Patents

Literature

318results about How to "Implement automatic transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

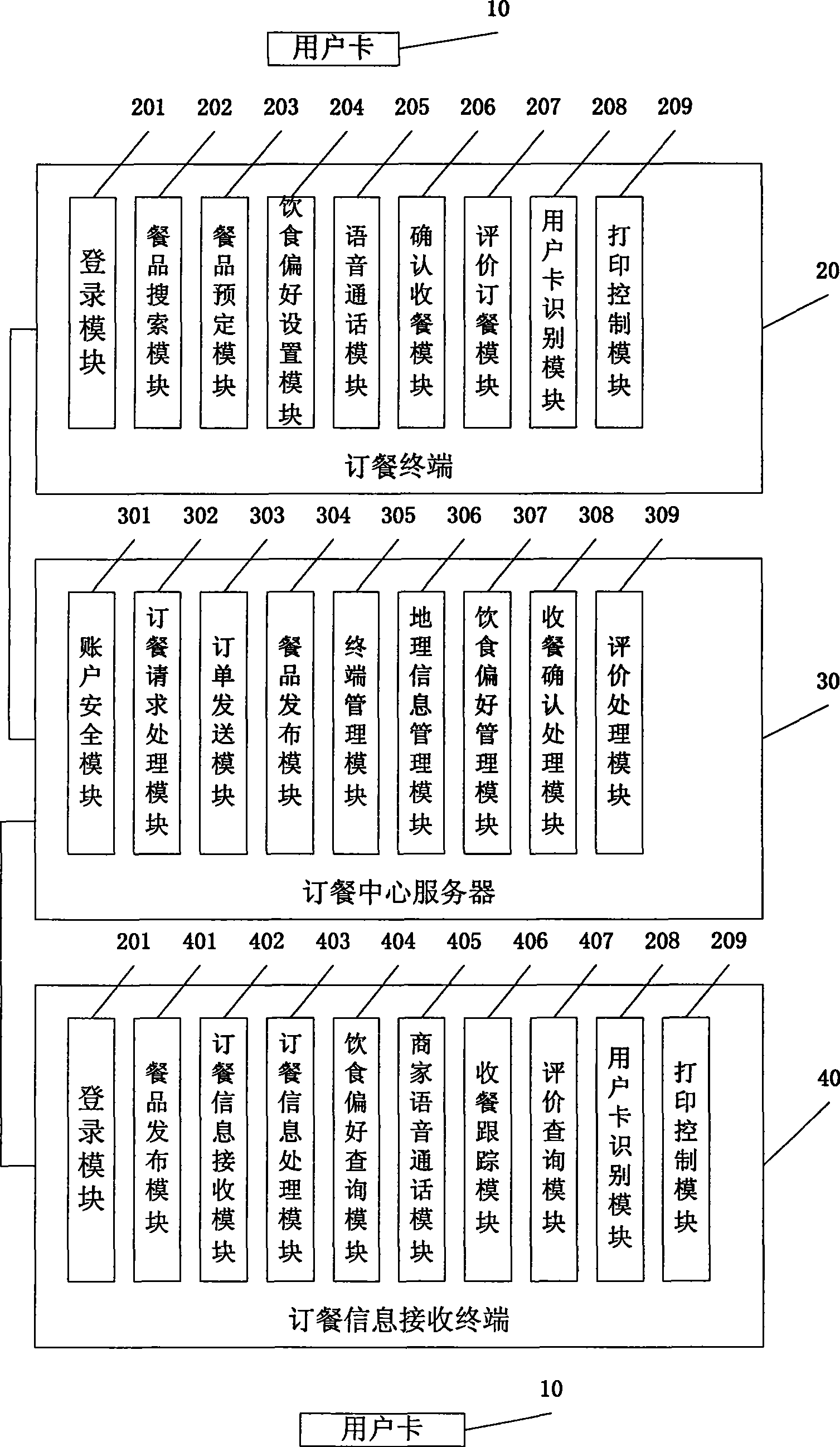

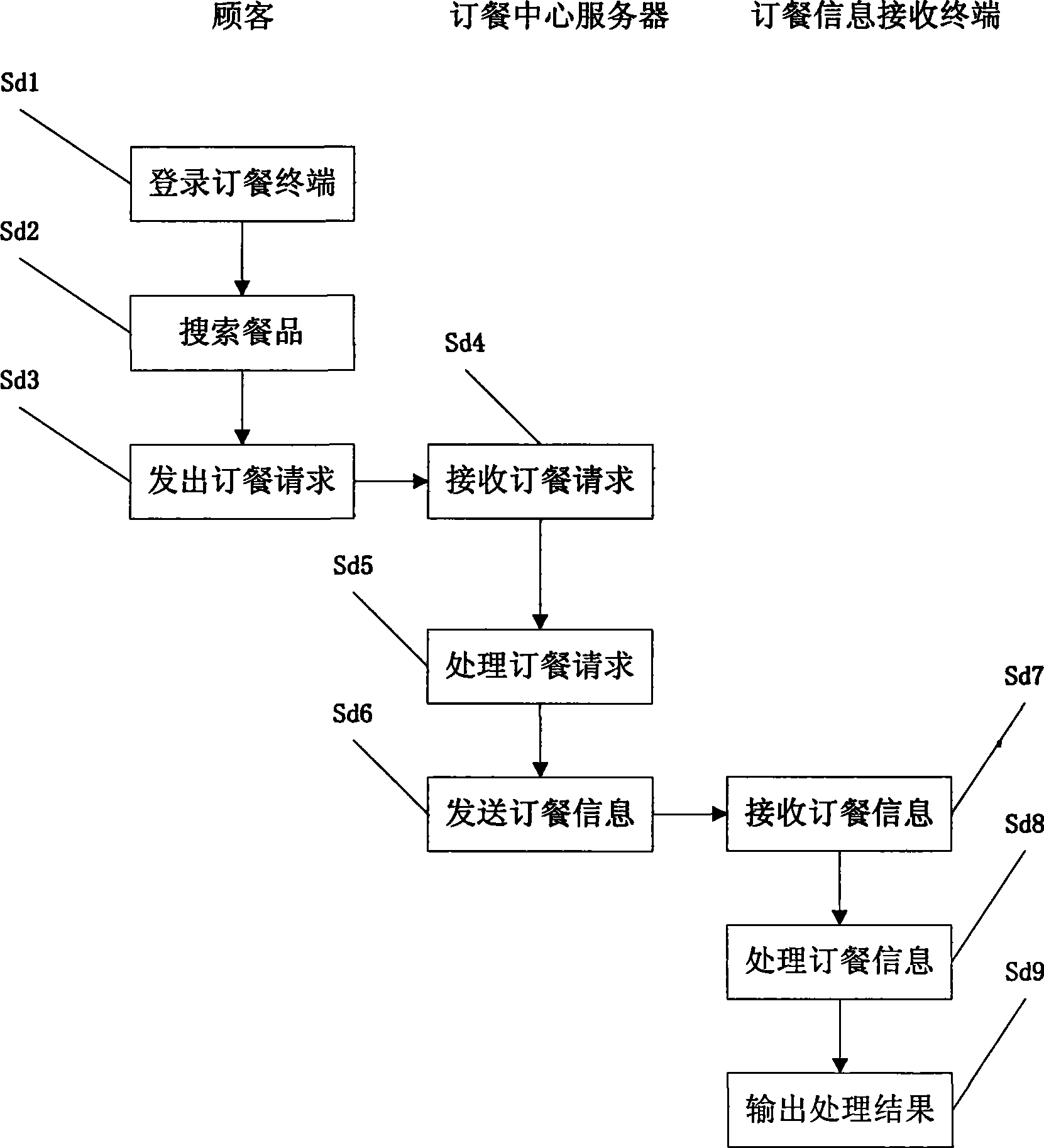

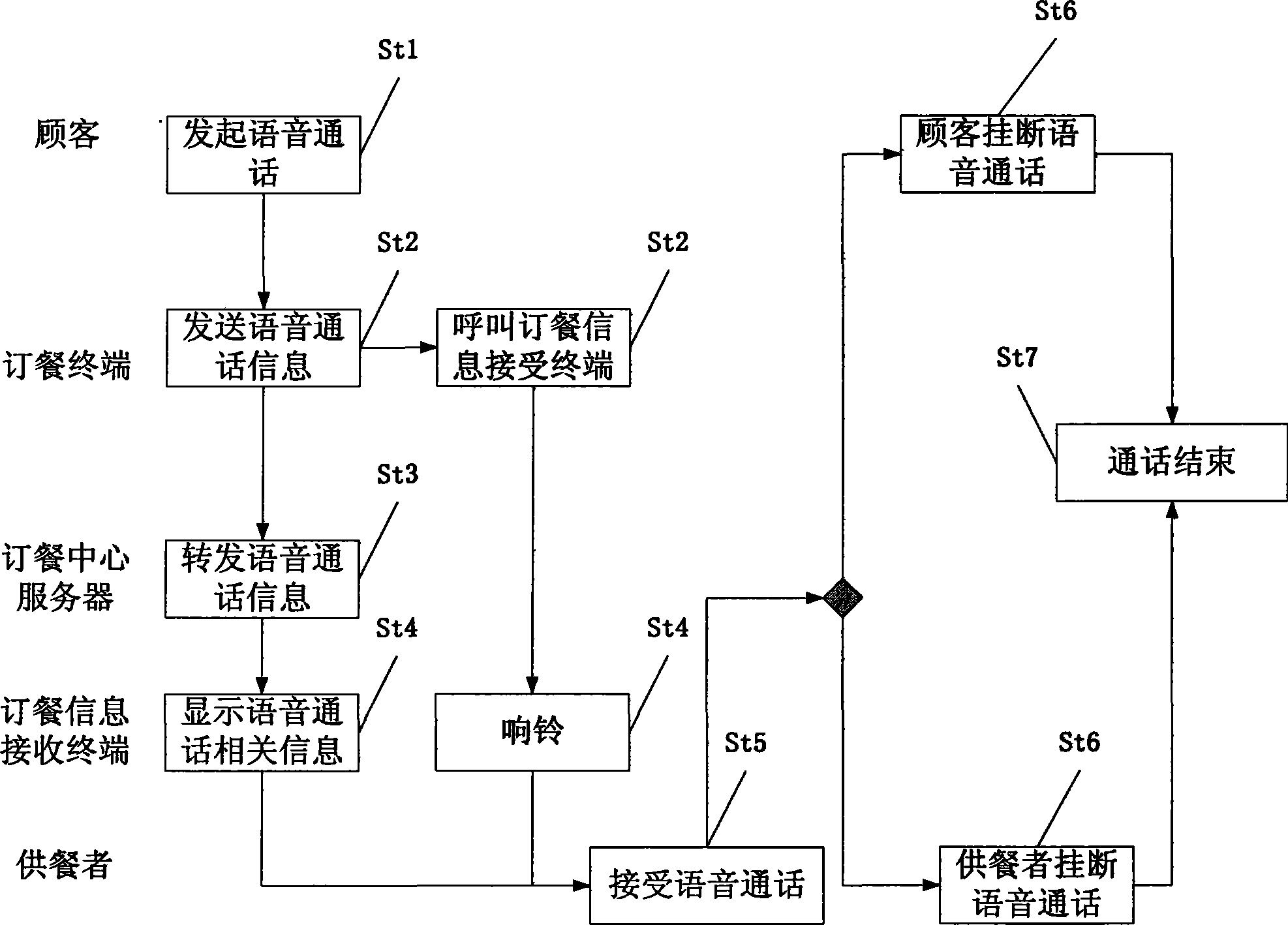

Network ordering system and method

InactiveCN101504740AImplement automatic transferSolve the problem of low efficiency in processing orderingReservationsCommerceFood deliveryArrival time

The invention discloses a system and a method for online food ordering. The system comprises a plurality of food ordering terminals used for customers to complete related operations, a plurality of food ordering information receiving terminals used for a food supplier to complete food ordering-related handling, and a food ordering central server used for receiving and forwarding food ordering requests. With the system and the method, a customer can acquire food information around the position of a food ordering terminal as well as food delivery distance and time with high efficiency when ordering food, and the customer can perform self-service food ordering, acceptance and evaluation on any food ordering terminal; the food supplier and the customer can make a high efficiency voice call; and the food supplier supplies food according to the food ordering information that the system outputs after automatic processing, and can track the arrival time of delivered food and the evaluation of the customer. Therefore, the system and the method solve the problems of failing to provide high efficiency food ordering service according to the position of the customer, low communication efficiency in a food ordering process and low food ordering handling efficiency of the supplier.

Owner:钟明

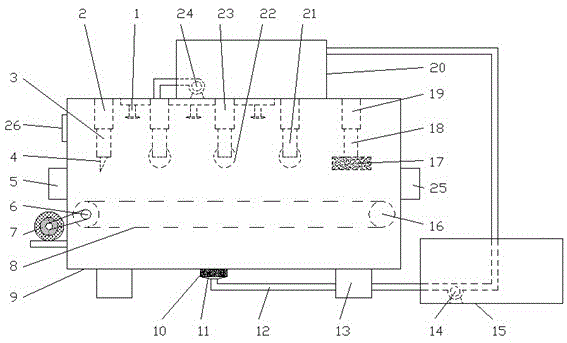

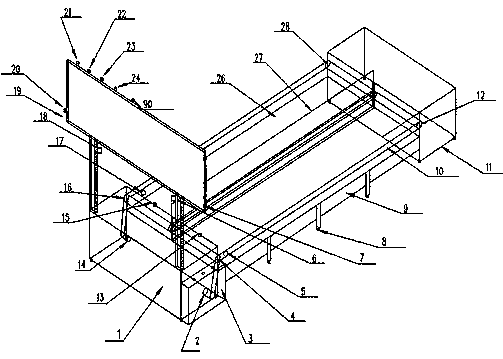

Plate cleaning machine

InactiveCN105618405AImprove cleaning efficiencyKeep clean and tidyCleaning using toolsCleaning using liquidsDrive wheelEngineering

The invention discloses a plate cleaning machine which comprises a housing and spray heads, wherein a driven wheel is arranged at the lower right end of an inner cavity of the housing, and is in transmission connection with a driving wheel through a conveying belt; the driving wheel is in transmission connection with a motor through a belt; the motor is arranged at the lower end of the left side of the outer surface of the housing; a first driving hydraulic rod is arranged at the left end of the top of the inner cavity of the housing; a first driven hydraulic rod is arranged at the bottom of the outer surface of the first driving hydraulic rod, and is connected with an inner cavity of the first driving hydraulic rod in a sleeving manner; a scraping plate is arranged at the bottom of the outer surface of the first driven hydraulic rod; second driving hydraulic rods are arranged at the right end of the outer surface of the first driving hydraulic rod; and second driven hydraulic rods are arranged at the bottoms of the outer surfaces of the second driving hydraulic rods, and are connected with inner cavities of the second driving hydraulic rods in a sleeving manner. The plate cleaning machine is provided with three hairbrush rolls, and can effectively clear away blots on the surface of a plate, and the cleaning efficiency of the plate is improved.

Owner:陈建荣

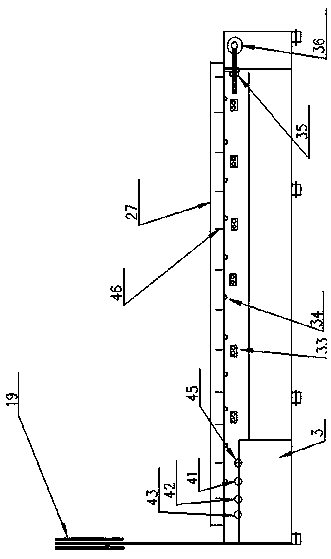

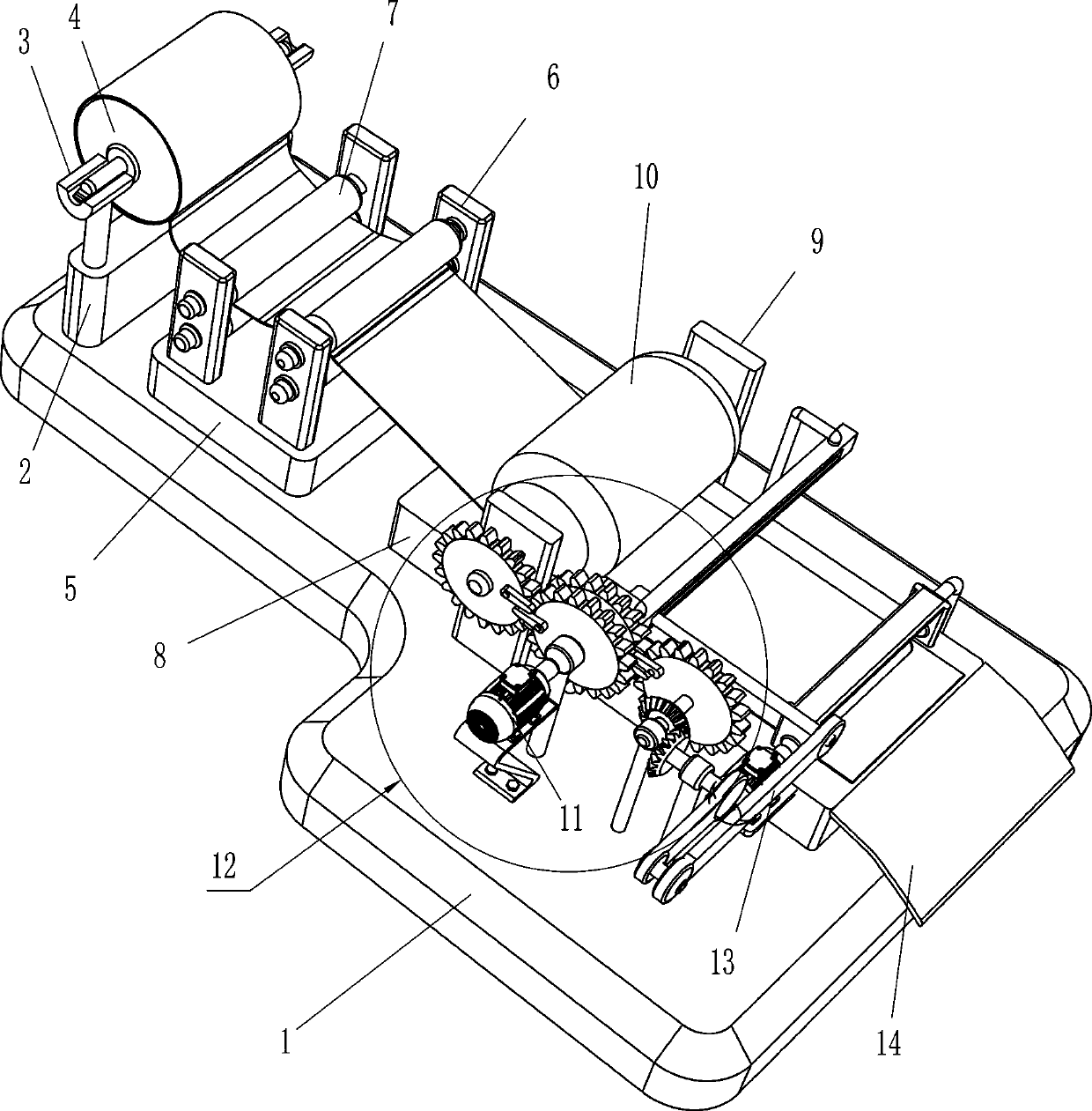

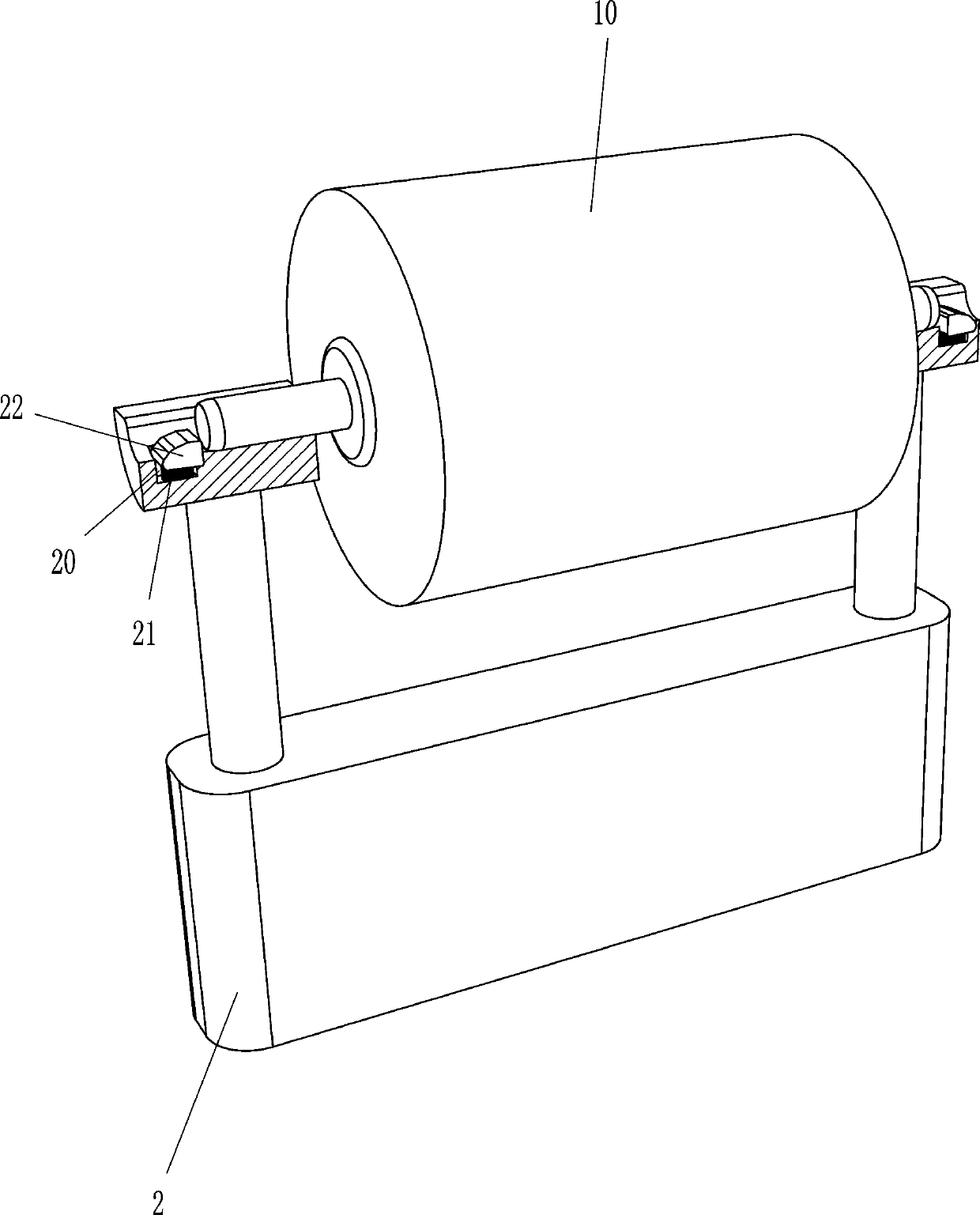

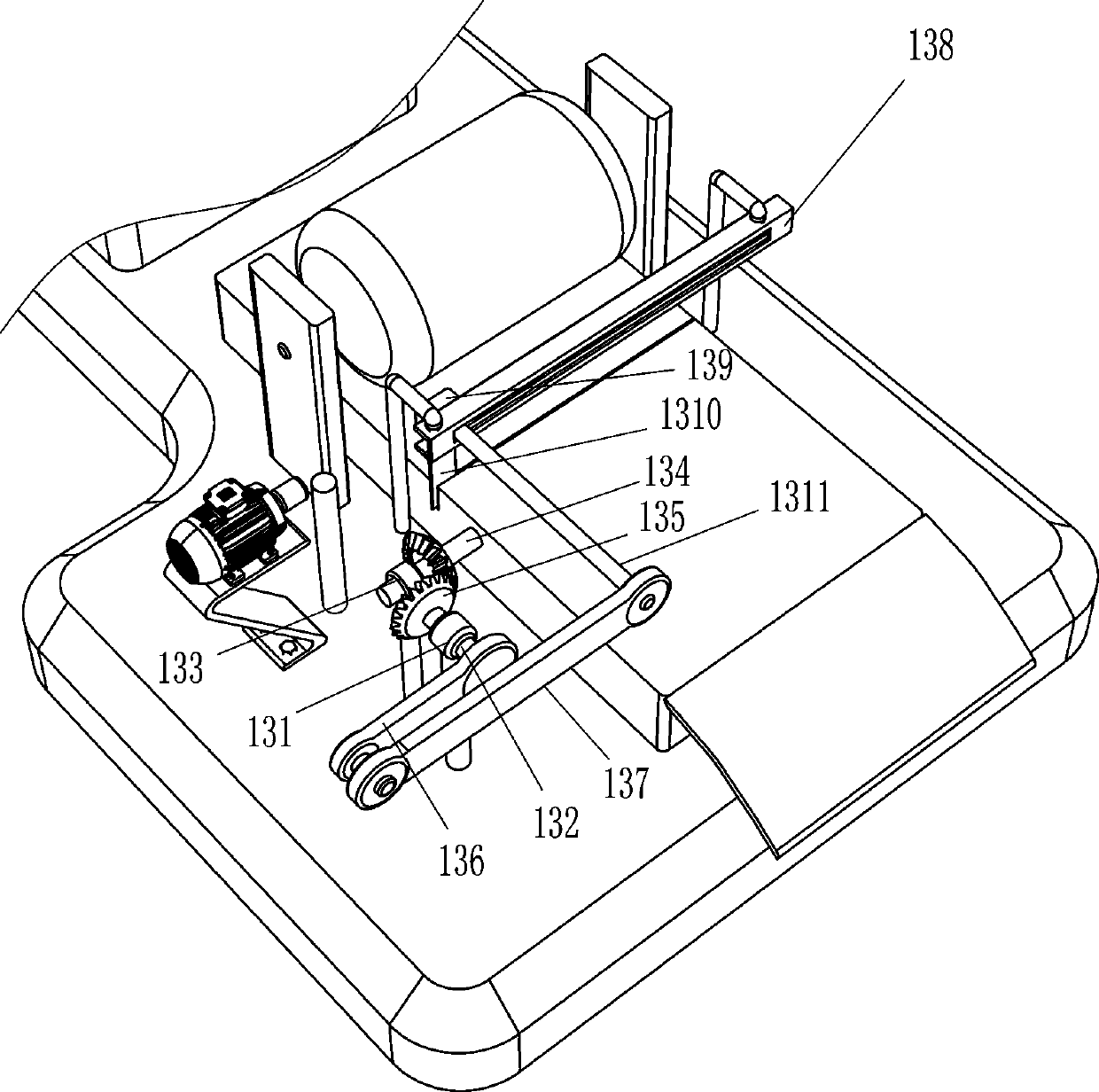

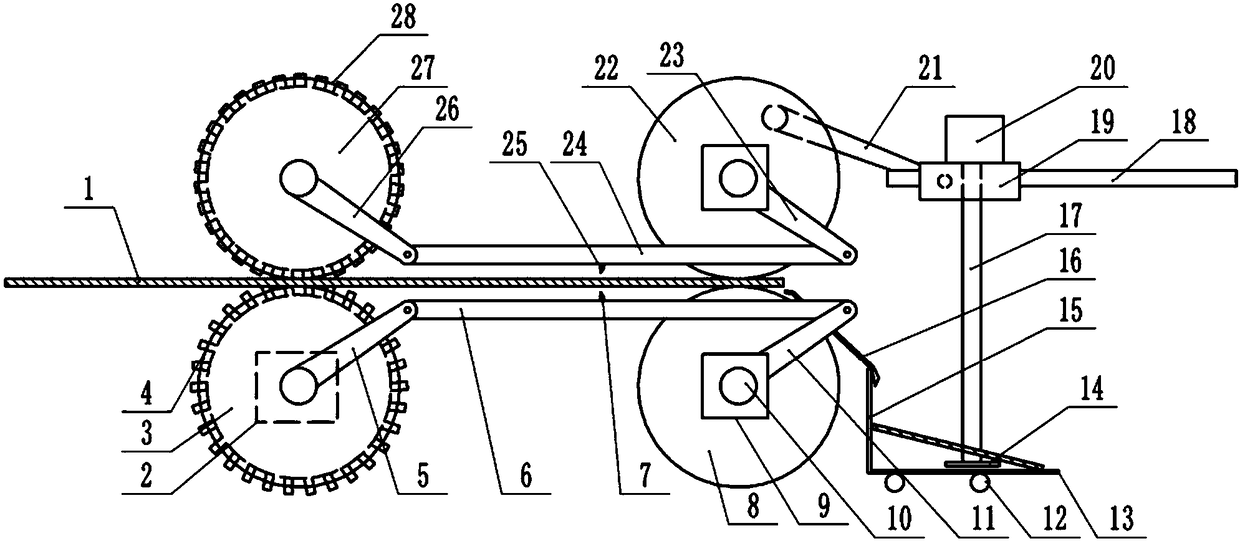

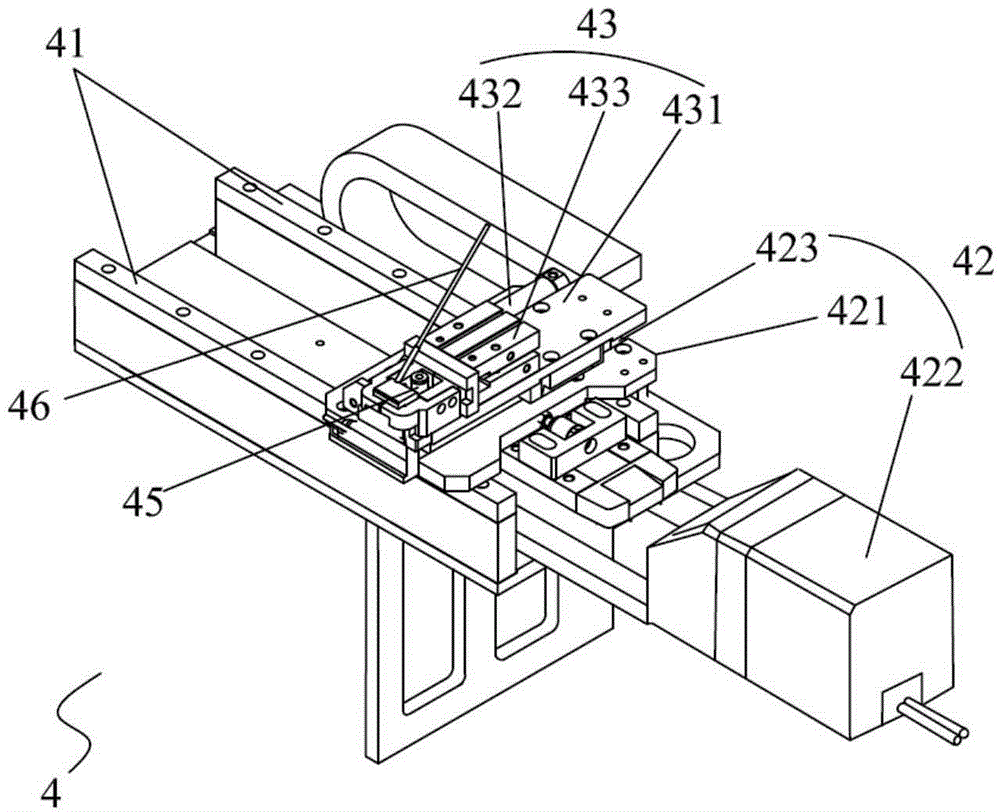

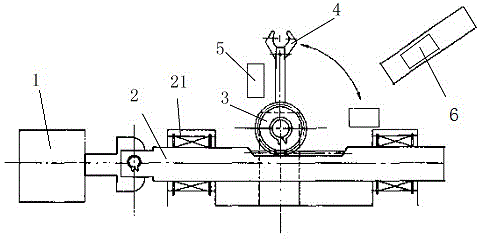

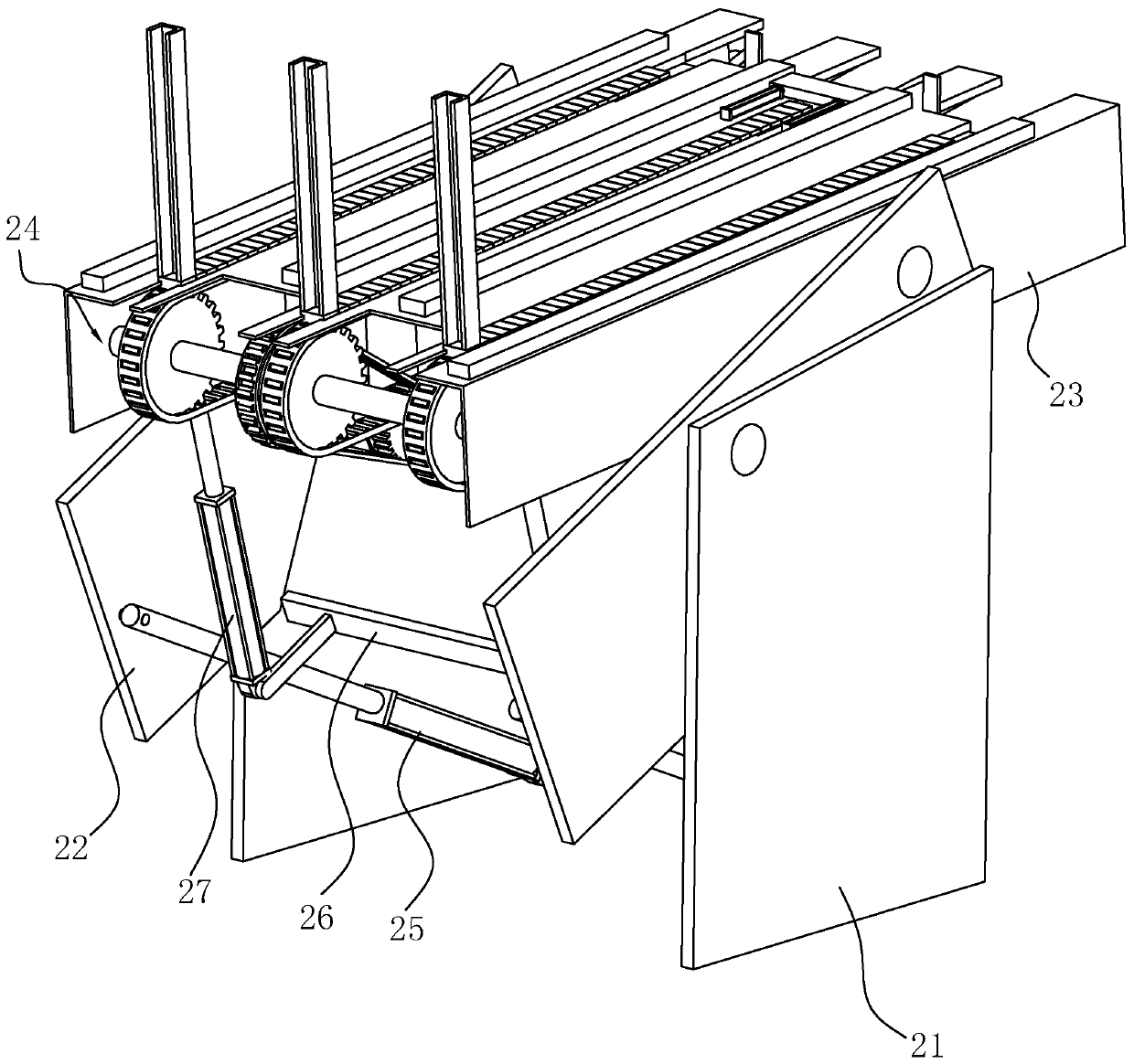

A cutting machine used for necktie fabric processing

InactiveCN105316928AImplement automatic transferIncrease transfer rateTextile selvedgesSevering textilesEngineeringMechanical engineering

