Patents

Literature

191results about How to "Guaranteed distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for the quick-speed and safe distribution of file based on P2P

InactiveCN101515947AFast transferDistribute quicklyEncryption apparatus with shift registers/memoriesPlaintextCiphertext

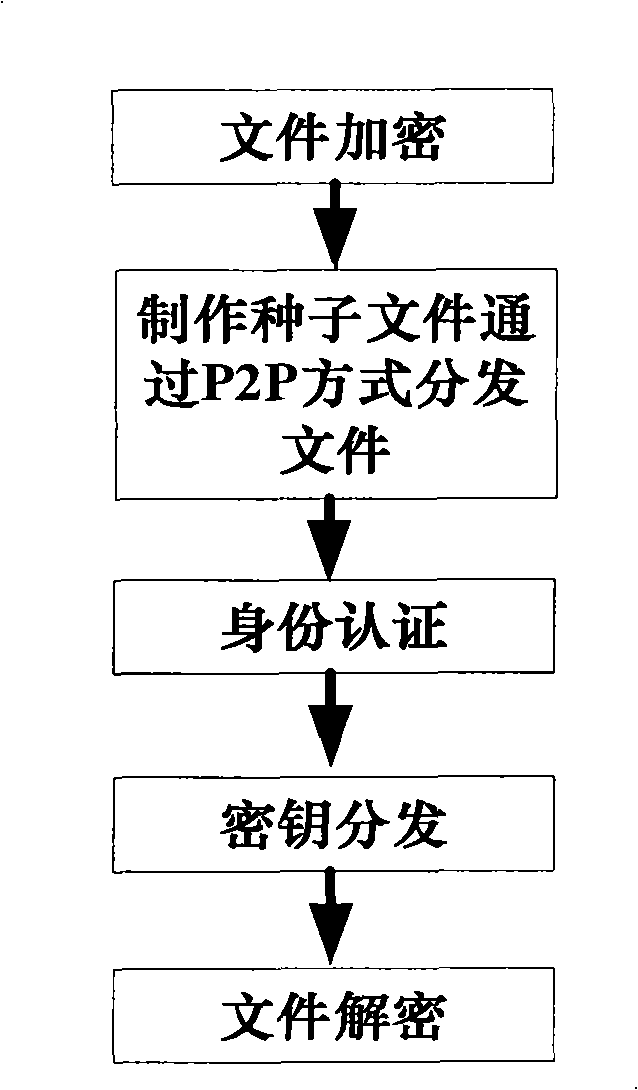

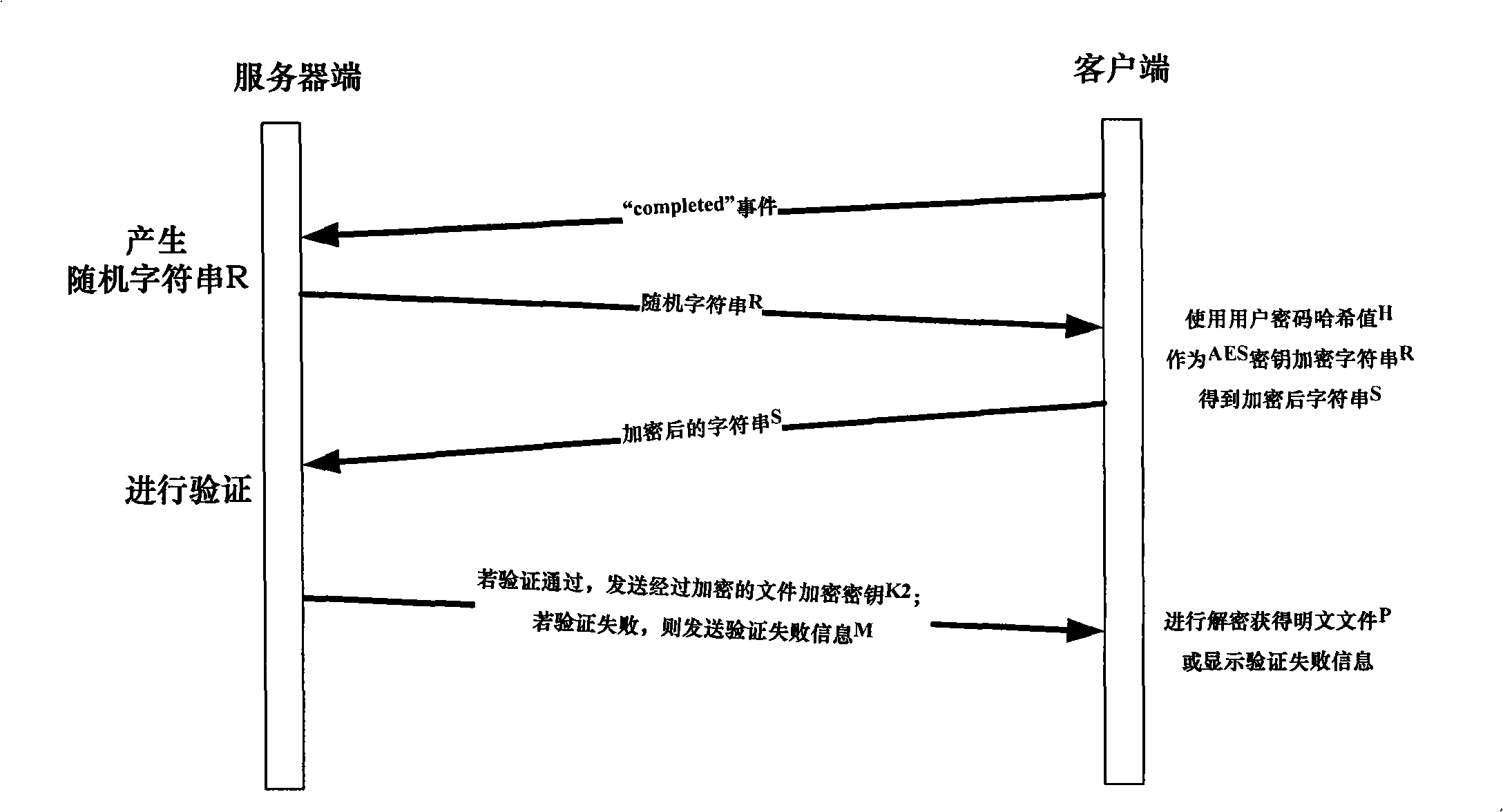

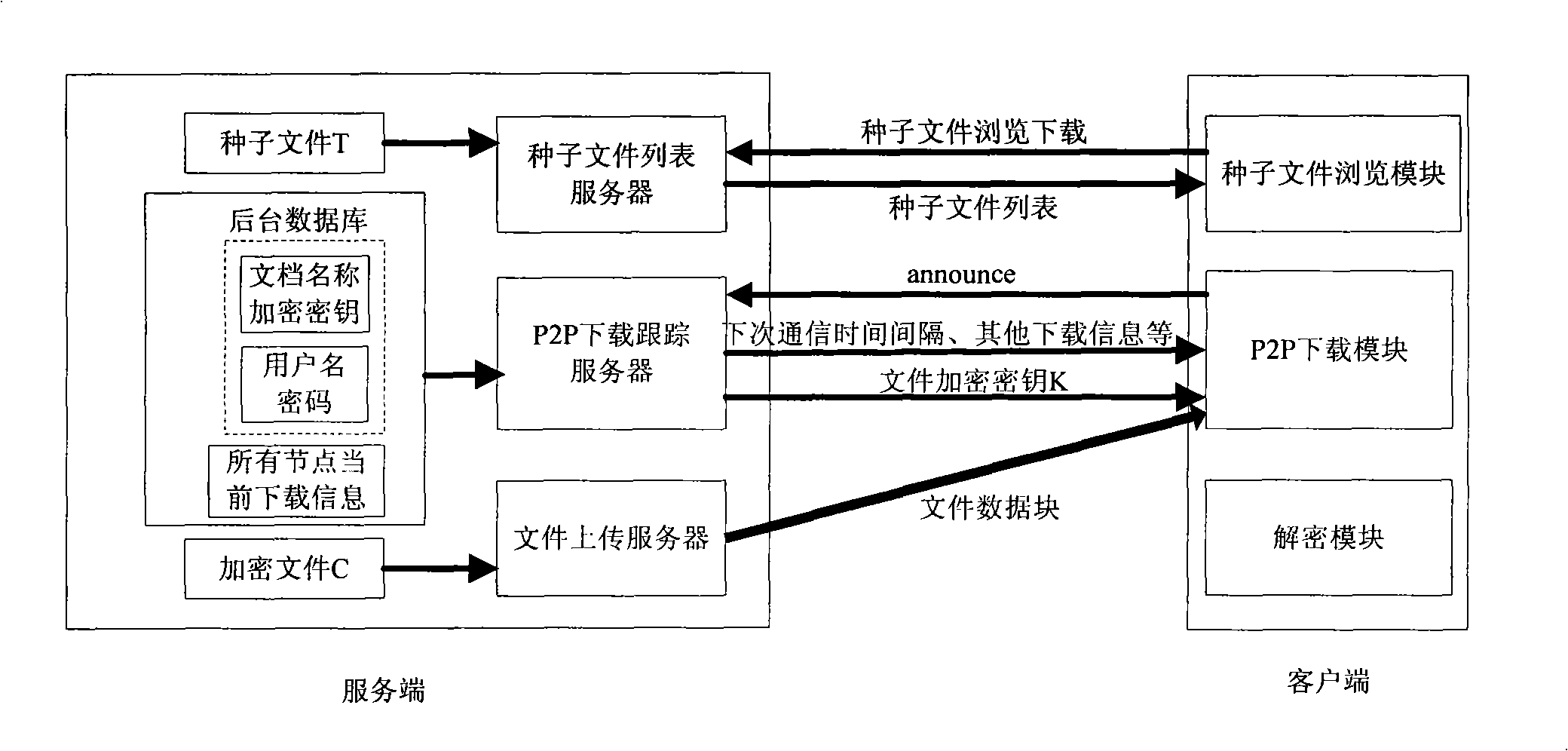

The invention discloses a method for the quick-speed and safe distribution of the file based on the P2P,including that: a, a proclaimed file is in the symmetric encrypting to form an encrypted file before being distributed and transferred, and the encrypted file is made into a seed file, which is placed in the service end and distributed in the P2P way; b, the customer end logins according to the user information, the seed file is selected and downloaded in the P2P way, then the customer is in the identity verification; c, the service end distributes the encryption key of the encrypted file for the certificated customer; d, the customer end obtains the proclaimed file through the symmetric deciphering of the encryption key and the encrypted file. The invention also discloses a system for the quick-speed and safe distribution of the file based on the P2P, comprising a service end and a customer end, wherein the service end comprises a data-base, a seed file list server, a P2P download tracking server and a file uploading server, the customer end comprises a seed file reading module, a P2P downloading module and a deciphering module. The method can satisfy the requirement for safely and quickly distributing and transferring the file under the certain condition.

Owner:ZHEJIANG UNIV

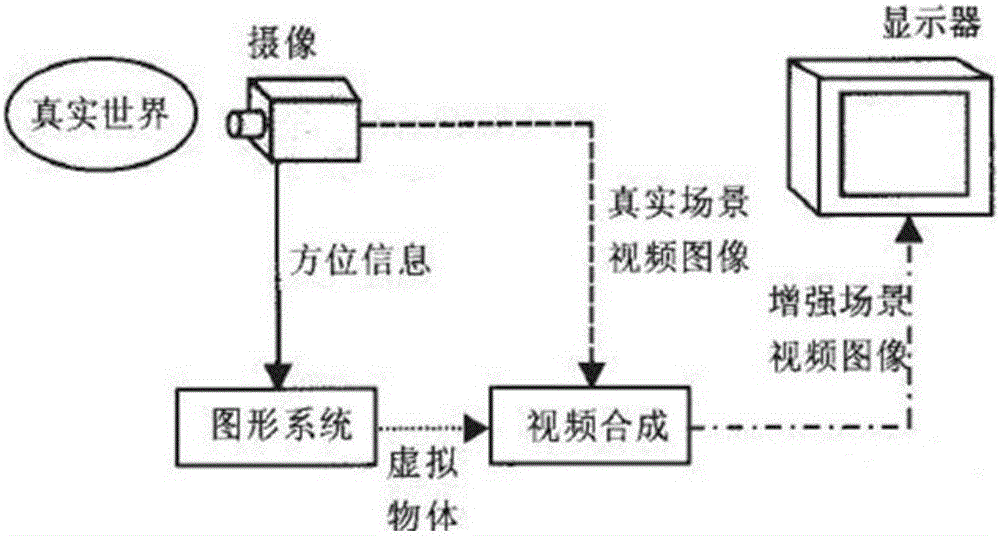

Sinology three-dimensional interactive learning system and method based on augmented reality and speech recognition

InactiveCN106408480AImprove recognitionImprove recognition accuracyData processing applicationsAnimationSpeech identificationImage identification

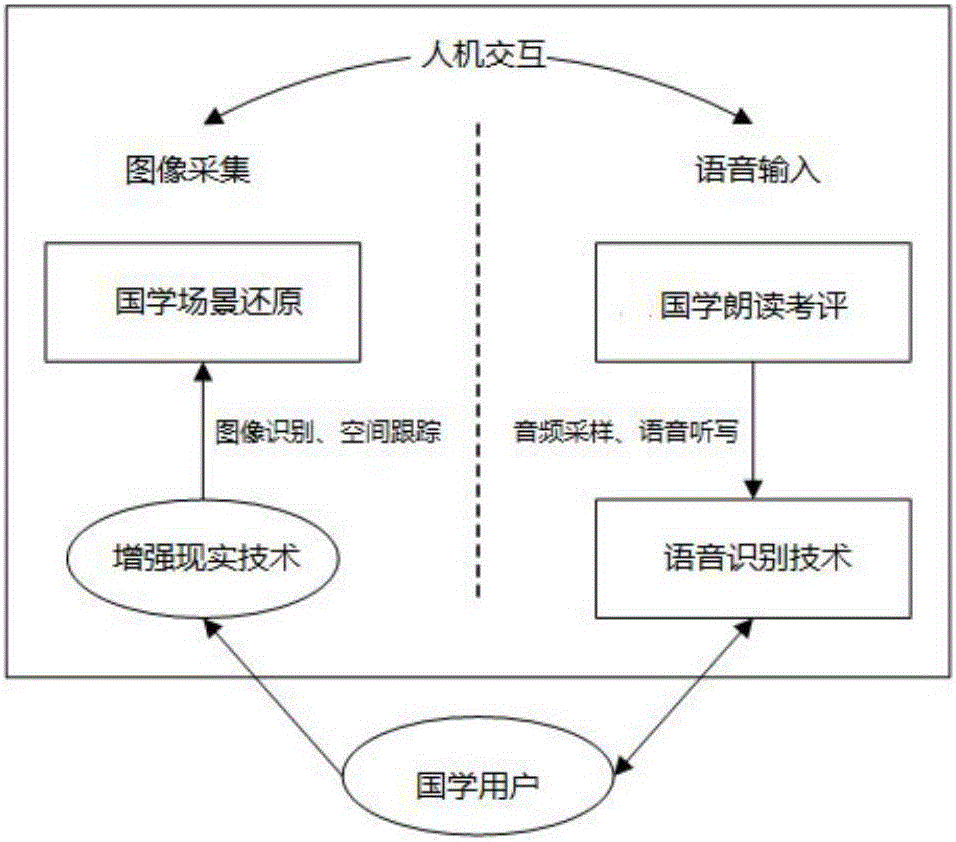

The invention discloses a sinology three-dimensional interactive learning system and method based on augmented reality and speech recognition technologies. The system comprises at least one page or card, a camera device, an image recognition processing module, a display device, a sound input device, a speech recognition module, a sound playback device, a program function module and a human-computer interaction sinology material library. The camera device collects image information. According to the collected information operation, a sinology scene is displayed in a real three-dimensional space to complete augmented reality interaction. Through voice collecting, voice content verification is carried out to acquire a collected sinology reading content and complete speech recognition interaction. At the same time, comparing with standard speech information is carried out for scoring. The principle and method solve the problems of abstract content, single form, being boring and the like of the current sinology education, have the advantages of easy operation and low cost, and are suitable for the promotion and popularization of traditional culture.

Owner:SHANDONG CONFUCIOUS CULTURAL IND DEV CO LTD

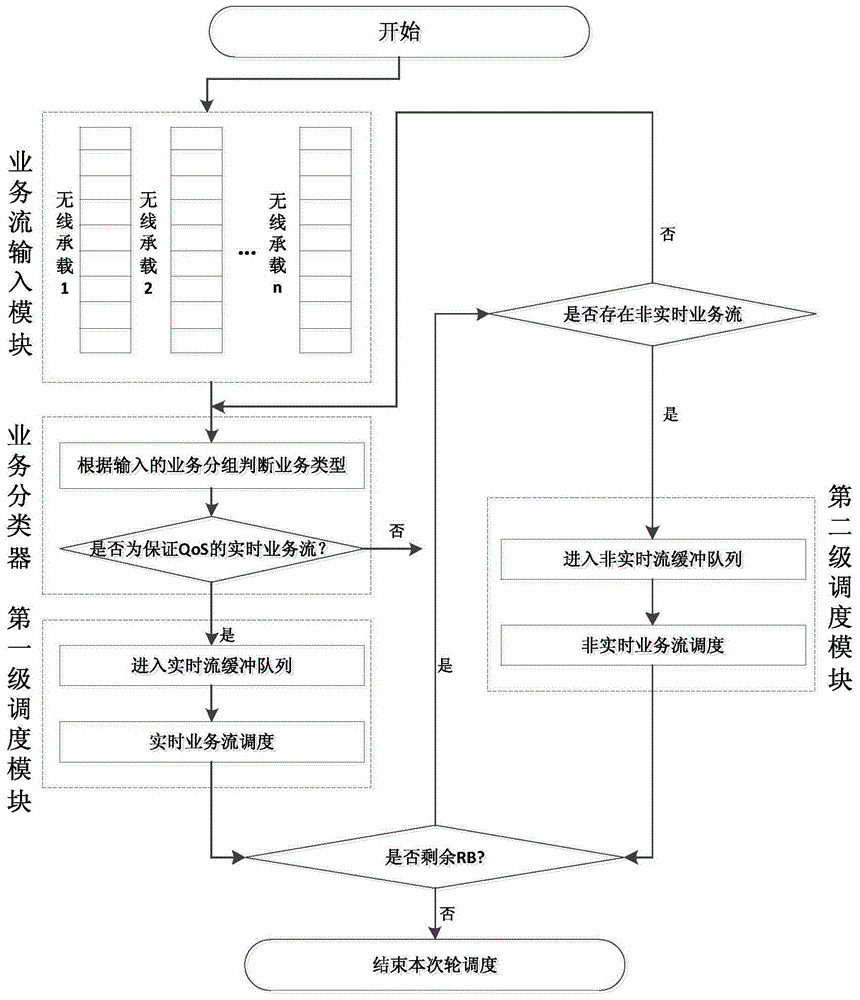

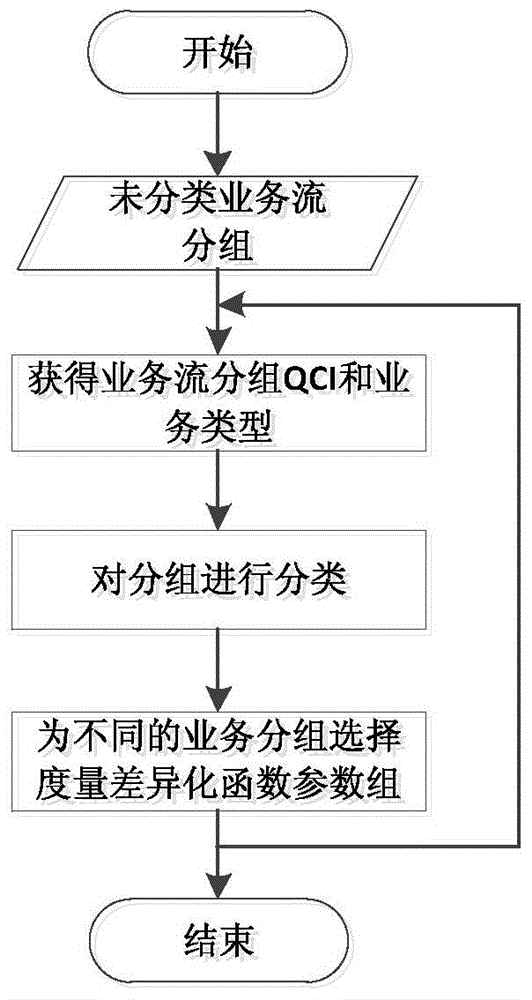

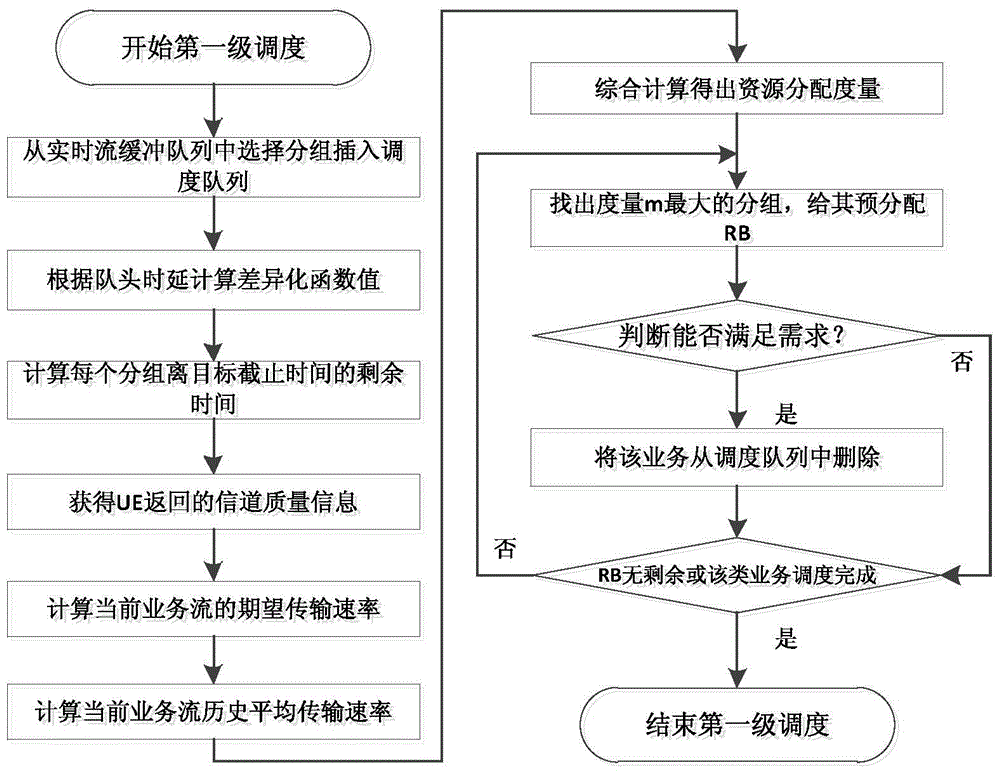

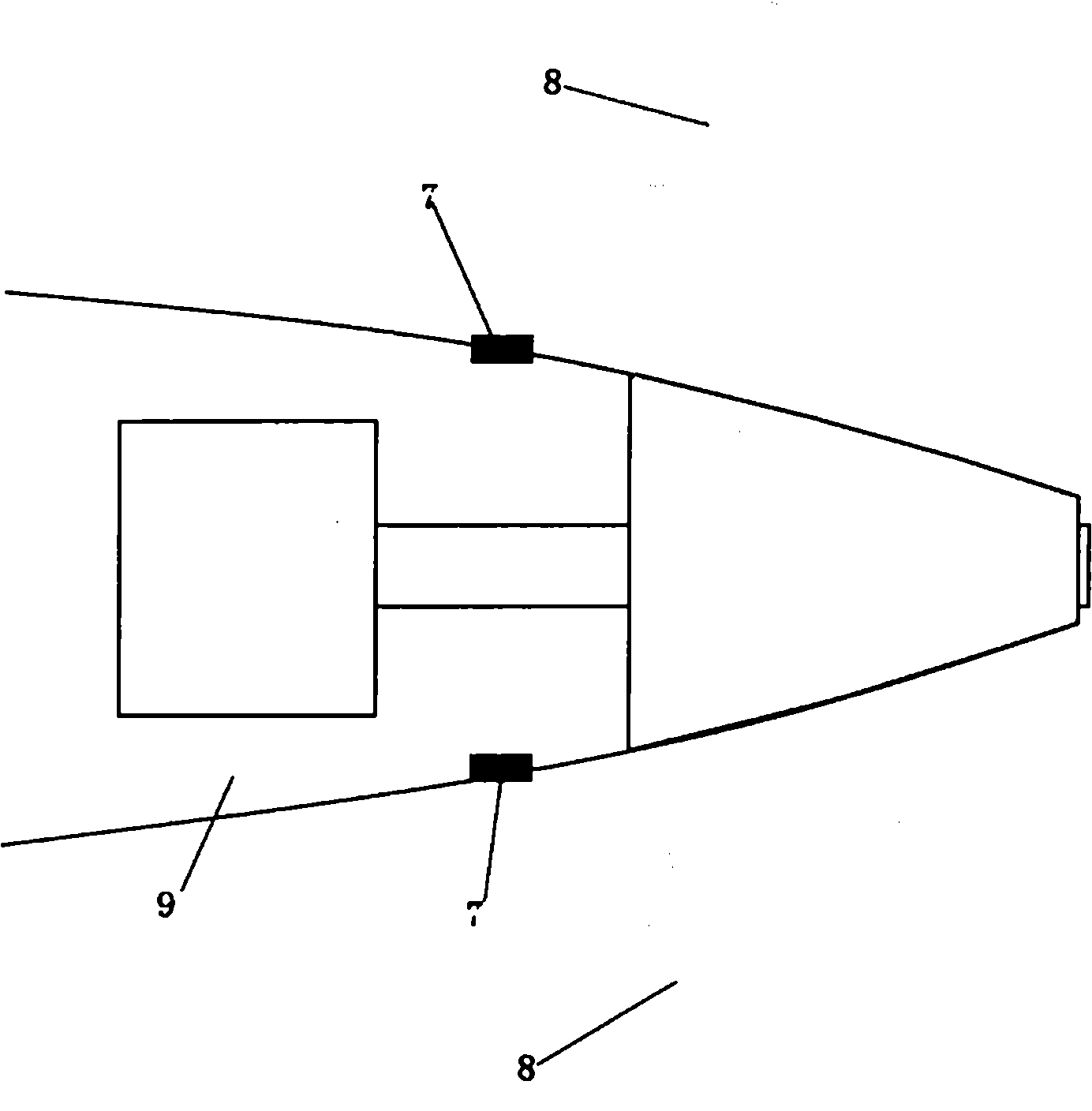

Vehicle-road communication downlink wireless resource distribution algorithm

ActiveCN104837205AGuaranteed distributionGuaranteed normal transmissionWireless communicationQuality of serviceNon real time

The invention provides a vehicle-road communication downlink wireless resource distribution system, comprising a business flow input module and a business classifier connected with the business flow input module. The business classifier is used for classifying business flows. The business classifier is connected with a first scheduling module and a second scheduling module. The first scheduling module is used for scheduling real-time business flows in a differentiate manner. The second scheduling module is used for scheduling non-real-time business flows. The first scheduling module is also connected with the second scheduling module, so that the real-time business flows are enabled to have the priority in scheduling. When the real-time business flows are scheduled and wireless resources are surplus, the scheduling of the non-real-time business flows is started. According to the algorithm provided by the invention, channel sensing requirements are met, time delay QoS (Quality of Service) guarantee of the real-time business flow is provided, the priority of business flows related to traffic safety and the fair scheduling of concurrent real-time business flows are both considered, and the balance among the throughput, the fair index and the QoS support is ensured.

