Patents

Literature

405results about How to "Reduce vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Infant feeding system

InactiveUS20080179311A1Avoid flowReduce creationElectric heating for furnacesWarming devicesThermal energyThermal energy storage

An apparatus for heating a liquid is described. The apparatus includes a housing. A liquid reservoir is contained within the housing. A fluid circuit conveys liquid from the reservoir to a dispenser. A thermal energy storage unit is contained within the housing and disposed to be in thermal contact with the fluid circuit. The thermal energy storage unit is constructed and arranged to heat liquid as it passes through the fluid circuit. The thermal energy storage unit can include a phase change material or a combination of a phase change material and a high thermal conductivity material.

Owner:BOSE CORP

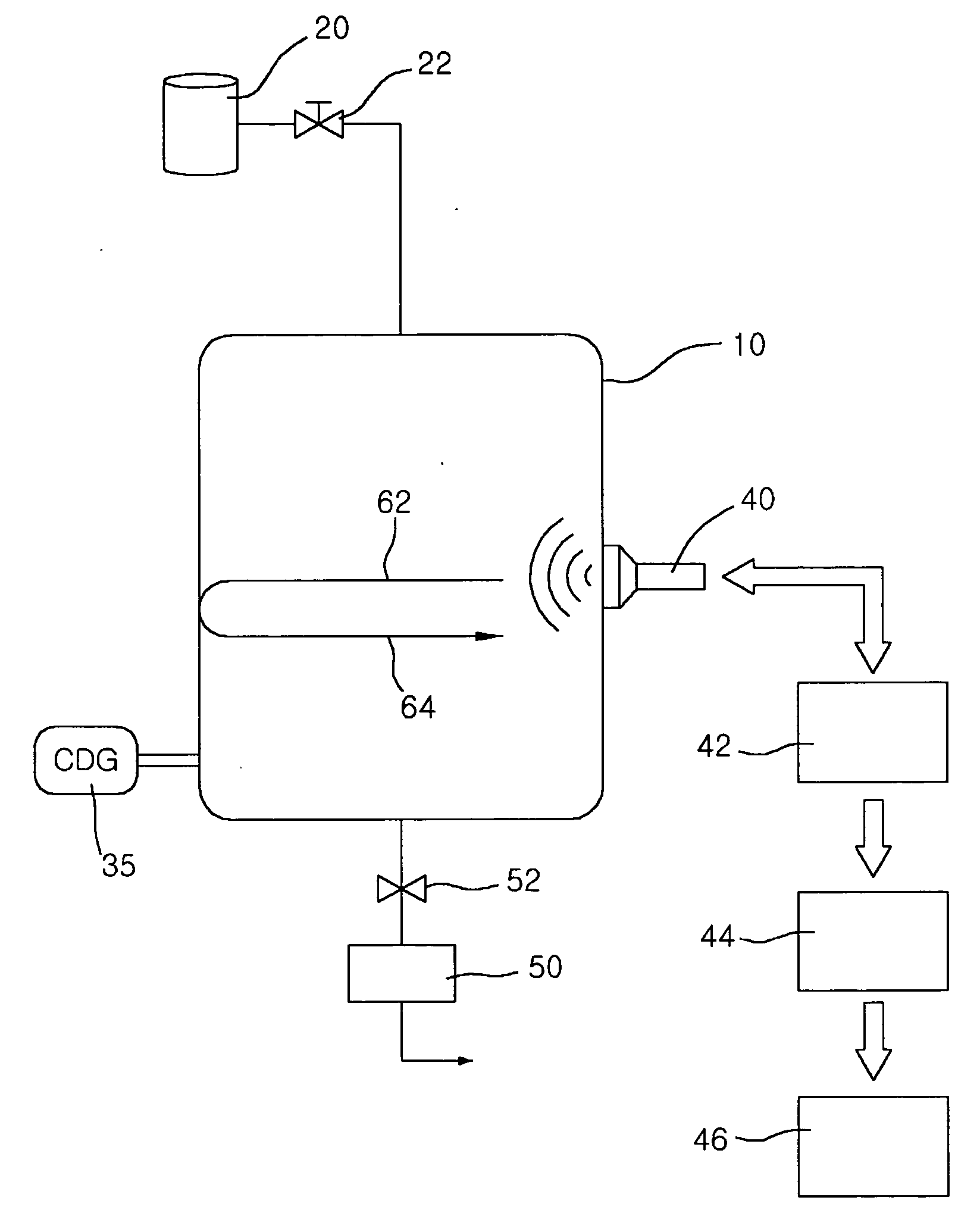

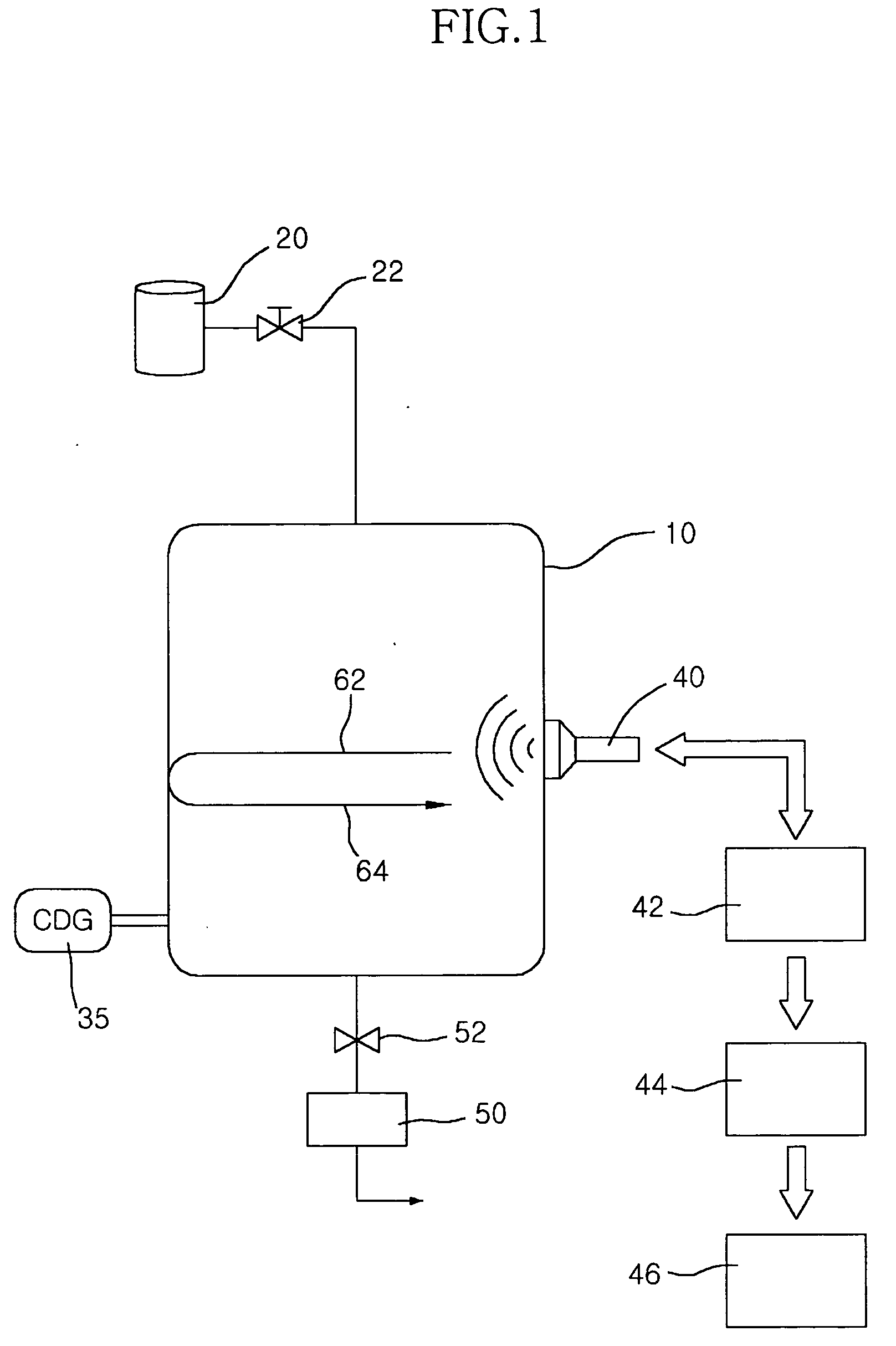

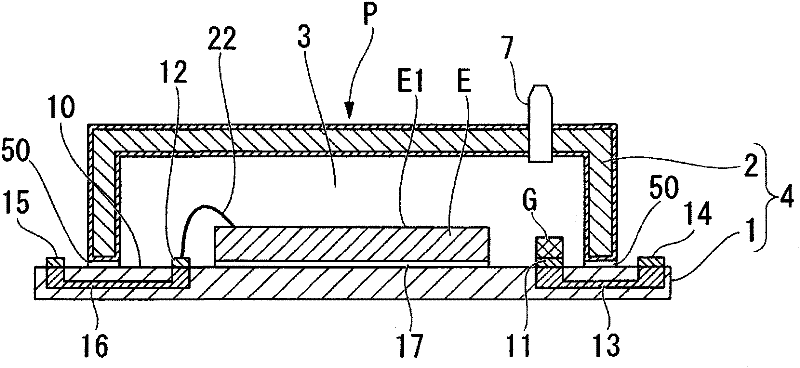

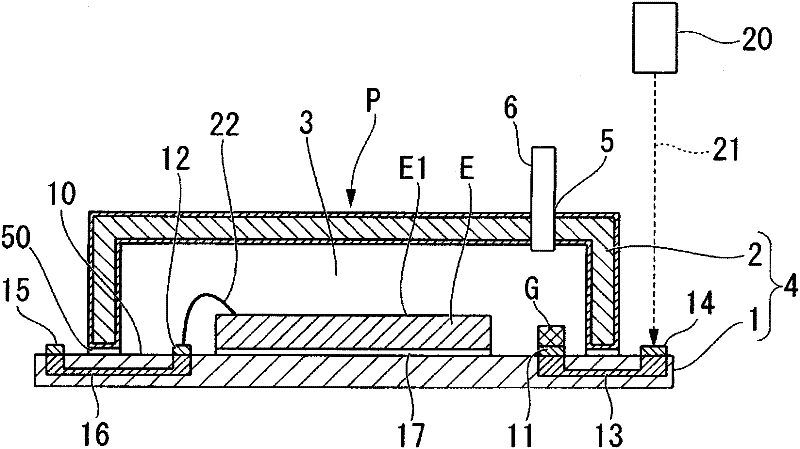

Pressure measuring system for vacuum chamber using ultrasonic wave

InactiveUS20070068260A1Reduce vacuumEasy to measureVacuum gaugesPressure difference measurement between multiple valvesReflected wavesVacuum chamber

Disclosed is a pressure measuring system for a vacuum chamber, in particular, a pressure measuring system for a vacuum chamber using ultrasonic wave. In this regard, there is provided a pressure measuring system for a vacuum chamber using ultrasonic wave, comprising a vacuum chamber 10 formed with desired vacuum at the inside thereof; ultrasonic wave-emitting means mounted close to an outer peripheral surface of the vacuum chamber 10 for emitting an ultrasonic wave 62 to the inside of the vacuum chamber 10; ultrasonic wave-receiving means for receiving a reflection wave 64 reflected after the striking of the ultrasonic wave 62 emitted from the ultrasonic wave-emitting means to the vacuum chamber; reflection wave-detecting means for detecting the reflection wave 64 from the ultrasonic wave-receiving means; and amplitude-analyzing means for analyzing the amplitude of the reflection wave 64 detected by the reflection wave-detecting means.

Owner:KOREA RES INST OF STANDARDS & SCI

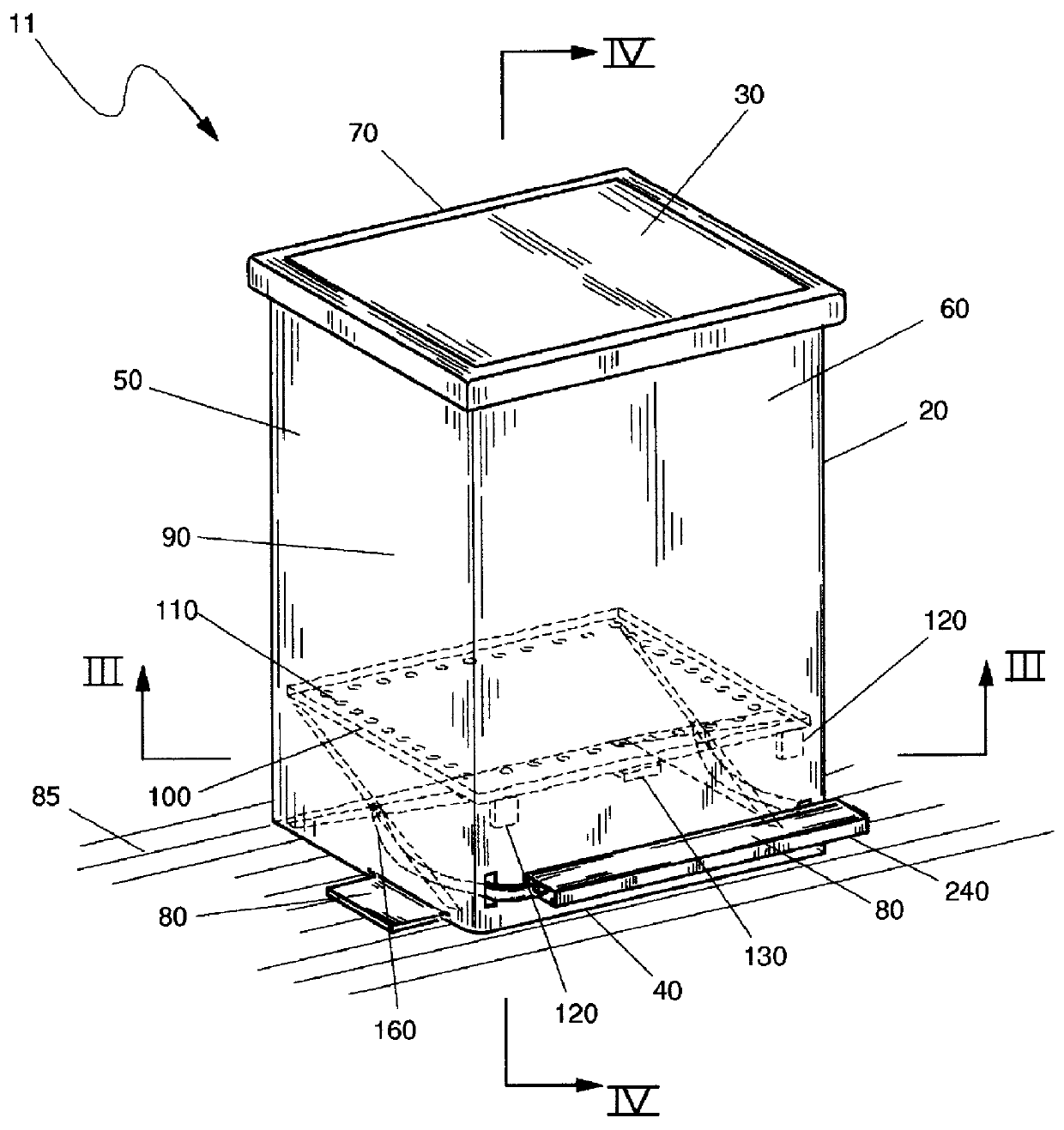

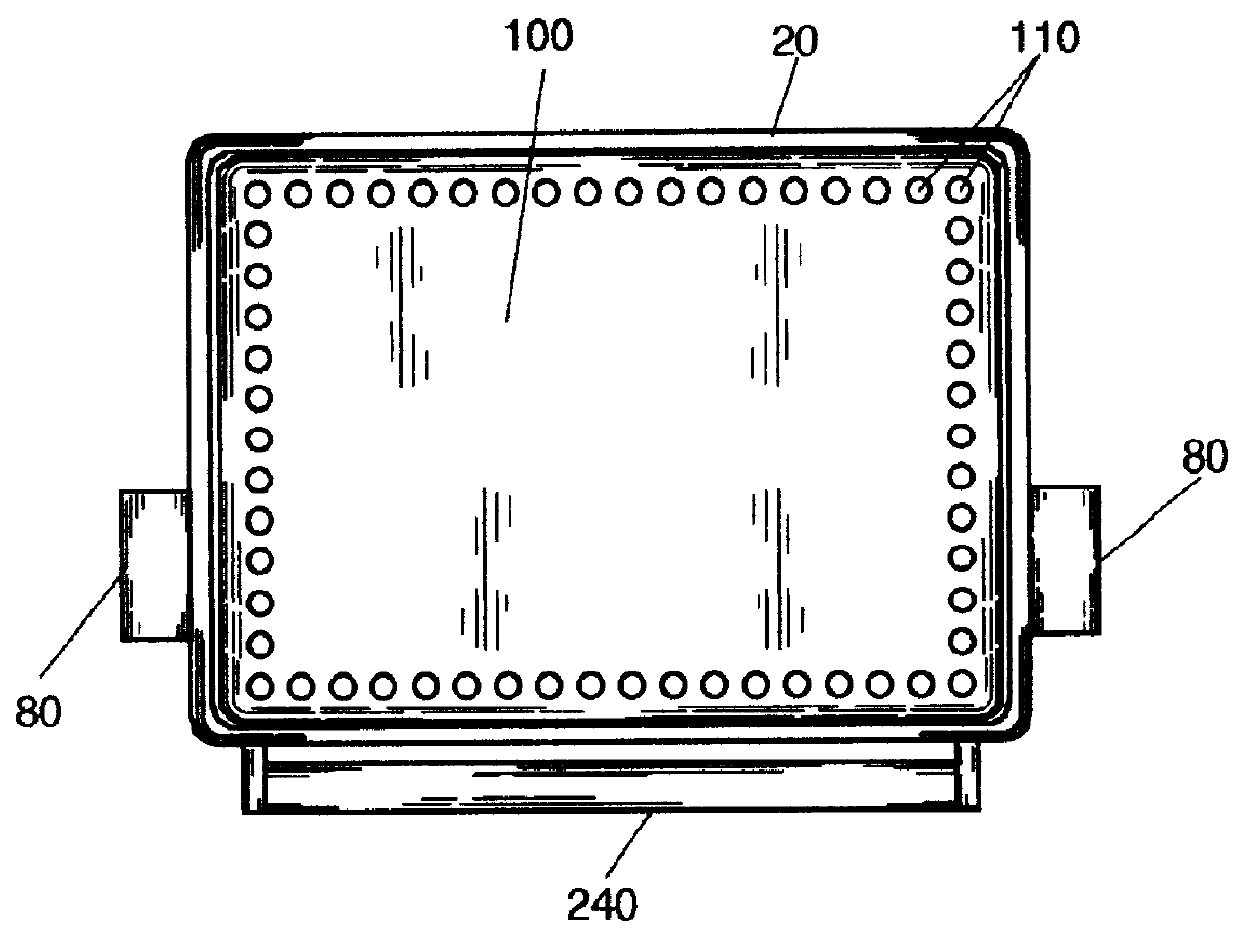

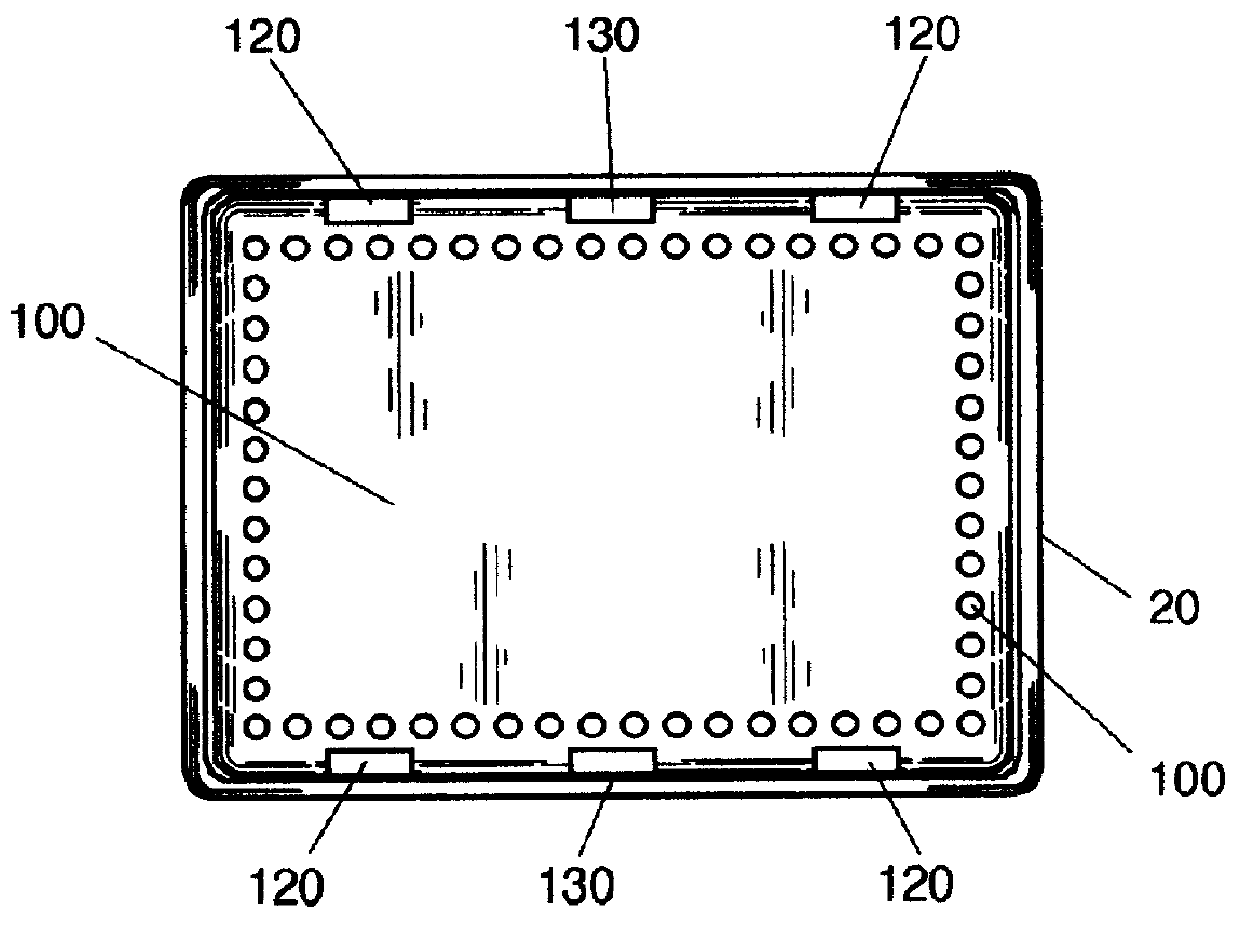

Step and lift refuse liner removal system

A step and lift refuse liner removal system is disclosed, consisting of a conventional refuse container main housing. A conventional refuse liner rests on a support plate, located inside the main housing, above the bottom of the main housing. Air holes in the support plate facilitate air flow throughout the main housing, thus reducing the vacuum between the refuse liner and the side walls of the main housing. A dual fulcrum and curved lever system permits the operator to lift the support plate by pressing down on a foot bar located outside the main housing near the ground. As such, the present invention facilitates the easy and effortless removal of a conventional refuse liner. A set of foot pads are provided to enable the operator to restrict the movement of the main housing relative to the ground.

