of the outer side of the combined part of the vibrating diaphragm. The micro loudspeaker disclosed by the invention has the advantages that the excessive glue groove is formed in the bonding surface of the vibrating diaphragm and the housing, so that excessive glue generated during the process of vibrating diaphragm fixing can be fully adsorbed, the situation that the periphery of the vibrating diaphragm cannot be fixed and a magnetic circuit system is damaged due to uneven gluing is avoided, and meanwhile, the normal flow direction of glue can be ensured and the glue is prevented from moving upwards, therefore, the fixing of the vibrating diaphragm is completed better and the performance of the loudspeaker is ensured.

Owner:GOERTEK INC

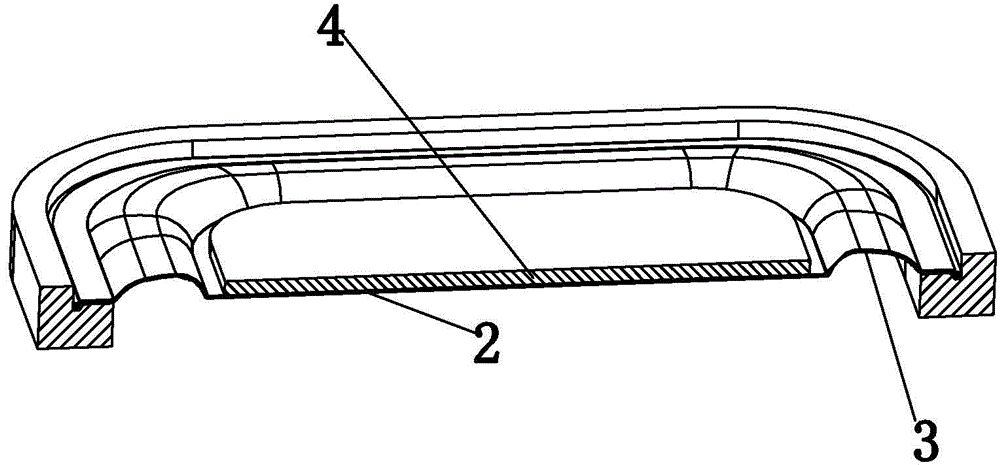

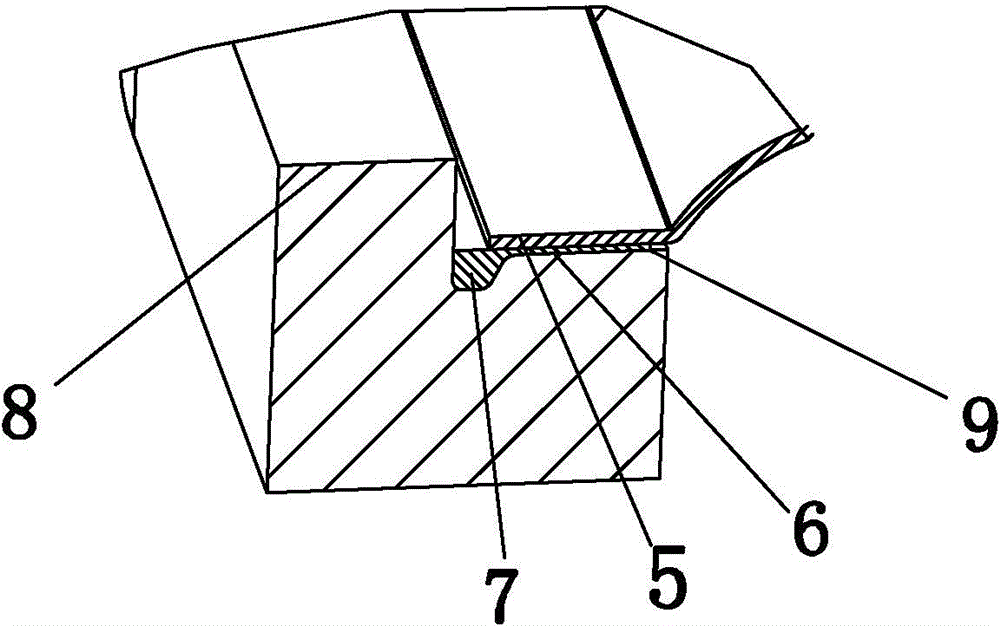

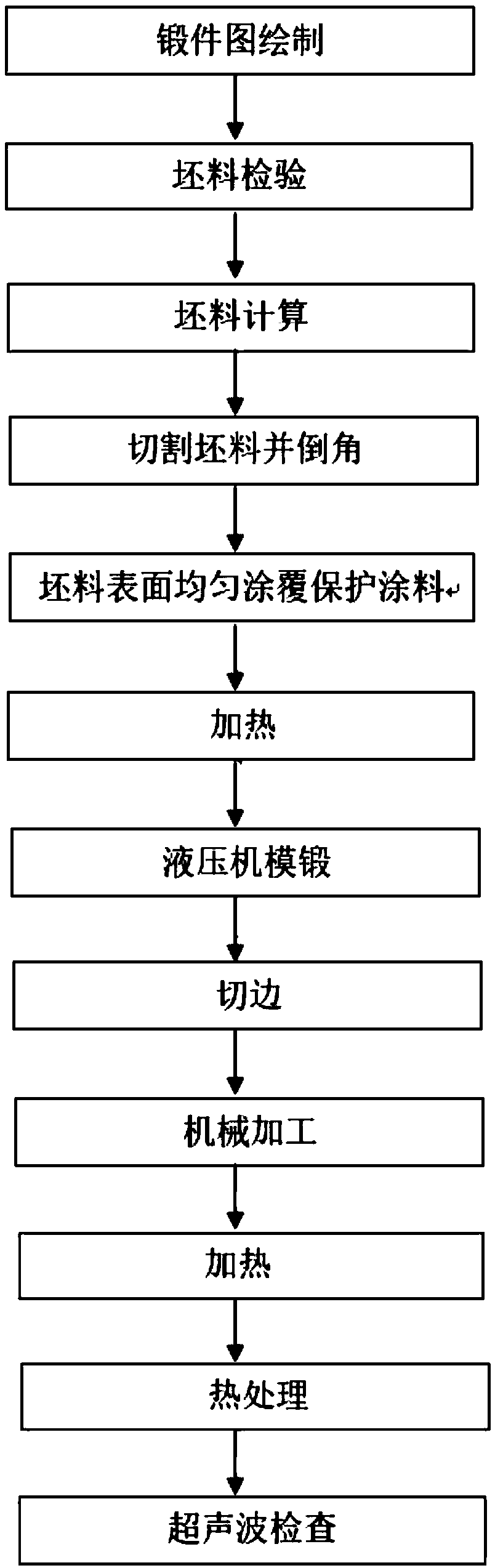

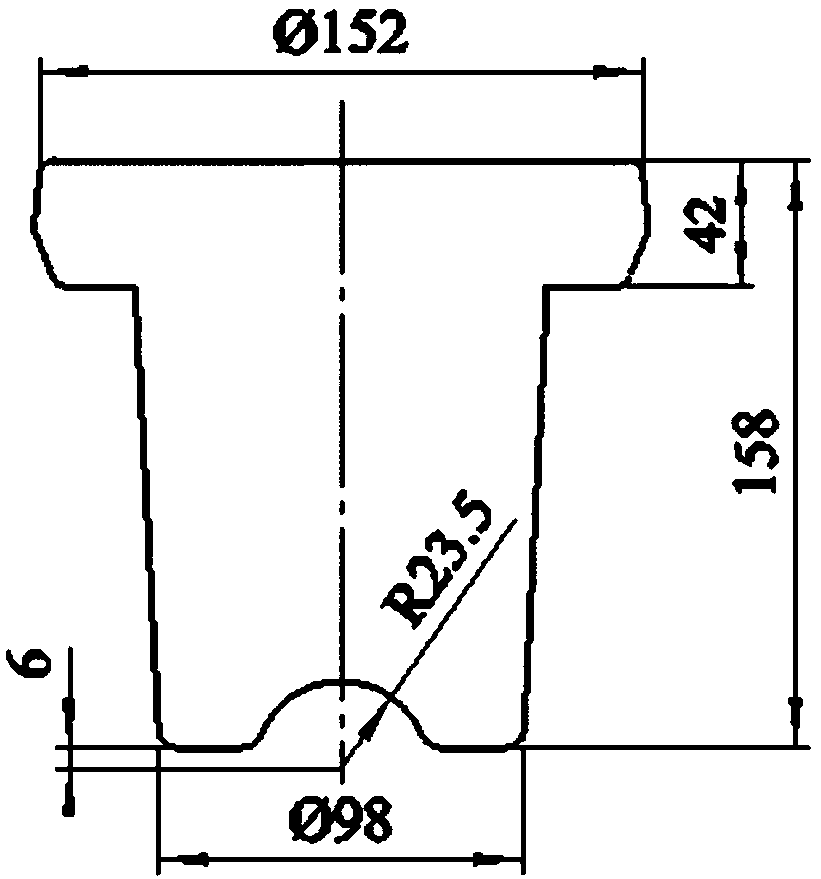

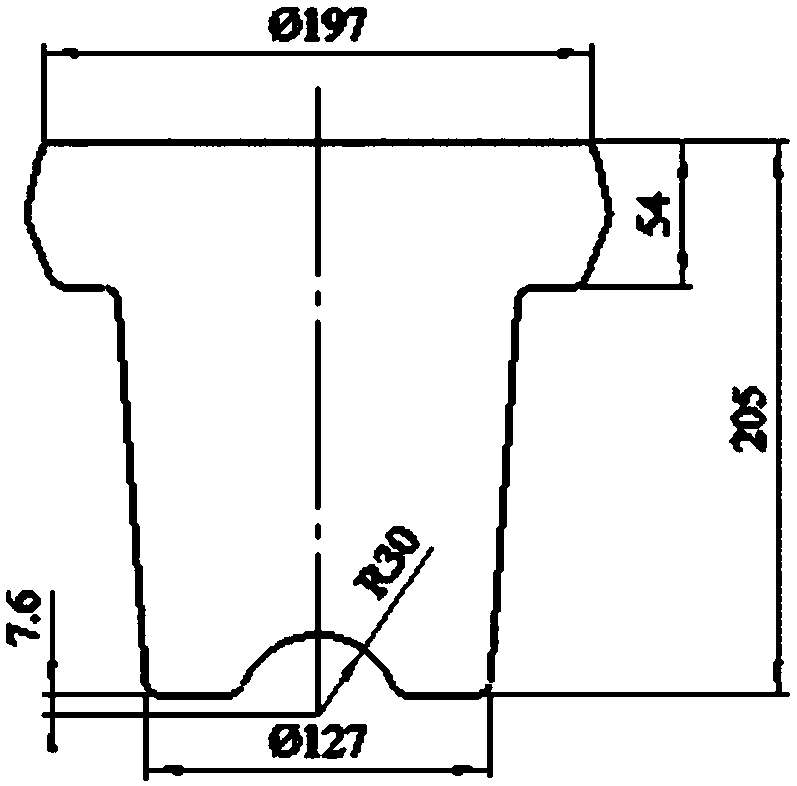

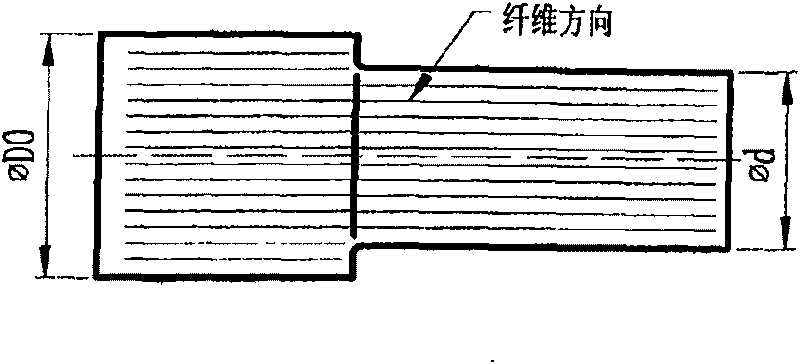

Die forging forming method of TC4 titanium alloy round-T-shaped forge piece

InactiveCN109352279AOptimizing the shape of the bottomGuaranteed flowHeating/cooling devicesMetal formingTitanium alloy

The invention discloses a die forging forming method of a TC4 titanium alloy round-T-shaped forge piece. The primary alpha phase of an adopted blank is 55 to 90%, heating before blank forging is carried out, and the process of one-time temperature rise and two-time heat preservation is carried out in an electric furnace. According to the method, raw materials are strictly controlled, according tothe proportion range of the blank primary alpha phase, the forging temperature is determined, the bottom shape of the force piece is optimized, metal forming is facilitated, precise control over the forge piece structure is achieved, fire forming is adopted, the streamline, the structure and the performance of the forge piece are ensured, and the forge piece structure and performance consistency are improved.

Owner:AECC AVIATION POWER CO LTD

Waste gas bypass valve of turbocharger

ActiveCN104948295AIncrease temperatureReduce absorptionInternal combustion piston enginesTurbochargerBypass valve

The invention discloses a waste gas bypass valve of a turbocharger. The waste gas bypass valve is provided with a bypass flow channel and a valve element, a gas inlet and a gas outlet of a turbine are communicated through the bypass flow channel, and the valve element is used for opening or closing the opening part of the bypass flow channel. The valve element comprises a valve rod part and a valve plate part connected to the valve rod part, the valve rod part can axially move so that the valve plate part can be driven to horizontally move along the end face of the opening part of the bypass flow channel, and the end face of the opening part is opened or closed through the valve plate part. The waste gas bypass valve can improve control precision of an engine under various load work conditions, and enhance sealing performance of the waste gas bypass valve of the engine under a high load.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

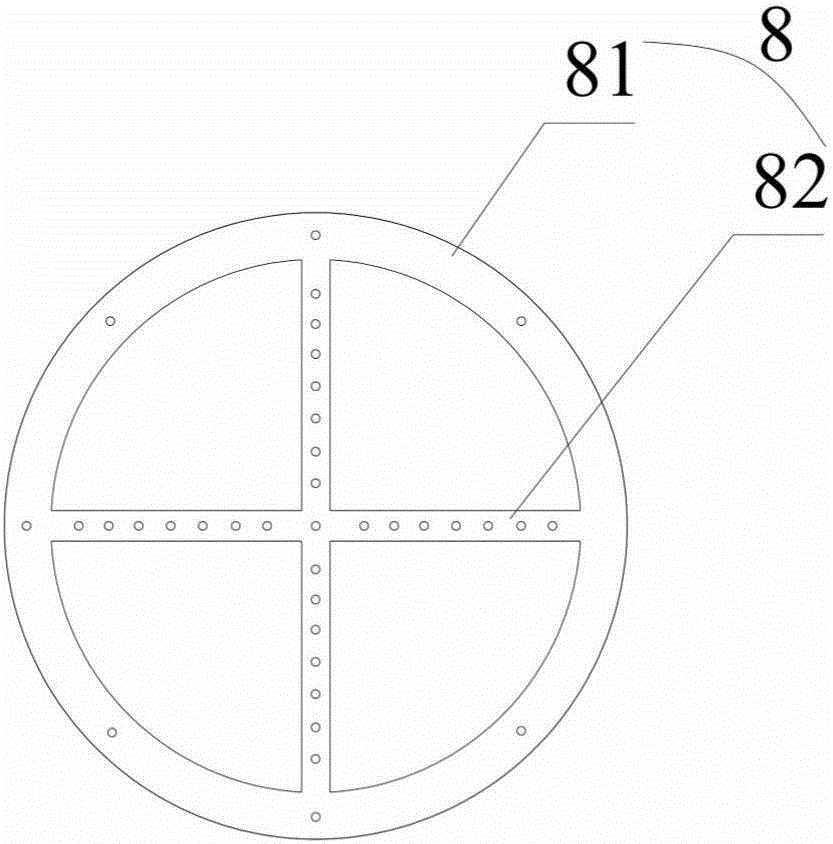

Rainwater inlet trash barrier sieve used for filtering initial rainwater

ActiveCN105401649AReduce pollutionReduce turbulenceFatty/oily/floating substances removal devicesSewerage structuresNitrogenEngineering

The invention discloses a rainwater inlet trash barrier sieve used for filtering initial rainwater. The rainwater inlet trash barrier sieve comprises a rainwater opening with the lower portion communicated with a municipal pipeline. A rainwater grate is arranged at the upper end of the rainwater opening. At least one filtering layer is arranged below the rainwater grate. Nitrogen and phosphorus adsorbing structures are arranged between the rainwater grate and the filtering layers. Flow guide plates guiding the rainwater to the filtering layers are arranged under the rainwater grate. The trash barrier sieve has the advantages that the nitrogen and phosphorus adsorbing structures are used for effectively adsorbing nitrogen and phosphorus elements in the rainwater, river channel pollution caused by the rainwater is effectively reduced, the filtering layers are used for filtering large blockages and small sundries carried in the rainwater, the situation that the municipal pipeline is blocked by impurities is effectively avoided, and by arranging the flow guide plates, it is effectively ensured that the rainwater passes through the filtering layers first and then flows into the municipal pipeline.