Owner:CHANGAN UNIV

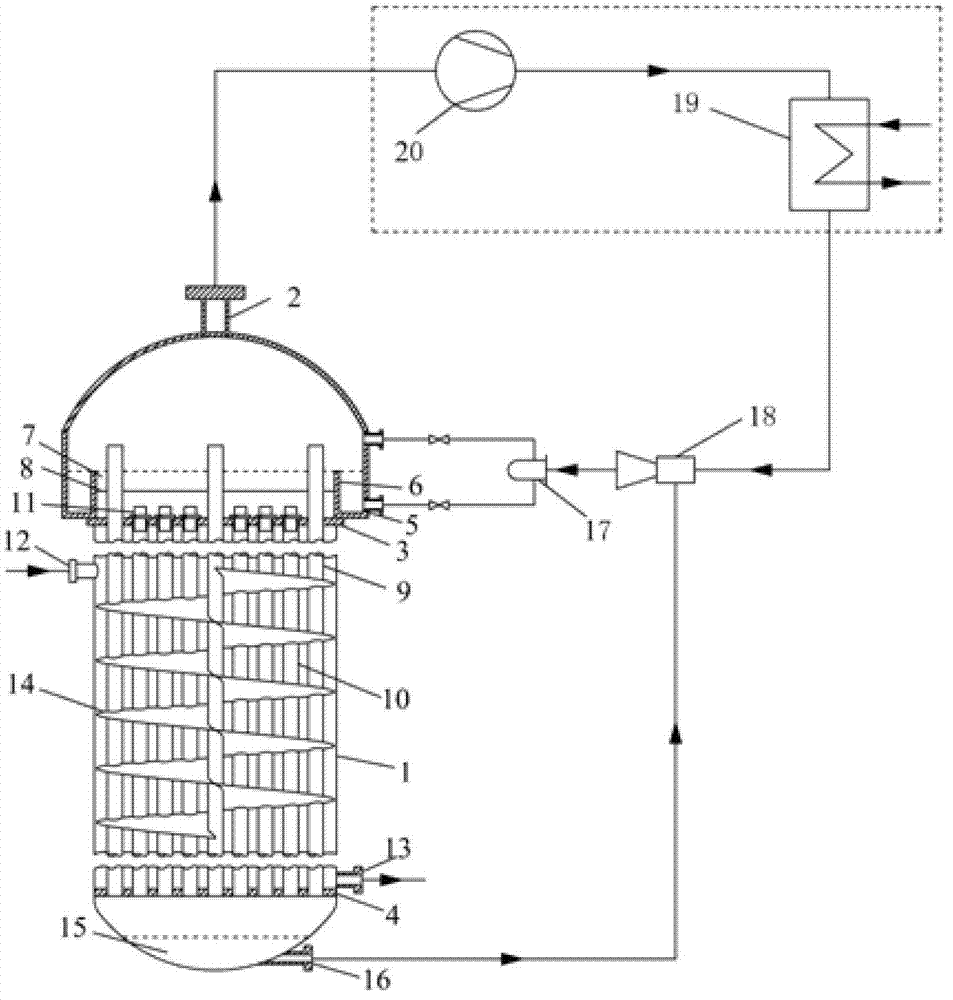

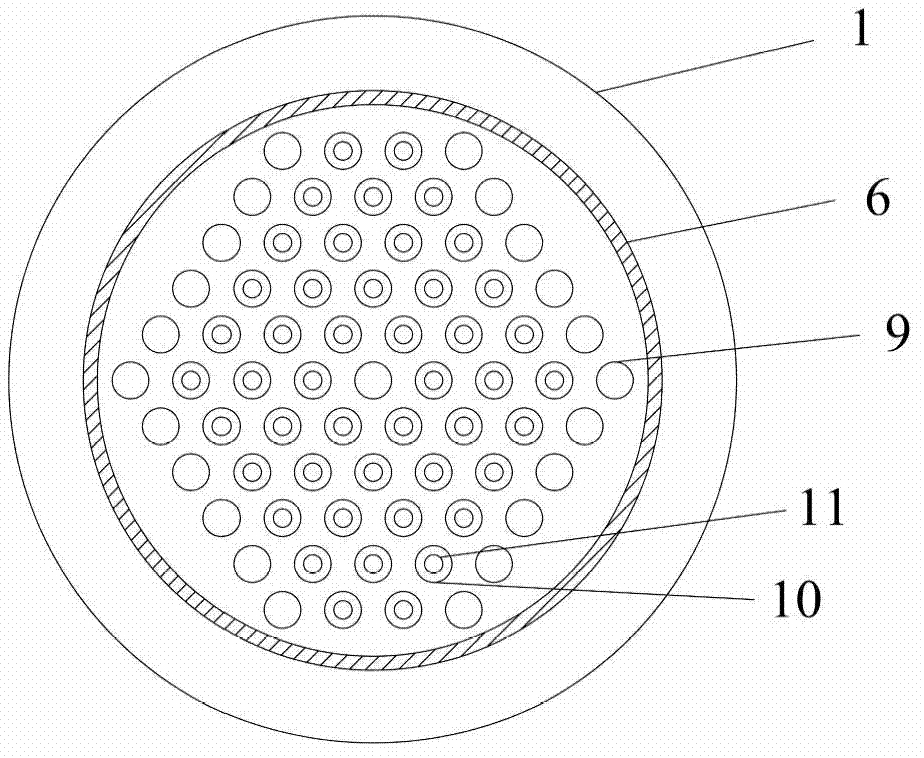

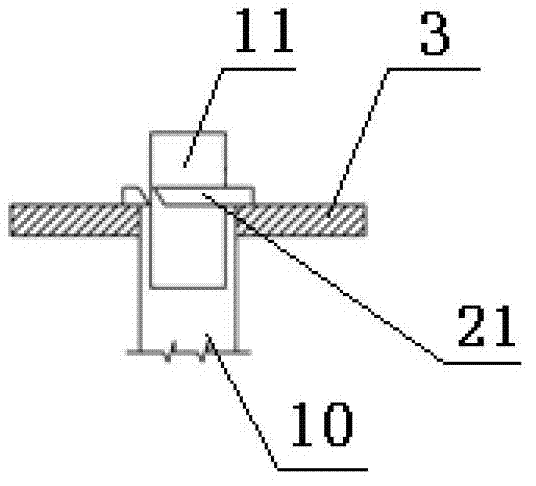

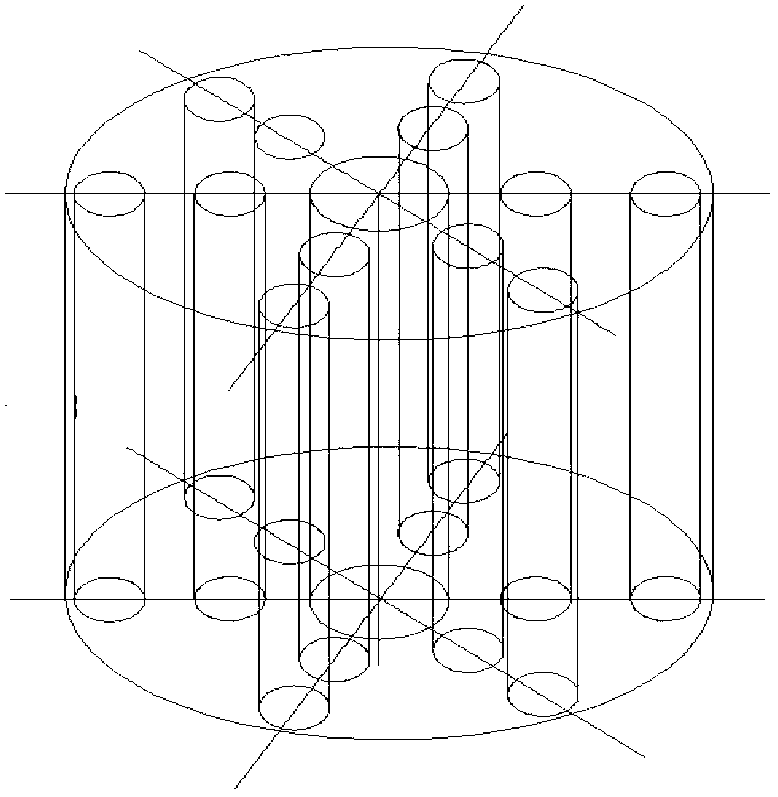

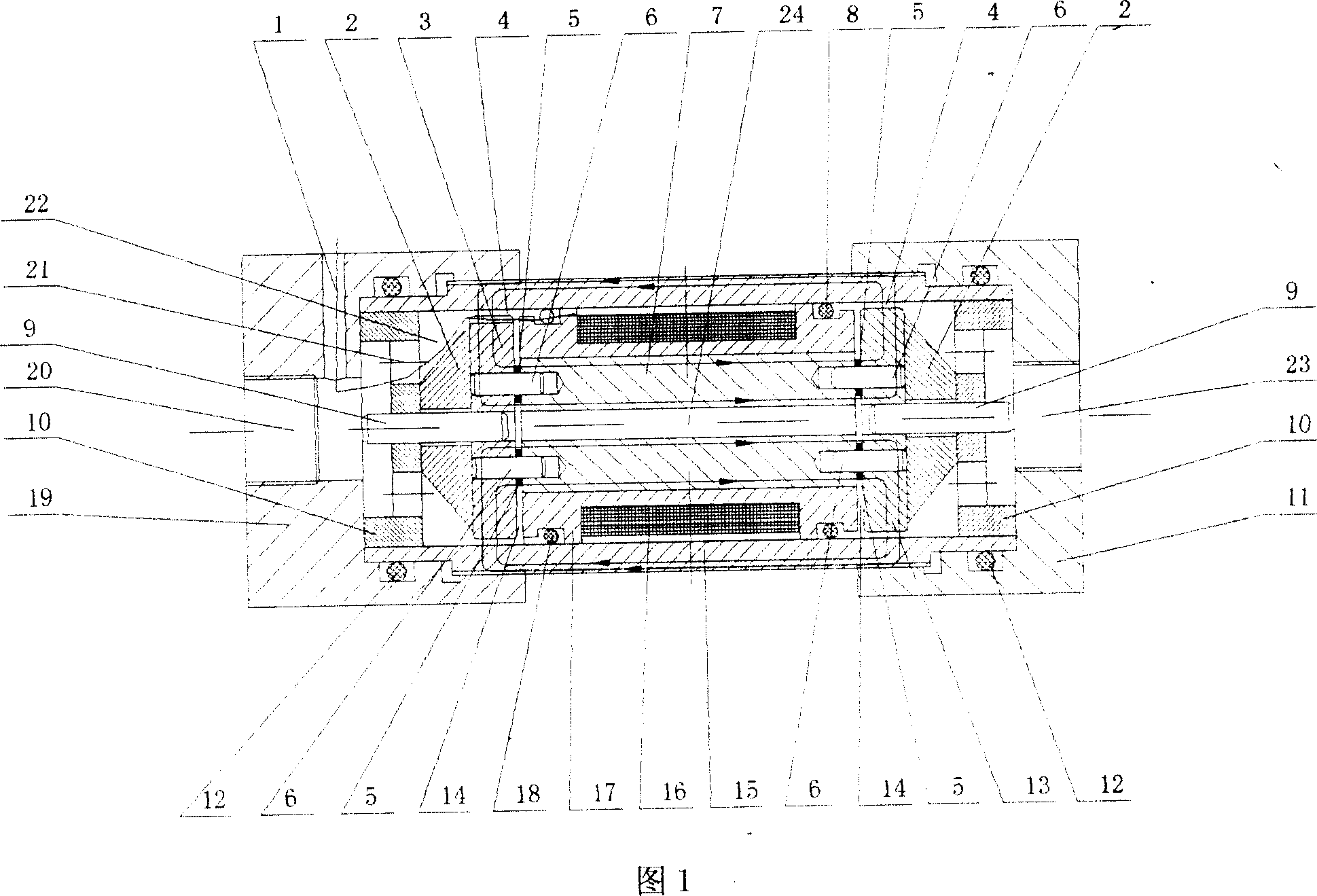

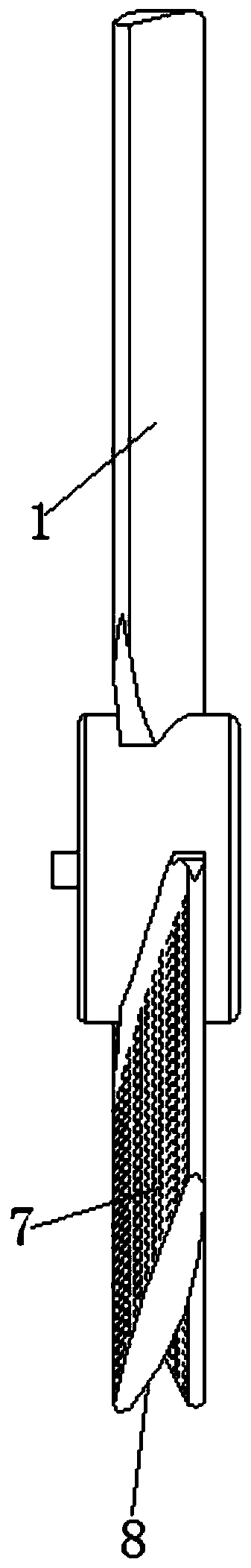

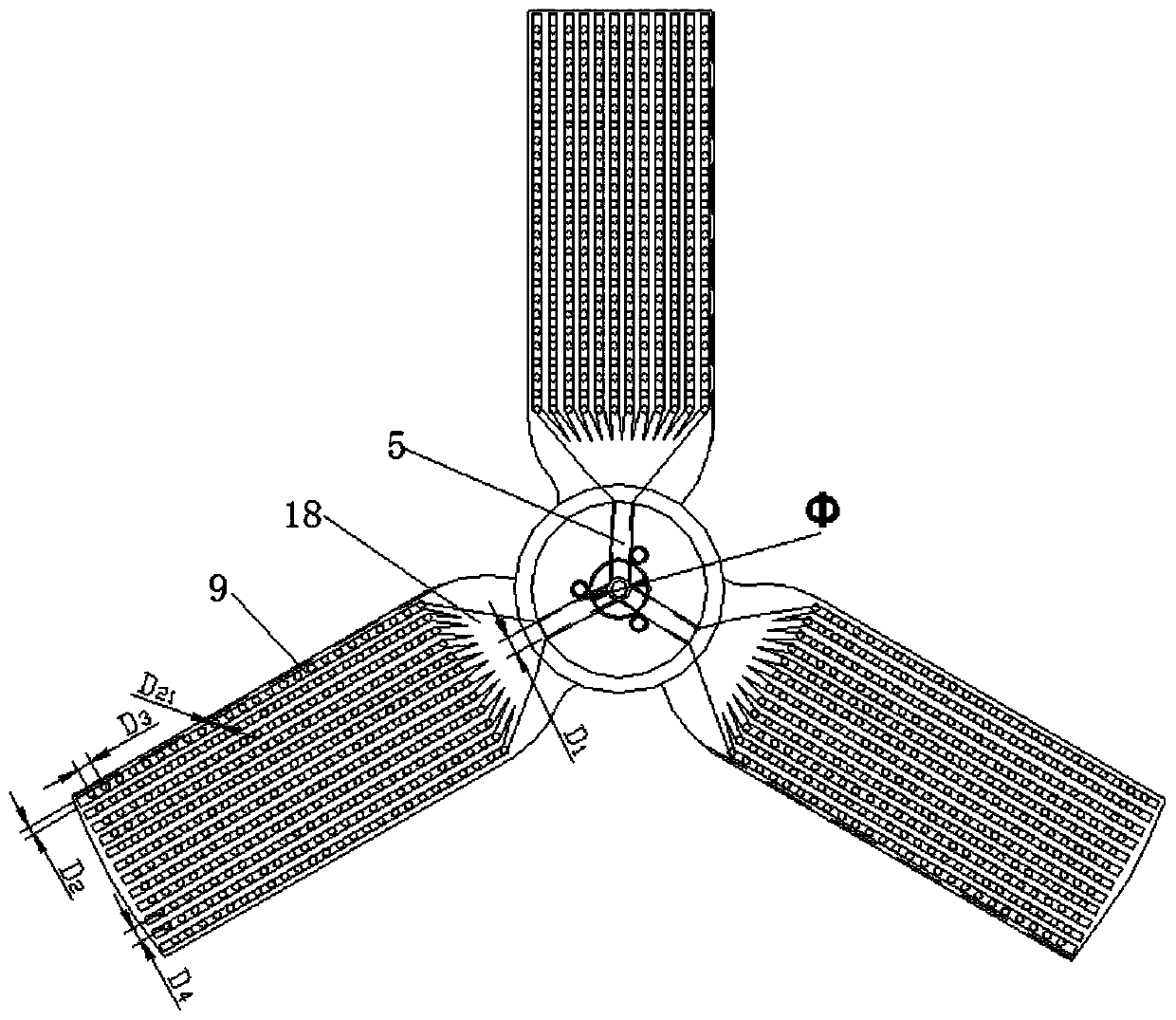

Riser spiral-flow type falling-film evaporator for refrigerating air conditioner

InactiveCN102759225AImprove heat transfer performanceSmall liquid holding capacityEvaporators/condensersHeat exchanger casingsRefrigerantFalling film evaporator

The invention discloses a riser spiral-flow type falling-film evaporator for a refrigerating air conditioner. The riser spiral-flow type falling-film evaporator comprises a shell, a refrigerant steam conveying pipe bundle, a falling-film evaporation pipe bundle, a damping hole plate and a spiral baffle plate, wherein the refrigerant steam conveying pipe bundle is arranged in the center in the shell and along the circumferential direction of the inner all of the shell, the falling-film evaporation pipe bundle is surrounded by the refrigerant steam conveying pipe bundle, the refrigerant steam conveying pipe bundle and the falling-film evaporation pipe bundle are both vertically arranged inside the shell, the upper part of an inlet of the falling-film evaporation pipe bundle is horizontally provided with the damping hole plate, the spiral baffle plate is fixed inside the shell and spirally arranged along a vertical direction, and is provided with through holes allowing the refrigerant steam conveying pipe bundle and the falling-film evaporation pipe bundle to pass through, an ejector is arranged between a refrigerant outlet pipe and a refrigerant inlet pipe, the inlet of the falling-film evaporation pipe bundle is provided with a flow guiding nozzle which has an outer diameter smaller than the inner diameter of the falling-film evaporation pipe bundle and is sealed at two ends, and the flow guiding nozzle is provided with a circular ring with three chutes formed along a circumferential direction uniformly. The riser spiral-flow type falling-film evaporator has the characteristics of small heat transfer temperature difference, high heat transfer coefficient, large evaporative power of unit area capable of preventing dry evaporation, low manufacture cost, less liquid holdup, small floor area and high safety.

