Patents

Literature

1956results about How to "Reduce accident rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

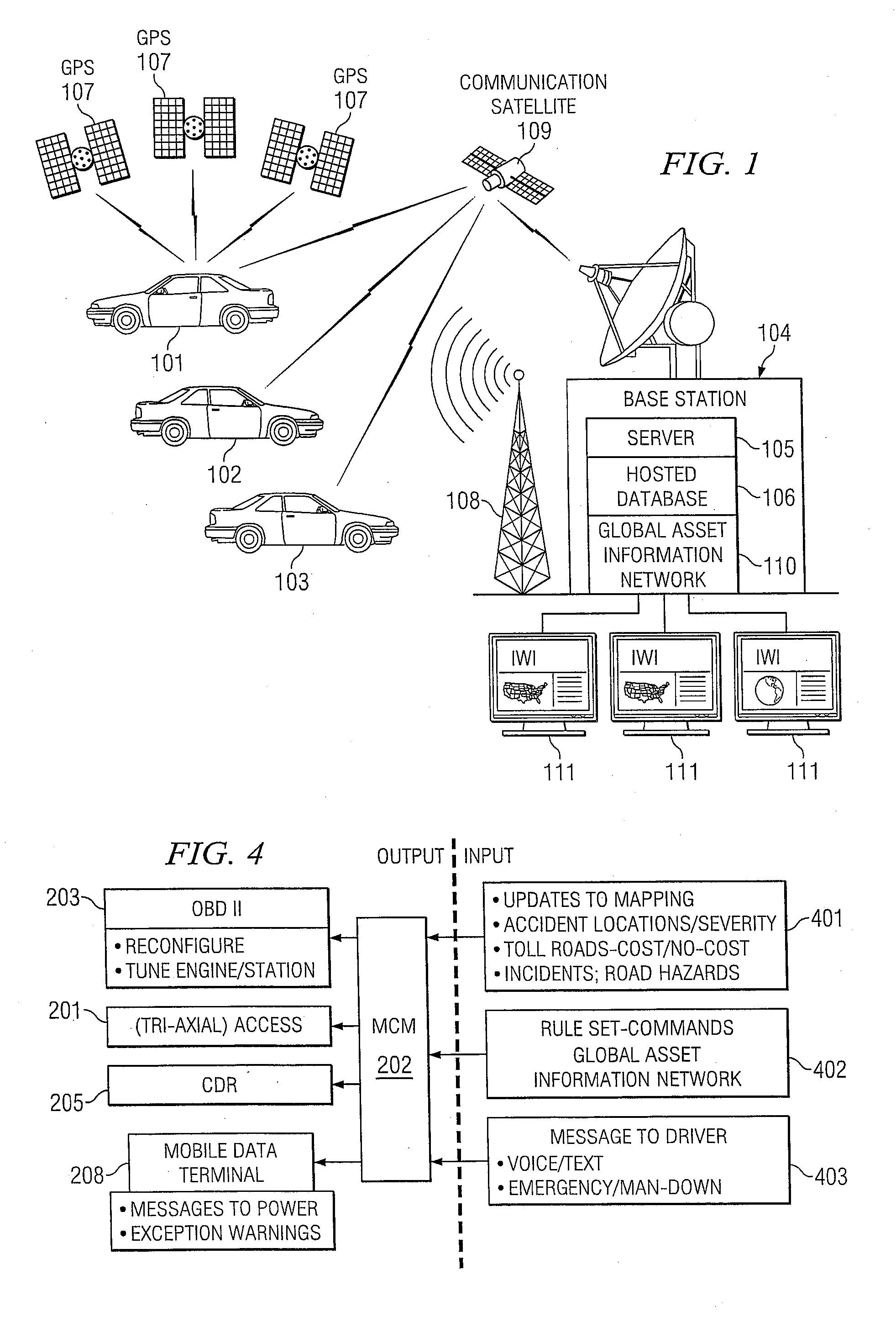

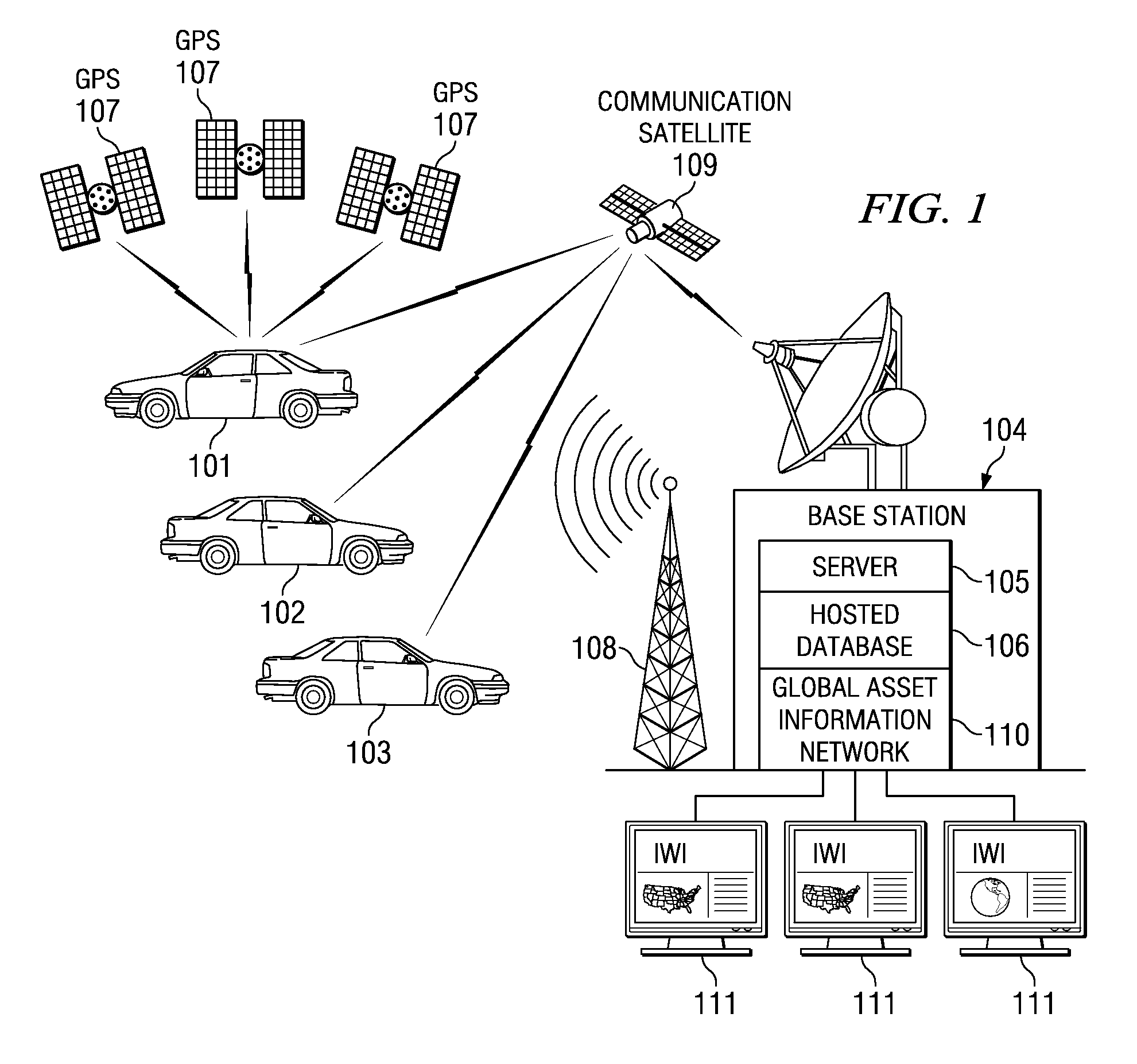

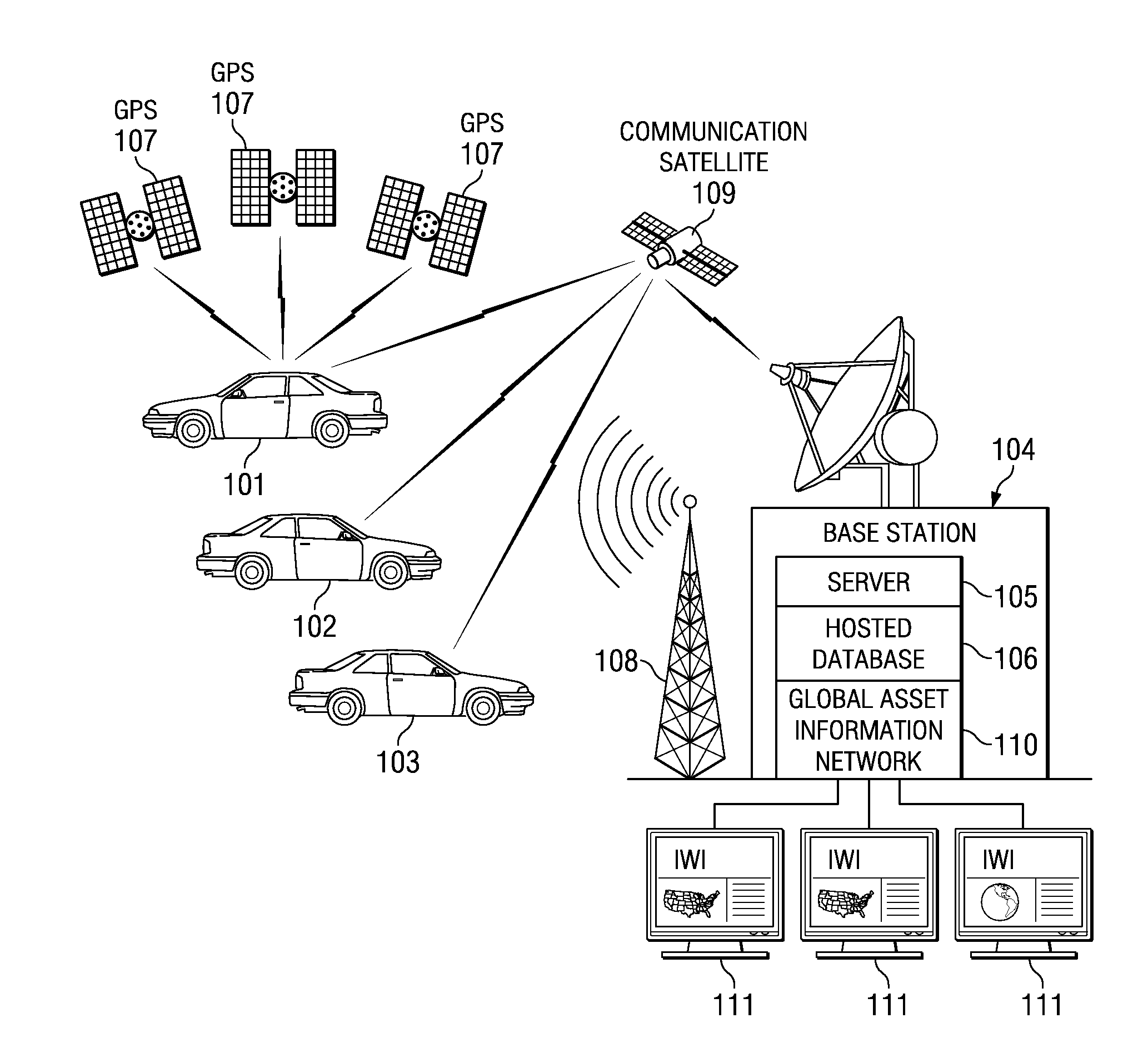

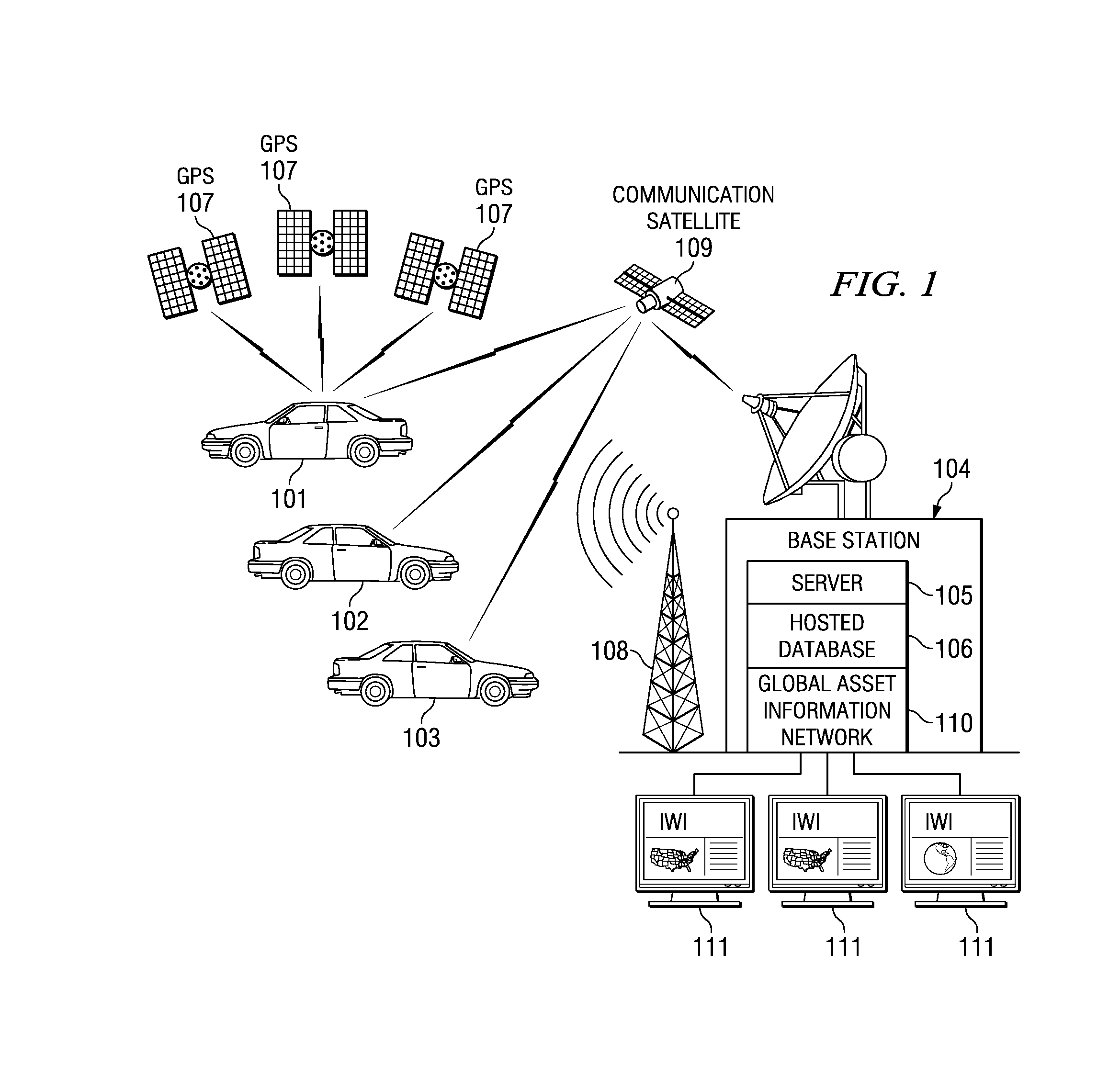

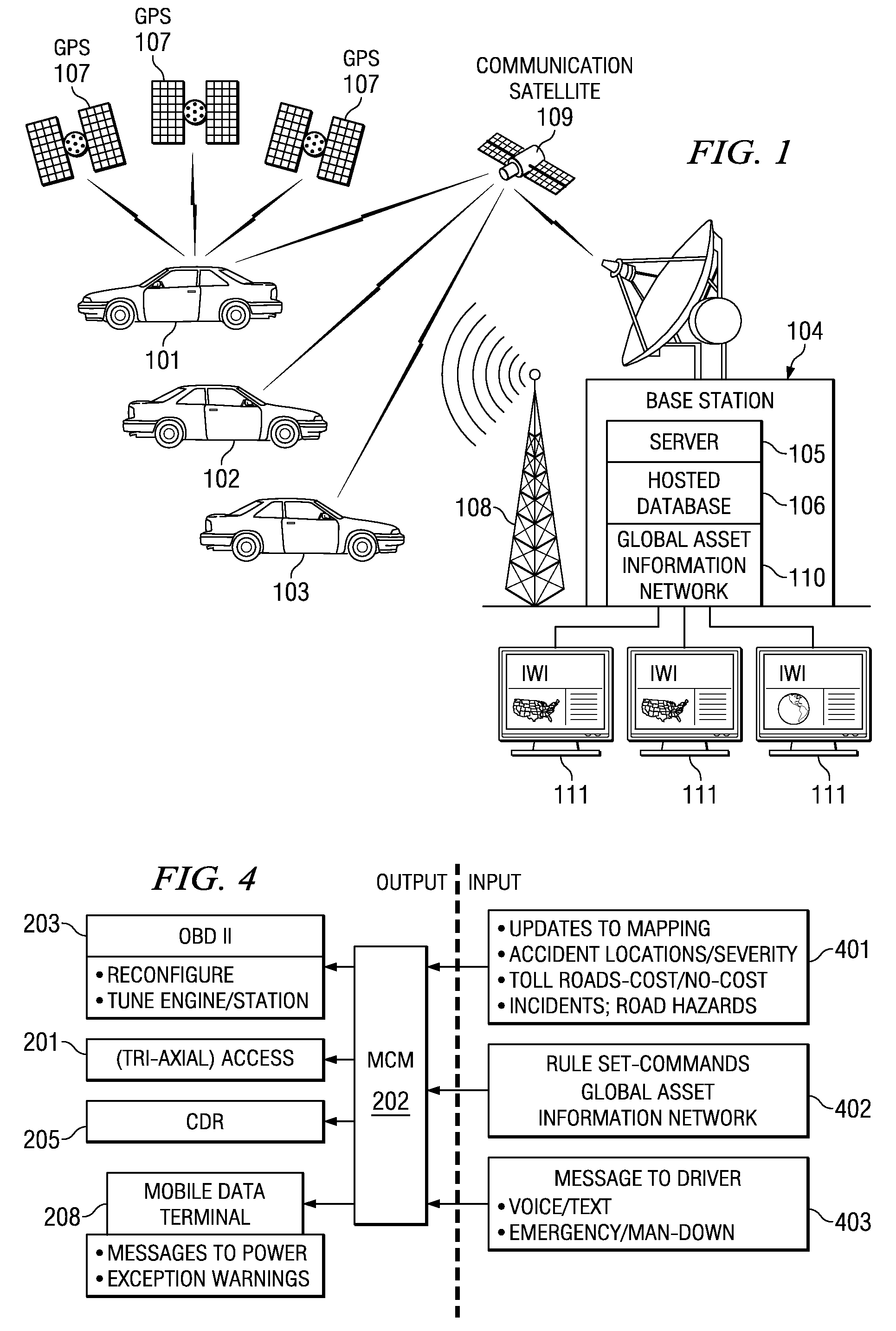

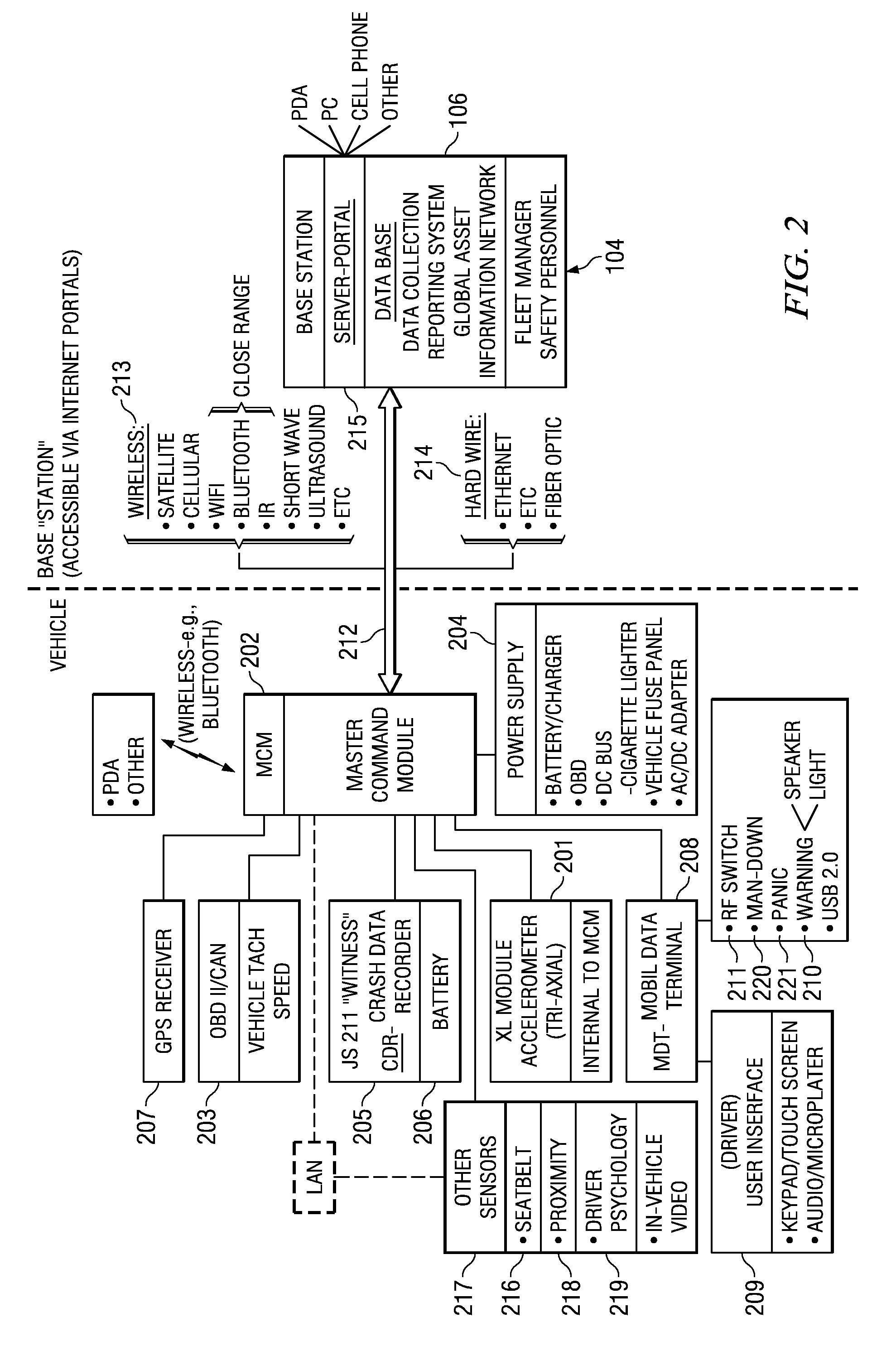

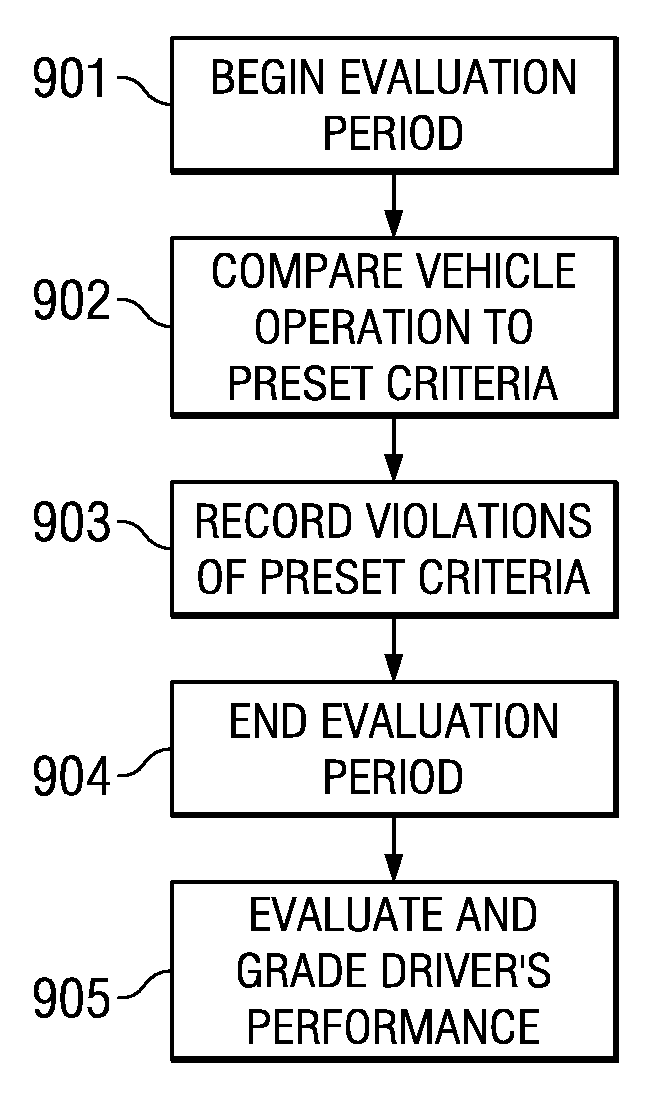

System and Method for Evaluating Driver Behavior

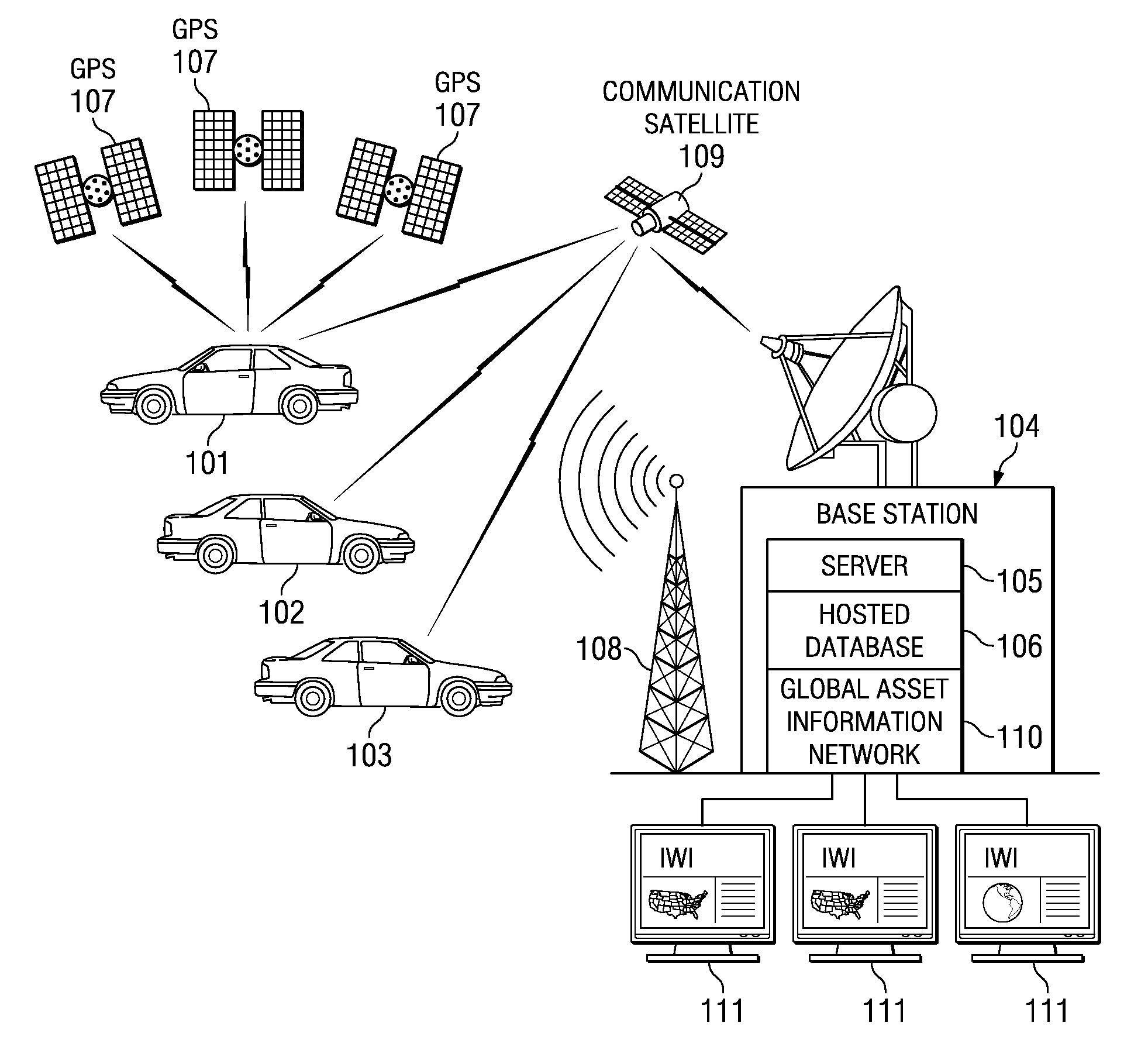

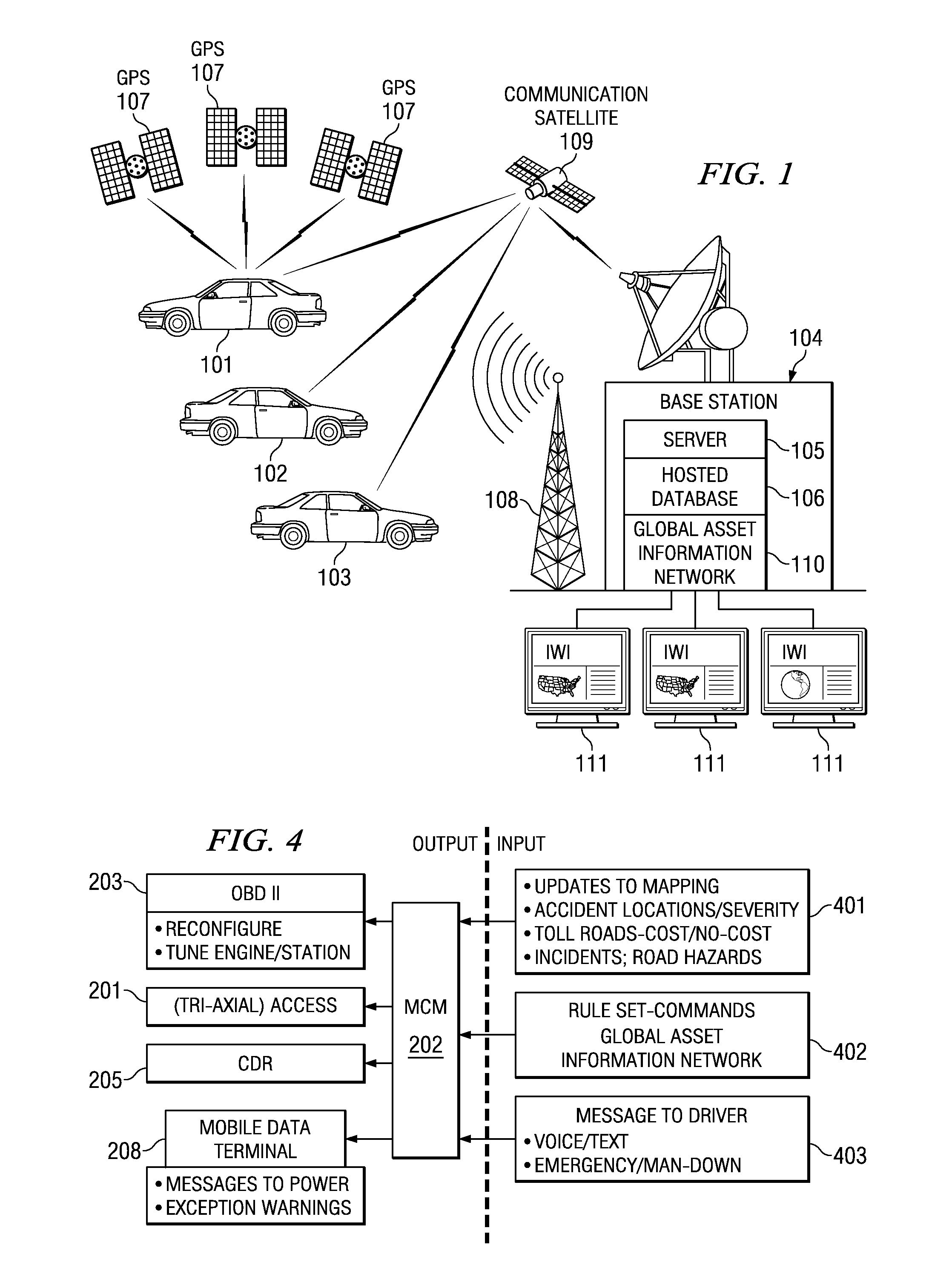

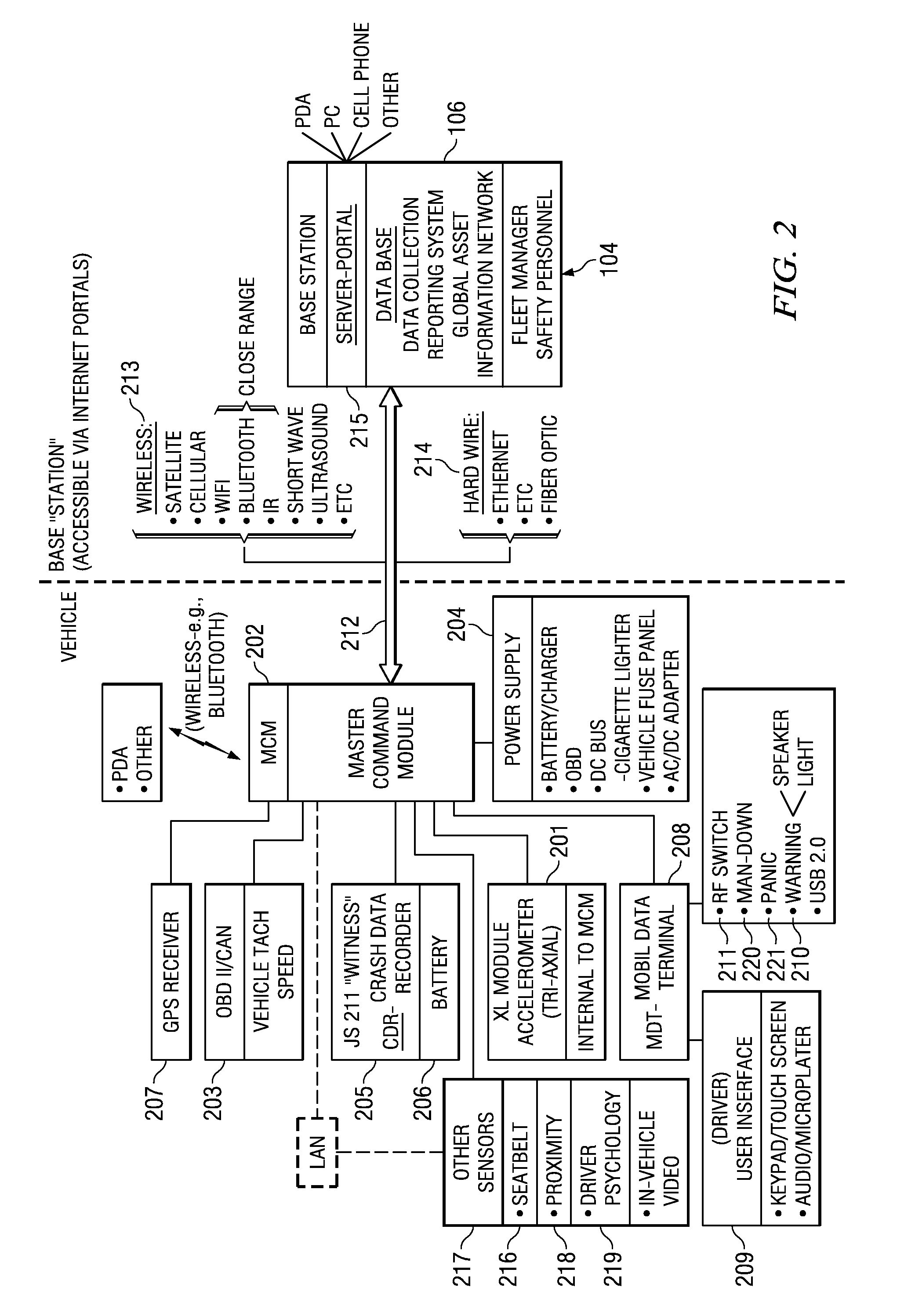

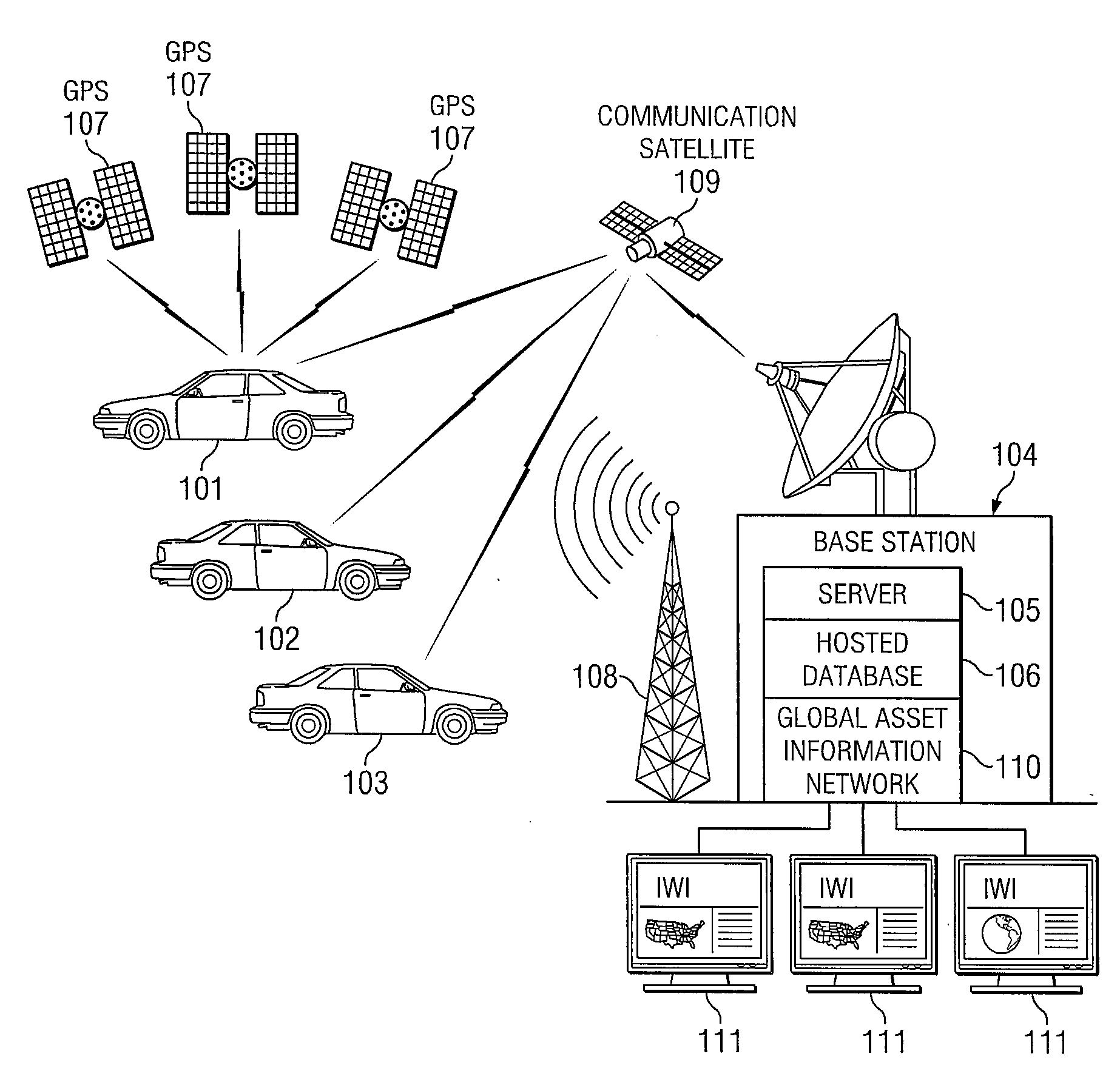

ActiveUS20080255722A1Accurate trackingPrevent speedingVehicle testingRegistering/indicating working of vehiclesDriver/operatorOn board