Owner:SHANDONG UNIV +1

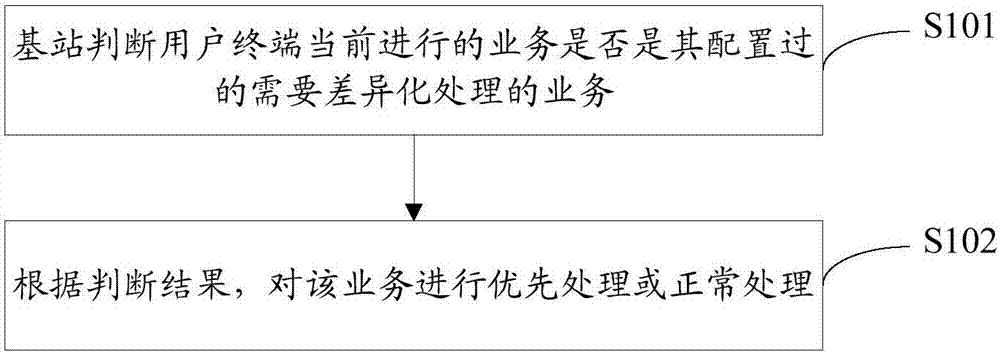

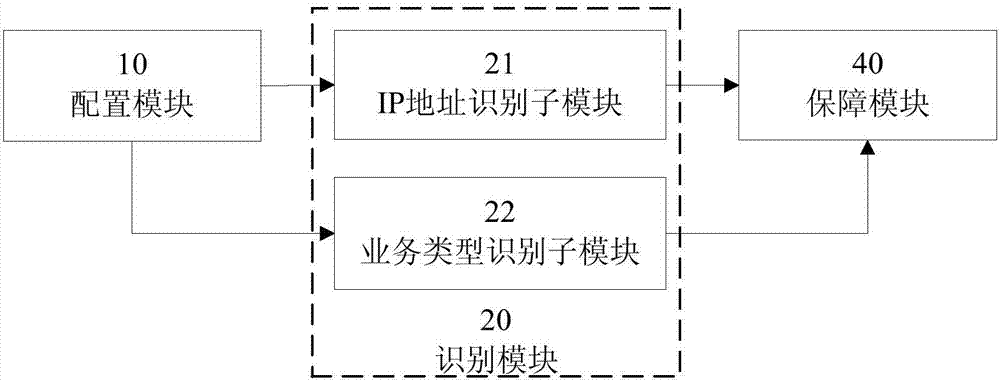

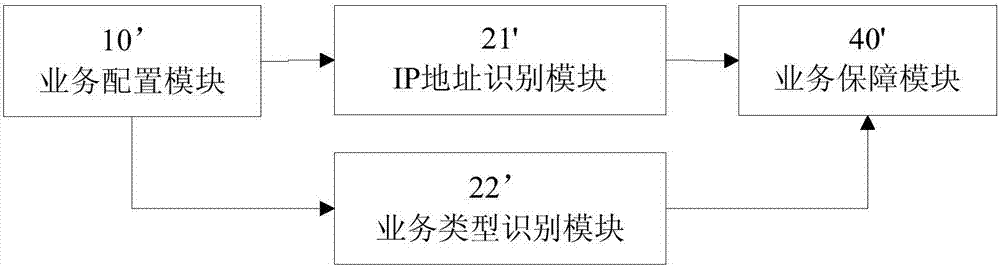

Differential service processing method and device

InactiveCN107548098AGuaranteed flowImprove experienceNetwork traffic/resource managementData switching networksDistributed computingBase station

The invention discloses a differential service processing method and device, and relates to the field of communication. The method comprises the following steps: judging whether a current service of auser terminal is a configured service that requires differential processing by a base station; if yes, then processing the service preferentially by the base station; and if not, then processing theservice normally by the base station. The embodiment of the invention can effectively guarantee the service traffic that needs to be guaranteed and improve user experience.

Owner:ZTE CORP

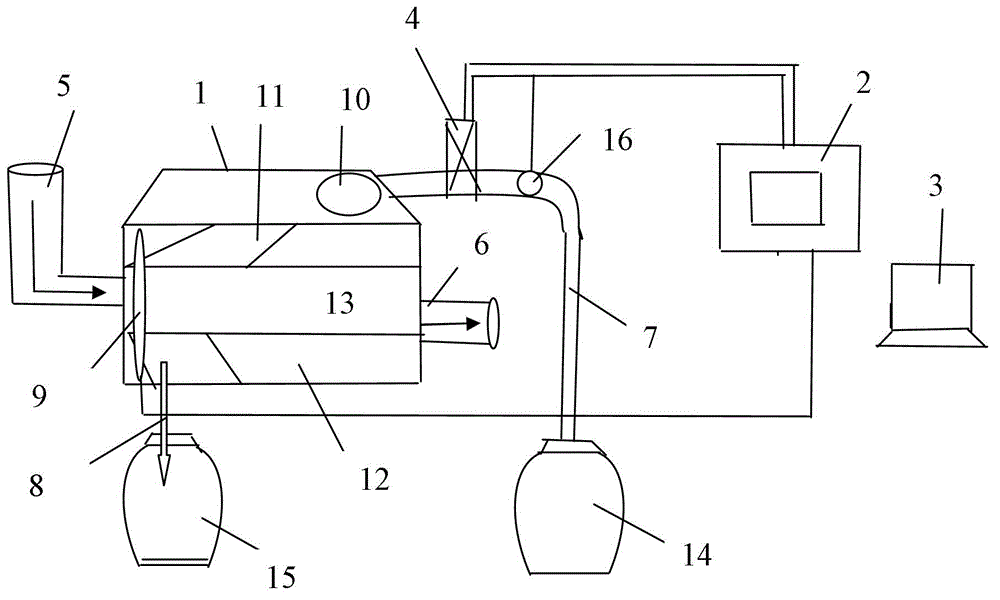

Unpowered environmental-protection type intelligent kitchen waste oil recovery monitoring system

InactiveCN102722159AGuaranteed flowPut an end to stealing oilLiquid separationTotal factory controlOil and greaseControl system

The invention relates to an unpowered environmental-protection type intelligent kitchen waste oil recovery monitoring system, which comprises a grease separator, a control system, a remote terminal, a motor operated valve and a gauge, wherein an oil level indicator is installed in the grease separator, and the motor operated valve and the gauge are installed on a grease discharging pipe; the oil level indicator, the motor operated valve and the gauge are connected with the control system through data lines; and the control system is connected with the remote terminal in a wireless mode. The unpowered environmental-protection type intelligent kitchen waste oil recovery monitoring system can systematically control the grease separator in the system, and the degree of automation is high, therefore personal factors can be rejected, the problems that lawless persons steal oil, kitchen waste oil production enterprises does not cooperate and the like are avoided, and the separated grease flowing to a formal channel is ensured. In addition, the system has the advantages that the oil receiving efficiency can be increased, the carbon emission is reduced, the occupied area of equipment is small, the installation is easy, and the system is suitable for promotion. In addition, as the grease separator is positioned on the ground, the system is convenient to install and wash.