Owner:XI AN JIAOTONG UNIV

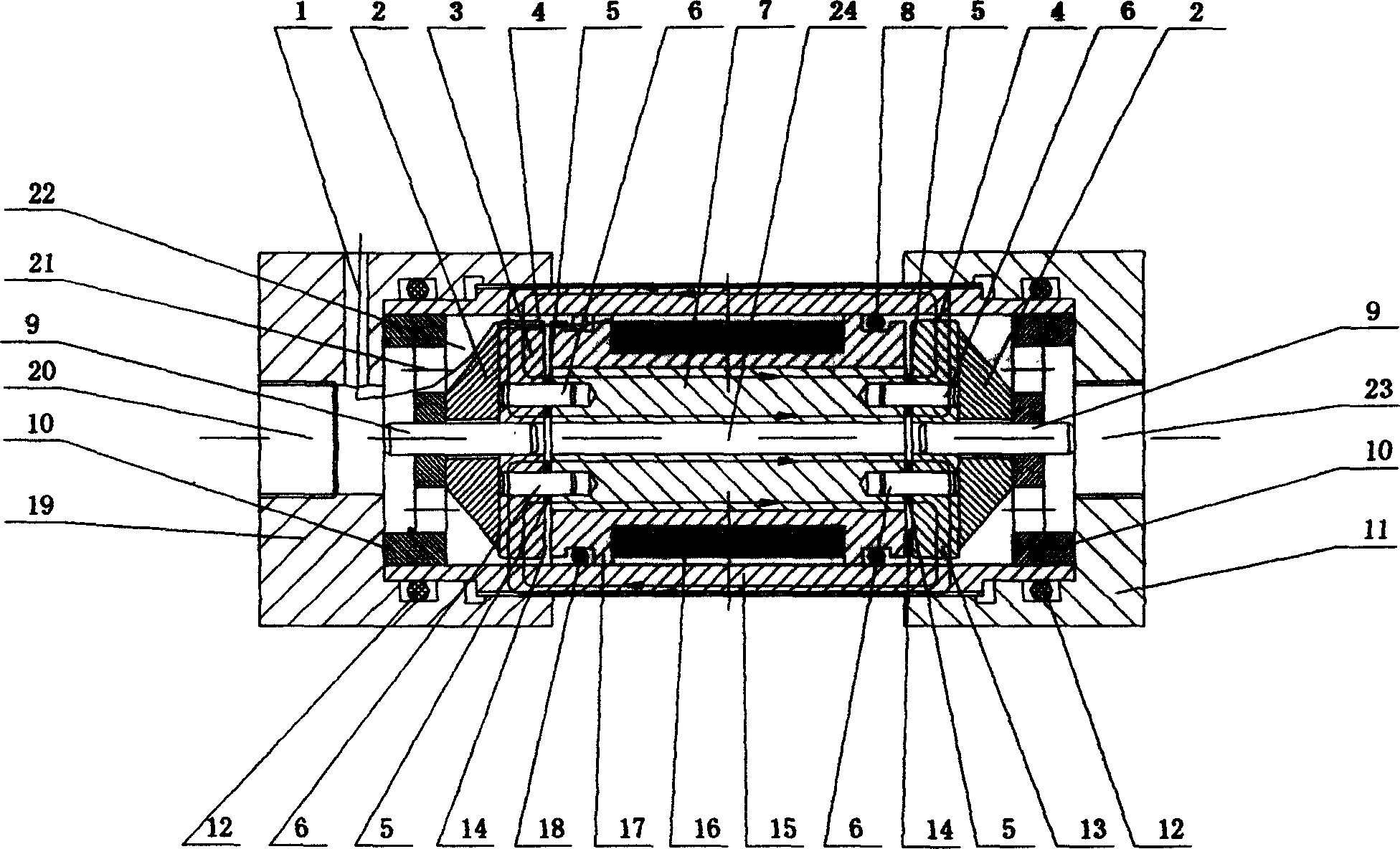

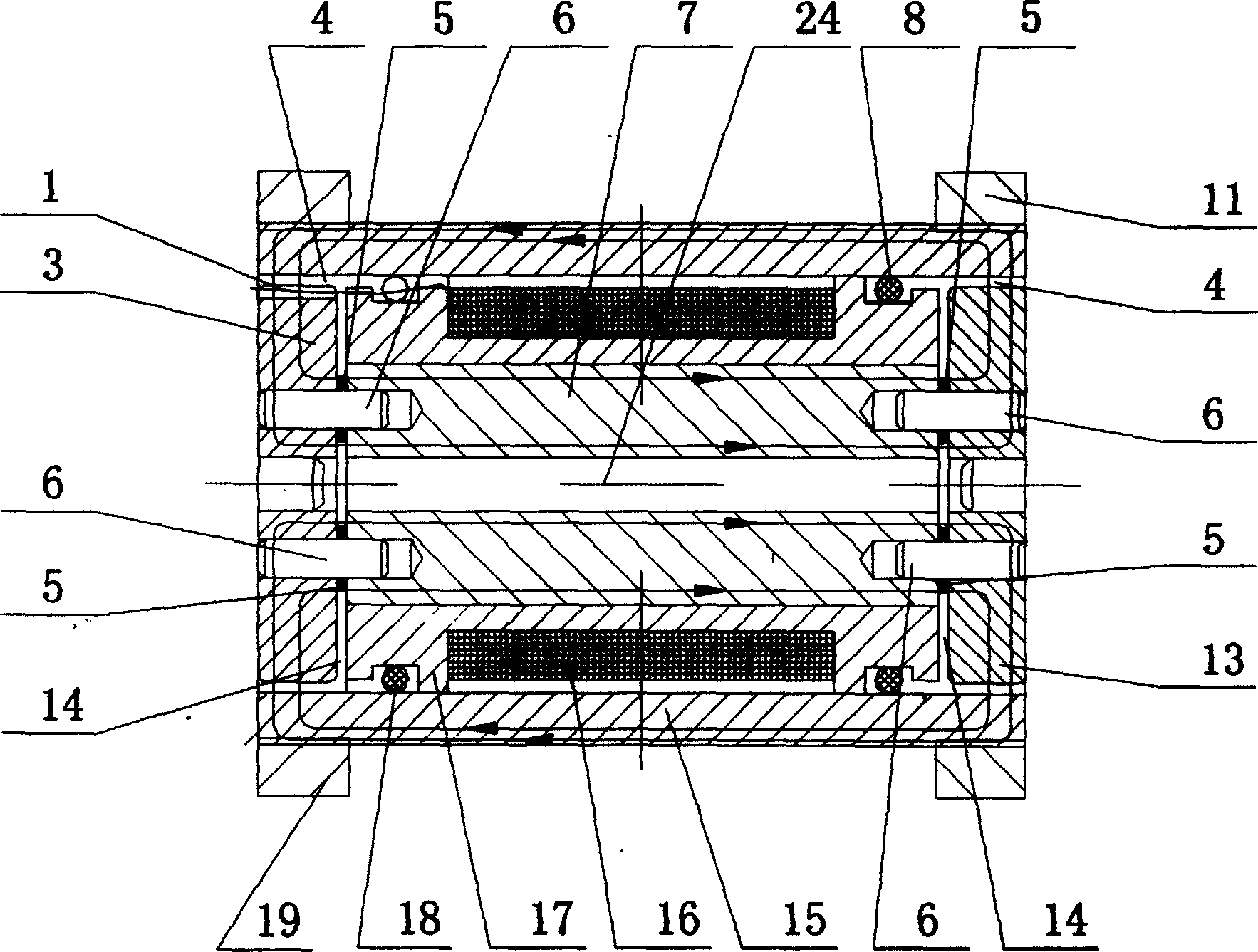

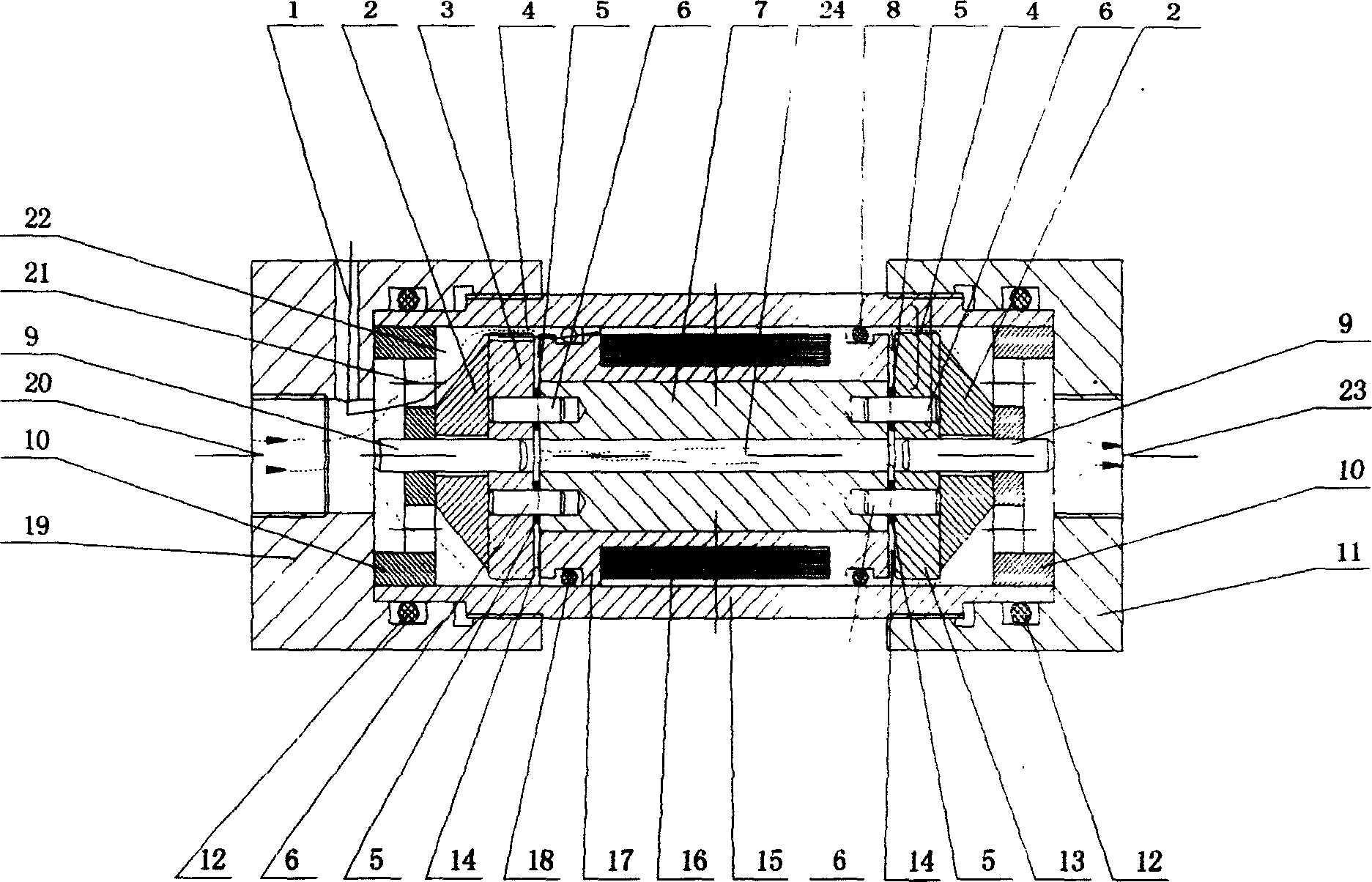

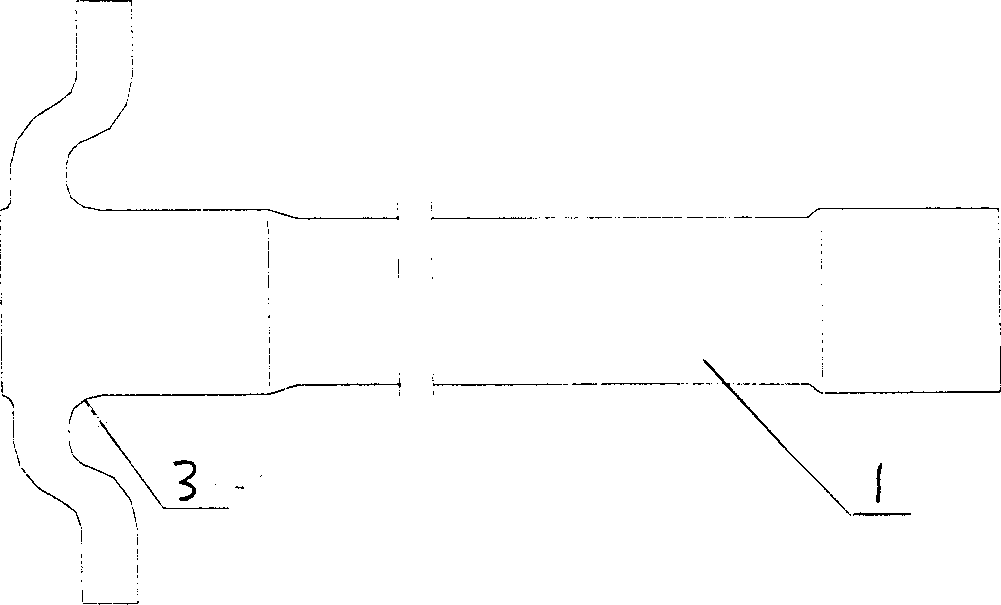

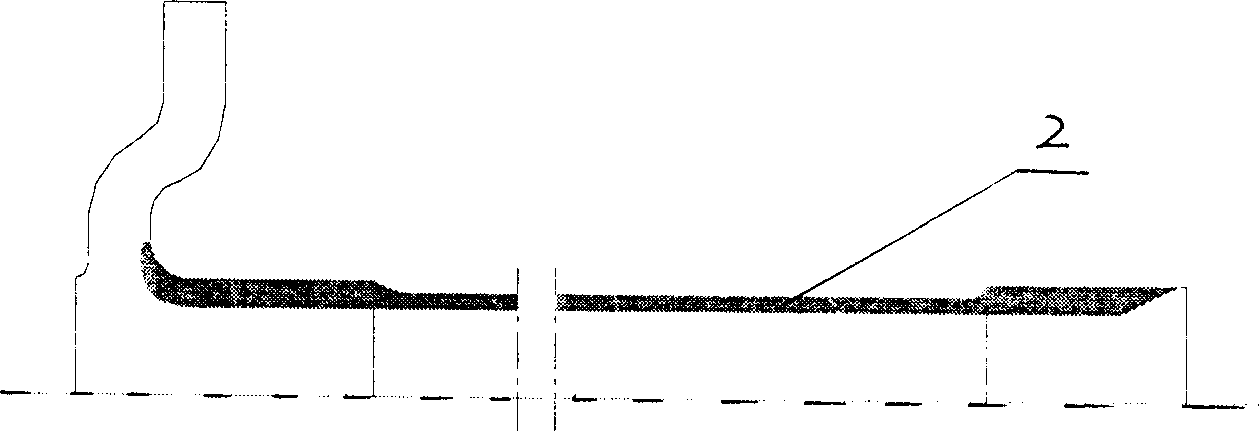

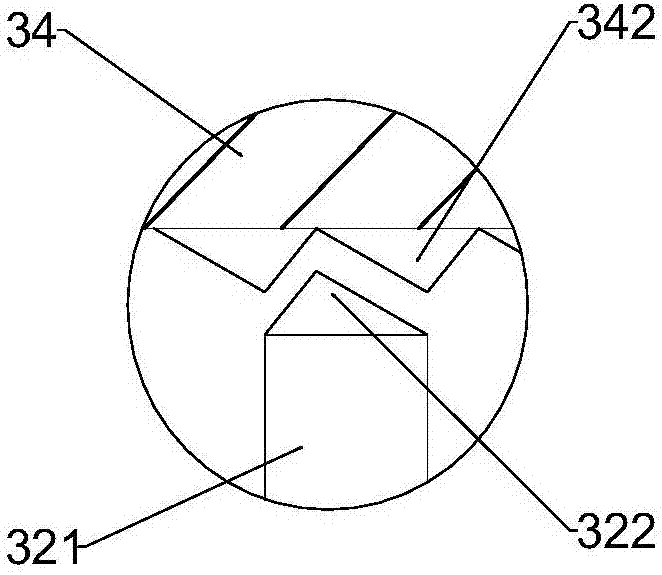

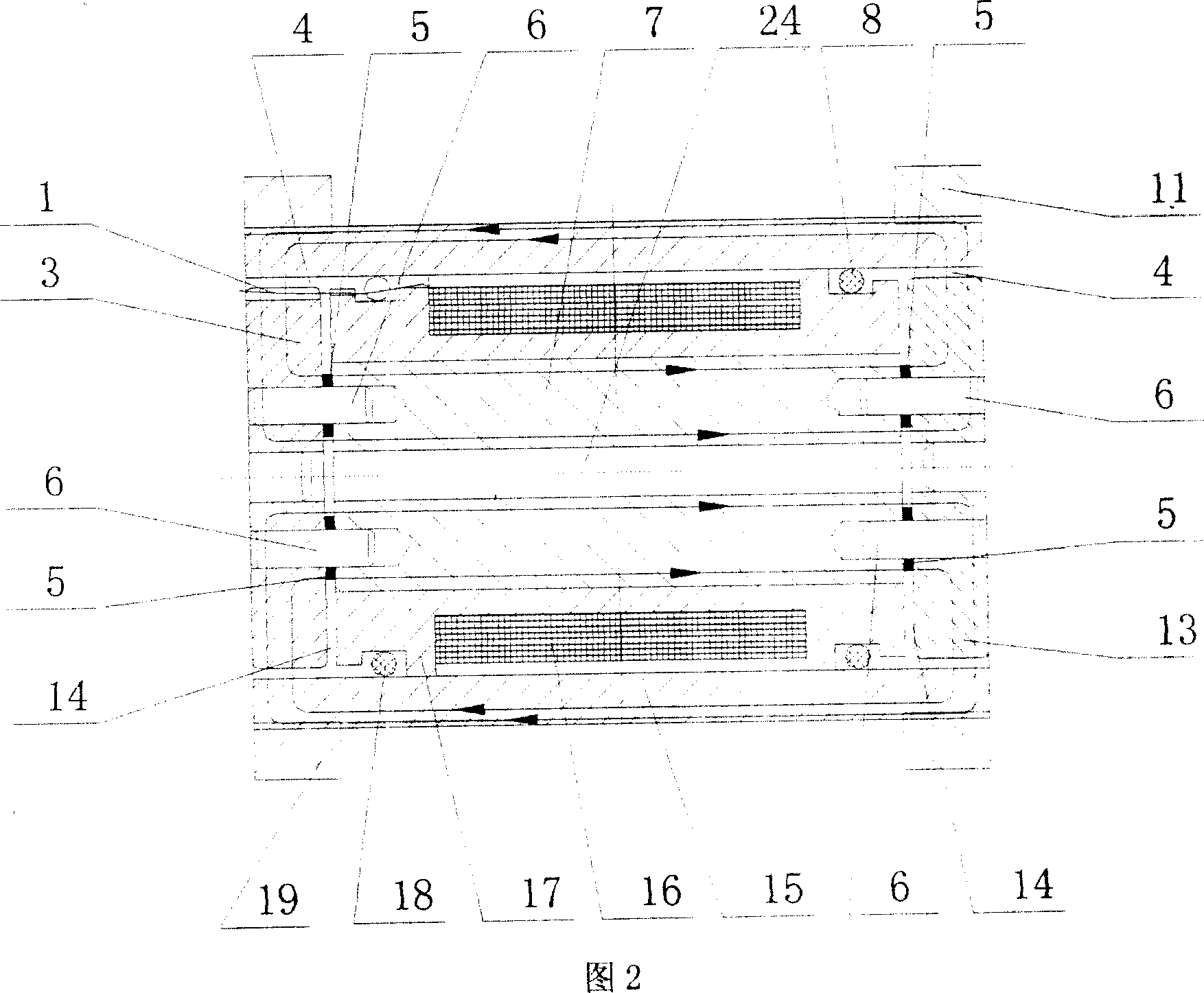

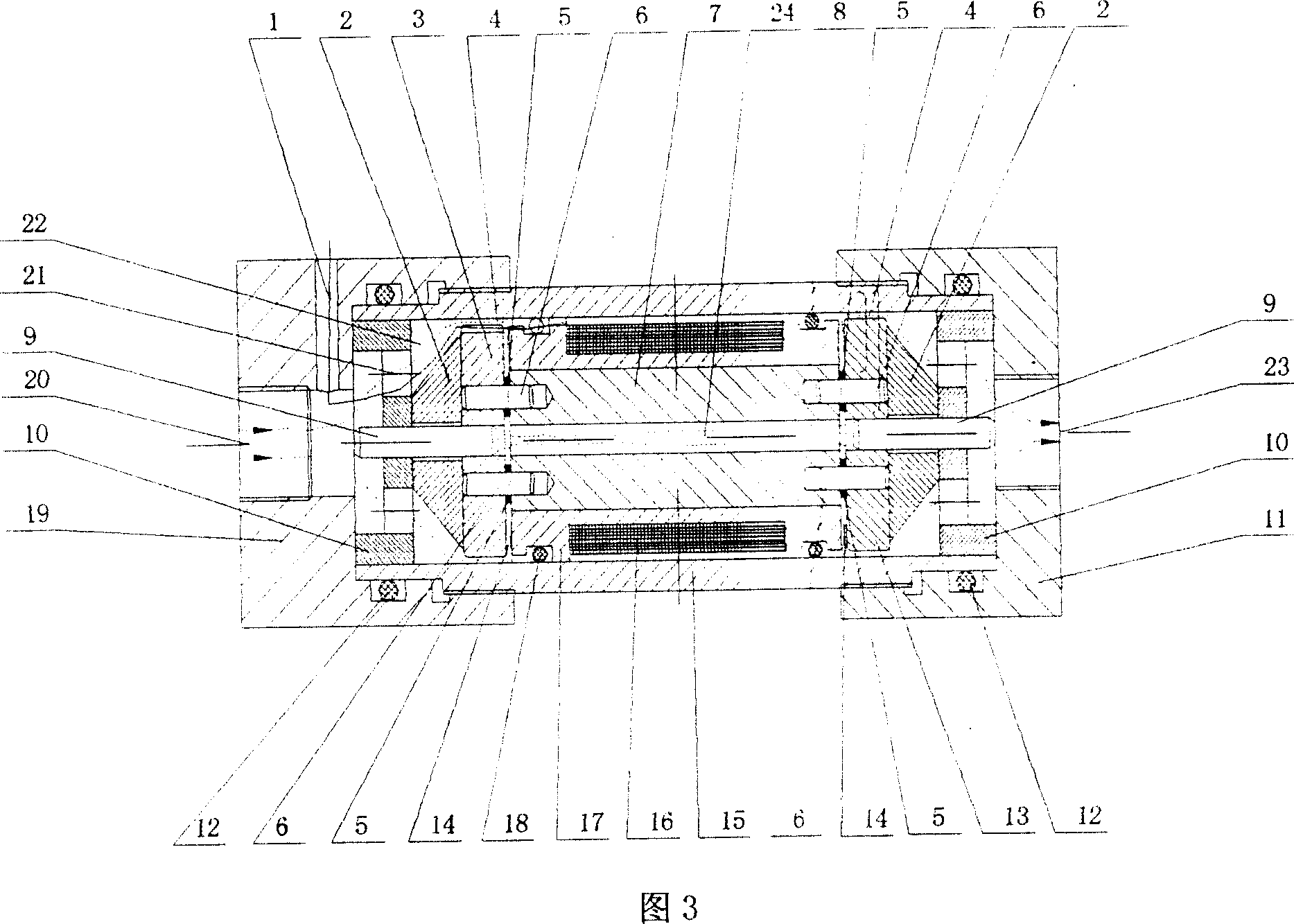

Magnetic flow liquid variable controllnig valve with two liquid flow resistance channels

InactiveCN1584347AReduce volumeSimple structureServomotorsFluid-pressure actuator componentsCircular discEngineering

A valve is used for continuous regulating and / or cutting-off magnetic rheological fluid. It has an annular drag channel and a circular drag channel. The external magnetic path is formed by a cylinder, a magnet-conducting disc and the said both channels. The core of the said valve is used as the internal magnetic path. The gap of the annular drag channel depends on precise transition fit of the cylinder and the positioning block, which is connected with the magnet-conducting disc by a pin. The thickness of the circular drag channel depends on cushions on a connecting pin of the said core. Neither pin nor cushions are of magnet-conducting material. A strong resistance of flow can be generated by a little electric current. The valve has a larger range of control, little energy consumption, small size and is light and simple, easy to mass production.

Owner:CHONGQING UNIV

Technological method for raising toughness and hardening layer depth of heavy truck axle shaft

InactiveCN1433900AHigh hardnessGuaranteed distributionIncreasing energy efficiencyFurnace typesTruckQuenching

The process for raising strong toughness and hardened layer depth of axle shaft of heavy lorry belongs to the field of heat treatment technology, and includes the following steps: blanking, forging; blank thermal refining, hardening temp. is at 850-890 deg.C, heating time is 140-160 min., hardening agent is diesel oil, tempering temperature is at 560-620 deg.C, heating time is 180 min.; cooling; machining; mild-frequency induction quenching, quenching temperature 870-900 deg.C, hardening liquid is 8-13% Jinyu hardening liquid, power supply output power is 65-70 KW, frequency is 1650-1700 Hz,work piece moving speed 1.8-2.1 mm / s, static heating time is 8-15s, delayed water-spraying time is 2s, gap between induction coil and axle shaft rod surface is 5-8 mm gap between induction coil undersurface and vertical direction of flange surface is 4-5 mm.

Owner:重汽(济南)车桥有限公司

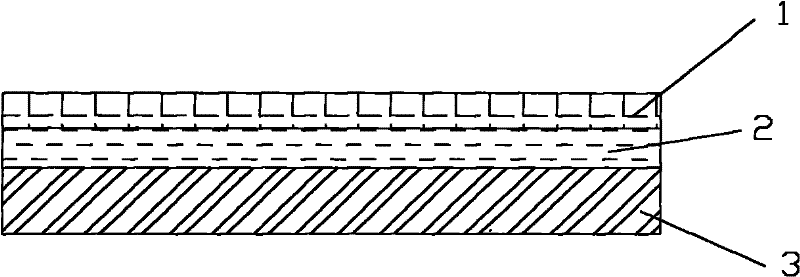

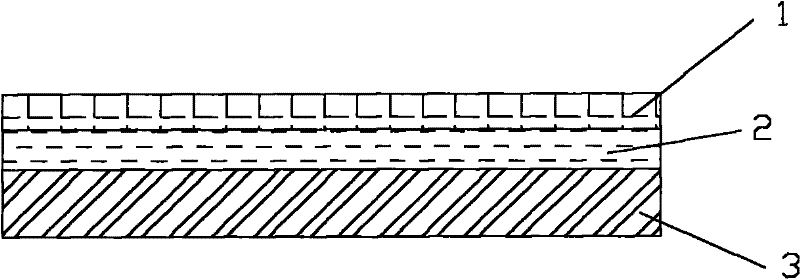

Deodorant warm-keeping fabric

InactiveCN102161248AReasonable structureSimple preparation processSynthetic resin layered productsWoven fabricsSOCKSDeodorant

The invention discloses a deodorant warm-keeping fabric which comprises an outer layer, a middle layer and an inner layer, wherein the outer layer is a warm-keeping and cold-resisting fabric; the middle layer is a viscose layer; and the inner layer is a deodorant fabric layer. The invention discloses a deodorant warm-keeping fabric which has the characteristics of reasonable structure and simple manufacture technique; the unique fabric fibre and processing technique of the outer layer provide the good warm-keeping effect of the fabric; the sustained-release type deodorant microcapsules of the inner fabric layer can enable the fabric to perfume for long time, so that the comfort level of the fabric is improved; and the fabric can be manufactured into various underclothes, socks, linings of super fine casual clothes and the like, so the application is quite wide.

Owner:WUJIANG HEXIN TRANSFER PRINTING

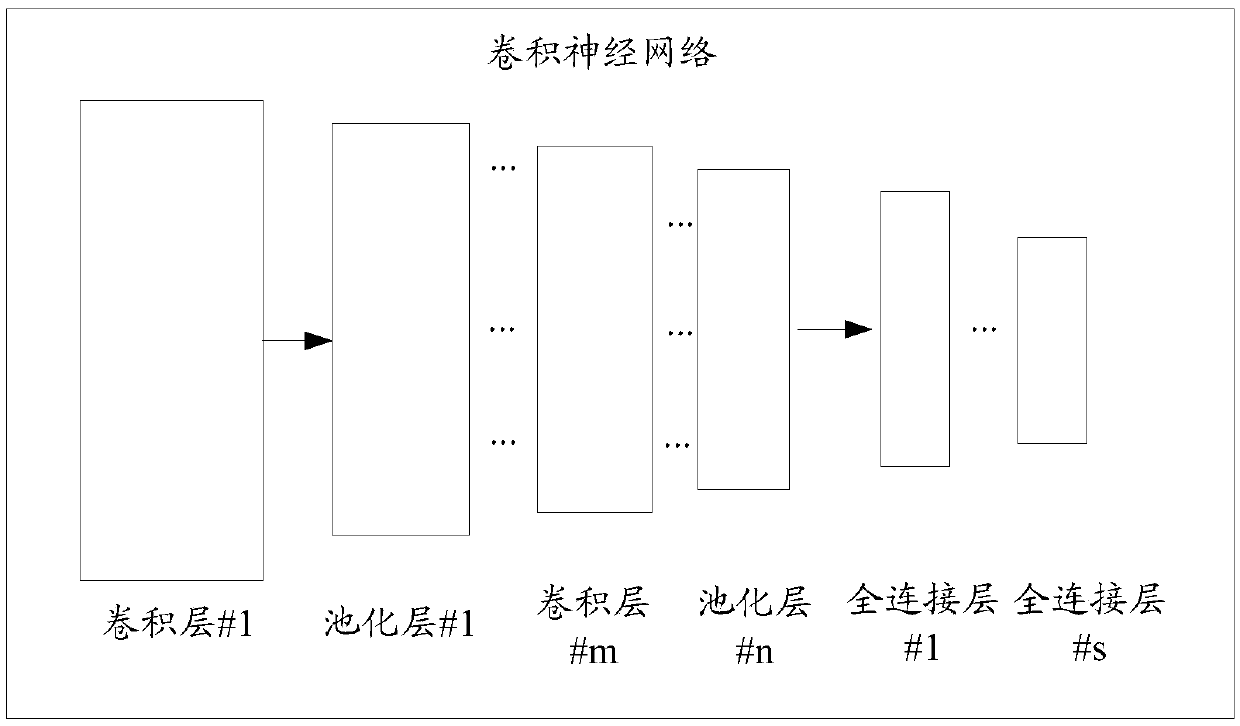

Image processing method and device based on convolutional neural network model

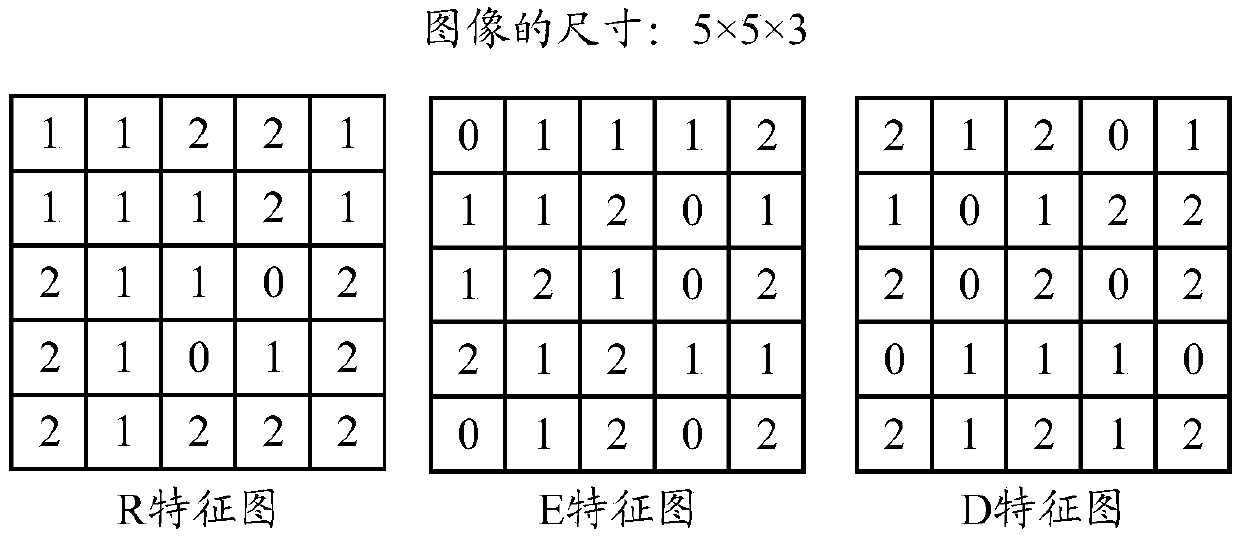

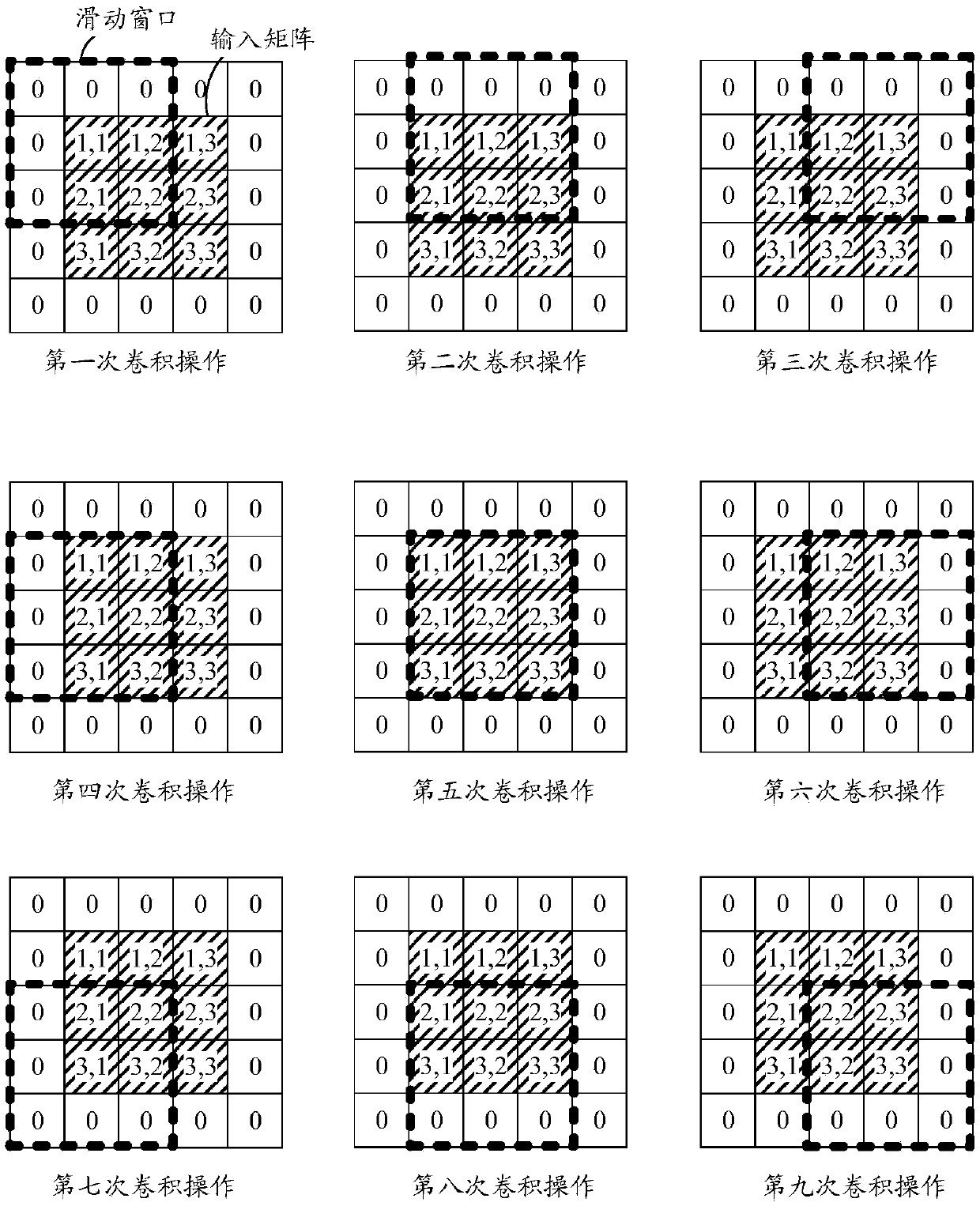

ActiveCN110363279AReduce mistakesHigh precisionGeometric image transformationNeural architecturesImaging processingAlgorithm

The invention provides an image processing method and device based on a convolutional neural network model. The method comprises: obtaining a first weight parameter set corresponding to a neural network layer, wherein the first weight parameter set comprises N1 first weight parameters, and N1 is an integer larger than or equal to 1; calculating the ratio of the N1 first weight parameters to the first numerical value m respectively, and obtaining N1 second weight parameters, wherein m is larger than or equal to |Wmax| and smaller than or equal to 2|Wmax|, and Wmax is the weight parameter with the maximum absolute value in the first weight parameter set; quantizing the N1 second weight parameters into the sum of at least two Q powers of 2, and obtaining N1 third weight parameters, wherein Qis smaller than or equal to 0, and Q is an integer; and obtaining a to-be-processed image; and processing the to-be-processed image according to the N1 third weight parameters to obtain an output image. According to the invention, errors caused by weight quantization can be reduced, so that precision loss is reduced.

