Preparation of stratified lithium ion anode material

A positive electrode material, lithium ion technology, applied in the field of lithium ion secondary battery positive electrode materials, can solve the problems of poor product reproducibility and consistency, uneven mixing of precursors and lithium sources, high solid-state reaction temperature, etc., to achieve the manufacturing method Ease of control, improved working voltage platform and safety, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

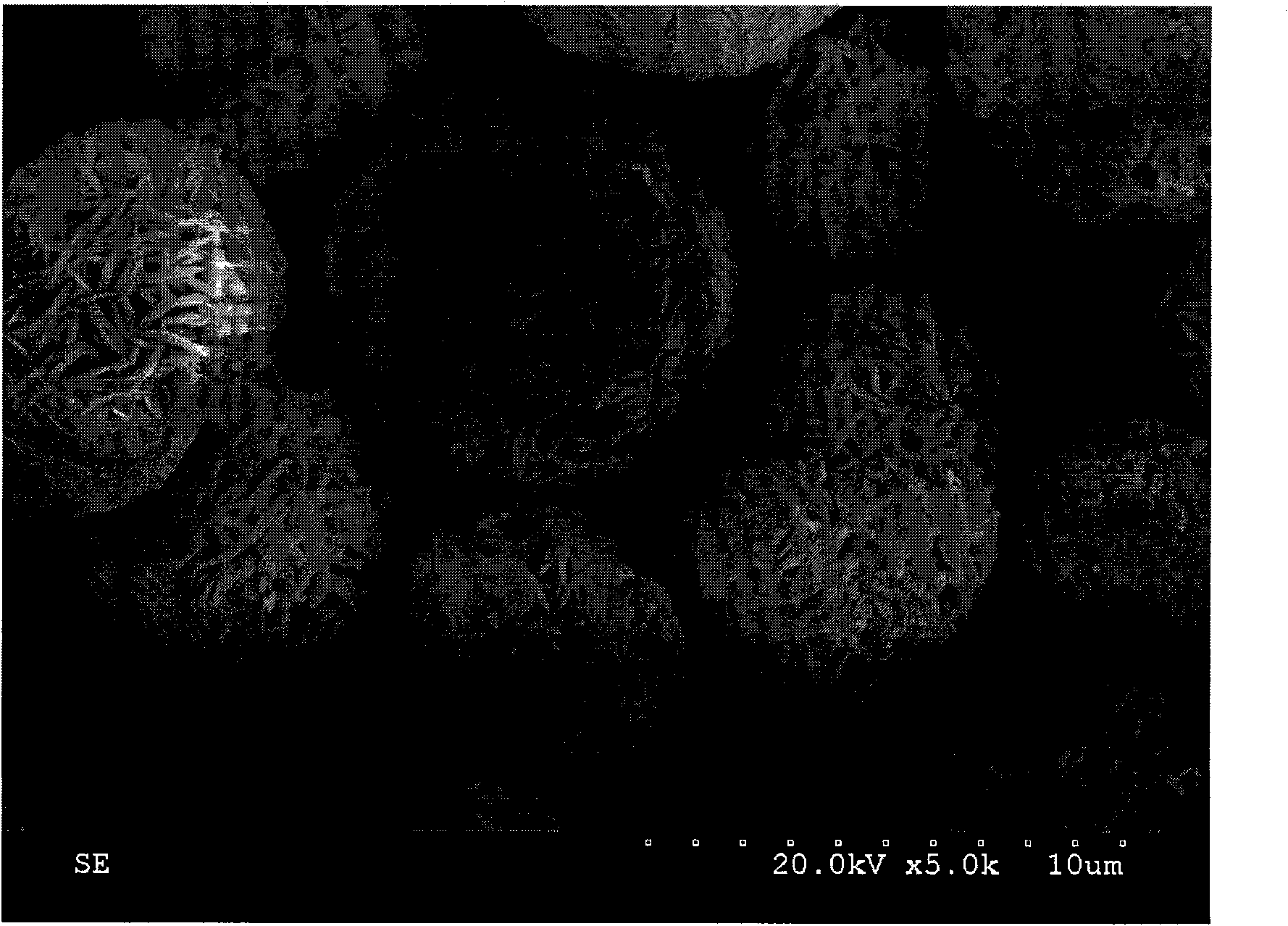

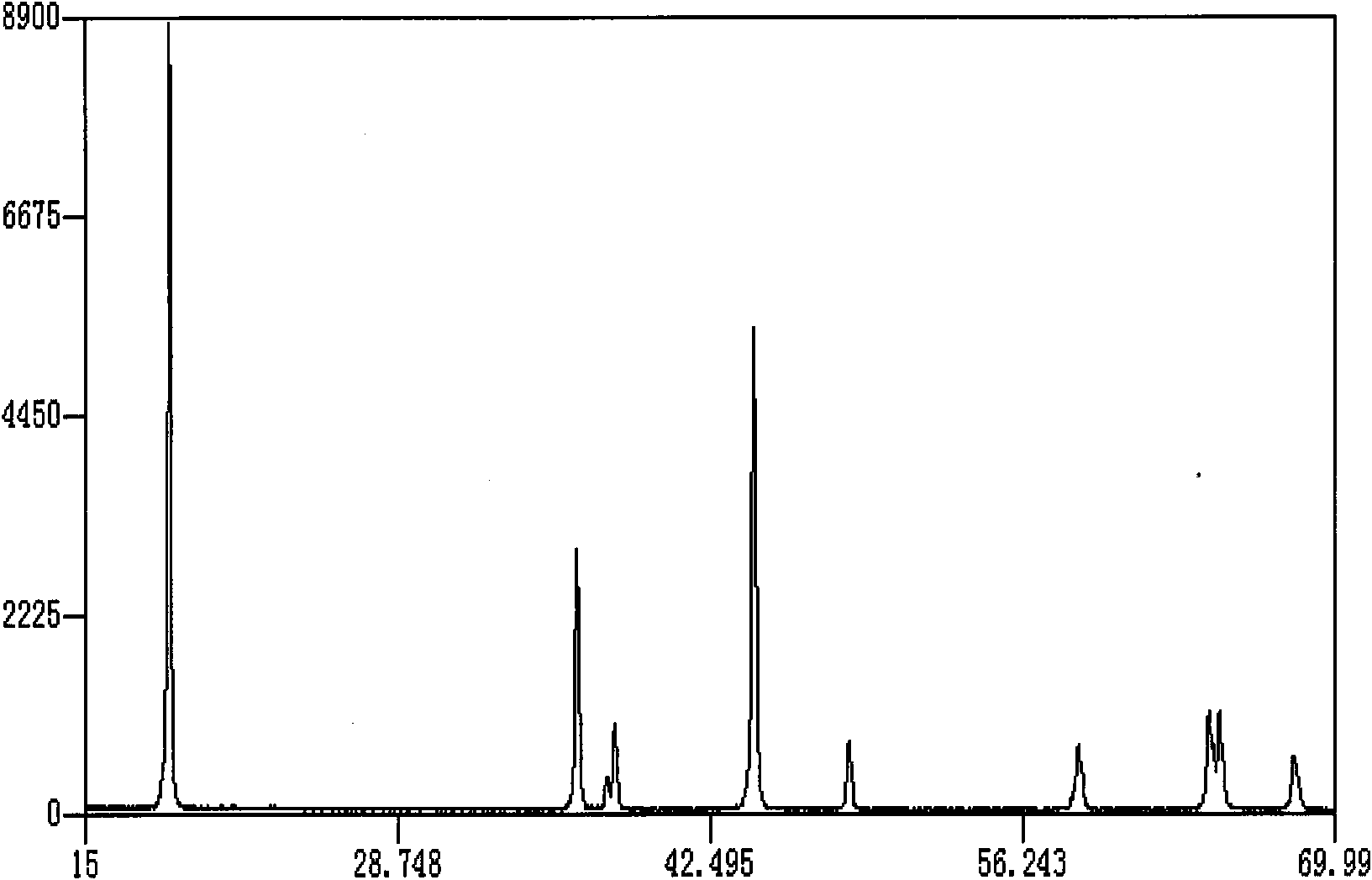

[0025] The synthetic chemical formula is LiNi 0.7 mn 0.2 Al 0.05 co 0.05 o 2 Taking the positive electrode material as an example, nickel, manganese, and Al-doped sulfate were prepared according to the stoichiometric ratio to prepare a 5 mol / L mixed salt solution, 3 mol / L ammonia solution and 1 mol / L NaOH solution. Use an electronic metering pump to inject the mixed salt solution, ammonia solution and NaOH solution into the reactor according to the flow rate of 15mL / min, 6mL / min and 8mL / min respectively, keep the reaction temperature at 75°C, and the pH value at 10.5, at 80r / min After reacting in the reactor for 5 hours at a rotating speed, uniform spherical Ni can be obtained after washing, filtering (600 mesh) and drying. 