Patents

Literature

37results about How to "Accelerates the carbonization process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

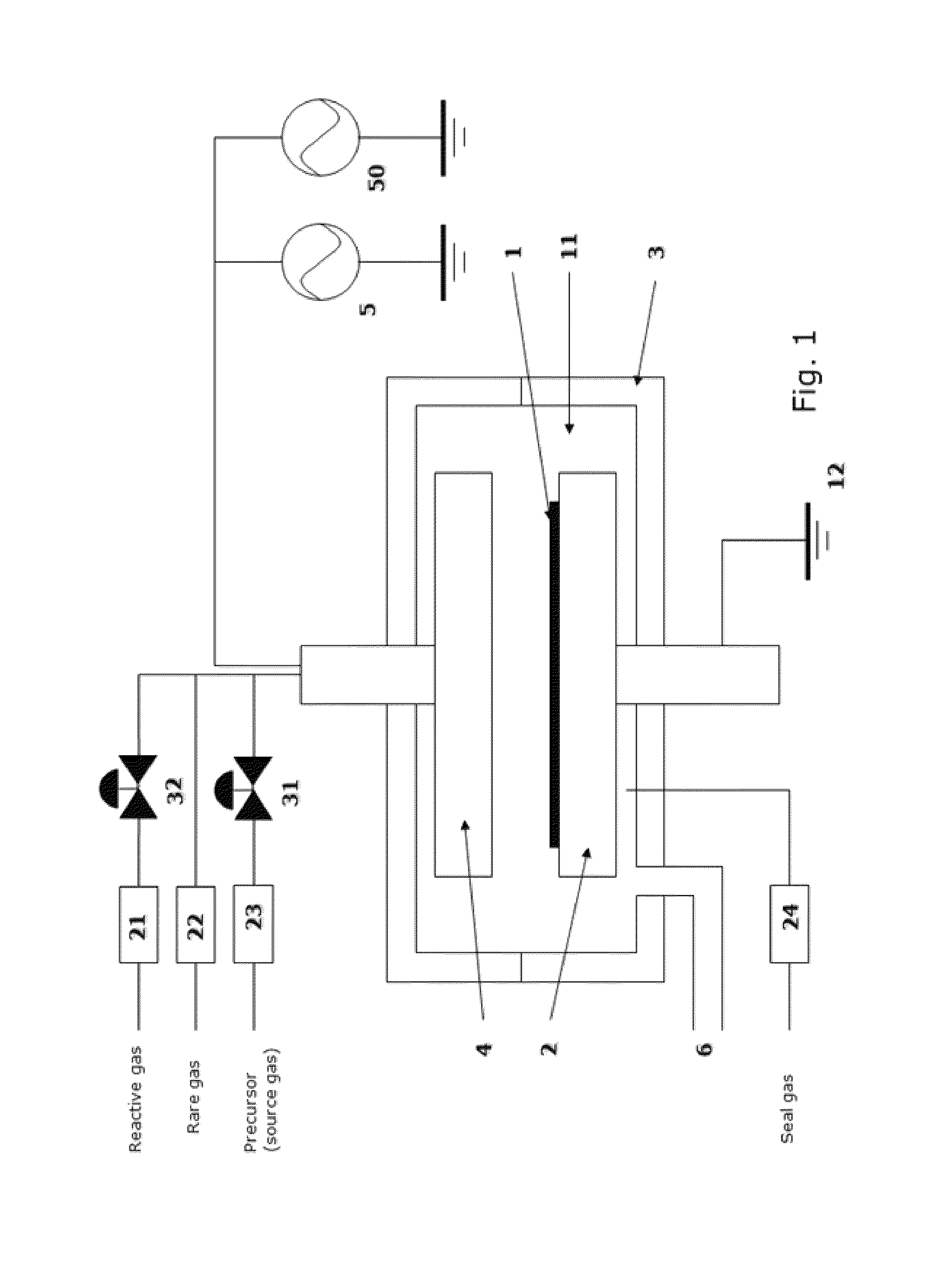

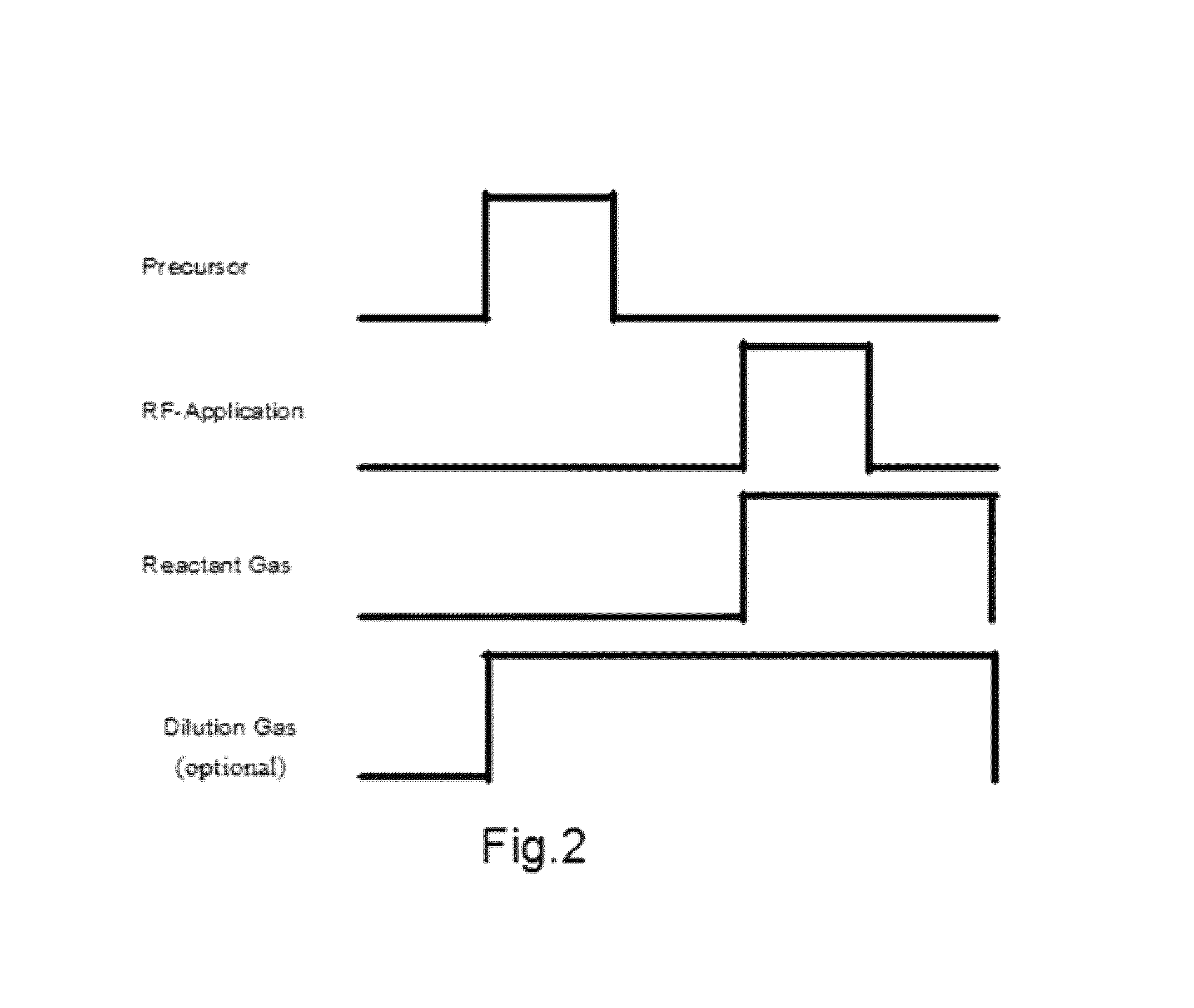

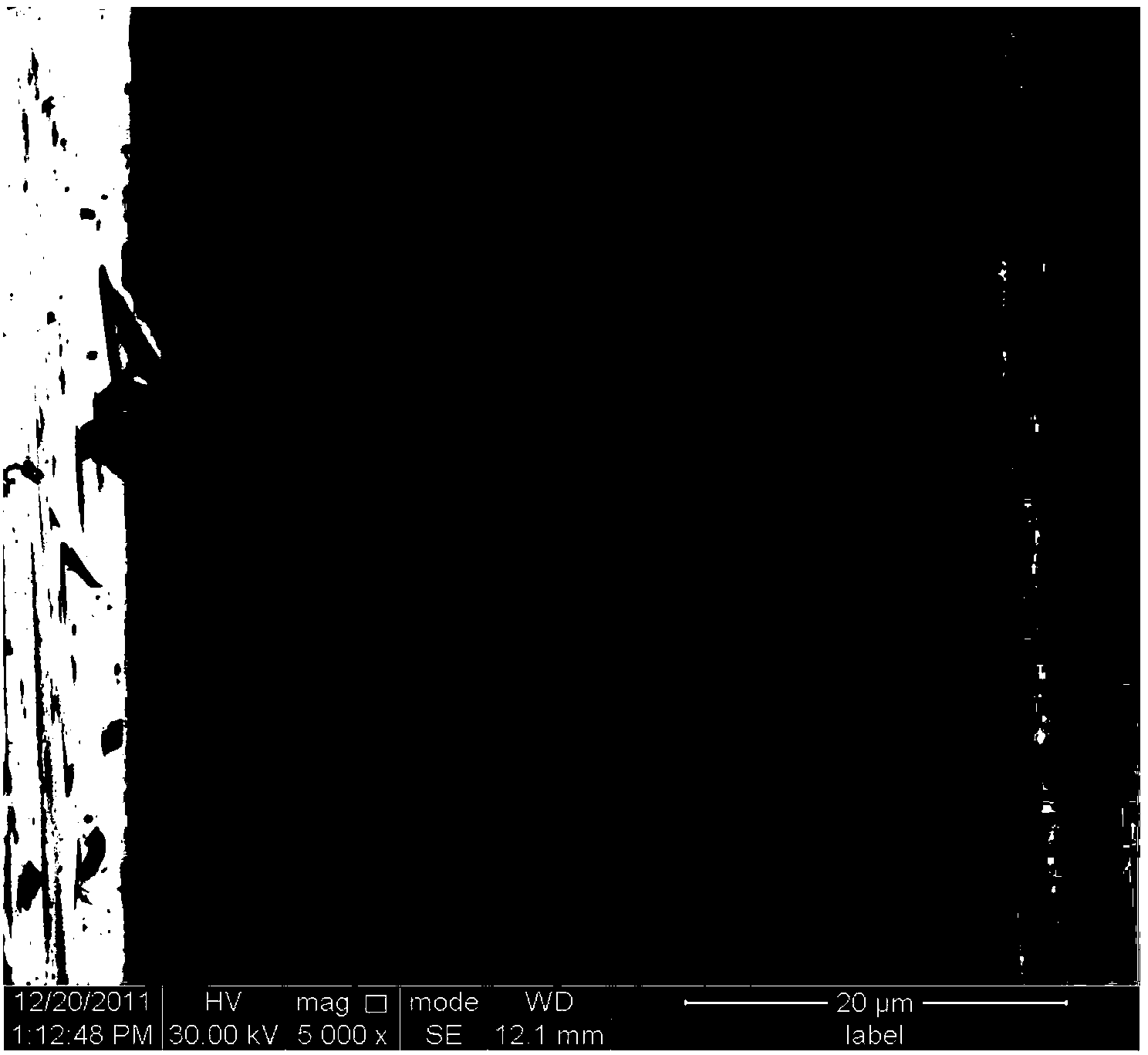

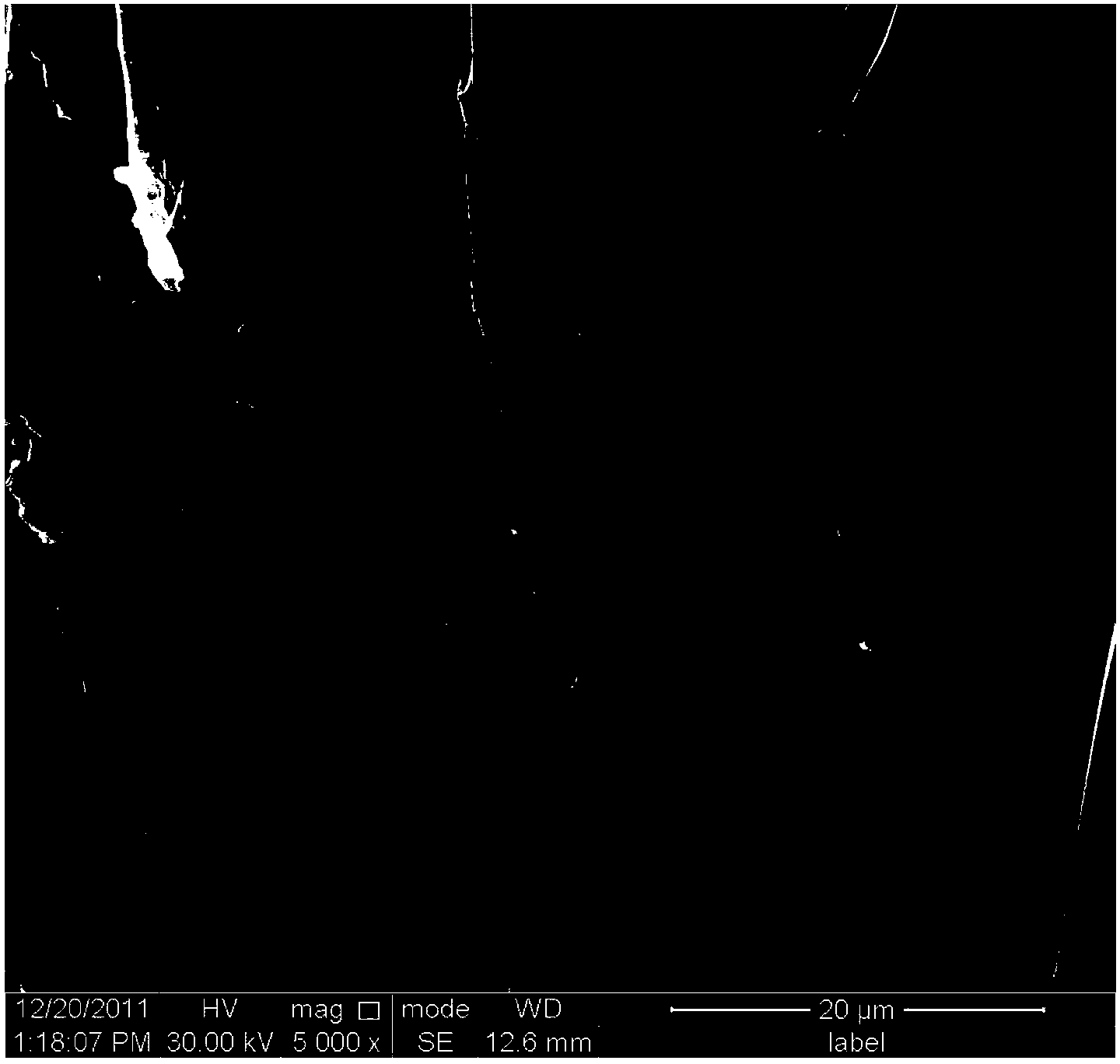

Method of depositing dielectric film by ALD using precursor containing silicon, hydrocarbon, and halogen

