PROFIBUS based fault setting system

A fault and bus technology, applied in the field of railway experimental training teaching aids, can solve the problems of insufficient training workload, few fault points, and failure to cover the basic principles and core technologies of the production line, etc., to achieve simple circuit design, convenient fault setting, The effect of training effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

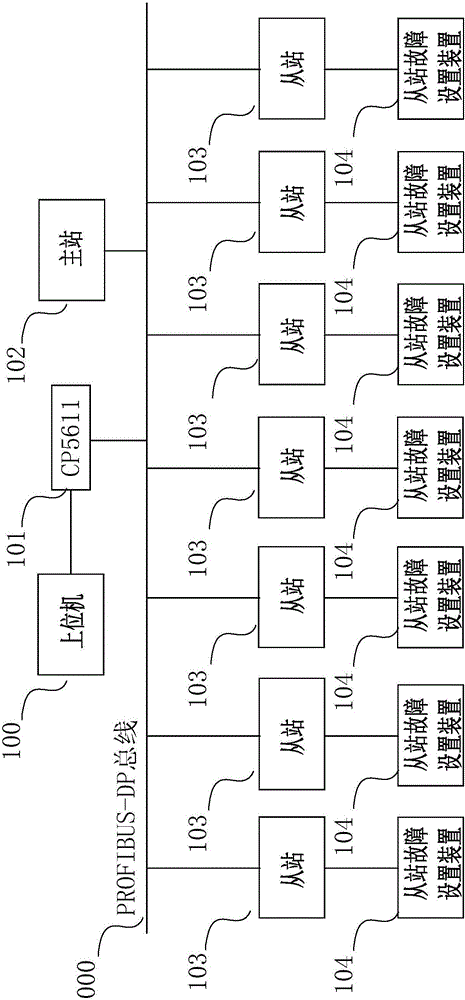

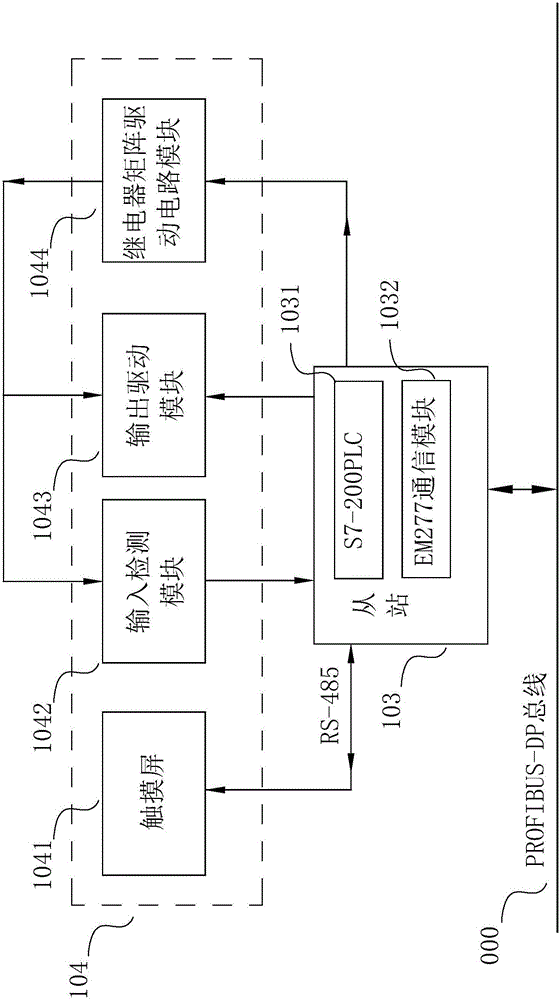

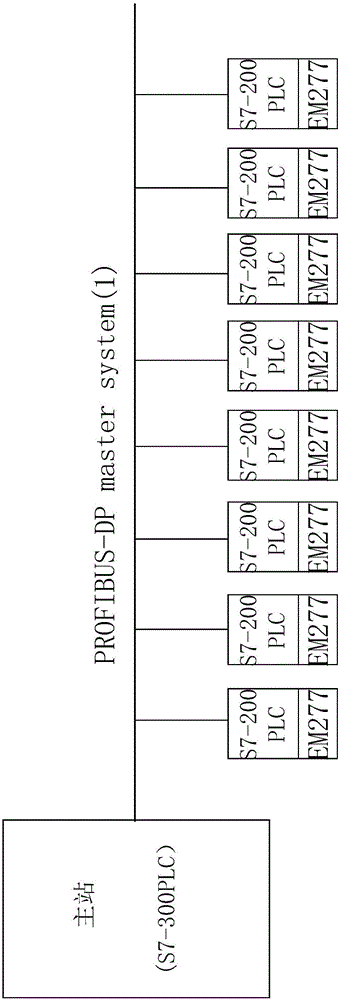

[0060] A fault setting system based on PROFIBUS bus, comprising PROFIBUS-DP bus 000, upper computer 100, CP5611 communication card 101, master station 102 and 7 slave stations 103, said master station includes master station programmable controller, DI / DO and guide rail, the slave station includes slave station programmable controller 1031 and EM277 communication module 1032, the master station programmable controller adopts S7-300PLC, and the slave station programmable controller adopts S7-200PLC;

[0061] The host computer is connected to the PROFIBUS-DP bus through the CP5611 communication card,

[0062] The master station is connected to the PROFIBUS-DP bus through the RS-485 communication interface;

[0063] The programmable controller of the slave station is connected to the PROFIBUS-DP bus through the extended EM277 communication module;

[0064] Described a kind of failure setting system based on PROFIBUS bus also includes slave station failure setting device 104, ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com