Patents

Literature

84results about How to "Round taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brewing method of fruit-flavored dry red wine

ActiveCN105219574AOutstanding FeaturesHighlight significant progressMicroorganism based processesWine preparationHarvest timeSteeping

The invention discloses a brewing method of fruit-flavored dry red wine. The brewing method comprises such processing steps as determining a harvest time and harvesting, removing stems, sorting, crushing, extracting juice, cold-steeping, undergoing alcoholic fermentation with peels, separating peels and dregs, undergoing alcoholic fermentation with clear juice, storing, stabilizing, blending, freezing, sterilizing, filling and the like, so that produced dry red wine is intense, elegant and exquisite in fruit flavor, smooth and soft in taste, and is balanced and coordinated in wine body.

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

Mixed sauce seasoning packet suitable for non-fried miscellaneous-grain instant noodles, and production method thereof

The invention discloses a mixed sauce seasoning packet suitable for non-fried miscellaneous-grain instant noodles. The seasoning packet comprises a sauce packet, and a powder packet. The sauce packet comprises the raw materials of: fresh meat, palm oil, refined butter, sesame oil, soybean paste, soy sauce, old ginger, fresh garlic, shallot, chili pepper, white granulated sugar, pepper powder, and food additives. The powder packet comprises the raw materials of: edible salt, monosodium glutamate, white granulated sugar, chili pepper powder, ginger powder, garlic powder, yeast powder, ginger powder, onion powder, maltodextrin, and pure chicken powder. A dried vegetable packet comprises the raw materials of: Chinese cabbage, caraway, and celery. The seasoning packet has the advantages that: nutrients in pork and fresh vegetables are converted into amino acids which are easy to absorb by human bodies, such that the seasoning packet is beneficial for human health. The color, fragrance, and taste are good. The production method is simple and is easy to command; the technology is mature; and the method provided by the invention is suitable for popularization.

Owner:SICHUAN JIUJIUAI FOOD

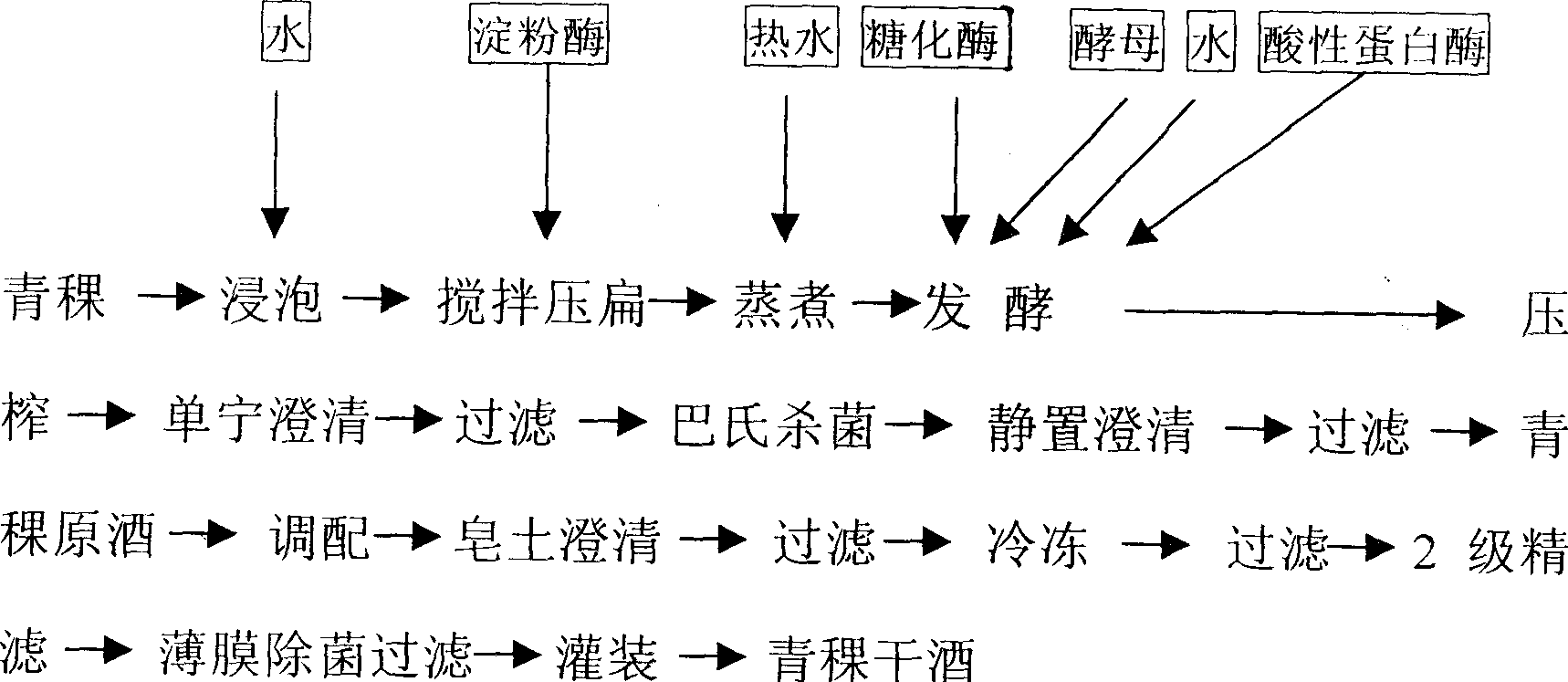

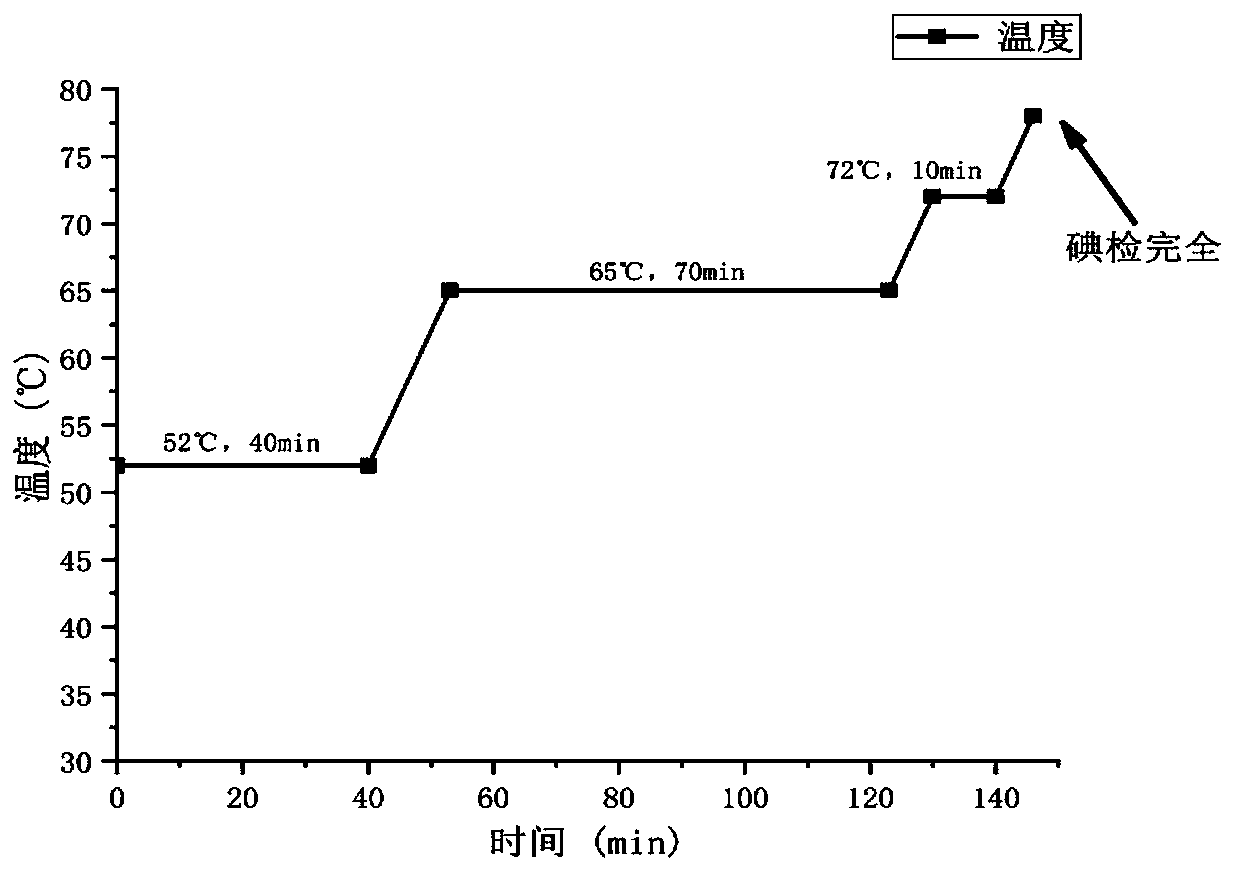

Process for preparing barley dry wine

InactiveCN1435475APaste smoothlyEase of evaluationAlcoholic beverage preparationPolymer scienceAlpha-amylase

A process for preparing dry highland barley wine includes soaking highland barley, steaming, mixing with high-temp.-resistant alpha-amylase, stirring, pressing, saccharifying, fermenting under 30 deg.C, squeezing, clarrifying, mingling and filtering. Its advantages are low content of sugar, and high quality and stability.

