Patents

Literature

649results about How to "Realize automatic discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

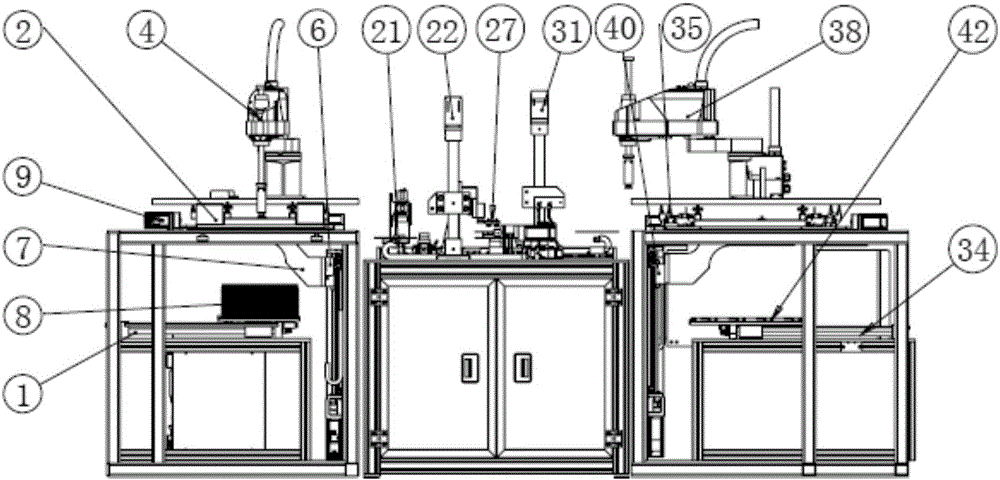

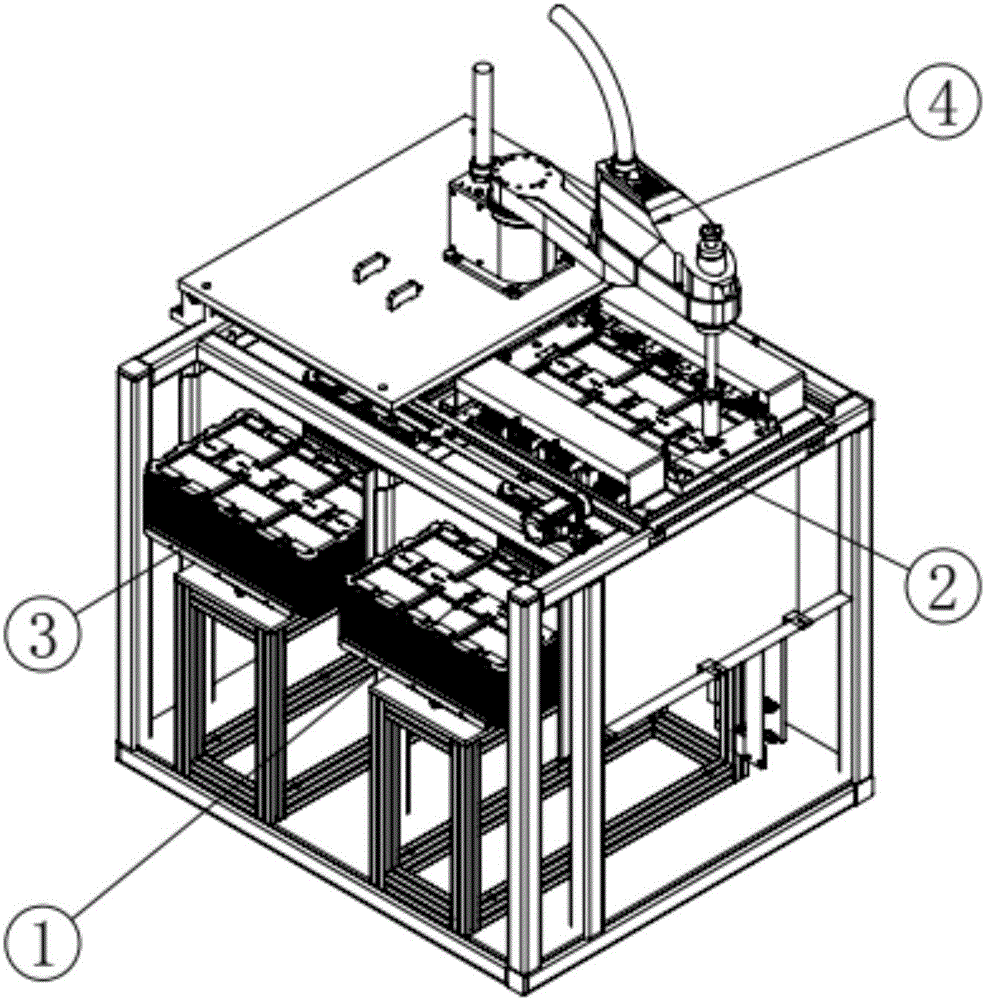

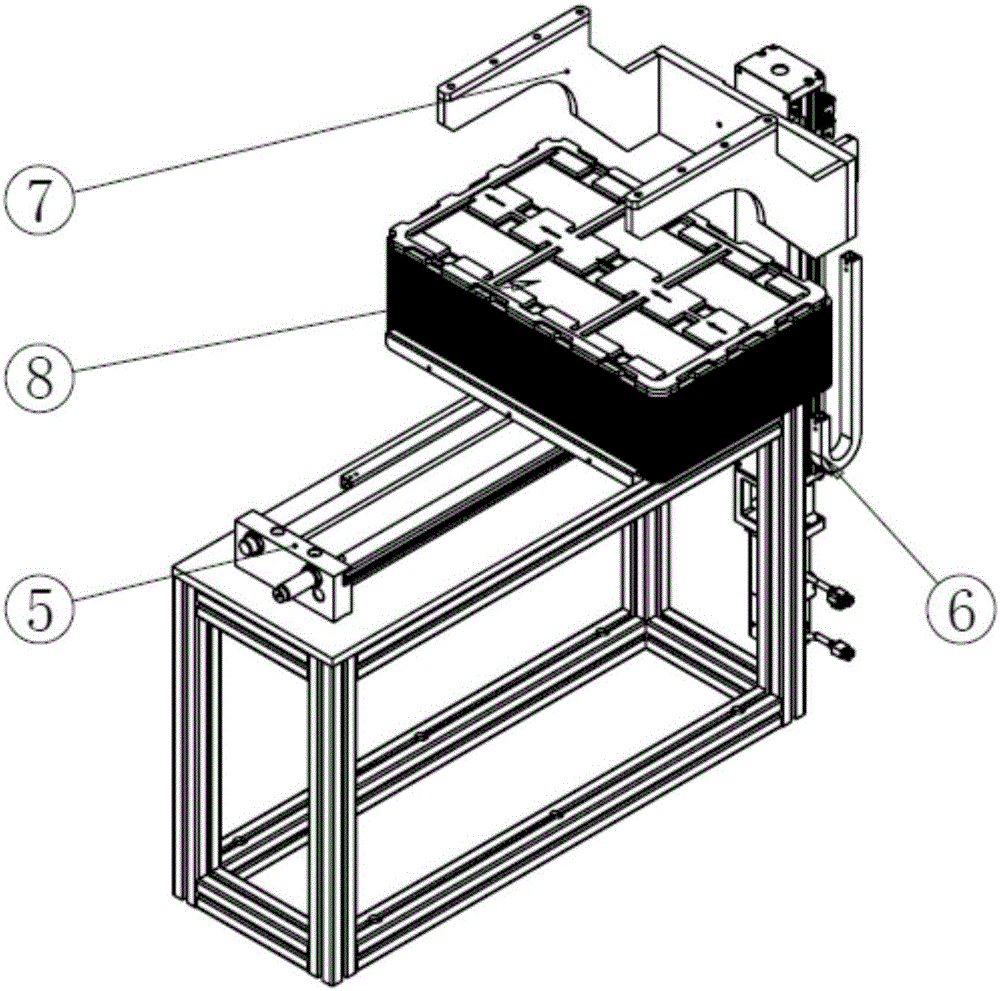

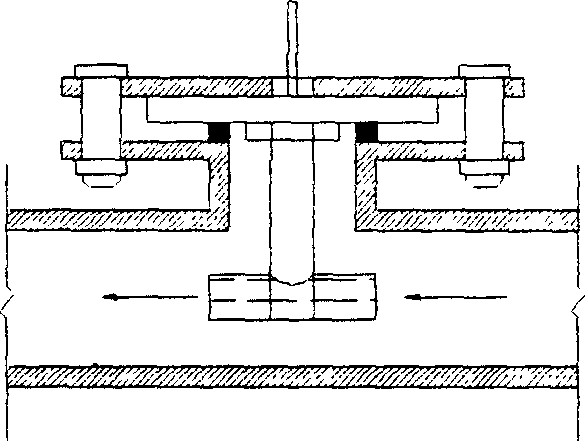

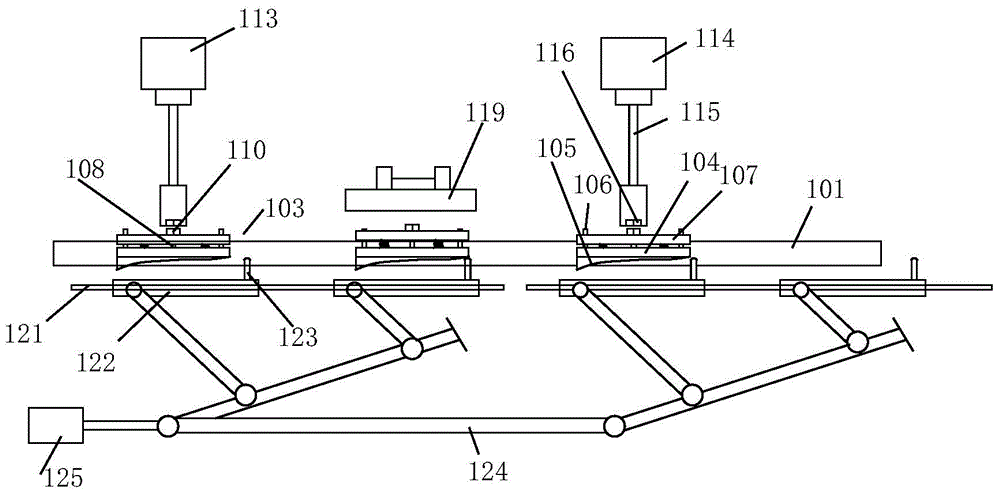

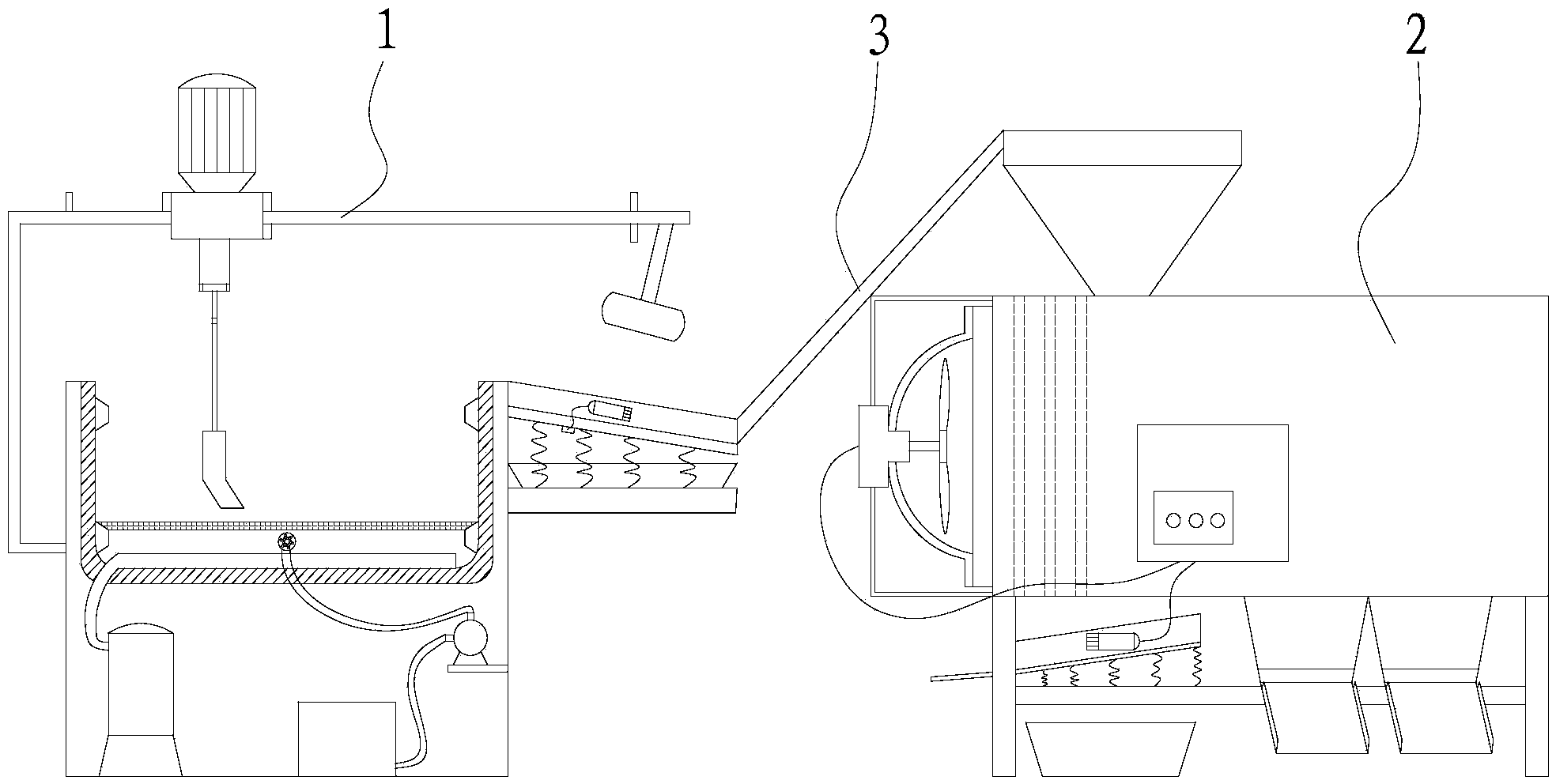

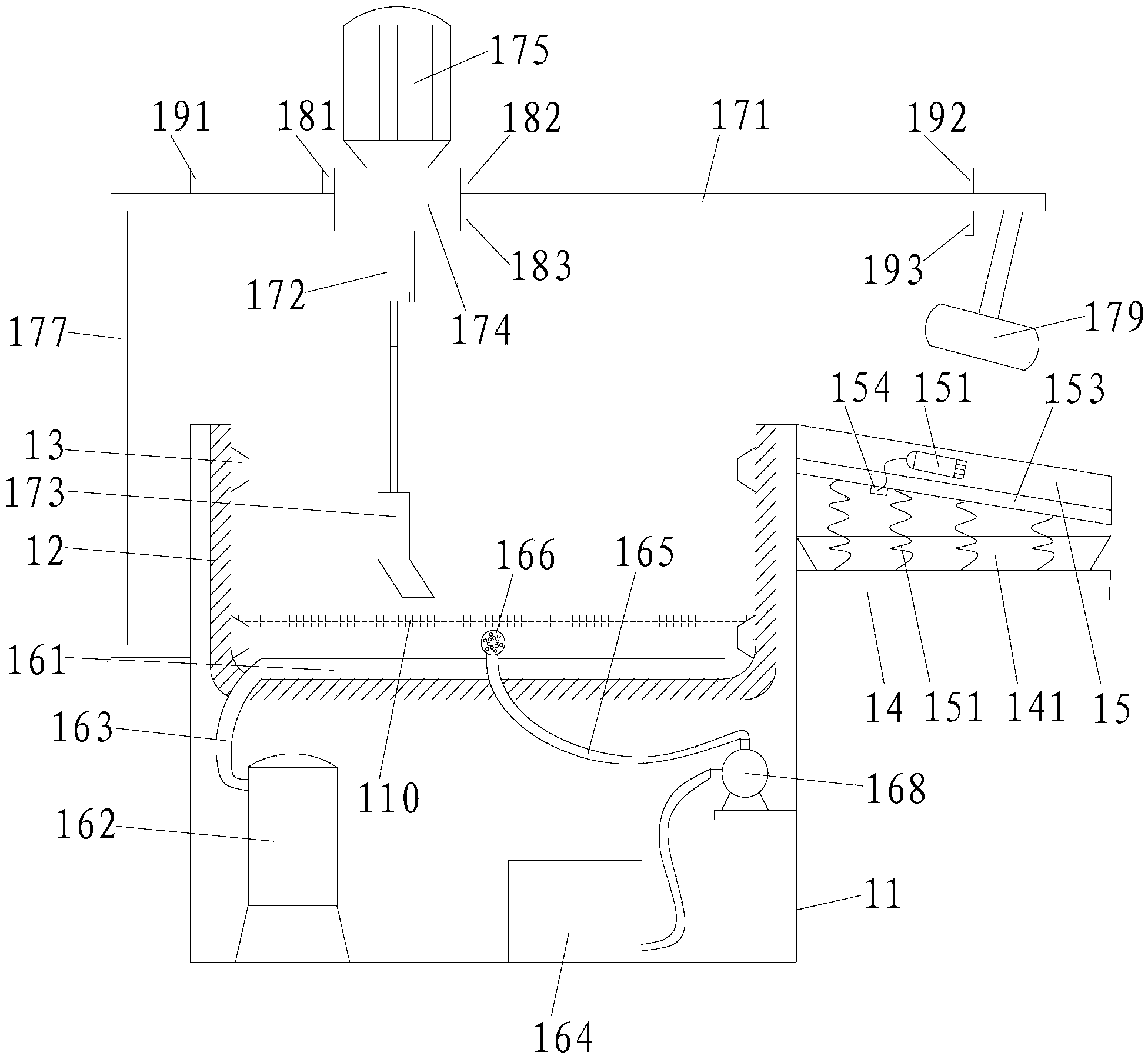

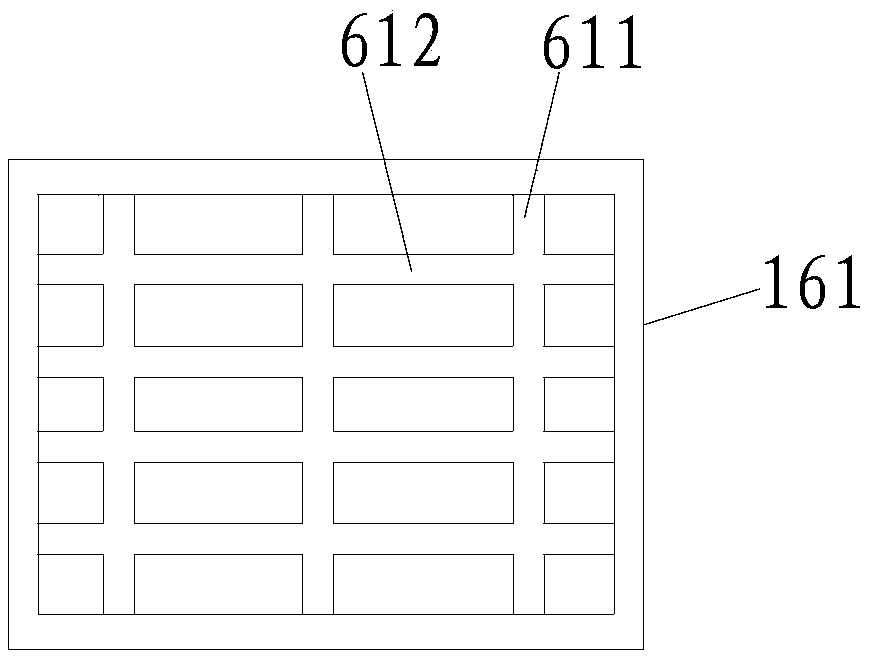

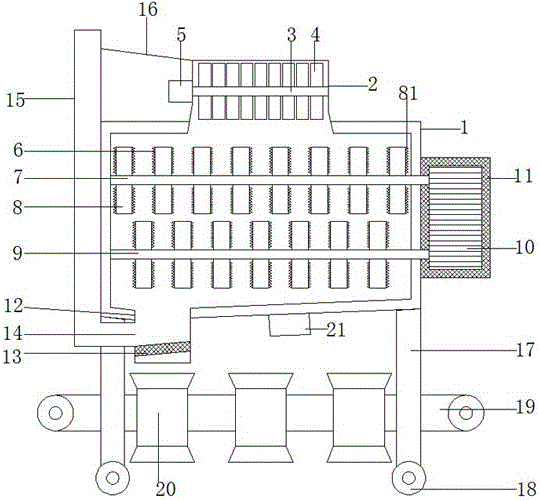

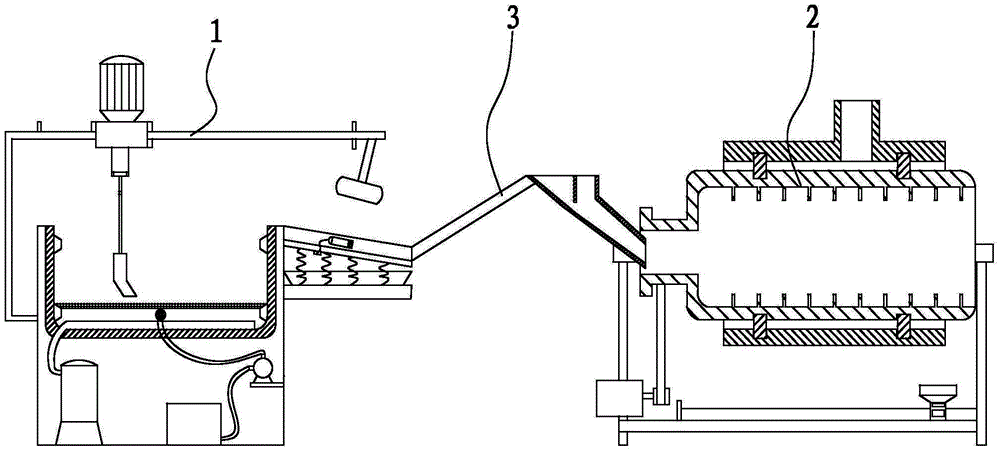

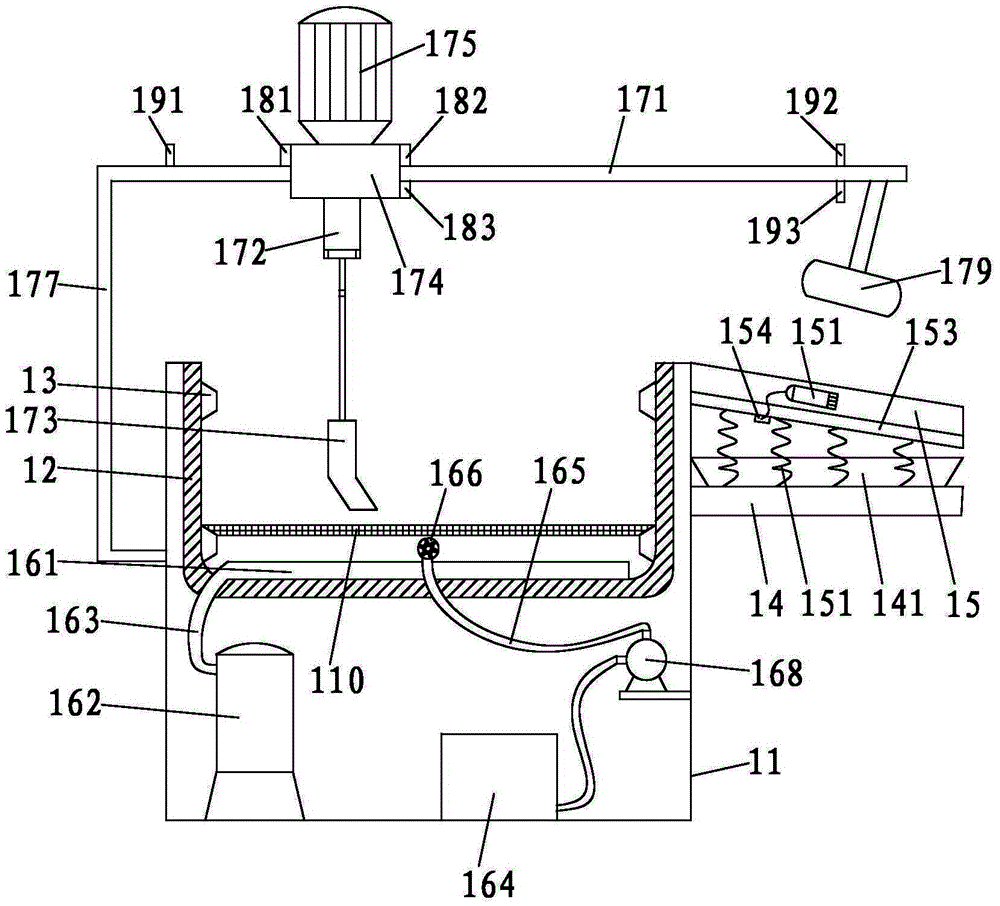

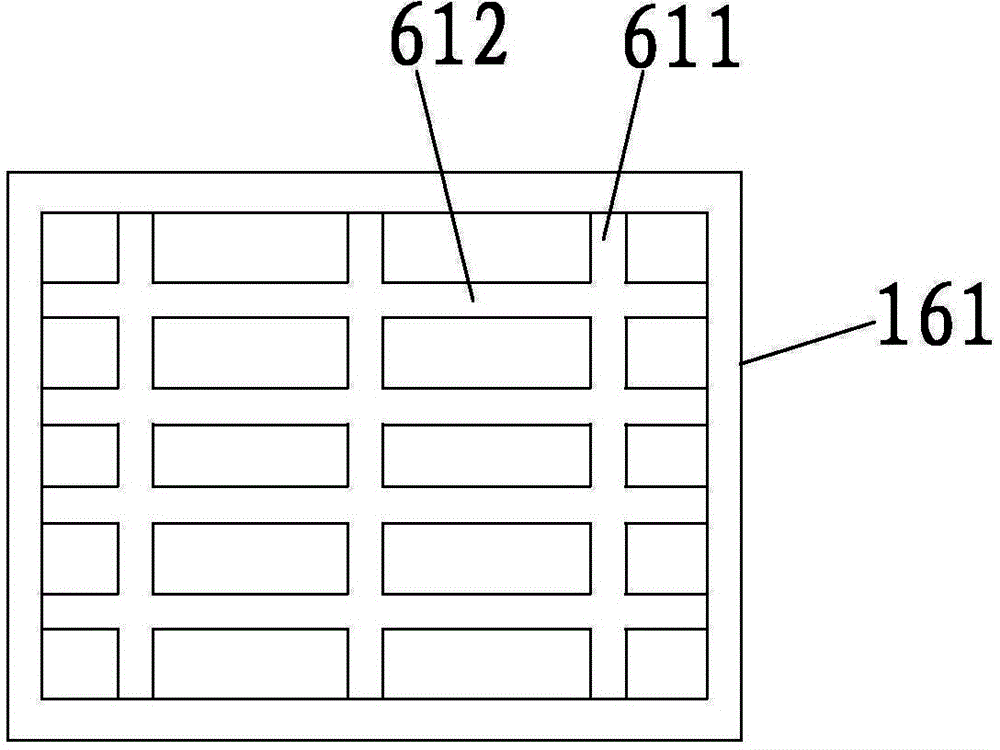

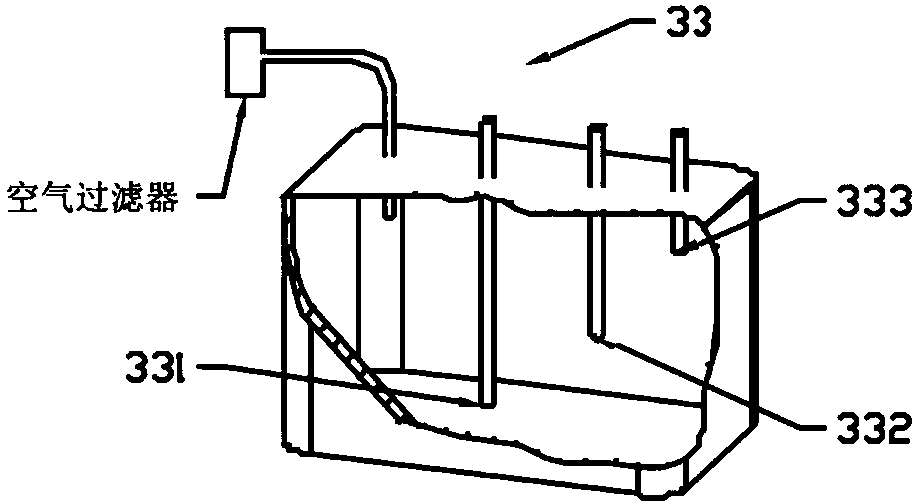

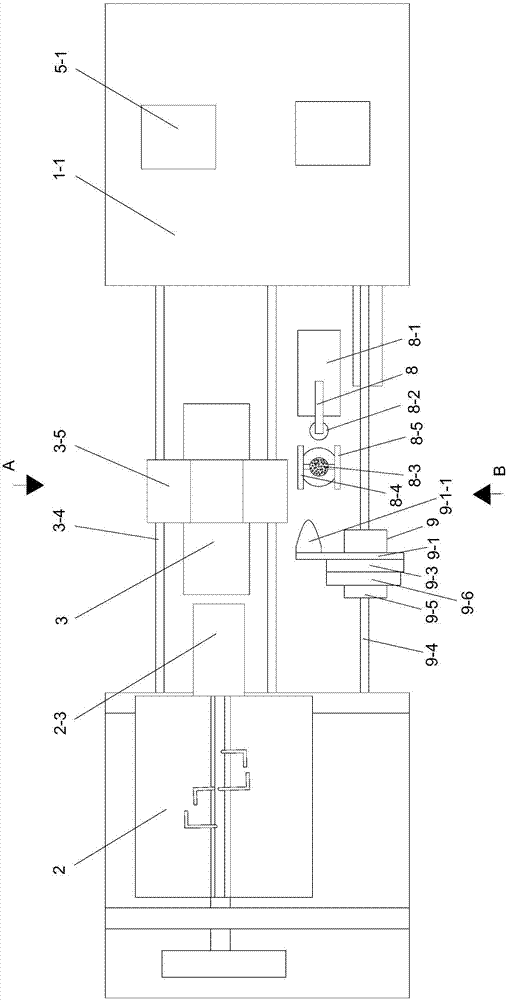

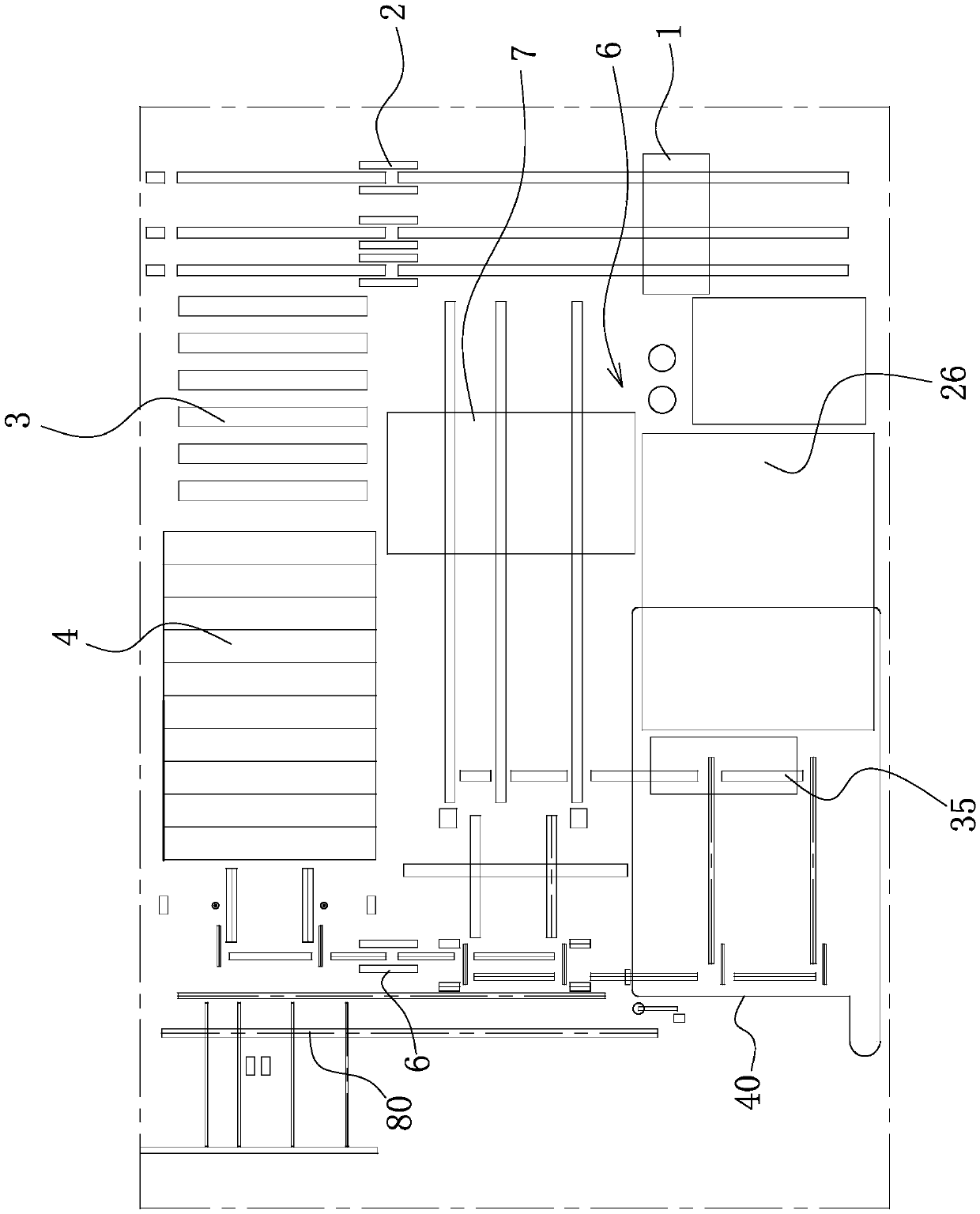

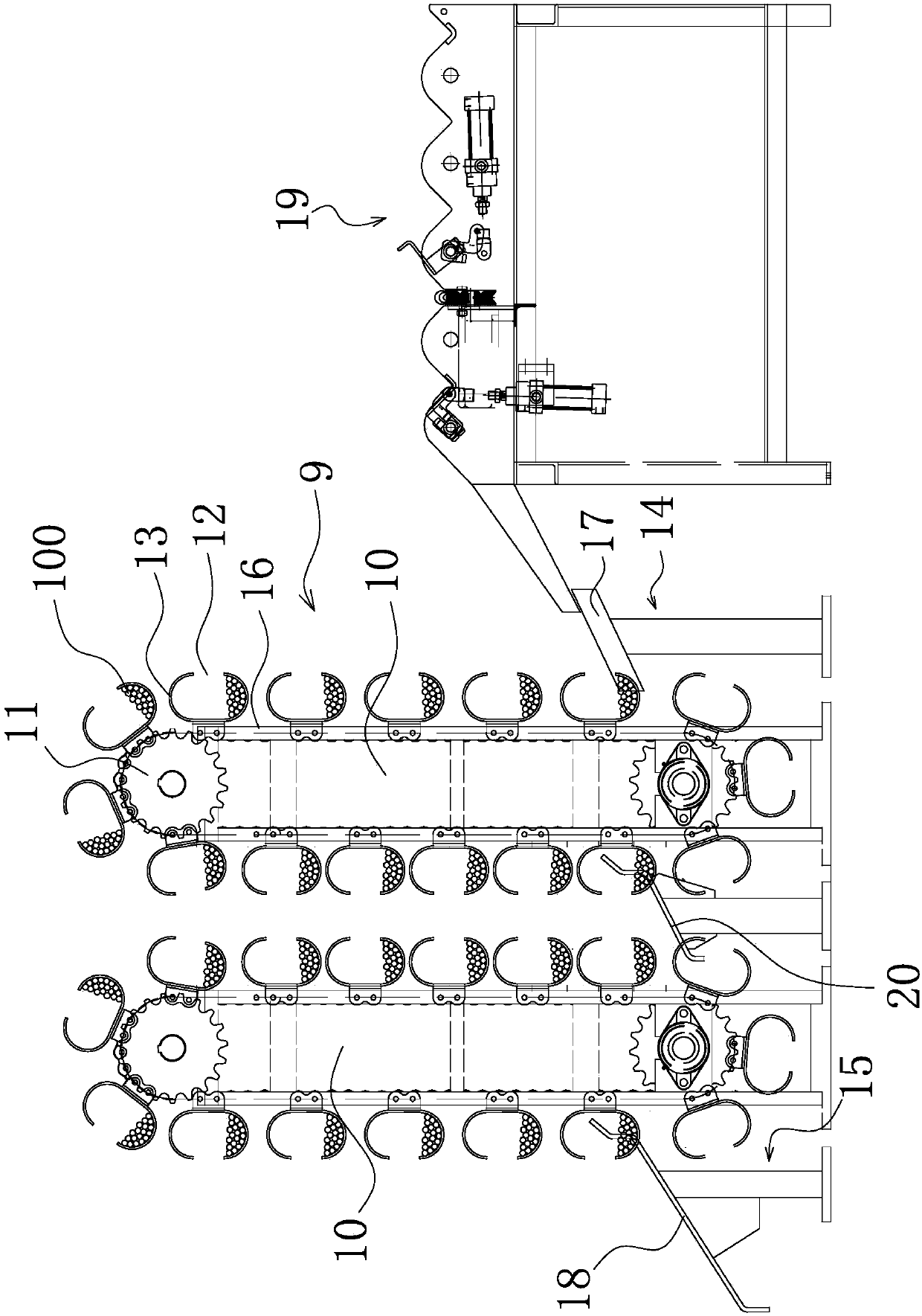

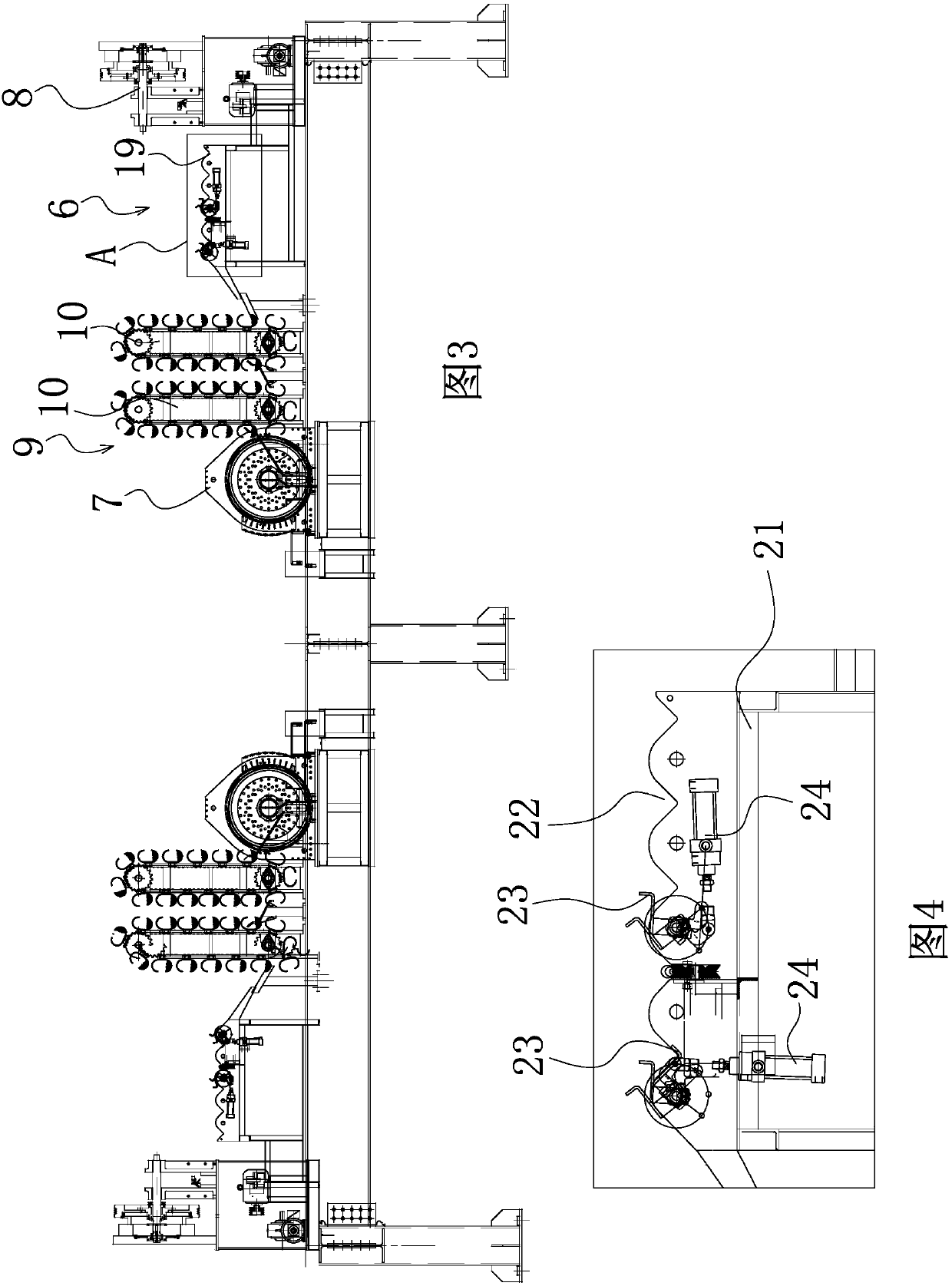

Full-automatic visual inspection system for screen defects

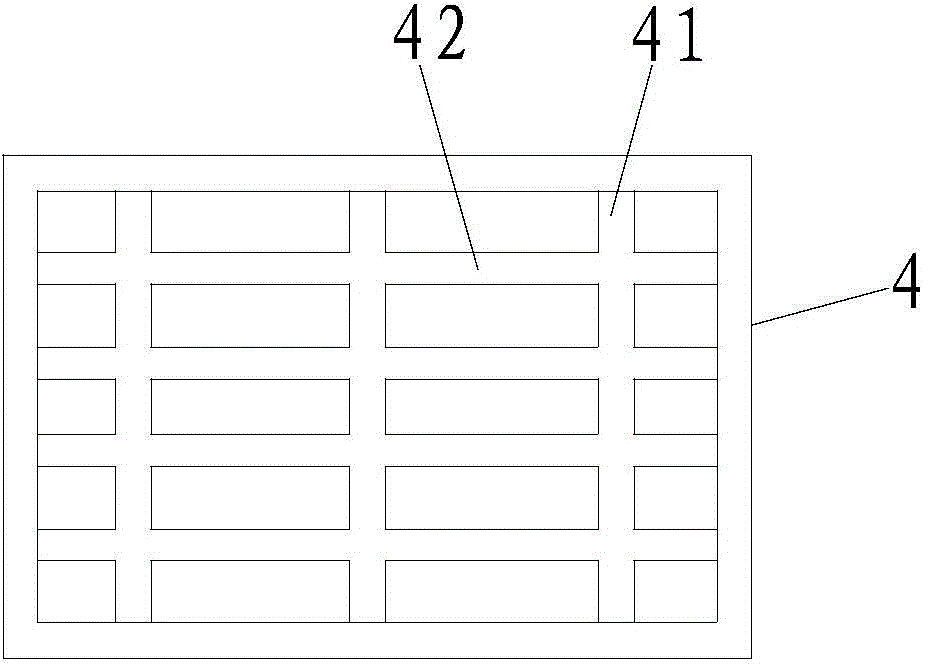

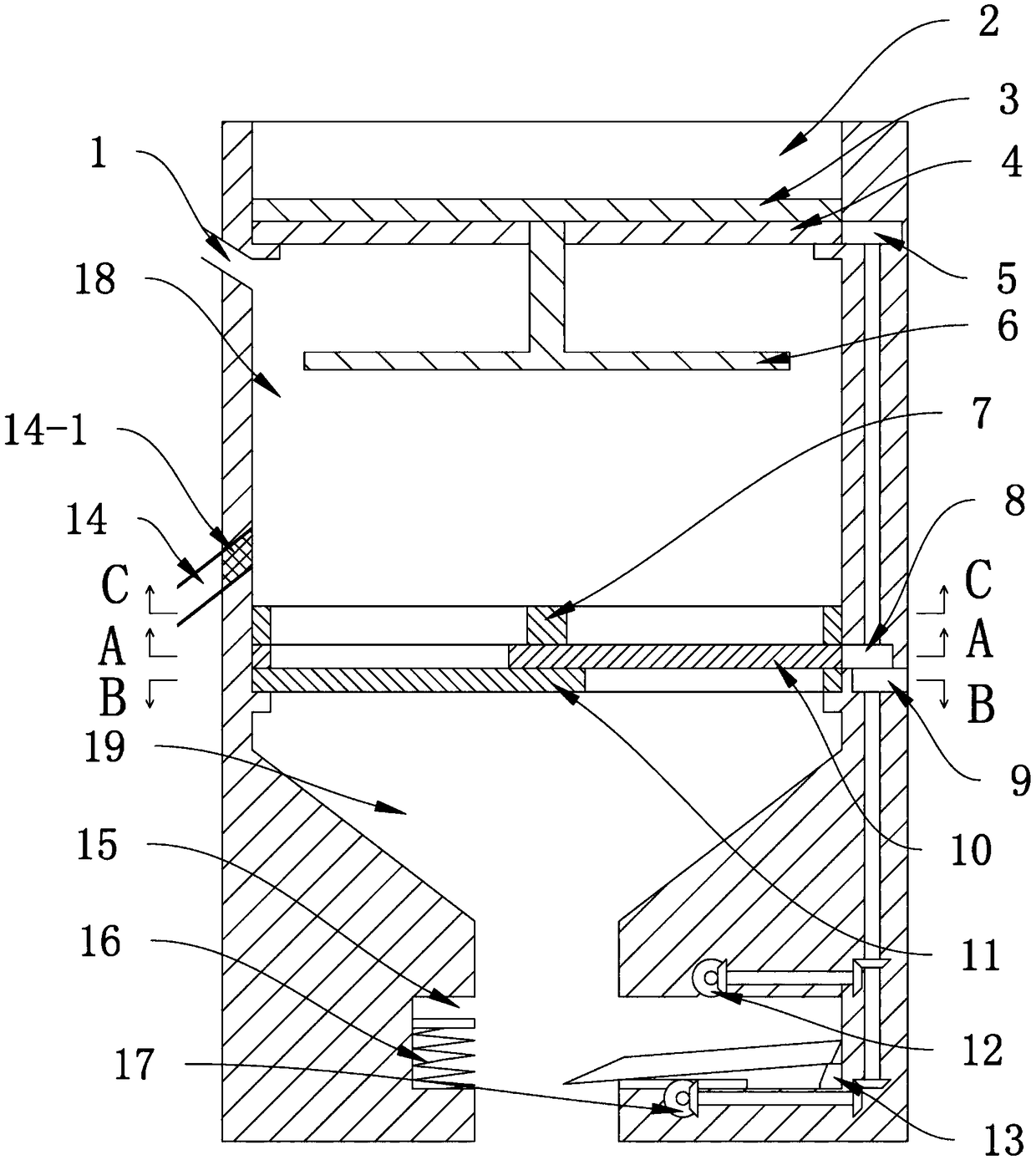

The invention relates to a full-automatic visual inspection system for screen defects. The system comprises a controller as well as an automatic feeding unit, an automatic inspection unit and an automatic classifying and discharging unit which are connected with the controller; the automatic feeding unit, the automatic inspection unit and the automatic classifying and discharging unit are sequentially arranged to form an automatic assembly line; the automatic feeding unit conveys to-be-inspected screens to the automatic inspection unit; the automatic inspection unit performs automatic defect inspection to determine whether the screens belong to non-defective products or defective products; and the automatic classifying and discharging unit acquires the inspected screens from the automatic inspection unit and performs classification and output according to inspection results. Compared with the prior art, the system has the advantages that the automation degree is high, the whole inspection process is simple to operate, the labor intensity of workers is reduced, the human capital is reduced, and the production efficiency is improved.

Owner:SHANGHAI WEISONG IND AUTOMATION

Circulating cooling water quality monitoring system and equipment

InactiveCN1514248AEmission reductionReduce processingMaterial analysisAutomatic controlMonitoring system