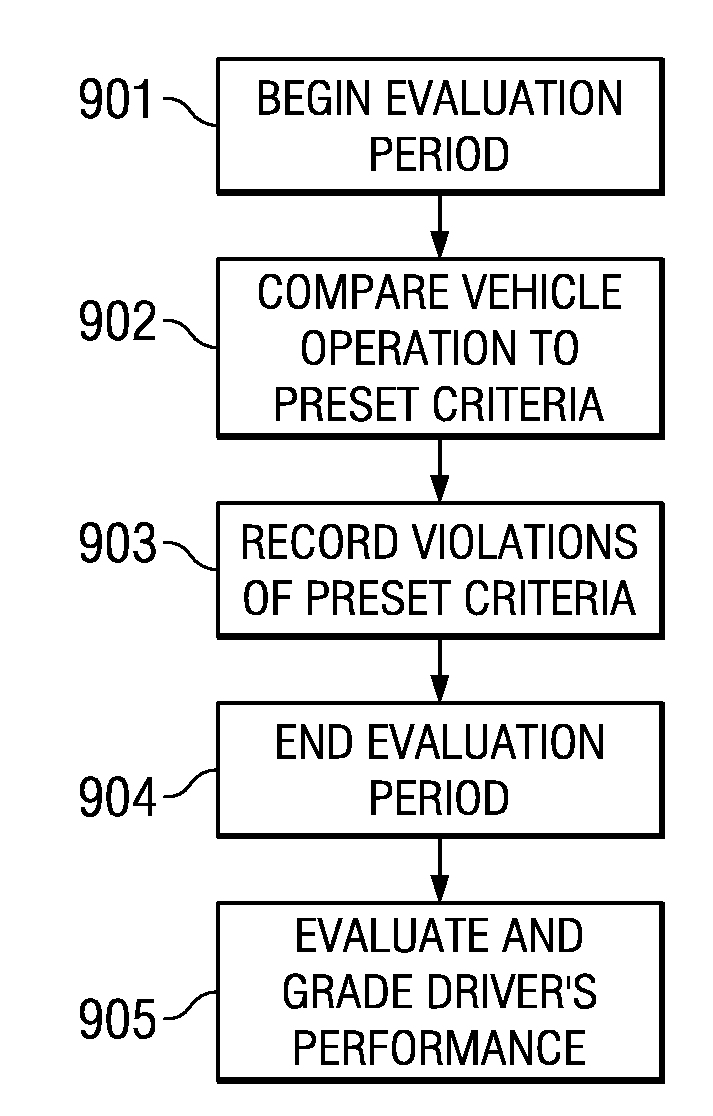

System and method for evaluating driver performance, comprising detecting operations of a vehicle using an on-board vehicle monitoring system, comparing the operations to predetermined criteria, identifying violations of the predetermined criteria, tracking violations that occur during an evaluation period, and, at the end of the evaluation period, calculating a grade associated with operation of the vehicle.

Owner:IWI

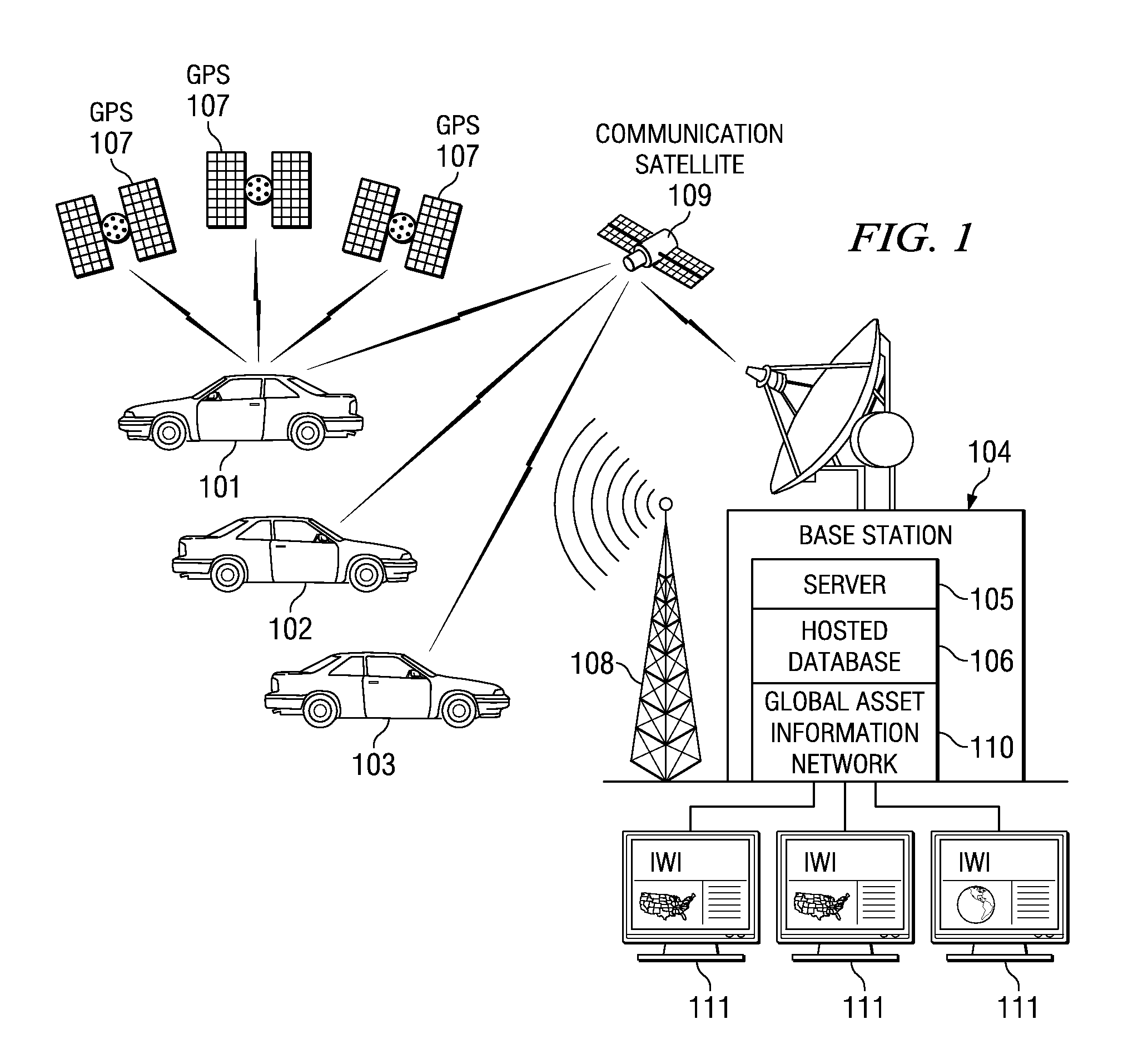

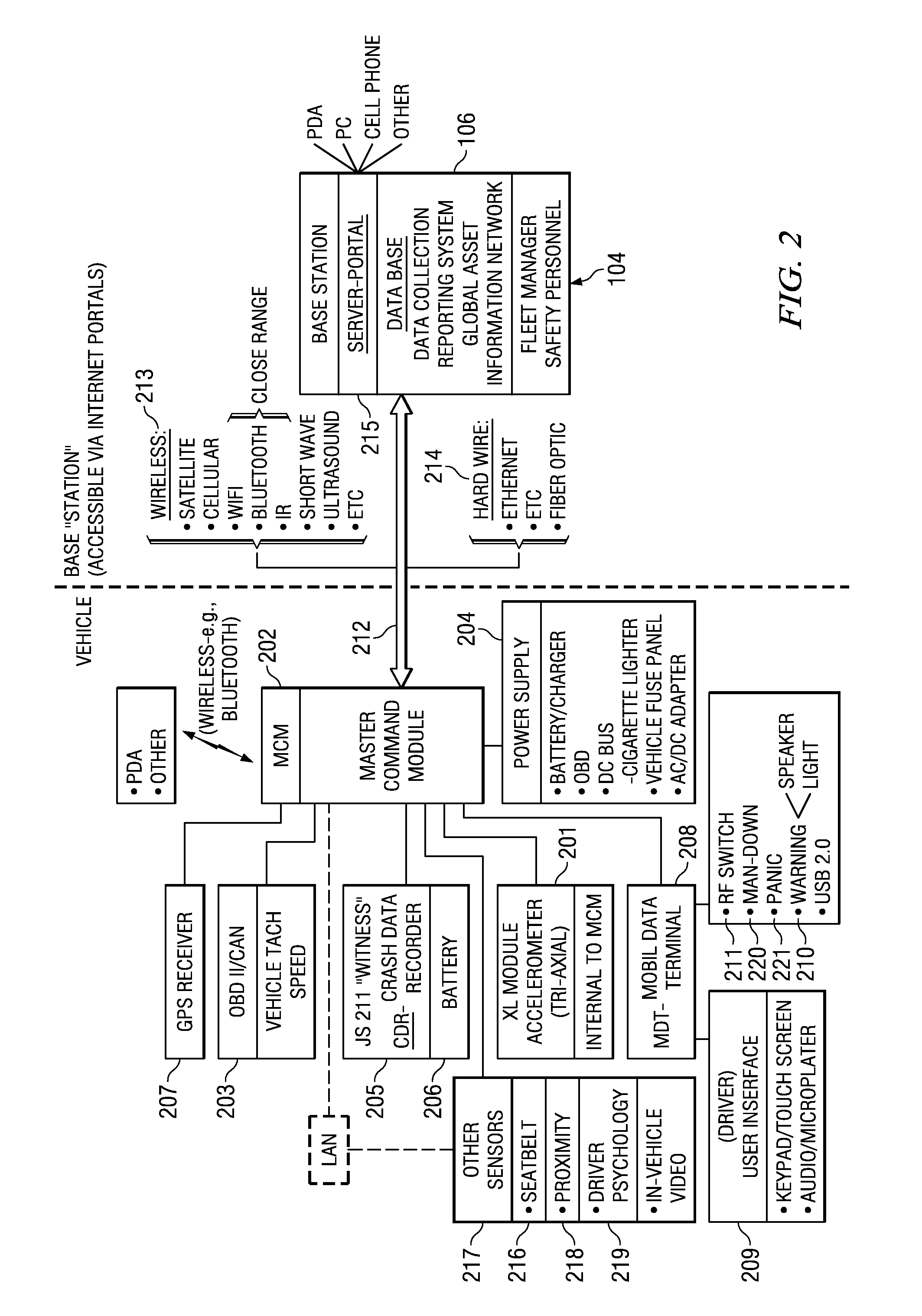

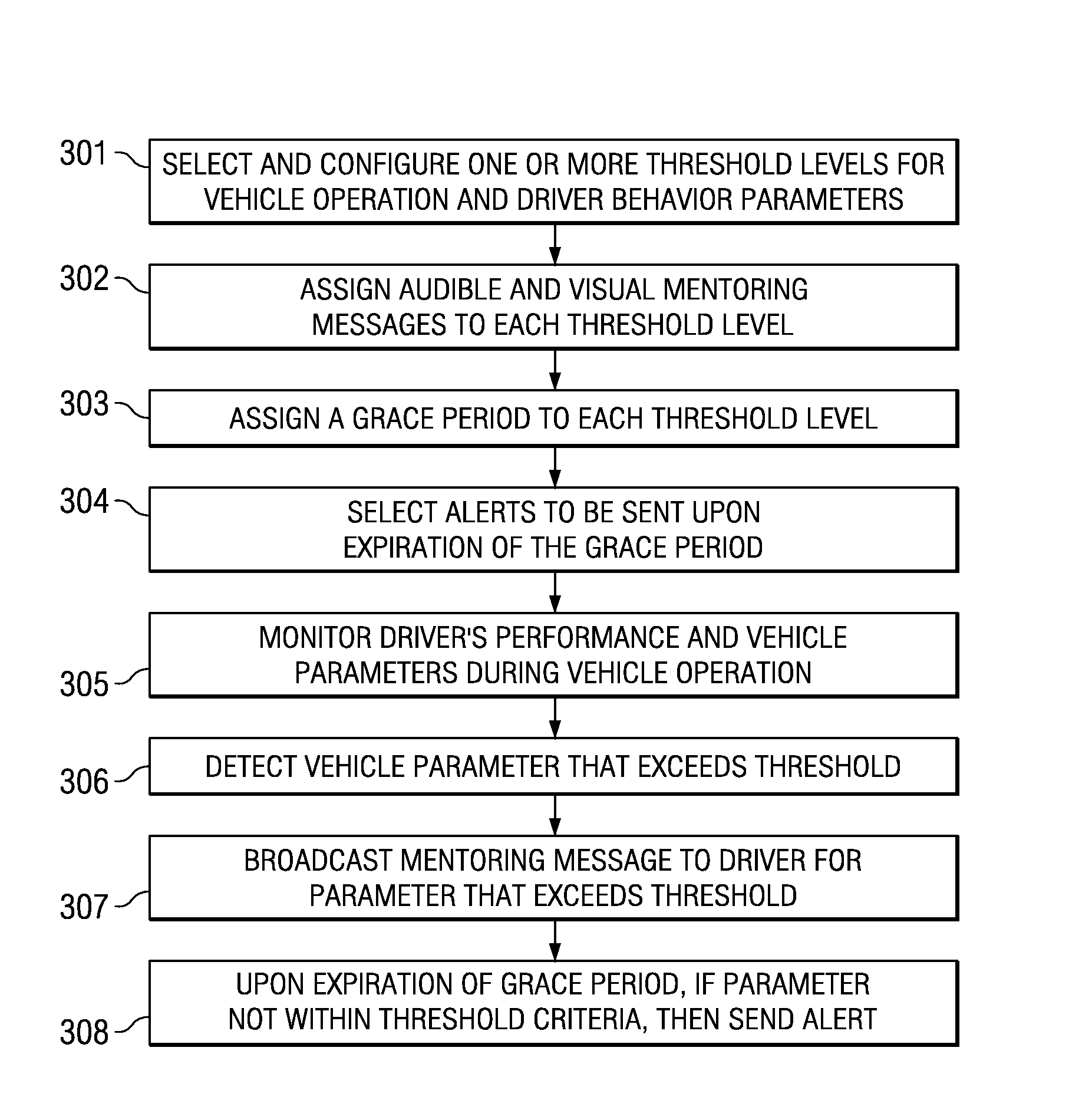

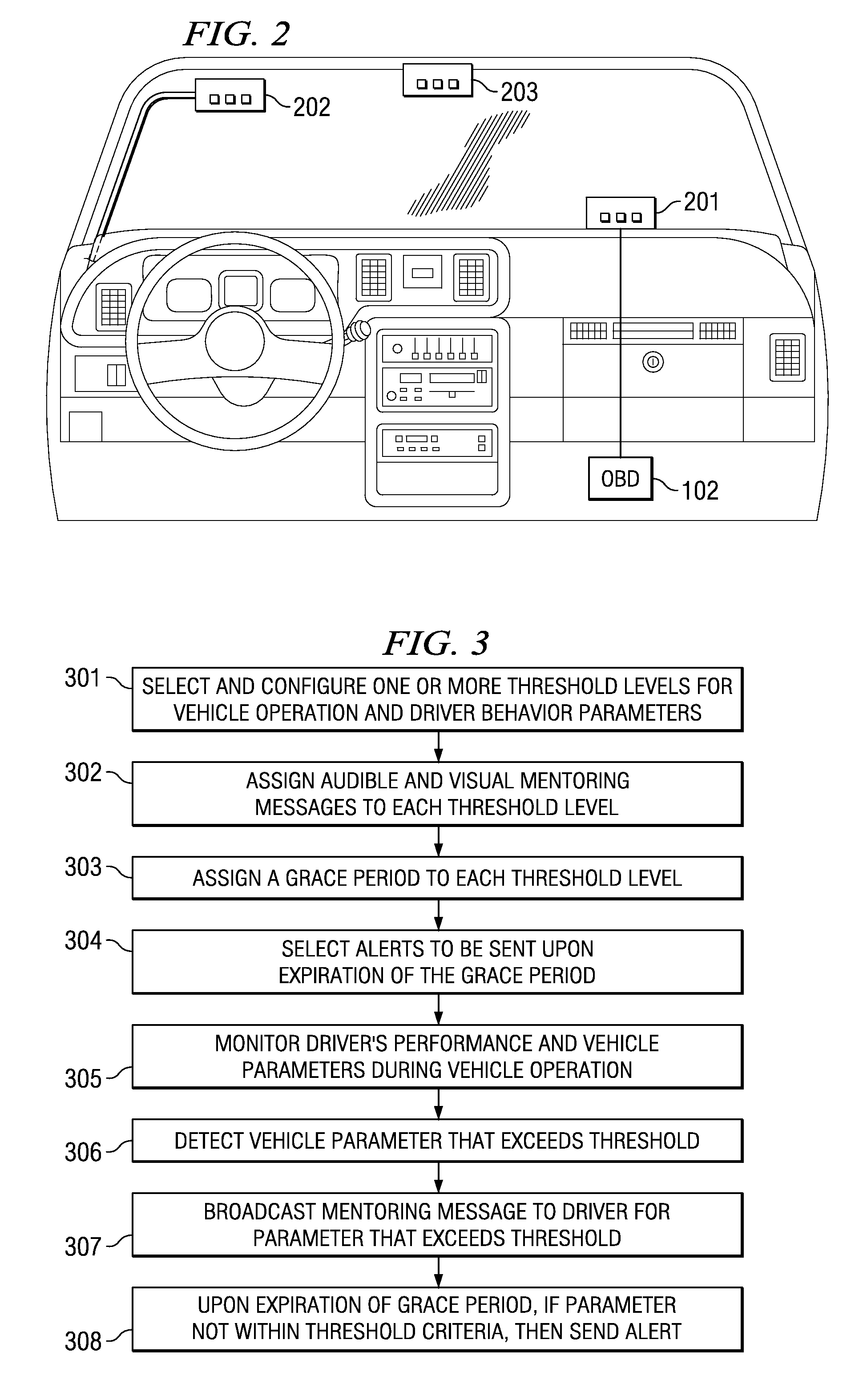

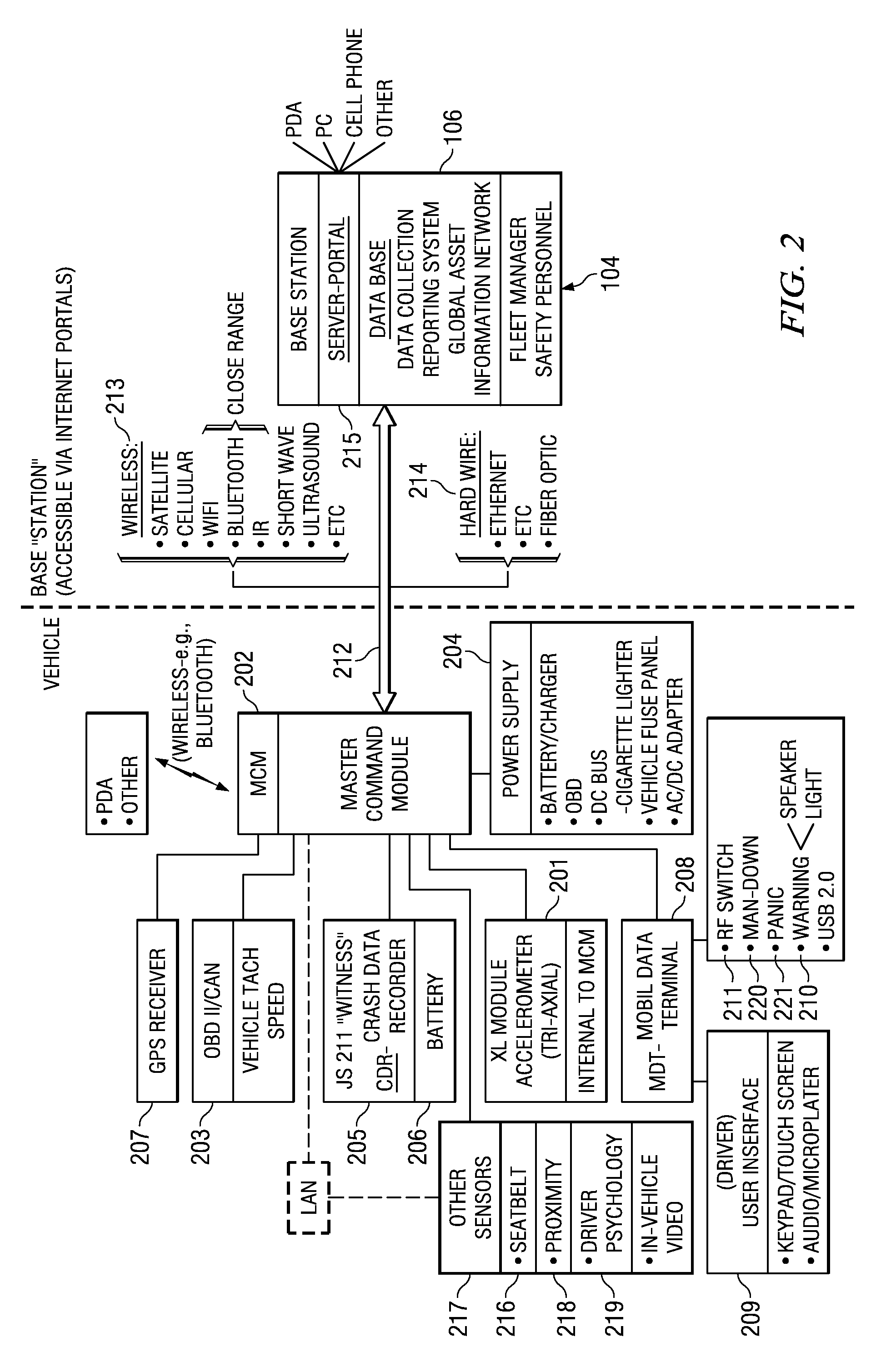

System and Method for Monitoring and Improving Driver Behavior

ActiveUS20080319602A1Reduce actionImprove securityVehicle testingRegistering/indicating working of vehiclesThird partyDriver/operator

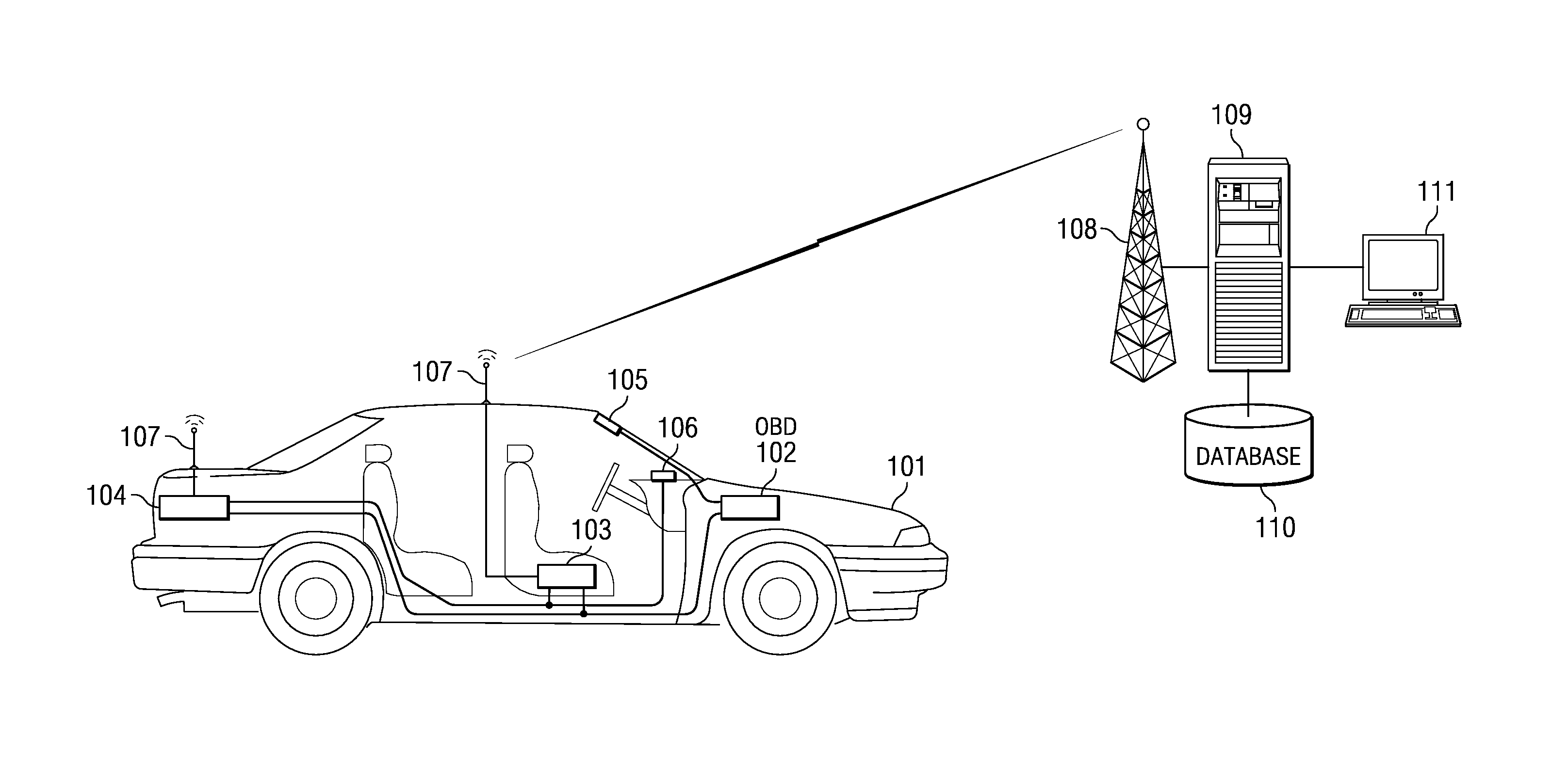

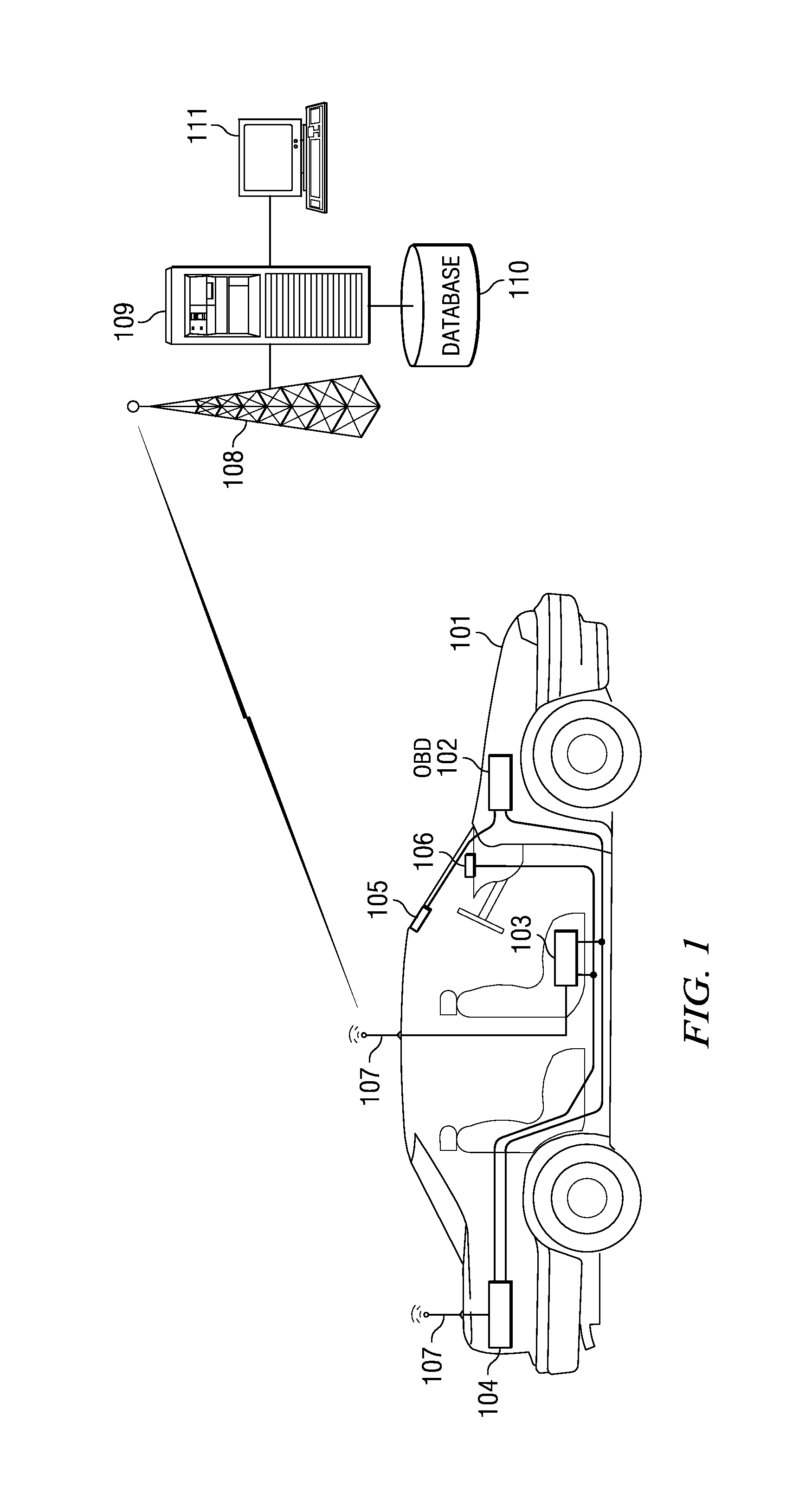

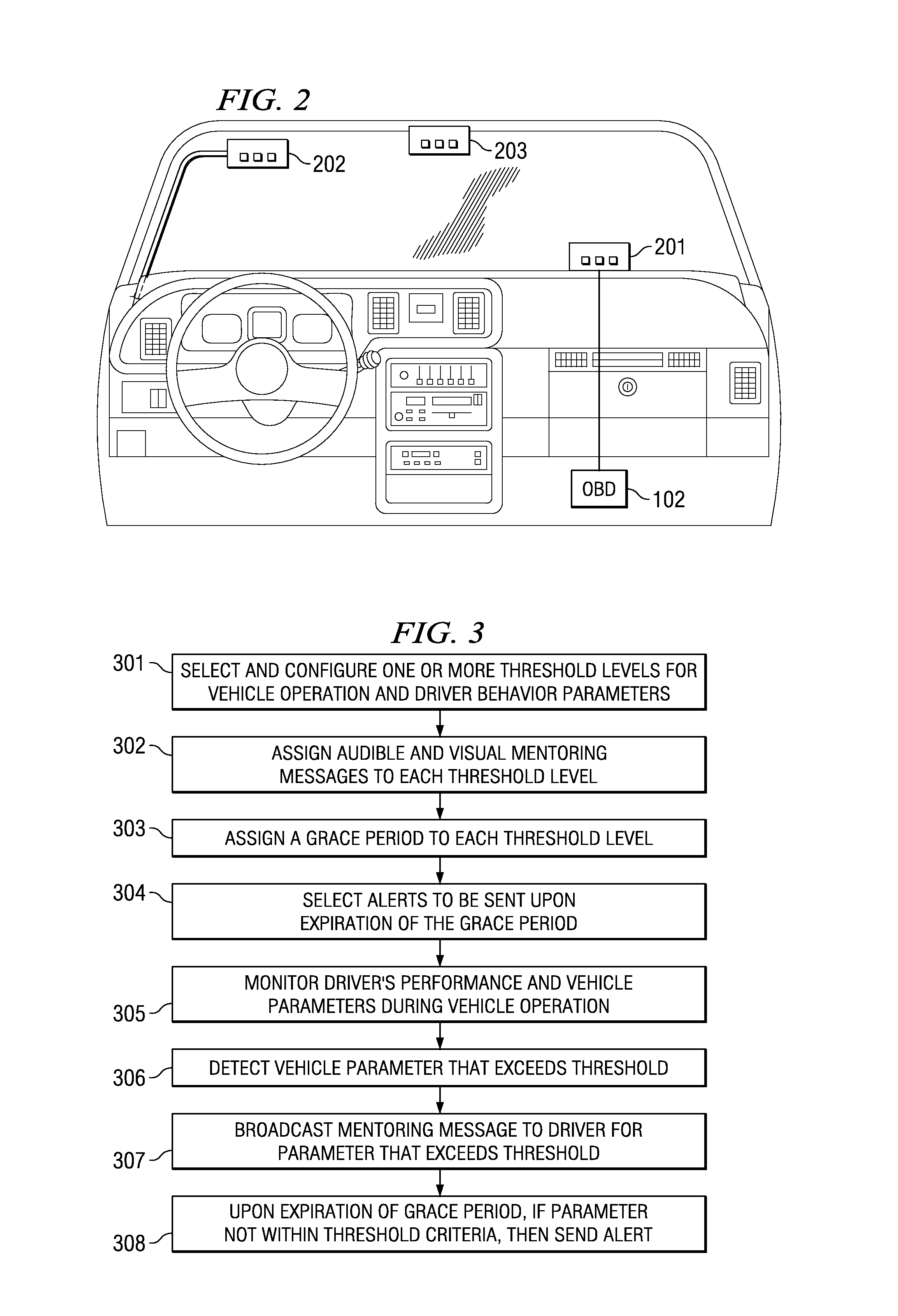

System and method for providing feedback to drivers. The system monitors selected vehicle parameters while a vehicle is being driven, and detects one or more vehicle operation violations by comparing the selected vehicle parameters to predetermined thresholds. A mentoring message is provided to the driver if the threshold is exceeded. If a vehicle operation violation has not been corrected within a preselected time period, then a violation report may be sent to a third party or a central server and / or a different mentoring message may be provided to the driver. Vehicle parameter data may be monitored from an on-board vehicle diagnostic system. The mentoring message may be an audible warning, such as a spoken message, or a visual warning, such as a text message. The selected vehicle parameters may be a vehicle speed, a vehicle acceleration, or a vehicle seatbelt use.