Owner:SHANGRI LA WINE CO LTD

Method for preparing elastic chocolate sauce

The invention discloses a method for preparing an elastic chocolate sauce, which is characterized by comprising: 1) mixing saccharide, grease, dairy product, cocoa and water to obtain mixed solution; 2) heating the mixed solution to above 50 DEG C till the color of the mixed solution turns brown and the state of the mixed solution changes suddenly, continuing to heat the mixed solution to 70 to 75 DEG C and keeping the temperature for 10 to 15 minutes; 3) adding water to fix the volume till the water content of the obtained chocolate sauce is 5 to 25 percent; and 4) cooling the obtained chocolate sauce to 40 to 45 DEG C. The sauce made by the method provided by the invention is strong and tough; and the elastic mouthfeel is realized by controlling the water content of the sauce rather than adding a colloidal substance.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Method for brewing wild bilberry ice wine

ActiveCN102618414ACons full of thin high acidThe shortcomings of being full of thin and high acid have been improved, and the characteristics of fruity fragranceAlcoholic beverage preparationPhysical approachFood flavor

The invention provides a method for brewing wild bilberry ice wine by utilizing complex enzyme enzymolysis and a low-temperature oxygen-free fermentation technology, and belongs to the field of alcoholic beverage preparation. The method comprises the following processes: putting off wild bilberry harvest when the temperature is lower than -5 DEG C, carrying out complex enzyme enzymolysis, carrying out low-temperature oxygen-free pure-bred yeast fermentation under the protection of carbon dioxide, adding blueberry laevulose for secondary fermentation, ending the fermentation according to a physical method, carrying out low-temperature storage with an oak barrel, bottling for storage, and the like. The method has the advantages that the defect that the conventional blueberry wine is thin and highly acid is overcome; and the fruity and the fragrant characteristics are enhanced. Therefore, the wild bilberry ice wine brewed according to the method tastes sweet and intense, has strong blueberry fruity flavor and bouquet, and looks clear and pretty.

Owner:大兴安岭北极冰蓝莓酒庄有限公司

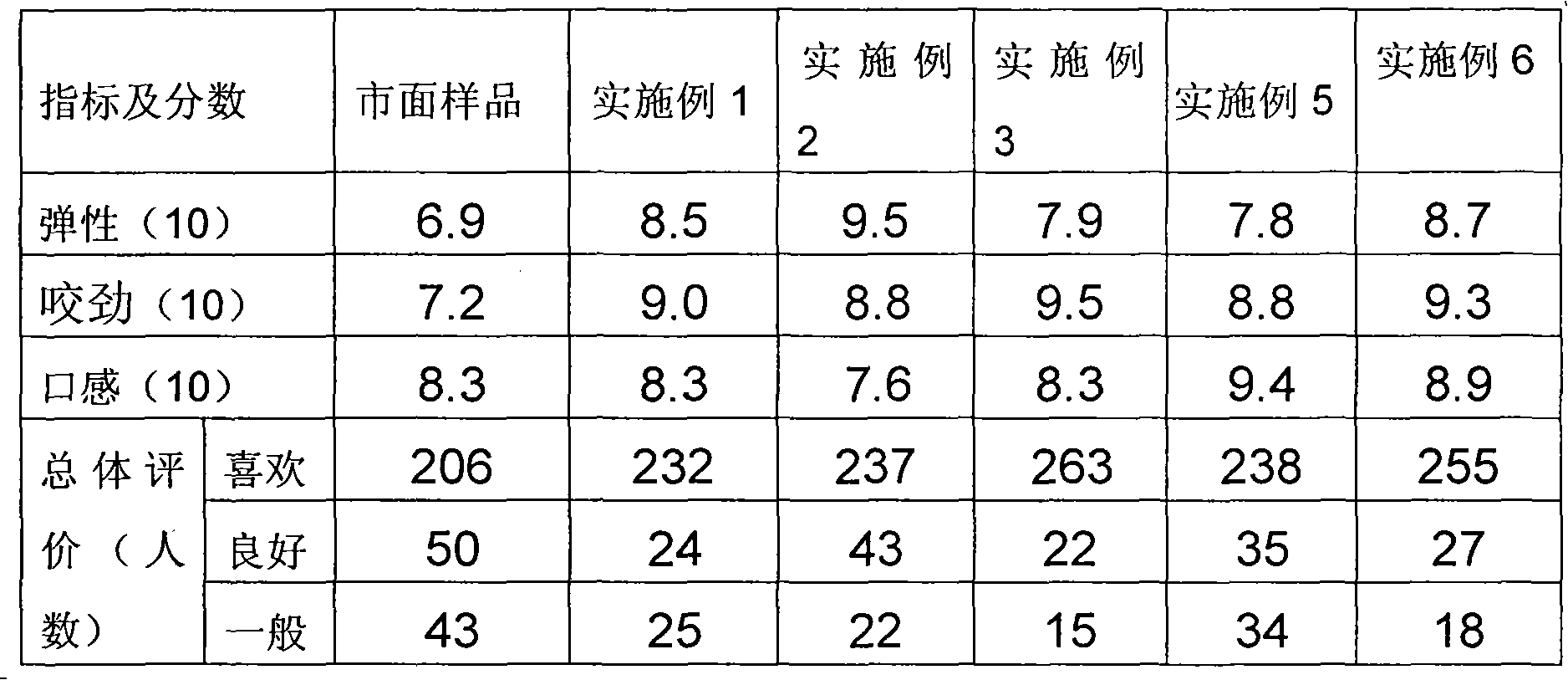

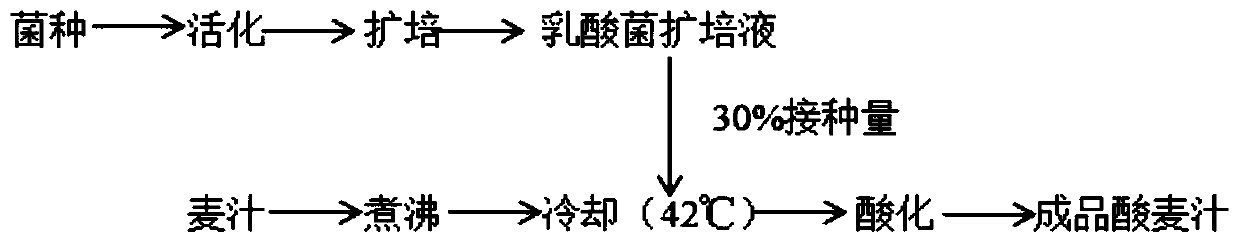

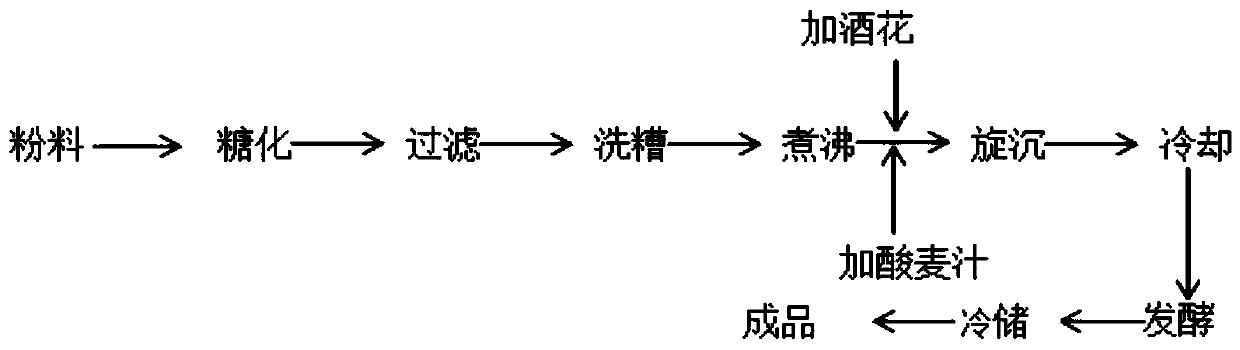

Brewing method of acid beer

InactiveCN111548874AThe brewing process is simpleEasy to operateBacteriaBeer fermentationBiotechnologyChaptalization

The invention relates to a brewing method of acid beer. According to the method, water, malt, hops and yeast are taken as main raw materials, sour wort is taken as an auxiliary raw material, malt is crushed and then subjected to wort saccharification, filtration and vinasse washing, wort obtained after vinasse washing is heated and boiled, hops are added in the boiling process, the sour wort is added in 5 min before boiling is finished, the adding amount of the sour wort is 1-10% of the mass of the wort, after boiling is finished, cyclotron precipitation is carried out to obtain raw wort, theraw wort is subjected to cooling and oxygenating, and beer yeast for fermentation is inoculated to obtain sour beer, wherein the sour wort is prepared by a biological acidification method. The sour beer is brewed by adding the sour wort in the wort boiling process, the brewing method is simple and easy to operate, the production cost is reduced, the brewing period is shortened, the brewed sour beer is rich in aroma, the malt aroma, the ester aroma and the hops aroma are mutually balanced and pleasant, the acidity is balanced, and the overall flavor and taste of the final beer are good.

Owner:QILU UNIV OF TECH

Air-drying red wine and brewing process thereof

The invention provides an air-drying red wine and a brewing process thereof. The brewing process comprises the following steps of: sorting raw material wine grape, checking, air drying, removing branches and crushing, performing alcoholic fermentation, fermenting apple emulsion, aging in wooden barrels, blending, settling, filling, storing in bottles, packing and warehousing. According to the invention, through grape variety selection, delayed grape pickup, natural air-drying condition selection, research on the aging process of air-dried grape and selection of yeasts and pectinases used in air-drying red wine, the quality of the air-drying red wine is improved, and the obtained red wine is deep ruby red, clear and transparent, fragrant and complex and has the advantages of aged wine fragrance, oak fragrance, black berry fragrance, dried fruit fragrance, mellow and full mouthfeel, gentle taste, long aftertaste, remarkable typicality, and has potential aging characteristic and unique sensory characteristics.