The invention provides a cutting machine used for necktie fabric processing. The cutting machine comprises a material holding stand, a material feeding device, a cutting platform and a cutter device. The material feeding device comprises an upper clamping roller and a lower clamping roller. A driving lever device is arranged below the upper clamping roller and comprises a driving lever and a driving lever cylinder. The top surface of the cutting platform is provided with a material falling groove and a protecting plate. The cutter device comprises a horizontal guide rail and a cutting knife. A heating device is arranged in the cutter device and comprises a heater, a heat conduction plate and a heat conduction tube. The cutting machine is simple in structure and highly practical; with the material feeding device, fabric can be conveyed more conveniently; with a gear assembly, the length of fabric cutting can be controlled and the transmission is more stable; with the heating device, the temperature of the cutting knife can be made to rise and through high temperature cutting, cut fabric has the advantages of high quality, smooth cuts and zero burr and the processing of the next procedure is facilitated; energy consumption is reduced and the comprehensive utilization rate is increased.

Owner:SHAOXING HENRY TIE FASHION

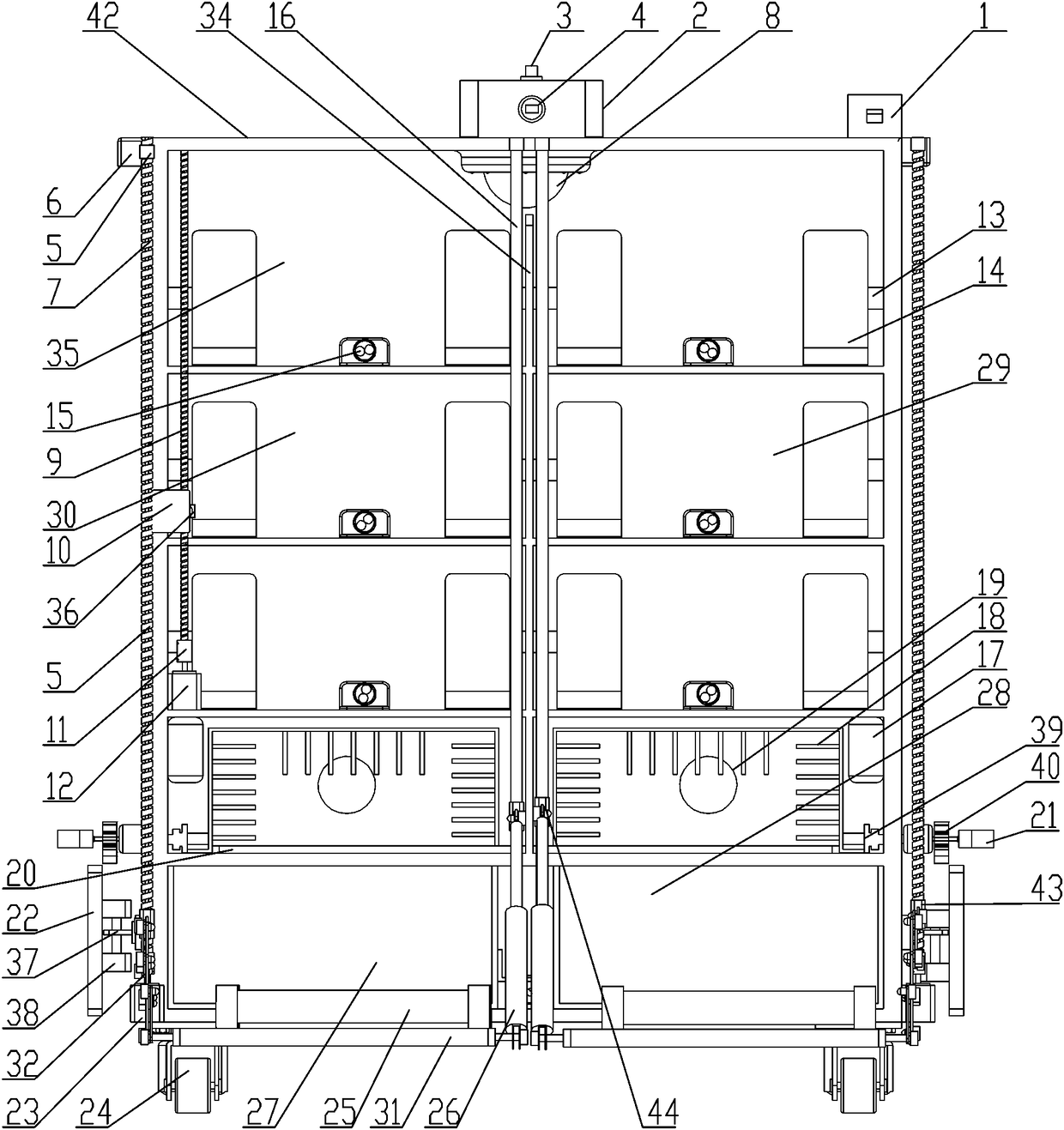

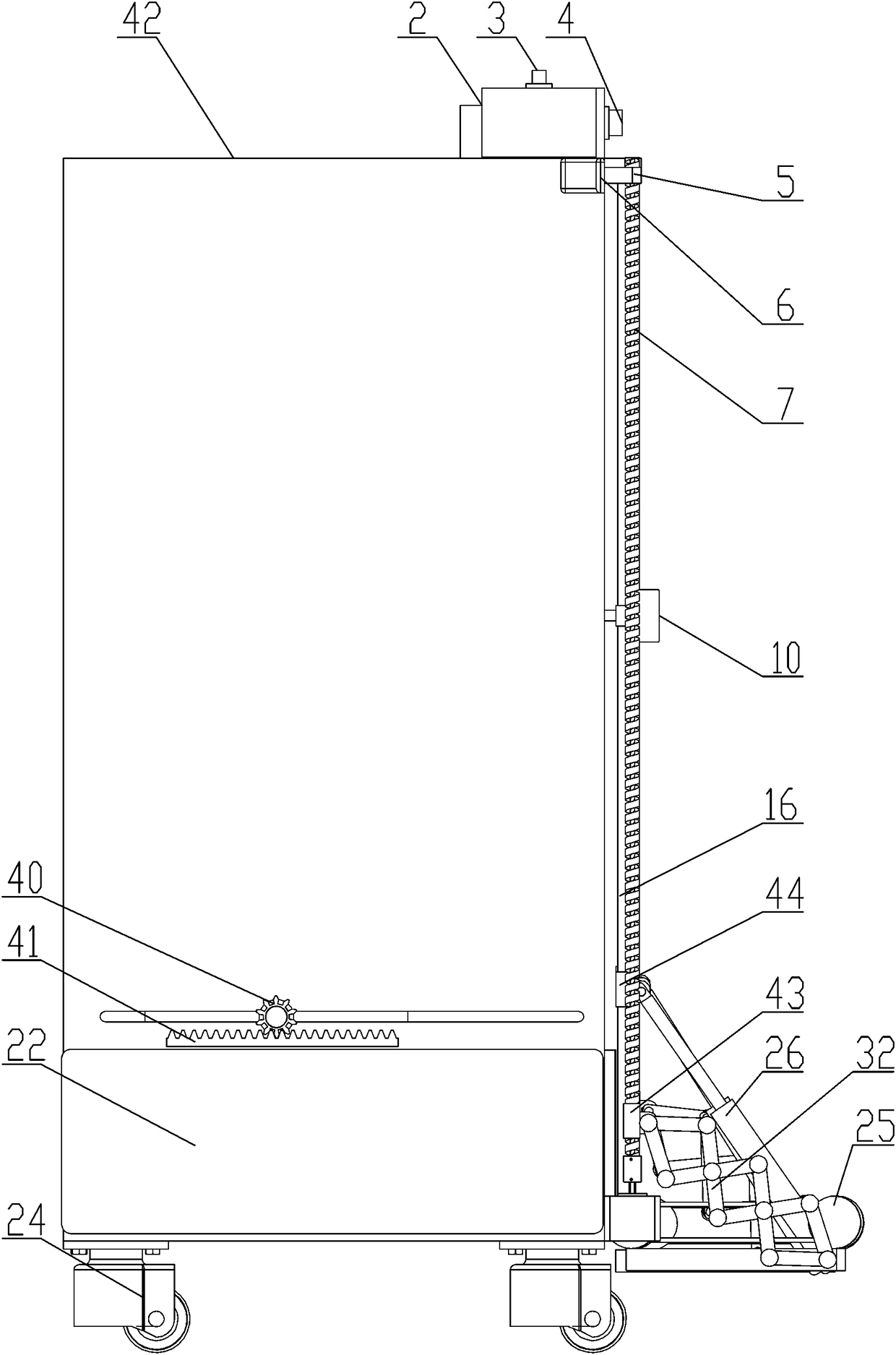

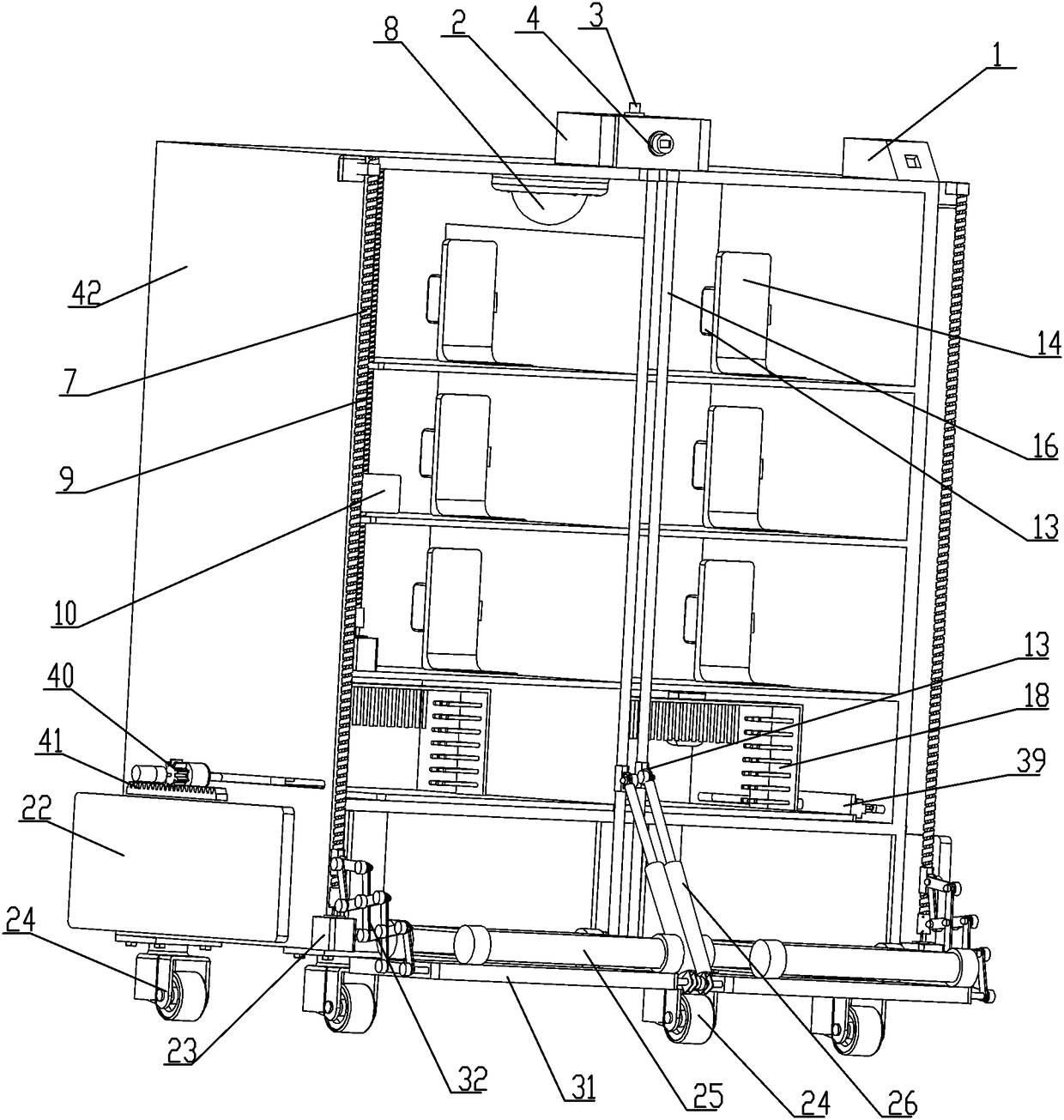

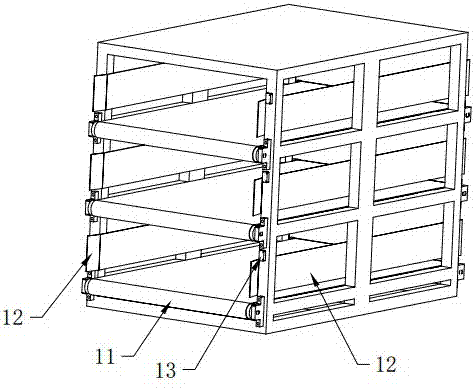

Multifunctional smart home shoe cabinet and using method

The invention relates to a multifunctional smart home shoe cabinet and a using method. The internal space of a shoe cabinet body is partitioned into multiple independent rectangular cavities through amiddle partition plate and multiple horizontal partition plates; a steering engine shoe pushing device used for pushing out shoes is installed inside each rectangular cavity; a lifting mechanism is arranged at the front end of the shoe cabinet body in the height direction of the shoe cabinet body, and a horizontal conveying device used for horizontally conveying the shoes is cooperatively installed on the lifting mechanism; a reciprocating sweeping mechanism for cleaning the shoes is installed inside the rectangular cavity in the bottom layer; a fingerprint recognition module is installed atthe top of the shoe cabinet body and connected with a main control chip. The multifunctional smart home shoe cabinet is convenient to use, easy to operate, high in cleanliness, high in intellectualization degree and more friendly to users, the sterilizing and disinfecting effect is good, the time and labor are saved, and the cabinet body is more convenient to move.

Owner:HUBEI THREE GORGES POLYTECHNIC

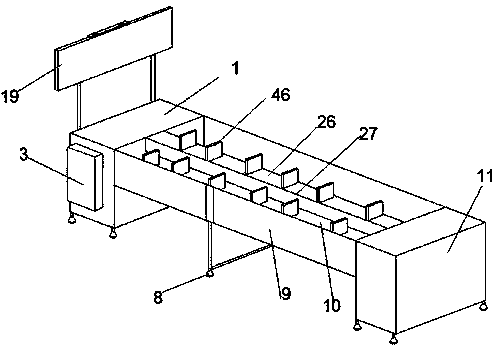

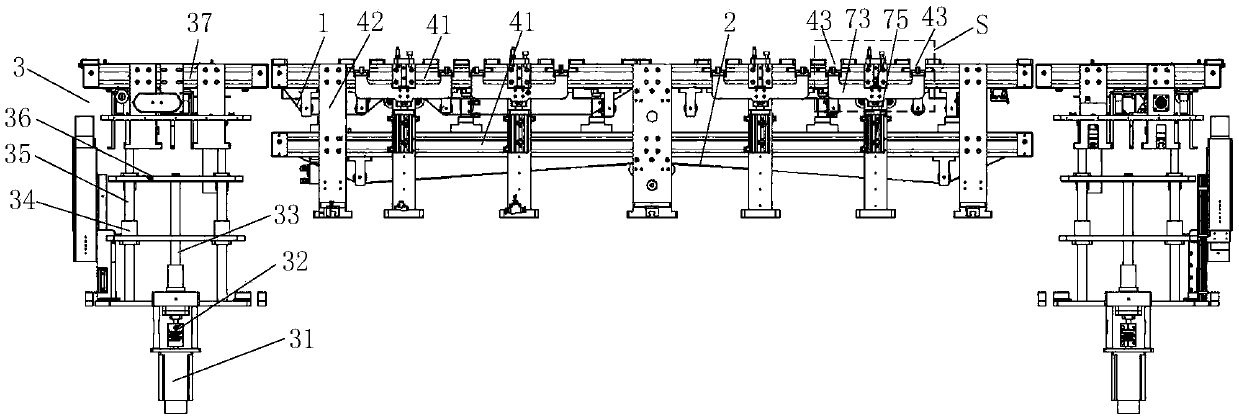

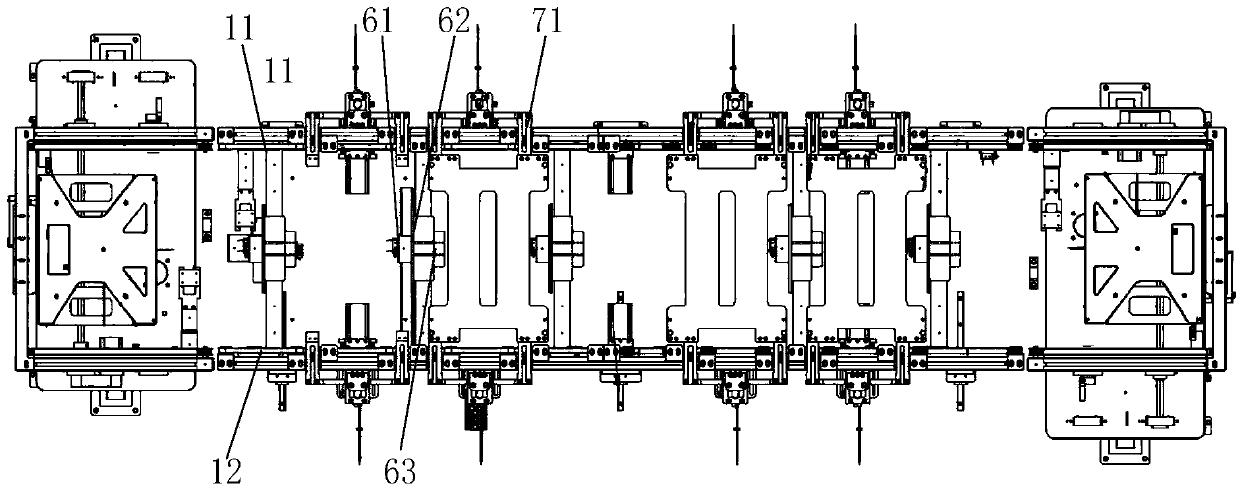

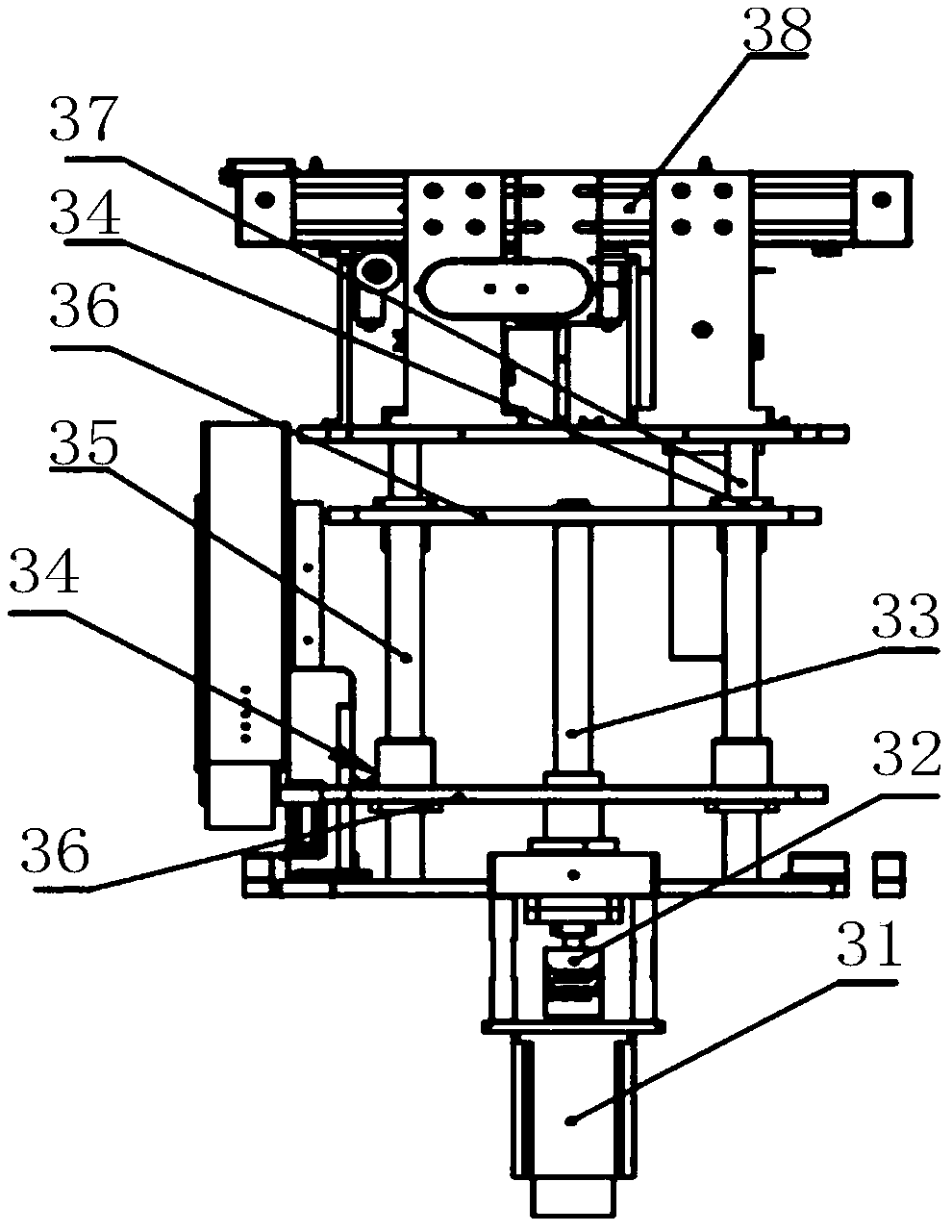

A single-line and double-line interchangeable intelligent beat assembly line system

ActiveCN107814133BIncrease or decrease quantityMeet production requirementsConveyorsControl devices for conveyorsProduction lineDisplay device

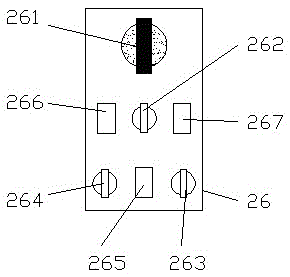

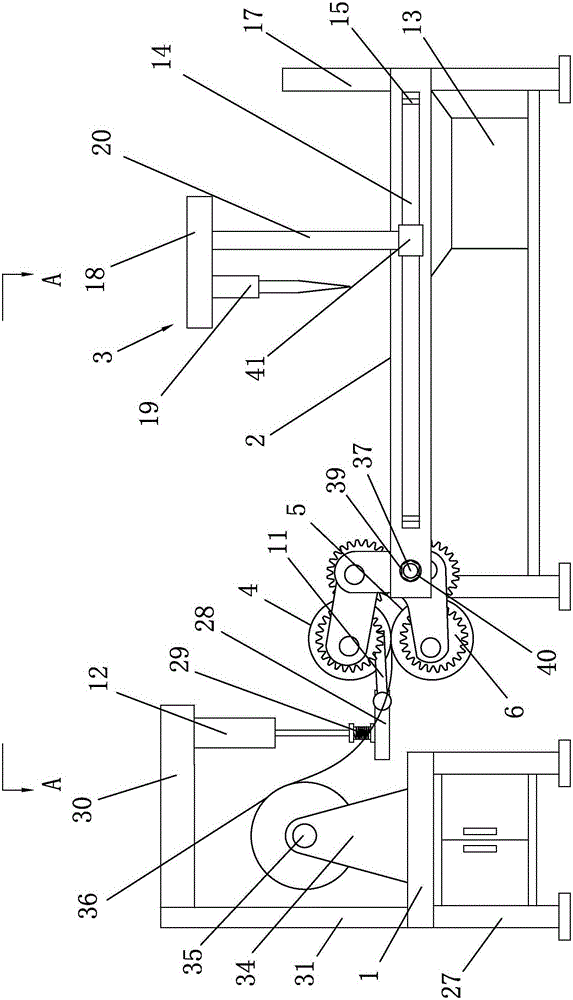

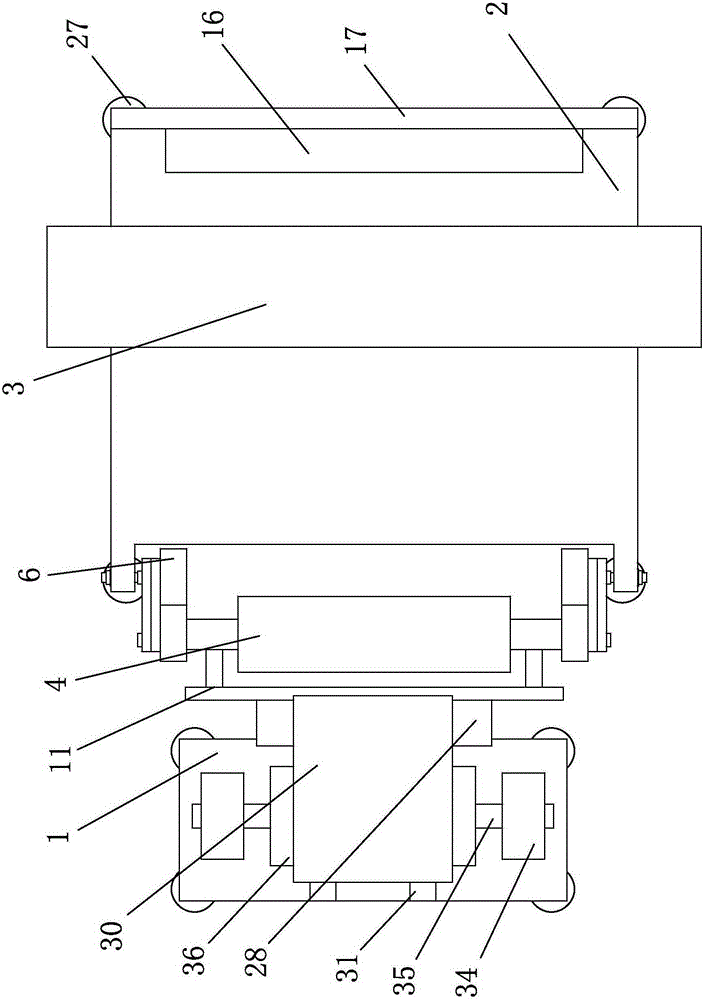

The invention discloses an intelligent pace production line system realizing single-line and double-line switching. The system comprises an equipment front part power main frame, a distribution box, an equipment middle part connecting frame, an equipment rear part frame, a front displayer and a rear displayer; the equipment front part power main frame, together with the equipment middle part connecting frame and the equipment rear part frame, forms whole equipment; an equipment levelness adjusting foot margin is installed at the bottom of the equipment; a supporting leg levelness adjusting nutis installed on the equipment levelness adjusting foot margin; the distribution box is installed on the equipment front part power main frame through a bolt; and the front displayer and the rear displayer are installed on the equipment front part power main frame through connecting rods. The system disclosed by the invention can realize single-line / double-line switching; when products of two styles are to be produced, two single lines run, production workers are divided into two groups for operation and processing; one wide line runs when the two lines run synchronously so as to complete moreworking procedures and manufacture a style requiring complicated technology, and moreover product quantity can be recorded intelligently, and the work efficiency can be reflected.