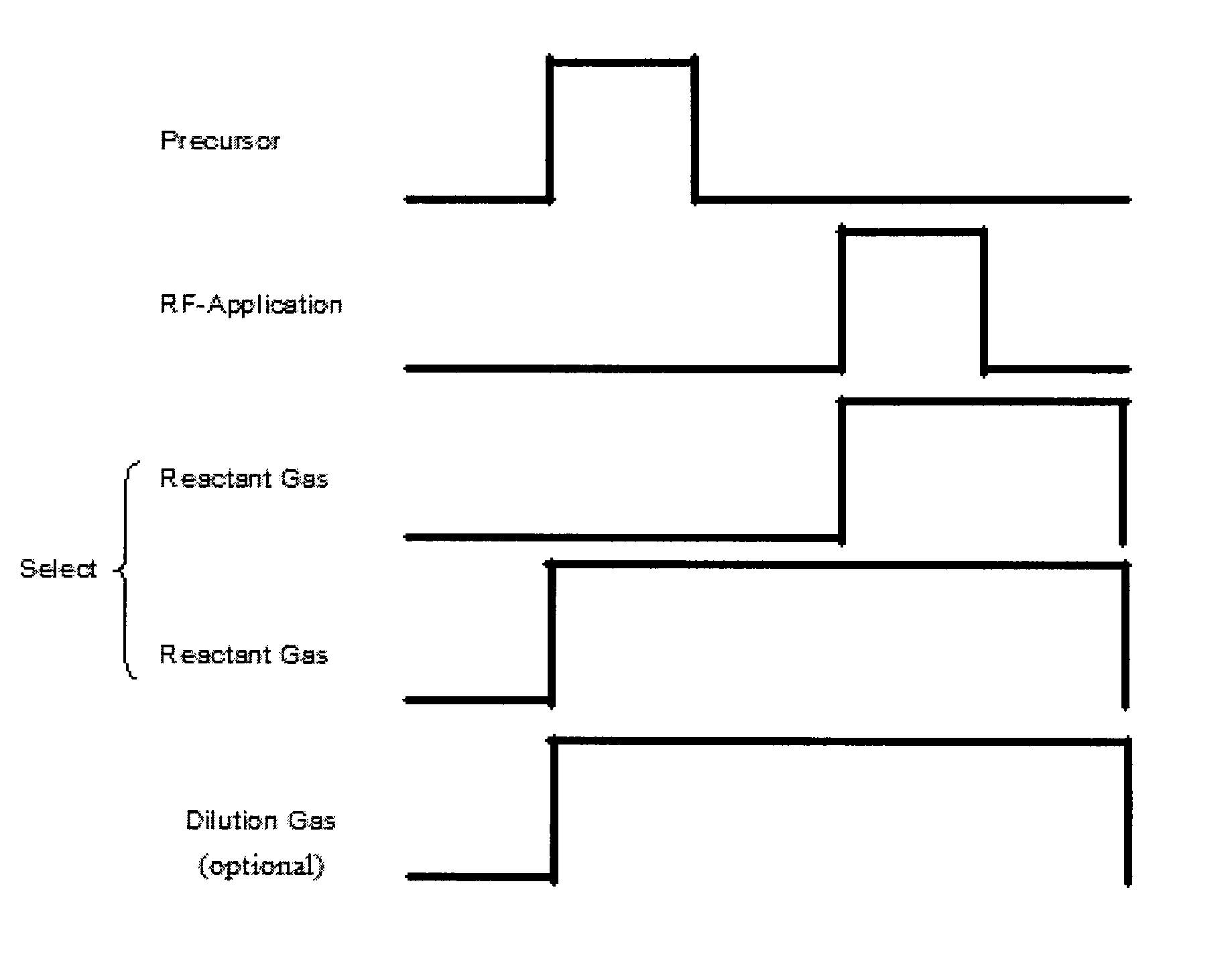

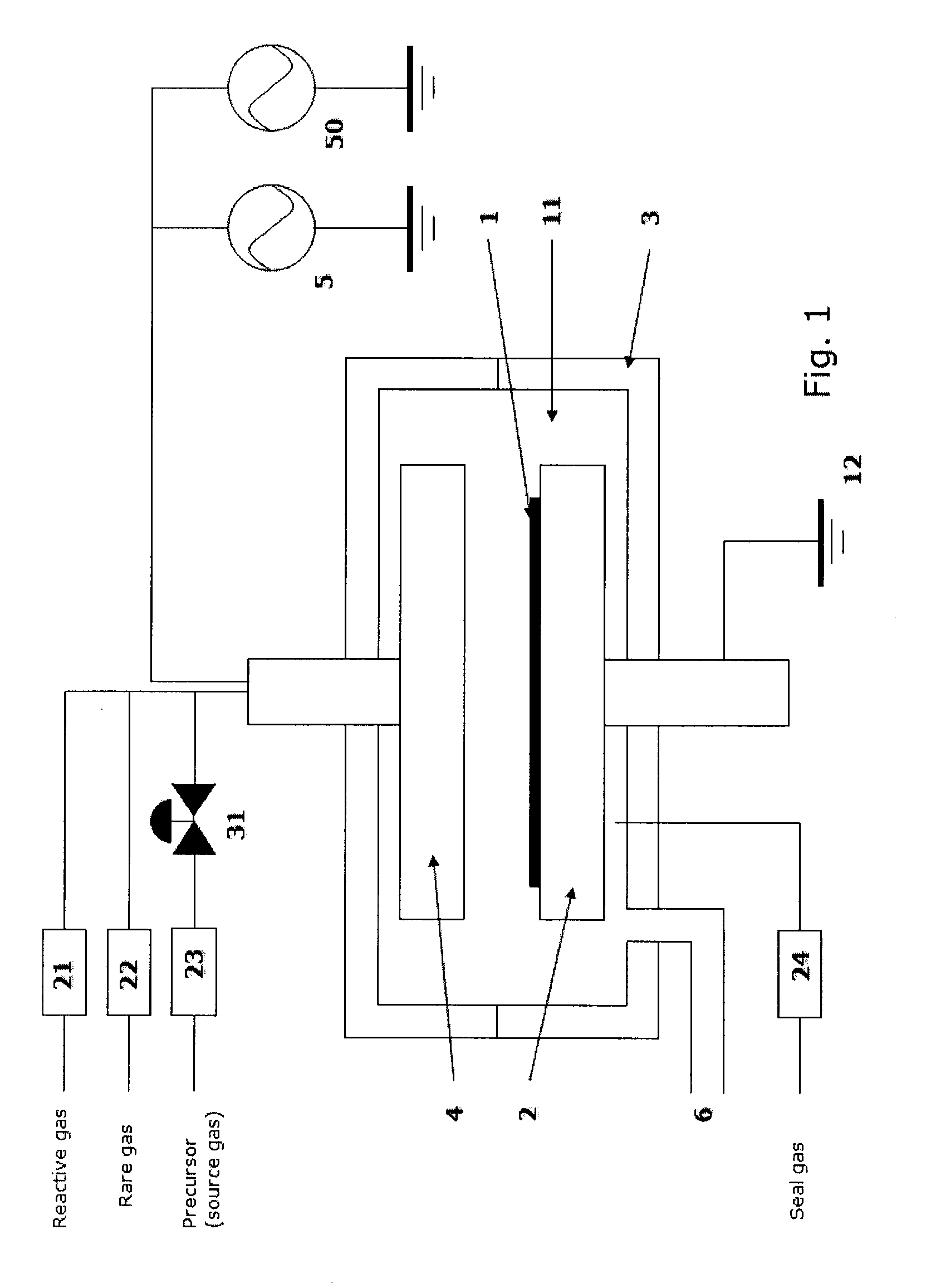

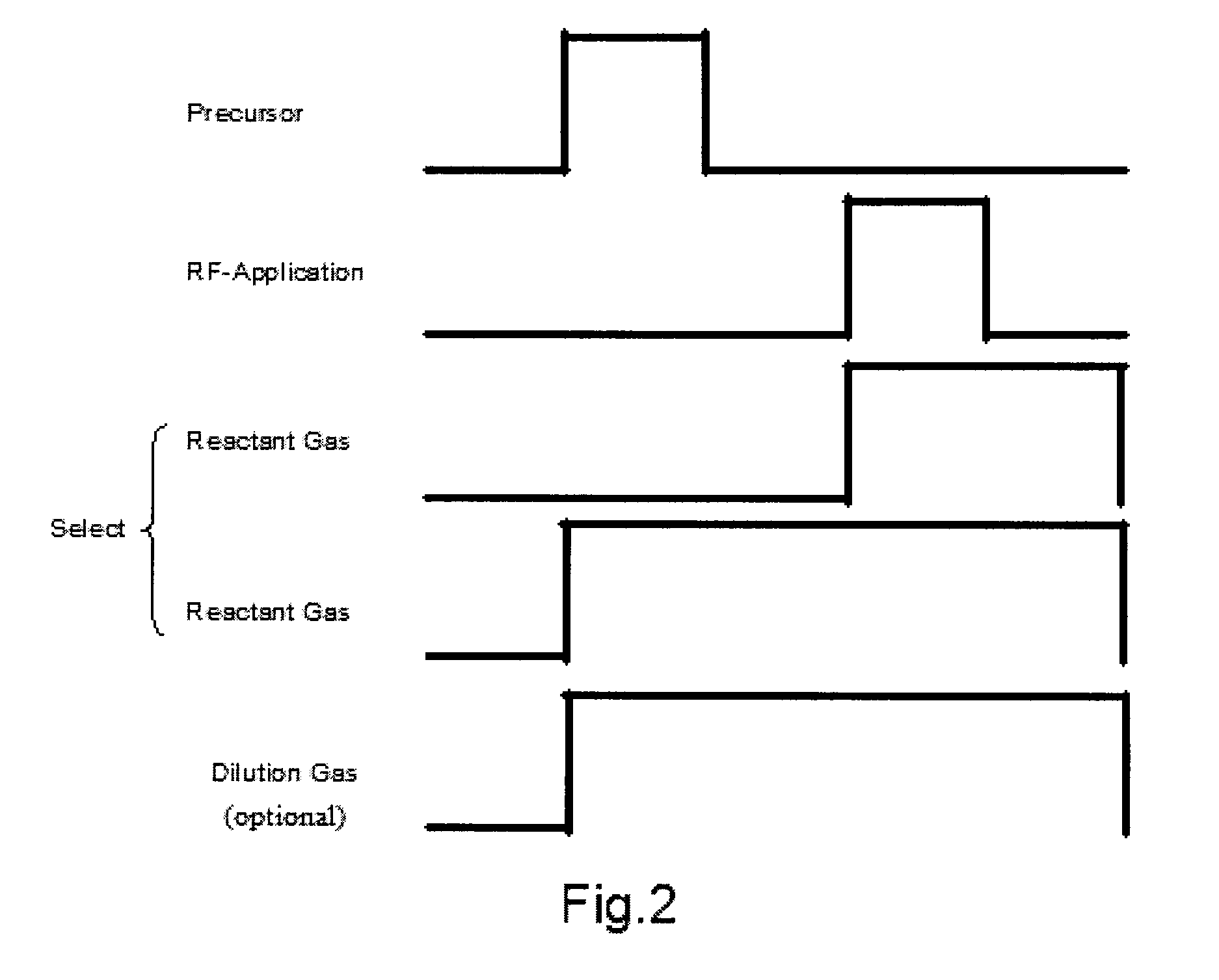

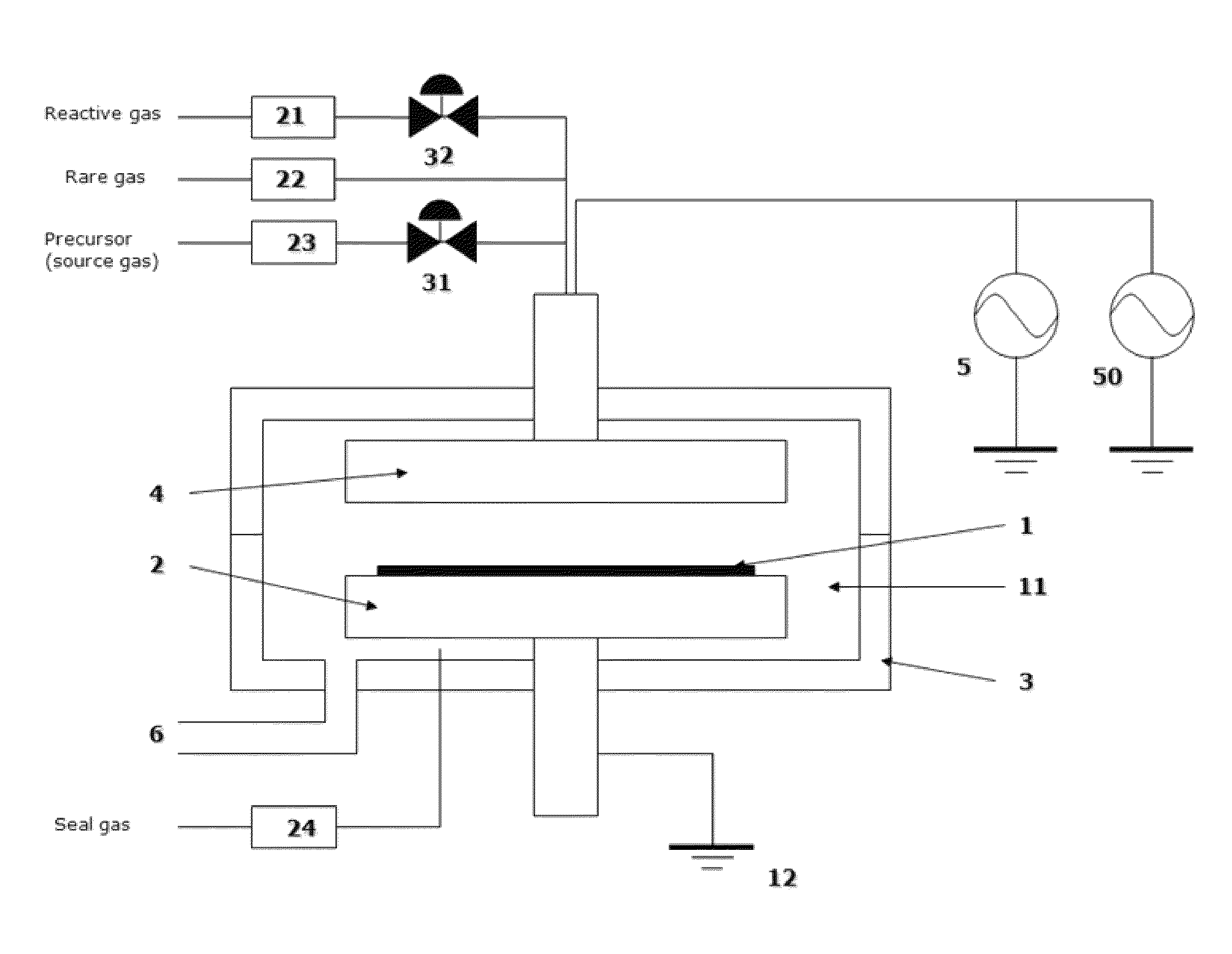

ActiveUS8329599B2Accelerates the carbonization processHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricHalogen

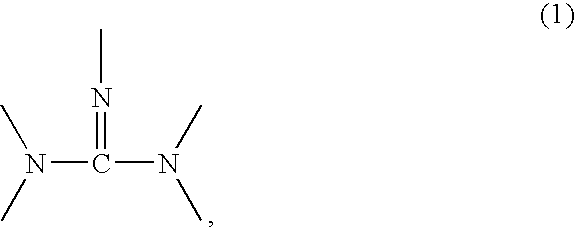

A method of forming a dielectric film having at least Si—N, Si—C, or Si—B bonds on a semiconductor substrate by atomic layer deposition (ALD), includes: adsorbing a precursor on a surface of a substrate; supplying a reactant gas over the surface; reacting the precursor and the reactant gas on the surface; and repeating the above steps to form a dielectric film having at least Si—N, Si—C, or Si—B bonds on the substrate. The precursor has at least one Si—C or Si—N bond, at least one hydrocarbon, and at least one halogen attached to silicon in its molecule.

Owner:ASM JAPAN

Method of depositing dielectric film by ALD using precursor containing silicon, hydrocarbon, and halogen

ActiveUS8563443B2Accelerates the carbonization processHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricHalogen

A method of forming a dielectric film having at least Si—N, Si—C, or Si—B bonds on a semiconductor substrate by atomic layer deposition (ALD), includes: supplying a precursor in a pulse to adsorb the precursor on a surface of a substrate; supplying a reactant gas in a pulse over the surface without overlapping the supply of the precursor; reacting the precursor and the reactant gas on the surface; and repeating the above steps to form a dielectric film having at least Si—N, Si—C, or Si—B bonds on the substrate. The precursor has at least one Si—C or Si—N bond, at least one hydrocarbon, and at least two halogens attached to silicon in its molecule.

Owner:ASM JAPAN

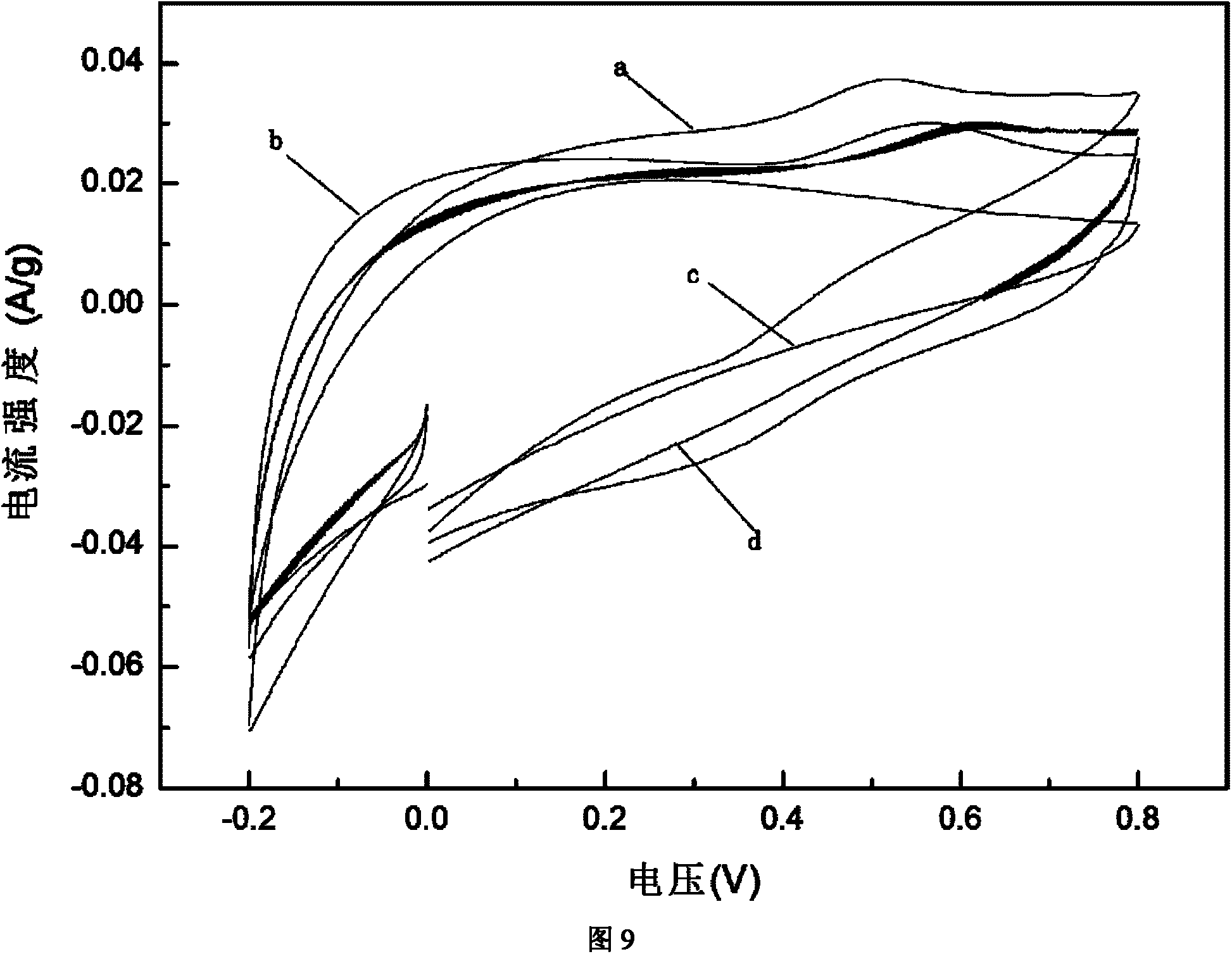

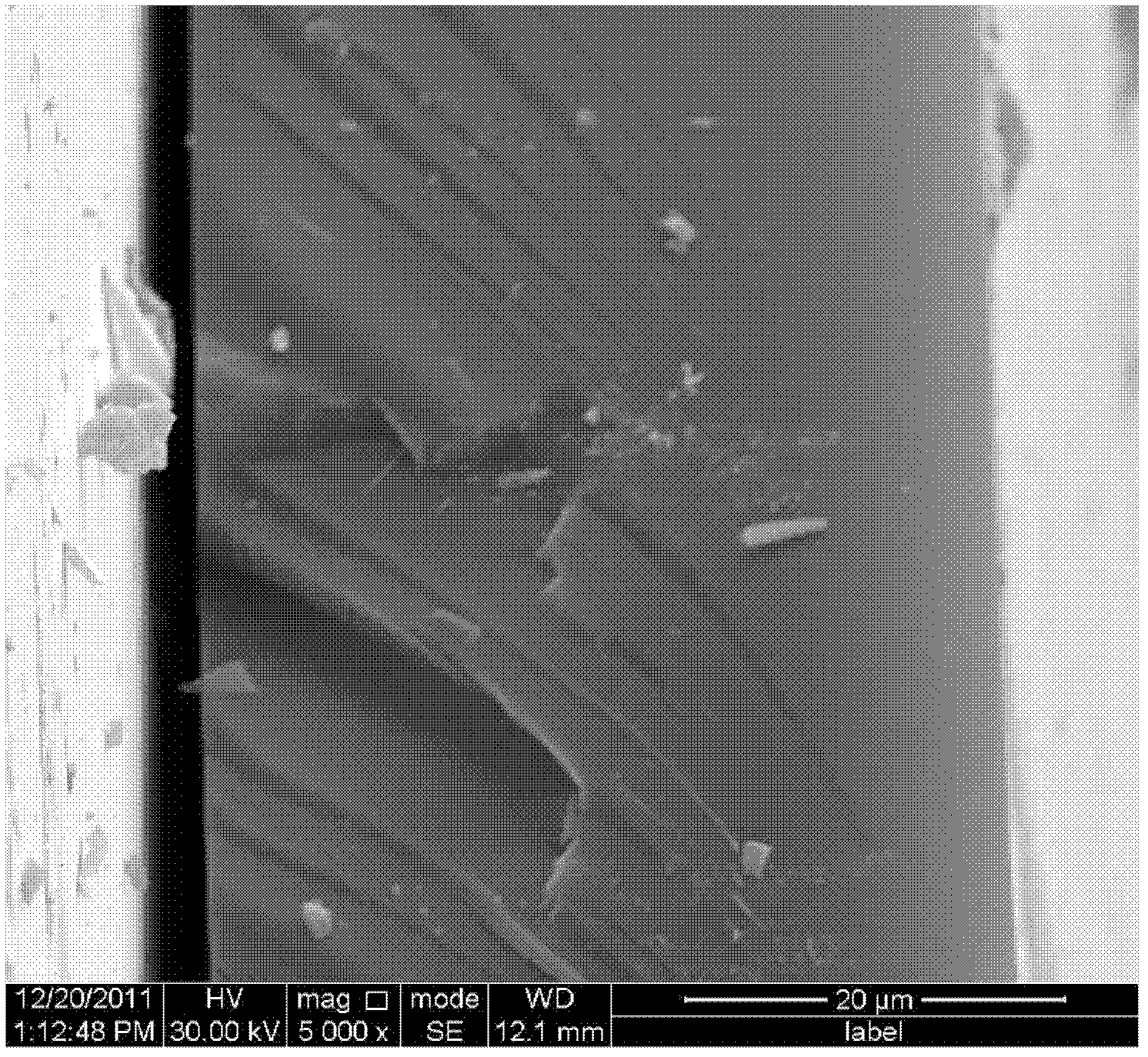

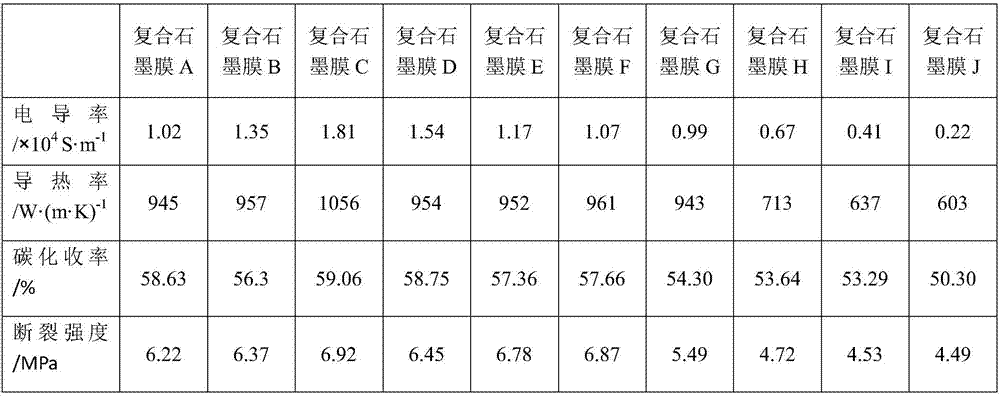

Method for preparing carbide film by carbonizing graphene reinforced polyimide resin

ActiveCN102560453AIncrease internal stressReduce brittlenessSolid/suspension decomposition chemical coatingCapacitancePolymer science

The invention discloses a method for preparing a carbide film by carbonizing graphene reinforced polyimide resin, and relates to a method for preparing a carbide film. The method solves the technical problems of high carbonizing temperature, high energy consumption, long carbonizing period and low carbonizing rate and low strength of the carbide film in the conventional method for preparing the carbide film. The method comprises the following steps of: 1, adding 4,4'-diamino diphenyl ether (ODA) and 3,3',4,4'-benzophenonetetracarboxylic dianhydride (BTDA) into N,N-dimethyl acetamide (DMAC), and performing mechanical stirring to obtain a polyamide acid (PAA) solution; 2, adding graphene into the PAA solution, and performing in-situ polymerization reaction to obtain a solution A; 3, spreading the solution A on a clean glass plate, heating to the temperature of 60 DEG C and preserving the heat for 2 hours, heating to the temperature of 100 DEG C and preserving the heat for 1 hour, heating to the temperature of 200 DEG C and preserving the heat for 1 hour, heating to the temperature of 300 DEG C and preserving the heat for 1 hour, and thus obtaining a composite film; and 4, carbonizing, naturally cooling to room temperature, and thus obtaining the carbide film. The carbide film has excellent mechanical properties; and because the adding proportion of the graphene is increased, the mechanical properties of the carbide film are improved, the specific capacitance of the graphene is also improved, and the carbide film is suitable to be used as an electrode material.