Owner:SINO FRENCH JOINT VENTURE DYNASTY WINERY

Method for making waxberry vinegar

InactiveCN102242047AAlcohol conversion rate is highFast acid productionMicroorganism based processesVinegar preparationFiltrationSubmerged fermentation

The invention discloses a method for making waxberry vinegar, which comprises the following steps of: 1, sorting, namely selecting waxberry materials; 2, deseeding; 3, squeezing; 4, performing ultrahigh temperature (UHT) sterilization; 5, performing primary fermentation, namely adding active dry yeast Q23 into a fermentation tank filled with waxberry juice, performing alcoholic fermentation on the waxberry juice to obtain waxberry wine, and controlling the fermentation temperature to be between 23 and 28DEG C; 6, performing secondary fermentation to obtain waxberry raw vinegar; 7, clarifying; 8, filtering; 9, performing secondary UHT sterilization, namely pumping the waxberry vinegar subjected to fine filtration into a UHT sterilizer for sterilization; and 10, filling. The waxberry juice is subjected to two-stage liquid state submerged fermentation to form the waxberry vinegar, and the waxberry vinegar is dark amber and clarified, and has luster, natural inherent aroma of waxberries, full, smooth and mild mouthfeel, and high typicality.

Owner:浙江聚仙庄饮品有限公司

Raw material wine-brewing direct adding composite bacterium preparation and preparing method thereof

The invention relates to a compound bacteria preparation used in the field of liquor-making with raw meal and a preparation method thereof, particularly to a ready-to-use compound bacteria preparation used in liquor-making with the raw meal and a preparation method thereof. The ready-to-use compound bacteria preparation comprises the following ingredients: rice flour or bran culture of rhizopus Q303 2-5 weight parts, bran culture of Su-16 aspergillus flavus strain 30-50 weight parts, bran culture of hay bacillus BF7658 10 weight parts, rice flour or bran culture of active dry yeast used for bran liquor 5-10 weight parts, and maltogenic amylase with 50000 units per gram 25-30 weight parts. According to the technical proposal, the rhizopus Q303, Su-16 aspergillus flavus, hay bacillus, and active dry yeast used for bran liquor, which can make good use of raw starch, are selected as functional bacteria of ready-to-use compound bacteria preparation used in liquor-making with raw meal. The ready-to-use compound bacteria can improve the taste of raw meal liquor. The functional strains are combined in an optimal proportion so as to effectively inhibit mixed bacteria from growing, prevent high acidity, eliminate or obviously alleviate the bitter taste of liquor, and prevent mash from generating peculiar smell.

Owner:JIANGXI GANLIANG INDAL

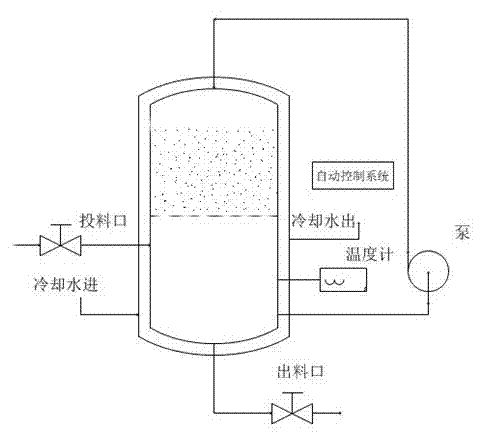

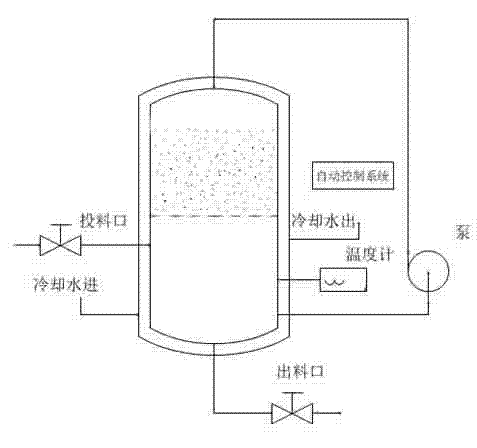

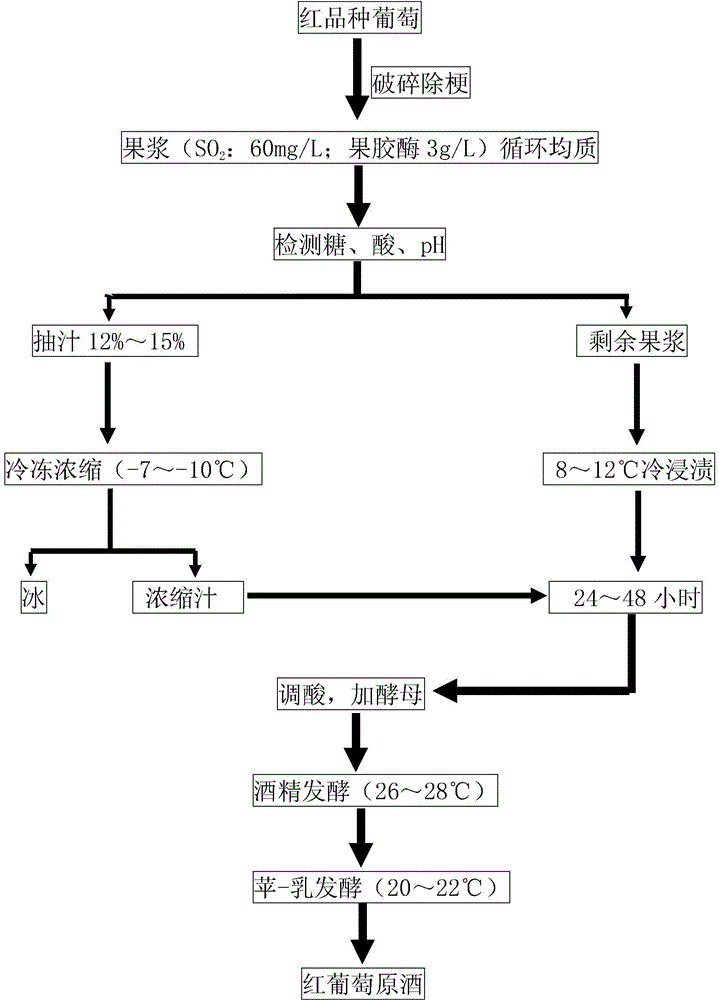

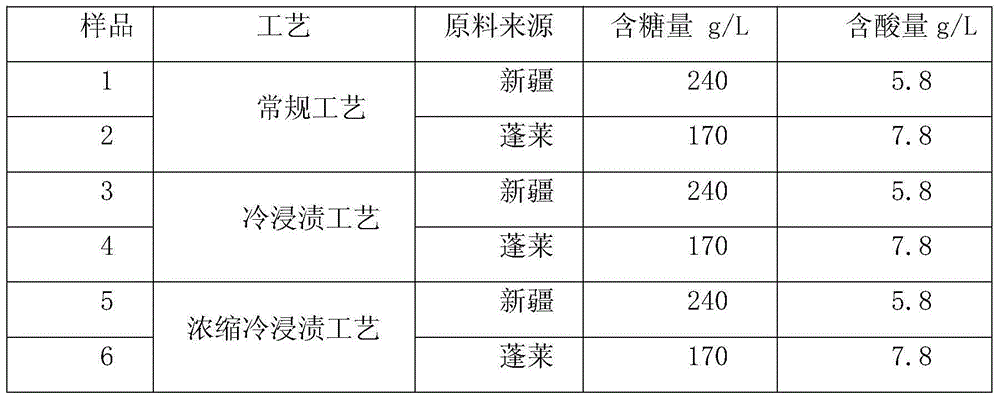

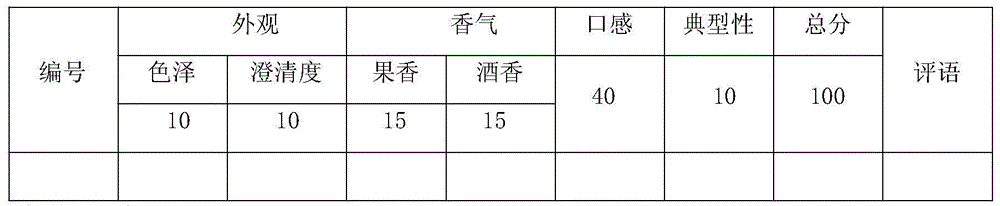

Condensed cold impregnated bulk wine and production method thereof

InactiveCN104357263AIncrease aromaGreat tasteMicroorganism based processesWine preparationPectinaseGrape juices

The invention provides condensed cold impregnated bulk wine and a production method thereof. The production method of the condensed cold impregnated bulk wine comprises the following steps: crushing and removing stems; adding sulphurous acid and pectinase; separating grape juice; freezing and concentrating the grape juice; cold-impregnating residual grape pulp for 48 hours; pumping the concentrated grape juice into the grape pulp; adding yeasts for fermentation; and fermenting by apple milk. By creatively combining a process of cold-impregnation with freezing concentration, the problem that the quality of wine in China is relatively low at present is solved, and the fragrance of the wine is enhanced and the taste of the wine is improved. Finally, a purpose of brewing high-quality wine which is rich in fragrance, is smooth, elegant, and has coordinated and fruity taste is achieved.

