Patents

Literature

1920results about How to "Avoid cuts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

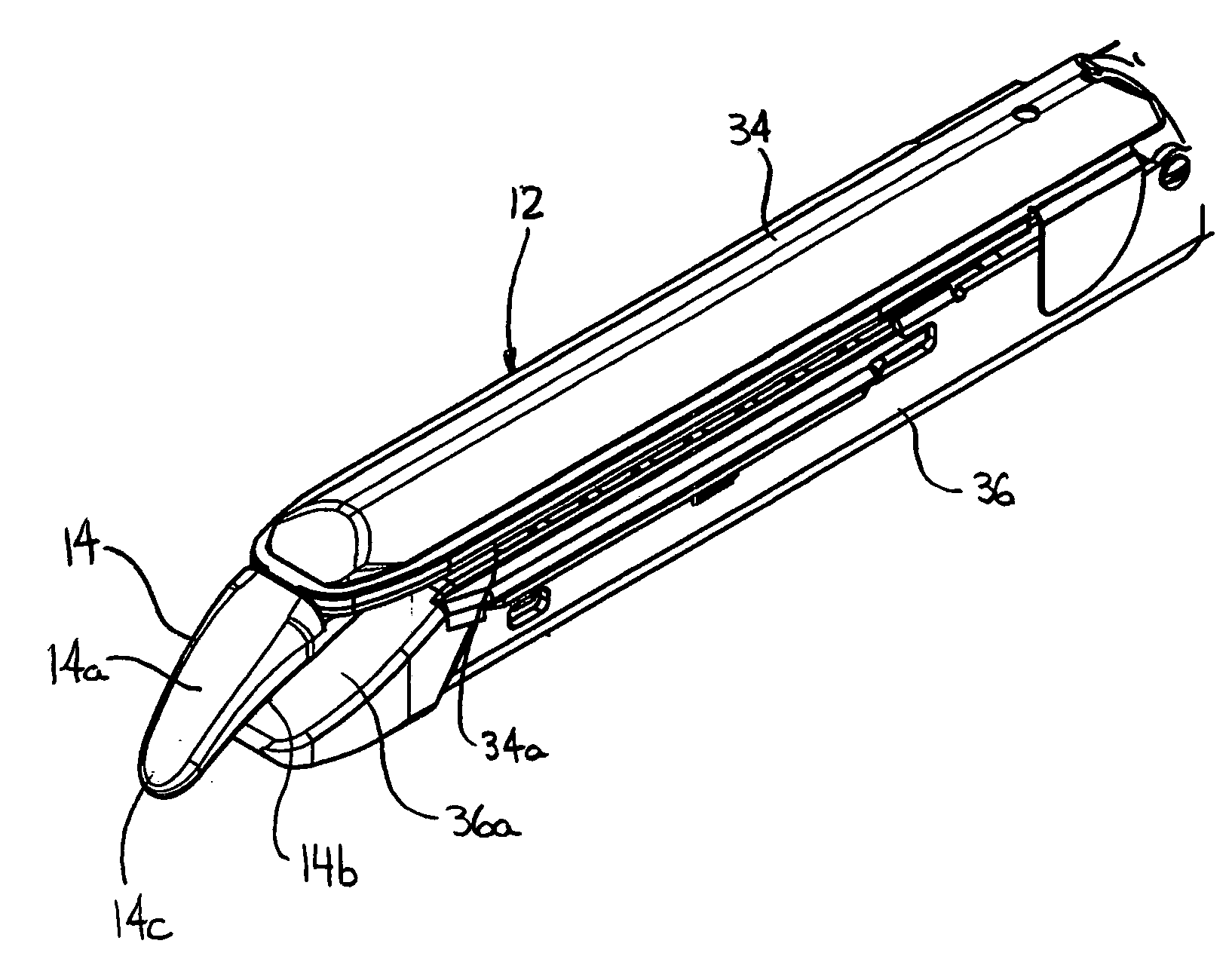

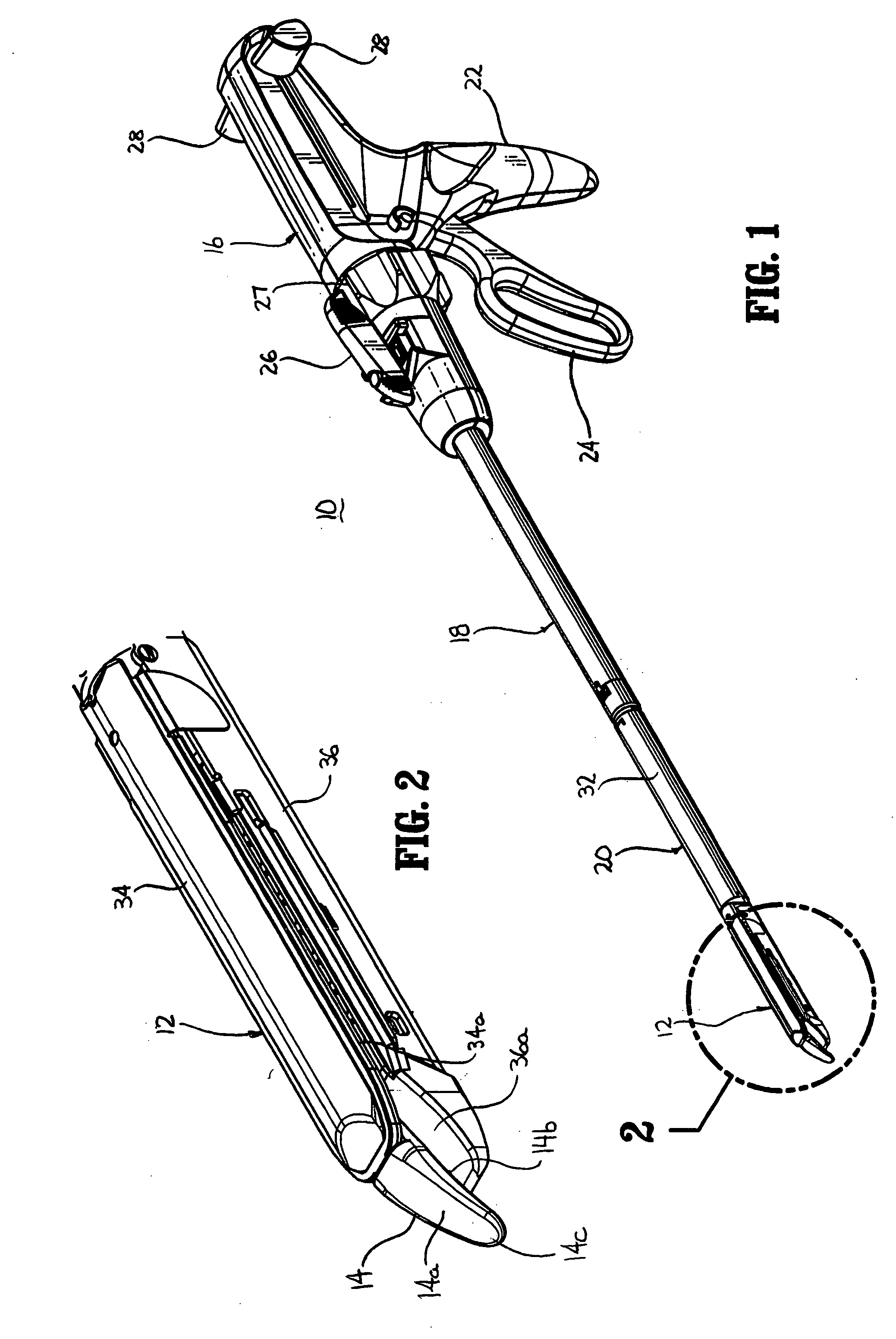

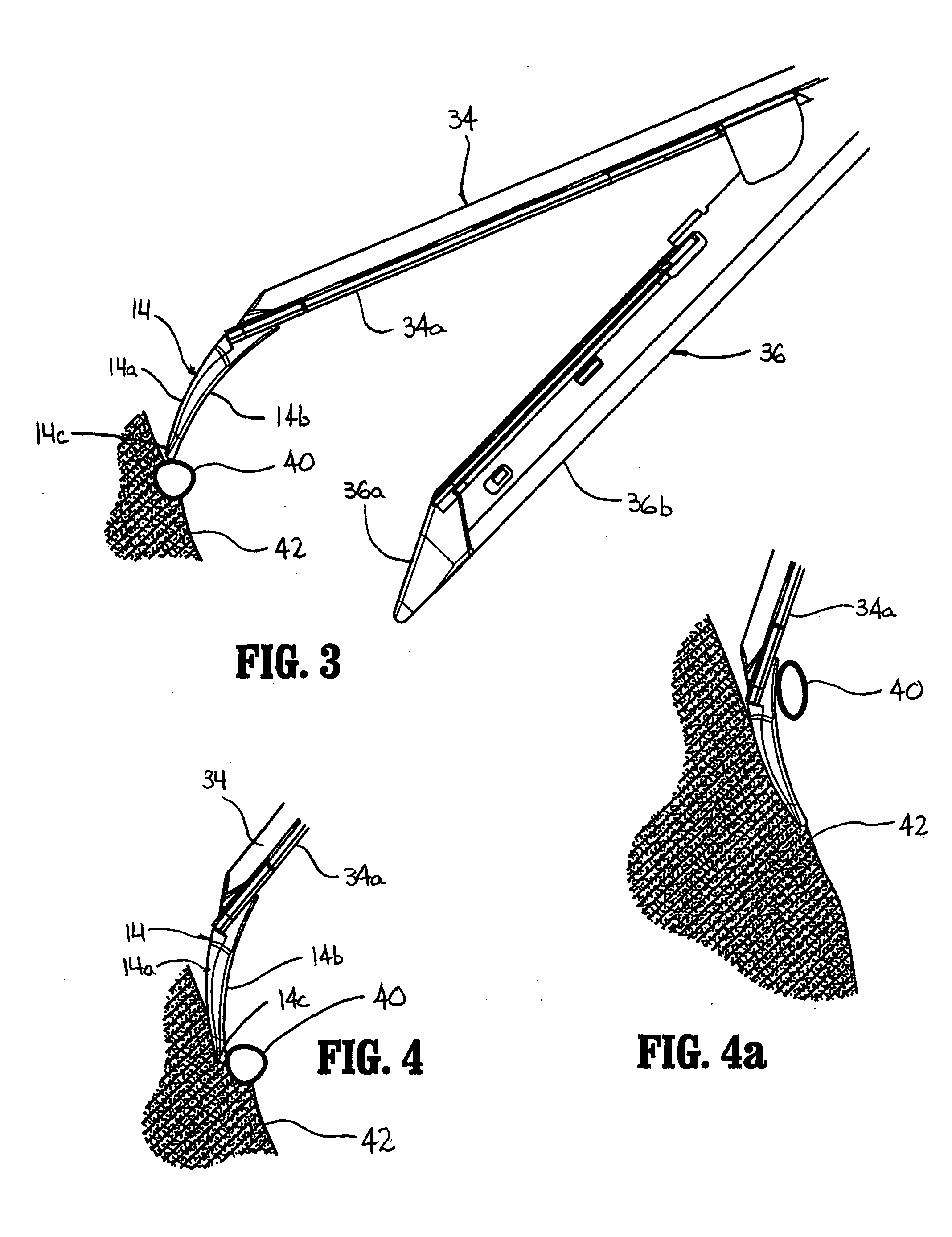

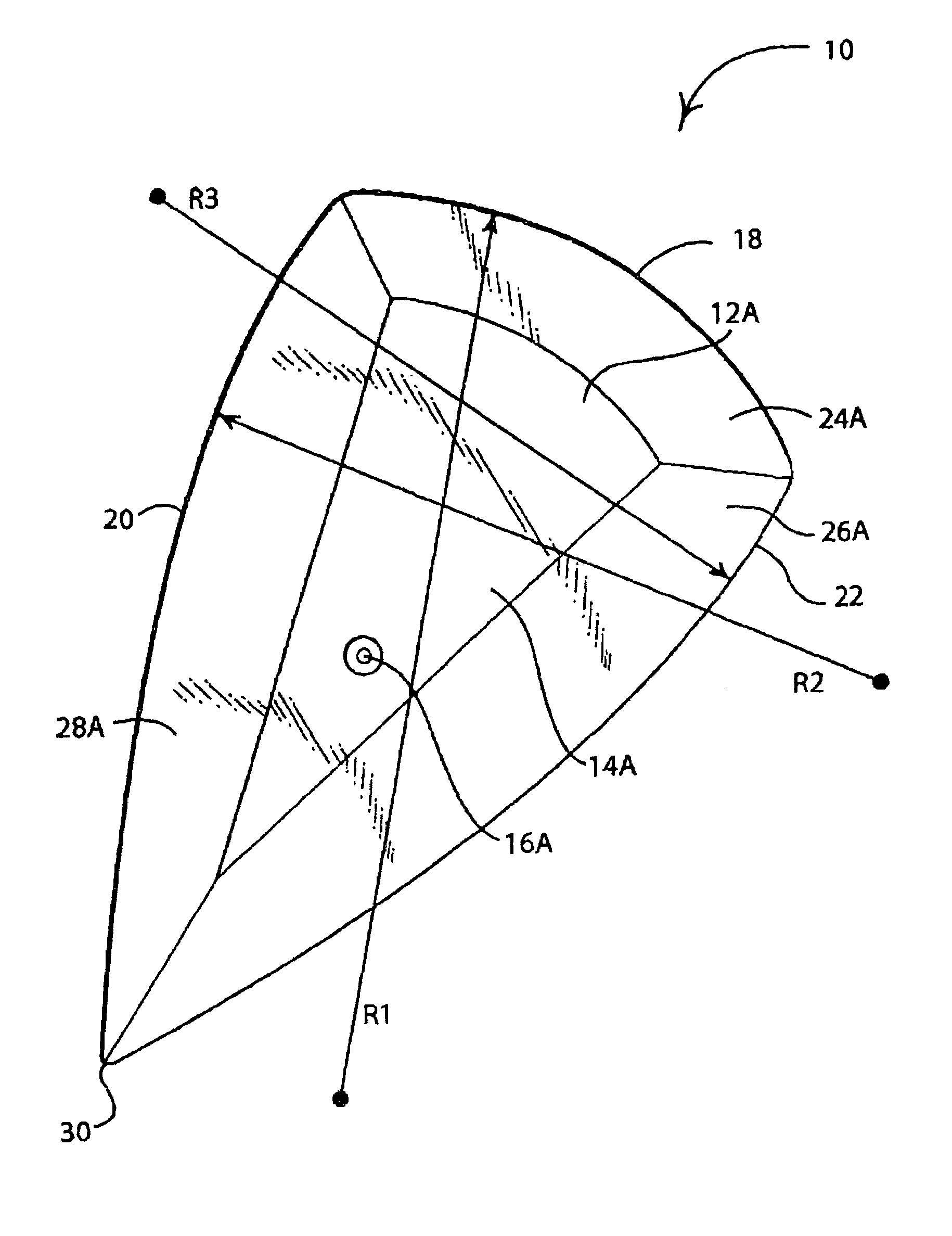

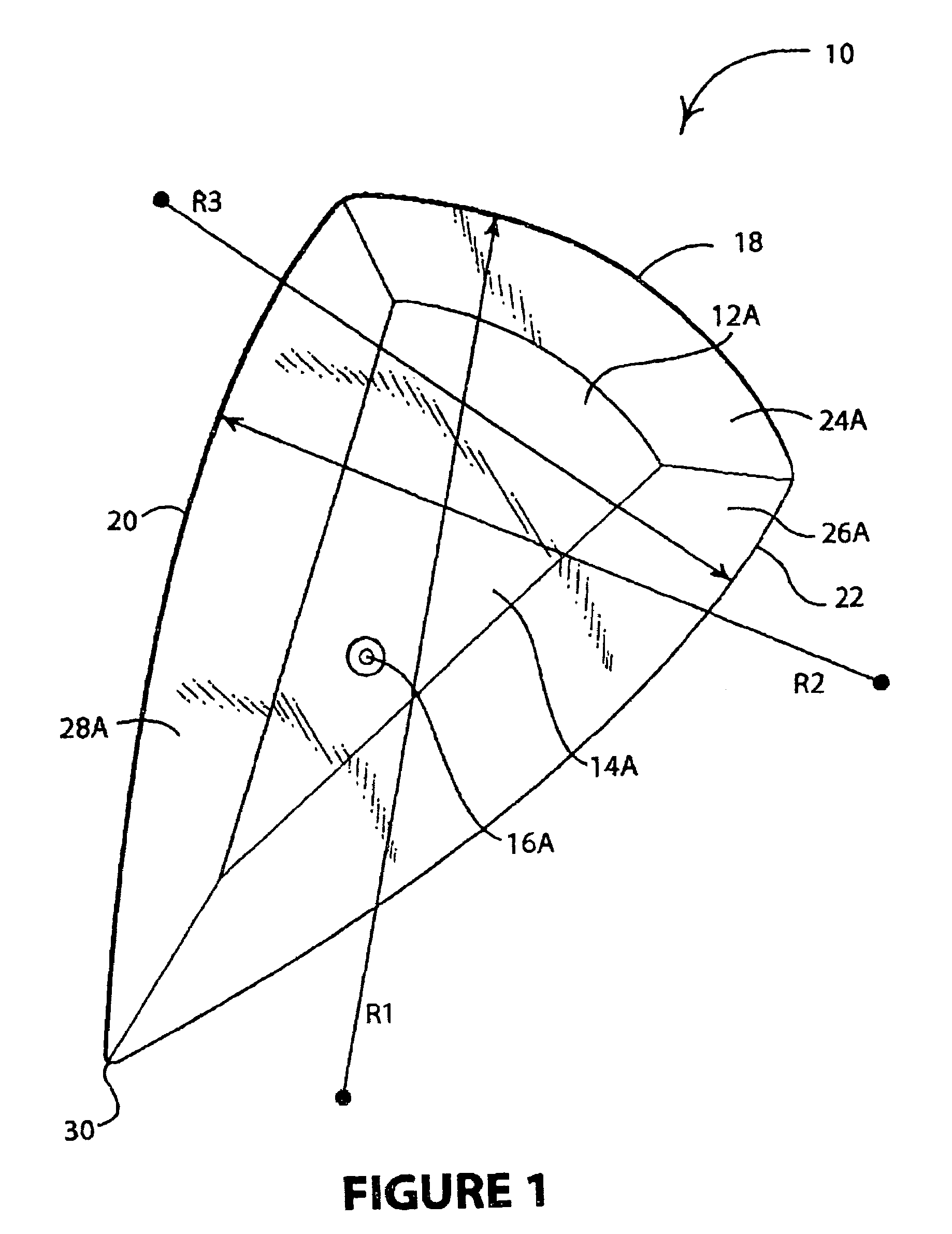

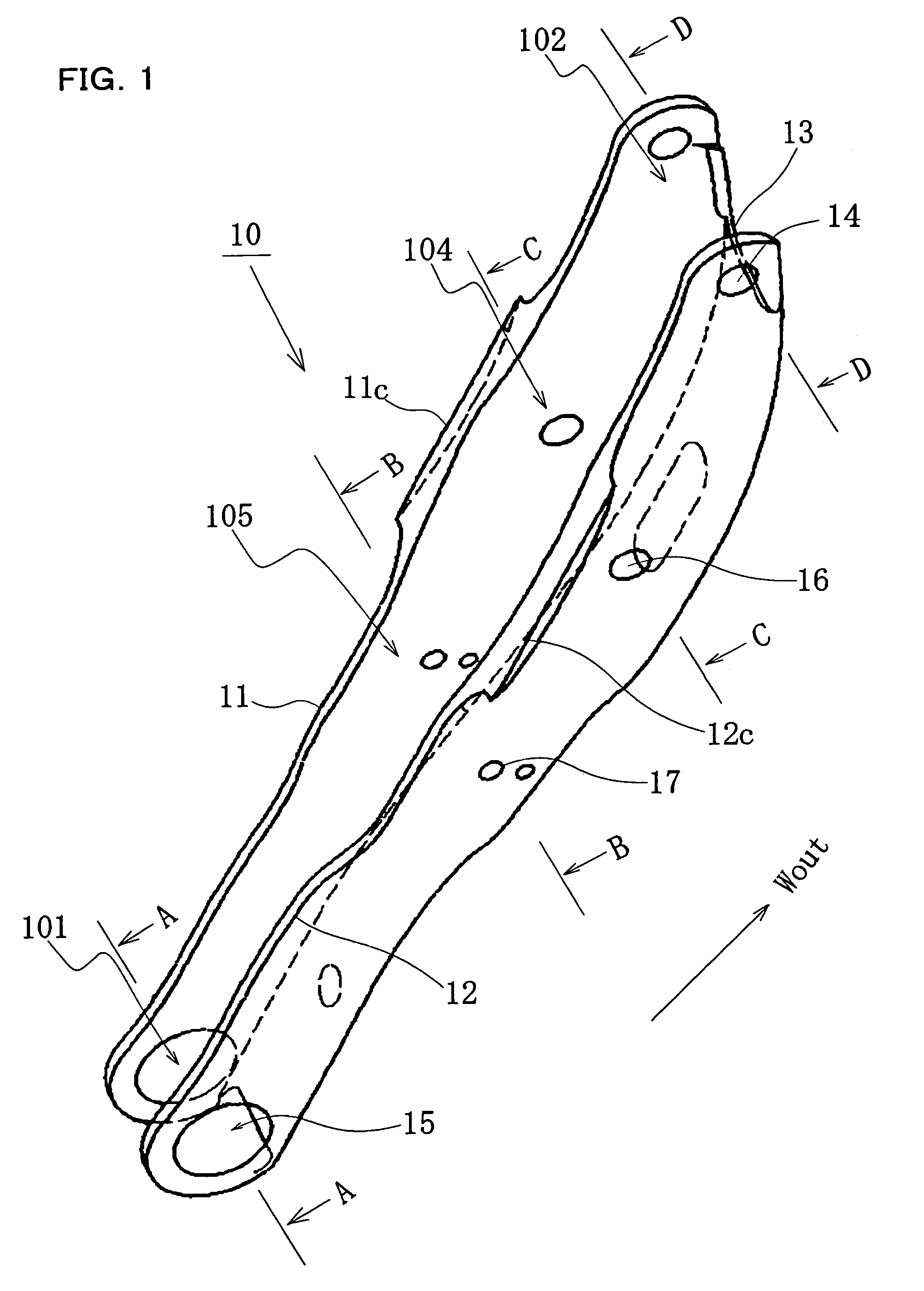

Surgical stapling device with dissecting tip

InactiveUS20050216055A1Prevent snaggingAvoid pullingSuture equipmentsStapling toolsActuatorSurgical department

A dissecting tip is provided for use with a surgical stapler or instrument. In one embodiment, the dissecting tip is secured to the end effector of the surgical instrument, e.g., to the cartridge assembly. The dissecting tip extends distally from the end effector and is configured to dissect or separate target tissue from certain tissue, e.g., adherent, connective, joined or other tissue.