A system uses PLC programmable controller as a core with nine attachment units as pH on line detection unit, electric conductivity on line detection unit, flow rate on line detection unit, hardness on line detection unit, corrosion resistance on line detection unit, C1 concentration on line detection unit, automatic control unit for proportionally adding medicine, water supplementing automatic control unit and pollution discharging automatic control unit so that automatic control for adding medicine, automatic discharging of concentrated water and automatic supplementing of fresh water can be realized.

Owner:UNIV OF SCI & TECH BEIJING

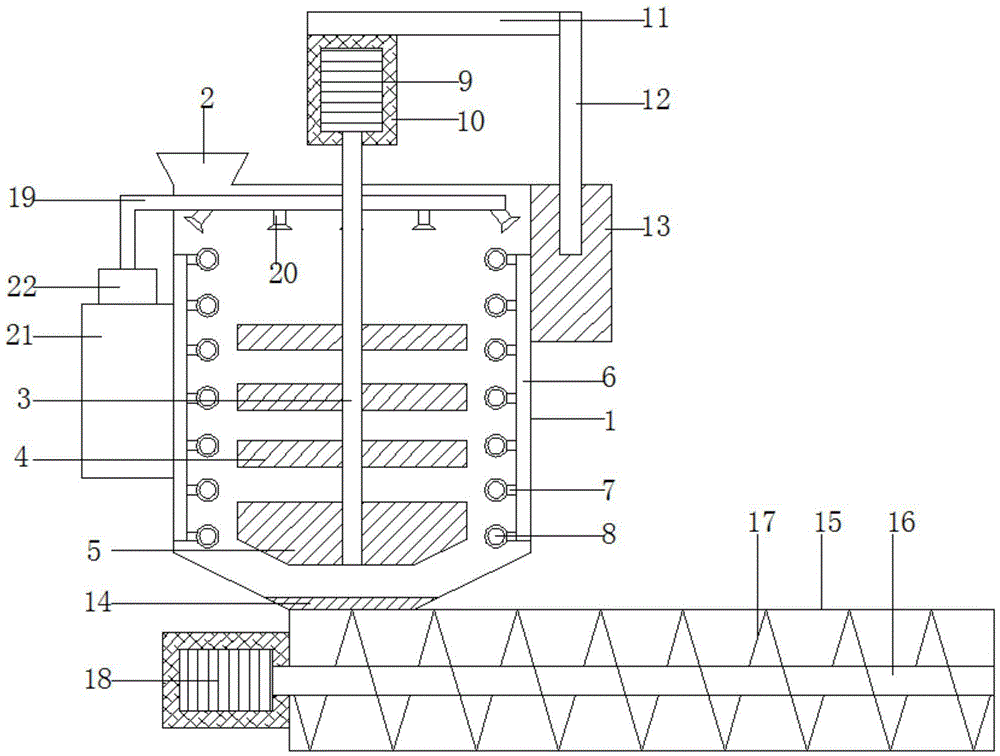

Efficient concrete mixer with water capable of being added automatically

InactiveCN104924462AQuality assuranceReduce noiseDischarging apparatusCement mixing apparatusHydraulic cylinderEngineering

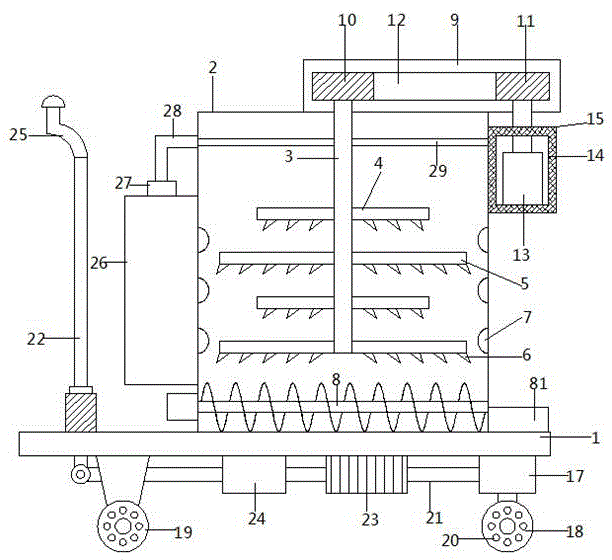

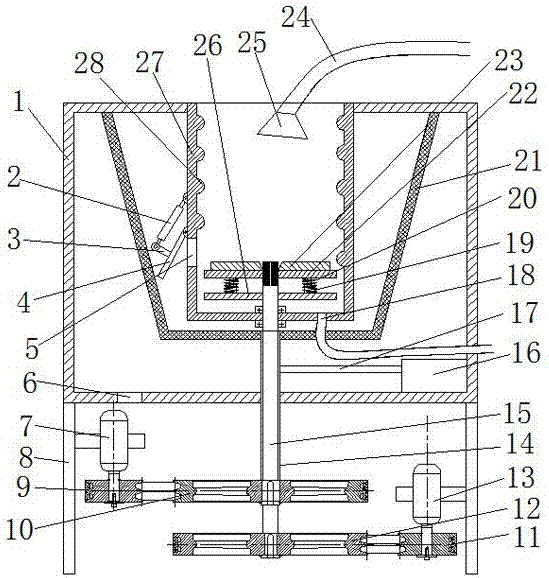

The invention discloses an efficient concrete mixer with water capable of being added automatically. The efficient concrete mixer comprises a mixing drum, a screw conveying drum and spray heads. A feeding funnel is arranged at the left end of the upper side of the mixing drum, a stirring rotating shaft is vertically arranged at the axis of the inside of the mixing drum, stirring blades are arranged on the outer wall of the middle section of the stirring rotating shaft in a left-right symmetrical mode, and the bottom of the stirring rotating shaft is connected with a stirring plate. According to the concrete mixer with water capable of being added automatically, the stirring blades, the stirring plate and stirring wheels are used for stirring concrete in the horizontal direction and the vertical direction at the same time, a hydraulic cylinder is used for driving a mixing mechanism to move up and down for stirring, hence, the stirring effect and working efficiency of the mixer are greatly improved, and the concrete quality is guaranteed; moreover, automatic discharging is achieved through a screw conveying mechanism, the concrete can be stirred continuously in the discharging process, and the working efficiency of the mixer is improved; in addition, noise of the mixer in the working process is small, and automatic water adding and cleaning can be achieved.

