Patents

Literature

90 results about "Over oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of fermented beef jerky

The invention discloses a production method of fermented beef jerky. The production method is characterized by comprising the steps of: cutting fresh beef into 3-4cm strips, soaking the strips by a mixing solution of CaCl2, composite phosphate and ginger juice for a whole night, adding glucose and a fermenting agent in the mixture, fermenting for 8 hours and roasting for 12 hours, boiling in boiling water and roasting for 1 hour, and implementing vacuum packaging and high-pressure sterilization to obtain the fermented beef jerky. The production method makes use of the acid production capacity of acid kumiss from natural fermentation and lactobacillus which is excellent in growth property, and is easy to control a fermentation process and short in fermentation cycle; the production method changes conventional processes of boiling twice, frying and the like, so that the deterioration of a later product due to over oxidation in the frying process is avoided and the shelf life is prolonged; and by adding a tendering pickling process and the fermentation process, the fermented beef jerky is unique in flavor, and has soft lactic acid taste and good color, reflects the fermentation property of lactobacillus, is soft and tender in texture, and is applicable to people of all ages.

Owner:贺银凤 +1

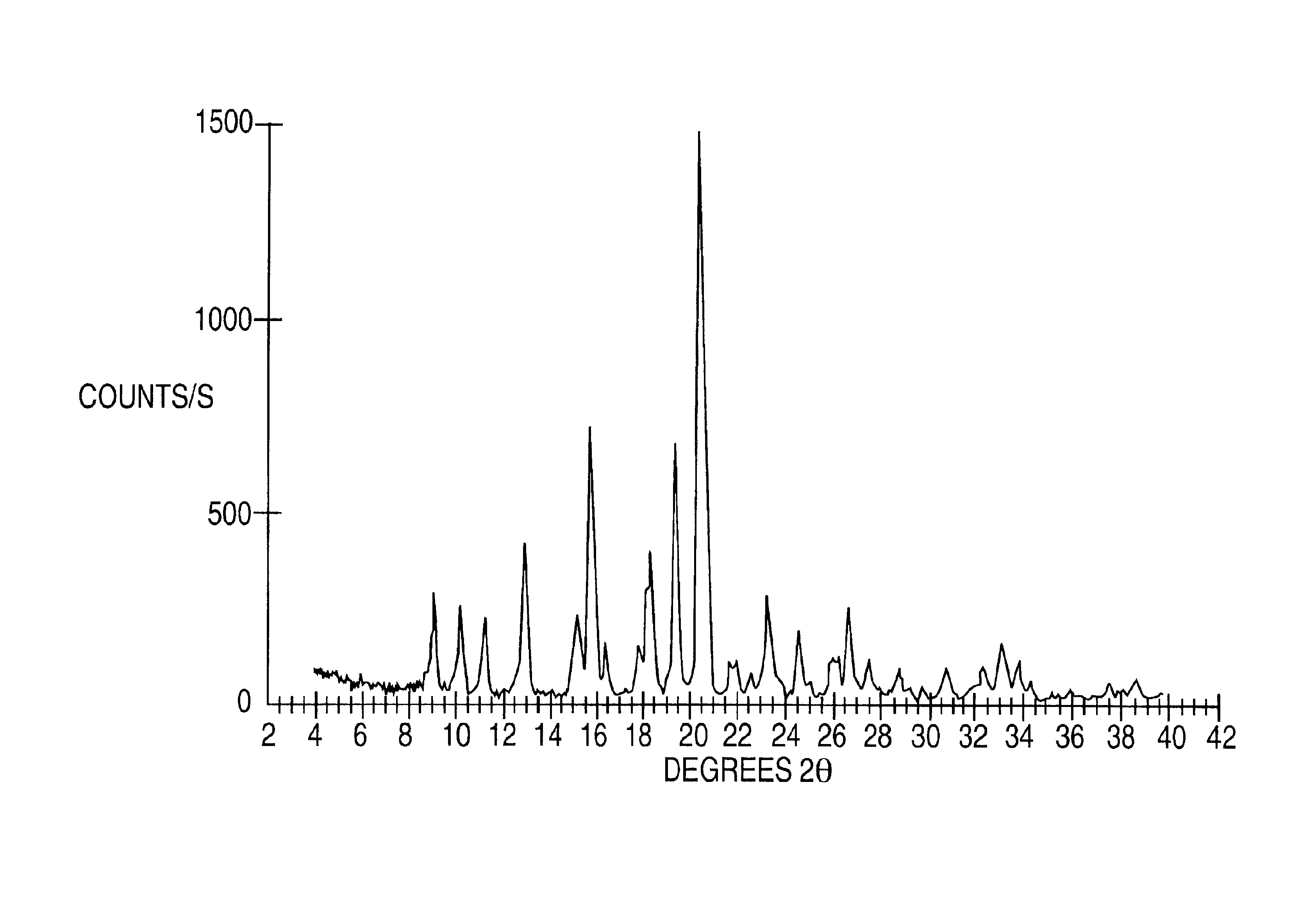

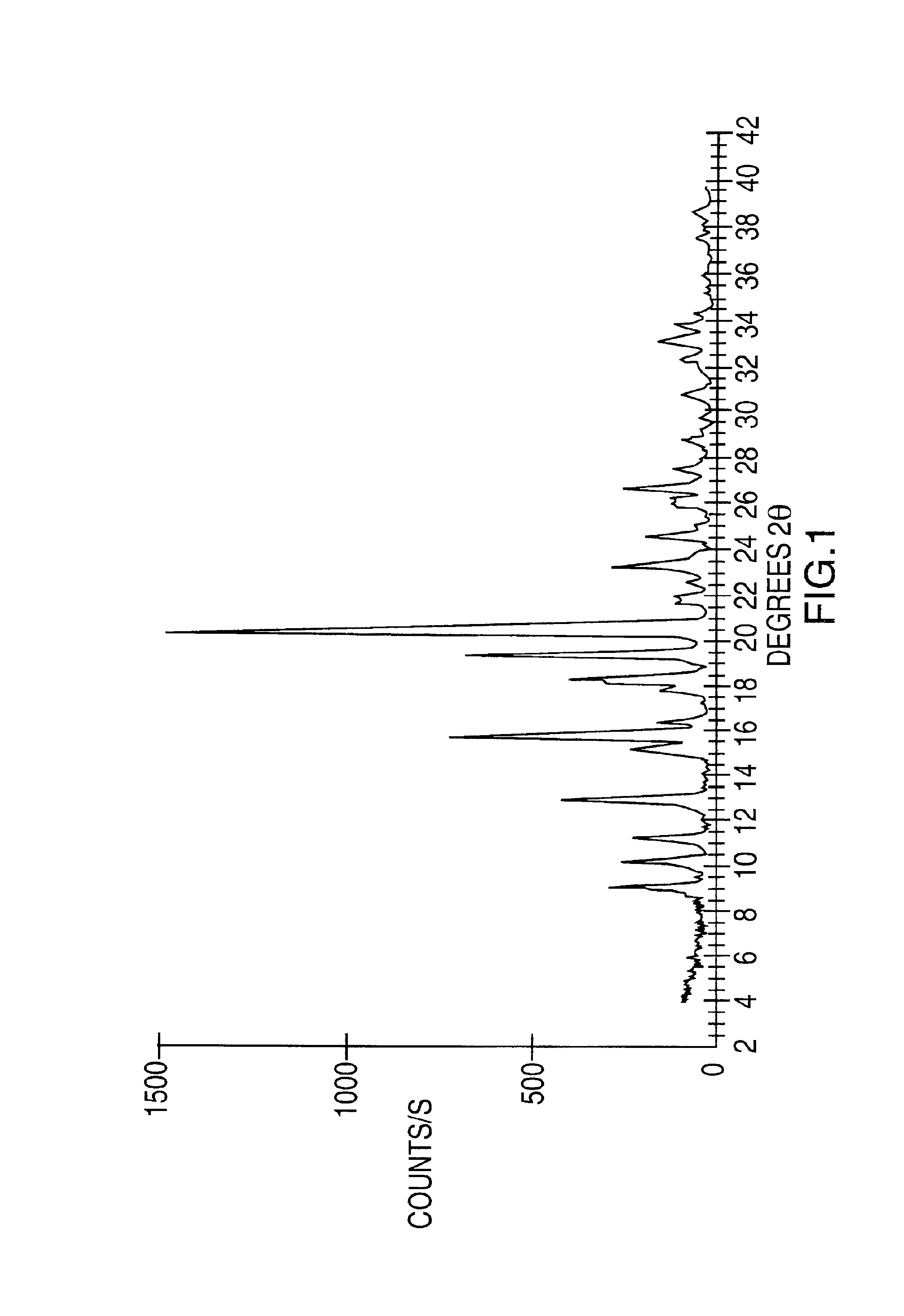

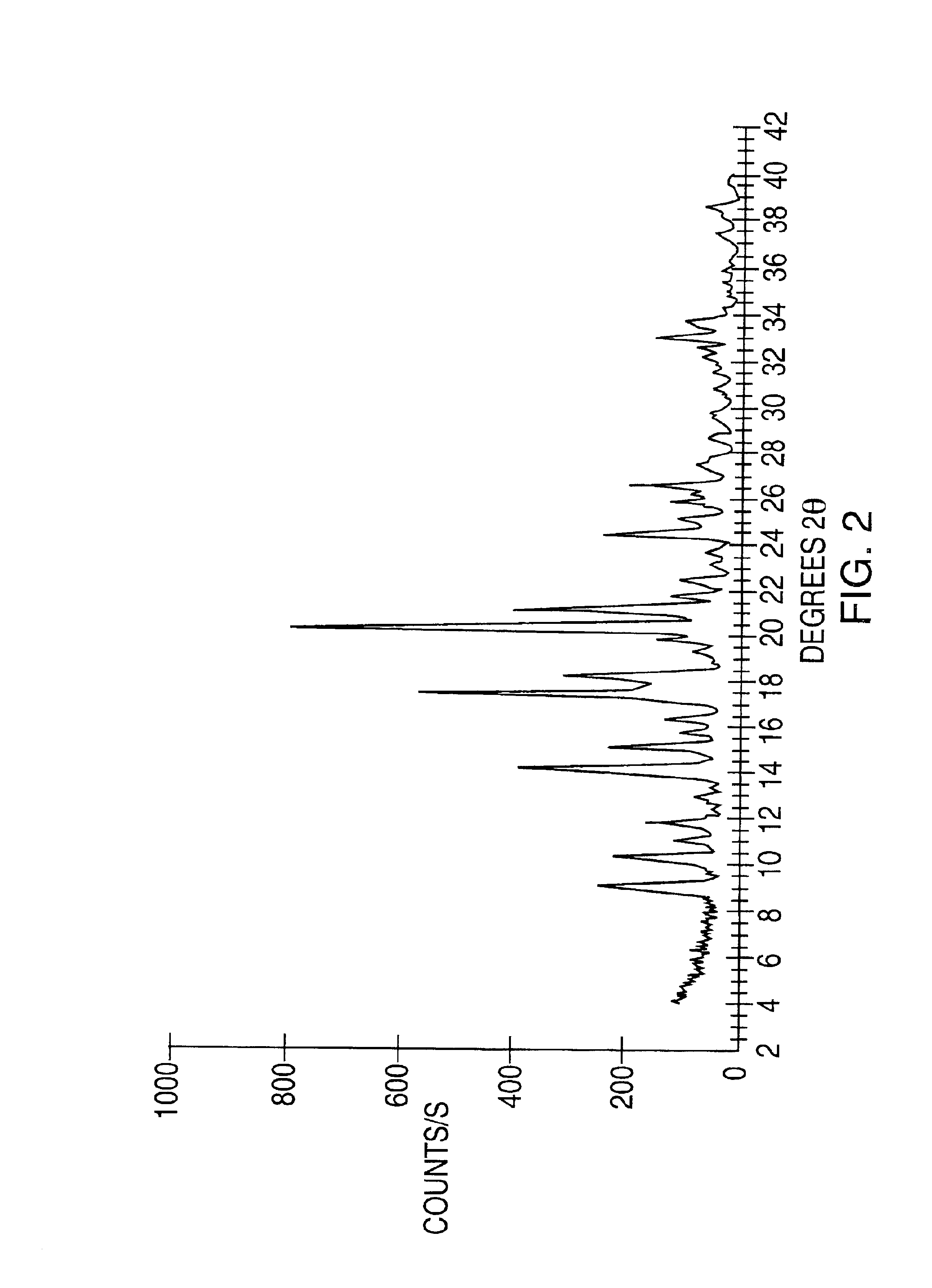

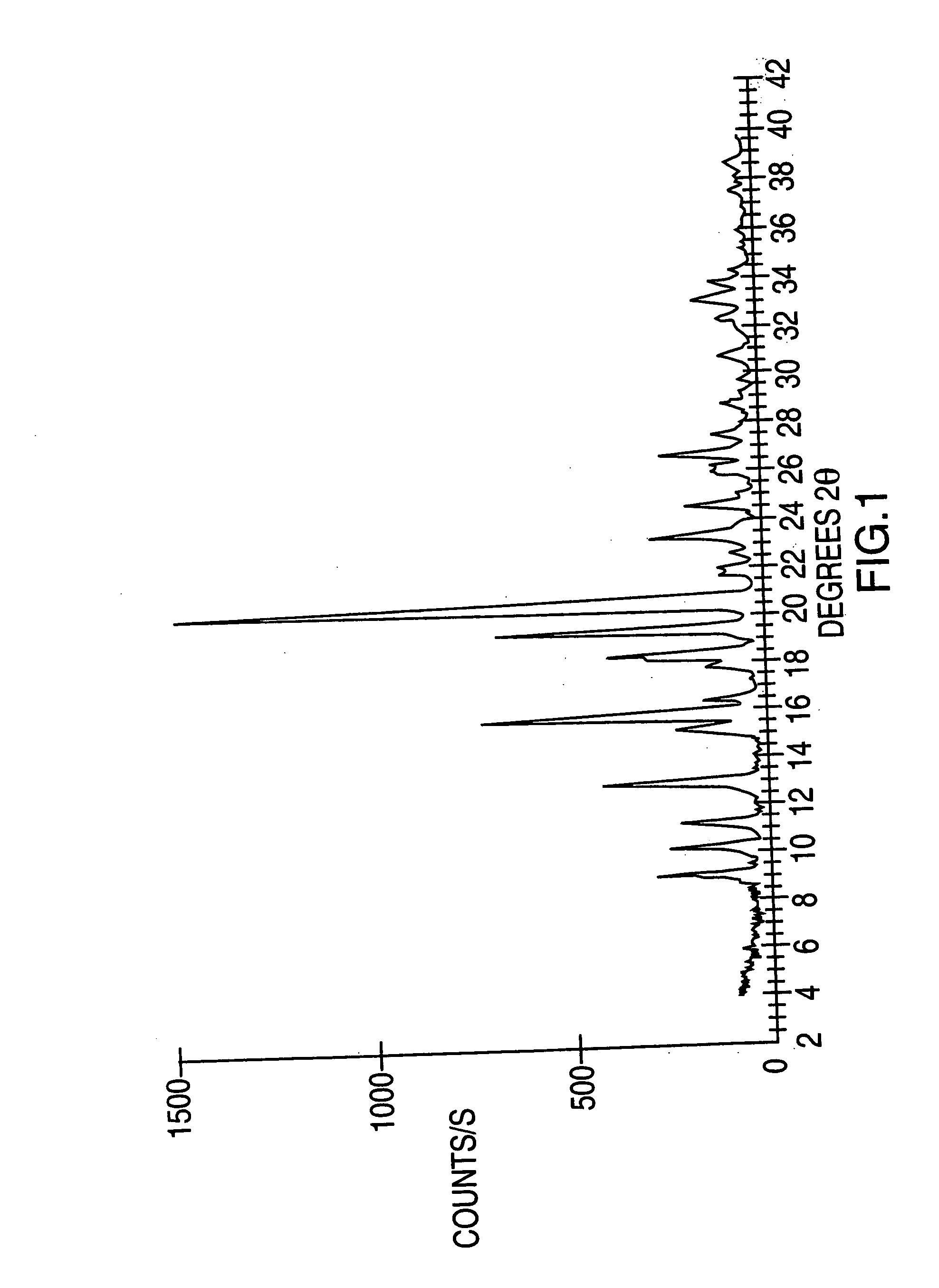

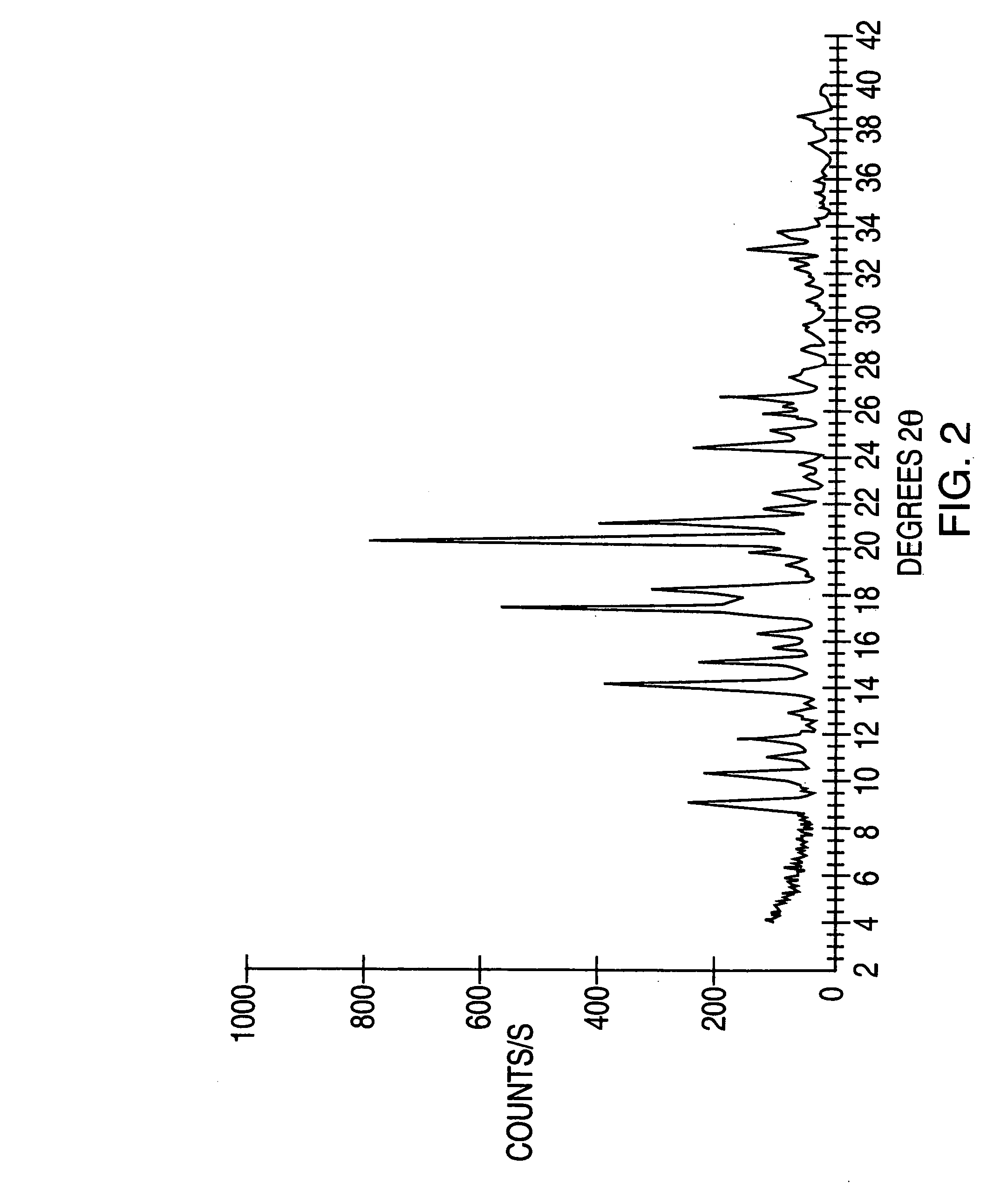

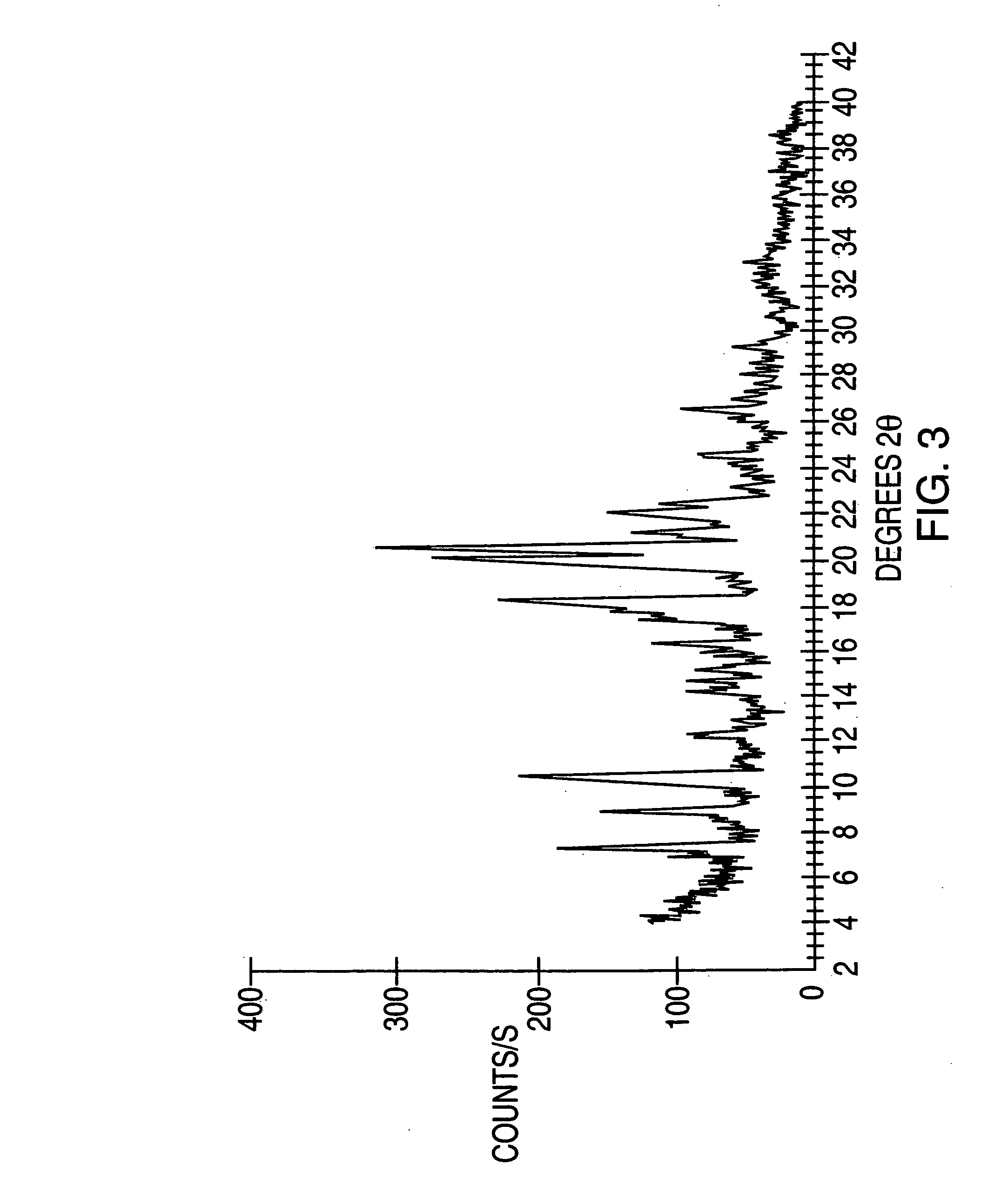

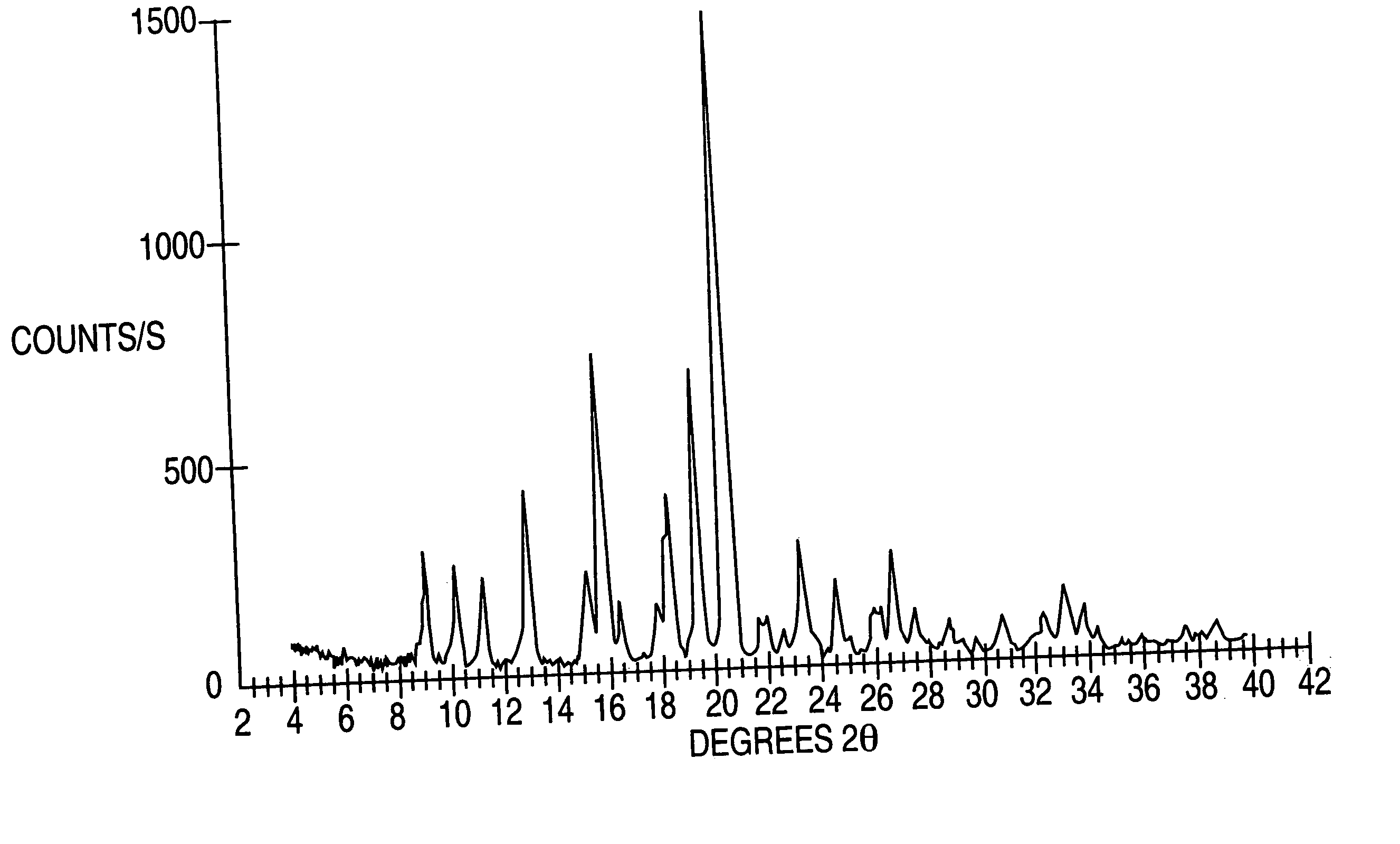

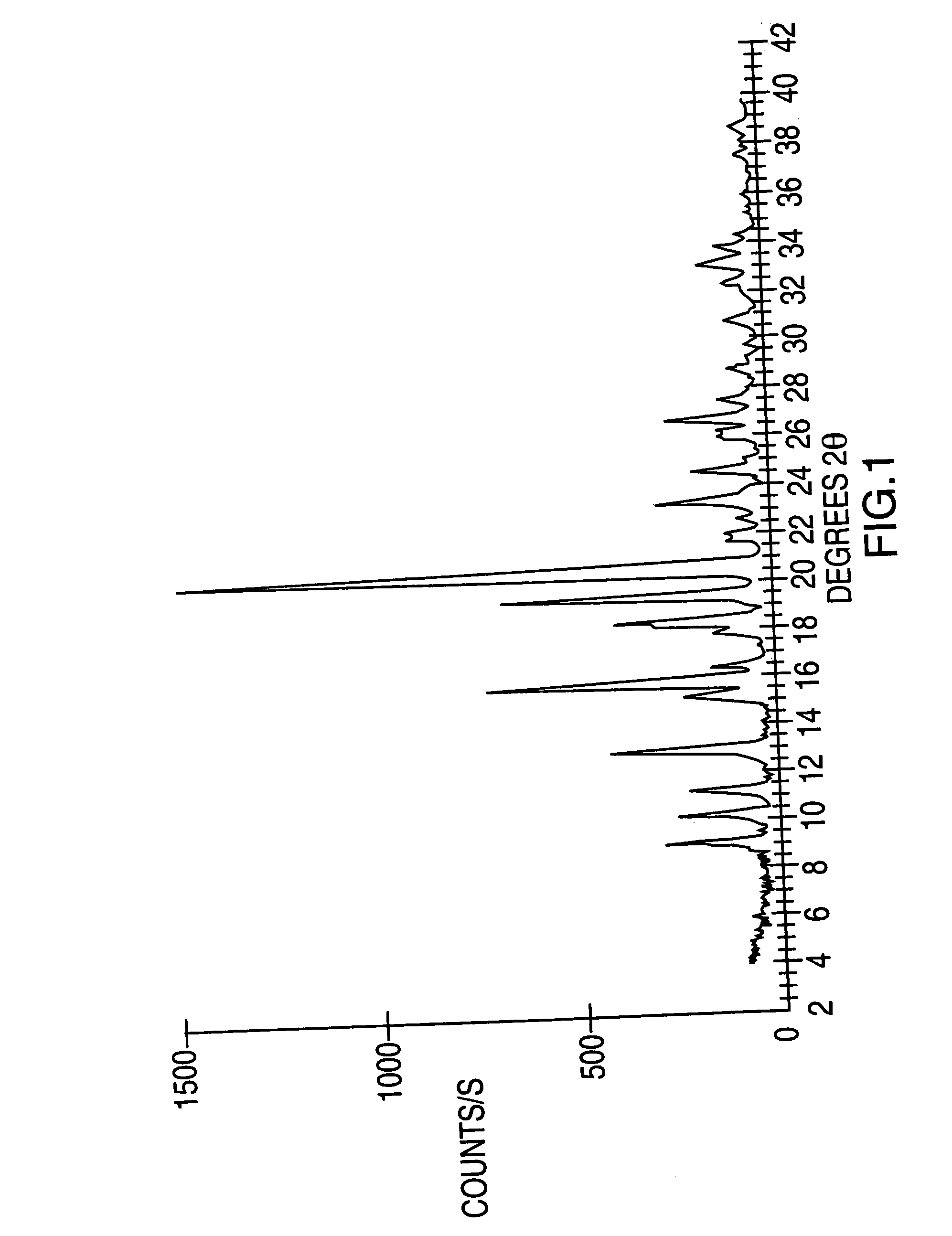

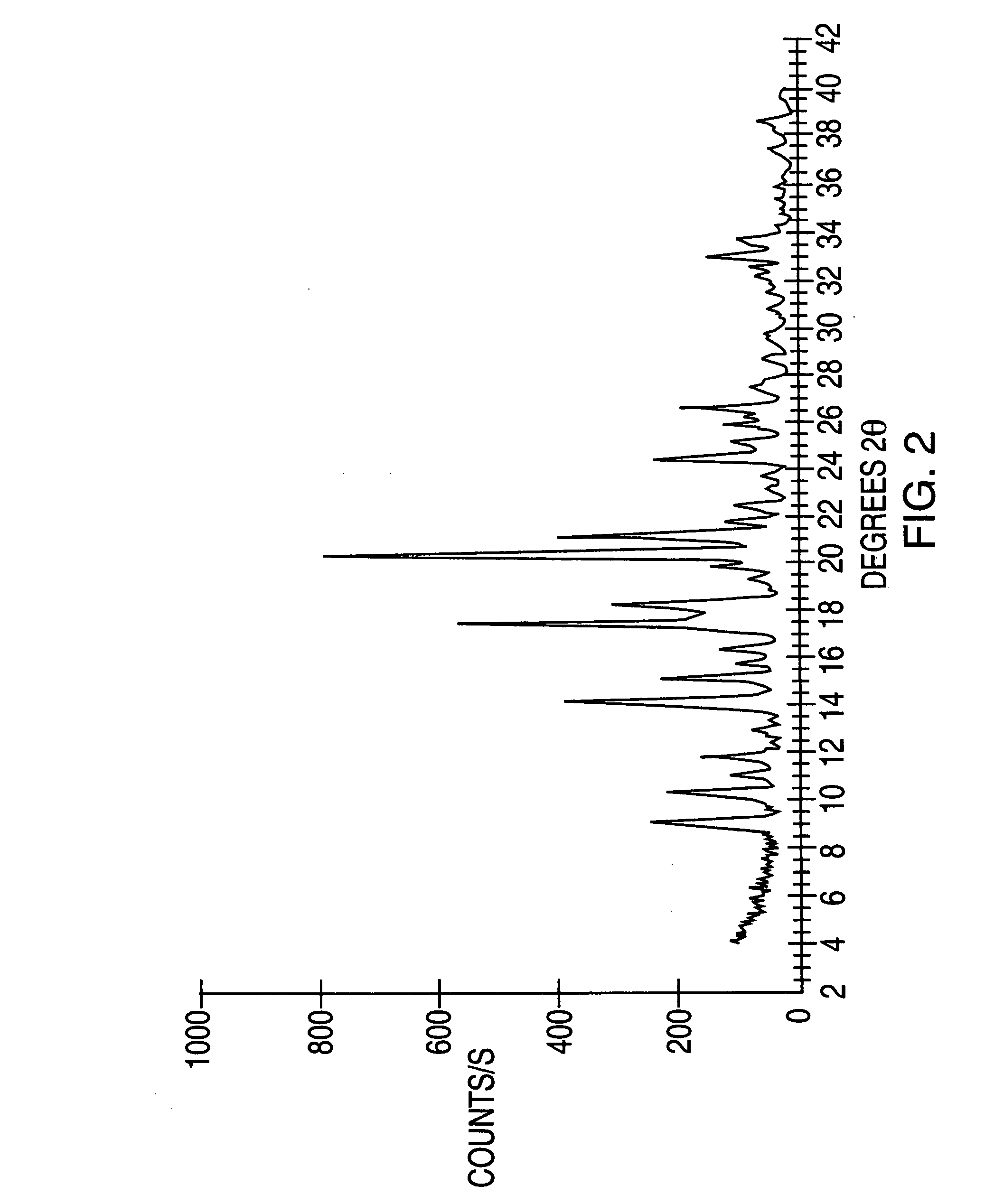

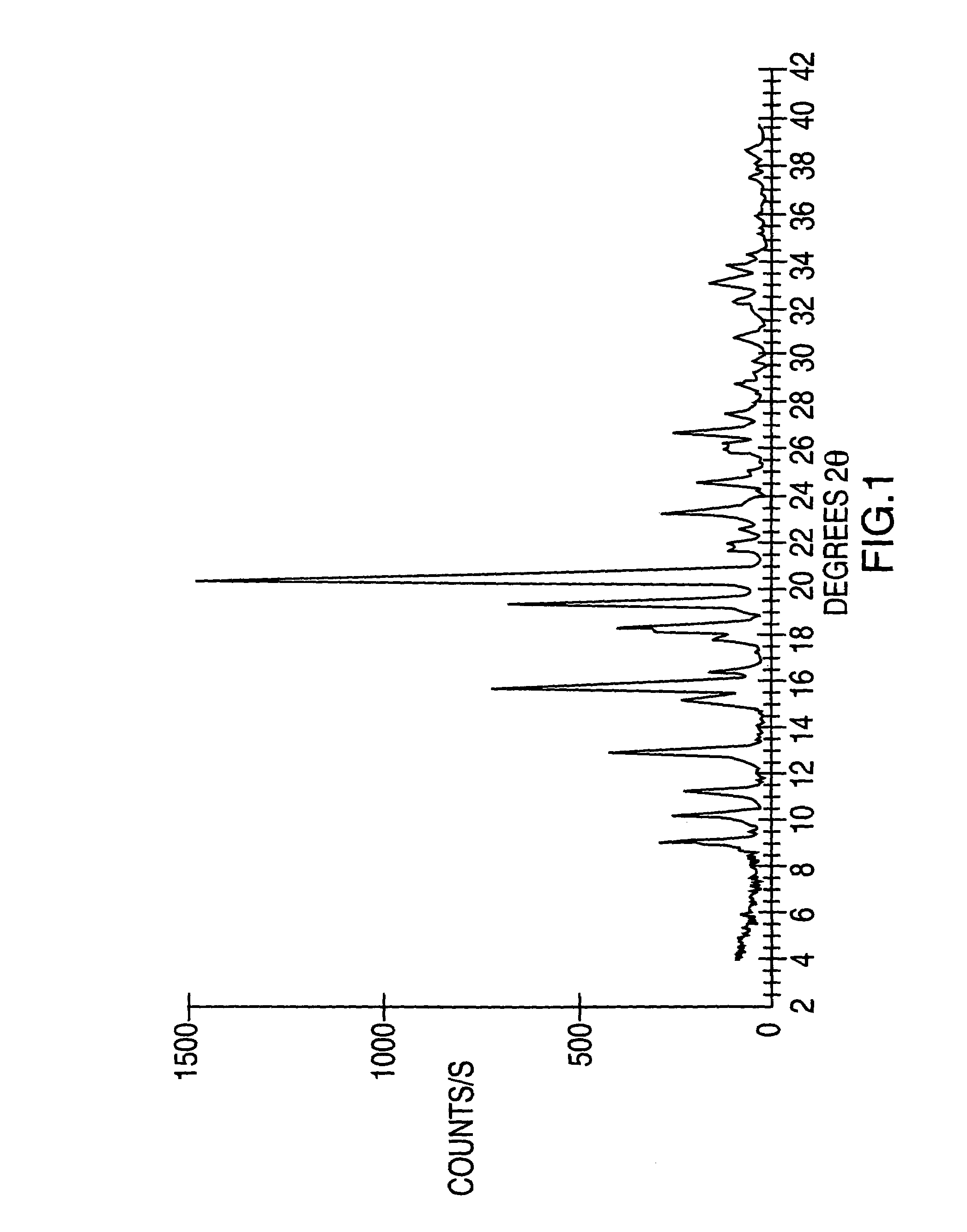

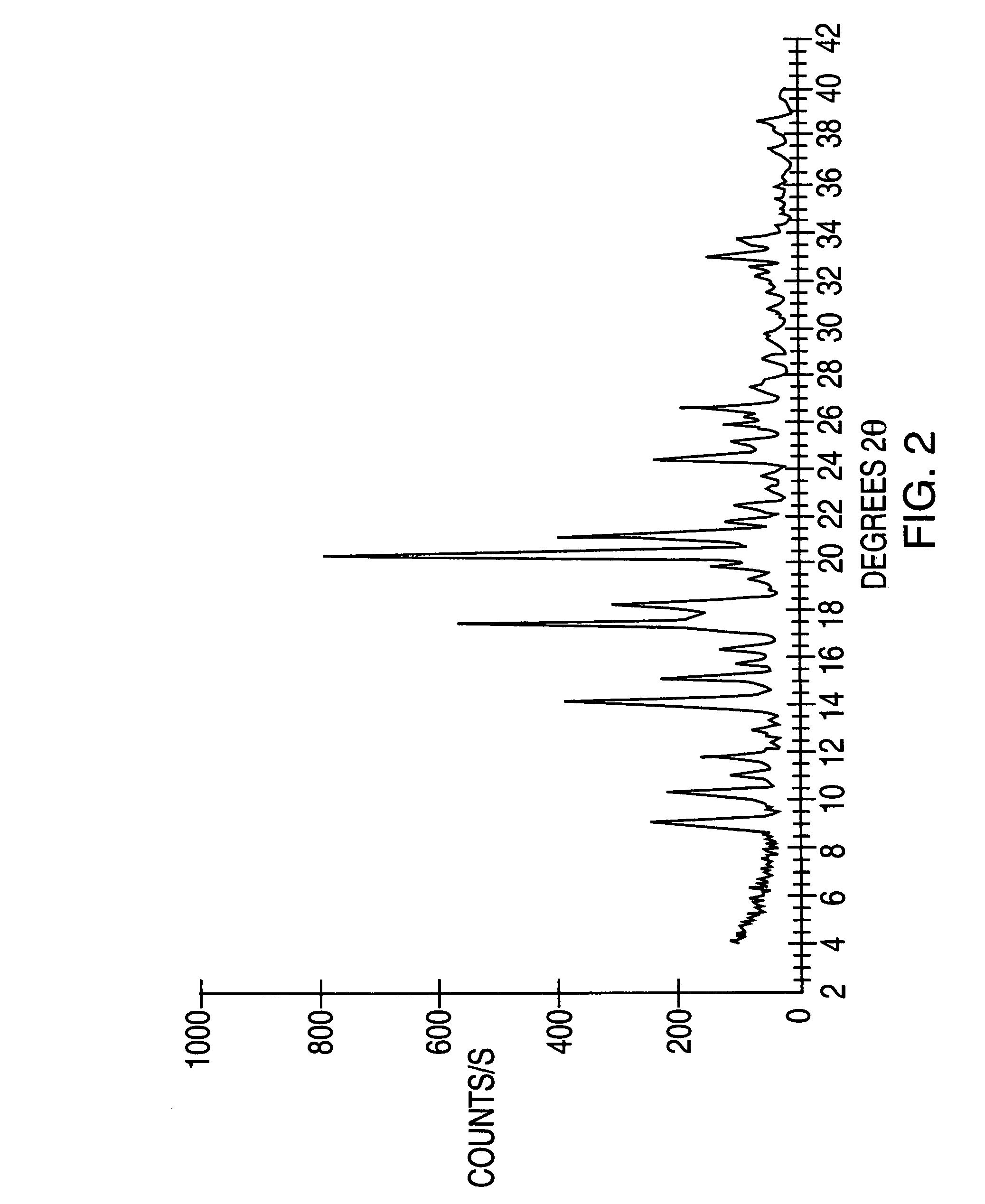

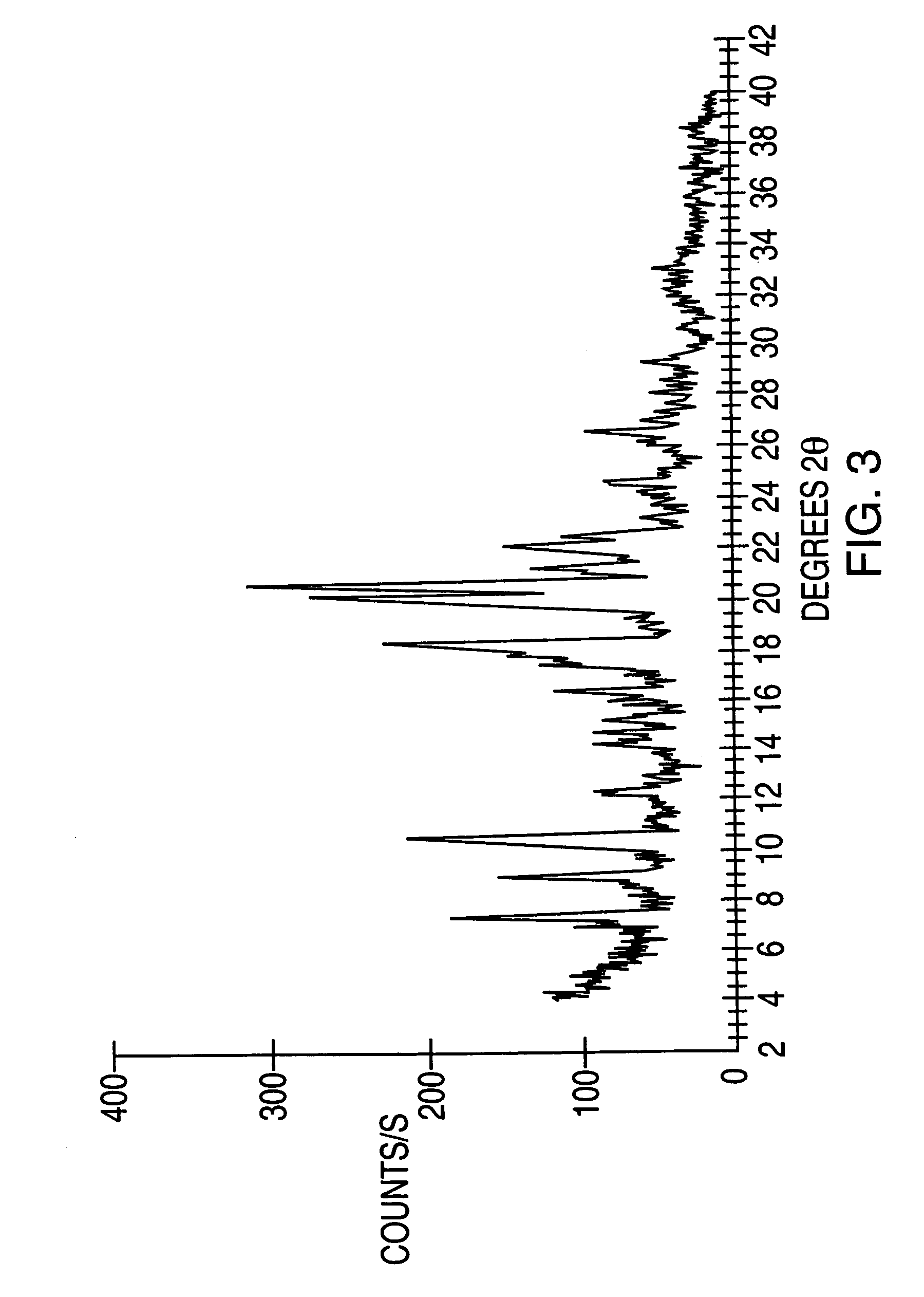

Oxidation method for preparing highly pure modafinil, crystalline forms of modafinil, and methods of preparing the crystalline forms

The present invention provides an improved process for preparing modafinil, whereby it may be isolated in high purity by a single crystallization. The process produces modafinil free of sulphone products of over-oxidation and other byproducts. The invention further provides new crystalline Forms II-VI of modafinil and processes for preparing them. Each of the new forms is differentiated by a unique powder X-ray diffraction pattern. The invention further provides pharmaceutical compositions containing novel modafinil Forms II-IV and VI.

