Patents

Literature

106results about How to "Increase reaction pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

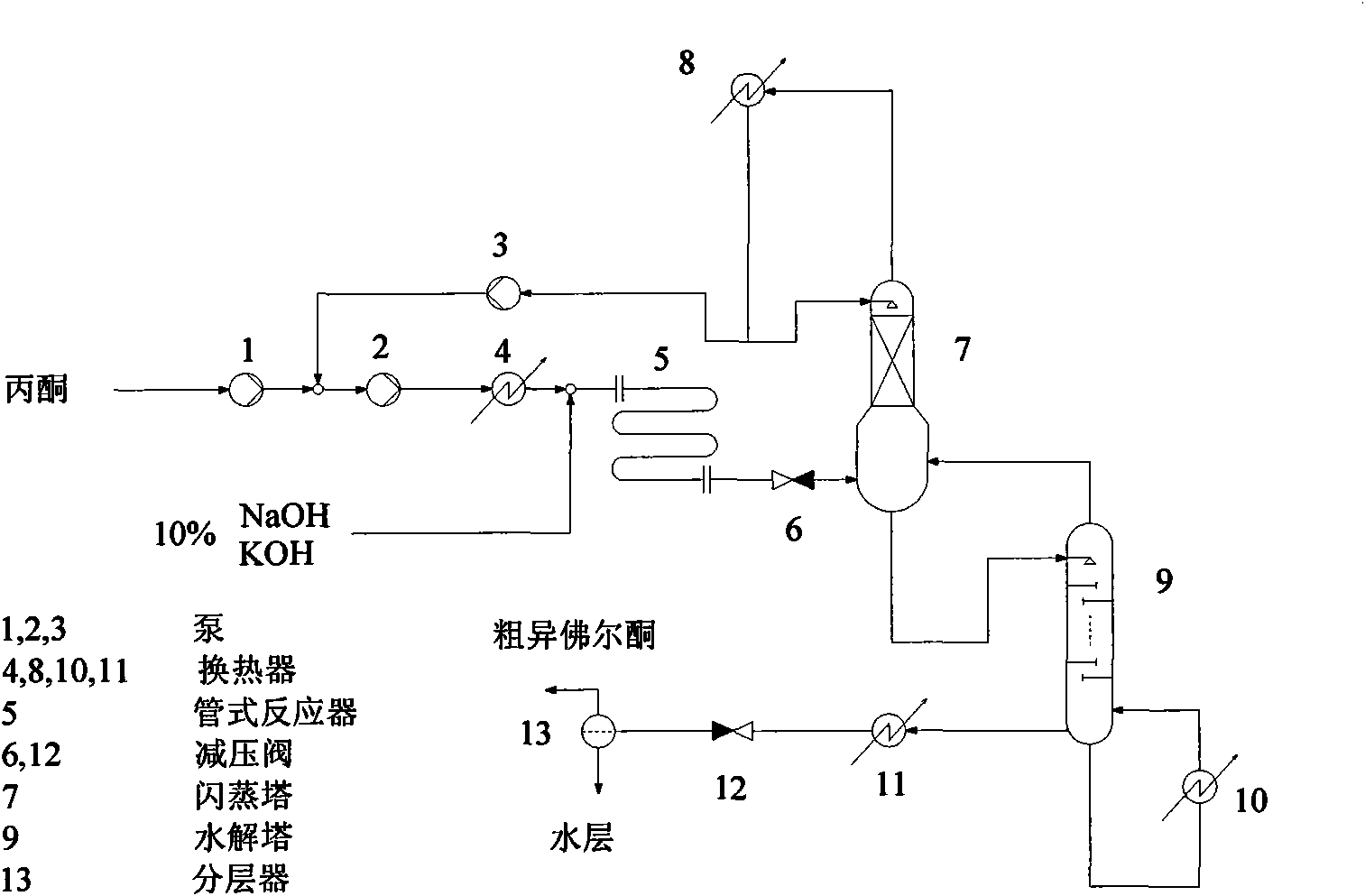

Method for preparing alpha-isophorone

ActiveCN101633610AReduce generationIncrease productivityOrganic compound preparationCarbonyl compound preparationIsophoroneChemistry

The invention discloses a method for preparing alpha-isophorone, which comprises the following steps: pressurizing a mixture of acetone and recycled acetone to 8.0-20.0MPa under the condition of continuous steady state operation and preheating to 280 DEG C-320 DEG C; then mixing the mixture with 10 percent of NaOH solution or 10 percent of KOH solution pressurized to the same pressure; carrying out super-critical reaction for 1-3 min in a pipe type reaction vessel; decompressing the reaction liquid to 3.0-4.0MPa and entering a flashing steam tower; obtaining the recycled acetone mixture from the top of the tower; leading tower kettle liquid to enter a hydrolyzing tower to hydrolyze polymers (C12 and C15); continuously extracting hydrolyzed reaction liquid from a tower kettle of the hydrolyzing tower, cooling, decompressing to normal pressure and layering in a layering device to obtain an alpha-isophorone rough product layer and a byproduct water layer. The method for synthesizing the alpha-isophorone has short needed reaction time, few byproducts and high reaction yield and is suitable for industrialized production.

Owner:ZHEJIANG UNIV +2

Glycol catalyst synthesized by hydrogenating oxalic ester and preparation method and application thereof

InactiveCN101524646AImprove hydrogenation activityLow investment costOrganic compound preparationHydroxy compound preparationHigh activityMetal

The invention discloses a glycol catalyst synthesized by hydrogenating oxalic ester and a preparation method and an application thereof. The catalyst has the chemical formula of CuO-AOx / Al2O3, wherein A is one or more than one metallic element of Zn, Mn, Mg and Cr, x is half of the valence number of A, the content of CuO accounts for 40 percent to 80 percent of the catalyst mass, the content of AOx accounts for 5 percent to 40 percent of the catalyst mass and the content of Al2O3 accounts for 5 percent to 30 percent of the catalyst mass. The catalyst has high activity and selectivity at low temperature and under low pressure, the energy and power consumption in production can be reduced greatly and the catalyst has good stability and long service life. The preparation method of the catalyst is simple and raw materials as industrial products are easily obtained and have low price.

Owner:DANYANG DANHUA COAL CHEM

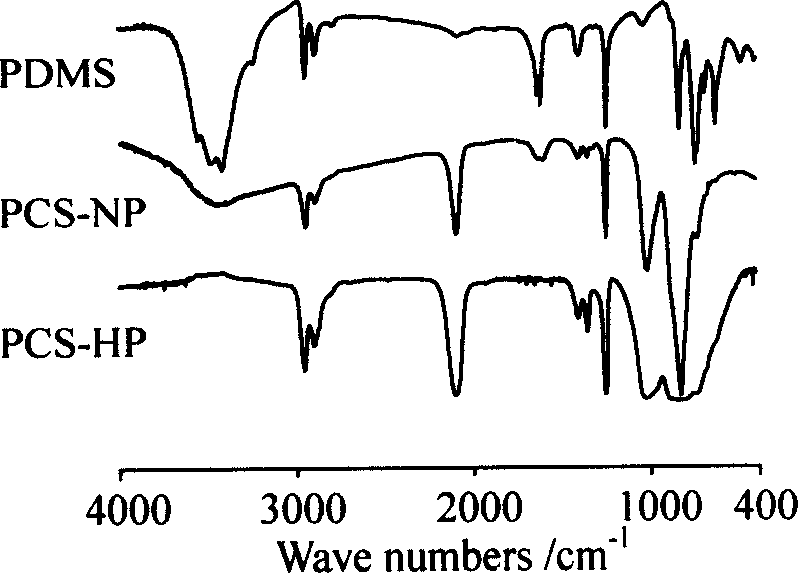

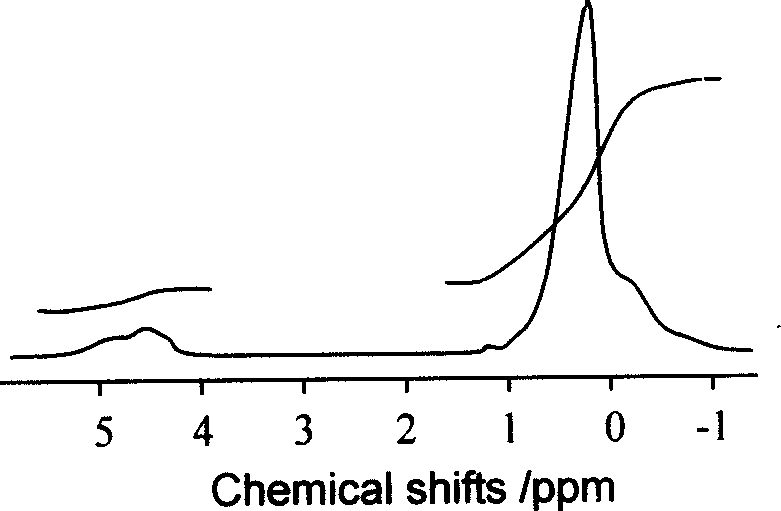

High temperature high pressure synthesis method for polycarbosilane

The invention provides a high temperature high pressure synthesis method for polycarbosilane which comprises the steps of, (1) loading small molecular PCS or LPS whose PDMS or average molecular weight is less than 2000 into hot pressing kettle, evacuating and replacing gas in the kettle with high purity nitrogen, charging 0.1-5Mpa of N2 and sealing, elevating the temperature to 430-490 deg. C, reacting time being 0.5-10 hours, (3) dissolving the crude product with xylene, filtering, and proceeding vacuum distillation to the filter liquor at 330-380 deg. C, finally cooling down to obtain the resin form product.

Owner:NAT UNIV OF DEFENSE TECH

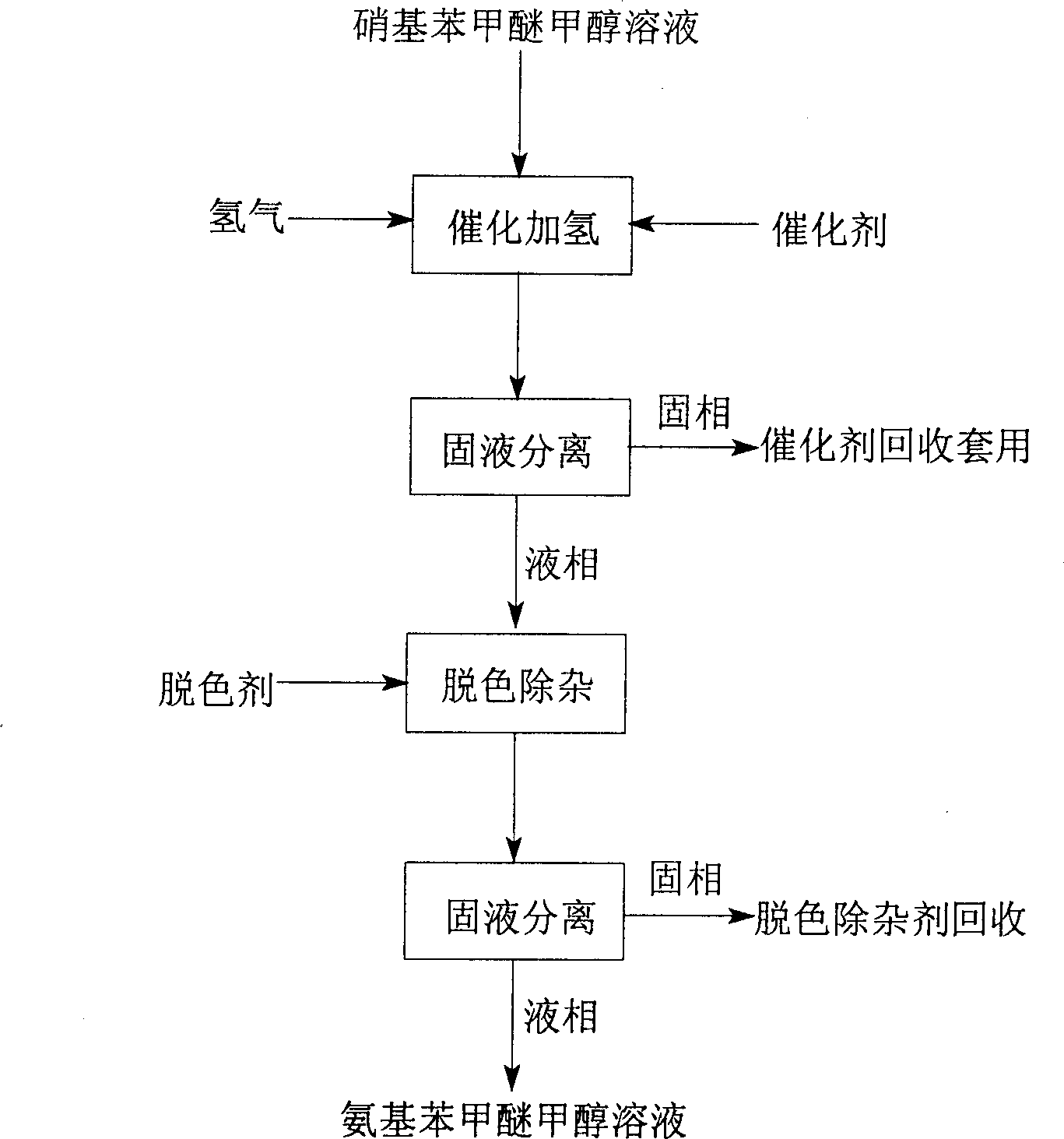

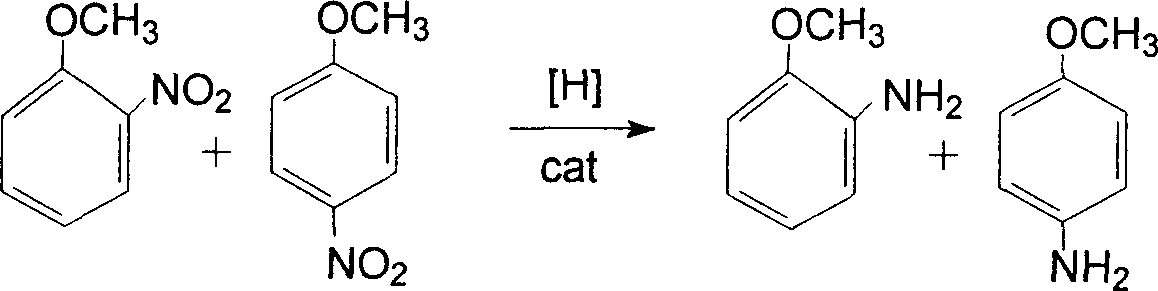

Tech. of preparing amino benz methyl-phenoxide by nitro methyl-phenoxide mixture catalyzing hydrogenation

InactiveCN1861570AImprove dispersionImprove recycling efficiencyOrganic compound preparationAmino-hyroxy compound preparationSolventImpurity

A process for preparing amino phenylmether from nitro phenylmether mixture by catalytic hydrogenating includes such steps as catalytic hydroreducing reaction between methanol, nitro phenylmether mixture and catalyst, recovering catalyst, decoloring, removing impurities, filtering to obtain liquid phase (the solution of amino phenylmether, methanol and water), separation and refining.

Owner:CHANGZHOU JIASEN CHEM +1

Method for preparing hydrogen by reforming methanol and water

InactiveCN102198935ALow reaction temperatureIncrease reaction pressureHydrogenMethanol waterPtru catalyst

The invention provides a method for preparing hydrogen by carrying out a reforming dehydrogenation reaction on a reactant of which the ratio of methanol to water is 1:1-3 in the presence of a solid catalyst with copper as a main component. In the method disclosed by the invention, hydrogen gas is generated by using the reactant of which the ratio of methanol to water is 1:1-3 as a gaseous phase or liquid phase and the solid catalyst at the temperature of 200-280DEG C, the air speed of 0.2-2h<-1> and the pressure of 0.1-2MPa; meanwhile, byproducts of CO2 and CO are generated, the conversion rate of methane is over 98 percent and the CO amount is below 2 percent.