Owner:苏晓玲

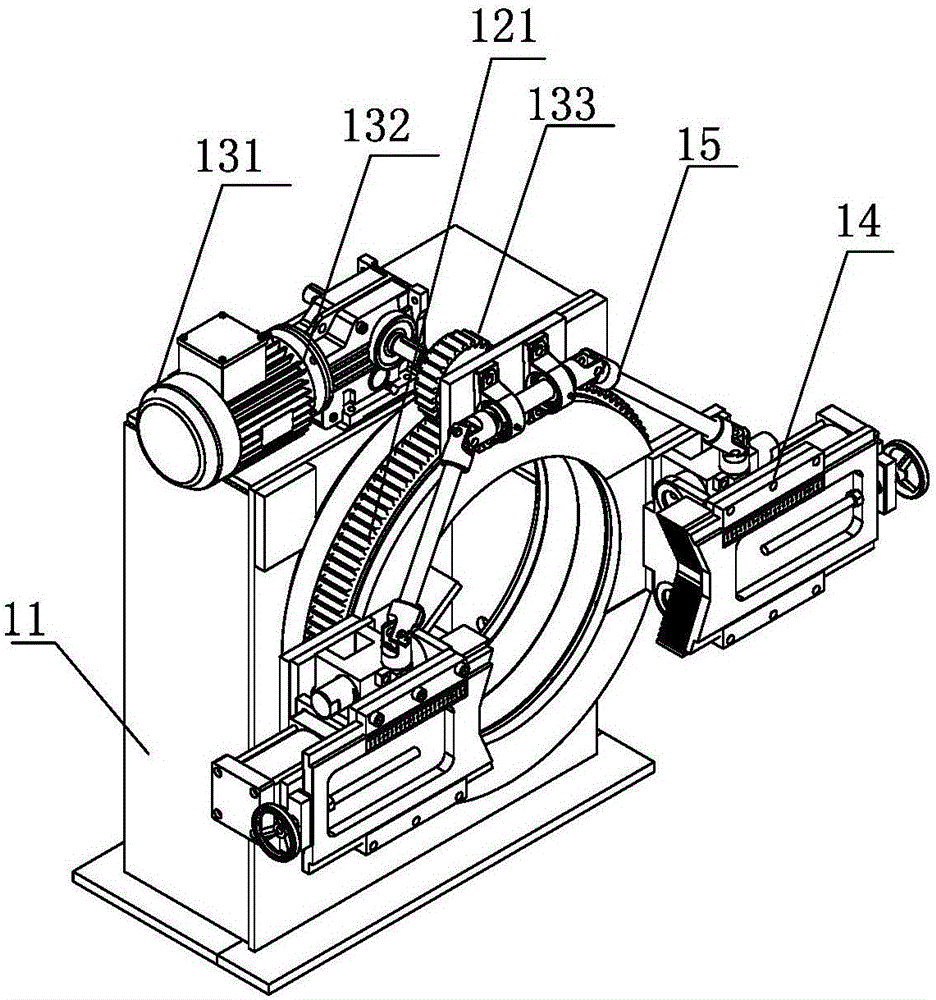

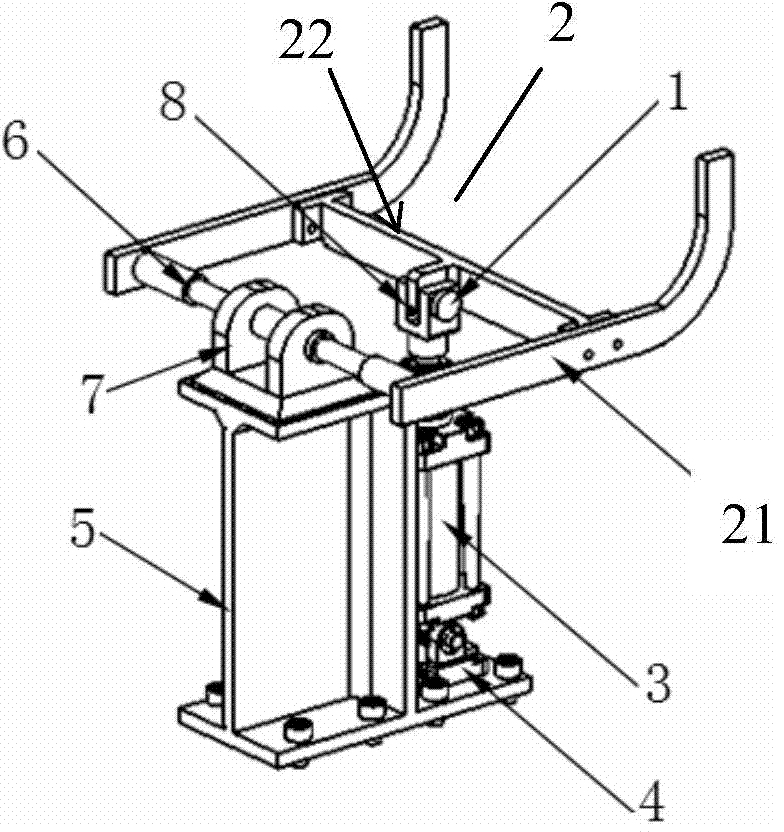

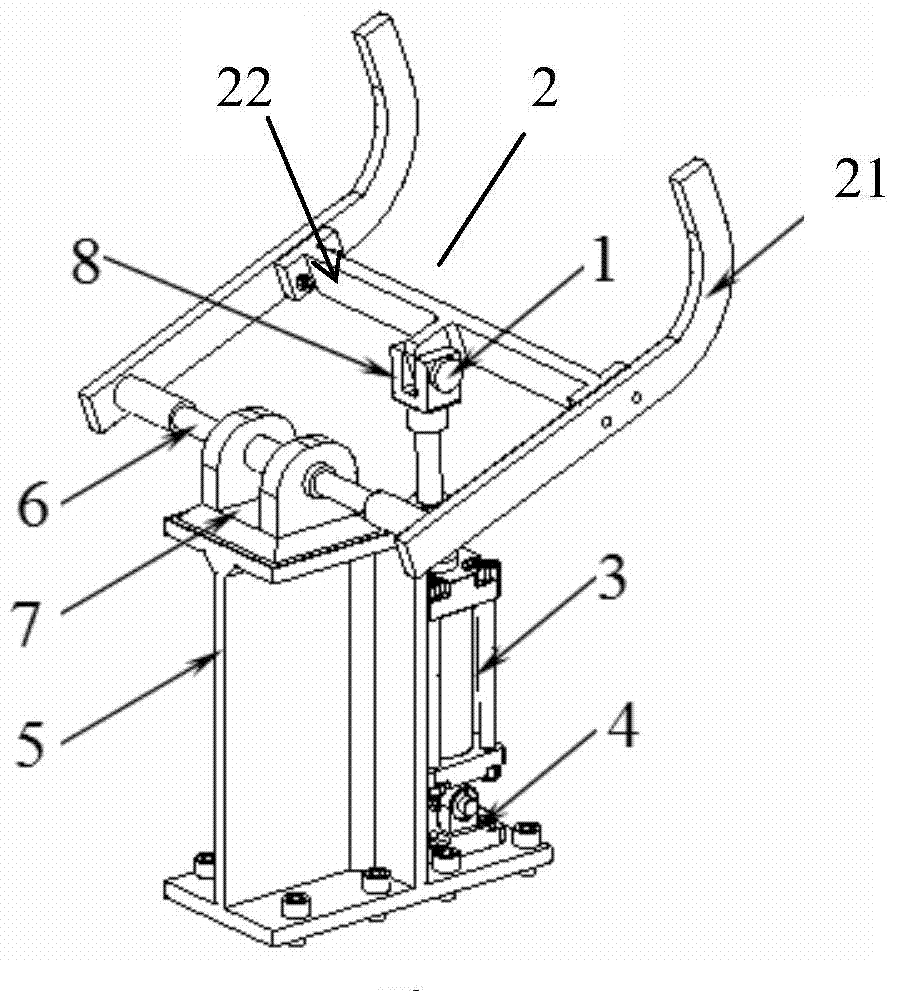

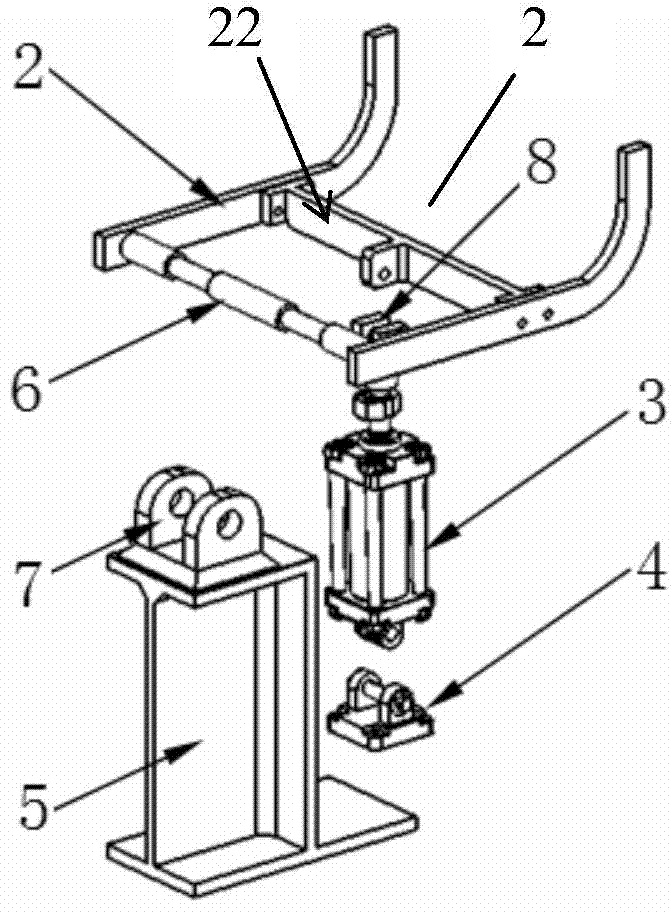

Double-direction synchronous rotating and clamping device for steel pipe cutting

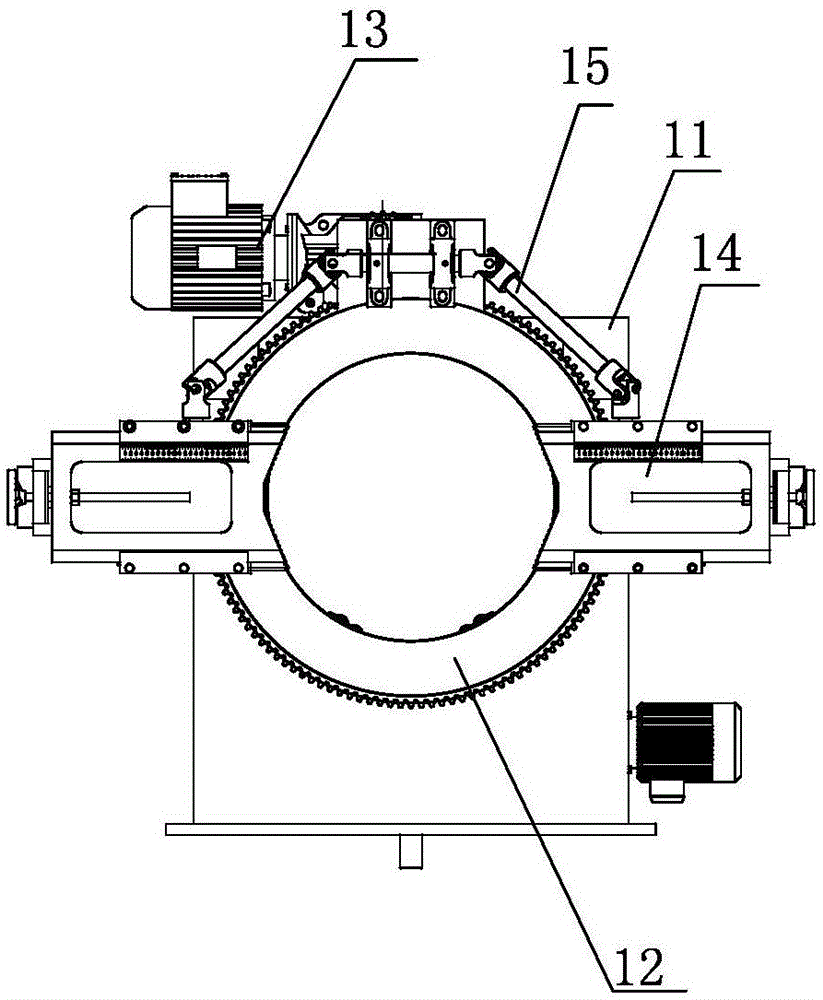

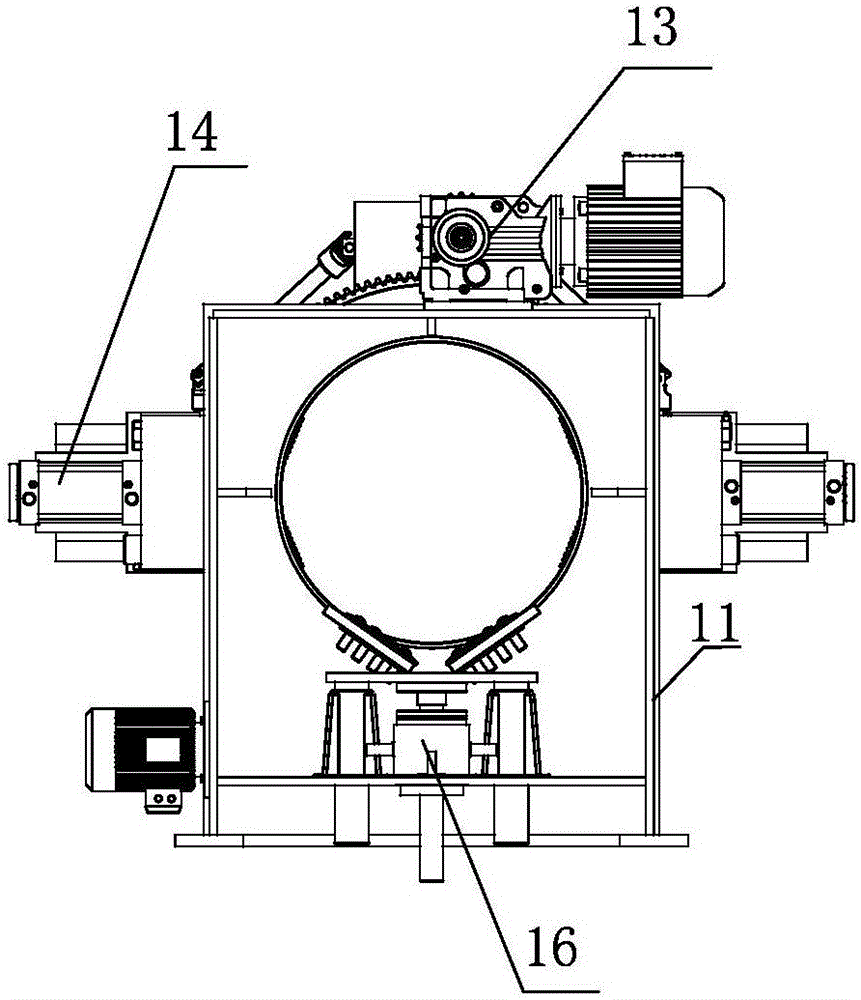

ActiveCN106238887AEfficient cuttingRealize two-way synchronous clampingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSteel tube

The invention provides a double-direction synchronous rotating and clamping device for steel pipe cutting. The technical problem that in the cutting process of a steel pipe, clamping and rotating can not be achieved is solved. The device comprises a clamping mounting frame, a rotary disc mechanism, a clamping mechanism and a double-direction synchronous clamping drive connection mechanism; a lifting mechanism is arranged at the rear end of the clamping mounting frame, and the clamping mechanism comprises a fine adjustment mechanism; a turnover discharging device is arranged in front of the rotating and clamping mechanism; the device has the beneficial effects that in the process of using a plasma cutting machine for cutting the steel pipe, the steel pipe is synchronously clamped in a double-direction manner and driven to rotate, and the steel pipe cutting process is more efficient.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

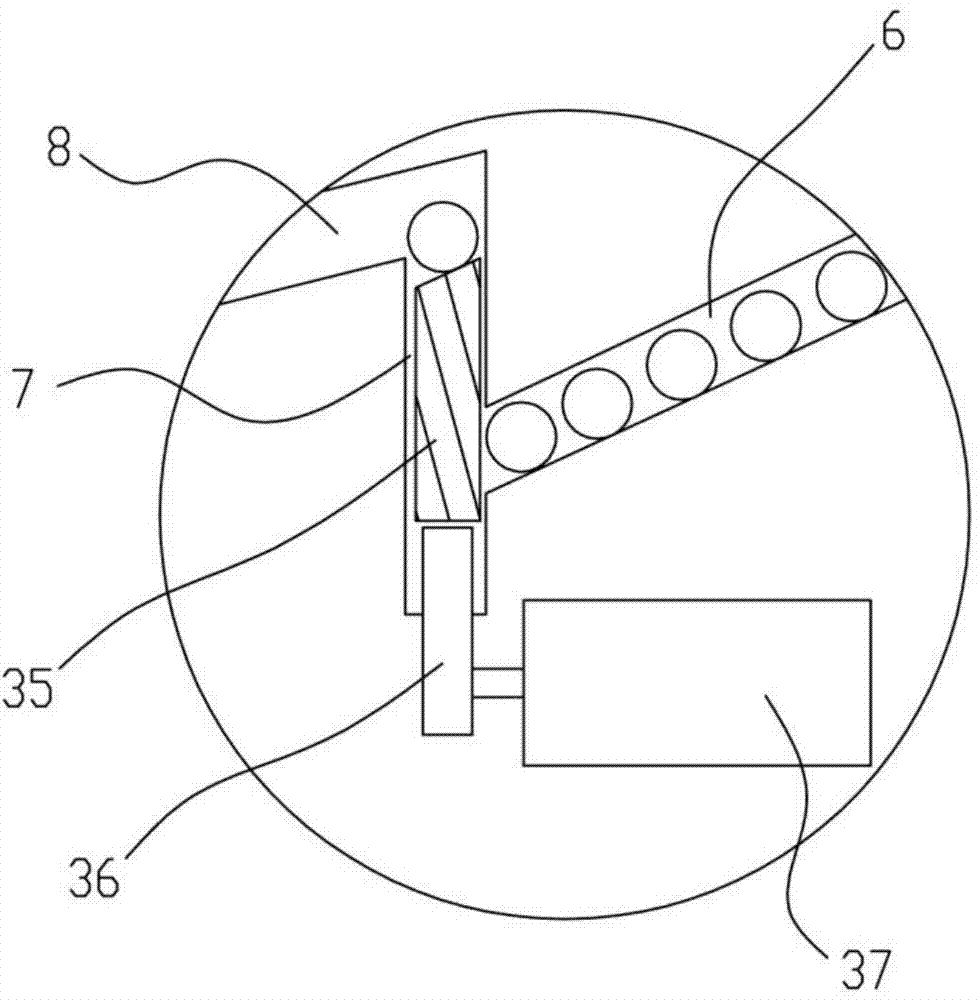

Automatic steel ball sorting device

The invention discloses an automatic steel ball sorting device, which comprises a frame, a loading bucket, a discharging bucket, a waste ball cabin, a quantitative ball supply device, a feeding box, a detection device and a control device, wherein the lower end of the loading bucket is provided with a gravity sensor; one side of the loading bucket is hinged to the frame; a single-side elevating device is arranged on the other side of the loading bucket; the loading bucket is connected with the quantitative ball supply device and the feeding box through a loading channel; the feeding box is connected with the detection device through a feeding channel; the detection device is connected with the waste ball cabin and the discharging bucket respectively through a discharging channel; a distance sensor is arranged above the discharging bucket; the lower end of the discharging bucket is provided with a horizontal elevating device. The automatic steel ball sorting device has the advantages of no need of manual attendance for a long time, lower processing cost, constant loading frequency, higher sorting efficiency and avoidance of secondary defects caused by falling of steel balls into the discharging bucket.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

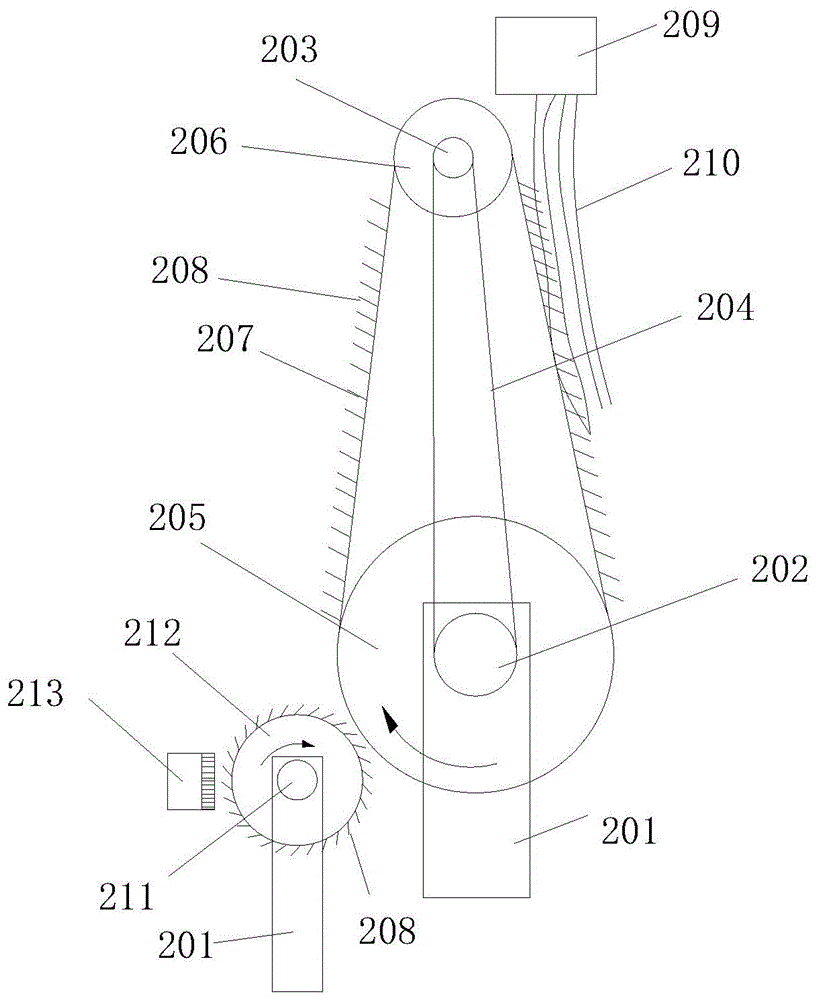

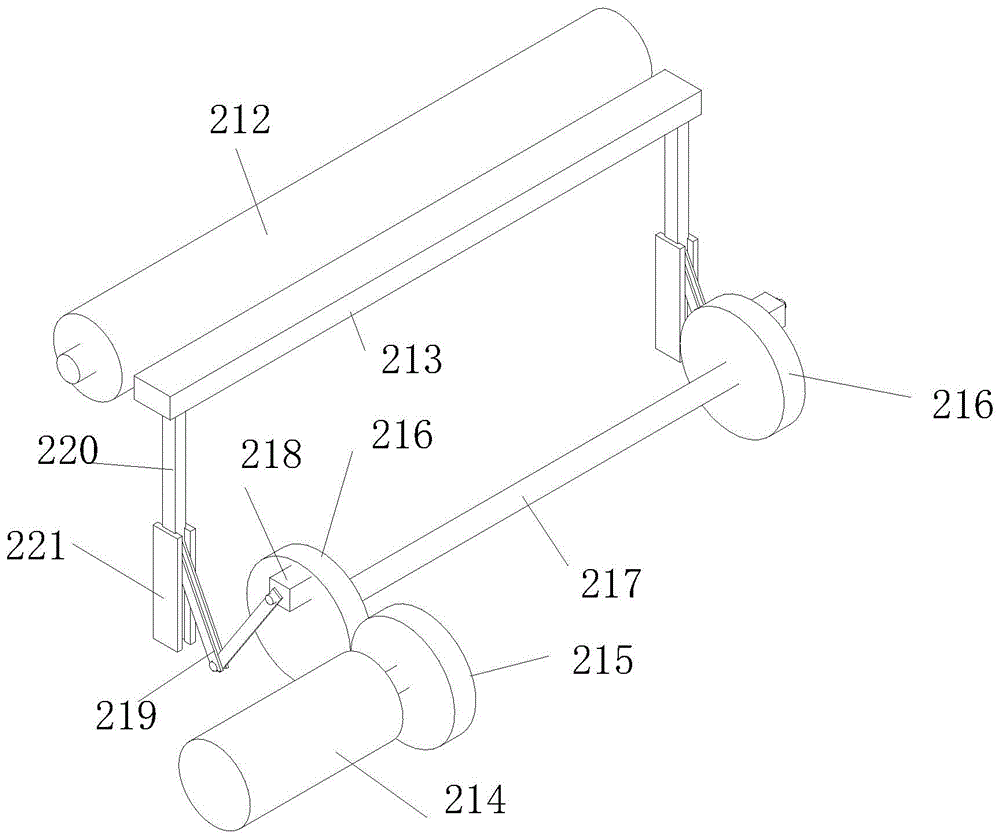

Hackling mechanism of flax hackling machine

The invention discloses a hackling mechanism of a flax hackling machine. The hackling mechanism is characterized in that a brushing shaft (211) which is erected on a framework (201) is arranged on a side surface of a main hackling drum (205), a brushing drum (212) is arranged on the brushing shaft (211), and steel brushes (208) are fully distributed on the surface of the brushing drum (212) and can intersect with steel brushes of a hackling track (207) at contact positions of the brushing drum (212) and the hacking track (207); a brush strip (213) is further arranged on a side surface of the brushing drum (212) and is in contact with the steel brushes of the brushing drum (212). The hackling mechanism has the advantages of simple structure, low failure rate and high efficiency. Besides, the problem of degradation of hackling effects due to the fact that flax fibers are easy to adhere on an existing main hackling drum can be solved by the aid of the hackling mechanism.

