Patents

Literature

49results about How to "Stoichiometric ratio is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

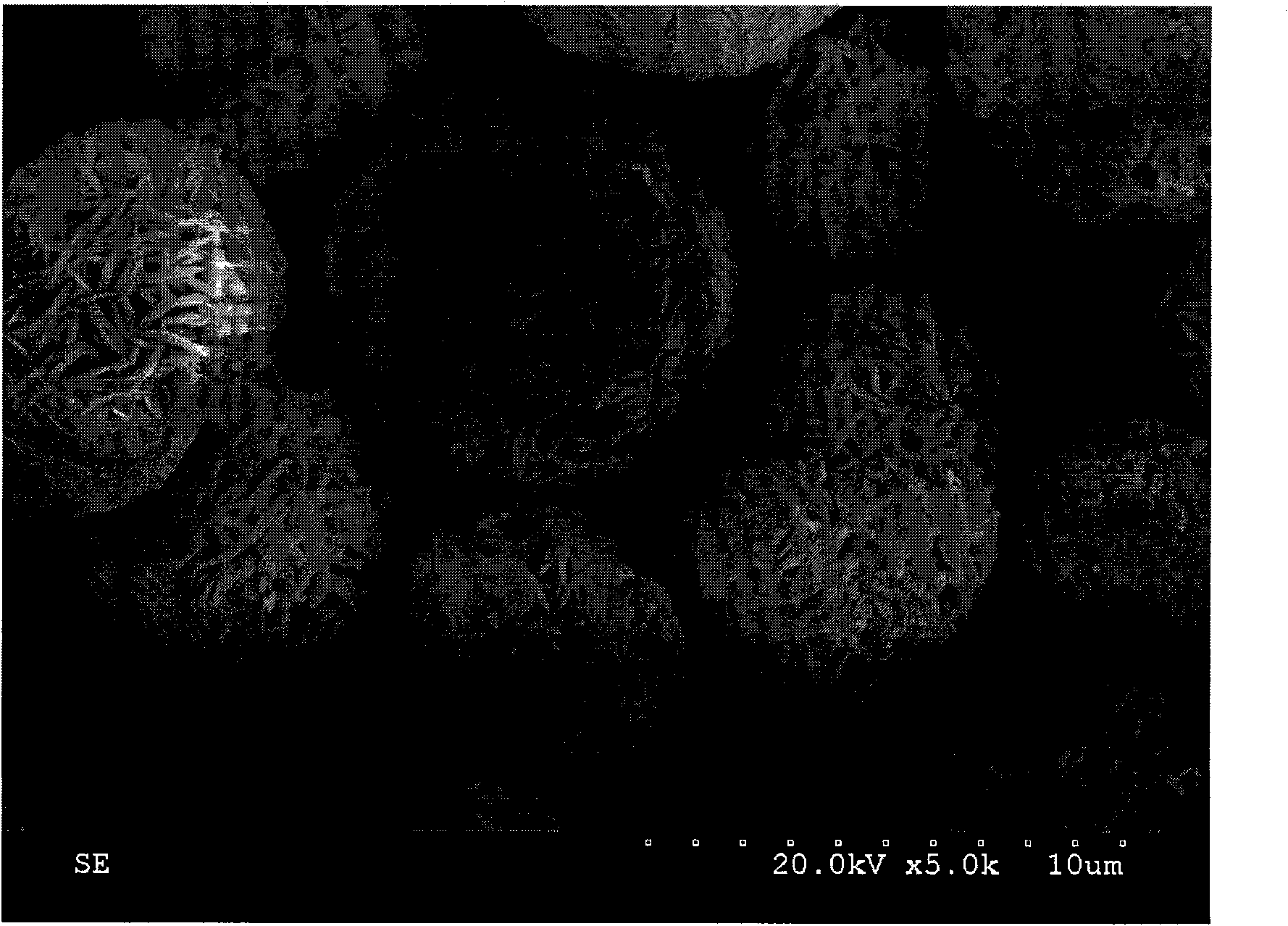

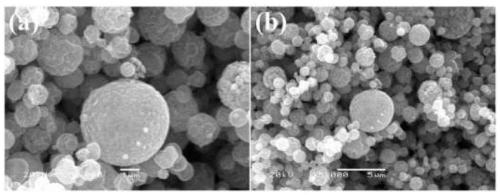

Method for preparing high-performance spherical lithium ion secondary battery cathode material

ActiveCN102110808AHigh densityHigh activityCell electrodesNickel compoundsHigh densityElectrical battery

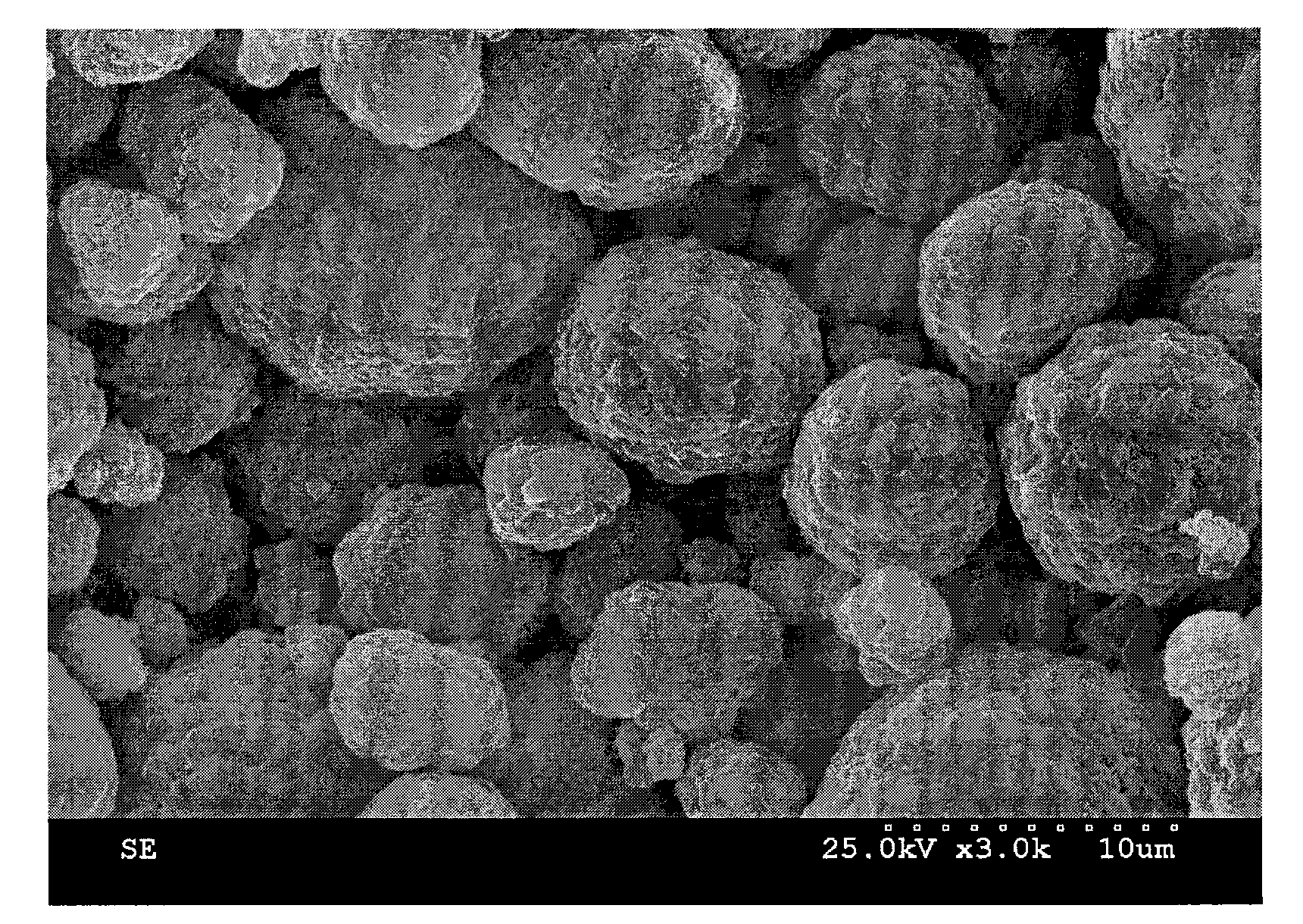

The invention provides a method for preparing a high-performance spherical lithium ion secondary battery cathode material. The method comprises the steps of synthesizing a NiaCobMn1-a-b(OH)2 precursor through adopting a coprecipitation-crystallization method, coating NicCodMn1-c-d(OH)2NieCofMn1-e-f(oh)2 composite layer on the surface of the precursor through adopting a chemical method, and then fully mixing with lithium salt to prepare a high-performance spherical lithium ion secondary battery cathode material LiNiaCobMn1-a-bO2(LiNicCobMn1)-c-dO2LiNieCofMn1-e-fO2) through stepwise sintering. The cathode material prepared by adopting the method has high density, good activity, and accurate stoichiometric proportion. Malignant interaction between the cathode material and an electrolyte is avoided, capacity decrease caused by non- electrochemical active substances is prevented, and the circulating life of materials is prolonged. The method is easy to control, has a low manufacturing cost, and is convenient for mass production, so as to create conditions for the development of high-capacity lithium ion batteries.

Owner:HENAN KELONG NEW ENERGY CO LTD

Preparation of stratified lithium ion anode material

ActiveCN101944610AHigh densityHigh activityElectrode manufacturing processesNickel compoundsManganeseSolid state reaction method

The invention relates to a preparation method of a stratified lithium ion anode material, which comprises the following steps: coating cobalt on the surface of a precursor containing nickel, manganese and a small amount of other metals by a chemical precipitation method; fully mixing with a lithium source; and then, adopting a solid reaction method to prepare the high nickel type lithium ion anode material. The chemical formula of the lithium ion anode material is as follows: LidNiaMnbMcCo1-a-b-c02, wherein 0.9<=d<=1.25, 0.5<=a<=1, 0<b<0.5, 0.9<=a+b+c<1, and M is one or a mixture of more than one of Al, Ti, Mg and Zn. The material has uniform chemical composition and high capacity. Besides, the cycle performance of the material is improved, and the operating voltage platform and the safety of a battery are enhanced, especially after the material is subject to doping and coating modification.

Owner:HENAN KELONG NEW ENERGY CO LTD

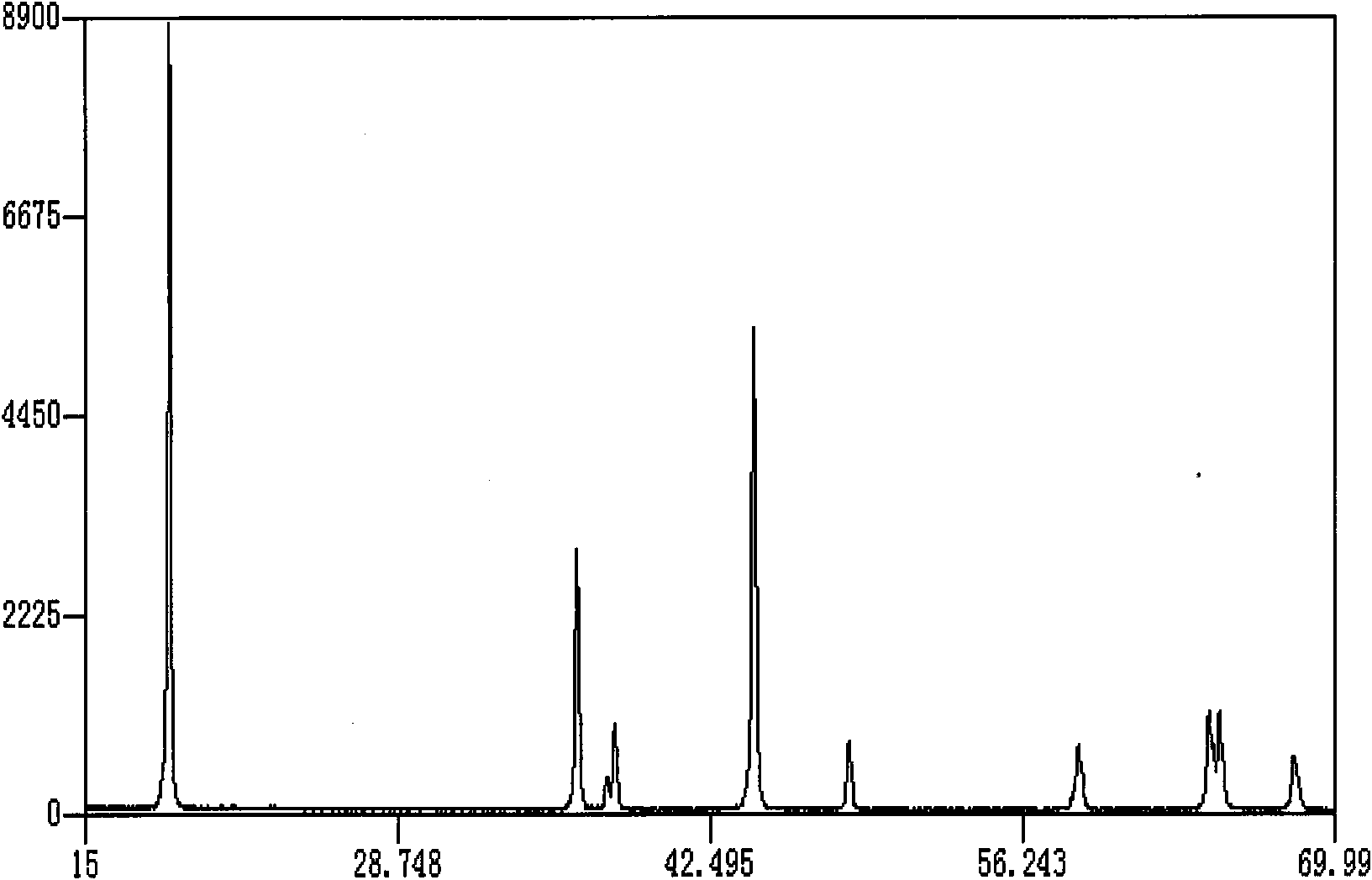

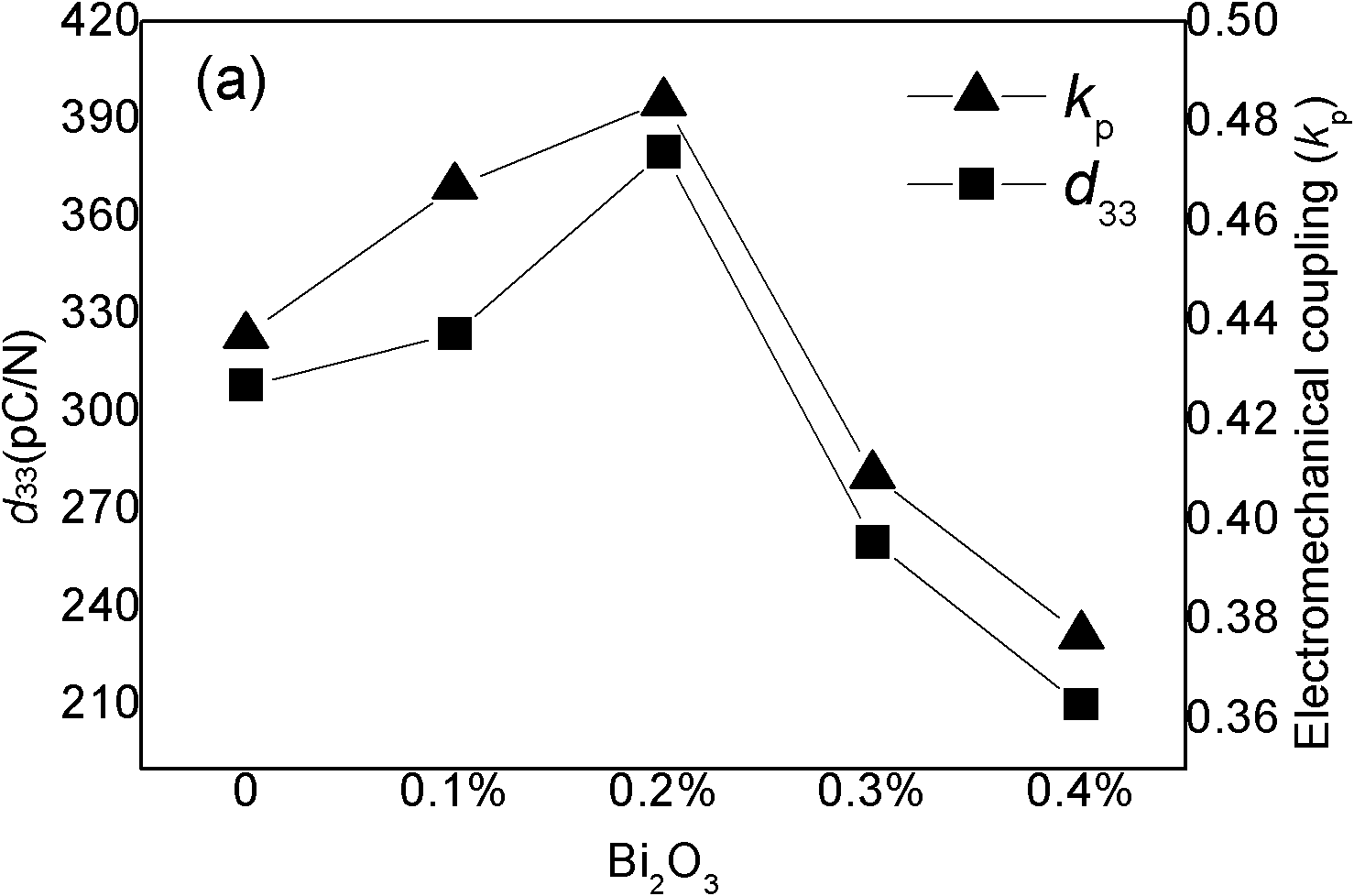

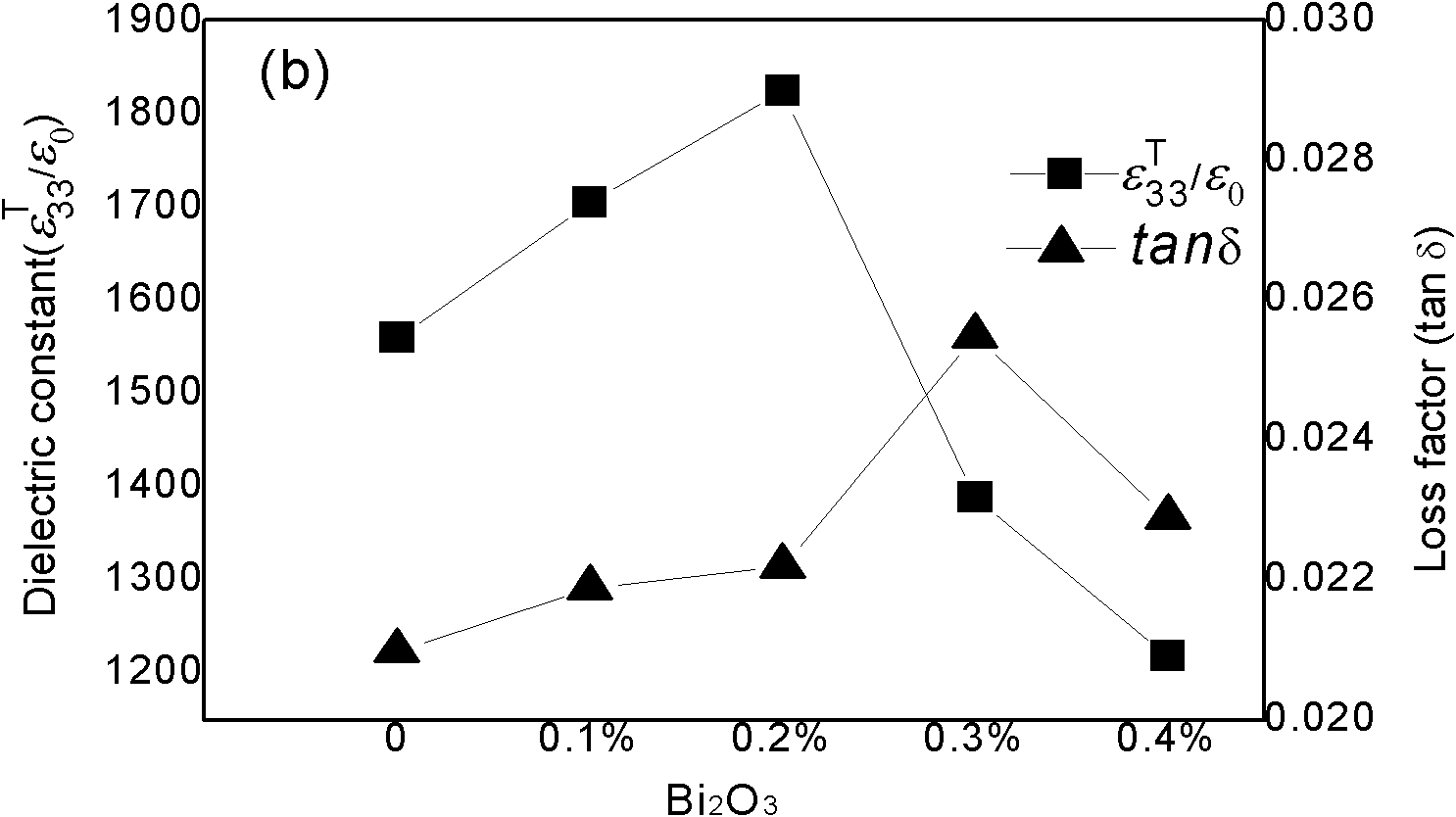

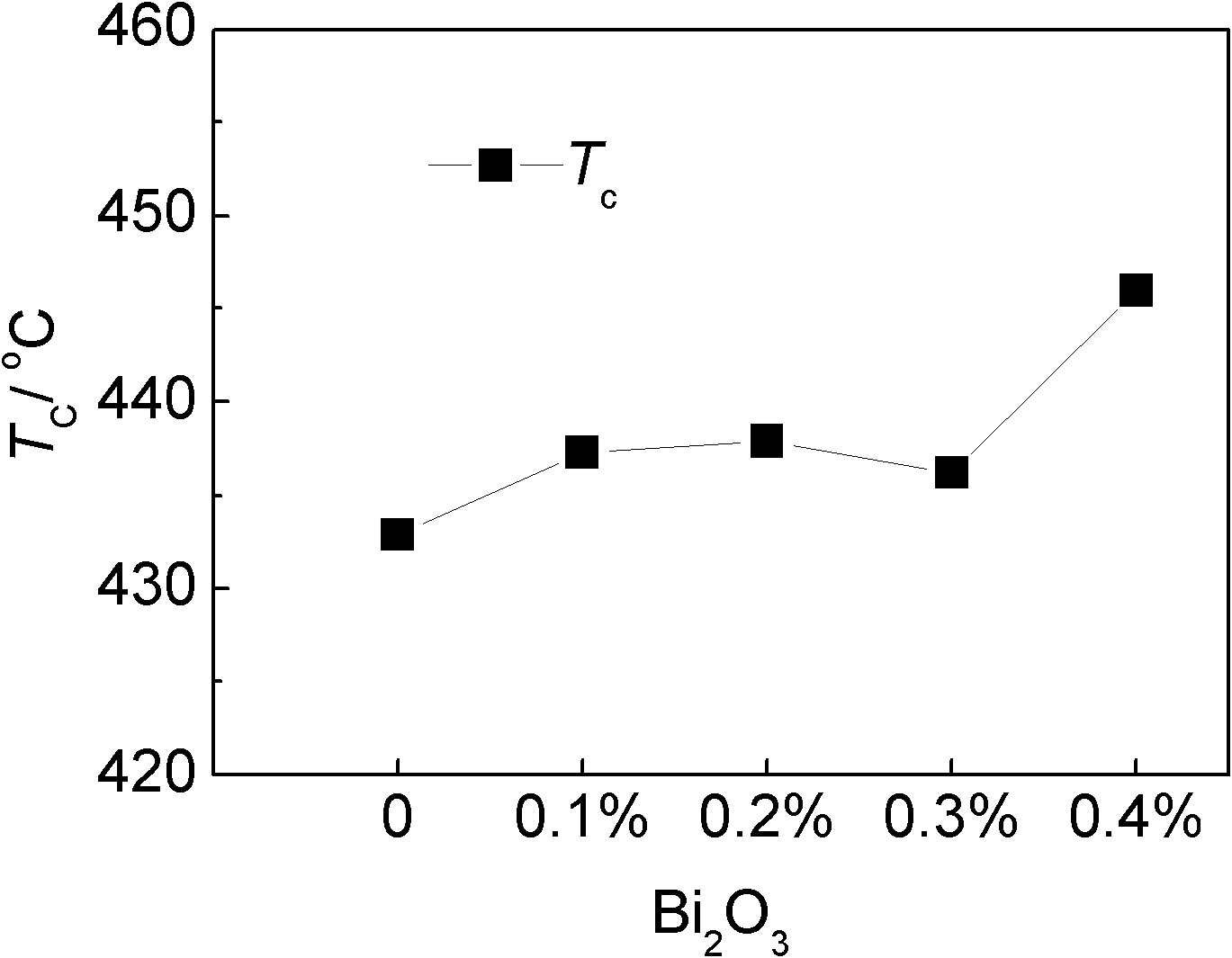

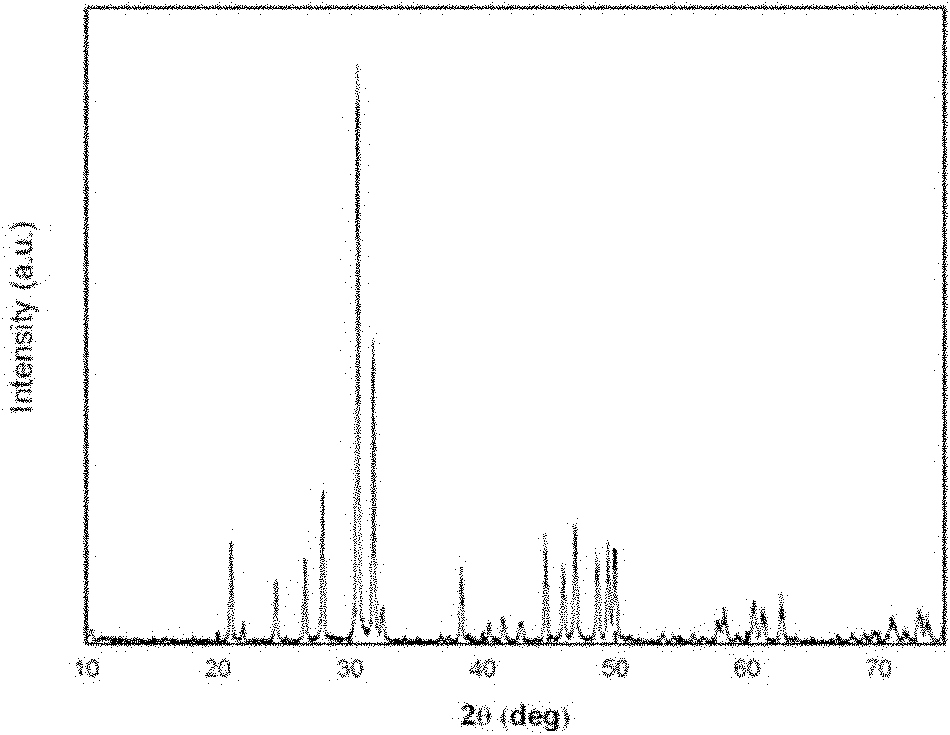

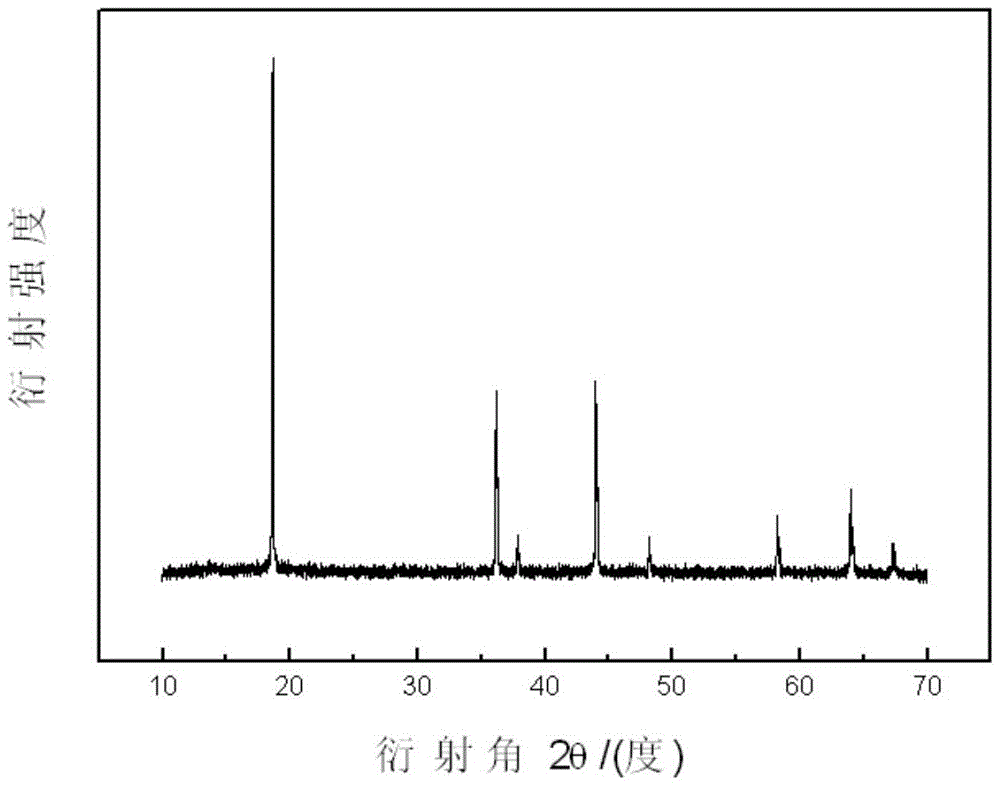

Bismuth scandate-lead titanate high-temperature piezoelectric ceramic material and preparation method thereof

InactiveCN102180665AStoichiometric ratio is accurateLower sintering temperatureCeramic sinteringCurie temperature

The invention discloses a bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material comprises a matrix with the chemical formula of xBiScO3-(1-x)PbTiO3 and bismuth trioxide (Bi2O3) in an amount which is less than 0.4 percent of the total weight of the matrix. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material is prepared by adding excess Bi2O3 into raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3, wherein x is 0.35 to 0.38; and the using amount of the excess Bi2O3 is 0.1 to 0.4 percent of the total weight of the raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material solves the problems that ceramic sintering temperature is increased and piezoelectric and dielectric properties are reduced due to deviation of a stoichiometric ratio caused by bismuth volatilization in the sintering process of BSPT ceramic, and has high Curie temperature, excellent piezoelectric property and an actual application value in high-temperature electronic equipment. The invention also discloses a preparation method for the bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. In the preparation method, the piezoelectric ceramic material is prepared by synthesizing and sintering at lower temperature, so production cost is reduced, process steps are simplified, and the material has actual application value.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

Preparation method for nickel cobalt lithium manganate LiNixConMn1-x-yO2 of anode material of lithium ion battery

InactiveCN102709568ASimple processOvercome ion segregationCell electrodesElectrical batteryManganate

The invention discloses a preparation method for nickel cobalt lithium manganate LiNixConMn1-x-yO2 of an anode material of a lithium ion battery, which belongs to the technical field of a novel material for energy source. The preparation method comprises the following steps of: 1, dissolving lithium source compound, nickel source compound, cobalt source compound and manganese source compound in deion water, adding complexant polyacrylic acid (PAA), and heating and stirring to obtain transparent red collosol; 2, heating and concentrating, evaporating unnecessary water to obtain red wet gel, and drying in a bake oven to obtain dried gel; and 3, carrying out calcination and heat treatment for ground dried gel in a muffle furnace to obtain powders of nickel cobalt lithium manganate LiNixConMn1-x-yO2. The method provided by the invention has the advantages of simple process, environment-protection, low energy consumption high efficiency and the like.