Owner:ZHANGJIAGANG HUIER CHEM TECH

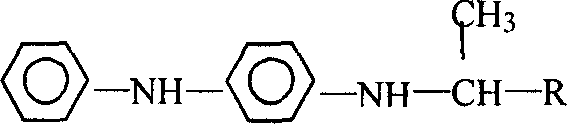

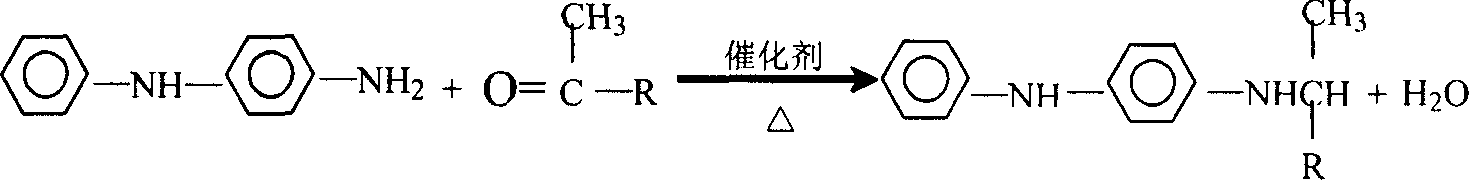

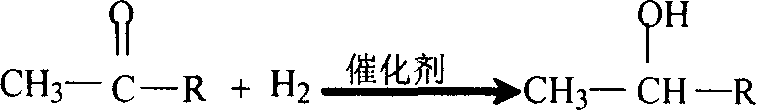

Condensating reductive alkylation catalyst, preparation method and uses thereof

ActiveCN101204658AAppropriate areaAvoid wastingPreparation by reductive alkylationMetal/metal-oxides/metal-hydroxide catalystsWater useOrganic acid

The invention provides a condensation reductive alkylation catalyst and preparation method and use thereof. The catalyst pertains to copper-based catalyst, and is prepared by coprecipitation method with acid or salt thereof as precipitator. The preparation method is energy saving and environment friendly for including no impurity natrium, which avoids environmental protection problem existing in catalysis preparation technology with traditional precipitation method and reduces washing water use. The specific surface area of the catalyst is 30.0 to 75.0m<2> / g and pore volume 0.08 to 0.15ml / g. The catalyst can be used in condensation technology of RT Base and aliphatic ketone to inhibit an unnecessary side reaction in production of anti-aging agent 4010NA and 4020, especially to a reaction of aliphatic ketone alkylation regent hydrogenated to corresponding mellow.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