Owner:吴江市辰龙骏纺织有限公司

Pressing plate device for manufacturing automobile engine hood

InactiveCN107263902ARealize continuous processingReduce workloadGrinding drivesPress ramHigh volume manufacturingEngineering

The invention discloses a pressing plate device for manufacturing an automobile engine hood. The pressing plate device for manufacturing the automobile engine hood comprises an outer frame; the left side of the bottom of the inner wall of the outer frame is fixedly connected with a first motor; one end of an output shaft of the first motor is fixedly connected with a lead screw; the surface of the lead screw is in threaded connection with a movable block; the top of the movable block is rotationally connected with a connection rod, the end, away from the movable block, of the connection rod is rotationally connected with a bottom pressing plate; the right side of the bottom of the inner wall of the outer frame is fixedly connected with a second motor; and a first belt wheel is fixedly connected to an output shaft of the second motor. The pressing plate device for manufacturing the automobile engine hood relates to the technical field of automobile manufacturing equipment. The pressing plate device for manufacturing the automobile engine hood achieves continuous machining of engine hoods, the work efficiency is greatly improved, the machining time is shortened, the workload of workers is relieved, large-batch production of a factory is facilitated, it is not needed to manually take out the engine hoods, convenience is brought to users, the engine hoods can be more skin-passed, subsequent installation is facilitated, and the practicability of the device is improved.

Owner:HUNAN UNIV OF ARTS & SCI

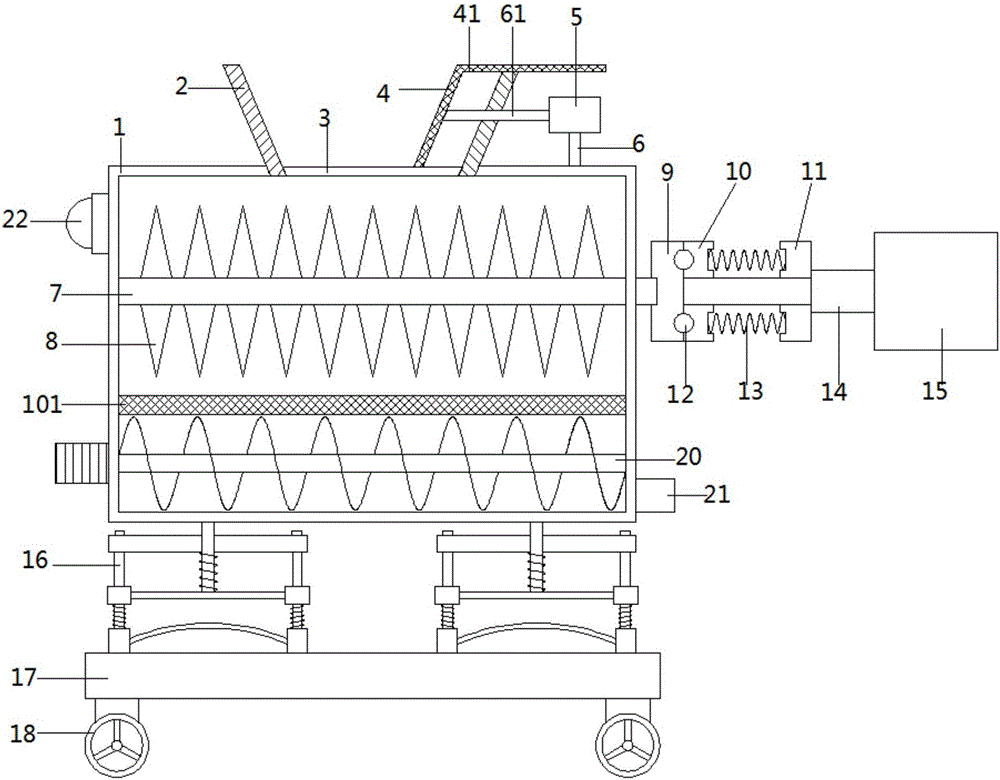

Efficient mixing machine convenient to move rapidly

InactiveCN105536614ASafe and reliable workReduce noiseRotary stirring mixersTransportation and packagingEngineeringLow noise

The invention discloses an efficient mixing machine convenient to move rapidly. The efficient mixing machine comprises a base, wherein a machine body is arranged in the center of the upper side of the base, a stirring rotating shaft is vertically arranged in the machine body, a connecting box casing is arranged on the upper right side of the machine body, a first belt pulley and a second belt pulley are arranged on the left and right inside the connecting box casing and connected through a drive belt, the first belt pulley is connected with the top end of the stirring rotating shaft, and a motor case is fixed on the outer wall of the right side of the machine body. The efficient mixing machine convenient to move rapidly adopts the belt pulleys for driving, is safe, reliable and stable in work, has low noise during work and can regulate the running speed; a drive device is arranged on the upper side of the machine body, sealing is not needed to be considered, the production and use costs are reduced, the stirring effect is good, the working efficiency is high, automatic cleaning and automatic discharging can be realized, time and labor are saved, and the working efficiency is further increased; besides, the efficient mixing machine can be moved rapidly and is high in convenience.

Owner:覃艺诗

Tea cleaning and sieving integrated machine

ActiveCN104138871AImprove cleaning efficiencyFacilitate subsequent processingSievingPre-extraction tea treatmentClassification treatmentUltrasonic generator

The invention discloses a tea cleaning and sieving integrated machine which comprises a cleaning machine, a sieving machine and a lifting mechanism, wherein the cleaning machine comprises a bracket, a water trough, ultrasonic generators, a slide bar, a lifting cylinder and a discharging platform; the sieving machine comprises a casing, a feeding hopper, an electric fan, a vibration mesh sieve and a plurality of air classification outlets; and two side surfaces and the bottom surface of the casing are communicated with the outside, a support is mounted at the bottom of the casing, a control electric box is mounted on the casing, and a discharging hopper is connected with the feeding hopper through the lifting mechanism. According to the tea cleaning and sieving integrated machine, the cleaning effect can be improved effectively, automatic discharging can be completed after cleaning, the cleaning efficiency is increased, complete tea leaves and tea dust can be separated after cleaning according to integrity of the tea leaves, then the complete tea leaves are subjected to classification treatment according to the size under the action of air, and the classification efficiency is high.

