Patents

Literature

385 results about "Profibus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

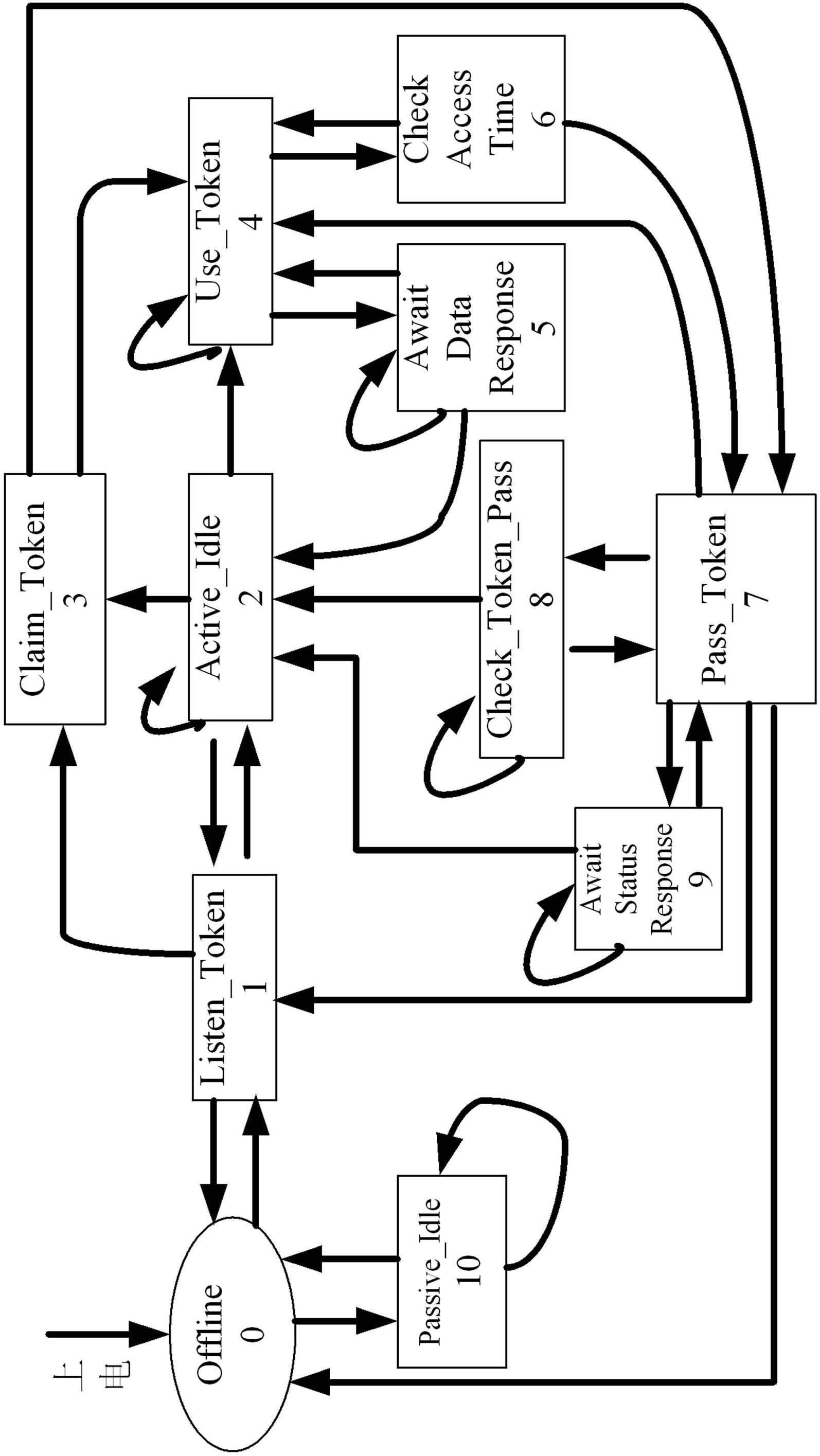

PROFIBUS (Process Field Bus) is a standard for fieldbus communication in automation technology and was first promoted in 1989 by BMBF (German department of education and research) and then used by Siemens. It should not be confused with the PROFINET standard for Industrial Ethernet. PROFIBUS is openly published as part of IEC 61158.

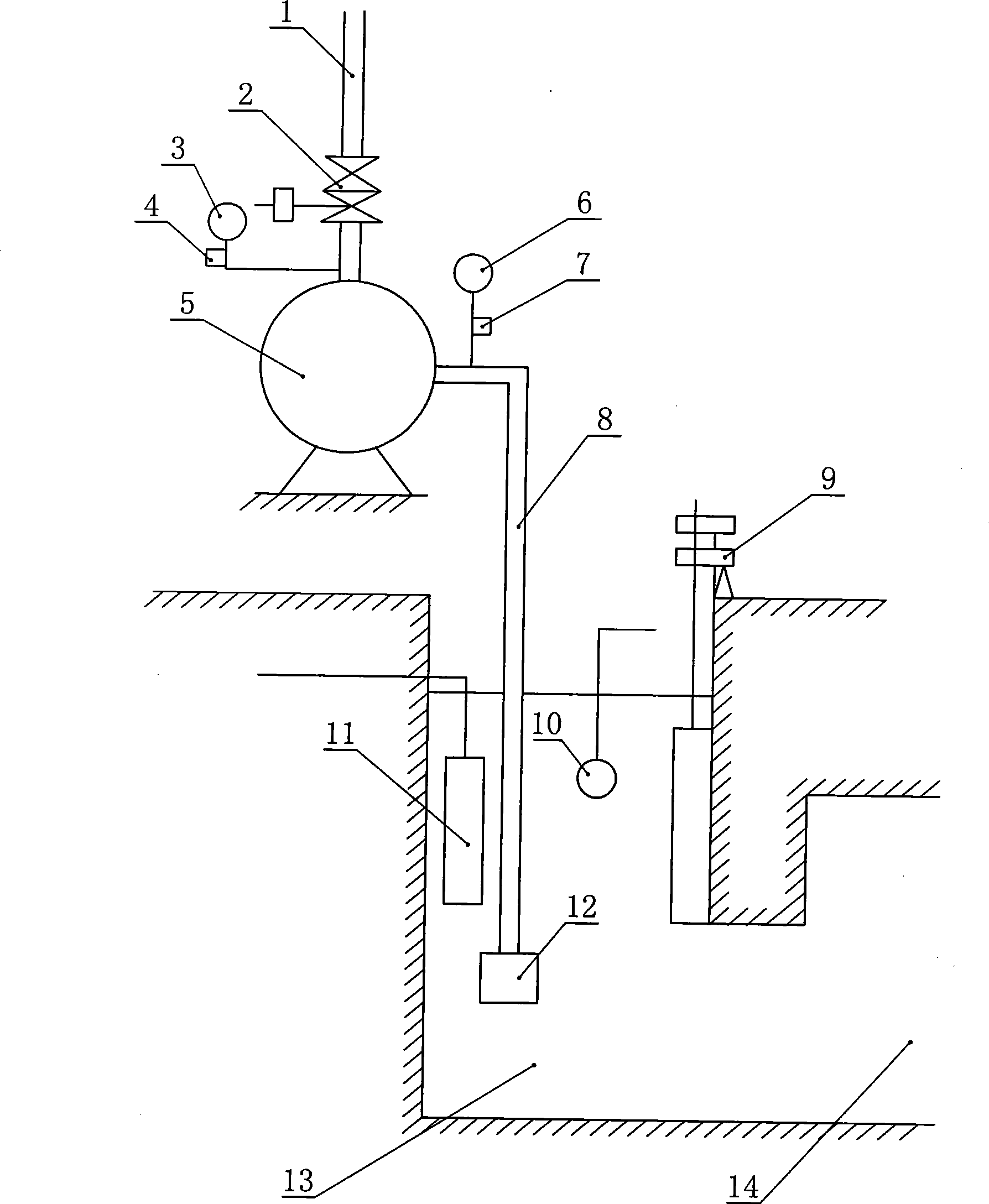

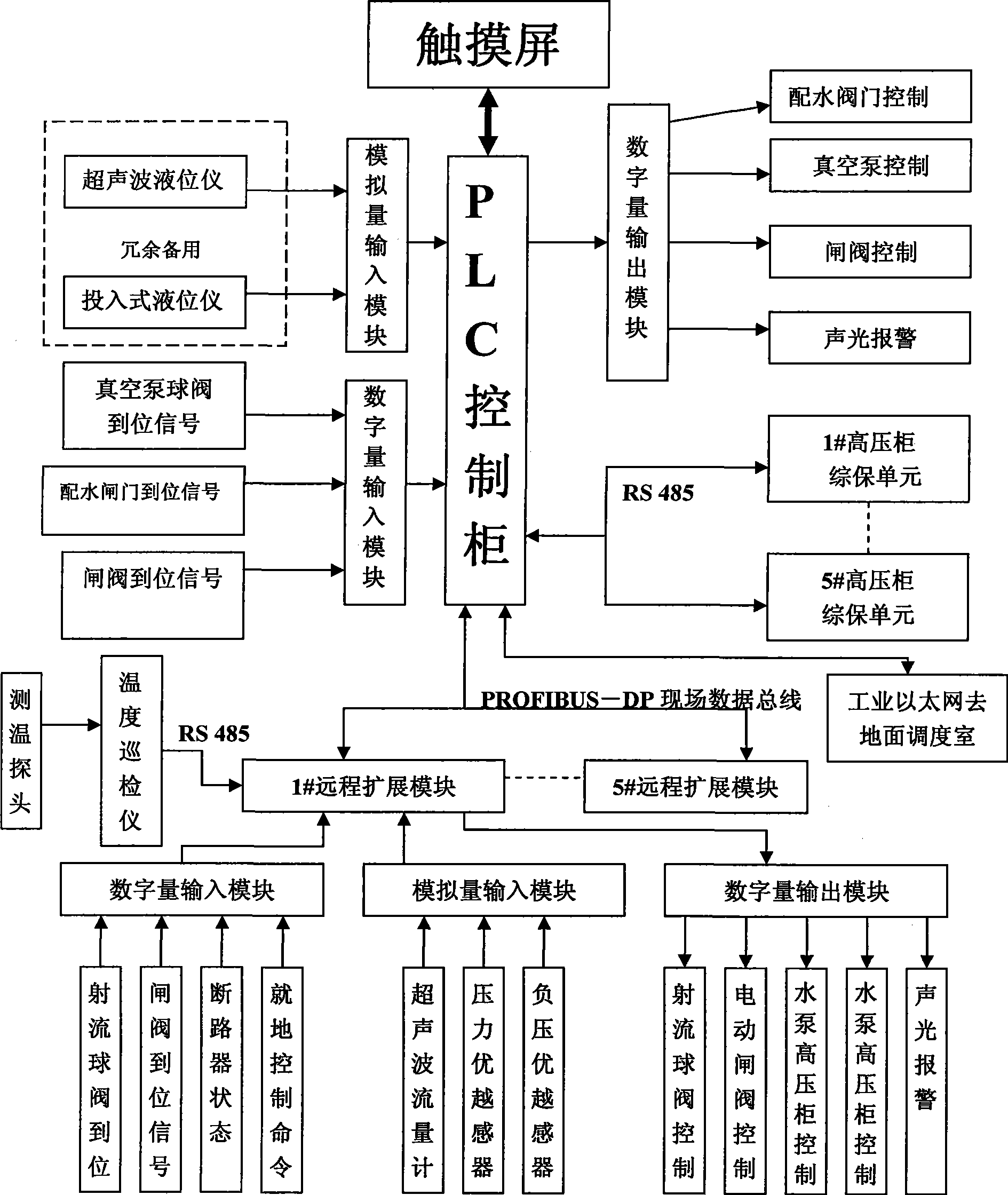

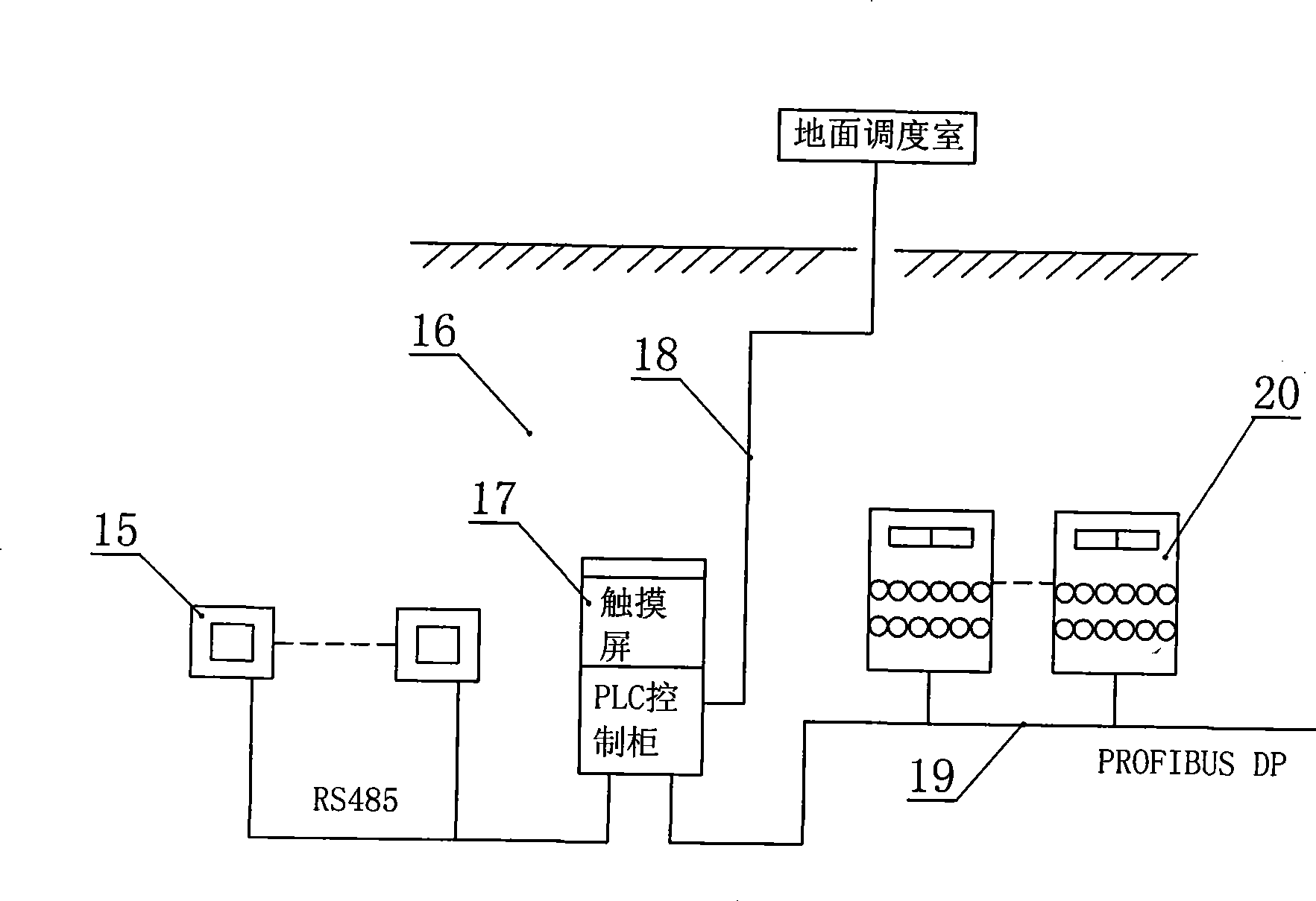

Automatic monitoring system for down-hole central pumping room drainage

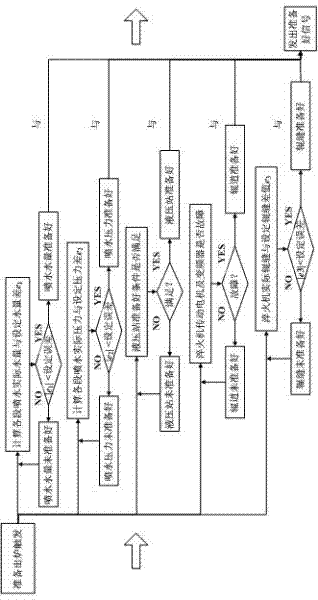

The invention relates to an underground central pump room draining automatic monitoring system, which comprises a PLC control cabinet, a remote expanding module, a site data bus, a contact screen, an analog quantity and switching value input module, various monitoring probes, a travel switch, a level instrument and an executable section. A monitoring net adopts a form of combining a PROFIBUS DP site data bus and an industrial ethernet. A monitoring method for the system comprises: (1) monitoring the absorbing well water level; (2) monitoring the state for starting a high pressure switching cabinet by a water pump; (3) judging the valve levels of a gate valve, a ball valve of a water jet pumping device and a water distribution gate; (4) judging the valve levels of a vacuum pump ball valve; (5) measuring each equipment temperature measuring point; (6) measuring signals of a pressure sensor and a negative pressure sensor; (7) judging system faults; (8) automatically controlling the start-stop and operation numbers of the water pumps according to the absorbing well water level conditions; and (9) setting power supply peak avoiding time periods, and automatically selecting starting time and numbers of a pump. The system improves the system working reliability, reduces the equipment fault rate, and adopts a three-stage monitoring structure for a draining system.

Owner:BINHU COAL MINE ZAOZHUANG MINING GRP

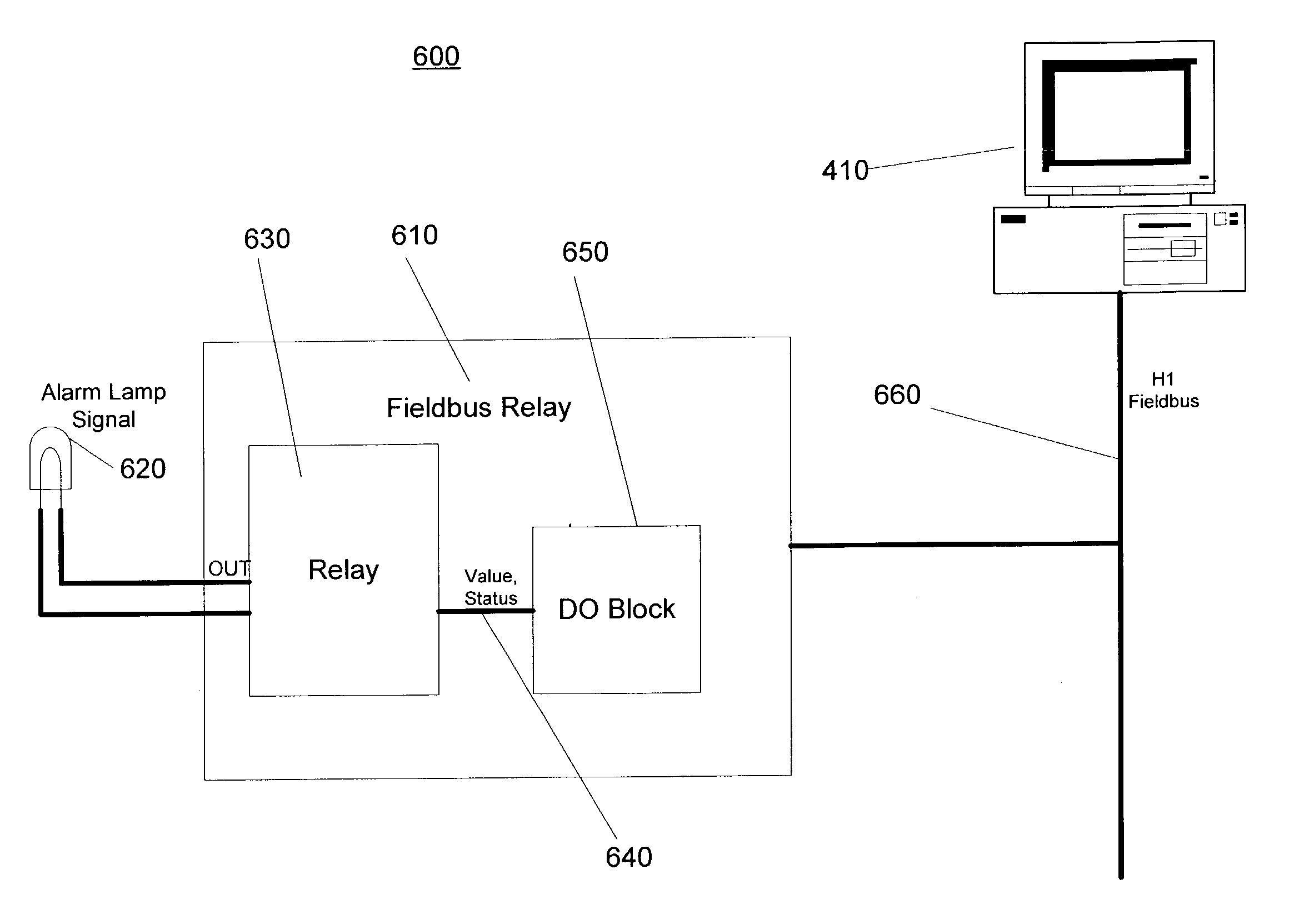

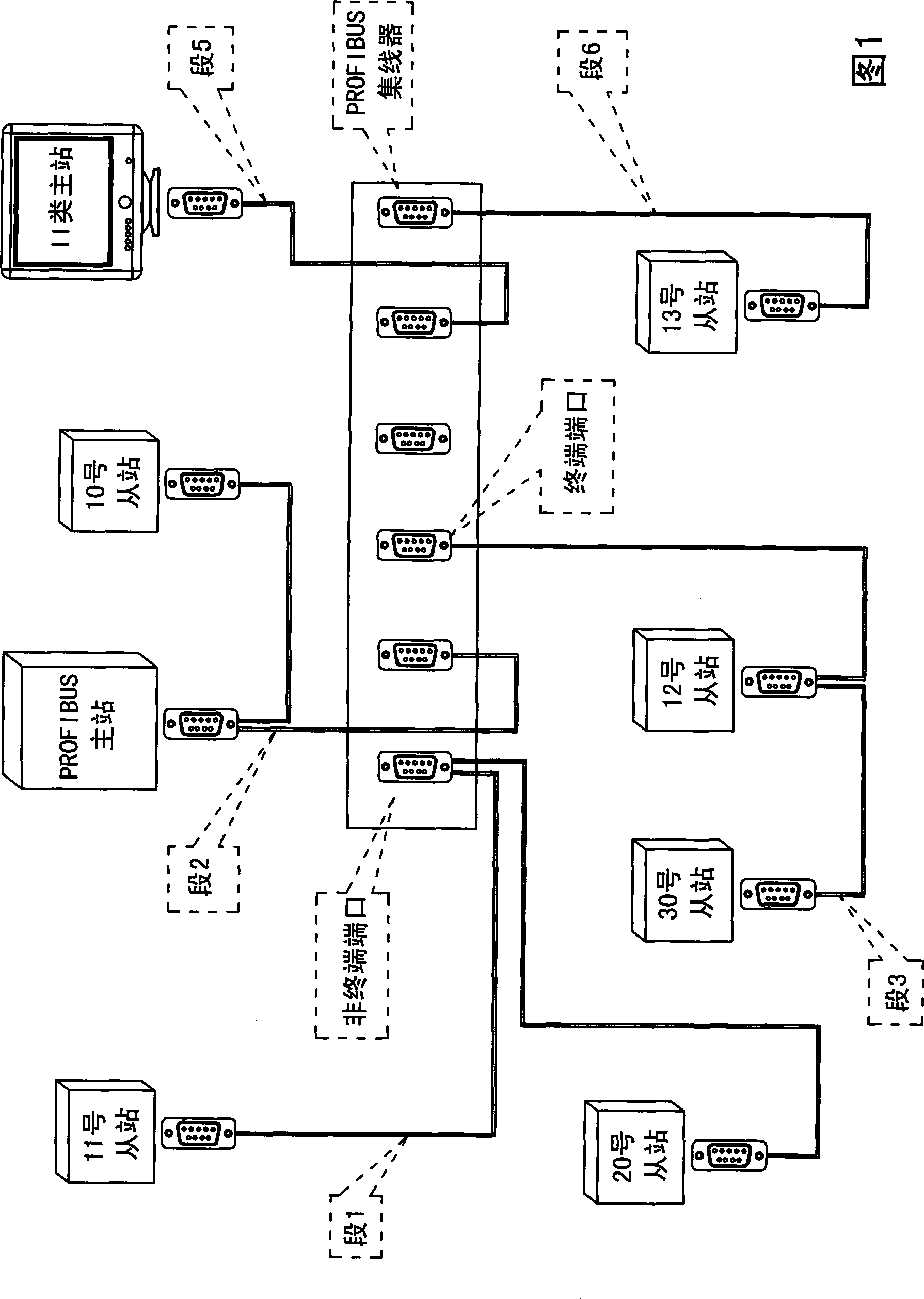

Fieldbus relay arrangement and method for implementing such arrangement

InactiveUS7035693B2Increased level of controlLimitation of conversionComputer controlSimulator controlProfibusWorld Wide Web

An arrangement operable to communicate with a fieldbus network and operate an attached relay and a method for implementing such arrangement is provided. The arrangement and method provide conventional discrete outputs from a fieldbus device using standard fieldbus function blocks, such as those used for Foundation® and Profibus® fieldbus networks. The arrangement and method may facilitate the integration of traditional discrete relay functions into these more advanced digital fieldbus networks, and also utilize additional functions available to standard Foundation® fieldbus and Profibus® fieldbus network devices.

Owner:SMAR RES CORP

Wireless communication module

InactiveUS7309260B2Electronics SimplifiedEliminate needCoupling device detailsNetwork connectorsWireless communication protocolWireless Application Protocol