Owner:TIANJIN DYNASTY UNITED IND DEV

Kernel dew and preparation method thereof

ActiveCN103976444AFull of nutritionUnique tasteFood ingredient functionsFood preparationFlavorFiltration

The invention discloses kernel dew and a preparation method thereof, in particular relates to fermented kernel dew prepared from kernels or fruits of prunus humilis bunge and a preparation method thereof, and belongs to the technical field of beverages. The invention adopts the technical scheme that the fermented kernel dew is prepared by using prunus humilis bunge kernels as a raw material through the processes of soaking, deodorization, grinding, filtration, preparation, enzymolysis, sterilization, fermentation, blending, homogenization, proportioning, secondary sterilization, filling and the like. The kernel dew is unique in taste, exquisite and round in mouthfeel, bright in color, rich in nutrition and strong in functional health care. Particularly, the prunus humilis bunge kernels have the functions of diminishing swelling, inducing diuresis and relaxing the bowels, and are suitable for consumer groups of different ages. An ultrahigh pressure cold sterilization technology is sequentially adopted for two times in the making process, so that the destroy of high temperature to the factors of the product such as flavor, mouthfeel, color and nutrients is effectively avoided; by adopting the enzymolysis process of plant proteinase, the kernel dew is more vigorous, exquisite and round in mouthfeel.

Owner:宁夏虹桥有机食品有限公司

Quick unfreezing technique of frozen skipjack

InactiveCN106879716AAntioxidantThaws quickly and evenlyMeat/fish preservation by freezing/coolingMicroorganismSaline water

The invention relates to an unfreezing method for skipjack. The unfreezing method comprises the following steps of (1) rapidly taking out desired skipjack from freezing environment being minus 50-minus 60 DEG C, putting the taken-out skipjack in saline water of which the mass concentration is 1-3% and of which the temperature is 20-30 DEG C, and soaking the skipjack in the salt water for 50-90s; and (2) then putting the soaked skipjack in a container which can be subjected to microwave treatment, putting the container in a microwave oven, and performing microwave unfreezing. The unfreezing method disclosed by the invention has the advantages of being simple in technology, easy to operate, low in production cost, environmental-friendly and pollution-free, and has significant effect of maintaining the texture, the color, the freshness and the microorganisms of the skipjack, the characteristics of the skipjack, including mellow and full mouth feel, fresh bright color and elastic meat quality of the skipjack can be well maintained, the shelf life is prolonged, and the unfreezing method can be suitable for processing and producing of valuable fish meat variety of tuna and has broad application prospects.

Owner:ZHOUSHAN FUSHI FOOD TECH CO LTD

Compound dragon fruit and watermelon beverage and making method thereof

ActiveCN106173683AIncrease appetiteEnhance physical fitnessFood ingredient as clouding agentLoss rateFruit juice

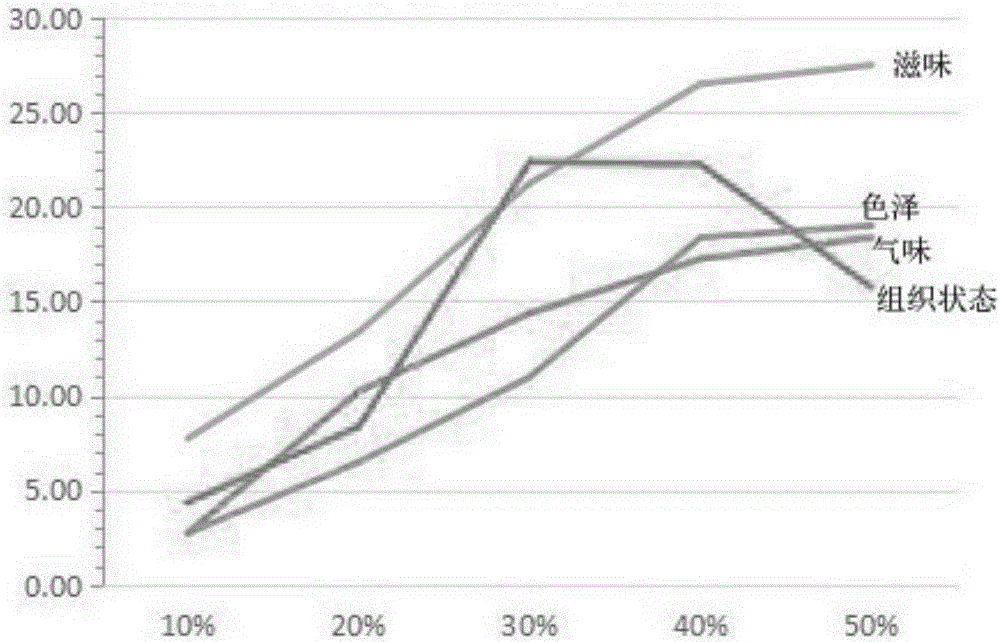

This invention provides a compound dragon fruit and watermelon beverage. The compound dragon fruit and watermelon beverage is made from, by mass, dragon fruit juice, watermelon juice, sugar, citric acid, a stabilizer, sodium ascorbate and distilled water, wherein the total content of the dragon fruit juice and the watermelon juice is 10-50%, the sucrose content is 6-14%, the citric acid content is 0.10-0.30%, the stabilizer content is 0.12-0.20%, and the mass ratio of the dragon fruit juice to the watermelon juice is 4:6. The compound dragon fruit and watermelon beverage has a mellow and full taste, a light fragrance and palatable sweetness and sourness, can be in a uniform state for a long time, contains less sediments and has a good stable effect. The betanin processing derating rate in the beverage is only 13.2%, and the betanin loss rate after three months is only 3.8%.

Owner:海南北纬十八度食品加工有限公司

Chili oil and preparation method thereof

The invention is applicable to the technical field of flavored food, and provides chili oil and a preparation method thereof. The chili oil is prepared from rapeseed oil, dried chilies, spices, Chinese prickly ash, sesame seeds, scallions, ginger, garlic and the like, wherein the spices comprise aniseed, cumin, fructus momordicae, dried tangerine peel, Chinese wolfberries and the like. The prepared chili oil is good in color, flavor and taste and moderately spicy and hot, has smooth mouthfeel and rich fresh fragrance, and can stimulate the sensory organs of consumers and raise the appetite ofthe consumers, thereby promoting appetite, promoting digestion and meeting the requirements of the consumers on taste and mouthfeel. The chili oil also contains higher nutritional value, is helpful tostrengthen the spleen, nourish the stomach, nourish the liver and kidney, tonify the blood, invigorate qi, promote appetite, promote digestion, promote blood circulation, dredge collaterals, reduce blood sugar and blood pressure, beautify skin, keep youthfulness, refresh mind, restore consciousness and the like, and realizes health-care effects of health-preserving dietary therapy.

Owner:深圳市喜欢上面餐饮管理有限公司

Processing method for fermented sea-buckthorn fruit juice

InactiveCN106071550AHas health benefitsUnique flavorYeast food ingredientsFood homogenisationPectinaseFruit juice

The invention provides a processing method for fermented sea-buckthorn fruit juice. Sea-buckthorn and water are mixed and then pulped, pectinase is added, standing is carried out, an upper floating oil layer and a lower sediment layer are removed in a centrifugation mode, calcium carbonate is added to reduce acidity so that the acidity can reach 0.4-0.8%, saccharose is added so that the sugar degree can reach 10-15%, lactic acid bacteria are added for primary fermentation, active cerevisin is added for secondary fermentation, after fermentation is completed, saccharose and a stabilizer are added, homogenizing is carried out, and the fermented sea-buckthorn fruit juice is obtained. By means of the lactic acid bacteria for primary fermentation and cerevisin for secondary alcoholic fermentation, the fruit juice can be unique in flavor and mellow and mild in mouthfeel and has the healthcare effect of a lactic acid bacterium beverage.