Owner:沈国华

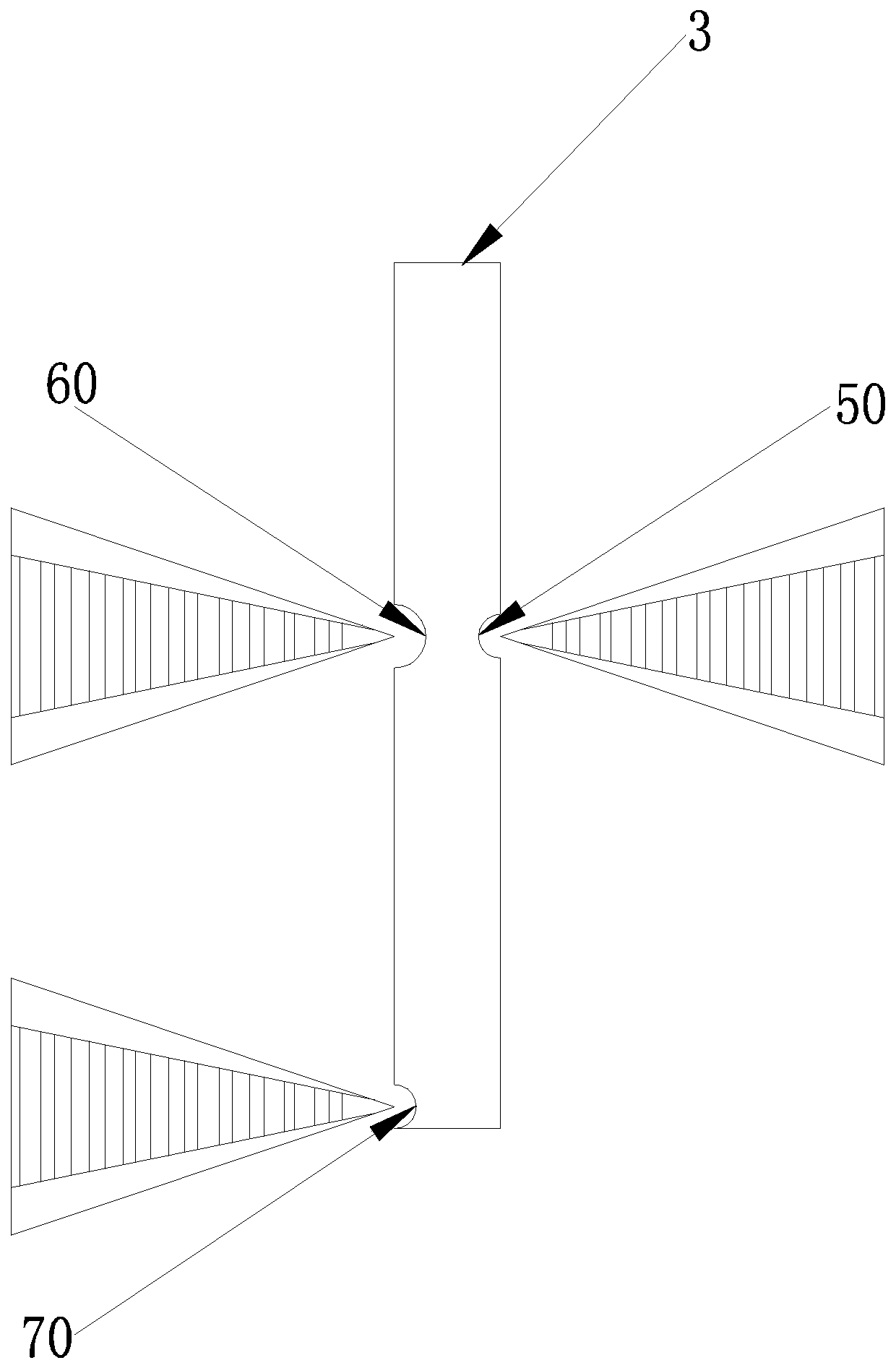

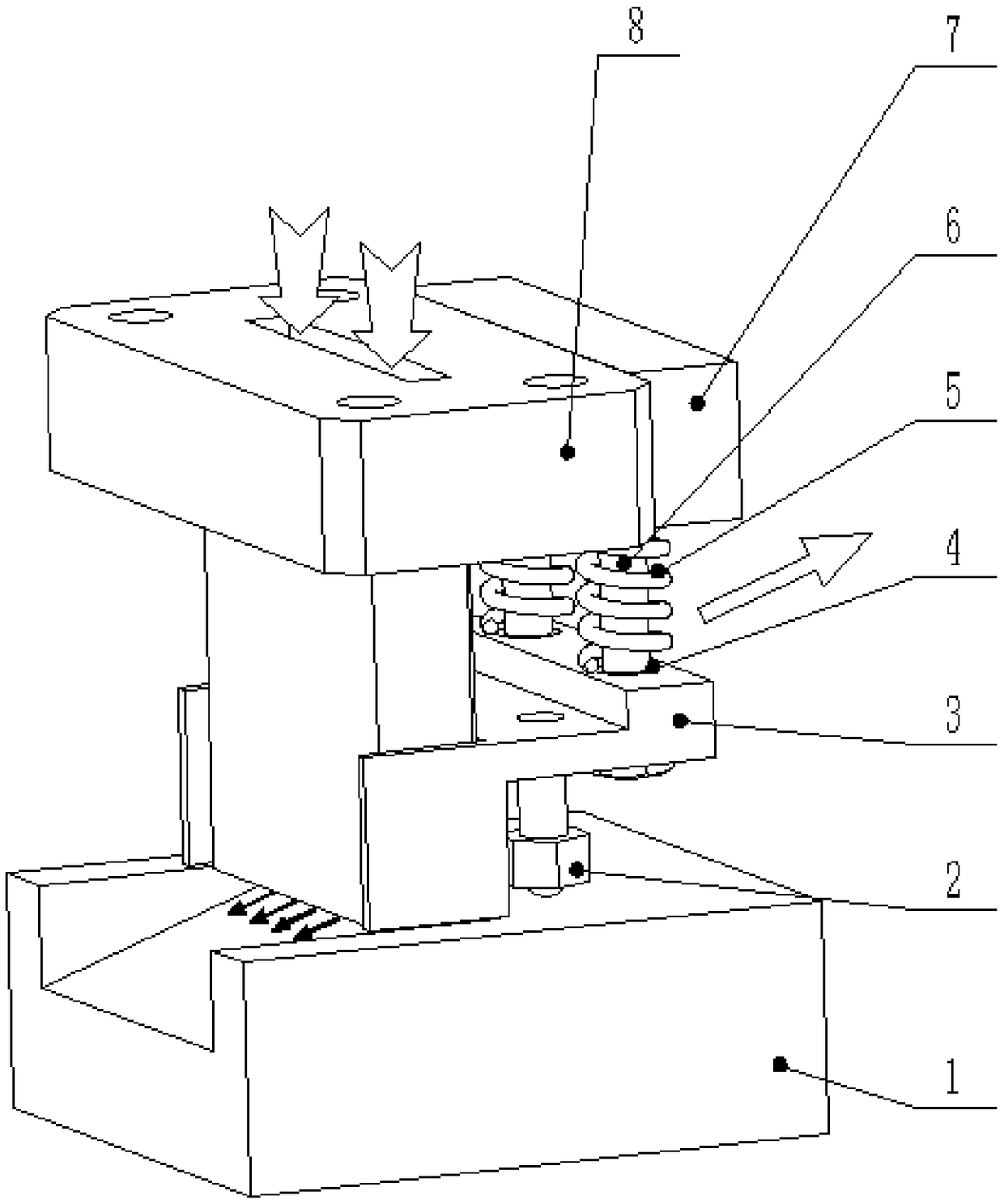

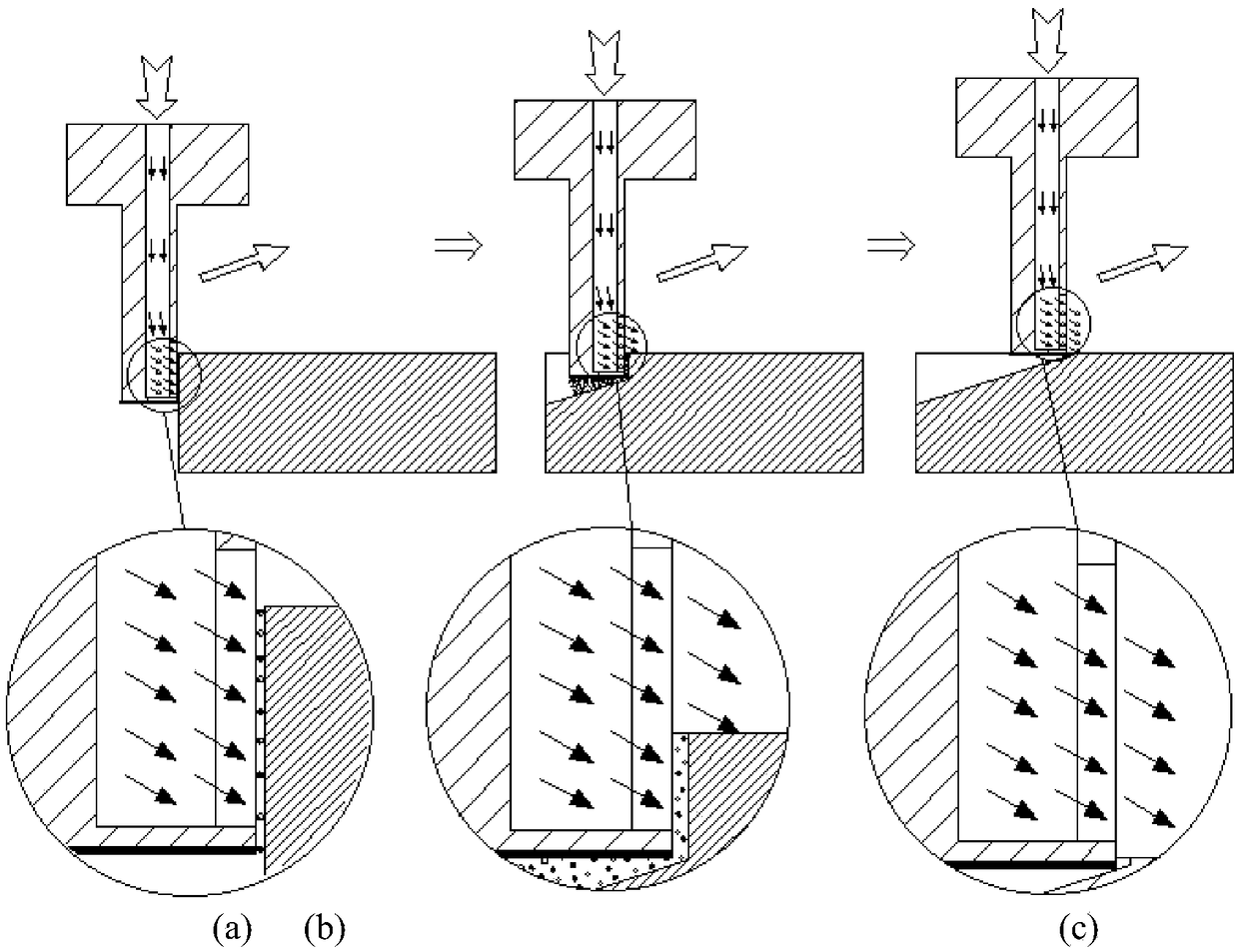

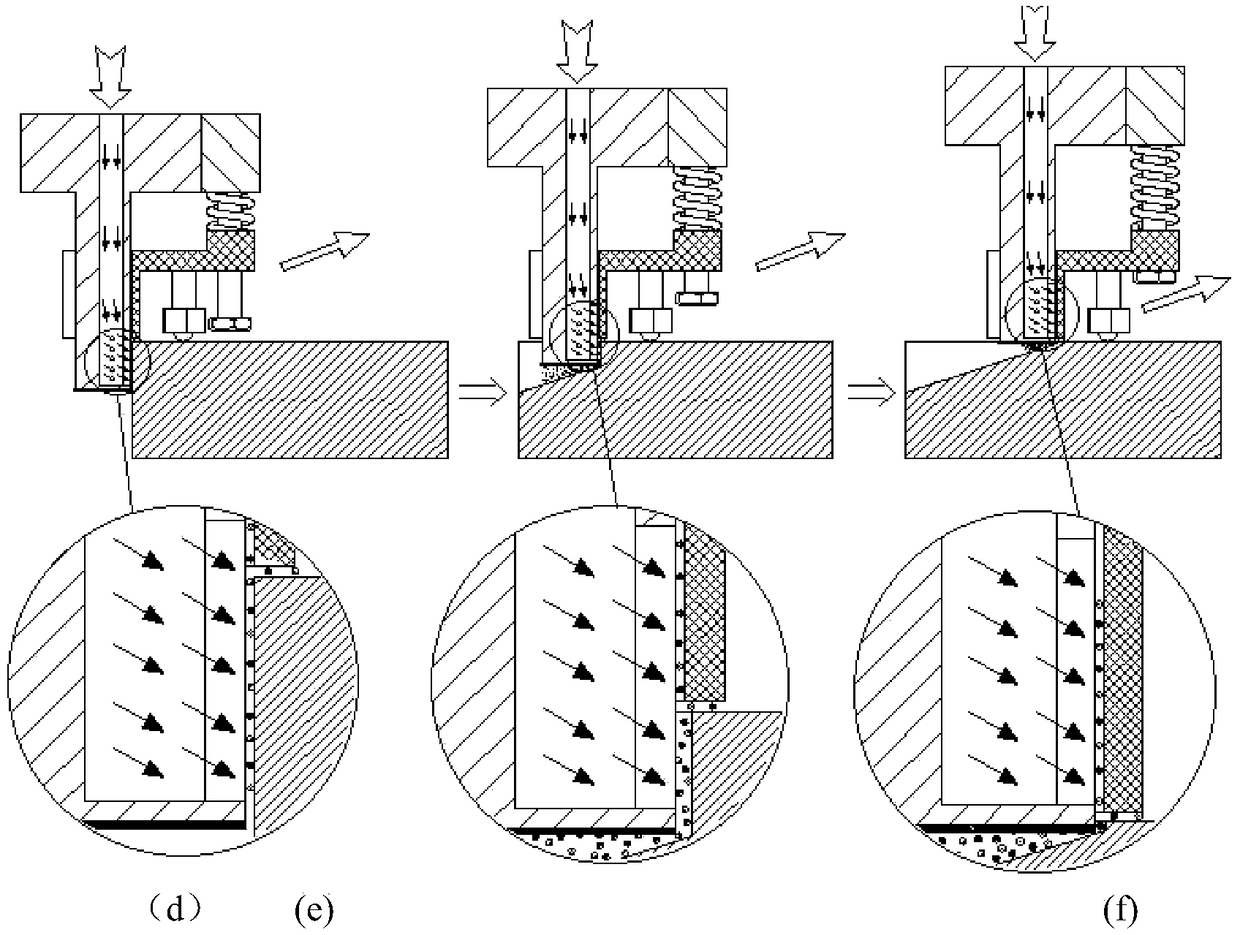

Device and method for processing inclined surface through follow-up sealing liquid cutting-in type electrolytic milling machining

ActiveCN109226913AGuaranteed flowReal-time change the size of the cross-sectional area of the waterElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolysisEngineering

The invention relates to a device and method for processing an inclined surface through follow-up sealing liquid cutting-in type electrolytic milling machining, and belongs to the field of electrolytic processing technology. The device mainly comprises a tool cathode, an upper supporting plate, guide rods, a spring, a linear bearing, a universal ball and a water blocking block. The upper supporting plate is fixed on the front of the tool cathode; the two guide rods are fastened on the upper supporting plate through threads; the guide rods are sequentially sleeved with the spring and the waterblocking block, the water blocking block can slide up and down along the axis direction of the guide rod through the linear bearing, the universal ball is arranged below the water blocking block and is contact with a work piece in real time, and the universal ball is pressed on a surface of the work piece under the action of the spring compression elasticity. When the tool cathode processes the inclined surface by using a cutting-in type electrolytic machining method, the follow-up sealing liquid device can float up and down according to the up-and-down movement of the tool cathode, so as to change the cross-sectional area, out of water, of the tool cathode, the spraying of the electrolyte liquid from a liquid outlet to a processing area is limited in real time, and the processing precision, the stability and the efficiency are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

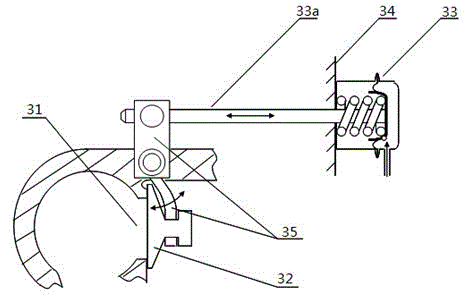

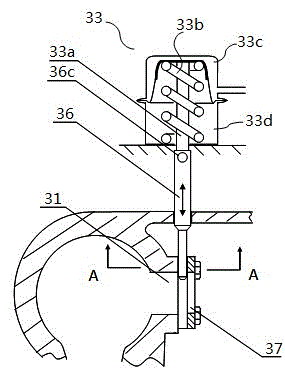

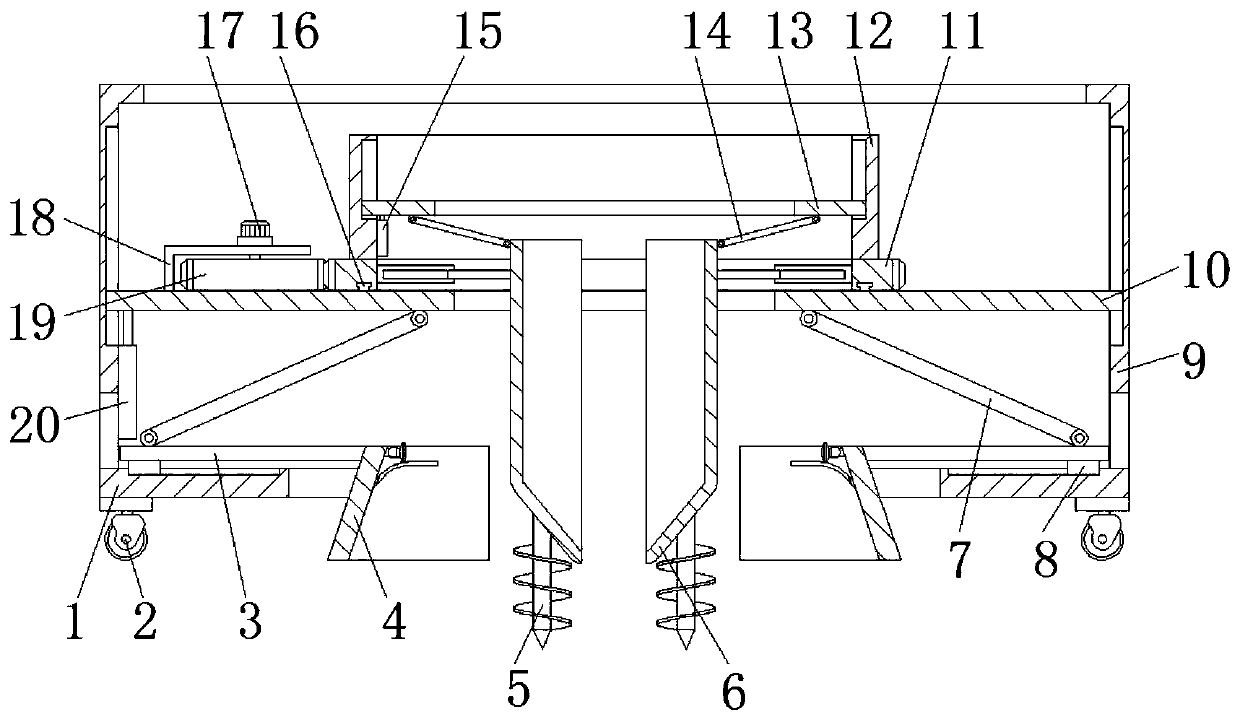

Seedling transplanting device for agricultural scientific research

ActiveCN109743932AEliminate squeezeImprove protectionPressurised distribution of liquid fertiliserTransplantingHydraulic cylinderAgricultural science

The invention belongs to the technical field of agricultural machinery, and particularly relates to a seedling transplanting device for an agricultural scientific research. The seedling transplantingdevice for the agricultural scientific research aims to the problems that seedling transplanting device is greatly harmful to seedlings and a seedling planting effect cannot be guaranteed. The following scheme is put forward including a base, wherein universal wheels are correspondingly fixed to the four corners of the outer wall of the bottom of the base through screws, and a supporting frame iswelded to the outer wall of the top of the base; a movable plate sliding groove is formed in the inner wall of one side of the supporting frame, and a movable plate is slidably connected to the innerwall of the movable plate sliding groove; and a hydraulic cylinder is fixed to the inner wall of one side of the supporting frame through screws, and one end of a piston rod of the hydraulic cylinderis fixed to the outer wall of the bottom of the movable plate through screws. According to the seedling transplanting device for the agricultural scientific research, the clamping placement is replaced by a placing mode, the extrusion force on the seedlings is eliminated effectively, the improvement of the protection effect on the seedlings is facilitated, the seedlings can be buried in soil timely, the planting effect can be guaranteed effectively, the improvement of the survival rate of the seedling transplantation is facilitated, and the cleanliness of the inner wall of a bulldozing plate is conveniently guaranteed.

