Patents

Literature

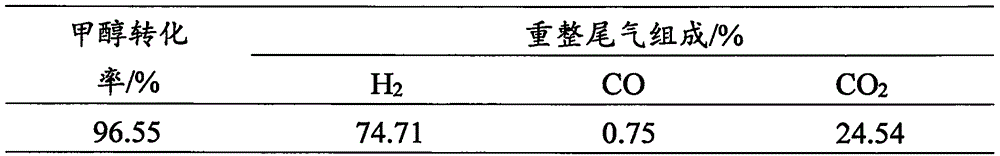

137results about How to "Reduce CO content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

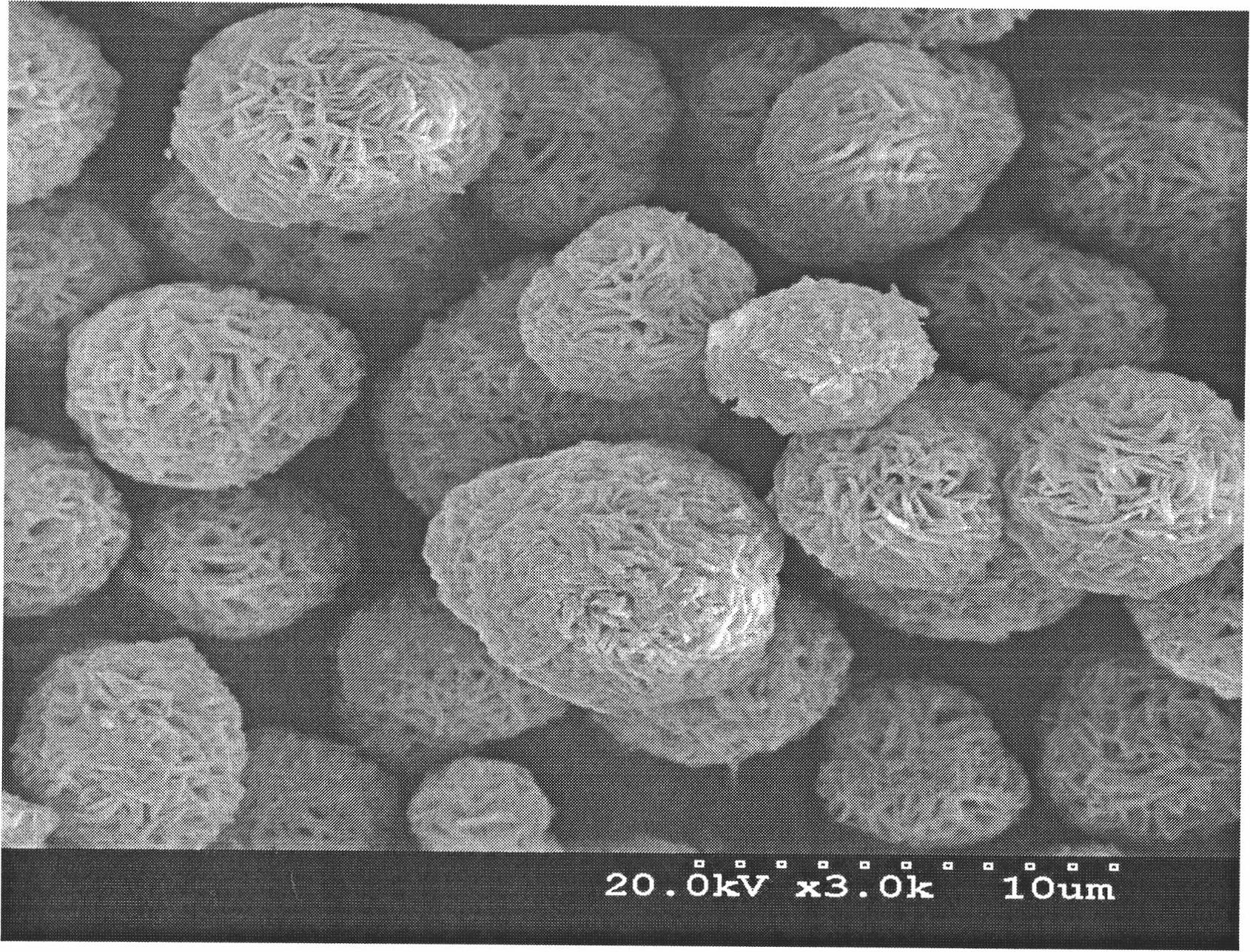

Method for preparing high-performance spherical lithium ion secondary battery cathode material

ActiveCN102110808AHigh densityHigh activityCell electrodesNickel compoundsHigh densityElectrical battery

The invention provides a method for preparing a high-performance spherical lithium ion secondary battery cathode material. The method comprises the steps of synthesizing a NiaCobMn1-a-b(OH)2 precursor through adopting a coprecipitation-crystallization method, coating NicCodMn1-c-d(OH)2NieCofMn1-e-f(oh)2 composite layer on the surface of the precursor through adopting a chemical method, and then fully mixing with lithium salt to prepare a high-performance spherical lithium ion secondary battery cathode material LiNiaCobMn1-a-bO2(LiNicCobMn1)-c-dO2LiNieCofMn1-e-fO2) through stepwise sintering. The cathode material prepared by adopting the method has high density, good activity, and accurate stoichiometric proportion. Malignant interaction between the cathode material and an electrolyte is avoided, capacity decrease caused by non- electrochemical active substances is prevented, and the circulating life of materials is prolonged. The method is easy to control, has a low manufacturing cost, and is convenient for mass production, so as to create conditions for the development of high-capacity lithium ion batteries.

Owner:HENAN KELONG NEW ENERGY CO LTD

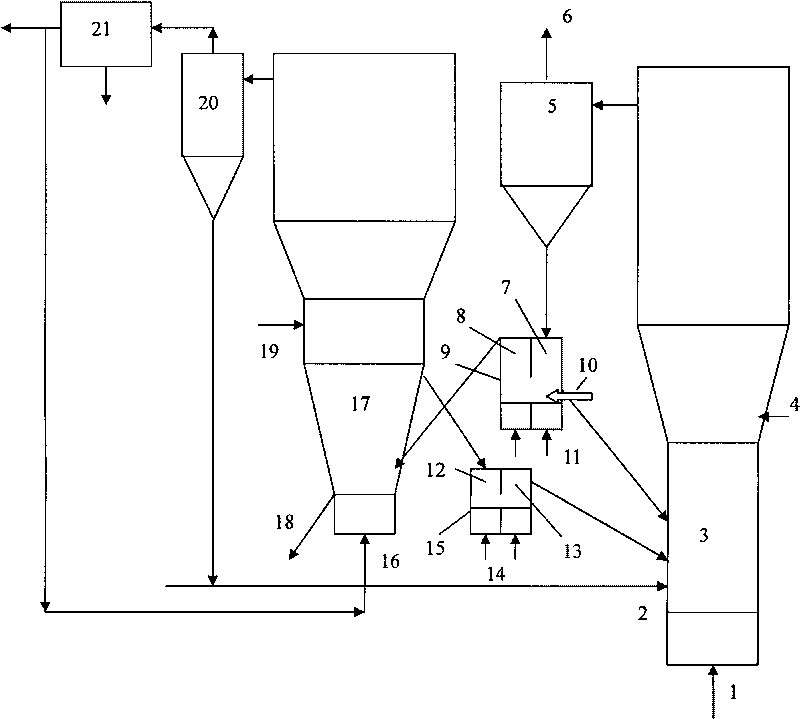

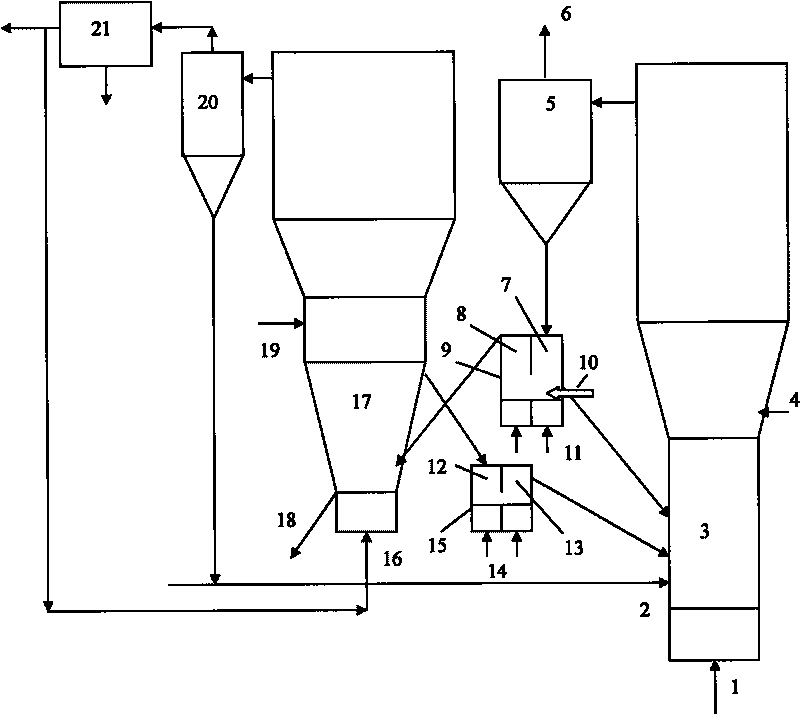

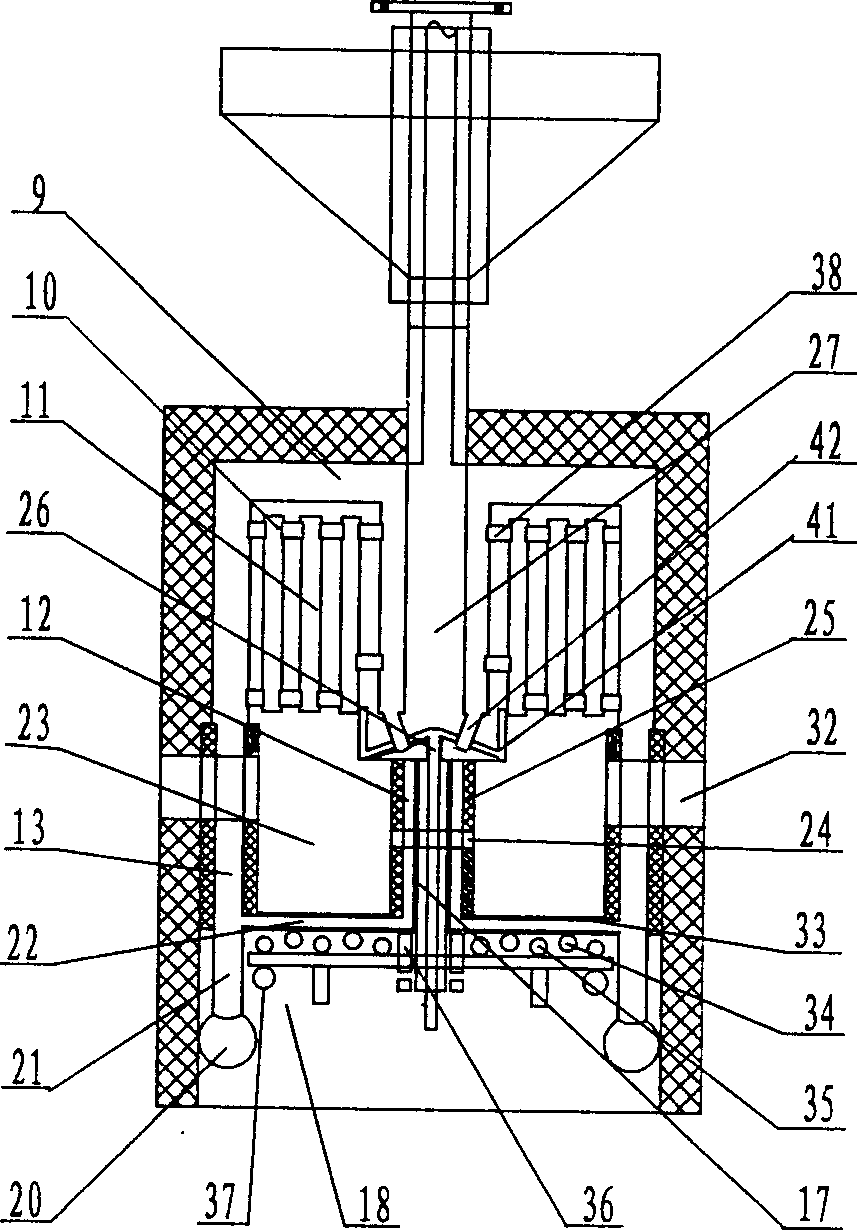

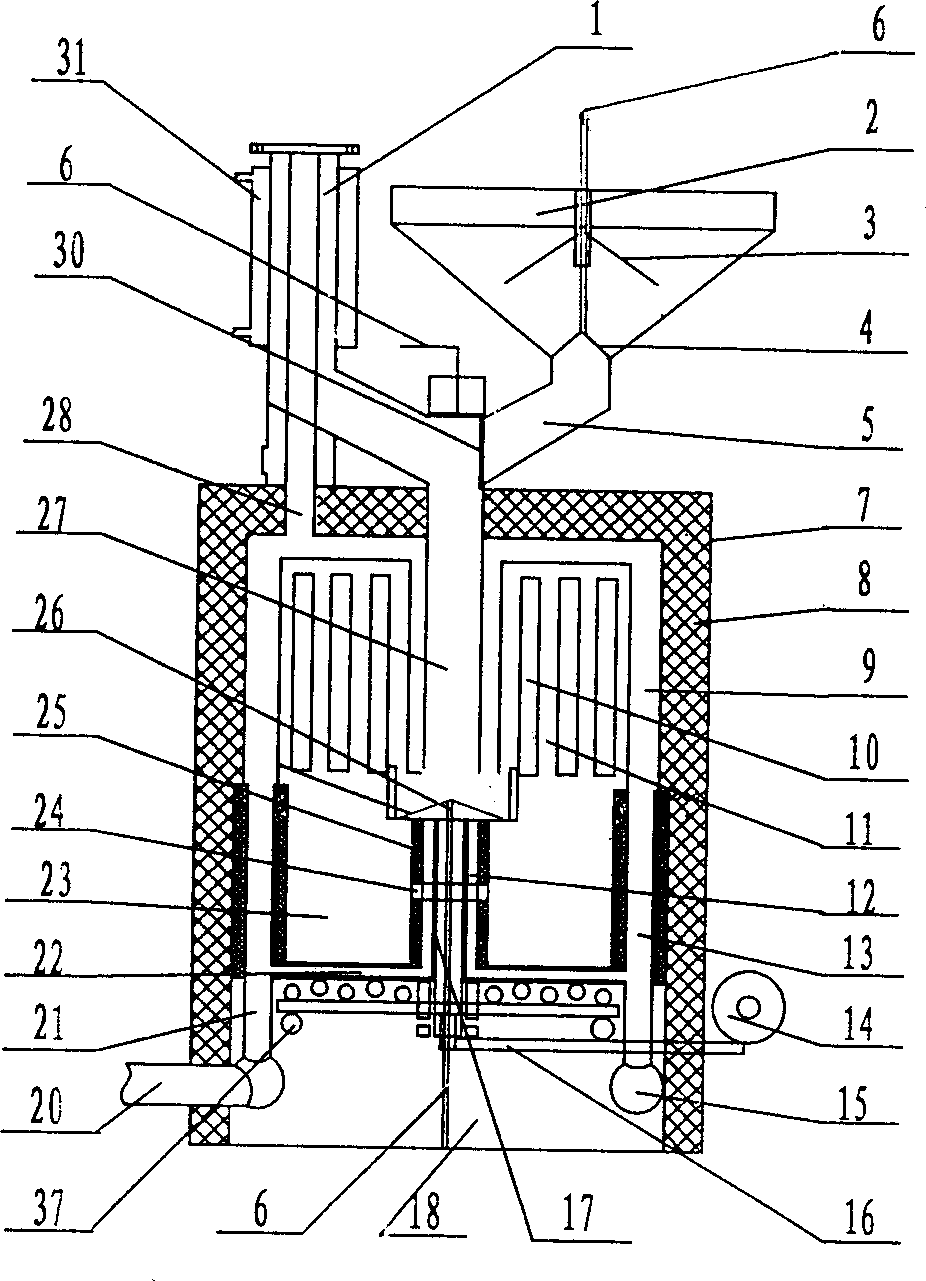

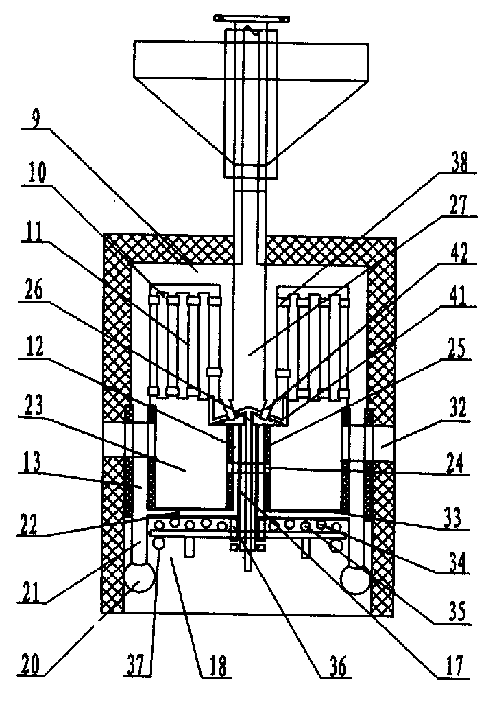

Coal-grading conversion poly-generation device and method for producing coal gas, tar and carbocoal on circulating fluid bed

ActiveCN101691501ARealize joint productionReasonable useSpecial form destructive distillationCombustible gas productionTarProcess engineering

The invention discloses a coal-grading conversion poly-generation device and a method for producing coal gas, tar and carbocoal on a circulating fluid bed. The device combines a circulating fluid bed gasification-furnace with a fluid bed gas retort. The gas retort is a normal-pressure fluid bed and uses circulating coal gas as the fluidizing medium; fuel is firstly heated and cracked in the gas retort to precipitate high-heating-value fugitive constituents comprising coal gas and tar; the heat absorbed by the gas retort is provided by a high-temperature thermal-circulation material in the circulating fluid bed gasification-furnace; the carbocoal part obtained after the coal is retorted is cooled and discharged through the bottom of the gas retort, and part of the carbocoal is conveyed to the circulating fluid bed gasification-furnace along with the circulating material to heat the circulating material; and the medium-temperature coal gas from the gas retort is processed in a dust removal way and cooled by a coal gas purification system, the tar is recycled, and the purified coal gas is output for industrial and civil use, thereby realizing the poly-generation of coal gas, tar and carbocoal in one set of device and realizing the grading conversion and the high-efficiency comprehensive utilization of coal.

Owner:ZHEJIANG UNIV

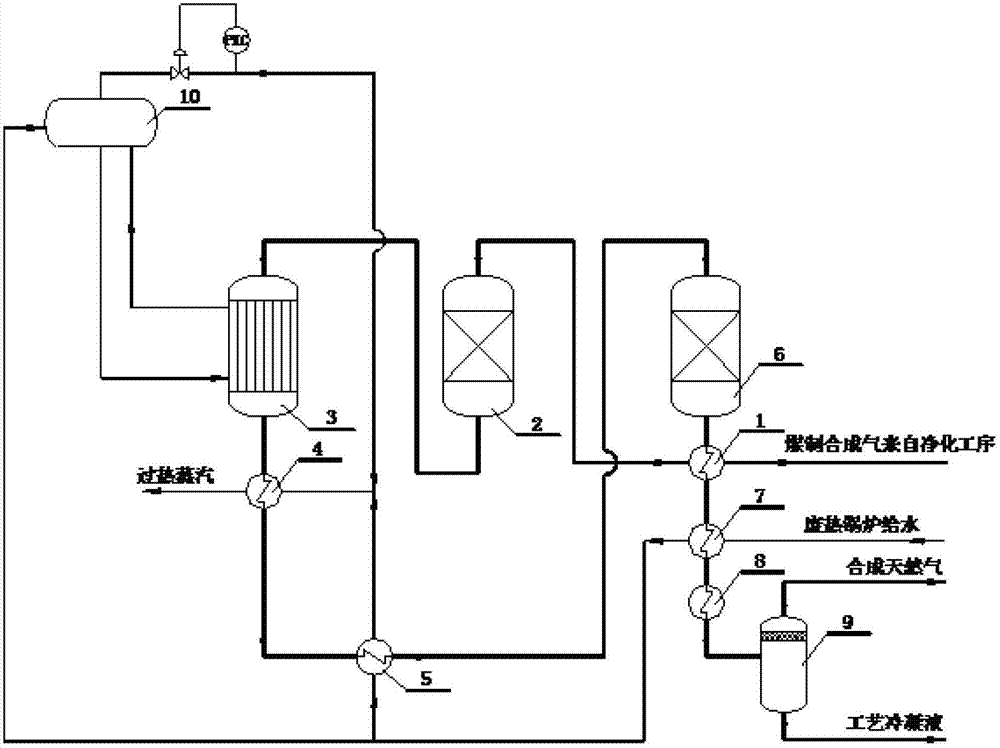

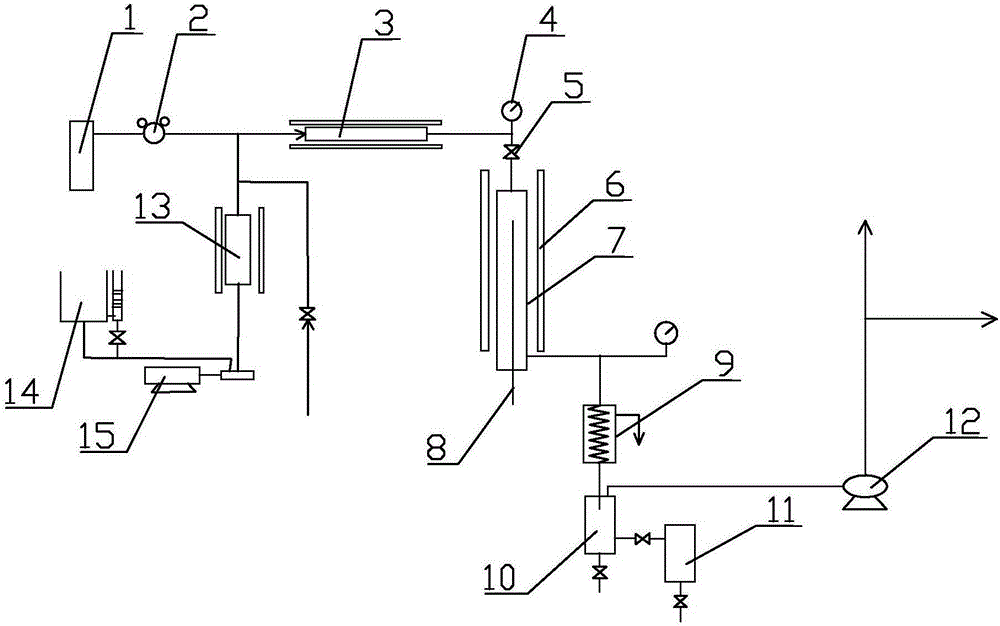

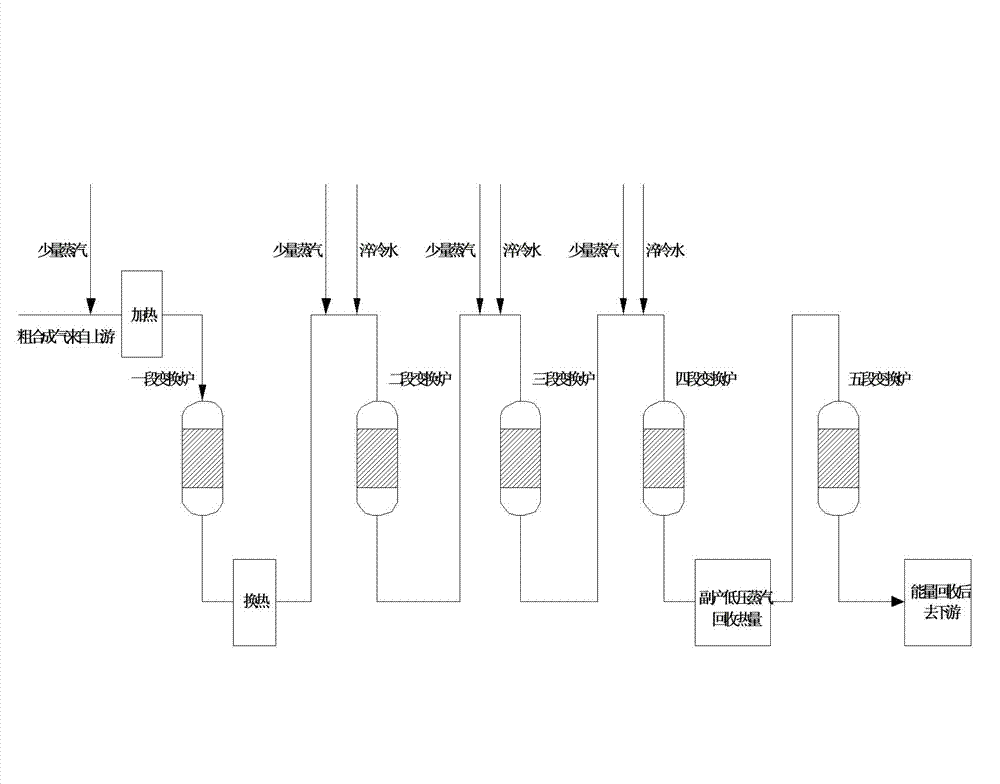

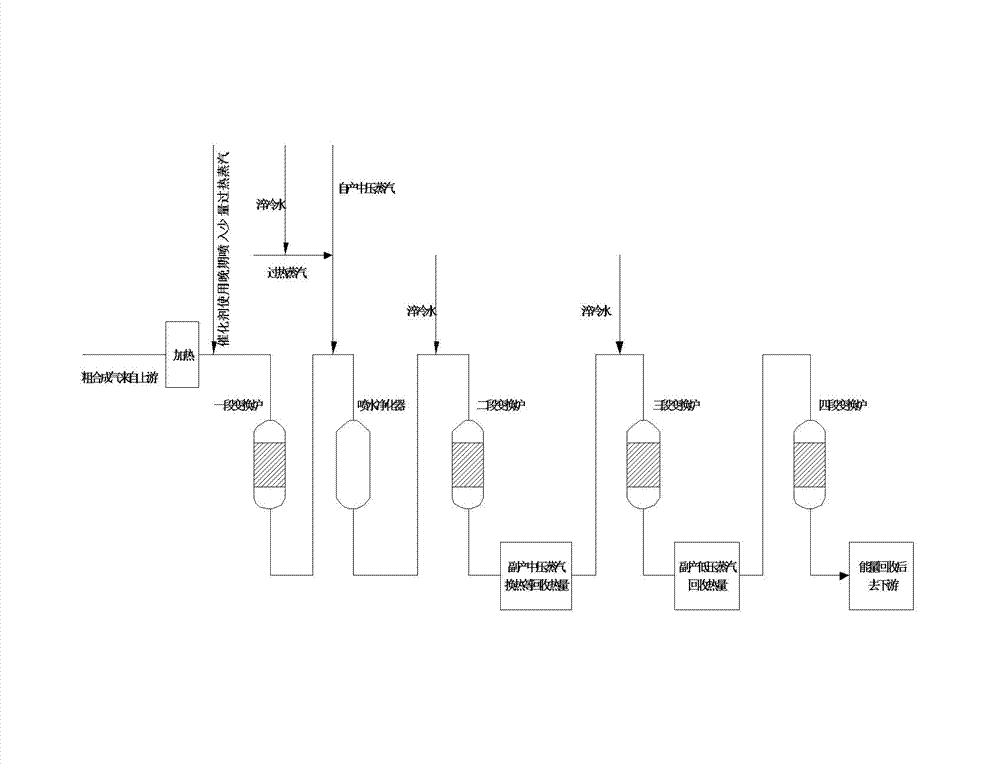

Isothermal methanation process method for coal to substitute natural gas

InactiveCN102827657AExtended service lifeLow running costGaseous fuelsMethanationSubstitute natural gas

The invention discloses an isothermal methanation process method for coal to substitute natural gas. Specifically, upstream purified synthetic gas enters one or more methanation reactors after fine desulfurization for undergoing a methanation reaction, and two-stage methanation is adopted in the methanation reactor(s). At a first stage, methanation is performed in one or more isothermal methanation reactors; and at a second stage, methanation is performed in a heat-insulated methanation reactor. The isothermal methanation process method has the advantages of saving in energy, environment friendliness, small investment and easiness in localization.