Owner:LANTRONIX

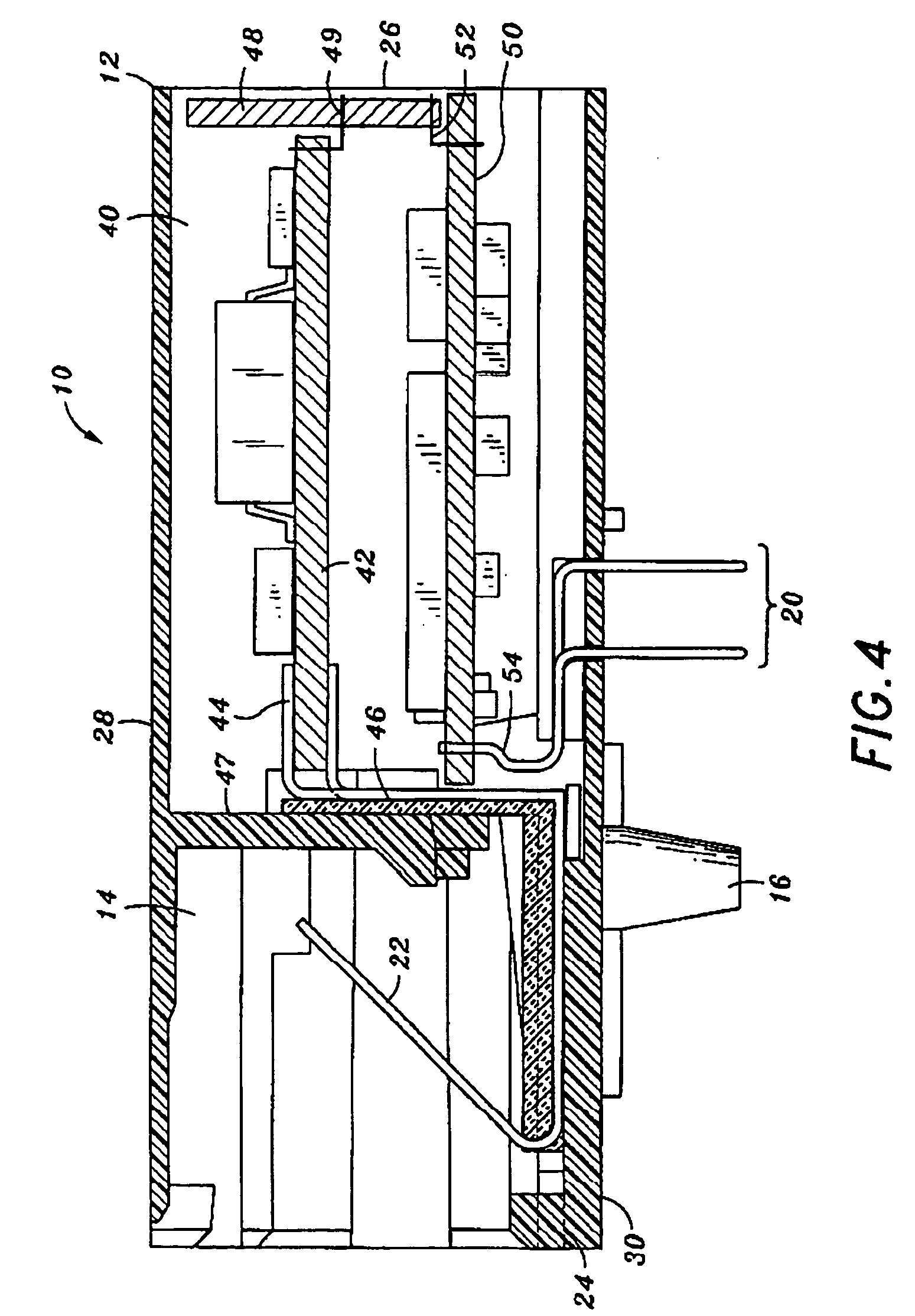

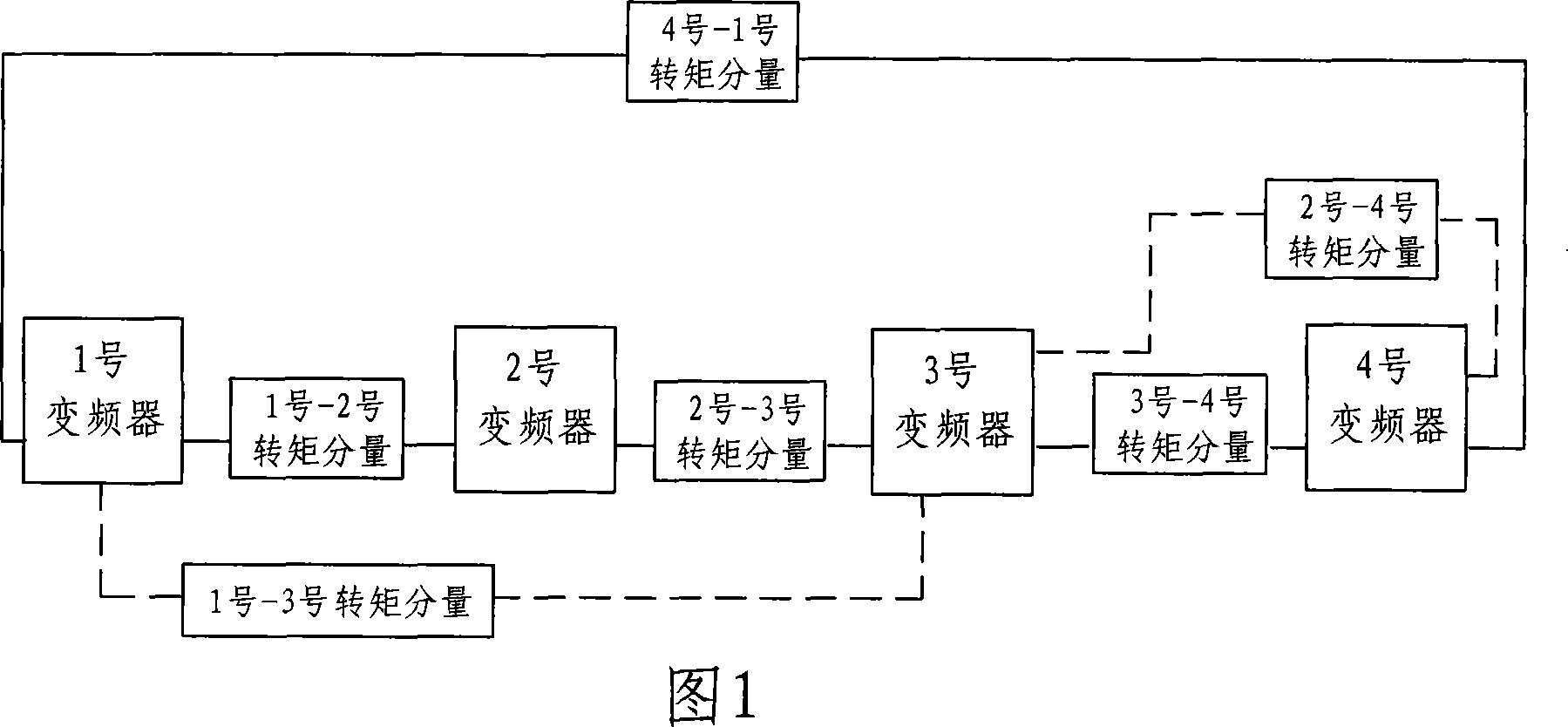

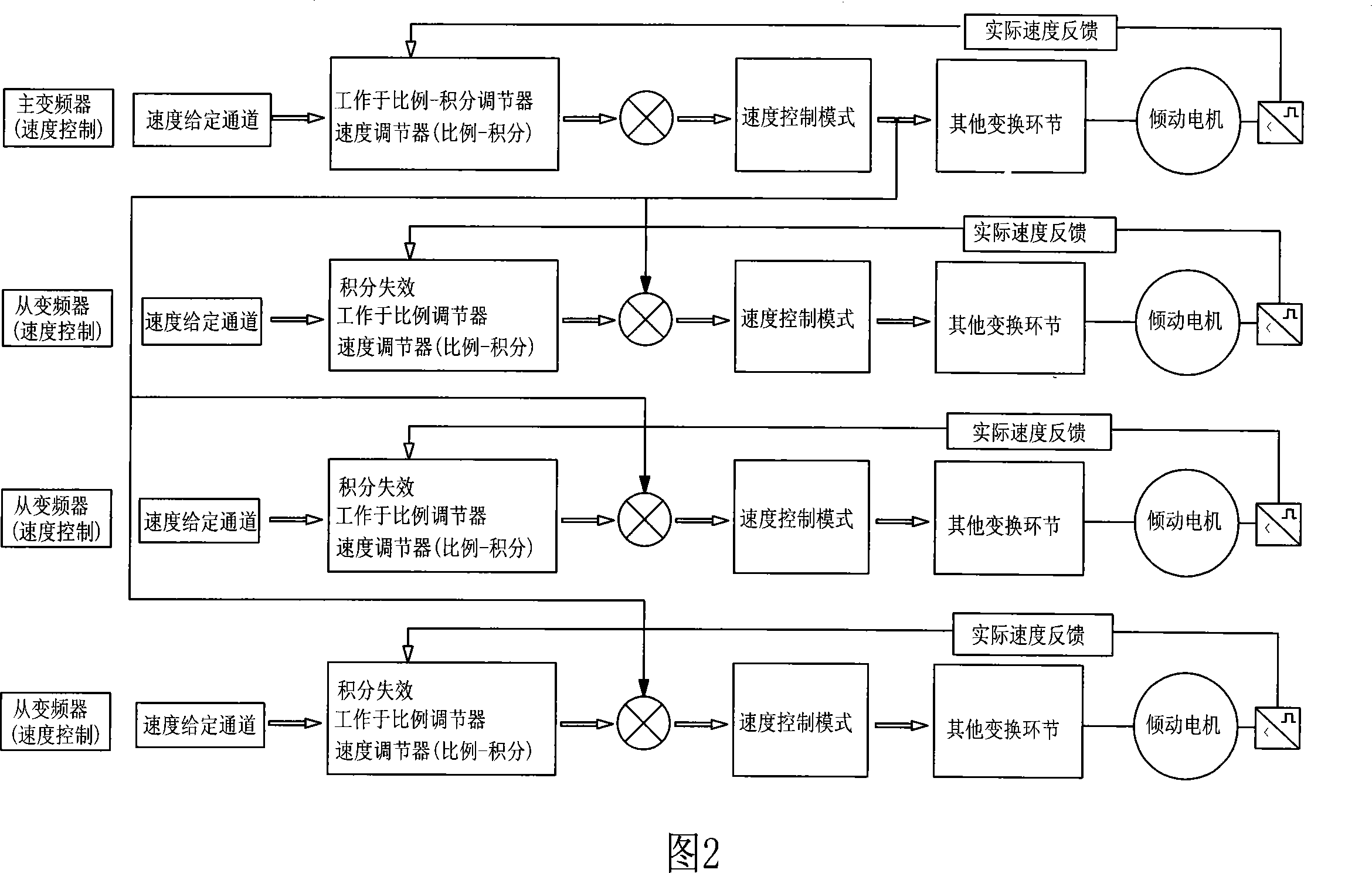

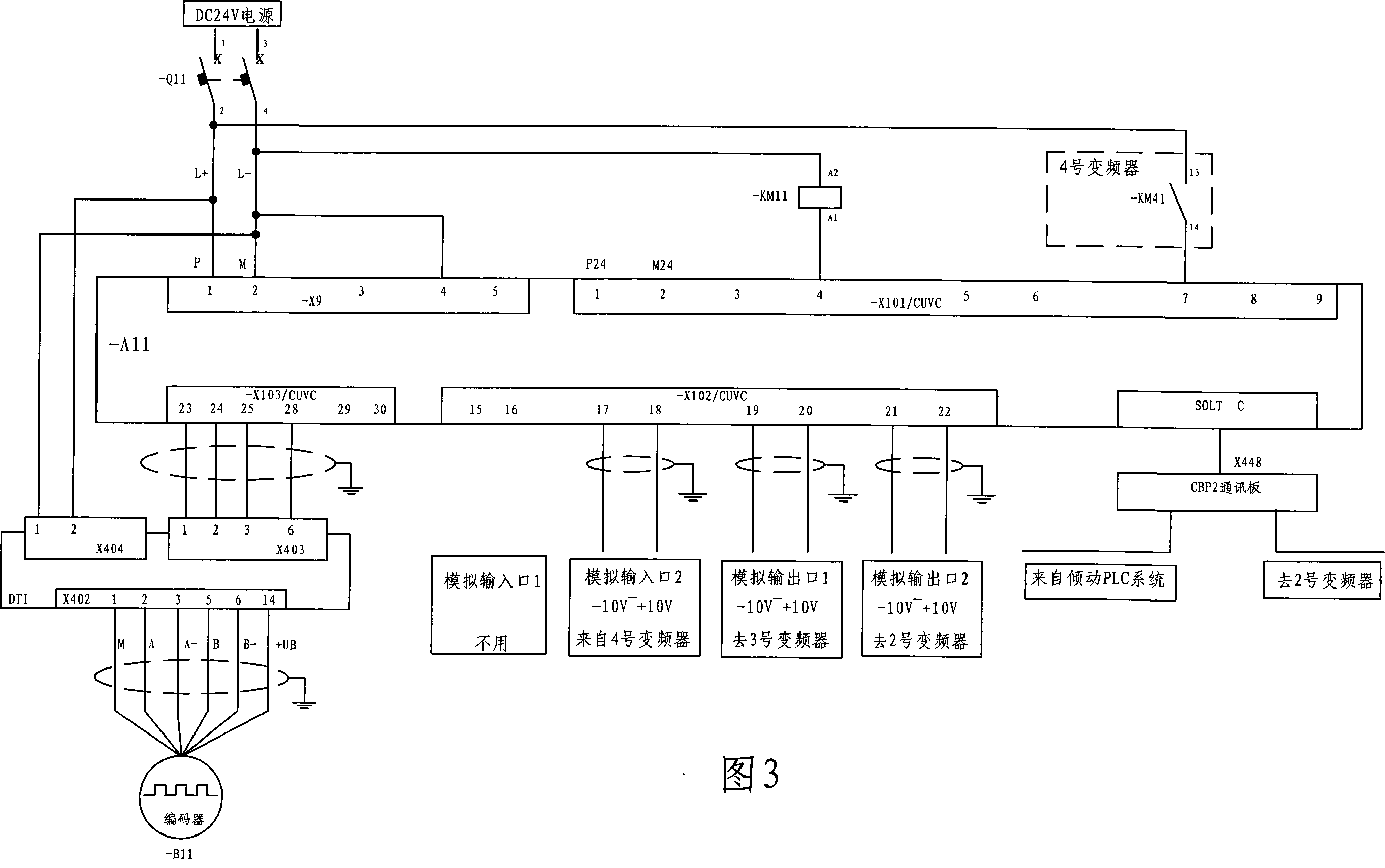

Converter tilting electric transmission and control system

InactiveCN101169656AExtended service lifeReduce the amount of manual maintenanceManufacturing convertersIncreasing energy efficiencyElectric power transmissionFrequency changer

The invention relates to a converter tilting electric drive control system, which comprises a plurality of frequency converters and a plurality of tilting electric motors which are respectively controlled by the inverters, wherein, a frequency converter is defined as a logic master frequency converter by a Master PLC, and others are defined as logic slave frequency converters by the Master PLC. All frequency converters are provided with CBP2 communication boards and communication that comprises given speed, control word and status words with the PLC through the Profibus-DP network is achieved;through analog channels that CUVC board comes with, a ring connection is formed among all frequency converters, to transmit torque components. The invention has the advantages of being simple and reliable, convenient on-line switching, high-precision control, fast dynamic response, and effectively solving the defects of poor balance, dynamic response slow and mechanical damage greater caused by that a speed controls three torque controls traditionally, or a control method that finds the balance torque by using the flexible machinery traditionally.

Owner:WISDRI ENG & RES INC LTD

Real time multiple task distributive control system based on VME bus

ActiveCN1987705AMeet multi-functional and complex control requirementsClear functional relationshipTotal factory controlProgramme total factory controlResponse controlEmbedded system

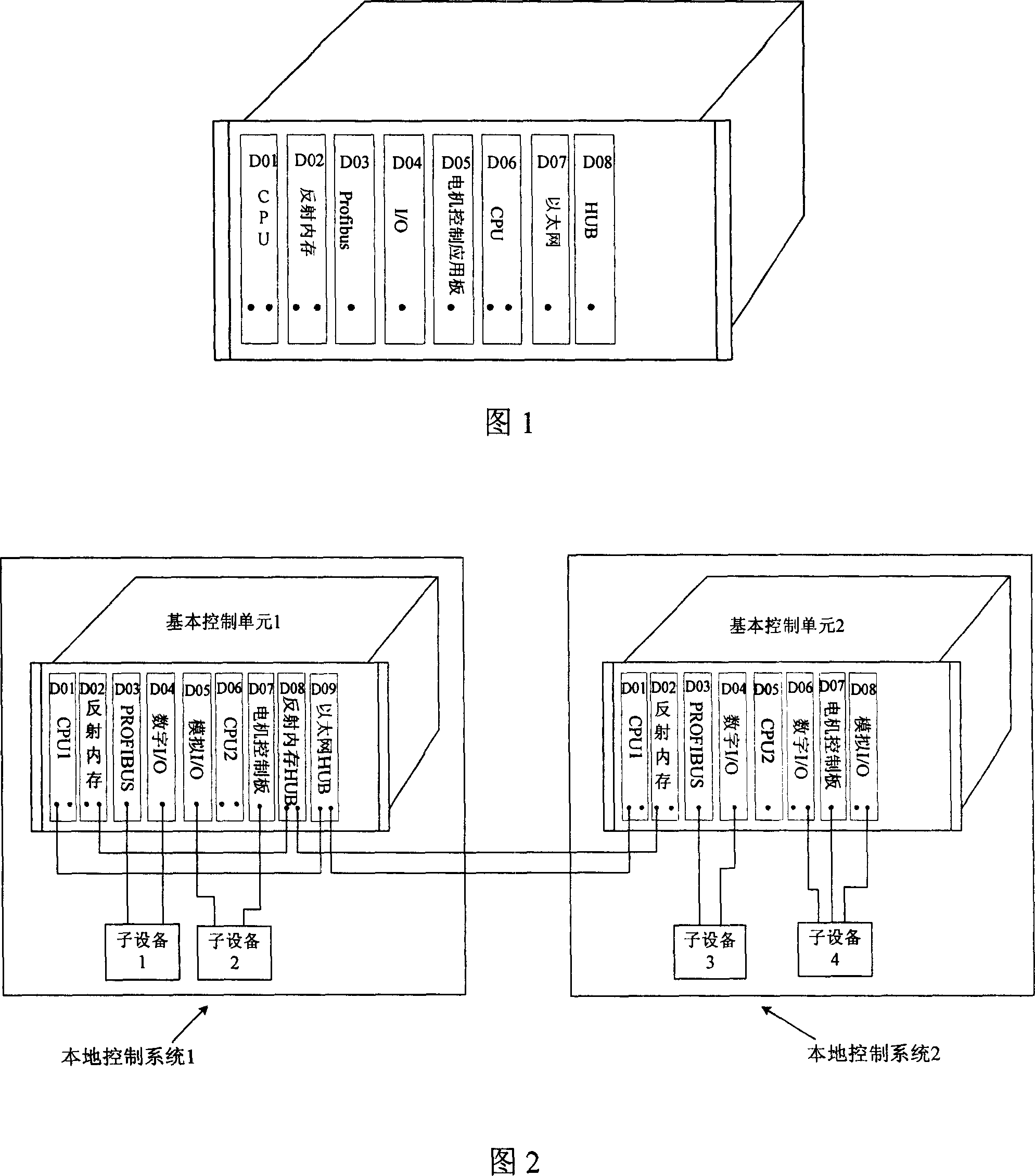

The control system includes VME bus chassis, CPU main board, Ethernet comm interface board (CIB), reflection memory CIB, PROFIBUS CIB, digital signal interface board, analog signal interface board, and electrical motor control board (MCB). Boards and cards are inserted to backboard inside the VME bus chassis. Through VME bus, boards and cards in backboards inside same chassis can communicate each other through VME bus. Each board contains VME bus controller. VME bus controller implements functions of gating board, bus arbitration, interrupt response control, and reading and writing data. Each board possesses own address. Through VME bus, gated board exchanges data to CPU board. Using shared memory exchanges data between CPU boards in same backboard bus. The reflection memory CIB executes remote comm and real time control among multiple control systems. MCB can exchange data to CPU main board, and control motor through optical fiber interface driven by power switch in bottom layer.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Ethernet-based redundancy control system and control method

ActiveCN104898620ARealize remote real-time monitoringImprove securityTotal factory controlProgramme total factory controlComputer moduleProfibus

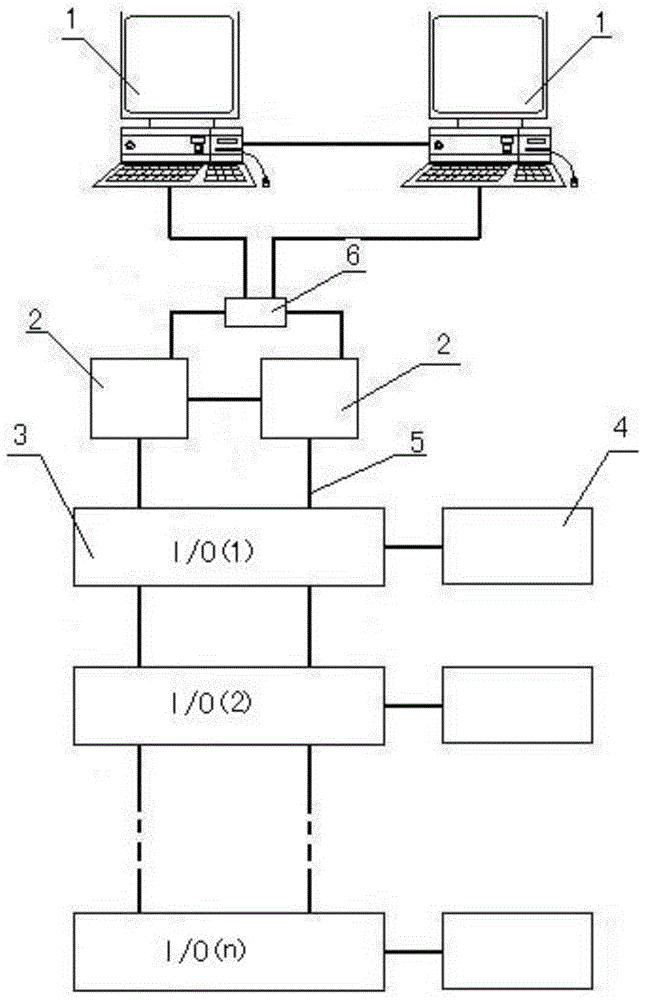

The invention discloses an Ethernet-based redundancy control system and a control method. The redundancy control system comprises an upper system, a control system and an execution system. The upper system comprises two industrial personal computers. A configuration software is installed on each of the industrial personal computers. The industrial personal computers form a local area network via a standard network card. The control system comprises two sets of PLC systems. Each of the PLC systems comprises a power supplying module, a redundancy CPU and an Ethernet communication module used for redundancy CPU communication. The redundancy CPUs in the PLC systems are connected via an optical fiber. The industrial personal computers are connected with the PLC systems via a switch and communicate with the Ethernet communication module via switches. The execution system comprises multiple I / O modules and multiple execution units. The PLC systems are separately connected with the I / O modules via Profibus-DP buses. The I / O modules are connected with the execution units. According to the invention, via the on-line real-time monitoring is performed via the industrial personal computers, and the PLC systems work concurrently, so safety, reliability and stability of operation of the system are greatly improved.

Owner:XIAN CHENYU ENVIRONMENT ENG

Automatic control system for moderate-thickness plate roller quenching machine

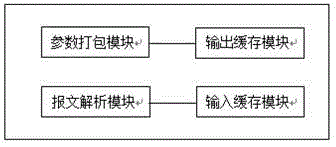

ActiveCN102409158AIncrease productivityImprove production accuracyHeat treatment process controlQuenching devicesData connectionAutomatic control

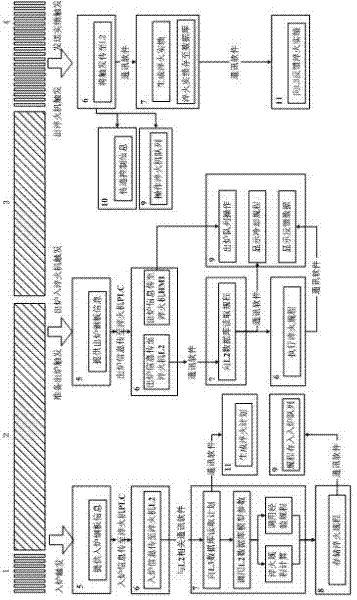

The invention discloses an automatic control system for a moderate-thickness plate roller quenching machine, and belongs to the technical field of heat treatment automatic control. The system consists of a PLC (Programmable Logic Controller) and interface system, a process control system and a track communication system, and is characterized in that: 1, water spray parameters are accurately controlled by using an intelligent algorithm to realize flow and pressure double-closed-loop control; 2, calculation is performed through procedure distribution, function trigger and quenching parameters to realize high-accuracy temperature control, plate shape control and model self-study; 3, a communication intermediate packet developed on the basis of TCP / IP (Transmission Control Protocol / InternetProtocol), OPC (Optical Proximity Correction) and PROFIBUS-DP can realize smooth data connection of the quenching machine and the MES (Manufacturing Execution System) as well as upstream and downstream equipment and meanwhile realize accurate transfer of data between subsystems; and 4, a trigger mechanism is adopted to realize queue macro tracking and position micro tracking of a steel plate of aquenching region. By adopting the system, the problems of complex control and low control accuracy of the roller quenching machine are solved well, and automatic and one-key operation of the roller quenching machine is realized.

Owner:NORTHEASTERN UNIV

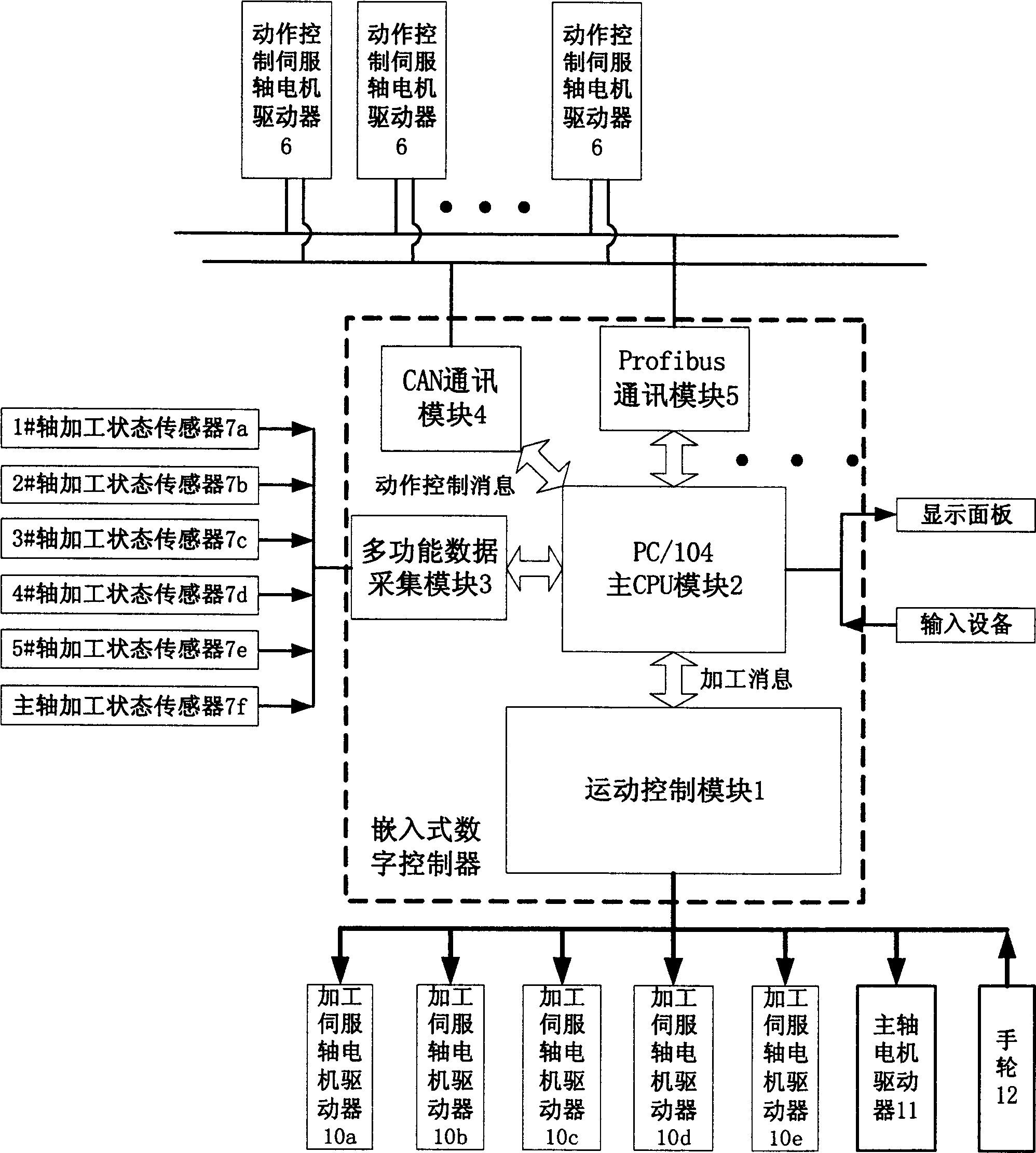

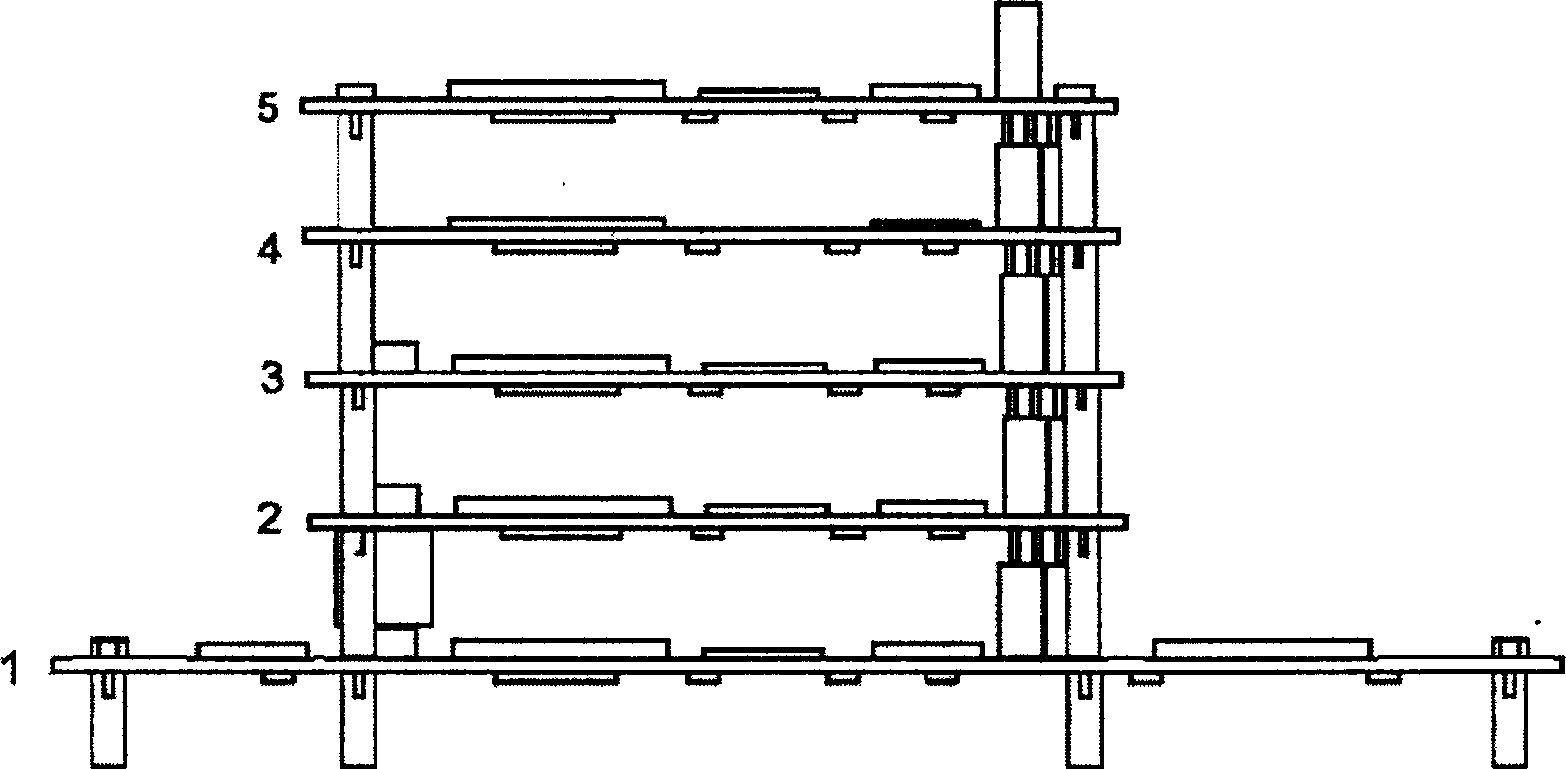

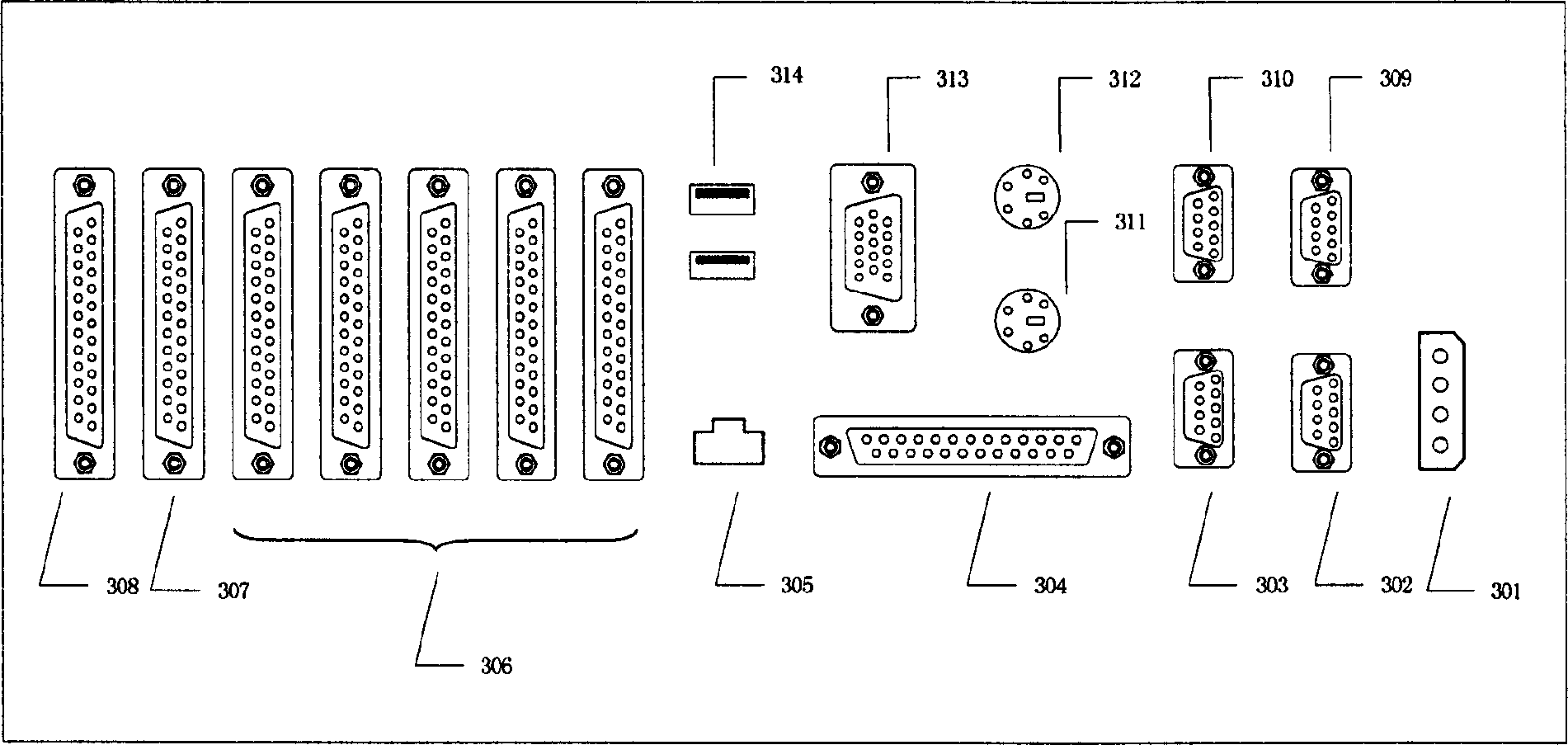

Embedded digital-control platform integrating control strategy of working state and its control method

InactiveCN1641503ACompact structureImprove seismic performanceComputer controlSimulator controlNumerical controlElectrical drive

This invention unfurls a kind of embedded model numerical control flat roof of processing state controlling politic integration and its control method. The hardware system of the numerical control flat roof includes the motion control module with PC / 104 - Plus interface, the CPU module based on PC / 104 - Plus, the multifunction data collecting module based on PC / 104 - Plus, the CAN communication module based on the PC / 104 - Plus, and the Profibus communication module. The controlling method is: the main system translates the operation instructions into motion control messages after receiving them, and sends the progressing messages to the motion control module, finally sends them to the processing servo axis electrical engine drive, the chief axis electrical engine drive and the handwheel; send the motion control messages to CAN communication module and the Profibus communication module, and send outside to the motion servo axis electrical drive. This invention can realize that the processing state is controllable and the progressing course is intelligent.

