Patents

Literature

569results about How to "Uniform chemical composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

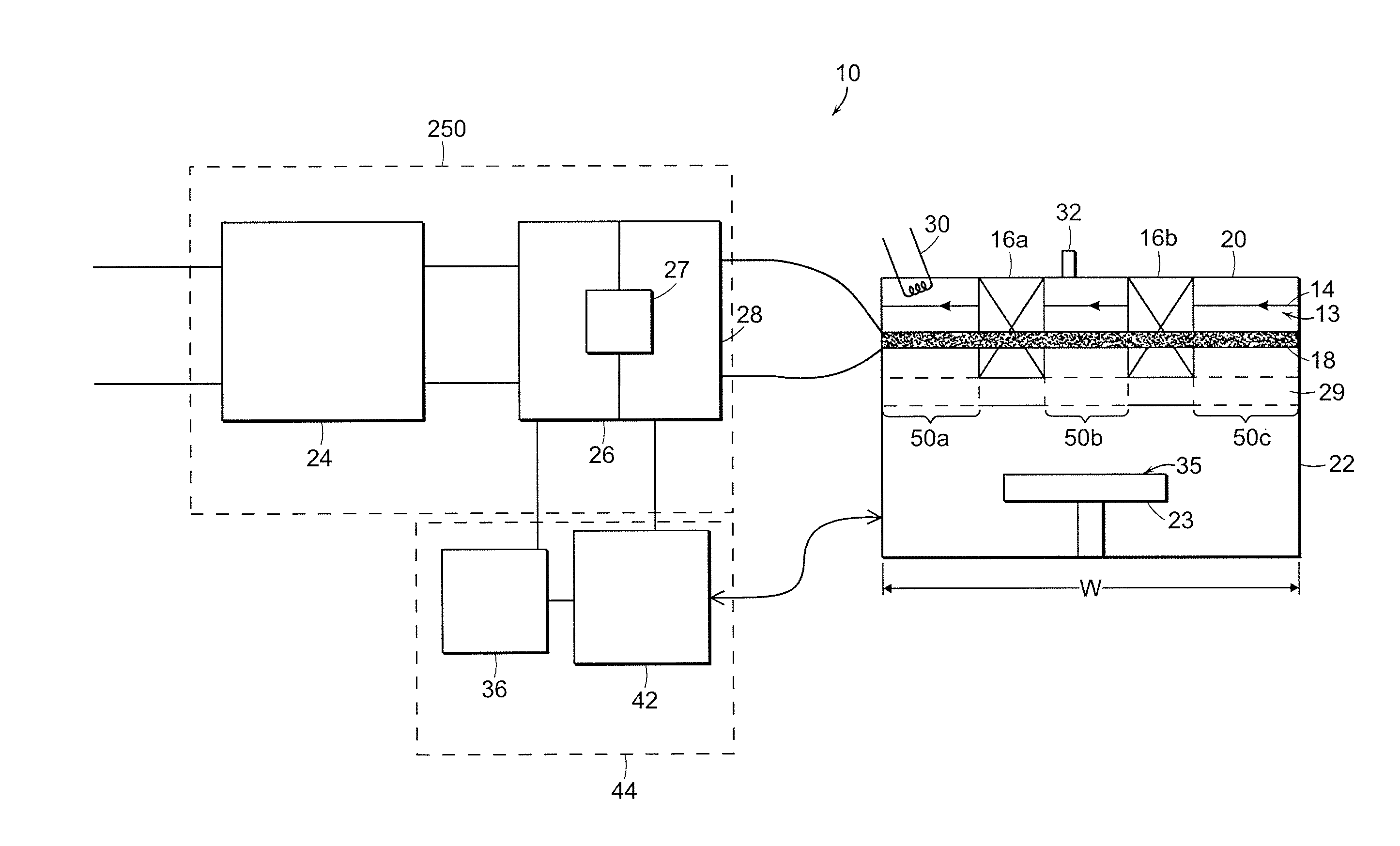

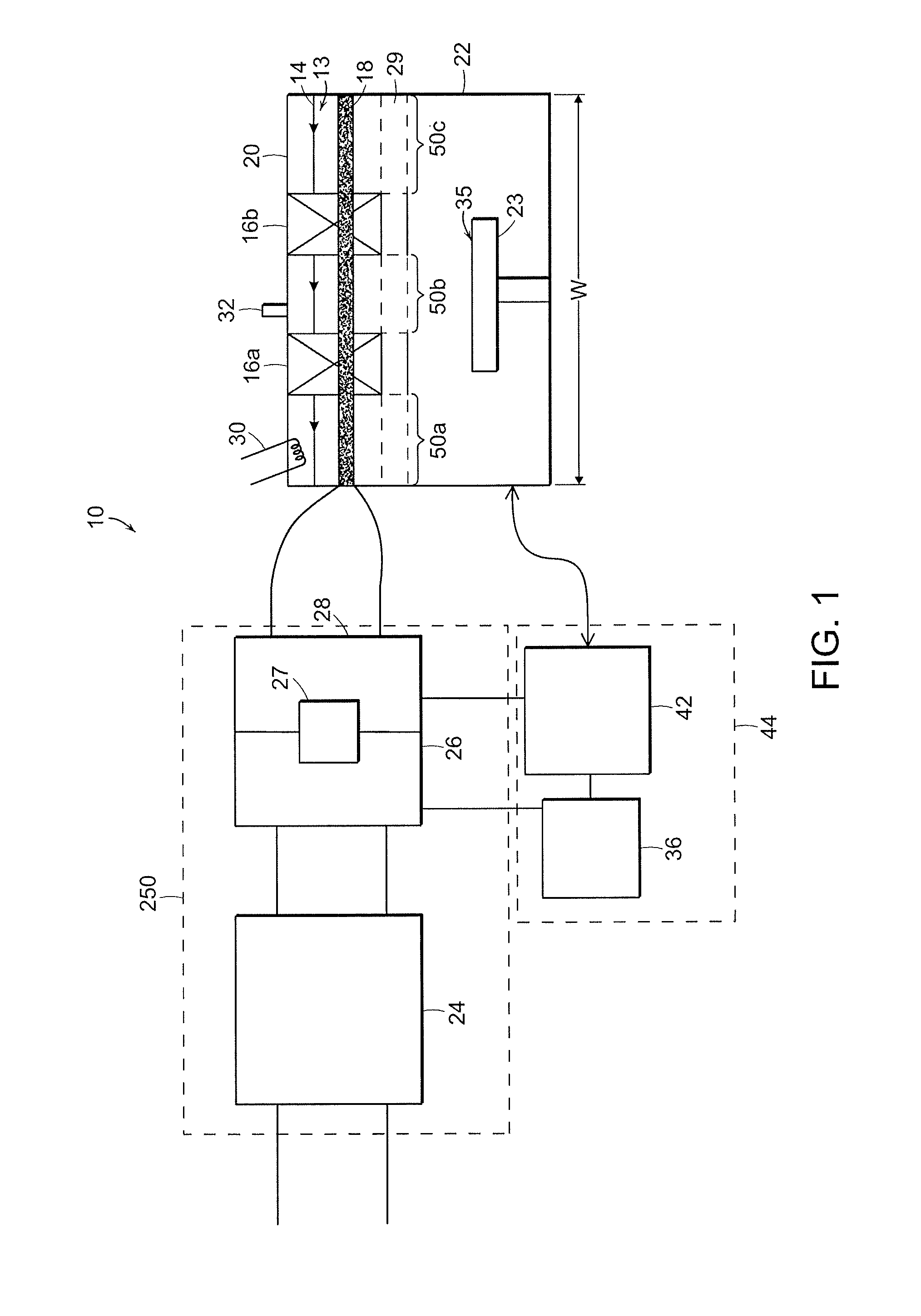

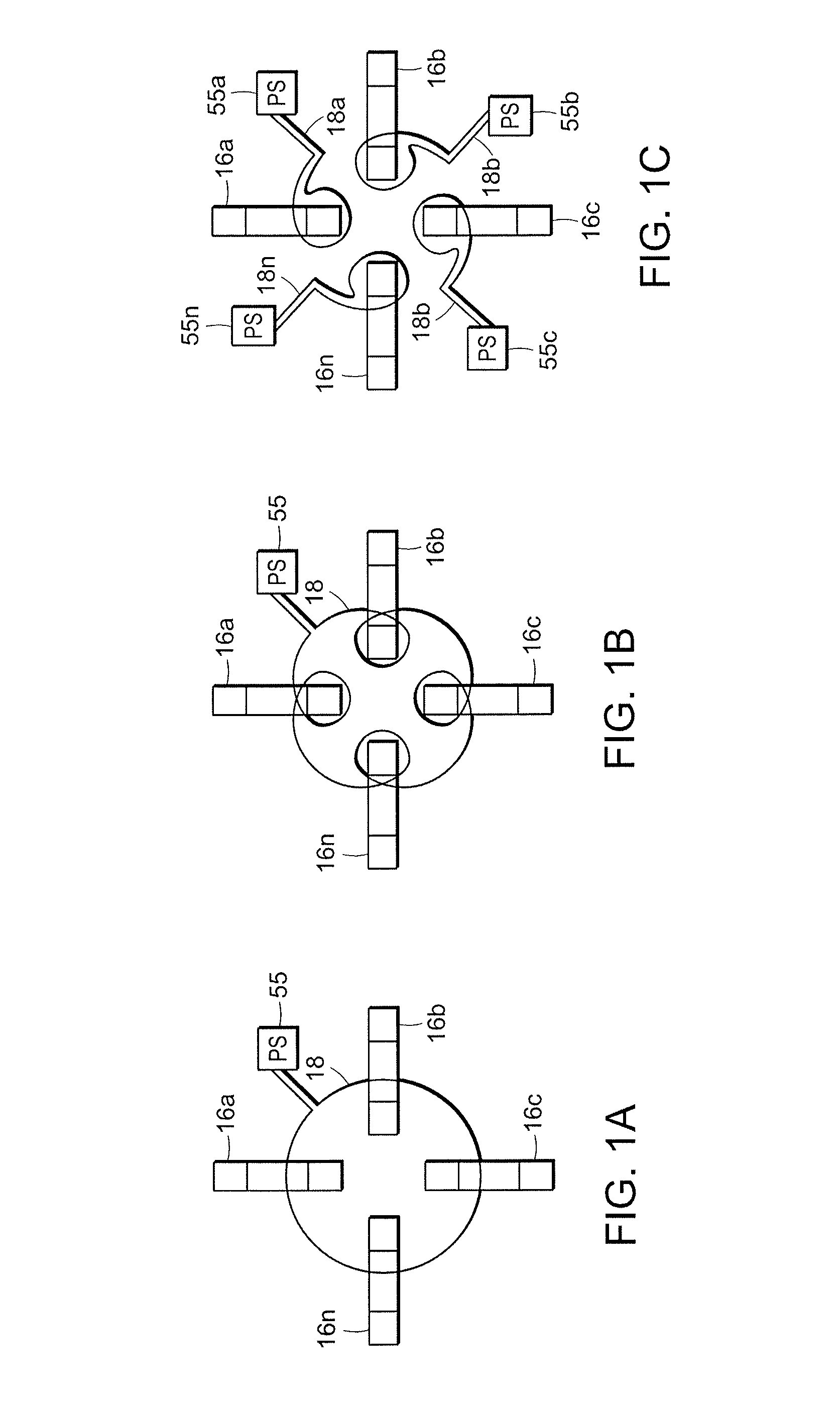

Method and Apparatus for a Large Area Inductive Plasma Source

InactiveUS20140062285A1Minimize lossDifferent life-timeElectric arc lampsSolid cathode detailsInduction plasma technologyMagnetic core

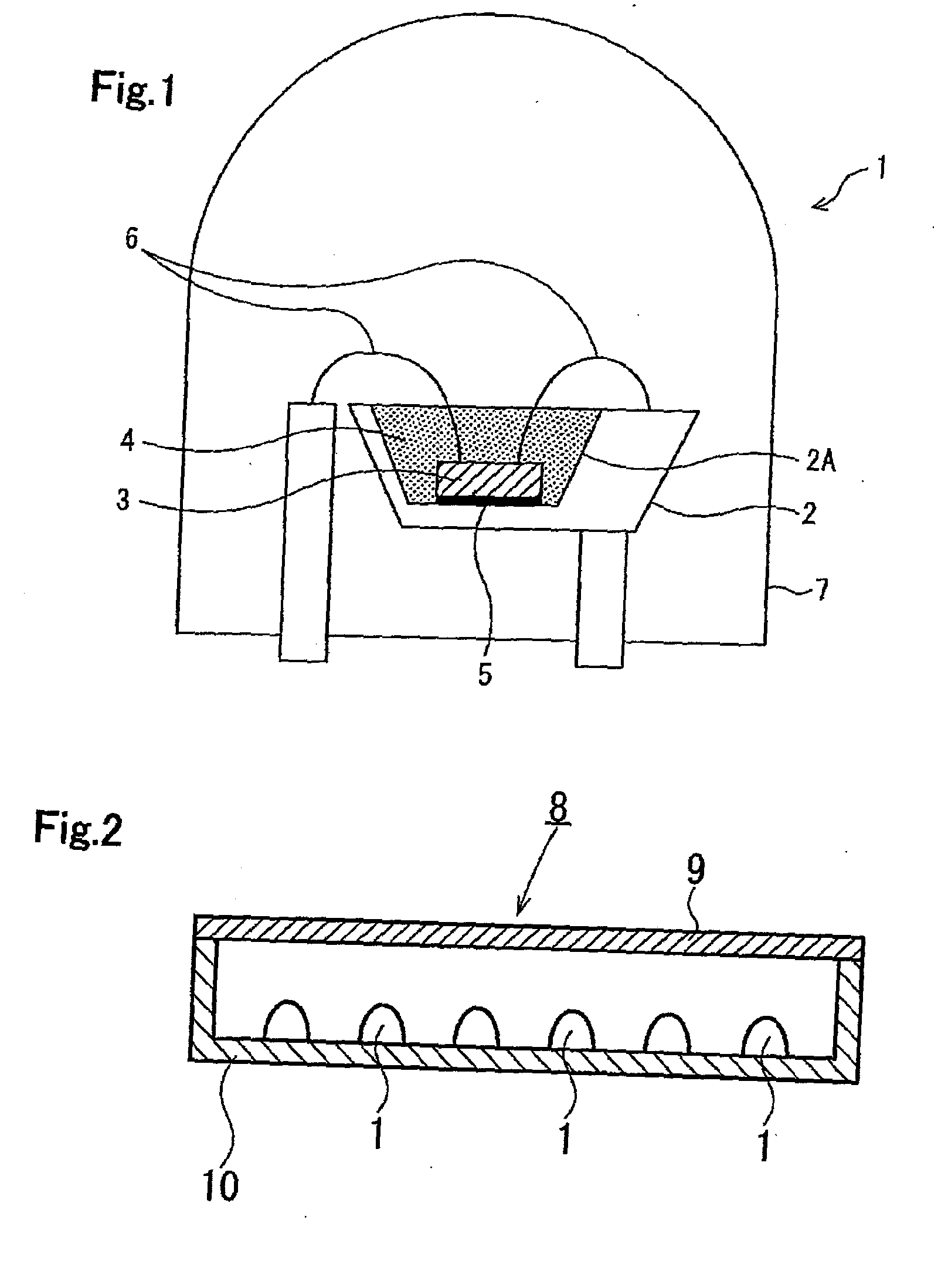

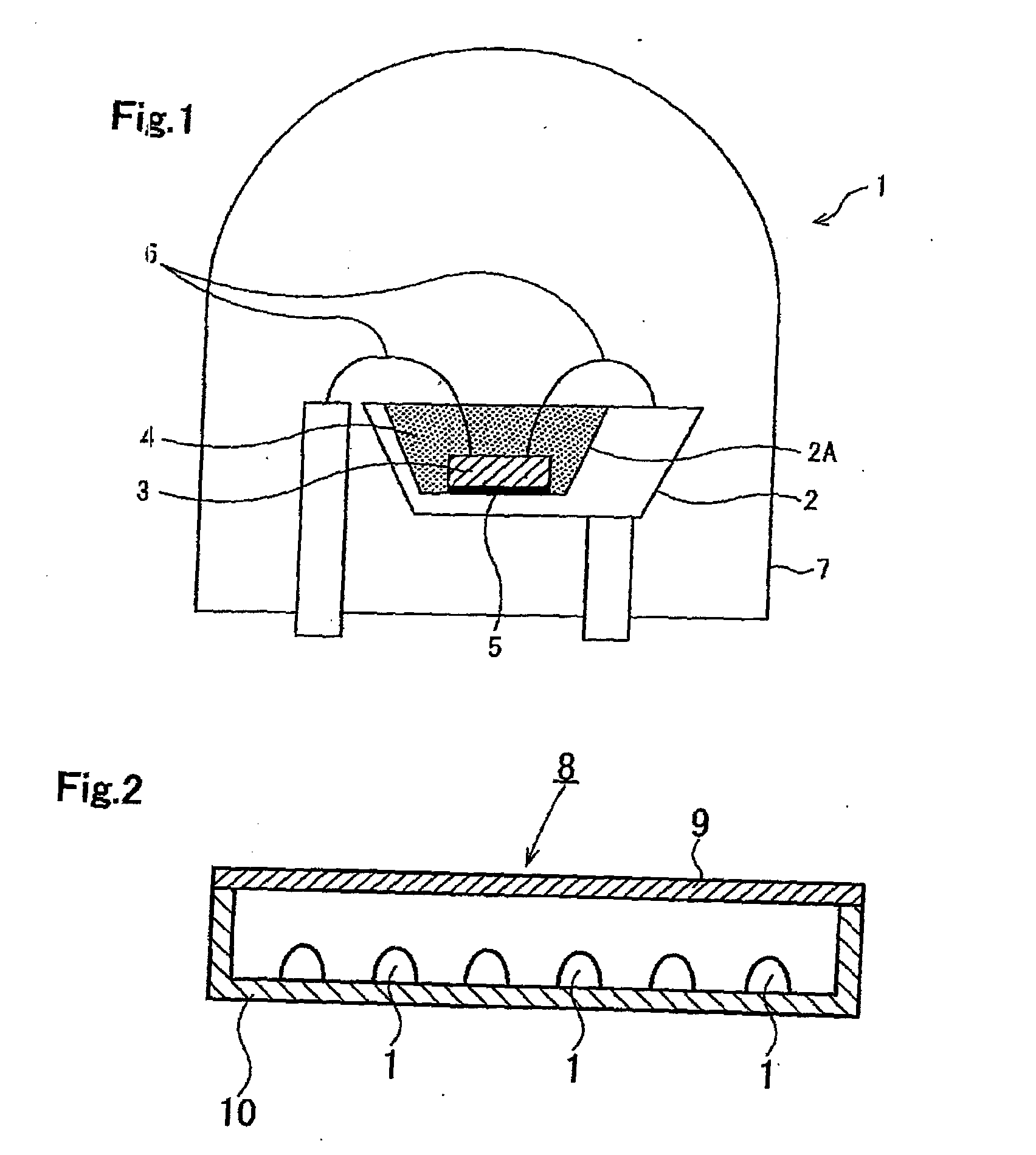

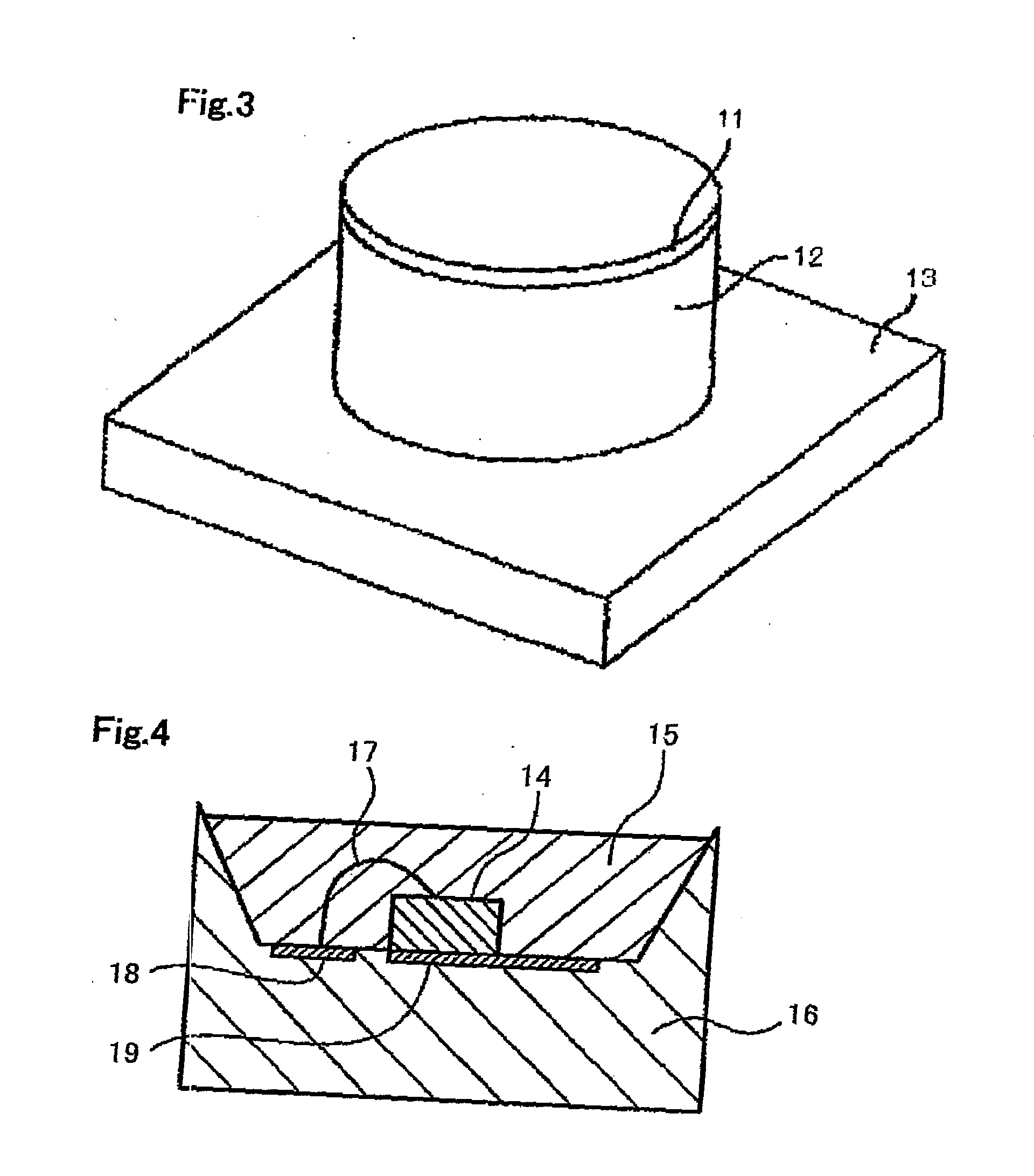

A plasma source for providing dissociated gas to semiconductor process chamber is provided. The plasma chamber can have at least one gas inlet and at least one chamber wall for containing the gas, a plurality of magnetic cores disposed relative to the plasma chamber such that the plasma chamber passes through each of the plurality of magnetic cores. A primary winding can be coupled to the plurality of magnetic cores. The plasma chamber can generate a toroidal plasma along a plane extending through the plasma chamber and which is at least substantially parallel to a top surface of a sample holder disposed within the semiconductor process chamber.