Owner:利胜智能装备(湖北)有限公司

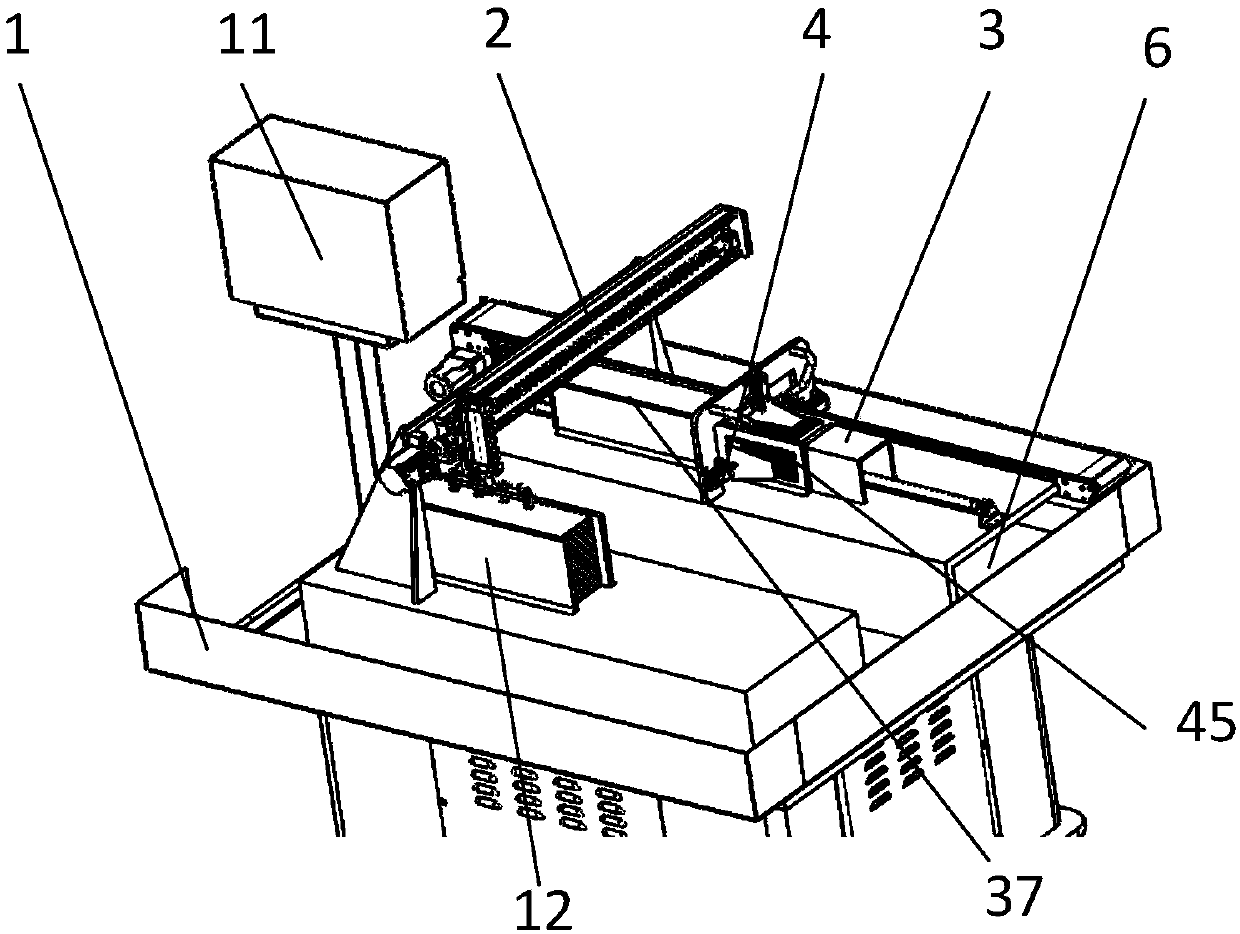

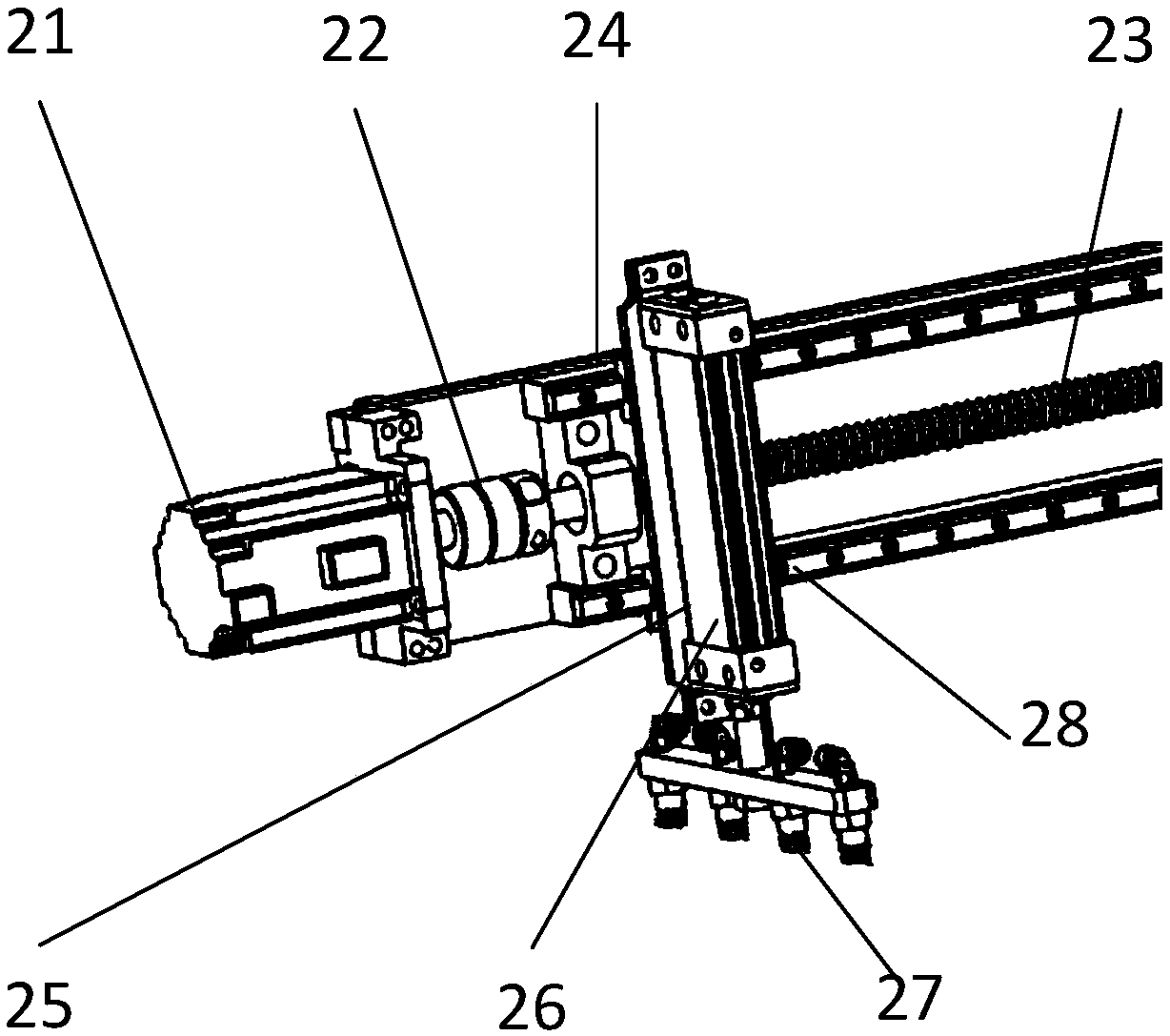

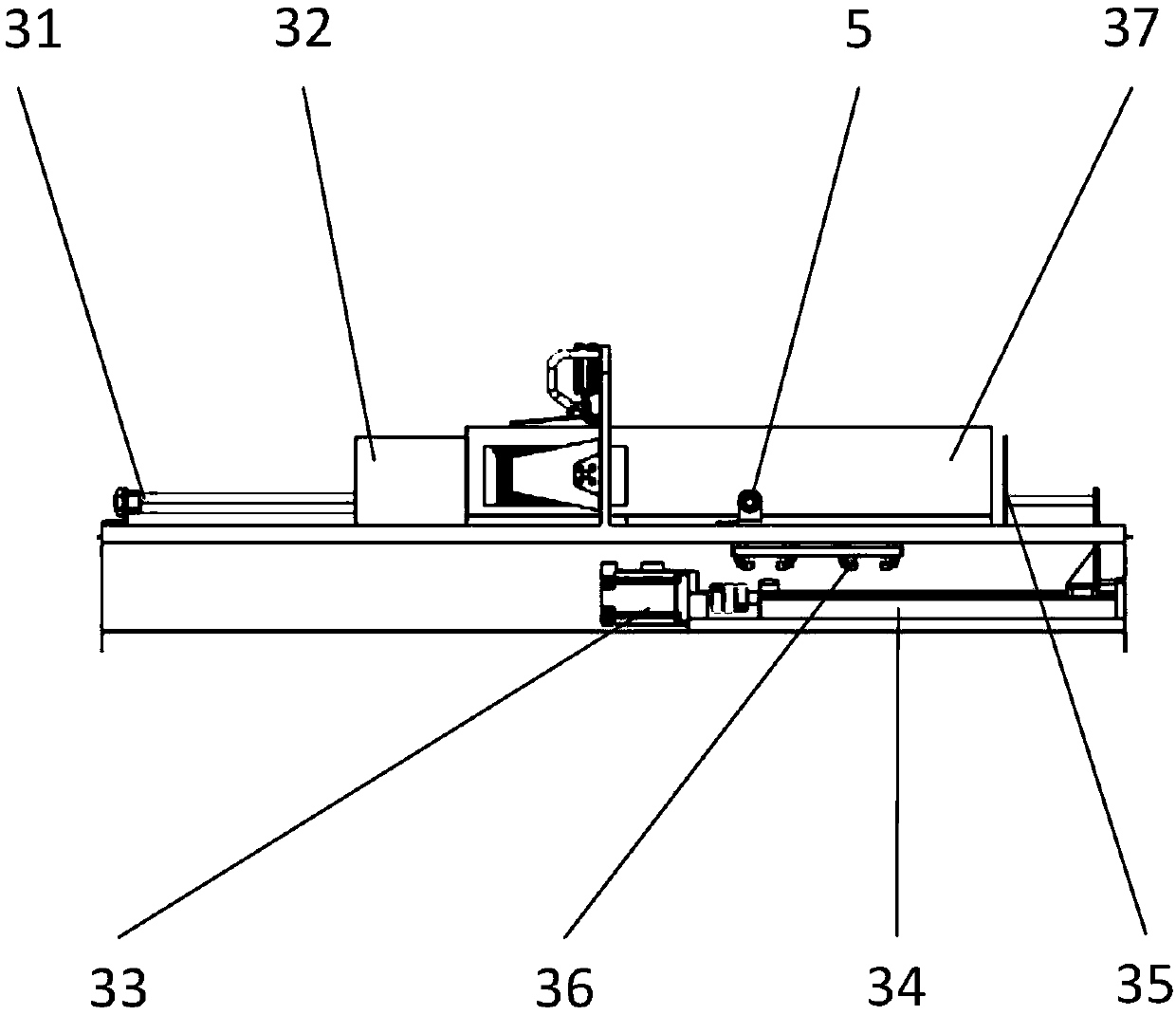

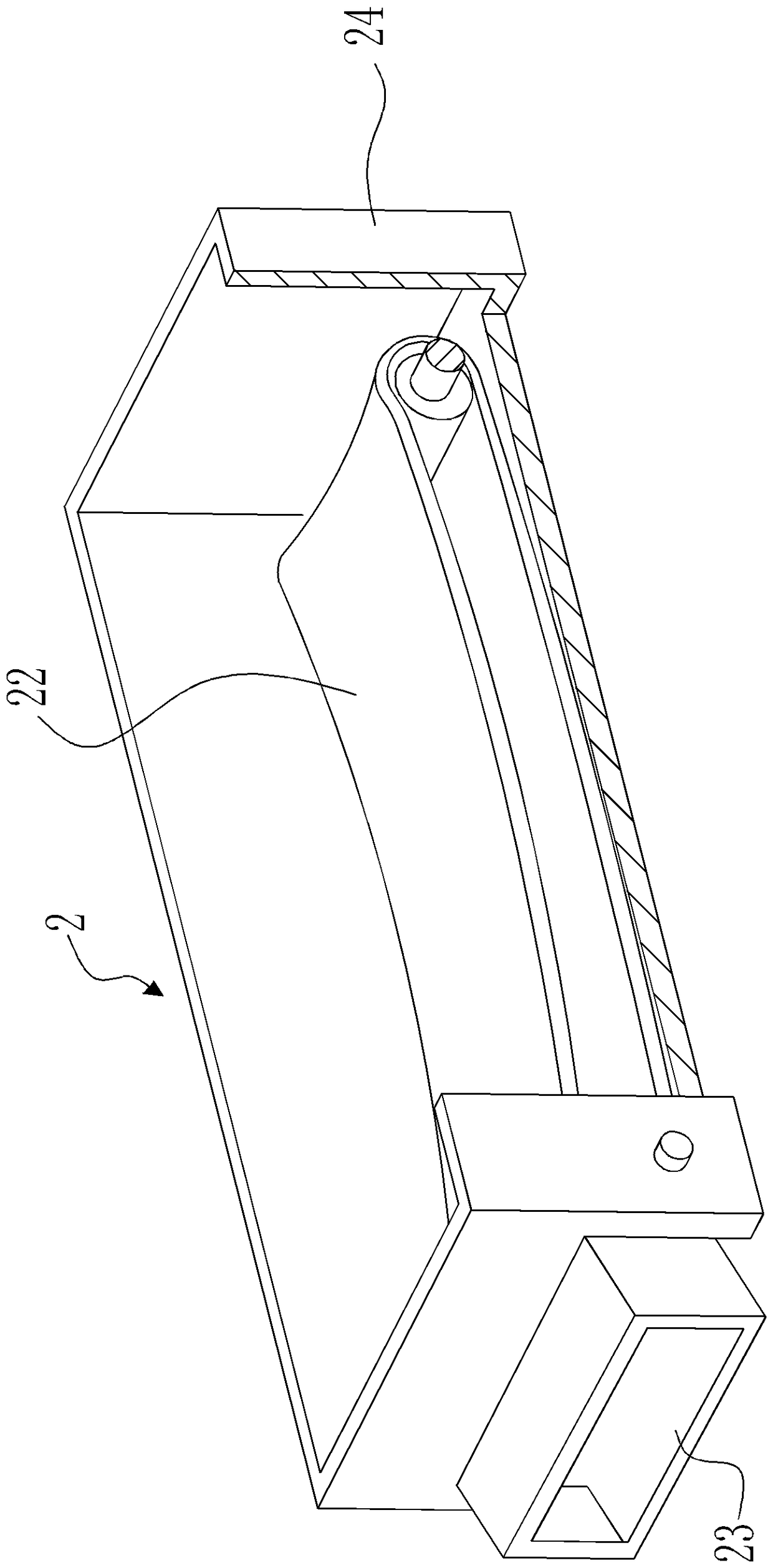

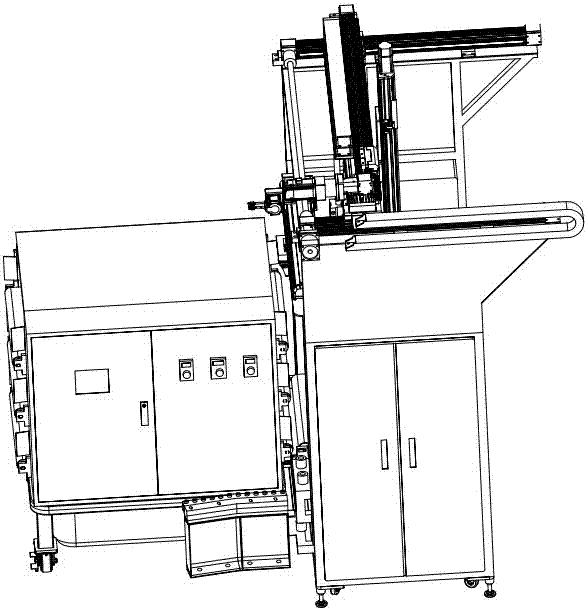

Section bar automatic packaging equipment

ActiveCN106218968AIncrease productivitySolve the low degree of automationWrapper folding/bending apparatusWrappingReciprocating motionUltimate tensile strength

The invention provides section bar automatic packaging equipment. The section bar automatic packaging equipment comprises a packaging paper feeding mechanism, a section feeding mechanism, a vertical folding mechanism, horizontal folding mechanisms, a packaging mechanism, a clamping and feeding mechanism, a pushing mechanism and a control mechanism, wherein the packaging paper feeding mechanism is used for lifting, pulling out and shearing and paving packaging paper on a platform; the section feeding mechanism is used for transferring and locating a section bar in the middle part of the platform where the packaging paper is paved; the vertical folding mechanism is used for adjusting the side edge separation distance of the packaging paper and bending the side edge of the packaging paper paved on the platform; the horizontal folding mechanisms are used for adjusting the side edge separation distance of the packaging paper and bending the side edge of the packaging paper paved on the platform and then horizontally folding the upper part of the side edge of the packaging paper, so that the packaging paper wrap the end surface of the section bar; the packaging mechanism is used for winding and sealing the packaging paper which wraps the section bar; the clamping and feeding mechanism is used for a reciprocating motion to transfer the section bar wrapped by the packaging paper to the packaging mechanism; and the pushing mechanism is used for compacting the opening of the packaging paper which wraps the end surface of the section bar. The section bar automatic packaging equipment provided by the invention can solve the problems that the efficiency is low and the labor intensity is great due to a manual operation, so that the packaging efficiency and quality of the section bar are improved.