Owner:SOUTH CHINA UNIV OF TECH

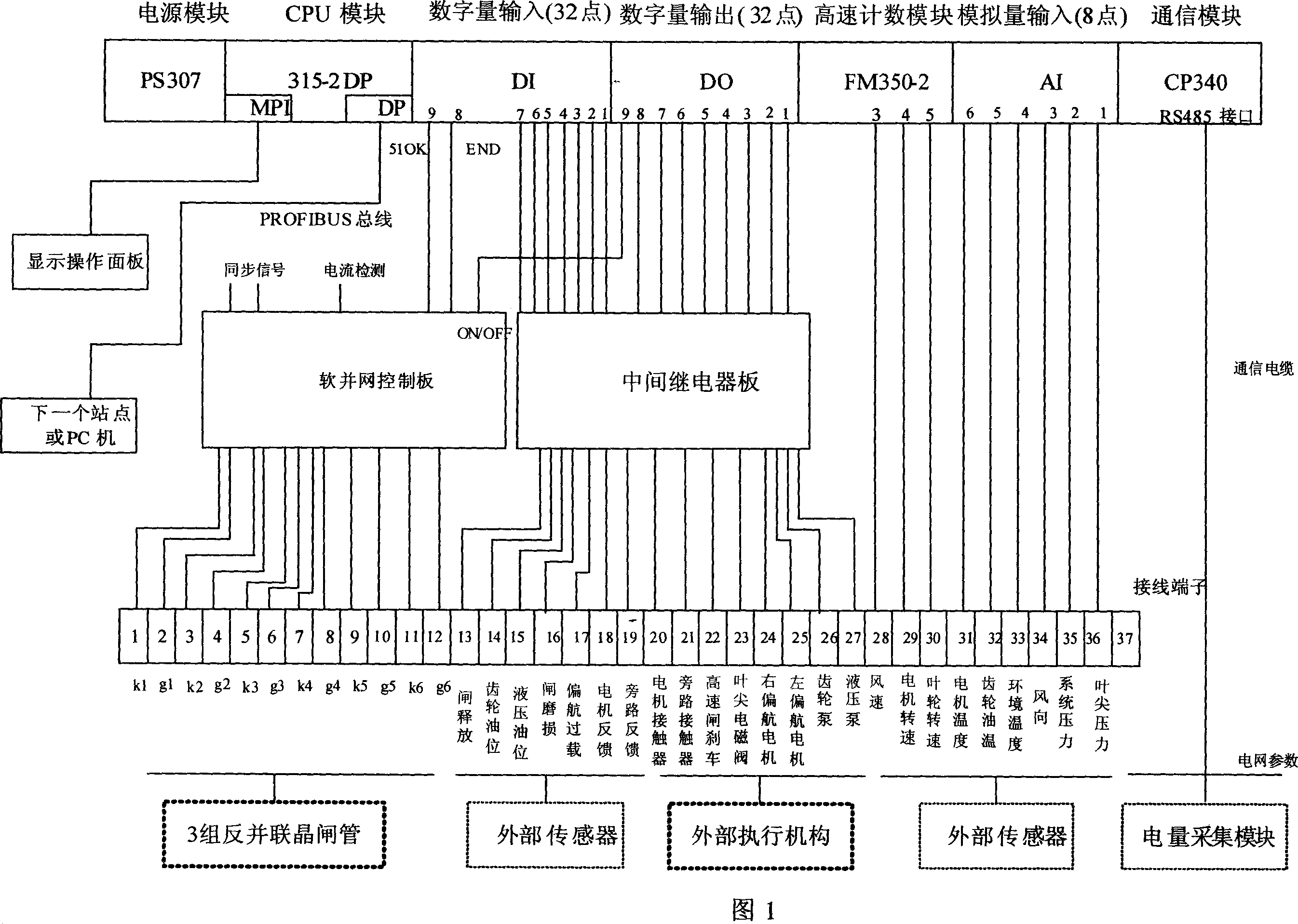

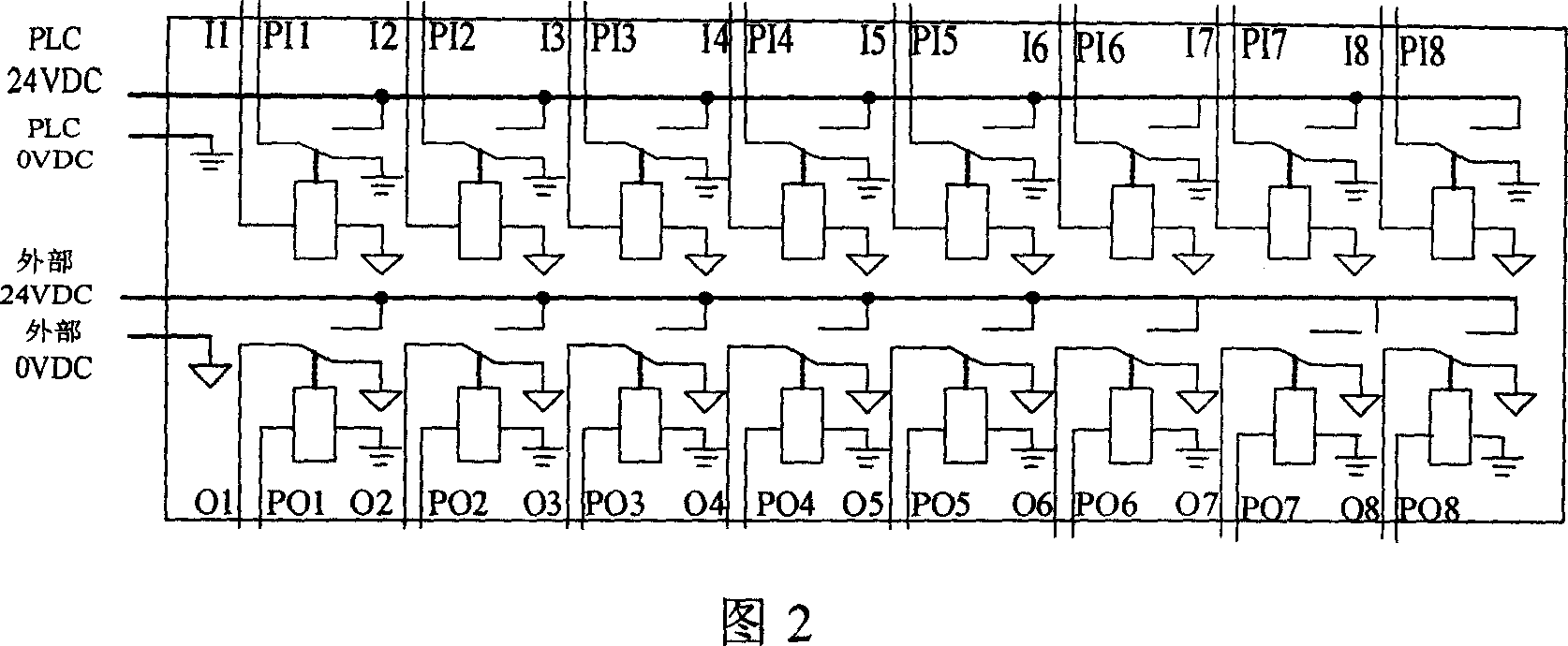

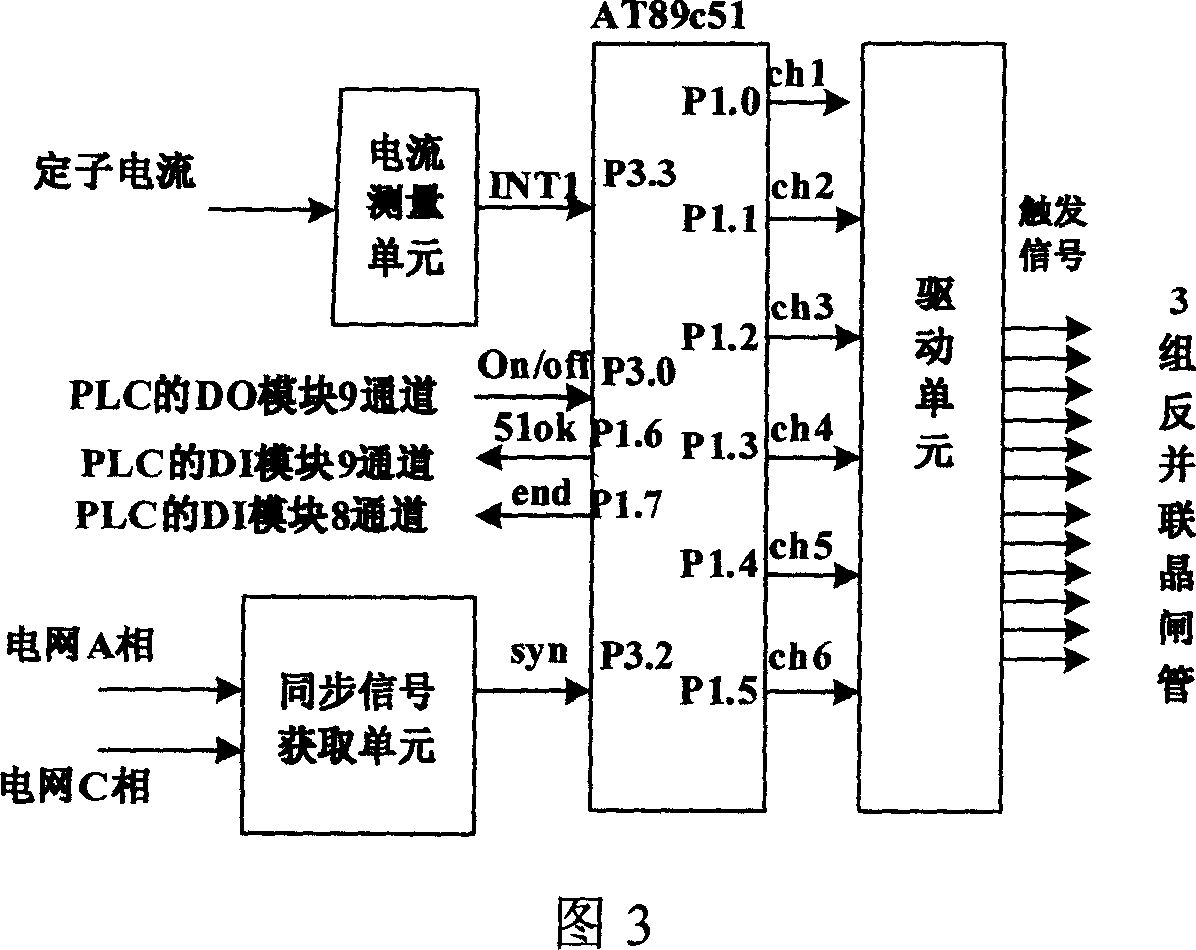

Control system of wind turbines

InactiveCN1992464AEnsure speedEnsure effectivenessWind motor controlComputer controlControl theoryDigital input

A wind-electric set control system includes the center controller PLC, the intermediate relay panel, the soft merge network control panel, the display operation panel and the connector. The center controller PLC mainly includes CPU module 315-2DP, digital input module DI, digital output module D0, high-speed counter module FM350-2, analog input module AI, communication module CP340; the intermediate relay panel comprises a number of DC coil relays. The intermediate relay panel and the soft merge network control plane respectively connect with the input and output modules of the center controller PLC, and connect with the controlled object through connector. The system uses the intermediate relay panel to isolate the input / output signal, which improves the resist interference ability of the system. The soft merge network control uses current-limit soft-cut-in control strategy, to make the merge network processing more stable. This invention limits the merge network number of the small motor in one hour, which cleverly solves the small stop problem of the wind-electric set, and it uses PROFIBUS field bus technology to communicate with the central monitor computer.

Owner:北京科诺伟业科技股份有限公司 +1

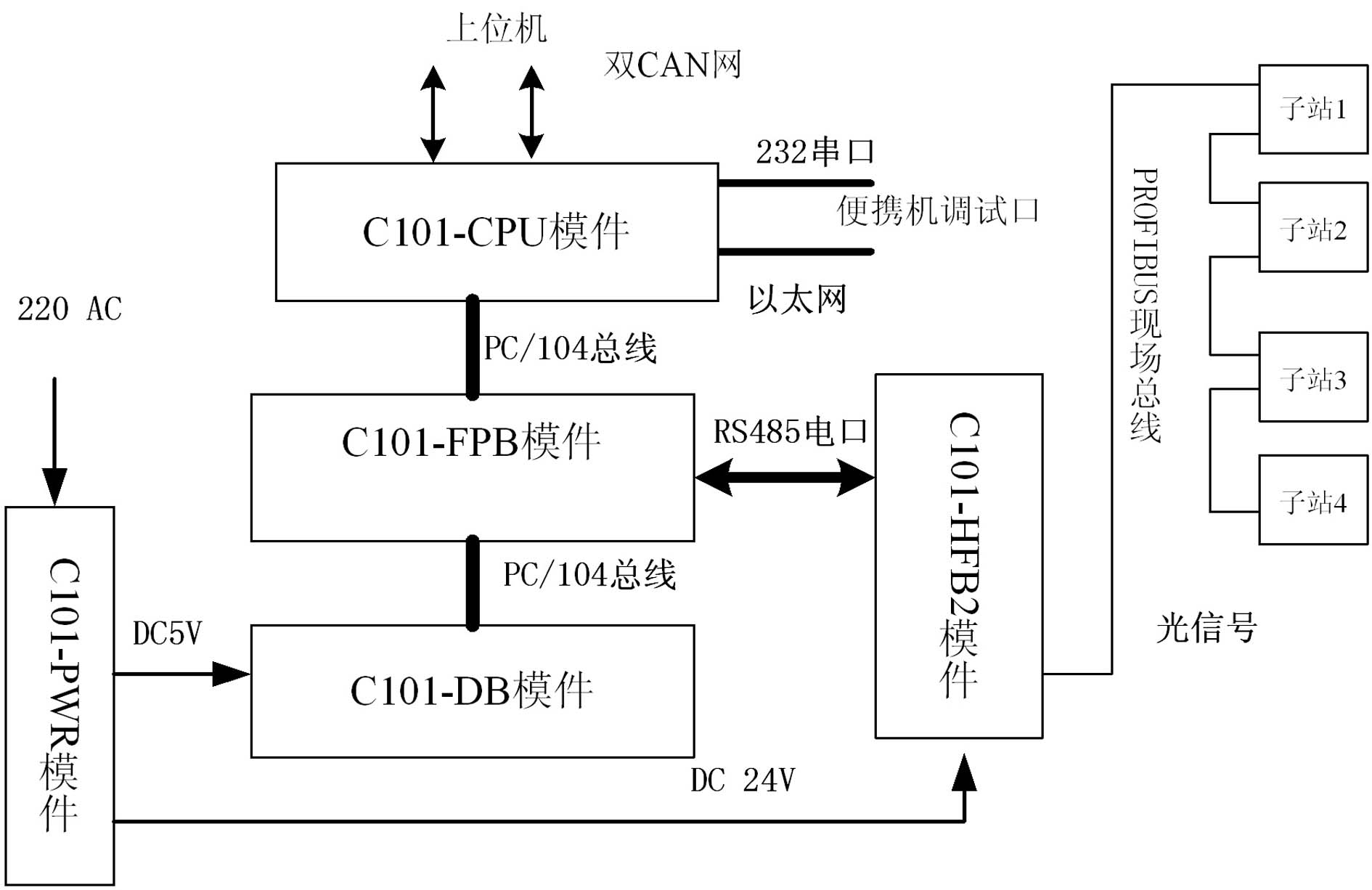

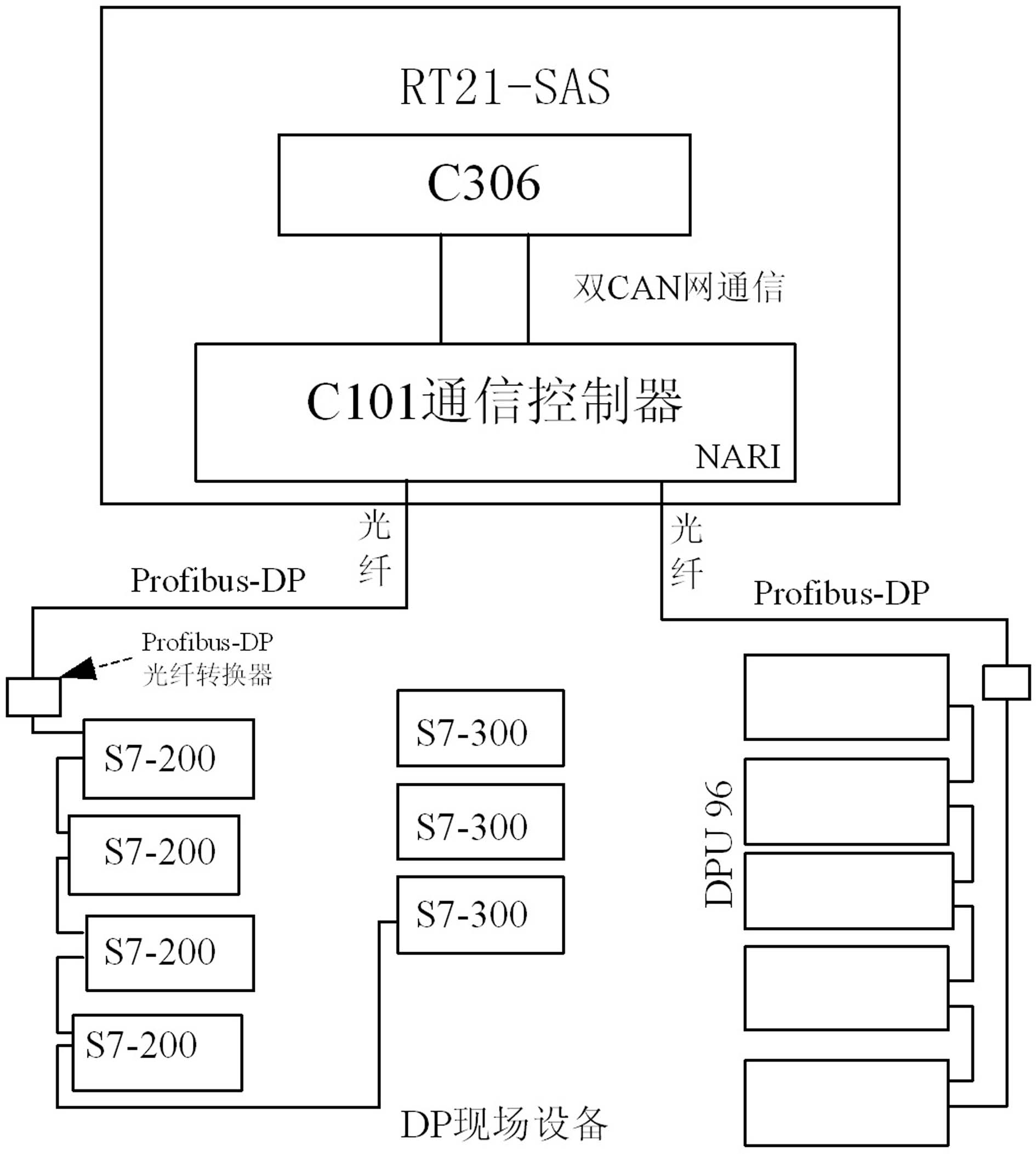

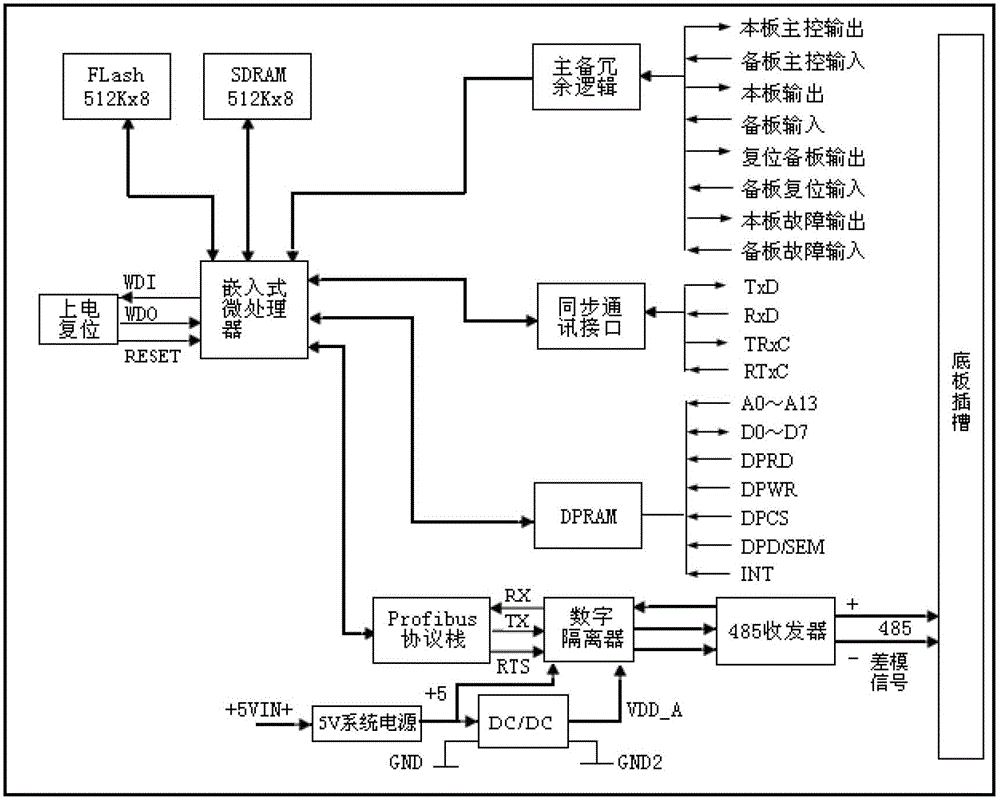

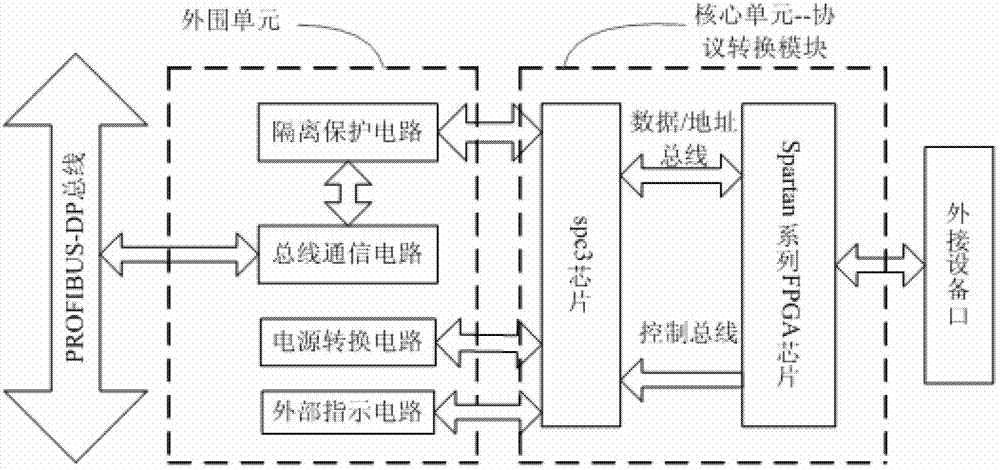

Protocol conversion device based on PROFIBUS-DP master station field bus

ActiveCN101964737AReduce development costsWith online download functionBus networksMaster stationProfibus

The invention discloses a protocol conversion device based on a PROFIBUS-DP master station field bus, which is characterized by comprising a C101-PFB module, a C101-CPU (Central Processing Unit) module and a C101-DB module. The C101-PFB module, the C101-CPU module and the C101-DB module exchange data through a 256k-byte high-speed shared memory; and the C101-PFB module is in networking interconnection with each PROFIBUS-DP substation through an RS485 serial electric port (or communicating with an HFB2 module to be converted to an optical port). The invention can reduce the development cost of the PROFIBUS-DP master station.

Owner:NARI TECH CO LTD +1

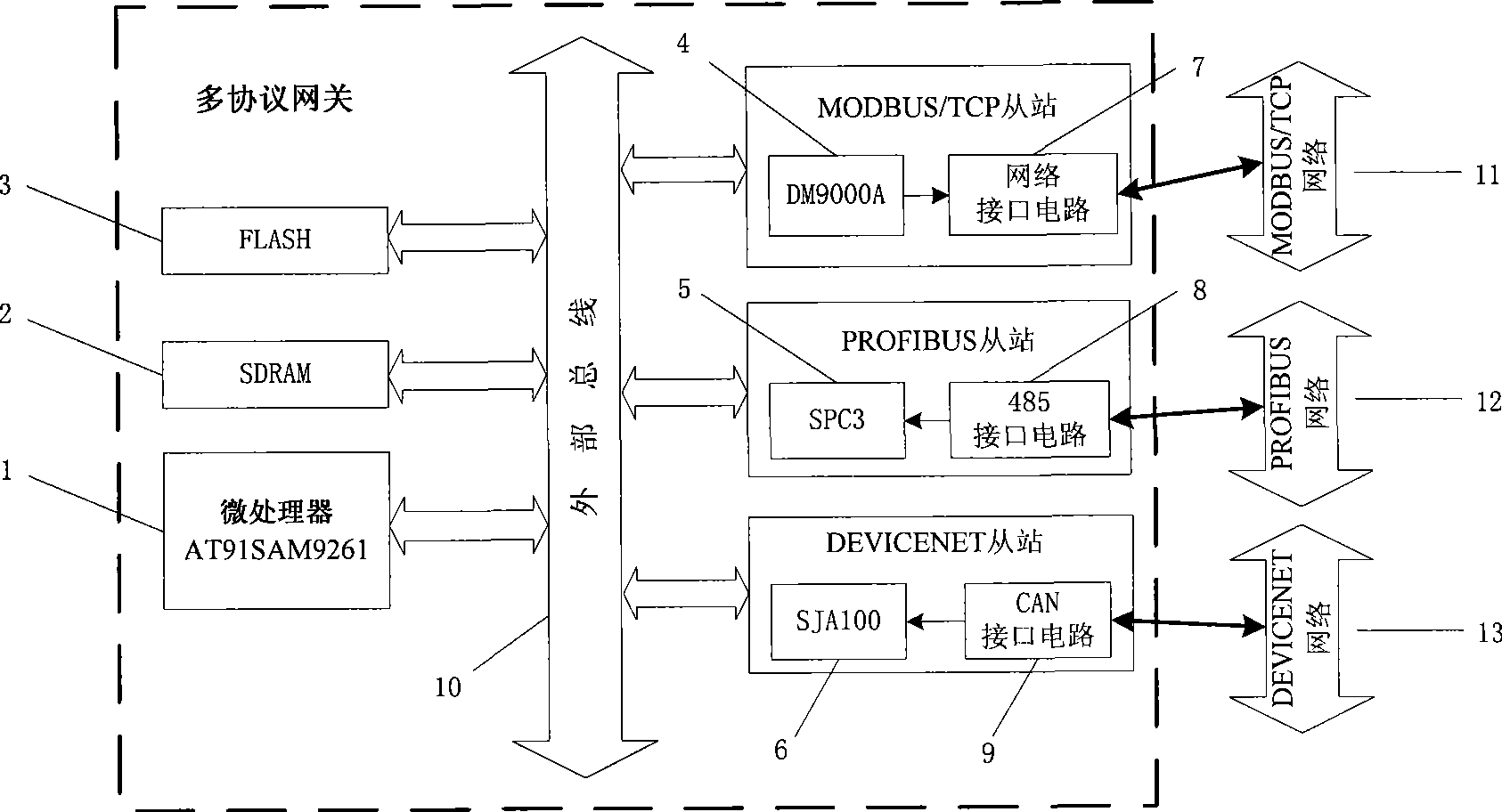

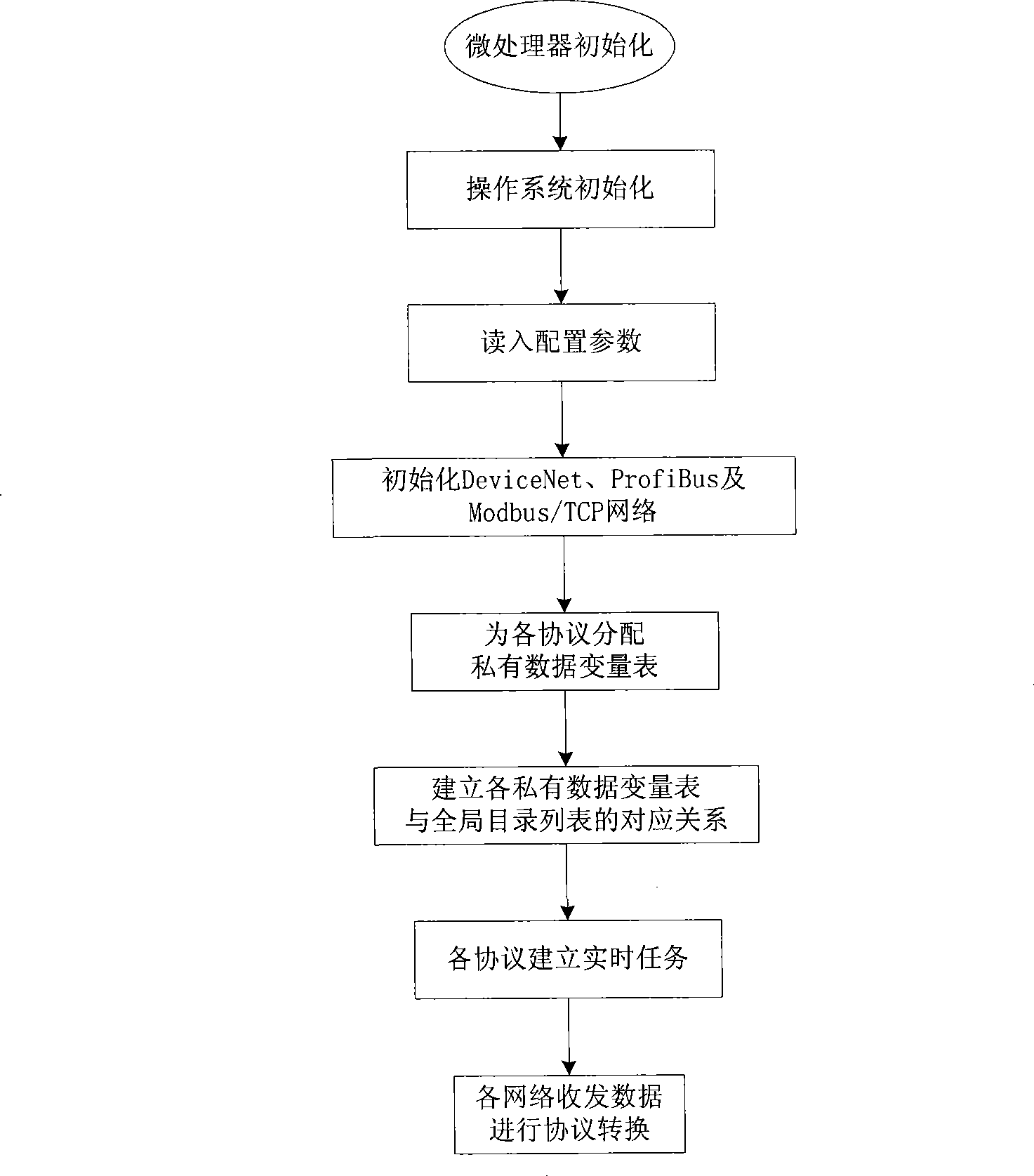

Conversion method between multiple protocol bus

ActiveCN101388889AImprove conversion efficiencyGuaranteed seamless connectionBus networksModbusOperational system

The invention relates to a converting method between multiple protocol buses. The method uses a microprocessor, a DeviceNet, a Profibus and the physical layer part circuit and microprocessor program of a Modbus / TCP network protocol to receive different protocol data, store them in the microprocessor, adopts system protocol converting method to realize the protocol converting between multiple protocols. While the task scheduling method using real time multi-task operation system is adopted in the whole protocol converting process, consequently, the real time interaction and updating control of multiple protocol converting data is realized.

Owner:SHANGHAI UNIV

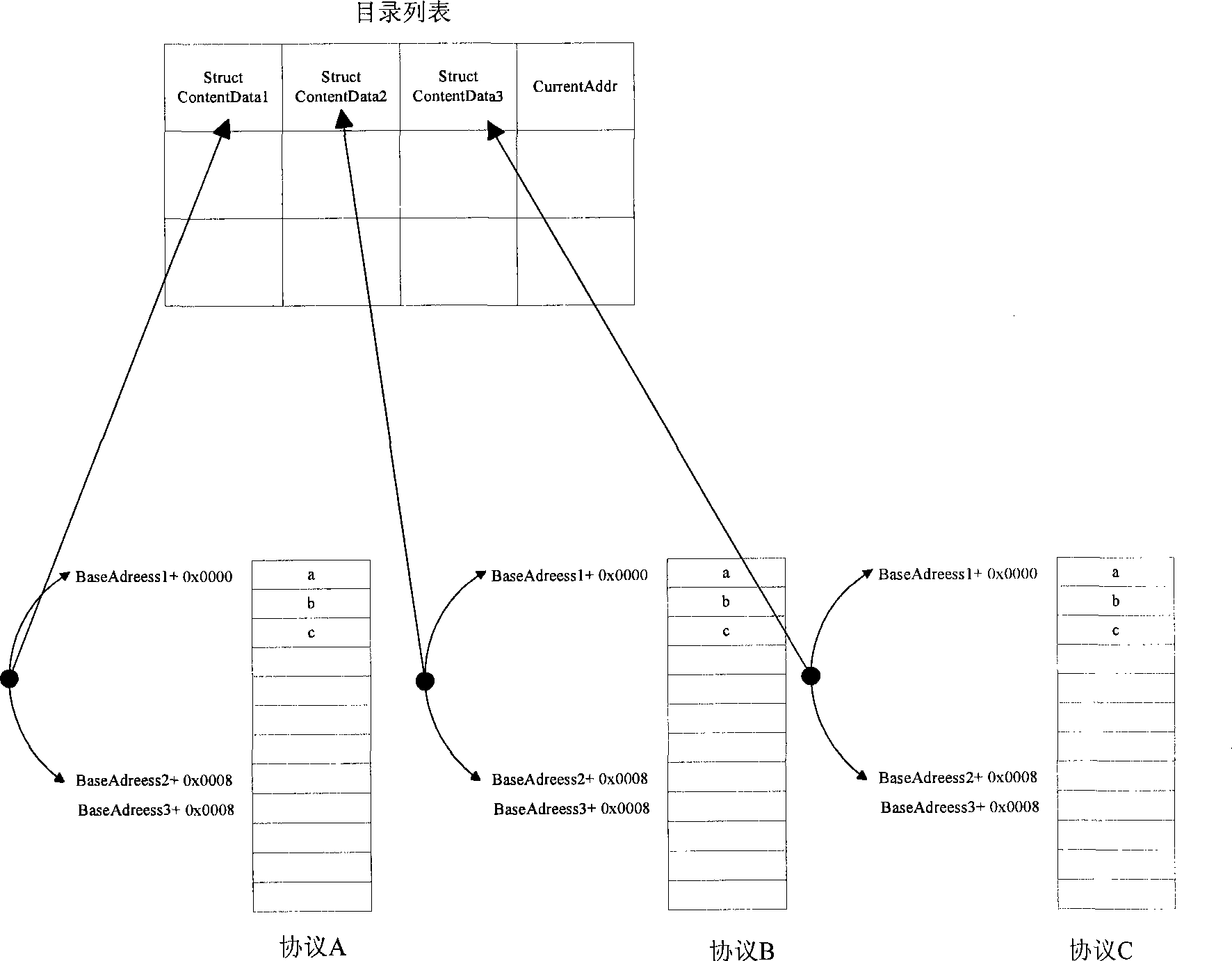

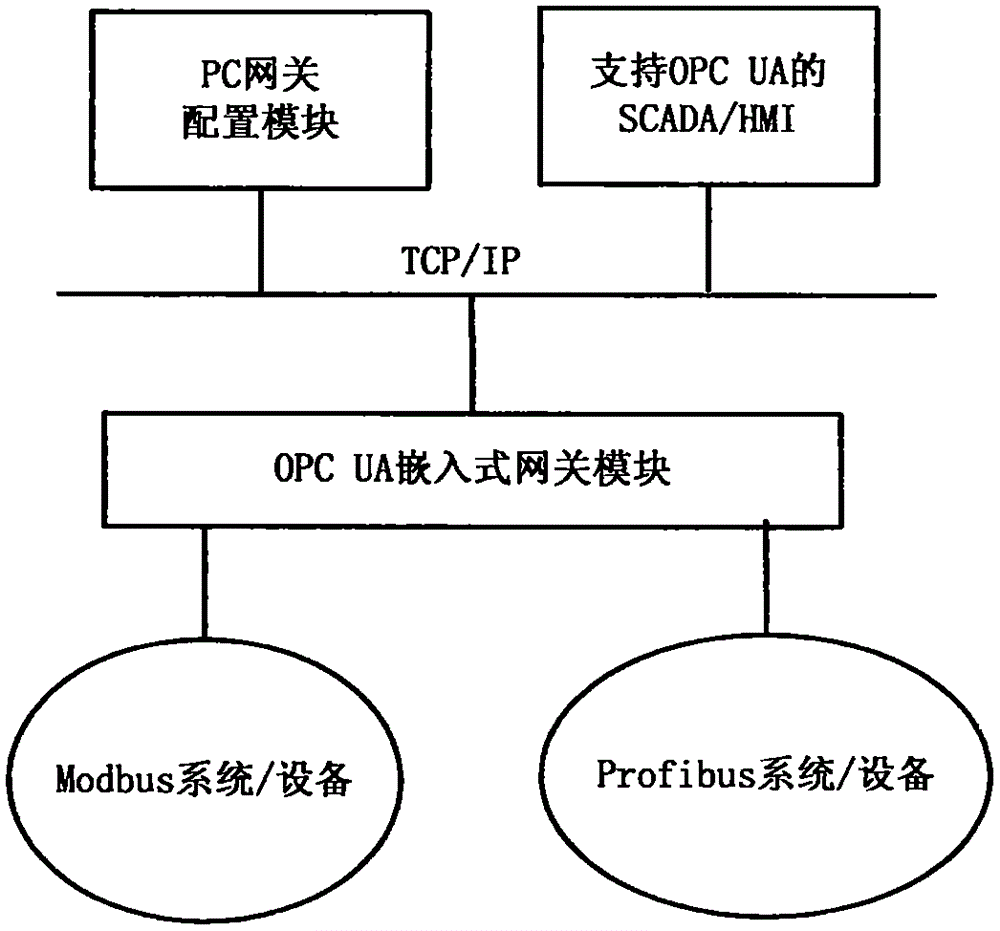

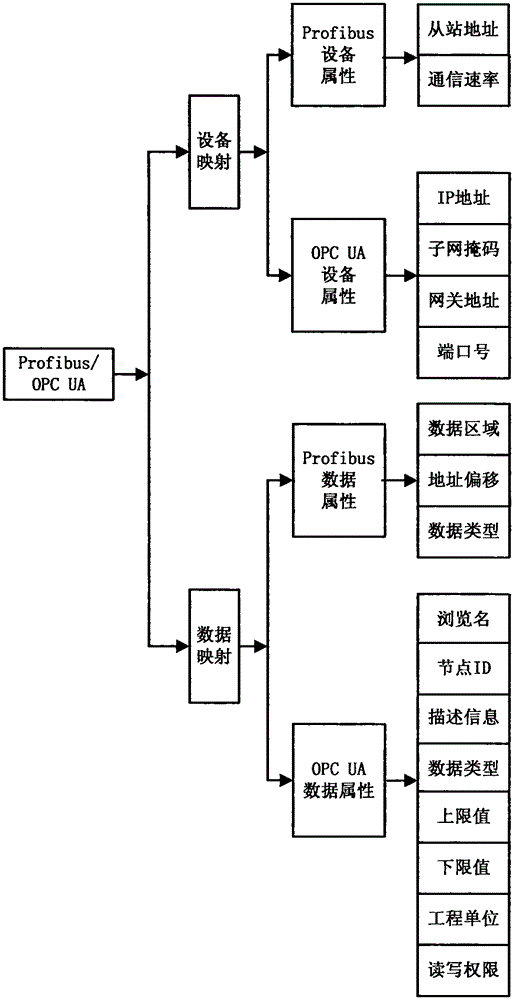

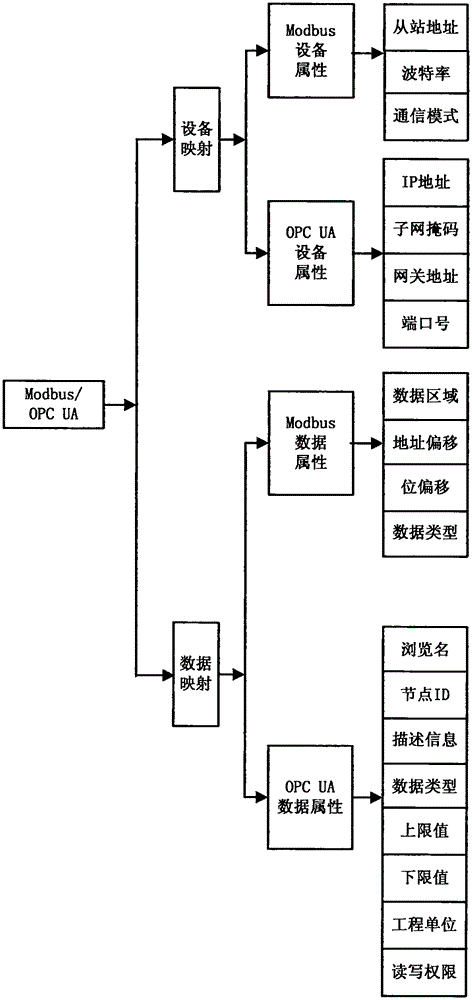

Method for automatically mapping multiple industrial protocols to OPC UA address space

ActiveCN105530240AVersatilityImprove scalabilityTransmissionProgramme total factory controlModbusField data

The invention discloses a method for automatically mapping multiple industrial protocols to an OPC UA address space. Functionally, the method comprises a mapping relation generator, a mapping relation file downloader, a mapping relation file receiver, a mapping relation interpreter and a mapping relation executer; the mapping relation generator mainly realizes the function of automatically mapping Profibus (Process Field Bus) and Modbus industrial protocols to the OPC UA address space and outputs mapping relation files; the mapping relation file downloader realizes the function of downloading the mapping relation files to an embedded OPC UA gateway; the mapping relation file receiver matches with the mapping relation file downloader and realizes the function of receiving the mapping relation files; the mapping relation interpreter interprets the automatic mapping relation used by the generator so as to construct memory mapping relation; the mapping relation executer realizes functions of converting, reading, writing and subscribing the data between the Profibus and Modbus devices and the OPC UA uniform interface. According to the invention, the functions can be realized on any platform; the bottom layer site data and the upper layer monitoring and management system in the industrial automatic field are integrated.