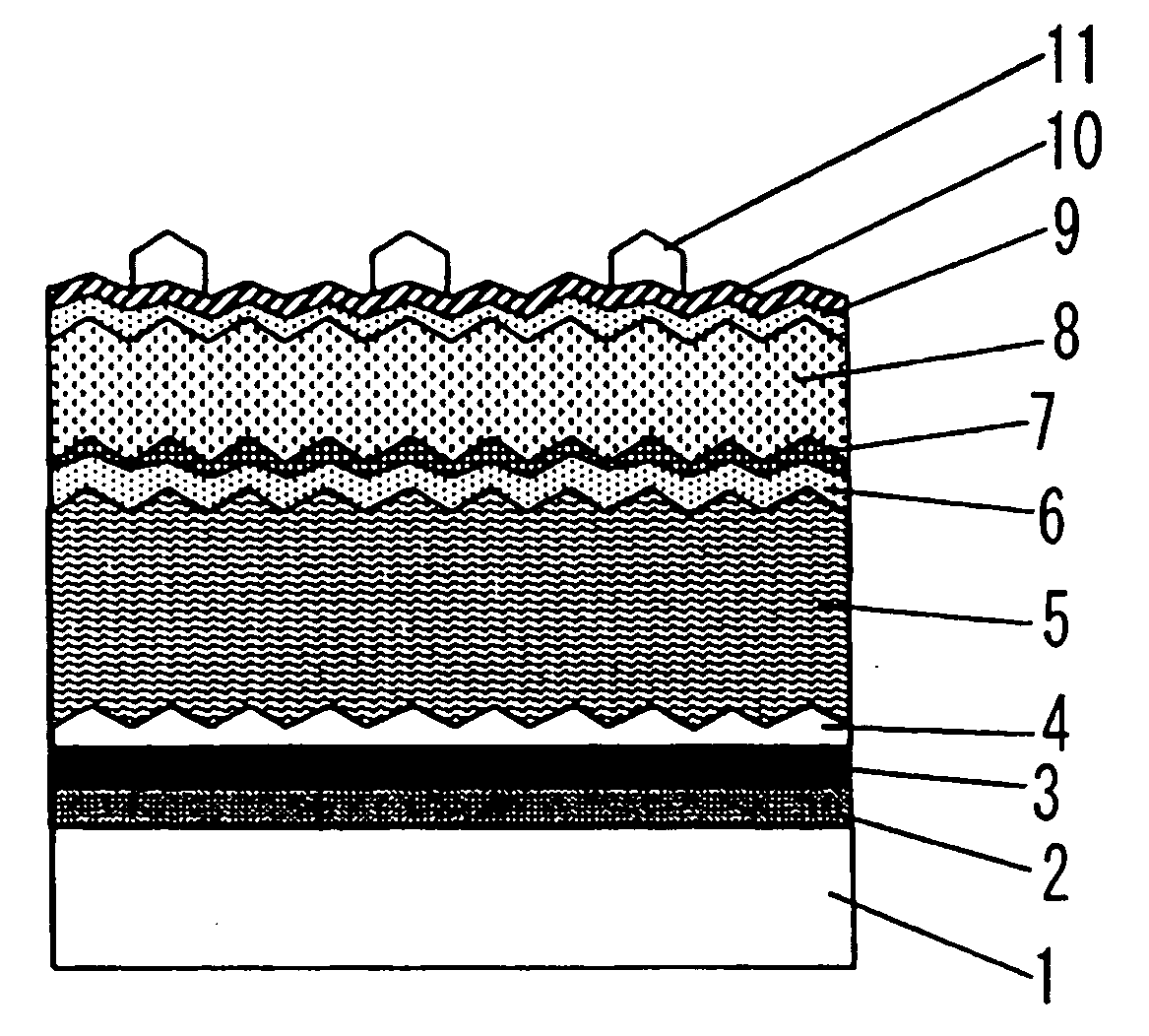

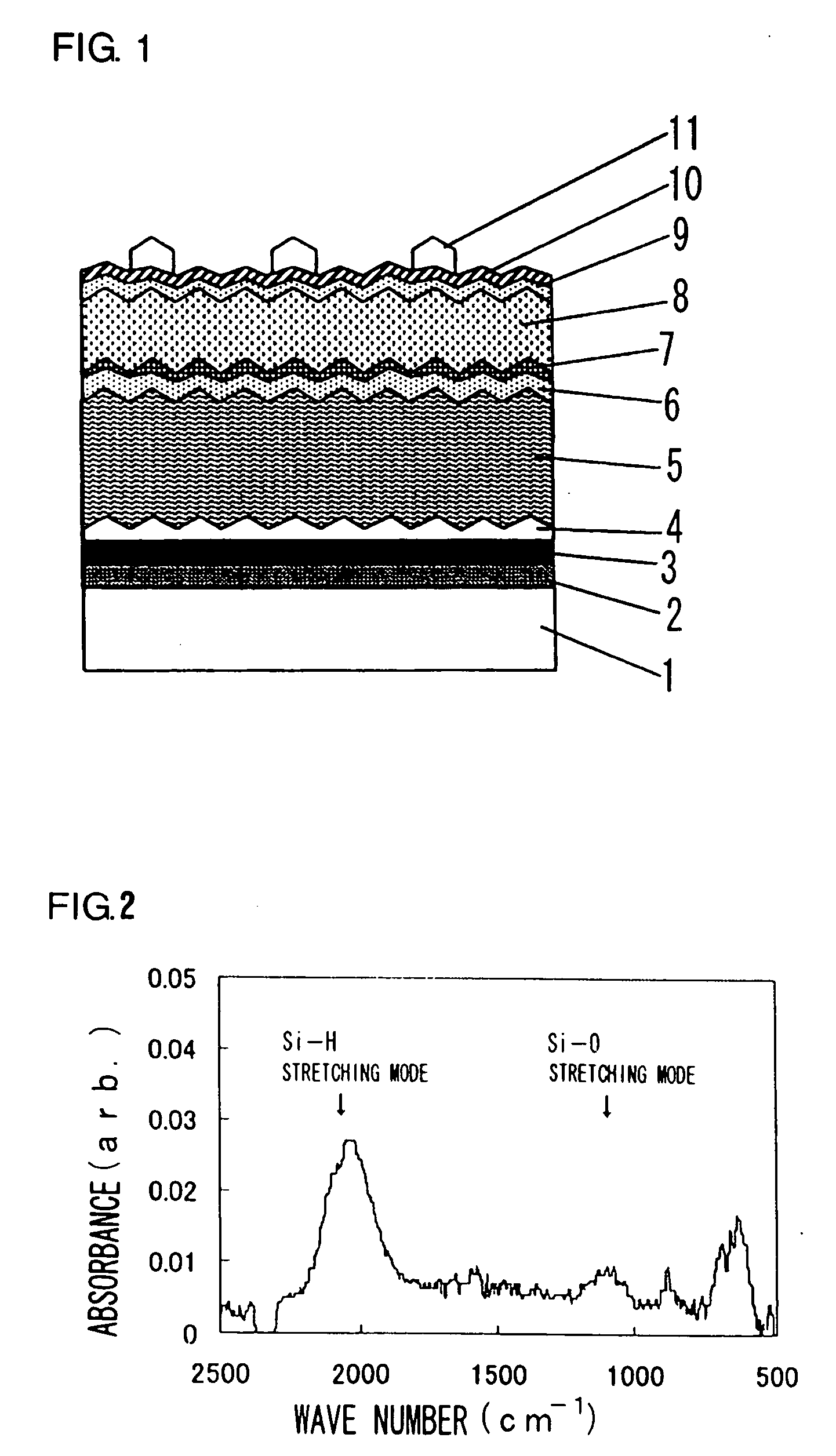

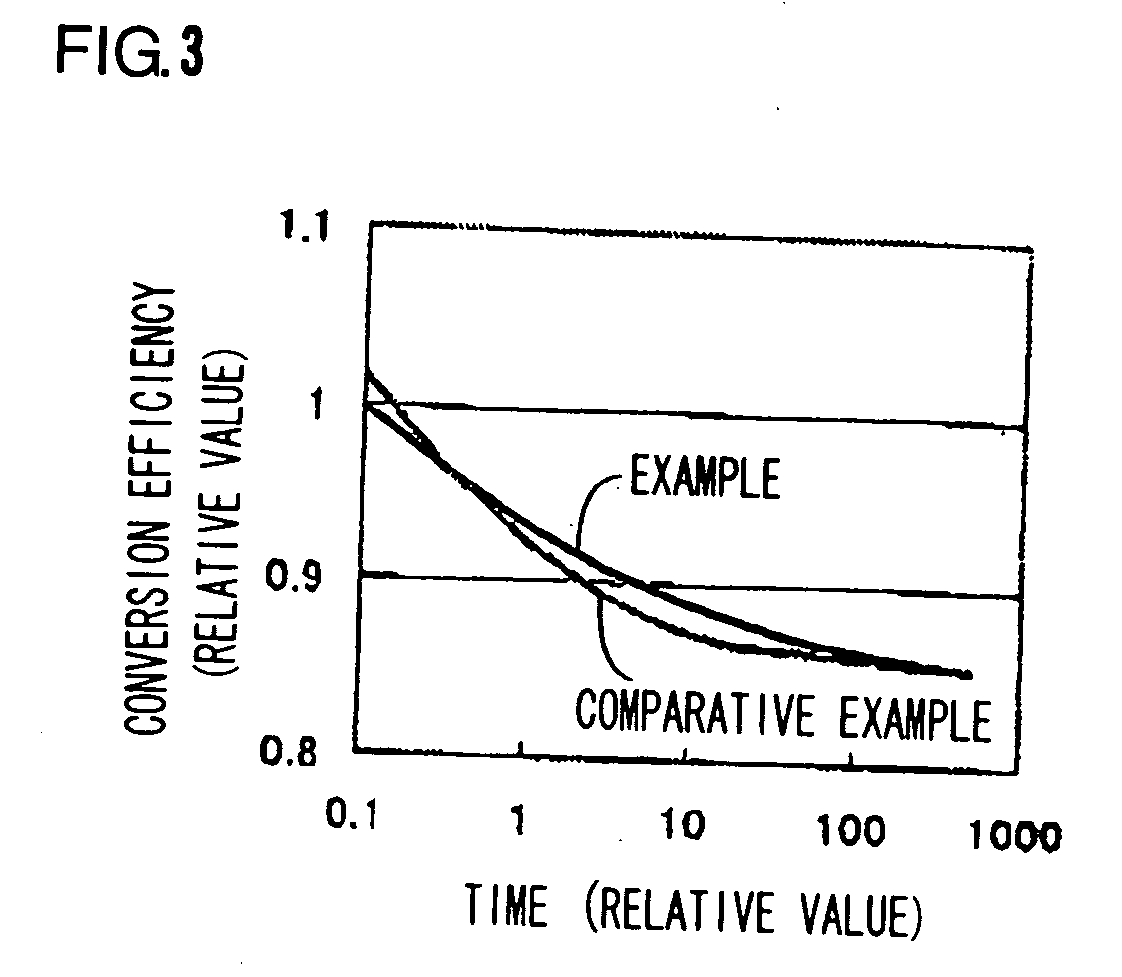

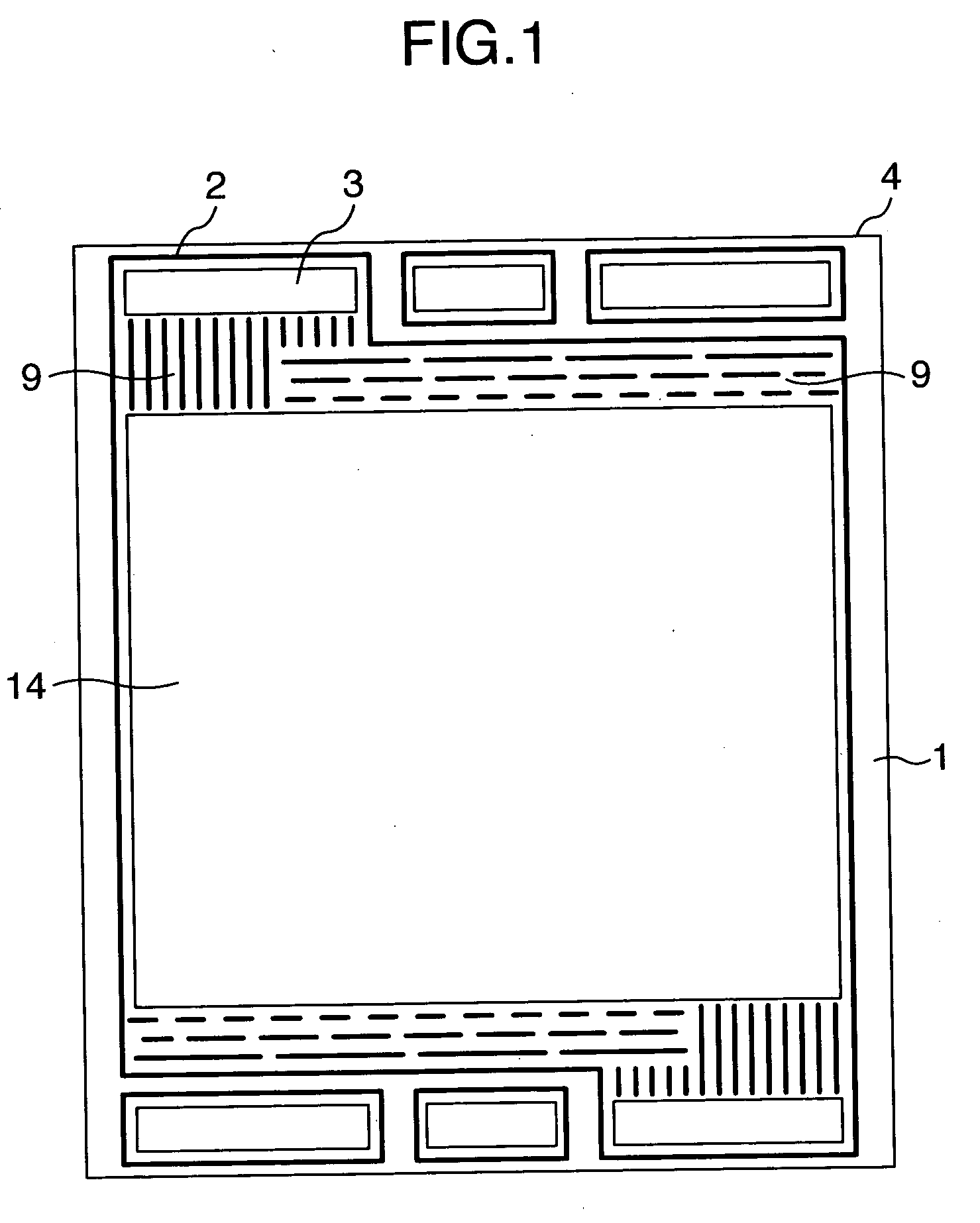

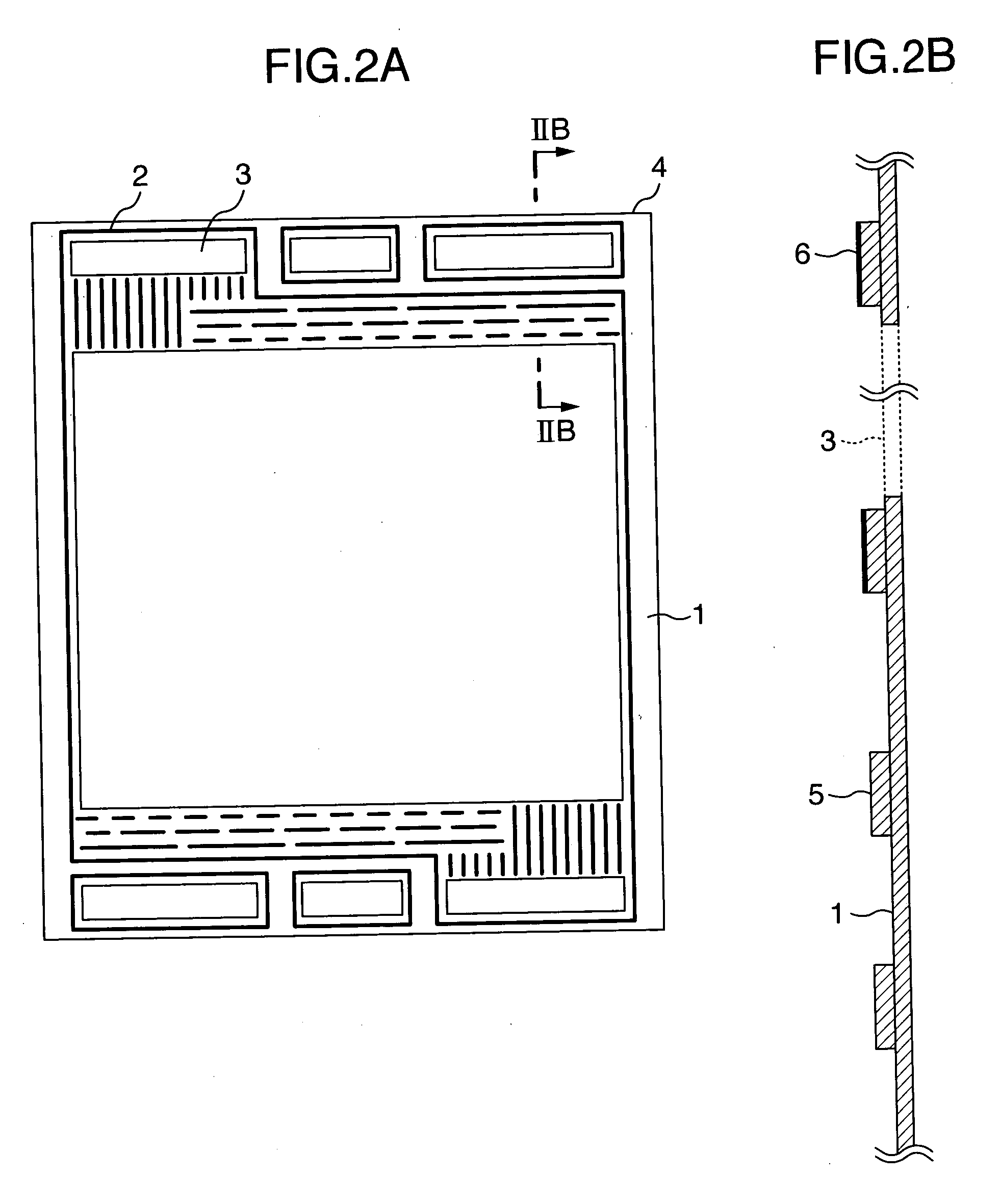

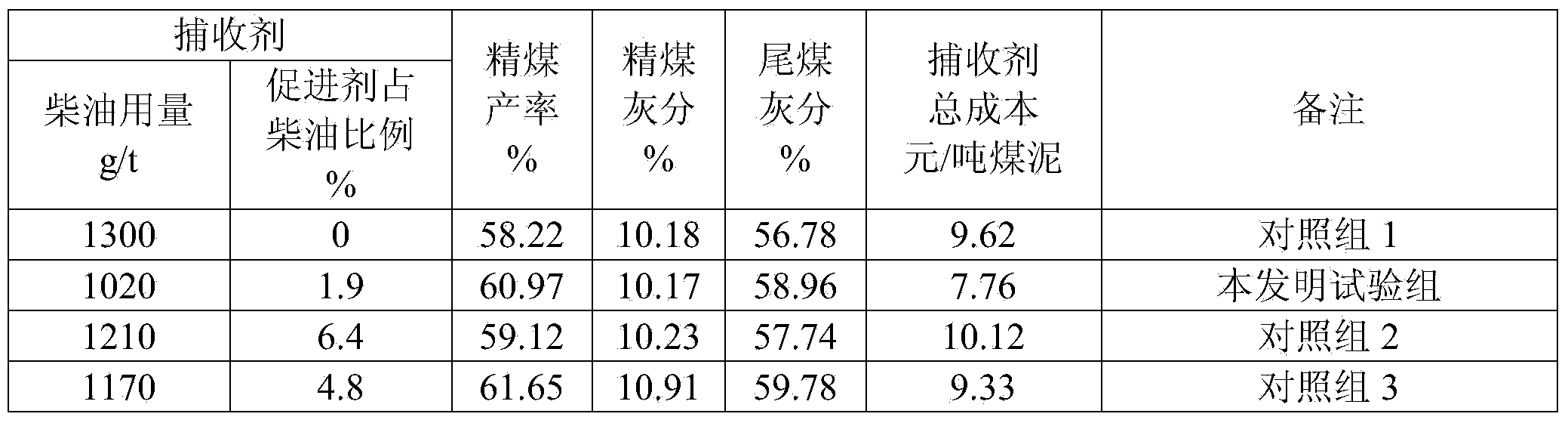

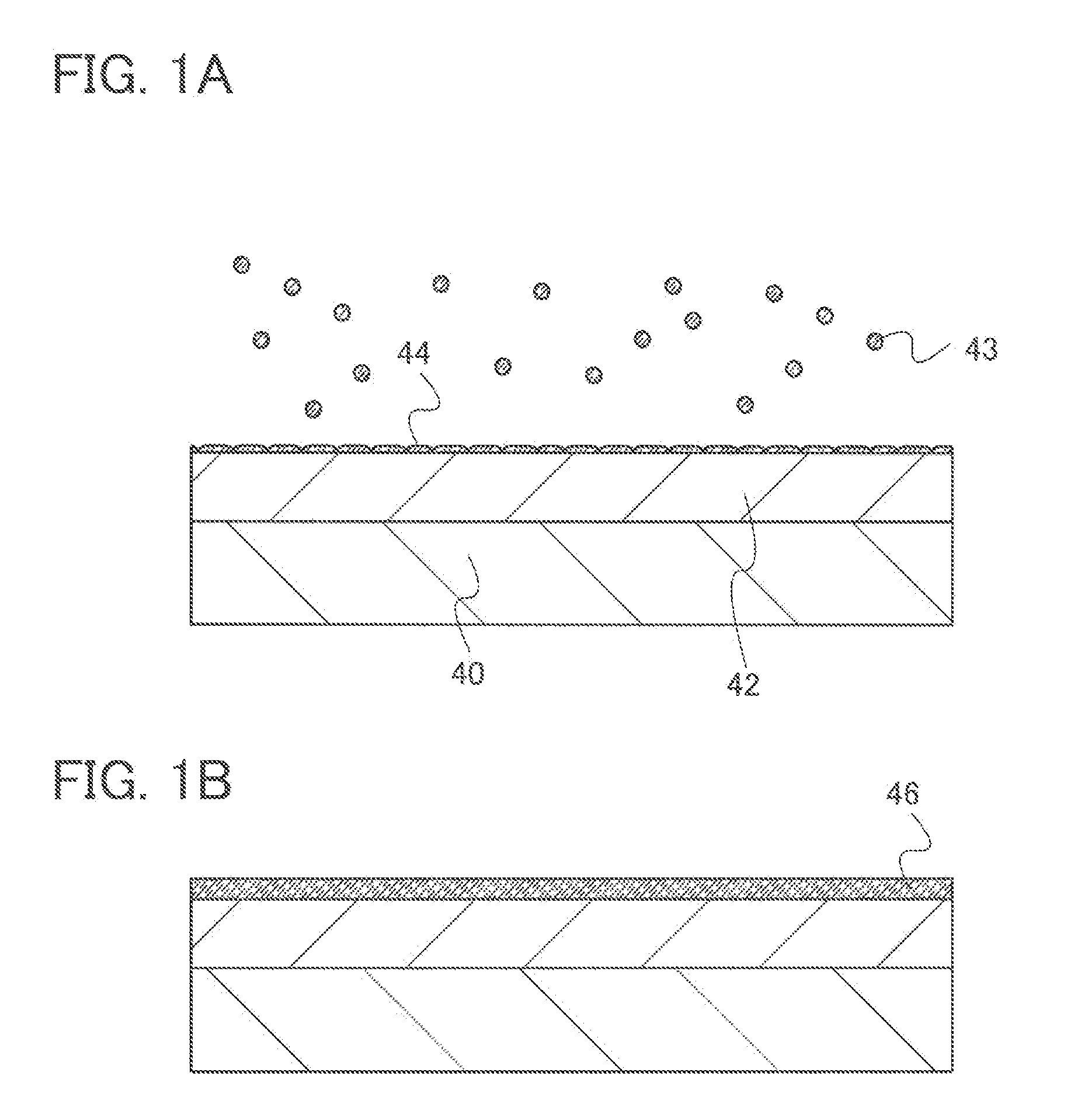

Stacked photovoltaic device

InactiveUS20070000538A1Generated energy is improvedIncrease oxygen contentPhotovoltaic energy generationSemiconductor devicesPhotoelectric conversionMicrocrystalline silicon

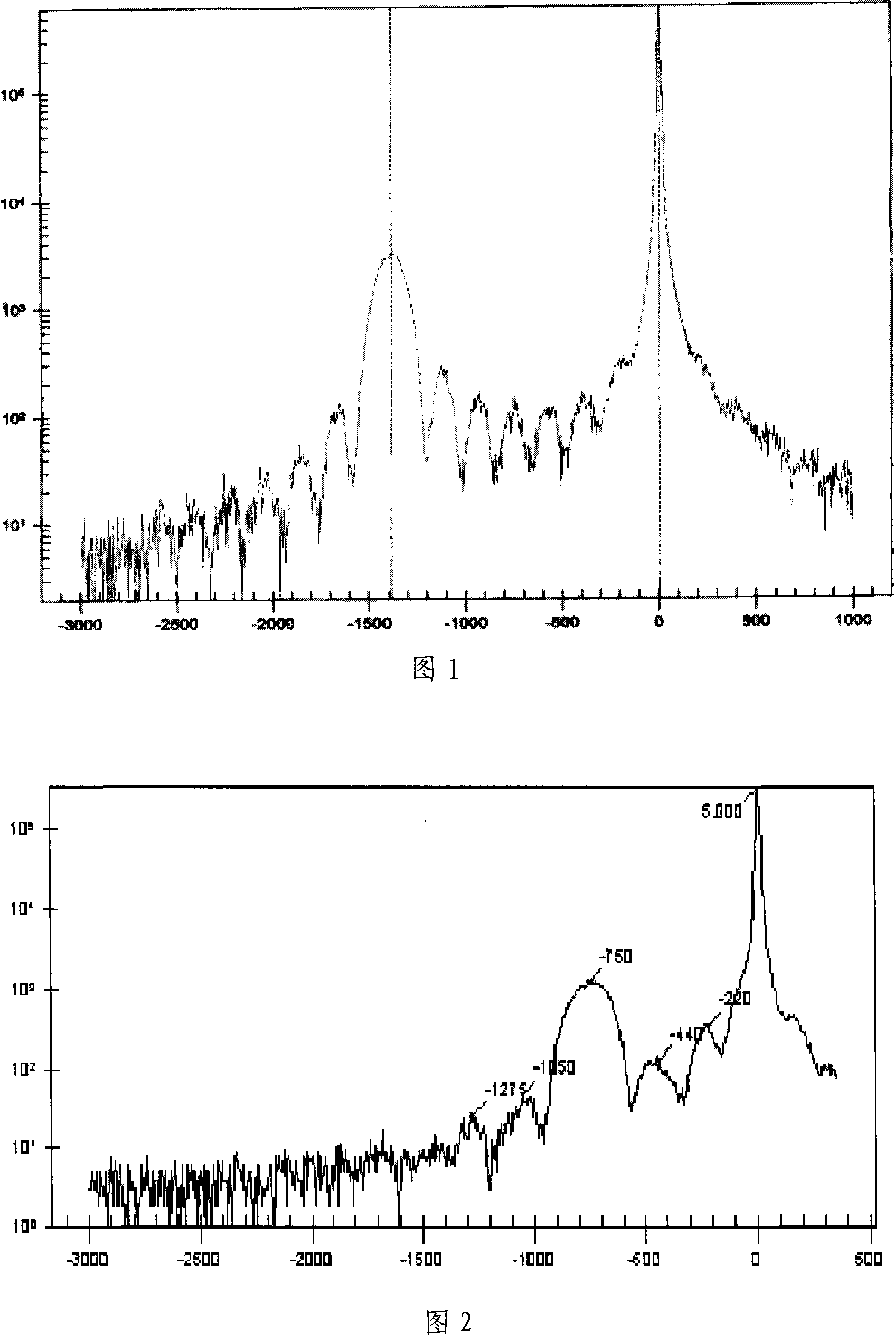

A stacked photovoltaic device which includes a first photovoltaic unit having an amorphous silicon layer 8 as a photoelectric conversion layer, and a second photovoltaic unit having a microcrystalline silicon layer 5 as a photo-electric conversion layer and succeeding backwardly from the first photovoltaic unit closer to a light incidence plane. The microcrystalline silicon layer 5 serving as the photoelectric conversion layer in the second photovoltaic unit has a ratio α2(=I(Si—O) / I(Si—H)) greater than a ratio α1(=I(Si—O) / I(Si—H)) of the amorphous silicon layer 8 serving as the photoelectric conversion layer in the first photovoltaic unit, where I(Si—O) is a peak area for the Si—O stretching mode of each silicon layer and I(Si—H) is a peak area for the Si—H stretching mode of each silicon layer when the amorphous and microcrystalline silicon layers 8 and 5 are measured by infrared absorption spectroscopy. Also, a short-circuit current Isc2 of the second photovoltaic unit is greater than a short-circuit current Isc1 of the first photovoltaic unit.