Owner:GRIMESEY CHRISTOPHER A +1

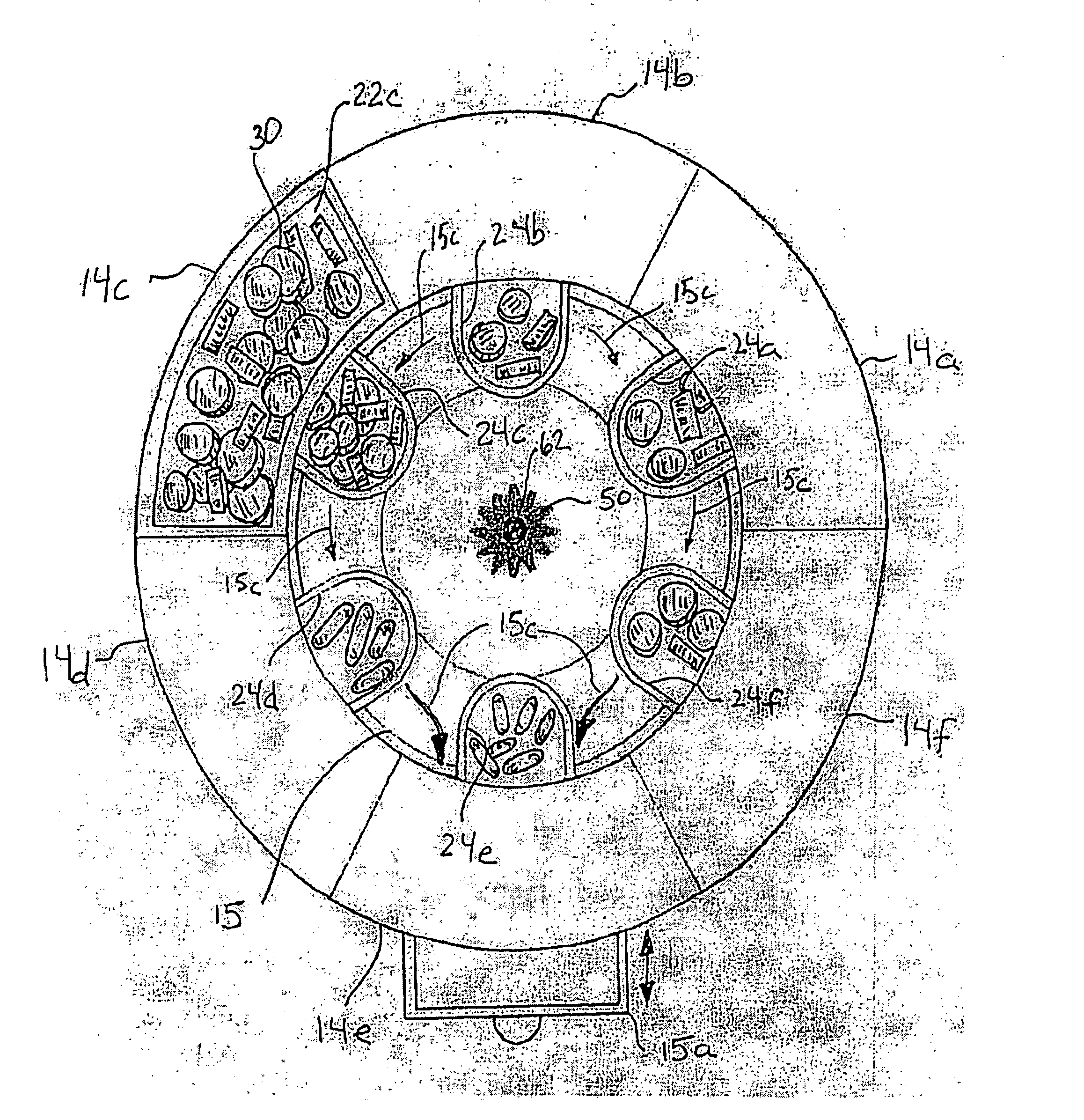

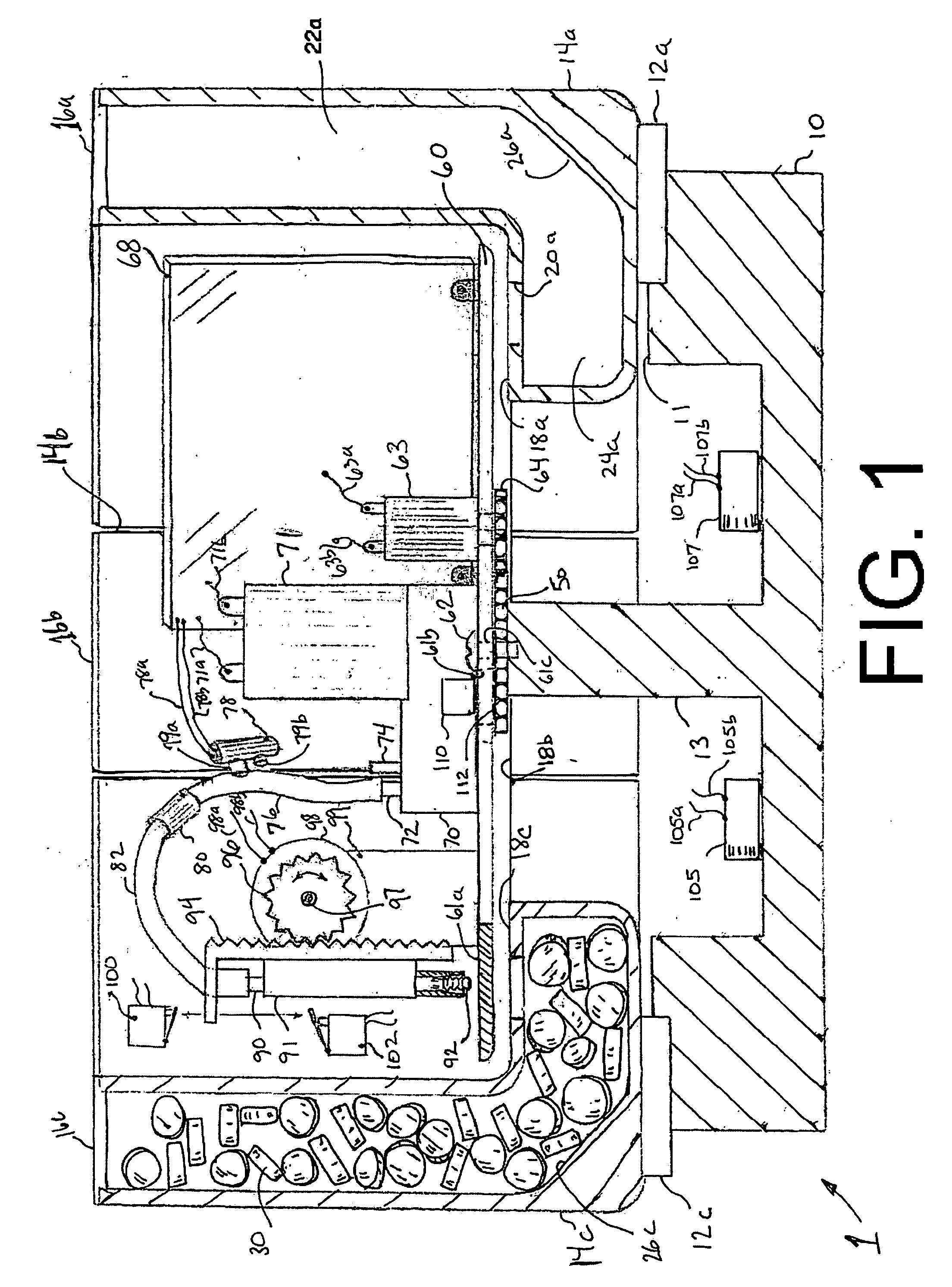

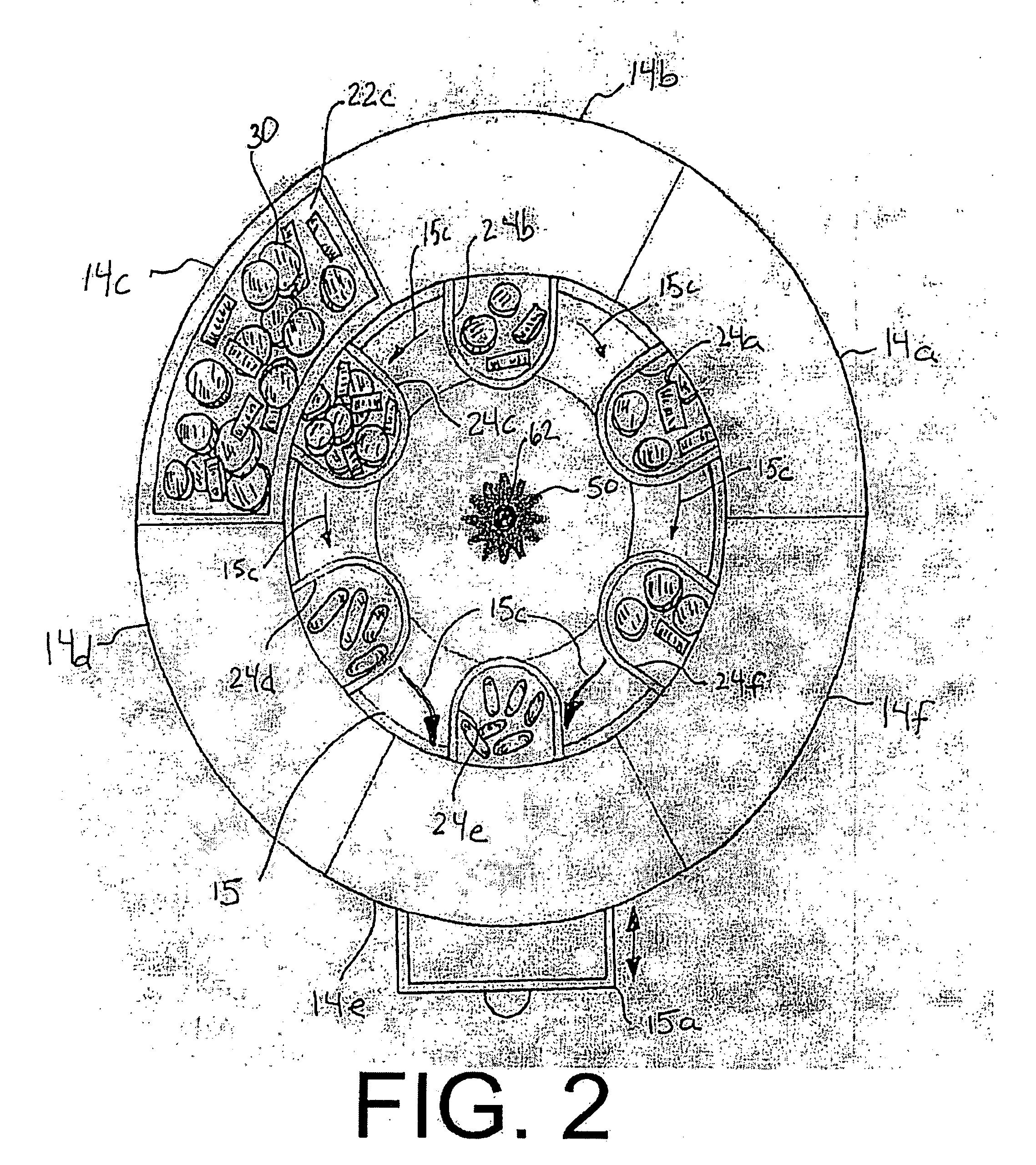

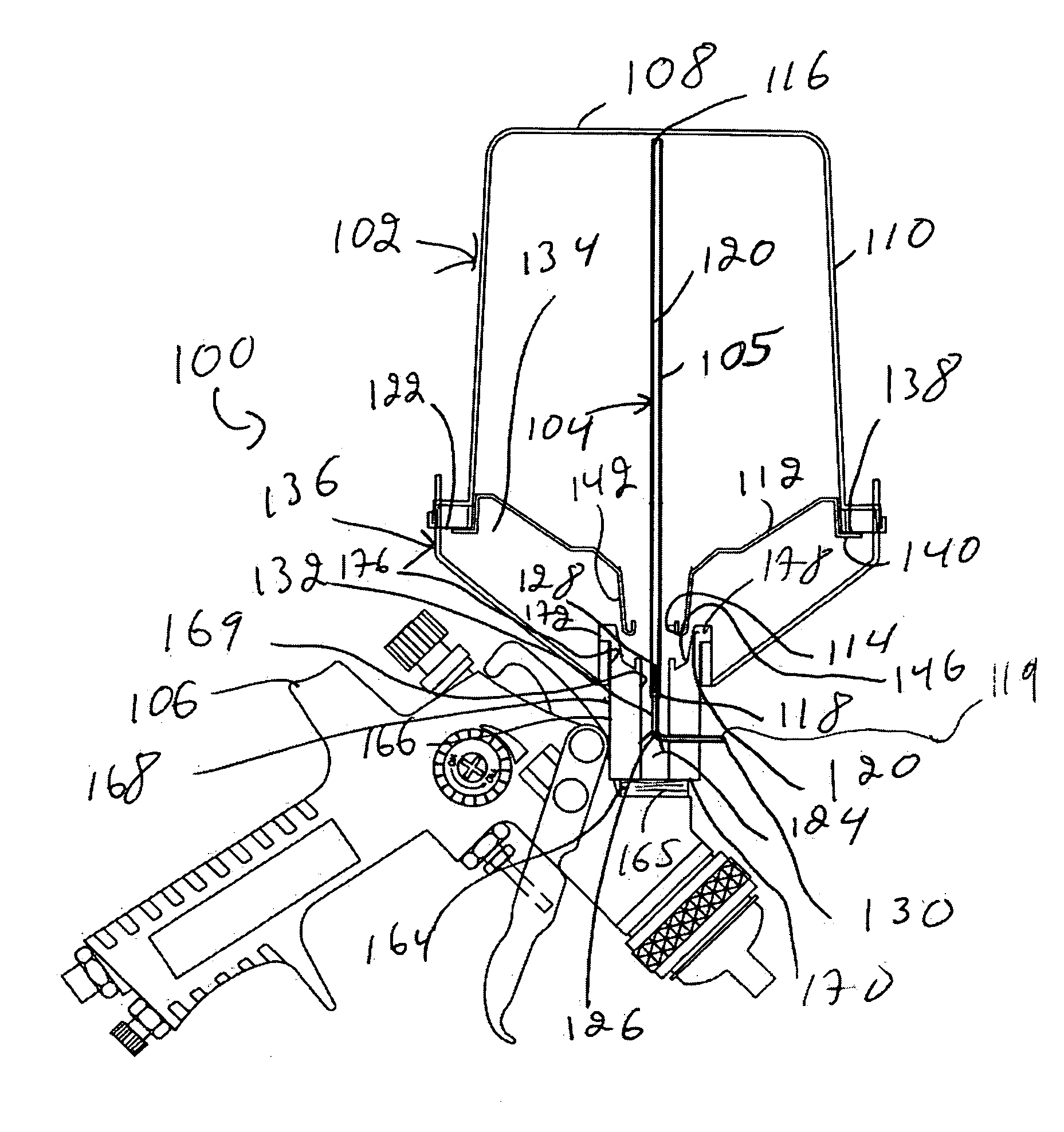

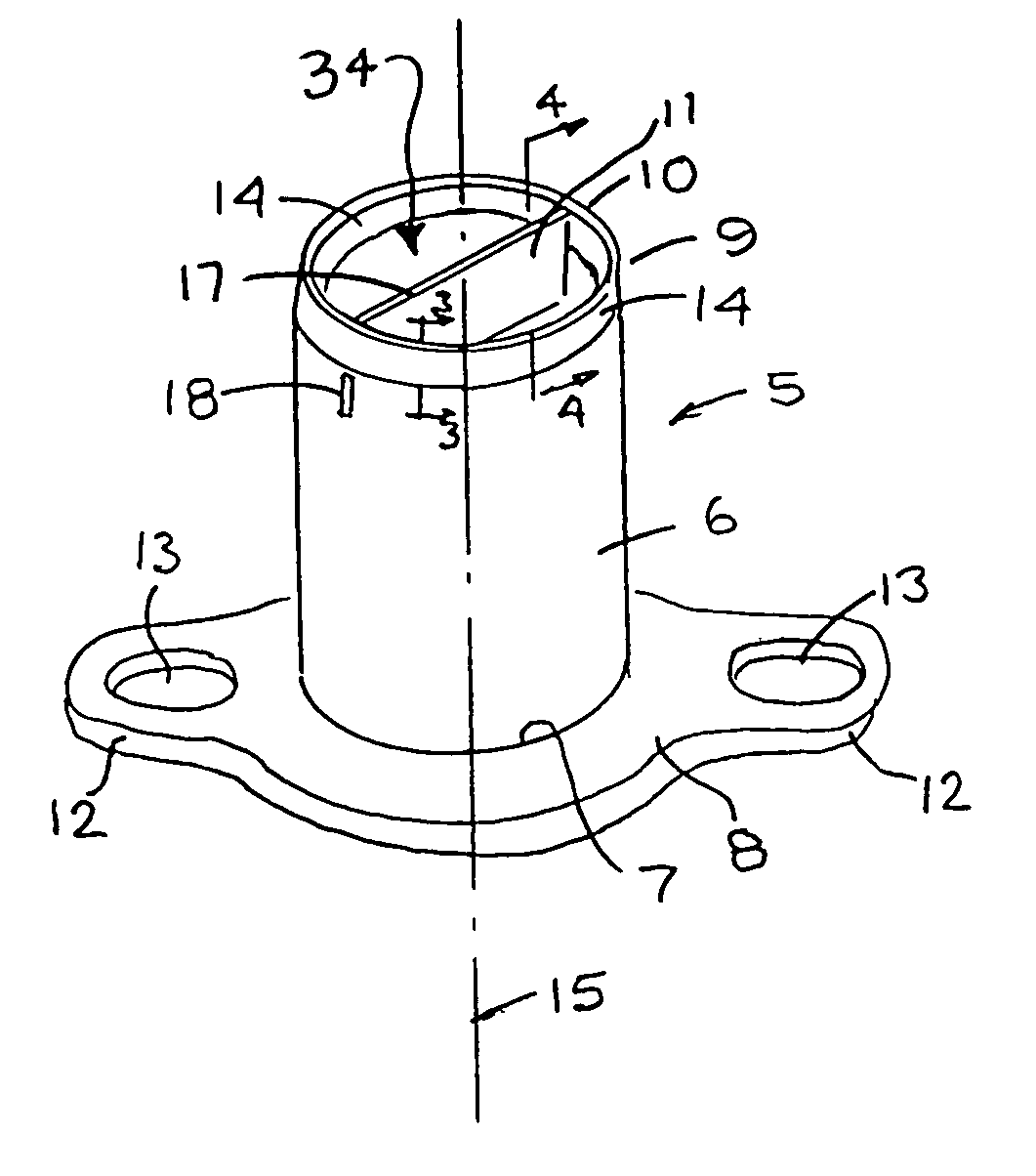

Pill dispensing apparatus

InactiveUS20060213921A1Assisted movementReduce vacuumCoin-freed apparatus detailsPharmaceutical containersEngineeringBellows

An automated pill dispenser includes a plurality of pill chambers peripherally disposed about a hub. The hub includes a rotatable plate capable of rotating to a selected pill chamber and removing a pill therefrom. A vacuum tip including a bellows extends through an access opening formed within the rotatable plate to withdraw a pill from a bottom portion of the selected pill chamber by grasping the pill from above. A reflective bar code is disposed beneath the rotatable plate and detectable through an opening through the plate to indicate plate position relative to the pill chambers. A computer enables a user to programmably operable the pill dispenser and select the pill chamber, dosage amount and time.

Owner:ANTIOCH HLDG

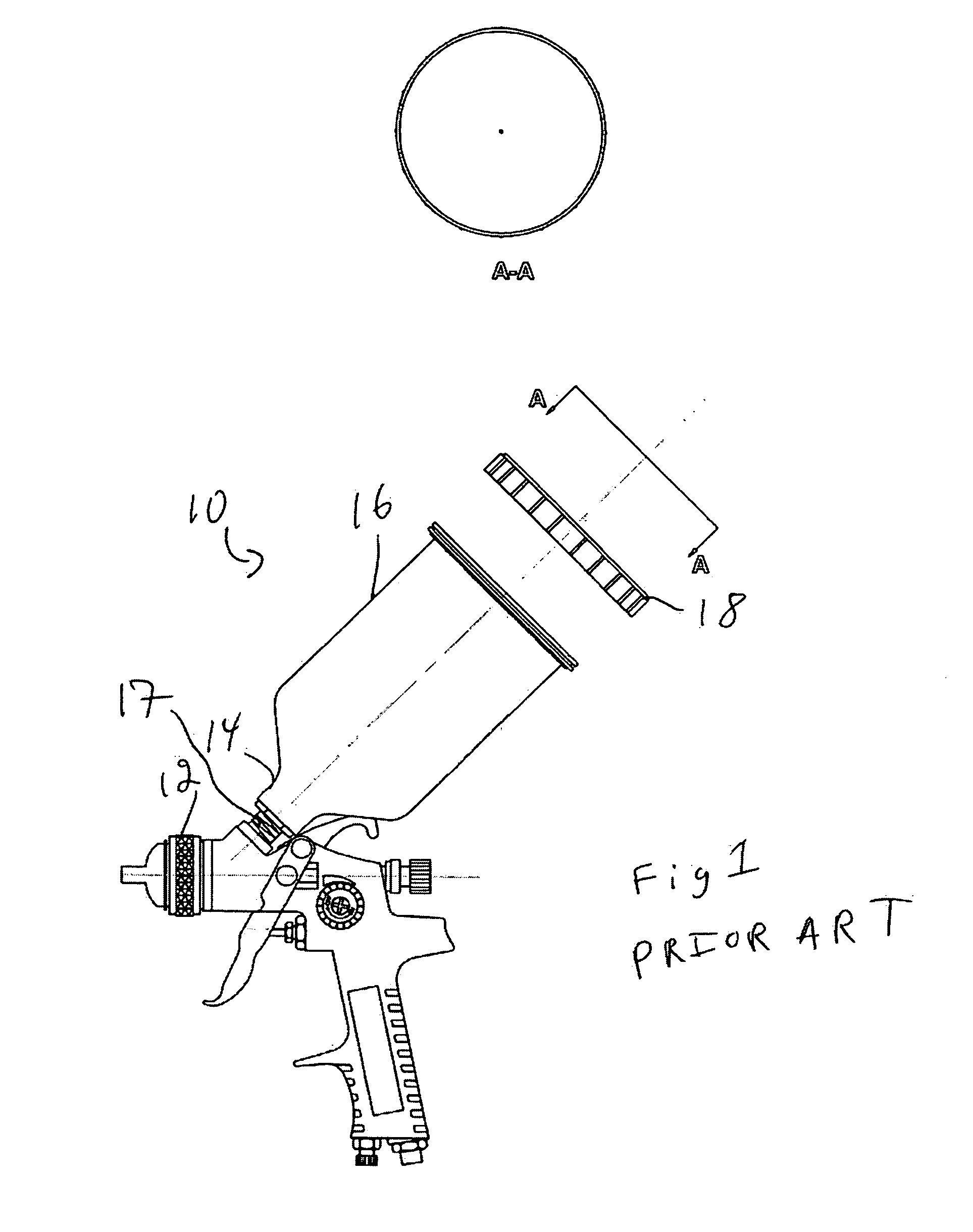

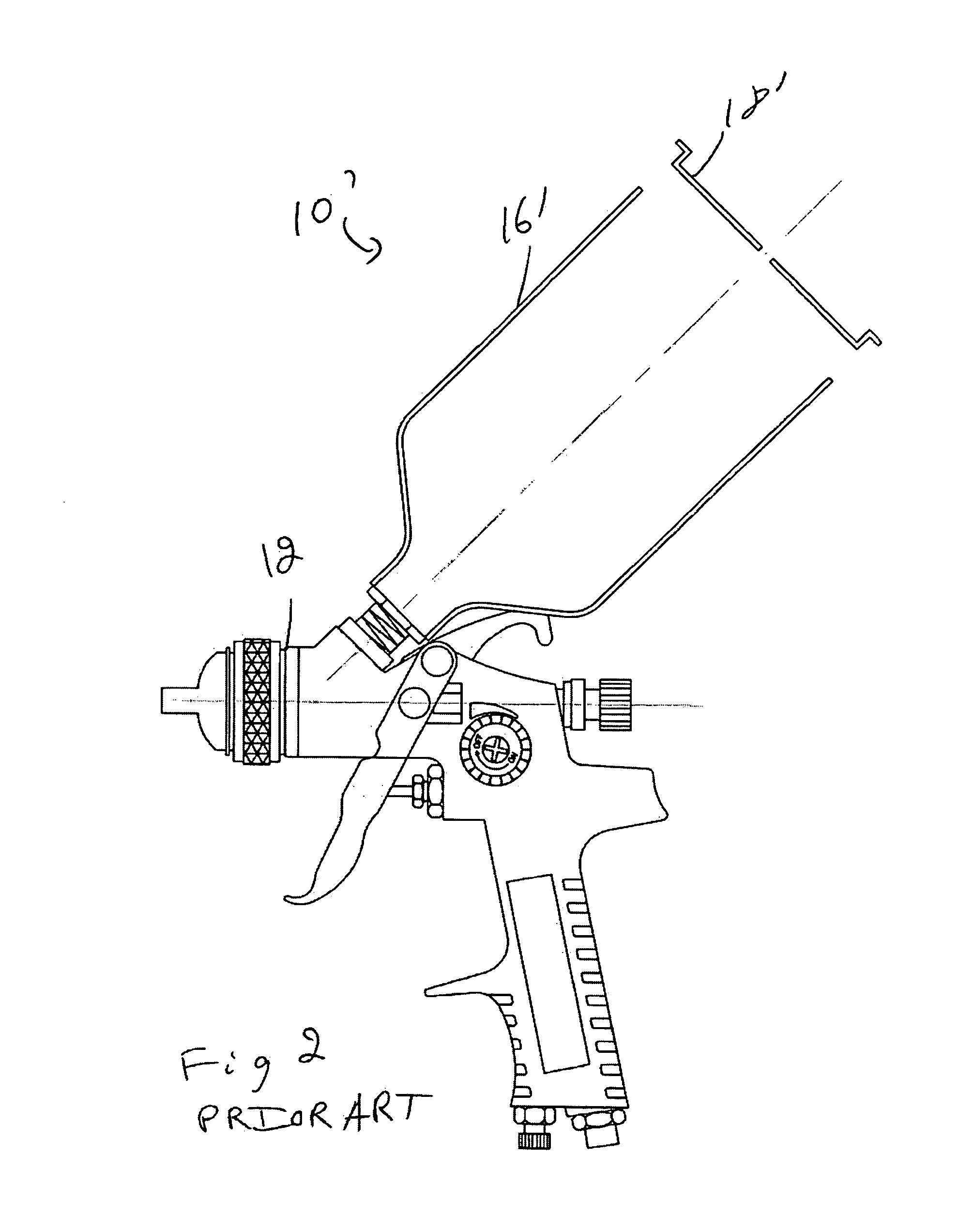

Liquid spraying assembly

InactiveUS20070018016A1Reduce vacuumReduce riskWatering devicesFire rescueEngineeringMechanical engineering

A spraying assembly for spraying a liquid. The spraying assembly includes a reservoir for containing the liquid, the reservoir defining a reservoir outlet; a venting tube defining a tube inlet, a tube outlet substantially opposed to the tube inlet and a tube passageway extending therebetween, the tube inlet being positioned within the reservoir; and a spray gun for spraying the fluid, the spray gun including a gun inlet couplable to the reservoir outlet so as to allow the liquid to flow from the reservoir into the spray gun. The tube outlet is in fluid communication with the exterior of the reservoir, thereby allowing venting the reservoir such as to reduce a vacuum created when the liquid flows out from said reservoir through the reservoir outlet.

Owner:YECHOURON SIMON

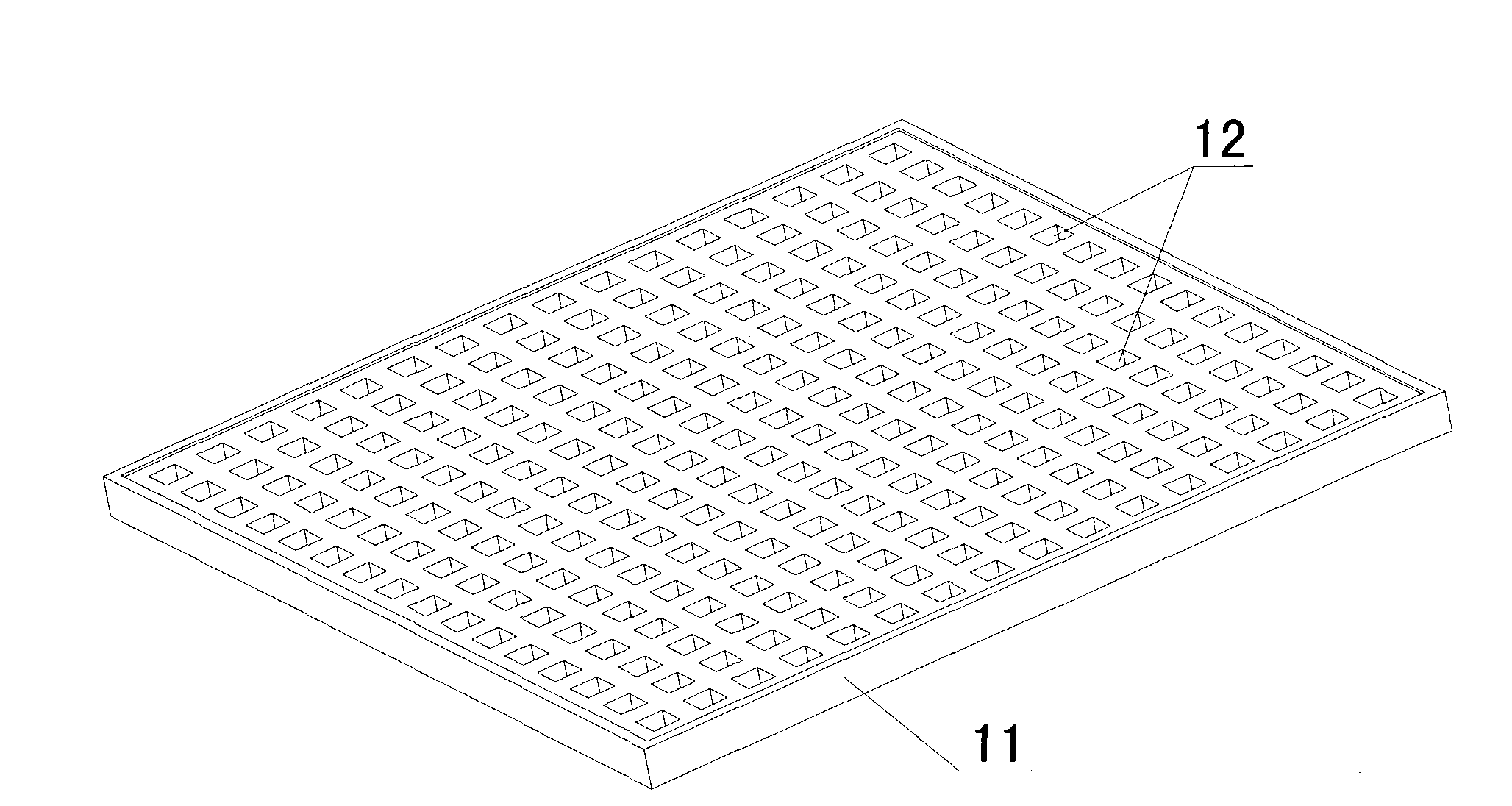

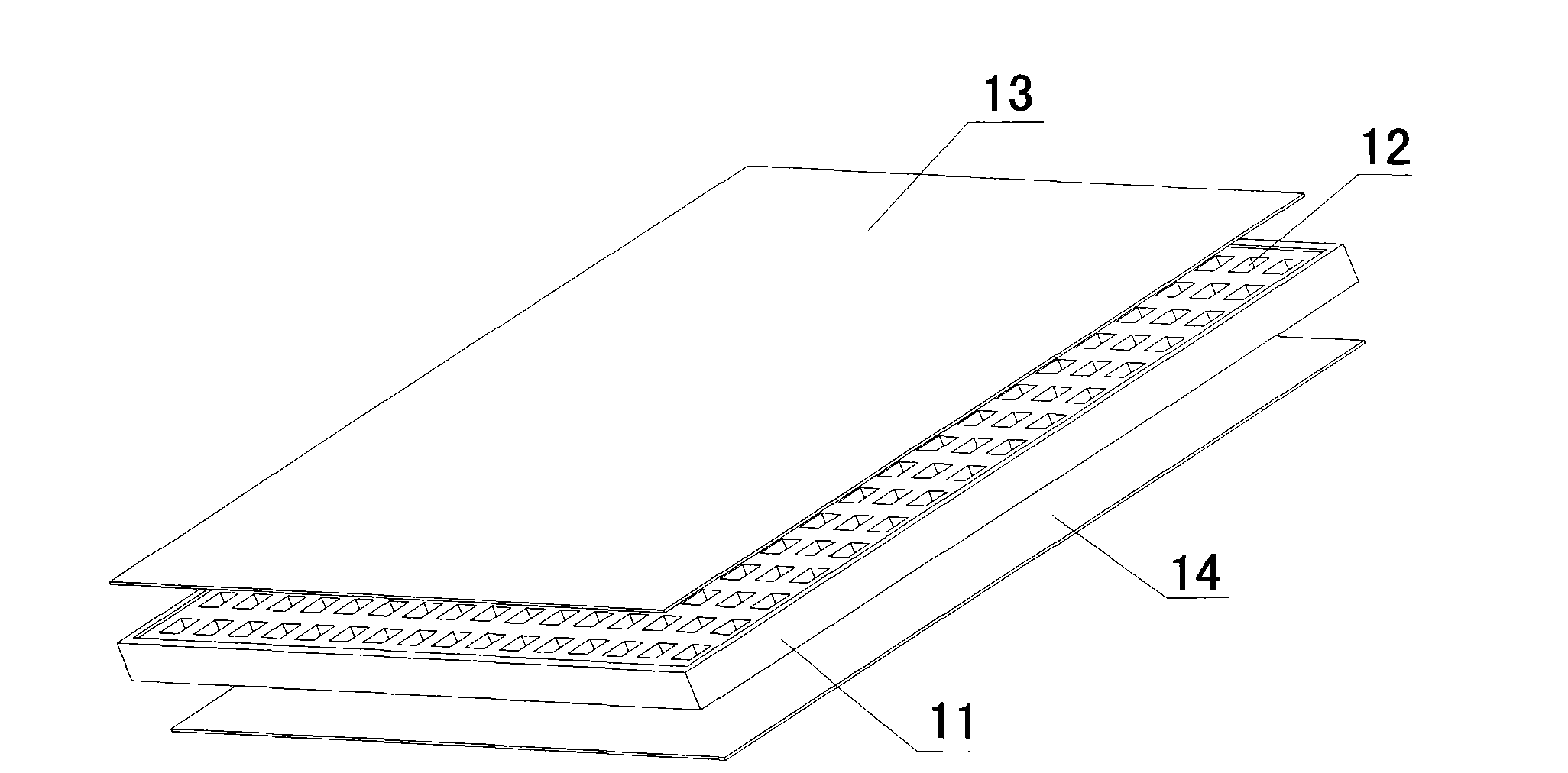

Vacuum thermal insulation component and manufacturing method thereof, as well as refrigeration device

InactiveCN102116402AImprove insulation effectLow efficiencyThermal insulationDomestic cooling apparatusThermal insulationEngineering

The invention discloses a vacuum thermal insulation component, which comprises a thermal insulation core plate, a first support plate, a second support plate, and a blocking film bag, wherein the first support plate is arranged on the upper surface of the thermal insulation core body, the second support plate is arranged on the lower surface of the thermal insulation core body, the first and the second support plates are used for supporting the thermal insulation core body, and a cavity is formed between the first and the second support plate; and the thermal insulation core body and the first and the second support plates are hermetically arranged in the blocking film bag, and the interior of the blocking film bag is vacuum. The vacuum thermal insulation component provided by the invention has excellent thermal insulation performance.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

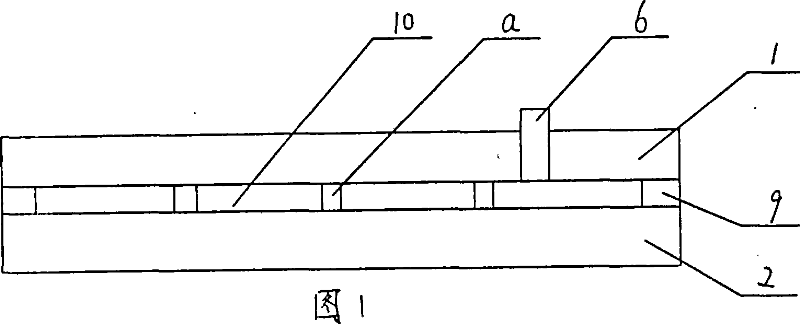

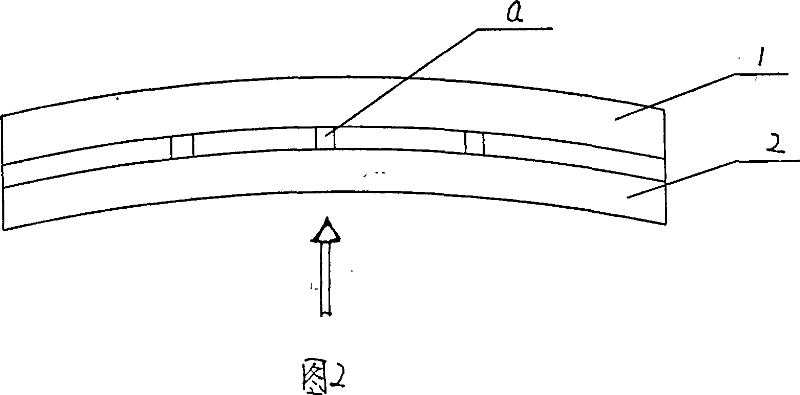

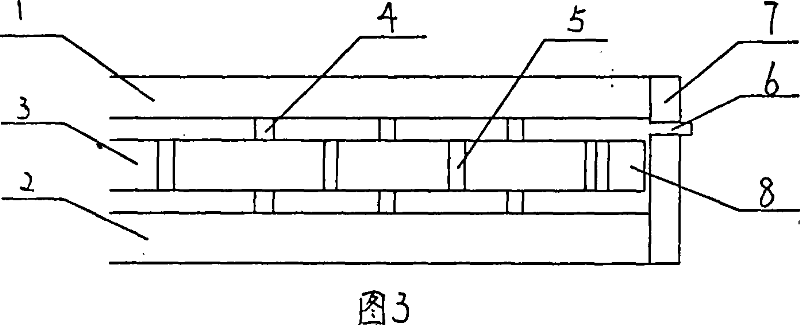

Suspending and balancing pressure type support safety vacuum glass

A suspended and pressure equalized support safe vacuum glass comprises closely connected up and down glass plates with sealed vitreum at four sides, a vacuum cavity in the middle which is formed by up and down glass plates and which has suspended support glass plates that has support at its six sides, corner of the suspended support glass plate having degasser. The vacuum glass has small deformation rate under pressure, high strength, free from after hollow or doubling, with simple structure, low cost, fine energy saving and noise reducing effect and higher social and economical value.