Owner:EAST CHINA ENG SCI & TECH

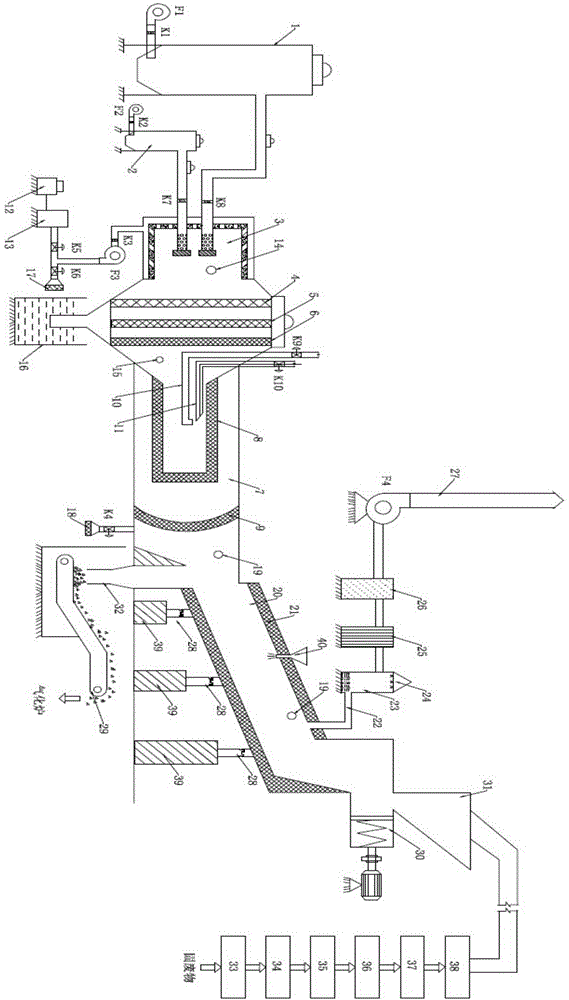

Solid waste innocent treatment device and method

ActiveCN104588402AExcellent emission indicatorsMeet environmental protection requirementsSolid waste disposalIncinerator apparatusCombustion chamberEmission standard

The invention discloses a solid waste innocent treatment device and a solid waste innocent treatment method. The solid waste innocent treatment device comprises a solid waste pyrolysis gasifier, a fuel gas oxygen replenishment premixing and filtering chamber, a fuel gas combustion chamber, a dechloridation and desulfurization drying device and a solid waste pretreatment device which are sequentially communicated; the solid waste innocent treatment device also comprises a biomass pyrolysis gasifier and a tail gas treatment device, wherein the biomass pyrolysis gasifier is communicated with the fuel gas oxygen replenishment premixing and filtering chamber; the tail gas treatment device is communicated with the top of the dechloridation and desulfurization drying device. When the method and the device are used for treating solid waste, the content of Dioxin in a detected emitted tail gas is lower than 0.023ng / m<3>, and the emission allowances of other gases, such as CO, SO2, HC1 and NOx, are also highly superior to the emission standard (GB18485-2014) issued by the nation in July 1st, 2014, and can completely meet the requirement of environment-friendliness.

Owner:深鹏环保工程有限公司

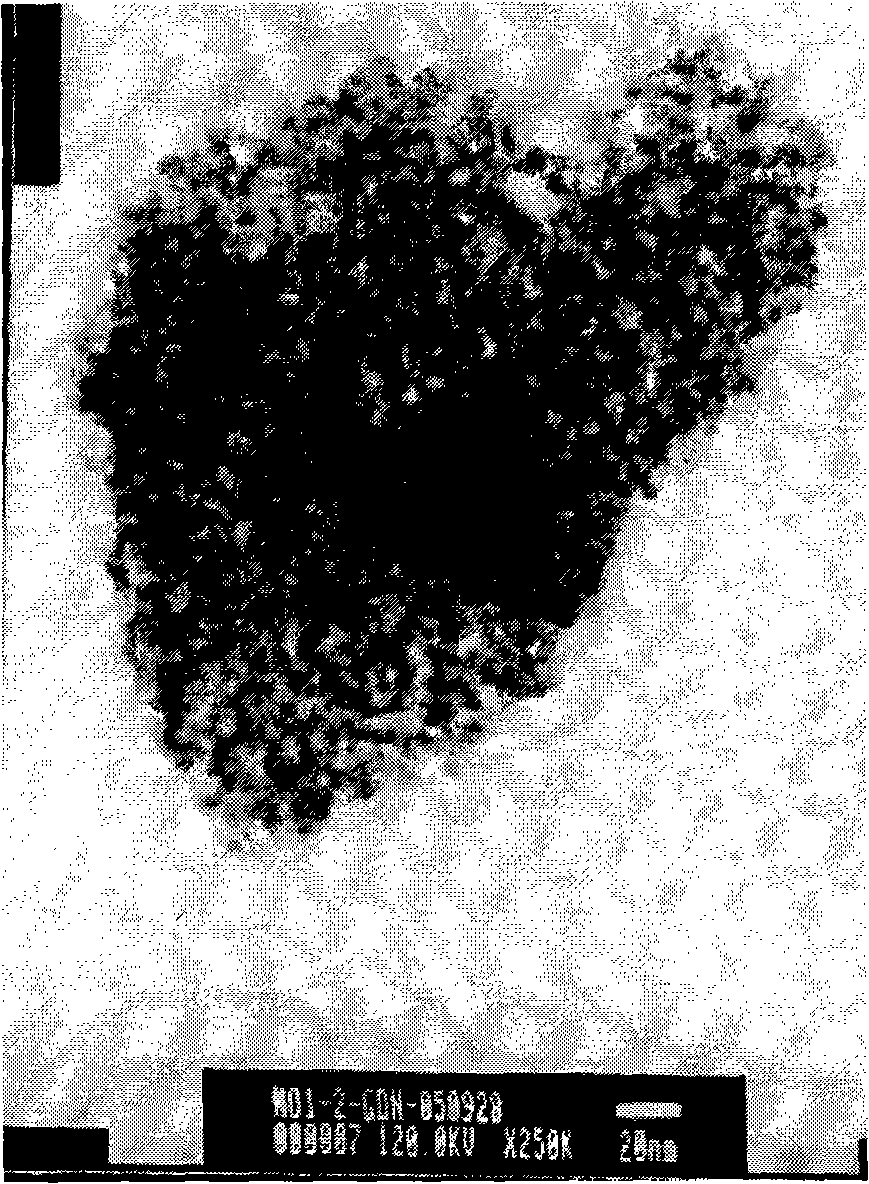

Self-heating reforming hydrogen production catalyst and preparation method thereof

InactiveCN101314128AHigh activityReduce CO contentHydrogenCatalyst activation/preparationAlkaline earth metalRare earth

The invention provides an autothermal reforming hydrogenation catalyst and a preparation method thereof. The catalyst takes one or more than one of platinum precious metal Pt, Pd, Ru, Rh and Ir as a main catalytic active component, and takes one or more than one of alkali metal and / or alkaline earth metal oxide Na2O, K2O, MgO, CaO, SrO and BaO, as well as a CeO2-based binary or ternary rare earth compound as a catalytic promoter. The catalyst can be applied in the form of a granular catalyst, and the entire catalytic active components and the catalytic promoter can also be borne on monolithic carriers such as honeycomb ceramics, metallic honeycomb, metal foam and so on, to produce a monolithic catalyst. The catalyst provided by certain embodiments has the advantages of high activity, low CO content in product gas, impact resistance, and long service life; and the quality of the catalyst can be further improved through the preparation method and a use method after the improvement, for example, a CeO2-based compound oxide is produced into a single-phase sosoloid, the catalyst is reduced before the use, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

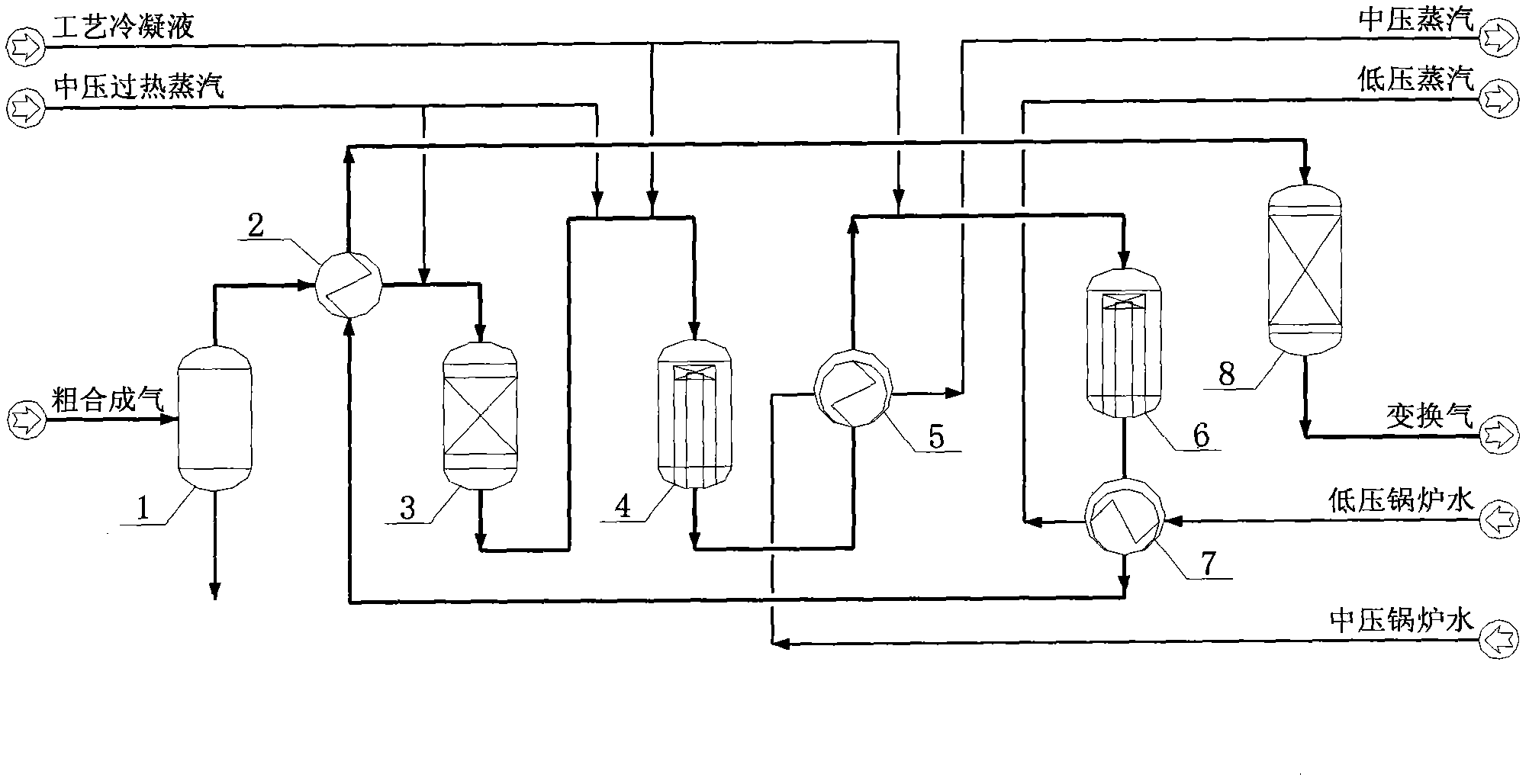

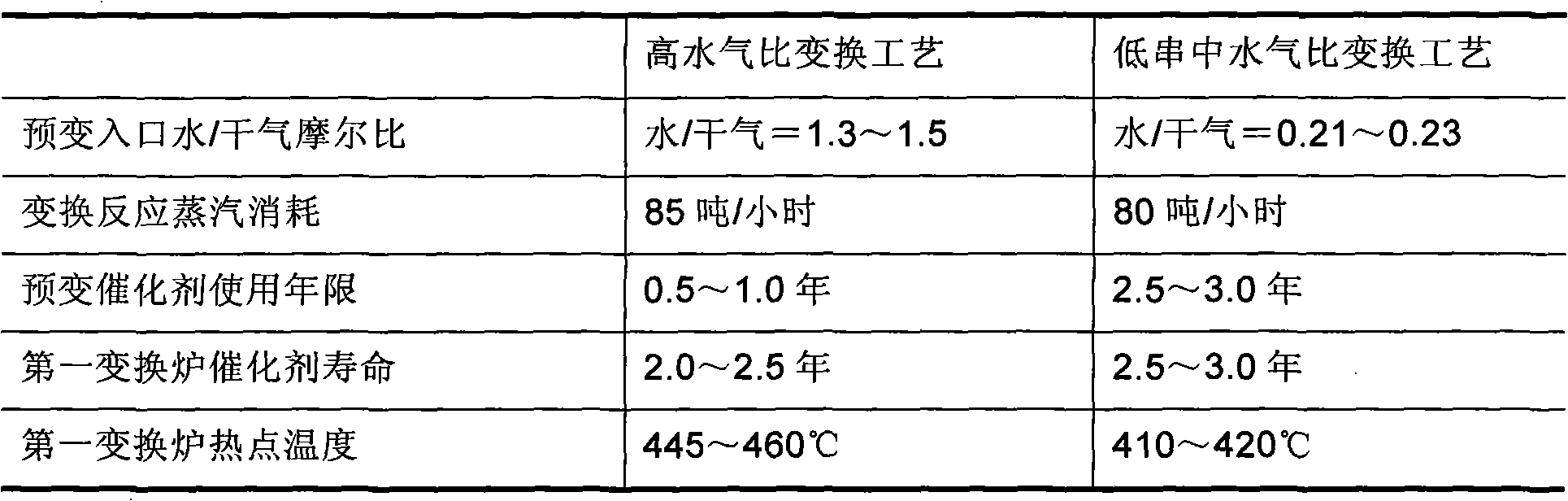

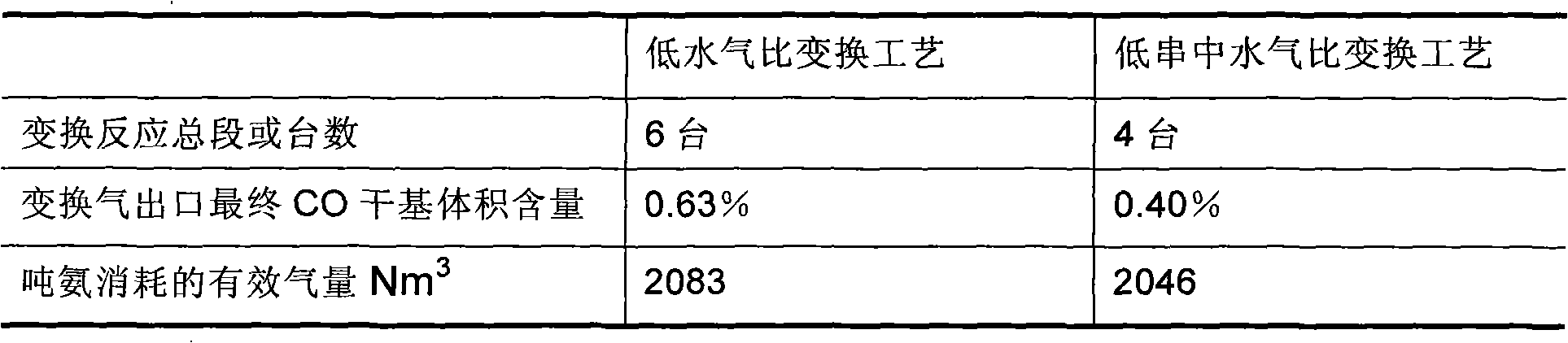

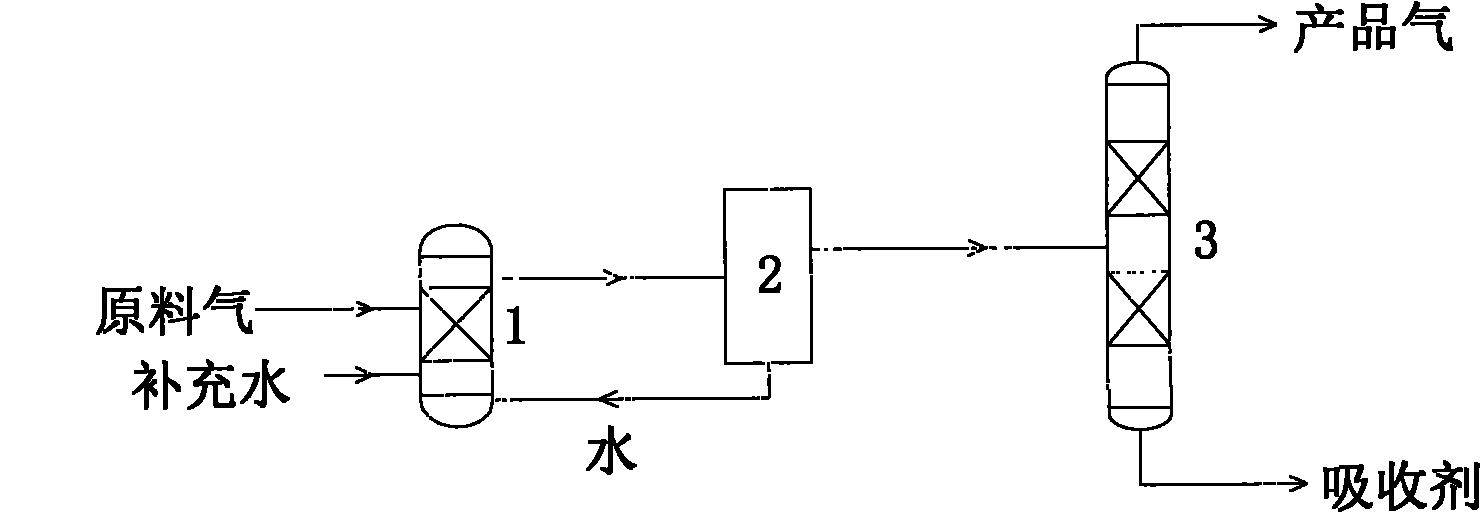

Low water-air ratio and middle water-air ratio carbon monoxide (CO) conversion process

ActiveCN102002403AReduce dosageReduce energy consumptionCombustible gas catalytic treatmentMixed gasDepth conversion

The invention relates to a low water-air ratio and middle water-air ratio carbon monoxide (CO) conversion process. The process comprises the following steps of: (1) feeding raw gas into a pre-converter, wherein the temperature of the raw gas entering the inlet of the pre-converter is between 210 and 250 DEG C and the mole ratio of water to dried gas is 0.21 to 0.23; (2) feeding pre-converted mixed gas into a first converter to perform depth conversion, wherein the temperature of the pre-converted mixed gas entering the inlet of the first converter is between 260 and 290 DEG C and the mole ratio of water to dried gas is 0.8 to 1.0; (3) feeding the mixed gas passing through the first converter into a second converter, wherein the temperature of the mixed gas entering the inlet of the secondconverter is between 220 and 250 DEG C and the mole ratio of water to dried gas is 0.5 to 0.7; (4) feeding the mixed gas passing through the second converter into a third converter, wherein the temperature of the secondary conversion mixed gas entering the inlet of the third converter is between 205and 235 DEG C; and performing conversion on the mixed gas by using the third converter to obtain the mixed gas with the CO content lower than 0.40 percent. The process is unique and has the characteristics of high CO conversion rate, low energy consumption in the conversion process and the like.

Owner:CHINA PETROLEUM & CHEM CORP +2

Cu-Zr catalyst for steam reforming of methanol to prepare hydrogen and its prepn

InactiveCN1772378ACtiveSelectiveHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogenHydrogen selectivity

The present invention discloses one kind of Cu-Zr catalyst for steam reforming of methanol to prepare hydrogen and its preparation process. The catalyst without Zn and Al components contains CuO10-80 mol%, ZrO2 20-90 mol% and MOx 0-20 mol%, where M is one of Ce, La, Fe, Y and Mn. The Cu-Zr catalyst is used for steam reforming of methanol to prepare hydrogen, and has high activity, high hydrogen selectivity and very high stability. Specifically, it has conversion rate in steam reforming of methanol of 90-99 %, hydrogen selectivity of 95-99 % and CO content in the product lower than 0.5 %.

