Lead-acid battery composite plate grid, pole plate and battery

A lead-acid battery, lead grid technology, applied in the direction of electrode carriers/current collectors, etc., can solve the problems of high cost, large lead consumption, heavy weight, etc., and achieve the effects of low production cost, overall weight reduction, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

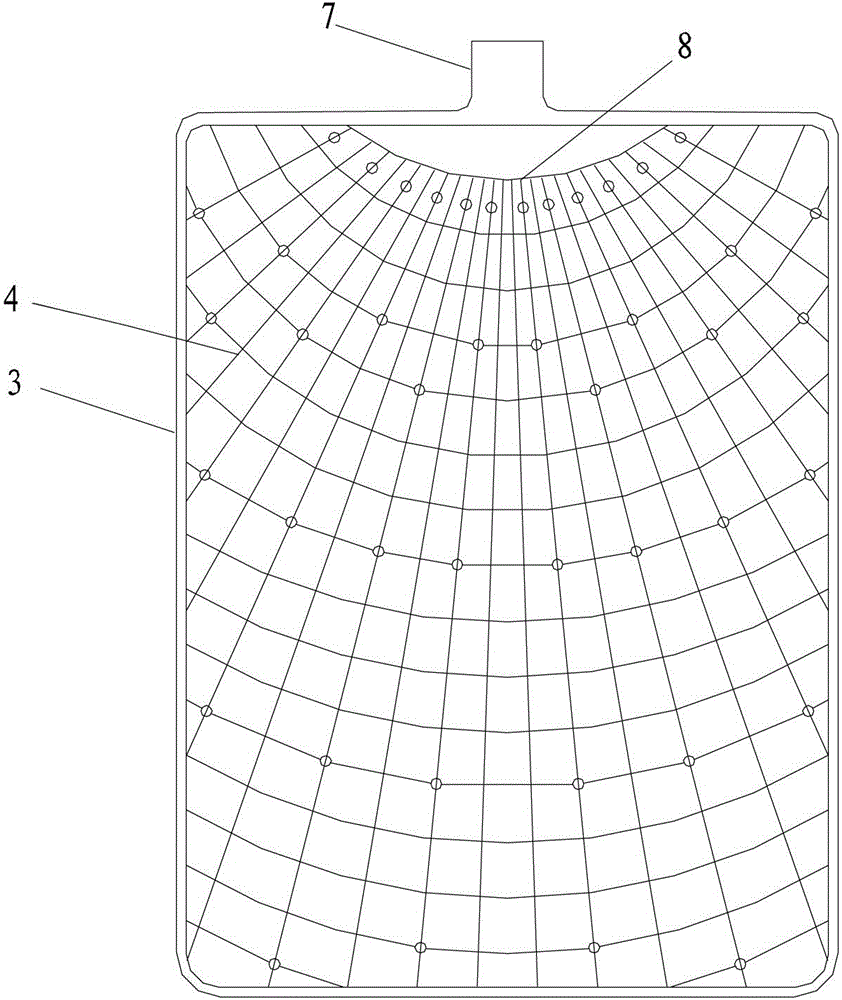

[0026] Such as figure 1 As shown, a lead-acid battery composite grid is composed of a lead grid 1 and a conductive polymer grid 2 stacked on top of each other.