Owner:HUAWEI TECH CO LTD

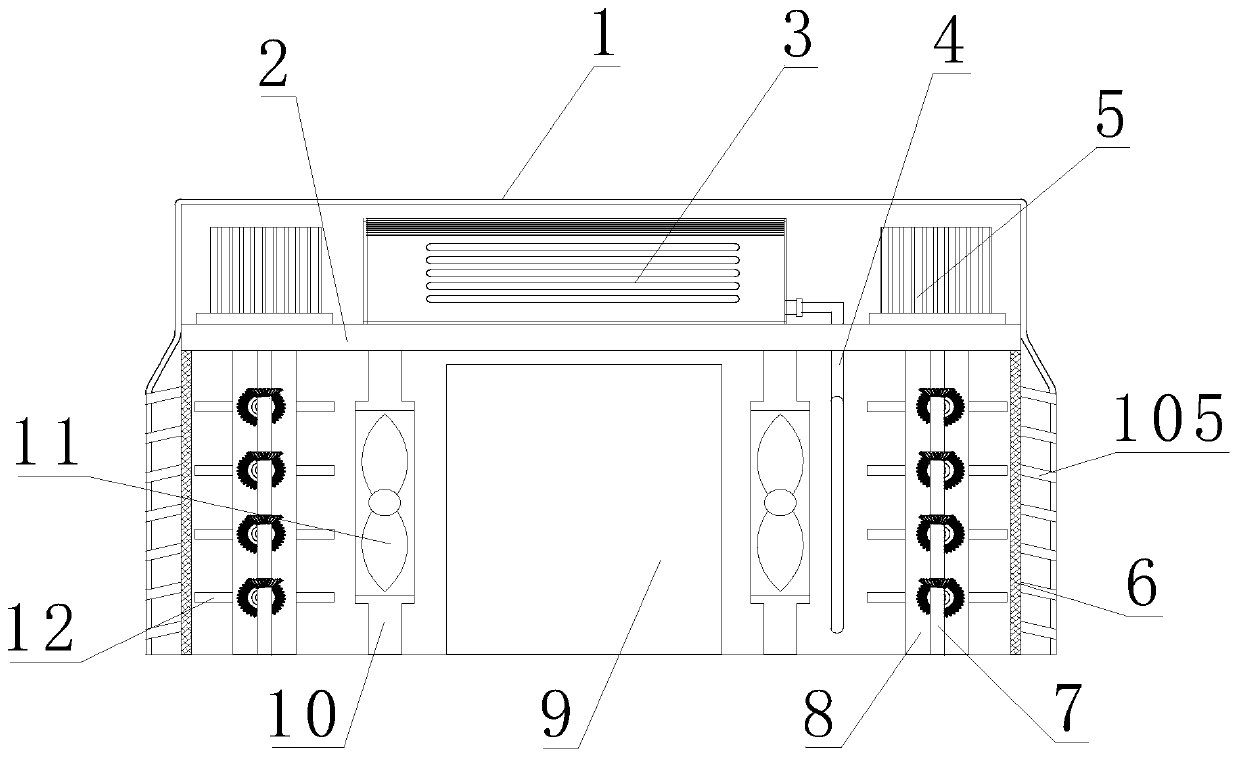

Heat dissipation mechanism for gearbox of wind driven generator

PendingCN111412118AImprove cooling effectFast circulationGear lubrication/coolingMachines/enginesWind drivenEngineering

The invention discloses a heat dissipation mechanism for a gearbox of a wind driven generator. A horizontal partition plate is fixedly arranged in an outer case, a water-cooling heat dissipation mechanism is installed at the upper end of the partition plate, a heat dissipation pipe is connected with the water-cooling heat dissipation mechanism, and the heat dissipation pipe extends downwards to the position below the partition plate; and the gear box is located in the middle of the lower end of the outer case, connecting frames are fixedly connected with the lower end of the partition plate, the two connecting frames are located on the two sides of the gear box correspondingly, and the connecting frames are parallel to the side wall, provided with a heat dissipation opening, of the outer case. According to the heat dissipation mechanism, two heat dissipation fans drive air around the gear box to distribution rapidly, low-temperature air dissipates heat of the gear box, the heat dissipation effect on the gear box is improved through air cooling circulation, meanwhile, circulated distribution cooling water in a water cooling heat dissipation mechanism conducts the heat of the gear box, and air cooling and water cooling are carried out synchronously, so that the heat dissipation efficiency and the heat dissipation effect of the gear box are ensured.

Owner:HUANENG NEW ENERGY CO LTD

Production technology of kraft vermicelli case board paper

InactiveCN105696395AHigh strengthIncrease the lengthPulp beating methodsPaper recyclingEnvironmental resistanceSurface layer

The invention discloses a production technology of kraft vermicelli case board paper. The production technology comprises the steps that recycled waste paper materials are screened, the recycled waste paper with low ash content is selected for pulping with softwood pulp, preliminary pulping is conducted through the processes of repulping, purifying, screening and the like, the fiber strength is emphatically improving in the grading and beating processes, longer fibers are screened to serve as surface layer pulp, the fiber beating degree is improved on the condition that the fiber strength is not damaged, and the fiber bonding strength is improved through the fiber arrangement mode on a net portion so as to improve the surface strength, toughness and folding strength of finished paper; by means of the measures of surface sizing, after-drying moisture precise control and finished paper coating, the product has the better explosion-proof line quality advantage and is more environmentally friendly, and the market share of the product is bound to be increased.

Owner:JIANGSU LEE & MAN PAPER MFG

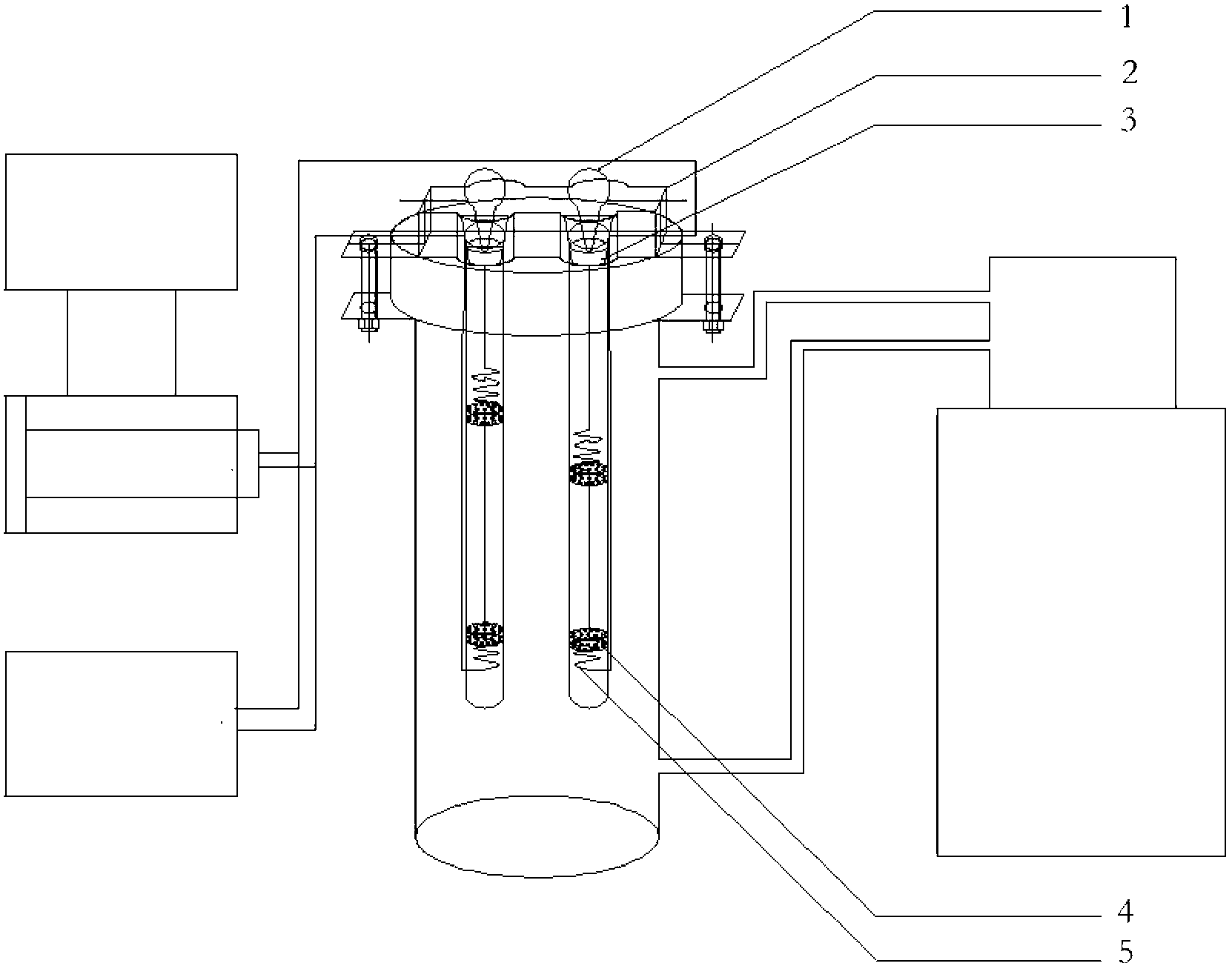

Optimal model based interactive image recolorating method

InactiveCN105893649AGuaranteed distributionIncrease global propagationImage analysisSpecial data processing applicationsLocal optimumColor image

The present invention discloses an optimal model based interactive image recolorating method. The method comprises nine steps of: converting a to-be-processed color image to perform manual line coloration; then separately performing matting based on global optimization and based on local optimization on the colorated image, so as to separately obtain a globally optimized matted image and a locally optimized matted image; performing binarization processing on the obtained globally optimized matted image and locally optimized matted image; combining binarized images by adopting an addition or subtraction policy according to a selected region attribute of line coloration; calculating a region that needs to be recolorated in the to-be-processed color image; converting an RGB color space of a colorated region to an HSV color space; adjusting a tone channel and a saturation channel in the colorated region in an interactive manner; converting the HSV color space of the image to the RGB color space; and finally, combining an image of which the region is reclorated with an original color image to obtain a recolorated image.

Owner:WENZHOU UNIVERSITY

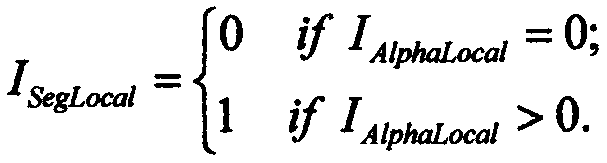

Device for measuring liquid heat conductivity coefficient based on transient dual-hot-wire method

InactiveCN103175862AEliminate the effects ofPrecise realization of constant temperature environmentMaterial heat developmentWater bathsData acquisition

The invention discloses a device for measuring liquid heat conductivity coefficient based on a transient dual-hot-wire method. The device needs short time for measurement, and can successfully avoid influence of natural conversion on a test result. Hot wires in the device can serve as both heating elements and temperature measuring elements, a complex structure of experimental devices is omitted, meanwhile, a thermal conductivity cell is endowed with a steady water bath temperature environment, and the device has high measurement accuracy. According to the invention, a thermal conductivity cell insulation barrel device, a glass test tube and a hot wire loading device are independently designed. By a series of processes that a low-temperature thermostat bath serves as a temperature controller so as to provide the constant water bath environment, a direct current calibrator serves as a power supply for measurement, a Wheatstone bridge measures the relation between the temperature variation and the resistance, and a data acquisition control unit serves as a data acquisition instrument for the unbalanced voltage of the Wheatstone bridge, the rate of change of the unbalanced voltage along with time is obtained, and sequentially, the liquid heat conductivity coefficient is solved.

Owner:JIANGSU UNIV

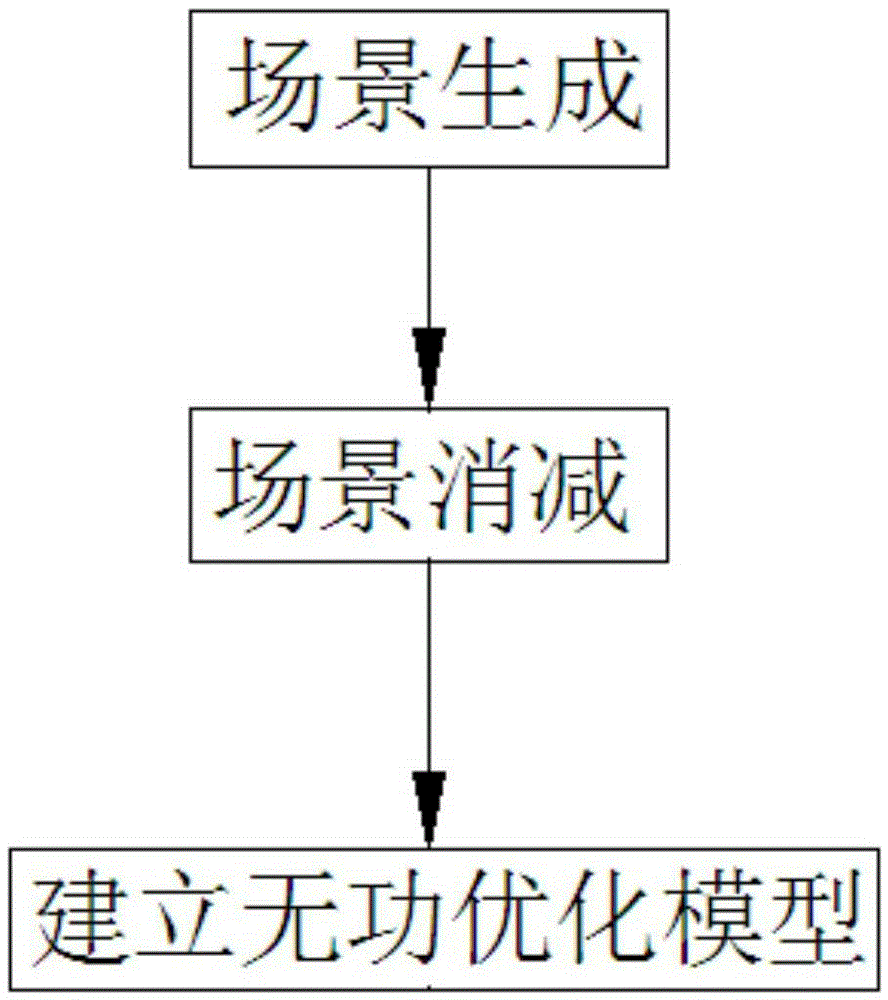

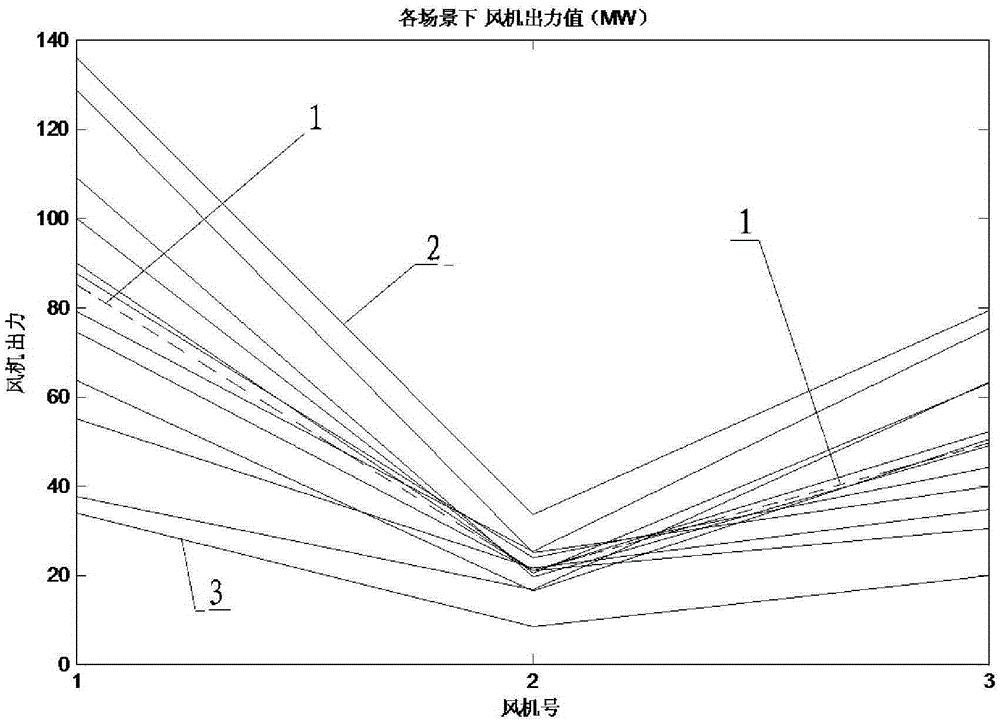

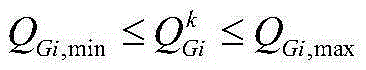

Reactive power optimization method for new energy grid connection

InactiveCN105244890AAvoid decimationGuaranteed distributionReactive power adjustment/elimination/compensationSpecial data processing applicationsNew energyComputational model

The invention relates to a reactive power optimization method for new energy grid connection. The method comprises the following steps of generating scenes, cutting down the scenes, and establishing a reactive power optimization model. The scenes that may occur are used to simulate random variables approximately, the total distribution of the random variables can be reflected via lower sampling frequency, and it is ensured that sampling points are distributed in all sampling areas; and it is avoided that an appeared sample is sampled in the sampling process, and it can be ensured that a low probability area also includes sampling points. The uncertainty of new energy is simulated by the scenes, a calculation scene is obtained by generating the scenes and cutting down the scenes, a combined optimization calculation model is used to obtain reactive power output values Qk of the different scenes, and the reactive power cost and grid loss of the scenes are made minimal under the condition that physical and operation constraints are met.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

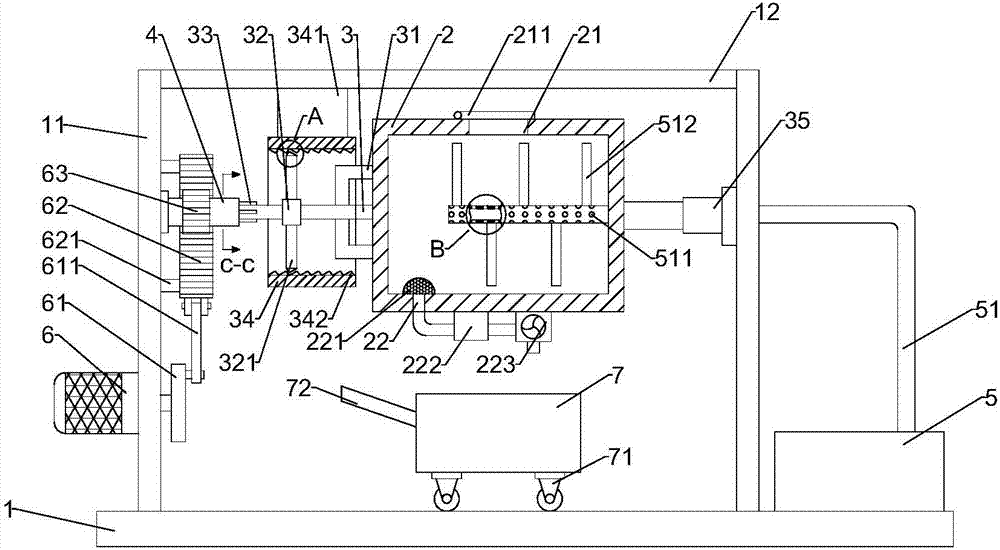

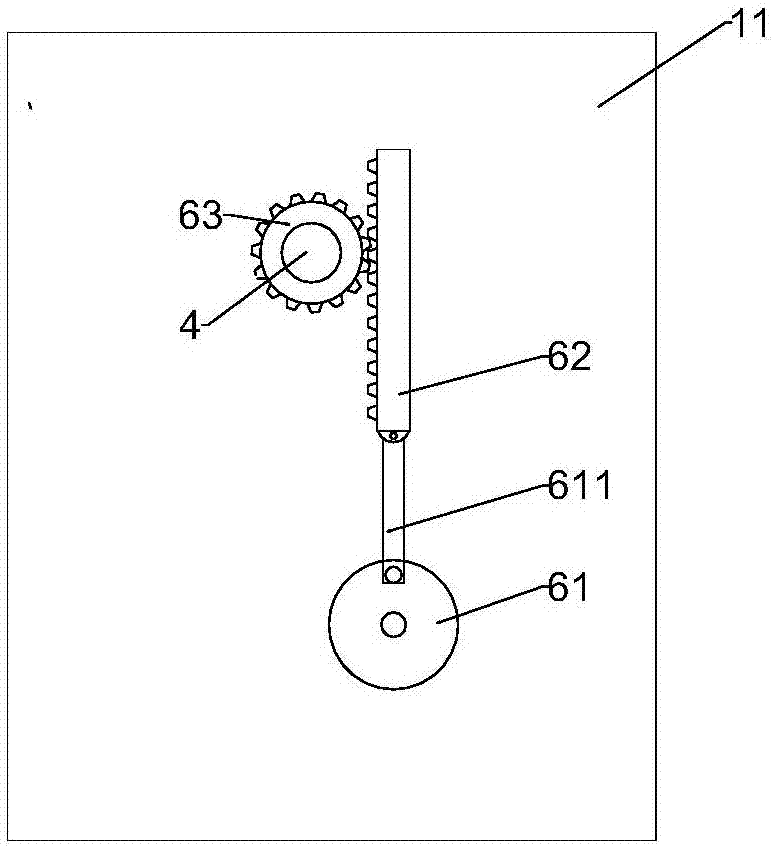

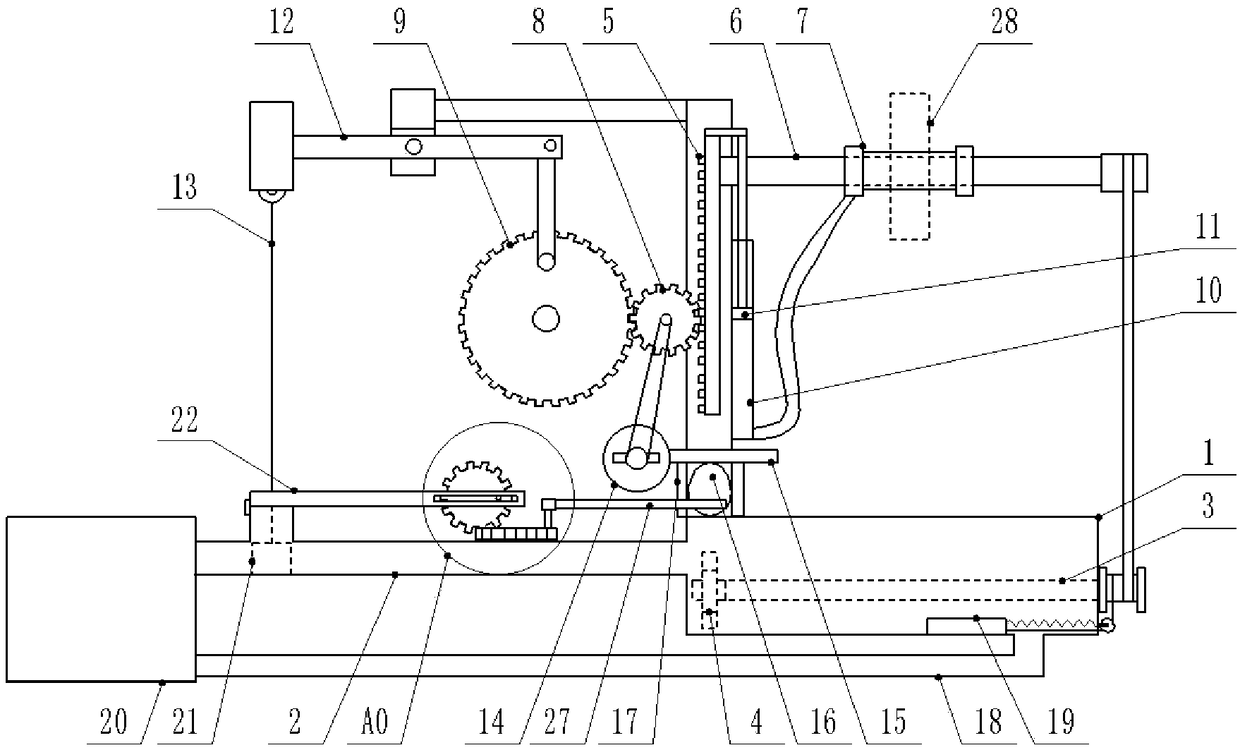

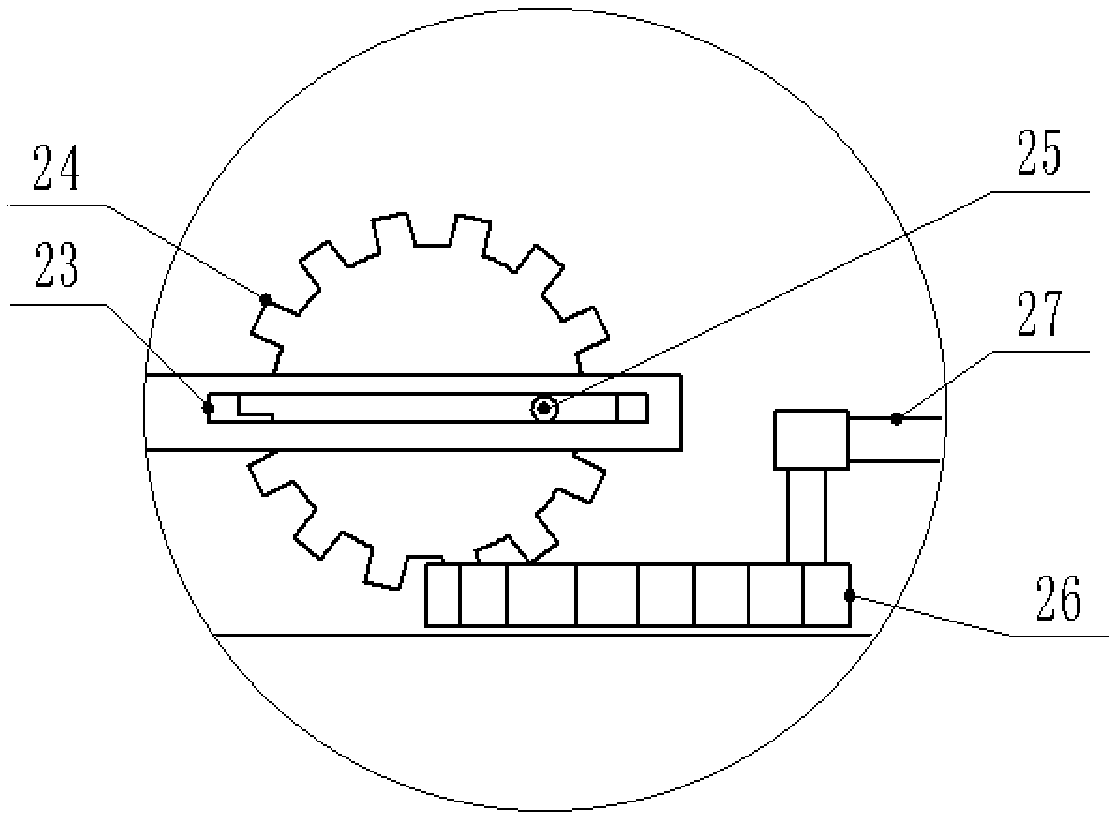

Roller type efficient mulberry leaf drying device

ActiveCN107990663AAffect nutritional valueAvoid uneven heatingDrying gas arrangementsDrying chambers/containersDrive shaftAgricultural engineering