Owner:FUDAN UNIV

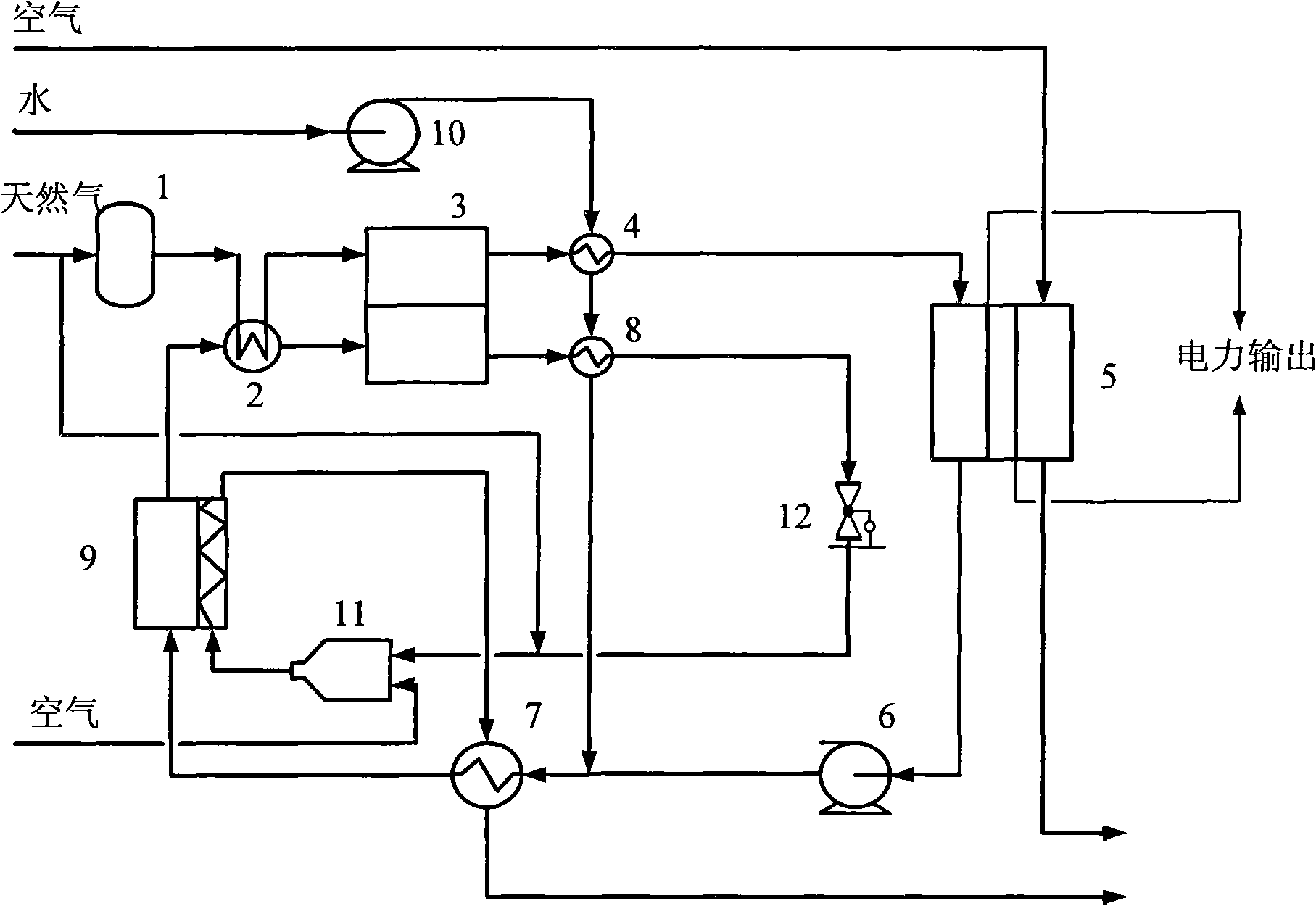

Natural gas hydrogen preparation and proton-exchange film fuel cell integrated generation method and device thereof

InactiveCN101540410AImprove power generation efficiencySimple designFuel cell controlSolid electrolyte fuel cellsNatural gasPalladium

The invention discloses a natural gas hydrogen preparation and proton-exchange film fuel cell integrated generation method and a device thereof. The high-temperature fluid side of a fourth heat exchanger of the device is respectively connected with the high-pressure side of a film separator and a pressure adjusting valve; the low-temperature fluid side is connected with a pipeline between a compressor and a third heat exchanger; the high-temperature fluid side of the third heat exchanger is respectively connected with a fuel gas outlet and an exhaust pipe of a reforming reactor, and the low-temperature fluid side is respectively connected with the compressor and the inlet of the reforming reactor. The invention utilizes hydrogen-preparing raw material gas harmless to the proton-exchange film fuel cell, namely the natural gas, as blowing gas at the inner side of a palladium film and decreases the partial pressure of the hydrogen at the inner side of the film so as to improve the hydrogen partial pressure difference inside and outside the film and improve the whole generation efficiency of the natural-gas reforming hydrogen preparation system and the fuel cell integrated generation system. The invention has simple design, good system heat match and high energy utilization rate and provides a new technological method for the natural gas reforming palladium film hydrogen preparation and proton-exchange film fuel cell integrated generation.

Owner:SOUTH CHINA UNIV OF TECH

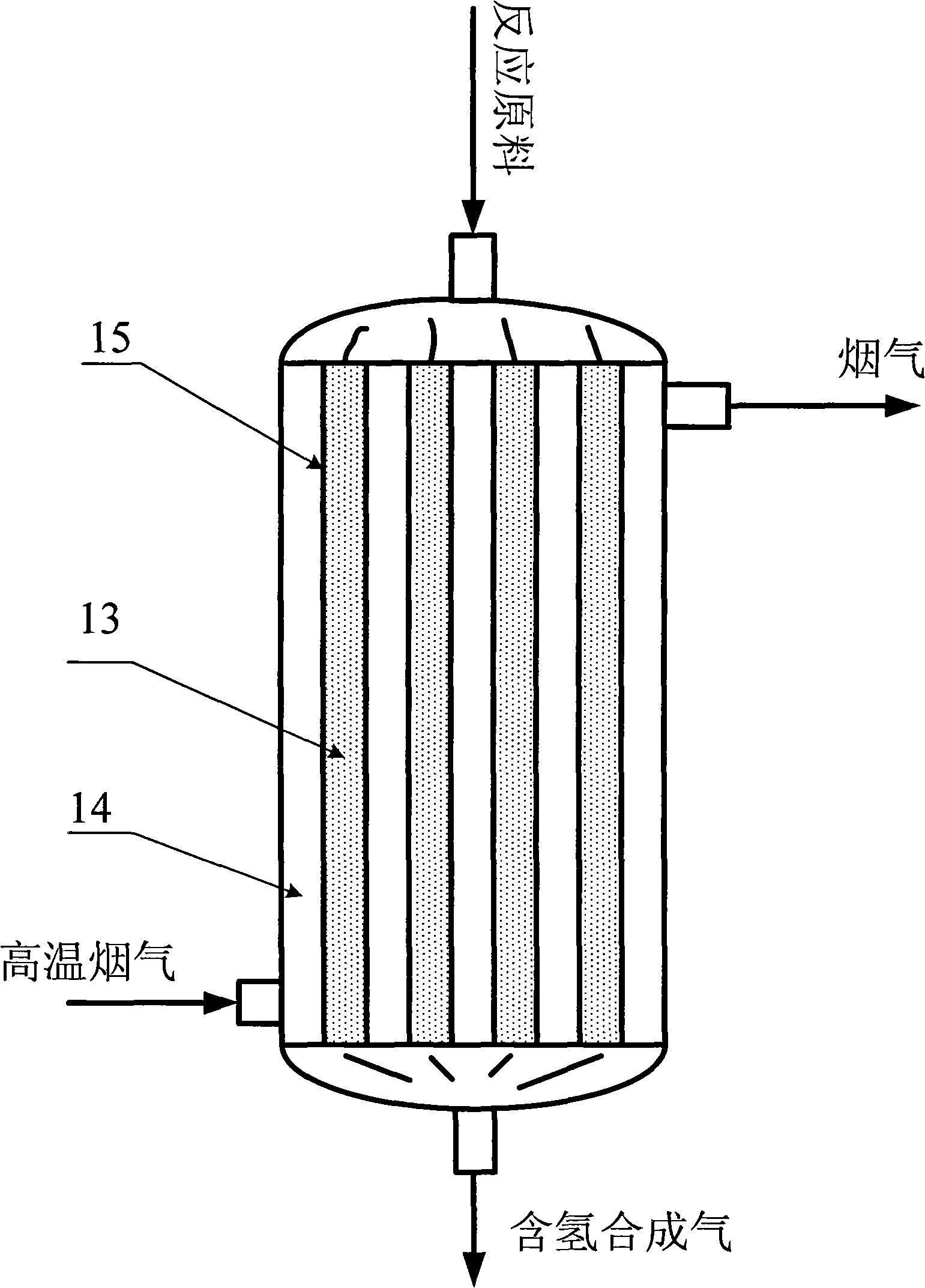

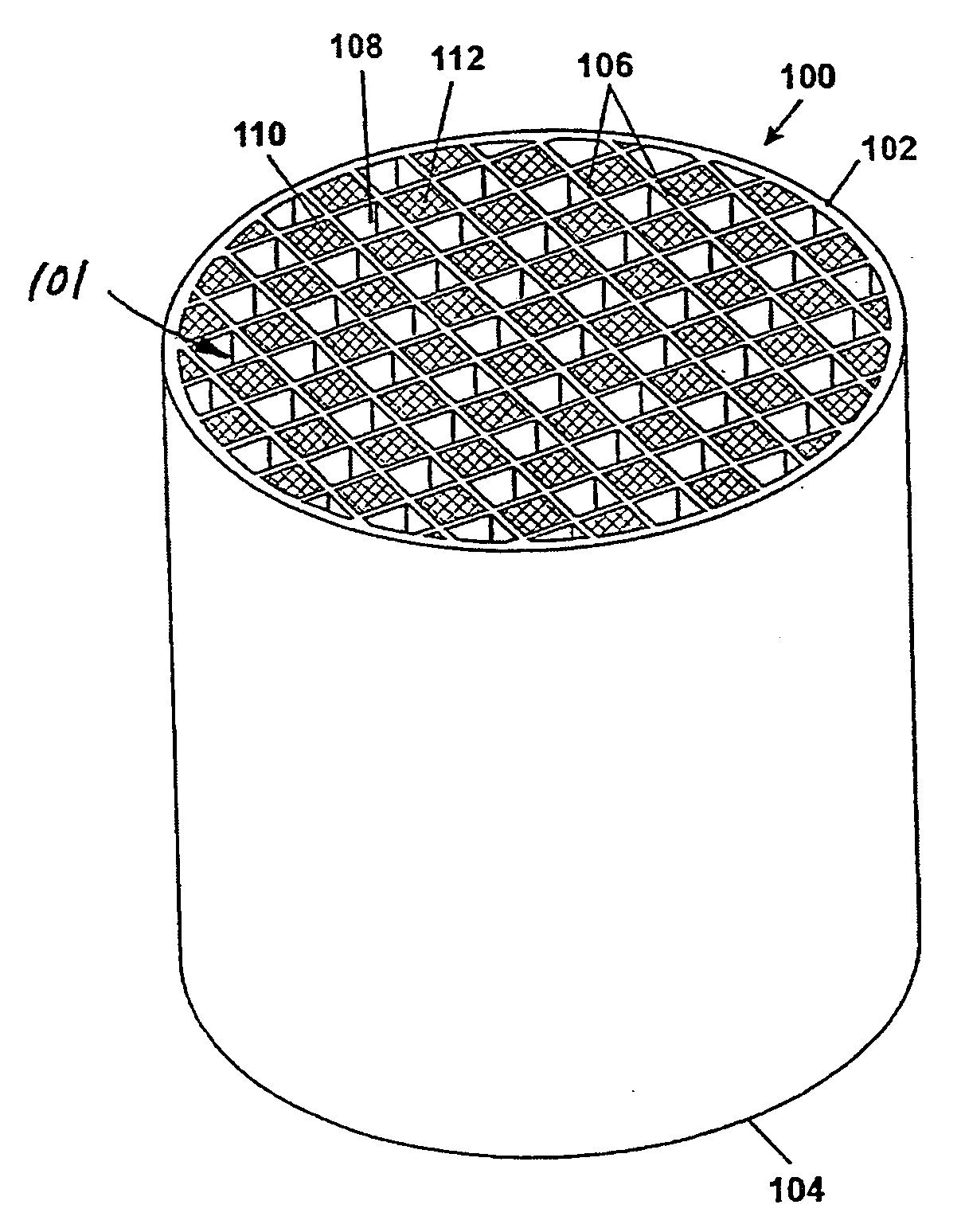

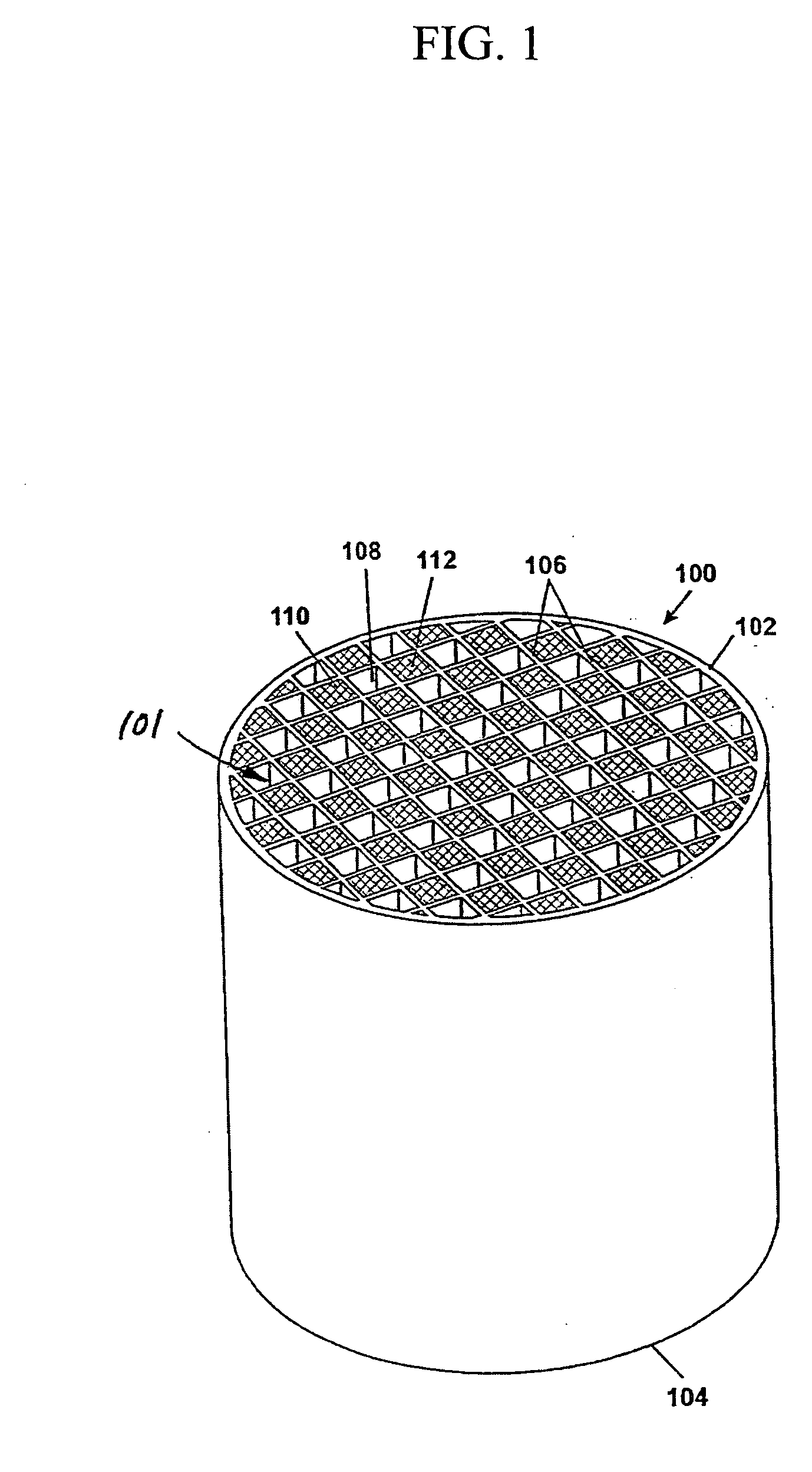

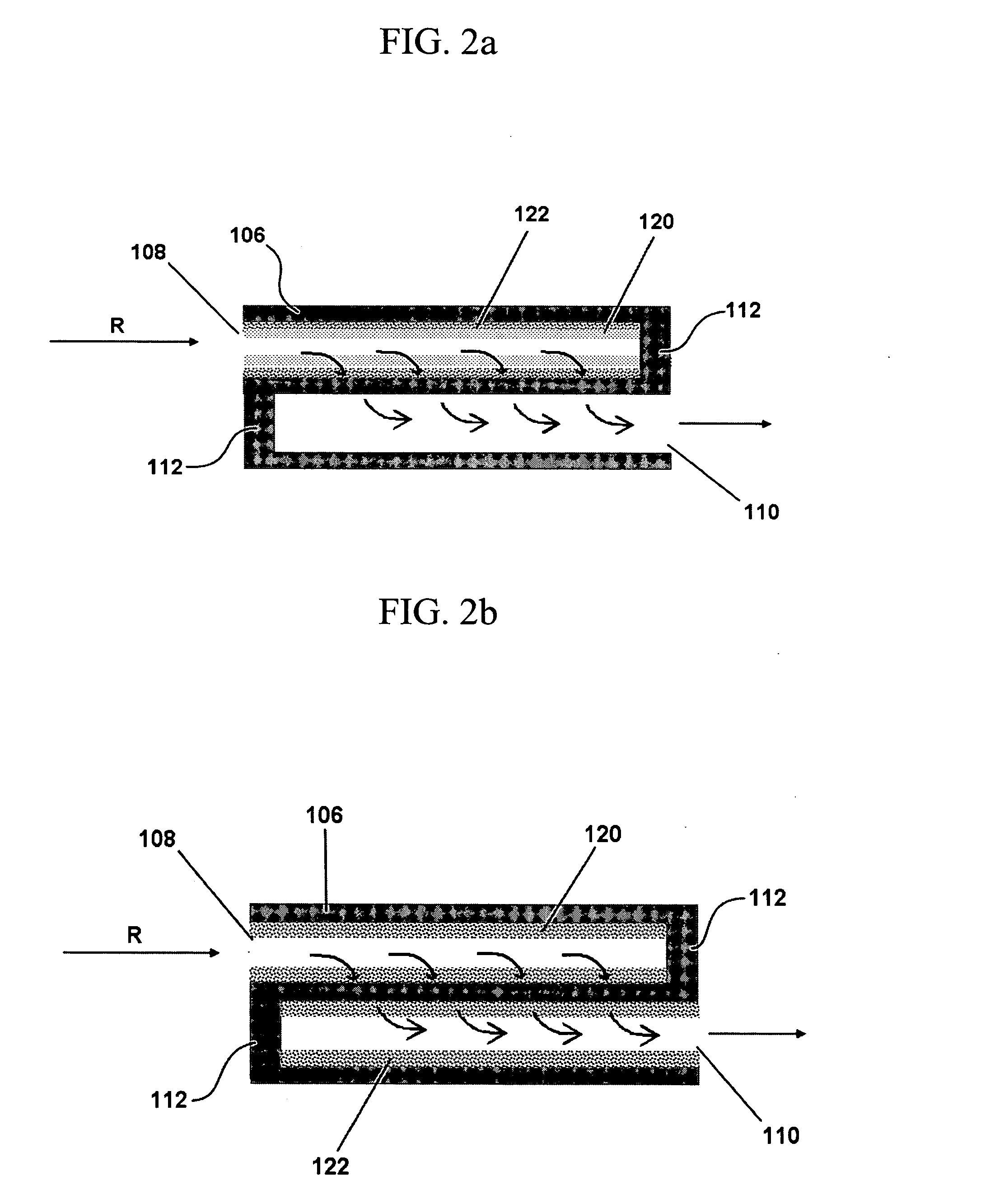

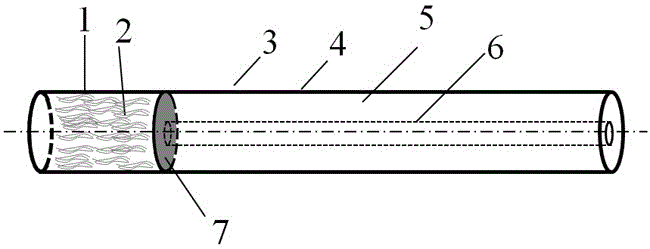

Wall flow reactor for hydrogen production

InactiveUS20080138273A1Raise the ratioMaximize productionCatalytic gas-gas reactionHydrogen productionHoneycombPorous channel

Disclosed herein are wall flow reactors that are suitable for the production of hydrogen gas from hydrocarbon and / or its derivative feed streams. The wall flow reactors are generally comprised a monolithic honeycomb substrate defining a plurality of cell channels bounded by porous channel walls that extend longitudinally from an upstream inlet end to a downstream outlet end; wherein a first portion of the plurality of cell channels are plugged at the downstream outlet end to form inlet cell channels and a second portion of the plurality of cell channels are plugged at the upstream inlet end to form outlet cell channels. A plurality of catalyst layers are positioned within at least a portion of the plurality of cell channels and comprise at least a first catalyst layer and a second catalyst layer. Also disclosed are methods for treating reactant feed streams.

Owner:CORNING INC

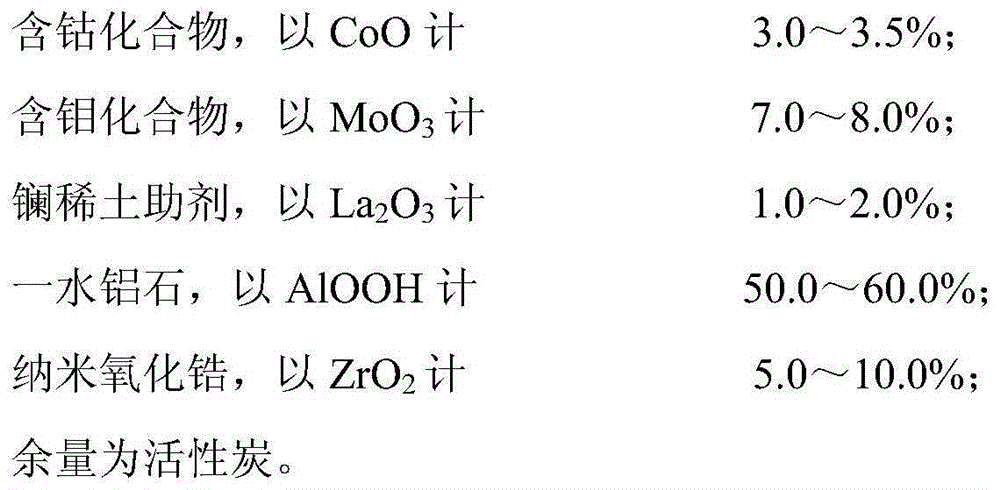

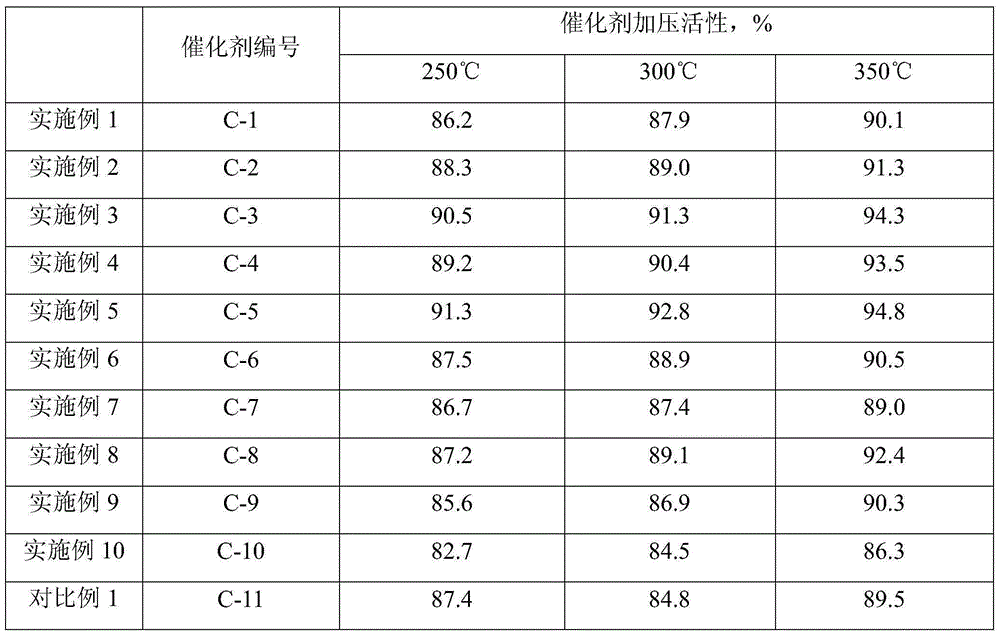

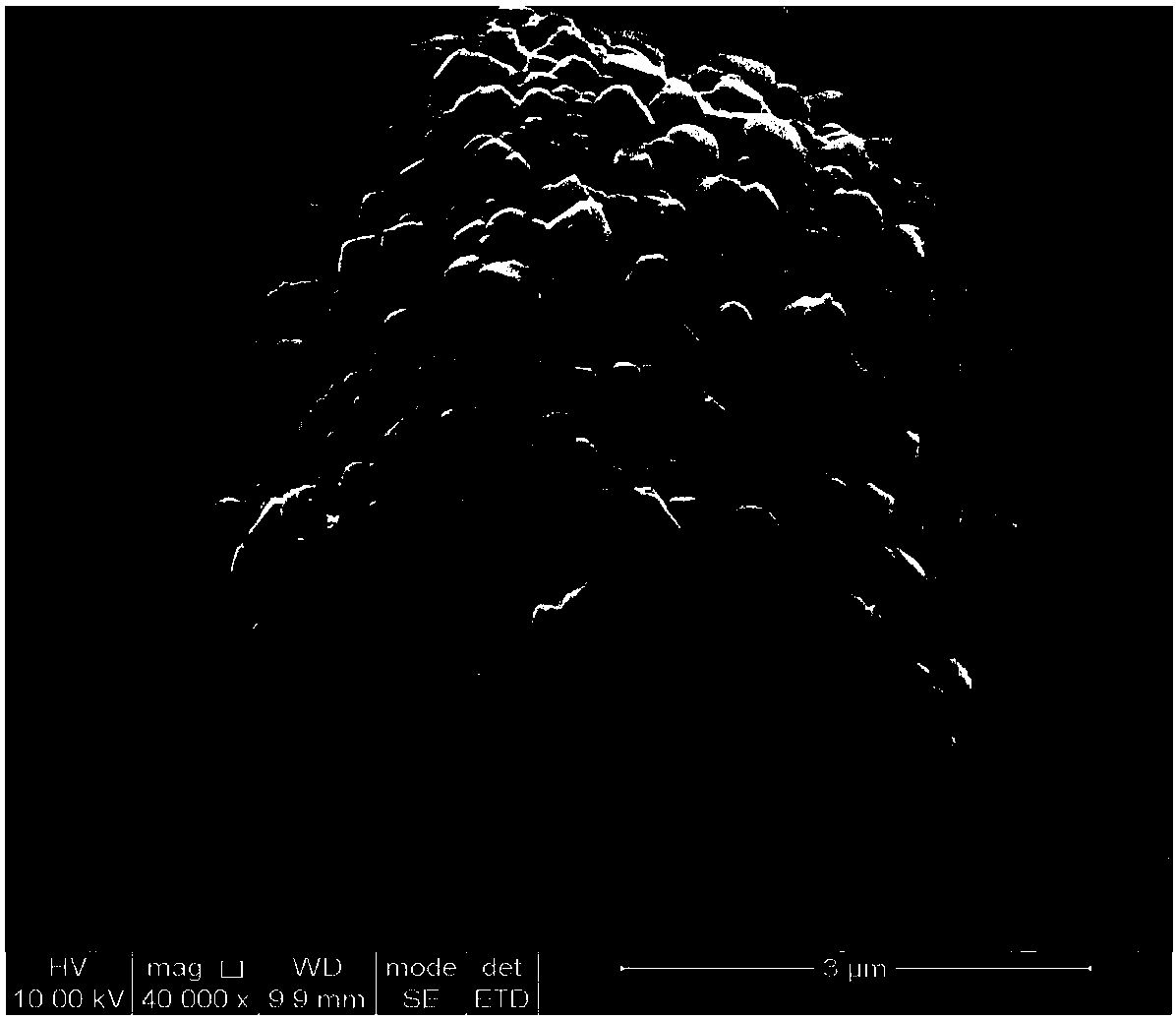

Cobalt-molybdenum low-temperature sulfur tolerant shift catalyst and preparation method thereof