Owner:IWI

System and Method for Remotely Deactivating a Vehicle

InactiveUS20080258890A1Reduce actionAccurate trackingRegistering/indicating working of vehiclesRoad vehicles traffic controlOn boardMonitoring system

System and method for remotely deactivating a vehicle, comprising monitoring operations of the vehicle using an on-board monitoring system, detecting when one or more of the operations meet one or more preset criteria, and disabling the vehicle via the on-board monitoring system.

Owner:IWI

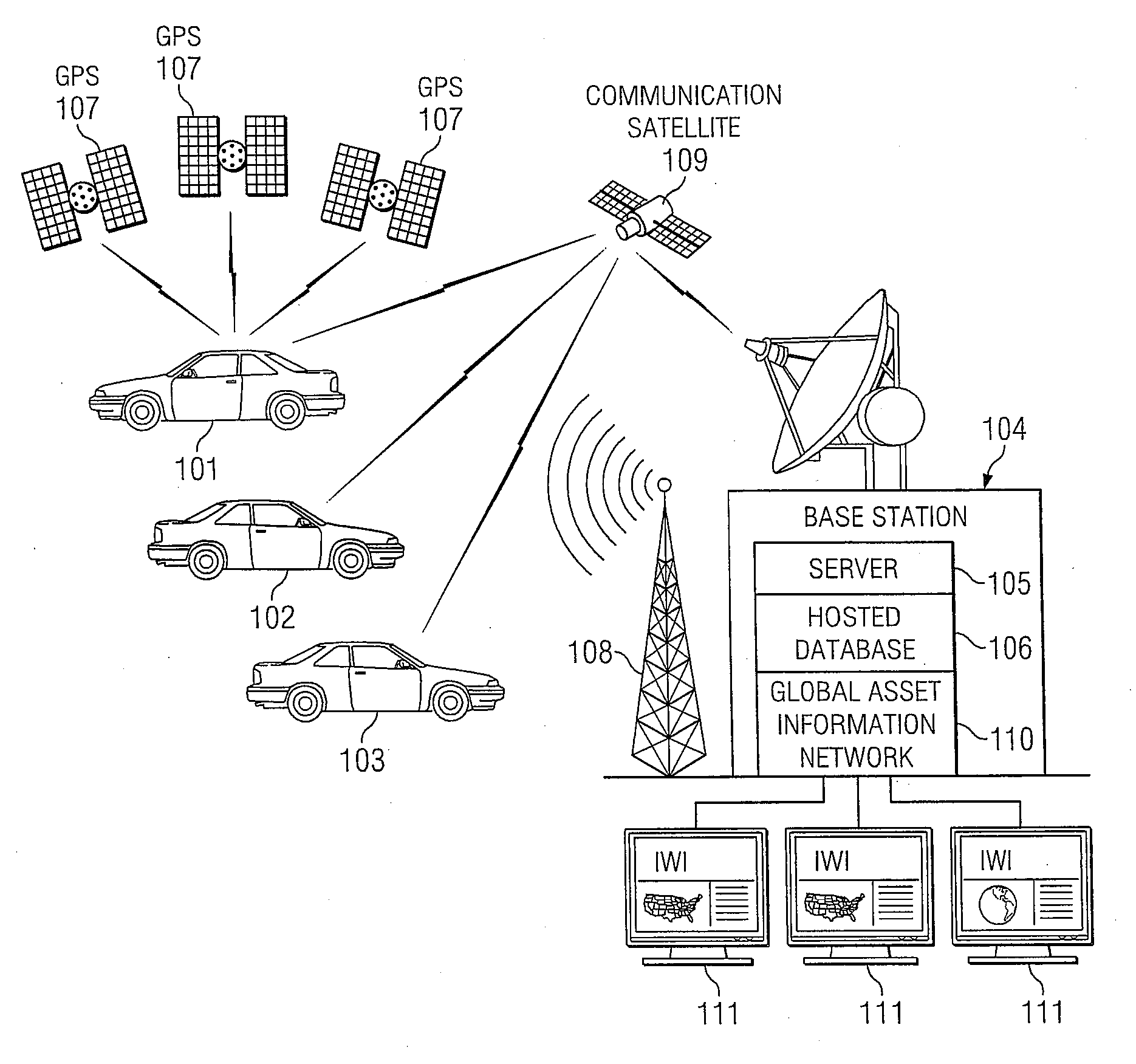

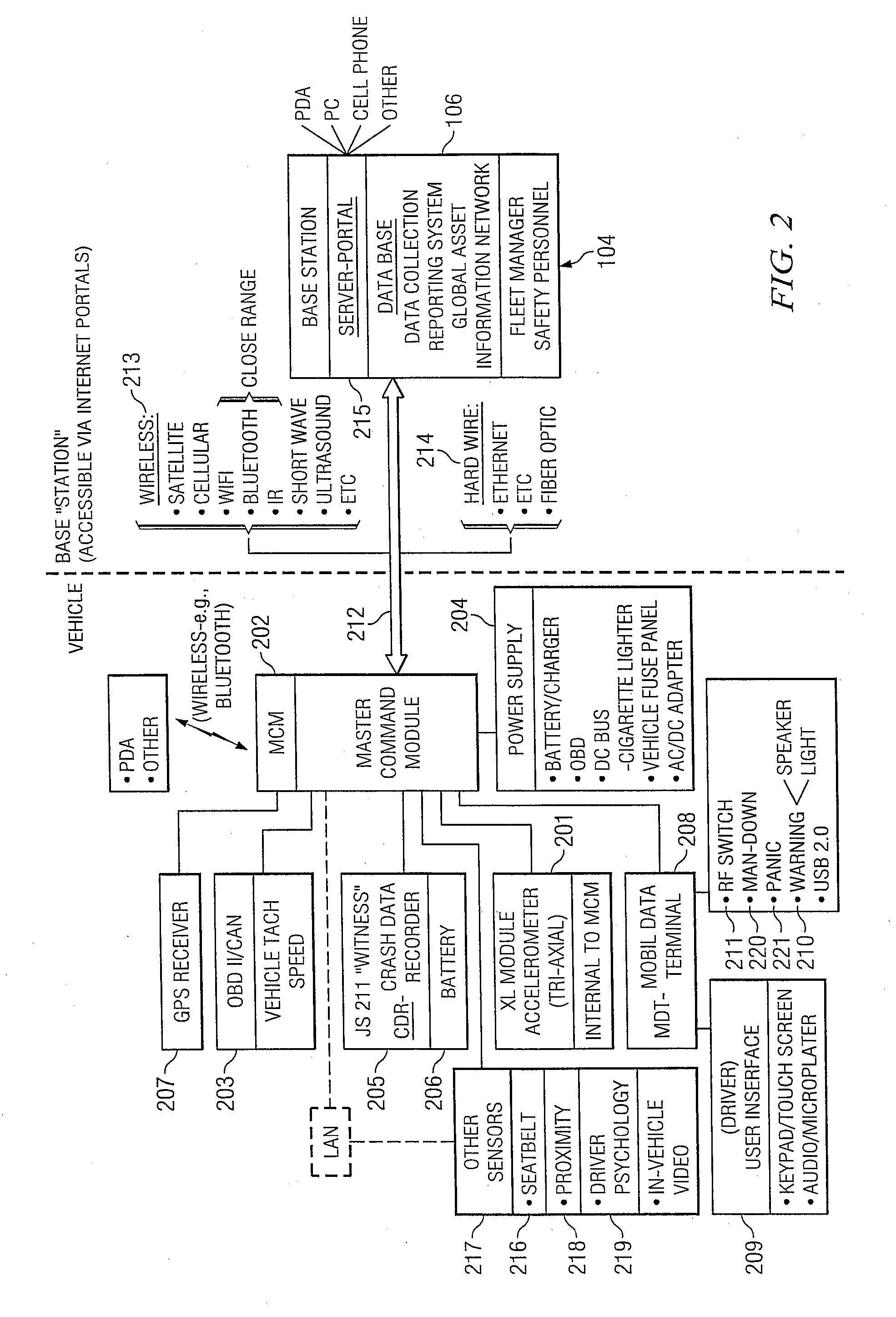

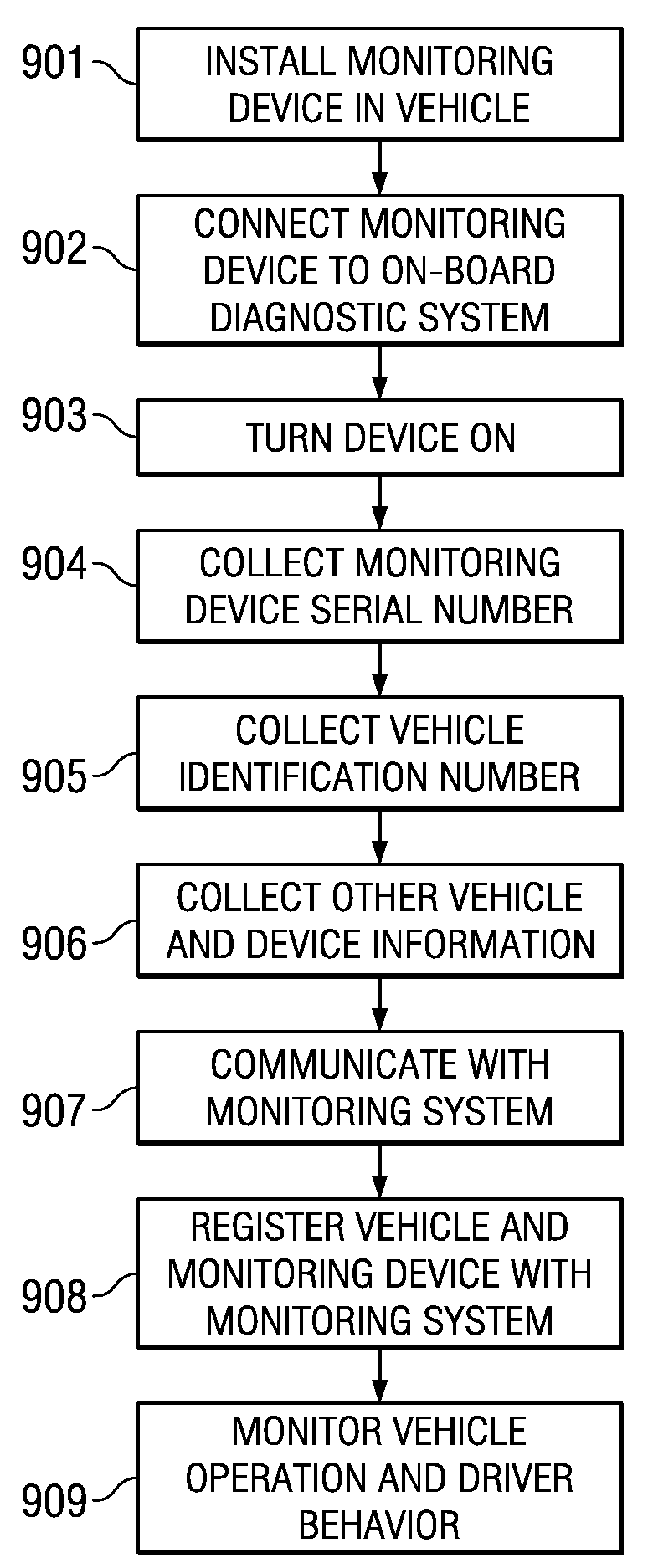

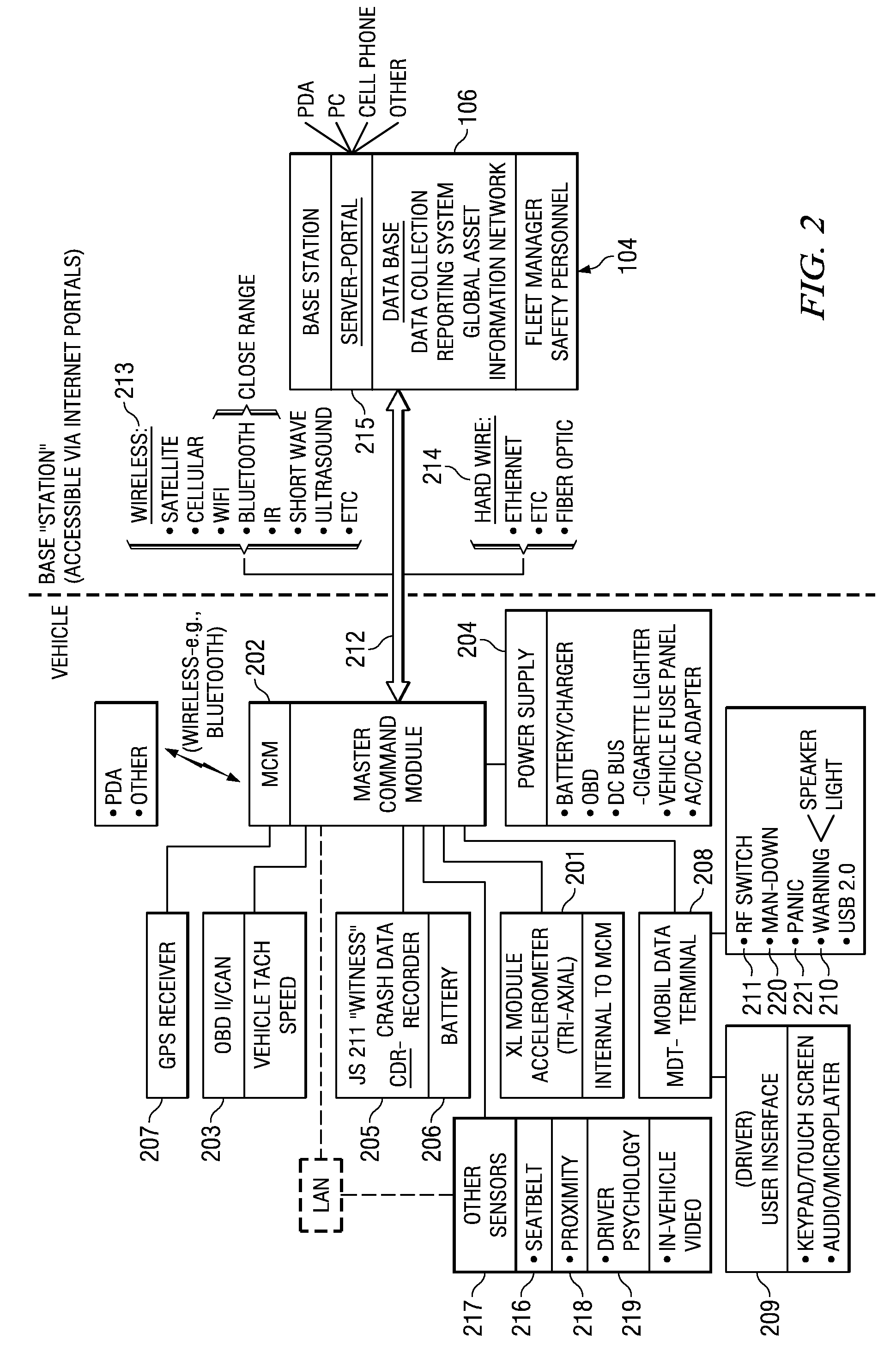

System and Method for Automatically Registering a Vehicle Monitoring Device

InactiveUS20080294690A1Reduce actionAccurate trackingRegistering/indicating working of vehiclesRoad vehicles traffic controlTelecommunications linkMonitoring system

System and method for registering a vehicle monitoring device with a central monitoring system, comprising determining a monitoring device identifier, determining a vehicle identifier from an on-board diagnostic system, establishing a communication link between the vehicle monitoring device and the central monitoring system, and sending the monitoring device identifier and vehicle identifier to the central monitoring system from the vehicle monitoring device.

Owner:IWI

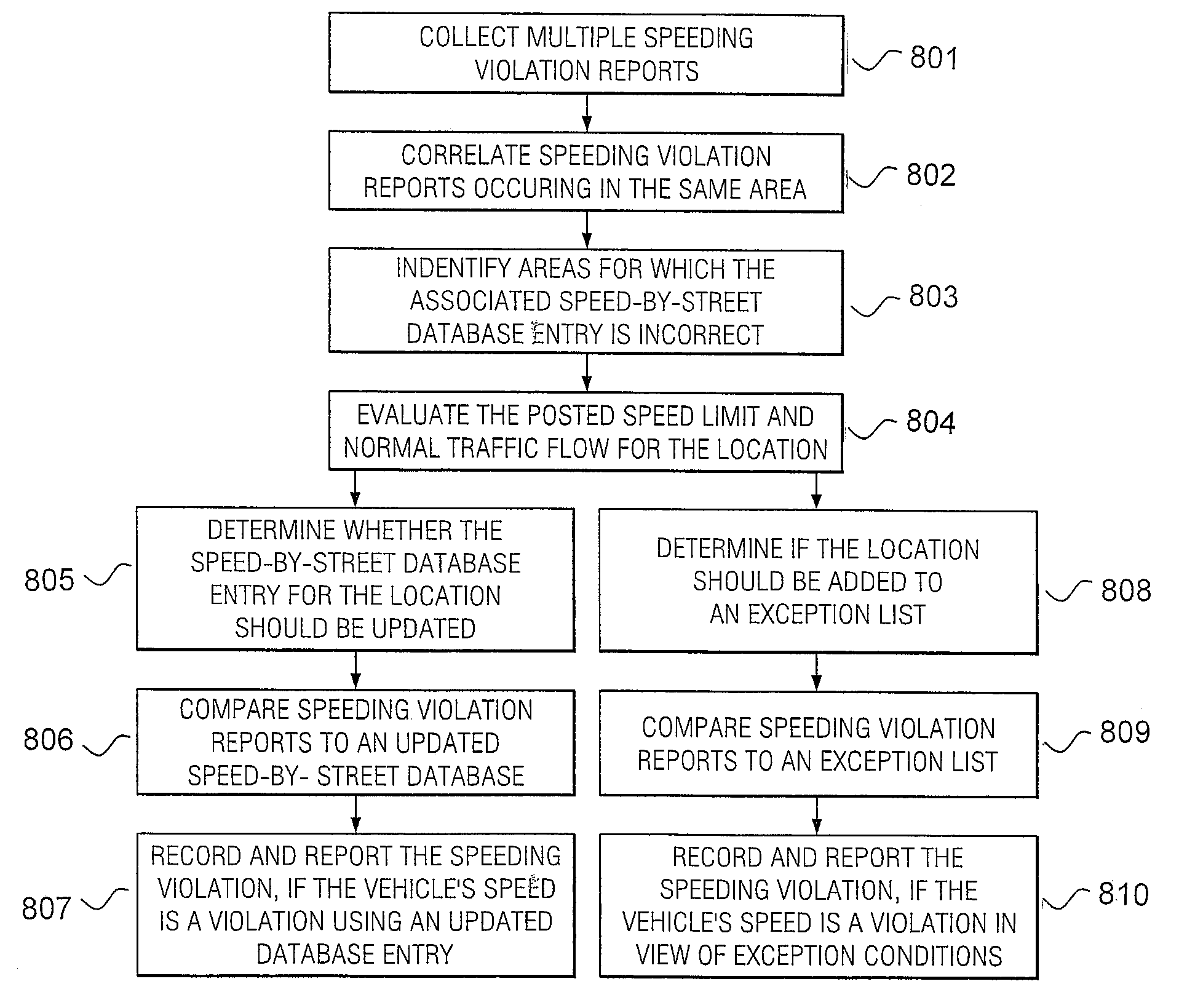

System and method for monitoring and updating speed-by-street data

ActiveUS20080252487A1Accurate trackingPrevent speedingAnalogue computers for vehiclesArrangements for variable traffic instructionsData systemIdentification error

System and method for identifying speeding violations, comprising determining a current speed and a current location of a vehicle, determining a posted speed limit for the current location from a speed-by-street database, comparing the current speed of the vehicle to the posted speed limit, and evaluating whether the current speed exceeds the posted speed limit. Errors are identified in the speed-by-street database by storing a plurality of speeding violation records, wherein the speeding violation records each include a speeding event location; analyzing the speeding violation records to identify one or more speeding event locations having multiple speeding violations; comparing a posted speed limit at the one or more speeding event locations having multiple speeding violations to corresponding speed limit data in the speed-by-street database; and identifying one or more speed limit entries in the speed-by-street database that do not match the posted speed limit.

Owner:IWI

System and Method for Detecting and Reporting Vehicle Damage

InactiveUS20090051510A1Improve driver safetyLower fuel costsRegistering/indicating working of vehiclesRoad vehicles traffic controlAccelerometerEngineering

System and method for monitoring a vehicle comprising an accelerometer unit capable of monitoring vehicle accelerations, a processor adapted to receive inputs from the accelerometer unit and to compare the vehicle accelerations to predetermined parameters, wherein an attack on the vehicle is identified when one or more vehicle accelerations exceed an attack threshold, and one or more transmitter units adapted to continuously transmit messages upon occurrence of an attack, wherein the messages comprise a vehicle location.

