Method for co-producing TC4 titanium alloy round ingots/flat ingots through VAR furnace and 7-gun cold cathode EB furnace

A combined production and cold cathode technology, applied in the engineering field, can solve the problems of high-density inclusions and low-density inclusions that are difficult to remove, the technical difficulty of stabilizing the composition, and the power of the hot cathode electron gun, etc., to achieve narrow composition fluctuations and good market competitiveness. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take titanium alloy flat ingot with specification 1050×210×8000mm (width×thickness×length) as TC4 (Ti-6Al-4V) as an example:

[0027] (1) According to the upper and lower limit requirements of the national standard of TC4 alloy, the average value of Al element and V element is taken as the reference value, that is, Al: 6.125%, V: 4.0%;

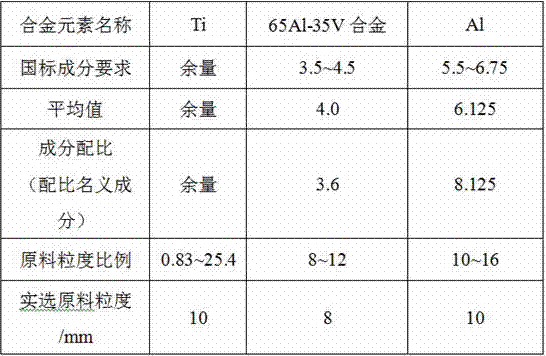

[0028] (2) Add 2.0% to the base value of the Al element, and drop 0.4% to the base value of the V element, as the nominal composition;

[0029]

[0030] (3) Proportioning is carried out according to the formulated nominal composition. Select titanium sponge with a particle size of 10mm, 65Al-35V alloy particles with a particle size of 8mm, and aluminum bean particles with a particle size of 10mm. The nominal composition is Ti-8.125Al-3.6V. Proportion, the pressed electrode is 25kg / root, weigh 4 parts of 65Al-35V alloy each weighing 0.6425kg, then weigh 4 parts of Al beans each weighing 0.09kg on the aluminum foil, and put a part of 6...

Embodiment 2

[0040] Take the titanium alloy round ingot with the specification of Φ220mm and the grade of TC4 (Ti-6Al-4V) as an example:

[0041] (1) According to the upper and lower limit requirements of the national standard of TC4 alloy, the average value of Al element and V element is taken as the reference value, that is, Al: 6.125%, V: 4.0%;

[0042] (2) Add 1.5% to the base value of the Al element, and drop 0.2% to the base value of the V element, as the nominal composition;

[0043]

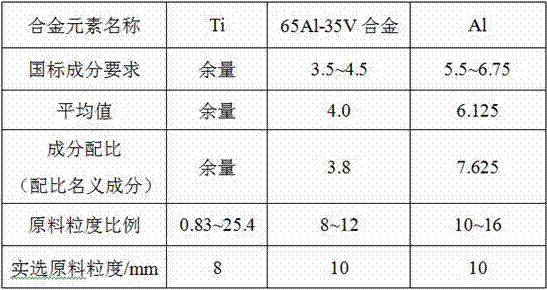

[0044] (3) Proportioning is carried out according to the established nominal composition. Select titanium sponge with a particle size of 8mm, 65Al-35V alloy particles with a particle size of 10mm, and aluminum bean particles with a particle size of 10mm. The nominal composition is Ti-7.625Al-3.8V. Proportion, the pressed electrode is 25kg / root, weigh 4 parts of 65Al-35V alloy each weighing 0.679kg, then weigh 4 parts of Al beans each weighing 0.035kg on the aluminum foil, and put a part of 65Al-35V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com