Owner:TYCO HEALTHCARE GRP LP

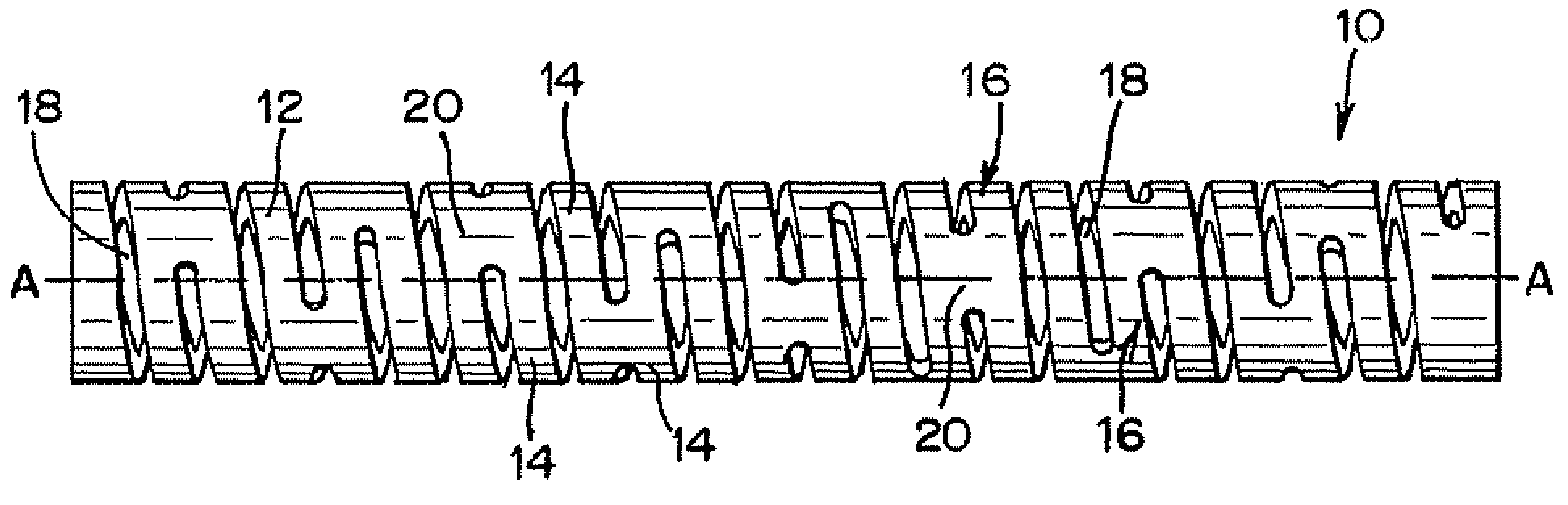

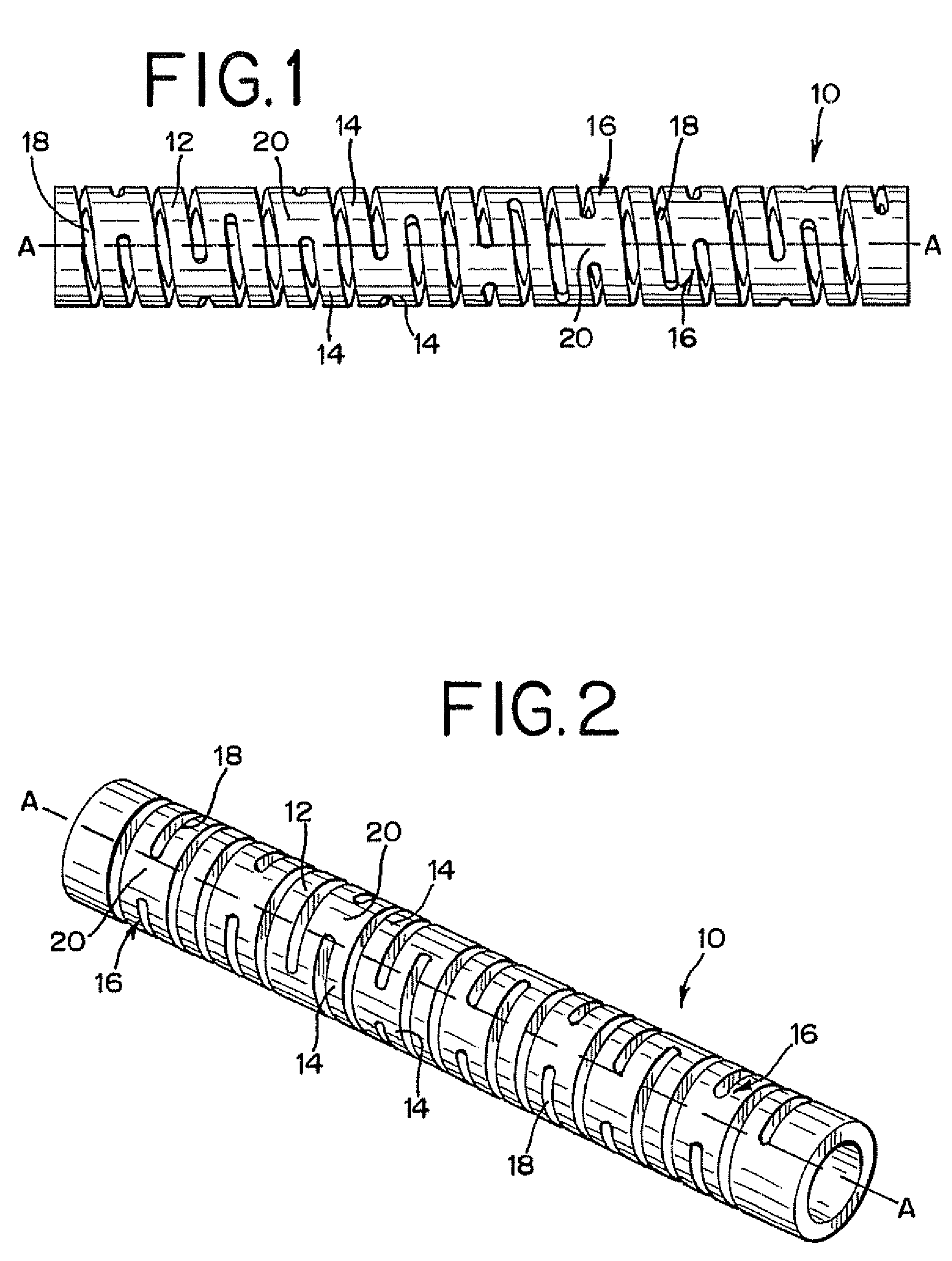

Interventional medical device component having an interrupted spiral section and method of making the same

A component for use as or incorporation within a medical instrument navigable through body vessels of a human subject is provided. The component includes a tubular portion with an interrupted spiral defined by alternating cut and uncut sections. The interrupted spiral has a rigidity between that of a continuous cut spiral and an uncut tube. The rigidity of the interrupted spiral along its length may be varied by changing its pitch or the number of bridge members or the length of each bridge member. According to a method of manufacturing such a component, a tubular member and a cutting member are provided. At least one of the tubular member and the cutting member is moved though an angle defining a helical path with respect to the other, while the cutting member is alternated between cutting and not cutting the tubular member to form an interrupted spiral.

Owner:CODMAN & SHURTLEFF INC

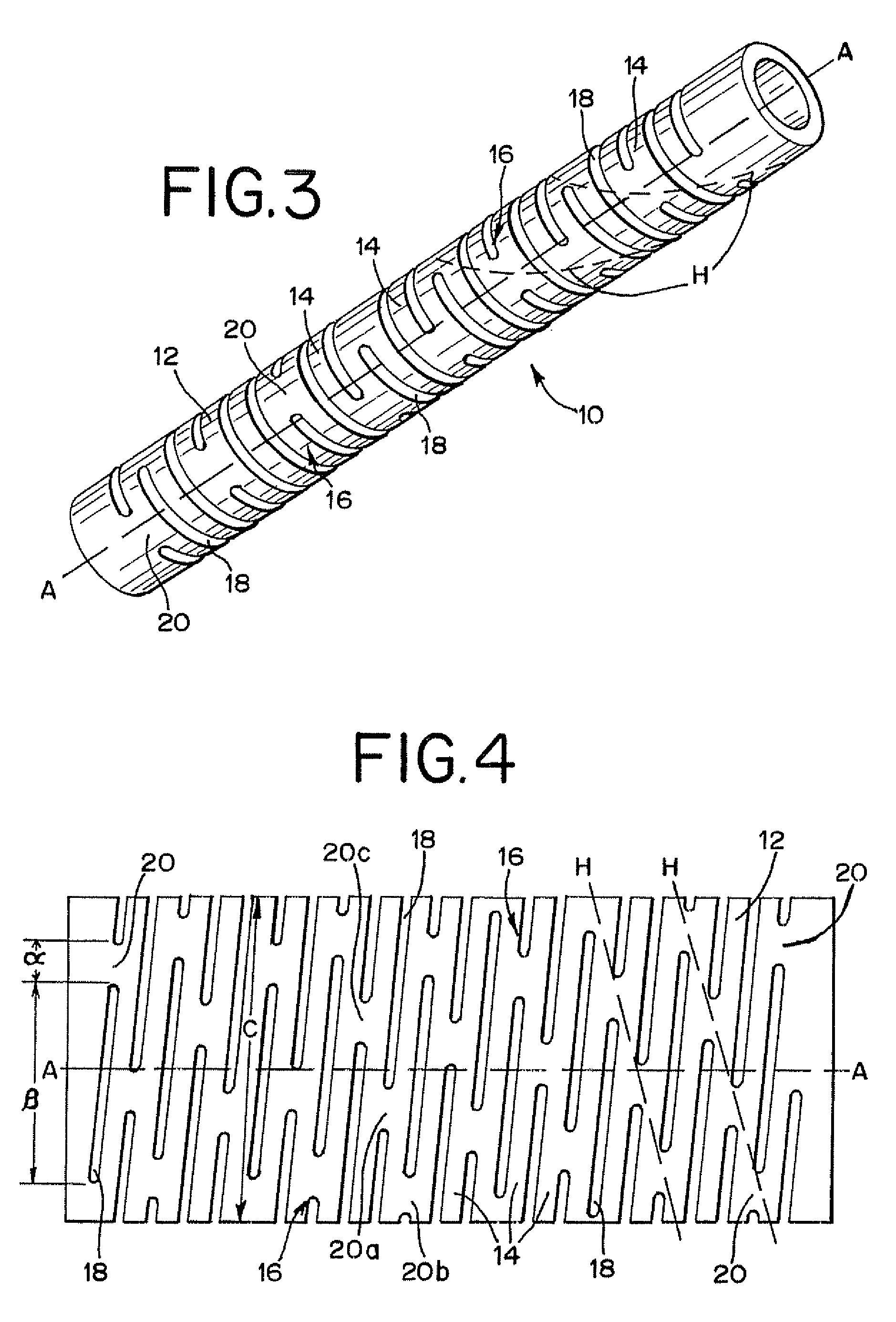

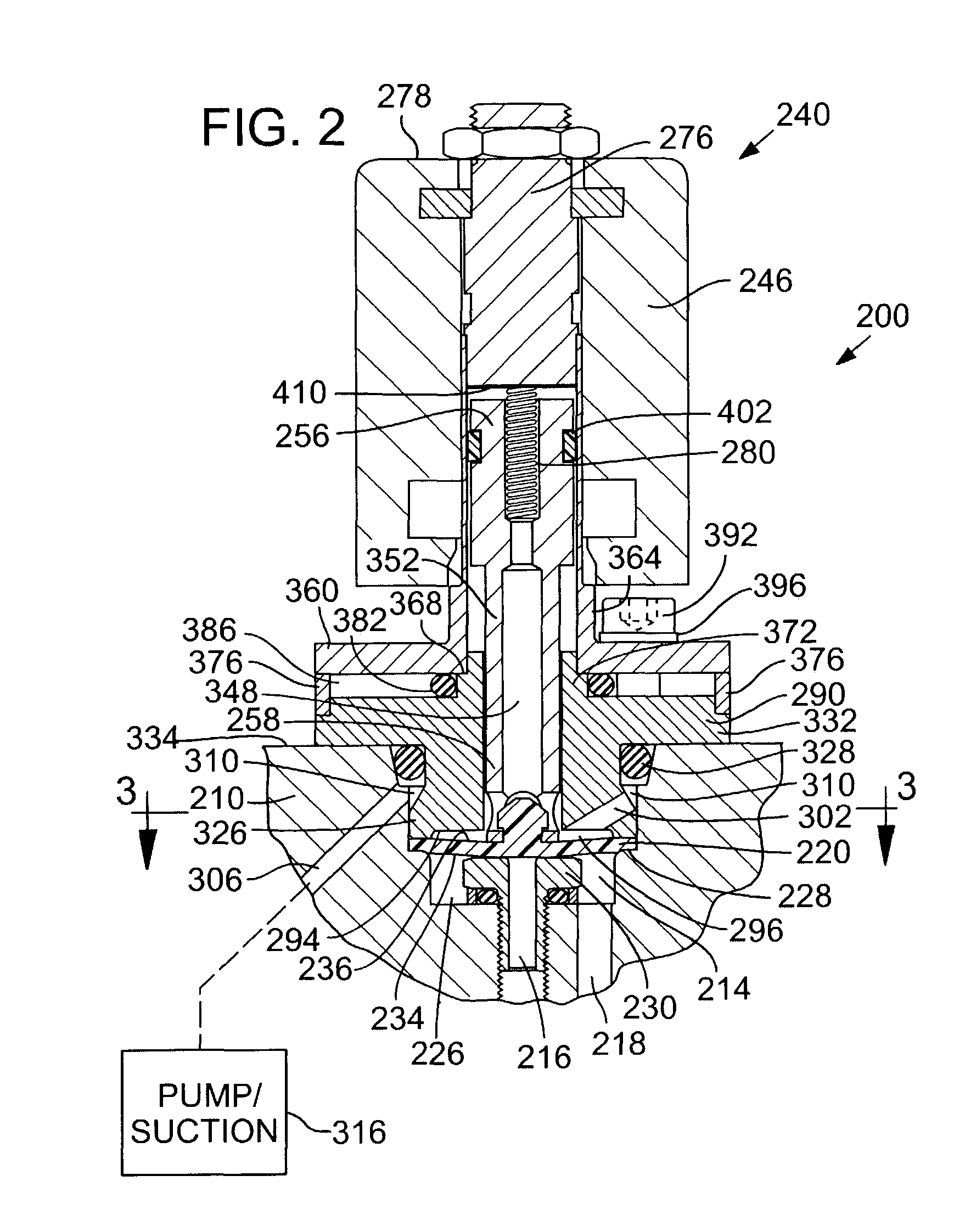

Diaphragm valve with reliability enhancements for atomic layer deposition

InactiveUS7021330B2Improve heat transfer performanceInhibiting condensingDiaphragm valvesOperating means/releasing devices for valvesEnhanced heat transferDiaphragm valve

A shut-off type diaphragm valve adapted for use in an atomic layer deposition system includes a valve seat having an annular seating surface that surrounds an inlet of the valve and extends radially therefrom. The seating surface contacts a substantial portion of the first side of a flexible diaphragm when the diaphragm is closed, to facilitate heat transfer and counteract dissipative cooling of the diaphragm, thereby inhibiting condensation of a medium flowing through the valve passage. The seating surface is preferably flat and smooth, to prevent shearing of an elastomeric diaphragm. For a plastic diaphragm, a ring-shaped seating ridge may extend from the seating surface to cause localized permanent deformation of the diaphragm and enhanced sealing, while still allowing a substantial portion of the diaphragm to contact the seating surface for enhanced heat transfer. Valve speed enhancements and other reliability enhancing features are also described.

Owner:BENEQ OY

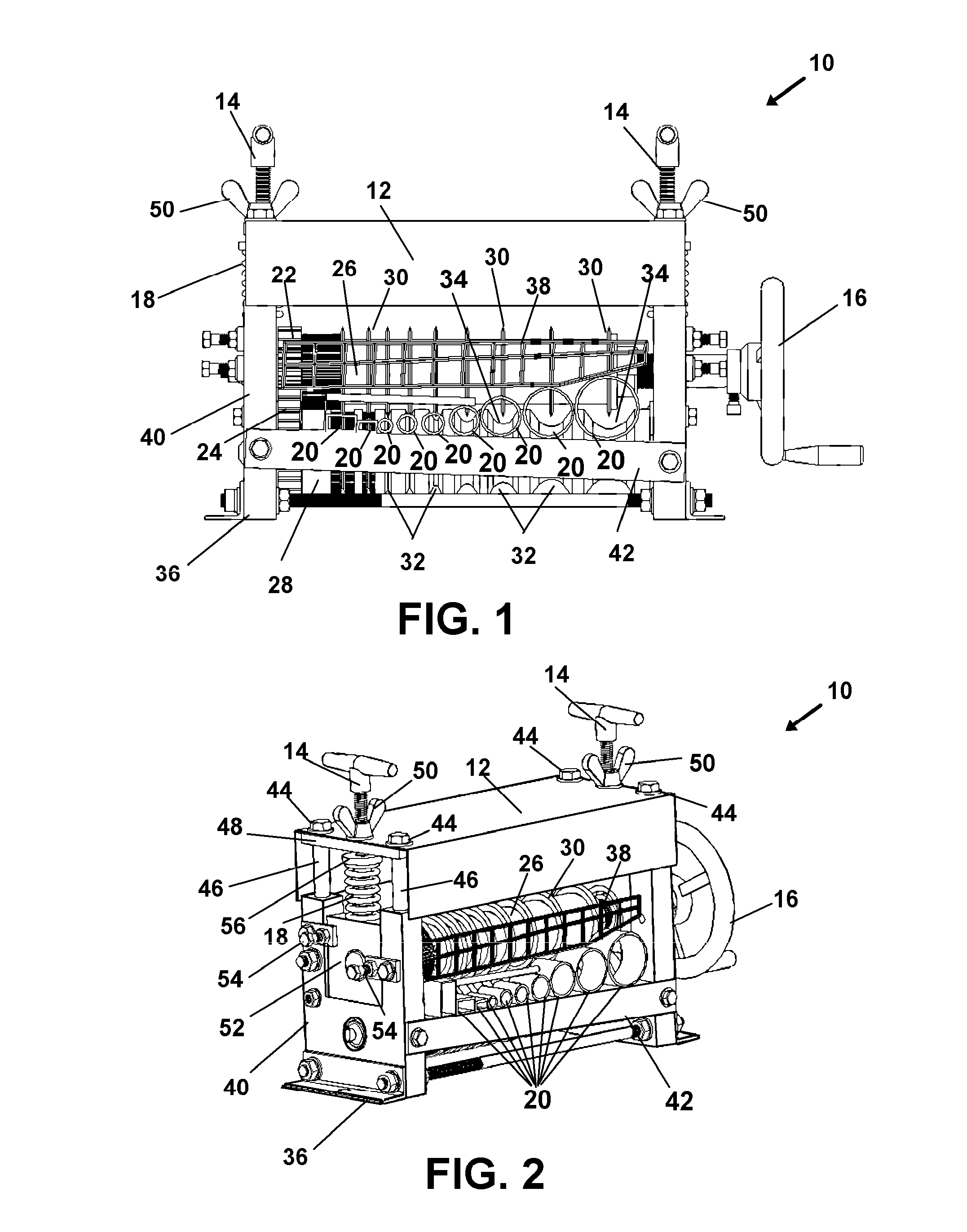

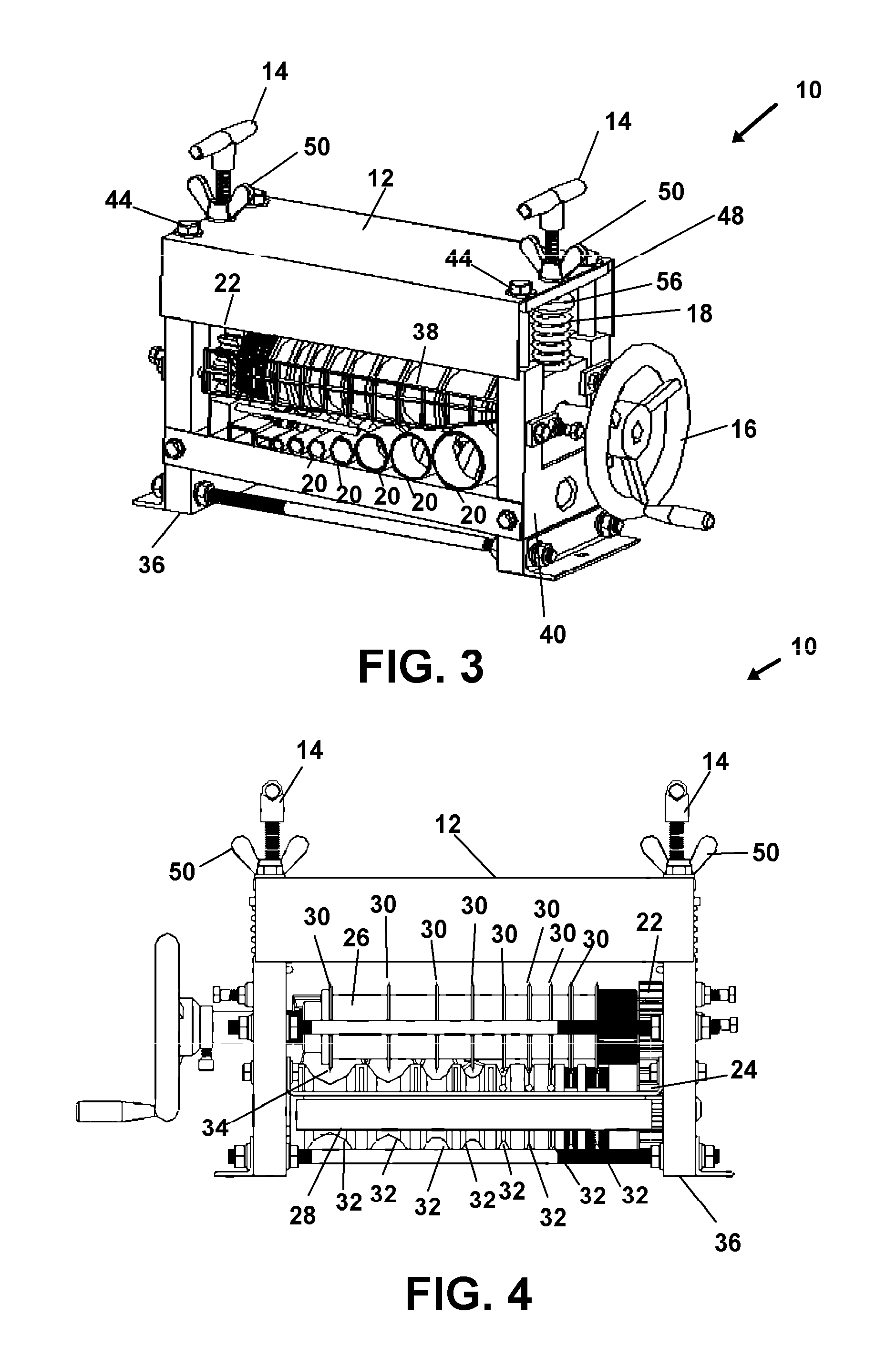

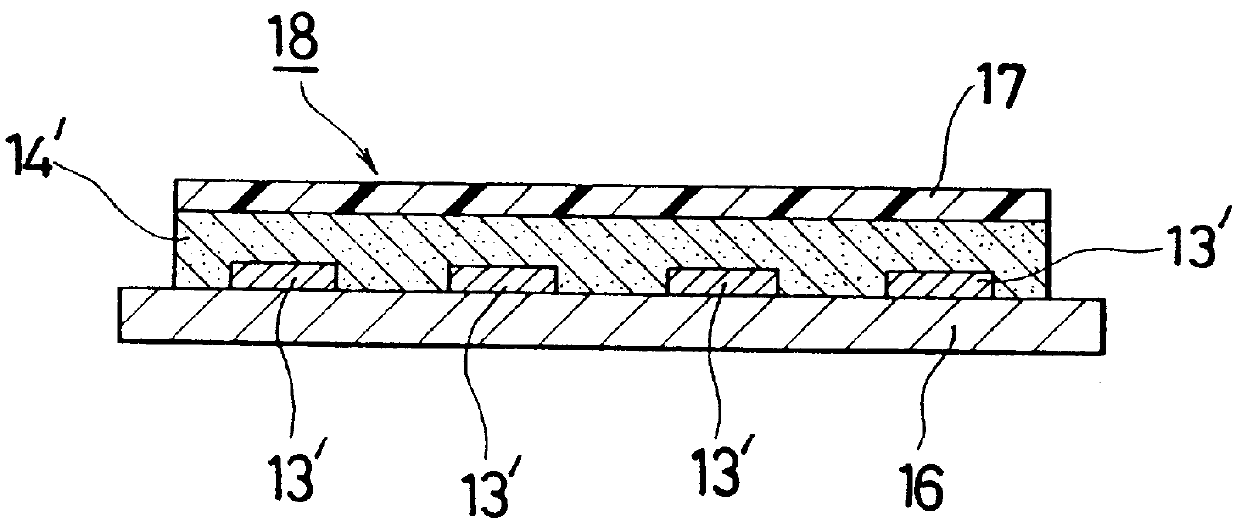

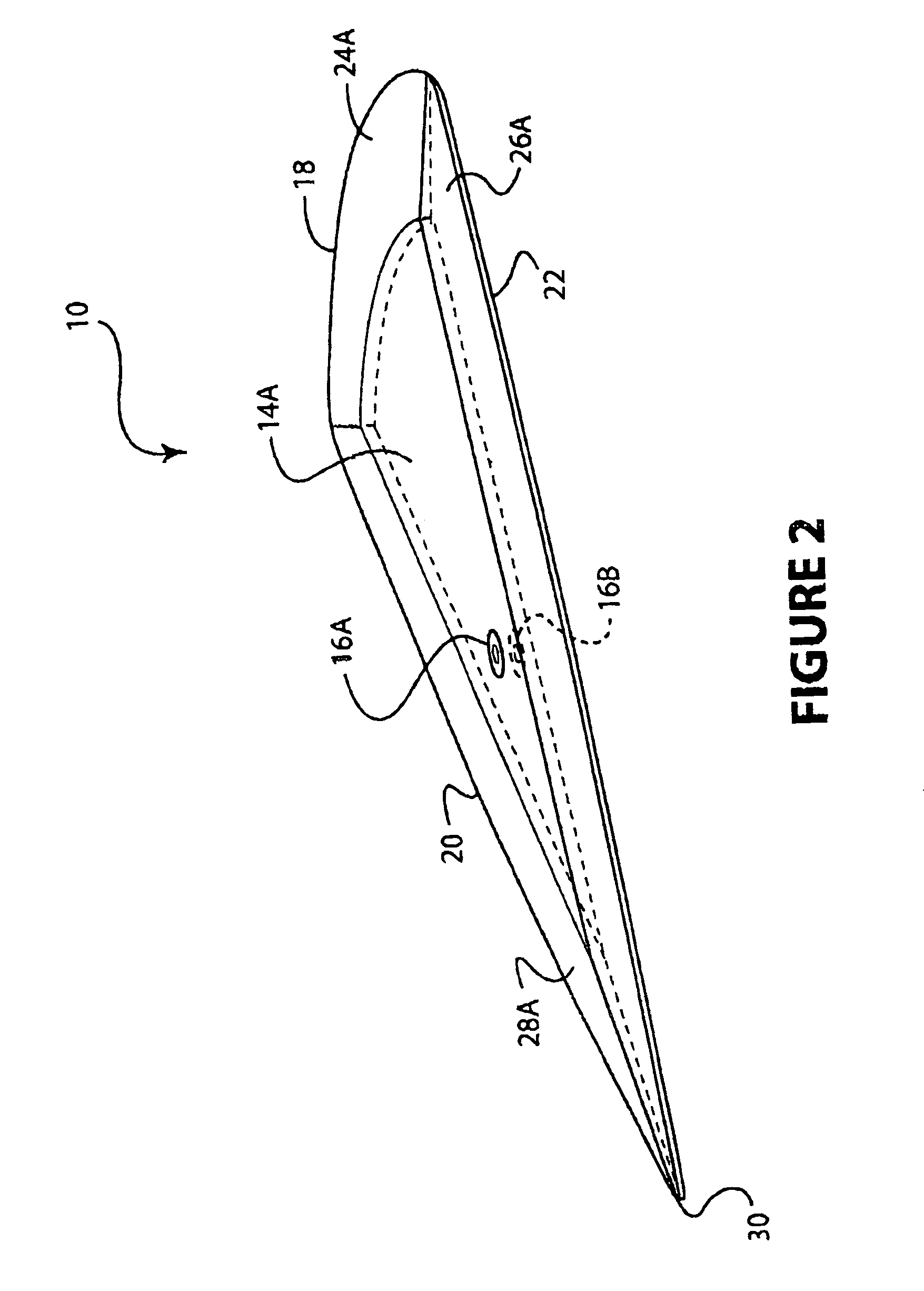

Ribbon feeder and printer

InactiveCN1914045AEliminate wrinklesUniform tensionPrinting mechanismsInking apparatusConductor CoilMechanical engineering

The invention relates to a ribbon feeder of printer. Ribbon tension detecting means (20, 21) each consisting of a plate-like lever body (35) are disposed upstream and downstream, respectively, of a ribbon path from a platen (7). The plate-like lever body (35) has first and second rollers (47, 48) disposed upstream and downstream of the ribbon path and swings around the axis of the rotary shaft of the second roller (48) according to the tension on the ribbon traveling as guided by these rollers (47, 48). When the amount of swing is above or below a fixed vale, a ribbon feed motor (18) or a ribbon winding motor (19) is driven. Further, the ribbon tension detecting means (20, 21) are each provided with a wrinkle eliminating member adapted to contact an ink ribbon (13) so as to eliminate wrinkles formed in the ink ribbon (13).