Owner:IWI

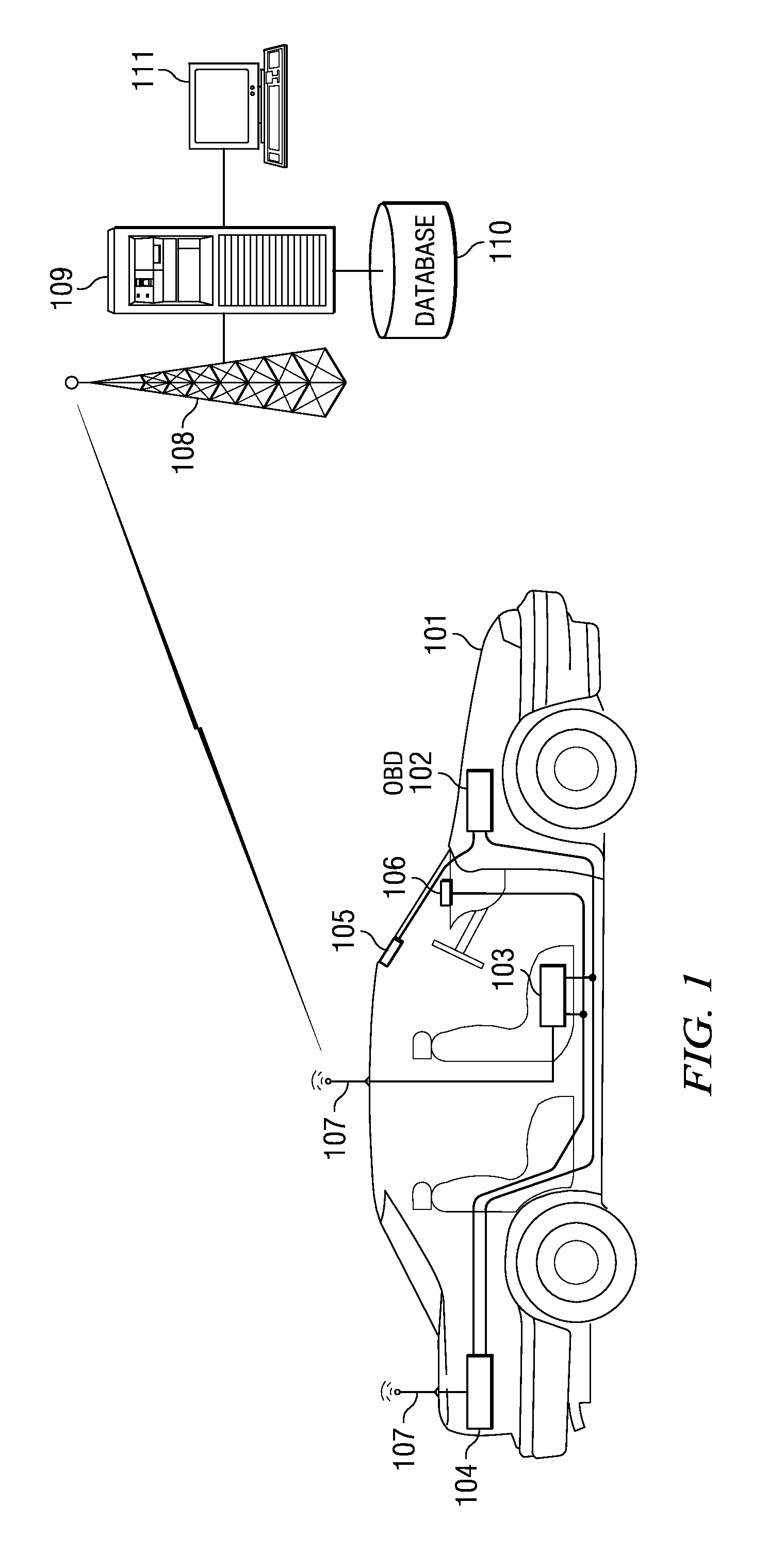

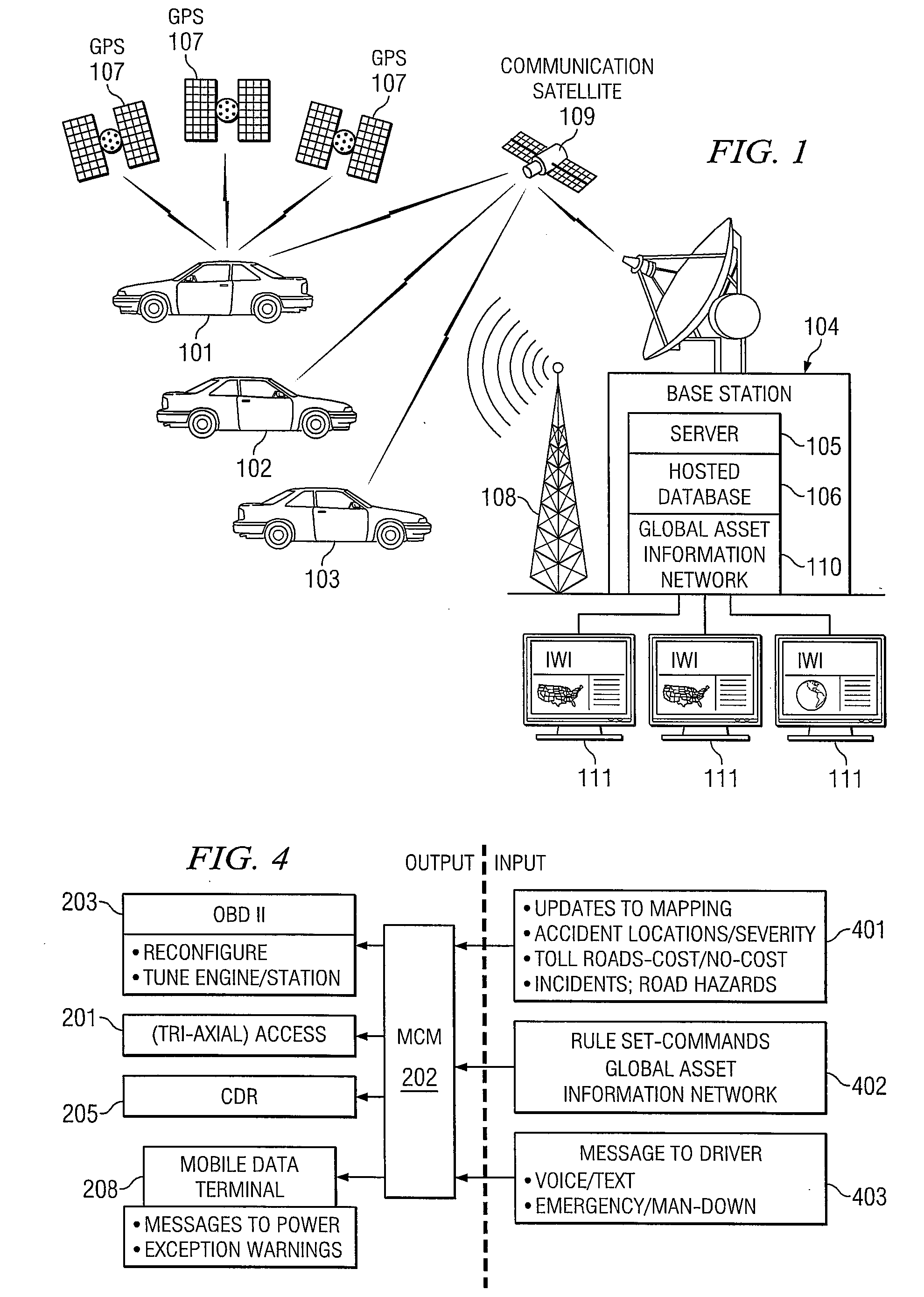

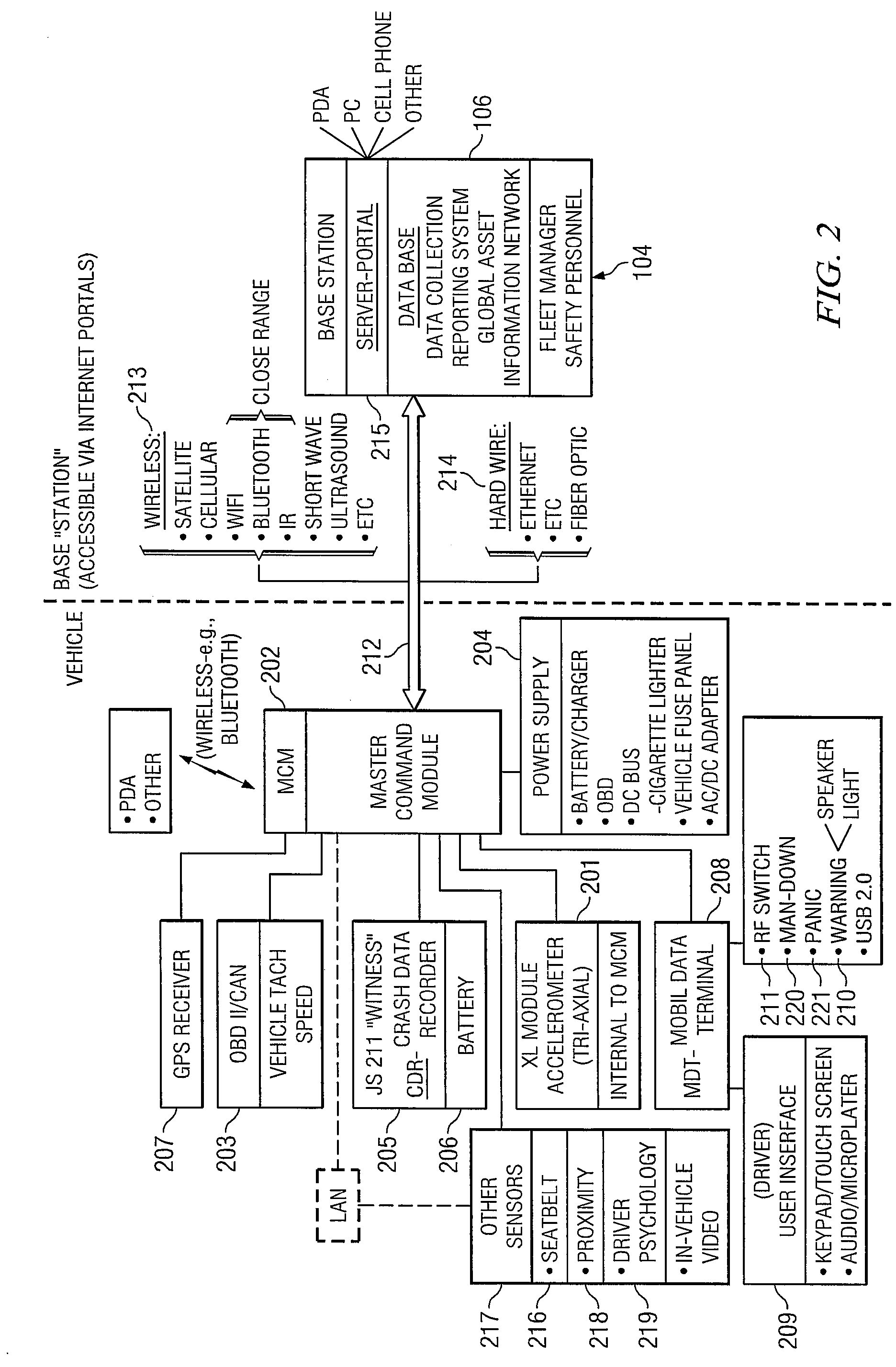

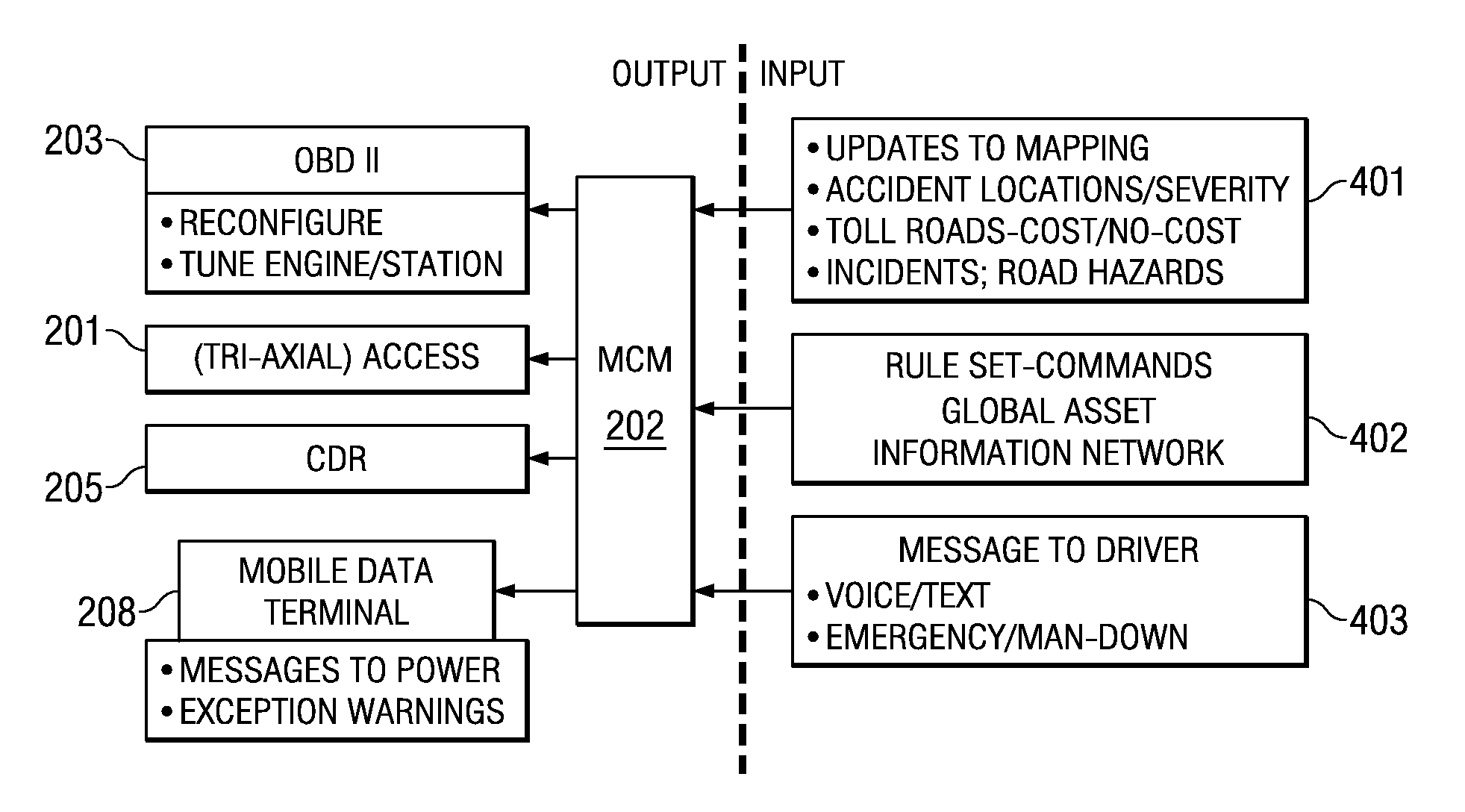

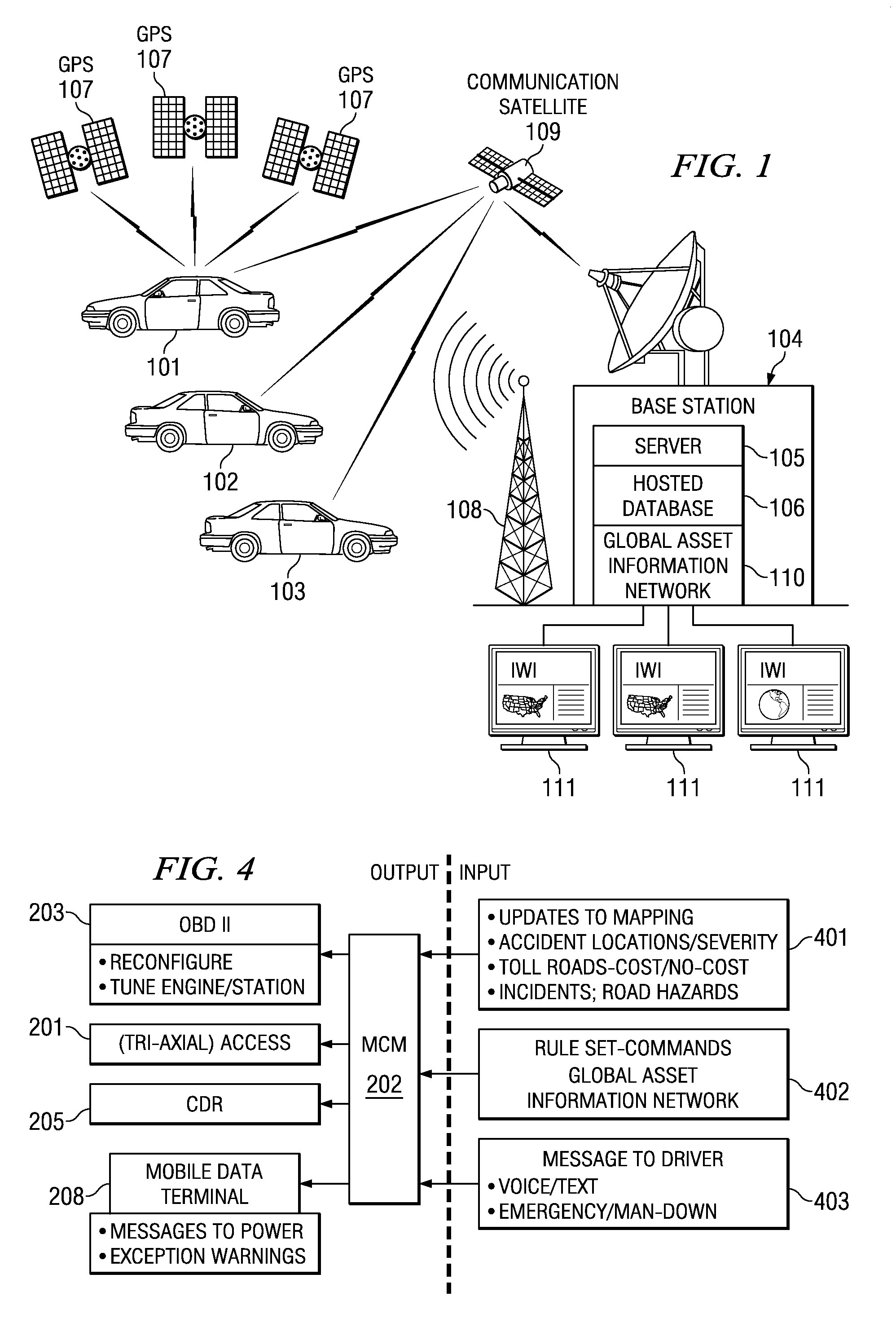

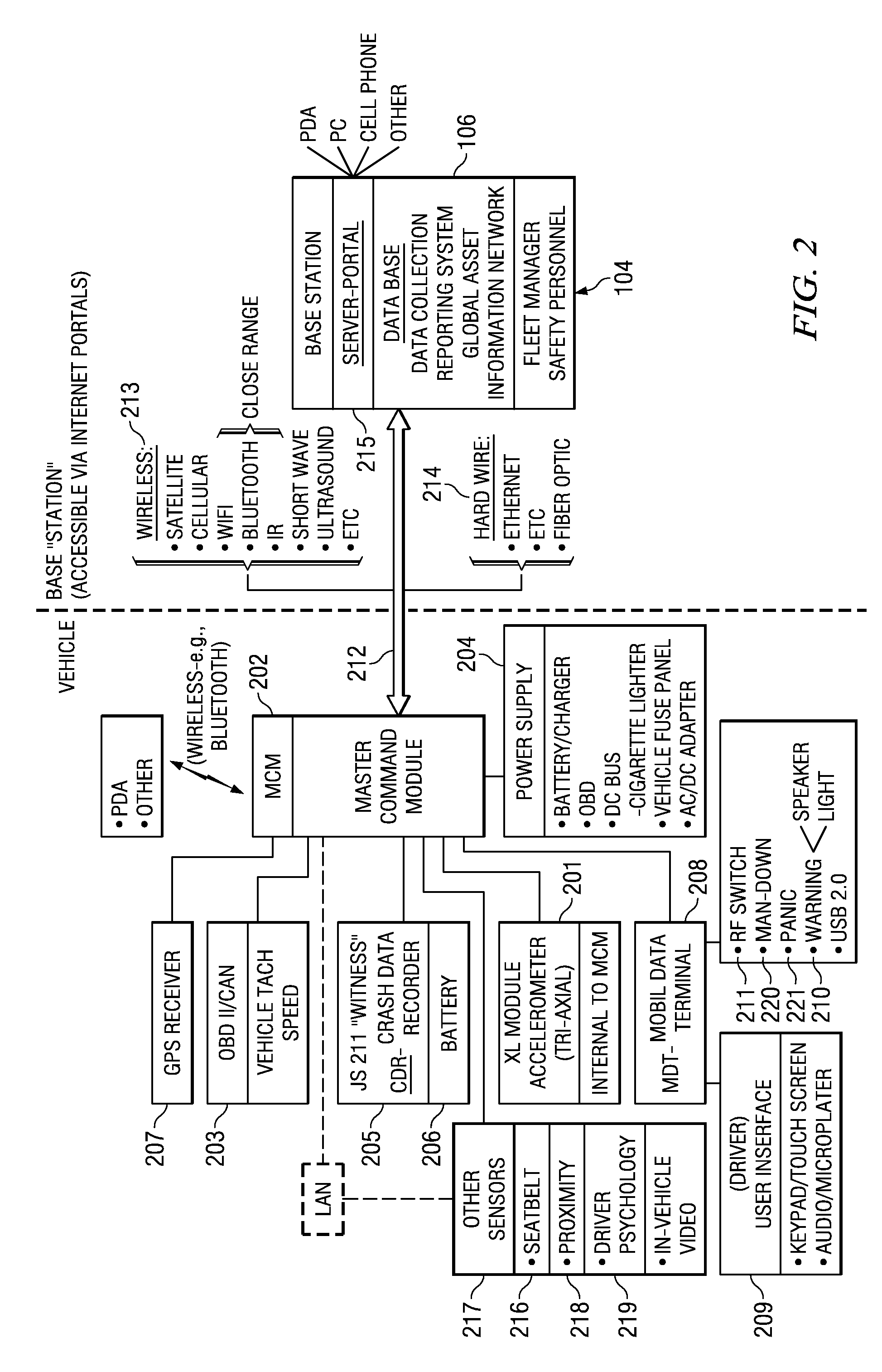

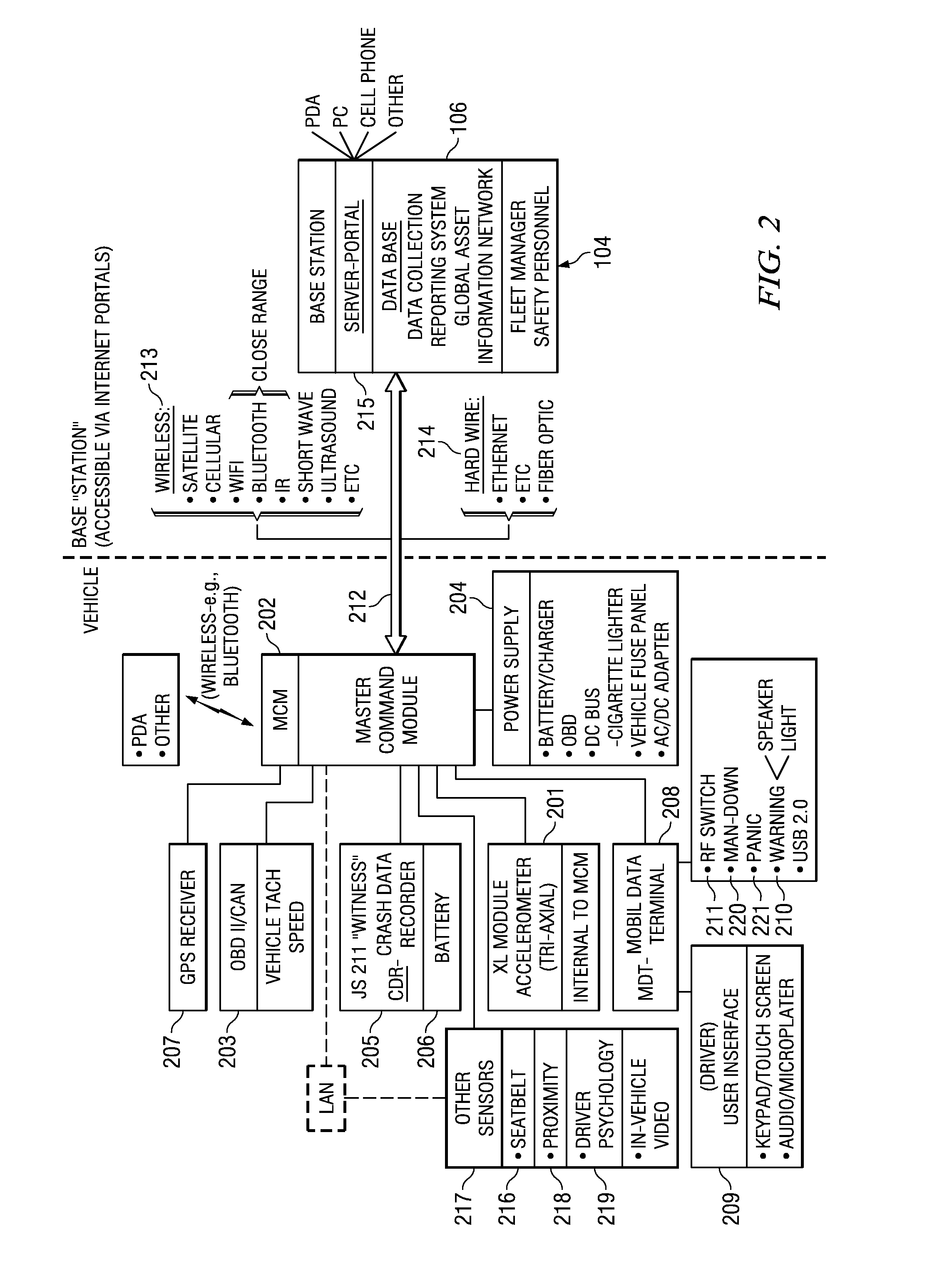

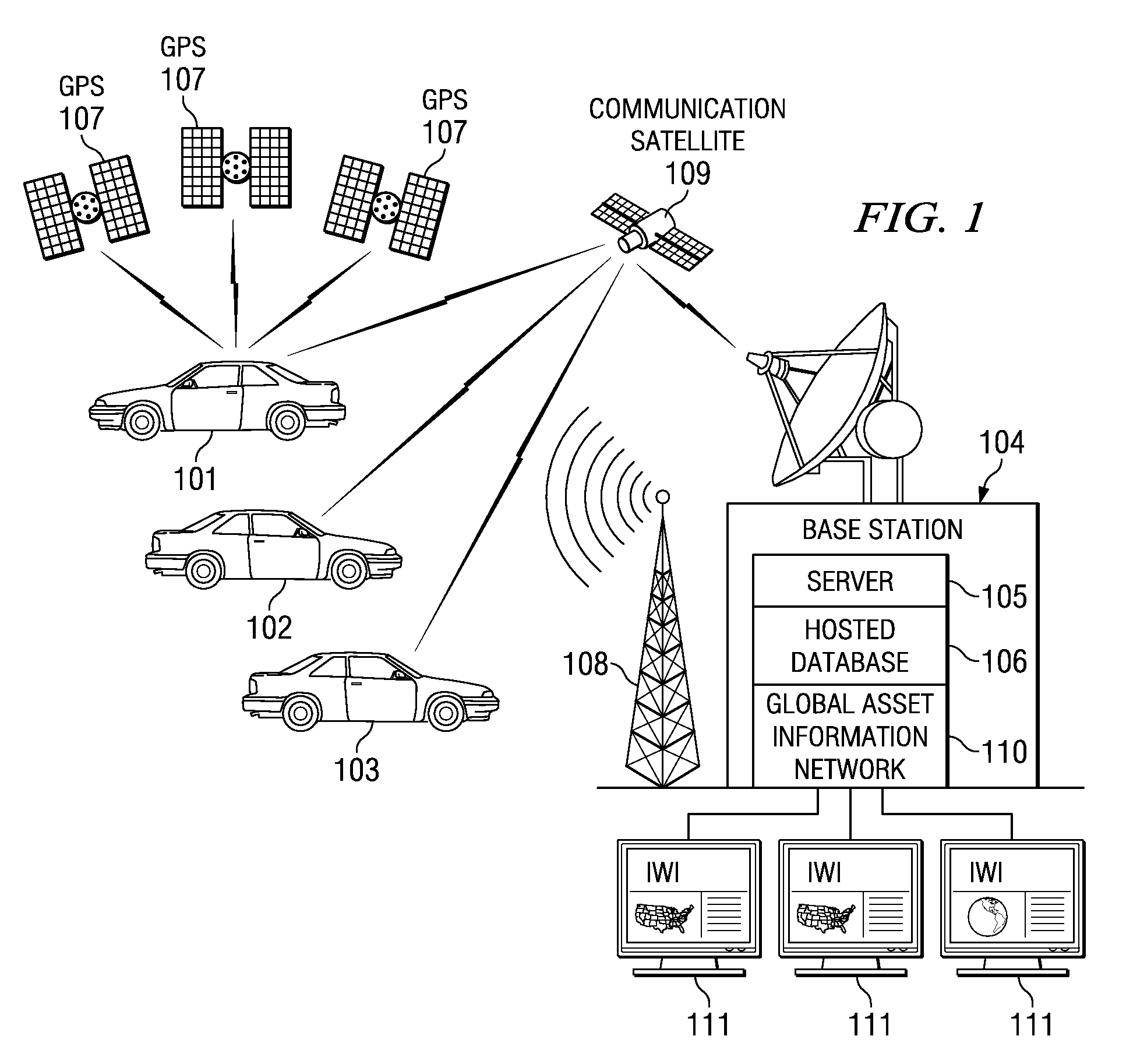

System and method for monitoring vehicle parameters and driver behavior

ActiveUS20080262670A1Reduce actionAccurate trackingVehicle testingRegistering/indicating working of vehiclesAccelerometerDriver/operator

System and method for monitoring the operation of a vehicle, comprising a housing having an accelerometer unit, and a global positioning system (GPS) unit, wherein the housing is adapted to be mounted in a window of the vehicle, and wherein the system is adapted to be powered by an on-board diagnostic system of the vehicle.

Owner:IWI

System and method for automatically registering a vehicle monitoring device

InactiveUS20160117871A1Reduce actionAccurate trackingRegistering/indicating working of vehiclesRoad vehicles traffic controlTelecommunications linkMonitoring system

System and method for registering a vehicle monitoring device with a central monitoring system, comprising determining a monitoring device identifier, determining a vehicle identifier from an on-board diagnostic system, establishing a communication link between the vehicle monitoring device and the central monitoring system, and sending the monitoring device identifier and vehicle identifier to the central monitoring system from the vehicle monitoring device.

Owner:IWI

System and method for monitoring and updating speed-by-street data

ActiveUS7859392B2Reduce actionAccurate trackingAnalogue computers for vehiclesArrangements for variable traffic instructionsData systemIdentification error

System and method for identifying speeding violations, comprising determining a current speed and a current location of a vehicle, determining a posted speed limit for the current location from a speed-by-street database, comparing the current speed of the vehicle to the posted speed limit, and evaluating whether the current speed exceeds the posted speed limit. Errors are identified in the speed-by-street database by storing a plurality of speeding violation records, wherein the speeding violation records each include a speeding event location; analyzing the speeding violation records to identify one or more speeding event locations having multiple speeding violations; comparing a posted speed limit at the one or more speeding event locations having multiple speeding violations to corresponding speed limit data in the speed-by-street database; and identifying one or more speed limit entries in the speed-by-street database that do not match the posted speed limit.

Owner:IWI

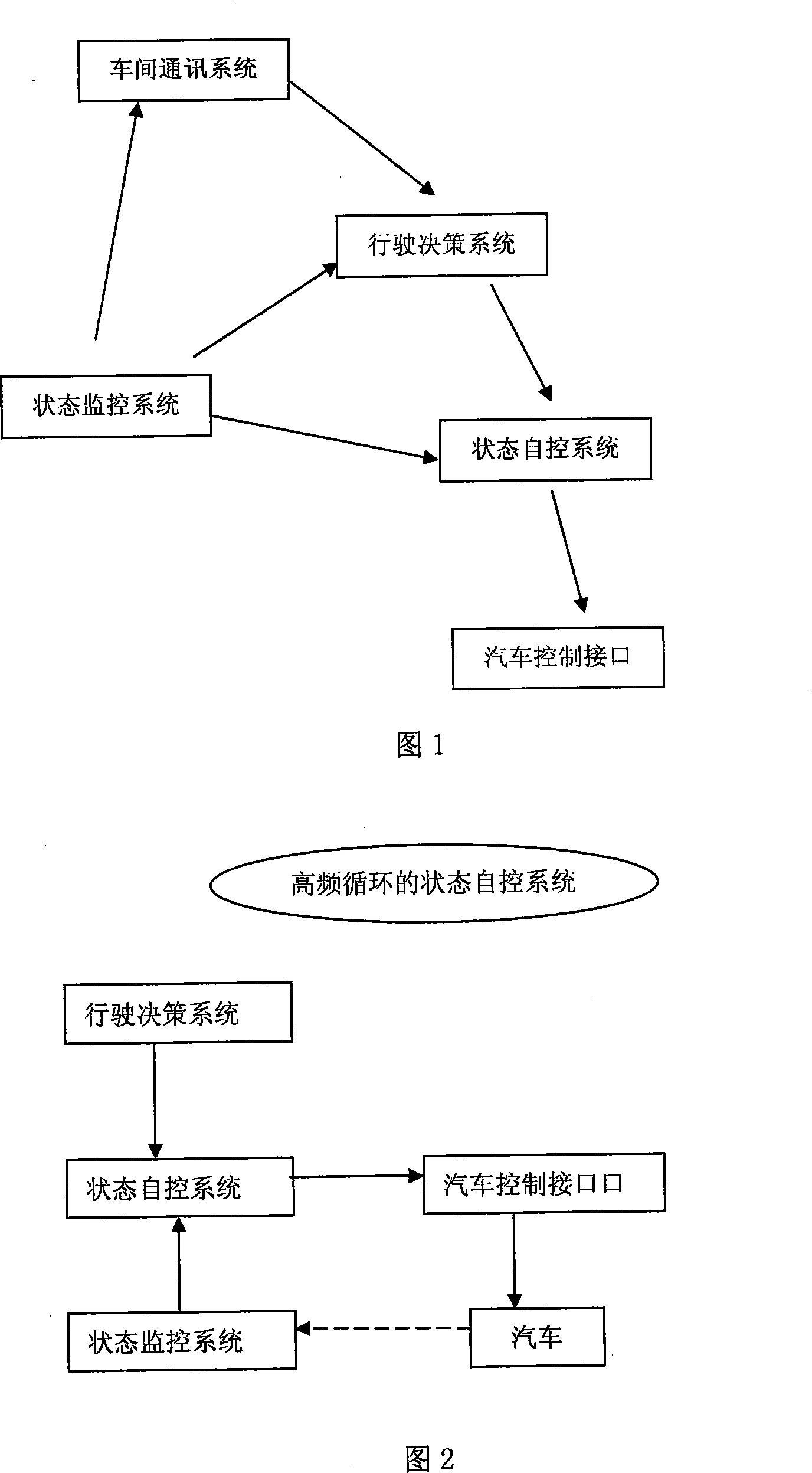

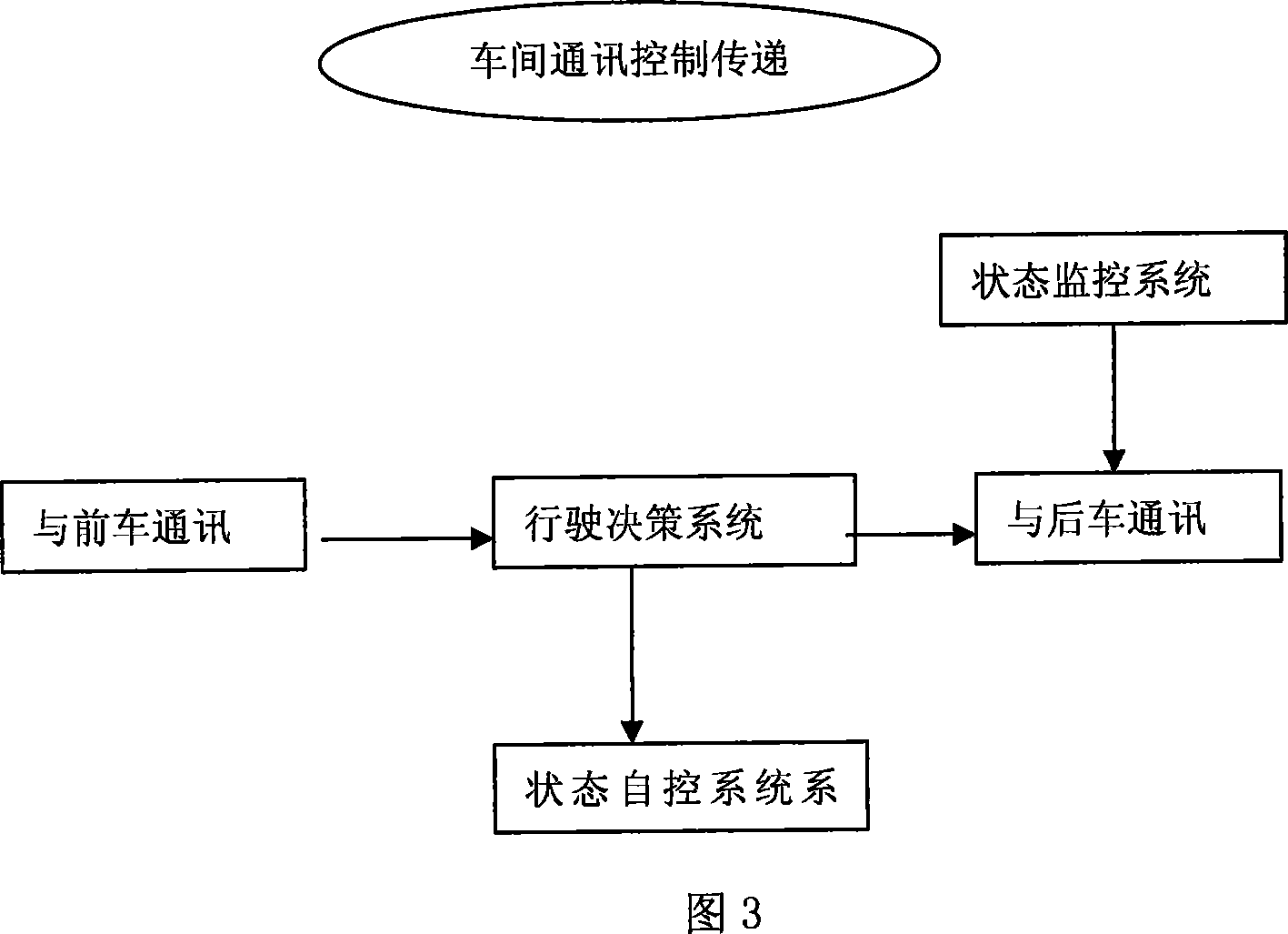

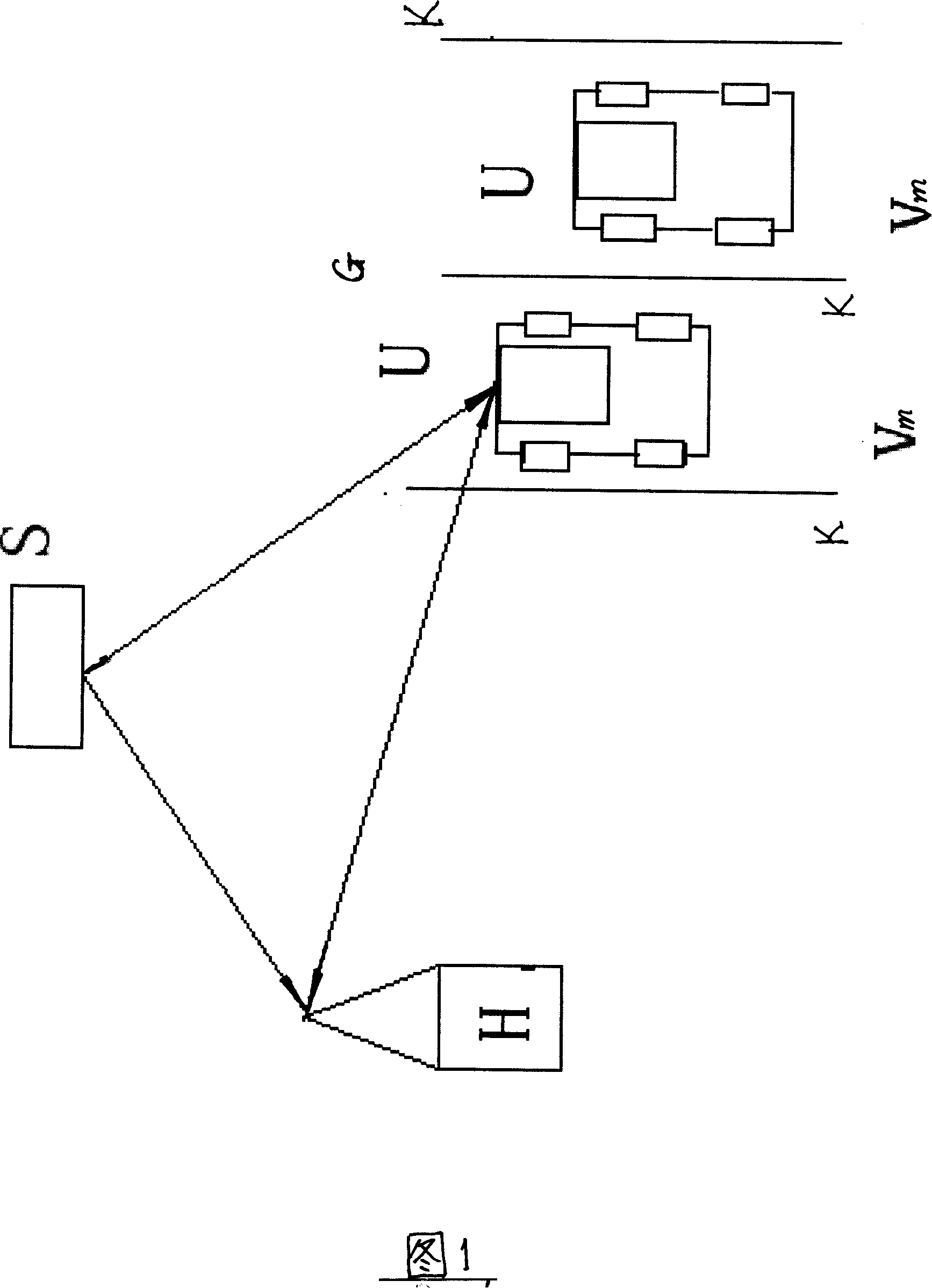

Automatic driving system for automobile information sharing between automobile and its control method

InactiveCN101101702AReduce fatigueReduce accident rateAnti-collision systemsExternal condition input parametersInformation sharingDriver/operator

This system includes a car series consisting of at least two cars. The inter-car comm. sub-system (ICS) of the leading car sends the running and situation info to the car behind. ICS of the latter sends info to the driving decision-making system (DD) of this car. When DD receives info, the situation supervision sub-system (SS) of this car offers the Driving Situation of this Car (DSC) to DD, too. DD combines and analyzes these two info then sends instruction to the situation self-control sub-system (SC). SC combines the instruction and the info from SS, then finally real time controls DSC via the car control port sub-system. This invention reduces the driver's tired degree, the accident occurring rate and driving cost.