Owner:TIANJIN POLYTECHNIC UNIV

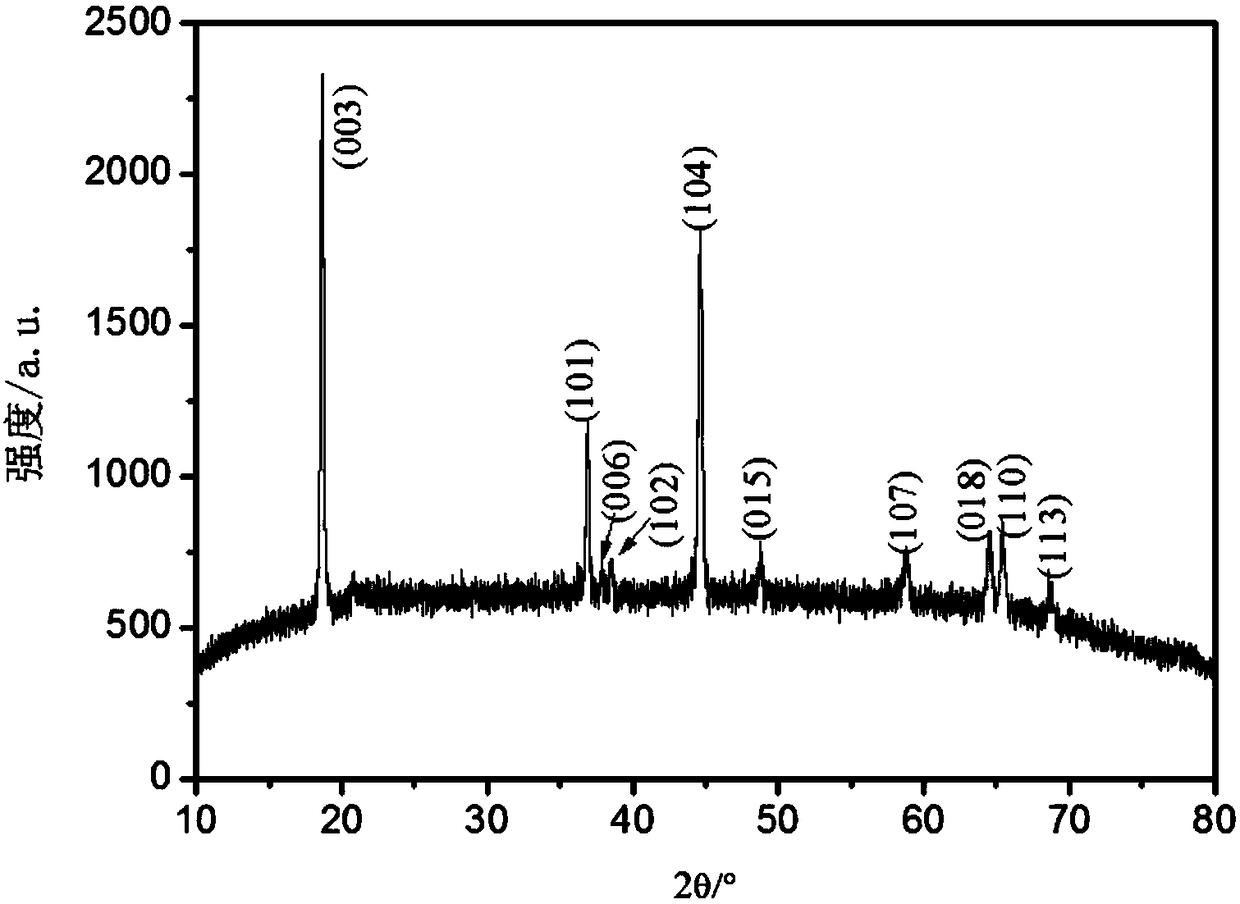

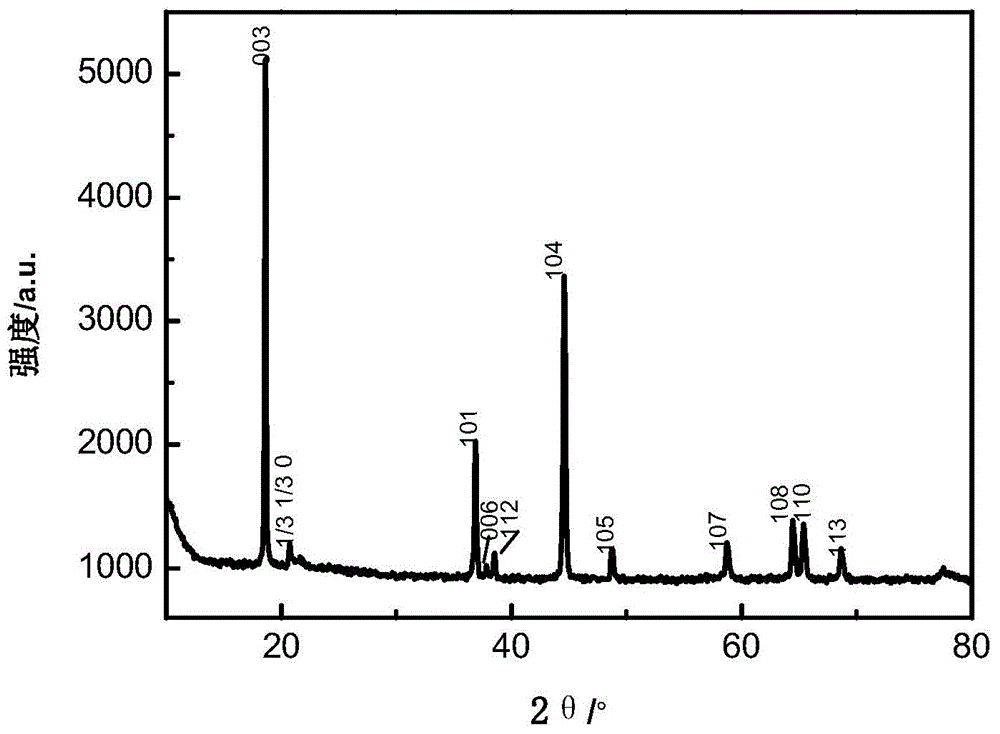

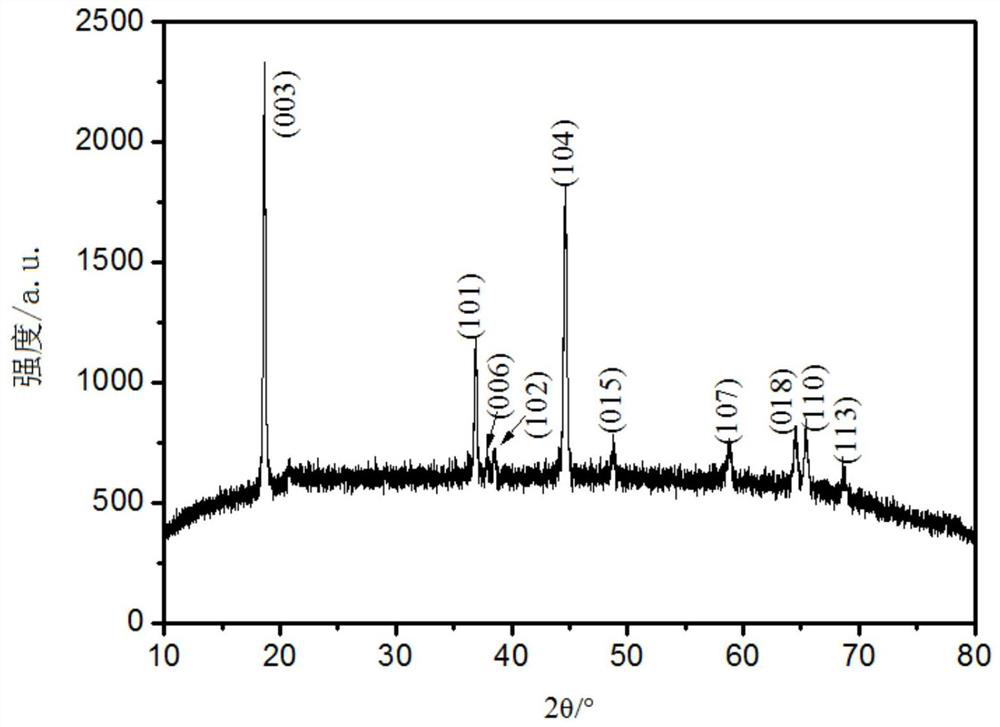

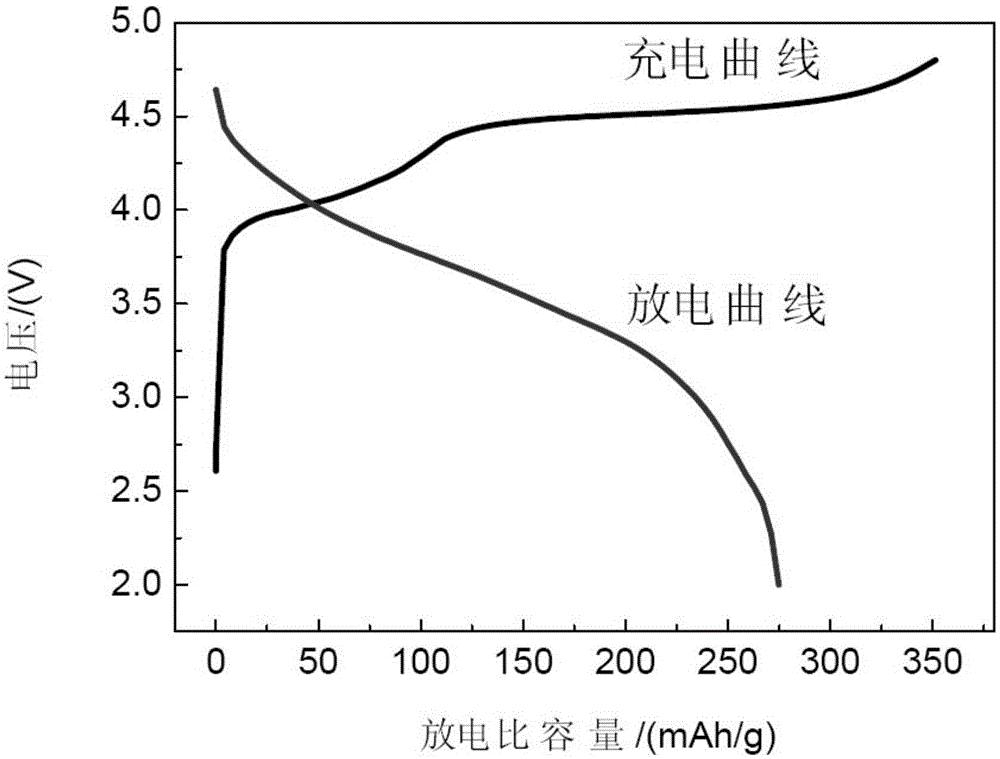

O3 type sodium ion battery cathode material and preparation method thereof

InactiveCN109873153AUniform particle sizeHigh reversible specific capacityCell electrodesSecondary cellsManganeseSodium-ion battery

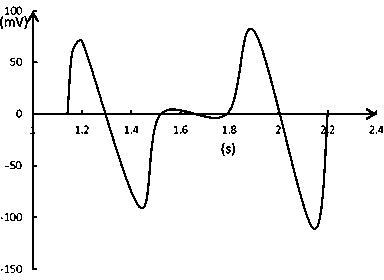

The invention provides an O3 type sodium ion battery cathode material and a preparation method thereof. The preparation method comprises the following steps: firstly preparing metal salt of nickel, manganese, iron, and aluminum into a precursor solution; performing spraying pyrolysis on the precursor solution to obtain powder product; and finally uniformly mixing the powder material and the sodiumsalt to perform tabletting and high-temperature sintering to obtain the O3 type sodium ion battery cathode material. The preparation method is simple in operation, high in production efficiency, large in capacity, and strong in adaptability. The manufactured cathode material is a sheet structure, the sheet diameter is 1-5 microns, the thickness is 0.5-0.1 micron, the morphology and particle sizeis uniform, the reversible specific capacity under high voltage is high, the cycling stability is good; the charging / discharging specific capacity is measured in the 2.0-4.2V voltage interval, the first discharging specific capacity is more than 148mAh.g-1, and the coulombic efficiency is more than 92%.

