Control system for subway safety door

A control system and safety gate technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as loss of system control, loss of station control, and inability to read, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

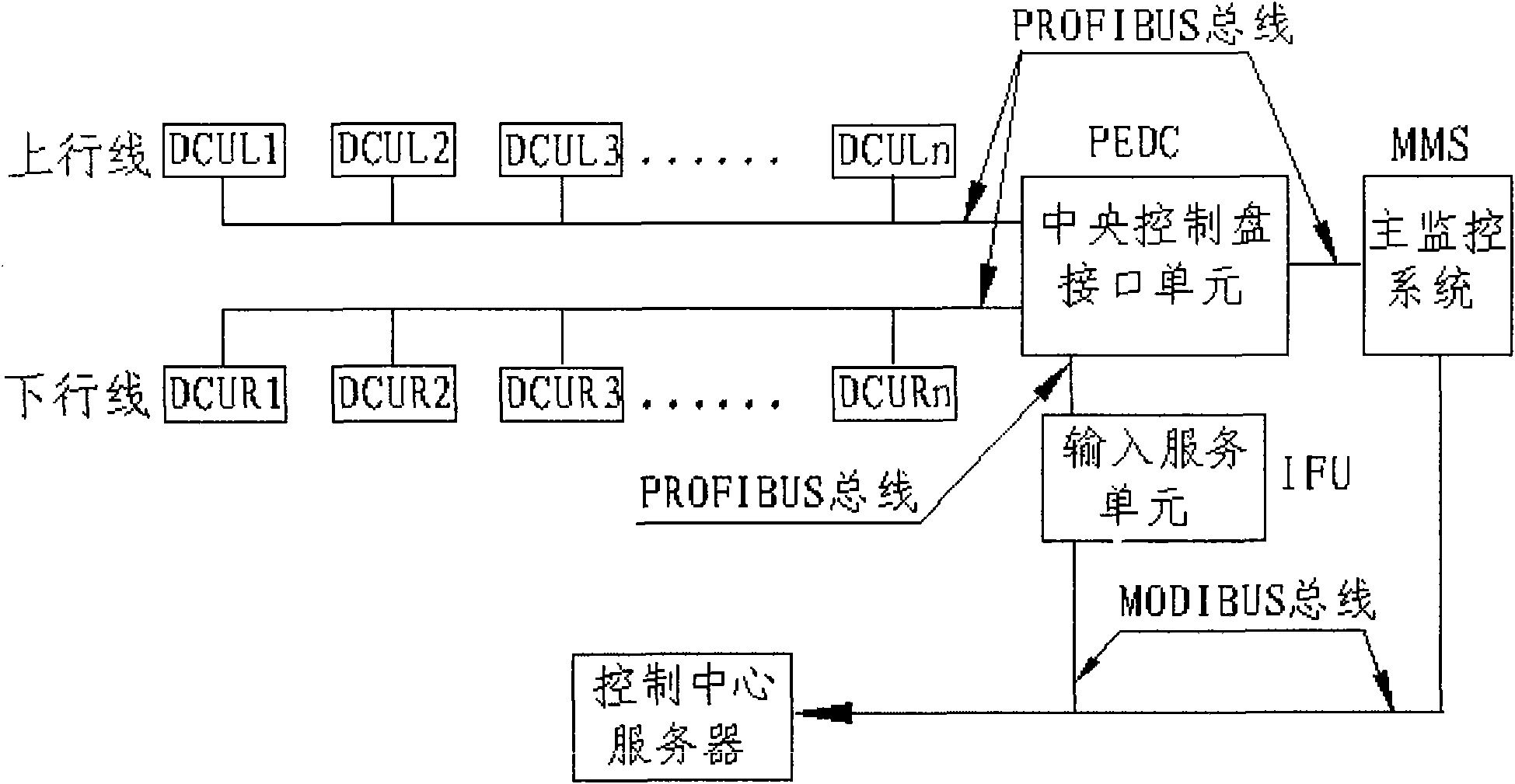

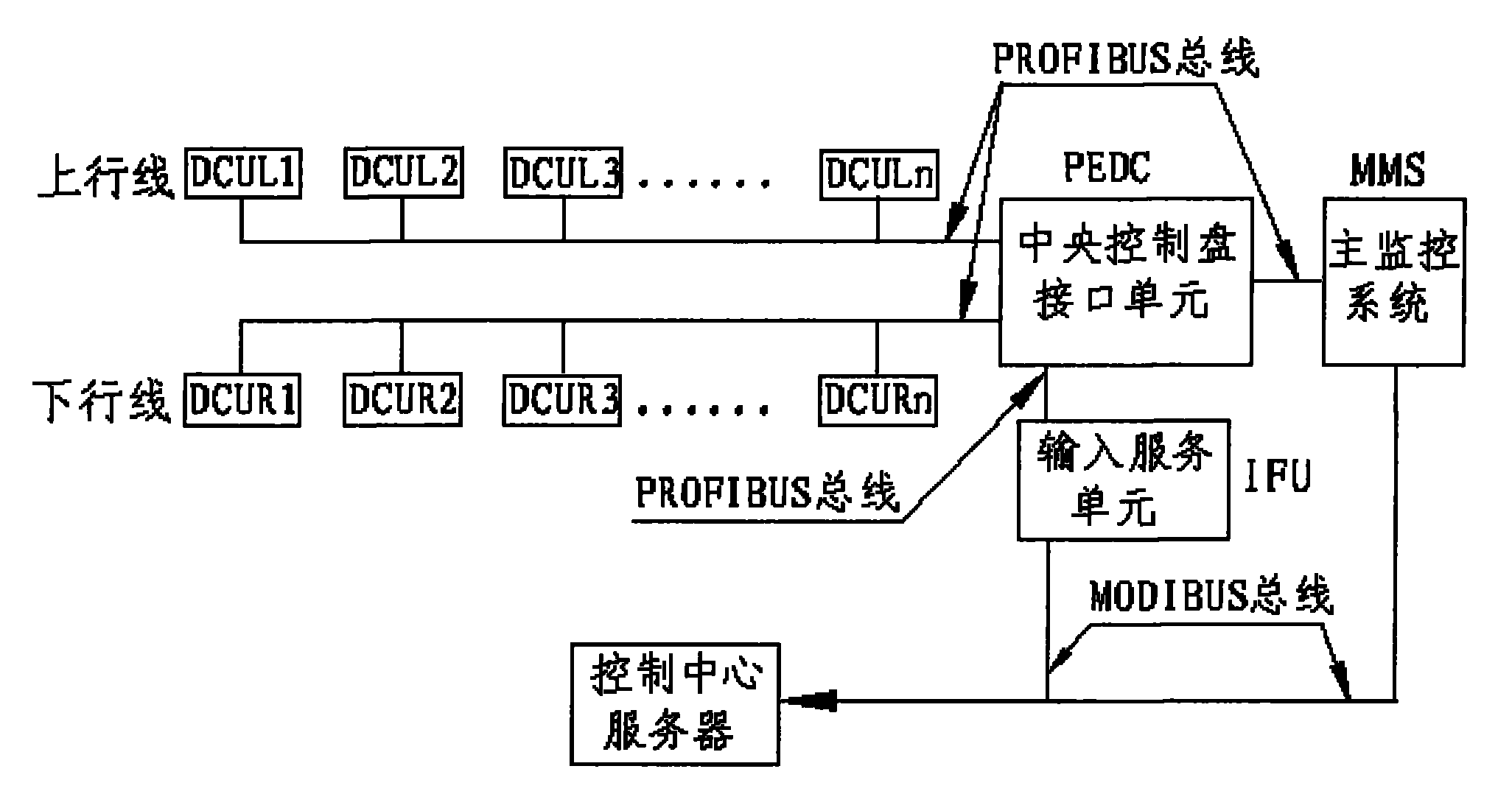

[0017] The present invention adds an embedded firmware IFU (input service unit, Input Fabricate Unit) in the subway safety door control system of prior art, finishes the conversion of communication protocol, and specially receives the control order of control center server; Embedded firmware IFU ( The input service unit) has solidified embedded software inside, which has low power consumption and is extremely stable and reliable compared with industrial computers, thus effectively avoiding the disadvantages of conventional system design.