Owner:张家界高山怡韵茶业有限公司

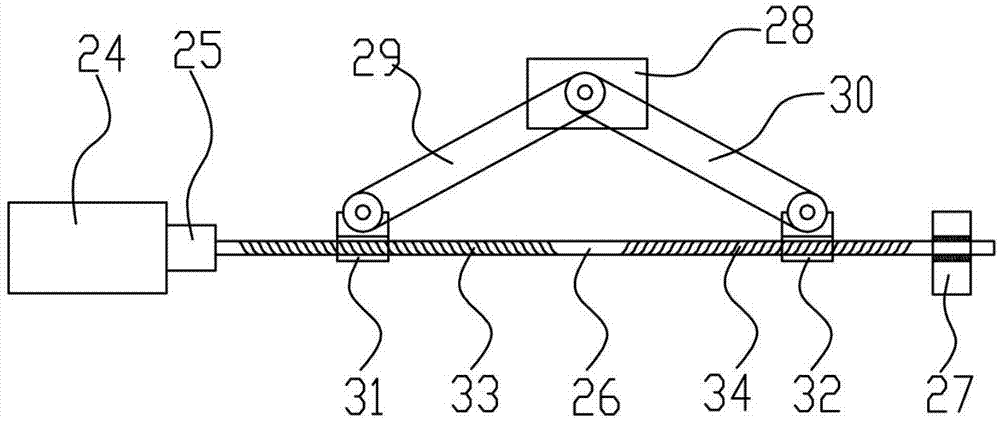

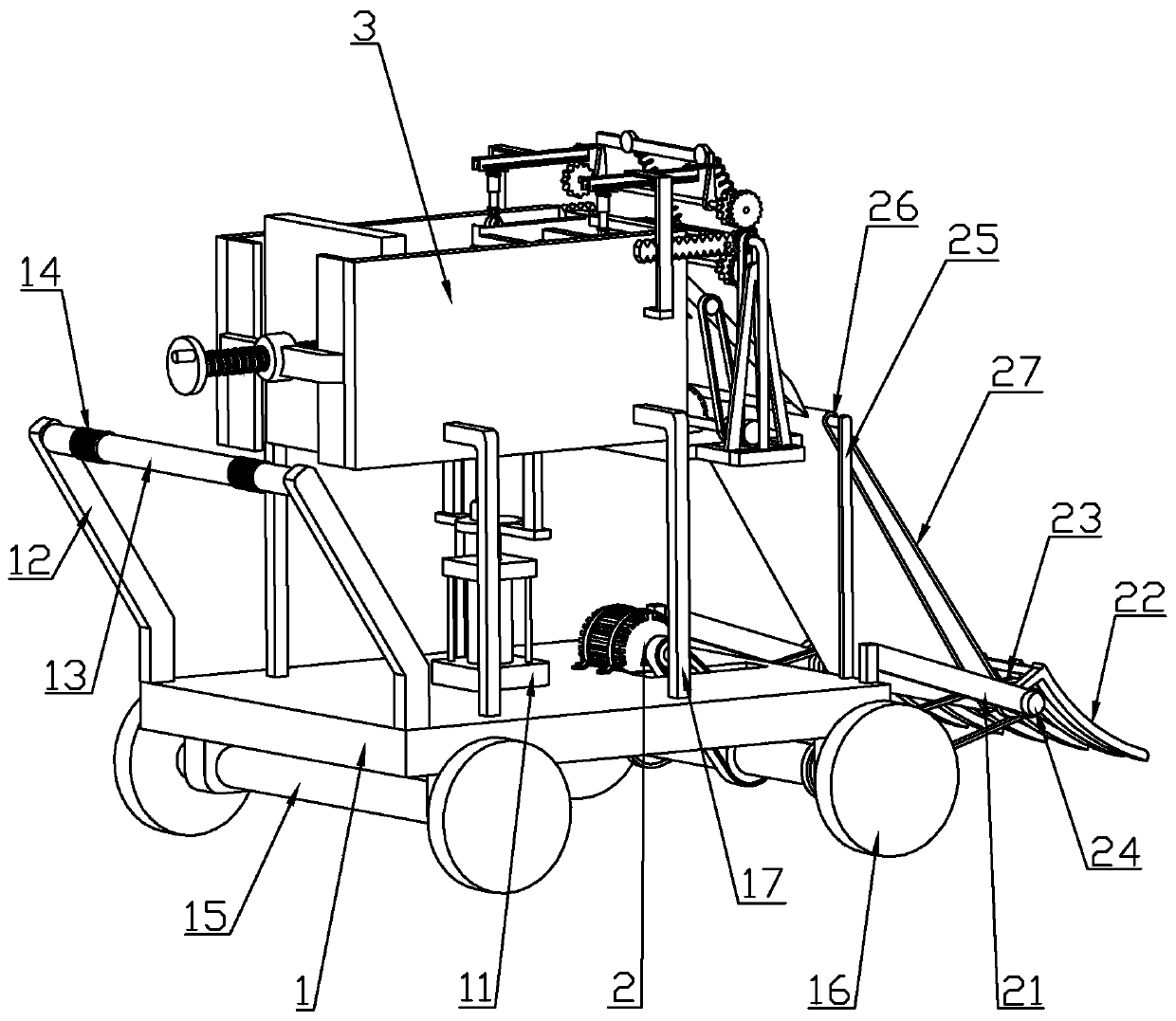

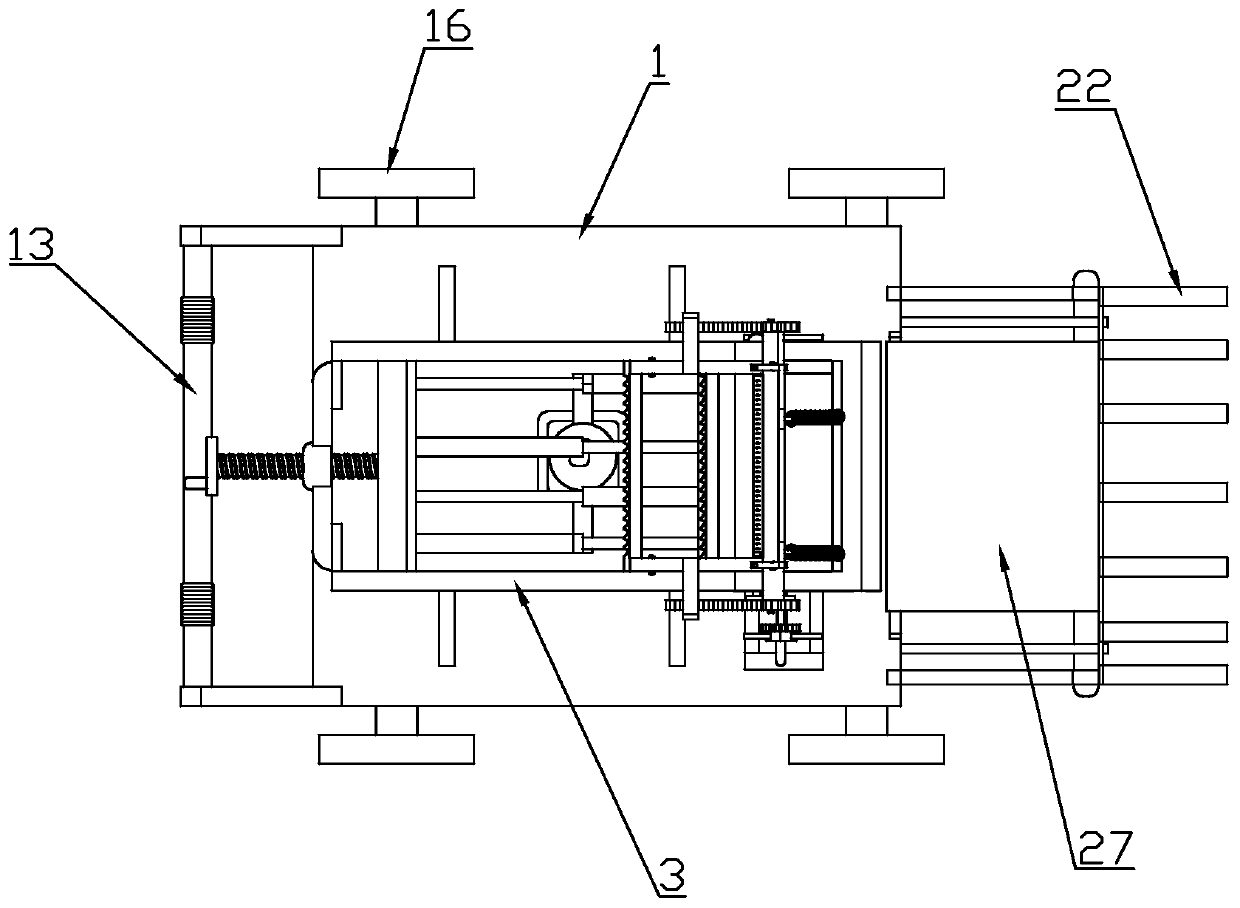

Fresh meat cutting and shredding device

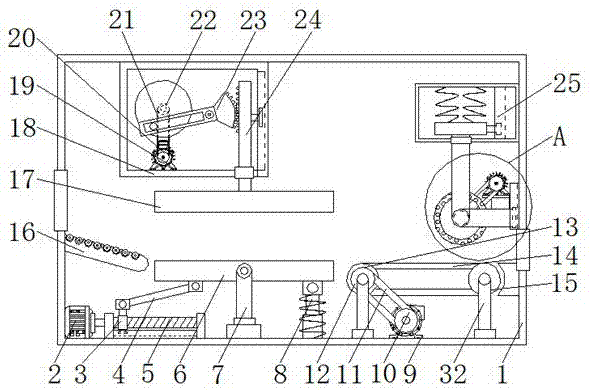

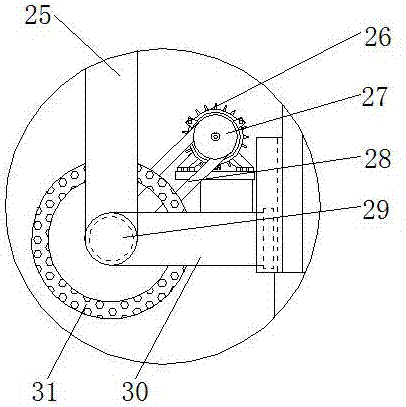

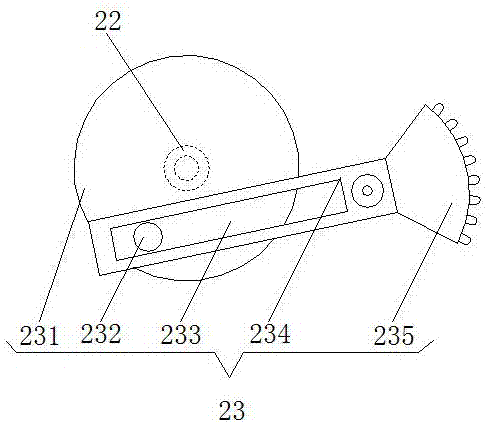

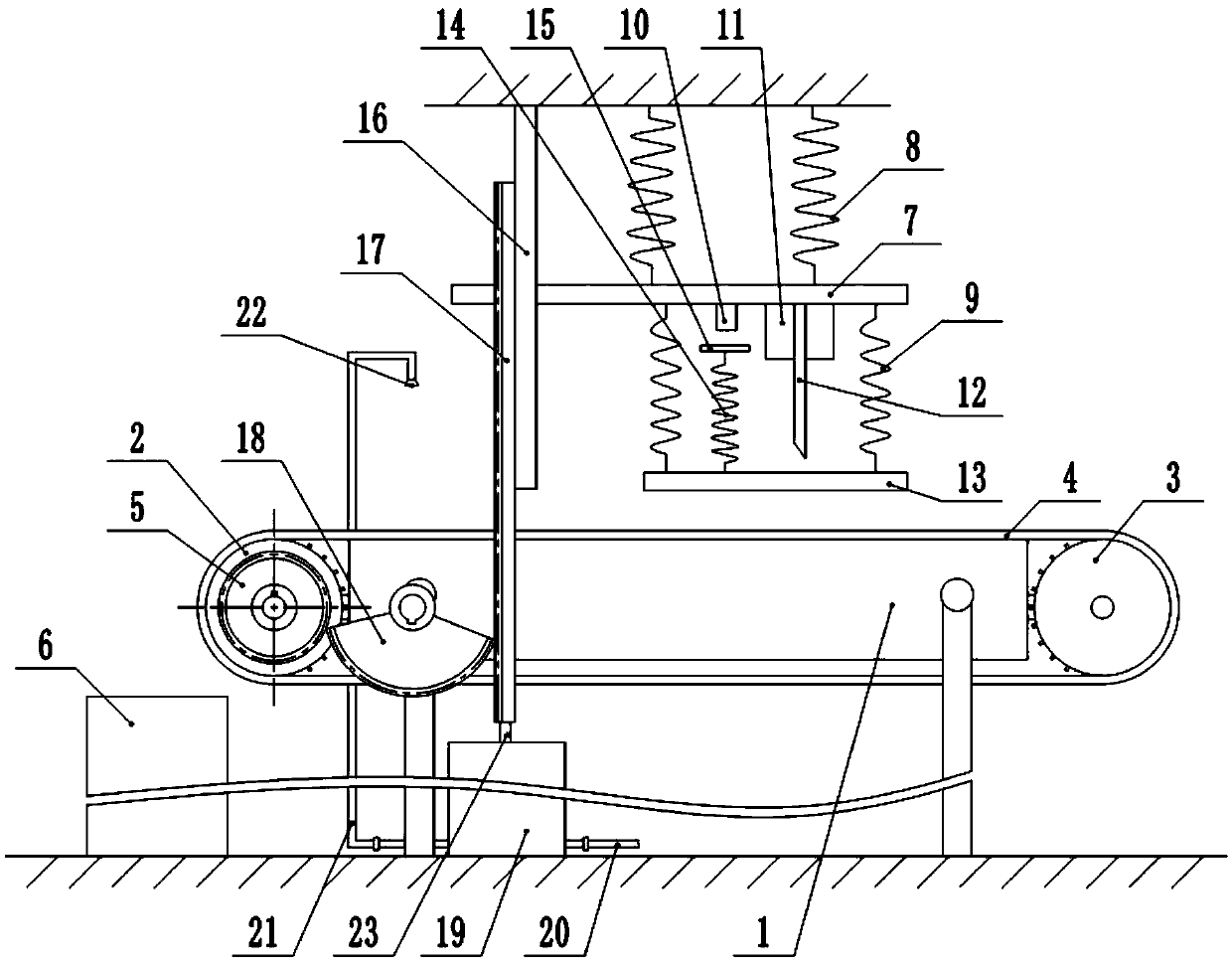

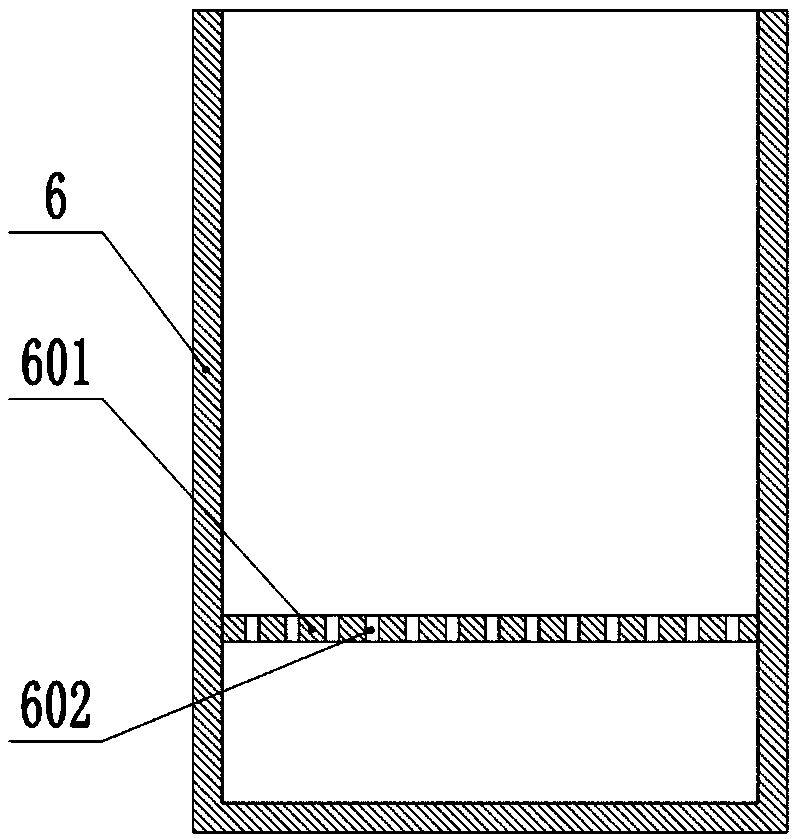

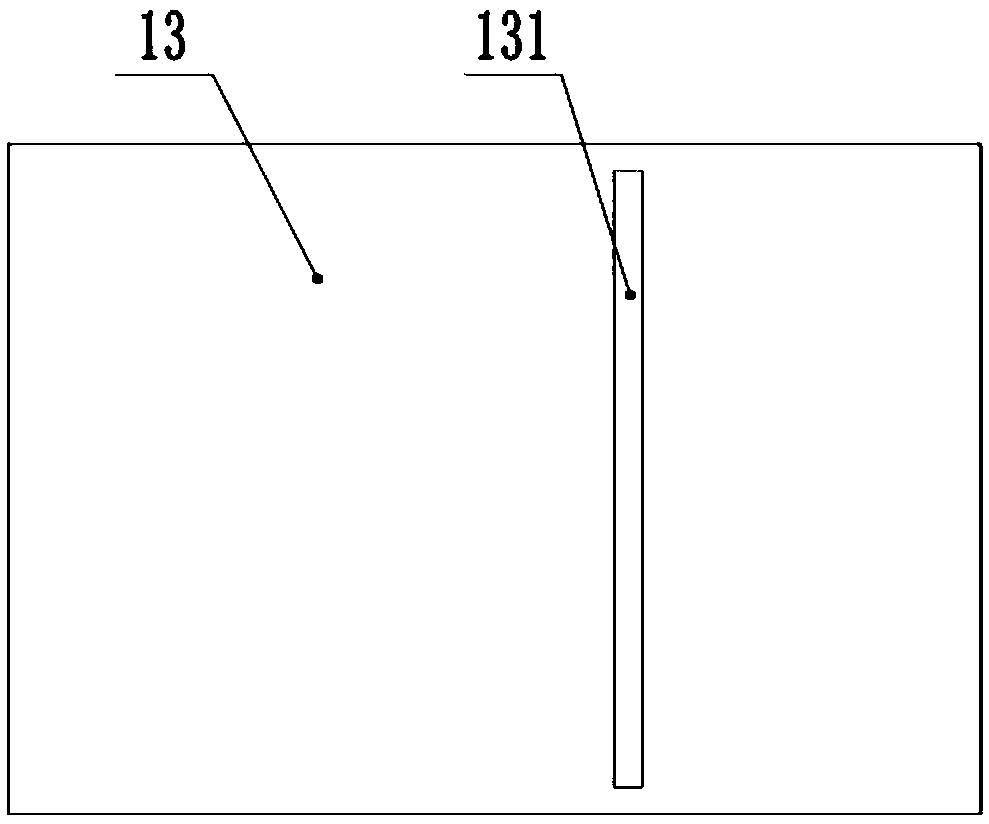

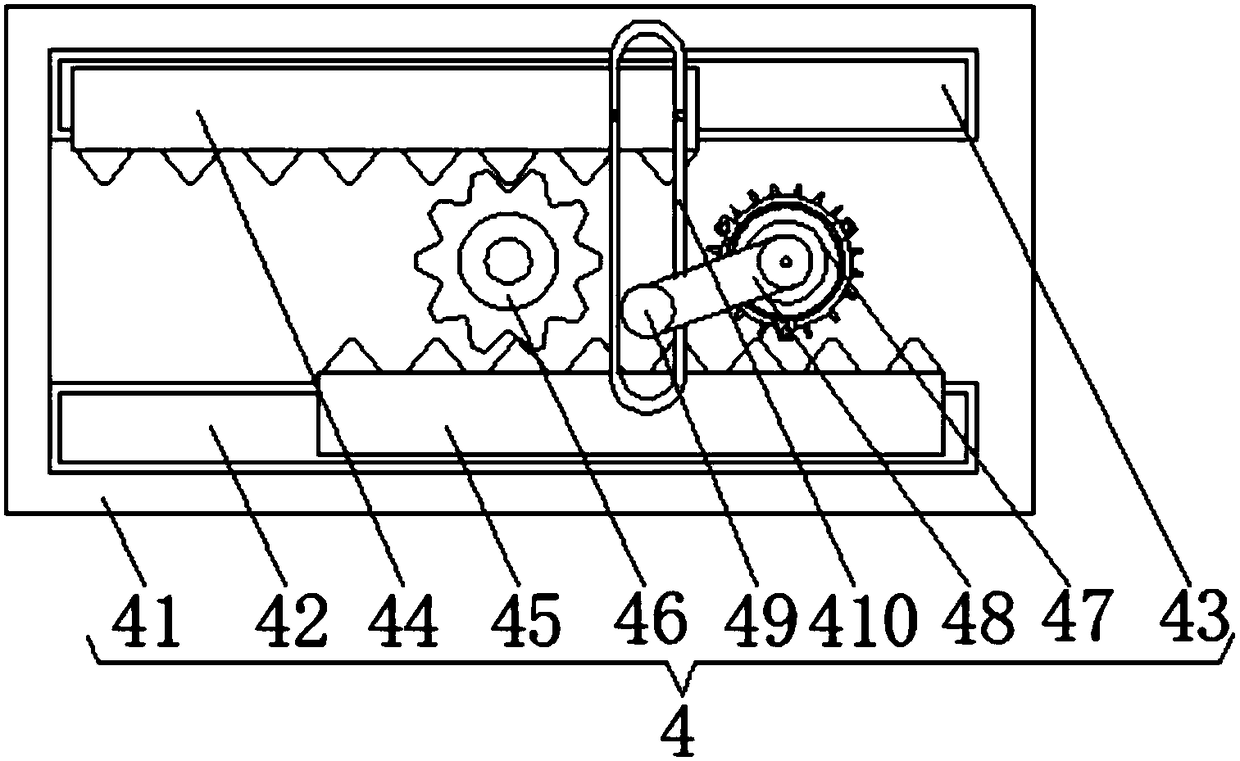

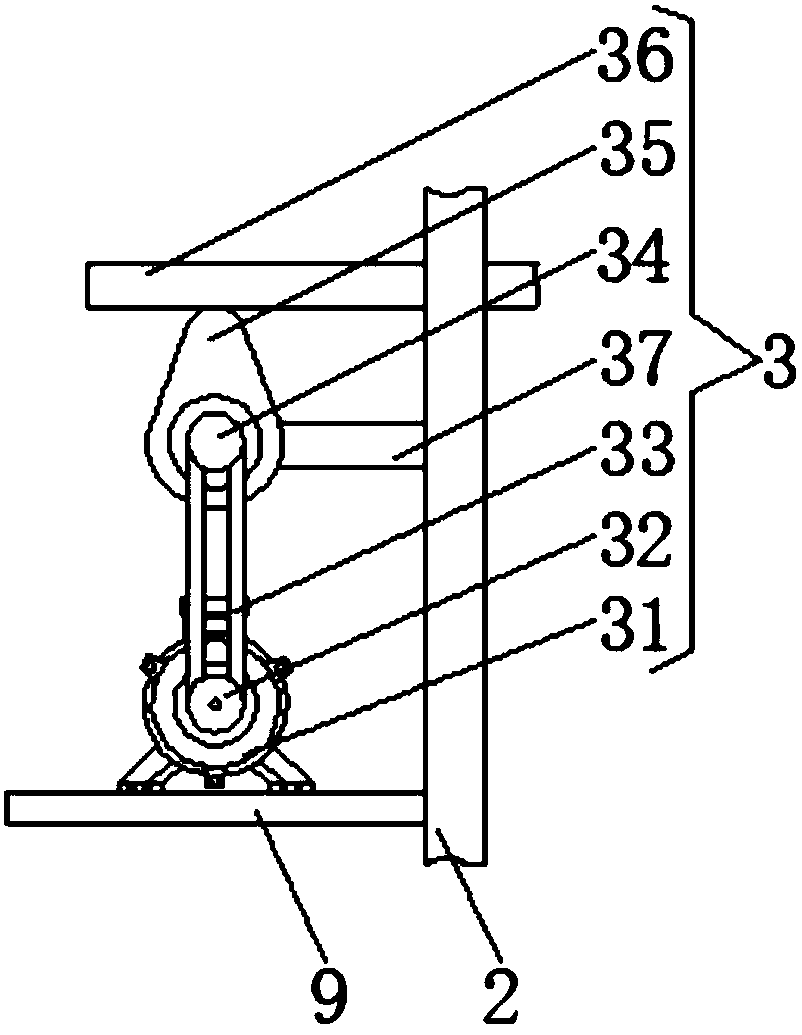

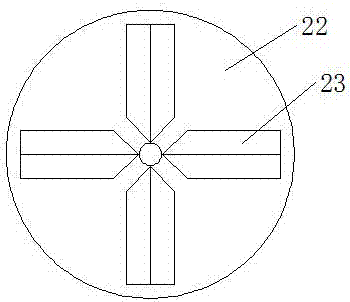

InactiveCN109591091ARealize automatic dischargeImprove cutting and decomposition efficiencyMeat holding apparatusMetal working apparatusDrive wheelEngineering

The invention relates to the technical field of food processing, and in particular discloses a fresh meat cutting and shredding device. The fresh meat cutting and shredding device comprises a rack anda cutting table, where the two ends of the cutting table are rotationally connected with a driving wheel and a driven wheel respectively, the driving wheel and the driven wheel are jointly wound witha plate-chain conveying belt, and the driving wheel is coaxially connected with a gear; a transverse plate is arranged above the cutting table and is connected onto the rack through a spring, and a press plate is arranged under the transverse plate and is connected with the transverse plate through a spring; a cutting knife is arranged on the side, facing the press plate, of the transverse plate,and a knife seam for enabling the cutting knife to pass is formed in the pres plate; the rack is fixedly connected with a fixed strip, and the fixed strip is vertically connected with a toothed rackvertically; the toothed rack is meshed with an incomplete gear; and the incomplete gear can be meshed with the gear in the rotation process. According to the fresh meat cutting and shredding device, by the meshing of the incomplete gear and the gear, the driving wheel is driven to rotate, and therefore automatic feeding and discharging of fresh meat is realized; by the meshing of the incomplete gear and the gear, the cutting knife is driven to move, and therefore cutting and shredding of the fresh meat are realized; and thus, the working efficiency is improved.

Owner:CHONGQING NIANJI FOOD

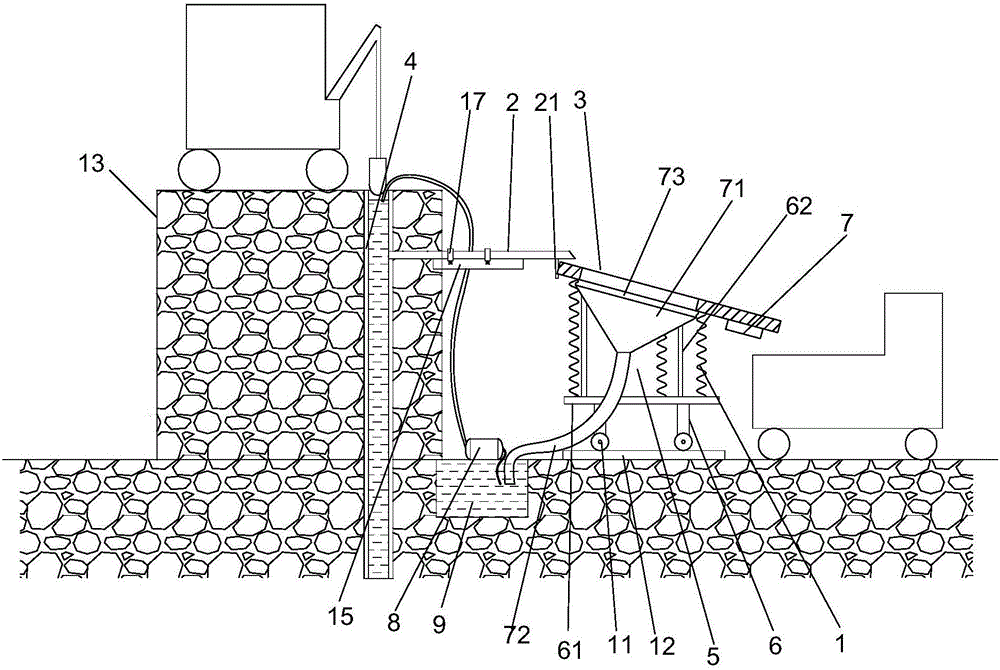

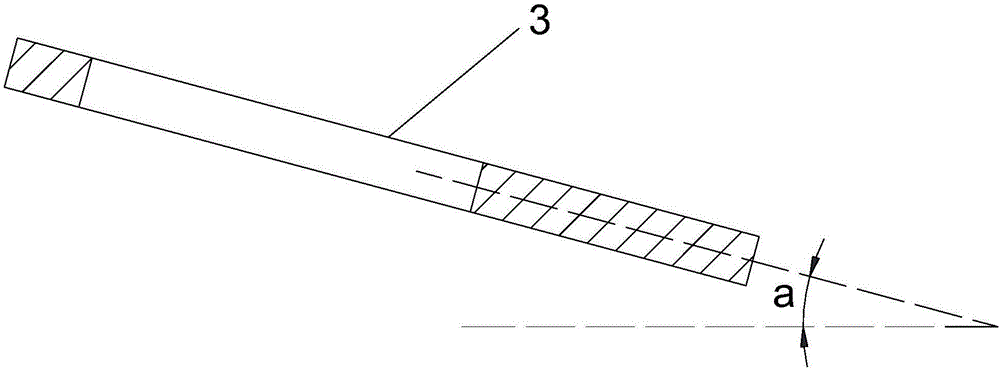

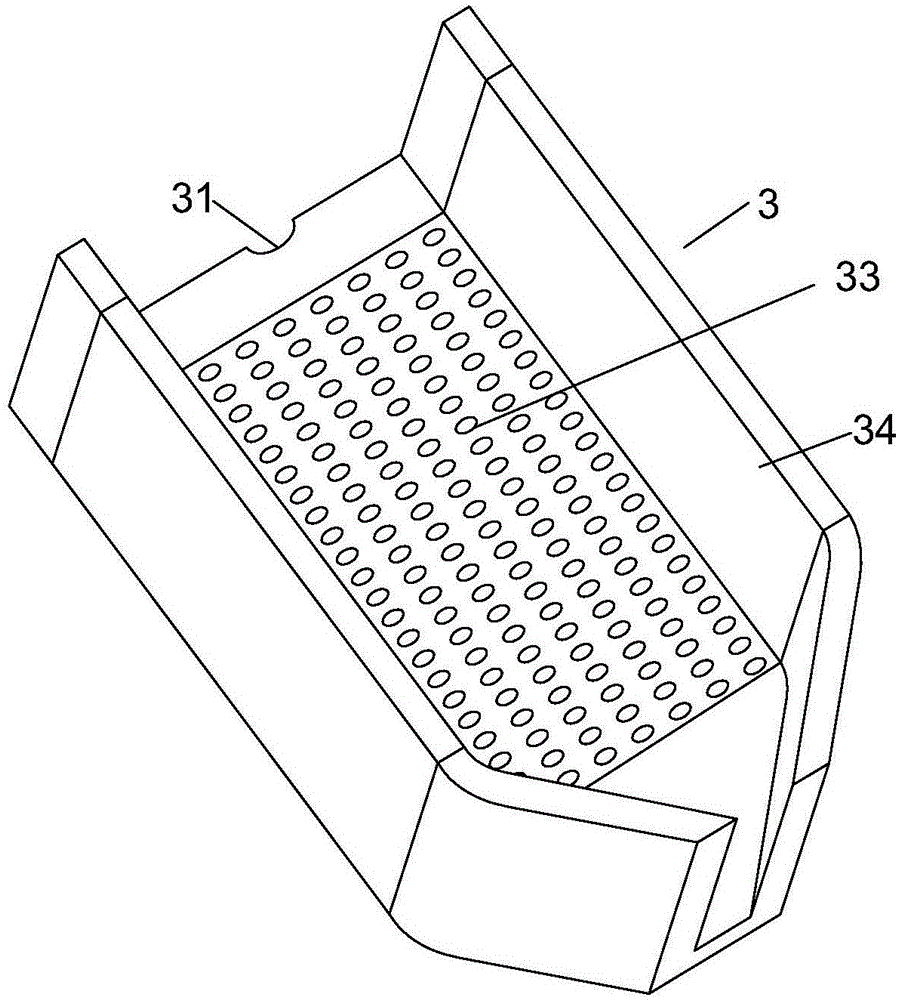

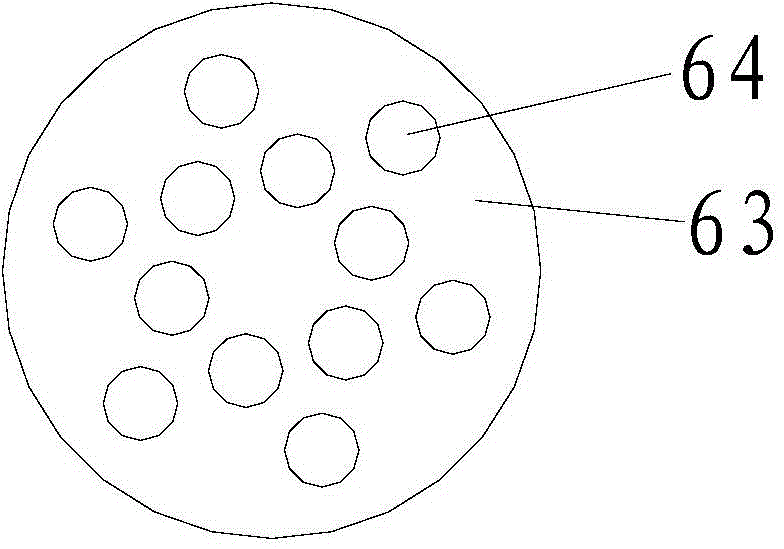

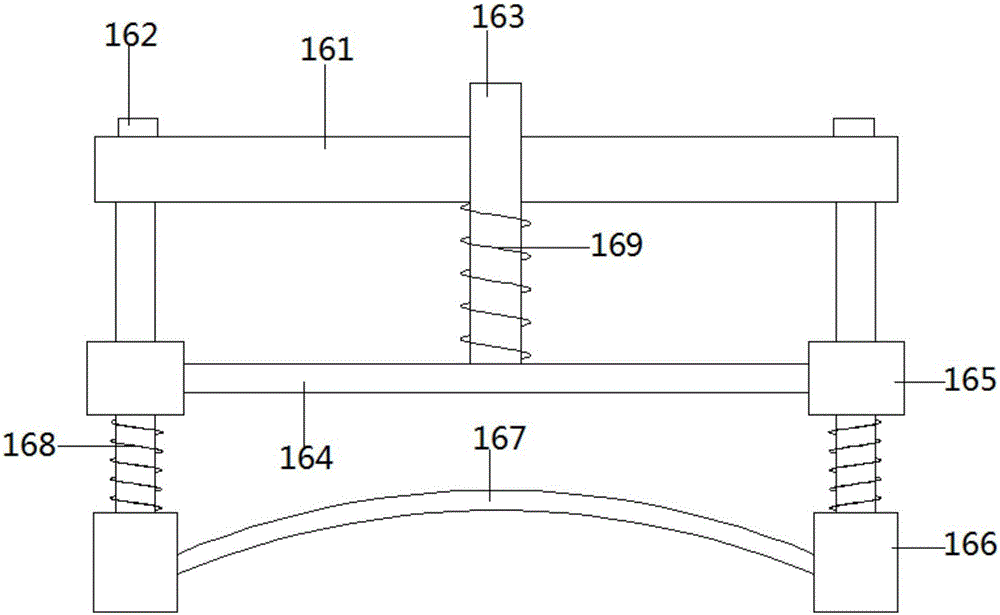

Mud treatment device for building pile foundation construction

The invention provides a mud treatment device for building pile foundation construction. The mud treatment device comprises a sand pump for pumping mud and drilling slag out of a drilled hole, a clean water tank for storing clean water, a water pump, a sand and water mixing pipeline, a screen and a net rack, wherein the input end of the water pump is communicated with the clean water tank, so that clean water can be pumped; the position of the input end of the sand and water mixing pipeline is higher than that of the output end of the sand and water mixing pipeline, the output end of the sand pump and the output end of the water pump are both connected to the input end of the sand and water mixing pipeline; the screen is of a circular-arc-shaped structure, the input end of the screen is located below the output end of the sand and water mixing pipeline, the position of the input end of the screen is higher than that of the output end of the screen, and an included angle between the axis of the screen and the horizontal line is 20-30 degrees; the net frame comprises at least two diagonal rods, the upper end of each diagonal rod is fixed with the edge of the screen, and the lower end of each diagonal rod is connected to a vibrating plate. The med treatment device has the following benefit: automatic discharge of drilling slag is realized after mud separation.

Owner:CHONGQING TECH & BUSINESS INST +2

Pulverizer for producing ceramics and achieving convenient discharge function

InactiveCN104923358AAvoid cakingImprove work efficiencyGrain treatmentsDischarge efficiencyEngineering

The invention discloses a pulverizer for producing ceramics and achieving a convenient discharge function. The pulverizer comprises a pulverizer body, a stirring rotating shaft and pulverizing blades. The upper side of the pulverizer body is provided with a feeding hopper. The lower side in the feeding hopper is horizontally provided with the stirring rotating shaft. The outer wall of the stirring rotating shaft is vertically and symmetrically provided with the pulverizing blades. A first pulverizing mechanism is horizontally arranged on the upper side in the pulverizer body. A second pulverizing mechanism is horizontally arranged on the lower side of the first pulverizing mechanism. According to the pulverizer for producing the ceramics and achieving the convenient discharge function, a stirring mechanism in the feeding hopper can pre-pulverize, stir and scatter materials, and the follow-up pulverizing effect and efficiency are improved; the two pulverizing mechanisms arranged in a staggered mode are adopted to pulverize materials fully, the pulverized materials are screened, the materials of which the size does not meet the requirement are lifted into the pulverizer in a circulation mode through a lifting machine to be pulverized, the pulverizing effect is guaranteed, the pulverizing efficiency is improved, discharging is driven through a conveying belt, no manual operation is needed, the discharging efficiency is improved, and the pulverizer is convenient and fast to use.

Owner:苏晓玲

Multifunctional tea leaf cleaning machine

ActiveCN104128327APlay the role of rollingRealize automatic dischargeCleaning using liquidsGas compressorEngineering

The invention discloses a multifunctional tea leaf cleaning machine which comprises a support, a water tank, a plurality of ultrasonic generators, a bubble generating pipeline, an air compressor, a slide bar, a lifting cylinder and at least one bucket. The water tank is mounted on the support, the ultrasonic generators are mounted in the water tank, a stirring roll is mounted in the water tank, a motor is connected to an end of the stirring roll, the air compressor is positioned below the water tank, the bubble generating pipeline is mounted in the water tank, the air compressor is connected with the bubble generating pipeline by an air delivery pipe, a cleanser storage tank is mounted on the support and is connected with the water tank by a liquid delivery pump, the slide bar is mounted on the support and is positioned above the water tank, a slider is mounted on the slide bar, a slide motor and the lifting cylinder are mounted on the slider, and the buckets are connected onto the lifting cylinder. The multifunctional tea leaf cleaning machine has the advantages that cleaning effects can be effectively improved, pesticides and other pollutants on the surfaces of tea leaves can be effectively removed, the tea leaves can be automatically discharged after being completely cleaned, and accordingly the cleaning efficiency can be improved.

Owner:紫阳县康硒天茗茶业有限公司

Material pulverizing device for construction site

InactiveCN106861880AGuaranteed to workAvoid cloggingDirt cleaningGrain treatmentsEngineeringRaw material

The invention discloses a material pulverizing device for a construction site. The material pulverizing device comprises a machine body. A feeding hopper is arranged on the left side of the machine body. A feeding port is formed in the left side wall of the machine body. The bottom end of the feeding hopper is connected with the feeding port through a discharging pipe. A downward pressing device is arranged at the upper end of the machine body. A downward pressing rod of the downward pressing device is provided a connecting spring. A pressing plate is arranged at the lower end of the connecting spring. Installing frames are arranged at the two ends of the pressing plate and provided with scrapers. According to the stone pulverizing device for the construction site and with a damping device, after stone enters the machine body, the stone is crushed and sufficiently pulverized, the pulverizing effect is guaranteed, and the situation of blockage of stone in the machine body can be avoided; dust generated in the pulverizing and discharging processes can be collected, the environment is protected, raw materials are saved, and automatic discharging can be achieved; and in addition, the damping effect is good, the work stability of the pulverizing device is improved, the service life is prolonged, and noise is lowered.

