Patents

Literature

373 results about "Mass Consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A description about the density of a mass.

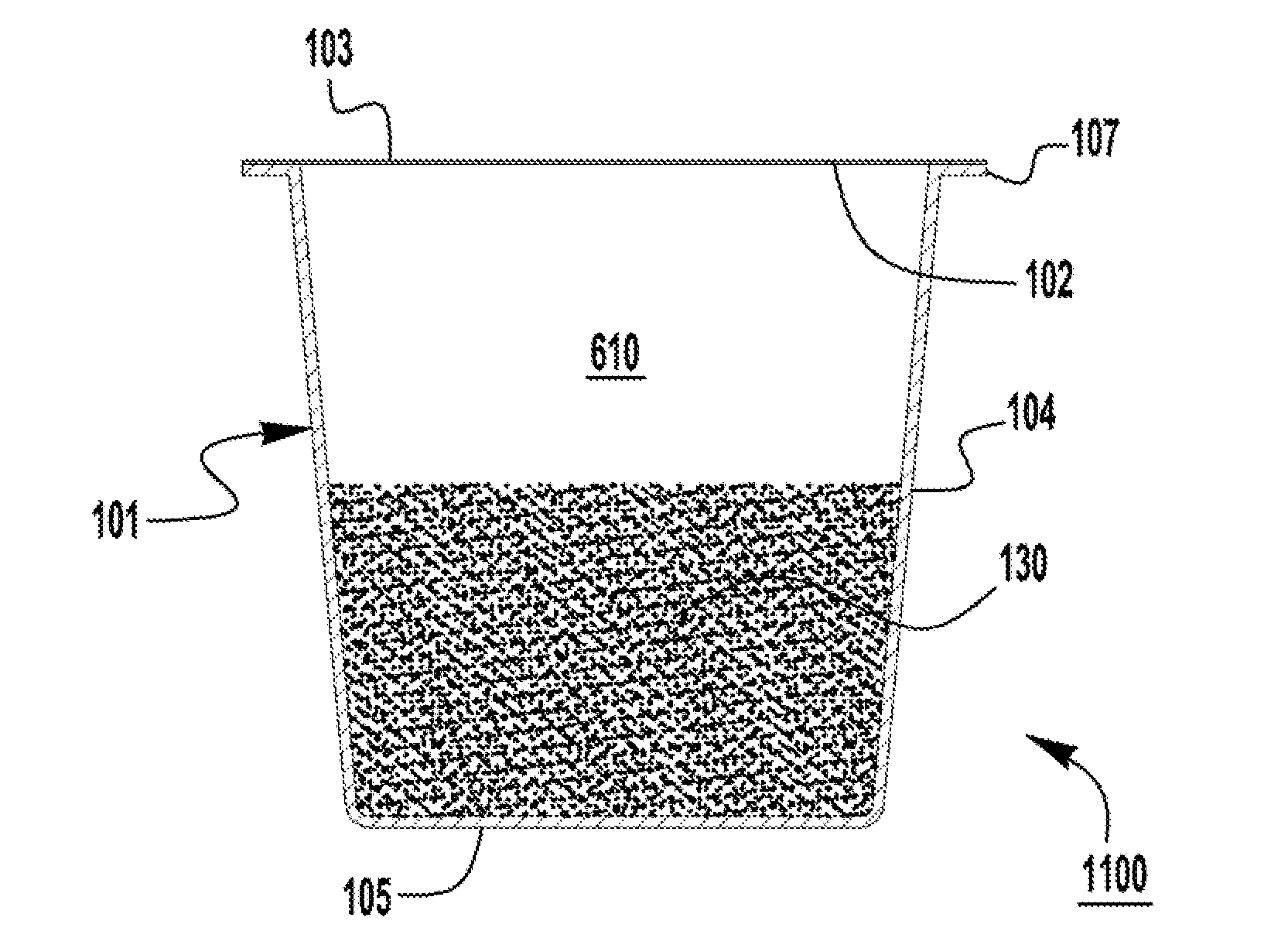

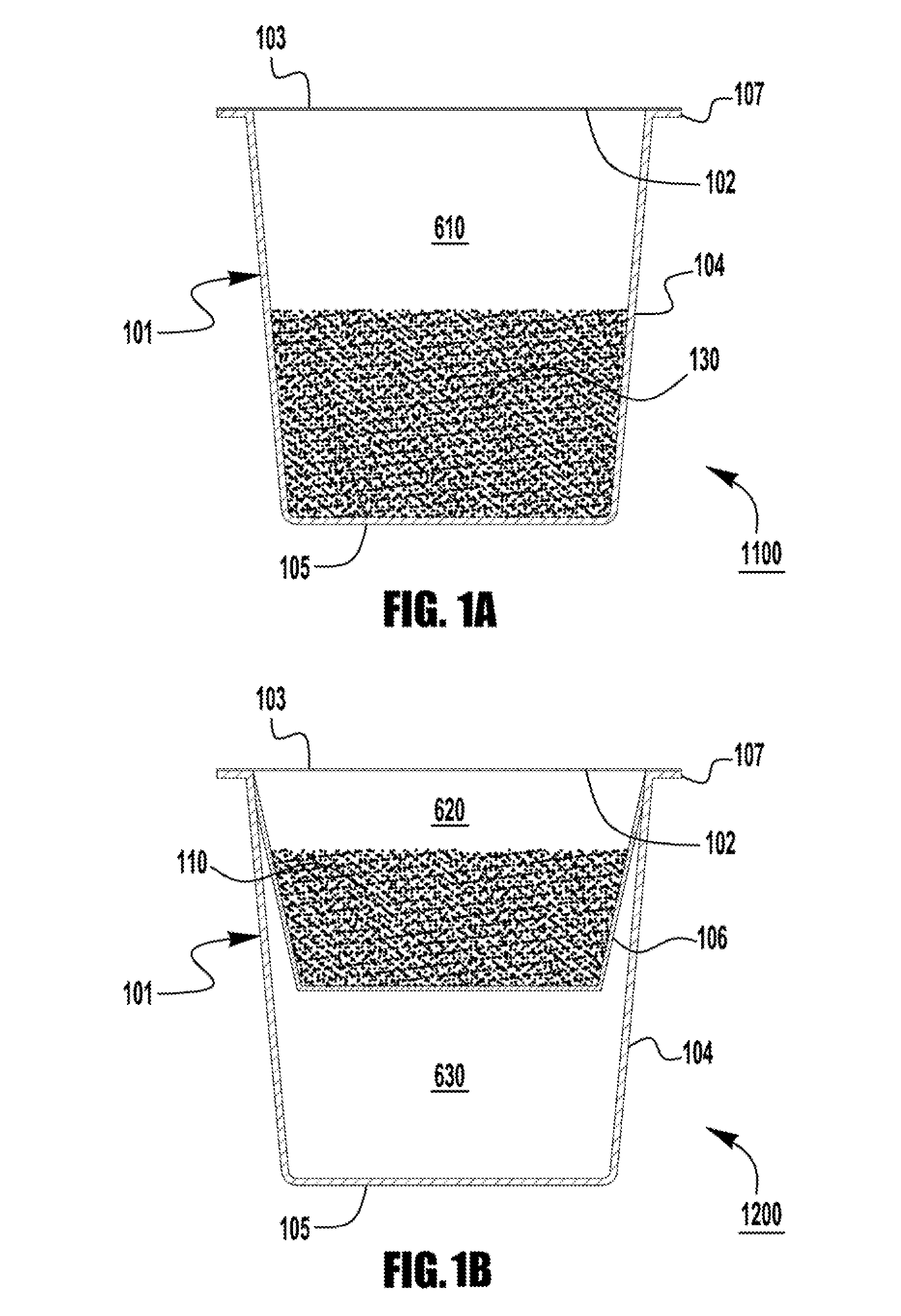

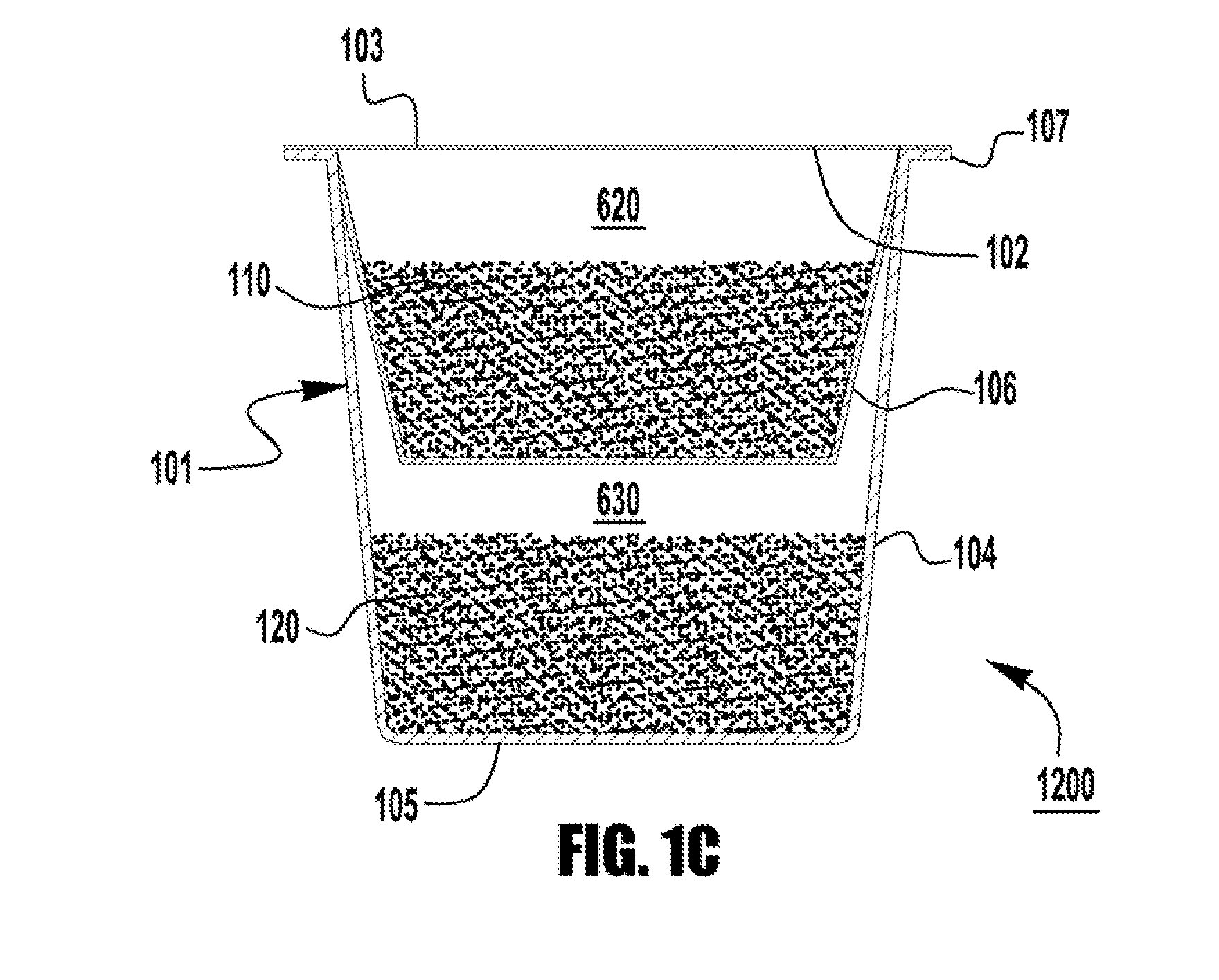

Coffee composition for use with a beverage unit and methods of using the same

The present invention provides a coffee composition for use with a single serve beverage unit. The beverage unit consists of a container having a first structure to enable the introduction of a liquid such as hot water into the container to contact the coffee composition and a second structure to enable the release of a coffee extract out of the container. The coffee composition comprises various coffee ingredients demonstrating an improved property, or an improved balance between two or more of properties, selected from aroma, strength, flavor, cup color, acidity, density, extractability, bed permeability, brewing time, yield, structural integrity, quality consistence and uniformity, and cost-effectiveness. Methods of using such coffees are also disclosed.

Owner:THE FOLGERS COFFEE

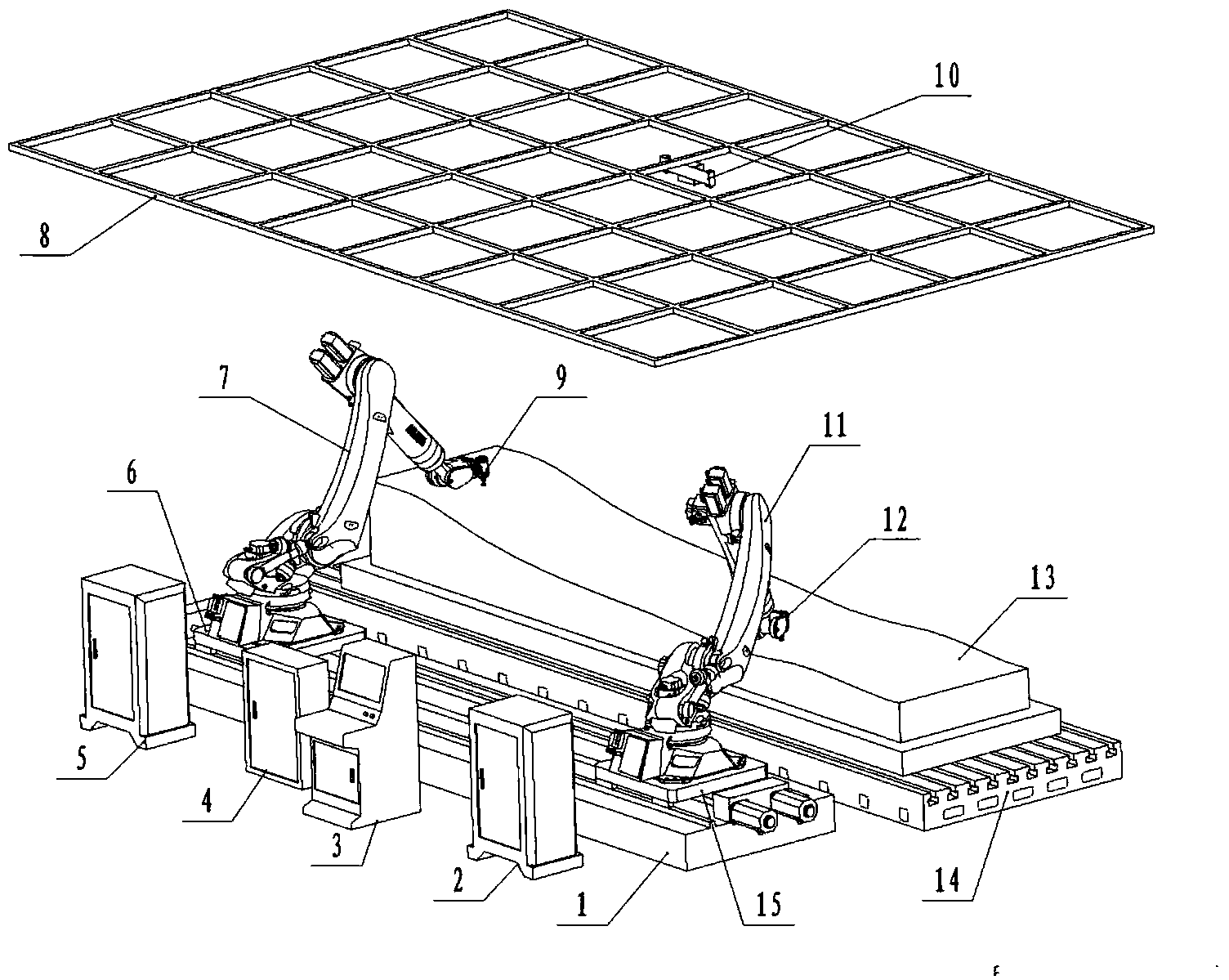

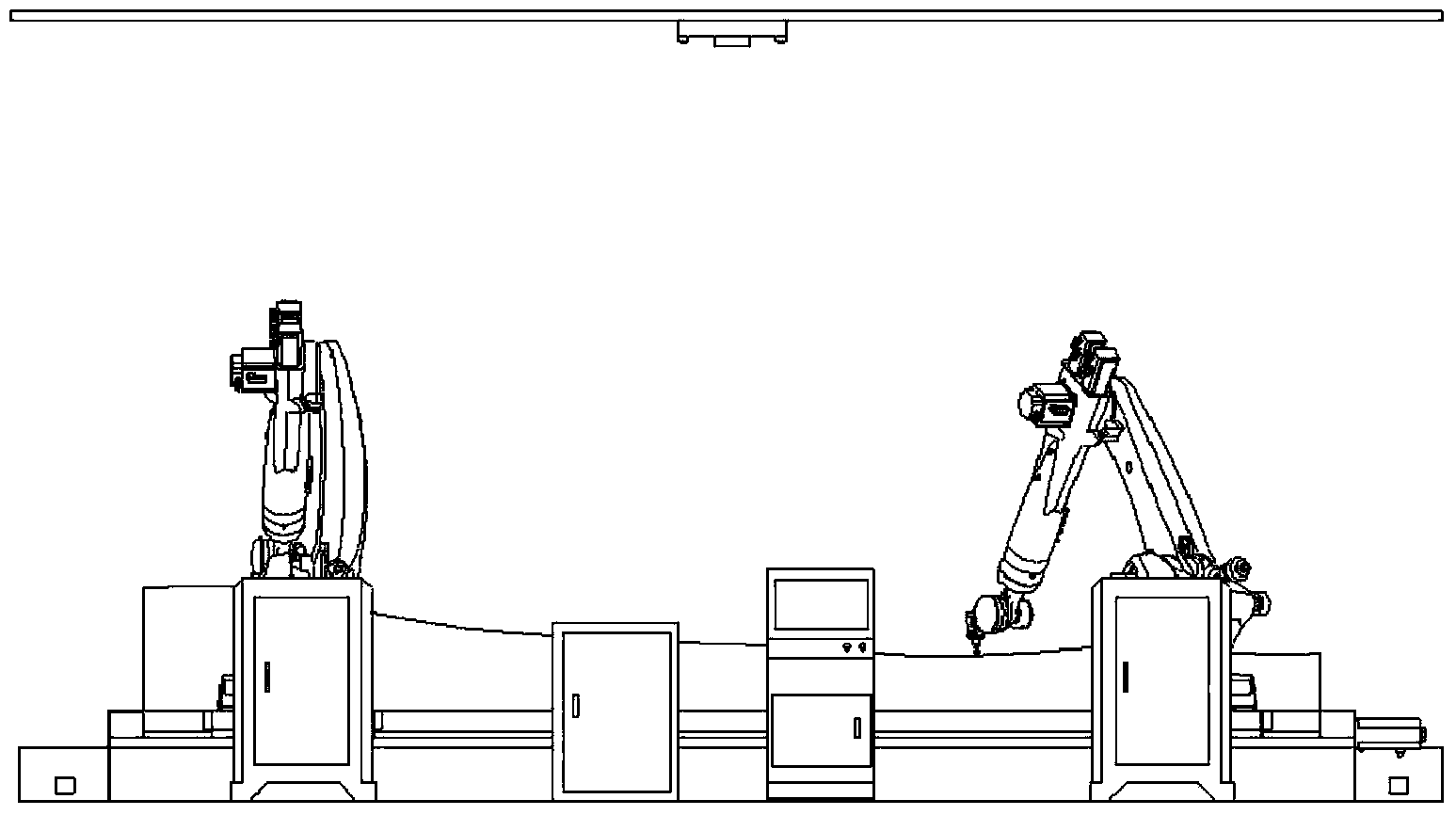

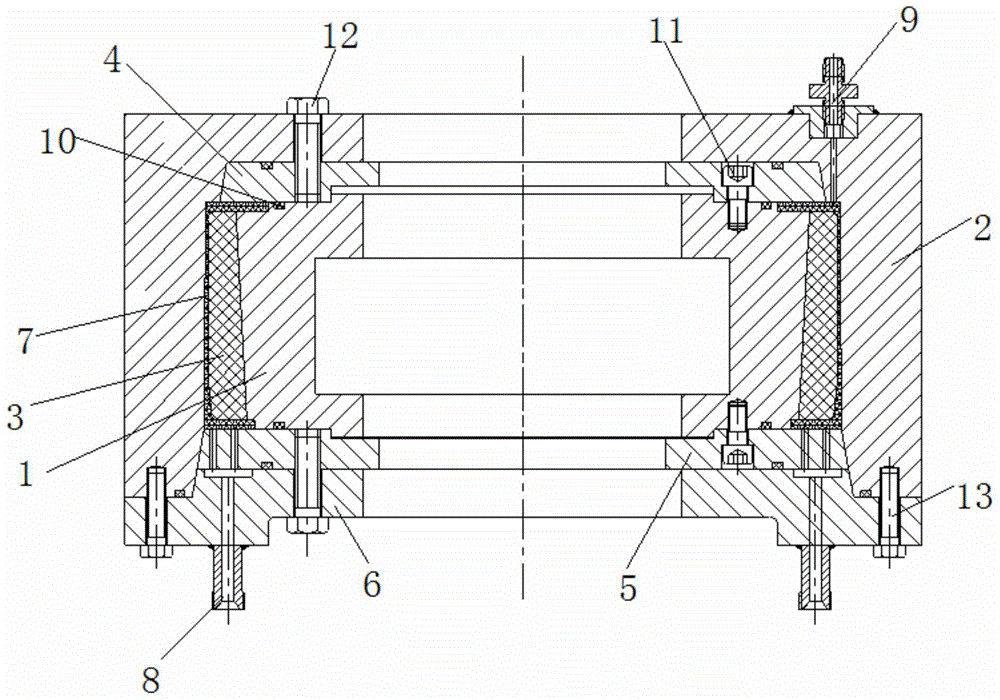

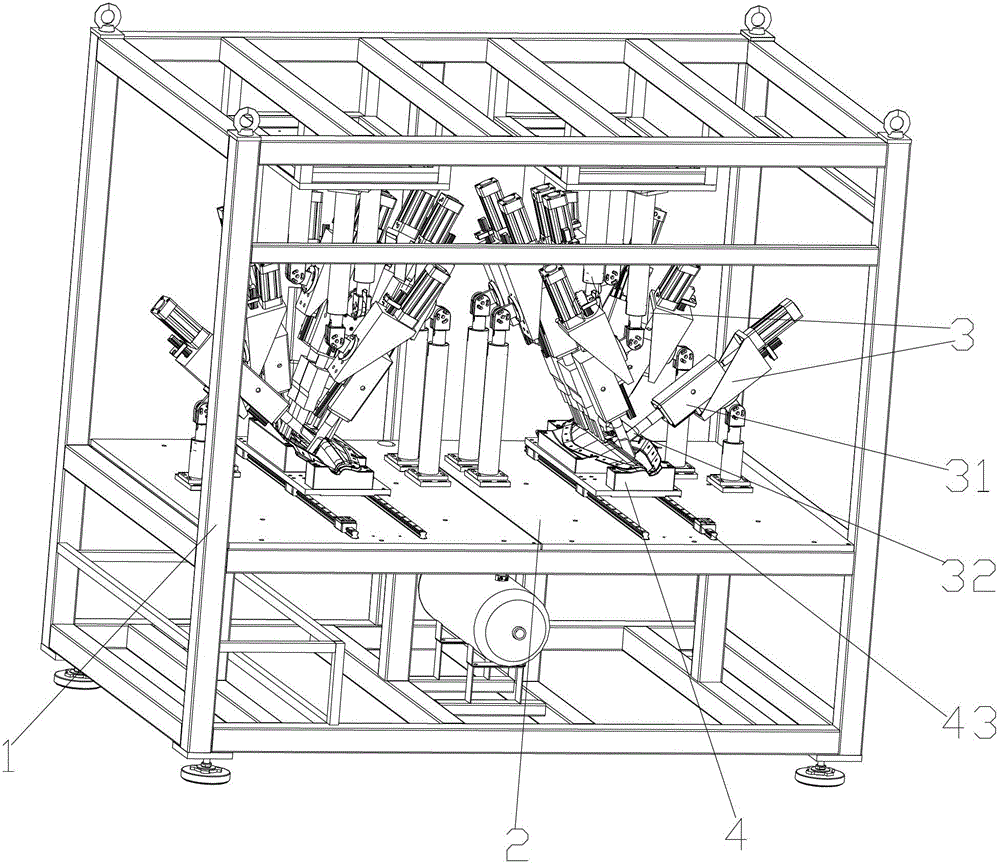

Robot parallel polishing system

ActiveCN103862340APressure controllableGuaranteed grinding removalEdge grinding machinesGrinding drivesSimulationSelf positioning

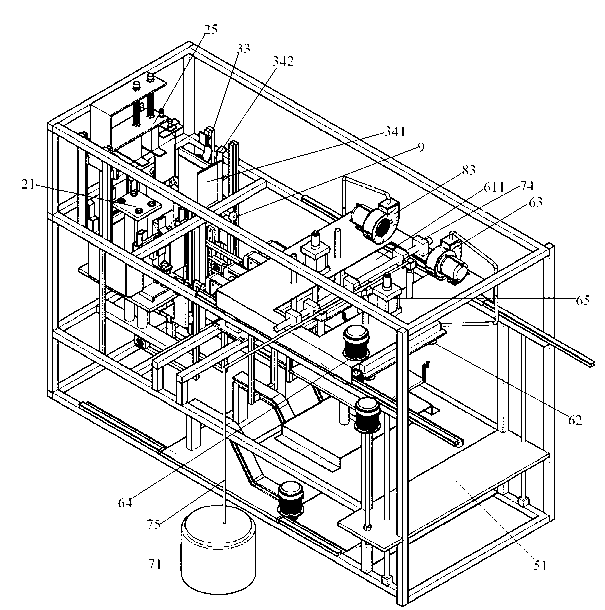

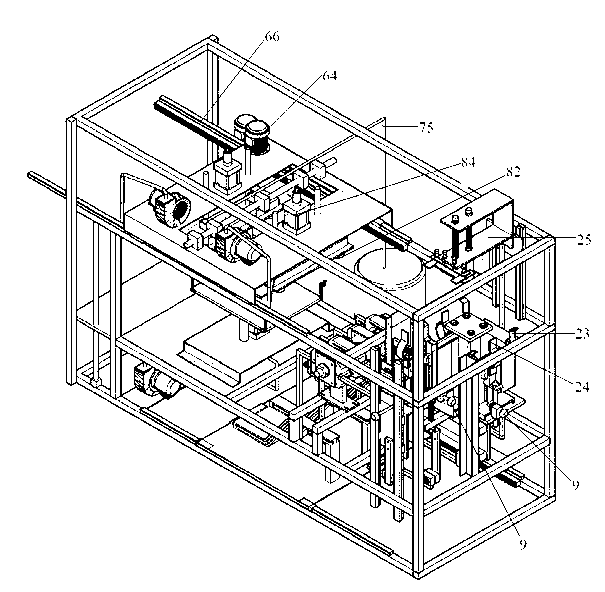

The invention discloses a robot parallel polishing system which comprises a coarse polishing system, a refined polishing system, a base component, a system control cabinet, a pneumatic control cabinet, a robot vision self-positioning system, workpieces and a working table. The workpieces with large free curved faces can be coarsely and finely polished through the polishing systems at the same time, simultaneous polishing on the two same workpieces can be achieved, the polishing accuracy can be effectively guaranteed, and the polishing efficiency is improved. Before the robot parallel polishing system works, the polishing areas are divided by path generative software according to three-dimensional models of the workpieces, the polishing paths are generated, standards of the workpieces are rapidly and accurately demarcated through the robot vision self-positioning system, two industrial robots drive a pneumatic polishing head to conduct coarse polishing and refined polishing on the polishing areas according to the planed paths, the pneumatic mild force control technology, the normal polishing force control technology and the path real-time calibration compensation technology are adopted in the polishing process, and the polishing accuracy and the coincidence of the polishing quality are effectively guaranteed.