Owner:佛山市嘉荣智能机械有限公司

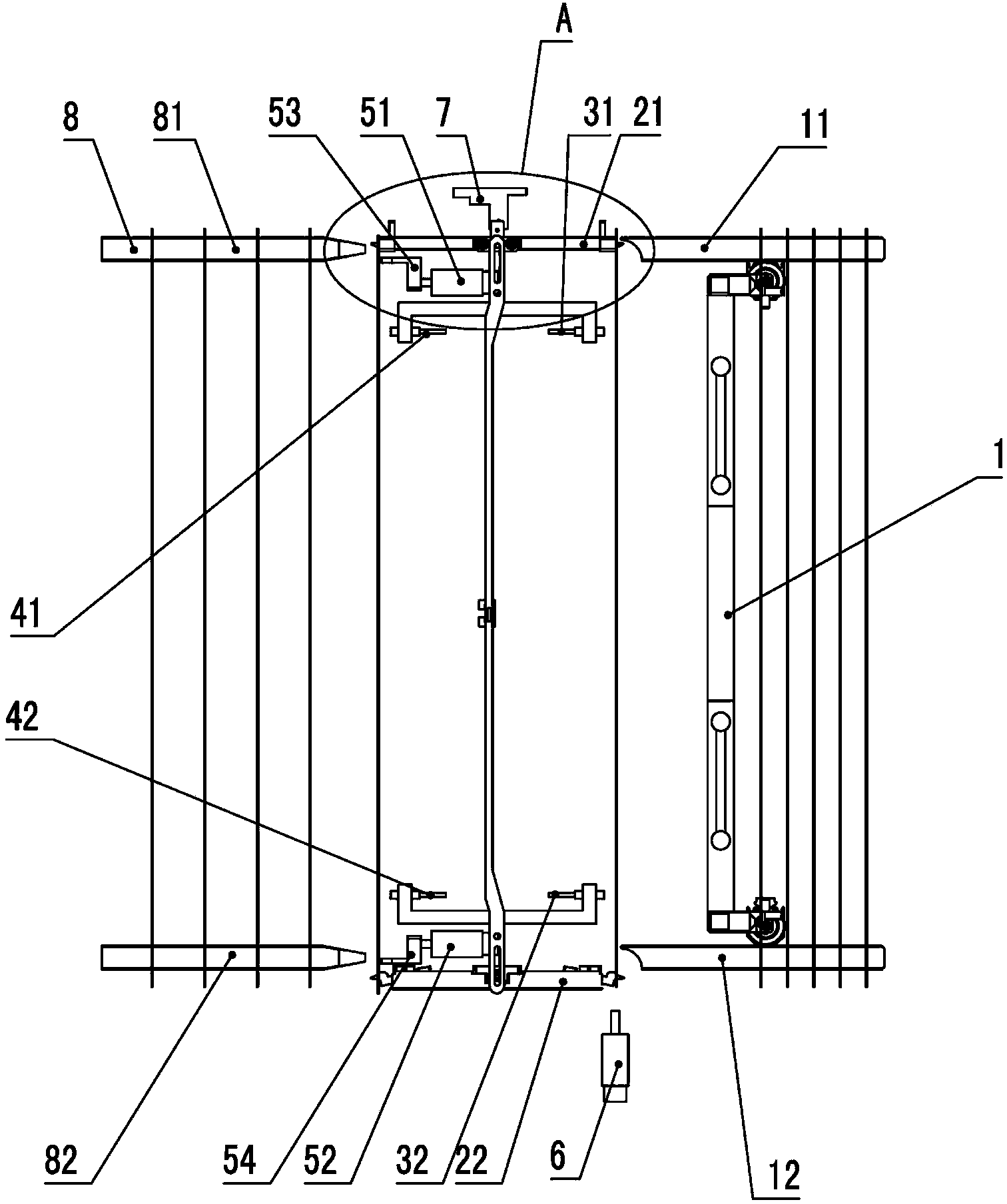

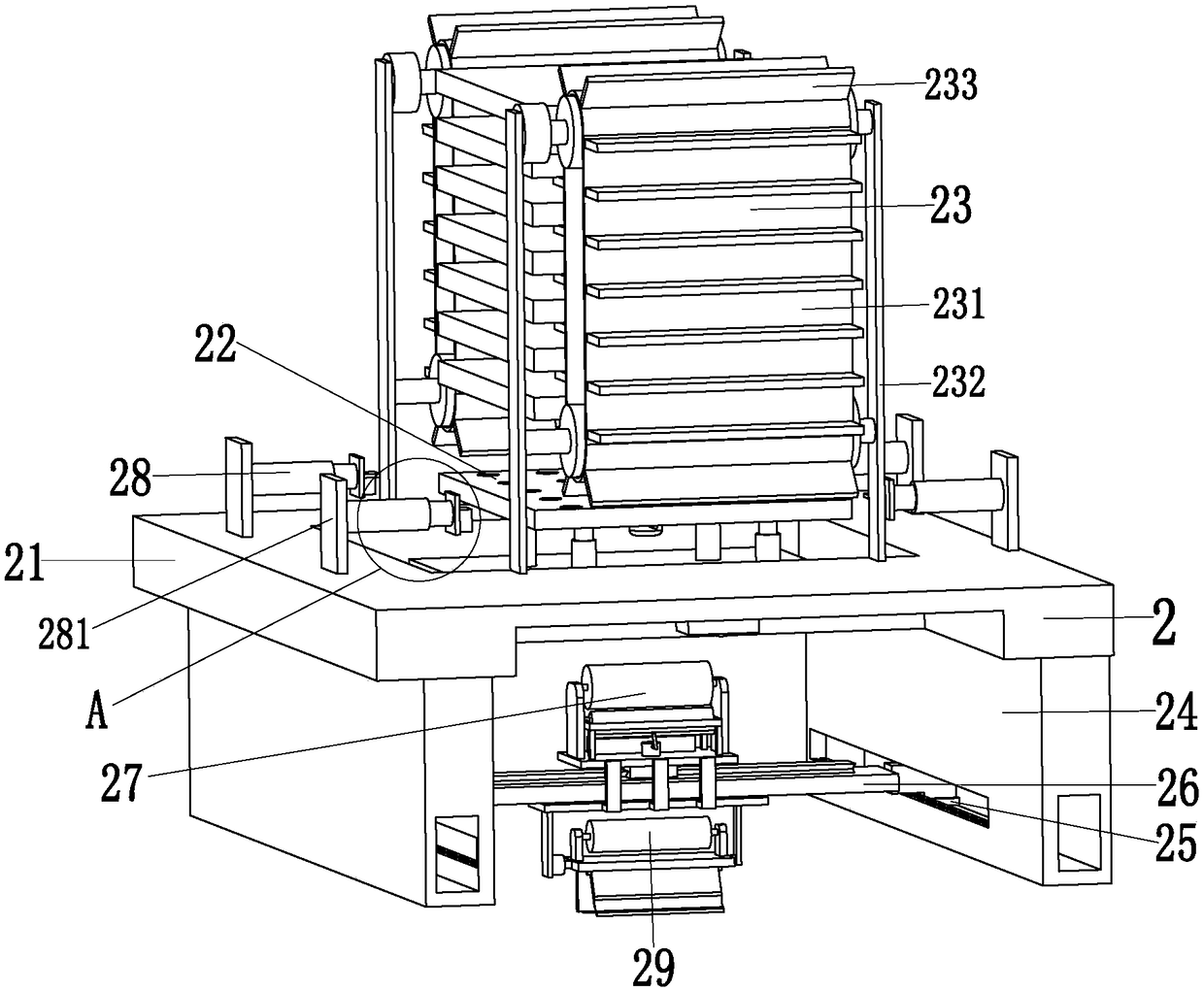

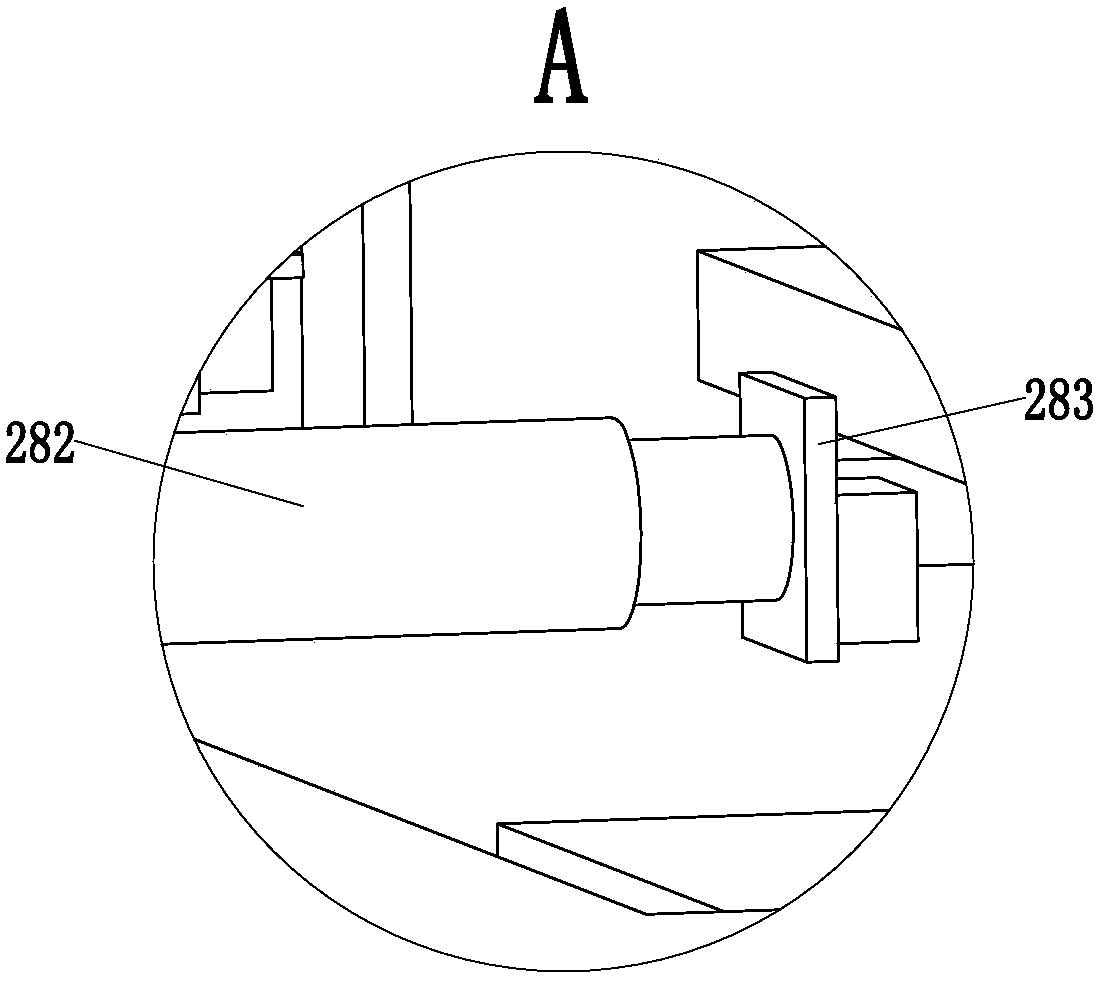

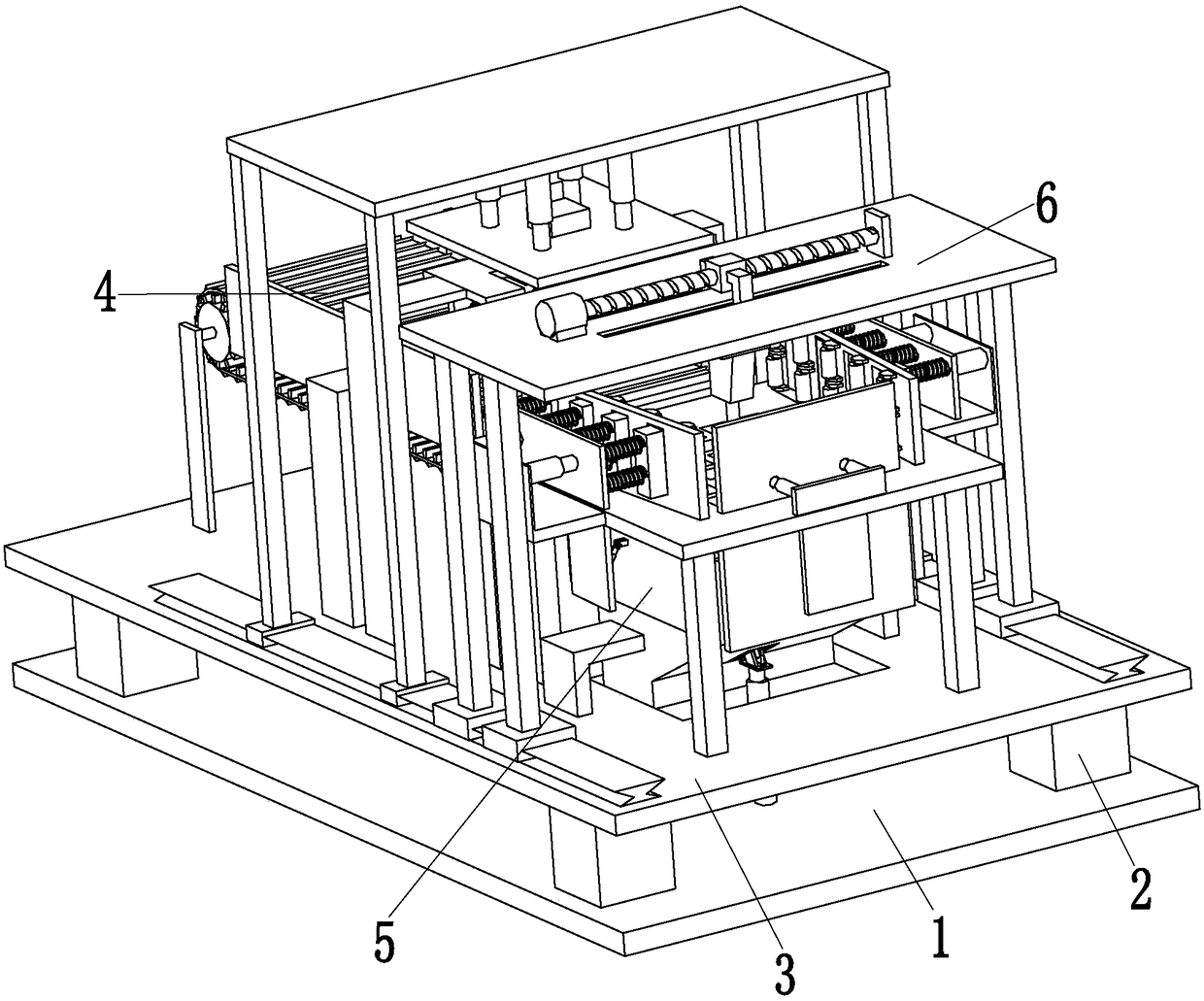

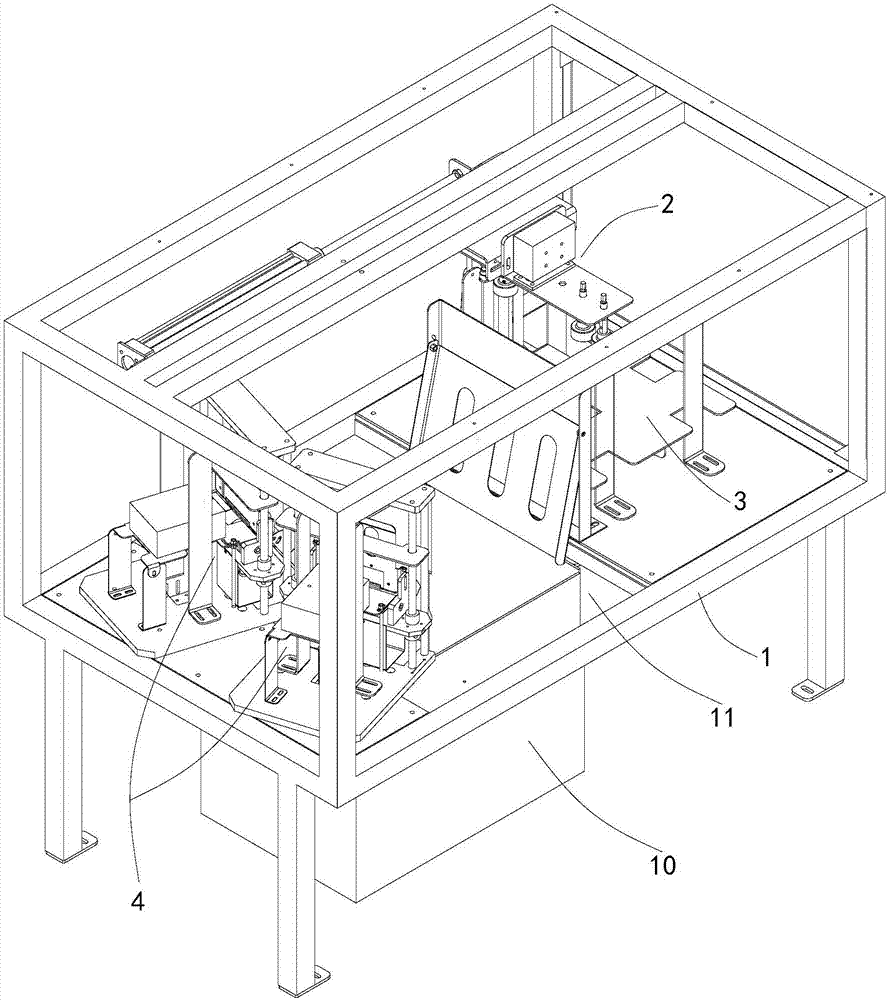

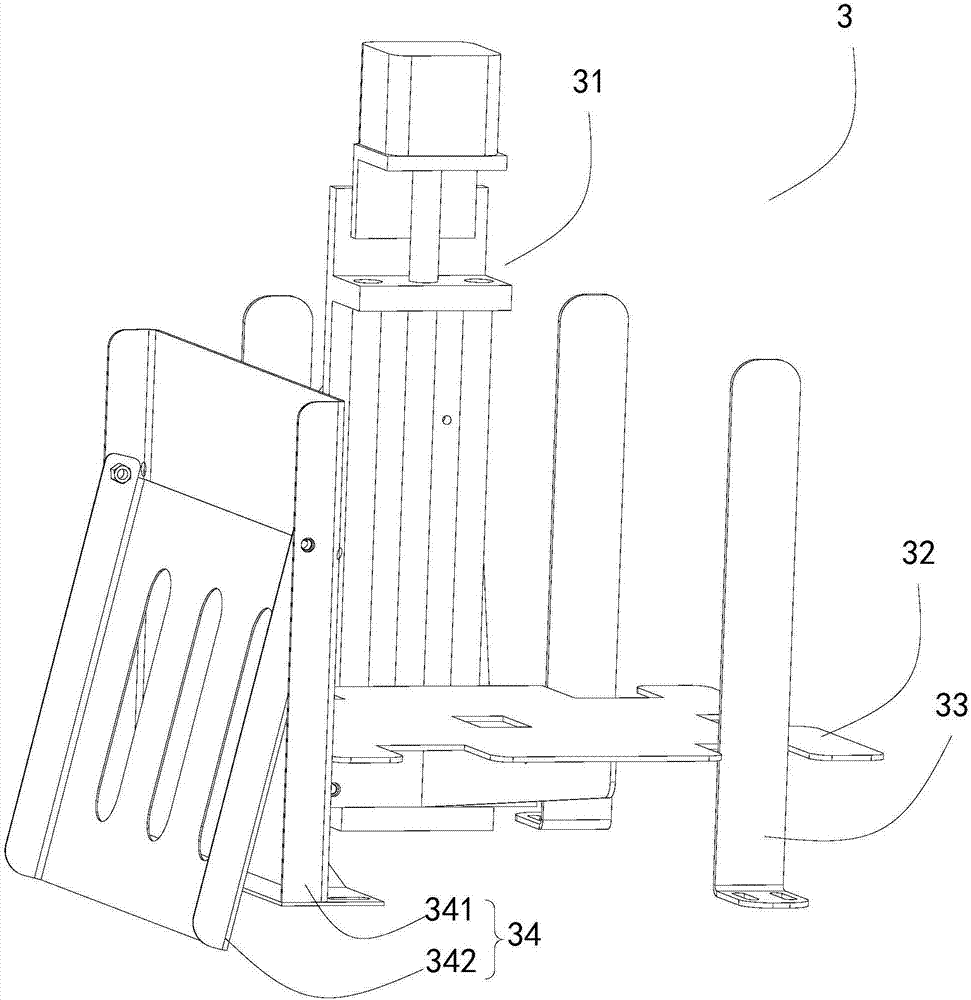

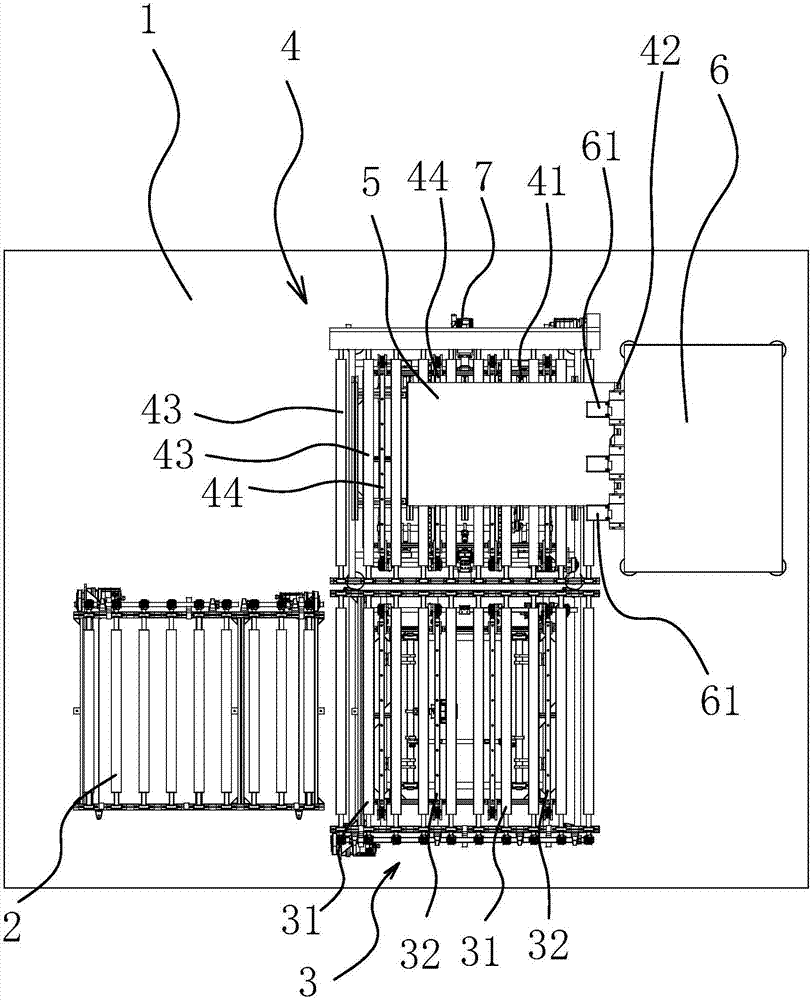

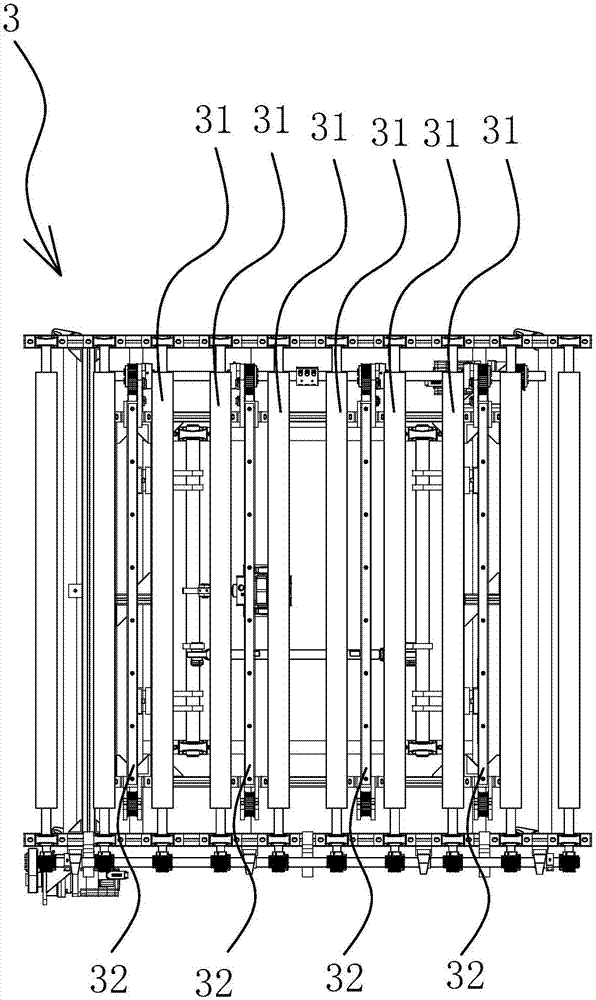

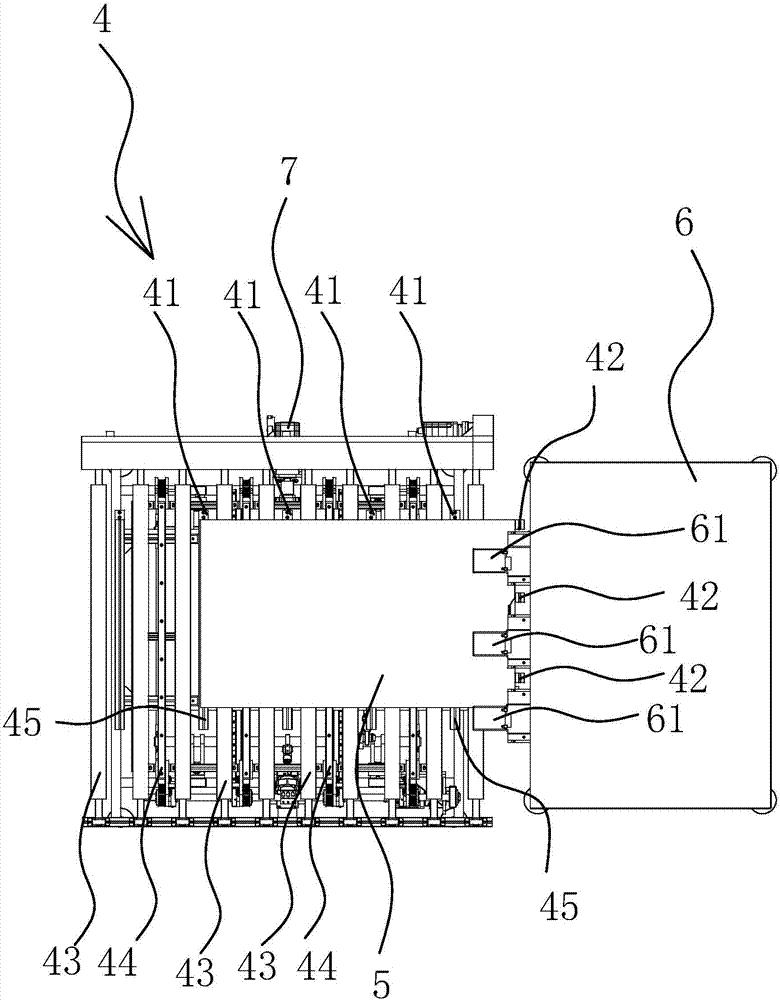

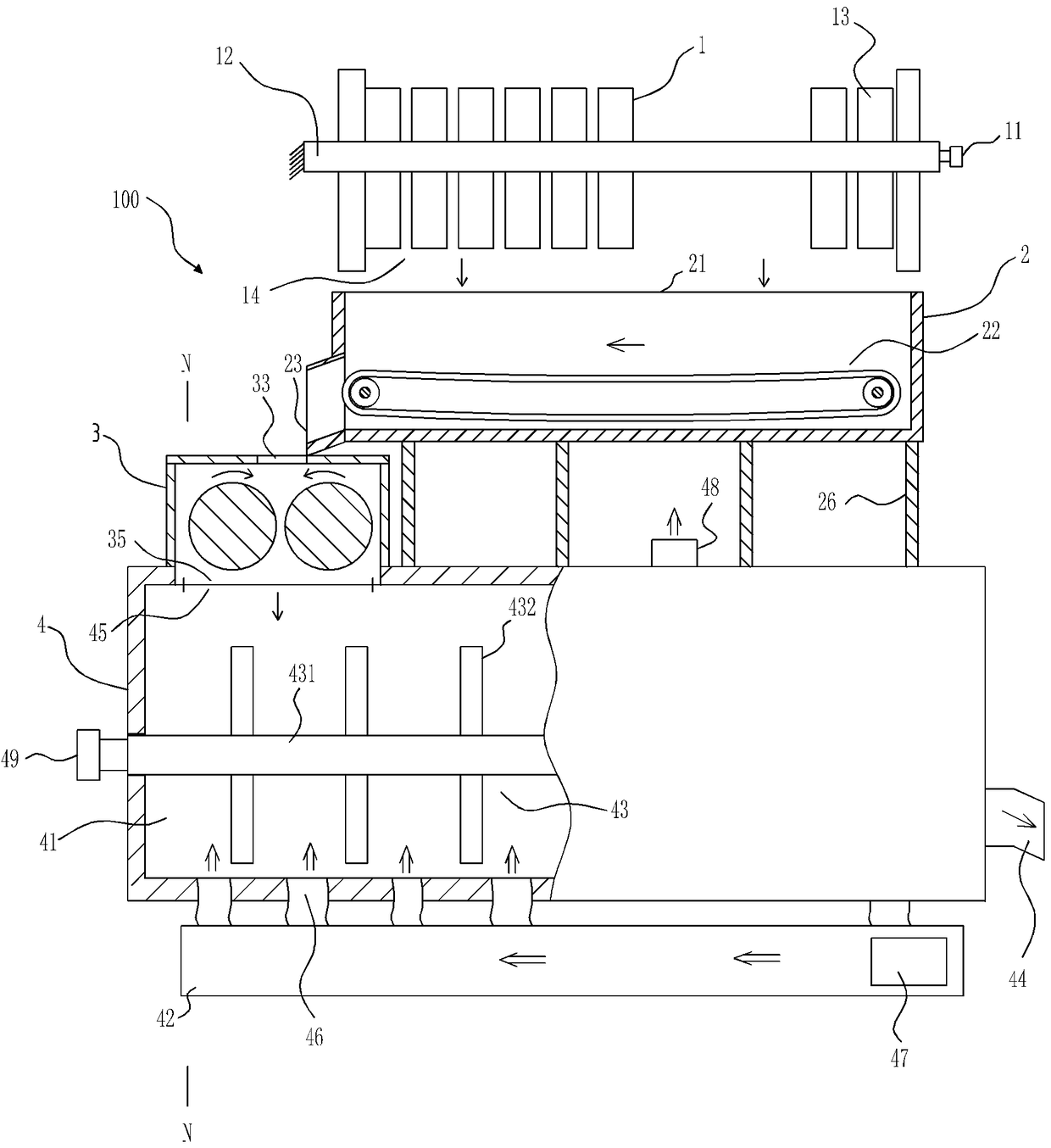

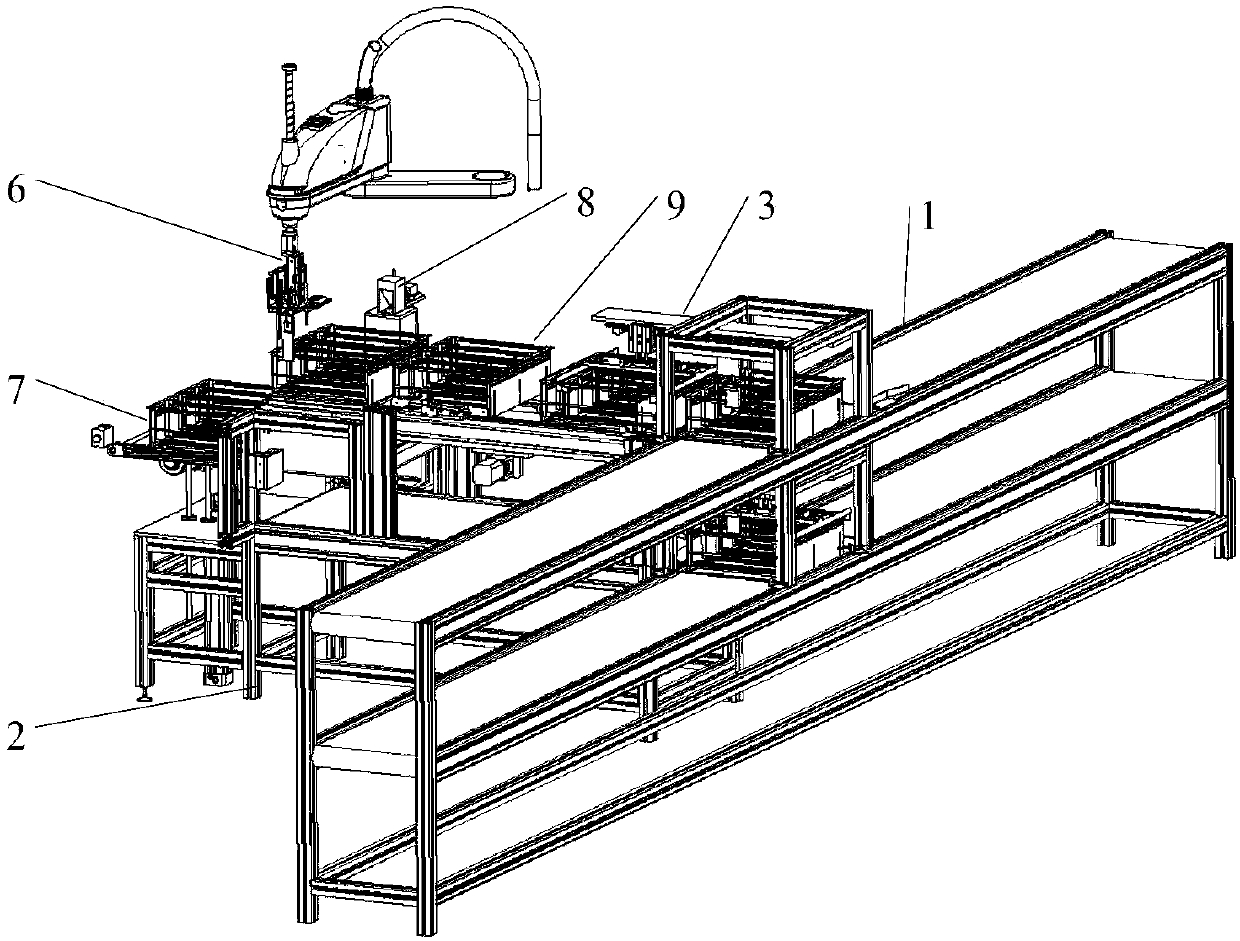

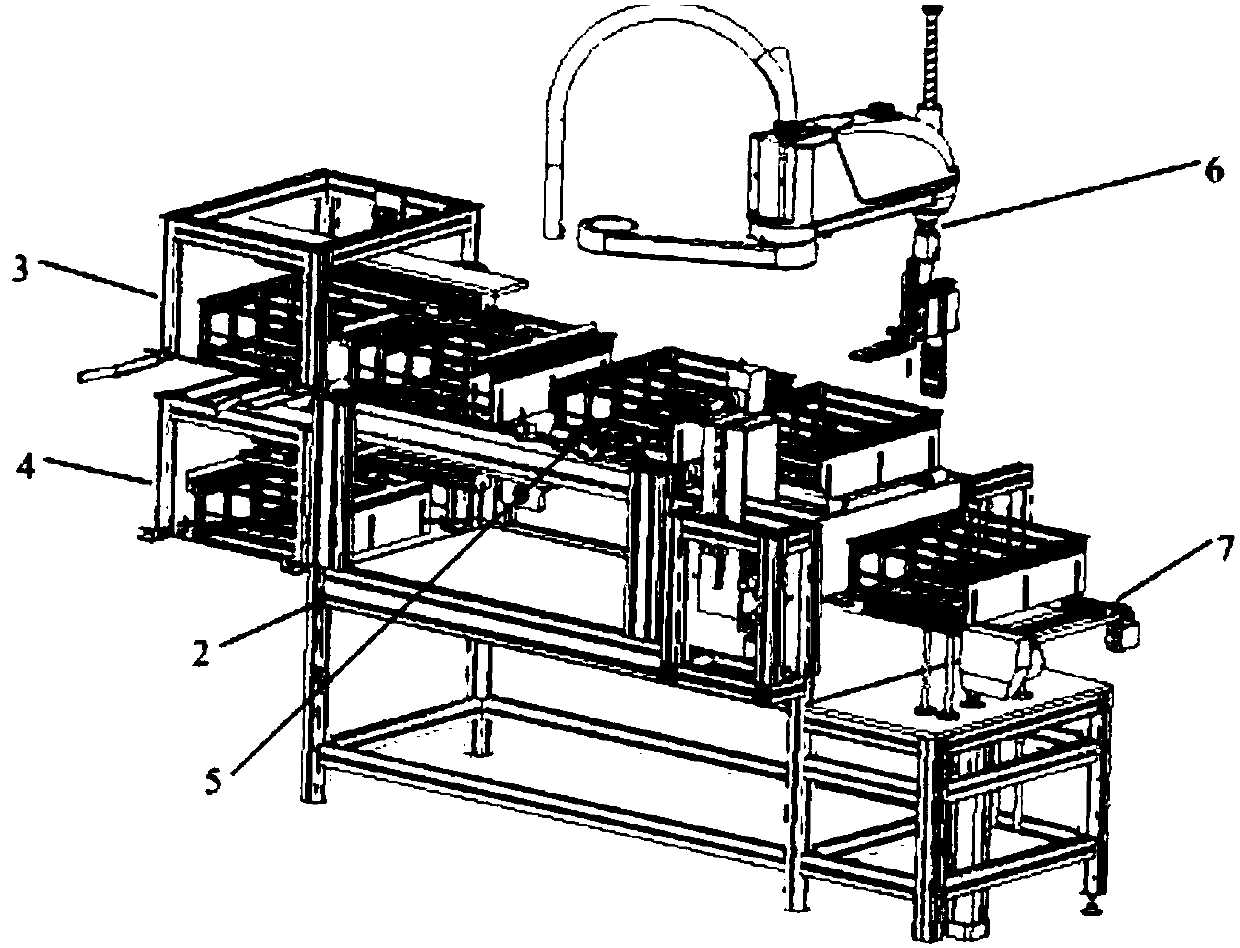

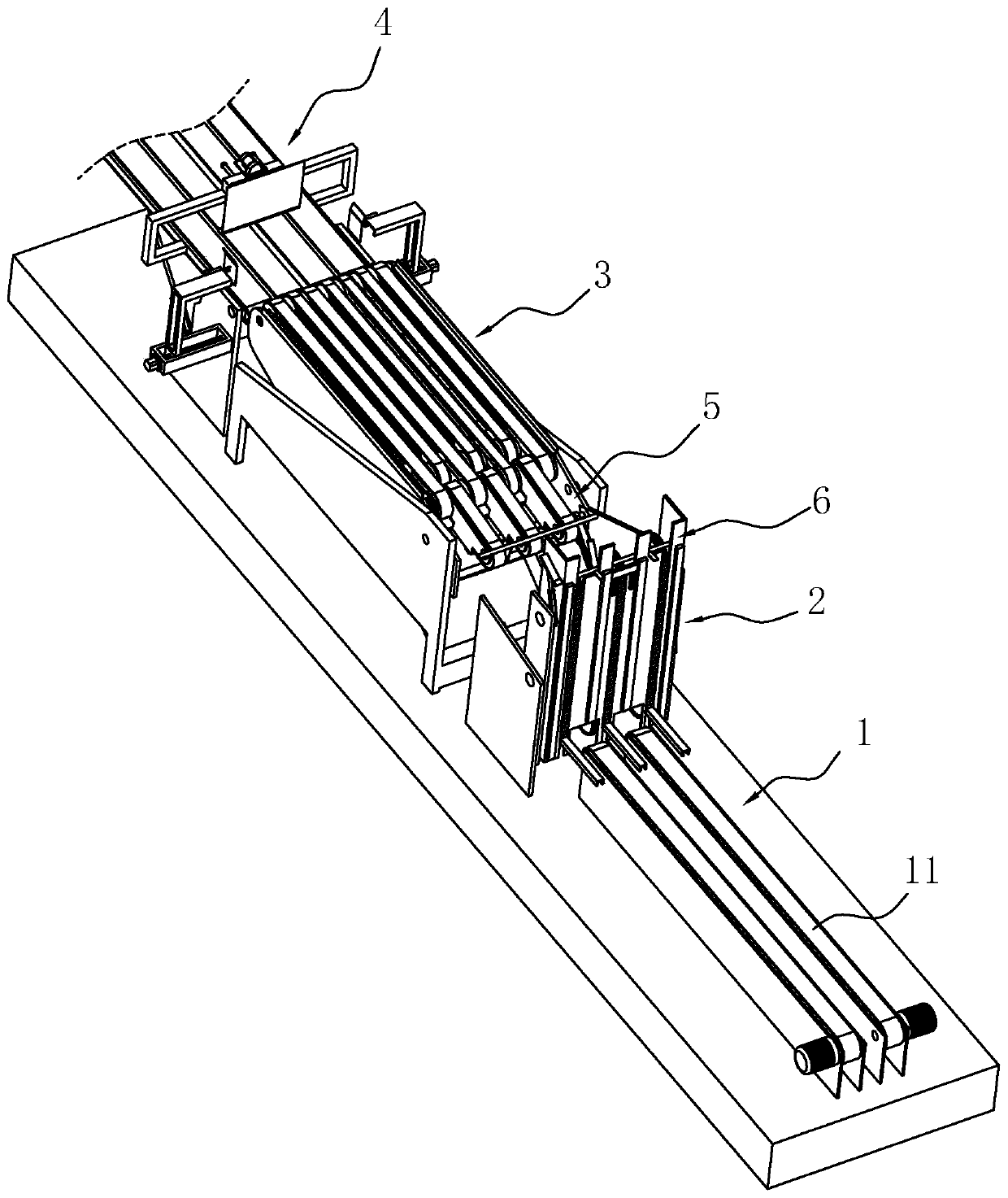

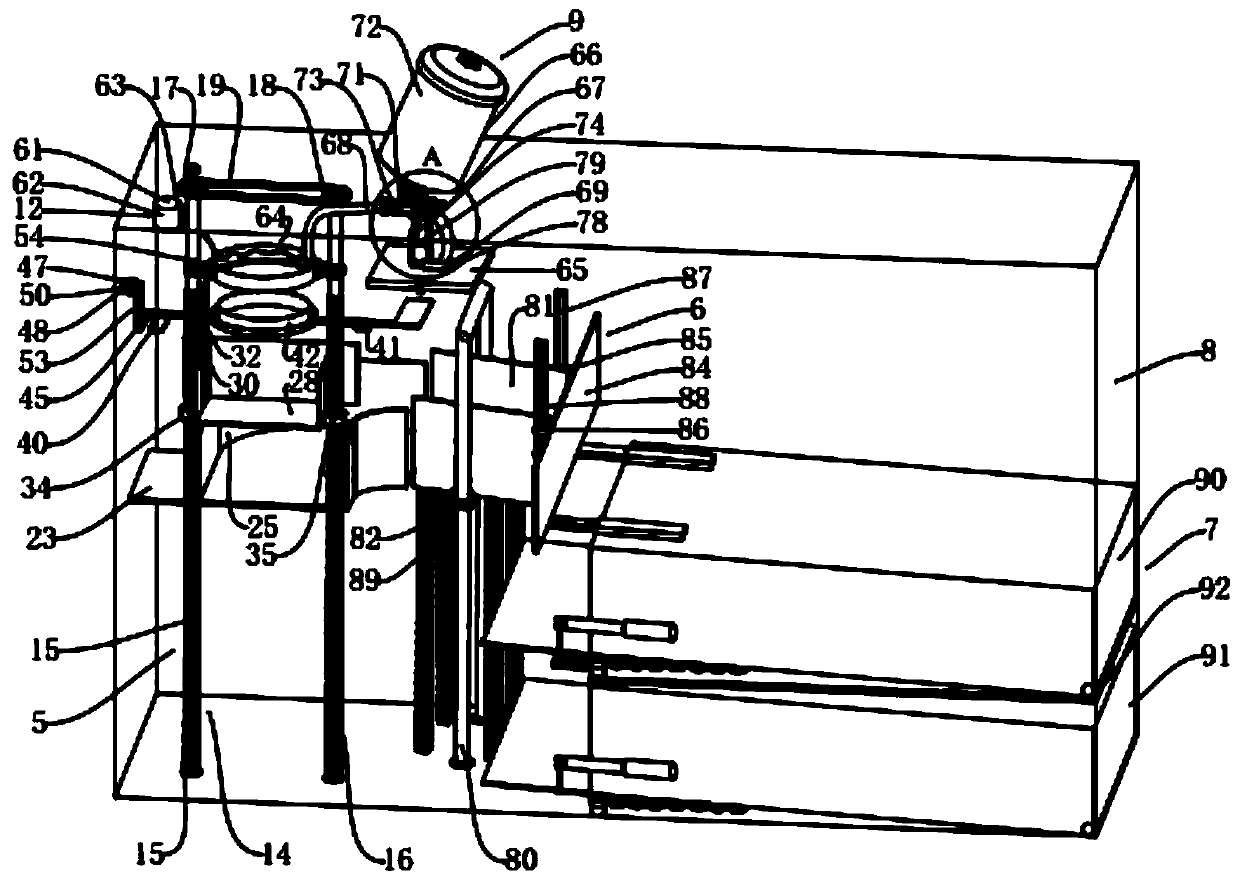

Assembly line for circulating carriers

PendingCN109573525AImplement automatic transferAchieve reflowControl devices for conveyorsMechanical conveyorsAssembly lineBackflow

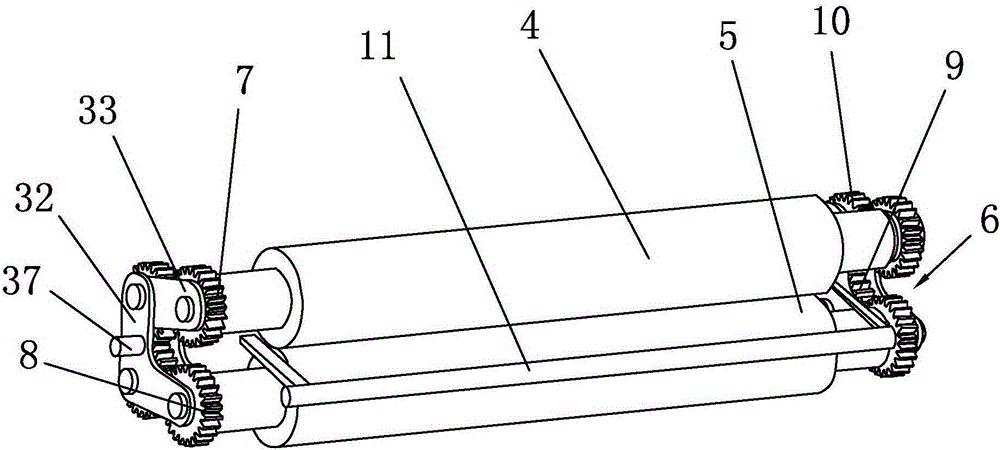

The invention discloses an assembly line for circulating carriers. The assembly line comprises an upper layer assembly line and a lower layer assembly line which are arranged up and down, and transferdevices respectively arranged at two ends of the upper layer assembly line and the lower layer assembly line; the upper layer assembly line is used for successively transferring a plurality of carriers to all work stations at intervals in a first transfer direction; the lower layer assembly line is used for transferring all carriers in a second transfer direction, wherein the first transfer direction and the second transfer direction are opposite; the transfer device is used for transferring all carriers between the upper layer assembly line and the lower layer assembly line; a plurality of work stations are uniformly distributed on the upper layer assembly line, and each of the work stations comprises a barrier climbing mechanism; and the carrier climbing mechanism is used for blocking the carriers transferred to all work stations to the corresponding work stations, and climbing the carriers to a height of at least one carrier. With adoption of the assembly line, automatic transfer and backflow of the carriers can be realized, the transfer of other carriers is not influenced when one carrier is transferred to one work station.