Owner:TEVA PHARM USA INC

Abstraction method for ben oil

InactiveCN101508936AHigh purityLow in phospholipidsFatty-oils/fats productionWater bathsOrganic solvent

The invention provides a method for extracting horseradish tree oil from horseradish tree seeds, which is characterized by comprising the following steps: horseradish tree kernel powder sieved with 60 meshes of a standard test sieve is blended with water according to the mass ratio of horseradish tree kernel powder: water equaling to 1:5-12, the Ph value of the mixture is adjusted to be 4-8, the mixture is added with enzyme according to the mass ratio of the horseradish tree kernel powder: enzyme equaling to 1:0.001-0.05, and then reacts for 8-48 hours in an enzymolysis way in water bath of 30-60 DEG C normal temperature; the mixture is separated and dissociation oil layer at the upper layer is separated; emulsion is centrifugalized again; the secondary dissociation oil layers are combined to obtain the horseradish tree oil. The horseradish tree oil which can be directly eat is obtained in the condition that an organic solvent is not used, has high purity, low phosphatide content, light color, and low acid number and over oxidation value. The method for extracting horseradish tree oil is safe, efficient, energy-saving and environment-friendly.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

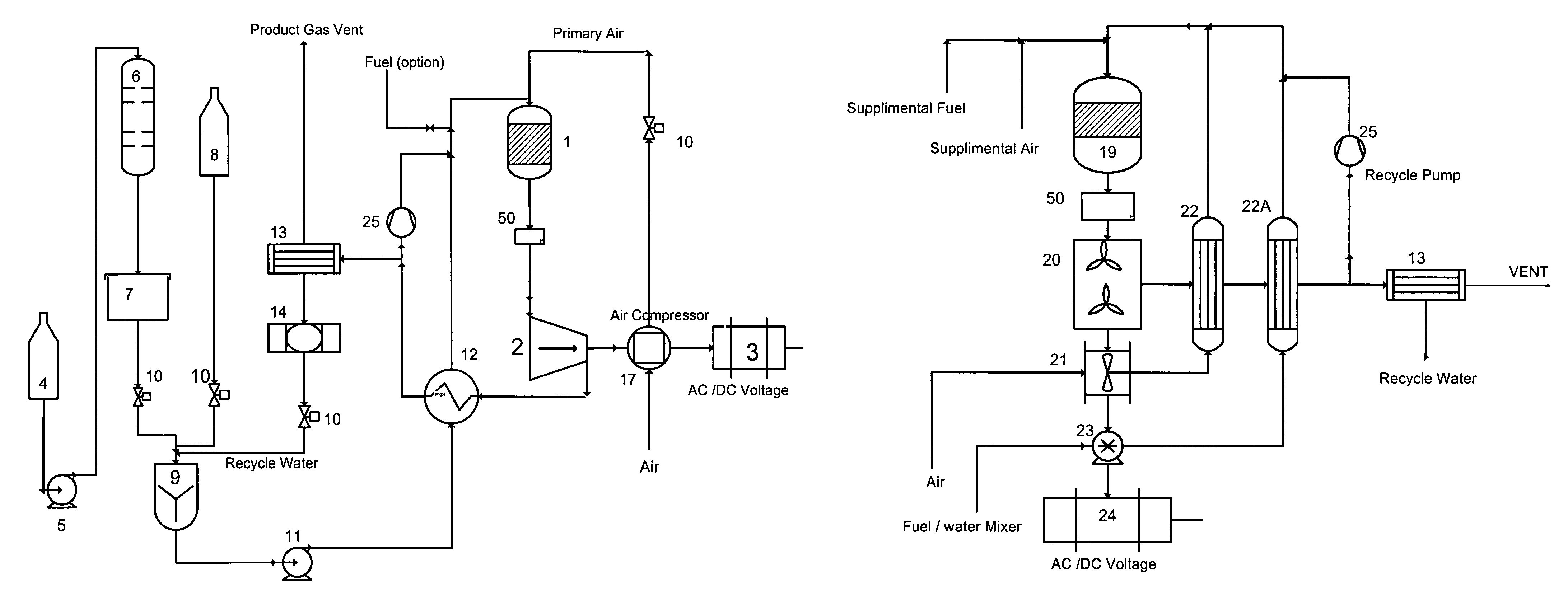

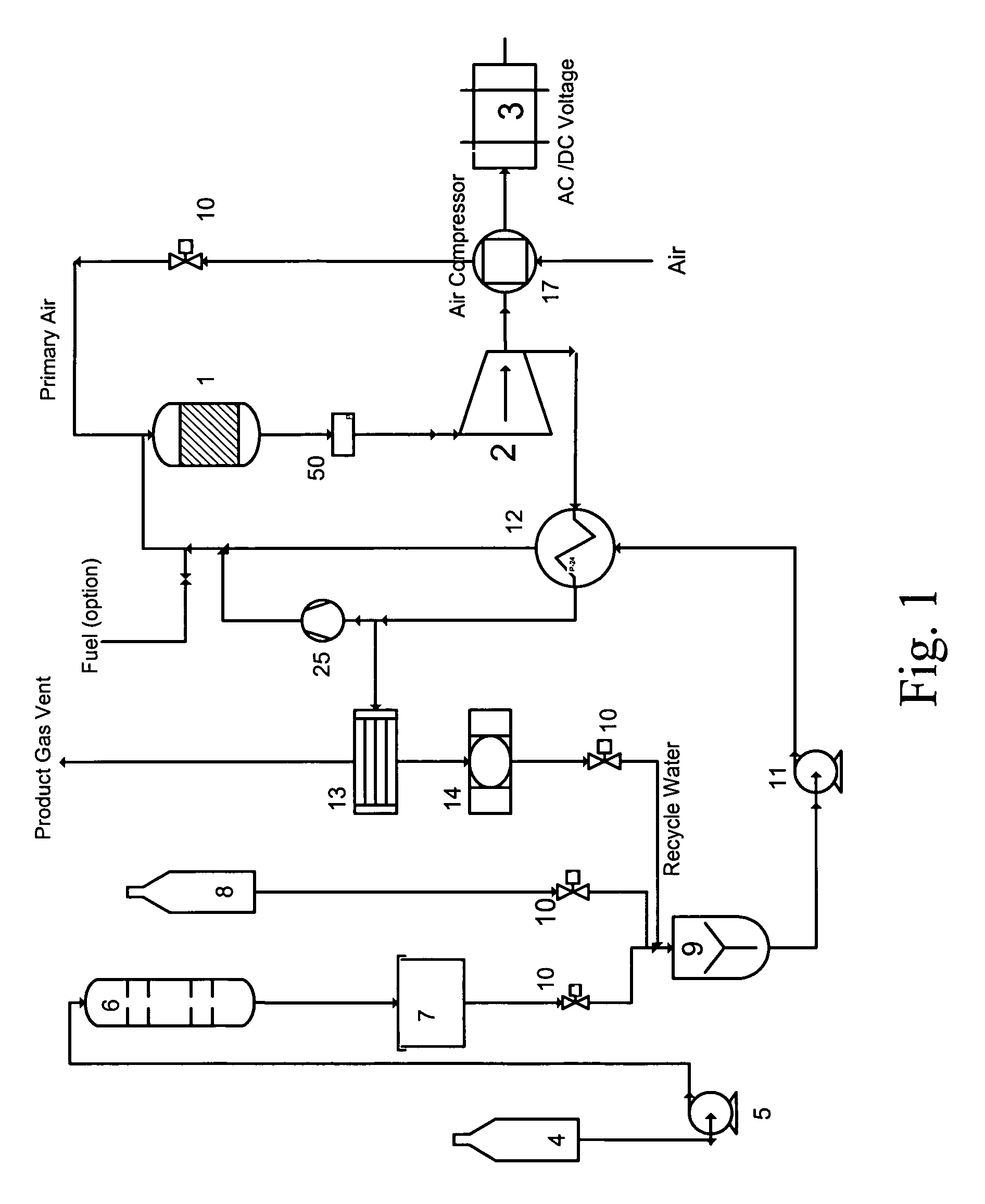

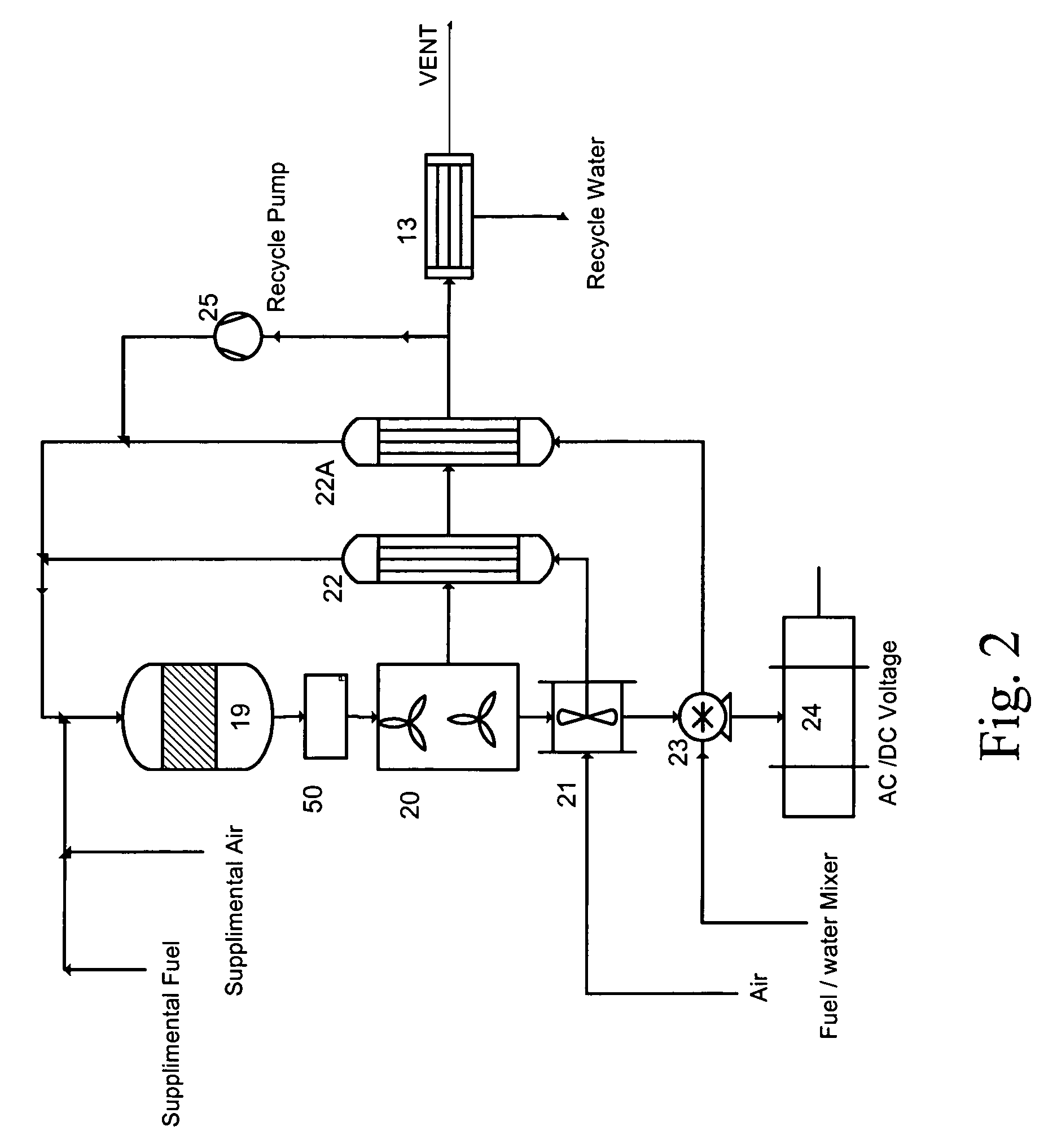

Catalytic engine

InactiveUS8397509B2Increased durabilityExtended service lifeTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionOver oxidationPower station

A catalytic engine comprises a catalytic reformer and a turbine, and it employs the process steps of introducing a reactant mixture of fuel, air, water and recycled exhaust gas into a reaction zone, reacting said fuel mixture over oxidation catalysts in the reaction zone by adjusting the CO2 / C, H2O / C, O2 / C ratios and the % fuel of the reactant mixture to maintain the reactor at a temperature between 150-1100° C. and a pressure between 1 to 100 atmosphere, and feeding said refromate stream from said reaction zone to drive a downstream turbine, a turbocharger or any kind of gas turbine. This catalytic engine can be connected to an electrical generator to become a stationary or mobile power station, which can be used in transportation, industrial, utility and household applications.

Owner:HWANG HERNG SHINN

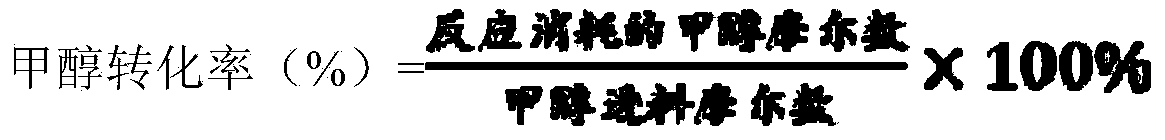

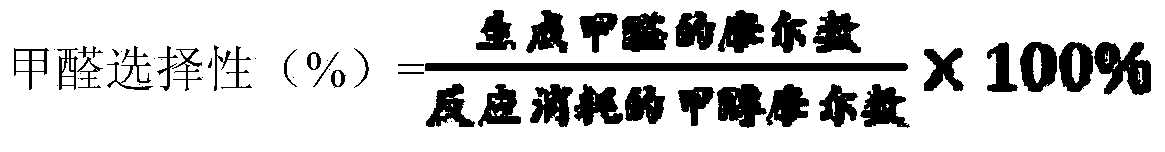

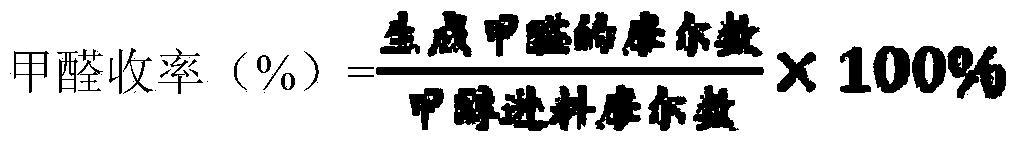

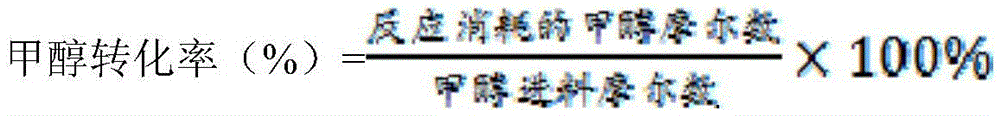

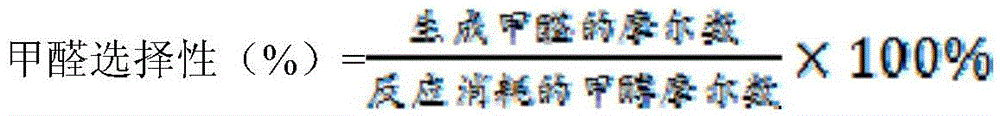

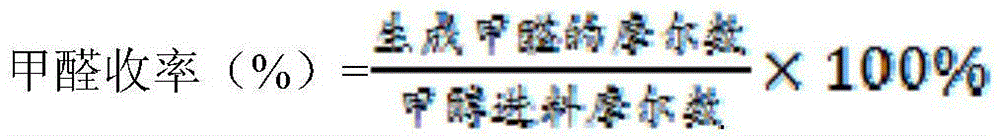

Catalyst for preparing formaldehyde by methanol oxidation

ActiveCN103933998AImprove stabilityHigh yieldOrganic compound preparationCarbonyl compound preparationOver oxidationRubidium

The invention discloses a catalyst for preparing formaldehyde by methanol oxidation. According to the embodiment of the invention, the catalyst takes Mo(a)Ni(b)Fe(c)Bi(d)Pr(e)Co(f)Ce(g)V(h)Cr(i)A(j)O(k) as an active ingredient, wherein A is one or more of lithium, sodium, potassium and rubidium; a, b, c, d, e, f, g, h, i, j and k are atomic number of the elements; a is 10.0-20.0; b is 3.0-7.0; c is 1.0-4.0; d is 0-4.0, e is 0-3.0, f, g, h and i are 0-3.0; j is 0-0.5; k is the number of required oxygen atoms meeting valence of other elements. According to the catalyst disclosed by the invention, the yield of the target product and the stability of the catalyst are improved. On the other hand, the optimal reaction temperature can be lowered by the catalyst disclosed by the invention, and loss of molybdenum in the catalyst and by-products of over oxidation of carbon dioxide and the like are reduced.

Owner:TSINGHUA UNIV

High-strength quick-drying energy-saving environment-protective cardboard box glue

The invention pertains to the field of new materials, particularly relates to a high-strength, drip-dry, energy-saving and environmentally-friendly paper carton adhesive. Water is filled in a high-speed stirred vessel, stirred, added with a catalyst and after a few minutes, added with flour, stirred and then added with an oxidant and a gelatinization agent, kept being stirred at a constant speed, added with a filler and finally added with a crosslinking agent, stirred for 10 min to 30 min so as to form the adhesive which is characterized in that: the components thereof calculated by weight percentage are 40 percent to 80 percent of the water, 0.01 percent to 0.5 percent of the catalyst, 10 percent to 30 percent of the flour, 1 percent to 8 percent of the oxidant, 2 percent to 8 percent of the gelatinization agent, 0 percent to 30 percent of the filler and 0.01 percent to 6 percent of the crosslinking agent. The adhesive of the invention has the functions of high strength, getting dry quickly and water resistance, and is technologically characterized in that: the speed, from oxidation to gelatinization to gelatinization, is quick; during the oxidation, an organic catalyst is combined with an inorganic metal salt and oxidation is combined with assisted oxidation, therefore, the substances such as starch, etc. can be oxidized into adhesive water with high viscosity and without wiredrawing at a high speed in a short time, and the problem of over-oxidation cannot occur.