Owner:MKS INSTR INC

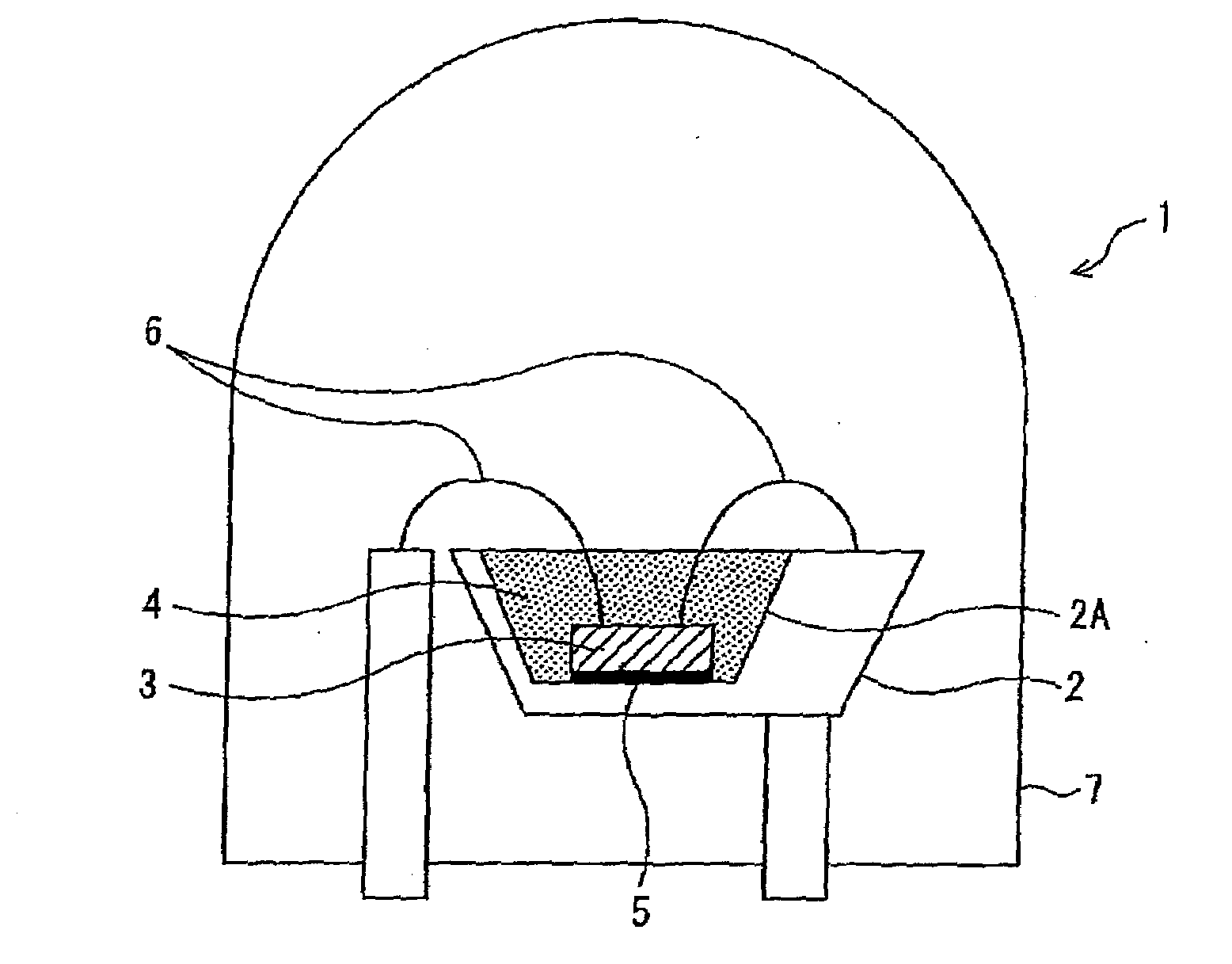

Alloy powder for aw material of inorganic functional material and phosphor

InactiveUS20090134775A1Proceed efficiently and uniformlyUniform chemical compositionDischarge tube luminescnet screensTransportation and packagingPhosphorNitrogen

The present invention provides an alloy powder that is a material for producing inorganic functional materials such as phosphors, a phosphor with high brightness, and a method for producing the phosphor. An alloy powder for an inorganic functional material precursor contains at least one metal element and at least one activating element M1 and has a weight-average median diameter D50 of 5 μm to 40 μm. A method for producing a phosphor includes a step of heating an alloy, containing two or more metal elements for forming the phosphor, in a nitrogen-containing atmosphere.

Owner:MITSUBISHI CHEM CORP

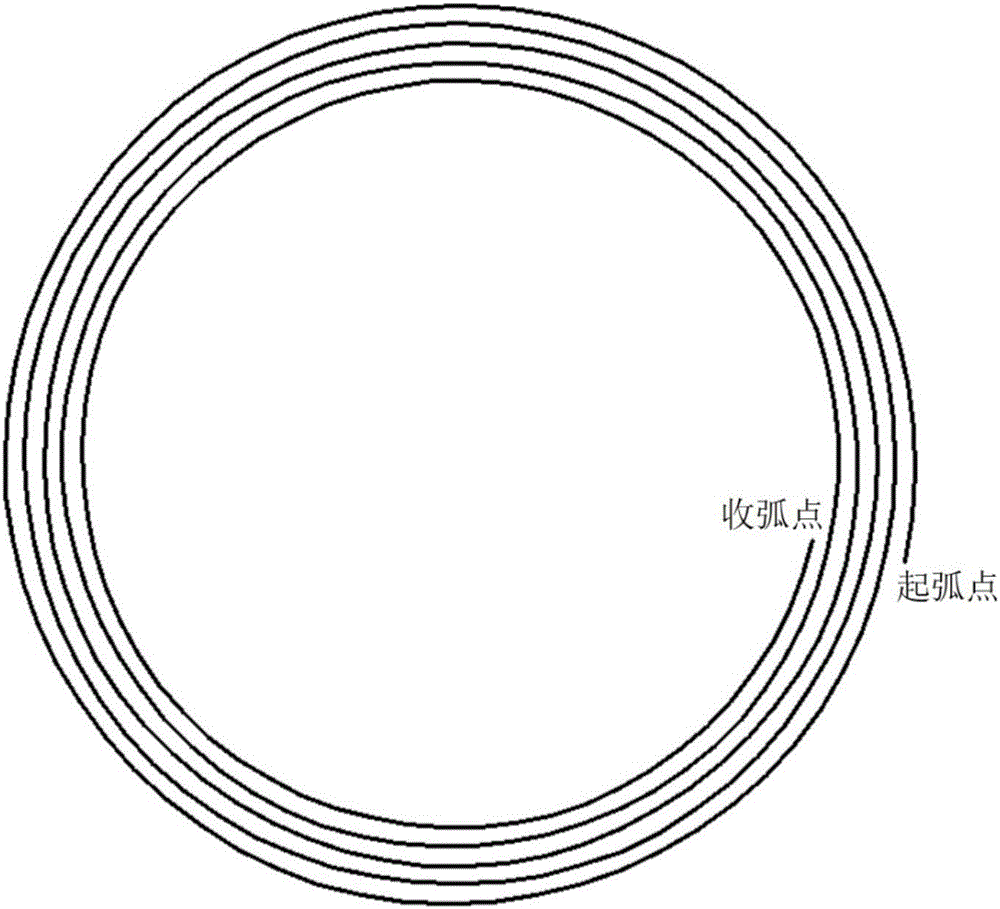

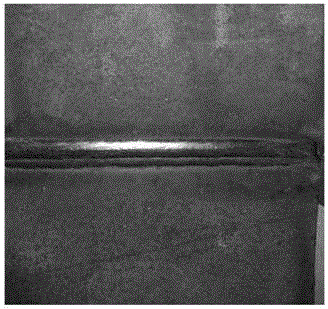

Manufacturing method of arc additive of titanium alloy structural part

ActiveCN102962547AImprove forming qualityUniform chemical compositionArc welding apparatusCrystalliteWeld bead

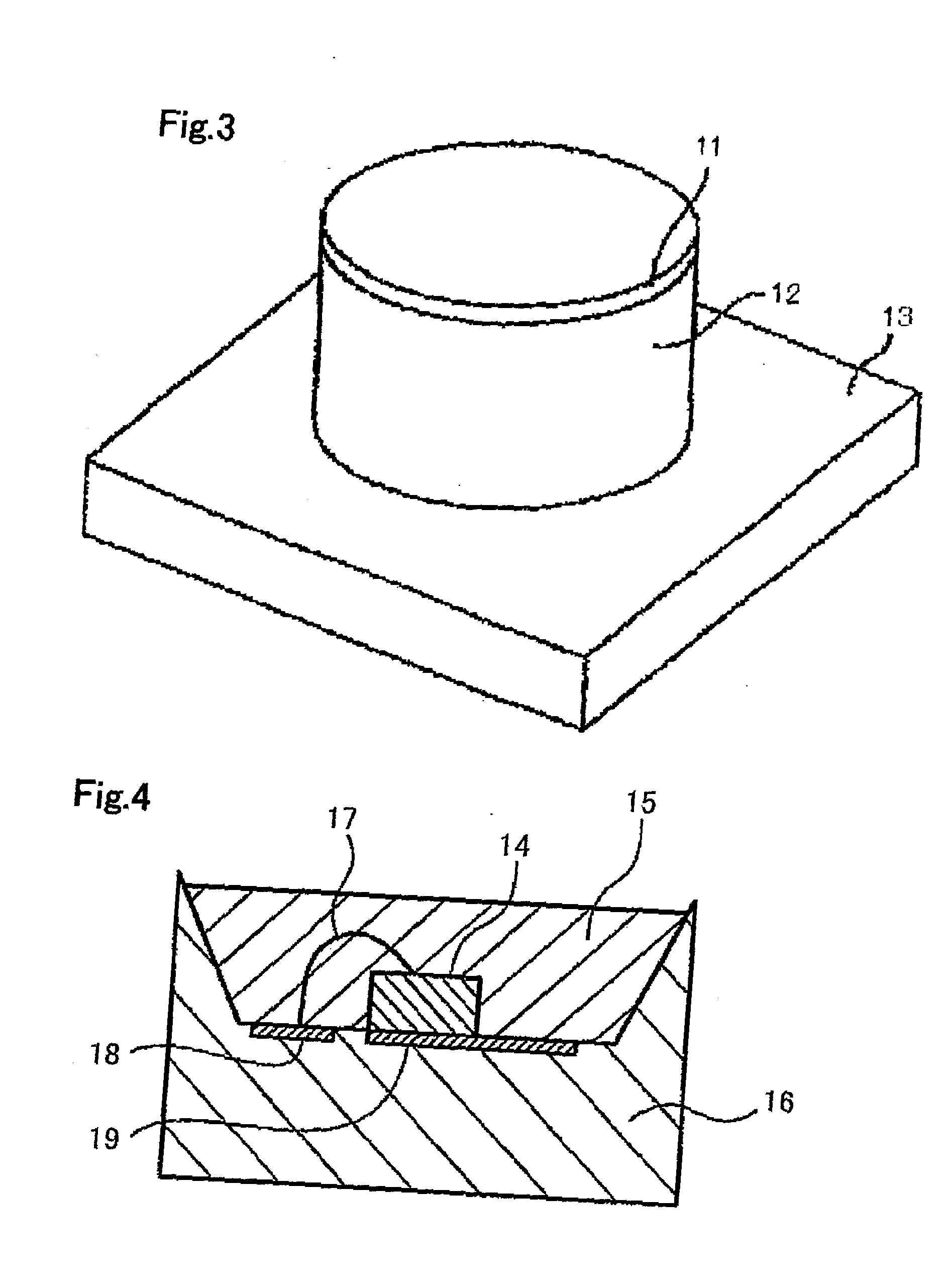

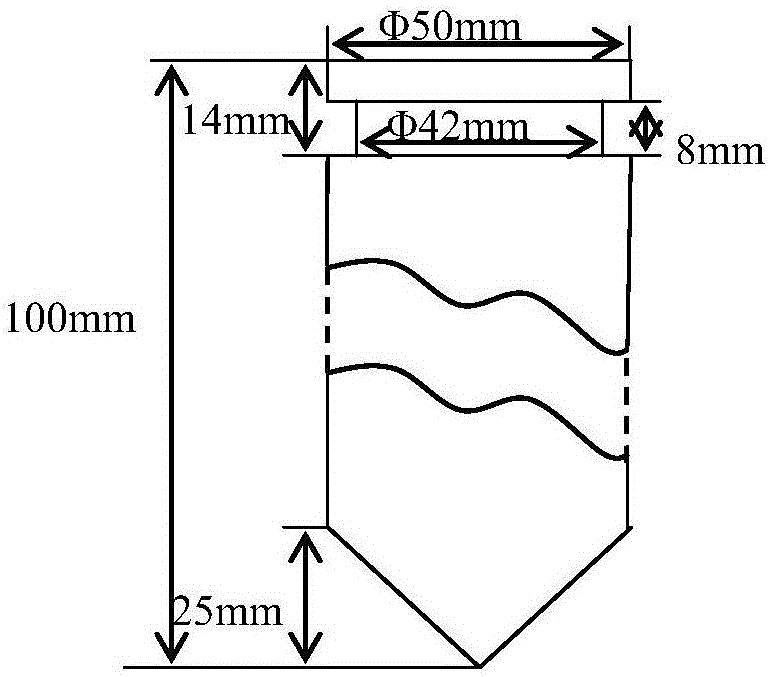

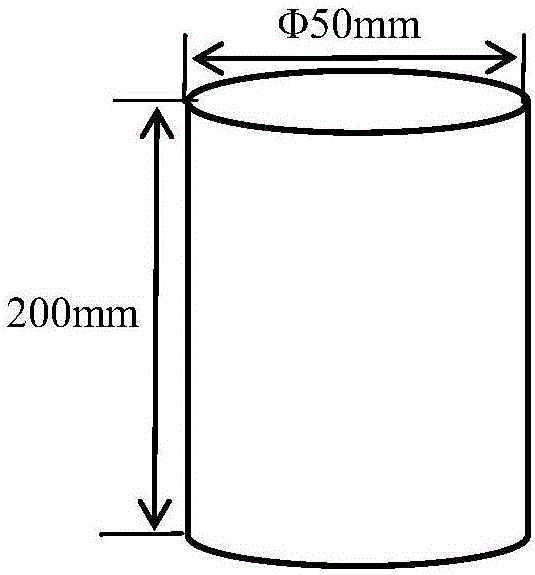

The invention provides a manufacturing method of an arc additive of a titanium alloy structural part. An arc wire feed additive manufacturing method is used to carry out welding of each layer of ring members, i.e., a wire feeder feeds welding wires, the welding wires are melted by a welding gun to weld, and ring welding beads from the inside to the outside are sequentially lapped to form a layer of ring members; and then one thickness of layer of the welding gun is increased, and the welding method is repeated to form another layer of ring members, and so forth; and finally, a plurality of layers of ring members are overlapped to form a titanium alloy structural part. The welding forming part provided by the invention has a fine and uniform grain size and good mechanical properties, and can meet or exceed the level of congruent castings, and the product has a short development cycle and high processing efficiency.

