Patents

Literature

279results about How to "Avoid excessive oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

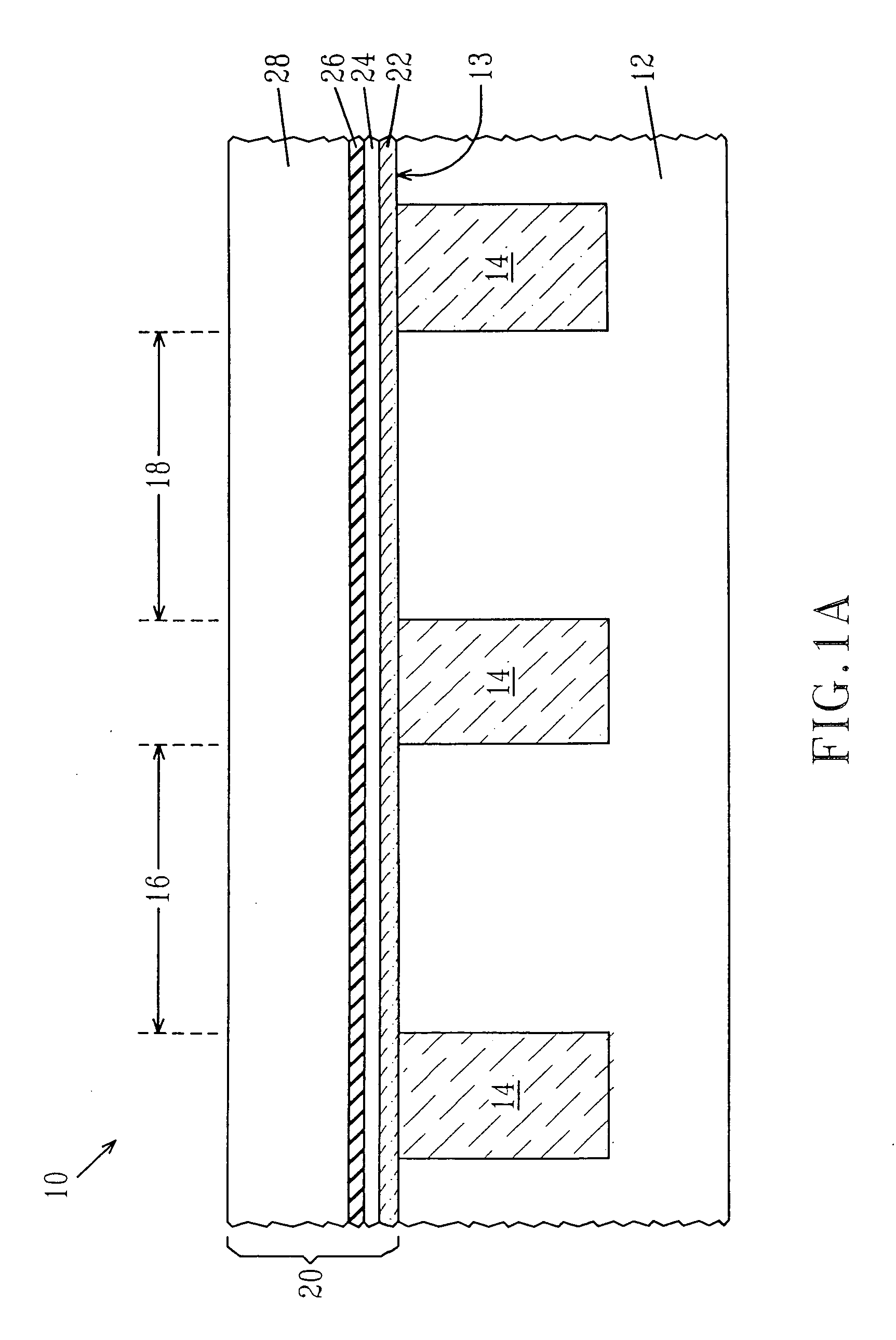

Removal of charged defects from metal oxide-gate stacks

InactiveUS7488656B2High carrier mobilityEliminate oxygen vacanciesTransistorSemiconductor/solid-state device manufacturingCapacitanceDielectric

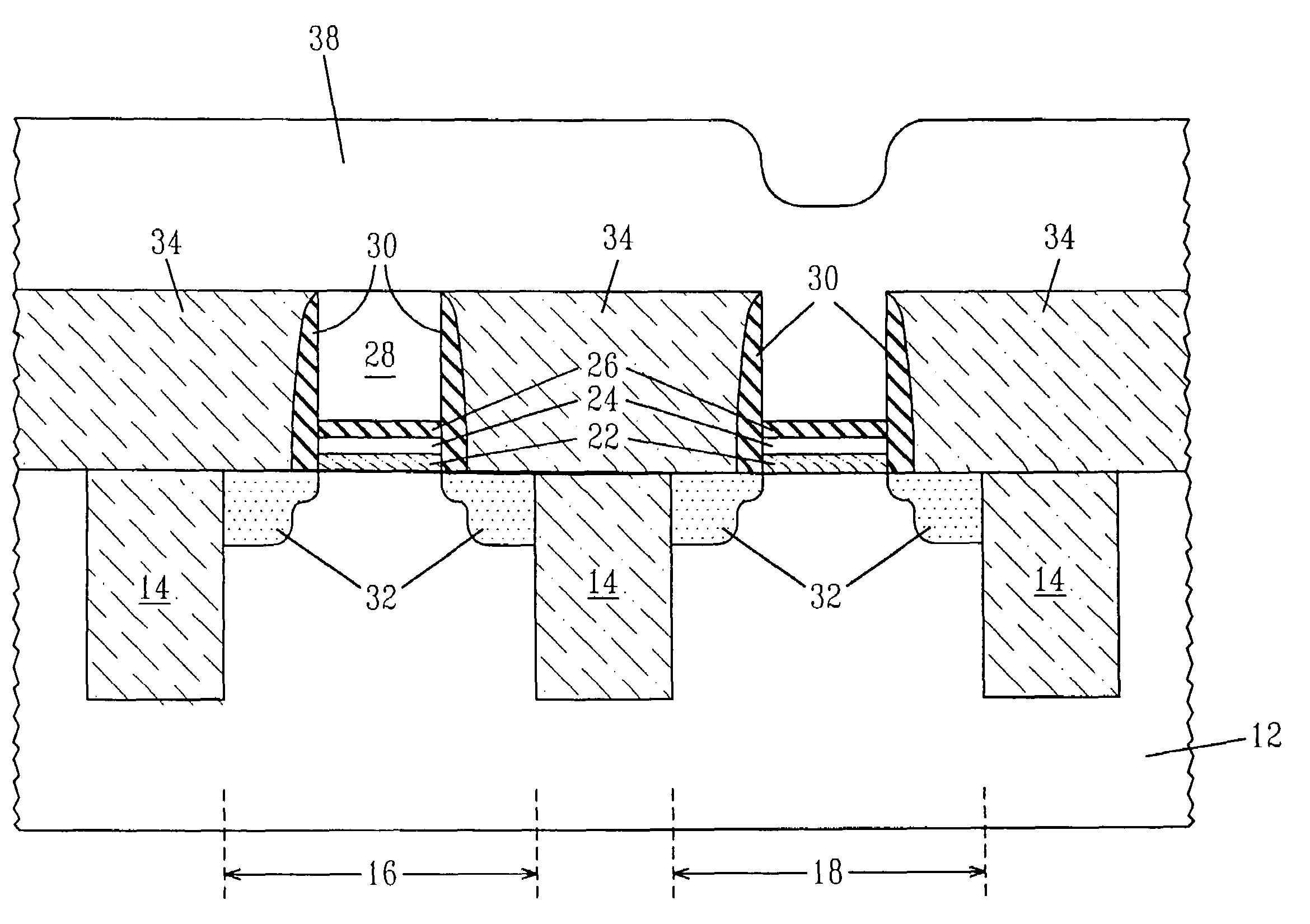

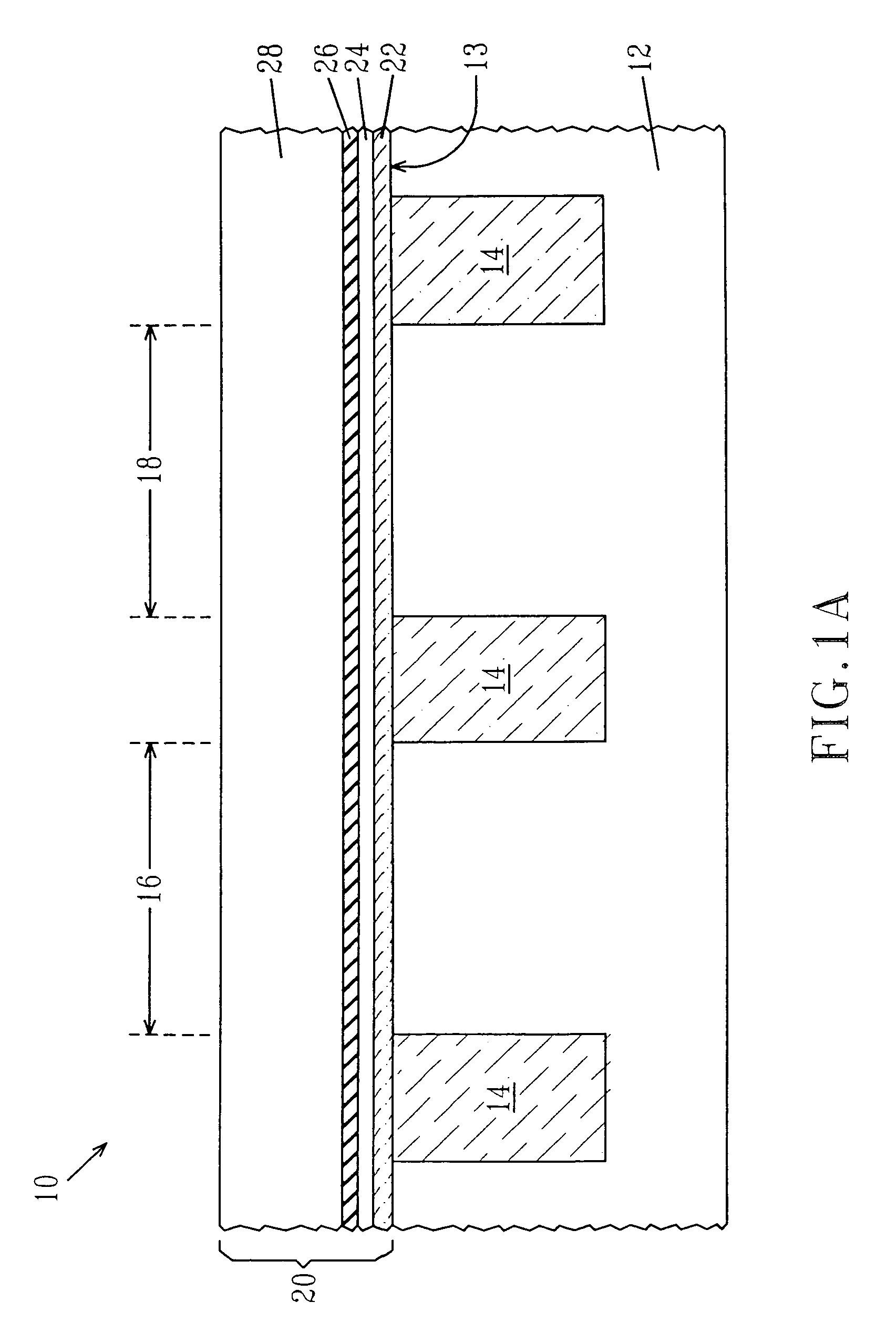

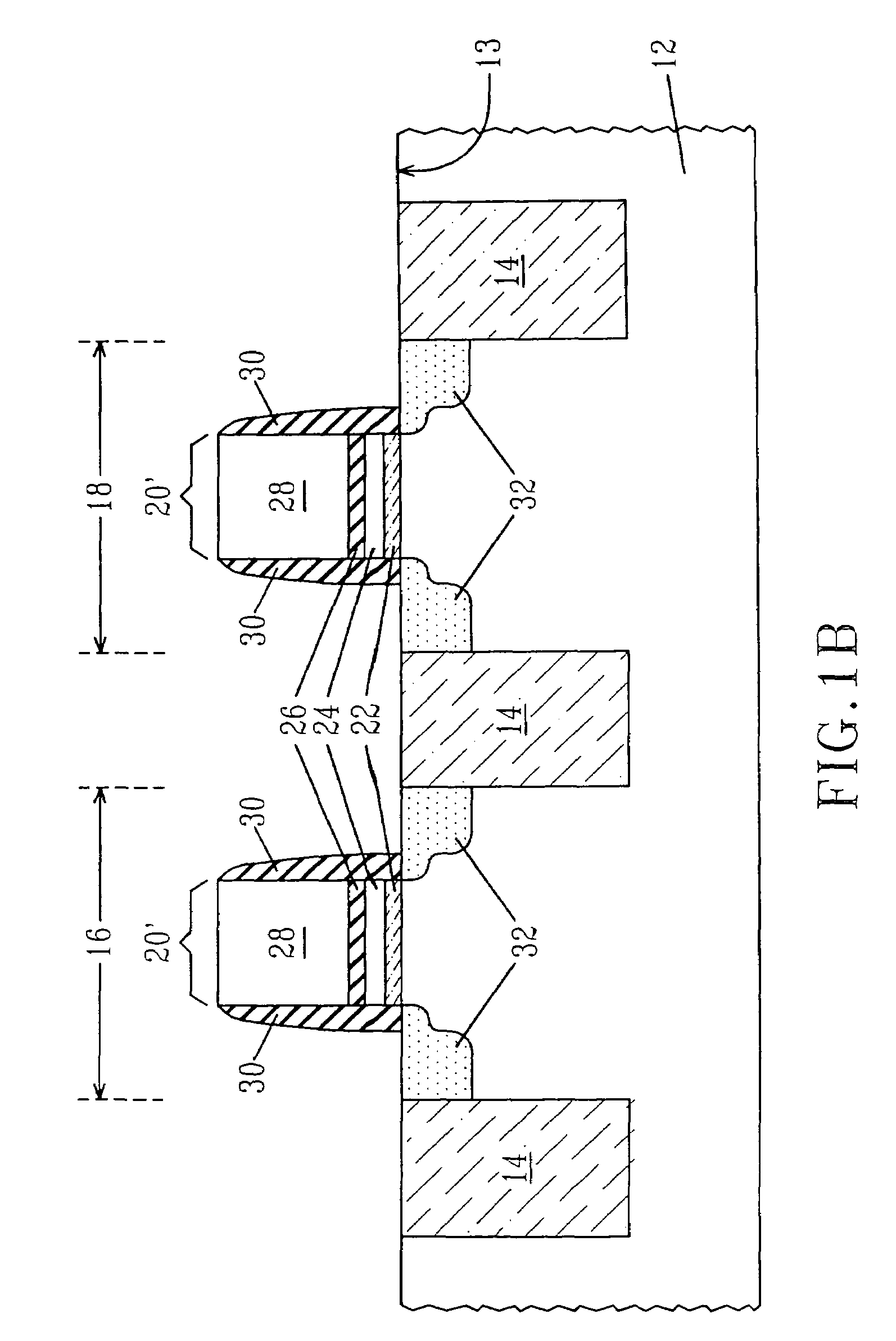

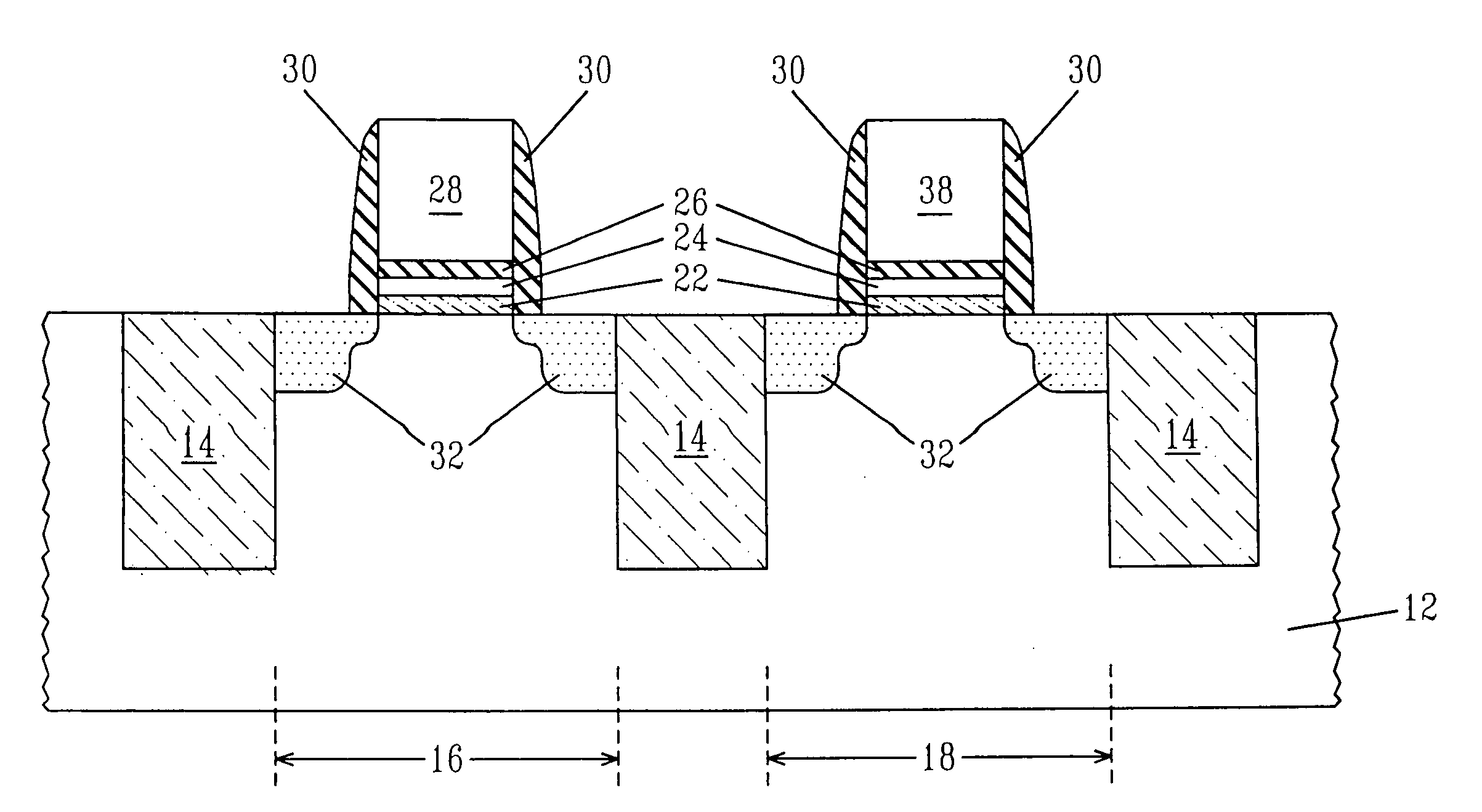

The present invention provides a method for removing charged defects from a material stack including a high k gate dielectric and a metal contact such that the final gate stack, which is useful in forming a pFET device, has a threshold voltage substantially within the silicon band gap and good carrier mobility. Specifically, the present invention provides a re-oxidation procedure that will restore the high k dielectric of a pFET device to its initial, low-defect state. It was unexpectedly determined that by exposing a material stack including a high k gate dielectric and a metal to dilute oxygen at low temperatures will substantially eliminate oxygen vacancies, resorting the device threshold to its proper value. Furthermore, it was determined that if dilute oxygen is used, it is possible to avoid undue oxidation of the underlying semiconductor substrate which would have a deleterious effect on the capacitance of the final metal-containing gate stack. The present invention also provides a semiconductor structure that includes at least one gate stack that has a threshold voltage within a control range and has good carrier mobility.