Owner:中科君胜(深圳)智能数据科技发展有限公司

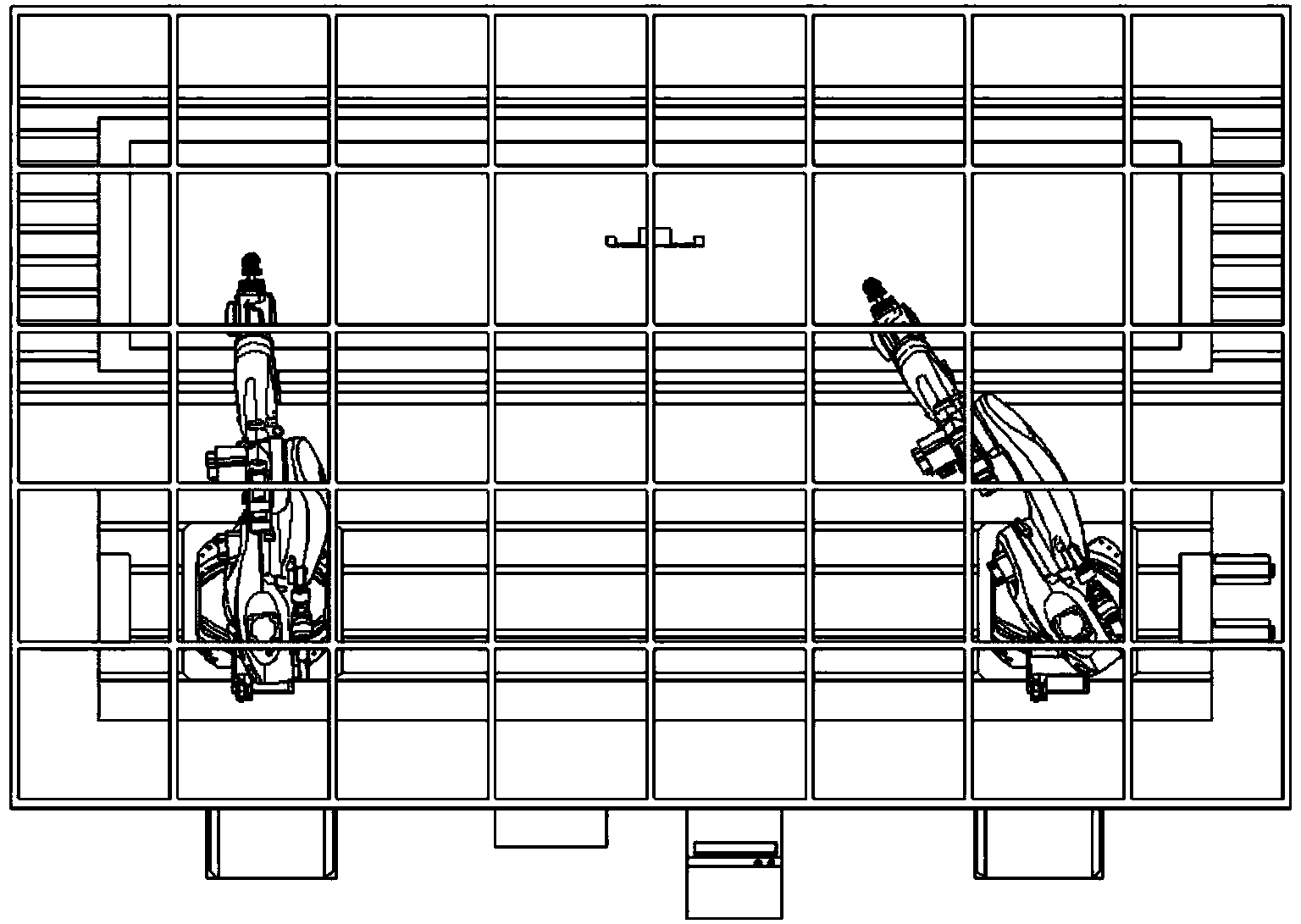

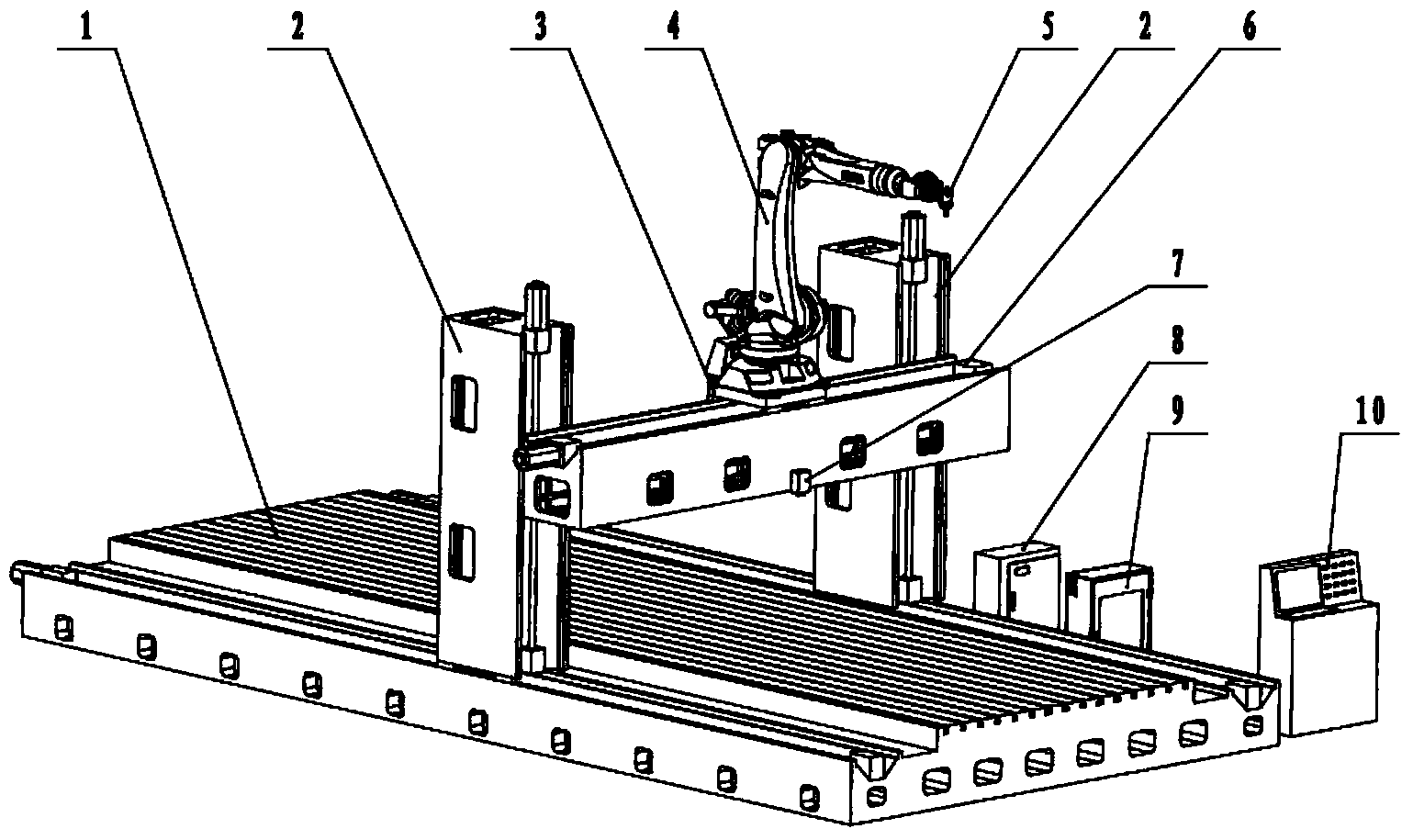

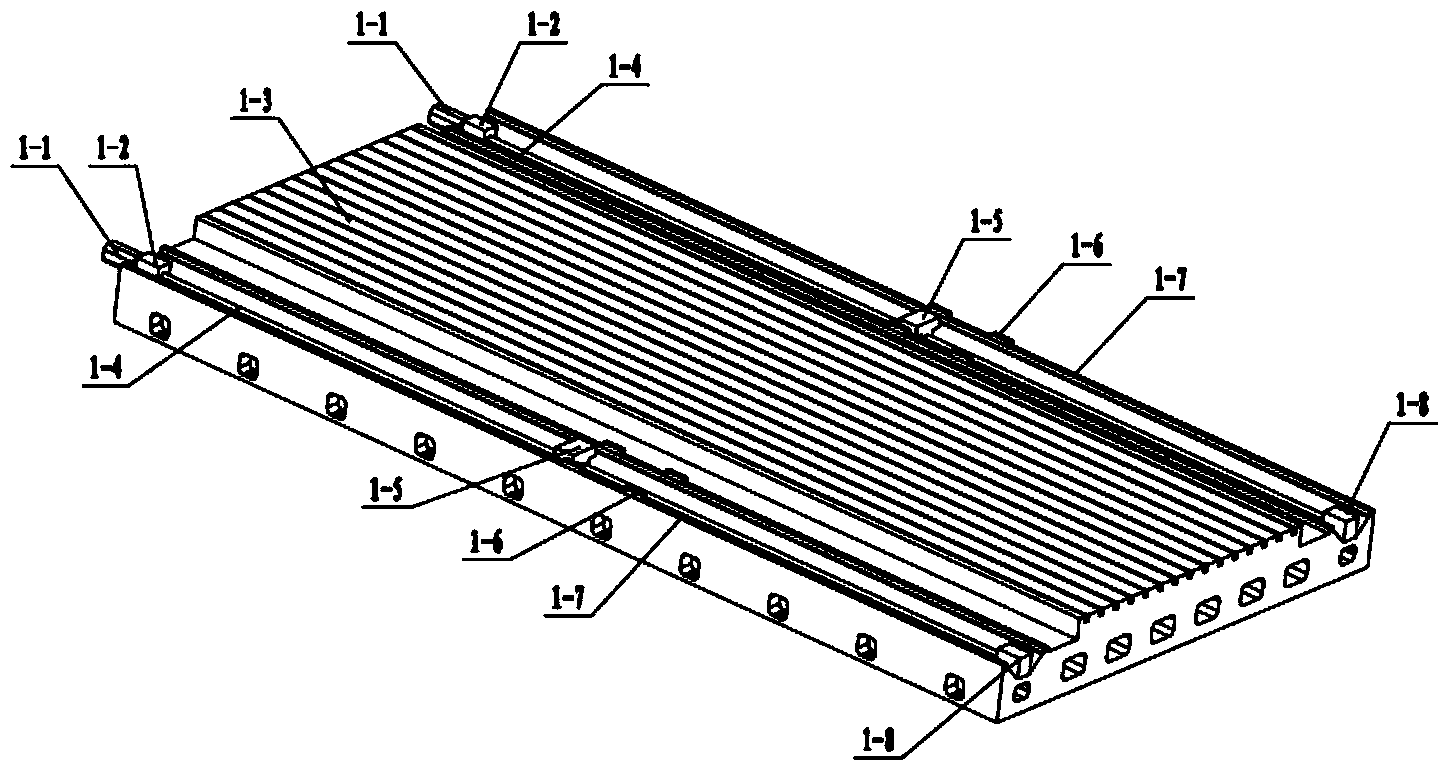

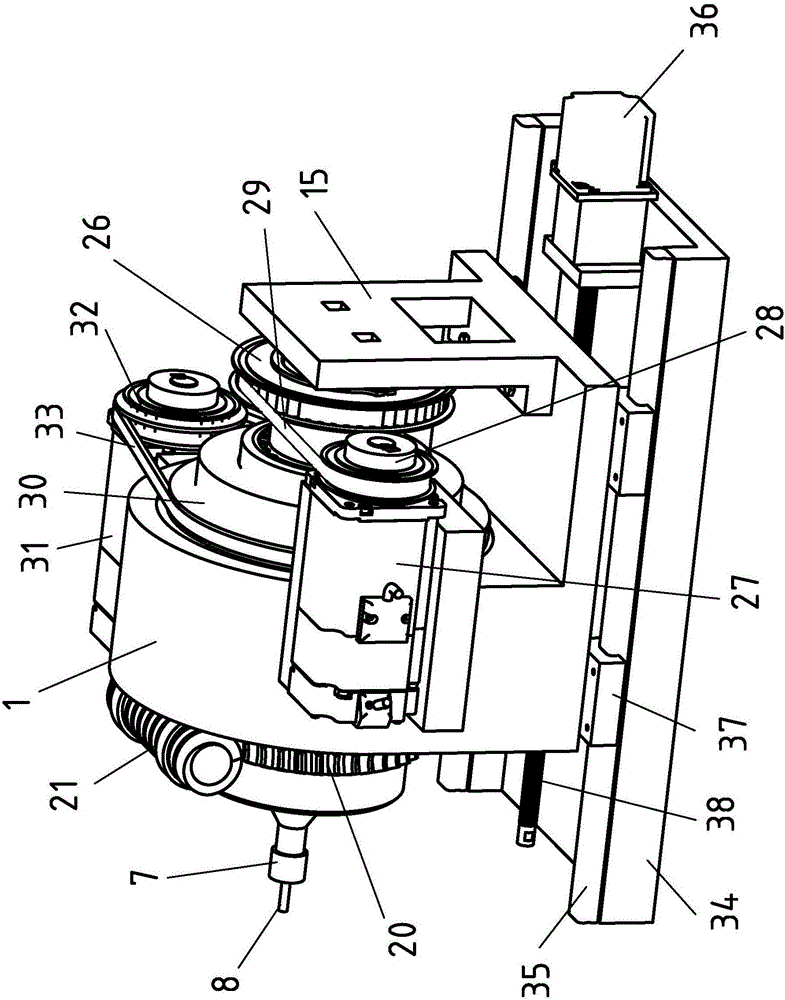

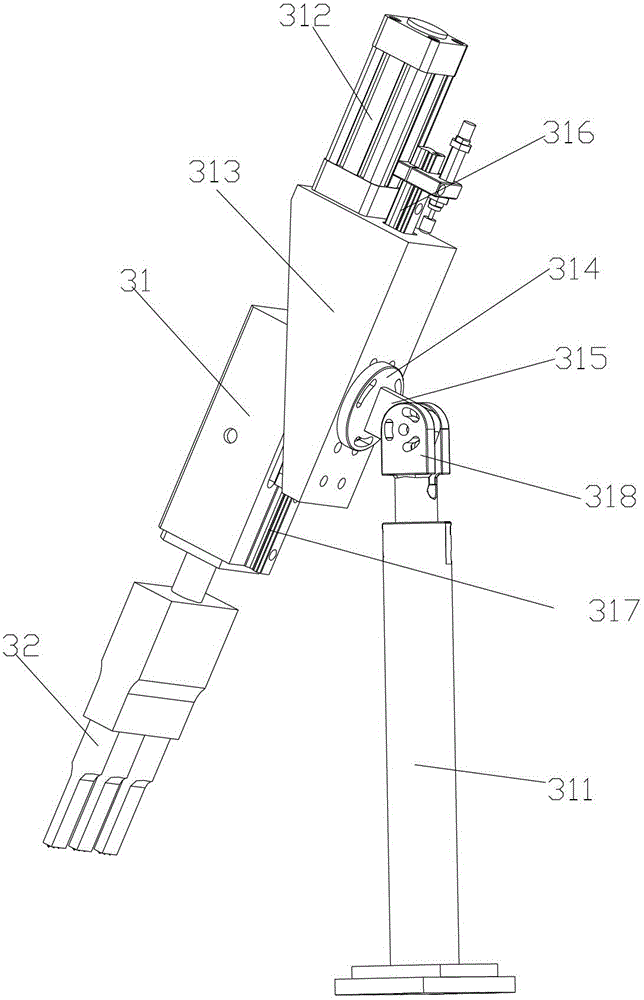

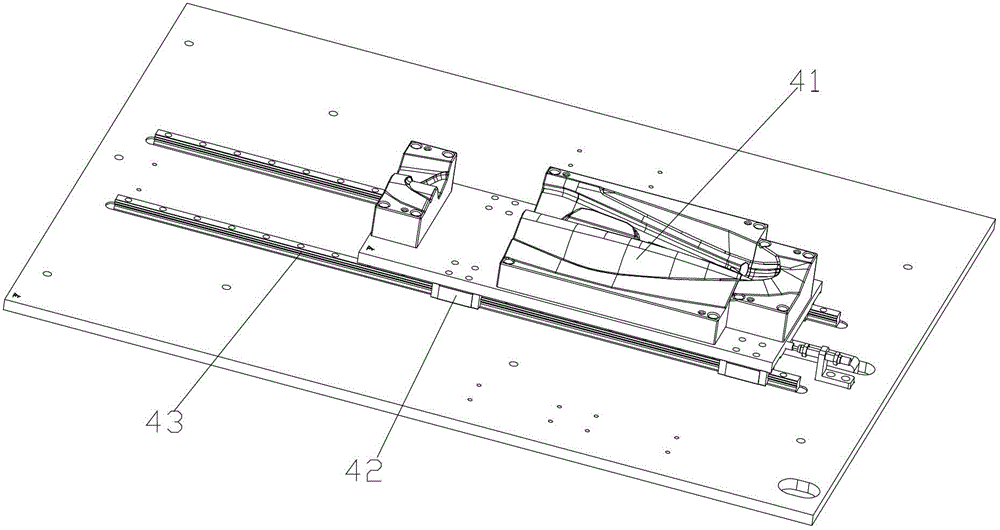

Large free-form surface robot polishing system

ActiveCN103831695AGrinding pressure is easy to controlGuaranteed grinding removalGrinding carriagesGrinding drivesFree formSimulation

The invention discloses a large free-form surface robot polishing system. The large free-form surface robot polishing system comprises a pneumatic polishing head, an industrial robot, a robot control cabinet, a traveler gantry, a visual system, a pneumatic control cabinet and a system control cabinet. When the polishing system works, a part standard is rapidly and accurately calibrated according to the standard accurate calibrating technique, the traveler gantry is used for driving the industrial robot to arrive at a target free-form surface, the pneumatic polishing head is driven by the industrial robot to polish the target free-form surface according to a planed path, the pneumatic smooth force control technique and the normal polishing force control technique are adopted in a polishing process, and consistency of polishing accuracy and polishing quality is effectively guaranteed; the industrial robot is driven by the traveler gantry to arrive at the next target free-form surface after the target free-form surface is polished, the industrial robot drives the pneumatic polishing head to conduct polishing according to the planed path again, and in this way, all free-form surfaces are polished step by step in sequence. The large free-form surface robot polishing system is simple in structure, wide in work range, and suitable for polishing the large free-form surfaces.

Owner:中科君胜(深圳)智能数据科技发展有限公司

Boron containing lithium iron phosphate/carbon composite material and preparation thereof

ActiveCN101364643AHigh bonding strengthHigh tap densityElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesCarbon layer

The invention relates to an anode material for secondary lithium batteries, in particular to a lithium iron phosphate / carbon composite material containing boron, and the preparation method thereof, and mainly solves the technical problems of lower bonding strength of coating the carbon layer and the lithium iron phosphate surface, relatively low product tap density, rapid growth of the grain size, non-uniform and non-centralized distribution, and poor uniformity in the electrical property of lithium iron phosphate and the product quality, etc., in the prior art. The chemical formula of the lithium iron phosphate / carbon composite material is Li1-xMxFe1-yNyP1-zSizO4.XiB2O3 / C or Li1-xMxFe1-yNyP1-zSizO4.ZetaLiBO2 / C. The preparation method comprises the following steps: adding a boric acid ester surface active agent or / and a fluxing agent to a ball milling tank filled with a solvent; stirring uniformly; further adding iron-source compounds, lithium-source compounds, phosphorus-source compounds and carbon-coated carbon source respectively and mixing; evaporating the solvent to dryness and sintering the obtained solid powder under the protection of inert gases; cooling and taking out; and pulverizing, grading and obtaining the finished product.

Owner:杭州金马新能源科技有限公司

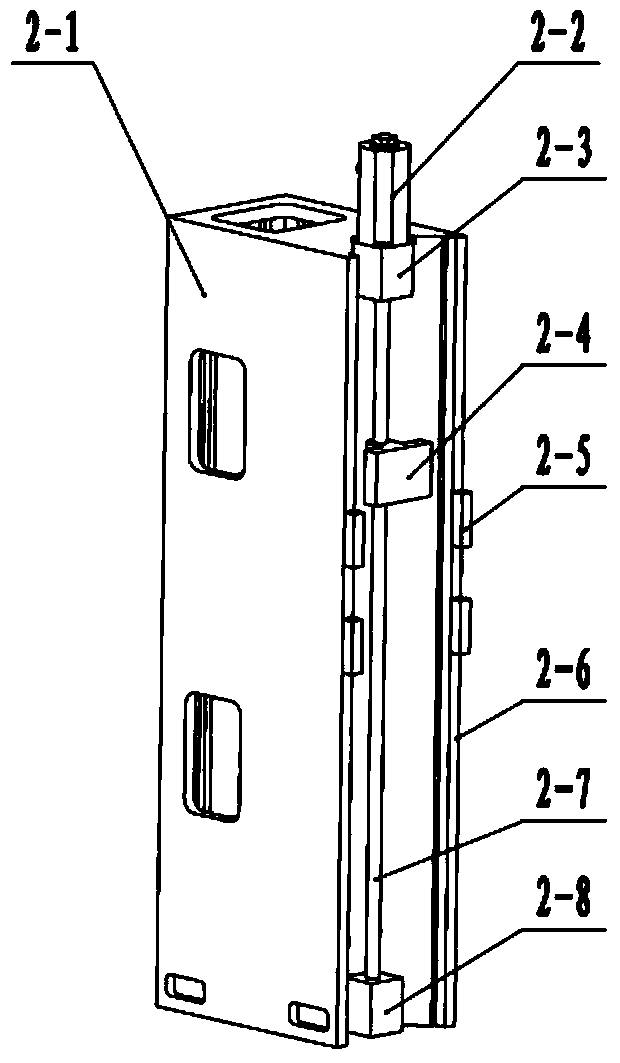

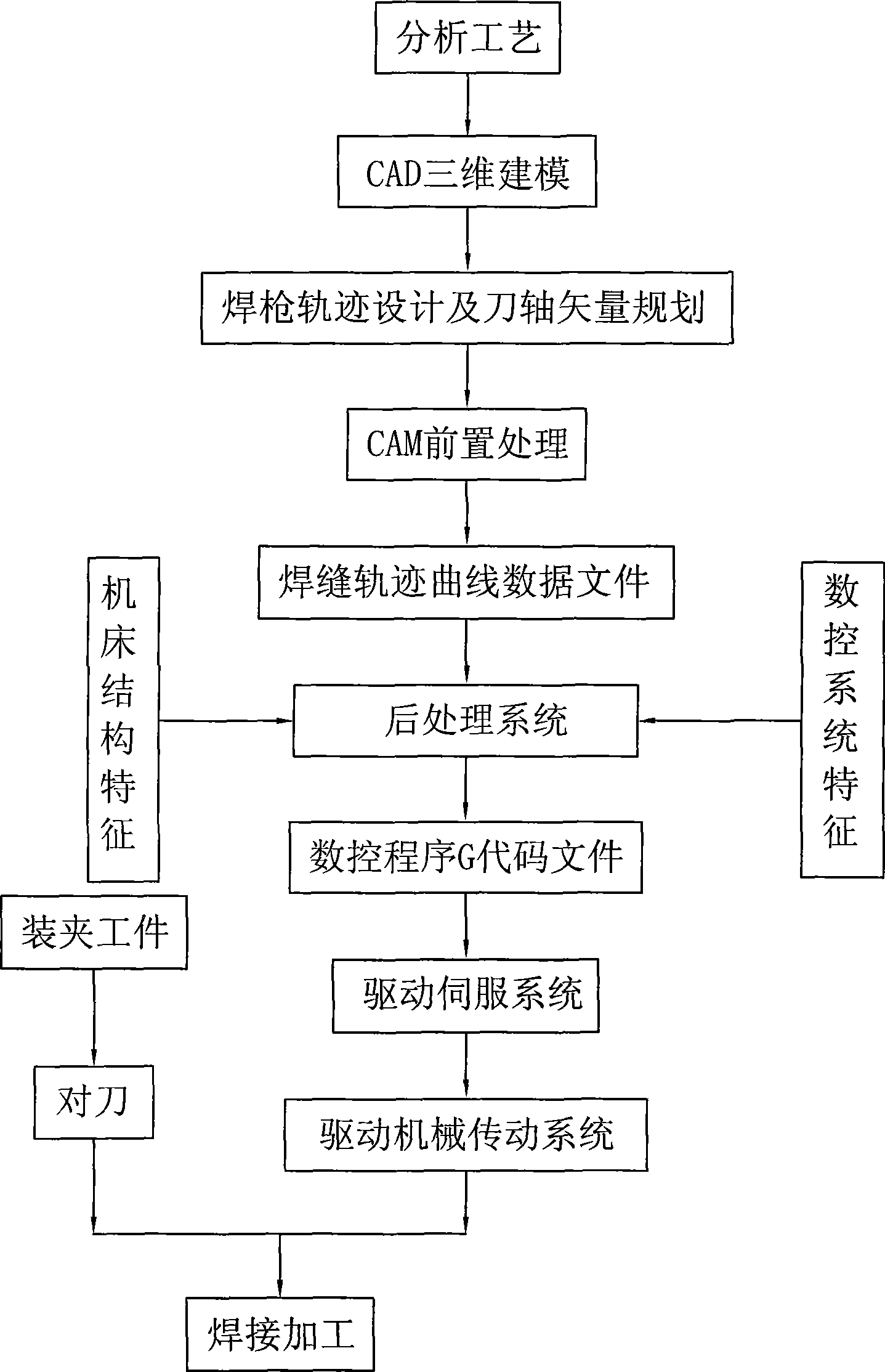

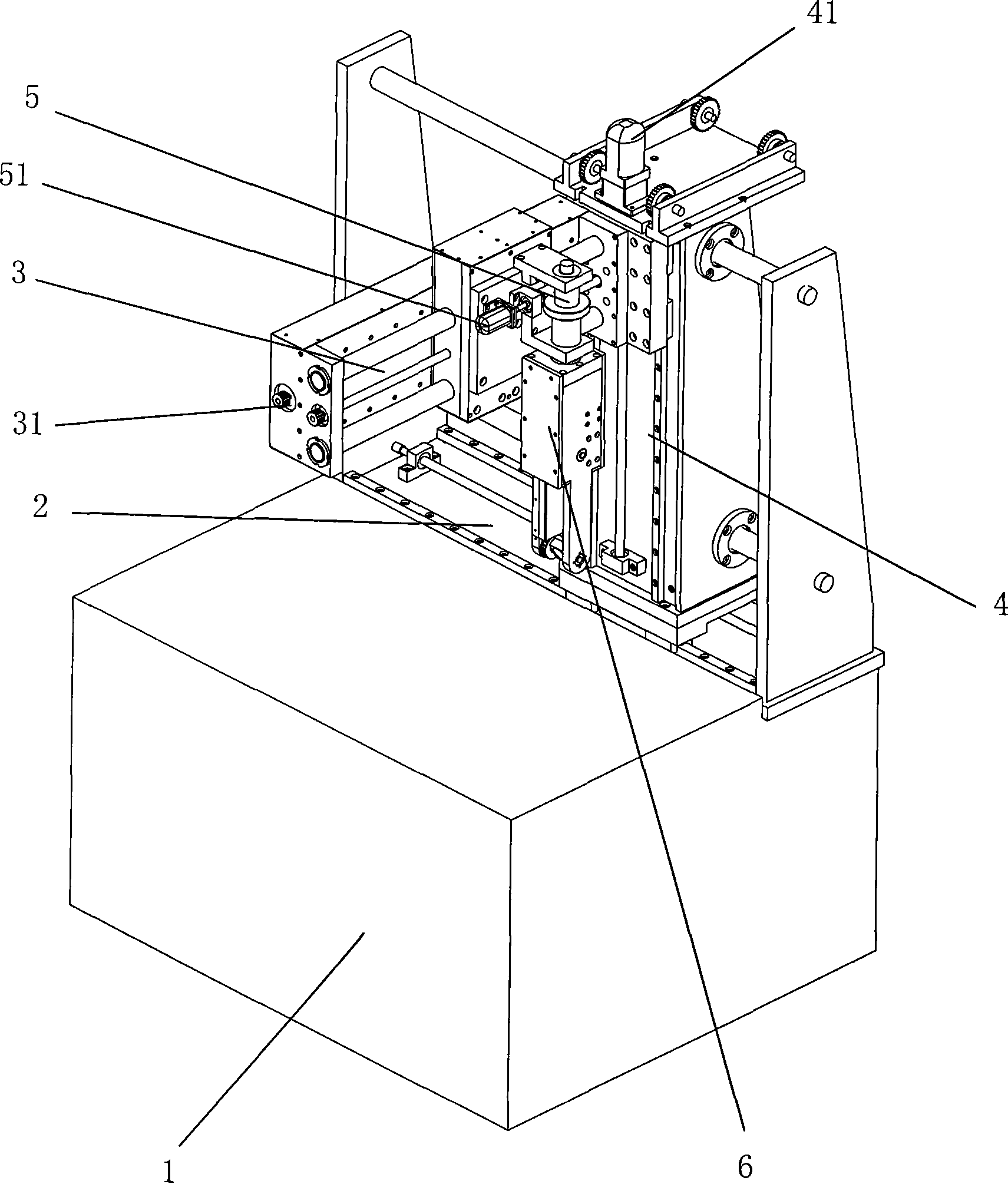

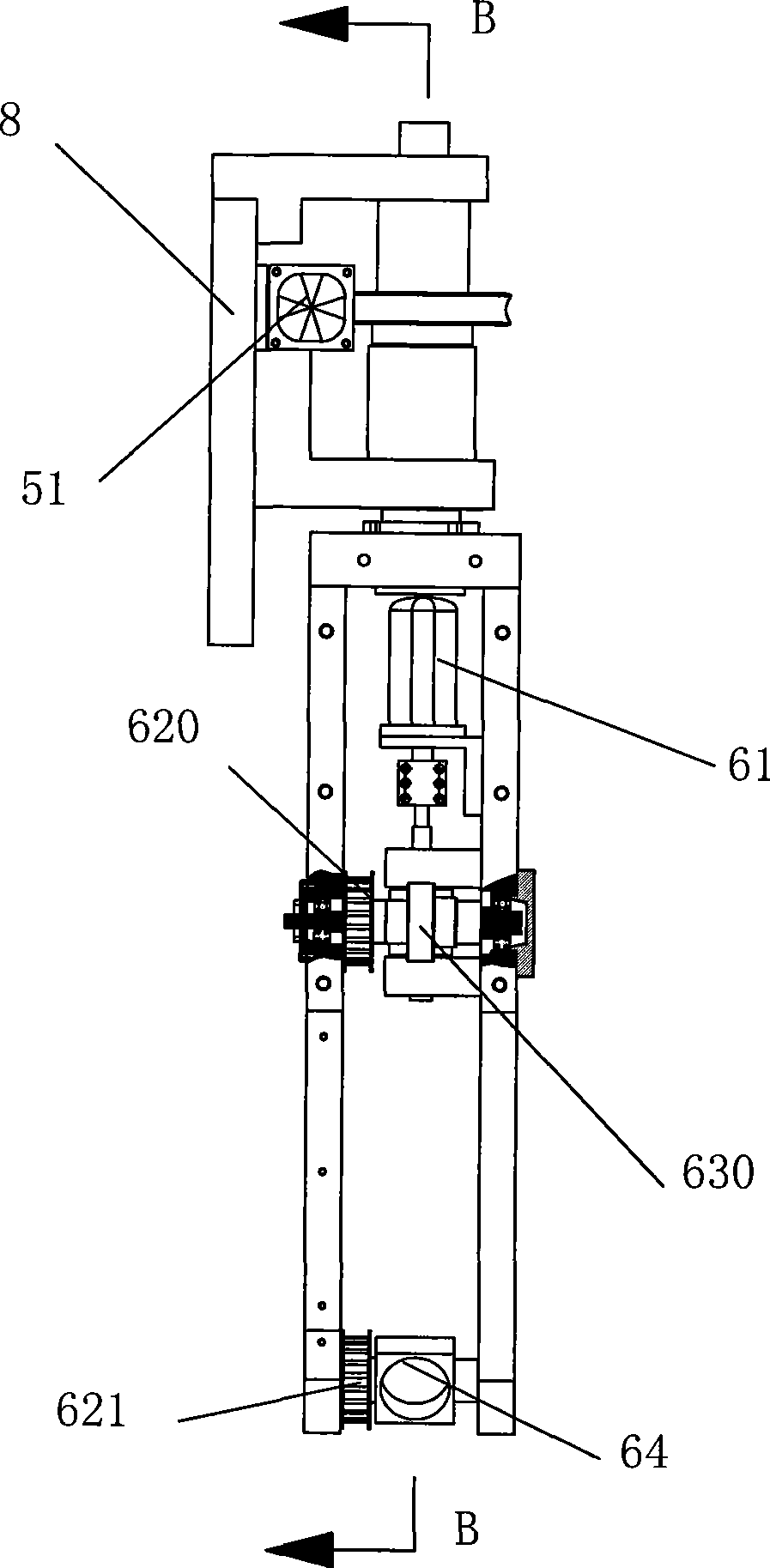

5-shaft linkage numerical control bonding machine and welding process control method thereof

InactiveCN101376198AGuaranteed translationIncrease the itineraryWelding/cutting auxillary devicesArc welding apparatusRotational axisEngineering

The invention relates to a five-axis linkage numerical control welding machine and the welding technique control method thereof. The welding technique control method comprises the following steps: adopting CAD / CAM to build a welding workpiece model; planning and outputting the specific welding spot sequence data; and then carrying out a coordinate conversion and generating a G-code numerical control program file by applying a specific machine tool kinematical formula. The mechanical transmission system ensures the five-axis linkage according to the converted specific welding-spot data, so as to optimize the position between the welding gun and the welding spot while welding, ensure that the welding product has the advantages of good quality uniformity, high repeatability precision, good movement and power performance, etc.; the mechanical transmission system includes three linear movement guide rails X, Y and Z which drive the welding guns to work, and two rotating shafts which drive the welding guns to rotate, wherein the linear movement guide rails can ensure that the rotating shafts can move transversely in any position in the working space, and the two rotating shafts which drive the welding guns to rotate can ensure that the welding guns can perform a 360-degree rotation round the welding spot, therefore, the welding machine and the control method thereof have the advantages of large machine tool stroke, no dead area, high generality, high suitability, etc.