Owner:王汉清

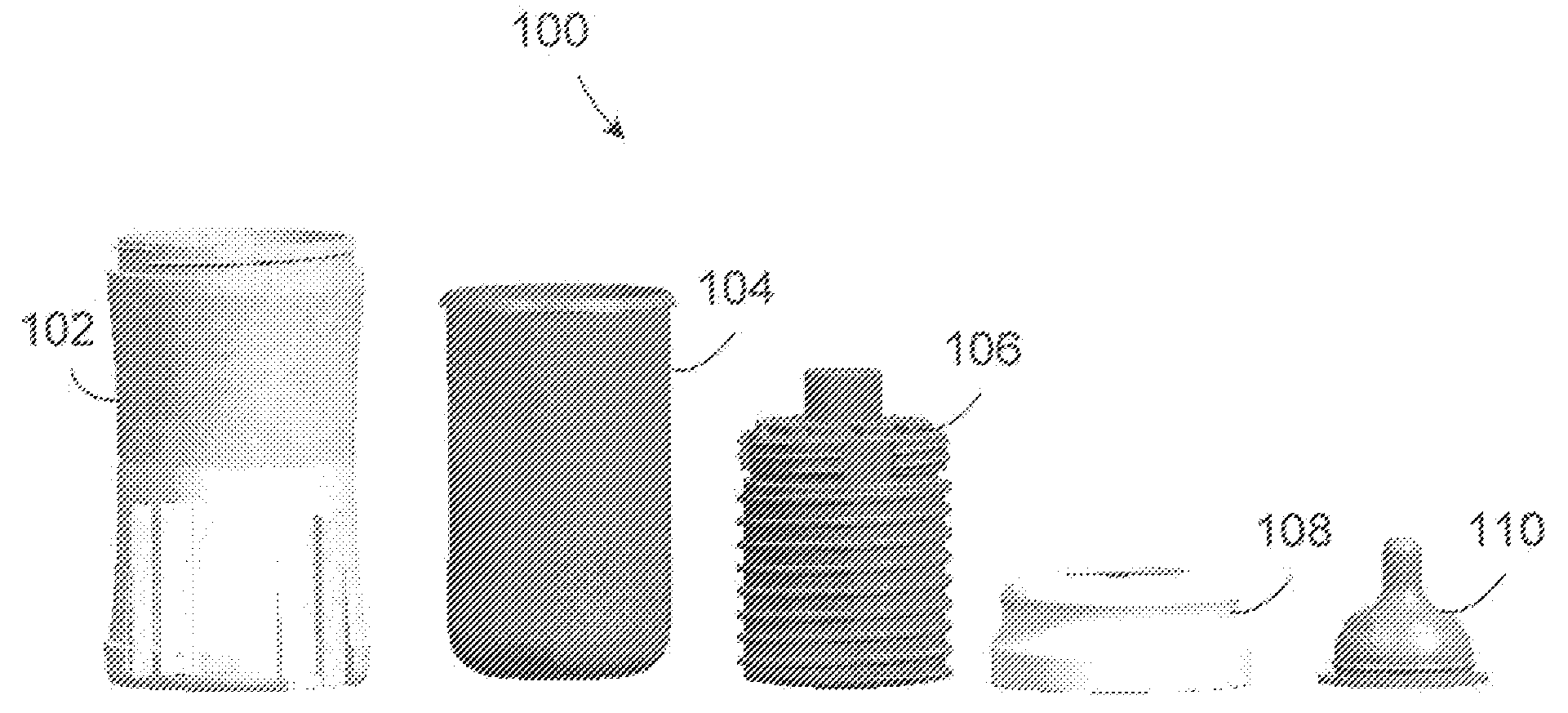

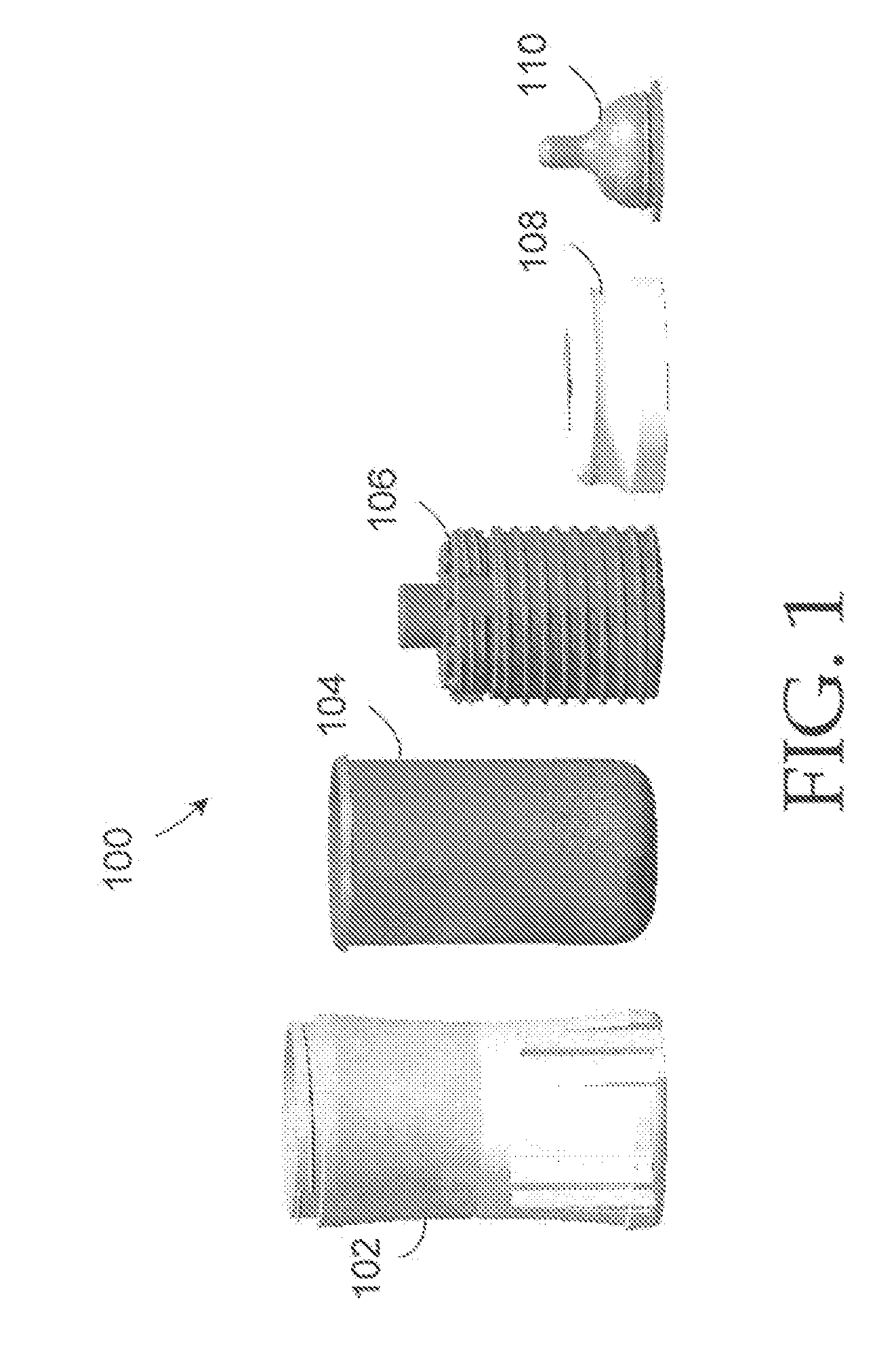

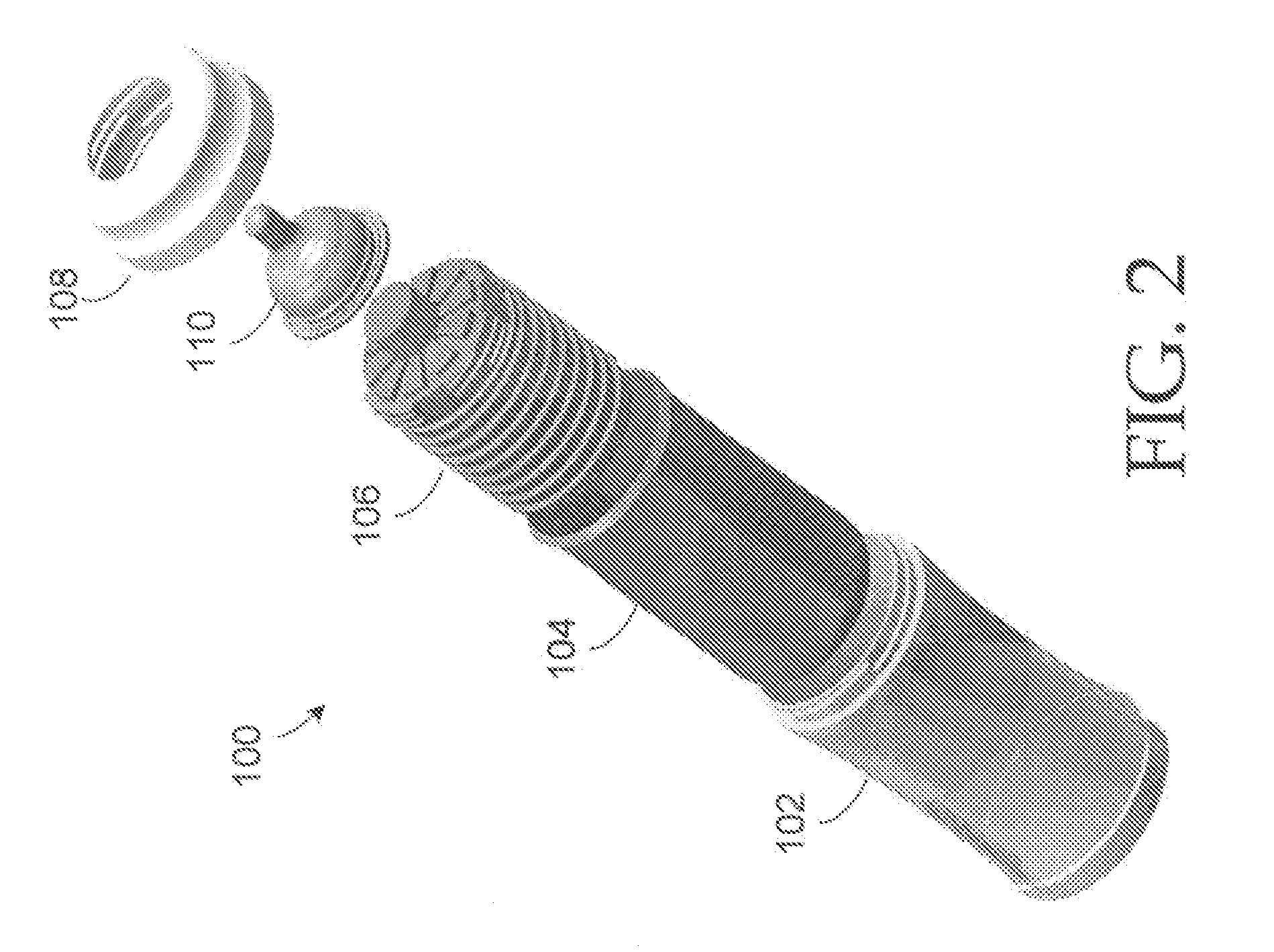

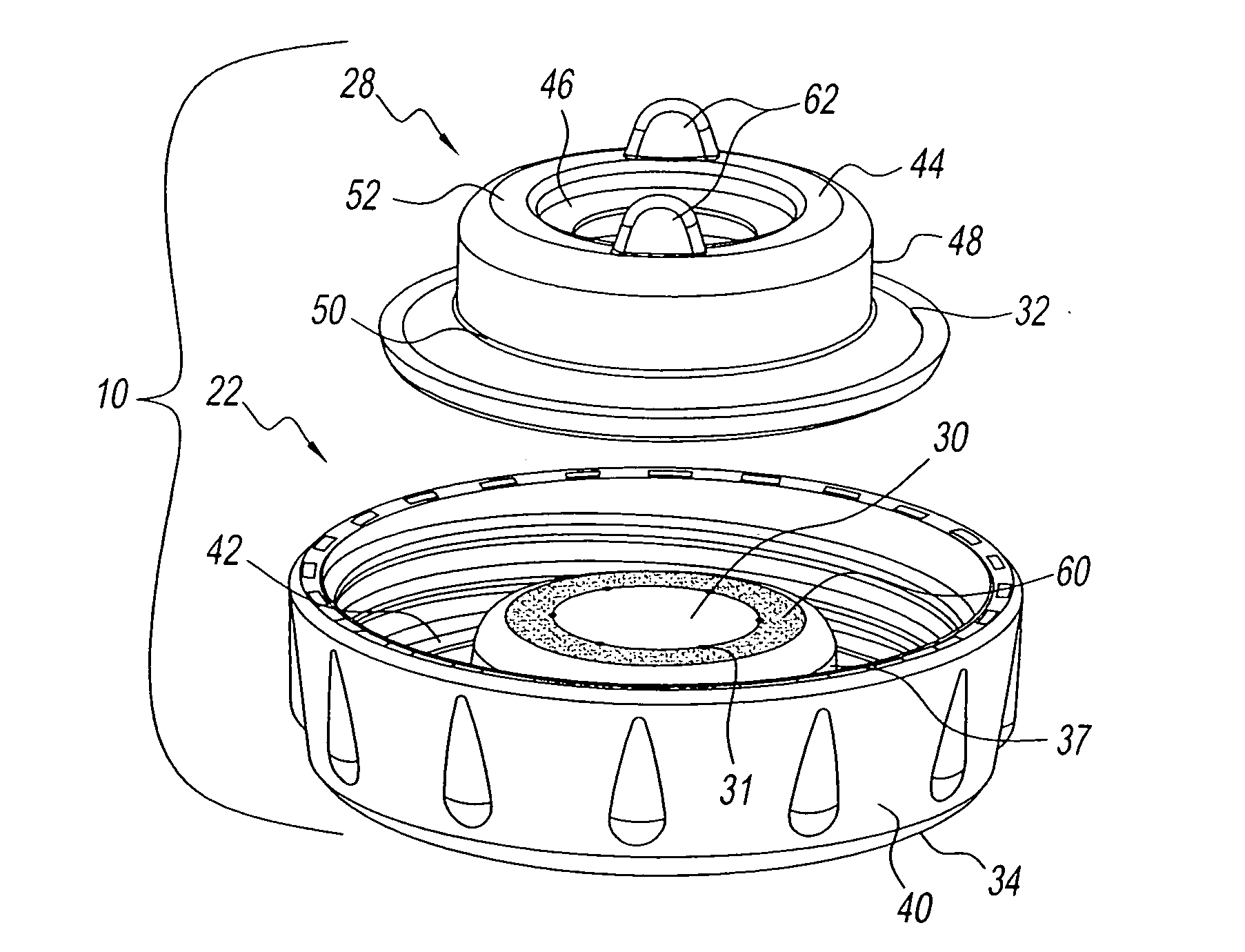

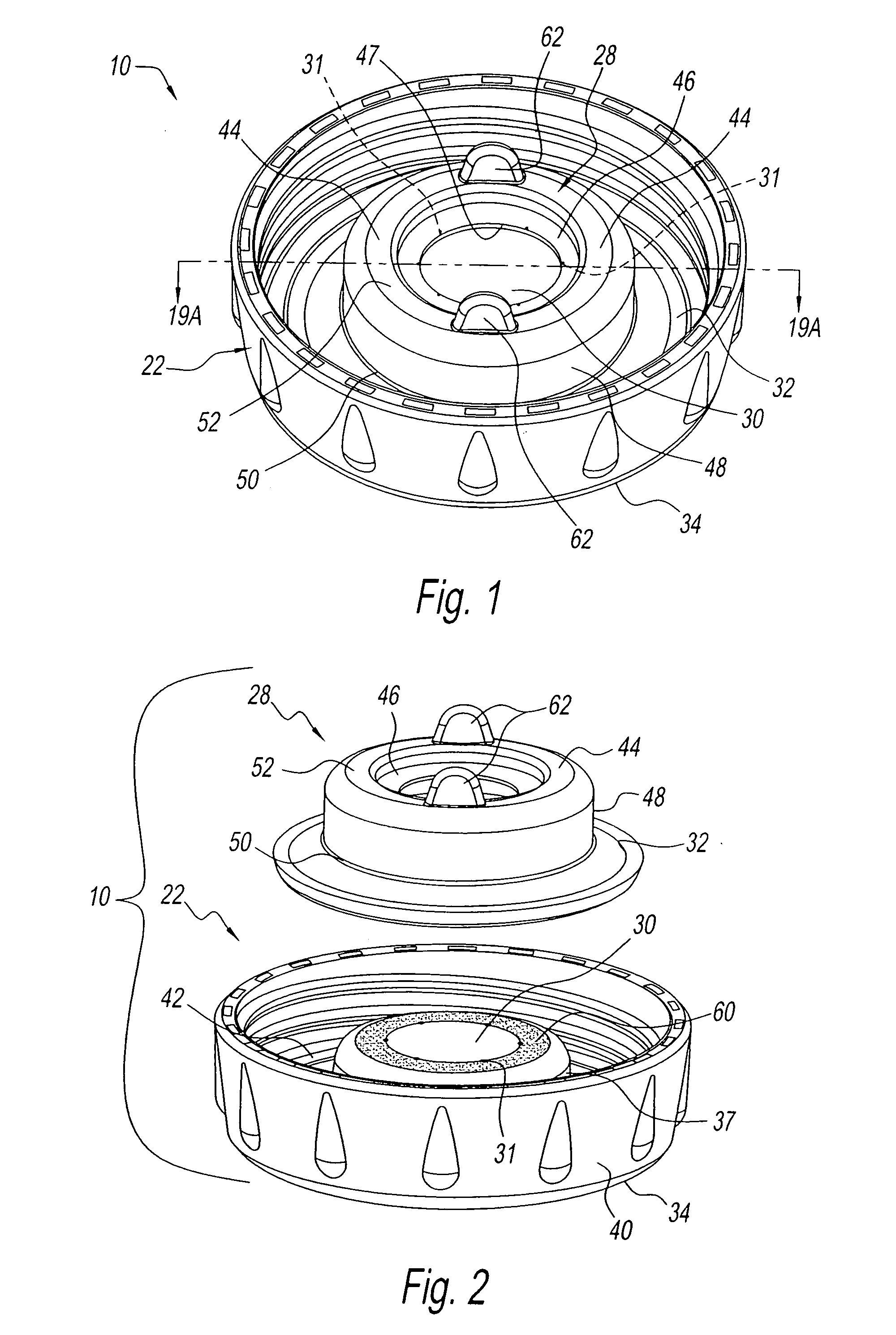

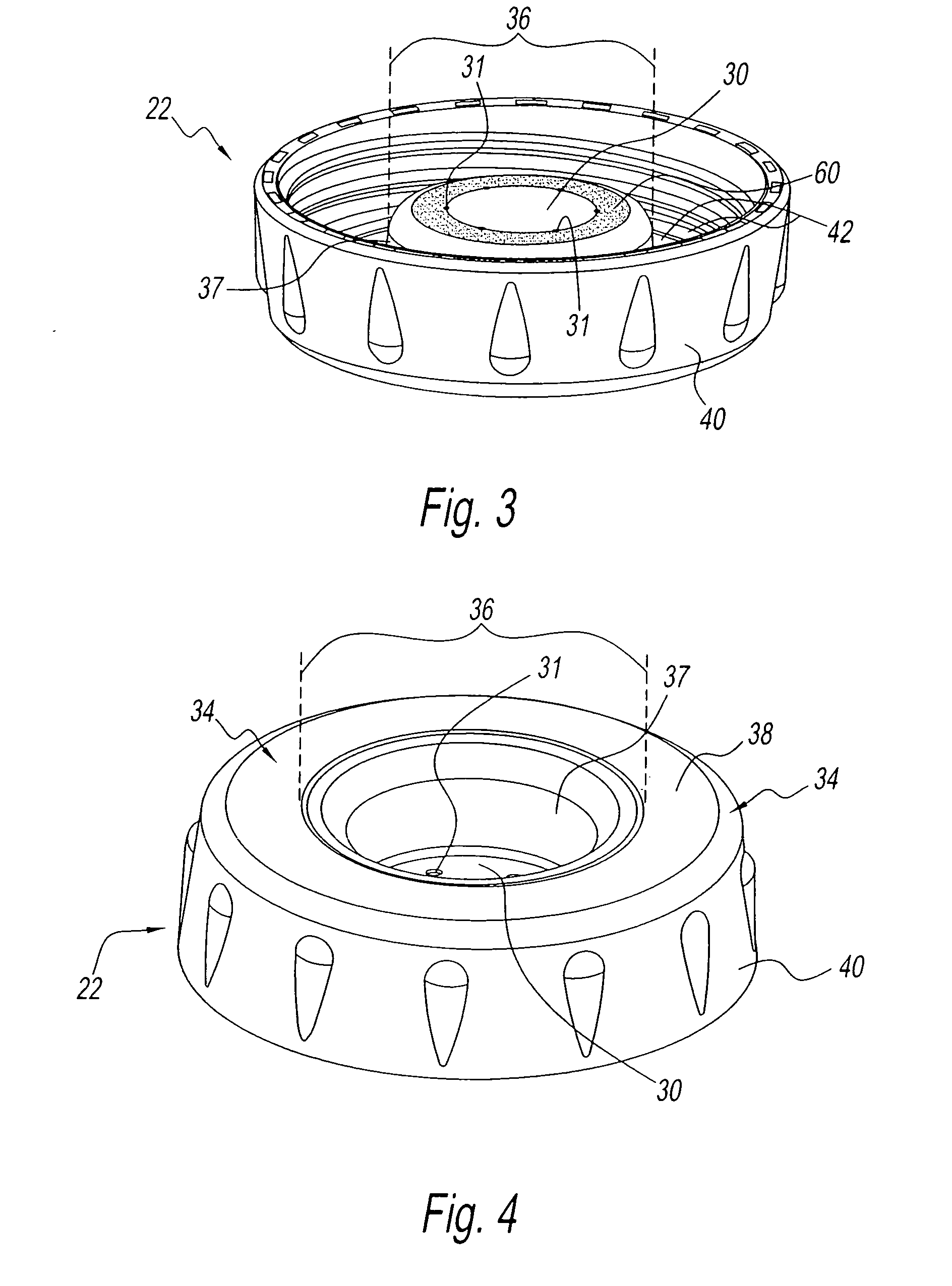

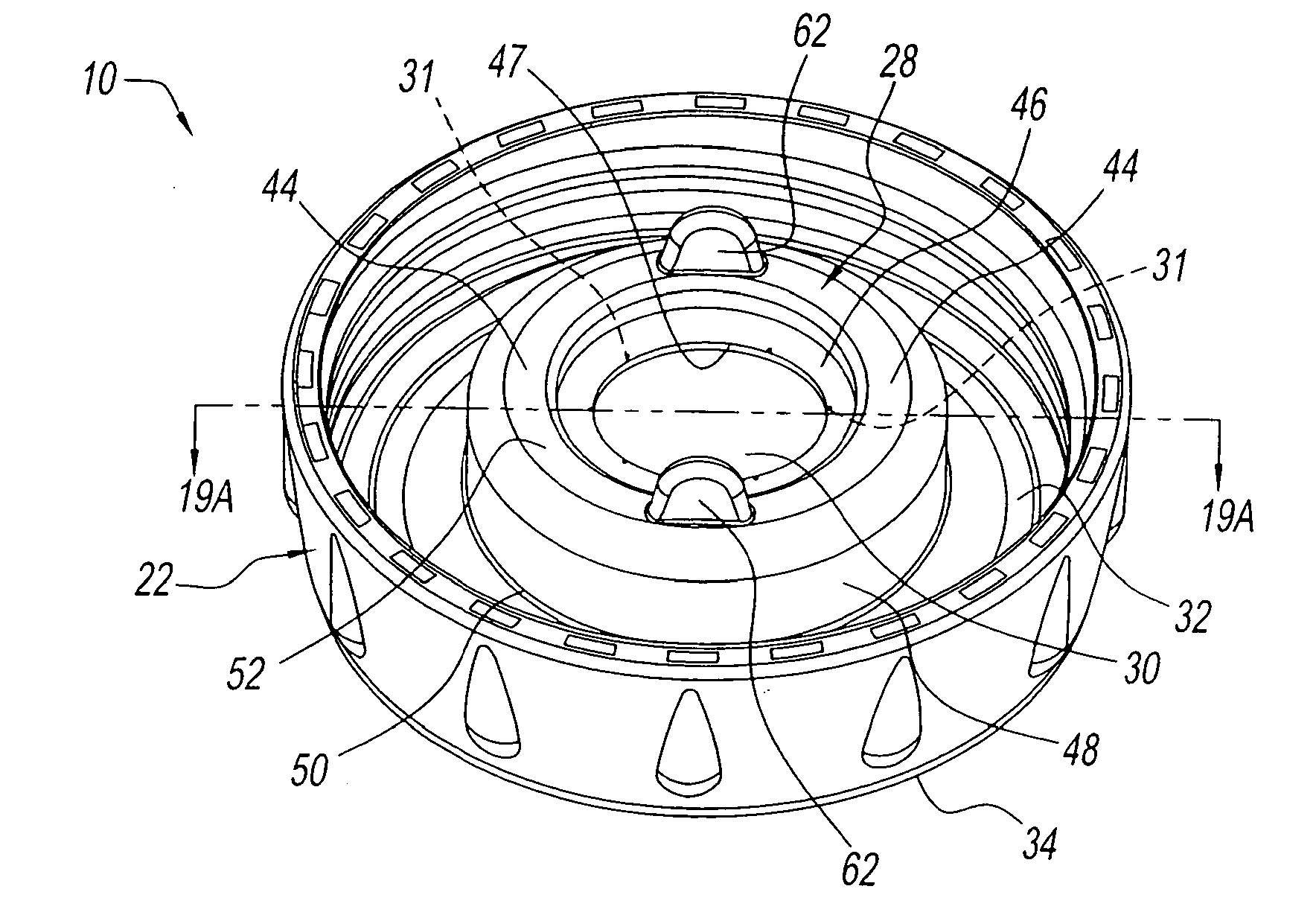

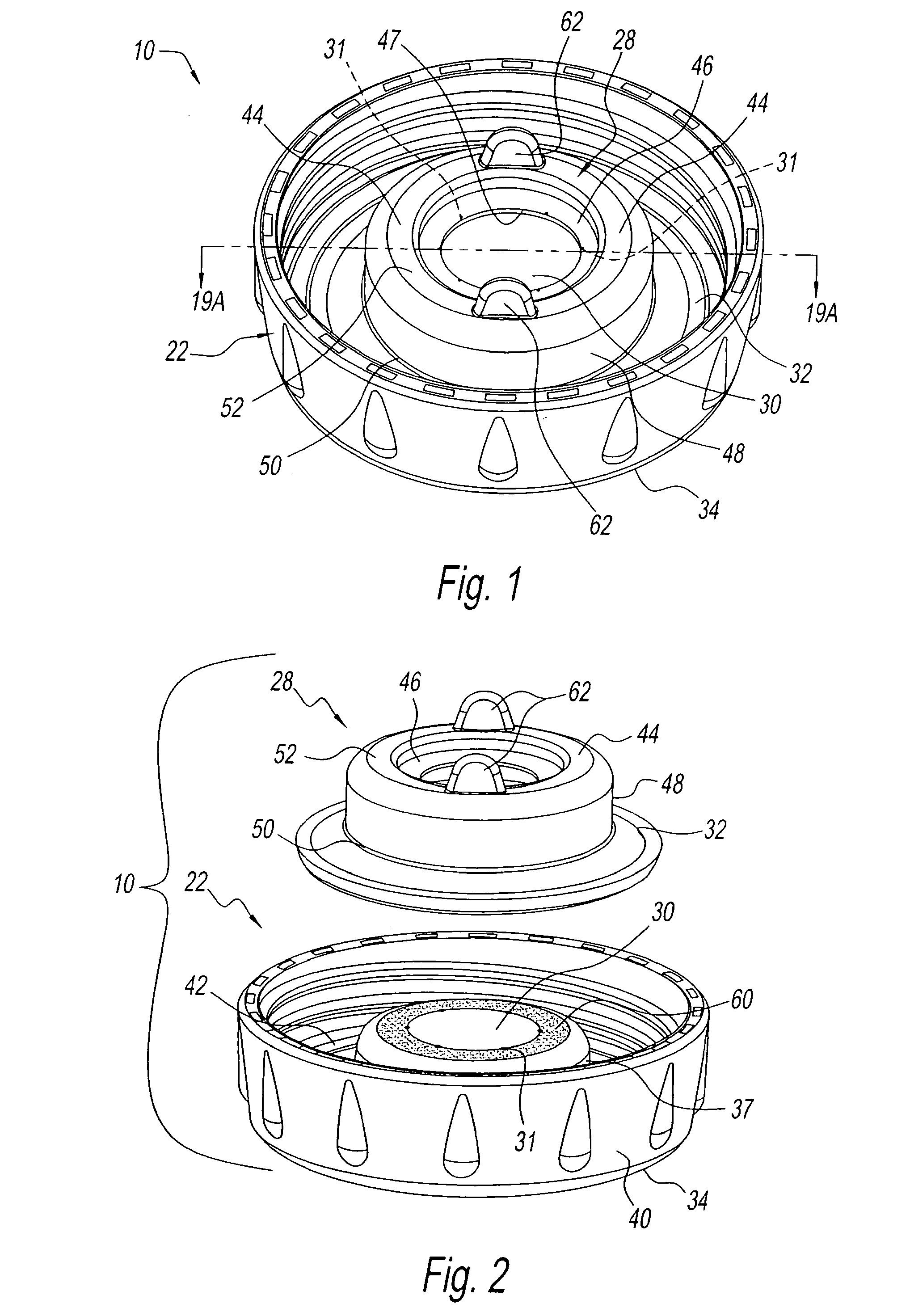

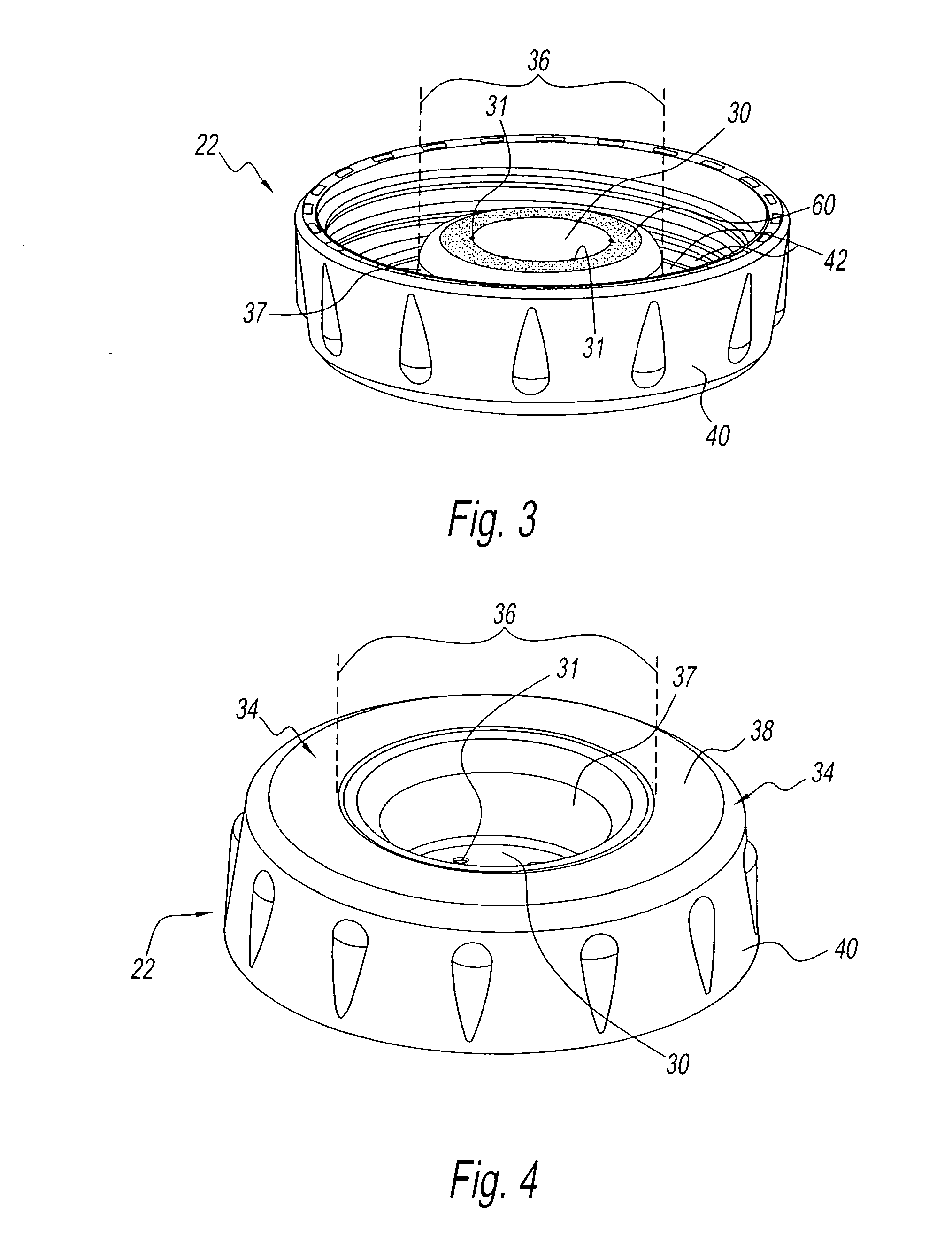

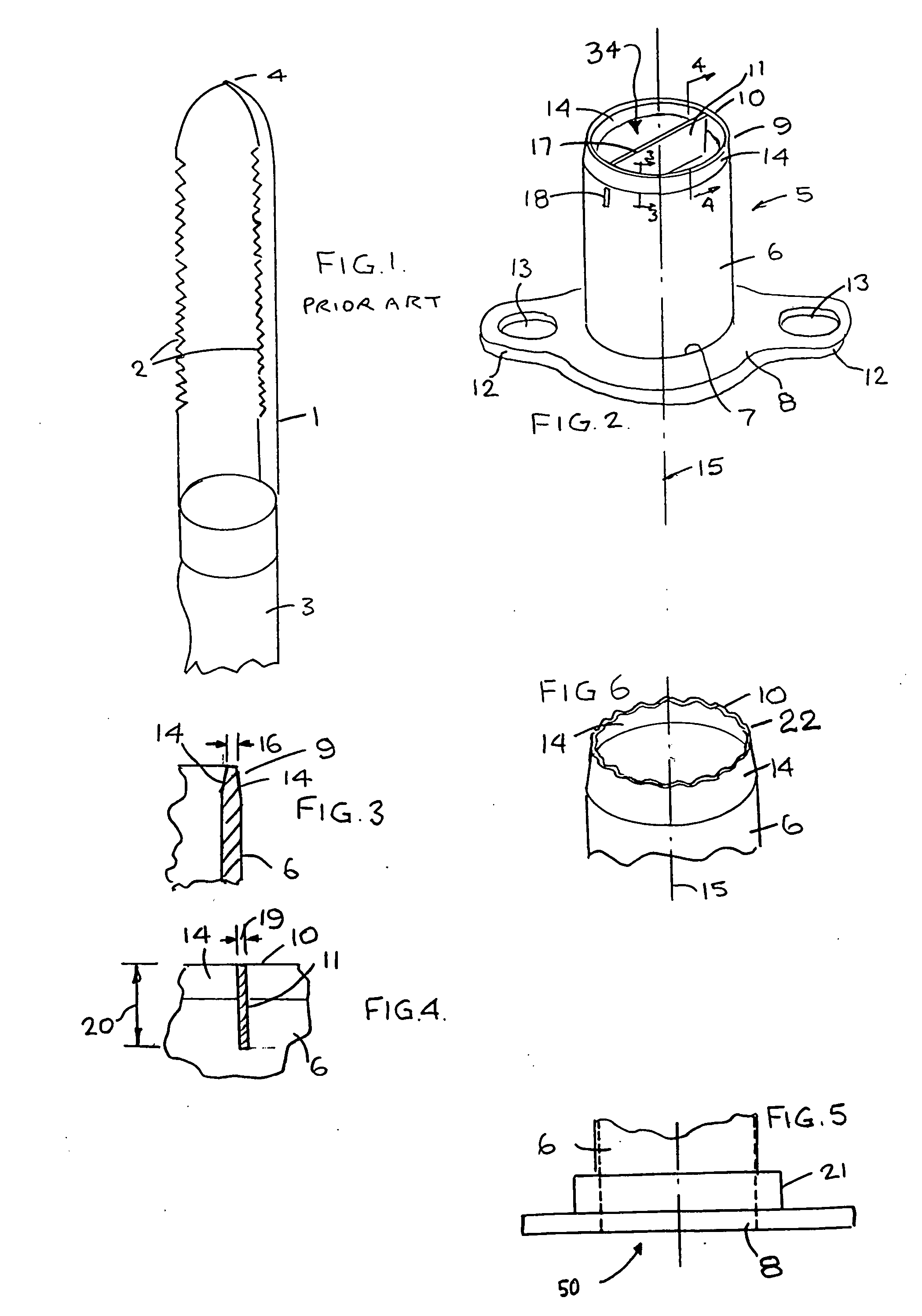

Vent valve assemblies for baby bottles

ActiveUS20080173612A1Reduce vacuumEasy to cleanCheck valvesEqualizing valvesExhaust valveEngineering

A vent valve, and a vent valve assembly, for a liquid dispensing container, employ a vent disc having small open vent holes in cooperation with an overlying thin flexible flap that covers and closes the vent holes to limit liquid pressure on the holes when the container is upright, yet require little suction pressure to move the flap to draw liquid or vent through the holes. The vent valve can be used in a bottom cap that is attachable to the bottom open end of the container. The vent valve assembly includes such a bottom cap, a sealing member for sealing the bottom cap to the container, and a vent valve. The vent valve and / or bottom cap have an elevated vent disc and a top portion having the thin flexible flap.

