Quad-element lithium ion battery anode material and preparing method

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high cost and poor stability, and achieve the effects of reducing costs, simple and reliable methods, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

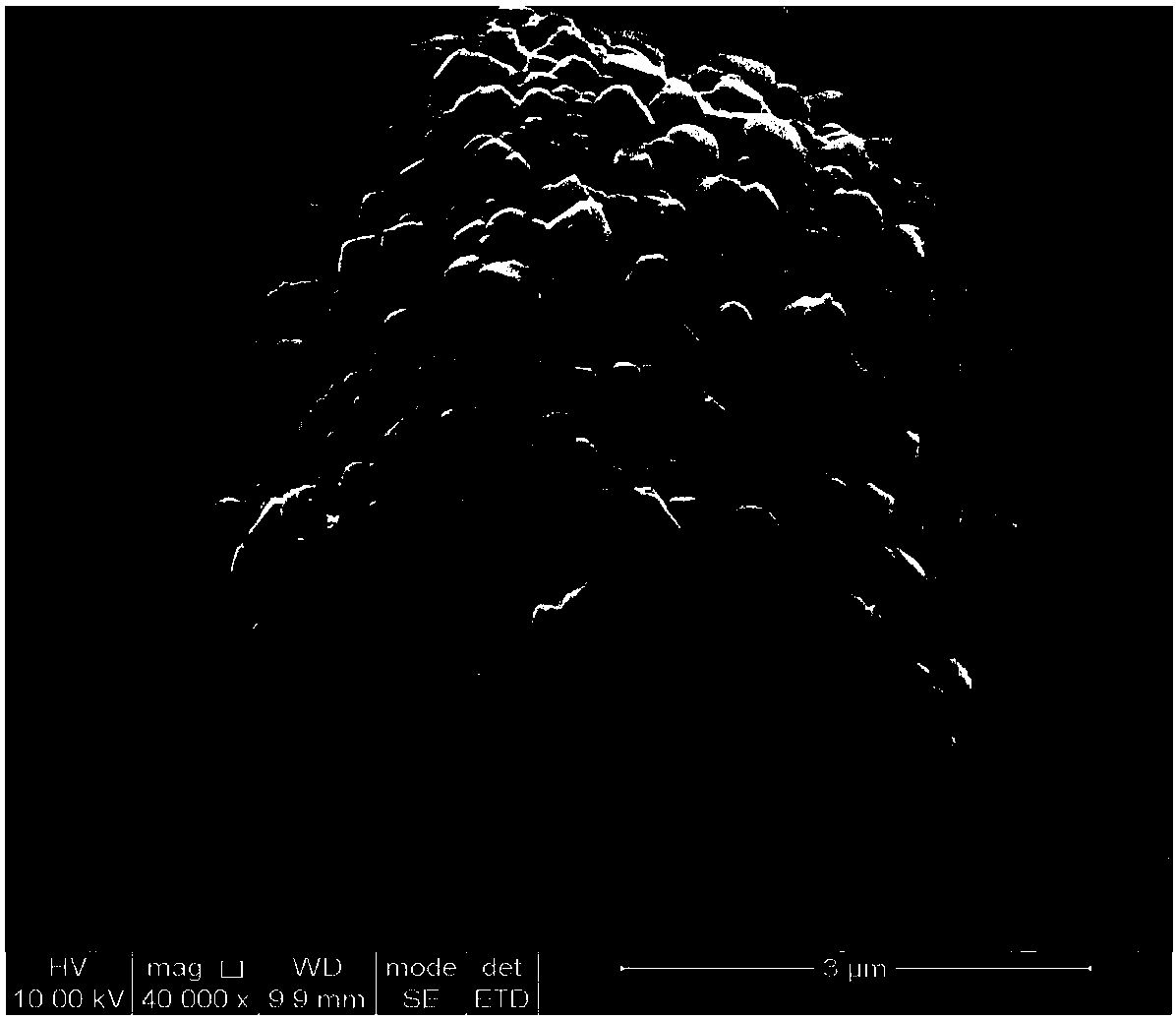

Image

Examples

Embodiment 1

[0026] Step 1, first calculate and weigh nickel acetate, cobalt acetate, manganese acetate, and iron sulfate according to the molar ratio of each element as Ni:Co:Mn:Fe=0.6:0.1:0.2:0.1, and add all the above raw materials into deionized water Carry out dissolving and be mixed with the solution A of 0.6mol / L;

[0027] Step 2, adding the precipitating agent oxalic acid into deionized water to dissolve and prepare 0.6mol / L solution B;

[0028] Step 3, using solution B as the base solution, add solution A to solution B at a rate of 3mL / min for stirring and mixing, the stirring rate is 700rpm, the temperature is 40°C, the pH is 2, and the reaction time is 6h; after the reaction is completed, put Suction filter, wash and dry the precipitate to obtain a homogeneous co-precipitated quasi-spherical nickel-cobalt-manganese-iron oxalate precursor. The drying temperature is 70°C, the drying time is 12 hours, and the drying time is 10 hours to obtain dry spherical nickel-cobalt-manganese-i...

Embodiment 2

[0033] Step 1, first calculate and weigh nickel nitrate, cobalt nitrate, manganese nitrate, iron nitrate according to the molar ratio of each element as Ni:Co:Mn:Fe=0.6:0.1:0.2:0.1, and add all the above raw materials into deionized water Carry out dissolving and be mixed with the solution A of 0.7mol / L;

[0034] Step 2, adding the precipitating agent oxalic acid into deionized water to dissolve and prepare 0.7mol / L solution B;

[0035] Step 3, using solution B as the base solution, add solution A to solution B at a rate of 6mL / min for stirring and mixing, the stirring rate is 740rpm, the temperature is 46°C, the pH is 3, and the reaction time is 7h; after the reaction is completed, put Suction filter, wash and dry the precipitate to obtain uniform co-precipitated quasi-spherical nickel-cobalt-manganese-iron oxalate precursor. The drying temperature is 78°C, the drying time is 13 hours, and the drying time is 13 hours to obtain dry spherical nickel-cobalt-manganese-iron-4 Pre...

Embodiment 3

[0039] Step 1, first calculate and weigh nickel sulfate, cobalt sulfate, manganese sulfate, and iron nitrate according to the molar ratio of each element as Ni:Co:Mn:Fe=0.6:0.1:0.2:0.1, and add all the above raw materials into deionized water Carry out dissolving and be mixed with the solution A of 0.8mol / L;

[0040] Step 2, adding the precipitating agent ammonium oxalate into deionized water to dissolve and prepare 0.8mol / L solution B;

[0041] Step 3, using solution B as the base solution, add solution A to solution B at a rate of 8mL / min for stirring and mixing, the stirring rate is 780rpm, the temperature is 50°C, the pH is 4.5, and the reaction time is 9h; after the reaction is completed, put Suction filter, wash and dry the precipitate to obtain uniform co-precipitated quasi-spherical nickel-cobalt-manganese-iron oxalate precursor. The drying temperature is 90°C, the drying time is 14 hours, and the drying time is 15 hours to obtain dry spherical nickel-cobalt-manganese-ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com