Method for preparing concentration liquid of ammonium nitrate

A technology of ammonium nitrate solution and ammonium nitrate, applied in the direction of separation method, ammonium nitrate, chemical instruments and methods, etc., can solve the problems of decreased secondary steam utilization efficiency, increased product energy consumption, and reduced operating pressure requirements, etc., to achieve Save investment and operating costs, low nitrogen loss, low nitrogen loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

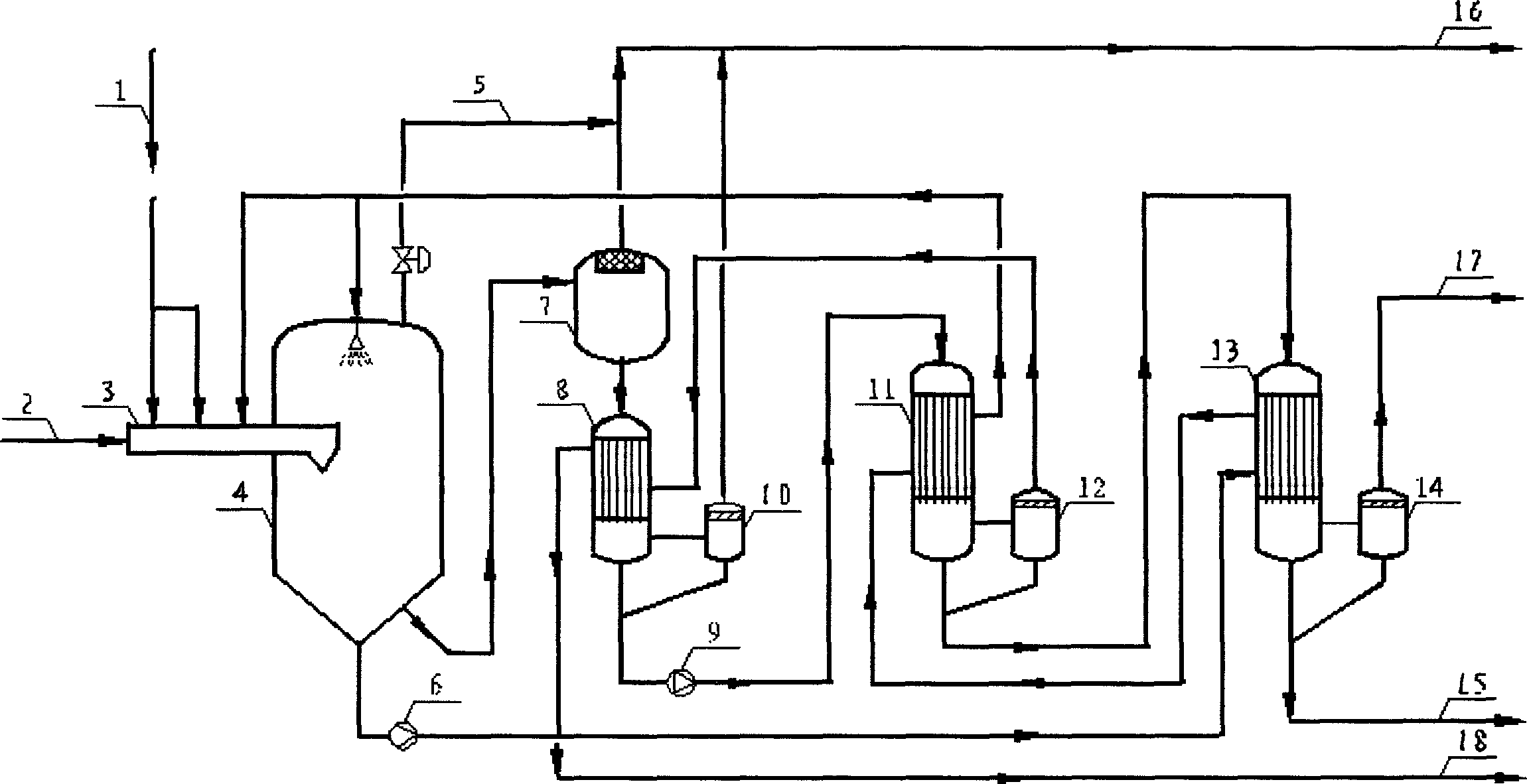

[0024] The nitric acid and ammonia of the present invention enter the tubular reactor 3 from the nitric acid inlet 2 and the ammonia inlet 1 respectively, and carry out a pressure reaction under the control of the pressure controller 5, and the generated ammonium nitrate solution enters the mixer 4 and exchanges from the first-stage evaporation. The circulating ammonium nitrate solution of the heater 11 is mixed to control the temperature, and then the mixed ammonium nitrate solution is flashed by the flash evaporator 7, preheated by the preheater 8 and separated by the separator 10, and then sent out by the hot ammonium nitrate solution pump 6. Then it is concentrated by the first-stage evaporative heat exchanger 11, the second-stage evaporative heat exchanger 13 is concentrated, the first-stage separator 12 is separated, and the second-stage separator 14 is separated. Finally, the concentrated ammonium nitrate solution 15 containing 96%-99.7% is sent down Granulation is carried ...

Embodiment approach 2

[0029]The present invention uses nitric acid with a concentration of 60% and a temperature of 40°C and ammonia with a concentration of 99.6% and a temperature of 20°C as raw materials, reacts at 0.61Mpa(abs) and 185°C, and produces 99.7 through flash evaporation, preheating and two-stage evaporation. % Concentrated ammonium nitrate solution to reach 300,000 t / a high-density product capacity scale. Investment can be saved by 22.65%, operating costs (solution preparation part) reduced by 60% (including: electricity consumption increased by 165%, steam consumption decreased by 95.2%, cooling water consumption decreased by 16.8%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com