Owner:JMBH HLDG LLC

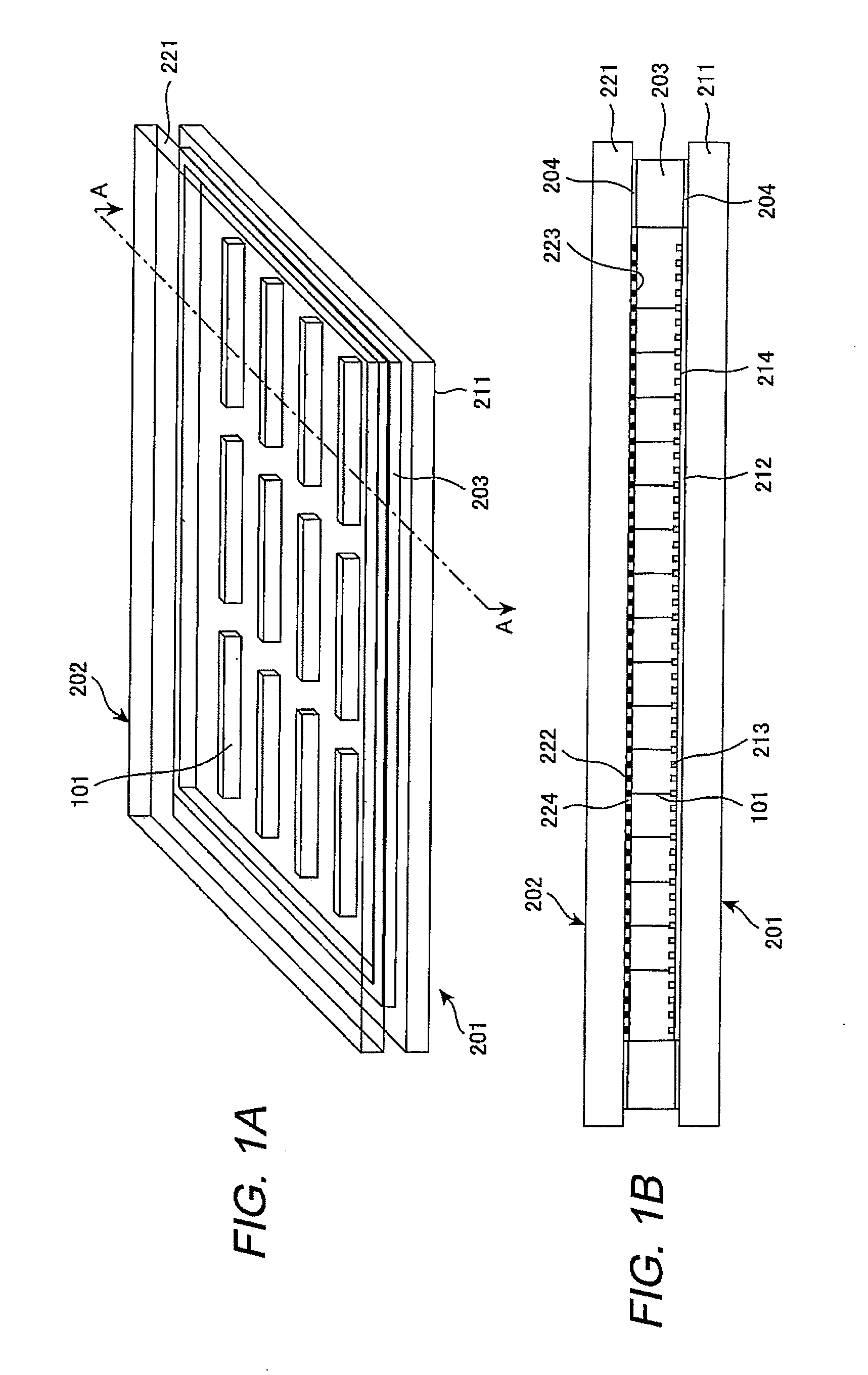

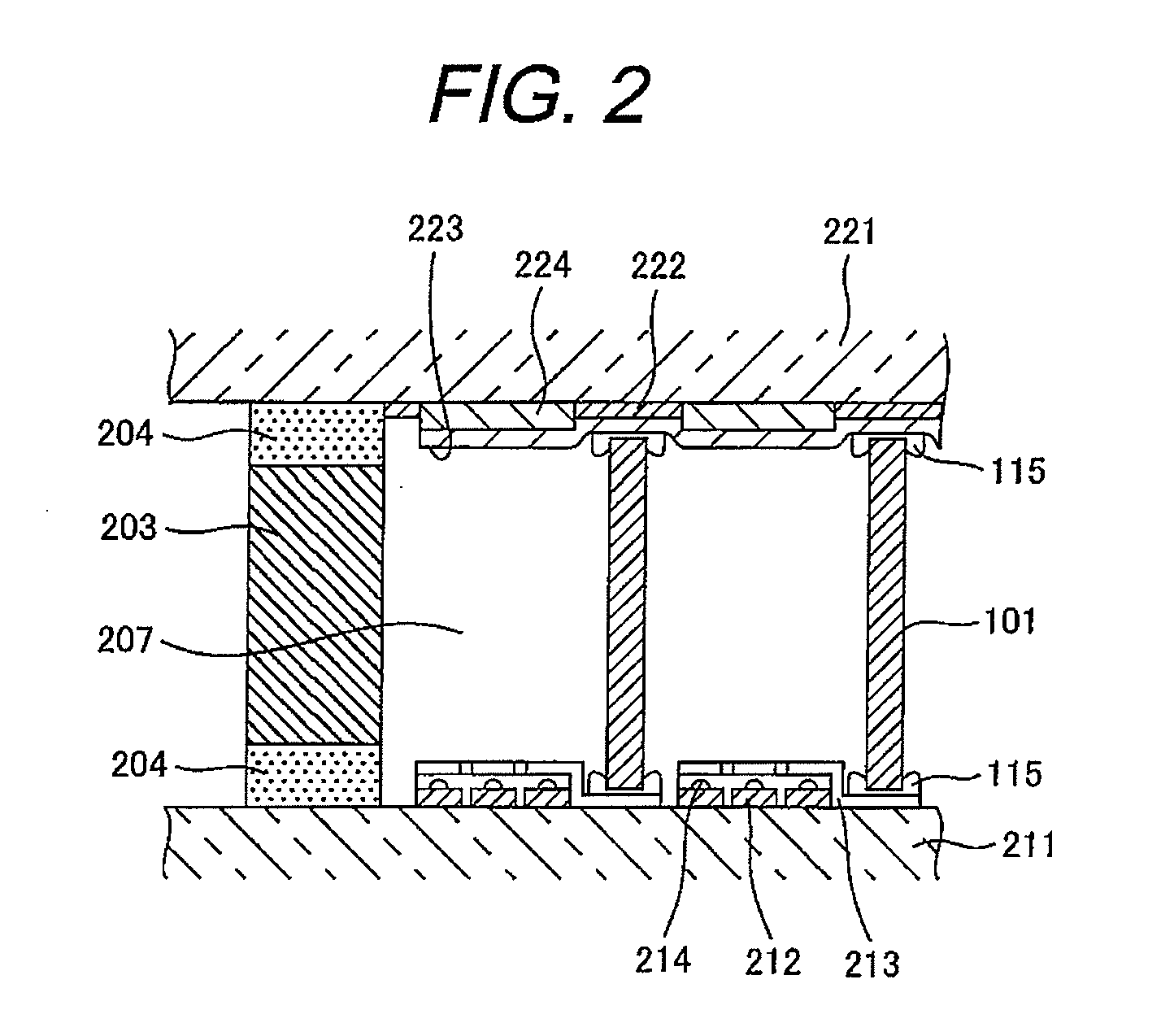

Display Apparatus

ActiveUS20070286973A1High bonding strengthAvoid environmental pollutionLiquid crystal compositionsStatic indicating devicesPhosphate glassVanadate

A sealing glass of a low melting point glass composition which is a phosphate glass that contains transition metal wherein the glass contains 15 to 35% of BaO and Sb2O3 (in total) and the ratio by weight of BaO to Sb2O3 or Sb2O3 to BaO is 0.3 or less. Particularly the transition metal is vanadium and the glass contains V2O5 of 45 to 60 wt % as vanadium oxide and P2O5 of 15 to 30 wt % as phosphorus oxide. The bonding material is a mixture of a filler and a vanadate-phosphate glass that contains V2O5 as the main ingredient and the glass contains V2O5 of 45 to 60%, P2O5 of 20 to 30%, BaO of 5 to 15%, TeO2 of 0 to 10%, Sb2O3 of 5 to 10%, and WO3 of 0 to 5%. The particle size of the filler is in the range of 1 to 150 μm and the ratio of filler is 80% by volume or less of the adhesive glass.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

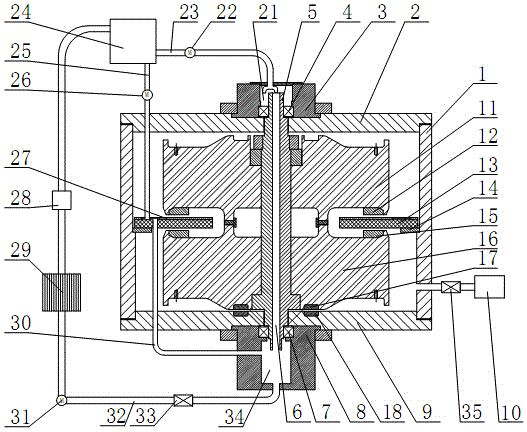

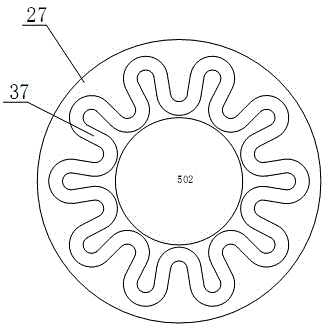

Cooling system of flywheel energy storage device

ActiveCN104578595ASafe and stable operationFull inlet pressureMagnetic circuit rotating partsVibration dampersCavitationFlywheel energy storage

The invention discloses a cooling system of a flywheel energy storage device. The flywheel energy storage device consists of a shell and an internal disc-type motor, wherein the shell has a vacuum sealing structure; an upper oil cavity and a lower oil cavity are respectively arranged at the upper part and lower part of the shell; the shell internally comprises at least one set of flywheel; a center shaft of each flywheel is a hollow mandrel, and an axle hole is formed in the center of the center shaft and is communicated with the upper oil cavity and the lower oil cavity; an oil tank is arranged outside the shell; the oil tank is communicated with the upper oil cavity by an upper oil pipe and is communicated with the lower oil cavity by an oil return pipe; the oil return pipe is provided with a third valve, an oil pump and a radiator. The cooling system can be used for cooling a rotor by the axle hole, so that a great deal of heat of the rotor which rotates at a high speed can be taken away in time, and safe and stable operation of the flywheel energy storage device is guaranteed. An upper bearing, a lower bearing and a stator disc are cooled in time by part of cooling oil, and the bearings can be lubricated, so that the reliable work of key parts can be guaranteed, and the defects of cavitation and the like of a pump caused by low pressure can be avoided.

Owner:ERZHONG DEYANG POWER TECH CO LTD

Glycolide preparation method

InactiveCN105272958ALow impurity contentImprove conversion rateOrganic chemistryDepolymerizationReaction temperature

The present invention relates to a glycolide preparation method. A purpose of the present invention is mainly to solve the problems of low purity and low yield of the prepared glycolide in the prior art. The technical scheme comprises: (1) melt condensation polymerization: a) normal pressure condensation polymerization, wherein a glycolic acid crystal is subjected to sectional reaction under a normal pressure in the presence of a condensation catalyst or a transesterification catalyst, the reaction is performed for 0.5-10 h by maintaining the reaction temperature between the glycolic acid melting point and the glycolic acid boiling point at the first stage normal pressure prepolymerization, and at the second stage normal pressure condensation polymerization, the condensation reaction or the transesterification reaction is performed at a reaction temperature of 112-220 DEG C until no water is distilled to obtain the molten glycolic acid oligomer, b) pressure reducing condensation polymerization, and c) strengthened condensation polymerization; and (2) high temperature depolymerization, wherein a depolymerization reaction is performed at a reaction temperature of 230-290 DEG C under a reaction pressure of 0.1-1 KPa so as to obtain the glycolide crude product. With the technical scheme of the present invention, the problems in the prior art are well solved, and the method can be used in the industrial glycolide production.

Owner:CHINA PETROLEUM & CHEM CORP +1

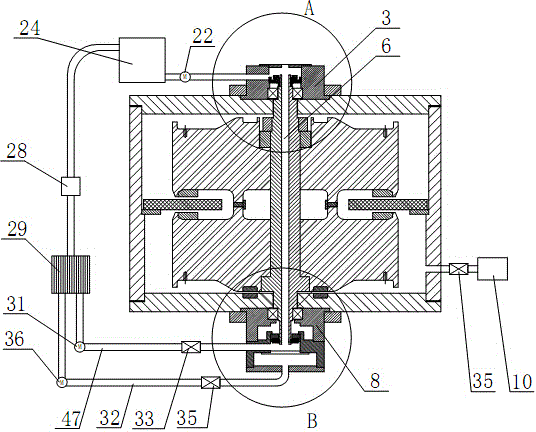

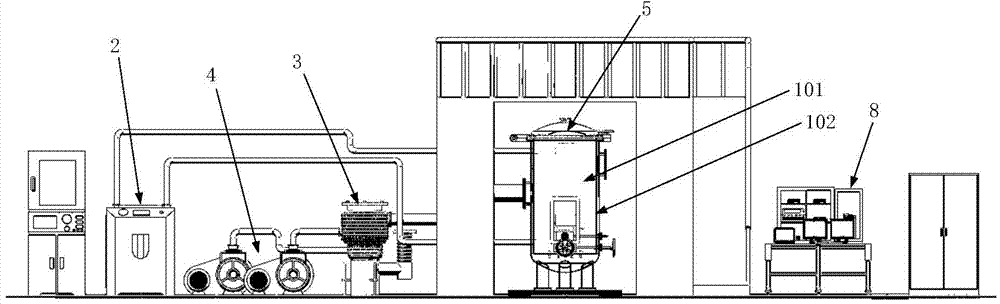

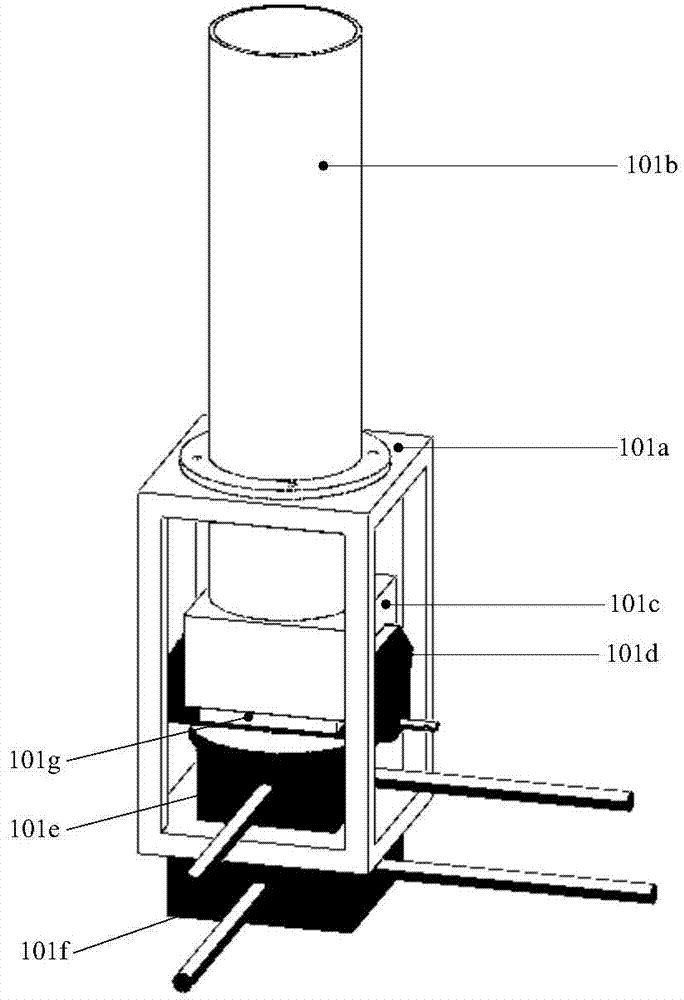

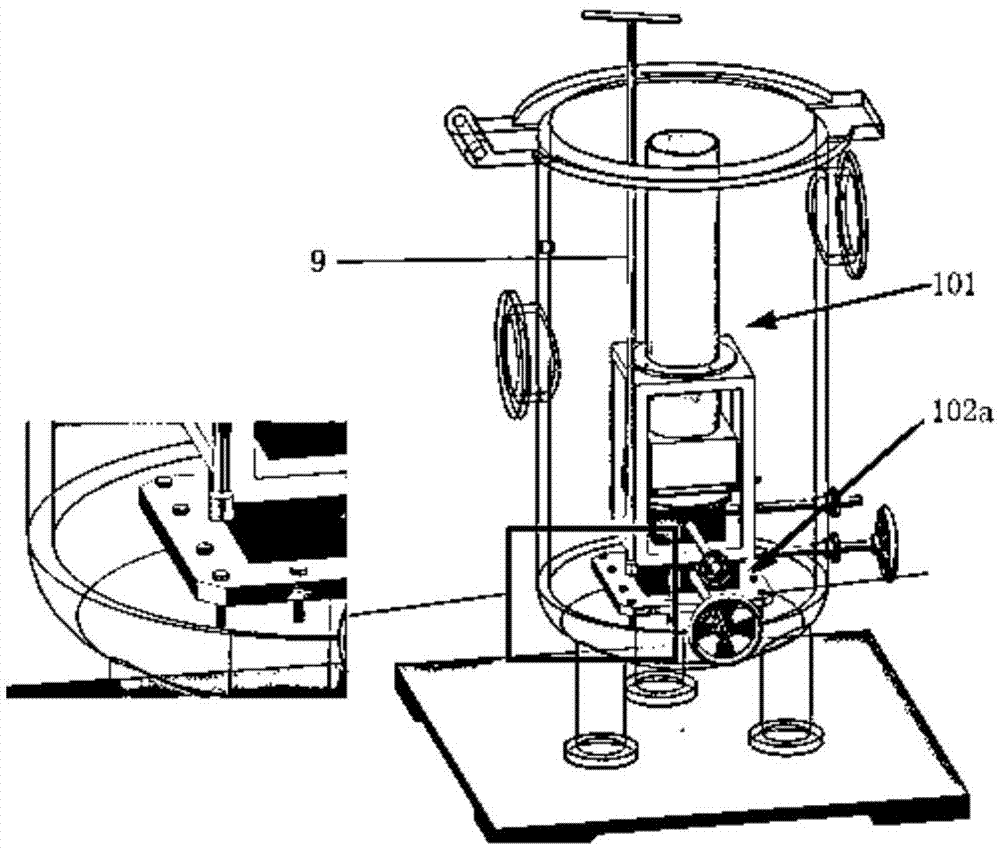

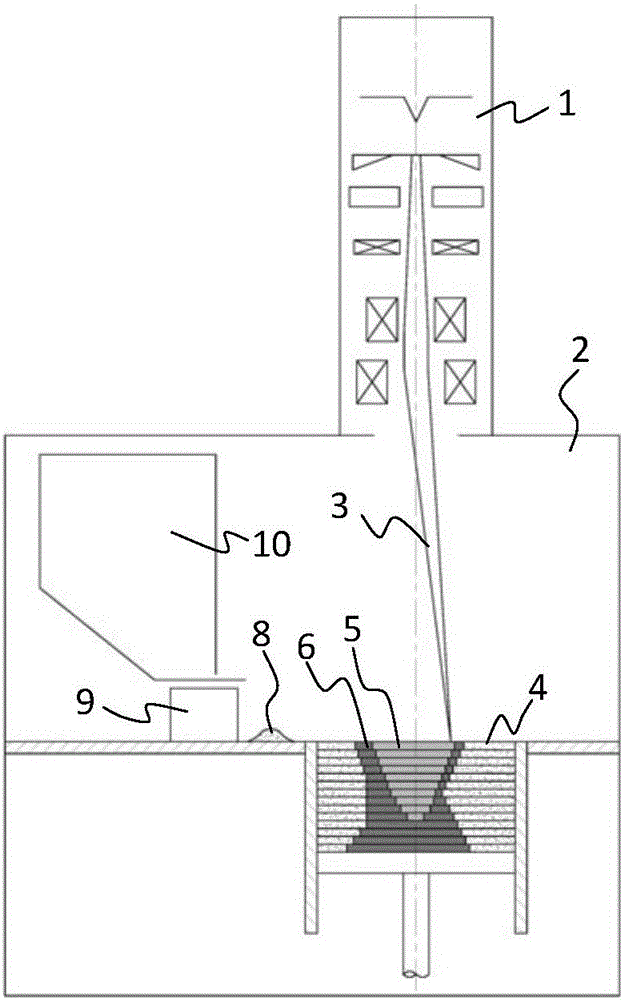

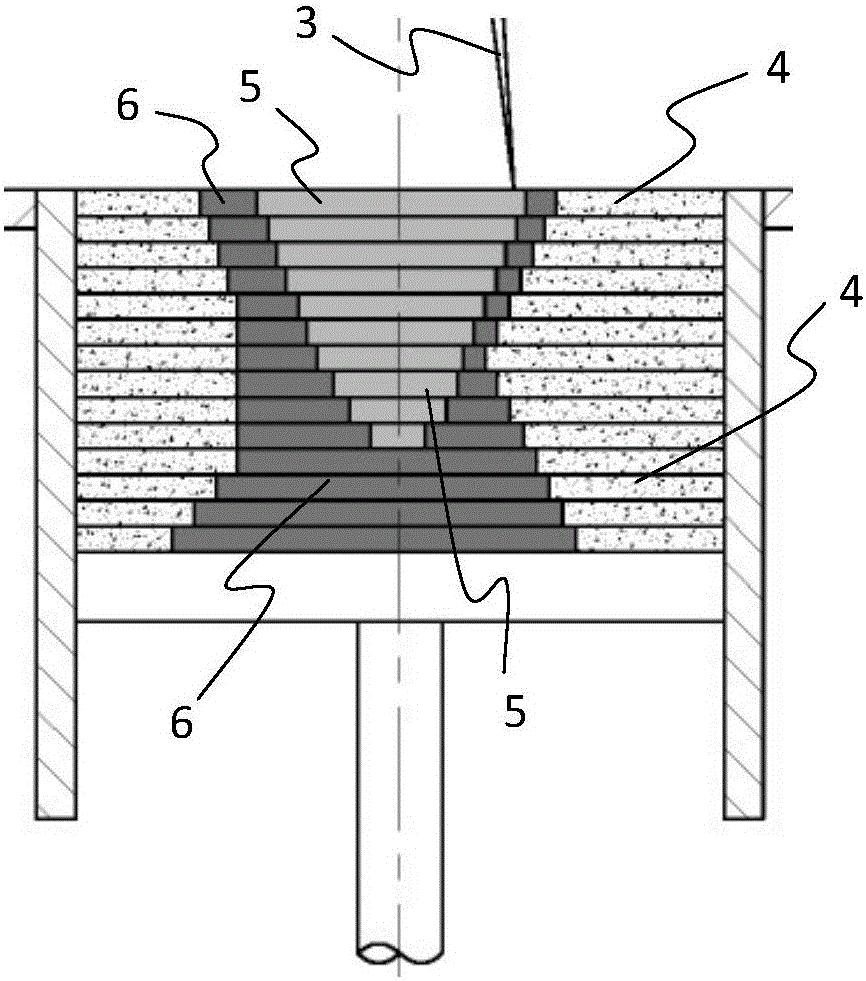

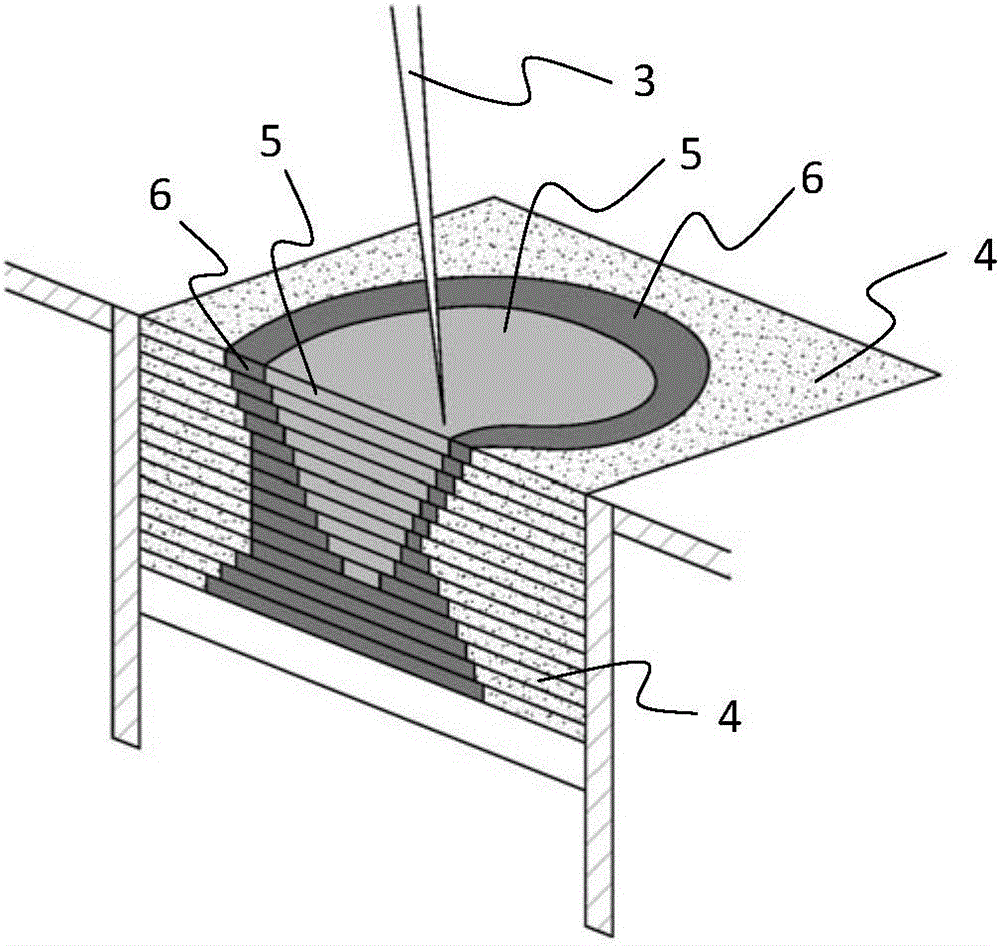

High and low temperature vacuum lunar soil environment simulator

The invention discloses a high and low temperature vacuum lunar soil environment simulator, which comprises a high and low temperature vacuum environment simulator including a simulant lunar soil containing device and a vacuum tank; a low temperature refrigeration cycle device; a diffusion pump; a mechanical pump and a heating component; the simulant lunar soil containing device is provided with a lunar soil drum for containing simulant lunar soil, and the location of the simulant lunar soil containing device is trimmed by a mobile platform; the simulant lunar soil containing device is arranged in the vacuum tank; the vacuum tank is vacuumized by a vacuum tube through the diffusion pump and the former mechanical pump; the low temperature refrigeration cycle device can refrigerate the lunar soil by a purple copper pipe which is designed on the wall of the lunar soil drum and is internally provided with a freezing medium; the surface of the simulant lunar soil is heated by an iodine-tungsten lamp arranged above the lunar soil drum. The high and low temperature vacuum lunar soil environment simulator has the advantages that daytime high temperature or night low temperature environment of surface-layer lunar soil and low temperature environment of deep-layer lunar soil under vacuum conditions can be simulated, and the high compactness of 1.9g / cm3 and moisture content less than 0.1% of the simulant lunar soil can be ensured.

Owner:BEIHANG UNIV

Additive manufacturing method for multi-material heterogeneous part

ActiveCN105945280ASimple processEasy to implementAdditive manufacturing apparatusIncreasing energy efficiencyMulti materialVapor pressure

The invention discloses an additive manufacturing method for a multi-material heterogeneous part. The additive manufacturing method for the multi-material heterogeneous part comprises the following steps that A, alloy powder is formed into forming layers through electron beam or laser selective melting, and the alloy powder comprises at least two elements, the elements are different in saturated vapor pressure and in volatilization degree; in the electron beam or laser selective melting process, different kinds of electron beam or laser energy are applied to different areas of each forming layer and / or the different forming layers, and the elements contained in the alloy powder are volatilized at the different degrees so that alloy with the different element contents can be obtained in the different areas and / or on the different forming layers; and B, the multiple forming layers and the different areas of the forming layers are subjected to fusion and stacking layer by layer, and finally the heterogeneous gradient part with the element component being in a three-dimensional change mode is obtained. The additive manufacturing method has the advantages of being simple in process, convenient to carry out, low in implementing cost and equipment requirement and the like.