Owner:CENT SOUTH UNIV

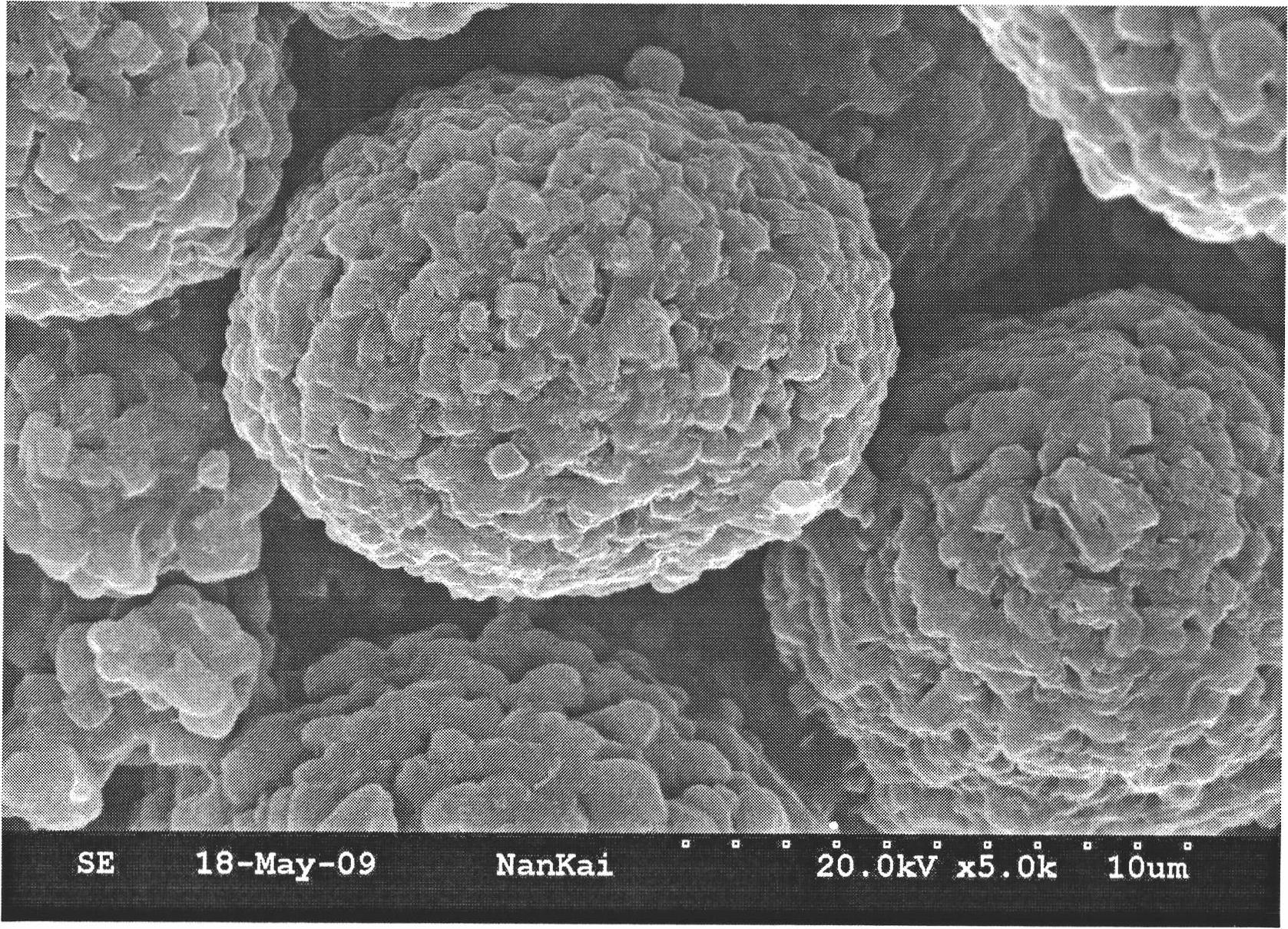

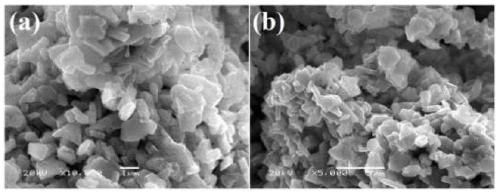

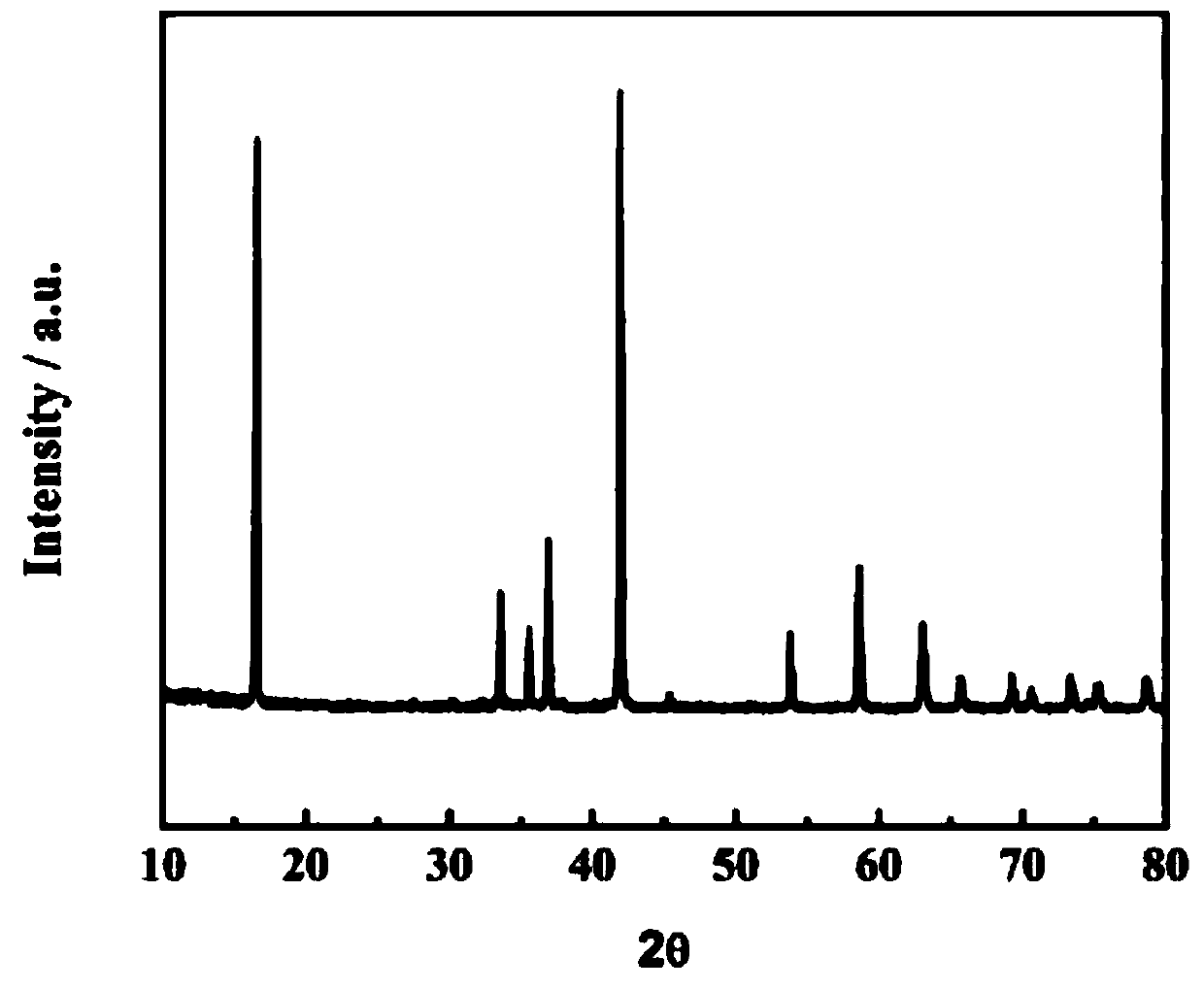

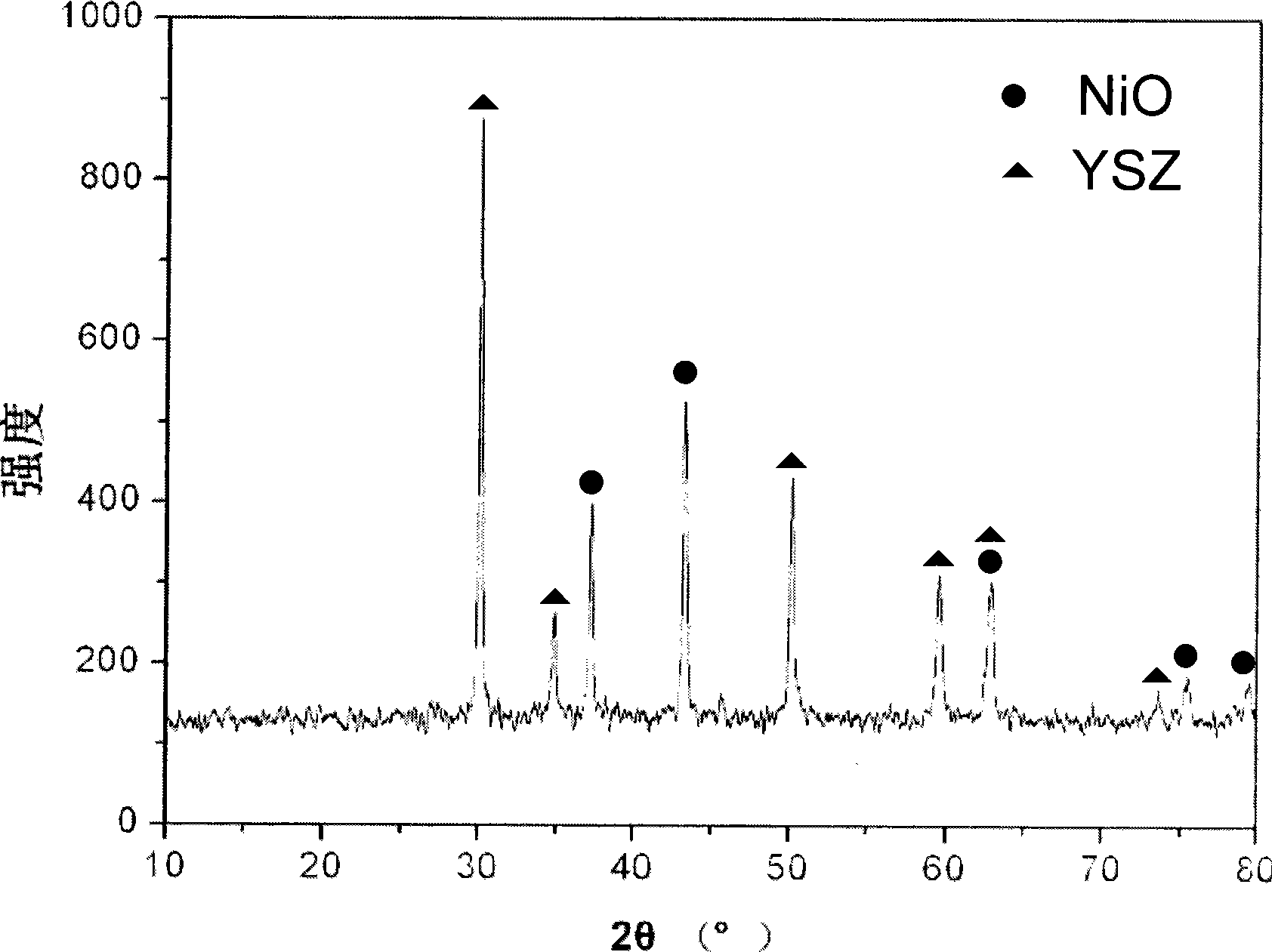

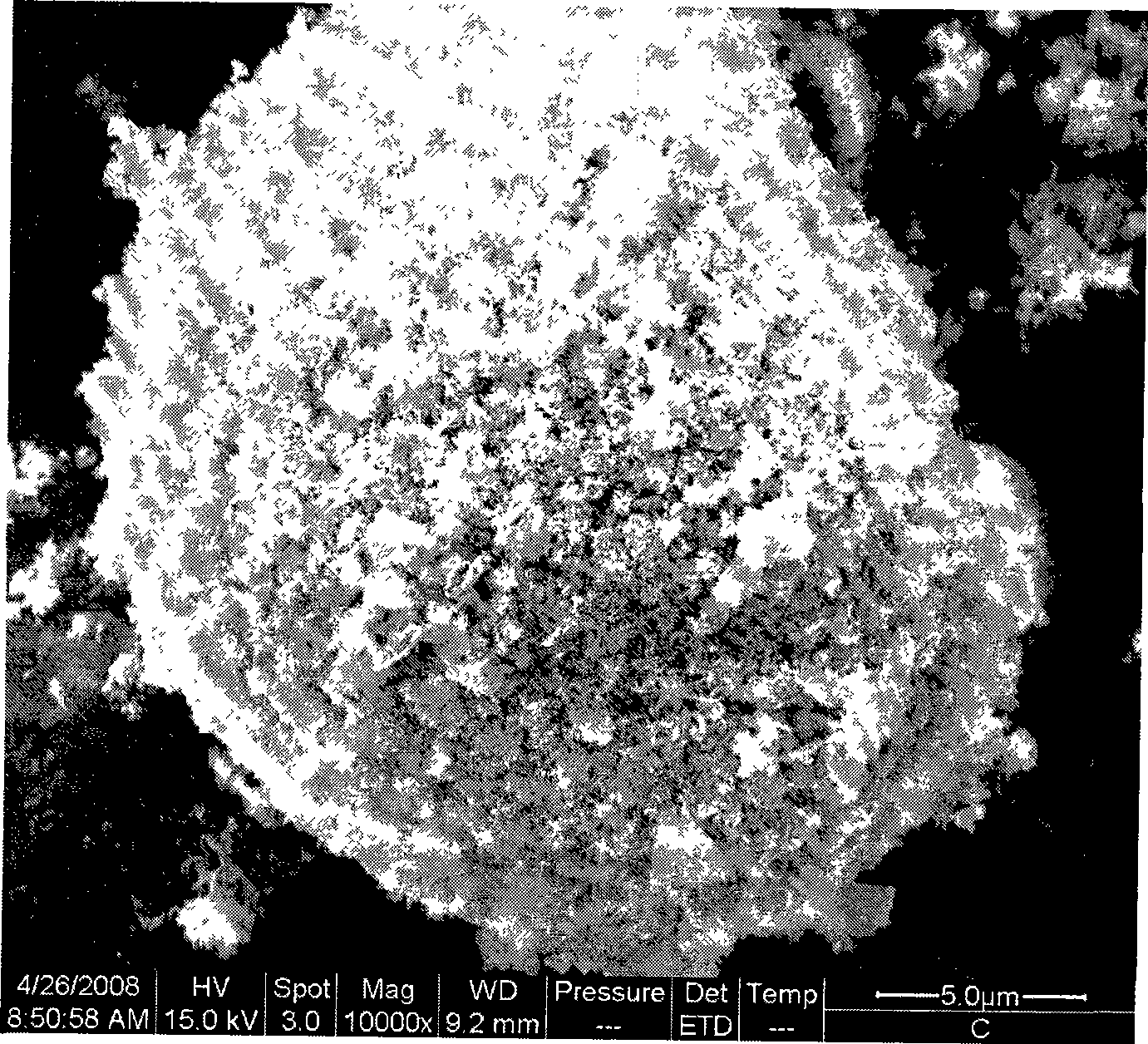

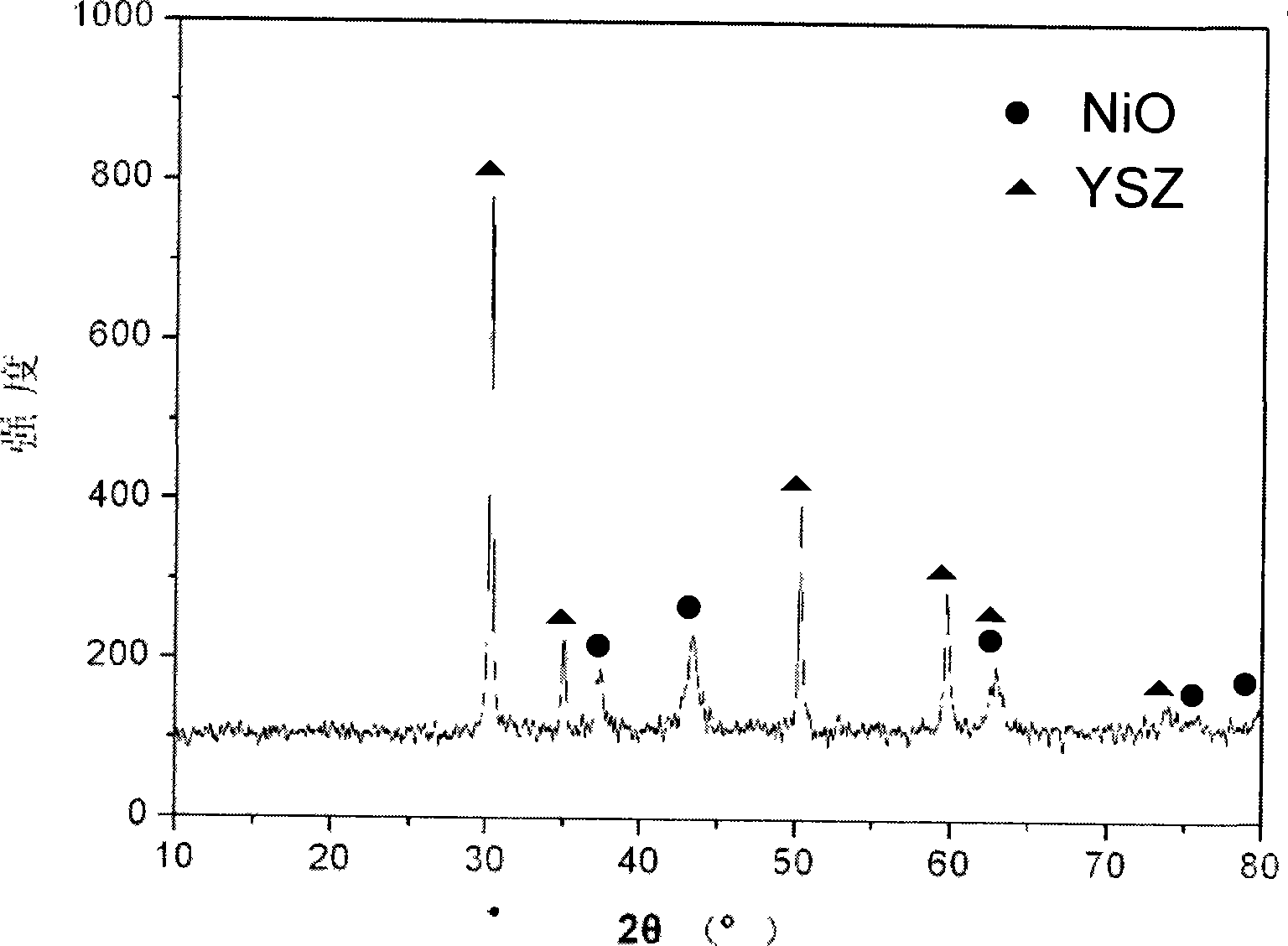

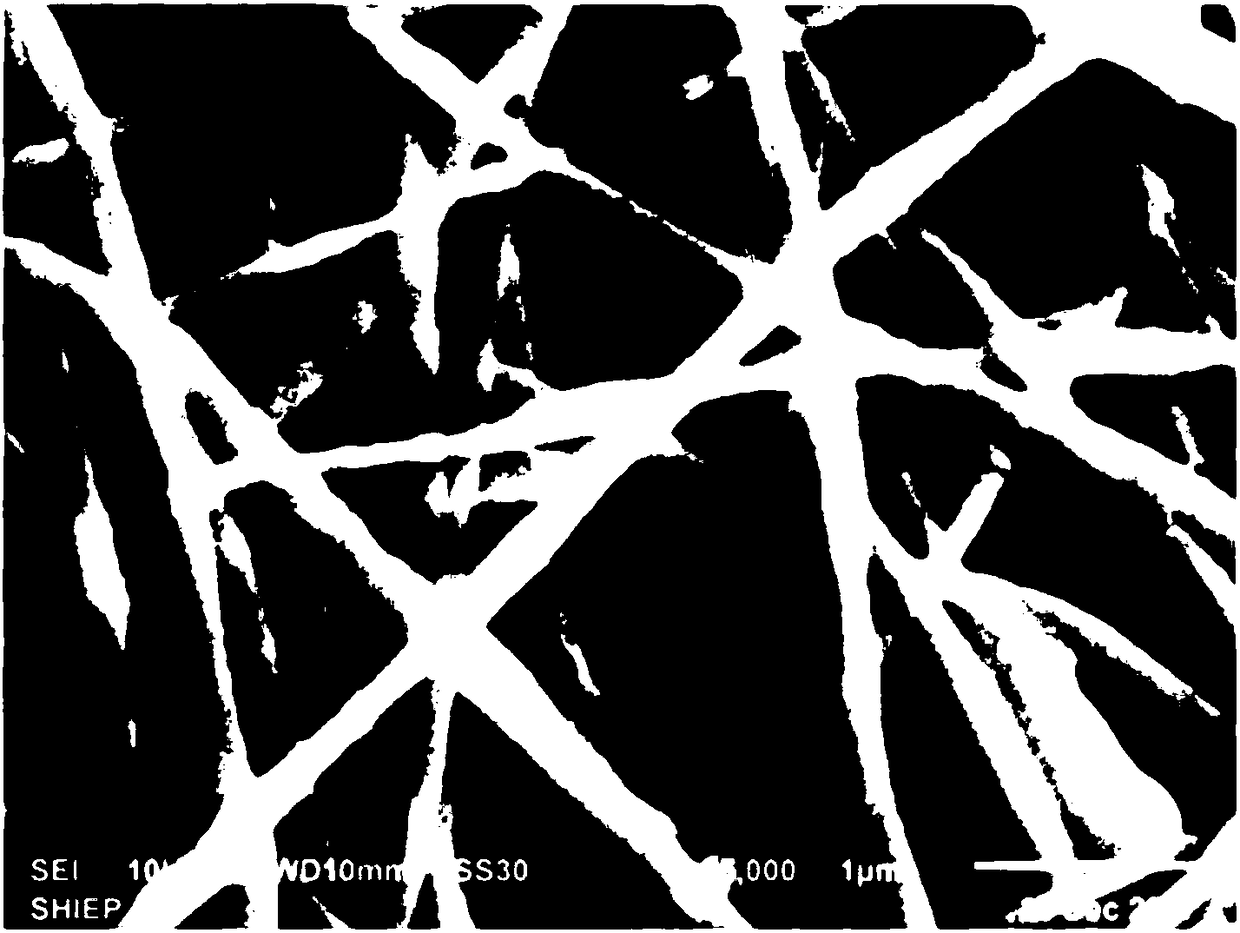

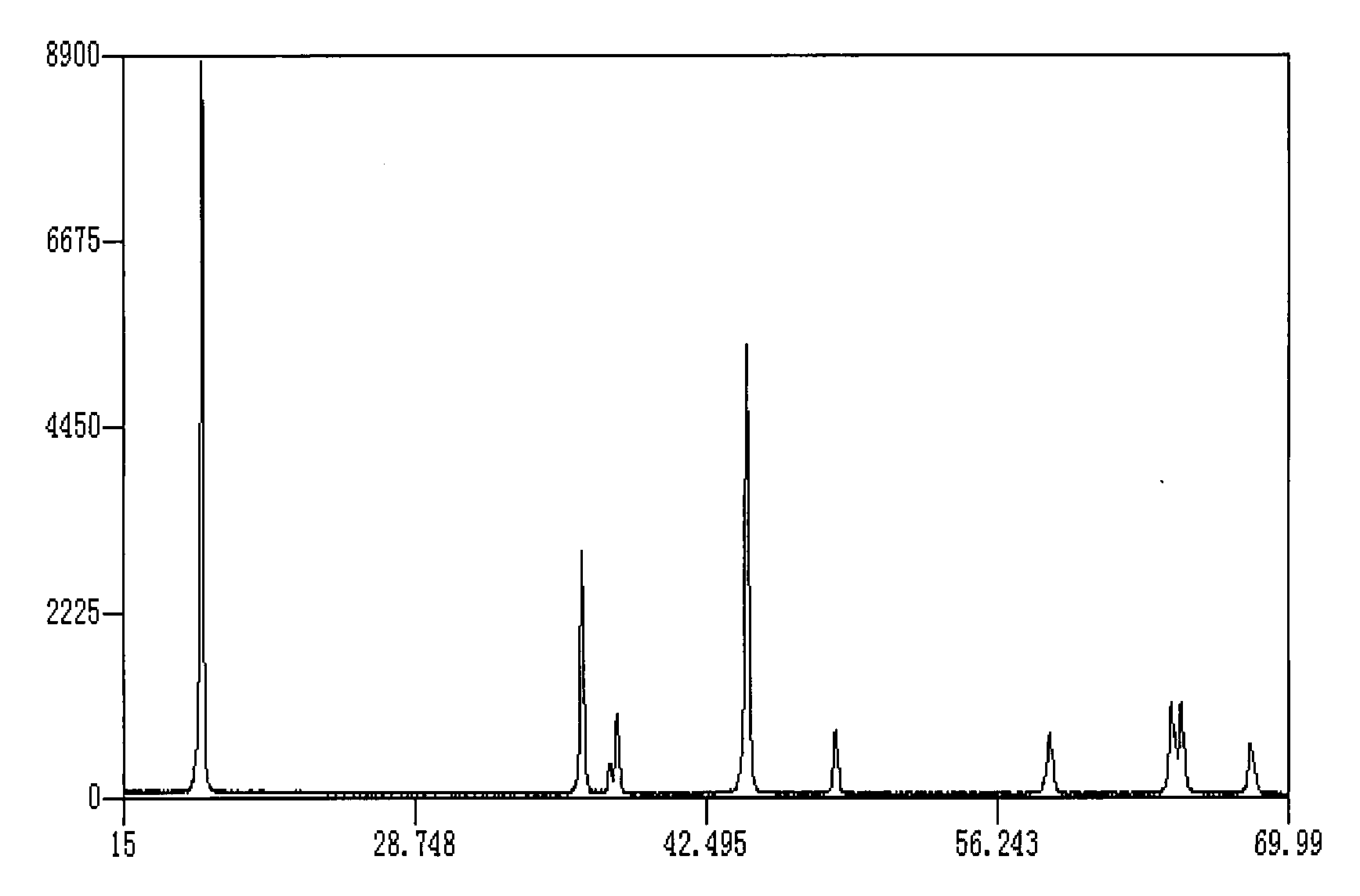

Preparation method of solid oxide electrolytic cell NiO-YSZ hydrogen electrode powder

InactiveCN101362205AGood adhesionEvenly dispersedCell electrodesElectrodesEquivalence ratioChemical measurement

The invention relates to a method for preparing solid oxide electrolytic cell NiO-YSZ hydrogen electrode powder, which belongs to the field of electrolytic hydrogen production with high temperature steam and the field of solid oxide electrolytic cell. The invention uses six hydrate nickel nitride, YSZ (yttira stabilized zirconia) powder, and ammonia as raw materials; an in-situ synthesis is adopted; nickel nitrate is adopted as the nickel source, ammonia as precipitant, and YSZ powder as a precipitation-coated core; by the optimized control of conditions of stirring speed, ultrasonic wave processing, pH value of solution, and dropping speed, etc. Ni(OH)2 is deposited on the YSZ grain and the YSZ is coated; then, after processing of curing, filtering, washing, and drying, etc. NiO is generated on the YSZ powder after roasting; therefore, high-performance solid oxide electrolytic cell NiO-YSZ hydrogen electrode powder is obtained. The method has the advantages of good adhesion between NiO and YSZ grains, even distribution, strong catalysis activity, accurate chemical equivalence ratio, and simple operation, etc.