Owner:吕家琪

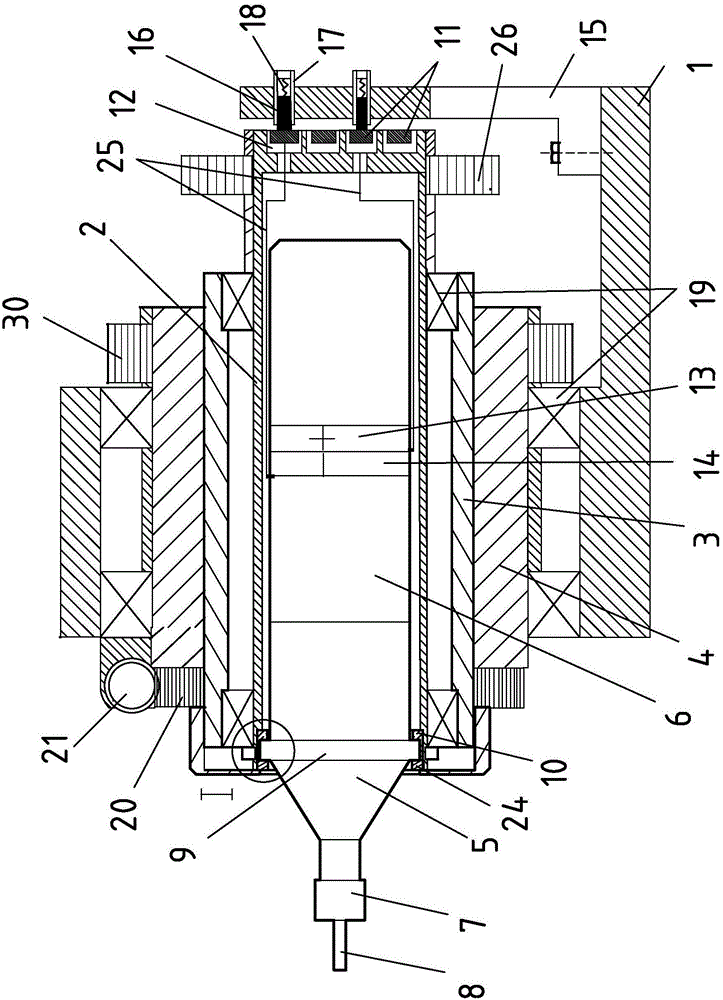

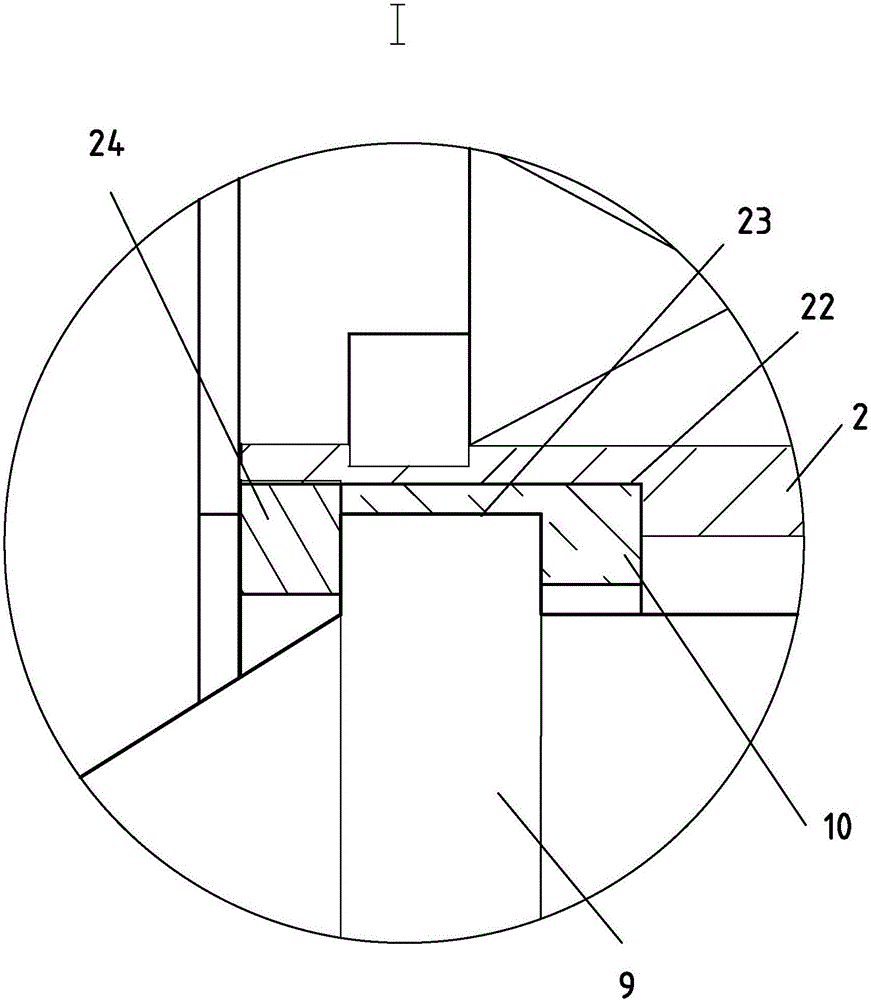

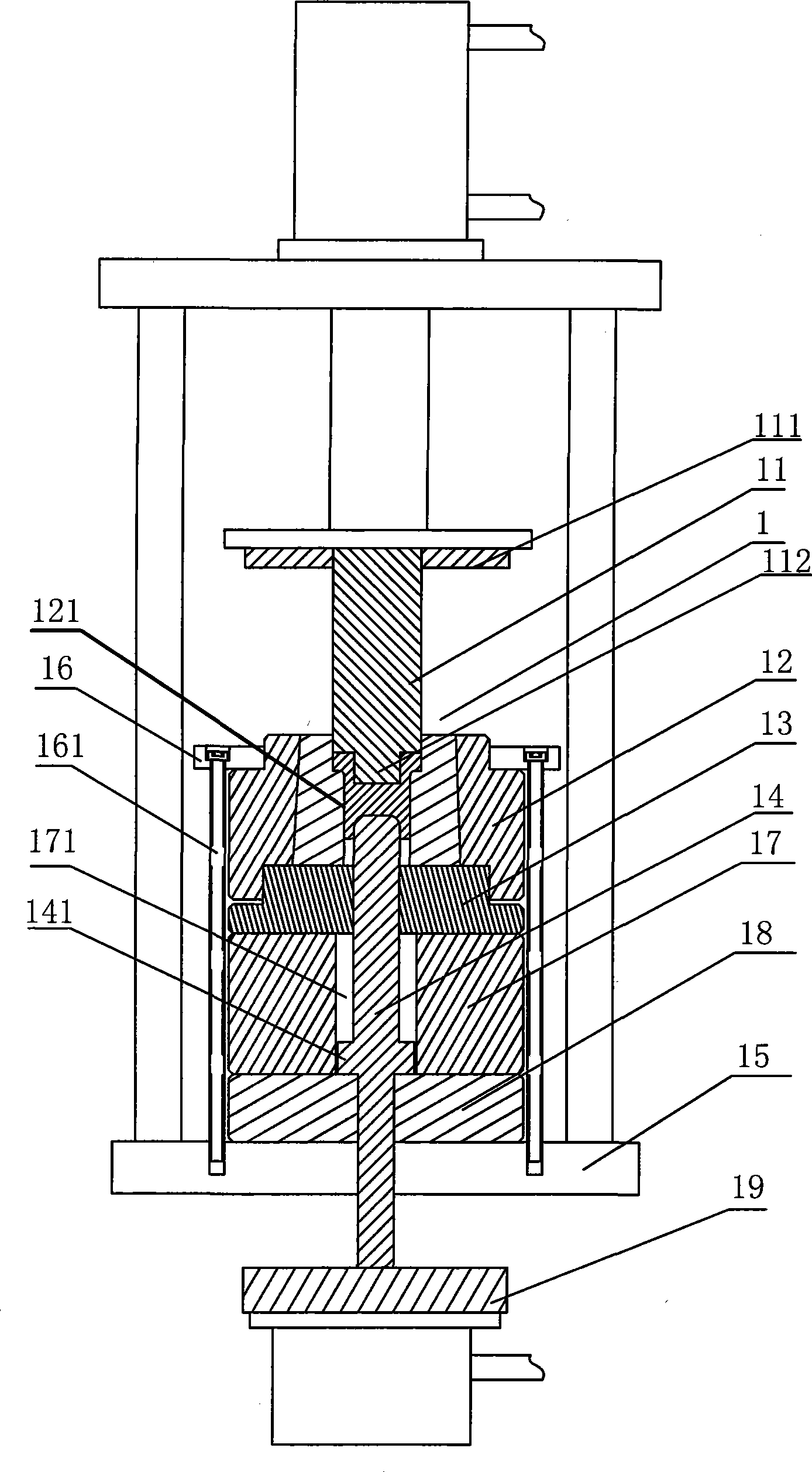

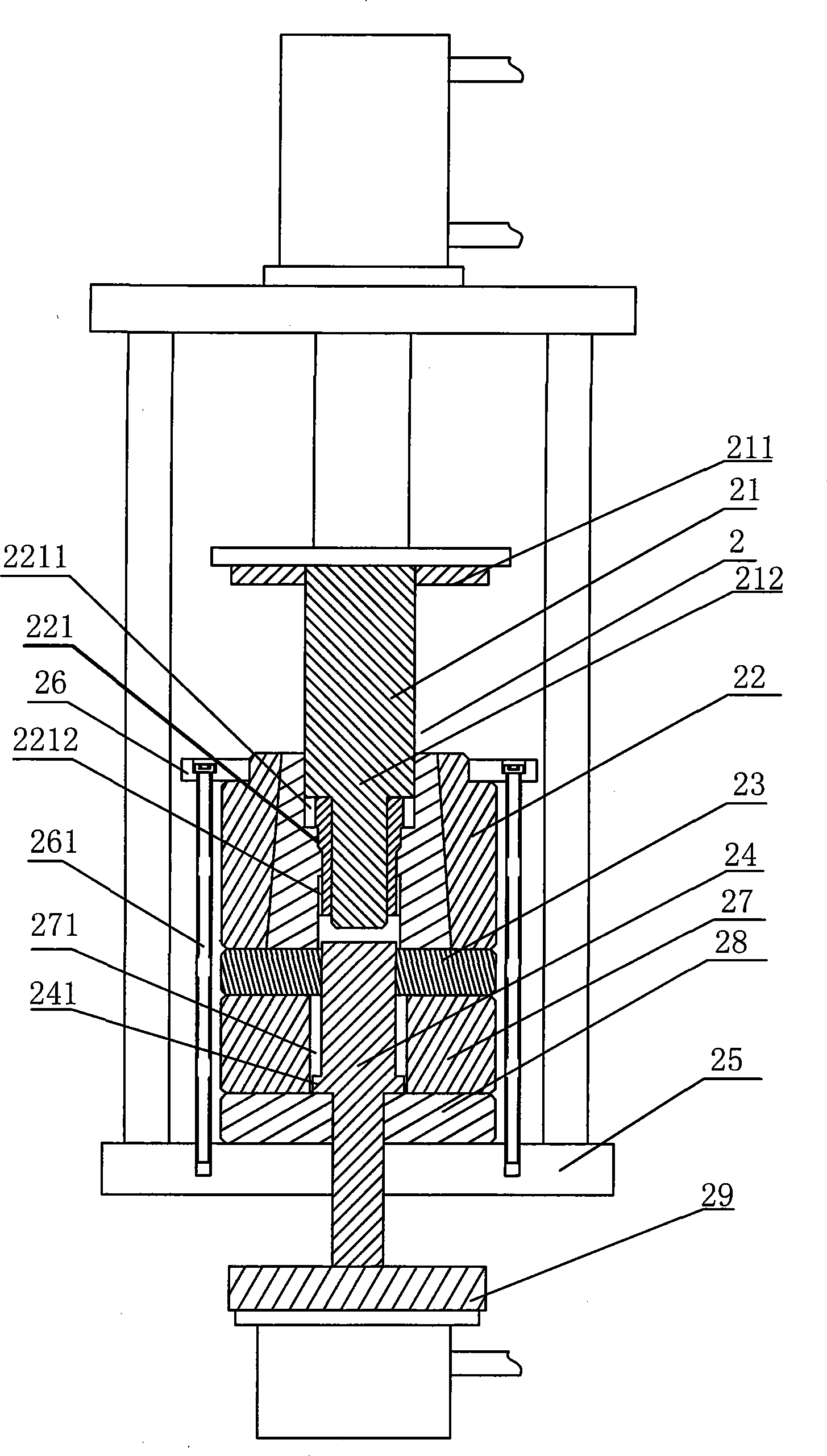

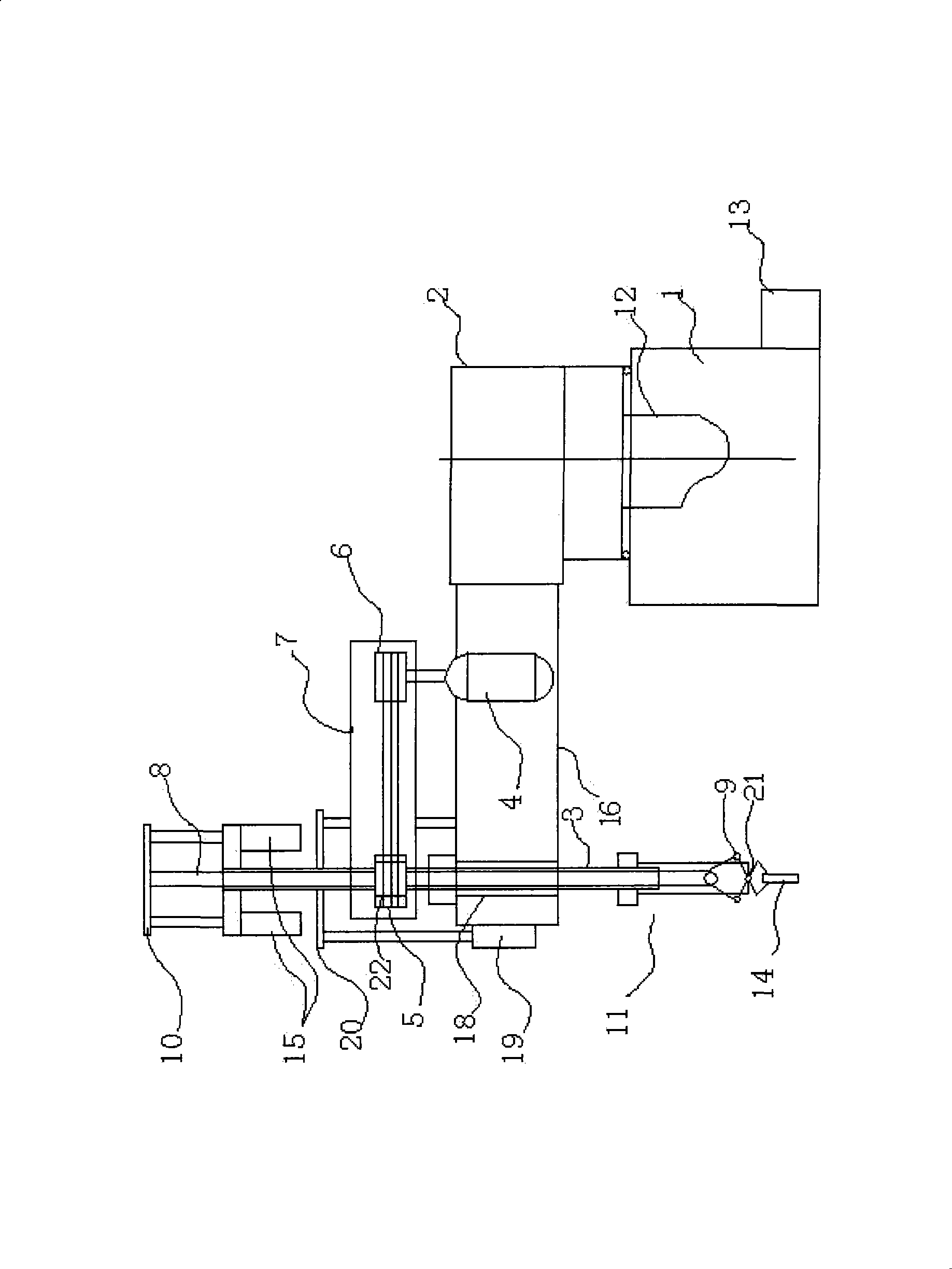

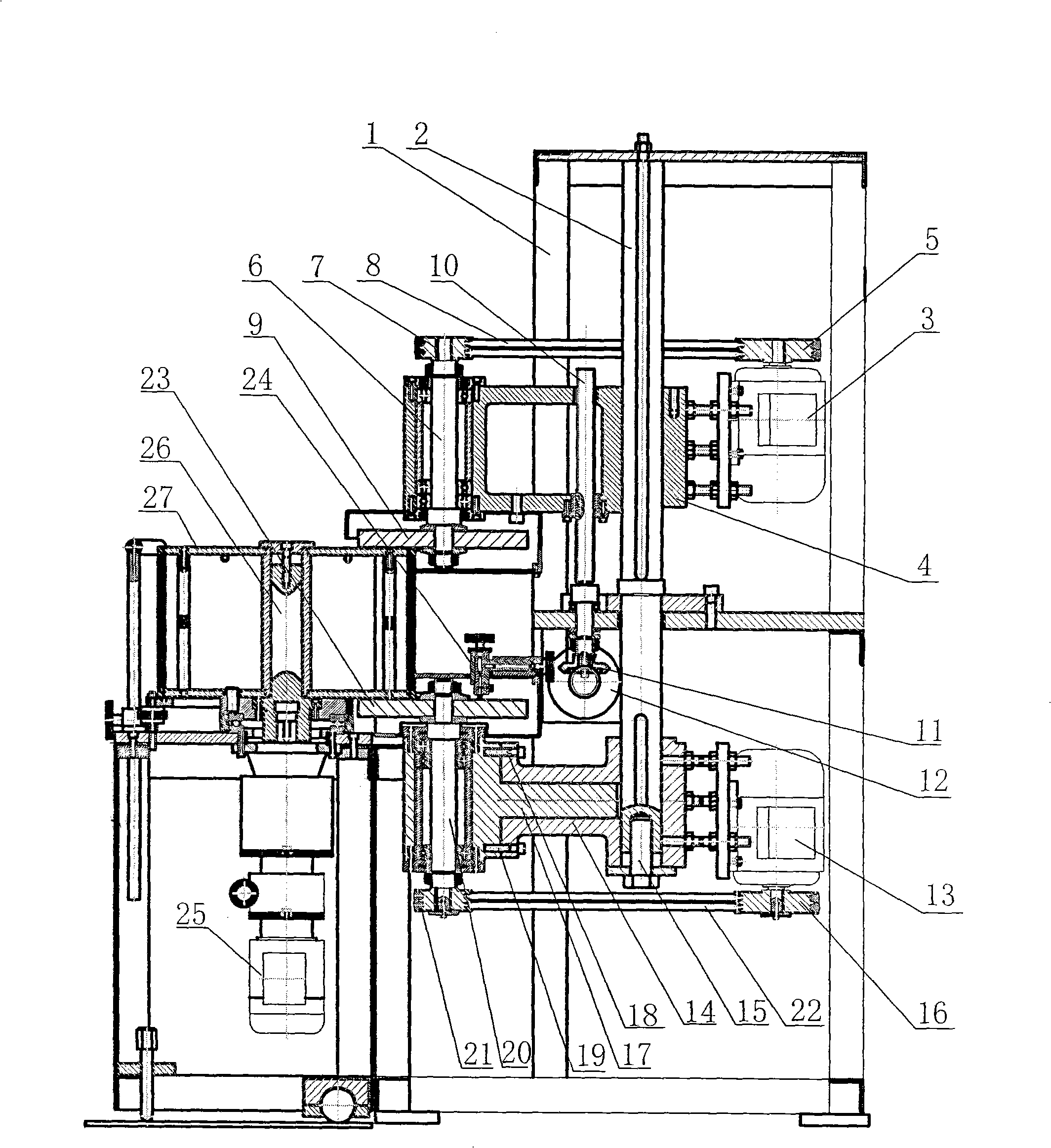

Ultrasonic helical hole milling device and machining method

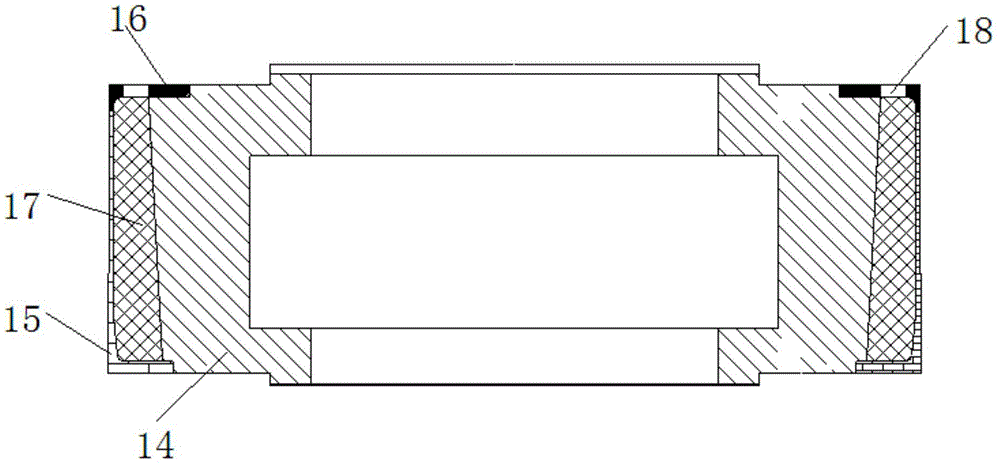

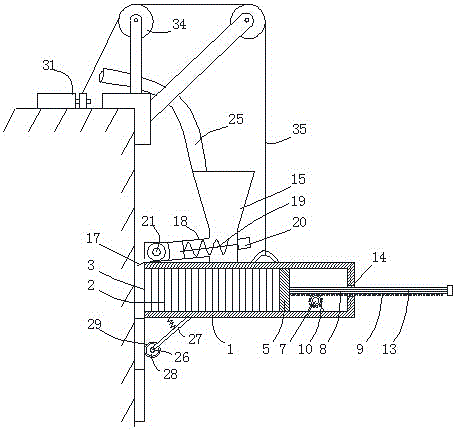

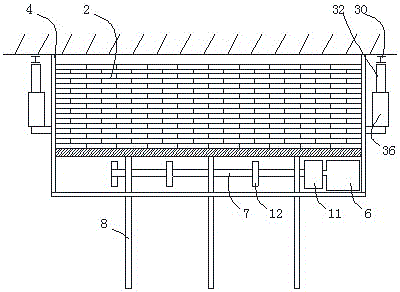

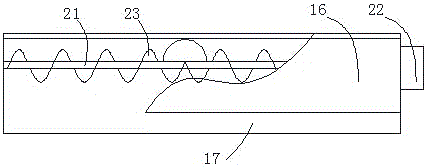

ActiveCN106077774AImprove hole qualityReduce cutting forceRevolution surface grinding machinesMilling equipment detailsMilling cutterTransducer

The invention discloses an ultrasonic helical hole milling device which comprises a spindle support, an ultrasonic sleeve, an inner eccentric sleeve, an outer eccentric sleeve, an amplitude-change pole and a transducer located in the ultrasonic sleeve. The amplitude-change pole is connected with a hole forming tool through a spring chuck, and the hole forming tool is a milling cutter or a grinding wheel. The amplitude-change pole is connected with the transducer through an annular flange which is connected with the inner wall of the ultrasonic sleeve through an annular force sensor used for measuring axial and radial force borne by the annular flange. The ultrasonic helical hole milling device further comprises a helical hole-milling rotation driving device connected with the ultrasonic sleeve, a helical hole-milling revolution driving device connected with the outer eccentric sleeve and a feeding system for driving the spindle support to conduct feeding along the axis of the amplitude-change pole. The invention further discloses a machining method for conducting ultrasonic helical hole milling through the ultrasonic helical hole milling device. The ultrasonic helical hole milling device and the machining method have the advantages that the hole forming quality is high, hole forming quality consistency is good, and machining stability is good.

Owner:DALIAN UNIV OF TECH

Composite material connecting skirt forming method and mold and inner rubber core mold forming mold

The invention discloses a composite material containing skirt forming method and mold and an inner rubber core mold forming mold. The method comprises the following steps: (1) manufacturing the forming mold, namely manufacturing an outer mold, an inner mold and the inner rubber core mold and sheathing the inner rubber core mold on the outer wall of the inner mold; (2) laying up; (3) preheating and vacuumizing the forming mold; (4) carrying out resin pretreatment; (5) injecting glue and solidifying, namely solidifying resin after glue injection, wherein the inner rubber core mold is expanded along with the increase of temperature to uniformly pressing a preform and enable the resin to fully infiltrate the preform; and (6) demolding and trimming. The forming mold structure adopts the inner rubber core mold; silicone rubber is adopted and a resin transfer molding (RTM) process is assisted to form the composite material containing skirt, and a double-sided mold is adopted, so that a product has the advantages of stable dimension, good quality consistence, controllable fiber and resin contents and the like; measures such as co-solidification and the adoption of the expandable core mold are adopted to reduce the porosity, increase the volume content of the fibers of the product and improve the mechanical property.