Owner:TSINGHUA UNIV

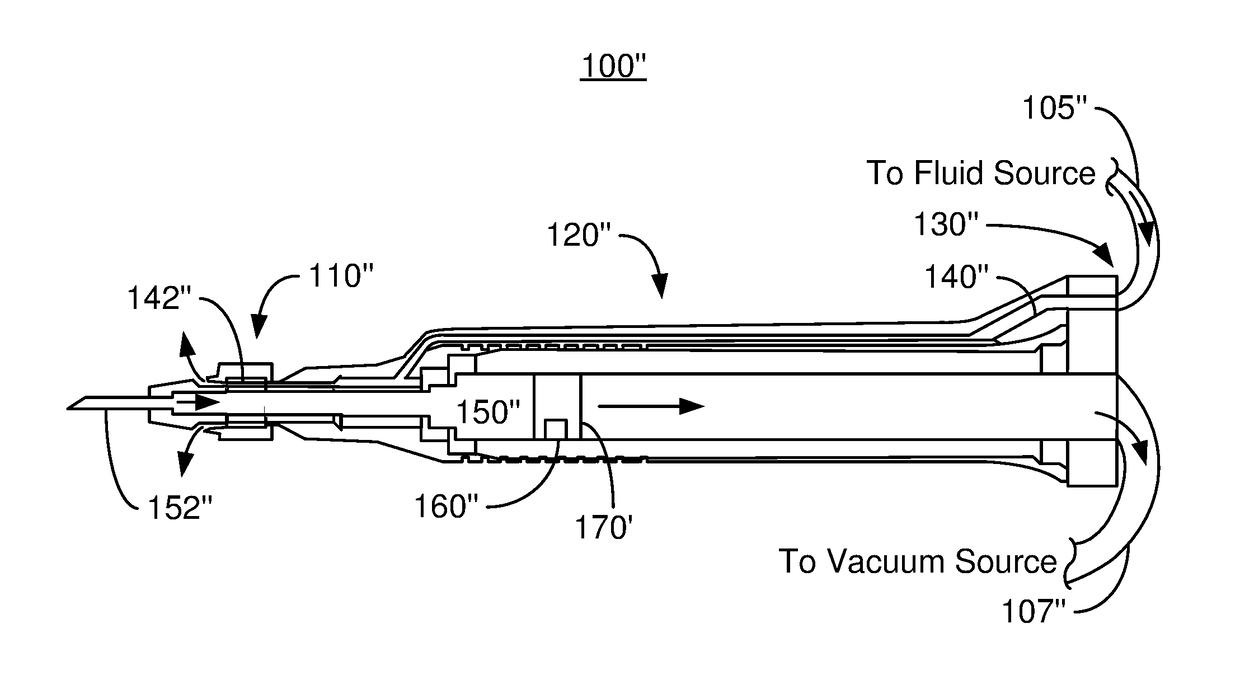

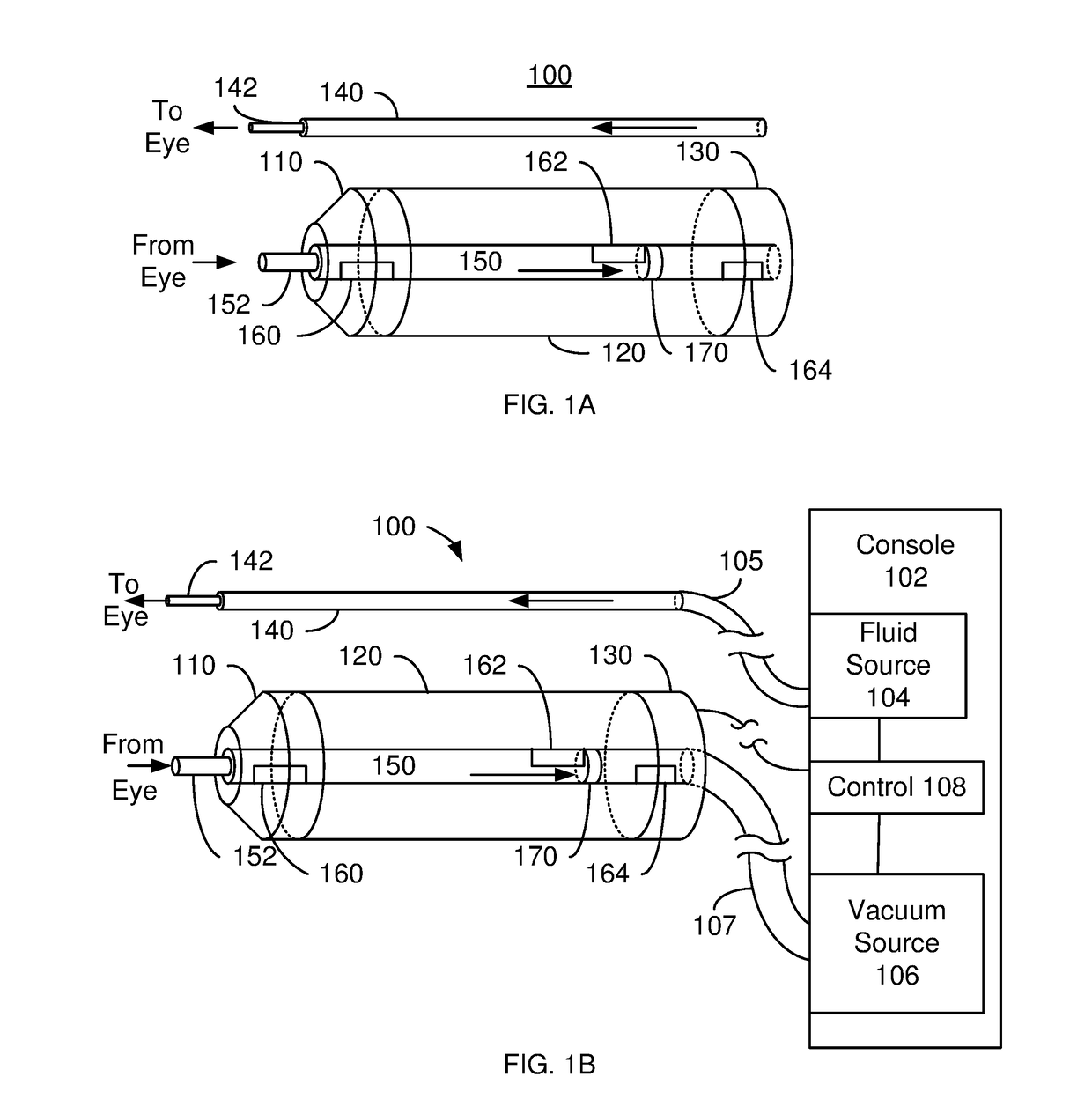

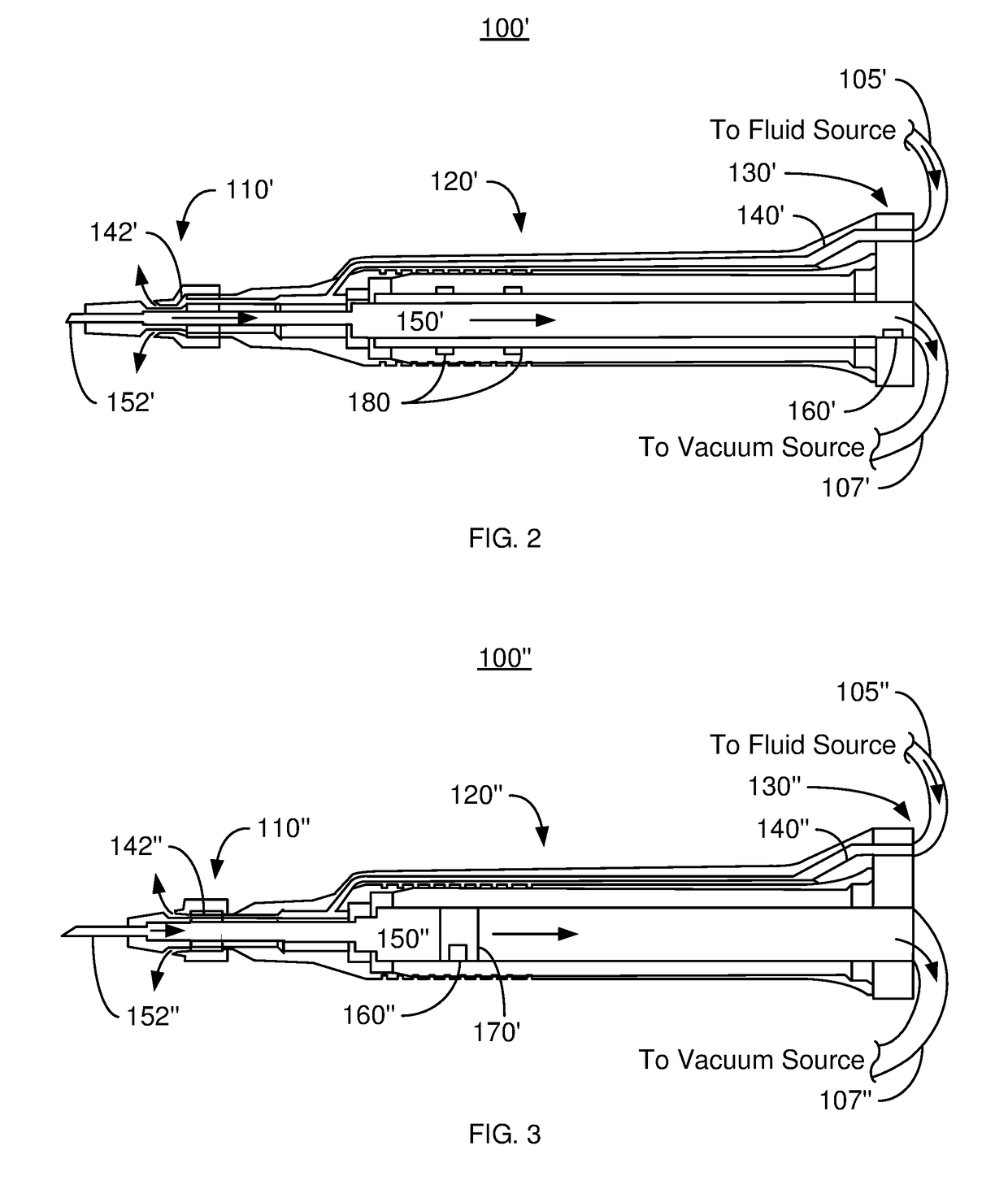

Surgical apparatus including aspiration device sensors

A method and system provide a surgical hand piece including an aspiration line, a tip and a sensor. The tip is coupled with the aspiration line. The sensor is in the aspiration line. The sensor measures a change in at least one of flow through the aspiration line, pressure in the aspiration line and motion of an additional portion of the hand piece within the aspiration line.

Owner:ALCON INC

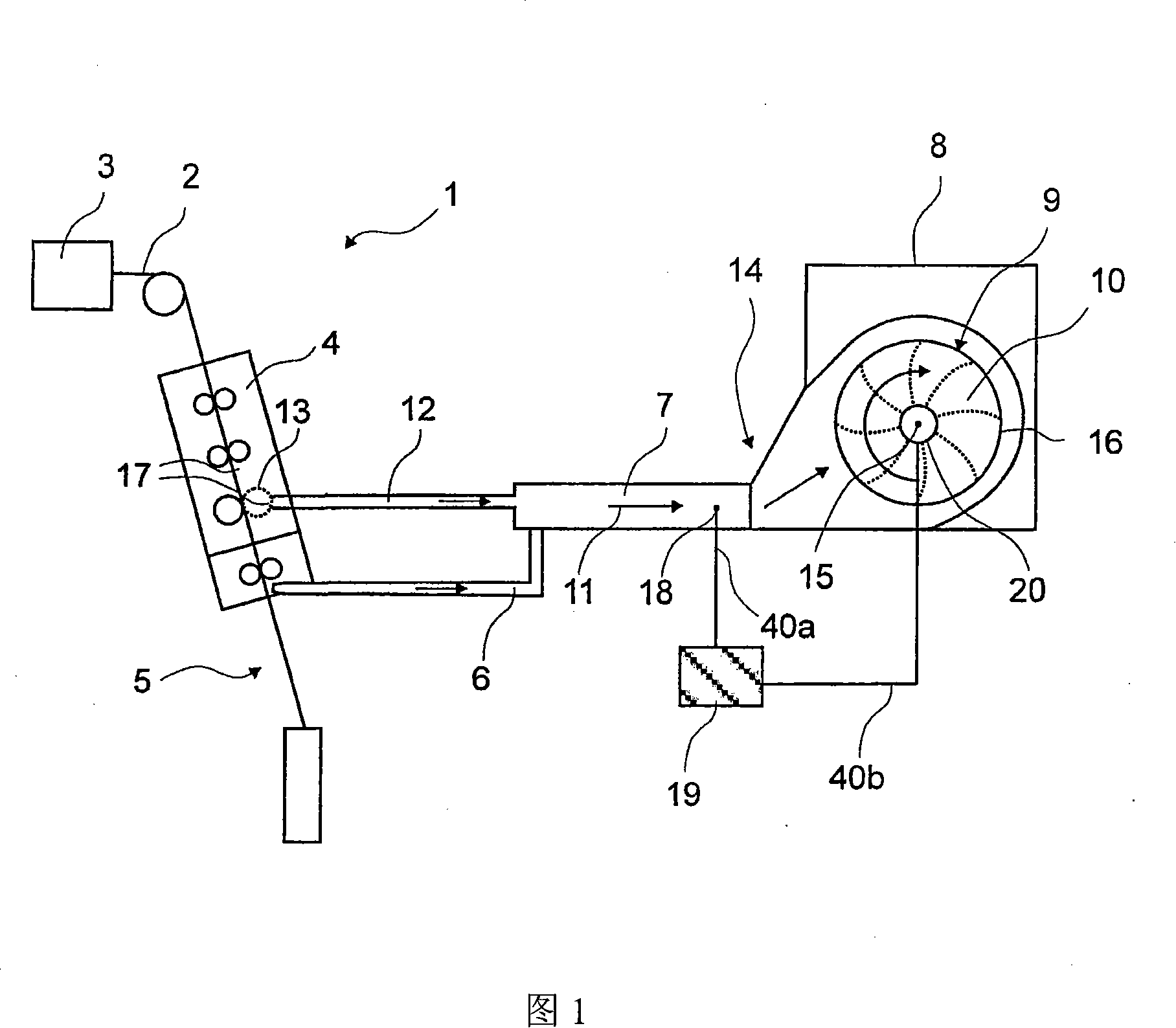

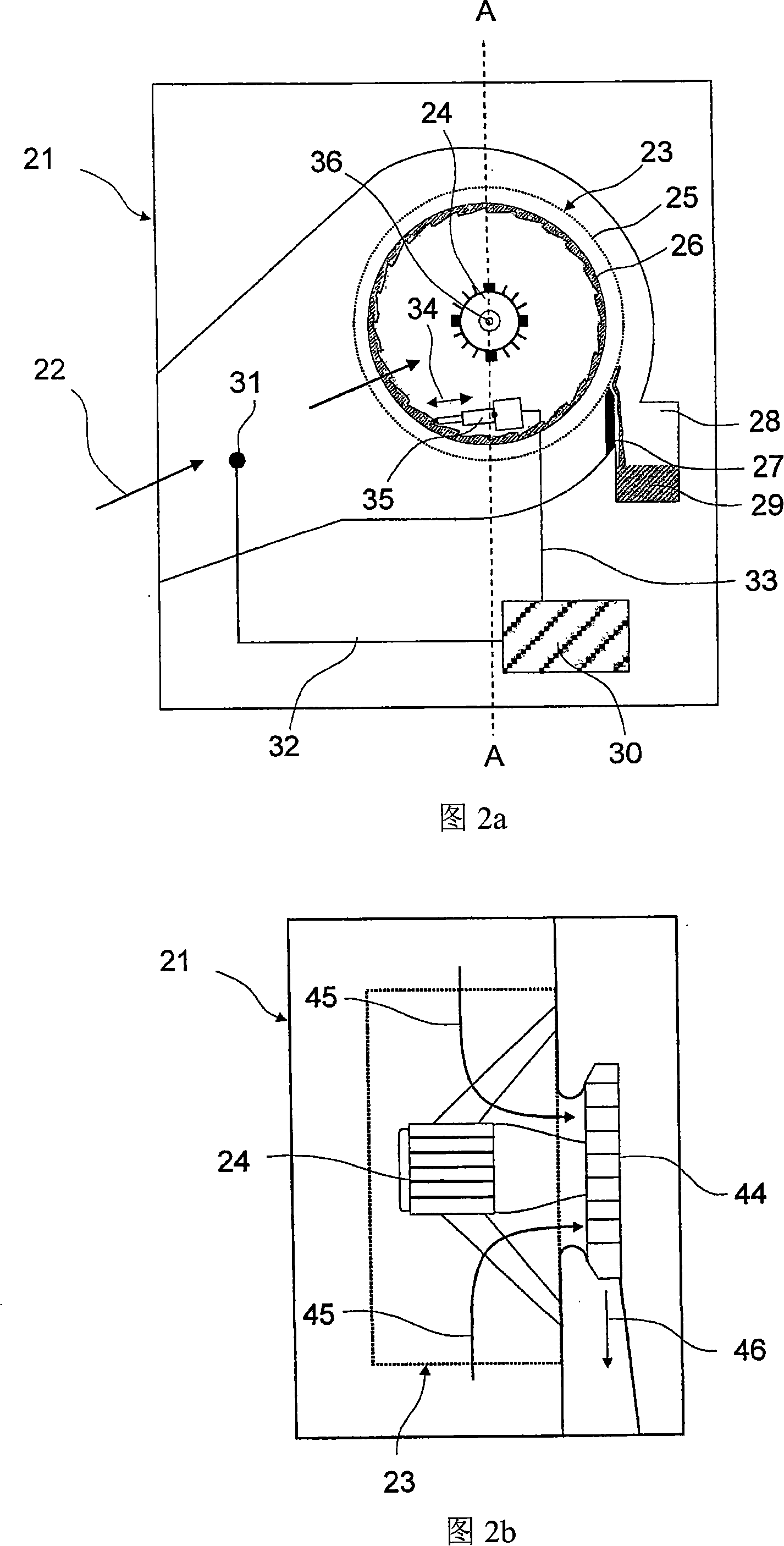

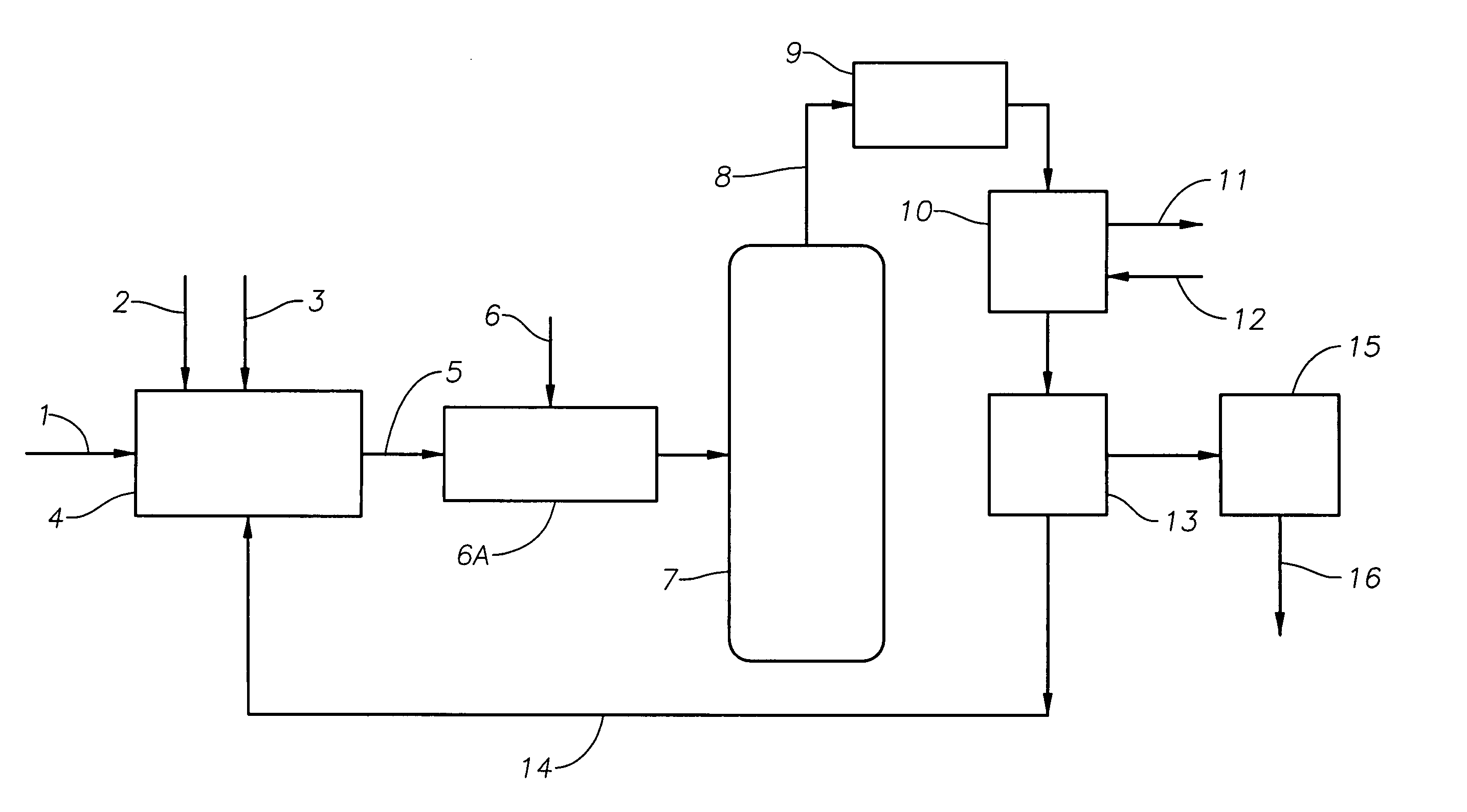

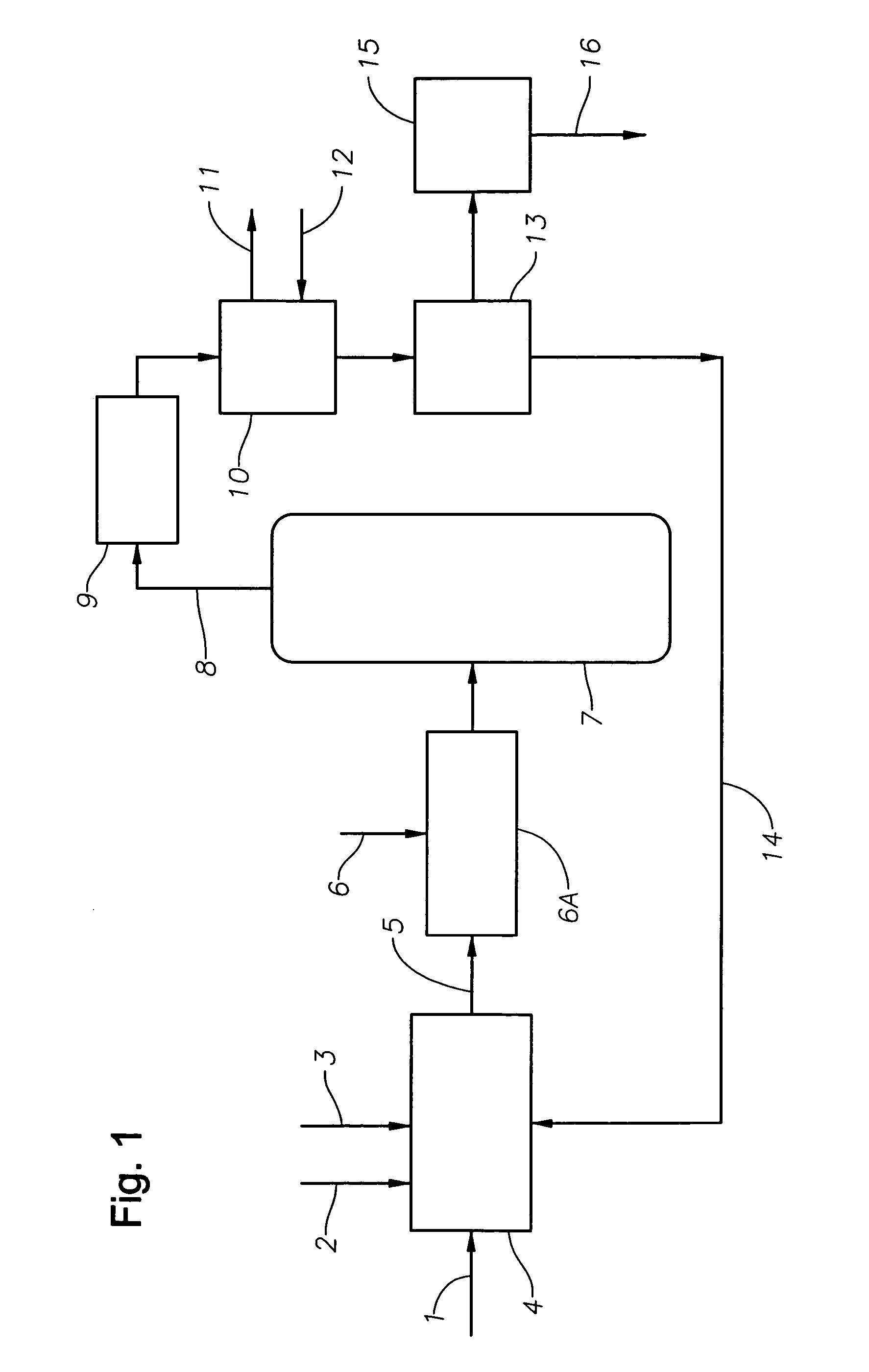

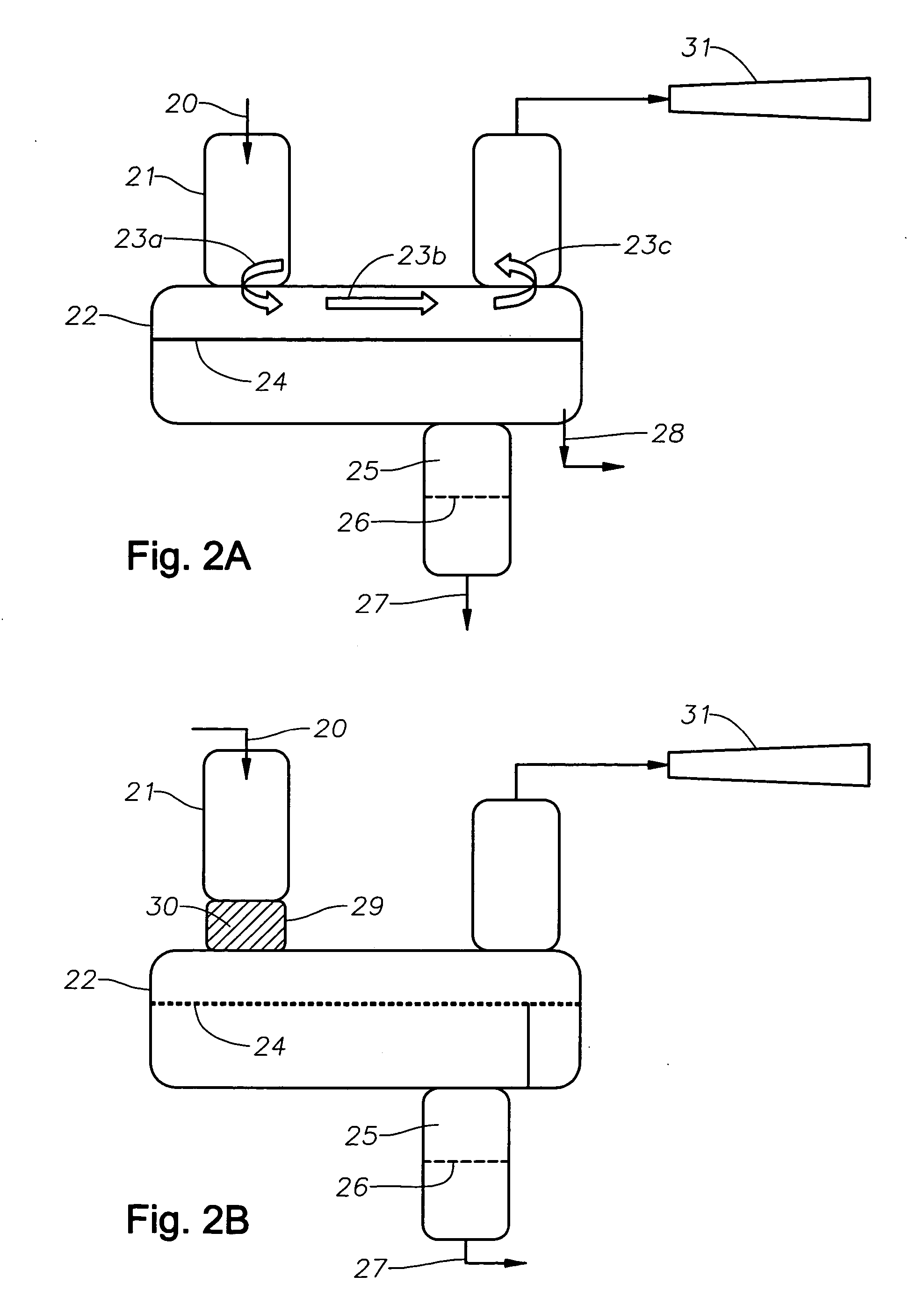

Device and method for pumping and filtering air containing dust and/or fibre on the spinning machine

InactiveCN101113537AEasy to storeEffectively fixedDispersed particle filtrationTransportation and packagingFiberMotor drive

The device for the suction and filtration of dust- and / or fiber loaded air on spinning machines (1), comprises working places consisting of a suction channel (7), a filtering device (8) with a filter forming a filtering surface (16), a system for removing the filter outflow from the filtering surface, a vacuum source (10) for generating an induced draft, an operating means for carrying out a filter cleaning process using a removal system, and a vacuum sensor arranged in the main suction channel for measuring the vacuum in a vacuum zone before and / or after the filtering. The device for the suction and filtration of dust- and / or fiber loaded air on spinning machines (1), comprises working places consisting of a suction channel (7), a filtering device (8) with a filter forming a filtering surface (16), a system for removing the filter outflow from the filtering surface, a vacuum source (10) for generating an induced draft, an operating means for carrying out a filter cleaning process by a removal system, and a vacuum sensor arranged in the main suction channel for measuring the vacuum in a vacuum zone before and / or after the filtering. The device contains a controller or regulator for vacuum in the vacuum zone before and / or after the filtering surface based on the vacuum values, vacuum target values or vacuum target value areas, which are measured by the vacuum sensor. The controller or regulator is connected with a driving mechanism for filter cleaning. The controlling or regulating of the vacuum takes places by the operation of the driving mechanism. The spinning place contains suction places (17), over which polluted air is sucked out and supplied over a central suction channel or -channel of the filter arrangement. The vacuum source contains an axial- or radial ventilator. The filter outflow is liftable or removable from the filtering surface using removal- or a lifting device and is fed to a collecting- or disposing device. The controller contains a signal converter and a control device, by which the measured values received by the vacuum sensor in the form of vacuum values are compared with the vacuum target values and vacuum target value areas. Controlling or regulating signals are generated for correcting the variation of actual value from the target value for operating on an actuator and / or a final control element containing driving means. The filtering device contains a filter drum with a cylinder shaped, fixed or flexible filter surface, which is arranged on the removal system. The driving mechanism comprises a drive system for turning the filter drum around the drum axis. The filter cleaning is carried out by a continuous or sequential turning of the filter drum, by which the filter surface is directed to the removal device and the filter outflow is removed. The driving mechanism contains a hydraulic or pneumatic piston drive, and a linear motor or electric cylinder, which is connected with a gear between the driving mechanism and the filter. A control is intended for thread count and / or equipment parameters of the pressure ratio in the channels and / or pipes are adjustable. The control consists of a means for changing the vacuum over the filter device and / or over the ventilator output. The filter device contains a continuous filter band forming a space, and electro motor driving mechanism for a circulatory movement of the filter band, which forms a layered filter surface. Independent claims are included for: (1) a spinning machine; and (2) a method for the suction and filtration of dust- and / or fiber loaded air on spinning machines.