Owner:SANYO ELECTRIC CO LTD

Separator for fuel cell and fuel cell using it

InactiveUS20060127744A1Sufficient sealing characteristicIncrease reaction pressureFuel cell auxillariesCell component detailsElastomerFuel cells

The present invention provides a separator for a fuel cell constructed using a metallic pressed plate, in which a gas channel from a manifold to an electrode surface is formed simply, and a good sealing characteristic is realized. The separator is comprised of a metallic pressed plate, a resinous frame member, and a sealing frame having a sealing material integrated therewith, and a channel for introducing a gas from the manifold to an electrode surface is formed by a metallic surface, the sealing material and a resinous surface. An elastomer such as a rubber is used for the sealing material. Thus, the gas channel from the manifold to the electrode surface can be formed simply, and an excellent sealing characteristic to the gas and water is obtained.

Owner:HITACHI LTD

Protective film and method for preparing same

InactiveUS20020146582A1Easy to produceImprove adaptabilityPhotosensitive materialsSynthetic resin layered productsTectorial membraneResist

A high-quality protective film for a dry film resist is provided. A film of a polyethylene is used as the protective film, the polyethylene being prepared by pressurizing ethylene with use of an ultra-high pressure compressor and then polymerizing the ethylene at a reaction temperature of 190° to 300° C. and a reaction pressure of not lower than 167 MPa in the presence of a radical polymerization initiator, or by pressuring ethylene with use of an ultra-high pressure compressor and then polymerizing the ethylene at a reaction temperature of 190° to 300° C. in the presence of a radical polymerization initiator while allowing a radical polymerization inhibitor to be present in the reaction system.

Owner:JAPAN POLYOLEFINS CO LTD

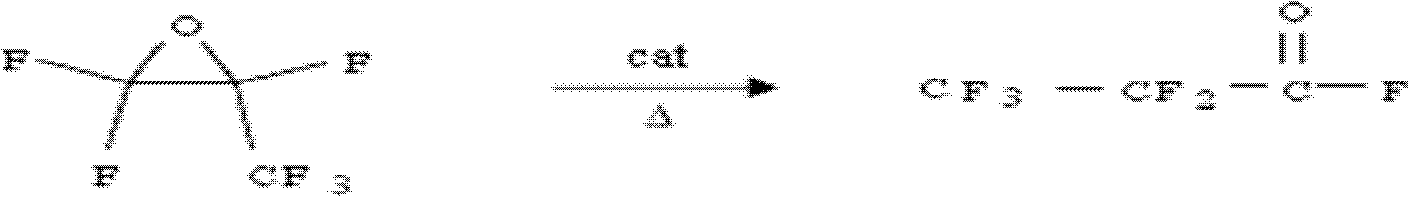

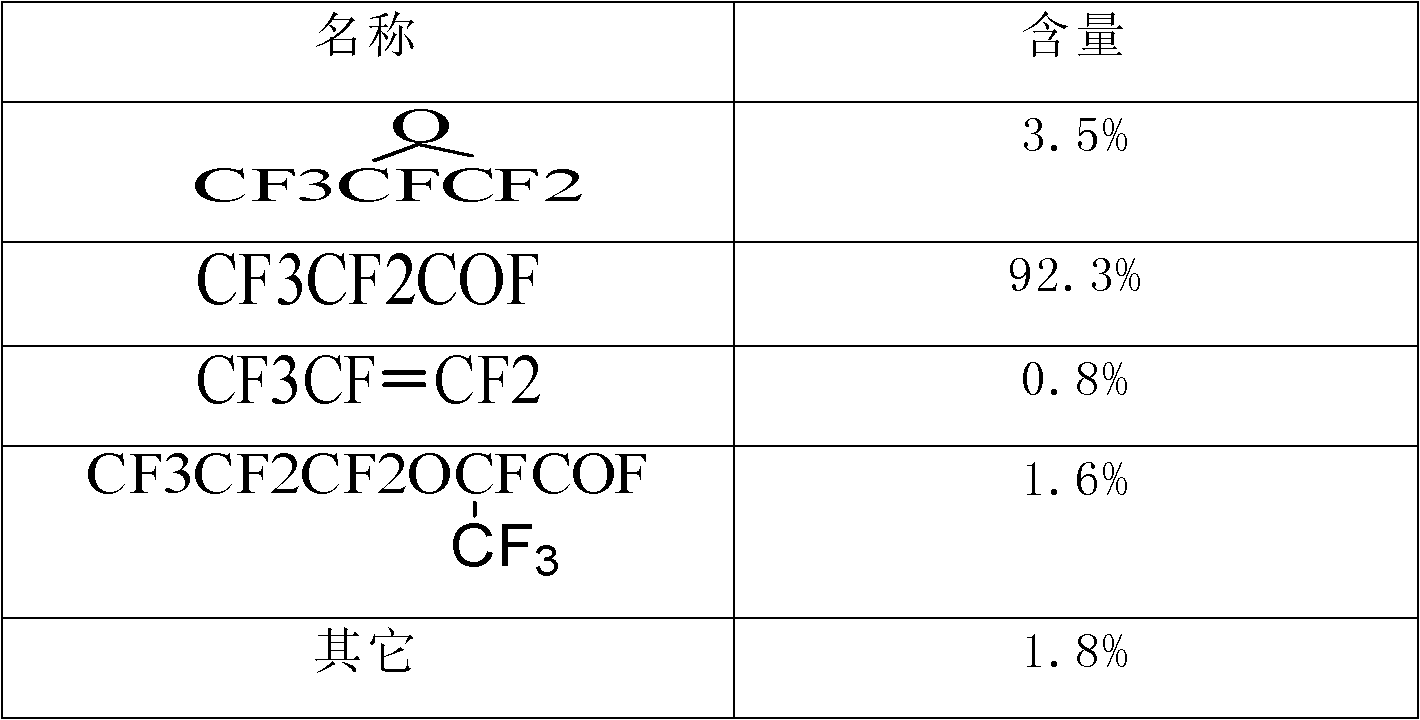

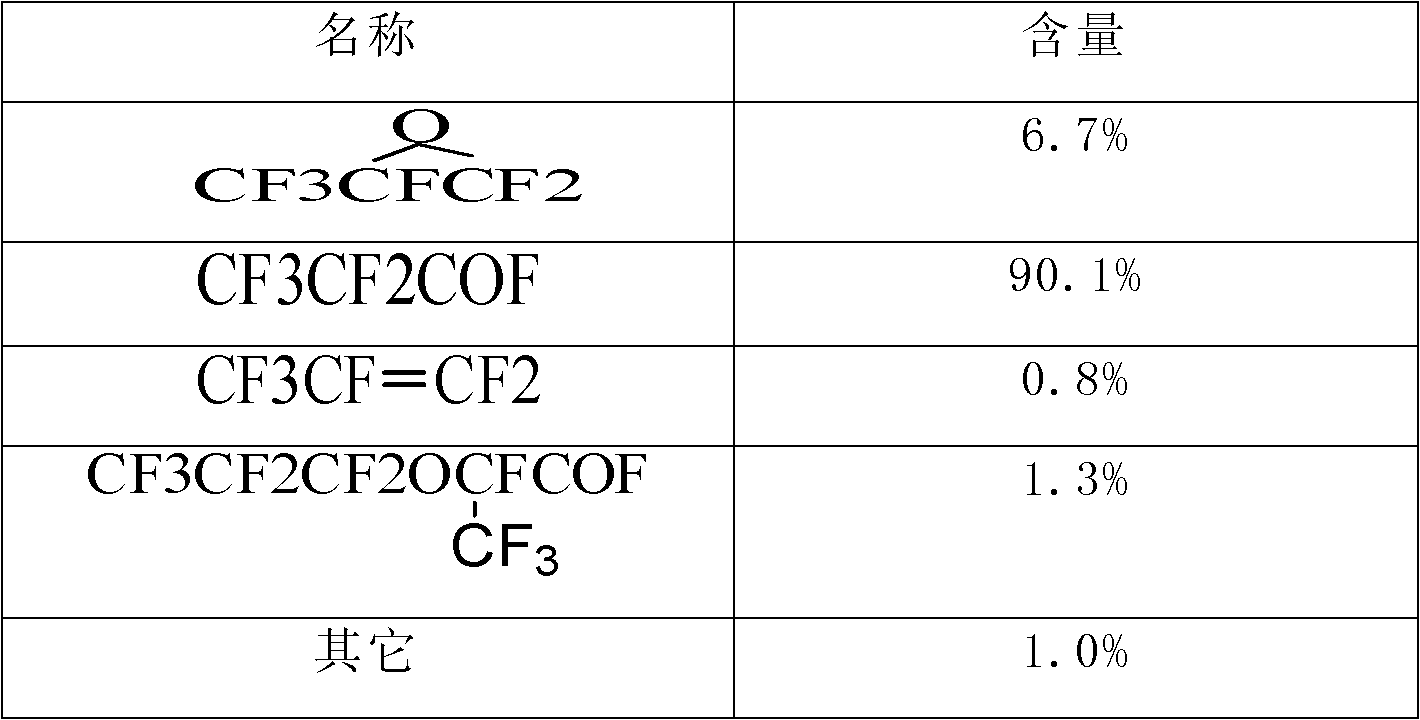

Method for synthesis of pentafluoropropionyl fluoride

InactiveCN103145544AImprove corrosion resistanceHigh yieldCarboxylic acid halides preparationArylVinyl ether

The invention discloses a method for synthesis of pentafluoropropionyl fluoride by using hexafluoropropylene oxide as a raw materisl. Under the effect of a catalyst, hexafluoropropylene oxide is subjected to isomerization reaction to synthesize pentafluoropropionyl fluoride. The catalyst comprises a main catalyst and a co-catalyst, wherein the main catalyst is organic amine compounds, five-or six-membered nitrogen-containing heterocycles or six-membered fused ring aromatic compounds; the co-catalyst is an alkali metal fluoride; and the quality ratio of the main catalyst to the co-catalyst is 100:1 to 5:1. The method provided by the invention has the advantages of mild preparation process, simple operations and high yield of synthesized pentafluoropropionyl fluoride. The prepared pentafluoropropionyl fluoride is suitable for preparing fluorine alkyl group-containing vinyl ethers and perfluoro-propionyl peroxides.

Owner:SINOCHEM LANTIAN +1

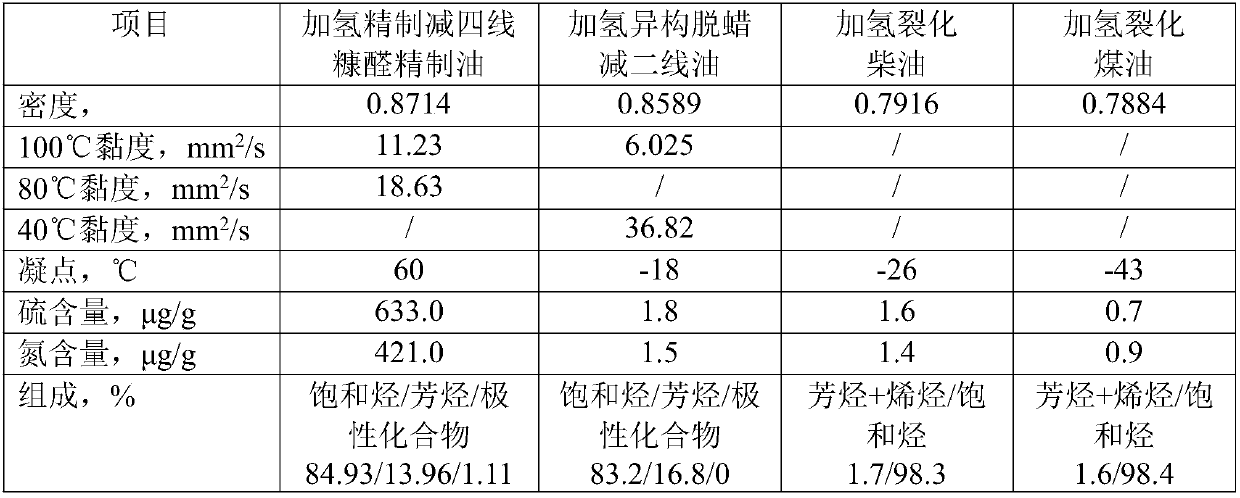

Regeneration method for isodewaxing catalyst

ActiveCN107866285AIncrease reaction pressureMolecular sieve catalystsCatalyst regeneration/reactivationDispersityNitrogen gas

The invention relates to a regeneration method for an isodewaxing catalyst. The isodewaxing catalyst is a precious metal / molecular sieve catalyst. The regeneration method is characterized by comprising the following steps: placing a deactivated catalyst into a reactor; and successively subjecting the deactivated catalyst to washing with cleaning oil, purging with inert gas, hydroconversion and hydrogenolysis, oxygen oxidation and hydrogen reduction so as to restore the activity of the catalyst. Different from conventional out-of-reactor regeneration methods, the method provided by the invention removes toxic matters and impurities on the surface and in the pore channels of the catalyst in the reactor through physical processes like on-line solvent cleaning and purging with inert gas such as nitrogen and chemical processeslike hydroconversion, hydrogenolysis and low-temperature oxidation without dismounting of the catalyst, so the method avoids dismounting and filling of catalyst duringout-of-reactor regeneration, degradation of noble metals due to high-temperature oxidation during out-of-reactor regeneration and deposition of sulfate converted from sulfur species on the surface ofthe catalyst during high-temperature oxidation of the sulfur species, and can effectively extend the service life of the catalyst.

Owner:PETROCHINA CO LTD

A growth method of silicon germanium material

InactiveCN101106079ASimple structureLow costSemiconductor/solid-state device manufacturingFrom chemically reactive gasesGas phaseWorking pressure

The invention discloses a production method of silicon and germanium materials. The equipment used in the invention is a device for growing SiGe material with SiH4 as the gas source RPCVD, and replacing silicon hydride with SiH2Cl2 as the gas source so as to grow silicon and germanium extended material with the pressure-reduction chemical gas-phase sedimentation method. Gases used in the growth include H2, N2, SiH2Cl2, GeH4, PH3, and B2H6, growth temperature 700-900 DEG C, and working pressure 60-100Torr. Since the exhausted gas generated in the production process of the invention does not contain silicon hydride, the gas can be treated in water with the hydrolytic method directly. Therefore, structure of the exhausted gas processor of production equipment can be extremely simple, and cost of exhaust gas treatment can be low relatively.

Owner:HEBEI POSHING ELECTRONICS TECH

Method for producing 2-butenoic acid

ActiveCN101979371AWell mixedIncrease reaction pressureOrganic compound preparationChemical/physical/physico-chemical nozzle-type rreactors2 Butenoic AcidsOxygen

The invention provides a method for producing 2-butenoic acid, which comprises the following steps: preparing mixed feed liquid from 2-butenoic aldehyde, normal hexane and water in a weight ratio of 1:1:0.05-0.08; mounting an ejector pump on an oxidation reaction kettle for spraying the mixed feed liquid into the oxidation reaction kettle; introducing oxygen into the oxidation reaction kettle to perform a reaction under a condition that the reaction pressure in the oxidation reaction kettle is 0.1 to 0.6MPa and a condition that the temperature is 25 to 35 DEG C to obtain oxidation reaction solution; distilling the oxidation reaction, distilling the remaining 2-butenoic aldehyde under a reduced pressure, recovering the 2-butenoic aldehyde, distilling the remaining normal hexane at normal pressure and obtaining filtrate; and cooling the filtrate to -5 DEG C to 5 DEG C, precipitating, crystallizing and filtering and drying the crystals to obtain the 2-butenoic acid product. The production method has the advantages that: the reaction speed is high; the product yield is high; the energy consumption is small; and the quality of the product obtained is high.