Owner:SHENZHEN YANMADE TECH CO LTD

Label paper cutting equipment

InactiveCN111590651AImplement automatic transferSave human effortMetal working apparatusStructural engineeringWorkbench

The invention relates to cutting equipment, in particular to label paper cutting equipment. The technical problem to be solved is to provide the label paper cutting equipment capable of automaticallyreleasing materials and automatically cutting. According to the technical scheme, the label paper cutting equipment comprises a bottom plate, a material rolling barrel, a mounting seat, a workbench, first bearing seats, a servo motor and an intermittent transmission mechanism, a fixing seat is arranged on the bottom plate, semi-ring placement blocks are symmetrically arranged on the fixing seat, the two semi-ring placement blocks are used for allowing the material rolling barrel to be placed, two mounting frames are symmetrically arranged on the bottom plate, two transmission rollers are rotationally arranged on the mounting frames at the same horizontal positions, the workbench is arranged on the other side of the bottom plate, the bottom plate is symmetrically provided with the first bearing seats with respect to the workbench, a rolling barrel is arranged between the two first bearing seats, and the servo motor is arranged at the position, close to the middle of the workbench, of the bottom plate. According to the label paper cutting equipment, the effects of automatic material releasing and automatic cutting are achieved.

Owner:廖裕兴

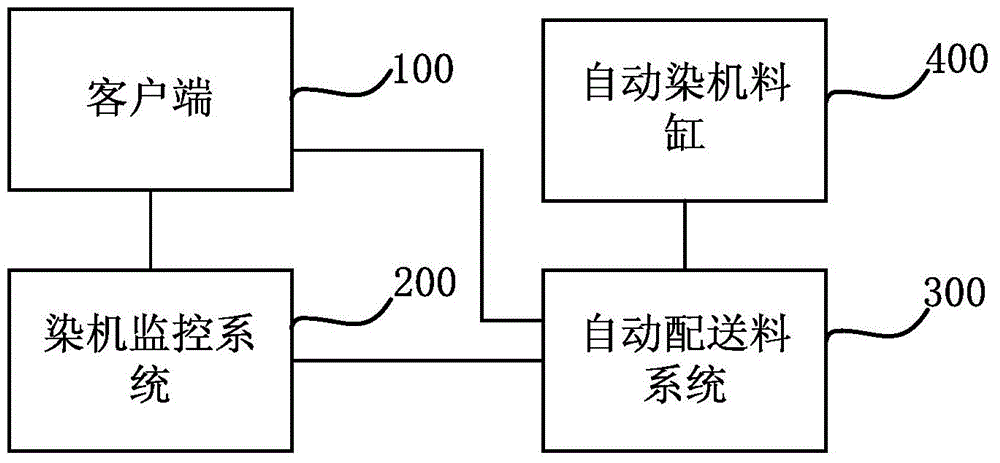

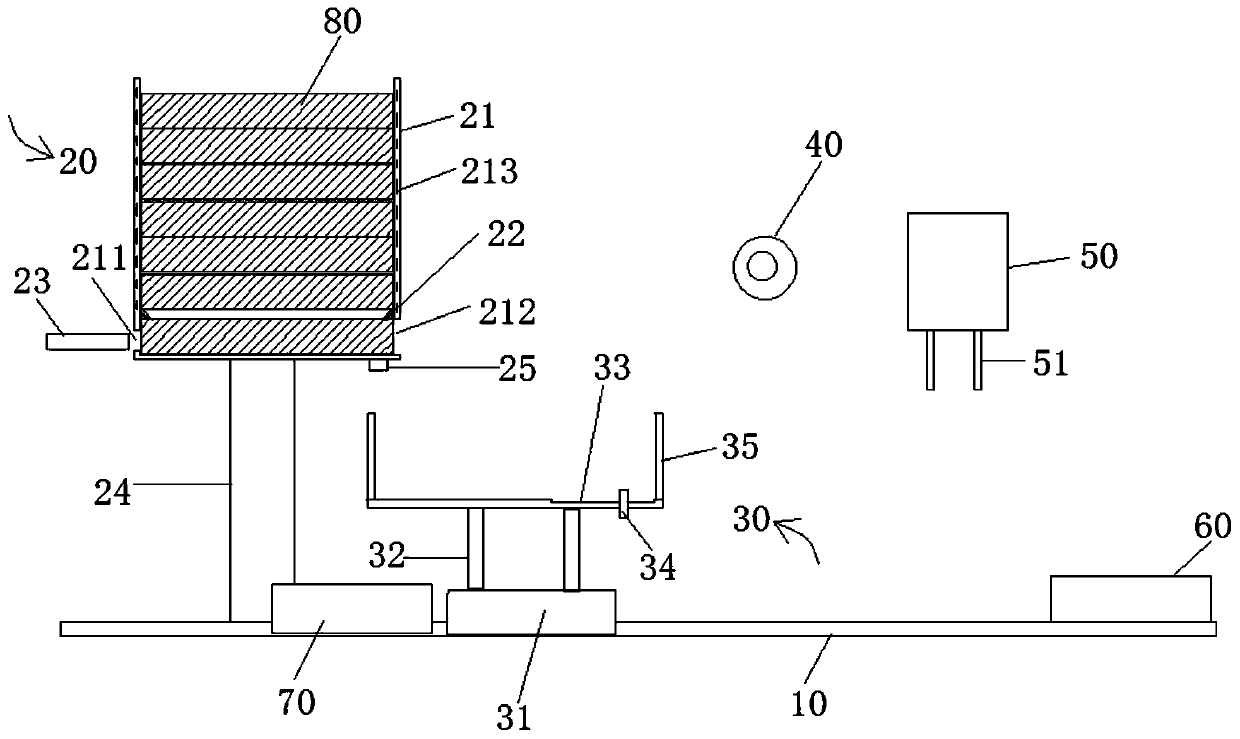

Method and system for automatically controlling textile dyeing

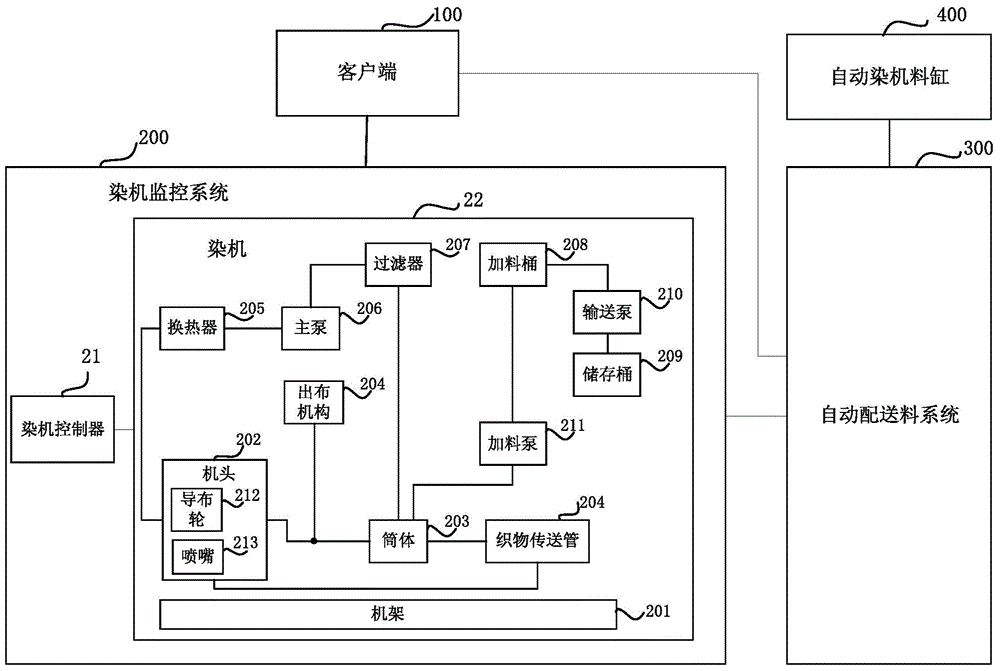

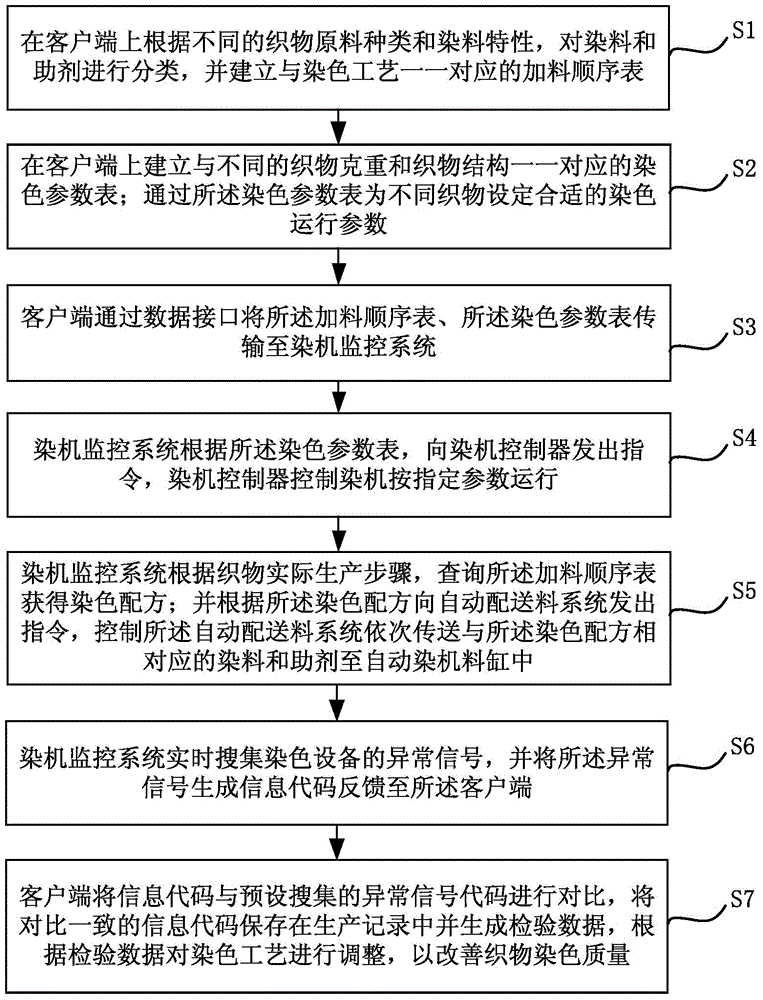

ActiveCN104593977ARealize automatic controlImplement automatic transferTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentControl systemMonitoring system

The invention discloses a system for automatically controlling the textile dyeing. The system comprises a client side, a dyeing machine monitoring system, an automatic material distributing and feeding system and an automatic dyeing machine material cylinder; wherein the client side is provided with a feeding sequence list which is in one-to-one correspondence with a dyeing technology and a dyeing parameter list of various textiles which are operated on a dyeing machine; the client side is used for transmitting the feeding sequence list to the dyeing machine monitoring system and sending an order to write parameters corresponding to the dyeing technology in the dyeing parameter list of the dyeing machine monitoring system; the dyeing machine monitoring system is used for writing the dyeing parameter list in a dyeing machine controller; the dyeing machine controller is operated according to the dyeing parameters and is used for querying the feeding sequence list according to actual production steps of textiles to obtain a dyeing recipe and controlling the automatic material distributing and feeding system to sequentially transmit dyestuff and auxiliaries into the automatic dyeing machine material cylinder. The invention also provides a method for automatically controlling the textile dyeing. The method and the system, provided by the invention, have the advantages of high stability and wide applicability.

Owner:TIANHAI LACE CO LTD

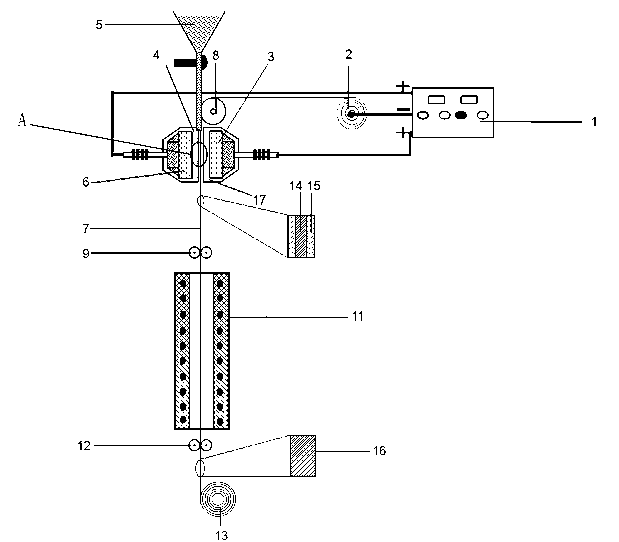

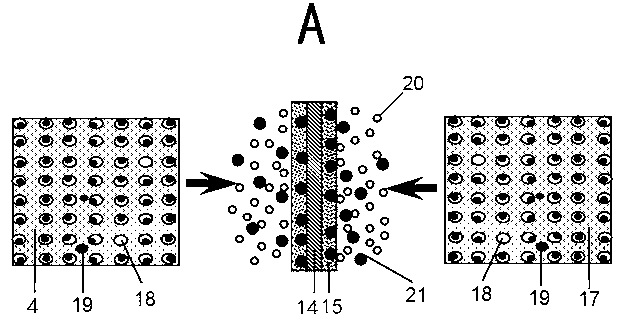

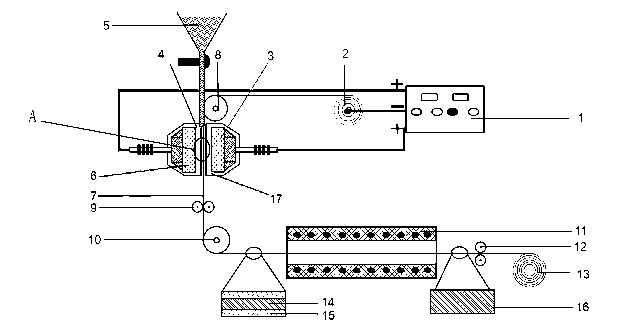

Method for preparing high-silicon steel ribbon through using electric brush composite plating method and continuous silicon steel ribbon preparing device

ActiveCN103320842AAvoid adverse effectsHigh cell voltageElectrolytic coatingsCarbon steelSilicon particle

The invention discloses a method for preparing a high-silicon steel ribbon through using an electric brush composite plating method. The method is characterized in that a pure iron ribbon, a low-carbon steel ribbon or a low-silicon steel ribbon is used as a cathode plating piece ribbon, an electric brush plating anode plate is used as an anode, a layer of iron-silicon iron particle composite plating layer is coated on the cathode plating piece ribbon through using an electric brush composite silicon plating process, a composite plating layer steel ribbon adopting a steel-ribbon substrate as a core part is formed, then the uniform dispersion heat treatment is carried out, silicon-contained particles in the iron-silicon iron particle composite plating layer are uniformly dispersed into the steel ribbon substrate of the core part, and the high-silicon steel ribbon can be continuously prepared. The invention also discloses a continuous silicon steel ribbon preparing device which comprises an unreeling guide device, a conveying device, an electroplating device, a dispersion heat treatment device and a rolling device. The high-silicon plating layer is electrically plated on the cathode plating piece ribbon, then the high-silicon steel ribbon with an excellent magnetic conduction performance is obtained through using a heat treatment process, the simplicity in operation can be realized, characteristics such as high efficiency and continuity in preparation can be achieved, and the preparation cost also can be greatly reduced.

Owner:SHANGHAI UNIV

Foaming plate cutting device

ActiveCN108177182AImplement automatic transferAvoid connectionMetal working apparatusGear wheelAgricultural engineering

The invention relates to a foaming plate cutting device. The foaming plate cutting device comprises a rack; the rack is rotatably connected with a first straight gear and a second straight gear; the first straight gear is connected with a first transfer roller, and the second straight gear is connected with a second transfer roller; the first transfer roller is connected with a first crank, and the second transfer roller is connected with a second crank; a third transfer roller and a fourth transfer roller are rotatably connected to the rack; the third transfer roller is connected with a thirdcrank, and the fourth transfer roller is connected with a fourth crank; a first connecting rod is connected between the first crank and the third crank, the two ends of the first connecting rod are rotatably connected to the first crank and the third crank correspondingly, and the first connecting rod is provided with a first cutting knife; a second connecting rod is connected between the secondcrank and the fourth crank, the two ends of the second connecting rod are rotatably connected to the second crank and the fourth crank correspondingly, and the second connecting rod is provided with asecond cutting knife; and a collecting mechanism and a correcting mechanism are arranged on the rack. According to the scheme, moving of a foaming plate and cutting of the cutting knives are conducted simultaneously.