ActiveCN106552637AHigh surface areaImprove adsorption capacityHydrogenMetal/metal-oxides/metal-hydroxide catalystsCrack resistanceRare earth

The invention relates to a cobalt-molybdenum low-temperature sulfur tolerant shift catalyst and a preparation method thereof and belongs to the technical field of carbon monoxide shifting. The catalyst comprises active ingredients, an accessory ingredient and carriers, wherein the active ingredients include a cobaltiferous compound and a molybdenum-containing compound, the accessory ingredient is a lanthanum rare earth accessory ingredient, and the carriers include boehmite, nano zirconium oxide and activated carbon. According to cobalt-molybdenum low-temperature sulfur tolerant shift catalyst, AlOOH is utilized to replace an Al2O3 ingredient commonly used in an industrial catalyst, so that the problem that a catalyst containing a gamma-Al2O3 carrier is subjected to phase transformation caused by soaking in water due to working condition changes during operation at a temperature approximate to the dew point can be avoided; the activated carbon ingredient has relatively high specific surface and adsorptive properties, is beneficial to uniform distribution of the active ingredients, and is capable of enhancing adsorptive collection of hydrogen sulfide, so that the shift activity is improved; nano zirconium oxide is capable of improving the crack resistance and tenacity of a common activated carbon carrier; the rare earth accessory ingredient can be used for improving the activity stability and structural stability of the shift catalyst; the preparation method is simple and practical and is easy in production.

Owner:CHINA PETROLEUM & CHEM CORP

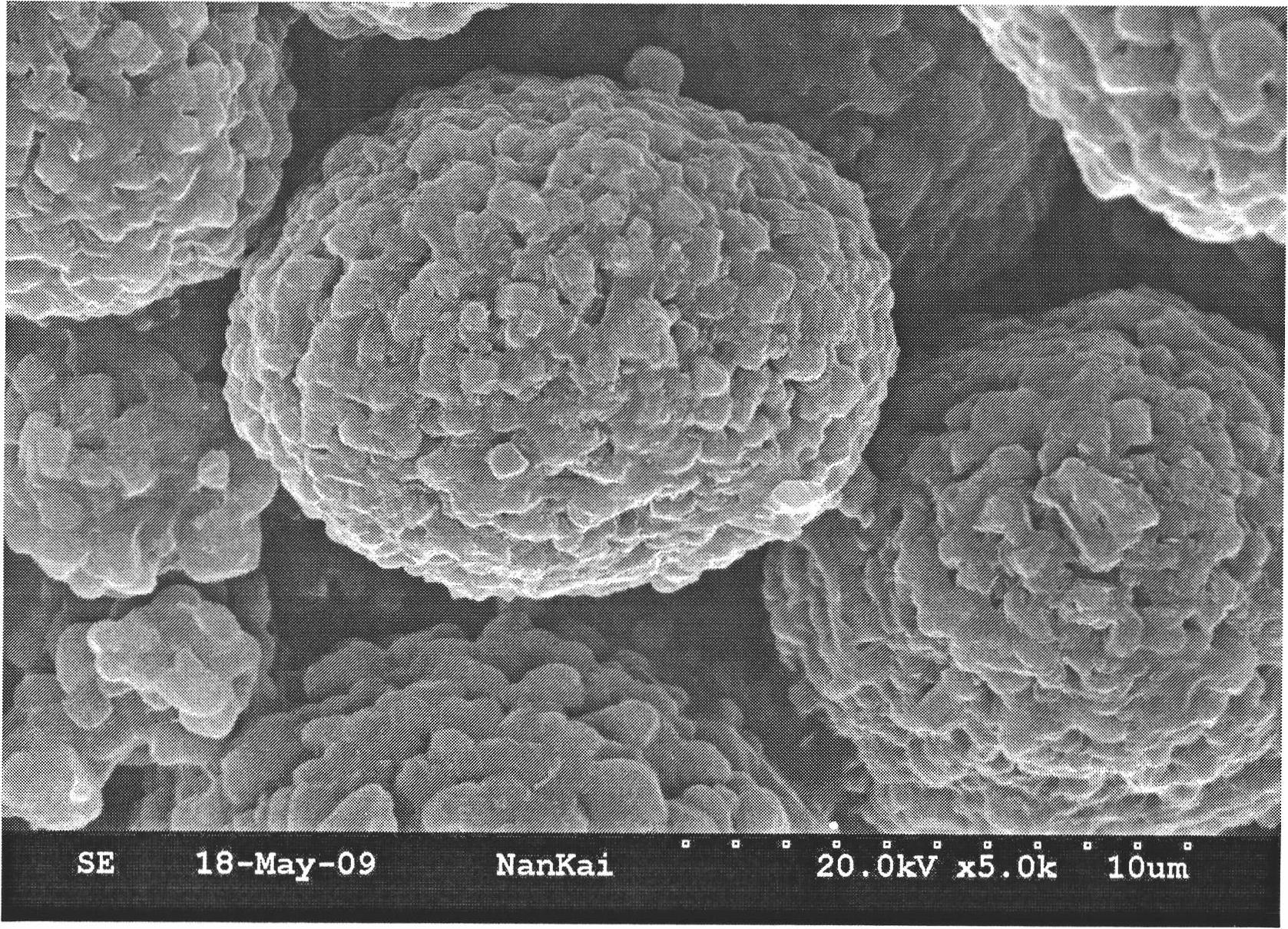

Quad-element lithium ion battery anode material and preparing method

InactiveCN108288711AImprove stability and securityImprove cycle stabilityCell electrodesSecondary cellsNickel saltFiltration

The invention discloses a quad-element lithium ion battery anode material and a preparing method. The molecular formula of the quad-element lithium ion battery material is LiNi0.6Co0.1Mn0.1Fe0.1O2. The preparing method of the battery anode material includes the following steps of weighing soluble nickel salt, soluble cobalt salt, soluble manganese salt and soluble iron salt, adding the salts to deionized water at the same time to be dissolved to prepare a mixed solution, adding a precipitant to the deionized water to be dissolved to prepare a precipitant solution, dropwise adding the mixed solution to the precipitant solution to be stirred and mixed, conducting coprecipitation, suction filtration, washing and drying to obtain a precursor for standing and ageing, evenly mixing the nickel-cobalt-manganese-iron four-element material precursor and a lithium source, and conducting presintering, grinding and secondary calcinating to obtain the nickel-cobalt-manganese-iron four-element anodematerial. By introducing the fourth element, namely iron, to a three-element material, since the radius and electronegativity of an introduced ion are close to those of a replaced element, damage cannot happen after introduction, the layer structure of the material can be stabilized, and the circulation stability of the material is improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

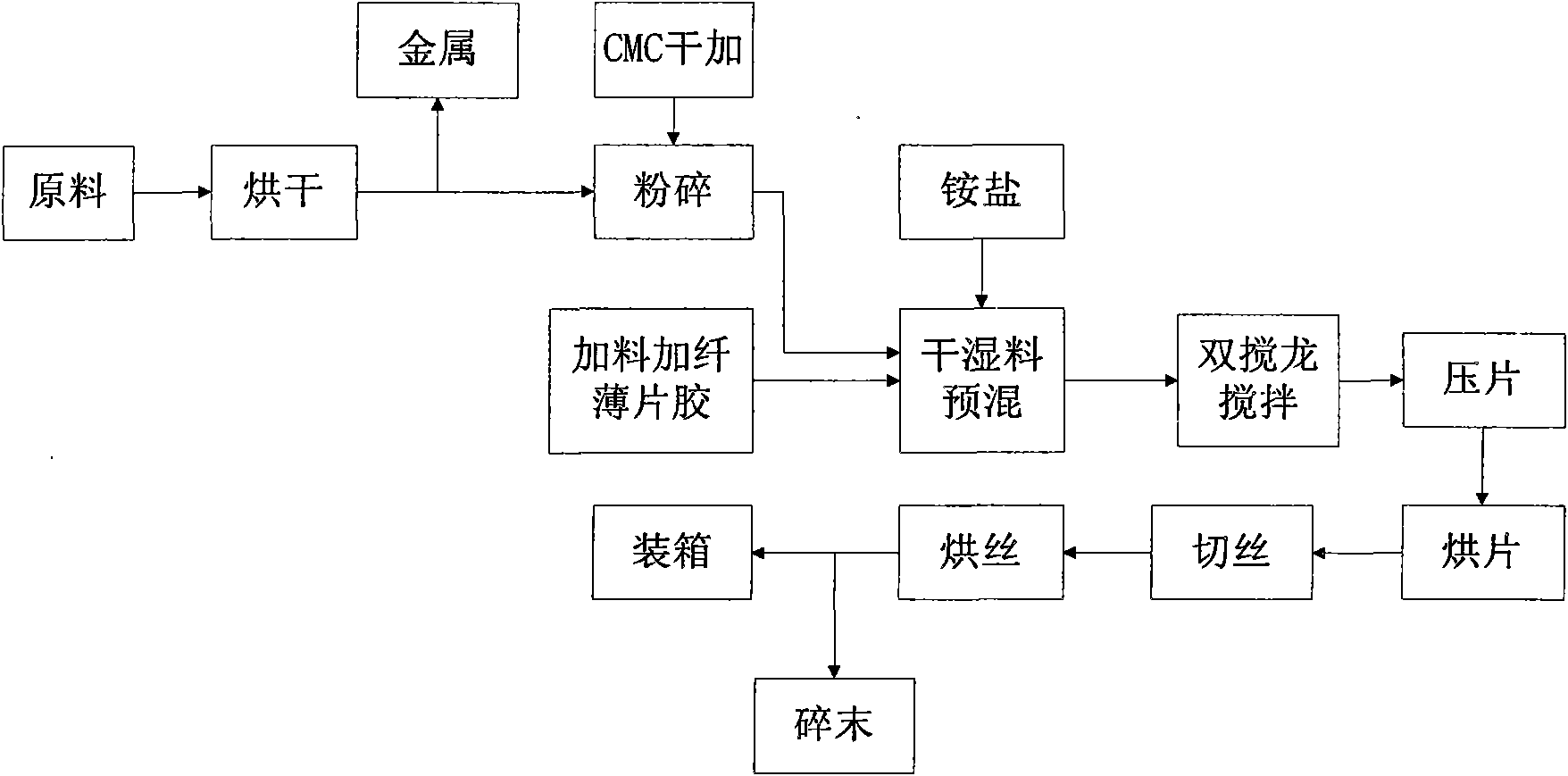

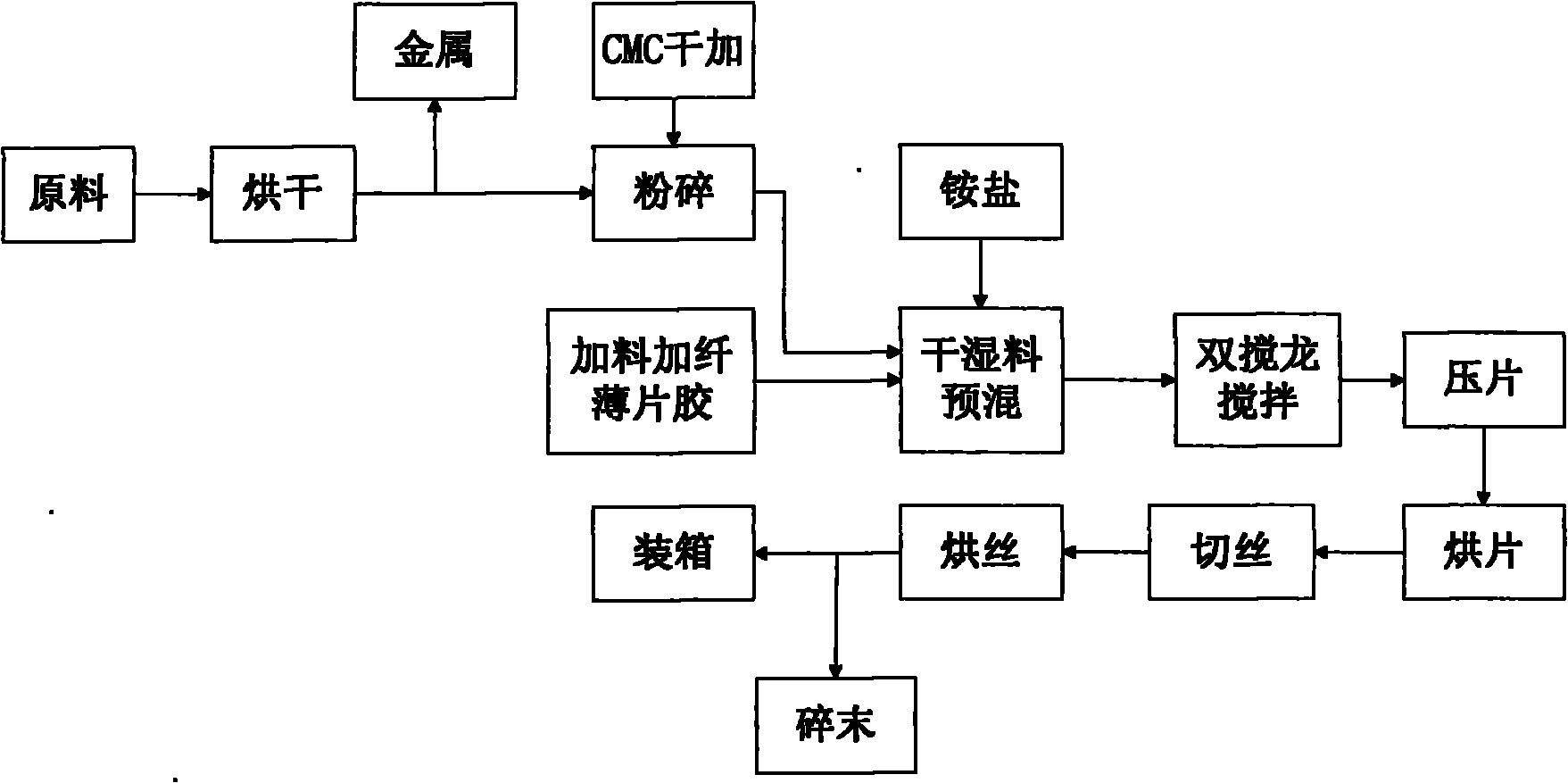

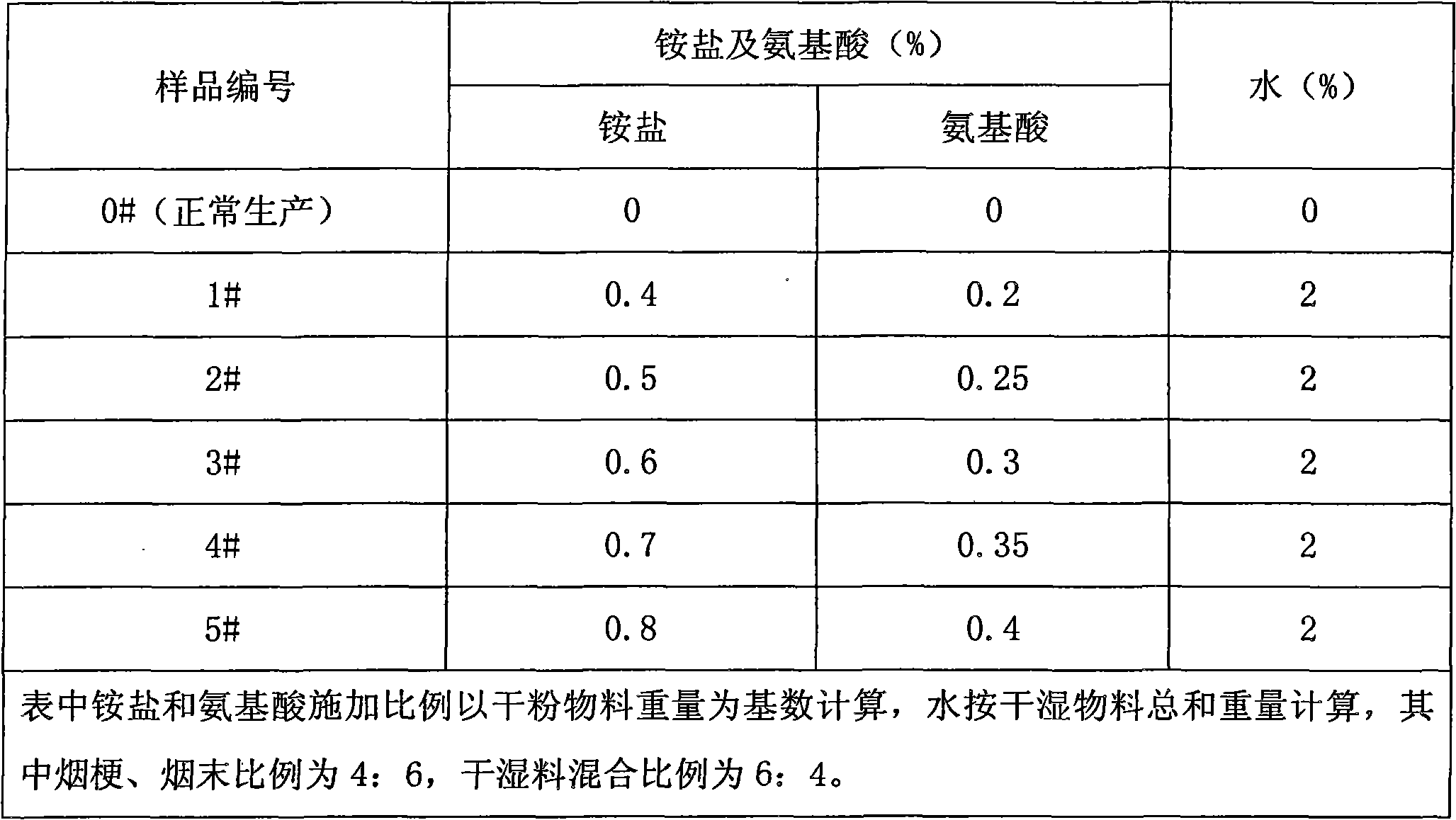

Ammonium salt-containing tobacco leaf reproduced by means of rolling

The invention relates to an ammonium salt-containing tobacco leaf reproduced by means of rolling. The tobacco leaf comprises the following components in parts by weight: 0.4-0.8 part of ammonium salt, 0.2-0.4 part of amino acid, 100 parts of dry material and 66-67 parts of wet material. Compared with the tobacco leaf reproduced by means of rolling, the ammonium salt and the amino acid are added into ammonium salt-containing tobacco leaf reproduced by means of rolling, thereby being capable of reducing the impure gas and the piquancy of the reproduced tobacco leaf, so that the ammonium salt-containing tobacco leaf has abundant fragrance; improves the remaining smell; leads the tobacco leaf with heavy impure gas, dirty oral cavity and piquancy feel to have natural tobacco fragrance; has unconspicuous impure gas and piquancy fell; leads the tobacco gas to have sweet and wet feel; can clean the oral cavity; and is smooth to a throat. The reproduced tobacco leaf not only improves the quality of sense organ, but also reduces the content of objectionable constituents such as phenol, CO and the like, and the content of tar, CO and the like in smoke indexes.

Owner:CHINA TOBACCO SHANDONG IND

Hydrogen production catalyst with high-temperature methyl alcohol water vapour and preparation method thereof

ActiveCN101632929AHigh reactivityImprove stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsCarrying capacityAlcohol

The invention discloses a catalyst and a preparation method thereof, in particular to a hydrogen production catalyst with high-temperature methyl alcohol water vapour and a preparation method thereof. The catalyst comprises active components of VIII group metal and auxiliary agent and also comprises modified Al2O3 spherules serving as a carrier, wherein, the sharing carrying capacity of the active components occupies 2.6-10wt% of the carrier, and the ratio of the active components to the auxiliary agent ZnO is 0.24-0.38:1. The catalyst has high reaction activity, high stability and simple manufacturing method, can lower cost and adopts the method of cocurrent flow dipping and ultrasonic dispersion, so that noble metal has small use amount and little waste, which can satisfy the requirement of the activity and service life of catalyst by industrialization. The catalyst of the invention can be applied in the fuel battery hydrogen supplying field on a large scale.

Owner:HANERGY TECH

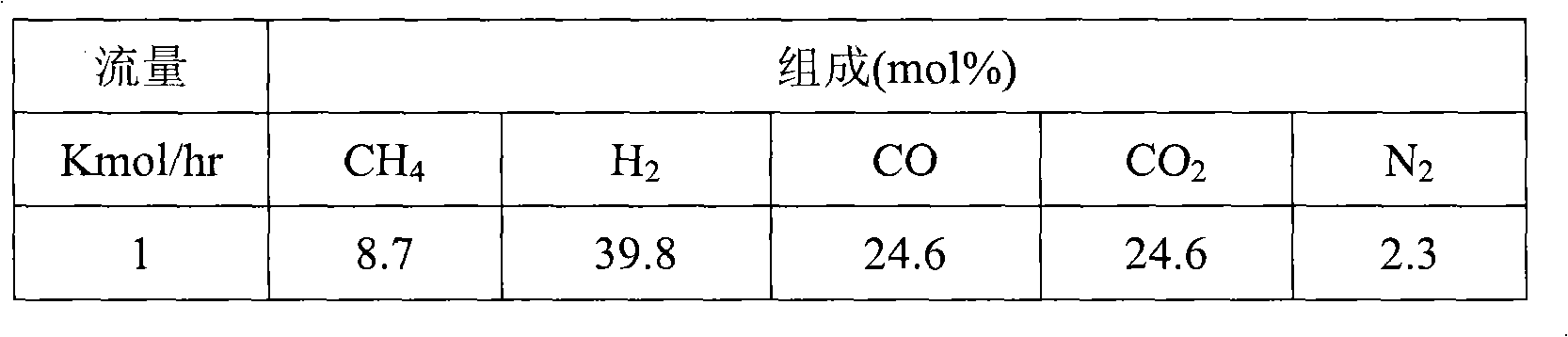

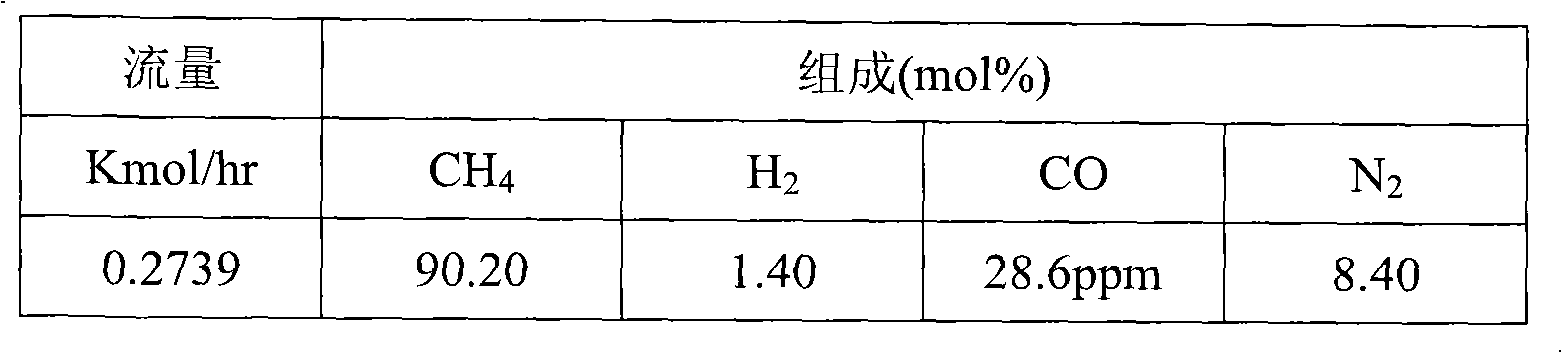

Method and device for preparing synthetic natural gas

ActiveCN101851537AEasy to operateReduce high temperature carbon depositionGaseous fuelsLiquid waterWater-gas shift reaction

The invention provides a method for preparing a synthetic natural gas. The method comprises the step of performing a methanation reaction on a raw material gas which contains CO, CO2 and H2 in the presence of liquid saturated water. The invention also provides a device for implementing the method. The device comprises a methanator which is provided with a raw material gas inlet, a product outlet,and a nickel-based catalysts and liquid water inlet. The method of the invention is convenient and easy, and is suitable for various raw material gases; the ratio of H2 to CO in the raw material gas is improved by a water gas shift reaction; and a great amount of heat released by the methanation reaction is removed fast by vaporizing the liquid saturated water, so that a reaction temperature is controlled effectively, high-temperature carbon deposit of a catalyst is slowed down and the service life of the catalyst is prolonged. The device of the invention has the characteristics of simple structure and convenient operation.