Owner:INT BUSINESS MASCH CORP

Removal of charged defects from metal oxide-gate stacks

InactiveUS20060246740A1Good carrier mobilityHigh carrier mobilityTransistorSemiconductor/solid-state device manufacturingOxygen vacancyCapacitance

The present invention provides a method for removing charged defects from a material stack including a high k gate dielectric and a metal contact such that the final gate stack, which is useful in forming a pFET device, has a threshold voltage substantially within the silicon band gap and good carrier mobility. Specifically, the present invention provides a re-oxidation procedure that will restore the high k dielectric of a pFET device to its initial, low-defect state. It was unexpectedly determined that by exposing a material stack including a high k gate dielectric and a metal to dilute oxygen at low temperatures will substantially eliminate oxygen vacancies, resorting the device threshold to its proper value. Furthermore, it was determined that if dilute oxygen is used, it is possible to avoid undue oxidation of the underlying semiconductor substrate which would have a deleterious effect on the capacitance of the final metal-containing gate stack. The present invention also provides a semiconductor structure that includes at least one gate stack that has a threshold voltage within a control range and has good carrier mobility.

Owner:IBM CORP

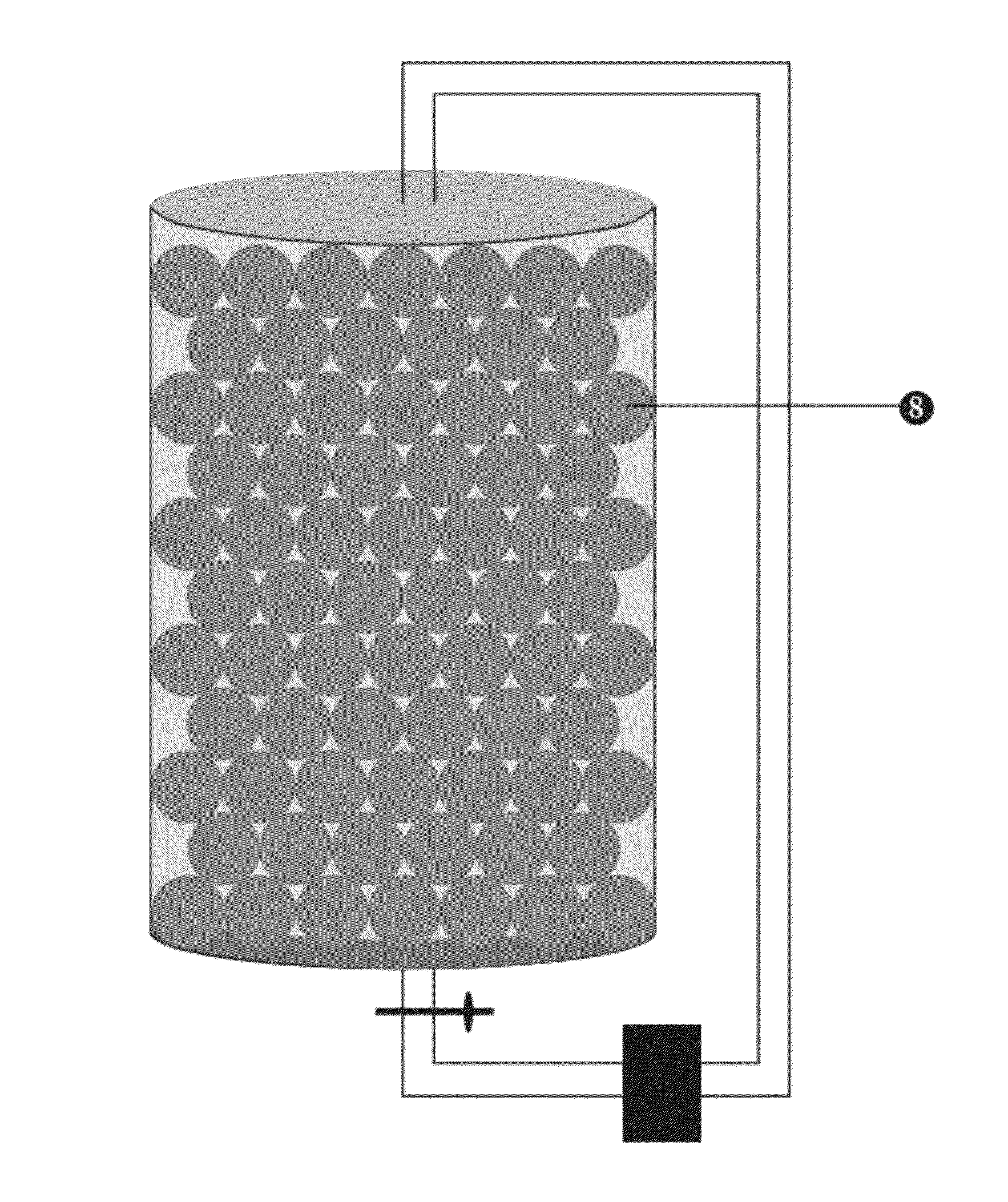

Accelerated Aging of Wines and Sprits

InactiveUS20120164300A1Avoid excessive oxidationLow costWine preparationAccelerated agingEngineering

Owner:NIAZI SARFARAZ K

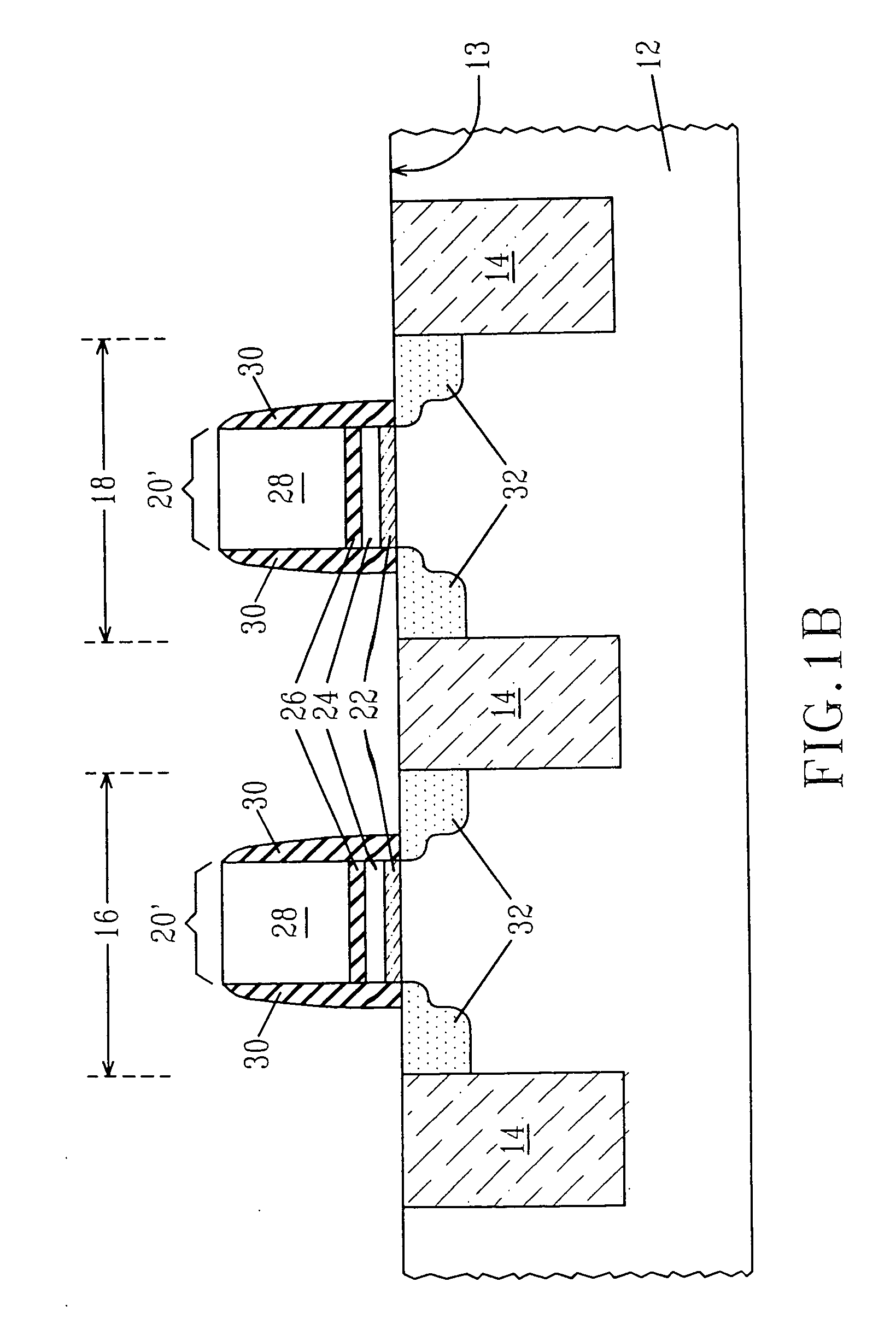

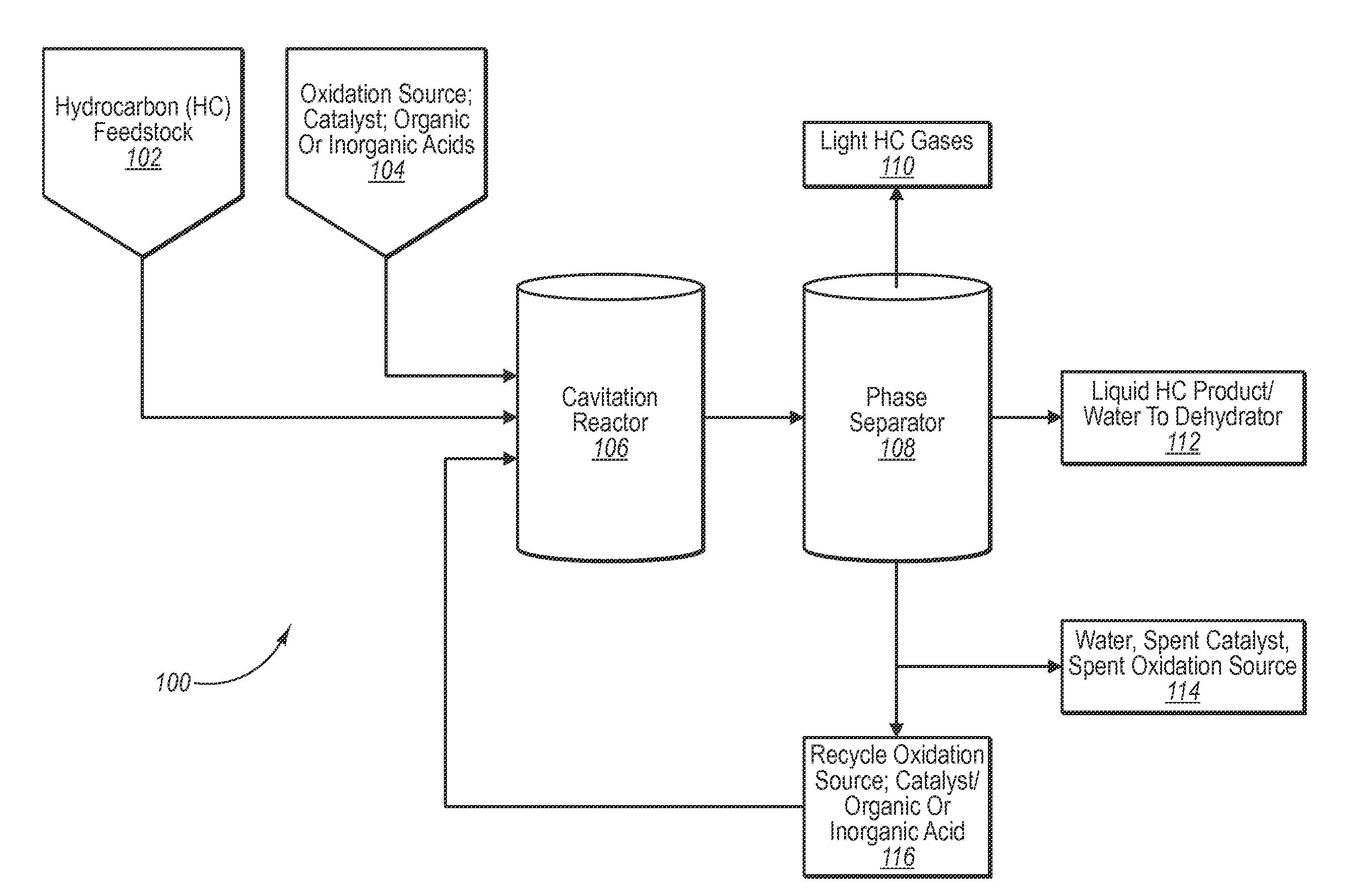

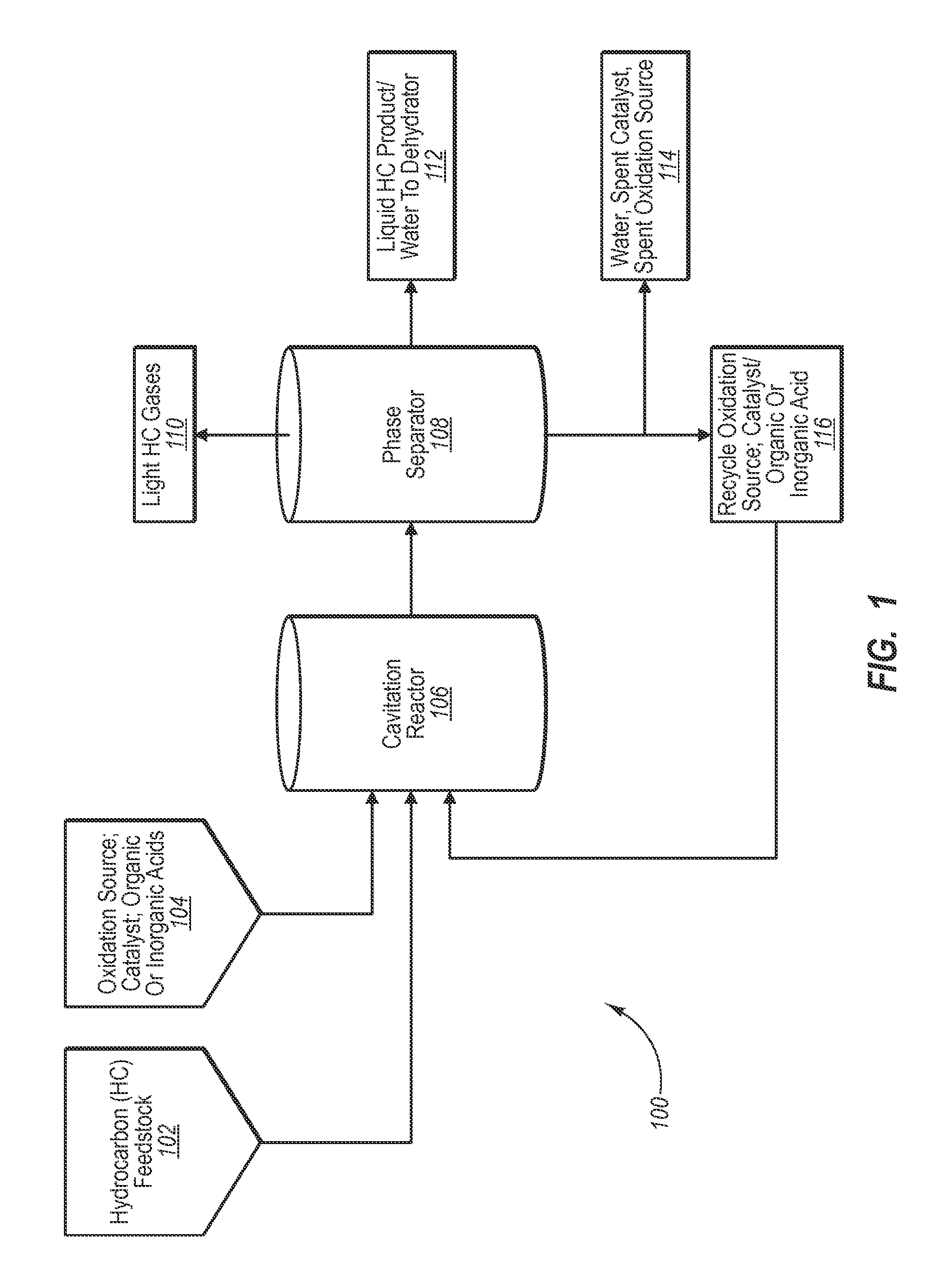

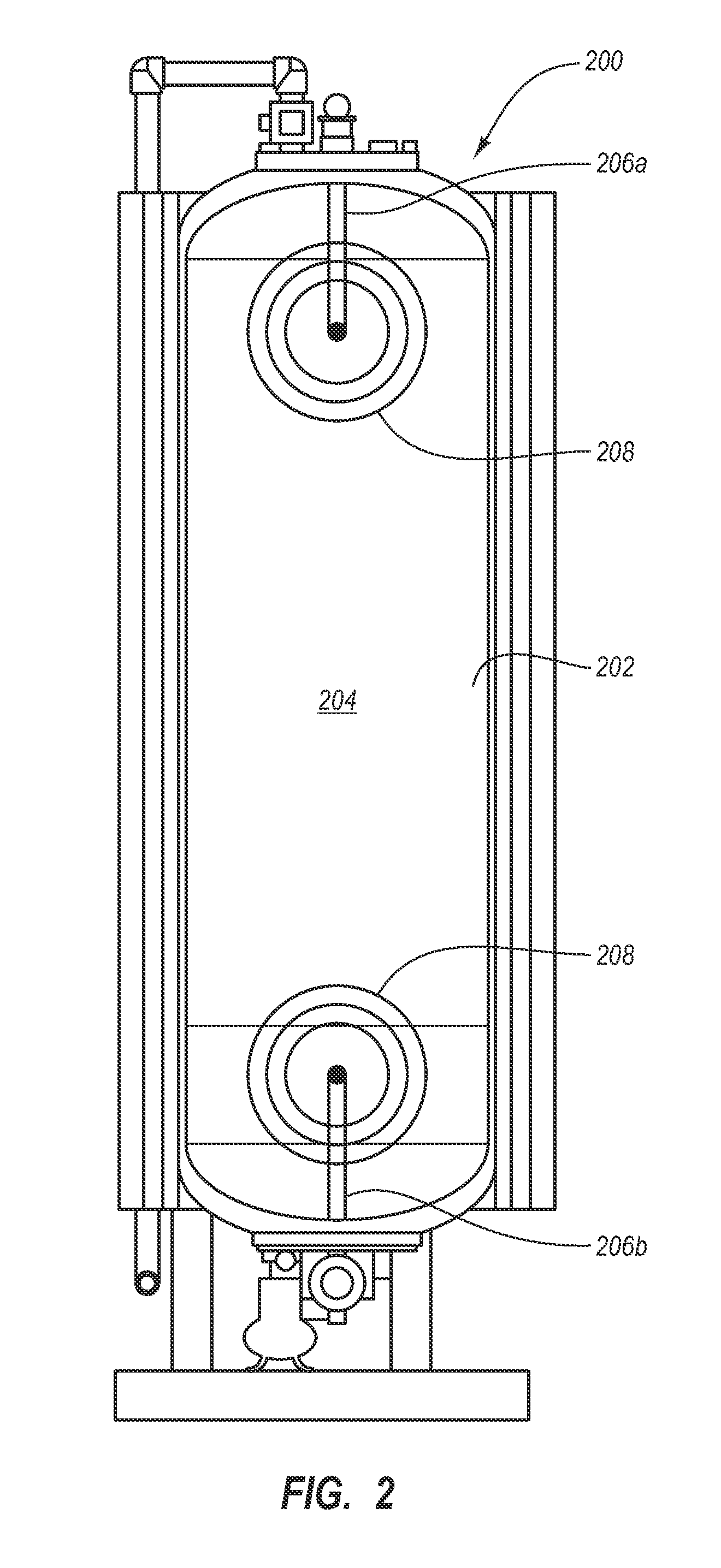

Method and system for oxidatively increasing cetane number of hydrocarbon fuel

InactiveUS20110065969A1Increase heightIntense release of energyRefining with halogen compoundsRefining with oxygen compoundsUltrasonic cavitationHigh energy

High energy (e.g., ultrasonic) mixing of a liquid hydrocarbon feedstock and reactants comprised of an oxidation source, catalyst and acid yields a diesel fuel product or additive having substantially increased cetane number. Ultrasonic mixing creates cavitation, which involves the formation and violent collapse of micron-sized bubbles, which greatly increases the reactivity of the reactants. This, in turn, substantially increases the cetane number compared to reactions carried out using conventional mixing processes, such as simple mechanical stirring. Alternatively, an aqueous mixture comprising water and acid can be pretreated with an oxidation source such as ozone and subjected to ultrasonic cavitation prior to reacting the pretreated mixture with a liquid hydrocarbon feedstock.