Owner:CITIZEN WATCH CO LTD

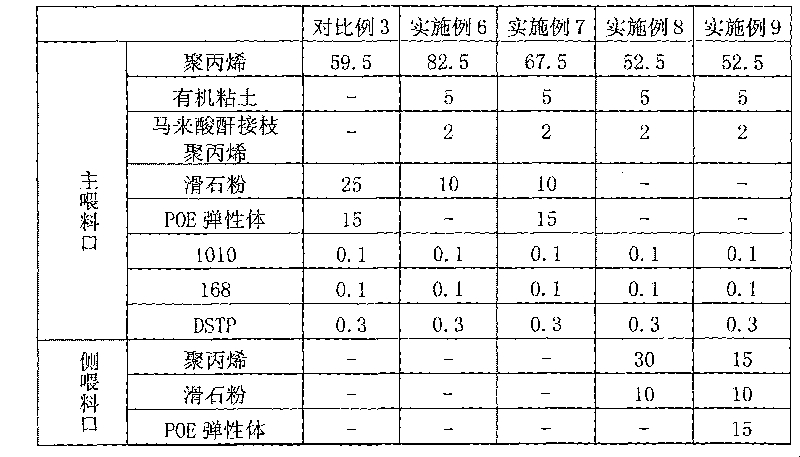

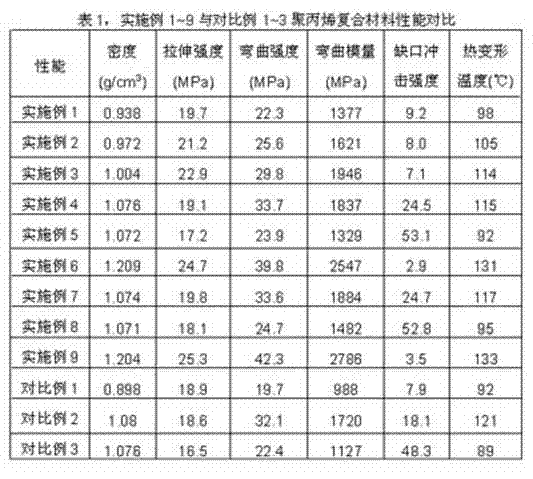

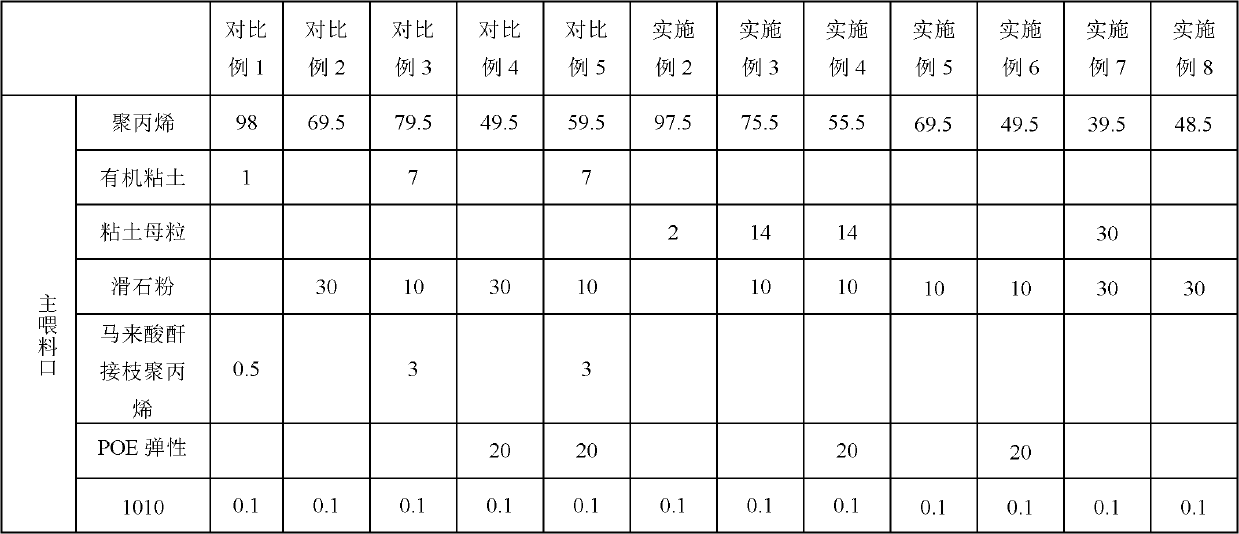

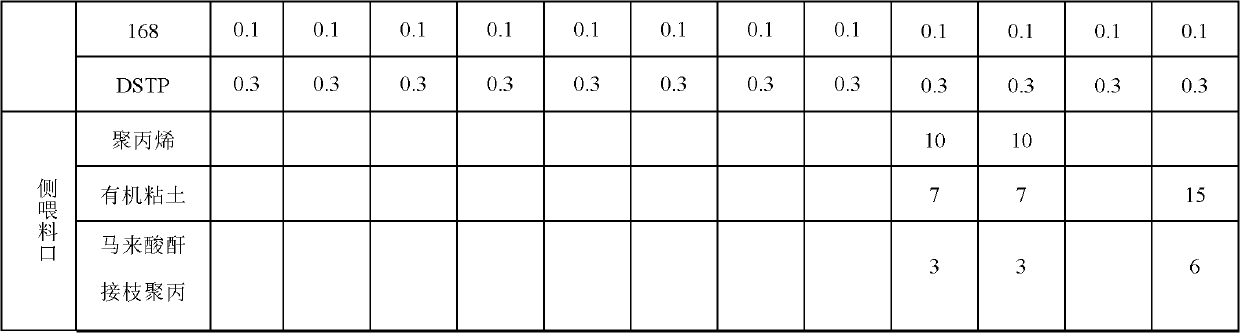

Low-density, high-rigidity and high-tenacity polypropylene nano composite material and preparation method thereof

InactiveCN101712780ALow content of inorganic componentsLow densityVolumetric Mass DensityLow density

The invention discloses a low-density, high-rigidity and high-tenacity polypropylene nano composite material and a preparation method thereof. The low-density, high-rigidity and high-tenacity polypropylene nano composite material consists of the following raw materials in percentage by weight: 55 to 98 percent of polypropylene, 1 to 15 percent of organic clay, 0 to 30 percent of inorganic filler, 0.1 to 10 percent of compatilizer, 0 to 20 percent of toughening agent, 0.2 to 2 percent of stabilizing agent, and 0 to 5 percent of other additives. The low-density, high-rigidity and high-tenacity polypropylene nano composite material and the preparation method have the following advantages that: 1, the density and the weight of a product are reduced for the help of reducing the weight and the energy consumption of a finished product; 2, the rigidity and the tenacity are higher; 3, the process flow is simplified and the production cost is reduced effectively; and 4, the influences on the cutting of nano clay and the dispersion process caused by other components are avoided to the utmost extent to further improve the performance of the composite material.

Owner:SHANGHAI PRET COMPOSITES

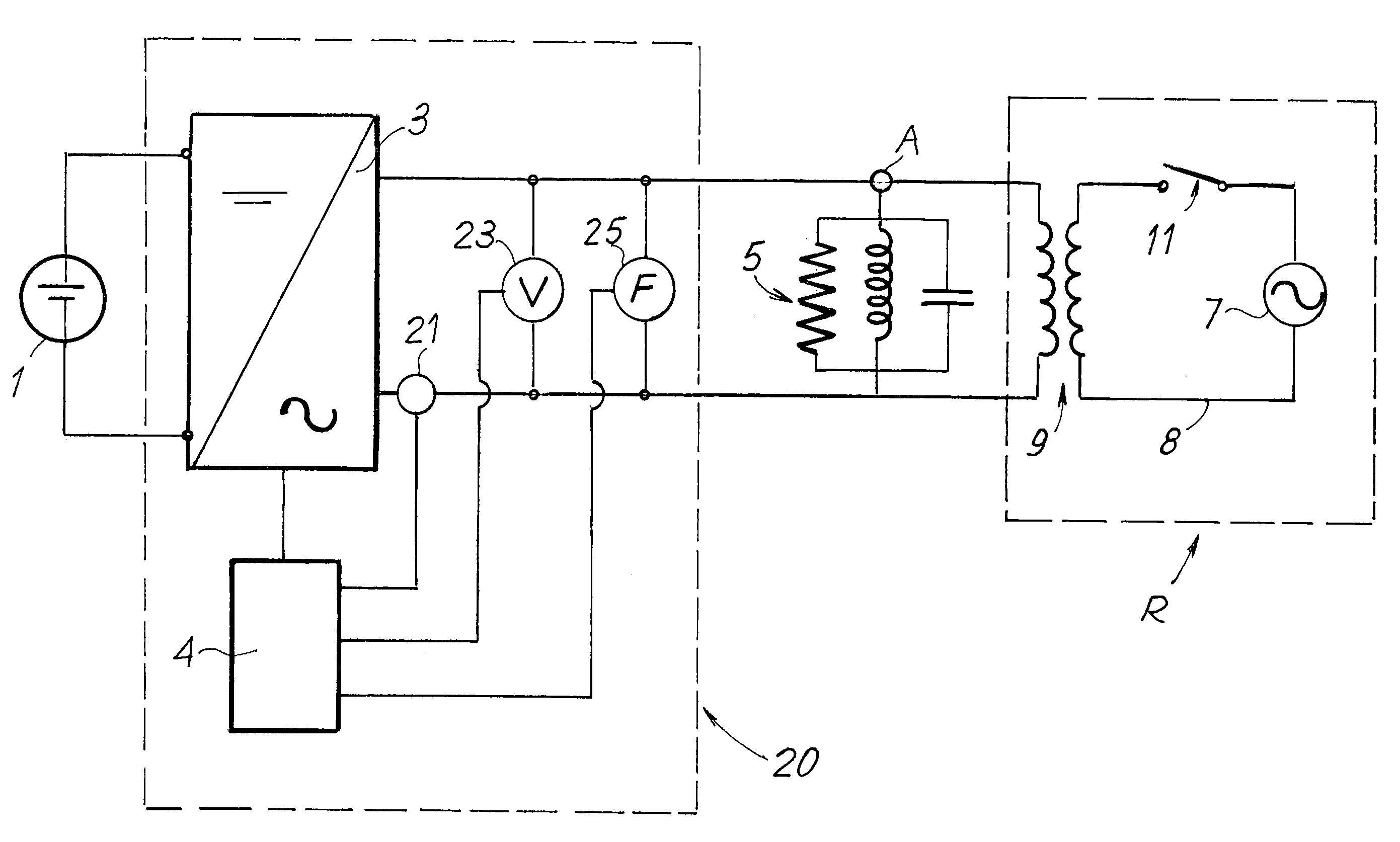

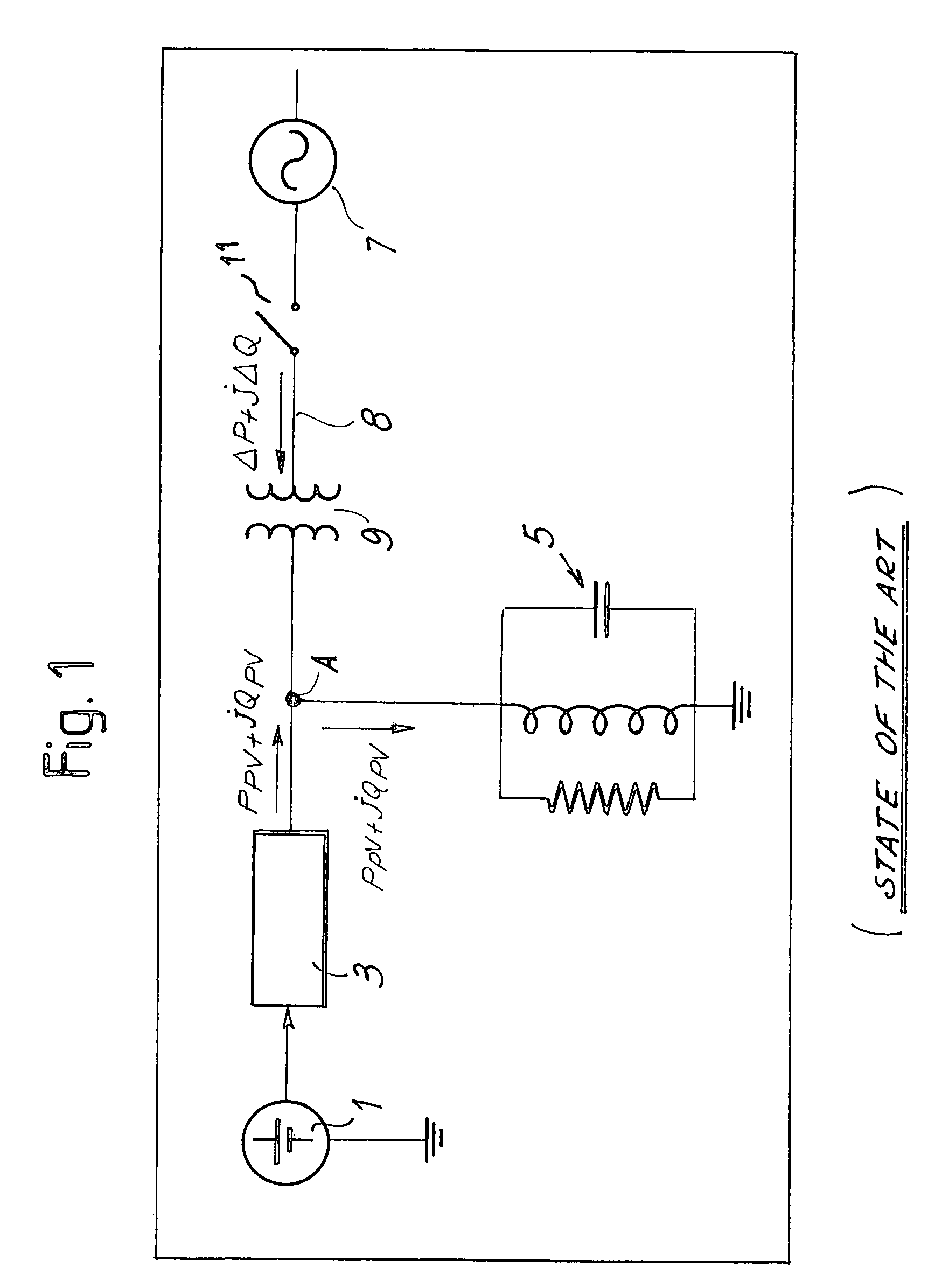

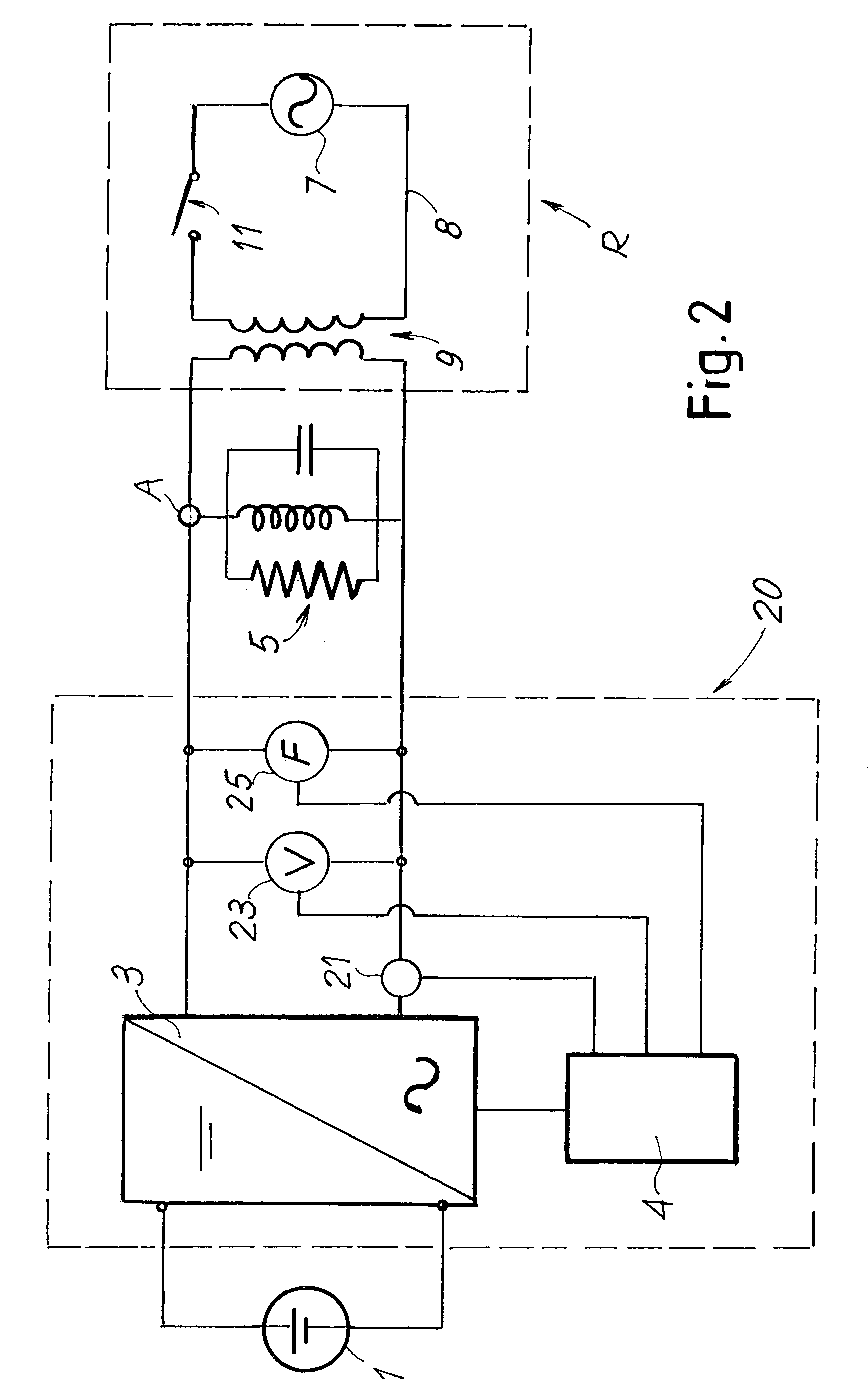

Anti-islanding method and system for distributed power generation systems

ActiveUS7408268B1Quick changeReduce power levelDc network circuit arrangementsSingle network parallel feeding arrangementsElectricityIslanding

An electrical power supply system connected to an electrical grid, includes at least one source of electrical power, an inverter which receives power from the electrical source and delivers power to a local load, and a connection to the electrical grid. The system also includes a control unit for controlling the inverter, which interrupts the delivery of power by the inverter when at least one electrical parameter of the system exceeds a threshold value. The system also includes anti-islanding logic which detects at least one symptom of an islanding condition of the system and, when the symptom is detected, to cause a variation in the power level delivered by the inverter.