Owner:MASCHINENFABRIK RIETER AG

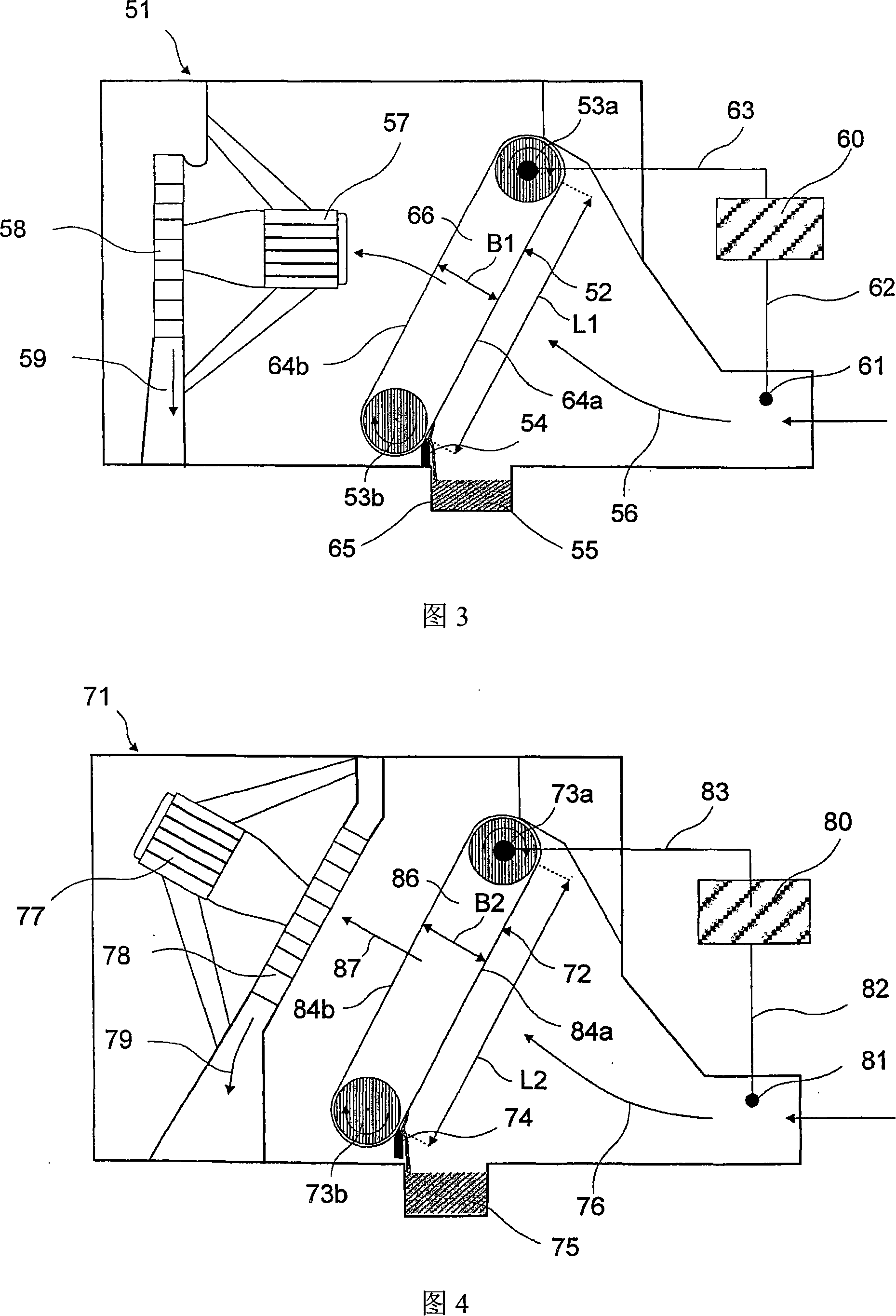

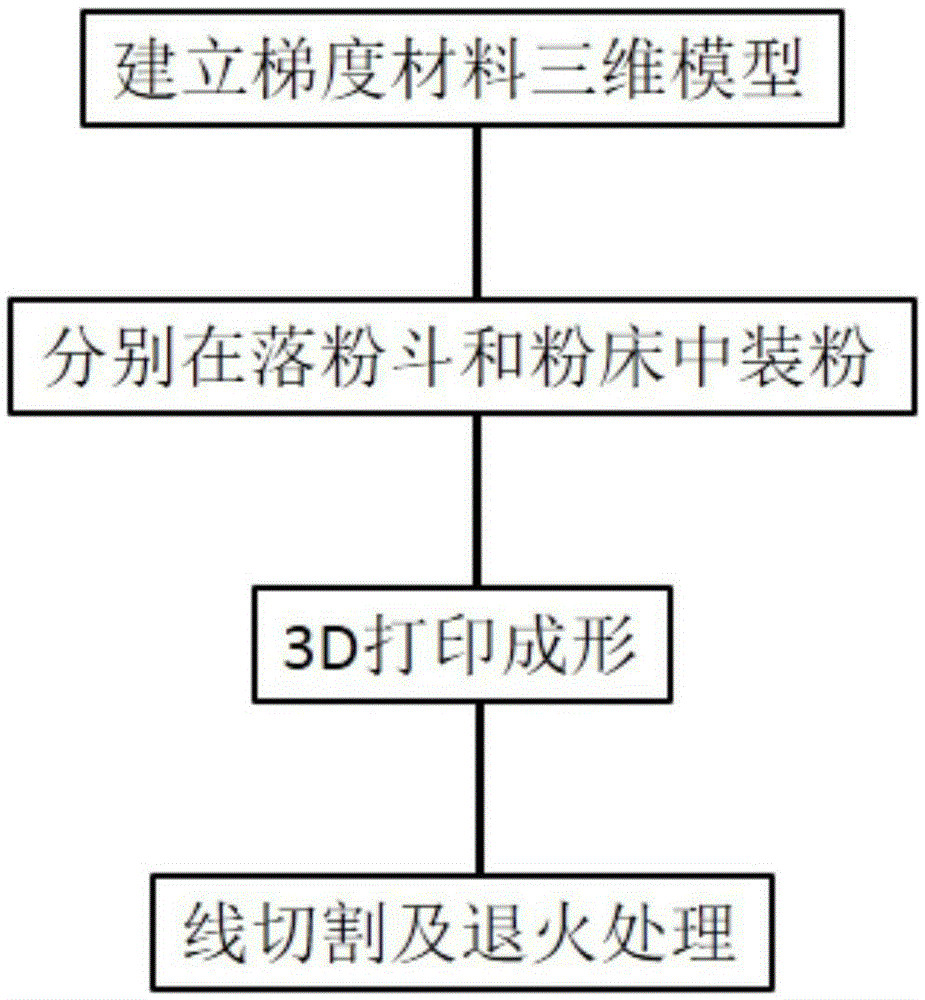

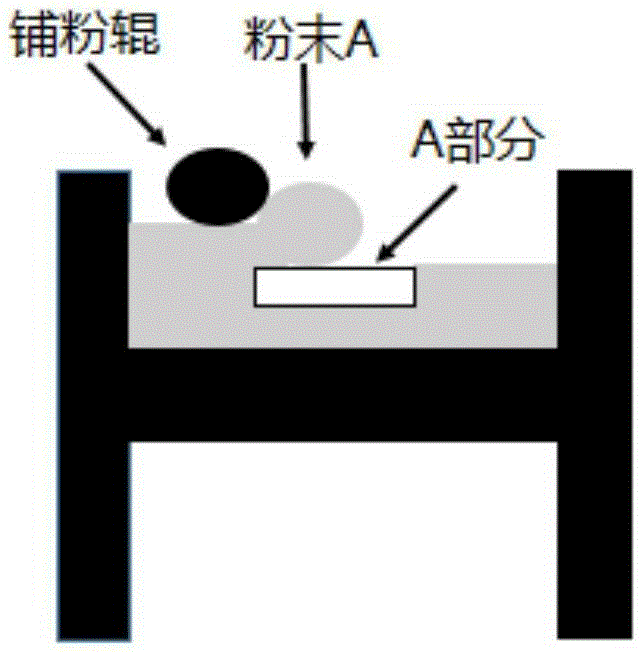

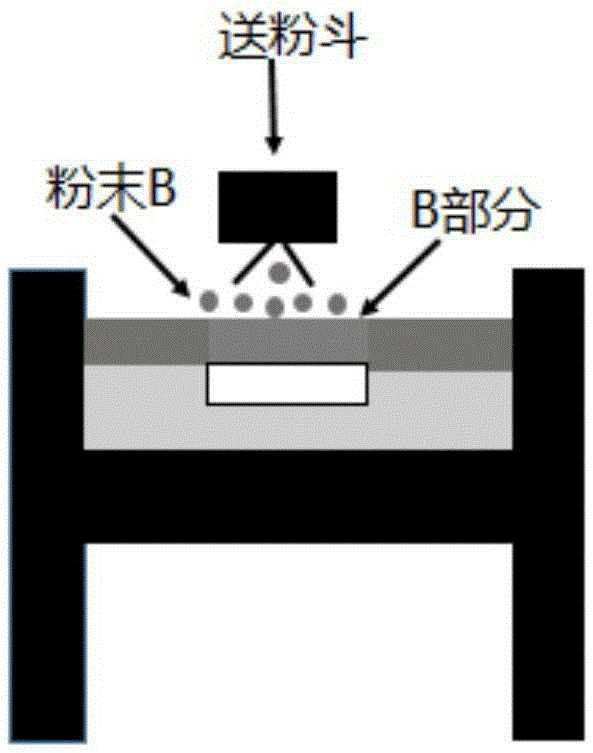

Method for forming functional graded part through selective laser melting

ActiveCN105386037AFast preparationSave overall forming timeMetallic material coating processesSelective laser meltingVacuum pumping

The invention discloses a method for forming a functional graded part through selective laser melting. The method includes the following steps that firstly, a part three-dimensional model is guided into a selective laser melting forming device; secondly, powder A is put into a powder feeding bed, and powder B is placed into a powder feeding bucket; thirdly, the powder A is formed firstly, and the powder B is formed; and fourthly, a linear cutting technology is used for separating the graded part from a base plate and annealed in a muffle furnace, and a finished product is obtained. According to the method for forming the functional graded part through selective laser melting, a powder bed used during powder bed additive manufacturing is used for laying powder, a powder feeding bucket powder discharging technology is combined, a functional graded material can be formed at a time, the total forming time is shortened, the number of times of vacuum pumping and argon charging is reduced, and production efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

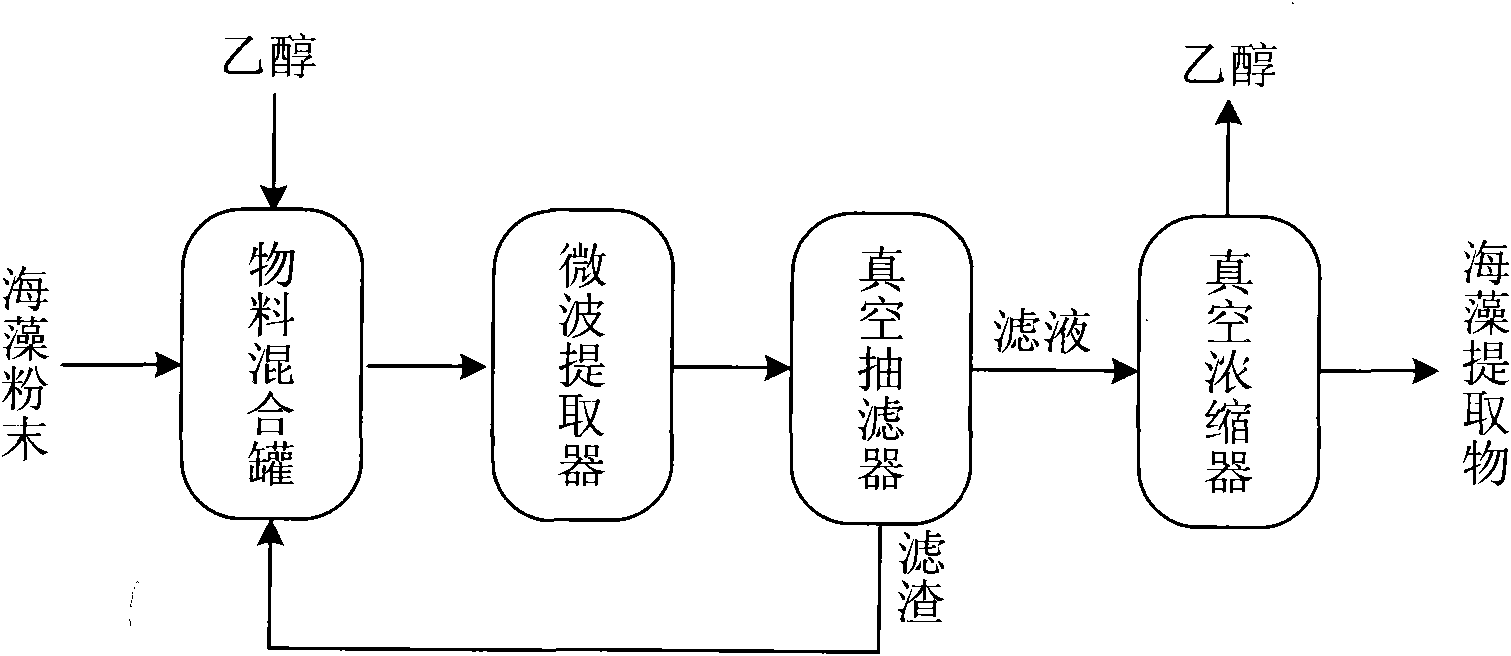

Seaweed flavor powder

The invention relates to edible seaweed, in particular to a seaweed flavor powder, and the flavor powder consists of 50 parts by weight of seaweed extract, 25-100 parts by weight of modified starch or / and dextrin and 1-5 parts by weight of emulsifier, wherein the emulsifier is glycerel monostearte or / and sucrose ester; the modified starch is crosslinked starch or / and gelatinized starch; and the seaweed extract is prepared by carrying out continuous microwave extraction on the edible seaweed by adopting 70-100% of ethanol. The seaweed flavor powder can retain aroma and taste of the seaweed and has the unique flavor of fresh, sweet, salty and fragrant. The seaweed flavor powder can be used as seaweed tea and seaweed soup, or be used on the surfaces of biscuits, cakes and bread or be added therein, or be added into dry noodles and instant noodles for producing foods with seaweed flavor.

Owner:GUANGZHOU UNIVERSITY

Catalyst recovery process

ActiveUS20060178545A1Emission reductionReduce vacuumDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionBoron trifluorideOrganocatalysis

A process for reducing boron trifluoride usage and emissions associated with PAO manufacture, the process comprising distilling a portion of the crude PAO product containing a boron trifluoride-organic catalyst at a temperature sufficient to cause the boron trifluoride-organic catalyst to dissociate to produce an overhead stream comprising uncomplexed boron trifluoride and an uncomplexed organic catalyst component, contacting the uncomplexed boron trifluoride and uncomplexed organic catalyst component in a condenser column having an internal structure that increases the recombination of the uncomplexed boron trifluoride and uncomplexed organic catalyst component to form a recycle boron trifluoride-organic catalyst.

Owner:EXXONMOBIL CHEM PAT INC

Vent valve assemblies for baby bottles

ActiveUS20110168714A1Reduce vacuumEasy to cleanEqualizing valvesSafety valvesExhaust valveEngineering

A vent valve, and a vent valve assembly, for a liquid dispensing container, employ a vent disc having small open vent holes in cooperation with an overlying thin flexible flap that covers and closes the vent holes to limit liquid pressure on the holes when the container is upright, yet require little suction pressure to move the flap to draw liquid or vent through the holes. The vent valve can be used in a bottom cap that is attachable to the bottom open end of the container. The vent valve assembly includes such a bottom cap, a sealing member for sealing the bottom cap to the container, and a vent valve. The vent valve and / or bottom cap have an elevated vent disc and a top portion having the thin flexible flap.

Owner:JMBH HLDG LLC

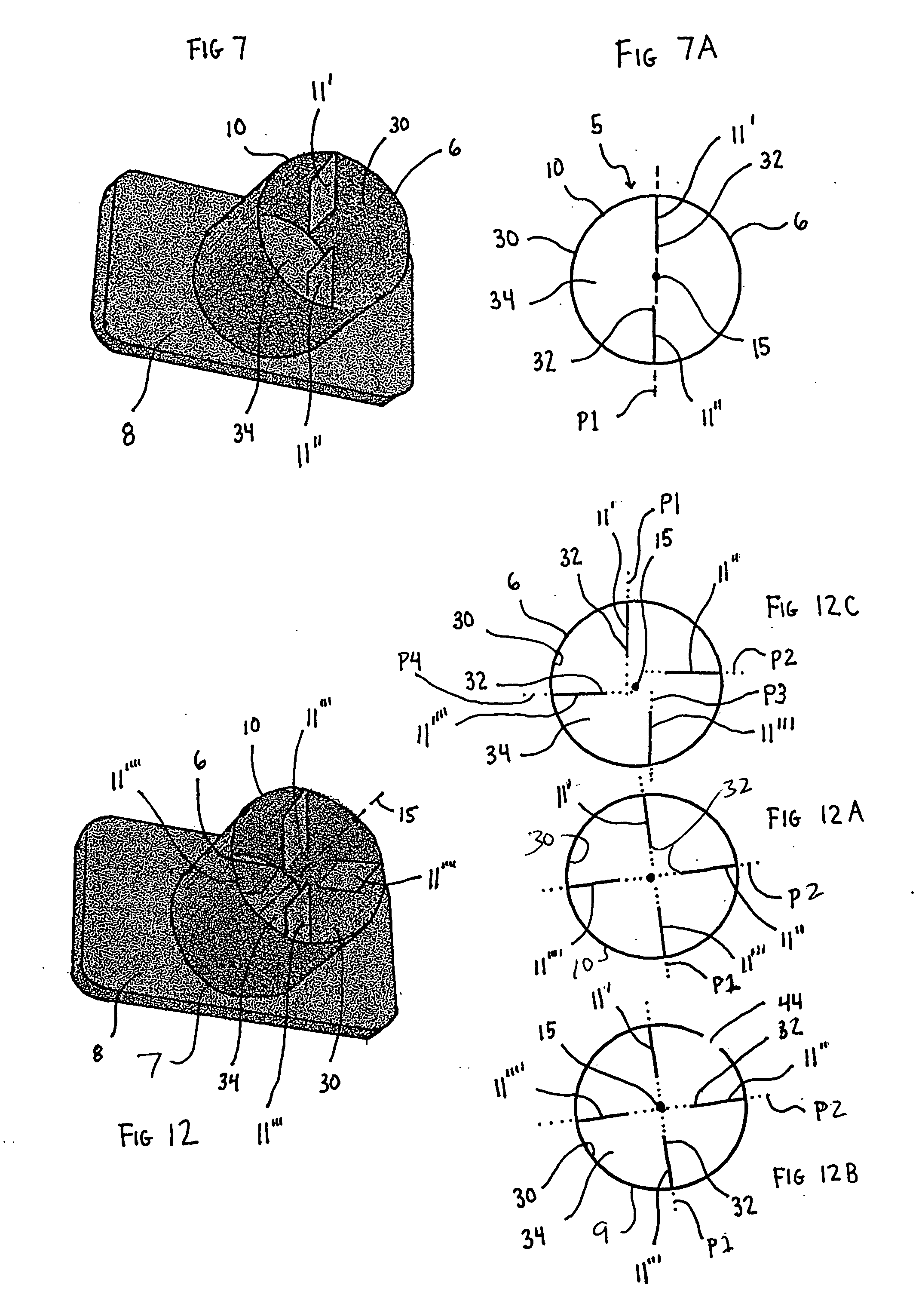

Fruit coring device for producing a closed bore

InactiveUS20040093738A1Easy to disassembleEconomical and easy to manufactureKitchen fruit stoningFruit coringKnife bladesBiomedical engineering

A fruit coring device including a handle and a tubular member having first and second ends. The tubular member defines a longitudinal axis and has an interior region. One end of the circular tubular member is integral or fast with the handle and the second end defines a member cutting edge. The fruit coring device includes a blade with a cutting edge supported within the circular interior of the circular tubular member substantially normal to the member cutting edge.

Owner:MAURO GEORGE

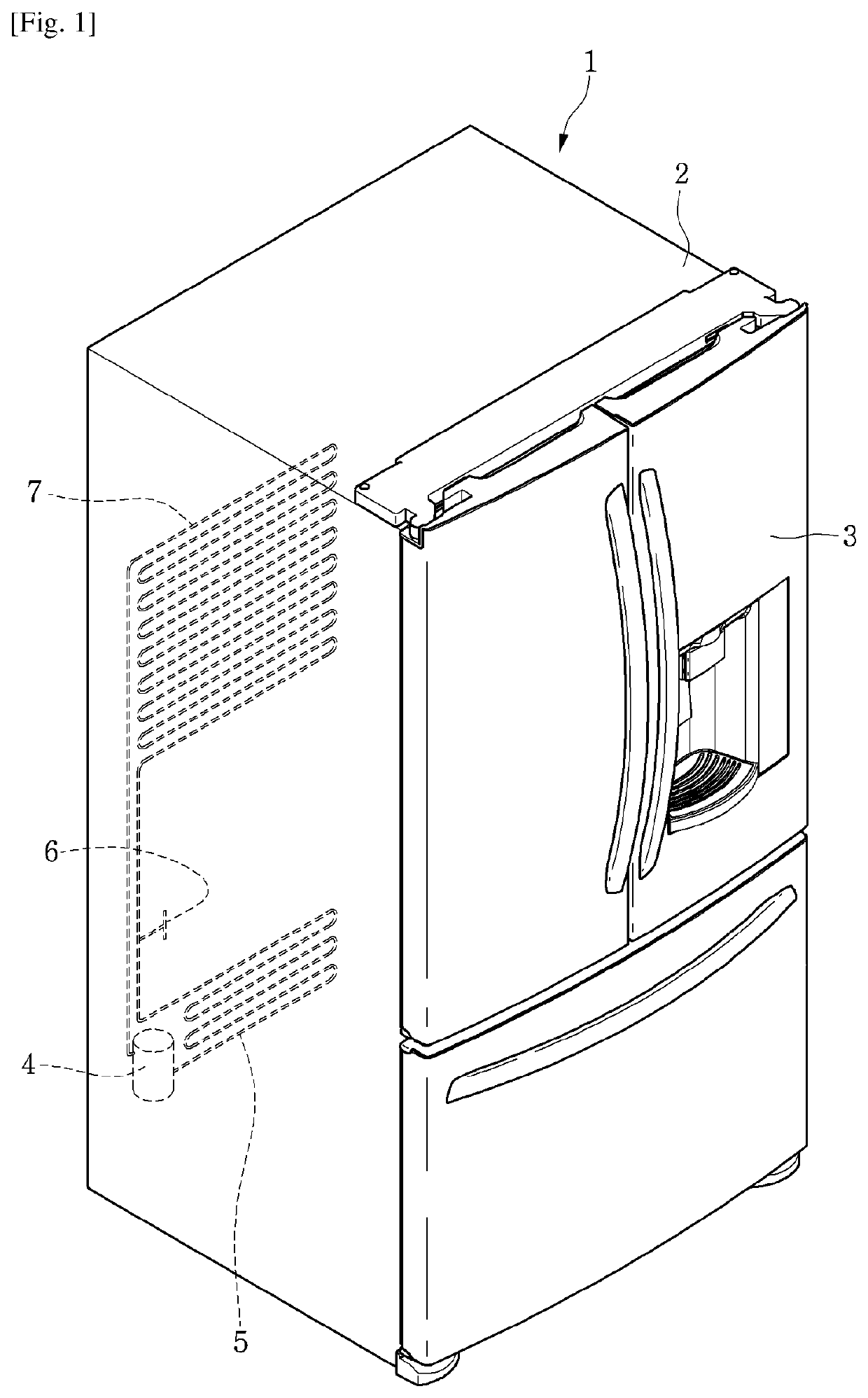

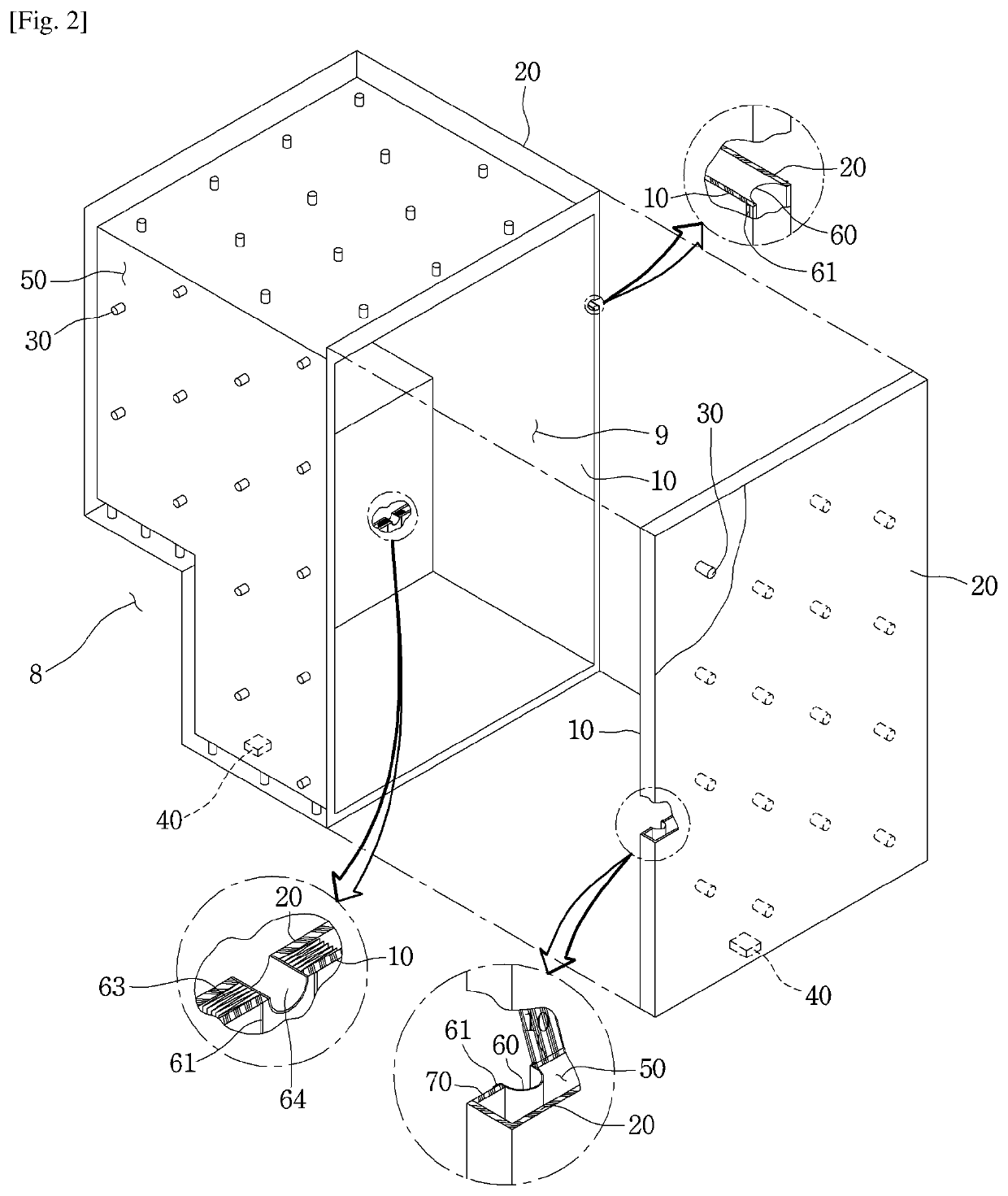

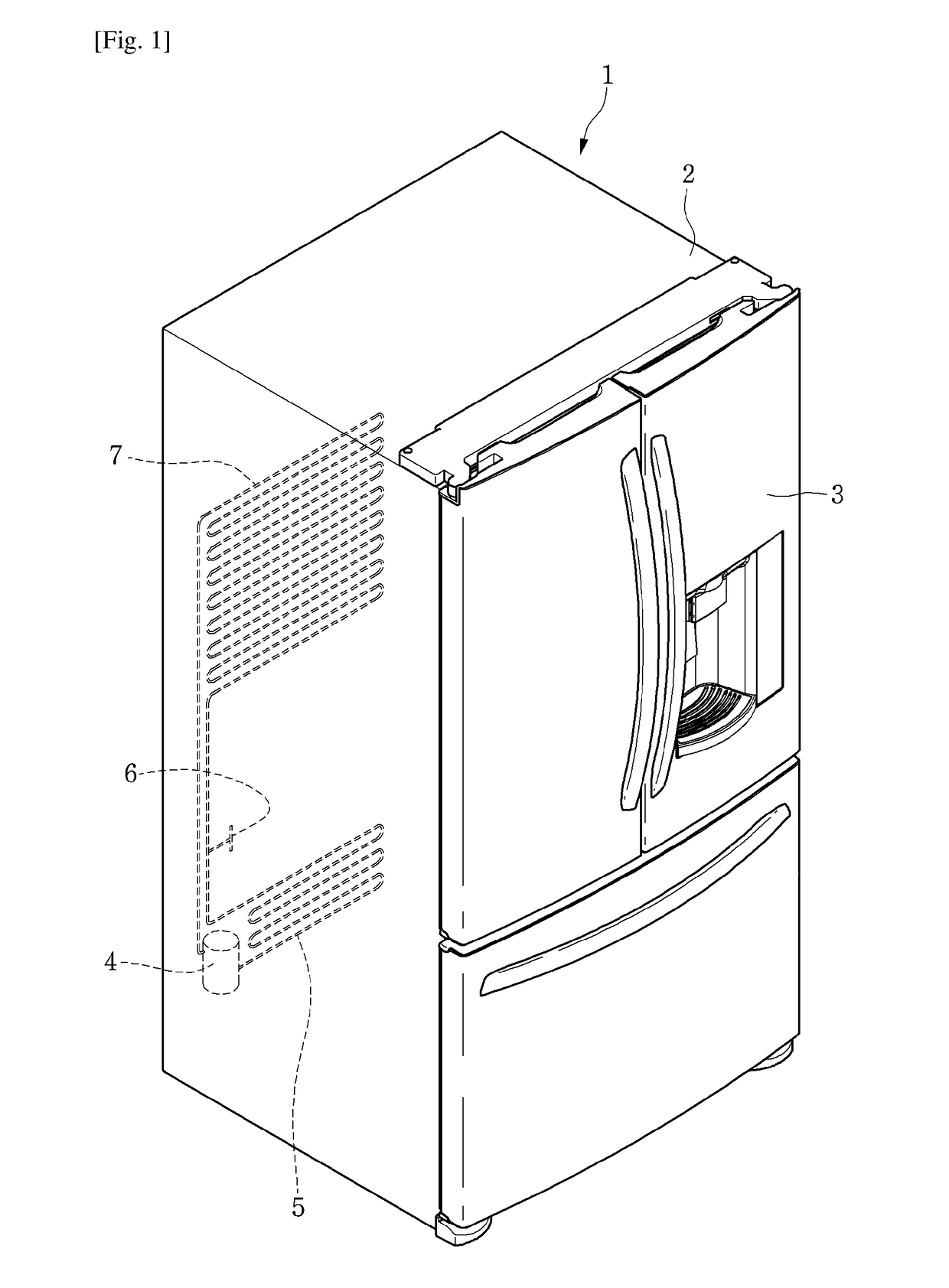

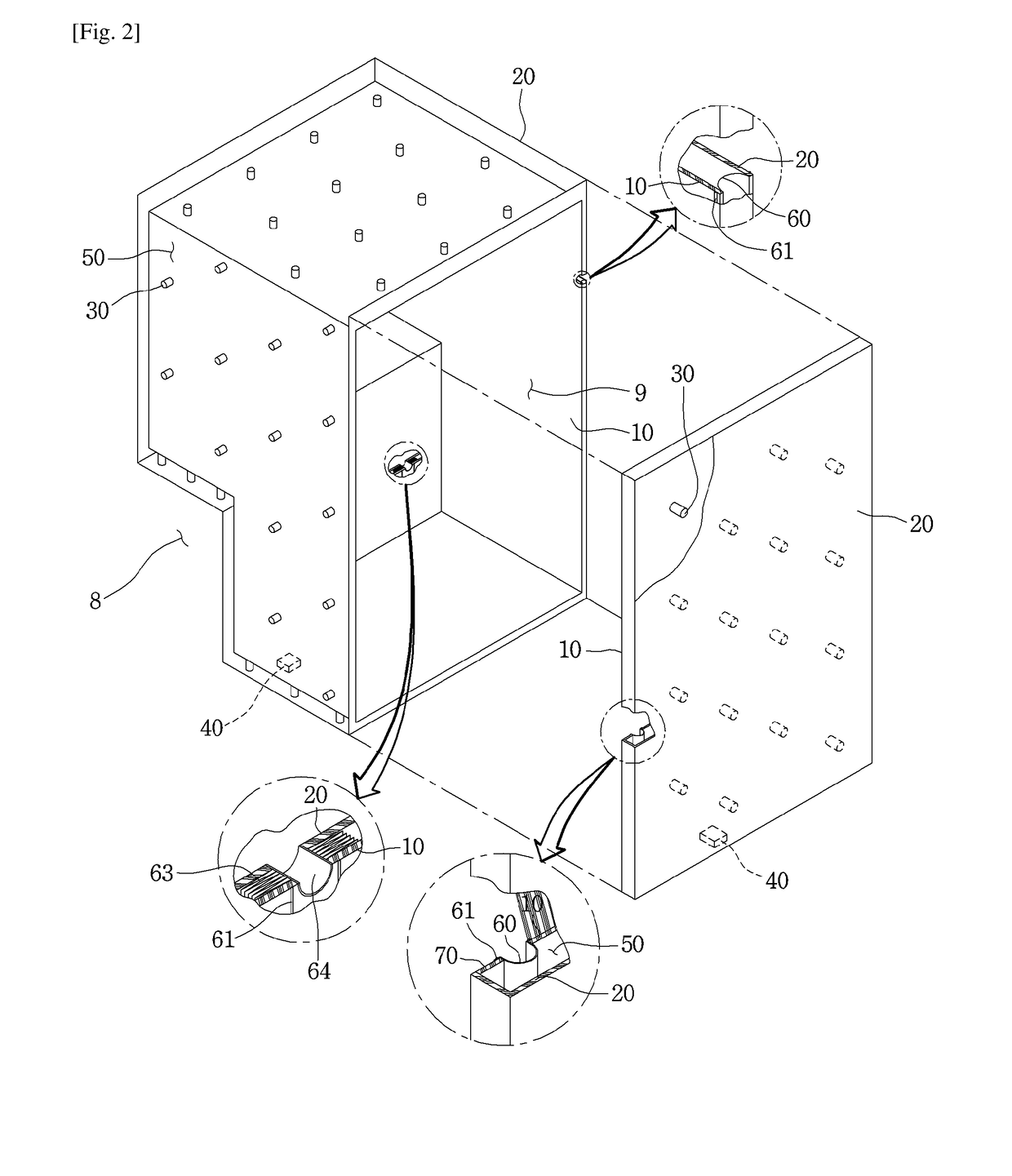

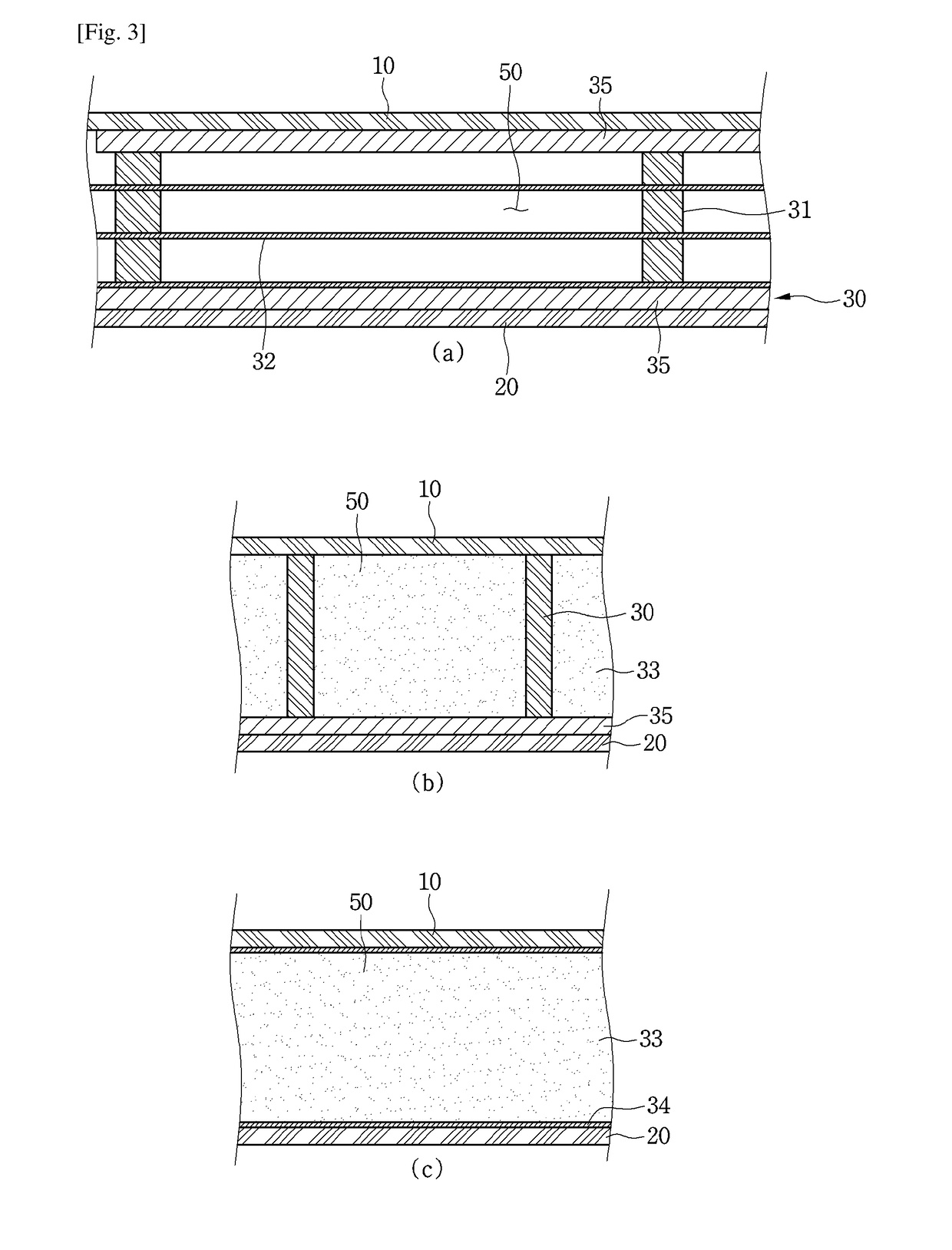

Vacuum adiabatic body and refrigerator

ActiveUS10837696B2Sufficient effectReduce vacuumThermal insulationInsulation for cooling apparatusGlass fiberPolycarbonate