Owner:CETAMAX VENTURES

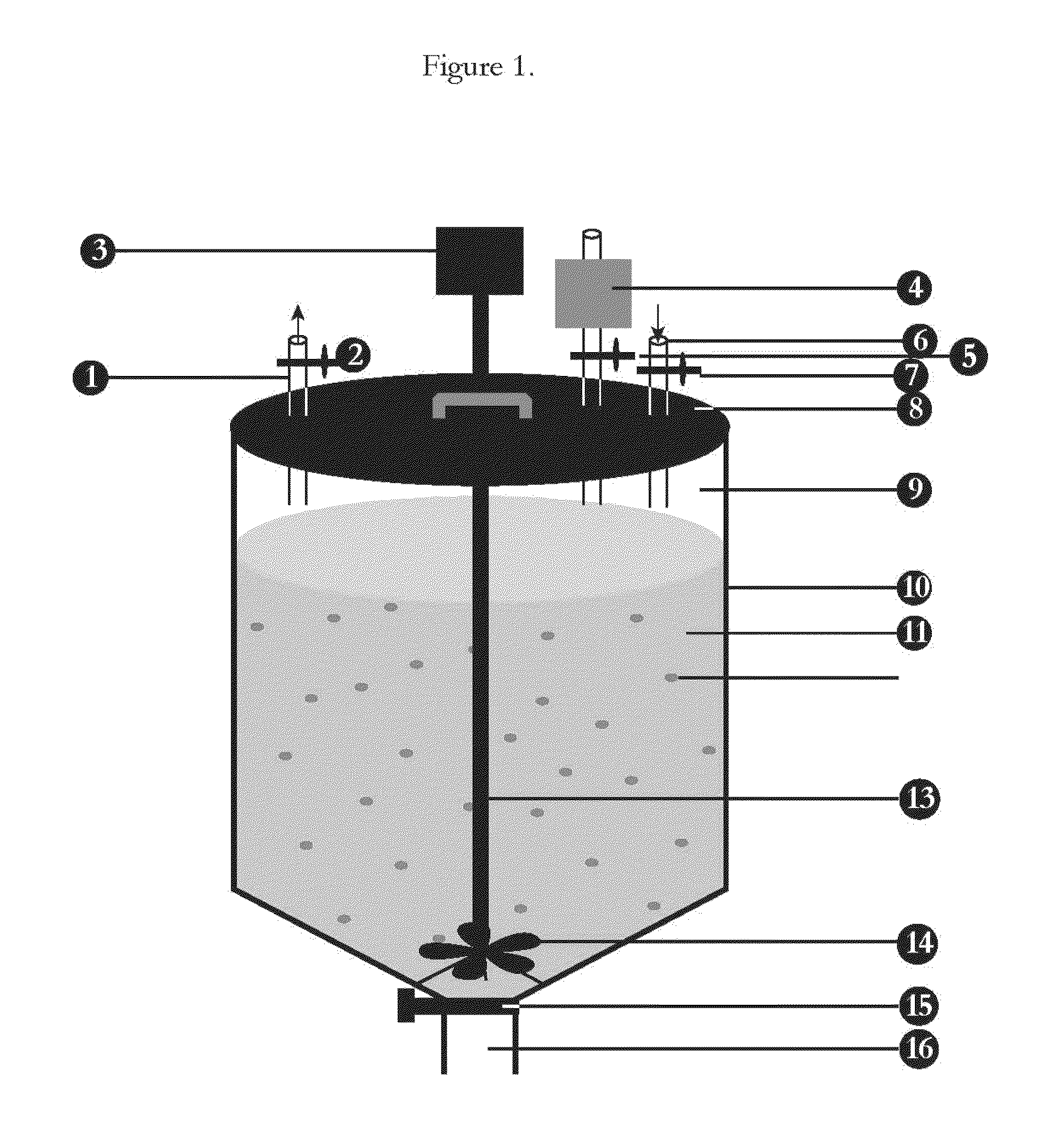

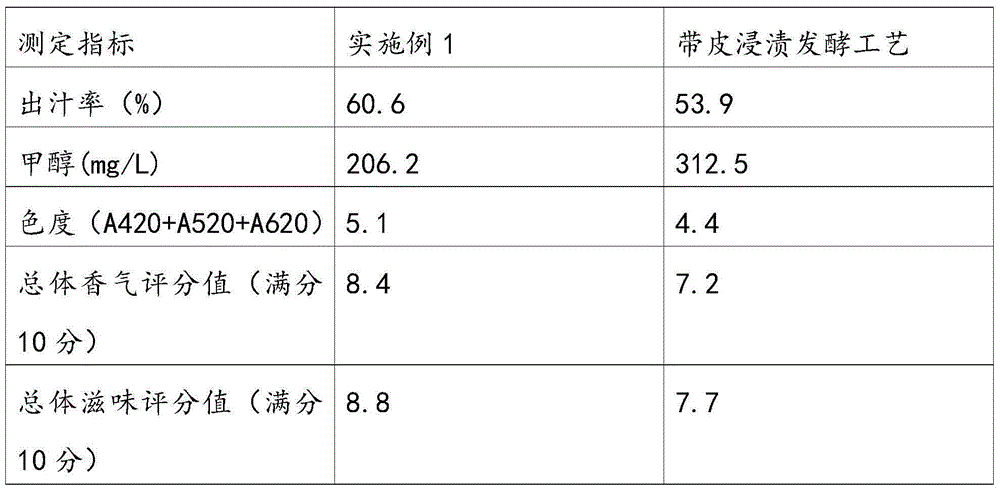

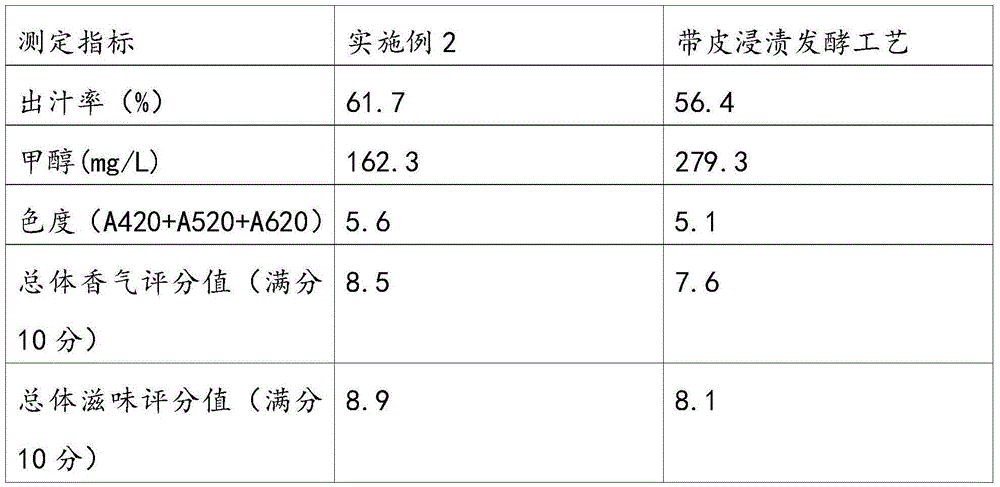

Brewing method of fruit-flavored dry red wine

ActiveCN105219574AOutstanding FeaturesHighlight significant progressMicroorganism based processesWine preparationHarvest timeSteeping

The invention discloses a brewing method of fruit-flavored dry red wine. The brewing method comprises such processing steps as determining a harvest time and harvesting, removing stems, sorting, crushing, extracting juice, cold-steeping, undergoing alcoholic fermentation with peels, separating peels and dregs, undergoing alcoholic fermentation with clear juice, storing, stabilizing, blending, freezing, sterilizing, filling and the like, so that produced dry red wine is intense, elegant and exquisite in fruit flavor, smooth and soft in taste, and is balanced and coordinated in wine body.

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

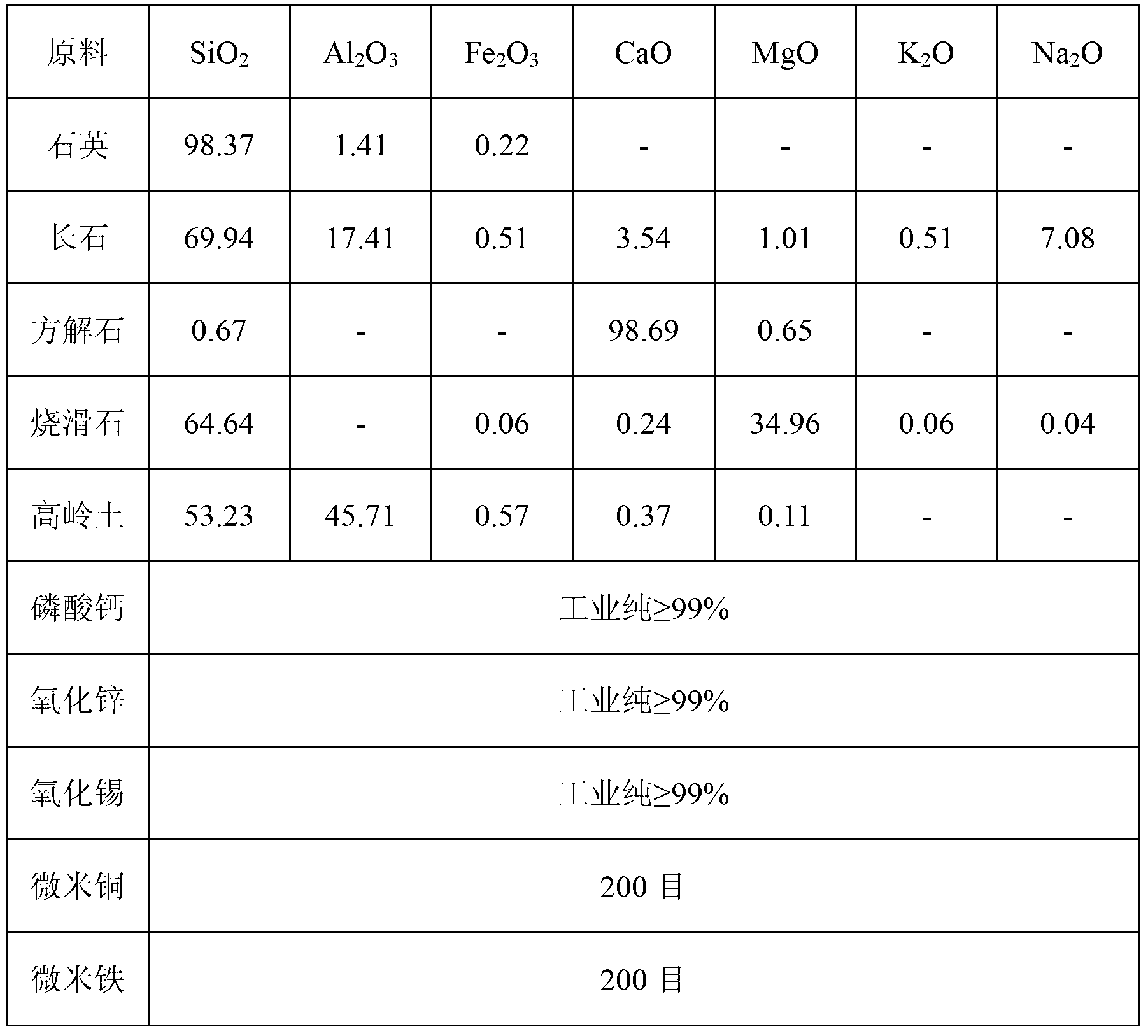

Reddish-black jun porcelain glaze prepared by utilizing metal copper and iron and preparation method of reddish-black jun porcelain glaze

InactiveCN103288493AImprove coloring abilityReduce energy consumption and pollutionCalciteCeramic glaze

The invention discloses a reddish-black jun porcelain glaze prepared by utilizing metal copper and iron and a preparation method of the reddish-black jun porcelain glaze, belonging to the preparation filed of ceramic glazes. The preparation method of the reddish-black jun porcelain glaze comprises the following steps of: (1), mixing the following components in percentage by weight: 45%-50% of feldspar, 20%-30% of quartz, 14%-17% of calcite, 5%-7% of talcum, 2.5%-3.5% of kaolin and 2.9%-3.5% of calcium phosphate, so as to obtain a material mixture, and adding and sufficiently mixing the following materials (based on the total weight of the material mixture): 0.3%-2% of ZnO, 1.5%-4% of SnO2, 0.2%-2% of Fe, 0.1%-1.5% of Cu, 0.1%-0.5% of cellulose and 0.5%-1.5% of sodium tripolyphosphate, so as to obtain a glaze mixture; (2), carrying out wet-process ball-milling on the glaze mixture to obtain glaze pulp; (3), applying the glaze pulp on a biscuit firing billet for firing for 20 minutes-40minutes in a neutral or weak oxidative atmosphere, and cooling to obtain the reddish-black jun porcelain glaze. The preparation method of the reddish-black jun porcelain glaze is simple and easy to implement, board in firing temperature range and easily controllable in firing atmosphere. And the reddish-black jun porcelain glaze obtained by the preparation method disclosed by the invention is simple in composition, smooth and flat in glazed surface, high in stability and bright in reddish-black color.