Owner:陈拙夫

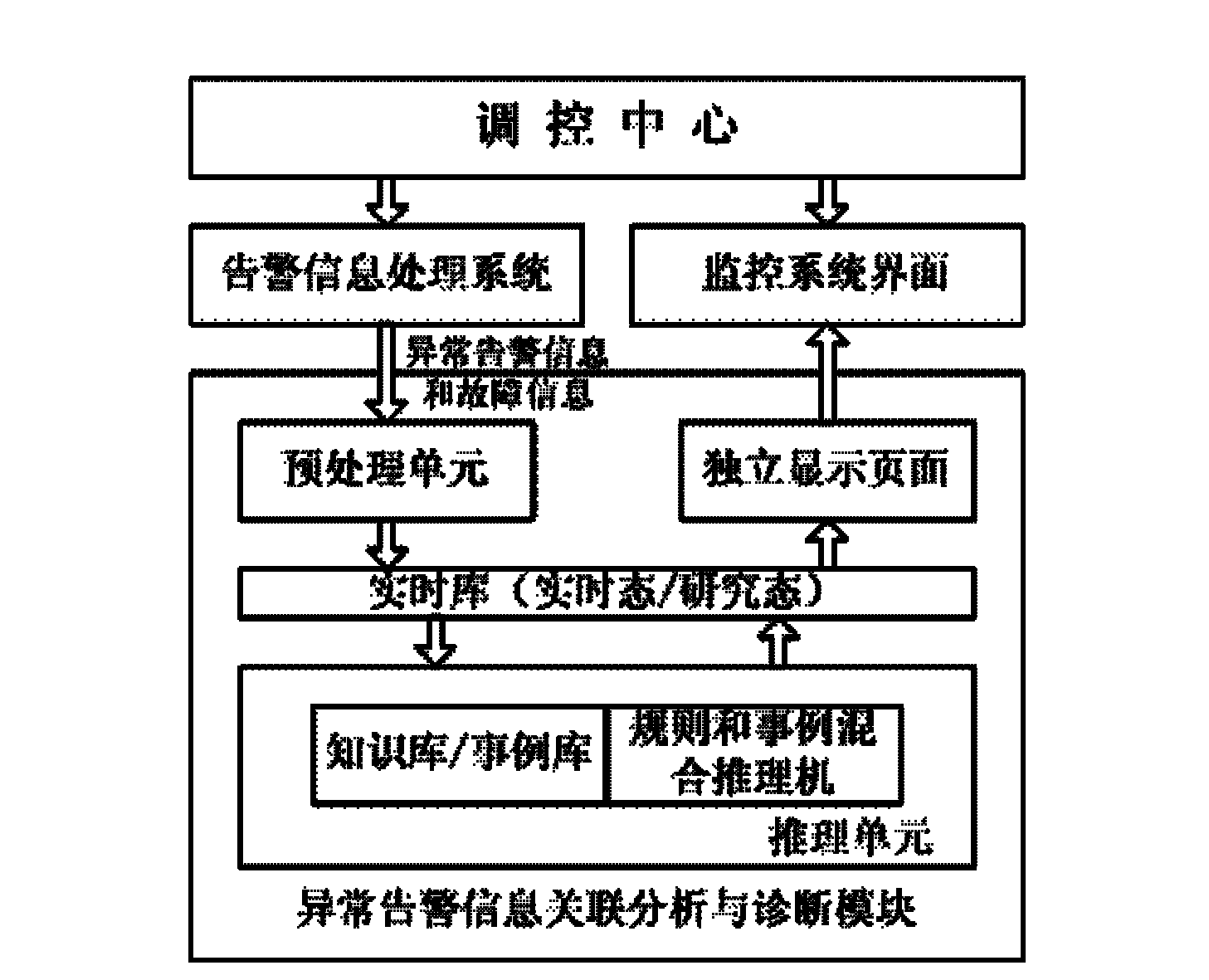

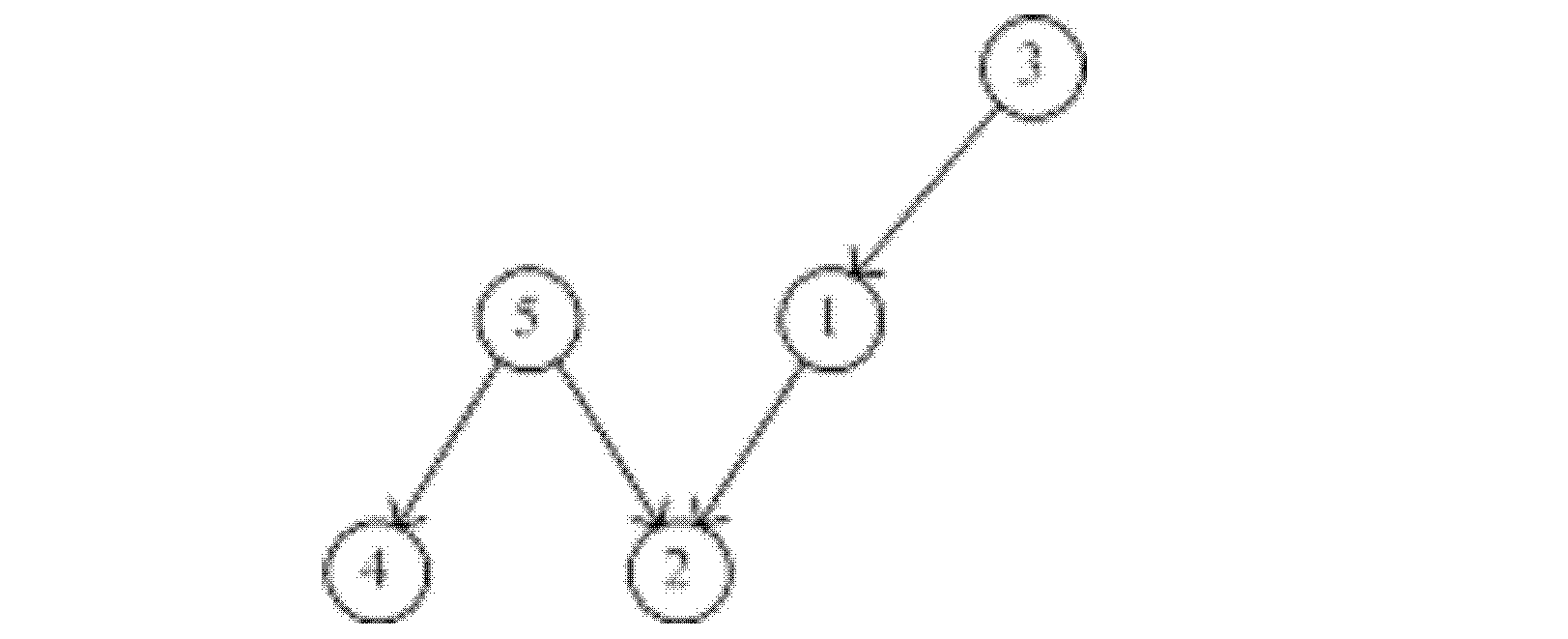

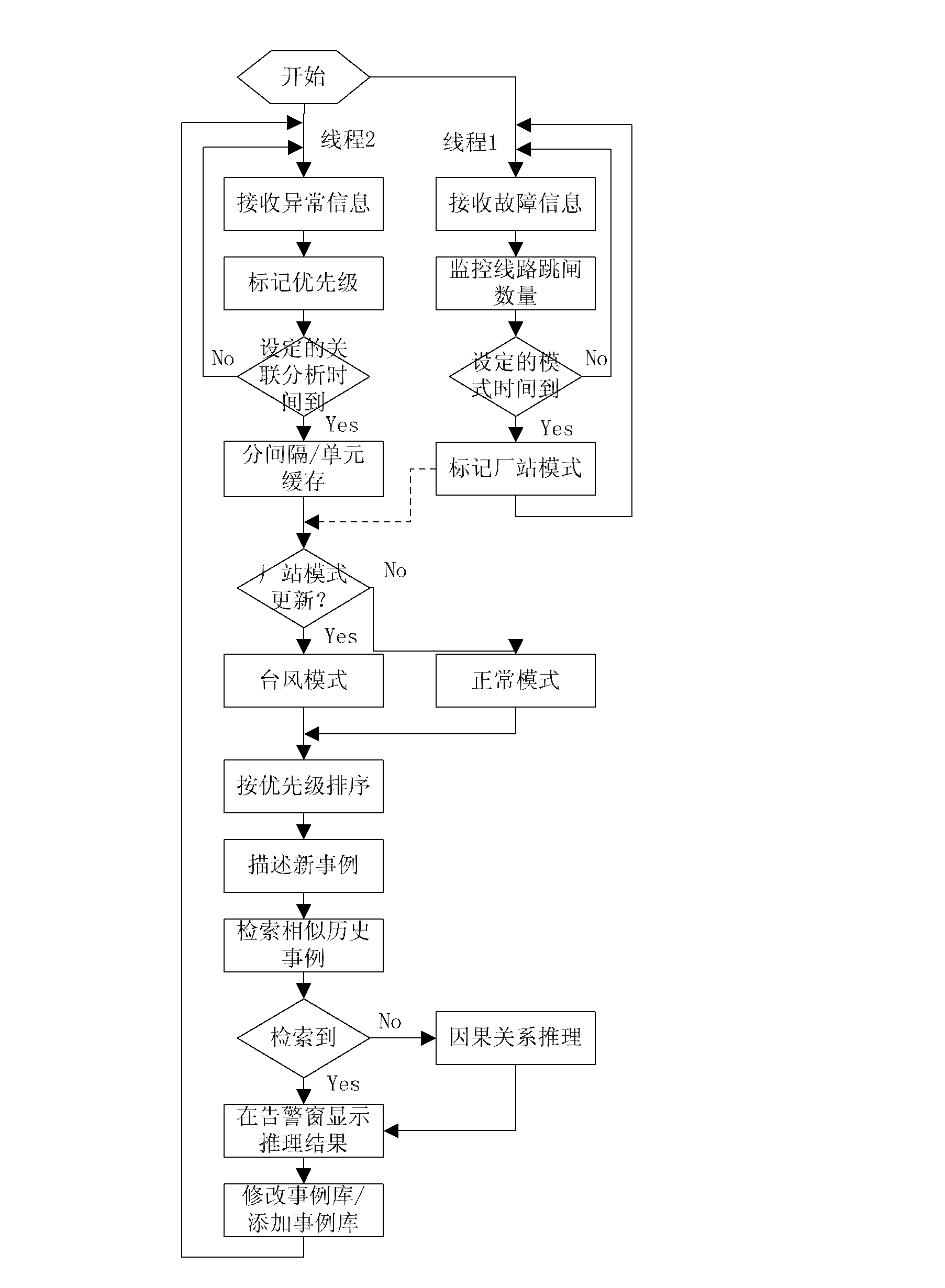

District power network equipment abnormal alarm signal association analysis and diagnosis method

InactiveCN102638100AIntegrity guaranteedGuarantee authenticityCircuit arrangementsInformation processingPower system scheduling

The invention discloses a district power network equipment abnormal alarm signal association analysis and diagnosis method in the field of automation of scheduling of electric power systems. According to the method disclosed by the invention, the weather situation of a plant station region at which abnormal alarm information is located can be automatically identified so as to determine the information processing mode. The method disclosed by the invention has the beneficial effects that by realizing intelligent association analysis and auxiliary decision making of the equipment abnormal alarm information under the real-time state, and performing playback on historical alarm information and performing real-time treatment on manual set information under the research state, the abnormal treatment time is greatly reduced, the incidence of accidents is reduced, a real-time, rich and intelligent auxiliary decision-making support is provided for regulation and control staff, and the safe, high-quality, economical and stable operation of an electric fence is further ensured.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

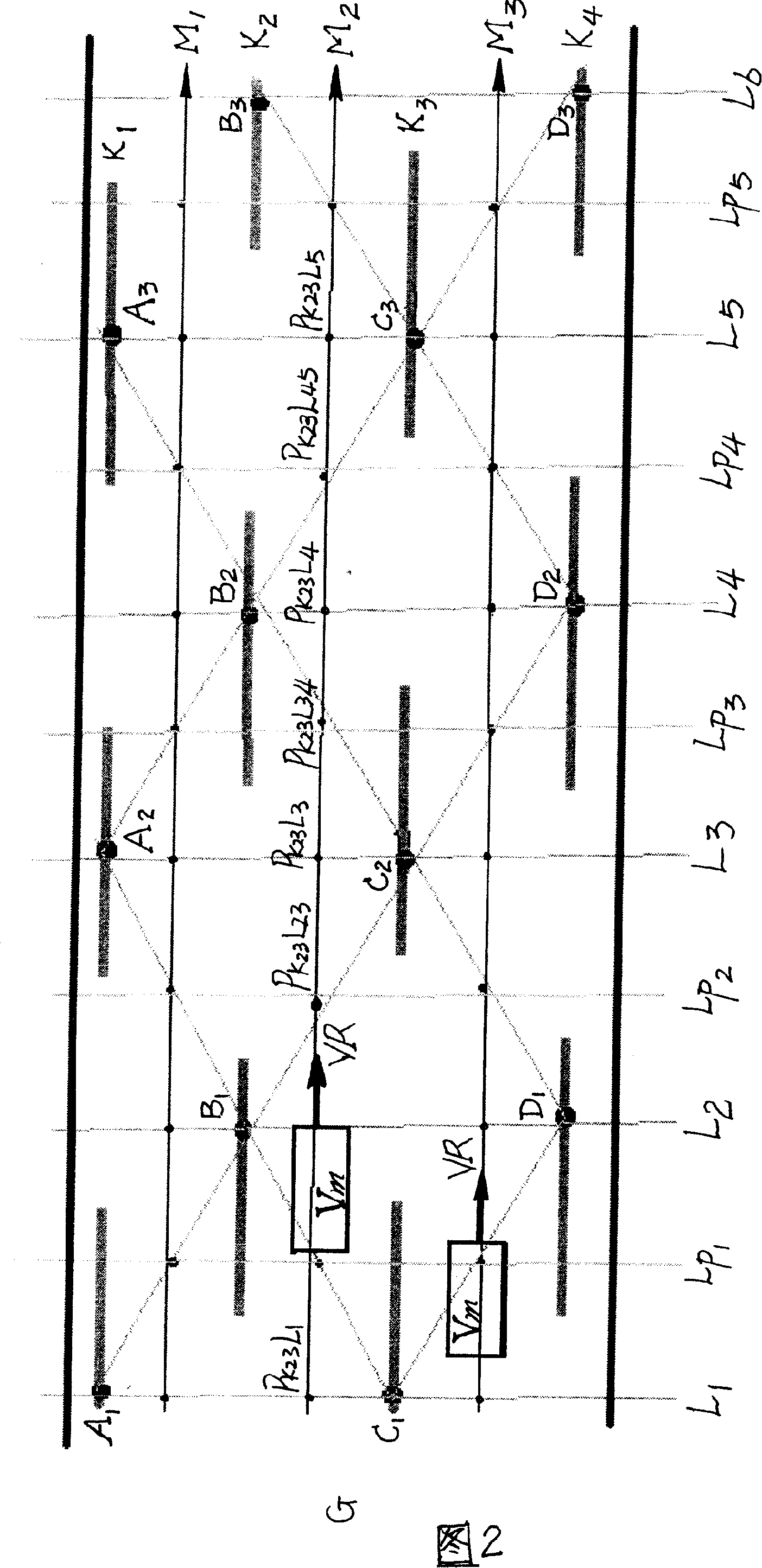

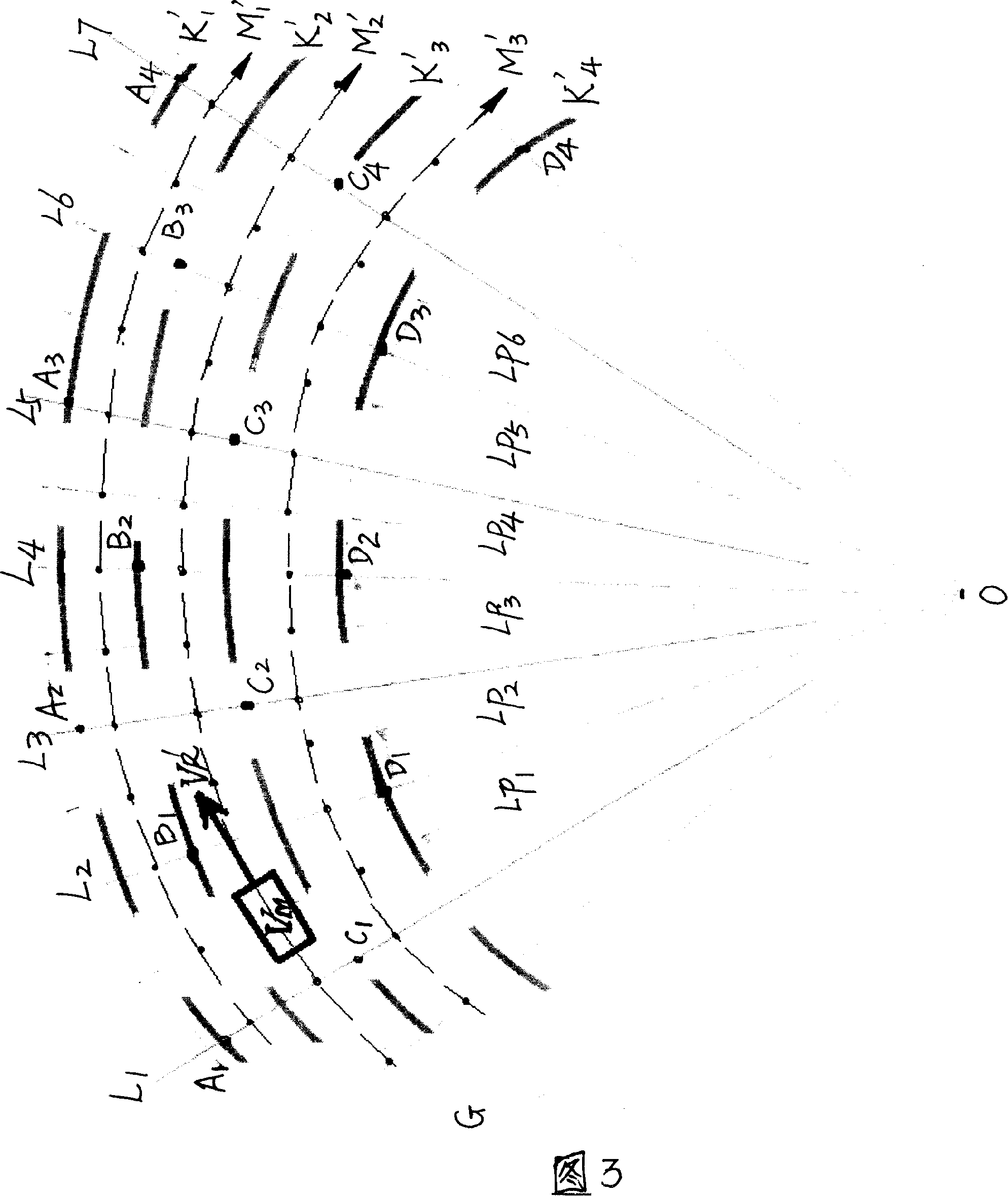

Automatic pilot system for road vehicle

InactiveCN101131588ARealize autonomous drivingPracticalPosition/course control in two dimensionsPilot systemAutomatic control

This invention relates to an automatic driving system of a road vehicle, especially to a system which providing automatic driving information indication for traveling vehicles and realizing vehicle automatic driving through the vehicle automatic control system, which is characterized by comprising: fixing markers at interval along a road travelling line, receiving information feedback by the fixed markers through a set relay information station and forming the vehicle and road information on the road, and constantly supplying the road and vehicle information of the road where the vehicle is to a vehicle automatic receiving processor after the received GPS(Global Position System) information and the vehicle and road information on the road are overall treated, installing an automatic driving software in a vehicle-mounted computer which can receive and treat relevant information of the relay information station at any time, constantly sending operation instructions to a vehicle automatic controller so as to keep the vehicle travelling information direction line consistent with the vehicle driving speed direction line, and sending instructions to the vehicle automatic controller according to the selected mode by a driver so as to realize vehicle automatic driving.

Owner:吴体福

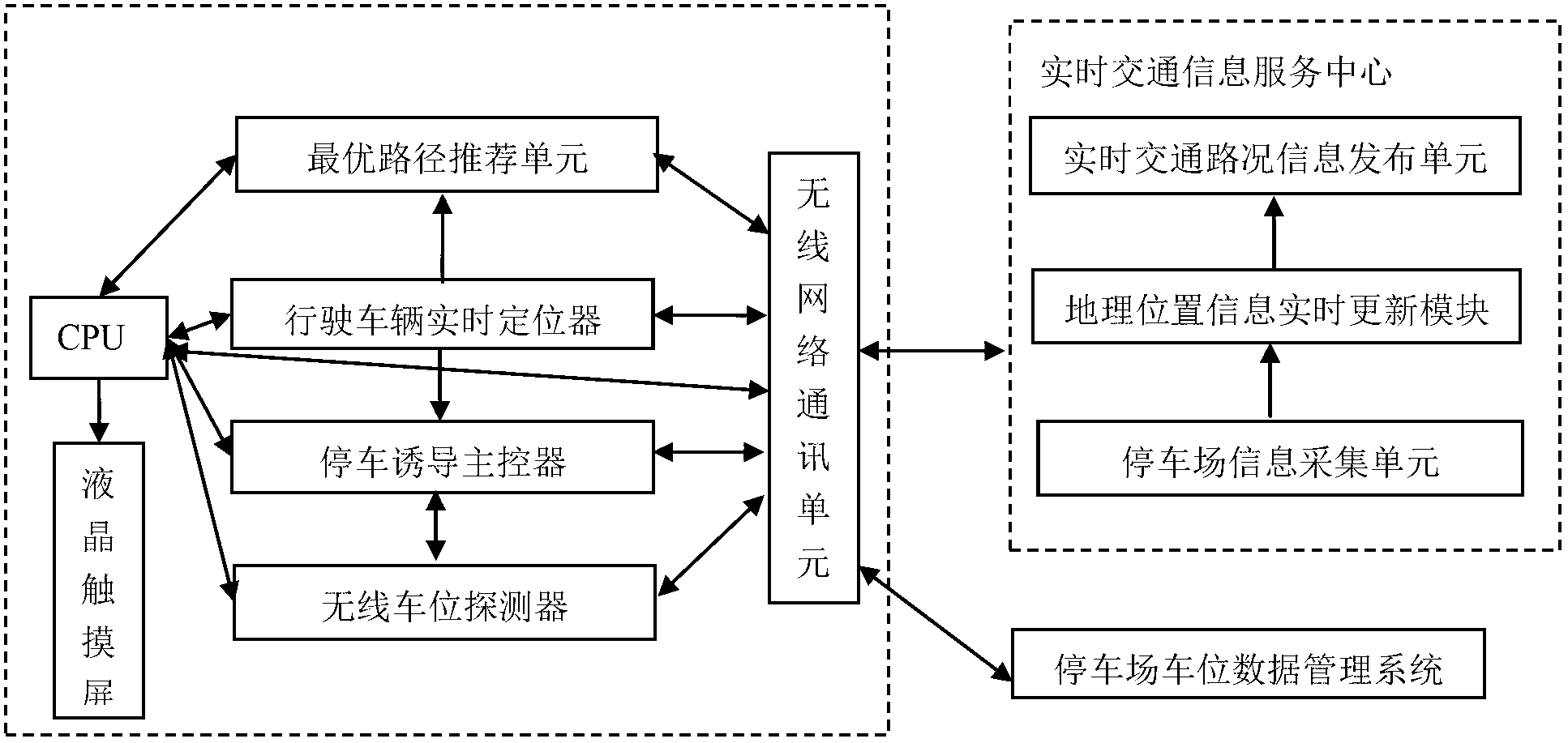

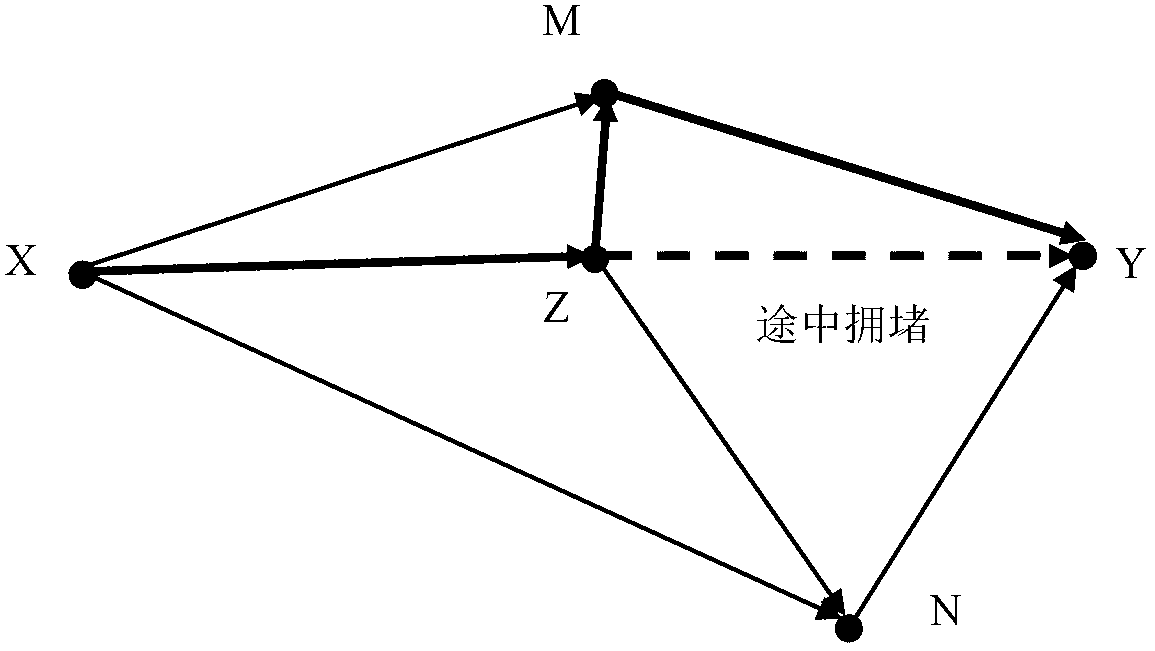

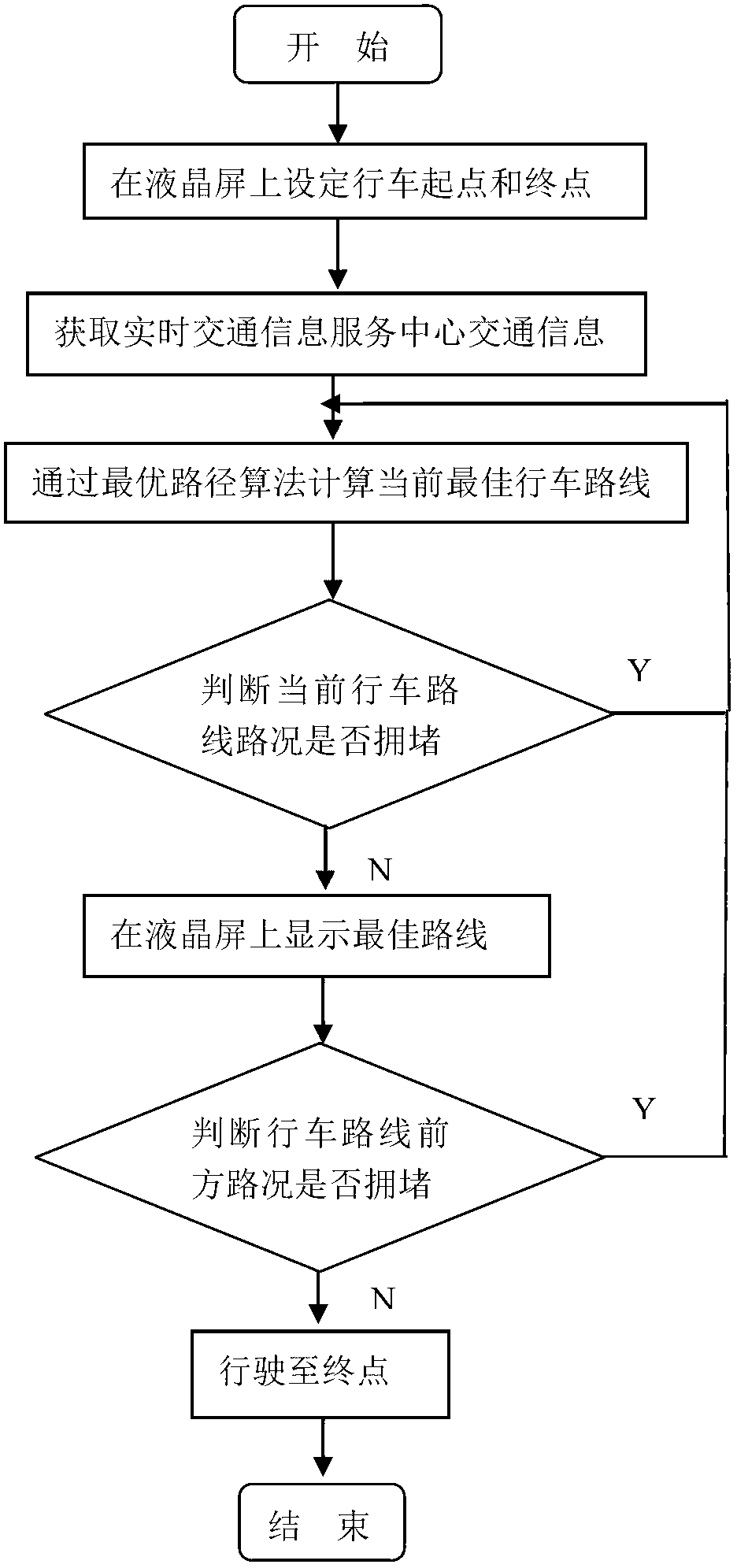

Intelligent going-out and best carport navigation system and navigation method thereof

ActiveCN103258438ARealize functionAvoid congested roadsIndication of parksing free spacesIntelligent lightingNavigation system

The invention discloses an intelligent going-out and best carport navigation system and a navigation method of the navigation system. The intelligent going-out and best carport navigation system comprises an optimal path recommendation unit, a traveling car real-time positioning device, a parking guidance master controller, a wireless carport probe, a wireless network communication unit, a central processing unit (CPU) and a liquid crystal touch screen. The best running route is timely recommended on a liquid crystal display by the optimal path recommendation unit according to real-time road conditions, and the optimal path recommendation unit helps an owner to keep away from a blocking road section, so that the owner can arrive at the destination at the top speed. The parking guidance master controller can provide convenient parking lot carport information on the liquid crystal display, so that the owner can find an appropriate parking lot and the best carport with a nearest road in a short time, troubles of the owner for finding the carport are removed accordingly, parking time is saved, and parking speed is quickened. The intelligent going-out and best carport navigation system and the navigation method achieve car dynamic route guiding and carport best guiding functions, provide accurate and comprehensive traffic guidance information on the liquid crystal display, and improve traveling and parking efficiency and quality.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

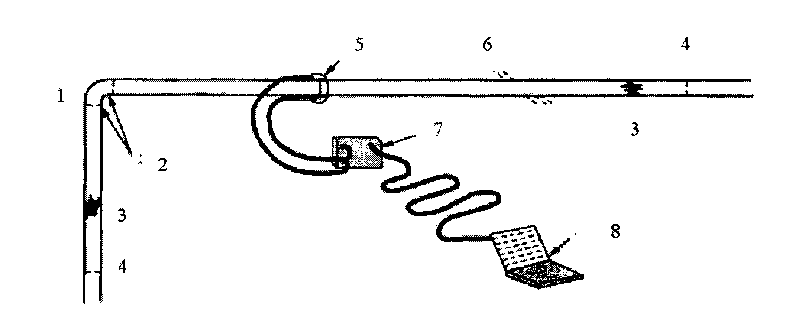

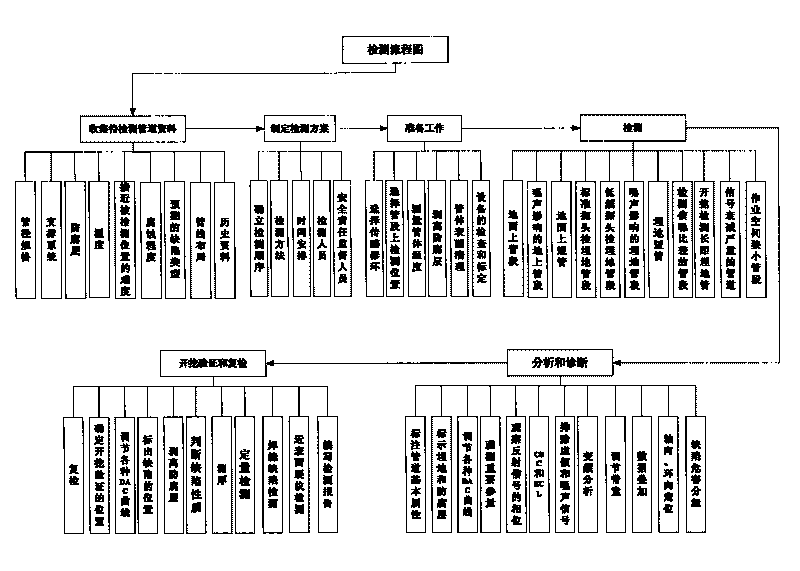

Method for rapidly detecting pipeline body defects

ActiveCN101762633ARaise the level of integrity managementReduce operational riskAnalysing solids using sonic/ultrasonic/infrasonic wavesSupporting systemLine tubing

The invention relates to a method for rapidly detecting pipeline body defects, which comprises the followings steps sequentially: 1) getting the specification, a support system, an anti-corrosion layer, the temperature, the corrosion degree, the pipeline layout and the historical information of a pipeline to be detected; 2) selecting a sensor ring, cleaning the surface of the pipeline to be detected, and inspecting and calibrating a detection system; 3) detecting each section of pipe on the ground only once, investigating with emphasis if problems are found, and determining detection times and positions of the buried pipelines according to different anti-corrosion layers and transmission media; 4) analyzing and diagnosing: labeling the basic properties of the pipeline, calibrating curves, comparing reflected signals and detection data in different positions, analyzing the variable frequency, diagnosing in a method of analyzing data in the same position in a superposition mode, observing the circumferential positions of the defects and classifying the degrees of the defects; and 5) determining a verification test pit and a detection test pit and analyzing pipe sections in the detection test pit according to diagnosis results, marking the positions of the defects, observing corrosion condition, measuring thickness, and finely scanning the defects to determine the positions, the properties and the sizes of the defects.