Owner:INSTR TECH & ECONOMY INST P R CHINA

Configuring And Providing Enhanced Access To Profibus Device Diagnostic Data

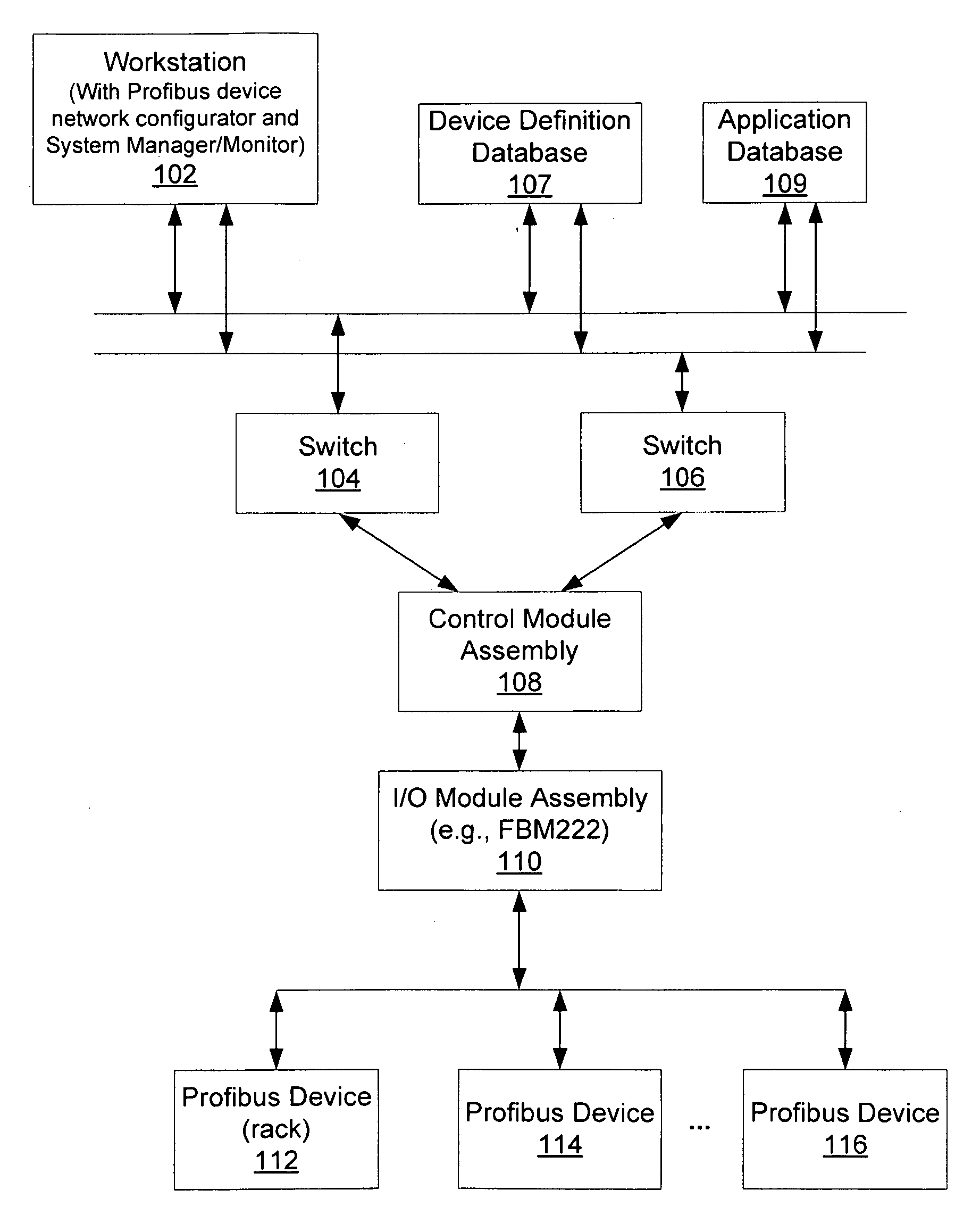

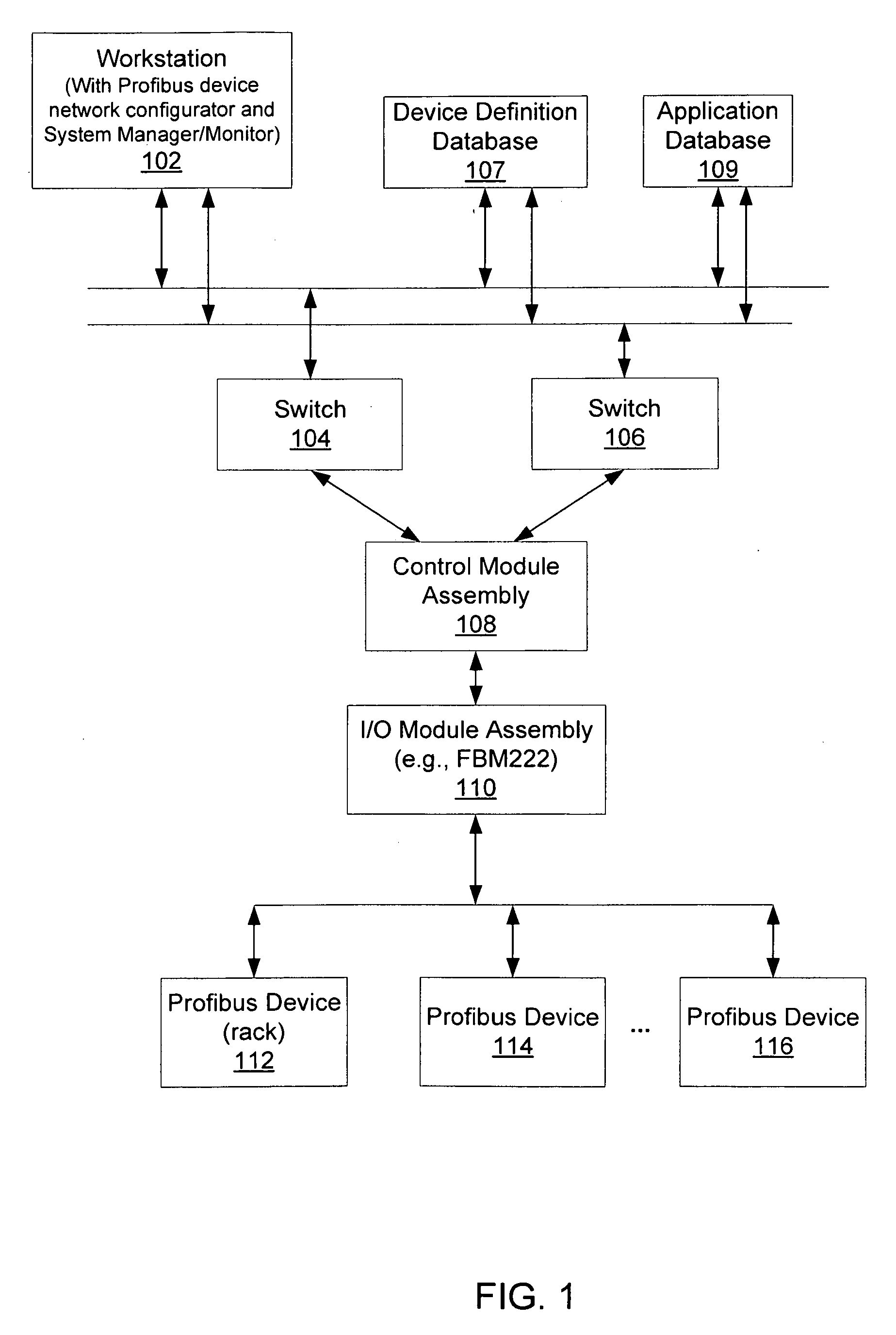

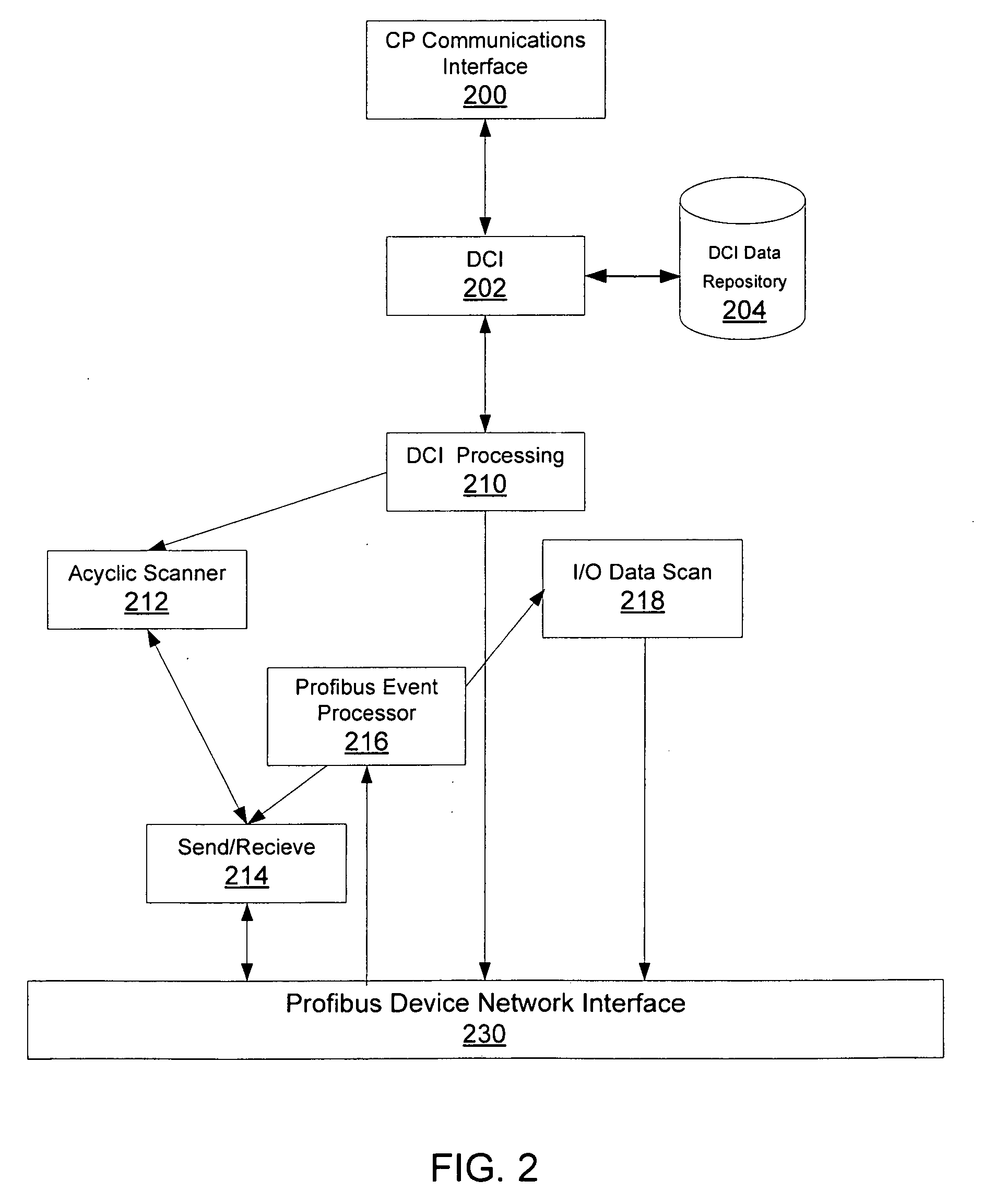

InactiveUS20100064297A1Highly configurableHighly configurable executableProgramme controlDatabase updatingDiagnostic dataDistributed control system

A method and system are disclosed for providing enhanced user access to Profibus device diagnostic data and cyclic data in a distributed control system. After receiving input parameter data originating from a Profibus device message, the I / O module assembly performs steps for processing, maintaining and providing the input parameter data to a requesting control processor. The processing step includes extracting parameter values from a received Profibus device message. The extracted parameter values are then deposited in a repository on the I / O module assembly. The parameter values include both input and diagnostic parameter values. The diagnostic parameter values are provided to a workstation executing a Profibus device commissioning / configuring application in the form of data bits. The application generates a set of diagnostic text messages, based upon current values of diagnostic data bits representing diagnostic statuses of the Profibus device, by applying a configurable set of diagnostic message definitions to the diagnostic parameter data bits.

Owner:INVENSYS SYST INC

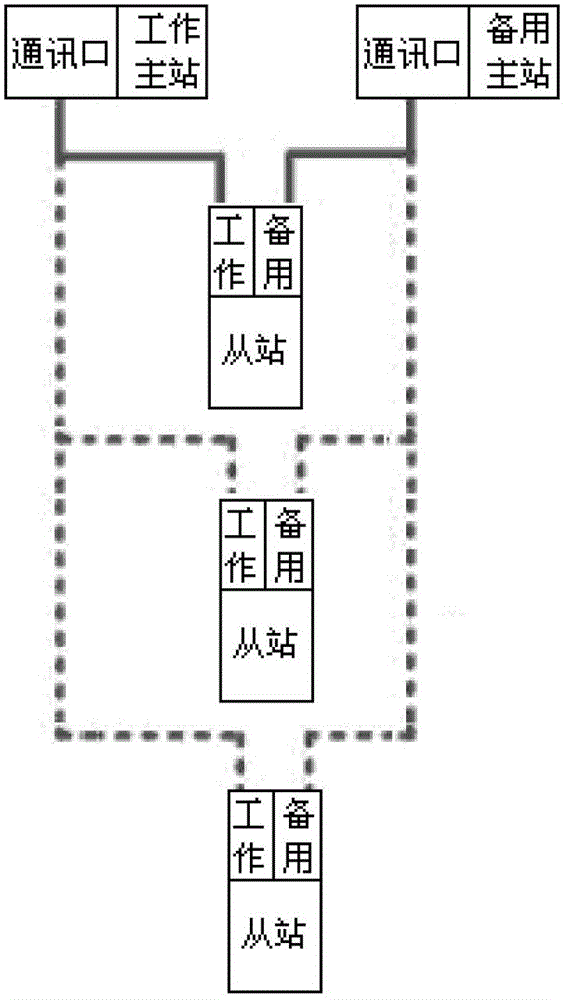

Profibus-DP communication protocol redundancy master station

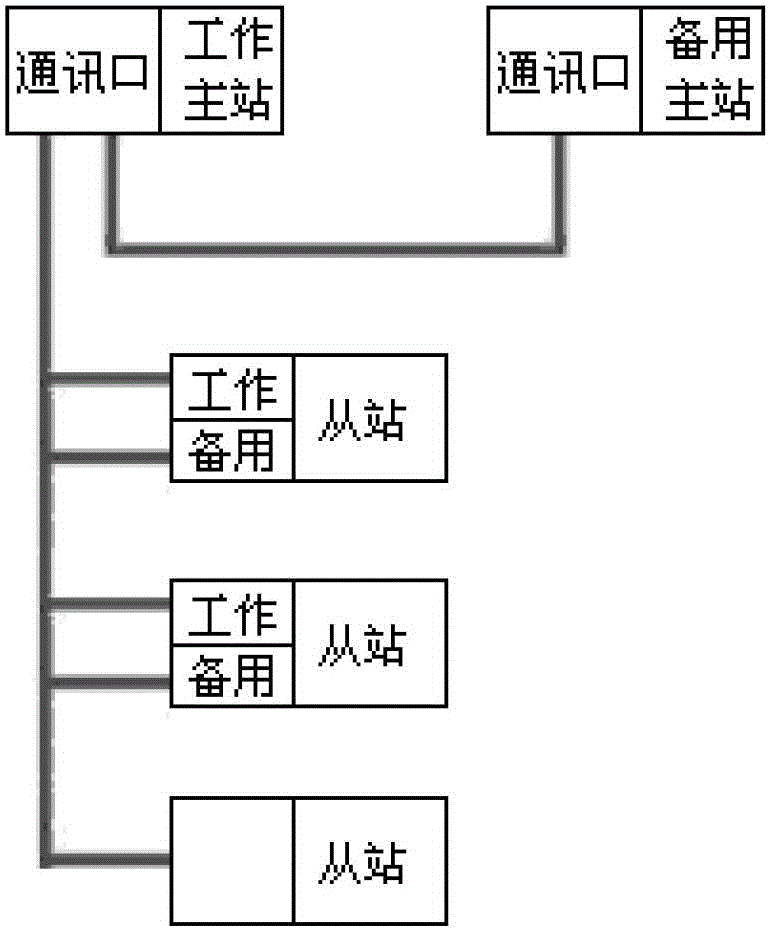

InactiveCN102724092AAchieve interference-free switchingFor trouble-free data communicationBus networksMaster CardNetwork Communication Protocols

The invention discloses a profibus-DP communication protocol redundancy master station which comprises a master station communication card and a master station backup card; the master station communication card is in a working state, exchanges data with a slave station through a display port (DP) interface circuit, and exchanges data with a central processing card piece through a dual port RAM (DPRAM) interface circuit; the master card communication card periodically backs up the parameter set of the master station communication card and the real-time input / output (I / O) data of the slave station to the master station backup card; and the master station backup card is in a heat backup waiting state, takes over the work of the master station communication card when the master station communication card fails to work, and periodically receives the parameter set of the master station communication card sent by the master station communication card and the real-time I / O data of the slave station. According to the Profibus-DP communication protocol redundancy master station, a working master station is not required to work together with a backup master station, can be connected with a DP slave station or directly connected with the redundancy master station products of the DP slave station; and the defects caused by the redundancy method of an existing master station that the selection of master station products is greatly restricted and the cost is increased after the single-DP slave station is connected in are overcome.

Owner:XIAN THERMAL POWER RES INST CO LTD

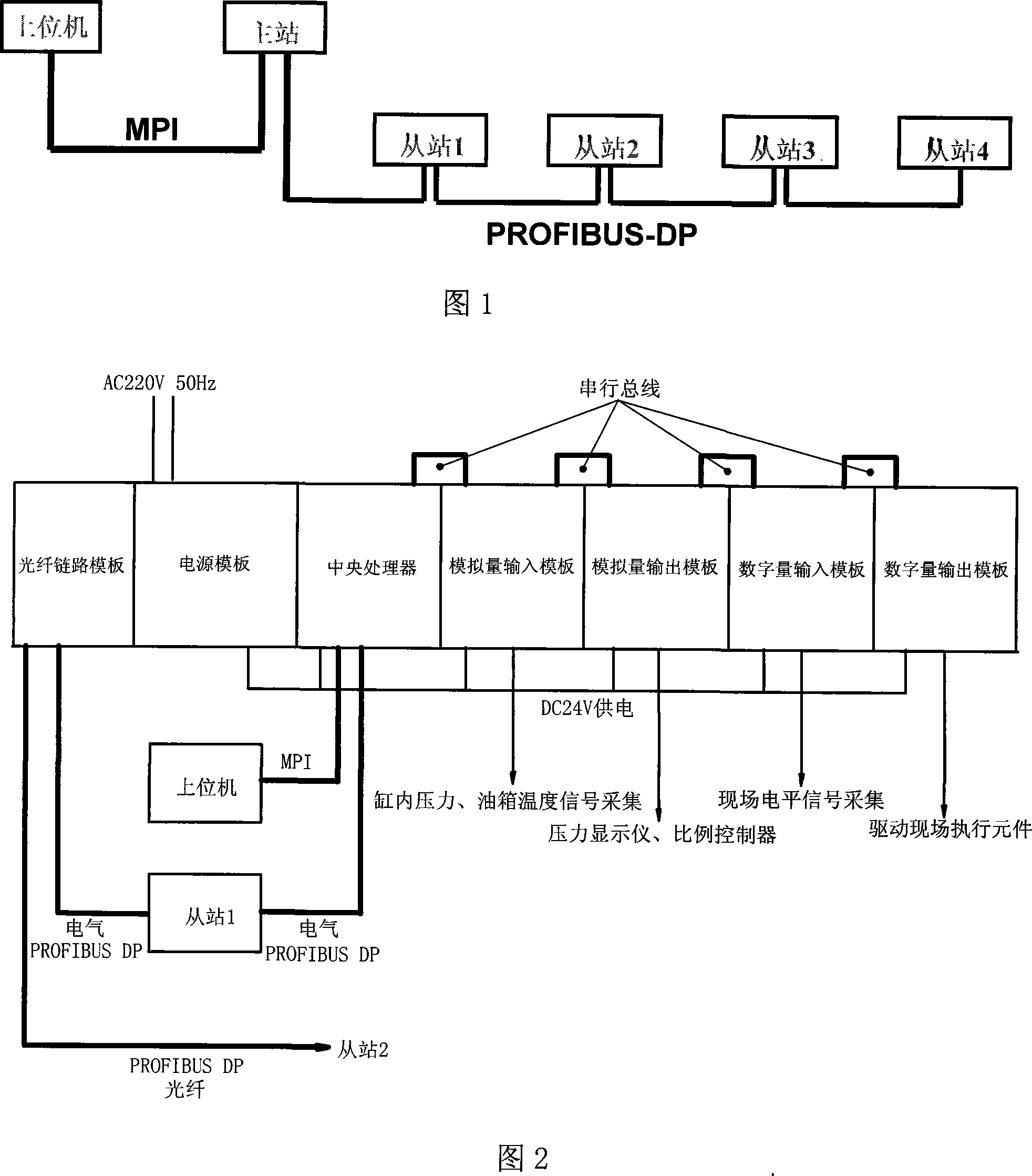

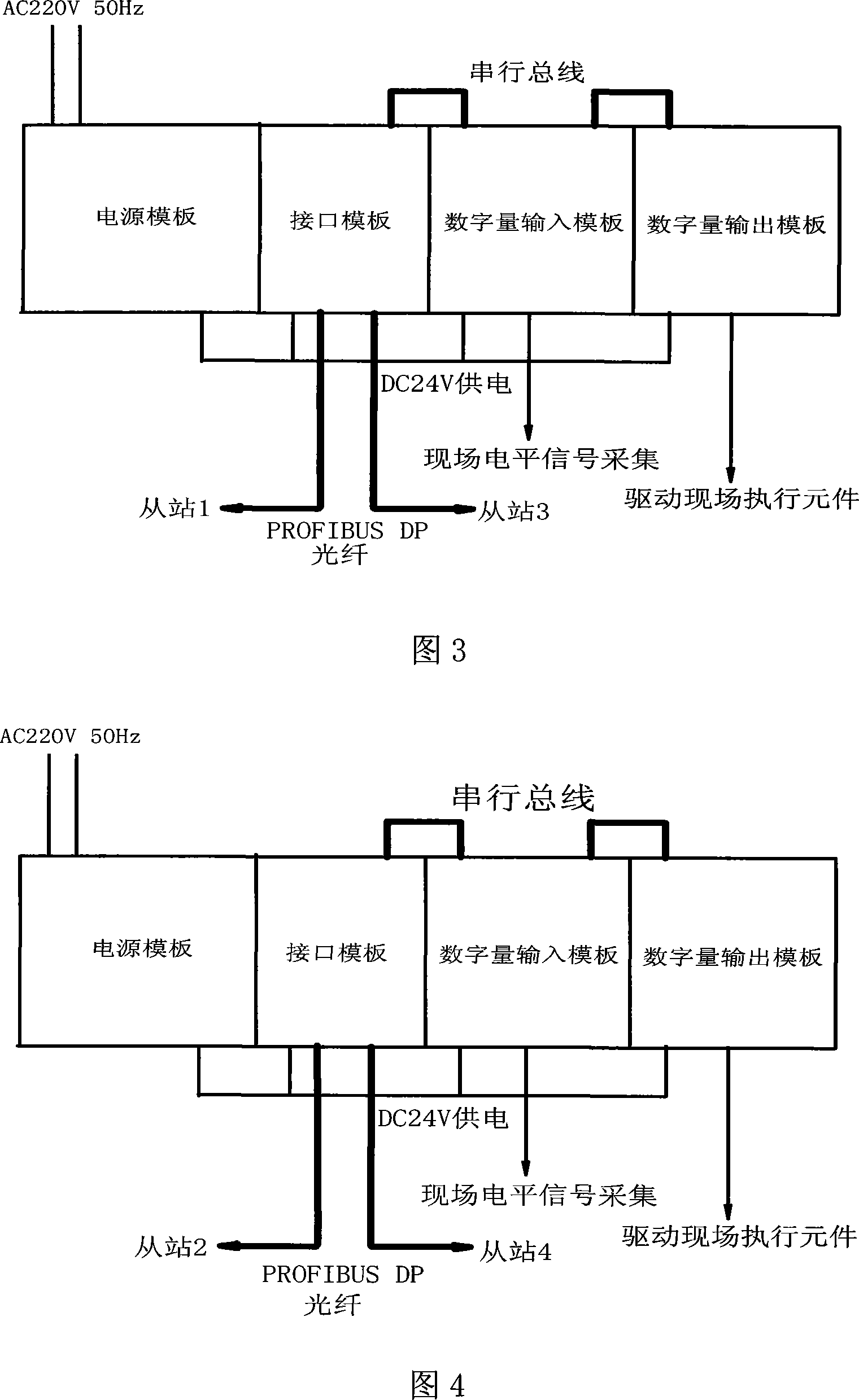

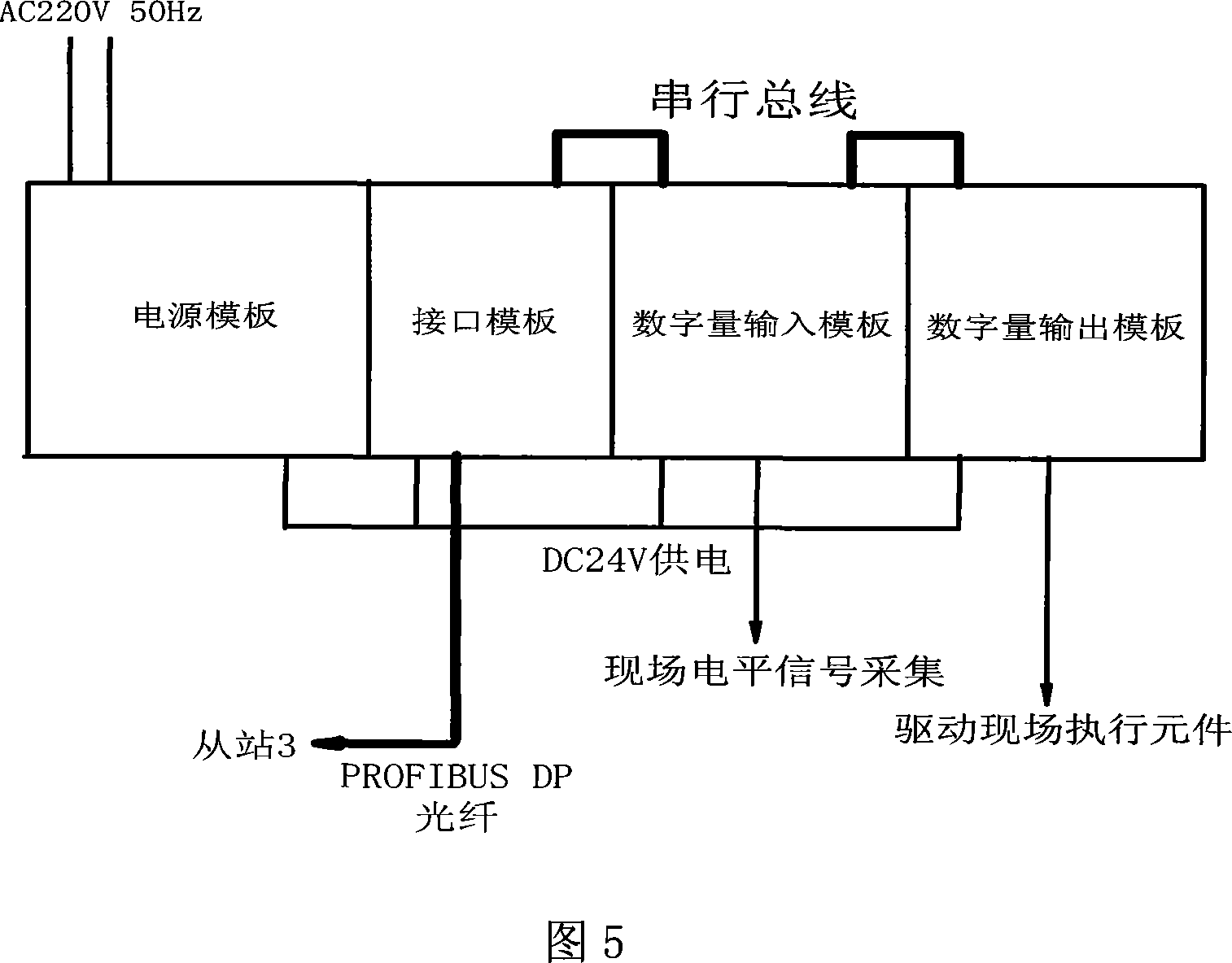

Electrical control workstation of macrotype isostatic pressing machine

InactiveCN101221438AReduce round tripsSimple designComputer controlSimulator controlData accessElectric control

The invention discloses an electric control work station of a large-scale isostatic press, comprising an upper computer provided with a programming software part and a monitoring software part, a master station with an on-the-spot and process communication PROFIBUS-DP interface and at least one slave station connected with a multi-branch communication network bus, wherein the master station through which a programmable controller (PLC) passes realizes bus communication control and management and completes periodic data access; a master station can control a plurality of slave stations on the bus; moreover, at least one logic link adopting round robin communication mode in information exchange is set up between the master station and each slave station. By means of the programmable controller, the invention sets up a high-performance industrial on-the-spot local area network through an on-the-spot and process communication field bus, thereby realizing network monitoring of process and reducing a great amount of wiring and cable investment; meanwhile, the communication network field bus with an all digital multi-branch structure improves system accuracy and reliability; moreover, the invention has low cost in installation, operation and maintenance, simpler operation and more visualized monitoring.