Owner:HENAN ZAITI BIO TECH

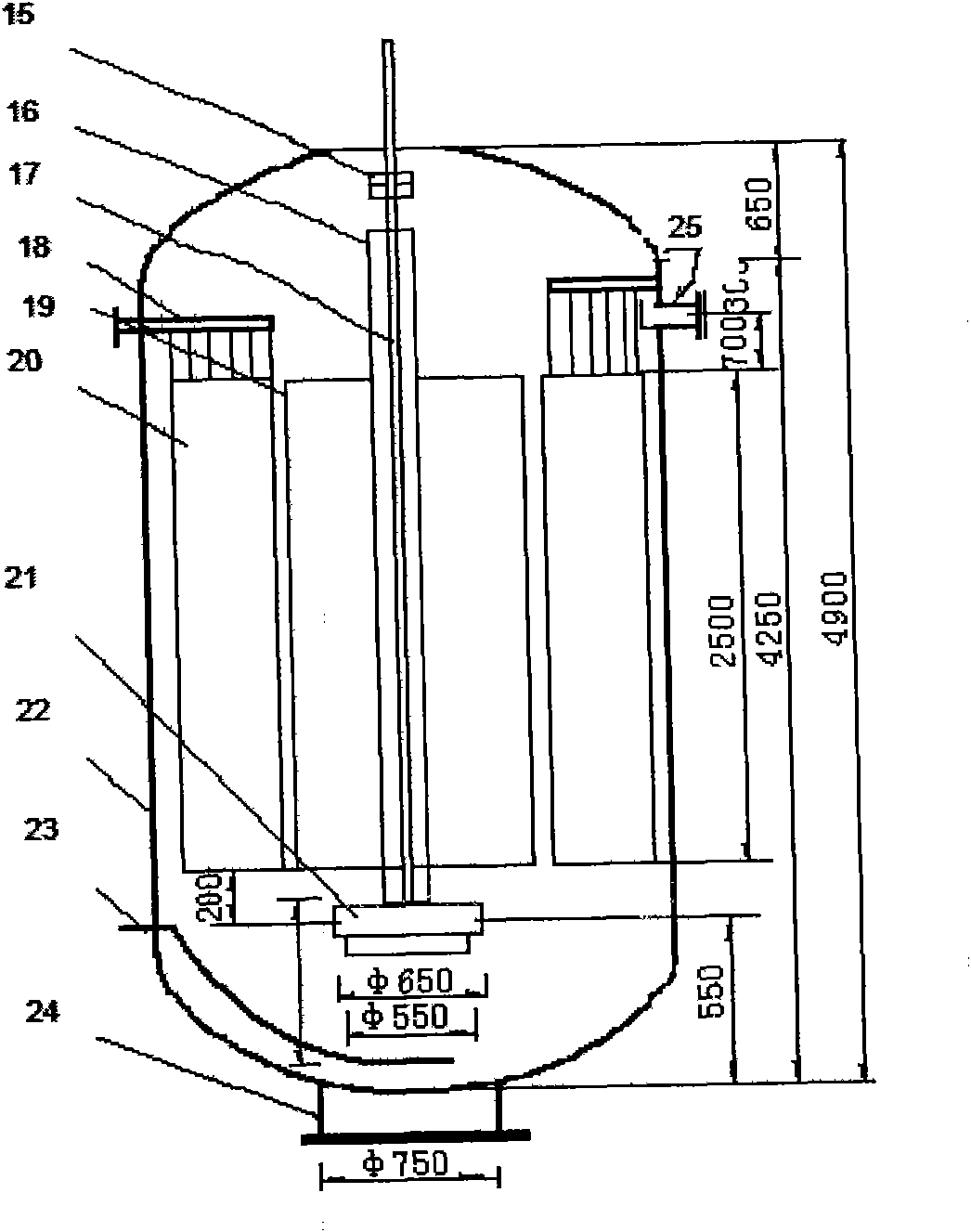

Method for preparing concentration liquid of ammonium nitrate

InactiveCN1907856AHigh final ammonium nitrate concentrationSave on investment costsAmmonium nitratesEvaporationHigh concentrationReaction rate

This invention discloses a preparation method for concentrated ammonium nitrate solution, which is characterized by (1) enhancing atomization at the nitric acid inlet by tubular reactor and increasing reaction rate and efficiency, (2) controlling reactor pressure higher than saturated vapor pressure according to different water conternt in nitric acid, therefore producing no secondary steam, avoiding drop formation from flash separation after reaction, and reducing investment cost markedly, and (3) totally taking advantage of reaction heat to prepare 96-99.7% ammonium nitrate according different requirements under different reaction temperature and different cycle temperature differences of ammonium nitrate and different vacuum degree, wherein the reaction heat is from vacuum-flash ammonium nitrate solution heated by 180-185DEG C ammonium nitrate with lower concentration. The invention is specifically applicable for high concentration nitric acid as raw material and preparation of high density ammonium nitrate.

Owner:太原海力丰科技发展有限公司

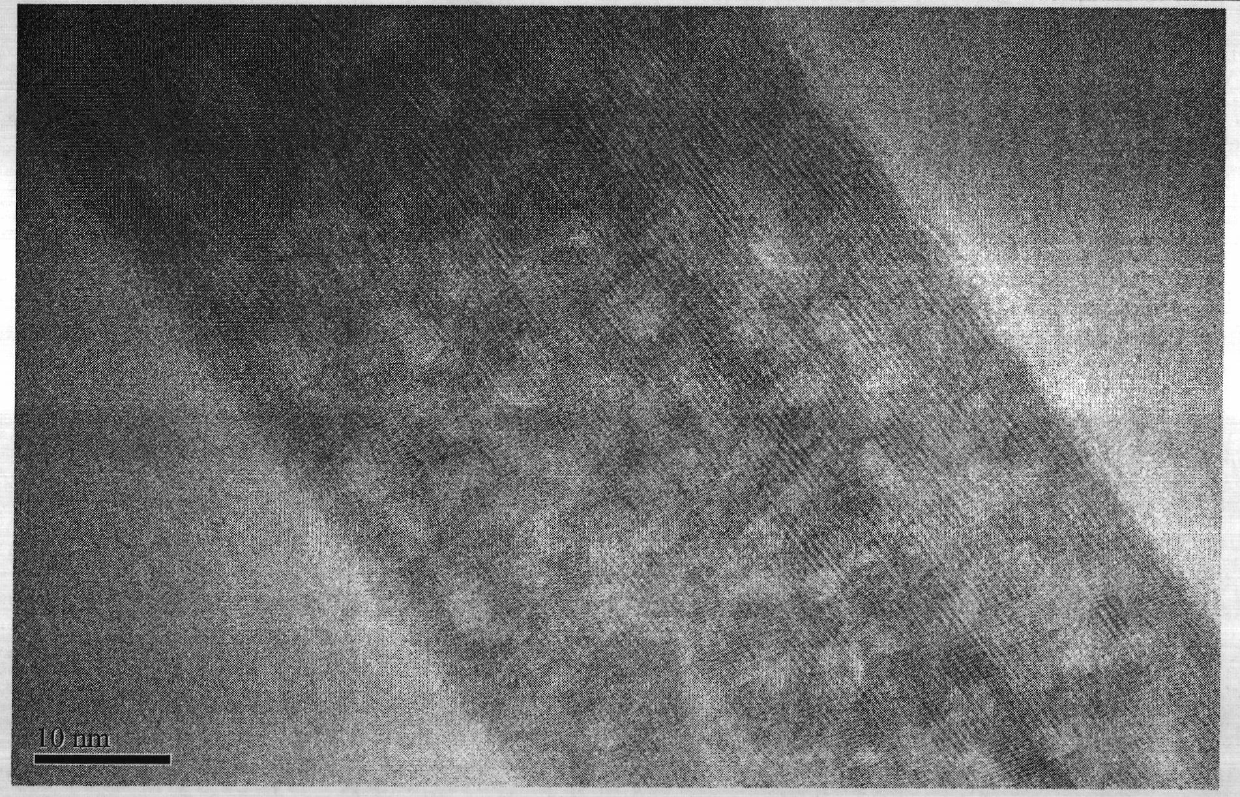

Process for preparing titanium dioxide mesoporous nano-belt material by solvothermal method

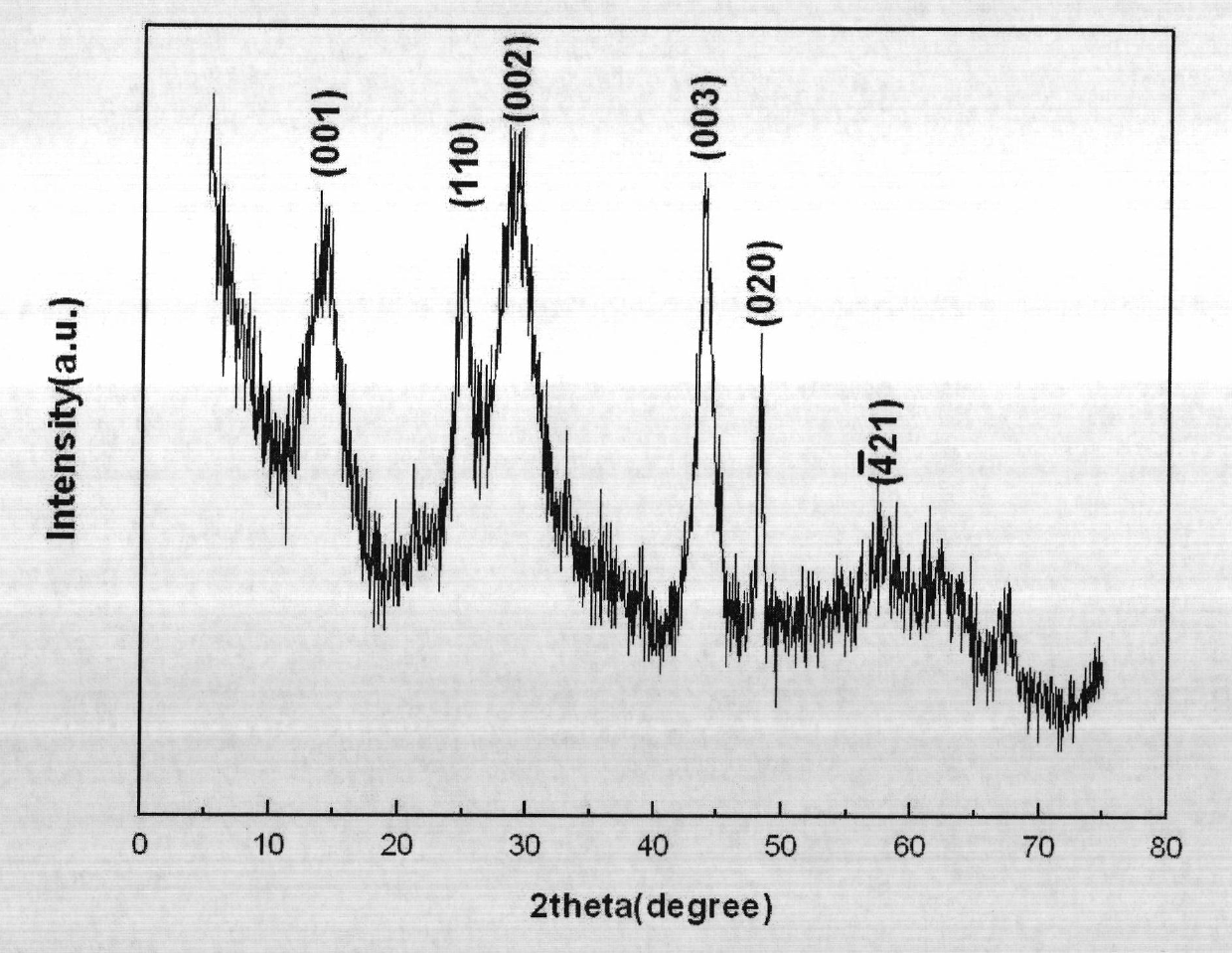

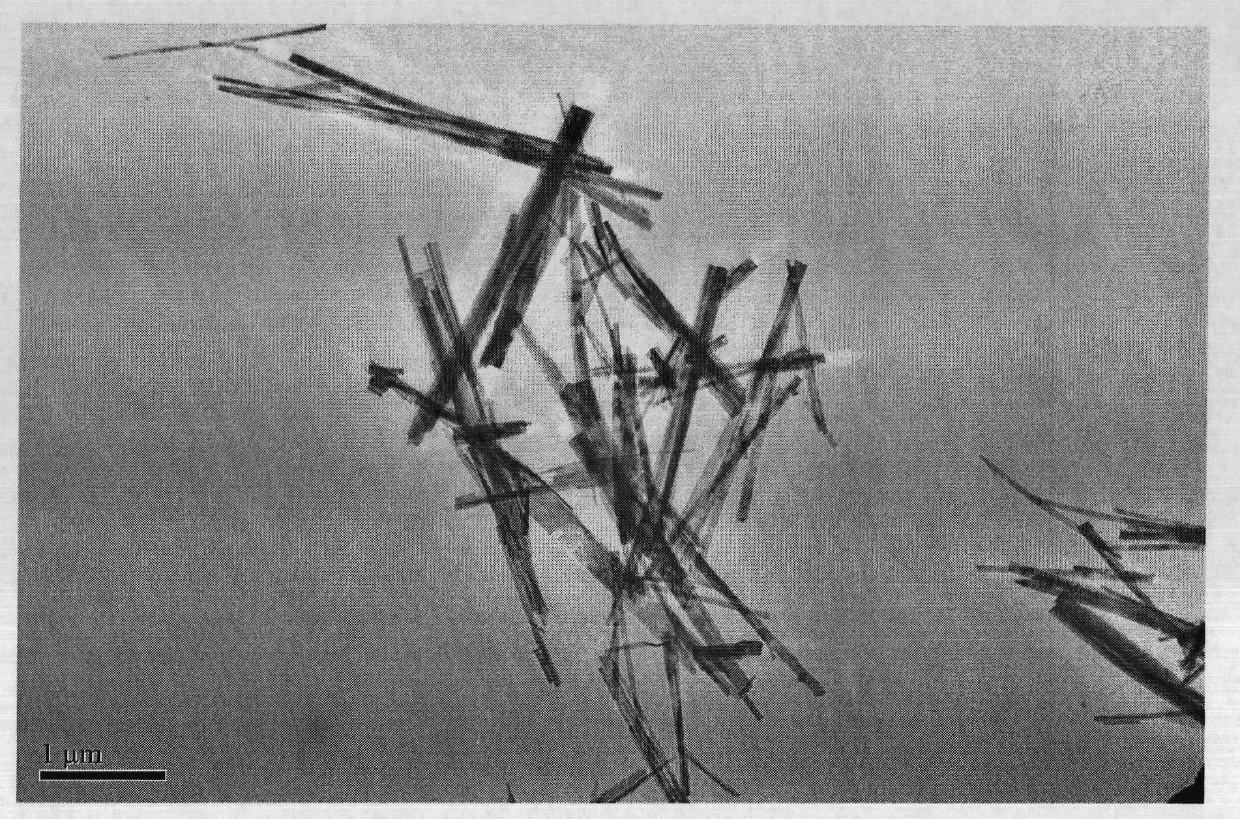

InactiveCN102381727AReduce the temperatureReduce energy consumptionNanotechnologyTitanium dioxidePhotocatalytic degradationIon exchange

The invention provides a process for preparing a titanium dioxide mesoporous nano-belt material by a solvothermal method. The process is characterized in that safe, nontoxic and cheap industrial titanium dioxide P25, a strong caustic soda aqueous solution and absolute ethyl alcohol are taken as raw materials, and then crystal structure dissociation and recombination are carried out in a concentrated alkaline environment by virtue of the P25 so as to finally obtain the titanium dioxide nano-belt. In the process, by adopting the low-boiling absolute ethyl alcohol, the needed reaction temperature is lowered, the reaction pressure is increased, the reaction time is effectively shortened and the energy consumption is reduced; and a mesopore is formed by an ion exchange technique. For the titanium dioxide mesoporous nano-belt material obtained by the process, the width is dozens of nanometers to hundreds of nanometers, the length is a few micrometers, and the mesoporous diameter is 4.6-4.8 nanometers; and the titanium dioxide mesoporous nano-belt material can be applied to fields such as solar batteries, hydrogen production based on water splitting, semiconductor components, photocatalytic degradation of organic pollutants, optical coatings and the like.

