Die forging production line intelligent control system

A technology of intelligent control system and production line, applied in general control system, control/adjustment system, program control and other directions, can solve the problems of poor consistency of forging processing quality, low degree of intelligence, high labor intensity, etc., and improve the consistency of processing quality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

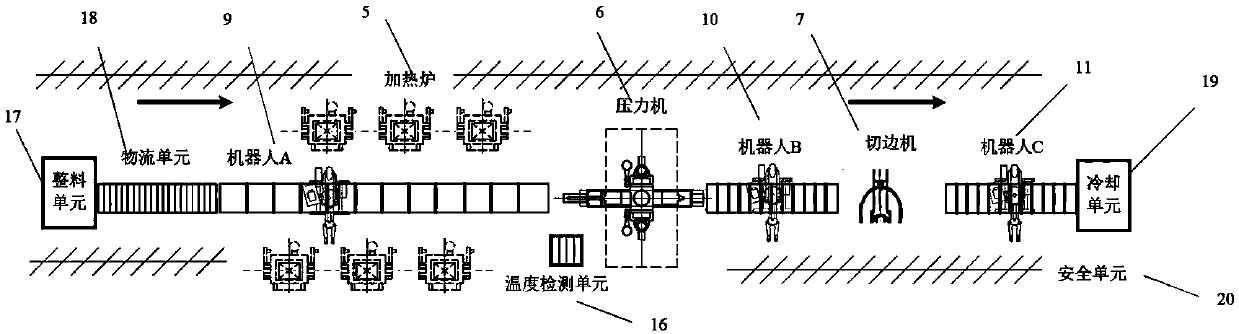

[0037] like figure 1 Shown is a schematic diagram of a die forging production line. The die forging production line of the present invention includes a heating furnace (5), a press (6), a trimming machine (7), a robot A (9), a robot B (10), and a robot C (11), monolithic unit (17), logistics unit (18), temperature detection unit (16), cooling unit (19) and safety unit (20) and other main equipment and units. The production line is arranged in order from left to right: logistics unit (18), logistics unit (18), robot A (9), heating furnace (5), temperature detection unit (16), press (6), robot B ( 10), trimming machine (7), robot C (11) and cooling unit (19), safety unit (20) is arranged on the periphery of the whole production line.