Owner:SHAANXI UNIV OF SCI & TECH

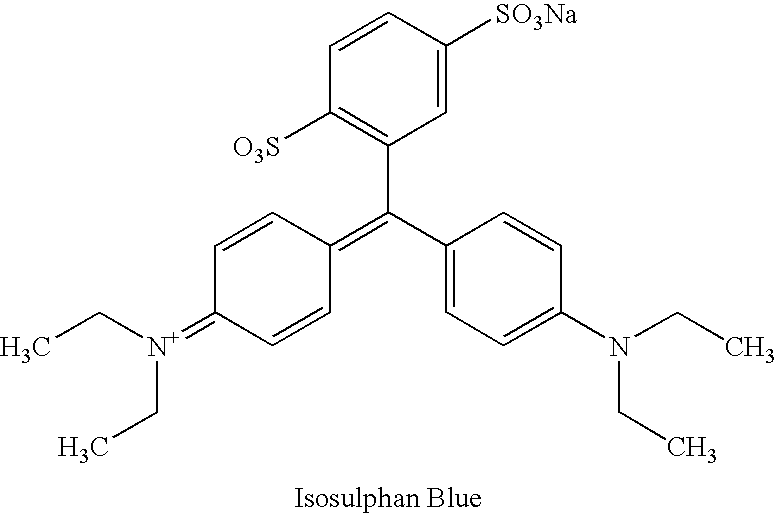

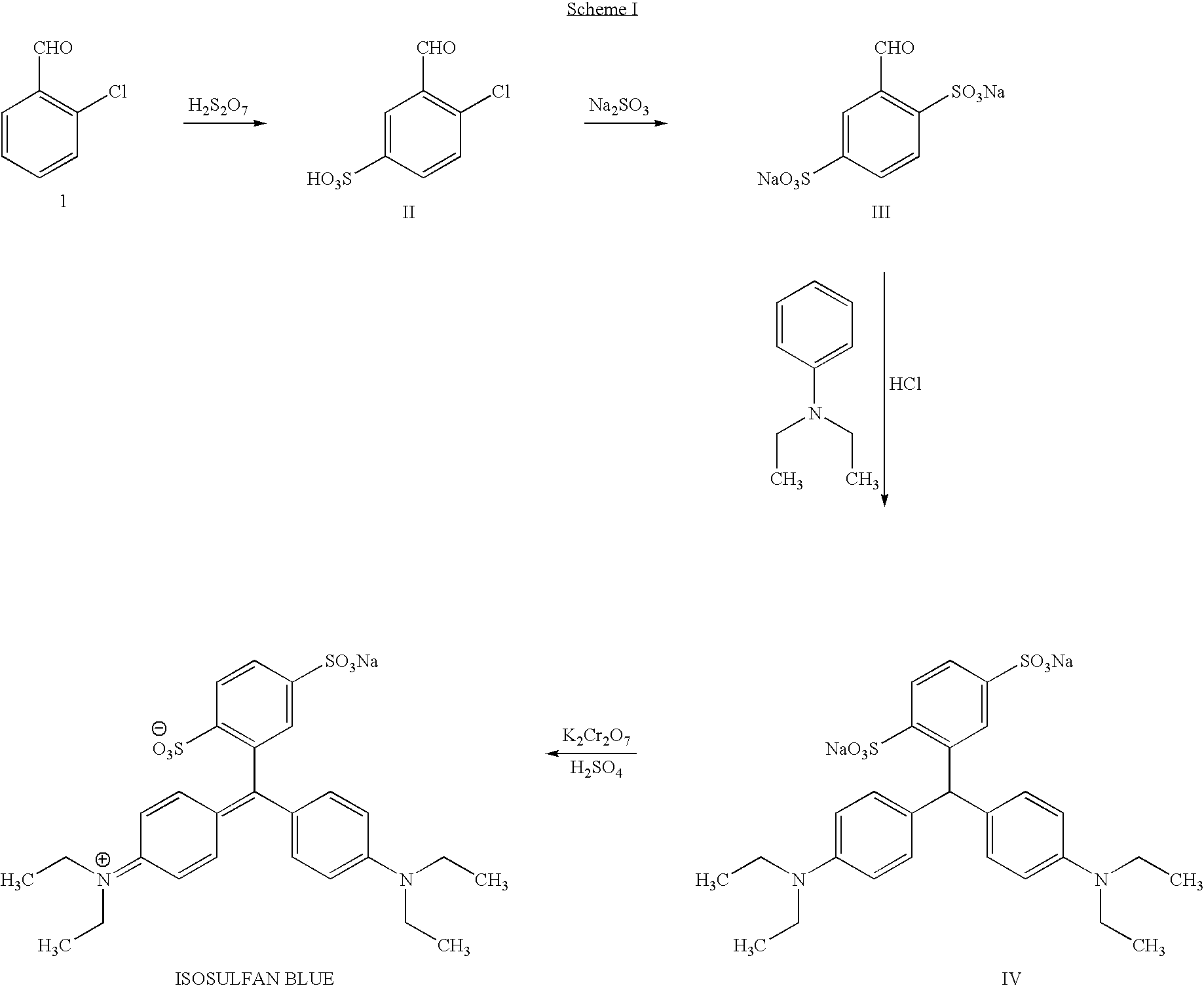

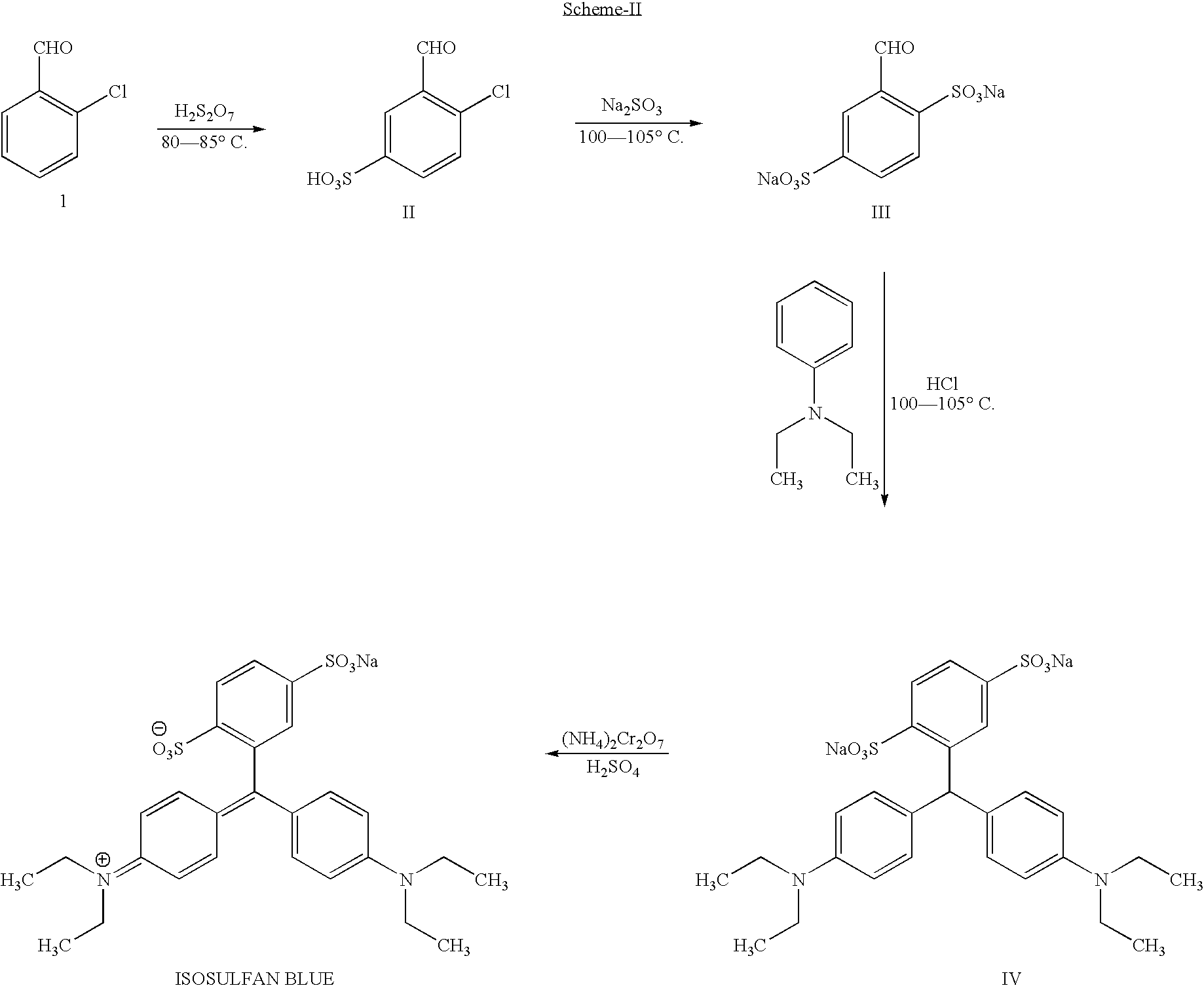

A process for the preparation of isosulphan blue

ActiveUS20060224003A1Avoid excessive oxidationOrganic chemistryDiaryl/thriaryl methane dyesSodium sulfitePhotochemistry

A process for the preparation of Isosulphan Blue is disclosed. The process comprises the following steps: Sulphonating orthochlorobenzaldehyde, treatment with sodium sulphite, basification, condensation and oxidation to obtain Isosulphan Blue.

Owner:CEYONE PHARMA LLC

Method for making shaddock, apple and tomato ferment health-care beverage

The invention provides a method for making a shaddock, apple and tomato ferment health-care beverage and belongs to the technical field of bioengineering. Shaddocks, apples and tomatoes serve as main fermentation raw materials and are peeled and mashed into pulp, raw honey and purified water are added, lactic acid bacterium strains are adopted as fermentation strains, fermentation bacterium liquid with the volume being 1-5% that of fermentation original fluid is added into a fermentation system, fermentation temperature is 25-35 DEG C, pH is 5.0-8.0, fermentation time is about 10 days, and the shaddock, apple and tomato ferment health-care beverage is produced and made. The beverage is fully fermented, various enzymes, vitamins, amino acid and trace elements in the beverage are fully released, the beverage has the special flavors of shaddocks, apples and tomatoes and is sweet, sour, delicious and rich in nutrition, and a traditional fermentation technology is adopted.

Owner:JIANGXI GUOGUO BIOTECH CO LTD

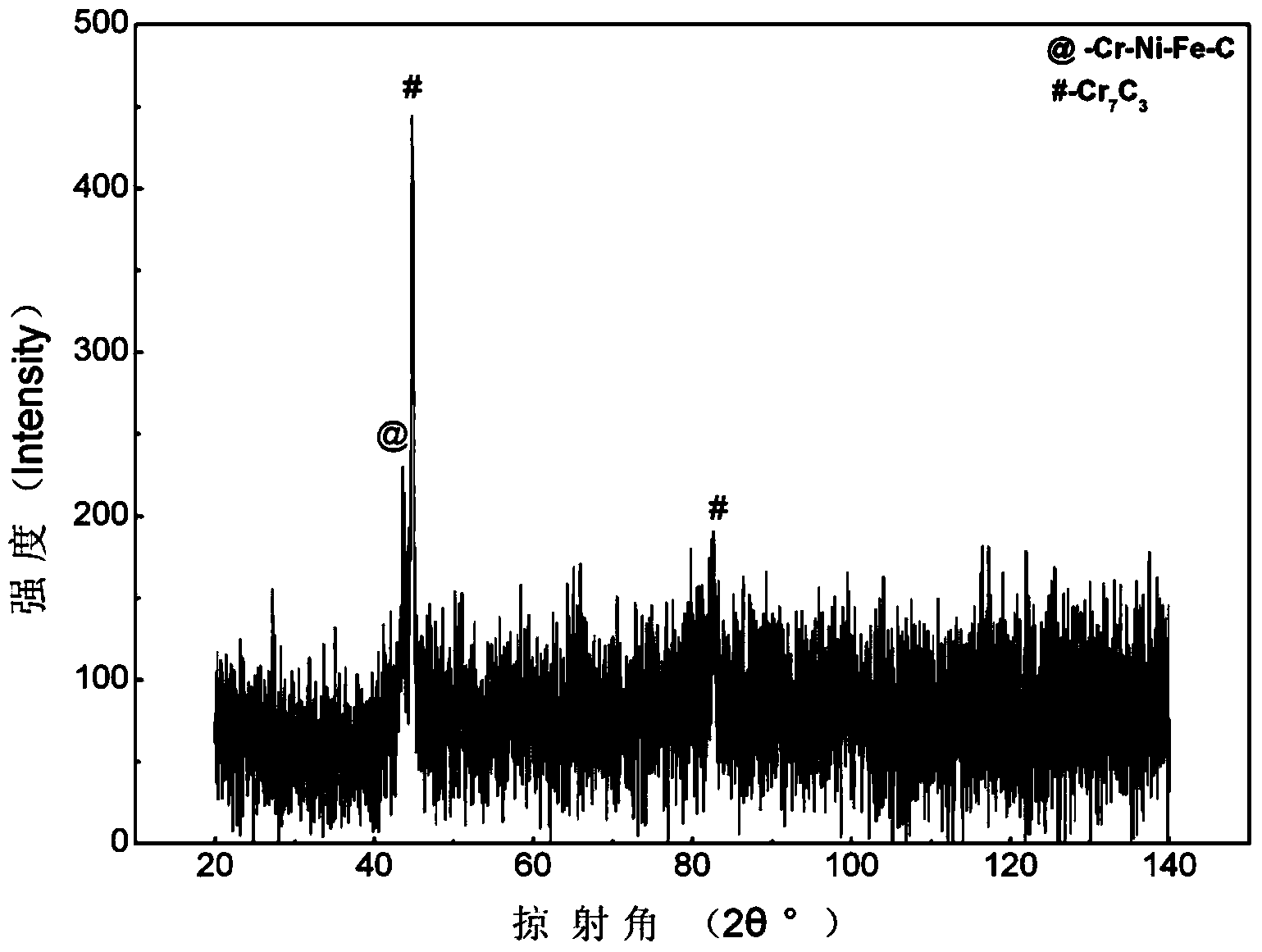

Plasma spray coating on aluminum alloy base surface and preparation method thereof

InactiveCN103643195AGood high temperature oxidation resistanceAvoid excessive oxidationMolten spray coatingChromiumNickel

The invention provides a plasma spray coating on an aluminum alloy base surface, which is composed of the following components in percentage by weight: 14-25% of chromium, 6-15% of nickel, 0.5-1.5% of carbon, 2.0-4.0% of silicon, 0.8-1.5% of manganese and the balance of iron. A Cr7C3 strengthening phase is dispersed in the austenite microstructure of the coating. The experiment proves that the coating has favorable wear resistance and antiseptic property, and is suitable for an aluminum alloy base surface working in a wearing and corrosive environment, such as an automobile engine cylinder made of an aluminum alloy material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Apple enzyme beverage production method

InactiveCN105029600AReduce lossesRetain activityFood ingredient functionsFood preparationTrace elementApple flavor

The present invention provides a method for preparing an enzyme beverage with apples. According to the present invention, apples are adopted as a main fermentation raw material, raw honey and Bainianshangshui provided by Wuxi Bainianshangshui beverage Ltd. are added, honey source bacteria, Lactobacillus casei and Lactobacillus plantarum are adopted as fermenting strains, the fermenting bacterial liquid is added to the fermenting system according to a volume ratio of the fermenting bacterial liquid to the fermenting raw liquid of 1-5%, the fermenting temperature is 25-35 DEG C, the fermenting pH value is 5.0-8.0, and the fermenting time is about 10 d, such that the apple enzyme health beverage is produced. According to the present invention, the fermenting is complete, such that a variety of enzymes, vitamins, amino acids and trace elements are completely released, the product has characteristics of apple flavor and unique flavor of nature honey, the traditional fermentation technology is used, and the method belongs to the technical field of biological engineering.

Owner:JIANGNAN UNIV

Preparation method of cathode barrier layer of metallic-propping solid oxide fuel cell

InactiveCN104269563AAvoid excessive oxidationInhibit sheddingCell electrodesFuel cellsCelluloseCerium

The invention discloses a preparation method of a cathode barrier layer of a metallic-propping solid oxide fuel cell. The preparation method comprises the following steps: adding cathode barrier layer material powder into an ethylene cellulose terpilenol solution proportionally and grinding to obtain paste; depositing the paste on a thick porous metal propping layer film / thin porous metal ceramic gradient transition layer film / thin porous anode layer film / thin compact electrolyte layer film half cell in a silk-screen printing manner; sintering for 2-4h at 1000-1200 DEG C in a vacuum atmosphere, controlling the temperature rise and temperature reduction rate to 0.5-5 DEG C / min, and cooling to room temperature to obtain a product. The cathode barrier layer is sintered at high temperature in a low vacuum atmosphere, so that a supporting body is prevented from being oxidized excessively, the film dropping caused by cerium valence reduction in a cerium-oxide-based electrolyte barrier layer in a reducing atmosphere is avoided, and the volatile loss of Ga in LaGaO3-based electrolyte barrier layer is also avoided, and therefore, a high-performance cathode material can be effectively prevented from reacting with zirconium-oxide-based solid electrolyte under a preparation condition.

Owner:SHANGHAI JIAO TONG UNIV

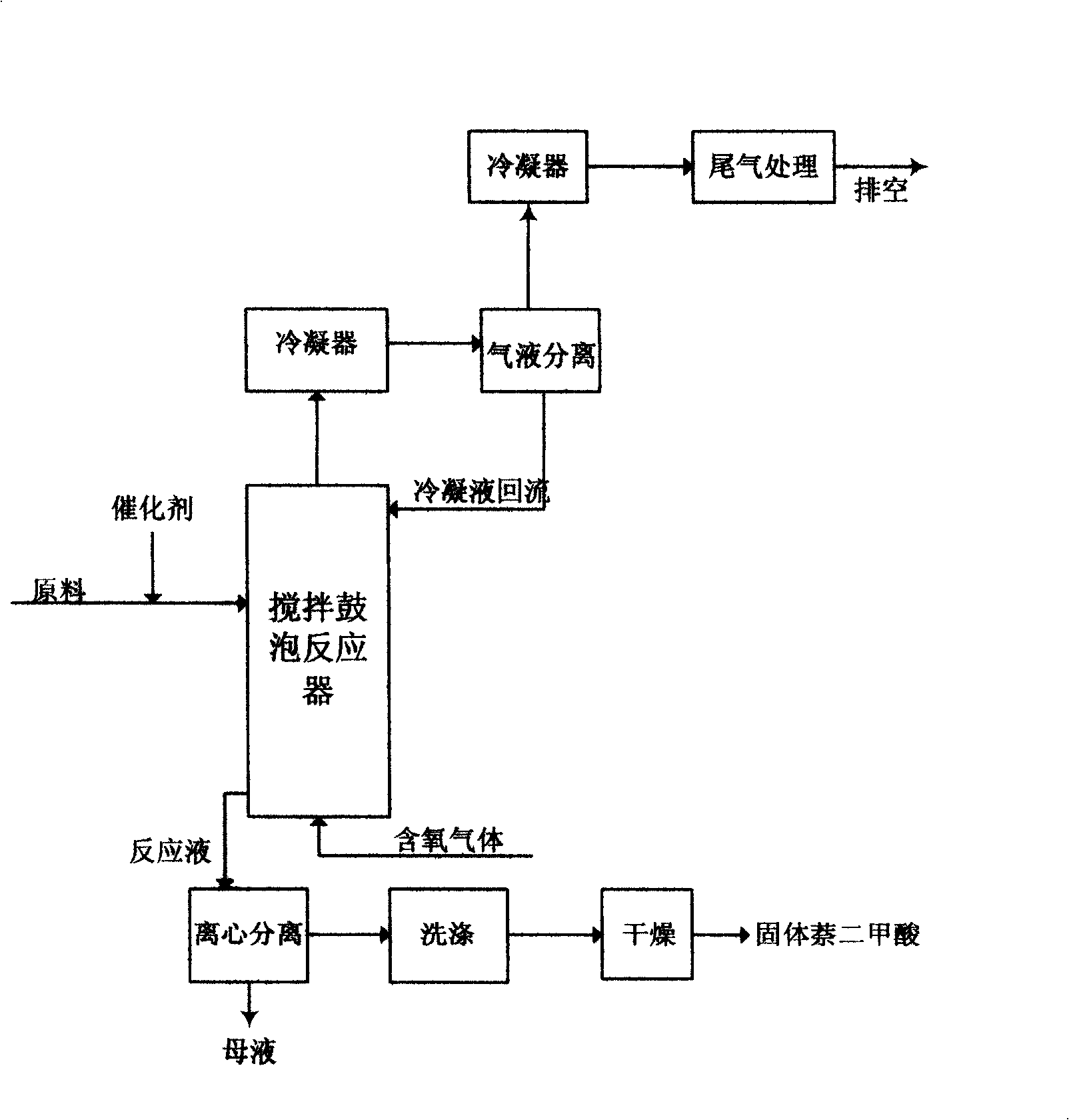

Process for producing 2,6-naphthalenedicarboxylic acid

InactiveCN101244997AReduce consumptionReduce generationOrganic compound preparationCarboxylic compound preparationBromineNickel compounds

The invention discloses a method for preparing 2, 6-naphthalene formic acid, which comprises a method for oxidizing 2, 6-diisopropyl naphthalene in liquid phase by using gas with oxygen in stirring and bubbling reactor, and using alkali metal compound or nickel compound as cocatalyst and using lower category aliphatic carboxyl acid under the condition with the existence of catalyst with cobalt compound, manganese compound and bromine compound. The method for preparing the 2, 6-naphthalene formic acid has the advantages of reducing the consumption of lower category aliphatic carboxyl acid, preparing the 2, 6-naphthalene formic acid product with high quality, and satisfying the need for producing naphthalene formic acid glycol ester with high quality.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