Owner:连云港赣榆沃龙农业开发有限公司

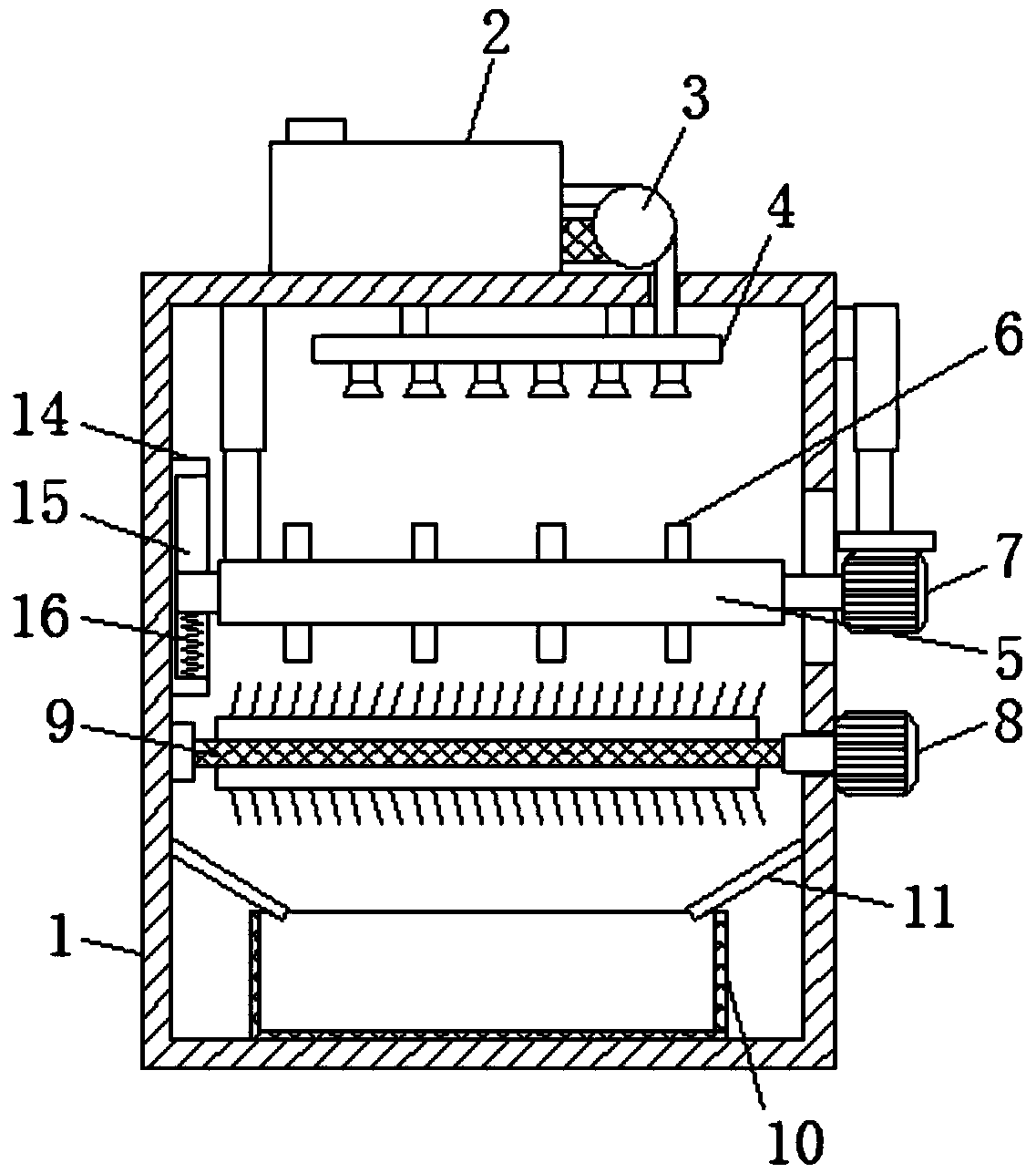

Construction gravel screening equipment with quantitative discharging function

InactiveCN108246598AReduce wasteEasy to collect and useSievingGas current separationArchitectural engineeringBuilding construction

The invention discloses construction gravel screening equipment with a quantitative discharging function. The construction gravel screening equipment with the quantitative discharging function comprises a tank, a feeding hopper, a discharging barrel, an oblique screening barrel and a guide barrel; the lower end of the feeding hopper communicates with the discharging barrel extending into the tank;the discharging barrel is a rectangular barrel; a horizontal pulling roller is arranged in the discharging barrel; a plurality of storage grooves are formed in the side wall of the pulling roller; arotating plate is coaxially arranged at the lower end of the interior of the oblique screening barrel; a first pulling plate is fixed to the edge of the left side of the rotating plate, and a plurality of oblique scattering rods are fixed to the left side face of the rotating plate; and the rotating plate is provided with a discharging outlet penetrating from the left to right. Through the pullingroller in the discharging barrel and the storage grooves, gravel falls off in the storage grooves in a following mode, the gravel falling amount is constant, the equipment runs more stably, and screening is more thorough; and the pulling plate on the rotating plate can carry the gravel to the upper position so that the gravel can be raised continuously, and fine gravel is separated out conveniently.

Owner:郑东亮

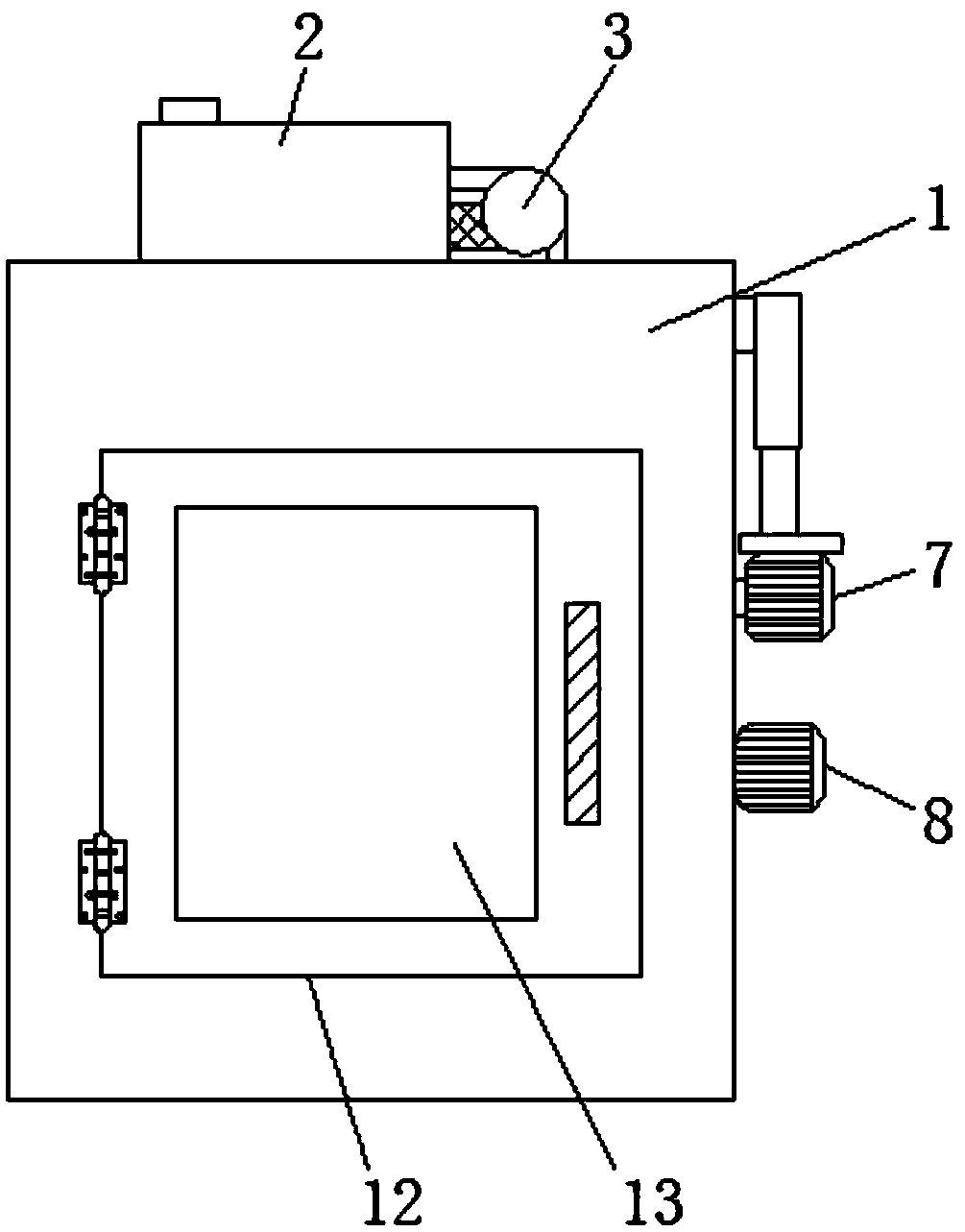

Electric automation washing device

InactiveCN108636869AImprove cleaning efficiencyGood practicalityCleaning using toolsCleaning using liquidsElectric machineryEngineering

The invention discloses an electric automation washing device. The electric automation washing device comprises a box body. The top of the box body is fixedly connected with a water tank. The right side of the water tank is fixedly connected with a water pump through a positioning plate. A water inlet pipe of the water pump communicates with the water tank. A water outlet pipe of the water pump penetrates the box body and extends into the box body to communicate with a communicating pipe. The bottom of the communicating pipe communicates with a washing head. The part, located below the washinghead, in the box body is provided with a placement plate. The top and the bottom of the placement plate are both movably connected with clamping plates. The right side of the box body is provided with a first motor. According to the electric automation washing device, by means of the arrangement of the water tank, the water pump, the communicating pipe, the placement plate, the clamping plates, the first motor, a second motor, a rotating shaft and a water collection trough, rotational washing can be carried out on articles on the placement plate, meanwhile, a brush can clean away dust on thesurfaces of the articles, the washing efficiency is improved, and meanwhile the problems that washing is incomplete, the consumed time is long, and consequently the practicality of the washing deviceis affected are solved.

Owner:梁溪区华恒工业设计工作室

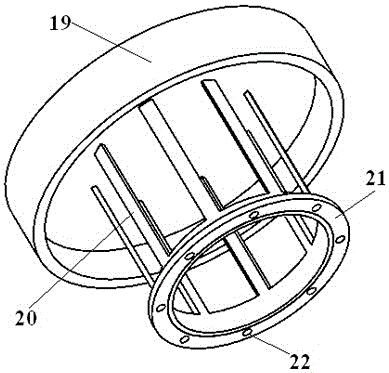

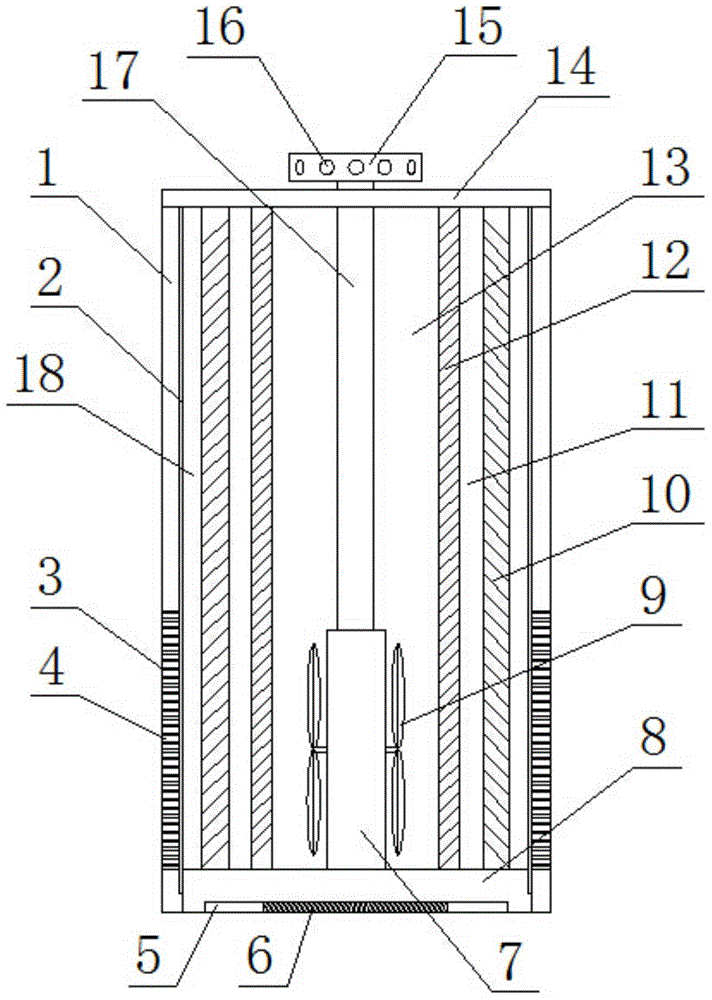

Air micro-nano particles-filtering and purifying device

ActiveCN104801140AImprove air qualityExpand the filter rangeCombination devicesMicro nanoManufacturing cost reduction

The invention discloses an air micro-nano particles-filtering and purifying device. The device comprises an upper cover, a housing body, a filtration device arranged in the housing body, an air blower, a rotating air-outlet device and a base, wherein the housing body adopts a cylindrical form; the upper cover is arranged at the upper part of the housing body; an air inlet zone is arranged at the lower part of the housing body; the filtration device is arranged inside the housing body; a purification chamber is arranged inside the filtration device; the base is arranged at the bottom of the purification chamber; the air blower is arranged on the inner side of the purification chamber; a groove is formed in the lower surface of the base; a foldable handle is arranged inside the groove; the foldable handle is fixedly connected with the rotating air-outlet device arranged above the upper cover through a rotating shaft on the air blower. The device is simple and compact in structure and easy to operate and can effectively remove the pollutants in air; the device is low in power consumption and saves electric energy; with high purification efficiency, the device can realize air purification without using various catalysts, so as to significantly reduce production cost; the device is wide in application range.

Owner:ZHONGSHAN JINCHENG PLASTIC PROD CO LTD

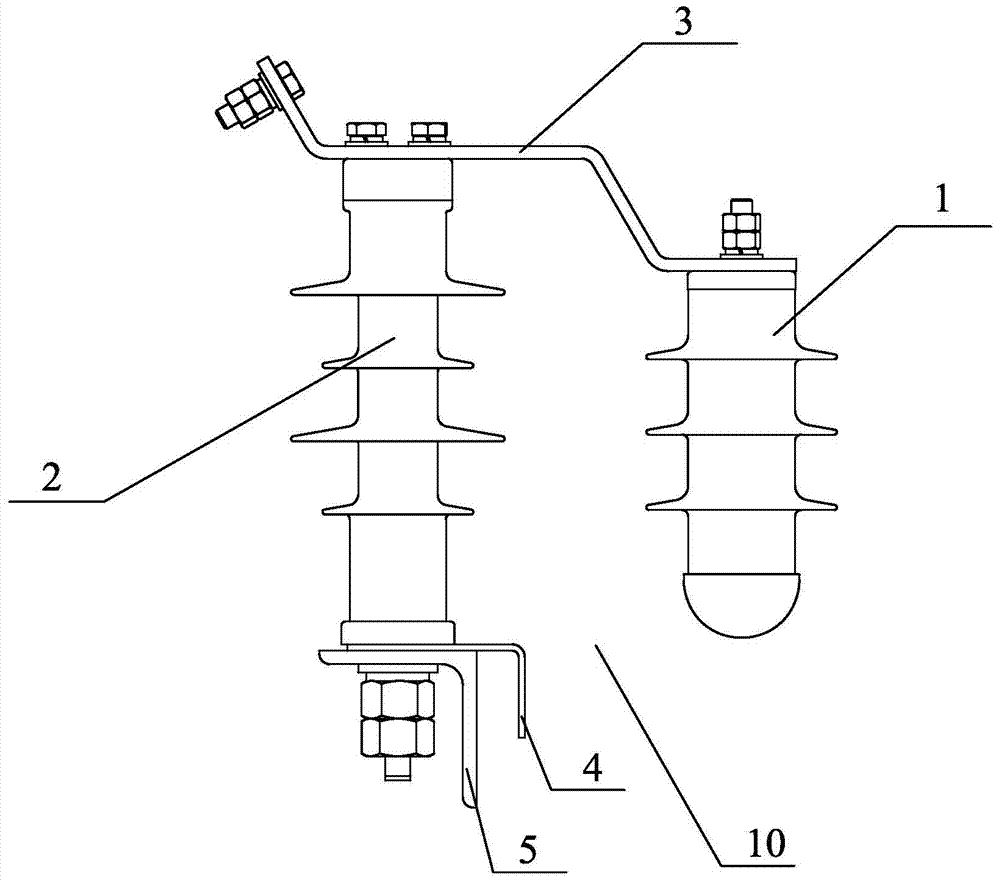

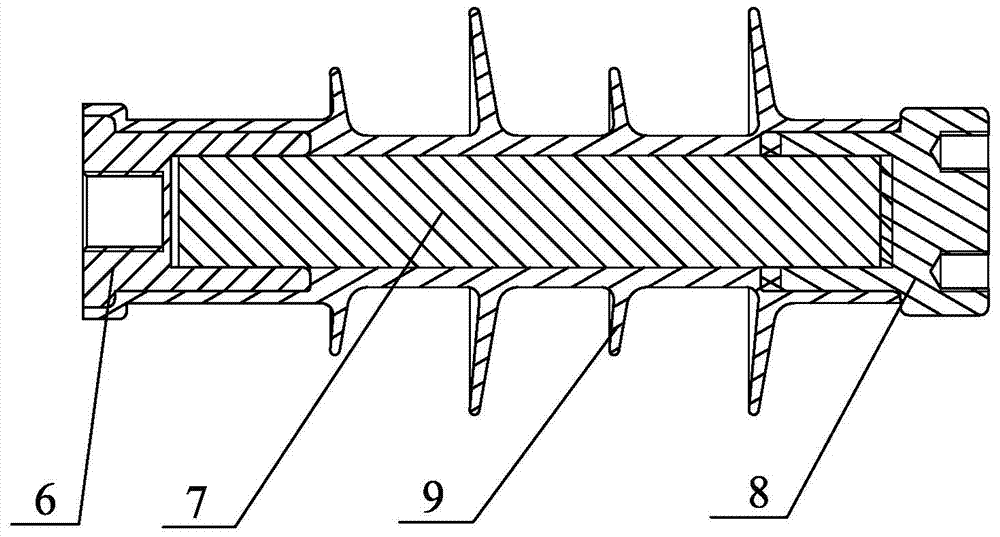

External column type voltage limiter for urban rail catenary

InactiveCN103490284AReduce volumeReduce weightOvervoltage protection resistorsOvervoltage arrestors using spark gapsElectricityEngineering

The invention relates to an external column type voltage limiter for an urban rail catenary. The external column type voltage limiter comprises a cross arm of a tower and further comprises a lightning arrester body and a post insulator. A spherical electrode is installed on the lightning arrester body, the lightning arrester body is connected with the post insulator through a conductive metal bar, a run-on plate is further installed between the tower cross arm and the post insulator and is in tight electric connection with the tower cross arm, the lightning arrester body is in tight electric connection with a fitting positioned on the post insulator, and an air gap is formed between the run-on plate and the spherical electrode. The external column type voltage limiter can be installed away from the insulator and provide multiple protections for the insulator and is suitable for being used on an urban rail catenary system.