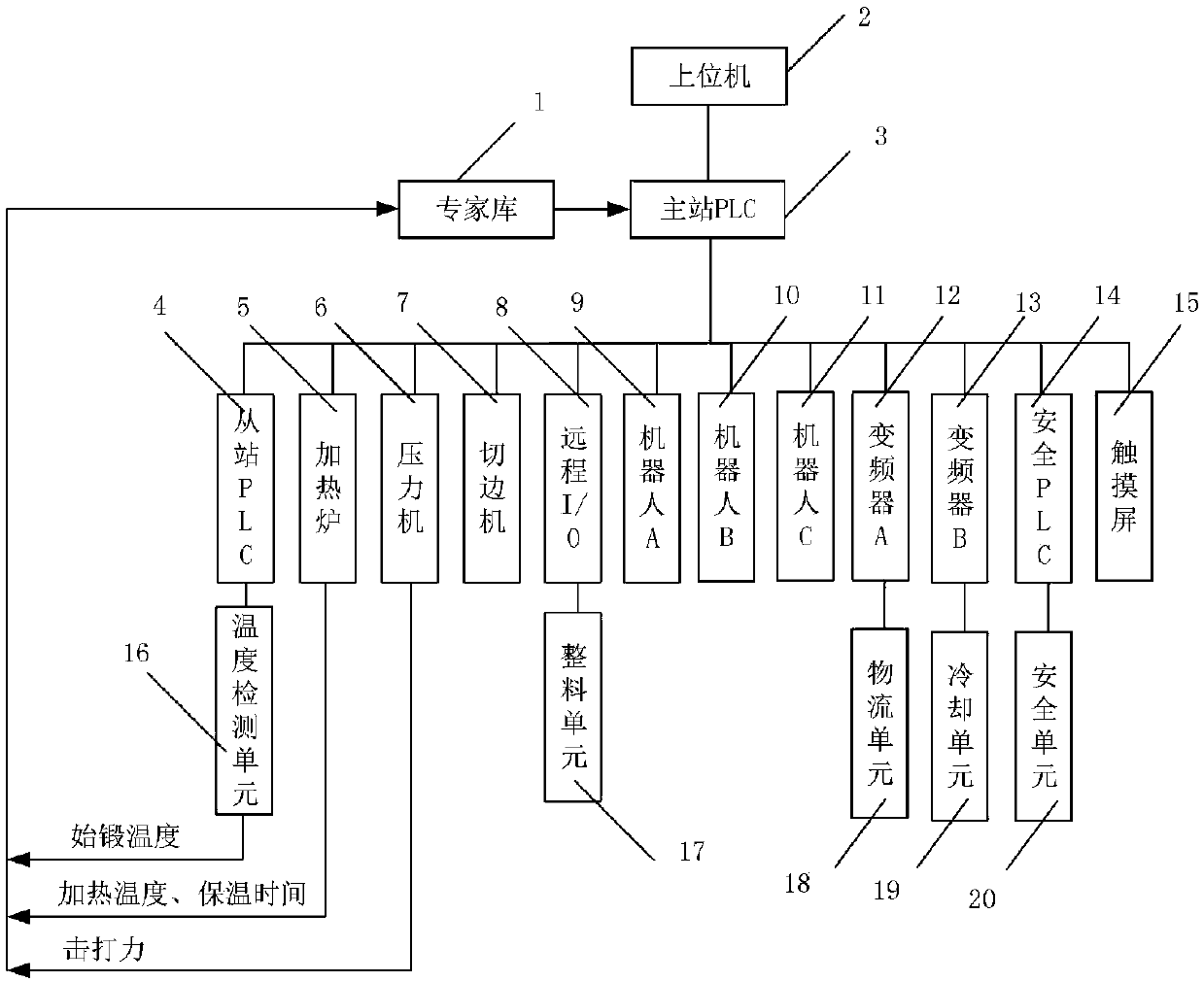

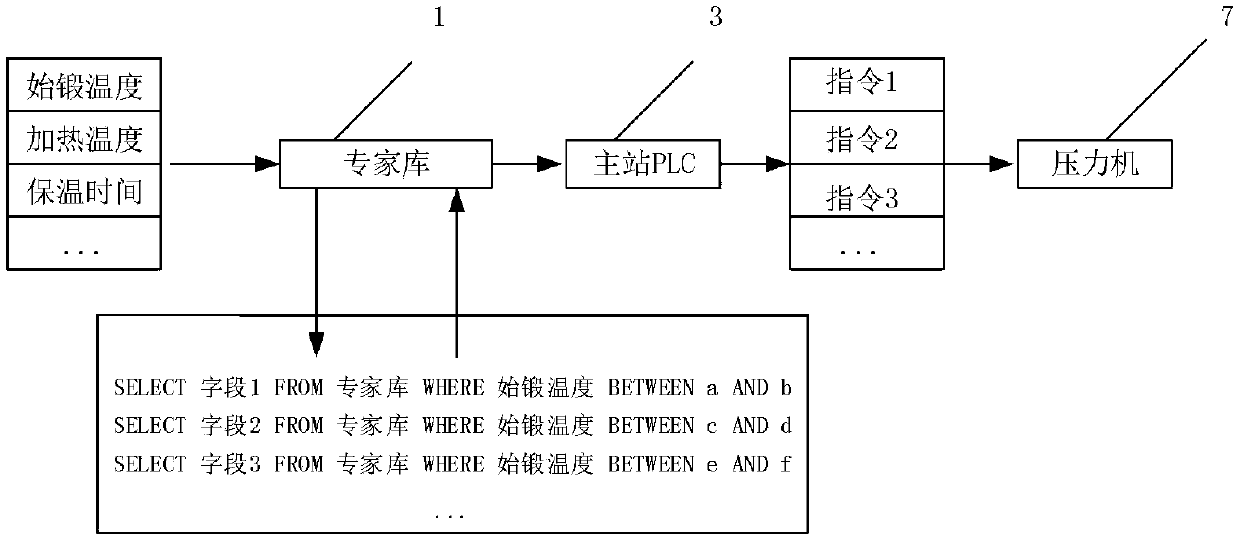

[0038] like figure 2 Shown is a schematic diagram of the control system of the die forging production line. The main station PLC (3) uses S7-415-2DP. The main station PLC (3) has two communication interfaces, one is MPI interface. The other i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com