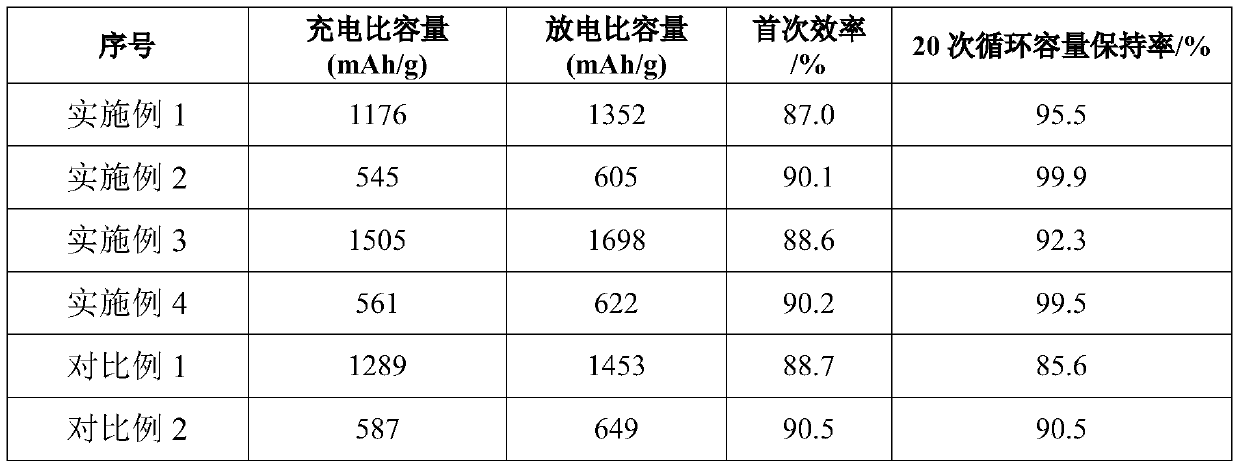

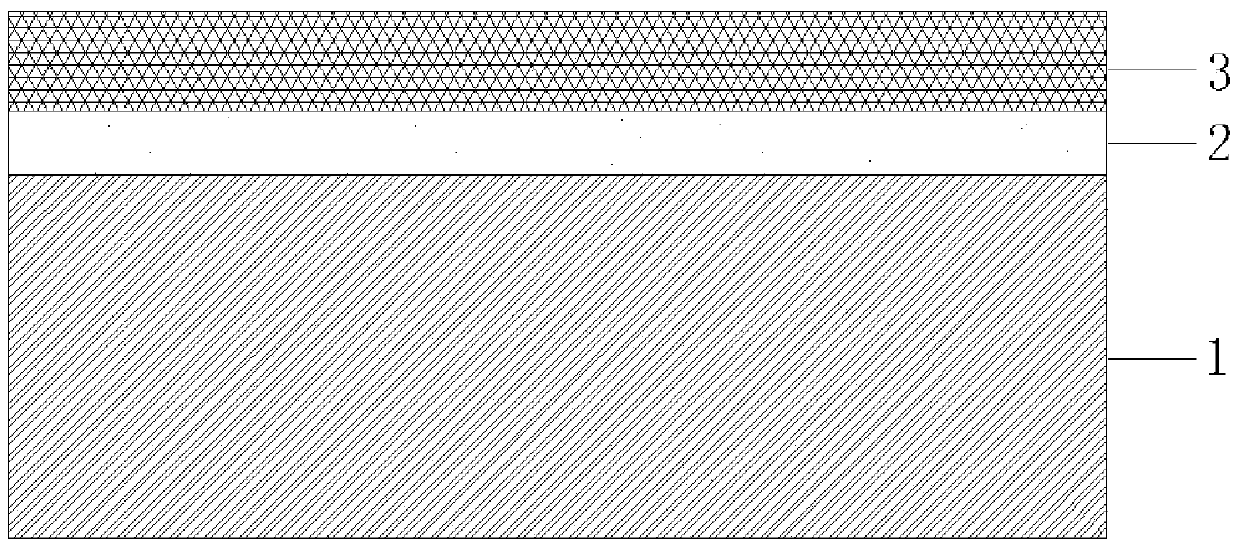

Lithium-ion battery silicon carbon negative electrode material and preparation method thereof

InactiveCN110504430AImprove cycle stabilityAchieving Controlled OxidationMaterial nanotechnologyNegative electrodesCyclic processCarbon coating

The invention provides a lithium-ion battery silicon carbon negative electrode material and a preparation method thereof. The preparation method of the lithium-ion battery silicon carbon negative electrode material comprises the following steps: S1, after mixing a silicon source and a solvent, wet grinding is performed under an oxidizing condition to form an oxide layer on the surface of the silicon source, wherein the mass of oxygen element accounts for 9.8% to 14% of the mass of the silicon source, and a slurry is obtained; S2, the slurry obtained in step S1 is compounded with a carbon material and dried to obtain a silicon carbon core material; S3, the silicon carbon core material obtained in step S2 is subjected to a fusion process treatment, and then mixed with a carbon coating material uniformly, and then calcined at a high temperature to be shaped; and S4, the material obtained in step S3 is crushed and sieved to obtain the silicon carbon negative electrode material. According to the invention, controlled oxidation of nano-silicon is realized during the wet grinding process, so that an oxide layer is formed on the surface of the silicon source; and the presence of the oxidelayer avoids side reactions between the silicon source and the electrolyte, and reduces the phenomenon of electrochemical agglomeration during the cyclic process at the same time; therefore, the cyclestability of the silicon carbon negative electrode material is significantly increased.

Owner:SHAANXI COAL & CHEM TECH INST

Preparation method of alginate oligosaccharides

InactiveCN101037456AControlling the degree of aggregation distributionReduce dosageSugar derivativesOligosaccharidesOver oxidationReaction temperature

A preparation method for alginate oligosaccharides includes following steps: adding the water to the alginic acid or metal salt or the produced high mannuronic acid, high guluronic acid section to dissolve or disperse in the water, adding it to the oxidant solvent in a radiation condition, heating the solution to 60-80 DEG C for 4-50 minutes, then cooling the solution, concentrating the solution by nanofiltration film, drying the concentrated liquid by spray. The invention improves the product quality by preventing the product over-oxidation by the radiation assistance in a lower temperature; effectively reduces the dosage of the oxidant by controlling the product degree of polymerization distribution in a low reaction temperature; avoids using organic solvent, reduces the product costs and saves the cost by nanofiltration film separation technique and spary drying technique which can be achieve the industry mass production. Therefore, the method has a practical application value.

Owner:NINGBO UNIV

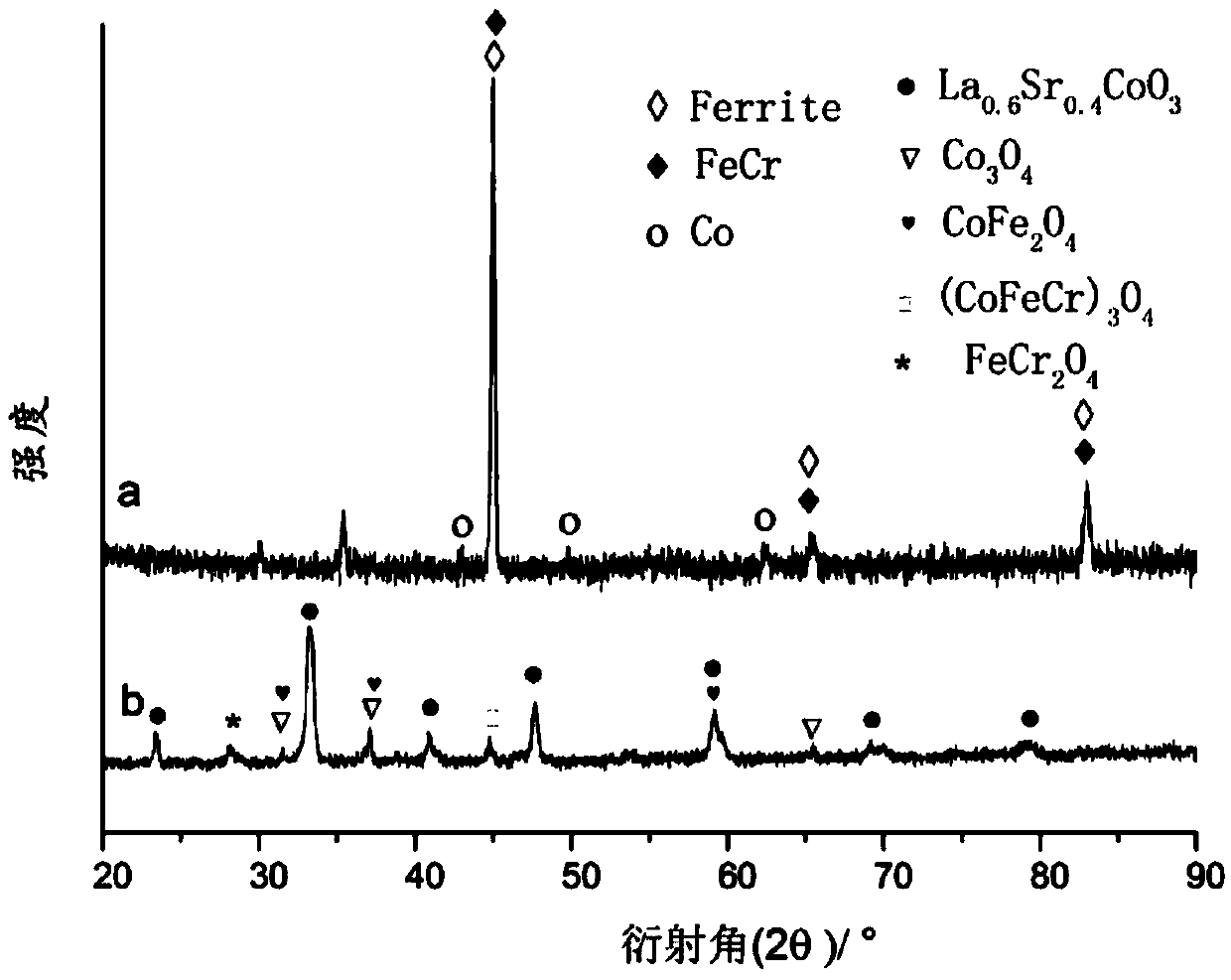

Double-layer coating on metal connector surface of high-temperature solid oxide cell and preparation method thereof

InactiveCN103746128AImprove bindingWell bonded and denseCell component detailsSolid electrolyte fuel cellsOxide compositeContact resistance

The invention discloses a double-layer coating on the metal connector surface of a high-temperature solid oxide cell and a preparation method of the double-layer coating. The coating comprises a first coating facing the metal connector surface and a second coating facing the environment, wherein the first coating consists of a main-phase oxide spinel structure and a first-phase composite oxide; the second coating consists of a main-phase composite oxide and a second-phase composite oxide. The first coating of the double-layer coating is bonded to a metal connector well and densely; the diffusion of chromium to an SOFC (solid oxide fuel cell) cathode or an SOEC (solid oxide electrolyser cell) anode can be effectively prevented; the main-phase composite oxide powder in the second coating adopts a precursor, high-temperature sintering can be realized in an non-oxidizing atmosphere to avoid excessive oxidation of the metal connector; the second coating is bonded well with the first coating; the phasing of the main-phase oxide composite is realized at low temperature before the cell is operated; high electric conductivity is obtained, and meanwhile, high thermochemical compatibility and low contact resistance between the coating and the SOFC cathode or the SOEC anode are realized.

Owner:SHANGHAI JIAO TONG UNIV

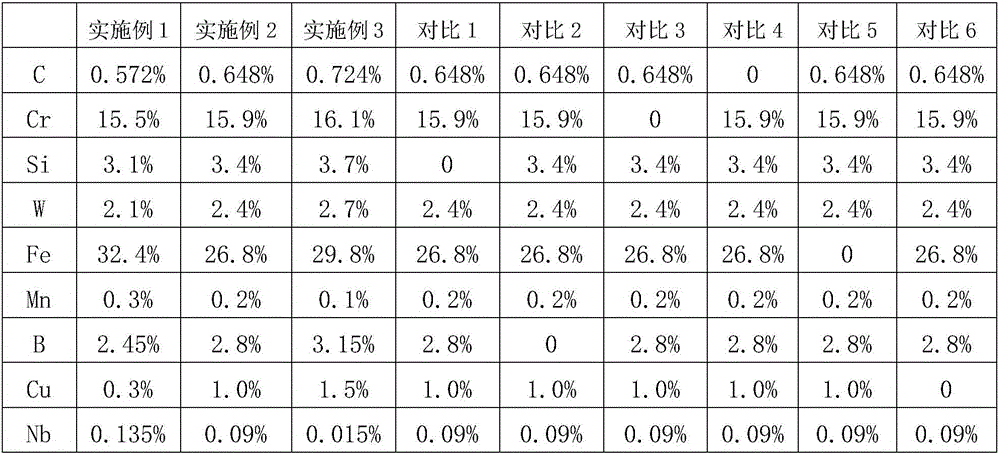

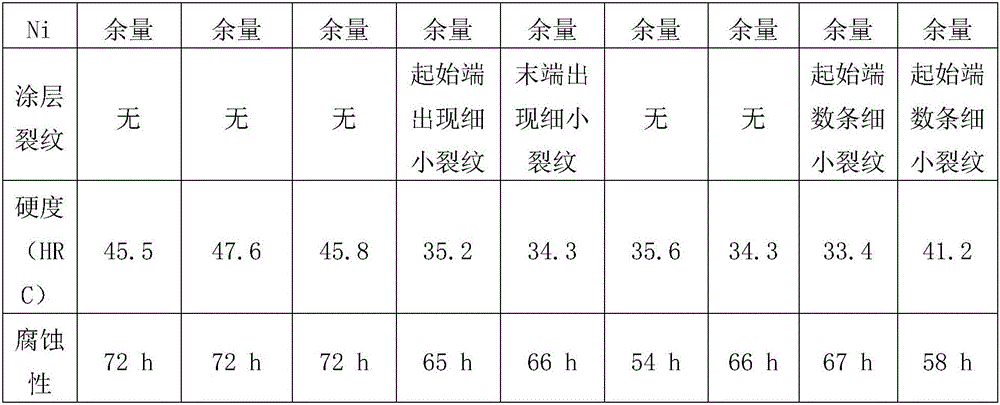

Nickel-based composite powder of laser cladding coating and method for preparing coating

InactiveCN106756994AAvoid excessive oxidationImprove wettabilityMetallic material coating processesMelting tankAlloy

The invention discloses nickel-based composite powder of a laser cladding coating and a method for preparing the coating. The composite powder comprises the following components by weight percent: 0.572% to 0.724% of C, 15.5% to 16.1% of Cr, 3.1% to 3.7% of Si, 2.1% to 2.7% of W, 26.8% to 32.4% of Fe, 0.1% to 0.3% of Mn, 2.45% to 3.15% of B, 0.3% to 1.5% of Cu and 0.015% to 0.135% of Nb, and the balance being Ni. The nickel-based composite powder of the laser cladding coating contains relatively high-content elements like Si and B, the elements have a slagging function and are preferentially fused together with oxygen in alloy powder and oxides on the surface of a workpiece, borosilicate with low melting point is generated, borosilicate covers the surface of a molten pool, and liquid metals are prevented from being excessively oxidized, so that the wetting ability of melt for a matrix metal is improved, the inclusion content and oxygen content in the cladding coating are decreased, and the technological shaping property of the cladding coating is improved.