Owner:SHANDONG XUNSHI ELECTRIC

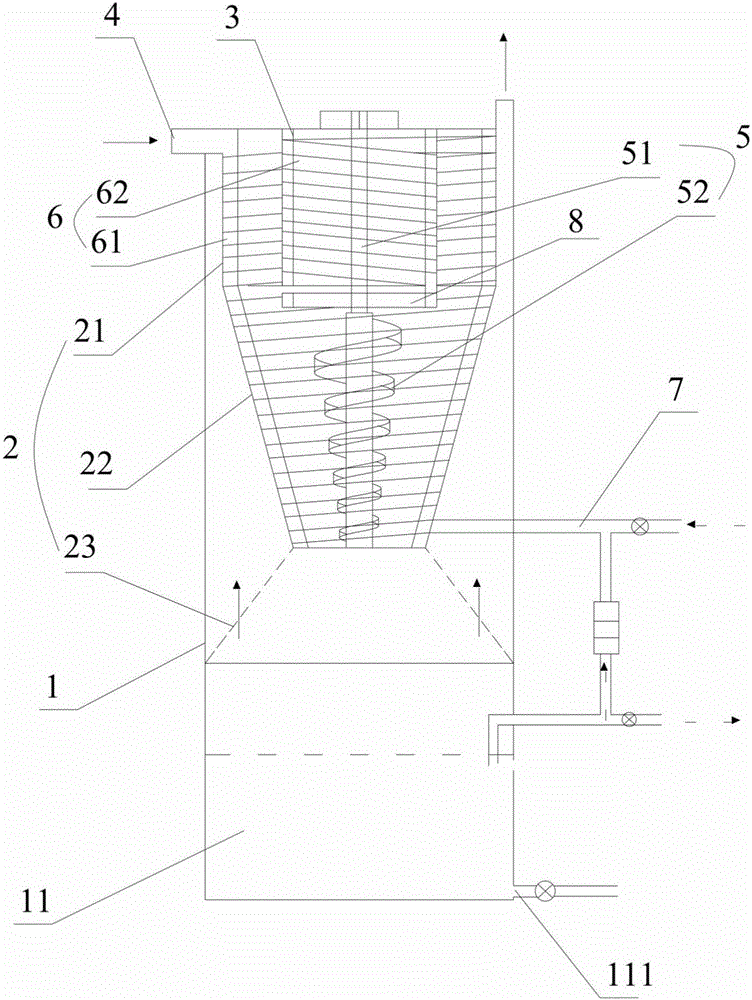

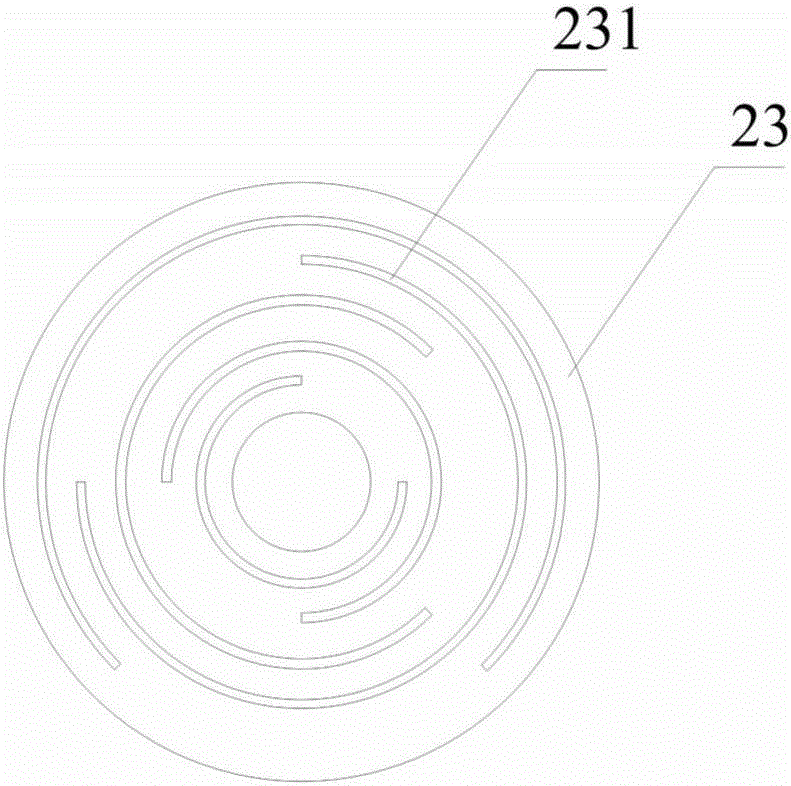

Dust collector suitable for high-temperature dusty tail gas recovery

ActiveCN105214428AAvoid contactImprove dust removal efficiencyCombination devicesEngineeringDust collector

The invention discloses a dust collector suitable for high-temperature dusty tail gas recovery. The dust collector comprises an outer cylinder, a first hollow inner cylinder, a second hollow inner cylinder, an air inlet pipe, a spiral stirring device, a spiral disc, an outer-layer heat exchange pipe, an inner-layer heat exchange pipe and a spraying device, wherein the first hollow inner cylinder is arranged inside the outer cylinder, and is sequentially provided with a first part, a second part and a third part from top to bottom, a first interlayer is formed by the first part and the outer cylinder, and the first part is communicated with the outside; the second part is conical; the third part is shaped like an inverted cone, the lower end of the third part props against the inner wall of the outer cylinder so as to form a second interlayer together with the second part and the outer cylinder, and the third part is provided with a plurality of arc-shaped air discharging holes; the second hollow inner cylinder is arranged inside the first hollow inner cylinder; one end of the air inlet pipe tangentially penetrates through the first part, and the other end of the air inlet pipe is communicated with the outside; the spiral stirring device comprises a rotary shaft; the spiral disc spirally extends along the other end of the rotating shaft; the outer-layer heat exchange pipe winds to the upper part of the first part along the second part, and the lower end of the outer-layer heat exchange pipe is communicated with a liquid inlet pipe; and the inner-layer heat exchange pipe winds along the second hollow inner cylinder, and the upper end of the inner-layer heat exchange pipe is communicated with the outer-layer heat exchange pipe. The dust collector disclosed by the invention has high efficiency.

Owner:广州迪斯环保设备工程有限公司

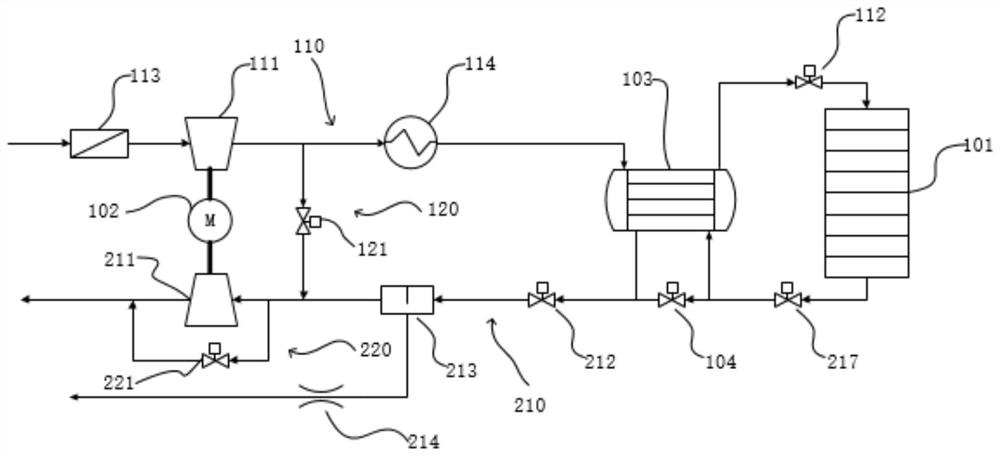

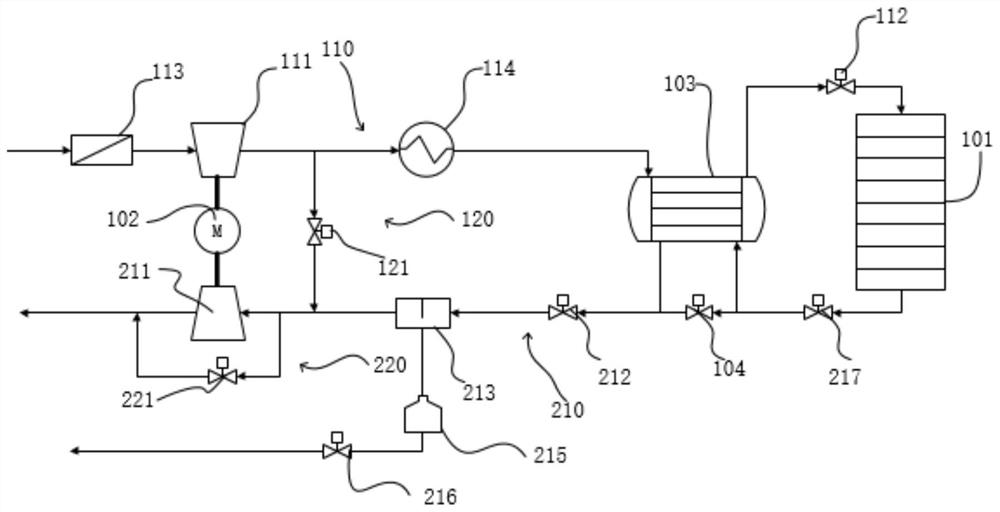

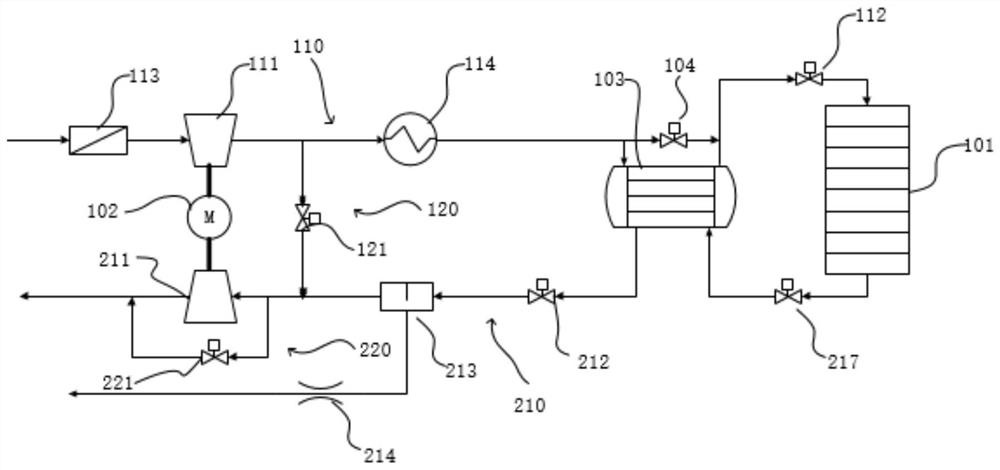

Fuel cell engine air supply system

InactiveCN112421075AGuaranteed flowReduce energy consumptionReactant parameters controlFuel cellsElectric machine

The invention discloses a fuel cell engine air supply system. The air supply system comprises a fuel cell stack, a gas supply main path, an exhaust main path, an air supply bypass branch and a drivingmotor; one end of the gas supply main path is connected with a cathode inlet of the fuel cell stack, the other end of the gas supply main path is communicated with the external environment, and a gascompressor is arranged on the gas supply main path; one end of the exhaust main path is connected with a cathode outlet of the fuel cell stack, the other end of the exhaust main path is communicatedwith the external environment, and a turbine is arranged on the exhaust main path; one end of the air supply bypass branch is connected with the air supply main path, the connecting point is located behind the air compressor, the other end of the air supply bypass branch is connected with the exhaust main path, the connecting point is located in front of the turbine, and a bypass valve is arrangedon the air supply bypass branch; and one end of an output shaft of the driving motor is connected with the air compressor, and the other end of the output shaft of the driving motor is connected withthe turbine. The air supply system can recover the exhaust energy of the fuel cell, and meanwhile surge of the air compressor is avoided.