Owner:SICHUAN AVIATION IND CHUANXI MACHINE

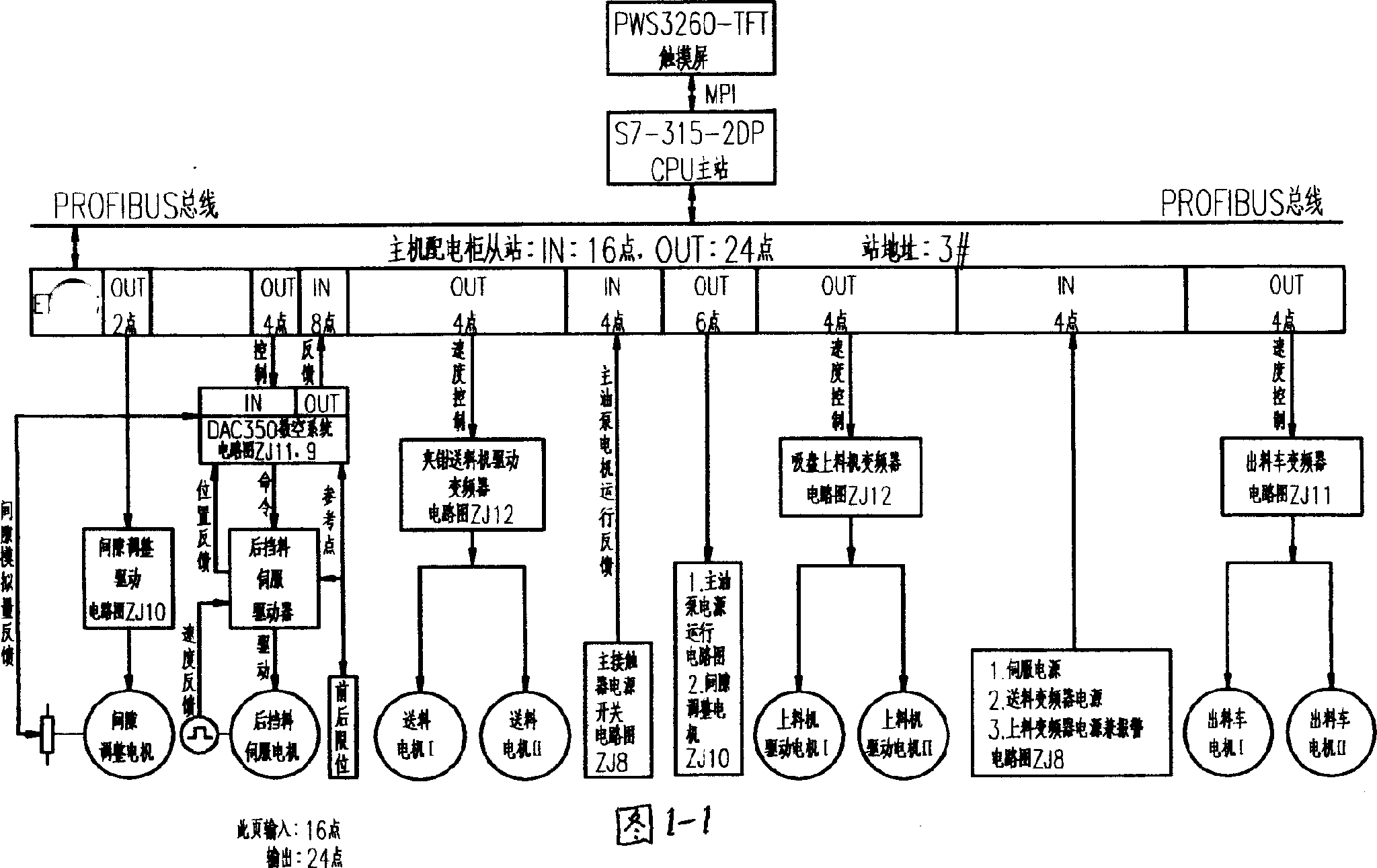

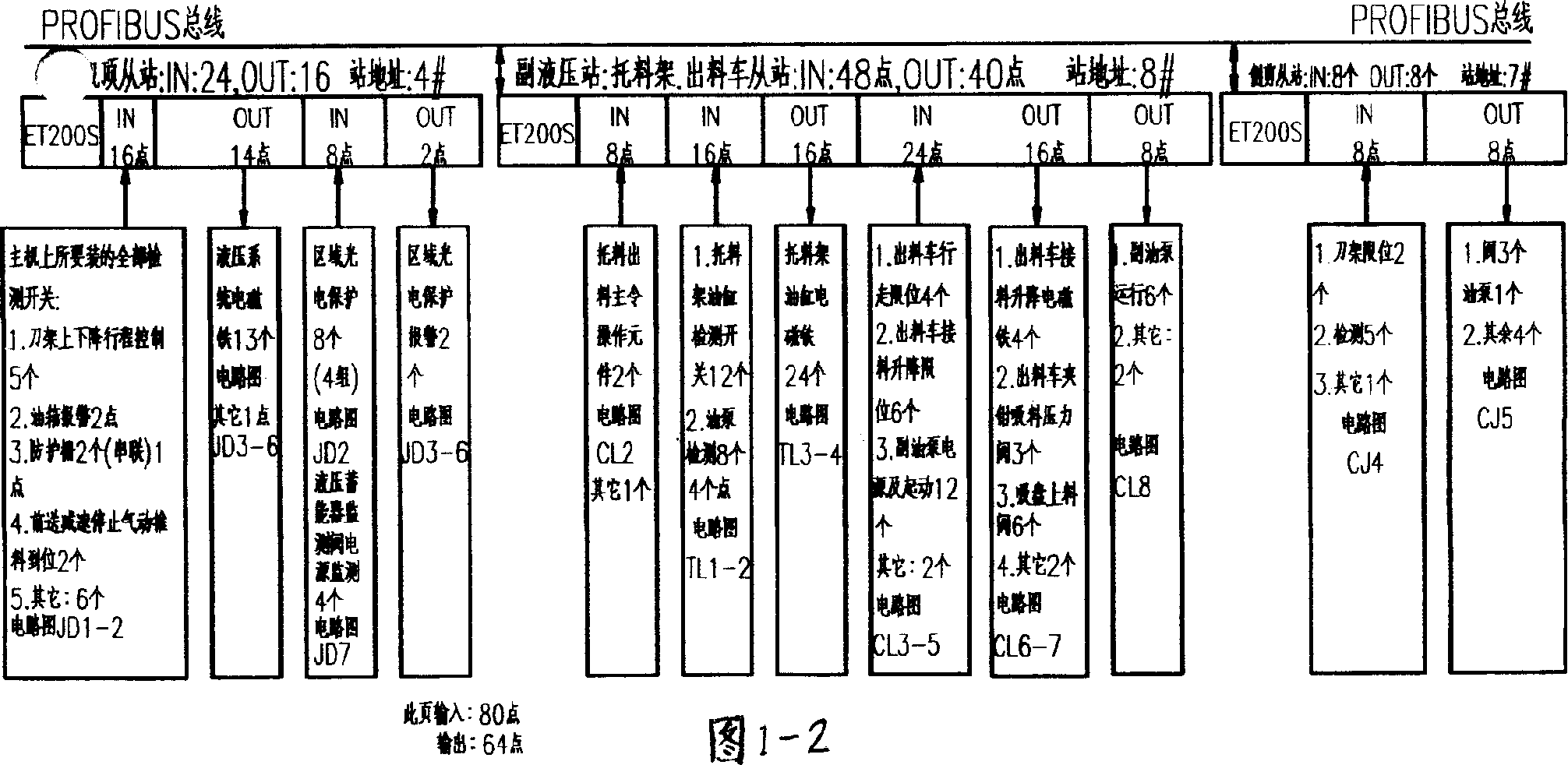

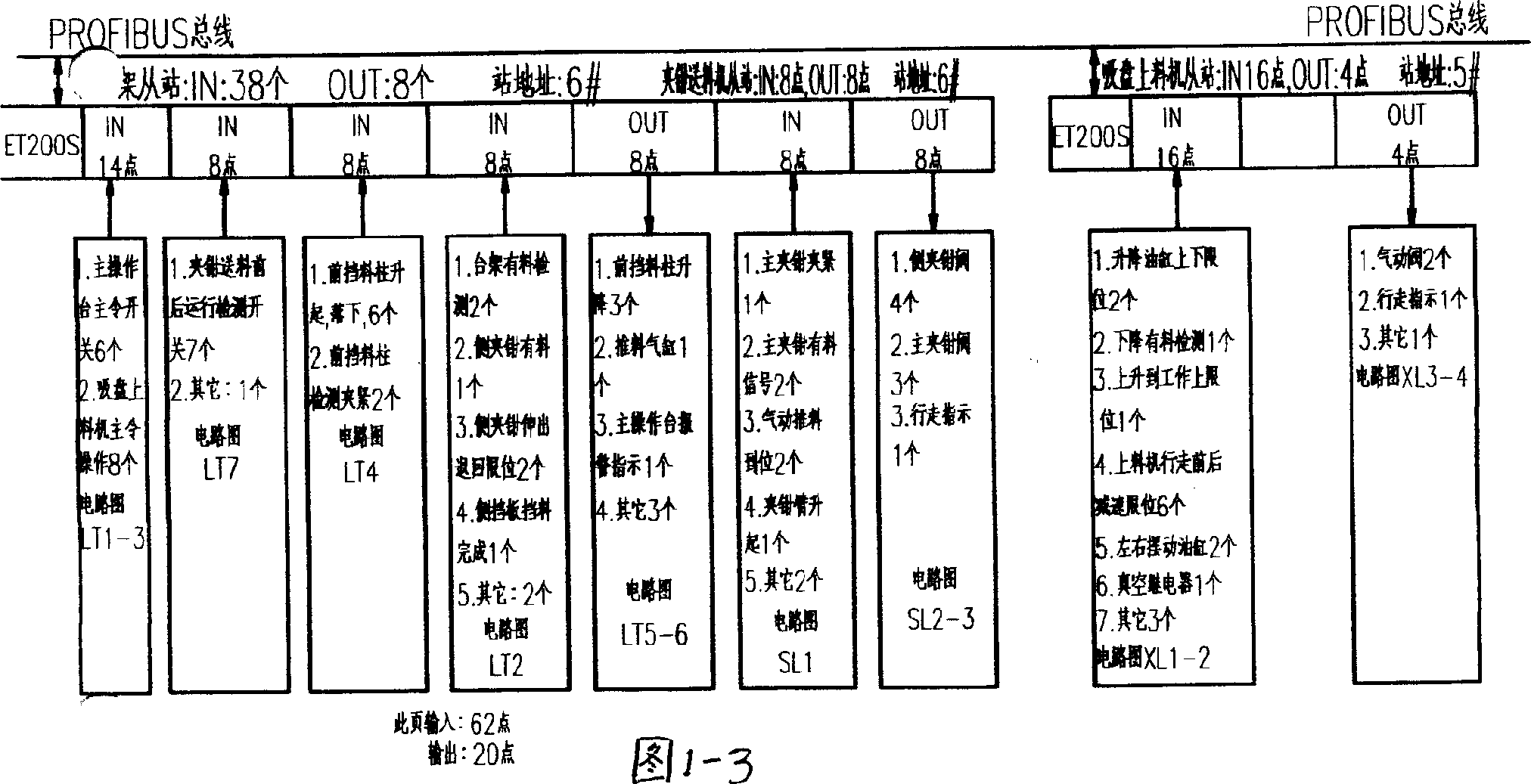

Fully-automatic plate-cutting apparatus

InactiveCN101024254AFully automaticFriendly man-machine interfaceShearing machinesTotal factory controlFrequency changerHuman–machine interface

The invention relates to full automatic sheet material shearing mechanism. It is formed by eights sets of machine tools and measurement control systems. The latter is DAC-350 numerical control system, combines with Siemens PLC and Profibus-DP bussing technique, touch screen human-machine interface, bus transducer hanging connecting control, position transducer hanging connecting control to realize full automatic unmanned operation. It has friend human-machine interface, self-diagnosis function, operation guiding, and real time operation help function.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

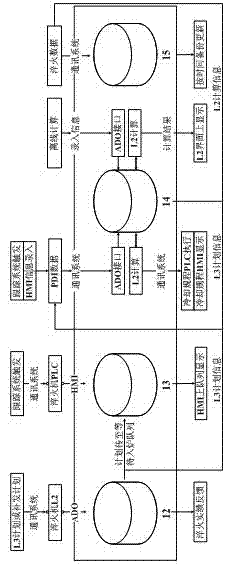

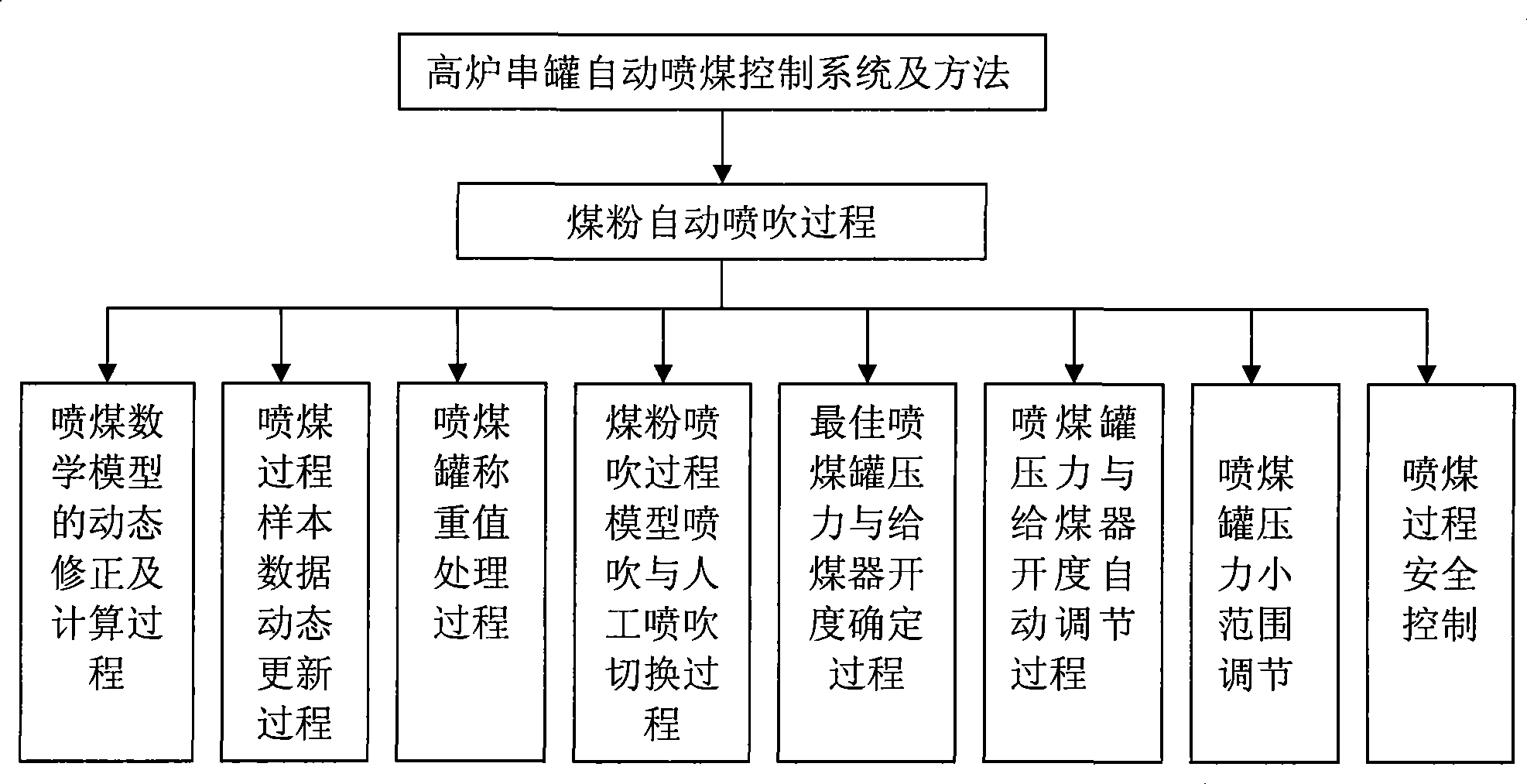

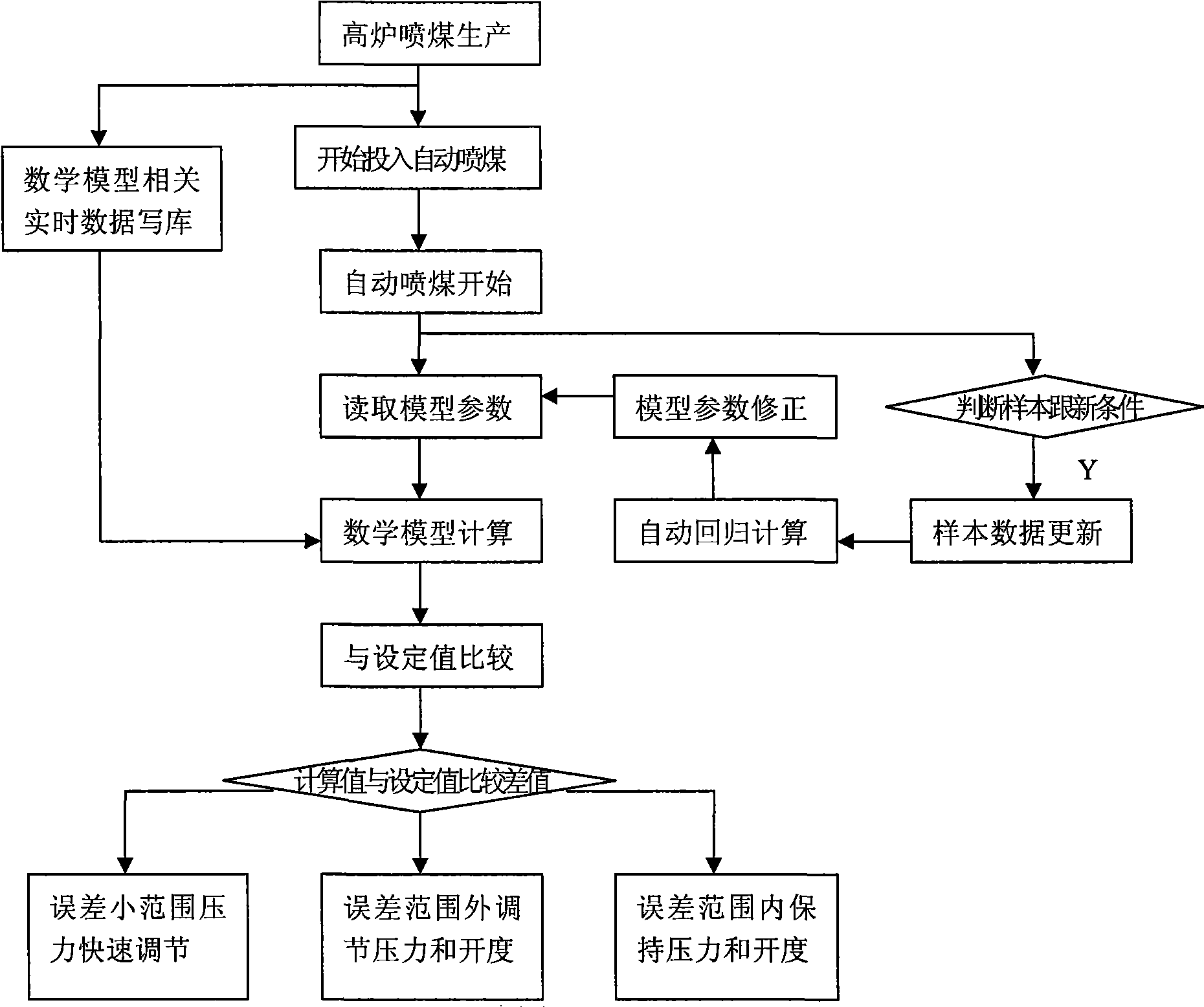

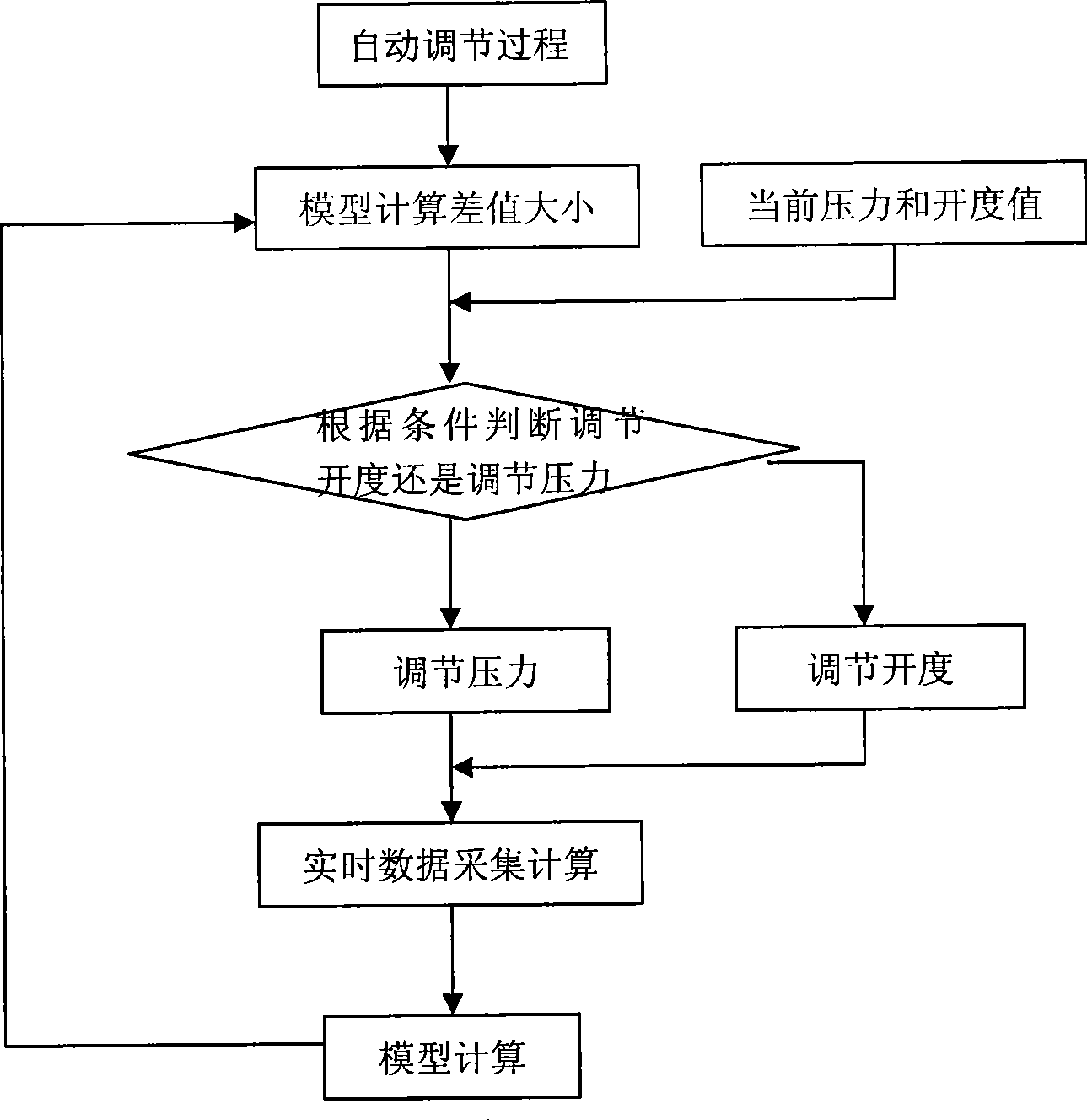

Serial automatic coal injection control system and method for blast furnace

InactiveCN101498554AGuaranteed uniformityGuaranteed accuracyTuyeresBlast furnace detailsMathematical modelData acquisition

The invention relates to a system and a method for controlling the automatic coal injection of a blast furnace serial pot, which belongs to the technical field of the automatic coal injection of a blast furnace serial pot. The system comprises a hardware monitoring system and a software processing module. The system is characterized in that a Siemens PLC control system and an upper monitoring system is connected by a Profibus network to monitor the state of each coal injection process; the real-time data communication of model calculation and automatic regulation with coal injection is realized by an Ethernet; the software processing module mainly comprises a data acquisition module, a sampled data renewing module, a mathematical model coefficient correction module, a mathematical model calculation module, a fuzzy regulation module and a fast-regulation module; and all parts of the software processing module run on an industrial computer. The system and the method overcome the difficulty that a weighting result of a coal injection system of a serial pot is affected by numerous factors, use many mathematical methods to handle a weighting result of a coal injection pot, are combined with a mathematical model and fuzzy control and realize the automatic coal injection control of a blast furnace serial pot.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH +1

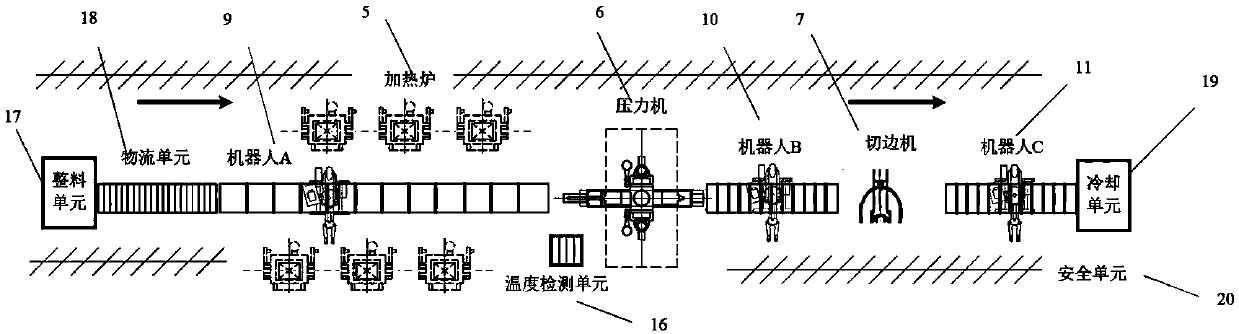

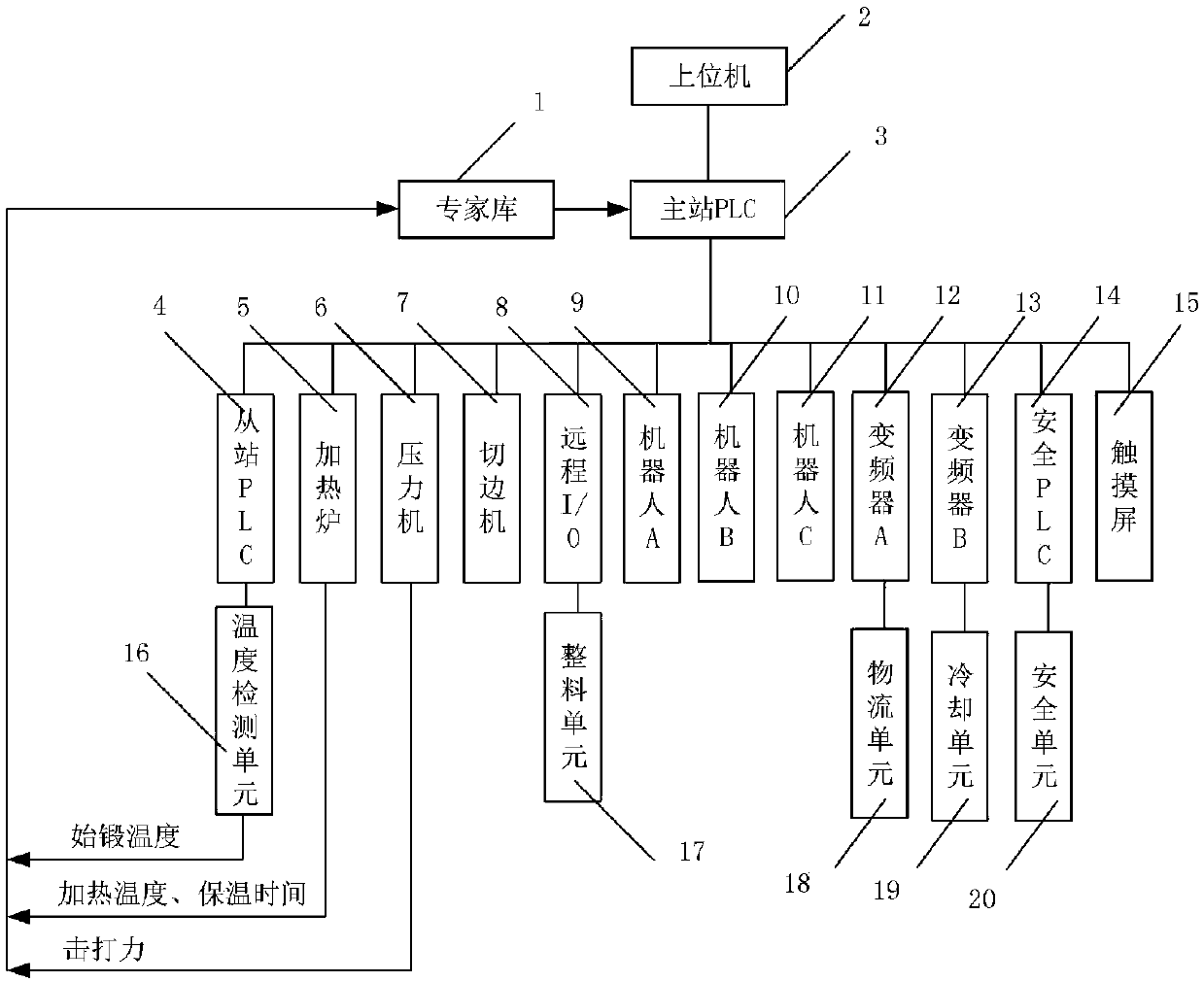

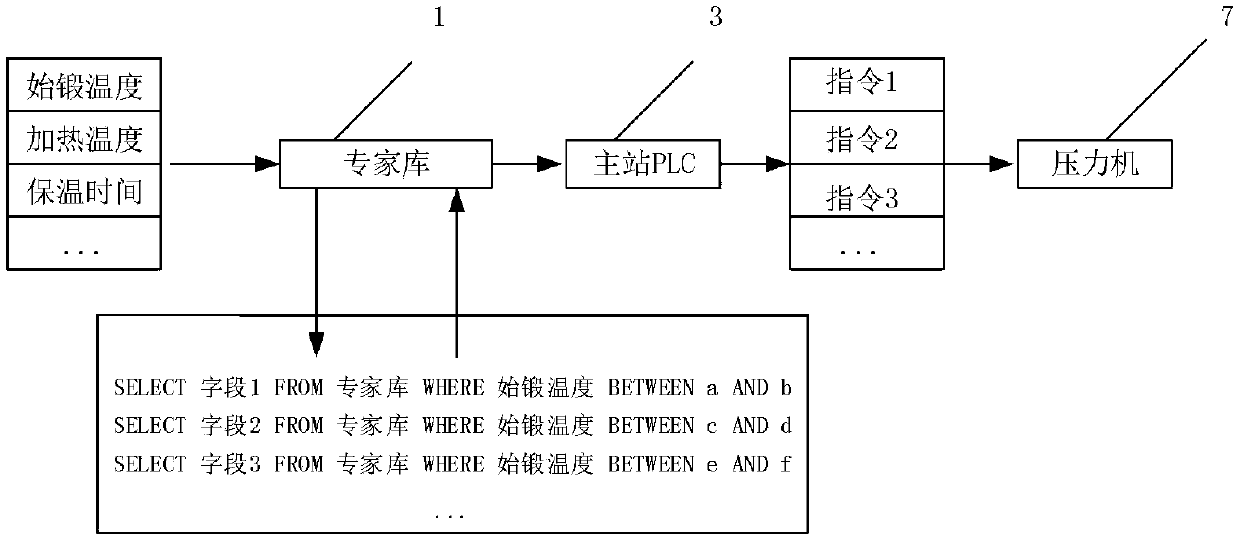

Die forging production line intelligent control system

InactiveCN109521737ADynamic adjustment of hitting forceImprove automationTotal factory controlProgramme total factory controlProduction lineEngineering

The invention discloses a die forging production line intelligent control system, and belongs to the field of automatic production line control. The system comprises a main station PLC, an upper computer, an expert database, a slave station PLC, a remote I / O, a frequency converter, a safety PLC, a touch screen, a heating furnace, a press machine, an edge trimmer, robots, a temperature detection unit, a logistics unit, a cooling unit and a safety unit. The main station PLC is connected with the upper computer through a TCP / IP protocol. The slave station PLC, the safety PLC, the remote I / O, thefrequency converter, the robot A, the robot B, the robot C, the heating furnace, the press machine and the edge trimmer are all connected with the main station PLC through a Profibus-DP. The touch screen is connected with the main station PLC through an MPI interface. The expert database is constructed to optimize and adjust the striking force according to different initial forging temperatures inthe machining process, so that the machining quality consistency is improved.