Owner:丽水市莲都区君正模具厂

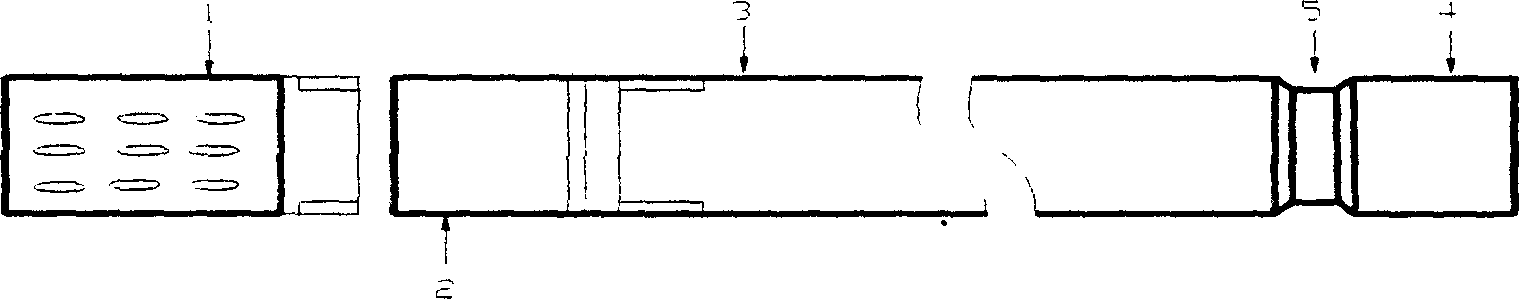

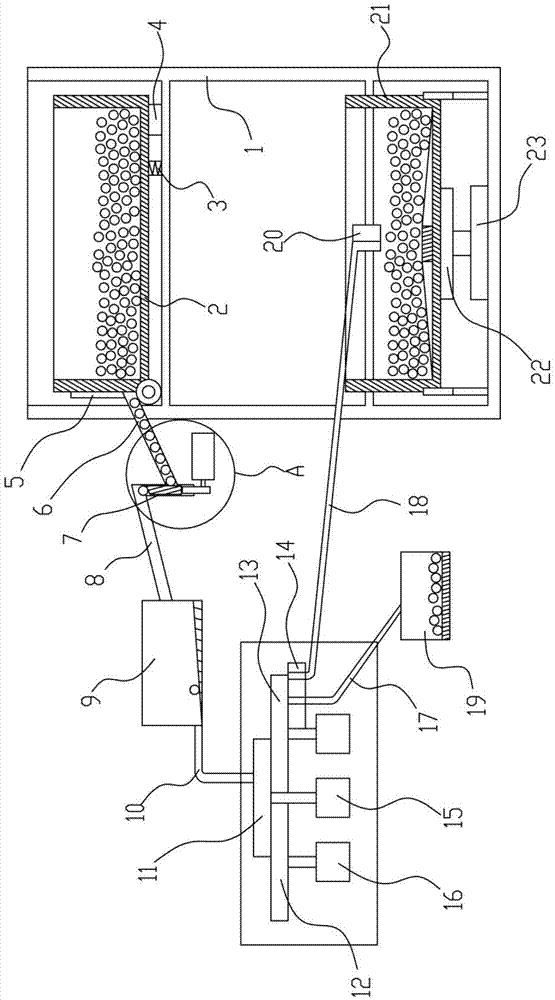

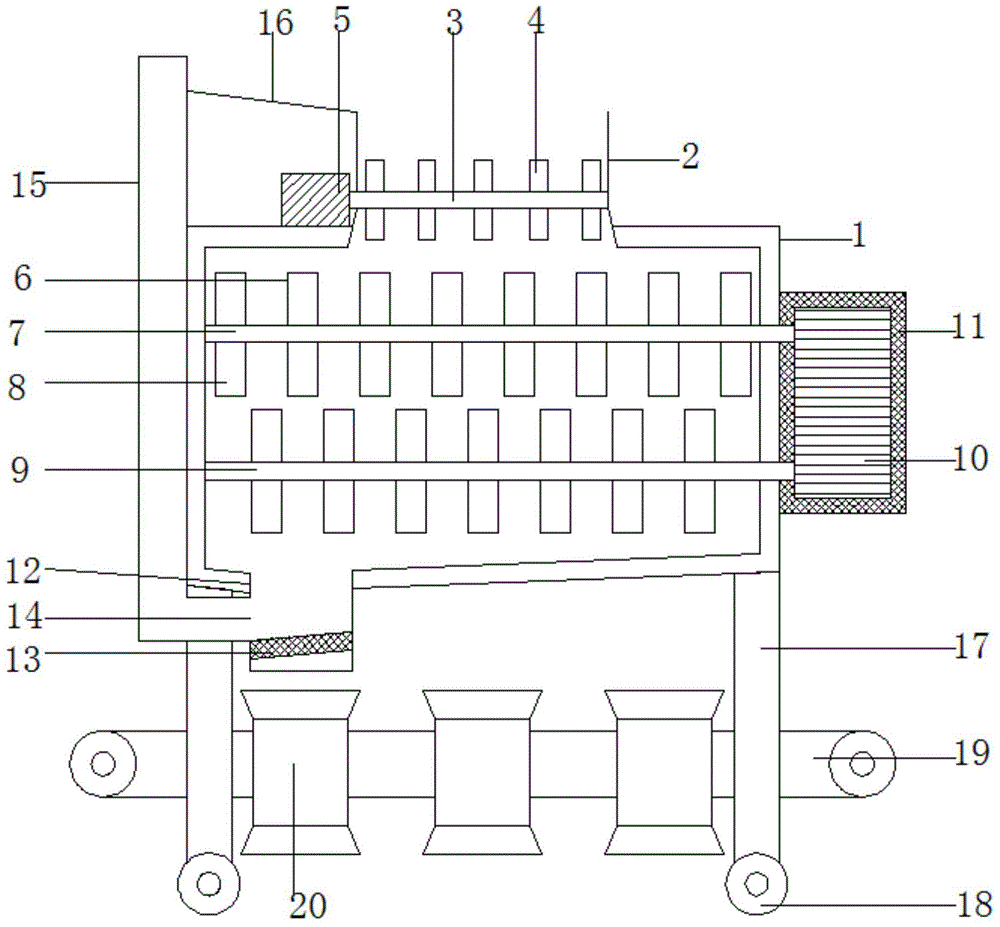

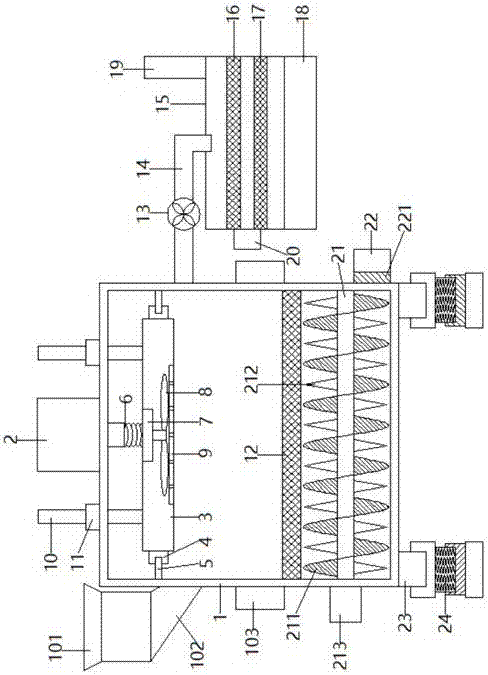

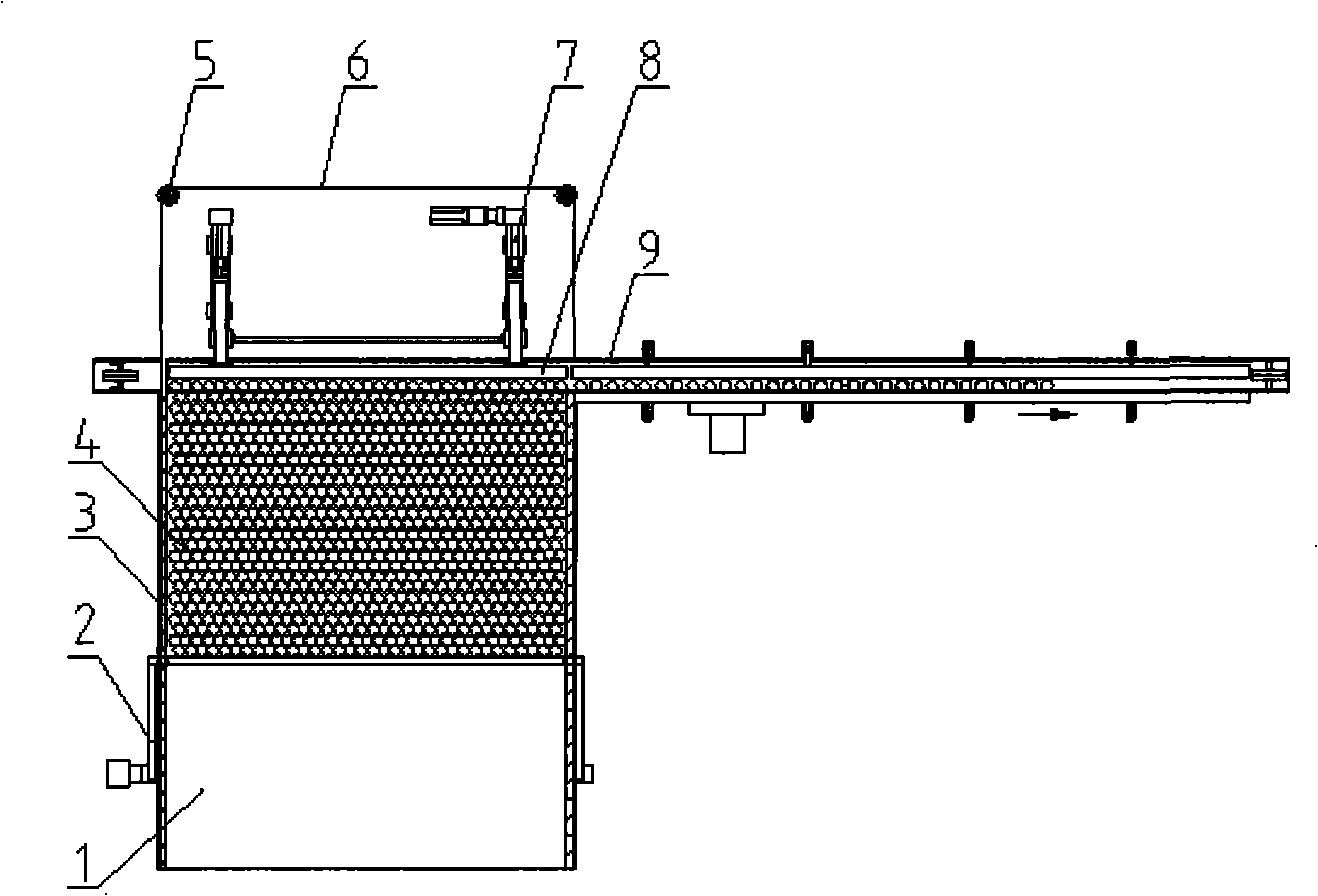

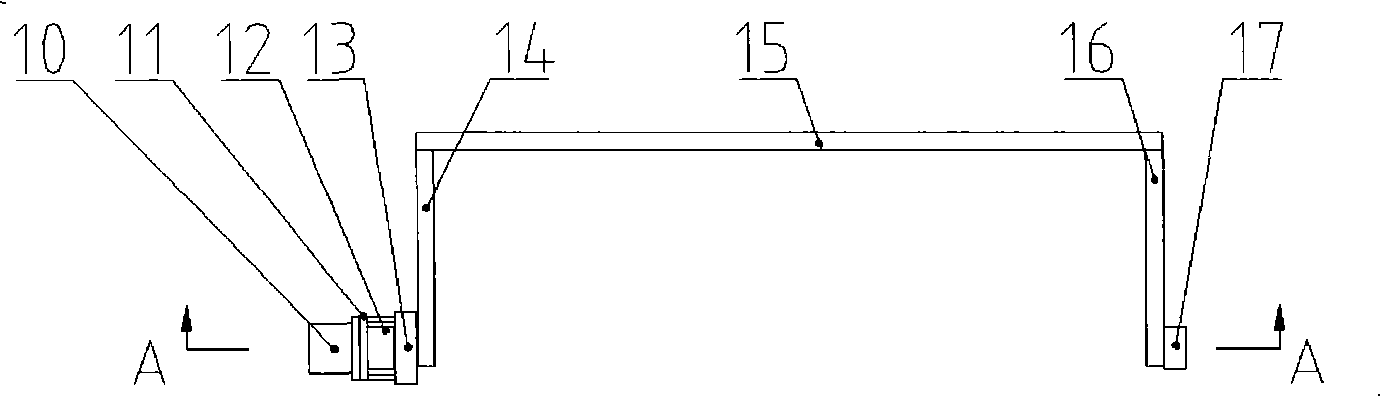

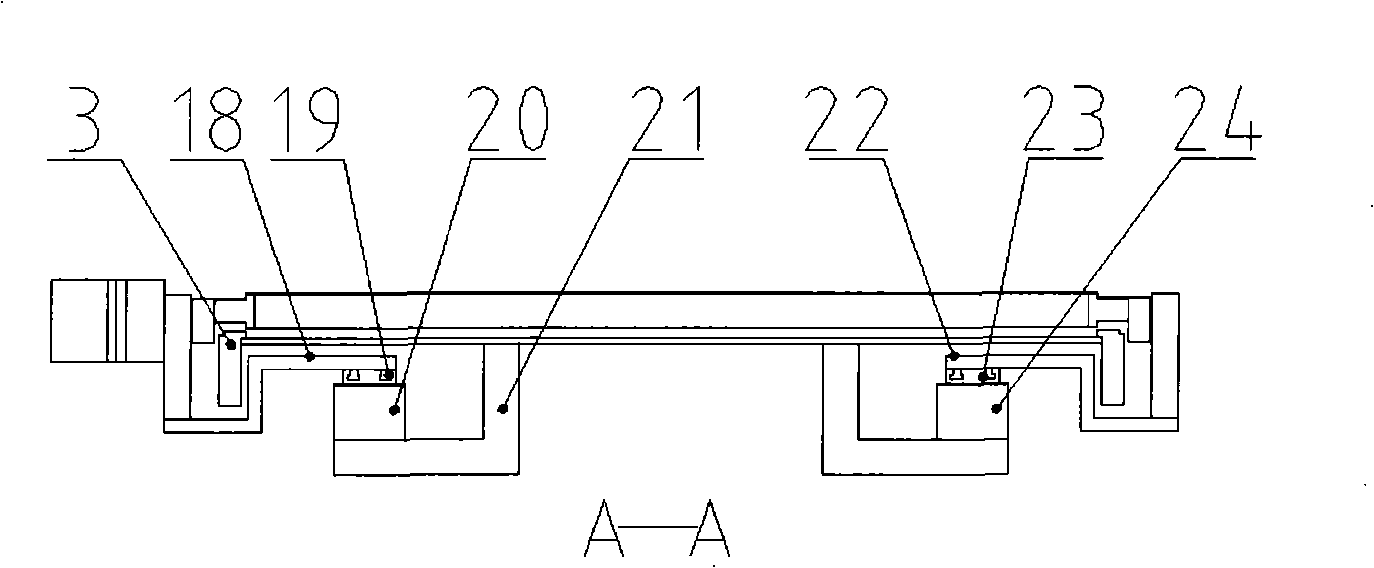

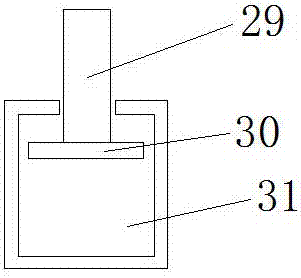

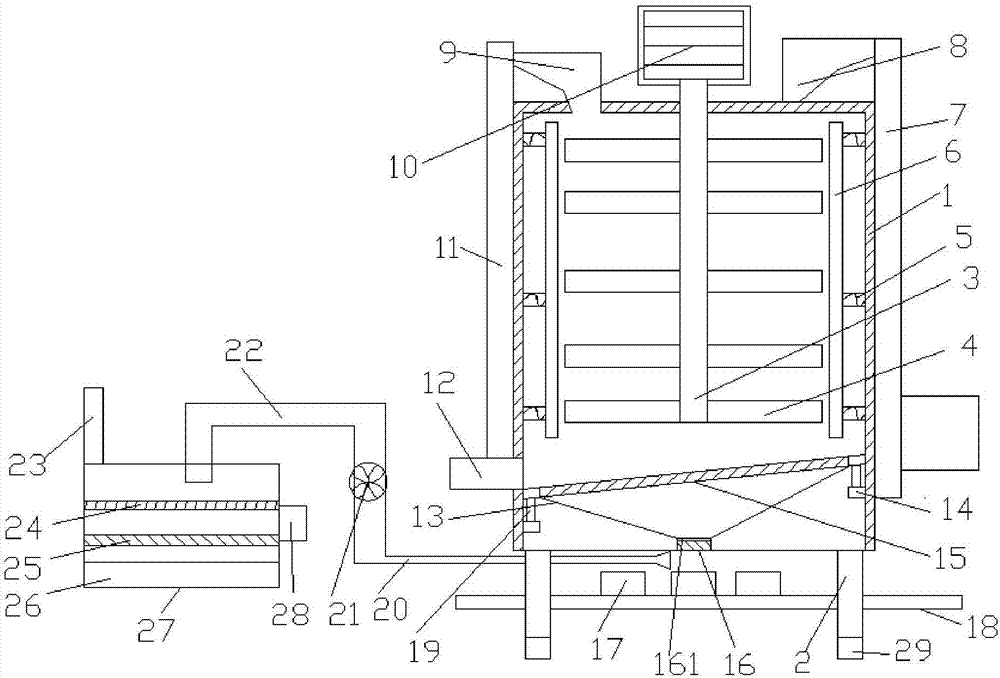

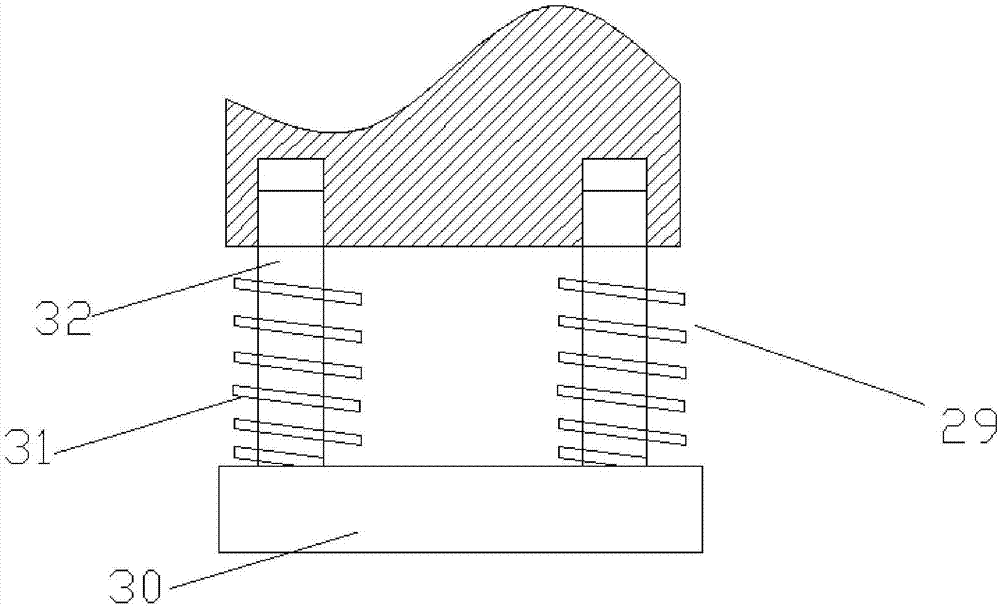

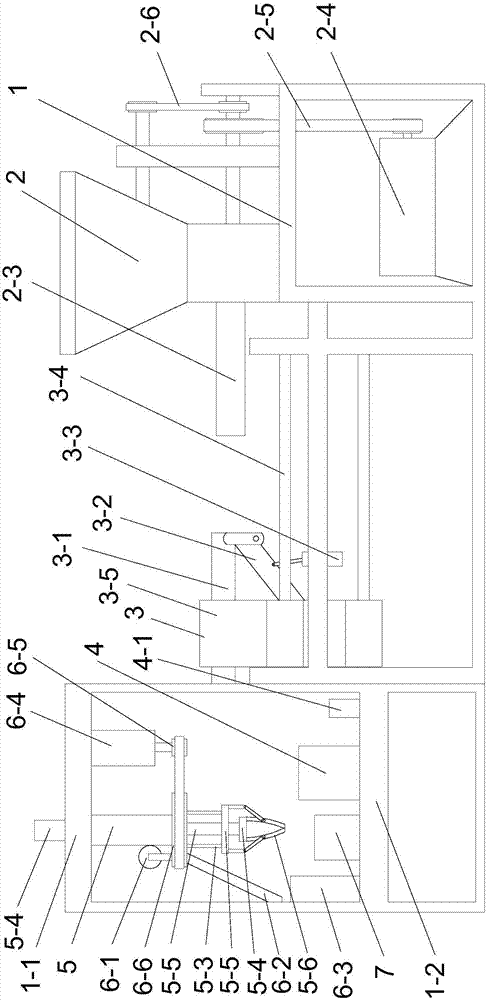

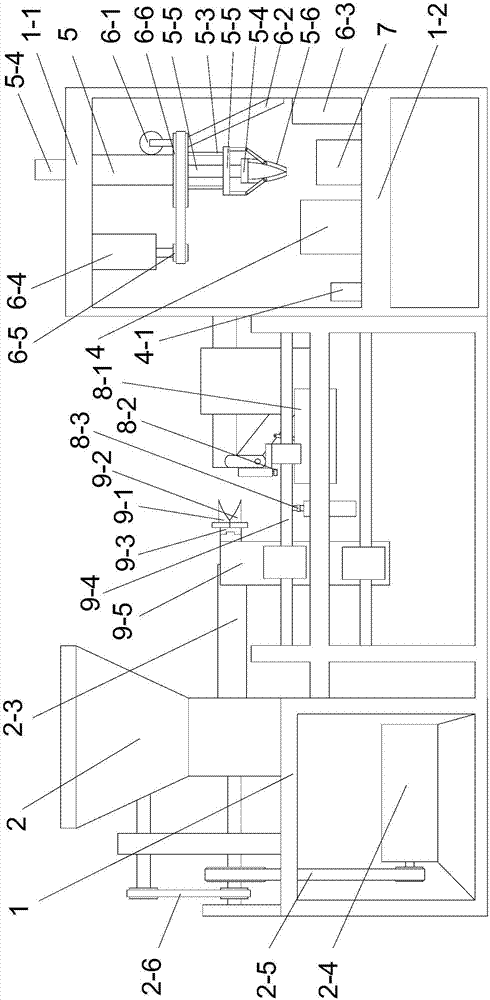

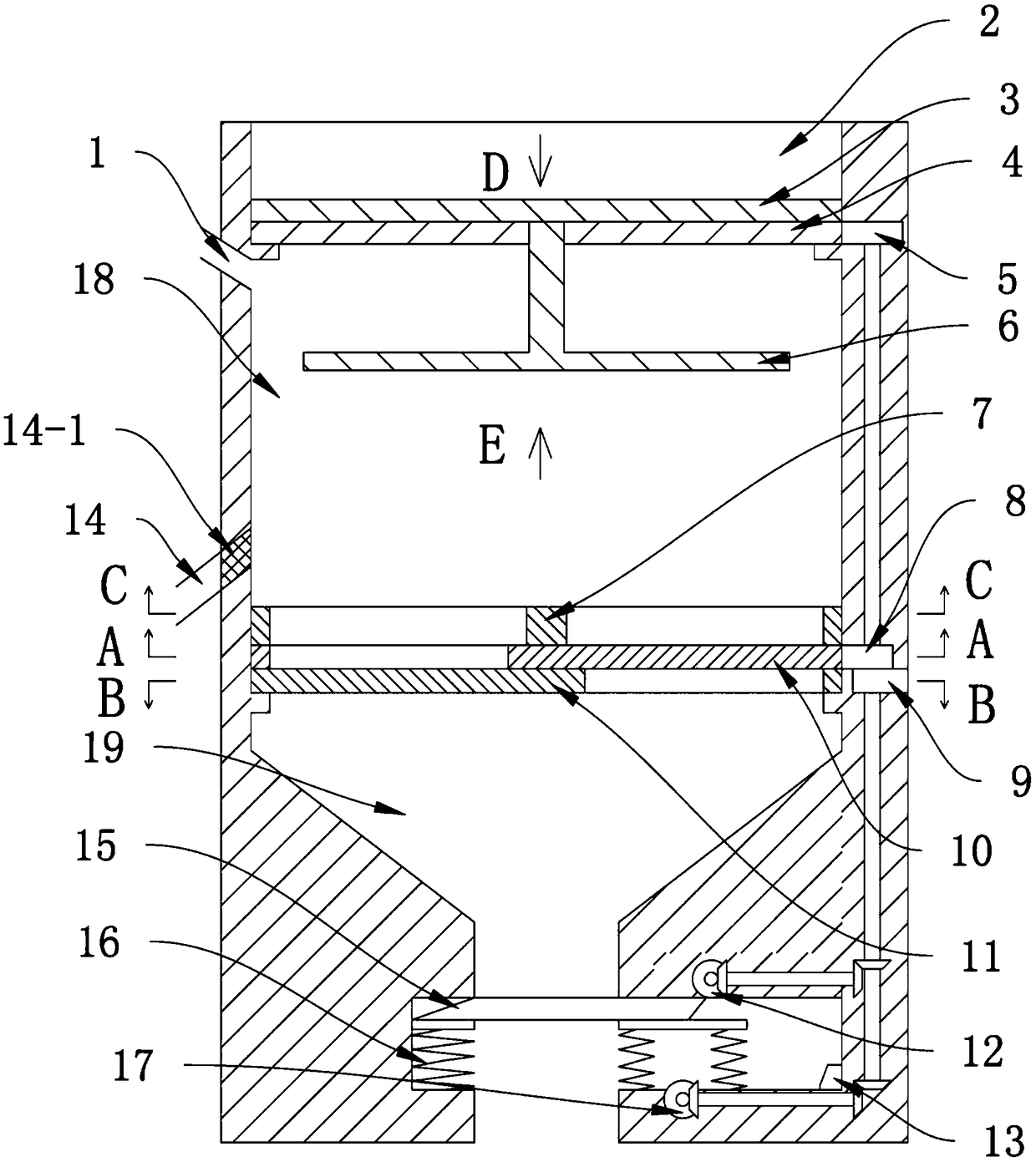

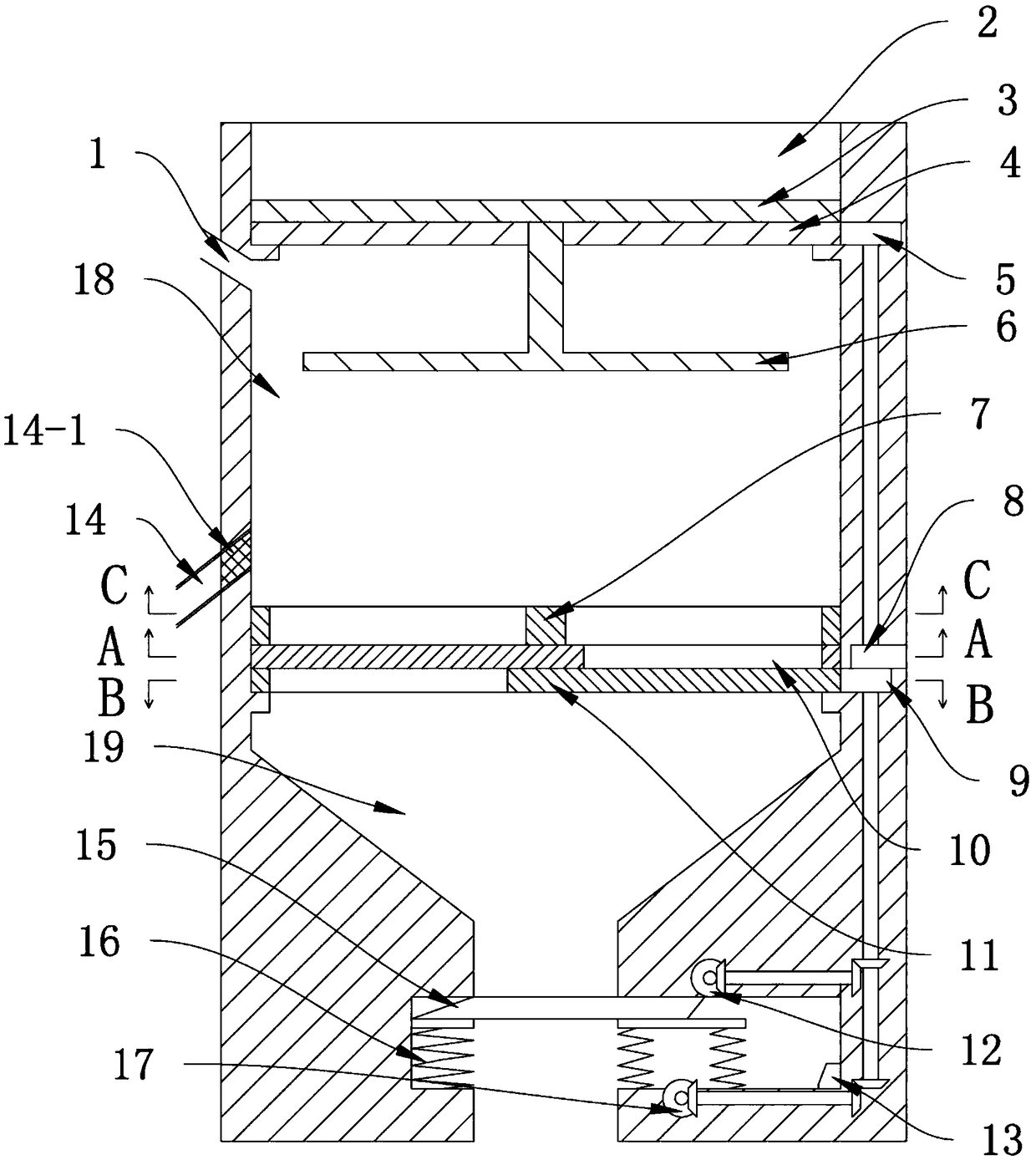

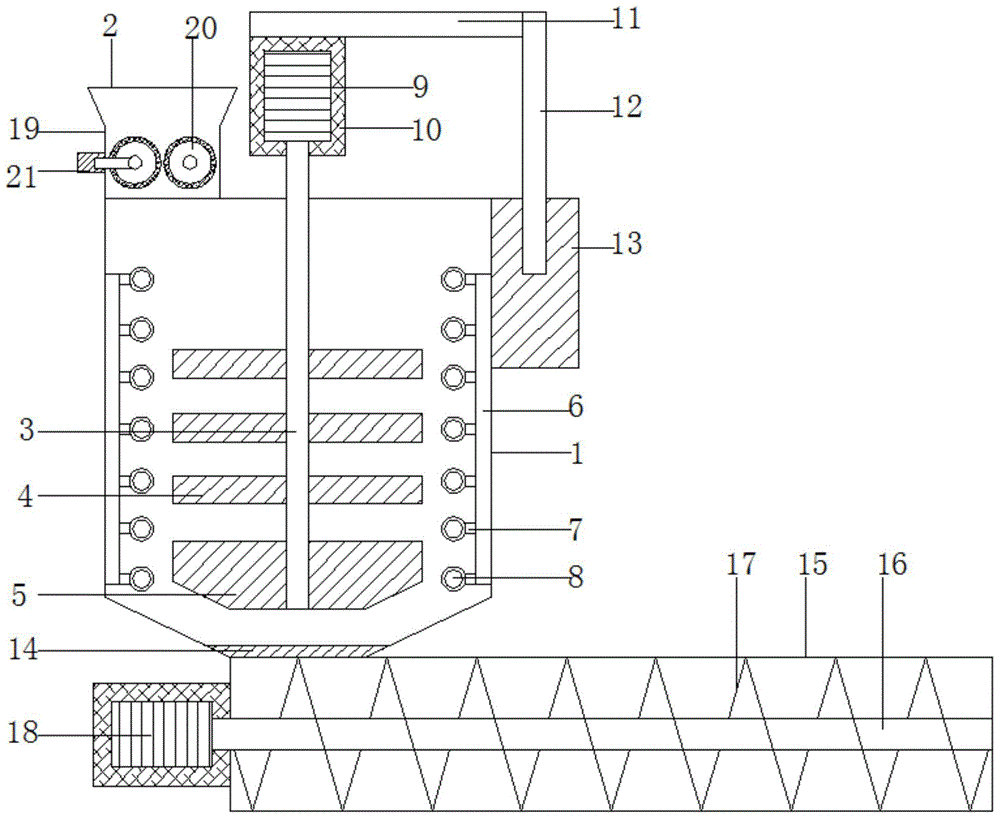

Silin bottle automatic drawing mechanism used for freeze-drying machine

ActiveCN101403563ARealize automatic dischargeRealize unmannedDrying solid materials without heatFreeze-dryingEngineering