Owner:FAW JIEFANG AUTOMOTIVE CO

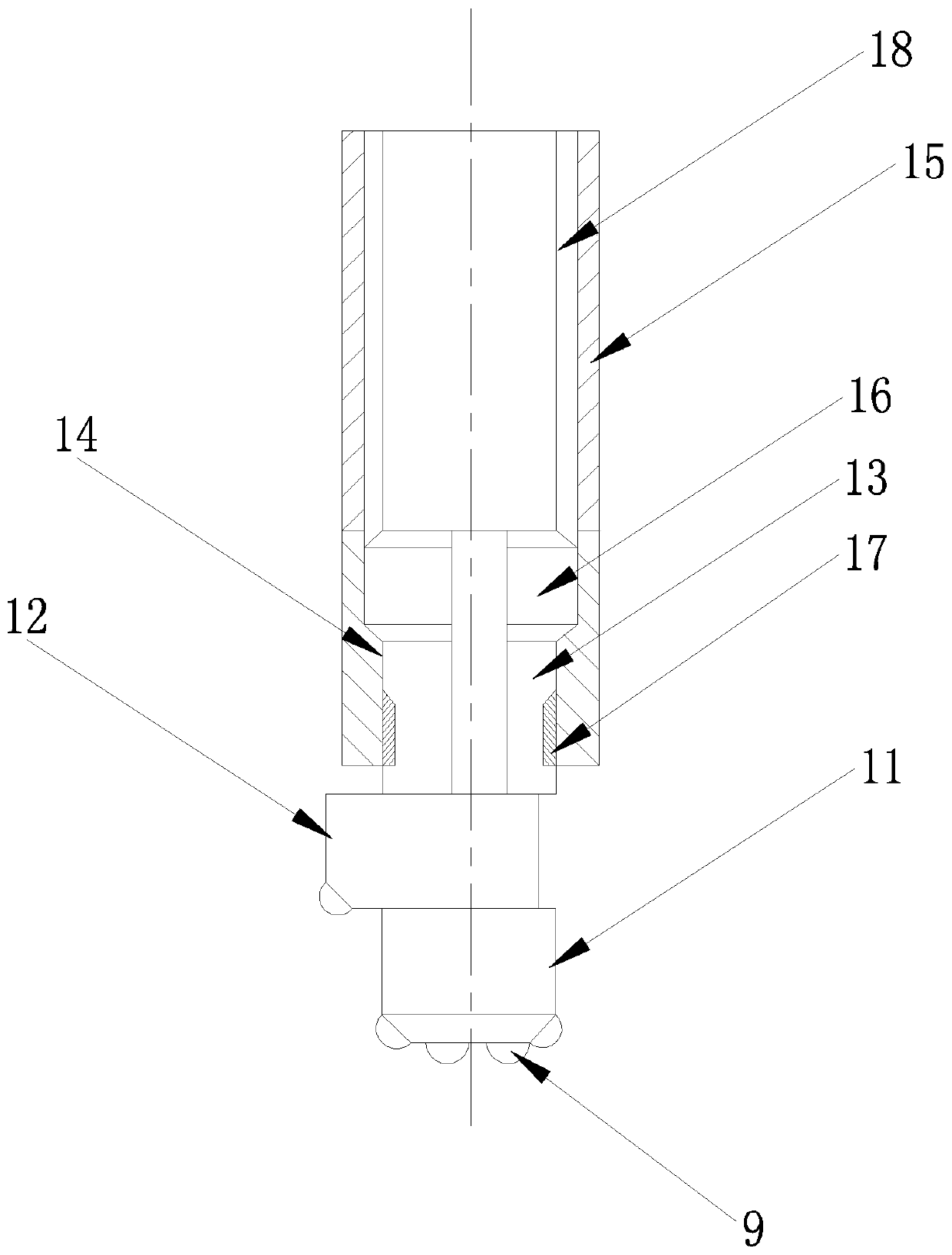

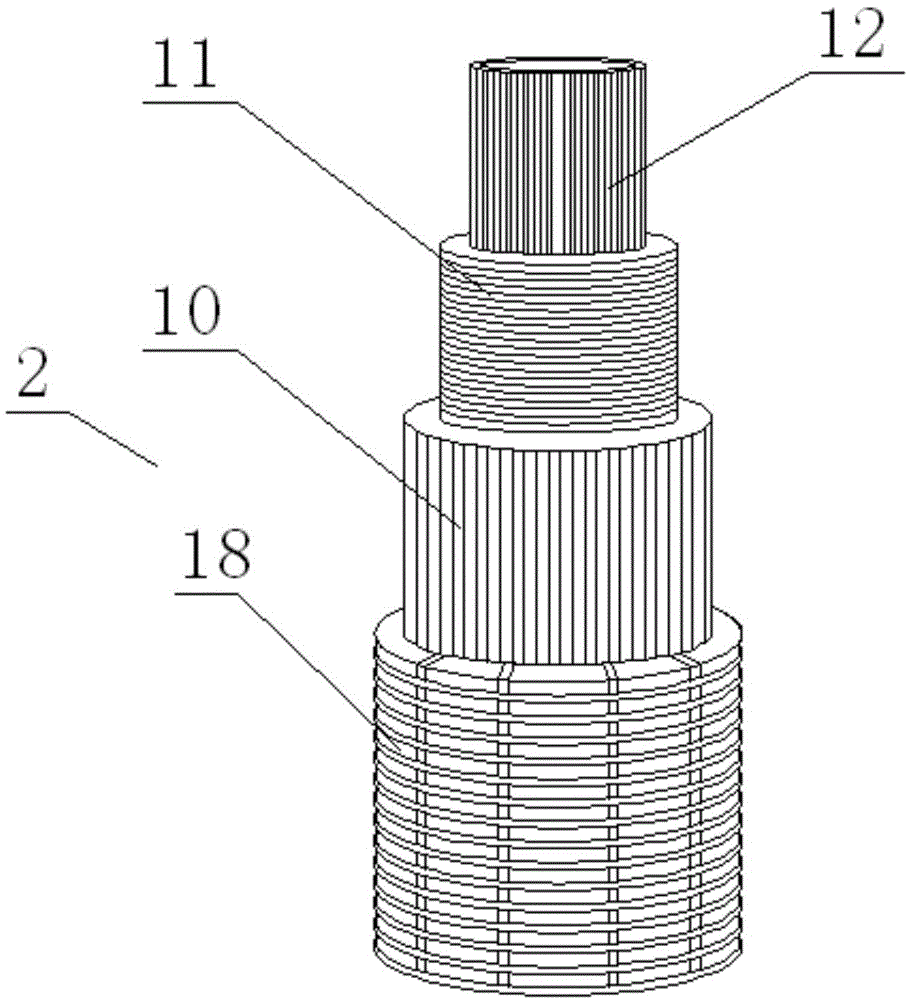

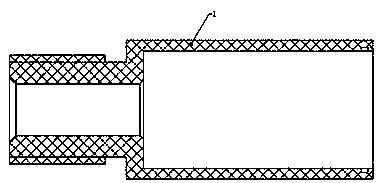

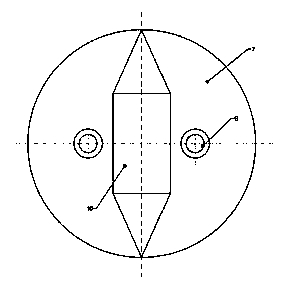

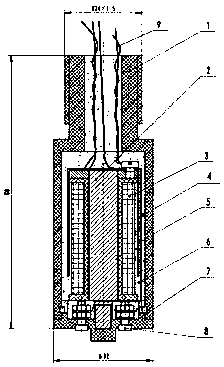

Plug-in type probe used for electromagnetic flowmeter

PendingCN109253764ASolve the problem that the side installation is easy to be damagedCompact structureVolume/mass flow by electromagnetic flowmetersEngineeringElectric signal

The invention discloses a plug-in type probe used for an electromagnetic flowmeter and belongs to the field of liquid flow measurement. The plug-in type probe comprises a cylindrical shell; an electric signal generating component, arranged at the interior of the shell, comprises a coil component, a pole shoe, a magnetic yoke and a plurality of electrode cables; a connecting part used for connecting an insertion rod is arranged at one end of the shell; a detachable connecting structure is separately arranged at the connecting part and the insertion rod; the outer diameter of the insertion rod is same as that of the shell; a choke plug is connected at the other end of the shell; two electrode components are arranged at the end face of the choke plug; and the two electrode components are provided with current guiders used for guiding current. The plug-in type probe used for an electromagnetic flowmeter solves the problems in the prior art that the outer diameter of the probe is inconsistent with that of the insertion rod, the concave-convex surface formed at the connecting position of the probe and the insertion rod increases the speed distribution distortion influences and the traditional electrodes arranged in the middle of the probe are easy to damage in the installation process.

Owner:KAIFENG INSTR

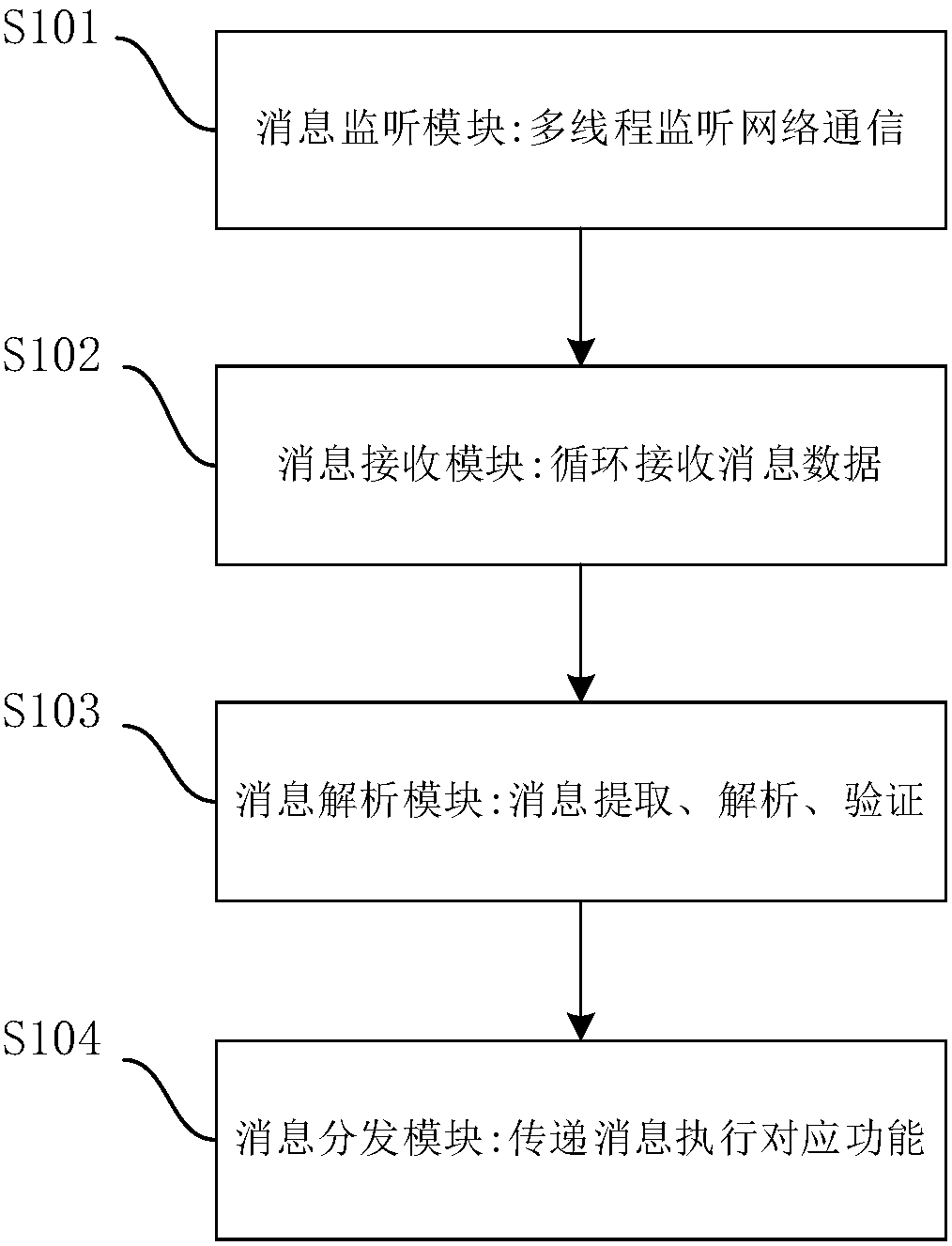

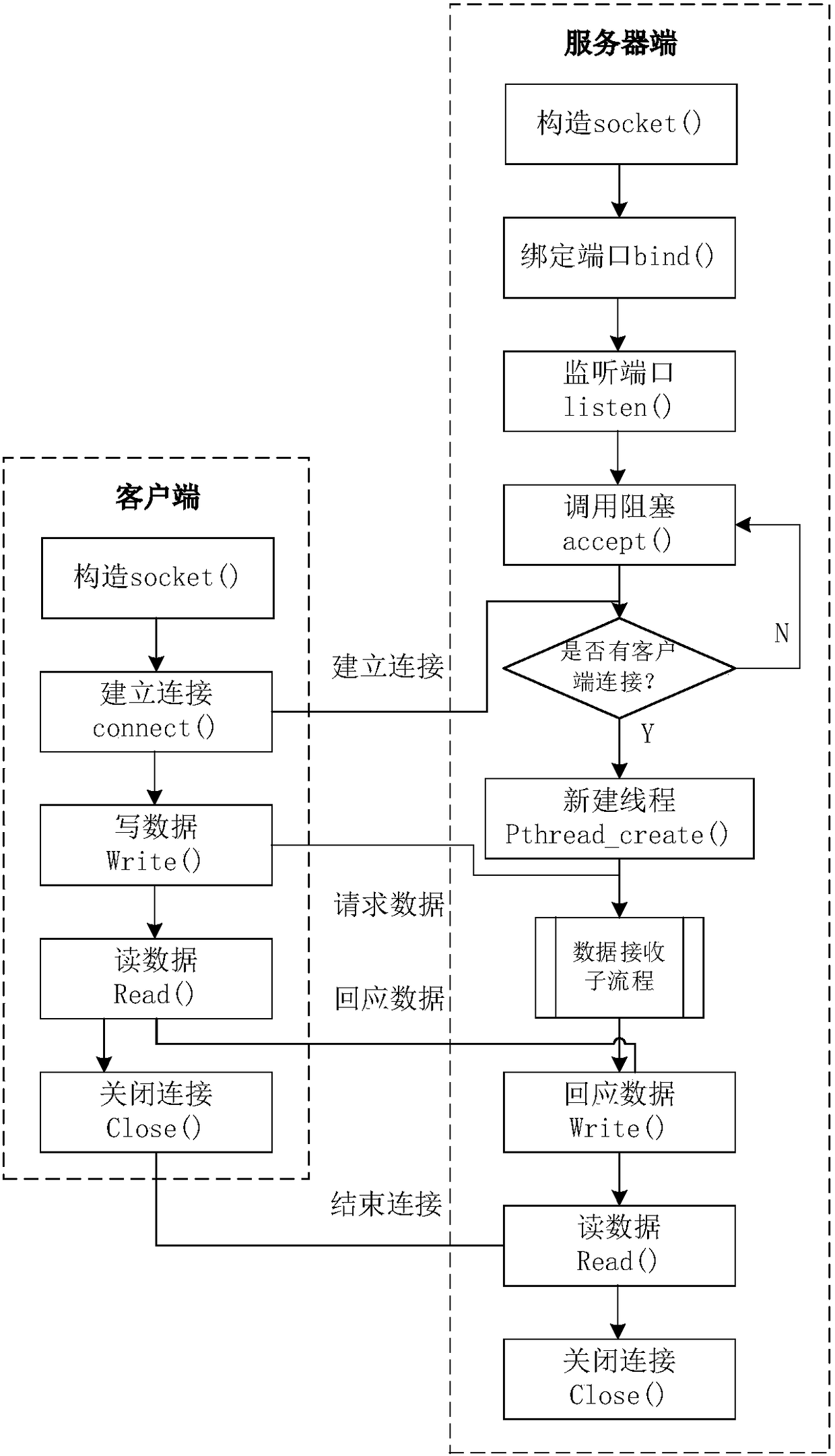

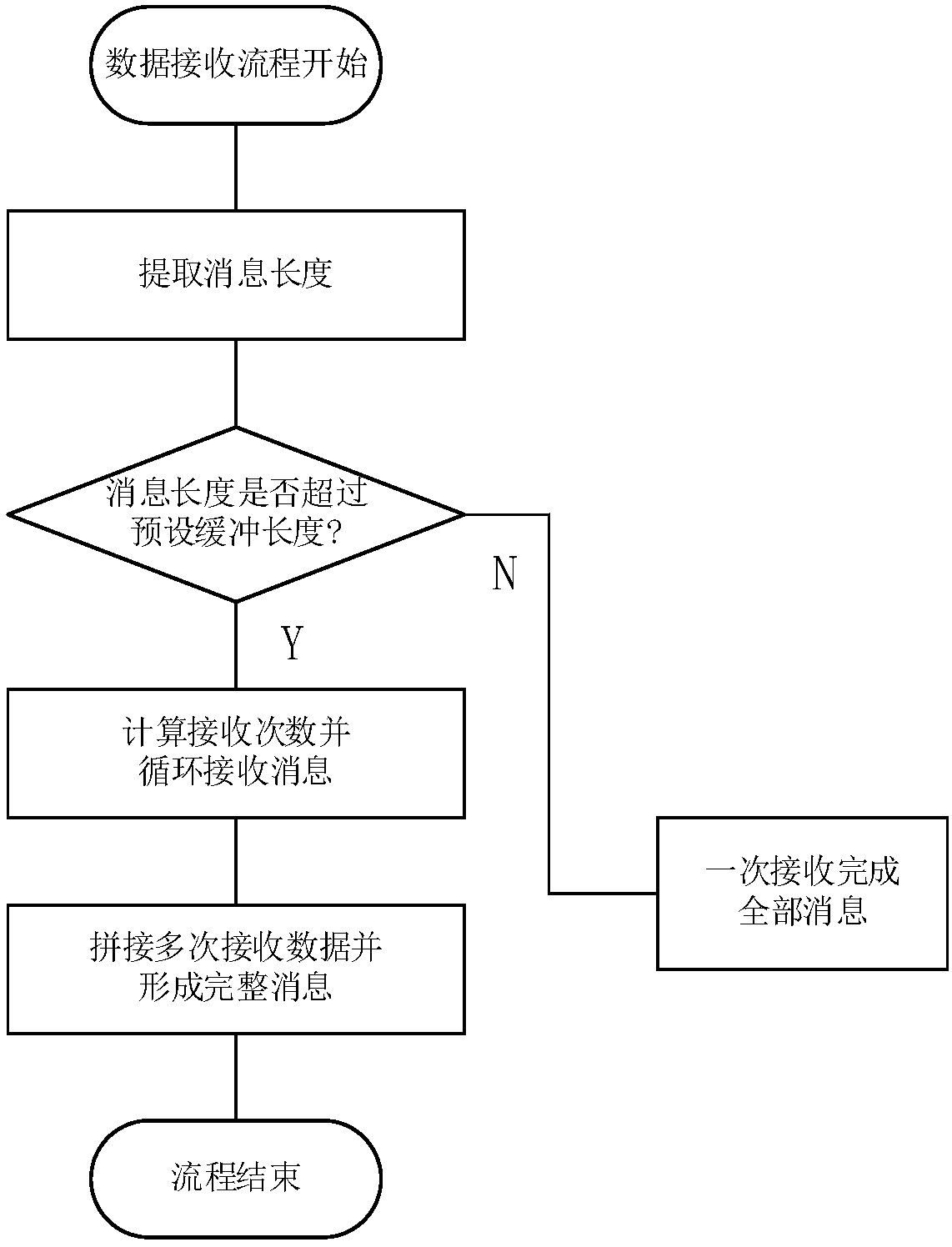

Implementation method for security protocol of satellite application layer and satellite message monitoring and distribution service system

ActiveCN108566390AGuaranteed flowImplement data message exchangeRadio transmissionService systemSatellite

The invention discloses an implementation method for a security protocol of a satellite application layer and a satellite message monitoring and distribution service system. The multi-thread satellitemessage monitoring and distribution service system comprises a message monitoring module, a message receiving module, a message parsing module and a message distribution module. The satellite messagemonitoring and distribution service system can carry out simultaneous transmission and reception, real-time transmission and parsing and checking of message data between a plurality of network equipment and a current satellite, after the message data is correctly distributed, execute corresponding functions can be executed on the satellite. By means of the system, a message receiving and transmitting mechanism of resource networking services can be guaranteed to run smoothly.