Owner:湖北三江航天江北机械工程有限公司

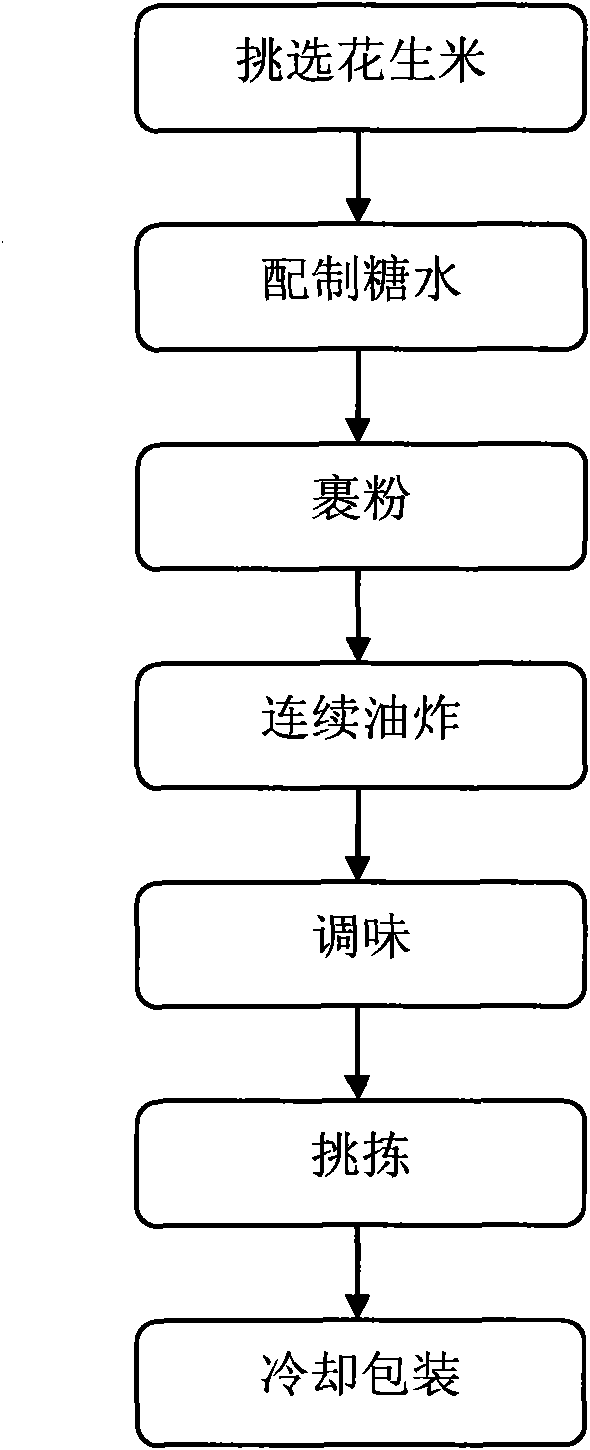

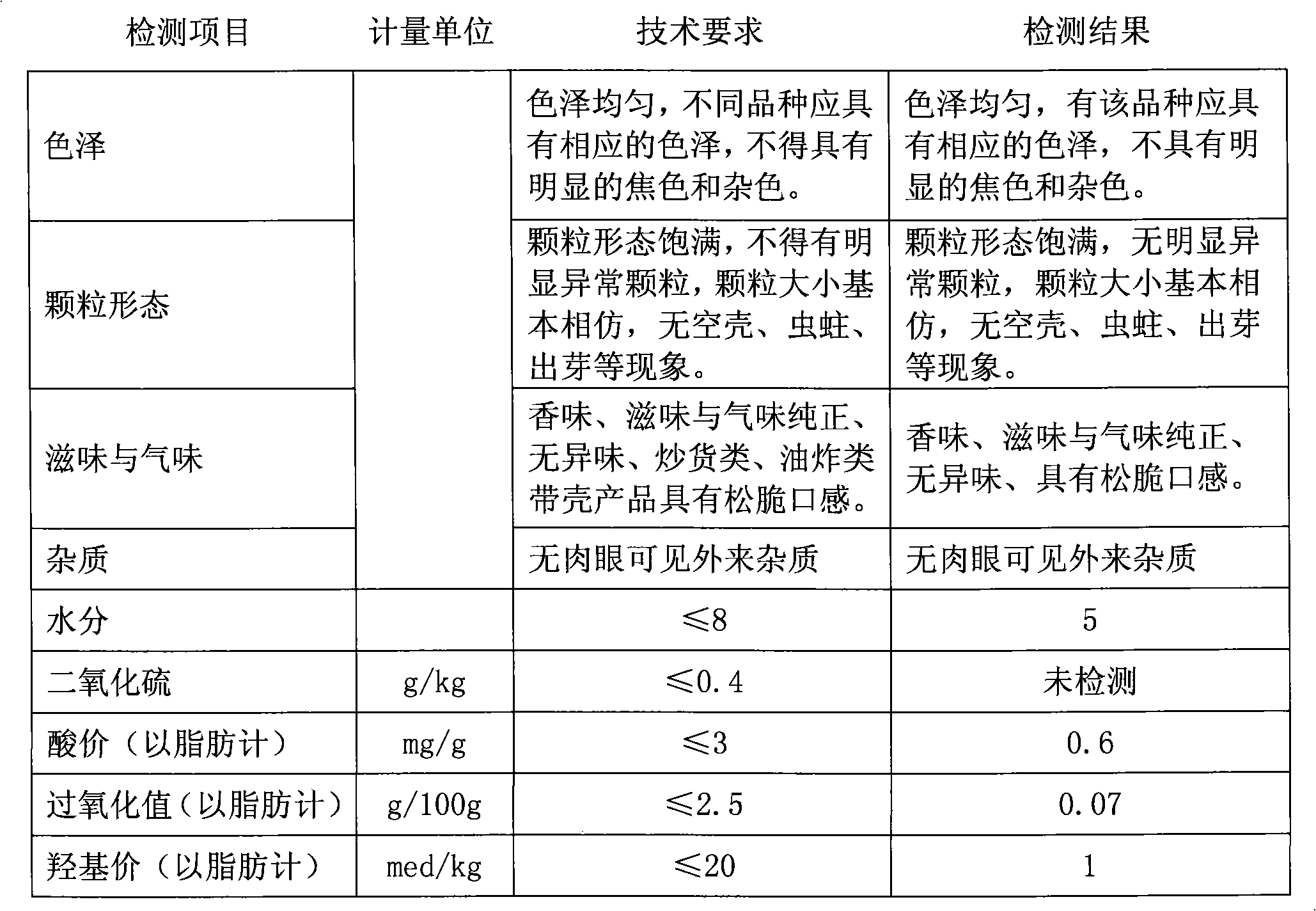

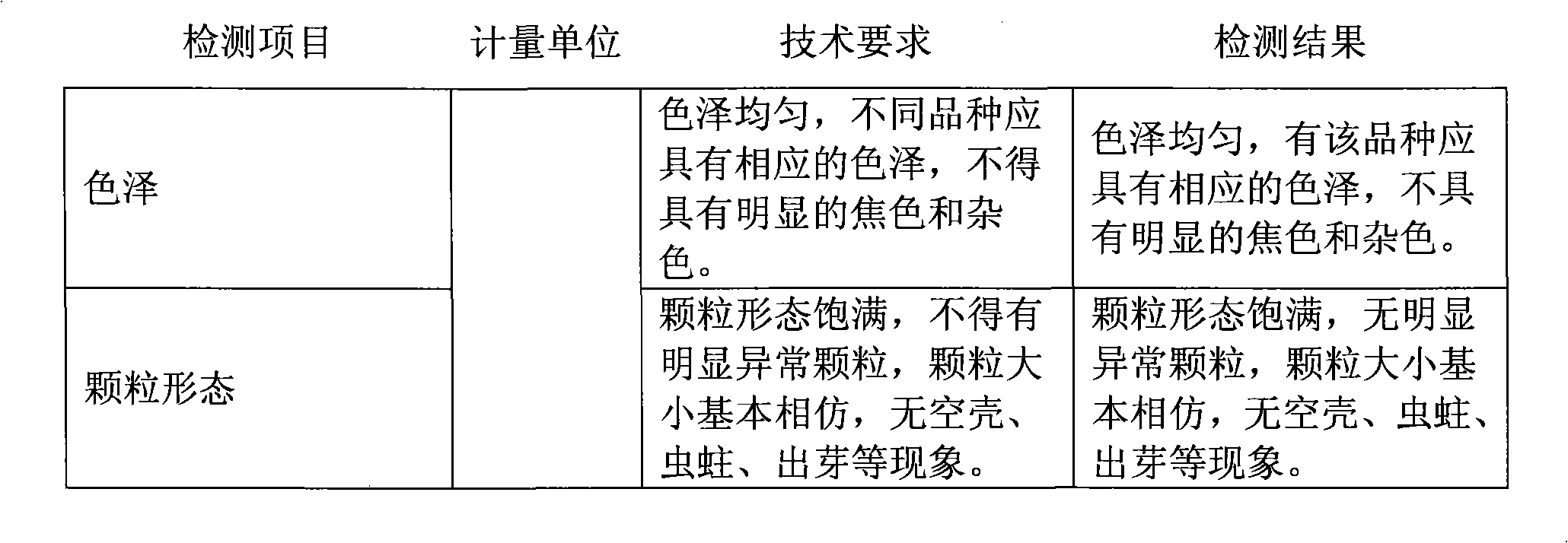

Coated peanuts and making method thereof

InactiveCN101933552AImprove performance indicatorsQuality improvementConfectionerySweetmeatsAdditive ingredientGARLIC POWDER

The invention discloses coated peanuts. In the formula of the coated peanuts, every 35 parts of peanuts comprise the following ingredients: 10-20 parts of white granulated sugar, 10-15 parts of flour and 1-2 parts of seasoner powder, wherein the seasoner powder comprises the following components of chilli powder, garlic powder, spice, gourmet powder and sugar with a weight part ratio of 2:1:2:1:1. The invention also discloses a method for making the coated peanut. The coated peanuts have the advantages of excellent consistency of the product appearance and the quality, unique taste, crispness, sweetness and piquancy. In the making method of the coated peanuts, a continuous frying production mode is adopted, and an oval roll pot rolling mode is used for seasoning and blending, thus the materials are more uniformly blended; a pneumatic rolling mode is used in a frying procedure, thus various indexes of the product appearance, physics, chemistry, and the like are more consistent; and the invention pushes the development of the coated peanuts.

Owner:SUZHOU KOUSHUIWA FOOD

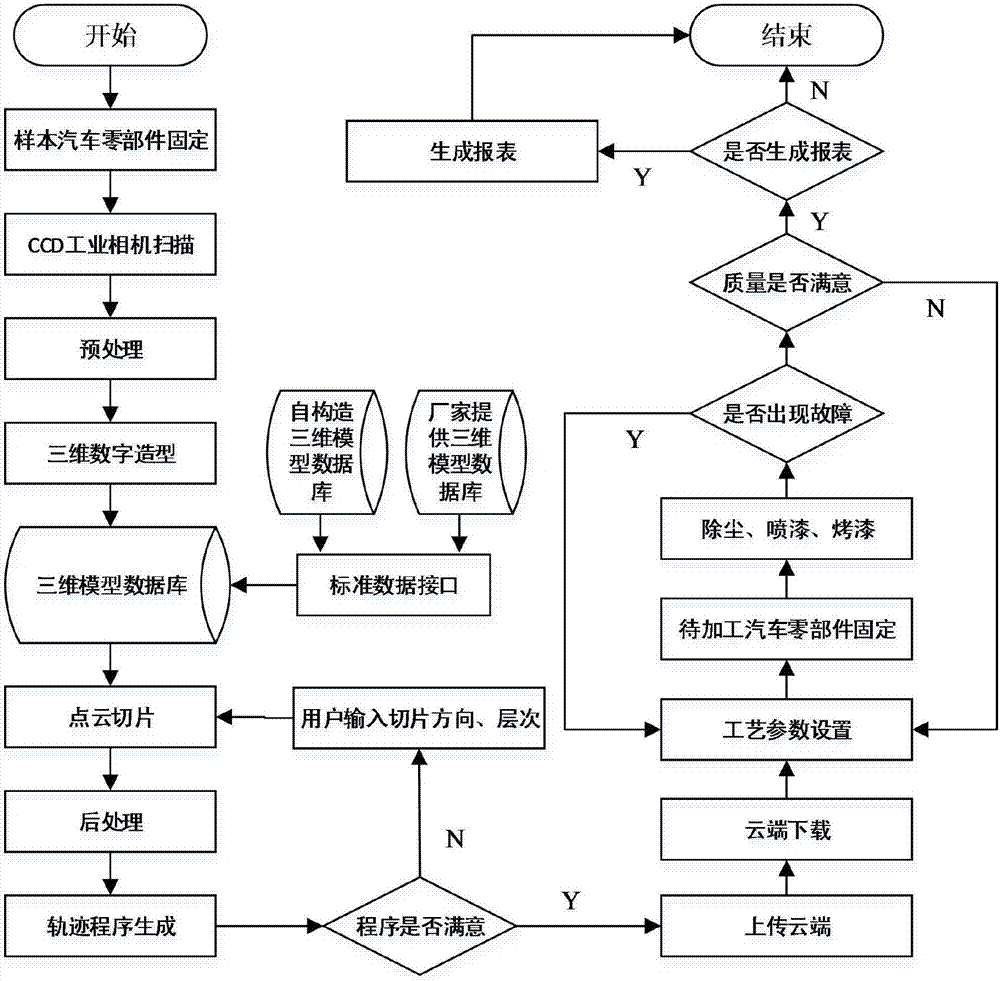

Intelligent automobile paint spraying method based on cloud computing

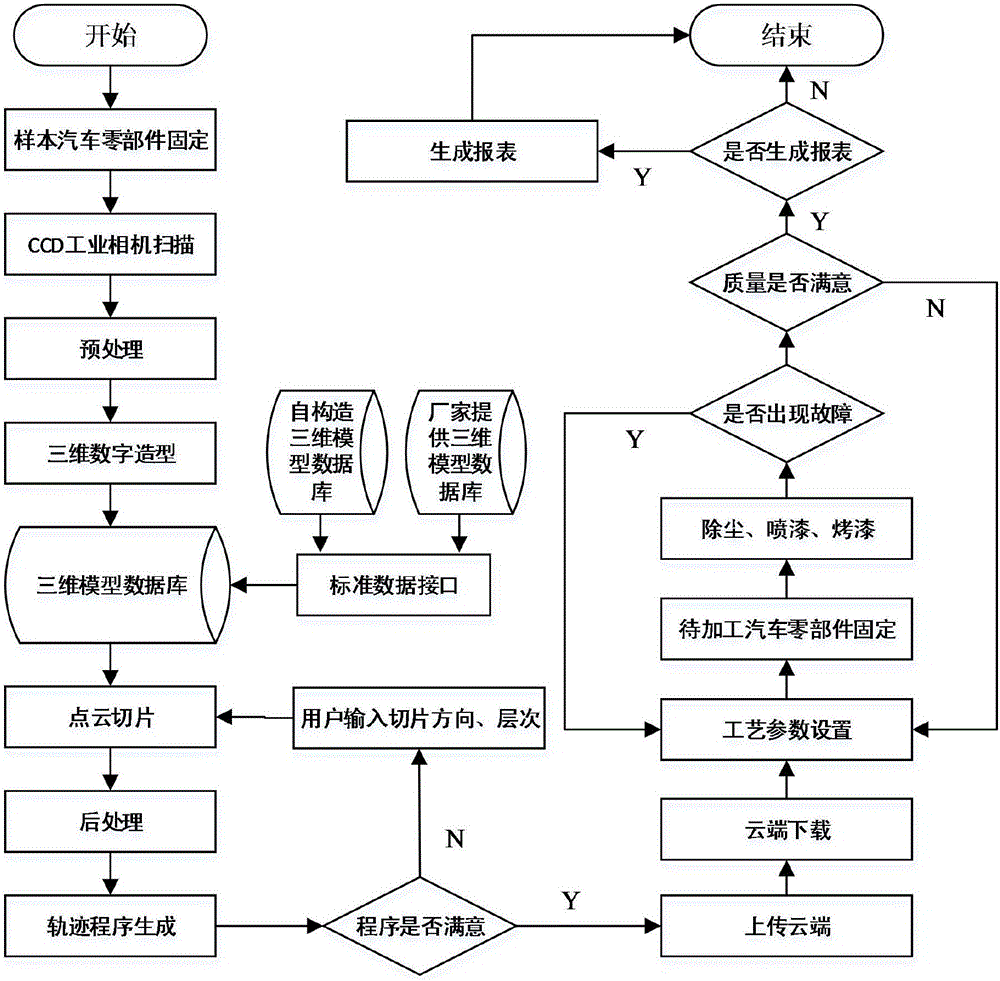

ActiveCN106853433AAvoid health damageAvoid inconsistenciesGeometric CADLiquid surface applicatorsPoint cloud3d scanning

The invention discloses an intelligent automobile paint spraying method based on cloud computing and relates to the field of paint spraying processes. The problems of high paint loss, poor quality consistency, influence on operator health, severe contamination, low efficiency and high cost of existing manual paint spraying are solved. The intelligent automobile paint spraying method based on cloud computing comprises the steps that firstly, a 3D scanning device scans automobile parts to generate point cloud data, the point cloud data are preprocessed to generate a three-dimensional digital model, and the model is stored in a three-dimensional model database; the three-dimensional digital model generates point cloud slices based on slicing directions and slicing levels input by a user; a spray gun pose is determined and a spray gun trajectory is optimized based on the point cloud slices to obtain a spray gun trajectory, and the spray gun trajectory is uploaded to a cloud platform; the cloud platform downloads programs corresponding to the parts and inputs processing parameters for spraying; after spraying is completed, the spraying quality is inspected, report forms for filing can be selected after quality conformance. The intelligent automobile paint spraying method is good in quality consistency, free of contamination, high in efficiency and low in cost.

Owner:吉林省天大精益智能制造技术有限公司

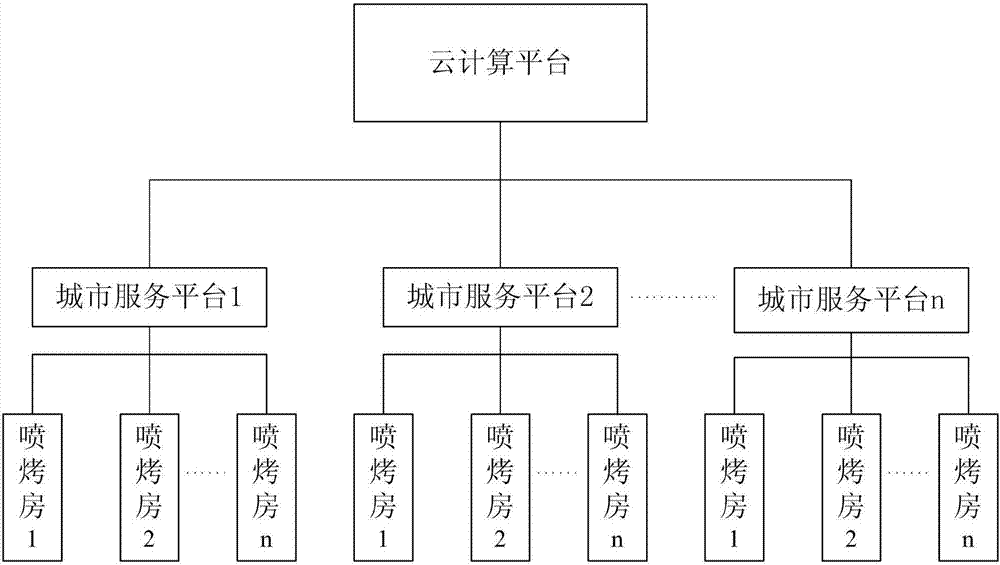

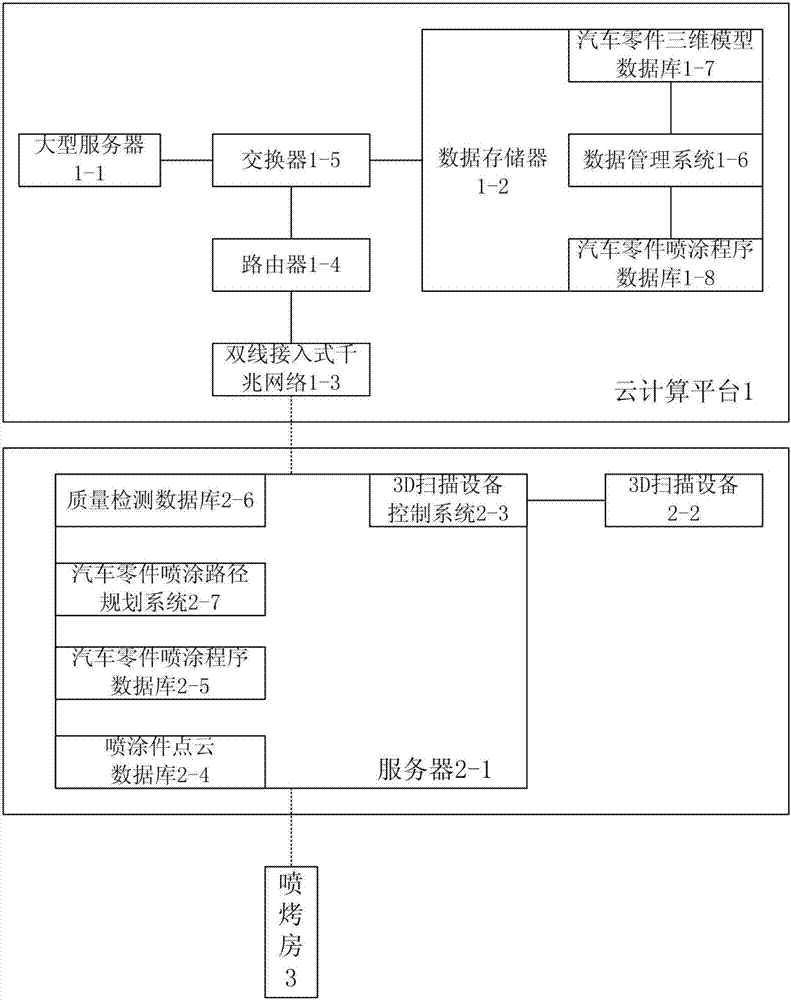

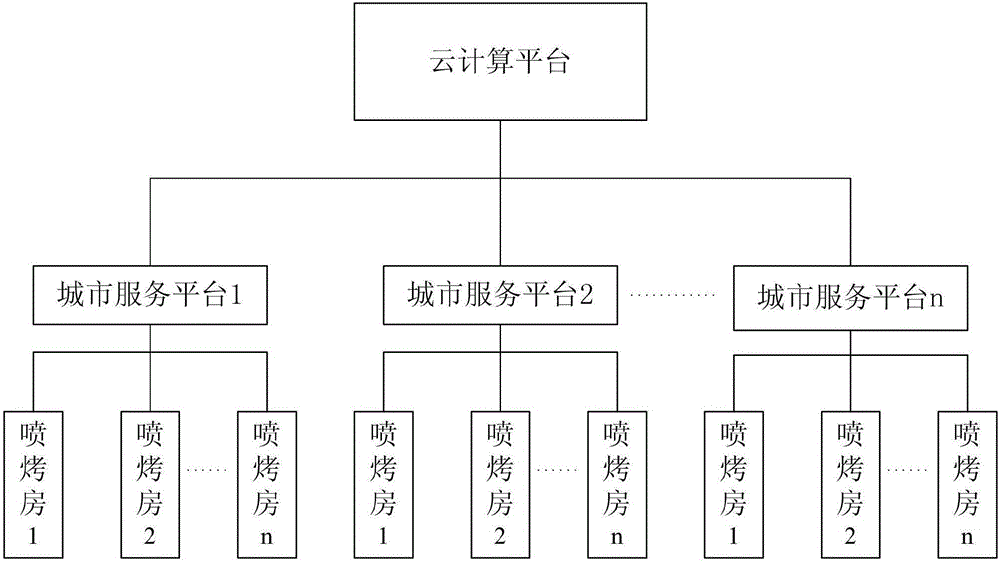

Automobile intelligent paint spraying system based on cloud computing

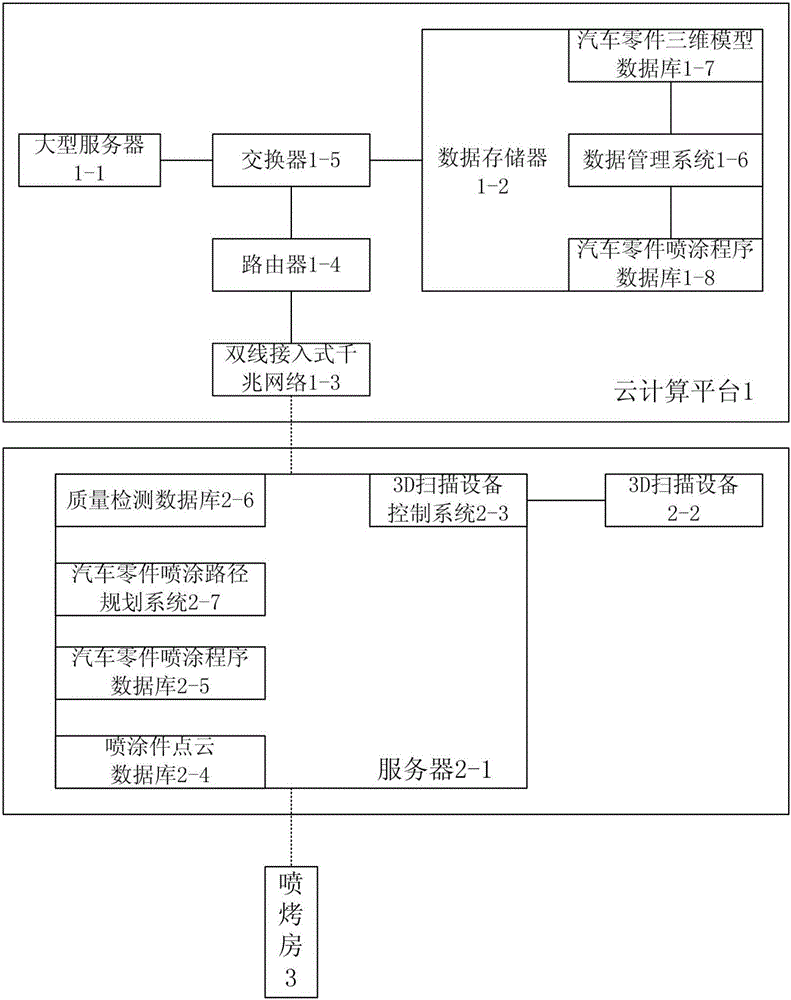

ActiveCN106527238AAvoid health damageAvoid inconsistenciesLiquid surface applicatorsCoatingsCooking & bakingData memory

The invention provides an automobile intelligent paint spraying system based on cloud computing, relating to the field of spray painting process. The problems of large paint loss, poor quality consistency, the affection of the health of operating personnel, serious pollution, low efficiency, and high cost in existing artificial painting are solved. The system comprises a cloud computing platform, multiple city service platforms, and a plurality of spraying and baking rooms. The cloud computing platform comprises a large server, a data memory, a double-wire-access type Gigabit network, a router, a switch, a data management system, an automobile spare part 3D model database, and an automobile spare part spraying program database. Each of the city service platforms comprises a high performance server, a 3D scanning device, a 3D scanning device control system, a spray piece point cloud database, an automobile spare part spraying program database, a quality inspection database, an automobile spare part spraying path planning system, and a double-wire-access type Gigabit network. Electric shutter doors are used to divide the spraying and baking rooms into spraying rooms and baking rooms. The system has the advantages of good quality consistency, no pollution, high efficiency and low cost.