Owner:MARICI HLDG THE NETHERLANDS BV

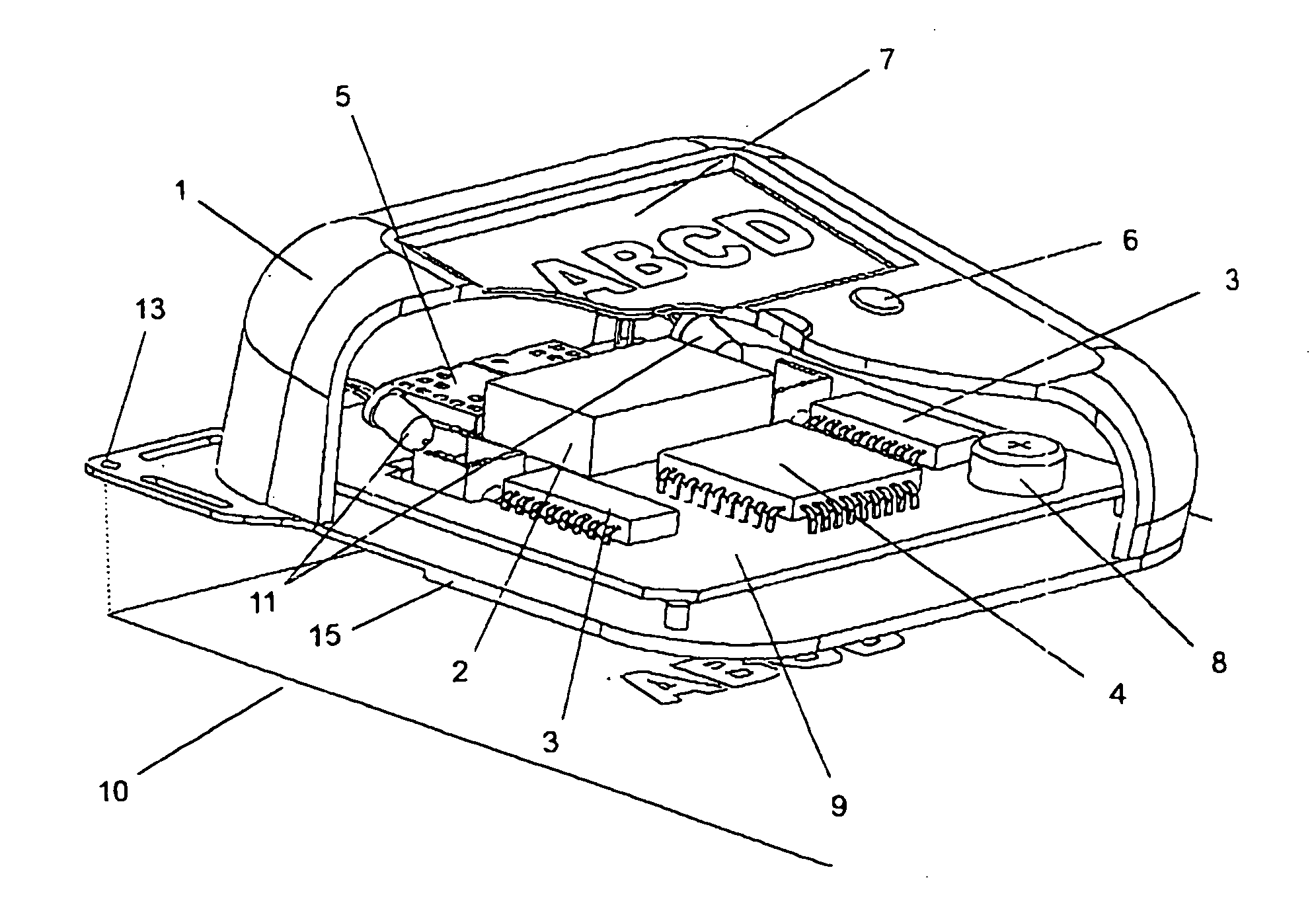

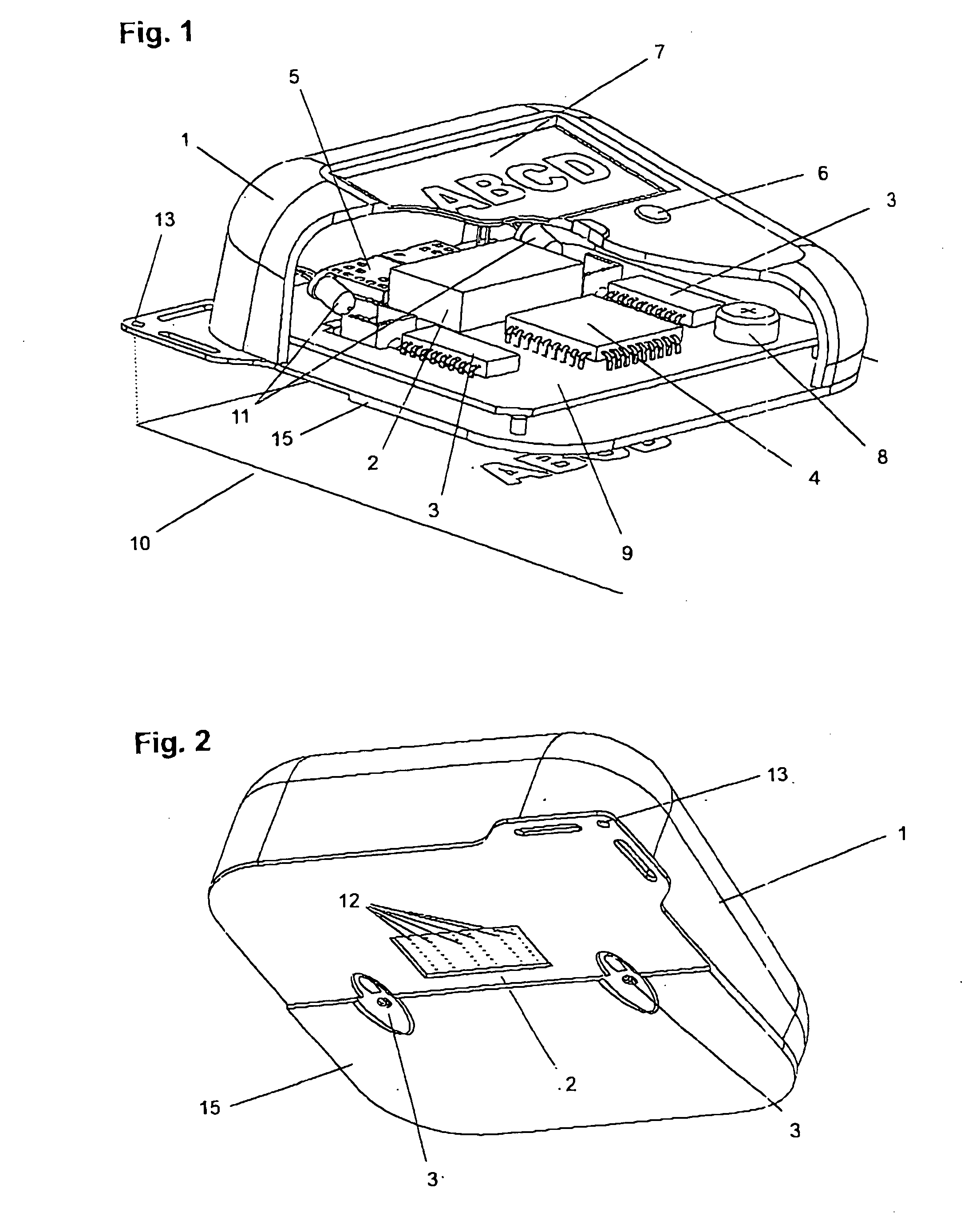

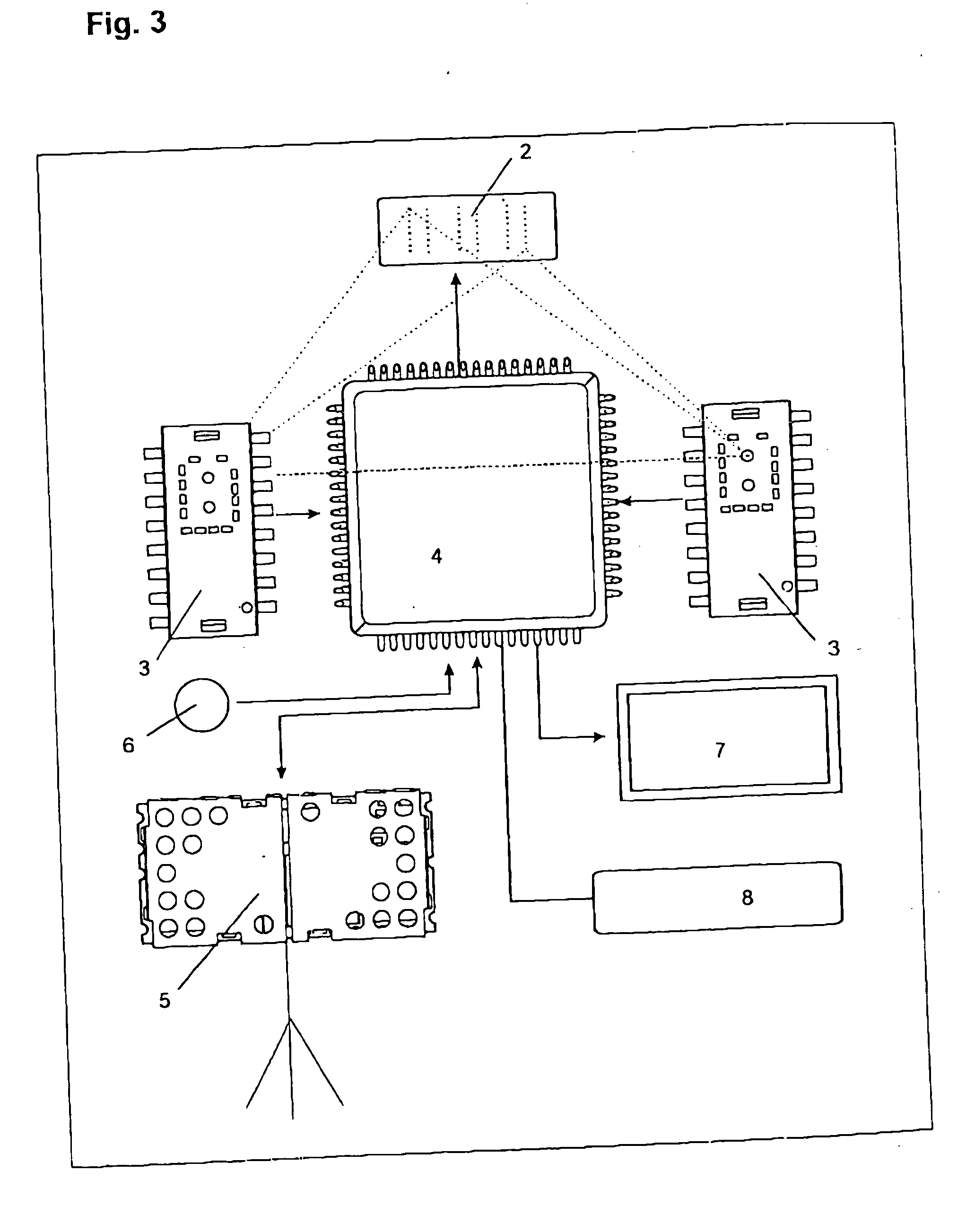

Hand held printing of text and images for preventing scew and cutting of printed images

InactiveUS20060061647A1Avoid skewAvoid cutsTypewritersInput/output processes for data processingEngineeringHand held

Owner:XPANDIUM

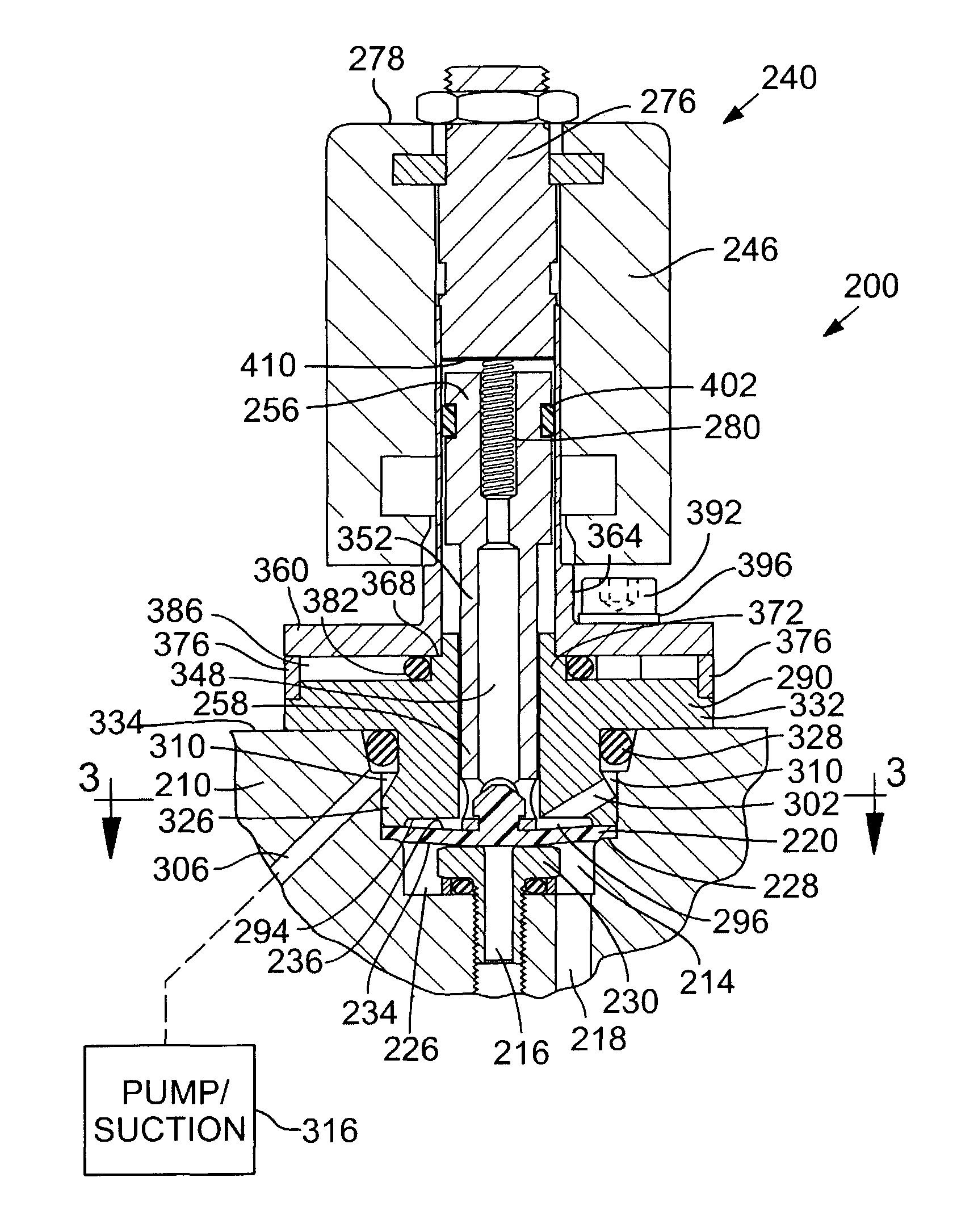

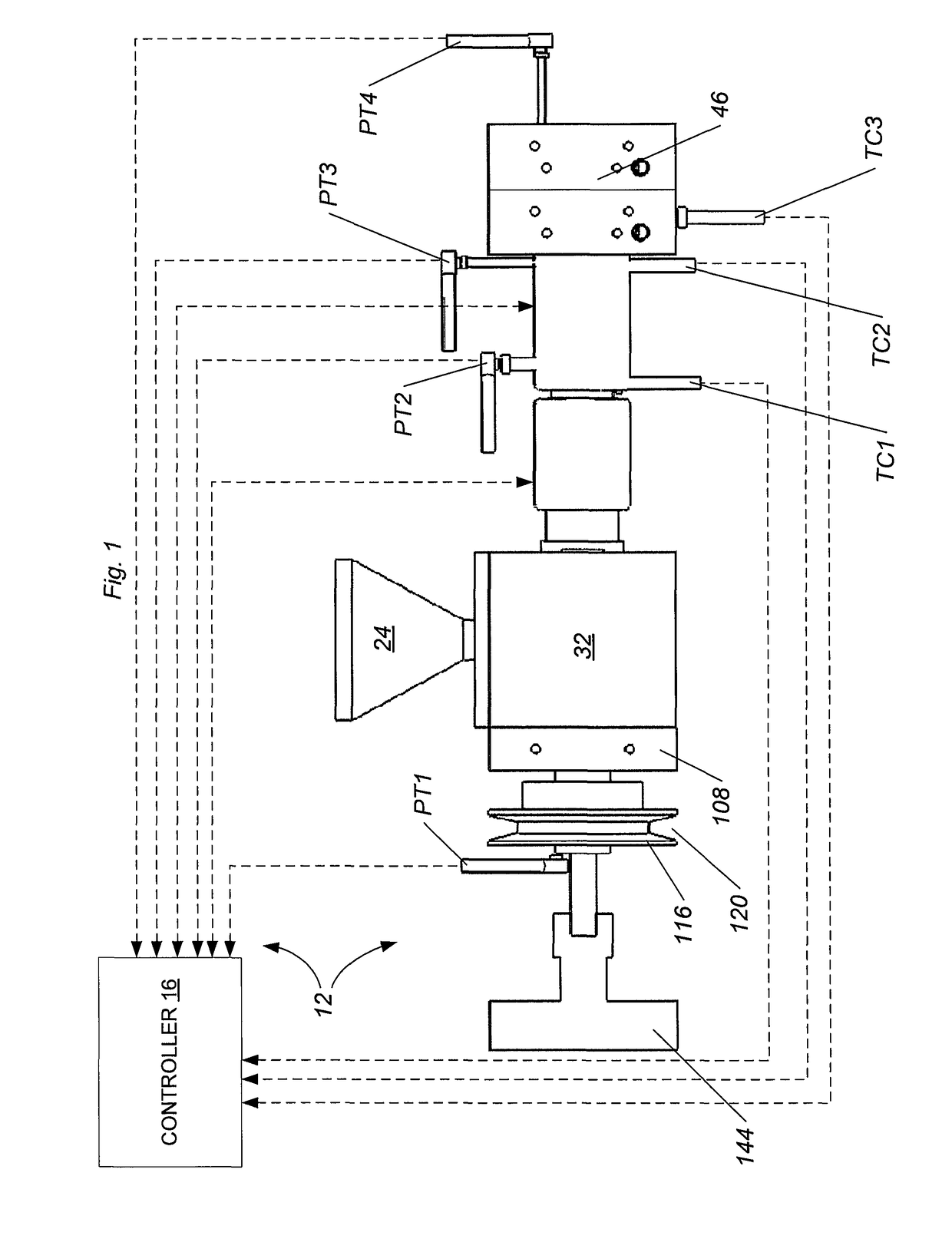

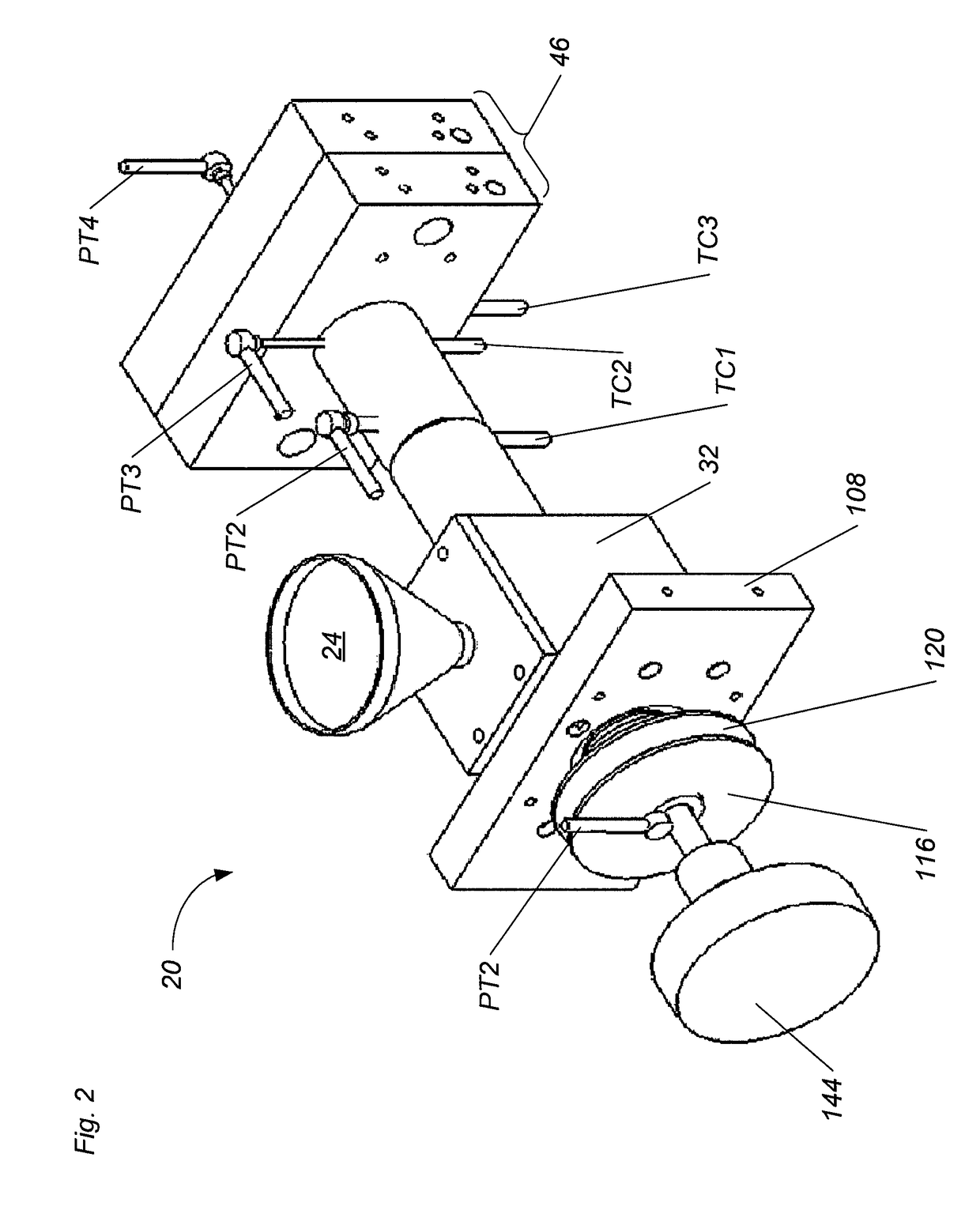

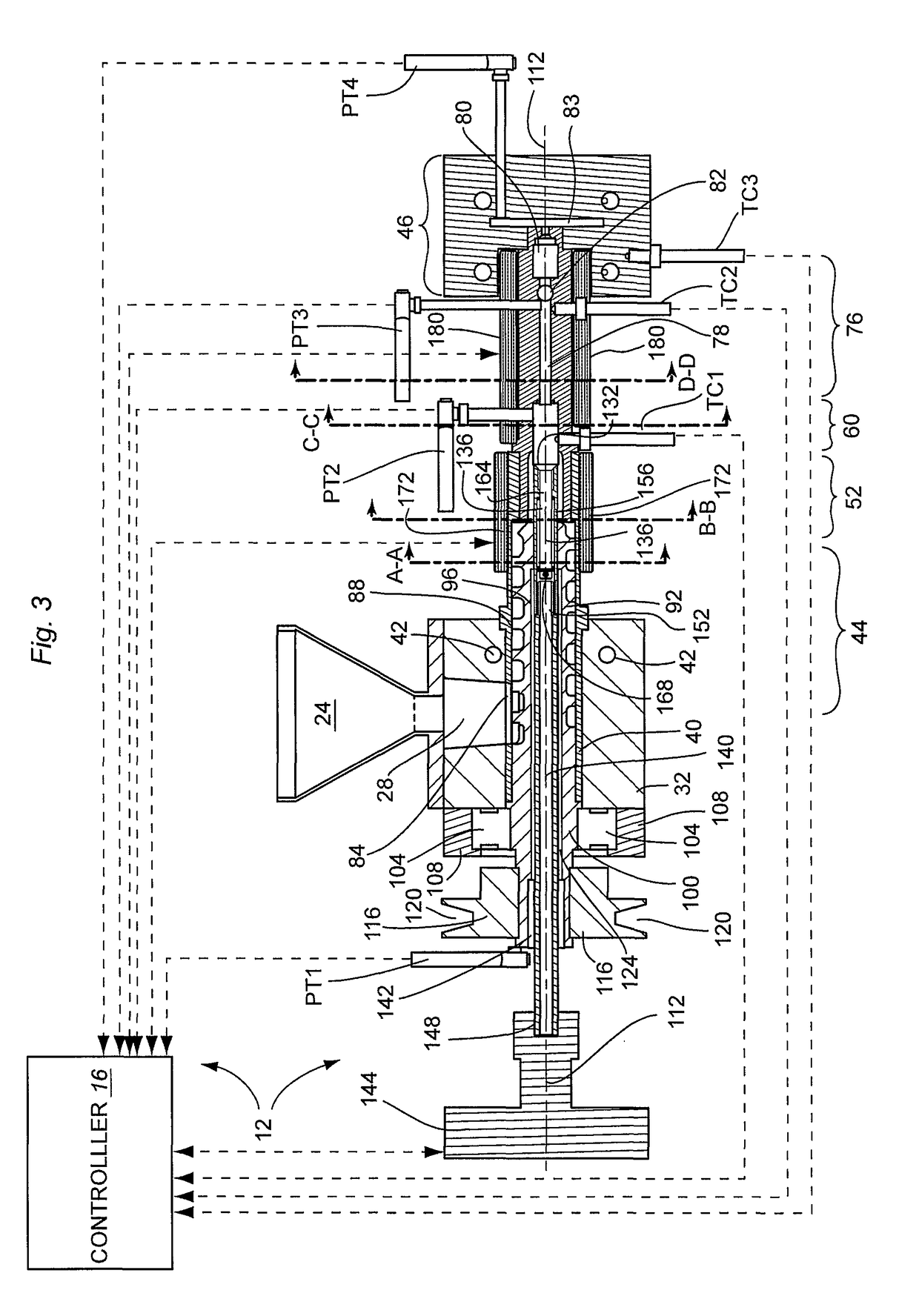

Injection molding method and apparatus

InactiveUS7906048B2Enhanced performance characteristicReduce pressure applyAuxillary shaping apparatusFood shapingSource materialInjection molding process

A thermoplastic injection molding system and method of use is described for molding parts from heated plastics and other organic resins. The machine uses heat sources located along the barrel to heat the source material while an auger screw transports the source material in the barrel. This transport step does not shear the source material, nor does it use friction to produce the heat necessary to melt the source material. The material becomes substantially liquid or melted during the heating process, and the melted material is forced, by the auger screw, into a chamber whereupon a plunger, situated concentrically with the auger screw, injects the material from the chamber into a mold. Sensors located along the barrel and in the chamber ensure consistency between mold cycles. The controller dynamically adjusts the injection molding process to achieve more consistent and reliable molded parts.