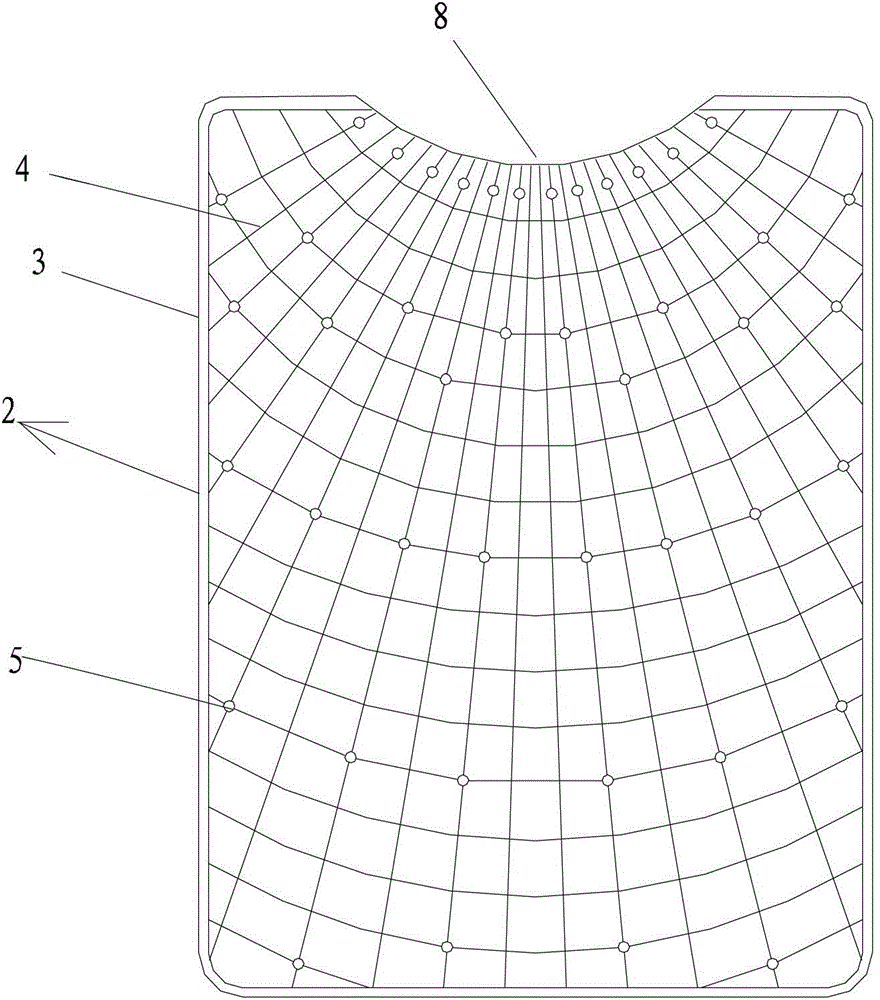

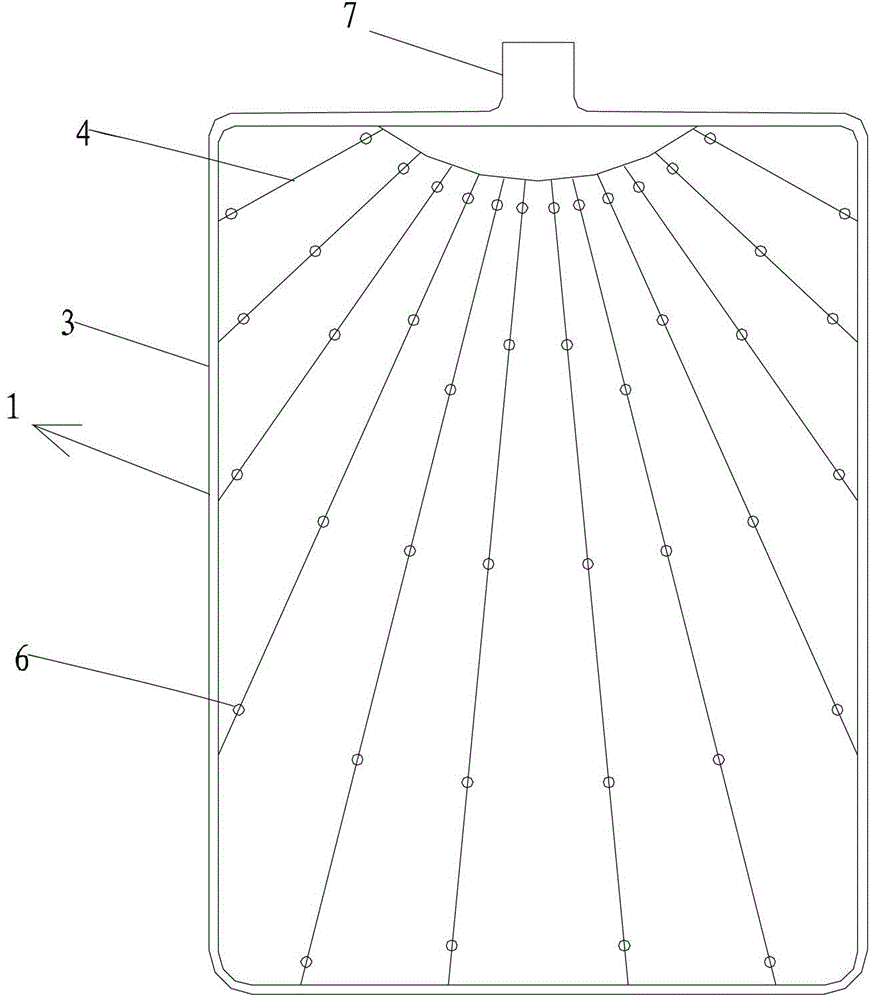

[0027] Such as figure 2 with image 3 The structural schematic diagrams of the conductive polymer grid and the lead grid are shown respectively, and it can be seen from the figure that the lead grid 1 and the conductive polymer grid 2 both include a frame 3 and ribs 4 distributed in the frame; The ribs 4 of the grid and the ribs 4 of the conductive polymer grid are respectively provided with corresponding embedded holes 5 and embedded points 6, and the embedded holes 5 are arranged on the ribs 4 of the conductive polymer grid 2 , The embedding point 6 is set on the rib 4 of the lead grid 1 . The lead grid and the conductive polymer grid are stacked opposite each other, and the lead grid 1 and the conductive polymer grid 2 are tightly combined through the plugging effect of the embedding point 6 and the embedding h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com