Owner:吉林省天大精益智能制造技术有限公司

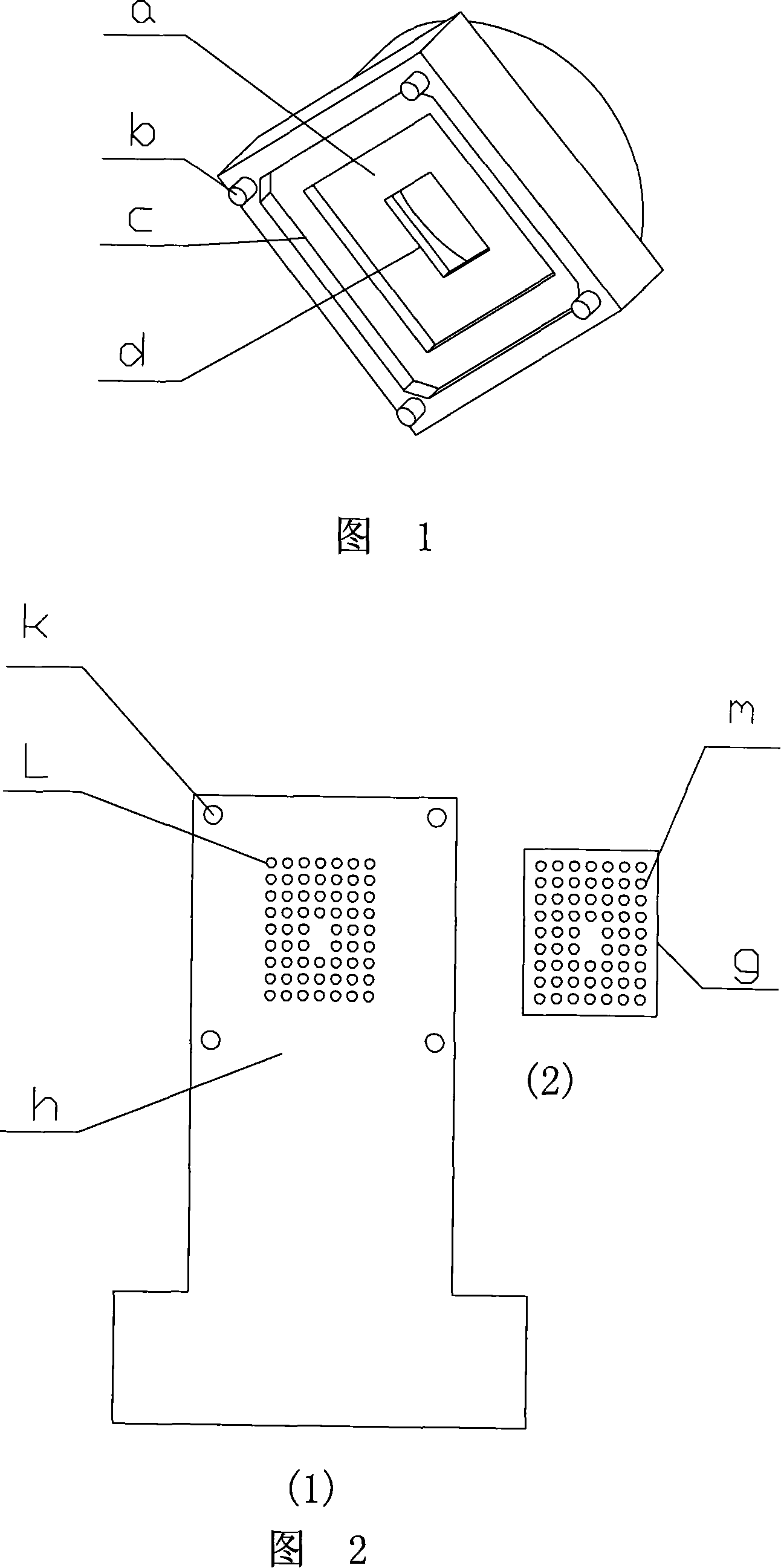

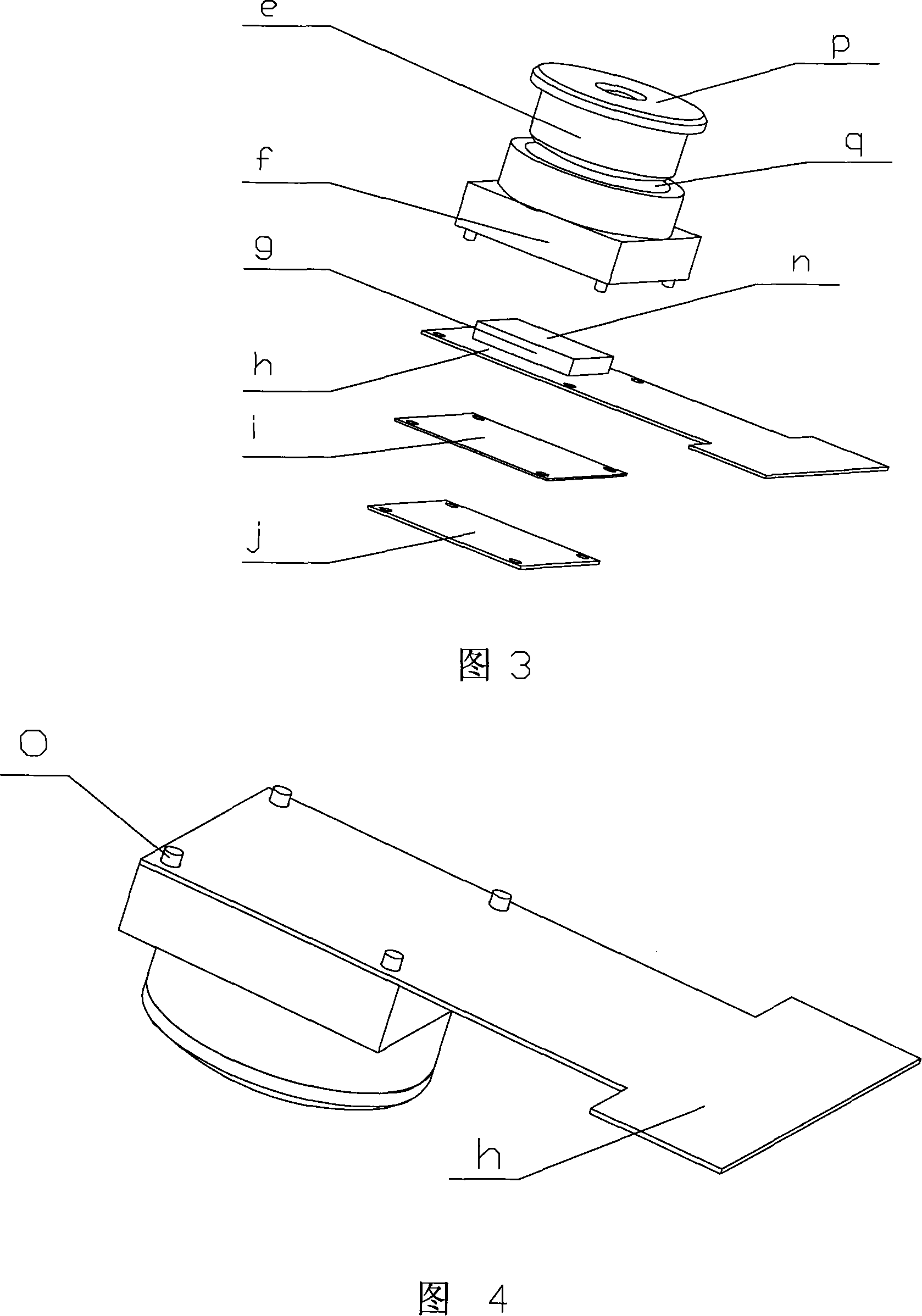

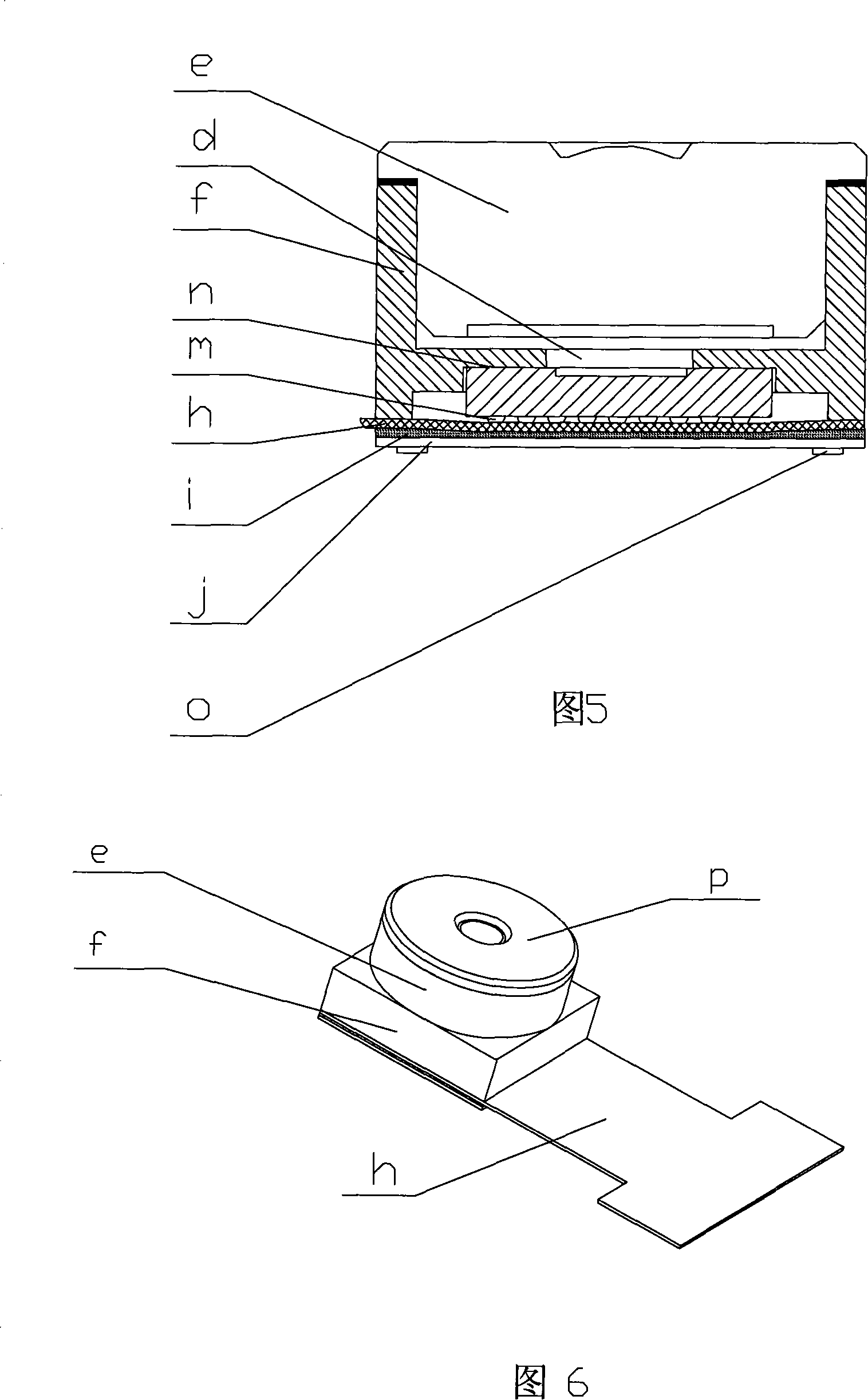

Chip packaged fixed focus focusing-free imaging module processing method

InactiveCN101149458AImprove quality consistencyReduce foulingSemiconductor/solid-state device detailsSolid-state devicesCamera lensSheet steel

This invention relates to the preparation method of the mobile phone, said concretely that it is a kind of chip encapsulation fixed focus mobile telephone image mould process method. According to the technology project provided by the specification, the chip encapsulation fixed focus mobile telephone image mould process method includes: A, compression: compresses the column surface p in the head of camera e and the mounting hole q of the microscope f by interference mating; B, pasting: pastes the image sensor n and device in soft circuit board h; C, joint locating: joints and locates locator surface slot plane of the microscope f and the surface n of image sensor g; D, bonding: pastes the microscope f and the soft circuit board h by adhesive; E, paste double glue: paste soft double glue I in the back camera lens of the soft circuit board h; F, sheet steel bonding, bonds the reinforcing sheet steel j and the back of the soft circuit board h by double glue I; G, hot driving: rivets the locator pole o of the microscope f and the reinforcing sheet steel j by rivet hot machine. This invention can save equipment investment and labor and product cost, improve the quality consistency and product effect of the fixed focus mould.

Owner:无锡凯尔科技有限公司

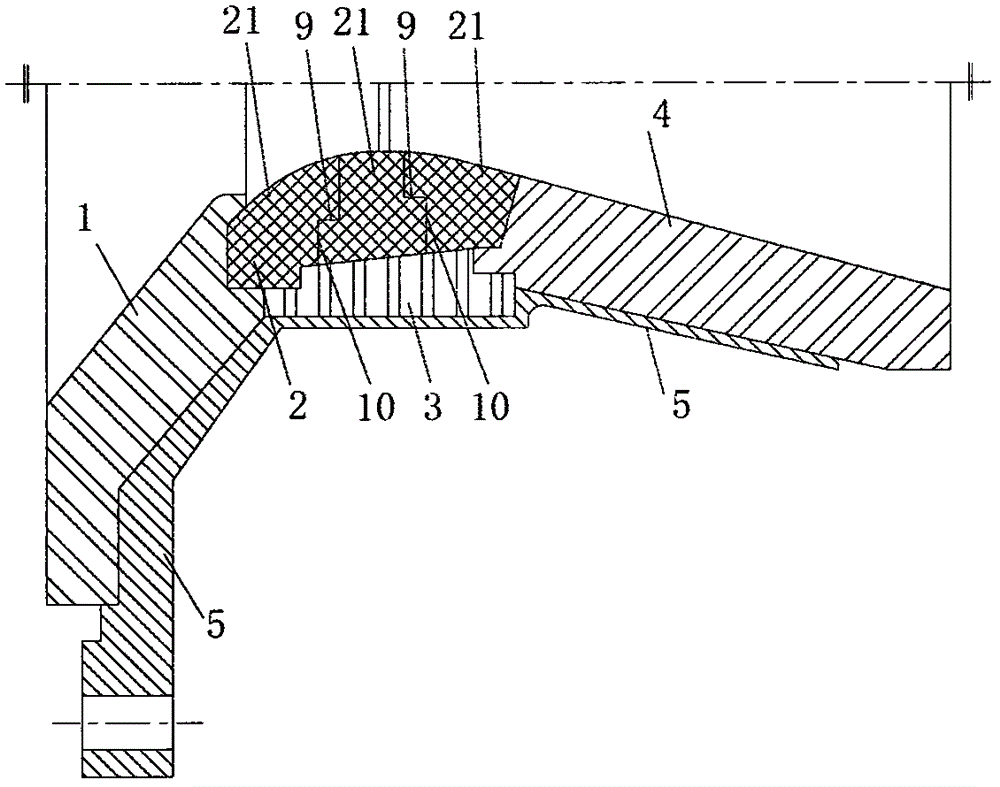

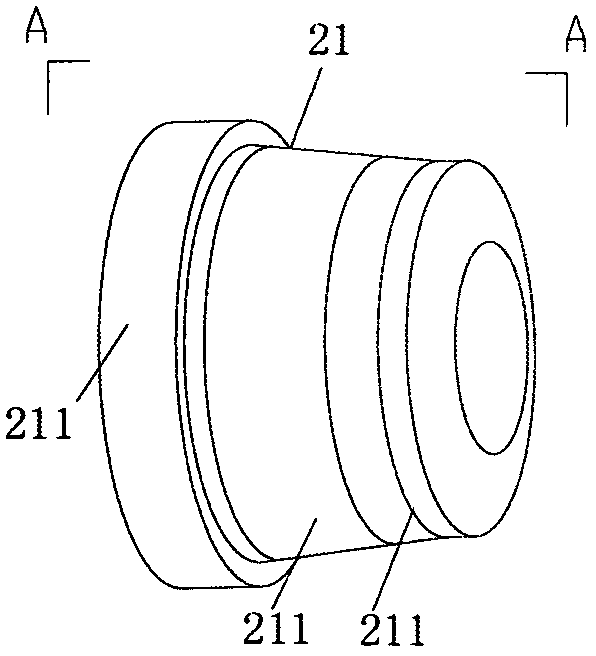

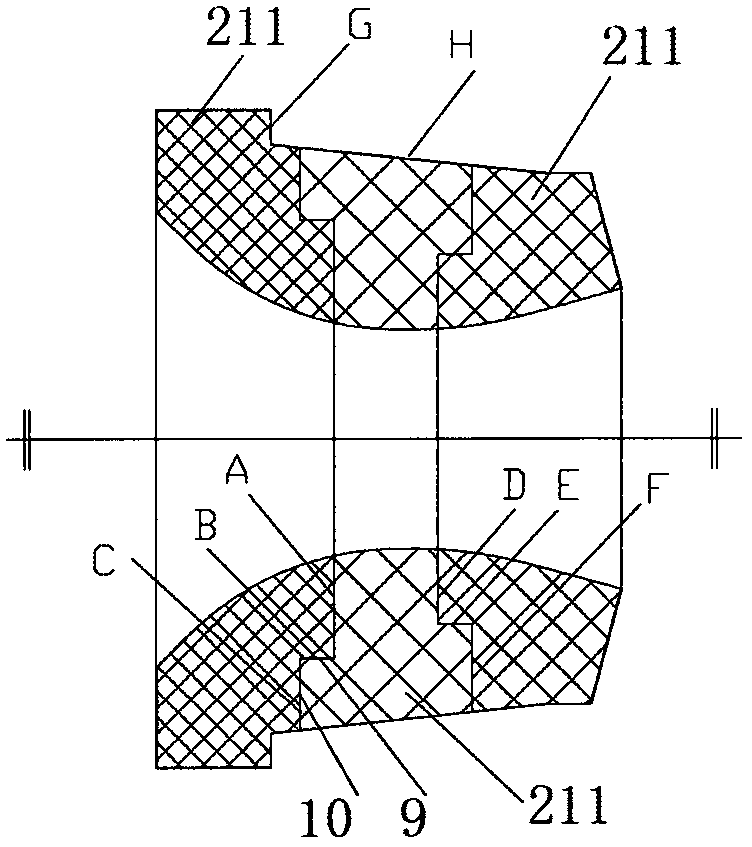

Combined throat liner spraying pipe of solid rocket engine and manufacturing method

ActiveCN106050477AReduce volumeReduce the difficulty of productionRocket engine plantsEngineeringStructural type

The invention discloses a combined throat liner spraying pipe of a solid rocket engine and a manufacturing method. The spraying pipe comprises axisymmetric rotating body structural components comprising a convergent segment heat insulating layer, a throat liner, a backing, a diffusion segment heat insulating layer and a spraying pipe shell; the components are connected and sealed through steps formed by axial cylindrical faces and end faces so as to be assembled into the spraying pipe; and the throat liner is a combined throat liner and combined by connecting and sealing a plurality of throat liner blocks in a step manner. According to the combined throat liner spraying pipe of the solid rocket engine, the integral throat liner is divided into the multiple throat liner blocks each of a special structural type; every two throat liner blocks are connected and sealed through an assembling process so that the combined throat liner can be formed; and then the combined throat liner and the other axisymmetric rotating body structural components of the spraying pipe are assembled into the spraying pipe according to an existing corresponding assembling manner. Raw materials can be effectively saved, and the process preparing and machining cost is also reduced; and meanwhile, because the size of each single throat liner block is reduced, the thickness is reduced, the carburizing is even, and the product quality consistency can be guaranteed more easily.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

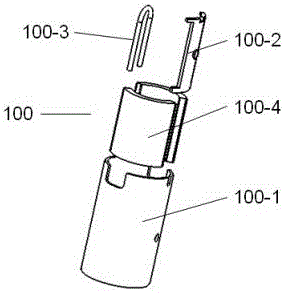

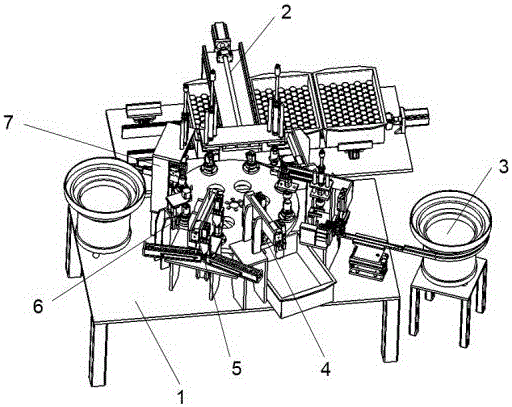

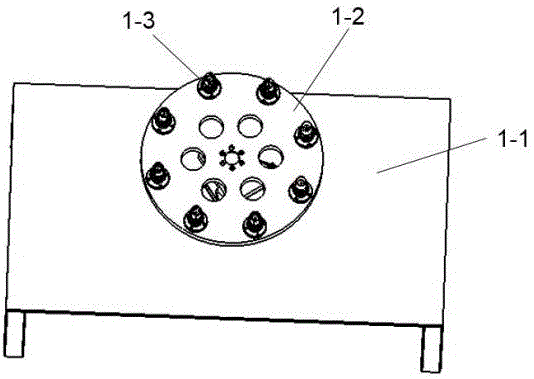

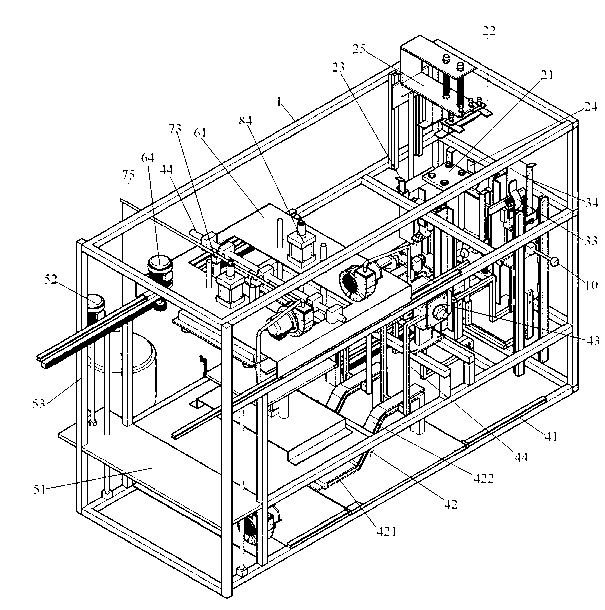

Automatic assembly device for electric fuel pump stator assembly

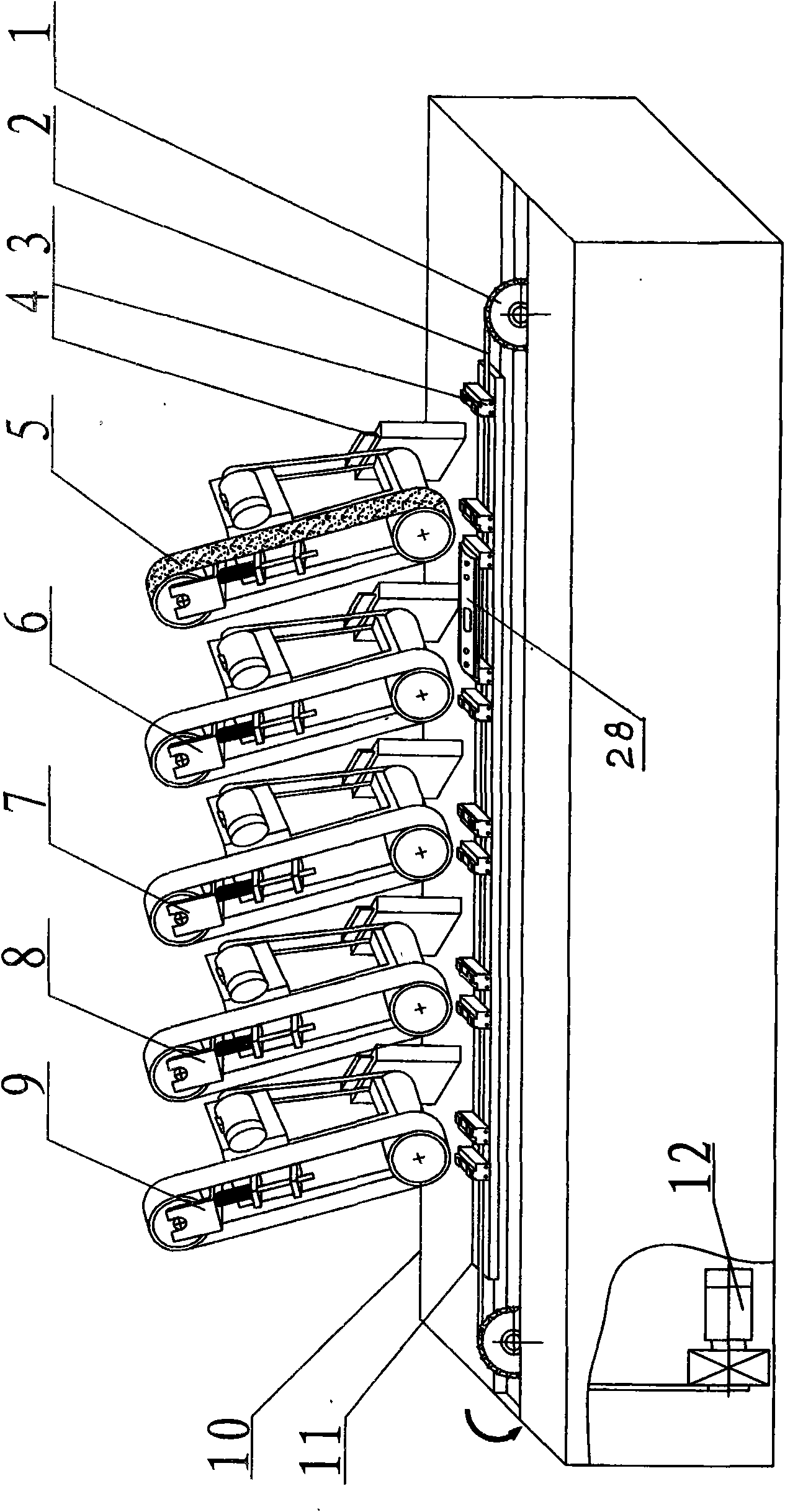

InactiveCN106624783AReduce processConsistent assembly qualityAssembly machinesPlastic filmUltimate tensile strength

The invention discloses an automatic assembly device for an electric fuel pump stator assembly. The automatic assembly device for the electric fuel pump stator assembly comprises an assembly platform, a feeding and discharging module, a plastic sheet assembly module, a plastic sheet assembly detecting module, a magnetic shoe assembly module, a magnetic shoe correcting module and a steel wire spring assembly module; the assembly platform is used for arranging the assembly station, and fixing a shell and a magnetic shoe; the feeding and discharging module is used for feeding of the shell and discharging of a stator assembly finished product; the plastic sheet assembly module is used for containing a plastic sheet into the shell; the plastic sheet assembly detecting module is used for detecting whether the plastic sheet is right contained in the shell; the magnetic shoe assembly module is used for containing the magnetic shoe into the shell; the magnetic shoe correcting module is used for correcting the magnetic shoe and making the magnetic shoe installed in place; and the steel wire spring assembly module is used for containing a steel wire spring into the shell. The automatic assembly device for the electric fuel pump stator assembly achieves automatic assembly of the electric fuel pump stator assembly, work procedures are few, the assembly quality consistency is good, the assembly efficiency and the assembly quality are improved, the manual intervention work amount is small, and the labor intensity is greatly relieved.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

Fully automatic paper box edgefold forming machine

ActiveCN102990980AEnsure cleanliness and aestheticsImprove work efficiencyPaper-makingBox making operationsEngineeringFully automatic

The invention belongs to the technical field of paper box forming devices, and particularly relates to a fully automatic paper box edgefold forming machine. A paper box feeding and intaking mechanism, a glue spray pre-folding mechanism and a forming mechanism are sequentially arranged on the rack, the forming mechanism comprises a box body forming mechanism and a box lid forming mechanism which are arranged adjacent to each other, and the box body forming mechanism and the box lid forming mechanism are both connected with a lifting control device. Compared with the prior art, through the coordinated action of the paper box feeding and intaking mechanism, the glue spray pre-folding mechanism, the box body forming mechanism and the box lid forming mechanism, the forming machine disclosed by the invention can carry out automatic glue spray and automatic forming on a paper box with a box lid, so that the working efficiency and the product quality consistency are improved, the production cost is reduced, and a situation that finished paper box products are neat and beautiful can be ensured.

Owner:JIESHENG INTELLIGENT TECH CO LTD

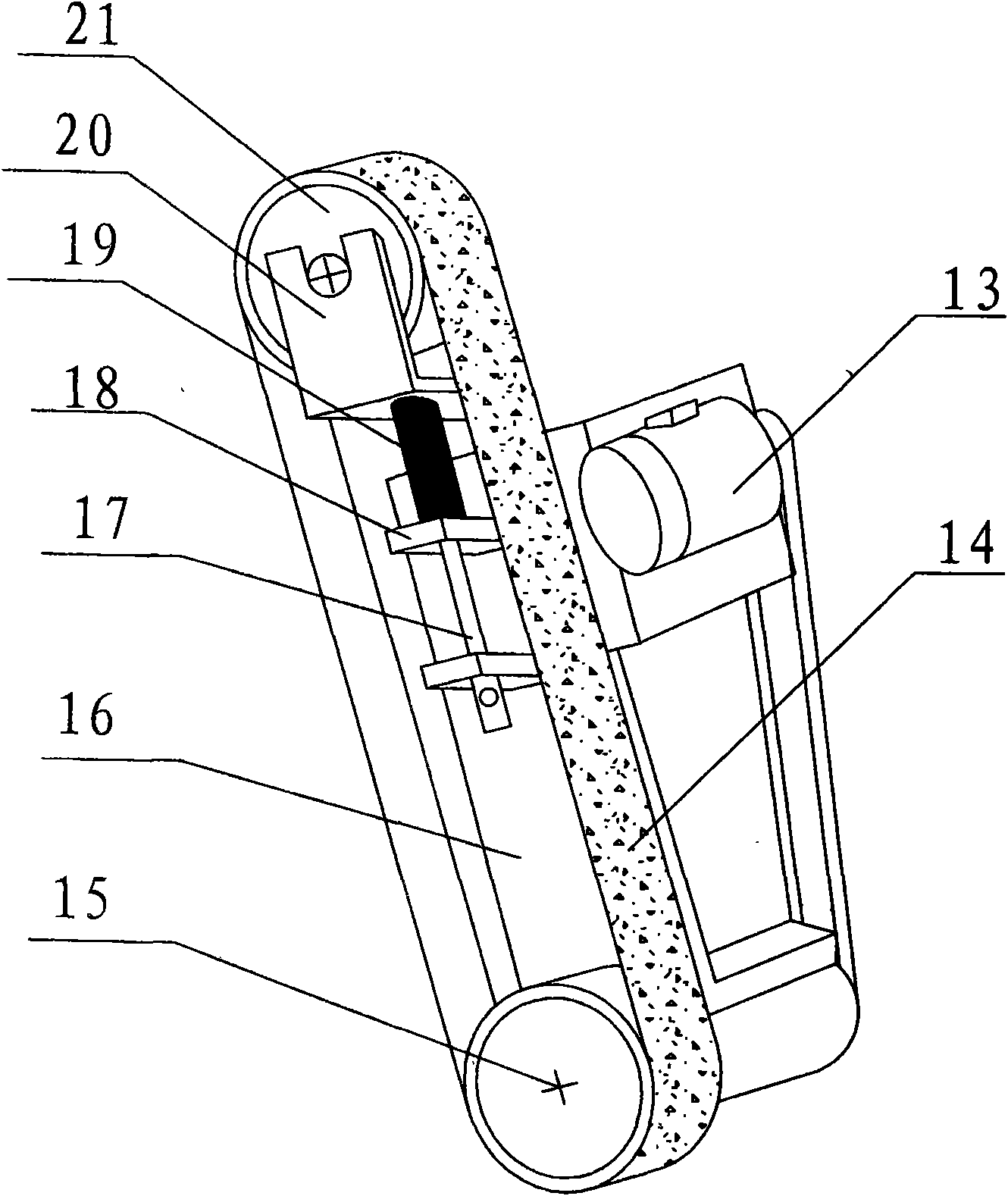

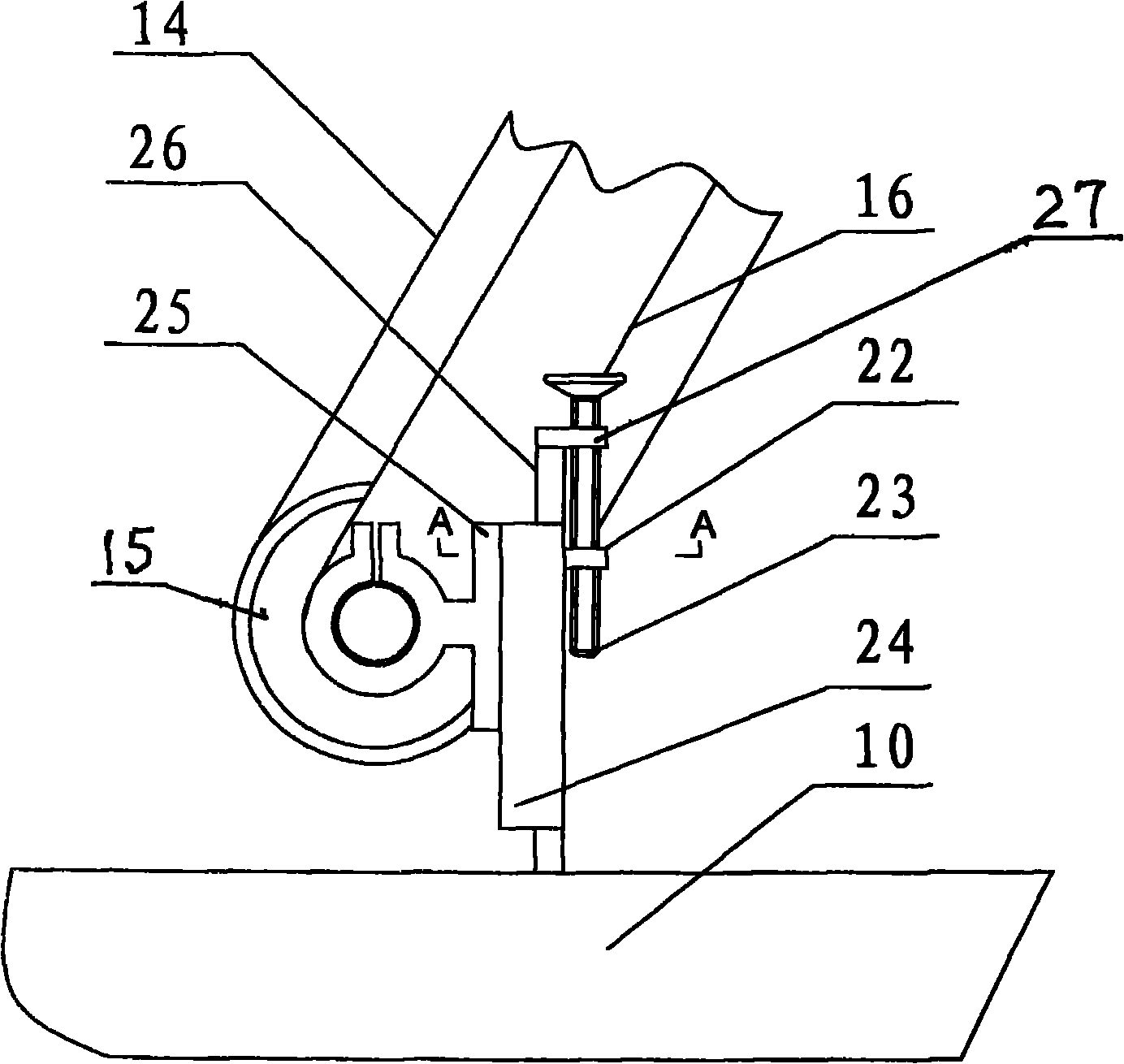

Polishing machine for panel of lock

InactiveCN101780655AImprove ergonomicsImprove securityBelt grinding machinesElectric machineryEngineering

The invention relates to a polishing machine for a panel of a lock. The polishing machine comprises a stander and a grinding head and a sprocket transmission motor which are connected to the stander, wherein the left and right ends of the stander are provided with a sprocket respectively; the sprocket at one end of the stander is connected with the sprocket transmission motor through a sprocket shaft; the sprockets at the two ends of the stander are connected with each other through a chain; the chain is fixed with a plurality of panel fixtures respectively; a guide rail is arranged between the sprockets at the two ends of the stander; the lower end of the panel fixture in an upper section of the chain is in slide contact with the guide rail; the grinding head is correspondingly arranged above the panel fixture in the upper section of the chain; grinding and polishing can be performed after the panel of the lock is put in the panel fixture and rotates to the lower side of the grinding head along with the chain. The polishing machine has the advantages of high work efficiency, high safety and good consistency of product quality and the like.

