A kind of preparation method of high-efficiency amine functionalized carbon composite adsorbent

A high-efficiency amine-based and amine-functional technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the performance problems of amine-functionalized carbon composite adsorbents that have not yet been seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

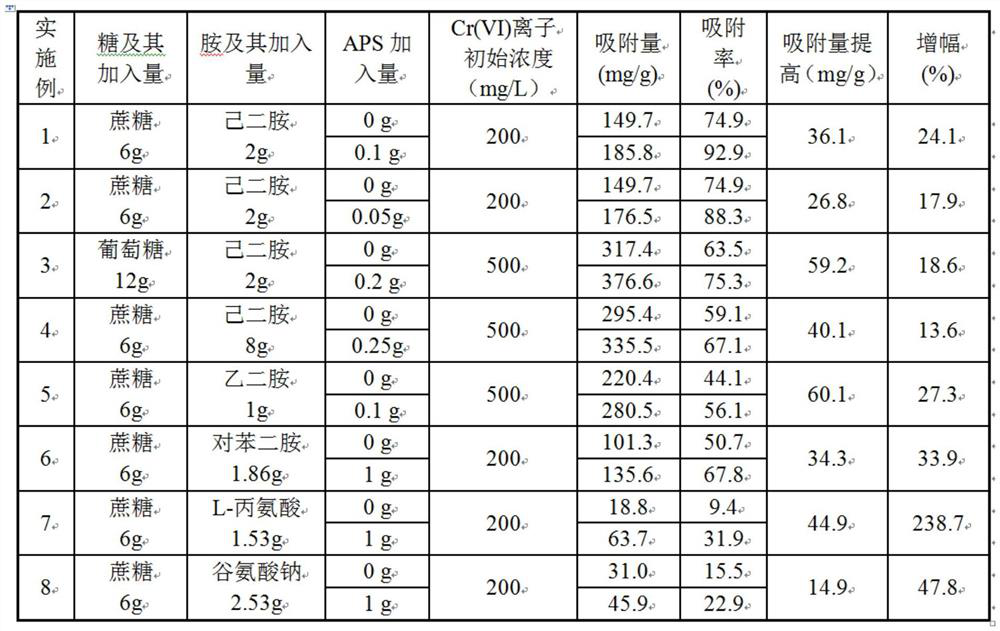

Embodiment 1

[0028] This embodiment relates to the preparation of an amine-based functionalized carbon composite adsorbent with improved performance and a comparative experiment. The specific steps include:

[0029] Sample (1): 6g of sucrose and 2g of hexamethylenediamine were dissolved in 40ml of deionized water, transferred to a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, and placed in an oven at 200°C for 12 hours.

[0030] Sample (2): Add 6g of sucrose, 2g of hexamethylenediamine, and 0.1g of APS into 40ml of deionized water to dissolve, transfer to a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, and carry out the same process as sample (1). operate.

[0031] After the reaction, the suspensions of the above two reactions were filtered respectively, the filter cake was washed three times with deionized water and rinsed once with ethanol, and the obtained filter cake was dried in an oven at 80° C. for 12 hours to obtain a brown powder...

Embodiment 2

[0035] Compared with Example 1, in this example, the amount of APS added in the sample (2) was changed to 0.05g, and a comparative experiment was carried out.

[0036] In Cr(VI) ion solution with an initial concentration of 200mg / L and pH=3, the adsorption capacities of samples (1) and (2) were 149.7mg / g and 176.5mg / g, respectively. The adsorption performance of the sample prepared by adding APS to assist hydrothermal treatment was significantly improved, and the adsorption capacity increased by 26.8mg / g, an increase of 17.9%.

Embodiment 3

[0038] Compared with Example 1, in this example, 12 g of glucose was used to replace 6 g of sucrose, and the amount of APS added in the sample (2) was 0.2 g, and a comparative experiment was carried out.

[0039] In the Cr(VI) ion solution with an initial concentration of 500 mg / L and pH=3, the adsorption capacities of samples (1) and (2) were 317.4 mg / g and 376.6 mg / g, respectively. The adsorption performance of the sample prepared by adding APS to assist hydrothermal treatment was significantly improved, and the adsorption capacity increased by 59.2mg / g, an increase of 18.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com