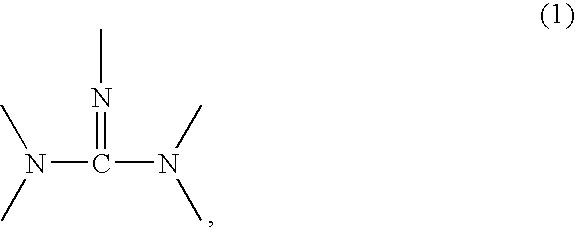

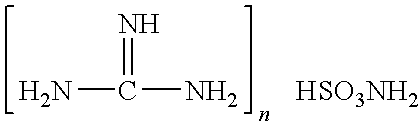

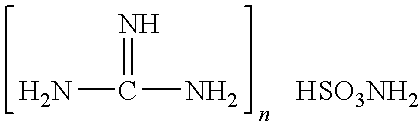

Flame retardant aqueous liquid composition, use thereof for producing flame retardant polyurethane foam, and flame retardant polyurethane foam article

A flame retardant aqueous liquid composition containing water, guanidine sulfamate, a citric acid compound including a metal salt of citric acid, and a water soluble polymer. A flame retardant polyurethane foam is produced by a process including the steps of providing a mixture of the above flame retardant aqueous liquid composition with a polyol and an isocyanate, and reacting the mixture in the presence of a catalyst.

Owner:NANKYO EFUNIKA

Method for the preparation of porous graphite carbon with high crystallinity using sucrose as a carbon precursor

InactiveUS20090041653A1High crystallinityHigh catalytic activityMaterial nanotechnologyCarbon compoundsSilica particleGraphite carbon

The present invention relates to a process for preparing a porous graphite carbon with high crystallinity, which comprises the steps of: (a) hydrothermally treating sucrose (i.e. carbon precursor), transitional metal precursor and uniform-sized silica particles at the same time to prepare a polymer; and (b) carbonizing the polymer, which can provide a porous graphite carbon with remarkably improved crystallinity suitable for a catalyst support for a fuel cell.

Owner:HYUNDAI MOTOR CO LTD

Use of flame retardant aqueous liquid composition in making flame retardant polyurethane foam article

A flame retardant aqueous liquid composition containing water, guanidine sulfamate, a citric acid compound including a metal salt of citric acid, and a water soluble polymer. A flame retardant polyurethane foam is produced by a process including the steps of providing a mixture of the above flame retardant aqueous liquid composition with a polyol and an isocyanate, and reacting the mixture in the presence of a catalyst.

Owner:NANKYO EFUNIKA

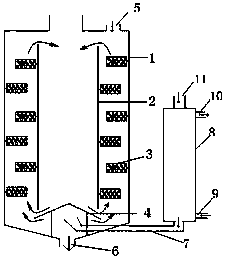

Carbonation reactor of energy-efficient nano calcium carbonate and preparation method of energy-efficient nano calcium carbonate

ActiveCN103738993AReduce energy consumptionReduce manufacturing costCalcium/strontium/barium carbonatesMaterial nanotechnologyCarbonizationCooling effect

The invention relates to a preparation method of energy-efficient nano calcium carbonate, the main steps are as follows: in carbonization, first a compressed kiln gas is cooled to 25 DEG C by deep well water, during the carbonization process, carbonized slurry is directly cooled by the kiln gas, the cooling effect is increased, the heat produced in the slurry carbonization process can be absorbed directly, and the carbonized slurry temperature is effectively controlled. During the carbonization, the kiln gas enters into an interlayer of an outer barrel and an inner barrel from the periphery of an umbrella-shaped gas distributor to drive the slurry in the interlayer to move from bottom to up, under the action of a porous helical baffle plate, on the one hand, a gas liquid passes through multiple holes of the helical baffle plate to make larger bubbles smaller by division; on the other hand, under the action of the helical baffle plate, the upward gas liquid forms a vortex for enhancement of mixing effects. The upward slurry in the interlayer returns back to the bottom through the inner barrel to form a slurry cyclic carbonation process to facilitate kiln gas absorption and accelerate the carbonation process.

Owner:WUHU ZHUOYUE NANO NEW MATERIALS

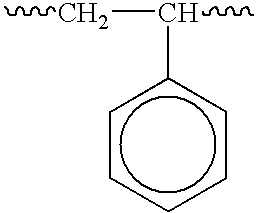

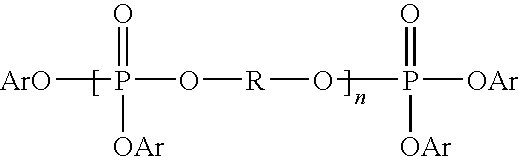

Halogen-Free Flame Retardant Compositions, Thermoplastic Compositions Comprising the Same and Methods of Producing the Compositions

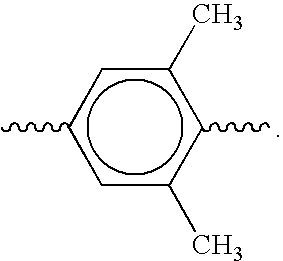

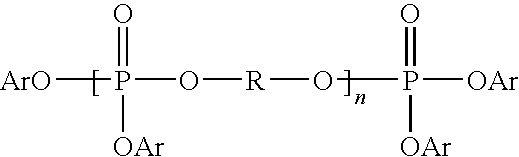

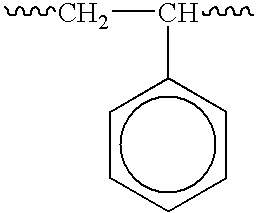

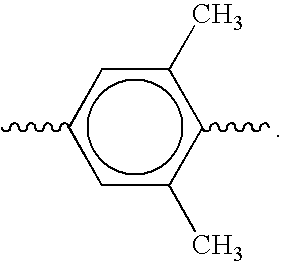

InactiveUS20100010128A1Easily blendableEasily processablePlastic/resin/waxes insulatorsDyeing processPhosphatePolystyrene

The present invention relates to a halogen-free or substantially halogen-free flame-retardant composition comprising a blend of (i) at least one of each highly charring polymer (ii) at least one low volatility phosphate ester, and (iii) at least one compound which splits off a high volatility phosphorus-containing fragment. The invention also relates to a flame retarded thermoplastic composition wherein the flame retardant composition is blended with at least one thermoplastic resin (iv), preferable a polystyrene resin. The invention also relates to a process for manufacturing a flame retardant composition and a thermoplastic composition containing the same.

Owner:ICL IP AMERICA INC

Halogen-free flame retardant compositions, thermoplastic compositions comprising the same and methods of producing the compositions

InactiveUS8026303B2Improve solubilityImprove flame retardant performancePlastic/resin/waxes insulatorsDyeing processPhosphoric Acid EstersPolymer science

Owner:ICL IP AMERICA INC

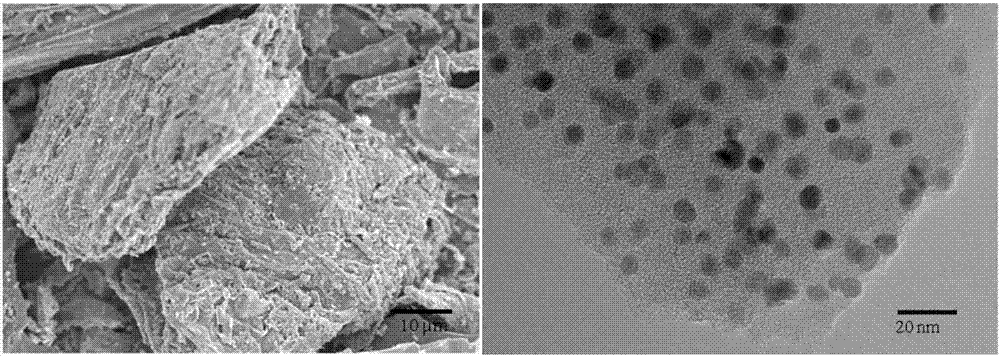

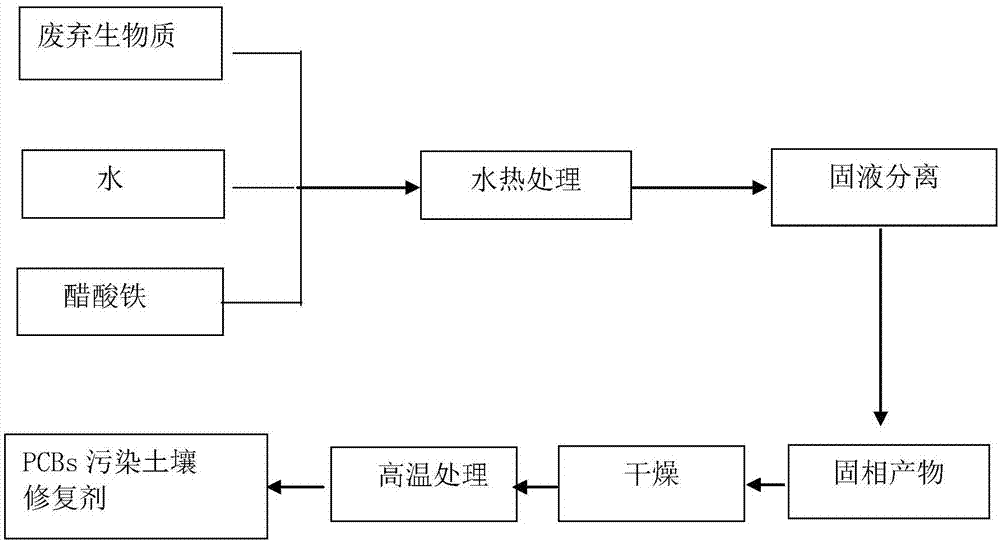

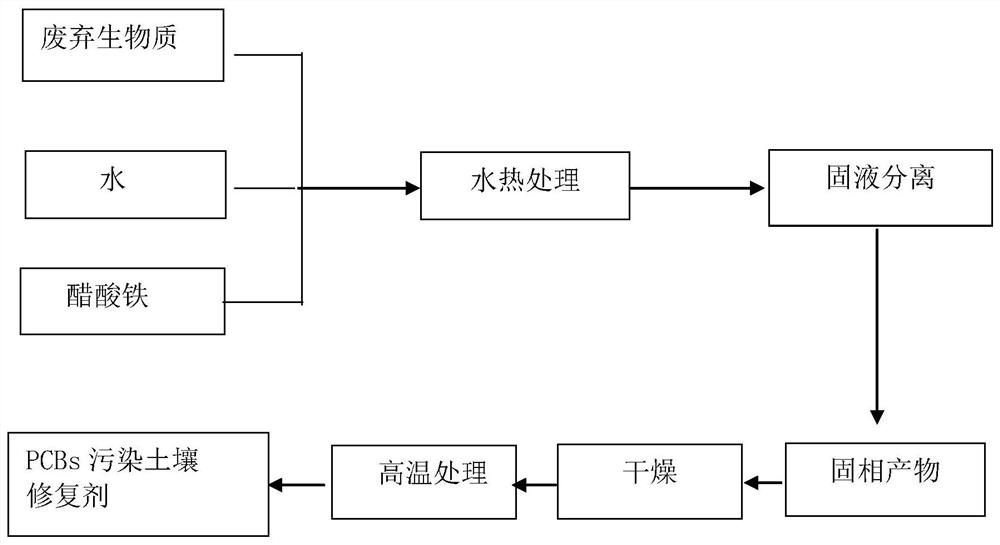

Preparation and using method for in-situ remediation agent for PCBs contaminated soil based on waste biomass

ActiveCN106881349AEasy to useEfficient degradationContaminated soil reclamationIn situ remediationEngineering

Combined with the current situations of serious contamination of soil PCBs and a huge quantity of waste biomass in China, the invention discloses a novel technology suitable for preparing an environmental-friendly in-situ remediation agent for PCBs contaminated soil with the waste biomass serving as raw materials. The novel technology comprises the following steps that (1) the biomass, water and ferric salts are mixed and subjected to hydrothermal coprocessing to prepare iron-loaded hydrothermal carbon; and (2) the iron-loaded hydrothermal carbon is obtained after high temperature heat treatment. The in-situ remediation agent for the PCBs contaminated soil is prepared with the waste biomass serving as a carbon source, the preparation process is simple, rapid and efficient dechlorination degradation of PCBs in the soil can be realized, and the remediation agent has the characteristics of environmental protection, low price and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