Owner:胡小爱

Multi-unit ultrasonic welding machine

InactiveCN102744881AImplement automatic transferExtended service lifeNon-electric welding apparatusMulti unitAutomatic transmission

The invention discloses a multi-unit ultrasonic welding machine, comprising a frame which is provided with a countertop plate, wherein at least one group of ultrasonic welding devices are disposed on the top of the frame or on the countertop plate, respectively; fixed mould conveyers are also disposed on the countertop plate, wherein each ultrasonic welding device comprises a ultrasonic welding head; and the ultrasonic welding heads are arranged above the fixed mould conveyers. Different welding points can be welded simultaneously by disposing a plurality of units of the ultrasonic welding devices according to different structures of welding members and different positions of the welding points, and by hanging upside down partial units of the ultrasonic welding devices on the top of the frame for saving floor area of the countertop plate. With the structure design of the fixed mould conveyers, the multi-unit ultrasonic welding machine realizes an automatic transmission of the welding members, can complete welding automatically, effectively improves work efficiency, and ensures the consistency of the qualities of the welding members, thereby improving the service life and stability of the welding members.

Owner:SUZHOU KEBER PRECISION MACHINERY

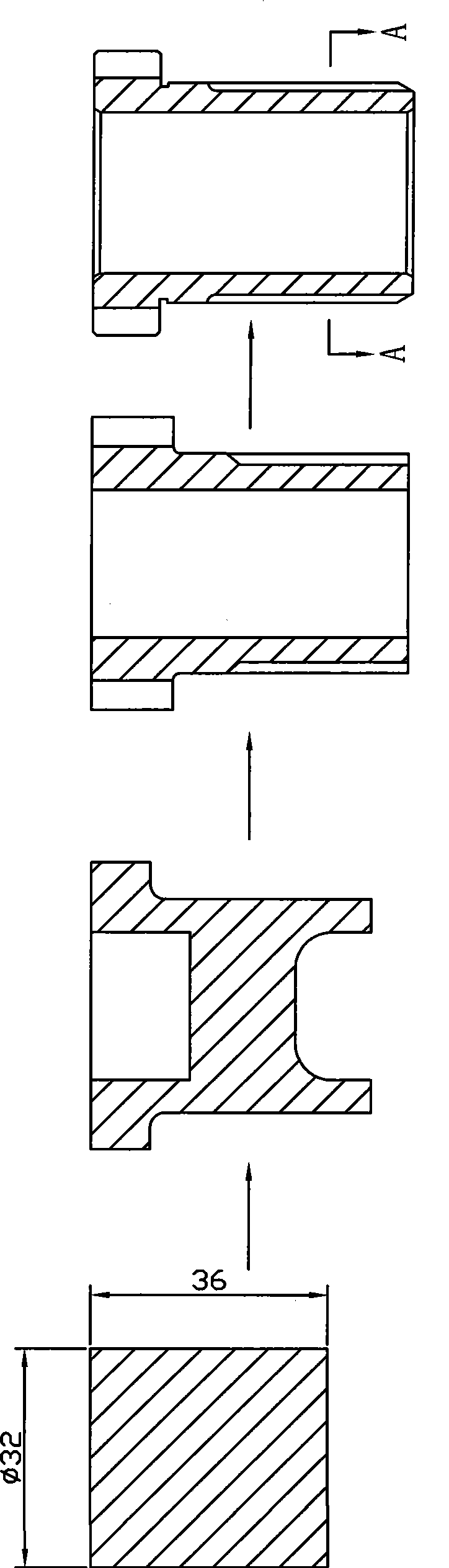

125 motorcycle engine starting gear cold extrusion forming method and dies thereof

The invention discloses a 125 motorcycle engine starting gear cold extrusion forming method. The method comprises the following steps: a) charging materials; b) carrying out cold extrusion on a starting gear blank; c) carrying out cold extrusion on gears and keyways of the starting gear so as to form a starting gear finished blank; and d) carrying out the finish turning on the starting gear. A cold extrusion device comprises a hydraulic press with upper and lower oil cylinders and dies. The dies comprise a blank extrusion die and a gears and keyways extrusion die which are arranged on the hydraulic press with the upper and lower oil cylinders respectively. The 125 motorcycle engine starting gear cold extrusion forming method adopts the two-step formation integrated with subsequent processing, saves raw materials, and has high work efficiency, low processing cost and good quality uniformity of products. The cold extrusion forming dies have novel design and a reasonable structure, and meet the requirements of the 125 motorcycle engine starting gear cold extrusion forming method.

Owner:张长国

Molding compound for sheet tantalum capacitor

InactiveCN1546566AMeet the requirements of production molding process parametersImprove product qualityCapacitorsEpoxyCombustion

The invention discloses a molded plastic compound for sheet tantalum capacitor, which is an epoxy resin compound and belongs to the field of special-purpose plastic encapsulating material in electronic industry. The molded plastic uses epoxy resin as the main block resin and phenolic resins as curing agent, prepared by adding solidification accelerating agent, filling material, releasing agent, combustion inhibitor, coloring agent, coupling agent, toughening agent and modifier though the steps of disintegrating, mixing, pugging, cooling down, disintegrating, batch mixing, pre-forming and packaging.

Owner:WUXI RES & DESIGN INST OF CHEM IND

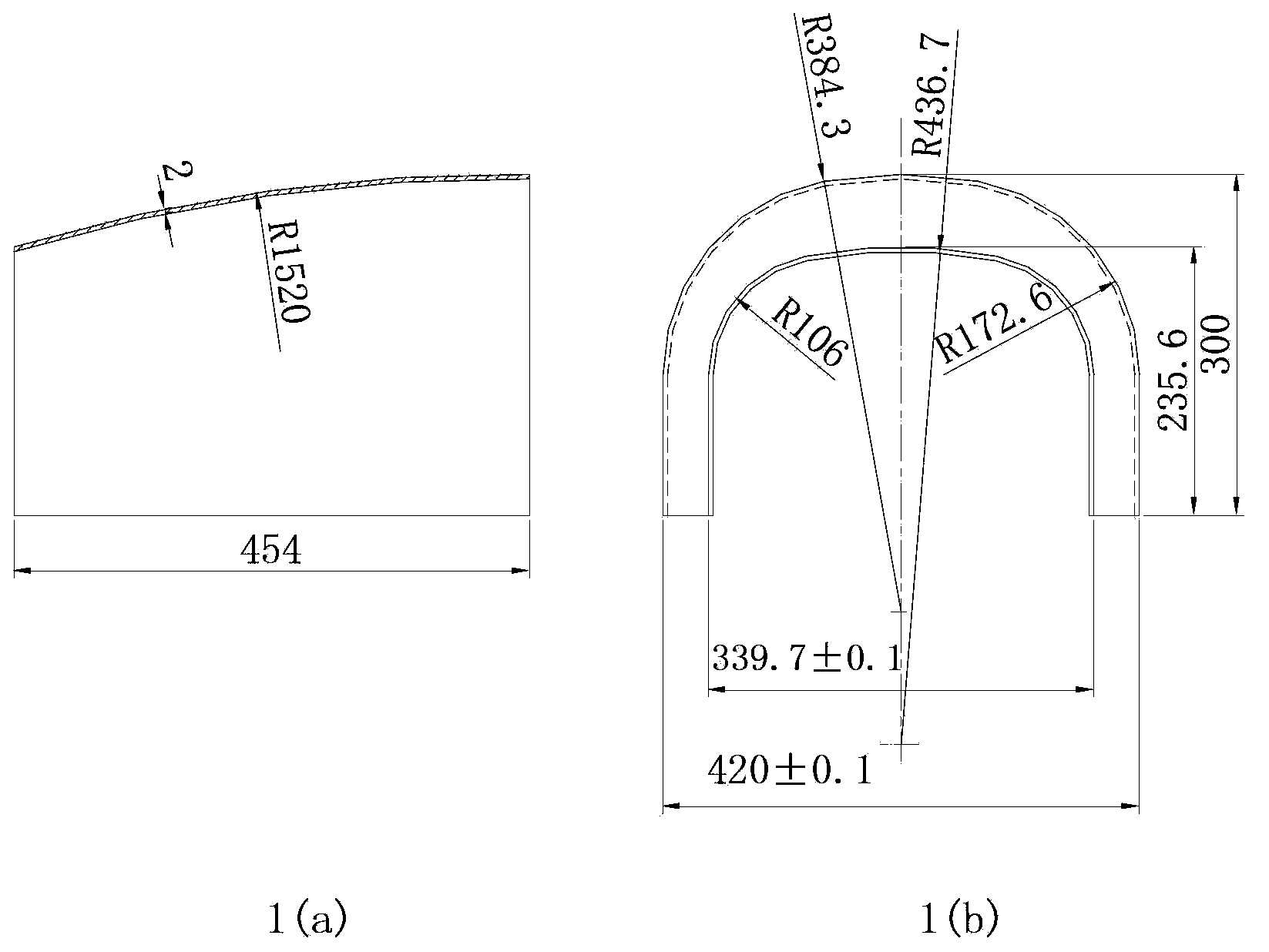

Thermoforming method of titanium alloy hook surface part

The invention discloses a thermoforming method of a titanium alloy hook surface part, which comprises the following steps: placing a forming die into a heating furnace of a press machine; placing the titanium alloy in the die, and heating the work blank and the die; conducting stamping forming on the work blank through the die by the press machine; opening the die after the workpiece and the die are cooled, taking out the workpiece, so as to accomplish titanium alloy surface part forming; the method provided by the invention is characterized in that the cooling is furnace cooling of the workpiece and the die, and the die is in a clamping state during the cooling process, that is the terrace die and the die are not separated. The invention further discloses a workpiece prepared by the method. According to the method provided by the invention, the heat shrinkable size is neglected, hook surface titanium skin, with a molded surface accuracy within 0.2 mm, can be conveniently processed, the quality consistency is good, and the heat formed die can be used as a test die base of the workpiece molded surface.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

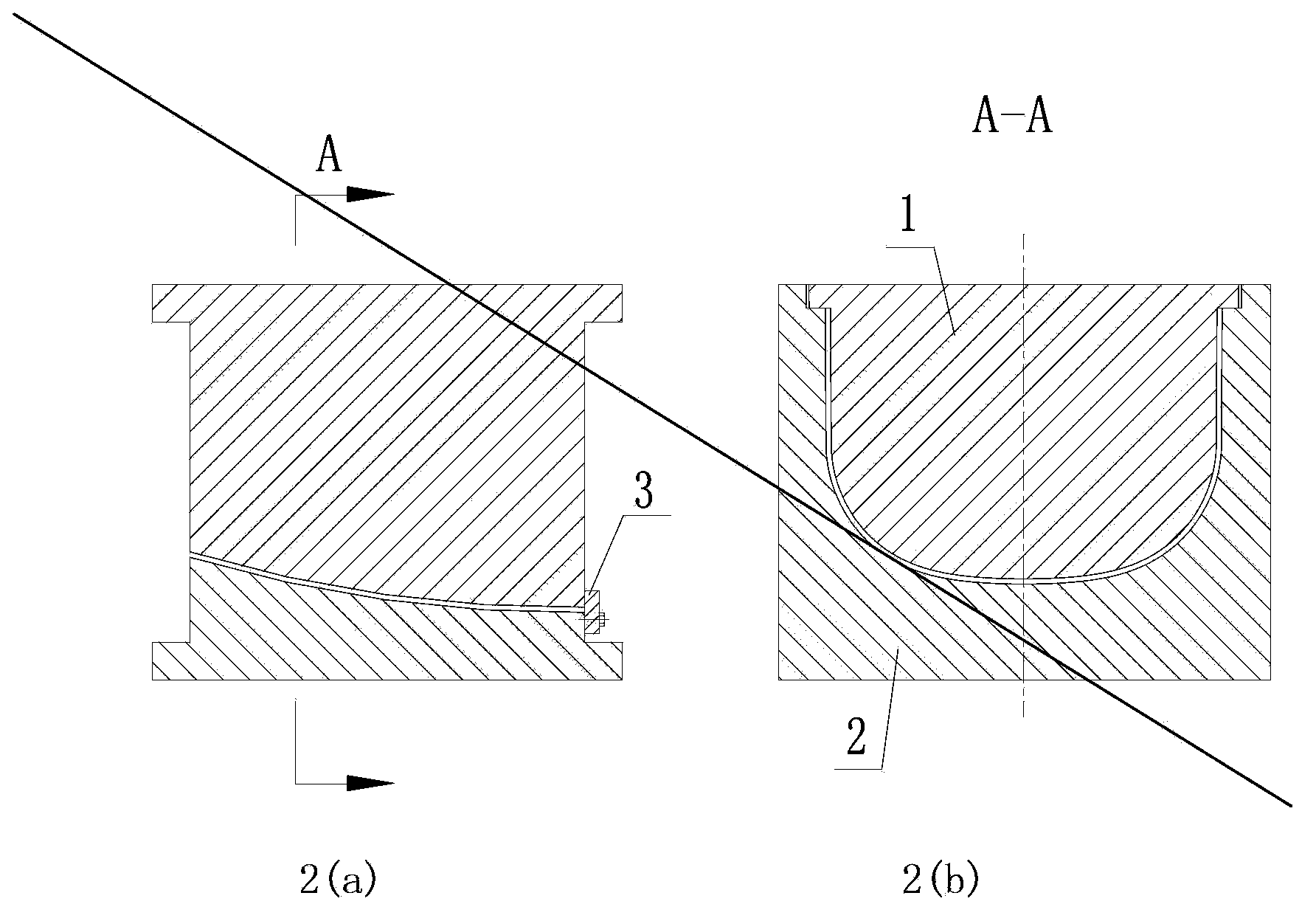

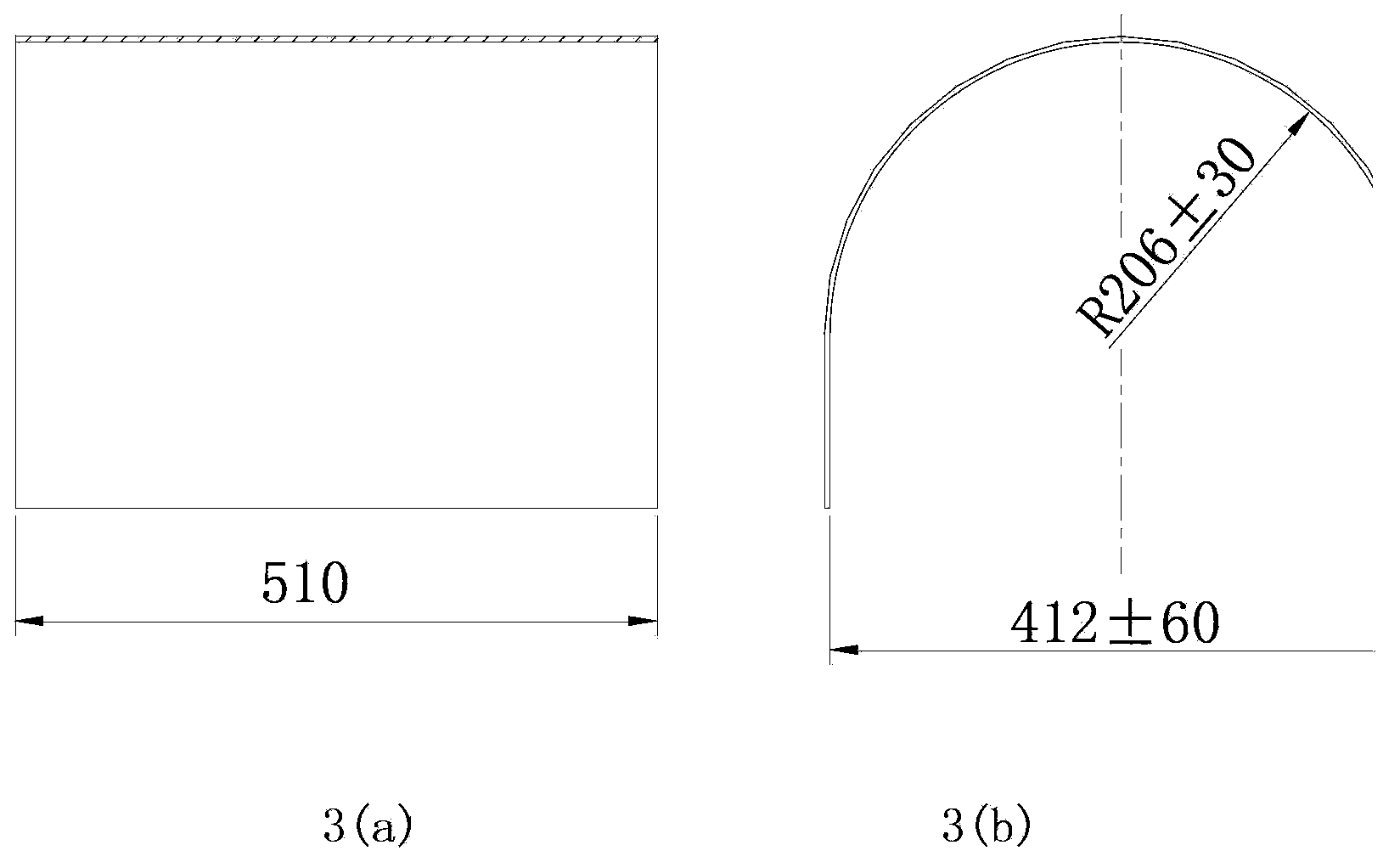

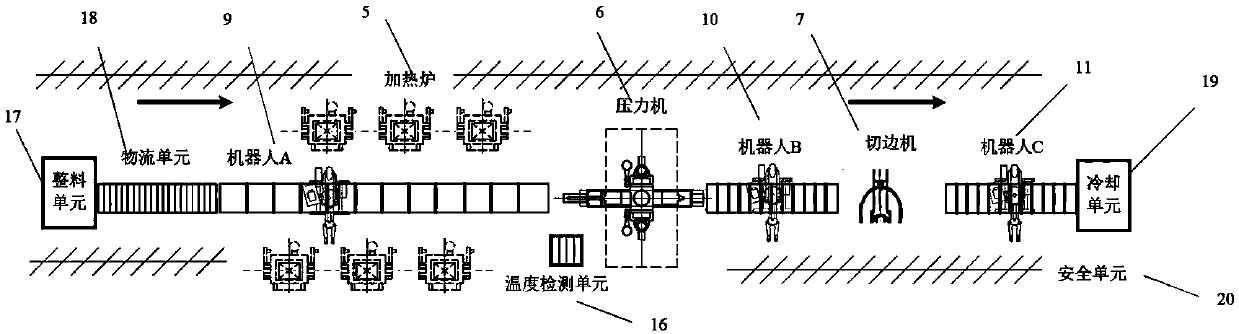

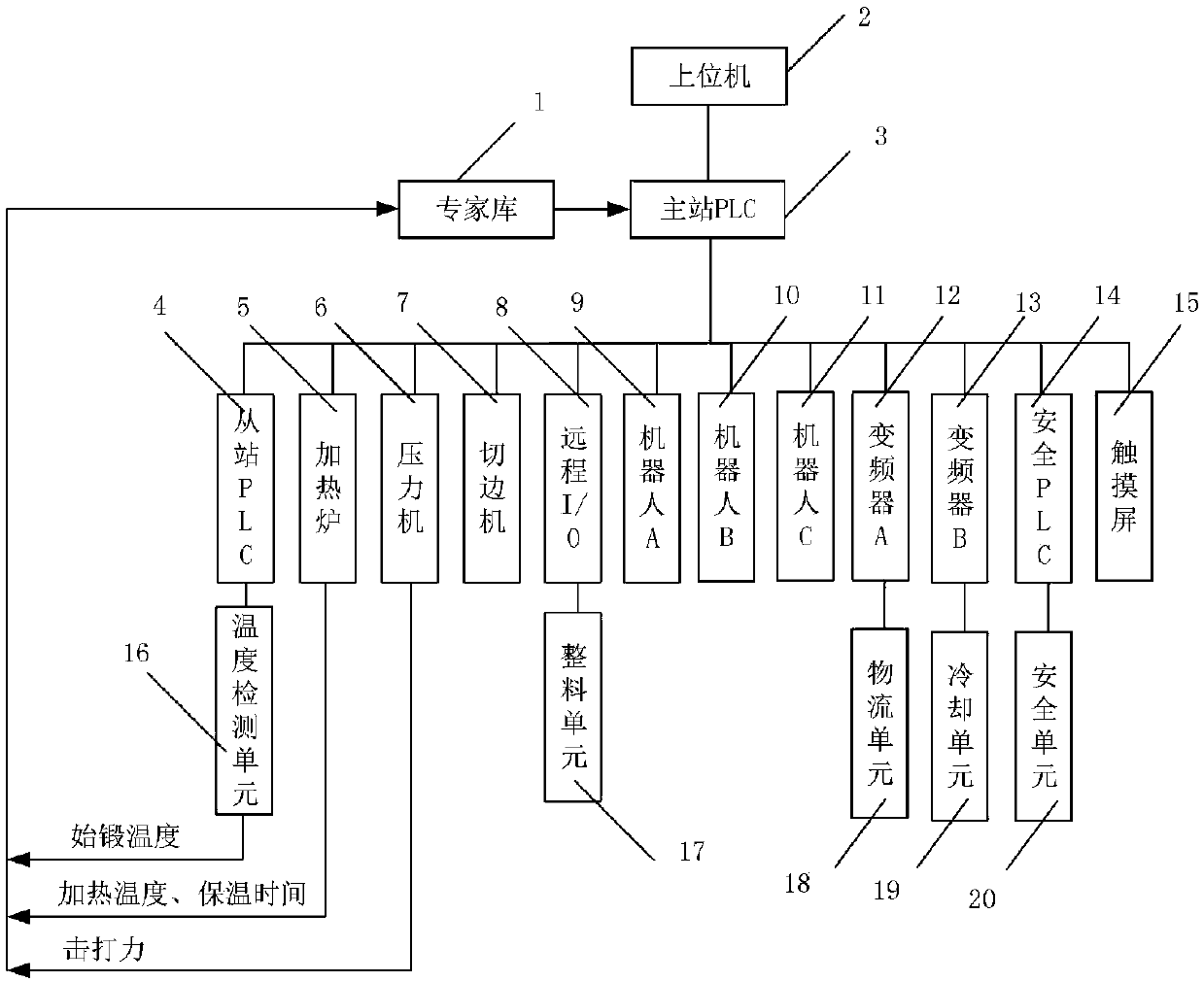

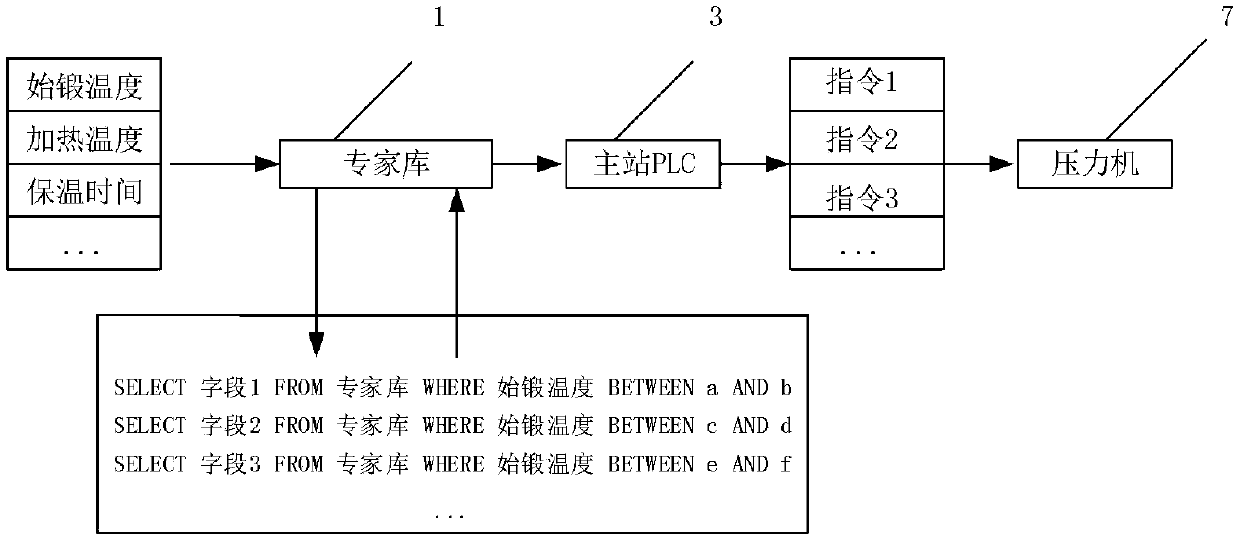

Die forging production line intelligent control system

InactiveCN109521737ADynamic adjustment of hitting forceImprove automationTotal factory controlProgramme total factory controlProduction lineEngineering

The invention discloses a die forging production line intelligent control system, and belongs to the field of automatic production line control. The system comprises a main station PLC, an upper computer, an expert database, a slave station PLC, a remote I / O, a frequency converter, a safety PLC, a touch screen, a heating furnace, a press machine, an edge trimmer, robots, a temperature detection unit, a logistics unit, a cooling unit and a safety unit. The main station PLC is connected with the upper computer through a TCP / IP protocol. The slave station PLC, the safety PLC, the remote I / O, thefrequency converter, the robot A, the robot B, the robot C, the heating furnace, the press machine and the edge trimmer are all connected with the main station PLC through a Profibus-DP. The touch screen is connected with the main station PLC through an MPI interface. The expert database is constructed to optimize and adjust the striking force according to different initial forging temperatures inthe machining process, so that the machining quality consistency is improved.