Owner:重庆翰邦汽车配件有限公司

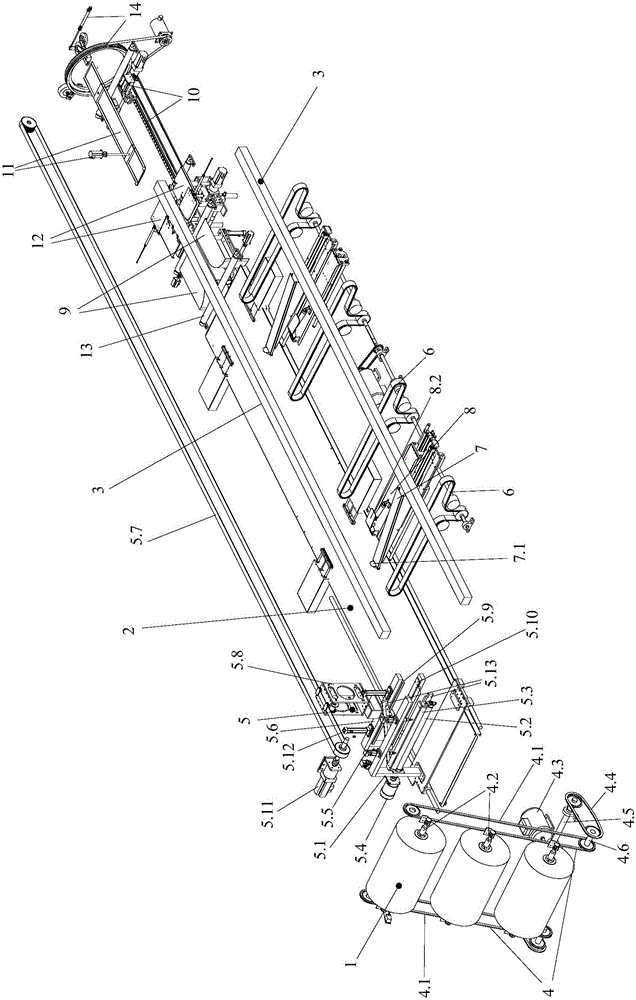

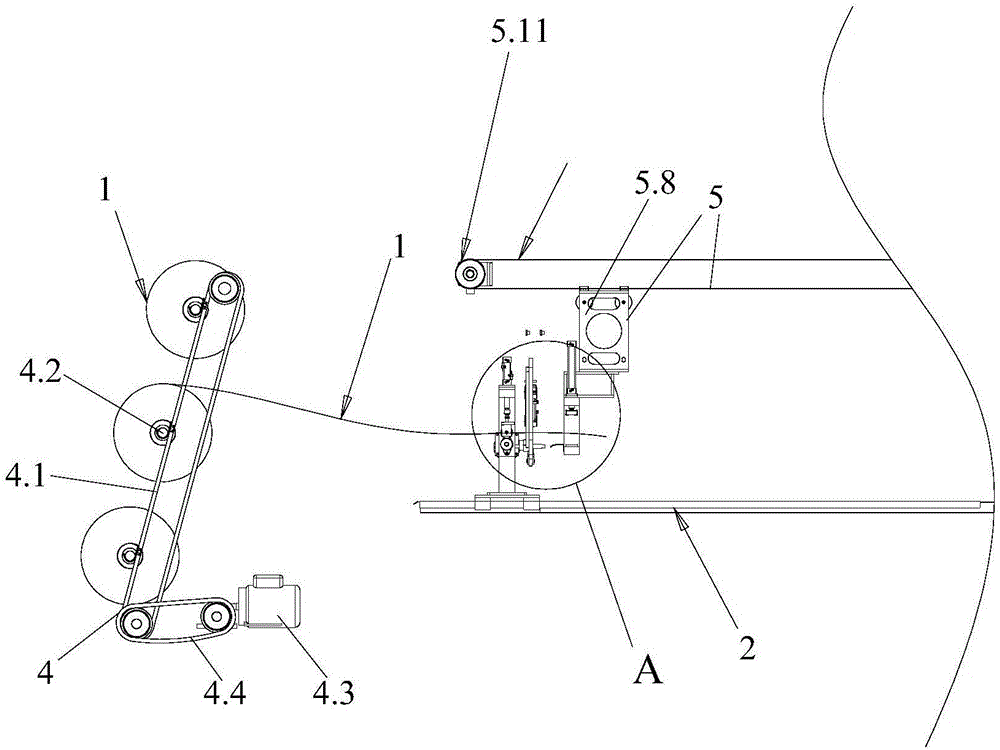

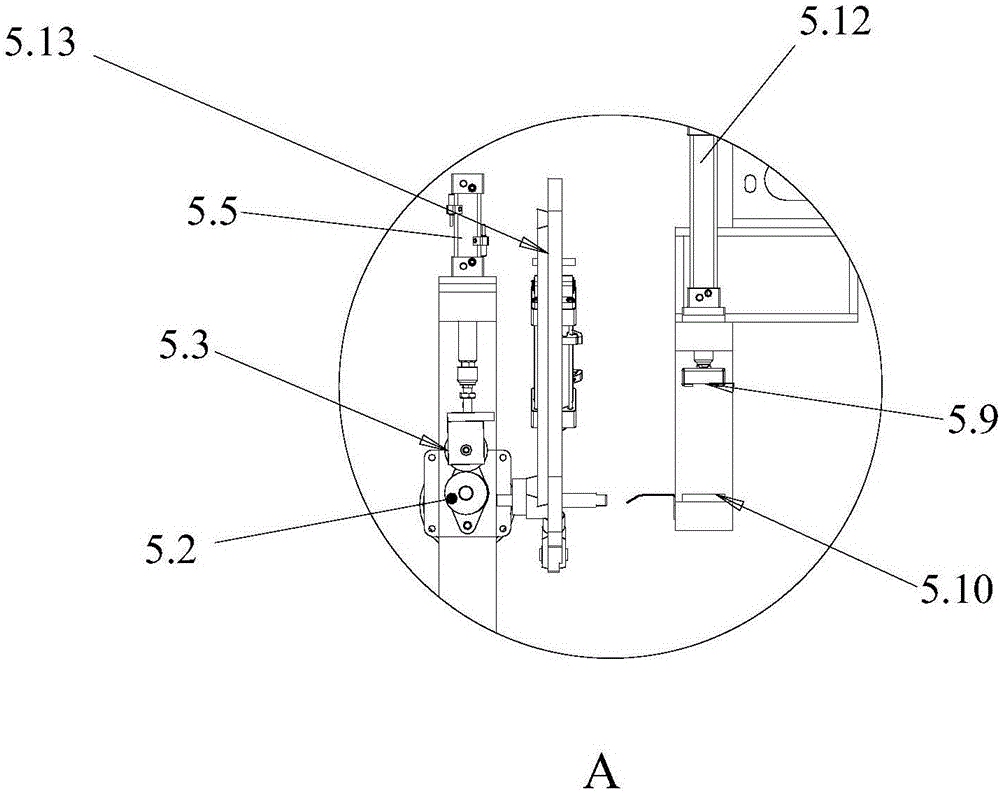

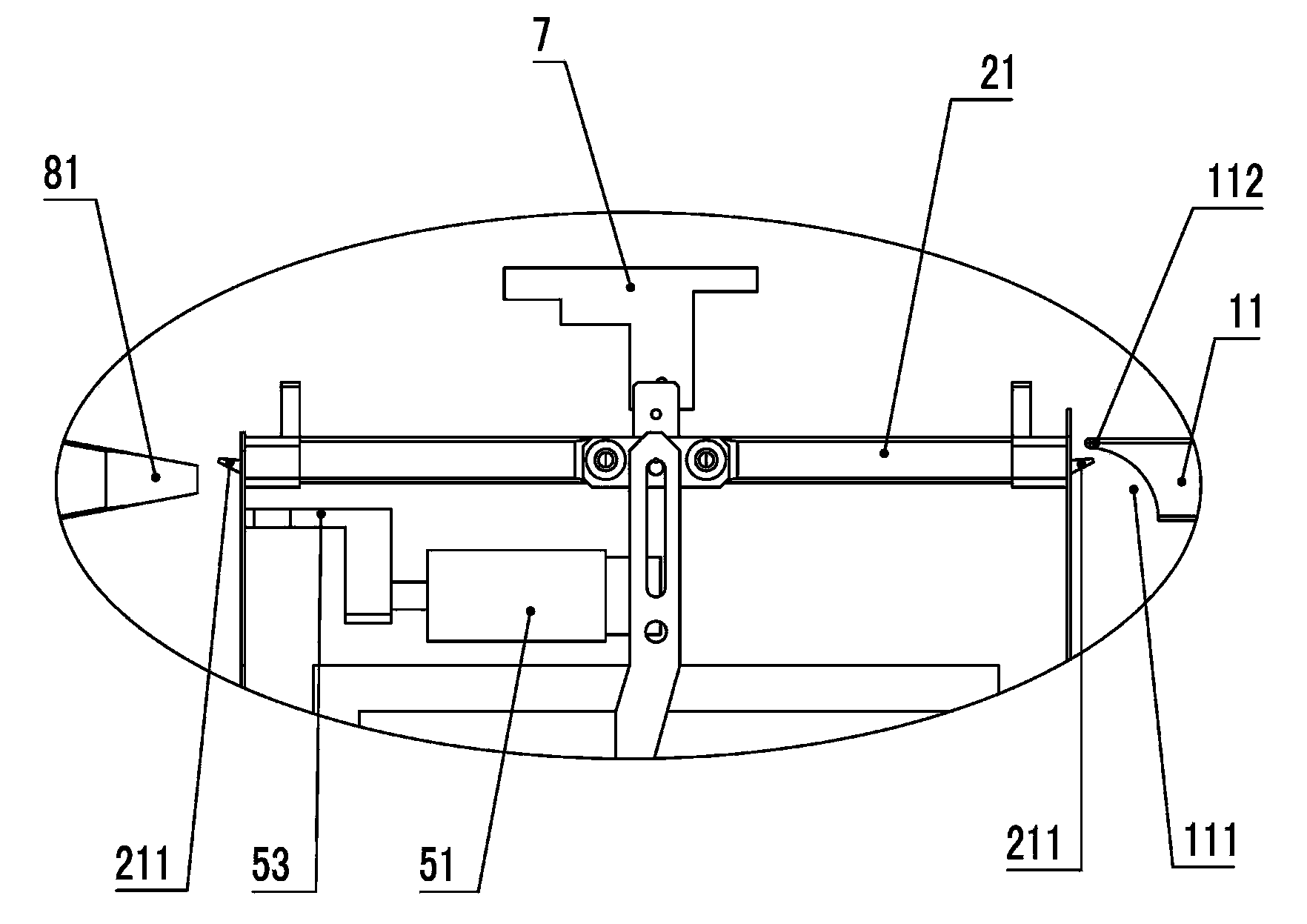

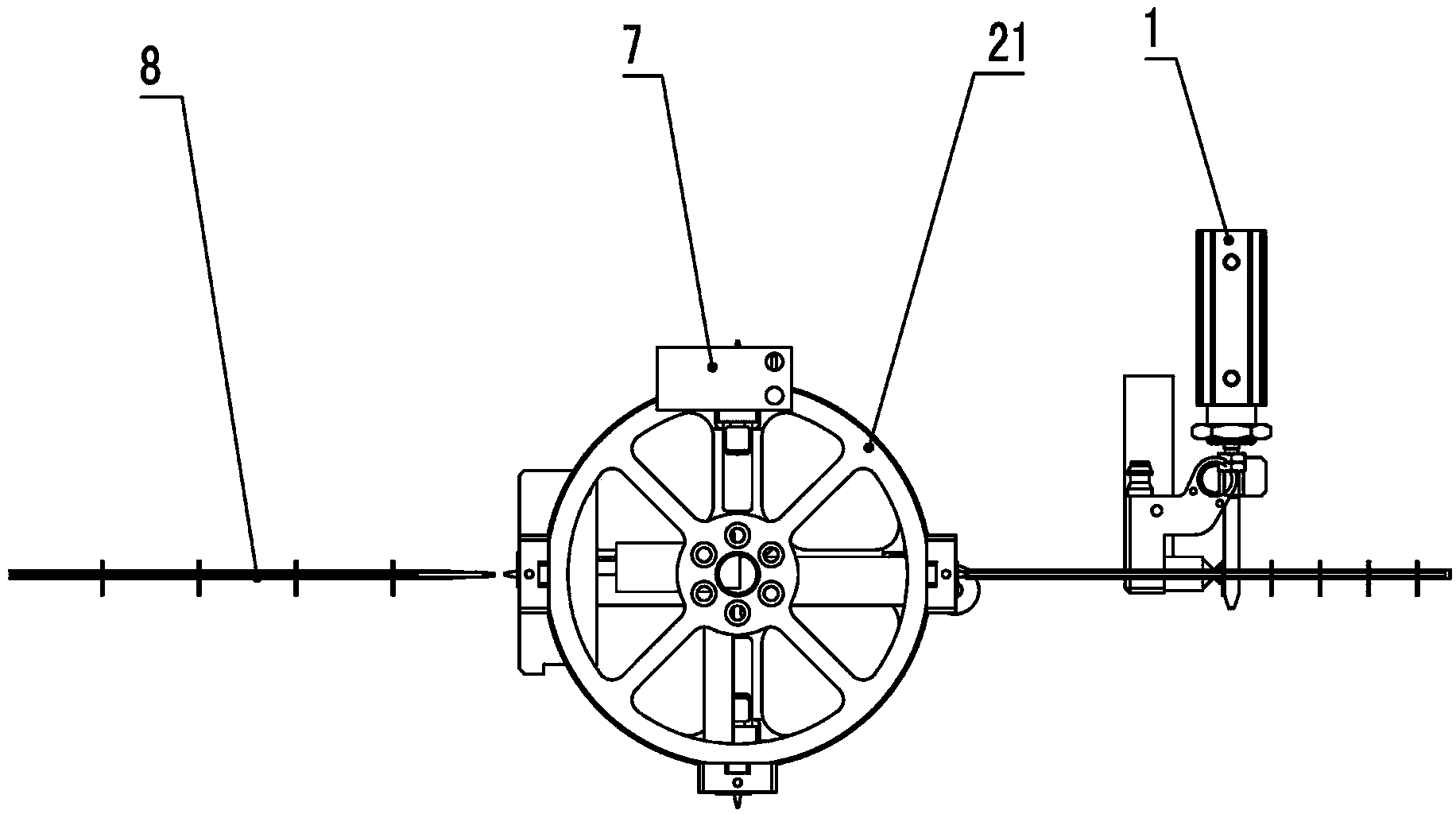

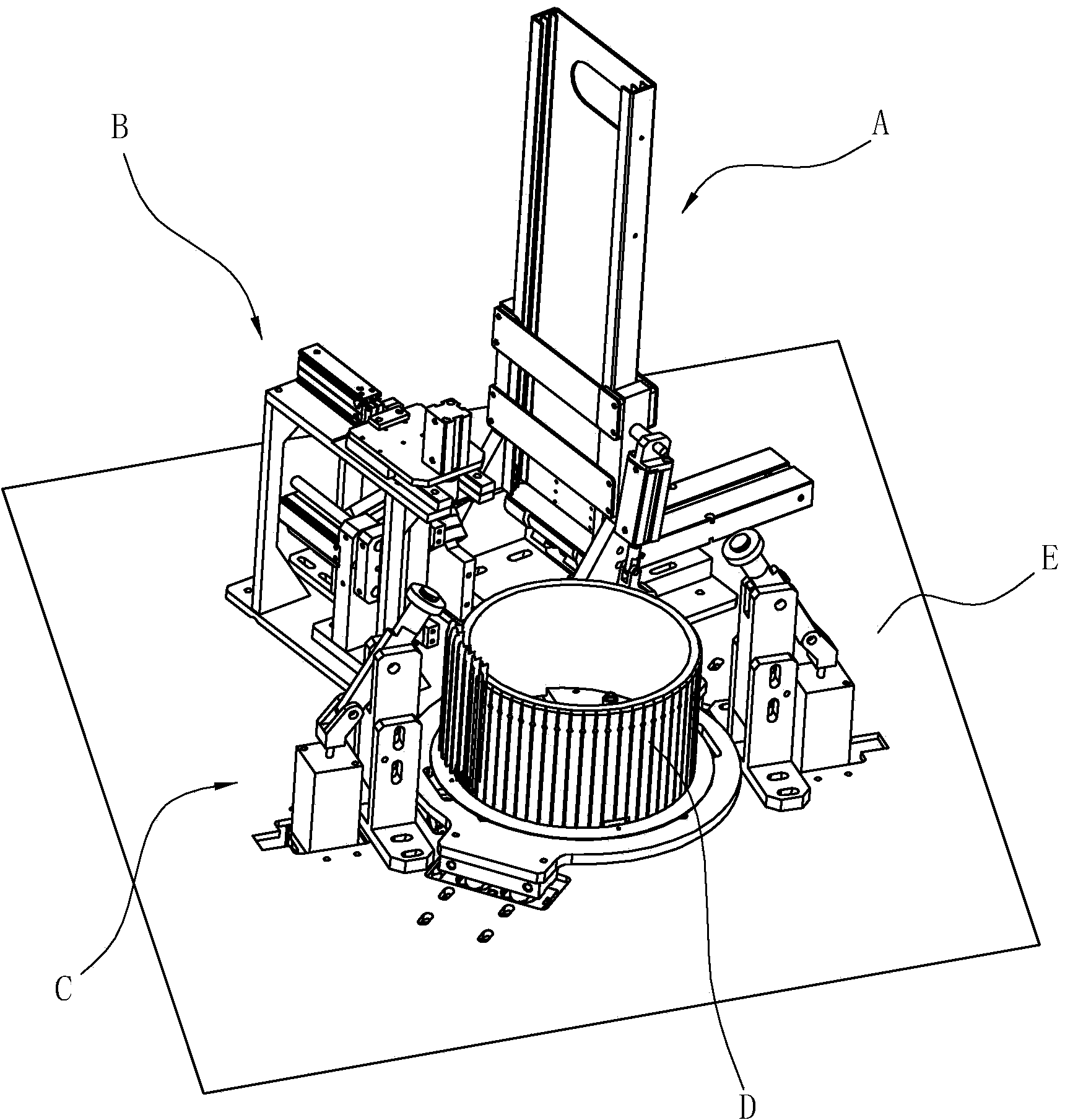

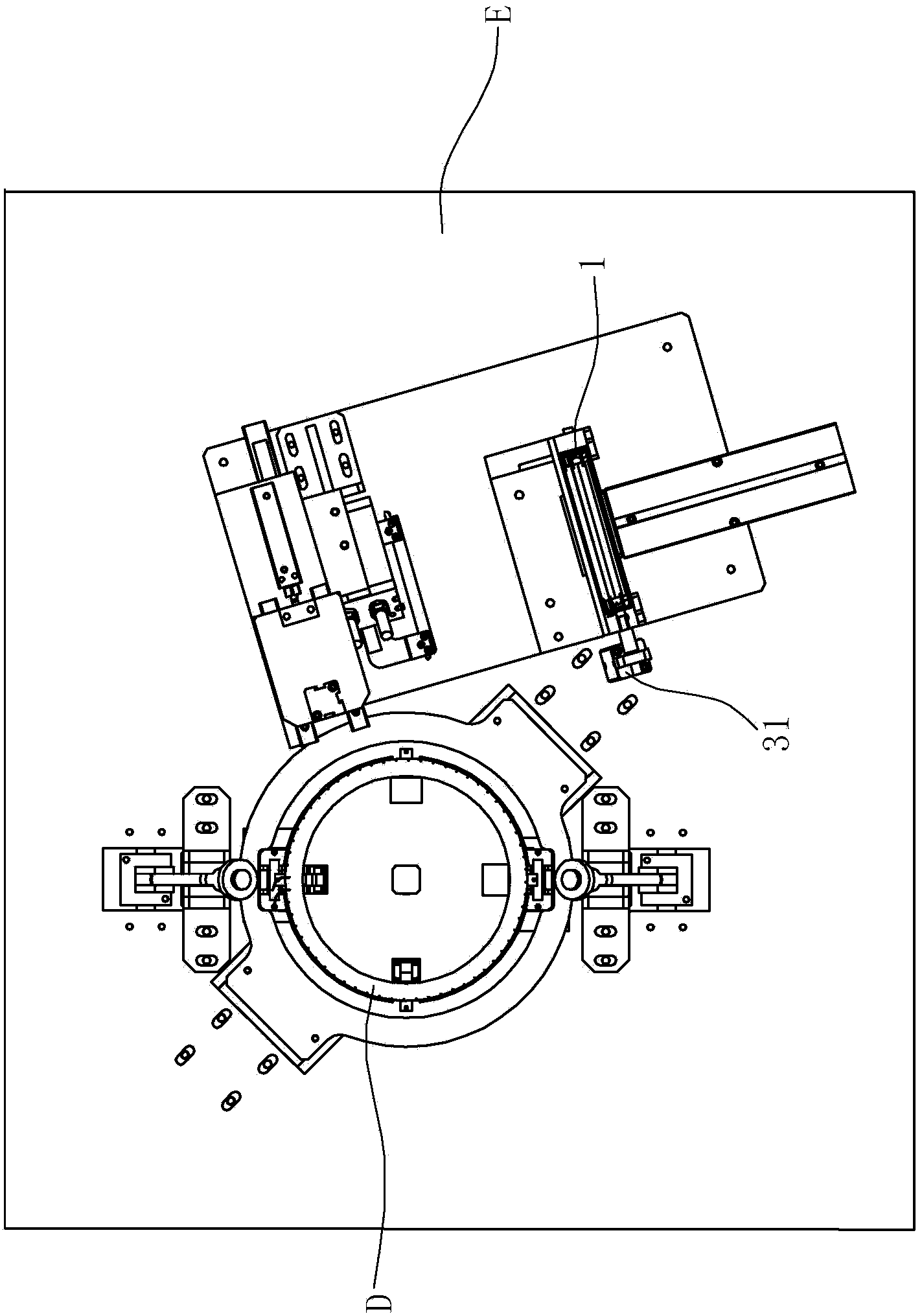

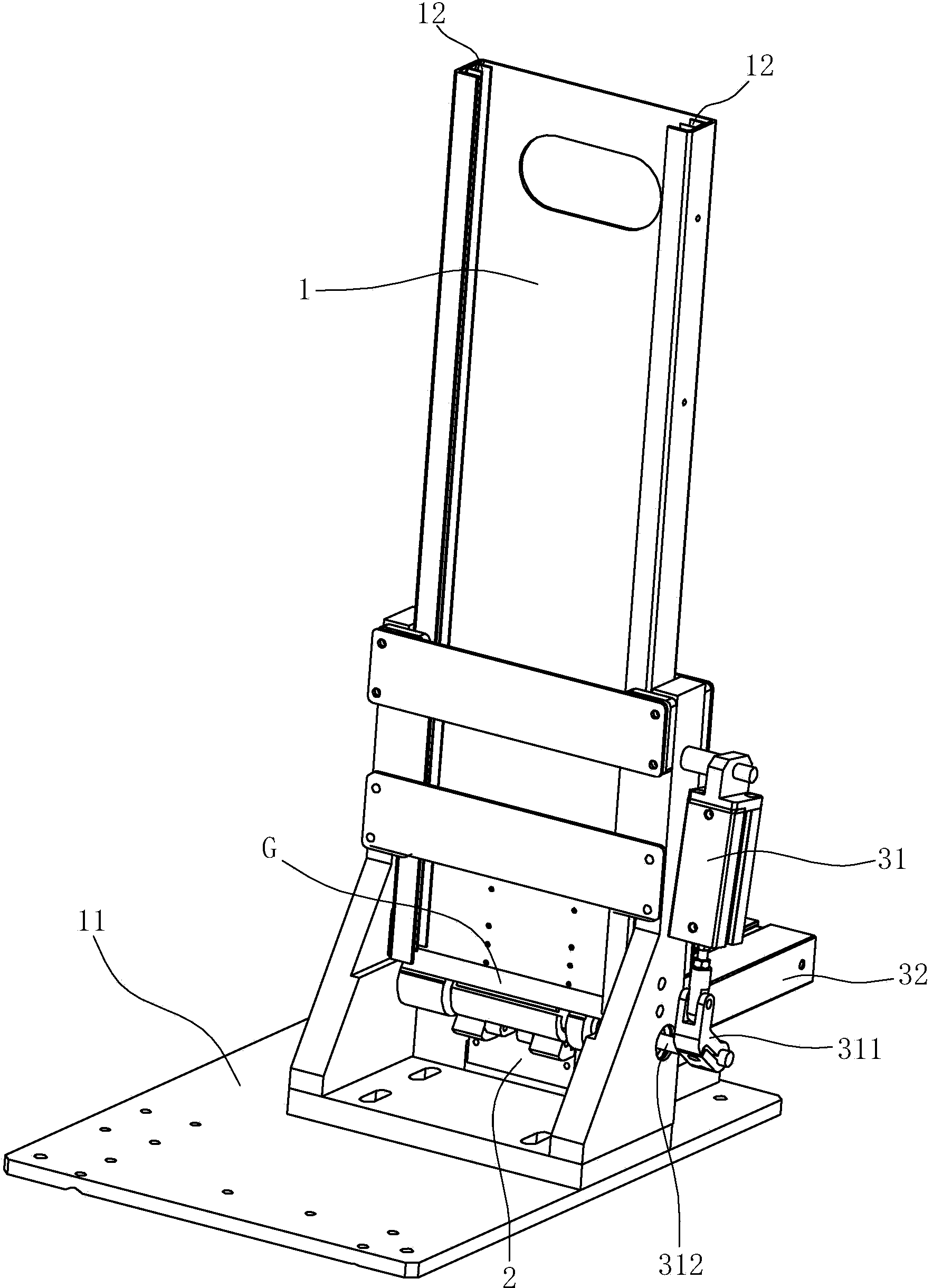

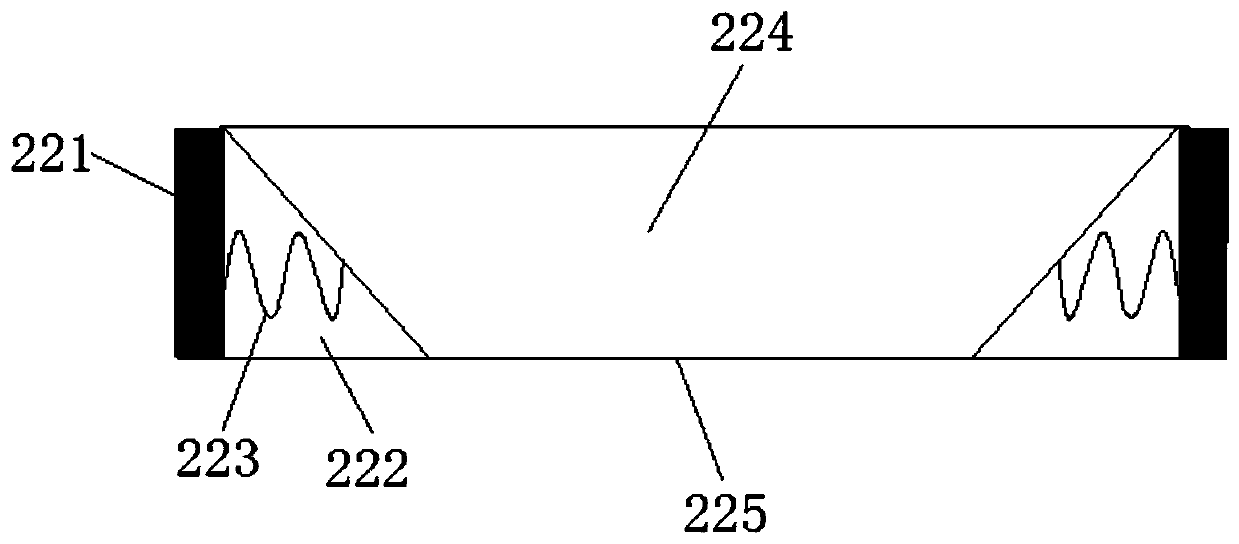

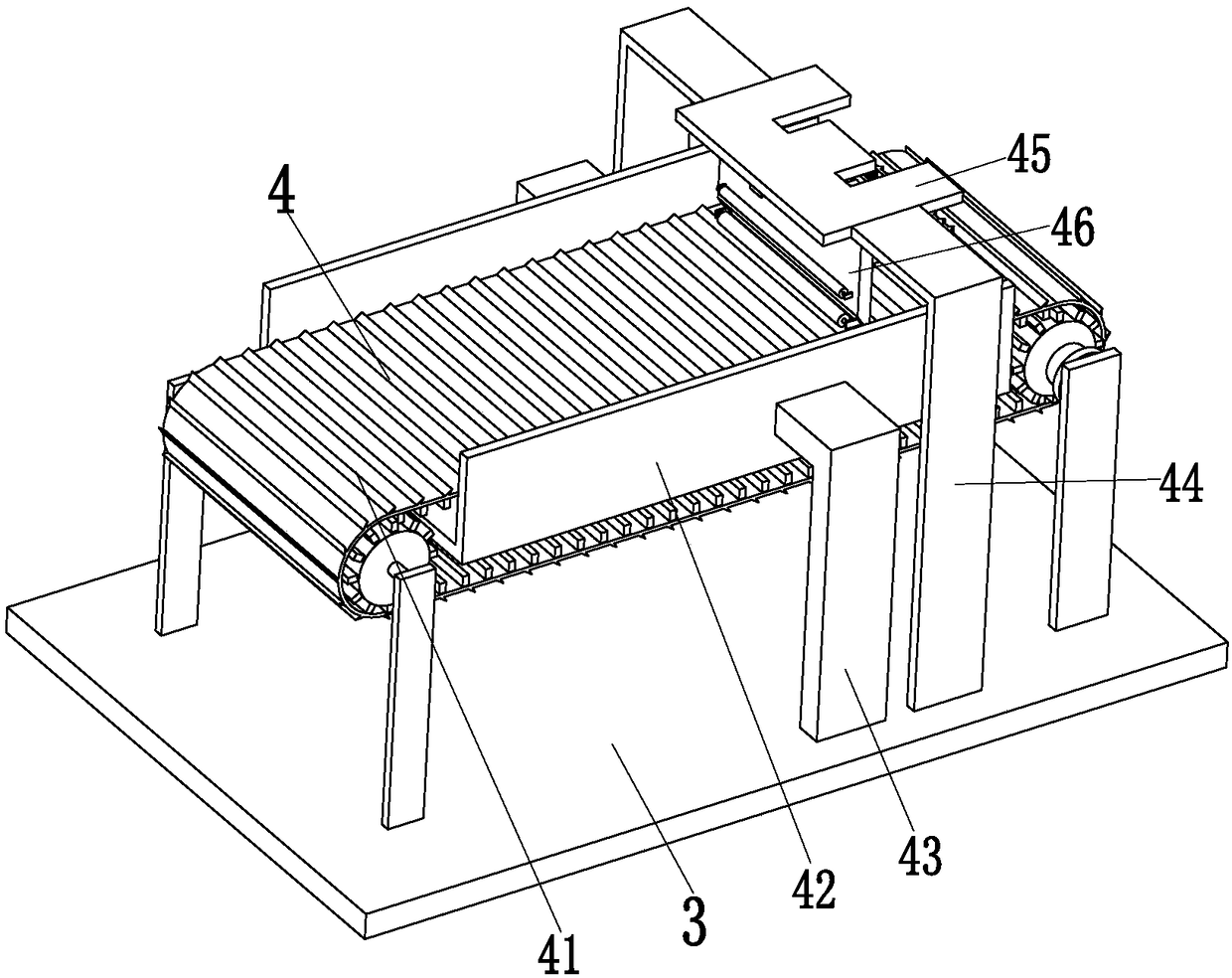

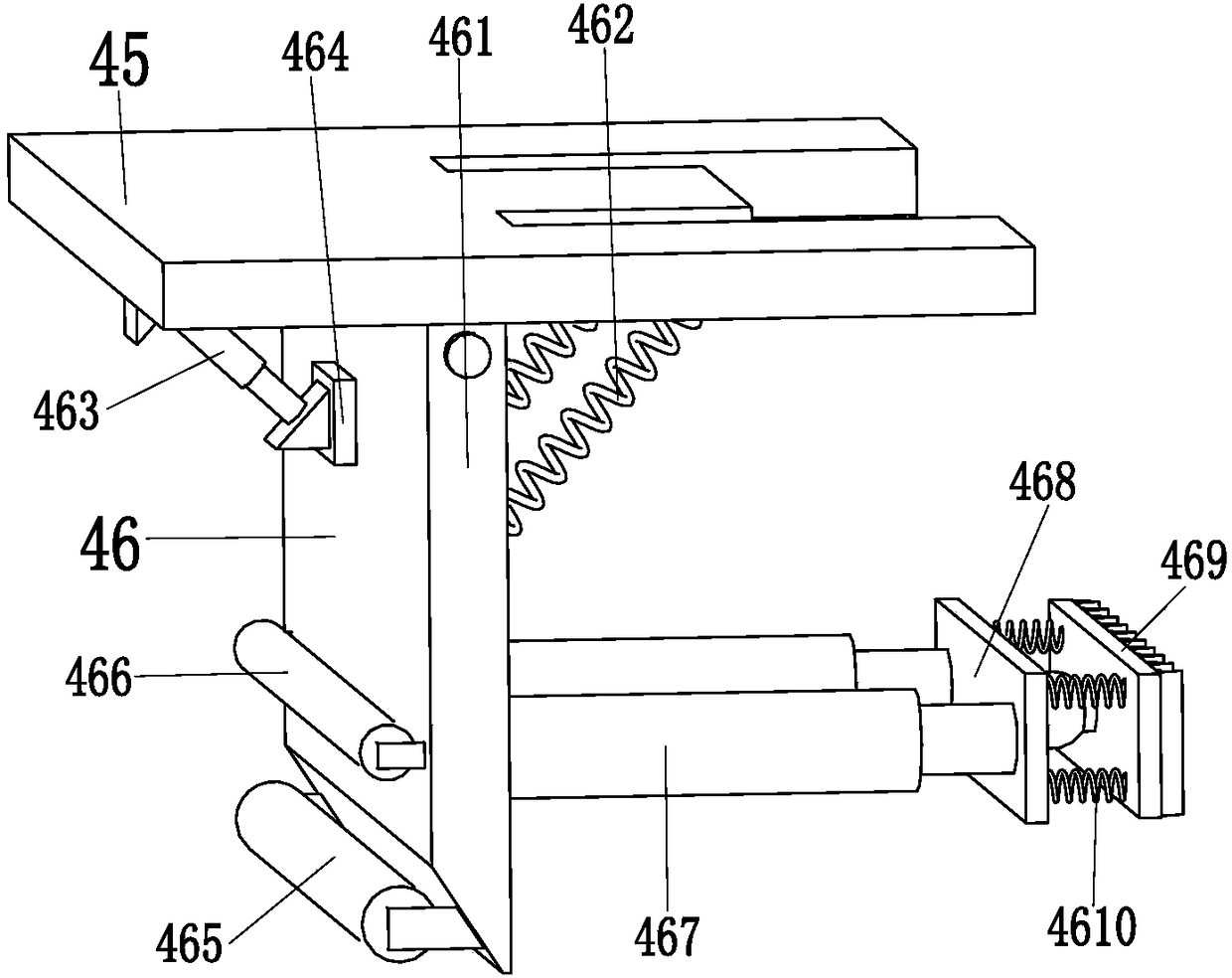

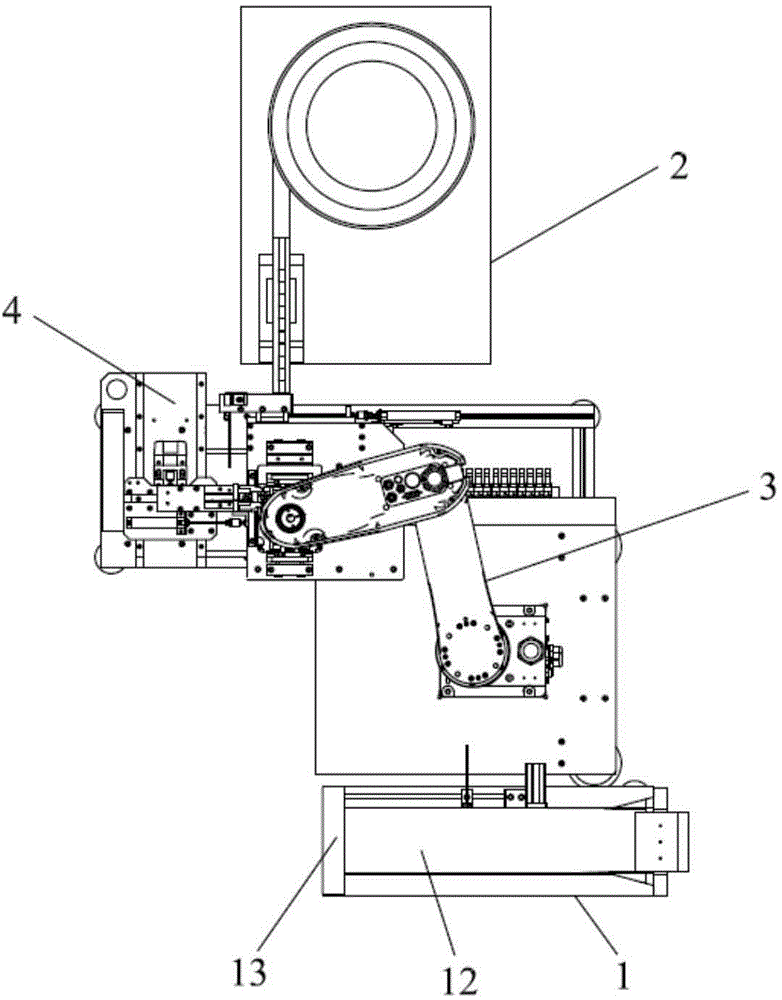

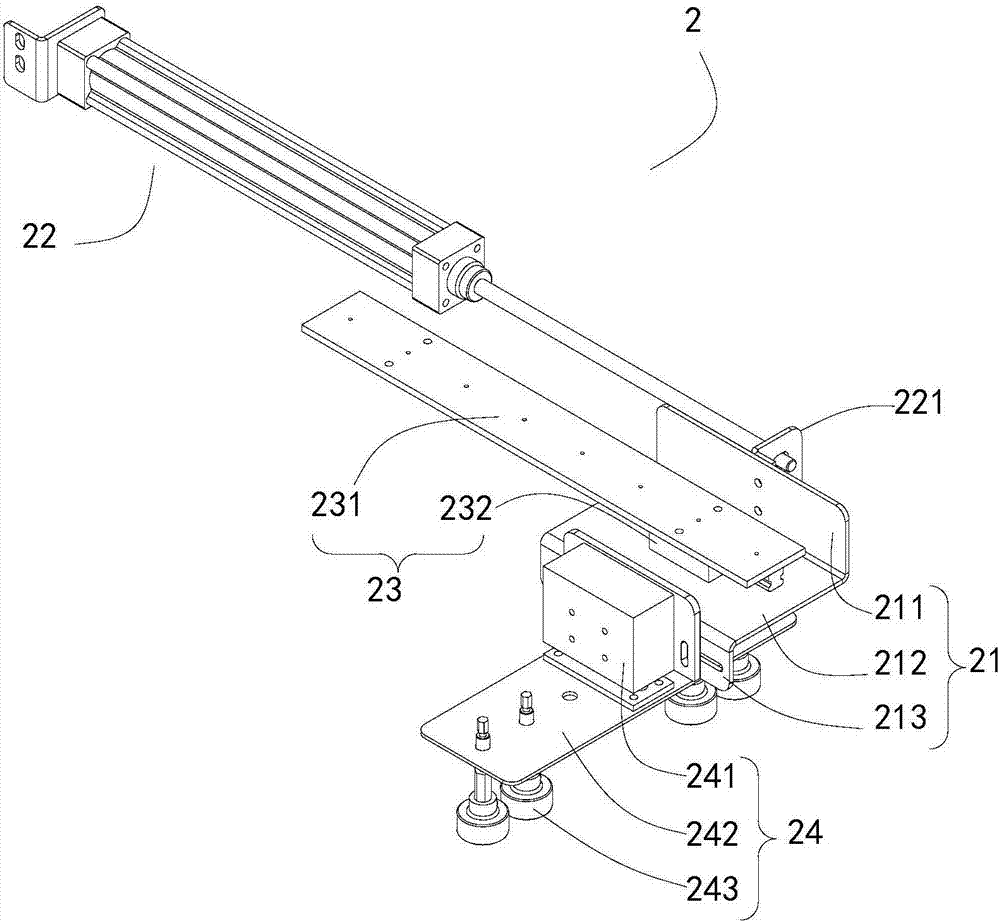

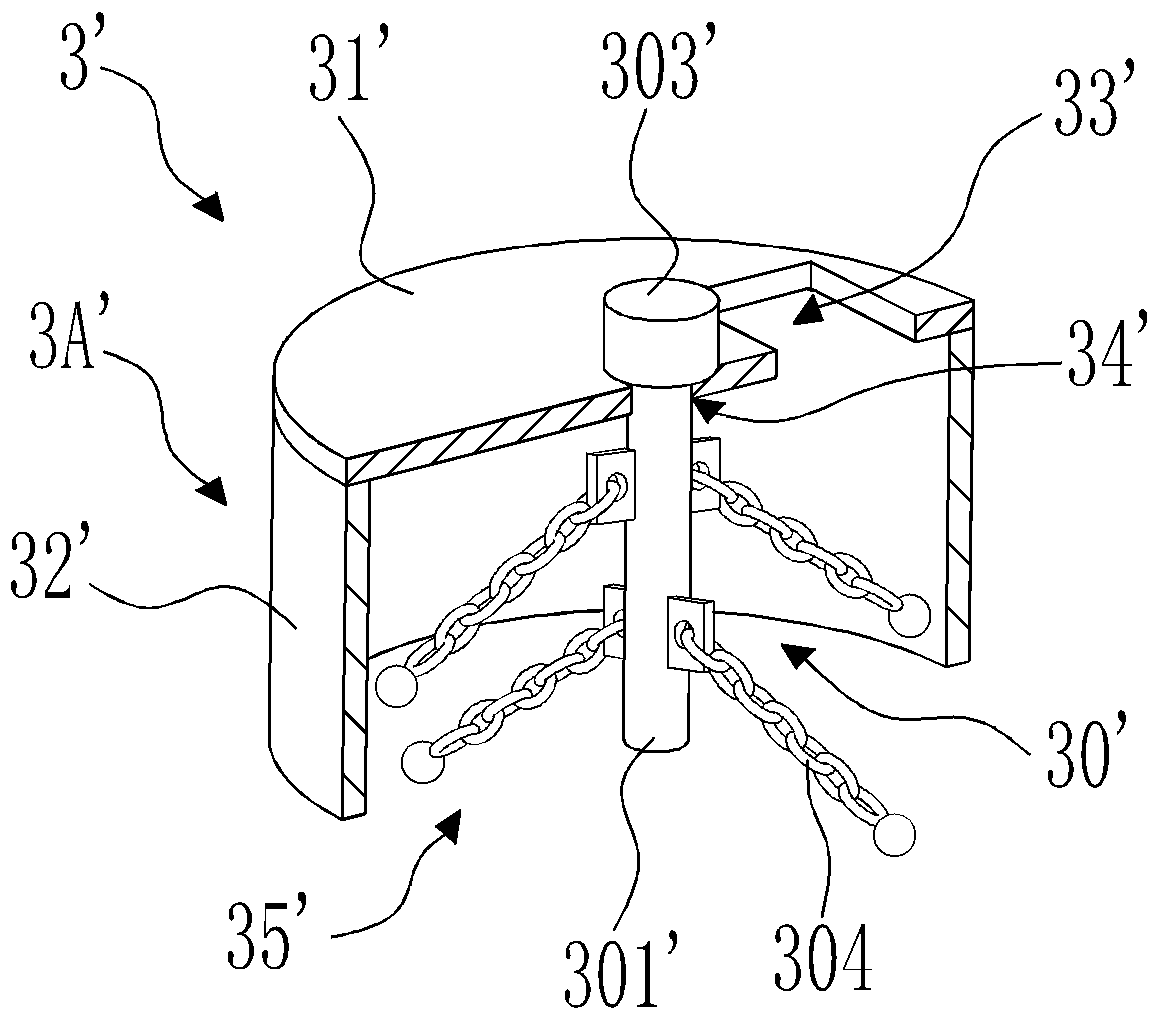

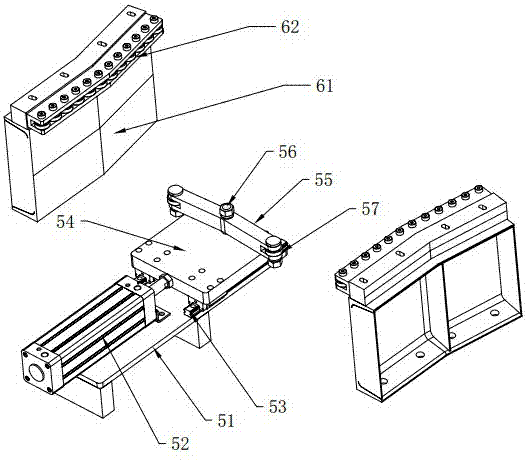

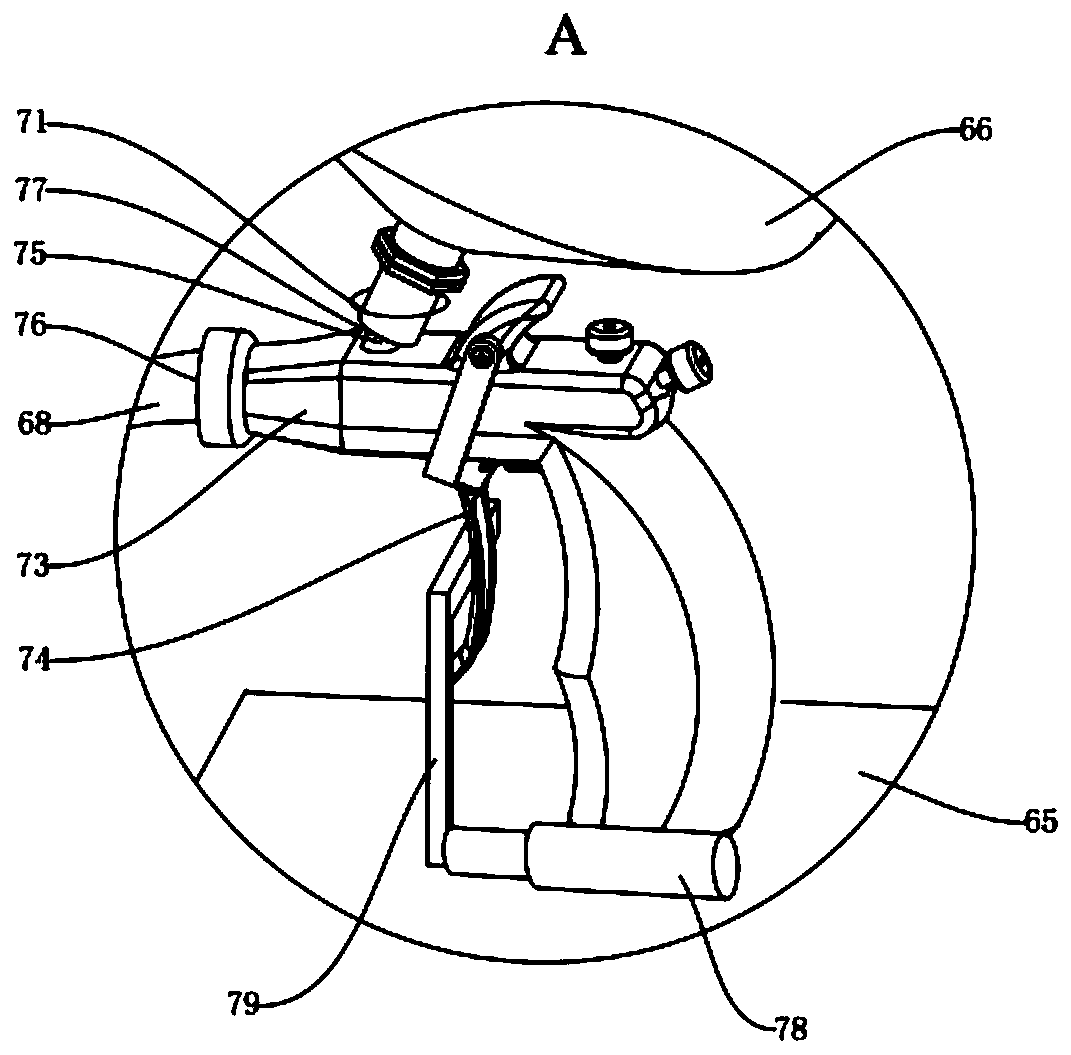

Device and method for harness wire transferring

ActiveCN103924365AImplement automatic transferHigh degree of automationAuxillary apparatusHealdsWire transferEngineering

The invention relates to textile devices, in particular to a device and method for harness wire transferring in the textile devices. The device for harness wire transferring comprises a machine base and a controller, a rotating driving device, an upper rotating disc and a lower rotating disc are arranged on the machine base, the upper rotating disc and the lower rotating disc are coaxially arranged, the rotating drive device is respectively connected with the upper rotating disc and the lower rotating disc through rotating shafts, upper supporting rods which are arranged in the radial direction of the upper rotating disc are arranged on the upper rotating disc, at least two upper supporting rods are arranged at intervals in the circumferential direction of the upper rotating disc, lower supporting rods which are arranged in the radial direction of the lower rotating disc are arranged on the lower rotating disc, at least two lower supporting rods are arranged in the circumferential direction of the lower rotating disc at intervals, the lower supporting rods are in rotation connection with the lower rotating disc, and the lower supporting rods are connected with elastic rotating tensioning mechanisms. A method for harness wire transferring is further provided. The method and device have the advantages of achieving automatic transferring of harness wire elements, being high in automation degree and improving efficiency.

Owner:SHENZHEN HAYHON EQUIP TECH

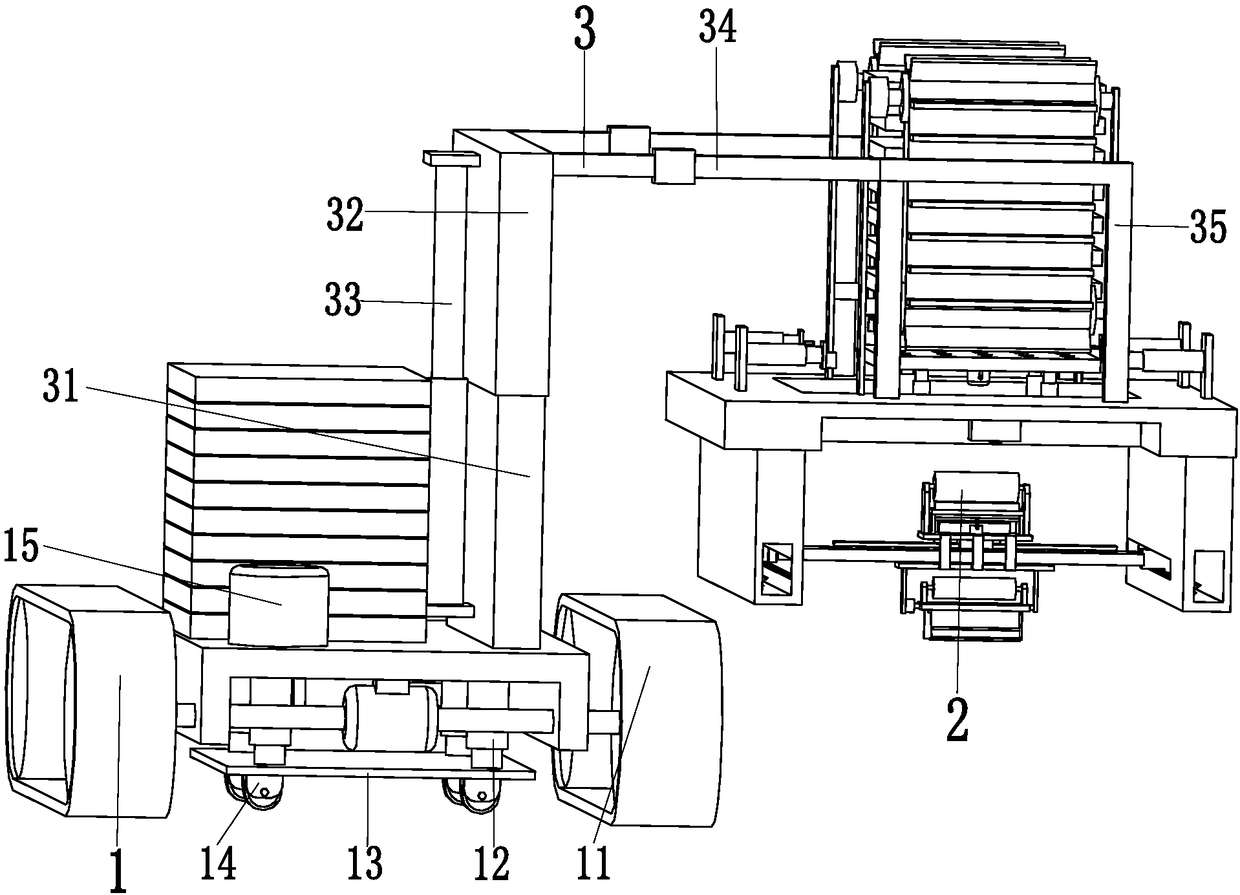

Building decoration equipment for automatic fixing and mounting of soft ceramic tiles

ActiveCN108590141AImplement automatic transferImprove work efficiencyBuilding constructionsAdhesiveEngineering

The invention relates to building decoration equipment for automatic fixing and mounting of soft ceramic tiles. The building decoration equipment comprises a moving device, a fixing and mounting device and a supporting mechanism, wherein the bottom of the left end of the supporting mechanism is mounted at the top of the moving device, and the fixing and mounting device is installed at the bottom of the right end of the supporting mechanism; the moving device comprises a moving platform, a moving push rod, a moving bottom plate, walking wheels and a counterweight; and the fixing and mounting device comprises a fixing and mounting supporting frame, a fixing and mounting suction mechanism, a conveying mechanism, a smearing moving frame, a moving frame sliding block, a smearing supporting plate, a smearing mechanism, a limiting mechanism and a scraping sweeping and rolling mechanism. The building decoration equipment can solve the problems of low working efficiency, need of manual handlingof the soft ceramic tiles, poor effect of manual applying adhesive on the soft ceramic tiles, deviation of the position of manual mounting of the soft ceramic tiles, need of manual cleaning of the fixing and mounting ground, dripping everywhere of adhesive liquid of adhesive applied soft ceramic tiles, need of manual rolling of the fixed and mounted soft ceramic tiles existing in the conventionalfixing and mounting of the soft ceramic tiles.

Owner:聊城泽润装饰工程有限公司

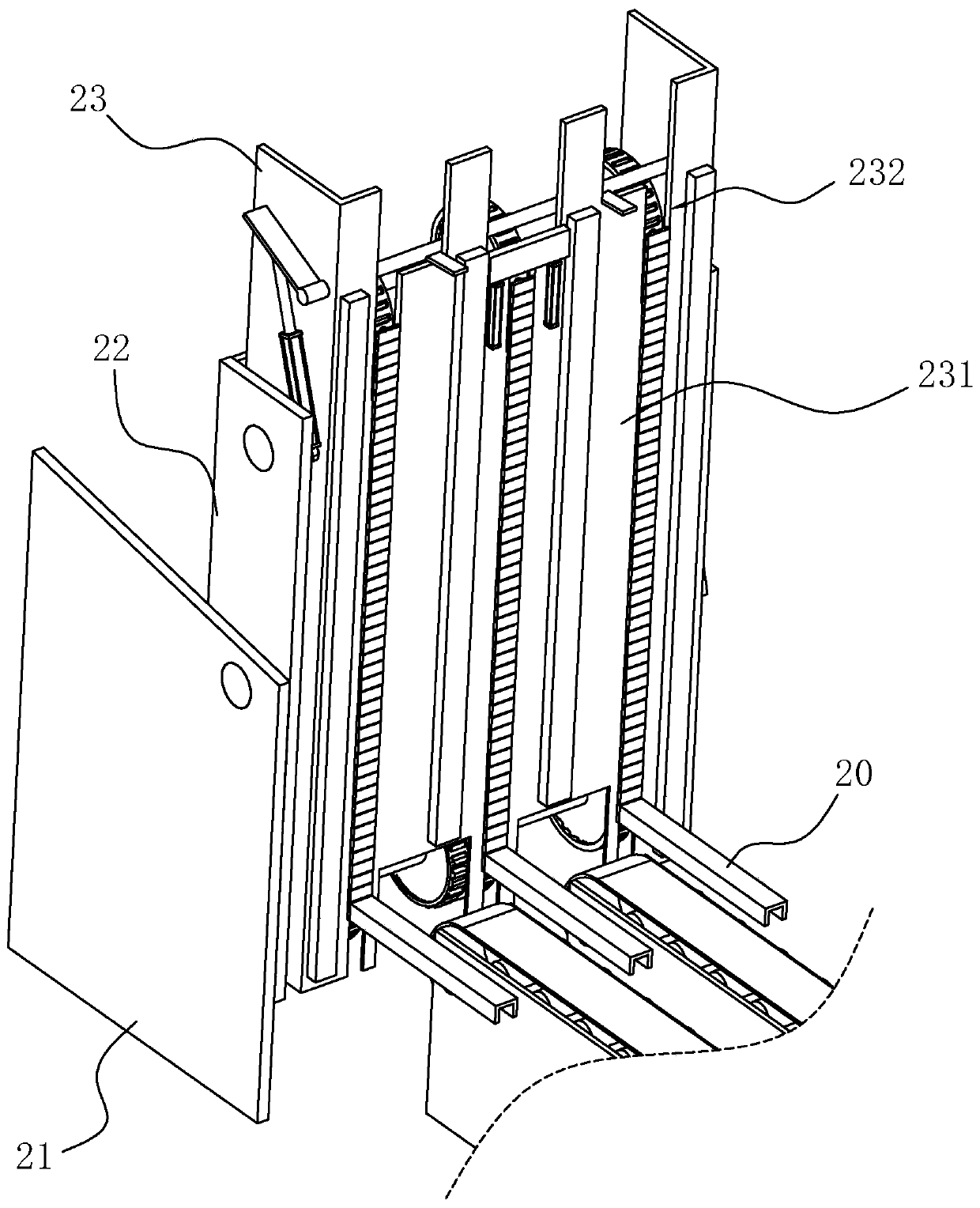

Feeding device of impeller insertion sheet

The invention discloses a feeding device of an impeller insertion sheet, which comprises a feeding hole and a discharge hole. The feeding device of the impeller insertion sheet is characterized by further comprising a material box and a first drive mechanism capable of driving an impeller to pull away from the material box, wherein the first drive mechanism comprises a first cylinder, a connecting rod, a rotating shaft, a second cylinder and a push block; the two ends of the connecting rod are respectively connected with a piston rod of the first cylinder and one end of the rotating shaft; the piston of the first cylinder is movably hinged to one end of the connecting rod; one end of the rotating shaft is fixedly connected with the other end of the connecting rod; the rotating shaft is arranged on the lower part of the discharge hole of the material box; the rotating shaft includes a circular arc surface adaptive to the profile of the impeller; the push block is located below the rotating shaft and includes a arc surface guide platform adaptive to the profile of the impeller; the piston rod of the second cylinder is connected with the push block. The feeding device of the impeller insertion sheet has the advantages of guaranteeing that one impeller can be taken out per each time as a rotary impeller taking mode is adopted, the impeller material taking precision is improved, automatic conveying of the impeller is realized, the automatic operation degree is improved, and the stability and reliability of the impeller in the material feeding process are guaranteed.