Owner:TSINGHUA UNIV

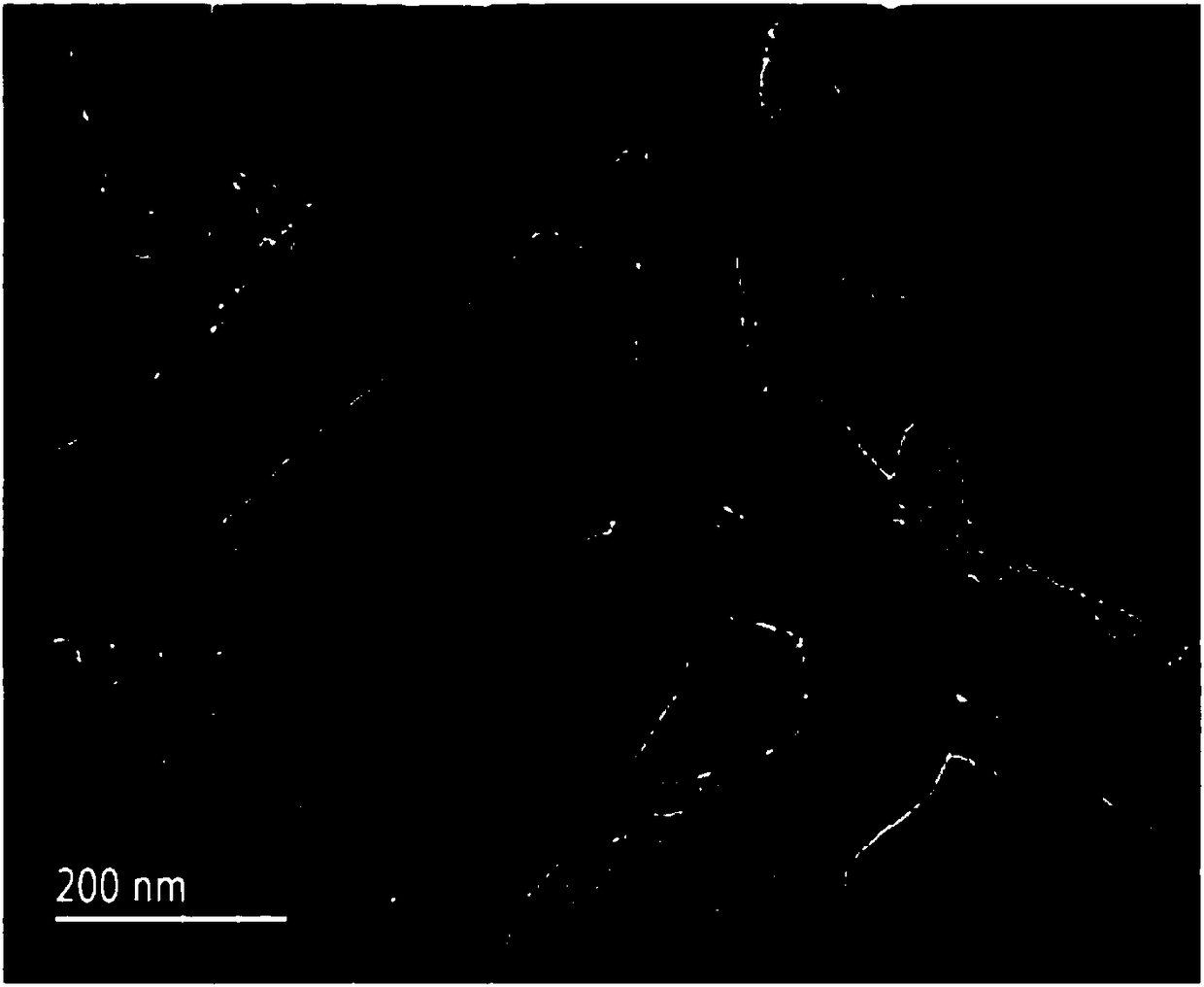

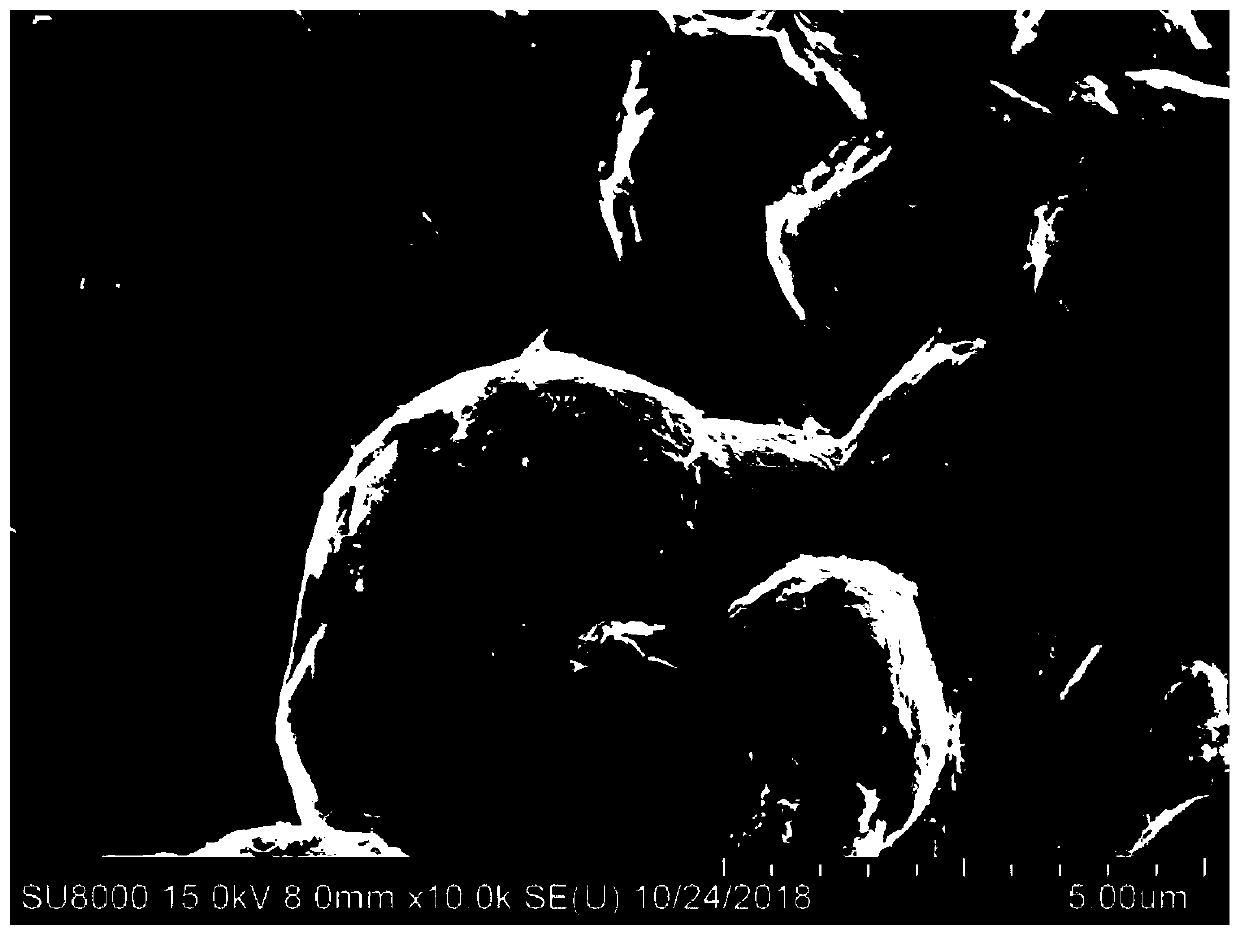

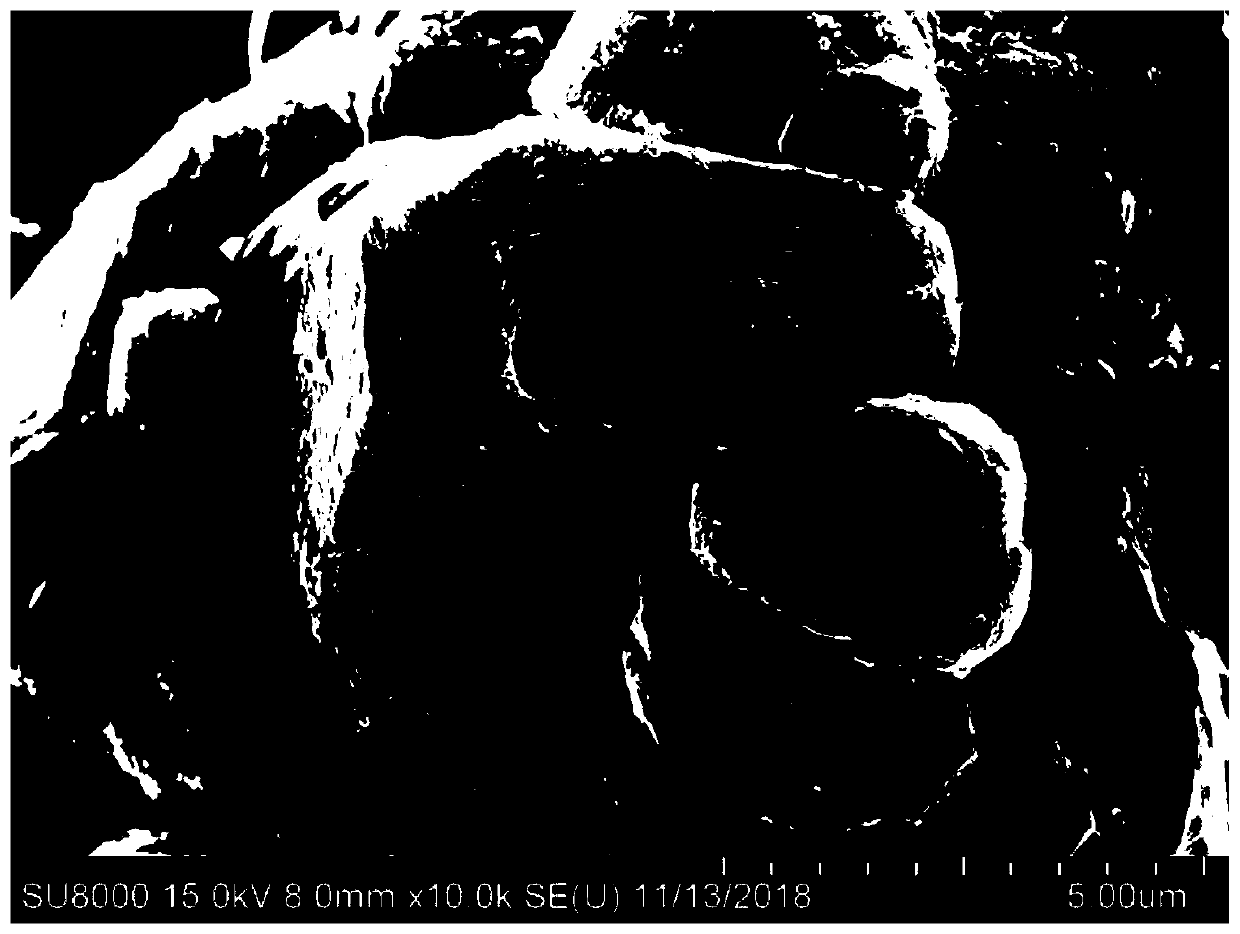

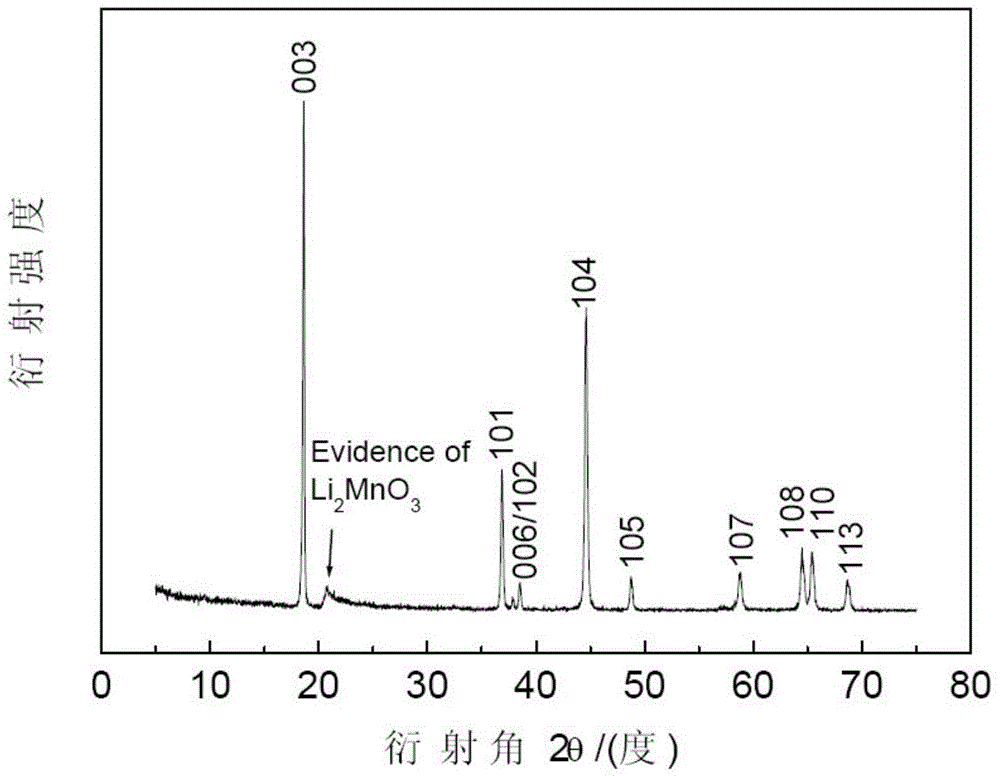

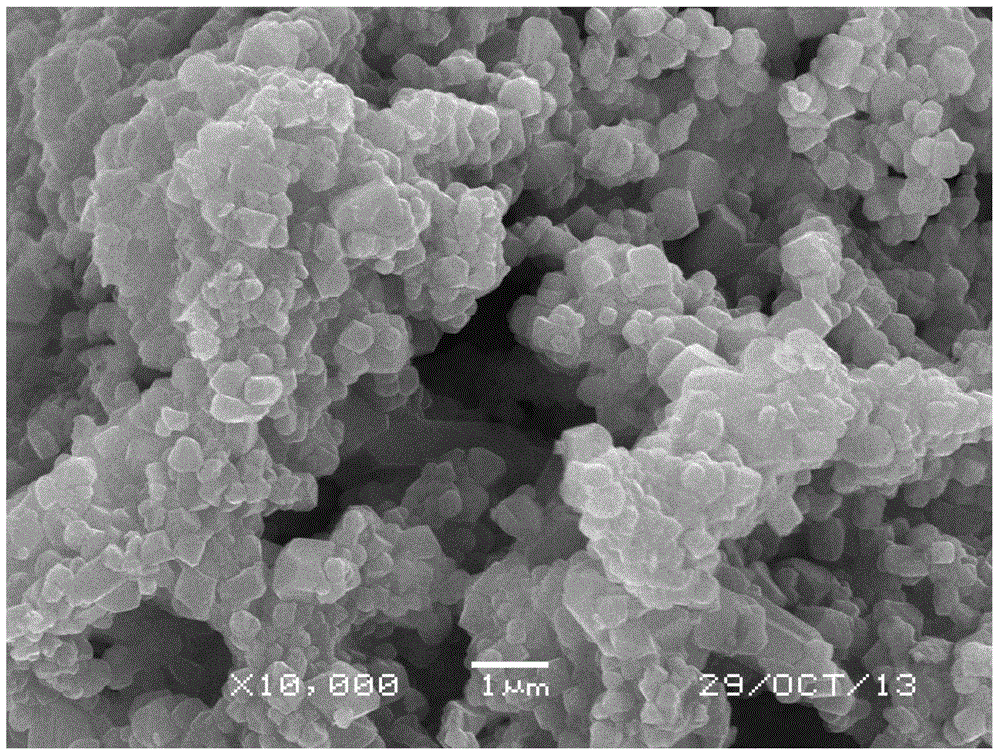

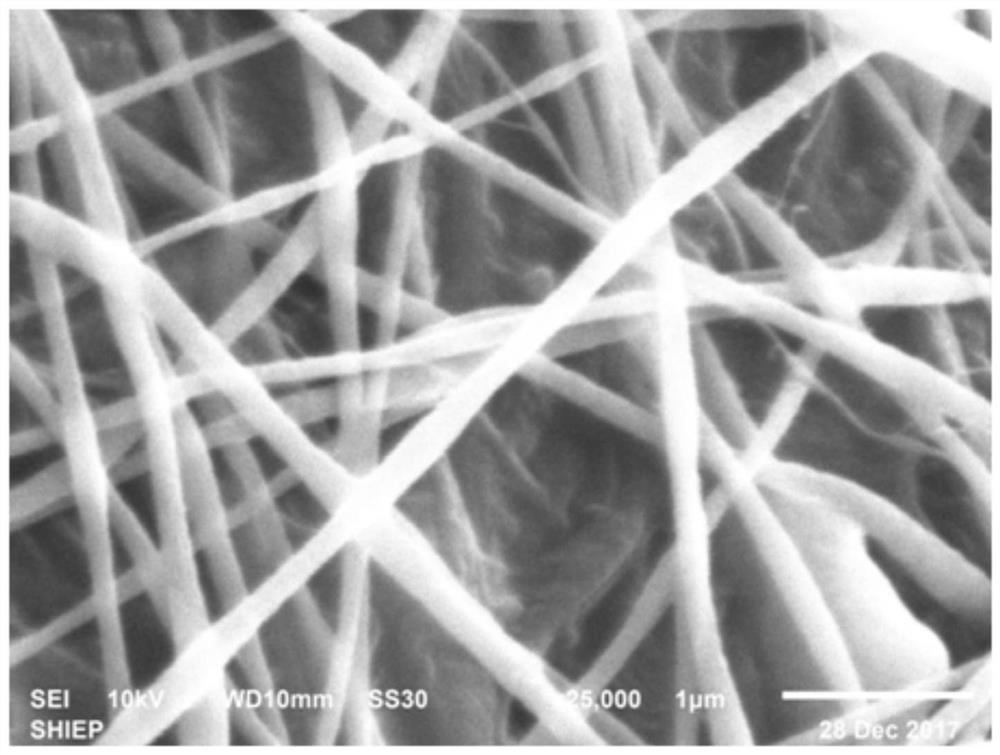

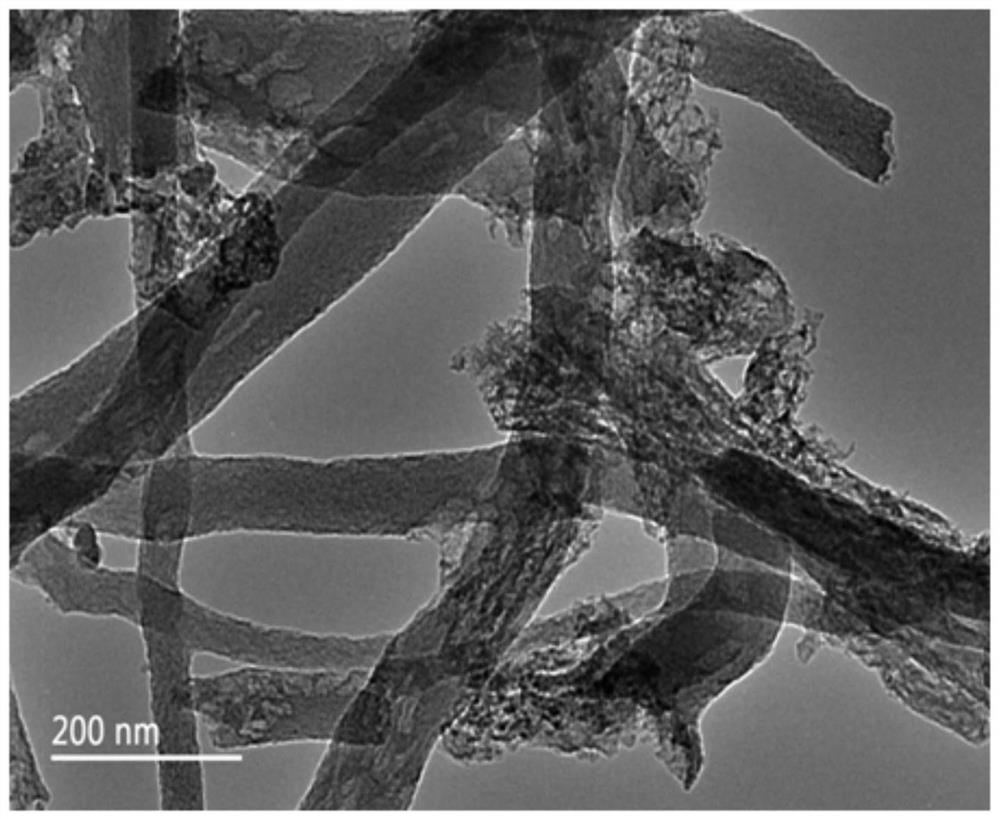

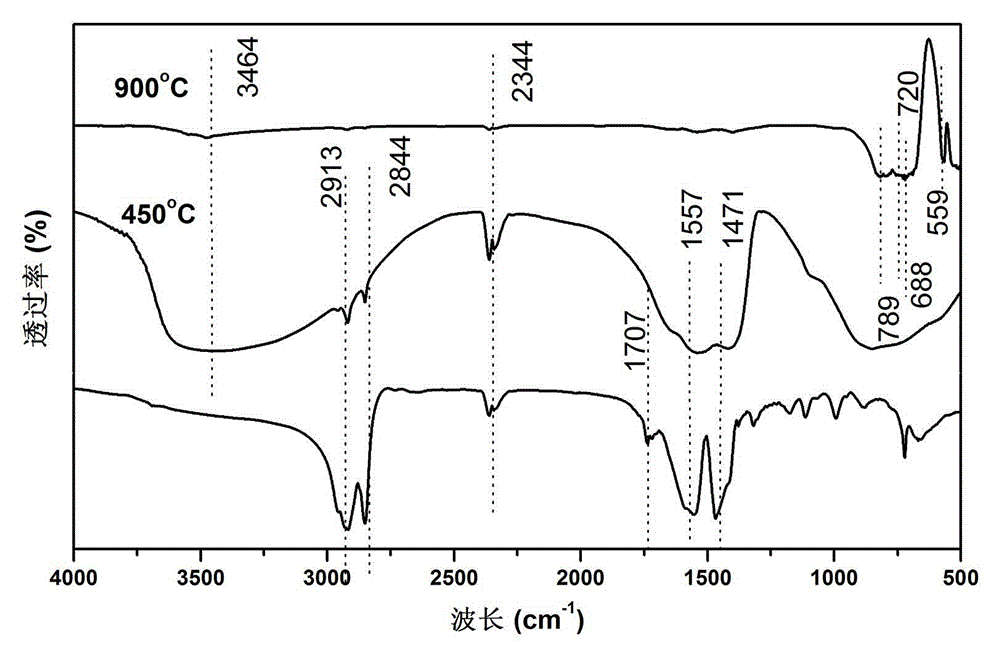

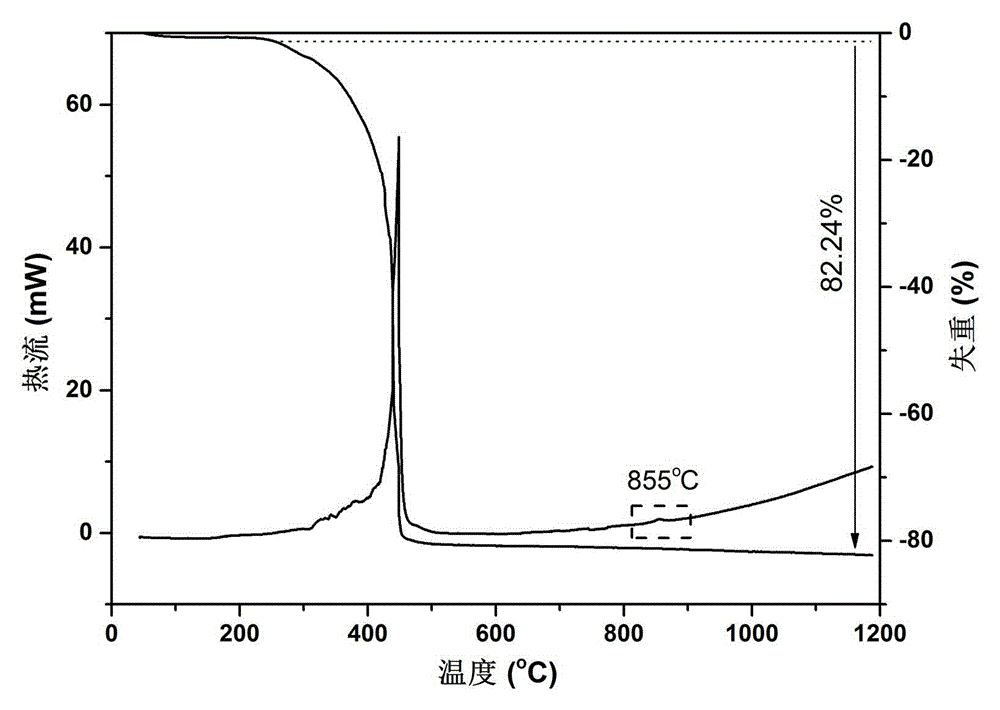

Preparation method of hollow tubular lithium-rich manganese-based positive electrode material

ActiveCN108574089AHigh crystallinityImprove electrochemical performanceCell electrodesSecondary cellsFiberNickel salt

The invention relates to a preparation method of a hollow tubular lithium-rich manganese-based positive electrode material. The preparation method includes the steps of (1), dissolving high-molecularpolymer A in an organic solvent to obtain spinning solution A; (2), dissolving lithium precursor, manganese salt, nickel salt and cobalt salt respectively obtain metal salt solution, dissolving high-molecular polymer B in an organic solvent to obtain a polymer solution, mixing the metal salt solution with the polymer solution uniformly to obtain spinning solution B; (3), taking the spinning solution A as an inner axle and the spinning solution B as an external axle, performing an co-axial electrospinning process to obtain nano-fiber; (4), drying the nano-fiber, calcining the nano-fiber at different stages, and then cooling to obtain a product. Compared with the prior art, the material synthesized by the method for preparing the hollow tubular lithium-rich manganese-based positive electrodematerial through the co-axial electrospinning process has the advantages of accurate stoichiometric ratio, uniform particle dispersion and the like, and also has excellent cycle performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

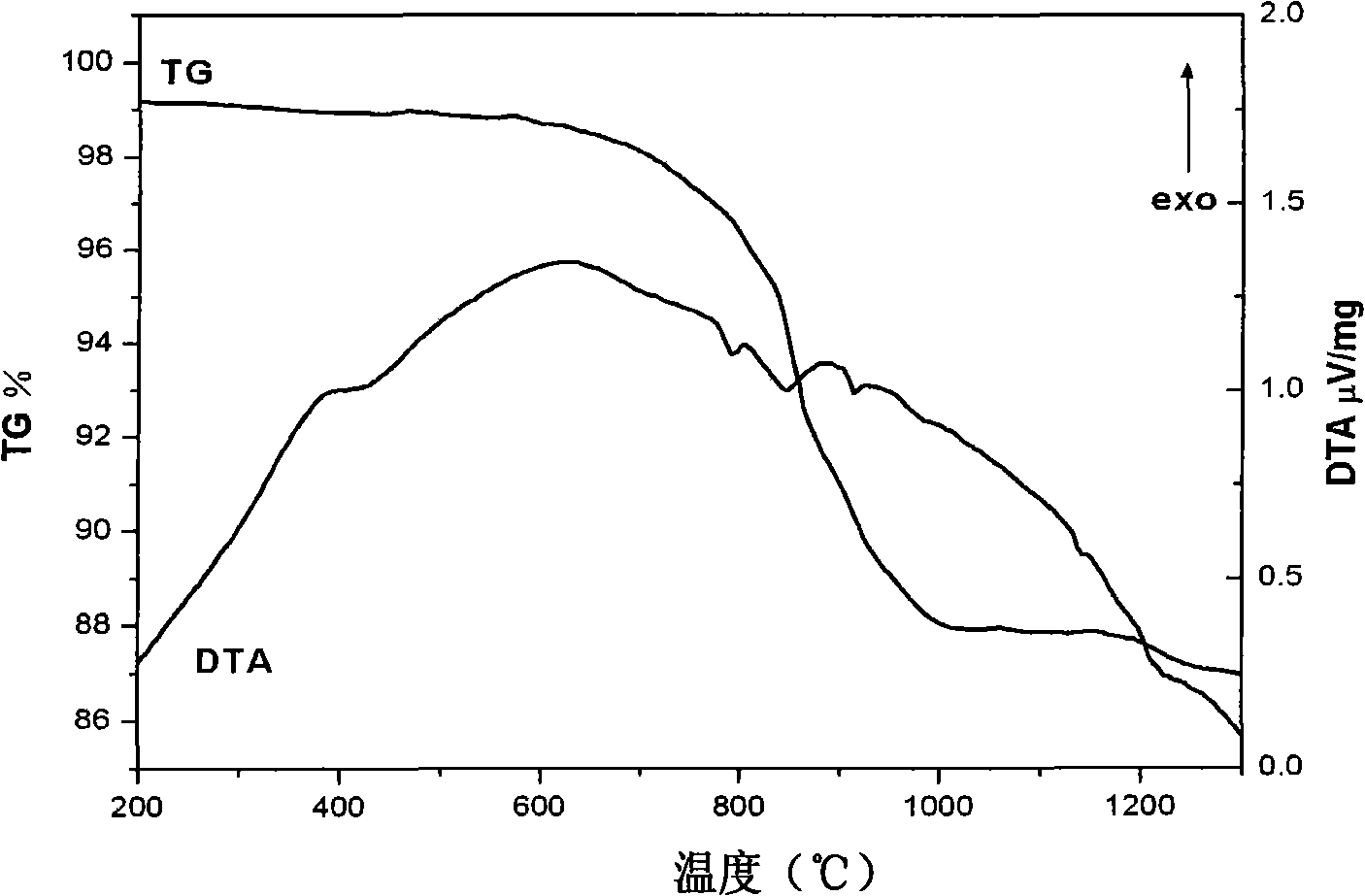

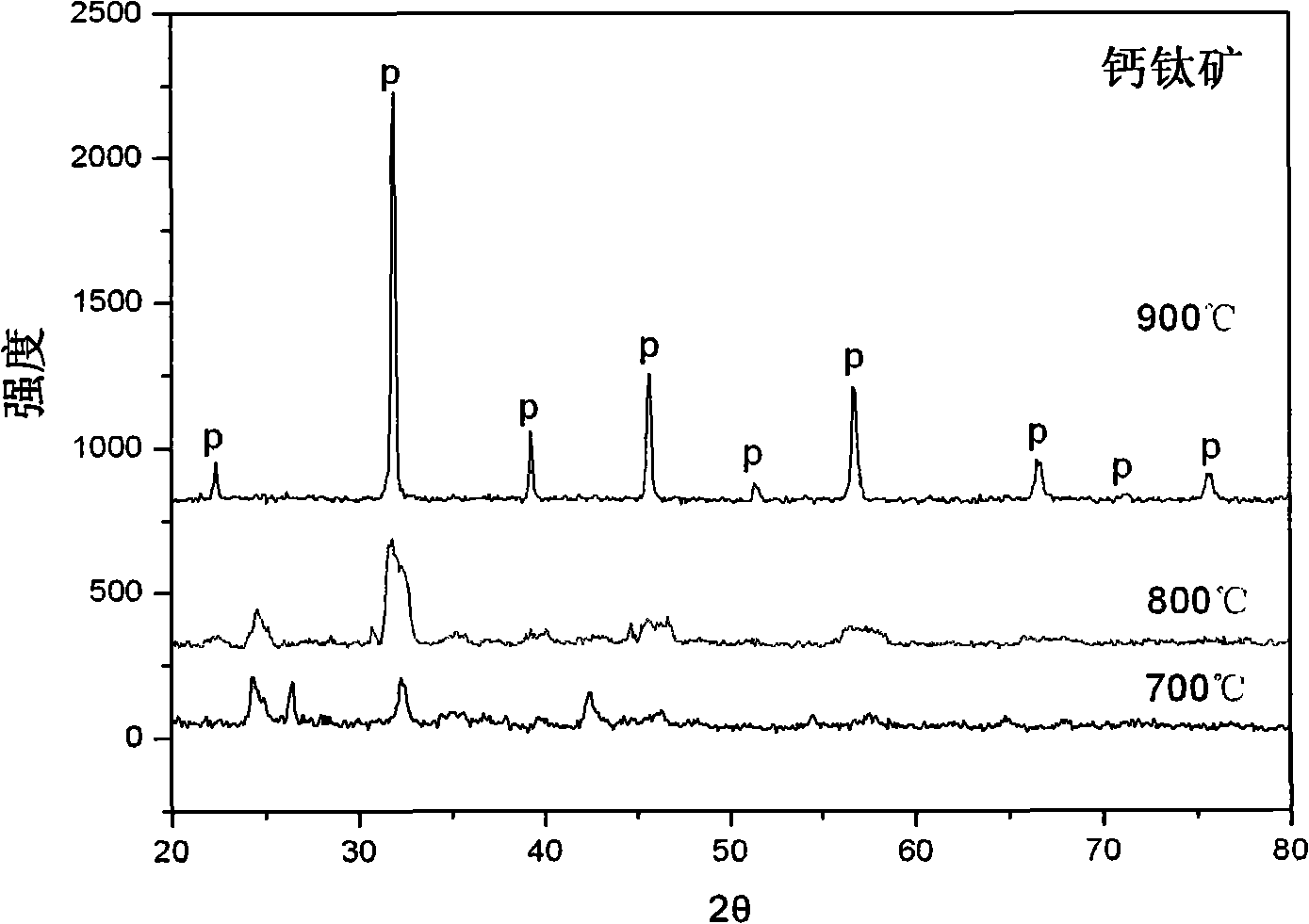

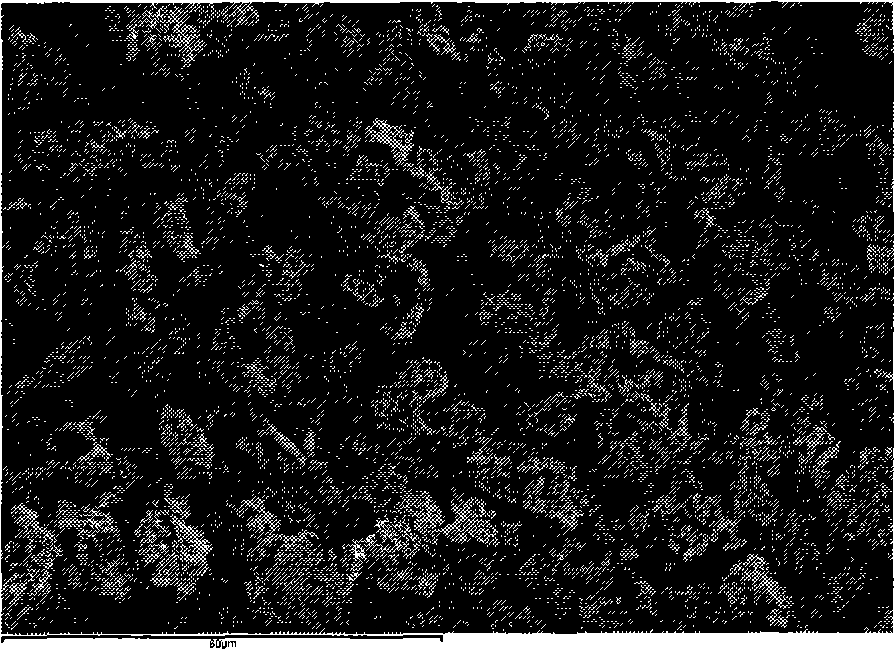

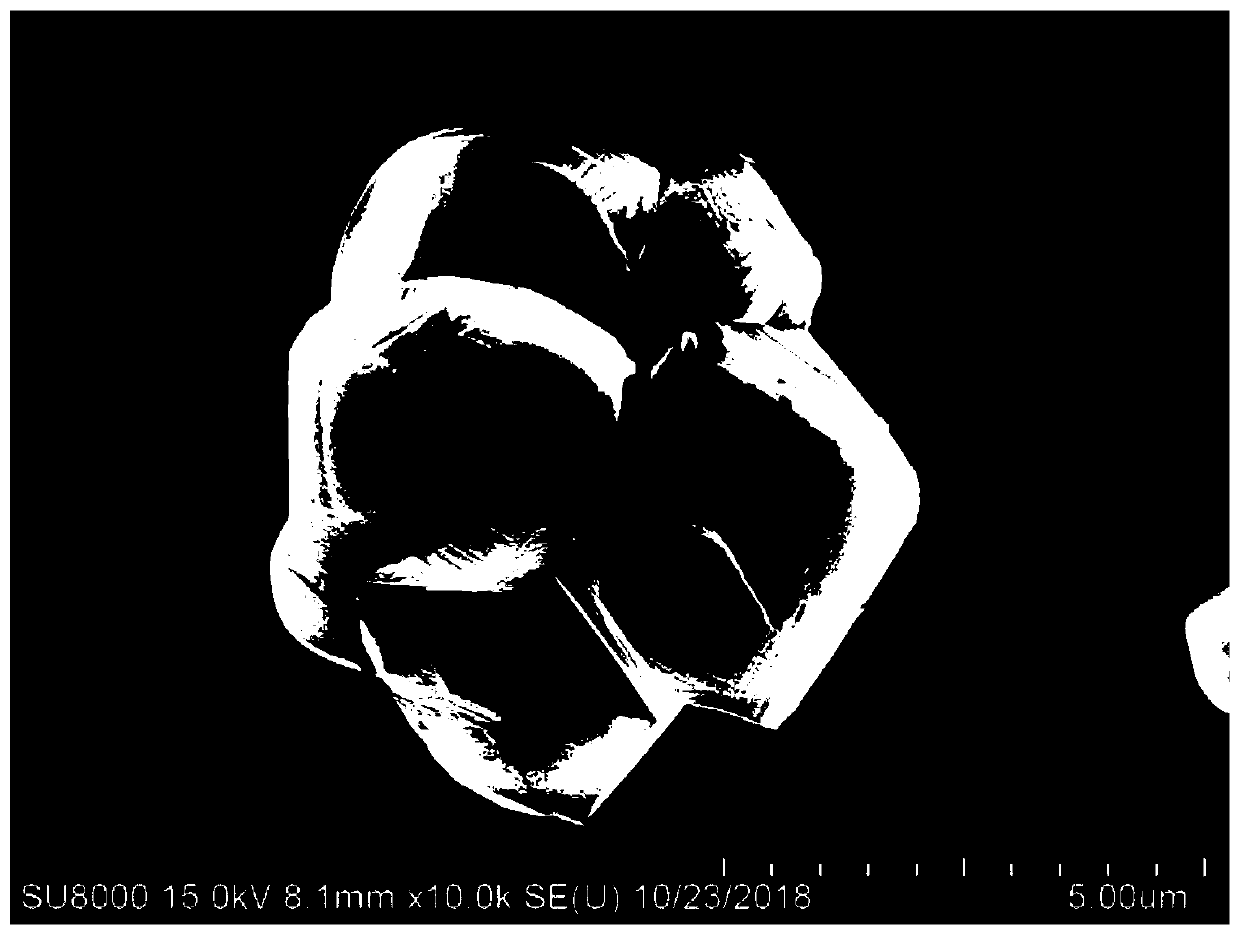

Preparation for high-performance solid oxidate electrolytic cell perovskite oxygen electrode powder

InactiveCN101275235ALarge specific surface areaSynthesis temperature is lowElectrolysis componentsWater vaporOxygen

The invention belongs to the high-temperature water vapor electrolyzing hydrogen preparation field, in particular to relating a preparation method of high performance solid oxide electrolytic cell oxygen electrode material. The method uses metal nitrate with the weight ratio of 5wt% to 30wt%, citric acid with the weight ratio of 1wt% to 10wt%, ammonium nitrate with the ratio percentage of 1wt% to 10wt%, ammonia with the weight ratio of 5wt% to 20wt% and deionized water with the weight ratio of 50wt% to 80wt% as raw material, and adopts a low-temperature self-propagating method to effectively prepare the powder. Firstly a plurality of metal nitrate solutions needed by the special oxygen electrode material are demarcated and prepared according to stoichiometric ratio, and after the metal nitrate solutions are mixed and stirred uniformly, incendiary agent citric acid and combustion improver ammonium nitrate are added, and ph value of the solutions is adjusted to the range of 7 to 9 by using the ammonia, and the mixed solution is evaporated till the solution changes into jelly, and then the jelly is heated continuously till the low-temperature self-propagating combustion is initiated to gain a first powder, then the first powder is processed heat treatment again to gain the aim powder. The method has the advantages of low operation temperature, high product ratio surface area, uniformed granularity, small average particle size, good sintering temperature activity, exact stoichiometric ratio and so on.

Owner:TSINGHUA UNIV

Preparation method of composite conductive agent coated monocrystal-like lithium-rich manganese-based positive electrode material

ActiveCN110364713AImprove cycle stabilityIncreased electron/ion mobilityCell electrodesCarbon blackCarbon nanotube

The invention discloses a preparation method of a composite conductive agent coated monocrystal-like lithium-rich manganese-based positive electrode material. The preparation method comprises the following steps: (1) regulating the Zeta potential of a multi-component composite conductive agent solution, so that the charge of the multi-component composite conductive agent solution is opposite to the charge of the monocrystal-like lithium-rich manganese-based positive electrode material solution, wherein the multi-component composite conductive agent solution is a mixed solution of graphene, carbon nanotubes and conductive carbon black; and (2) carrying out ultrasonic dispersion on the multi-component composite conductive agent solution, and then carrying out stirring dispersion, filtering,washing, drying and sintering on the multi-component composite conductive agent solution and the monocrystal-like lithium-rich manganese-based positive electrode material solution to obtain the composite conductive agent-coated monocrystal-like lithium-rich manganese-based positive electrode material. According to the invention, matrix materiasl and the graphene sheets, and the carbon nanotubes and the conductive carbon black are intertwined to form a 'point-line-surface' three-dimensional porous network structure, so that the capacity, the cycle performance and the rate capability of the material are remarkably improved.

