Device and method for controlling electronic-controlled engine

An electronically controlled engine and engine technology, applied in the direction of engine control, machine/engine, program control, etc., can solve the problem of not being able to test the electronically controlled engine, and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

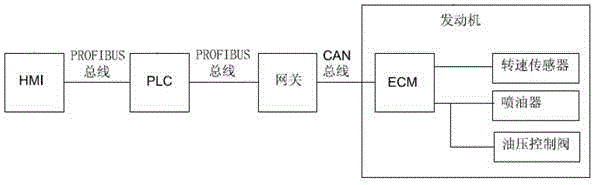

[0049] figure 1 It is a block diagram of the HMI principle of the industrial computer of the present invention: a device for controlling an electronically controlled engine of the present invention includes an industrial computer with a touch screen, a programmable logic controller PLC, a gateway, an electronic control module ECM of an electronically controlled engine, a speed sensor, and a fuel injection The industrial computer is connected to the PLC through the ProfiBus bus, the PLC is connected to the gateway through the ProfiBus bus, the gateway is connected to the electronic control module ECM through CAN, and the electronic control module ECM is connected to the engine sensor, fuel injector and connected to the oil pressure control valve.

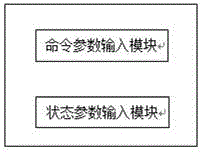

[0050] figure 2 It is a functional block diagram of the industrial computer HMI of the present invention.

[0051] The industrial computer HMI includes a command parameter input module and a status parameter output module. Comman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com