Owner:PIPECHINA SOUTH CHINA CO

System and method for monitoring and improving driver behavior

ActiveUS9129460B2Reduce actionImprove securityVehicle testingRegistering/indicating working of vehiclesThird partyDriver/operator

Owner:IWI

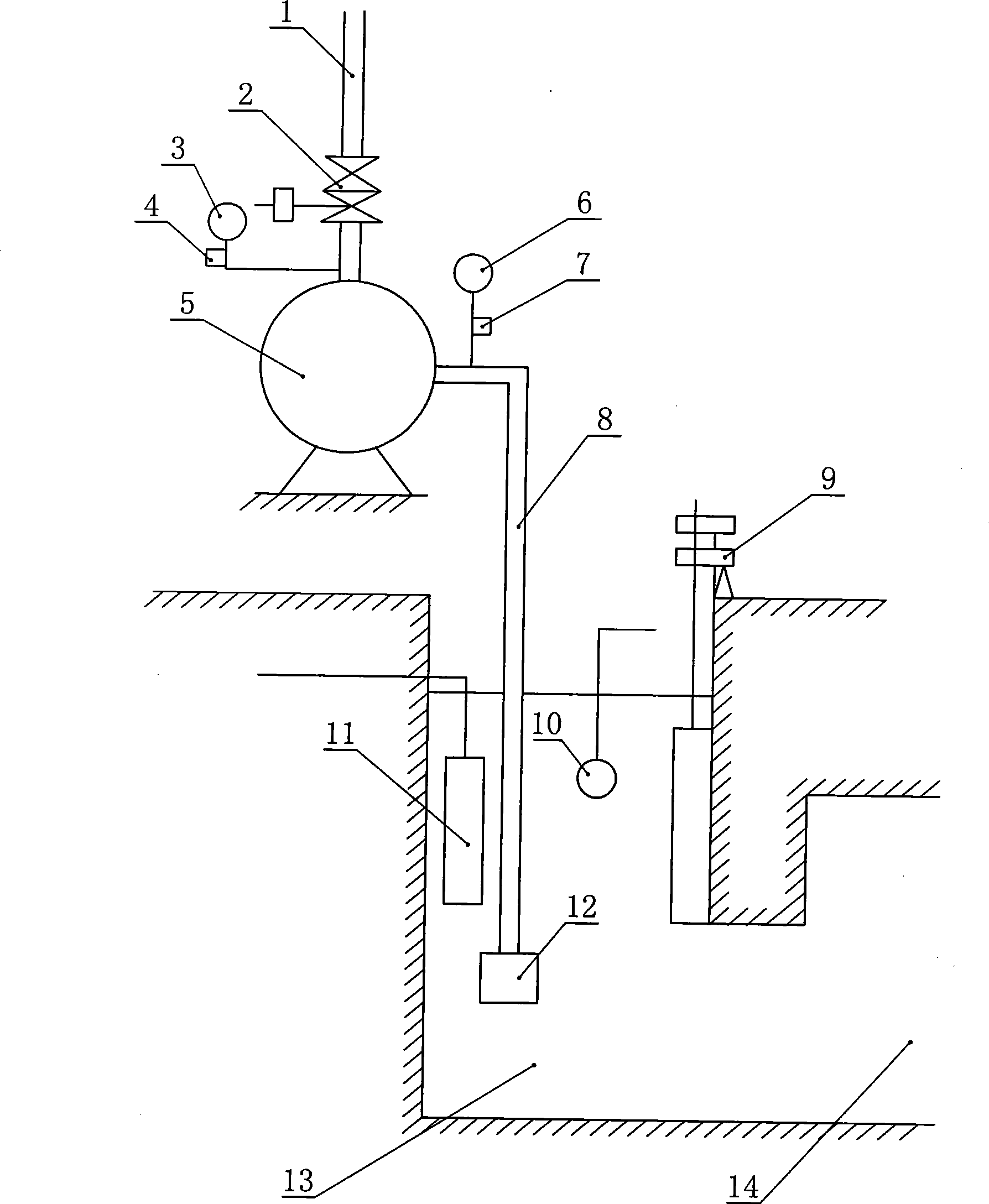

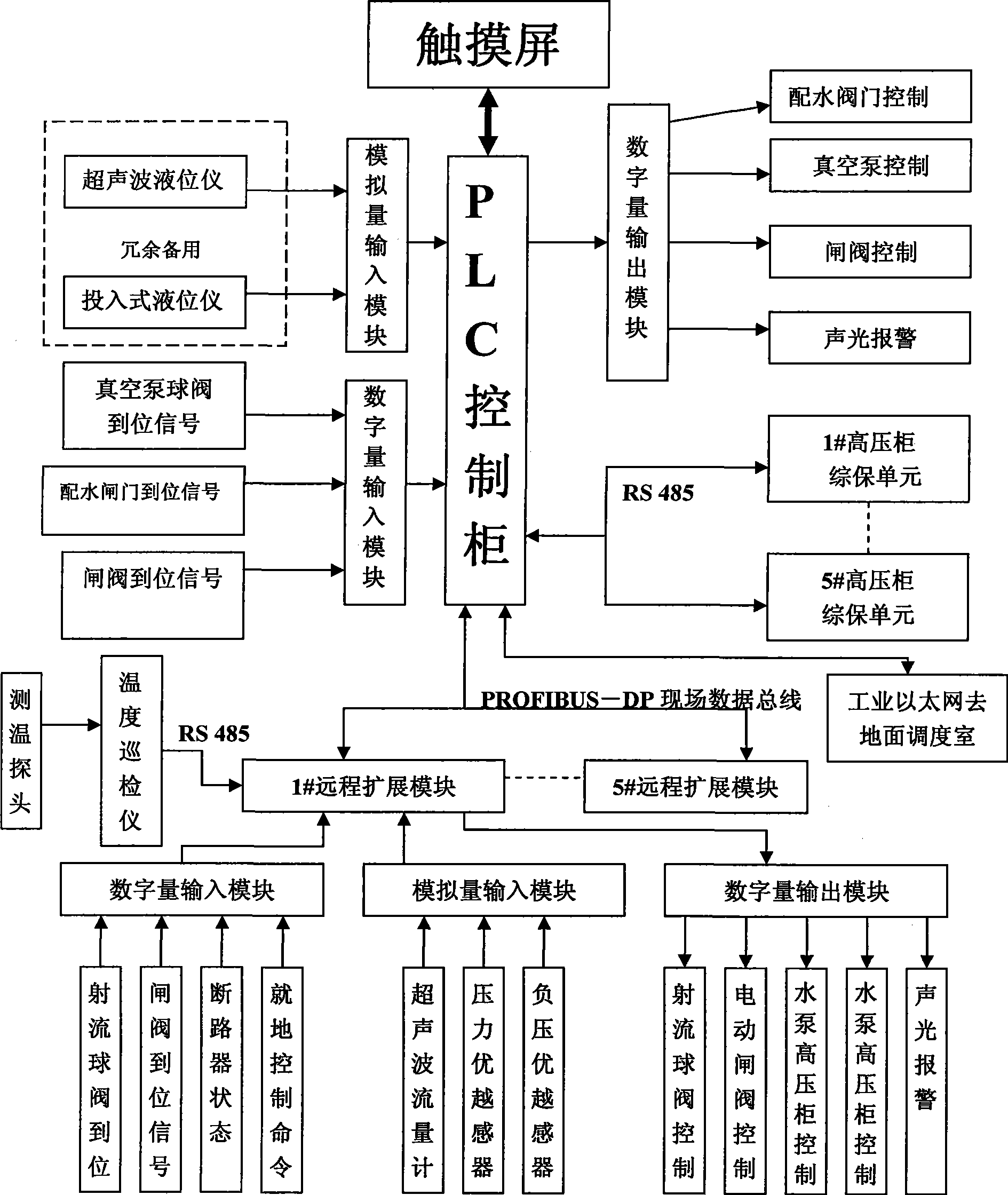

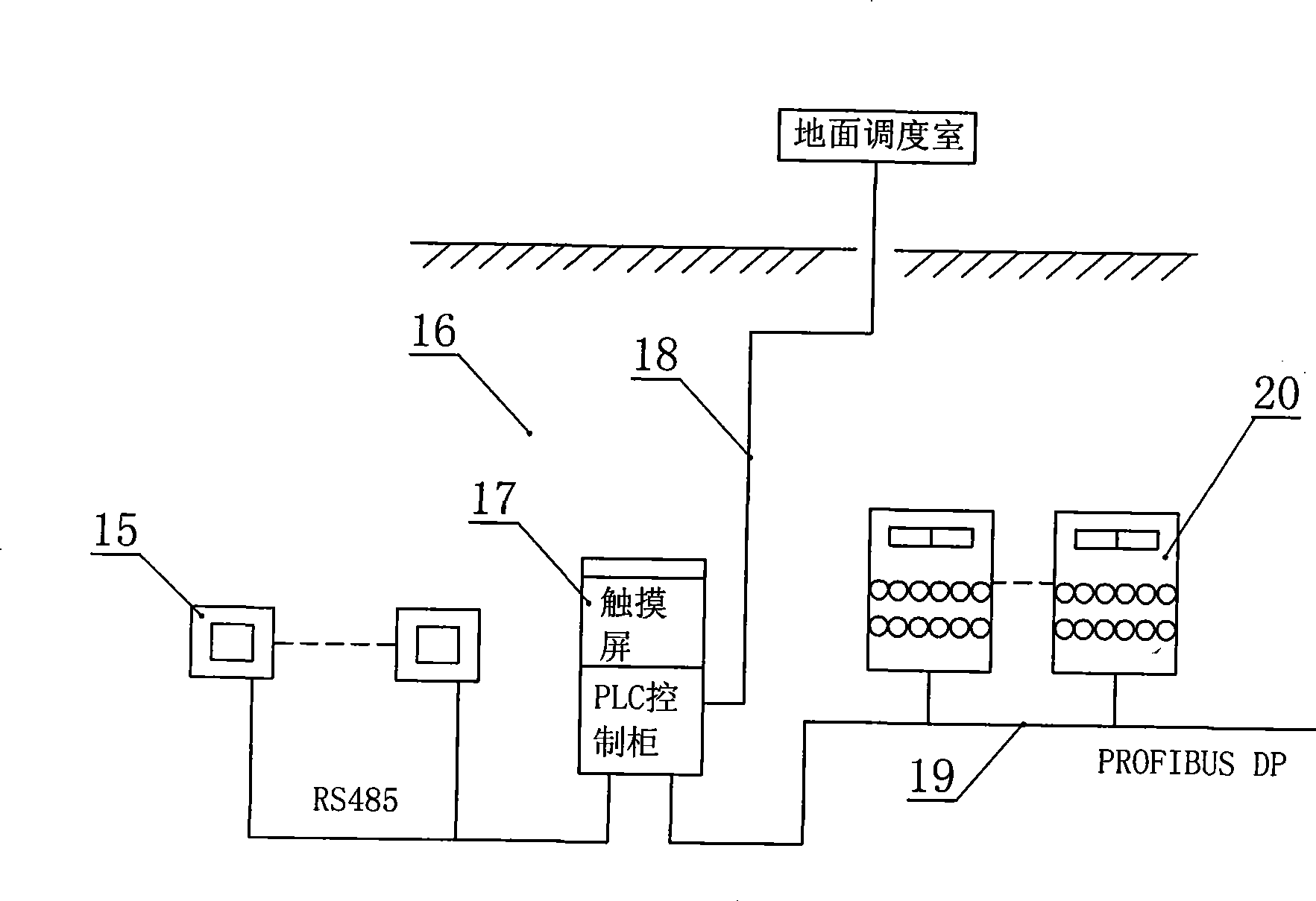

Automatic monitoring system for down-hole central pumping room drainage

The invention relates to an underground central pump room draining automatic monitoring system, which comprises a PLC control cabinet, a remote expanding module, a site data bus, a contact screen, an analog quantity and switching value input module, various monitoring probes, a travel switch, a level instrument and an executable section. A monitoring net adopts a form of combining a PROFIBUS DP site data bus and an industrial ethernet. A monitoring method for the system comprises: (1) monitoring the absorbing well water level; (2) monitoring the state for starting a high pressure switching cabinet by a water pump; (3) judging the valve levels of a gate valve, a ball valve of a water jet pumping device and a water distribution gate; (4) judging the valve levels of a vacuum pump ball valve; (5) measuring each equipment temperature measuring point; (6) measuring signals of a pressure sensor and a negative pressure sensor; (7) judging system faults; (8) automatically controlling the start-stop and operation numbers of the water pumps according to the absorbing well water level conditions; and (9) setting power supply peak avoiding time periods, and automatically selecting starting time and numbers of a pump. The system improves the system working reliability, reduces the equipment fault rate, and adopts a three-stage monitoring structure for a draining system.

Owner:BINHU COAL MINE ZAOZHUANG MINING GRP

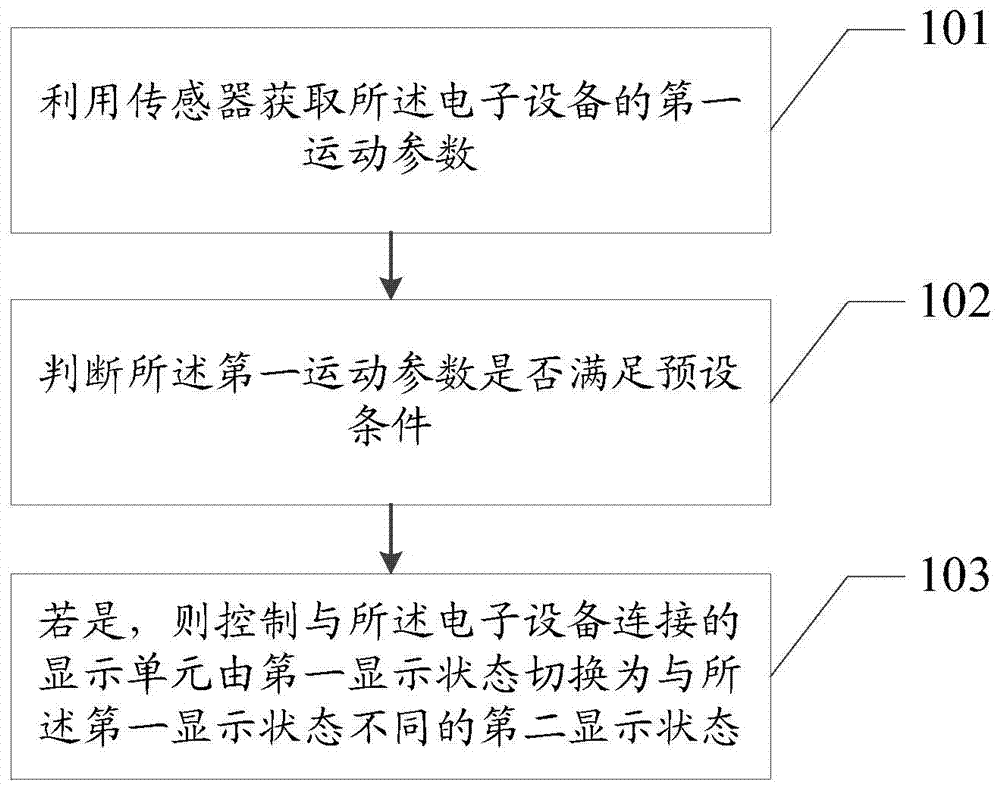

Information processing method and electronic device

ActiveCN104750249AReduce the probability of accidentsAvoid dangerInput/output for user-computer interactionGraph readingOccurrence probabilityComputer hardware

The invention discloses an information processing method and an electronic device. Whether movement parameters of the electronic device meet preset conditions or not is obtained through a sensor, and therefore the result showing whether the electronic device is about to collide with barriers or not or the result showing whether the electronic device is doing dangerous actions or not is obtained. If the electronic device is about to collide with the barriers or the electronic device is doing dangerous actions, a display unit is controlled to be switched to a second display state from a first display state, wherein the second display state is different from the first display state, and therefore the technical effects of prompting a user that dangers are about to happen and lowering the accident occurrence probability can be achieved.

Owner:LENOVO (BEIJING) CO LTD

Method for continuous casting, continuoccs rolling intermediate and thin sheet blanket

InactiveCN1483521ASmall temperature differenceImprove surface qualityMetal rolling arrangementsAutomatic controlThin slab

The production method of sheet billet conticasting tandem-rolling coil sheet is characterized by that said invention adopts the following technical measures: using conticasting machine and making pulling rate of casting blank low, and making the blank material have reasonable section; compactly arranging conticasting machine and heating furnace, making the conticasting blank output roller conveyer and inlet roller conveyer of heating furnace have double purpose, making inlet temp. of casting blank be above 900 deg.C; adopting double furnace and hating; and adopting small-cross charging and tapping process; two-high reversing rougher for three passes, four-high reversing rougher for one pass; and adopting thermal coiler box process of workpiece so as to raise coil sheet quality and reduce its production cost.

Owner:ANGANG STEEL CO LTD

System and method for evaluating driver behavior

ActiveUS9067565B2Reduce actionAccurate trackingVehicle testingRegistering/indicating working of vehiclesDriver/operatorIn vehicle

System and method for evaluating driver performance, comprising detecting operations of a vehicle using an on-board vehicle monitoring system, comparing the operations to predetermined criteria, identifying violations of the predetermined criteria, tracking violations that occur during an evaluation period, and, at the end of the evaluation period, calculating a grade associated with operation of the vehicle.

Owner:IWI

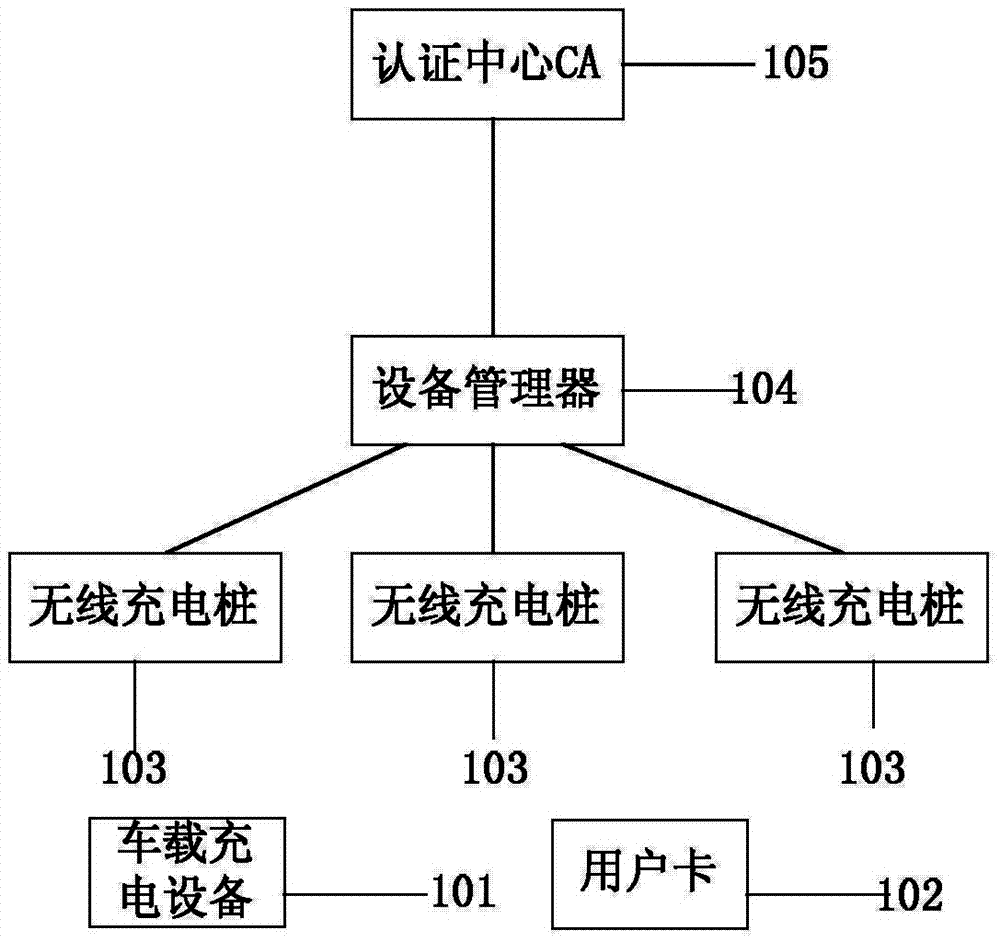

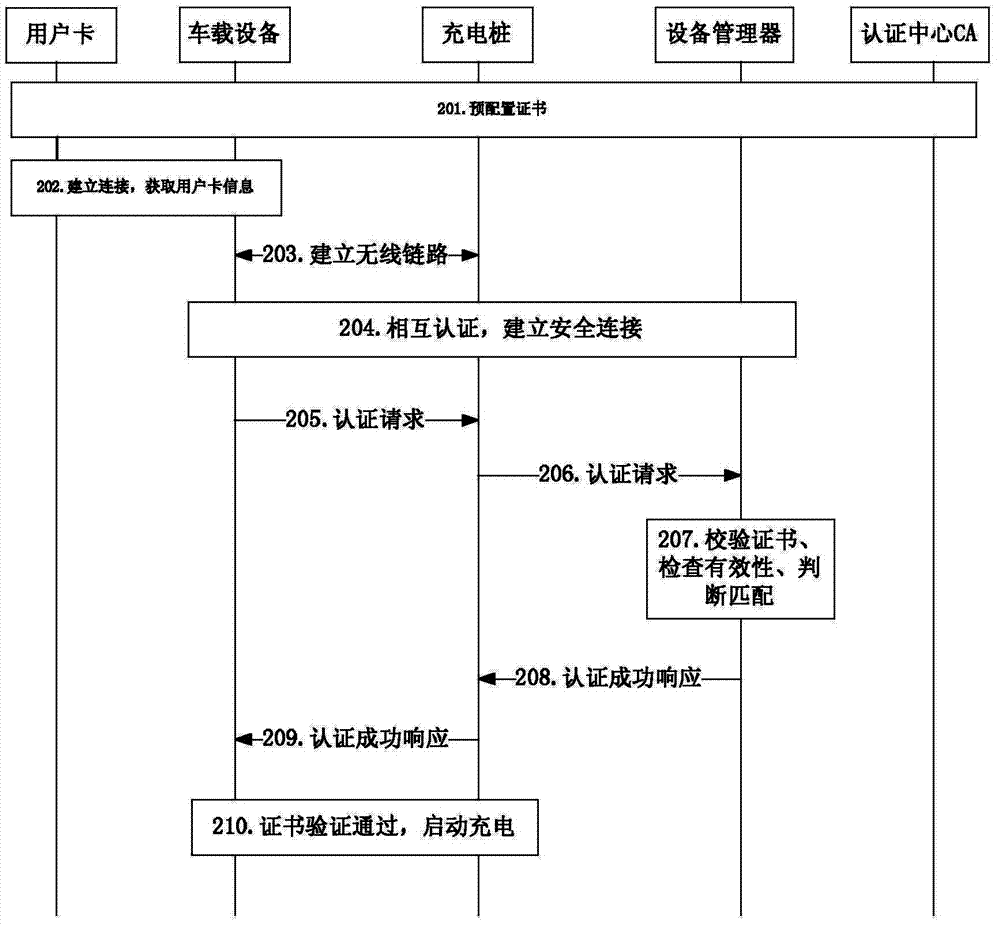

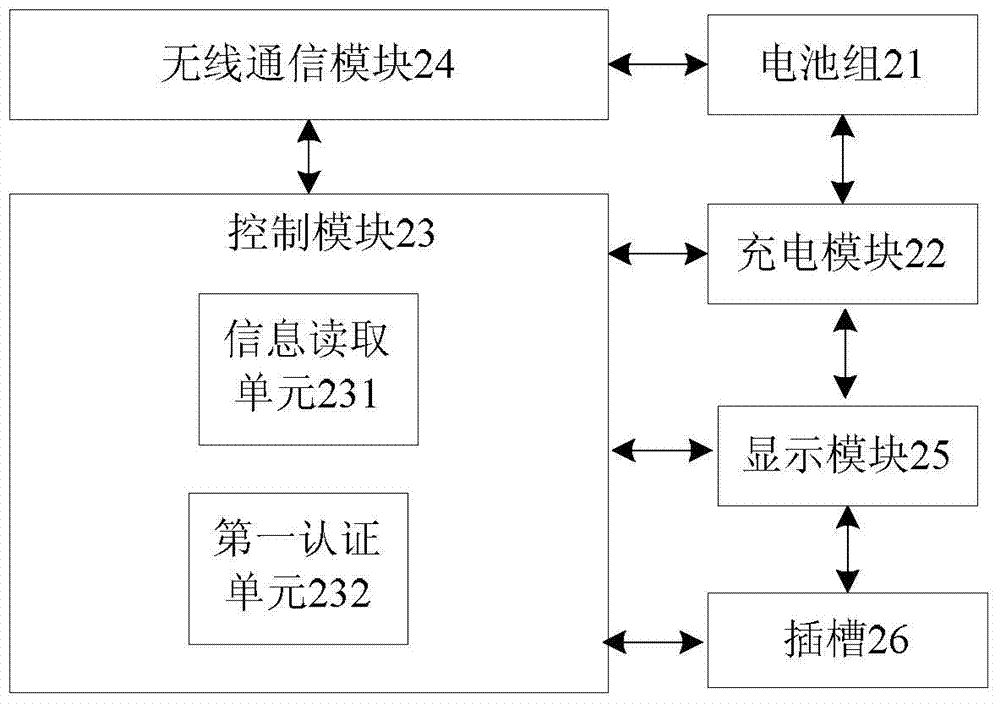

Authentication method for vehicle-mounted charging device, and corresponding device

InactiveCN104518529AImprove securityReduce accident rateElectromagnetic wave systemCharging stationsElectricityIn vehicle

An authentication method for a vehicle-mounted charging device and a corresponding device, which are applied to the authentication when a vehicle-mounted charging device which is provided with a user card accesses a charging station serving network. The method comprises: reading, by a vehicle-mounted charging device, a user identity identifier and a user certificate from a user card; establishing a wireless link with a wireless charging pile, sending an authentication request to a device manager through the wireless charging pile, and carrying the user identity identifier, the user certificate and device information about the vehicle-mounted charging device; and after the authentication of the device manager of a serving network of the user identity identifier, the user certificate and the device information about the vehicle-mounted charging device, and after it is judged that the vehicle-mounted charging device matches the wireless charging pile, returning an authentication success response. The solution can effectively improve the security of wireless charging, reduce the accident rate and prevent electricity theft.

Owner:ZTE CORP

Online monitoring and condition maintenance management system

InactiveCN102436226AImprove power supply reliabilityImprove economyTotal factory controlProgramme total factory controlData centerElectric power system

The invention relates to an online monitoring and condition maintenance management system, which is a layered and distributed data management and computer system, faces to a plurality of substation high-voltage equipment and adopts a multi-server level-to-level management system. The online monitoring and condition maintenance management system comprises an online monitoring equipment layer, a substation data network layer and a remote data center. By constructing and applying the management system, the online monitoring system is promoted to be transitioned to an all-round, networked, intelligent and comprehensive condition monitoring, diagnosis and service management system from the traditional isolated and static experimental system. The system provides a powerful technical supporting platform for overcoming periodic maintenance blindness, reducing maintenance times, reducing maintenance expenses, delaying maintenance cycle to the utmost extent, truly realizing condition maintenance for power system operation and management departments and further improving the operation rate of the equipment and the safety of power grids.

Owner:文存润 +1

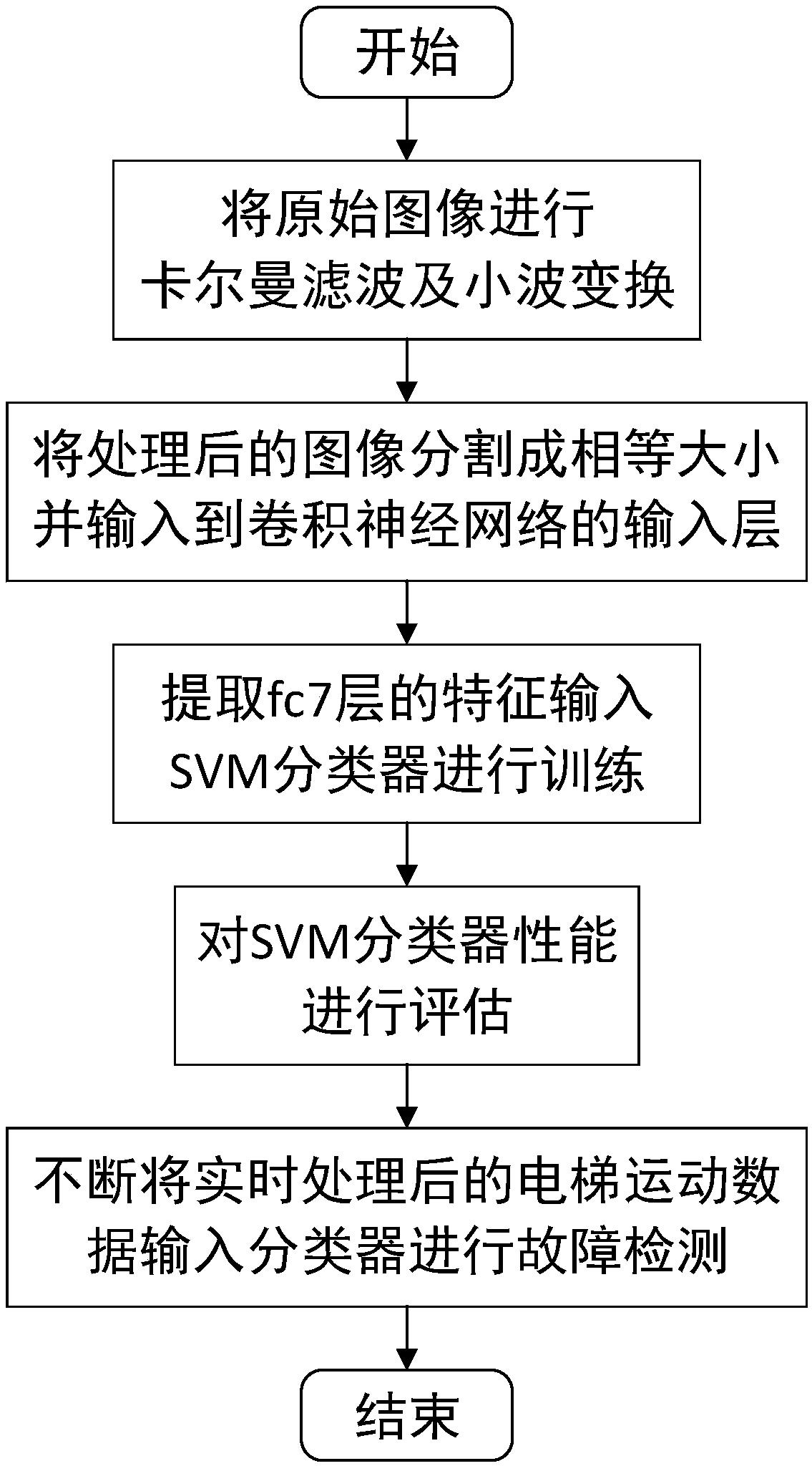

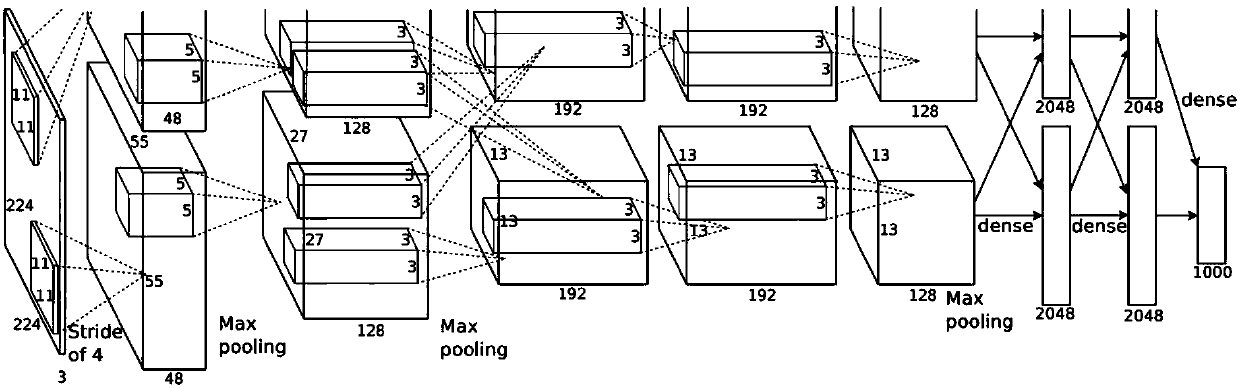

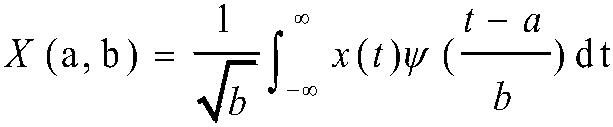

Elevator failure recognition method based on convolutional neural network

InactiveCN108178037AInnovative meansReduce accident rateCharacter and pattern recognitionElevatorsPrediction rateSvm classifier

The invention discloses an elevator failure recognition method based on a convolutional neural network. The elevator failure recognition method comprises the steps that 1, elevator motion data are collected and are converted into a time-spectrogram as a sample set through wavelet transform; 2, the time-spectrogram in the sample set is divided into a training set and a test set, failure types and failure degrees of samples in the training set are marked as known labels of data samples; 3, the convolutional neural network is built, the time-spectrogram in the training set is input to the convolutional neural network, and the characteristics of the previous layer are extracted and classified; 4, according to the labels given in the step 2 and the characteristics extracted in the step 3, a multi-class SVM classifier is trained; 5, after training, the prediction rates, for all types of failures, obtained through the SVM classifier are obtained; and 6, detection and recognition are conducted. The elevator failure recognition method which is novel in angle, consistent to actual situation and high in accuracy is achieved, the requirement for hardware is low, and portability is high.