Owner:JIANGSU UNIV OF SCI & TECH

Metallized films

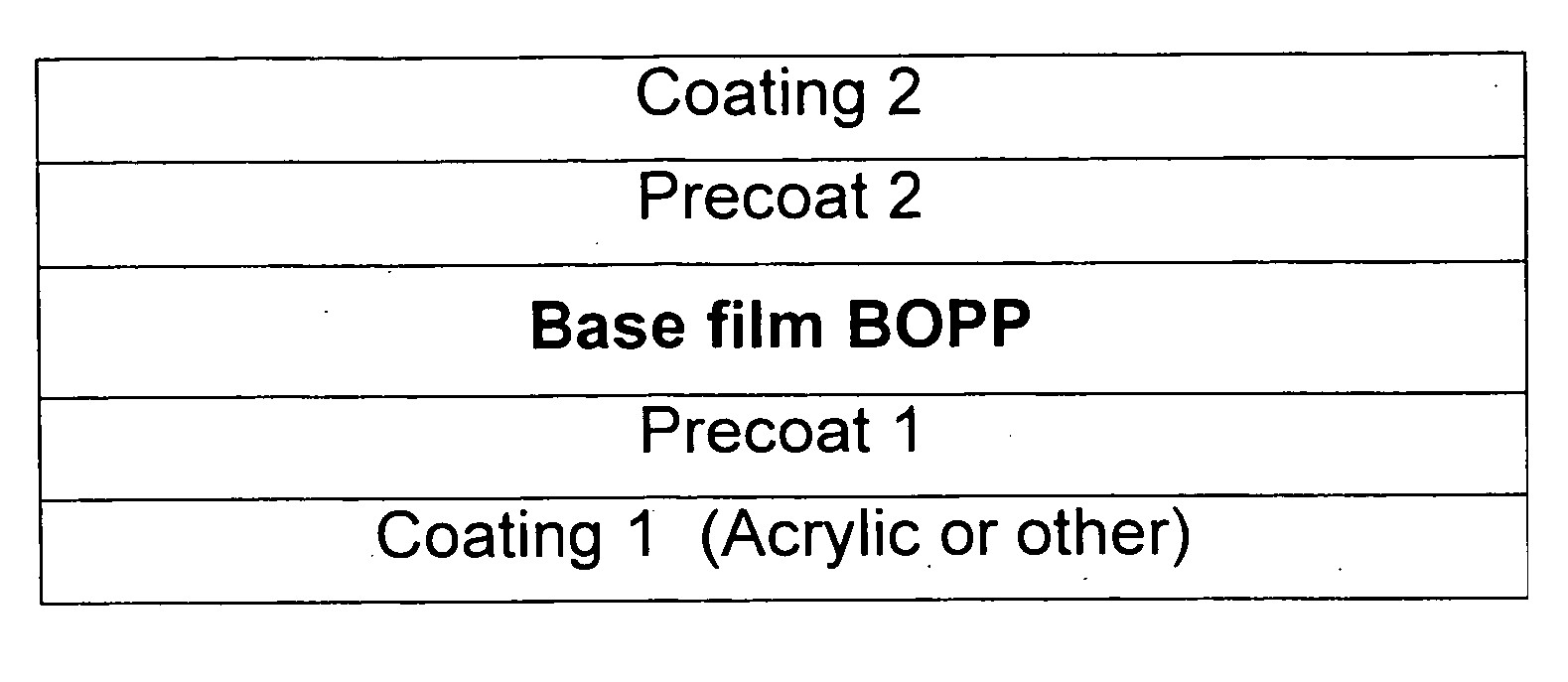

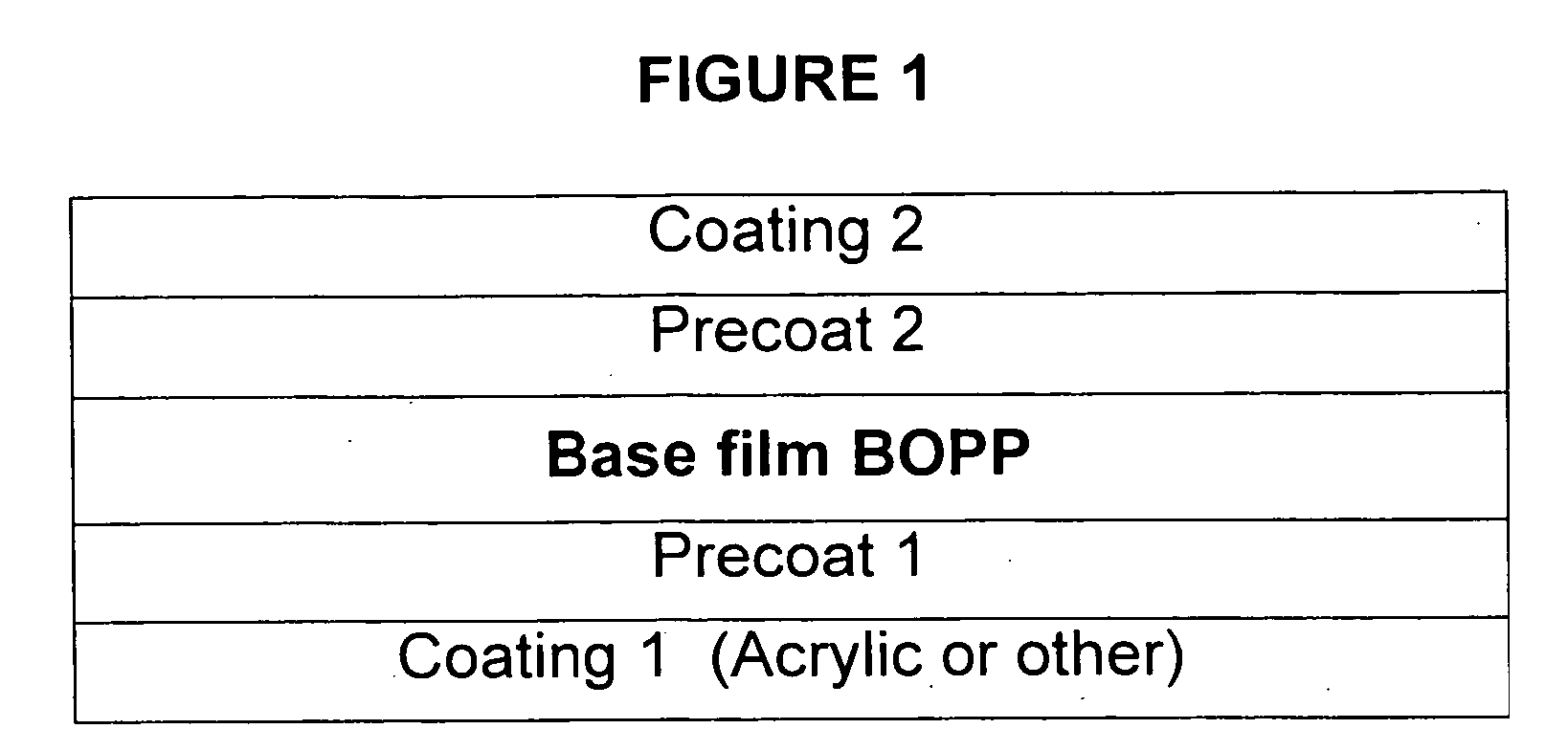

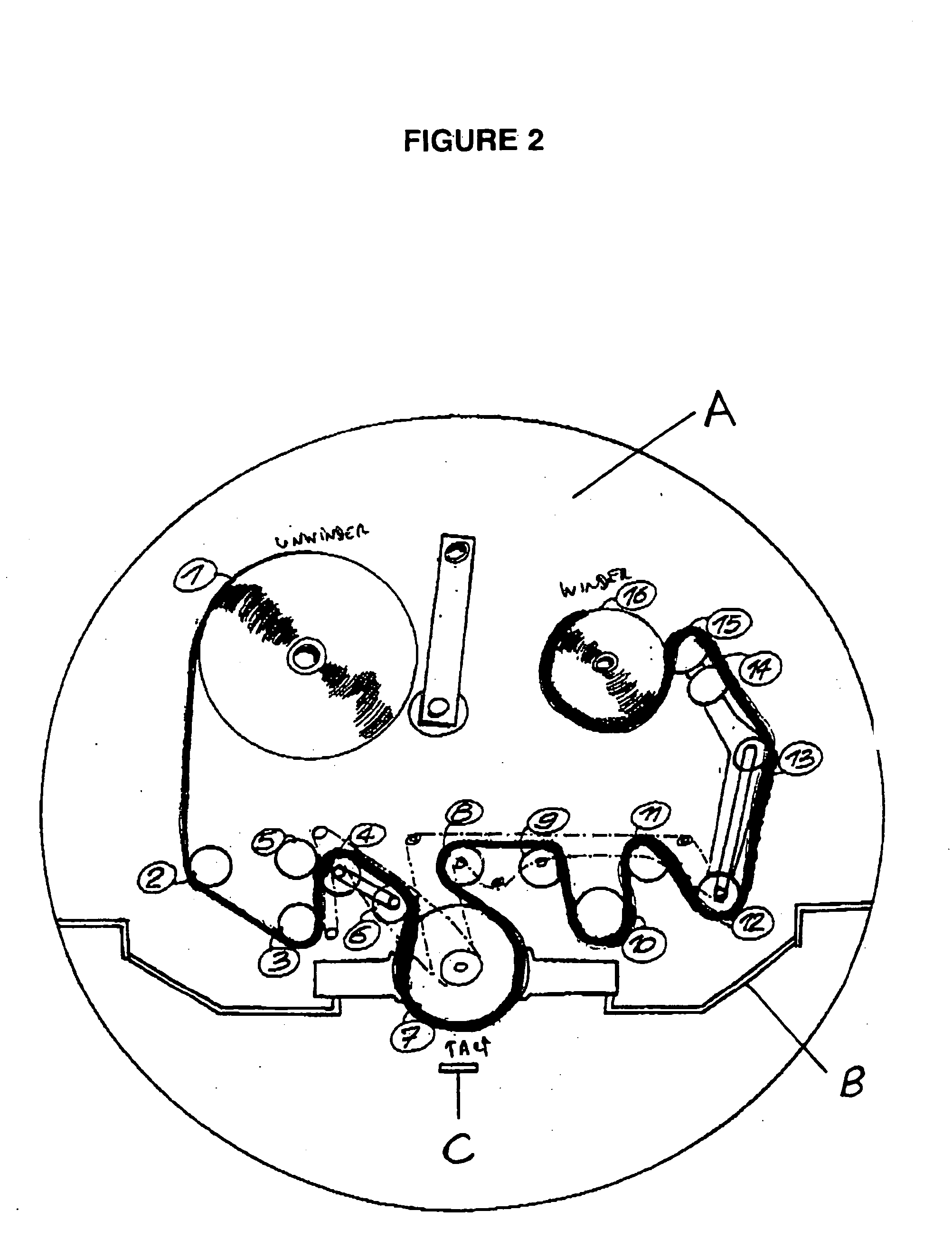

InactiveUS20050019591A1Improve barrier propertiesFew stepsLamination ancillary operationsSynthetic resin layered productsPolymerPolymer science

Metallized films having enhanced barrier properties consist of a first polymer layer, a barrier layer, and a metal layer coated with a heat seal and / or printable layer which has been transferred onto the metal layer.

Owner:FRANCOIS JEAN MARC

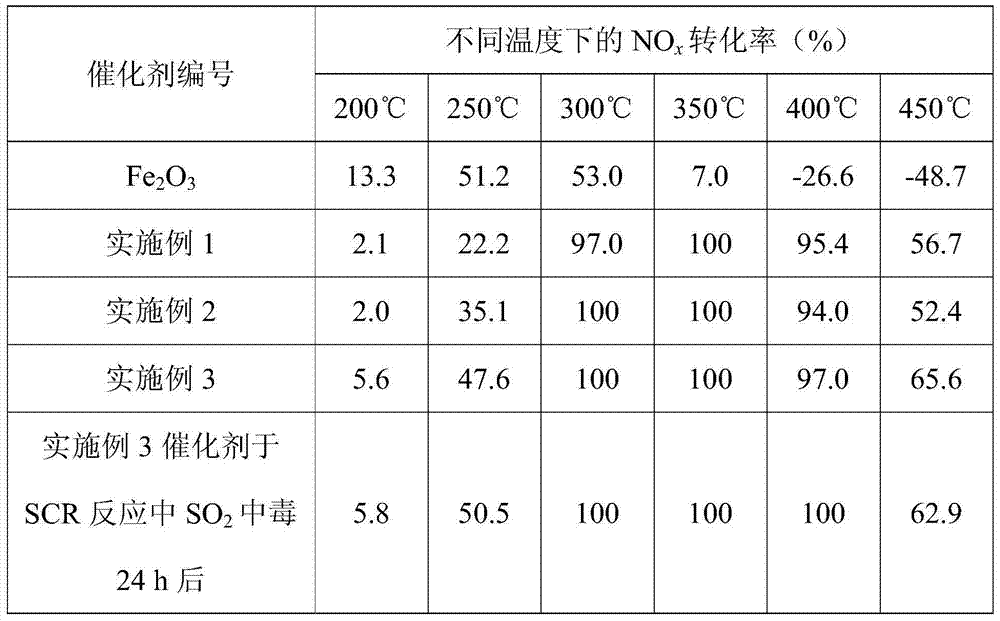

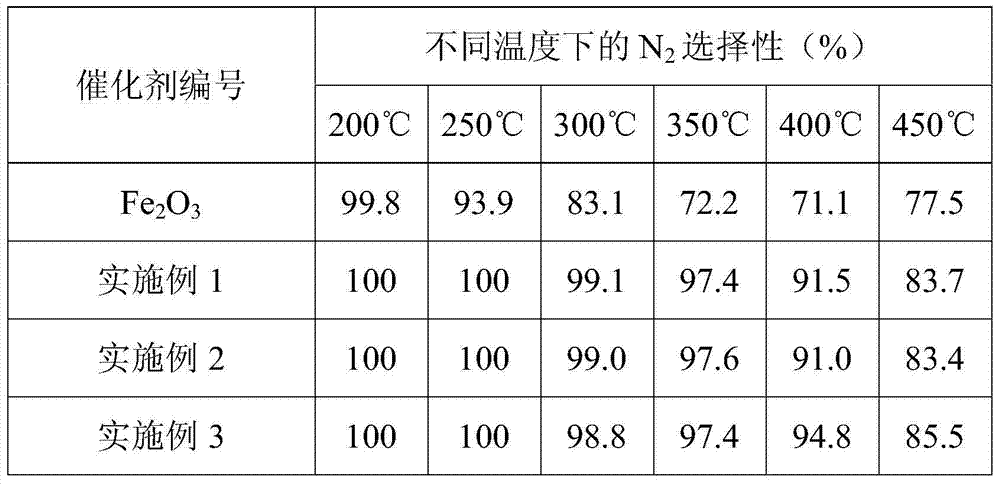

Catalyst for surface sulfation of ferric oxide, as well as preparation method and application thereof

InactiveCN103785420ALow priceEfficient redox processPhysical/chemical process catalystsDispersed particle separationSulfationBlack ferric oxide

The invention discloses a preparation method of a catalyst for surface sulfation of ferric oxide. The method comprises the following steps: (1) preparing ferric oxide; (2) performing sulfation treatment on the surface of the ferric oxide to obtain a ferric oxide catalyst of which the surface is sulfated. The ferric oxide catalyst with the enhanced surface acidity and the proper oxidation-reduction capacity is synthesized for the first time through performing sulfating process on the surface of the ferric oxide, so that the NOx purification activity of middle and high temperature sections in NH3 selectively reducing NOx (namely NH3-SCR) reaction is obviously improved, an operation temperature window is obviously broadened, and the catalyst has the extremely excellent SO2 poisoning resistance performance and is very applicable for catalytic elimination of a stationary source and a mobile source NOX.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

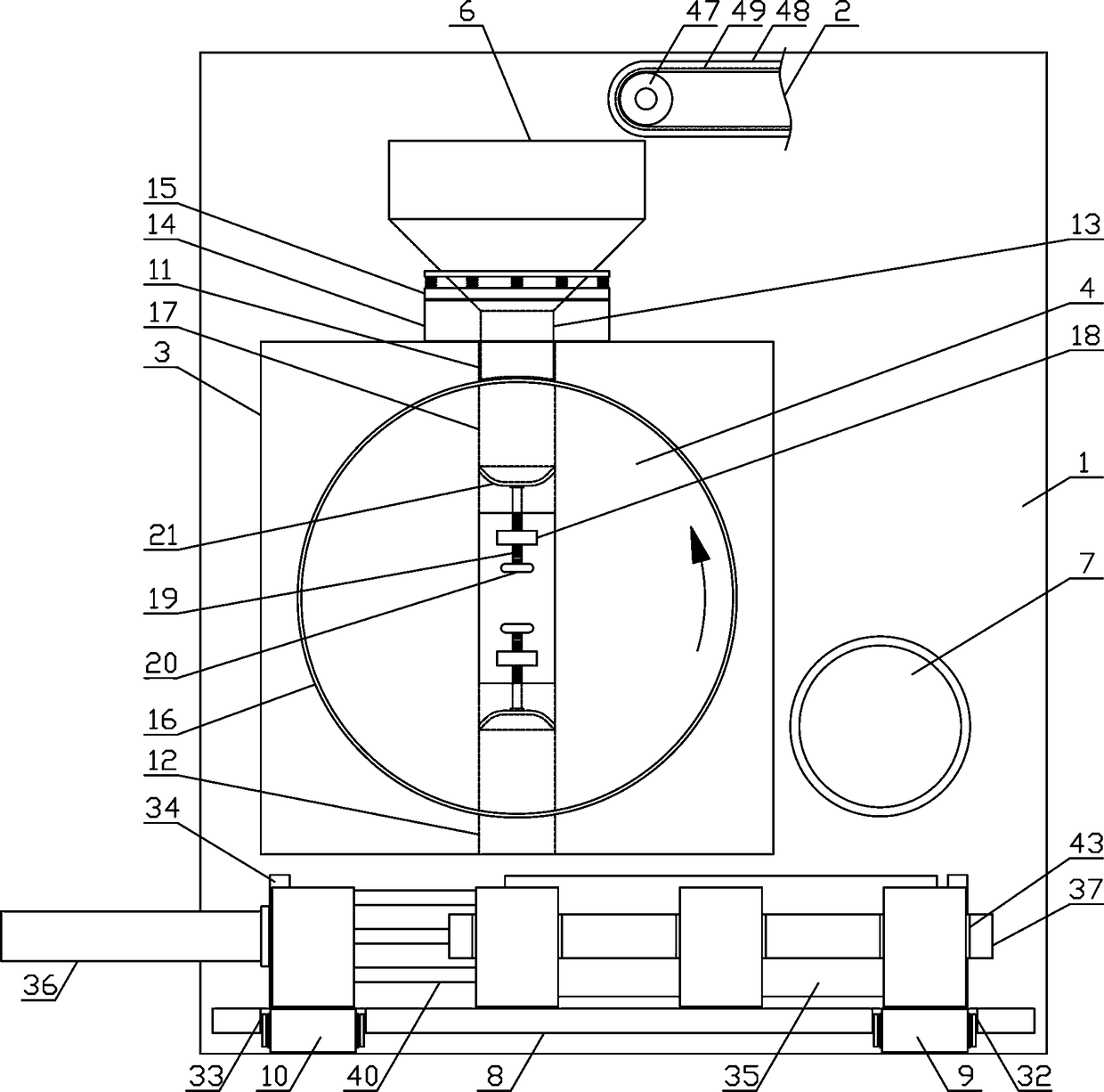

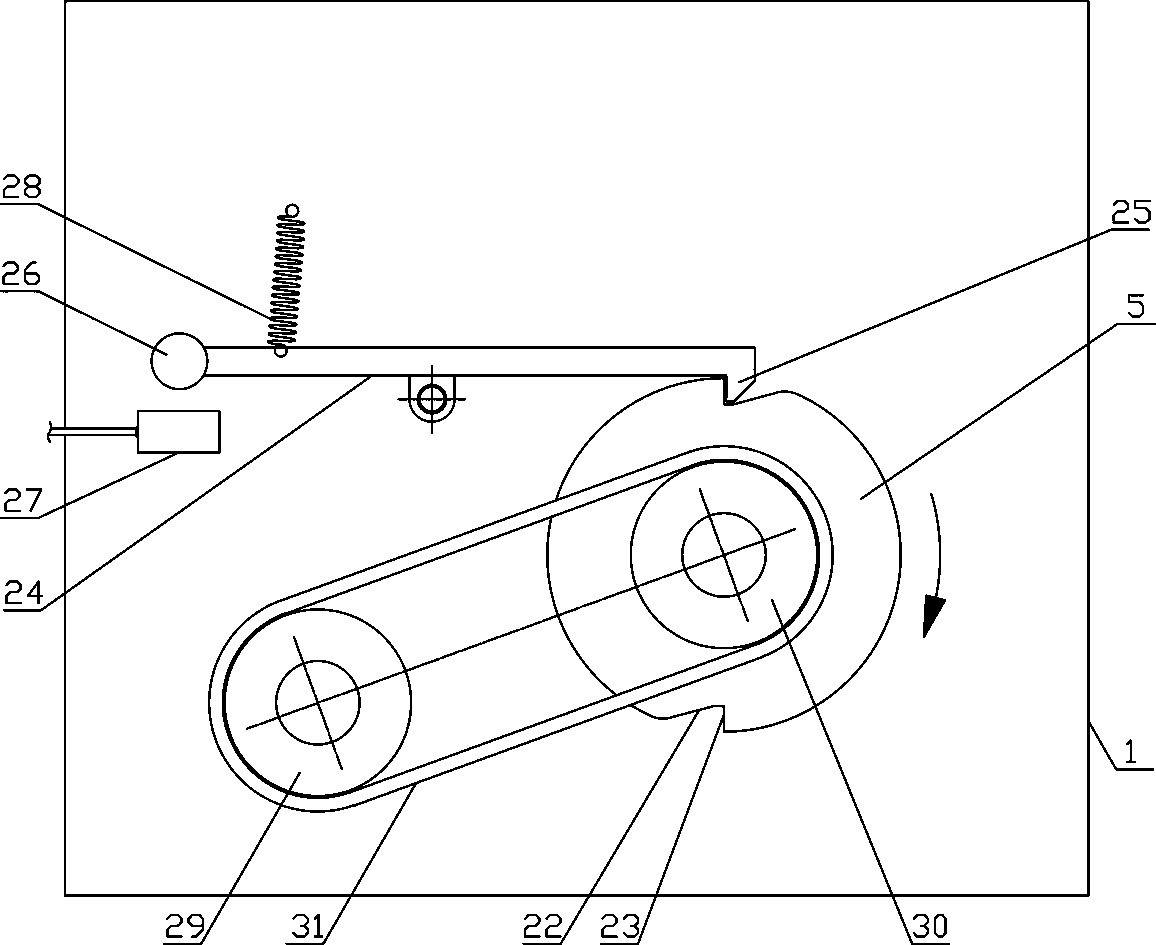

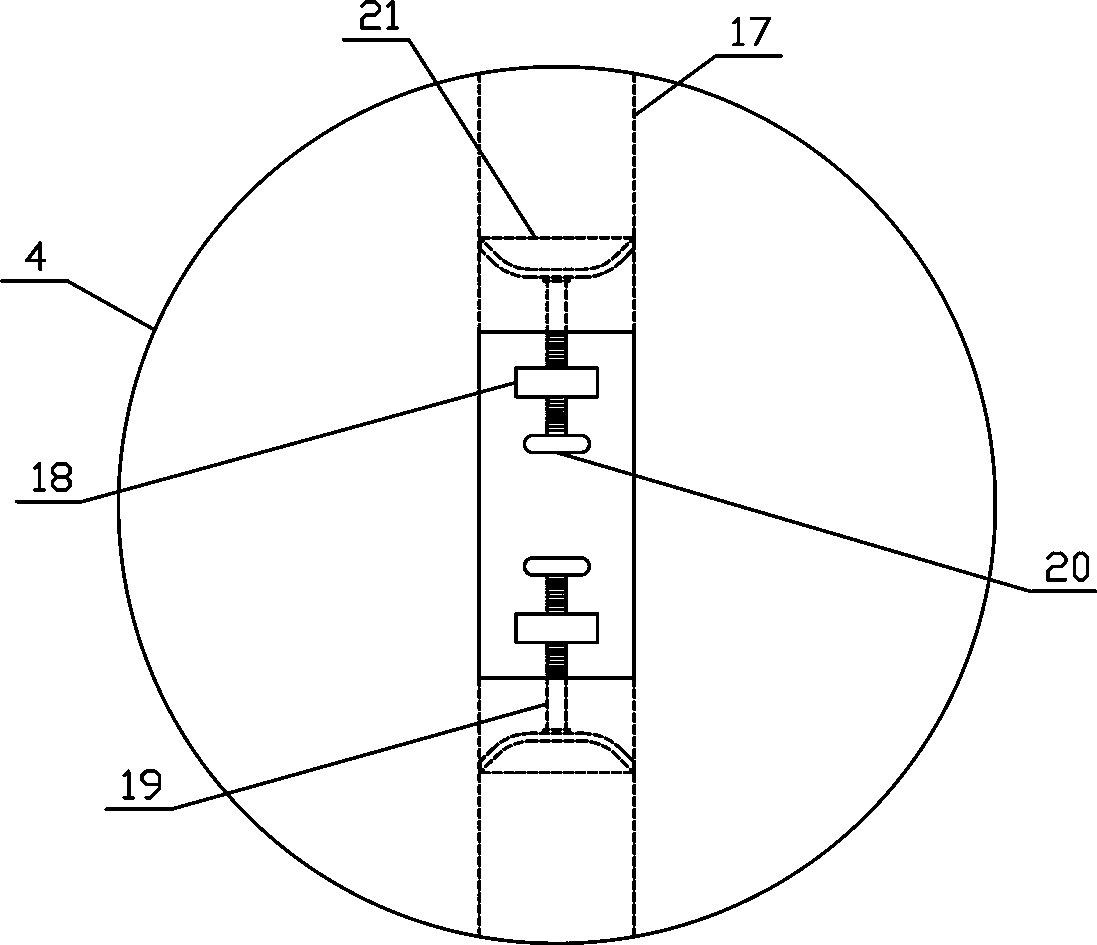

Continuous and quantitative granule filling mechanism

ActiveCN108910166AReduce storageAvoid excessive oxidationSolid materialEngineeringMechanical engineering