Owner:OCEAN UNIV OF CHINA

Preparation of hydrodesulfurization catalyst for coking benzene and using method of the catalyst

ActiveCN104258900AGood catalytic hydrogenation performanceReduce the temperatureMolecular sieve catalystsHydrocarbonsHydrodesulfurizationReaction temperature

A hydrodesulfurization method of coking benzene is provided. A preparation process of a hydrodesulfurization catalyst used in a hydrodesulfurization reaction includes: respectively dipping an aluminium oxide-titanium dioxide mixed power carrier into solutions containing active metal elements comprising molybdenum, nickel, cobalt and tungsten, with the solutions containing citric acid; dipping a NaZSM-5 molecular sieve into a solution containing copper and / or zinc; drying; calcinating; mixing the dipped aluminium oxide-titanium dioxide mixed power carrier and the dipped NaZSM-5 molecular sieve; processing the coking benzene by a rectifying tower before hydrodesulfurization; and performing pre-hydrogenation, main hydrogenation and removal of inorganic sulfur to finish sulfur removal. The NaZSM-5 molecular sieve loaded with an active component has an effect of selective adsorption for thiophene. The aluminium oxide-titanium dioxide mixed power carrier loaded with the active metals has good catalytic hydrogenation effects for the thiophene. By cooperation of the NaZSM-5 molecular sieve loaded with the active component and the aluminium oxide-titanium dioxide mixed power carrier loaded with the active metals, good removing effects can be achieved even at a low reaction temperature. The citric acid promotes formation of an active phase, improves hydrogenation activity of the catalyst and prolongs maintaining time of the activity of the catalyst.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Protective film and method for preparing same

InactiveUS20030207139A1Improve adaptabilityIncrease reaction pressurePhotosensitive materialsSynthetic resin layered productsTectorial membraneResist

A high-quality protective film for a dry film resist is provided. A film of a polyethylene is used as the protective film, the polyethylene being prepared by pressurizing ethylene with use of an ultra-high pressure compressor and then polymerizing the ethylene at a reaction temperature of 190° to 300° C. and a reaction pressure of not lower than 167 MPa in the presence of a radical polymerization initiator, or by pressuring ethylene with use of an ultra-high pressure compressor and then polymerizing the ethylene at a reaction temperature of 190° to 300° C. in the presence of a radical polymerization initiator while allowing a radical polymerization inhibitor to be present in the reaction system.

Owner:JAPAN POLYOLEFINS CO LTD

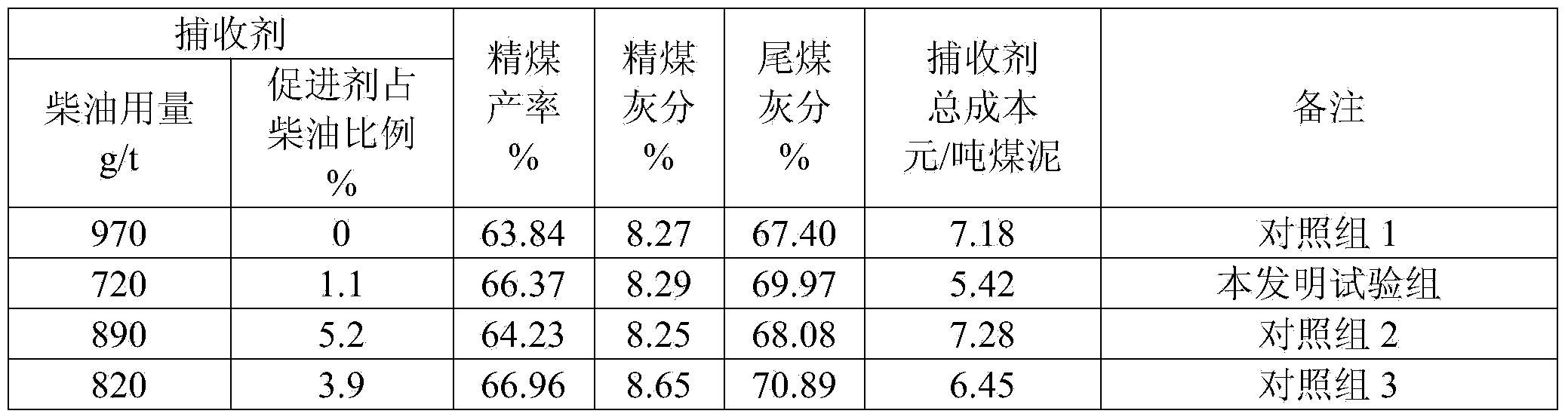

Preparation method of coal slime flotation accelerant and coal slime flotation method

ActiveCN104028385AImprove conversion rateGood harvesting effectFlotationReaction temperatureAlkylphenol

The invention discloses a preparation method of coal slime flotation accelerant and a coal slime flotation method. The accelerant uses alkylphenol polyoxyethylene ether and sulfamic acid with the polymerization degree n=4-12 as raw materials, the mole ratio of the alkylphenol polyoxyethylene ether to the sulfamic acid is 1:0.5-1:0.6, reaction temperature is controlled at 70-90 DEG C, stirring is performed constantly during synchronization, reaction time is 30-40 minutes, and products are cooled to normal temperature after reaction to obtain the accelerant. When the accelerant is used for coal slime flotation, the amount of the accelerant accounts for 0.5-2wt% of that of collecting agent. Compared with methods independently using the hydrocarbon oil collecting agent, the coal slime flotation method using the accelerant has the advantages that under the situation of equivalent cleans ash, clean coal yield can be increased by 2-3wt%, oil saving rate can reach 20-30wt%, use amount of the hydrocarbon oil collecting agent is reduced favorably, separation index can be optimized, and overall economical benefits can be increased.

Owner:SHANDONG UNIV OF SCI & TECH

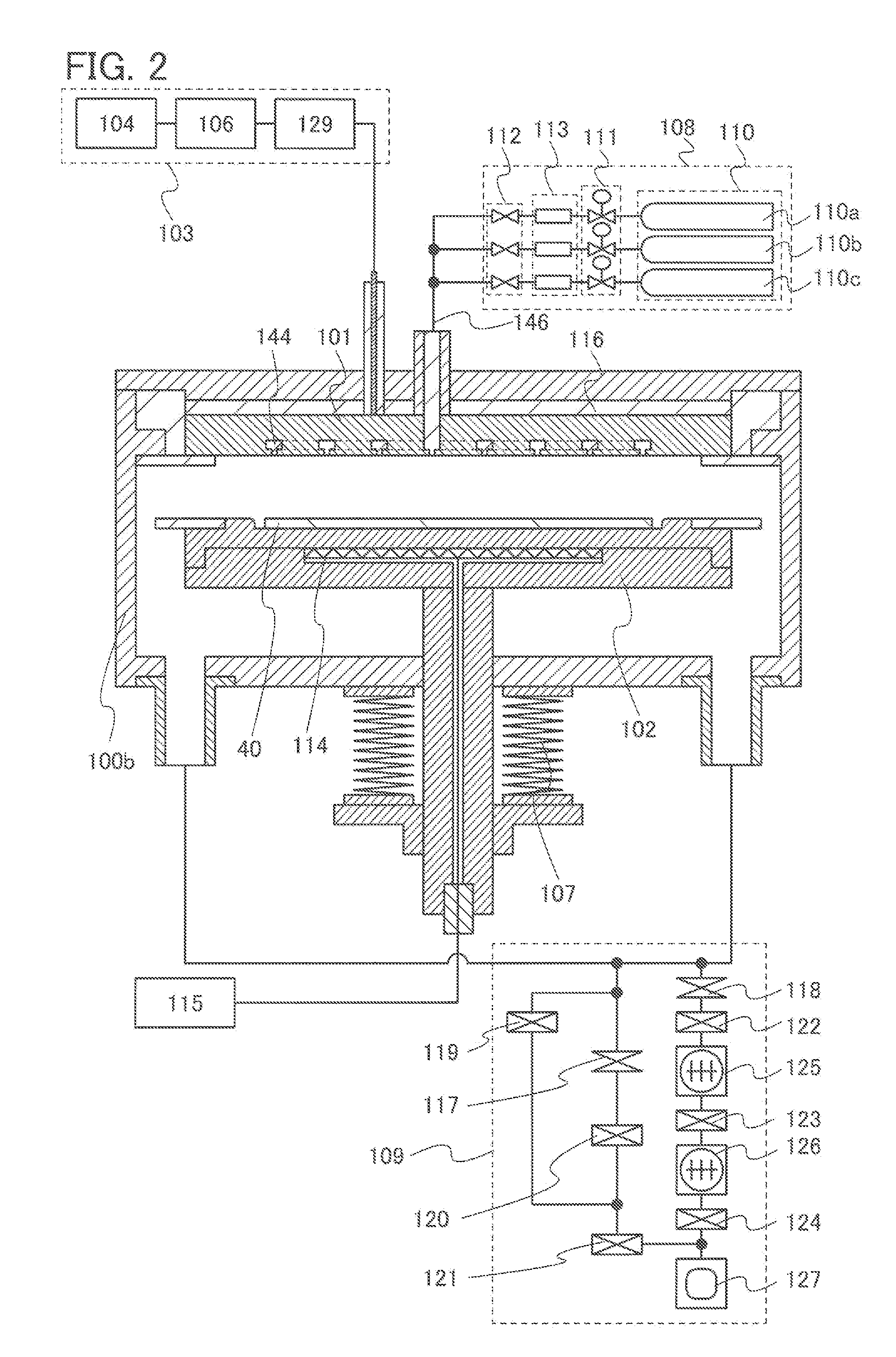

Method of manufacturing photoelectric conversion device

InactiveUS20110053311A1Reduce distanceIncrease probabilityFinal product manufactureSemiconductor/solid-state device manufacturingHigh frequency powerReactive gas

Provided is a technique for manufacturing a photoelectric conversion element using a dense crystalline semiconductor film without a cavity between crystal grains. A method of manufacturing a photoelectric conversion device having a first electrode, a unit cell, and a second electrode over a substrate includes the steps of: forming a plasma region between a first electrode and a second electrode by supplying high-frequency power of 60 MHz or less to the first electrode under a condition where a pressure of a reactive gas in a chamber of a plasma CVD apparatus is set to from 450 Pa to 13332 Pa, and a distance between the first electrode and the second electrode of the plasma CVD apparatus is set to from 1 mm to 20 mm, preferably, 4 mm to 16 mm; forming deposition precursors including a crystalline semiconductor in a gas phase including the plasma region; forming a crystal nucleus having a grain size of from 5 nm to 15 nm by depositing the deposition precursors; and forming a semiconductor film having a first conductivity type, a semiconductor film effective in photoelectric conversion, or a semiconductor film having a first conductivity type in the unit cell, by growing a crystal from the crystal nucleus.

Owner:SEMICON ENERGY LAB CO LTD

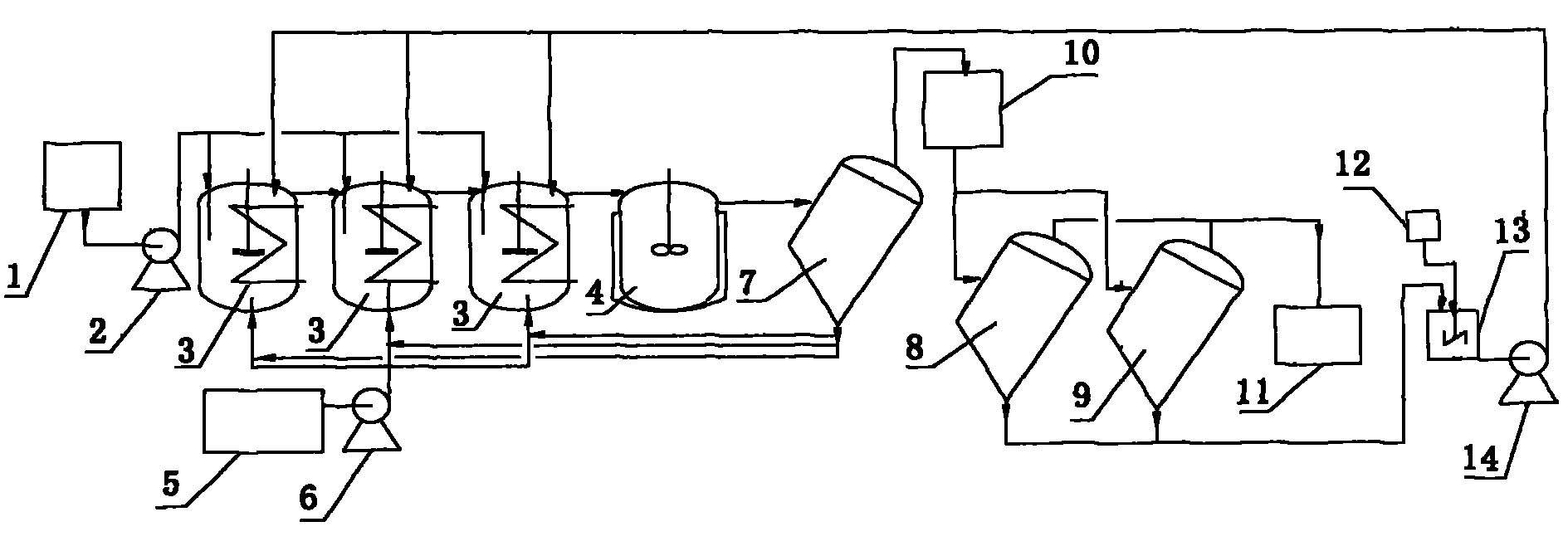

High-efficiency hydrogenation device and dinitrotoluene hydrogenating method

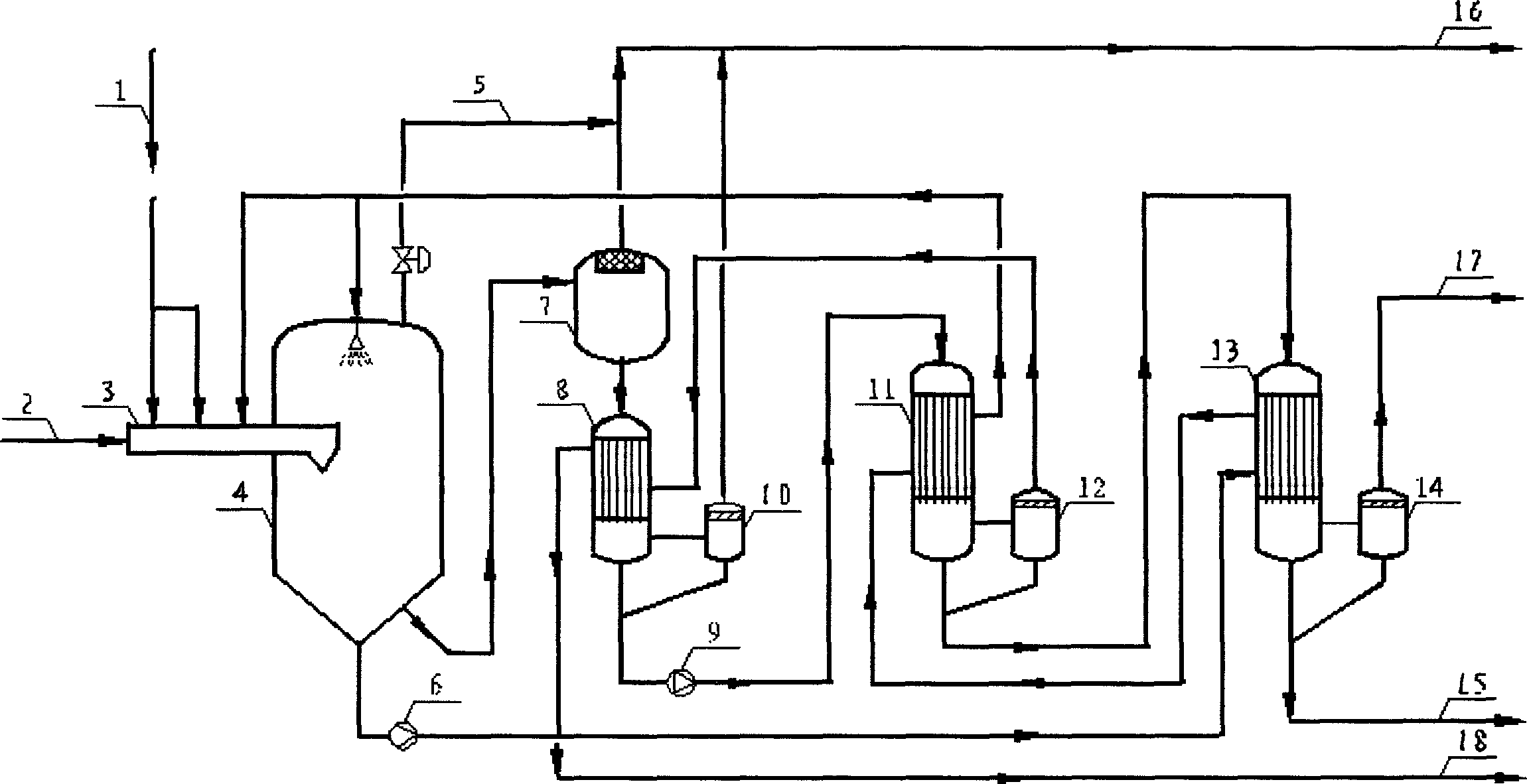

ActiveCN102151525AIncreased reaction driveStirring speed adjustmentOrganic compound preparationAmino compound preparationDiaphragm pumpHydrogenation reaction