Owner:CAPITAL AEROSPACE MACHINERY +1

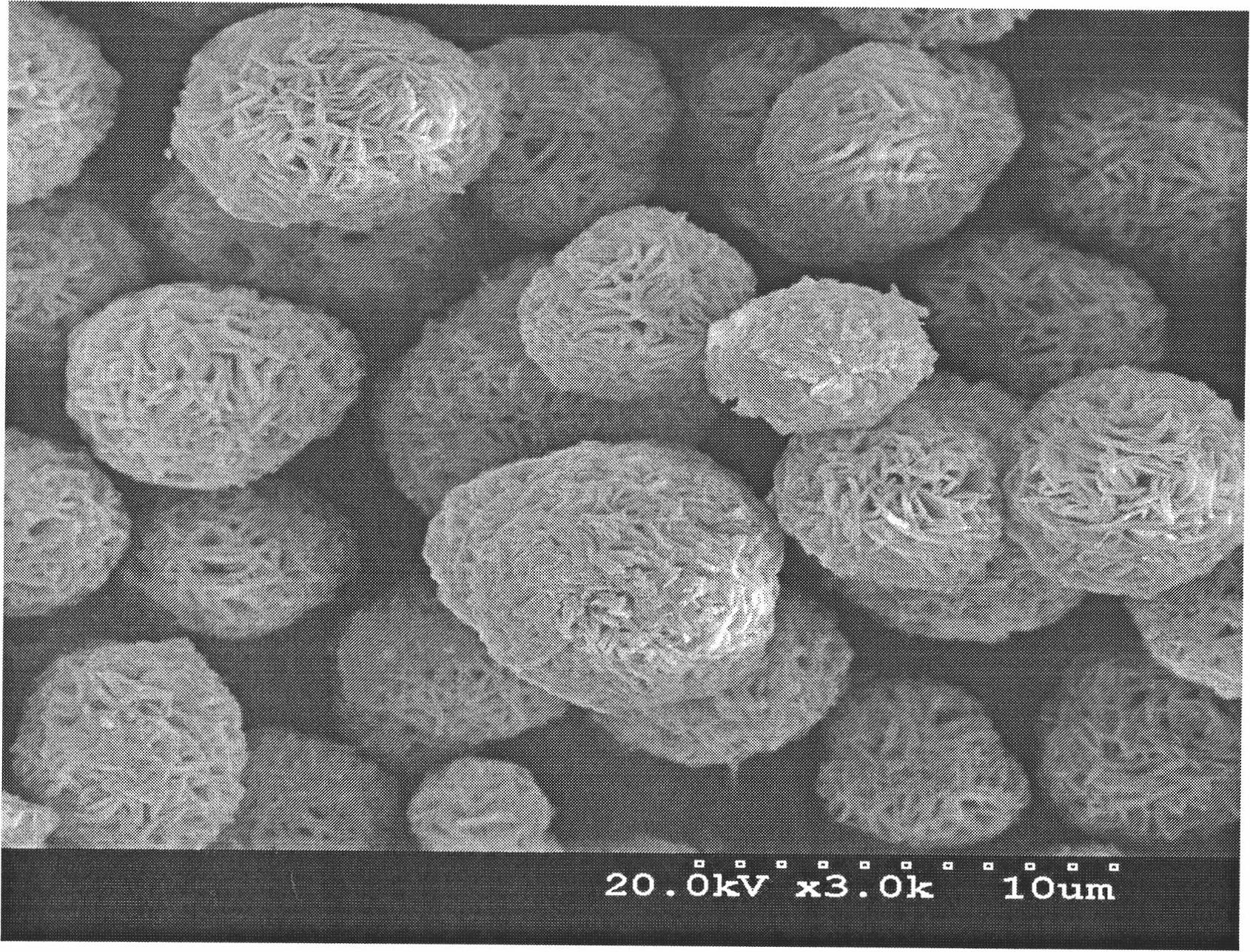

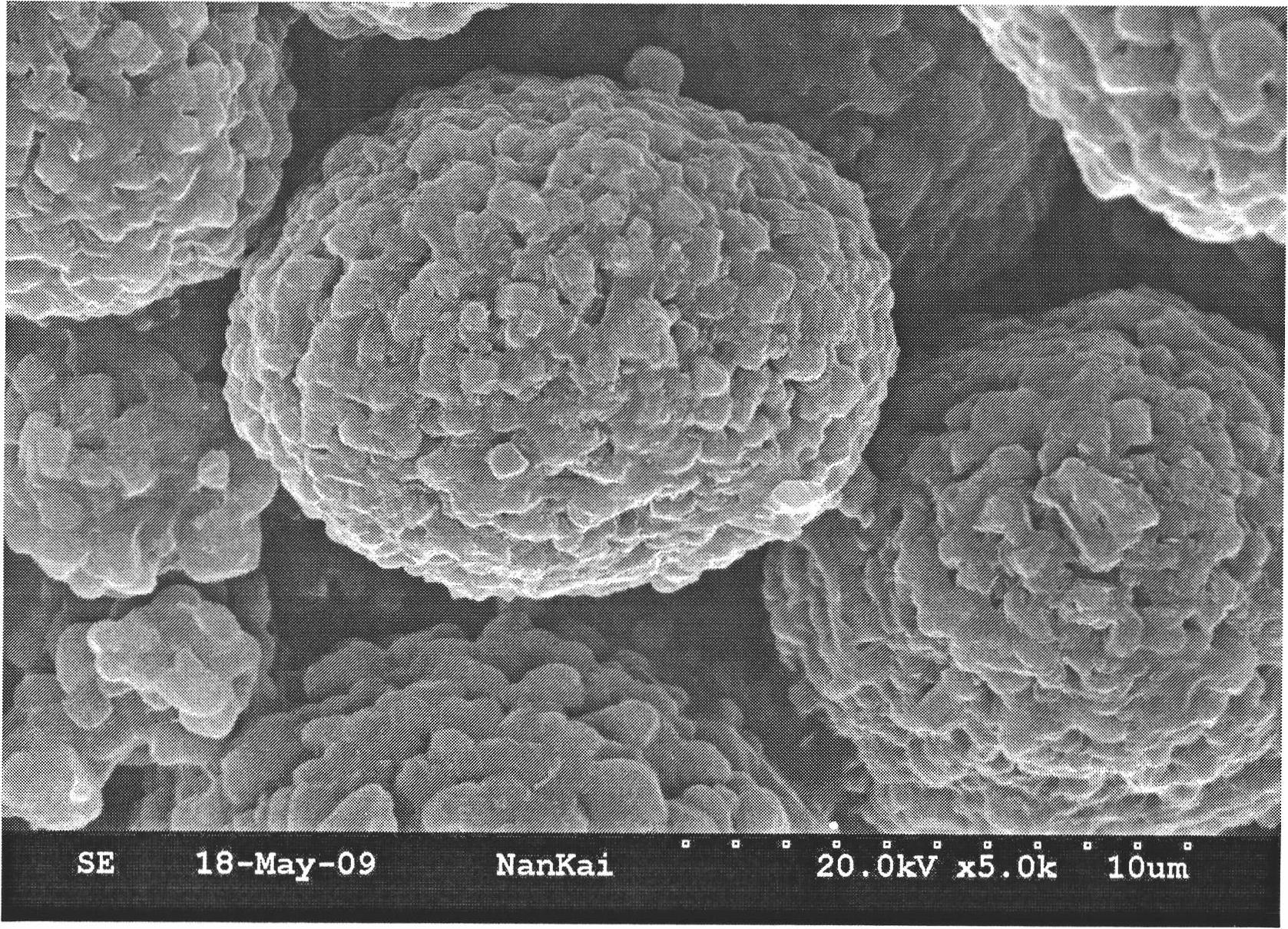

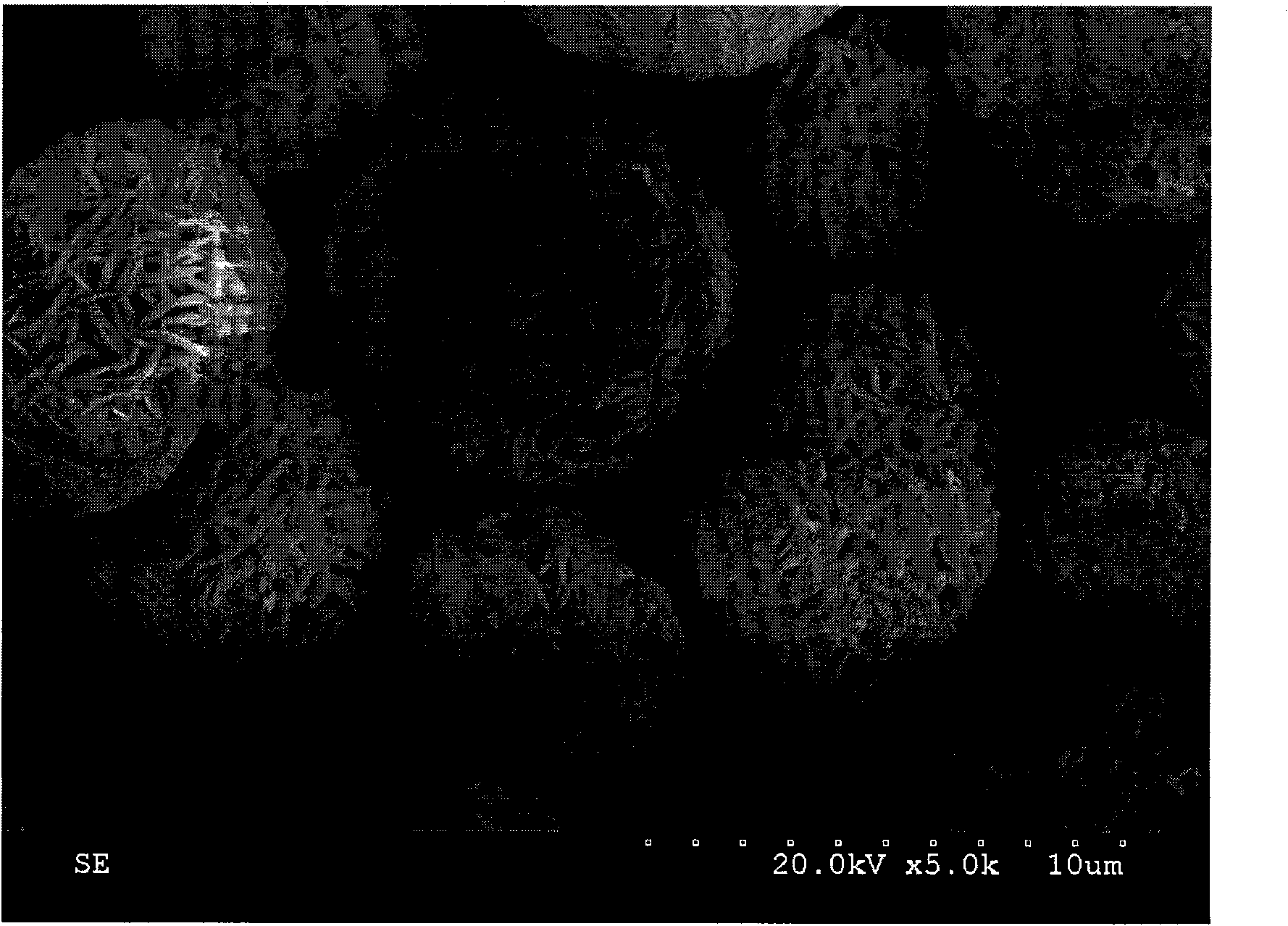

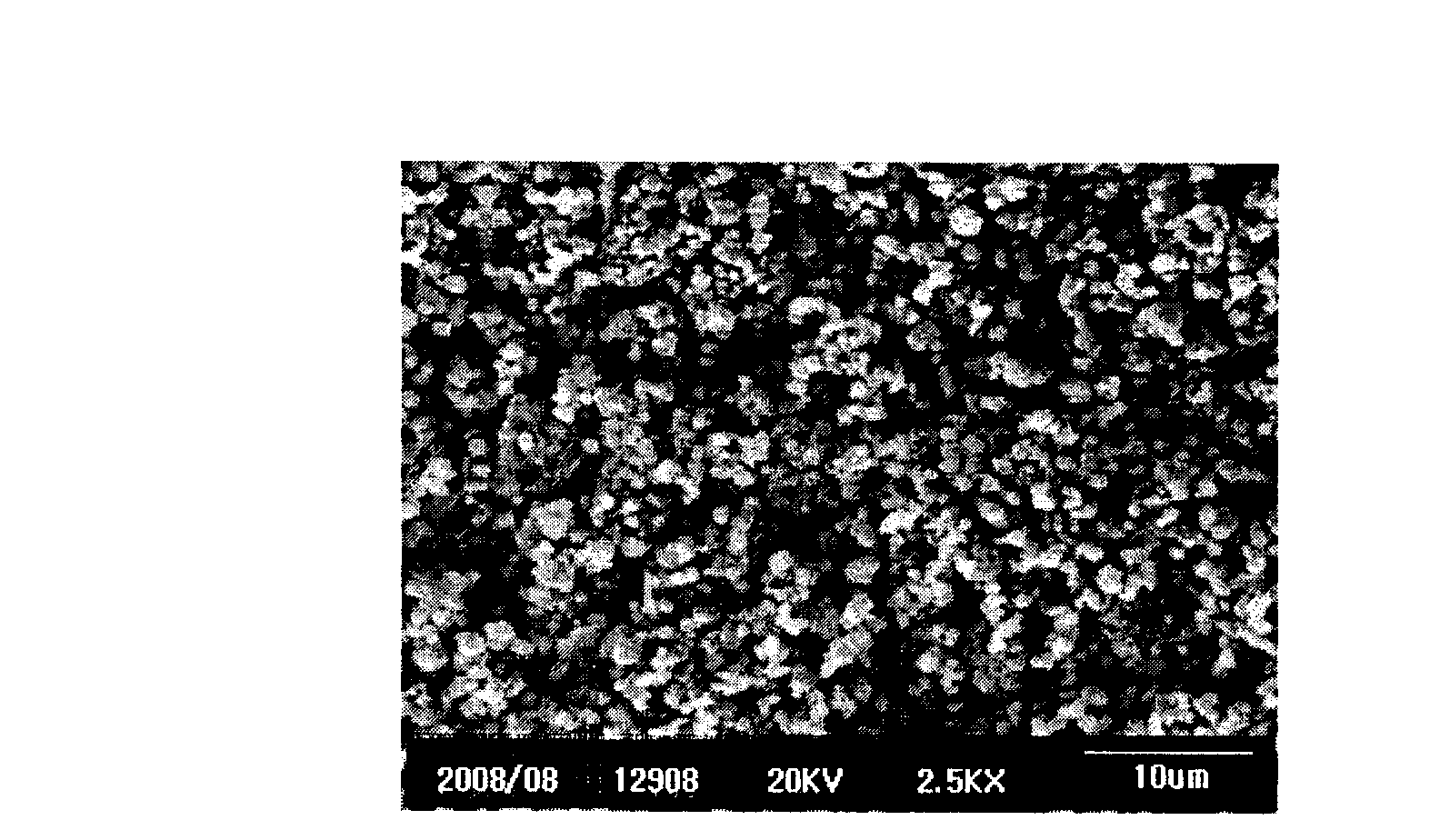

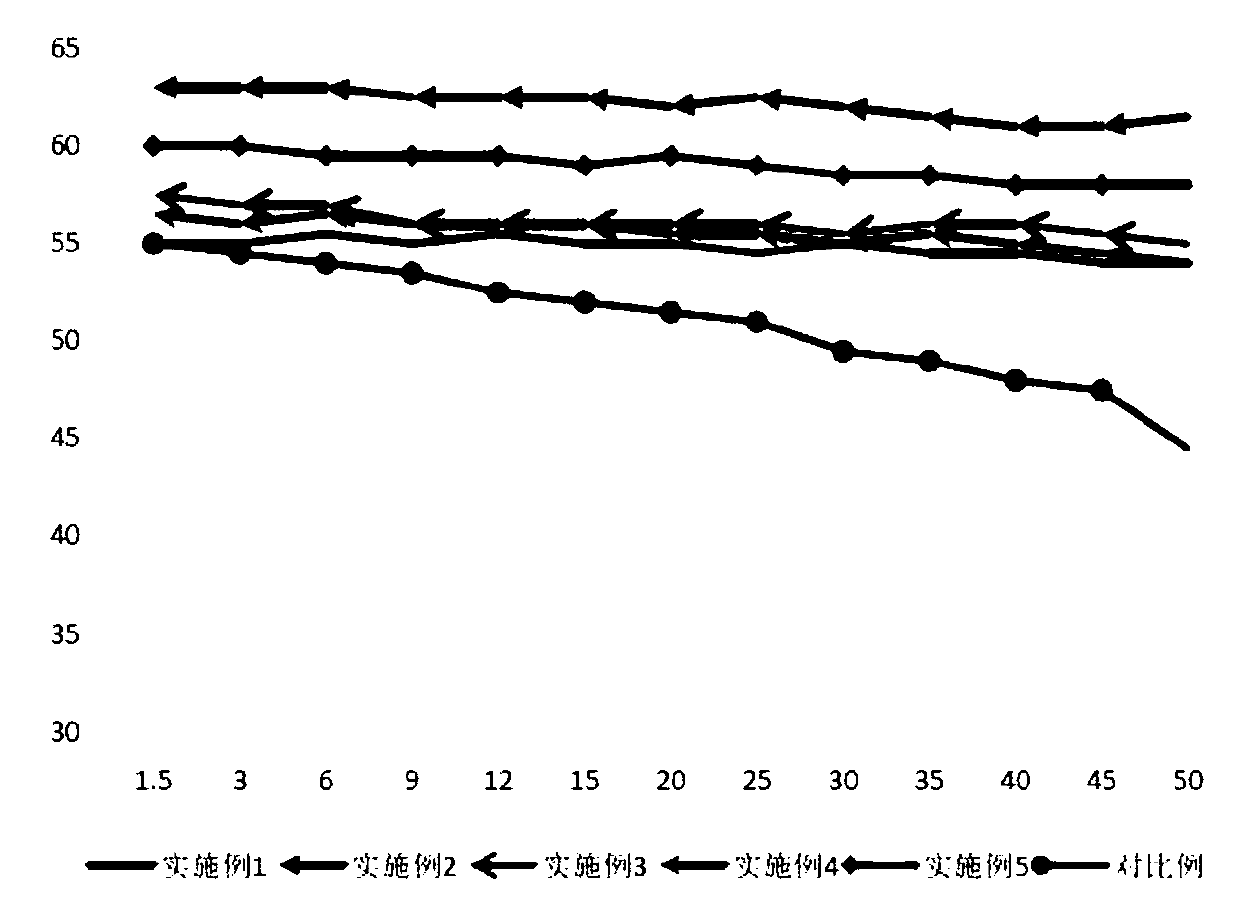

Method for preparing high-performance spherical lithium ion secondary battery cathode material

ActiveCN102110808AHigh densityHigh activityCell electrodesNickel compoundsHigh densityElectrical battery

The invention provides a method for preparing a high-performance spherical lithium ion secondary battery cathode material. The method comprises the steps of synthesizing a NiaCobMn1-a-b(OH)2 precursor through adopting a coprecipitation-crystallization method, coating NicCodMn1-c-d(OH)2NieCofMn1-e-f(oh)2 composite layer on the surface of the precursor through adopting a chemical method, and then fully mixing with lithium salt to prepare a high-performance spherical lithium ion secondary battery cathode material LiNiaCobMn1-a-bO2(LiNicCobMn1)-c-dO2LiNieCofMn1-e-fO2) through stepwise sintering. The cathode material prepared by adopting the method has high density, good activity, and accurate stoichiometric proportion. Malignant interaction between the cathode material and an electrolyte is avoided, capacity decrease caused by non- electrochemical active substances is prevented, and the circulating life of materials is prolonged. The method is easy to control, has a low manufacturing cost, and is convenient for mass production, so as to create conditions for the development of high-capacity lithium ion batteries.

Owner:HENAN KELONG NEW ENERGY CO LTD

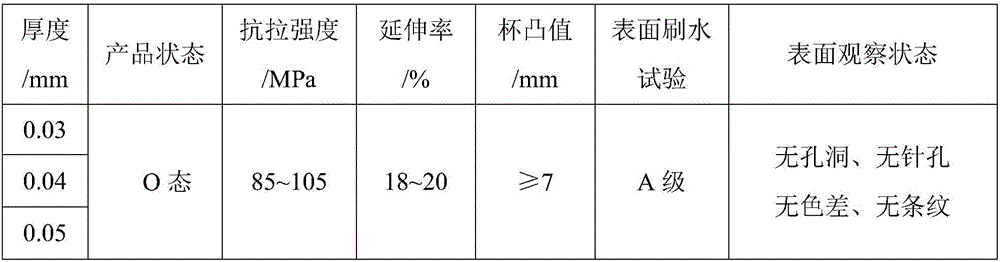

Lithium-battery 8021 soft packaging aluminum foil and production method thereof

ActiveCN106191544AReduce hydrogen contentImprove sealingJackets/cases materialsMetallurgyIngot casting

The invention discloses lithium-battery 8021 soft packaging aluminum foil and a production method thereof. Aluminum alloy containing Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti and the balance Al is smelted and subjected to ingot casting, then an ingot is subjected to surface milling and soaking treatment; and the lithium-battery 8021 soft packaging aluminum foil is obtained after the steps of hot rolling, cold rolling, annealing, foil rolling, roll combining, combined roll annealing and roll dividing. The lithium-battery 8021 soft packaging aluminum foil prepared through the good technological process is a finished product in the O state, the ductility reaches 18-20%, the cupping value is larger than or equal to 7 mm, and the fracture resistance, stamping resistance and the like of the soft packaging aluminum foil are effectively improved. The aluminum foil has no holes or pinholes completely, so that a lithium battery soft package prepared from the aluminum foil has good airtightness and is free of liquid leakage and safe to use. The lithium-battery 8021 soft packaging aluminum foil has good social and economical benefits and broad application prospects.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

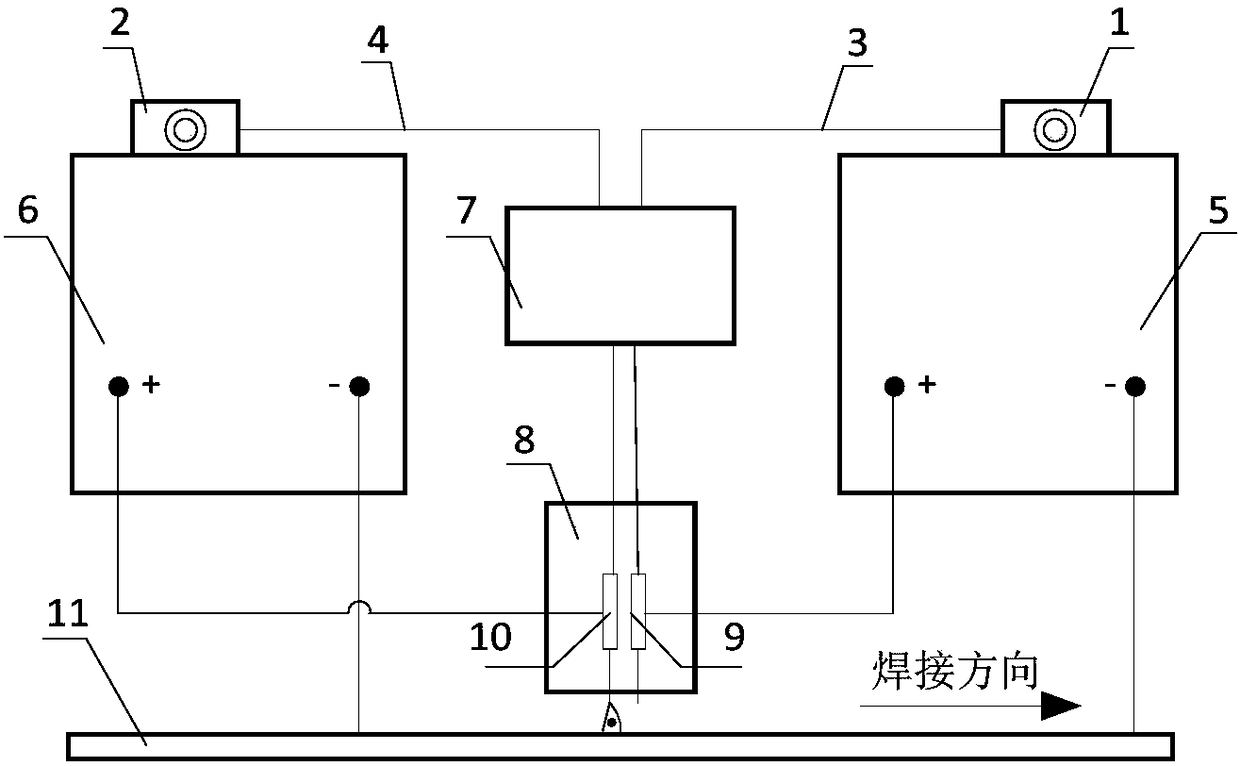

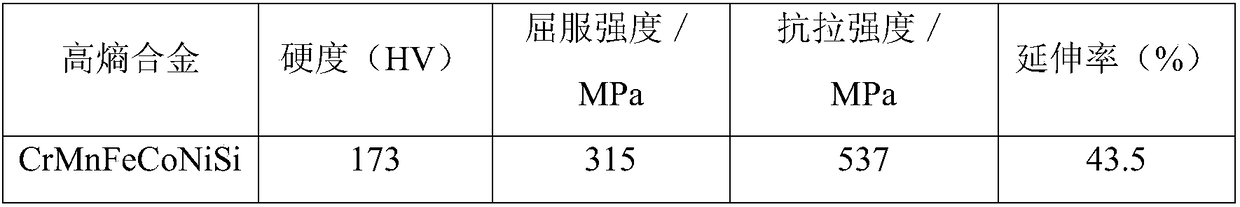

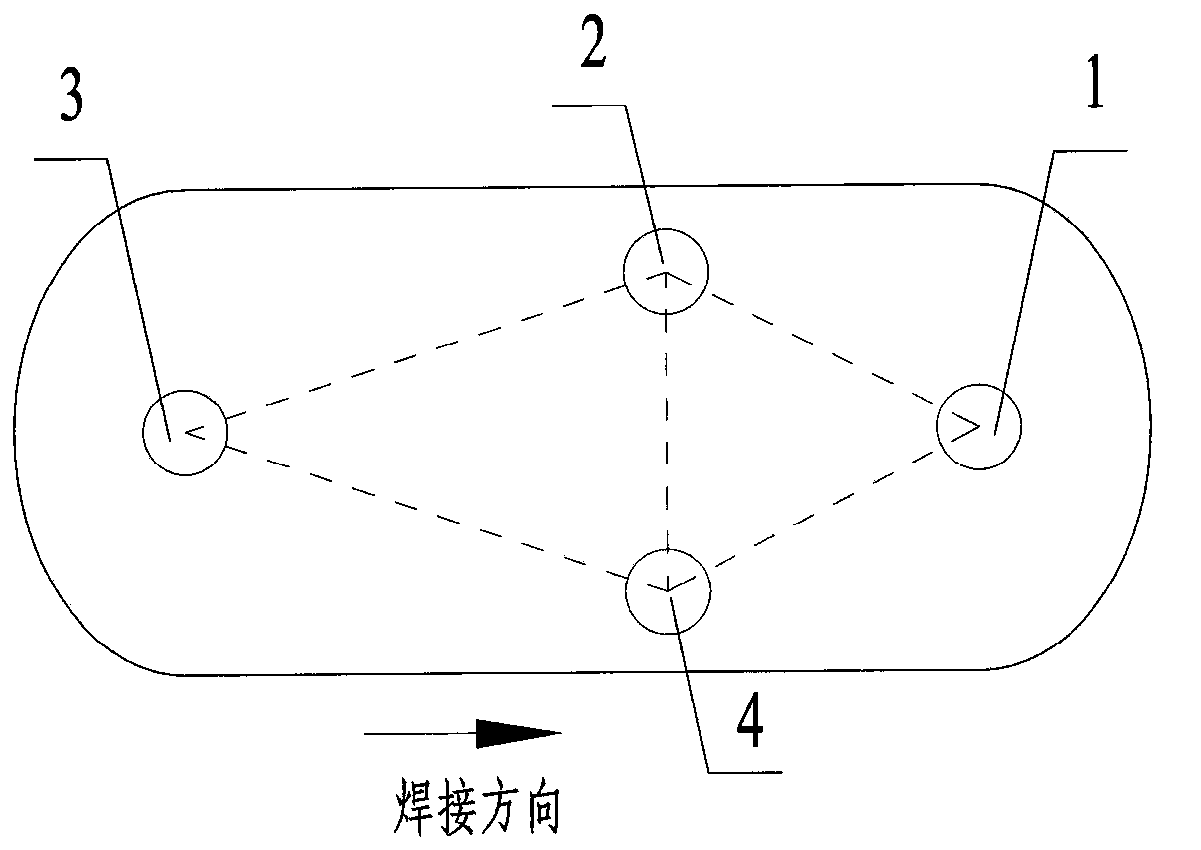

Double-arc fuse collaborative additive manufacturing method of high-entropy alloy

ActiveCN108326427AEasy to adjust ingredientsEasy to adjust grain sizeAdditive manufacturing apparatusLaser beam welding apparatusManufacturing technologyHigh entropy alloys

The invention relates to the technical field of high-entropy alloys, and specifically discloses a double-arc fuse collaborative additive manufacturing method of a high-entropy alloy. The method is characterized in that raw materials are supplied based on a formula of the high-entropy alloy, wherein the raw materials include an alloy strip and flux core powder; the alloy strip and the flux core powder are prepared into a flux cored welding wire; and then a double-arc fuse collaborative additive manufacturing method is carried out to obtain a part or a blocky alloy as requirement. The method isstable in processes, high in cladding efficiency, high in preparation efficiency, wide in heat input adjusting range, low in cost, convenient to adjust the components of the alloy and the size of crystal grains; in addition, the method is applicable to manufacturing of massive high-entropy alloys as well as precise high-entropy alloy parts.

