Anti-surge early warning control method of COREX gas compressor

A technology of gas compressor and control method, which is applied in pump control, mechanical equipment, machine/engine, etc., can solve the problem that the anti-surge valve cannot be closed, the anti-surge adjustment monitoring and maintenance flow adjustment are not considered, etc. further deterioration of the situation, facilitate analysis and technical intervention, and improve the effect of safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

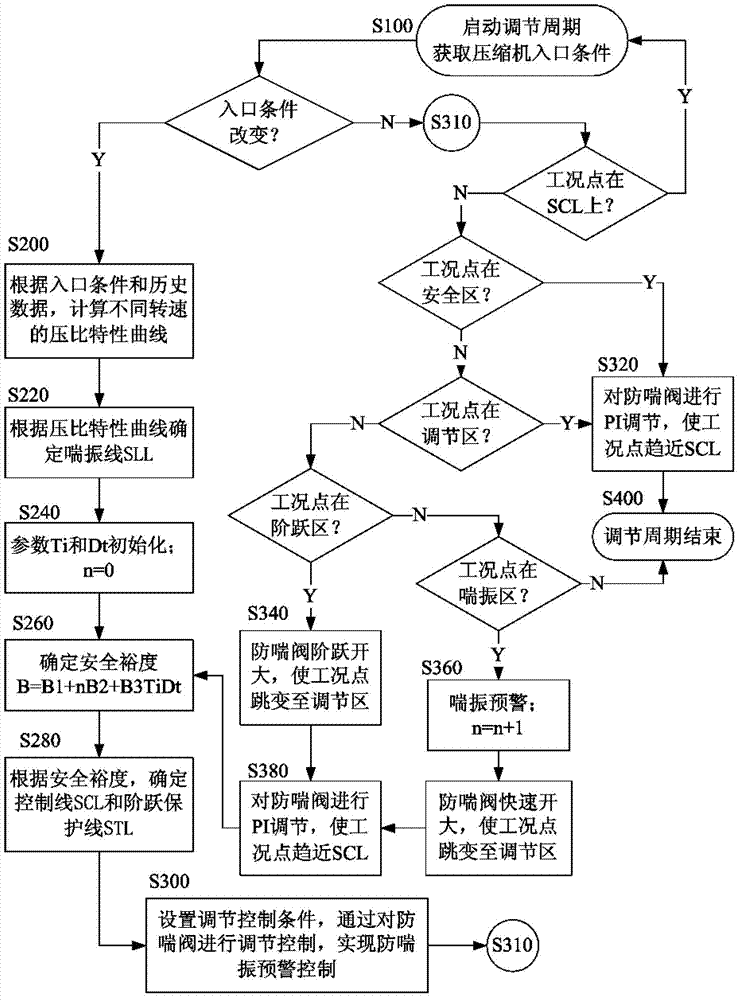

[0053] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

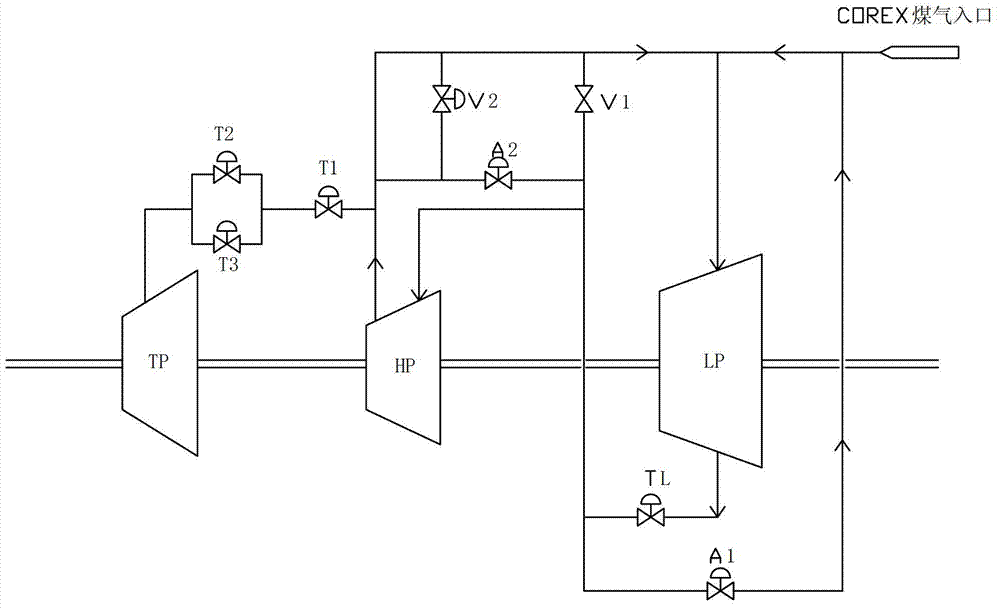

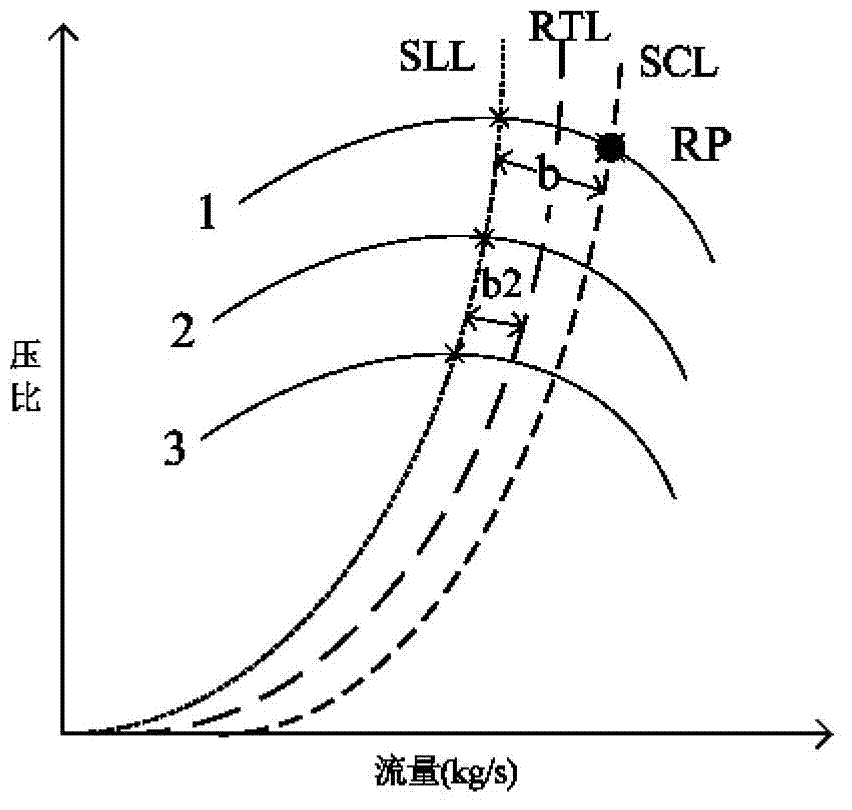

[0054] image 3 It is a flowchart of the anti-surge early warning control method of the COREX gas compressor of the present invention, and the control method can be used as a control method in the computer monitoring system of the CCPP unit for low-pressure coal compressors and / or high-pressure coal compressors Surge detection early warning and regulation control. Process diagram of COREX gas compressor system figure 1 As shown, including compressors (low-pressure coal compressor LP and high-pressure coal compressor HP), anti-surge valves (low-pressure coal compressor anti-surge valve A1 and high-pressure coal compressor anti-surge valve A2), gas flow regulating valve TL, gas Bypass valve V1, gas bypass regulating valve V2 and gas regulating valves T1, T2, T3; COREX gas is compresse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com