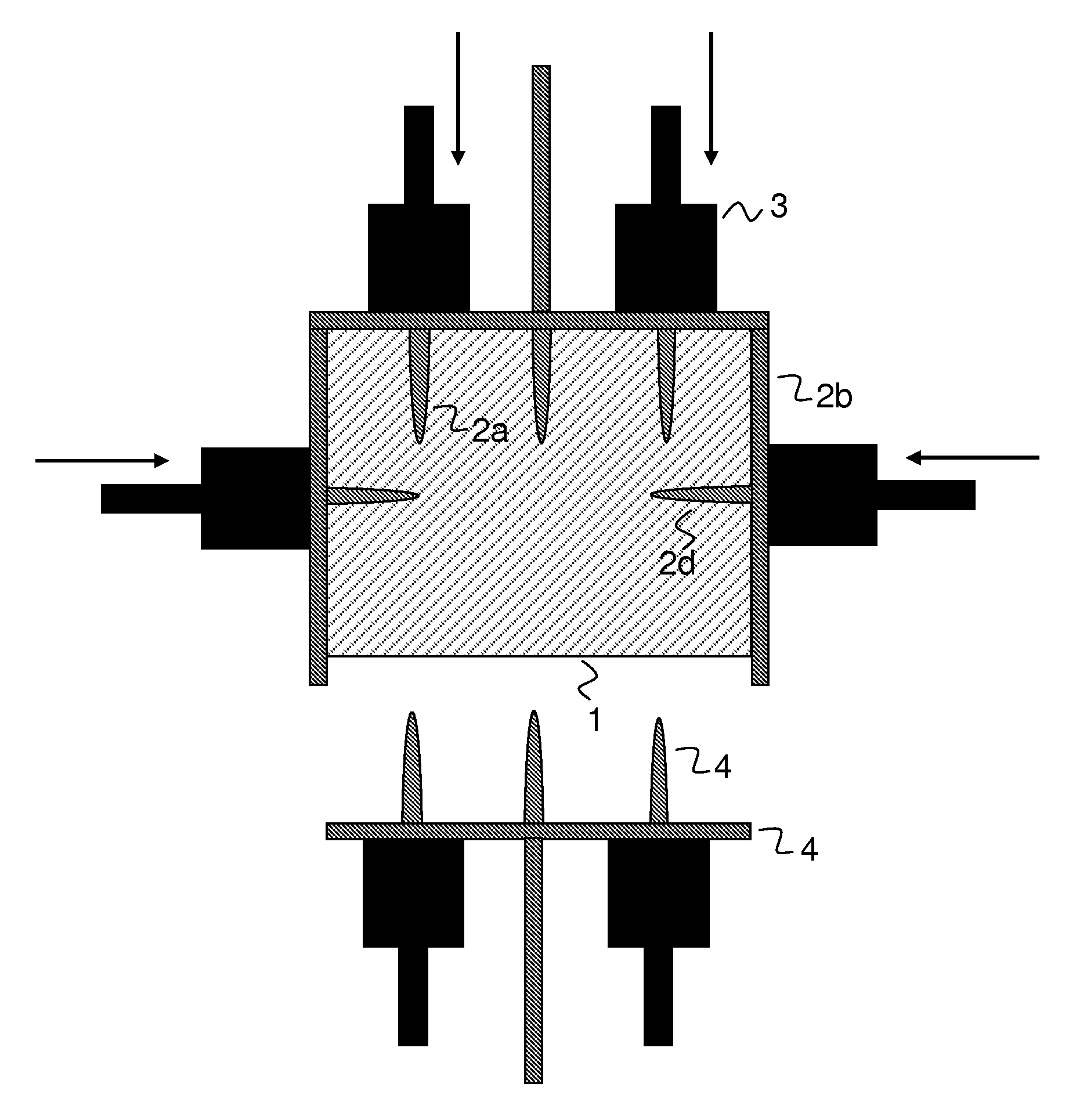

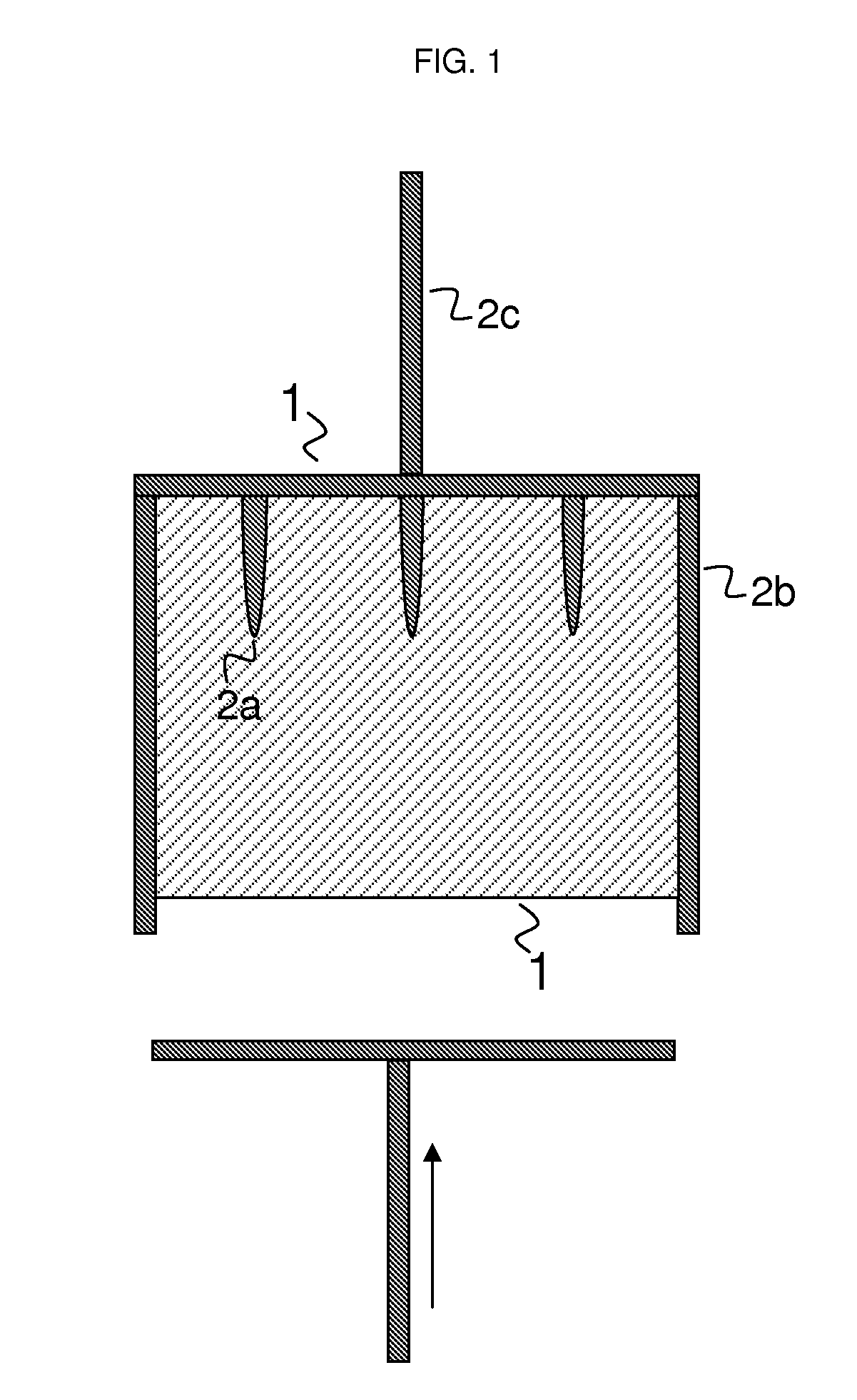

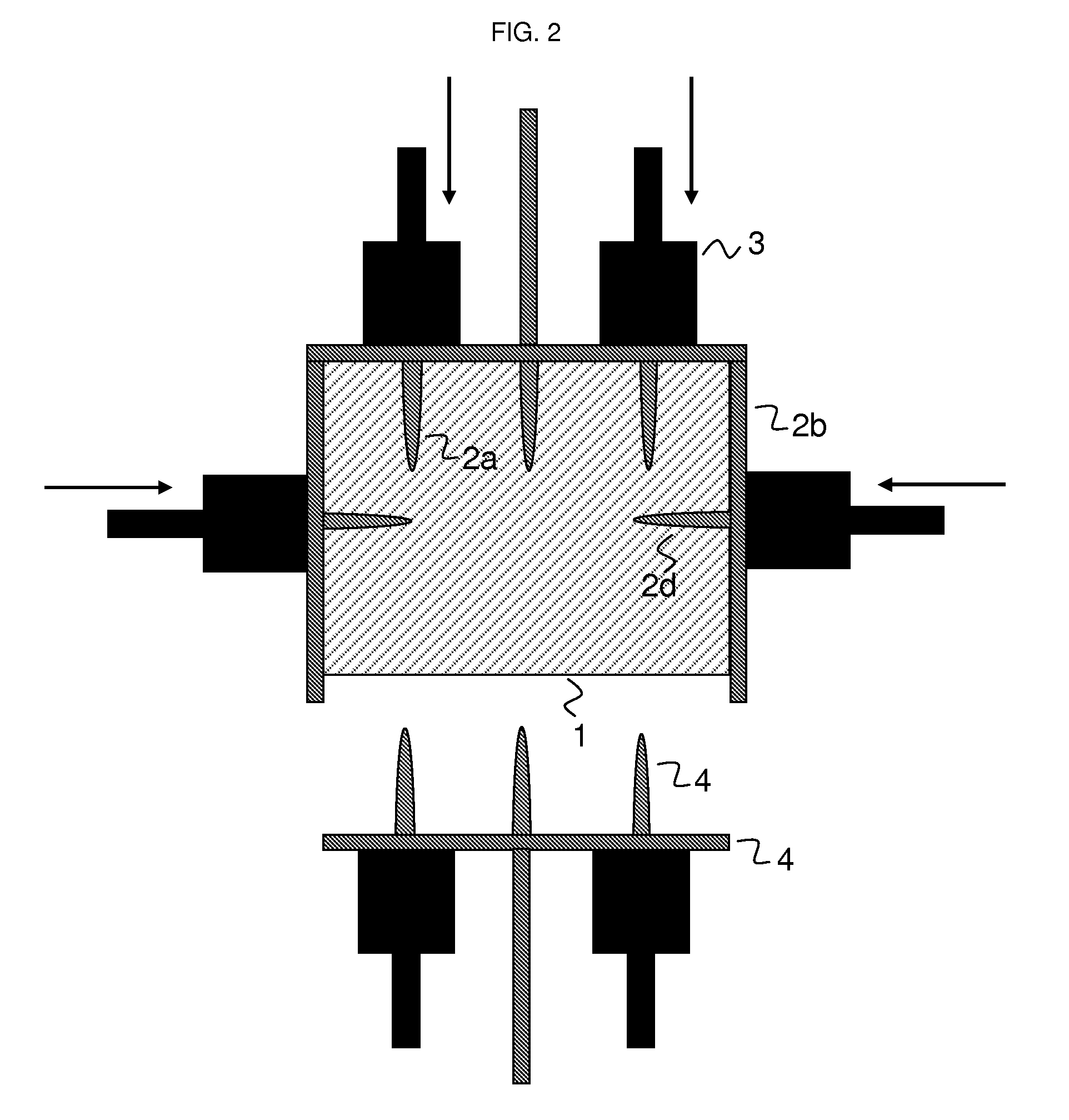

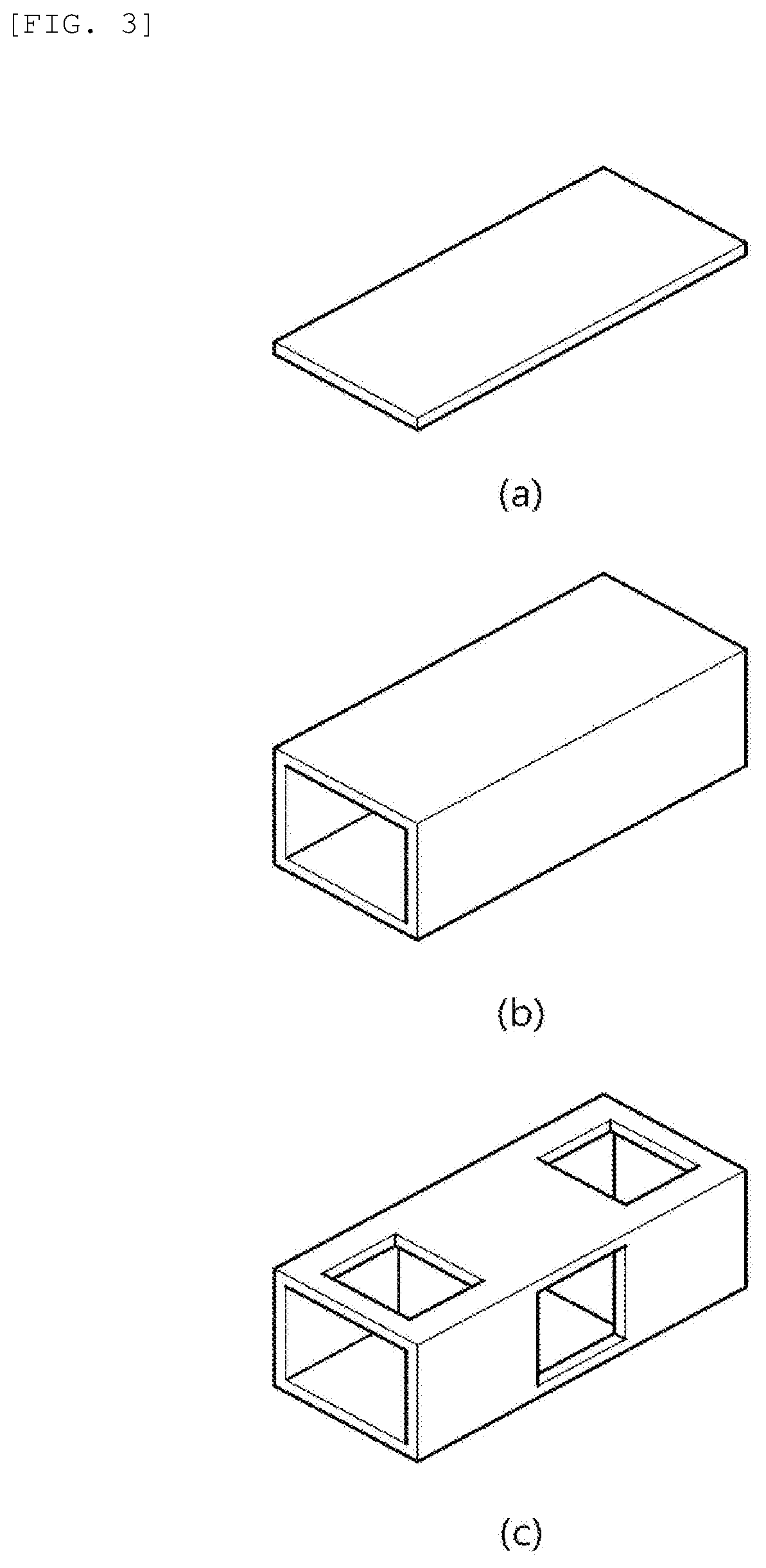

Method for producing single coal compacts suitable for coke chambers

InactiveUS8652372B2Speed up heat exchangeAccelerates the carbonization processCoke ovensConfectioneryCoke ovenProcess engineering

Coal compacts which are suitable for coking in coke oven chambers are prepared by pressing and compacting coal in a pressing device having a design which shapes the surface of the coal compacts to provide higher surface area. Already compacted coal blocks can be pressed to generate the surface shape. The resulting coal compacts exhibit significantly improved properties during the coking process, resulting in improved gas and heat exchange. A device for compacting coal preferably contains a plate provided with shaping elements on the pressing surface.

Owner:THYSSENKRUPP IND SOLUTIONS AG

Non-quenched and tempered composite shaft part

InactiveCN105886941AImprove performanceAccelerates the carbonization processSolid state diffusion coatingReaction temperatureCarburizing

The invention relates to the field of shaft parts, in particular to a non-quenched and tempered composite shaft part. The non-quenched and tempered composite shaft part is prepared from, by mass, 0.6%-1.25% of C, 0.55%-0.62% of Si, 1.00%-1.18% of Cr, 0.2%-0.3% of Mo, 0.01%-0.03% of Al, smaller than or equal to 0.038% of P, smaller than or equal to 0.04% of S, smaller than or equal to 0.03% of Cu and the balance Fe and unavoidable impurity elements. A method for manufacturing the non-quenched and tempered composite shaft part comprises the following steps that 1, shaft part pretreatment is conducted; 2, the pretreated shaft part is put into a furnace to be subjected to carburizing operation; 3, carburizing is conducted for 8 h, the shaft part is taken out, and the quality of a surface carburized layer is inspected. According to the method, surface severe plastic deformation pretreatment is conducted on the shaft part, and then carburizing is conducted, so that the carbonation process is accelerated, the reaction temperature is decreased, and meanwhile the comprehensive effects of improving the comprehensive property of the part and reducing the cost are achieved; the cost is reduced, the structure is refined, and the strength and impact toughness are significantly improved.