Owner:KOALESCE

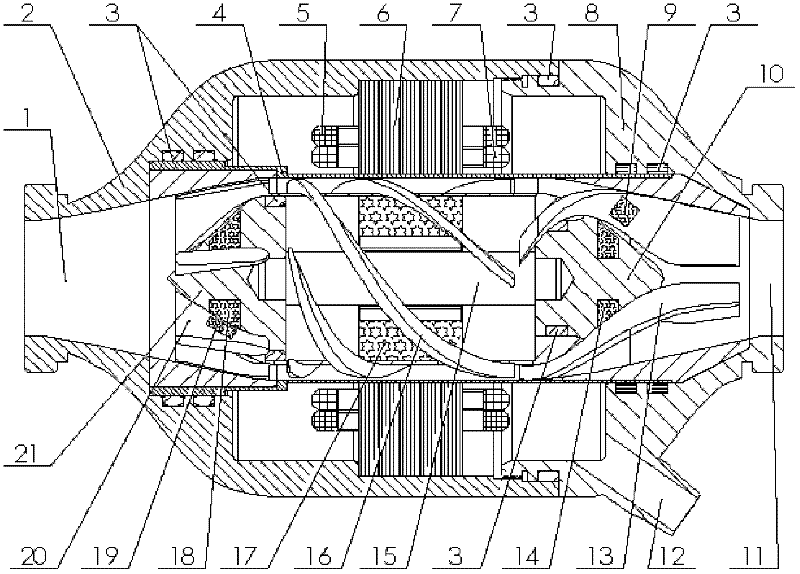

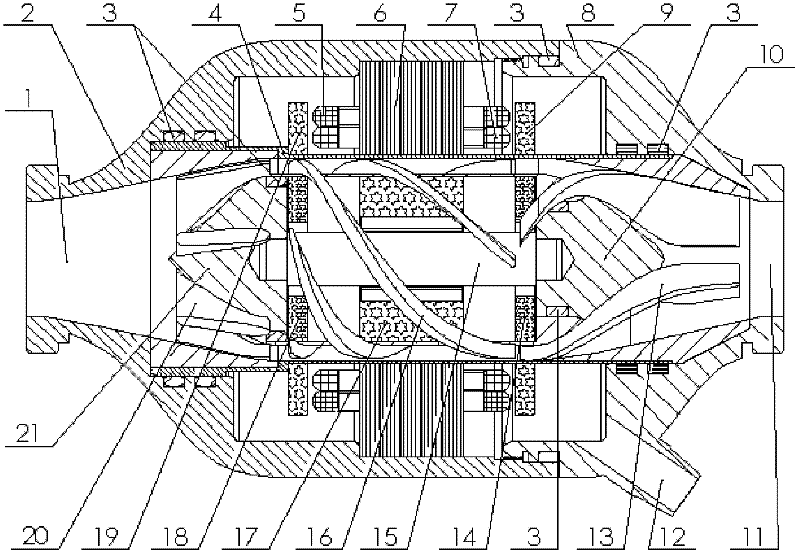

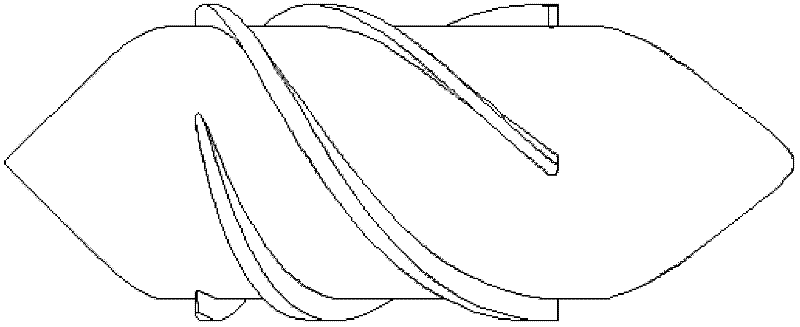

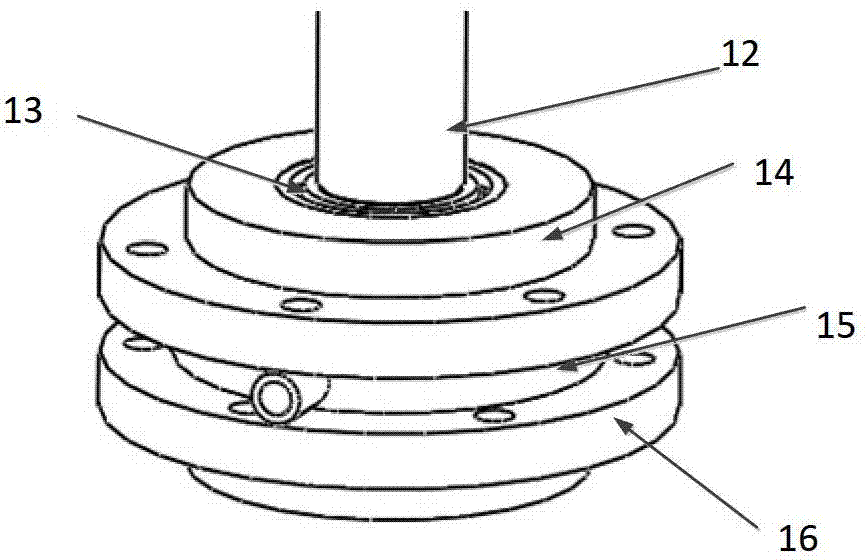

Compact axial-flow magnetic-levitation artificial heart pump

The invention provides a compact axial-flow magnetic-levitation artificial heart pump, in particular to an artificial heart pump characterized in that two permanent magnet bearings and a mix of radial magnetic bearing suspension, and the radial magnetic bearing and a permanent magnet motor share a stator and a rotor. The compact axial-flow magnetic-levitation artificial heart pump has the structure that the compact axial-flow magnetic-levitation artificial heart pump comprises a stator assembly, a rotor assembly, a front guidance impeller and a rear guidance impeller; a taper-shaped or axial permanent magnet bearing is respectively formed by a first permanent magnet (9) and a right permanent magnet ring (14) as well as a second permanent magnet (19) and a left permanent magnet ring (18) to realize the purpose that the rotor axially supports in a suspension mode; a torque coil (5) and a suspension coil (7) are respectively wound on a motor stator (6); and with a certain decoupling control algorithm, the motor stator not only generates torque force but also generates radial suspension support force. In the compact axial-flow magnetic-levitation artificial heart pump, the rotor is supported by permanent magnetic force and electromagnetic force, and the compact axial-flow magnetic-levitation artificial heart pump has the advantages of small damage on blood, less radiation, compact structure and the like, is easy to transplant, is suitable for patients suffering from cardiac function failure, heart diseases and the like and can be used for ventricular assisting for a long time or a short time.

Owner:WUHAN UNIV OF TECH

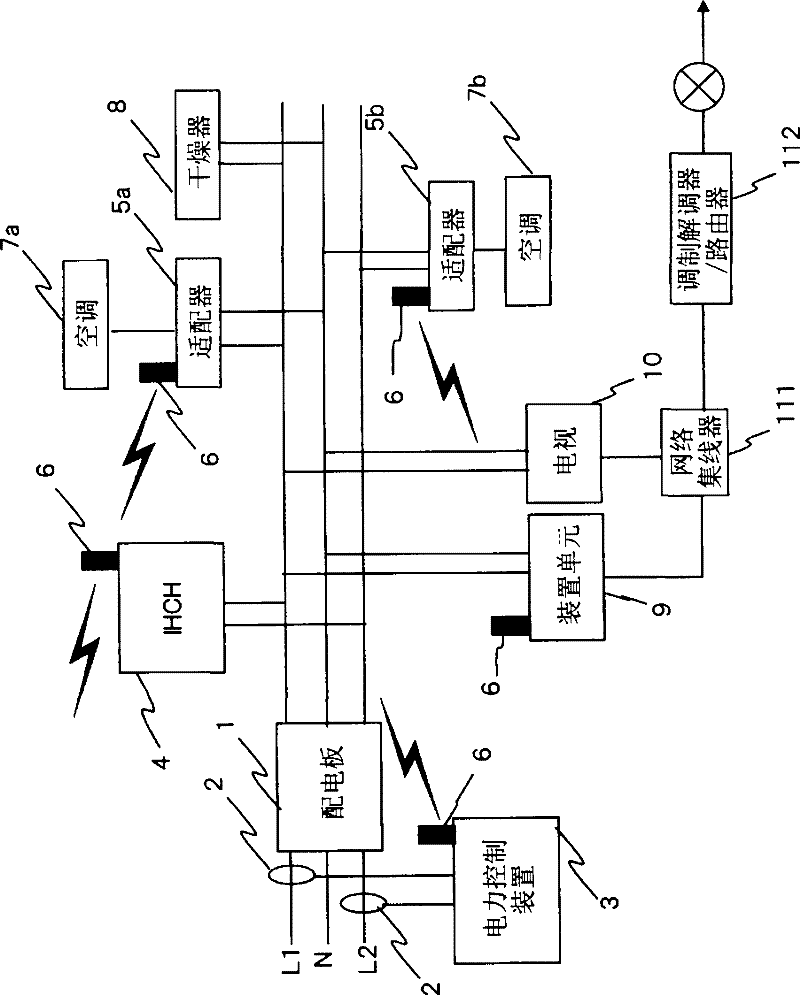

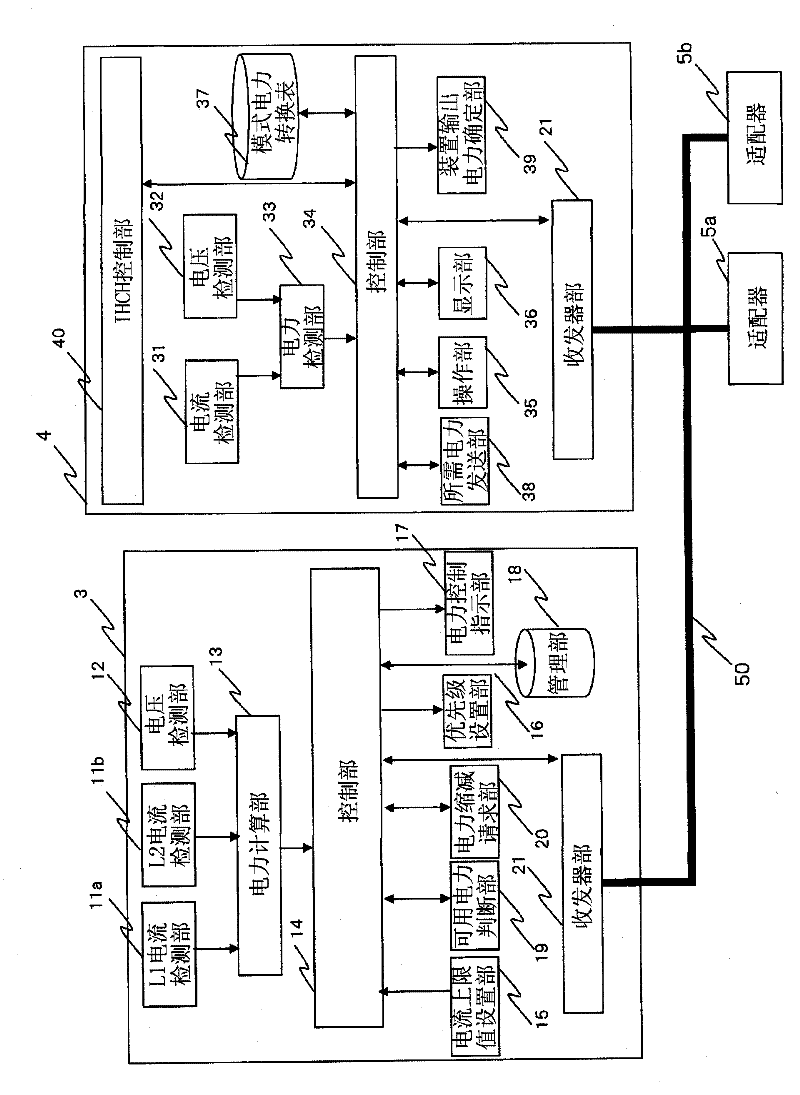

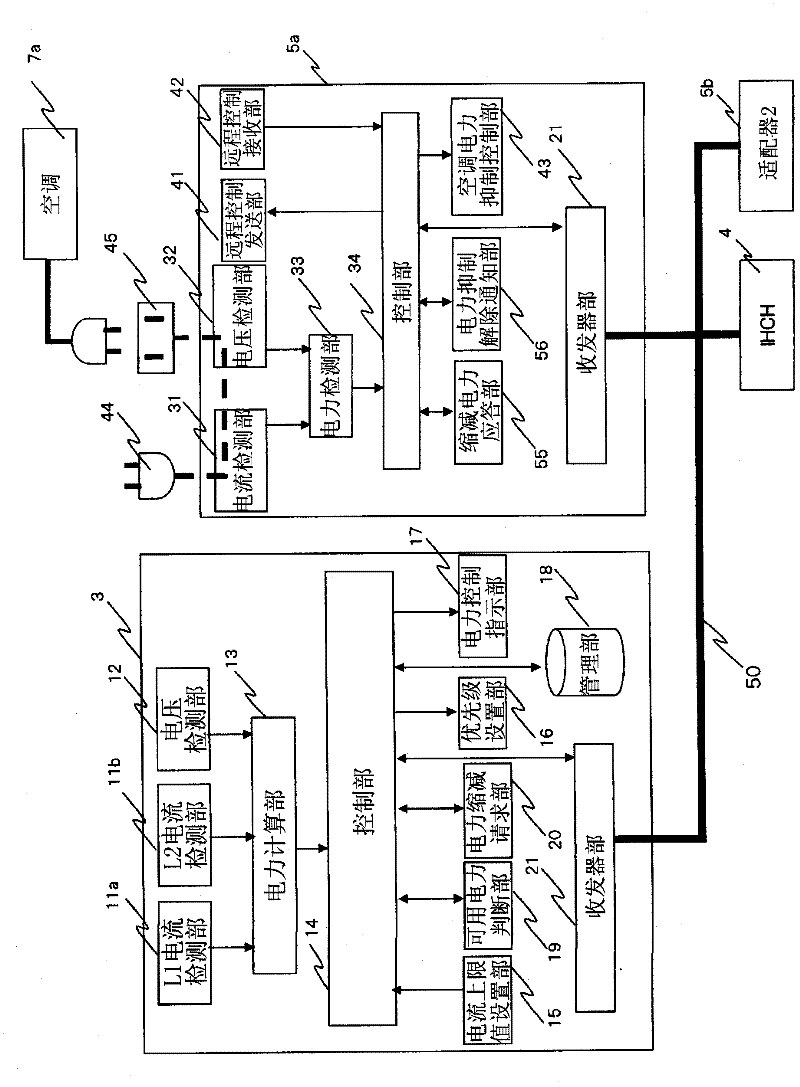

Power control system and method and program for controlling power control system

InactiveCN102341991AAvoid cutsEfficient cuttingTelemetry/telecontrol selection arrangementsPower network operation systems integrationControl systemPower control system

When a user wants to operate a device, if electric power is being used at a level such that a circuit breaker will shut off, he cannot use the device he wants to use unless he himself intentionally reduces the electric power being used for the other devices to increase the amount of usable power. A power control device (3) is provided with a priority setting unit (16) that is capable of setting usage priorities for household devices connected by wire or wirelessly or for adaptors connected to the household devices. A household device or an adaptor connected to the household device operates within the usable power resulting from an inquiry to the power control device (3). When there is no excess in usable power over the power required in the inquiry, the power control device (3) reduces the power used by a device which has a lower priority than the device which made the inquiry in order to allow the device with the higher priority to be used.

Owner:PANASONIC CORP

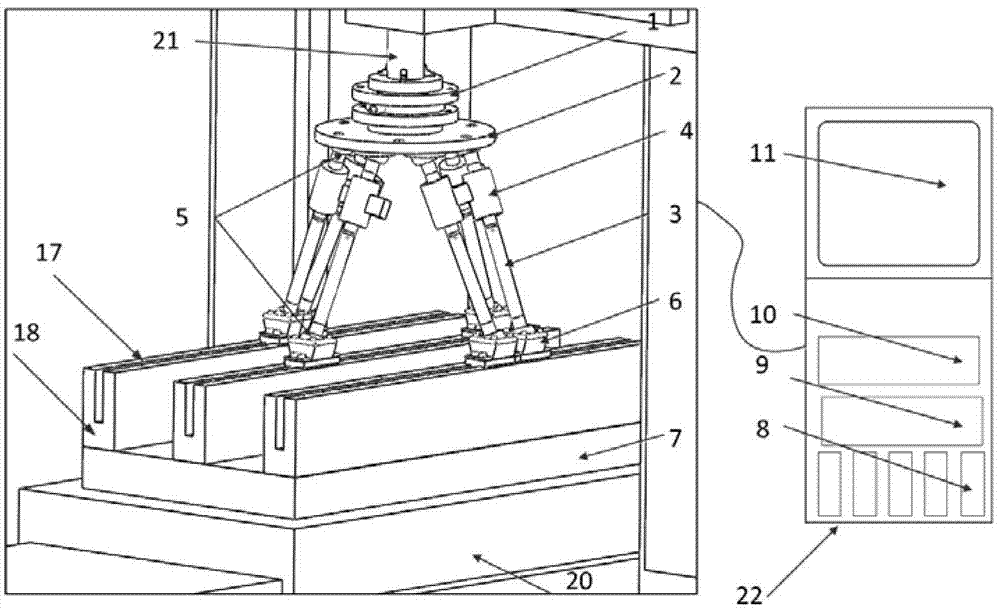

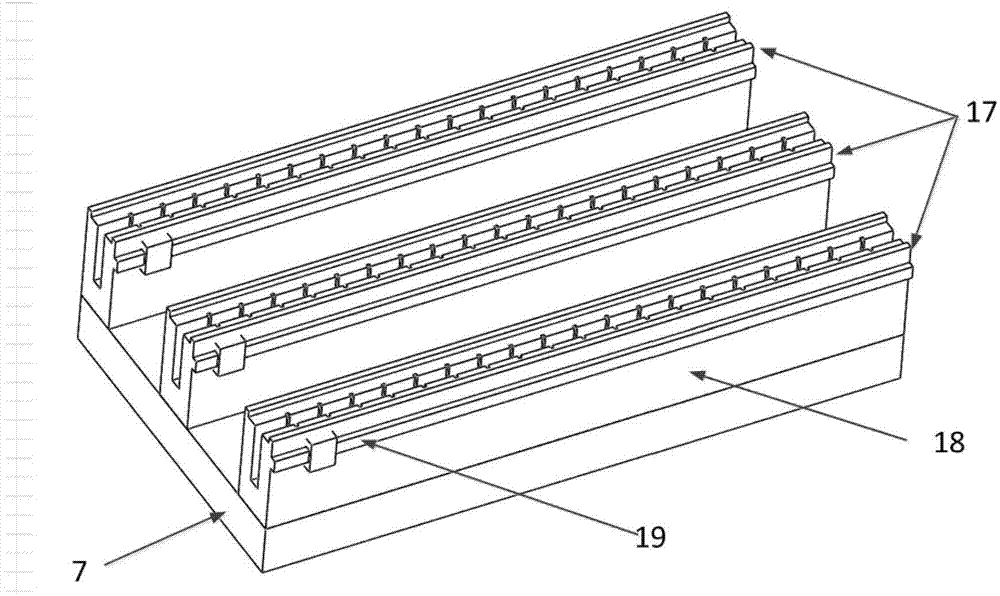

Five-axis linkage loading test device and loading test method for machine tool

InactiveCN102866030AAvoid cuttingLow costStructural/machines measurementAutomotive engineeringMovement control

The invention discloses a five-axis linkage loading test device for a machine tool. The device consists of a following loading mechanism mechanical part and a measurement and control system. The following loading mechanism mechanical part applies a load to a spindle through an interface of the spindle of the machine tool. The measurement and control system is used for realizing servo motor control, mechanism motion control, load calculation and signal processing functions of the following loading mechanism mechanical part. The five-axis linkage loading test method for the machine tool comprises the five major steps of: 1, measuring load data; 2, establishing a load spectrum; 3, organizing tool path data; 4, performing hardware solidification of the data; and 5, calibrating and correcting a database. The device and the method are universal and widely applicable to various types of tests in the reliability of the machine tool, and have practical significance and reference value for the research and development of high-performance load simulators in China.

Owner:BEIHANG UNIV

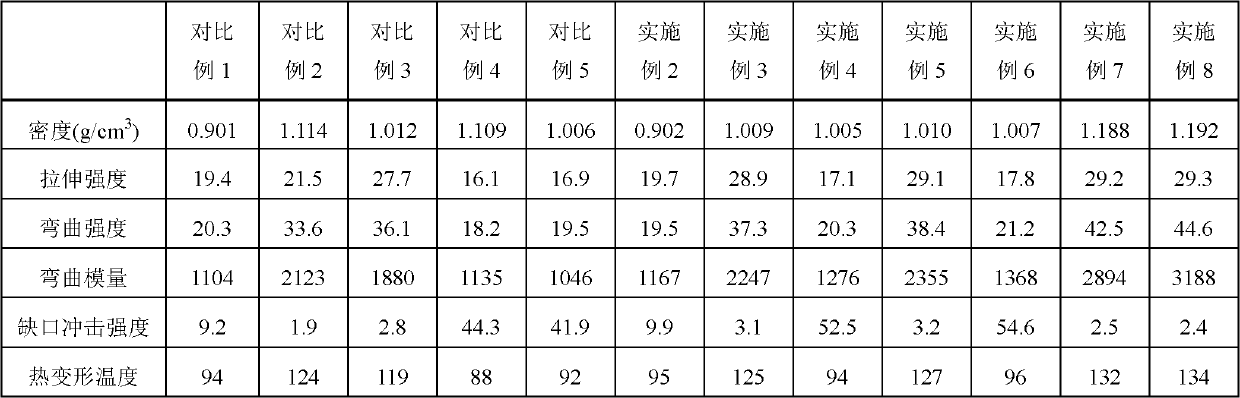

Nano talcpowder modified polypropylene composite material and preparation method thereof

ActiveCN102532685AHigh rigidity and toughnessWide range of applicationsMicron scalePolypropylene composites

The invention provides a nano talcpowder modified polypropylene composite material and a preparation method thereof. A nano-scale talcpowder filler is added and a proper amount of traditional micro-scale talcpowder is added for synergistic modification of polypropylene, an agglomeration phenomenon of the nano filler is avoided to the greatest extent by a special feed and extrusion process, and the composite material with higher comprehensive performance and wider application range is obtained under the conditions of relatively low material density and cost.

Owner:SHANGHAI PRET COMPOSITES

High-performance polypropylene nano composite material and preparation method thereof

The invention discloses a high-performance polypropylene nano composite material and a preparation method thereof, and belongs to the field of polymer modification and processing. The high-performance polypropylene nano composite material comprises the components in percent by weight: 39 to 98% of polypropylene, 1 to 15% organic clay, 0 to 30% of inorganic filling material, 0.1 to 6% of compatilizer, 0 to 20% of flexibilizer, 0.2 to 2% of stabilizer, and 0 to 4% of other additive. Through the cooperative modification of nanoscale organic clay and micron-sized talcum powder to polypropylene, a nano composite material with higher rigidity, higher tenacity and other performance is obtained at a lower material density.