A vacuum adiabatic body is provided. The vacuum adiabatic body may include a first plate, a second plate, a seal, a support, a heat resistance device, and an exhaust port. The support may include at least two bars to support the first plate and the second plate. Each of the at least two bars may include a material having a lower emissivity than emissivities of each of the first and second plates, and each bar may be fabricated using at least one material selected from the group consisting of polycarbonate (PC), glass fiber PC, low outgassing PC, polyphenylene sulfide (PPS), and liquid crystal polymer (LCP).

Owner:LG ELECTRONICS INC

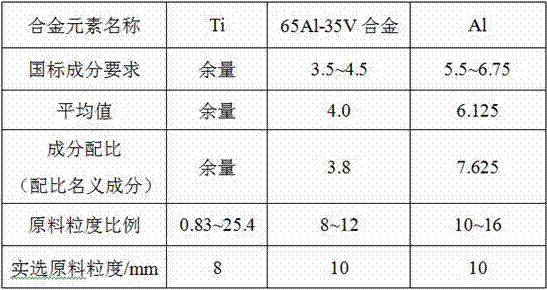

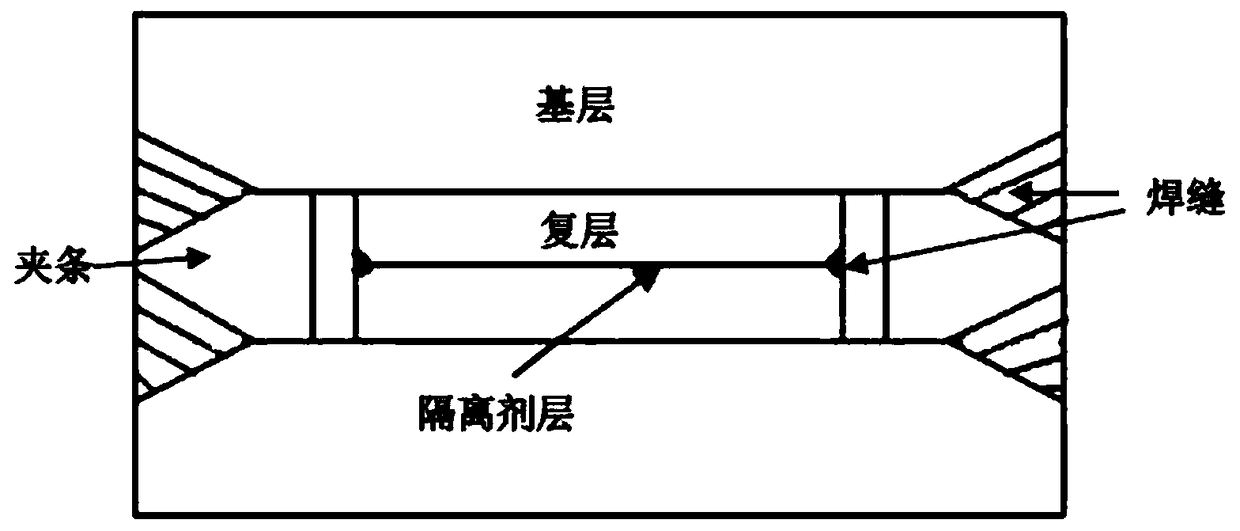

Method for co-producing TC4 titanium alloy round ingots/flat ingots through VAR furnace and 7-gun cold cathode EB furnace

The invention discloses a method for co-producing TC4 titanium alloy round ingots / flat ingots through a VAR furnace and a 7-gun cold cathode EB furnace. The method comprises the following steps of: averaging within a component range stipulated by the national standards as a datum value; increasing a datum value of an element Al and reducing a datum value of an element V, and then, taking the elements Al and V as proportioning components of brinqueting batch; covering alloy package in proportion, pressing sponge titanium and alloy package into an electrode block, and adopting a plasma welding machine to weld the electrode block into a long electrode; and smelting the long electrode into primary cast ingot through the VAR furnace, and performing secondary smelting on the primary ingot smelted by the VAR furnace through the 7-gun cold cathode EB furnace, thereby obtaining very-large-scale high-quality TC4 titanium alloy round ingots / flat ingots. The method is convenient to operate, can realize control on elements aluminum and vanadium, can greatly improve stability of the elements aluminum and vanadium in cast ingots of the TC4 titanium alloy, and further improves quality of the conventional TC4 titanium alloy product, so that the product obtains good market competition ability.

Owner:YUNNAN TITANIUM IND

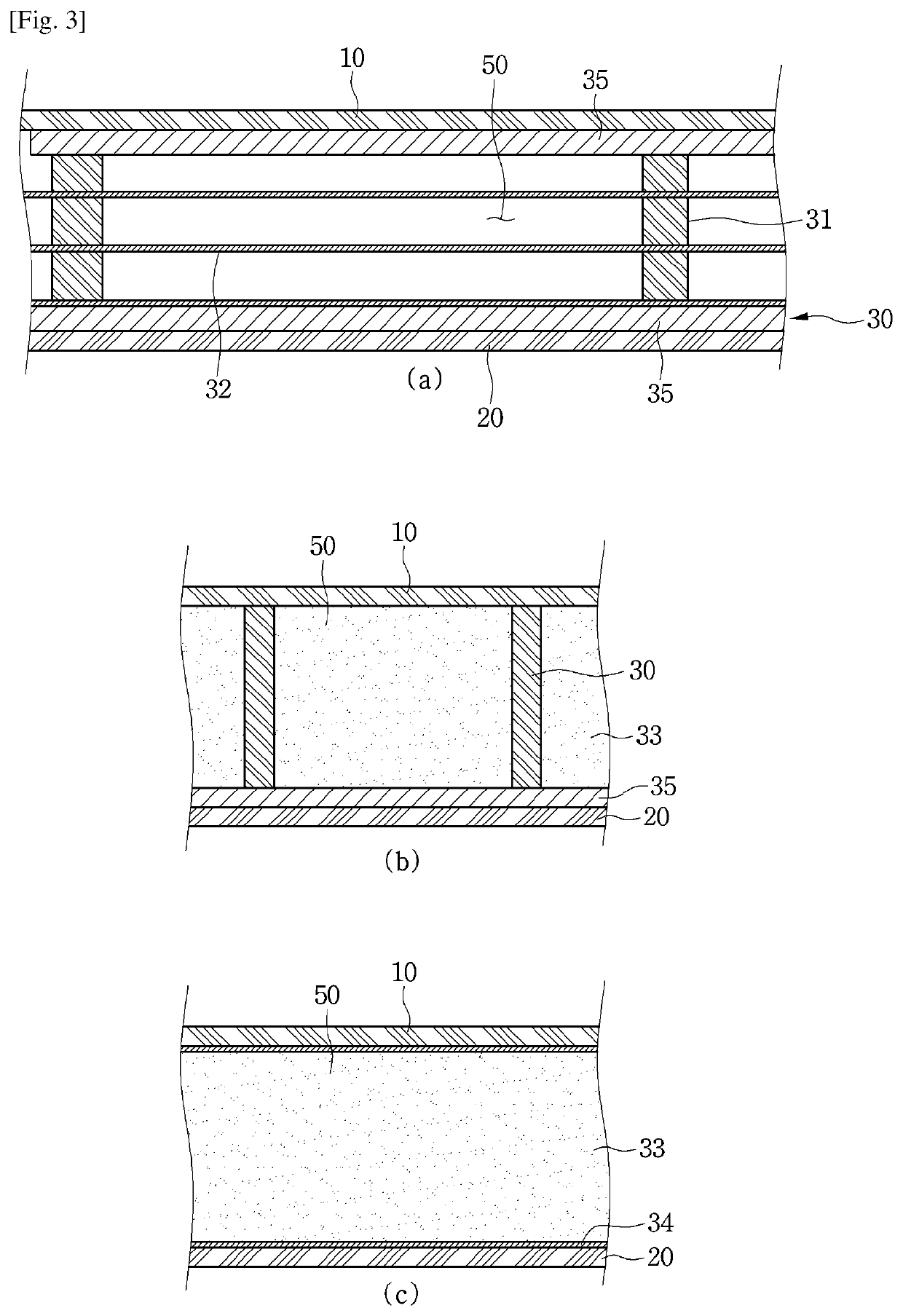

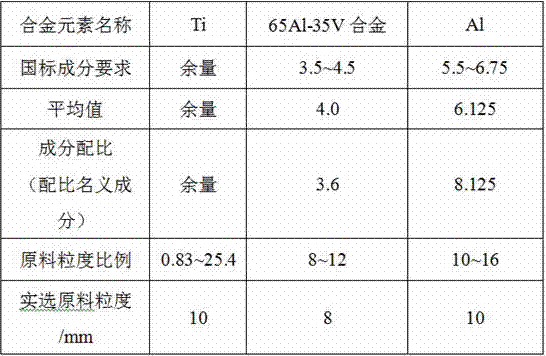

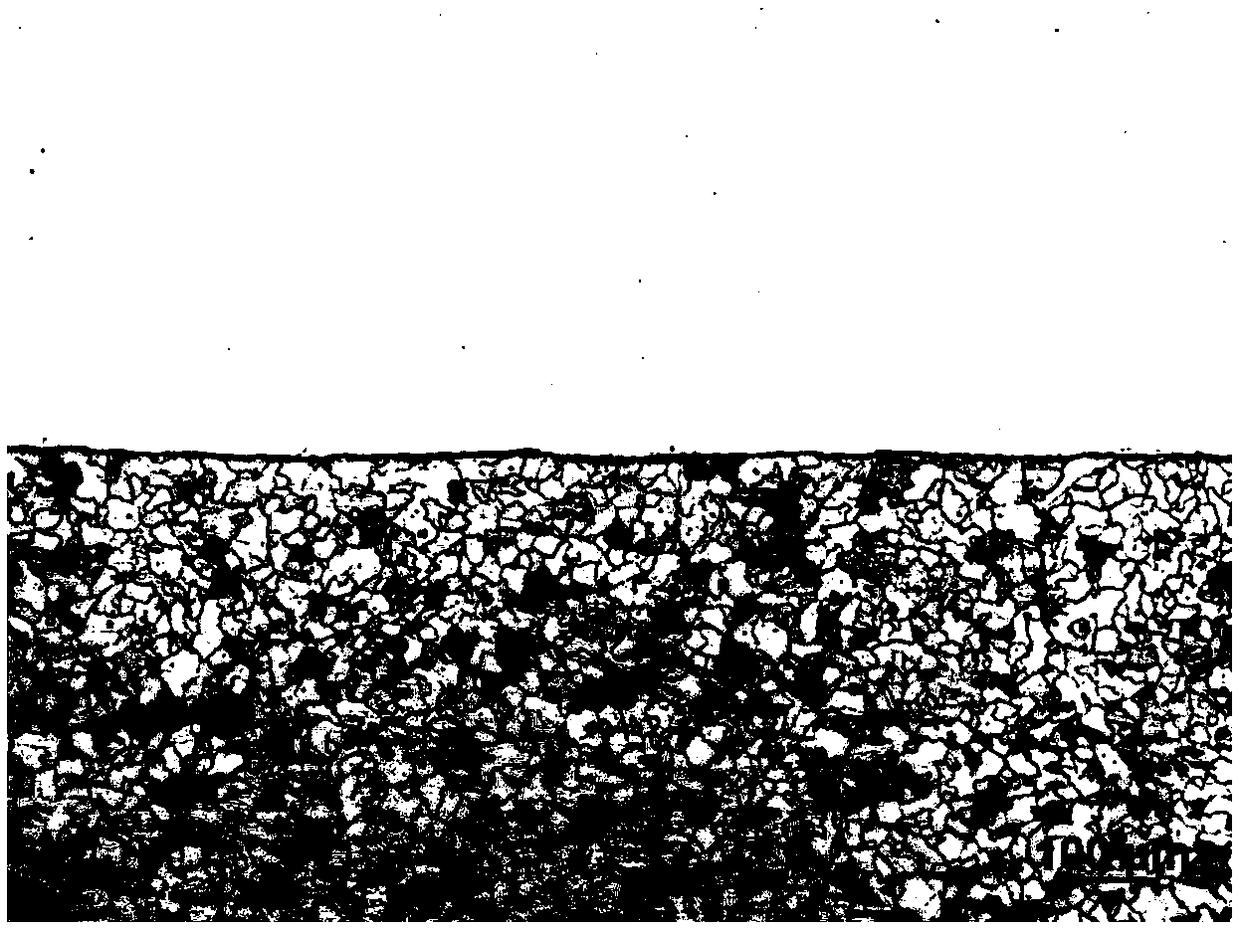

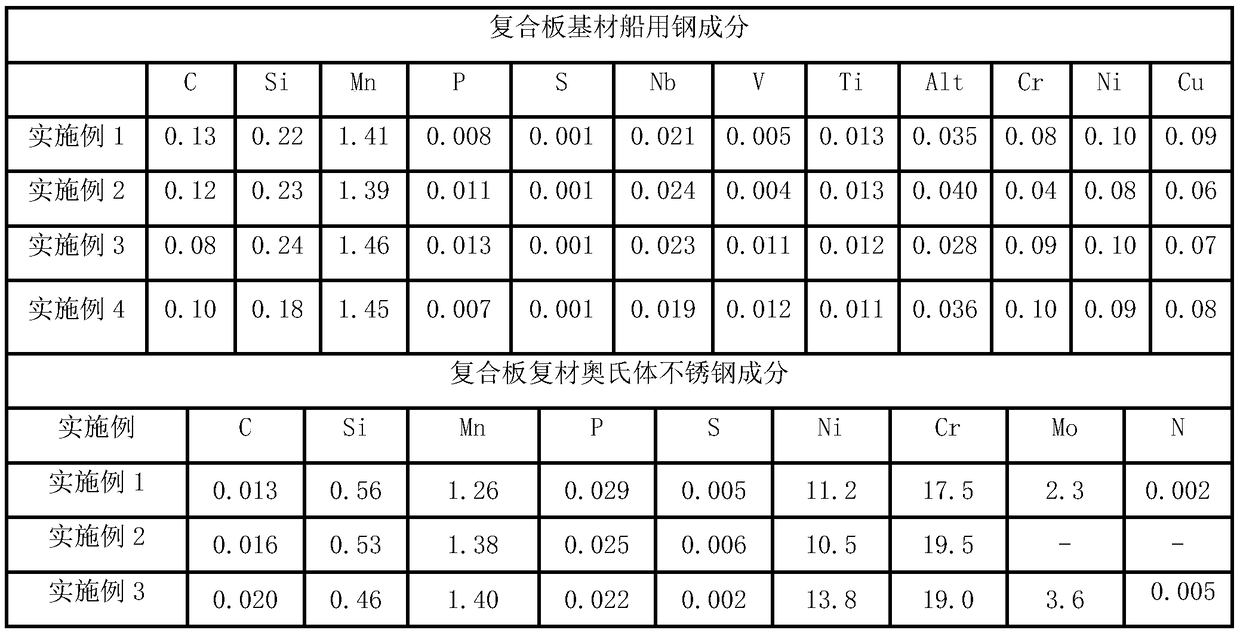

TMCP type marine austenitic stainless steel composite plate and preparation method thereof

InactiveCN108943911ASolve the problem of corrosion resistanceSimple processLamination ancillary operationsLaminationAustenitic stainless steelAusforming

The invention discloses a TMCP type marine austenitic stainless steel composite plate and a preparation method thereof and relates to the technical field of bimetal composite manufacture. The preparation method comprises blank preparation, surface grinding, isolating agent brush-coating, assembly blank sealing, electron beam soldering and sealing, heating, rolling and cooling, straightening, and cutting separation. The TMCP type marine austenitic stainless steel composite plate effectively solves the problem of corrosion resistance of the composite austenitic stainless steel in the composite plate, and in the blank preparation process, the steps of drilling and vacuuming are avoided. The preparation method has simple processes and a high rolling yield.