Owner:HUNAN CHANGYUAN LICO CO LTD

Preparation method of trace Mo-doped lamellar lithium-enriched ternary positive electrode material

InactiveCN104900857AHigh crystallinityExcellent electrochemical performanceCell electrodesTube furnaceNickel salt

The invention relates to a preparation method of a trace Mo-doped lamellar lithium-enriched ternary positive electrode material. The molecular formula of the prepared ternary positive electrode material is Li1.2(Mn0.54Ni0.13Co0.13)(1-x)MoxO2 (x is more than 0 and smaller than 1). The adopted preparation method is an organic co-precipitation method and comprises the steps of stirring an organic precipitator in a water bath with constant temperature, and dissolving the organic precipitator into an organic solvent so as to obtain a solution A; then dissolving soluble cobalt salt, nickel salt, manganese salt, molybdenum salt and lithium salt into deionized water to obtain a solution B; after thorough dissolution, dropwise adding the solution B into the solution A at a constant speed, reacting and drying, increasing the temperature of the obtained solid powder in a high-temperature tube furnace system, and calcining so as to obtain the trace Mo-doped lamellar lithium-enriched ternary positive electrode material. The material has uniform particles and regular polygonal morphology feature, and has relatively good electrochemical performance, the preparation process is relatively simple, and the ternary positive electrode material is suitable for industrialized scale production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

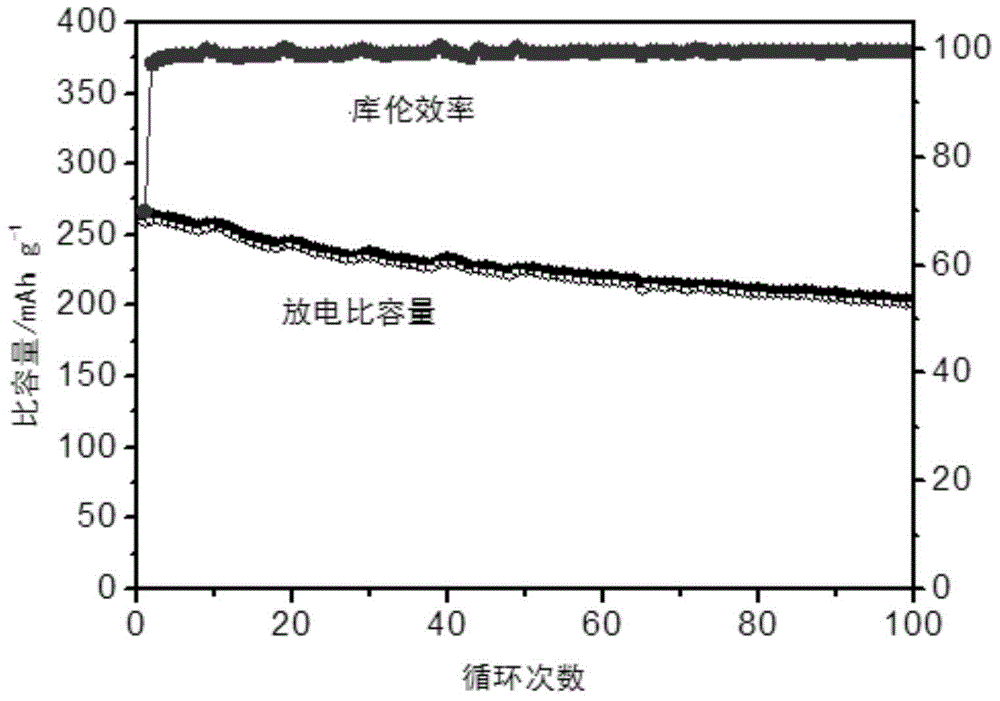

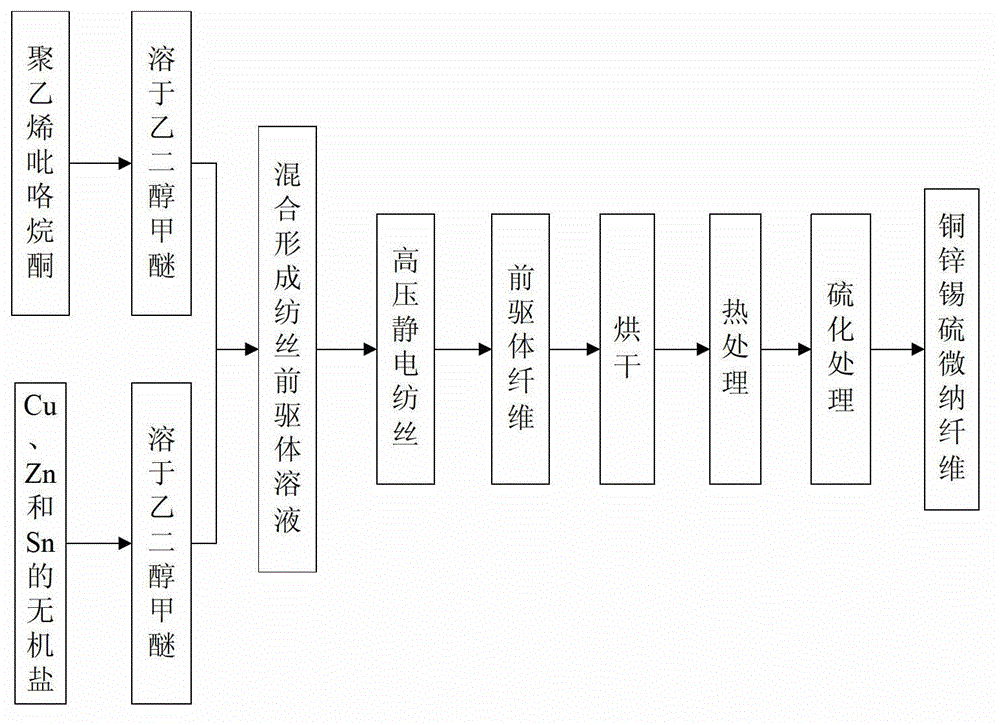

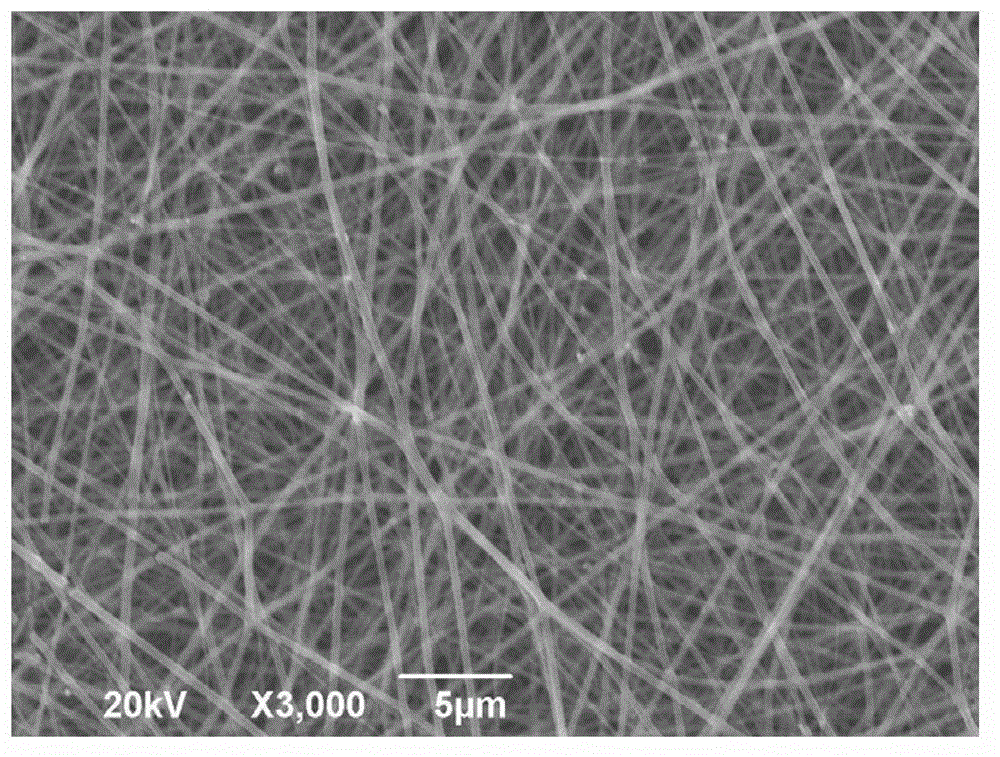

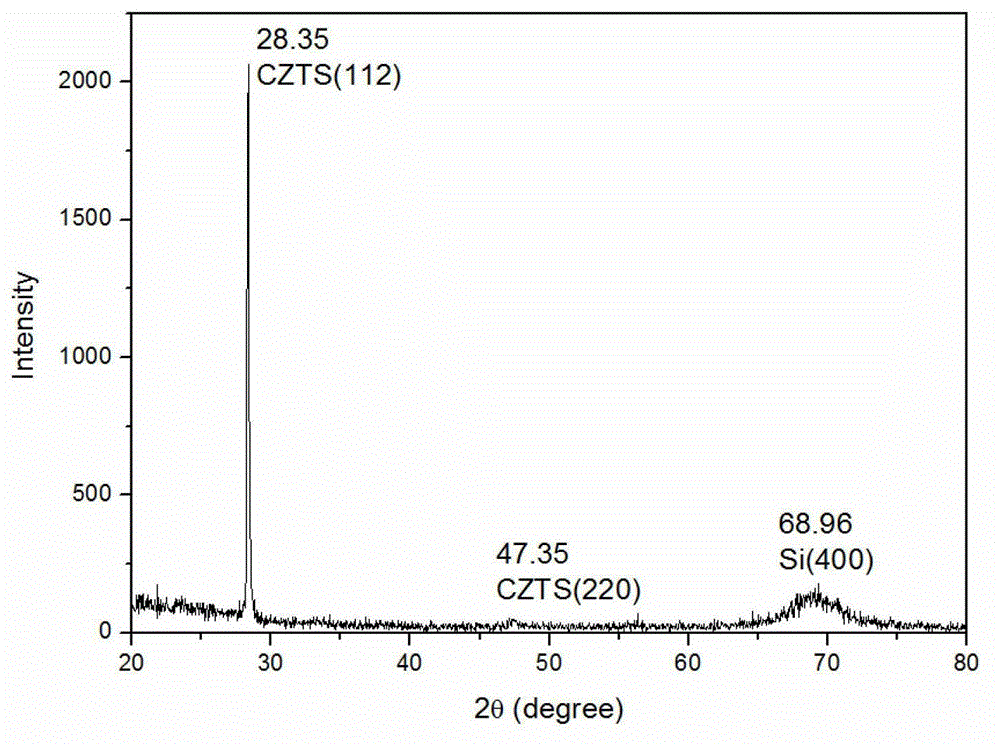

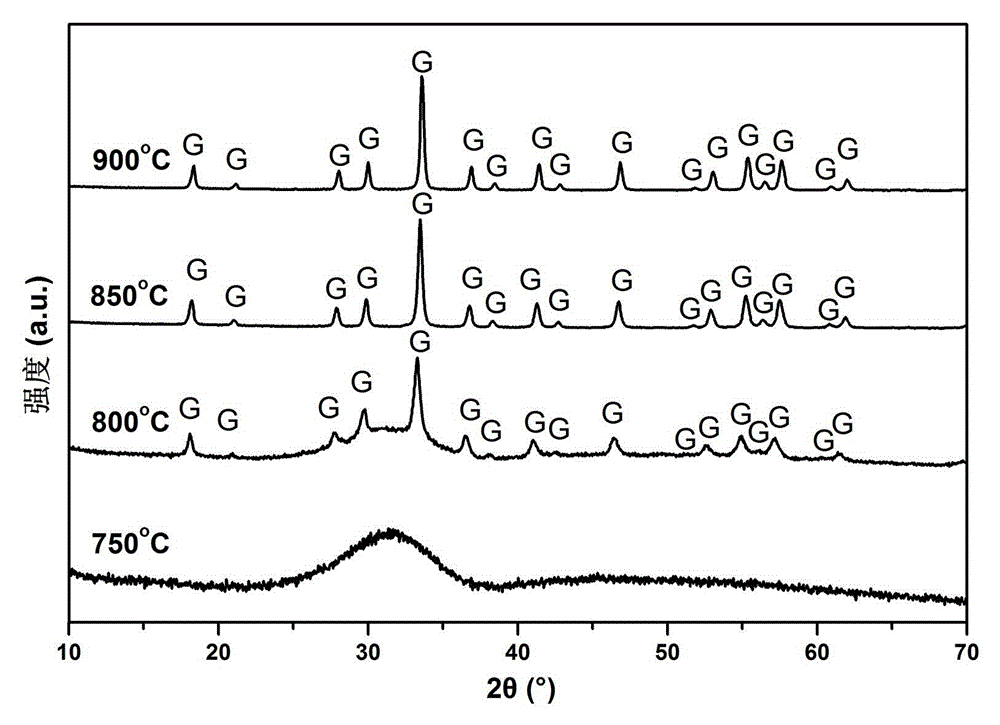

Copper-zinc-tin-sulfur micro/nano-fiber material and method for preparing same

InactiveCN102978746AStoichiometric ratio is accurateGood crystal formInorganic material artificial filamentsFilament/thread formingSingle phaseInorganic salts

A copper-zinc-tin-sulfur micro / nano-fiber material and a method for preparing the copper-zinc-tin-sulfur micro / nano-fiber material belong to the technical field of the electronic functional material. The micro / nano-fiber material contains four elements Cu, Zn, Sn and S, has the diameter ranging from 300 to 800 nanometers, and has a zinc stannite crystal structure, wherein the mol ratio of the four elements of Cu: Zn: Sn: S is 2: 1: 1: 4. During preparation, inorganic salts of Cu, Zn and Sn and PVP (Polyvinyl Pyrrolidone) are used as the raw materials, firstly, spinning precursor solution, then spraying the spinning precursor solution to a substrate to form precursor fibers through a high-voltage electrospinning process, and finally, obtaining the targe product through certain thermal treatment and vulcanization treatment. The method provided by the invention is simple in preparation equipment, low in cost, simple and convenient to operate, and the process is easy to control; and the target product prepared has accurate stoichiometric ratio, excellent crystal habit and single phase structure, thereby having potential application in the field of efficient solar photovoltaic cells.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

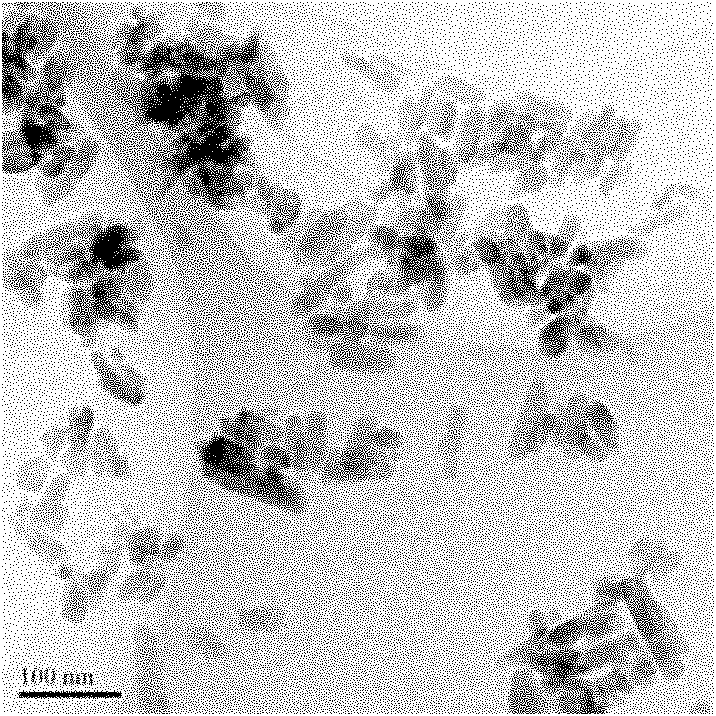

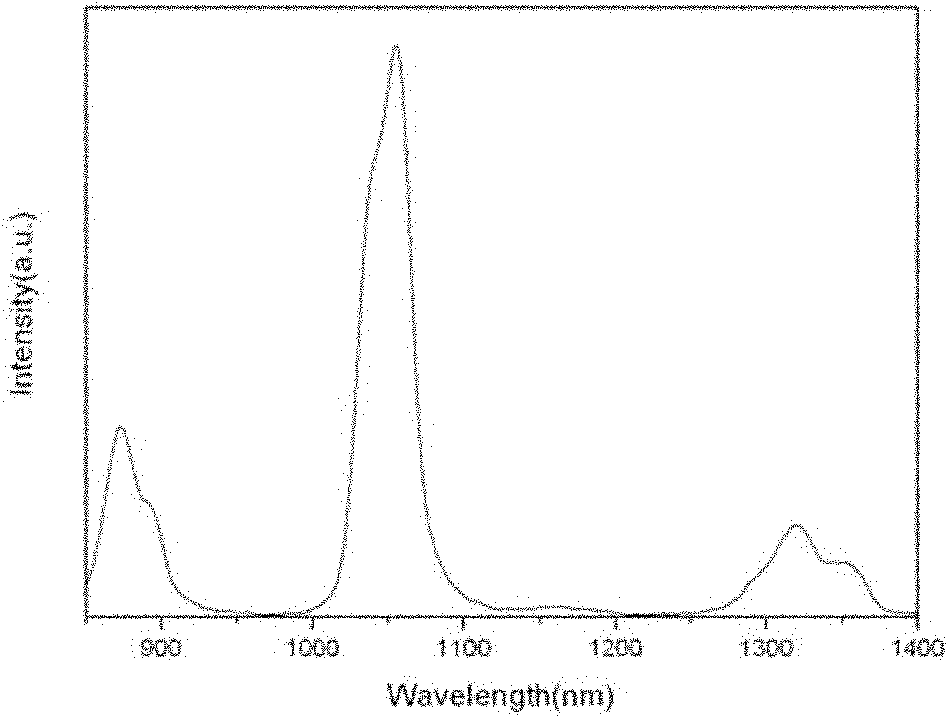

Preparation method of rare-earth-doped strontium fluorophosphate nanoparticles

InactiveCN102127434AStoichiometric ratio is accurateHigh fluorescence intensityNanotechnologyActive medium materialPhosphateFluorescence

The invention belongs to the technical field of optical materials, and particularly discloses a preparation method of rare-earth-doped strontium fluorophosphate nanoparticles. The preparation method comprises the following steps of: firstly, mixing a rare earth compound with a strontium salt aqueous solution and uniformly stirring; secondly, adding an aqueous solution of monohydric phosphate and fluoride, adjusting the pH value of the solution to 3 and reacting for 1 hour, thirdly, adjusting the pH value of the solution to 7, reacting for 1 hour and circulating 5-10 times; reacting for multiple hours in a polytetrafluoroethylene-lined stainless steel reaction kettle by undergoing a normal temperature reaction or adopting a hydrothermal synthesis method at the controlled temperature of between 100 DEG C and 200 DEG C; and lastly, separating, washing, and drying in vacuum to obtain the rare-earth-doped strontium fluorophosphate nanoparticles. The method has the characteristics of simple preparation processes, practicability, low cost, wide applicability and application prospect and the like, and meanwhile, is beneficial to overcoming of the defect of high content of hydroxyl on the surface of a nanometer material in a preparing process and prolonging of the fluorescent lifetime of a rare-earth-doped nanometer material.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

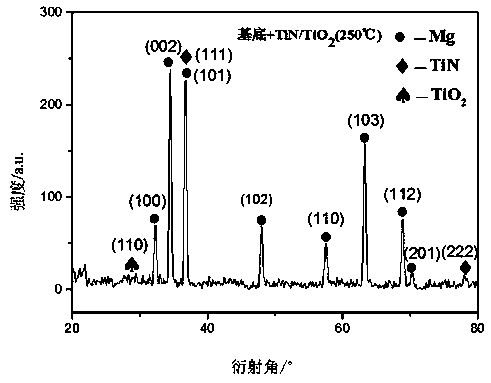

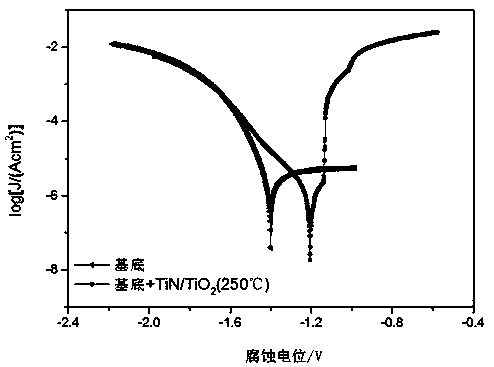

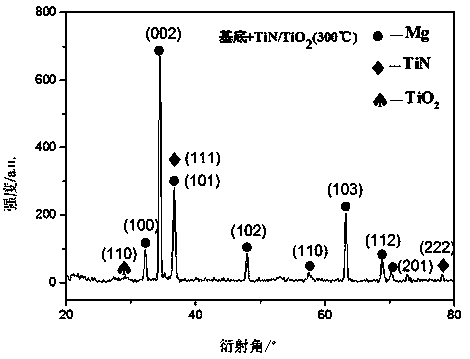

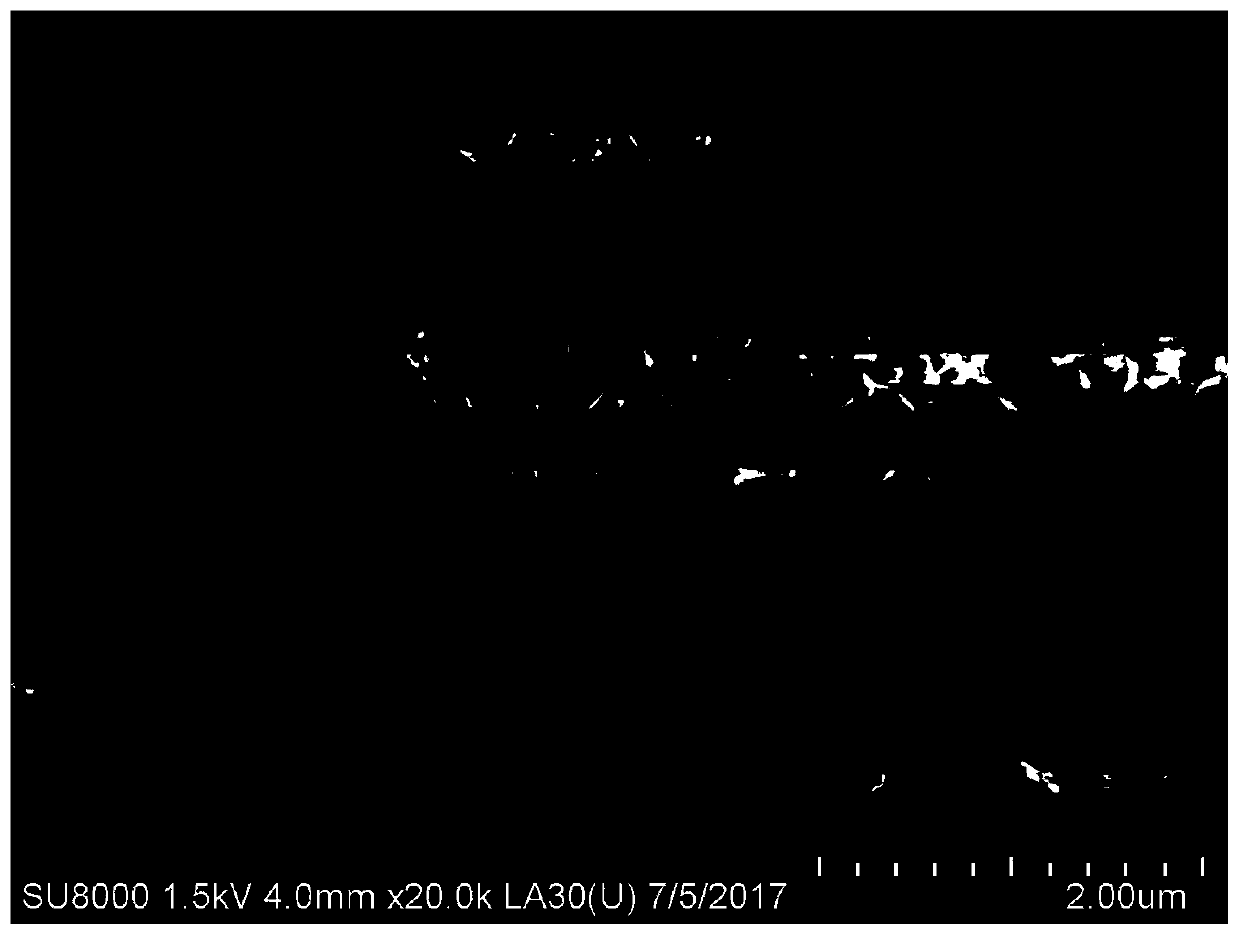

Preparation method of magnesium alloy surface multistage nano coating controllable and adjustable in corrosion resistance

ActiveCN107723680ACorrosion resistance can be adjustedStoichiometric ratio is accurateNanotechnologyTissue regenerationHydrogenSingle stage

The invention relates to a preparation method of a magnesium alloy surface multistage nano coating controllable and adjustable in corrosion resistance. The preparation method comprises the following steps: removing hydrogen from the magnesium alloy, preparing a PE-ALD working chamber, preparing the multistage nano coating and reducing the PE-ALD working chamber, wherein the multistage nano coatingis formed from single stage nano coating by one or more times of overlaying; the overlaying times N is the number of stages; and the single stage nano coating is TiNx (X=0.5-2.0) / TiO2. According to the preparation method of the magnesium alloy surface multistage nano coating controllable and adjustable in corrosion resistance, the prepared coating has the advantages as follows: the coating with an accurate stoichiometric ratio, good coverage performance and precise thickness can be formed on arbitrarily shaped surfaces (two-dimensional or three-dimension), the corrosions resistance of the coating is controllable and adjustable, the coating materials are non-toxic and harmless to the human body, and therefore the coating can not only be used for corrosion resistance control and adjustmentof magnesium and the magnesium alloy, can but also be used for surface corrosion resistance control and adjustment of other orthopedic implant active metal materials.