Owner:INST OF INFORMATION ENG CAS

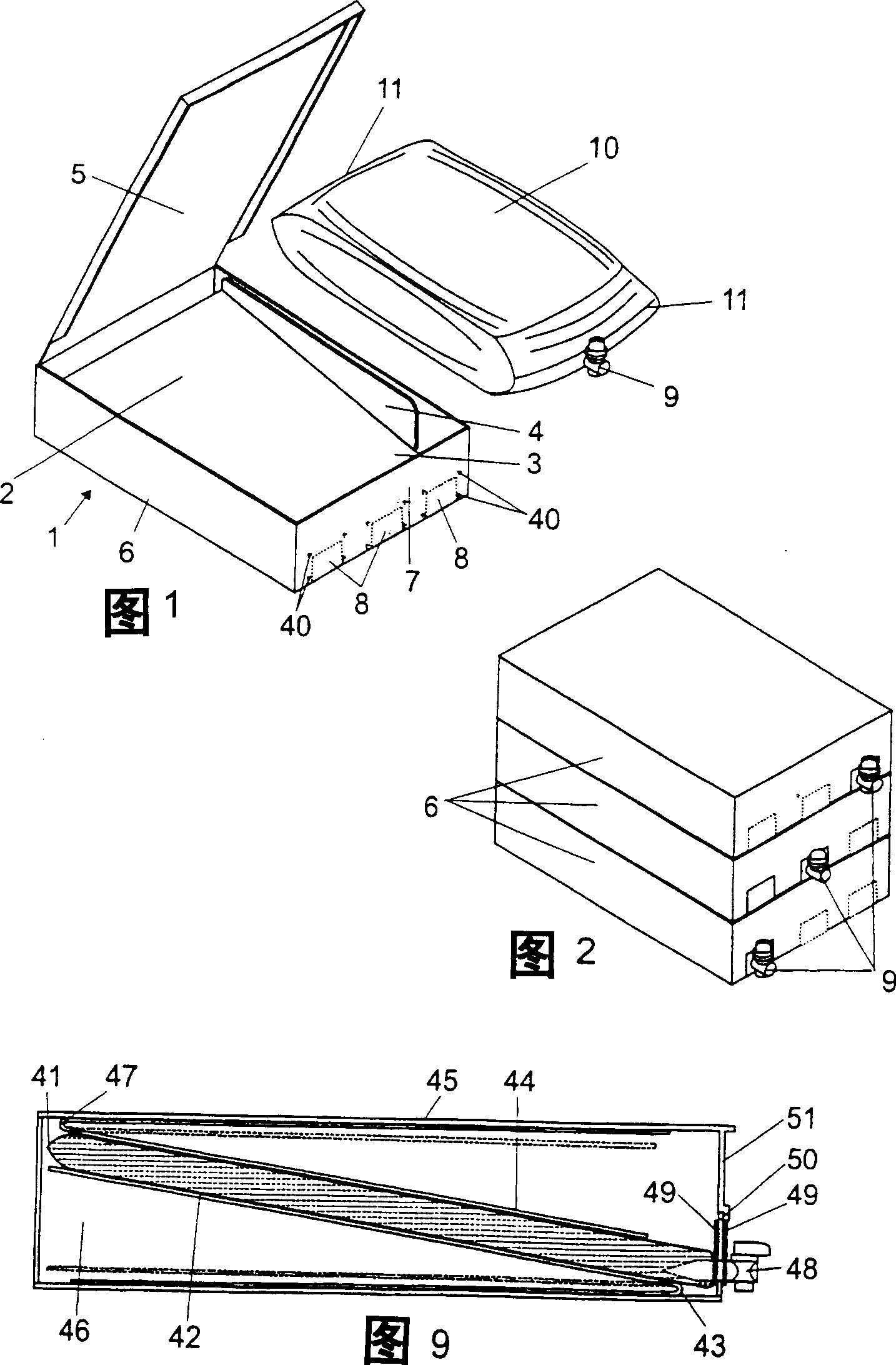

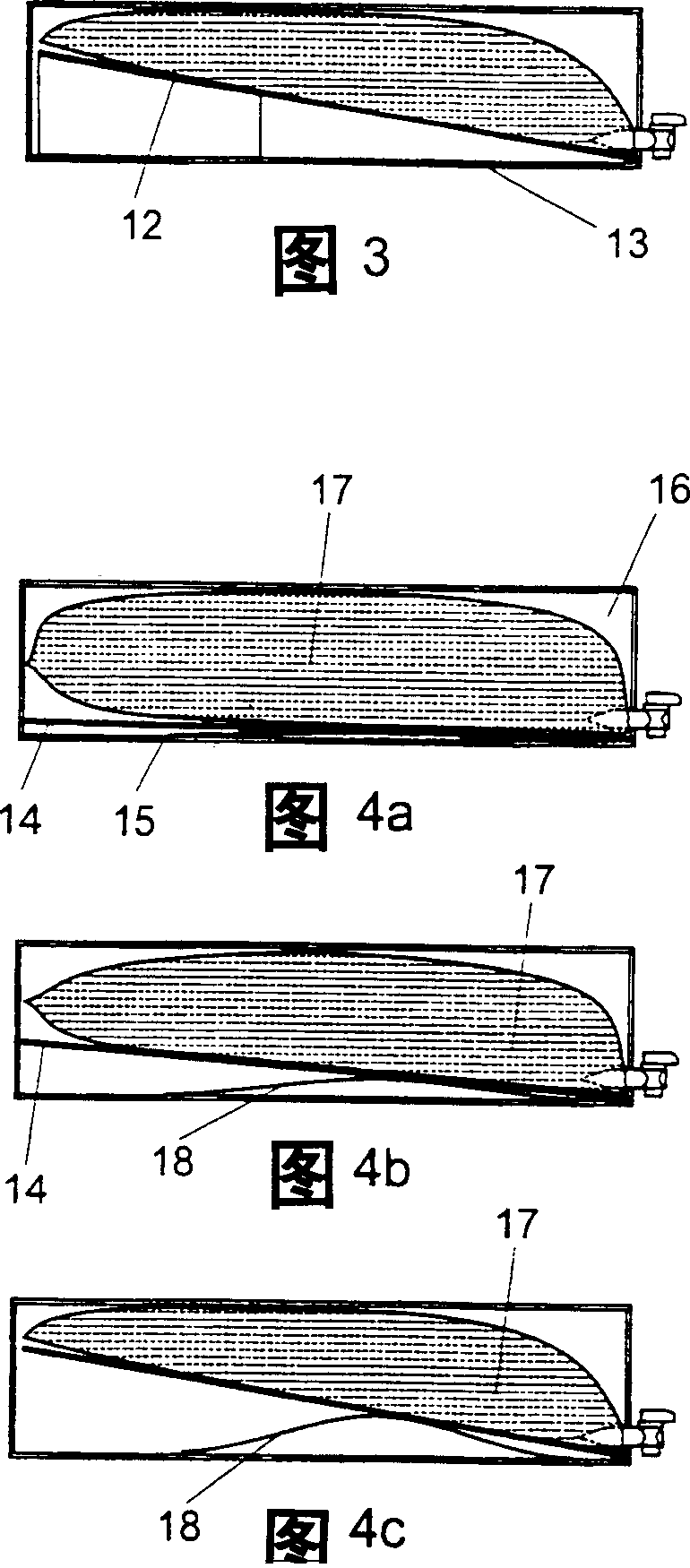

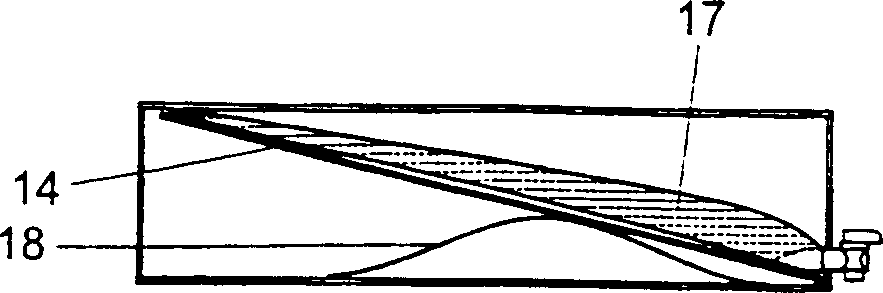

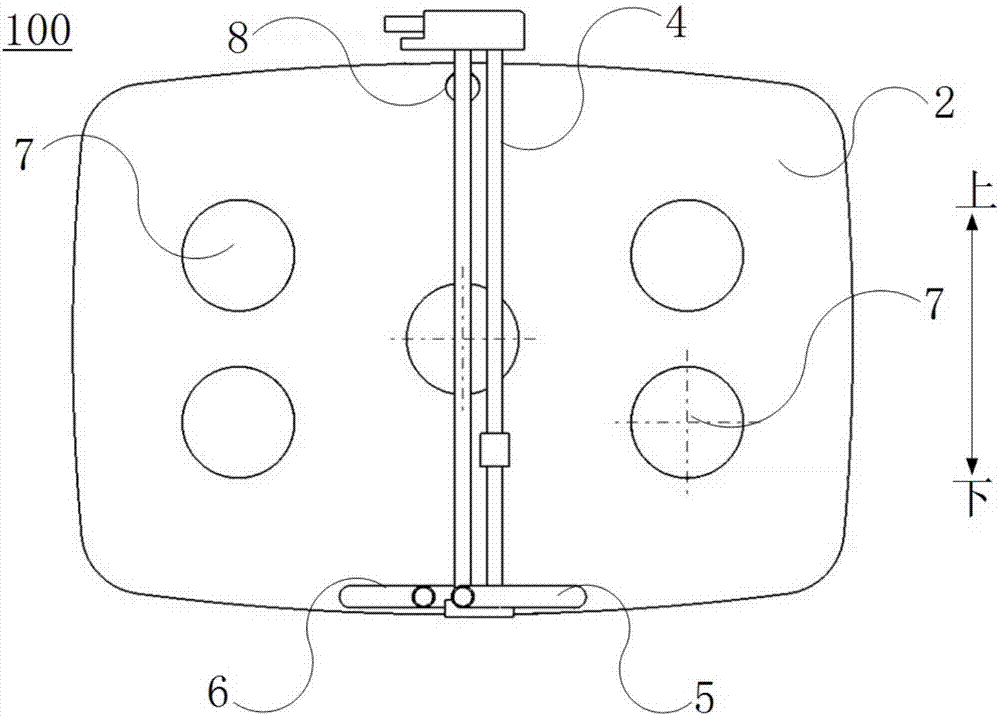

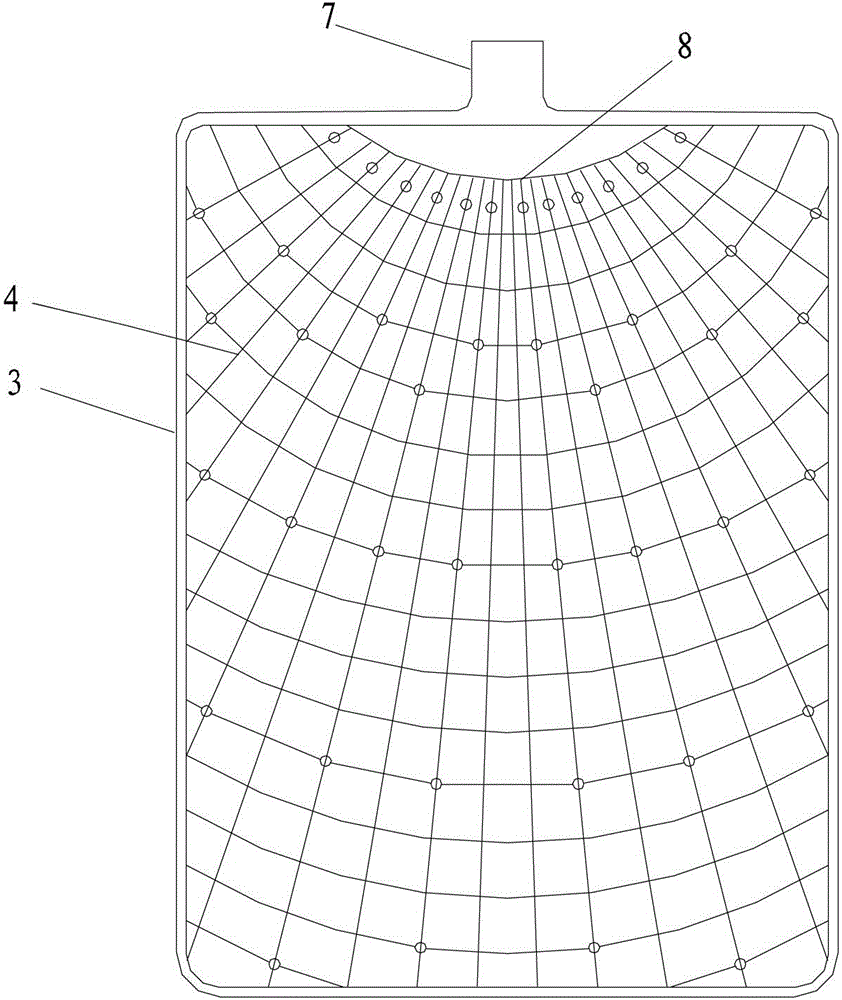

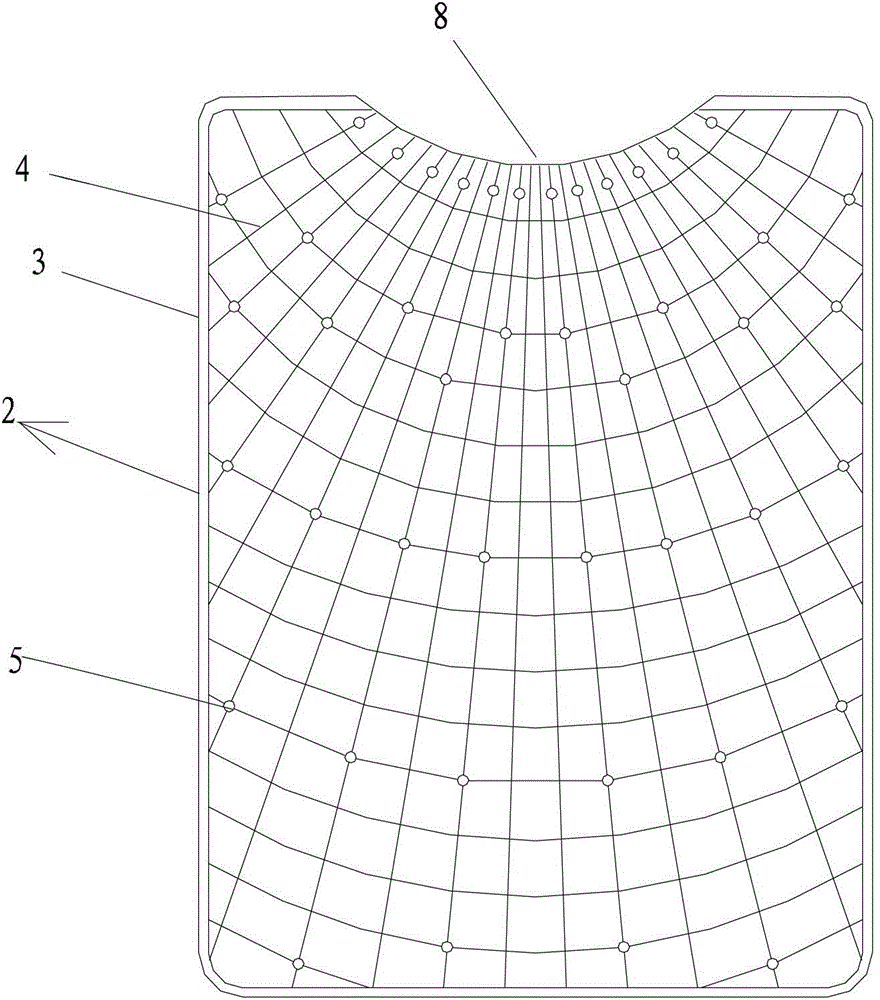

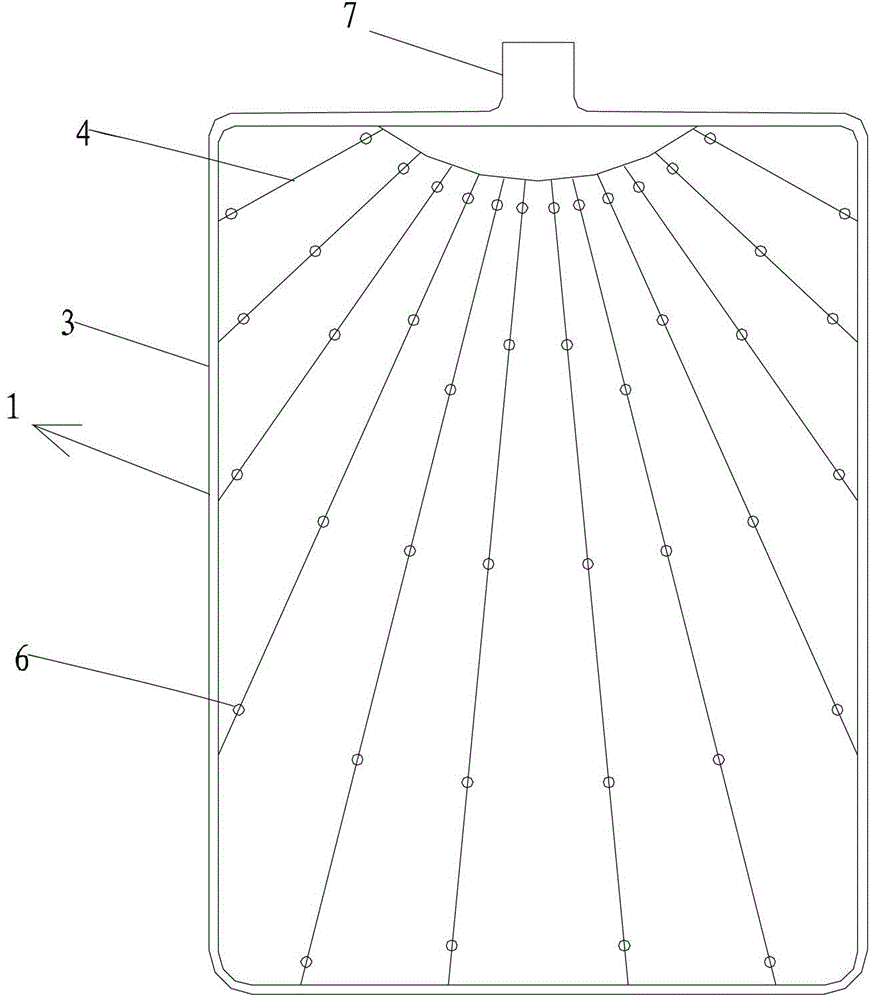

Flexible packaging bag and support unit

InactiveCN1371335AEfficient use ofGuaranteed flowDispensing apparatusHole piercing devicesLiquid productPhysics

A support unit is provided for a liquid filled flexible packaging bag having a length, width, and thickness, and which enables such a bag to be stored horizontally while enabling liquid contained within the bag to be withdrawn as and when required. The storage unit (1) has a support panel (2, 12, 14, 19, 26, 42) for a liquid filled flexible packaging bag which is adapted to support the packaging bag in an inclined orientation at least after a proportion of the initial content of the bag has been removed. The support panel corresponds generally in plan view to the length and width of the packaging bag and is usually located inside a flat shape of box (6, 46) capable of storage on a shelf of low height. The support panel may be arranged to move from a horizontal position to a progressively more inclined position as liquid is removed from the bag. A liquid supply system is also disclosed.

Owner:TAP IT LIQUID SOLUTIONS

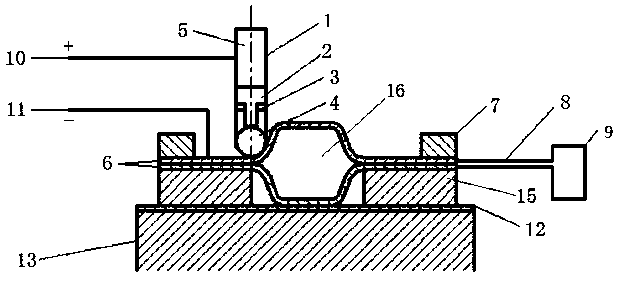

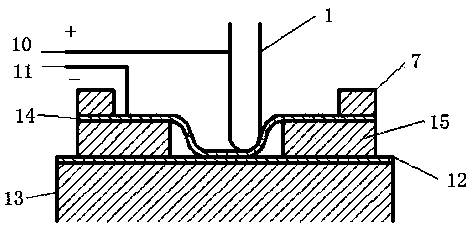

Forming method and forming device for doubling plate structural members

ActiveCN108480924ADiffuse join implementationLow costOther manufacturing equipments/toolsEngineeringTitanium

The invention relates to a forming method and a forming device of doubling plate structural members. The forming device comprises a machining tool head, a machining platform and a plurality of metal plate materials. A fixed clamp and two cushion blocks are installed on the machining platform. Every two corresponding metal plate materials are welded into a workblank piece through argon arc welding.A workblank molding cavity is formed in each workblank piece after welding. Each workblank piece is installed on the corresponding cushion block through the fixed clamp. The machining tool head actson the workblank pieces. The machining tool head is connected with the positive pole of a power source through a positive pole wire. The workblank pieces are connected with the negative pole of the power source through negative pole wires. The workblank piece molding cavities communicate with a vacuum pump through titanium pipes. The workblank pieces are electrified so that heat can be generated,the workblank pieces are heated to the diffusion bonding temperature of the materials through a self-resistance heating mode, the machining tool head moves along a machining track under the control ofNC, no mold is needed in the molding technique of plates, the forming method is low in cost, and the period is shortened.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

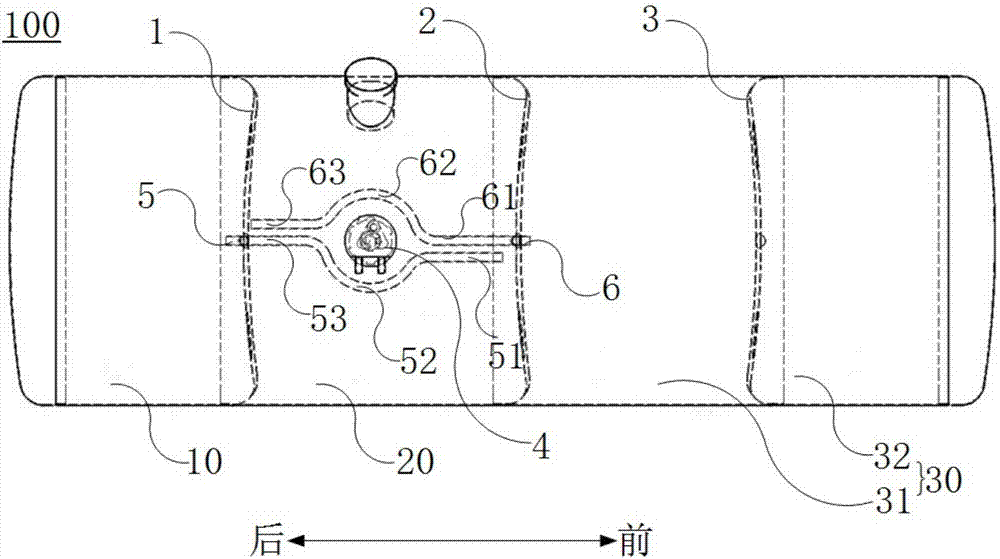

Oil tank of vehicle

PendingCN107458217AGuaranteed current limitingRaise the liquid levelUnderstructuresFuel supplyInterior spaceFuel tank

The invention discloses an oil tank of a vehicle. T he oil tank comprises an oil tank body, a first separating plate and a second separating plate. The first separating plate and the second separating plate are each provided with oil holes, a flow limiting device is arranged below the lowest oil hole of each of the first separating plate and the second separating plate. The fuel oil flowing section of each flow limiting device is smaller than the fuel oil flowing section of each oil hole. The first separating plate and the second separating plate divide the interior space of the oil tank body into a first oil cavity, a second oil cavity and a third oil cavity in the length direction, a fuel oil sensor used for sucking oil is arranged in the second oil cavity, and the flow limiting devices and the oil holes are used for enabling every two adjacent oil cavities to communicate correspondingly. According to the oil tank, the fuel oil sensor can suck fuel oil for a longer time when a vehicle goes uphill or downhill, and normal running of the vehicle when the vehicle goes uphill or downhill is guaranteed to the larger extent.