Owner:SHANGHAI PRET COMPOSITES

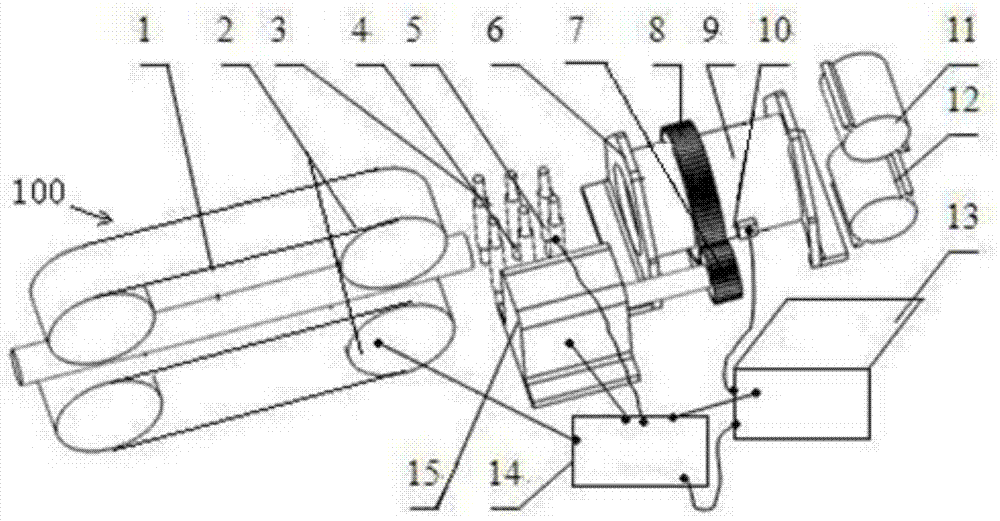

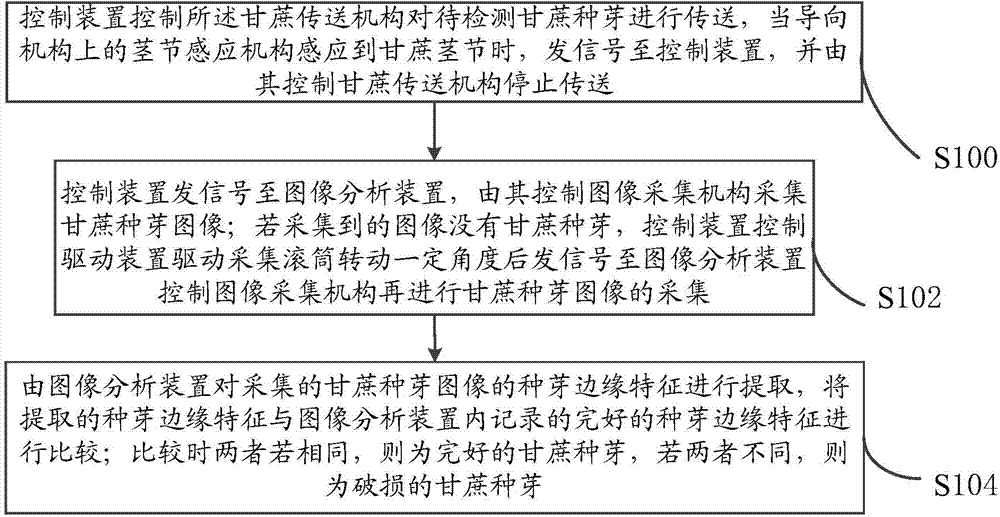

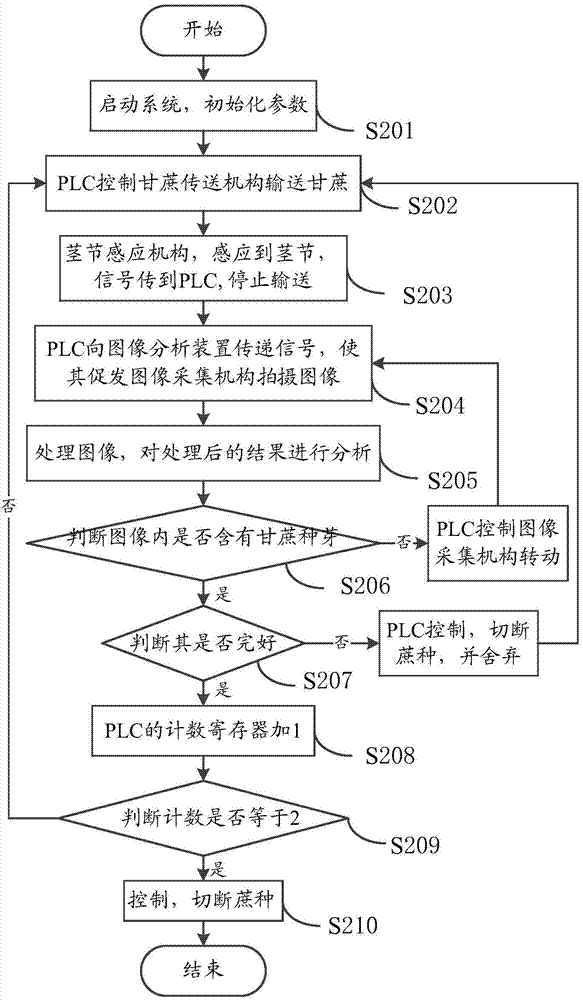

Sugarcane seedling integrity detection system and method

InactiveCN104115589ANo breakage rateImprove germination rateSeed and root treatmentMaterial analysis by optical meansImaging processingImaging analysis

The invention discloses a sugarcane seedling integrity detection system and method, and the detection system includes a sugarcane conveying mechanism, a guiding mechanism, a collecting drum and a driving device; the large bell end of the guiding mechanism is corresponding to the output port of the sugarcane conveying mechanism, and a stem node induction mechanism is arranged on a sugarcane conveying travel path at the small bell end of the guiding mechanism; the two ends of the collecting drum are arranged on an installation base in a mode of capable of rotating, one end tube opening of the collecting drum is corresponding to the small bell end of the guiding mechanism, and the drum wall of the outer surface of the collecting drum is fixedly connected with a first gear, and is provided with a collecting round hole passing through the drum wall; a shaft of the driving device is provided with a second gear engaging with the first gear; an image acquisition mechanism is installed in the collecting round hole; the stem node induction mechanism, the stem node induction mechanism and the driving device are connected with a control device; the control device is connected with an image processing device, an image analysis device is connected with the image acquisition mechanism; and the system combining the corresponding method can detect sugarcane seedling integrity.

Owner:GUANGXI UNIV

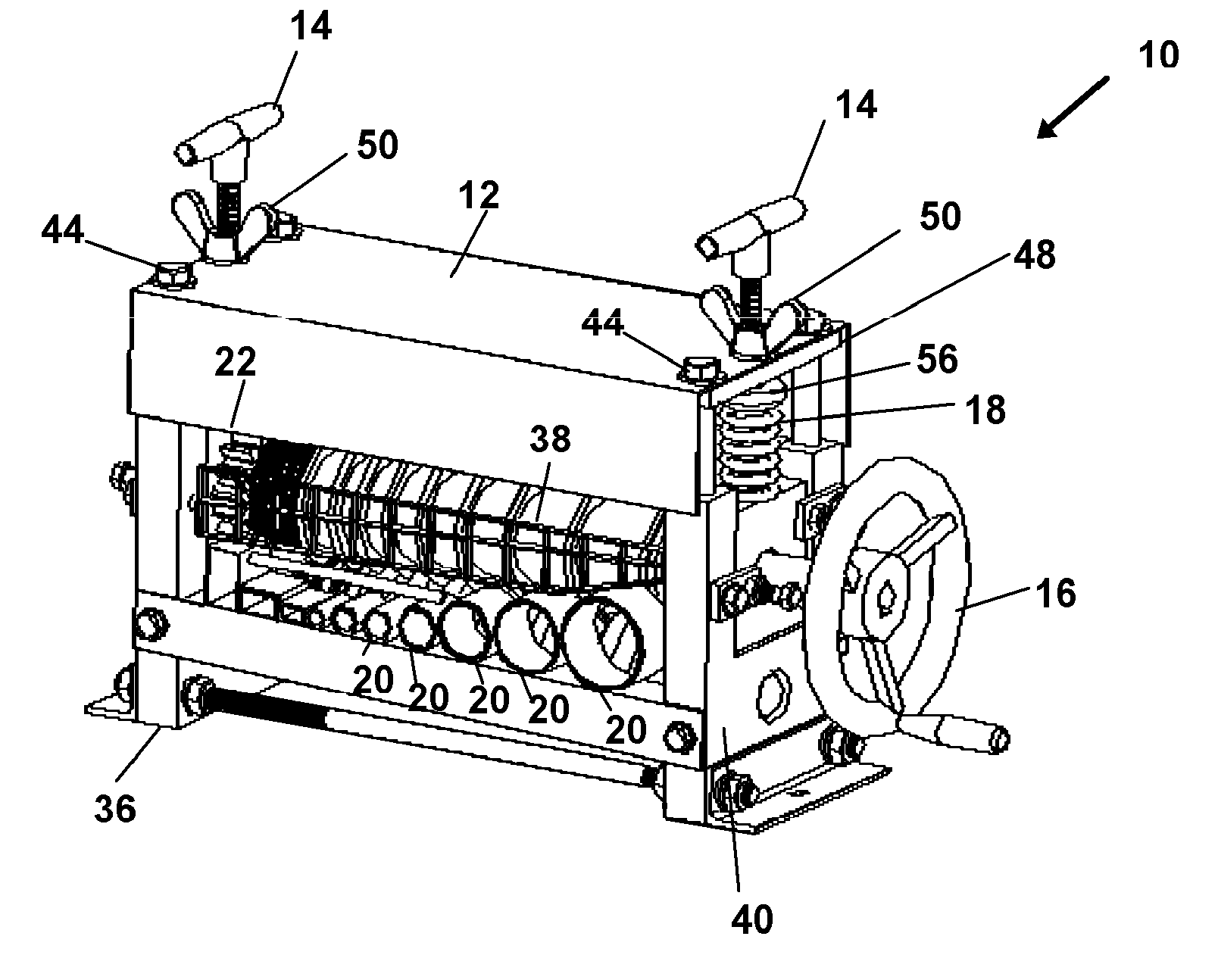

Wire Stripping Device

ActiveUS20120167719A1Easy to useEncourages recyclingBasic electric elementsApparatus for removing/armouring cablesEngineeringElectric wire

A device for removing an insulation jacket from a wire core of an insulated wire or cable is provided for encouraging recycling. The device employs cutting blades engaged to a first roller to cut a slice along the length of an inserted insulated wire or cable. A frictional engagement between the distal edge of the blade and an opposing recess surface provides for translation of the length of wire through the device during rotation of one or both of the blade and recess surface. Translational movement of the blades and a biasing force can enhance the frictional engagement and provide a distance of travel to prevent cutting of the insulated wire or cable.

Owner:THE NEWMAN TRADING COMPANY

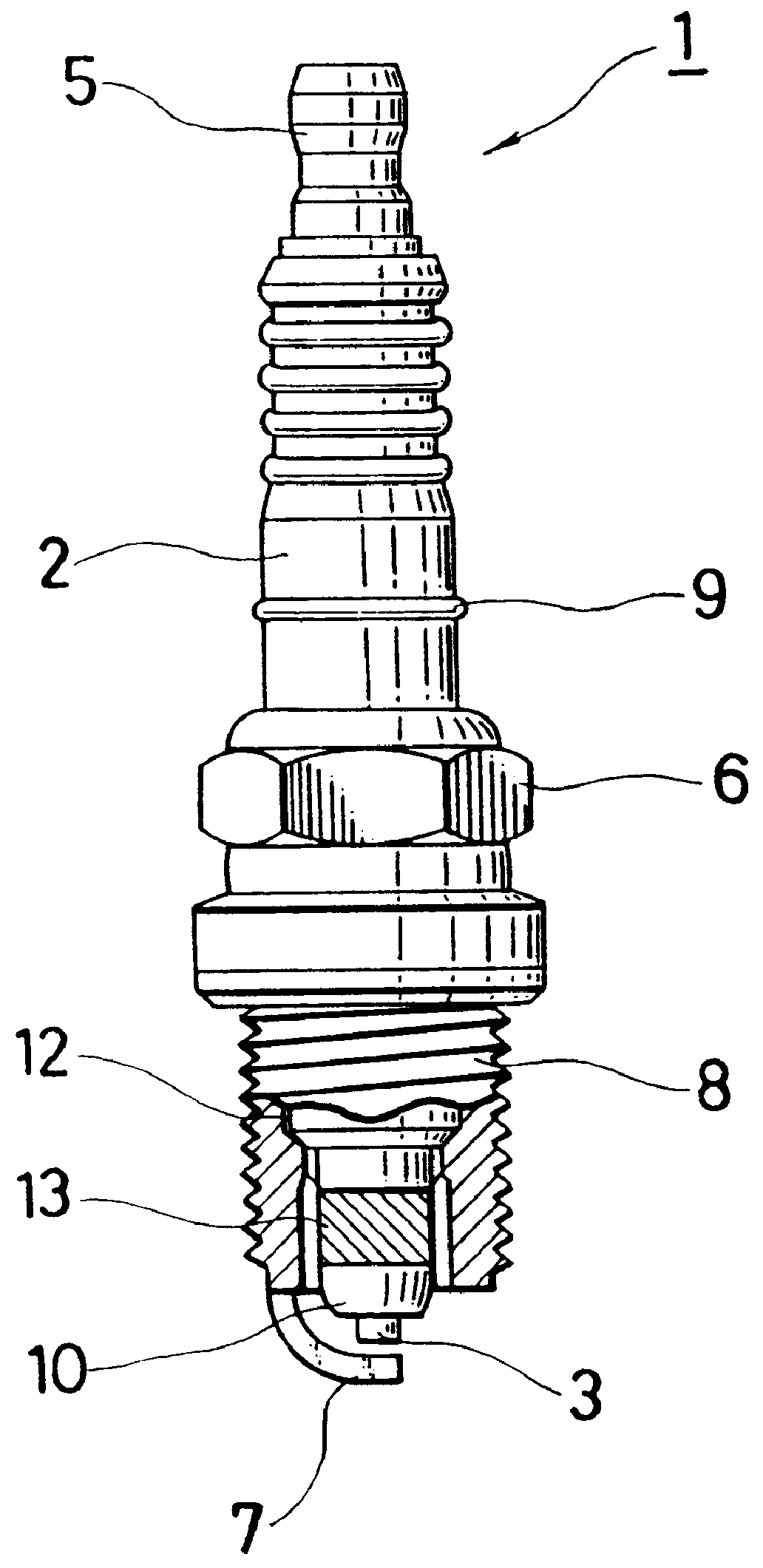

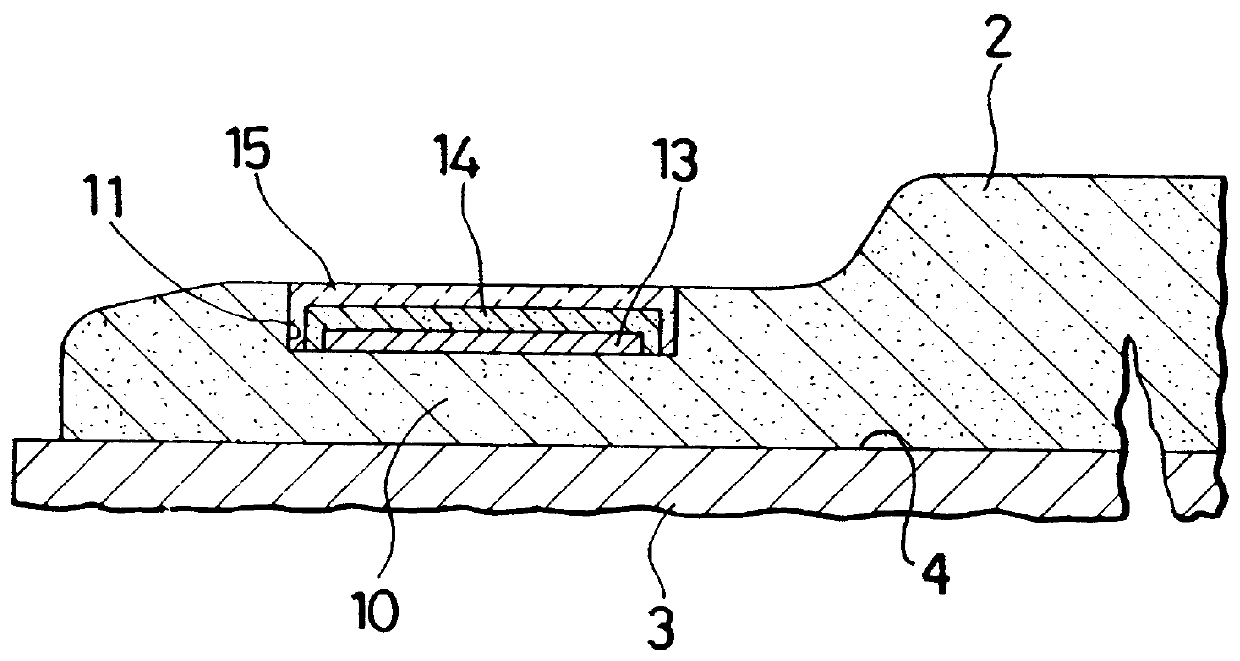

Heater equipped spark plug

InactiveUS6060821ASufficient voltage withstand performanceImprove insulation performanceSpark gapsGenerator generated ignition energyEngineeringMetal

A heater-equipped spark plug comprises an insulator having an insulator nose which holds thereon a center electrode in the vicinity of a free end of an axial bore, a lead wire arranged along a surface of the insulator, a heater formed on the insulator nose by baking a metal paste and connected to the lead wire; and a high softening-point glass layer covering and holding the heater in place with an alumina layer interposed between the high softening-point glass and the heater. Preferably, the alumina layer can have a thickness of 20-200 mu m and the high softening-point glass layer can have a thickness of 30-500 mu m.

Owner:NGK SPARK PLUG CO LTD

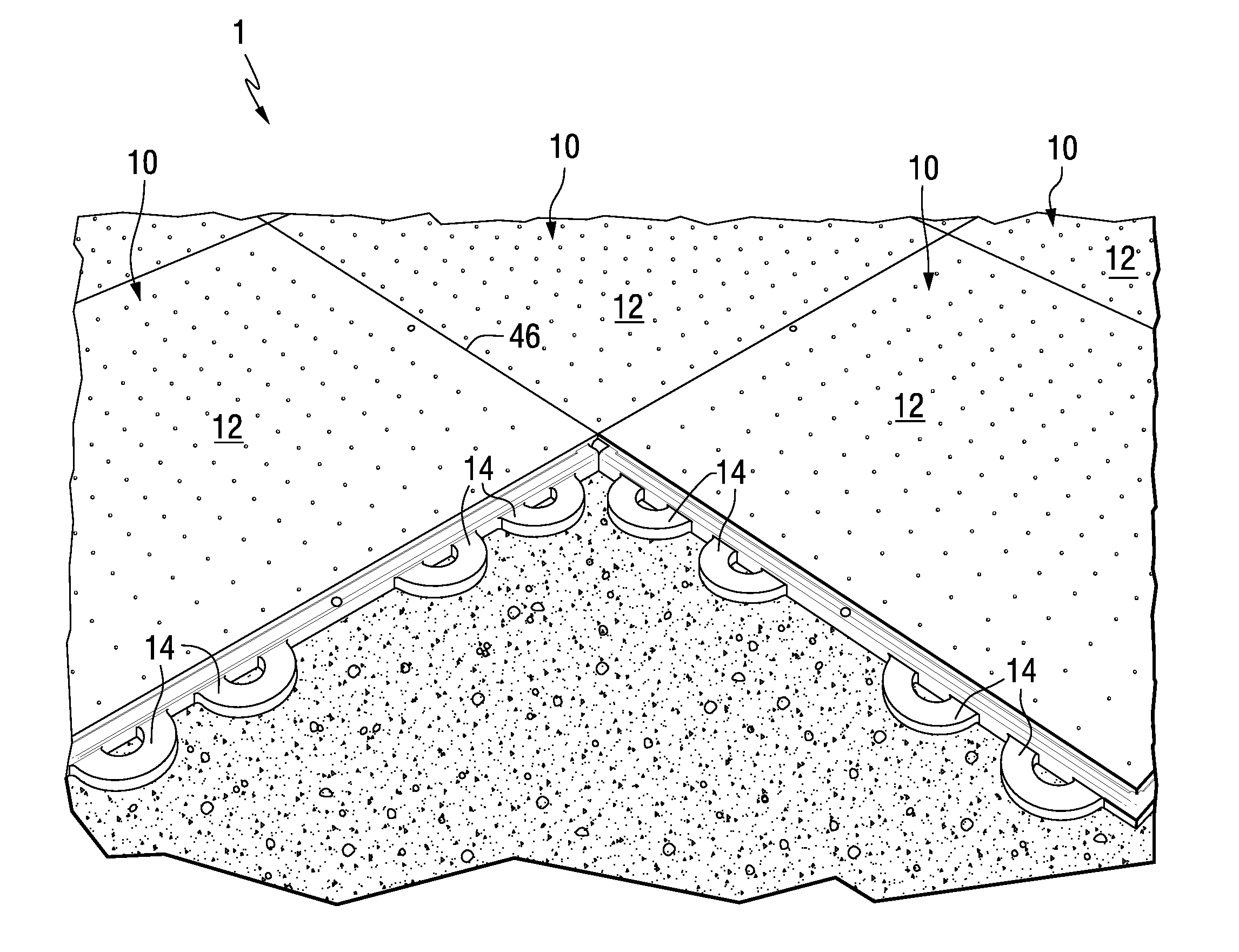

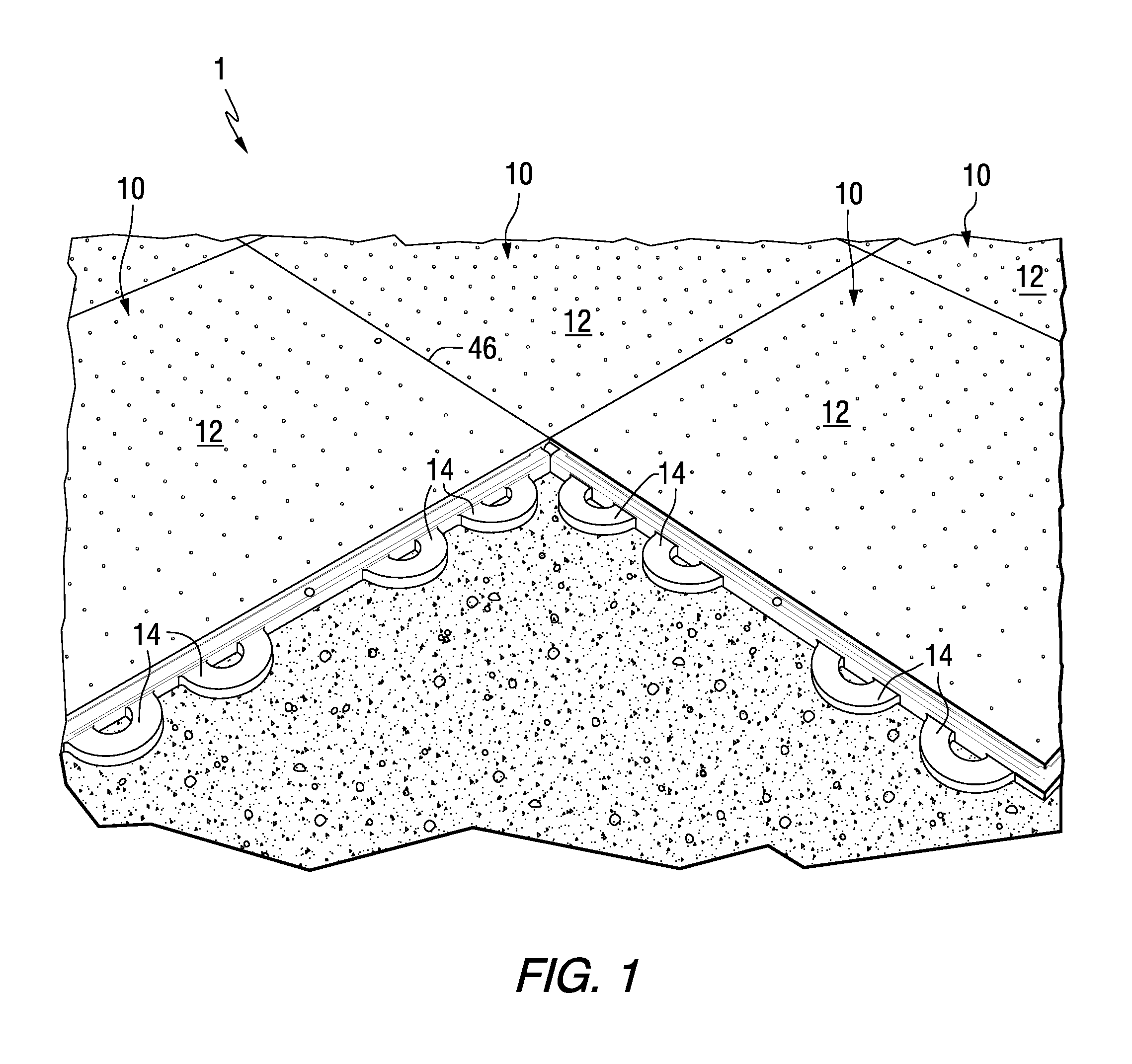

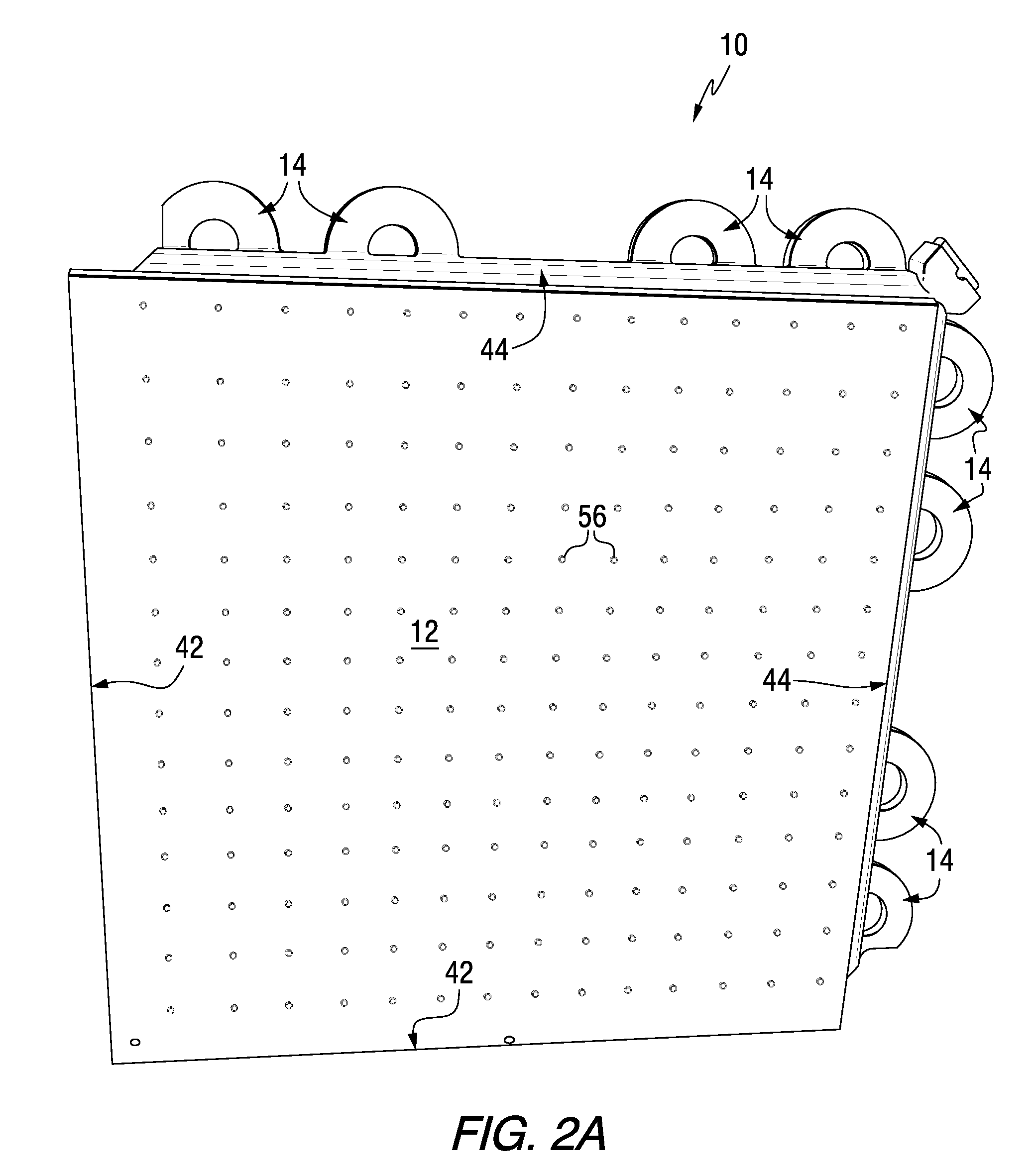

Modular flooring system

ActiveUS20110252730A1Provide durabilityProvide strengthClimate change adaptationTemporary pavingsModularityCam

A modular flooring system is disclosed which is designed to support heavy loads while providing stability and ground protection. The invention contemplates a modular tile with fully integrated connector loops, receiver pins and optional metal cam locks located in the corners of the floor tile or along the tile edges. The tiles contain an overlap edge, which engages with an underlay edge on an adjacent tile. This arrangement allows the tiles to overlap at an angle other than 90 degrees, providing greater strength at the point where adjacent tiles meet. The underlay edge contains a liquid capture channel which traps liquids which may seep between the adjacent tiles. The tiles are also provided with longitudinal recesses which extend through the top and bottom surfaces to the surface below, allowing for ventilation that is critical for grass and turf surfaces. The modular flooring system provides increased strength and stability and protection of the subsurface.