Owner:SHIJIAZHUANG TIEDAO UNIV

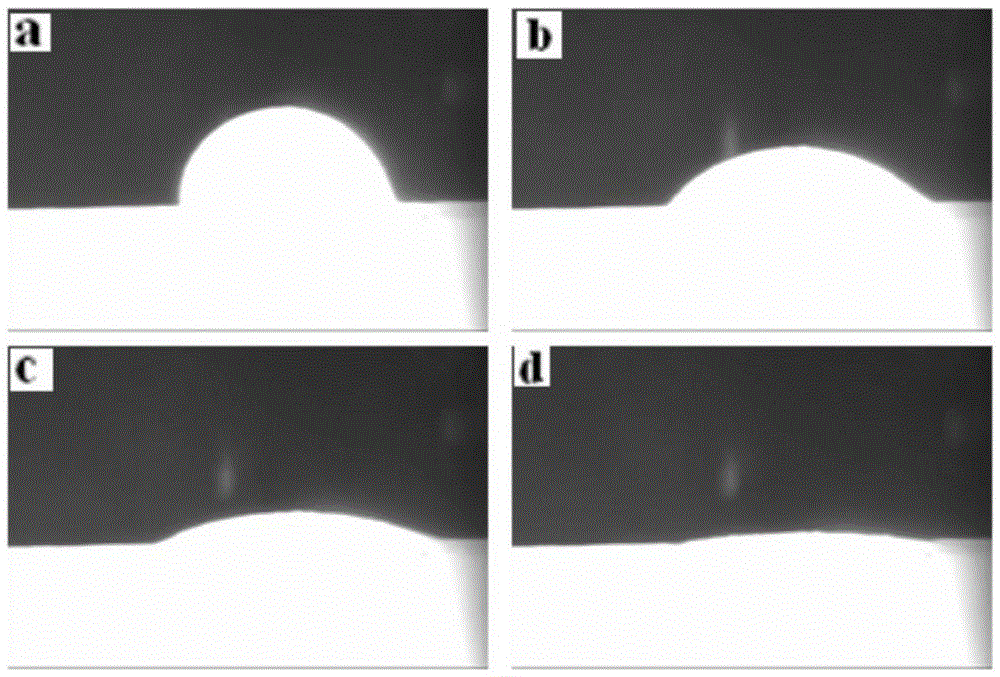

Boron-containing titanium-based amorphous solder for braze welding Si3N4 ceramic and preparation method thereof

The invention relates to braze welding Si3N4 ceramics containing the boron Ti-based amorphous solder and the preparation method thereof, and belongs to the brazing material in the field of amorphous state and metallurgy. The ingredients of the brazing material consist of the following according to the mass percent: Zr of 12.0-28.0 percent, Ni of 12.0-28.0 percent, Cu of 12.0-28.0 percent, and B of 0.05-0.5 percent, and the remains is Ti. The melting scope of the brazing material ranges 1,150K to 1,250K, and the brazing temperature is from 1,273K to 1,373K. The Ti-Zr-Ni-Cu-B amorphous braze vacuum braze welding Si3N4 ceramics, which is produced by the rapid solidification technology, has superior high-temperature performance to Ag-Cu-Ti solder and Ti-Zr-Ni-Cu solder. The tie-in high-temperature bend strength reaches 145MPa under 673K DEG,108MPa under 773K DEG, and still 93MPa under 873K DEG.

Owner:JIANGSU UNIV OF SCI & TECH

High silicon cast aluminium spectrum standard sample and its preparation method

InactiveCN1410572AUniform chemical compositionDense tissuePreparing sample for investigationAnalysis by material excitationChemical compositionStandard samples

The standard specimen contains chemical elements with following weight ratios in pure aluminium Si: 1.03-13.70, Fe: 0.147-1.50, Cu: 0.125-7.44, Mn: 0.090-1.05, Mg: 0.049-1.53, Zn: 0.052-1.05, Ti: 0.034-0.274 etc. Since the Al-Sr modification is adopted, thus the specimen provides the features of even chemical elements, compact structure, free of bulky initializing coarse grains as well as raised processability. The long-playing diffusion fusion technique adopted makes silicon diffuse to aluminium adequetely so as to increase uniformity of chemical elements in the specimen evidently.

Owner:SOUTHWEST ALUMINUM GRP

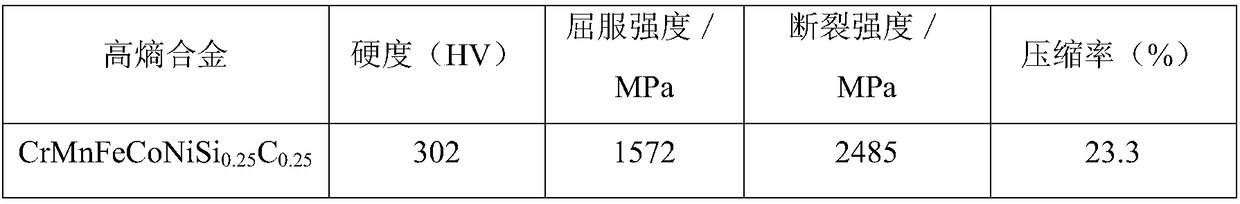

Alloyed spherical powder preparation device and method for laser 3D (three-dimensional) printing

InactiveCN106424748AWith mechanical controlWith automatic controlAdditive manufacturing apparatusTransportation and packagingAutomatic controlCollection system

The invention relates to a high-performance alloyed spherical powder preparation device and method for laser 3D (three-dimensional) printing. The device comprises a vacuum acquirement and inflation system, an induction smelting system, an atomization powder preparation system, a power collection system and a power system. The preparation method includes that: (1) the induction smelting system selects a non-crucible induction system or a crucible induction system; (2) alloy bars are fixed on a continuous feeder, or nickel-based / cobalt-based alloy bars are put in a smelting chamber; (3) the smelting chamber, an atomizing chamber and a power collection device are vacuumized prior to be fed with inert gas; (4) induction smelting is started, when alloy reaches preset temperature, alloy droplets are enabled to enter the atomization powder preparation system, and nozzles are started to perform atomization powder preparation; alloyed power prepared in the atomization chamber is collected through the powder collection device. The device can realize mechanical control, automatic control and real-time monitoring; the prepared alloy powder is high in yield, uniform in particle size distribution, good in degree of sphericity, uniform in chemical component, good in mobility, low in oxygen content and low in hollow sphere rate.

Owner:NORTHEASTERN UNIV

Preparation of stratified lithium ion anode material

ActiveCN101944610AHigh densityHigh activityElectrode manufacturing processesNickel compoundsManganeseSolid state reaction method

The invention relates to a preparation method of a stratified lithium ion anode material, which comprises the following steps: coating cobalt on the surface of a precursor containing nickel, manganese and a small amount of other metals by a chemical precipitation method; fully mixing with a lithium source; and then, adopting a solid reaction method to prepare the high nickel type lithium ion anode material. The chemical formula of the lithium ion anode material is as follows: LidNiaMnbMcCo1-a-b-c02, wherein 0.9<=d<=1.25, 0.5<=a<=1, 0<b<0.5, 0.9<=a+b+c<1, and M is one or a mixture of more than one of Al, Ti, Mg and Zn. The material has uniform chemical composition and high capacity. Besides, the cycle performance of the material is improved, and the operating voltage platform and the safety of a battery are enhanced, especially after the material is subject to doping and coating modification.

Owner:HENAN KELONG NEW ENERGY CO LTD

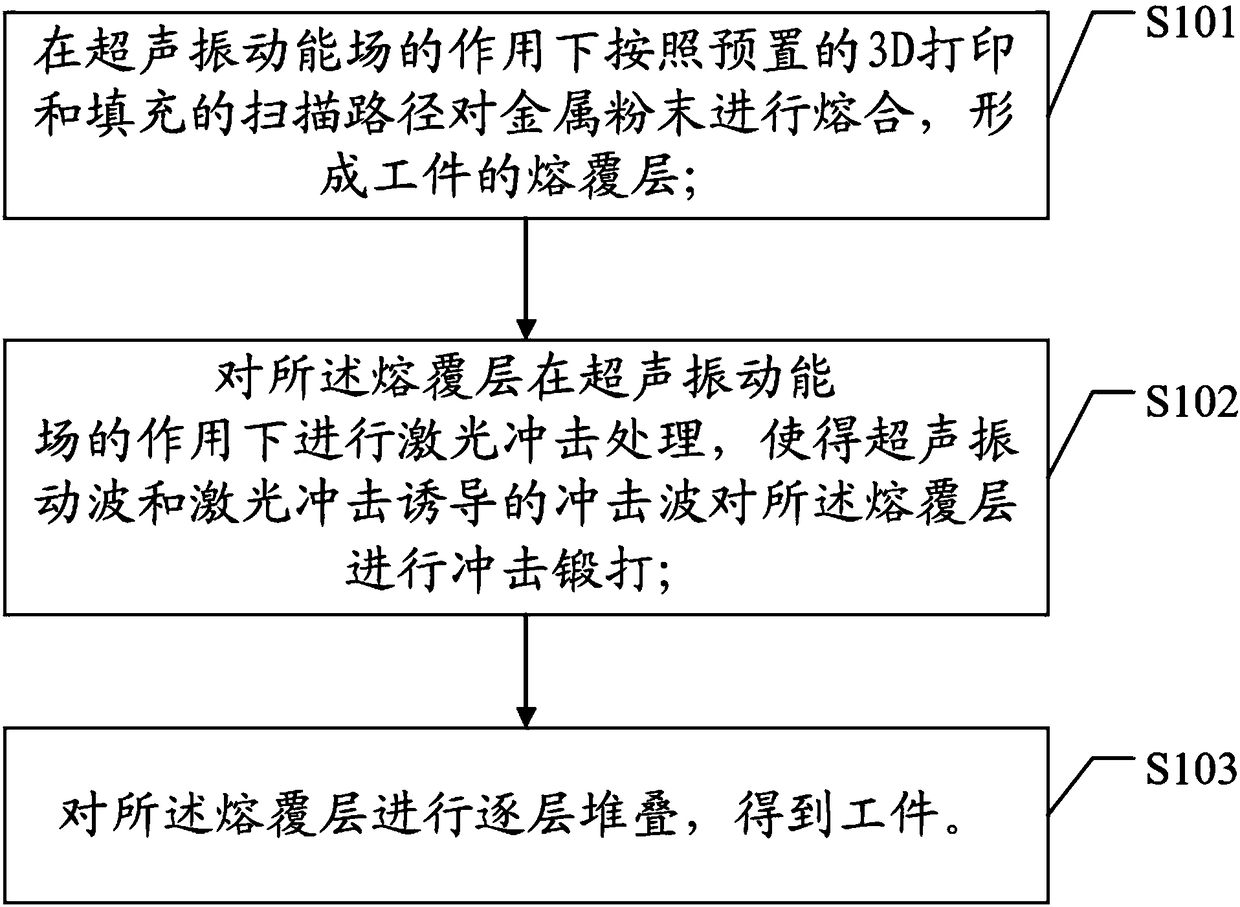

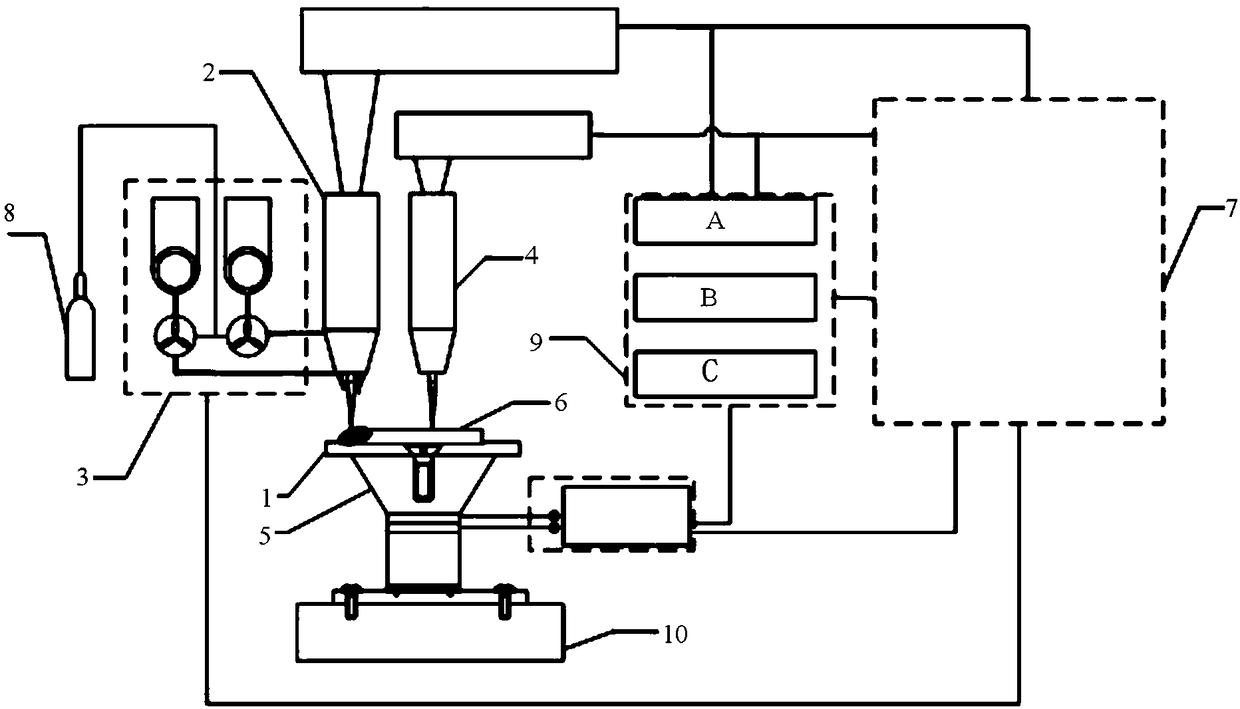

Method and device for carrying out 3D (Three-Dimensional) printing and composite manufacturing on metal

PendingCN108176857AImprove internal qualityImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyShock waveUltrasonic vibration

The invention belongs to the technical field of 3D (Three-Dimensional) printing, and particularly relates to a method and a device for carrying out 3D printing and composite manufacturing on metal. The method for carrying out the 3D printing and the composite manufacturing on the metal comprises the following steps: S101, fusing metal powder under the action of an ultrasonic vibration energy fieldaccording to a preset 3D printing and filling scanning path, thus forming cladding layers of a workpiece; S102, simultaneously carrying out laser shock processing on the cladding layers under the action of the ultrasonic vibration energy field, and impacting and forging the cladding layers through ultrasonic vibration waves and shock waves induced by laser shock; S103, stacking the cladding layers layer by layer, thus obtaining the workpiece. Aiming at the problem existing when an existing metal 3D printing technology is used for manufacturing metal parts, the method disclosed by the invention has the advantages that internal defects of pores, poor fusion, shrinkage porosity and cracks of metal cladding layers and thermal stress can be removed to the maximum, the internal quality and themechanical dynamical comprehensive performance of the metal parts can be increased, and the problems of macroscopic deformation and cracking can be effectively controlled.

Owner:GUANGDONG UNIV OF TECH

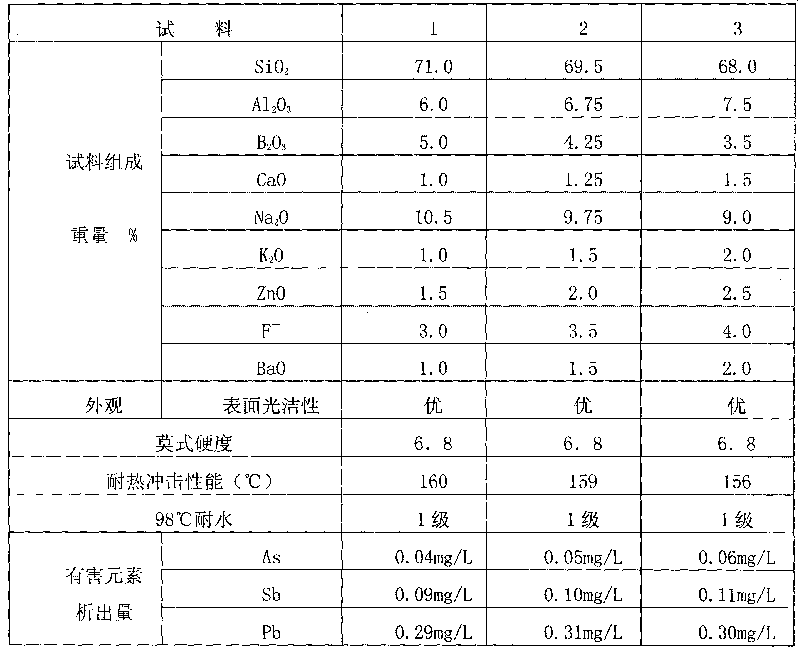

Opal glass suitable for full electrofusion forming and preparation process thereof

InactiveCN101717191AUniform chemical compositionReduce dosageElectric furnaceThermal dilatationPhysical chemistry

The invention discloses an opal glass suitable for full electrofusion forming and a preparation process thereof. The opal glass is prepared by composing a batch mixture by mixing a base material, an auxiliary material and an additive and adopting a full electrofusion method at the temperature of 1480-1520 DEG C; and the components of the batch mixture comprise the following components expressed as oxides in percentage by weight: 68.0-71.0% of SiO2, 6.0-7.5% of Al2O3, 1.0-1.5% of CaO, 9.0-10.5% of Na2O, 3.0-4.0% of F-, 1.5-2.5% of ZnO, 3.5-5.0% of B2O3, 1.0-2.0% of BaO and 1.0-2.0% of K2O. The opal glass prepared by the process has thermal expansion coefficient alpha less than or equal to 7.8*10-6 / DEG C, saves the energy by 50 percent as compared with the transitional method, achieves the mohs hardness of 6.8, the thermal shock resistance more than 125 DEG C and the water resistance of a primary standard, has main performance indexes all achieving or exceeding the level of similar imported products, meets the requirements for environmental protection and health and is an ideal substitute of the transitional porcelain product.

Owner:CHINA HOUSEHOLD ELECTRIC APPLIANCE RES INST

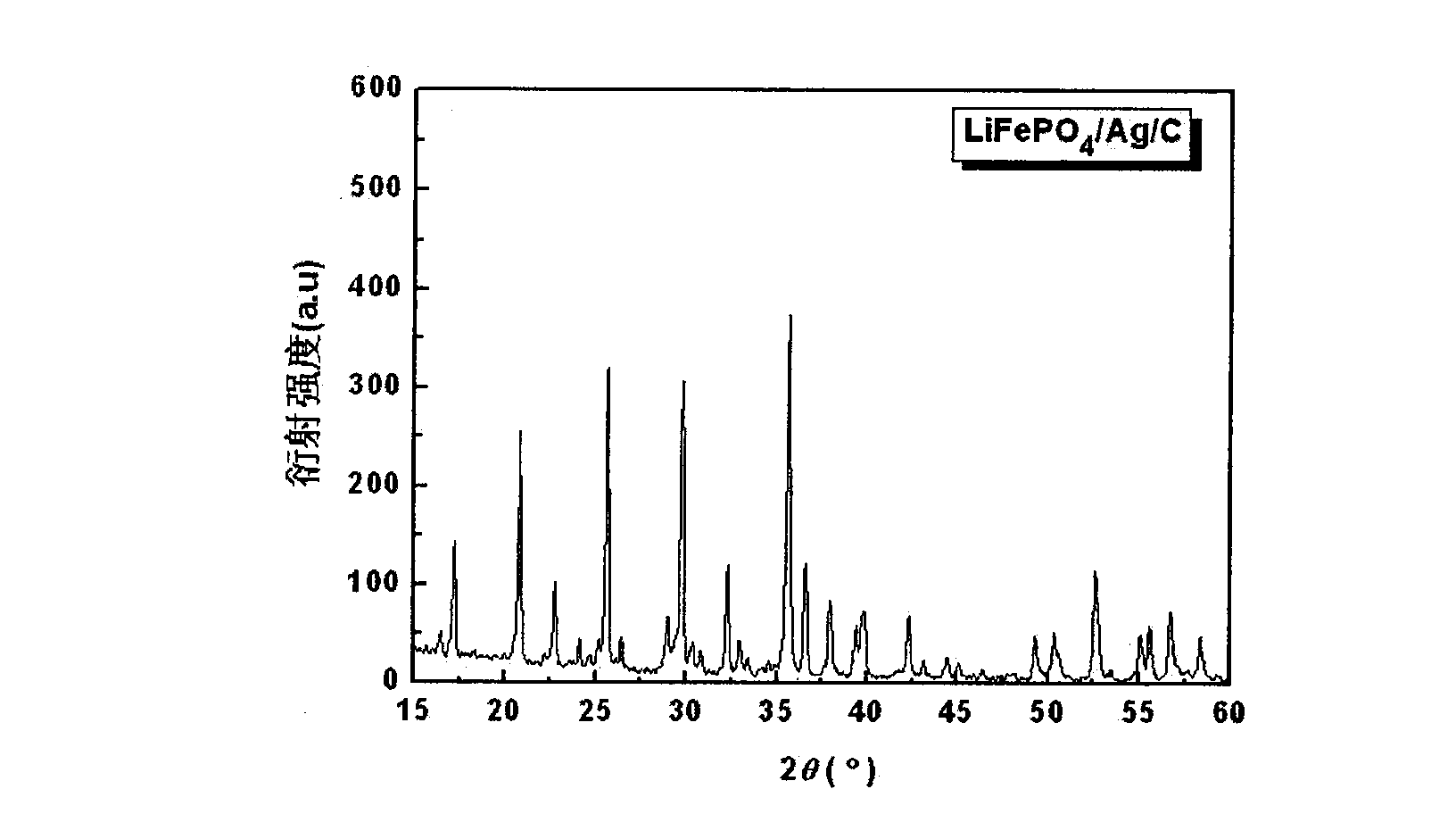

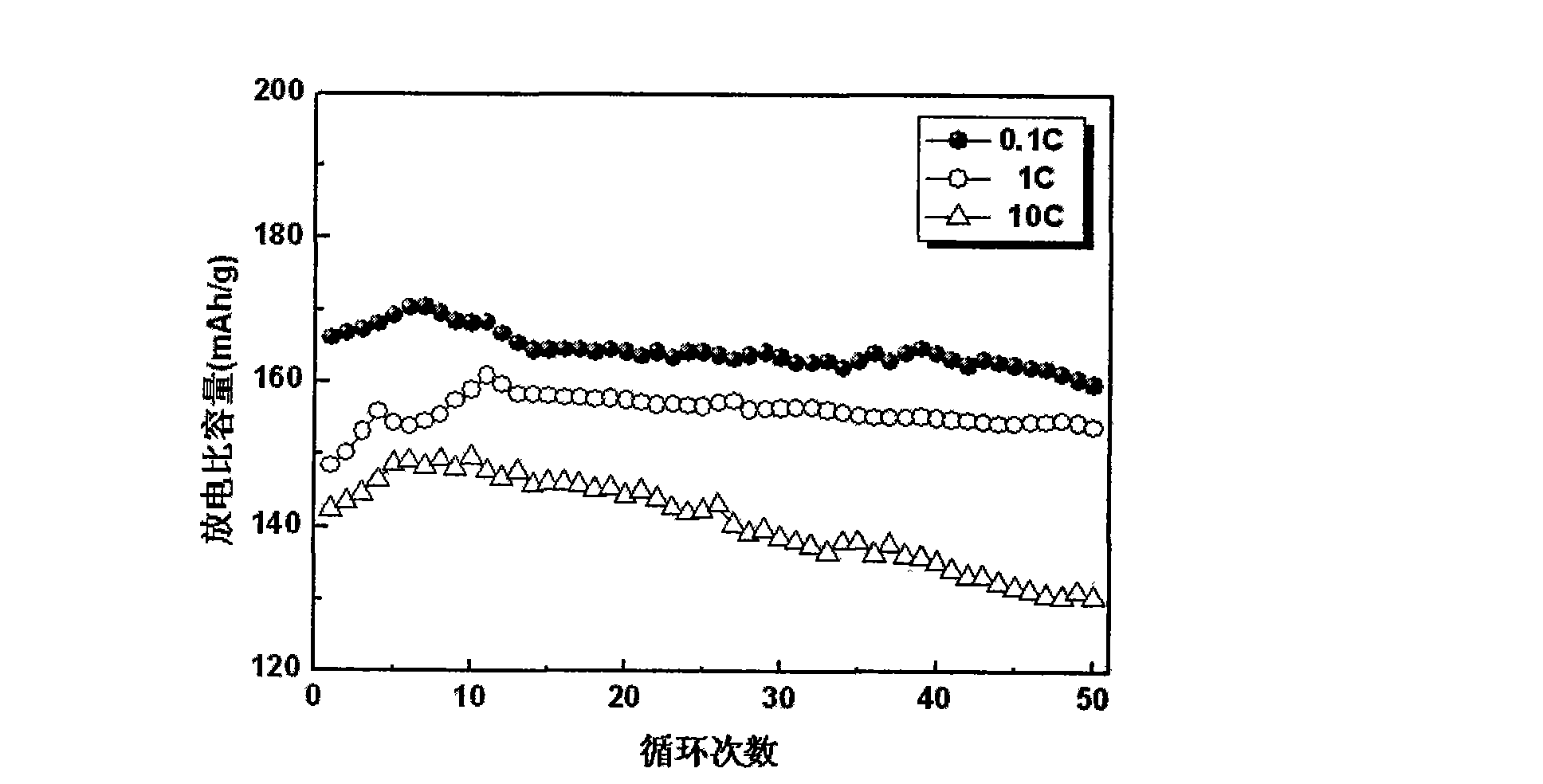

Method for preparing metal-silver-doped carbon-covering lithium iron phosphate of lithium-ion battery cathode material

The invention discloses a method for preparing metal-silver-doped carbon-covering lithium iron phosphate of lithium-ion battery cathode material, comprising steps: A. mixing lithium compound, phosphate and silver compound together according to the mole ratio of Li: P: Ag, and dissolving by water; sequentially adding citric acid and glycol, and stirring to prepare collosol; B. adding organic sugar with the molar weight of 1-2 times of that of silver salt into the collosol, adding iron compound with the mole number being the same as that of lithium salt and carbon reducing agent with the equal molar weight based on pure carbon, and evenly mixing, vacuum drying and ball-milling the mixture; then, pressing the mixture powder to be molded after ball-milling, and preparing precursor of synthesized lithium iron phosphate; C. putting the obtained precursor into a vacuum reaction furnace to have reaction under the condition of certain vacuum degree, and ball-milling to obtain the metal-silver-doped carbon-covering lithium iron phosphate LiFePO4 / Ag / C cathode material. The method has the advantages of simple technique, easy amplification, good electric conduction performance, excellent high-rate discharge performance, high specific capacity and electrochemistry efficiency, small particle size distribution range and high tap density.