The invention relates to a vial automatic discharging device used for a freeze dryer. The device is characterized by consisting of a material containing desk, a discharging system subassembly, guide tracks, a bracket, a decorative board, a thruster system subassembly, a handspike subassembly and a transmitter system subassembly, wherein, the material containing desk, the decorative board and the thruster subassembly are arranged on the bracket which can be slightly adjusted, the transmitter system subassembly is connected with the end of the material containing desk, the thruster system subassembly is arranged on the decorative board which is arranged at the side end of the transmitter system subassembly, the handspike subassembly is connected with a slider in the thruster system subassembly, and the discharging system subassembly is arranged on the guide tracks which are arranged at two sides of the material containing desk. The device has the advantages of providing the possibility of unmanned operation in a clean room, and and reducing pollution sources, thus providing higher guarantee for the sterility of products and effectively improving the labor productivity.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Sieving method for processing sweet potato powder

InactiveCN108188023AHigh speedReduce the amount of manual laborSievingScreeningEngineeringFeeding tube

The invention discloses a sieving method for processing sweet potato powder. The sieving method comprises the steps that the sweet potato powder is poured from a feeding hopper, and a rotary table isdriven by rotation of a motor to rotate; a rotating rod is driven by the rotation of the rotary table to perform circular motion, and a grooved pulley is driven by the rotating rod to perform intermittent rotation, so that the bottom of the feeding hopper is intermittently blocked; the sweet potato powder is fell down to the surface of a sieving mesh through a feeding tube, a first belt pulley isdriven by the work of a vibrating motor to rotate, and a second belt pulley is driven by the rotation of the first belt pulley to rotate through a belt. According to the sieving method for processingthe sweet potato powder, the sieving mesh is driven by the work of the vibrating motor to move and sieve the sweet potato powder, manual sieving is not required, the labor capacity is reduced, the speed of sieving is accelerated, and the working efficiency is improved; and the rate of feeding is controlled to enable the sweet potato powder to be intermittently and continuously fed, the stacking ofthe sweet potato powder due to too fast feeding is prevented to lead the device cannot work normally, and the use effect of the device is improved.

Owner:安吉县安信信息有限公司

Potato peeling and shredding all-in-one machine

InactiveCN107495423AAchieve peeling effectRealize automatic dischargeVegetable peelingMetal working apparatusAgricultural engineeringWater spray

The invention discloses a potato peeling and shredding all-in-one machine and belongs to the field of food processing machinery. The potato peeling and shredding all-in-one machine comprises a shredding mechanism, a peeling and cleaning mechanism, a pushing mechanism and a transmission mechanism, wherein the peeling and cleaning mechanism comprises an inner tube and a rotary disc; the rotary disc is connected with an inner shaft; the inner shaft is connected with the transmission mechanism; a grinding layer is arranged on the inner wall of the inner tube, as well as the upper end of the rotary disc; a sprinkler head is arranged in the inner tube and positioned above the rotary disc; a water spray pipe is connected to the sprinkler head; a first discharge opening is formed in the wall of the inner tube; a discharge control device is arranged at the first discharge opening; the shredding mechanism comprises an outer tube and a shredding tube fixedly arranged in the outer tube; shredding holes are formed in the shredding tube; the diameter of the upper end of the shredding tube is larger than that of the lower end; the shredding tube is connected with an outer shaft; the outer shaft is connected with the transmission mechanism; a second discharge opening is formed in the bottom of the outer tube; and the outer shaft sleeves the inner shaft in an embedding manner. The potato peeling and shredding all-in-one machine can realize the functions of peeling, cleaning and shredding of the potatoes, peeling and shredding of the potatoes are simplified, and the working efficiency is greatly improved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Efficient environmentally friendly automatic grinding machine for grinding ceramic raw materials

InactiveCN107876163AAvoid wastingAvoid noiseDispersed particle filtrationDirt cleaningElectric machineryIndustrial engineering

The invention discloses an efficient environmentally friendly automatic grinding machine for grinding ceramic raw materials. The efficient environmentally friendly automatic grinding machine comprisesa grinding machine body and supporting columns, and the supporting columns are located on the lower portion of the grinding machine body; a regrinding feeding opening and a feeding inlet are formed in the left and the right of the upper side of the machine body, a screw rod shaft is vertically arranged in the center of the interior of the grinding machine body, and grinding tools are correspondingly arranged on the left side and the right side on the outer wall of the screw rod shaft; and the top end of the screw rod shaft extends out of the outer side of the grinding machine body and is connected with a motor, baffles are vertically arranged around the interior of the grinding machine body, a screen net connected with a vibration device is arranged in the middle section of the interior of the grinding machine body, and the lower portion of the screen net is connected with a discharging opening. According to the efficient environmentally friendly automatic grinding machine for grinding the ceramic raw materials, automatic feeding and regrinding of the materials which are not completely grinded can be achieved, the grinding effect is good, the efficiency is high, automatic discharging and quantitative collecting can be achieved, dust generated in the grinding and discharging process can be collected, the environment is protected, and the raw materials are saved.

Owner:WUXI HUIOU CERAMIC CO LTD

High-efficiency crushing device for chemical production

InactiveCN106311422AAvoid cakingQuality assuranceMagnetic separationGrain treatmentsDischarge efficiencyIron removal

The invention discloses a high-efficiency crushing device for chemical production, comprising a crusher body, wherein a feeding hopper is arranged on the upper side of the crusher body; an iron removal rotation shaft is horizontally arranged on the lower side inside the feeding hopper; permanent magnets are arranged on the outer wall of the rotation shaft in longitudinal symmetry; a first crushing mechanism is horizontally arranged on the upper side inside the crusher body and a second crushing mechanism is horizontally arranged on the lower side of the first crushing mechanism. By the crushing device, iron can be removed from materials and the quality of materials is ensured; materials are fully crushed by two crushing mechanisms and crushing gears arranged in a staggered way, crushed materials are filtrated and materials without meeting the size are recurrently lifted to the crusher for being crushed by a lifter, the crushing effect is ensured, the crushing efficiency is increased, materials are discharged through vibration to prevent from stoppage and are discharged with driving of a conveyor belt and without manual operation, the discharging efficiency of materials is increased, and the crushing device is convenient and quick to operate.

Owner:GUANGXI UNIV

Efficient tea-leaf cleaning and fixation equipment

InactiveCN104012692ARealize automatic dischargeImprove qualityPre-extraction tea treatmentCleaning using liquidsWater storage tankLifting gas

The invention discloses efficient tea-leaf cleaning and fixation equipment. The efficient tea-leaf cleaning and fixation equipment comprises a cleaner, a fixation device and a lifting mechanism, wherein the cleaner comprises a bracket, a water slot, a ultrasonic-wave generator, a slide rod, a lifting gas cylinder and a discharge table, wherein the discharge table is arranged on one side of the bracket; a discharge hopper is arranged on the discharge table; the discharge hopper and the discharge table are fixedly arranged by a first spring; a first vibrating motor is arranged on the discharge hopper; the bottom layer of the discharge hopper is a water-permeable mesh layer; a water storage tank is arranged on the discharge table; the fixation device comprises a rack, a motor, a sleeve, a roller and a heating furnace; the sleeve is fixed on the rack; a rolling wheel is arranged in the sleeve; the sleeve and the roller are arranged in a rolling manner by the rolling wheel; one end of the roller is connected with an electric motor through a belt wheel and a belt; a plurality of dispersing blades are arranged on the roller; a tea feeding channel is fixed on the rack; a moisture exhausting hole is formed in the tea feeding channel; the discharge hopper and the tea feeding channel are connected with each other by the lifting mechanism. The efficient tea-leaf cleaning and fixation equipment disclosed by the invention can effectively improve a cleaning effect and can complete automatic discharging after cleaning.

Owner:山东万平农业开发有限公司

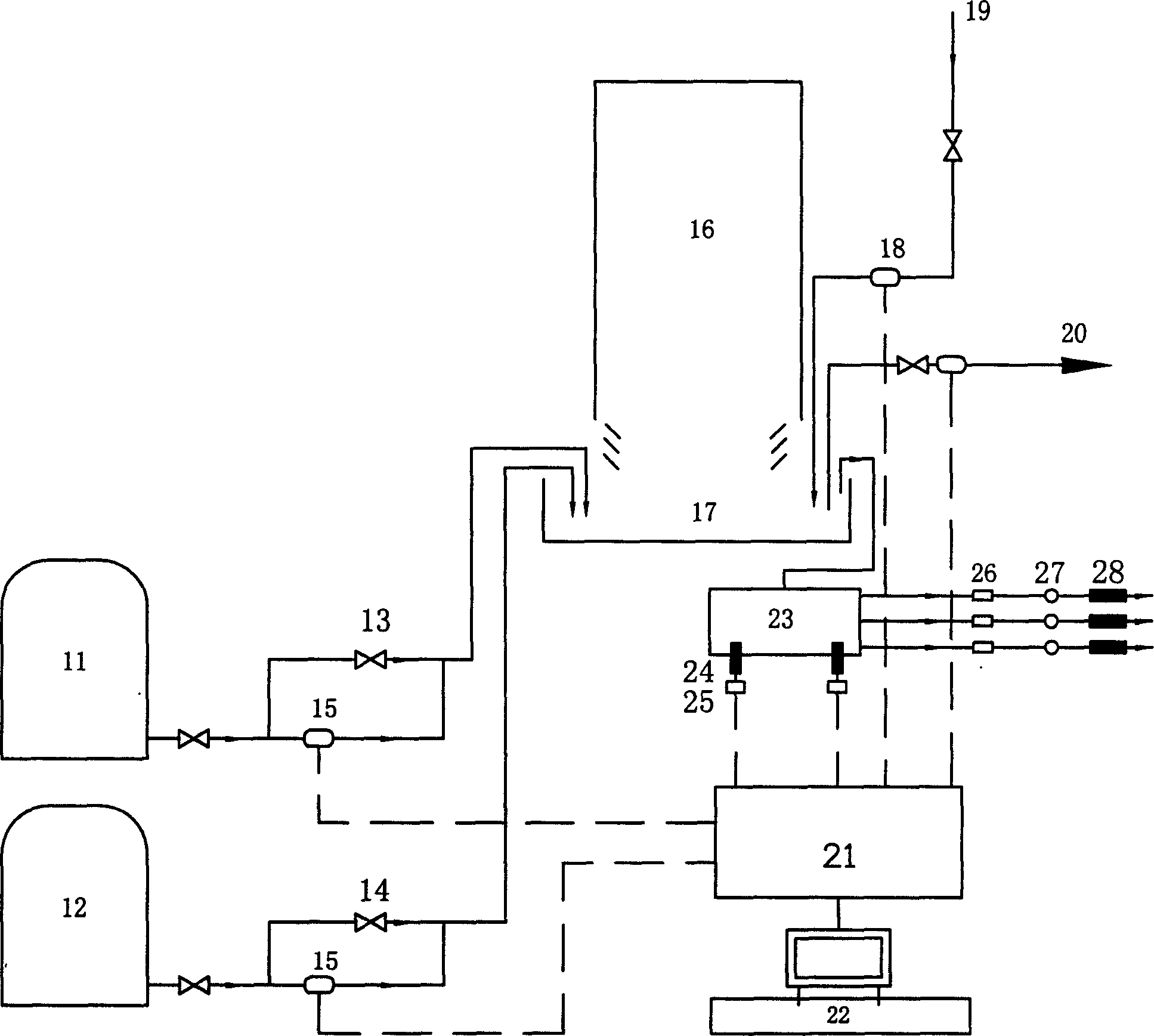

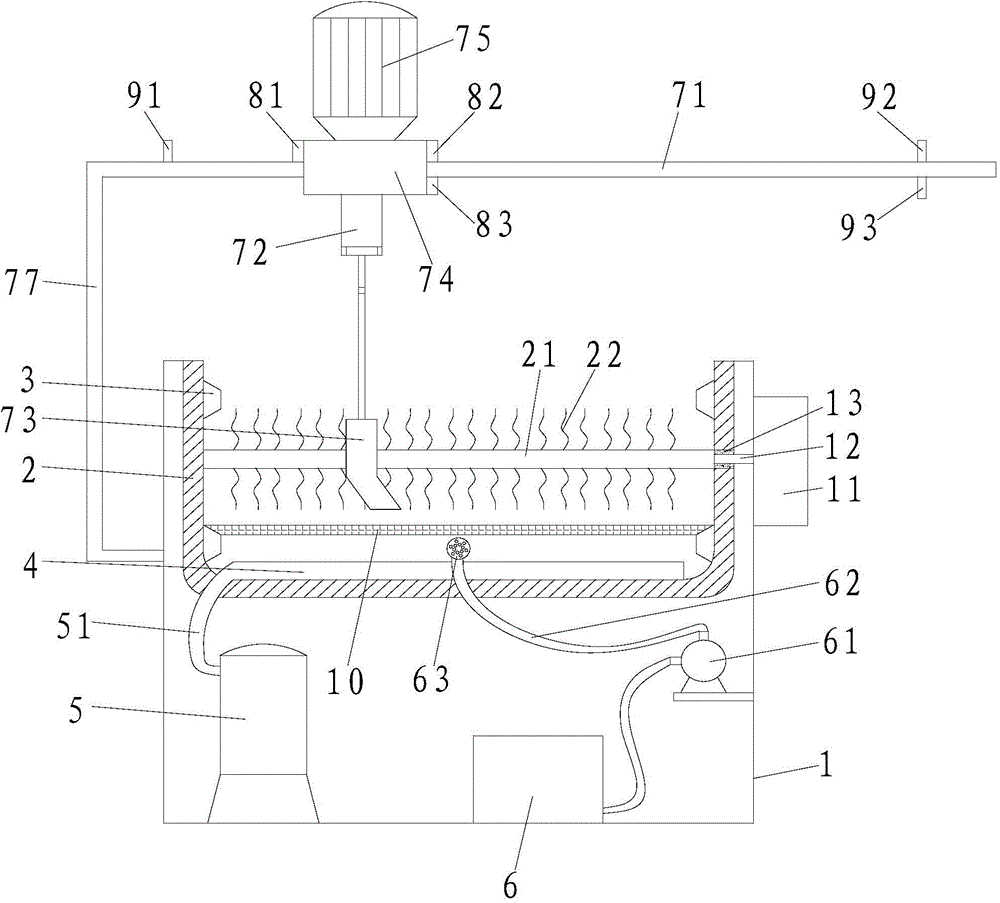

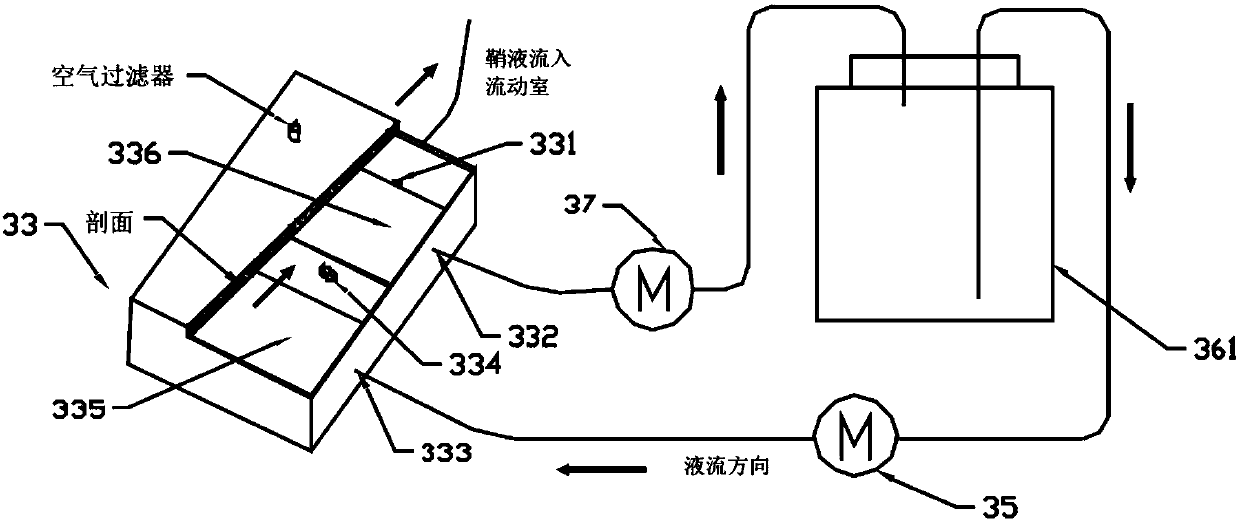

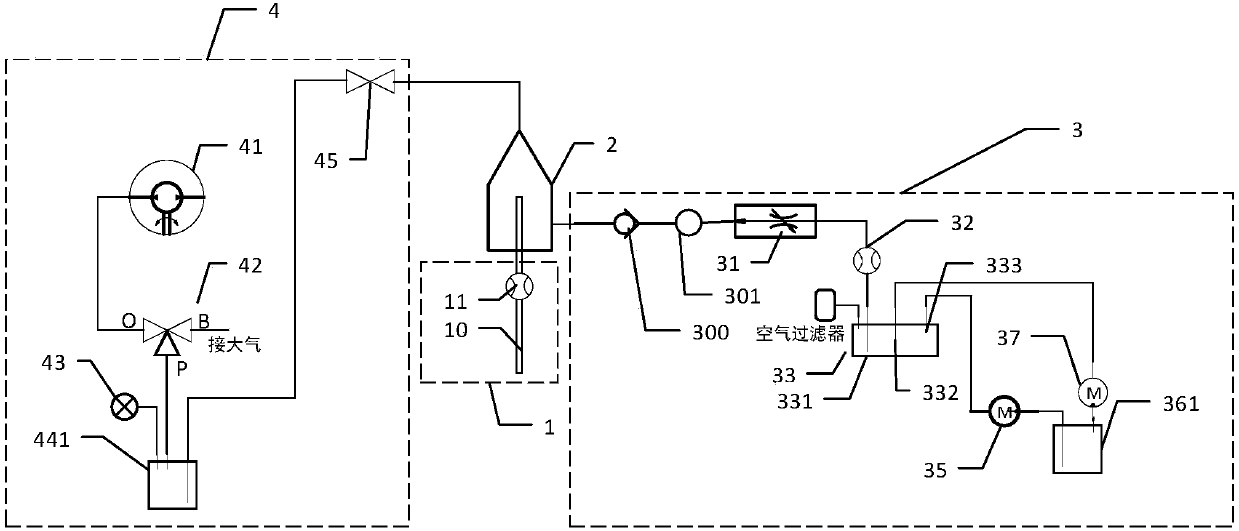

Fluid flow system of flow cytometry and control method thereof

PendingCN107782657AEliminate sheath fluid pulsationFacilitate cleaning and decloggingIndividual particle analysisBiomedical engineeringCirculating pump

The invention discloses a fluid flow system of a flow cytometry and a control method. The fluid flow system comprises a sample fluid passage, a sheath fluid passage, a negative pressure source passageand a flowing chamber, wherein the sample fluid passage, the sheath fluid passage and the negative pressure source passage are respectively connected with the flowing chamber; the sheath fluid passage is provided with a position potential energy stabilizing device; the position potential energy stabilizing device comprises a sheath fluid container, a sheath fluid buffer device, a first sheath fluid circulating pump and a second sheath fluid circulating pump; the sheath fluid buffer device is provided with a sheath fluid inlet and two sheath fluid outlets; an inlet of the first sheath fluid circulating pump is communicated with the sheath fluid container, and an outlet of the first sheath fluid circulating pump is communicated with the sheath fluid inlet of the sheath fluid buffer device;one sheath fluid outlet of the sheath fluid buffer device is communicated with the flowing chamber, one sheath fluid outlet of the sheath fluid buffer device is communicated with an inlet of a secondsheath fluid circulating pump, and an outlet of the second sheath fluid circulating pump is communicated with the sheath fluid container; the sheath fluid outlet connected with the second sheath fluidcirculating pump in the sheath fluid buffer device is higher than the sheath fluid outlet connected with the flowing chamber. The fluid flow system has the advantages that the sheath fluid is precisely controlled, and the pulsation of the sheath fluid is prohibited.