Owner:嘉兴市朗盛机械有限公司

Computer hardware anti-fall performance detecting platform

ActiveCN110160727AImplement automatic storageRealize automatic picking functionShock testingElectricityEngineering

The invention discloses a computer hardware anti-fall performance detecting platform, comprising a slide rail, a computer hardware feeding device, a slide fall platform, a camera and a hardware performance detecting device. The computer hardware feeding device comprises a feeding cylinder, an elastic isolation member, a telescopic push rod, a feeding lifting rod and an infrared sensor; and an electric heating wire is built in a wall surface of the feeding cylinder, and the elastic isolation member is arranged on an inner wall surface of the feeding cylinder between the bottommost layer of computer hardware and the last but one layer of computer hardware. The slide fall platform comprises a slide base, a fall lifting rod and a fall receiving cylinder; a jacking rod with an adjustable heightis arranged in a detecting groove; and overturning side plates are arranged on both of a left side wall and a right side wall of the wresting receiving cylinder. The computer hardware anti-fall performance detecting platform disclosed by the invention has a high degree of automation, and can automatically convey the computer hardware after falling to the hardware performance detecting device forautomatic detection. At the same time, the anti-fall performance detection in a high temperature state in use can be simulated, and the reliability of the detection result is high.

Owner:WUXI SOUTH OCEAN COLLEGE

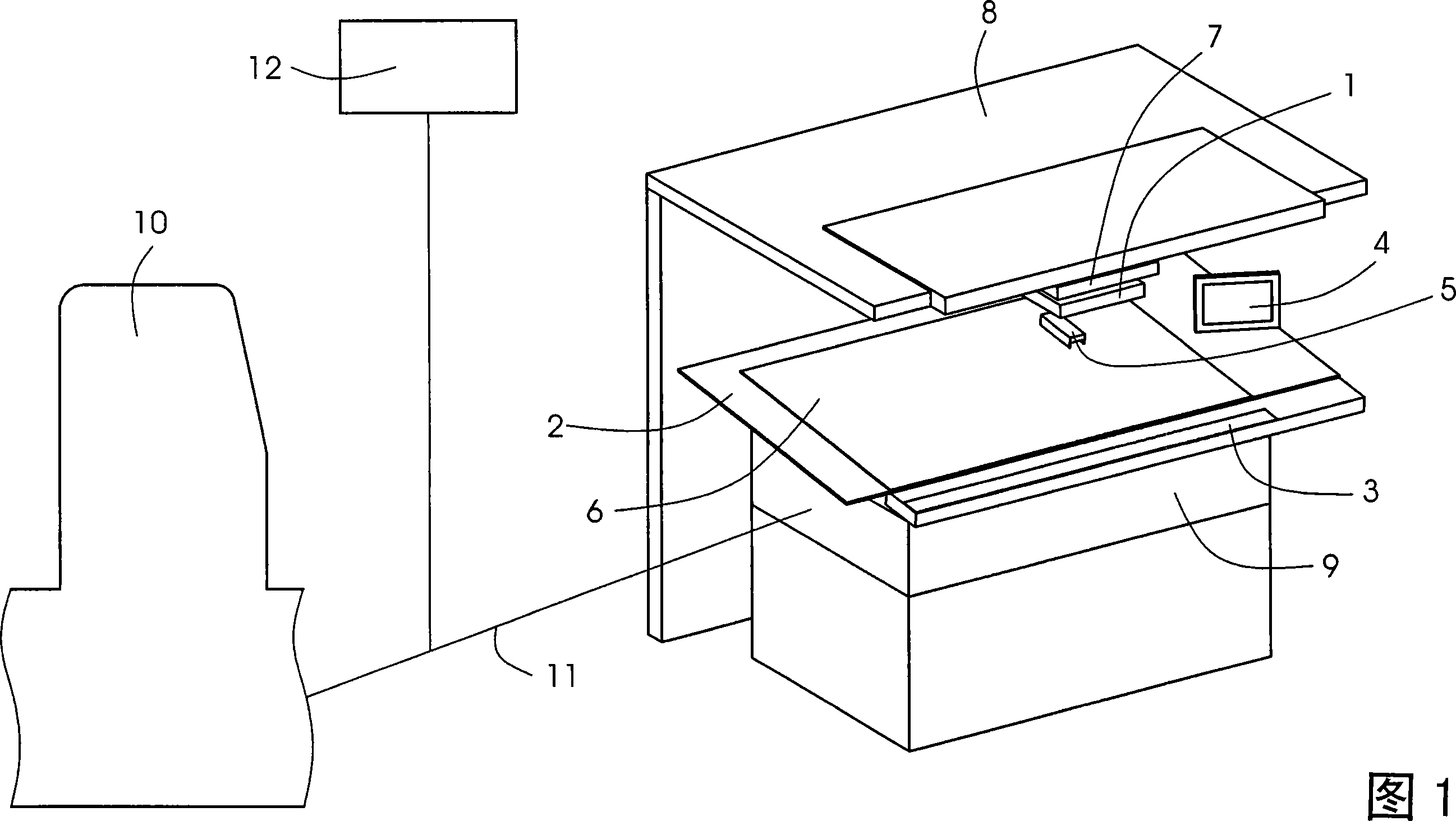

Operating device for printing machine

ActiveCN101077649AImplement automatic transferReduced risk of unsuitable operating elementsPrinting press partsRecording and playback systemsDigital image dataComputer engineering

The invention relates to a method of a control operation process or a measurement process which is corresponding to a printing image which is acted on a printing article (6); wherein, an image device (1) senses the image information of the printing image on the printing article (6); the data sensed by the image device (1) is compared with the digital image data of the printing image in a computer (9) and the operation process or the measurement process is triggered by the computer (6) according to the recognised printing image on the printing article. The method is characterized in that the printing article (6) is arranged on a placing platform (2) and the image device (1) recognises the object or person which covers the printing article (6), by which the determined operation process or the measurement process is carried out.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Automatic conveying, crushing and separating machine for concrete blocks of municipal road engineering

The invention relates to an automatic conveying, crushing and separating machine for concrete blocks of municipal road engineering. The automatic conveying, crushing and separating machine for the concrete blocks of the municipal road engineering comprises a support seat, a support column, a support bottom plate, a conveying device, a discharge device and a crushing device, wherein the support bottom plate is arranged at the top part of the support seat through the support column; the conveying device is arranged at the top part of the rear end of the support bottom plate; the discharge deviceis positioned at the front side of the conveying device, and is connected with the support bottom plate; the crushing device is arranged at the top part of the support bottom plate. The automatic conveying, crushing and separating machine can solve the difficult problems of larger labor intensity, failure to automatically convey the concrete blocks, complicated adjusting of concrete block crushing position, failure to automatically separate reinforcements of concrete block, failure to directly control direct recycling of crushed concrete blocks in concrete block crushing process, artificial recycling of reinforcements and the like in the existing reinforcement separation process of the concrete blocks.

Owner:WENZHOU JIEGAO SCI & TECH

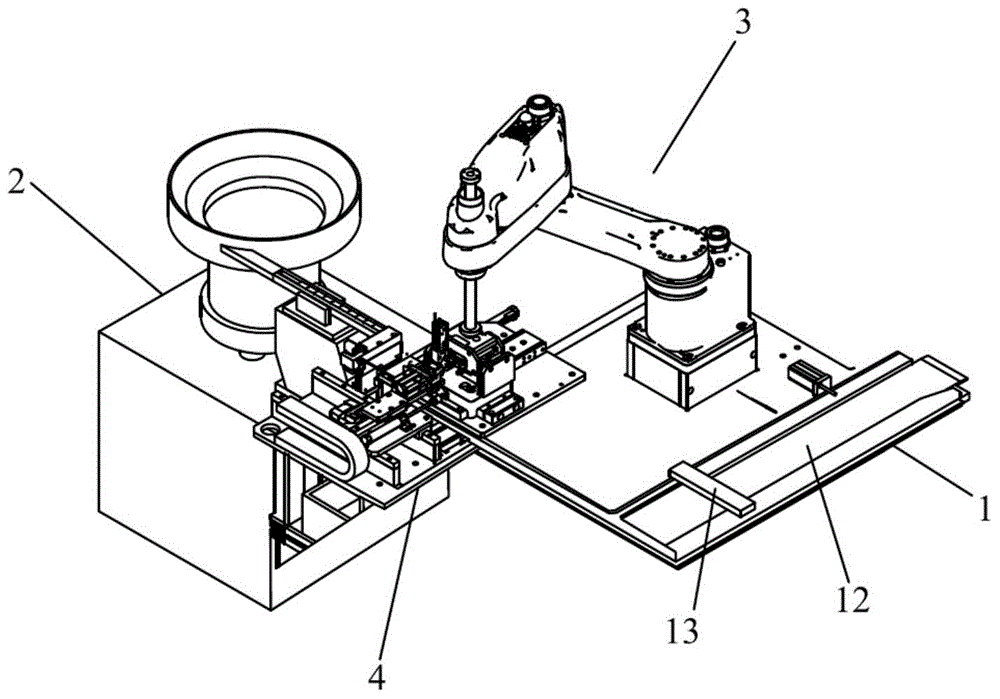

Automatic sealing device for electric meter programming door switch

ActiveCN104931744ARealize automatic dischargeImplement automatic transferManufacture of electrical instrumentsEngineeringSmart meter

The invention relates to an automatic sealing device for an electric meter programming door switch. Automatic discharging of an electric meter is realized via an electric meter discharging unit; tidy and ordered sealing and automatic discharging are realized via a sealing discharging unit; automatic transfer of the station of the electric meter sealing process is realized via an electric meter clamping unit; and automatic sealing of the electric meter programming door switch is realized via a sealing unit. According to the automatic sealing device, the automation of sealing operation of an intelligent electric meter programming door is effectively realized, the conventional manual sealing method is replaced, the labor intensity of work personnel and the production cost are greatly reduced, and the production efficiency and the production output of the product are effectively improved.