Owner:BEIJING UNIV OF TECH +1

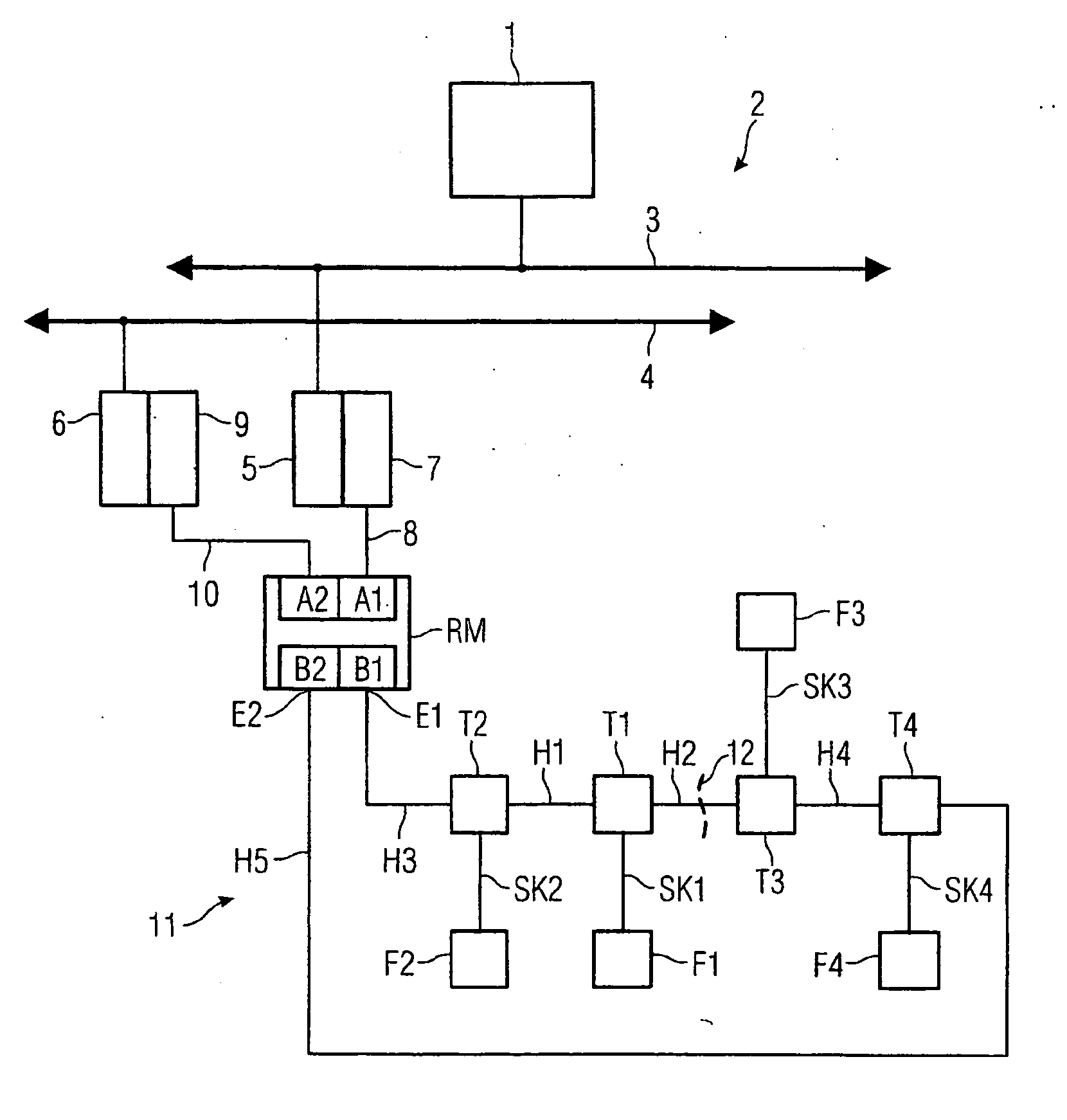

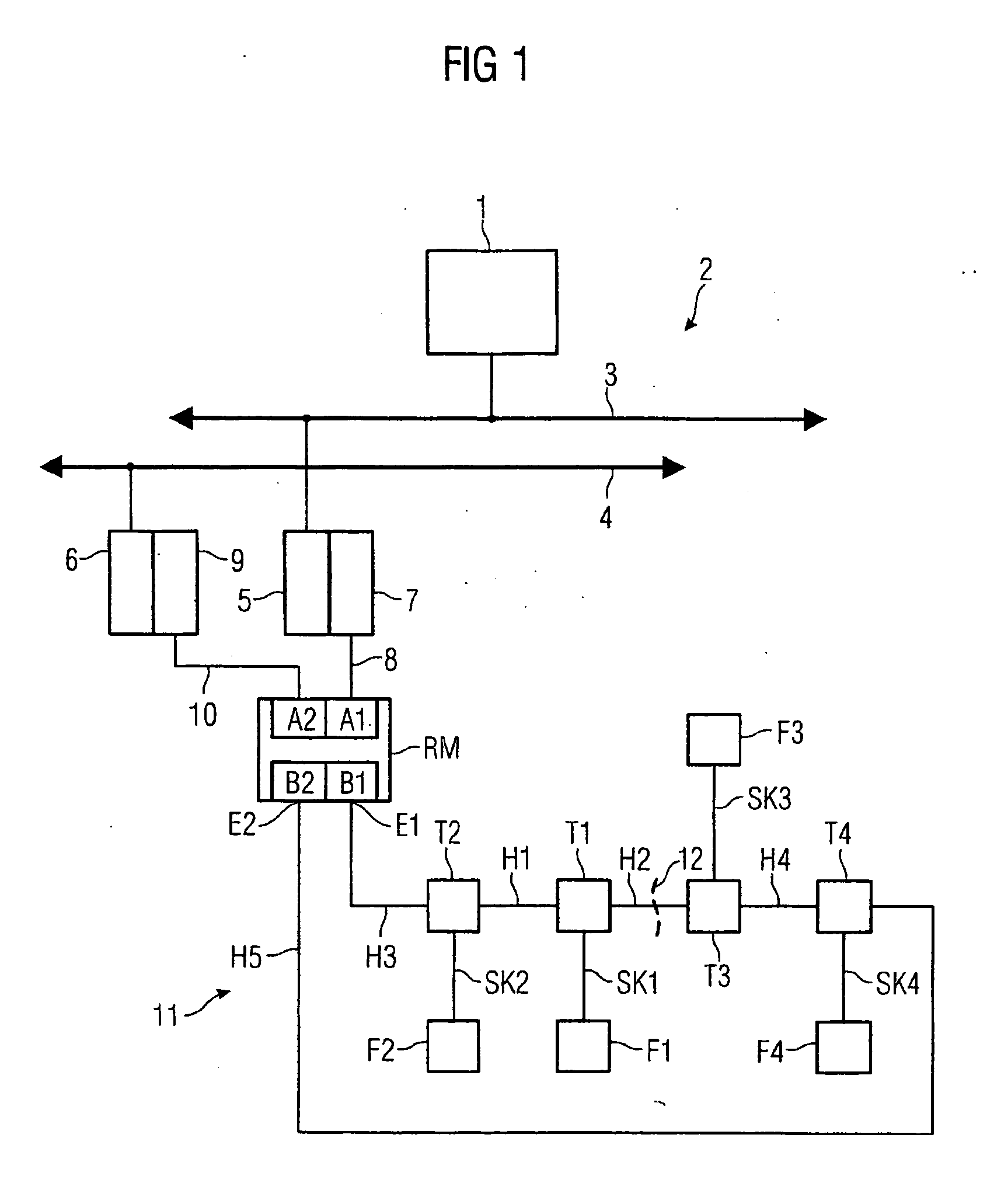

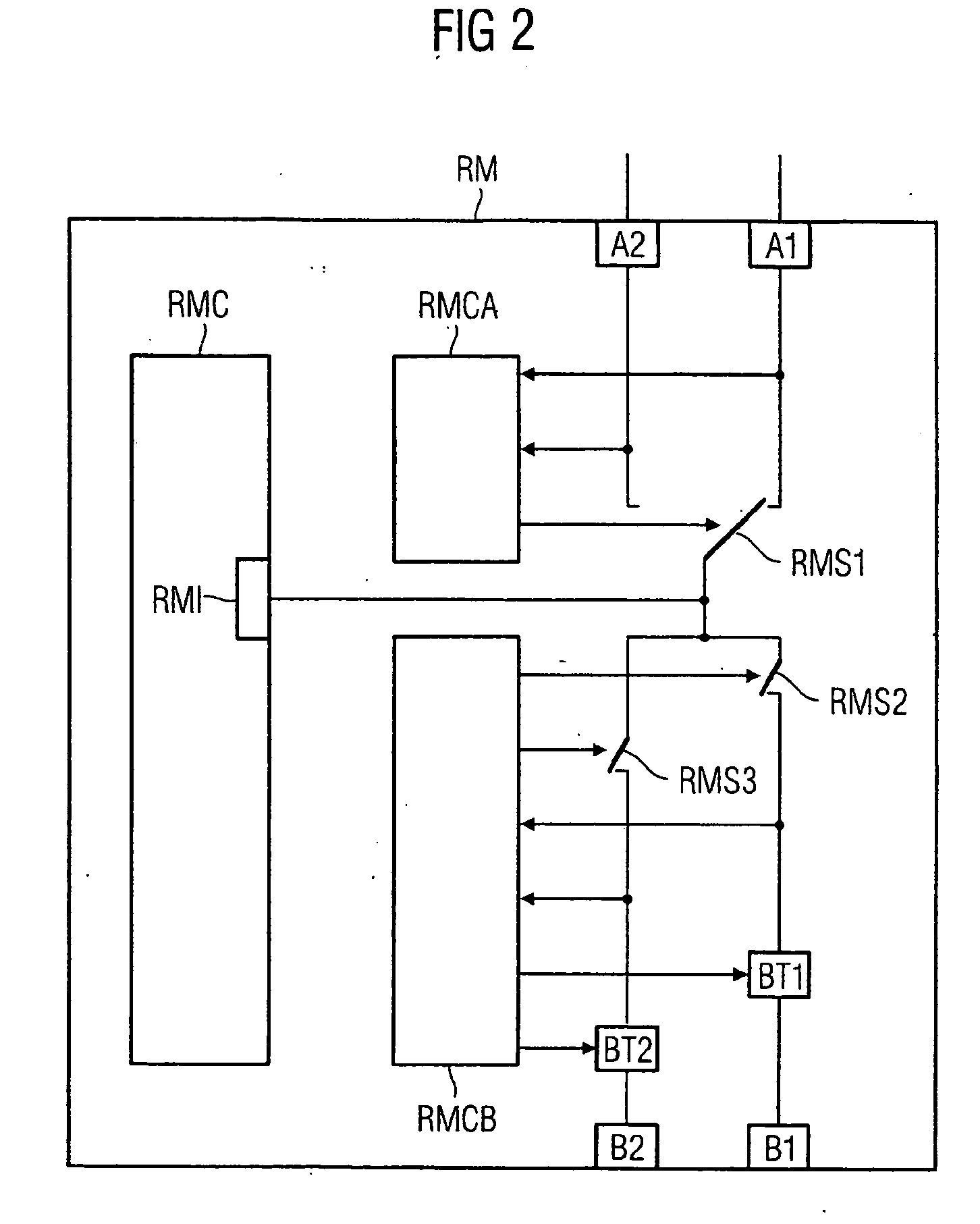

Network with redundancy properties, a branching unit for a user device in a network, redundancy manager for a network with redundancy properties and method for operating a network with redundancy properties

ActiveUS20070109958A1Network errorKeep in touchProgramme controlError preventionUser deviceNetwork connection

The invention relates to a network, in particular a PA PROFIBUS network having redundant properties and a linear topology. Two line ends are connected to a redundancy manager which disconnects said line ends in error-free conditions and connects them in error conditions. Said redundancy manager supplies voltage to the first line end for operating customers' mobile telephones each of which is connected to the network by a branching unit. After receiving a supply voltage on one connection thereof, said branching units check the state of a cable which is connected to the other network connection and transmit the supply voltage in the faultless condition thereof only. When the redundancy manager does not detect the supply voltage on the other end of the line end at least during a predetermined space of time after voltage supply, said redundancy manager supplies the voltage thereto. A cable having a disturbance is then disconnected from the line by the adjacent branching units.

Owner:SIEMENS AG

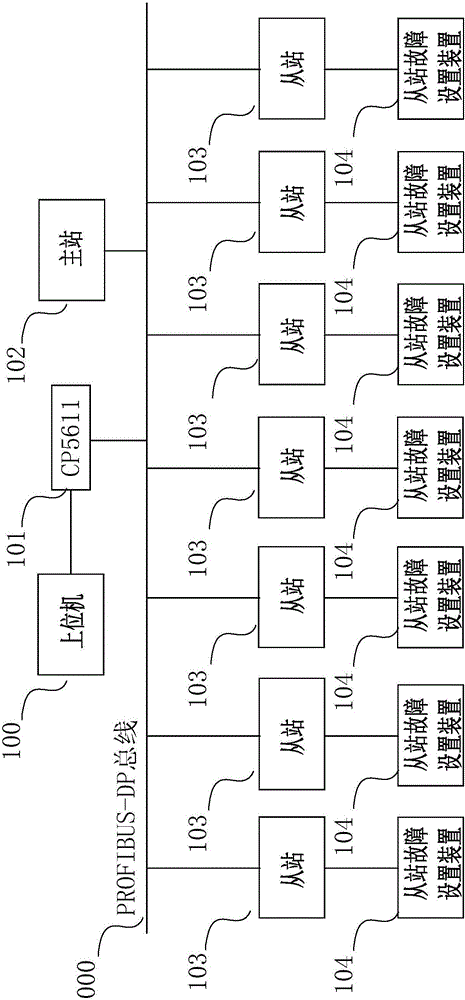

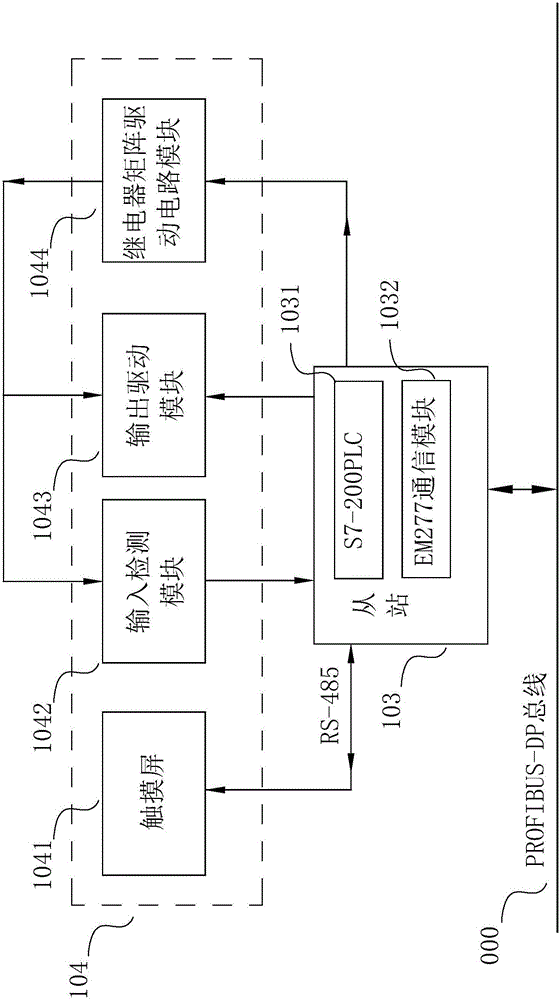

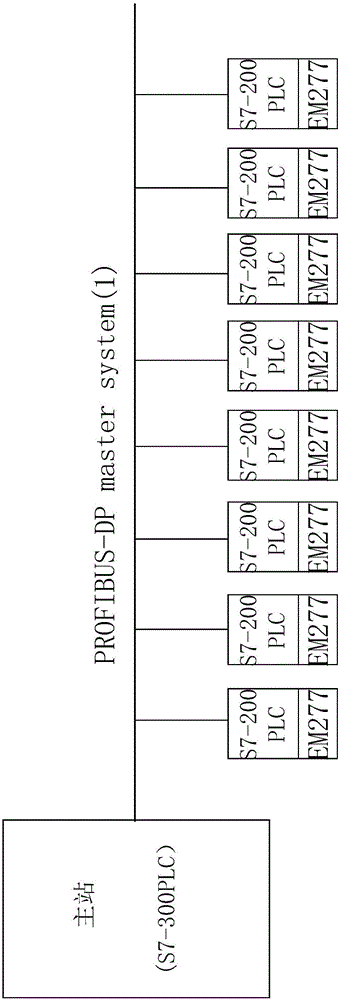

PROFIBUS based fault setting system

InactiveCN104966456AReduce workloadConvenient self-assessment self-assessmentEducational modelsMaster stationProfibus

The invention relates to a PROFIBUS based fault setting system, which comprises a PROFIBUS-DP bus, an upper computer, a CP5611 communication card, a master station and seven slave stations, wherein the master station comprises a master station programmable controller, a DI / DO and a guide rail, and each salve station comprises a slave station programmable controller and an EM277 communication module. The PROFIBUS based fault setting system is characterized by further comprising slave station fault setting devices, a PROFIBUS-DP bus based hardware configuration and touch screen configuration fault setting interface and an upper computer WINCC monitoring interface; and the salve station fault setting devices of the seven slave stations are identical in structure, and each slave station fault setting device comprises a touch screen, an input detection module, an output driving module, a relay matrix driving circuit module and an RS-485 communication cable. The fault setting system provided by the invention is high in automation degree, user-friendly in interface, easy to operate, convenient and flexible in fault setting, high in efficiency, reliable in operation and low in maintenance cost; and home station faults can be set at the upper computer or a lower computer, effects of practical training teaching are obvious.

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

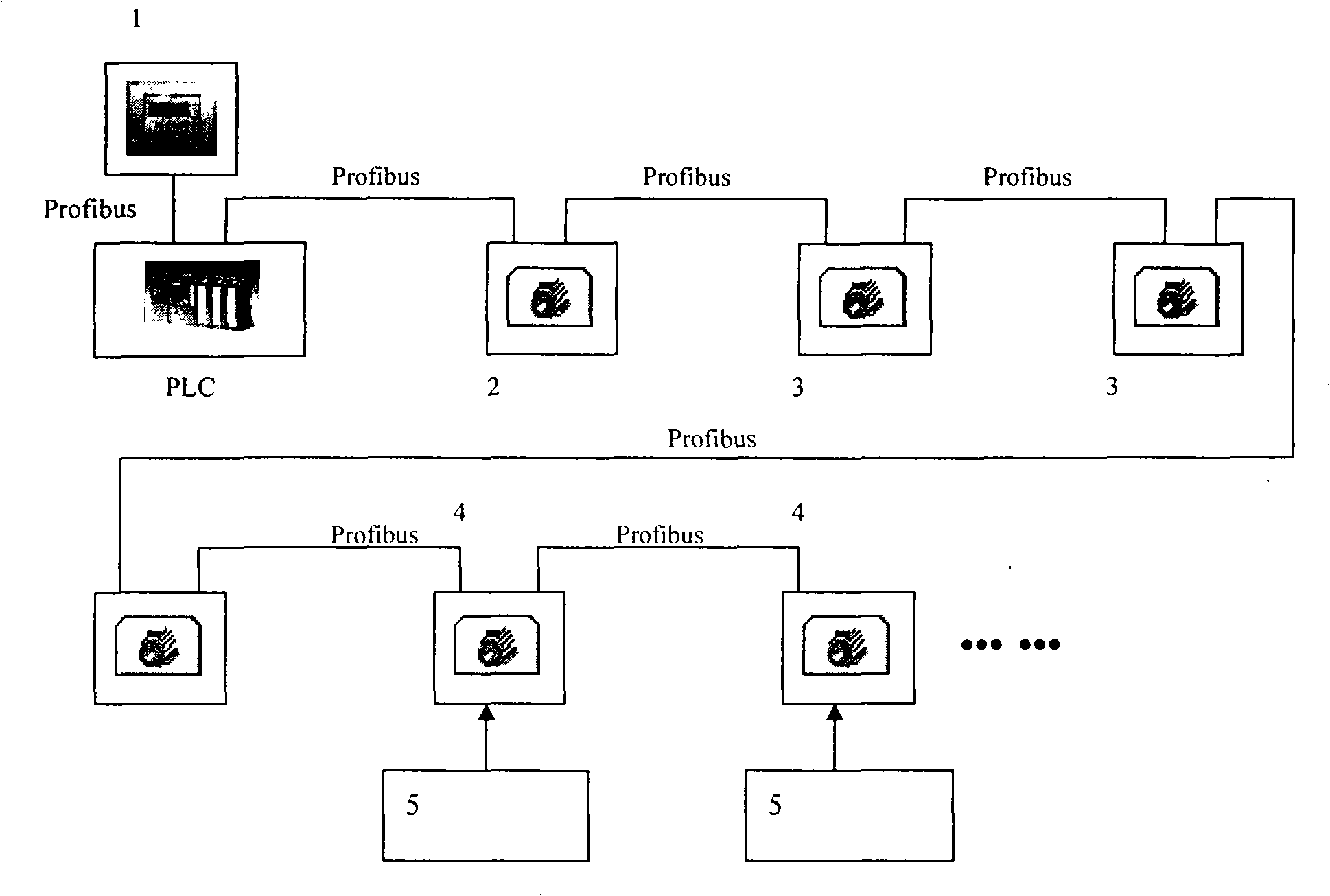

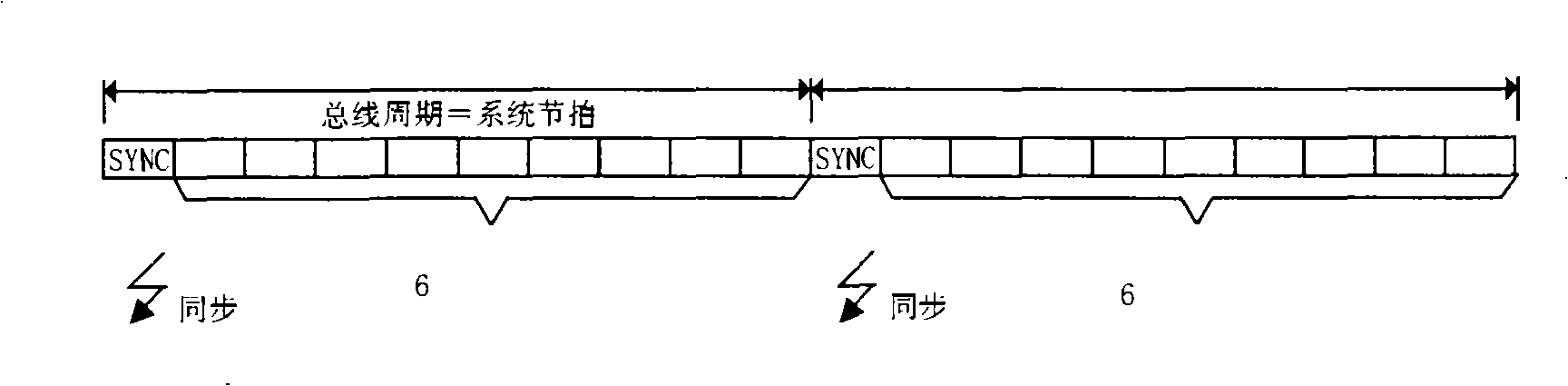

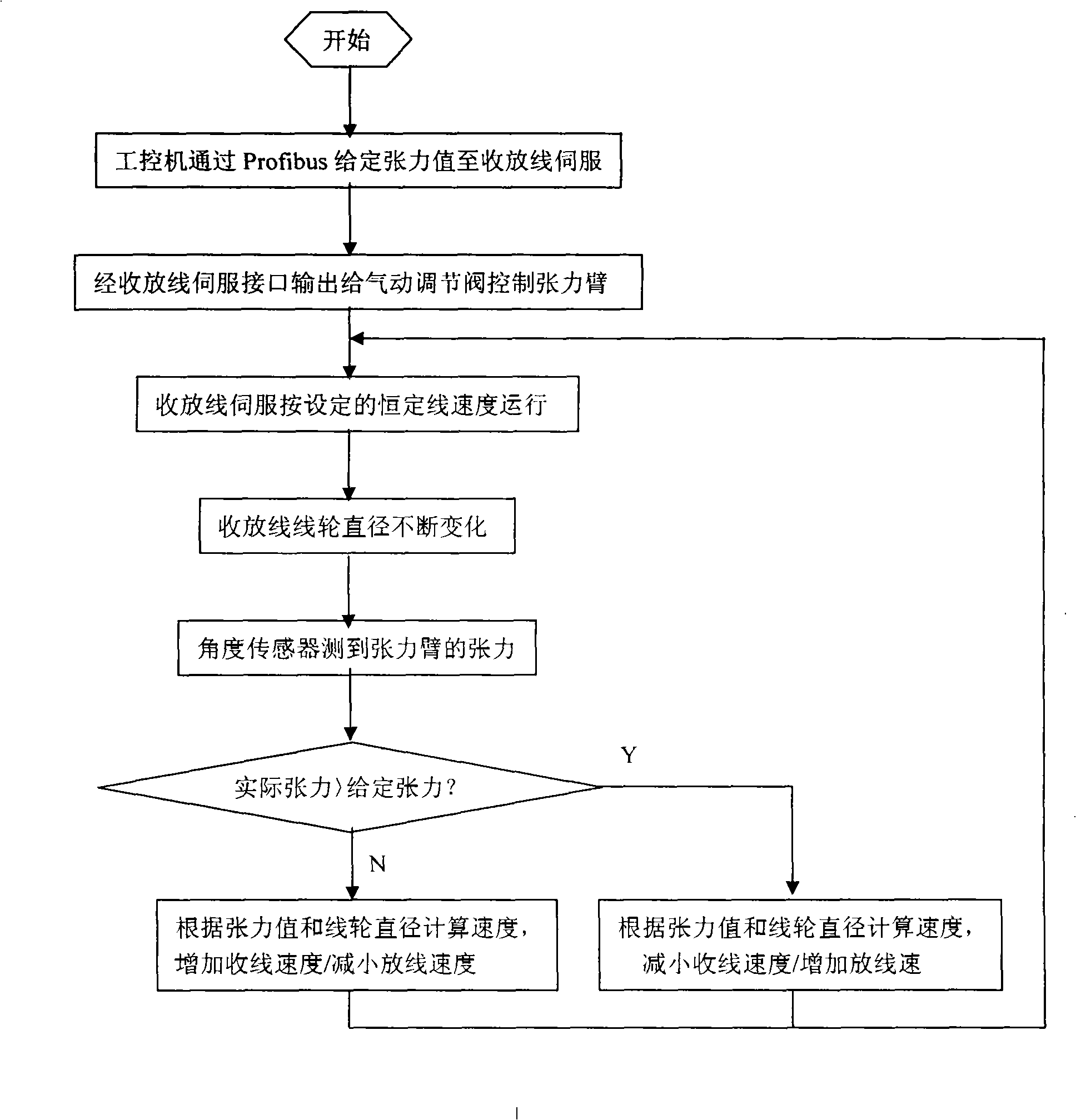

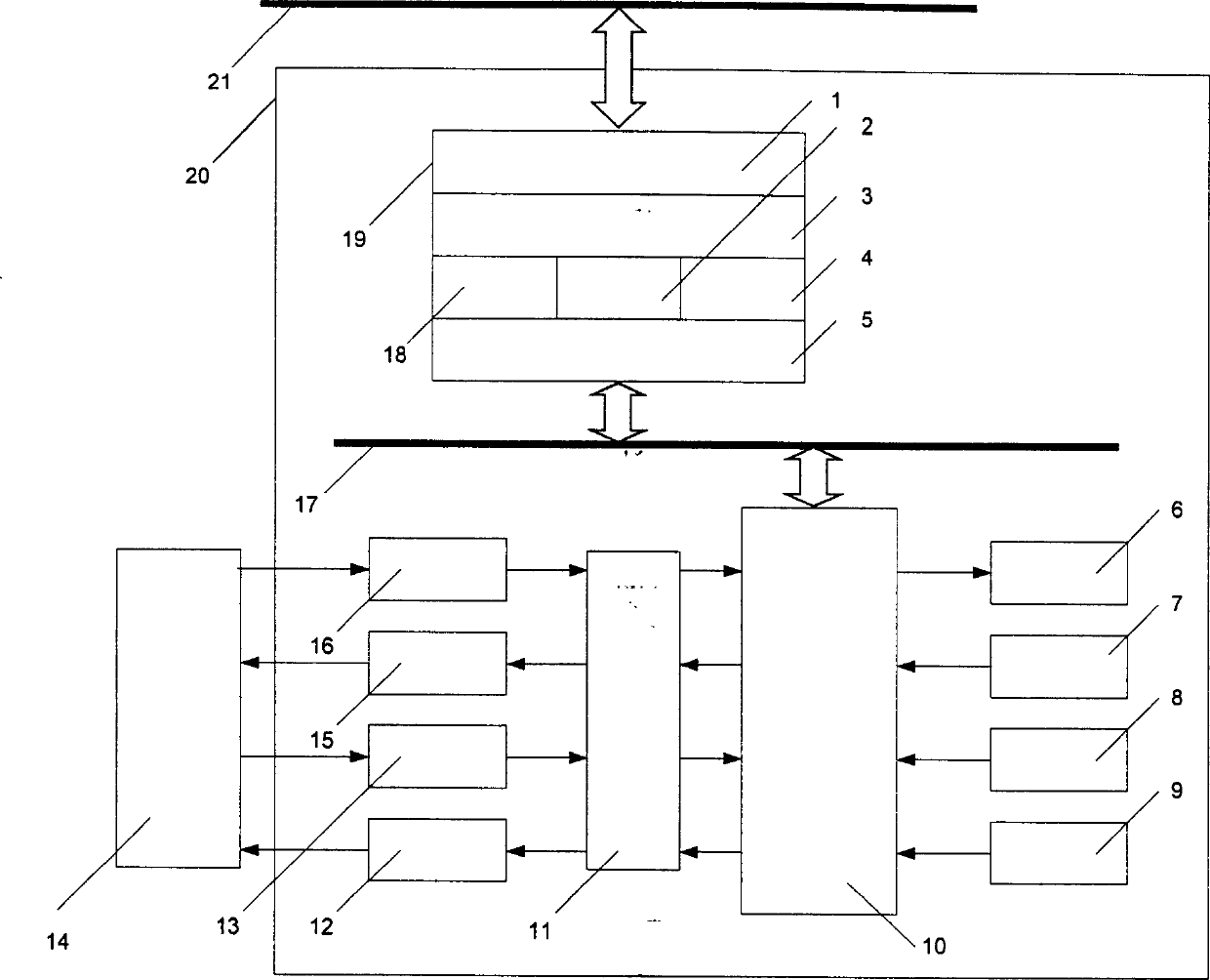

Multi-line cutting machine in-phase servo drive and constant tension control system

ActiveCN101284401ASolve communication tasksTempo syncFine working devicesElectric machineryWire cutting

The invention relates to a control system for a multi-wire cutting machine. A multi-wire cutting machine synchronous servo drive and constant tension control system includes an industrial personal computer, a main serve motor, a secondary serve motor and a take-up and pay-off serve motor. The invention is characterized in that the industrial personal computer sets a standard specified value which is sent to a main servo drive, at the same time, high-speed data transmission is carried out between the industrial personal computer and each servo drive via Profibus, the specified value and the data of the main drive are quickly sent to three secondary drive serve motors and the take-up and pay-off serve, the dependence on the synchronous character of each message is synchronously realized, the value synchronous with the main servo is calculated by the take-up and pay-off serve according to the above data and the diameter of the prior take-up reel and the line tension in the industrial personal computer, and the result is transferred to the take-up and pay-off serve via the Profibus bus.

Owner:DALIAN LIANCHENG NUMERICAL CONTROL MACHINE

On-site intelligent unit supporting industrial communication protocol and operating method thereof

InactiveCN1604582AImplement agreementImplement Profibus-DP protocolData switching networksElectric digital data processingĆuk converterControl unit

This invention relates to a spot intelligent unit and its operation method supporting industry communication network agreement, which comprises control unit and communication port module. The communication port module realizes the MODBUS / TCP industry Ethernet agreement or DeviceNet spot bus agreement or Profibus-DP spot bus agreement. The control unit has a microprocessor connected with A / D converter, D / A converter through light couple device, wherein its switch input, output and A / D converter and D / A converter are connected with the control subject.

Owner:SHANGHAI UNIV

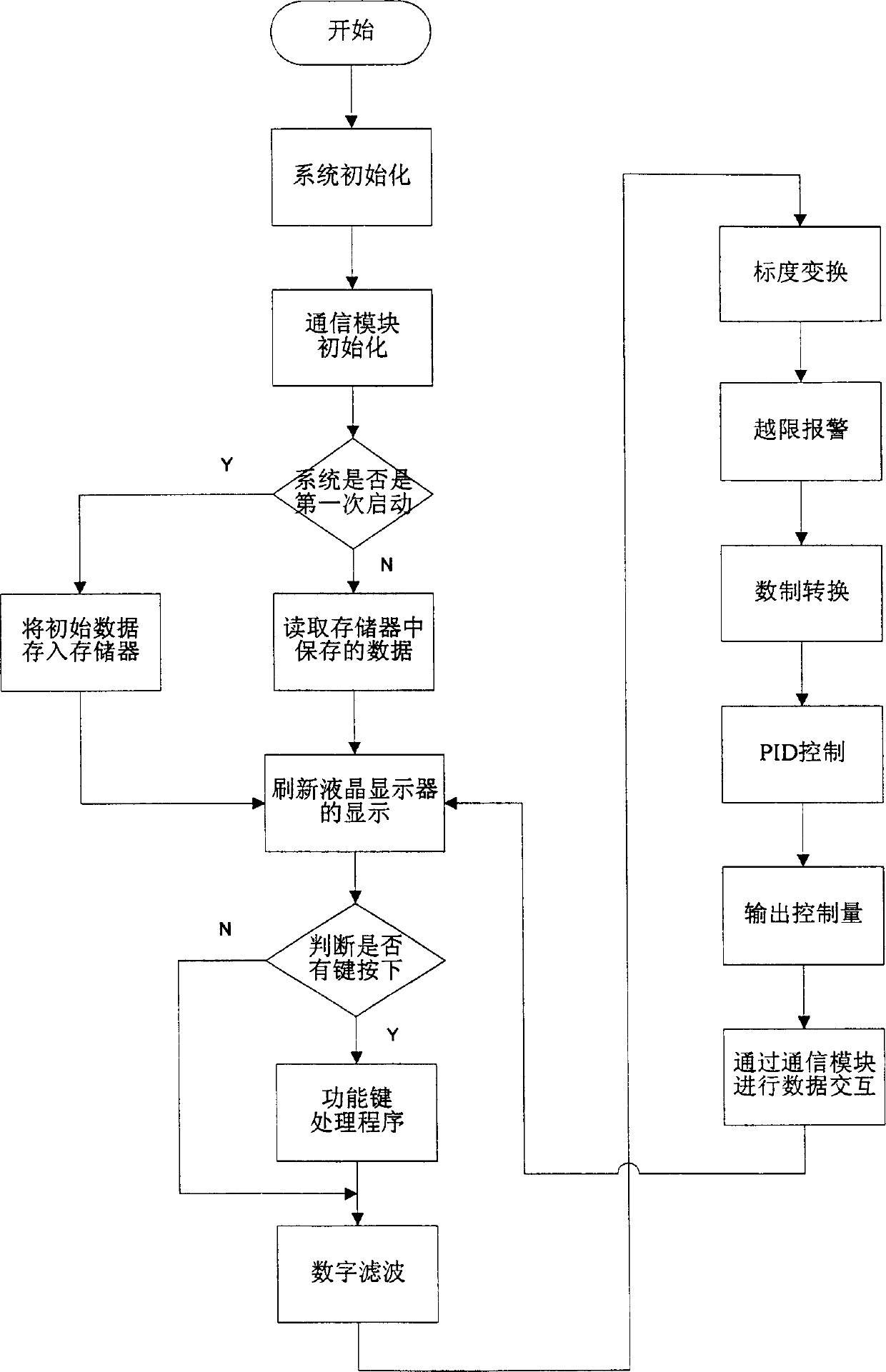

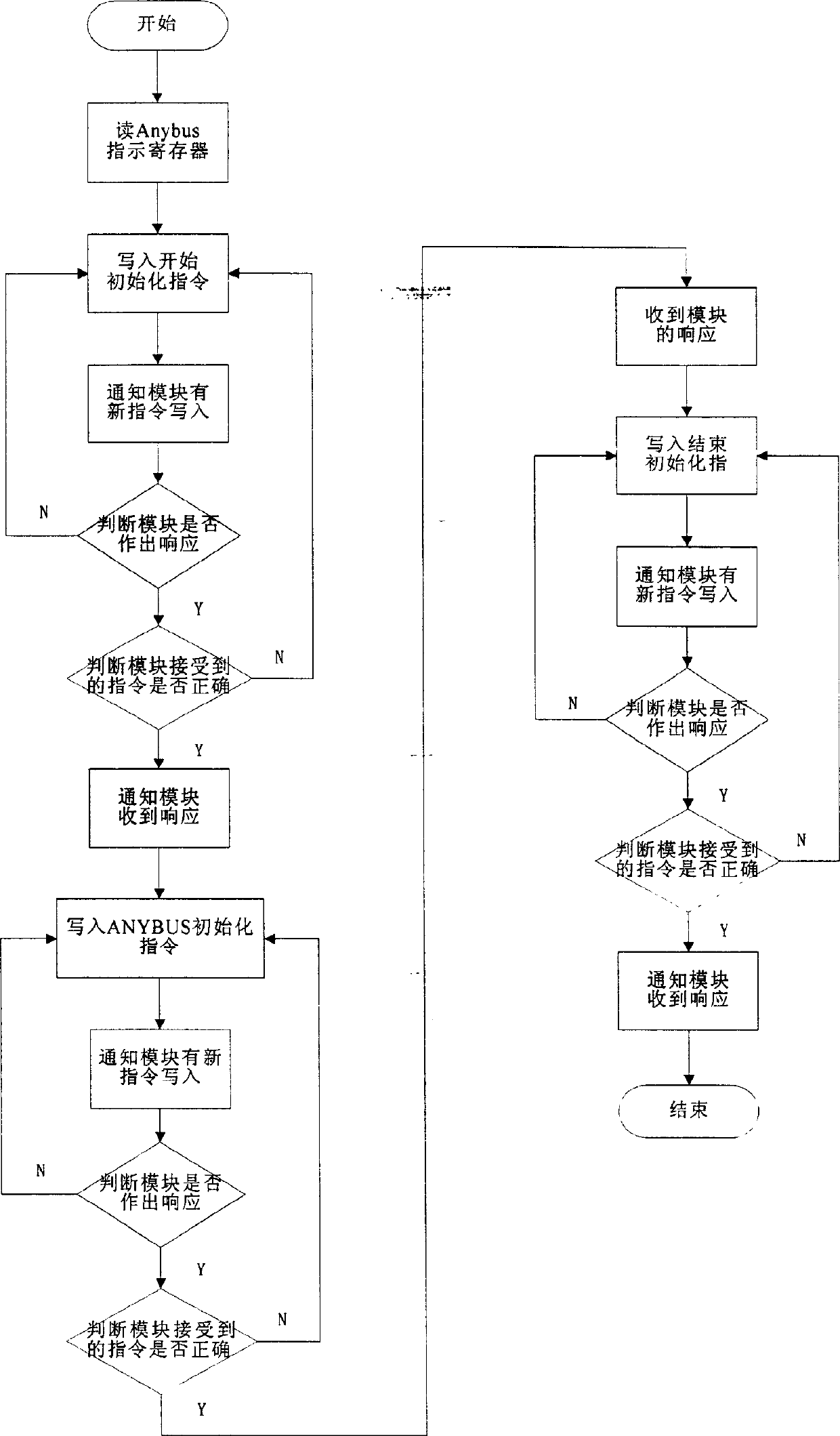

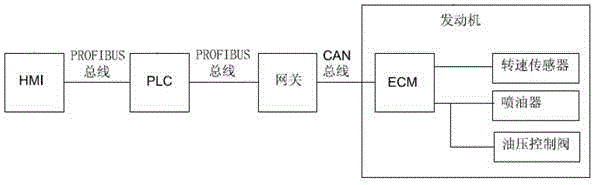

Device and method for controlling electronic-controlled engine

ActiveCN103334842ARealize monitoringEasy to controlProgramme-controlMachines/enginesProgrammable logic controllerProfibus

The invention discloses a device and method for controlling an electronic-controlled engine. The device comprises an IPC (Industrial Personal Computer) with a touch screen, a PLC (Programmable Logic Controller), a gateway, an ECM (electronic control module) of an electronic-controlled engine, a rotating speed sensor, an oil atomizer and an oil pressure control valve, wherein the gateway integrates a ProfiBus system and a CAN bus system into a whole, so as to enable the IPC attached to the ProfiBus system to send command values of rotating speed, torque and accelerator opening degree to the ECM attached to the CAN bus system, and then the ECM controls an engine to operate; meanwhile, the ECM can send the actual values of the rotating speed, the torque and the accelerator opening degree of the engine to the IPC, so as to realize the monitoring and control for the electronic-controlled engine; the PLC places parameters read from the IPC into an output cache module inside the PLC; the ProfiBus-J1939 gateway reads parameters from the output cache module of the PLC and sends the parameters to the ECM of the engine through the CAN bus; the ECM obtains the engine command value parameters to control the operation of the engine.