Owner:NANCHANG UNIV

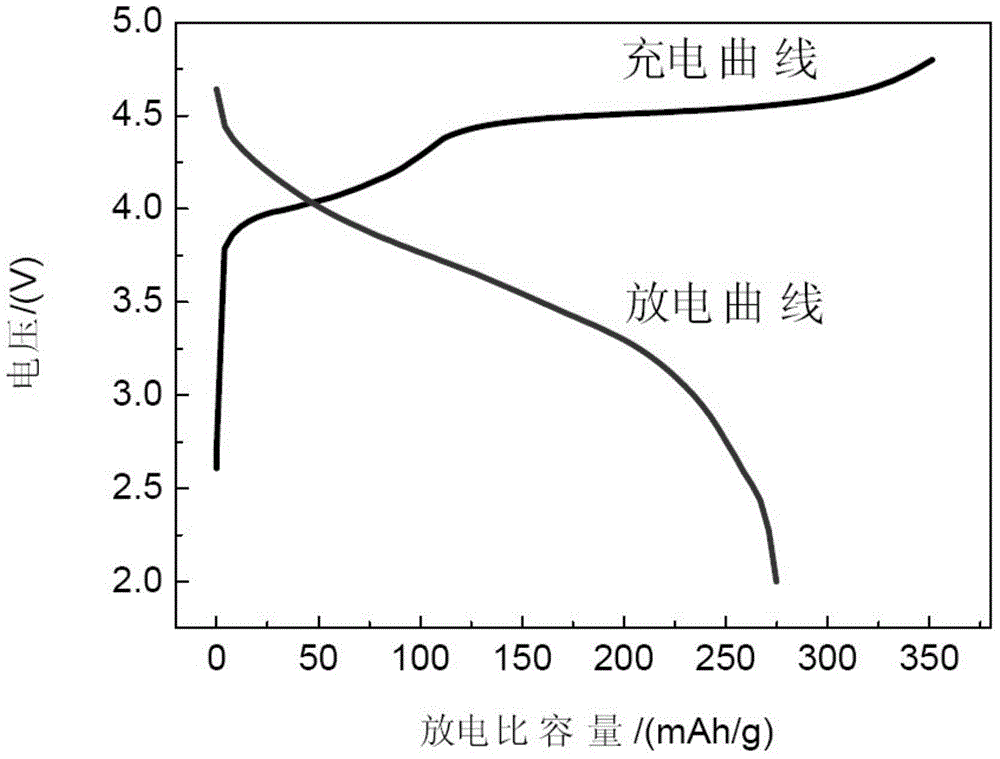

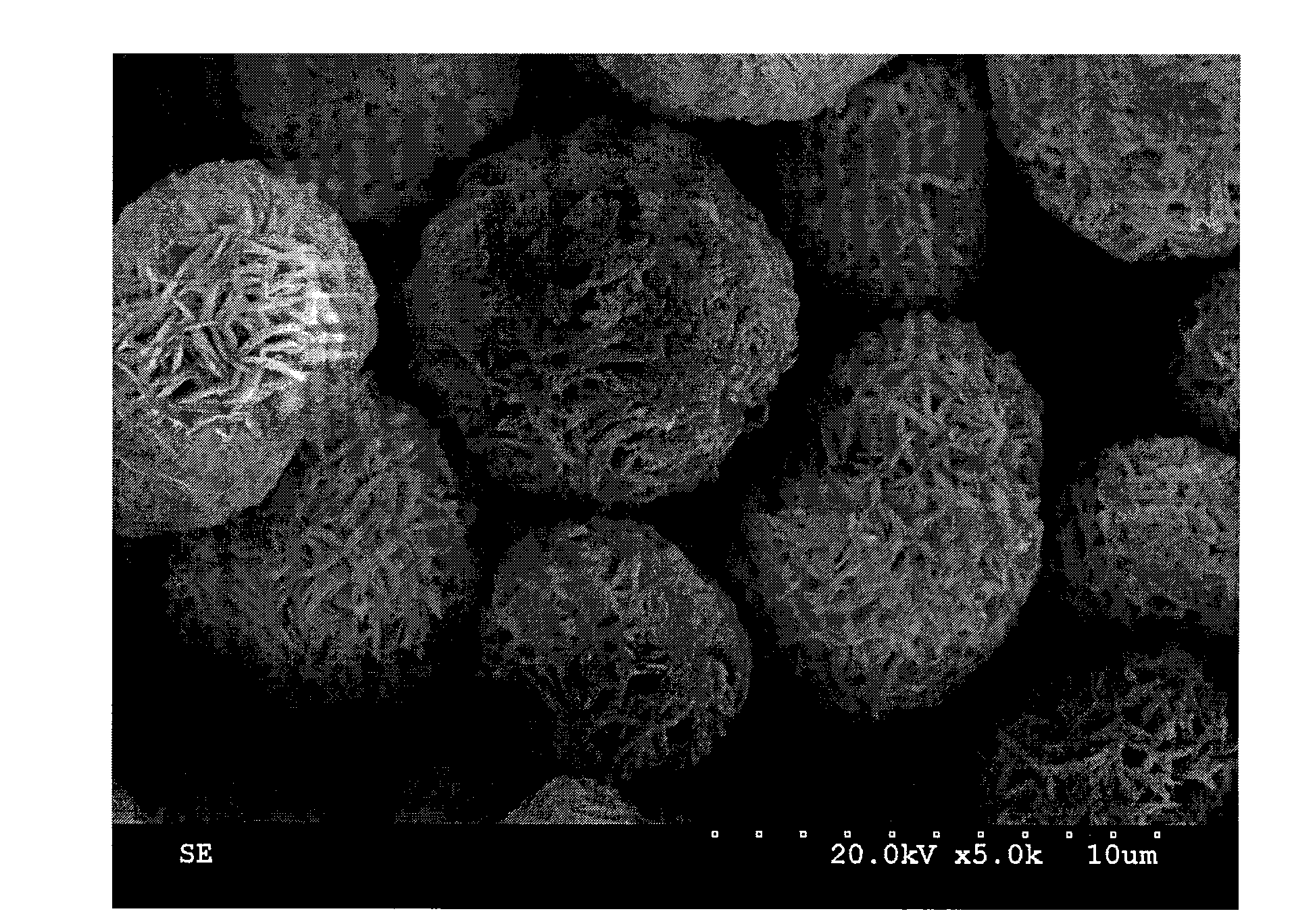

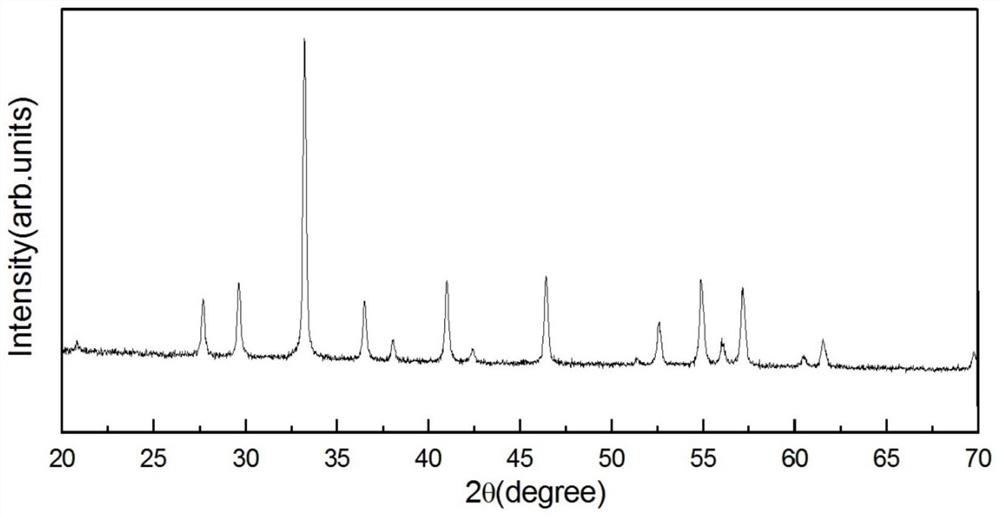

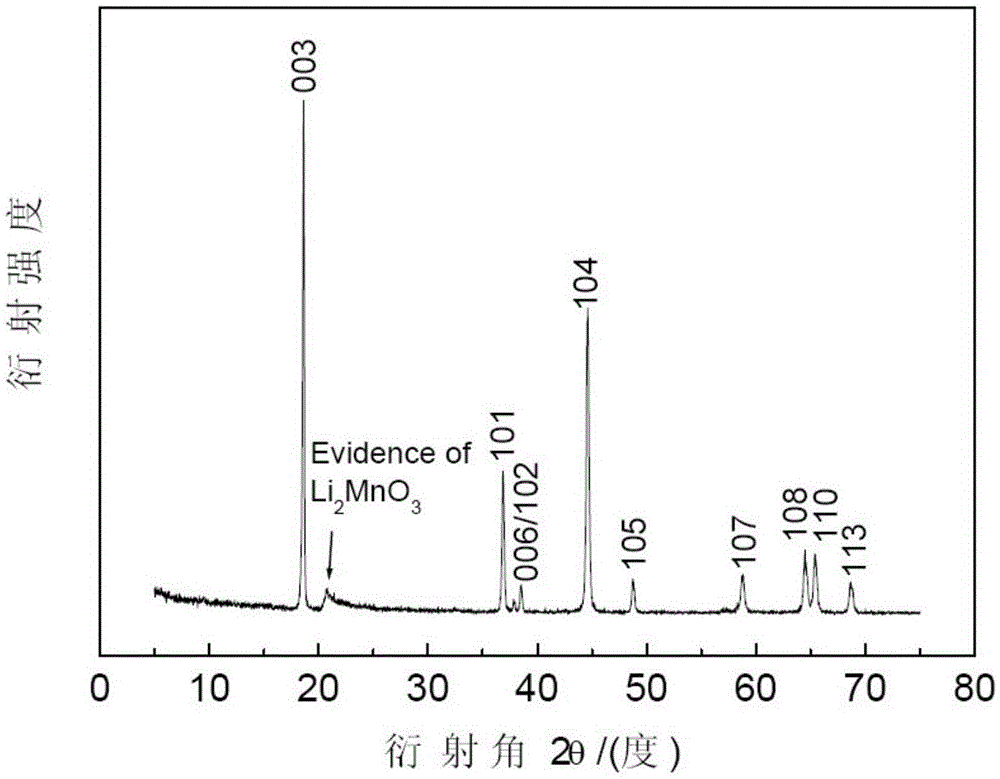

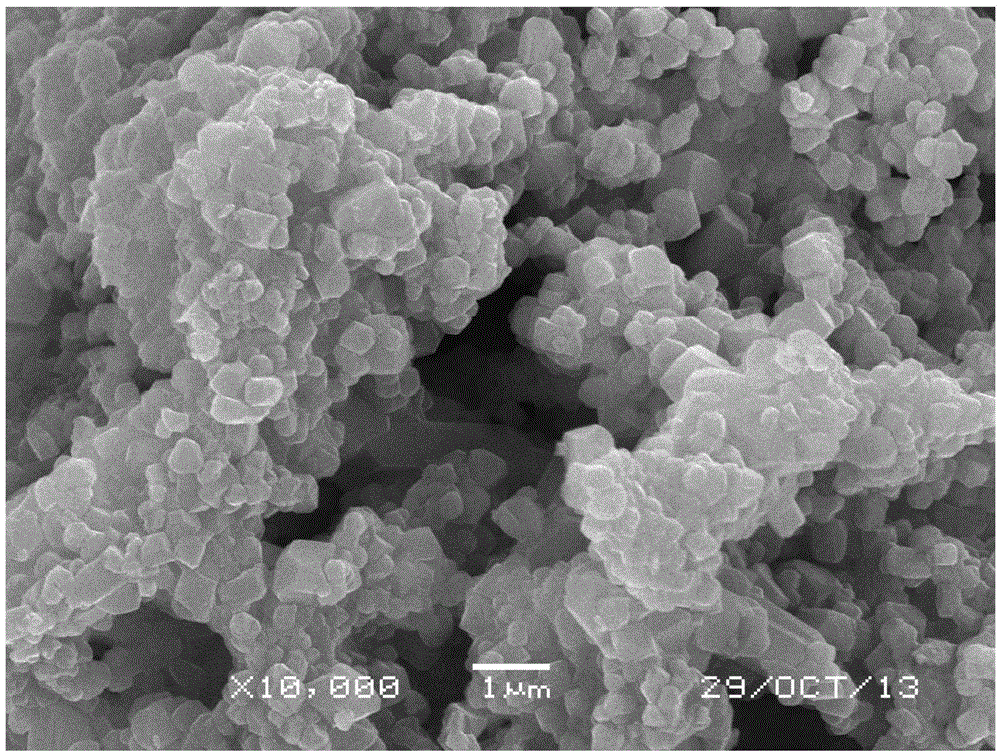

Lithium rich manganese based layered lithium battery cathode material and preparation method thereof

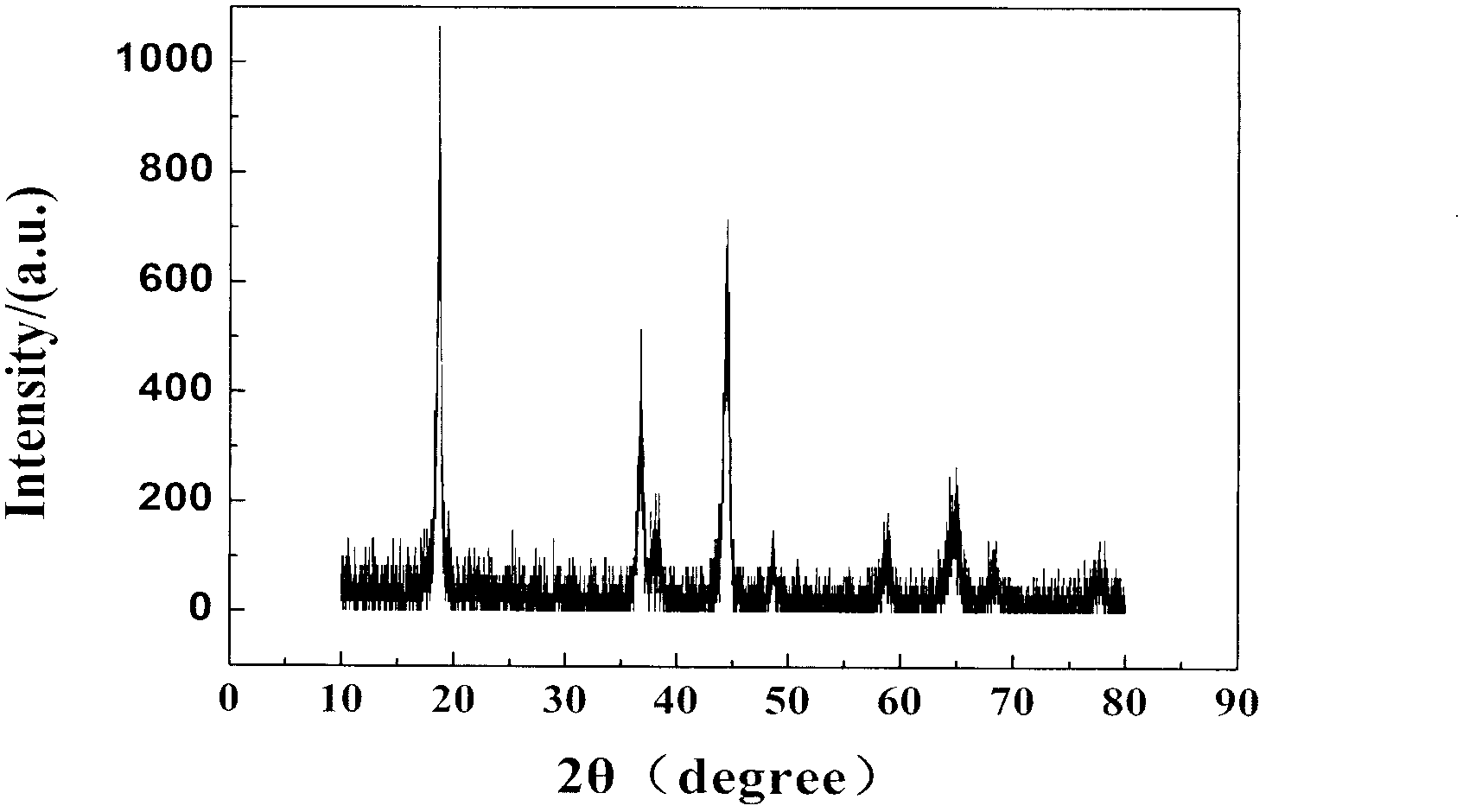

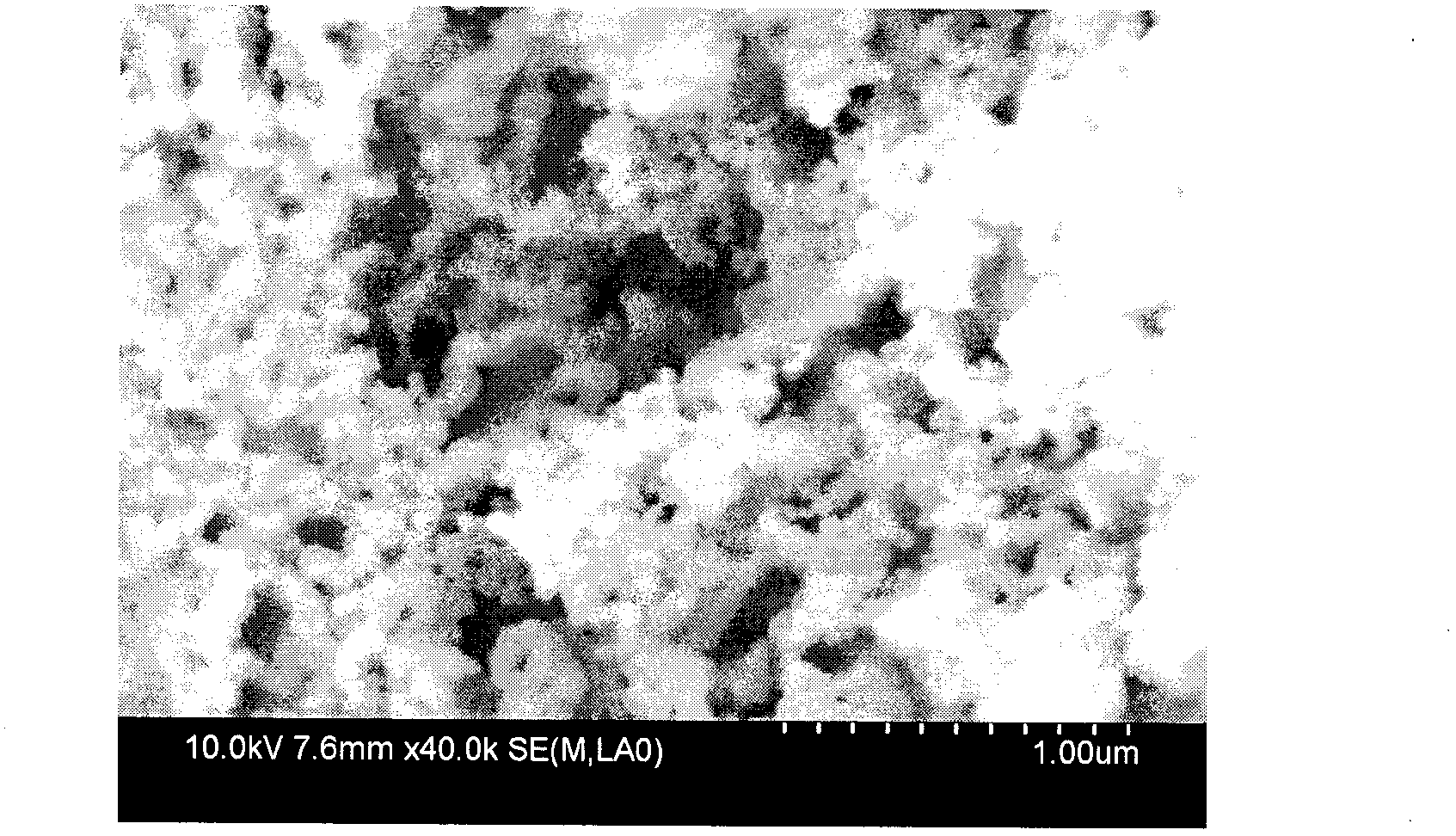

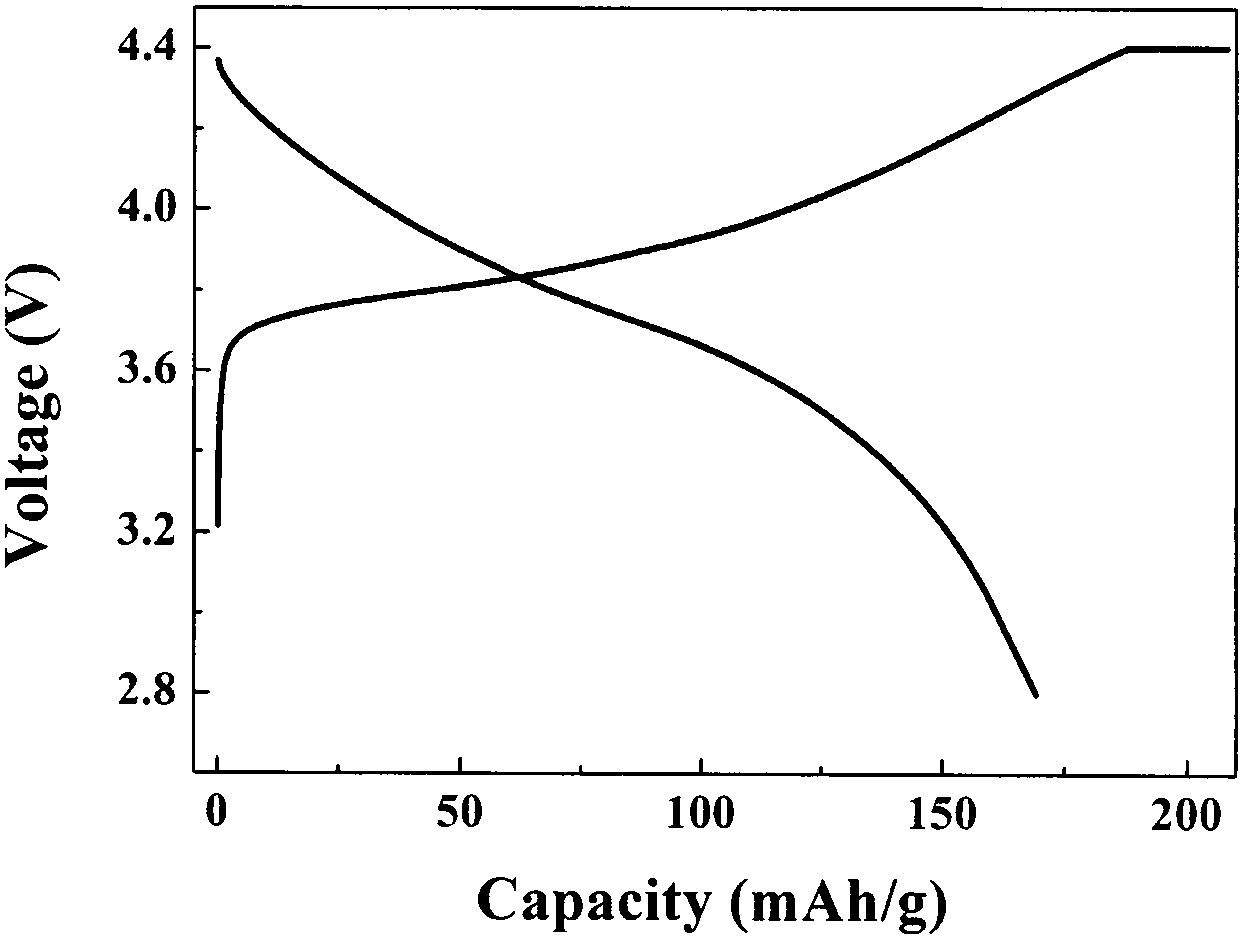

ActiveCN104134794AImprove performanceStoichiometrically accurateCell electrodesSecondary cellsManganeseCobalt

The invention relates to a lithium rich manganese based layered lithium battery cathode material, the formula is Li[Li<1-x-y-z>NixCoyMn2]O2, wherein x is more than zero and less than 0.5, y is more than zero and less than 0.5, z is more than 0.1 and less than 0.7, (1-x-y-z) is more than zero and less than 0.5, D50 is 10 to 20 micrometers, the specific surface area is 1-4 square meters per gram, and the discharging capacity reaches 200 to 300mAh per gram at charging / discharging current density of 12.5mA per gram. The preparation method comprises the following steps of: firstly, preparing a lithium source, a nickel source, a cobalt source and a manganese source; secondly, mixing original materials according to proportion to prepare a mixed salt solution; thirdly, adding polyacrylic acid and citric acid and uniformly mixing; fourthly, heating to form a stable sol, evaporating water to form gel, and drying the gel to form xerogel; and finally, sintering to obtain the lithium rich manganese based layered lithium battery cathode material. The cathode material disclosed by the invention has the advantages of high specific discharging capacity, good safety, low production cost and high performance cost rate.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

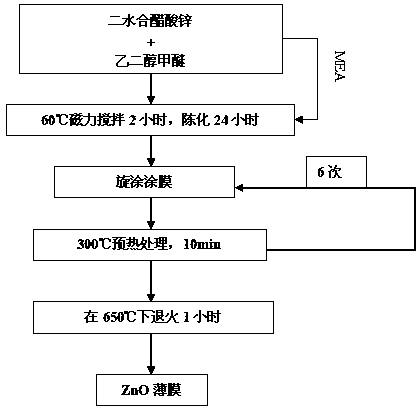

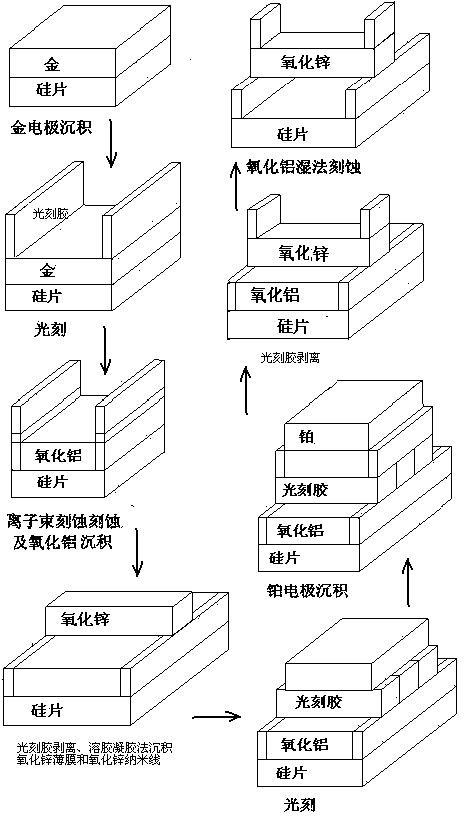

Large area manufacturing method for zinc oxide nano micro generators

ActiveCN104037320ASynthesis temperature is lowOptimizing Process ParametersPiezoelectric/electrostrictive device manufacture/assemblyNanogeneratorEvaporation

A large area manufacturing method for zinc oxide nano micro generators comprises depositing a gold electrode on a substrate; coating photoresist in a spinning mode to form into a photoresist nano micro wire structure in the Y direction; etching gold electrode materials which are free of photoresist protection through ion beam etching, depositing hard mask material, namely aluminum oxide and etching aluminum oxide materials on the lateral wall to enable the photoresist to be exposed; stripping the photoresist and aluminum oxide on the photoresist through acetone and depositing a zinc oxide film through a sol-gel method; performing photoresist stripping through the ion beam etching and the acetone to form into zinc oxide nano wires; coating photoresist in a spinning mode and exposing the zinc oxide nano wires at two ends after exposure and forming; depositing a platinum electrode through electron beam evaporation, stripping the photoresist through the acetone and etching the aluminum oxide to form into a piezoelectric nano generator structure; exposing the piezoelectric nano generator to a vibration source to generate piezoelectric conversion and nano micro piezoelectric power generation. The large area manufacturing method for the zinc oxide nano micro generators achieves large area controllable production and manufacture of the low cost high mechanical energy to electric energy conversion nano generators.

Owner:NANJING YIDEGUAN ELECTRONICS TECH +1

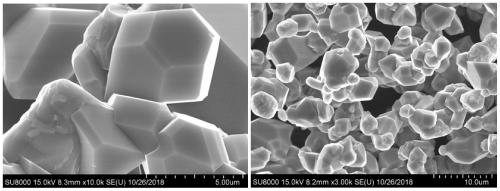

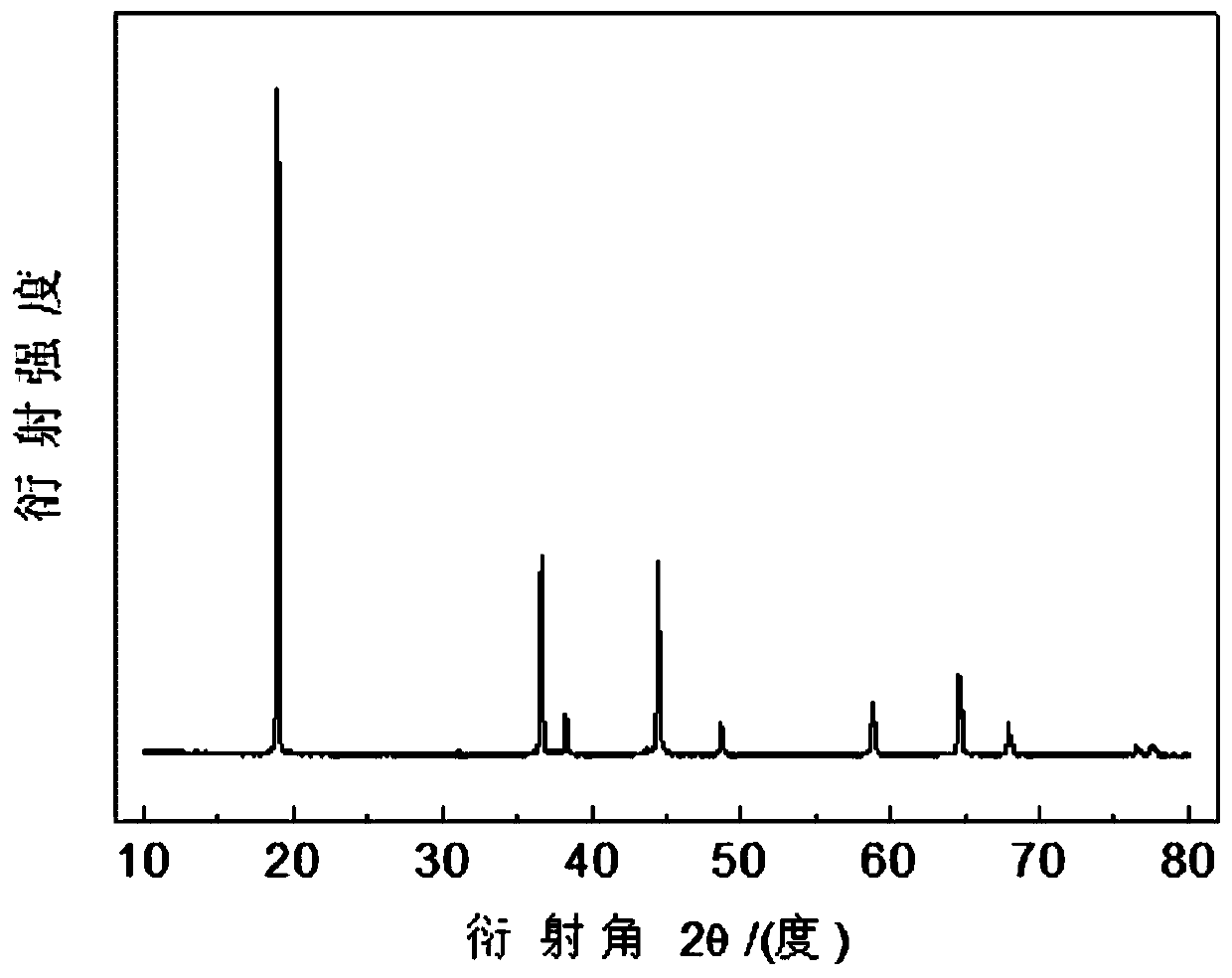

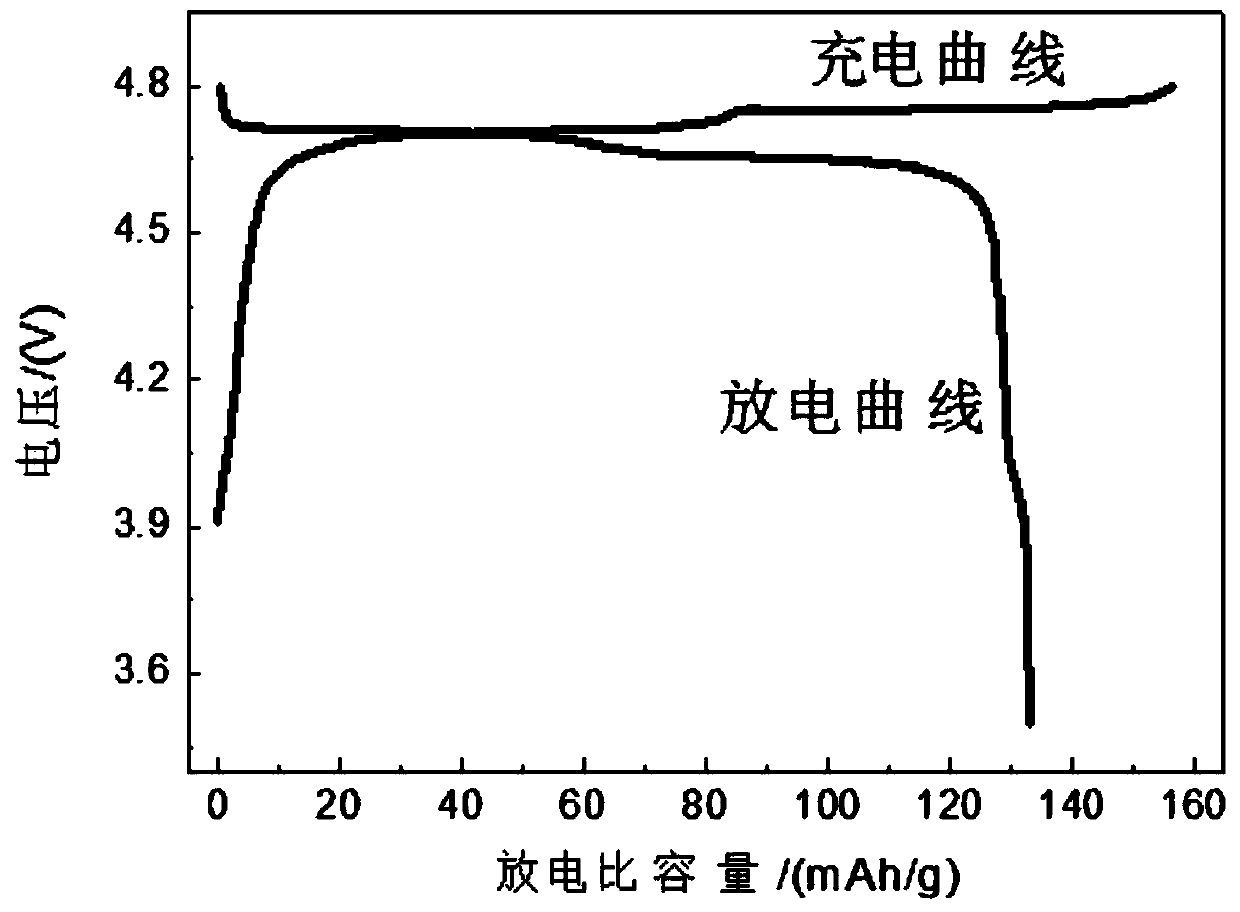

Preparation method of sharpened monocrystal high-voltage spinel lithium nickel manganese oxide cathode material

ActiveCN110438557AIncrease profitSimple and efficient operationPolycrystalline material growthCell electrodesManganese oxideNickel

The invention discloses a preparation method of a sharpened monocrystal high-voltage spinel lithium nickel manganese oxide cathode material. The preparation method comprises the steps that (1) a lithium source, a nickel source, a manganese source, dopants, a fluxing agent and organic acid are mixed evenly; (2) a heating furnace is heated up to 80-300 DEG C and subjected to heat preservation, thena mixed material obtained in the step (1) is put into the heating furnace to be subjected to heat preservation for 0.5-30 h at the temperature, and a low-temperature eutectic mixture is formed; and (3) the low-temperature eutectic mixture obtained in the step (2) is placed into the heating furnace at the preset temperature of 300-700 DEG C to be heated and ignited, then sintered and naturally cooled with the furnace, and thus the sharpened monocrystal high-voltage spinel lithium nickel manganese oxide cathode material is obtained. The preparation method is simple in process, high in efficiencyand low in equipment requirement, the raw material mixing level of a liquid phase combustion method can be reached, raw material splashing in the liquid phase combustion method ignition process is further avoided, and large-scale production is easy to realize.