Owner:WUHAN UNIV

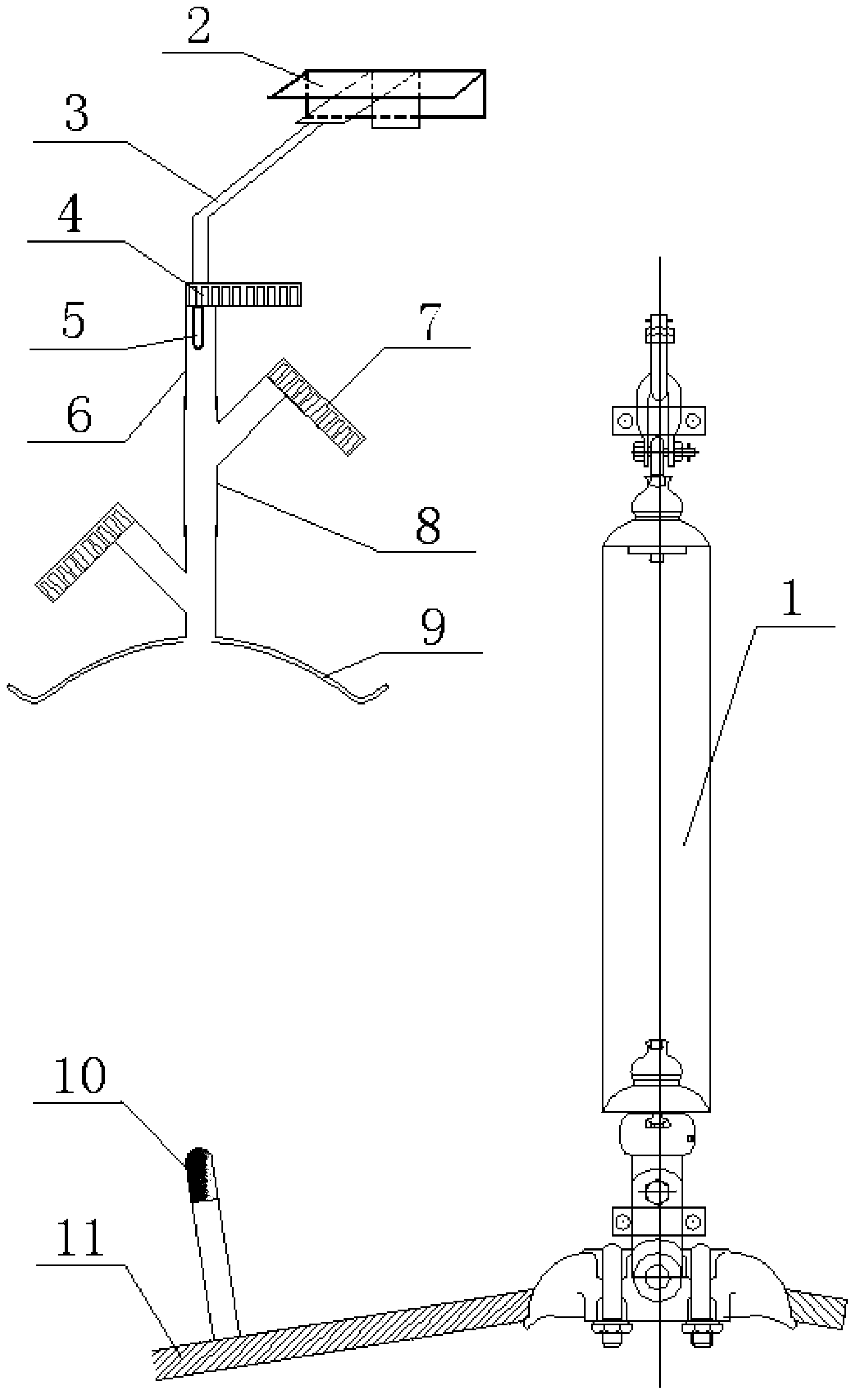

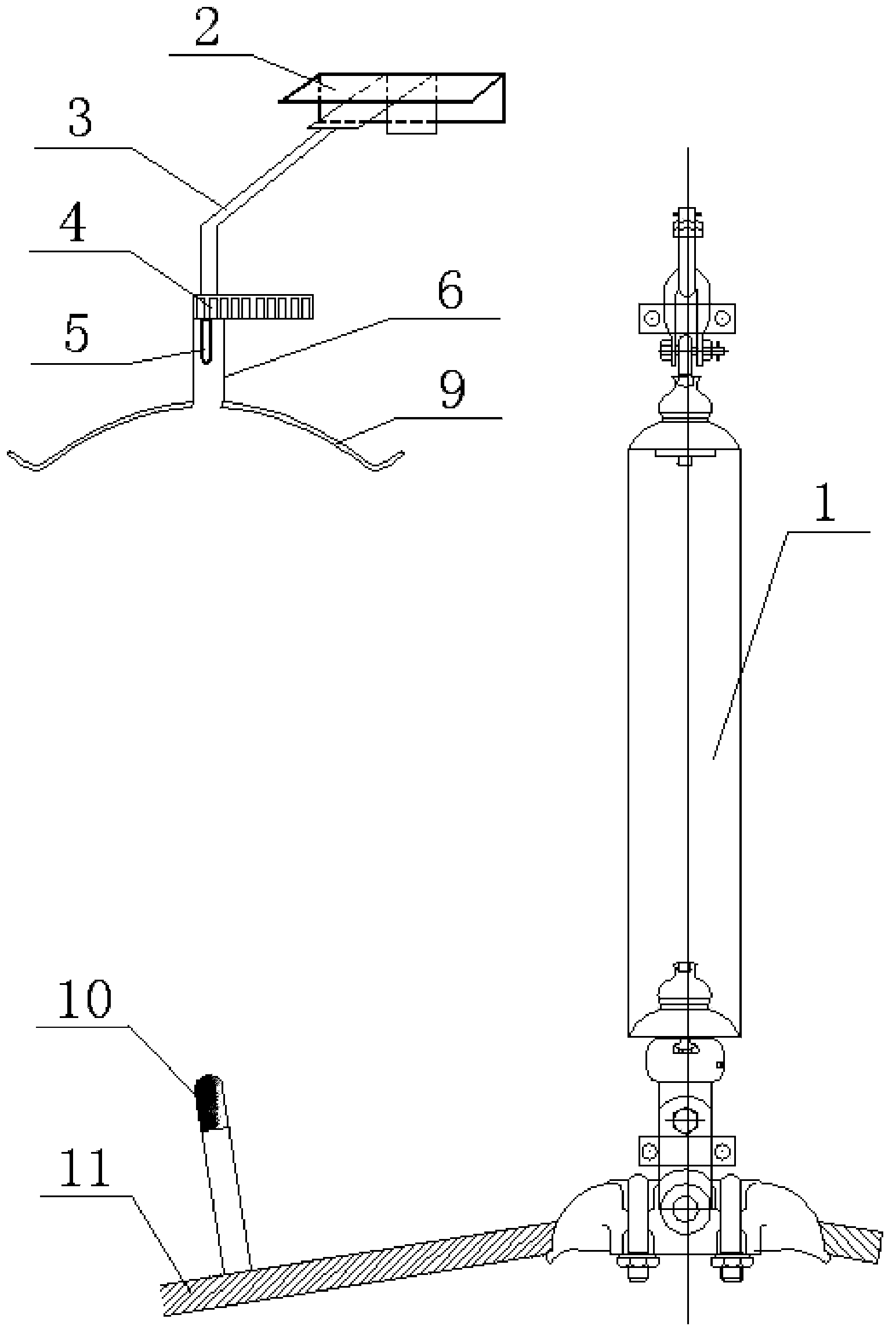

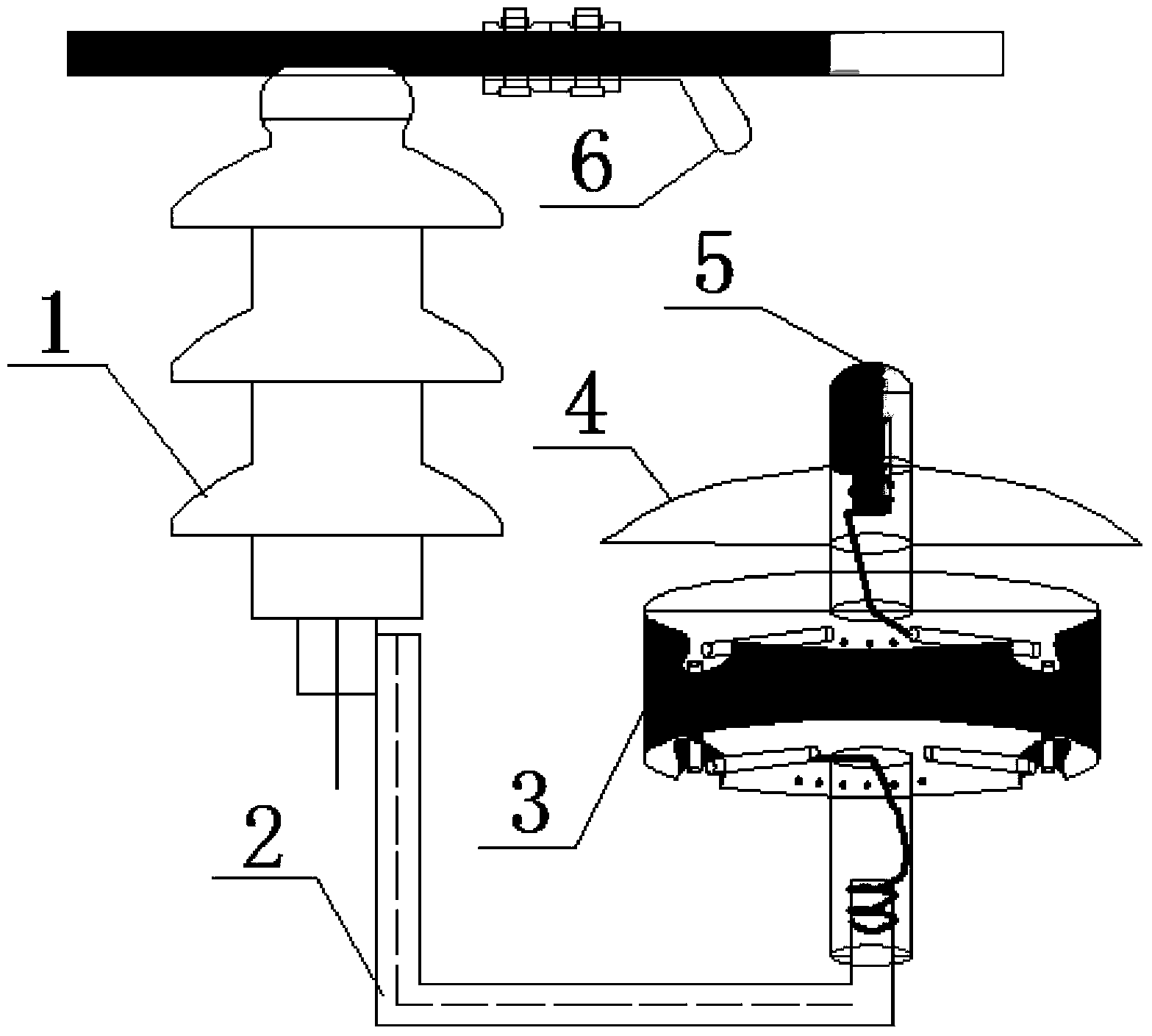

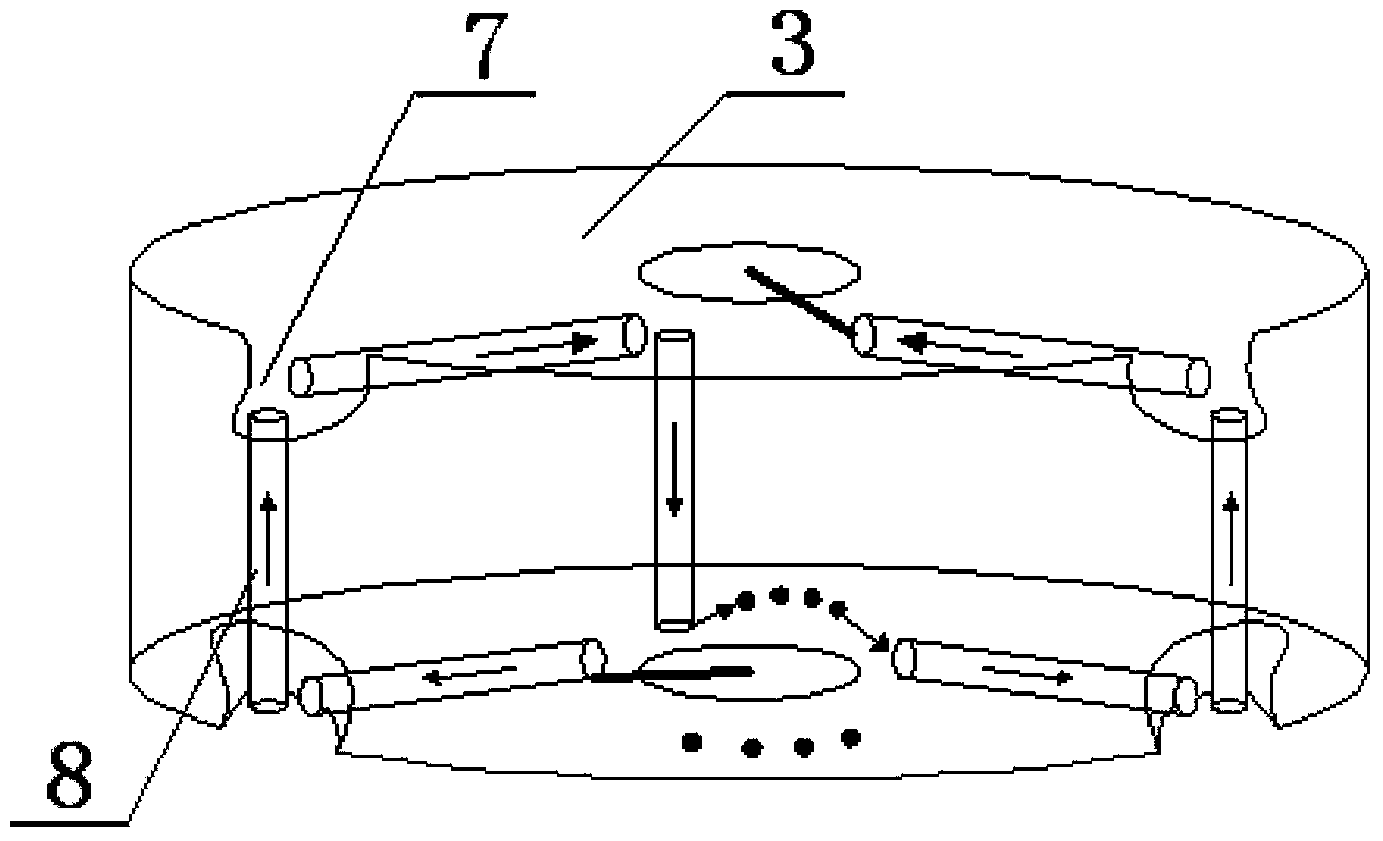

Different-voltage-class subsection arc-extinguishing anti-thunder gap device

ActiveCN103368075ANot affected by lightningImprove stabilitySpark gap detailsOvervoltage arrestors using spark gapsElectric power systemLow voltage

A different-voltage-class subsection arc-extinguishing anti-thunder gap device comprises an arc-extinguishing device and a protective gap device which is arranged nearby an insulator chain in parallel. The protective gap device is mainly composed of a low-voltage end electrode and a high-voltage end electrode; the arc-extinguishing device comprises an arc-extinguishing cylinder and an arc-extinguishing projectile storage bin I in a disc shape, wherein a trigger coil, a trigger electrode, a projectile trigger position, arc-extinguishing projectiles and a plane scroll spring are arranged inside the arc-extinguishing projectile storage bin I; one end of the trigger electrode is connected with the trigger coil, and the other end of the trigger electrode extends to the projectile trigger position and is connected with the arc-extinguishing projectiles; the plane scroll spring is arranged at the center of the arc-extinguishing projectile storage bin I; the arc-extinguishing projectiles are arranged in a projectile storage rail of the arc-extinguishing projectile storage bin I; one end of the low-voltage end electrode is arranged on a pole and tower cross arm through a connection hardware fitting, and the other end of the low-voltage end electrode is arranged in the trigger coil of the arc-extinguishing device; one end of the high-voltage end electrode is arranged on an overhead conductor, and the other end of the high-voltage end electrode points to the low-voltage end electrode. The different-voltage-class subsection arc-extinguishing anti-thunder gap device is easy to install and replace, long in service life, and capable of greatly improving stability of an electrical power system.

Owner:南宁超伏电气科技有限公司

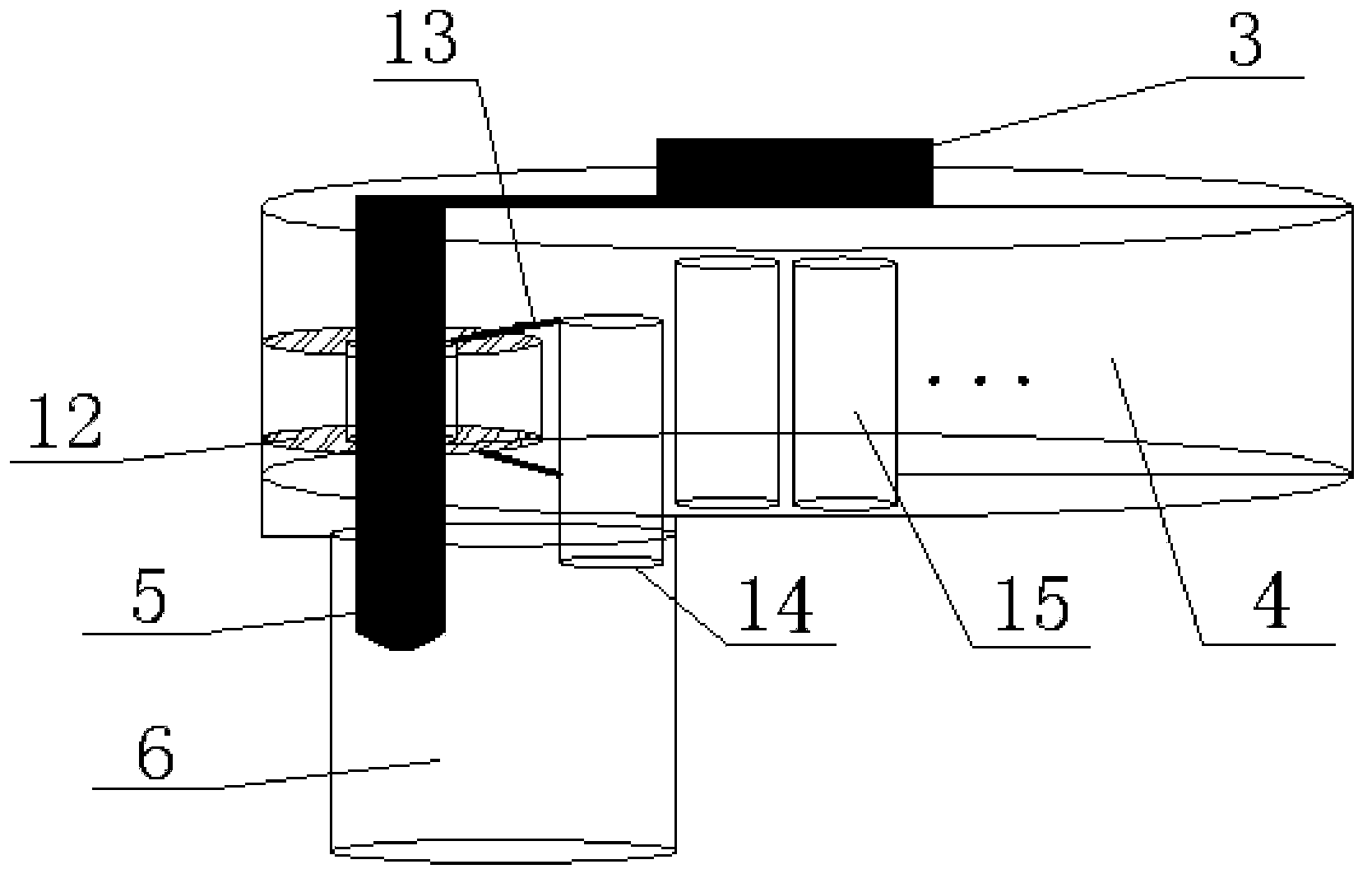

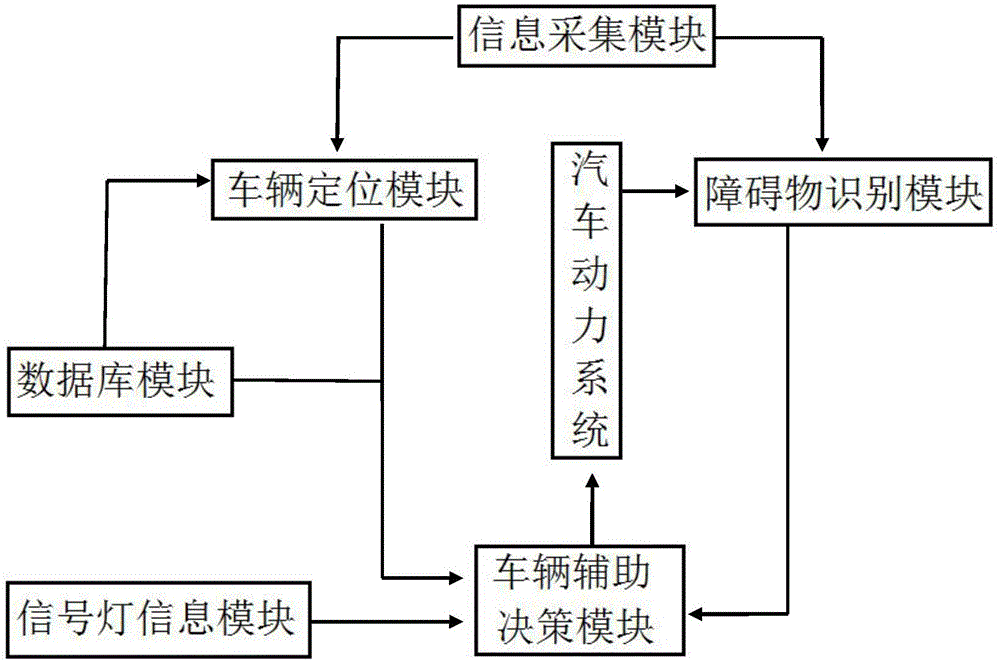

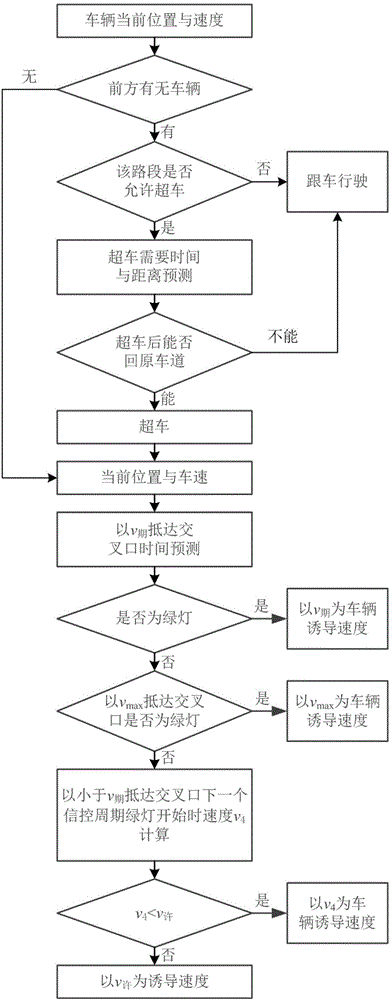

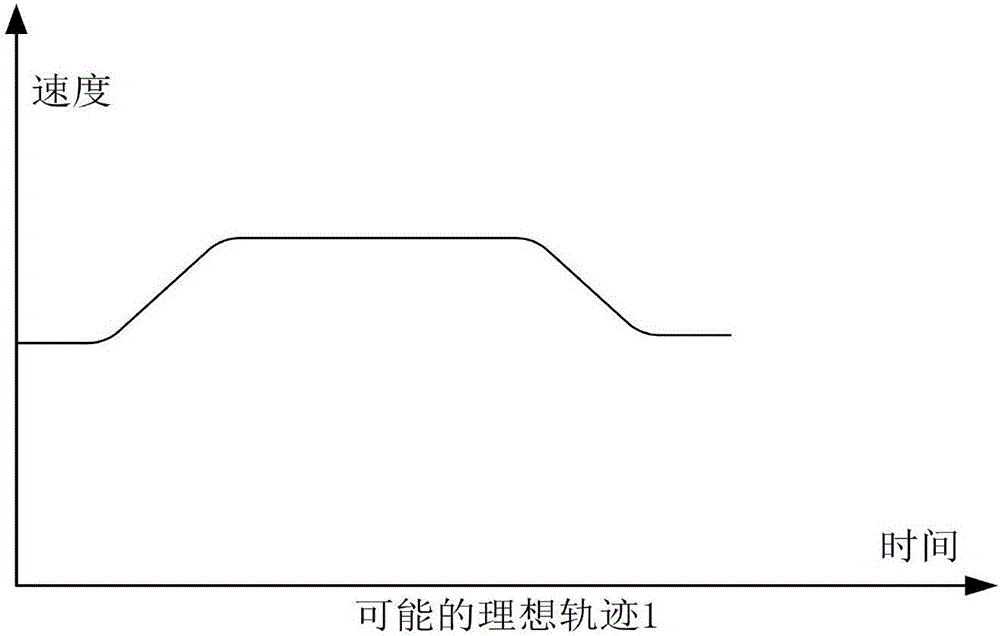

Auxiliary driving system and method for rapid passing of vehicle in crossing

InactiveCN106485931ATo achieve the purpose of energy savingReduce pollutionRoad vehicles traffic controlComputer moduleThe Internet

The invention discloses an auxiliary driving system and method for rapid passing of a vehicle in a crossing. The system comprises an information collection module, a vehicle positioning module, a barrier identification module, a database module, a signal lamp information module, a vehicle auxiliary decision module and an automobile power system. According to technical features of road traffics and physical features of drivers, a method including guiding information through which each crossing can be passed rapidly and smoothly and a vehicle in front can be overtaken is provided for the driver in the driving process, the guiding information including whether to overtake, the concrete driving speed and the like, and thus, when the vehicle is driven according to the guiding speed and manner, the crossing can be passed without stop, and core technical support is provided for development of Internet of vehicles and automatic driving technologies.

Owner:HEBEI UNIV OF TECH

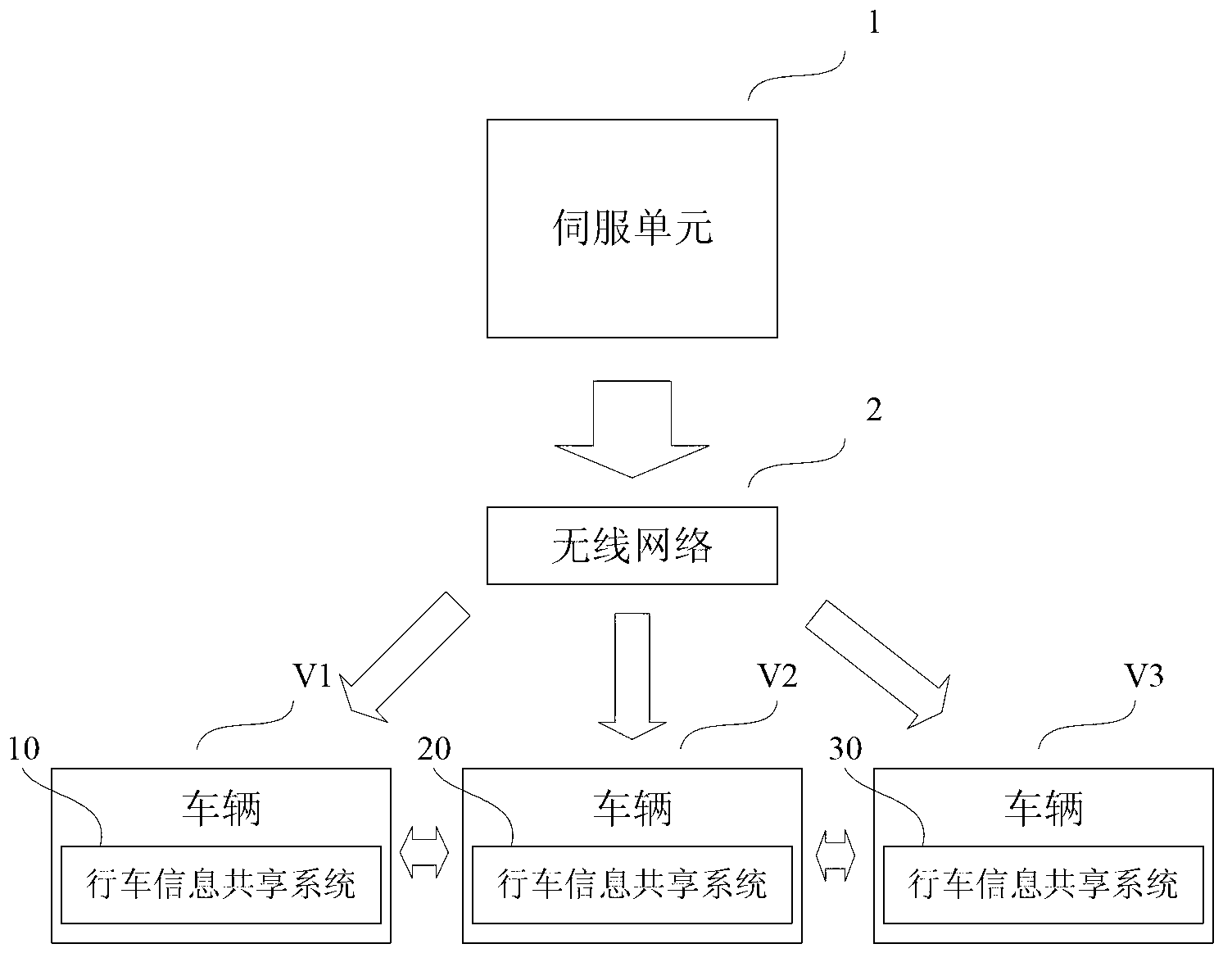

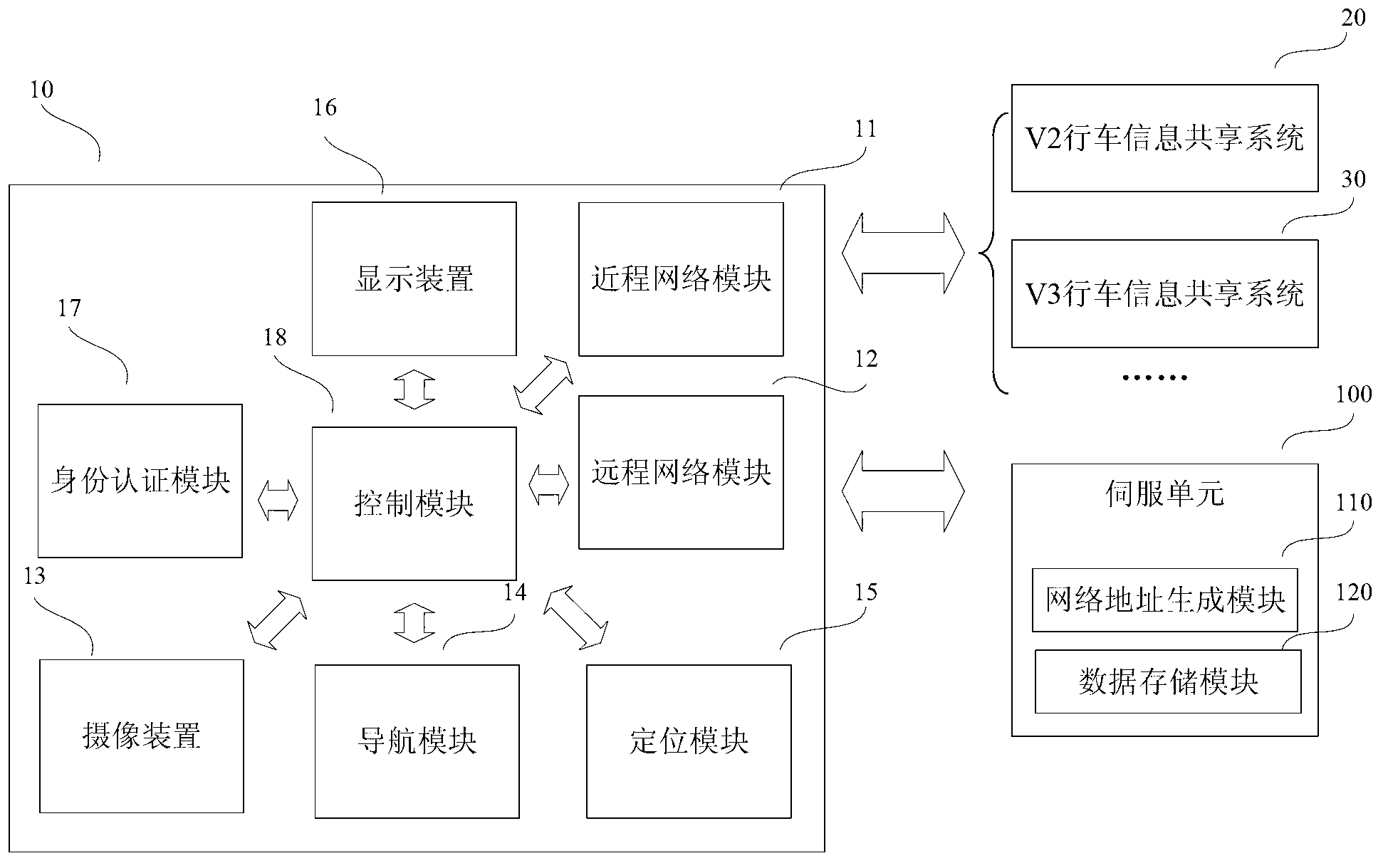

Traveling information sharing system and control method thereof

ActiveCN102938199AImprove real-time performanceImprove fluencyRoad vehicles traffic controlRadio transmission for post communicationThird partyNetwork connection

The invention provides a traveling information sharing system which is connected with a servo unit and installed on a first vehicle. The traveling information sharing system comprises a short-range network module and a remote-range network module, wherein the short-range network module is used for enabling the first vehicle to build local area network connection with a third party vehicle to achieve data transmission among vehicles; and the remote-range network module is used for enabling the first vehicle to build network connection with the servo unit to achieve data transmission between the first vehicle and the servo unit. When the first vehicle needs to acquire the road condition information around the third party vehicle, the remote-range network module builds network connection with the servo unit to obtain the network address information of the third party vehicle, and the short-range network module builds local area network connection with the third party vehicle according to the network address information to obtain the road condition information. The traveling information system reduces the load of data transmission between the servo unit and the vehicles to a certain extent and further improves the instantaneity and smoothness in sharing of the traveling information.

Owner:QISDA SUZHOU +1

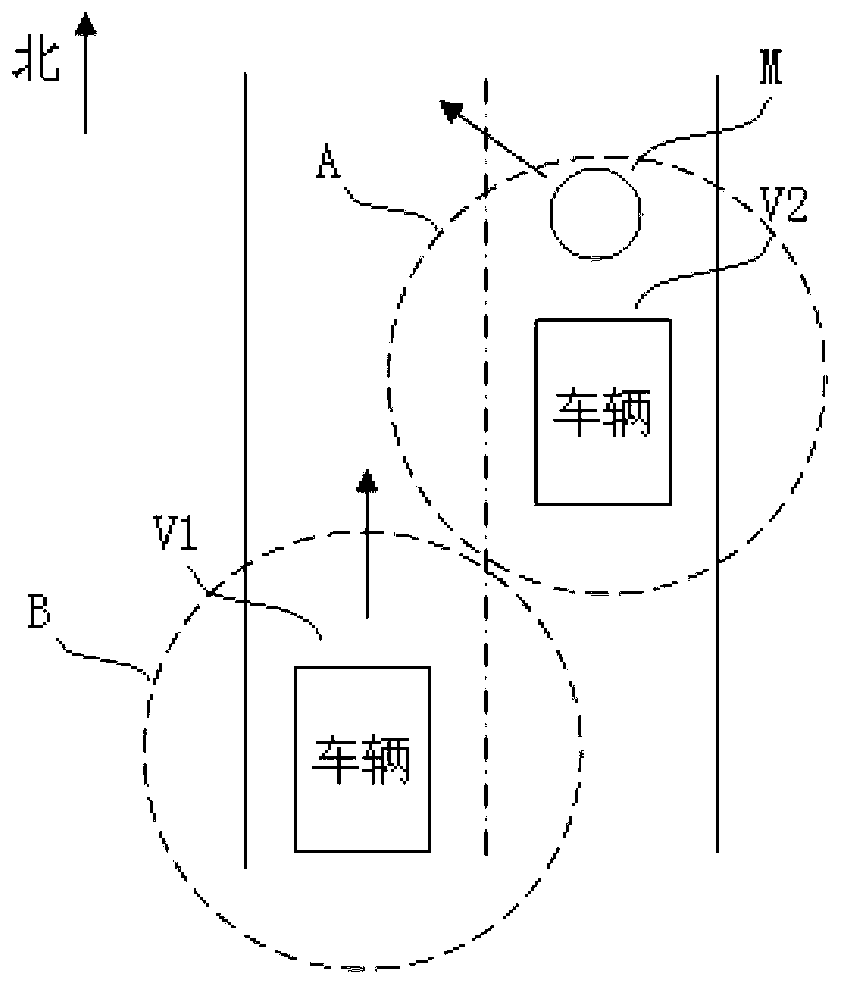

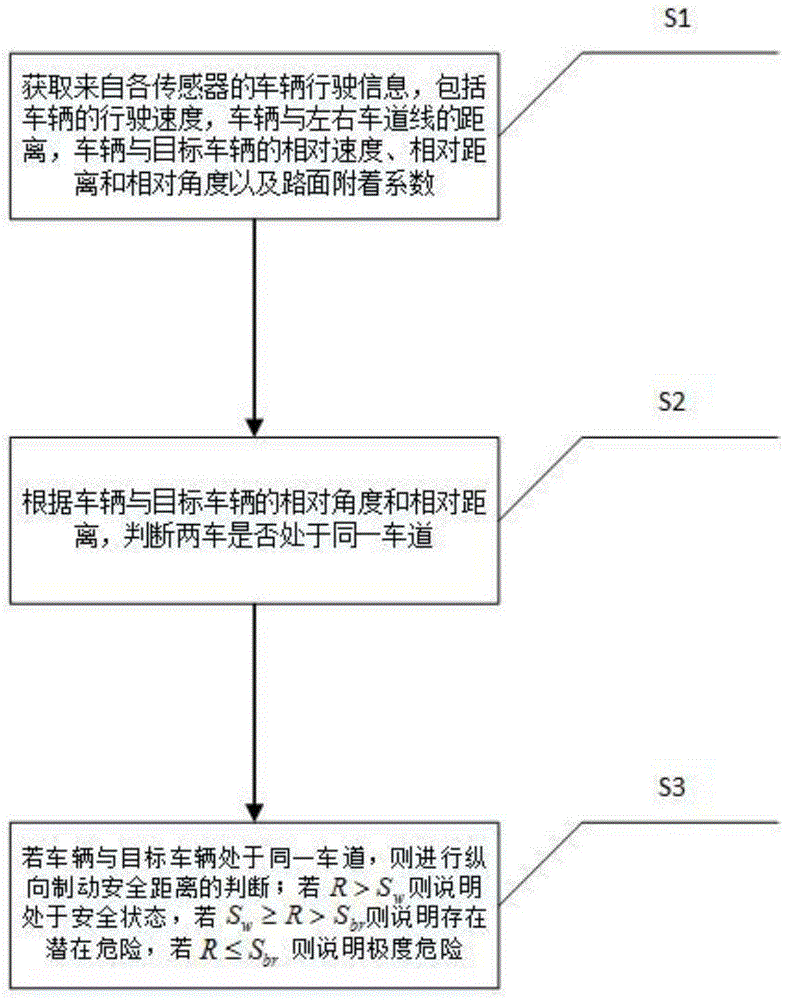

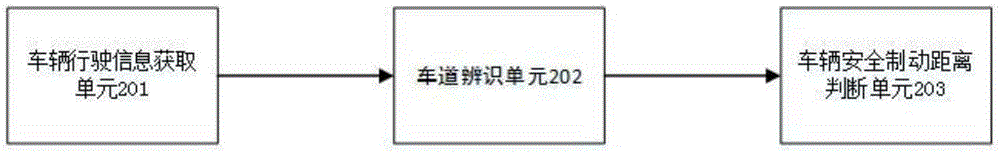

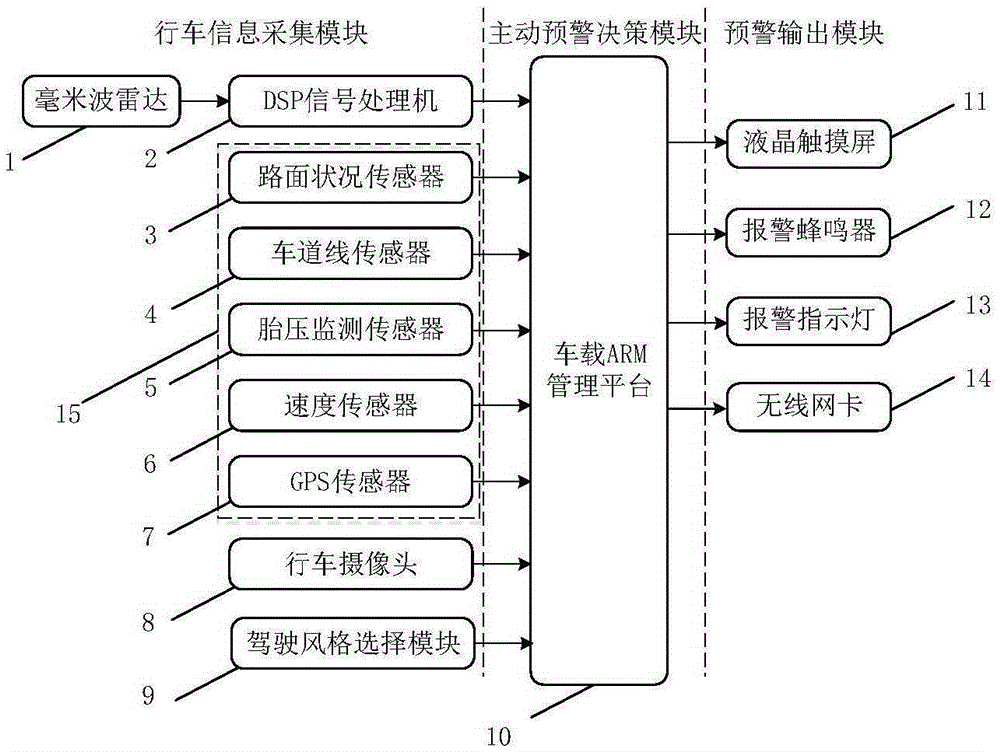

Vehicle active forewarning method, system and device based on millimeter wave radar

ActiveCN105313769AReduce accident rateReduce signal processing timeSignalling/lighting devicesEngineeringVehicle driving

The invention discloses a vehicle active forewarning method, system and device based on millimeter wave radar. The forewarning method comprises following steps: obtaining vehicle driving information from each sensor; determining whether two vehicles are in a same lane based on the relative angle and relative distance between a vehicle and an objective vehicle; determining the longitudinal safe braking distance if the two vehicles are in a same lane, wherein Sw represents a warning safe distance, Sbr represents a safe braking distance, and R represents the relative distance; if R>Sw, the vehicle is in a safe driving state; if Sw>=R>Sbr, the vehicle is faced with a potential risk of collision; and if R<=Sbr, the vehicle is in an extremely dangerous state. By use of the forewarning method, system and device, the safety state of a vehicle is pre-estimated and early warning is made; accident rate is effectively reduced; the signal processing time is in milliseconds; the device is easy to install and maintain; good using effect is achieved.