The invention discloses a roller type efficient mulberry leaf drying device. The roller type efficient mulberry leaf drying device comprises a base, a roller, a transmission mechanism and an air heater; two stand plates are arranged on the left and right sides of the top of the base; a cross beam is connected to the tops of the stand plates on the two sides; the roller is arranged above the base;a left rotating shaft and a right rotating shaft are respectively connected to the centers of the end surfaces on the two sides of the roller; the right rotating shaft is an extension shaft with a hollow design; a transmission shaft for driving the left rotating shaft to rotate is arranged on the left side of the left rotating shaft; the transmission shaft is provided with a transmission mechanismfor driving the transmission shaft to rotate; the air heater is mounted on the right side of the base; a hot air pipe upwards extends to penetrate through the stand plate on the right side, and extends into the roller in the axis direction of the right rotating shaft; exhaust ports are densely formed in the hot air pipe; and an overturning rod is arranged at the outer periphery of a pipe body ofthe hot air pipe. The mulberry leaf drying device can effectively prevent nutrient loss of mulberry leaves to guarantee no influence on nutritional value of the mulberry leaves, and meanwhile, is uniform in heating of the mulberry leaves and excellent in drying effect to guarantee the quality grade of dried finished products.

Owner:HUNAN NONGYOU SHENGTAI AGRI TECH +1

Magnetic flow liquid variable controllnig valve with two liquid flow resistance channels

InactiveCN1314903CReduce volumeSimple structureServomotorsFluid-pressure actuator componentsCircular discEngineering

Owner:CHONGQING UNIV

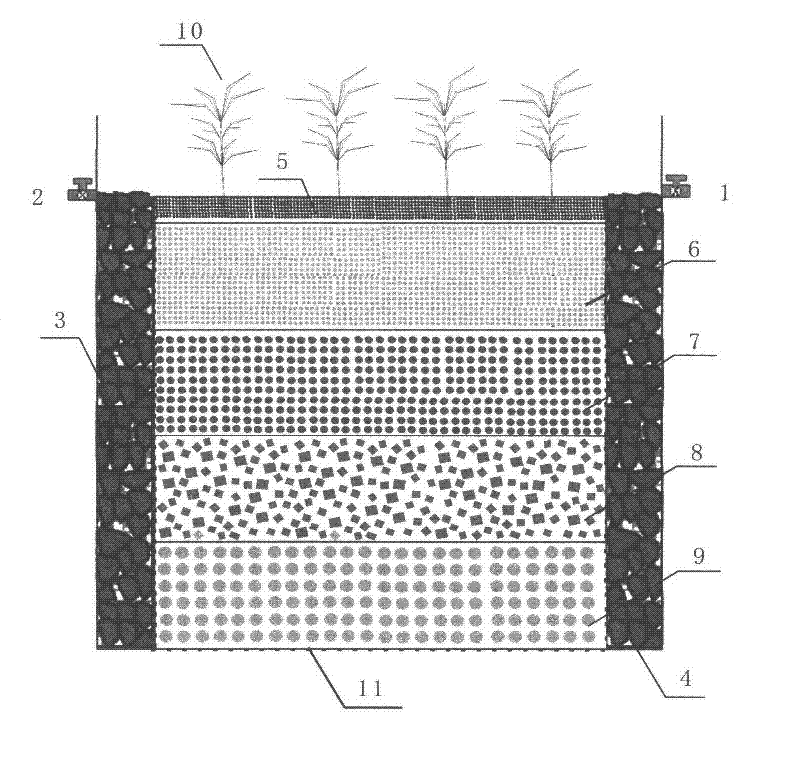

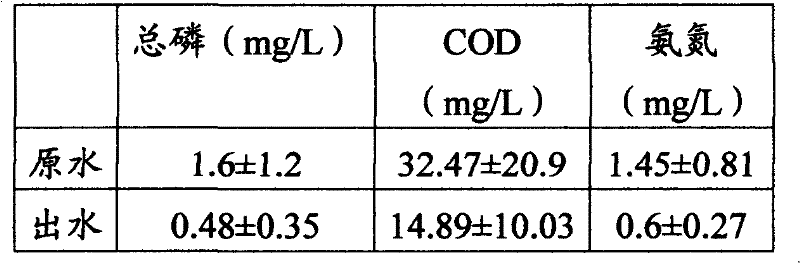

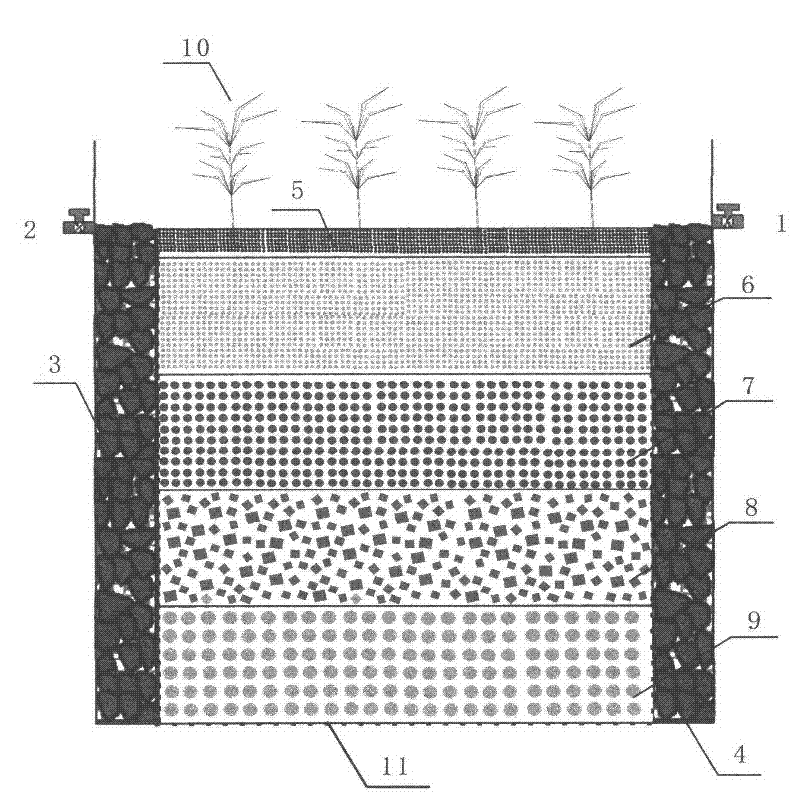

Water purifying method of uniform flow constructed wetland

ActiveCN102381767AAvoid formingFull play of physicsSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater flow

The invention discloses a water purifying method of a uniform flow constructed wetland. A constructed wetland is established; a water inlet end is arranged on one wall of the wetland pool, and a water outlet end is arranged on the other wall of the wetland pool; the water inlet end and the water outlet end are respectively provided with a water distributing zone and a water gathering ground, which are filled with cobblestones with a particle size of 30-50mm; a main body filling material zone comprises, from top to bottom: a first layer filter pack filled with a quartz sand filling material with a particle size of 0.1-1 mm, a second layer filter pack filled with a quartz sand filling material with a particle size of 0.1-3mm; a third layer filter pack filled with a quartz sand filling material with a particle size of 1-3 mm; a fourth layer filter pack filled with a quartz sand filling material with a particle size of 1-5 mm; a fifth layer filter pack filled with a quartz sand filling material with a particle size of 3-7 mm; and humidogene emergent aquatic plant plants are planted on top of the first layer filter pack. The invention can be used in treatment of household sewage in cities and towns and industrial wastewater of food processing industry and slaughter industry, etc., so as to avoid current short flow and formation of a dead zone and remove pollutants efficiently.

Owner:恒晟水环境治理股份有限公司

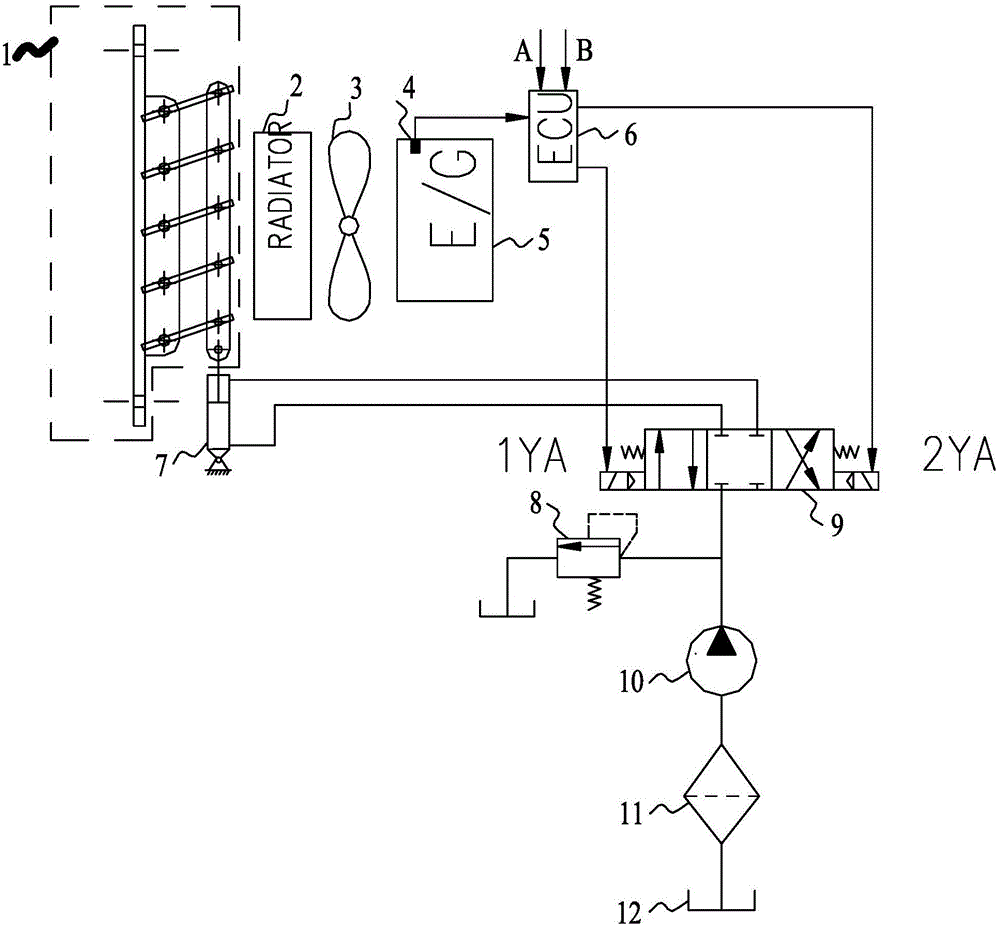

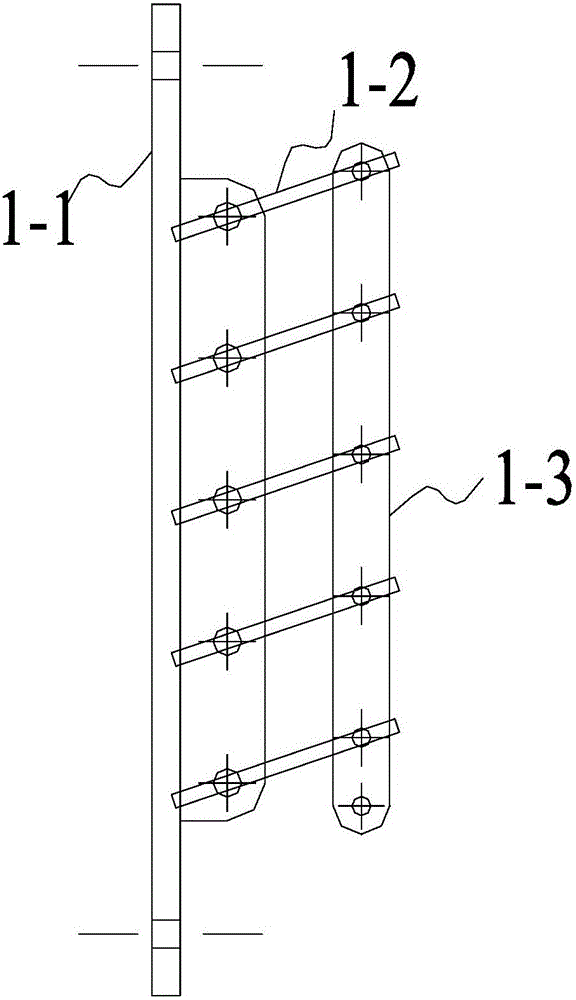

Intelligent regulating type guard fence

InactiveCN105857227AAdjust the tilt angleAdjust the air volumeComponent optimizationRadiatorsHydraulic cylinderElectricity

The invention discloses an intelligent regulating type guard fence. The intelligent regulating type guard fence comprises a front guard fence body, a radiator, a fan and an electronic control unit, and the electronic control unit is electrically connected with the radiator and the fan. The intelligent regulating type guard fenceis characterized in that the front guard fence body comprises a mounting plate with ventilation holes, and M air guide plates are hinged to one side of the mounting plate; and the M air guide plates are arranged in parallel, wherein M is a natural number larger than 1. The intelligent regulating type guard fence at leastfurther comprises a temperature sensor used for detecting the temperature information of an engine, connection rods chained to the air guide plates, a hydraulic oil cylinder used for driving the connection rods to act, and a magnetic valve set used for controlling the hydraulic cylinder to act, wherein the output terminal of the temperature sensor is electrically connected with the electronic control unit; and the magnetic valve set and the electronic control unit are electrically connected. By means of the intelligent regulating type guard fence, the problems that the air exhaust quantity of a prior engineering vehicle radiator cannot be adjusted as the opening degree of a front guard fence body cannot be actively regulated in real time along with the temperature changes of the engine, and sundries between the front guard fence body and the radiator cannot be removed in time are solved.

Owner:CENT RES INST OF TIANJIN BENEFO MECHANICAL EQUIP GRP CO LTD

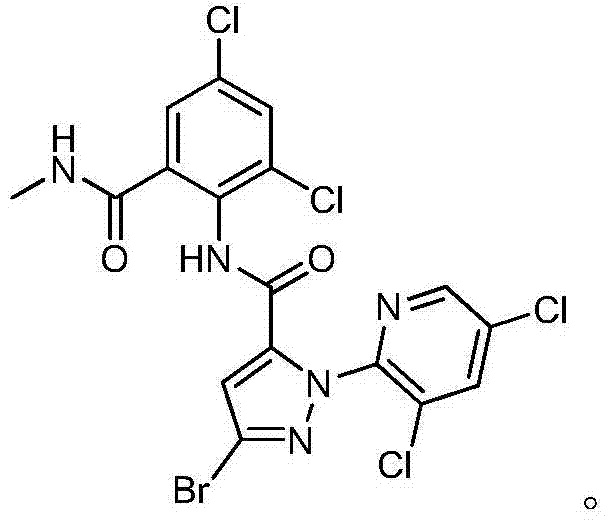

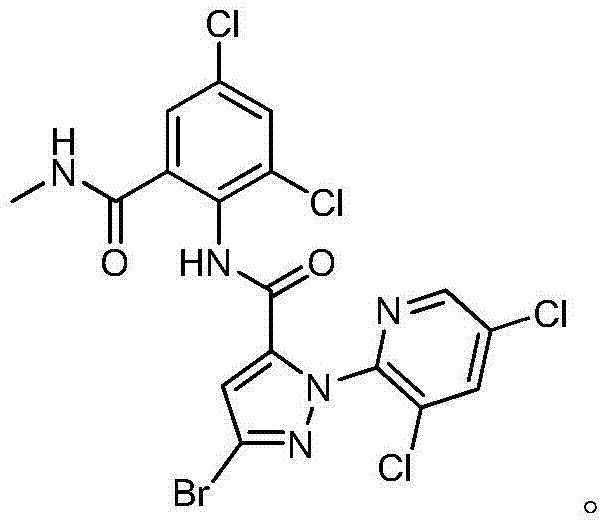

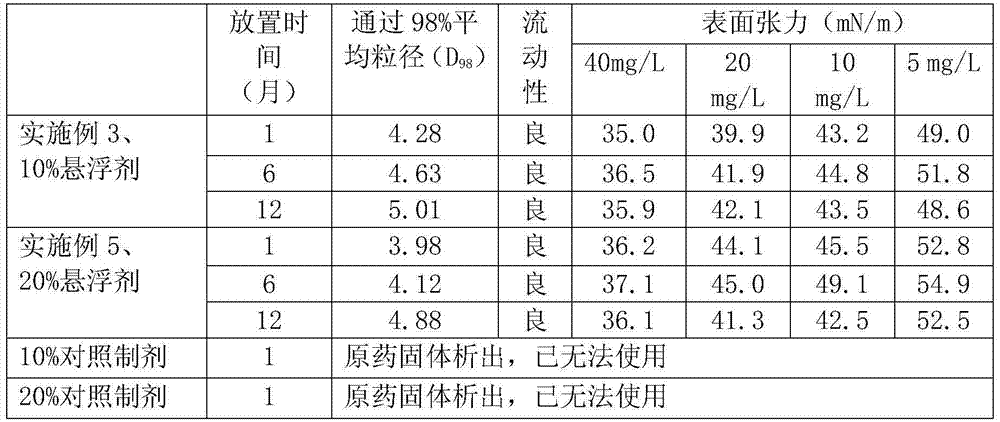

Insect disinfestation preparation and use method thereof

InactiveCN104705295AImprove retentionExtended stayBiocideAnimal repellantsEffervescent granulesUltra-low volume

The invention belongs to the field of insecticides, specifically to an anthranilamide compound insect disinfestation preparation and a use method thereof, wherein the active component in the insect disinfestation preparation is the compound having the structure represented by the following figure, the active component, at least a carrier and at least a surfactant are mixed to prepare emulsifiable concentrate, aqueous emulsion, microemulsion, soluble liquid agent, dispersible oil agent, ultra-low volume agent, powder, wettable powder, suspension, dispersible oil suspension, seed treatment agent, granules, water dispersible granules, emulsifiable powder, emulsifiable granules, effervescent granules, effervescent tablets, microcapsule granules, microcapsule suspension, sustained-release granules, ointments, aerosol or smoke agent, and in any case, the selection of the type of the preparation depends on the physical, chemical and biological properties of the active component. According to the present invention, with the preparation type, Chilo suppressalis, Ostrinia nubilalis, Mythimna separata, Plutella xylostella, Spodoptera exigua Hiibner larva and other pests can be efficiently prevented and controlled.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

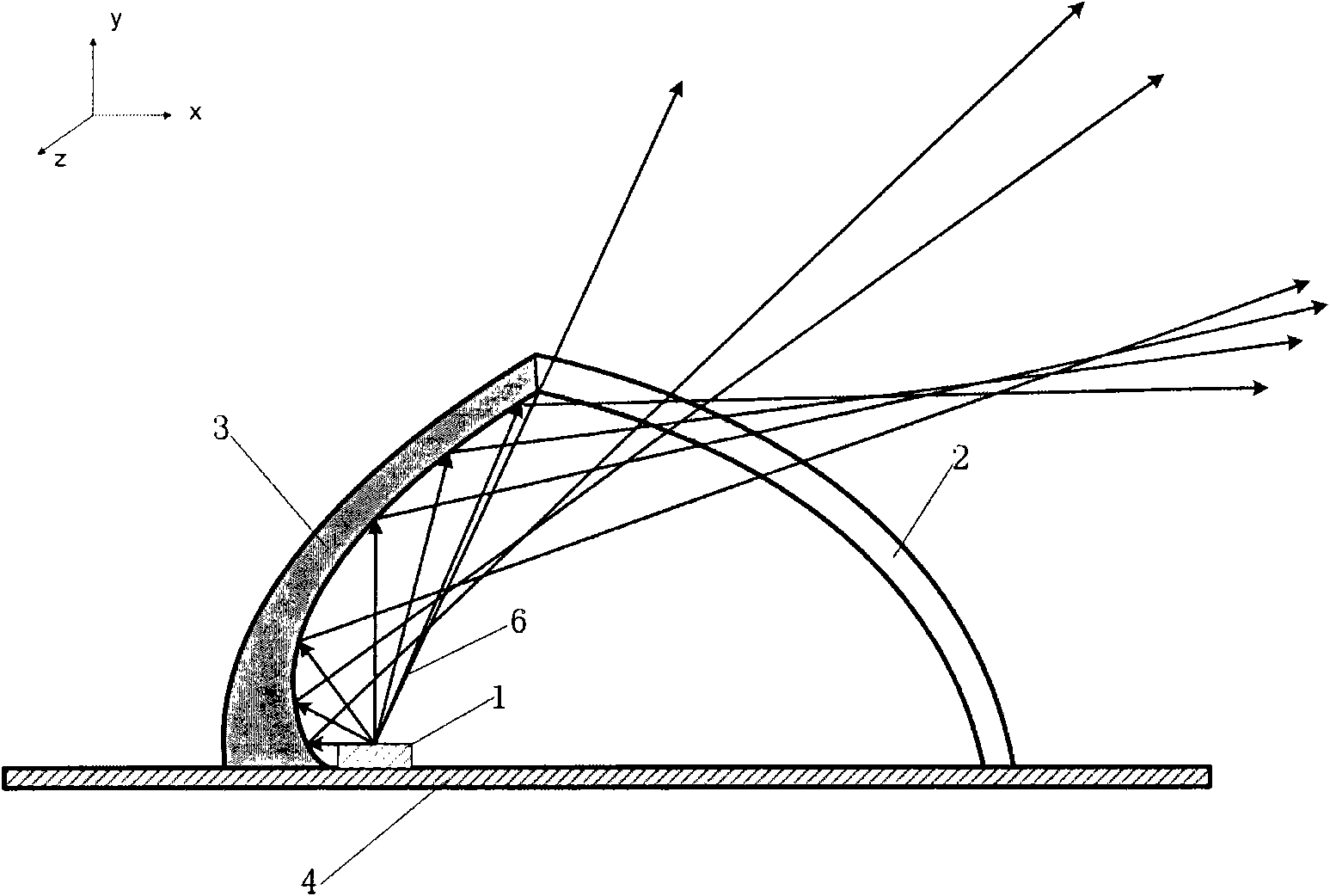

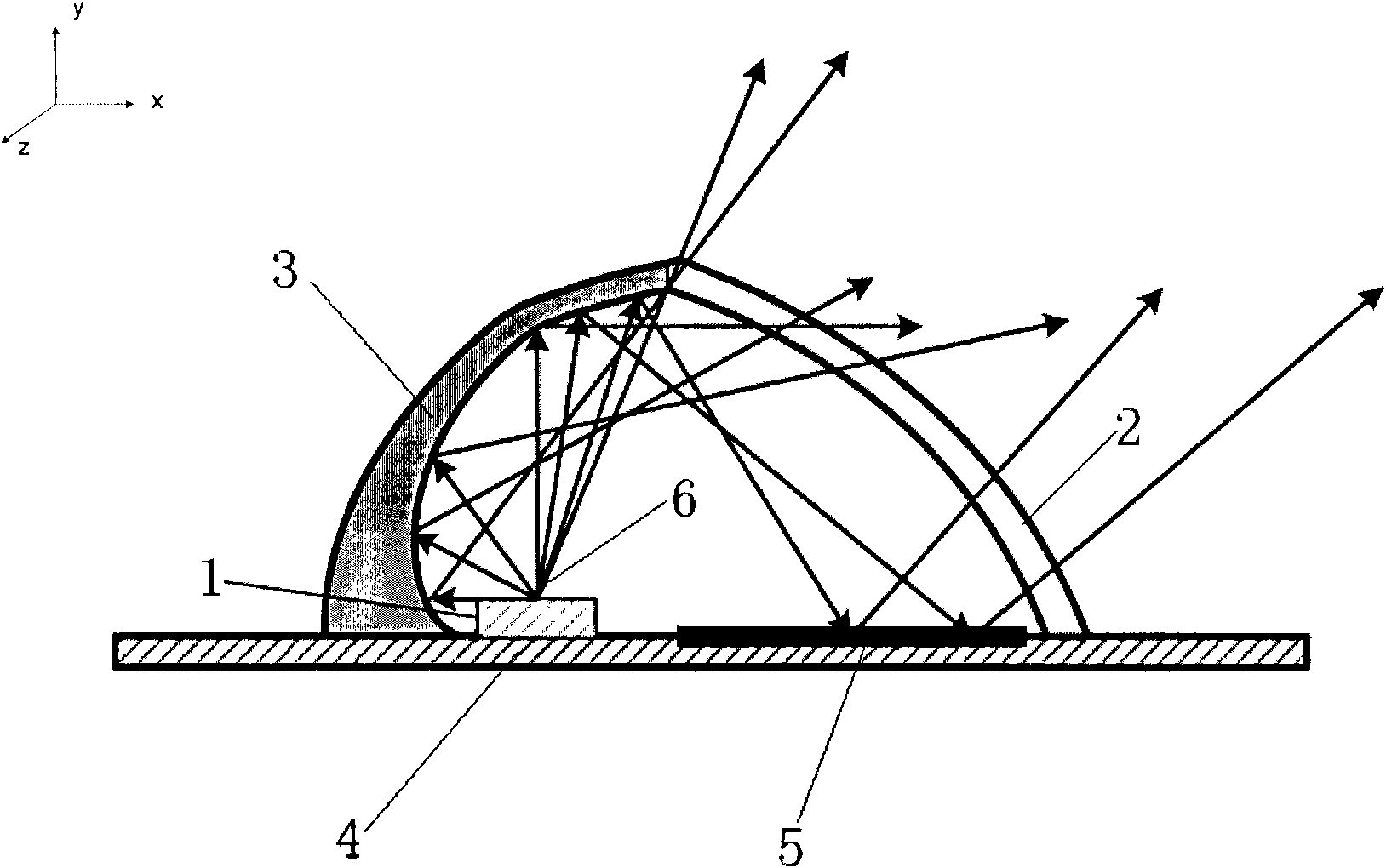

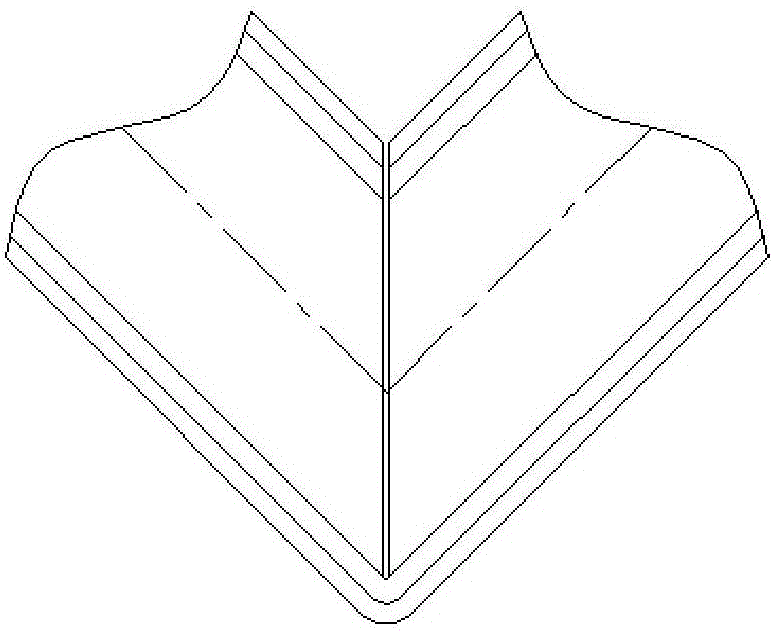

Reflecting face cover for navigation lamp and navigation lamp using same

ActiveCN102121661ACompact structureGuaranteed light distributionAircraft lightsGlobesOptoelectronicsLight source