The invention relates to a high-efficiency hydrogenation device and a dinitrotoluene hydrogenating method. Three hydrogenation reactors are connected in parallel and are all connected with a hydrogenation aging machine in series; the bottom part of an inclined grid plate separator (7) is connected with the bottom parts of the three hydrogenation reactors in parallel, and the top part of the inclined grid plate separator (7) is connected with a steam-liquid separator tank which is connected with inclined grid plate separators (8) and (9) in parallel; the top parts of the inclined grid plate separators are connected with a tolylenediamine finished product tank in parallel, and the bottom parts of the inclined grid plate separators are connected with a catalyst recovery tank in parallel; andthe bottom part of the catalyst recovery tank is connected with the top parts of the three hydrogenation reactors in parallel through a diaphragm pump. In the invention, the size of the hydrogenationreactors are reduced considerably, the power of a stirring motor is lowered, and the energy conservation and consumption reduction of the device are realized.

Owner:甘肃银光聚银化工有限公司 +1

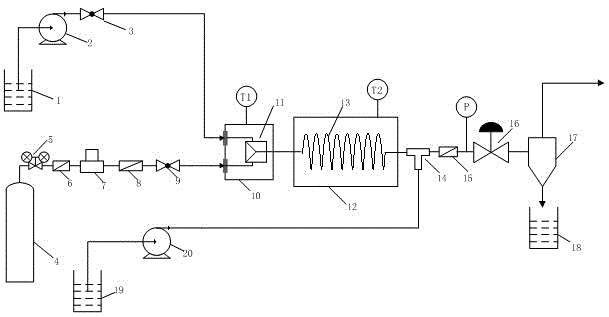

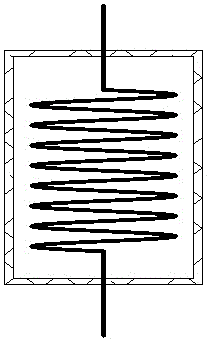

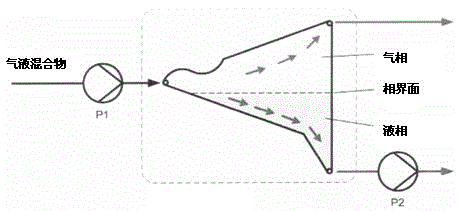

Cosynthesis device and method of cyclohexanol, cyclohexanone and adipic acid in microchannels

InactiveCN102746111AGood mass and heat transfer performanceEliminate potential safety hazardsPreparation by oxidation reactionsOrganic compound preparationCyclohexanoneGas phase

The invention discloses a cosynthesis device and method of hexanol, cyclohexanone and adipic acid in microchannels. The method comprises the steps of mixing and preheating cyclohexane and oxygen or air by a gas-liquid micro mixer, entering a micro reaction tube in an air thermostat, and reacting, wherein the cyclohexane flow is controlled by a laminar flow pump, the oxygen or air flow is controlled by a mass flow controller, the cyclohexane flow and the oxygen or air flow are kept at a certain ratio, and the reaction pressure is controlled by a back pressure valve; and separating the reaction product by a gas-liquid micro separator, collecting the liquid-phase product by a storage tank, and discharging the gas phase. According to the invention, continuous production of cyclohexanol, cyclohexanone and adipic acid is realized; because the gas-liquid micro mixer, the micro reaction tube, and the gas-liquid micro separator are adopted, the specific surface area of the fluid passing through the channels is large, heat transfer effect of mixing, reaction, separation and other processes is good, pure oxygen and air can be used as an oxidant in the reaction, operation can be carried out at higher reaction pressure and reaction temperature, the reaction safety is greatly improved, and the selectivity and conversion rate are greatly improved.

Owner:ZHEJIANG UNIV

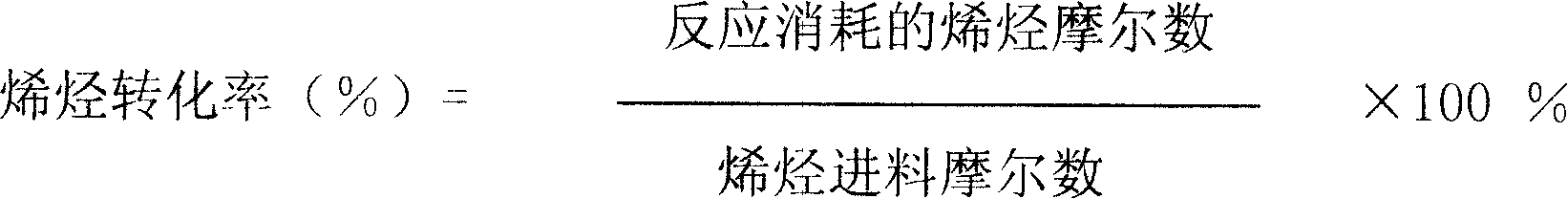

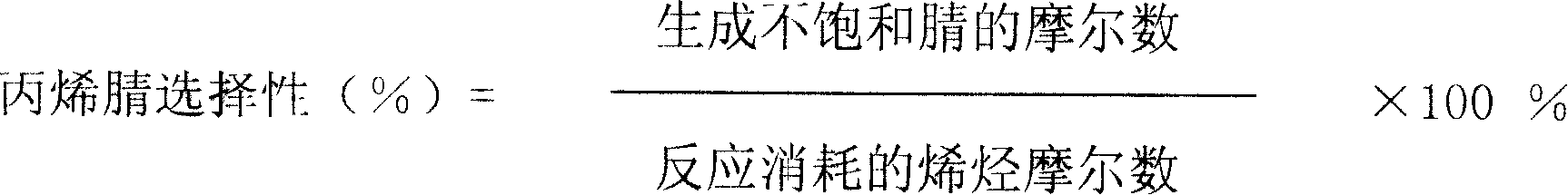

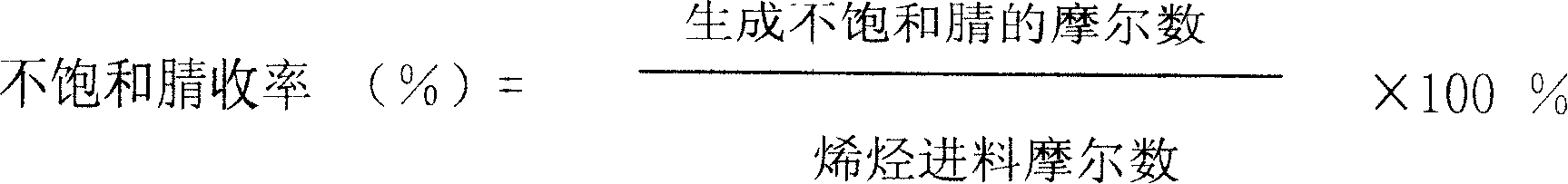

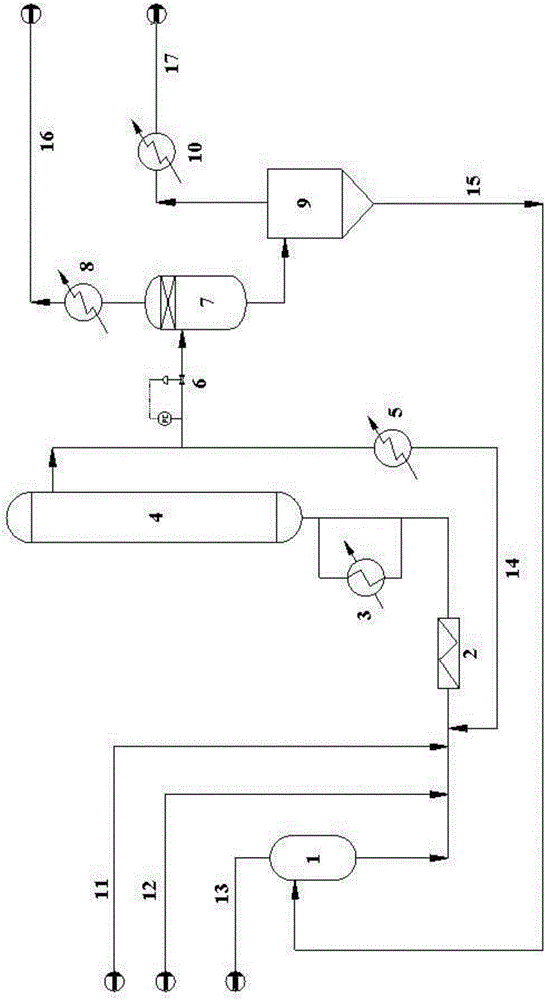

Catalyst for olefin ammoxidation producing unsaturated nitriles

ActiveCN101168129AIncrease reaction pressureExtended service lifeCatalyst carriersCarboxylic acid nitrile preparationReaction temperatureCerium

The invention is a catalyst used in the producing of unsaturated nitriles by the ammonoxidation of olefin, in particular to a catalyst adaptable for the producing of acrylonitrile and methacrylonitrile by the ammonoxidation of propylene and butylenes. A general formula of the active component of the catalyst is a complex of catalytic oxidation of BiaFebNicMgdLaeC1gAlhAiBjCkMo12Ox, wherein the A isone element or a compound of more than two elements of lithium, potassium, rubidium and caesium, the B is one element or a compound of more than two elements of cerium, gadolinium and samarium, and the C is one element or a compound of more than two elements of zinc, manganese, cobalt, calcium, copper, wolfram and phosphorus. The catalyst is capable of producing unsaturated nitriles of which theyield rate reaches to 84% or higher under the condition of high catalyst load, high reaction pressure, low reaction temperature, low ratio of air and olefin and low ratio of ammonia and olefin, and with the adoption of the catalyst, the catalyst is capable of long-term operation under the condition of low reaction temperature, and the catalyst has long service life. Further, reaction products havea small amount of impurity substances, and the catalyst is environment friendly.

Owner:PETROCHINA CO LTD +1

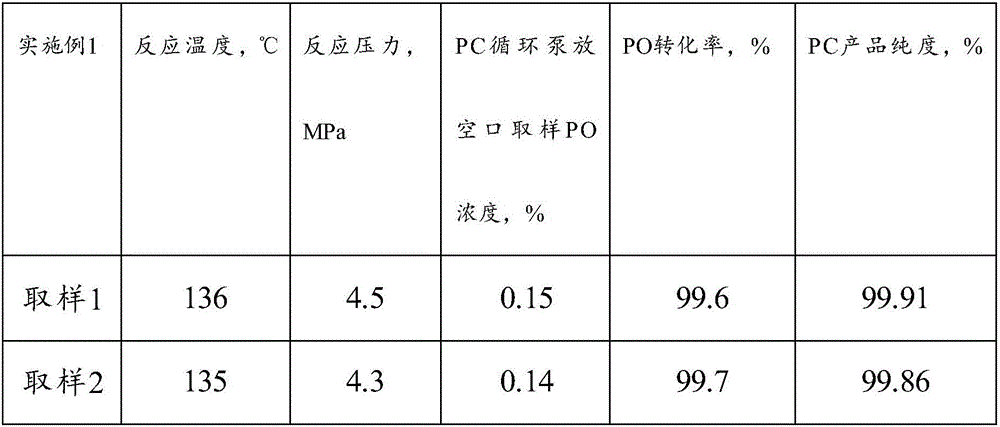

System and process for preparing cyclic carbonate by using composite ionic liquid catalyst

PendingCN106588863AHigh purityImprove conversion rateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCarbonate esterStraight tube

The invention provides a system for preparing cyclic carbonate by using composite ionic liquid catalyst; the system comprises a pipeline mixer, a straight tube reactor connected with an outlet of the pipe mixer, a flashing device connected with an outlet of the straight tube reactor, and an evaporative separator connected with a liquid outlet of the flashing device; a liquid outlet of the evaporative separator is connected with an inlet of the mixer. Refining and combining are carried out creatively in the invention, and the pipeline mixer and the straight tube reactor are integrated; in terms of mixing, the pipeline mixer is used to carry out mixing, mass transfer effect of propylene oxide and carbon dioxide later in the reaction process of the straight tube reactor is improved, and conversion rate of epoxides is increased; in addition, the purity and conversion rate of cyclic carbonate can be increased, the process is stable, is applicable to industrial large-scale production, and is a reusable efficient green process.