Owner:李元杰

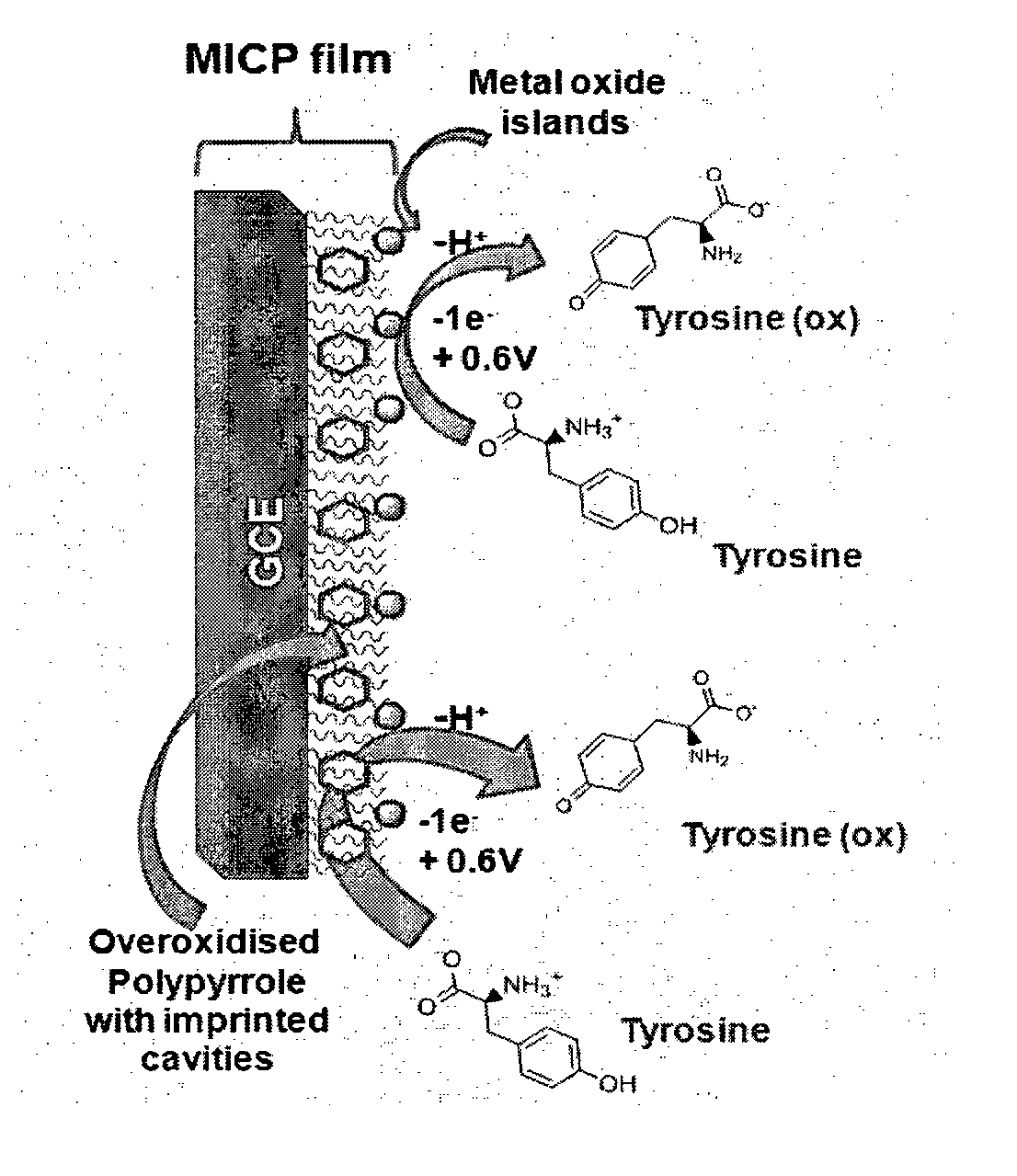

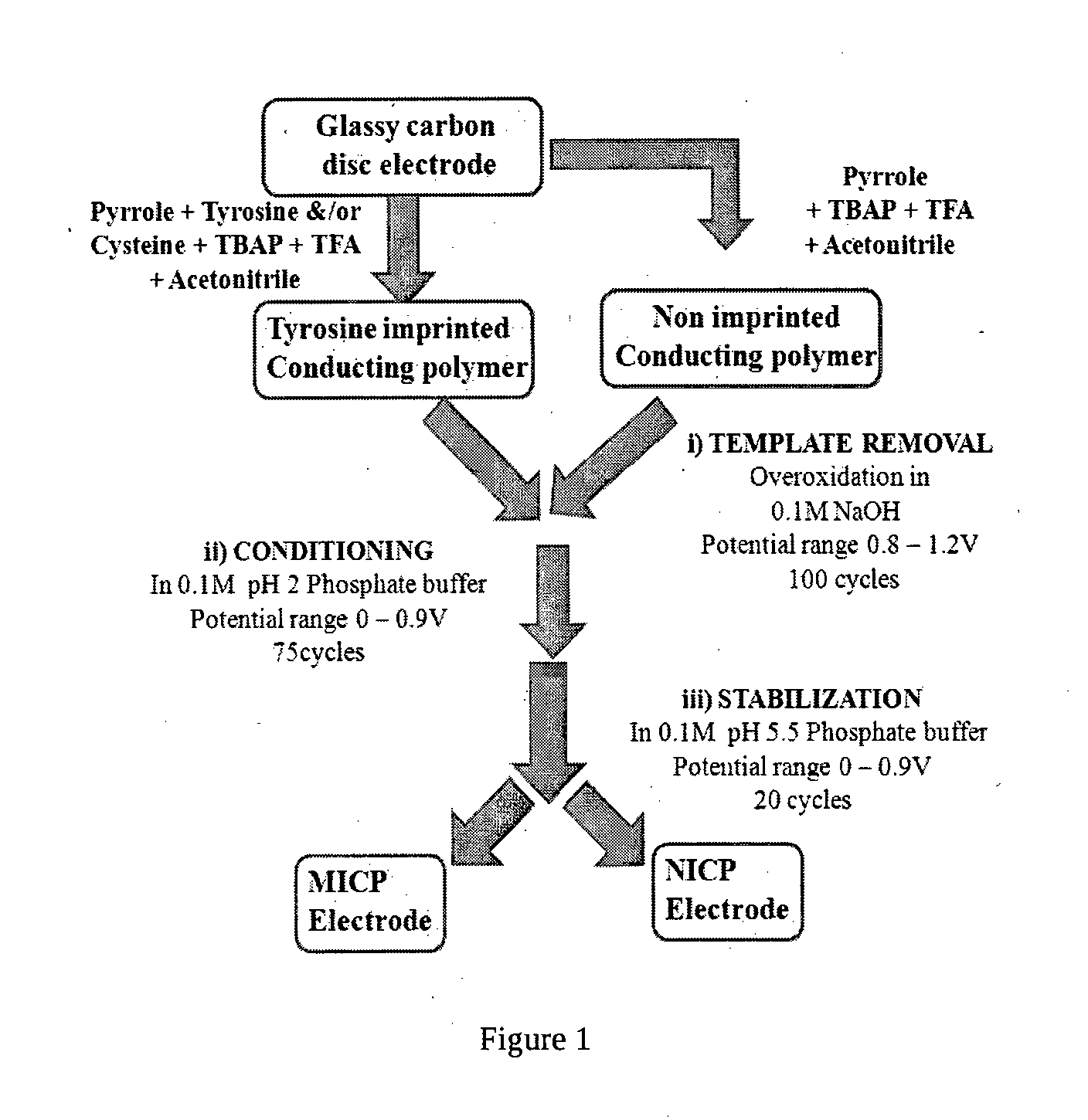

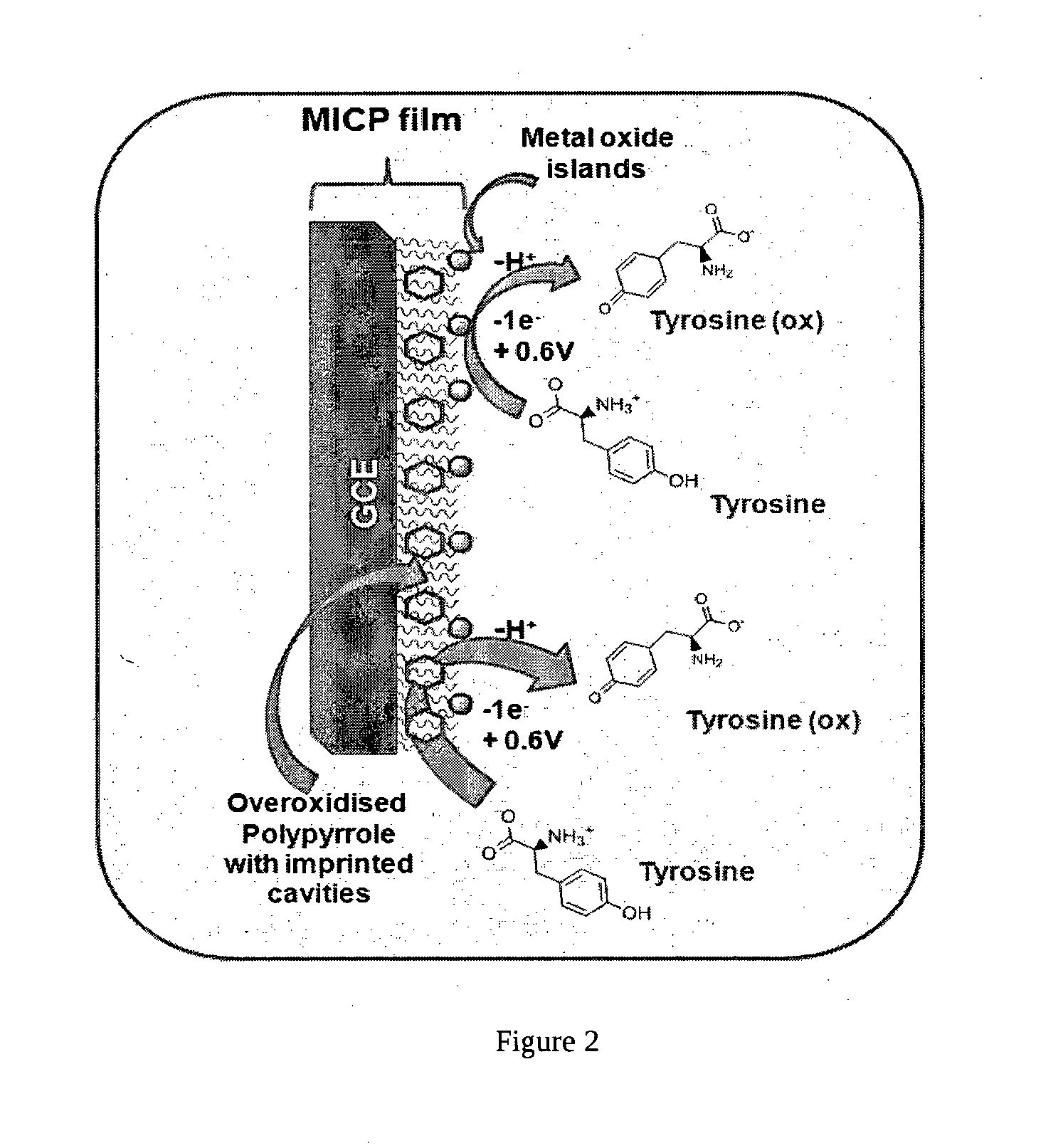

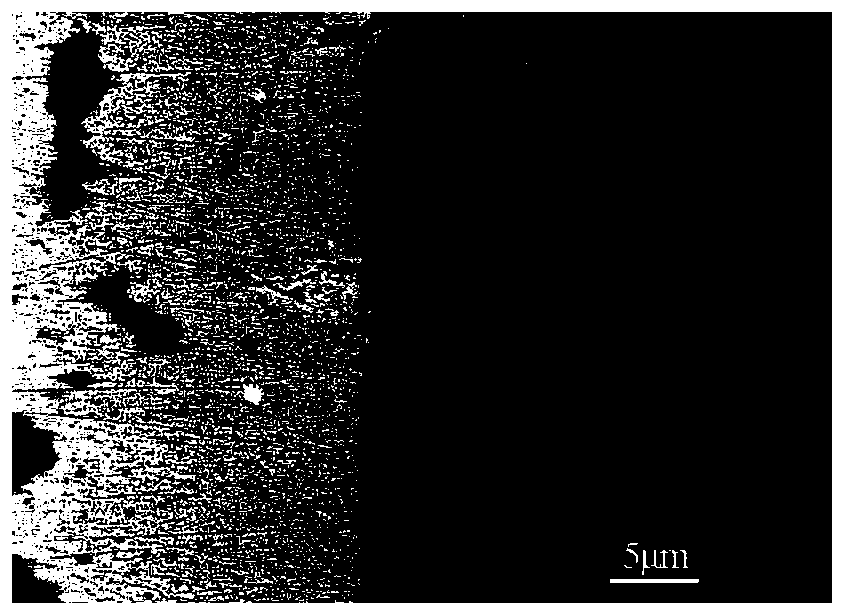

Molecularly Imprinted Conducting Polymer Film Based Aqueous Amino Acid Sensors

Molecularly imprinted conducting polymer (MICP) films were electro-polymerized on glassy carbon electrode having specific recognition sites for amino acid viz. L-tyrosine and / or L-cysteine. The amino acid templates in various imprinted films were ejected out by over-oxidation followed by washing and stabilization. Again, the template leached MICP films were modified with metal oxides [oxides of Cu2+, Hg2+, Pd2+, Au3+, Pt4+ etc]. The resultant leached MICP and metal oxide modified template leached MICP film based GCE will now selectively sense L-tyrosine and / or L-cysteine in aqueous media by direct and catalytic means respectively employing differential pulse voltammetric waveform. The sensitivity and selectivity of the sensors prepared by the invention are high and the stability is good, which will be widely used in clinical diagnostics, chemical industry, environment protection and other related fields.

Owner:COUNCIL OF SCI & IND RES

Process for synthesizing electron donor substituted polyaniline derivatives

InactiveCN1667020AImprove solution processabilityGood solubility and processabilityPotassium persulfatePolyaniline derivatives

This invention is synthesis method of supply electron naphthylmercuric replacing polyanion derivant. It relates the synthesis method of supply electron naphthylmercuric replacing electron conduction polyanion derivant poly-2, 5-dimethoxyaniline. This invention provides the synthesis method of supply electron naphthylmercuric replacing polyanion derivant. Supply electron naphthylmercuric replacing polyanion derivant. Poly-2, 5-dimethoxyaniline is synthesized through emulsion polymerization, deionized water and emulsifying agent is added in tank and heated dissolve. Xylene solution of 2, 5-dimethoxyaniline is added with protection of nitrogen gas. Potassium persulphate and ammonium persulfate solution is dissolved in water and then added to reaction system. The tank is changed into distillation plant to make emulsion breaking, then through filtration, scrubbing, drying. Improving the dissolve workability of polyaniline has little affection to conductivity. Polymer over oxidation, crosslinking, degradation by electrochemistry polyreaction is avoide, polymerisate molecular weight can be improved, and half oxidation state polymer of good electrochemistry is got. Polymer film of certain conductivity and thickness is easy to get, it is good to decorate electrode.

Owner:XIAMEN UNIV

Preparation method of alginate oligosaccharides

InactiveCN101037456AControlling the degree of aggregation distributionReduce dosageSugar derivativesOligosaccharidesOver oxidationReaction temperature

A preparation method for alginate oligosaccharides includes following steps: adding the water to the alginic acid or metal salt or the produced high mannuronic acid, high guluronic acid section to dissolve or disperse in the water, adding it to the oxidant solvent in a radiation condition, heating the solution to 60-80 DEG C for 4-50 minutes, then cooling the solution, concentrating the solution by nanofiltration film, drying the concentrated liquid by spray. The invention improves the product quality by preventing the product over-oxidation by the radiation assistance in a lower temperature; effectively reduces the dosage of the oxidant by controlling the product degree of polymerization distribution in a low reaction temperature; avoids using organic solvent, reduces the product costs and saves the cost by nanofiltration film separation technique and spary drying technique which can be achieve the industry mass production. Therefore, the method has a practical application value.

