Protocol conversion device based on PROFIBUS-DP master station field bus

A protocol conversion and field bus technology, applied in the field of bus network, data exchange through path configuration, electrical components, etc., can solve the problems of inability to master the underlying technology of PROFIBUS, poor translation of Chinese translation, and increase the difficulty of technical implementation. Achieve the effect of meeting normal communication requirements, simplifying development, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

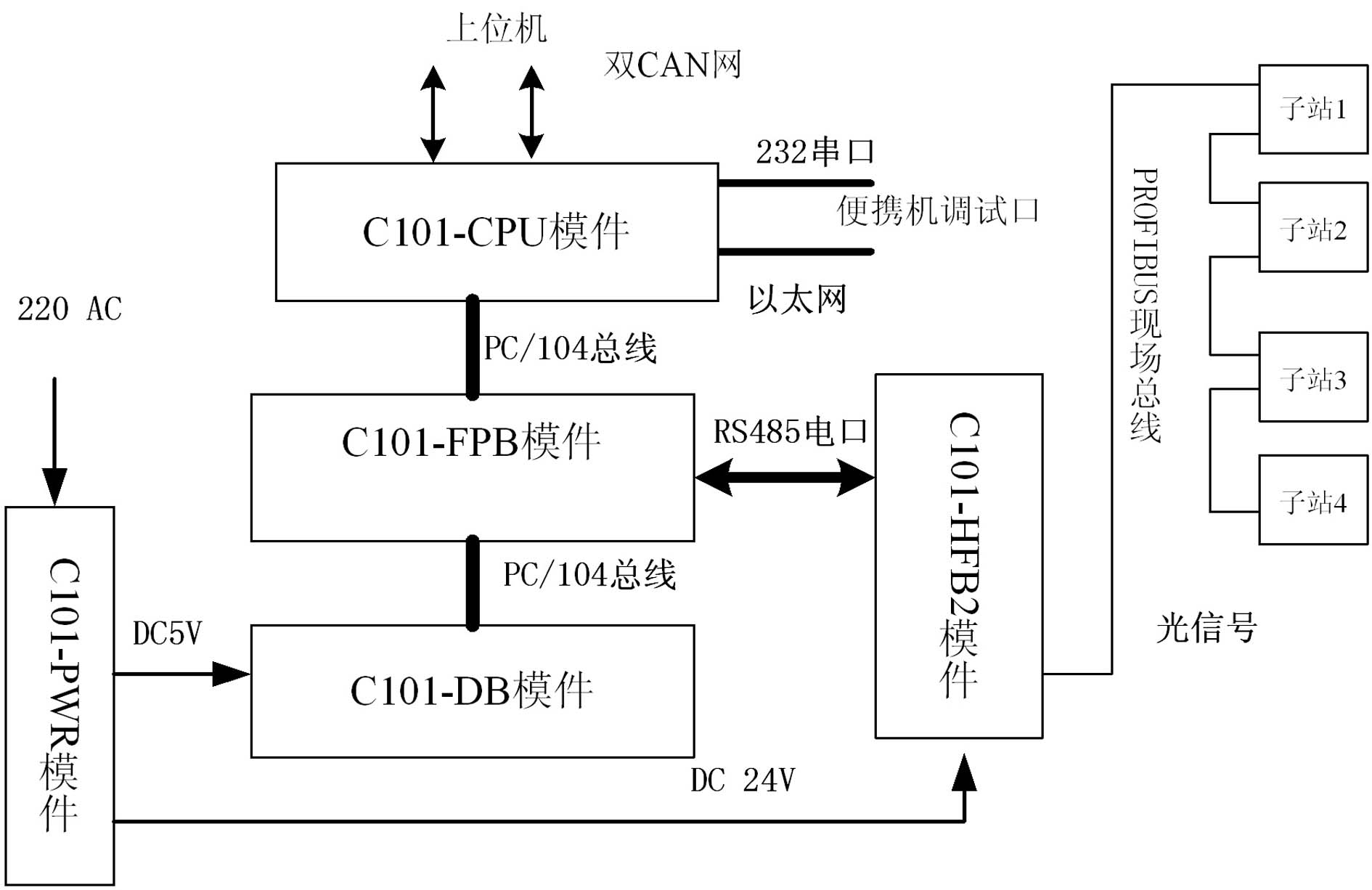

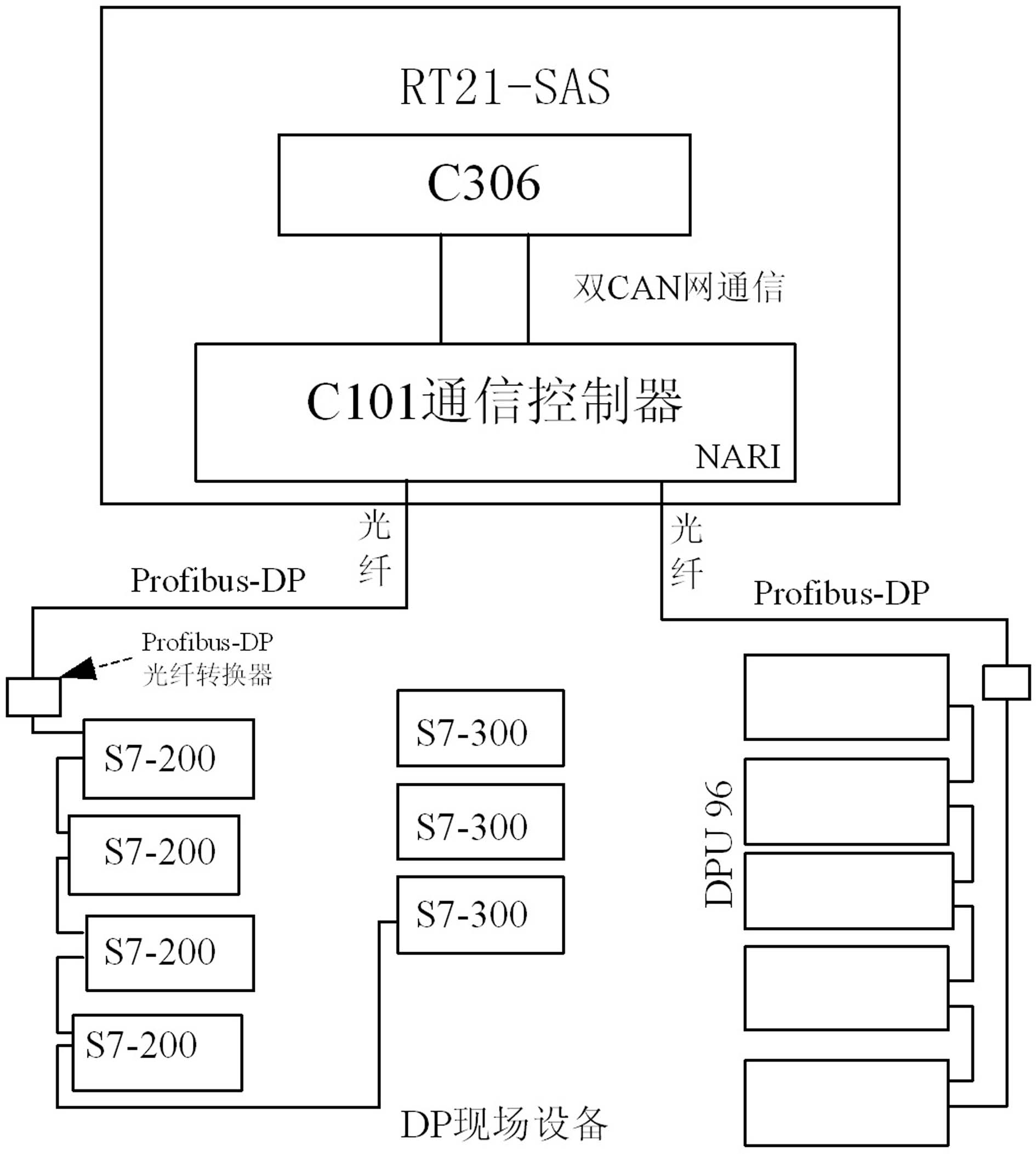

[0045] figure 1 What is given is the hardware functional block diagram of the C101 communication controller based on the PROFIBUS-DP master station. C101 communication controller is a PC / 104-based PROFIBUS-DP master interface device. It is an important part of Guodian NARI series communication controllers. It provides a complete solution for rail transit PROFIBUS-DP interface and follows the EN 50170 standard. It converts the PROFIBUS protocol into the CAN2.0B protocol for communication with the master controller. It can be used both as a DP master and as a DP slave. It widely supports various transmission rates of the PROFIBUS-DP standard, and can connect up to 126 PROFIBUS slave stations. The device is mainly composed of 3 modules: C101-PFB, C101-CPU, C101-DB. The first two are smart boards, and they exchange data through 256K bytes of high-speed shared memory. The C101-DB board realizes the dual CAN network completely isolated from the master control C306, PC104 clock b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com