Owner:SIGNATURE SYST GRP LLC

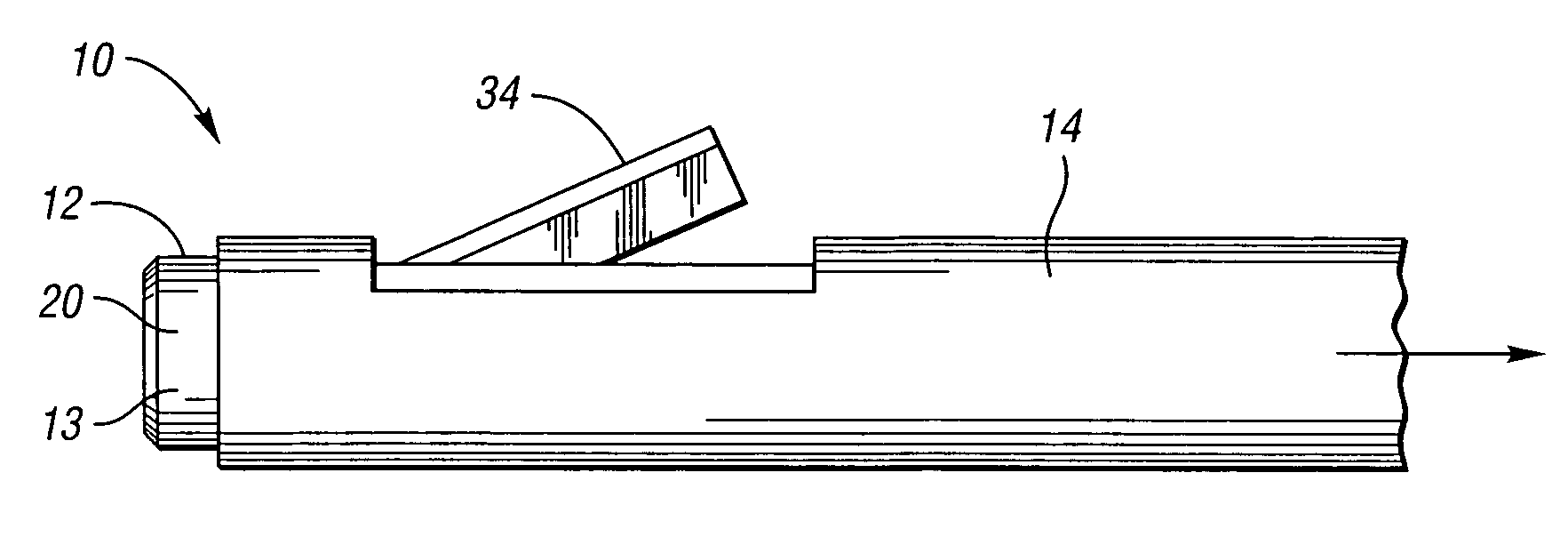

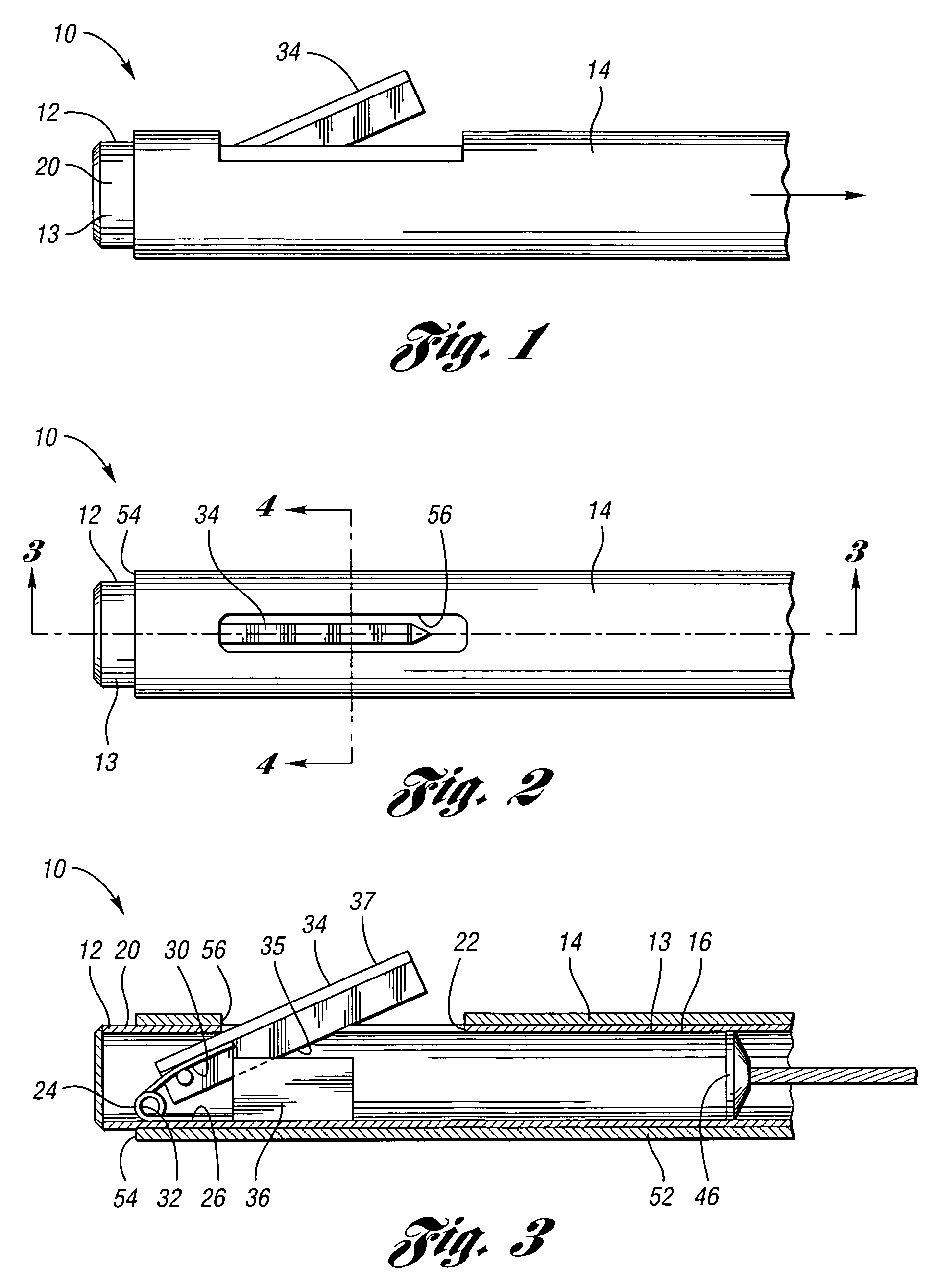

Endoscopic cutting device

ActiveUS7520886B2Effective and relatively sharp dissectionAvoiding shearing and broad cutsSuture equipmentsCannulasEndoscopeCatheter device

An endoscopic cutting device is disclosed. The device comprises an inner catheter including an inner wall having an opening formed therethrough. The inner wall further has a cutting blade moveably disposed thereon and biasingly extends through the opening. The inner wall has a receiving member disposed thereon and is configured to cooperatively receive the cutting blade. The device further comprises an outer catheter including an outer wall moveably disposed about the inner catheter. The outer wall has an aperture formed therethrough. The aperture is configured to moveably align with the opening of the inner wall for allowing the cutting blade to biasingly extend through the opening and biasingly engage the cutting blade with the receiving member to cut.

Owner:COOK MEDICAL TECH LLC

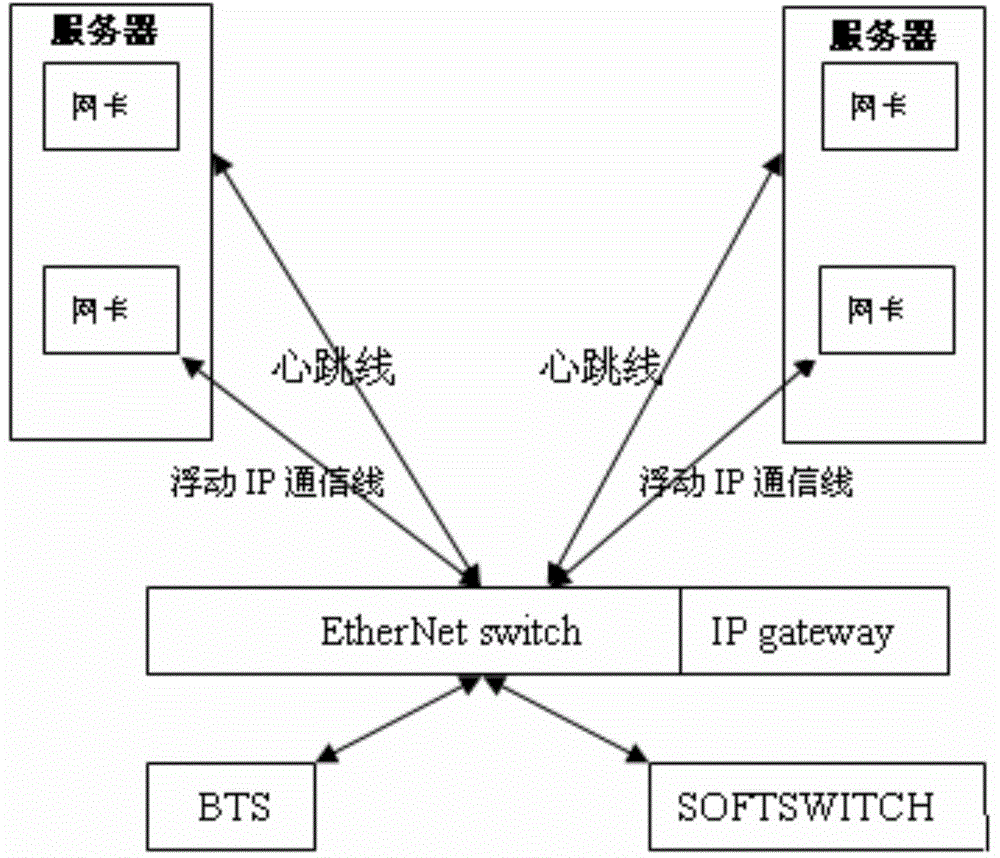

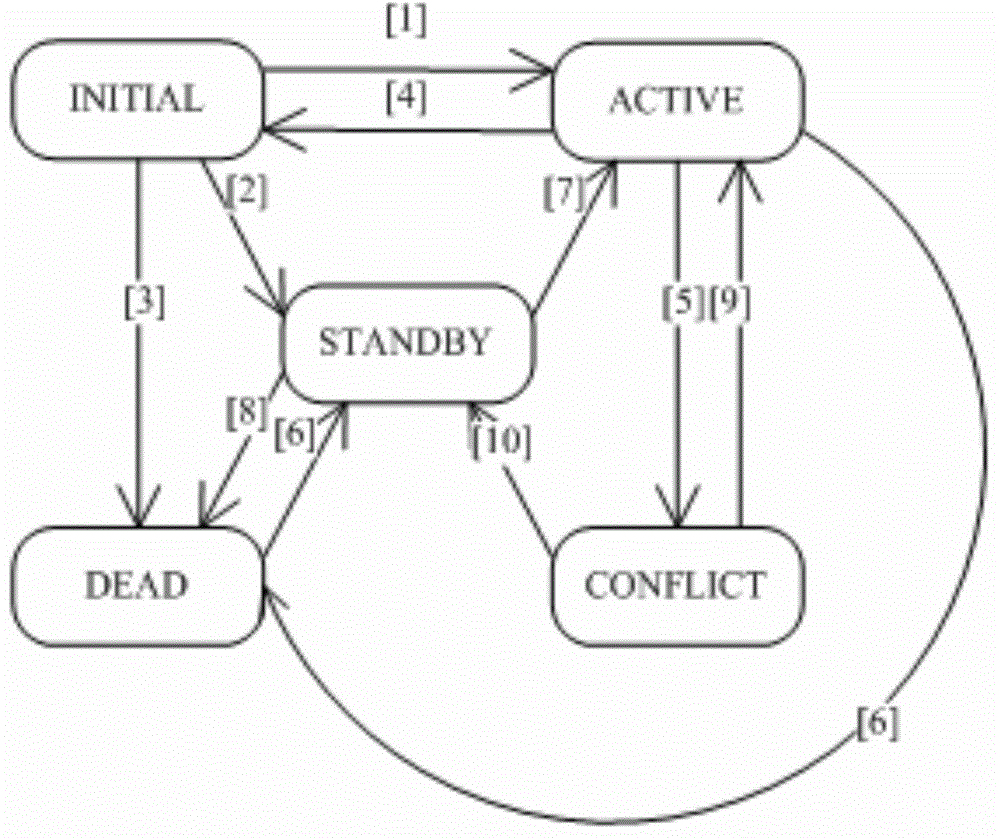

Method, device and system for achieving high reliability of server

InactiveCN104660441AAvoid cutsGuaranteed operational reliabilityData switching networksReal-time dataIp address

The invention discloses a method for achieving high reliability of key equipment. The method comprises the following steps: deploying a first server and a second server; appointing an IP address, namely a floating IP shared by the two servers; mutually monitoring states of the two servers through heartbeat, and performing real-time data synchronization; when the first server is abnormal, updating the floating IP to the second server from the first server, and taking over the service of the first server from the second server through the floating IP.

Owner:BEIJING XINWEI TELECOM TECH +1

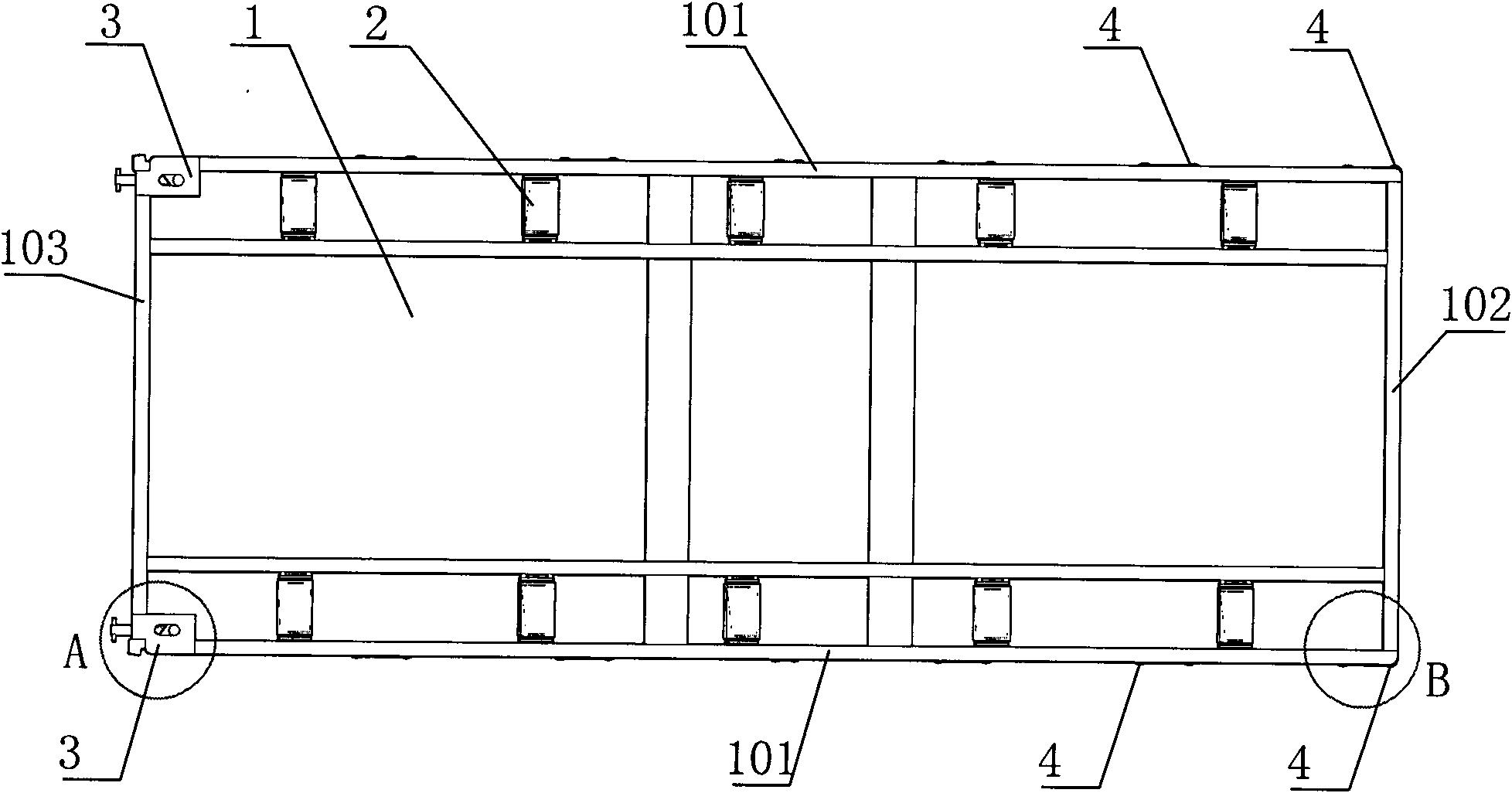

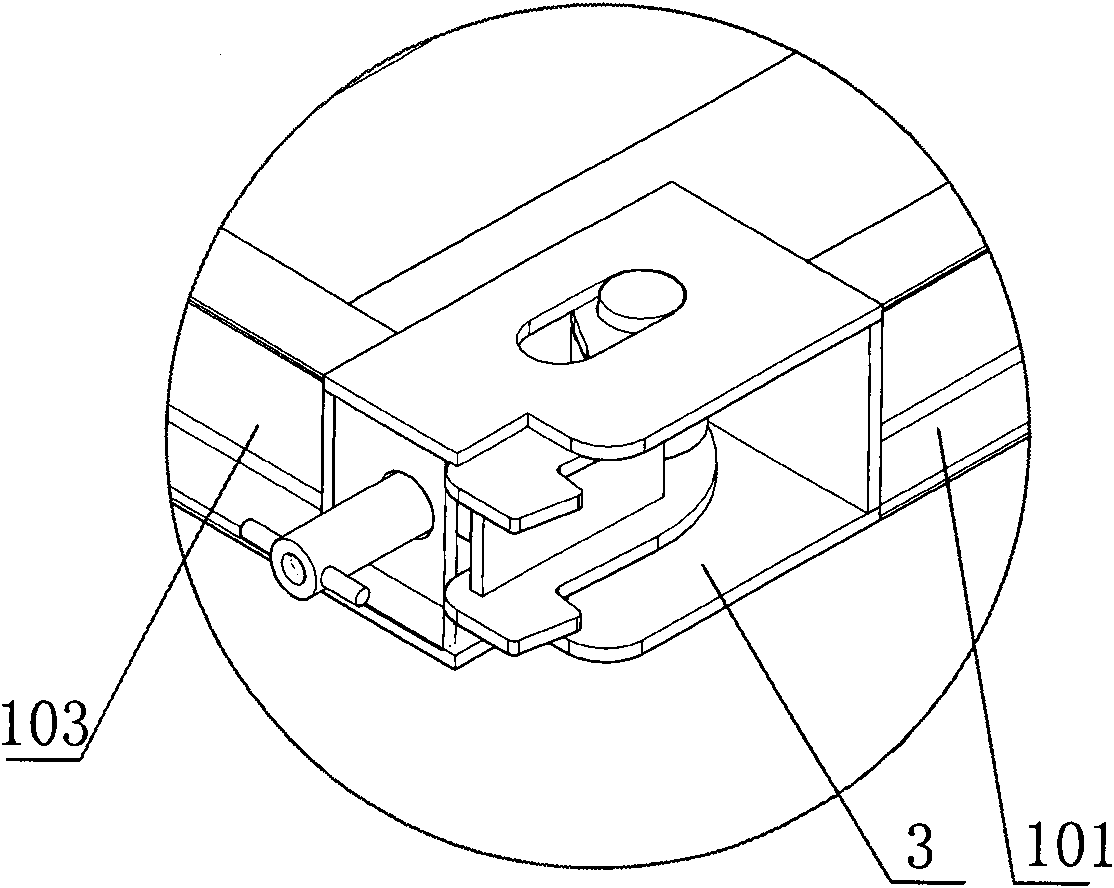

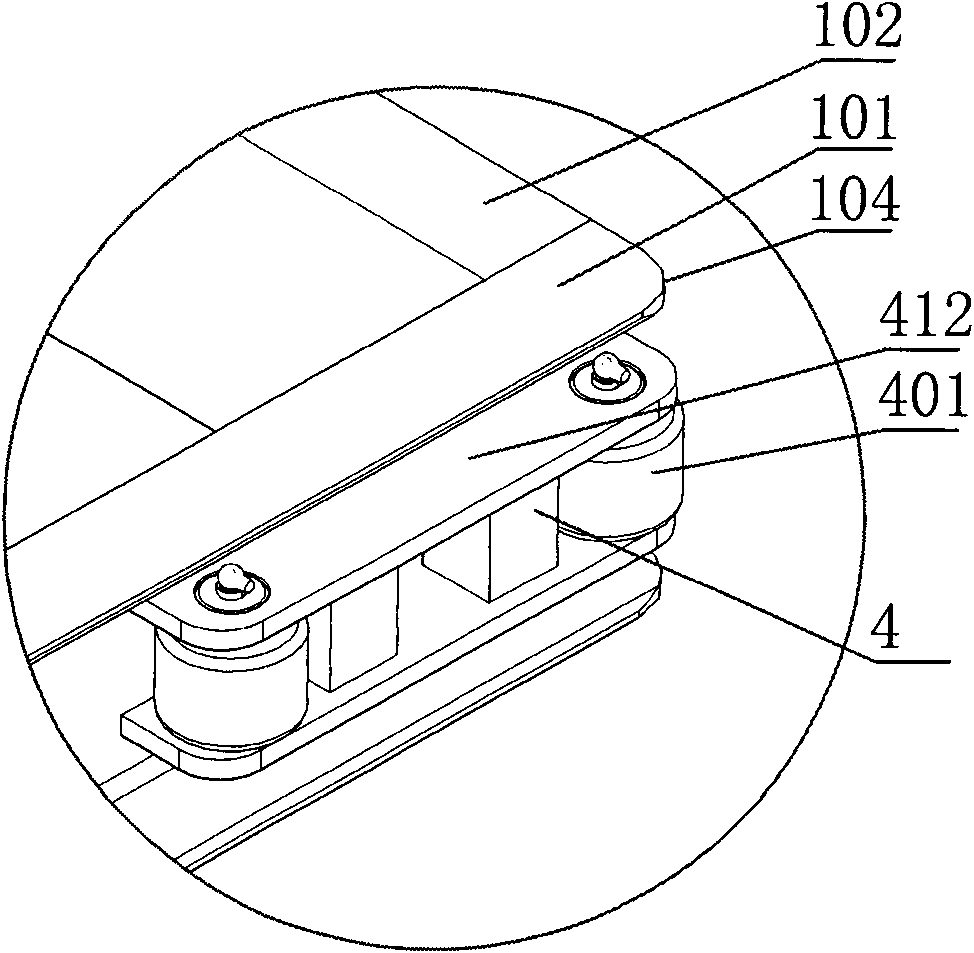

Built-in mobile pallet of container

InactiveCN101891046AEffective protectionAvoid cutsLarge containersRigid containersRolling resistanceFront edge

The invention relates to a built-in mobile pallet of a container, comprising a rectangular chassis with rolling wheels at the bottom, wherein a plurality of guide devices are arranged at two lateral parts and the edge corner parts of the chassis; the guide devices are of guide wheel structures, and the peripheral surface of each guide wheel protrudes out of the lateral side of the chassis; and locking devices are arranged at two corner parts of the rear edge of the chassis. In the invention, the guide wheels are arranged at the lateral parts and the edge corner parts of the chassis, which converts sliding friction with larger resistance into rolling friction with smaller resistance; the peripheral surface of each guide wheel at the edge corner part is firstly in contact with a firm door frame of the container in the loading process, therefore, the relatively parallel position between the pallet and the container is well regulated basically; in addition, the guide wheels at the lateral parts can self-adaptively regulate the relative position between the pallet and the container in the continuous conveying process, thereby preventing the wall of the container from being crashed, even lacerated and effectively protecting the container; and locking hooks arranged at the rear edge corner parts are reasonable in structure, convenient to use and reliable to lock.