Owner:NINGBO UNIV

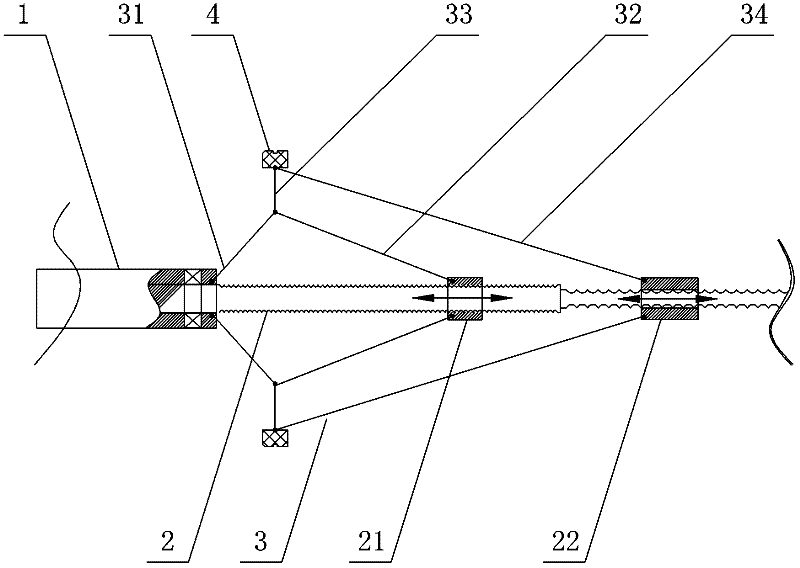

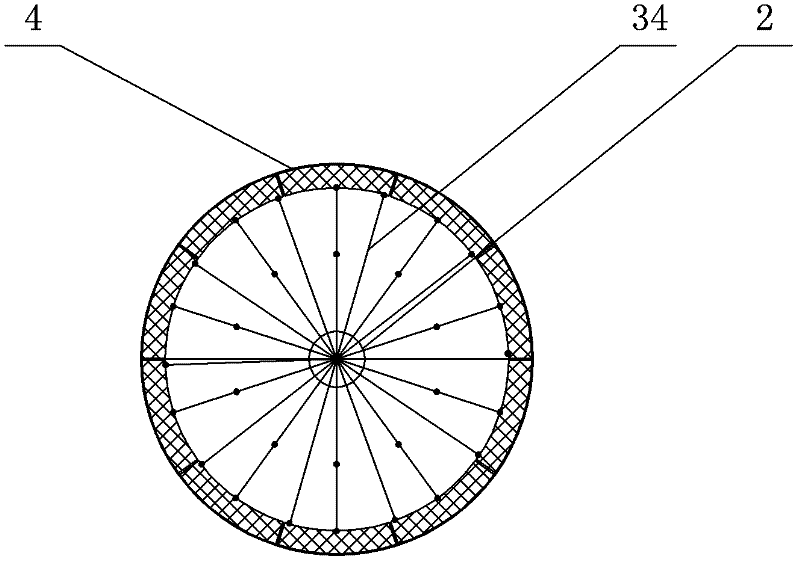

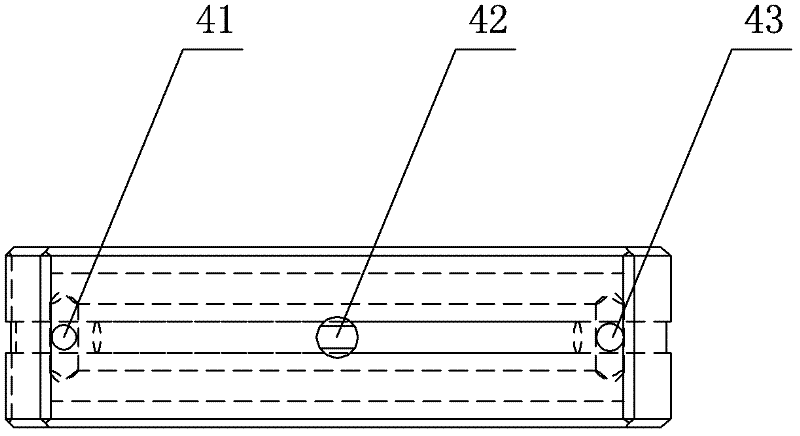

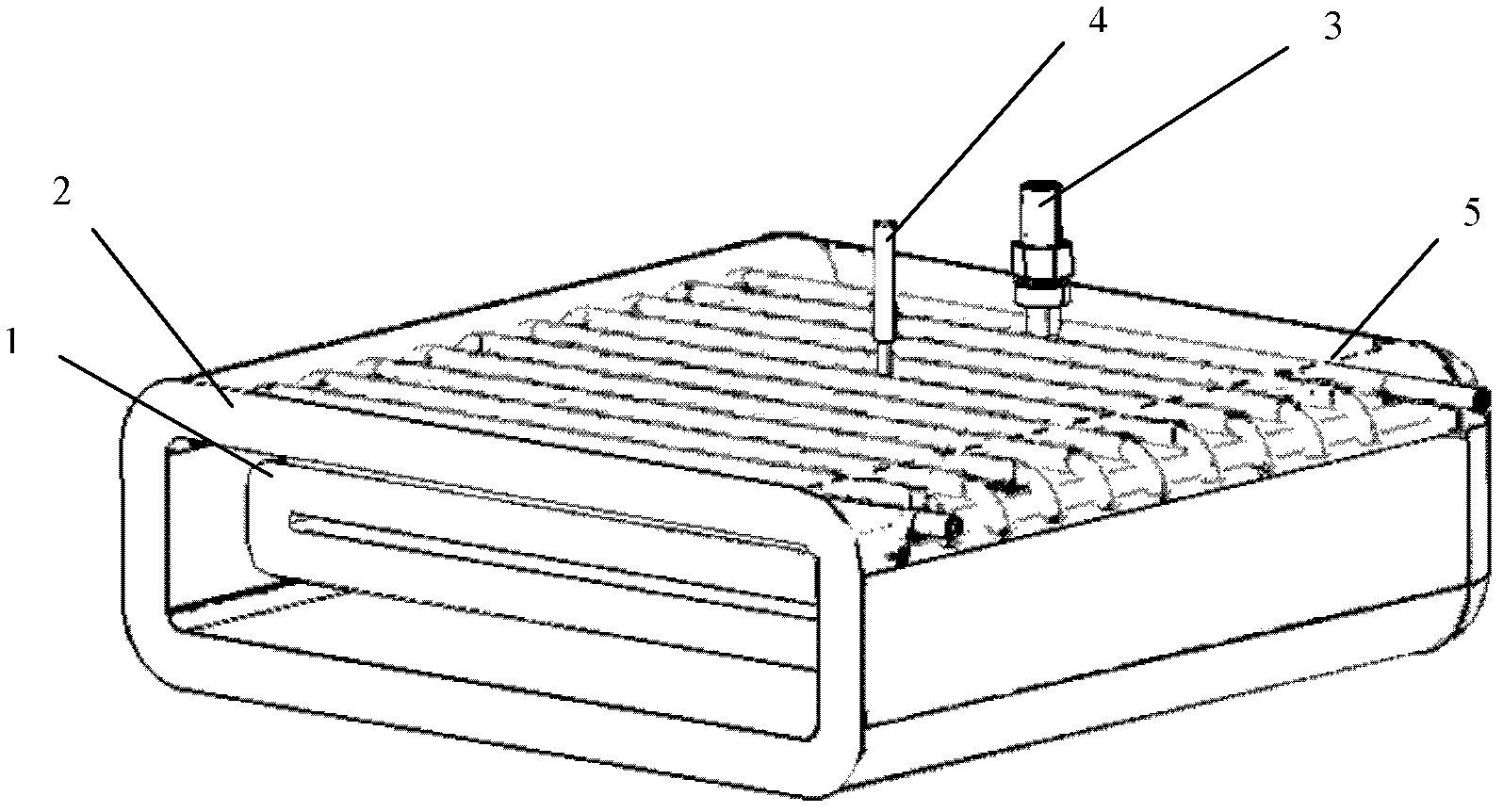

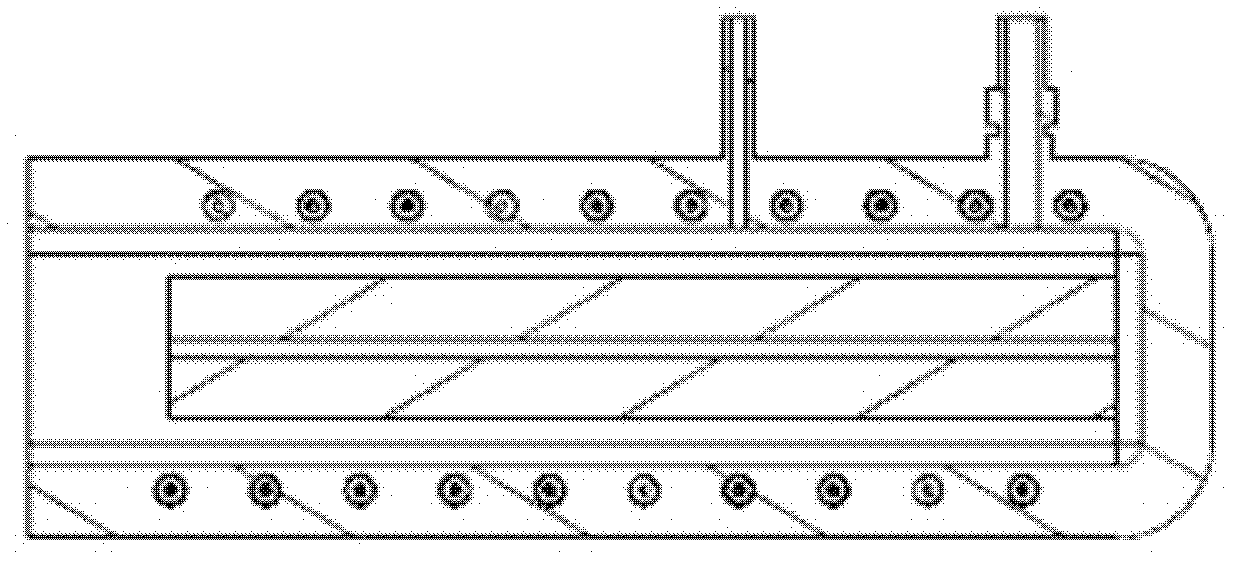

Circumferential seam butt welding protection device

ActiveCN102528343AGuarantee welding qualityAchieve front and back protectionWelding/cutting auxillary devicesAuxillary welding devicesOver oxidationButt welding

A circumferential seam butt welding protection device comprises a fixed sleeve and a rotating shaft. One end of the rotating shaft is inserted into the fixed sleeve, a plurality of link mechanisms are arranged on the fixed sleeve, two thread sections with different thread pitches are arranged on the rotating shaft, an opening-closing slider is arranged on the first thread section, a rotating slider is arranged on the second thread section, and the link mechanisms are respectively connected with the rotating slider and the rotating slider. When the circumferential seam butt welding protection device is in welding preparation, the umbrella-shaped link mechanisms on the rotating shaft play a role, a plurality of back protection cooling blocks form a circumferentially arrayed device by means of synchronous sliding of the opening-closing slider and the rotating slider. During welding, the circumferentially arrayed device can be used for protecting the fronts and the backs of circumferential seams of an end cap and a cylinder body of a closed cylindrical container by means of back cooling and gas protection for a workpiece to be welded. By the aid of the circumferential seam butt welding protection device, the welding quality of the circumferential seams can be ensured, and crevice corrosion and over oxidation of the backs of the circumferential seams in conventional circumferential seam lap welding are avoided.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD

Highly pure modafinil

The present invention provides an improved process for preparing modafinil, whereby it may be isolated in high purity by a single crystallization. The process produces modafinil free of sulphone products of over-oxidation and other byproducts. The invention further provides new crystalline Forms II-VI of modafinil and processes for preparing them. Each of the new forms is differentiated by a unique powder X-ray diffraction pattern. The invention further provides pharmaceutical compositions containing novel modafinil Forms II-IV and VI.

Owner:TEVA PHARMA IND LTD

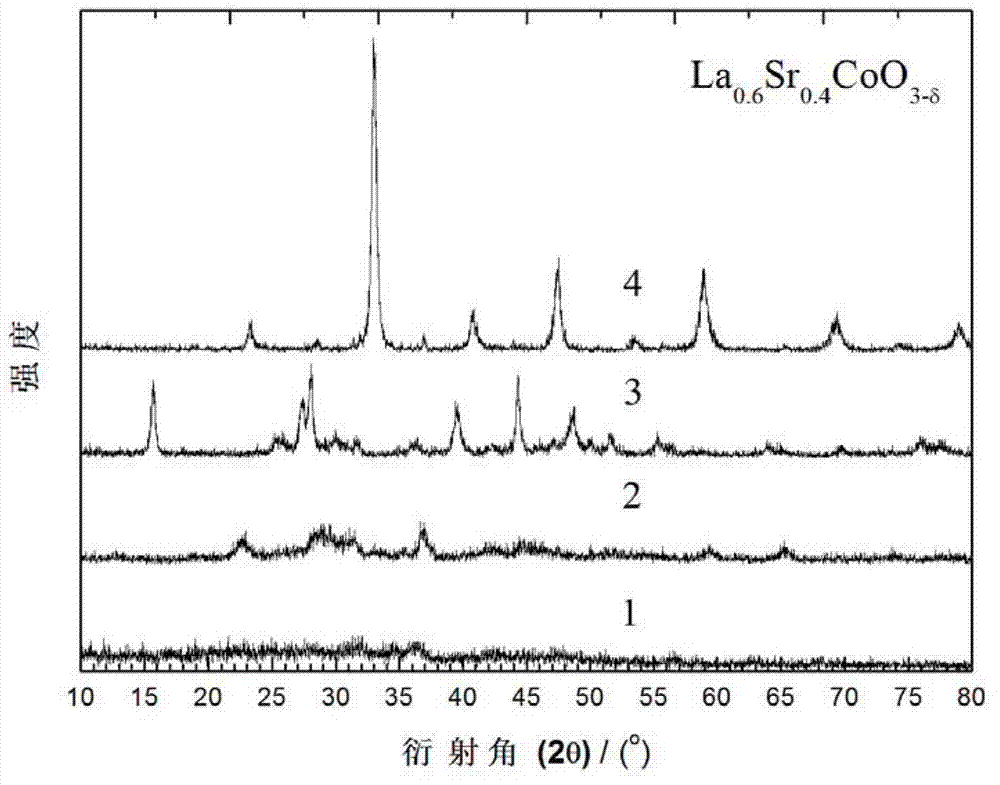

Preparation method of functional gradient cathode of intermediate low temperature solid oxide fuel cell

InactiveCN103199269AImprove electrode performanceAvoid excessive oxidationCell electrodesFuel cellsOver oxidation

The invention discloses a preparation method of a functional gradient cathode of an intermediate low temperature solid oxide fuel cell. The preparation method comprises the following steps of: preparing cathode precursor powder and composite cathode precursor powder; depositing composite cathode precursor functional layer size prepared by adding the composite cathode precursor powder to an ethyl cellulose terpilenol solution on a reaction barrier layer between a compact sold electrolyte thin film and a cathode thin film to form a composite cathode precursor functional layer; depositing cathode precursor current collection layer size prepared by adding the cathode precursor powder to an ethyl cellulose terpilenol solution on the composite cathode precursor functional layer to form a cathode precursor current collection layer; and sintering the cathode precursor current collection layer and the composite cathode precursor functional layer in non-oxidizing atmosphere, and annealing in air to form phase before the battery works, thus obtaining the functional gradient cathode of the intermediate low temperature solid oxide fuel cell. The preparation method of the functional gradient cathode can be used for avoiding the over oxidation of a battery support, and simultaneously improving the electrode performance of the functional gradient cathode.

Owner:SHANGHAI JIAO TONG UNIV

Crystalline forms of modafinil

InactiveUS20050034652A1High purityOrganic active ingredientsPolycrystalline material growthOver oxidationX-ray

The present invention provides an improved process for preparing modafinil, whereby it may be isolated in high purity by a single crystallization. The process produces modafinil free of sulphone products of over-oxidation and other byproducts. The invention further provides new crystalline Forms II-VI of modafinil and processes for preparing them. Each of the new forms is differentiated by a unique powder X-ray diffraction pattern. The invention further provides pharmaceutical compositions containing novel modafinil Forms II-IV and VI.

Owner:TEVA PHARMA IND LTD

Nano superoxide dismutase and preparation method

InactiveCN1563368AImprove energy utilizationImprove crushing efficiencyPeptide/protein ingredientsOxidoreductasesOver oxidationHalf-life

When the diameter of a nanometer super oxide dismutase is 10-200nm, its antioxidative activity increases more than 10 times, skin and mucosa absorption rate is over 90%, half-life prolongs to more than tow orders, it can play the role of clearing free radicals in cells with stronger resisting over oxidation to lipid. The preparation is to take SOD from plants or animals as the raw material applying a nm super high voltage uniformity technology to process it to SOD moleculars, then applying slight emulsification or liposome technolgies to scatter the nm moleculars to form nm SOD micro drops or applying supersonic fluid technology to produce SOD micro capsules.

Owner:王成余

Method and device for rapid high-temperature heating of plates

InactiveCN102618703AHeating evenlyFast heating temperature control corresponding speedIncreasing energy efficiencyFurnace typesOver oxidationClosed loop

Disclosed are a method and a device of rapid high-temperature heating of plates. The method includes: filling a cement heating chamber with inert gas, starting an induction heating power supply to heat an inner graphite chamber to a certain degree, putting a metal sample plate in a gap of the inner graphite chamber, heating the metal sample plate to the set temperature, keeping the plate at the temperature, using a thermocouple to monitor the temperature of graphite in the heating chamber in real time during heating, and using a thermostat to control heating power of an induction coil. By means of closed-loop control with feedback, stable and controllable heating is guaranteed. In addition, water is filled into hollow copper tubes during heating to cool the induction coil, so that the coil is protected from damage by high heat. By the method and the device, the plates are heated evenly and successfully, the plates are quickly heated to the ultrahigh temperature up to 950 DEG C, and the samples are protected from over-oxidation. The device is compact in structure, easy and convenient in manufacture, small in occupied space, energy-saving, environment-friendly, fast in heating temperature control, and stable and reliable in operation.

Owner:BAOSHAN IRON & STEEL CO LTD

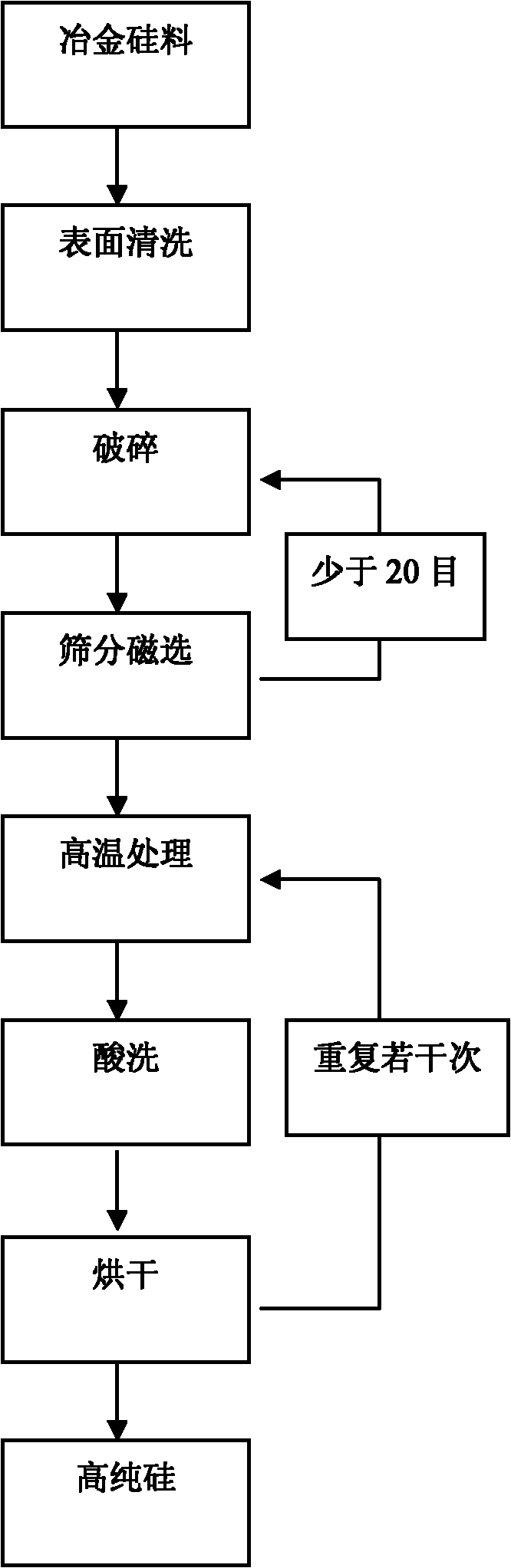

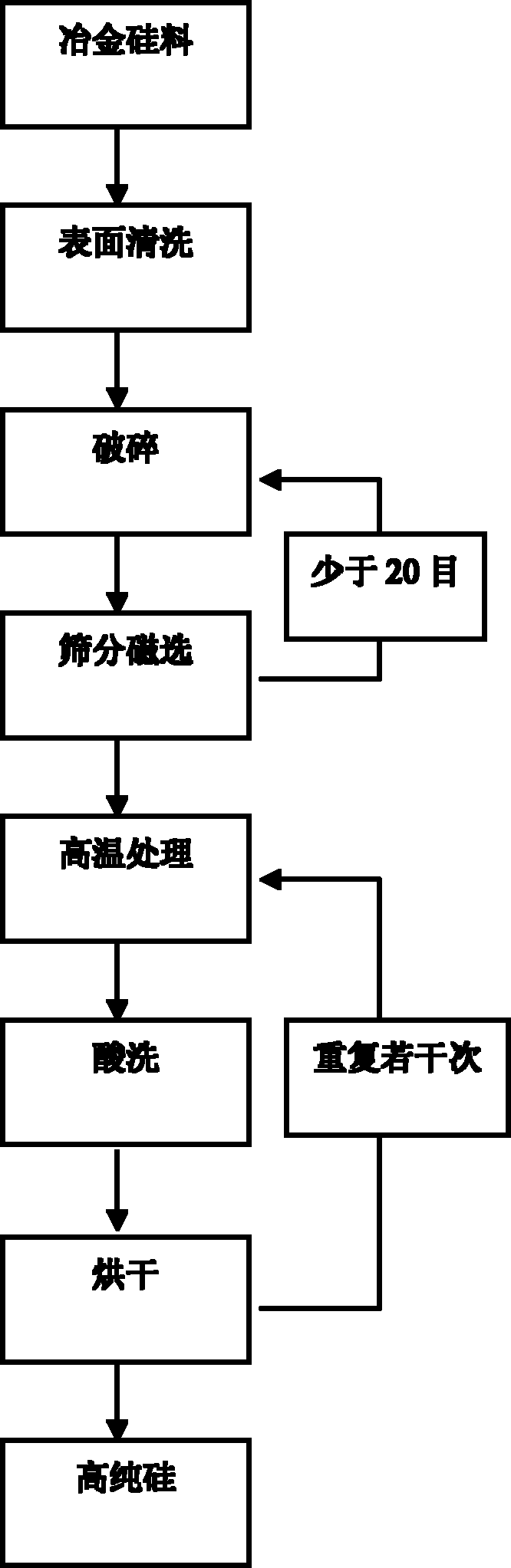

Method for removing impurities from large-particle metallurgical silicon material

InactiveCN102079523AGood removal effectReduce energy consumptionSilicon compoundsProcess equipmentOver oxidation

The invention discloses a method for removing impurities from a large-particle metallurgical silicon material, which is to select a metallurgical silicon material, make metal impurities disperse into the surfaces or grain boundary of silicon material particles through high temperature treatment, and remove the metal impurities by acid leaching to prepare high-purity silicon. The method obviates the need of deeply crushing the silicon material and therefore avoiding secondary pollution to the silicon material and the over oxidation of the surface; meanwhile, the method solves such problem that dust cannot be used in subsequent processes, simplifies process equipment, reduces cost, improves environmentally friendliness and is convenient for industrial application.