Owner:NANJING IRON & STEEL CO LTD

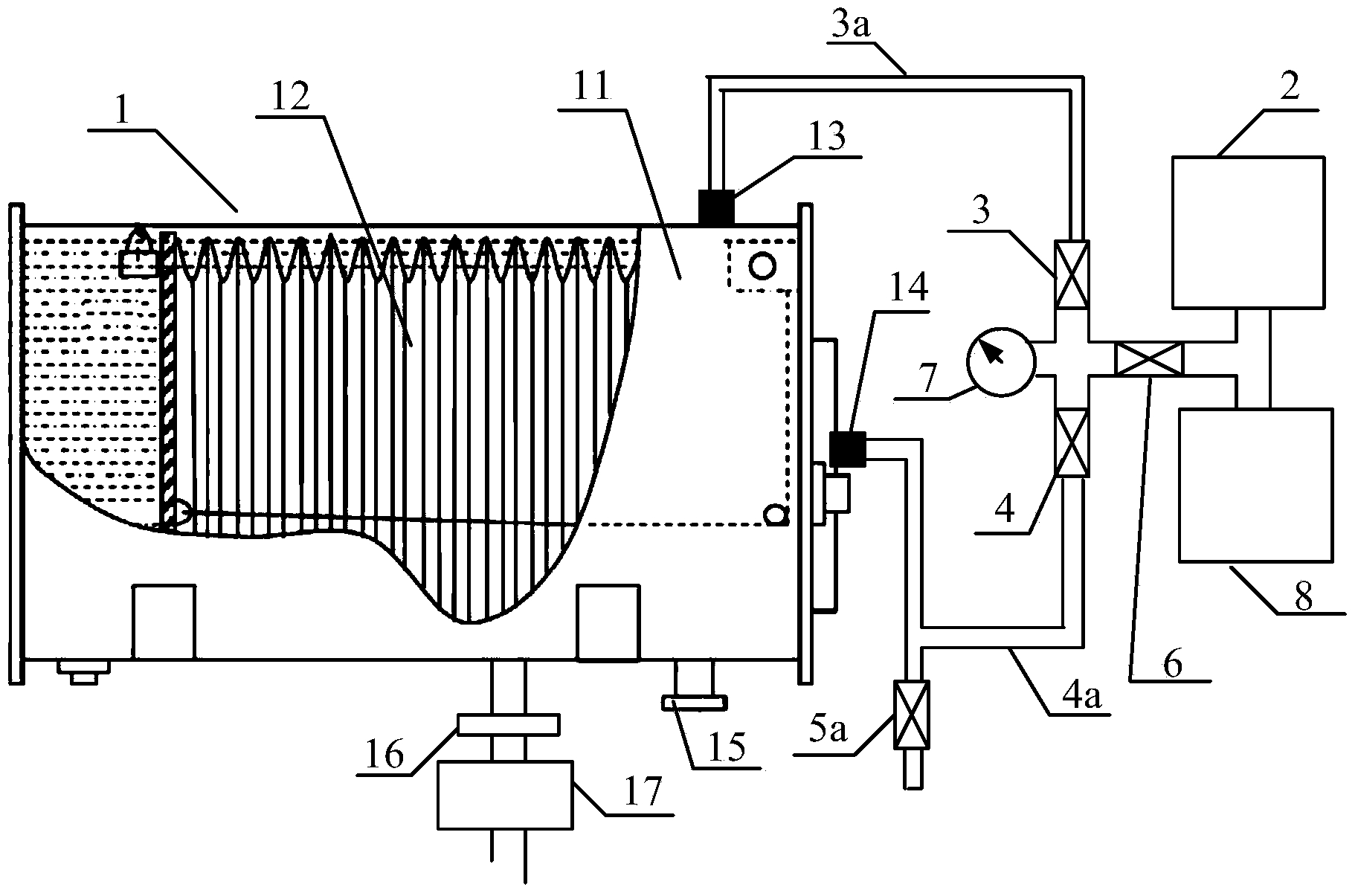

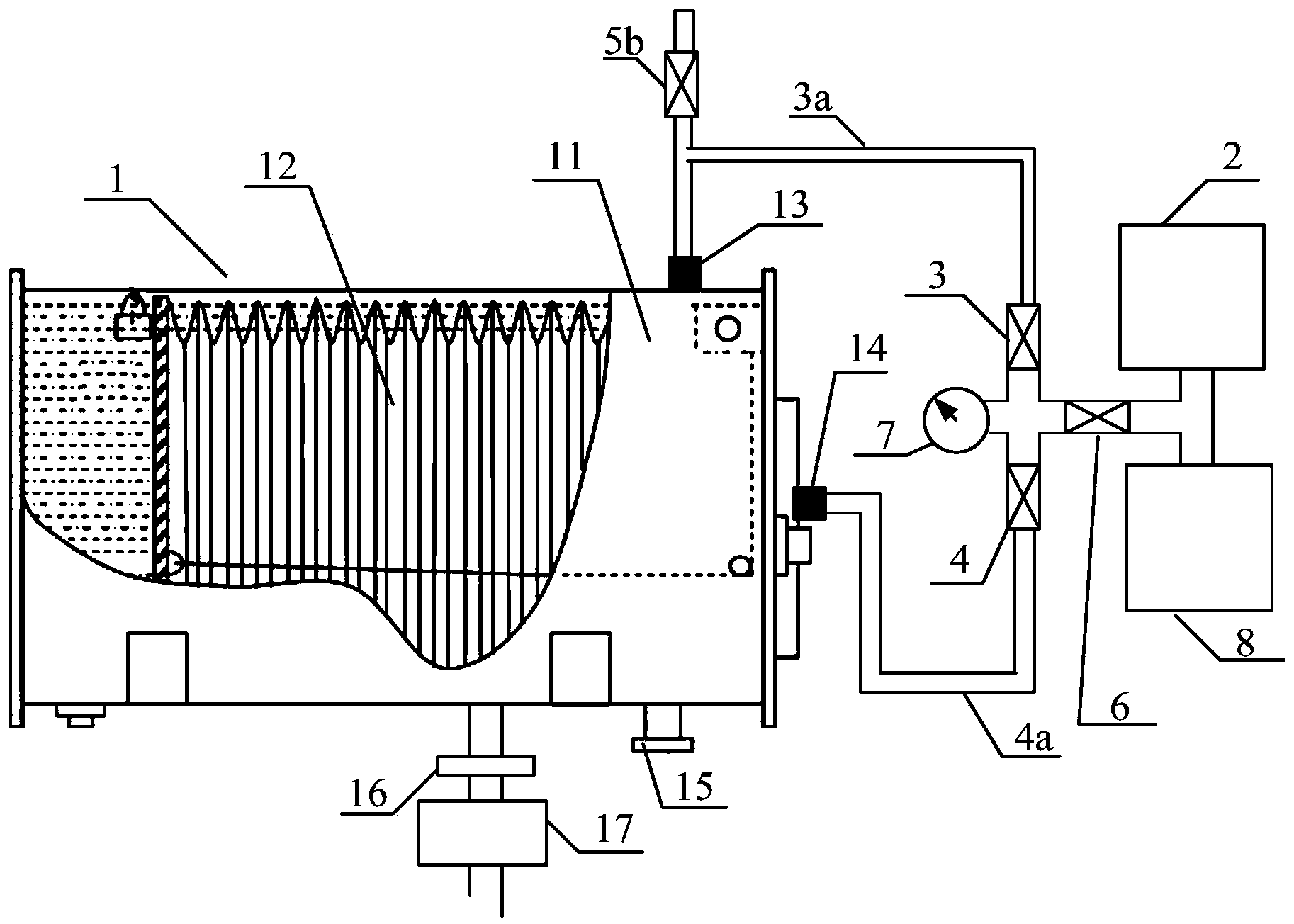

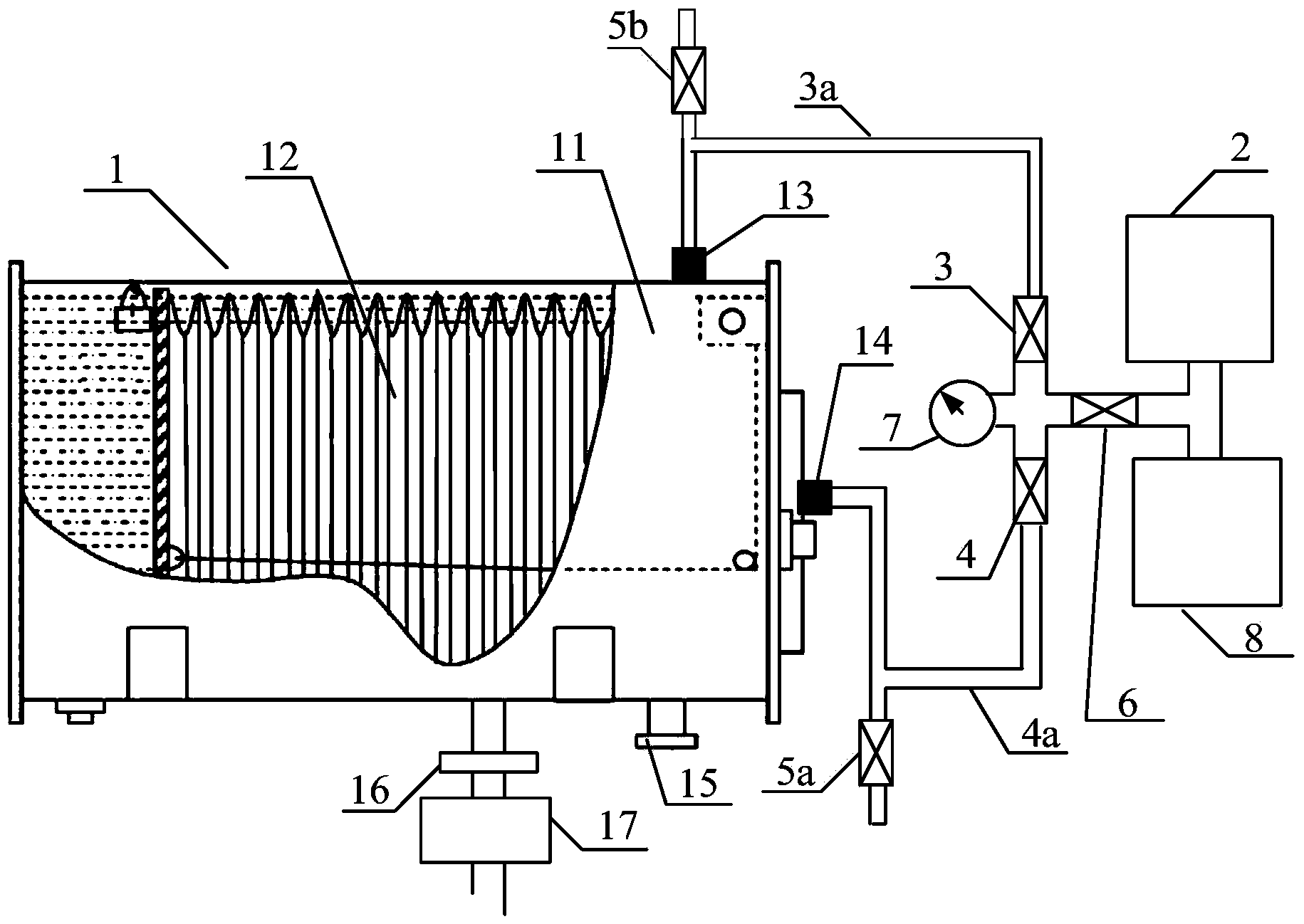

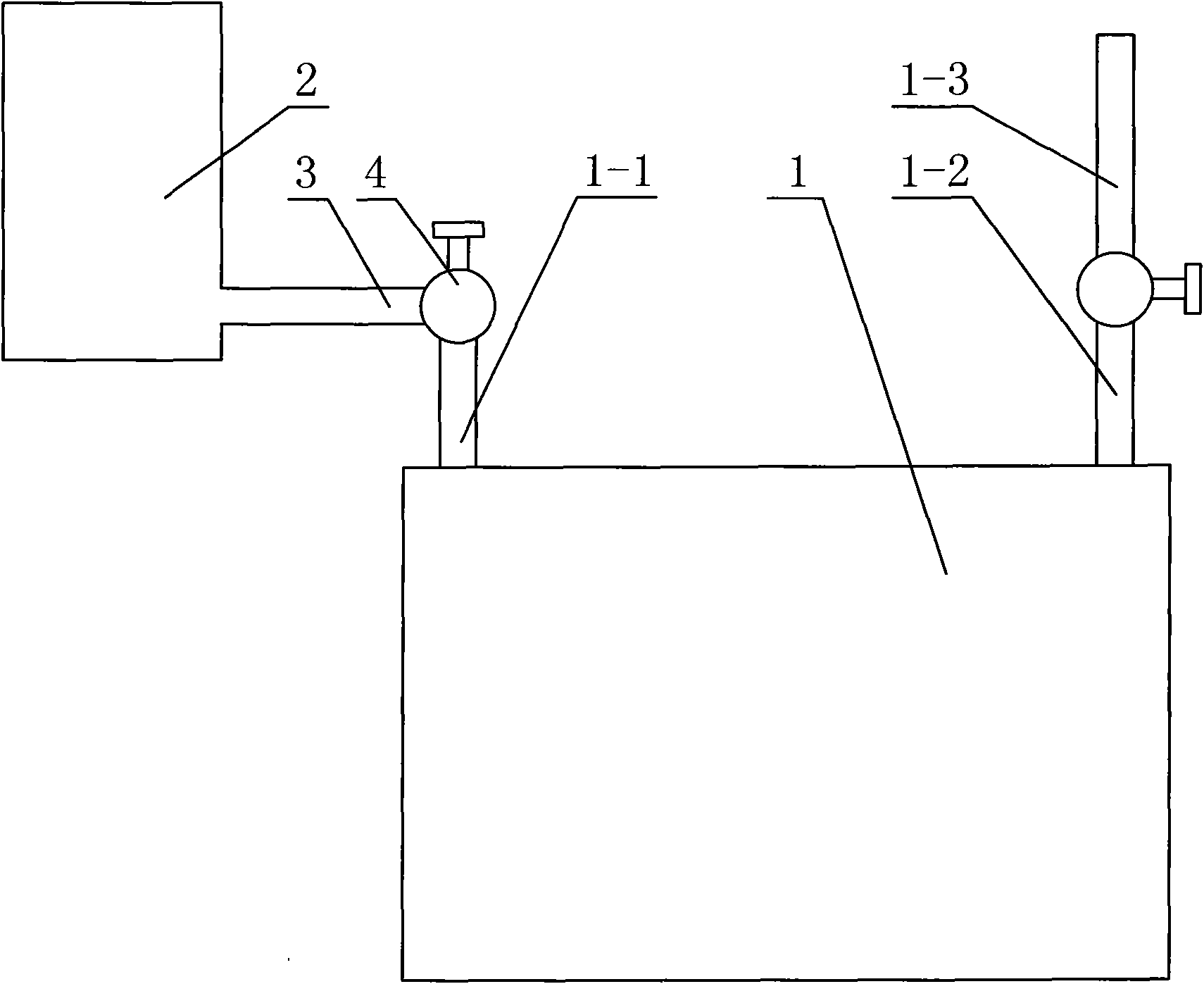

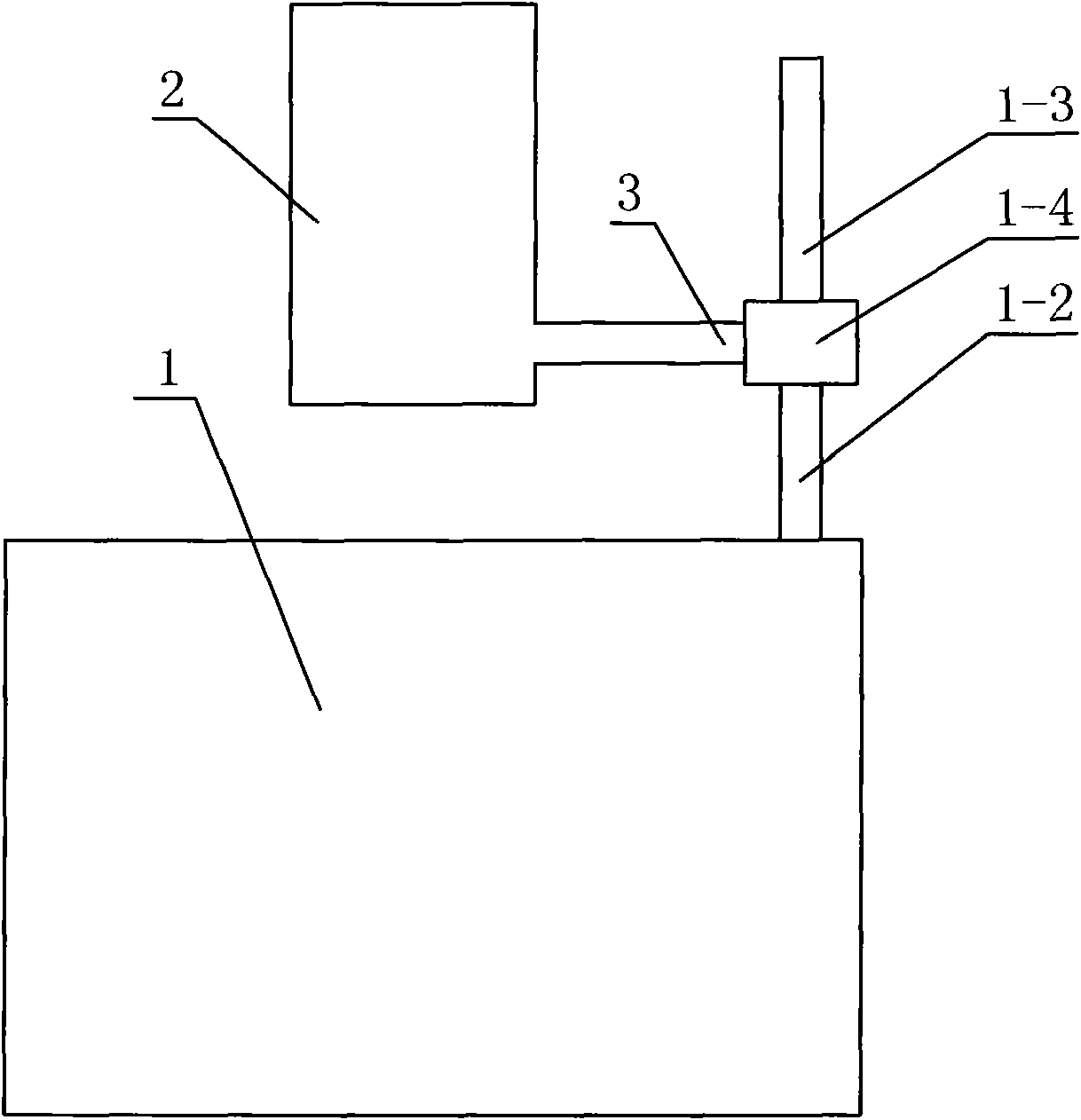

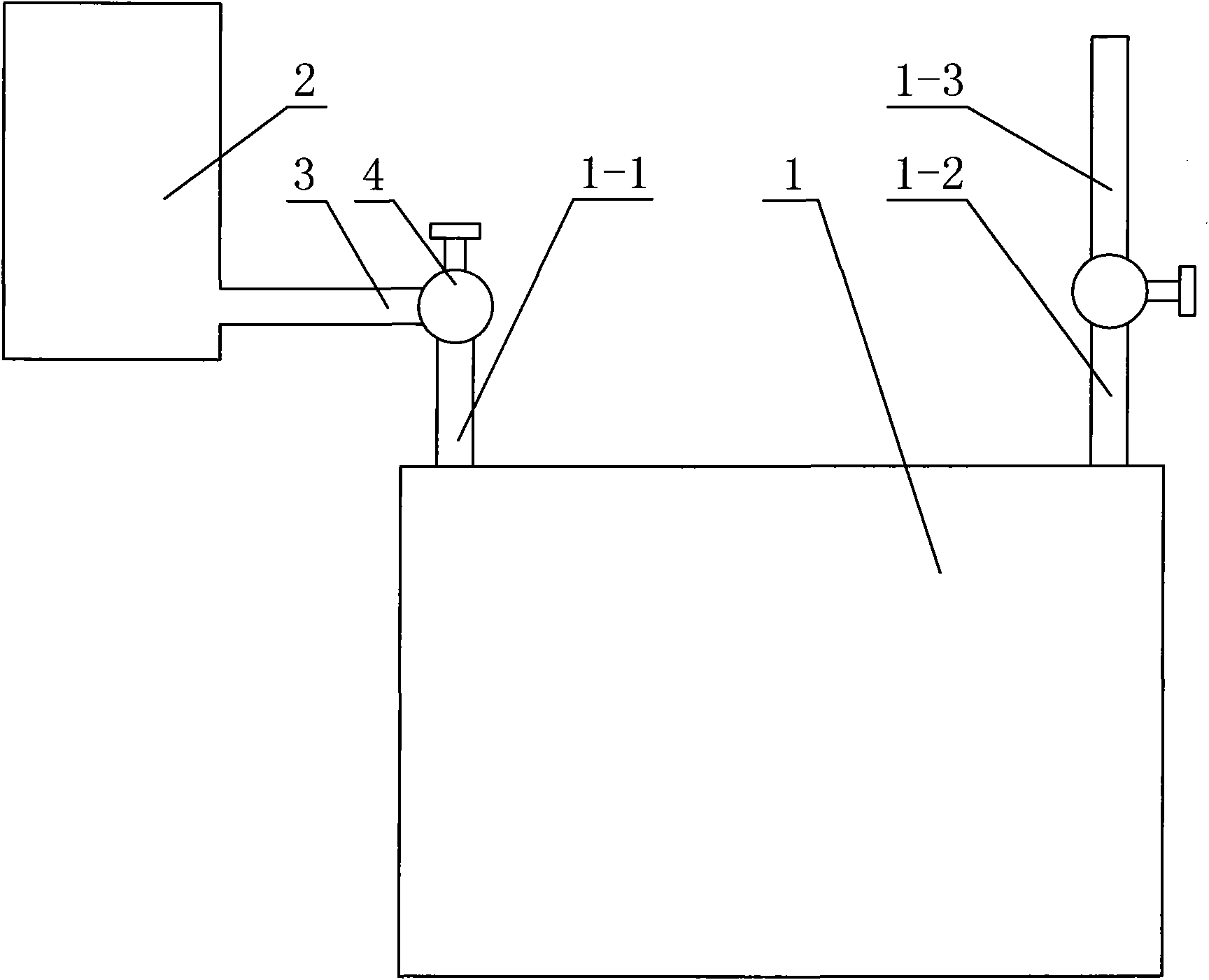

Vacuum oil filling and detecting system for transformer

ActiveCN103680829AAvoid irreversible damageIncrease oil injectionTransformers/inductances coolingFluid-tightness measurement using fluid/vacuumTransformerElectrical and Electronics engineering

The invention relates to a vacuum oil filling and detecting system for a transformer. The vacuum oil filling and detecting system comprises a corrugated oil conservator and a vacuumizing device; a cavity between an oil conservator shell and a corrugated pipe is communicated with an exhaust port; an inner cavity of the corrugated pipe is communicated with an air port; the exhaust port is communicated with the vacuumizing device through a first connecting pipe in a sealed mode; an exhaust port vacuumizing valve is arranged on a first connecting pipe, and the cavity between the oil conservator shell and the corrugated pipe and the vacuumizing device are controlled to be communicated or not through opening or closing of the exhaust port vacuumizing valve; the air port is communicated with the vacuumizing device in a sealed mode through a second connecting pipe; an air port vacuumizing valve is arranged on the second connecting pipe, and the inner cavity of the corrugated pipe and the vacuumizing device are controlled to be communicated or not through opening or closing of the air port vacuumizing valve; one end of an adjusting valve is connected to the outside of the air port and / or exhaust port, the other end of the adjusting valve is communicated with air, and the air port and / or air exhaust port and the air are controlled to be communicated or not through opening or closing of the adjusting valve.

Owner:STATE GRID SHANDONG ELECTRIC POWER

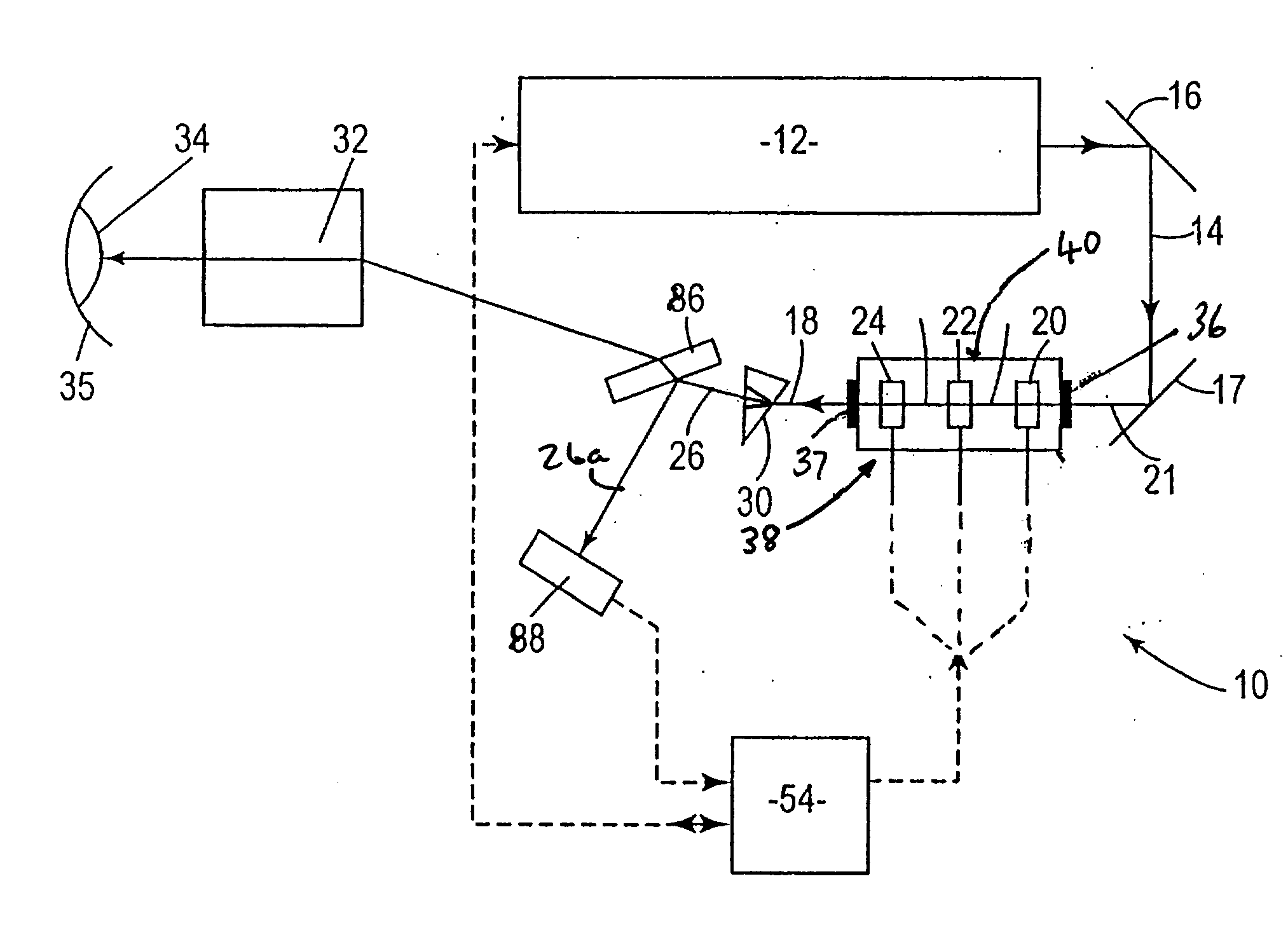

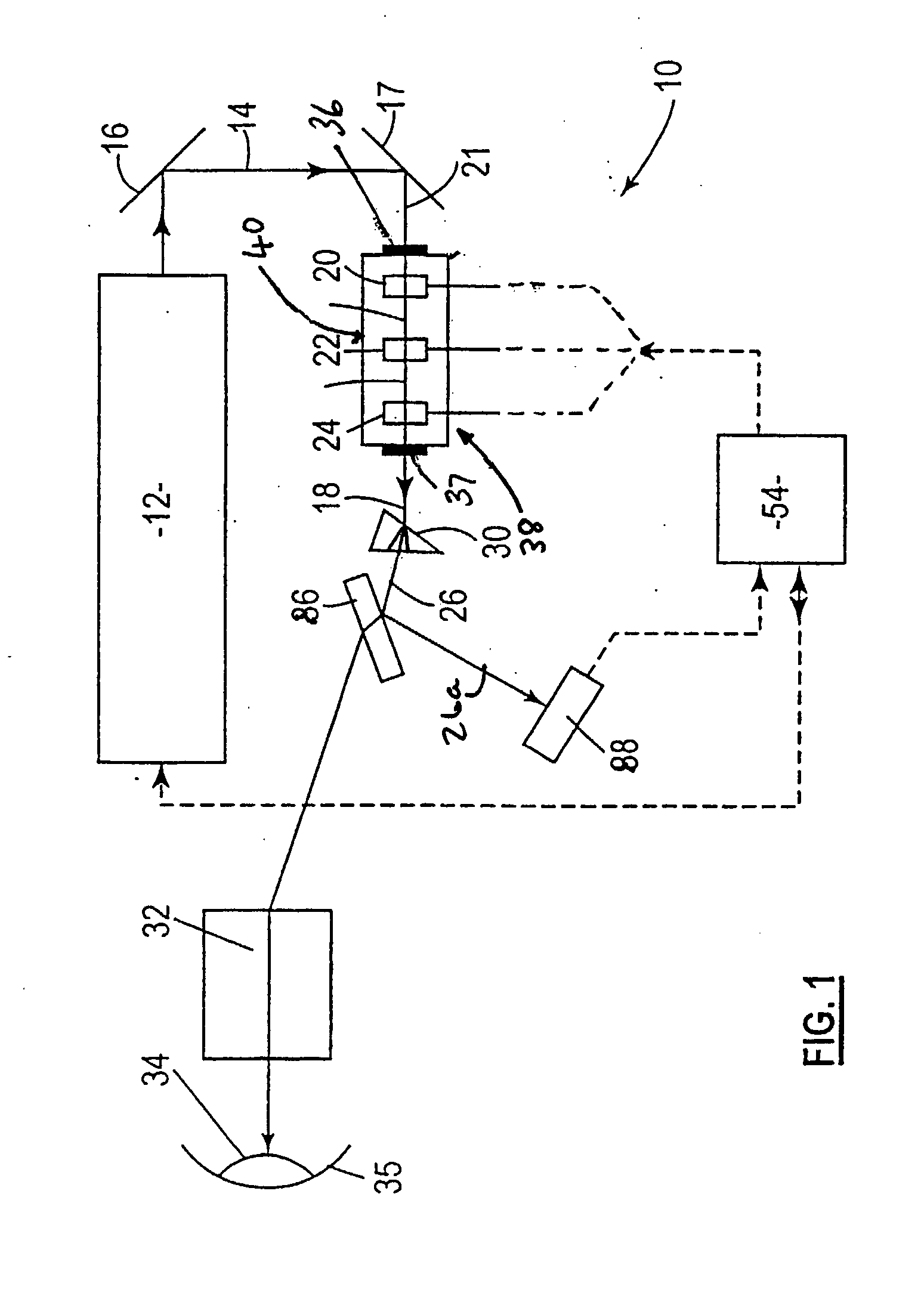

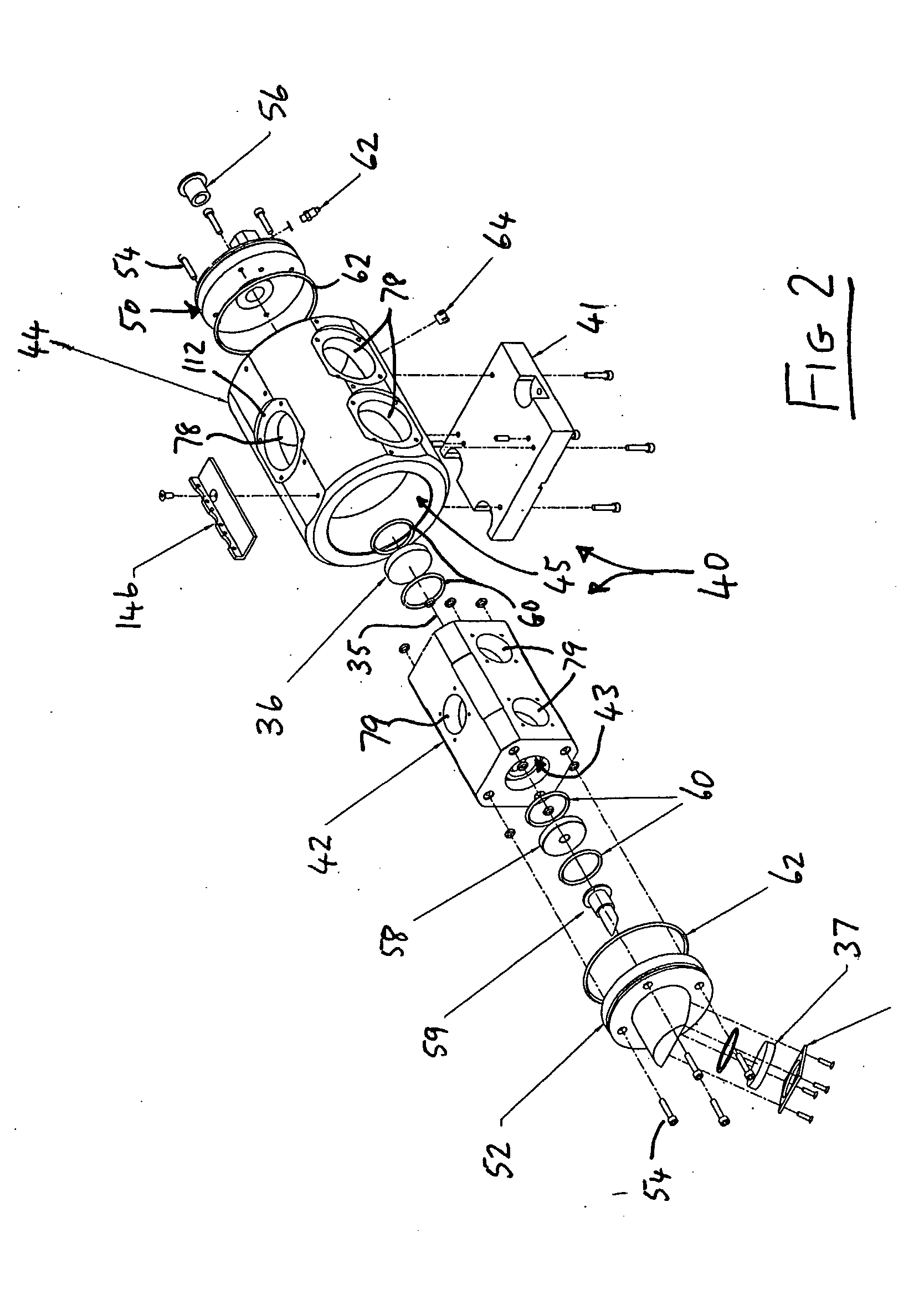

Housing for Harmonic Generation Crystals in Solid State Laser Systems

InactiveUS20070223541A1Prevent cyclic re-absorptionReduce vacuumLaser surgeryLaser detailsFrequency conversionHarmonic

Apparatus for effecting harmonic conversion of a laser beam of predetermined frequency to provide plural harmonic components of the laser beam at frequencies different from the predetermined frequency, includes a housing (40) defining a hermetically sealed chamber able to be maintained at a pressure below atmospheric pressure. Also provided are port means for evacuating the chamber, and means (36, 37) defining an optical path for the laser beam and the components thereof through the housing and the chamber. A plurality of individual holders (20, 22, 24) are arranged for retaining respective frequency conversion crystals at spaced locations in the optical path. The crystals (20, 22, 24) can be individually aligned and heated within the chamber.

Owner:CUSTOMVIS

Continuous cleaning device for vacuum pump and method thereof

The invention discloses a continuous cleaning device for a vacuum pump and a method thereof. The device comprises a cleaning solution supply system, wherein the cleaning solution supply system is provided with a cleaning solution storage barrel filled with cleaning solution, a cleaning solution delivery pipeline and a switching valve arranged on the cleaning solution delivery pipeline; the cleaning solution delivery pipeline is connected with the cleaning solution inlet which is arranged on the pump body of a vacuum pipe and communicated with the inner cavity of the pump body; or the cleaning solution delivery pipe and the work solution delivery pipeline of the vacuum pump are connected with the inlet of a shuttle valve; and the outlet of the shuttle valve is connected with a work solution inlet on the pump body of the vacuum pump. By using the method, the work solution is regularly changed into the cleaning solution to clean the inside of the vacuum pump. The continuous cleaning device for the vacuum pump and the method need not halting in a cleaning process without influencing production or detaching equipment, save time and labor and have no consumption on equipment. Therefore, the device and the method ensure that the vacuum degree of the vacuum pump is not reduced, and the product quality is ensured.

Owner:常州丰盛光电科技股份有限公司

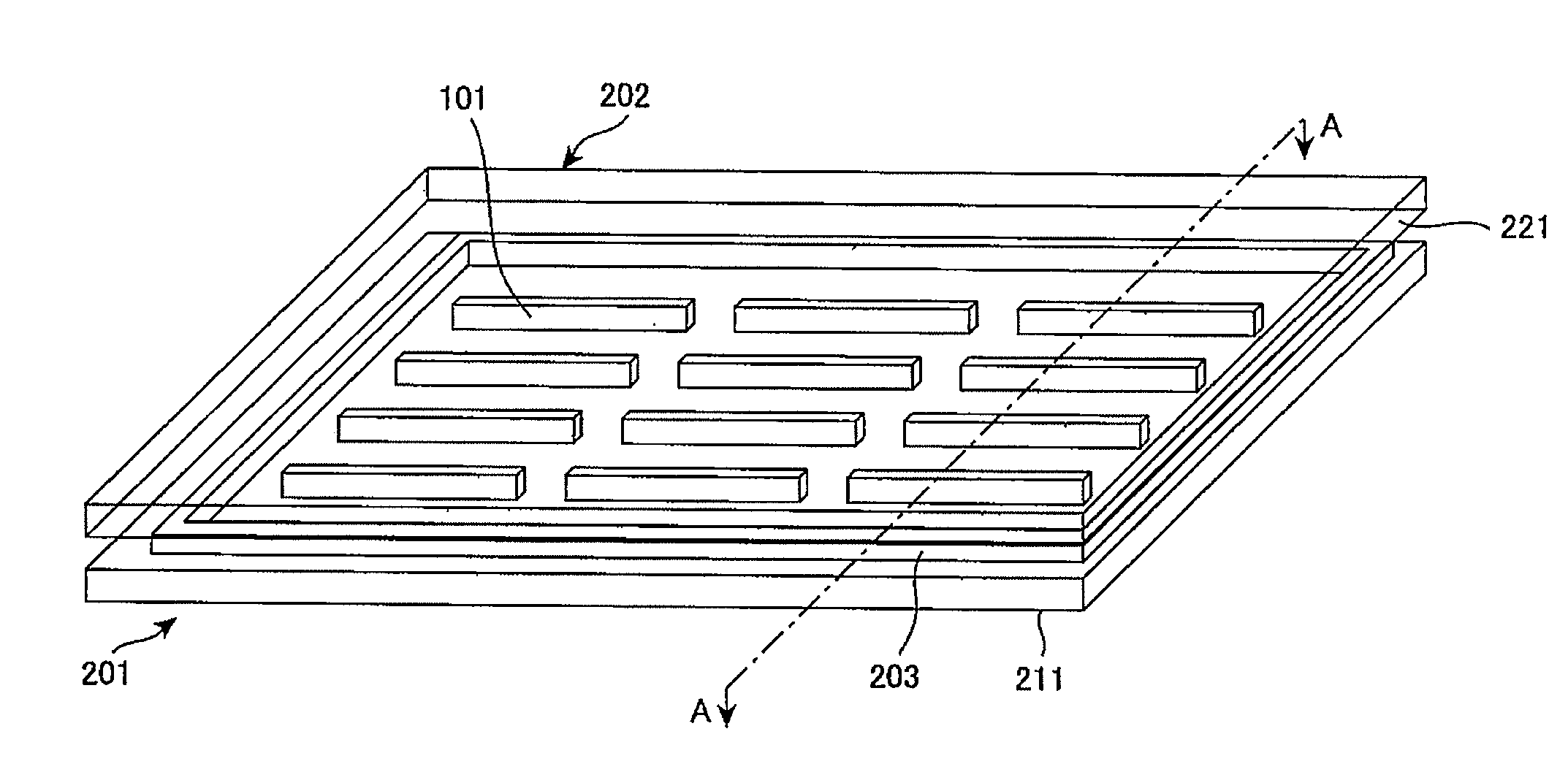

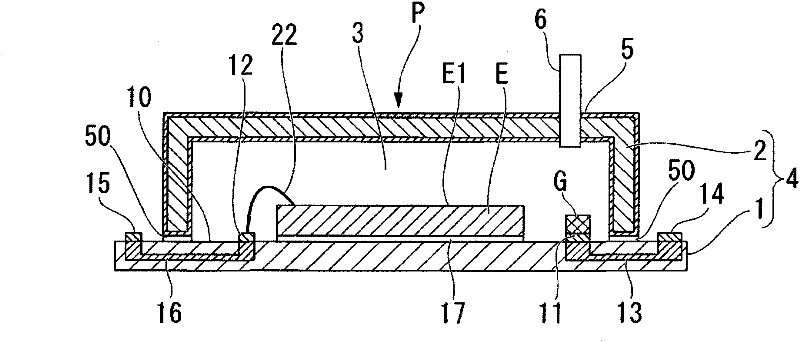

Vacuum sealed package, printed circuit board having vacuum sealed package, electronic device, and method for manufacturing vacuum sealed package

InactiveCN102318060AGuaranteed vacuumReduce vacuumRadiation pyrometrySemiconductor/solid-state device detailsElectrical conductorHeat conducting

Disclosed is a vacuum sealed package which comprises a package main body in which a first main body part and a second main body part are joined together with a hollow part interposed therebetween, and a getter material and an electronic device which are provided within the hollow part. The vacuum sealed package is obtained by sealing the package main body with a sealing member, while maintaining the hollow part in an evacuated state by means of a through hole by which the inside and the outside of the hollow part are communicated with each other. The getter material and the electronic device are connected with a first conductor pad and a second conductor pad. The first conductor pad is connected with a third conductor pad through a heat conducting material, and the second conductor pad is electrically connected to a fourth conductor pad that is on a wiring substrate.

Owner:NEC CORP

Method of processing porous building materials

InactiveUS20070014922A1Improve water resistanceIncrease pressurePretreated surfacesLiquid/solution decomposition chemical coatingBrickAtmospheric pressure

A method of processing porous building materials in an impregnation chamber is disclosed. The are placed into the chamber and subjected to a vacuum for about 10 minutes. Then a mixture of a dye with a hydrophobic impregnant (liquid) is sprayed into the chamber at the pressure of 6 to 30 atm, thereby creating gas-like misty environment. The material is subjected to the misty environment for 0.5 to 10 minutes while gradually increasing the pressure in the chamber until the atmospheric pressure. Latex or acrylic based dyes with diffusion qualities and silicone based hydrophobic liquids possessing film qualities are used. Materials processed include bricks, cement and qypsum-based materials, natural stone, wood and timber based products, and ceramics.

Owner:NOVAATORID GRUPP AN ESTONIAN CORP

Low vacunm bonding method of polydimethylsiloxane chip

InactiveCN1484021ASimple equipmentReduce vacuumMicrobiological testing/measurementBiological testingEngineeringHigh pressure

The invention refers to a low-vacuum bonding method for a polydimethylsiloxane chip, its steps: freshly peel off the polymerized silicon latex sample to obtain chip subassembly, place in vacuum cavity, vacuumize, wash by oxygen again and again, and eliminate the remnant gas; vacuumize again, exert high pressure to make the oxygen light up in the vacuum cavity, to make oxygen plasm bombardment on the chip subassembly's surface, the air pressure equal to the atmospheric pressure, open the vacuum cavity, and joint the chip subassembly. It has very high bonding intensity, able to surpass that of PDMS noumenon.

Owner:XIAMEN UNIV

Vacuum adiabatic body and refrigerator

ActiveUS20180356147A1Sufficient effectReduce vacuumThermal insulationInsulation for cooling apparatusGlass fiberHeat resistance

A vacuum adiabatic body is provided. The vacuum adiabatic body may include a first plate, a second plate, a seal, a support, a heat resistance device, and an exhaust port. The support may include at least two bars to support the first plate and the second plate. Each of the at least two bars may include a material having a lower emissivity than emissivities of each of the first and second plates, and each bar may be fabricated using at least one material selected from the group consisting of polycarbonate (PC), glass fiber PC, low outgassing PC, polyphenylene sulfide (PPS), and liquid crystal polymer (LCP).

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com