Cooling system of flywheel energy storage device

A technology of heat dissipation system and flywheel energy storage, applied in the field of heat dissipation system of flywheel energy storage device, can solve the problems of cavitation, low pump inlet pressure, inability to work normally, and inability to dissipate heat, and achieve the effect of avoiding cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

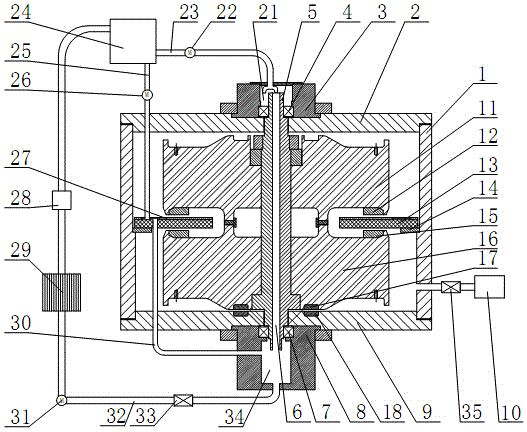

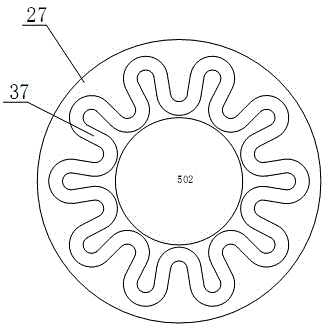

[0029] like figure 1 As shown in the figure, the flywheel energy storage device of the present invention is composed of a casing and an internal disc motor, the rotor of the disc motor and the flywheel are combined into one, and the disc motor can be used as a motor to drive the flywheel to rotate; it can also be used as a generator, which is Flywheel drive to generate electricity. The shell is composed of a cylinder body 1, an upper cover plate 2 and a lower cover plate 9. An upper bearing seat 3 and a lower bearing seat 8 are respectively fixed in the center of the upper cover plate 2 and the lower cover plate 9, and the upper bearing 4 is embedded in the upper bearing seat 3. An upper oil cavity 21 is formed inside, and the lower bearing 7 is embedded in the lower bearing seat 8 to form a lower oil cavity 34 . The material of the housing can be steel, aluminum, plastic, glass fiber reinforced plastic, carbon fiber, concrete, and combinations thereof, etc. with certain stre...

Embodiment 2

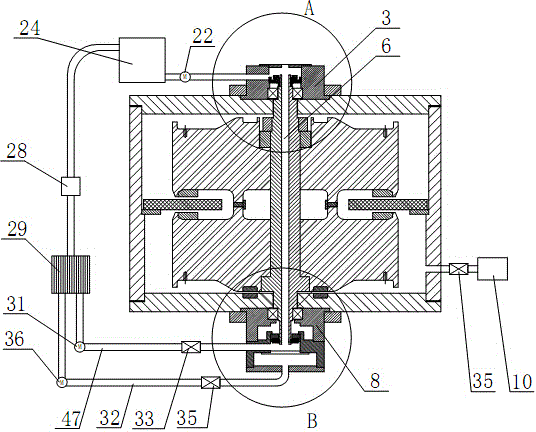

[0038] like Figure 4 As shown, in this embodiment, the upper bearing seat 3 is located above the upper bearing 4 , and an upper seal 42 is provided to separate the original upper oil cavity 21 into an upper shaft hole cavity 41 and an upper bearing cavity 43 . like Figure 5 As shown, in this embodiment, the lower bearing seat 8 is located below the lower bearing 7 , and a lower sealing member 45 and a separator 48 are provided to separate the original lower oil chamber 34 into a lower bearing chamber 44 and a lower shaft hole chamber 46 . like image 3 As shown, the upper shaft hole 41 and the lower shaft hole 46 are communicated with the shaft hole 6 , the upper shaft hole 41 is communicated with the upper oil pipe 23 , and the lower shaft hole 46 is communicated with the first oil return pipe 47 . The upper bearing cavity 43 and the lower bearing cavity 44 are communicated with the inner cavity of the container, and the lower bearing cavity 44 is communicated with the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com