Owner:PUJING CHEM IND SHA

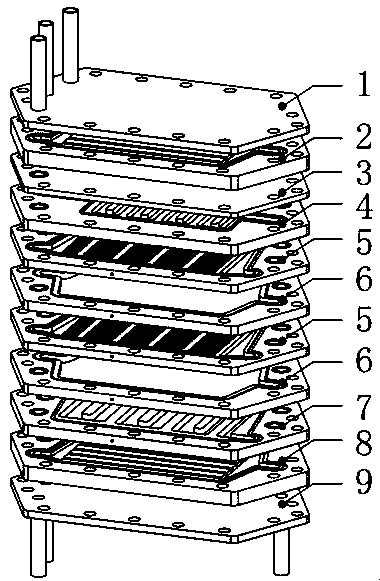

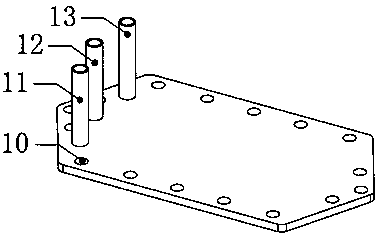

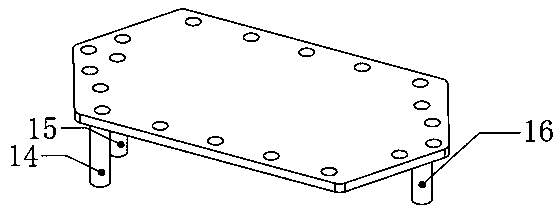

Self-heating methanol reforming hydrogen production reactor integrating CO selective methanation

ActiveCN110155945AAchieve removalSave the water vapor inverse conversion processHydrogen separation using solid contactHydrogen separation using liquid contactMethanol waterMethanation

The invention discloses a self-heating methanol reforming hydrogen production reactor integrating CO selective methanation. The reactor comprises an upper cover plate, an upper heat exchange plate, aheat exchange plate separation layer, an evaporation plate, a first methanol catalytic combustion plate, a first methanol water vapor reforming plate, a second methanol catalytic combustion plate, a second methanol water vapor reforming plate, a CO selective methanation reaction plate, a lower heat exchange plate and a lower cover plate from top to bottom. A CO selective methanation reaction is integrated in the reactor, and the CO selective methanation reaction is completed by directly using hydrogen in reformed gas; after the reformed gas which is reformed and prepared by a methanol water vapor reaction is subjected to CO selective methanation treatment, the CO content is reduced; in a CO removal process of the reactor, other reactants are not introduced, and the content of hydrogen in final product gas is 70% or above. Gradient distribution of the temperature in the reactor is realized through the laminating sequence and connecting gas paths of all the reaction plates, so that eachof two different catalysts is located in an optimum working temperature; and the heat exchange plates are respectively designed at the upper end and the lower end of the reactor for preheating and recycling, so that the energy utilization rate is improved.

Owner:ZHEJIANG UNIV

Cigarette with porous material

A cigarette with a porous material comprises a filter tip and a tobacco shred stick, and is characterized in that a hollow tube is axially arranged in the tobacco shred stick, and the porous material is arranged at a position where the hollow tube is connected with the filter tip. The structure of the cigarette is improved, and enough air is provided for combustion of tobacco shreds in a burning and smoking process of the cigarette to reduce CO gas generated by incomplete combustion of the tobacco shreds at high temperature. The original overall size of the cigarette is not changed, the CO release amount of the cigarette and smoking temperature of mainstream smoke can be reduced obviously on the premise of not changing the original smoking taste, and therefore, consumers can receive the cigarette.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

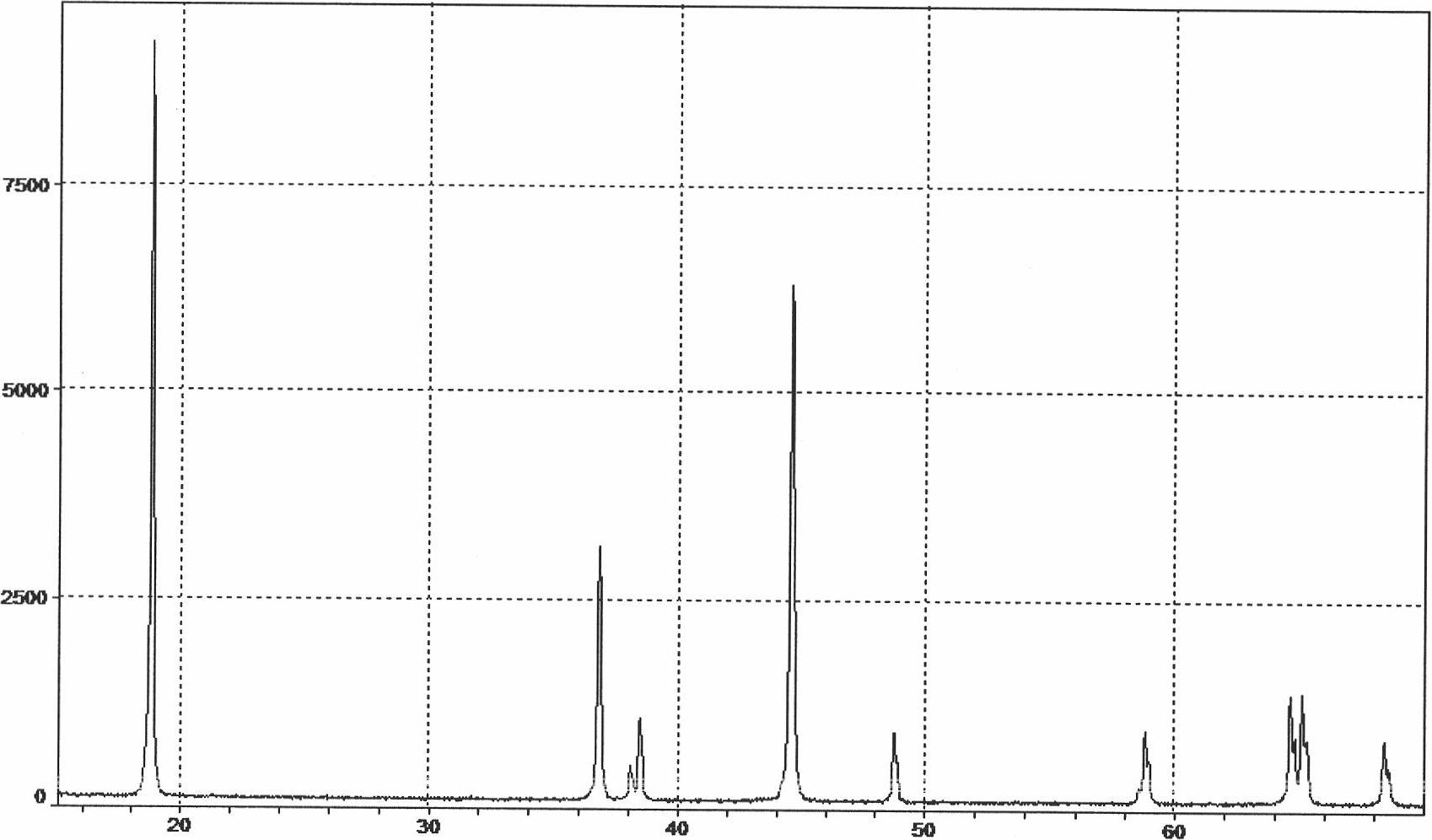

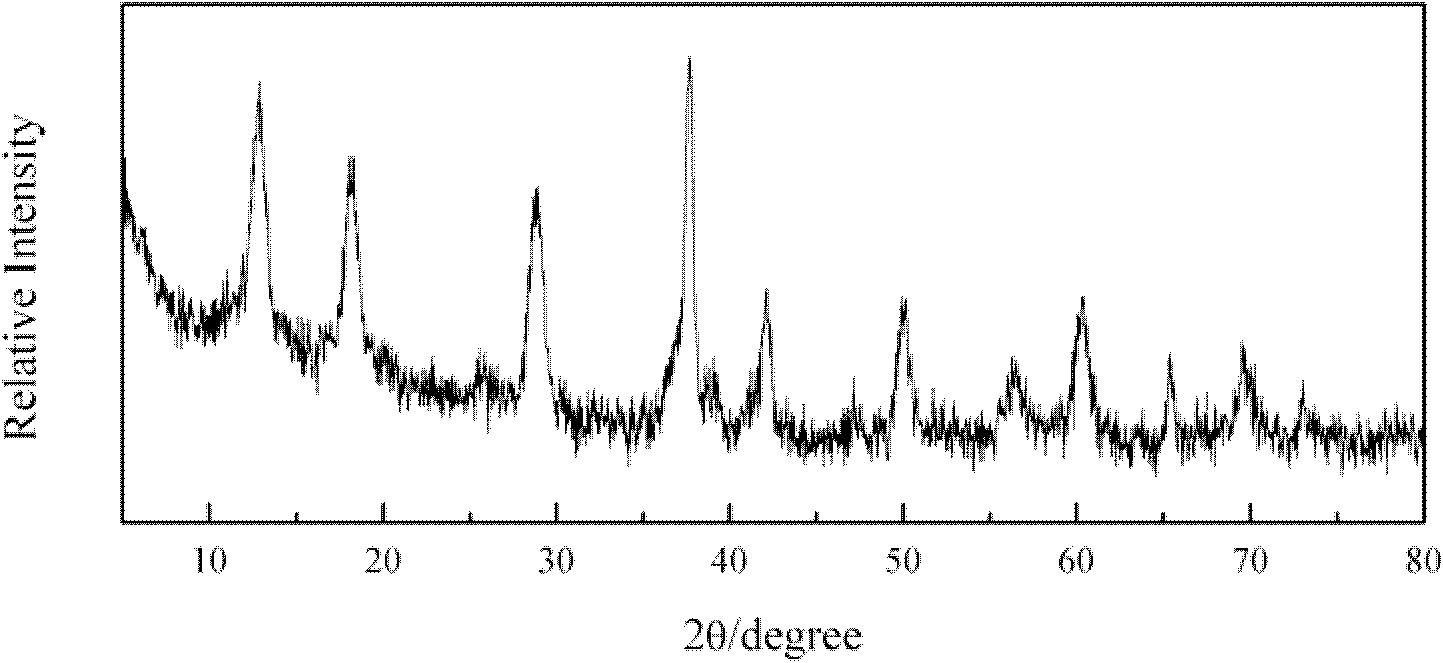

Catalyst for reducing CO content in cigarette smoke, and preparation and application thereof

ActiveCN102218327AReduce manufacturing costSimple production processTobacco smoke filtersMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention belongs to the technical field of the cigarette material preparation, and relates to a catalyst capable of effectively reducing CO content in cigarette, and preparation and application thereof. The catalyst for reducing the CO content in the cigarette smoke of the invention is a transition metal-manganese composite oxide catalyst, and the crystalline phase of the catalyst is alpha-MnO2 phase, gamma-MnO2 phase or the mixed phase of the two crystalline phases. In application, the transition metal-manganese composite oxide catalyst of the invention is added to an acetate fibre bundle and then coiled to form a filter tip which is capable of effectively reducing the CO content in the cigarette smoke by a reduction ratio of 4-11%. The production cost of the transition metal-manganese composite oxide catalyst of the invention is low, and the production process of the catalyst is simple; the properties of the catalyst are stable; and the catalyst is capable of overcoming the influence caused by the change of the environment during industrial production and sales processes.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

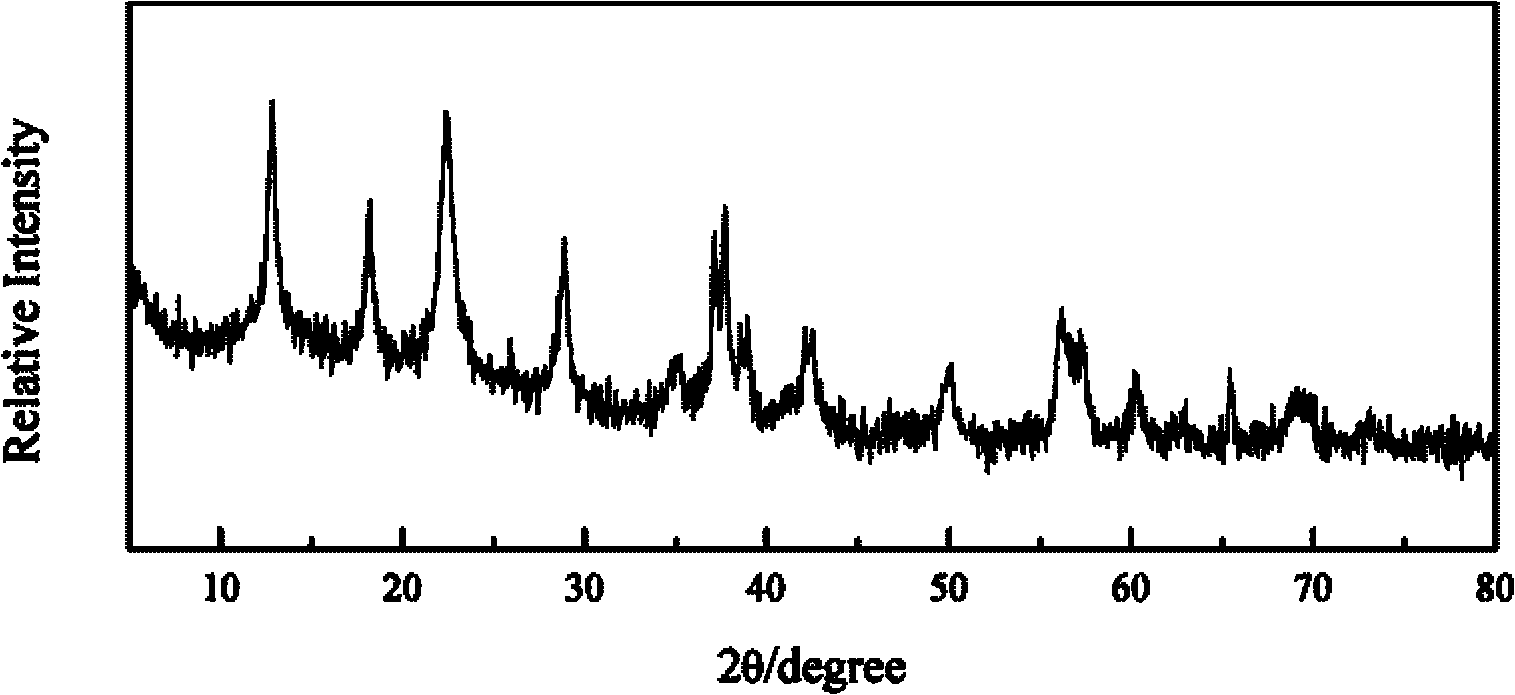

Low cost hydrogen storage alloy, preparation method and application thereof

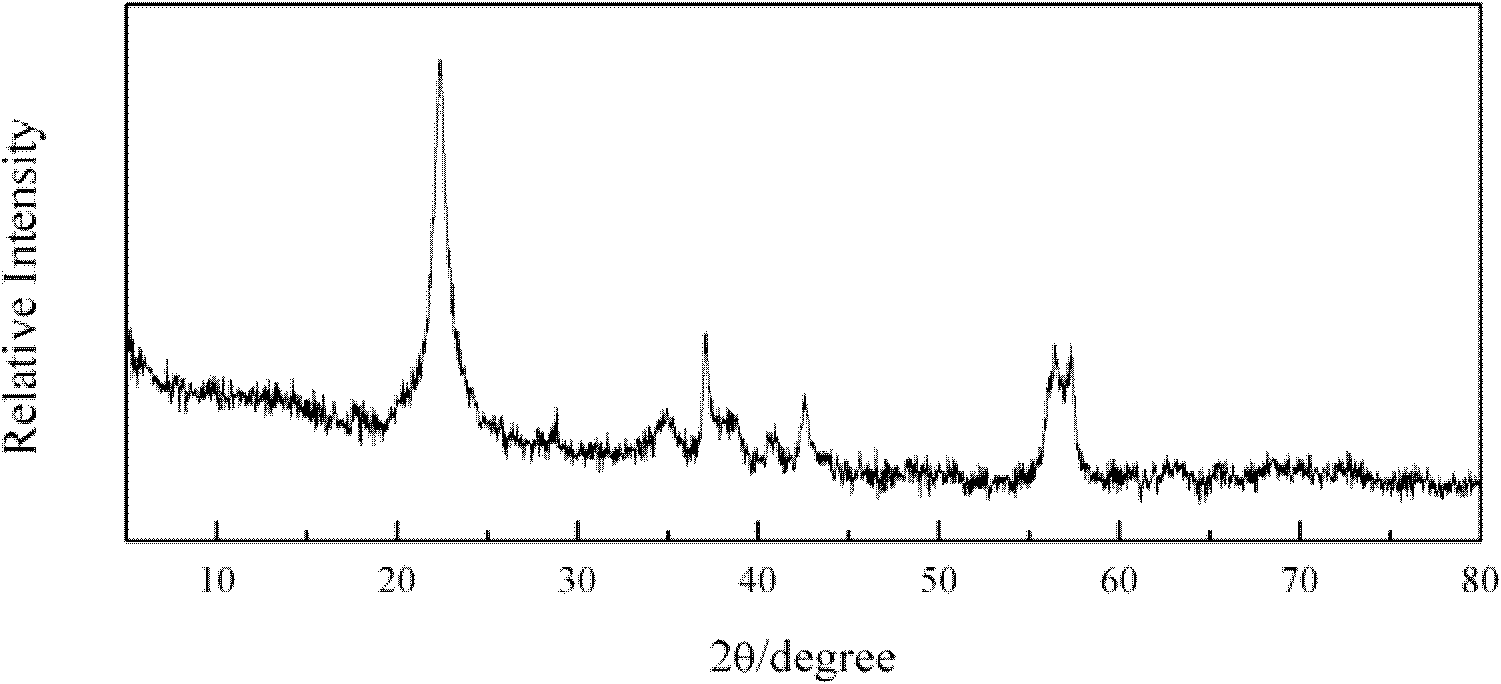

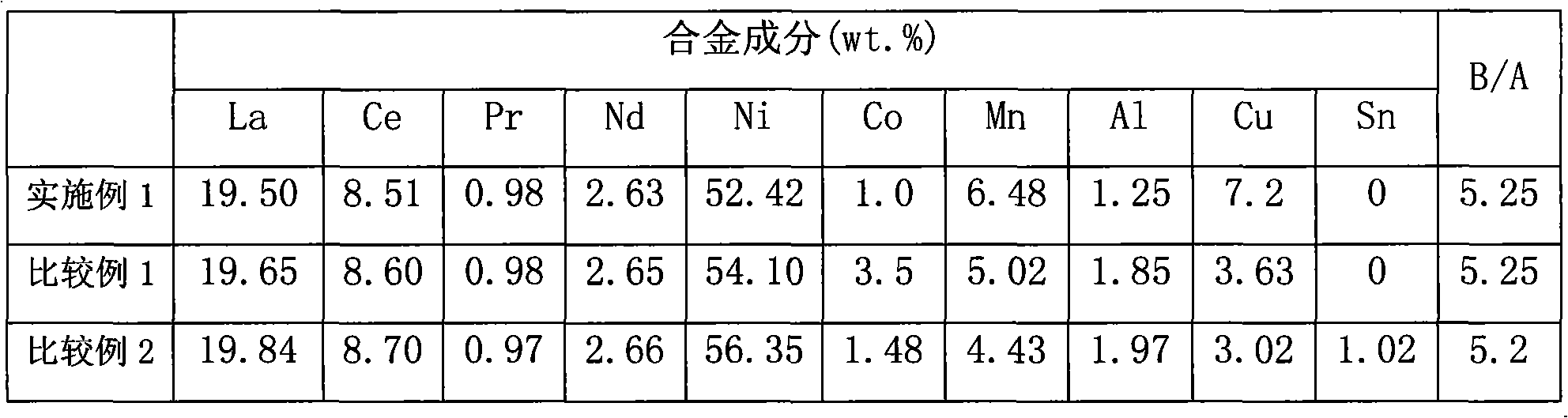

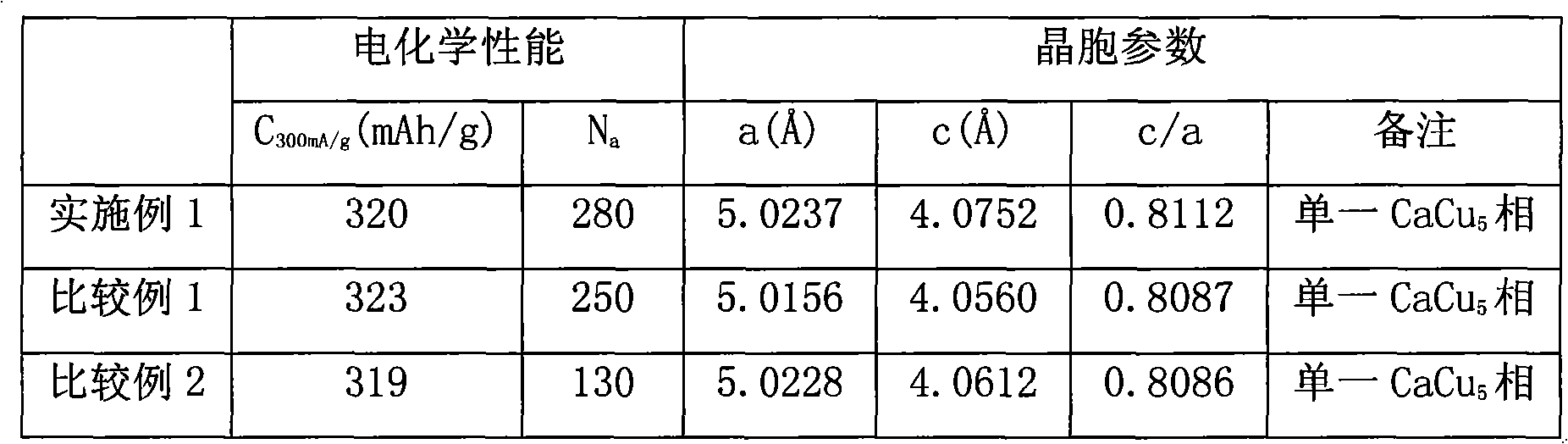

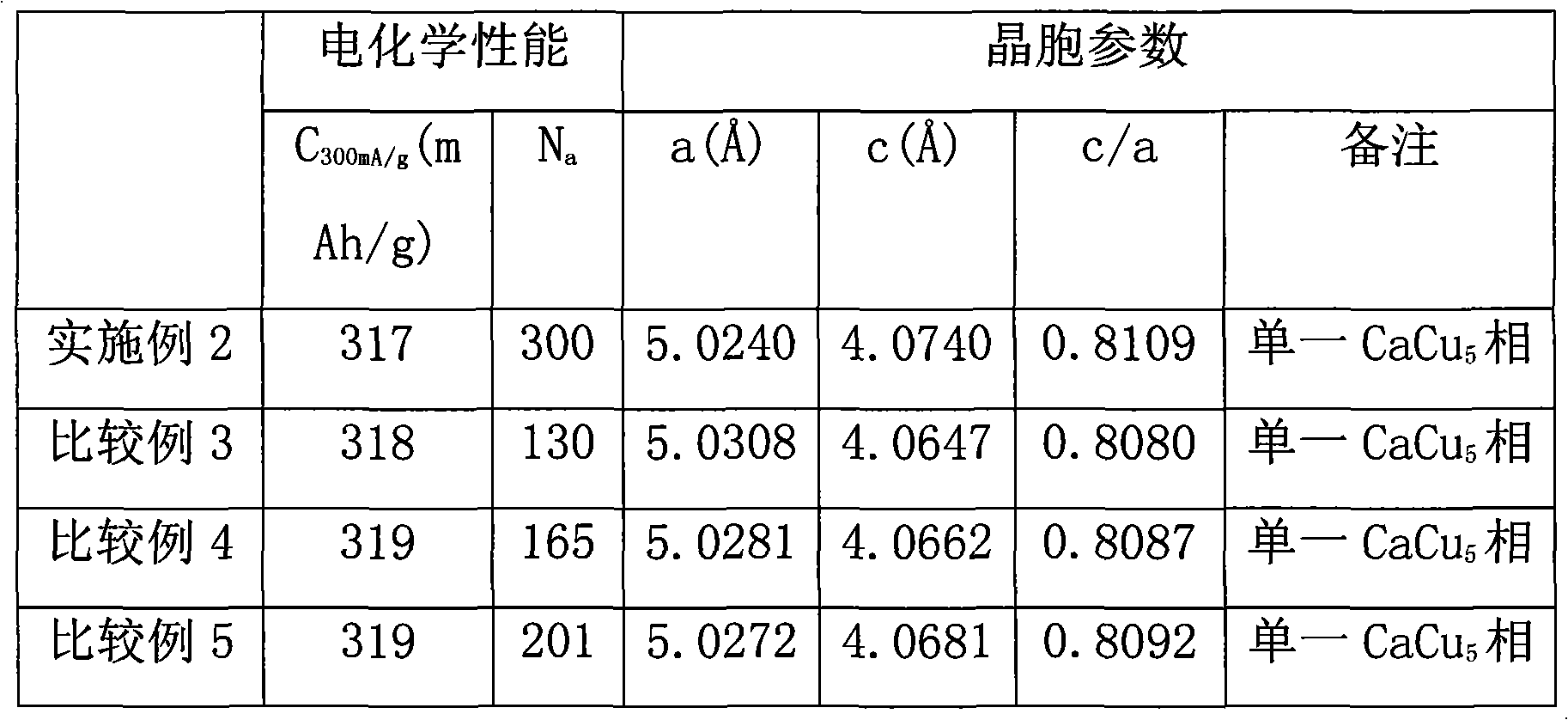

ActiveCN101613818ALow costReduce CO contentAlkaline accumulator electrodesCrystal structureBiological activation

