Preparation method of functional gradient cathode of intermediate low temperature solid oxide fuel cell

A solid oxide and functionally gradient technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of cumbersome single-cell preparation process, and achieve the effects of facilitating scale-up and large-scale manufacturing, improving electrode performance, and avoiding excessive oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

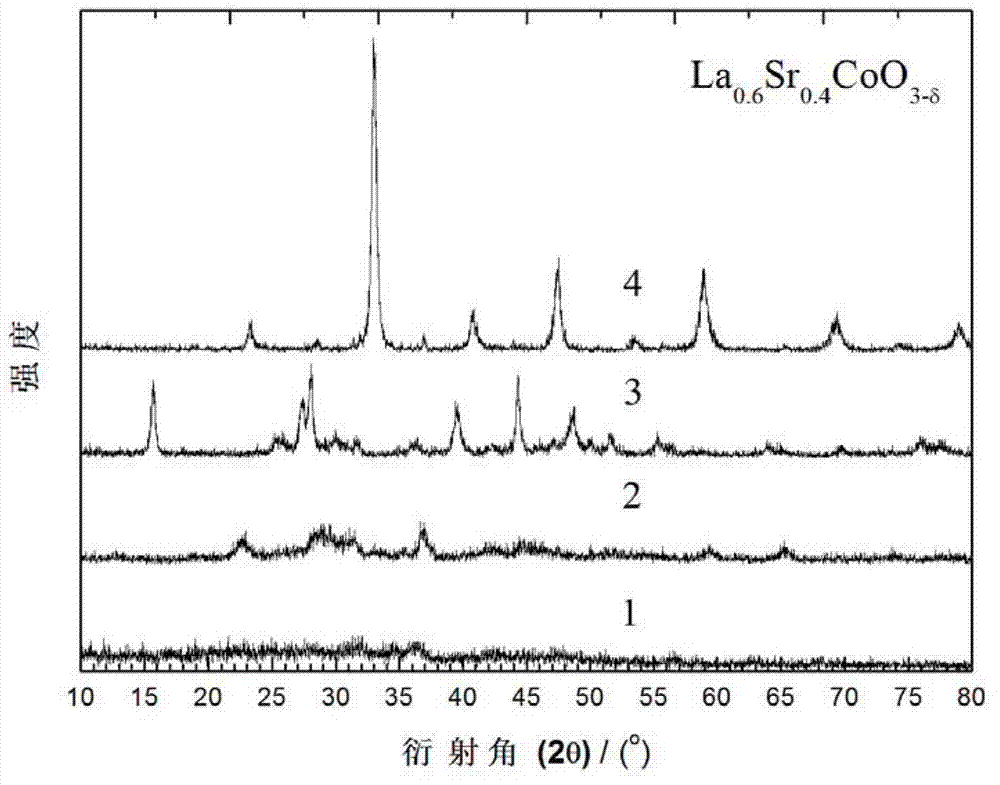

[0034] The first step, using metal salt as raw material, according to the chemical formula La 0.6 Sr 0.4 CoO 3-δ Prepare the aqueous solution of metal salt, according to the number of moles of citric acid and La 0.6 Sr 0.4 CoO 3-δ The total molar ratio of metal ions in the medium is 4:1, adding citric acid, adding ethylene glycol according to the molar ratio of ethylene glycol to citric acid molar ratio of 4:1, stirring while heating to make the solution into a sol, and then forming a gel, Then the gel was calcined in air at 400°C for 2 hours, then calcined in Ar atmosphere at 700°C for 6 hours, and finally the calcined powder was ball milled for 24 hours, and then dried to obtain La 0.6 Sr 0.4 CoO 3-δ Cathode precursor powder.

[0035] The second step, using metal salts as raw materials, according to the chemical formula La 0.6 Sr 0.4 CoO 3-δ Prepare the aqueous solution of metal salt, press La in this solution 0.6 Sr 0.4 CoO 3-δ with Ce 0.8 Gd 0.2 o 2-δ Add C...

Embodiment 2

[0042] The first step, using metal salts as raw materials, according to the chemical formula PrBaCo 2 o 5+δ Prepare an aqueous solution of metal salt, stir while heating to turn the solution into a sol, and then form a gel, then calcinate the gel at 450°C for 4 hours, and finally ball mill the calcined powder for 24 hours. Dry to obtain PrBaCo 2 o 5+δ Cathode precursor powder.

[0043] The second step, using metal salt as raw material, according to the chemical formula PrBaCo 2 o 5+δ Prepare an aqueous solution of metal salts, in this solution press PrBaCo 2 o 5+δ with Ce 0.8 SM 0.2 o 2-δ Add Ce at a weight ratio of 80:20 0.8 SM 0.2 o 2-δ Powder, heated while stirring to make the solution into a sol, and then form a gel, and then the Ce 0.8 SM 0.2 o 2-δ and the gel complex were calcined at 450°C for 4 hours, and finally the calcined powder was ball milled for 24 hours, and then dried to obtain PrBaCo 2 o 5+δ / C 0.8 SM 0.2 o 2-δ Composite cathode precursor p...

Embodiment 3

[0049] The first step, using metal salt as raw material, according to the chemical formula Nd 2 NiO 4+δ Prepare an aqueous solution of the metal salt, then slowly add the mixed solution to excess NaOH and NaOH with constant stirring 2 CO 3混 Precipitate in alkali solution, control the pH value of the precipitation end point, after the reaction is complete, continue to stir for 1 hour for suction filtration, wash the precipitate several times with distilled water, then use absolute ethanol for further washing and suction filtration, and dry at 100°C to prepare The precursor was obtained, and finally the dried powder was ball-milled for 48 hours, and Nd 2 NiO 4+δ Cathode precursor powder.

[0050] The second step, using metal salts as raw materials, according to the chemical formula Nd 2 NiO 4+δ Prepare an aqueous solution of metal salts, press Nd in this solution 2 NiO 4+δ with Ce 0.75 Y 0.25 o 2-δ Add Ce at a weight ratio of 75:25 0.75 Y 0.25 o 2-δ Powder, after f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com