Owner:汤海涛

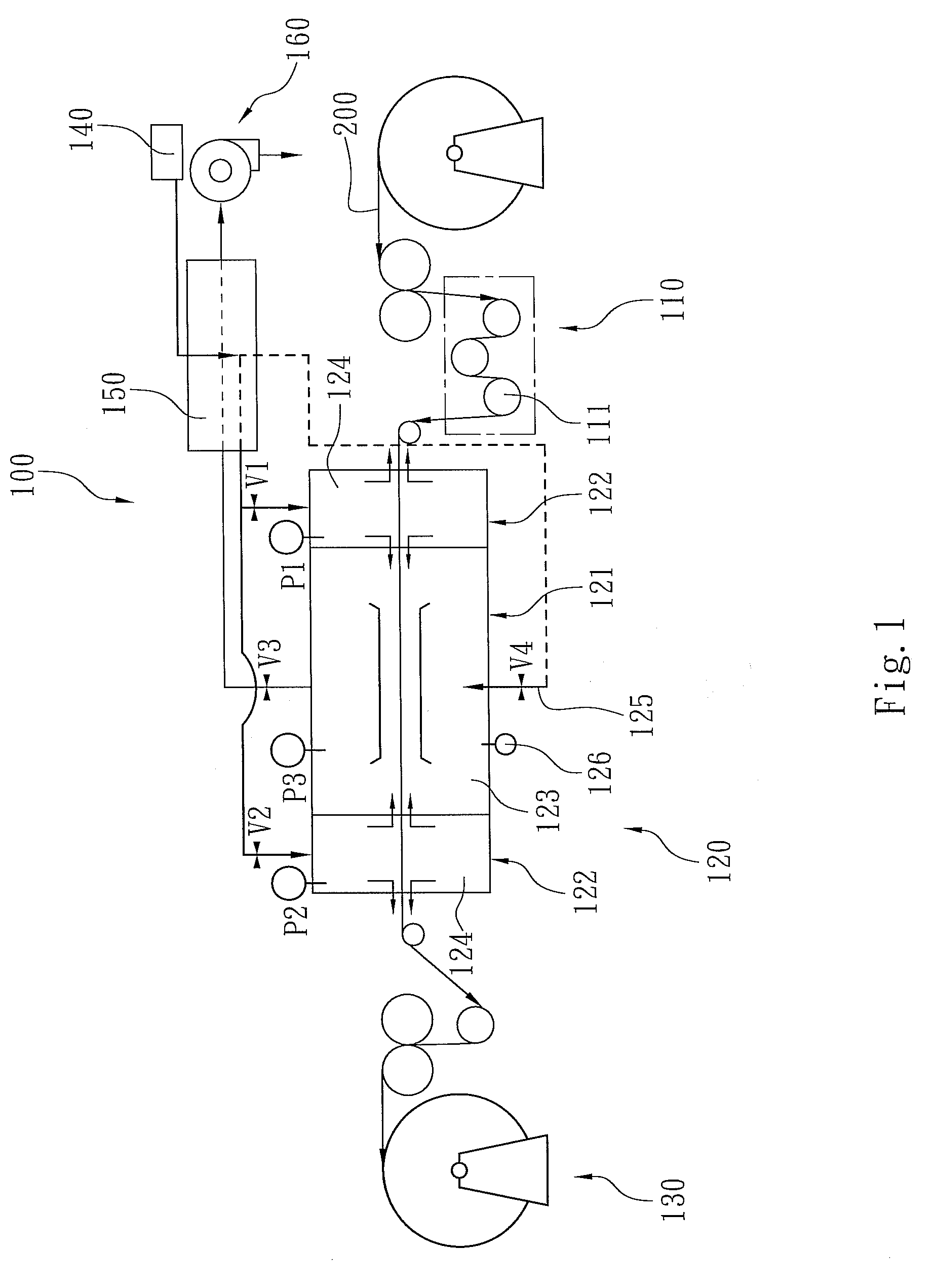

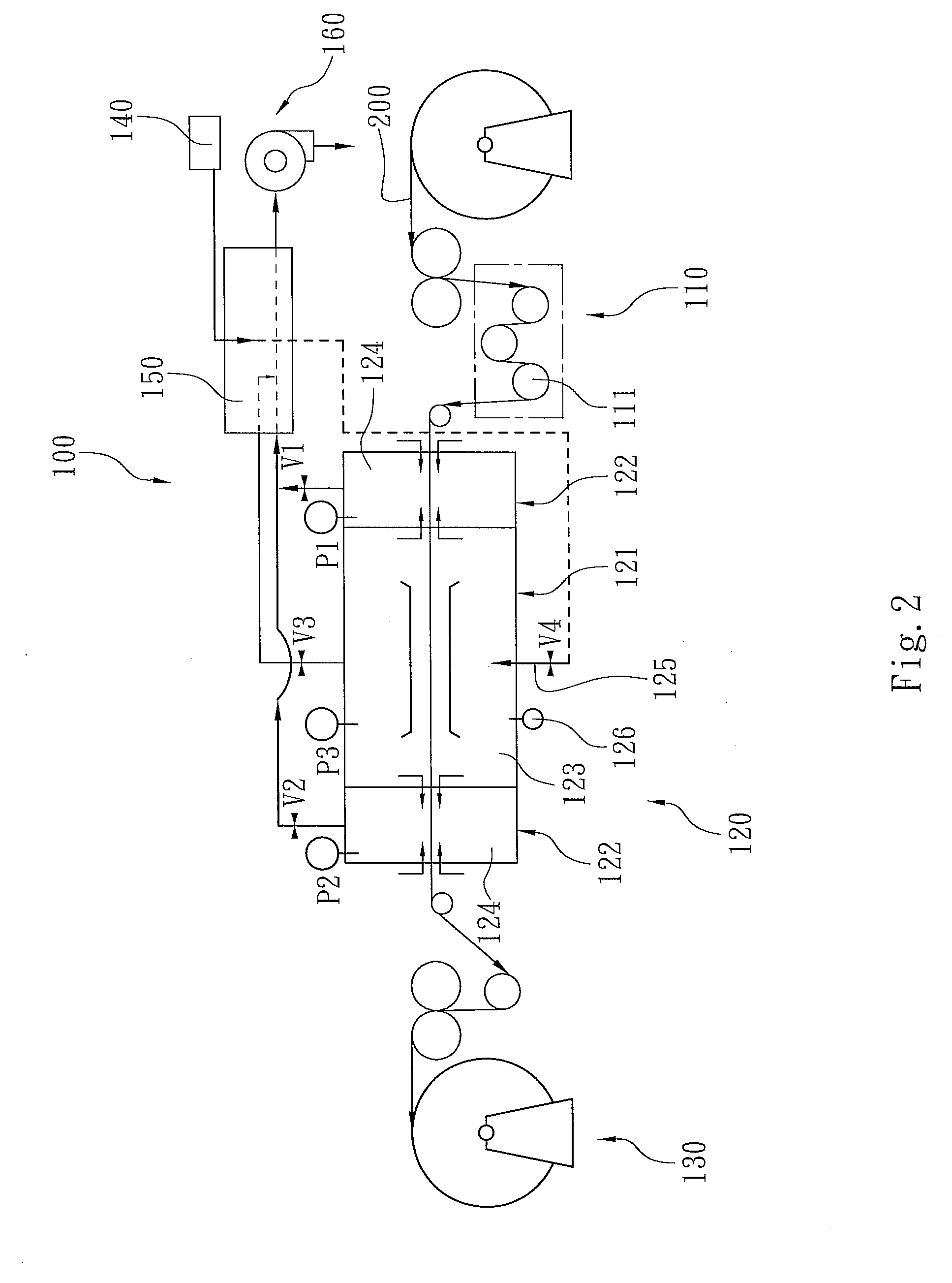

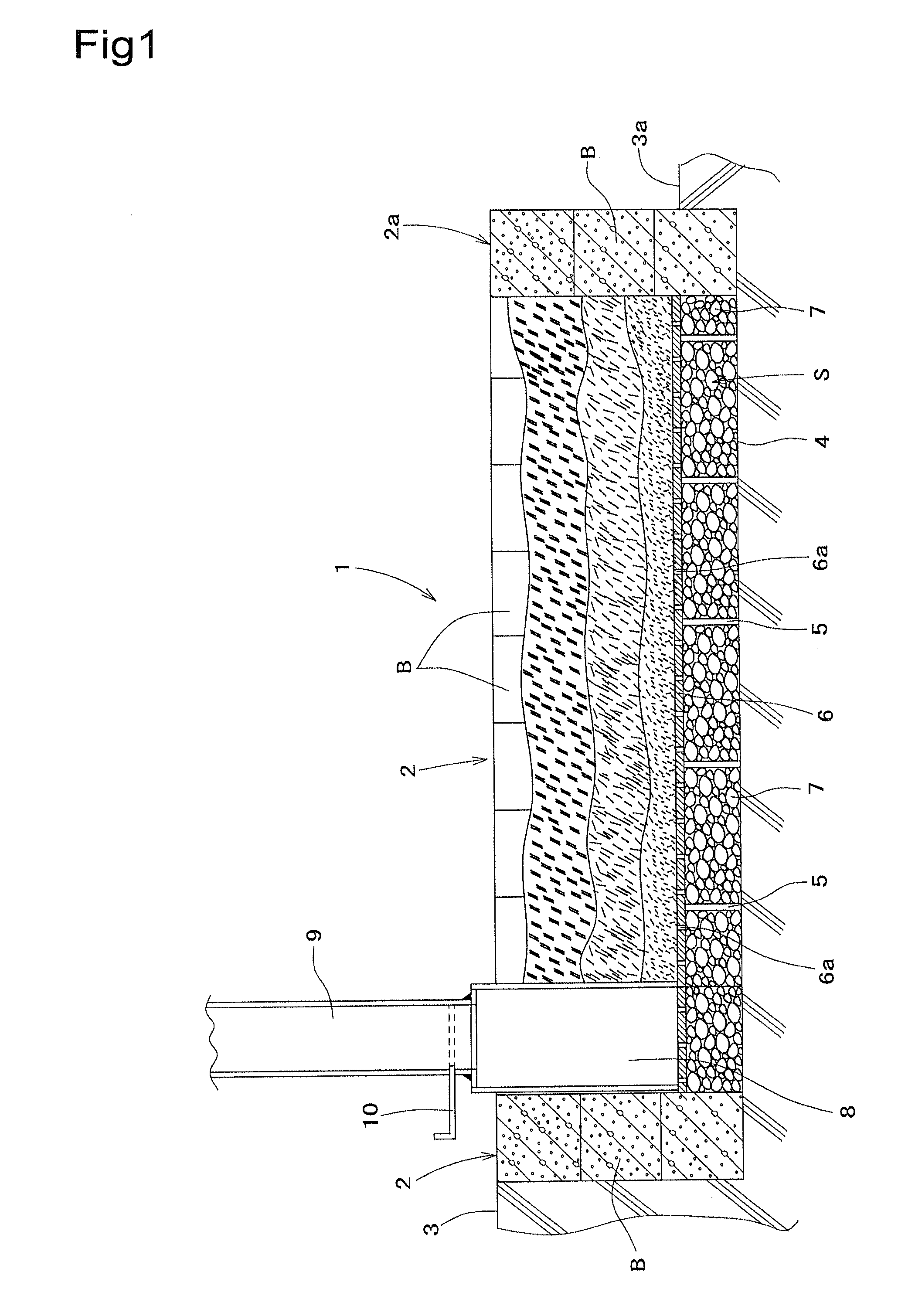

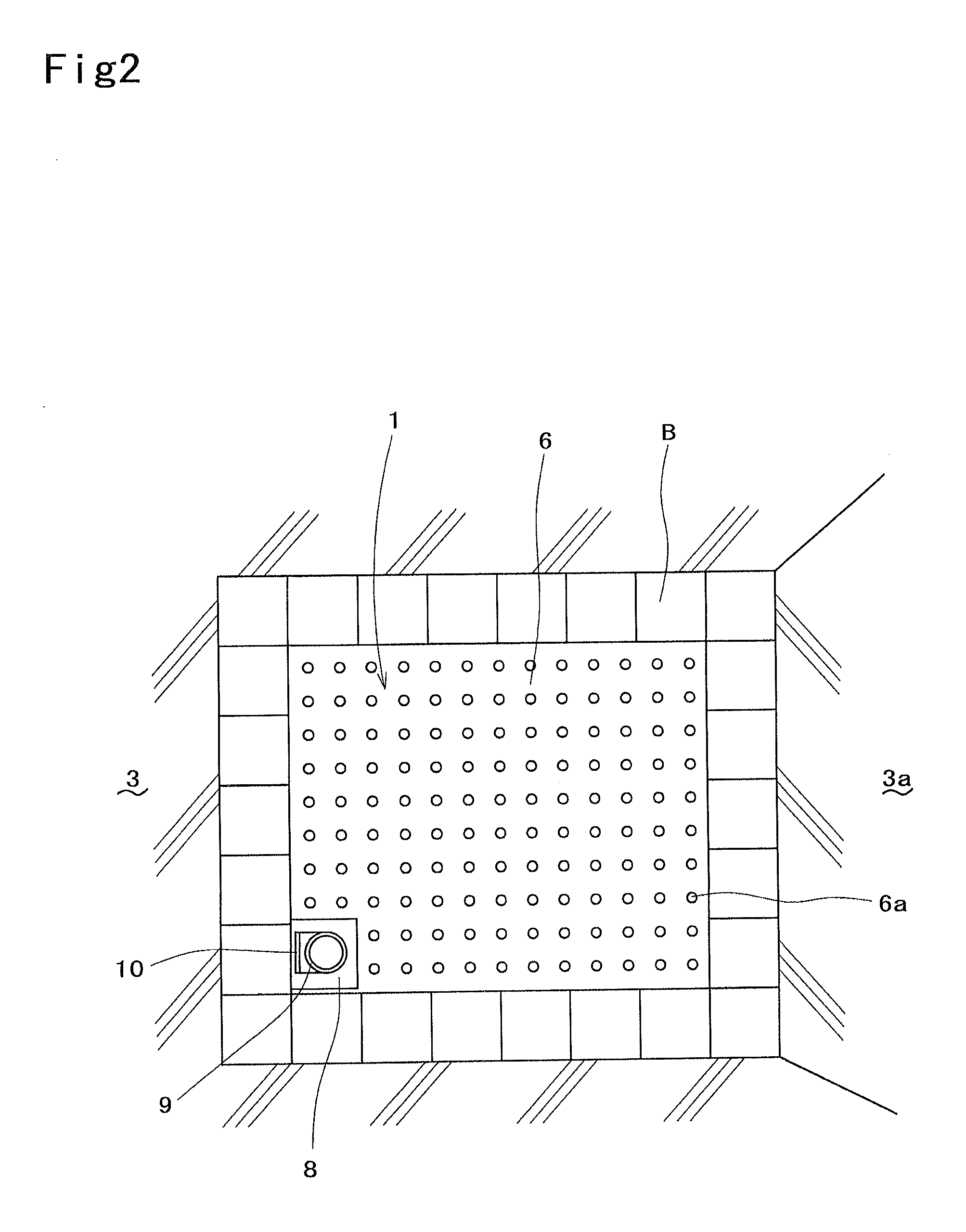

Carbonization apparatus and method of the same

InactiveUS20100189627A1High degreeEasy to disassemblePhysical/chemical process catalystsCarbon preparation/purificationCarbonizationAtmospheric pressure

A continuous negative pressure carbonization apparatus includes a material feeding device, a carbonizing chamber and a material collecting device. The material feeding device feeds the raw material. The carbonizing chamber receives and carbonizes the raw material and it includes a carbonization device and two buffering devices. The carbonization device has a carbonization chamber. The carbonization chamber has a material inlet and a material outlet. The buffering devices are respectively mounted and connected to the material inlet and the material outlet. The material collecting device collects the carbonized product from the carbonization chamber. When the raw material is carbonized in the carbonization chamber, the pressure of the carbonization chamber is kept at a negative pressure state smaller than the atmospheric pressure.

Owner:LINKWIN TECH

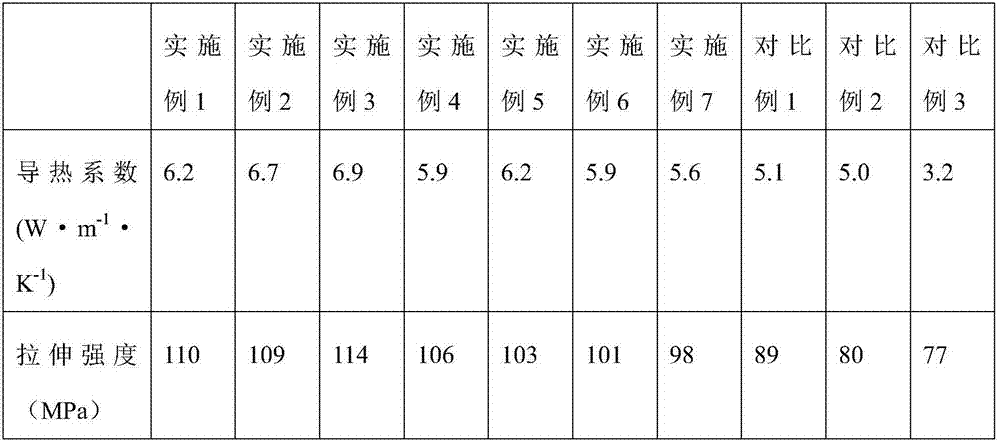

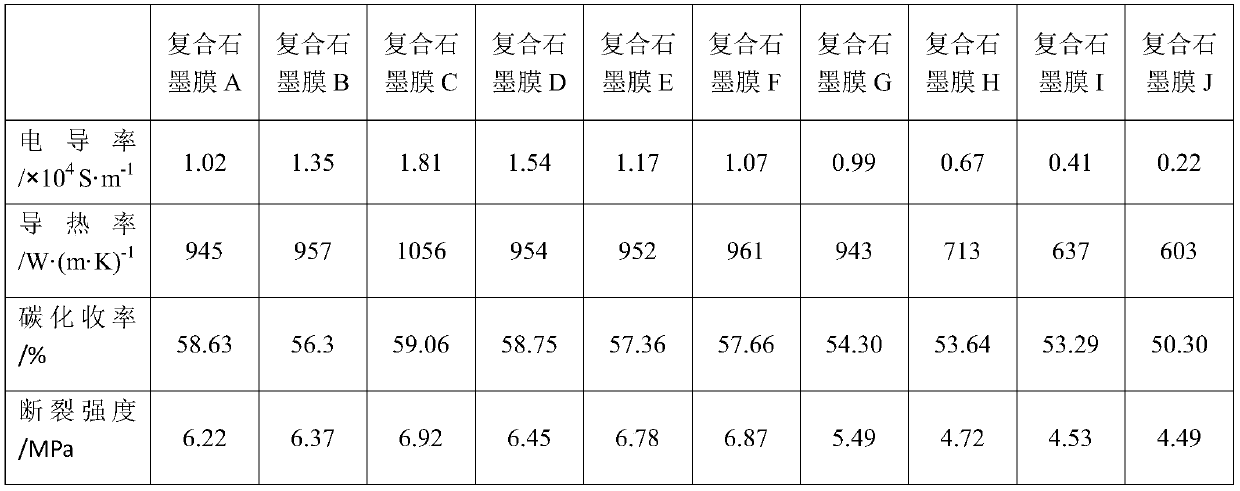

Composite graphite film and preparation method and application thereof

The invention discloses a composite graphite film and a preparation method and application thereof. The preparation method comprises the following steps: preparing a polyimide composite film formed by nano-diamond and polyimide; under the protection of an inert gas, performing carbonization and graphitization, and then removing graphite paper to obtain the composite graphite film formed by nano-diamond and polyimide. In the carbonization and graphitization process, as a crystal nucleus, nano-diamond promotes carbonization and graphitization of polyimide, so that the heat-conducting property and the electric conductivity of a composite carbon film are improved.

Owner:北京兴科迪电子技术研究院

Metal Treatment Composition and Method of Treating Rubbing Surfaces

InactiveUS20140037864A1Reduce frictionReduce coefficient of frictionPretreated surfacesMechanical vibrations separationSurface layerCarbonization

A durable anti-wear coating for friction assemblies, a method of making the same and a method of using the same is provided. The method of use results in the formation of an anti-wear coating and selective carbonization of any ferrous surfaces by impregnating the surface layer with carbon, and makes it possible to selectively optimize the clearances between any bearing surface (ferrous or nonferrous). The method may take place during the standard operating process of the mechanism, without disassembly or with only partial disassembly.

Owner:SERGACHEV TECH

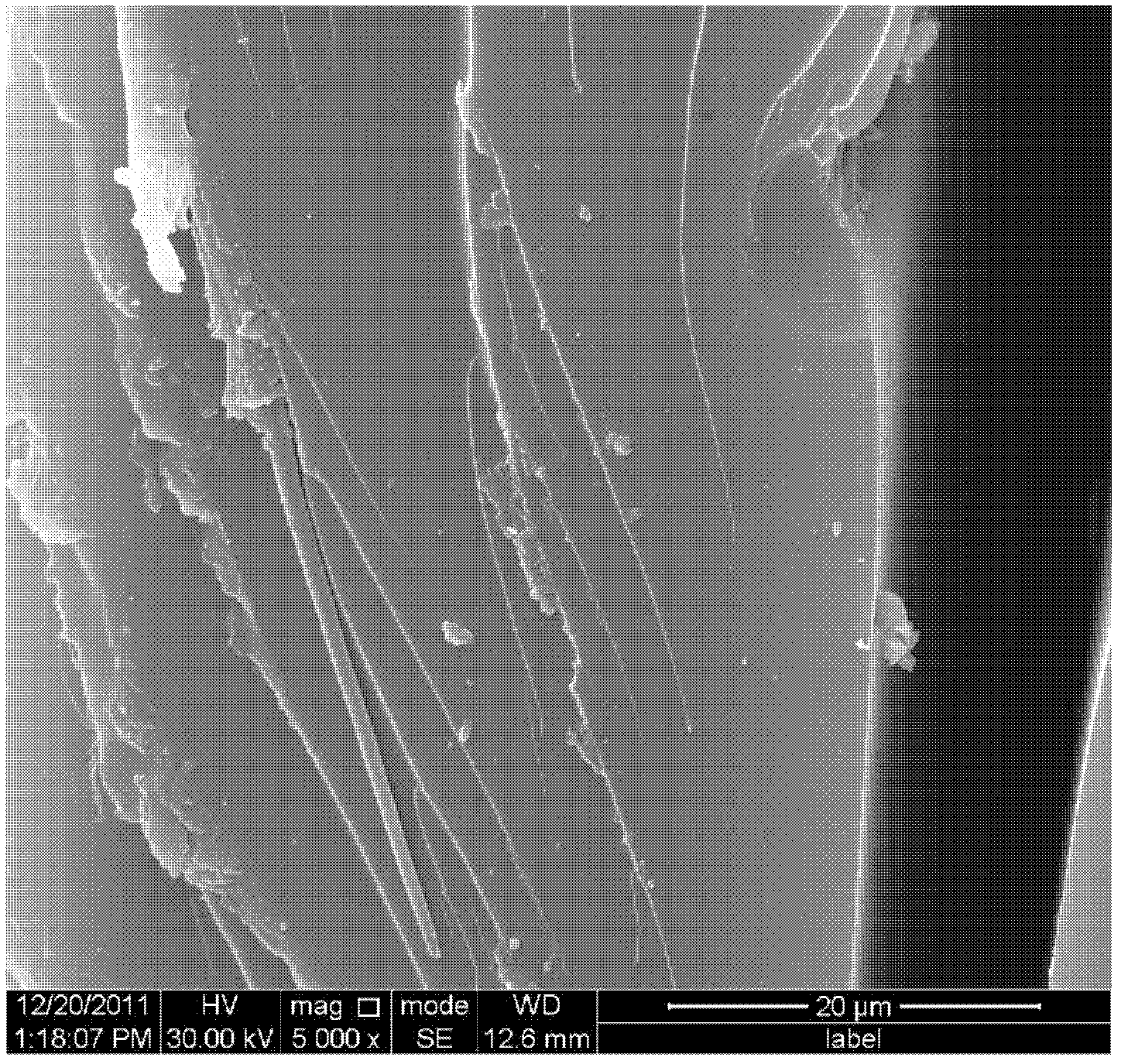

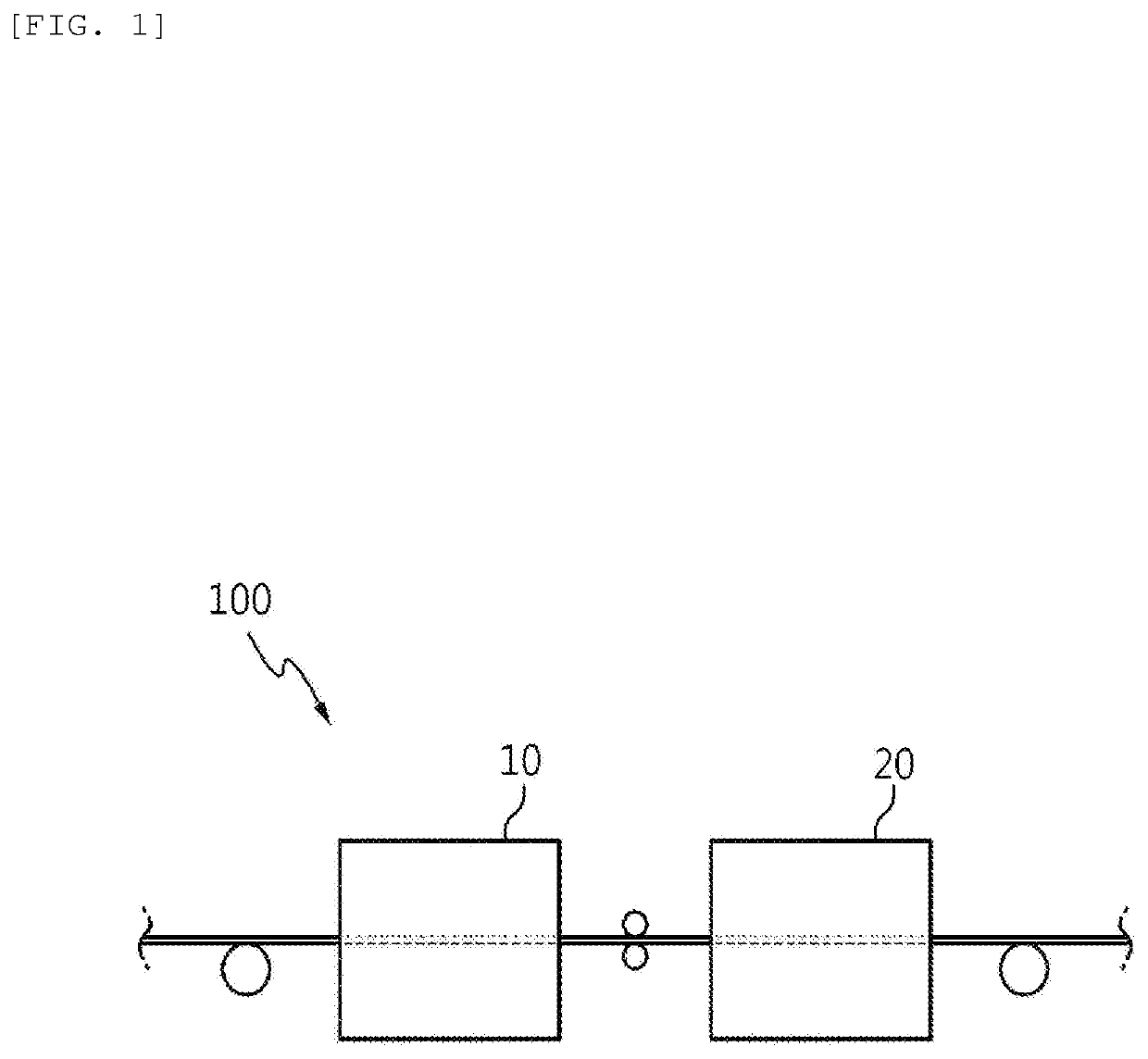

Apparatus for manufacturing carbon fiber by using microwaves

PendingUS20200056306A1Accelerates the carbonization processImprove energy efficiencyRadio/micro wave fibre treatmentFibre chemical featuresPolymer chemistryFiber

The present invention relates to an apparatus for manufacturing carbon fiber by using microwaves, and more particularly, to an apparatus for manufacturing carbon fiber by using microwaves, which directly or indirectly heats and carbonizes a carbon fiber precursor by using microwaves, so that energy efficiency is improved because an entire carbonization furnace is not heated, and a property of the precursor is adjusted by a simpler method by using microwaves.