Owner:倪圣洁

Gradual transition layer for metal-based film sensor and preparation method

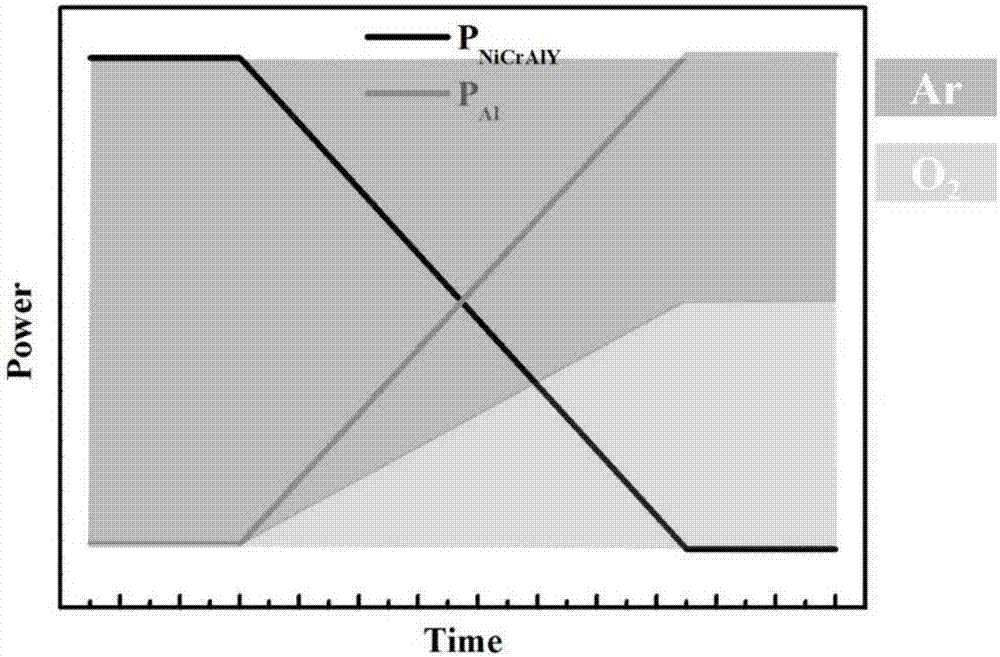

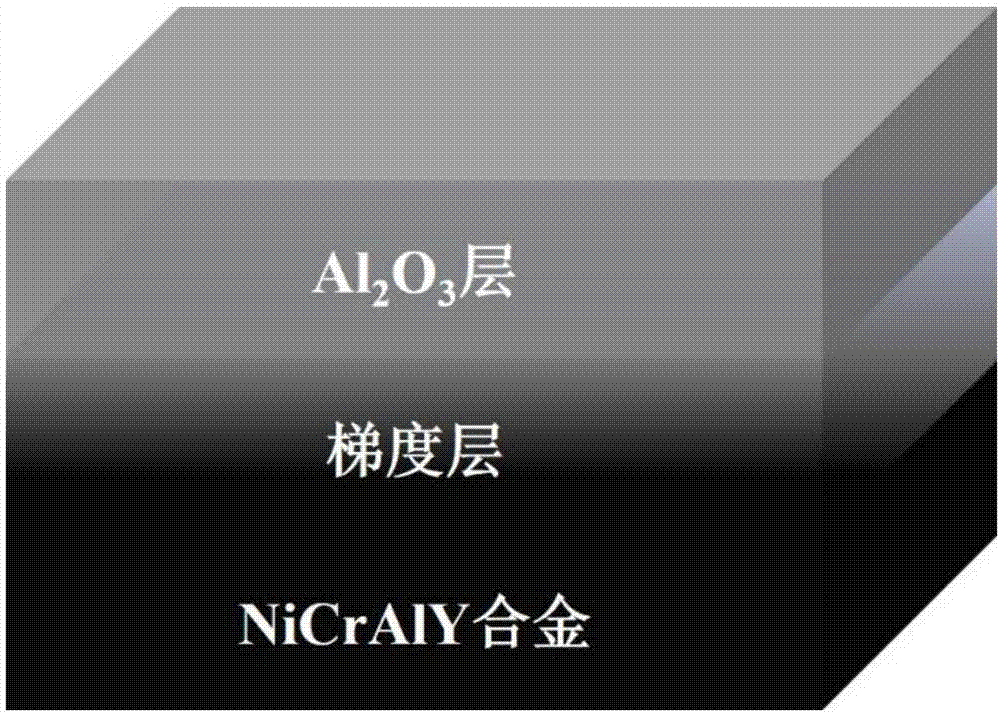

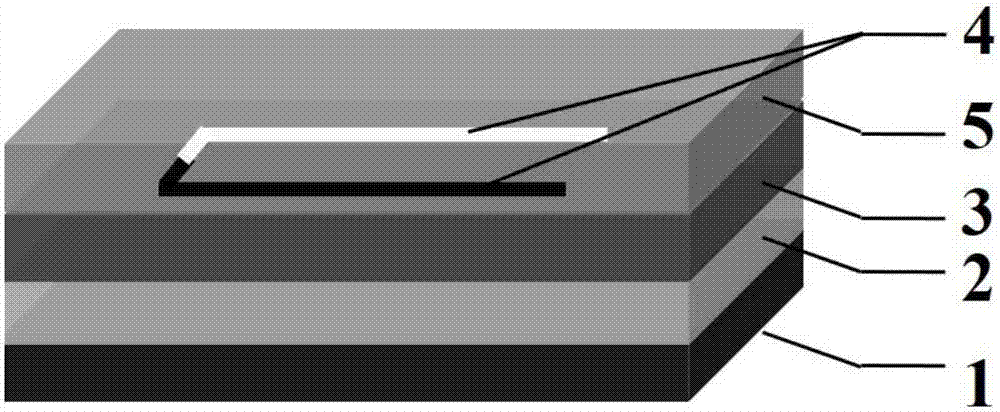

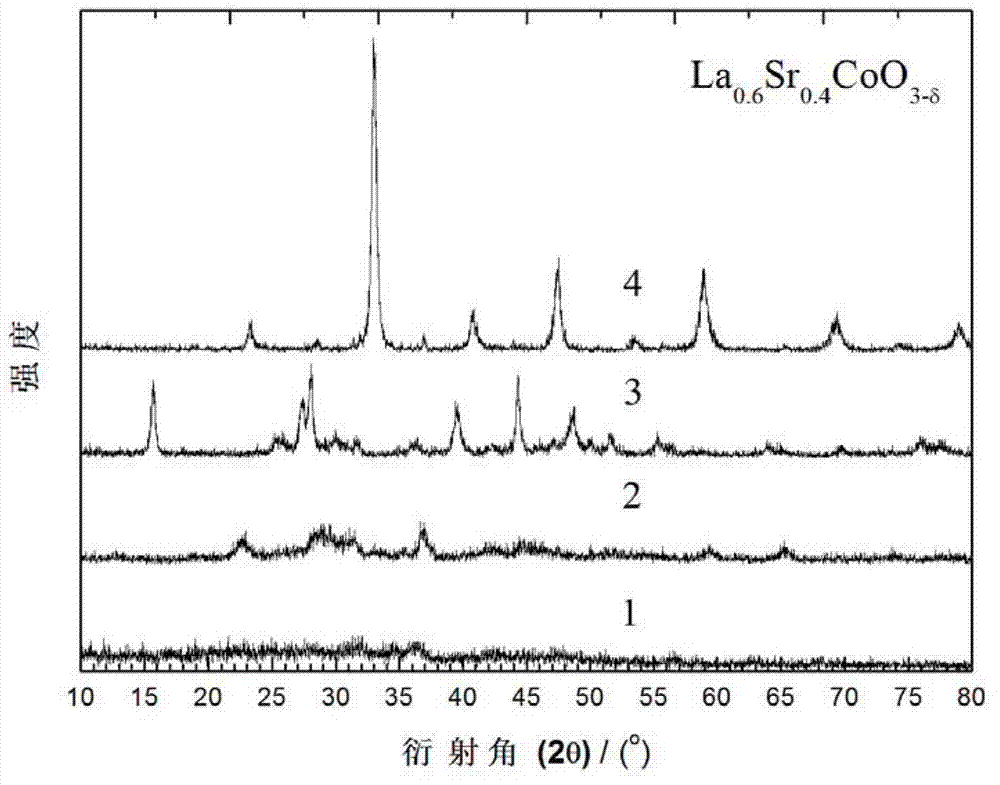

ActiveCN107574415ASlow self-diffusionAvoid excessive oxidationVacuum evaporation coatingSputtering coatingAlloyOxygen

The invention provides a gradual transition layer for a metal-based film sensor and a preparation method and belongs to the technical field of film sensors. The gradual transition layer comprises three layers of structures including a NiCrAlY alloy layer, a NiCrAlY alloy and Al2O3 gradient layer and an Al2O3 layer from bottom to top in sequence, wherein in the NiCrAlY alloy and Al2O3 gradient layer located in the middle, the concentration of NiCrAlY alloy decreases gradually in the growth direction of the film, and the concentration of Al2O3 increases gradually in the growth direction of the film. Compared with an existing transition layer, the gradual transition layer has the advantages that the heat treatment temperature is reduced by 200-400 DEG C; the heat treatment time is shortened by 50% or more; self-diffusion of nickel base alloy during high-temperature treatment and the rate and degree of mutual diffusion of the nickel base alloy and the NiCrAlY alloy are retarded; meanwhile,the heat treatment atmosphere is changed from a traditional oxygen-enriched environment to the atmospheric environment, and excessive oxidation of elements in the nickel base alloy is avoided to someextent.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of functional gradient cathode of intermediate low temperature solid oxide fuel cell

InactiveCN103199269AImprove electrode performanceAvoid excessive oxidationCell electrodesFuel cellsOver oxidation

The invention discloses a preparation method of a functional gradient cathode of an intermediate low temperature solid oxide fuel cell. The preparation method comprises the following steps of: preparing cathode precursor powder and composite cathode precursor powder; depositing composite cathode precursor functional layer size prepared by adding the composite cathode precursor powder to an ethyl cellulose terpilenol solution on a reaction barrier layer between a compact sold electrolyte thin film and a cathode thin film to form a composite cathode precursor functional layer; depositing cathode precursor current collection layer size prepared by adding the cathode precursor powder to an ethyl cellulose terpilenol solution on the composite cathode precursor functional layer to form a cathode precursor current collection layer; and sintering the cathode precursor current collection layer and the composite cathode precursor functional layer in non-oxidizing atmosphere, and annealing in air to form phase before the battery works, thus obtaining the functional gradient cathode of the intermediate low temperature solid oxide fuel cell. The preparation method of the functional gradient cathode can be used for avoiding the over oxidation of a battery support, and simultaneously improving the electrode performance of the functional gradient cathode.

Owner:SHANGHAI JIAO TONG UNIV

Mulberry enzyme health beverage production method

The present invention provides a method for preparing a health beverage through mulberry fermentation. The process characteristics are that mulberry is adopted as a main raw material, Bacillus amyloliquefaciens H47 preserved in China Center for Type Culture Collection on June 29, 2013 and having the preservation number of CCTCC M 2013283 and lactic acid bacteria are adopted as fermentation strains, mulberry, raw honey and purified water added according to a volume ratio of the mulberry to the raw honey to the purified water of 2-5:1-3:7-2, uniform mixing is performed to prepare a mulberry fermentation raw liquid, a honey source bacterial and lactic acid bacterial seed liquid is inoculated into the mulberry fermentation raw liquid according to a ratio of 1-5%, fermentation is performed for 6-14 d at a temperature of 25-35 DEG C under the pH value of 5.0-8.0 to obtain a mulberry enzyme beverage crude product, coarse filtration is performed with a 20-32 mesh filtration sieve to primarily filter out large particle residue, and fine filtration is performed with a 80-100 mesh filtration sieve to further filter out small particle residue to make the liquid present the clear state so as to obtain the mulberry enzyme health beverage finished product.

Owner:JIANGNAN UNIV

Waste paper modified coated control release fertilizer and preparation method thereof

The invention relates to a waste paper modified coated control release fertilizer and a preparation method thereof. The preparation method comprises the following steps: first, adding waste paper or carton powder into a liquefier A to prepare a liquefied matter and modify; and then, uniformly mixing the modified liquefied matter and a curing agent C in a weight ratio of 1:1 as a coating material which is sprayed to the surfaces of fertilizer particles to be cured to films to obtain the coated control release fertilizer, wherein the coating material accounts for 2-8% of total weight of the fertilizer, the modified liquefied matter accounts for 0.5% of total weight of the fertilizer and the curing agent C accounts for 0.5% of total weight of the fertilizer. Compared with processing of common control release fertilizers, the fertilizer provided by the invention has the characteristics of few coating materials required, low production energy consumption, environment friendliness, production cost conservation and the like.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