Owner:广州云通锂电池股份有限公司 +1

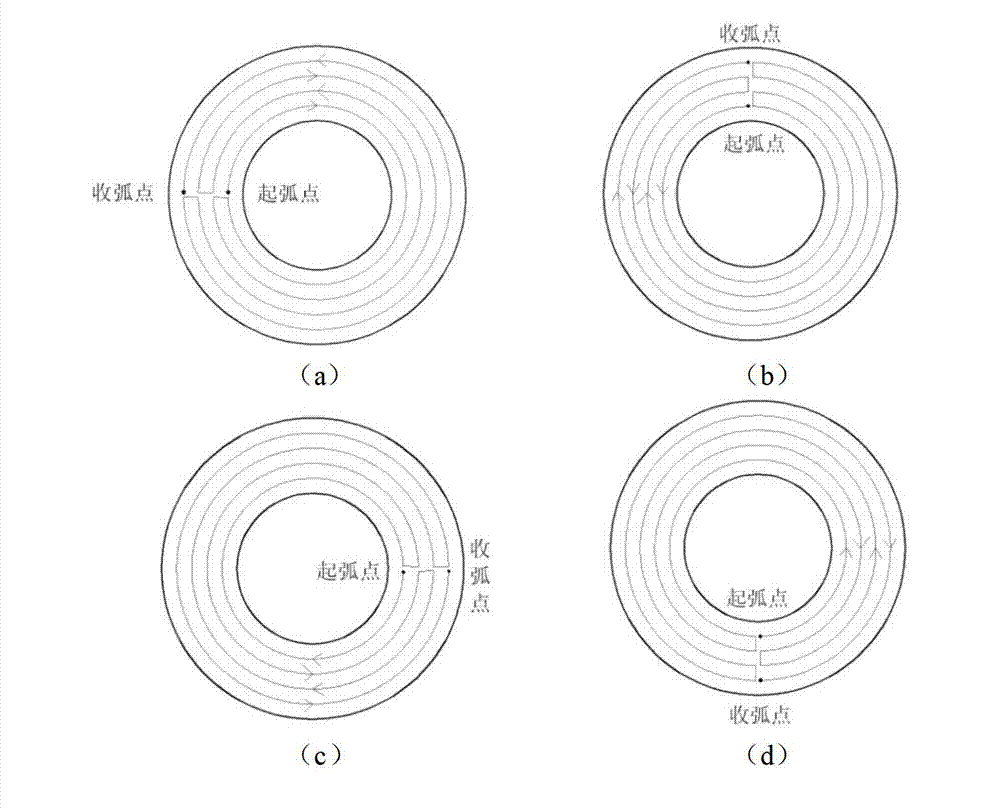

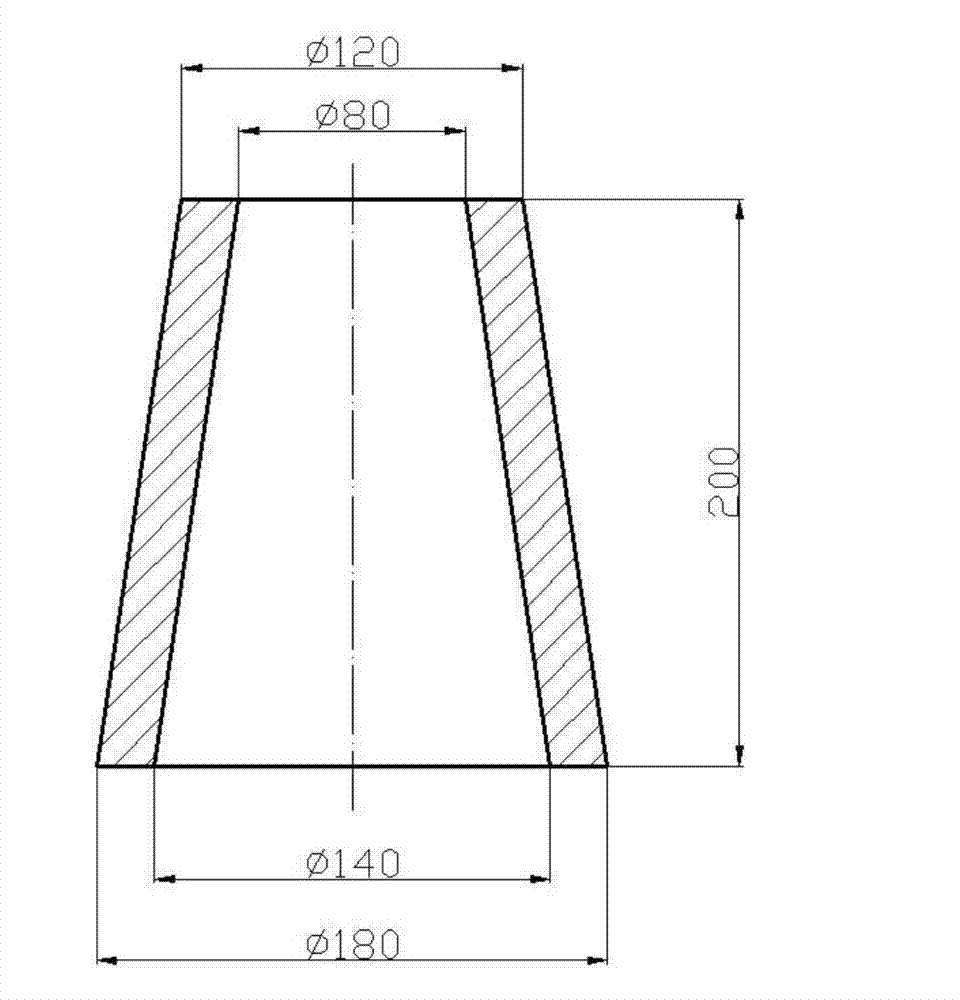

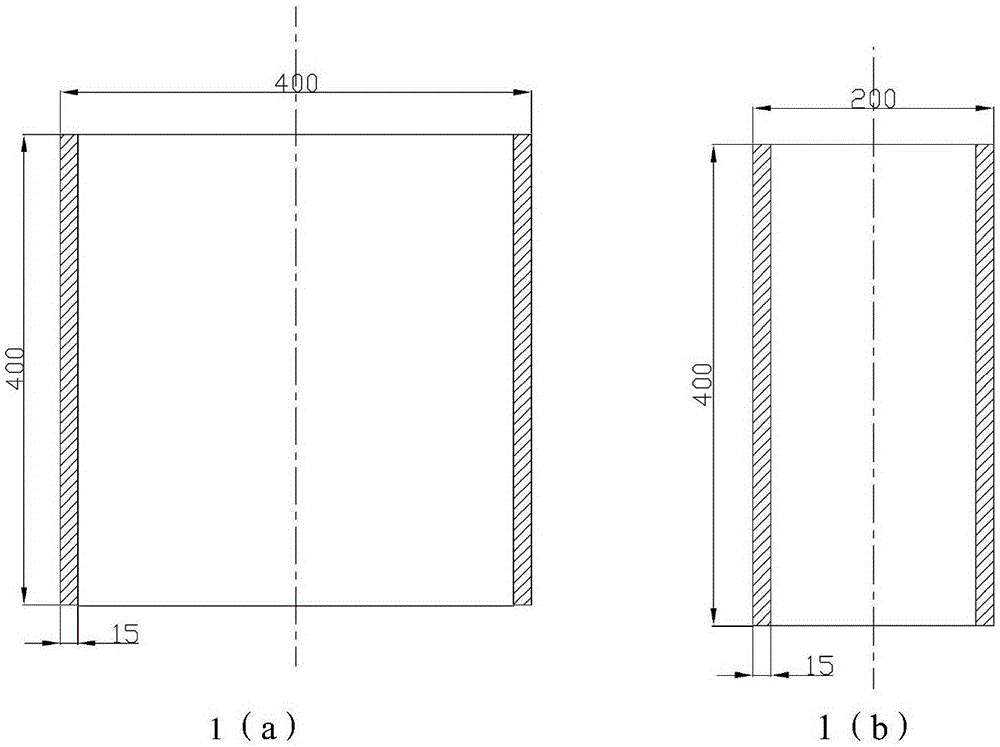

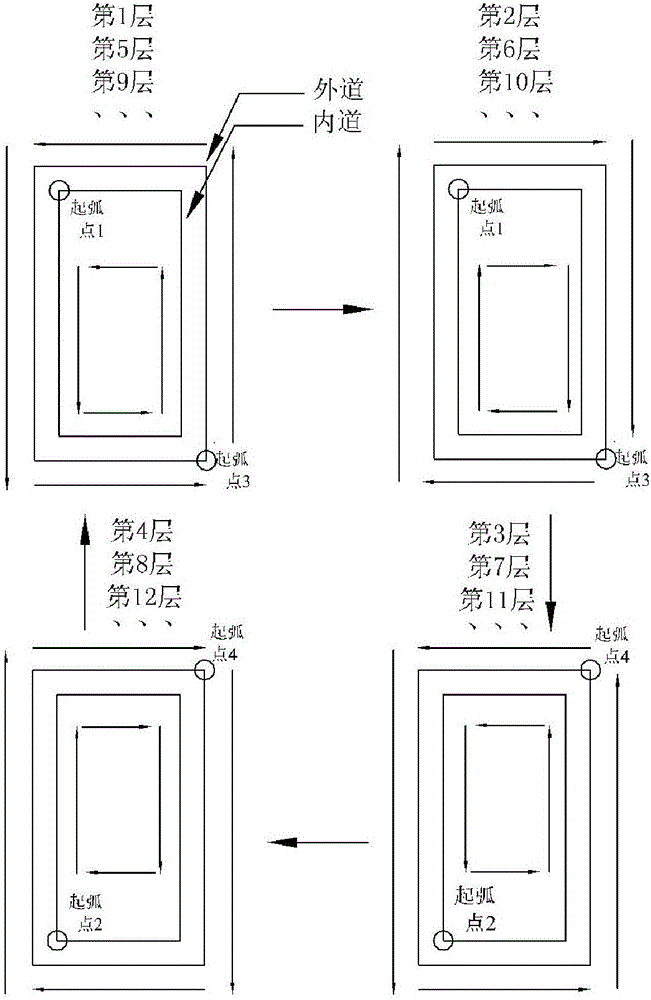

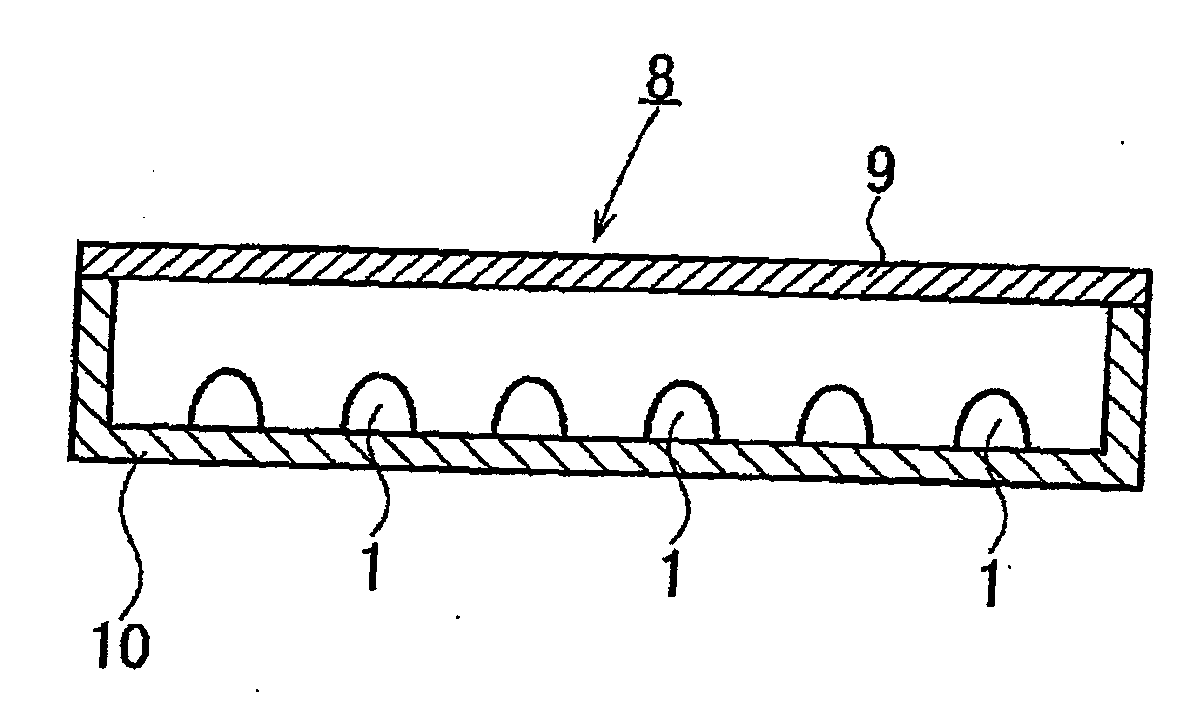

Multi-layer double-channel electric arc additive manufacturing method for aluminum alloy structural component

ActiveCN106825859AIncrease profitLess investmentArc welding apparatusSurface roughnessMechanical property

The invention provides a multi-layer double-channel electric arc additive manufacturing method for an aluminum alloy structural component. According to the method, a welder is adopted for supplying a heat source and matched with a mechanical arm for electric arc additional manufacturing of the aluminum alloy structural component in a route planning mode. Three layers at the bottom adopt electric current which is about 20-50 A larger than forming electric current for priming; and the forming electric current is adopted by the upper portion for entity piling up, the arcing points of an inner channel and an outer channel of each layer are a pair of diagonal points, reciprocating is conducted in this way, and finally the multi-layer double-channel aluminum alloy structural component is obtained. By adjusting parameters, electric arc material addition of the aluminum alloy structural component with the wall thickness being 10-25 mm can be achieved, so that specific dimension requirements are met. The aluminum alloy structural component formed through electric arc additive manufacturing provided by the invention is good in mechanical property, low in surface roughness, free of crack defects, high in material utilization rate and short in production period; the effect of quick manufacturing of a large-wall-thickness aluminum alloy structural component in a development stage is achieved; and meanwhile, the problems of a long production period and the like which are caused due to the fact that moulds need to be manufactured in a traditional casting method are solved, and product cost is effectively reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

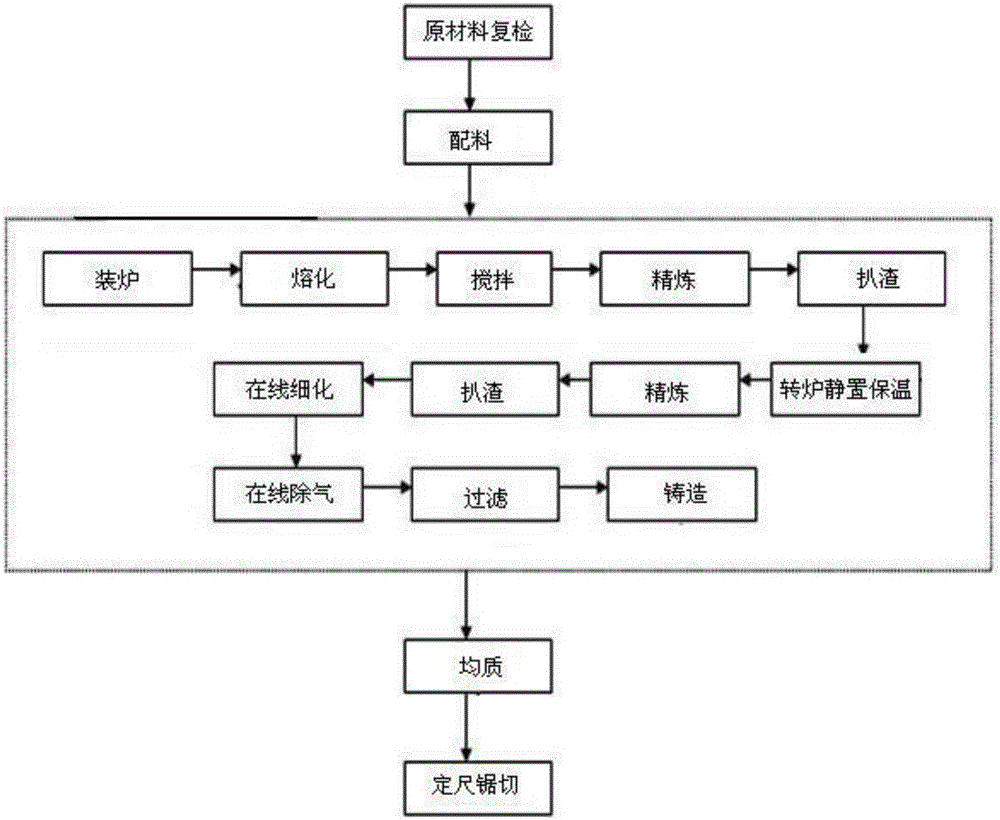

Hot top casting process for phi 784-mm 7xxx-series superhard aluminum alloy round bar

The invention discloses a hot top casting process for a phi 784-mm 7xxx-series superhard aluminum alloy round bar. The aluminum alloy round bar is composed of, by mass, 0.25% of Si, 0.4% of Fe, 1.55-1.65% of Cu, 0.25% of Mn, 2.55-2.65% of Mg, 0.19-0.25% of Cr, 5.6-5.7% of Zn, 0.15% of Ti, 0.03% of Zr and the balance Al. The manufacturing process comprises the steps of a, material preparation; b, smelting; c, stirring; d, refining; e, slagging-off; f, heat preservation and standing; g, online thinning; h, online degassing; i, filtration; j, casting; k, homogenizing. Through the process, the defects, such as cracks, component segregation, bright grains, thick grains and loose pores, which often appear when a direct condensation casting technology is adopted for large-diameter superhard aluminum alloy are overcome, and by the adoption of hot top casting, the defects of surface segregation tumors, thick coarse-grain layers and the like are overcome.