Owner:HUNAN CHANGYUAN LICO CO LTD

Preparation method of titanium nitride/titanium dioxide nano-composite anti-corrosion coating

InactiveCN108823552AStoichiometric ratio is accurateIncrease coverageChemical vapor deposition coatingTitanium nitrideAtomic layer epitaxy

The invention discloses a preparation method of a titanium nitride / titanium dioxide nano-composite anti-corrosion coating. The preparation method comprises the following steps of (1) ALD working cavity preparing; (2) titanium nitride / titanium dioxide nano-composite anti-corrosion coating preparing, specifically, a titanium nitride film is prepared, part of titanium nitride is converted into titanium dioxide through self-oxidation, and finally the titanium nitride / titanium dioxide nano-composite coating is obtained; and (3) ALD working cavity reducing. According to the titanium nitride / titaniumdioxide nano-composite anti-corrosion coating prepared through an atomic layer epitaxy technology, a nano coating with the precise stoichiometric ratio, the good covering property and the precise film thickness can be formed on the surfaces of any shapes (two-dimensional or three-dimensional), and the repeatable stability of the technology is good. Coating materials are poisonless and harmless toa human body and can improve the corrosion resistance of metals, especially active metals such as magnesium and zinc.

Owner:NANCHANG UNIV

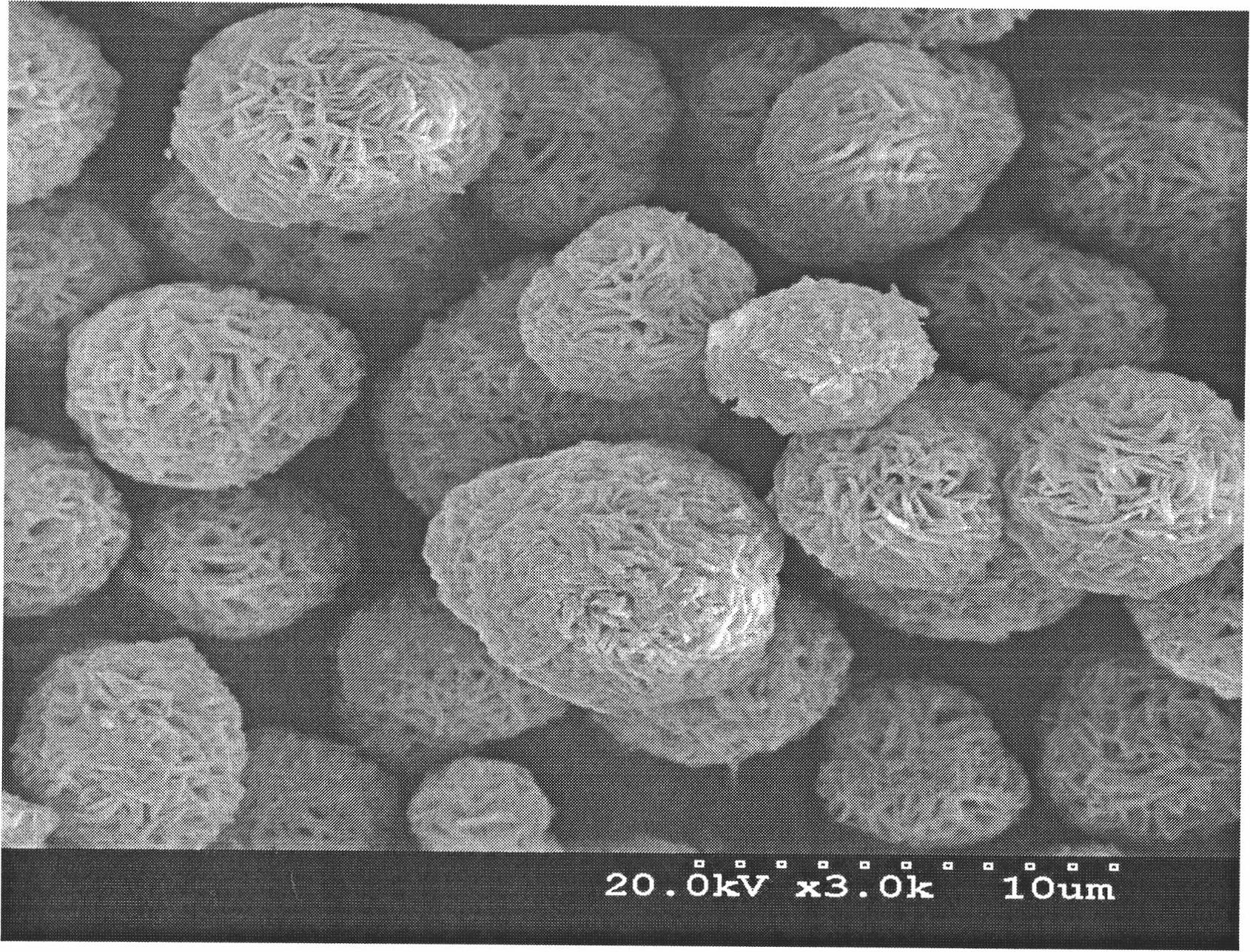

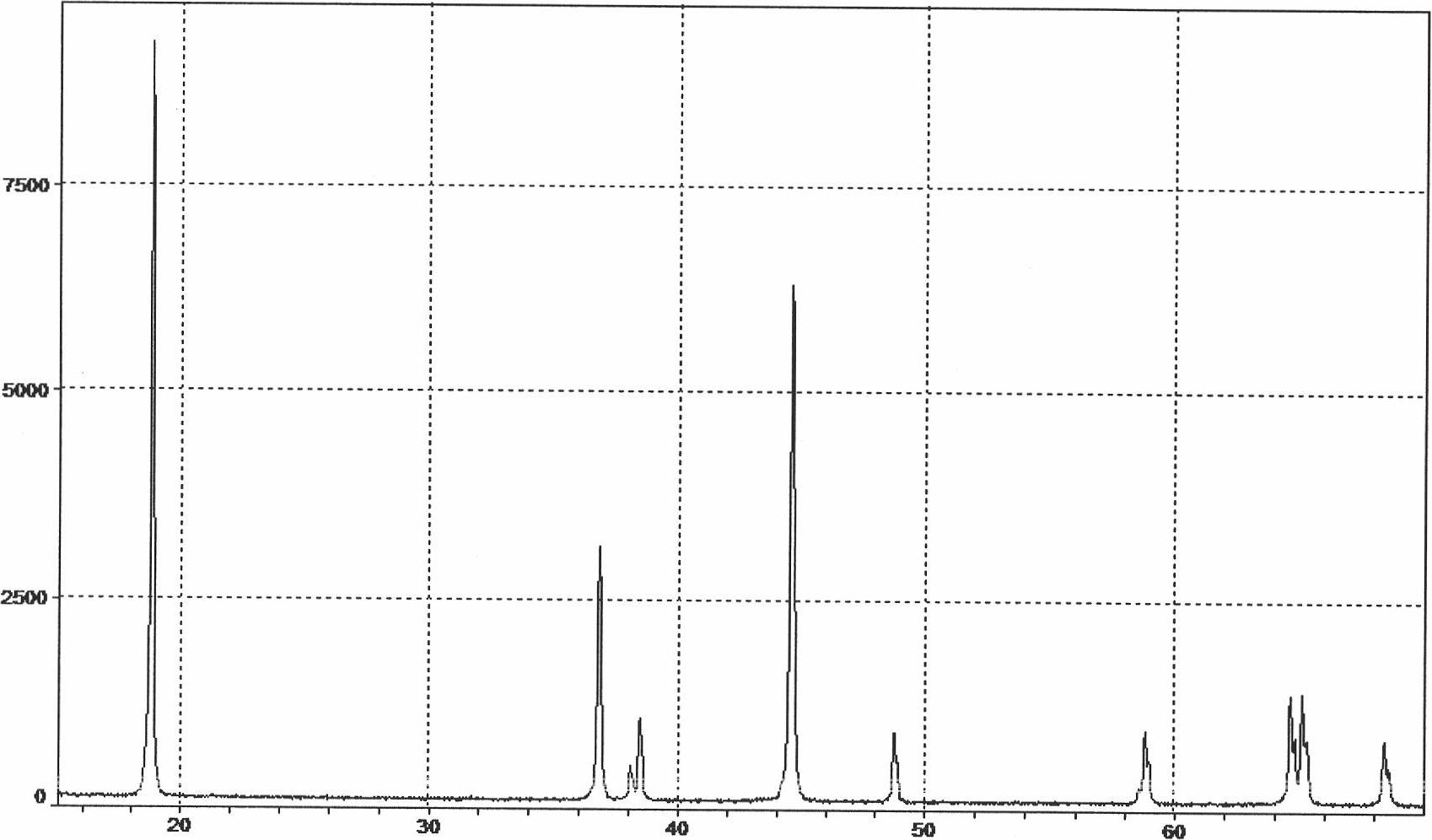

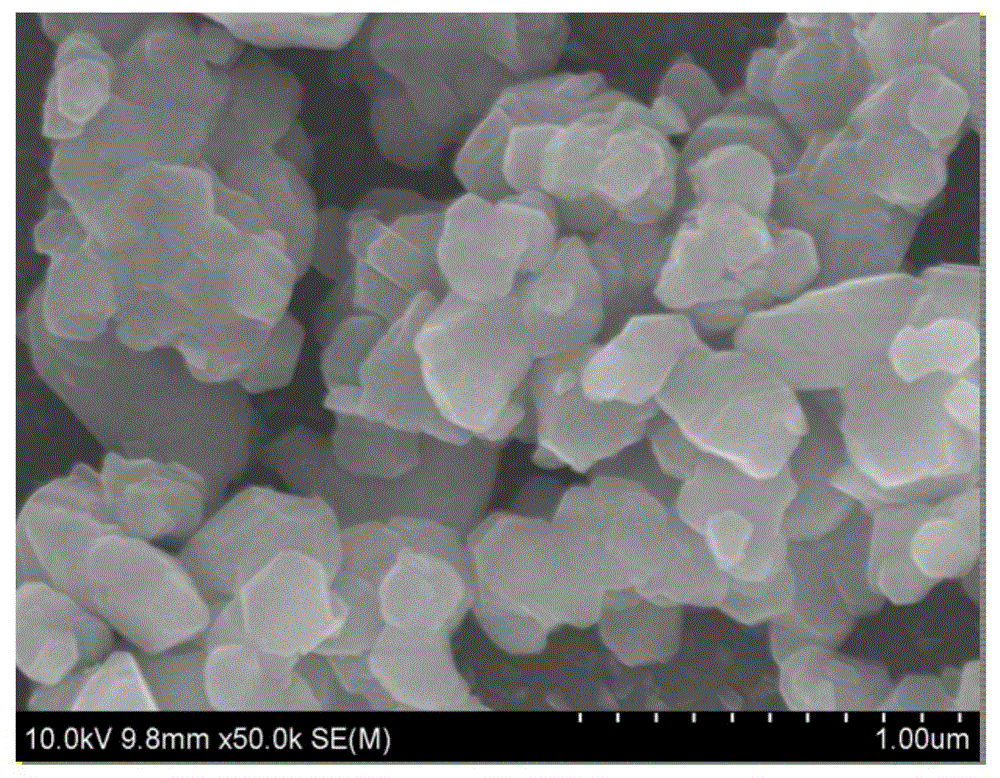

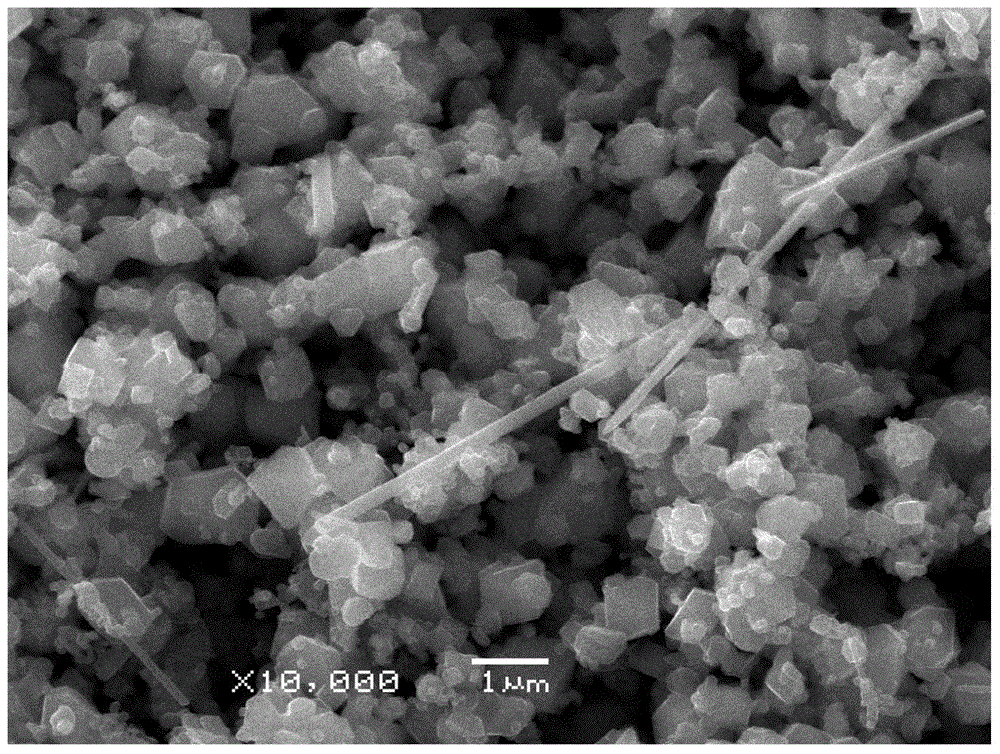

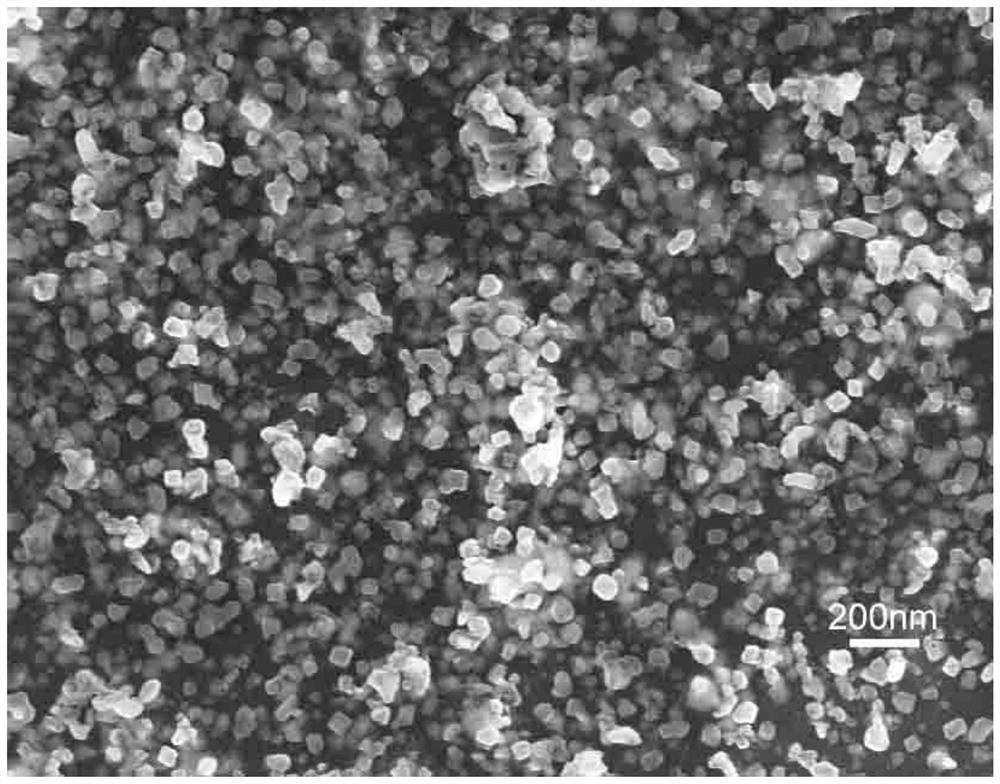

A kind of nickel-aluminum co-doped trimanganese tetraoxide and preparation method thereof

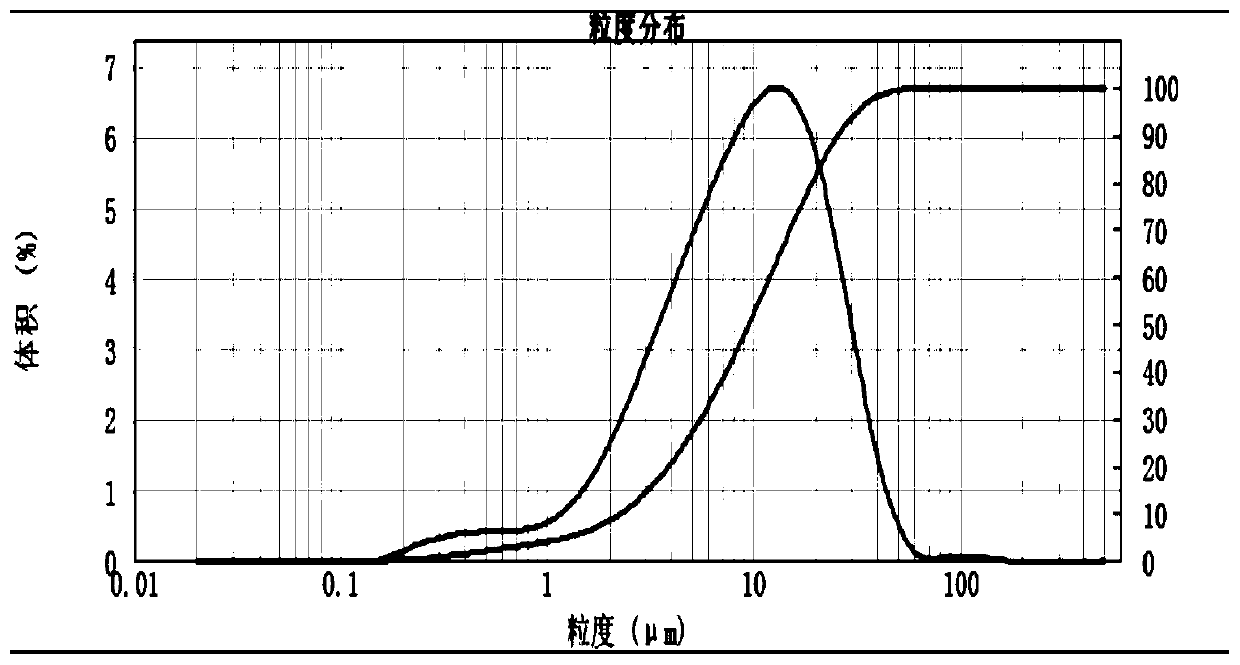

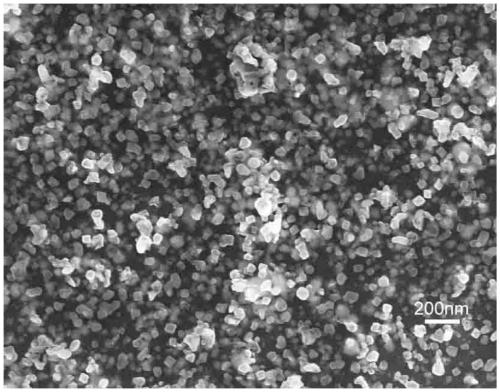

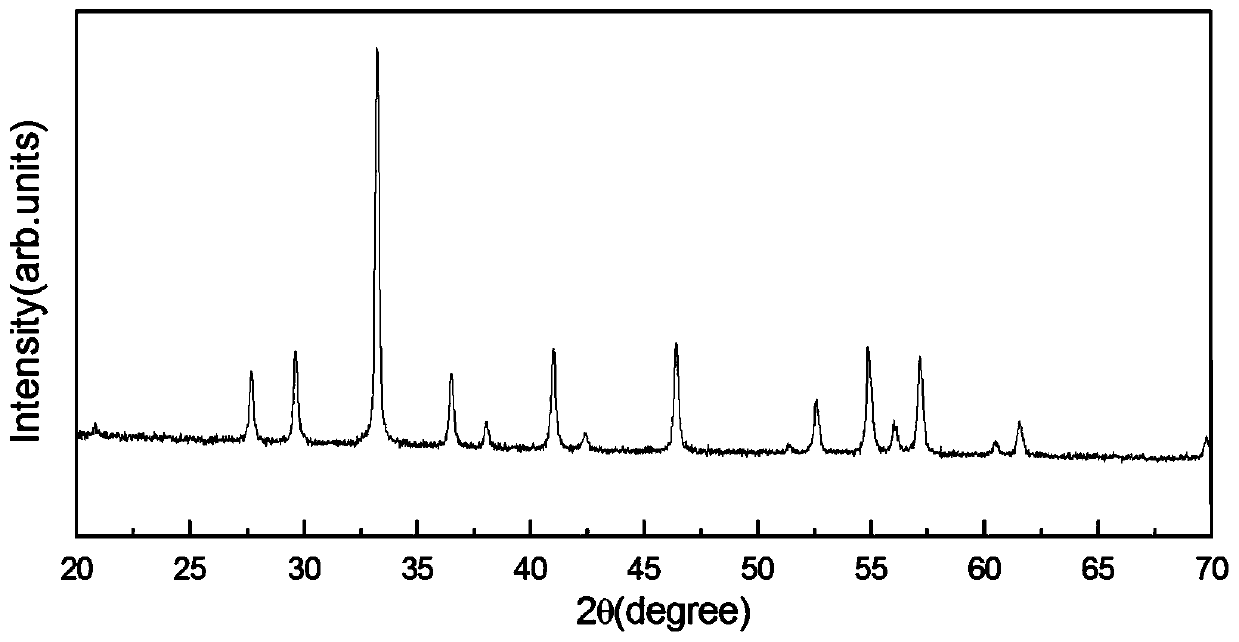

ActiveCN107482213BLarge specific surface areaSmall grainCell electrodesNickel saltManganous-manganic oxide

The invention provides nickel-aluminum co-doped manganous-manganic oxide. The nickel-aluminum co-doped manganous-manganic oxide has the molecular formula: (MnxNiyAlz)3O4, the ratio of x, y and z is (0.7-0.8):(0.2-0.3):(0.005-0.1) and has the particle size D50 ranging from 5 mu m to 15 mu m, the specific surface area ranging from 30 m<2> / g to 50 m<2> / g and the tap density larger than or equal to 0.4 g / cm<3>. The invention further provides a preparation method of the nickel-aluminum co-doped manganous-manganic oxide. A heterogeneous reaction of metal manganese and water and a co-precipitation reaction of nickel salt and aluminum salt can occur simultaneously in a water solution by adjusting proper technical parameters, and manganese elements, nickel elements and aluminum elements are uniformly mixed in a product on an atomic level and are distributed completely uniformly on a micro level. The nickel-aluminum co-doped manganous-manganic oxide prepared with the method has the characteristics of large specific surface area, small crystal particles, high activity and accurate stoichiometric ratio.

Owner:HUNAN CHANGYUAN LICO CO LTD

Magnesium alloy surface corrosion-resistant coating preparation method

InactiveCN107164744AUniform stoichiometric ratioStoichiometric ratio is accurateChemical vapor deposition coatingSelf limitingHydrogen

The invention discloses a magnesium alloy surface corrosion-resistant coating preparation method. The magnesium alloy surface corrosion-resistant coating preparation method comprises the following steps: (1) removing hydrogen from a magnesium alloy; (2) preparing an ALD (Atomic Layer Deposition) working cavity; (3) preparing a corrosion-resistant by adopting ALD; (4) reducing in the ALD working cavity. According to the magnesium alloy surface corrosion-resistant coating preparation method, an Atomic Layer Deposition technology is adopted; the self-limiting properties (adsorption self-limiting property and reaction self-limiting property) of a preparation process are utilized, various types of oxides, nitrides and composite corrosion-resistant coatings which are good in thickness uniformity, precise in component control and high in compactness and have strong combining property with a magnesium alloy substrate are prepared on the surface of the magnesium alloy. In the preparation, the coating can be prepared on a surface of any shape, and the temperature is the only process parameter; the controllability and the process stability are high.

Owner:NANCHANG UNIV

Method for preparing yttrium aluminum garnet powder

ActiveCN111574215AReduce consumptionReduce pollutionRare earth metal compoundsCrystallographyPhysical chemistry

The invention discloses a method for preparing yttrium aluminum garnet powder. The chemical formula of yttrium aluminum garnet is Y3Al5O12. The preparation method comprises the steps of solution preparation, precipitation, washing, mixing, hydrolysis, hydrothermal reaction, filtration, drying and calcination. The prepared yttrium aluminum garnet polycrystalline powder has the advantages of high purity, accurate stoichiometric ratio, uniform composition and uniform dispersion.

Owner:PUTIAN UNIV

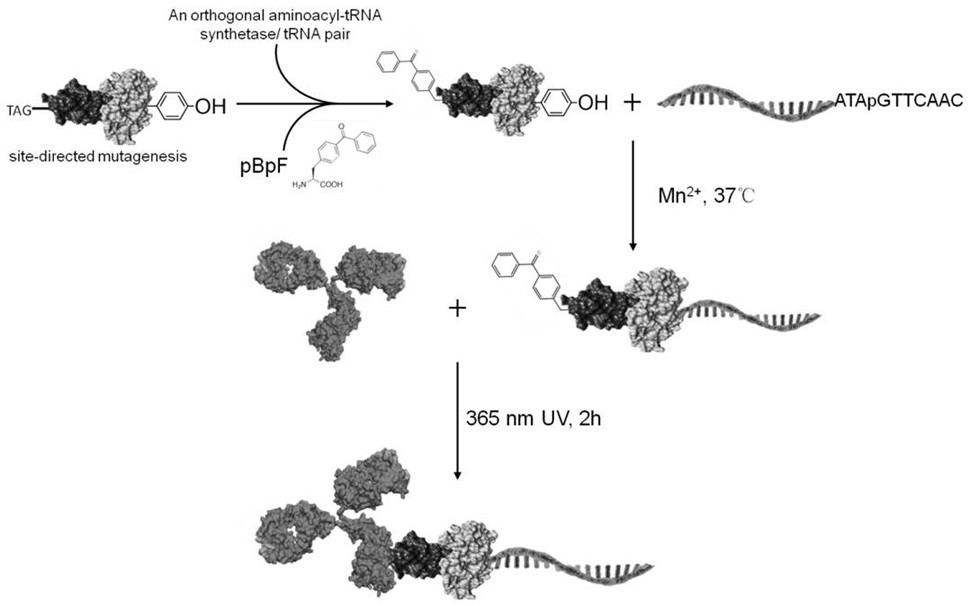

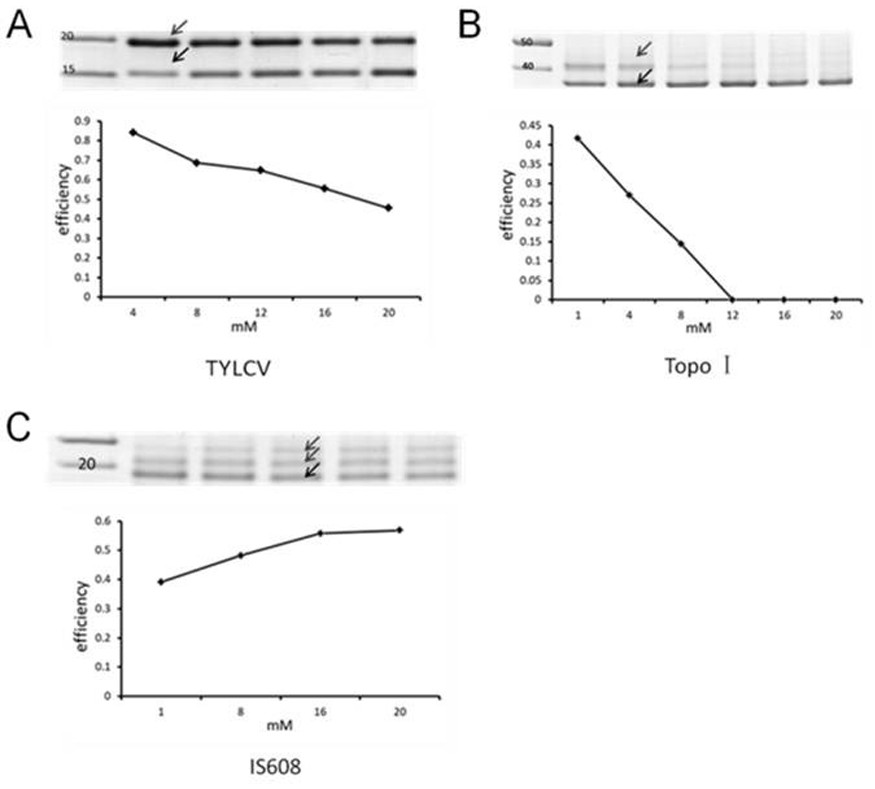

Precise antibody nucleic acid directional connection method

PendingCN112778426AStoichiometric ratio is accurateAchieving absolute quantitative detectionAntibody mimetics/scaffoldsMicrobiological testing/measurementFunctional modificationProtein G

The invention discloses a precise antibody nucleic acid directional connection method. The precise antibody nucleic acid directional connection method comprises the following steps: (1) connecting HUH endonuclease with Protein G through a flexible Linker molecule to obtain a fusion protein; (2) synthesizing single-stranded DNA, wherein the single-stranded DNA contains a site which can be recognized by the HUH endonuclease; (3) mixing and reacting the fusion protein and the single-stranded DNA to obtain a protein nucleic acid compound; (4) mixing the protein nucleic acid compound with a target antibody, and performing reacting under the illumination catalysis condition to realize directional connection of a target antibody and the single- stranded DNA, wherein the step (1) and the step (2) are interchangeable. A codon of a non-natural amino acid specifically cross-linked by a light-induced site is inserted into a specific site of the Protein G gene. The method does not need any chemical or functional modification on the antibody and nucleic acid, and does not influence the antigen recognition capability of the antibody and the property and function of nucleic acid molecules. Only one nucleic acid molecule is connected to one antibody of the obtained antibody nucleic acid compound.