Owner:SHIHEZI UNIVERSITY

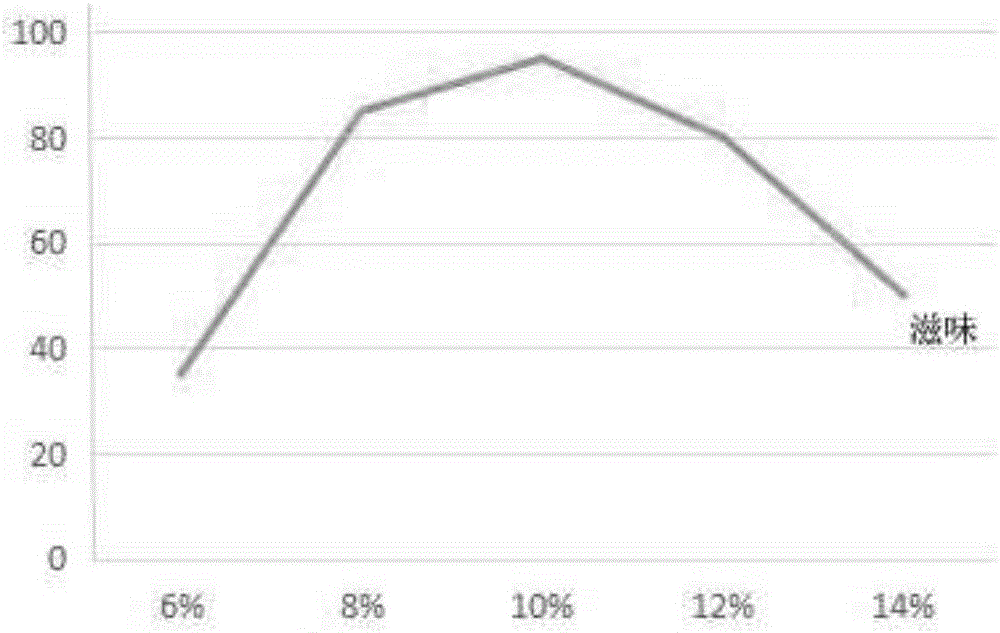

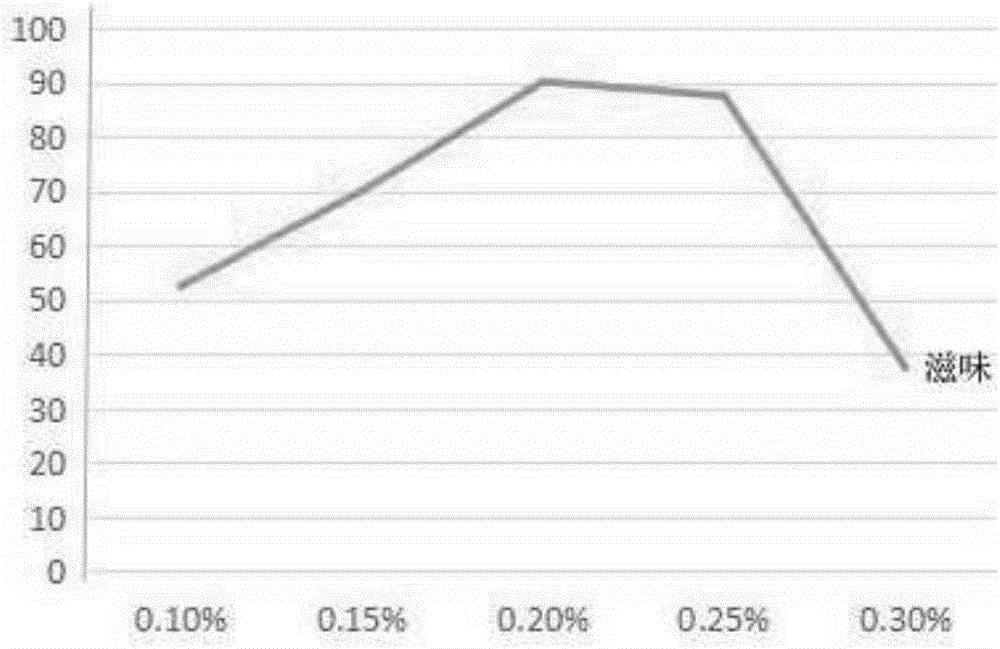

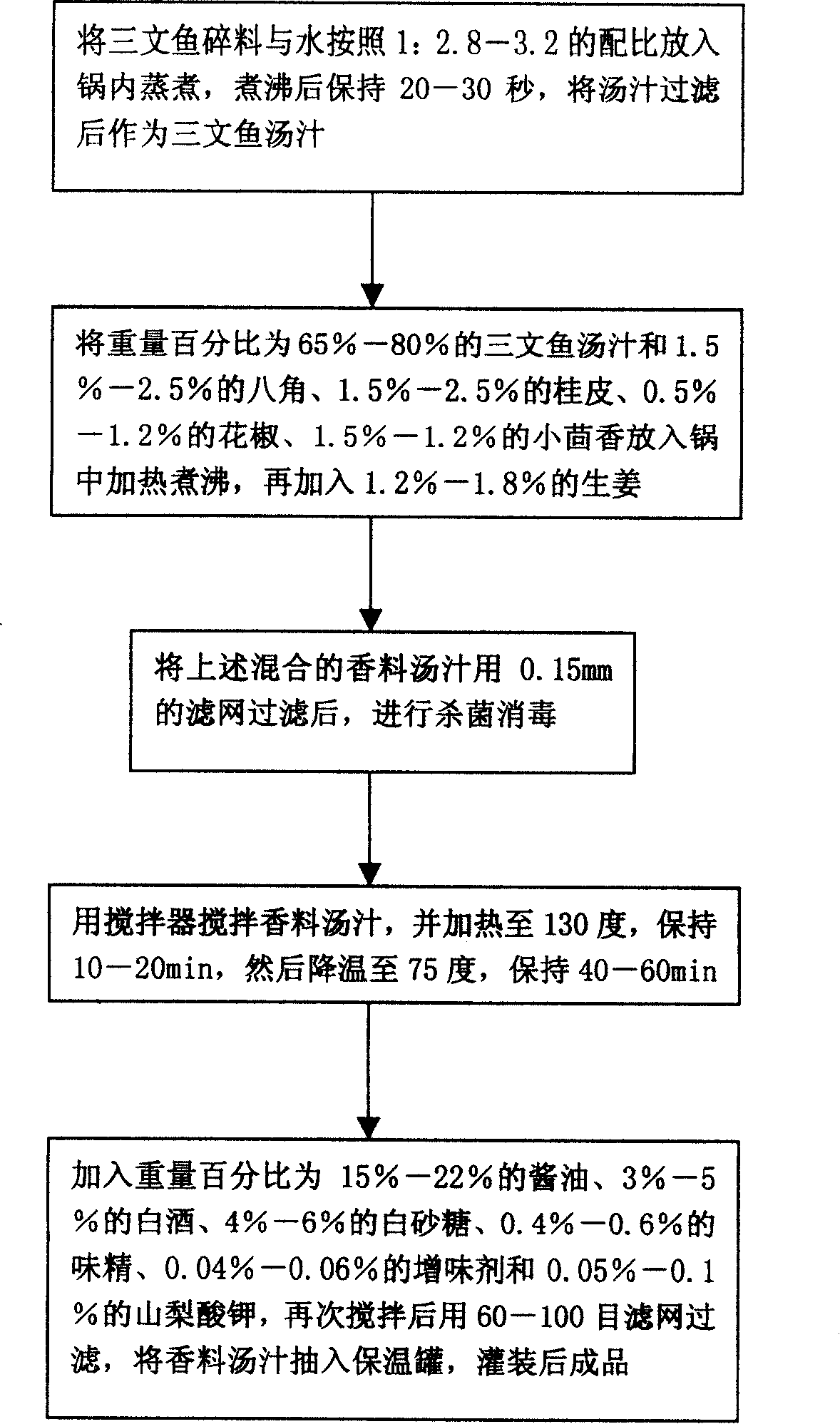

Salmon fish soy sauce and making method thereof

The present invention relates to a formula of sanwenyu fish sauce. Its formula includes (by wt%) 65%-80% of sanwenyu fish soup juice, 15%-22% of soy sauce, 1.5%-3% of star anise, 1.5%-2.5% of cinnamon bark, 0.5%-1.5% of xanthoxylum, 1.0%-1.5% of fennel, 3%-6% of white liquor, 1.2%-1.8% of fresh ginger, 4%-6% of white granulated sugar and 0.05%-0.1% of potassium sorbate. The sum of their weight percentages is 100%. Said fish sauce has brown-red colour, and has unique flavour and seasoning effect.

Owner:徐泽民

Brewing method for blueberry wine

The invention relates to the technical field of wine brewing and especially relates to a brewing method for blueberry wine. The method comprises the following steps: picking fresh blueberry fruits; cleaning, and then uniformly mixing with rock candy at the weight ratio of rock candy to fresh fruits being (2-5):(15-18); putting the mixture into a fermentation tank; adding yeast and then fermenting under constant temperature; filtering; sealing in a wooden barrel and standing for a period of time, and then adding egg white the weight of which is 0.2-0.3% of the weight of the mixture; sealing and standing for a period of time, thereby obtaining a clear wine liquid; and absorbing and removing ethyl alcohol, filtering, sterilizing and filling the clear wine liquid. According to the brewing method provided by the invention, the problem of higher total acid of blueberry wine can be solved; the dissolution rate of the effective constituents in the blueberries can be increased; under the synergic effect of the nutritional ingredients, the absorbed rate of the nutrient substances can be increased; the taste, fragrance and color of the blueberry wine can be improved; and due to the reasonable technological setting and parameter control, the brewing rate of the blueberry is increased, the wine is clear, the wine is in rosy color and the taste is sweet and mellow.