Owner:CHINA ZHONGWANG

Active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, preparation method for active amorphous brazing filler metal and brazing process

InactiveCN105252169AImprove wettabilityImprove toughnessWelding/cutting media/materialsSoldering mediaUltra-high-temperature ceramicsRoom temperature

The invention discloses active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, a preparation method for the active amorphous brazing filler metal and a brazing process, particularly relates to Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal for brazing ZrB2-SiC ultra-high-temperature ceramic materials, a preparation method for the Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal and a brazing process, and belongs to brazing filler metal in the amorphous and metallurgy fields. The components of the brazing filler metal comprise, by atomic percentage, 36.0-42.0% of Cu, 30.0-35.0% of Ti, 16.0-23.0% of Zr and the balance Ni. The melting temperature of the active amorphous brazing filler metal is 1110-1150 K, and the brazing temperature is 1183-1273 K. The Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal obtained through the rapid condensation technology has good wettability. The room temperature shearing strength of the ZrB2-SiC ultra-high-temperature ceramic materials brazed through the amorphous brazing filler metal in a vacuum brazing mode can be as high as 160 MPa and much higher than that of Cu-based and Ag-based brazing filler metal.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

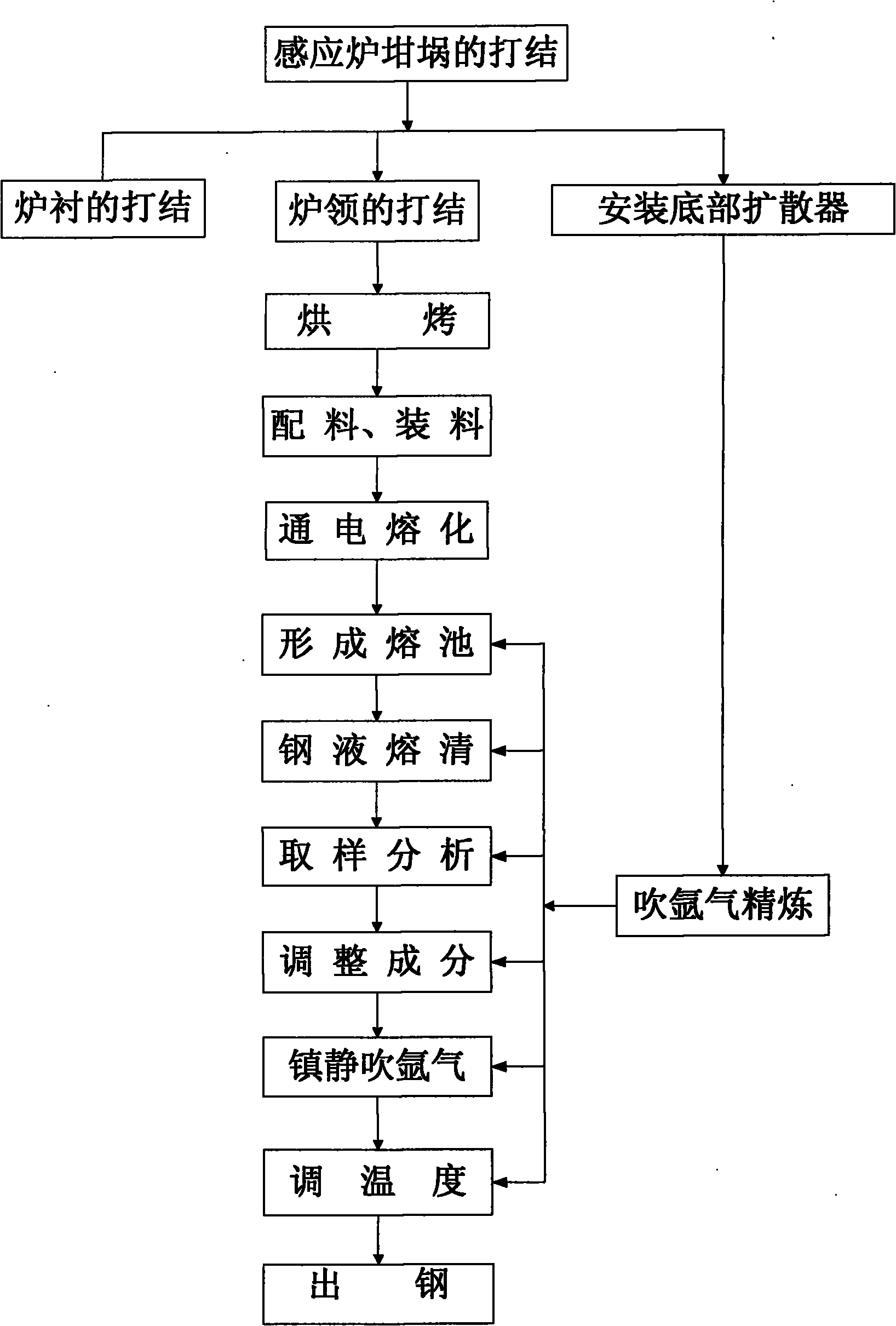

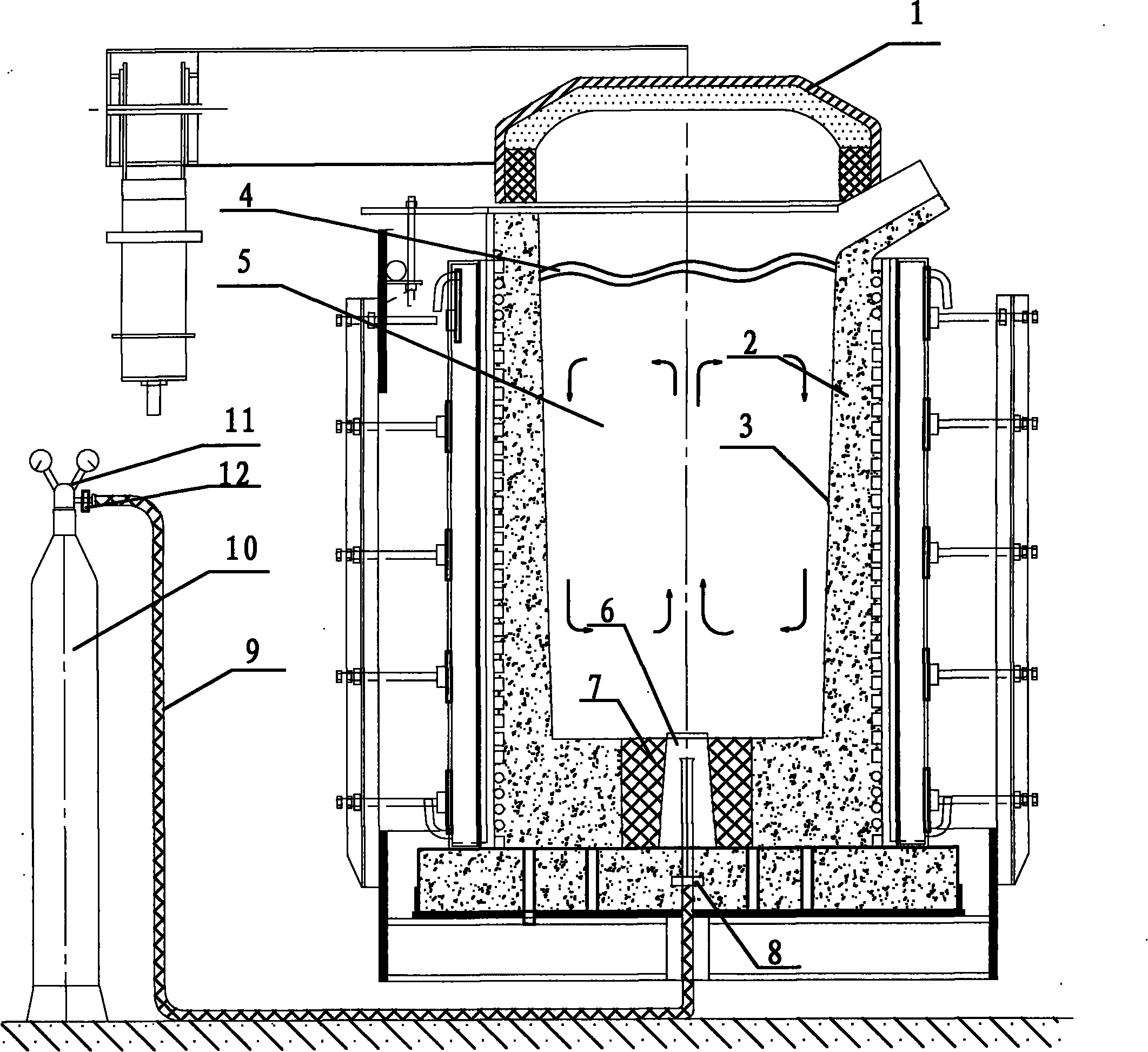

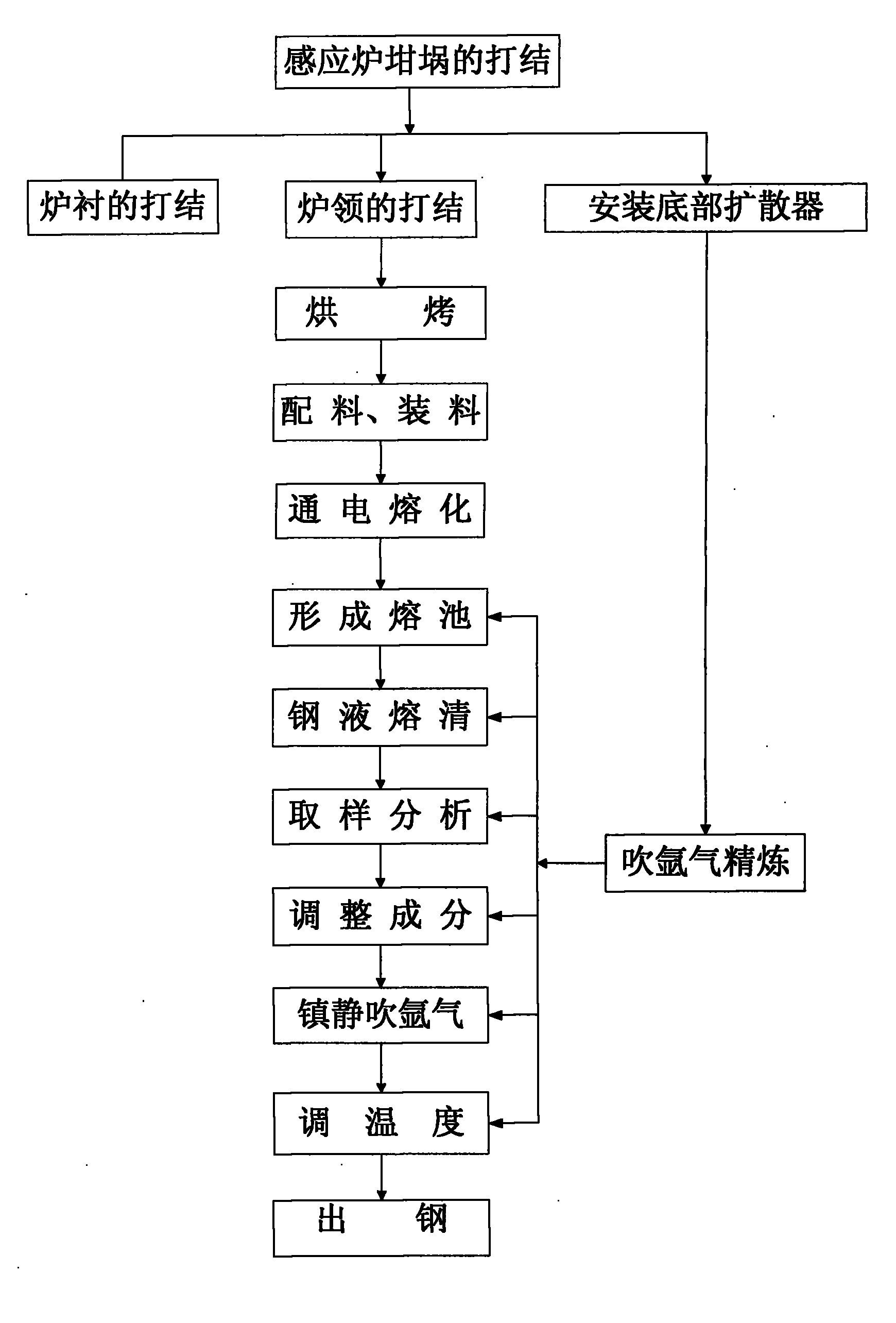

Process method for refining austenitic manganese steel by blowing argon gas into medium frequency induction furnace

ActiveCN102010936ALess investmentThe operation process is simpleNon-metallic inclusionsDeoxidization

The invention discloses a process method for refining austenitic manganese steel by blowing argon gas into a medium frequency induction furnace, comprising the following steps of: (1) designing and manufacturing a gas diffuser; (2) mounting the gas diffuser in the center of the bottom of the medium frequency induction furnace and connecting the medium frequency induction furnace with an argon gasblowing system; (3) when furnace charge is molten to form a about 1 / 3 molten pool, quickly melting at high power and starting to blow argon gas into the furnace from the gas diffuser at the bottom; (4) controlling the pressure and the flow rate for blowing the argon gas according to the capacity of molten steel so as to fully remove harmful gas and inclusion in the molten steel and homogenize thetemperature and components; (5) cutting off a power supply and cooling and continuously blowing the argon gas; and (6) measuring the temperature, tapping and casting. By blowing the argon gas to refine, gas and nonmetallic inclusion in the molten steel can be effectively removed, the desulfuration and the deoxidization can be achieved and the components and the temperature of the molten steel canbe homogenized. By using the method, the purified molten liquid can be molten, thereby improving the metallurgical quality of the molten steel.

Owner:广西长城机械股份有限公司

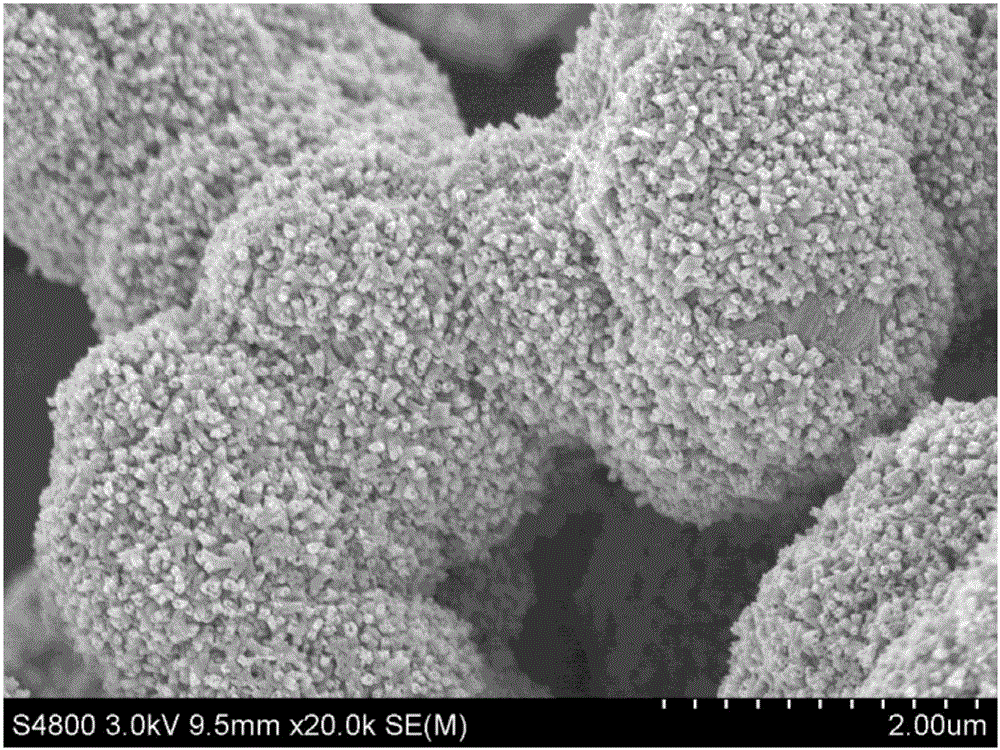

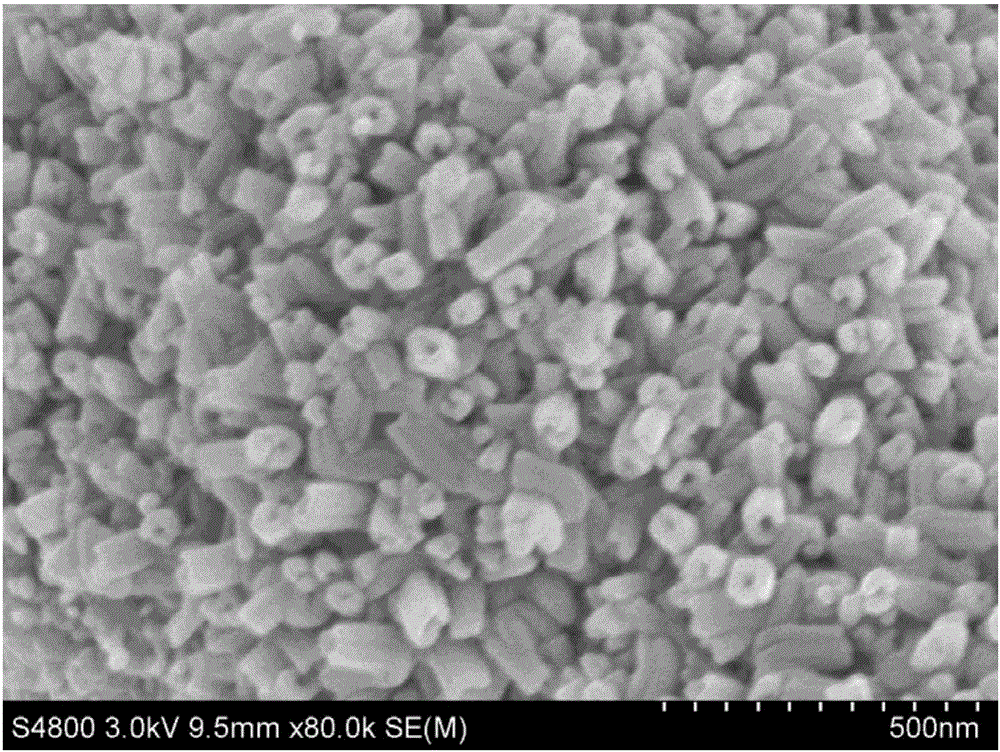

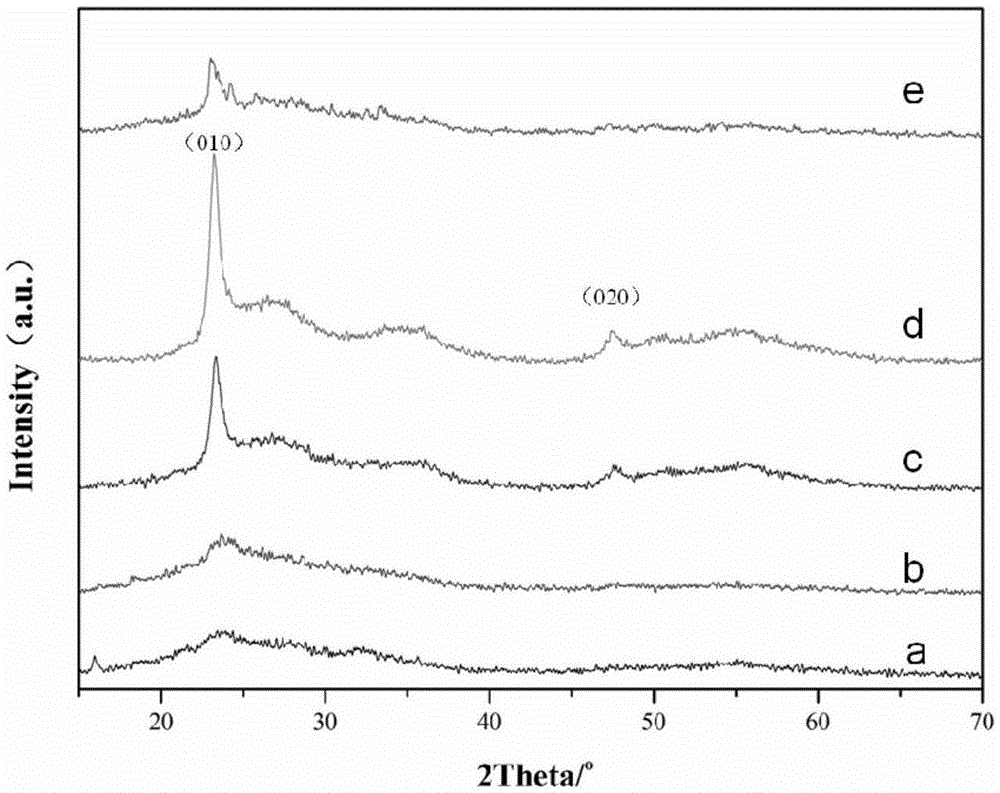

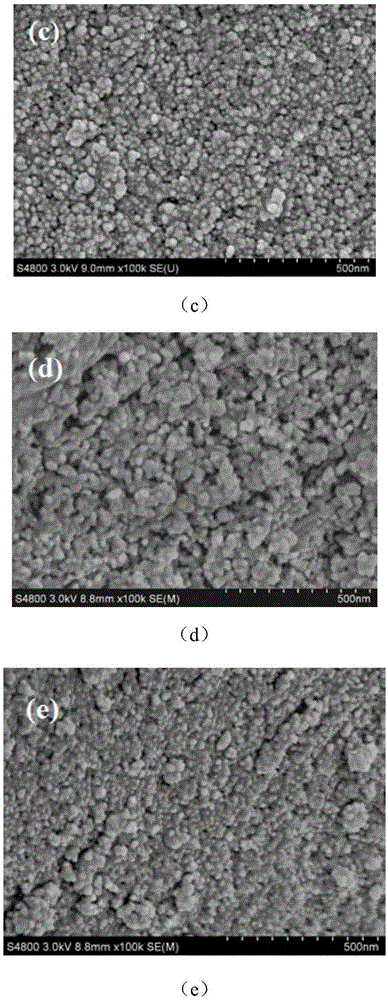

Multilevel-structured VS4 nano-powder, and preparation method and application thereof

ActiveCN105923652AUniform chemical compositionHigh purityPhysical/chemical process catalystsHybrid capacitor electrodesLithiumChemical composition

The invention provides a multilevel-structured VS4 nano-powder, and a preparation method and an application thereof. According to the invention, a vanadium source solution and a sulfur source solution are mixed under stirring, wherein the molar ratio of vanadium to sulfur is controlled at 1:1-1:2, such that a mixed liquid is obtained; the mixed liquid is subjected to a hydrothermal reaction; when the reaction is finished, cooling, washing, collecting and drying are carried out, such that the multilevel-structured VS4 nano-powder is obtained. The process is simple and is easy to control. The prepared VS4 nano-powder has uniform chemical composition and relatively high purity. The nano-powder shows excellent electrochemical performance when used as a lithium / sodium ion battery electrode material. Also, the method overcomes a defect of high temperature of a traditional calcination method, and does not need large equipment and harsh reaction conditions. The raw materials are cheap and are easy to obtain; cost is low; yield is high; no post treatment is needed; and the method is environment-friendly. The method is suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

Production process for preparing silica ceramic crucible by use of pressure grouting method

InactiveCN102528899AAccelerate the injection molding speedImprove work efficiencyCeramic shaping apparatusSmall footprintPolycrystalline silicon

The invention relates to a production process for preparing a silica ceramic crucible by use of a pressure grouting method and belongs to the technical field of high-grade refractory materials in a polycrystalline silicon industry. The pressure grouting comprises steps of preparation of pouring slurry, die assembling, molding by pouring slurry and demolding for fetching a green body, i.e., (1) ball-milling fused silica grain composition into slurry; and (2) fixing a resin die and assembling the die, grouting, pressurizing quartz slurry with the initial pressure being 0.1-0.2Mpa, enhancing the pressure to 0.3-1.5Mpa after a die cavity is filled with quartz slurry, keeping the pressure for about 5 minutes to filter water in the silica slurry by virtue of a micro-reticular resin mold to form a square crucible green body, and during demolding of the green body, and applying pressure of 0.2-0.3Mpa to the surface of the green body through the back layer of the micro-reticular resin mold by utilizing compression air. The green body of the silica ceramic crucible, prepared by the process, has high intensity, does not have residual air holes and is easy to demold, the product is good in thermal shock resistance and high in temperature resistance, and can meet the process requirements of polycrystalline silicon production; and the process has the advantages of high biscuit drying speed, small occupied area for production, shortened manufacturing period, low cost, and suitability for scale production.

Owner:咸阳陶瓷研究设计院有限公司

Method for preparing nanoscale granular W18O49 material

ActiveCN105271420AMore exposureEvenly dispersedMaterial nanotechnologyTungsten oxides/hydroxidesOxalateAlcohol

The invention provides a method for preparing a nanoscale granular W18O49 material. The method comprises the steps of adding WC16 into absolute ethyl alcohol to prepare a solution A; adding oxalic acid into the solution A to obtain a solution B, wherein the mass ratio of the oxalic acid to the WC16 to is (5 to 10) to 1; sealing the solution B, stirring, and then performing ultrasonic treatment, so as to obtain a solution C; enabling the solution C to react in a homogeneous reactor, and obtaining the nanoscale granular W18O49 material after the reaction. The prepared homogeneously dispersed nanoscale granular W18O49 material is uniform in chemical constitution, high in purity, and uniform in shape, and the W18O49 is a nano-particle with the diameter being 20nm. The W18O49 material has relatively large specific surface area, and more active crystal faces are enabled to exposed at the same time, so that catalytic efficiency is greatly improved. The reaction temperature is low, the condition is mild, the energy consumption is less, the preparation process is simple, the cost is lower, the process is easy to control, the preparation period is short, and the method is easy to implement and is friendly to environment.