Owner:WUHAN UNIV OF TECH

Multi-gap self-swelling strong-air-current longitudinal blow-out arc anti-thunder protecting device

ActiveCN103594210AImprove arc extinguishing effectHigh vulnerabilityInsulatorsCorona dischargeElectricityElectric power system

The invention discloses a multi-gap self-swelling strong-air-current longitudinal blow-out arc anti-thunder protecting device which comprises a longitudinal blow-out arc device arranged at an insulator string earthing terminal through a grounding side connecting hardware fitting, a grounding side electrode arranged on the longitudinal blow-out arc device, and a guide line side electrode arranged on an off-contact guide line. A protecting gap formed by the grounding side electrode and the guide line side electrode is parallel to an insulator string. The longitudinal blow-out arc device comprises an arc extinguishing device body and arc extinguishing tubes. The arc extinguishing device body is provided with a plurality of through holes for placing the arc extinguishing tubes. An angle formed by two arc extinguishing tubes which are arranged in the arc extinguishing device body is 90 degrees, and end portions of the two arc extinguishing tubes are in contact with each other. Each arc extinguishing tube is in a spiral shape. The grounding side electrode is connected with a first arc extinguishing tube through a guide line, and the grounding side connecting hardware fitting is connected with a last arc extinguishing tube through a guide line. The device is simple in structure, low in manufacture cost, safe and reliable, effectively reduces the power system transmission line thunderstrike tripping rate and the accident rate, and improves the stability of a power system.

Owner:王巨丰 +1

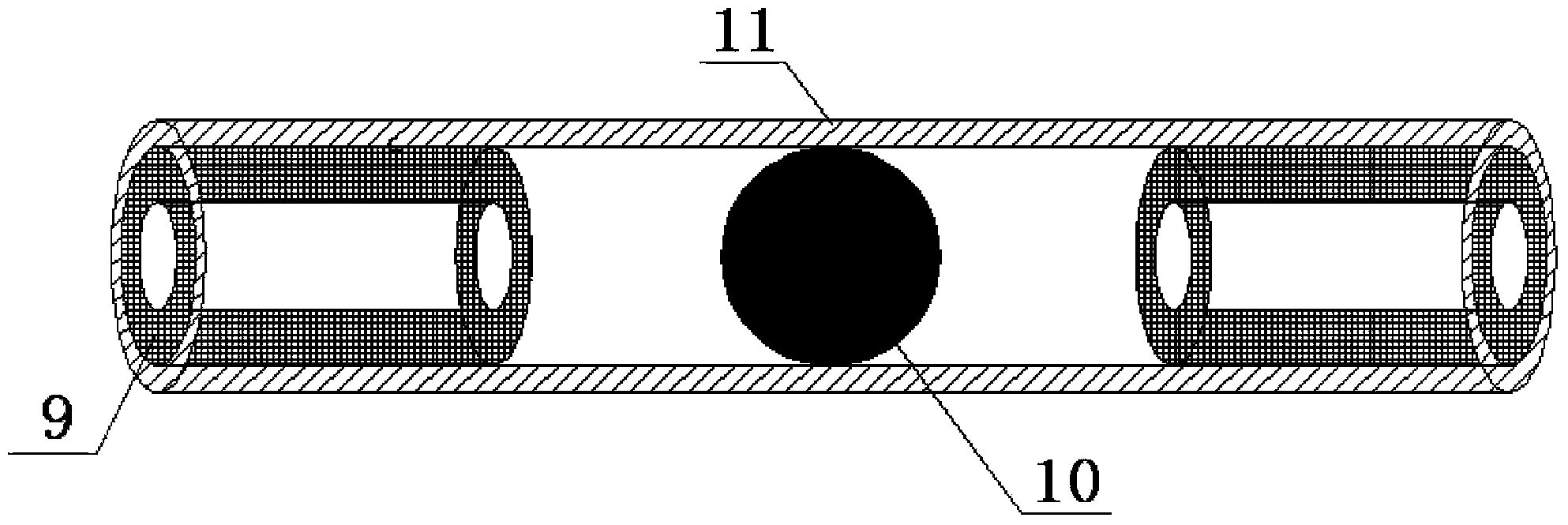

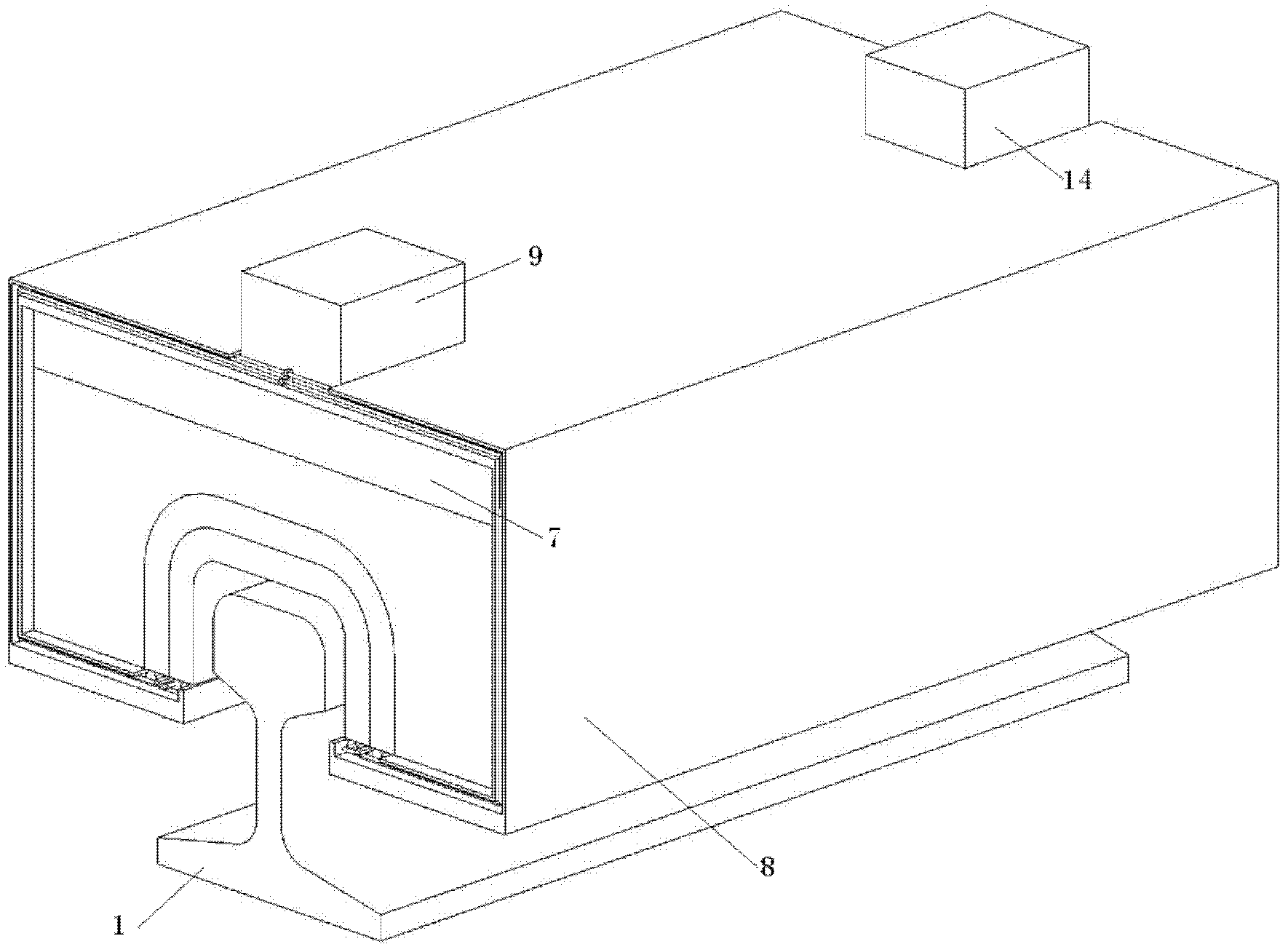

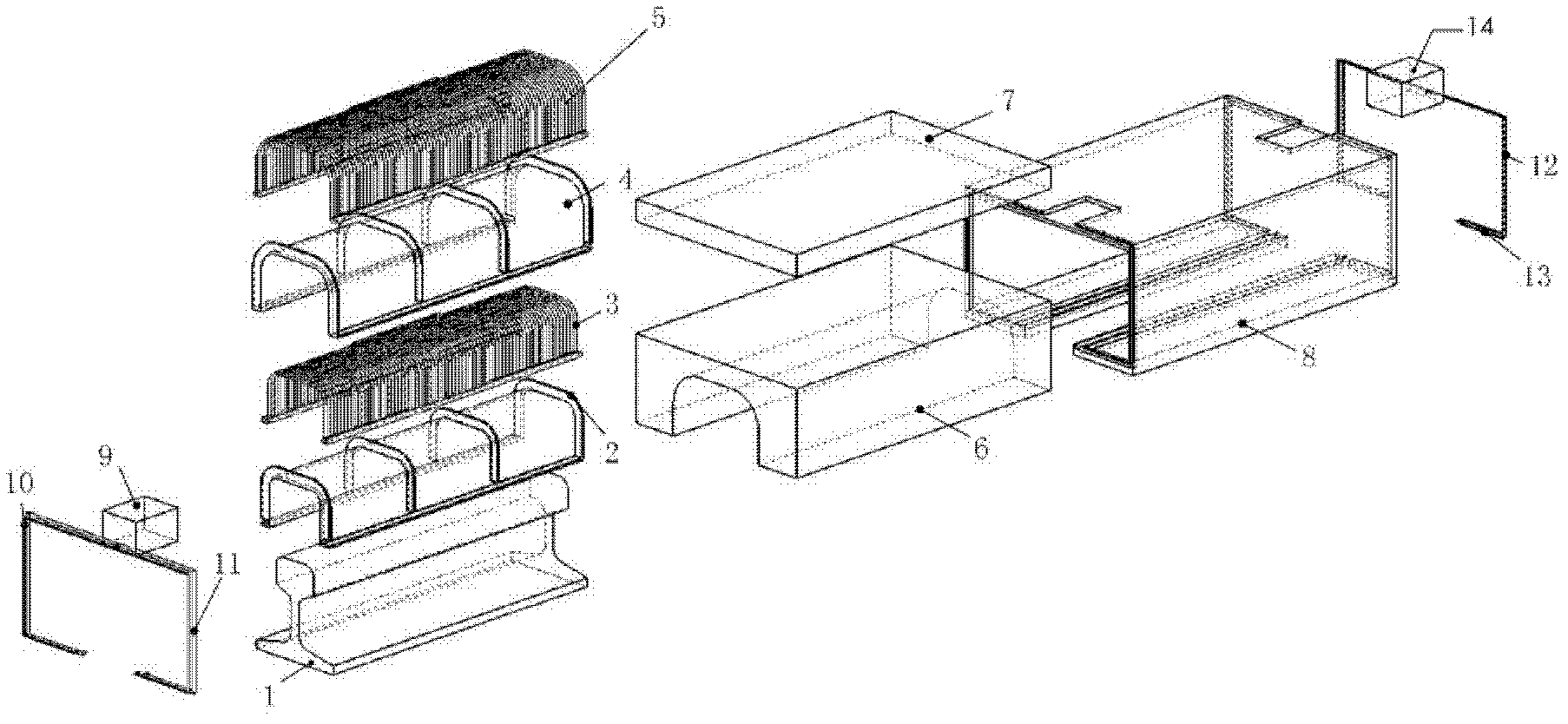

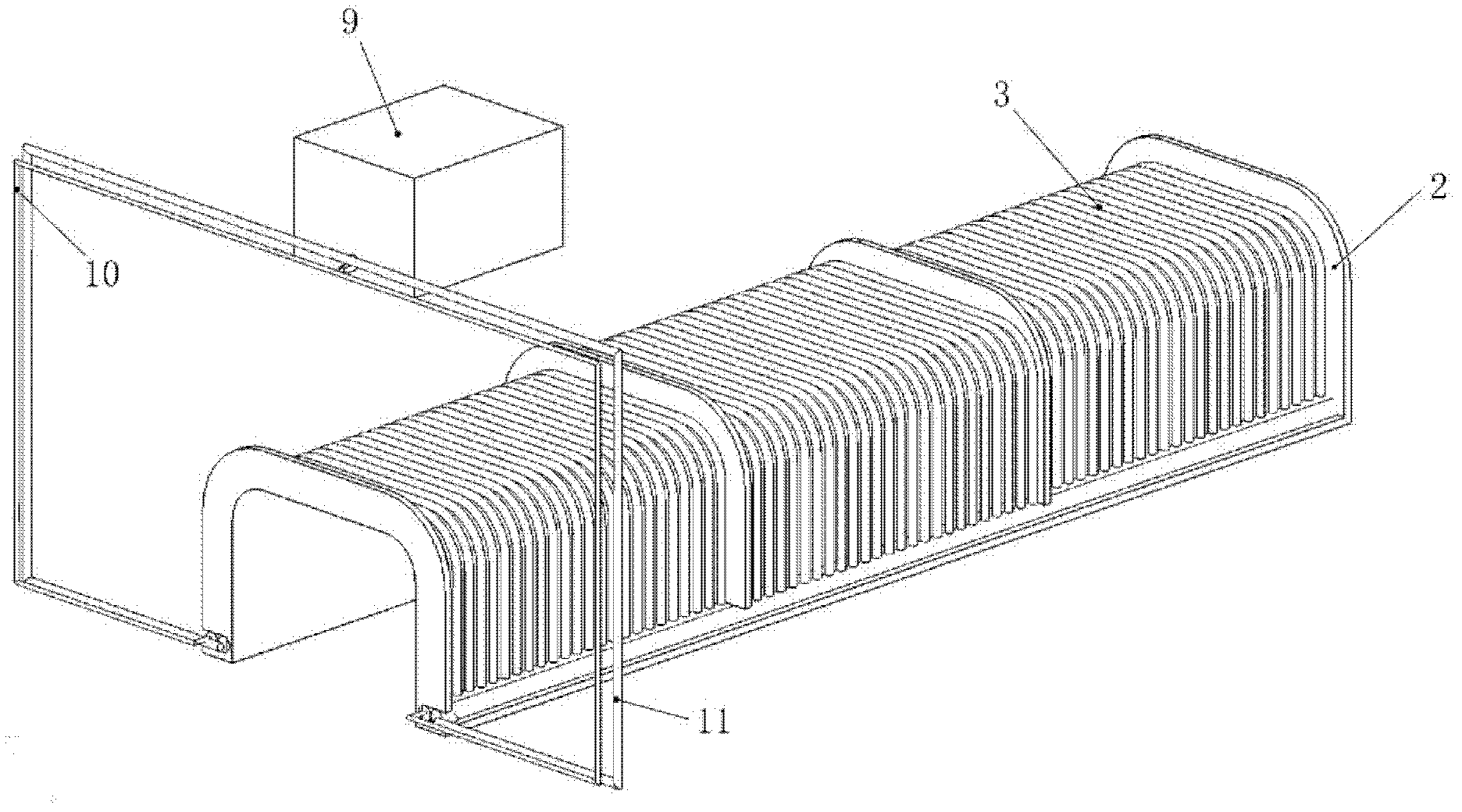

Rail destruction detection device and method based on magnetostriction and longitudinal ultrasonic guided wave

ActiveCN102520068AImproving the efficiency of early identification of damageEnabling non-contact damage detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringElectromotive force

The invention discloses a rail damage detection device and method based on magnetostriction and longitudinal ultrasonic guided wave, which are applied in the field of railway traffic nondestructive detection. The rail damage detection device comprises a shell, wherein an inner wire support, an inner coil, an outer wire support, an outer coil, a yoke and a permanent magnet are arranged in the shell; a current input port, an inner coil current input electric wire and an inner coil current output electric wire are arranged at one end of the shell; an outer coil current output electric wire, an outer coil current loop electric wire and a voltage output port are arranged at the other end of the shell; and the upper part of the shell is fixedly connected with a rail detection vehicle. The rail damage detection method comprises the following steps of: exciting induced electromotive force by utilizing magnetostriction and longitudinal ultrasonic guided wave, and indirectly measuring time and strength generated by a defect reflective waveguide signal according to the induced electromotive force, and further determining the destruction position and the destruction size. The rail damage detection device and method can be used for carrying out accurate detection on trace destruction inside and outside the rail, and have the advantages of long detection distance and high detection efficiency.

Owner:JINAN UNIVERSITY

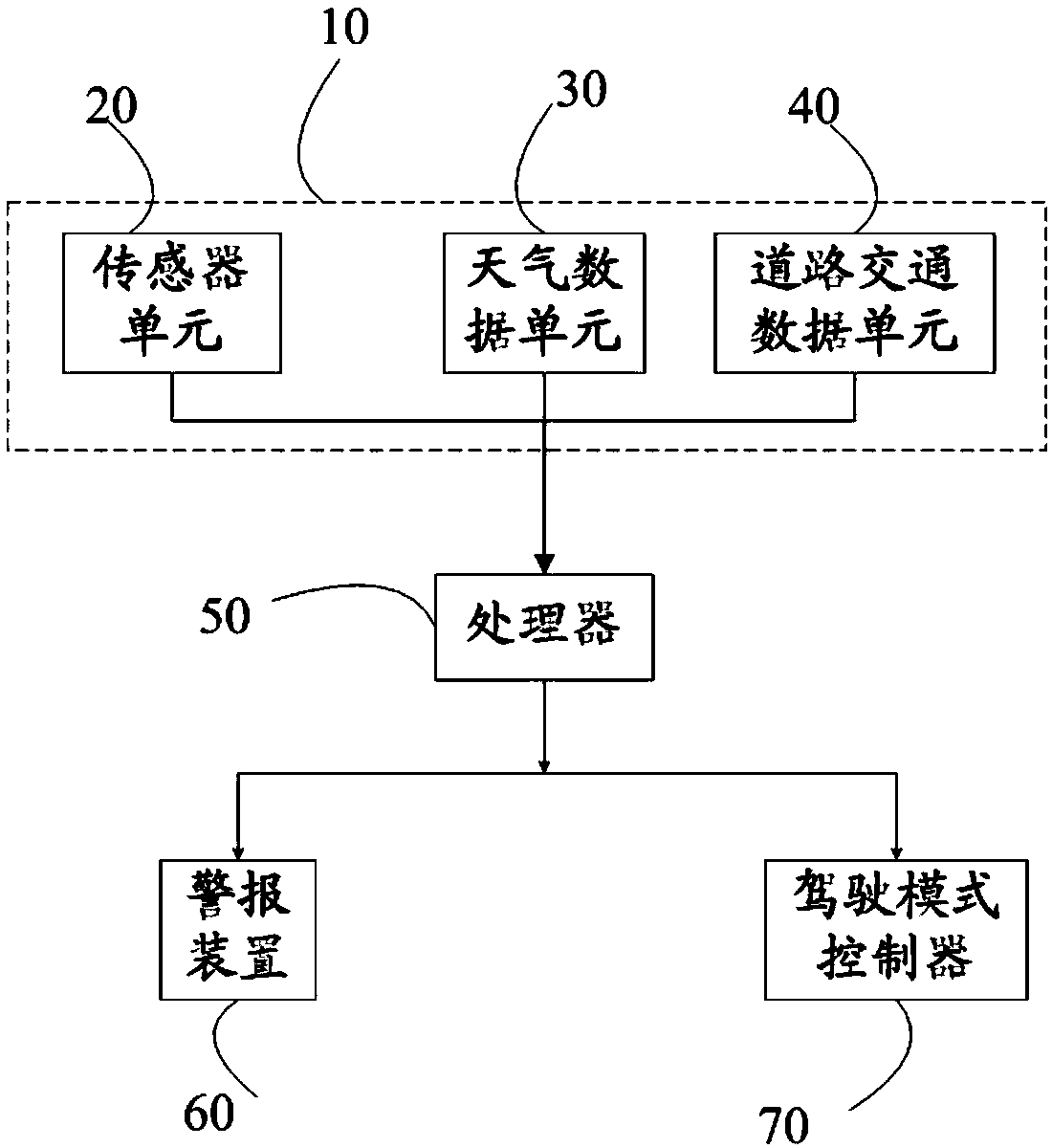

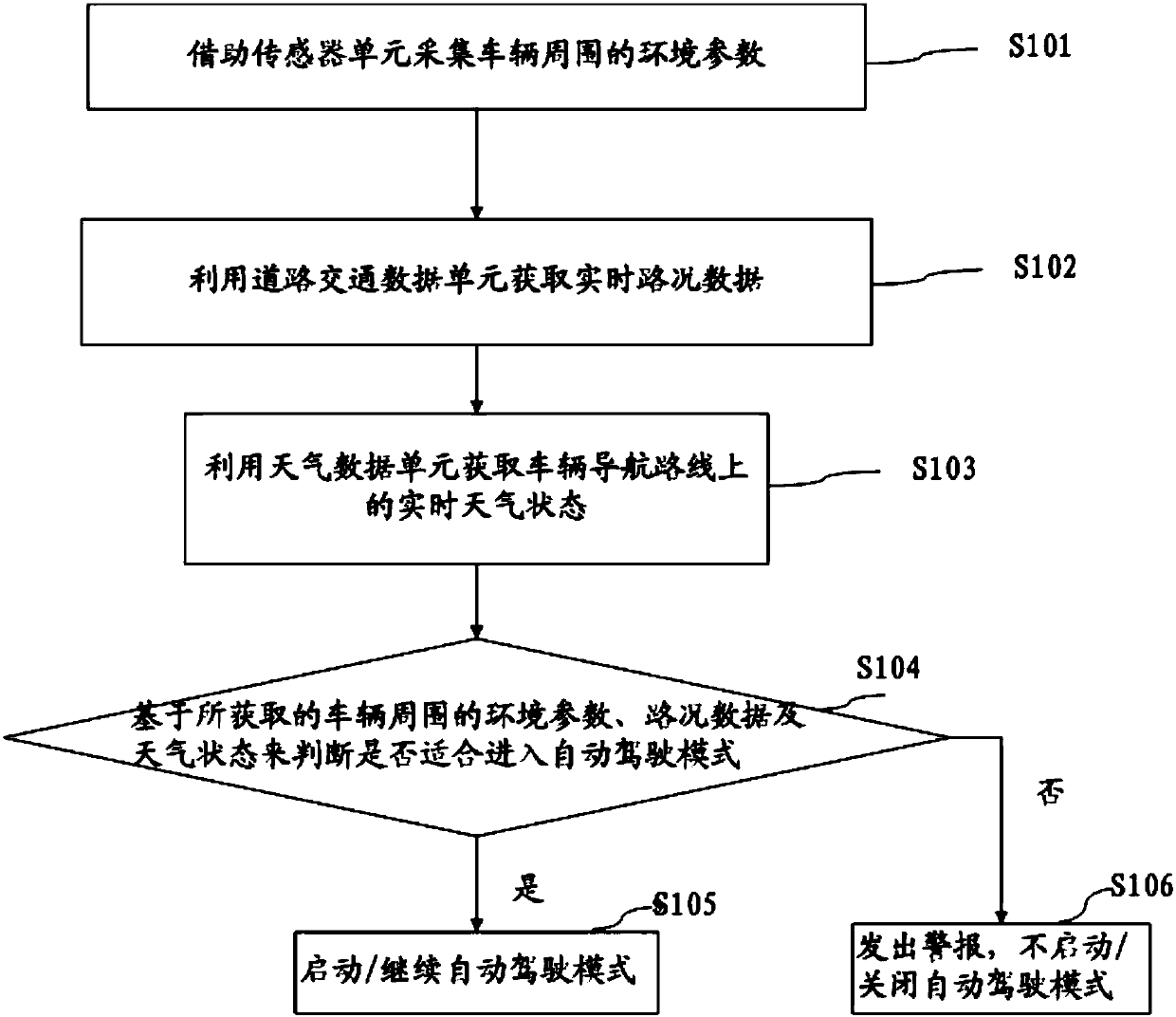

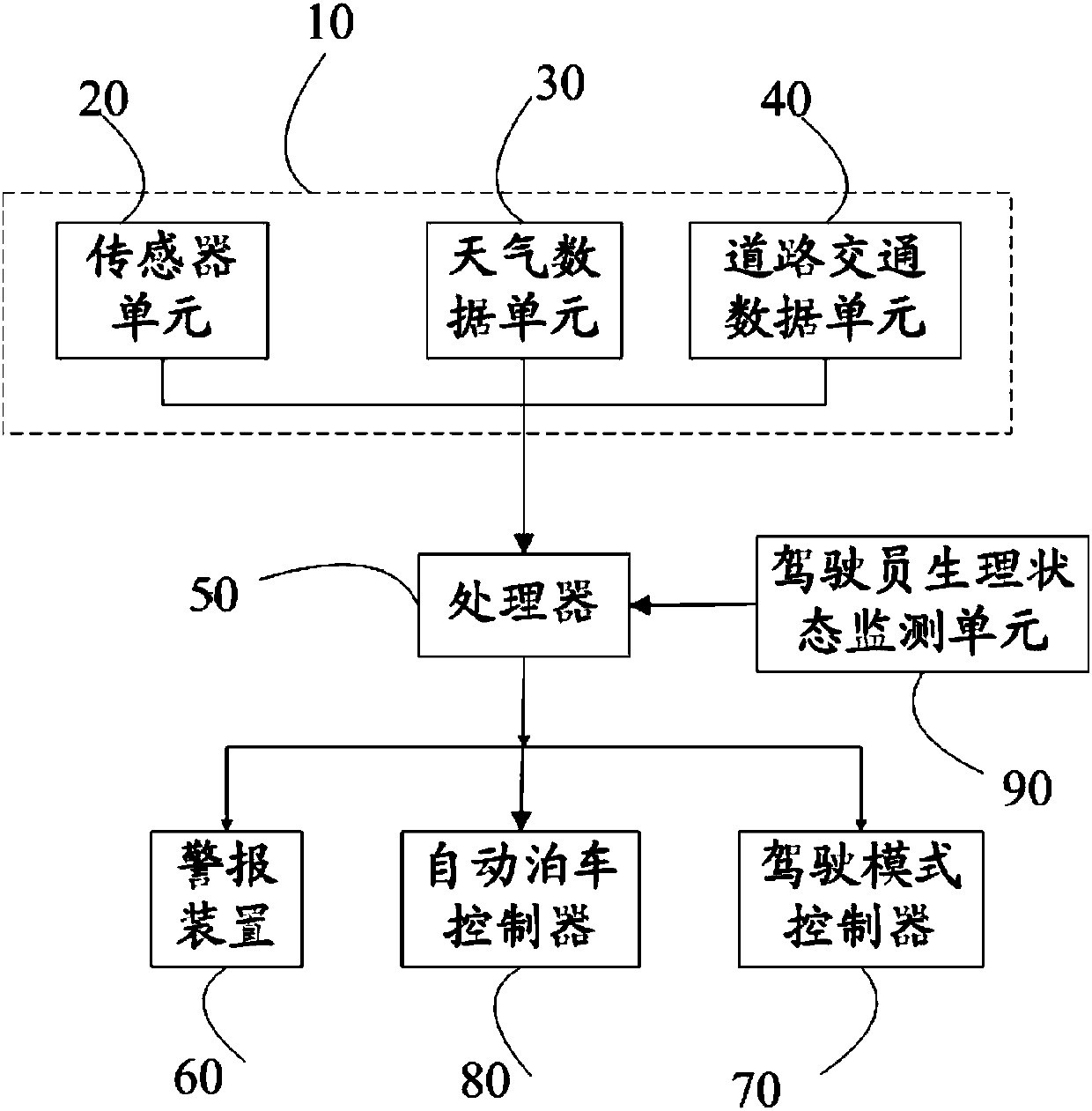

Intelligent driving control system and method for vehicle

InactiveCN107650911AReduce accident rateExternal condition input parametersDriver input parametersControl systemEngineering

The invention relates to an intelligent driving control system for a vehicle and further relates an intelligent driving control method for the vehicle. The intelligent driving control system can comprise a sensor unit, a weather data unit, a road traffic data unit, a processor and a driving mode controller. The sensor unit is used for collecting the parameters of the environment around the vehicle. The weather data unit is used for obtaining the real-time weather condition and weather forecast along a road and a navigation route where the vehicle travels currently. The road traffic data unit is used for obtaining the traffic condition of the road. The processor receives information obtained by the sensor unit, the weather data unit and the road traffic data unit, judges whether automatic driving is suitable for being conducted or not on the basis of the information and outputs corresponding control instructions according to the judgment results. The driving mode controller receives thecontrol instructions from the processor and responds to the received control instructions to execute corresponding driving control.

Owner:DAIMLER AG

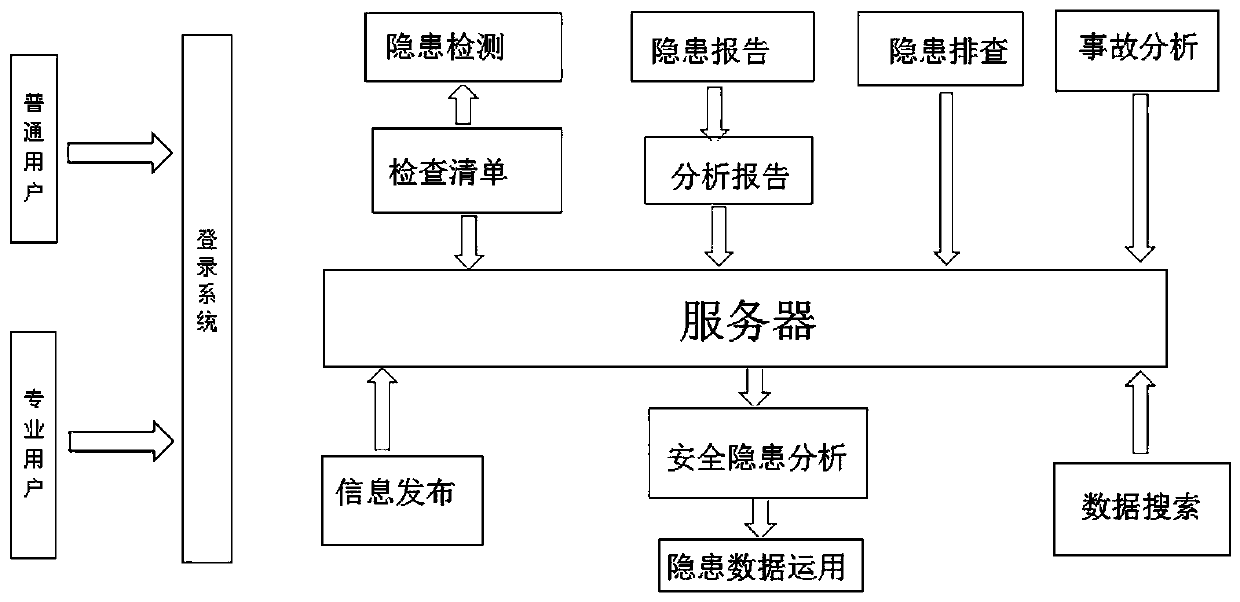

Factory hidden danger identification method and system

InactiveCN107609765ASimplify the difficulty of operationImprove user experienceChecking time patrolsResourcesItem generationTask control

The invention relates to the technical field of on-site safety management, and especially relates to a factory hidden danger identification method and system. The system includes a check subsystem, ahidden danger report subsystem and a safety accident analysis subsystem which are in communication connection with a server provided with a database and a task controller. The database stores check task lists corresponding to items to be checked, typical accident analysis data, and check item generation templates. The task controller includes a task calling program, a task writing program, a taskallocation program, and a checker management program. A checker logs into the account to establish a new check task. The task controller identifies the level of the checker and the type of the task, calls a corresponding check task list from the database, and sends the check task list to the checker. The checker transmits the check record and problems found to the task controller after completingcheck. The task controller writes the check record to the database, and allocates the problems found in check to the accounts of corresponding persons in charge. All the staff on site can log into thesystem to participate in on-site safety management based on a variety of handheld devices, paperless check recording and reporting can be completed on site, the results can be responded to quickly and tracked correspondingly, and the coverage is wide.

Owner:中国东方电气集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com