Owner:BEIJING UNIV OF TECH +1

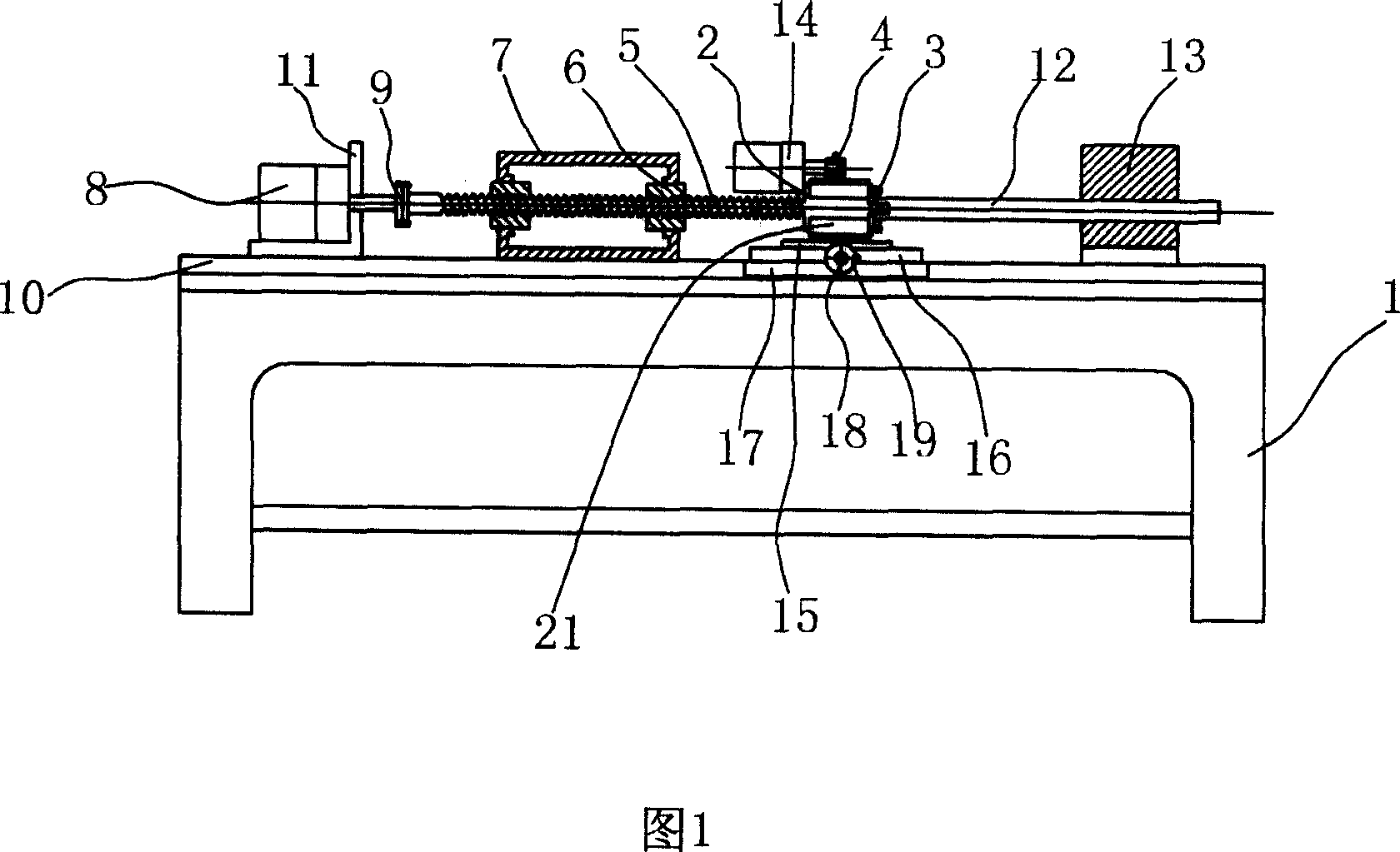

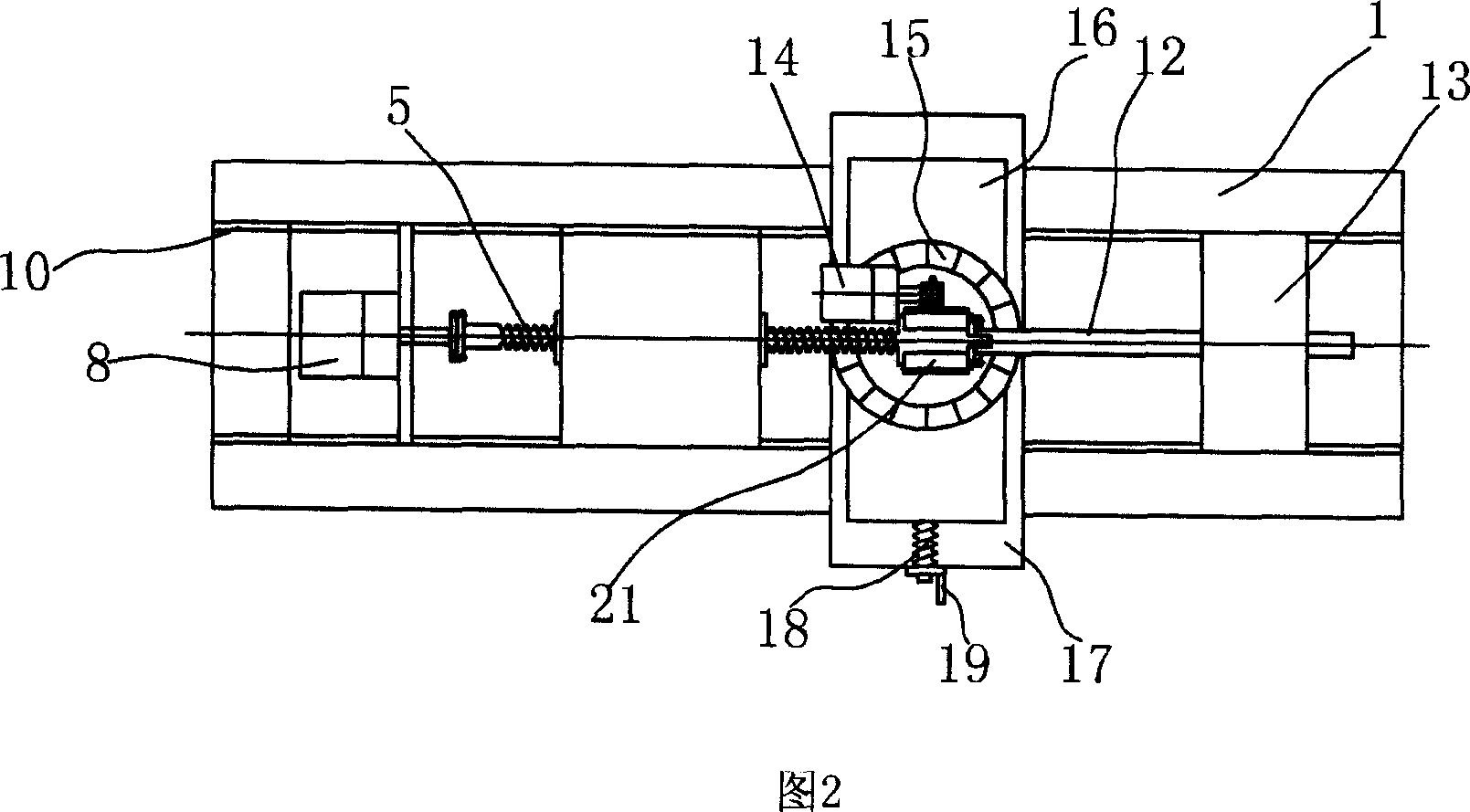

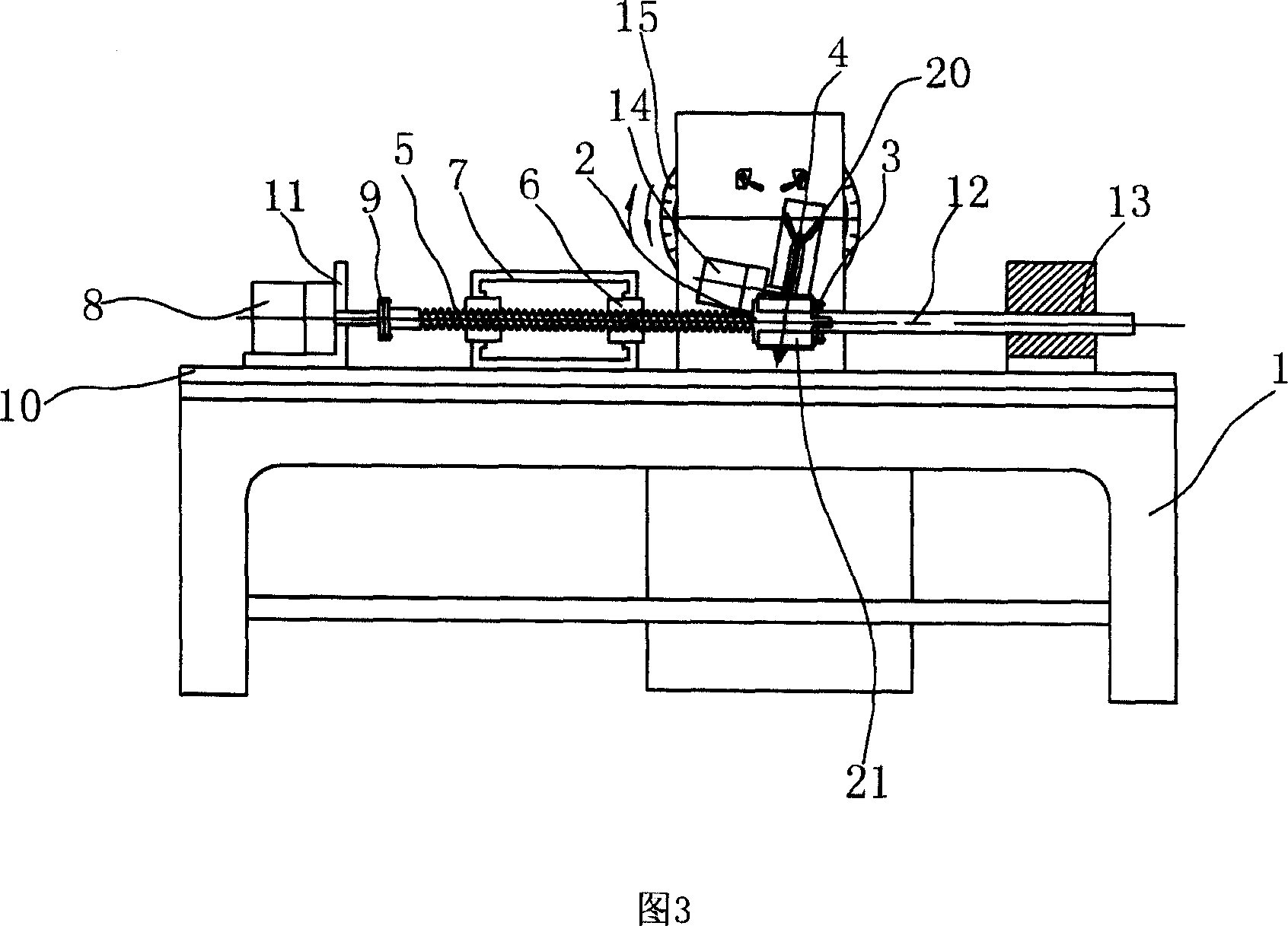

Worm and screw processing device

InactiveCN101053917AImprove machining accuracyImprove consistencyThread cutting machinesFeeding apparatusScrew threadMachining

The invention relates to a worm lead screw processing equipment, belonging to the worm and lead screw processing equipment technology field, comprising a bed and a workpiece fixture, cutters corresponding to one side of workpiece fixture for clamping the workpiece and a workpiece feeding mechanism for driving the workpiece fixture to rotate and axially translate. The workpiece feeding mechanism at least comprises a dynamic thread body and a static thread body fixed on the bed which are match with each other by thread, wherein one end of the dynamic thread body is driving connected with an output end of a power supply, and the other end of the dynamic thread body is fixing connected with the workpiece fixture. The invention has advantages of high machining precision, simple structure, low cost, convenient operation and good quality consistency of the processed worm lead screw.

Owner:ZHEJIANG LINIX MOTOR

External wall brick paving method

InactiveCN105863228AReduce the labor intensity of layingImprove work efficiencyBuilding constructionsBrickStructural engineering

The invention discloses an external wall brick paving method. The external wall brick paving method is characterized in that wall bricks are vertically arranged in rows; the wall bricks of all rows are gathered and arranged from front to back according to the actual paving sequence from bottom to top and put in a wall brick containing box of which one end is an outlet and the wall brick paving surfaces directly face the outlet; the outlet of the wall brick containing box directly faces a to-be-paved wall surface, and the wall brick containing box is controlled to be lift gradually; and in the lifting process, plaster is applied to the wall surface in front of the outlet of the wall brick containing box to achieve plastering, then the wall bricks are controlled to be pushed out in rows and attached to the already applied plaster, and paving is finished. Accordingly, the effect of paving the wall bricks in rows can be achieved, and the wall brick paving efficiency is greatly improved. By means of the external wall brick paving method, automatic flow paving of the building external wall surface bricks can be achieved, and the labor intensity of wall brick paving is relieved. The external wall brick paving method has the advantages that the working efficiency is high, the project quality is good, and the project quality consistency can be guaranteed.

Owner:YANGTZE NORMAL UNIVERSITY

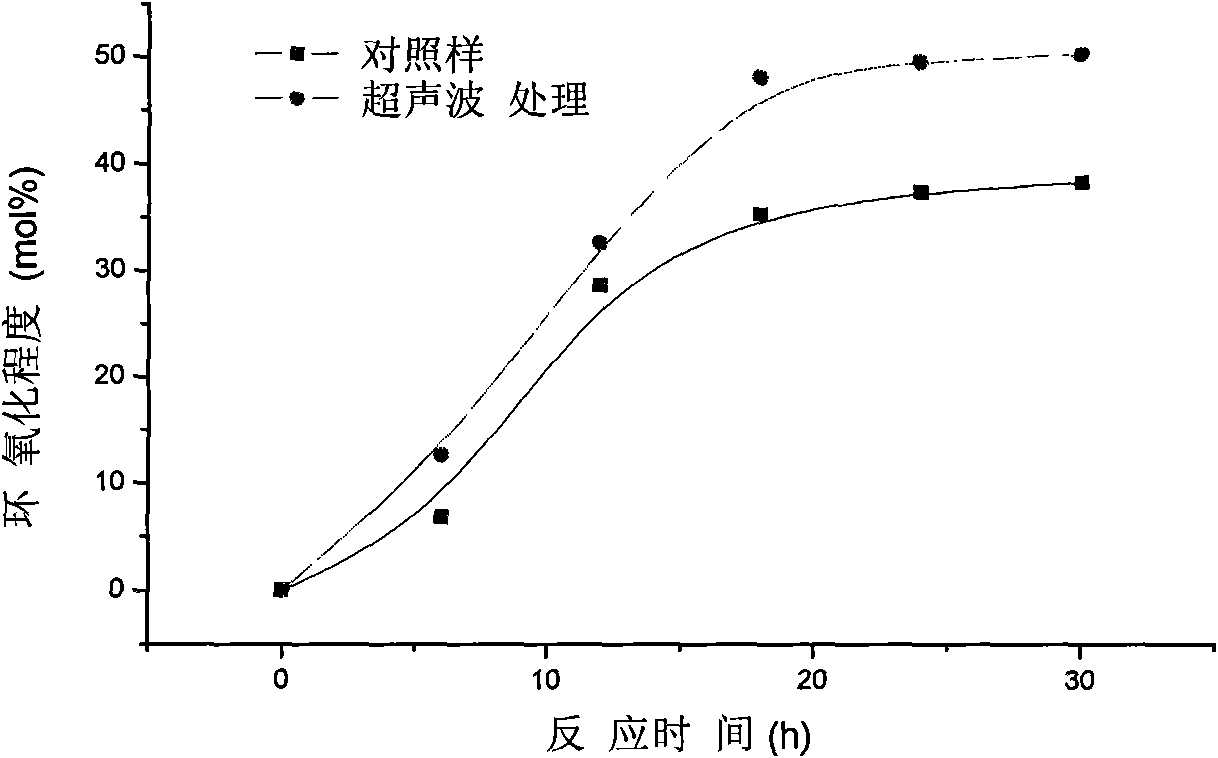

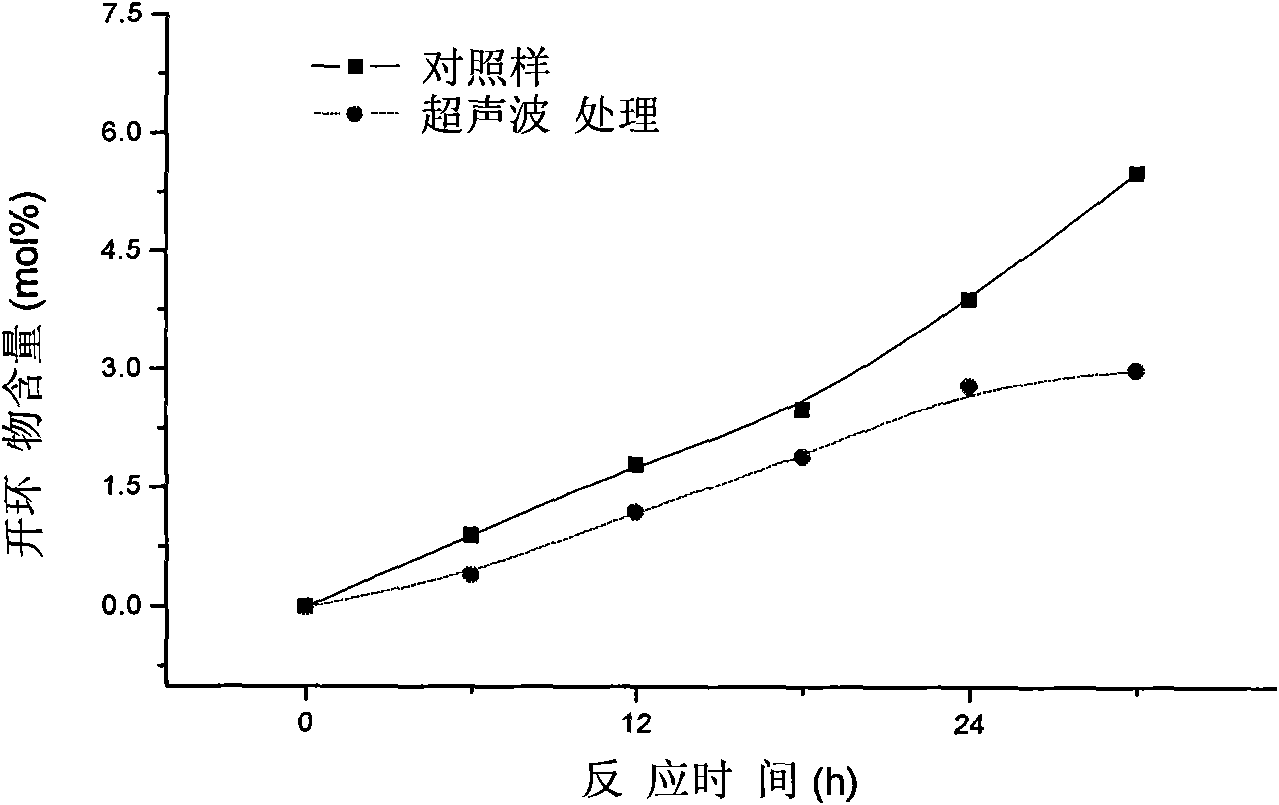

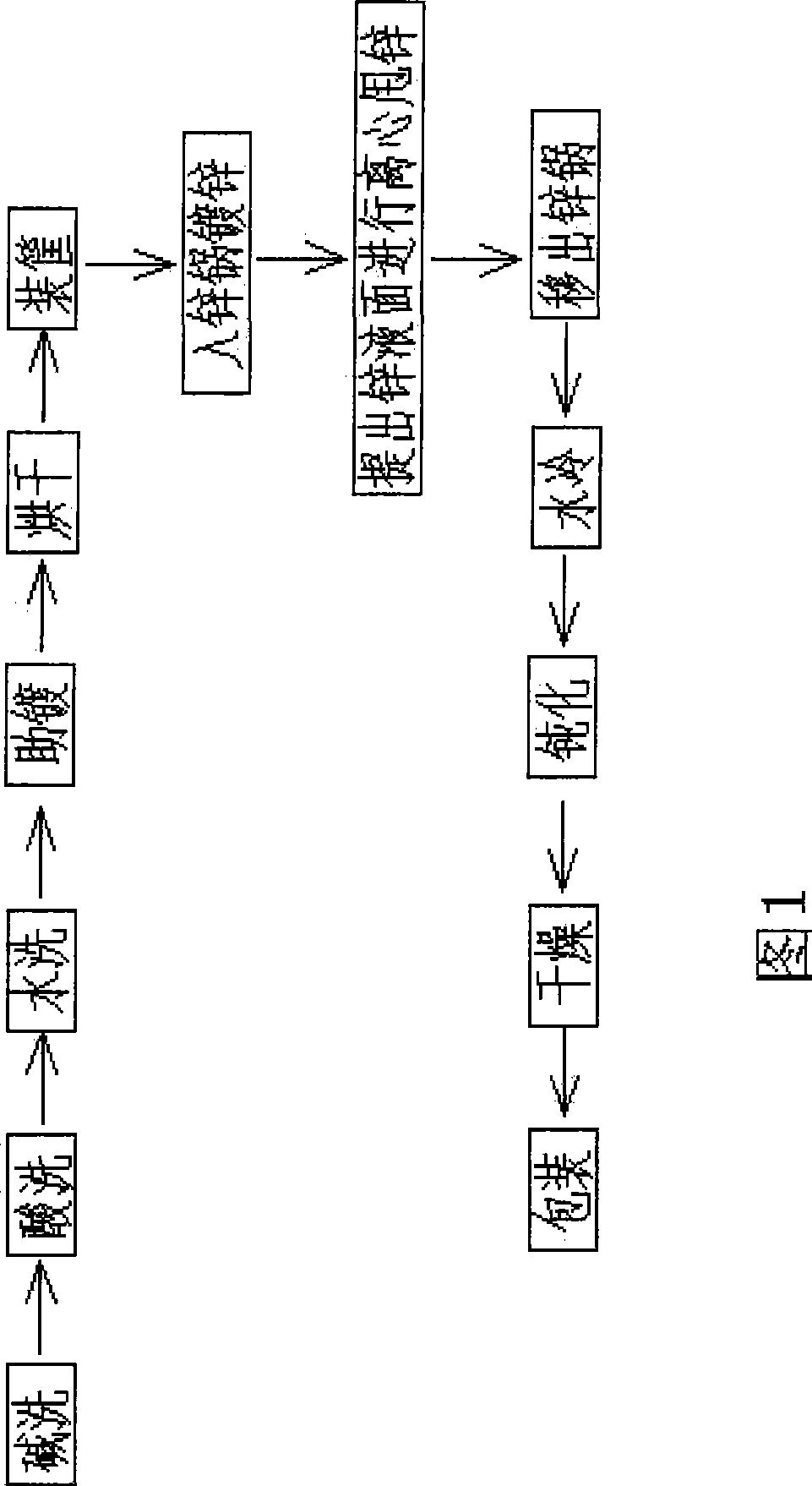

Method for preparing epoxidized natural rubber

InactiveCN101942043AGood effectPrecise control of the degree of epoxidationTotal solid contentReaction temperature

The invention discloses a method for preparing epoxidized natural rubber, which comprises the following steps of: diluting 100 parts of condensed natural rubber latex with the total solid content of 60 percent with deionized water until the total solid content is 30 percent, adding 1 to 3 parts of 20 percent polyoxyethylene lauryl ether with stirring, stabilizing the mixed solution for 2 hours, slowly adding 16 to 24 parts of 86 percent formic acid and 35 to 45 parts of 30 percent hydrogen peroxide, finishing reaction at certain reaction temperature, for a certain reaction time and in an ultrasonic treatment way, adjusting a pH value to 8 to 9 with ammonia water, and performing coagulation, dehydration, rinsing, granulation and drying to prepare the epoxidized natural rubber with the epoxidization degree of 10 to 50 percent, the ring-opening substance content of less than 3.0 percent, relatively higher quality consistency and capability of satisfying needs in application performance.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Automatic hot galvanizing technique for steel fastener

InactiveCN101368253AGuaranteed accuracyGuaranteed StrengthHot-dipping/immersion processesAutomatic controlAcid washing

The invention discloses an automatic pot galvanizing technique of a steel fastener which orderly includes the working procedures like caustic washing, acid washing, water washing, assistant plating, drying, crating, galvanizing, centrifugal zinc throwing, water cooling, passivating, drying, packaging, and the like. The galvanizing temperature is between 450 and 480 DEG C; the working procedures of galvanizing and centrifugal zinc throwing are automatically controlled; the centrifugal zinc throwing is to hoist a galvanized workpiece out of a galvanized surface with a galvanizing material basket and lead the galvanized workpiece to horizontally rotate with the galvanizing material basket to make centrifugal movement. The technique leads the galvanized workpiece to instantly carry out zinc throwing without pouring the basket; the temperature drop of the workpiece is small; the galvanizing temperature can be reduced below 480 DEG C; energy is saved; the coherence for the intensity, the precision and the quality of the fastener is ensured; the service life of a zinc boiler is prolonged; the production cost is reduced; the processes for galvanizing and zinc throwing are automatic, safe and effective; besides, the working intensity is low. The technique provided by the invention can be used for carrying out pot galvanizing on the steel fasteners like bolts, nuts, nails, and the like.