The invention discloses a low cost hydrogen storage alloy which is AB5 type alloy with the general formula of Laa M(1-a) Nib Coc Mnd Ale Cuf, wherein M is at least one in Ce, Pr, Nd, Pm, Sm, Dy, Y, Zr and Ti; a, b, c, d, e and f represent mole ratio with the number range: a is more than or equal to 0.3 and less than or equal to 0.8, b is more than 3.6 and less than or equal to 4.1, c is more than 0 and less than or equal to 0.15, d is more than or equal to 0.3 and less than or equal to 0.65, e is more than or equal to 0.04 and less than or equal to 0.35, f is more than or equal to 0.3 and less than or equal to 1.0, and the sum of b, c, d, e and f is more than or equal to 5.1 and less than or equal to 5.35. The hydrogen storage alloy has CaCu5 crystal structure, and the ratio (c / a) of lengths of c axis and an axis of the CaCu5 crystal structure is more than or equal to 0.81. The invention also discloses a preparation method of the hydrogen storage alloy as well as the application thereof in negative pole material of a nickel-metal hydride battery. The hydrogen storage alloy has low cost, good activation performance, large discharge capacity and long cycle life.

Owner:XIAMEN TUNGSTEN

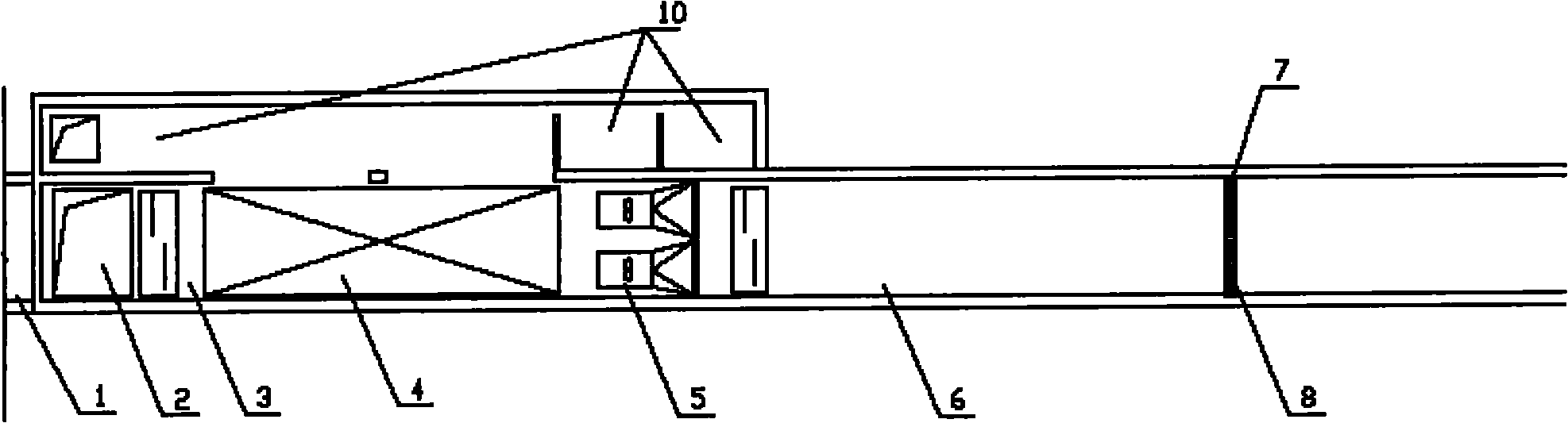

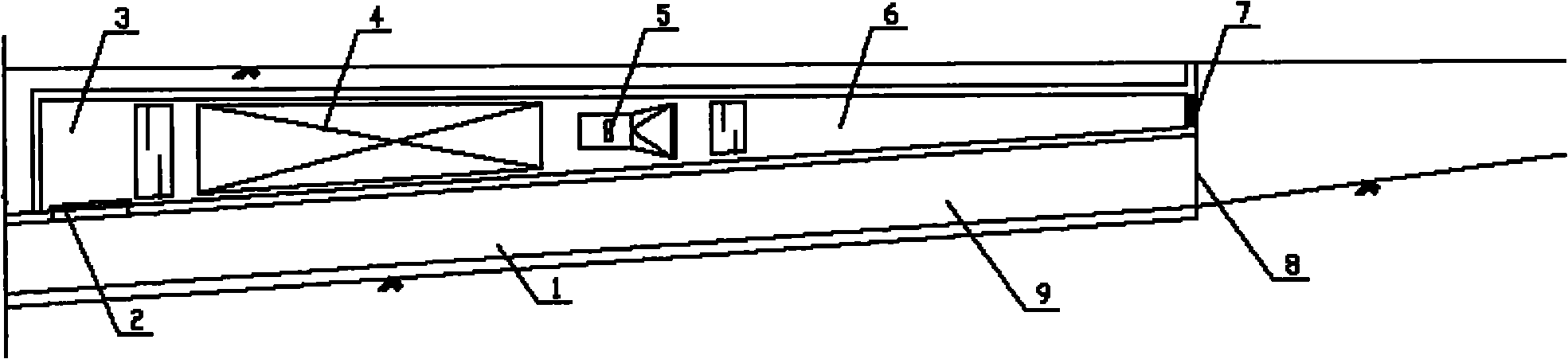

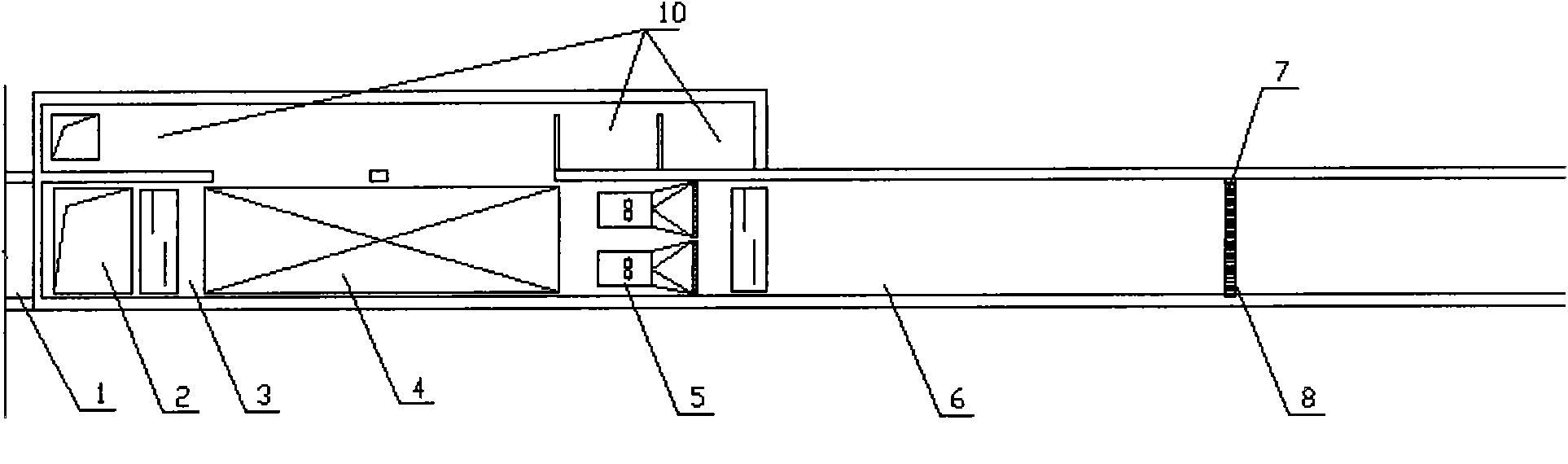

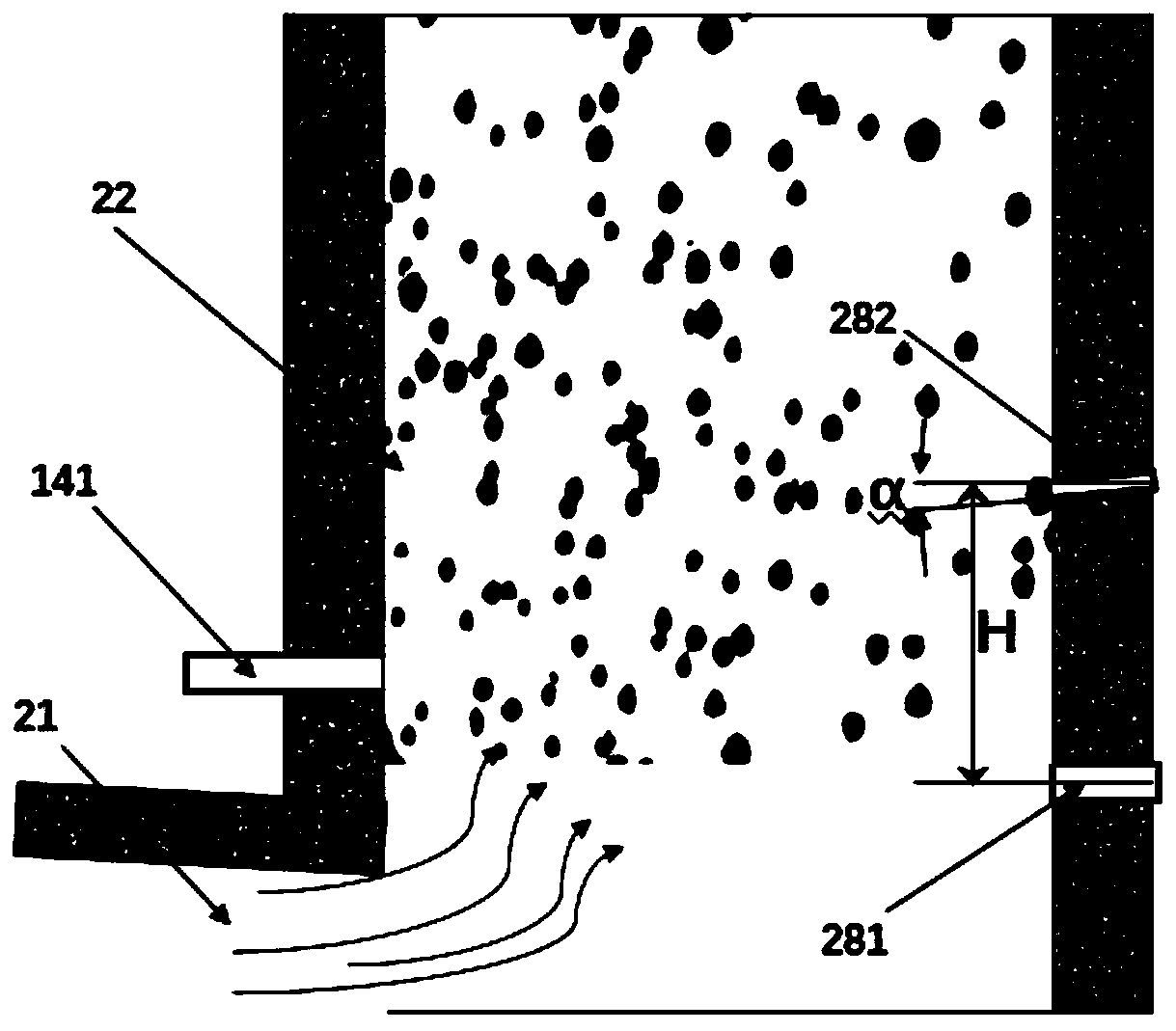

Exhaust airway-free purifying exhaust structure for road tunnel

InactiveCN102080559AReduce CO contentCatalyst powder coatingElectrostatic separationDispersed particle separationTuyerePollution

The invention discloses a purifying exhaust structure for a road tunnel, which comprises a draught opening, a draught pipe communicated with the draught opening, a tunnel polluted air purifying device connected with the draught pipe, a fan connected with the tunnel polluted air purifying device, an exhaust pipe connected with the fan, and air exhaust opening communicated with the exhaust pipe. The structure overcomes the drawbacks of an exhaust airway and exhaust tower scheme and a tunnel opening direct polluted air exhaust scheme, radically solves the problem that the sites of the exhaust airway and exhaust tower for the road tunnel are difficult to select and the problem that the exhaust airway and exhaust tower for the road tunnel are unfavorable for landscape and greatly reduces the pollution of the tunnel to the atmospheric environment.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

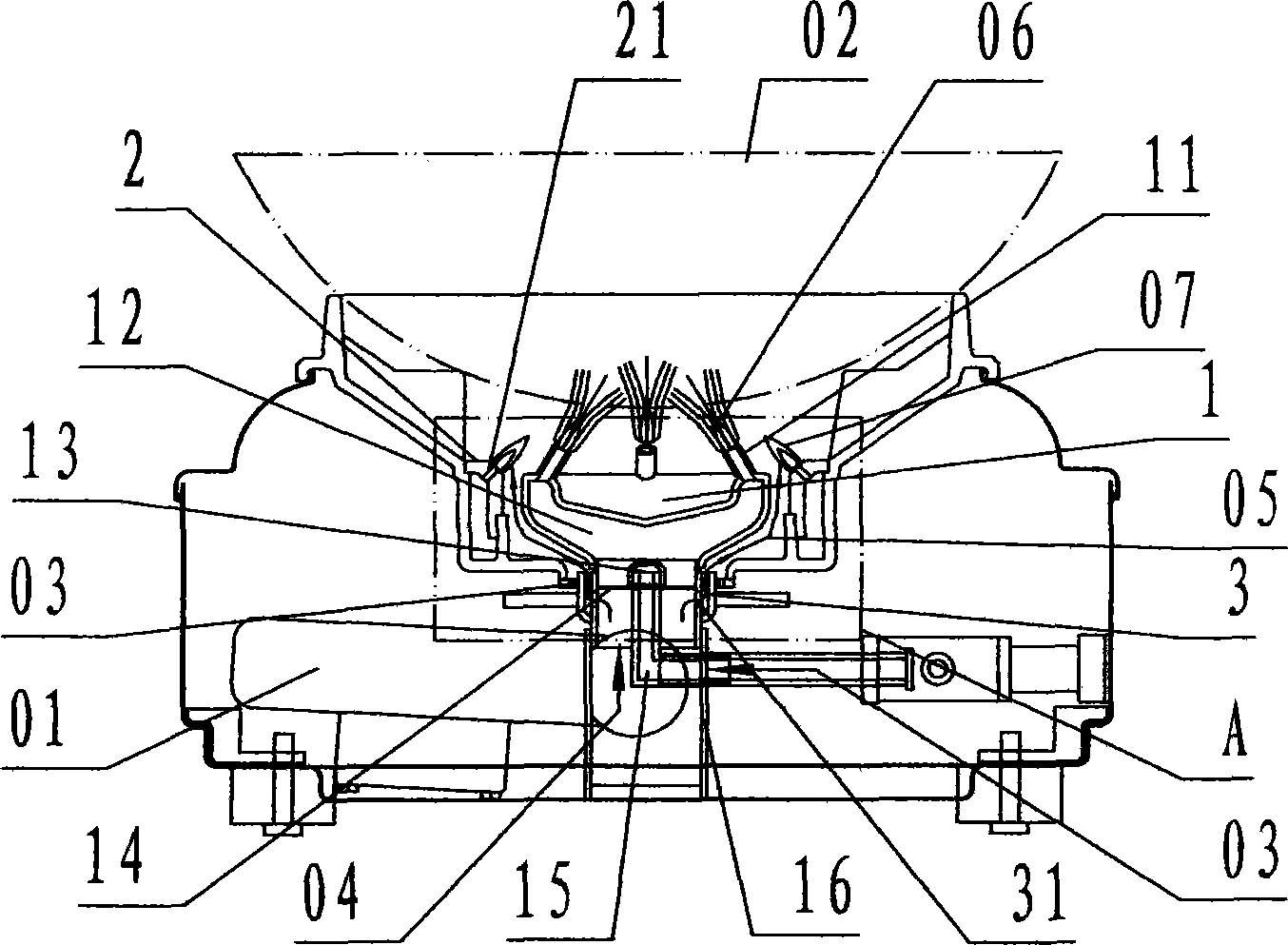

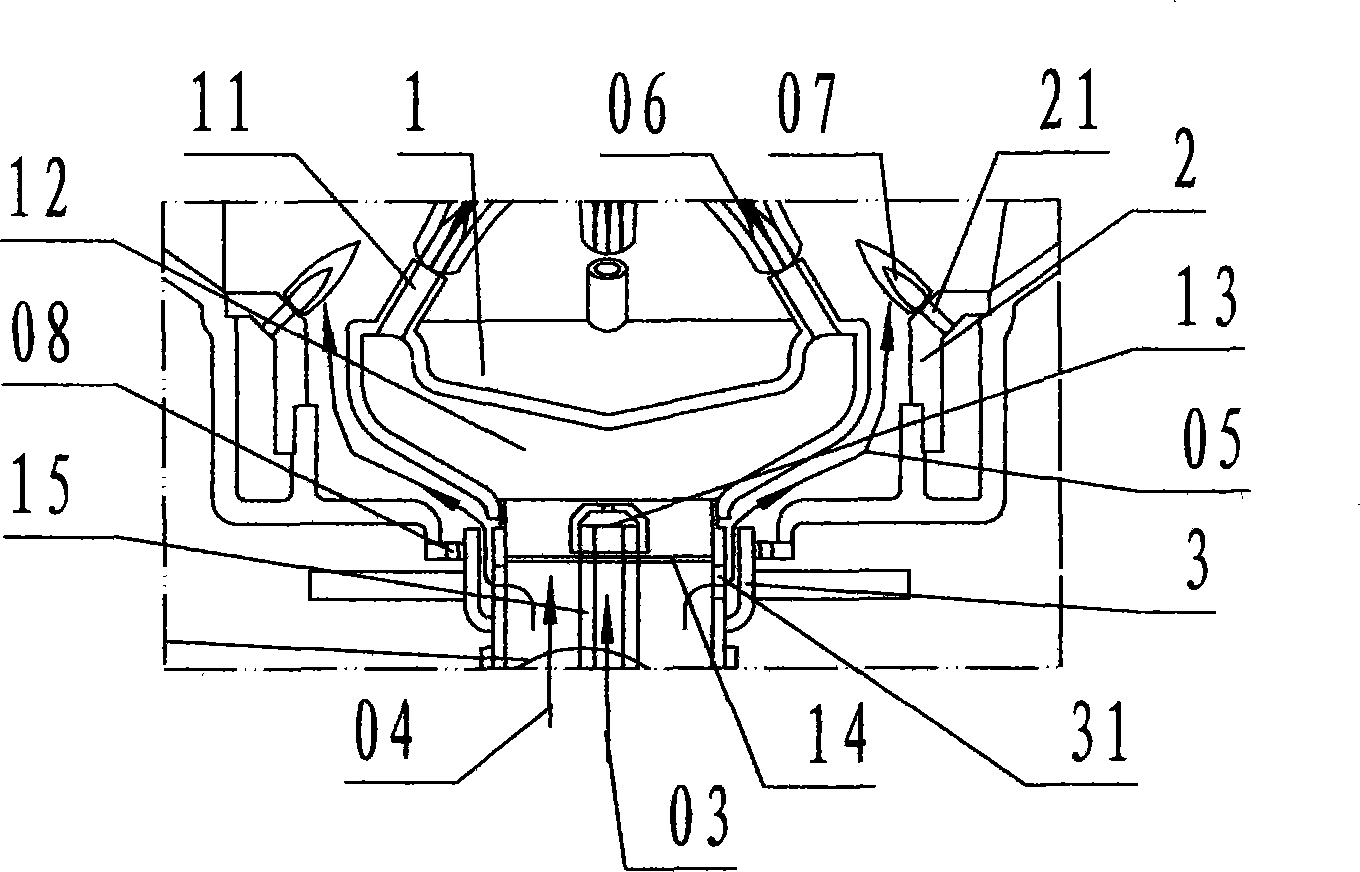

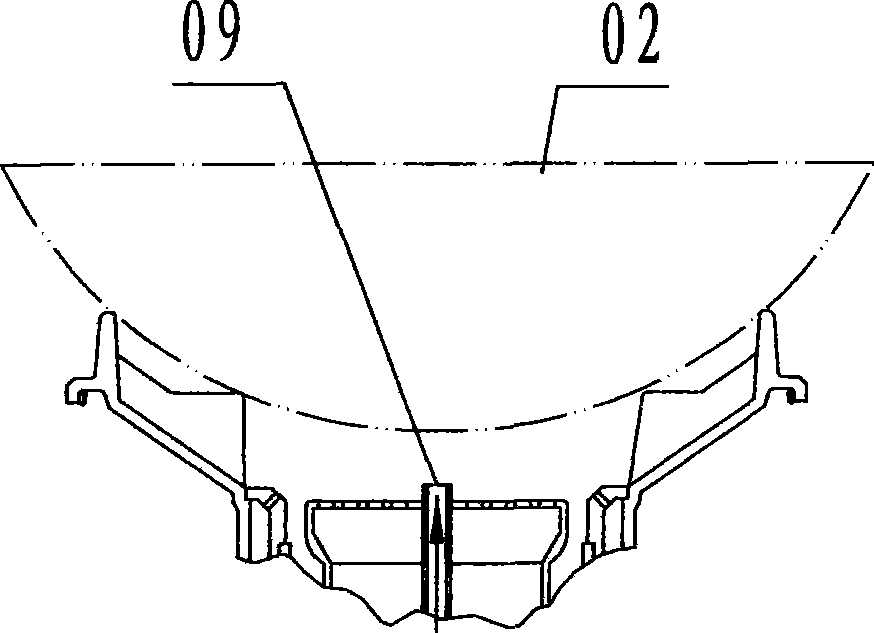

High-efficiency burner of blast type gas cooking appliance

ActiveCN103267287ADoes not interfere with normal combustionAvoid incomplete combustion due to lack of oxygenGaseous fuel burnerCombustorEngineering

The invention discloses a high-efficiency burner of a blast type gas cooking appliance. The high-efficiency burner comprises a main burning torch (1), an eternal torch (2) and an air ring (3). The air ring, which is in the shape of an annular groove and surrounds the outer wall of the lower part of the main burning torch, is arranged between the main burning torch and the eternal torch; when the burner works, air flow supplied by a fan enters the air ring through an auxiliary air hole in the lower part of the main burning torch, and then is guided by the air ring to form air jet flow which surrounds the outer wall of the main burning torch, is positioned between the main burning torch and the eternal torch and is jetted upwards; when no iron pan is erected on the gas cooking appliance, the air jet flow does not interfere the normal burning of main burning torch flames and eternal torch flames; when the iron pan is erected, the air jet flow automatically participates in pan bottom mixed torch flames consisting of the main burning torch flames and the eternal torch flames to help burning, so that incomplete burning of the pan bottom mixed torch flames due to oxygen insufficiency is avoided according to the technical scheme. Therefore, the blast type gas cooking appliance achieves the aims of enhancing the burning rate, stabilizing the burning and lowering the content of CO in waste gas.