0.7 mn 0.2 Al 0.05 (OH) 2 Precursor. Its SEM picture is attached figure 1 . Then carry out surface coating treatment to it according to the following scheme: by mass ratio m (Ni0.7Mn0.2Al0.05(OH)2) :m PTFE =25:1 Weigh polytetrafluoroethylene (PT...

Embodiment 2

[0030] Synthetic formula LiNi 0.6 mn 0.2 Ti 0.02 Mg 0.02 Zn 0.02 co 0.14 o 2 As an example, nickel, manganese and sulfates doped with metals Ti, Mg and Zn are prepared respectively according to the stoichiometric ratio to prepare 5 mol / L solution, 2 mol / L ammonia solution and 2 mol / L NaOH solution. The mixed salt solution, ammonia solution and NaOH solution were injected into the reactor at a certain flow rate of 12mL / min, 7mL / min and 7mL / min respectively with an electronic precision pump, and the reaction temperature was kept at 80°C and the pH value was 11. After reacting in the reactor at 80r / min for 5 hours, the uniform spherical Ni can be obtained after washing, filtering (600 mesh) and drying. 0.6 mn 0.2 Ti 0.02 Mg 0.02 Zn 0.02 (OH) 2 Precursor. Then carry out surface coating treatment to it according to the following scheme: by mass ratio m (Ni0.6Mn0.2Ti0.02Mg0.02Zn0.02(OH)2) :m PTFE =20:1 Weigh styrene-butadiene rubber (SBR), add water to form a 45% suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com