Owner:深圳伯生生物传感技术有限公司 +1

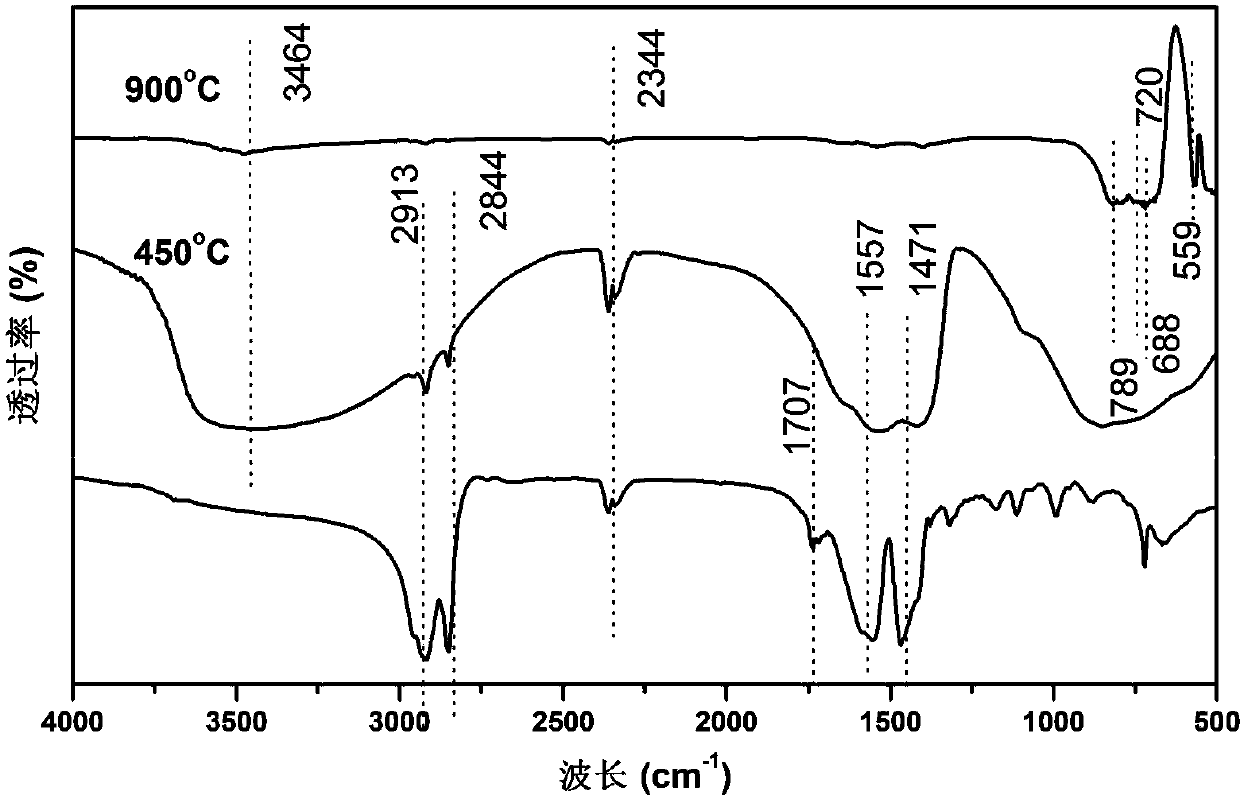

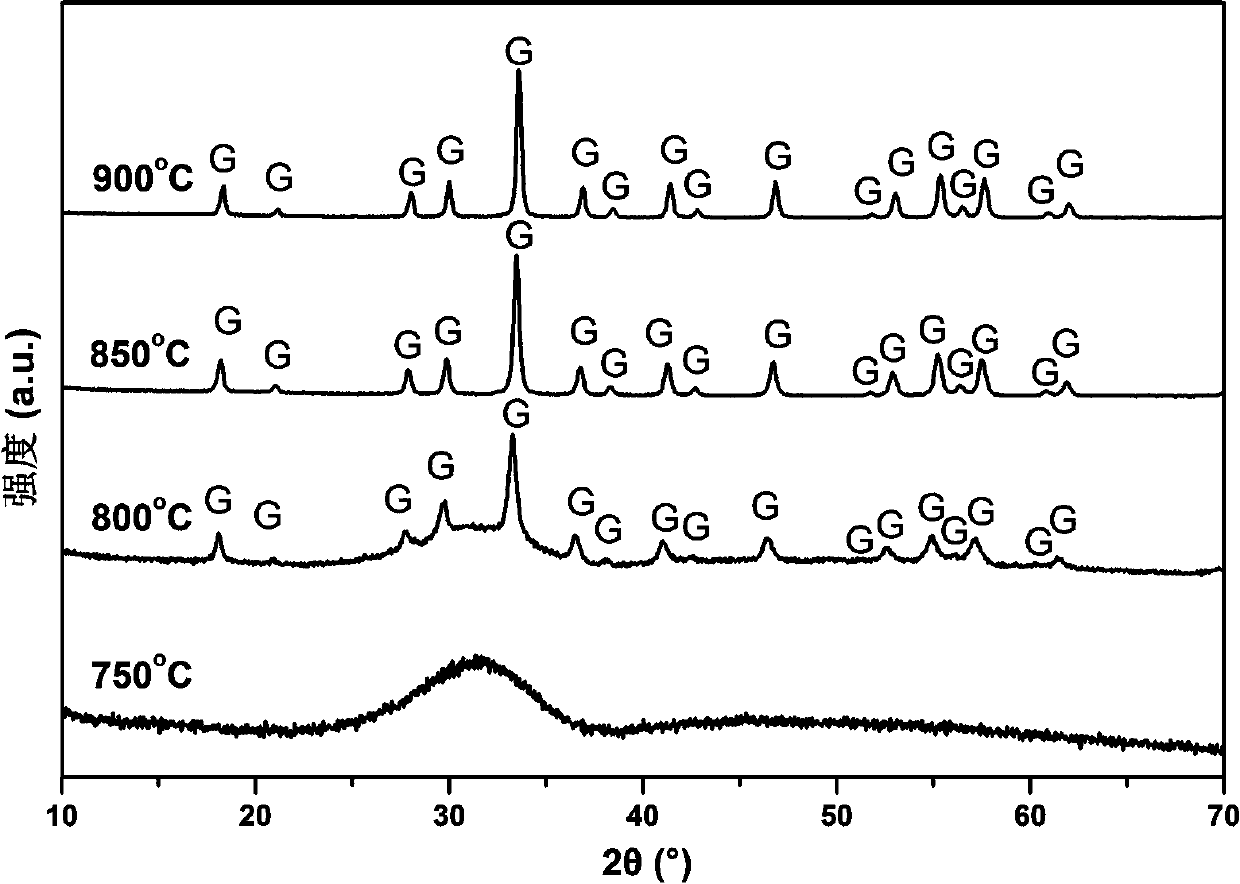

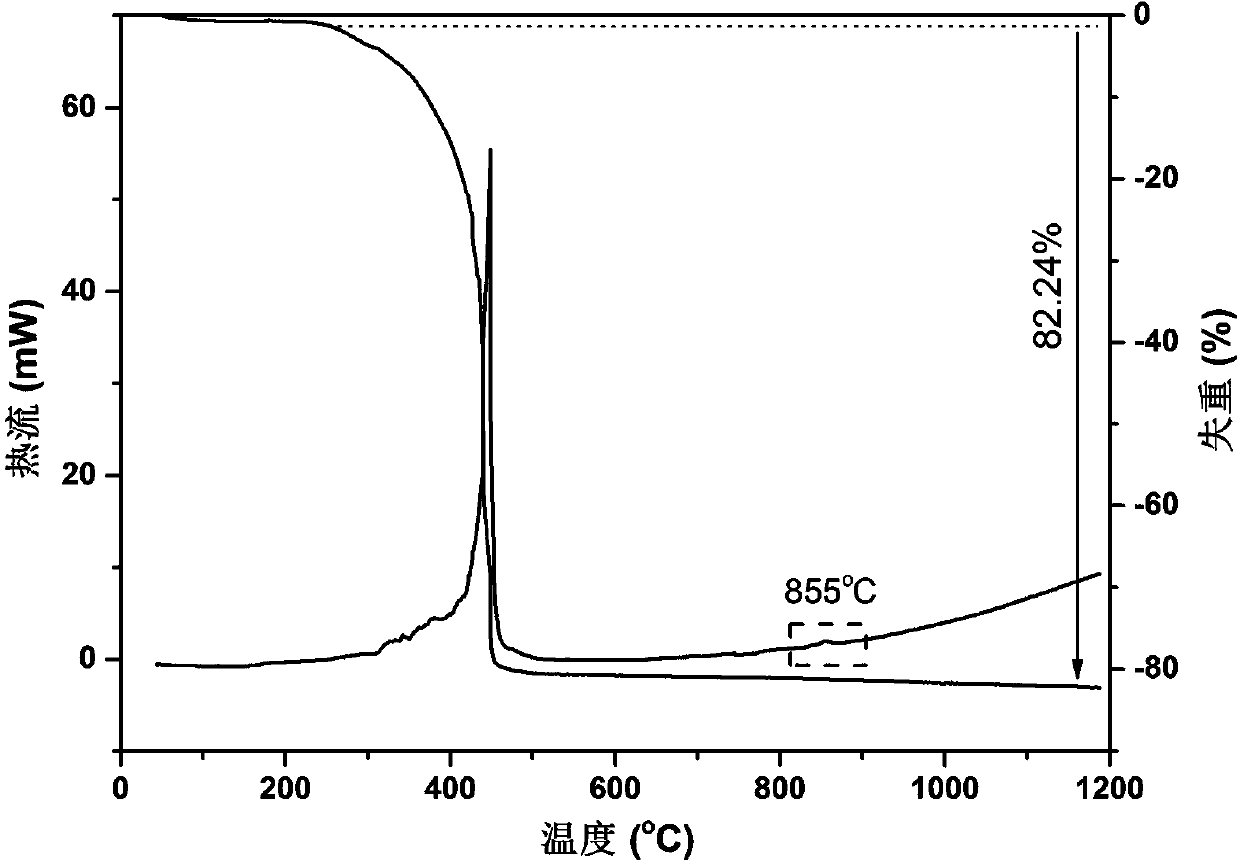

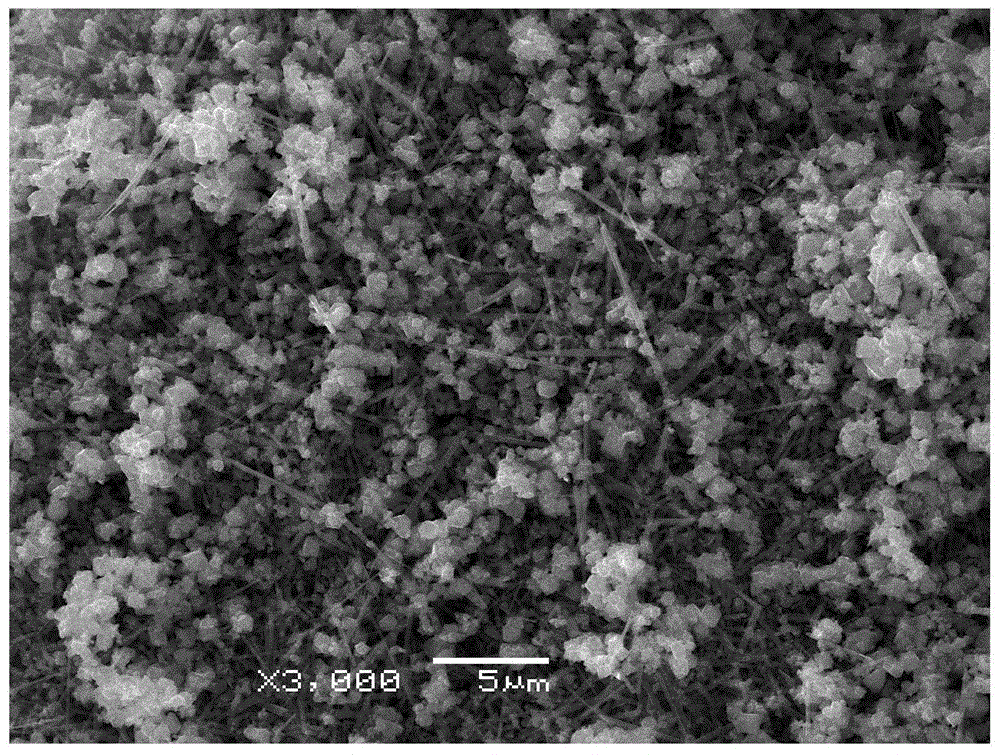

Preparation method of a hollow tubular lithium-rich manganese-based positive electrode material

ActiveCN108574089BHigh crystallinityImprove electrochemical performanceCell electrodesSecondary cellsFiberSpinning

The invention relates to a preparation method of a hollow tubular lithium-rich manganese-based positive electrode material. The preparation method includes the steps of (1), dissolving high-molecularpolymer A in an organic solvent to obtain spinning solution A; (2), dissolving lithium precursor, manganese salt, nickel salt and cobalt salt respectively obtain metal salt solution, dissolving high-molecular polymer B in an organic solvent to obtain a polymer solution, mixing the metal salt solution with the polymer solution uniformly to obtain spinning solution B; (3), taking the spinning solution A as an inner axle and the spinning solution B as an external axle, performing an co-axial electrospinning process to obtain nano-fiber; (4), drying the nano-fiber, calcining the nano-fiber at different stages, and then cooling to obtain a product. Compared with the prior art, the material synthesized by the method for preparing the hollow tubular lithium-rich manganese-based positive electrodematerial through the co-axial electrospinning process has the advantages of accurate stoichiometric ratio, uniform particle dispersion and the like, and also has excellent cycle performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for preparing yag nanometer powder by stearate melting method

ActiveCN103553112BWell mixedStoichiometric ratio is accurateMaterial nanotechnologyRare earth metal compoundsMolten statePhysical chemistry

A method for preparing YAG nanopowder by stearate melting method, which belongs to the field of material technology and is carried out according to the following steps: (1) Mix stearic acid ethanol solution and yttrium nitrate solution to prepare yttrium-stearic acid mixed solution; (2) After heating, add ammonia dropwise and keep it warm to make yttrium stearate emulsion; (3) Centrifuge, wash and dry the solid phase to make yttrium stearate powder; (4) Mix ethanol stearate with The solution is mixed with the aluminum nitrate solution to make an aluminum-stearic acid mixed solution; (5) After heating, add ammonia dropwise and keep it warm to make an aluminum tristearate emulsion; (6) Centrifuge, and the solid phase is washed and dried. Aluminum tristearate powder is made; (7) The two powders are mixed and heated until melted and stirred evenly to form a solid precursor; (8) Calcined to make YAG nanopowder. The YAG nanopowder of the present invention has high purity, uniform particles and good dispersion, and is suitable for making phosphor powder and laser transparent ceramics; the method of the present invention has the advantages of high reaction temperature, low environmental pollution, and easy promotion.

Owner:NORTHEASTERN UNIV LIAONING

Method for preparing YAG (yttrium aluminum garnet) nano-powder through stearate melting method

ActiveCN103553112AWell mixedStoichiometric ratio is accurateMaterial nanotechnologyRare earth metal compoundsMolten stateReaction temperature

The invention discloses a method for preparing YAG (yttrium aluminum garnet) nano-powder through a stearate melting method and belongs to the technical field of materials. The method comprises the following steps: (1) mixing a stearic acid ethanol solution and a yttrium nitrate solution to prepare a yttrium-stearic acid mixed solution; (2) heating the yttrium-stearic acid mixed solution and dropwise adding ammonia water, insulating the heat and preparing yttrium stearate emulsion; (3) performing centrifugal separation, washing a solid phase, drying and preparing yttrium stearate powder; (4) mixing the stearic acid ethanol solution and an aluminum nitrate solution to prepare an aluminum-stearic acid mixed solution; (5) heating the aluminum-stearic acid mixed solution, dropwisde ammonia water, insulating the heat and preparing aluminum tristearate emulsion; (6) performing centrifugal separation, washing a solid phase, drying and preparing aluminum tristearate powder; (7) mixing the two powders, heating into a molten state, uniformly stirring, thus obtaining a solid precursor; and (8) calcining to prepare the YAG nano-powder. The prepared YAG nano-powder is high in purity, uniform in particles and high in dispersibility and is suitable for preparing fluorescent powder and laser transparent ceramics. The method has the advantages of low reaction temperature, simplicity in popularization and the like and hardly causes environmental pollution.

Owner:NORTHEASTERN UNIV

A kind of preparation method of acicular spinel type lithium manganese oxide cathode material

ActiveCN105271424BLarge specific surface areaShort lithium ion transport pathCell electrodesManganates/permanganatesManganateSpinel

The invention discloses a preparation method of a needle-like spinel lithium manganese oxide positive electrode material. The preparation method comprises the steps of preparing raw materials comprising lithium sources and manganese sources, a strong oxidant and a strong reducing agent at first; evenly mixing the raw materials in a water solution according to a certain molar ratio, adding the strong oxidant and the strong reducing agent into the solution, and obtaining mixed slurry after a sufficient reaction; filtering, washing and drying the mixed slurry to obtain a precursor; finally, placing the precursor in air or oxygen-enriched atmosphere for primary sintering or secondary sintering to obtain the needle-like spinel lithium manganese oxide positive electrode material. The preparation method has the advantages that the technology is simple and easy to control, and production efficiency is high, and the obtained product is uniform in ingredient, stable in quality and excellent in physical and chemical performance and electric performance.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Preparation of stratified lithium ion anode material

ActiveCN101944610BHigh densityHigh activityElectrode manufacturing processesNickel compoundsManganeseSolid state reaction method

The invention relates to a preparation method of a stratified lithium ion anode material, which comprises the following steps: coating cobalt on the surface of a precursor containing nickel, manganese and a small amount of other metals by a chemical precipitation method; fully mixing with a lithium source; and then, adopting a solid reaction method to prepare the high nickel type lithium ion anode material. The chemical formula of the lithium ion anode material is as follows: LidNiaMnbMcCo1-a-b-c02, wherein 0.9<=d<=1.25, 0.5<=a<=1, 0<b<0.5, 0.9<=a+b+c<1, and M is one or a mixture of more than one of Al, Ti, Mg and Zn. The material has uniform chemical composition and high capacity. Besides, the cycle performance of the material is improved, and the operating voltage platform and the safety of a battery are enhanced, especially after the material is subject to doping and coating modification.

Owner:HENAN KELONG NEW ENERGY CO LTD

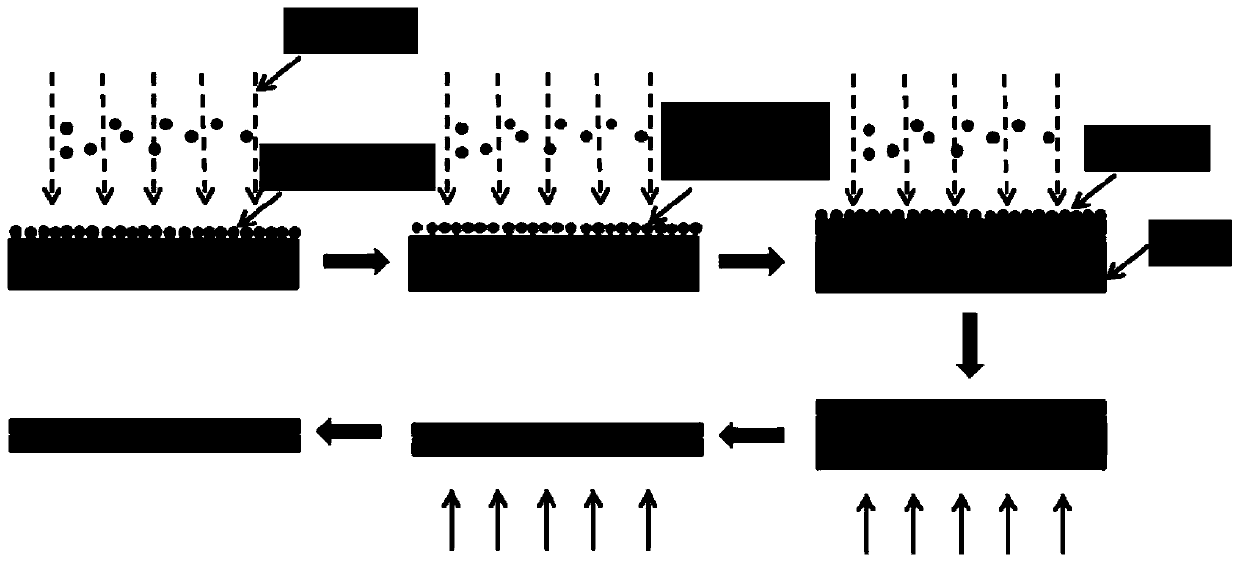

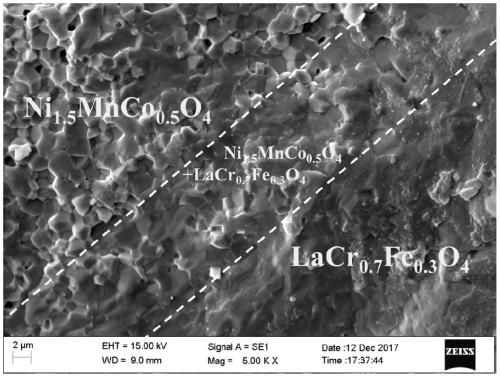

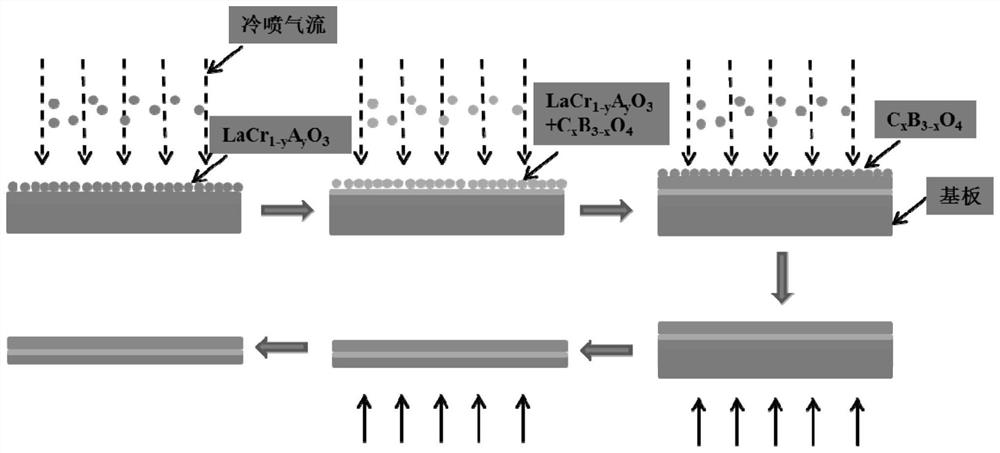

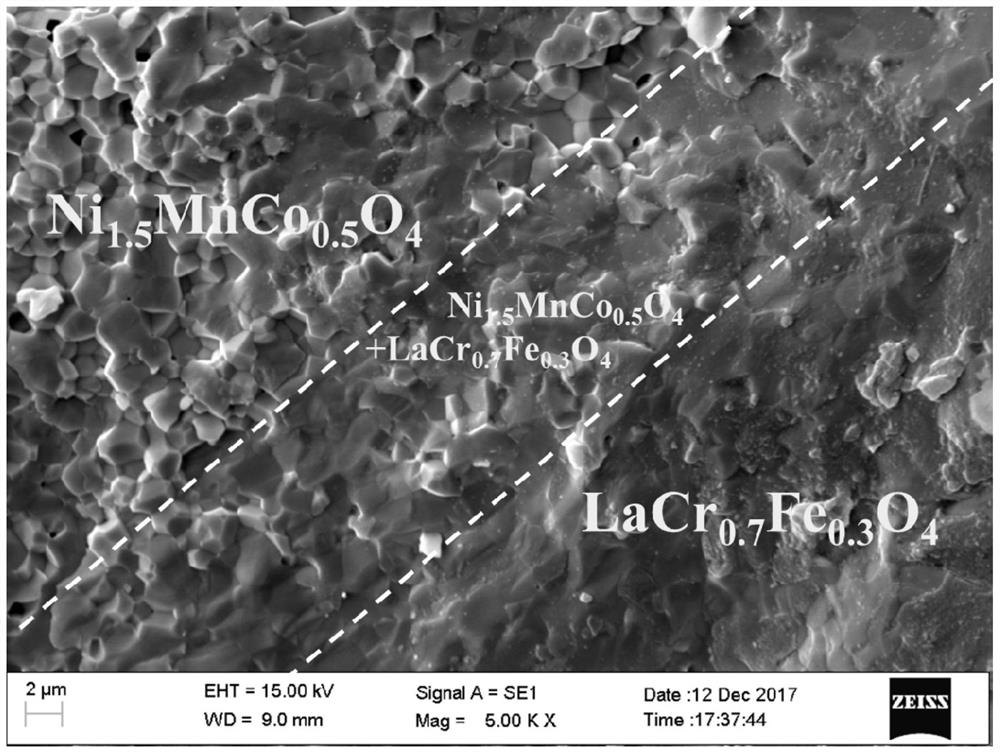

In-situ-generated layered composite negative-temperature-coefficient thermal-sensitive ceramic material, preparation method and application

ActiveCN109942285AGood conductivity and stabilityHigh interface shrinkage matchingLayered structureCeramic

The invention belongs to the technical field of negative-temperature-coefficient thermistors and particularly relates to an in-situ-generated layered composite negative-temperature-coefficient thermal-sensitive ceramic material, a preparation method and application. The thermal-sensitive ceramic material structurally comprises a base layer, a transition layer and a sensitive layer in sequence. Thecomposition of the base layer is a perovskite phase or a doped perovskite phase, the composition of the sensitive layer is a spinel phase or a doped spinel phase, and the composition of the transition layer is a mixture formed by mixing the perovskite phase or the doped perovskite phase with the spinel phase or the doped spinel phase in an isopyknic mode. A cold spraying technology is introducedinto preparation of layered-structure composite thermal-sensitive ceramics, the in-situ-generated layered composite negative-temperature-coefficient thermal-sensitive ceramic material is prepared, thedefect of a traditional method is overcome, the thickness of the sensitive layer and the microstructure of the material are effectively regulated and controlled, and the material has important significance on preparation of low-resistance-value, high-B-value and high-stability NTC thermal-sensitive ceramic materials for inhibiting the surge current.

Owner:UNIV OF JINAN

An in-situ-generated layered composite negative temperature coefficient thermosensitive ceramic material and its preparation method and application

ActiveCN109942285BImprove stabilityLower resistanceCeramic layered productsPerovskite (structure)Thermistor

The invention belongs to the technical field of negative temperature coefficient thermistors, and in particular relates to an in-situ-generated layered composite negative temperature coefficient thermosensitive ceramic material, a preparation method and an application thereof. The structure of the heat-sensitive ceramic material is a base layer, a transition layer, and a sensitive layer in sequence, wherein: the base layer is composed of a perovskite phase or a doped perovskite phase, and the sensitive layer is composed of a sharp Crystal phase or doped spinel phase, the composition of the transition layer is: perovskite phase or doped perovskite phase and spinel phase or doped spinel mixed in equal volumes mixture. Introducing the cold spraying technology into the preparation of layered structure composite heat-sensitive ceramics, the in-situ generation of layered composite negative temperature coefficient heat-sensitive ceramic materials was prepared, which overcomes the shortcomings of traditional methods and realizes the sensitivity to the thickness of the sensitive layer and the microstructure of the material. The effective control of NTC is of great significance for the preparation of NTC thermosensitive ceramic materials with low resistance, high B value and high stability for suppressing surge current.

Owner:UNIV OF JINAN

A kind of method for preparing yttrium aluminum garnet powder

ActiveCN111574215BReduce consumptionReduce pollutionRare earth metal compoundsPhysical chemistryHydrolysis

The invention discloses a method for preparing yttrium aluminum garnet powder, the chemical formula of the yttrium aluminum garnet is Y 3 Al 5 o 12 ; The preparation method includes solution preparation, precipitation, washing, mixing, hydrolysis, hydrothermal reaction, filtration, drying and calcination. The yttrium aluminum garnet polycrystalline powder prepared by the invention has the advantages of high purity, precise stoichiometric ratio, uniform components and uniform dispersion.

Owner:PUTIAN UNIV

Lithium-rich manganese-based layered lithium battery cathode material and preparation method thereof

ActiveCN104134794BImprove performanceStoichiometrically accurateCell electrodesSecondary cellsManganeseHYDROSOL

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com