Owner:GUIZHOU XINGMIAOMIAO AGRI SCI & TECH DEV

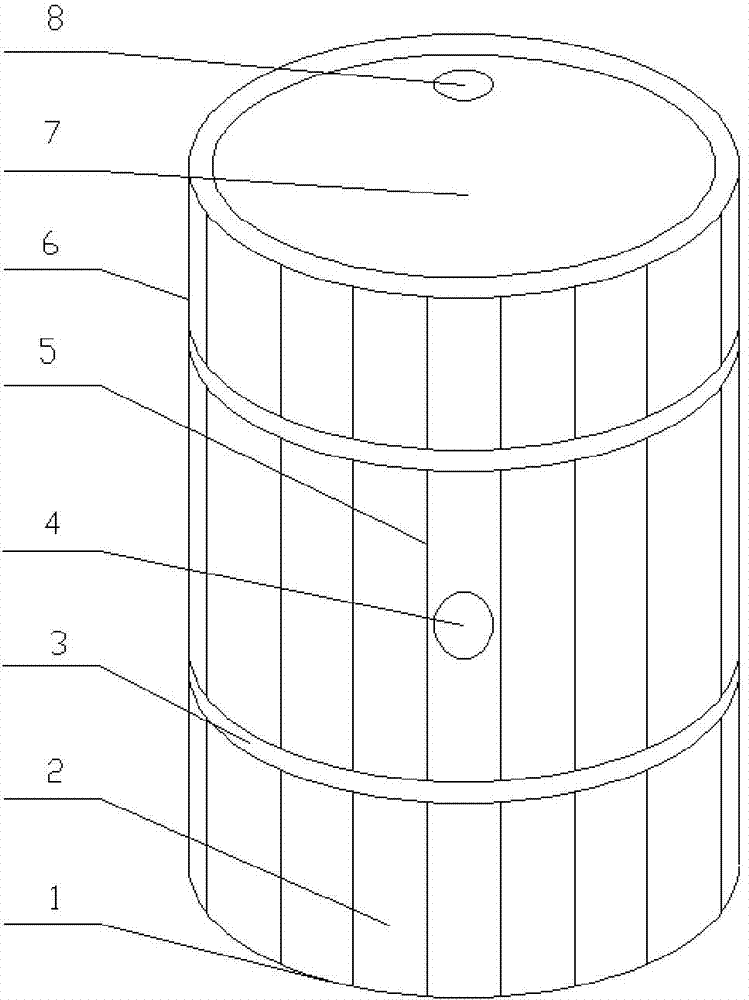

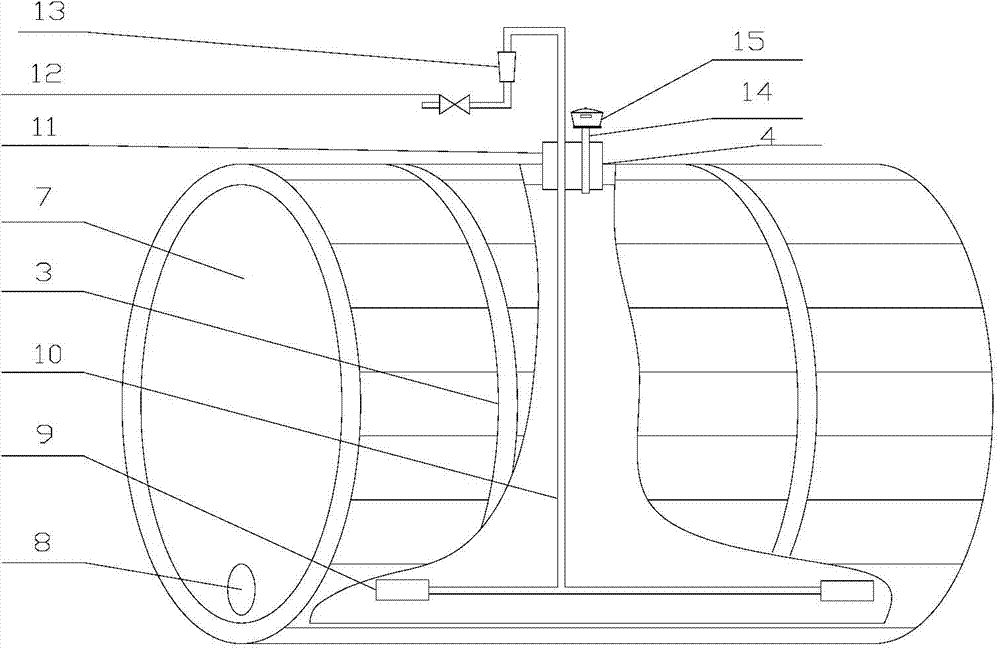

Lychee barrel for ageing and distilling liquor as well as preparation method and application process thereof

ActiveCN103695278AUnique aromaSpeed up agingAlcoholic beverage preparationWood working apparatusFlavorPulp and paper industry

The invention discloses a lychee barrel for ageing and distilling liquor as well as a preparation method and an application process thereof, belonging to the technical field of brewing wine. The invention provides a lychee barrel for ageing and distilling liquor and further provides a lychee barrel for ageing and distilling liquor, with a micro-aerobic device, and provides a preparation method of the lychee barrel for ageing and distilling the liquor, with the micro-aerobic device, and an ageing process. The lychee barrel for the lychee barrel for ageing and distilling the liquor, with the micro-aerobic device, provided by the invention, is internally provided with a stainless steel gas pipe and a micropore gas distributor, which are used for accelerating the oxygen required by distilling the liquor in an ageing process and accelerating the volatilization of impurities in wine, are capable of playing a role in stirring the liquor to accelerate the collision of trace components for reaction, and enabling the aged liquor to have a special flavor.

Owner:广东省九江酒厂有限公司

Method for preparing red wine with health maintenance function

InactiveCN103740521AAttractive colorStrong aromaDigestive systemMicroorganism based processesNutritive valuesPectinase

The invention discloses a method for preparing red wine with health maintenance function. The method comprises the following steps: (1) mixing grapes with passionfruits, crushing, and adding pectinase to obtain grape-passionfruit mixed liquor for later use; taking onion and ginger, and respectively slicing for later user; mixing the grape-passionfruit mixed liquor with the onion and the ginger, and adding white sugar to obtain raw material mixed liquor; (2) inoculating activated active dry yeast of grapes in the raw material mixed liquor, carrying out pre-fermentation, and filtering the wine dregs to obtain wine base; (3) filling the obtained wine base in a port, sealing and carrying out post fermentation; separating out supernatant by using a siphon method after the post fermentation is finished, wherein the supernatant is the red wine with health maintenance function. The red wine is prepared from fermentation with grapes, passionfruits, onion and ginger as raw materials, is rich in nutritive value and has healthcare functions such as supplementing nutrient, building body, improving immunity of the organism, reinforcing the immunity of the organism, and the like, so that the red wine has a significant health maintenance function.

Owner:LIUZHOU BOLONG FOOD

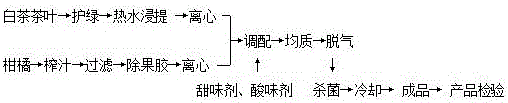

Tangerine-white tea compound beverage and preparation method thereof

The invention provides a tangerine-white tea compound beverage and a preparation method thereof. The beverage is prepared from the following ingredients in parts by mass: 43-47 parts of white tea soup, 43-57 parts of clear tangerine juice, 3-5 parts of a sweetening agent, 0.05-0.15 part of a sour agent and 0.1-0.2 part of a food stabilizer. The method comprises the following steps: performing soaking, filtration and centrifugation treatment on white tea, thereby obtaining the white tea soup; performing juicing, pectinase-based enzymolysis, sterilization, filtration and centrifugation treatment on tangerine fruit flesh, thereby obtaining the clear tangerine juice; mixing the clear tangerine juice, the sweetening agent, the sour agent and the food stabilizer according to a ingredient formula of the beverage, thereby obtaining mixed liquid; and homogenizing the mixed liquid for 1-2min under a pressure of 20-30MPa, thereby obtaining the tangerine-white tea compound beverage. The tangerine-white tea compound beverage is rich in nutrition, properly sour and sweet in taste and high in taste layering, has green-yellow color, has no precipitate and gelatinous substances, and is good in uniform stability.

Owner:YANGTZE NORMAL UNIVERSITY

Production method of highly flavored type baijiu

PendingCN107557210AGreat tasteSoft tasteAlcoholic beverage preparationProcess engineeringThermal water

The invention relates to a production method of highly flavored type baijiu. The production method comprises the following steps: (1) selecting raw materials and auxiliary materials; (2) carrying outgrain moistening; (3) carrying out grain steaming; (4) carrying out fermenting, namely, after the completely steamed grain is removed from a steamer, adding water with the weight being 85-100% of thatof the raw materials, maintaining for 10-15 min, carrying out cooling on a spreading cooling machine till the temperature is 20-25 DEG C, adding a wrapped starter, carrying out stirring, wherein theuse amount of the starter is 23-28 % of that of the raw materials, placing the stirred grain with the starter into a pond, and carrying out fermentation in a sealed manner; (5) placing the fermented product into the steamer and carrying out distilling, wherein the ratio of fermented grains on the bottom layer to the raw materials is 3 to 1, adding 30% of rice husks, carrying out uniform mixing, sothat a loose state is obtained, wherein the steamer loading time is controlled to be 40-45 min, the wine flowing speed is 2.5kg / min, after wine steaming, acid discharge to the atmosphere is increasedto be 15min from the normal 10min, after removal from the steamer, adding treated hot water at 95 DEG C or above, wherein the use amount of the hot water is 100% of that of the raw materials; and (6)carrying out foreshot collecting, namely, intercepting first-grade wine from two fermenting grain parts with high starch content at the bottom, wherein the intercepting for the first-grade wine is finished when the wine degree is 60 degrees, and the mixed wine degree is 70 degrees. Through detection, the ratio of acid to ester in the baijiu product produced by adopting the method is about 1 to 5,and the body of the wine has durable taste, and soft and mellow mouthfeel.

Owner:HEBEI SANJING WINE CO LTD

Grape brandy health-preserving wine

ActiveCN104109595APromote decompositionPromote absorptionDigestive systemWine preparationNutritive valuesVitis vinifera

The invention discloses a grape brandy health-preserving wine. By using grape brandy as the wine base, the health-preserving wine is composed of 2-7 wt% of cinnamon, 2-7 wt% of raspberry, 3-10 wt% of wolfberry fruit, 2-5 wt% of rhizoma polygonati, 1-3 wt% of kudzu root, 1-5 wt% of broomrape and the balance of grape brandy. The six health-care food materials are brewed into the 42-48 %vol grape brandy health-preserving wine by a static low-temperature immersion technique. The high-alcohol-content wine is fermented from grapes without adding water, and is fermented from 100% pure grape juice. By adding the grape spirit, the health-preserving wine has the nutritive value of wine and high alcohol content, and is beneficial to decomposition and absorption of nutritional ingredients. The health-preserving wine has the advantages of diffused aroma and smooth mouthfeel, and has the functions of enhancing the constitution and rejuvenating people.