Owner:徐建波

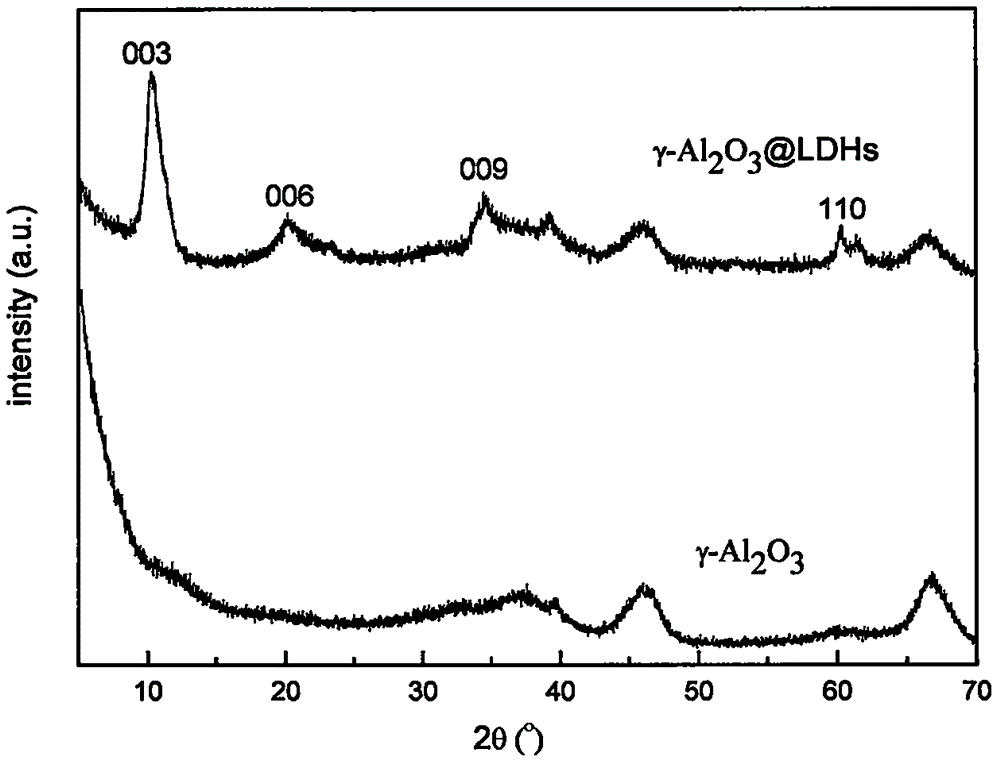

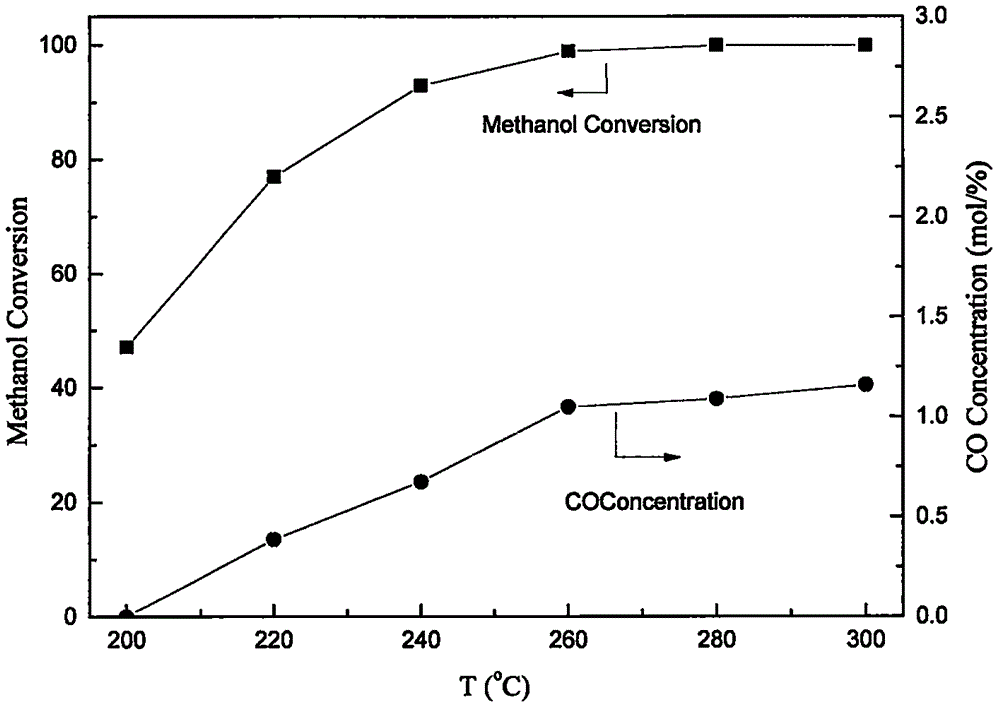

Catalyst used for catalytic reforming of methanol and steam to produce hydrogen, and preparation method and application thereof

InactiveCN106076346AEasy to prepareReduce CO contentHydrogenHeterogenous catalyst chemical elementsCatalytic reformingWater vapor

The invention provides a catalyst used for catalytic reforming of methanol and steam to produce hydrogen. The catalyst adopts Cu metal oxide as an active component, oxide obtained after roasting zinc aluminum hydrotalcite is used as a catalyst carrier, and the zinc aluminum hydrotalcite is prepared through an in situ synthesis technology with gamma-Al2O3 as an aluminum source; and the catalyst comprises, by mass, 1-30% of the active component (by oxide) and 70-99% of the carrier (by oxide), and the catalyst carrier comprises, by mass, 5-30% of zinc (by oxide). The zinc aluminum hydrotalcite is prepared through the in situ synthesis technology, the Cu-supported metal oxide catalyst is prepared by using the "structure memory" function of the zinc aluminum hydrotalcite, and the catalyst has high activity, low CO selectivity and high stability in the process of methanol and steam catalytic reforming for producing hydrogen.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

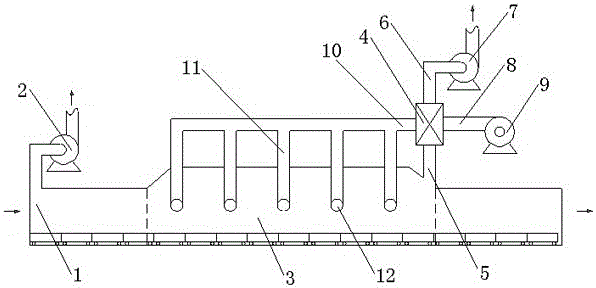

Magnetizing roasting self-heating balancing device and method for iron ore tunnel kiln

InactiveCN105091576ALower unit costIncrease profitFurnace typesWaste heat treatmentTunnel kilnCold air

The invention discloses a magnetizing roasting self-heating balancing device and method for an iron ore tunnel kiln. A heat-accumulating type heat exchanger is arranged outside a tunnel kiln heating reduction zone. A high-temperature smoke inlet of the heat-accumulating type heat exchanger is connected with a smoke exhaust port of the tunnel kiln heating reduction zone. A heating reduction zone smoke exhauster is arranged at a smoke outlet of the heat-accumulating type heat exchanger. An air blower is arranged at a cold air inlet of the heat-accumulating type heat exchanger. A hot air outlet of the heat-accumulating type heat exchanger is connected with a hot wind pass-in channel arranged on the side wall of the tunnel kiln heating reduction zone through a hot wind pipeline. According to the magnetizing roasting self-heating balancing device and method for the iron ore tunnel kiln, the ratio of the quantity of exhaust smoke exhausted out of a kiln feeding end to the quantity of exhaust smoke exhausted out of the heating reduction zone is adjusted, so that the smoke exhaust temperature at the kiln feeding end of the tunnel kiln and the heat loss due to the fact that heat is taken away by the smoke are reduced; in addition, material heating with coal as fuel is achieved when the tunnel kiln does not use externally supplied gas fuel, and the smoke exhaust temperature at the smoke outlet is reduced below 250 EDG C at the same time; the energy utilization rate is increased and unit cost of iron ore magnetizing roasting is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

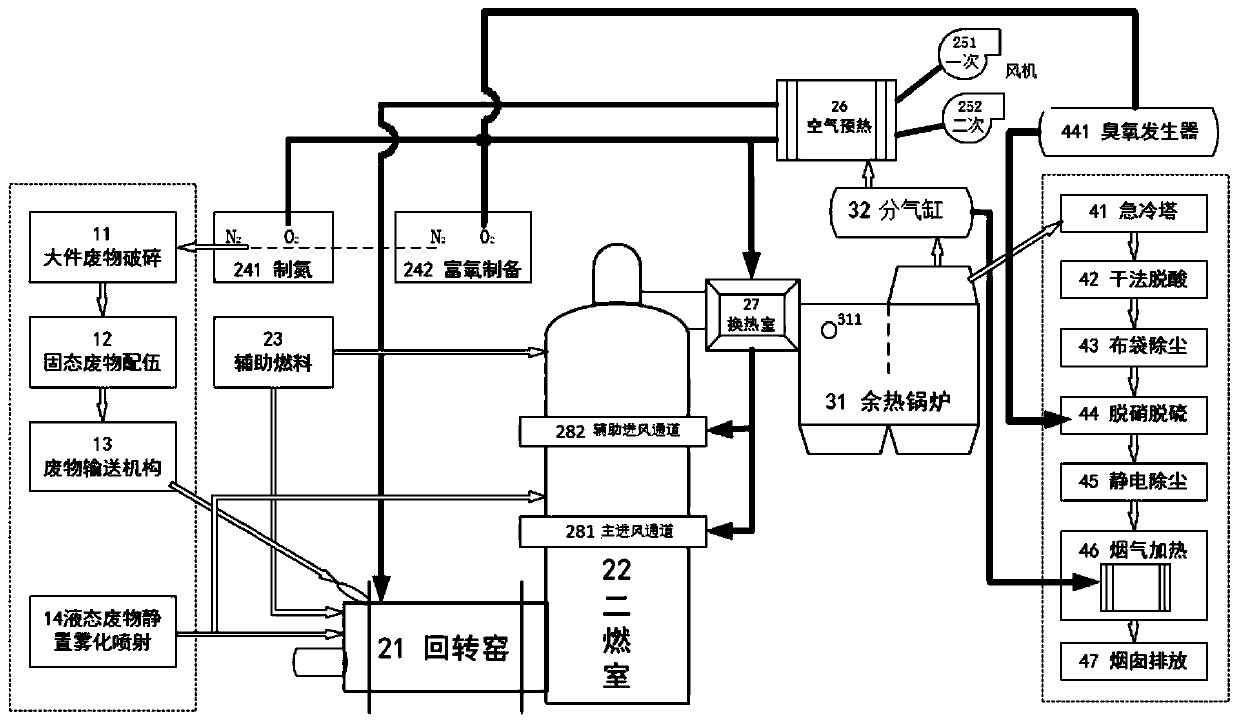

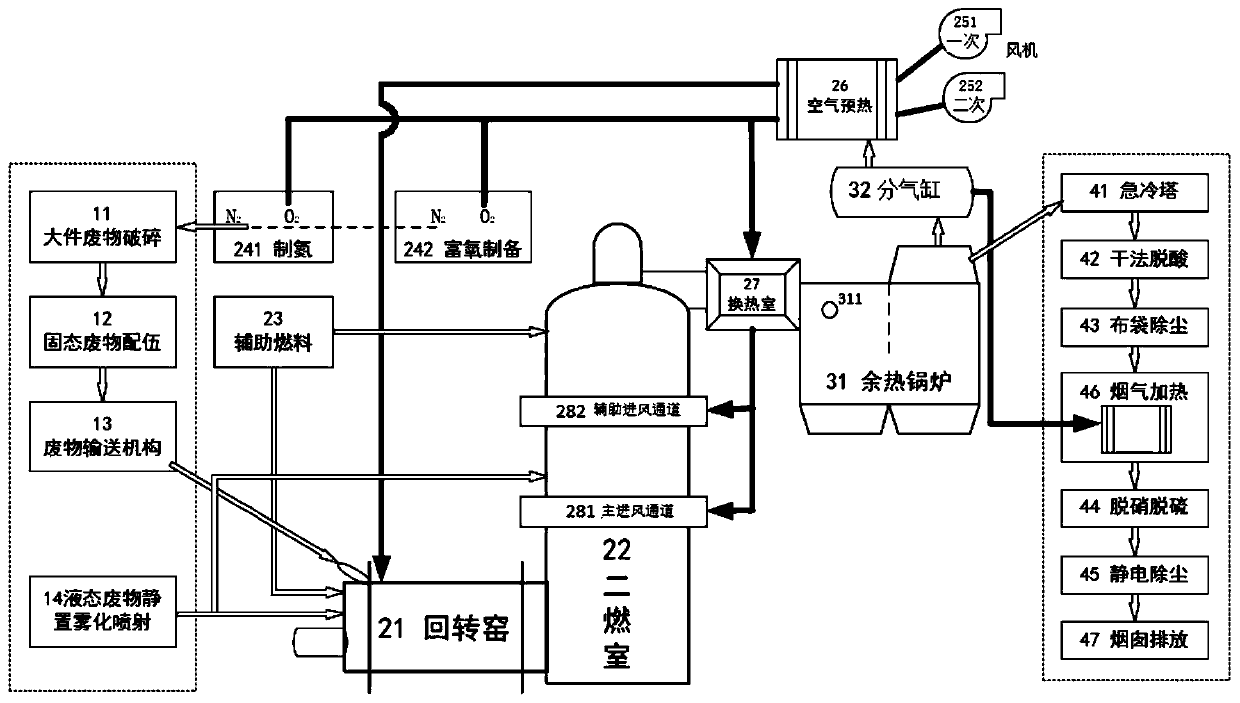

Green and efficient incineration method for hazardous waste in rotary kiln based on oxygen enriched air supply in secondary combustion chamber

PendingCN111306549ARaise the incineration temperatureInhibit synthesisEnergy inputIndirect carbon-dioxide mitigationLiquid wasteCombustion chamber

The invention discloses a green and efficient incineration method for hazardous waste in a rotary kiln based on oxygen enriched air supply in a secondary combustion chamber. The method comprises the steps of (1) adding solid waste, liquid waste and a first combustion-supporting gas to the rotary kiln for performing treatment; (2) feeding the waste and the liquid waste which are treated by means ofthe rotary kiln and a second combustion-supporting gas into a secondary combustion chamber for performing combusting treatment; and (3) exhausting the gas which is obtained after the combustion in the secondary combustion chamber, wherein the second combustion-supporting gas is formed by mixing air and an oxygen enriched gas; the incineration temperature in the secondary combustion chamber is risen to 1,100 to 1,200 DEG C; the oxygen concentration of the second combustion-supporting gas is 23 to 28 percent; the oxygen content of a combustion environment in the secondary combustion chamber isimproved, and a technical means of the preheating is effectively utilized, which are beneficial to removing nitrogen oxides from flue gas in a waste heat utilization system under the condition of ensuring complete decomposition of the harmful substances, such as dioxin; the production and emission of secondary environment pollution substances in an incineration processing process are avoided or remarkably reduced; and efficient and green treatment of maximum reduction of the hazardous waste is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

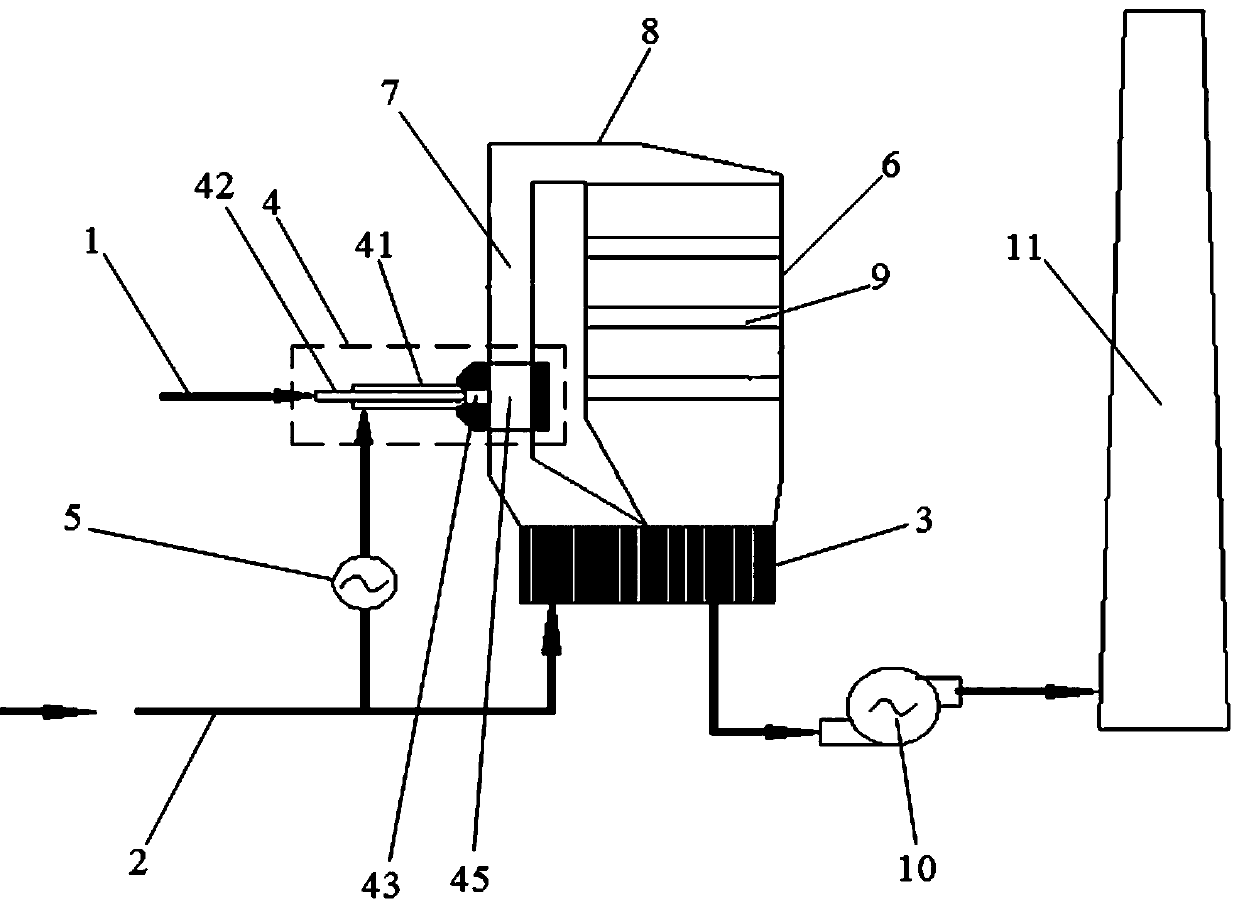

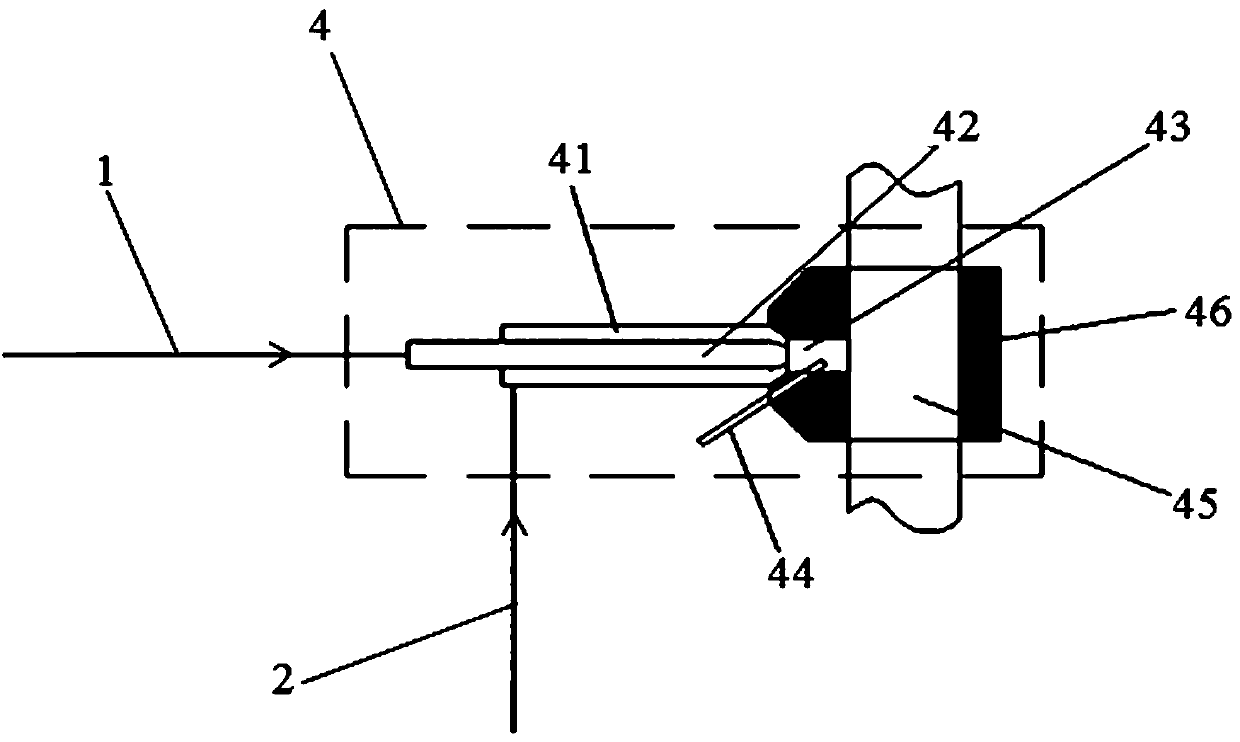

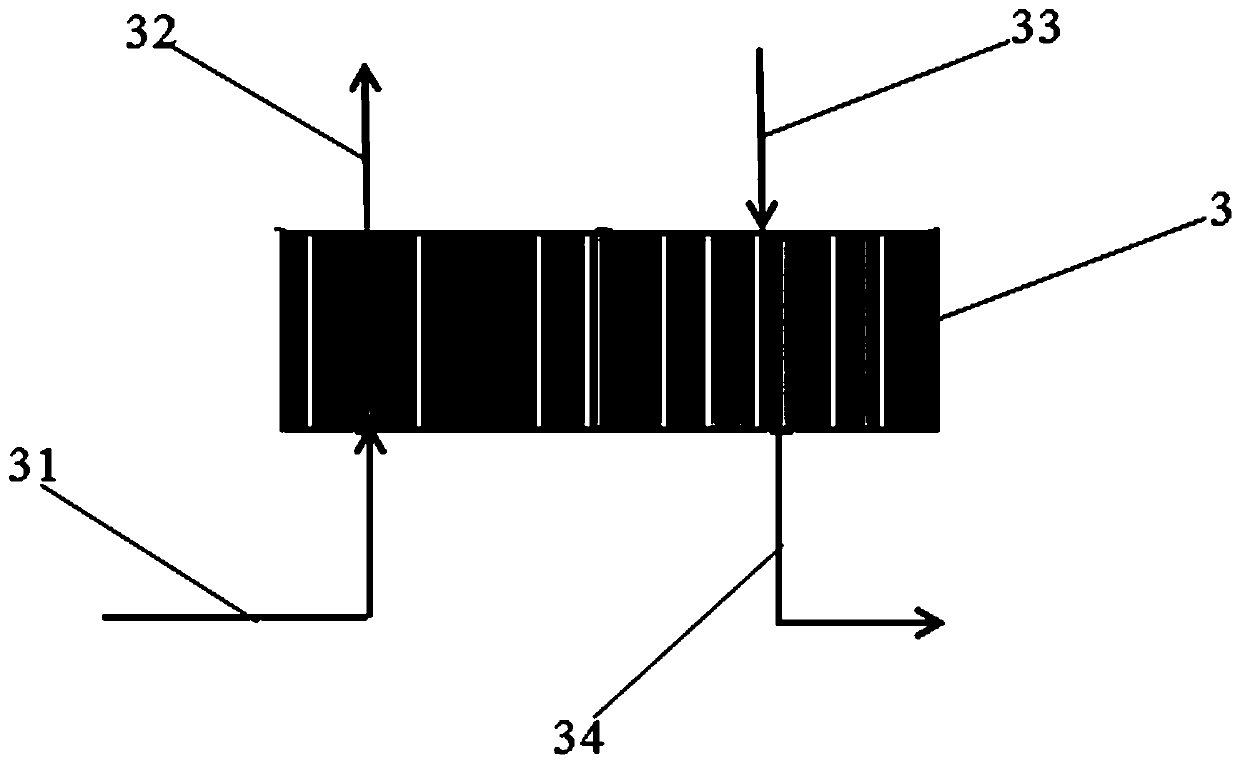

Sintering flue gas denitration direct-fired type heating device and method

PendingCN111306564AReduce CO contentEmission reductionEmission preventionIndirect carbon-dioxide mitigationPtru catalystCombustion chamber