Owner:JIANGMEN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID

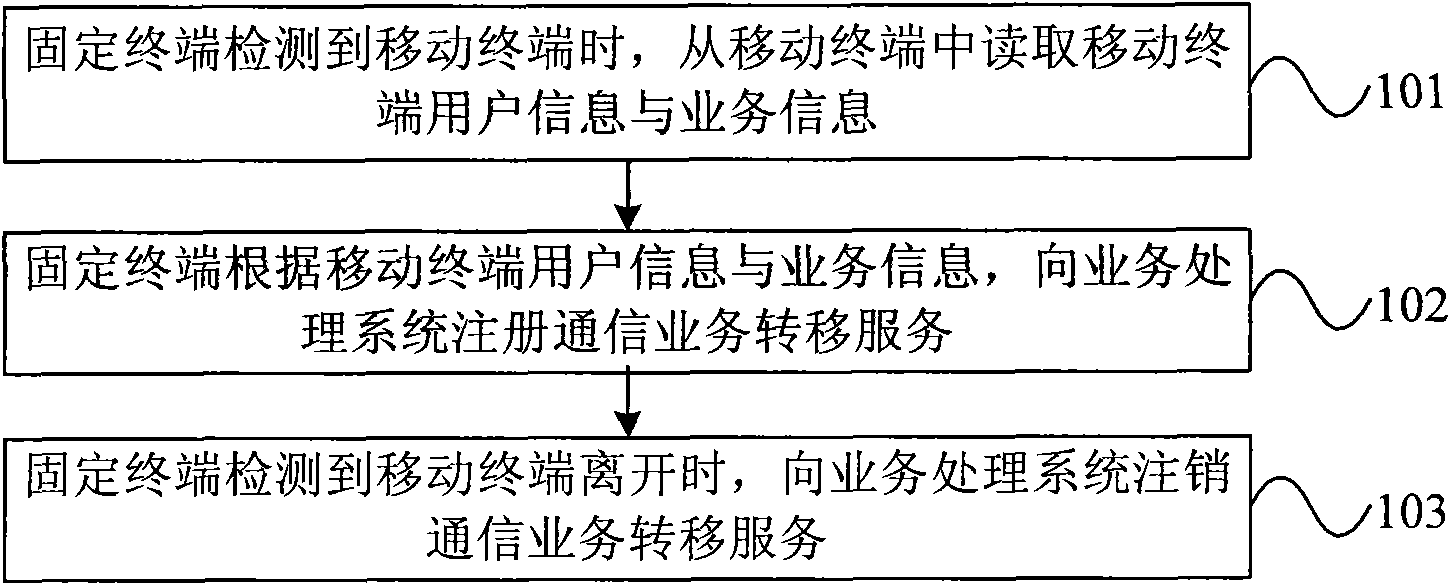

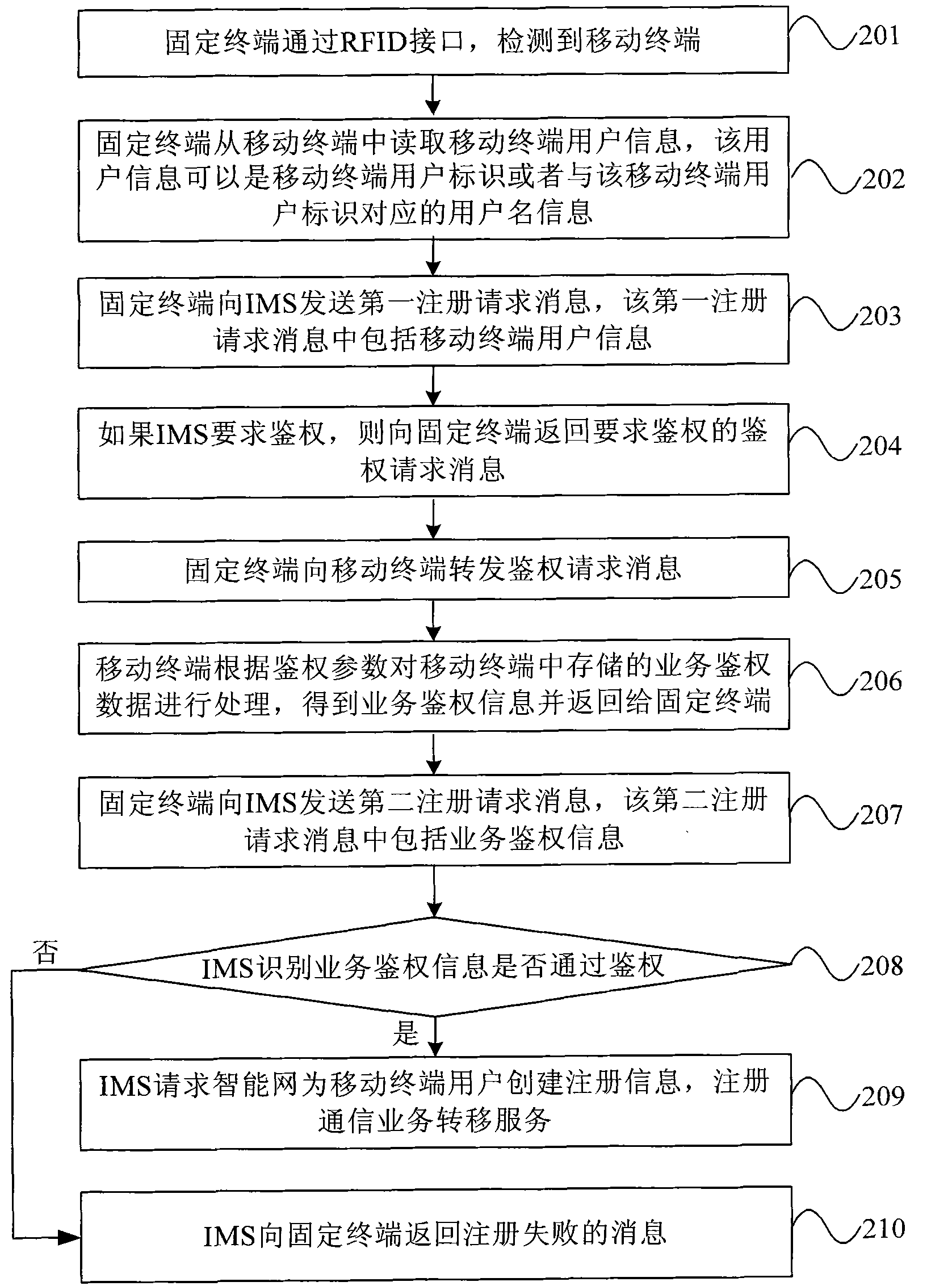

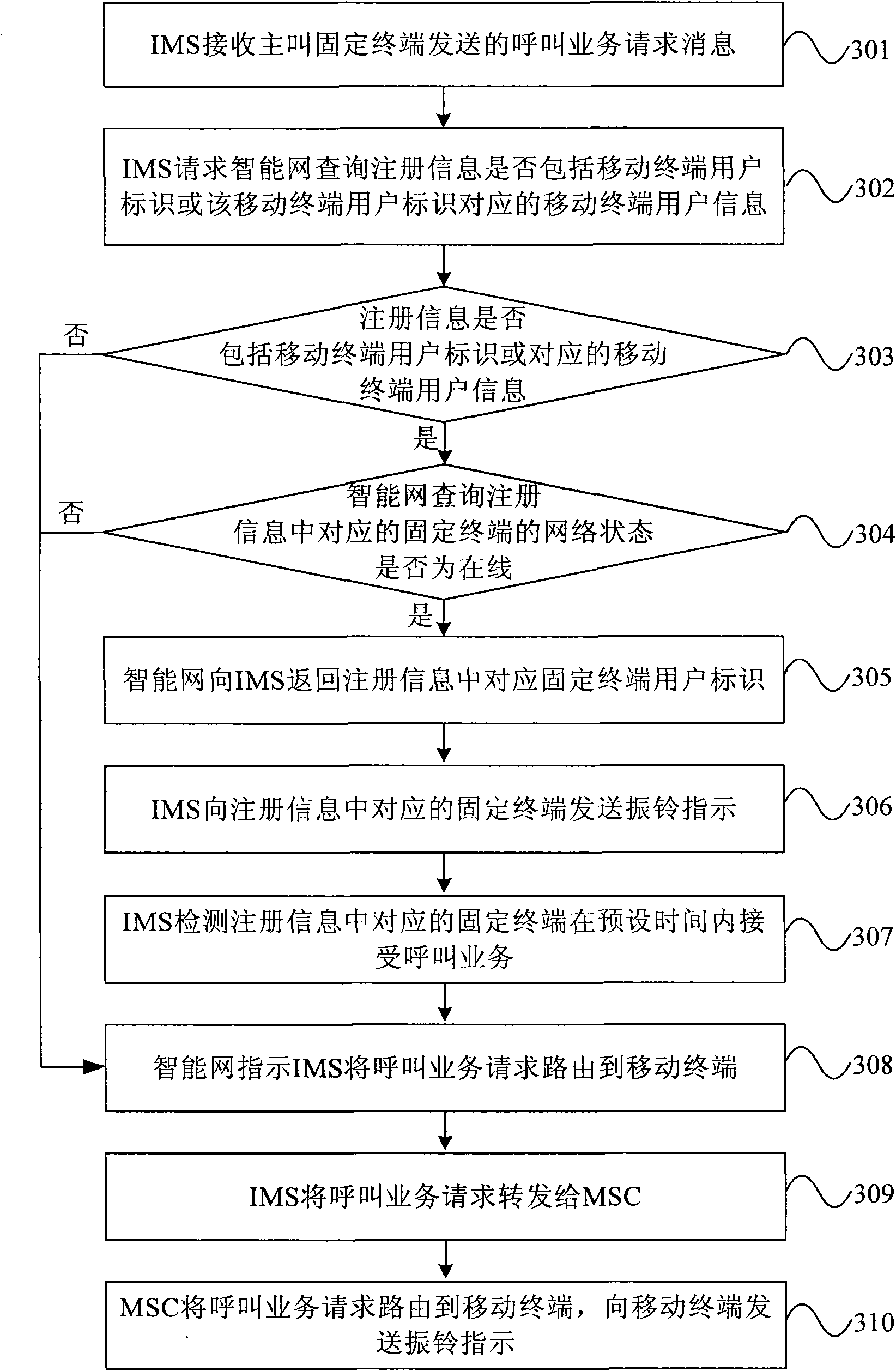

Method and system for service transfer handling as well as fixed terminal

InactiveCN102123365AImplement automatic transferCommmunication supplementary servicesSecurity arrangementService informationUser information

The invention discloses a method and system for service transfer handling as well as a fixed terminal. The method comprises: when detecting a mobile terminal, the fixed terminal reads the user information and service information of the mobile terminal from the mobile terminal, wherein the service information contains communication service types accessible to mobile terminal users; the fixed terminal registers communication service transfer service in a service handling system according to the user information and service information of the mobile terminal, thus communication service on the mobile terminal can be handled through the fixed terminal. By utilizing the embodiment of the invention, the automatic transfer between the mobile terminal and the fixed terminal can be achieved, thereby solving the problems such as complex operation and loss of call service caused by manual selection and setting of call forwarding service.

Owner:HUAWEI DEVICE CO LTD

Pneumatic quick swing type workpiece transfer device

The invention provides a pneumatic quick swing type workpiece transfer device comprising a cylinder and a support seat. The cylinder is fixed on the support seat. A piston rod of the cylinder is fixedly connected to a horizontal rack which is fixed on the support seat through two guide bearings. The middle tooth face of the rack is engaged with a gear, the rotary shaft of the gear is hinged to the support seat, and a jaw is fixed on the gear. Since the cylinder is adopted as a power device, stretching of the piston rod of the cylinder drives the rack to perform reciprocating movement on the support seat; since the gear is engaged with the rack, and the rotary shaft of the gear is hinged to the support seat, by means of driving of the reciprocating movement of the rack, the jaw fixed on the gear swings around the gear freely between a workpiece feeding position and a workpiece discharging position. The stretch range of the cylinder piston rod can be adjusted freely, and accordingly the swing range of the jaw can be adjusted by adjusting the cylinder to meet the using requirements.

Owner:CHONGQING FENGGUO QIYANG TECH DEV

Full-automatic label feeding machine

The invention relates to a full-automatic label feeding machine. The full-automatic label feeding machine is used for feeding labels into a packing box and comprises a rack, a sucker mechanism, a paper supply mechanism and a twisting distributing mechanism. A feeding opening is formed in the rack, and the packing box is positioned below the feeding opening; the sucker mechanism comprises a sliding plate, a translation cylinder assembly, a guide track assembly and a sucker assembly, the sliding plate is a bent structure, and the sliding plate is fixedly connected with a cylinder output end of the translation cylinder assembly, the lower end surface of the guide track assembly and a side surface of the sucker assembly respectively; the paper supply mechanism is mounted on the inner side wall of the rack, is positioned below the sucker mechanism, and comprises a linear sliding table module, a first paper loading plate and a first paper stopping plate; and the twisting distributing mechanism is positioned on the feeding opening and comprises an upper fixing block, a guide shaft, a twisting distributing base, a paper loading assembly and a paging device. By the full-automatic label feeding machine, labels in various specifications can be simultaneously fed into the packing box.

Owner:SICHUAN SUNRETRO CONVEYRE

Automatic glass punching machine

ActiveCN107030402AMeet the needs of the hole positionImplement automatic transferLaser beam welding apparatusPunchingTransmission belt

The invention provides an automatic glass punching machine, and belongs to the technical field of glass machining machines. The automatic glass punching machine solves the problems that an existing automatic glass punching machine still needs to be manually operated, consequently, the work efficiency is too low, and full automation cannot be achieved. The automatic glass punching machine comprises a rack and a conveying roller bed arranged on the rack. The rack is internally further provided with a lifting platform and a positioning platform. The lifting platform is internally provided with a plurality of first carrier rollers driving workpieces to move in the X-axis direction and a plurality of first conveying belts capable of driving the workpieces to move in the Y-axis direction. The first conveying belts can convey the workpieces located on the lifting platform to the positioning platform, the positioning platform is provided with a plurality of first positioning blocks distributed in the X-axis direction, and a plurality of second positioning blocks distributed in the Y-axis direction. The positioning platform is provided with a plurality of second carrier rollers and a plurality of second transmission belts. The automatic glass punching machine can achieve automatic workpiece conveying and positioning.

Owner:ZHEJIANG JIAFU GLASS CO LTD

Paper bag packaging machine for packaging medical gauze

PendingCN107902148AThe process of entering the paper bag is smoothDoes not damage the structureWrapper twisting/gatheringPackaging machinesPulp and paper industryFront and back ends

The invention belongs to the field of packaging, and discloses a paper bag packaging machine for packaging medical gauze. The packaging machine comprises a working table, a transferring module, an unfolding module and a packaging module, wherein the transferring module is arranged on the working table. The transferring module is used for realizing the longitudinal movement and the transverse movement of a first sucker, so that the transferring of a paper bag is completed. The unfolding module comprises a forming cavity, an unfolding sliding block, a shaping plate and a second sucking disc, theforming cavity is used for containing the paper bag to be machined, the second sucking disc is arranged below the forming cavity, and the paper bag is separated from the paper bag by the combined action of the first sucking disc and the second sucking disc. The unfolding sliding block and the shaping plate are oppositely arranged at the front end and the rear end of the forming cavity, a slidingrail penetrating through the forming cavity is arranged in the forming cavity, the shaping plate and the unfolding sliding block move on the sliding rail to achieve the unfolding of the paper bag. Thepackaging module is used for packaging the packaged paper bag. According to the packaging machine, the process of packaging the gauze by a double-layer paper bag is realized, and the use is convenient. The packaging machine is compact in structure, convenient to manufacture and use and wide in application range.

Owner:HUAZHONG UNIV OF SCI & TECH

Combined device for drying sludge and sludge drying method thereof

PendingCN108083600AImprove drying efficiencyReduce energy consumptionSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention provides a combined device for drying sludge. The device consists of a plate-and-frame filter press at the upper part, a belt conveying adjustment apparatus, a crusher, and a horizontalsingle-cavity drying machine located at the lower part, wherein the conveying adjustment apparatus and the crusher are located between the filter press and the drying machine, and the position of theconveying adjustment apparatus is higher than the crusher and includes a conveyor for receiving and conveying sludge blocks, and the conveying speed of sludge blocks to the crusher can be controlled by adjusting the operation of the conveyor. The invention also provides a method for drying sludge with the combined device.

Owner:广州正晟科技有限公司

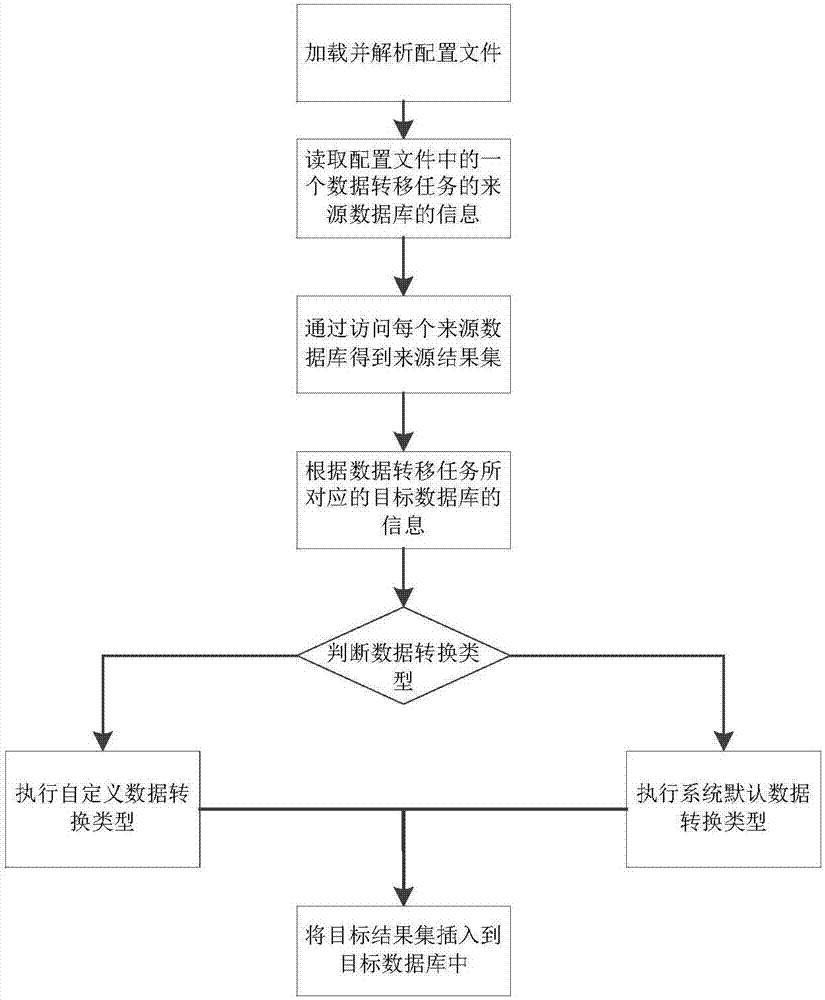

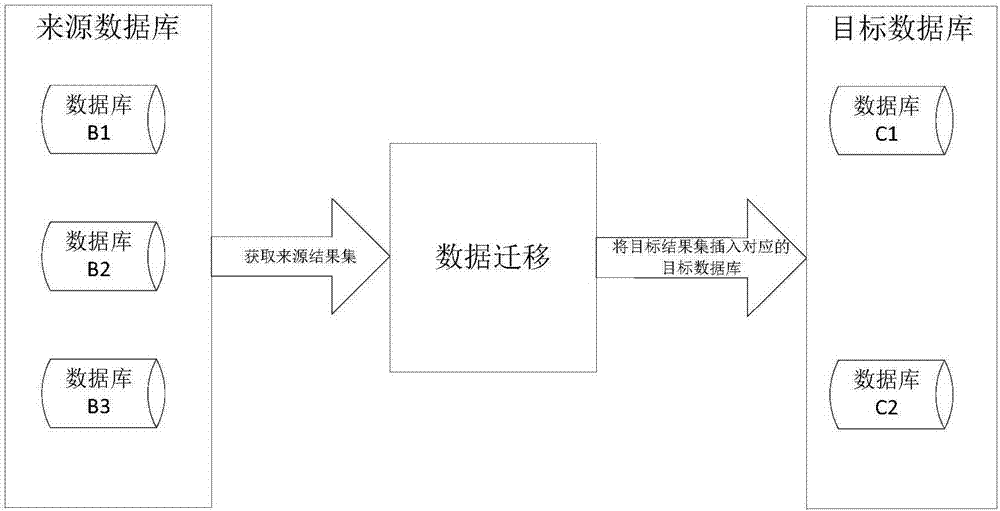

Automatic data migration method and apparatus supporting multiple data sources

InactiveCN107423334AImplement automatic transferSpecial data processing applicationsData sourceResult set

The invention discloses an automatic data migration method supporting multiple data sources. The method comprises the following steps of loading and analyzing a configuration file; obtaining information of each source database according to the configuration file and accessing each source database to obtain a source result set; obtaining corresponding target database and data conversion type according to the configuration file, and converting the source result set into a target result set according to the data conversion type; and inserting the target result set into the target database. The invention furthermore provides an automatic data migration apparatus supporting the data sources. According to the method and the apparatus, the data from different data sources or servers is automatically transferred to the target database, so that the problem that a mainstream framework does not support data transfer of the data sources in the prior art is solved.

Owner:云宏信息科技股份有限公司 +1

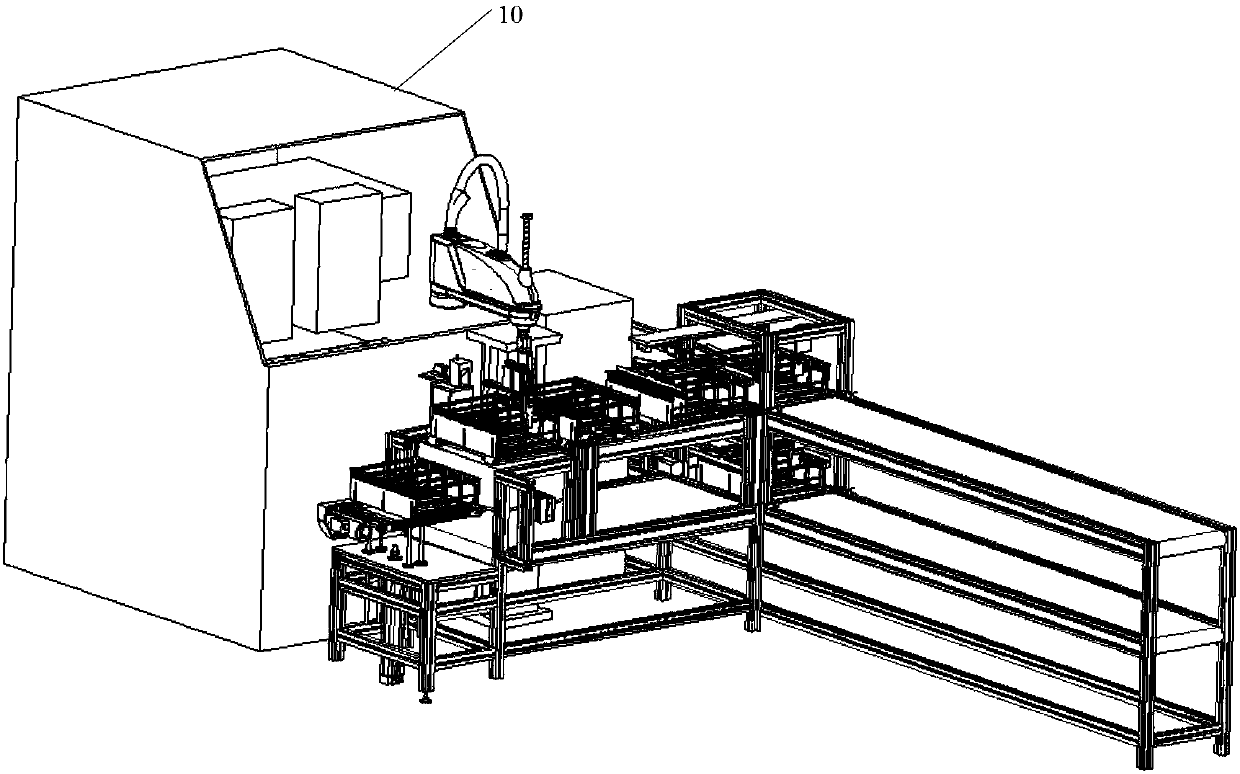

Efficient CNC glass feeding and discharging machine

PendingCN107628442ASave space and manpowerImprove efficiencyCharge manipulationConveyor partsManipulatorLeather belt

The invention discloses an efficient CNC glass feeding and discharging machine. The efficient CNC glass feeding and discharging machine comprises a first conveying device, a second conveying device, afirst material frame clamping device, a second material frame clamping device, a positioning device, a mechanical arm device and a lifting transferring device. The first material frame clamping device clamps a material frame to the second conveying device from the first conveying device. The positioning device is used for positioning the material frame. The mechanical arm device is used for grabbing materials in the positioned material frame to a CNC machine tool for machining, and the machined materials are placed back into the material frame. The lifting transferring device is used for moving the material frame to a lower layer belt line of the second conveying device from an upper layer belt line of the second conveying device. The second material frame clamping device is used for clamping the material frame to the first conveying device from the second conveying device. During CNC machine tool machining, automatic feeding and discharging can be achieved, the labor cost is effectively reduced, and losses caused by human factors are reduced.

Owner:深圳市德望科技有限公司

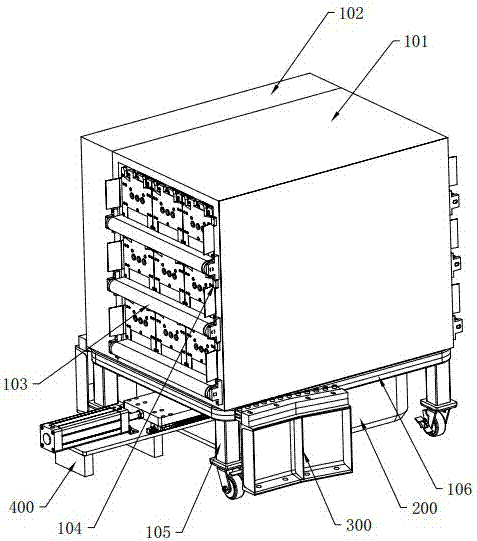

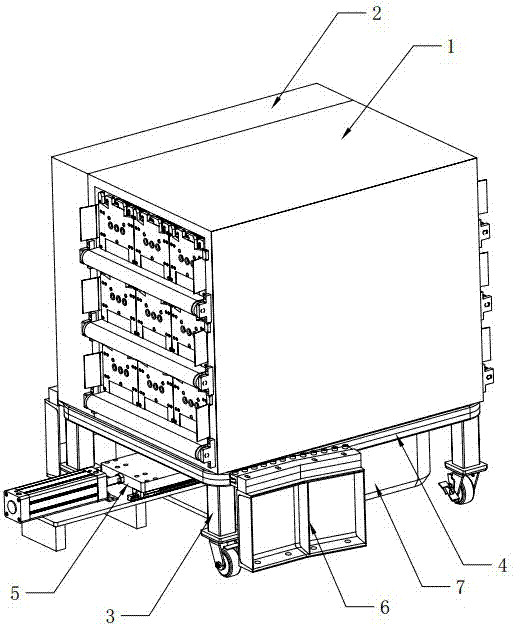

Automatic conveying, taking and supplying system for battery piece baskets

ActiveCN107954181AAvoid damageImplement automatic transferCharge manipulationConveyor partsProduction lineElectrical battery

The invention discloses an automatic conveying, taking and supplying system for battery piece baskets. The automatic conveying, taking and supplying system for battery piece baskets comprises a conveying mechanism, a taking mechanism and a supplying mechanism, wherein the conveying mechanism comprises a bin, an AGV trolley and a positioning mechanism; the AGV trolley is used for carrying the bin;the positioning mechanism positions the bin unloaded from the AGV trolley; the taking mechanism is connected with the bin and comprises an outer side main support, hoisting electric cylinders, a conveying and overturning mechanism base, a conveying mechanism, an overturning mechanism and a horizontal carrying mechanism; the conveying and overturning mechanism base is mounted on the hoisting electric cylinders; the conveying mechanism and the overturning mechanism are mounted on the conveying and overturning mechanism base side by side; the horizontal carrying mechanism is used for transferringthe baskets between the conveying mechanism and the overturning mechanism; and the supplying mechanism comprises longitudinal linear modules mounted on the upper part of the outer side main support,a transverse linear module, a vertical electric cylinder and a basket clamping jaw mounted at the tail end of the vertical electric cylinder. Conveying, taking and supplying of the battery piece baskets can be realized fully automatically, the battery piece baskets are supplied for equipment of a production line, the working efficiency is improved, and the production cost is saved.

Owner:湖南艾博特机器人技术有限公司

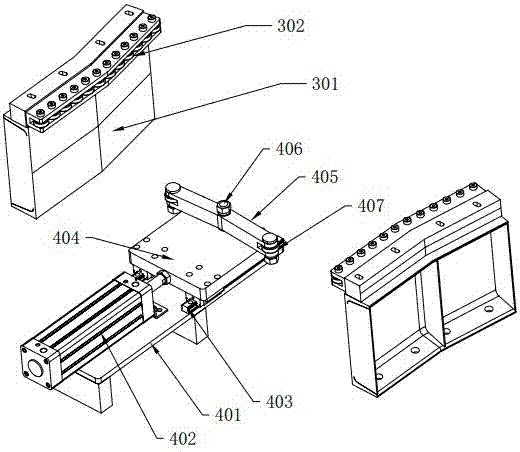

Automatic conveying mechanism for battery piece baskets

ActiveCN107963409AImprove work efficiencyReduce manufacturing costFinal product manufactureMechanical conveyorsEngineeringMouth shape

The invention discloses an automatic conveying mechanism for battery piece baskets. The automatic conveying mechanism comprises a material bin, an AGV trolley and a positioning mechanism. The materialbin comprises a material bin body and a universal wheel type support frame for supporting the material bin body. At least one layer of storage space is arranged on the material bin body. An electricroller conveying belt is arranged at the bottom of each layer of the storage space. The AGV trolley is used for carrying the material bin. The positioning mechanism is used for positioning the material bin unloaded from the AGV trolley. The positioning mechanism comprises a guide mechanism and a traction mechanism. The guide mechanism comprises two guide-in plates arranged in a horn mouth shape. The narrow ends of the two guide-in plates are parallel. A row of rolling wheels I is arranged on each of the inner sides of the two guide-in plates. The traction mechanism is used for pulling the material bin to the portion between the two guide-in plates arranged in the horn mouth shape. By the adoption of the automatic conveying mechanism, automatic conveying of the battery piece baskets is achieved, no manual operation is needed in the whole process, the working efficiency is provided, the production cost is saved, and the damage of manual operation to battery pieces is avoided.

Owner:湖南艾博特机器人技术有限公司

Multifunctional paperboard loading machine

The invention relates to a multifunctional paperboard loading machine. The multifunctional paperboard loading machine comprises a primary conveying unit arranged on the ground, a turnover lifting unit arranged on the tail of the primary conveying unit, and a secondary conveying unit arranged on the side, deviating from the primary conveying unit, of the turnover lifting device. A pair of guide plate turnover units for plate turnover are mounted at the connecting position of the turnover lifting unit and the secondary conveying unit, a pushing turnover unit for assisting plate turnover is arranged in the turnover lifting unit, and a collecting conveying unit for setting a plate right and conveying the plate again is mounted on the tail of the secondary conveying unit. The loading machine has the advantages that automatic operation is achieved instead of manpower, labor intensity is reduced, and production efficiency is improved.

Owner:上海飓尔包装机械有限公司

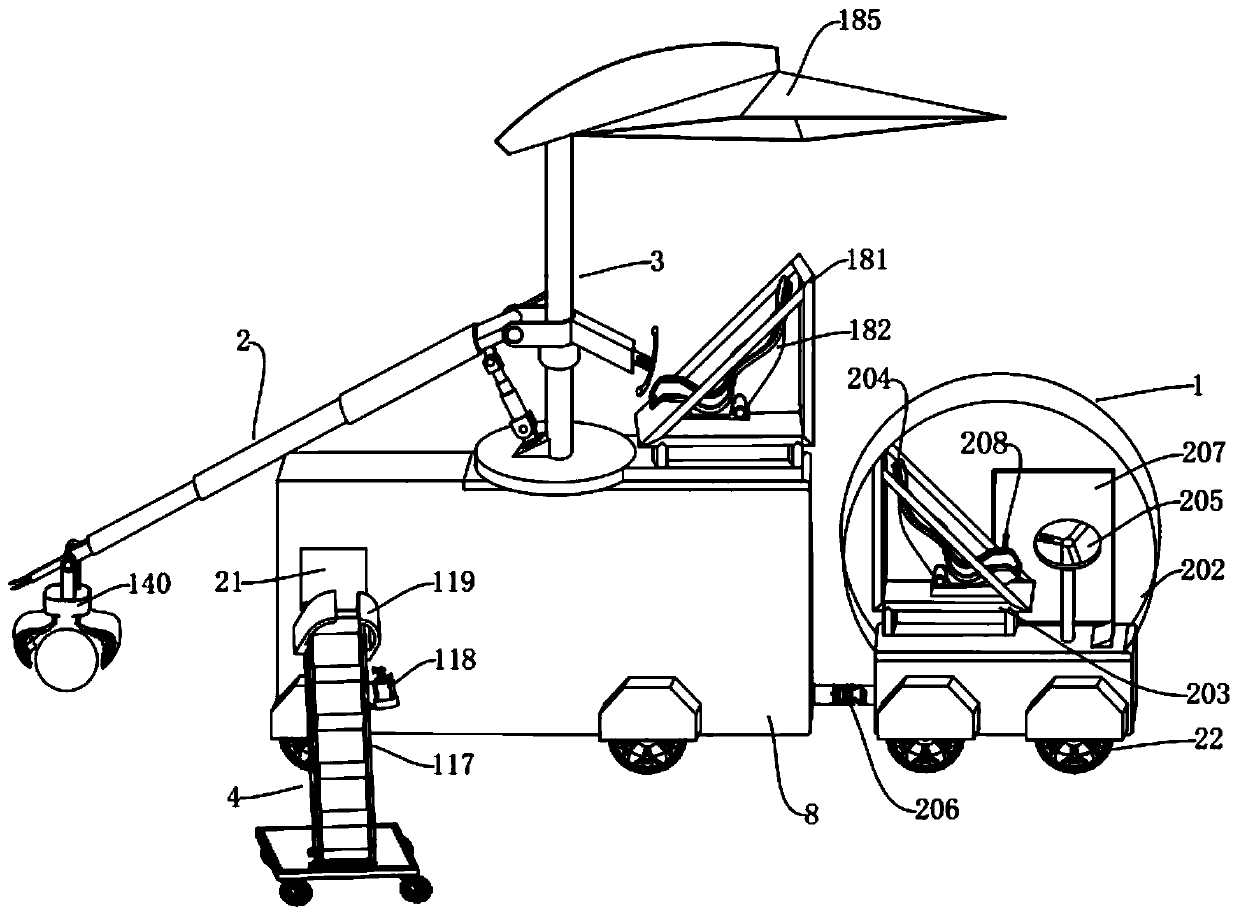

Preset full-retention non-Newtonian fluid wrapping type wing-shaped anti-rolling watermelon vehicle

InactiveCN110089268AImprove practicalityEasy to operateFruits/vegetable preservation by coatingPicking devicesEngineeringNewtonian fluid

The invention discloses a preset full-retention non-Newtonian fluid wrapping type wing-shaped anti-rolling watermelon vehicle which comprises a protective movement mechanism, a flexible pit preset full-retention harvesting claw, a positioning picking mechanism, a non-Newtonian fluid wrapping conveying mechanism, a wing-shaped foaming material flexible wrapping piece forming wrapping mechanism, a compression conveying mechanism, an oblique watermelon dislocating and loading mechanism and a wrapping, conveying and loading mechanism. The invention belongs to the technical field of watermelon picking machinery and provides a harvesting claw provided with a flexible pit. The shape of any part in the pit can be optionally changed, and a food-grade non-Newtonian fluid conducts wrapping type zero-scratch protection on harvested watermelons in real time to achieve an omnibearing safety protection and fresh-keeping effect. In the scheme, a watermelon wing-shaped anti-rolling concept is creatively proposed during the harvesting process, and the technical problem unsolved for a long time is solved that watermelons are easy to roll and are easily crushed.

Owner:江苏乐虎安全技术发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com