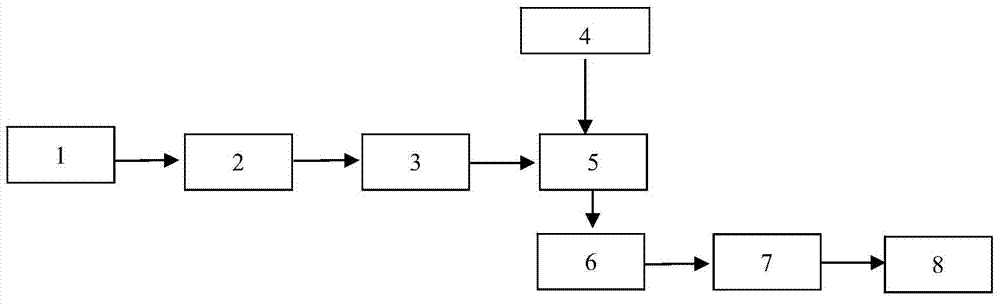

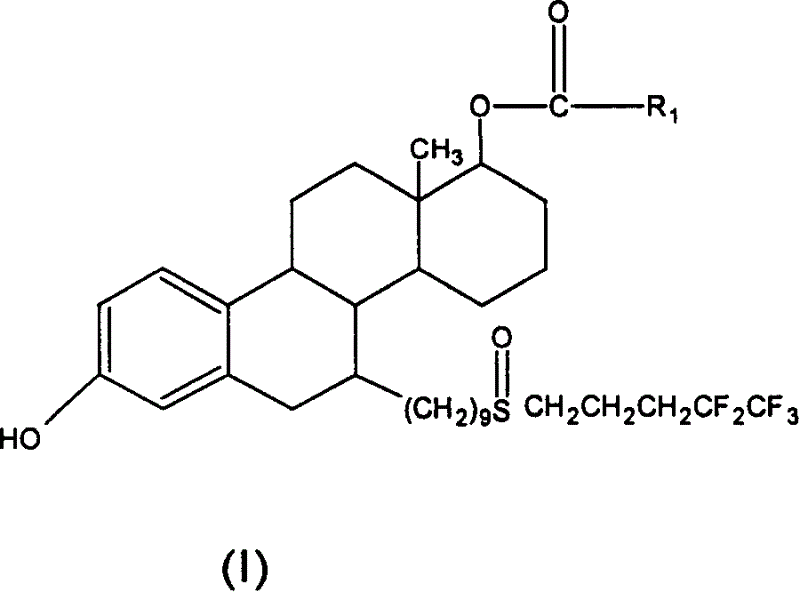

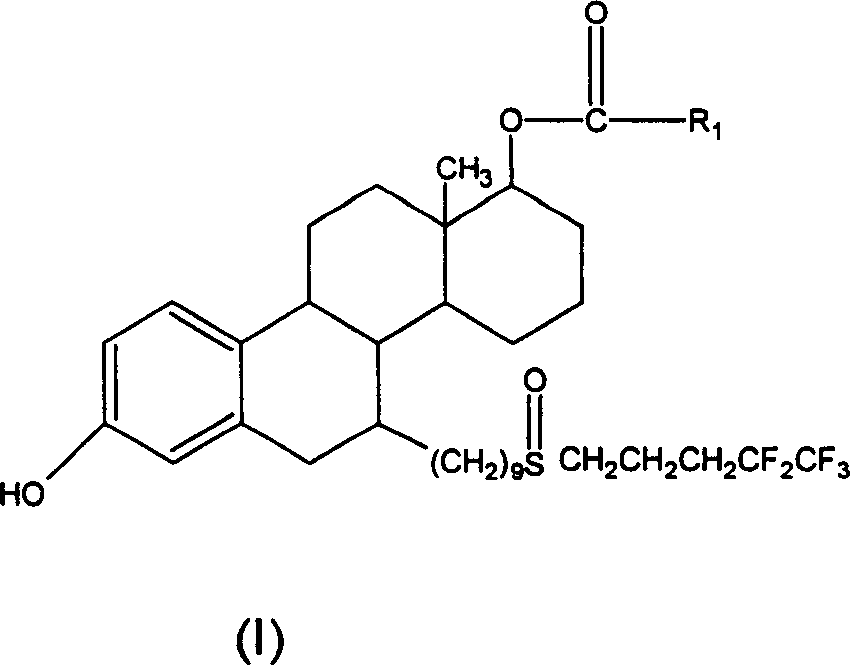

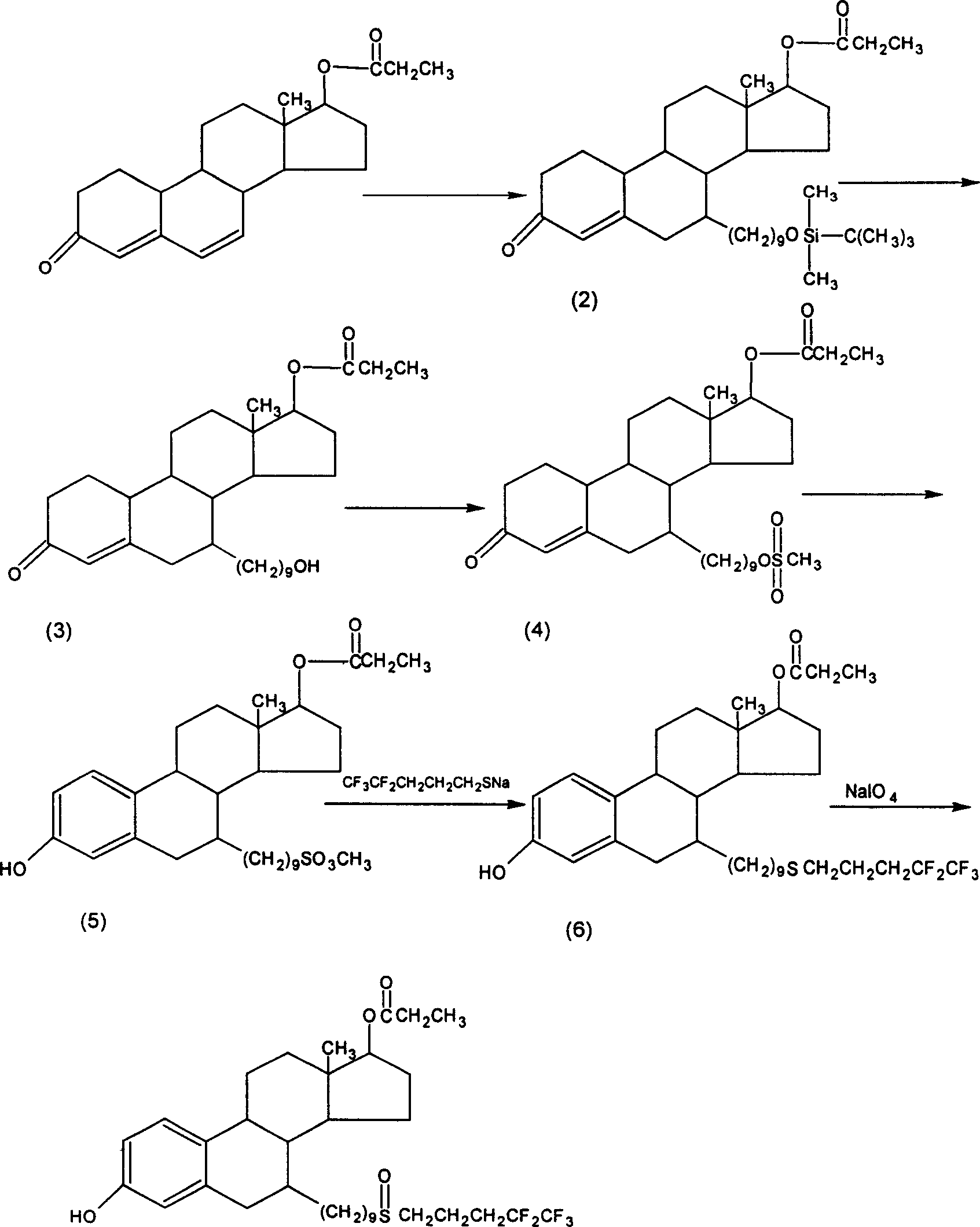

Steroid derivatives

InactiveCN1690073ASmall side effectsBlock stimulationOrganic active ingredientsSteroidsAlkanePhotochemistry

The invention relates to the compound and its salt in formula(ó±), wherein R1 represents linear or branched chain alkane with one to four carbon atoms, or halogenated linear or branched chain alkane; and bittern atoms mean fluorine atom, chlorine atom, bromine atom and iodine atom. Such compound is provided with therapeutic activity in breast cancer.

Owner:JIANGSU HANSOH PHARMA CO LTD

Preparing Method of Microporous Polyolefin Film Through Effective Extrusion

InactiveUS20100041779A1Avoid excessive oxidationIncreased durabilityCharging stationsElectric devicesPolyolefinPolymer science

The present invention relates to a process for manufacturing a microporous polyolefin film which can be used for various battery separators, separating filters and membranes for microfiltration. The process for manufacturing a microporous polyolefin film according to the invention comprises mixing / extrusion through efficient and separate injection of 15-55% by weight of polyolefin (Component I), and 85-45% by weight of a diluent (Component II) which forms thermodynamic single phase with the polyolefin and a diluent (Component III) which can undergo thermodynamic liquid-liquid phase separation with the polyolefin, into an extruder.

Owner:SK INNOVATION CO LTD

Preparation method of health-care grapefruit enzyme drink

InactiveCN105581209AReduce the loss of nutrientsRetain enzyme activityFood scienceFlavorLactobacillus plantarum

The invention provides a method for preparing a health-care enzyme drink from grapefruits and belongs to the technical field of bioengineering technologies. According to the method, the grapefruits are taken as a main fermentation raw material, are peeled and mashed to be pulpy, raw honey and purified water are added, nectariferous bacteria, lactobacillus casei and lactobacillus plantarum strains are taken as fermentation strains, a fermentation liquid which is 1%-5% of the volume of a fermentation stock solution is added to a fermentation system, the fermentation temperature is 25-35 DEG C, pH ranges from 5.0 to 8.0, the fermentation time lasts for about 10d, and the health-care grapefruit enzyme drink is prepared. According to the method, complete fermentation is realized, various enzymes, vitamins, amino acid and micro elements are sufficiently released, the product has a unique flavor of grapefruits, is palatably sweet and sour and has rich nutrition, and a traditional fermentation technique is adopted.

Owner:JIANGXI GUOGUO BIOTECH CO LTD

Health food containing plurality of trace nutrient elements

ActiveCN103599137ASufficient supplyQuantitative proportional balance and coordinationSenses disorderHydrocarbon active ingredientsDiseasePantothenic acid

The invention provides a healthcare food containing a plurality of trace nutrient elements, and belongs to the technical field of trace nutrient element healthcare food. The healthcare food is composed of twenty eight kinds of materials, namely calcium, magnesium, zinc, iron, selenium, manganese, copper, chromium, cobalt, molybdenum, vitamin A, vitamin C, vitamin E, vitamin D, vitamin B1, vitamin B2, vitamin B6, vitamin B12, nicotinamide, pantothenic acid, biotin, folic acid, resveratrol, procyanidine, astaxanthin, lycopene, xanthophylls, and zeaxanthine. The healthcare food organically compounds a plurality of essential mineral substances, vitamins, and antioxidant plant extracts together and presses the materials into tables or capsules. The elements in the healthcare food cooperates with each other to generate a balanced and synergetic effect; the supply amount of biological elements is sufficient; the element ratio is balanced and harmonious, is totally in a safe range of diet recommended amount provided by Chinese Nutrition Society, and the health food provides an enough amount of nutrient elements for body physiological activities and body functions of preventing diseases and removing toxicity on the basis of safety.

Owner:李桂霞

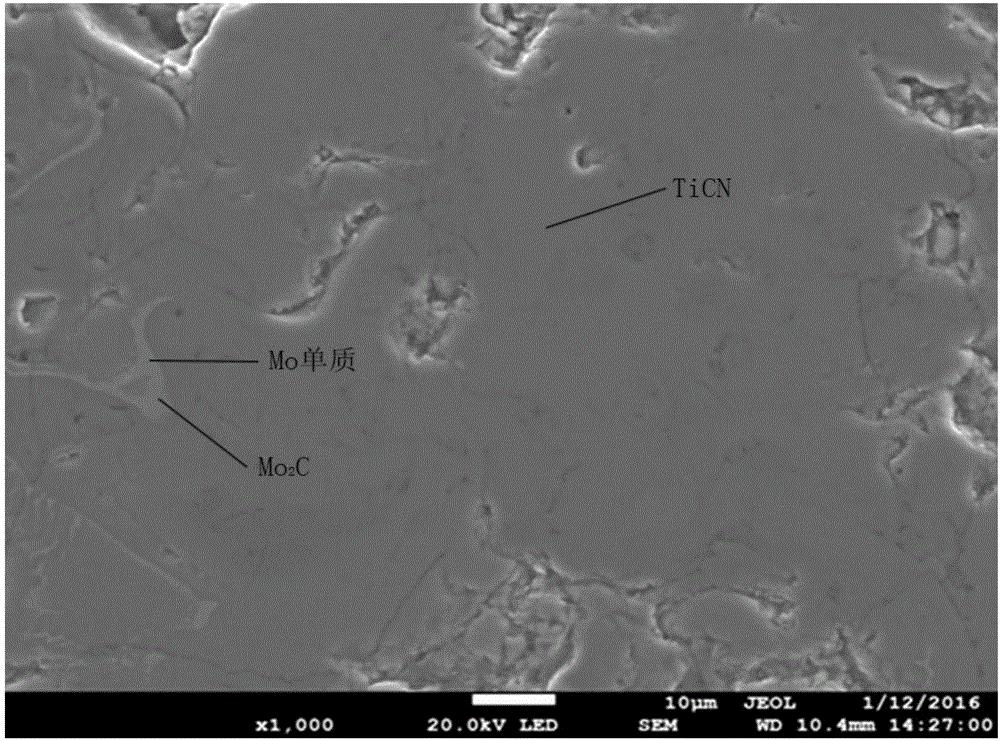

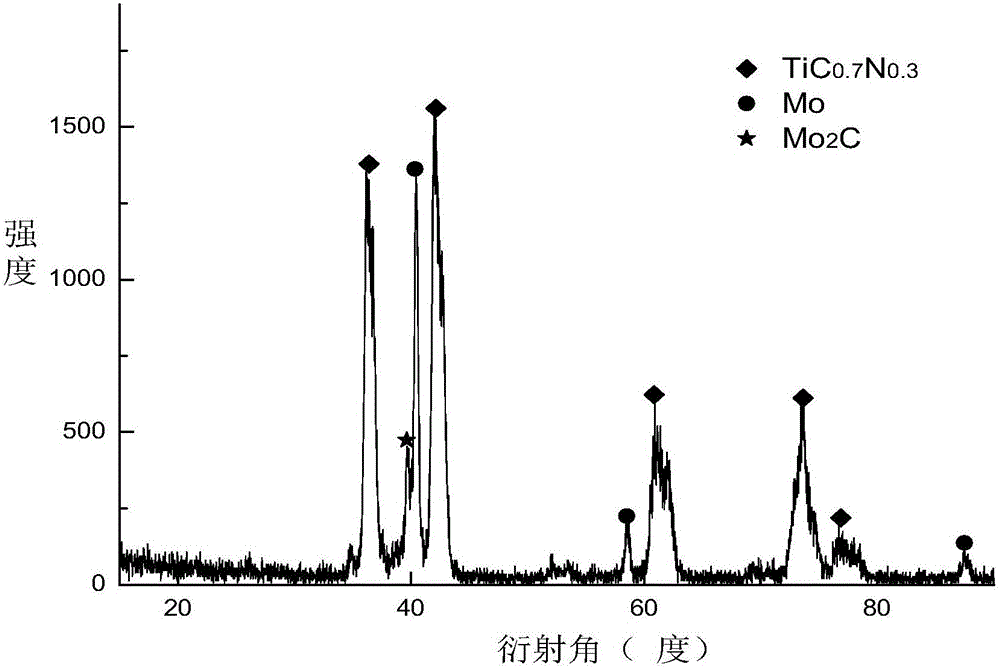

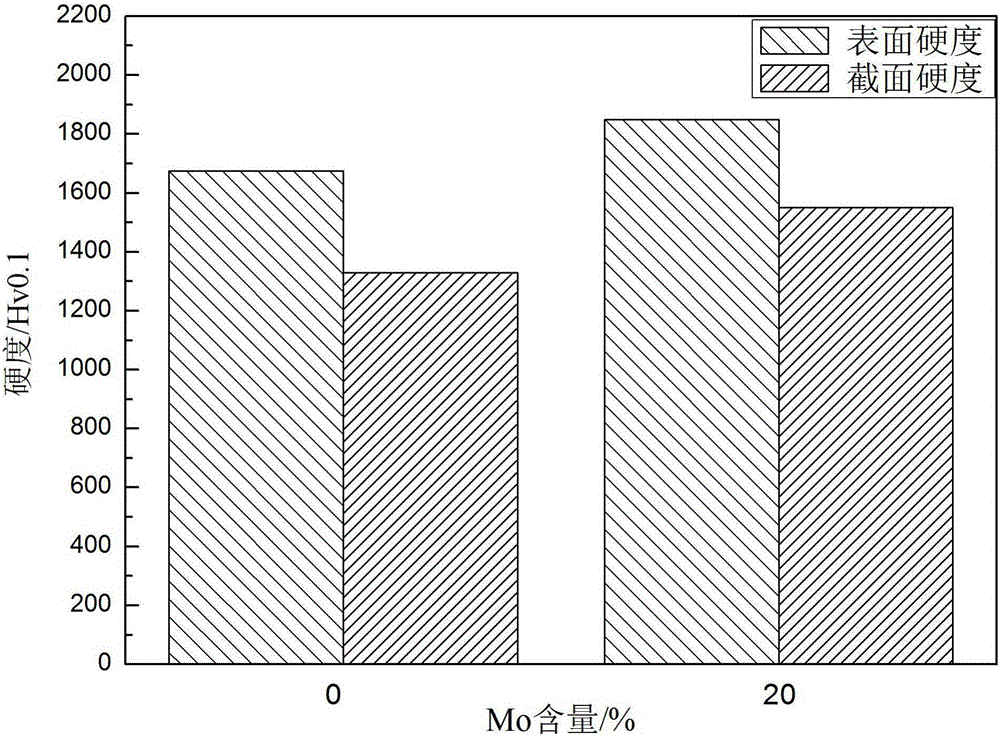

Preparation method of Mo-containing TiCN-based composite coating

InactiveCN106435444AHigh hardnessImprove wear resistanceMolten spray coatingCeramic compositeHardness

The invention discloses a preparation method of a Mo-containing TiCN-based composite coating. The method comprises the following steps that firstly, the surface of a substrate sample is roughened; secondly, Ti / C composite powder and Mo powder are mechanically blended to obtain original feed composite powder; thirdly, the surface of a substrate is pre-coated with Ni-10%wtAl self-refluxing alloy power, so that a base layer with the thickness being 90-120 [mu]m is obtained; and fourthly, the surface of the base layer is coated with the original feed composite powder, so that a TiCN-Mo metal-based ceramic composite coating with the thickness being 300-500 [mu]m is obtained. The plasma-spraying TiCN-Mo metal-based ceramic composite coating is high in hardness, good in abrasion resistance and corrosion resistance, suitable for workpieces, such as cutters, drill bits, moulds and the like in the fields of machinery, automobile making, aerospace and the like, under abrasive and corrosive environment conditions, and the plasma-spraying TiCN-Mo metal-based ceramic composite coating has extremely wide application prospects.

Owner:HEBEI UNIV OF TECH

Processing technology for perfuming, corrosion-prevention and bacteria-prevention of folding fan bamboo ribs

ActiveCN104858952APromote absorptionAvoid excessive oxidationBiocideWood treatment detailsFiberCotton cloth

The invention discloses a processing technology for perfuming, corrosion-prevention and bacteria-prevention of folding fan bamboo ribs, and belongs to the field of folding fan bamboo material processing technologies. The processing technology is characterized by comprising the steps of preparation of an anti-bacterial and anti-corrosion solvent, preparation of anti-bacterial and anti-corrosion perfume, stewing, spraying and obtaining a patina layer. In addition, a surfactant, a detergent dispersant and sodium carboxymethylcellulose are added into the anti-bacterial and anti-corrosion solvent for use to enable all the anti-bacterial and anti-corrosion components to integrate, and the maximization and optimization of the anti-bacterial and anti-corrosion effect are realized under the synergistic effect; the bamboo ribs are subjected to phased baking perfuming by adopting pure natural plant perfume, so that fragrance can go deep into the bamboo fibers slowly, a fumigation smoke smell is avoided, and the fragrance added is fresh for a long time; the surfaces of the bamboo ribs are wiped repeatedly by cotton cloth until a glossy patina layer appears, so that anti-oxidation layers on the surfaces can be compacted, the weather resistance is effectively improved, anti-bacterial and anti-corrosion effective components going deep into the bamboo ribs are not easy to lose, and fragrance can also be slowly released; therefore, the bamboo ribs are quieter, more attractive and elegant in sense and smell.

Owner:QIDONG CHUANGLYU GREENING ENG CO LTD

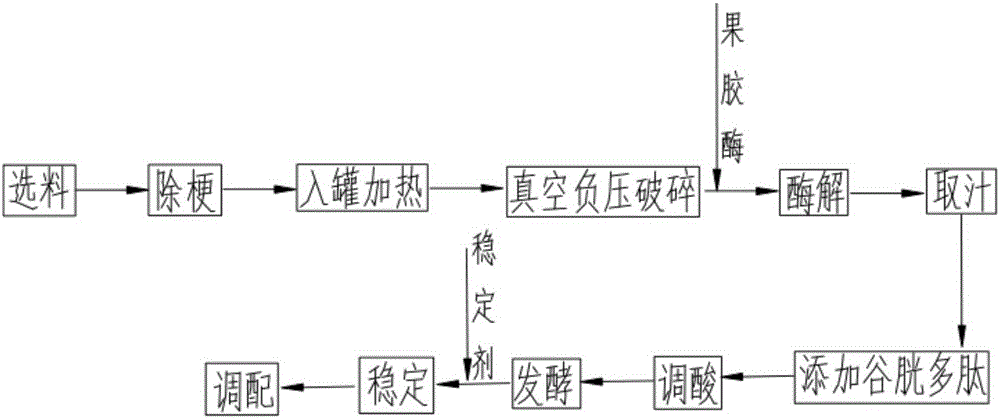

Making method for cherry fruit wine

InactiveCN105176752AQuick extractionFully extractedMicroorganism based processesAlcoholic beverage preparationFruit wineTannin

The invention relates to a making method for cherry fruit wine. The method comprises the steps of material selecting, stalk removing, heating, breaking, enzymolysis performing, juice extracting, glutathione adding and acidity regulating, fermenting, stabilizing, blending and the like. According to the making method for the cherry fruit wine, due to the fact that a quick heating and vacuum negative pressure fruit breaking extracting technology is adopted, on one hand, the cherry peel tissue is immediately broken, pigment and high-quality tannin in the peel can be quickly and fully extracted, bitter and astringent tannin in the seeds cannot be extracted, and on the other hand, microorganisms, oxidase and the like of cherries can be killed, and bad flavor is prevented from being generated due to oxidation or natural fermentation.

Owner:LUDONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com