Dielectric layers and methods of forming the same

a dielectric layer and dielectric layer technology, applied in the direction of basic electric elements, solid-state devices, electric apparatus, etc., can solve the problems of increasing the required capacitance per unit of footprint, complex fabrication steps, and increasing the processing cost. , to achieve the effect of reducing the average of leakage curren

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

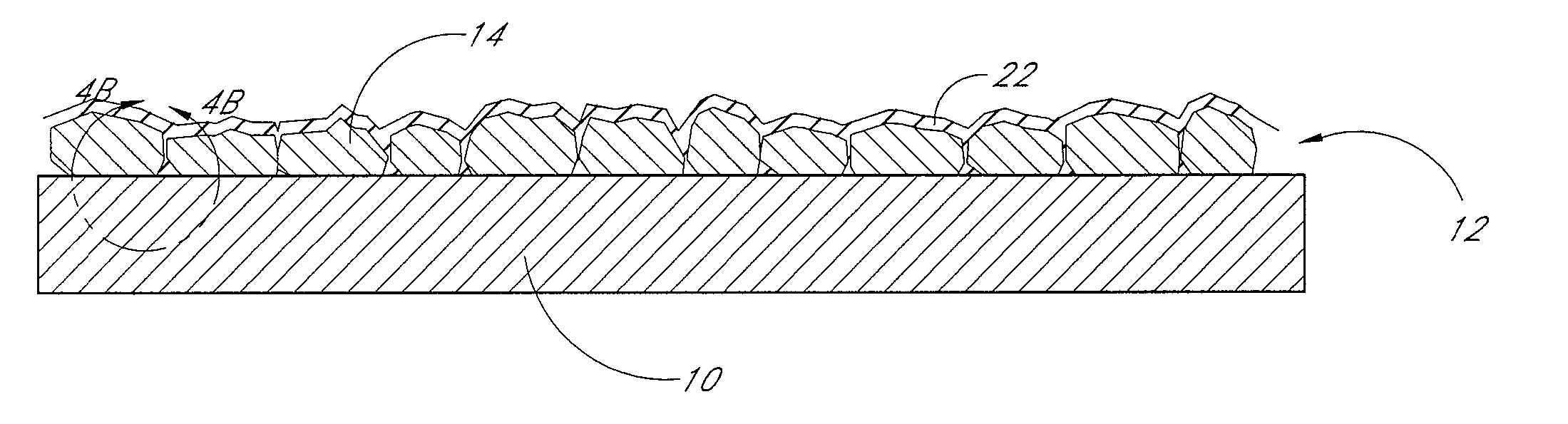

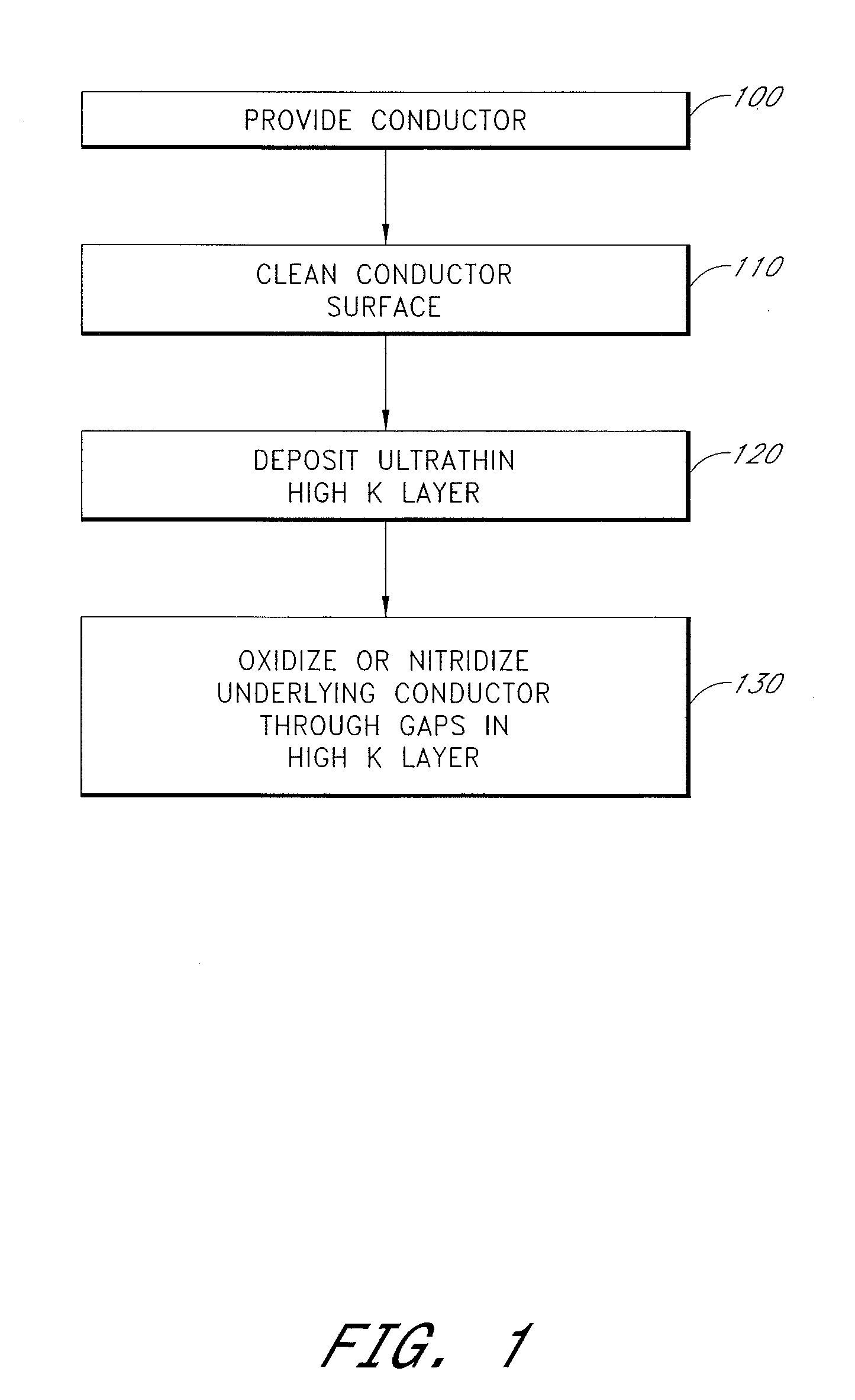

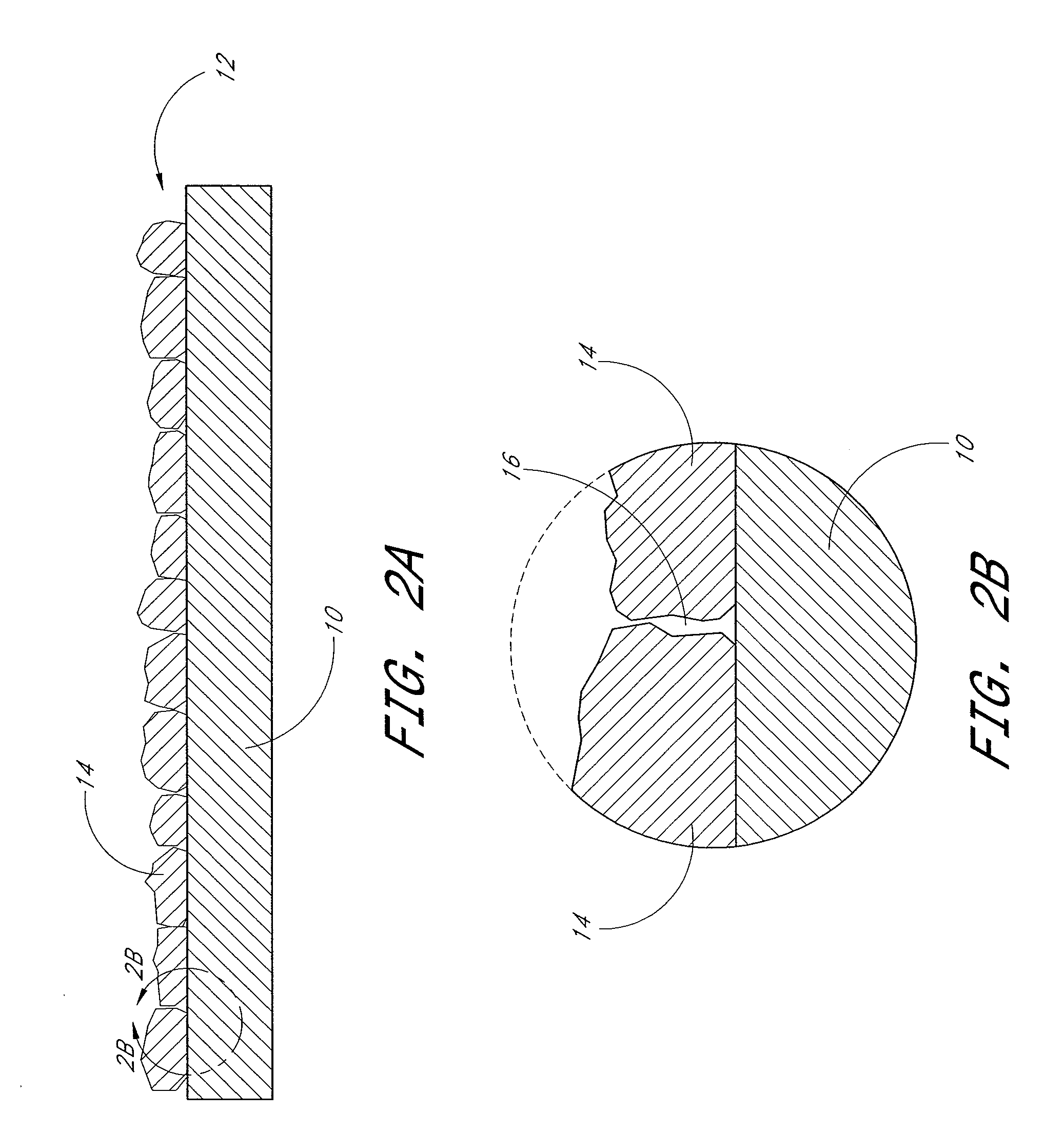

Image

Examples

example 1

[0060] In this example, a high-k dielectric layer is formed on a silicon substrate by ALD. The skilled artisan will appreciate, however, that the high-k dielectric material can be formed by any suitable method (e.g., MOCVD).