Owner:DONGFENG CUMMINS ENGINE

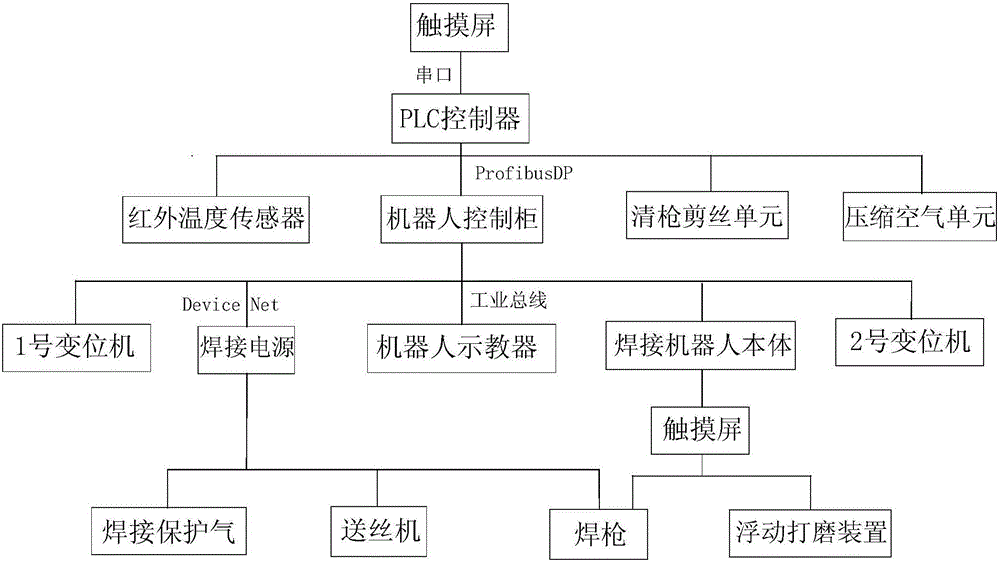

Marine low-speed machine air valve welding robot work station control system

ActiveCN106444638AAchieve global controlRealize monitoringNumerical controlWelding power supplyComputer module

Owner:NANJING INT MARINE EQUIP & SPARES

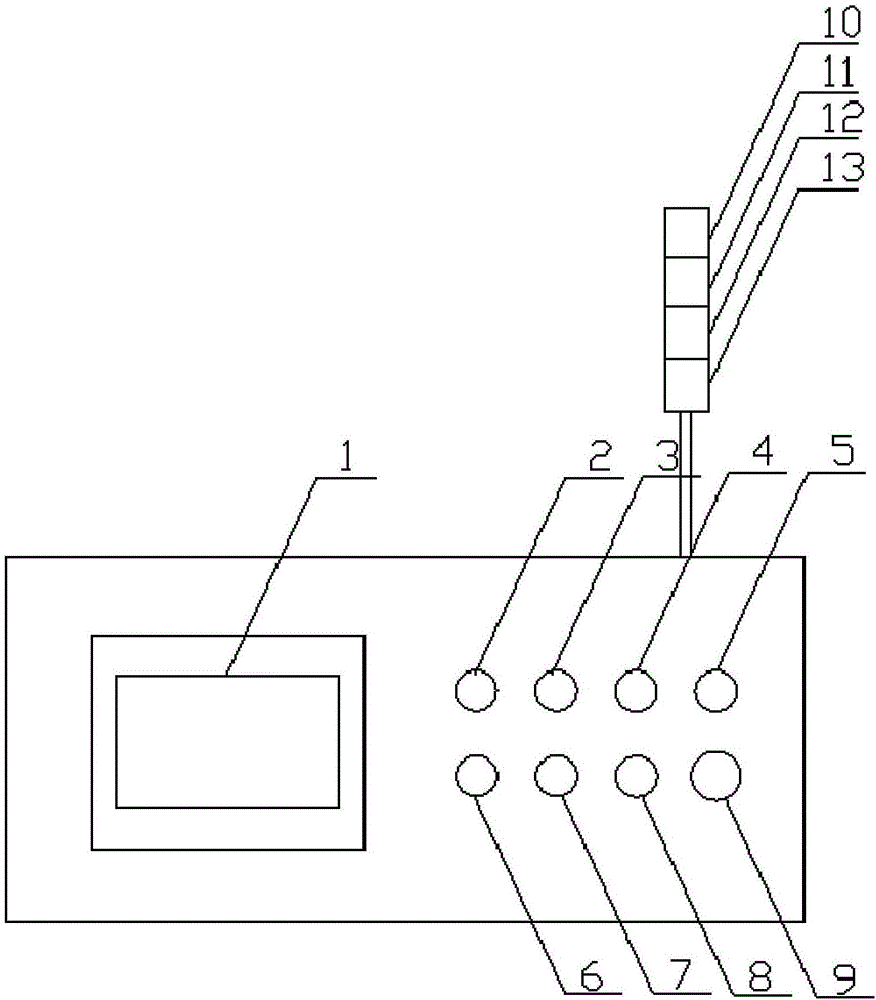

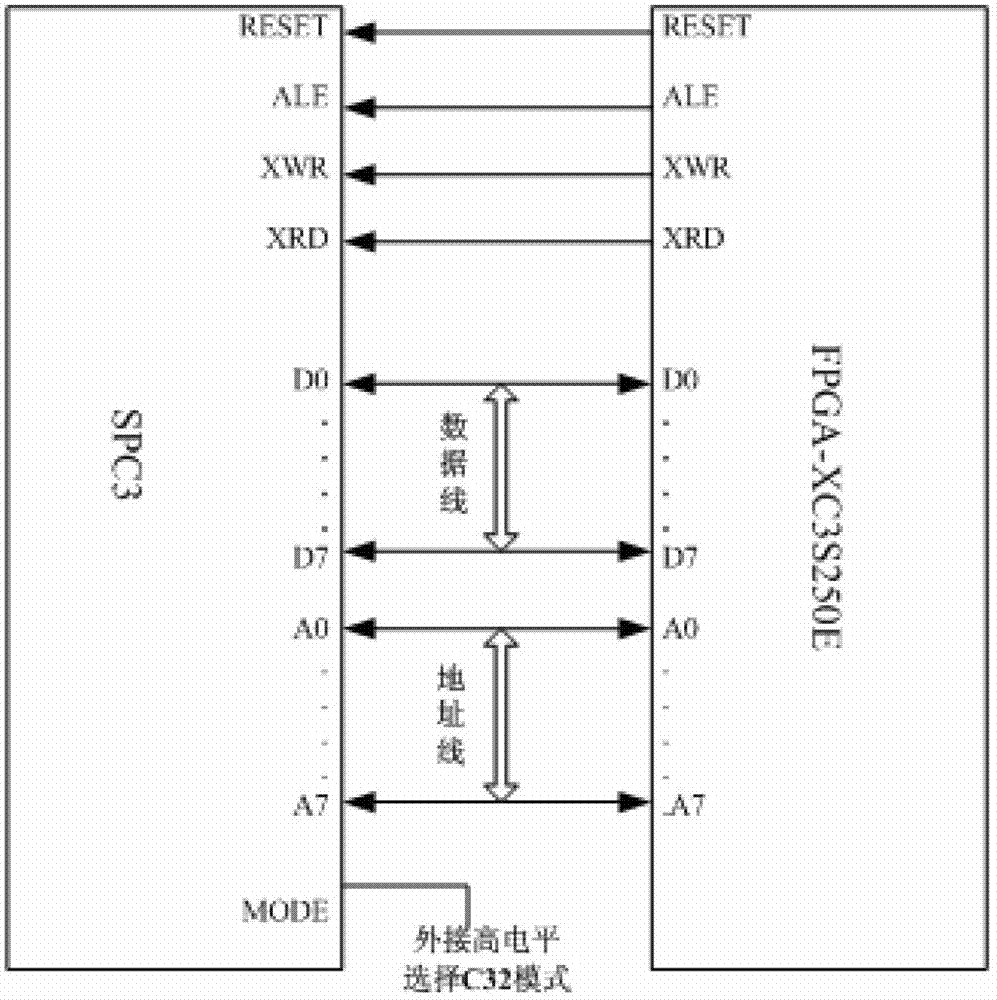

Profibus-DP slave station device on basis of FDGA (Field Programmable Gate Array)

InactiveCN102833142AEasy for secondary developmentWide versatilityBus networksCommunication interfaceSignal quality

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

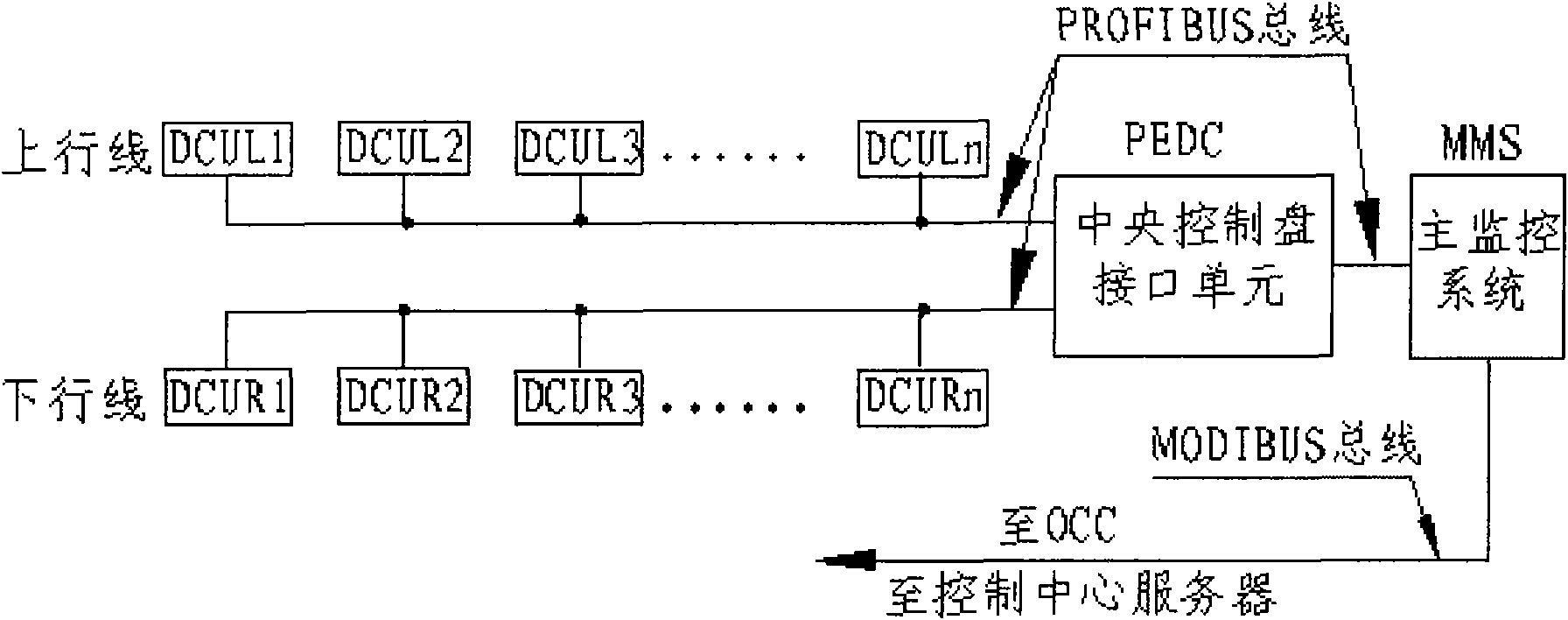

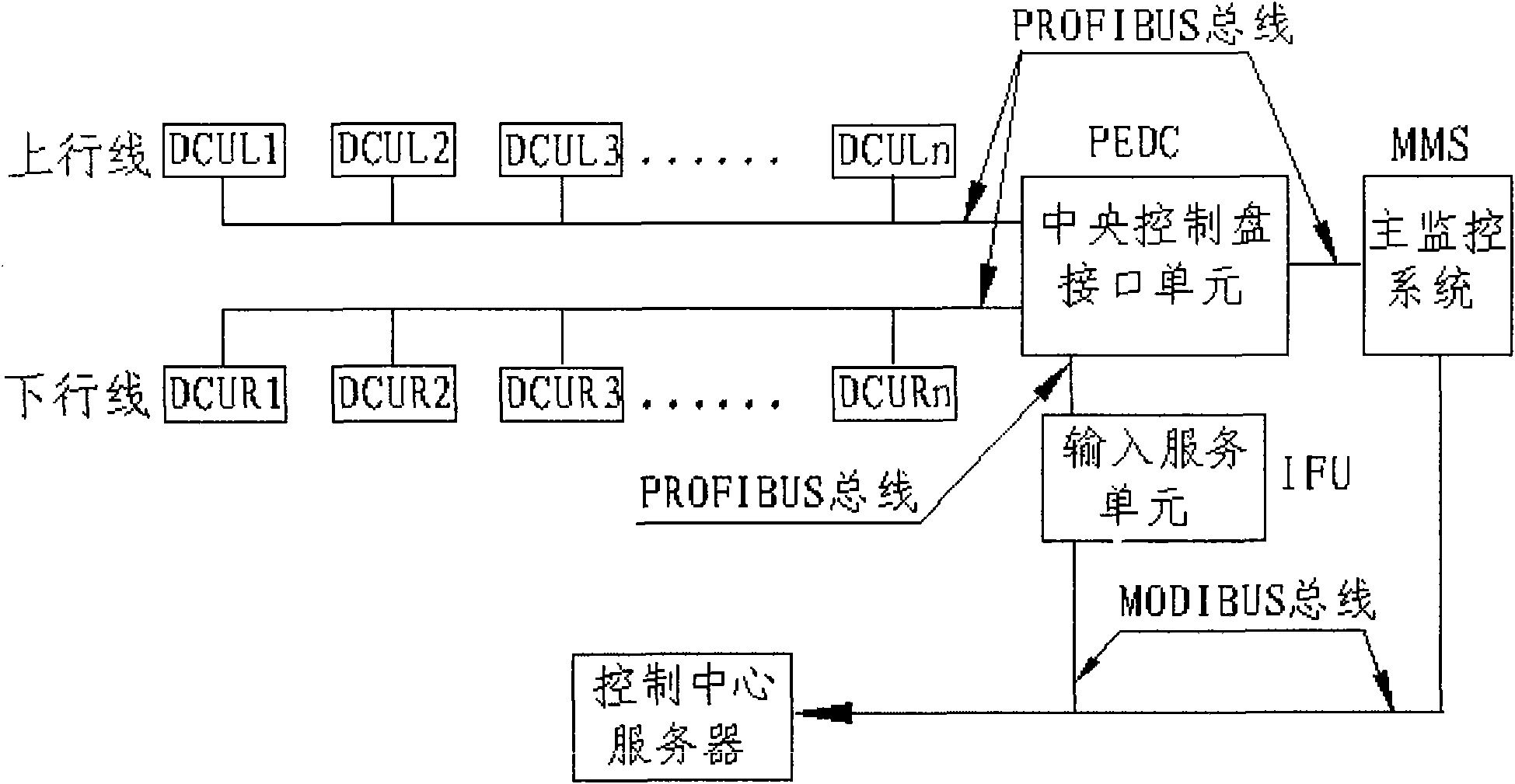

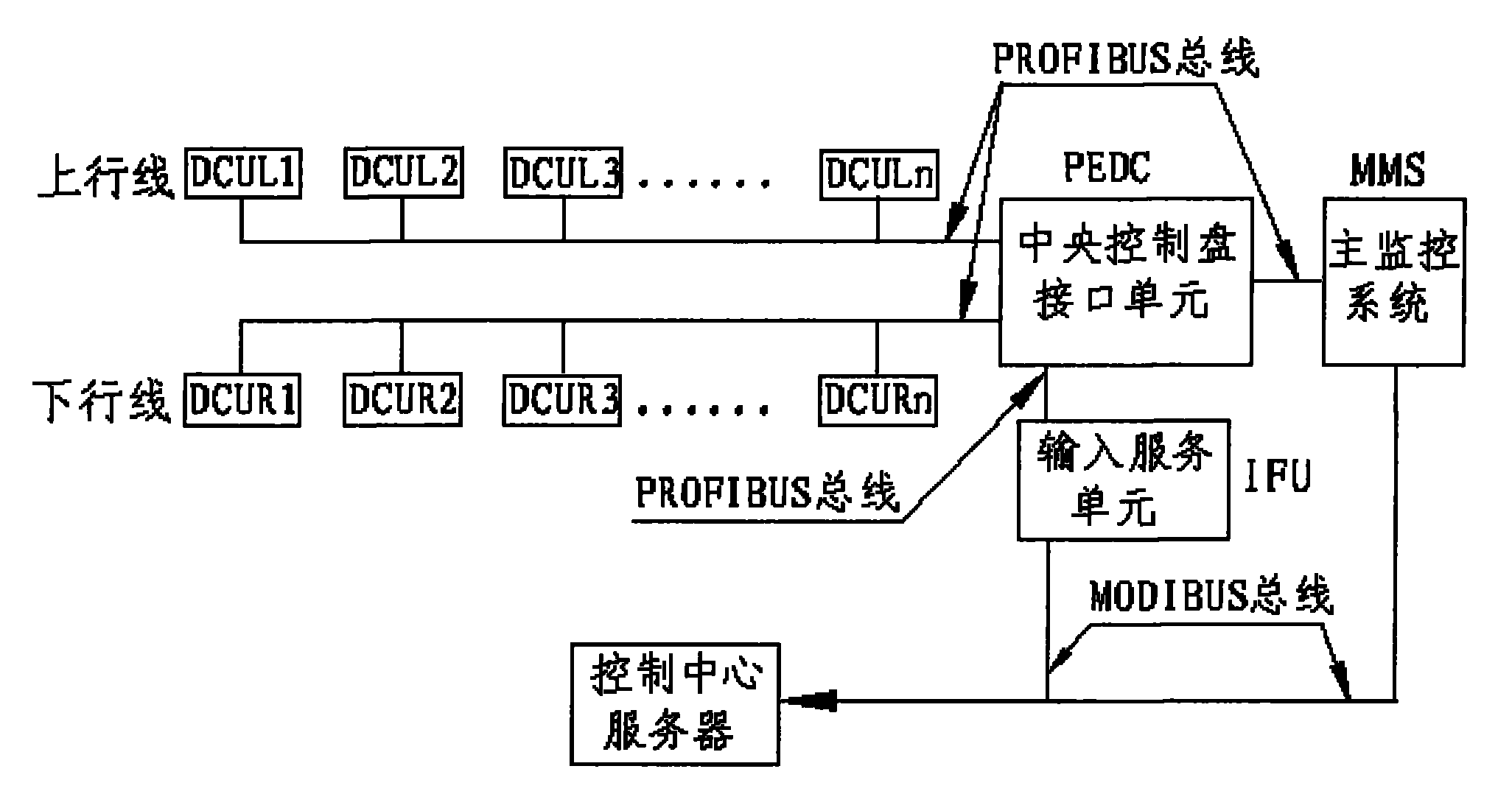

Control system for subway safety door

ActiveCN102122150AImprove securityTotal factory controlProgramme total factory controlMonitoring systemProfibus

The invention discloses a control system for a subway safety door, comprising: a master monitor system, a central control panel interface unit, an input service unit, a control center server and a plurality of door unit controllers, wherein the master monitor system is connected with the central control panel interface unit through a PROFIBUS bus; the master monitor system is connected with the input service unit and the control center server through a MODIBUS bus; the input service unit is connected with the central control panel interface unit through the PROFIBUS bus; the central control panel interface unit is connected with the plurality of door unit controllers through the PROFIBUS bus; and when the master monitor system have faults and cannot work normally, the input service unit is communicated with the control center server through the MODIBUS bus, so as to transmit state information of the safety door to the control center server. The system provided by the invention can improve the safety of the subway.