Owner:辽宁华原葡萄酒庄有限公司

Grape aloe fresh juice

A grape-aloe juice as a health-care fruit juice beverage is prepared from grape juice 50-60 portion, aloe juice 5-8, white sugar 6-10, honey 3-5, citric acid 0.3-0.5 and purified water 30-40. Its advantages are high nutritive value, and sure health-care function of preventing heart disease, hypertension and cancer, beautifying face and improving immunity.

Owner:王源

Formula and production technology of fragrant blueberry fruit wine

InactiveCN108660032AColor stableSoft tasteAlcoholic beverage preparationFruit wineAdditive ingredient

The invention discloses a formula and a production technology of fragrant blueberry fruit wine. Wild blueberries and red raspberry fresh fruits are selected, and the blueberries are quickly frozen andplaced in a refrigeration house for standby application after being screened and cleaned; the raw materials are selected from the wild blueberries in Lesser Khingan Mountains and Shangzhi red raspberries produced in the home of the red raspberries in China, the raw materials are sorted manually, stalk and leaf impurities and raw, green and rot fruits are removed, the frozen blueberries are thawedbefore pulping and pulped with the fresh red raspberries, and an obtained product is added to a fermentation tank. The formula and the production technology of the fragrant blueberry fruit wine havethe characteristics of improving fragrance, taste and flavor of the blueberry wine and increasing clarity and stability of the blueberry wine, blueberry anthocyanins and nutritional ingredients such as softening acid and the like in the red raspberry fruits are reserved, alcoholic strength of the blueberry wine is 7%VOL-13%VOL, total acid is larger than or equal to 5 g / L, and sugar-free extract islarger than or equal to 18 g / L; the wine body of the fragrant blueberry fruit wine is ruby red, and the fragrant blueberry fruit wine has strong fruit flavor, full body and long-lasting aftertaste and is mellow and harmonious.

Owner:伊春市山野饮品有限公司

A preparing method of a ginkgo-milkvetch root-Chinese wolfberry composite healthcare beverage

InactiveCN104738772AGood for hyperlipidemiaRich and mellow fragranceFood preparationNutritionSucrose

A preparing method of a ginkgo-milkvetch root-Chinese wolfberry composite healthcare beverage is disclosed. The preparing method includes following steps of: (1) screening ginkgo fruits; (2) preparing ginkgo slurry, complexing, and debitterizing; (3) preparing milkvetch root-Chinese wolfberry composite slurry; (4) mixing monoglyceride, sodium alginate, carrageenan and sucrose ester to obtain a composite stabilizing agent; (5) blending the ginkgo slurry, the milkvetch root-Chinese wolfberry composite slurry, xylitol, citric acid, natural tea polyphenol and corn plant ester powder according to a ratio of 25:25:6:0.125:2:1.5:1, and adding the composite stabilizing agent; (6) performing two times of high-pressure homogenization; (7) performing composite enzymatic hydrolysis; (8) treating by a gelatin-tannin method; and (9) degasing and sterilizing. The preparing method is advantageous in that: flavor and nutrients which are special to ginkgo are maintained, the beverage also have taste and nutrients of the milkvetch root and the Chinese wolfberry, various nutrients are prone to absorption by human bodies, the clarity can be higher than 98%, and the beverage is free of precipitation and layering after being stored for 4 months.

Owner:JIANGYAN JING LONG NUTRITION FACTORY

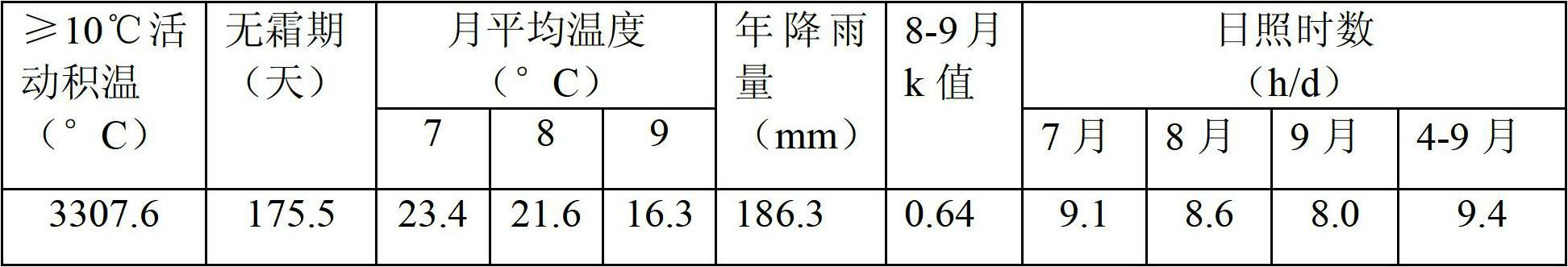

Brewing process of natural sweet grape wine

InactiveCN103966039BRound tasteFruityMicroorganism based processesWine preparationYeastVitis vinifera

The invention relates to a brewing process of grape wine, in particular to a brewing process of natural sweet grape wine. The brewing process of the natural sweet grape wine is characterized by comprising the following steps: (1) processing a raw material: picking ripe grapes with the sugar content of more than 20%, and cooling and pre-cooling the grapes in a pre-cooling house within two hours after the grapes are picked, as to enable the kernel temperatures of the grapes to reach 5-10 DEG C; (2) removing stems and sorting: removing the stems of the pre-cooled grapes, and removing bad fruits and secondary fruits; (3) freezing; (4) squeezing for obtaining juice; (5) clarifying; (6) fermenting and ageing: warming the obtained grape juice to 14-16 DEG C, adding activated grape wine yeast, and fermenting at the controlled temperature of 16-18 DEG C; (7) performing cold stabilization; (8) sterilizing and filling. By adopting the brewing process of the natural sweet grape wine, the consumption demand of ordinary consumers on high-grade sweet grape wine can be easily met.

Owner:宁夏林业研究院股份有限公司

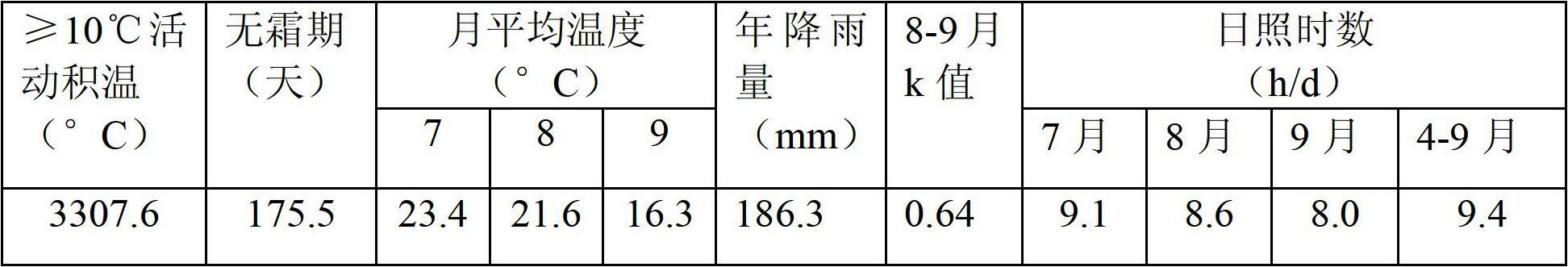

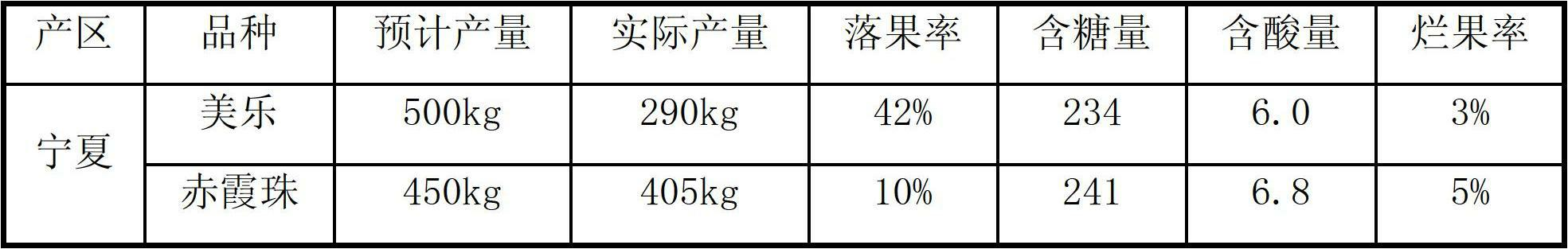

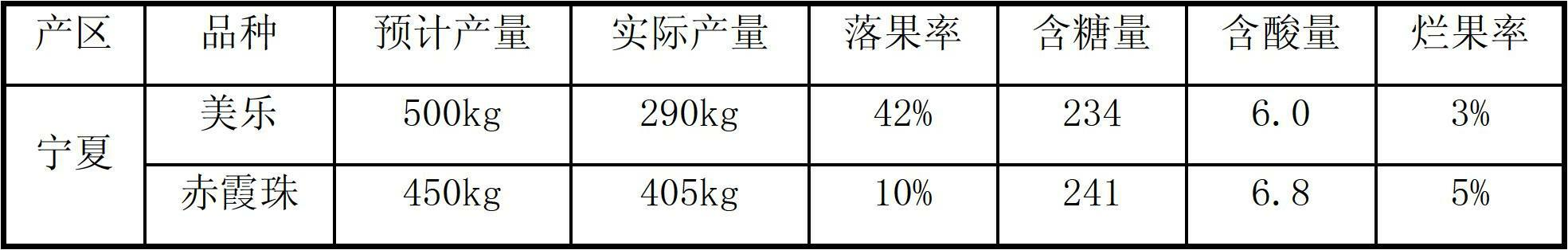

Air-dried grape wine and brewing method thereof

ActiveCN102649923AHigh in sugarShorten the natural drying processWine preparationVitis viniferaGrape wine