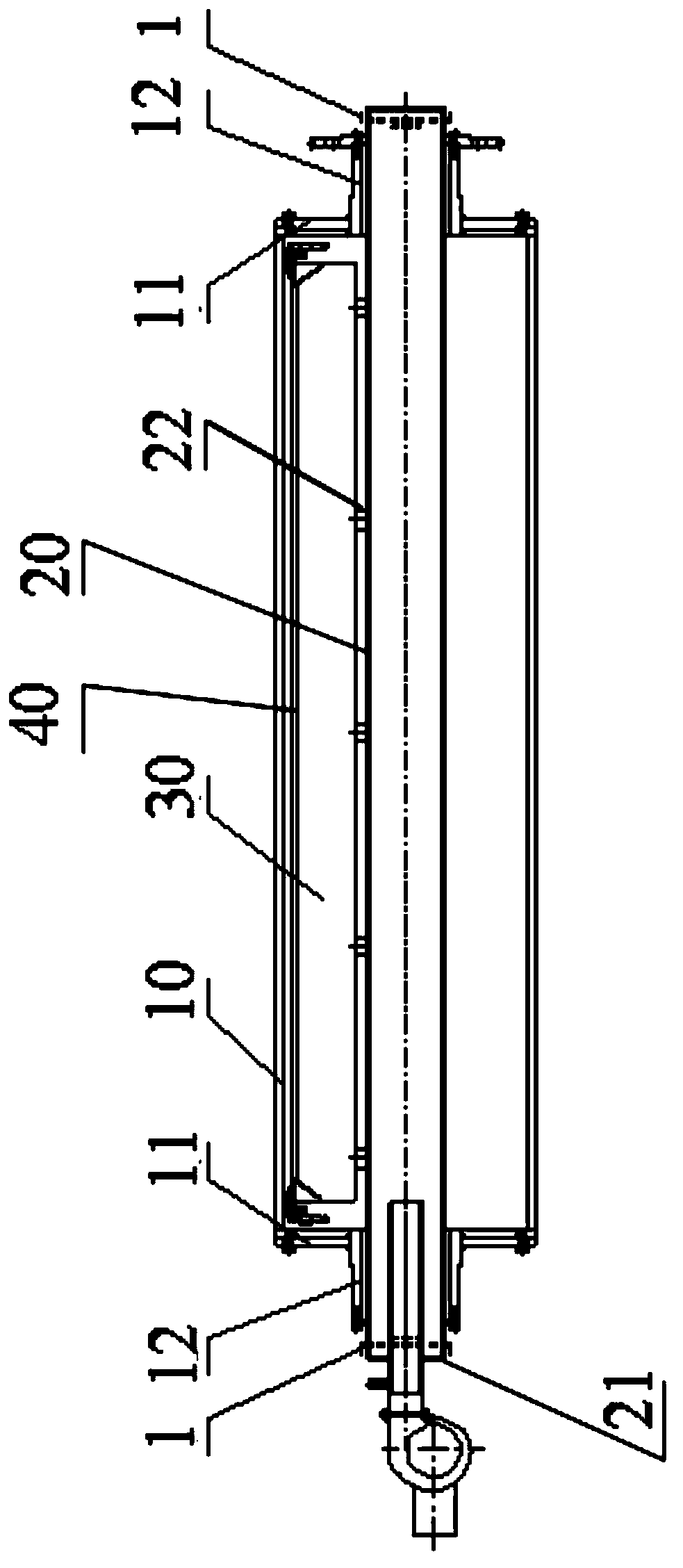

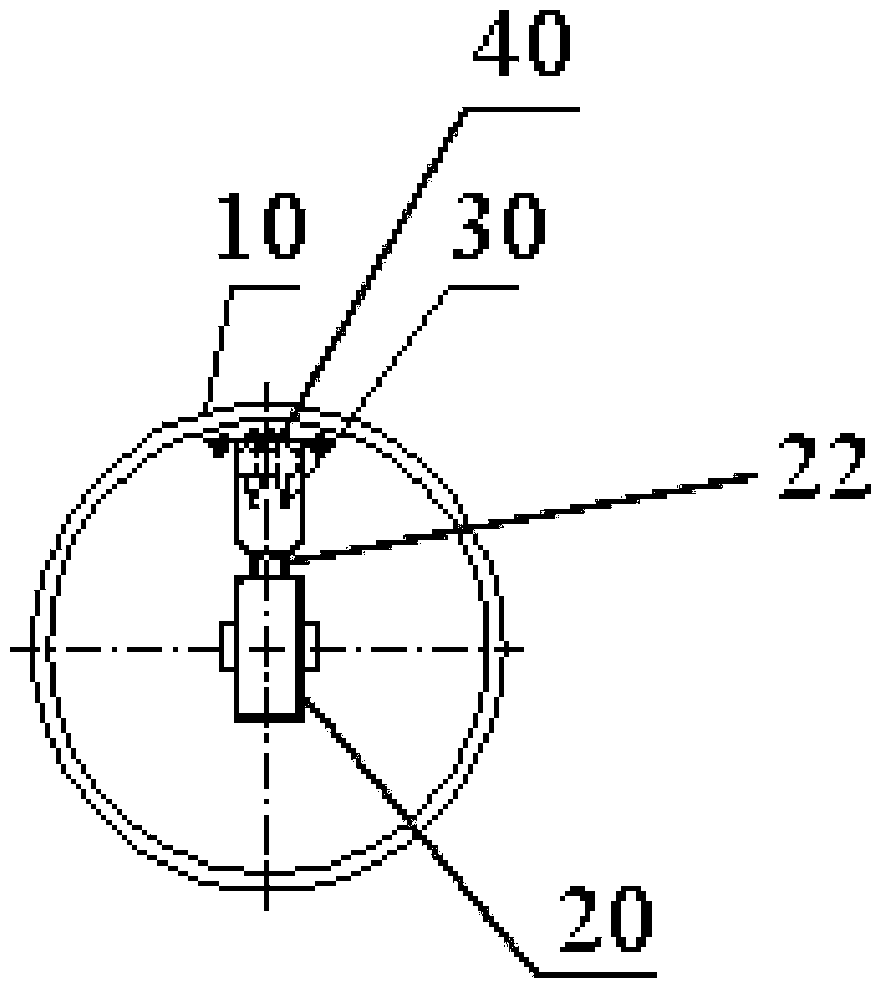

The invention relates to a sintering flue gas denitration direct-fired type heating device. The sintering flue gas denitration direct-fired type heating device comprises a gas pipe (1) and a sinteringflue gas pipe (2), wherein the gas pipe and the sintering flue gas pipe are respectively connected with a gas chamber (42) and an oxidant gas chamber (41) of a direct-fired heating device body (4), and the oxidant gas chamber (41) and the gas chamber (42) are sequentially connected with a mixing combustion chamber (43) and a flue gas heating chamber (45), an inlet of flue gas heating chamber (45)is connected with a GGH heat exchanger (3), an outlet of the flue gas heating chamber (45)is connected with a denitration flue (7), an ammonia injection gird (8) is arranged above the denitration flue (7), a denitration catalyst (9) is arranged in a denitration reactor (6), the denitration reactor (6) is connected with the GGH heat exchanger (3), the GGH heat exchanger (3) is connected with an induced draft fan (10), and an outlet of the induced draft fan (10) is connected with one chimney (11). The sintering flue gas denitration direct-fired type heating device has the advantages of ensuringthe denitration efficiency, reducing CO content in flue gas and heated gas volume, and energy conservation and emission reduction.

Owner:NANJING JINHAN ENVIRONMENTAL PROTECTION TECH CO LTD

Ironing machine drying drum employing gas and infrared ray for heating

InactiveCN103437137AImprove screed efficiencySimple transmission structureIroning machinesTextiles and paperInfraredPulp and paper industry

The invention discloses an ironing machine drying drum employing gas and infrared ray for heating. The ironing machine drying drum comprises a barrel, a square air supply tube, an infrared burner and a heat transfer net, wherein a connecting flange and a hollow shaft are arranged at two ends of the barrel and used for supporting the barrel and inputting rotary power; the square air supply tube is arranged inside the barrel; two ends of the square air supply tube extend out of hollow shafts arranged at two ends of the barrel; the square air supply tube is fixed on an ironing machine frame through a support plate; the infrared burner is fixed above the square air supply tube through a plurality of connecting pipes, so as to be suspended inside the barrel; the plurality of connecting pipes are used as air supply pipelines; and the heat transfer net is arranged at the top end of the infrared burner and leans against the inner wall of the barrel, so as to play roles in heat storage and infrared radiation. According to the ironing machine drying drum, heat radiation is adopted to transfer heat; the ironing efficiency is improved; a drying drum main body is made of a thin-wall steel tube; and the drying drum is large in thermal capacity and good in ironing effect.

Owner:SHANGHAI GAMESAIL WASHING MACHINE

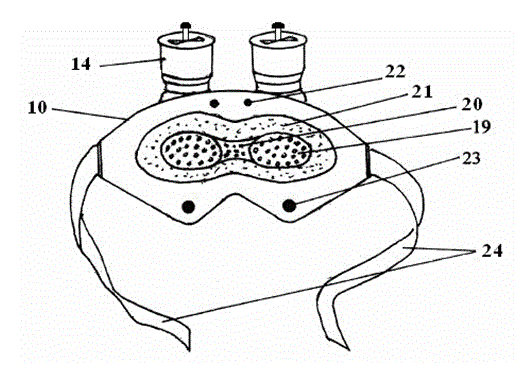

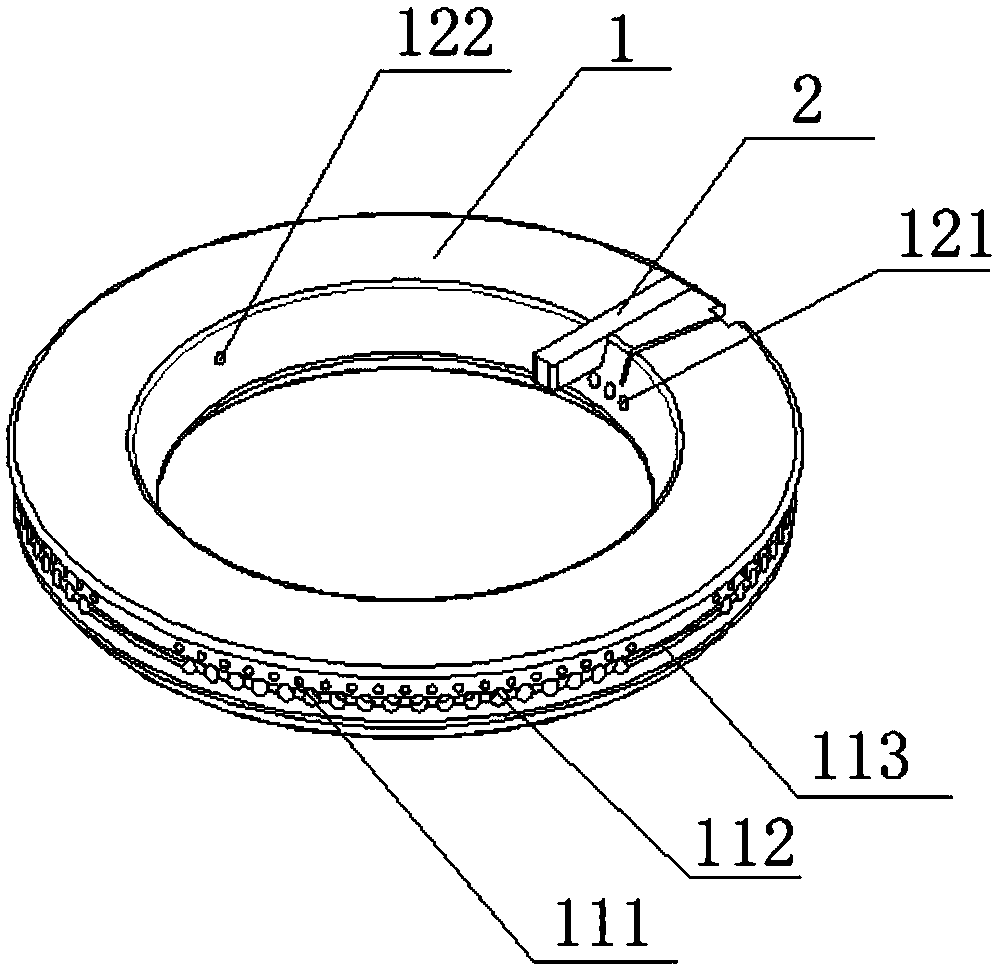

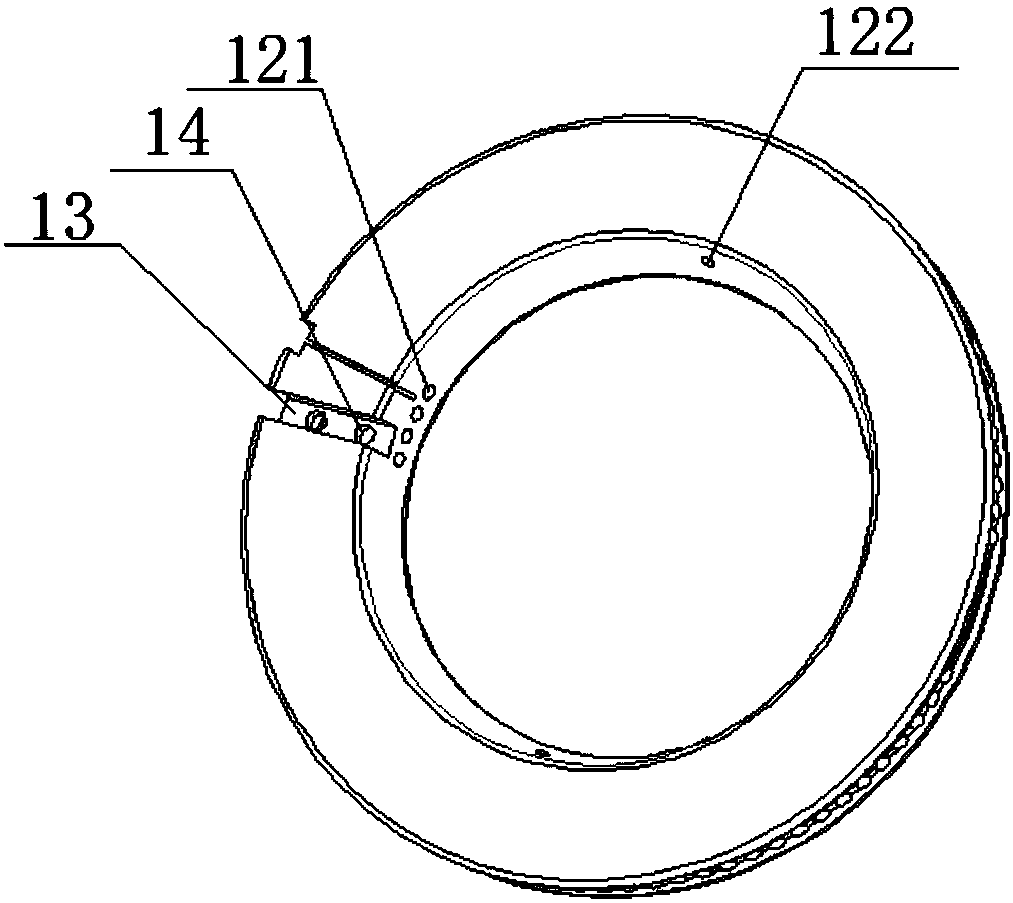

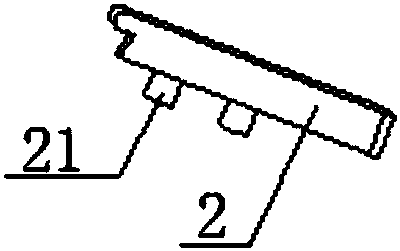

Ophthalmic therapy device

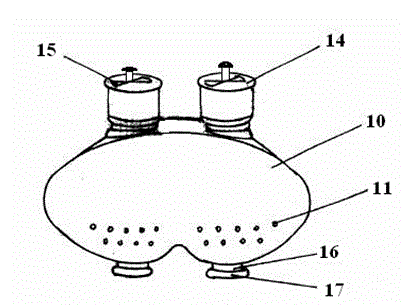

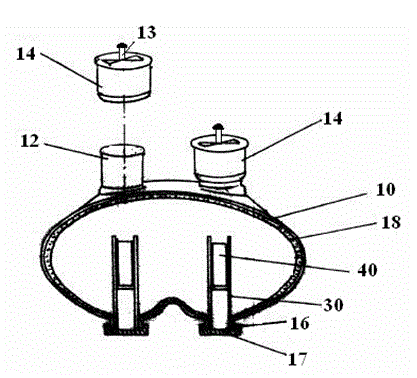

ActiveCN104856799AOvercome the defects of high temperature deformationPromote combustionDevices for heating/cooling reflex pointsElectrotherapyNasal bridgeOPHTHALMOLOGICALS

The invention discloses an ophthalmic therapy device. The ophthalmic therapy device comprises a periscope shell, wherein a plurality of convection holes are formed in the shell; an eyelet cushion is arranged on the open end at the reverse side of the shell, and porous lenses communicated with the inner part of the shell are arranged on left and right parts of the eyelet cushion; a nose bridge cushion is arranged between left and right porous lenses, left and right smoke discharging columns are arranged at the upper end of the shell, smoke discharging holes are formed in the tops of the left and right smoke discharging columns, smoke discharging caps are sleeved on the left and right smoke discharging columns, left and right ash outlets are formed at the lower end of the shell, ash receiving slots are formed in the shell, and moxibustion cone fixing tables for placing moxibustion cones are erected in the left and right ash receiving slots. The ophthalmic therapy device has a certain effect to relief and treat ophthalmic diseases such as amblyopia, shortsightedness, hyperopia and strabismus in young children and senior cataracts.

Owner:连云港市一明医疗科技有限公司

Outer burner cap with flame avoiding and flame propagation properties

PendingCN107726319ANo flame out phenomenonGuaranteed stabilityGaseous fuel burnerFlame propagationCombustor

The invention relates to an outer burner cap with flame avoiding and flame propagation properties. The outer burner cap comprises an outer burner cap body and a flame leading plate; the outer burner cap body comprises an outer burner cap body outer ring and an outer burner cap body inner ring; an upper row of through flame holes and a lower row of through flame holes are formed in the outer burnercap body outer ring; the upper row of through flame holes are smaller than the lower row of through flame holes; the upper and lower rows of through flame holes are discontinuously distributed on theouter burner cap, thereby ensuring that stove stand feet can be avoided from flame; flame propagation grooves are formed in the positions, where the upper and lower rows of through flame holes are discontinuously distributed, of the outer burner cap body outer ring, and communicate with main burning through flame holes, namely the lower row of through flame holes; the flame leading plate is arranged on the outer burner cap body; and ignition holes are formed in the positions, corresponding to the flame leading plate, of the outer burner cap body inner ring. The outer burner cap has the beneficial effects that the upper row of through flame holes are smaller than the lower row of through flame holes, so that main flame from the lower row of through flame holes can get in sufficient contactwith the outside air, and the stability of the whole flame can be ensured through flame stabilizing holes, namely the upper row of through flame holes; furthermore, all the through flame holes are disconnected at certain angles, so that the service life of a stove stand can be prolonged and the content of CO in burning products can be lowered; and the flame avoiding positions of the outer burnercap body outer ring are connected by adopting the flame propagation grooves, so that the flame propagation reliability can be ensured.

Owner:ZHEJIANG SHUAIKANG ELECTRIC

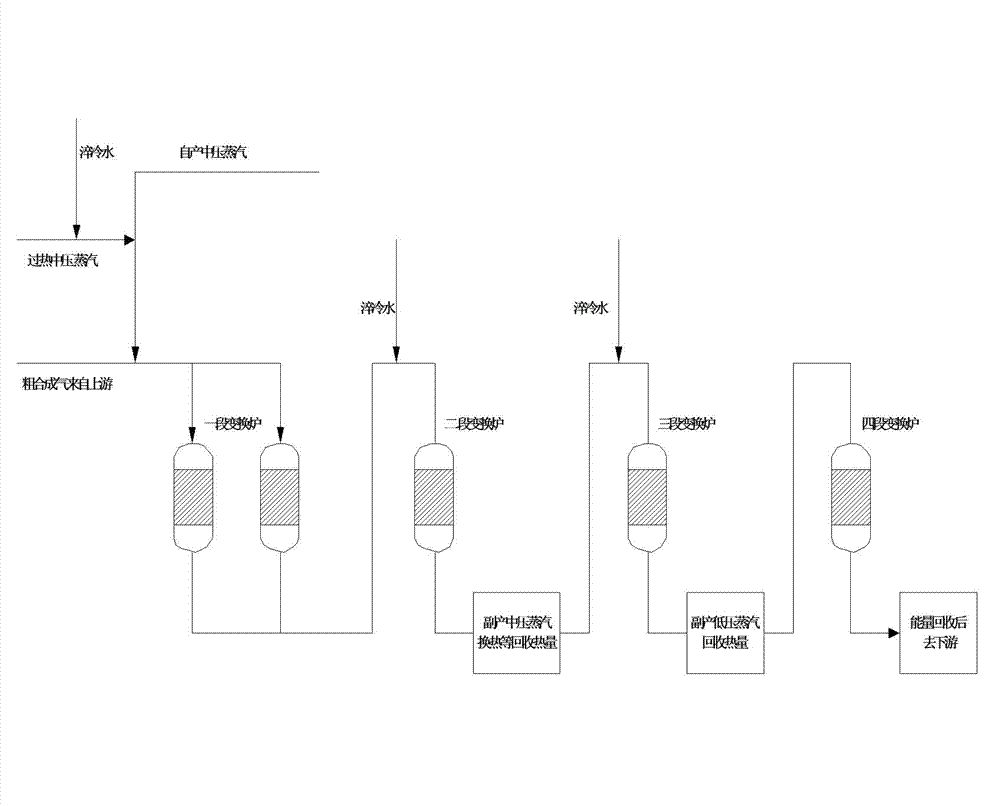

Fine coal gasification product crude synthetic gas CO sulfur-tolerant shift technology

InactiveCN102732329AExtend your lifeReduce consumptionCombustible gas catalytic treatmentGranular/pulverulent flues gasificationSyngasThermodynamics

The invention relates to a fine coal gasification product crude synthetic gas CO sulfur-tolerant shift technology. According to the invention, a low and high water / gas mixed process is adopted. A low water / gas technology and a low water / gas catalyst are adopted in a first stage. Through the controlling over the water / gas of crude synthetic gas, the reaction depth and bed layer hot spot temperature of a pre-shifting furnace are controlled. Therefore, on a basis that no methanation side reaction occurs, the crude synthetic gas containing high-density CO is subjected to the sifting reaction under low water / gas technical conditions. A high water / gas technology is adopted in subsequent stages. The second stage adopts one-time middle-pressure superheated vapor and a proper amount of technical condensate, such that the water / gas ratio of the synthetic gas reaches 1.30-1.35. Sufficient shifting reaction driving force is provided, such that a purpose of controlling shifting outlet CO content is achieved. The technology provided by the invention is advantaged in mild low water / gas process operation conditions, smooth operation, no methanation side reaction, and substantially reduced vapor usage amount. With the high water / gas processes, relatively low shifting outlet CO content can be well controlled.

Owner:CHINA PETROLEUM & CHEM CORP

Boiler

A low-height boiler is composed of chimney, main body, firebox consisting of upper heat exchanging chamber and lower combustion chamber, coal feeder, ash discharger and power unit for coal feeder andash discharger. Said upper heat exchanging chamber is composed of common channel for exhausting smoke and feeding coal, reverse U-shaped water jacket, heat exchanging tubes, and water outlet tube. Said combustion chamber consists of external and internal water tubes and horizontal water tube. Its advantages are less floor area, big heat exchange area and high thermal efficiency.

Owner:刘毅

Direct rapid kinetic oil having self-repairing function

InactiveCN101082011AWith self-healing functionReduce coefficient of frictionAdditivesBase oilPour point

The present invention is one kind of fast kinetic energy oil possessing self repairing function. The fast kinetic energy oil consists of base oil and additives, which includes catalyst, mineral matter, metallic detergent, antiwear agent, dispersant, antioxidant, pour point depressant and defoaming agent. The fast kinetic energy oil possesses self repairing function, energy saving effect, environment friendship and long oil replacing period.

Owner:孙国中 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com