Owner:东海晶澳太阳能科技有限公司

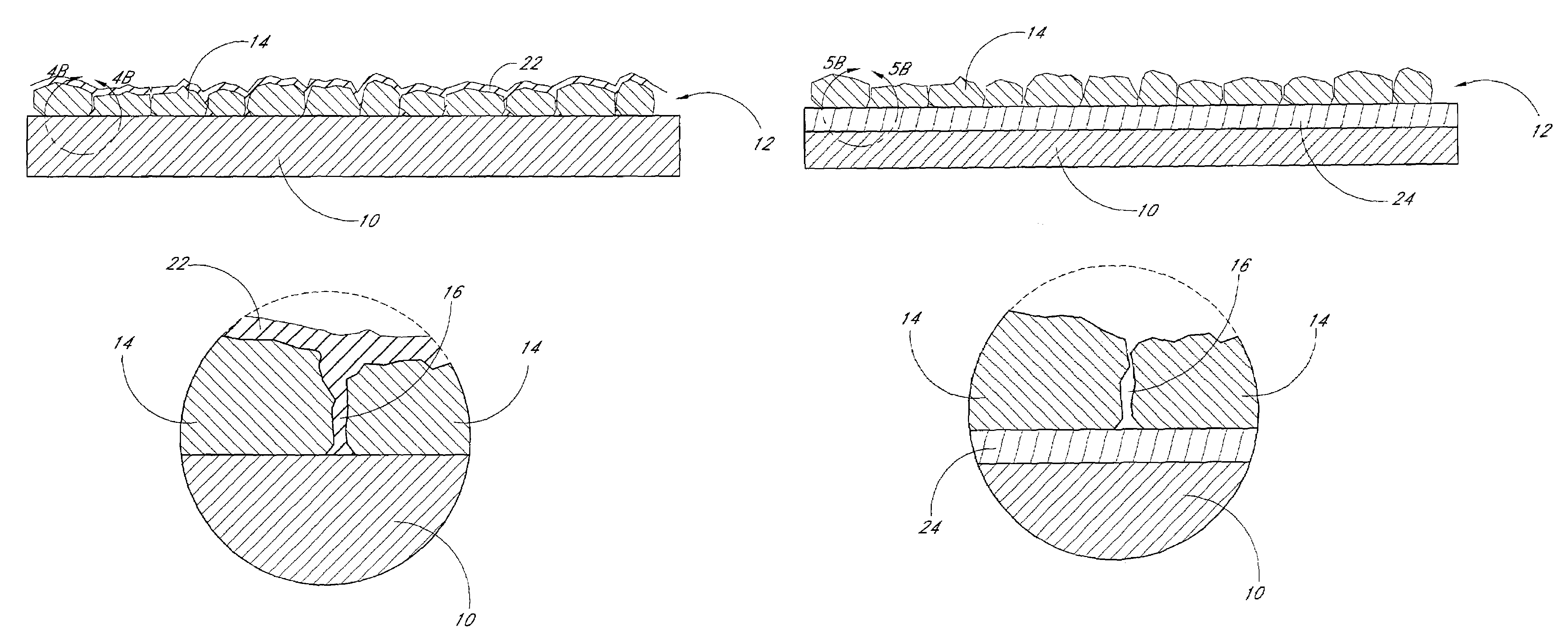

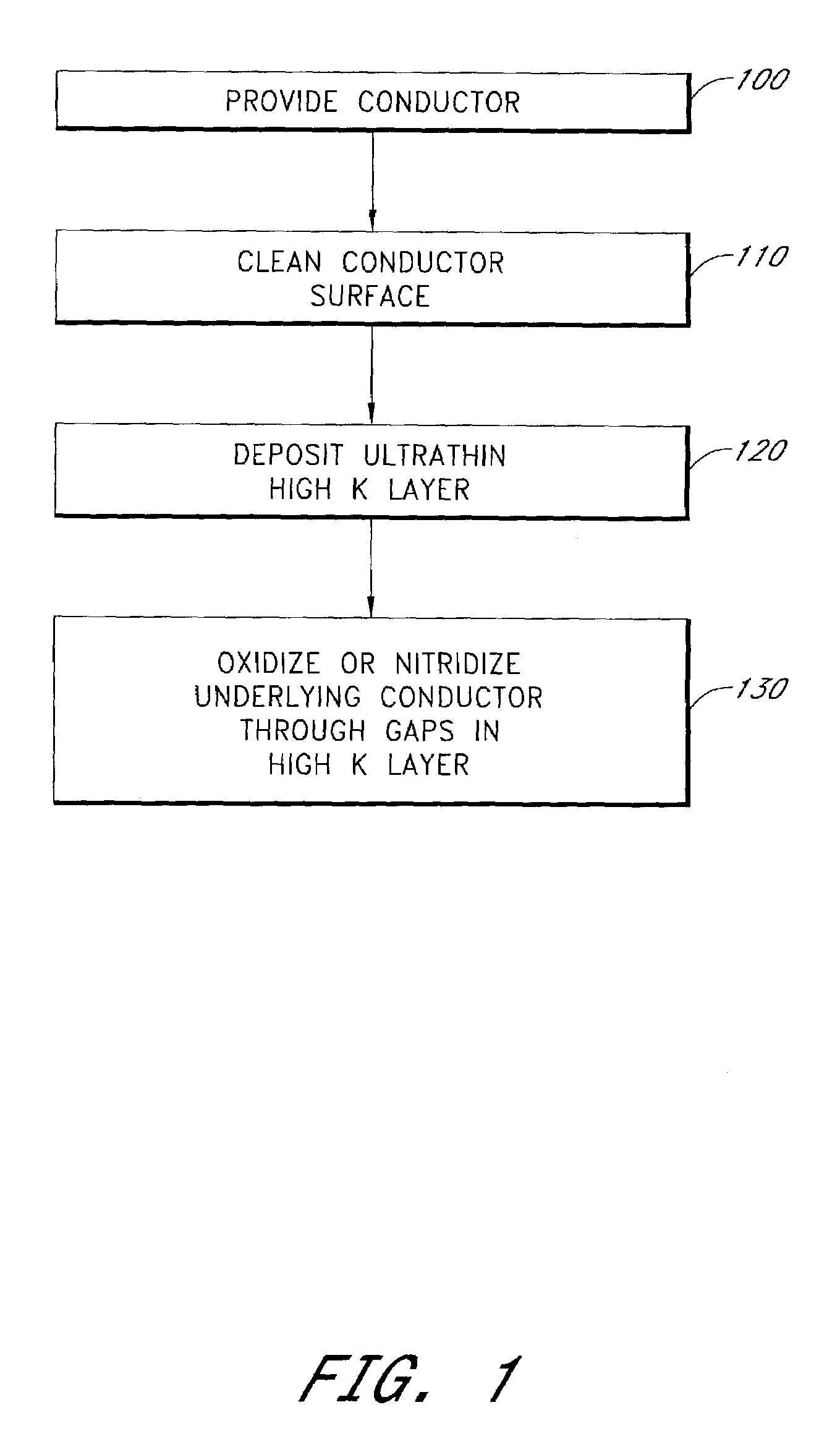

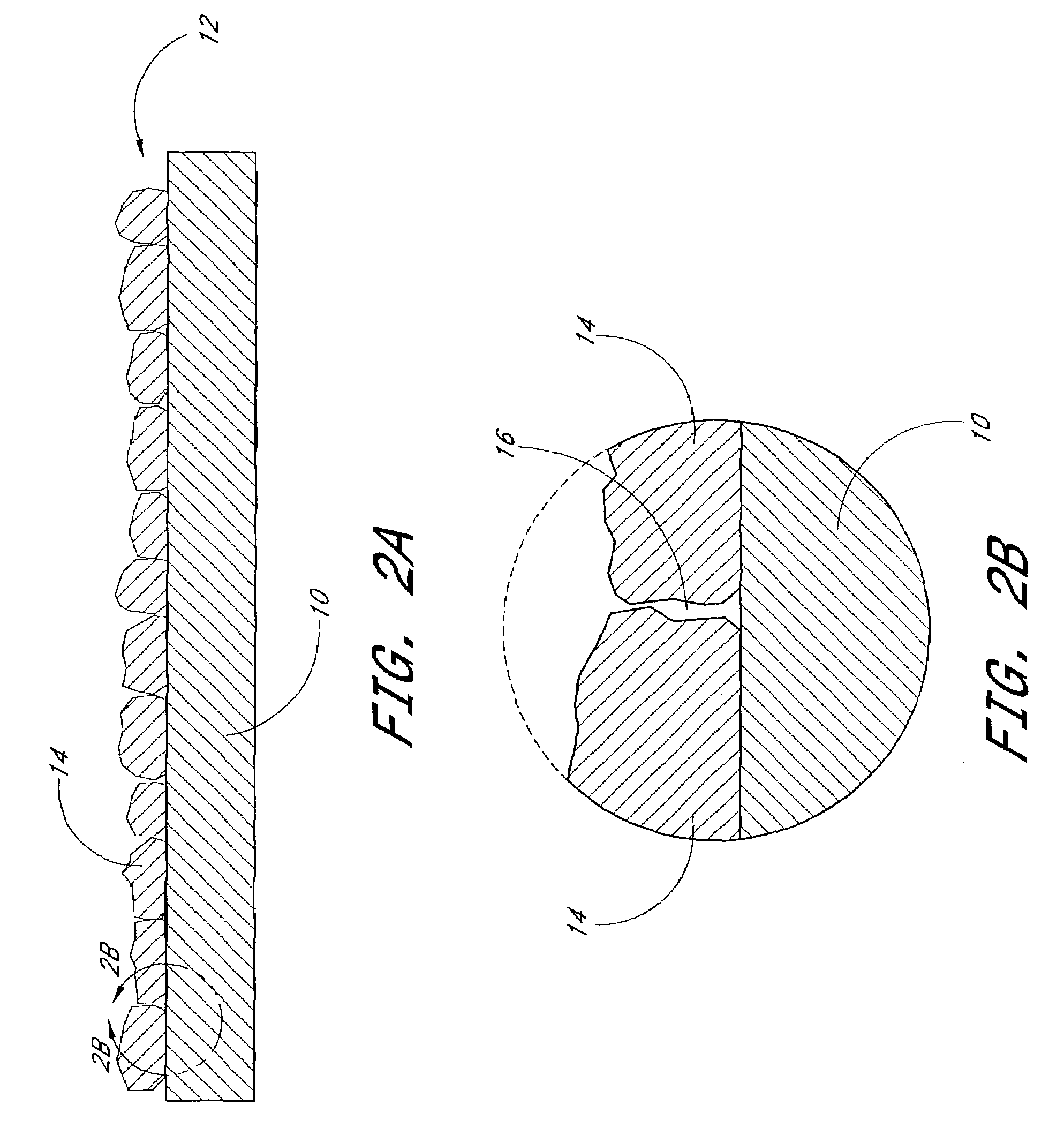

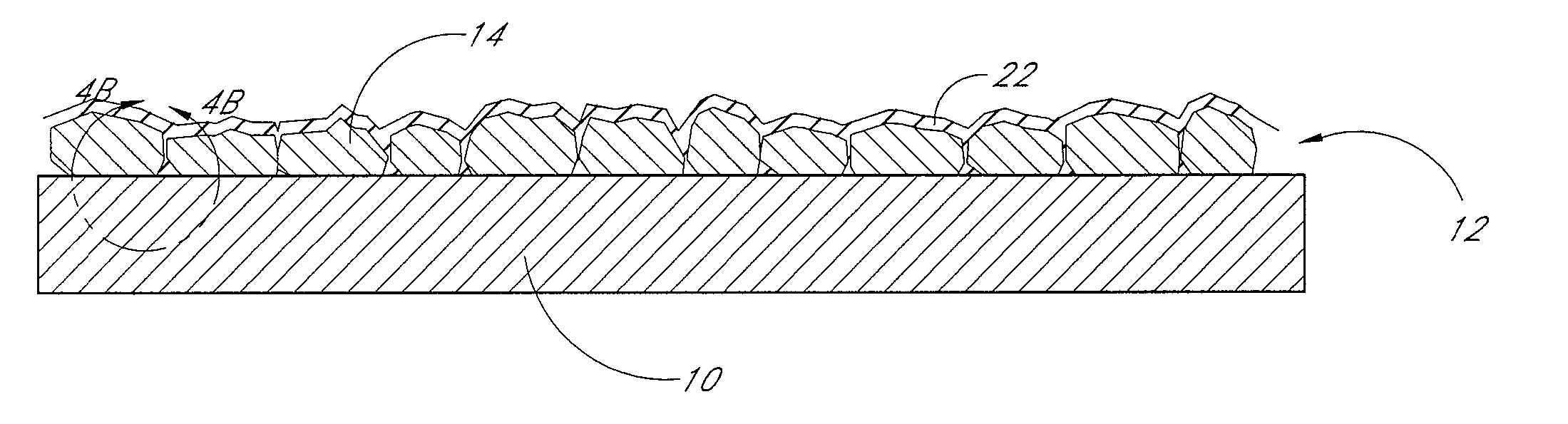

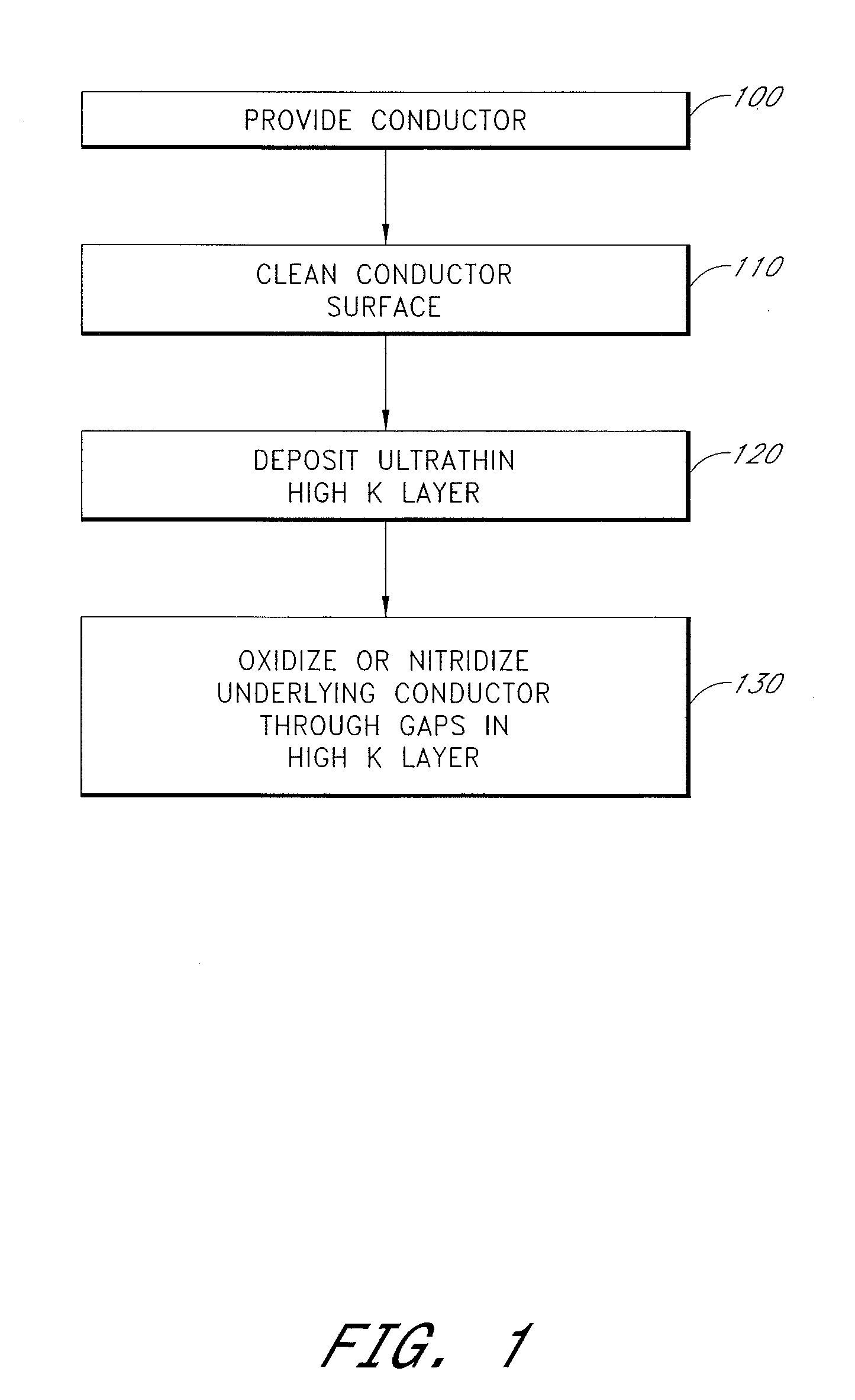

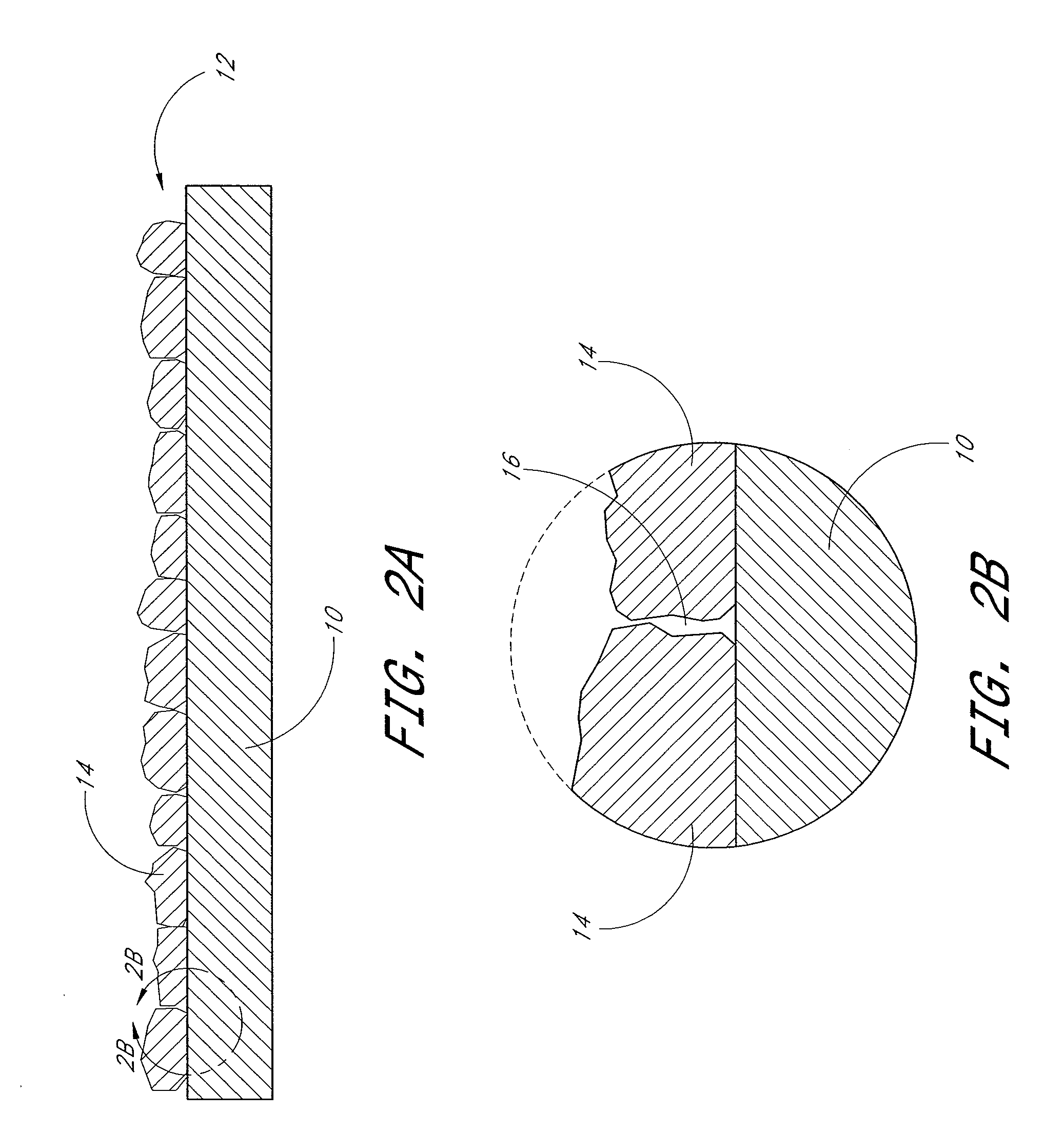

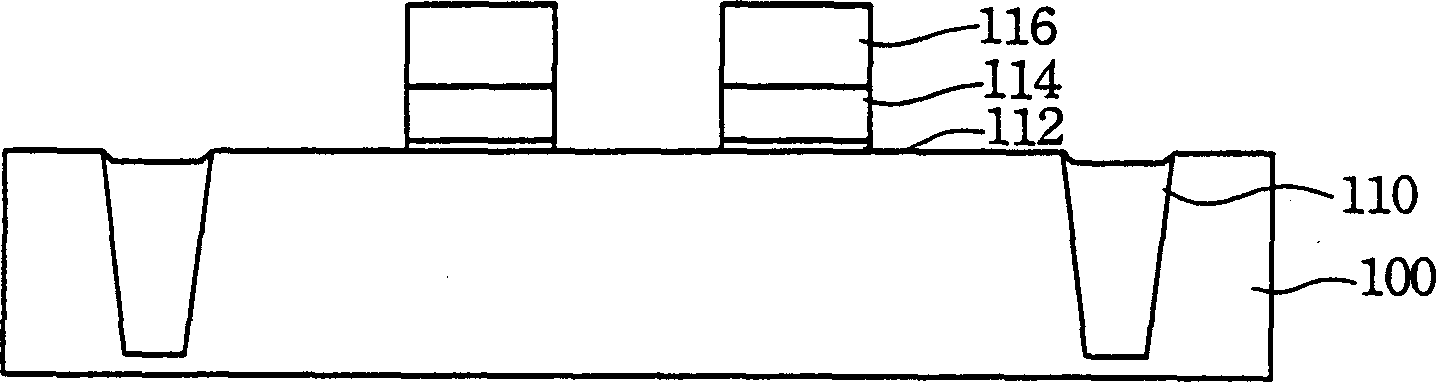

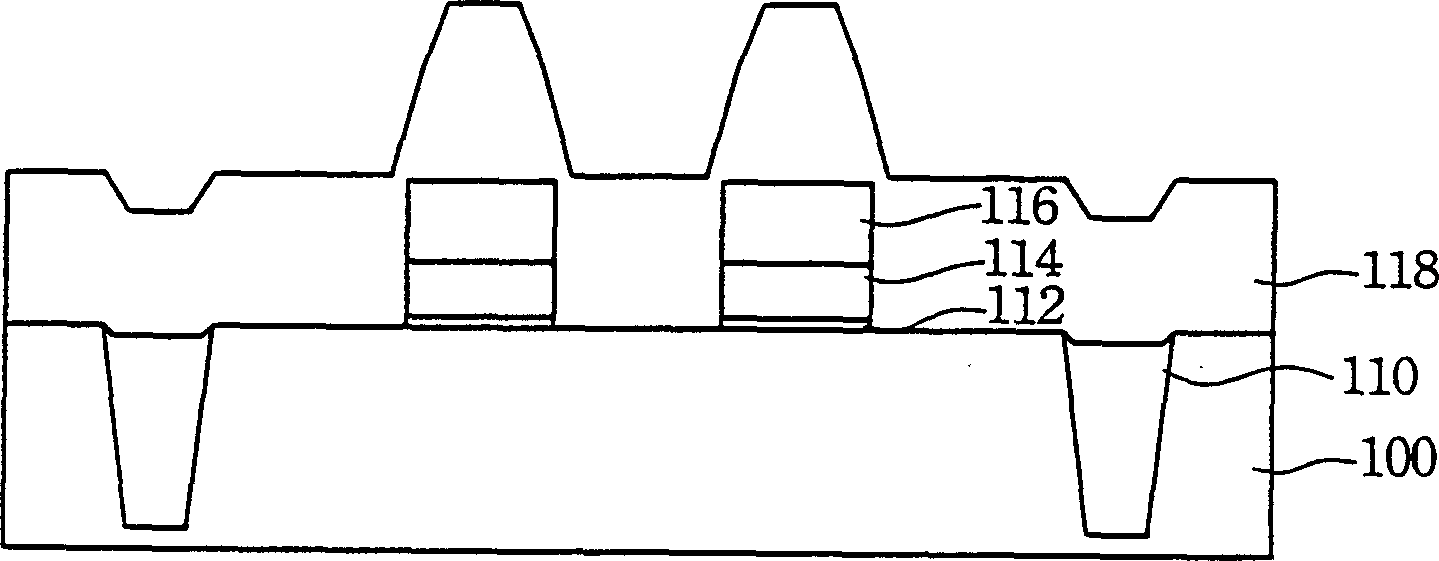

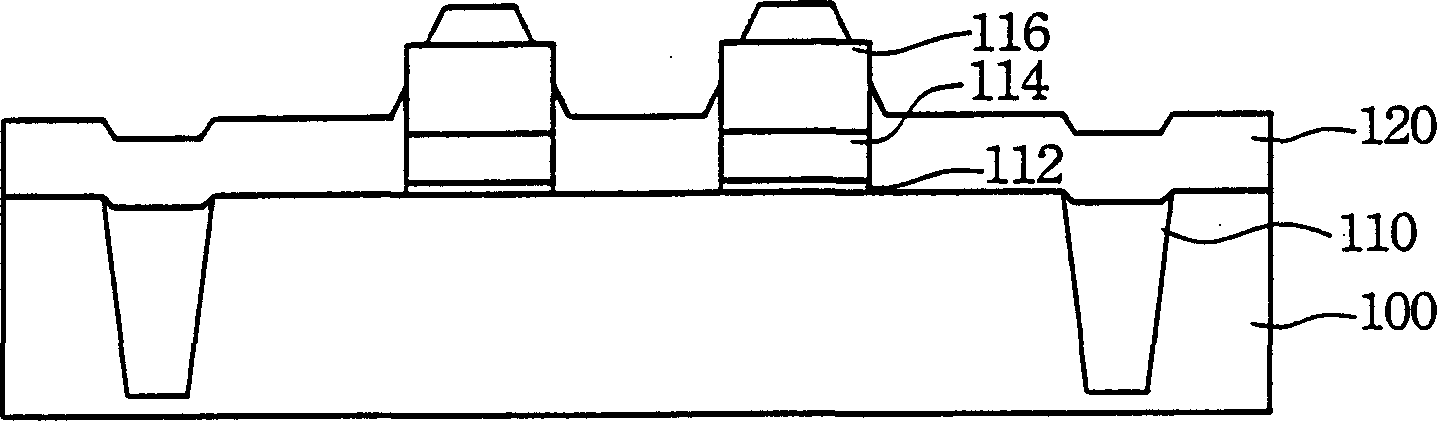

Dielectric layers and methods of forming the same

High dielectric constant (high-k) materials are formed directly over oxidation-susceptible conductors such as silicon. A discontinuous layer is formed, with gaps between grains of the high-k material. Exposed conductor underneath the grain boundaries is oxidized or nitridized to form, e.g., silicon dioxide or silicon nitride, when exposed to oxygen or nitrogen source gases at elevated temperatures. This dielectric growth is preferential underneath the grain boundaries such that any oxidation or nitridation at the interface between the high-k material grains and covered conductor is not as extensive. The overall dielectric constant of the composite film is high, while leakage current paths between grains is reduced. Ultrathin high-k materials with low leakage current are thereby enabled.