Owner:成都索尔恩科技有限公司

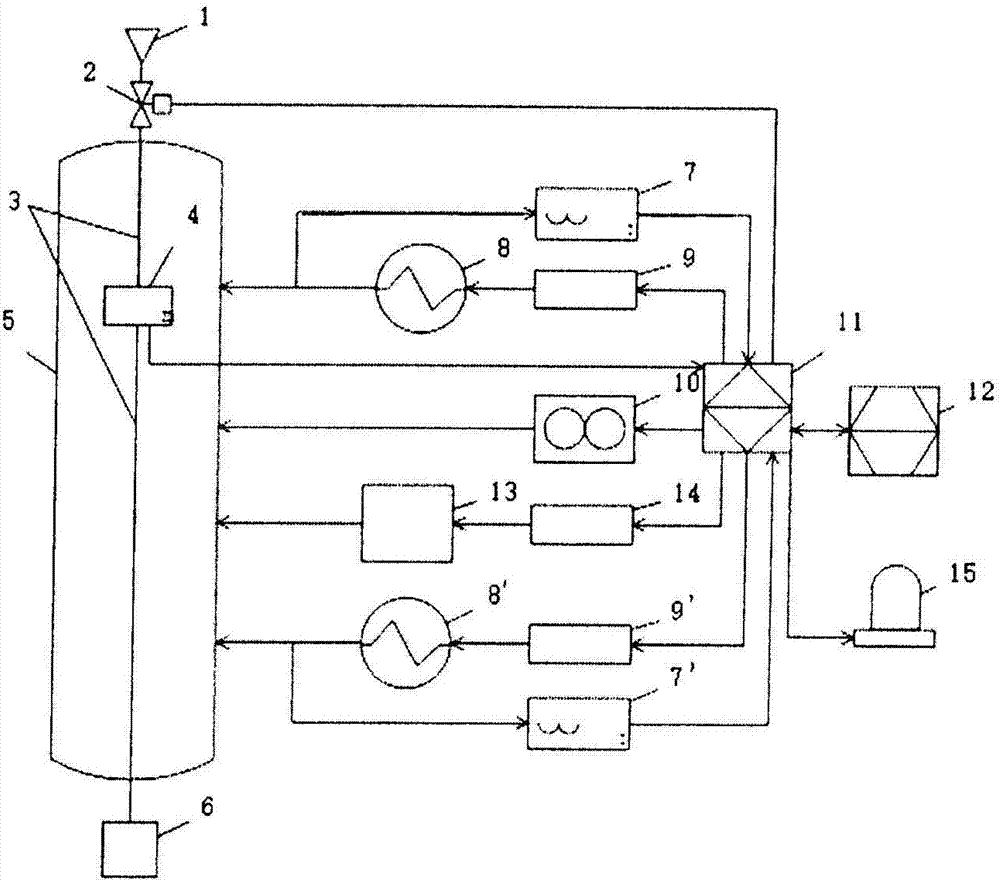

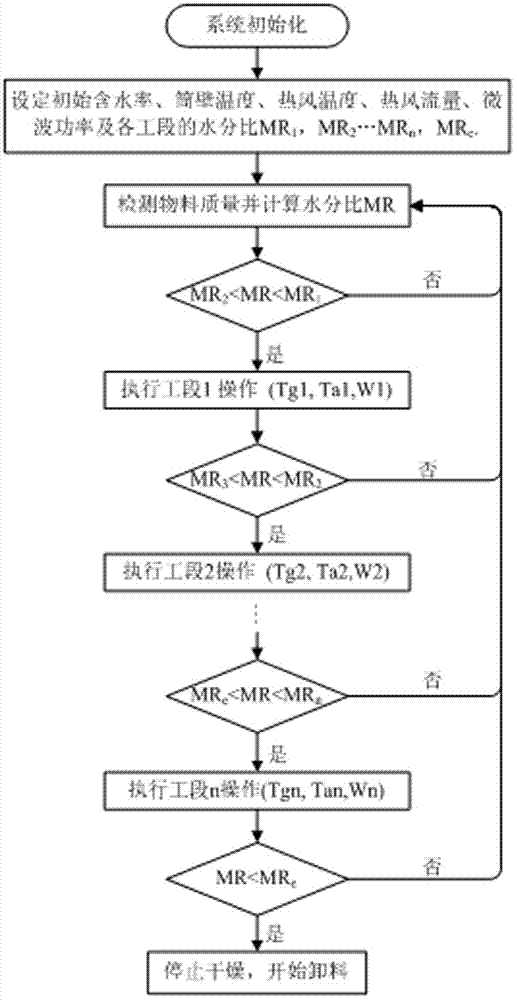

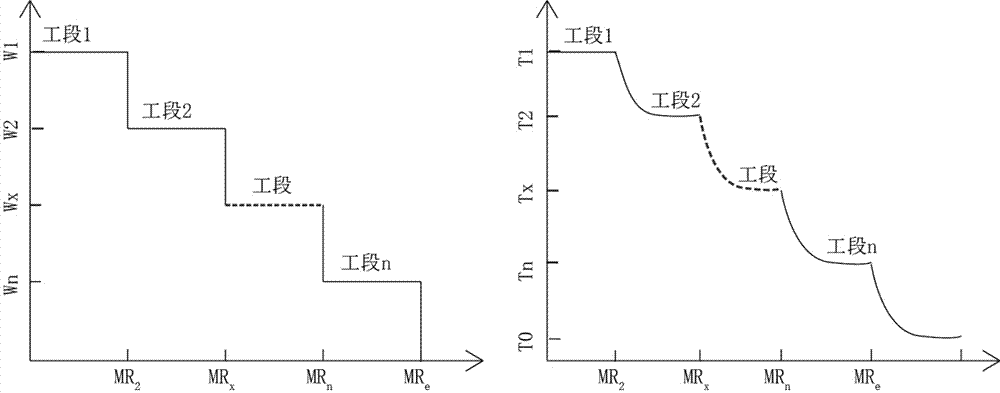

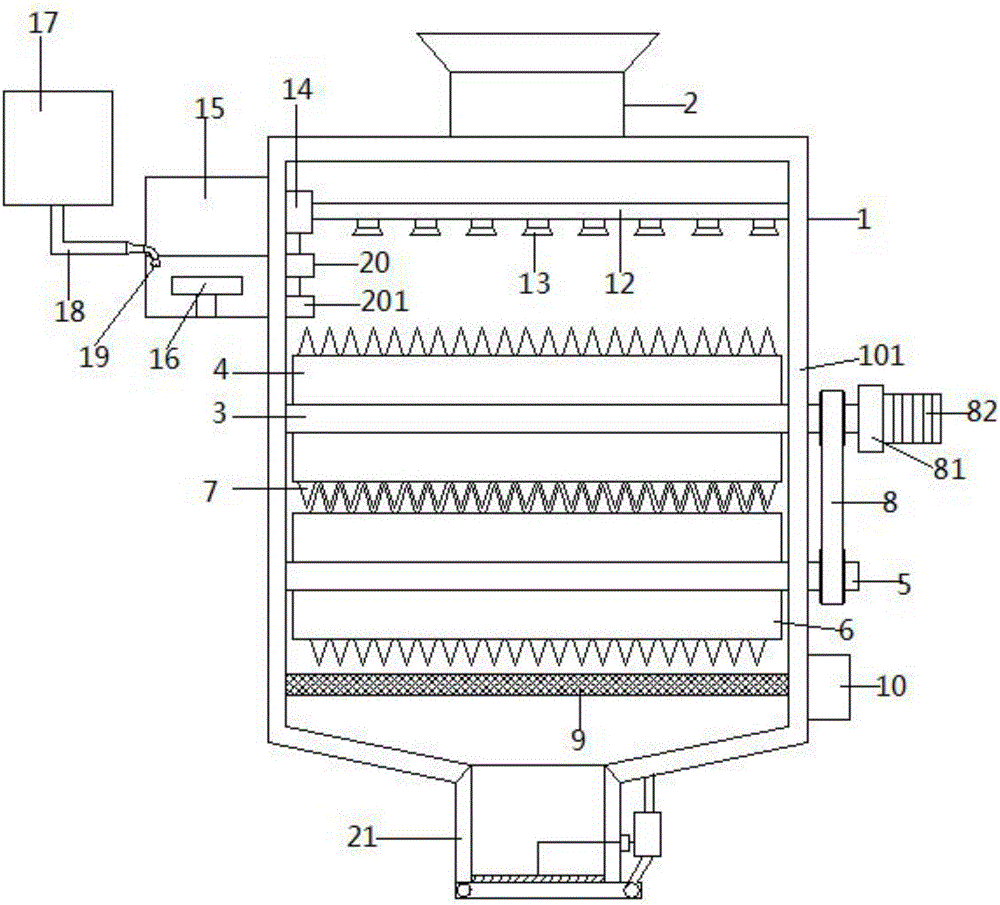

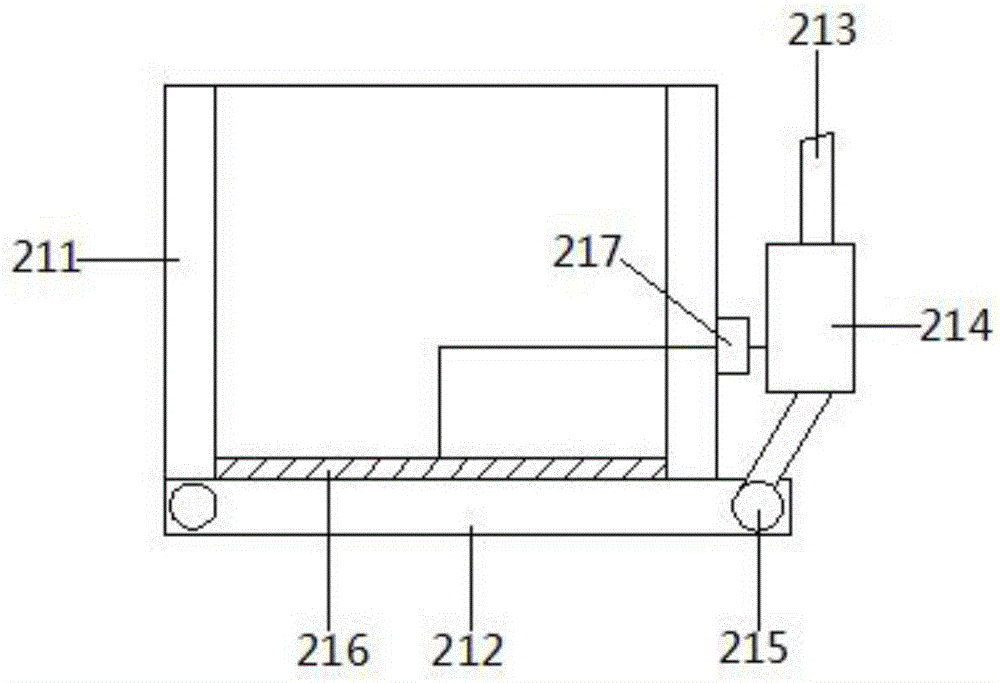

Automatic tobacco material drying intensity regulating system applicable to microwave and fixed bed hot air combined drying process as well as method using regulating system

ActiveCN106954878ARealize automatic feedingRealize automatic dischargeTobacco preparationTemperature control using electric meansProcess engineeringProgrammable logic controller

An automatic tobacco material drying intensity regulating system applicable to a microwave and fixed bed hot air combined drying process comprises a drying equipment body as well as an automatic feeding and discharging control unit, a hot air drying control unit, a cylinder wall temperature control unit, a detection control unit and a microwave power control unit which are connected with the drying equipment body and capable of controlling the working process and condition of the drying equipment body, wherein the feeding and discharging control unit consists of a feeding port, a discharging valve, a chute, a hanging basket and a receiver; each of the hot air drying control unit and the cylinder wall temperature control unit consists of a temperature sensor, an electric heater and a driving device; the detection control unit comprises a PLC (programmable logic controller), a computer and the like; the microwave power control unit comprises a microwave generator and a driving device of the microwave generator; each control unit is connected with the PLC and the computer and receives and executes instructions of the PLC and the computer. The system can control the power of each drying unit according to the moisture ratio in the material drying process, and combined dried products with more stable quality can be obtained finally.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Environment-friendly smashing device with quantitative discharging function

InactiveCN106423387AGood crushing effectSpeed up the fallUsing liquid separation agentGrain treatmentsEnergy consumptionMechanical engineering

The invention discloses an environment-friendly smashing device with a quantitative discharging function. The environment-friendly smashing device comprises a device body. A silencing layer is arranged on the outer wall of the device body. A feed hopper is arranged on the upper side of the device body. A first rotary shaft is arranged on the upper side of the inside of the device body. A first squeeze roller is arranged on the outer wall of the first rotary shaft. A second rotary shaft is arranged below the first rotary shaft. A second squeeze roller is arranged on the outer wall of the second rotary shaft and arranged parallel to the first squeeze roller. Smashing teeth are arranged on the outer walls of the first squeeze roller and the second squeeze roller. According to the environment-friendly smashing device with the quantitative discharging function, the smashing teeth on the two squeeze rollers arranged vertically are engaged to smash materials, and the smashing effect is good; the two squeeze rollers are driven by one motor, so that the energy consumption is lowered; water mist can be sprayed into the device body through an atomizing device, the water mist fully covers the materials, the materials are humidified while dust is reduced, and the quality of the materials is guaranteed; and in addition, automatic discharging can be achieved, the discharging quantity in the discharging process can be controlled, and quantitative discharging is achieved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

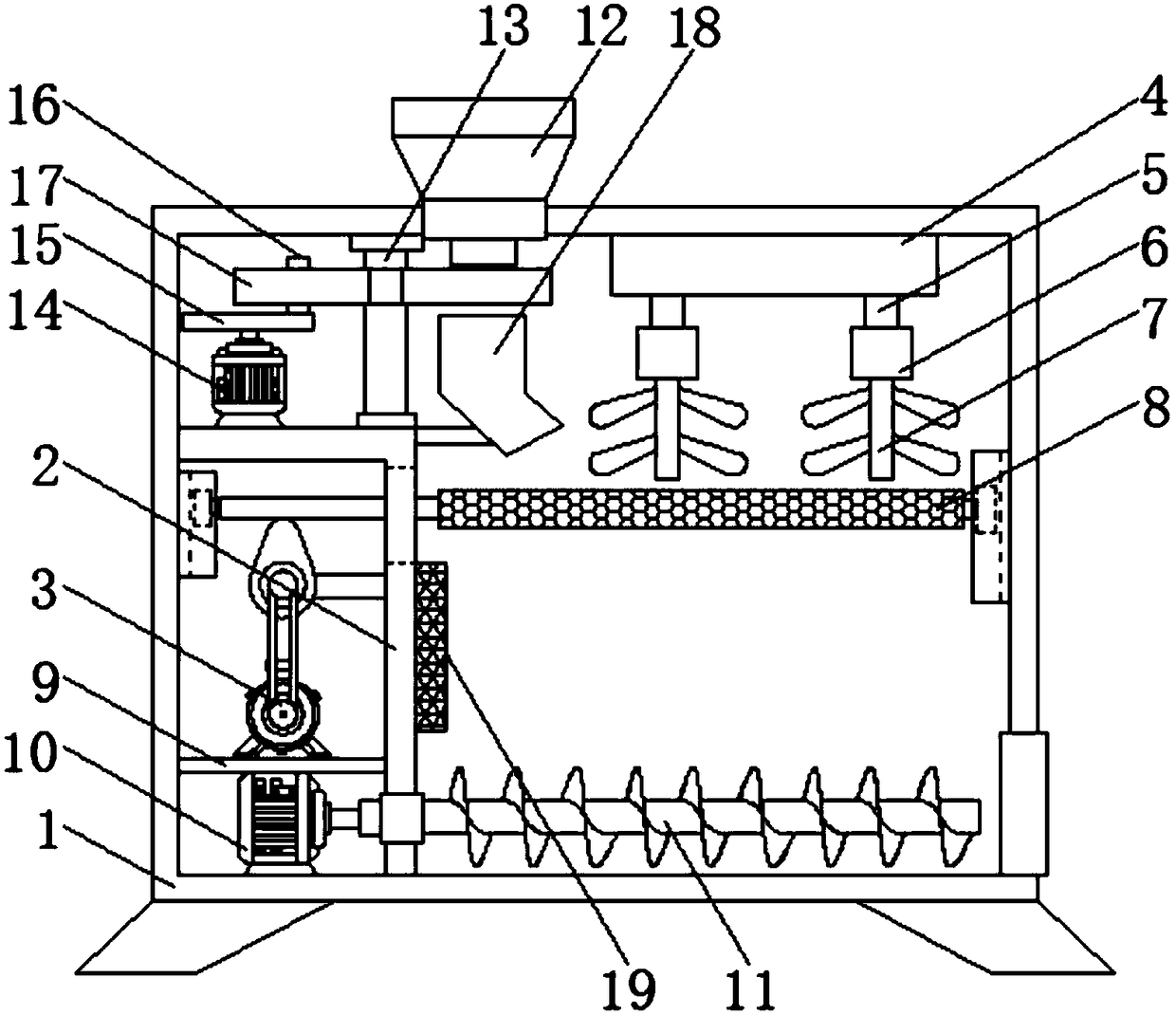

Fully automatic packaging device for fungus sticks

ActiveCN106982647AStir wellRealize automatic dischargeCultivating equipmentsMushroom cultivationStrappingEngineering

The invention relates to a fully automatic packaging device for fungus sticks. The device comprises a rack, a feed hopper is arranged on the rack, a discharge tube extends laterally from the lower part of the feed hopper, and a holding tube, which can move horizontally and be arranged on the discharge tube in a sleeving mode, used for holding a fungus stick, is arranged by side in the axial direction of the discharge tube. A bag sucking mechanism used for opening the bag opening of a fungus bag is arranged on the side in the radial direction of the holding tube. A bagging mechanism which can move horizontally and vertically so as to put the fungus bag on the discharge tube is arranged on the side of the bag sucking mechanism. A clamping compaction mechanism used for clamping the bag opening of the fungus bag and compacting the fungus sticks and a strapping and sealing mechanism used for sealing the bag opening of the fungus bag are installed on an air cylinder mounting plate. According to the fully automatic packaging device for the fungus sticks, the bag opening of the fungus bag is tied with an iron wire, and the rotation of a rope arm is driven by rotation of a gear carrier; as one end of the iron wire is fixed in a blade, the rotation of the rope arm drives the iron wire to strap around the bag opening, automatic opening strapping of the fungus sticks is achieved, and the packaging efficiency is high.

Owner:许銮塑

Environment-friendly layered sewage treatment device

ActiveCN108654150ASimple and efficient operationAchieve separationSettling tanks feed/dischargeTreatment involving sedimentationImpellerEnvironmentally friendly

The invention discloses an environment-friendly layered sewage treatment device. The environment-friendly layered sewage treatment device comprises a device shell which is provided with a blanking chamber, a separating settling chamber and a sediment discharging chamber, wherein the separating settling chamber is provided with a water inlet and a water outlet, an impeller turntable device, which is driven by using intake water of a water inlet to control a flocculant of a blanking room to fall, is arranged between the blanking chamber and the separating settling chamber, a separating disc device, which is used for controlling sediments to fall, is arranged between the separating settling chamber and the sediment discharging chamber and is connected with the impeller turntable device through a gear device, and a baffle device, which is opened and closed by using own weight of the sediments, is arranged at the lower part of the sediment discharging chamber and is connected with the geardevice. According to the environment-friendly layered sewage treatment device, the separated layering and discharging of filtering water and the sediments can be achieved, and automated discharge canbe achieved according to accumulation volume of the sediments; and the device is free of a motor, is free of manual operation, is energy-saving and environmentally friendly and is simple and convenient in operation.

Owner:江苏国态环保集团有限公司

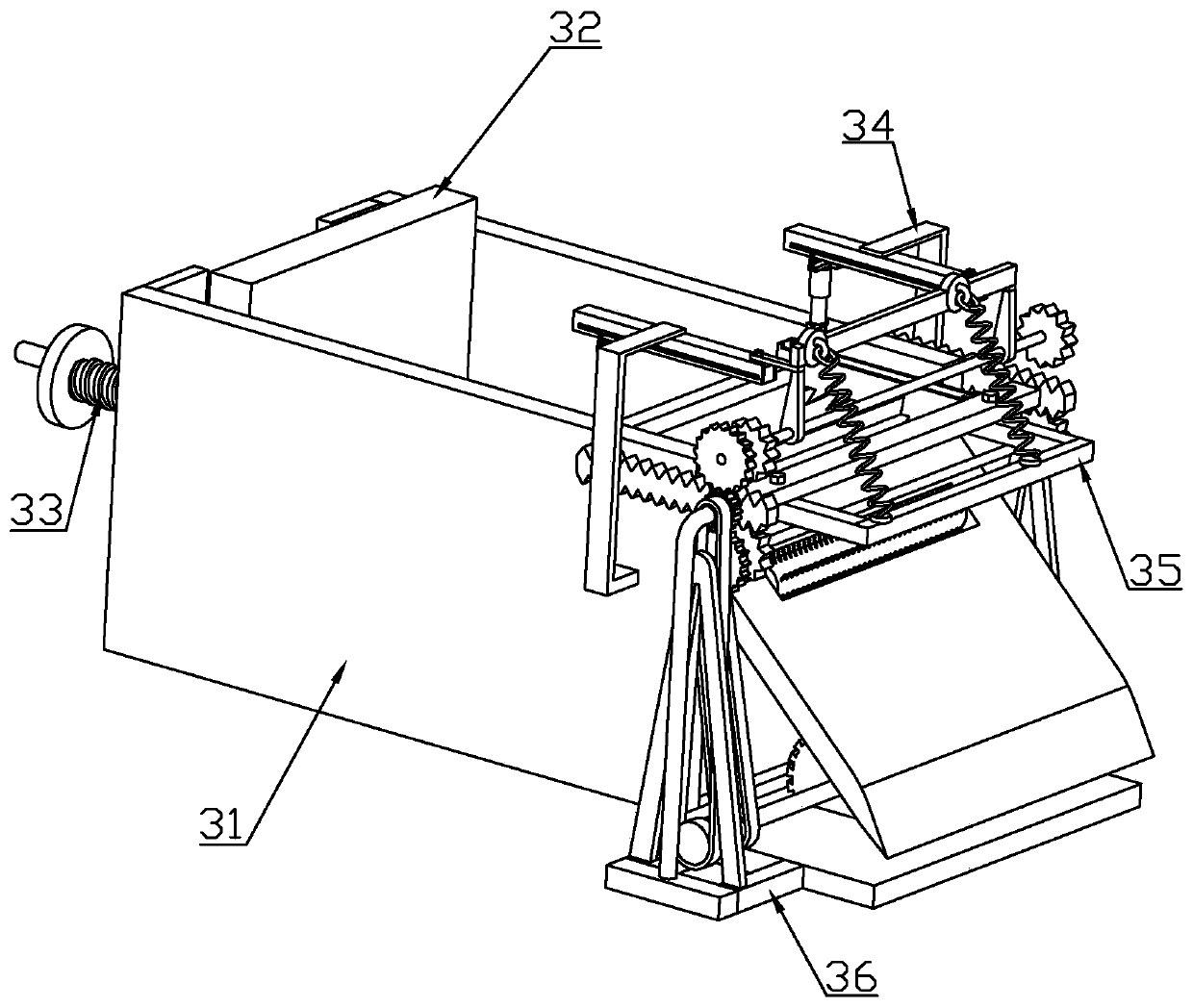

Urban garden square turf laying machine

ActiveCN109845590AFree laborImprove efficiencyHops/wine cultivationTurf growingVehicle frameStorage tank

The invention discloses an urban garden square turf laying machine. The urban garden square turf laying machine comprises a carrier vehicle, a conveying mechanism and a feeding mechanism, wherein thecarrier vehicle comprises a vehicle frame plate, a hydraulic lift and moving wheels; both ends of the bottom of the vehicle frame plate are provided with horizontal shafts, and both ends of the horizontal shafts are provided with the moving wheels for moving the urban garden square turf laying machine; the feeding mechanism comprises a storage tank, a pressure rack, a pulling rack, a transmissiongroup and a support bracket; the storage tank is arranged at the top of the hydraulic lift, fixed by vertical rods and formed by assembling two tank frames, one end of the storage tank is provided with a notch, inside the side of the storage tank where the notch is formed is slidingly connected with a push plate, one side of the push plate is provided with a screw which are threadedly connected toone side of the body of the storage tank, and by screwing the screw, the push plate can be pushed to move towards the inside of the storage tank to an appropriate position for limiting turfs. The urban garden square turf laying machine is reasonable in structure and simple in operation and can greatly improve the turf laying efficiency and save labor.

Owner:山东天智信息科技有限公司

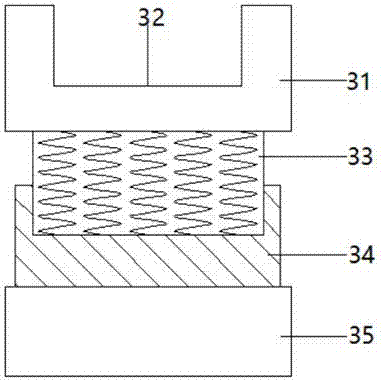

Ripper die scrap material ejecting and sliding mechanism

InactiveCN103878268ARealize automatic dischargeSmooth dischargeEjection devicesFixed frameEngineering

The invention discloses a ripper die scrap material ejecting and sliding mechanism. The ripper die scrap material ejecting and sliding mechanism comprises a fixing frame, a material ejecting and sliding frame and an ejecting mechanism, wherein the material ejecting and sliding frame is arranged at the top end of the fixing frame in a pivot mode, the ejecting mechanism is arranged on one side of the fixing frame, and the ejecting mechanism can eject and lower the material ejecting and sliding frame to enable the material ejecting and sliding frame to be pivoted at the top end of the fixing frame. According to the ripper die scrap material ejecting and sliding mechanism, the material ejecting and sliding frame and the ejecting mechanism are arranged, the material ejecting and sliding frame is ejected and lowered through the ejecting mechanism, scrap materials can be discharged automatically, the phenomenon of material jamming of the scrap materials can be avoided, discharging is smooth, and a line is stable.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Efficient concrete stirrer with crushing device

InactiveCN104960092AQuality improvementQuality assuranceDischarging apparatusMixing operation control apparatusHydraulic cylinderEngineering

The invention discloses an efficient concrete stirrer with a crushing device. The efficient concrete stirrer comprises a stirring barrel, a spiral conveying barrel and a crushing cavity. A feeding hopper is arranged at the left end of the upper side of the stirring barrel. The lower side of the feeding hopper is connected with the crushing cavity. Two crushing rollers are arranged inside the crushing cavity side by side. A crushing gap is arranged between the two crushing rollers. According to the efficient concrete stirrer with the crushing device, concrete is stirred in the horizontal direction and the vertical direction at the same time through stirring blades, a stirring plate and stirring wheels. A hydraulic cylinder is utilized for driving a stirring mechanism to move up and down to perform stirring, the stirring effect and the working efficiency of the stirrer are greatly improved, and the quality of the concrete is guaranteed; automatic discharging is achieved through a bolt conveying mechanism, concrete continues to be stirred in the discharging process, and the working efficiency of the stirrer is improved; in addition, the noise of the stirrer is low in the working process, concrete raw materials can be sufficiently crushed, and the size of crushed particles can be controlled.

Owner:苏晓玲

Fully automatic pipe pile production line

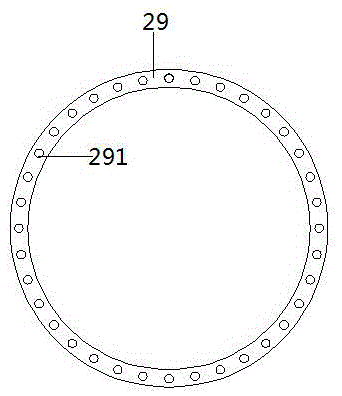

ActiveCN105599128BReliable disengagementSafe escapeCeramic shaping plantsShaping reinforcementsProduction lineDrive shaft

The invention belongs to the technical field of construction and relates to a fully-automatic tubular pile production line. The fully-automatic tubular pile production line comprises a material distribution device, die assembly devices, centrifugal devices, steaming-curing and maintaining devices, a die disassembly device and a cage making device and further comprises an automatic pile outputting device; the automatic pile outputting device comprises pile outputting and overturning arms and a pile outputting maintaining frame, the pile outputting overturning arms are connected with pile outputting and overturning arm drivers, the pile outputting and overturning arm drivers are provided with drive shafts capable of rotating in the peripheral direction, the pile outputting maintaining frame is connected with a maintaining frame driver, and the maintaining frame driver is provided with a drive shaft capable of rotating in the peripheral direction; when the pile outputting and overturning arms drive a pipe die to rotate, the pile outputting maintaining frame is pressed into a tubular pile of the pipe die and can conduct synchronous rotation with the pile outputting and overturning arms. By means of the fully-automatic tubular pile production line, continuous demoulding can be achieved, and thus production efficiency is improved.

Owner:浙江兆弟技术有限公司

High-efficiency smashing device for food processing

The invention discloses a high-efficiency smashing device for food processing, which comprises a body. A feed hopper is arranged on an upper side of the body. Sliding rails are arranged at both front and rear sides of the internal bottom end of the feed hopper. An adjusting plate is connected to the sliding rails in a sliding manner. A cover plate is horizontally connected to the top end of the adjusting plate. A cylinder is arranged at the right end of the upper side of the body, and the bottom end of the cylinder is fixed to the upper surface of the body by means of a fixing frame. A telescopic rod is connected to the left end of the cylinder, and the telescopic rod runs across the feed hopper and is fixedly connected to the right sidewall of the adjusting plate. The high-efficiency smashing device for food processing in the invention can control the feed quantity of food raw materials, avoid blockage, and reduce the workload of the smasher. The device is high in smashing effect, and can effectively prevent motor damage caused by excessive material resistance during smashing, thereby prolonging the service life. Furthermore, the device can achieve automatic discharge with improved working efficiency. In addition, the device can effectively absorb shock with a good shock absorption effect, thus reducing noise and prolonging the service life.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com