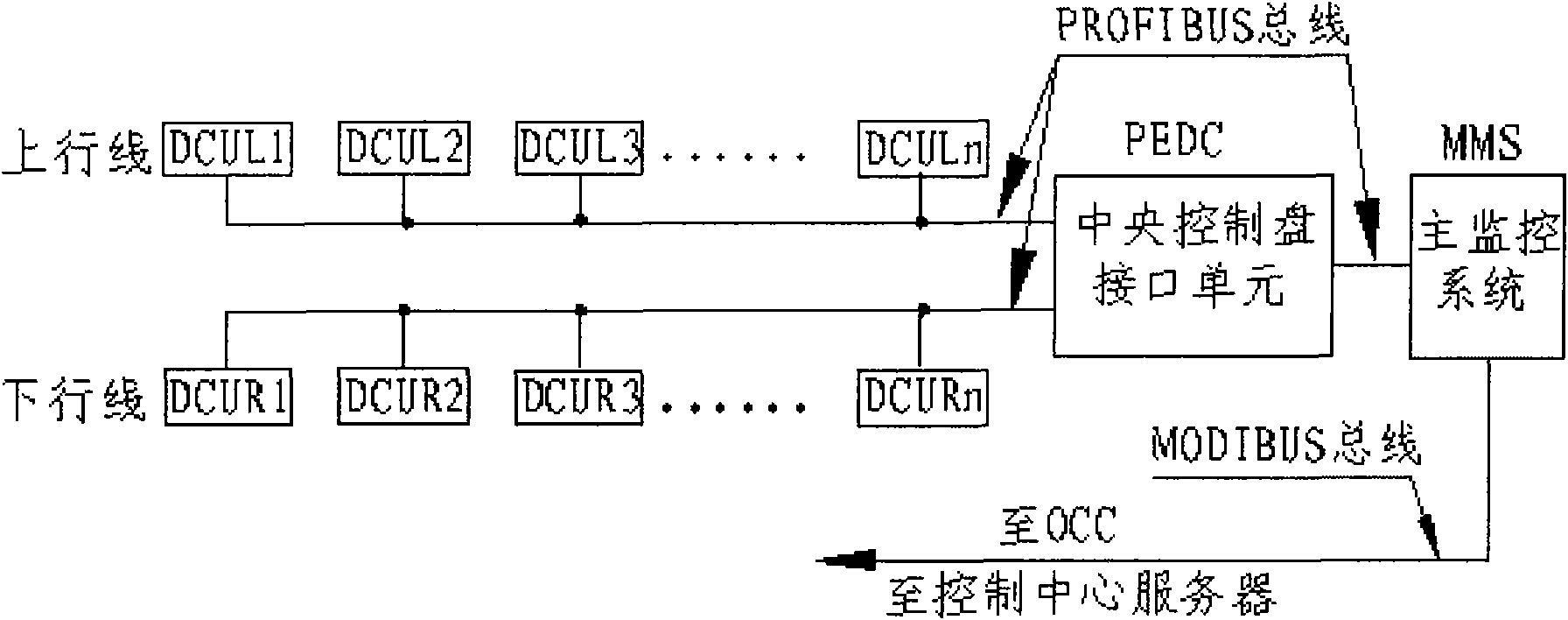

[0018] Such as figure 2 As shown, it is a schematic diagram of a network of a subway safety door control system according to an embodiment of the present invention. The subway safety door control system mainly includes: a main monitoring system (MMS), a central control panel interface unit (PEDC, Platform Electrical Door Controller), an input Service unit (IFU), control center server (OCC) and multiple door unit controllers (DCU, Door Contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com