Owner:ASM INTERNATIONAL

Dielectric layers and methods of forming the same

InactiveUS20080093711A1Semiconductor/solid-state device detailsSolid-state devicesDielectricElectrical conductor

High dielectric constant (high-k) materials are formed directly over oxidation-susceptible conductors such as silicon. A discontinuous layer is formed, with gaps between grains of the high-k material. Exposed conductor underneath the grain boundaries is oxidized or nitridized to form, e.g., silicon dioxide or silicon nitride, when exposed to oxygen or nitrogen source gases at elevated temperatures. This dielectric growth is preferential underneath the grain boundaries such that any oxidation or nitridation at the interface between the high-k material grains and covered conductor is not as extensive. The overall dielectric constant of the composite film is high, while leakage current paths between grains is reduced. Ultrathin high-k materials with low leakage current are thereby enabled.

Owner:ASM INTERNATIONAL

Crystalline forms of modafinil

Owner:TEVA PHARMA IND LTD

Catalyst for Methanol Oxidation to Formaldehyde

ActiveCN103933998BImprove stabilityHigh yieldOrganic compound preparationCarbonyl compound preparationOver oxidationRubidium

Owner:TSINGHUA UNIV

Method for removing residual polycrystalline silicon

InactiveCN1434484AEfficient removalAvoid erosionSemiconductor/solid-state device manufacturingOver oxidationOxygen ions

A method for removing residual of polycrystalline silicond is first of all to insert oxygen ions in polysilicon remains with tilt ionic inserting method in which the residual area fuel of oxygen ionsand convert to SiO2 completely by oxygen an nealing to reduce conductivity of the polysilicon and oxygen erosion will not occur which not only eliminate polysilicon remain but also avoid the erosion resulted in over oxidation by tilt oxygen ion insertion to recuce heat predict and reach the aim of converting to converting to SiO2 completely.

Owner:MACRONIX INT CO LTD

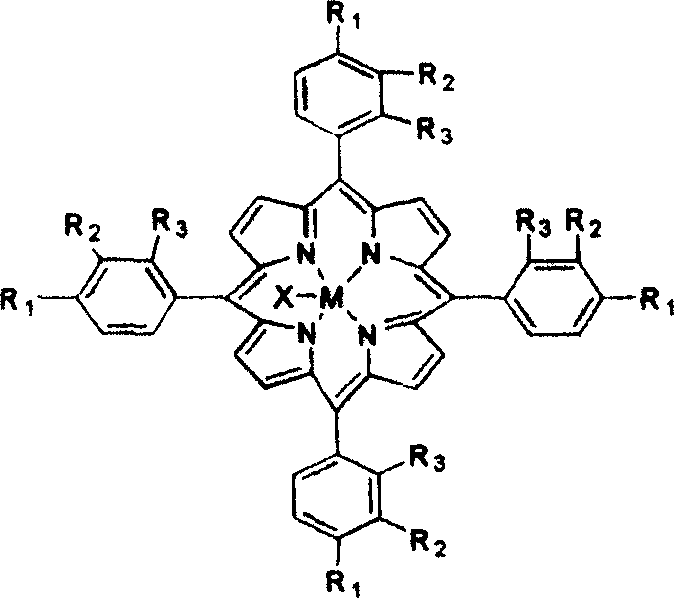

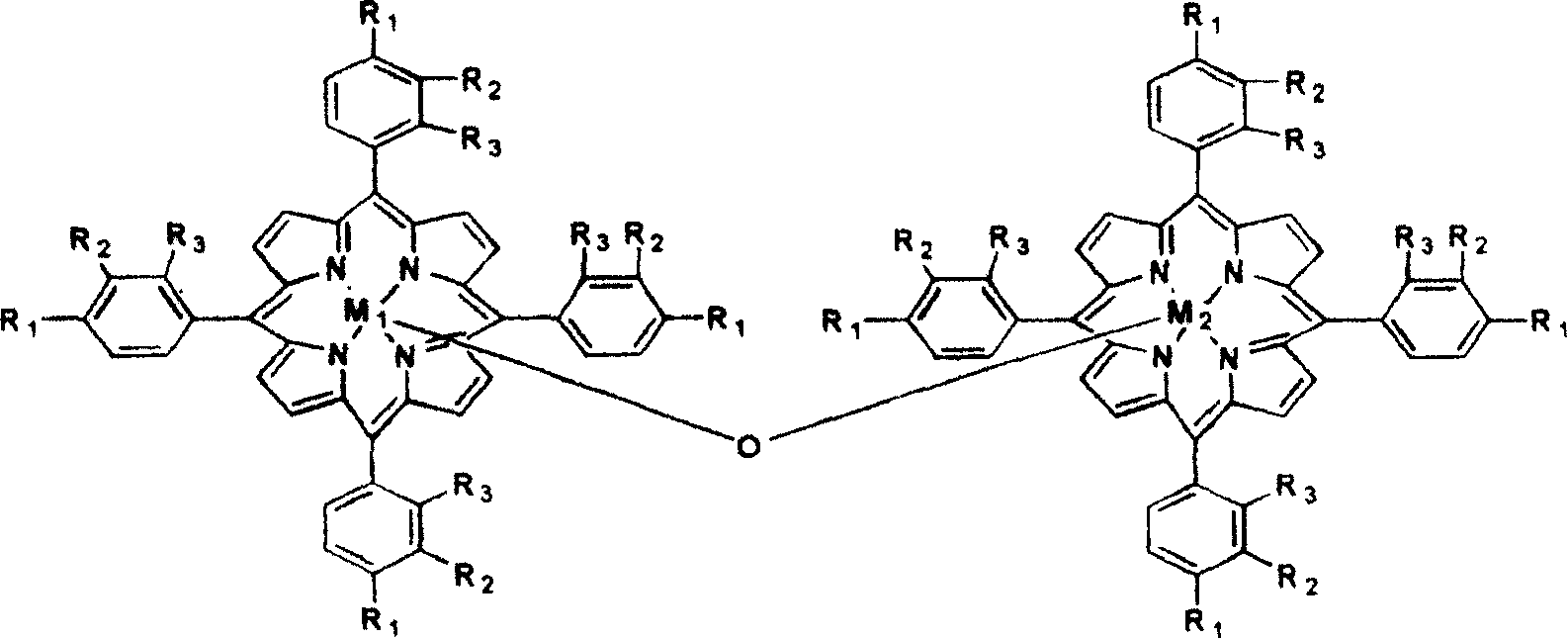

Method for preparing hydroperoxidation p-menthane by catalytic air oxidation p-menthane

InactiveCN101225067AImprove conversion rateShort reaction timeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOver oxidationPorphyrin

The invention discloses a method that menthane is catalyzed and oxygenated selectively by air into hydrogen peroxide p-menthane, which is characterized in that: the oxidant is air or oxygen-enriched air or oxygen; the pressure controlling the reaction is atmospheric pressure (at an atmospheric pressure); reaction temperature is 80 to 140 DEG C; Mu-oxygen-metalloporphyrin and single metalloporphyrin or the supported object of general formula (I) or (II) are selected as main catalyst with the concentration of 1 to 90 ppm; transition metal salts or oxide are used as co-catalyst; molar ration between the main catalyst and co-catalyst is 1: (0.5 to 5); reaction period is 1 to 10 hours; the reaction can be made at single constant temperature and also can be firstly made at constant temperature for one period before temperature is immediately decreased to certain temperature point for continuous reaction. The method that menthane is catalyzed and oxygenated selectively by air into hydrogen peroxide p-menthane has the advantages of short reaction period, high single-pass conversion rate upon menthane, good selectivity of hydrogen peroxide p-menthane, high recovery rate, high purity and easy separation and purification, and thus can avoid producing over-oxidation products.

Owner:HUNAN UNIV

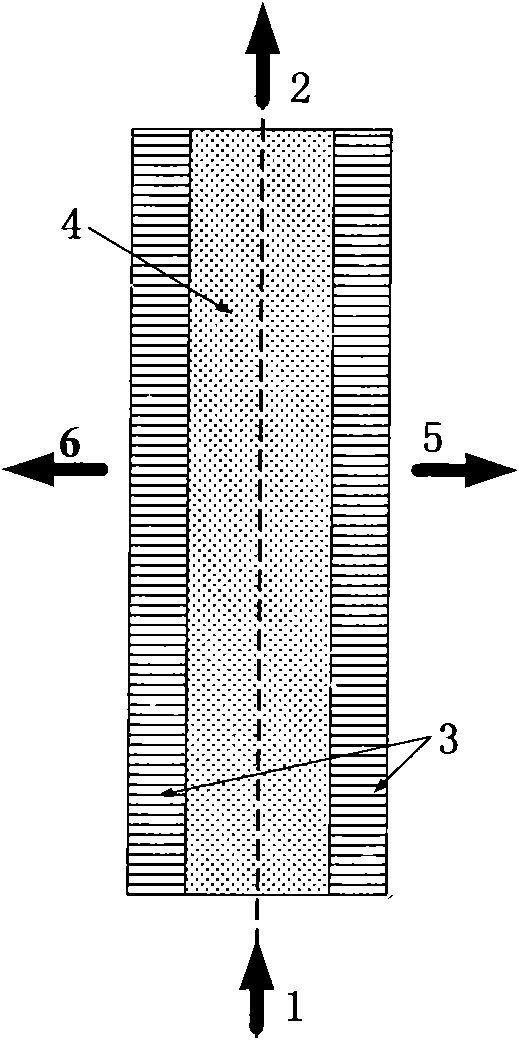

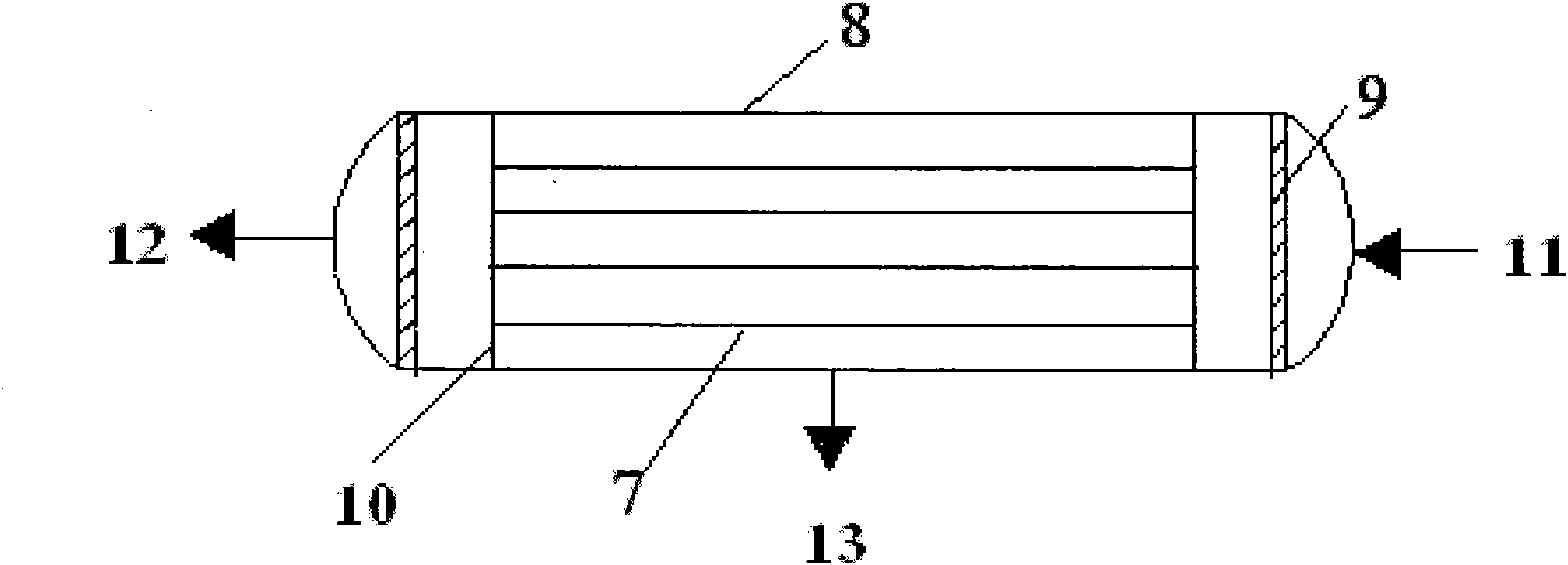

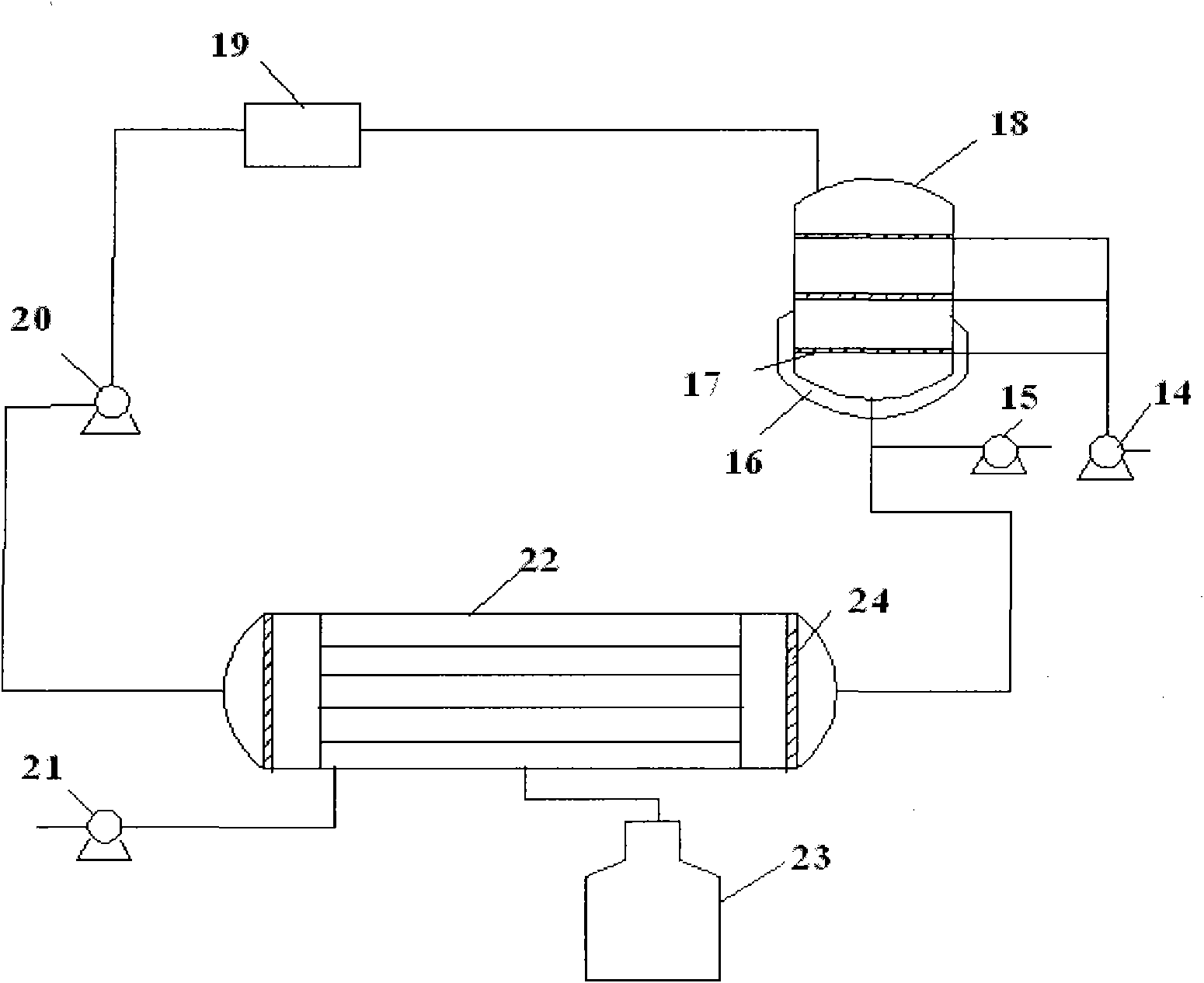

Membrane reactor for use in hydrocarbon oxidization reaction-separation coupling process

InactiveCN101862625AHigh selectivityReduce generationPreparation by oxidation reactionsOrganic compound preparationOver oxidationFiber bundle

The invention discloses a membrane reactor for use in a hydrocarbon oxidization reaction-separation coupling process, which comprises a shell, a membrane pipe and supporting plates, wherein the supporting plates are arranged in and at the two ends of the shell; the membrane pipe is formed into a fiber bundle shape; and the two ends of the membrane pipe are fixed on the supporting plates. The membrane reactor overcomes the drawbacks of low raw material conversion rate, low target product selectivity and series byproducts generated by easy over oxidation of oxides, of the traditional hydrocarbon oxidization reaction equipment. As oxides are separate out during oxidization reactions in time, the membrane improves the selectivity of the reactions, reduces byproducts and, compared with the traditional distillation, reduces energy consumption.

Owner:XIANGTAN UNIV

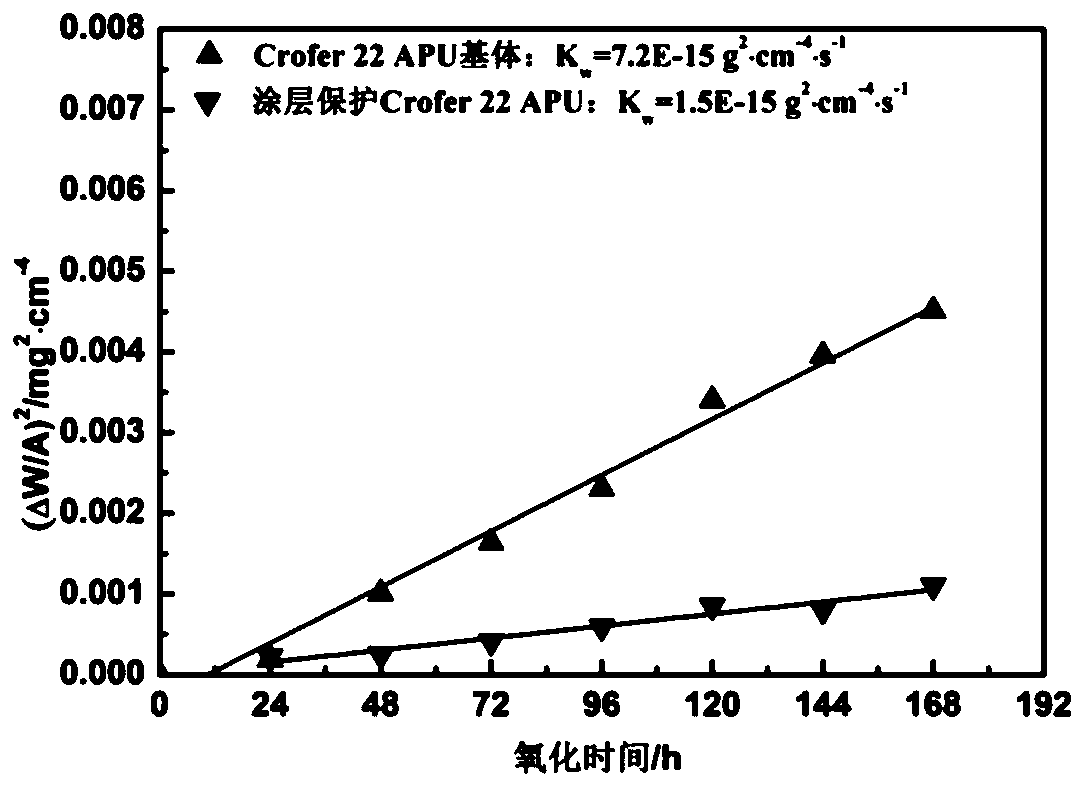

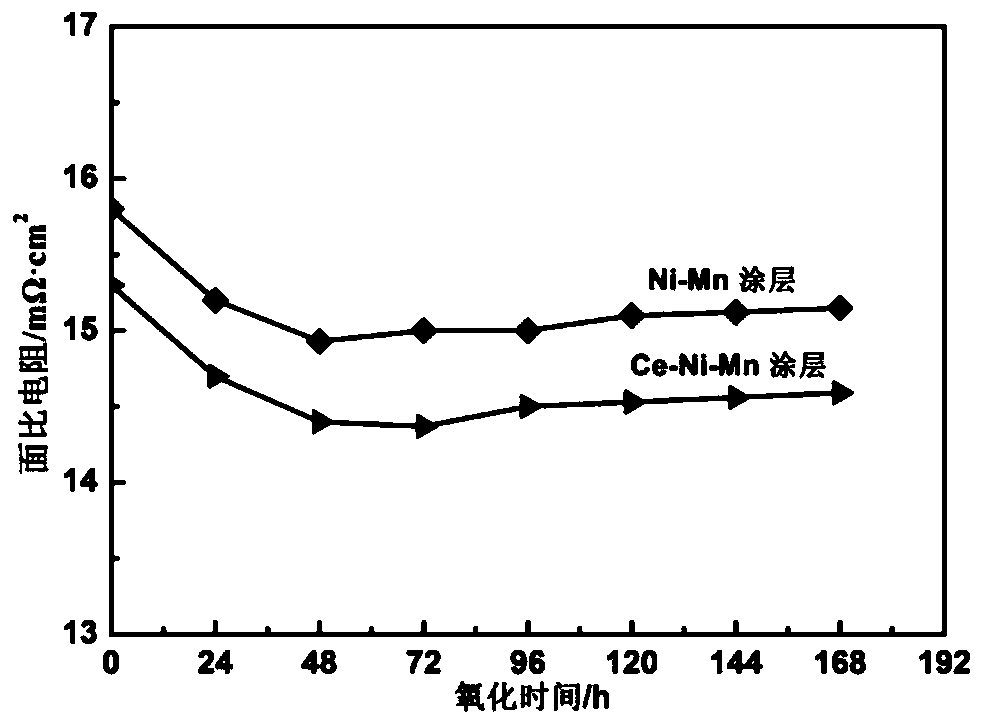

Preparation method of metal connection body surface spinel coating in solid oxide fuel cell

Owner:CHANGAN UNIV +1

Preparation method of fermented bean curds

The invention provides a preparation method of fermented bean curds. The method comprises steps of bean curd preparing, flavoring coating and blending, fermenting, and the like. According to the invention, through precise controlling upon the temperature procedure, an over-oxidation phenomenon of fermented bean curd protease is avoided, and odor is prevented from appearing. Also, a special rich flavoring which promotes a reversed flavor is blended in the fermented bean curds, such that the fermented bean curd mouthfeel and flavor which are maintained for thousands of years are innovated, and a novel mouthfeel is created. The fermented bean curds have a refreshing primary fragrance, a rich and long lasting flavor, a delicious and spicy taste, and a long-lasting reversed flavor.