Owner:陈冬

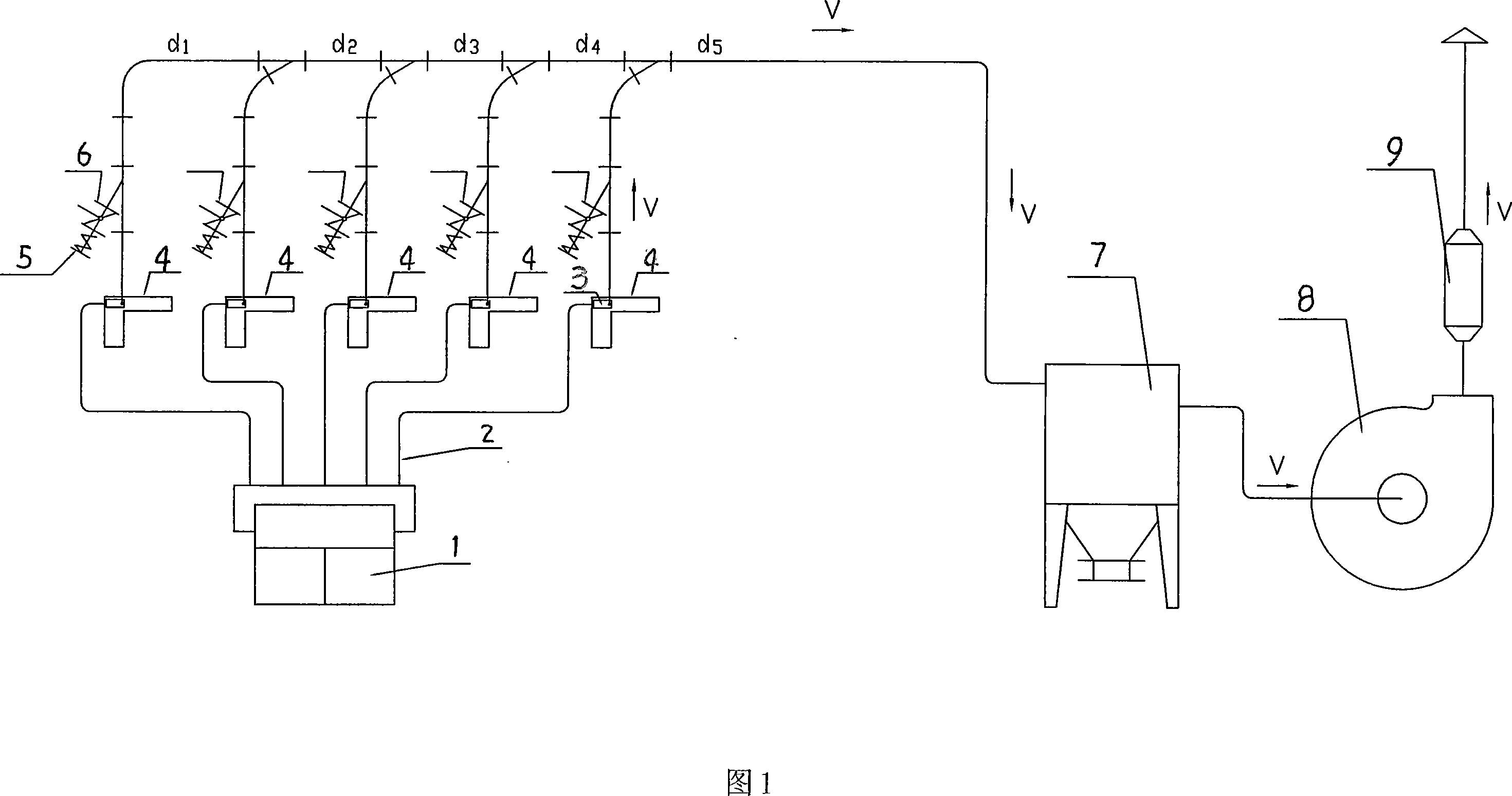

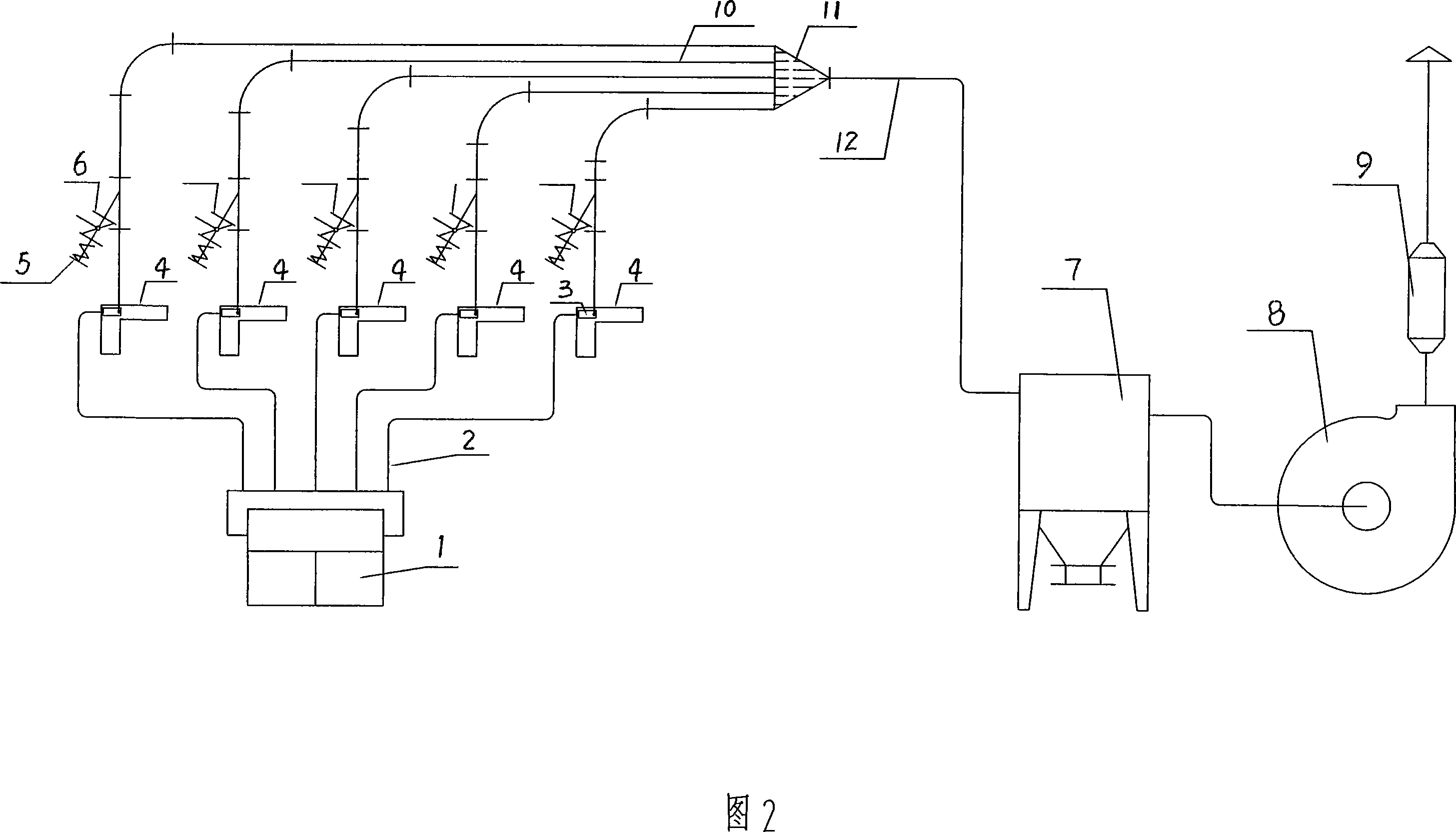

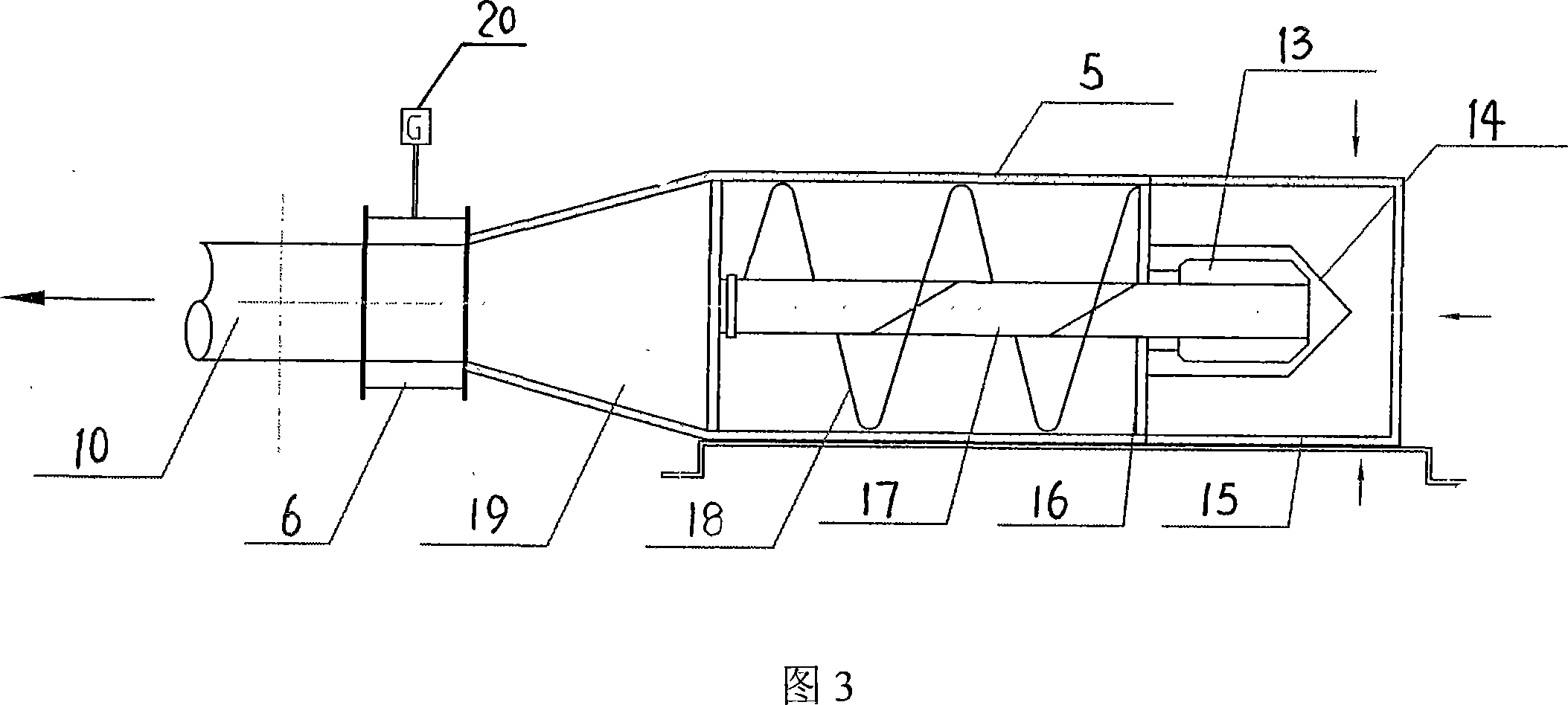

Binary isogram replacing constant-speed pneumatic conveying method

ActiveCN101134531ADampen wild swingsGuaranteed uptimeCigarette manufactureBulk conveyorsMaterial consumptionWorking set

The binary equivalent substitution constant speed pneumatic conveying process for multiple branch pipe negative pressure dilute phase pneumatic conveying system features that in a working set possessing branch pipes with pneumatic valve and damper and when some branch pipe is cut off suddenly, each of the other branch pipes inside the system is equivalently supplemented with corresponding air quantity and wind pressure. The process can convey material reliably and fluently in balance with minimized physical and chemical damage, and reach the aims of lowering material consumption, lowering cost and raising product quality.

Owner:邝勇兴

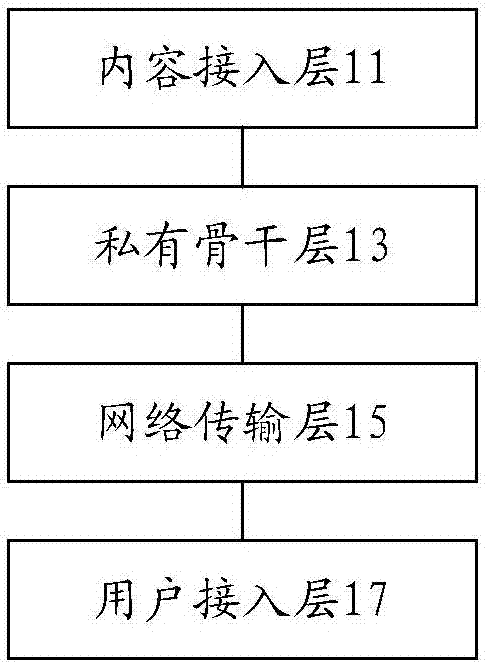

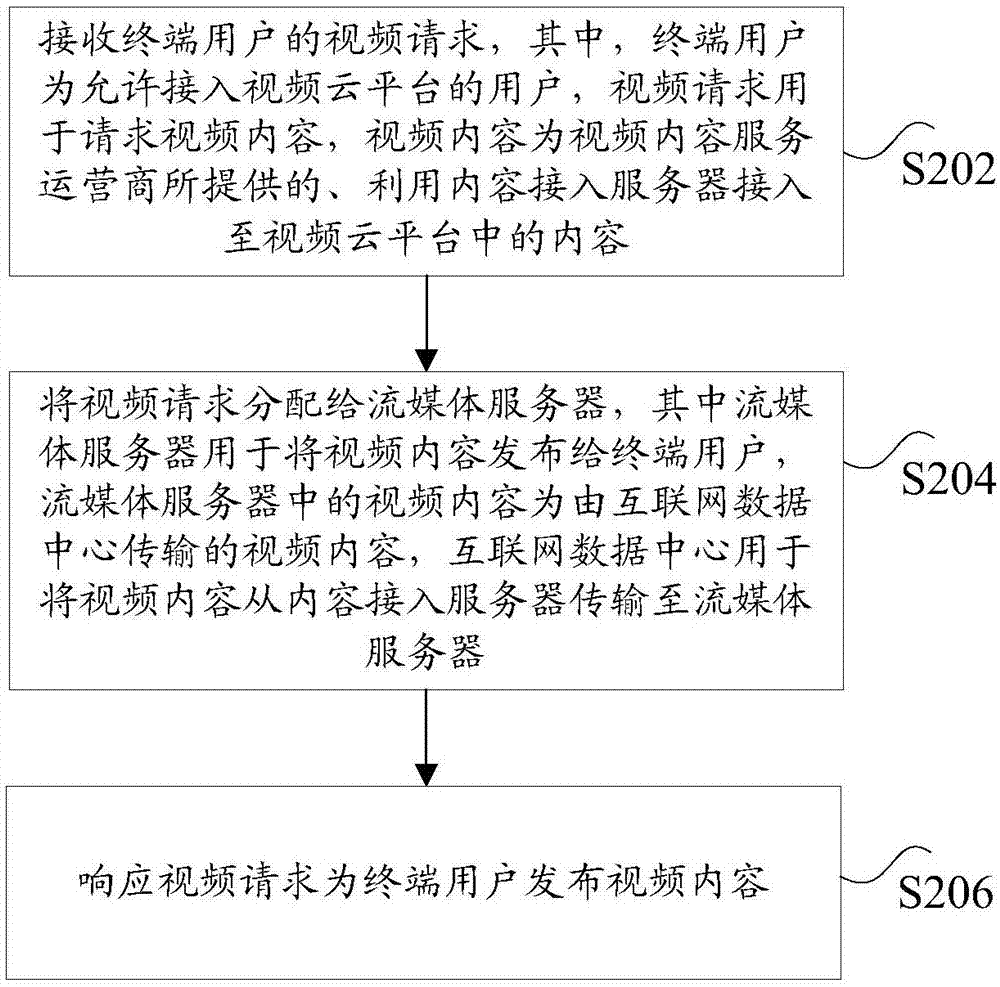

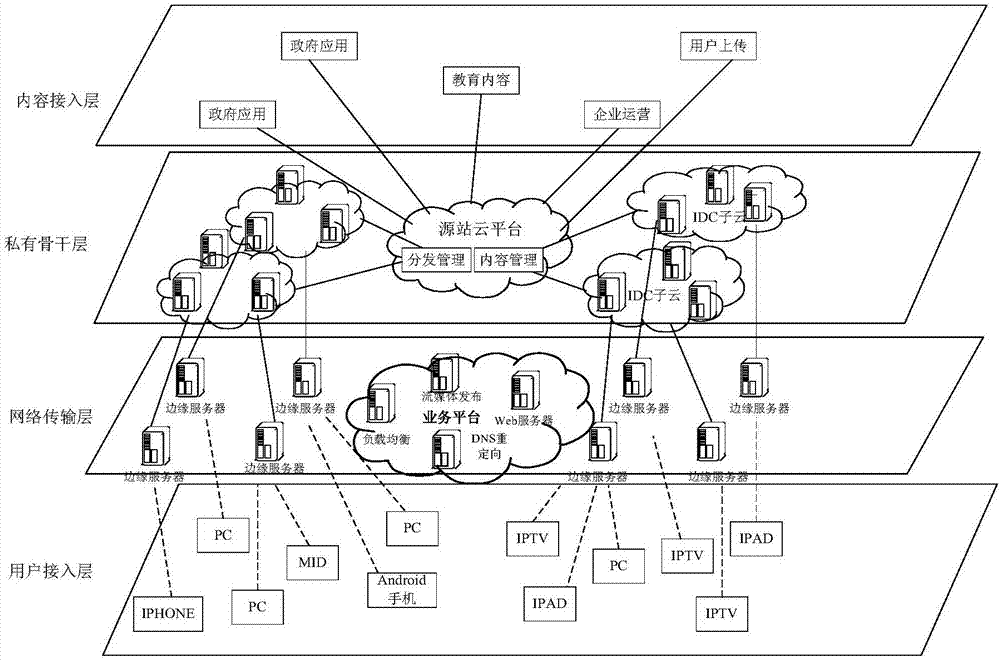

Video cloud platform system, video request processing method, storage medium and processor

The invention discloses a video cloud platform system, a video request processing method, a storage medium and a processor. The video cloud platform system comprises a content access layer comprisinga content access server used for accessing video contents provided by a video content service operator to a video cloud platform; a private backbone layer comprising an Internet data center interconnected by an optical fiber, wherein the Internet data center is used for transmitting the video contents from the content access layer to a streaming media server; a network transmission layer comprising the streaming media server used for issuing the video contents to a terminal user; and a user access layer used for accessing at least one terminal user to the video cloud platform, and the terminaluser successfully accessing the video cloud platform is allowed to access the video contents. By adoption of the video cloud platform system, the following technical problems are solved: content distribution and streaming media related platforms are difficult to serve as a platform to meet different levels of operation needs of different video operators, and it is difficult to achieve the consistency of quality of service, the controllability of cost and the diversity of services.

Owner:卫小刚

Special purpose grinder for piston ring helical supporting spring head face

InactiveCN101352822AOvercome slenderOvercome softnessEdge grinding machinesPlane surface grinding machinesPiston ringCoil spring

A grinding machine specialized for piston ring coil-spring loaded terminal surfaces relates to the grinding machine technique field of processing piston ring coil-spring loaded terminal surfaces. In the invention, a guide lever is vertically fixed at a machine frame; an upper wheel head assembly and a lower wheel head assembly are connected with the guide lever respectively; the upper wheel head assembly comprises an upper grinding disc and the lower wheel head assembly comprises a lower grinding disc; the machine frame is provided with a rotating feeder; an output terminal of the rotating feeder is connected with a rotating shaft parallel to the guide lever; the rotating shaft is fixedly connected with a cylindrical frock which is arranged between the upper grinding disc and the lower grinding disc. The invention can completely avoid the processing error owing to anthropogenic factors; therefore, the consistence of the product quality is good and steady and the processing efficiency can be raised.

Owner:仪征市润扬动力配件有限公司

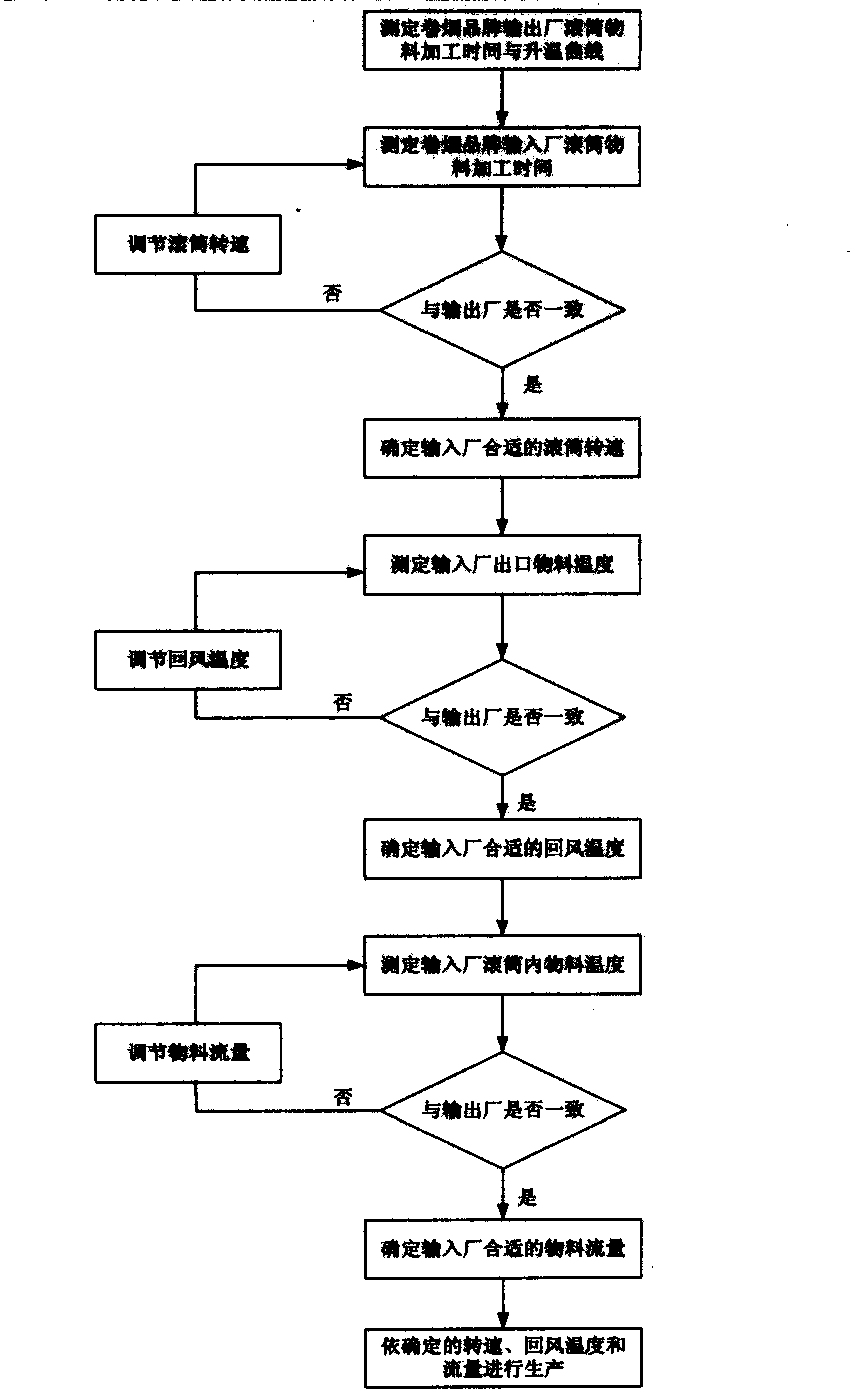

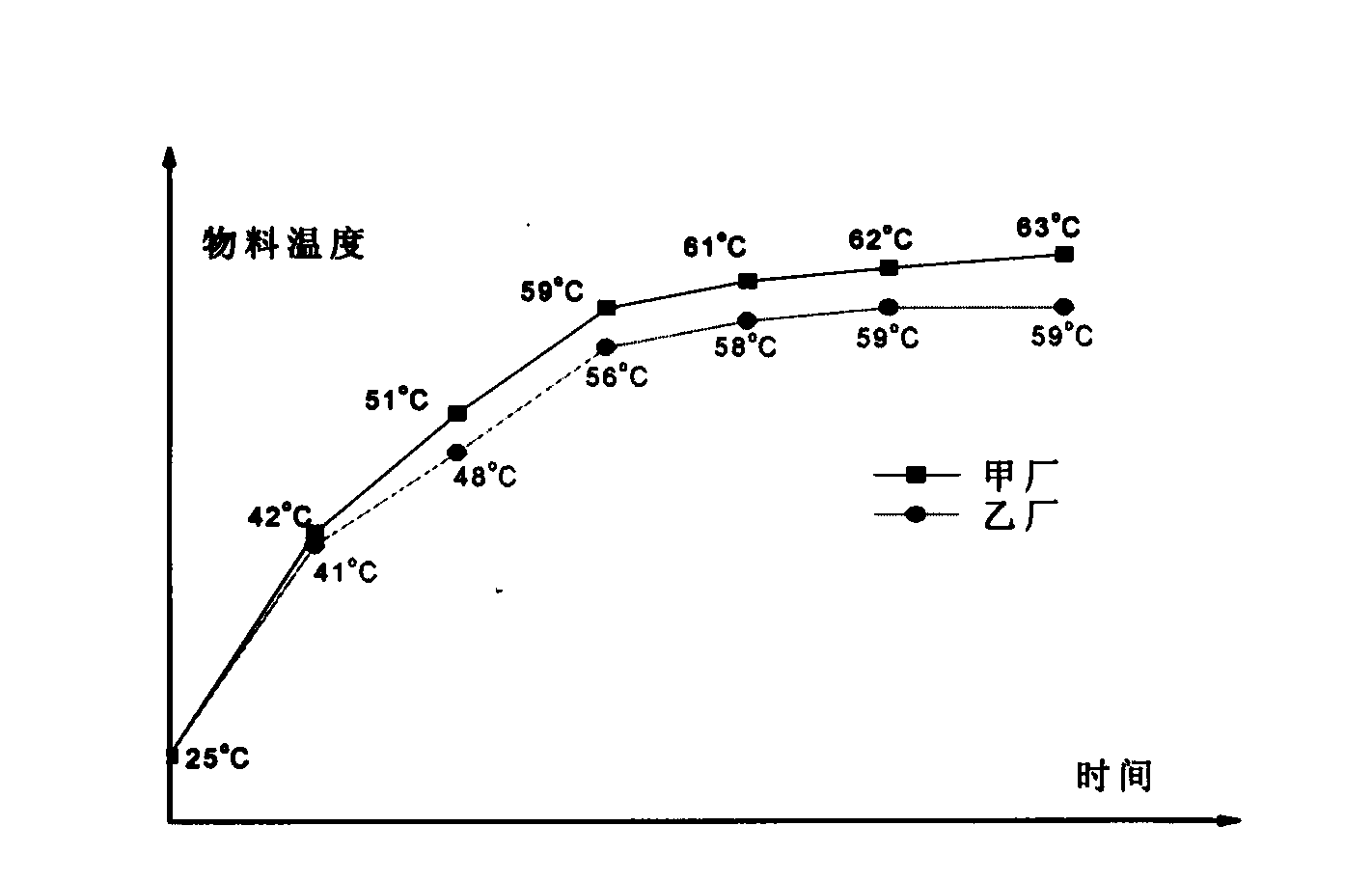

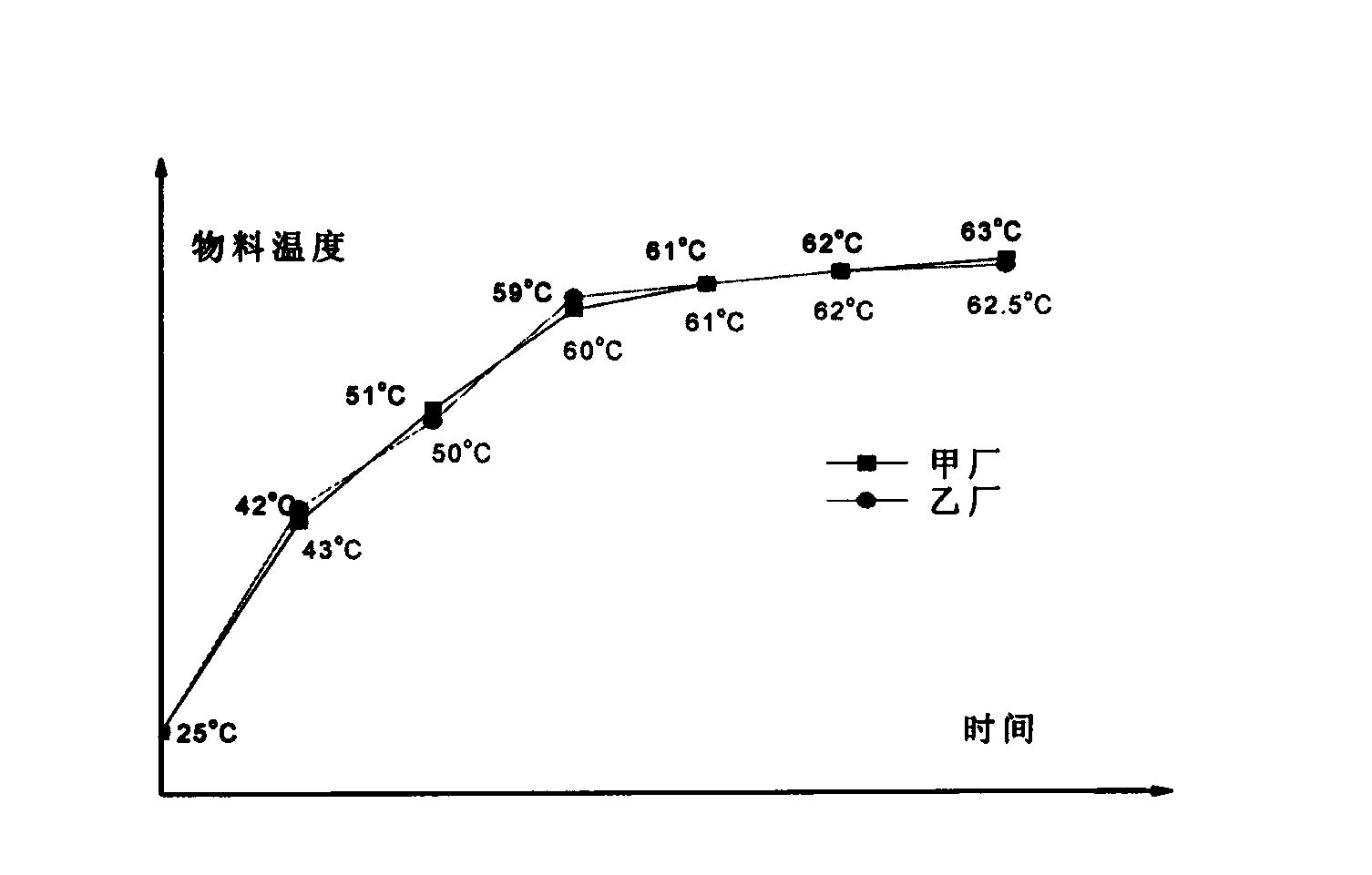

Method for controlling consistency of processing quality in heating processes of tobacco shred processing rollers

ActiveCN101912145AConsistent temperatureConsistent heating timeTobacco preparationProcess qualityHeating time

The invention discloses a method for controlling the consistency of processing quality in heating processes of tobacco shred processing rollers. The method is characterized by comprising the following steps of: (1) determining a processing time and a heating curve of materials in a roller of a tobacco brand output plant; (2) determining the processing time of the materials in the roller of a tobacco brand input plant; (3) comparing to obtain a difference between the two processing times; adjusting the rotating speed of roller of the input plant; making the processing time of the output plant consistent with that of the input plant; and determining the rotating speed of the roller of the input plant; (4) determining related data of the input plant and drawing the heating curve; (5) comparing heating curves of the input plant and the output plant; adjusting related processing process parameters of the input plant; and making the heating curve of the input plant consistent with that of the output plant as much as possible; and (6) determining the related processing process parameters of the input plant and performing normal production. The method has the advantages of capacity of ensuring the consistency of a material temperature and a heating time of the tobacco shred processing rollers in heating processing processes and contribution to ensuring the consistency of the processing quality in the same process of different manufacturing plants.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method for fermenting cigar filling leaves

The invention discloses a method for fermenting cigar filling leaves. The method is characterized by comprising the following steps: controlling the water content of the cigar filling leaves which are subjected to impurity removal and modulation to be 30+ / -2%, and tidying the cigar filling leaves into cigar leaf bundles of which the leaf tips are towards the same direction; stacking the cigar leaf bundles to form a rectangular cigar leaf stack; covering a layer of hessian cloth on the surface of the cigar leaf stack to be used as an air permeable heat-insulating layer; inserting temperature measuring probes into the cigar leaf stack; overturning the stack when the stack filling temperature measured by any temperature measuring probe reaches the alarm upper limit temperature or is in the trend of reducing; after the fermentation is finished, airing the cigar leaves, reducing the moisture of the cigar filling leaves to be 20+ / -2%, and packaging for storage. According to the method, the appearance, the absorbed smell and the quality consistency of the cigar filling leaves can be obviously improved, the content of a harmful ingredient NNK in raw materials can be reduced, and the industrial availability of the cigar leaves can be improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Microporous polyethylene film having excellent physical properties, productivity, and quality consistency, and method of producing same

InactiveUS20060228540A1Increase production capacityStable batterySynthetic resin layered productsCell component detailsProduction rateDiluent

Disclosed herein is a microporous polyethylene film for a battery separator and a method of producing the same. The microporous polyethylene film is made from a resin composition. The resin composition comprises 100 parts by weight of a polyethylene composition including 10-50 wt % polyethylene having a weight average molecular weight of from 2×105 to less than 5×105 (component I) and 90-50 wt % diluent (component II), and 0-150 parts by weight of inorganic powder (component III). The film has a puncture strength of 0.20 N / μm or more and a gas permeability (Darcy's permeability constant) of 1×10−5 Darcy or more. The microporous polyethylene film has excellent physical properties, thus improving the performance and stability of a battery.

Owner:SK INNOVATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com