Owner:LG CHEM LTD

High-carbon preservative bamboo wallboard and production method

ActiveCN106808550AImprove anti-corrosion performanceDoes not affect glossConstruction materialDomestic articlesHigh carbonPreservative

The invention discloses a high-carbon preservative bamboo wallboard production method, which comprises the steps of (1) removing tabasheer from a fresh bamboo and rolling the bamboo to obtain a silky bamboo splint; (2) drying the bamboo splint until the water content is lower than 6-9%; (3) carbonizing the bamboo splint that meets the water content requirement in a carbonization chamber at normal pressure, and selecting qualified and removing the unqualified bamboo splint after carbonization; (4) processing the qualified carbonized bamboo splint by impregnation, and drying the bamboo splint until the water content is between 13-17% after processing; and (5) processing the bamboo splint for health preserving and balancing in a health preserving room; (6) performing hot pressing moulding to obtain a bamboo sheet; (7) processing the bamboo sheet to obtain the bamboo wallboard. The invention also relates to a bamboo wallboard obtained by the above method. The bamboo preservative performance of the bamboo wallboard can be greatly improved by carbonization; the production period is short; the operation is simple; the appearance quality is high; and advantages like safety and environmental protection are provided.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Preparation method for gel material

InactiveCN108395190AHigh tensile strengthImprove impact resistanceDimethylaniline N-oxidePolymer science

The invention discloses a preparation method for a gel material, and belongs to the field of building materials. Potassium hydroxide, methyl alcohol, water and tung oil are mixed to regulate a pH (Potential of Hydrogen), and reduced pressure distillation, cooling and dewatering are carried out; anhydride is taken, activated carbon is added for standing, and supernate, unsaturated polyester resin,benzoyl peroxide and N,N-dimethylaniline are mixed to obtain stirring mixture for standby use; potassium dichromate, distilled water, concentrated sulfuric acid and polypropylene fibers are added intomixed liquid; polypropylene fibers is taken out for cleaning with distilled water and drying, and a drying object is added into carbon fibers to be mixed to obtain mixture; vinyltriethoxysilane is added into dibenzoyl peroxide, nitrogen is introduced for protection, mixed and cooled to room temperature, coolant is added into emulsifier OP-10 and polyethylene glycol to be mixed, and the mixture isadded into mixed liquid to raise temperature to be stirred to obtain gel material base materials; lime, metakaolin, calcium stearate, palygorskite powder, sepiolite, stirring mixture and gel materialbase materials are mixed and cooled to room temperature to obtain the gel material.

Owner:王景硕

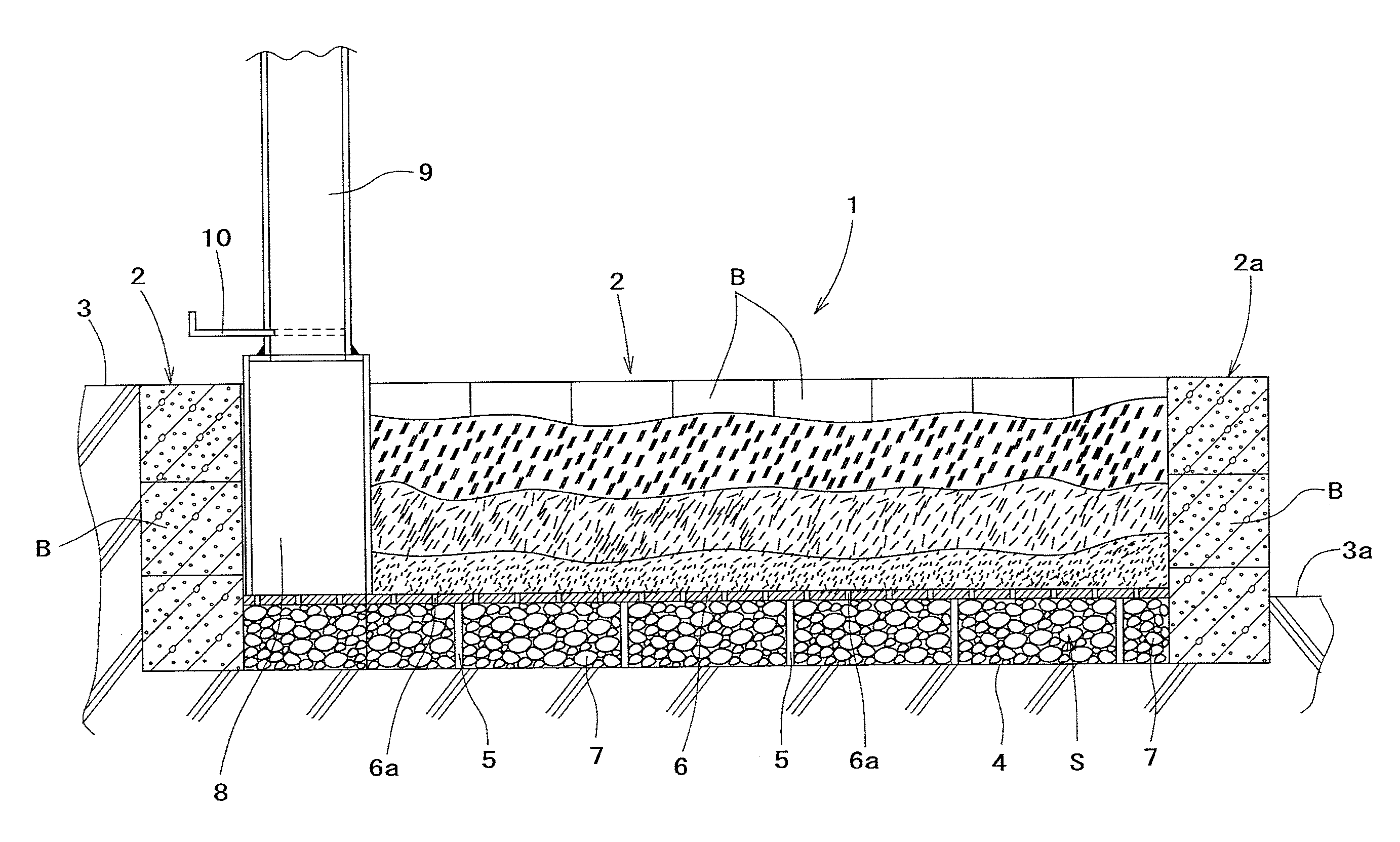

Carbonized material production kiln

ActiveUS20160160125A1Avoid crackingSolution to short lifeDirect heating destructive distillationBiofuelsRetention efficiencyCarbonization

To enable a carbonized material production kiln to be maintained in a simple manner when an exposed surface on a side wall of the kiln is cracked, to prevent the kiln from easily cracking by heat to thereby prolong the life of the kiln itself, and to increase heat retention efficiency to thereby increase carbonization efficiency even during periods of cold temperatures such as the winter season. The carbonized material production kiln is formed by stacking cubic concrete blocks each having no reinforcing iron so that recombination of up to six faces of each cubic concrete block becomes possible, wherein a heat storage / retention member such as stones is filled in an exhaust space formed between a kiln floor iron plate and a kiln bottom so as to store heat, thereby preventing a decrease in carbonization efficiency even at cold temperatures.

Owner:YAMAMOTO BIO CHARCOAL MFG

Metal treatment composition and method of treating rubbing surfaces

InactiveUS8906834B2Accelerates the carbonization processReduce frictionMixingAdditivesSurface layerCarbonization

A durable anti-wear coating for friction assemblies, a method of making the same and a method of using the same is provided. The method of use results in the formation of an anti-wear coating and selective carbonization of any ferrous surfaces by impregnating the surface layer with carbon, and makes it possible to selectively optimize the clearances between any bearing surface (ferrous or nonferrous). The method may take place during the standard operating process of the mechanism, without disassembly or with only partial disassembly.

Owner:SERGACHEV TECH

Method for preparing carbon material from waste high polymer material

InactiveCN113461006ALow costRealize large-scale productionEnergy inputCarbon nanotubesPolymer scienceCarbonization

The invention discloses a method for preparing a carbon material from a waste high polymer material, which comprises the following steps: putting the waste high polymer material in a solvent dissolved with an activating agent for swelling treatment to obtain a treated sample; and then heating the treated sample to obtain the carbon material, separating the swelling solvent in a low-temperature section of heating treatment, and recycling after condensing. According to the method provided by the invention, full contact and uniform carbonization and activation reaction of the activating agent and the high polymer material from the molecular level are realized, and the catalytic reaction rate and the yield of a high-value carbon material product are improved to the maximum extent.

Owner:HEBEI UNIV OF ENG

Method for preparing carbide film by carbonizing graphene reinforced polyimide resin

ActiveCN102560453BIncrease internal stressReduce brittlenessSolid/suspension decomposition chemical coatingCapacitancePolymer science

The invention discloses a method for preparing a carbide film by carbonizing graphene reinforced polyimide resin, and relates to a method for preparing a carbide film. The method solves the technical problems of high carbonizing temperature, high energy consumption, long carbonizing period and low carbonizing rate and low strength of the carbide film in the conventional method for preparing the carbide film. The method comprises the following steps of: 1, adding 4,4'-diamino diphenyl ether (ODA) and 3,3',4,4'-benzophenonetetracarboxylic dianhydride (BTDA) into N,N-dimethyl acetamide (DMAC), and performing mechanical stirring to obtain a polyamide acid (PAA) solution; 2, adding graphene into the PAA solution, and performing in-situ polymerization reaction to obtain a solution A; 3, spreading the solution A on a clean glass plate, heating to the temperature of 60 DEG C and preserving the heat for 2 hours, heating to the temperature of 100 DEG C and preserving the heat for 1 hour, heating to the temperature of 200 DEG C and preserving the heat for 1 hour, heating to the temperature of 300 DEG C and preserving the heat for 1 hour, and thus obtaining a composite film; and 4, carbonizing, naturally cooling to room temperature, and thus obtaining the carbide film. The carbide film has excellent mechanical properties; and because the adding proportion of the graphene is increased, the mechanical properties of the carbide film are improved, the specific capacitance of the graphene is also improved, and the carbide film is suitable to be used as an electrode material.