Owner:广西自贸区见炬科技有限公司 +1

Preparation method of vanadium tetrasulfide nano-powder and application

InactiveCN105810942ASimple and easy to control chemical compositionUniform chemical compositionCell electrodesSecondary cellsLithiumChemical composition

The invention provides a preparation method of vanadium tetrasulfide nano-powder and an application. The method comprises the following steps: firstly, mixing a vanadium source solution with a sulfur source solution, stirring the mixture until semi-clear and then adding an acid or alkali solution to adjust the pH of a reaction liquid; transferring the reaction liquid to a homogeneous reaction instruction for hydrothermal reaction; and finally cooling the reacted product and then washing, collecting and drying the product to obtain the vanadium tetrasulfide nano-powder. According to the method, the technology is is simple and easy to control; and the prepared vanadium tetrasulfide nano-powder is uniform in chemical composition and relatively high in purity, and demonstrates excellent electrochemical properties when used as an electrode material for a lithium / sodium-ion battery. Furthermore, the disadvantage of a high temperature of a traditional calcination method is overcome; large equipment and harsh reaction conditions are not needed; and the method is cheap and available in raw material, low in cost, high in productivity, free of after-treatment and friendly to environment, and can be suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

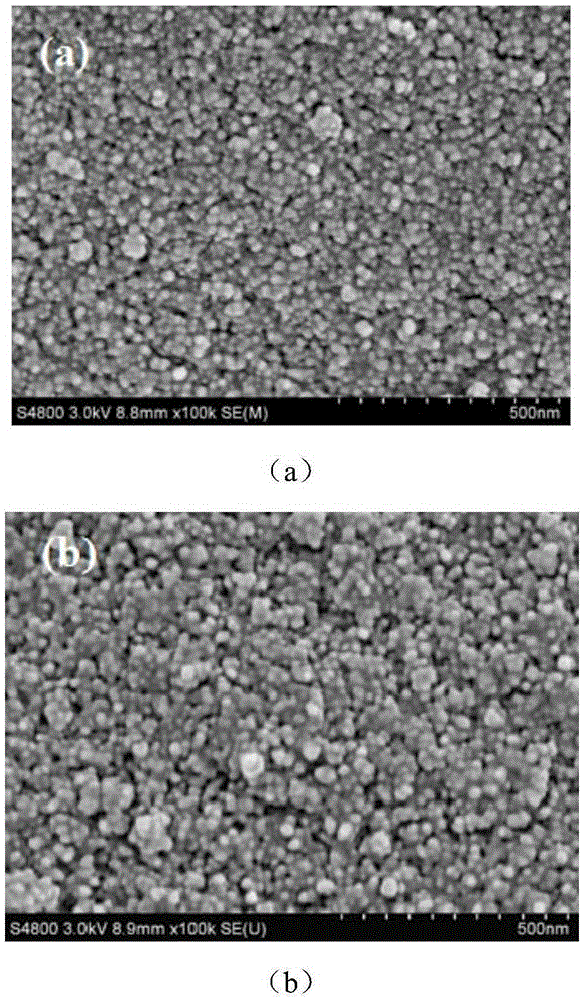

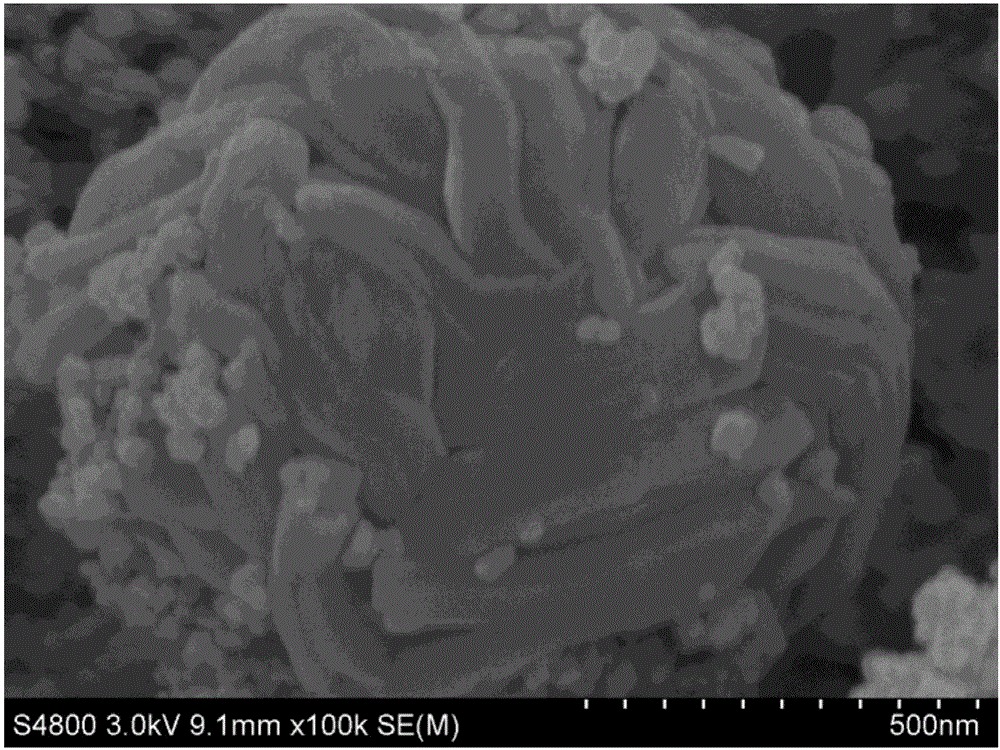

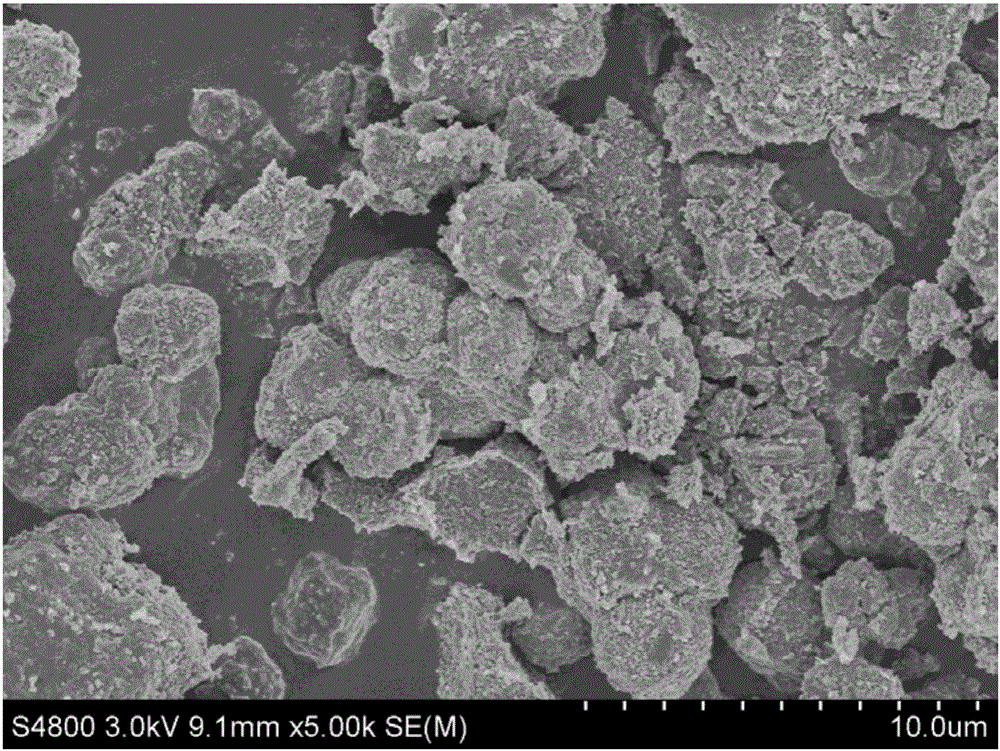

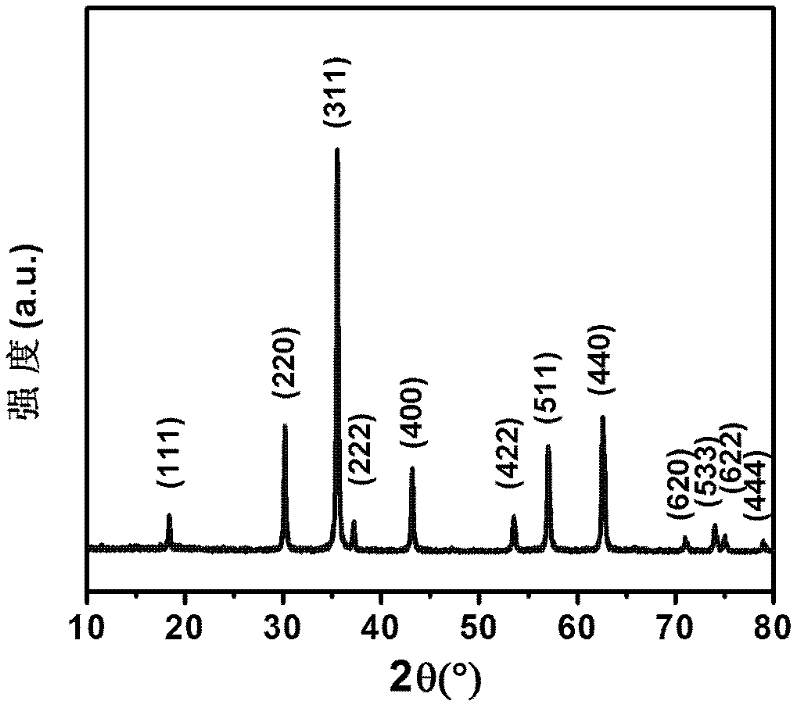

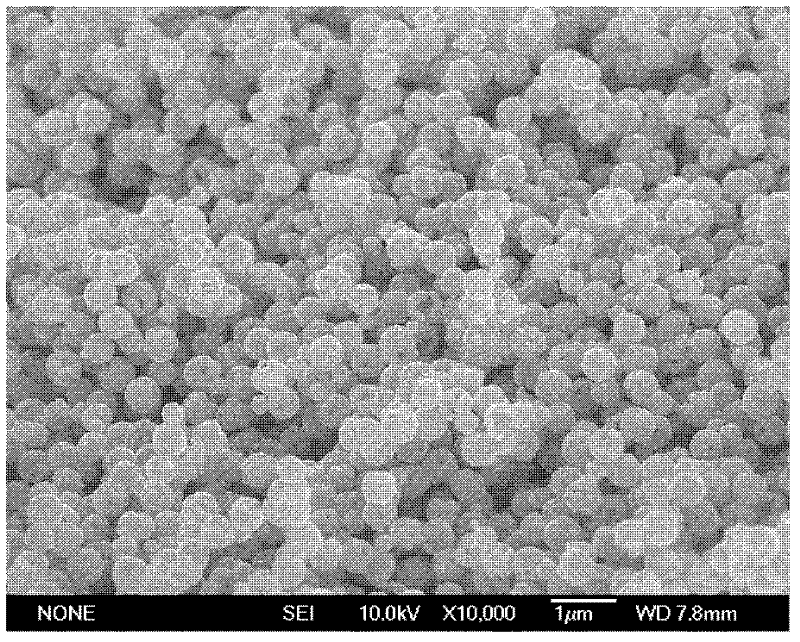

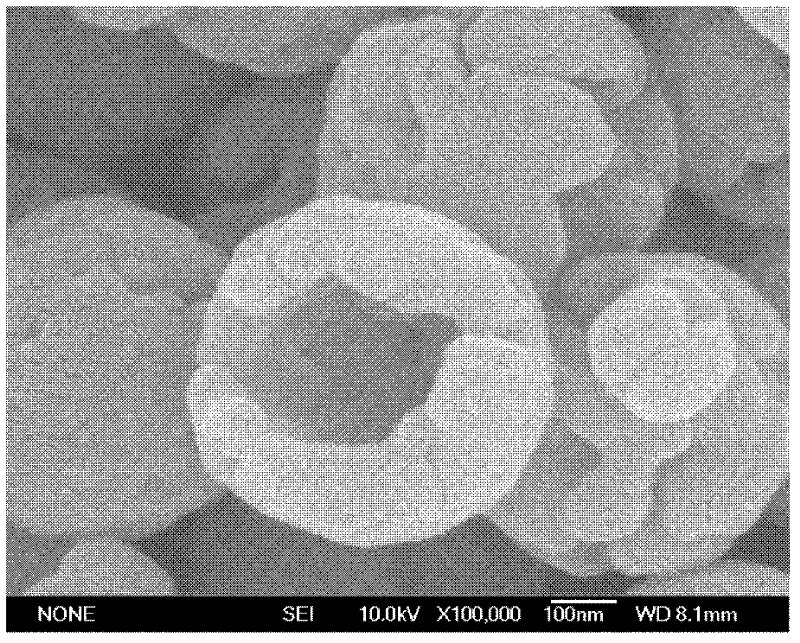

Spherical ferrate having hollow structure and preparation method thereof

InactiveCN102531066APromote formationHigh viscosityNanotechnologyIron compoundsPhysical chemistryNanocrystal

The invention discloses spherical ferrate having a hollow structure and a preparation method thereof. The ferrate MFe2O4 is of a hollow-structured spherical particle formed by self-assembling of nanocrystals having a particle size of 10-50nm, wherein M is Co, Ni or Zn, the diameter of the particle is 0.1-1mu m, and the thickness of a shell layer is 30-200nm. The spherical ferrate can be used as a negative electrode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

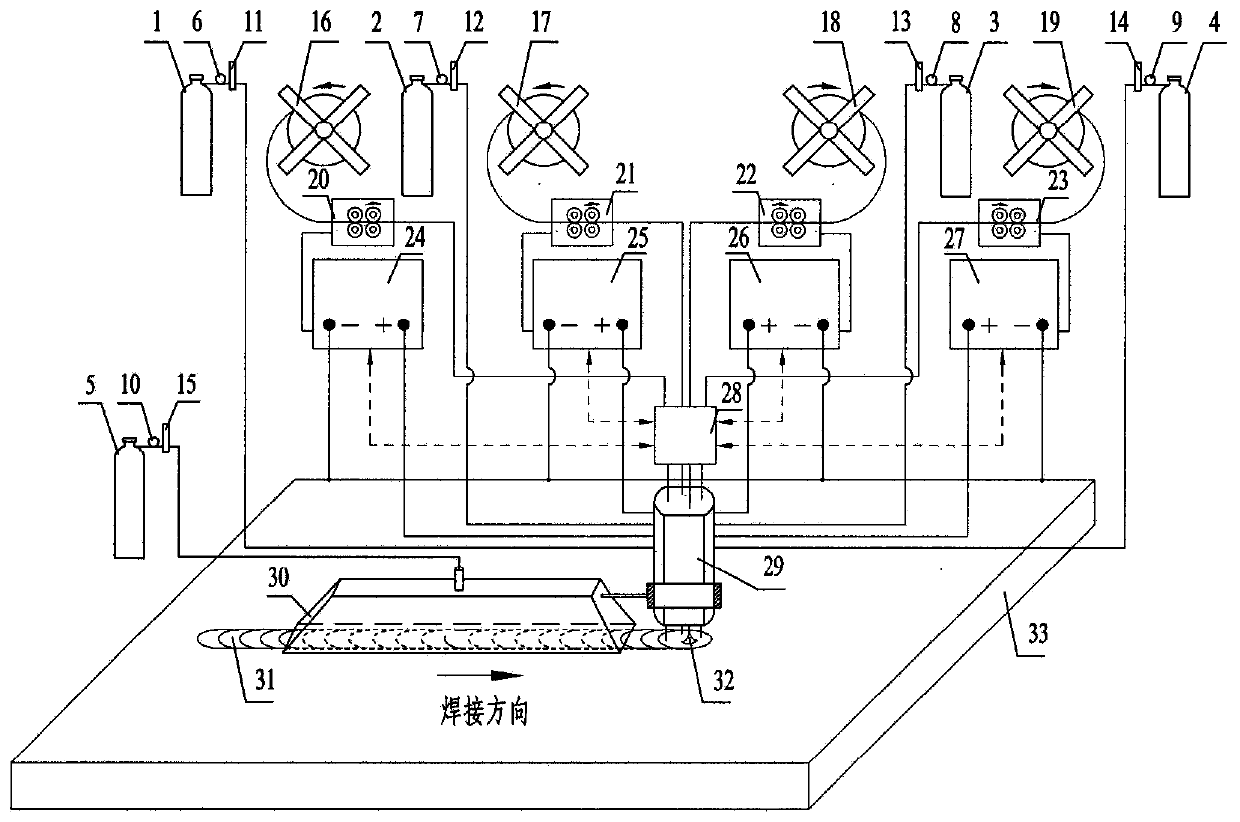

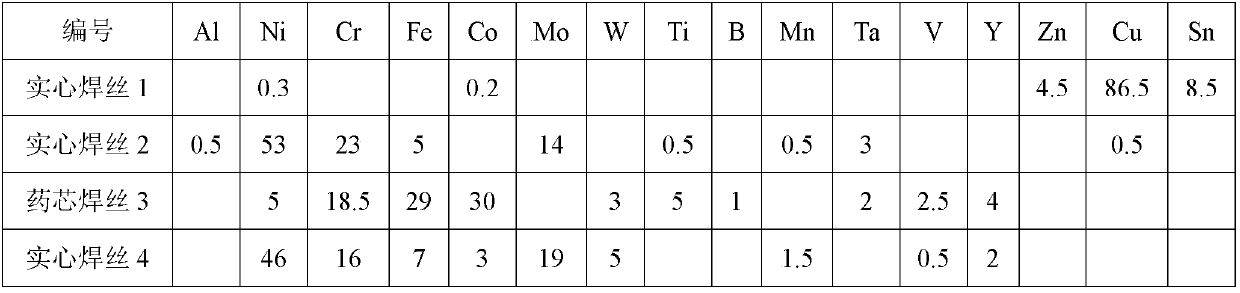

High-entropy alloy double technology preparation method

The invention relates to the technical field of high-entropy alloy, in particular to a high-entropy alloy double technology preparation method. The high-entropy alloy double technology preparation method comprises the steps that firstly, types of four welding wires and components, contents, existence forms and existence positions of welding wire elements are decomposed and designed according to the element components, contents and physico-chemical properties of high-entropy alloy needing to be prepared, and the welding wires are prepared; secondly, an integrated four-wire pulse gas shielded welding technology is adopted to cooperate with additional materials to manufacture the high-entropy alloy; and finally, a vacuum self-consumption remelting technology is adopted to refine the high-entropy alloy. According to the high-entropy alloy double technology preparation method provided by the invention, the technology is stable, the preparation efficiency is high, the cost is low, the heat input adjusting range is wide, the optional alloy element range is wide, the quantity of types of prepared high-entropy alloy is large, alloy component adjusting is convenient and accurately controllable, chemical components are uniform, the structure is compact and uniform, the degree of purity is high, and the inner quality is good.

Owner:SHIJIAZHUANG TIEDAO UNIV

Preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming

The invention relates to a preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming, belongs to the technical field of preparation of acid-pickling steel strips, and aims at solving the technical problem of providing a low-cost preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming. According to the method, C and Mn serve as main elements, and the C content is increased; on the condition that alloy elements such as Nb, Ti, V, B, Mo, La and Cr are not added, on the premise of ensuring steel purity and chemical component uniformity of a cast blank by controlling the smelting procedure, and by means of reasonable rolling control and cooling control technological processes, hot-rolled steel plates which are moderate in strength and high in elongation rate are obtained, the hot-rolled steel plates are subjected to trimming, blanking and heating and then subjected to hot forming and hot treatment, and parts which are moderate in strength and high in ductility and toughness are obtained finally. The steel strips are widely applied to automotive structural parts and can replace part of hot-rolled and cold-rolled continuous annealing steel plates and steel strips which are high in alloy content and product cost and are used for high-strength automobile structures.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