Owner:FANGDA INTELLIGENT INNOVATION TECH CO LTD

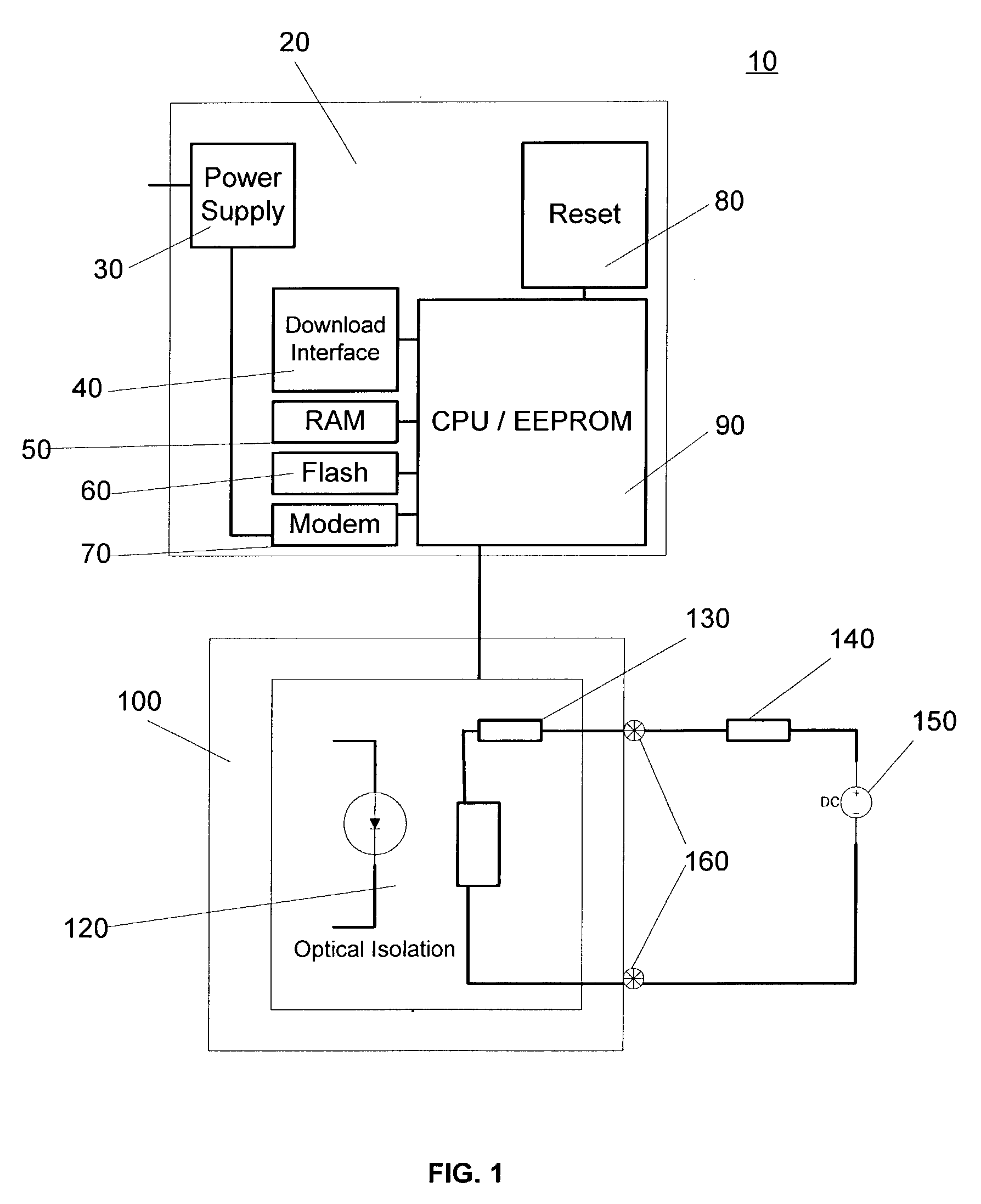

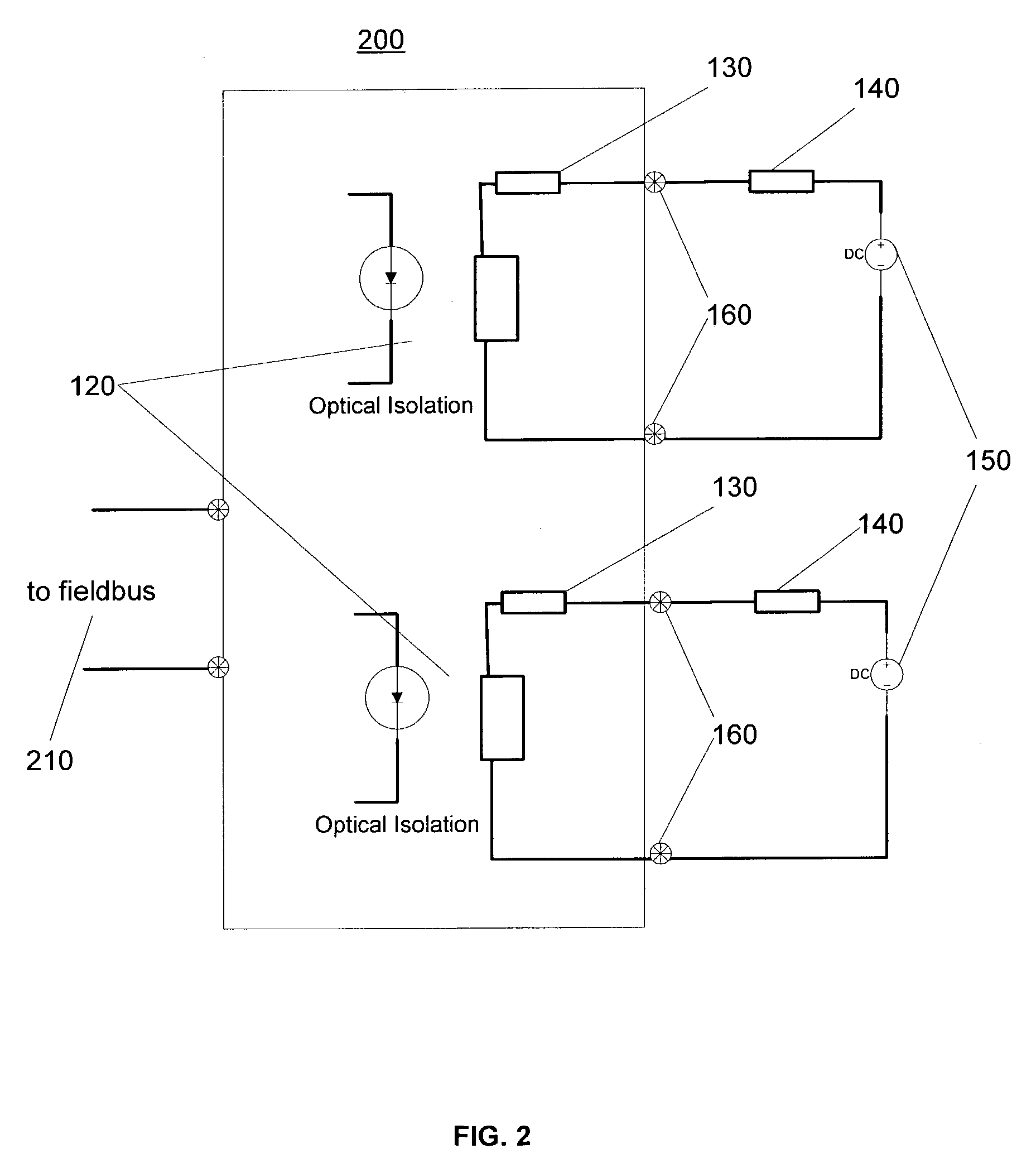

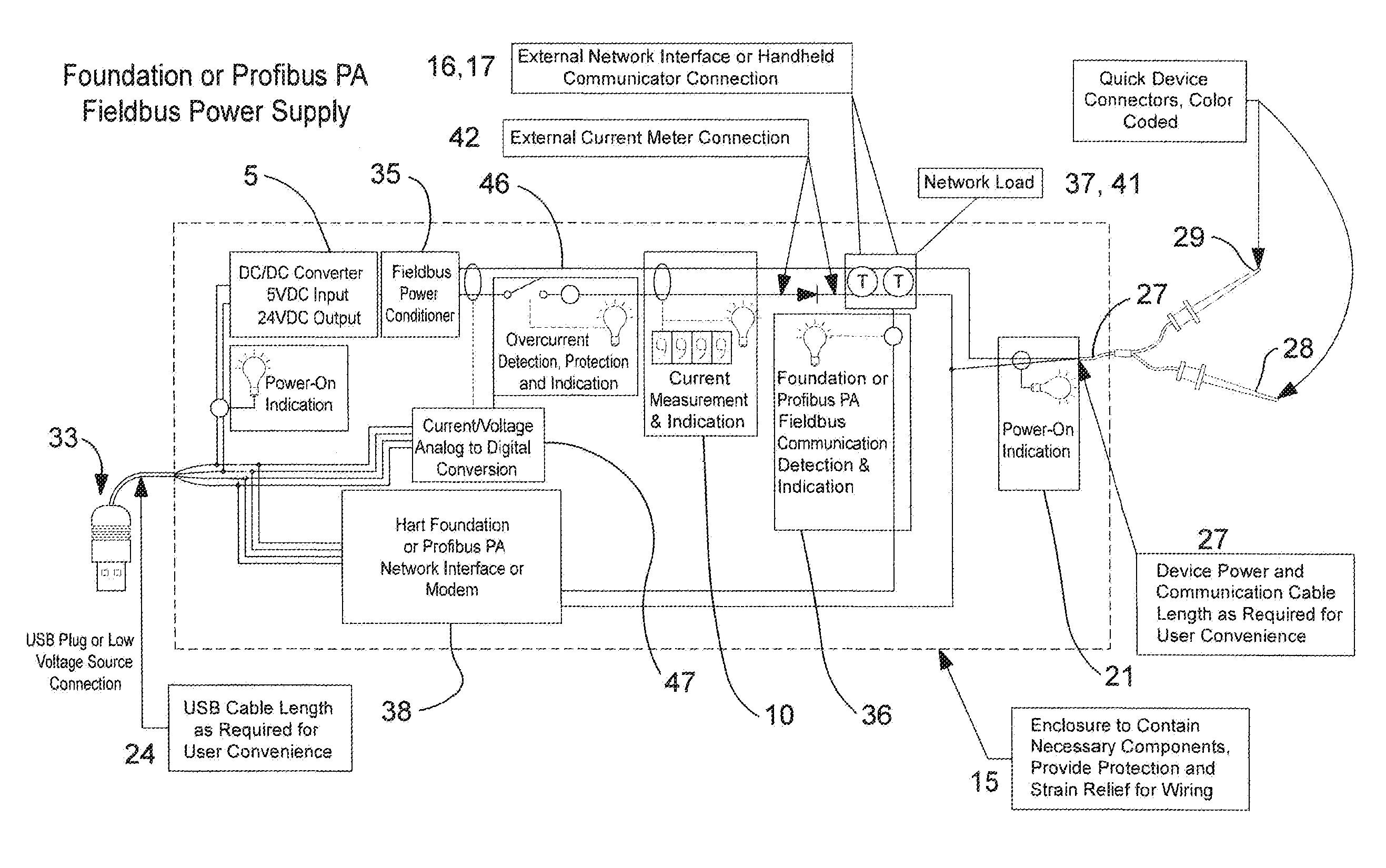

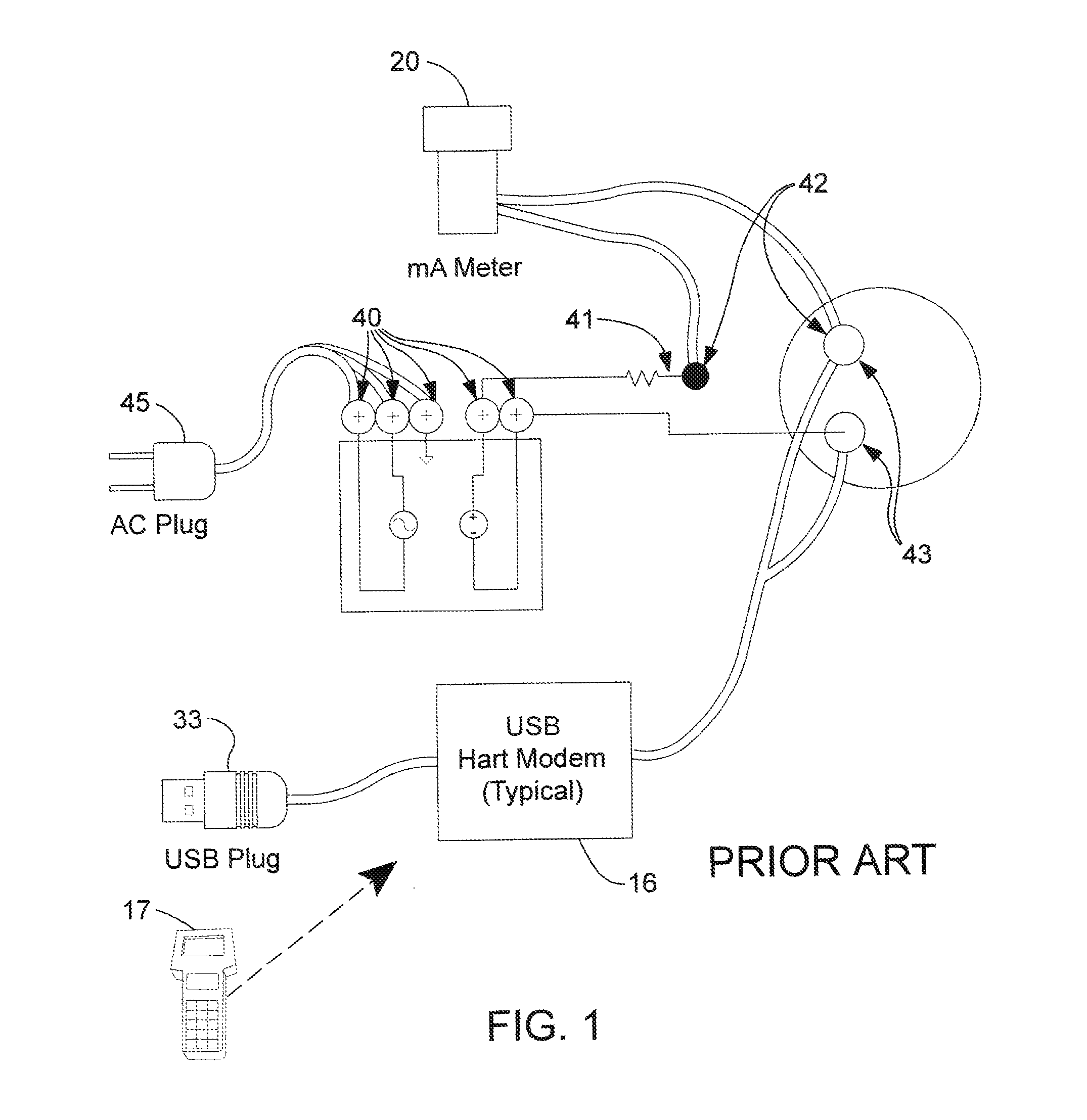

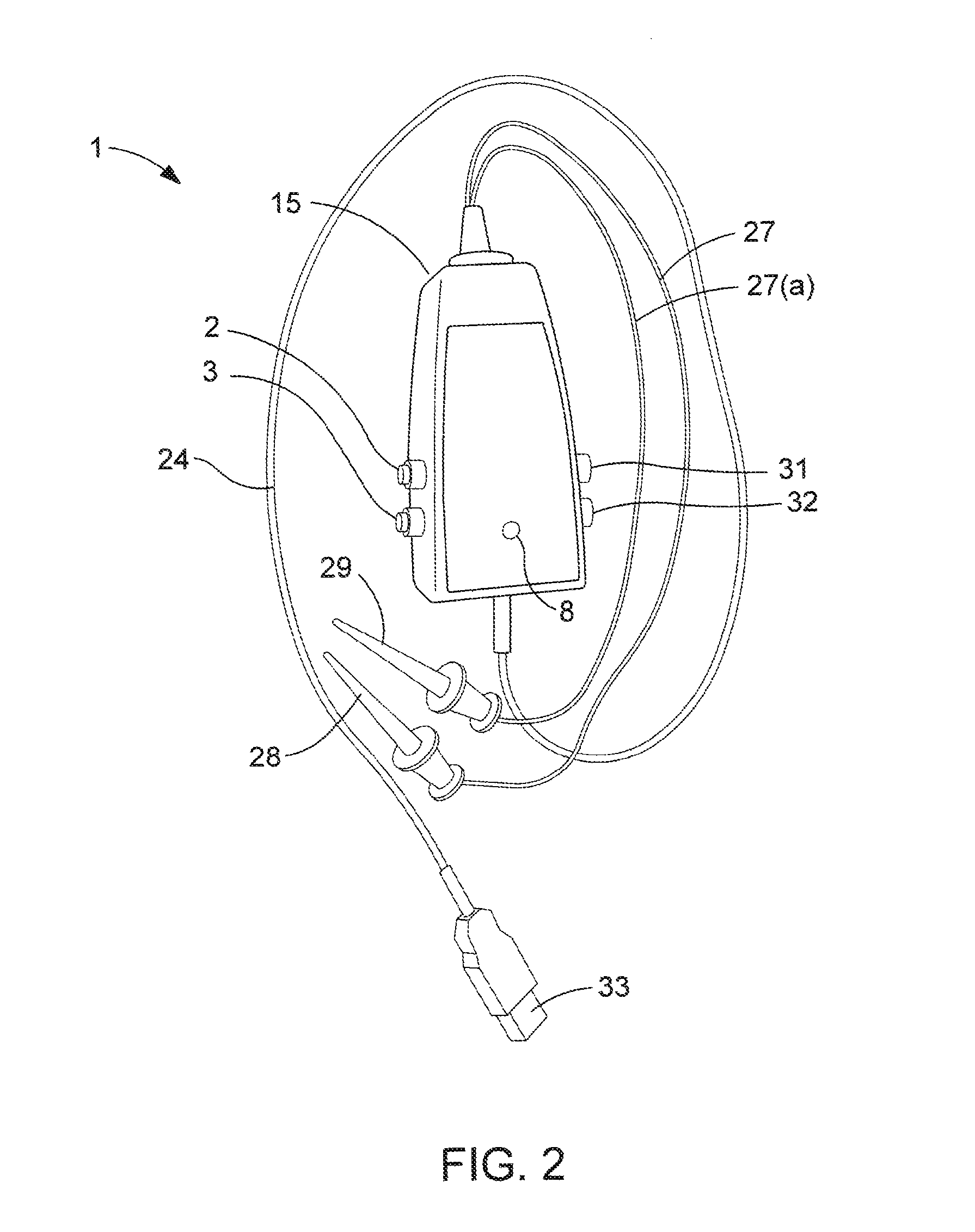

Apparatus and method to power 2-wire field devices, including HART, foundation fieldbus, and profibus PA, for configuration

Disclosed is a power assembly for supplying electrical power to 4-20 mA 2-wire field devices, including HART-enabled, short run Profibus PA, and Foundation Fieldbus protocols. A preferred embodiment of the power assembly is designed to simplify the testing, troubleshooting, and configuration of HART 2-wire field devices. The disclosed device is compatible with hand-held or PC-based configuration software, and utilizes the available power from the USB port of a laptop, or any other compatible source of low-voltage DC. An internal circuit converts the low voltage DC to 24-volt DC to provide 2-wire power for the field devices. The power supply includes the necessary network communication load and / or resistance and may provide a quick modem / network interface and / or milliamp meter connection. All the necessary connections to the 2-wire field device are made with a single pair of quick-disconnect fittings.

Owner:MICALLEF CHARLES JOHN +2

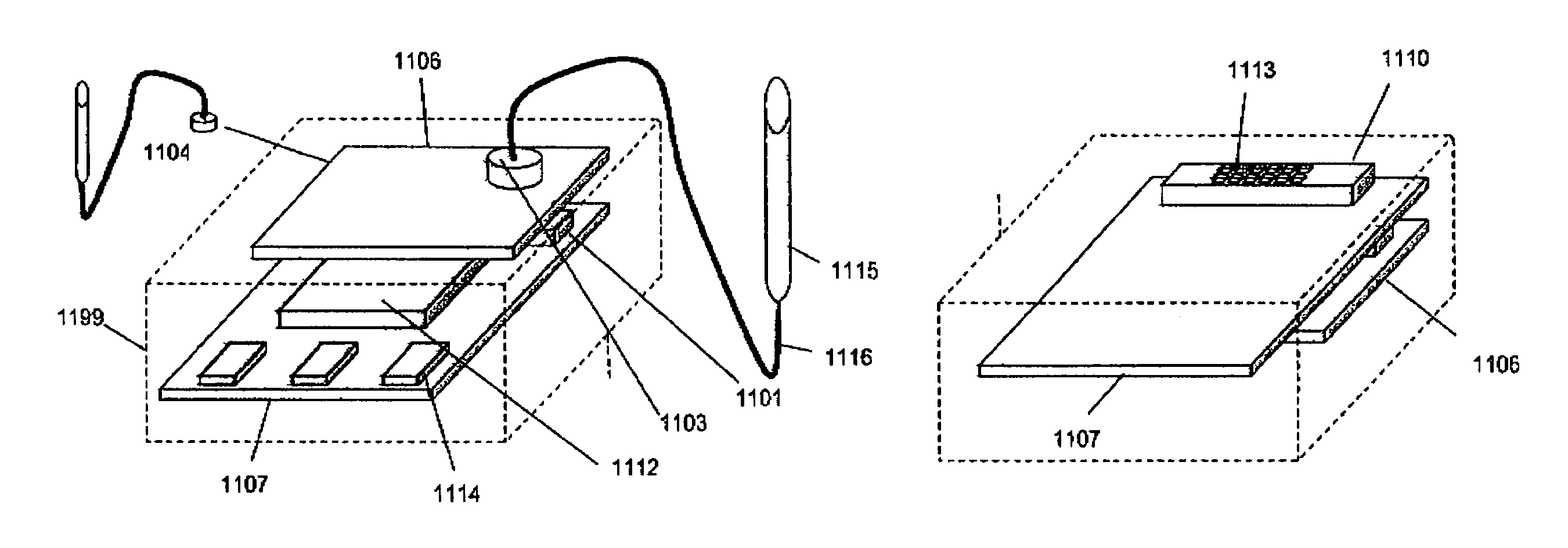

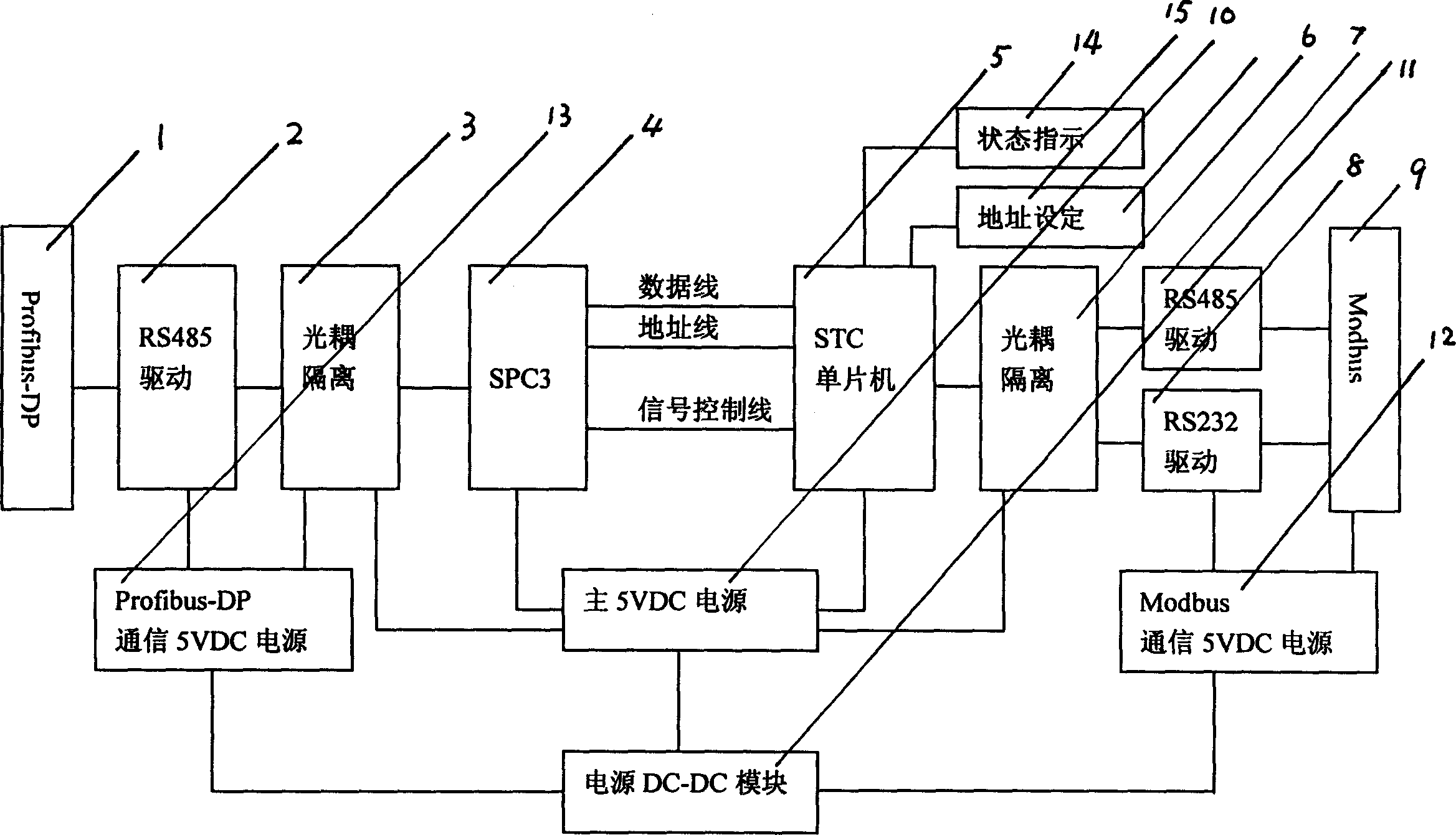

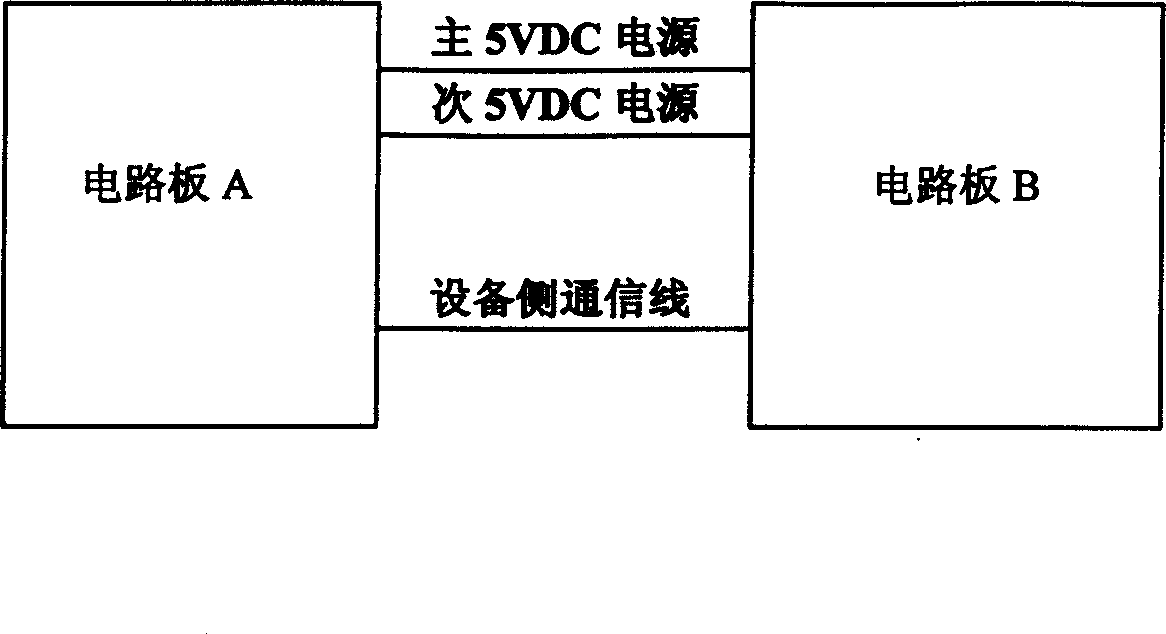

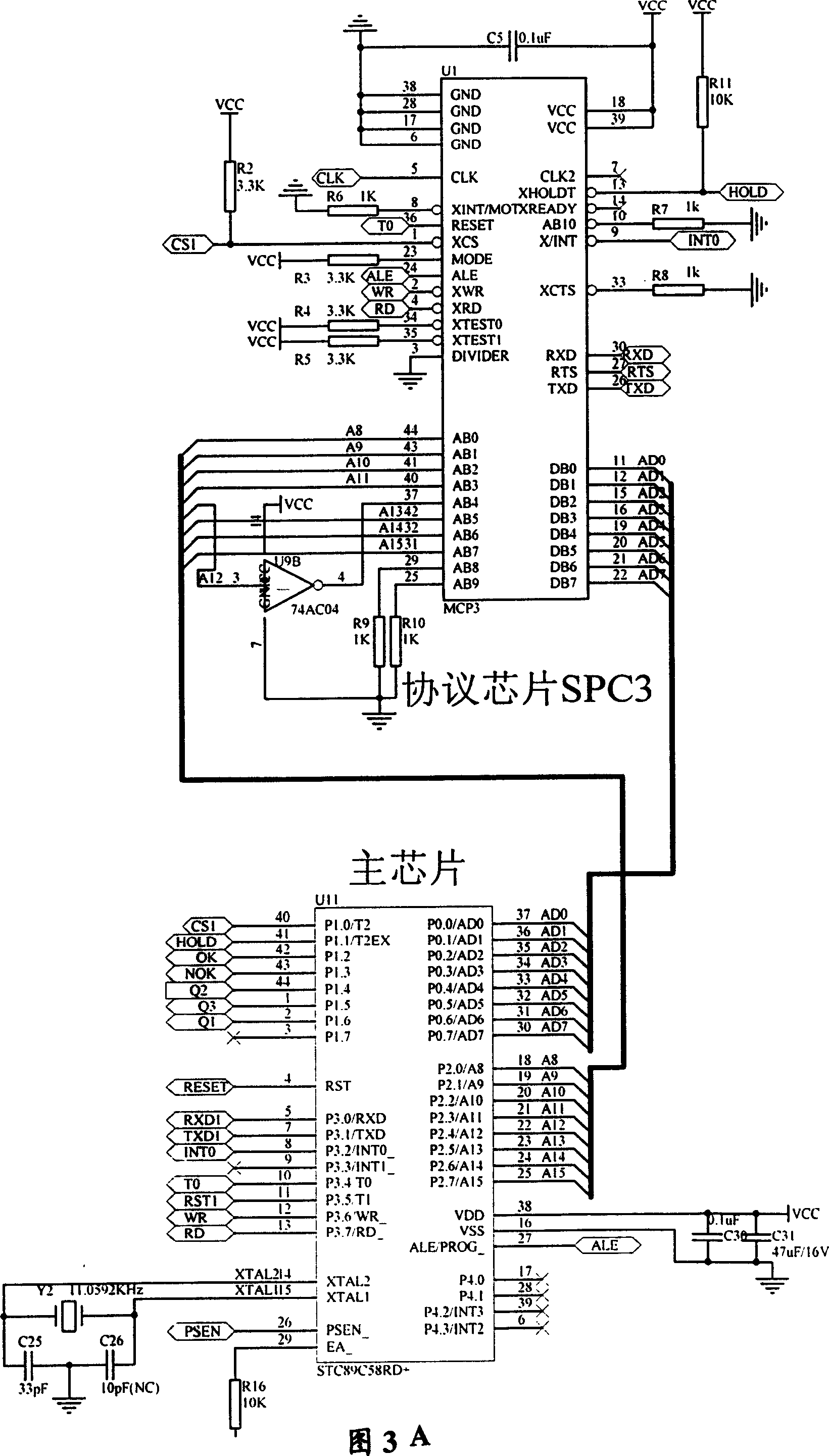

Communication adapter

This invention relates to a communication adaptor for converting and matching network protocols in different bus devices including profibus-DP, drive RS485, light-couple isolation, SPC3, single-chip processor STC, light couple isolation, device RS485, device RS232, Modbus, a primary 5VDC supplier, a DC-DC supply module, a Modbus communication 5VDC supplier, a profibus-DP communication 5VDC supplier, a state indication and address design. The circuit signals are transmitted from profibus-DP via RS485 light couple isolation SPC3 and processed by STC, then via light-couple isolation, RS485, RS232 and Modbus conversion to be delivered to profibus-DP inversely. The software includes SPC3 flows primary program flow and interruption program flow.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP

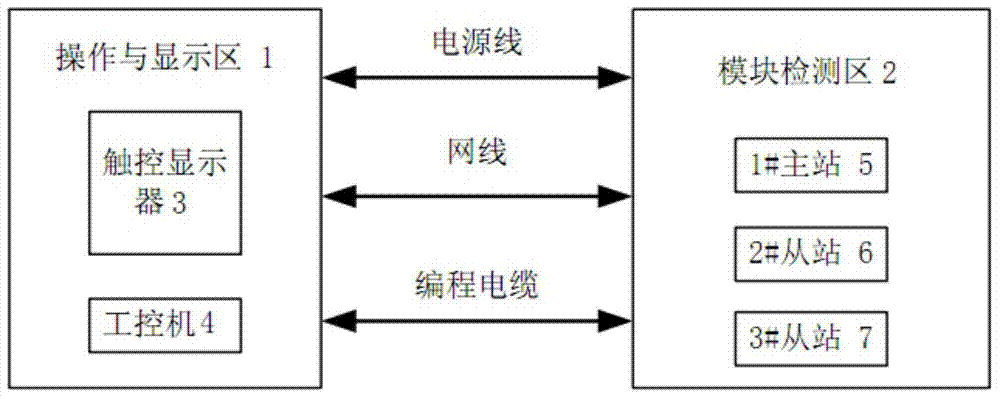

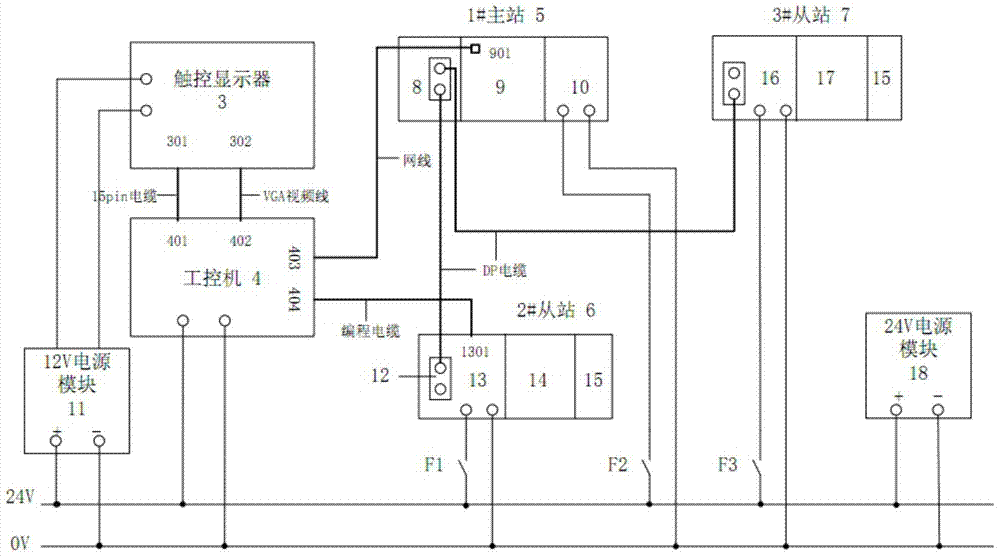

Detection platform and method for Beckhoff PLC modules

The invention discloses a detection platform and method for Beckhoff PLC modules. The detection platform for the Beckhoff PLC modules comprises a touch displayer, an industrial personal computer, a 1# master station, a 2# slave station, a 3# slave station and a power supply unit, wherein the 1# master station comprises a profibus master station module, a basic CPU module and a power module; the 2# slave station comprises a bus terminal controller, an I / O level module which comprises a digital quantity output module, and a terminal module; the 3# slave station comprises a bus terminal coupler, an I / O level module which comprises a digital quantity input module, a digital quantity output module, an analog quantity input module and an analog quantity output module, and a terminal module; the touch displayer is connected with the industrial personal computer, the basic CPU module is connected with the industrial personal computer, the profibus master station module is connected with the bus terminal controller and the bus terminal coupler, the bus terminal controller is connected with the industrial personal computer, and all the Beckhoff PLC modules or part of the Beckhoff PLC modules can serve as Beckhoff PLC modules to be detected. According to the detection platform and method for the Beckhoff PLC modules, due to the fact that a bus system is established, performance of the Beckhoff PLC modules can be detected, and the maintenance pass rate or the ex-factory pass rate is improved.

Owner:BEIJING TIANYUAN SCI & TECH CREATION WINDPOWER TECH

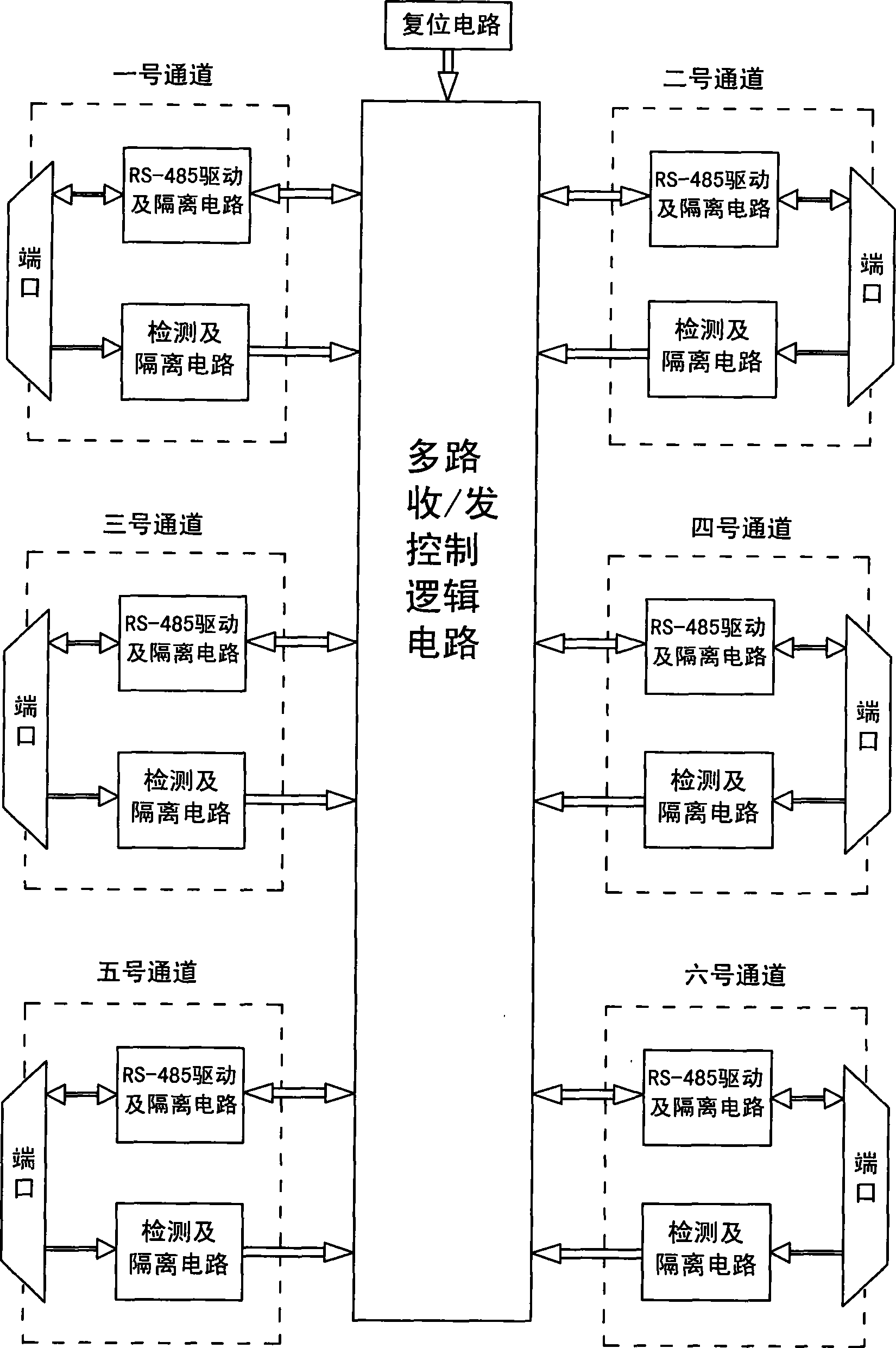

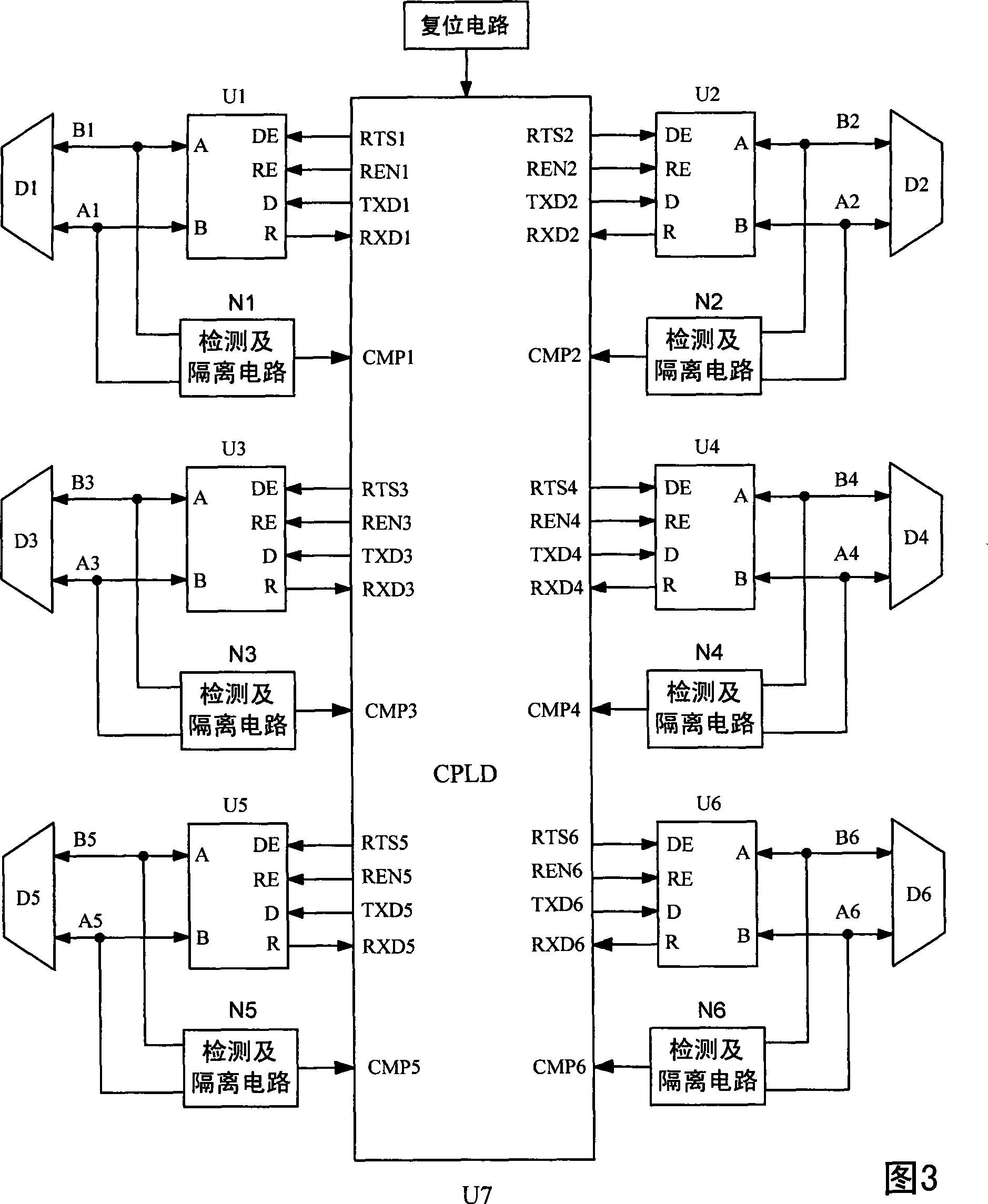

Rapid discriminating multiport control method based on PROFIBUS packet

InactiveCN101374115AReduce overheadHigh speedError preventionData switching networksPower-on resetProfibus

The invention provides a multi-port control method based on the rapid PROFIBUS message identification. The method comprises the following steps: (1) electrification setting; (2) detecting the port signal level by a detecting and isolating circuit detection; (3) detecting the port PROFIBUS signal level by the detecting and isolating circuit, wherein when the signal level is converted from a release state to a transmission state, whether the port receives a message starting signal can be determined; (4) allowing the other ports to be in a transmission state by a multi-path receiving / transmitting control logic circuit, converting the received message into a transmission message signal and outputting the signal to the other ports via a driving and isolating circuit; (5) transmitting a second wave trigger signal when the conversion of the signal level from the transmission state to the release state is detected by the detecting and isolating circuit detection; (6) determining the completion of the message transmission by determining the last time of the second wave trigger signal with the multi-path receiving / transmitting control logic circuit, and closing the other ports; and (7) returning to the step (2). By adopting the method, the message resolution and the baud rate test can be obviated, therefore, the method is a rapid and baud rate-self-adaptive message data flow judgment method.

Owner:BEIJING D&S FIELDBUS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com