Owner:HARBIN INST OF TECH

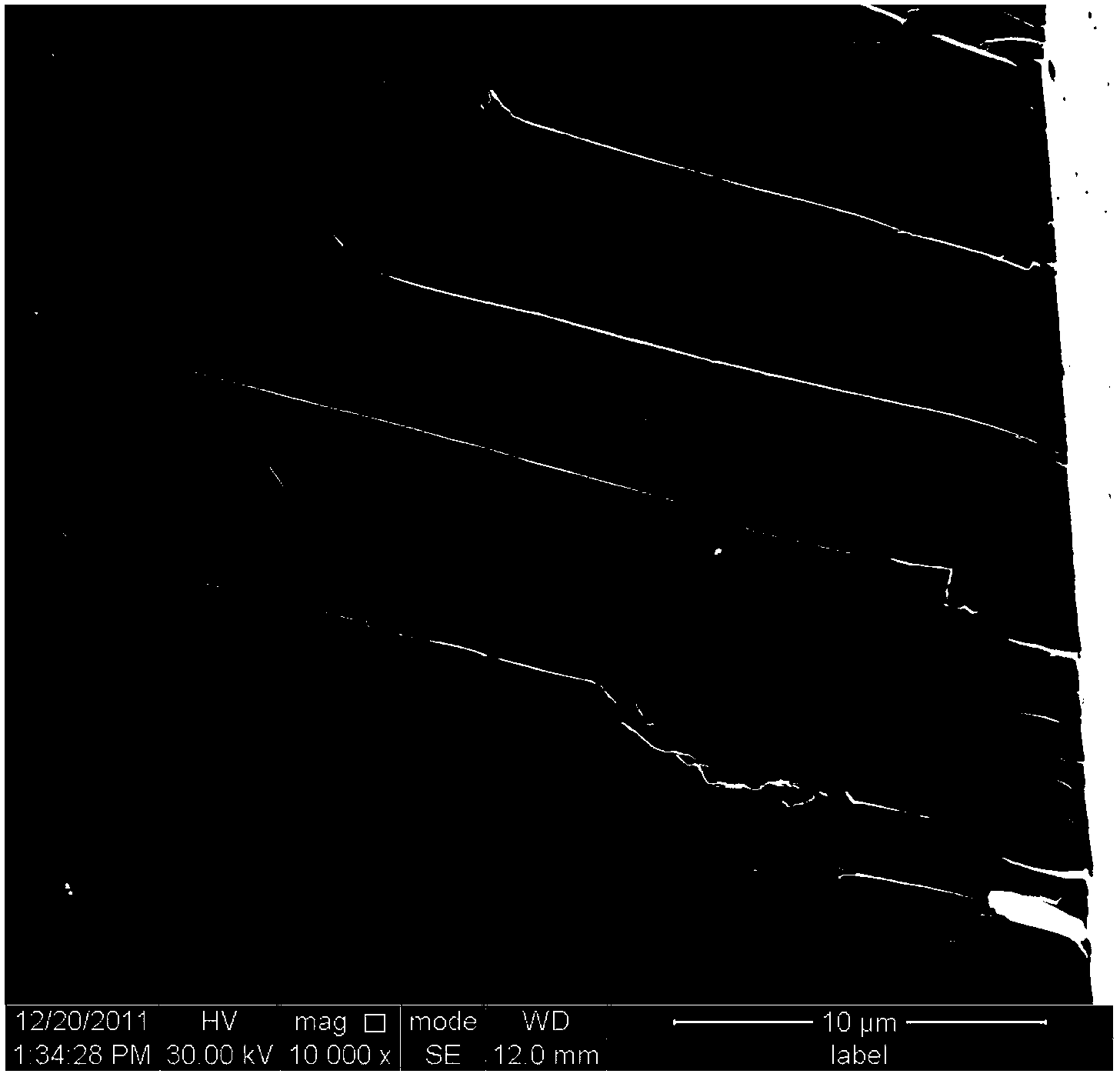

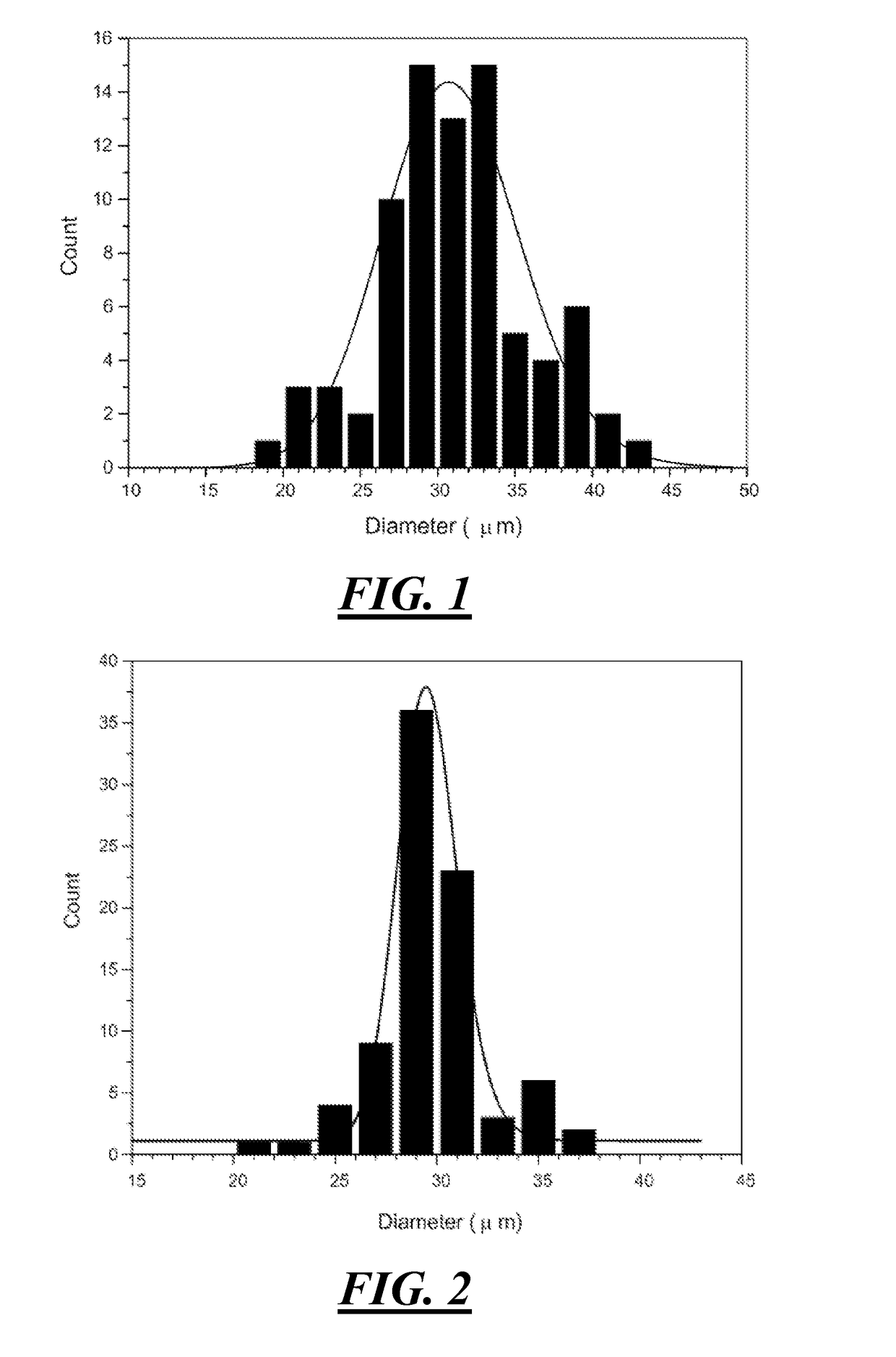

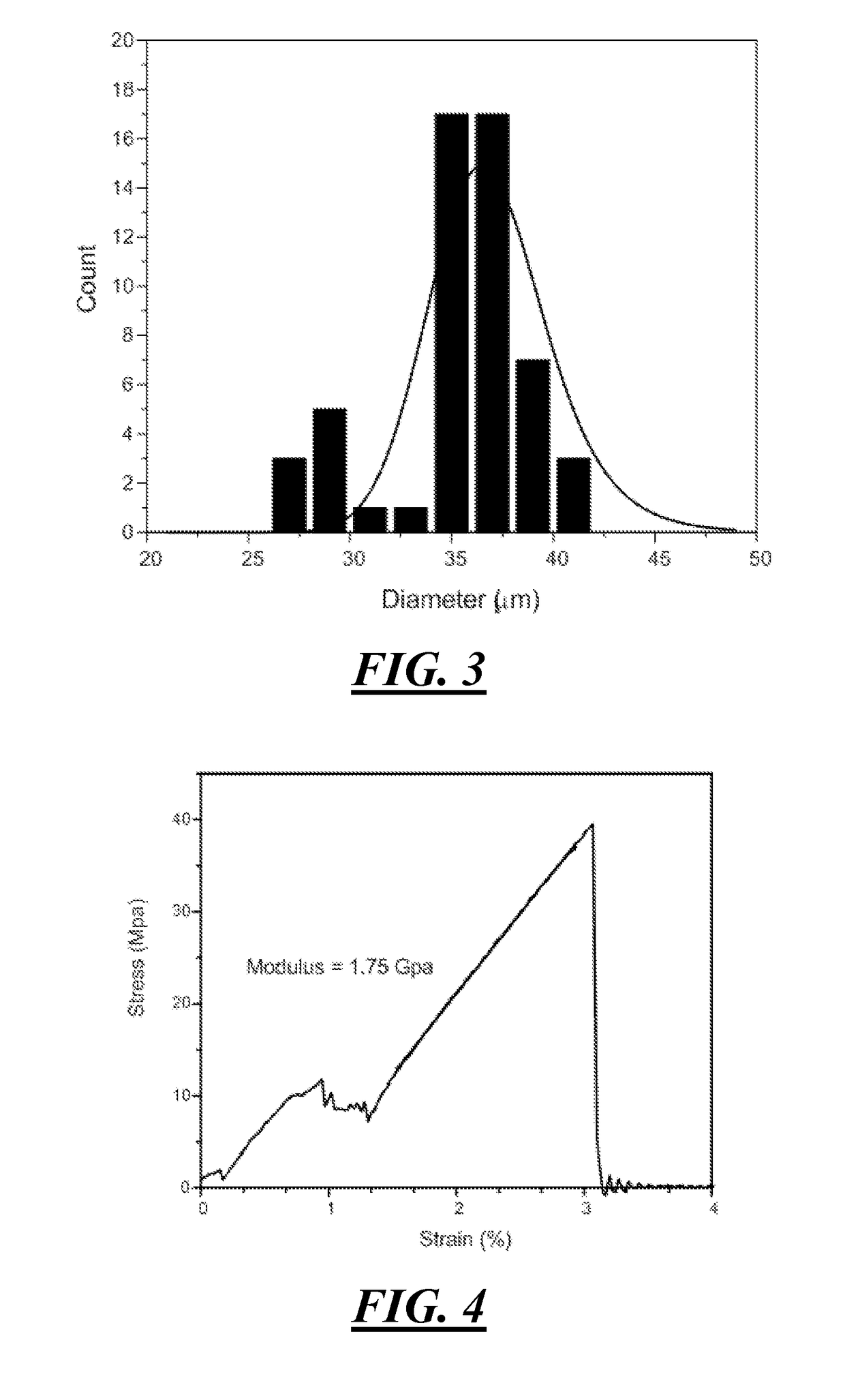

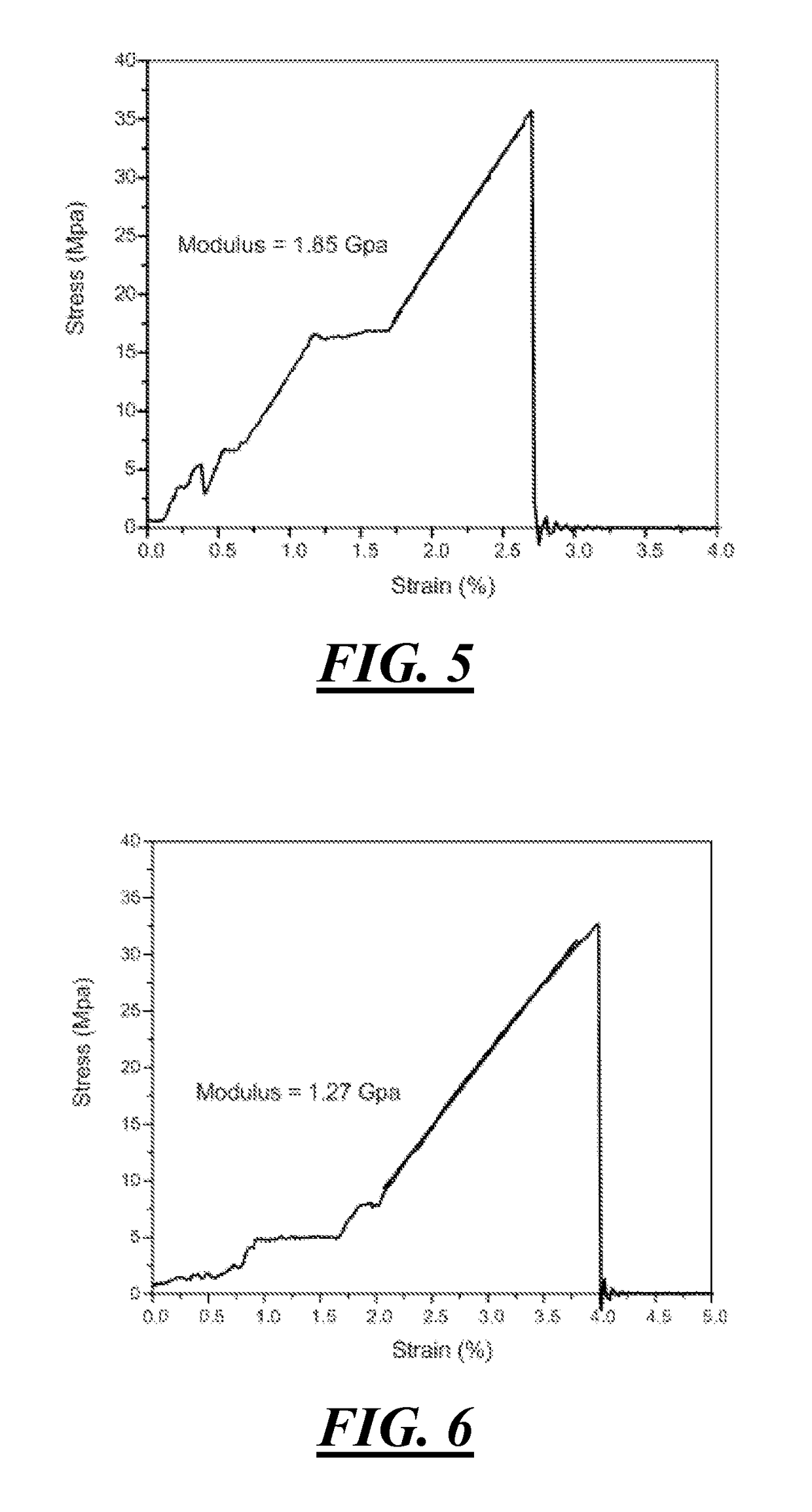

Stabilization of Lignin Fibers

ActiveUS20170137451A1Short timeMaintaining diameterArtificial filament heat treatmentLignin derivativesFiberMaterials science

A process for stabilizing lignin fibers, stabilized lignin fibers made by the process and carbonized fibers made from stabilized lignin fibers. The process includes heating lignin fibers to a temperature ranging from about 100° to about 220° C. while the fibers are in an atmosphere of air and HCl gas, generated as air is bubbled through concentrated hydrochloric acid for a period of time sufficient to stabilize the lignin fibers.

Owner:PRISMA RENEWABLE COMPOSITES LLC

Stabilization of lignin fibers

ActiveUS10316051B2Improve performanceSimple structureArtificial filament heat treatmentLignin derivativesFiberMaterials science

A process for stabilizing lignin fibers, stabilized lignin fibers made by the process and carbonized fibers made from stabilized lignin fibers. The process includes heating lignin fibers to a temperature ranging from about 100° to about 220° C. while the fibers are in an atmosphere of air and HCl gas, generated as air is bubbled through concentrated hydrochloric acid for a period of time sufficient to stabilize the lignin fibers.

Owner:PRISMA RENEWABLE COMPOSITES LLC

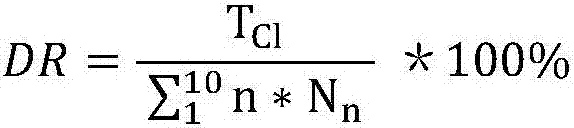

A preparation and application method of PCBS-contaminated soil in-situ remediation agent based on waste biomass

ActiveCN106881349BHigh yieldDestroy crystal structureContaminated soil reclamationIron saltsIn situ remediation

Combining the serious soil PCBs pollution and the huge amount of waste biomass in my country, the present invention establishes a new process suitable for preparing an environmentally friendly PCBs-contaminated soil in-situ remediation agent using waste biomass as a raw material, including the following steps: 1) The hydrothermal co-processing of biomass, water and iron salt is carried out to prepare iron-loaded hydrothermal charcoal; 2) the iron-loaded hydrothermal charcoal is obtained after high-temperature heat treatment. The invention uses waste biomass as a carbon source to prepare a PCBs-contaminated soil in-situ remediation agent. The preparation process is simple, and not only can realize the rapid and efficient dechlorination and degradation of PCBs in soil, but also the remediation agent has the characteristics of greenness, environmental protection, and low price.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