Owner:BEIJING FOTONDAIMLER AUTOMOTIVE

Lead-acid battery composite plate grid, pole plate and battery

ActiveCN102931415BEffective combinationGuaranteed distributionElectrode carriers/collectorsState of artConductive polymer

The invention discloses a lead-acid battery composite plate grid which is composed of a lead plate grid and a conductive polymer plate grid which are mutually superposed. The invention also discloses a lead-acid battery pole plate which comprises a plate grid and an active material layer coated on the plate grid. The lead-acid battery pole plate is characterized in that the plate grid is the lead-acid battery plate grid. The invention also discloses a lead-acid battery which comprises a pole plate, wherein the pole plate comprises the lead-acid battery plate grid and an active material layer coated on the plate grid. According to the invention, the effective combination of a lead plate grid and a conductive polymer plate grid is realized through the combination of the lead plate grid and the conductive polymer plate grid; and compared with the prior art, according to the invention, the distribution and flow direction of current in a charge-discharge process of a battery are guaranteed, the lead loss is saved, the weight is light, the material cost is reduced, and the market competitiveness is improved.

Owner:TIANNENG BATTERY GROUP

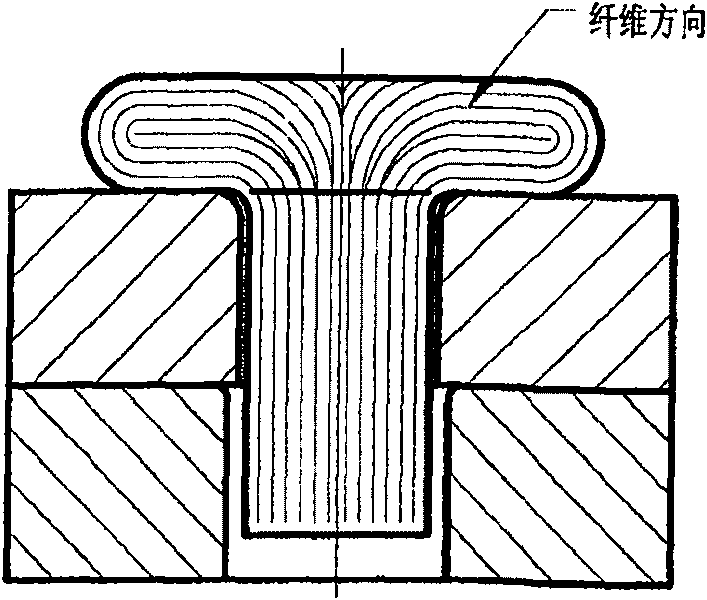

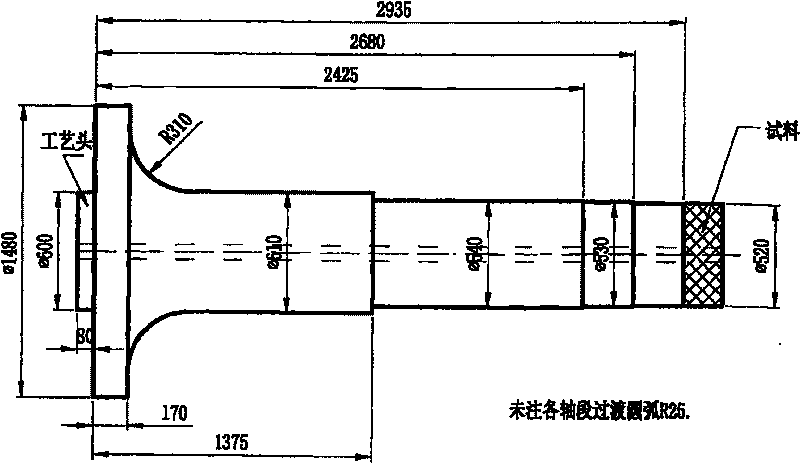

Method for producing wind-electricity principal axis by gathering stock full fibre upset forging

InactiveCN101314202BExtended service lifeGuaranteed fatigue strengthShaftsFurnace typesElectricityIngot

The invention relates to a method for producing a wind-power mainshaft by local continuous upsetting and all-fibre upset forging. The method comprises the following: step one, the heating of steel ingot; step two, forging; step three, first heat processing; step four, rough machining and ultrasonic inspection; step five, quenching and tempering and heat processing; step six, fine machining, wherein, during the step two, the forging comprises that: (1) a first fire, during which, a steel ingot is subject to upset forging at a forging temperature of between 1250 and 900 DEG C; firstly, the bottom of the steel ingot is sawed off, and the steel ingot is subject to capping and upset forging; (2) a second fire, during which, the steel ingot is stretched towards various directions, marked and subject to intermediate billet cogging; after a pole part is molded, scrap on a T end is chopped and removed; after the forging is finished, the steel ingot returns to a heating furnace for being reheated; (3) a third fire, during which, the steel ingot is subject to local continuous upsetting and all-fibre upset forging; (4) a fourth fire, during which, the steel ingot is subject to rolling and leveling; the pole part is stretched; the disc edge of a hub end on the head part of an intermediate billet material after the local continuous upsetting and all-fibre upset forging is subject to rollingoperation; after the rolling, the intermediate billet material is inserted into a leaking disc component again; the end face of the disc is pressed and leveled; after the shaping of the disc end is completed, a manipulator clamps the disc and stretches the pole part of the intermediate billet material to a dimension of a forgeable piece; thus, the mainshaft forging is completed. The method can improve the fatigue resisting strength of a wind-power mainshaft forging piece.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com