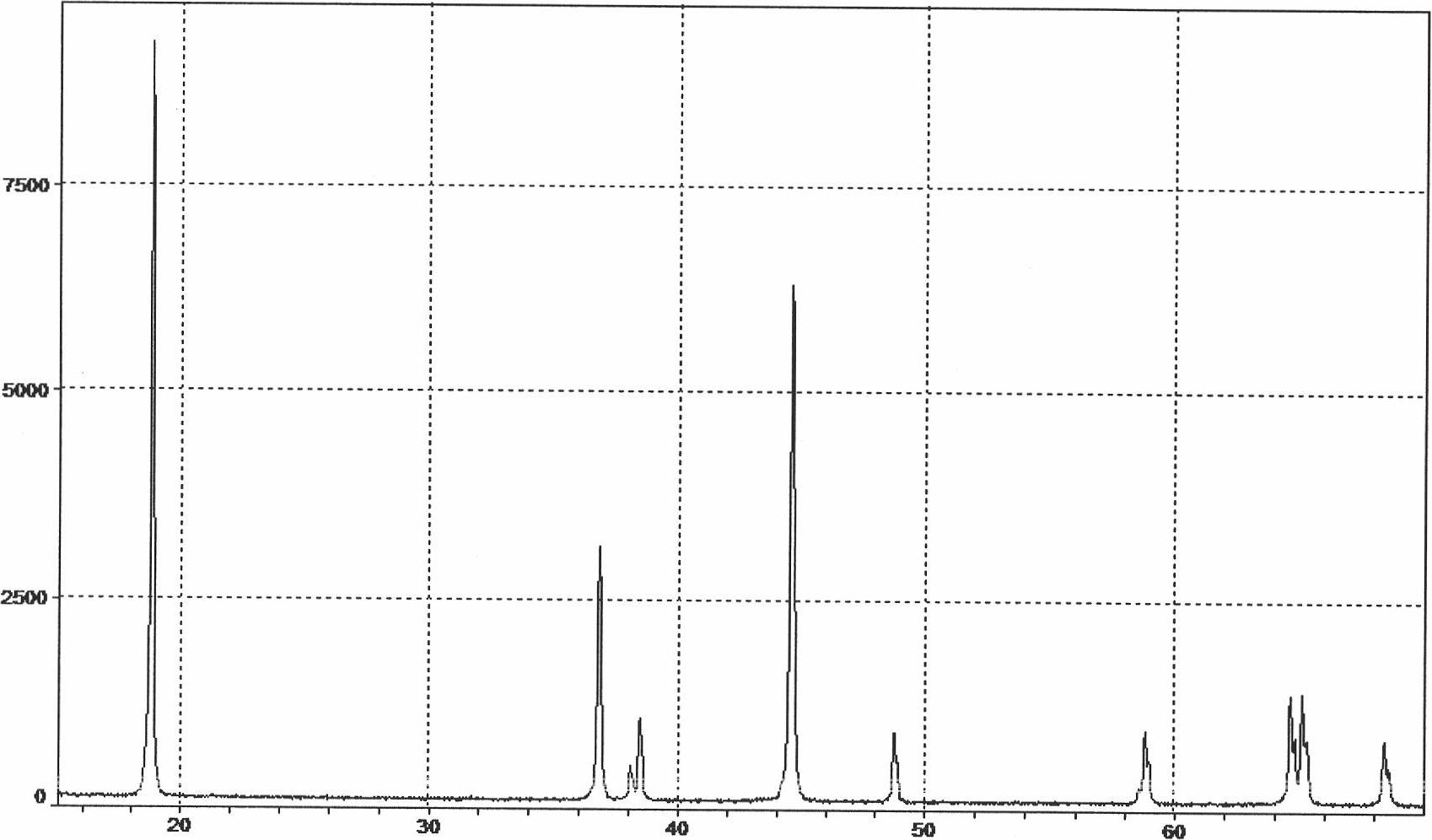

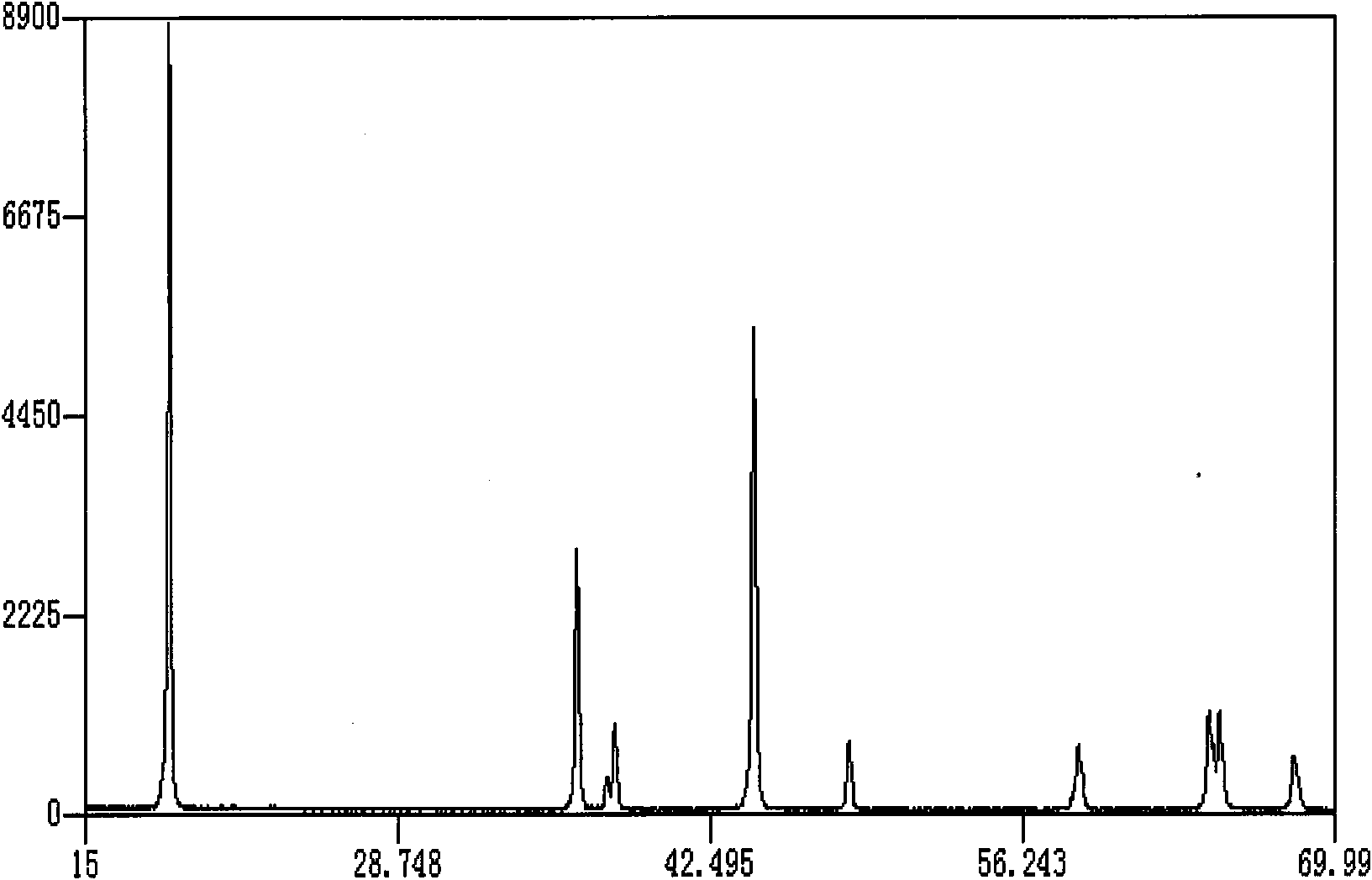

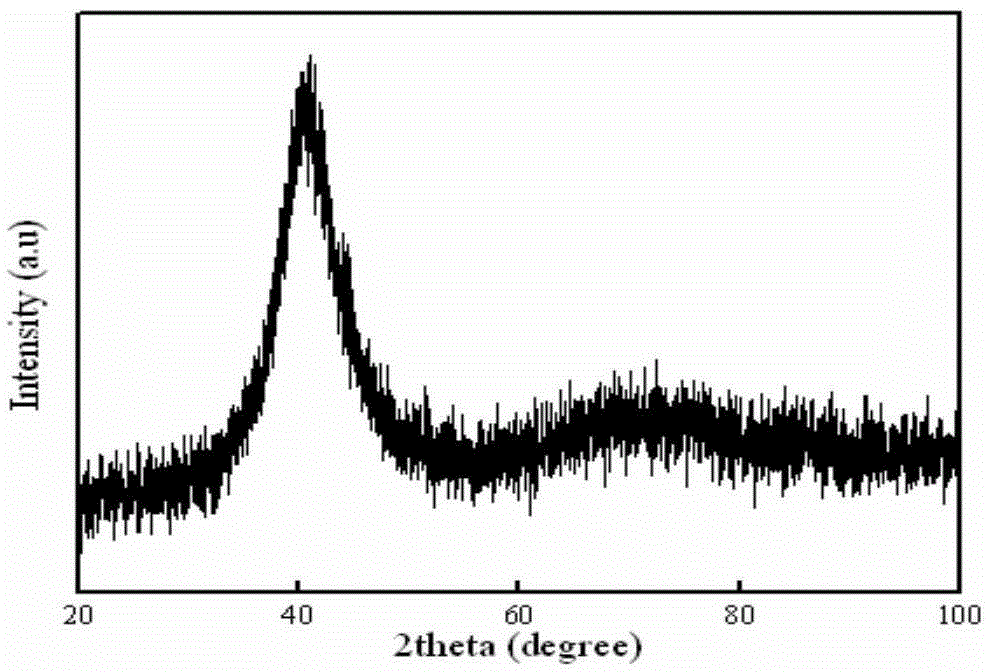

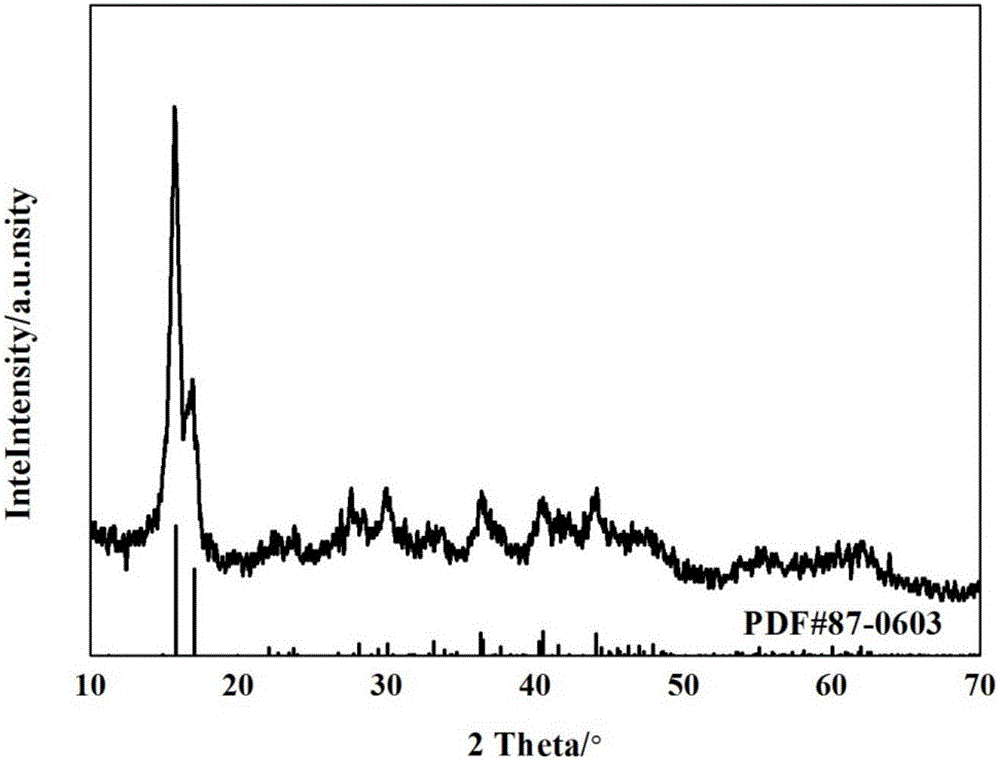

Alloy powder for aw material of inorganic functional material and phosphor

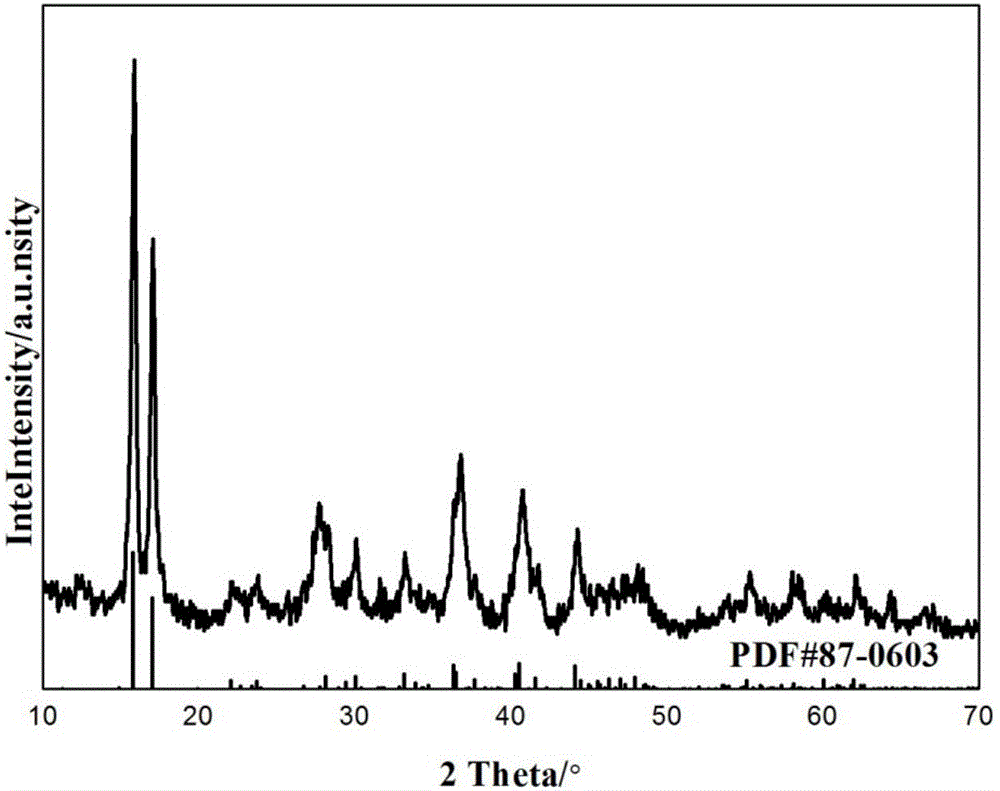

ActiveUS20100052515A1Proceed efficiently and uniformlyUniform chemical compositionDischarge tube luminescnet screensTransportation and packagingPhosphorX-ray

The present invention relates to a phosphor comprising a nitride or an oxynitride, comprising an X-ray powder diffraction pattern comprising at least one Region having at least one peak with an intensity ratio I of 8% or less, the X-ray powder diffraction pattern measured in the 2θ range from 10° to 60° using a CuKα line (1.54184 {acute over (Å)}), wherein the Region is the 2θ range from 41.5° to 47°, the intensity of each peak is a value obtained after background correction, and the intensity ratio I is defined by the formula (Ip×100) / Imax (%), where Imax represents the height of the most intense peak present in the 2θ range from 34° to 37° and Ip represents the height of each peak.

Owner:NAT INST FOR MATERIALS SCI

Additive manufacturing method and additive manufacturing device for aluminum alloy based on laser-double-MIG composite heat source

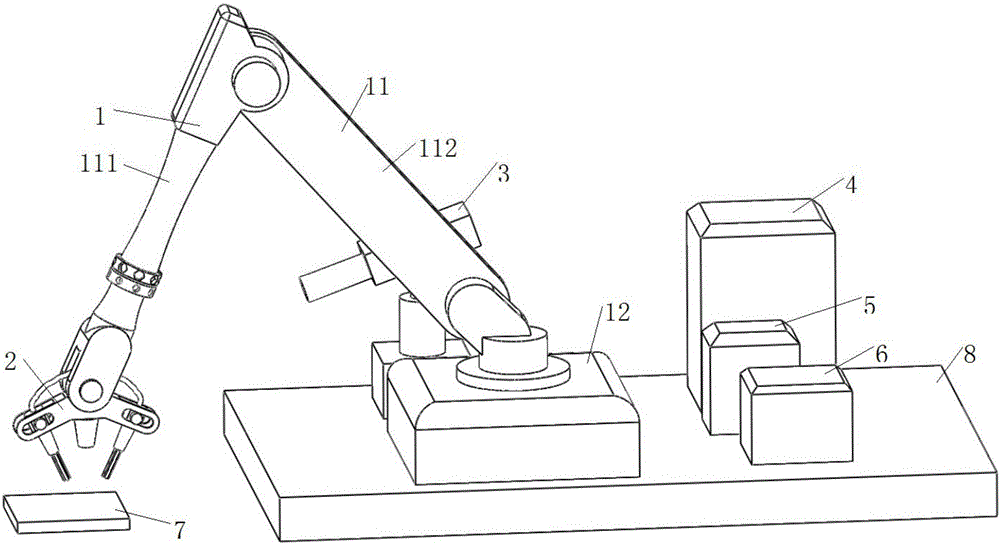

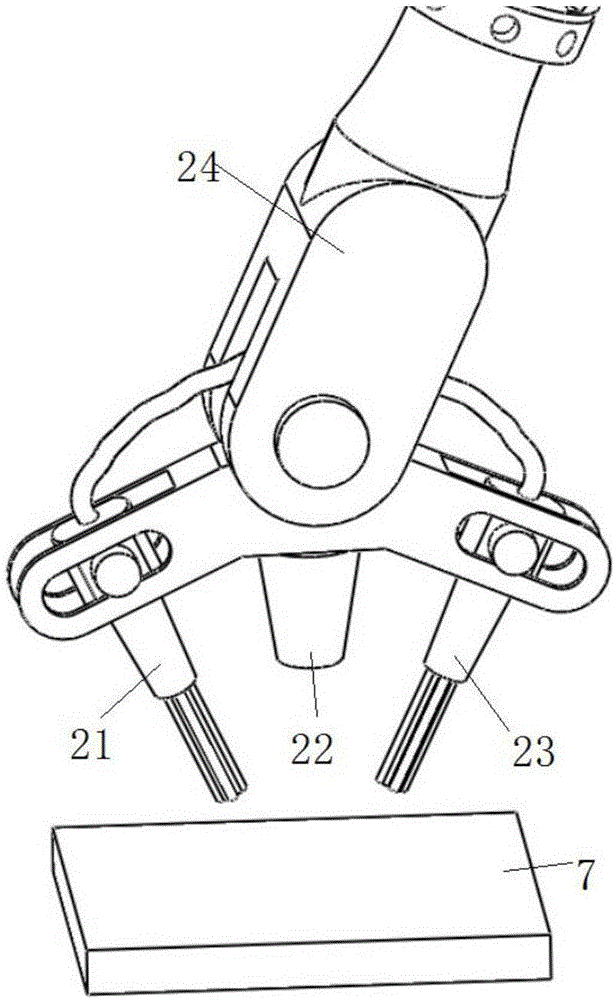

InactiveCN106392348AImprove molding qualityUniform chemical compositionWelding apparatusChemical compositionControl system

The invention discloses an additive manufacturing device for aluminum alloy based on a laser-double-MIG composite heat source. The device comprises an automatic welding robot, a composite heat source system and a digital control system; the automatic welding robot comprises a first arm; the composite heat source system is connected with one end of the first arm and comprises a front MIG welding gun, a rear MIG welding gun and a laser welding head; the digital control system is connected with the automatic welding robot and is used for controlling the automatic welding robot to drive the composite heat source system to implement surfacing operation of additive manufacturing according to a set program; the invention also discloses an additive manufacturing method for aluminum alloy based on the laser-double-MIG composite heat source. Thus, a welded part welded by utilizing the composite heat source system is uniform in chemical ingredients and compact in structure; the digital control system is used for controlling the automatic welding robot to perform surfacing for additive manufacturing, and the overall additive manufacturing process can be precisely controlled, so higher manufacturing efficiency is realized and the welded part is better in quality.

Owner:GUANGDONG INST OF INTELLIGENT MFG

Smelting flux for submerged-arc welding and preparation method and application of smelting flux

ActiveCN106041371AUniform chemical compositionSmooth bead surface shapeArc welding apparatusWelding/cutting media/materialsHigh intensityAlloy

The invention discloses a smelting flux for submerged-arc welding and a preparation method of the smelting flux. The smelting flux comprises the following components in percent by mass: 24-48 percent of CaF2, 8-16 percent of CaO, 5-27 percent of MgO, 10-30 percent of SiO2, 7-20 percent of Al2O3, 4-10 percent of MnO2, 0.5-2 percent of TiO2, 0.5-2 percent of K2CO3, 0.5-2 percent of Li2O, 5-10 percent of BaCO3, and 0.2-3 percent of FeO. The ratio of CaF2 to CaO is strictly controlled to be within the range of (3:1). The total mass percent of the components is 100%. The novel smelting flux prepared according to the preparation method is simple in preparation method, and a high-quality flux material is provided for welding low-alloy high-strength steel after an appropriate amount of welding wires are added.

Owner:CHANGZHOU UNIV

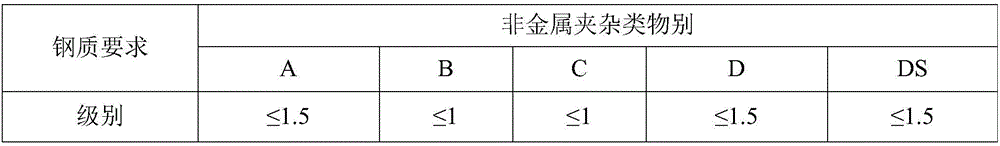

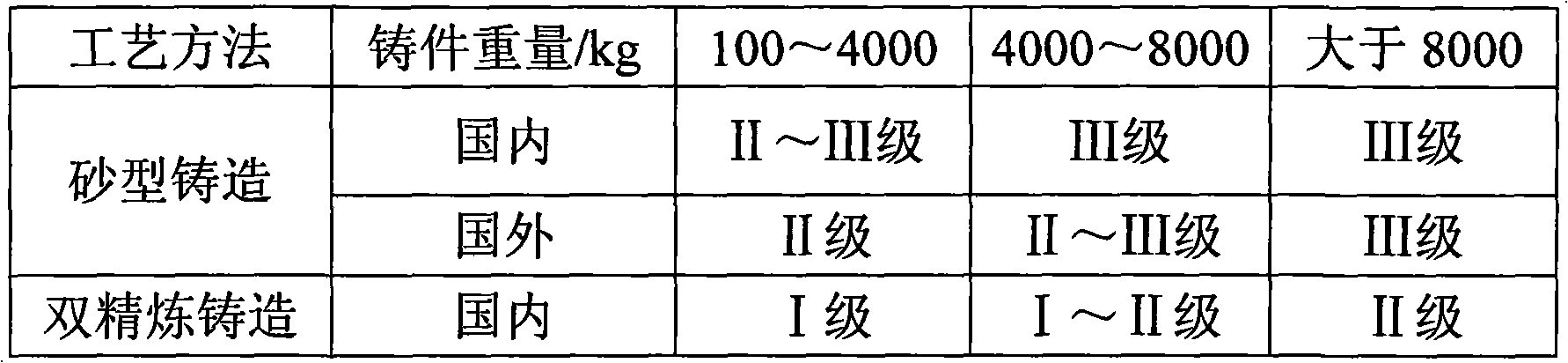

Electroslag smelting casting method of fixed blades of water turbine

The invention relates to an electroslag smelting casting method of fixed blades of a water turbine. Consumable electrodes are prepared by adopting a voltaic arc furnace refining method and the fixed blades are prepared by adopting an electroslag smelting casting process through a mould. The chemical components of the consumable electrodes are controlled as follows: C is 0.14-0.19 percent, Si is less than or equal to 0.6 percent, Mn is 1.5-1.9 percent, P is less than or equal to 0.035 percent, S is less than or equal to 0.035 percent, V is 0.02-0.15 percent, Nb is 0.015-0.06 percent, Ti is 0.15-0.25 percent, Al is more than or equal to 0.015 percent, O is less than or equal to 0.0040 percent, N is less than or equal to 0.0080 percent, H is less than or equal to 0.00035 percent, and the balance is Fe. The electroslag smelting casting system and the electroslag guide are controlled as follows: CaF2 is 60-80 percent, Al2O3 is 40-20 percent, or less MgO and CaO (the total is less than or equal to 20 percent); and the electroslag amount is usually 1.5-5 percent of the weight of a casting. The invention has less amount of oxide and sulfide, small size, even distribution, clean casting base body, high cooling speed, large crystallization temperature gradient at the front of solid and fluid, compact casting texture, high size precision and little distortion, and can greatly improve the product property of the refined casting.

Owner:SHENYANG RES INST OF FOUNDRY

Low temperature synthesis of ultra-fine ZnO-SiO2 microwave dielectric ceramic powder by sol-gel method

The invention discloses a preparation method of sol-gel to synthesize the ultrafine microwave dielectric ceramic powder of ZnO-SiO2 in the low temperature, which comprises the steps that: the zinc salt and the tetraethyl orthosilicate are respectively dissolved in the anhydrous ethanol to form the ethanol solution of zinc salt and the ethanol solution of tetraethyl orthosilicate; the two solutions are stirred and mixed with the mole ratio of Zn to Si being 2 : 1, then proper anhydrous ethanol is added to control the density of the zinc salt in the mixed solution within a range of 0.5 to 1 mol / l; deionized water is added to promote hydrolytic polymerization; at least one of nitric acid and acrylic acid is added dropwise to adjust the pH value; proper dispersing agent is added to overcome the powder agglomeration; and the gel is obtained after even stirring, sealing and standing of the obtained solution, and then the obtained gel is dried and calcined to obtain the ultrafine microwave dielectric ceramic powder of ZnO-SiO2. The preparation method has the advantages that the ultrafine powder with an adjustable particle size of 80 to 200 nm can be calcined and synthesized under the low temperature condition of 800 to 850 DEG C; and the powder has good microwave property after sintering.

Owner:ZHEJIANG UNIV

Mineral high-strength wear-resistant material and preparation method thereof

The invention discloses a mineral high-strength wear-resistant material which is prepared from the following raw materials in percentage by weight: 0.30-0.50% of C, 0.10-0.65% of Si, less than or equal to 1.0% of Mn, 1.0-4.5% of Cr, 0.05-3% of Ni, 0.15-1.5% of Mo, 0.05-0.5% of V, 0.010-0.5% of Nb, 0.01-0.5% of Al, less than or equal to 0.025% of P, less than or equal to 0.015% of S and the balanceof Fe. A chain wheel manufactured from the mineral high-strength wear-resistant material is excellent in alloy element proportion, is pure in steel, is uniform in structure, has excellent comprehensive performance, is high in chain gear hardness, is uniform in hardness and is good in wear resistance; and meanwhile, a base body part has good impact toughness and strength. The defects that a commonChinese chain wheel is poor in comprehensive performance and is low in coal passing amount are solved. The mineral high-strength wear-resistant material greatly improves the coal passing amount of the chain wheel, reduces chain wheel use cost, and improves economic benefits.

Owner:YINGKOU SPECIAL STEEL FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com