Potato peeling and shredding all-in-one machine

An all-in-one machine and shredding technology, which can be used in vegetable or fruit peeling, metal processing, food science, etc., and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

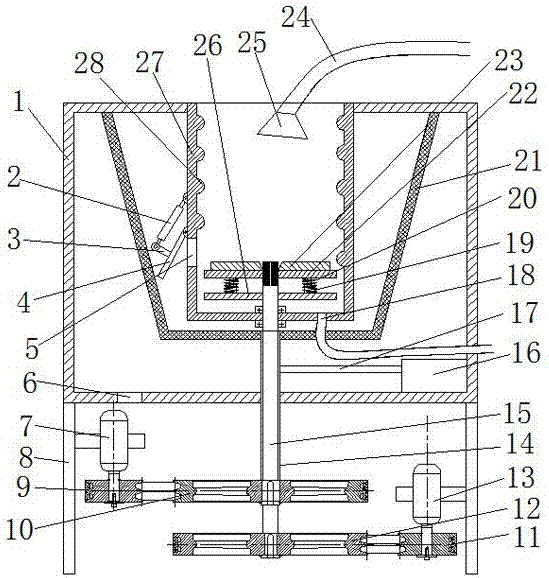

[0029] Such as figure 1 As shown, a potato peeling and shredding integrated machine includes a shredding mechanism arranged above the bracket 8, a peeling and cleaning mechanism arranged inside the shredding mechanism, a pushing mechanism arranged under the shredding mechanism, and a The transmission mechanism at the bottom of the support 8;

[0030] Such as figure 1As shown, the peeling and cleaning mechanism includes an inner cylinder 27 fixed on the support 8 and a rotating disk 22 coaxially positioned in the inner cylinder 27. The diameter of the rotating disk 22 is smaller than the diameter of the inner wall of the inner cylinder 27, so that the edge of the rotating disk 22 is in contact with the inner cylinder. There is a gap between the inner walls of the 27 for the passage of the ground potato peels and other impurities. The rotating disc 22 is connected to the inner shaft 15, and the inner shaft 15 is connected to the transmission mechanism. The inner wall of the inn...

Embodiment 2

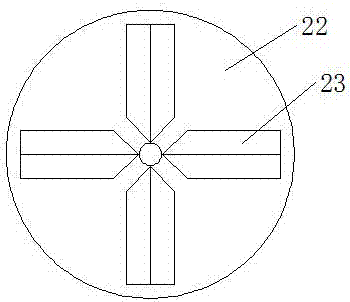

[0041] It differs from Embodiment 1 in that: as figure 1 and figure 2 As shown, four protrusions 23 are evenly distributed on the rotating disc 22, and the cross section of the protrusions 23 is triangular, so that when the rotating disc 22 rotates, in addition to centrifugal force, collision force and frictional force, the potatoes can be peeled, and the potatoes can also be peeled. Generate the power that potatoes are thrown upwards, so that the potatoes at the bottom can also rub against the inner wall of the inner cylinder 27 to achieve a good peeling effect.

[0042] The inner wall of the inner cylinder 27 is provided with a hemispherical protrusion 28, which can increase the peeling effect on irregularly shaped potatoes or potatoes with pits.

Embodiment 3

[0044] It differs from Embodiment 1 in that: as figure 1 As shown, the rotating disk 22 is an eccentric rotating disk, so that the potatoes can spread upwards and on both sides, and will not accumulate in the center of the inner cylinder 27, so that the potatoes can better contact and rub against the inner wall of the inner cylinder 27 to achieve good peeling Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com