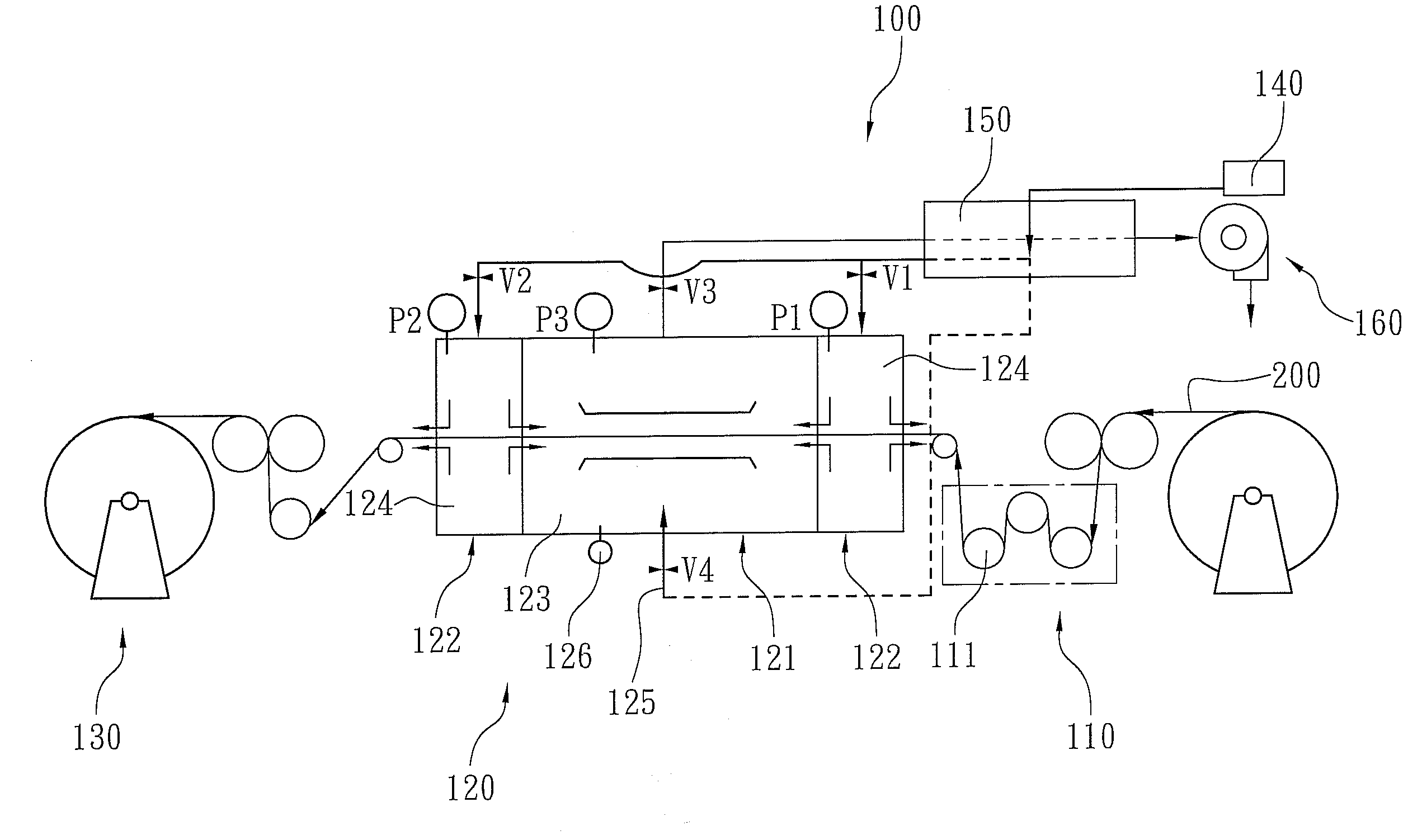

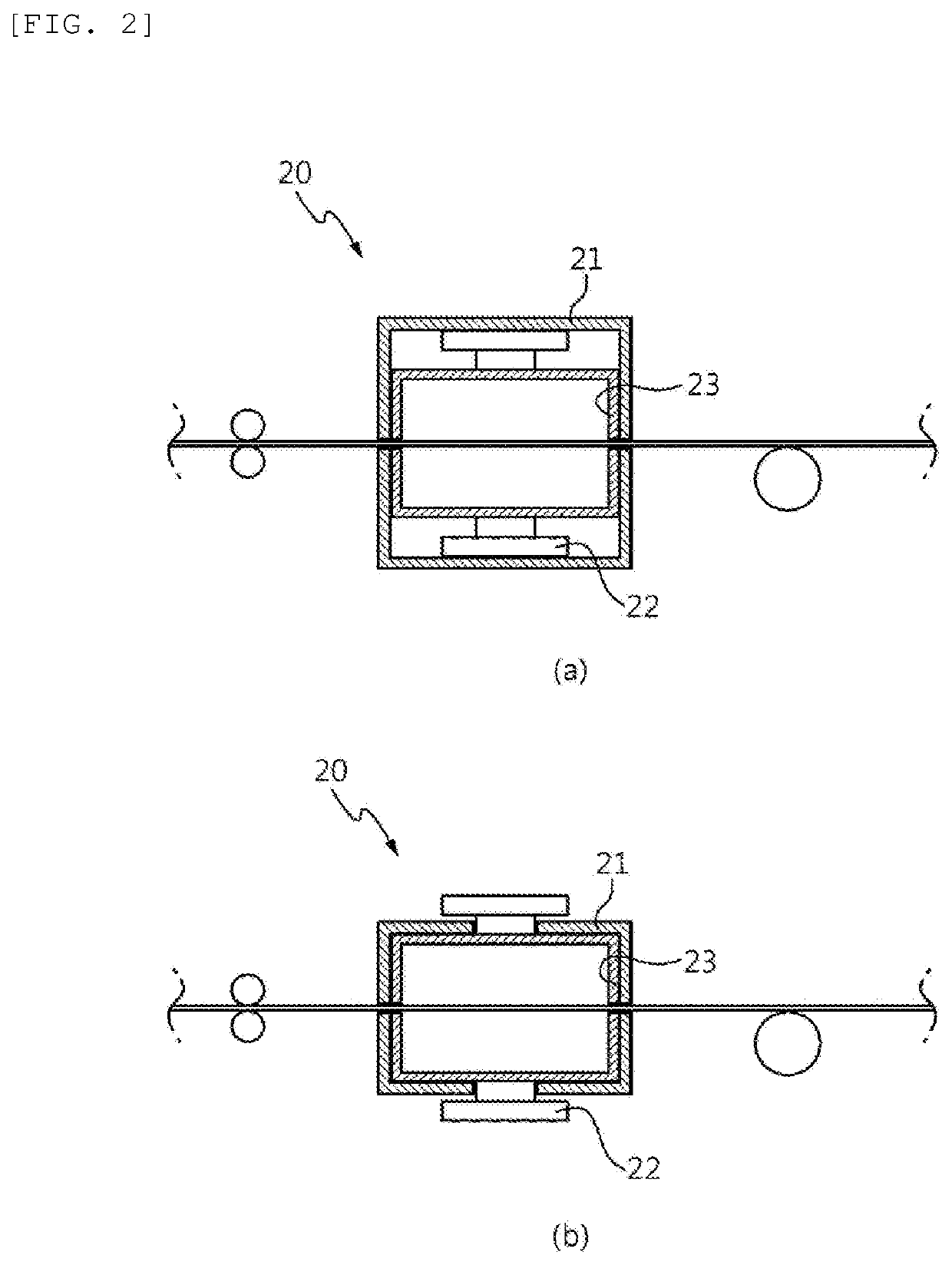

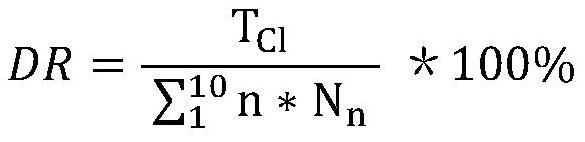

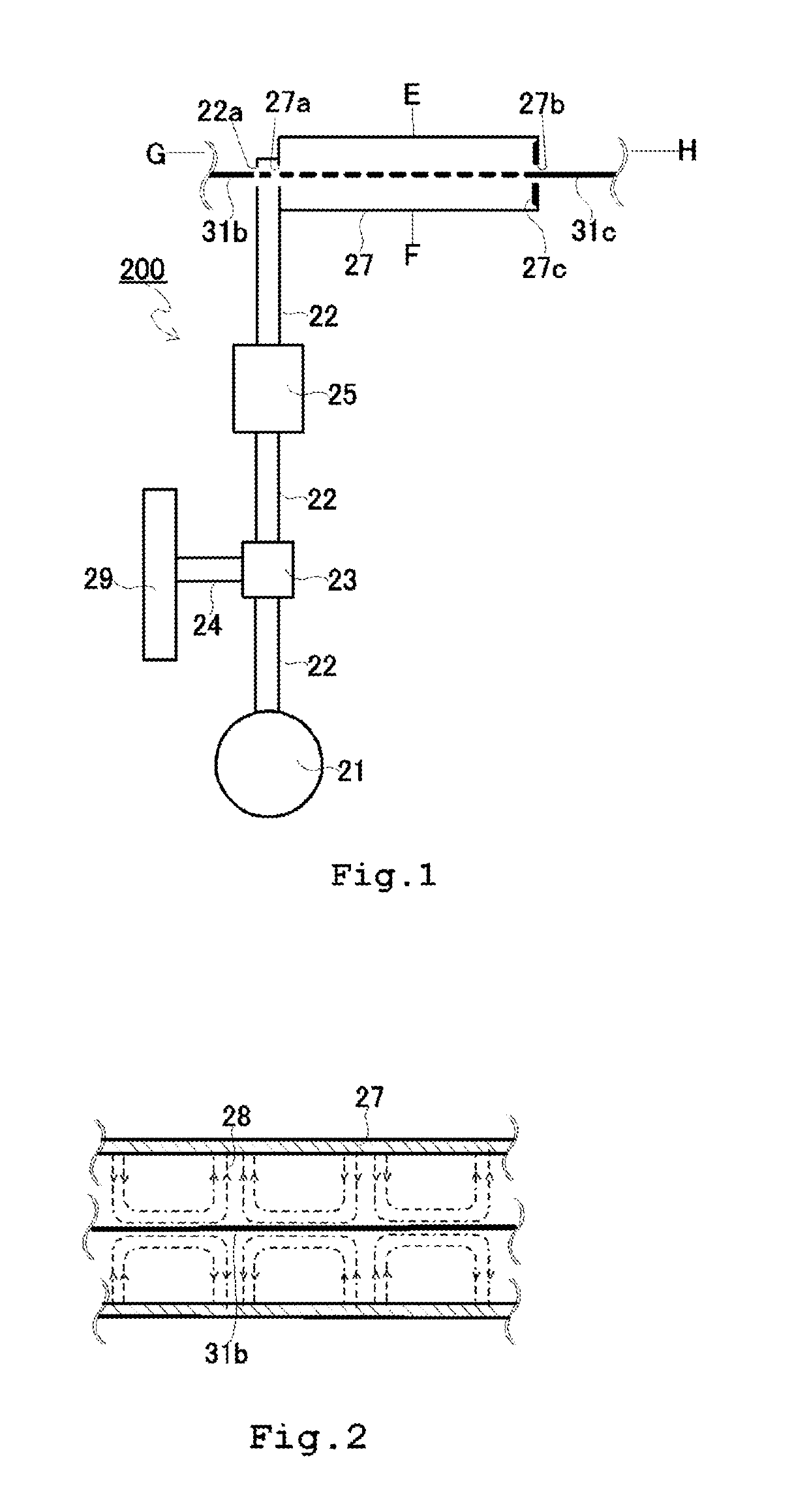

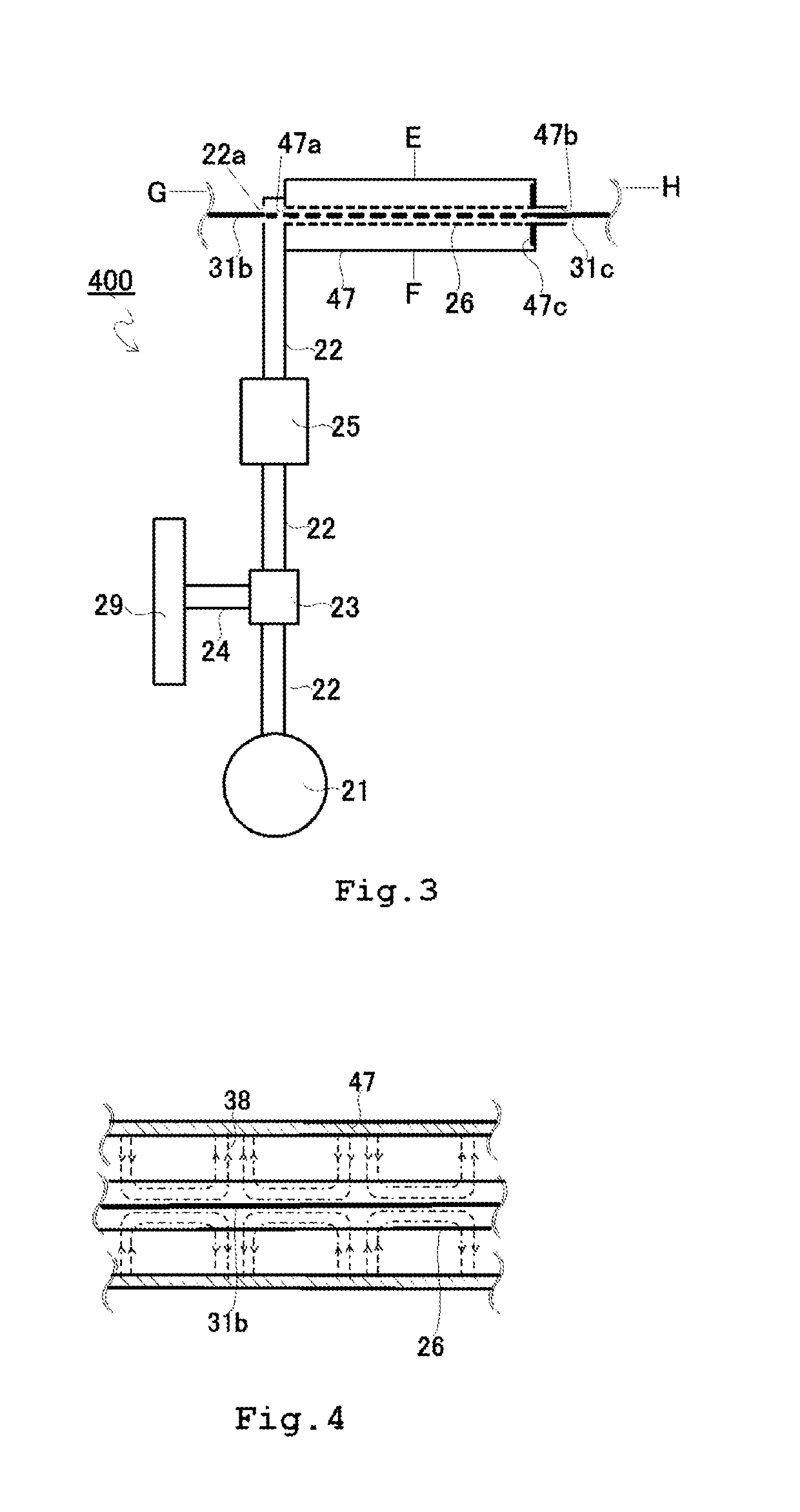

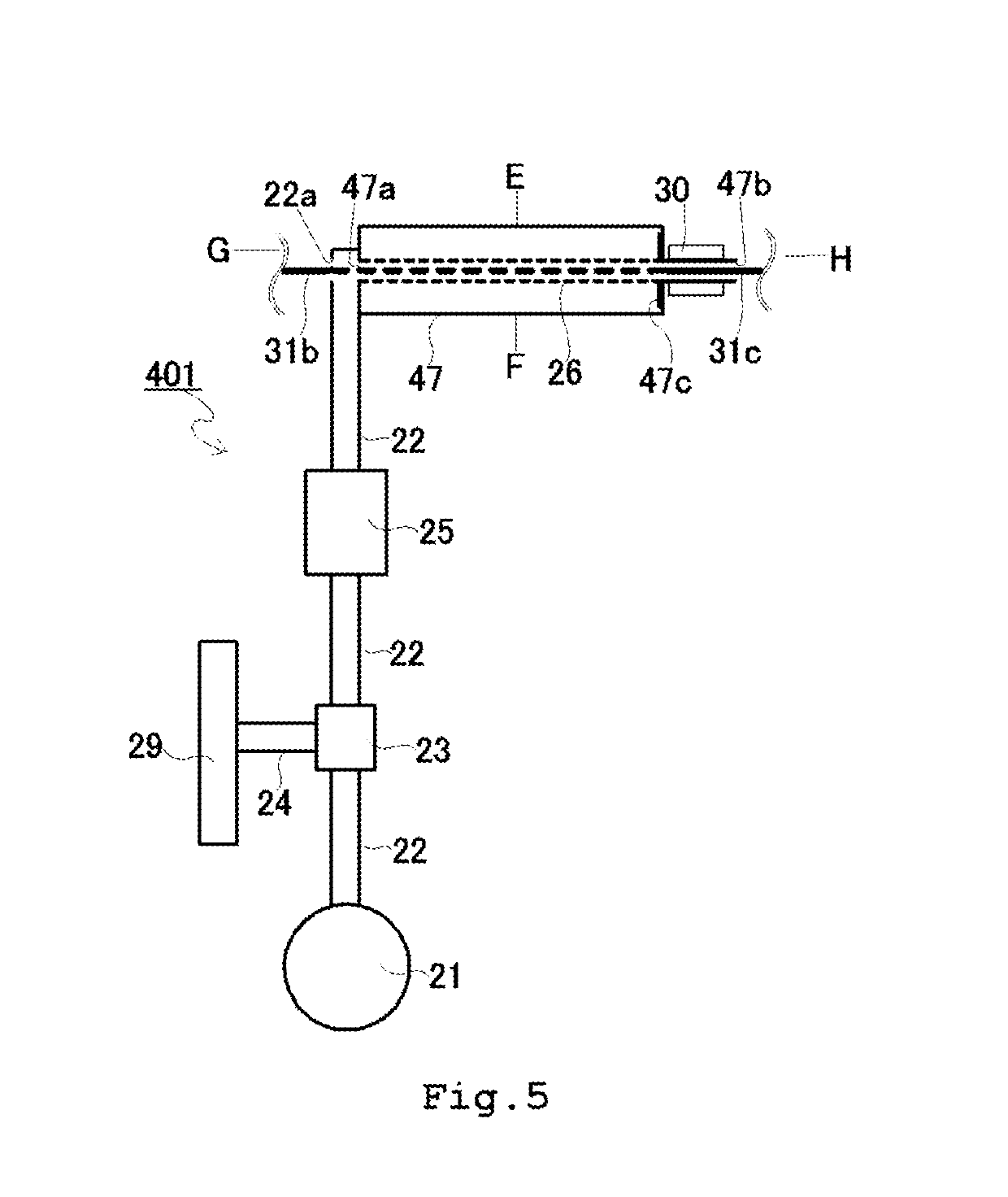

Carbon fiber manufacturing device and carbon fiber manufacturing method

ActiveUS10260173B2Carbonized quicklyIncrease contentRadio/micro wave fibre treatmentFibre chemical featuresElectromagnetic wave absorberFiber

The problem of the present invention is to provide a carbon fiber manufacturing device in which fiber to be carbonized is irradiated with microwaves and thereby heated, wherein the carbon fiber manufacturing device is compact and capable of performing carbonization at atmospheric pressure without requiring an electromagnetic wave absorber or other additives or preliminary carbonization through external heating. This carbon fiber manufacturing device (200) includes: a cylindrical furnace (27) comprising a cylindrical waveguide in which one end is closed, a fiber outlet (27b) being formed in the one end of the cylindrical waveguide and a fiber inlet (27a) being formed in the other end of the cylindrical waveguide; a microwave oscillator (21) for introducing microwaves into the cylindrical furnace (27); and a connection waveguide (22) having one end connected to the microwave oscillator (21) side and the other end connected to one end of the cylindrical furnace (27).

Owner:TEIJIIN LTD +2

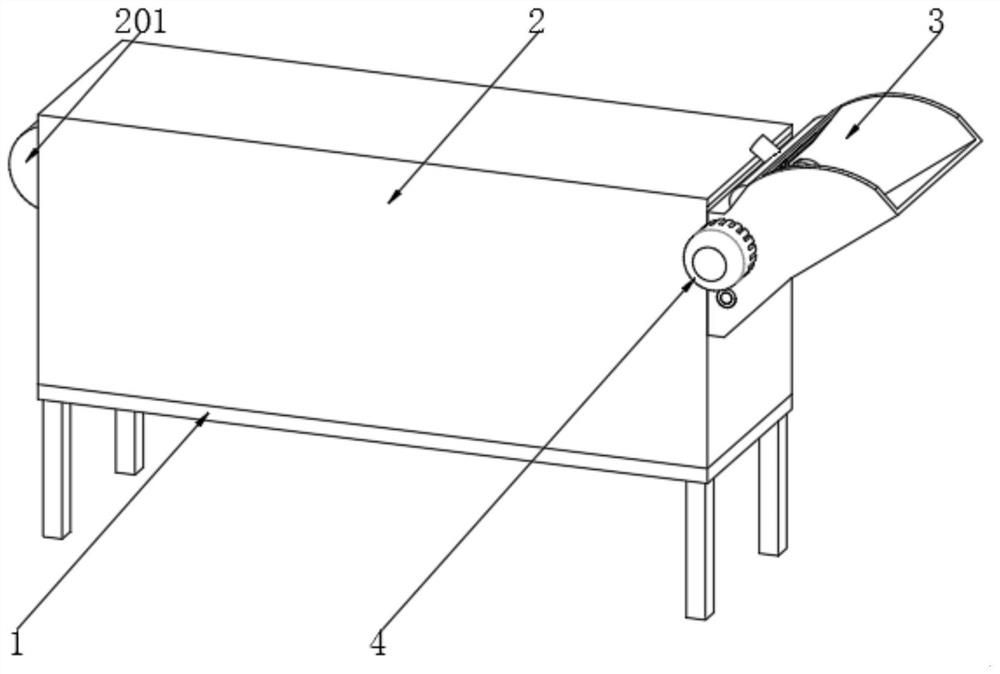

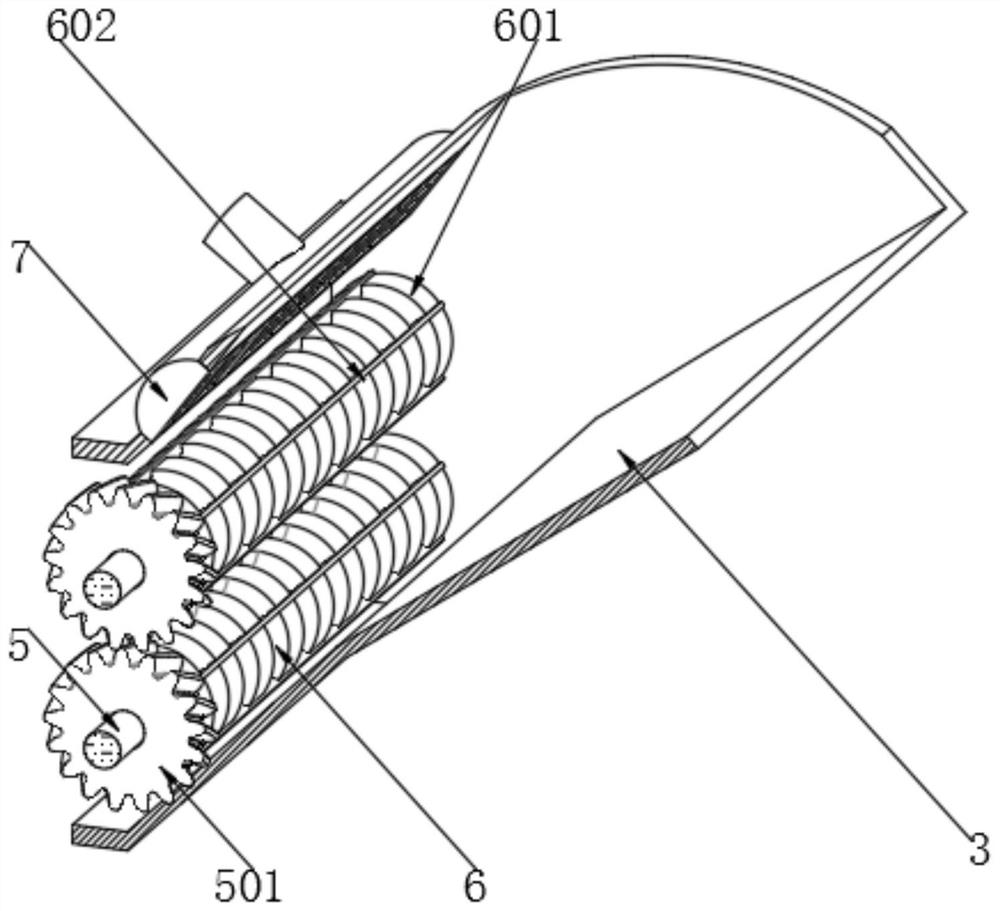

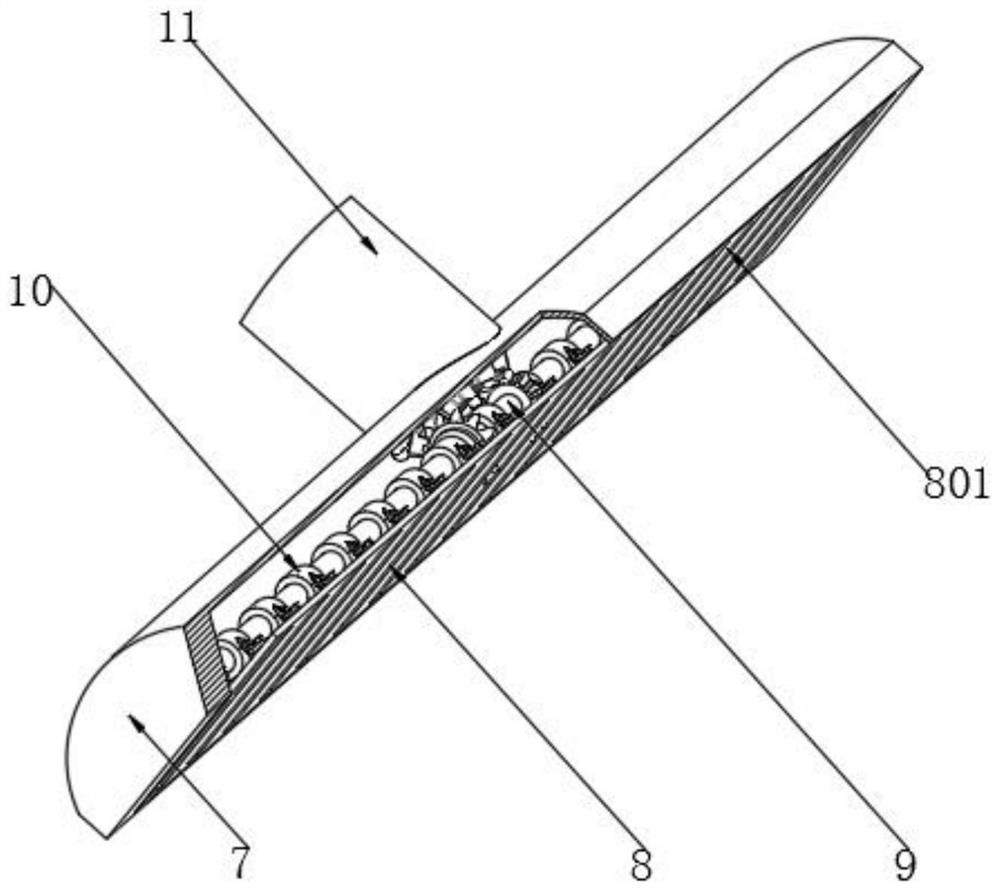

Carbonization and activation energy-saving integrated system for preparing activated carbon

InactiveCN113666371AEvenly heatedAccelerates the carbonization processCarbon compoundsChemical industryActivated carbonElectric machine

The invention discloses a carbonization and activation energy-saving integrated system for preparing activated carbon, and relates to the technical field of activated carbon preparation. According to the carbonization and activation energy-saving integrated system for preparing the activated carbon, through the arrangement of the raw material treatment assembly, when raw materials are fed, a driving motor can be started, and the starting of the driving motor can drive a rotating shaft in a feeding cover to rotate through the cooperation of the output end of the driving motor and two transmission gears; a rotating shaft is driven by a transmission gear to rotate relatively, the grinding rollers connected to the outer side of the rotating shaft in a sleeving mode can be driven to operate at the same time, the two grinding rollers operate, the fed organic raw materials are extruded and smashed, the smashed raw materials fall into a carbonization area from the interiors of a plurality of concave grooves, and meanwhile through segemetation of a plurality of cutting plates, the rolled raw materials can be divided into blocks with the same volume, so that the raw materials are heated more uniformly when being conveyed into the carbonization area and the activation area, and the carbonization and activation effects of the raw materials can be improved while the energy-saving effect is achieved.

Owner:淮北市森化碳吸附剂有限责任公司

A kind of composite graphite film and its preparation method and application

The invention discloses a composite graphite film and a preparation method and application thereof. The preparation method comprises the following steps: preparing a polyimide composite film formed by nano-diamond and polyimide; under the protection of an inert gas, performing carbonization and graphitization, and then removing graphite paper to obtain the composite graphite film formed by nano-diamond and polyimide. In the carbonization and graphitization process, as a crystal nucleus, nano-diamond promotes carbonization and graphitization of polyimide, so that the heat-conducting property and the electric conductivity of a composite carbon film are improved.

Owner:北京兴科迪电子技术研究院

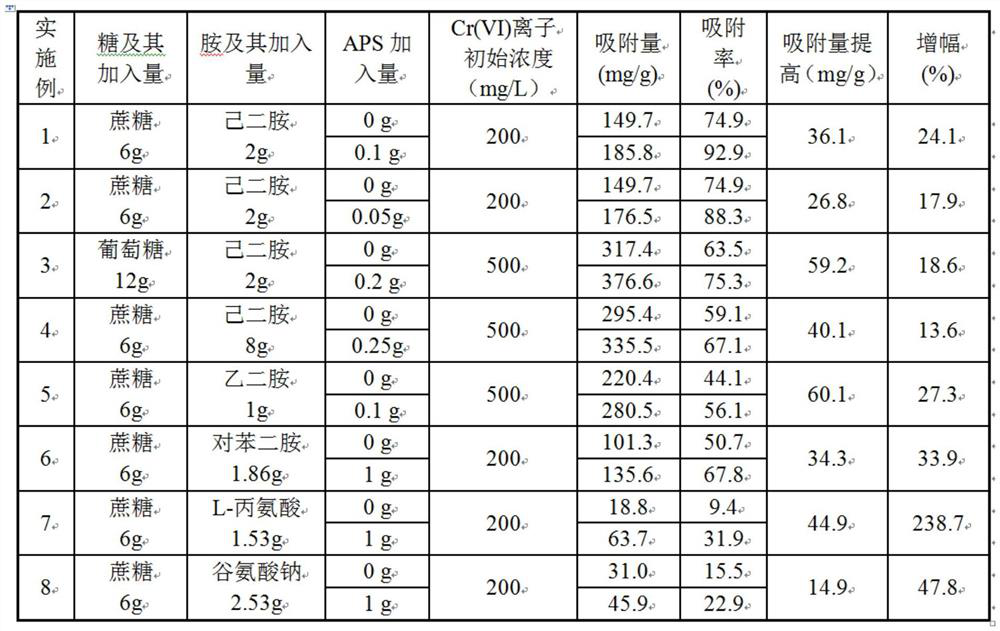

A kind of preparation method of high-efficiency amine functionalized carbon composite adsorbent

InactiveCN108579690BImprove adsorption capacityIncrease the number ofOther chemical processesWater contaminantsCarbon compositesSucrose

The invention discloses a preparation method of a high-efficiency amine-based functionalized carbon composite adsorbent. The method is as follows: a mixed aqueous solution of sucrose, organic amine and ammonium persulfate (APS) is subjected to a hydrothermal reaction, and the Cr(VI ) ions with amine-based functionalized carbon composite adsorbents with high adsorption performance. In the invention, by adding a small amount of APS in the reaction liquid, the adsorption capacity of the adsorbent for Cr(VI) ions in waste water is significantly improved. Compared with the sample prepared without adding APS, the adsorption capacity of Cr(VI) ions on the amino-functionalized carbon composite adsorbent prepared after adding APS increased by 14.9-60.1 mg / g, an increase of 13.6-238.7%.

Owner:WUHAN UNIV OF TECH

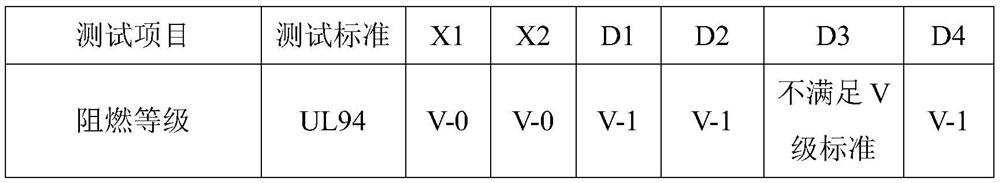

A kind of polyolefin flame retardant masterbatch and its preparation method and application

The invention discloses a polyolefin flame-retardant masterbatch and its preparation method and application. The preparation method comprises the following steps: (1) adding soluble magnesium salt and aluminum salt to water to prepare solution A; (2) preparing a mixed alkali solution , recorded as solution B; (3) solution A, solution B, and sodium dodecylbenzenesulfonate were mixed to obtain solution C; (4) solution C was aged, filtered, washed, and dried to obtain modified LDH; (5) Modified LDH, intumescent flame retardant, pentaerythritol, polyolefin, erucamide, and antioxidant are mixed to obtain a compound; (6) The compound is extruded and granulated to obtain a polyolefin flame-retardant masterbatch. The LDH of the present invention is organically modified by sodium dodecylbenzene sulfonate, which can improve its compatibility with polyolefins, make it uniformly dispersed in the polyolefin matrix, and the modified LDH has a synergistic effect with the intumescent flame retardant The flame retardant effect can well improve the flame retardant performance of polyolefin composite materials.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com