The invention discloses a navigation lamp. The navigation lamp comprises a light source, a transparent lamp shade, a reflecting face cover and a bottom plate, wherein the reflecting face cover and the transparent lamp shade are connected into a whole and are fixed on the bottom plate together; the light source is arranged on the bottom plate and is close to the reflecting face cover; light rays emitted by the light source are reflected by the reflecting face cover and then emitted from the transparent lamp shade. The navigation lamp has a compact structure, and reduces pneumatic influence on the premise of ensuring light distribution.

Owner:COMAC +1

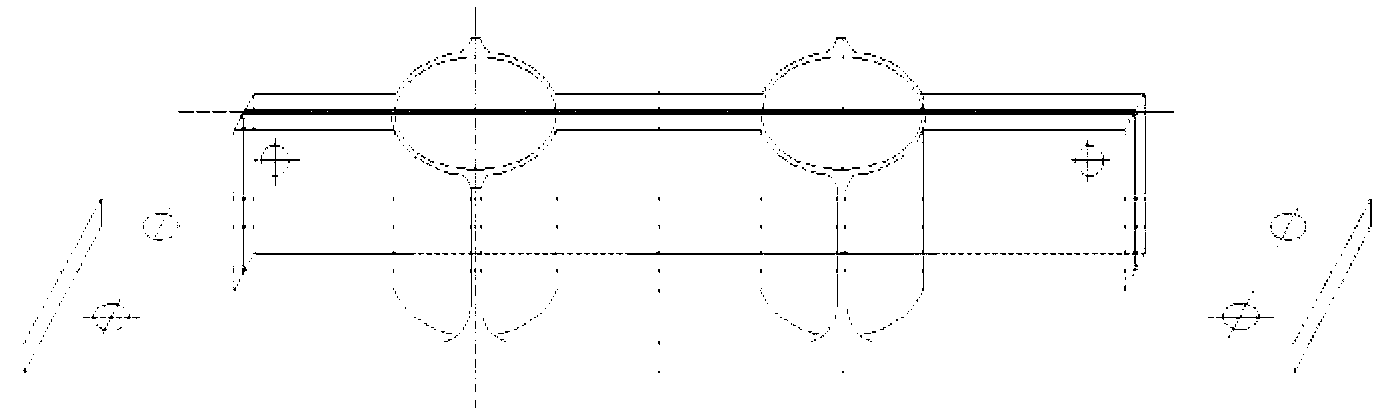

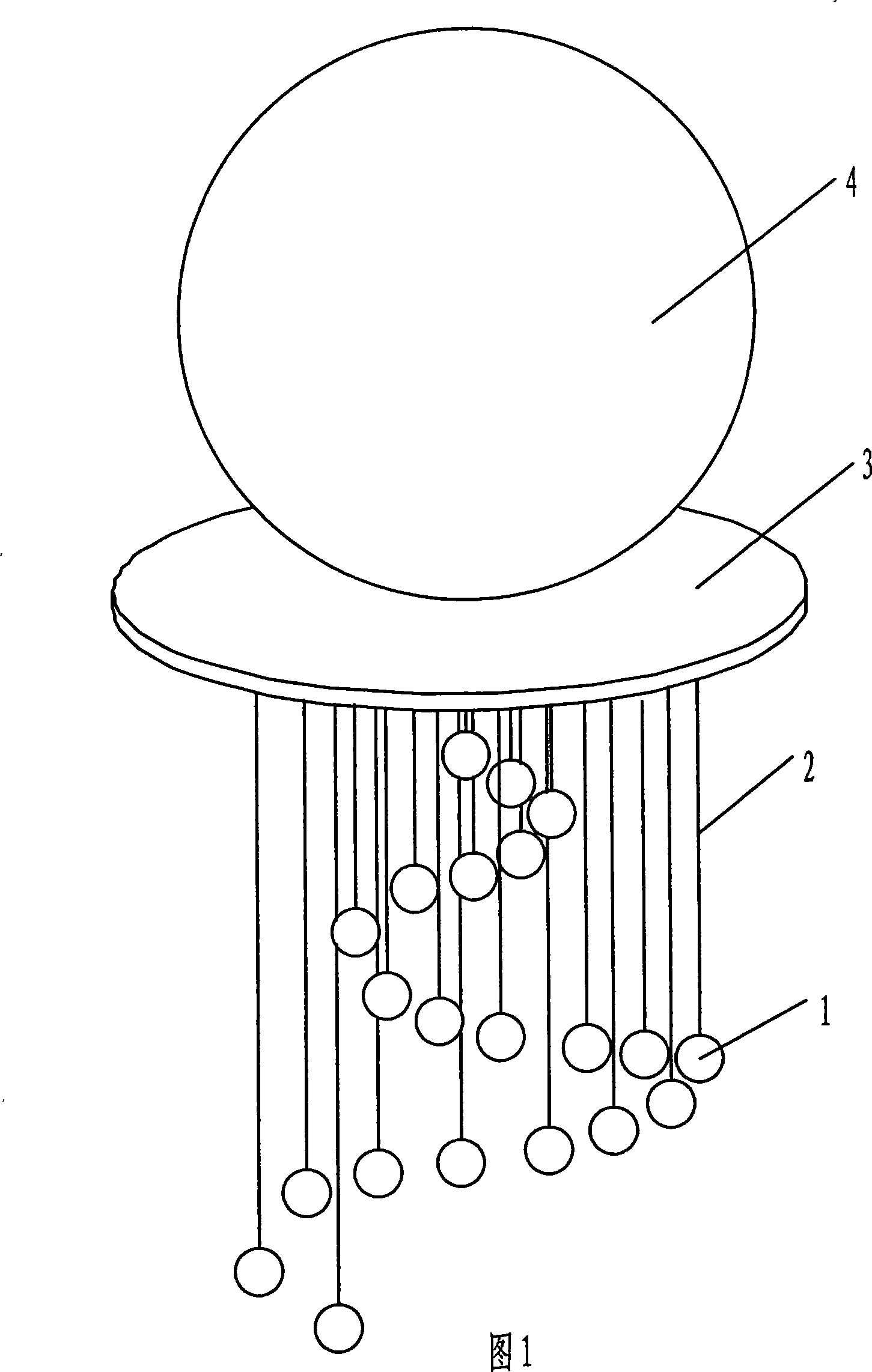

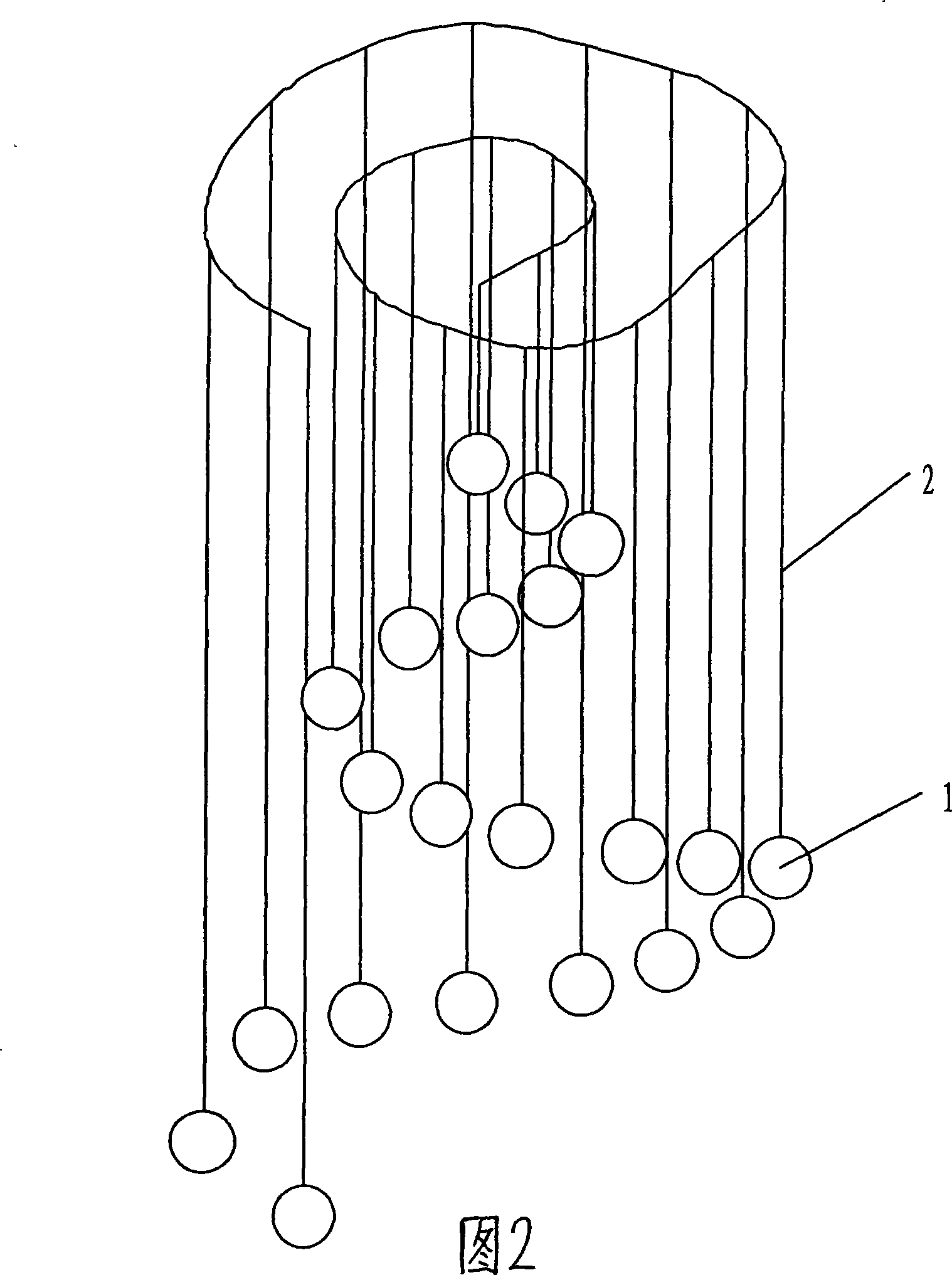

Spiral suspended type red mud membrane bag adsorption and dephosphorization apparatus

InactiveCN101456602AGet the most out of mobileAvoid filter recycling problemsWater/sewage treatment by sorptionFiltrationRed mud

The invention provides a spiral suspended type red mud film bag absorption dephosphorization device, which consists of film bags, a rack and a floater. The film bags are hung under the rack through ropes. The floater is connected with the top of the rack. The insides of the film bags are provided with supports and are filled with modified red mud. Seen from upside, the film bags hung under the rack are distributed in a spiral shape from inside toward outside and with respect to the arrangement of heights. The device carries out dephosphorization absorption through the film bags wrapping red mud, effectively avoids filtration and recovery of the red mud after absorption, is simple and convenient in operation, keeps the shapes of the film bags under water pressure and ensures the red mud in the film bags uniformly distributed in various layer of a sewage poll, thereby achieving the maximum absorption dephosphorization effect of the red mud. In addition, the device makes full use of the action of water flow on the film bags and the floatation of the floater in water to allow the film bags to move freely under the action of the floater and the water flow so as to dephosphorize uniformly through absorption, thereby reducing capital investment.

Owner:SHANDONG UNIV

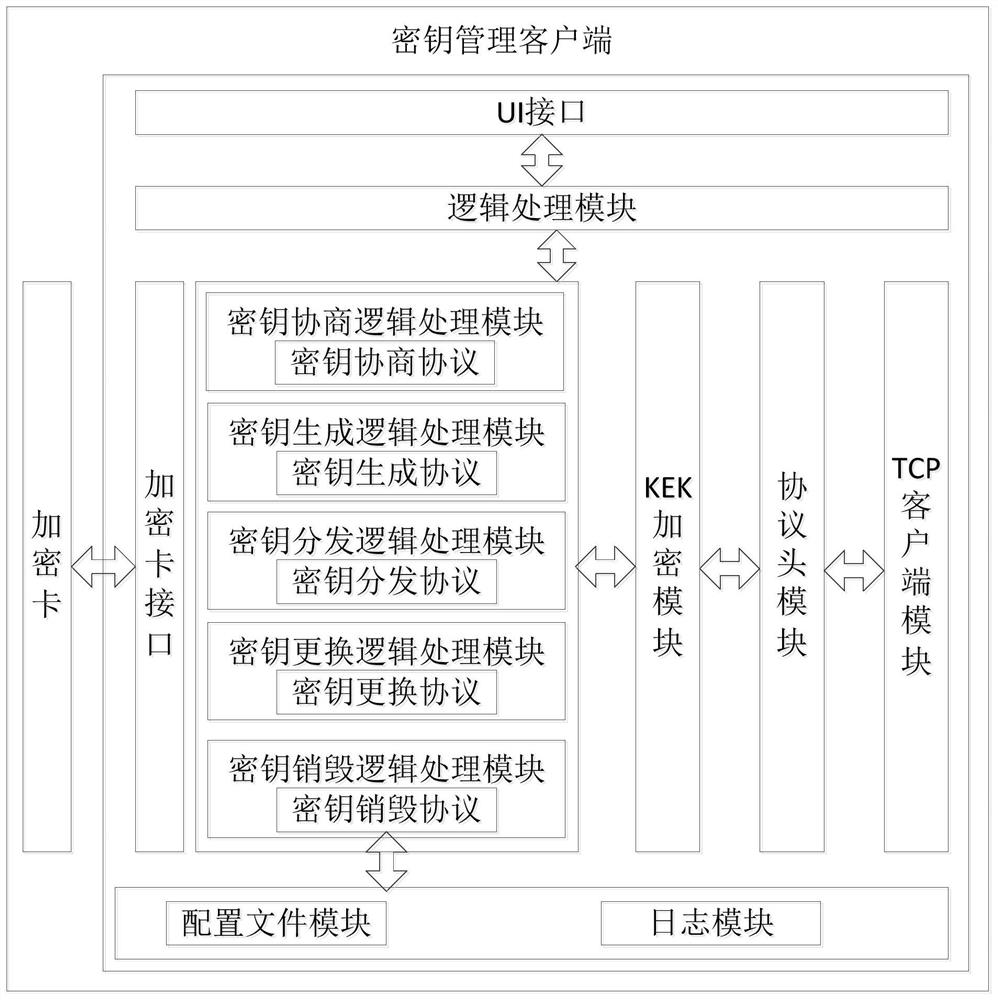

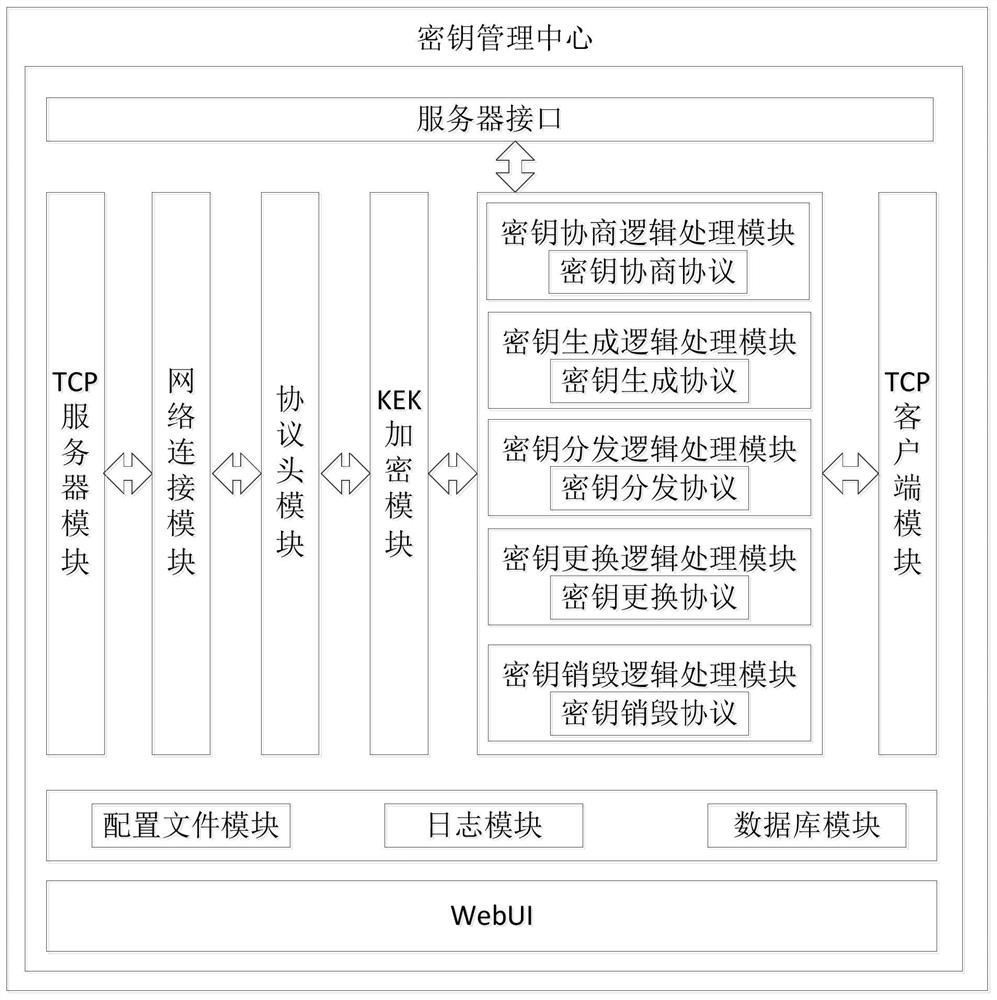

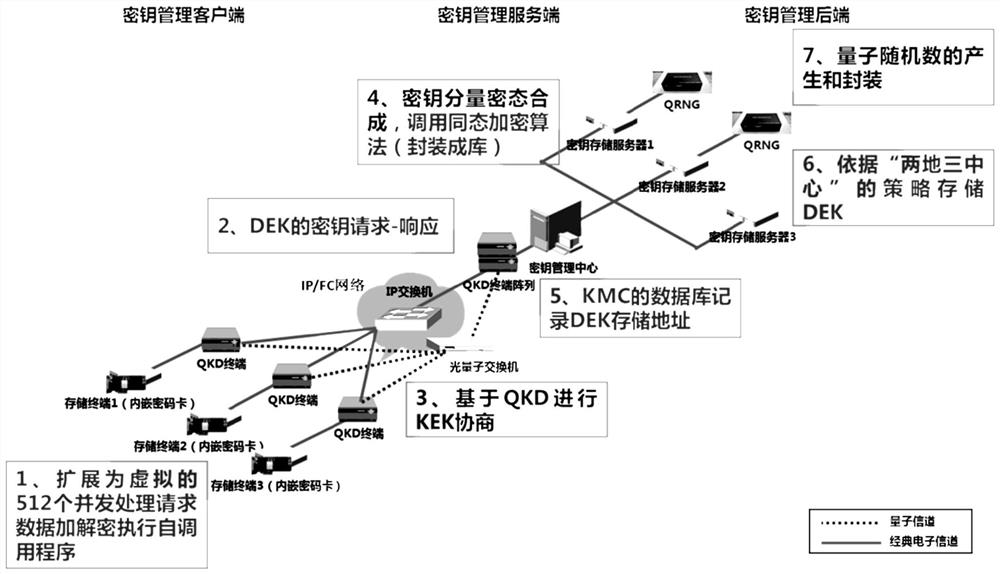

Secure storage-oriented key management protocol design method and system

ActiveCN112800439AGuarantee privacy and securityImprove production efficiencyDigital data protectionDigital data authenticationResource poolProtocol design

The invention discloses a secret key management protocol design method and system oriented to secure storage. The method comprises the steps: constructing a secret key request message through a secret key management client, transmitting the secret key request message to a secret key management center, receiving and analyzing a response message of the secret key management center, and providing a processing result of the request message for an application program; when the key management client obtains the key, the key is loaded into the password card to realize password operation; centralized password management is provided through a key management center, services which comprises key registration, query and revocation are provided, a key resource pool is partitioned, configured and managed, and administrator access, log recording and audit tracking are provided; secret keys are respectively generated and stored through a secret key generator and a secret key storage center in the secret key resource pool. According to the invention, the safety of the whole life cycle of key generation, distribution, storage, updating and destruction in the storage environment can be ensured.