Owner:DONGYING HI TECH SPRING CHEM IND

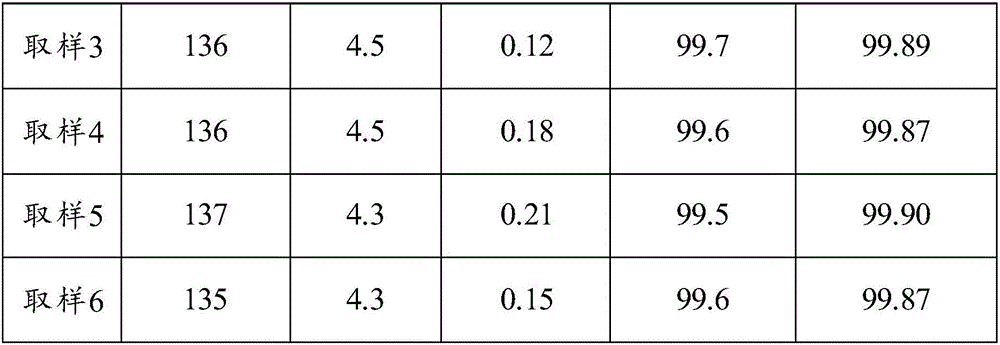

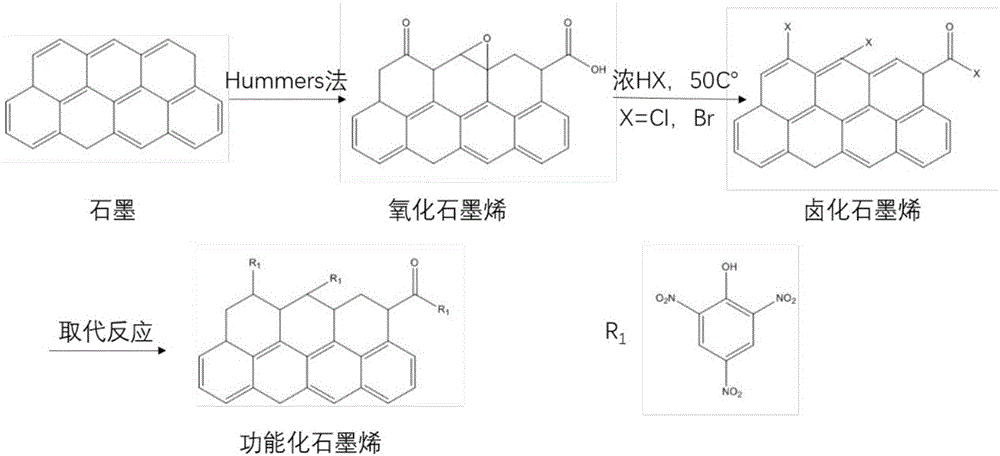

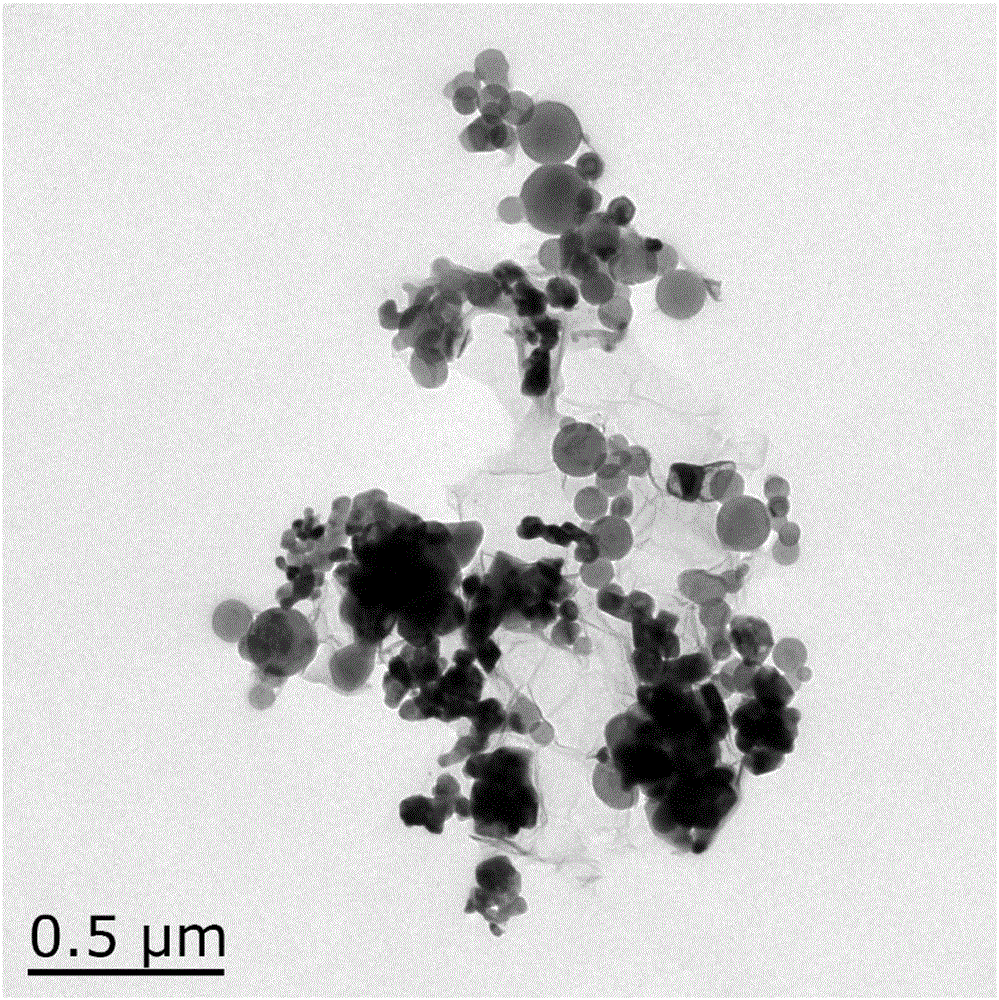

Nano energy-containing material prepared by functional graphene and method thereof

The invention provides a nano energy-containing material prepared by functional graphene and a method thereof. The method is characterized in that a halogenation agent and graphene oxide are subjected to electrophilic addition to generate halogenated graphite, then an energy-containing compound is grafted to graphene through a substitution reaction, the functional energy-containing graphene can be formed, then nano aluminum and nano metal oxide are arranged on the energy-containing graphene through a self assembly method, so that high-performance ternary energy-containing material can be prepared. The energy-containing material increases the ordering performance of a mixture in the nano thermite component and can reduce the agglomeration of the nano particles at certain degree, the energy-containing compound grafted on the graphene contains lots of energy-containing groups such as nitro-group, and the energy-containing material has important promotion effect for increasing the heat released by the nano thermite and increasing the reactive properties.

Owner:NANJING UNIV OF SCI & TECH

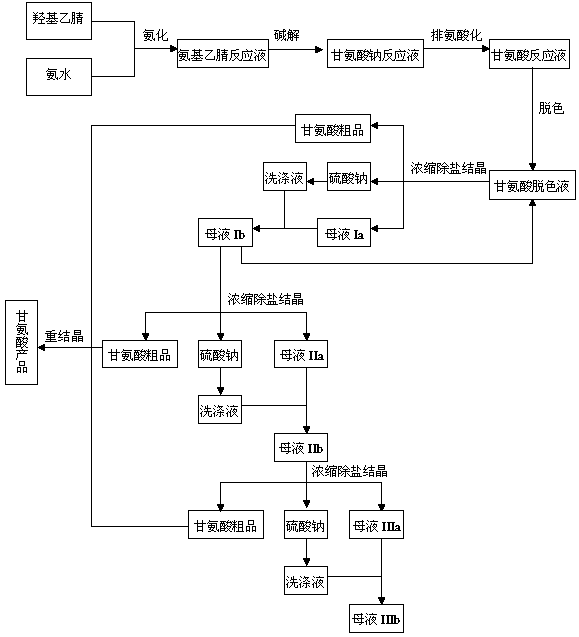

Preparation process of glycine

InactiveCN102432478BReduce pyrolysis polymerizationHigh yieldOrganic compound preparationAmino-carboxyl compound preparationReaction temperatureAlkaline hydrolysis

The invention discloses a preparation process of glycine, which comprises amination, alkaline hydrolysis, ammonia discharge acidification, decolorizing, concentration, desalting, crystallization and recrystallization steps, wherein in the amination step, hydroxyacetonitrile and ammonia water are mixed in a tubular reactor, and a reaction is undergone at the temperature of 50-100 DEG C under the pressure of 0.5-2.0 MPa for 4-10 minutes; and in the alkaline hydrolysis step, 30-50 percent of sodium hydroxide solution is added into an alkaline hydrolysis reactor in advance, an amination liquid is collected from an amination liquid outlet, a reaction is undergone at the temperature of 60-90 DEG C under the pressure of between -0.01 MPa and -0.09 MPa, and ammonia in a system is recovered simultaneously. In the process, the tubular reactor is taken as an amination reactor, so that the reaction temperature and pressure are raised, the reaction time is shortened, and raw material decomposition, pyrolytic polymerization of aminoacetonitrile and the generation of byproducts are reduced; alkaline hydrolysis is performed during the collection of the amination liquid, the concentration of an alkaline liquor and the alkaline hydrolysis temperature are raised simultaneously, and ammonia in the system is recovered under reduced pressure, so that the alkaline hydrolysis reaction is more complete, the speed is higher, and the generation of colored impurities is reduced; and a mother liquor circular utilizing mode is established, so that the treatment amount of waste mother liquor is reduced, the product yield is increased, and the production cost is reduced.

Owner:CHONGQING UNISPLENDOUR CHEM

Biphasic process for epoxidation of olefinic compound using chromate or dichromate catalyst

The present invention relates to a biphasic process for the epoxidation of an organic compound by organic compound by organic hydroperoxide. More particularly, the present invention relates to a biphasic process for the epoxidation of an organic compound by organic hydroperoxide to the corresponding epoxide, using chromate or dichromate anions as the catalyst in aqueous medium.

Owner:CHOUDHARY VASANT RAMCHANDRA +1

Process for producing lower olefins under negative pressure

ActiveUS20090105512A1High yieldHigh selectivityCatalytic crackingHydrocarbonsReaction temperatureAlkene

The present invention provides a process for producing lower olefins. The technical problem mainly addressed in the present invention is to overcome the defects presented in the prior art including high reaction pressure, high reaction temperature, low yield and selectivity of lower olefins as the target products, poor stability and short life of catalyst, and limited suitable feedstocks. The present process, which is carried out under the conditions of catalytic cracking olefins and adopts as a feedstock an olefins-enriched mixture containing one or more C4 or higher olefins and optionally an organic oxygenate compound, comprises the steps of: a) letting the feedstock contact with a crystalline aluminosilicate catalyst having a SiO2 / Al2O3 molar ratio of at least 10, to thereby produce a reaction effluent containing lower olefins; and b) separating lower olefins from the reaction effluent; wherein, the reaction pressure is from −0.1 MPa to <0 MPa. The present process, which desirably solves the above technical problem, can be used in industrial production of lower olefins.

Owner:CHINA PETROCHEMICAL CORP +1

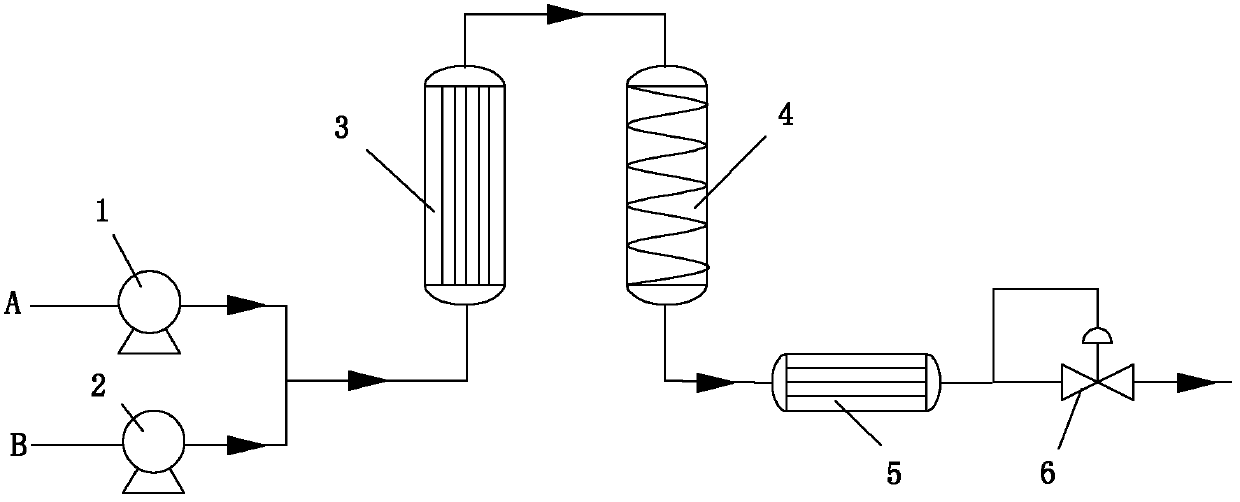

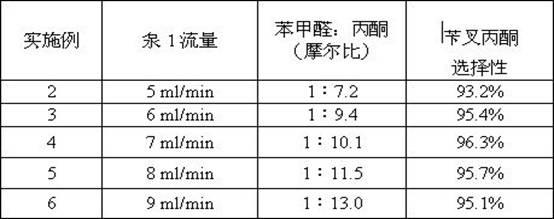

Method for preparing benzalacetone under supercritical condition

ActiveCN102584552AAchieve separationHigh selectivityOrganic compound preparationCarbonyl compound preparationPtru catalystBenzaldehyde

The invention discloses a method for preparing benzalacetone under the supercritical condition. According to the conventional synthetic method, reaction is realized by an autoclave, and is intermittent, low in space time yield of the reaction and high in energy consumption. According to the method, the benzalacetone is prepared by performing the one-step condensation reaction of benzaldehyde and acetone which serve as raw materials under the supercritical condition, wherein the conversion rate of the benzaldehyde is over 99 percent, and the reaction yield of the benzaldehyde is over 92 percent. According to method, other solvents and acid or base catalysts are not needed to be added, the residual acetone can be recycled directly, so the method has the advantages of environment friendliness, no pollution, high selectivity and the like.

Owner:ZHEJIANG NHU CO LTD +1

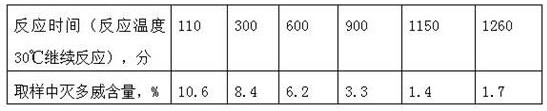

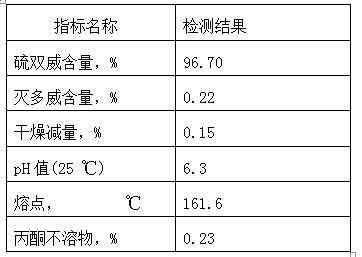

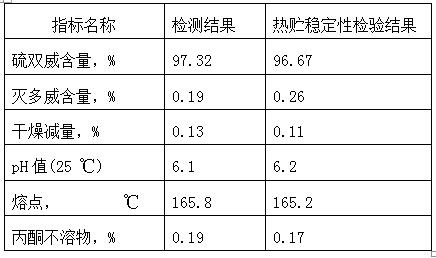

Synthesis method of thiodicarb

ActiveCN112479957AImprove heat storage stabilityImprove conversion rateOrganic chemistryPtru catalystReaction temperature

The invention provides a synthesis method of thiodicarb, and the method comprises the following steps: synthesizing a ligand, and synthesizing thiodicarb. According to the invention, trialkyl tertiaryamine is used as a catalyst for synthesis of thiodicarb, and during synthesis of thiodicarb, the reaction pressure is increased, and the industrial synthesis reaction time is shortened to 5 hours; inthe thiodicarb synthesis process, the temperature is controlled in three stages, the reaction temperature is controlled at 10-15 DEG C for 1-1.5 hours, the reaction temperature is controlled at 20-25DEG C for 1-1.5 hours, the reaction temperature is controlled at 30-35 DEG C for 1-2 hours, and gradient heating is adopted, so the defect of multiple side reactions caused by always reacting at a relatively high temperature is avoided.

Owner:潍坊海邦化工有限公司

Melt/solid state polycondensation preparation method for polylactic acid

The invention relates to a melt / solid state polycondensation preparation method for polylactic acid, which mainly solves the problems of long reaction time, difficult continuous production or high cost in the prior art. The method comprises the following steps of: 1) performing a dehydration oligomerization reaction of lactic acid at the temperature of between 100 and 160 DEG C under the absolute pressure of between 6,000 and 25,000 Pa and under the action of a catalyst A for 0.5 to 5 hours first, and continuing the ehydration oligomerization reaction at the temperature of between of 120 and 180 DEG C under the absolute pressure of between 200 and 1,500 Pa and under the action of the catalyst A for 0.5 to 5 hours to generate a product I; 2) performing a melt polycondensation reaction of the product I at the reaction temperature of between 150 and 200 DEG C under the absolute pressure of between 30 and 600 Pa and under the action of a catalyst B for 0.5 to 15 hours to generate a polylactic acid prepolymer and lactide serving as a by-product, and refluxing the lactide to a reaction mixture at the reflux temperature of between 70 and 95 DEG C; 3) pelletizing the polylactic acid prepolymer obtained in the step 2), and crystallizing in an inertia airflow at the temperature of between 50 and 130 DEG C for 0.5 to 10 hours; and 4) performing a solid state polycondensation reaction of the polylactic acid prepolymer processed in the step 3) in the inertia airflow at the temperature of between 120 and 170 DEG C for 5 to 40 hours to obtain the polylactic acid. The technical scheme of the invention better solves the problem, and can be used for the industrial production of the polylactic acid.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com