The invention provides an air-dried grape wine and a brewing method thereof. The brewing method comprises the following steps of: sorting and inspecting of grapes for brewing serving as raw material, air drying, removing stems, breaking, alcoholic fermentation, cavity milk fermentation, brewing with wooden bucket, blending and preparation, precipitation treatment, filling, bottle storage, packaging and warehousing; grapes for brewing serving as the raw material are selected from cabernet sauvignon in Ningxia production area; the harvesting period of the cabernet sauvignon is the first ten days of October, the sugar content of the grape in harvesting is more than or equal to 230g / L, and the acid content is 6.5-8.5g / L; a natural air drying way is adopted, so that the sugar content of the cure grape is more than or equal to 260g / L, the Ningxia production area with temperature of 5-35 DEG C and the relative humidity being less than 50 percent is selected as an air drying place to be ventilated and to avoid direct sunshine; and the content of volatile acid when removing stems and breaking the air-dried grapes is less than 0.2 g / L. The grape wine prepared by the brewing method is in dark ruby red and clear and transparent, has mature fragrance of ageing wine, is rich and soft and has long aftertaste and remarkable typicality.

Owner:SINO FRENCH JOINT VENTURE DYNASTY WINERY

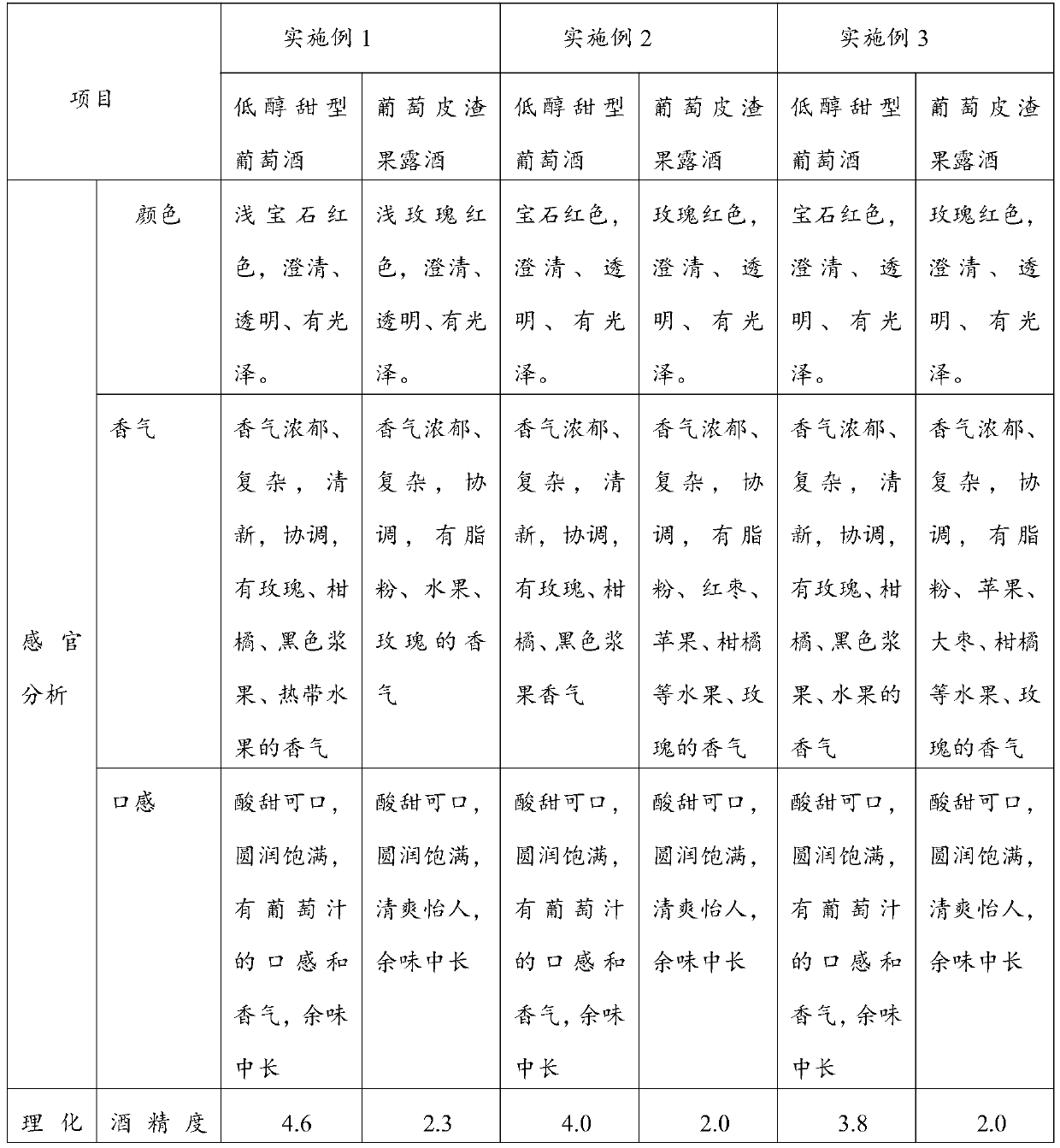

Method for continuously producing low-alcohol sweet wine and grape skin-residue fruit juice wine

The invention discloses a method for continuously producing low-alcohol sweet wine and grape skin-residue fruit juice wine, and relates to the wine brewing field. The method comprises the following steps: (a) removing stems of grapes, carrying out crushing, adding sulfur dioxide and pectase, carrying out uniform stirring, and carrying out low-temperature steeping for 3 days; (b) pumping grape juice A into a freezing tank, and squeezing solid parts, so as to obtain grape juice B and solid residue, wherein the mass ratio of the grape juice A to the grape juice B to the solid residue in the grapes is (40-50) to (20-25) to (20-35); (c) adding yeast into the grape juice B for realizing complete fermentation, carrying out standing at 3-10 DEG C for 14-30 days, pumping clear wine liquid into thefreezing tank to be mixed with the grape juice A, adding tangerine peel, the pectase and bentonite, and carrying out uniform circulation, standing, filtration, blending, stability treatment and sterilization, so as to obtain low-alcohol sweet wine; and (d) fermenting the solid residue obtained in the step (b) with glutinous rice, pearl barley, fresh red dates and the tangerine peel, carrying out cooling, squeezing and aging, and carrying out filtration, blending, stability treatment and sterilization, so as to obtain grape skin-residue fruit juice wine.

Owner:NINGXIA VOCATIONAL TECH COLLEGE

Kiwifruit NFC juice and preparation method thereof

The invention discloses a kiwifruit NFC juice and a preparation method thereof, and belongs to the technical field of food processing. The kiwifruit NFC juice is obtained by selecting, washing, soaking, color protection, pulping, adjusting the ratio of sugar to acid and adding natural antibacterial substance nisin in combination with the ultra-high pressure sterilization technology. The juice aimsto overcome the defects caused by the heat sterilization technology and retain the original fresh characteristics and nutritional characteristics of the kiwifruit NFC juice to the utmost extent. Themethod has the advantages of being simple and efficient, nutritious, healthy and low in production cost. The prepared kiwi NFC juice has taste, flavor and nutritional value closer to those of fresh fruit, and is rich in flesh and unique in flavor.

Owner:SHAANXI UNIV OF SCI & TECH

Novel pharmaceutical composition for preventing and treating anthracnose of citrus

InactiveCN106490012ASolve outputSolving low sugar content ratePlant growth regulatorsBiocideCarrageenanMagnesium salt

The invention discloses a novel pharmaceutical composition for preventing and treating the anthracnose of citrus. The novel pharmaceutical composition is prepared from the following raw materials: herba portulacae, folium artemisiae argyi, tea tree leaves, pyrethrum, mangnolia officinalis, melia azedarach, angled bittersweet, ailanthus, asparagus lettuce, mint, castor, potassium salt, phosphor salt, nitrogen salt, calcium salt, magnesium salt, iodine salt, boron salt, molybdenum salt, zinc salt, manganese salt, copper salt, iron salt, vitamins, amino acid, indolebutyric acid, gibberellins, 6-benzylaminopurine, naphthylacetic acid, agar, kinetin, polyvinylpyrrolidone, sodium methylene bis-naphthalene sulfonate, a Dupont EEA2112AC compatilizer, earthworm powder, alkyl potassium sulfate, acrylate, epoxypropoxy propyl trimethoxy silane, carrageenan and ethanol. According to the novel pharmaceutical composition for preventing and treating the anthracnose of the citrus, the yield and the sugar content can be increased, the citrus is good in taste, mellow and full in surface colors and high in quality, and the use effect is superior to that of a conventional pharmaceutical composition.

Owner:钟山县绿森农业开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com