Lychee barrel for ageing and distilling liquor as well as preparation method and application process thereof

A technology of distilled wine and lychee wood, which is applied in the field of lychee wooden barrels for aging distilled wine and its preparation, to achieve the effects of coordinating aromas, saving aging time, and speeding up the collision reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

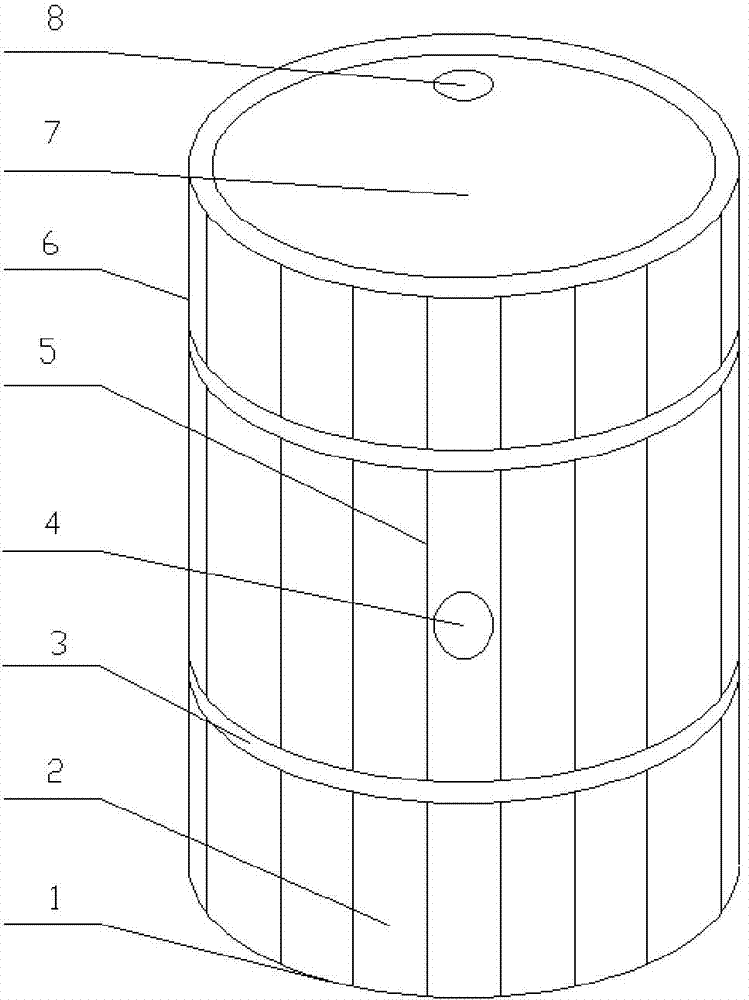

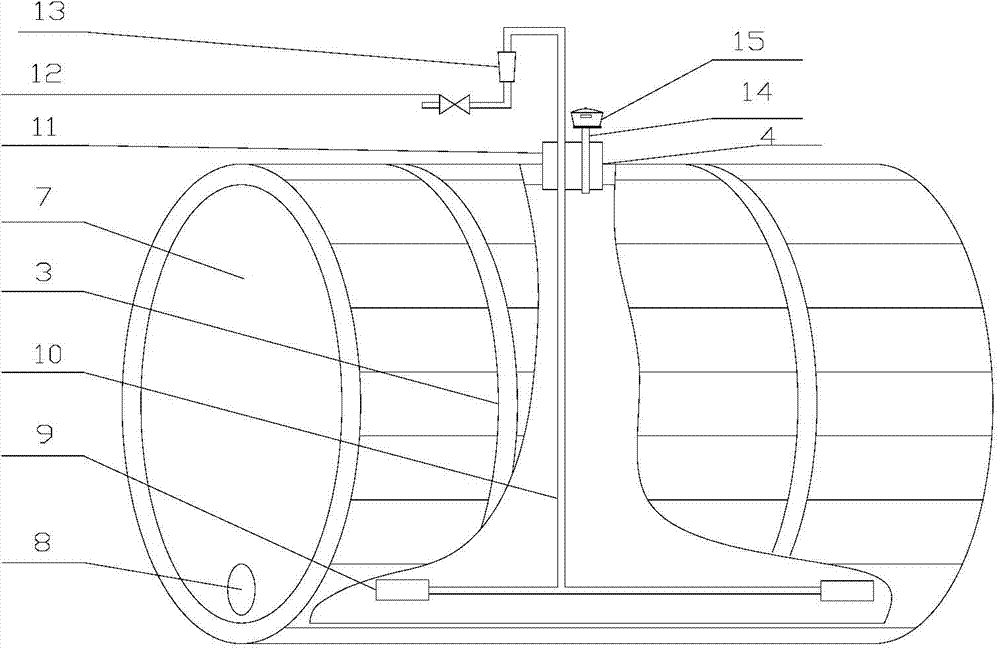

[0052] Embodiment 1 has the processing technology of the lychee wooden barrel for aging distilled wine with micro-oxygen device

[0053] A method for preparing a lychee wooden barrel for aging distilled wine with a micro-oxygen device, mainly comprising the following steps: material selection of lychee wood—drying of lychee wood—making of lychee wood boards—screening of lychee wood boards—molding design of lychee wooden barrels—assembly of lychee wooden barrels - Roasting of lychee barrels - Joining and roasting of upper and lower covers of lychee barrels - Cleaning of lychee barrels - Strengthening of lychee barrels - Testing of lychee barrels - Punching of lychee barrels - Installation of lychee wood Barrel micro-oxygen distribution device.

[0054] 1. Litchi wood selection: trunks with a diameter of more than 0.5 meters, the color of the trunk section is reddish brown, with the unique aroma of litchi wood, no insects, strong and not rotten;

[0055] 2. Drying of lychee woo...

Embodiment 2

[0068] The aging process of embodiment 2 lychee wooden barrels:

[0069] Freshly distilled liquor with soy flavor is stored in large stainless steel tanks, the temperature of the liquor is kept at 30°C, and high-purity nitrogen is introduced into the liquor at the same time, 1 nitrogen per ton of liquor, and the flow rate is 0.2L / min. After three days of storage, transfer to lychee wooden barrels for aging. The aging conditions are space temperature of 15°C, humidity of 70%. Stirring, contact with lychee barrels and oxidative aging. After 30 days of storage, according to the needs of the wine body design, different batches and different periods of aging wines are blended with each other. After the blending is completed, the wine liquid is frozen, inspected and packaged to obtain the finished wine.

Embodiment 3

[0070] The aging process of embodiment 3 lychee wooden barrels:

[0071] Rice-flavored freshly distilled liquor is stored in large stainless steel tanks. The temperature of the liquor is kept at 32°C. At the same time, high-purity nitrogen is introduced into the liquor. 3L of nitrogen is injected per ton of liquor, and the flow rate is 0.4L / min. After three days of storage, transfer to lychee wooden barrels for aging. The aging conditions are space temperature of 20°C and humidity of 75%. Stirring, contact with lychee barrels and oxidative aging. After 30 days of storage, according to the needs of the wine body design, different batches and different periods of aging wines are blended with each other. After the blending is completed, the wine liquid is frozen, inspected and packaged to obtain the finished wine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com