[0061] Zirconium dioxide (ZrO2) was deposited by ALD onto a silicon substrate as follows. In pulse A, ZrCl4 vapor was introduced to the reaction chamber, exposing the wafer surface for 1.5 s. In purge A, the reaction chamber was purged with nitrogen gas for 3.0 s to remove excess ZrCl4 and reaction byproducts. Pulse A and purge A are together referred to as the “metal phase.” In pulse B, water vapor was introduced to the reaction chamber, exposing the wafer surface for 3.0 s. In purge B, residual H2O and reaction byproducts were removed by purging the reaction chamber with nitrogen gas for 4.0 s. Pulse B and purge B are together also referred to as the “oxygen phase.” During each of the reaction phases, the reactants were supplied in sufficient quantities to sat...

example 2

[0069]FIGS. 6-9 illustrate experimental results of oxidation and nitridation anneals of 4.0 nm ALD Al2O3 or HfO2 layers on 0.5 nm RTO (rapid thermal oxide) SiO2, an interfacial layer (24 in FIG. 5A). Anneals were performed at from 600° C. to 1000° C. for 60 s. The wafers were then annealed at 400° C. under forming gas before measurement of an EOT parameter. This second anneal does not affect the interface oxide. In these examples, an EOT parameter was measured using a Corona-Oxide-Si (COS) method on a COS Quantox system (KLA-Tencor Corp.). The EOT parameter (GateTox™) is the accumulation capacitance, expressed in Å.

[0070]FIG. 6 illustrates the EOT of Al2O3 dielectric layers under a series of oxidation annealing conditions. The EOT increased under higher oxygen concentrations (40 Torr and 3×10−2 Torr) at higher temperatures. The Al2O3 high-k layer was stable up to from about 900° C. to about 1000° C. under sufficient oxygen concentrations. EOT decreased in lean oxygen anneals. The E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com