Owner:NO 30 INST OF CHINA ELECTRONIC TECH GRP CORP

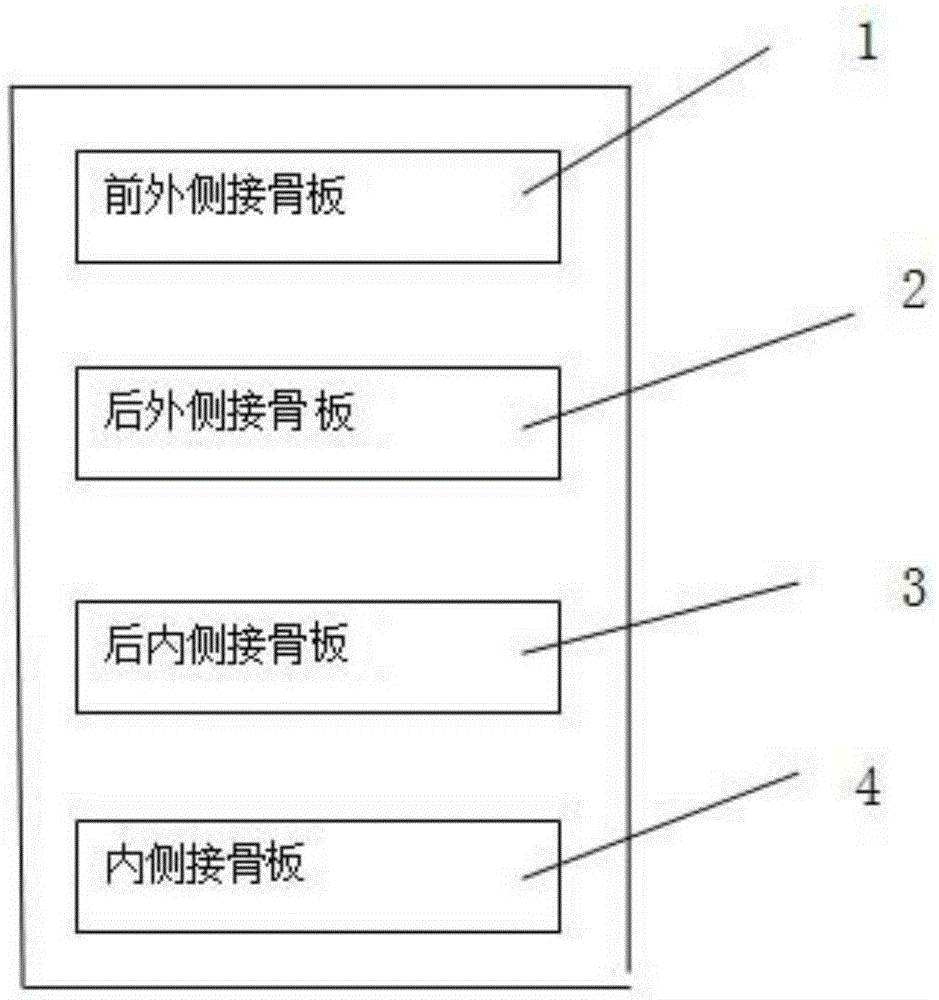

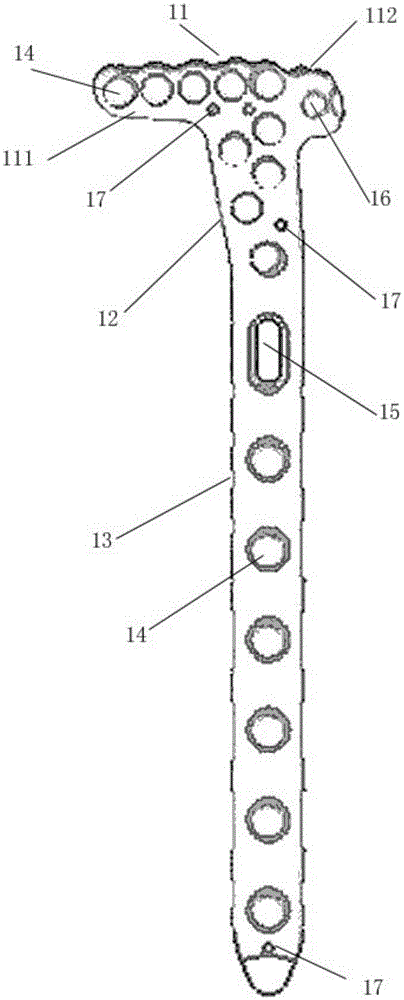

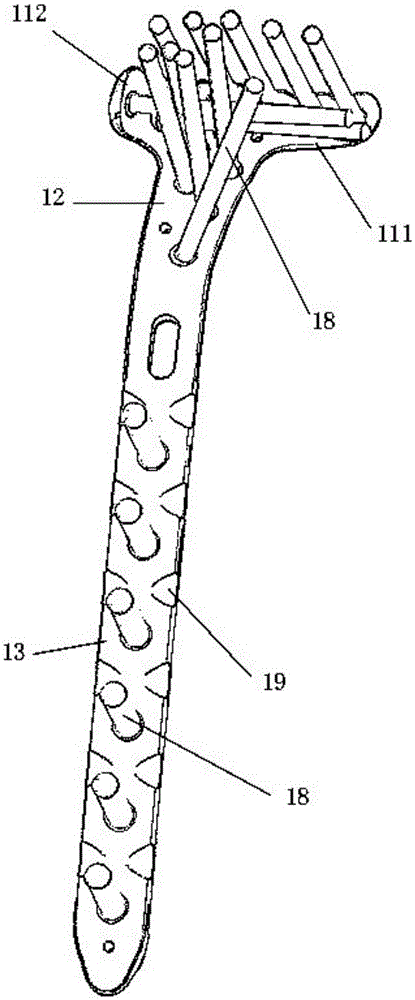

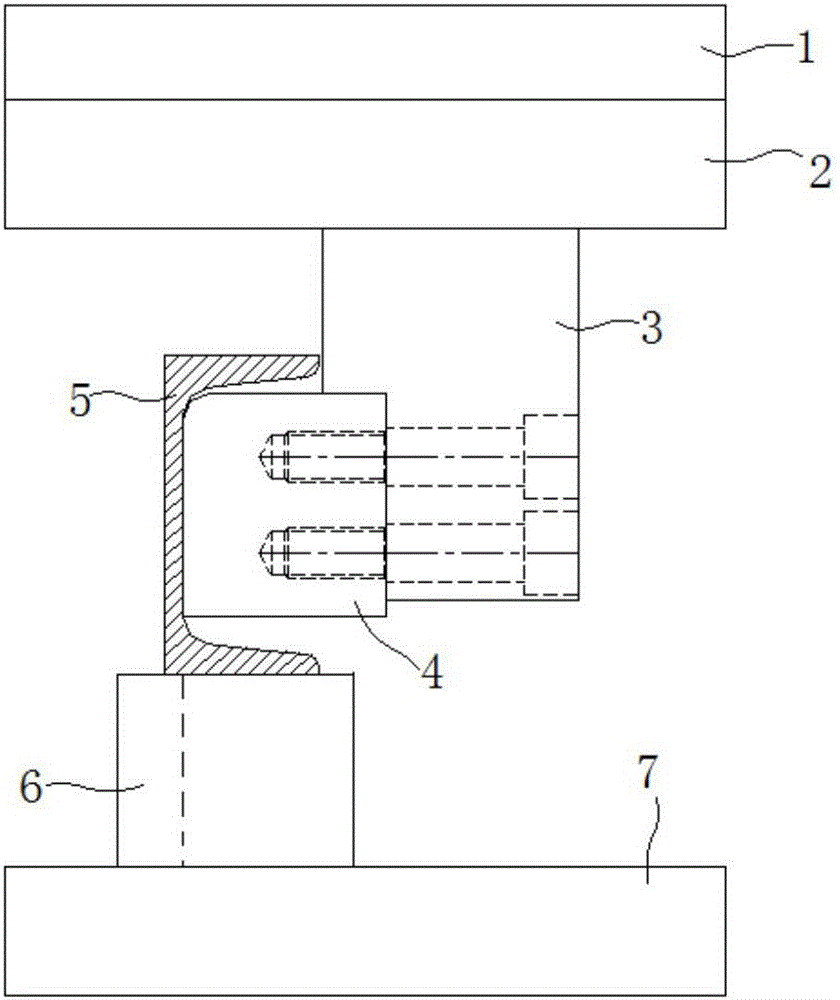

Proximal tibia fracture plate system

InactiveCN105395242AFixed exactEasy to fixInternal osteosythesisBone platesIliac screwProximal tibia

The invention relates to proximal tibia fracture plate system which comprises a front outside bone fracture plate, a rear outside bone fracture plate, a rear inside bone fracture plate and an inside bone fracture plate. The proximal tibia fracture plate system has the advantages that the special bone fracture plates are designed for different directions of a tibia platform, the shape, angle and fixing length are determined in advance based on an anatomy measurement result, the reasonable screw destruction and nail entering direction are ensured, and the fixing space of the tibia platform and the structural form of the tibia are sufficiently utilized, so that the bone fracture plate corresponding to the tibia platform is exact in fixing and good in fixing effect, and bone fracture of the tibia platform can achieve anatomical reduction.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

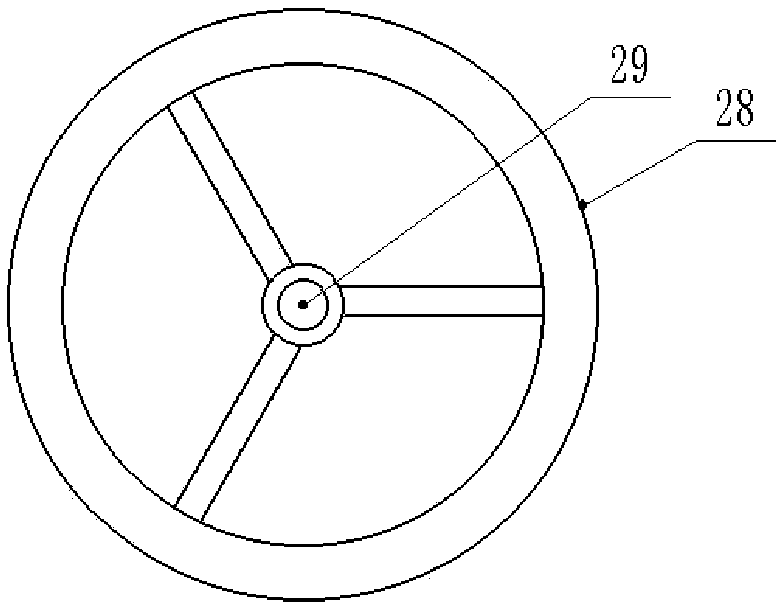

Painting device for valve handwheel

InactiveCN108212670AImprove cleanlinessFirmly connectedLiquid surface applicatorsCoatingsGear wheelEngineering

The invention relates to the field of valve production, and discloses a painting device for a valve handwheel. The painting device comprises a paint groove; a rack is arranged on the paint groove; a rack is slidably connected onto the rack; a small gear is meshed with the rack; a cross rod is rotatably connected to the rack; a fixed position is arranged on the cross rod; the fixed position is sleeved with an elastic inflation barrel; a vertical pipe is arranged on the rack; a piston which is in clearance fit with the vertical pipe is arranged in the vertical pipe; the inside of the vertical pipe is divided into an upper pipeline and a lower pipeline by the piston; a connection rod is arranged in the upper pipeline; two ends of the connection rods are separately hinged to the rack and the piston; an inflation pipe is connected between a lower end of the lower pipeline and the elastic inflation barrel; a paint inlet pipe is connected with the paint groove; a rotary shaft is rotatably connected into the paint groove; a turbine is fixedly connected to one end of the rotary shaft and is located at a connection opening of the paint inlet pipe and the paint groove; and an elastic belt isconnected between the other end of the rotary shaft and the cross rod. By adopting the painting device, while the handwheel is painted, a through hole of the handwheel is prevented from being paintedwith paint; and machining efficiency of the handwheel is improved.

Owner:CHONGQING QIANYAN MACHINERY CO LTD

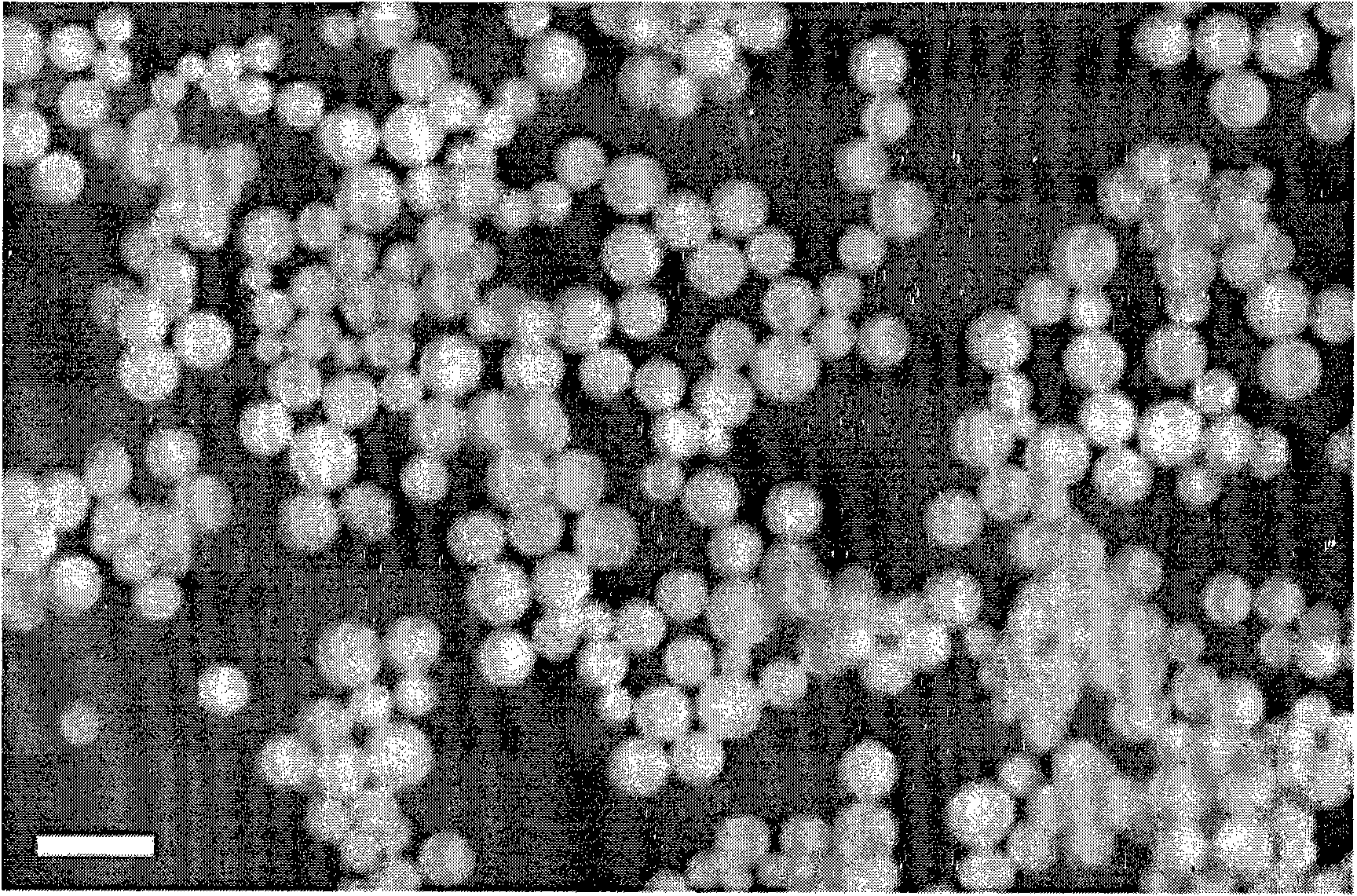

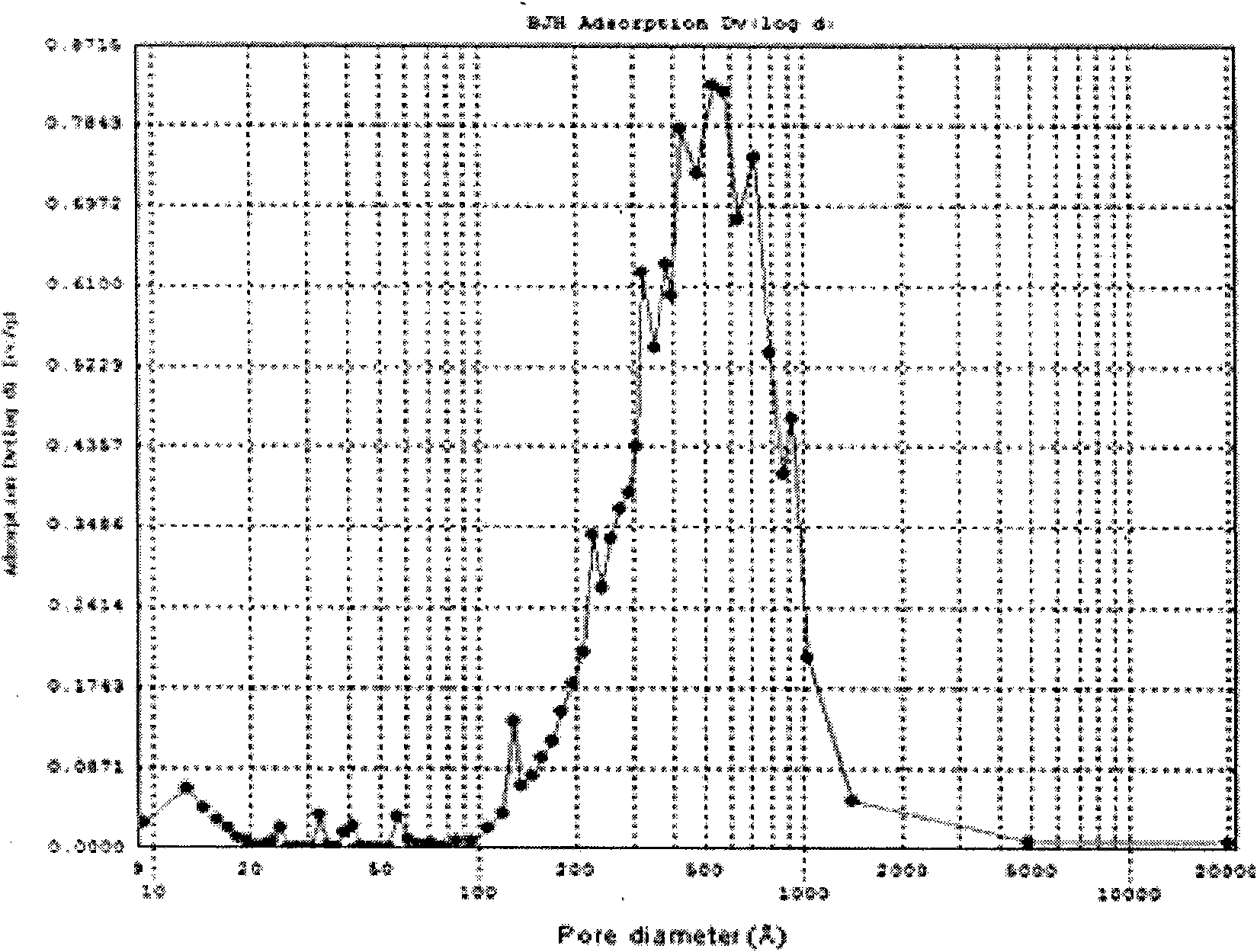

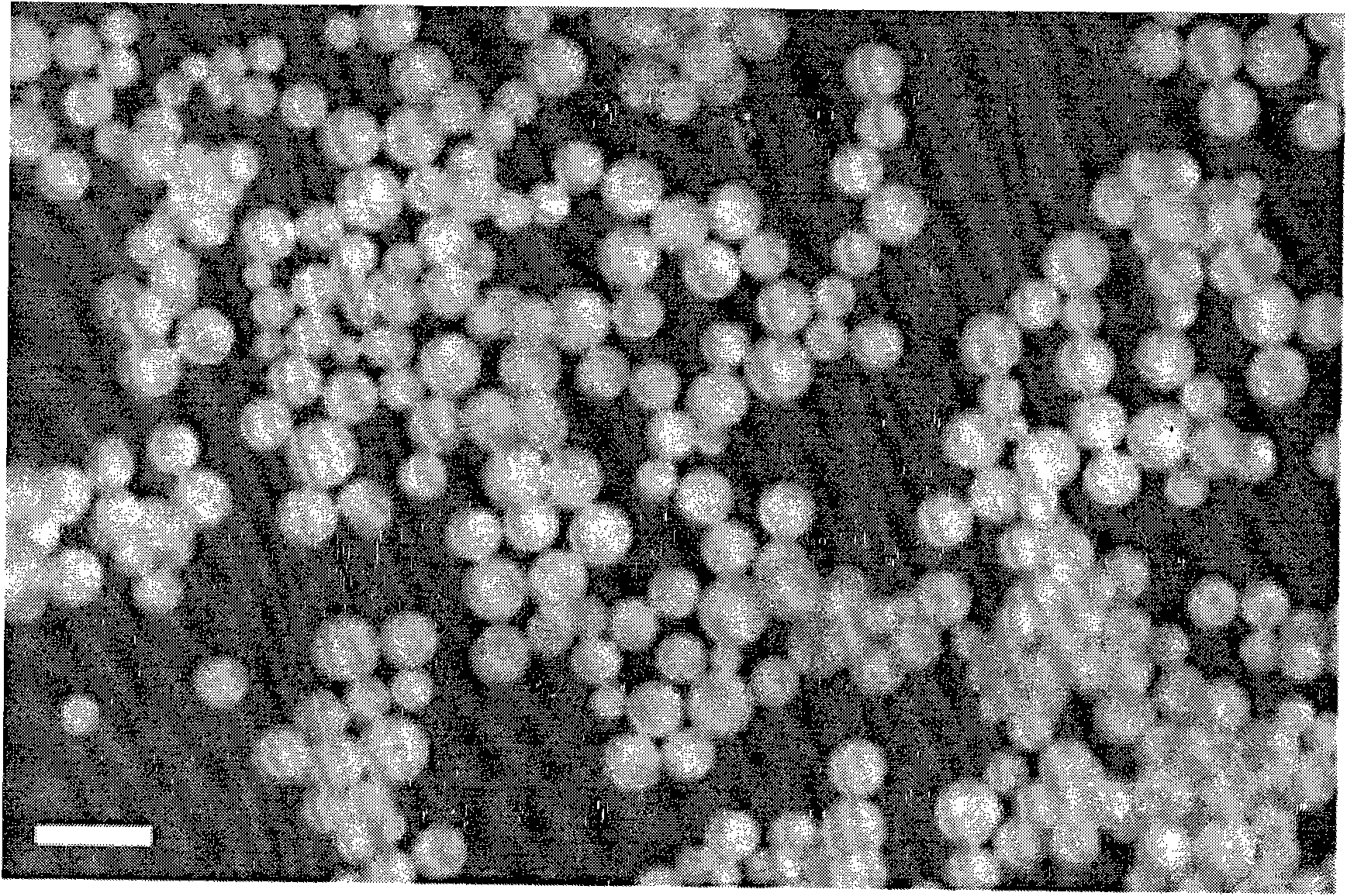

Preparation method for functionalized crosslinked polymer resin microspheres

InactiveCN101880348AGuaranteed distributionGood particle size monodispersityResin microspherePolymer resin

The invention discloses a preparation method for functionalized crosslinked polymer resin microspheres, which belongs to the technical field of crosslinked polymer resin preparation. The method includes the following steps: dissolving water-soluble polymer in deionized water to form aqueous solution; under the protection of inert gas, adding monomer molecules, crosslinking agent, initiator, pore-forming agent and functionalized surfactant into the aqueous solution; emulsifying the aqueous solution, and carrying out emulsion polymerization on the emulsified aqueous solution; and washing, extracting and drying emulsion polymerization product. Since the invention uses the surfactant with a functional group to functionalize the surfaces of the polymer resin microspheres, not only is the grain diameter monodispersity of the obtained microspheres good, but also all the functional group can be distributed on the surfaces of the microspheres and the pores.

Owner:季生象 +1

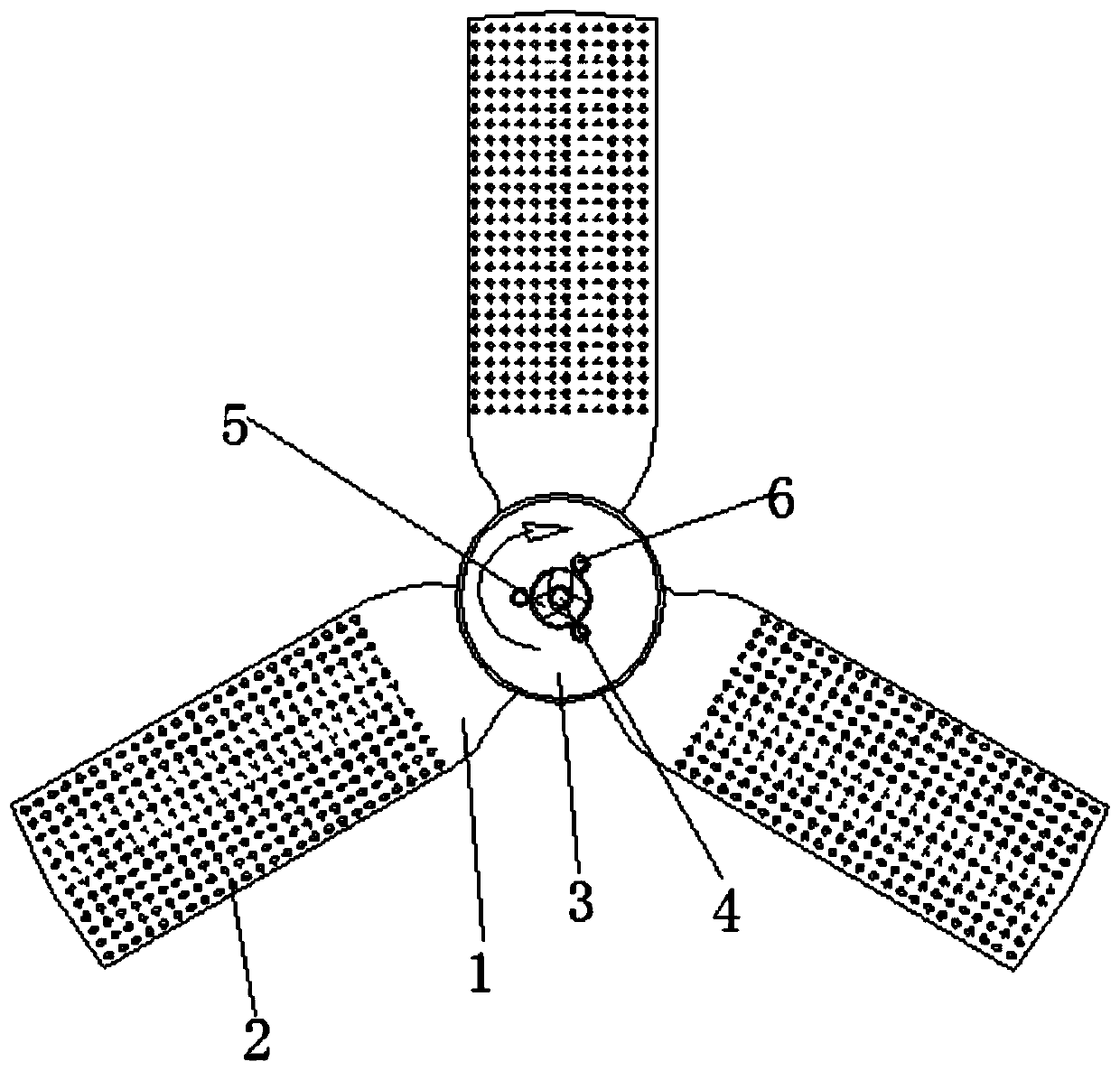

Draught fan and air conditioner with draught fan

PendingCN109737097ACompact structureReduce resistanceCondensate preventionPump componentsAirflowEngineering

The invention relates to the technical field of air conditioners, in particular to a draught fan and an air conditioner with the draught fan. The draught fan comprises a rotating body, at least two blades arranged on the rotating body, microhole runners arranged in the blades and communicating with water sources in the blade rotating process, and ventilation holes formed in the force suction facesof the blades and communicating with the microhole runners, wherein the force suction faces of the blades are the faces, of which the peripheral air flow pressure is lower than the atmospheric pressure, of the blades in the rotating process, the ventilation holes are used for introducing the negative pressure into the microhole runners to accelerate vaporization of water in the microhole runners,and the vaporized vapor is sent out through the rotating blades. Due to the fact that the microhole runners are arranged in the blades of the draught fan, due to gravity or centrifugal force generated by blade rotating, feeding of water in the microhole runners in the blades is achieved; and due to the fact that the ventilation holes are formed in the force suction faces of the blades, the ventilation holes are used for introducing the negative pressure into the microhole runners, and therefore vaporization of water in the microhole runners is accelerated, and the moisture content of the airis rapidly increased.