Owner:JINSHI SHIBAZI FOOD

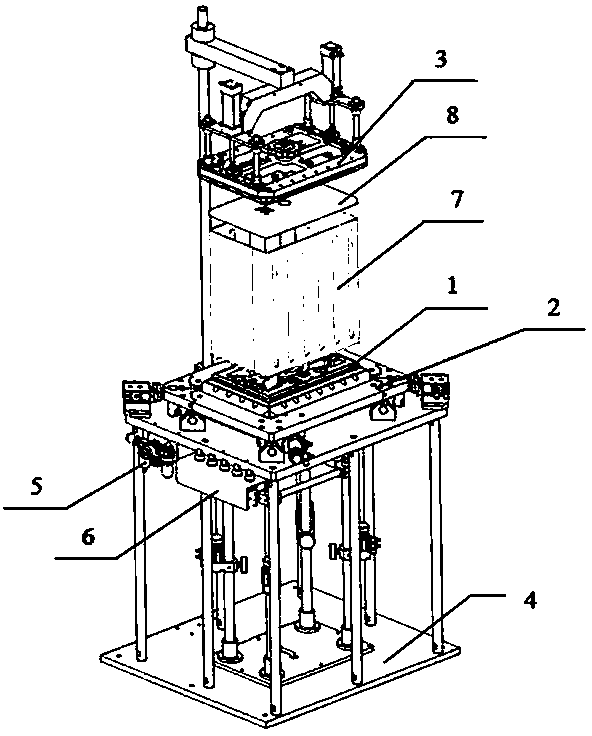

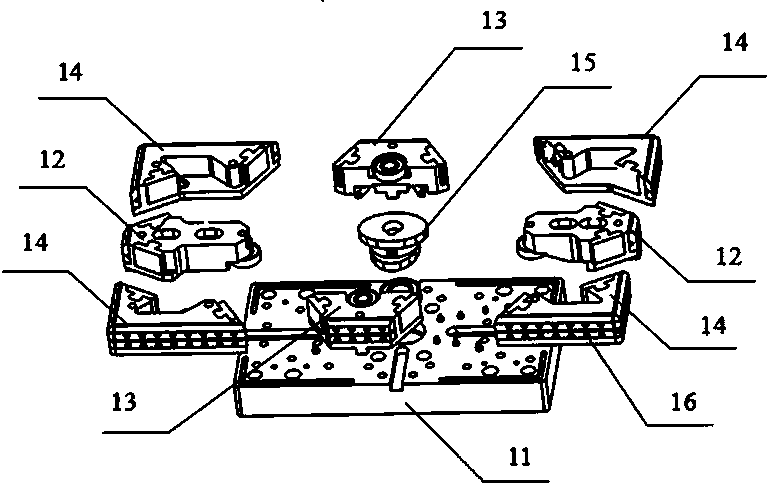

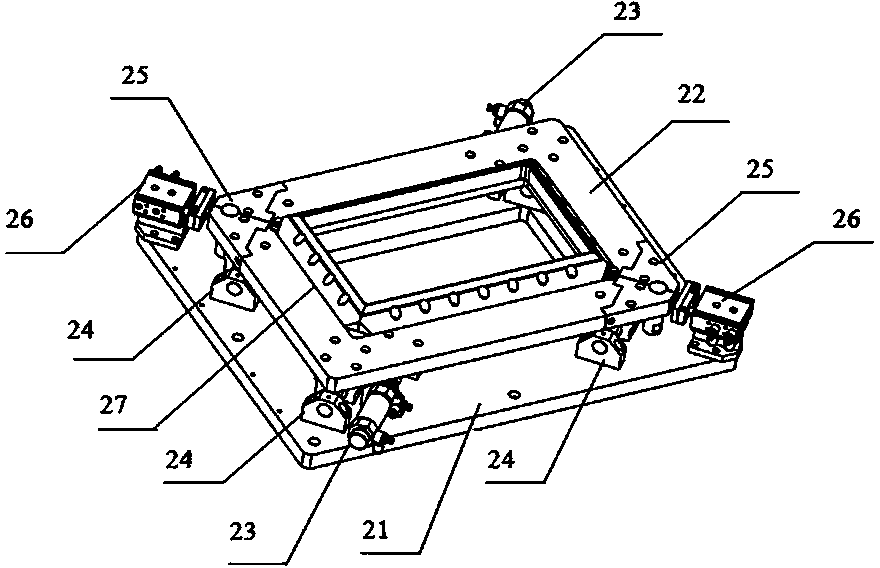

Circular seam welding tool for enclosed container

ActiveCN103769730AFit tightlyAvoid excessive oxidationWelding/cutting auxillary devicesAuxillary welding devicesOver oxidationShielding gas

The invention discloses a circular seam welding tool for an enclosed container. The circular seam welding tool is provided with a barrel body fixture, an end cover fixture and a planar slide block mechanism, wherein the planar slide block mechanism consists of a plurality of components taking planar slide blocks as connecting pieces, can extend outwards in a plane according to a certain moving track, and can be used for clamping the barrel body of a workpiece and the inner and outer walls of an end cover by cooperating with the barrel body fixture and the end cover fixture; the planar slide block mechanism is provided with an inner cooling block assembly acting on the inner wall of the workpiece; a protection groove is formed in the middle of each cooling block; a plurality of air outlet holes which are communicated protective gas are distributed in the protection grooves; the barrel body fixture and the end cover fixture are provided with outer cooling blocks acting on the outer wall of the workpiece. By adopting the circular seam welding tool, the phenomena of seam corrosion and over oxidation of welding seams in the conventional circular seam overlap welding are avoided, and superior quality performance, high efficiency and reliability are achieved. The circular seam welding tool is suitable for argon tungsten-arc welding of the circular seam butting structures of sheet enclosed containers of various shapes.

Owner:海宁红狮宝盛科技有限公司

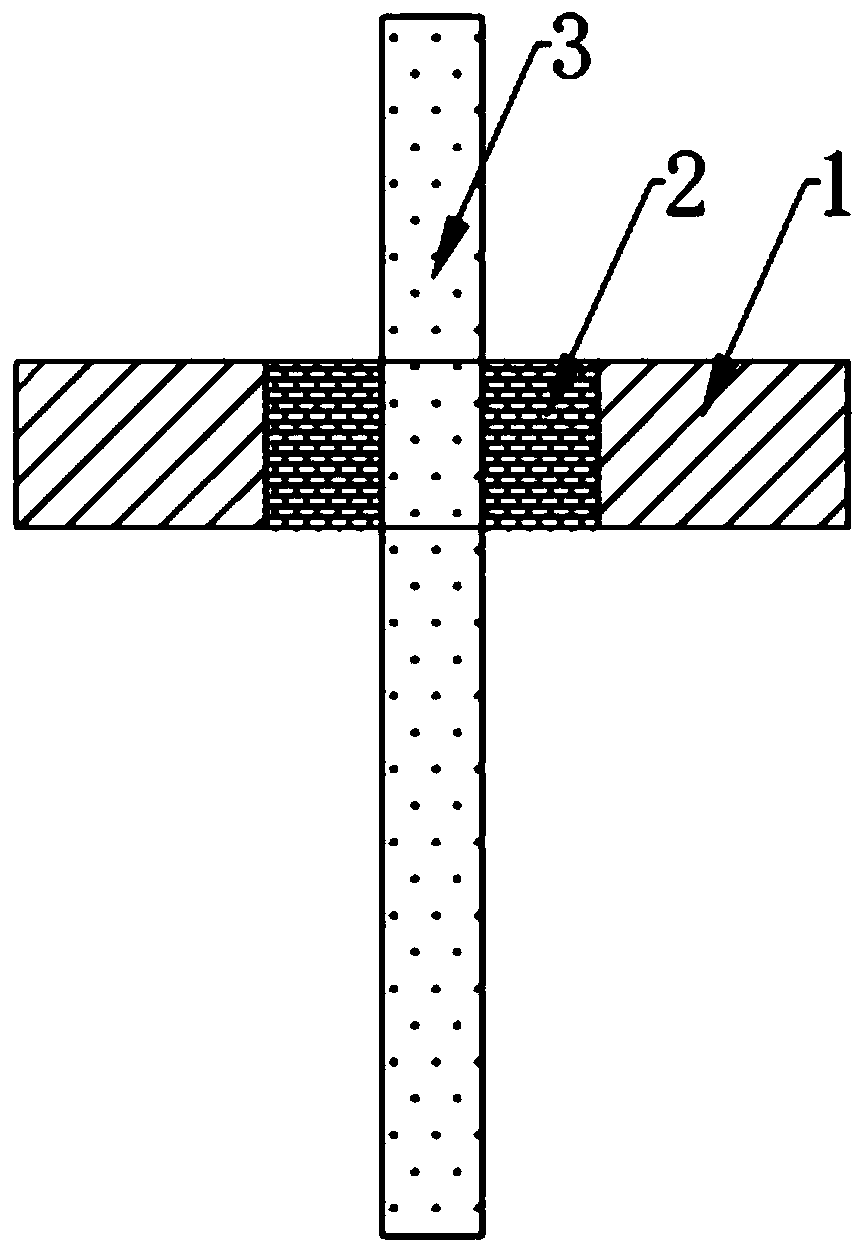

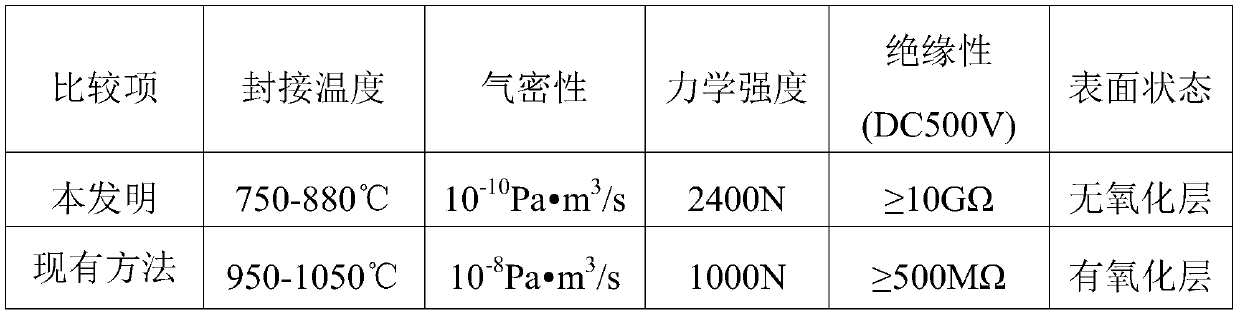

Sealing method for titanium-glass seal assembly

PendingCN110981224AStress reliefEliminate potential safety hazardsSolid state diffusion coatingElectrical conductorOver oxidation

The invention discloses a sealing method for a titanium-glass seal assembly. A to-be-sealed titanium metal shell and metal conductor core column are respectively pre-oxidized at the temperature of 300-500 DEG C, so the wettability of metal and glass is improved, and the problem that the wettability of titanium and a titanium alloy with glass is poor is solved; a low-temperature oxidation layer isused as a protective layer to prevent the metal from being excessively oxidized at high temperature; the consistency of a sintered assembly is further ensured, and subsequent surface treatment is facilitated; a sealing mold provided with a sealing part into a sintering furnace for sintering; nitrogen and hydrogen binary atmosphere is introduced as protective gas; the formation of nitrides and oxides on the metal surfaces of titanium and the titanium alloy is eliminated, and the seal assembly surface treatment process is eliminated; the sintered sealing part is subjected to heat preservation atthe temperature of 500-550 DEG C so as to eliminate stress in the seal assembly, potential safety hazards in the using process of the seal assembly are eliminated, then the titanium-glass seal assembly can be obtained after the seal assembly is cooled to the room temperature, and the process is simple.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Muscular soreness relieving and massaging cream and preparing method thereof

The invention relates to a muscular soreness relieving and massaging cream and a preparing method thereof. The muscular soreness relieving and massaging cream is prepared from various bioactive constituents including chavicol methylether, matricaria azulene, alpha-bisabol, sesquiterpene lactone, menthol, menthone, citral and the like. The muscular soreness relieving and massaging cream has the main effect of rejuvenating the musculoskeletal system, and has the functions of diminishing inflammation, relieving pain, recovering muscles, the brain, the heart and the elasticity of the skin and the like. The muscular soreness relieving and massaging cream is suitable for rheumatism, arthritis and muscular soreness. Essential oil of the muscular soreness relieving and massaging cream is prepared from essence extracted from plants, and is natural, organic, free of any artificially-synthesized constituent, free of removal of any original constituent, free of decloration, free of rectification and free of over oxidation. Thus, the muscular soreness relieving and massaging cream is free of toxic or side effects on the human body. In addition, due to the fact that chemical molecules are small and are lipid soluble molecules, the muscular soreness relieving and massaging cream can quickly seep into the corium layer or the blood capillary of the skin, and has the advantage of being fast in absorption. When the muscular soreness relieving and massaging cream is used, the skin is fine, moist and smooth. The product is convenient to carry and use and applicable to a wide range of objects.

Owner:SHANGHAI UNIV

Method for high selective preparation of aromatic aldehyde from toluene compound

InactiveCN107935828ASimple operation processEasy to recycleOrganic compound preparationCarbonyl compound preparationOver oxidationCatalytic oxidation

The invention discloses a method for high selective preparation of aromatic aldehyde from a toluene compound. The method includes: mixing the toluene compound, a catalytic system and a solvent, carrying out reaction in an air or oxygen atmosphere, and adding an inhibitor into the reaction system, wherein the inhibitor is an aromatic alcohol compound. The invention provides a method for high selective preparation of aromatic aldehyde from the toluene compound, by adding the inhibitor into the reaction system, over oxidation of aromatic aldehyde in the catalytic oxidation process can be effectively suppressed, and the selectivity of aromatic aldehyde is significantly improved.

Owner:ZHEJIANG UNIV +1

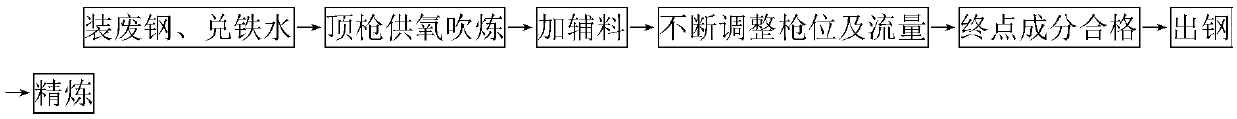

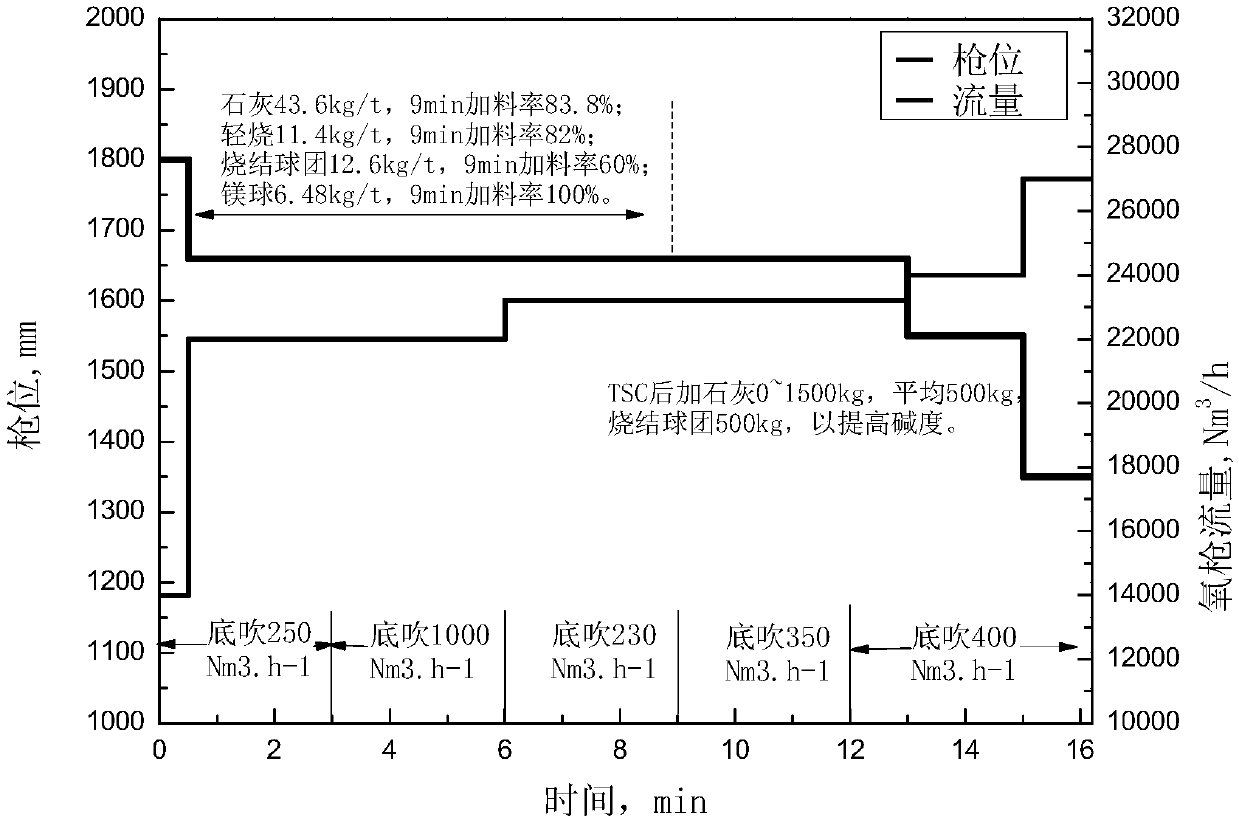

High-carbon dephosphorization method for high-carbon steel in converter smelting

ActiveCN109628697AIncrease alkalinityMaintain dephosphorization capacityManufacturing convertersSteelmakingAlkalinity

The invention discloses a high-carbon dephosphorization method for high-carbon steel in converter smelting, and belongs to the technical field of converter steelmaking. The technological thought of high gun position soft blowing and improving slag alkalinity is adopted, and the high-alkalinity slag is prepared with variable flow and variable gun position. Compared with the traditional process, thebiggest different is that the oxygen supply system with high gun position and low oxygen flow is adopted in the early and middle stages of smelting, the adding amount of the lime is increased to 40-45 kg / t, in contrast to an adding mode of adding materials in batches and small amounts of the traditional process, the steelmaking auxiliary materials are added to be more than 80% before 9 minutes. The purpose of adopting the high gun position and the low oxygen flow is to rapidly generate a large amount of FeO in the furnace slag, so that slagging is facilitated; the purpose of adding as early as possible is to combine with a soft blowing oxygen supply system, so that the FeO has the effect of promoting the melting of the lime, the utilization rate of the lime is increased to 85%, the high-alkalinity slag is generated so as to facilitate early-stage dephosphorization. The alkalinity of the terminal slag can be controlled to be larger than 3.2, the FeO in the slag is controlled to be 16-20%, and over-oxidation of the molten steel is avoided. The method has the advantages that the practical guidance is provided for producing low-cost and high-quality molten steel by the converter.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com