Owner:GREE ELECTRIC APPLIANCES INC

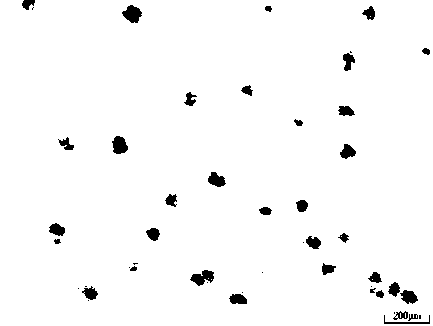

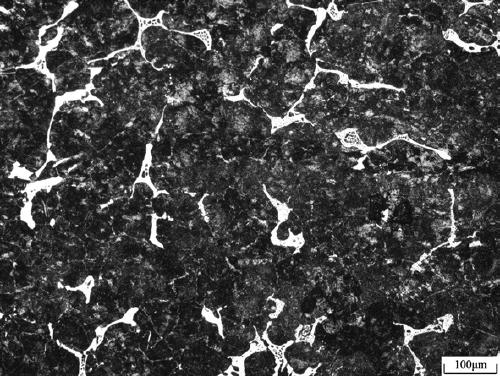

High-wear-resistance graphite steel edging roller of profile steel-rail beam rolling mill and manufacturing method thereof

InactiveCN111101058AModerate hardnessAvoid crackingElectric furnaceProcess efficiency improvementFerrosiliconMolten steel

The invention relates to a high-wear-resistance graphite steel edging roller of a profile steel-rail beam rolling mill and a manufacturing method thereof, and belongs to the technical field of edgingrollers. The manufacturing method mainly comprises the steps of smelting, pouring and heat treatment, wherein inoculation treatment comprises ladle bottom inoculation before tapping, stream inoculation in the tapping process and stream inoculation in the pouring process, the inoculants are Fe-Si particles and Si-Ca particles, and 5-10 Kg of inoculants are added into 1 ton of molten steel; spheroidizing treatment uses a rare-earth ferrosilicon magnesium spheroidizing agent, and the rare-earth ferrosilicon magnesium spheroidizing agent rushes into the molten steel in the tapping process; and after tapping, the molten steel in the ladle is subjected to argon blowing treatment to ensure that the temperature of the molten steel reaches the pouring temperature which is higher than the melting point temperature of the molten steel by more than 50 DEG C, and then pouring is carried out. The high-wear-resistance graphite steel edging roller has high wear resistance, excellent hot crack resistance and accident impact resistance, and can improve the steel adhesion resistance of the edging roller and improve the on-machine period and the rolling efficiency.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

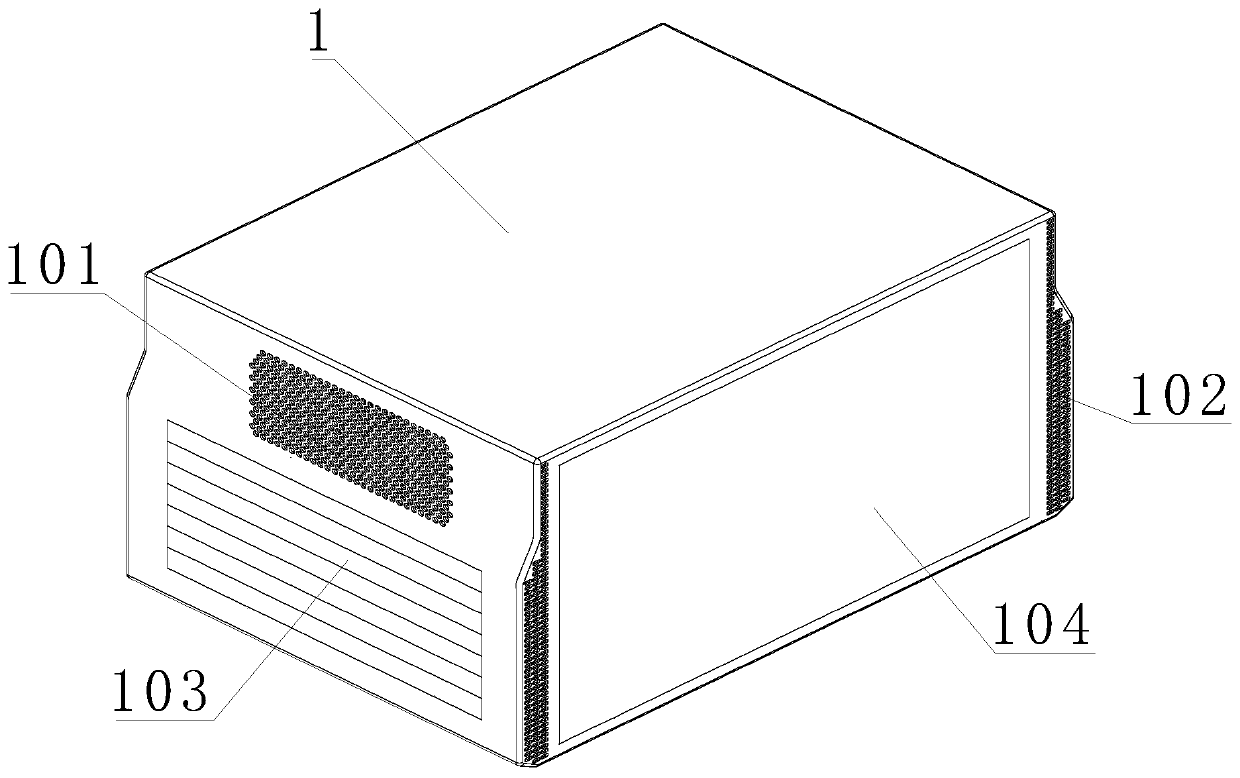

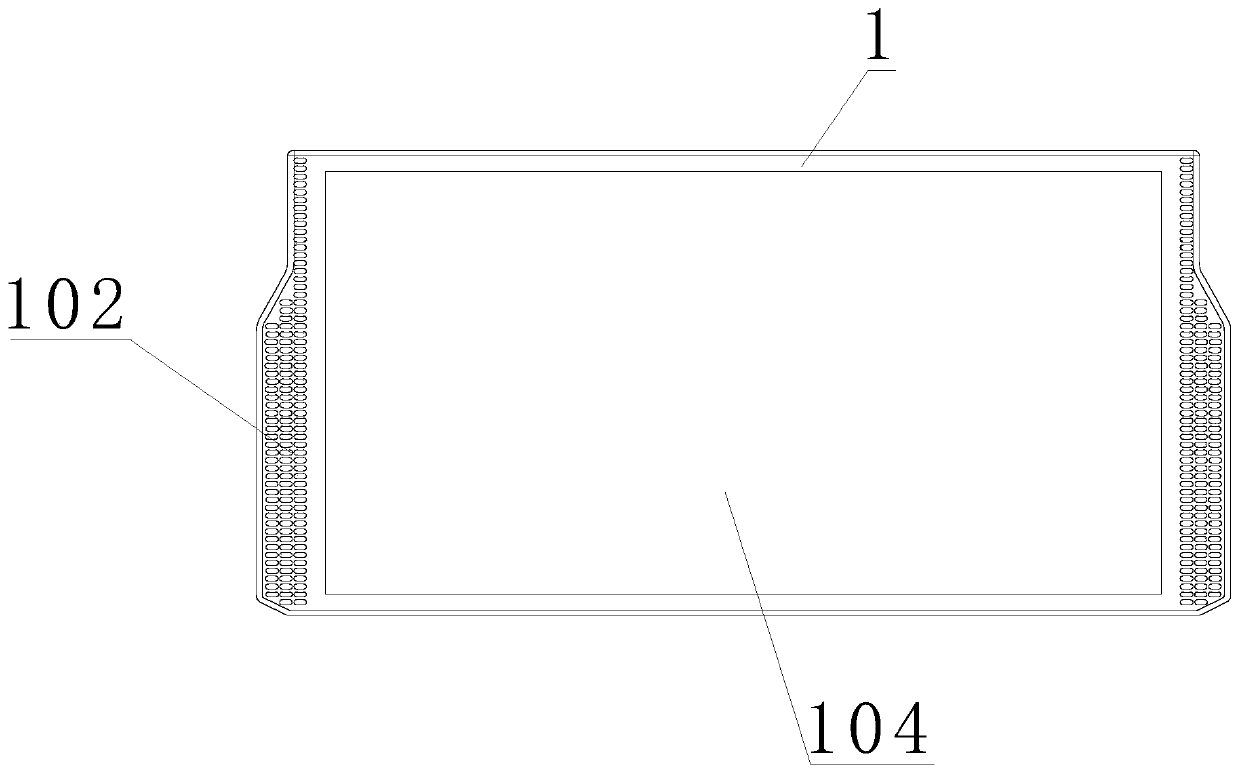

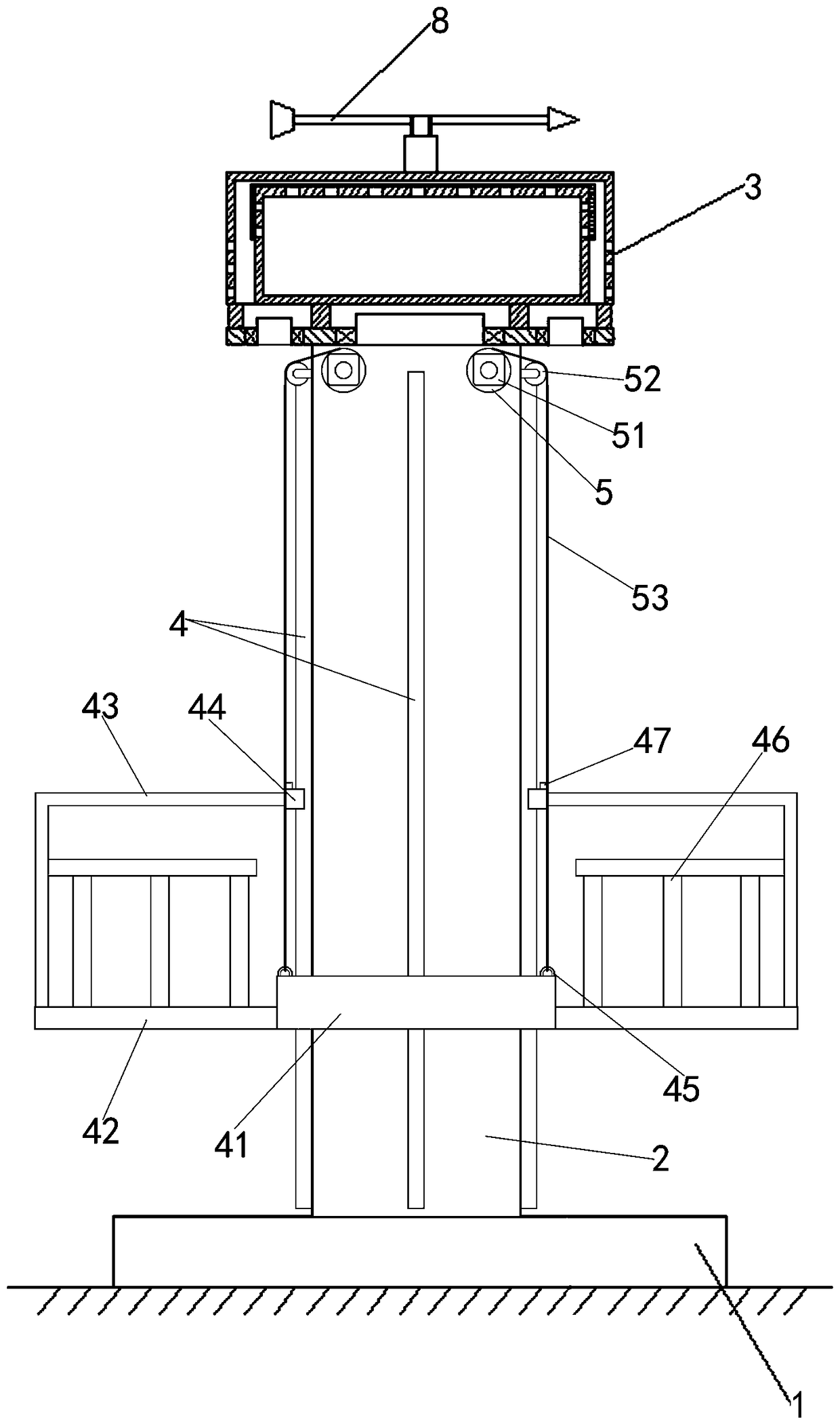

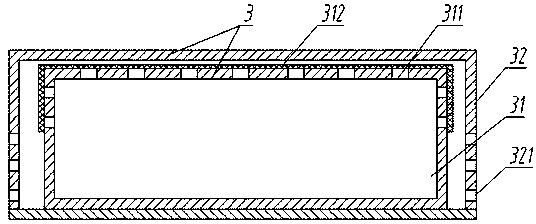

Vertical-lifting-type communication equipment for repairing

The invention discloses vertical-lifting-type communication equipment for repairing. The vertical-lifting-type communication equipment comprises a base, a vertical column and a communication box. Thevertical column is arranged into a quadrangular prism shape and provided with a lifting repairing assembly. The lifting repairing assembly comprises guide rails which are vertically arranged on the side faces of the vertical column correspondingly. A movable frame is annularly connected to the four guide rails, is horizontally arranged, and can move in a vertical reciprocating mode along with theguide rails. An annular rectangular bottom plate is horizontally arranged on the outer side face of the movable frame, and the outer side faces of the bottom plate are each upwards provided with an L-shaped connecting plate. A sliding block is arranged at the front end of each connecting plate, and the siding blocks are connected to the corresponding guide rails. The communication box comprises aninner box body and an outer box body, and a heat dissipating interlayer is formed between the inner box body and the outer box body. Ventilating holes are formed in the lower portions of the side faces of the outer box body, and heat dissipating holes are formed in the upper portions of the side faces and the top of the inner box body. The vertical-lifting-type communication equipment has the advantages of being reasonable in design, good in safety, capable of reducing manpower movement, convenient to repair and maintain, rapid in repairing and maintaining and the like.

Owner:U COM TELECOM EQUIP CO LTD

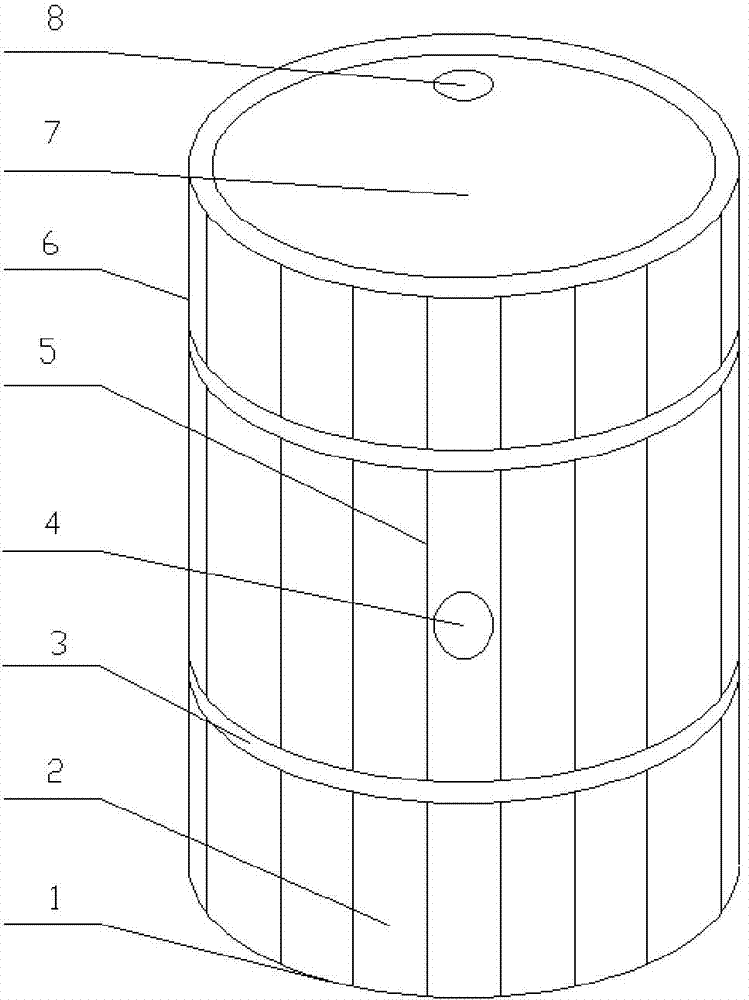

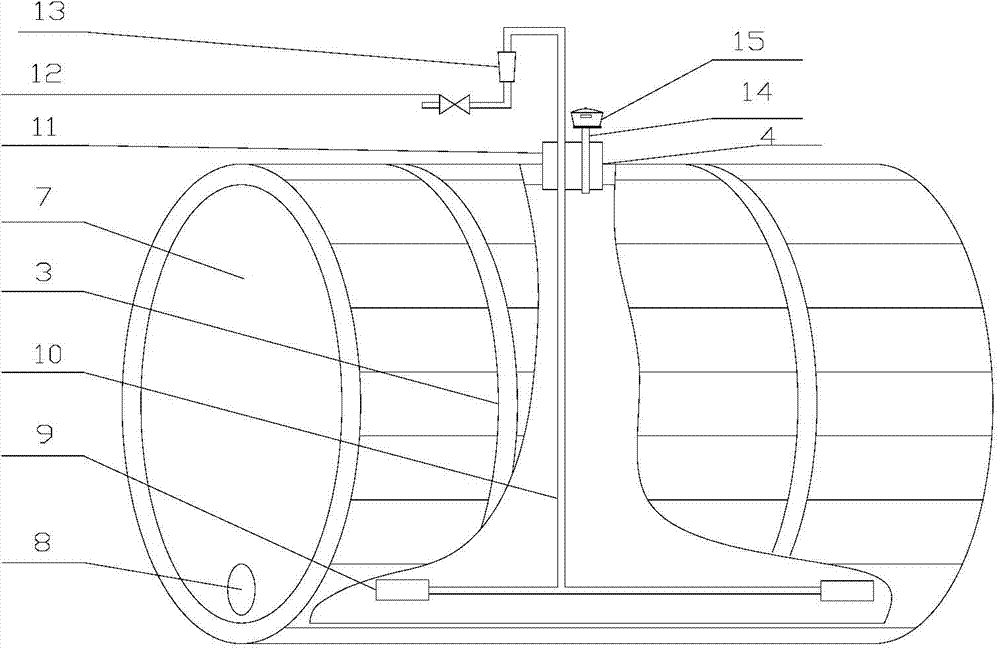

Lychee barrel for ageing and distilling liquor as well as preparation method and application process thereof

ActiveCN103695278AUnique aromaSpeed up agingAlcoholic beverage preparationWood working apparatusFlavorPulp and paper industry

The invention discloses a lychee barrel for ageing and distilling liquor as well as a preparation method and an application process thereof, belonging to the technical field of brewing wine. The invention provides a lychee barrel for ageing and distilling liquor and further provides a lychee barrel for ageing and distilling liquor, with a micro-aerobic device, and provides a preparation method of the lychee barrel for ageing and distilling the liquor, with the micro-aerobic device, and an ageing process. The lychee barrel for the lychee barrel for ageing and distilling the liquor, with the micro-aerobic device, provided by the invention, is internally provided with a stainless steel gas pipe and a micropore gas distributor, which are used for accelerating the oxygen required by distilling the liquor in an ageing process and accelerating the volatilization of impurities in wine, are capable of playing a role in stirring the liquor to accelerate the collision of trace components for reaction, and enabling the aged liquor to have a special flavor.

Owner:广东省九江酒厂有限公司

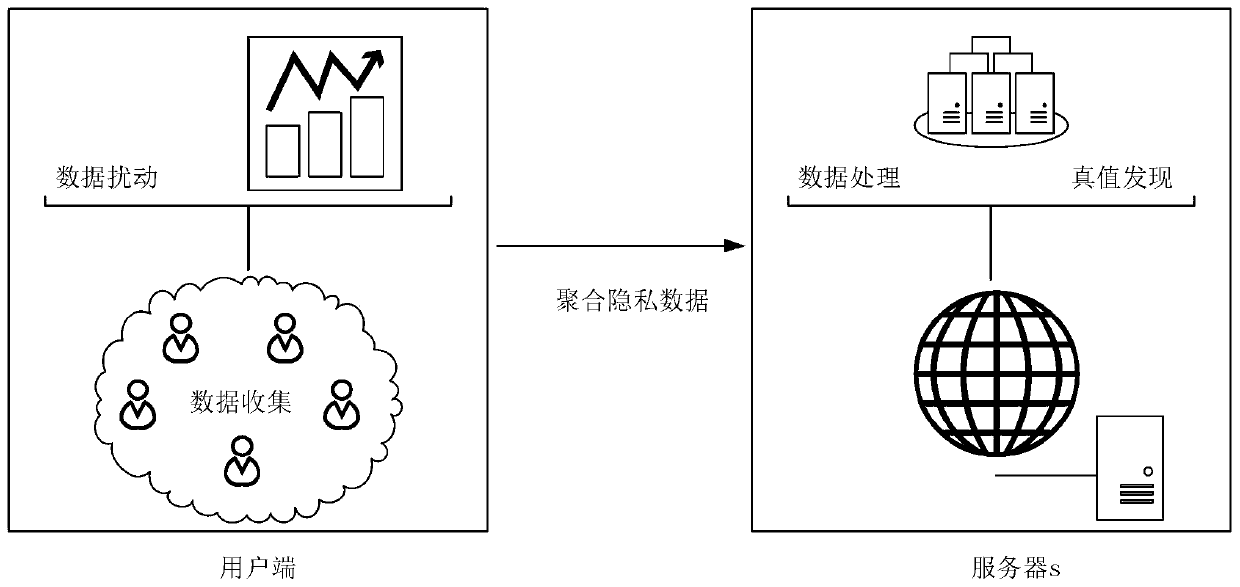

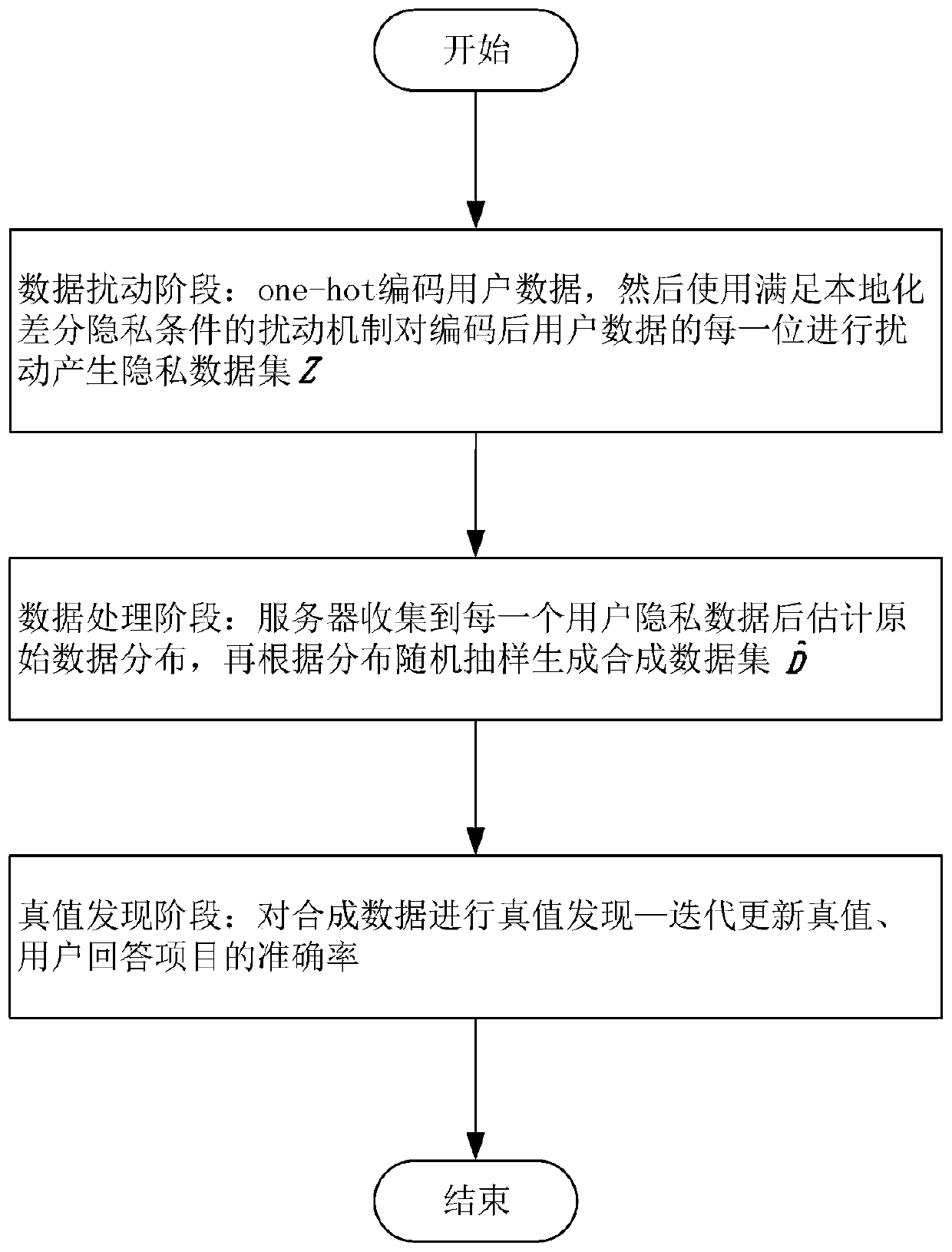

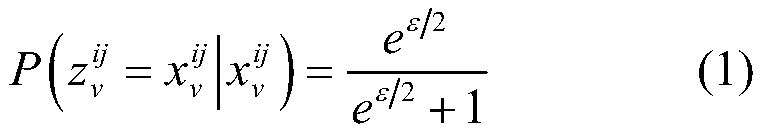

Multidimensional crowdsourcing data truth value discovery method based on localized differential privacy

The invention discloses a multidimensional crowdsourcing data true value discovery method based on localized differential privacy, which is applied to a crowdsourcing platform comprising n users, an untrusted server s and m projects, and is carried out according to the following steps of: 1, a data disturbance stage of disturbing crowdsourcing data answered by the users by using a random responsemechanism to generate private data; 2, a private data processing stage of processing private data to generate estimated synthetic data; and 3, a truth value discovery stage of performing truth value discovery on the estimated synthetic data to obtain a final accurate answer. According to the invention, data protection is carried out on data of a user by using a strong privacy protection mechanism-localization differential privacy; and information leakage is prevented, through utilizing truth value discovery, result inaccuracy caused by conflicts among the data and inconsistent user quality issolved, truth value updating accuracy is guaranteed, and user privacy and data availability can be guaranteed in the crowdsourcing platform.

Owner:ANHUI UNIVERSITY

Machining device and method for steel channel grooving and bending combined assembly

ActiveCN106734518AAvoid bending deformationImprove processing efficiencyShaping toolsEngineeringMechanical engineering

The invention discloses a machining device and method for a steel channel grooving and bending combined assembly and belongs to the technical field of shearing and bending machining. The machining device comprises a rectangular groove cutting machining mold, a triangular groove cutting machining mold and a bending machining mold, wherein the rectangular groove cutting machining mold comprises a first movable cutter and a first fixed cutter; the first movable cutter is fixedly connected with a first movable cutter base, and the shearing edge face of the first movable cutter is a V-shaped face with the middle portion sunken downwards; the first fixed cutter is installed on a first fixed cutter base and forms a "rightward-right-angle-u-shaped" structure; the triangular groove cutting machining mold comprises a second fixed cutter and a second movable cutter; the second movable cutter is fixedly connected with a second movable cutter base; the shearing edge face of the second movable cutter is a plane inclined to the other side from the position of a sharp corner of the plane; and the second fixed cutter is installed on a second fixed cutter base and forms an "L-shaped" structure. By adopting the machining device to perform grooving and bending machining on steel channels, the machining efficiency and the machining quality can be remarkably improved, and the precision and the quality of the combined assembly are made to meet the using requirements.

Owner:马鞍山市欧姆科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com