Owner:WUXI CLS MASCH CO LTD

Film applicator tool with arcuate edges

InactiveUS7225848B2Sufficient flexibilityAvoid cutsLiquid surface applicatorsCovering/liningsHardnessEngineering

Film applicator tools are provided which have at least two arcuate edges which are sufficiently flexible and resilient to permit application of adhesive films to smooth surfaces without leaving air bubbles, creases or other defects. The tools are molded of polymeric materials which have hardness values effective to permit the application of smooth and uniform pressure without tearing or abrading the films.

Owner:WILLIAMS ROBERT D

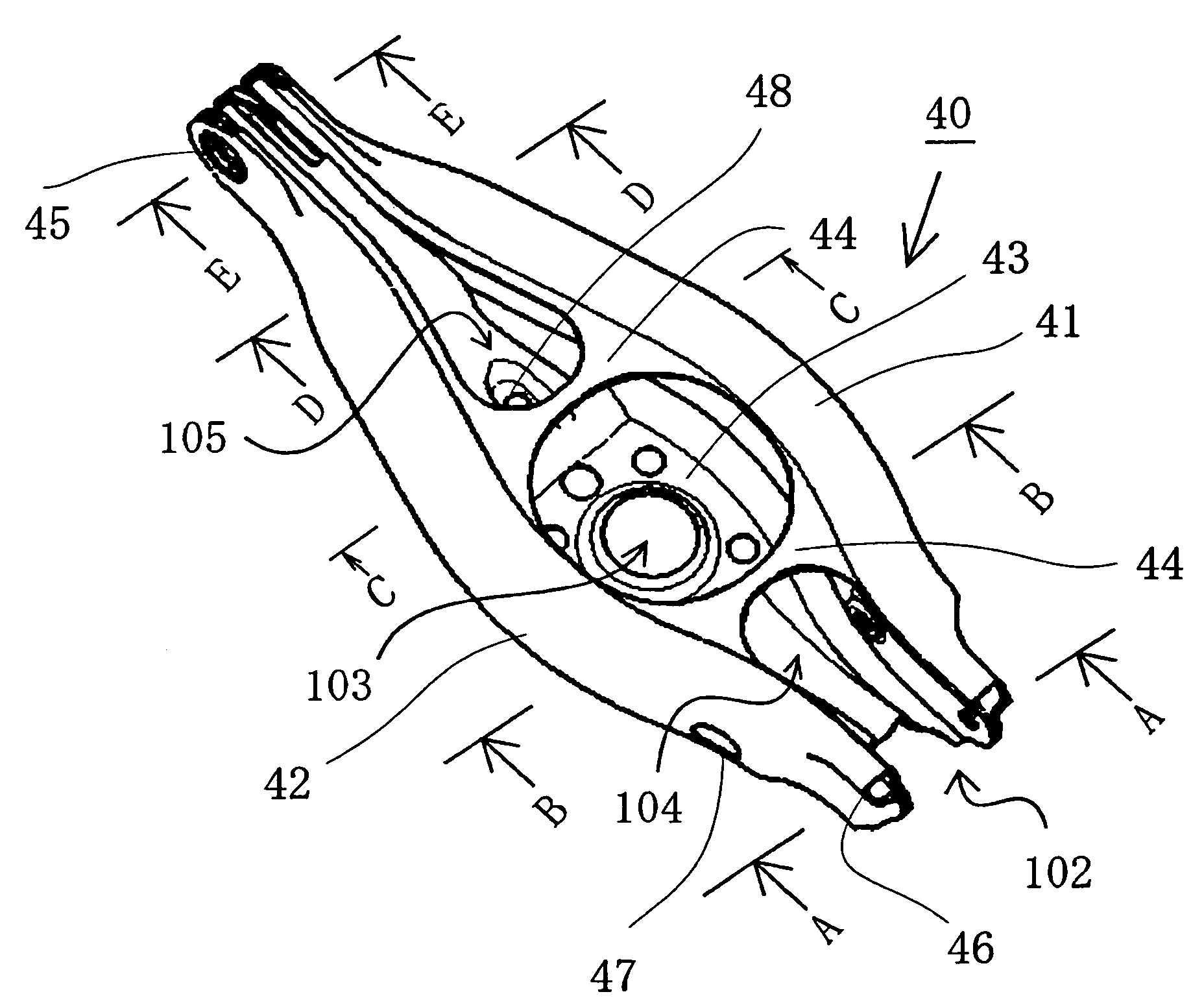

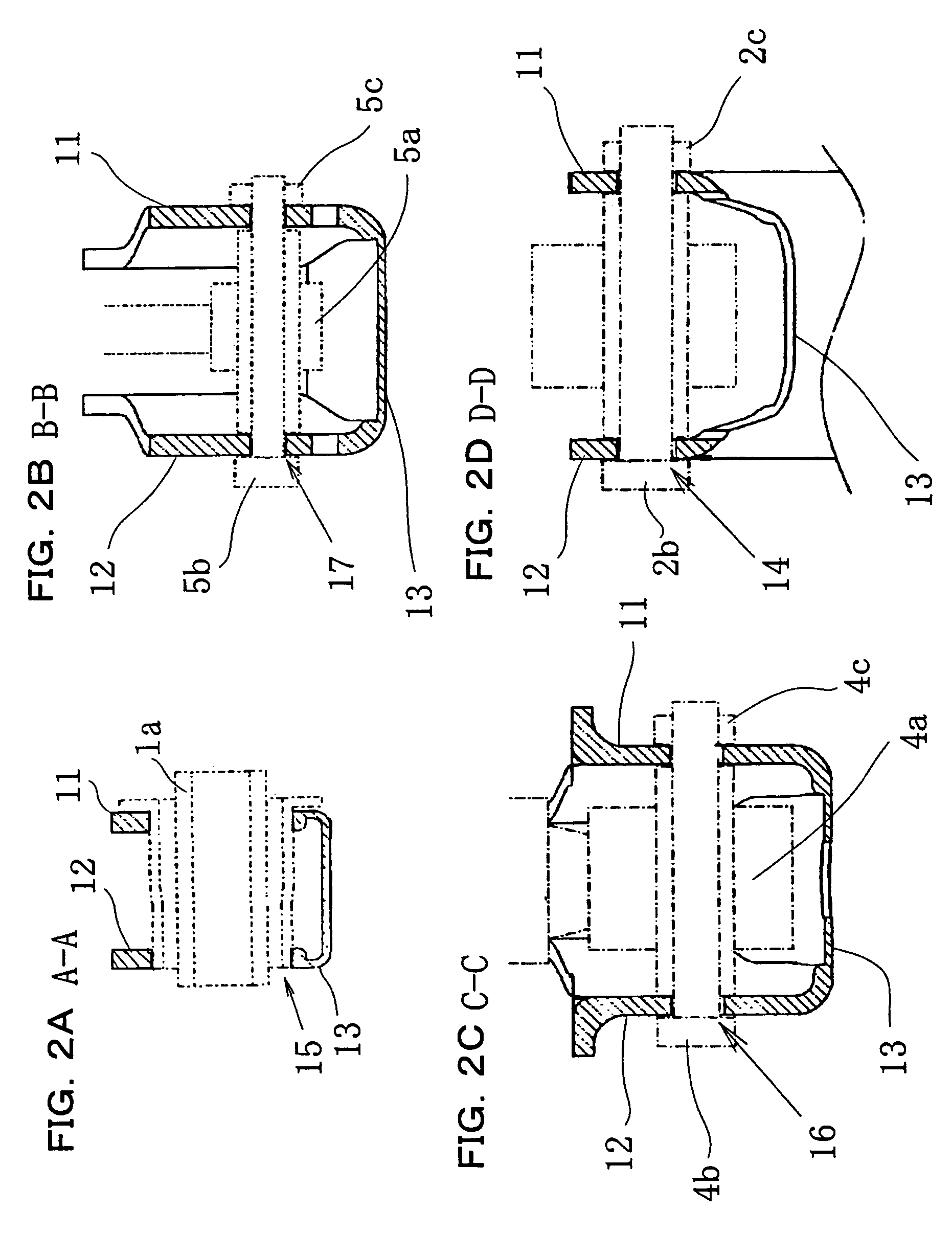

Suspension arm

A suspension arm made of an aluminum alloy extruded profile having a portion forming a bottom portion, portions forming at least two vertical walls, and a horizontal rib which connects the two vertical walls, wherein a suspension part lower end support portion is formed between the two vertical walls or at the bottom portion by removing a part of the horizontal rib. It is preferable to gradually change the interval between the two vertical walls in the portion in which the horizontal rib is removed.

Owner:AISIN KEIKINZOKU CO LTD +1

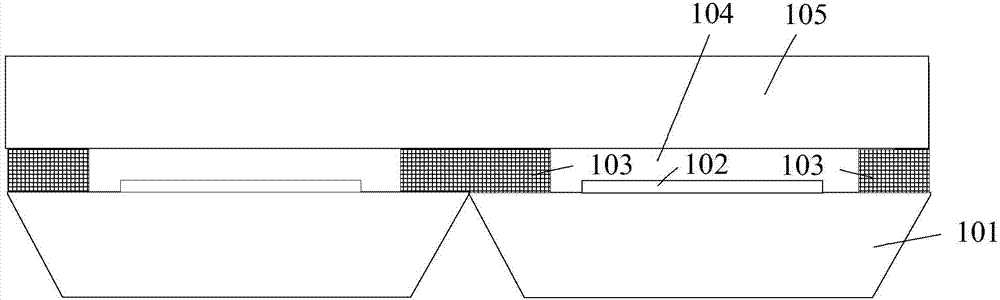

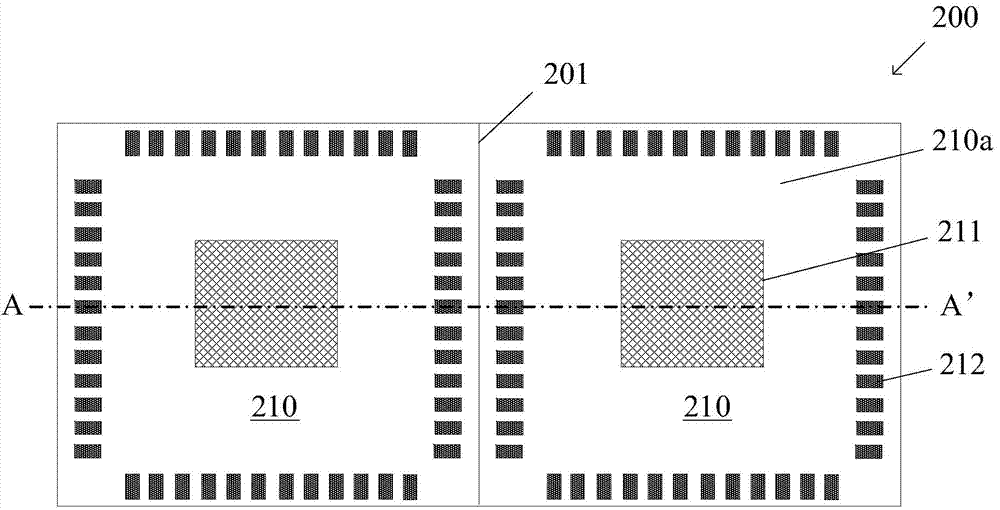

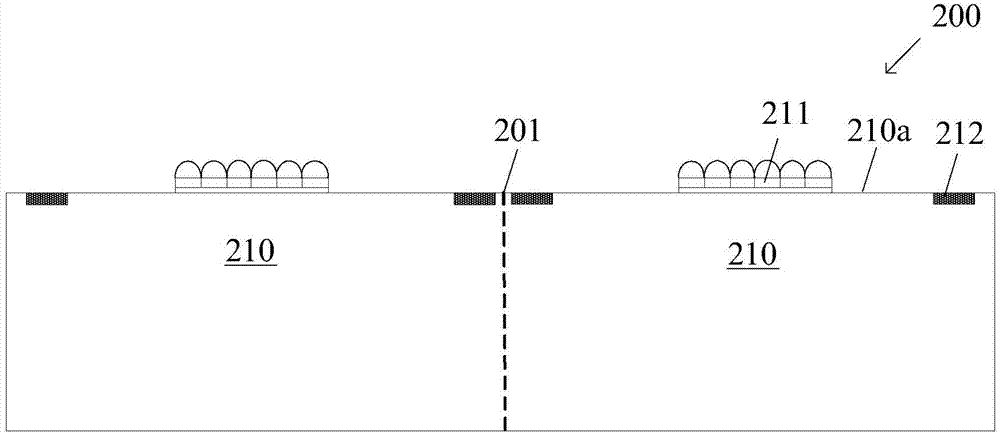

Wafer-level packaging method of image sensor chips

ActiveCN103489885AImprove reliabilityAvoid cuttingSemiconductor/solid-state device detailsSolid-state devicesImage sensorWafer-level packaging

A wafer-level packaging method of image sensor chips comprises the steps of providing wafers, mixed substrates and carrier plates. The wafers comprise a plurality of image sensor chips, and the mixed substrates comprise a supporting frame and a plurality of transparent substrate units. The supporting frame comprises a plurality of windows, the transparent substrate units cover the windows correspondingly, and the wafers, the mixed substrates and the carrier plates are fixed together in sequence in an overlapped mode. The back faces of the wafers are subjected to a line redistribution process and a welding flux protrusion manufacturing process, and the wafers and the mixed substrates are cut along cutting channels, so that the image sensor chips are separated to a plurality of image sensor chip modules which comprise separated mixed substrate units and image sensor chip units bonded with the mixed substrate units. By means of the method, the image sensor chips are maintained to be clean in the whole packaging process without being damaged, and the packaged image sensor chip modules have high reliability.

Owner:格科微电子(浙江)有限公司

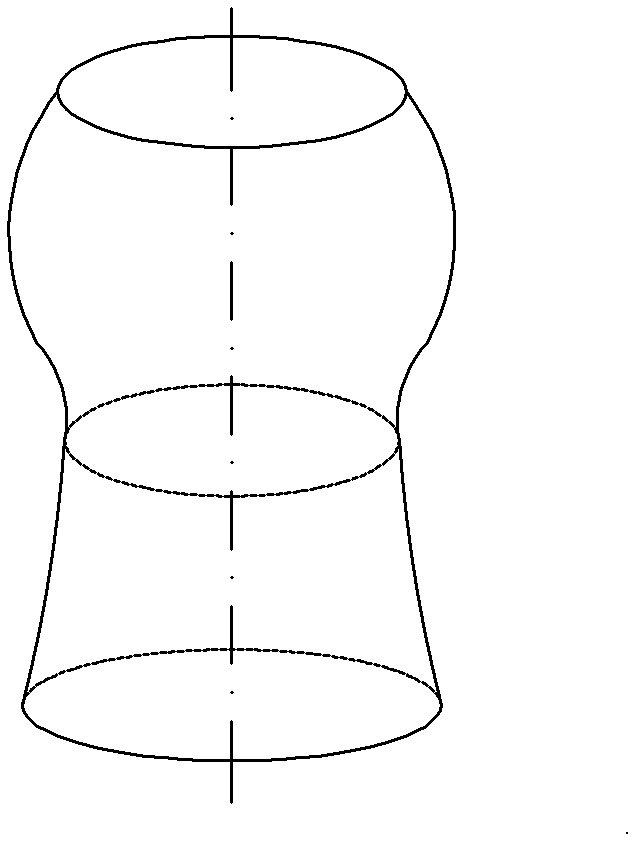

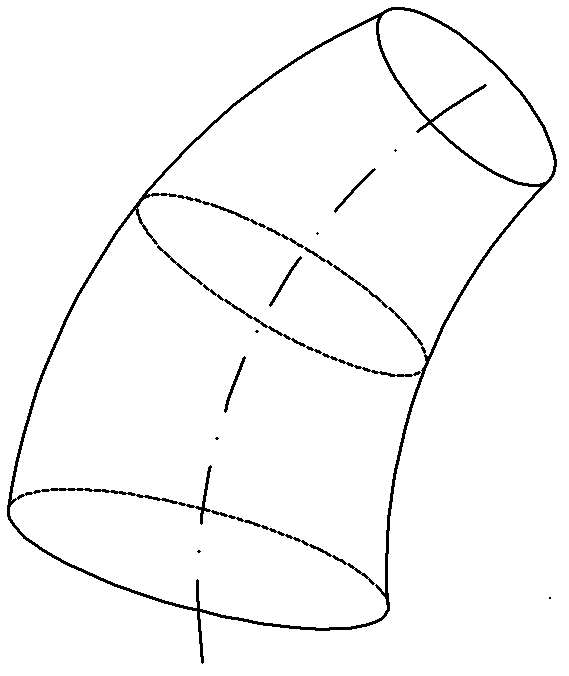

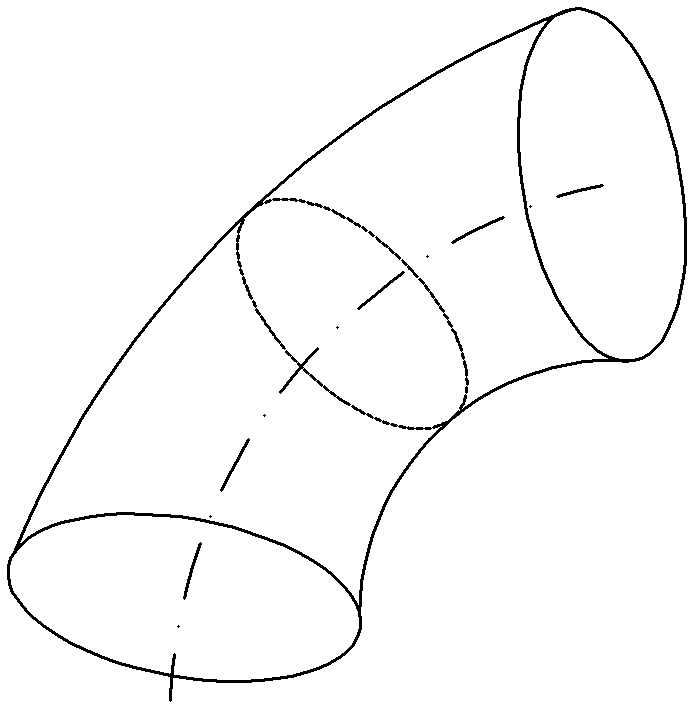

Automatic fiber laying variable-angle path planning method for non-developable curved surface part

The invention discloses an automatic fiber laying variable-angle path planning method for a non-developable curved surface part, which relates to a fiber laying path plan making method for a non-developable curved surface part and is used for solving the problem that in the complexity of a fiber laying process, the appearance accuracy and various properties of a composite material are influenced by inevitable shearing and re-conveying phenomena occurring in the automatic fiber laying process of the non-developable curved surface part. In a scheme I, the method comprises the following steps of: acquiring data information from a non-developable revolving barrel part; calculating the laying reference angle of a presoaked tow on each intersection line; determining points on an initial path; determining points on other paths; and making a path line. A scheme II is different from the scheme I in that data information is acquired from a non-developable curved surface variable-section conical shell part; and a scheme III is different from the scheme I and the scheme II in that data information is acquired from a non-developable curved surface variable-section joint part. The method is used for planning an automatic fiber laying variable-angle path on the outer surface of the non-developable curved surface part.

Owner:HARBIN INST OF TECH

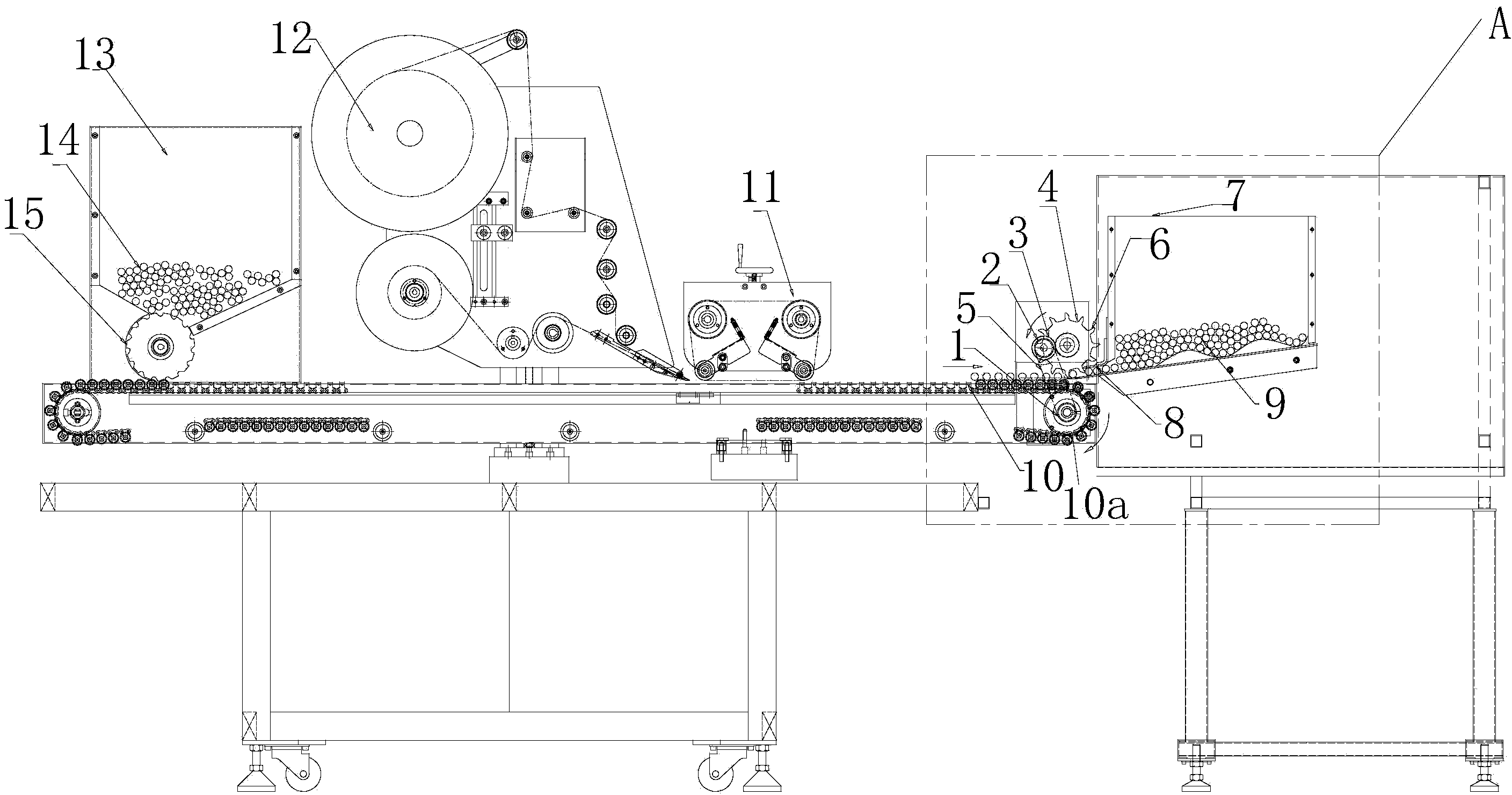

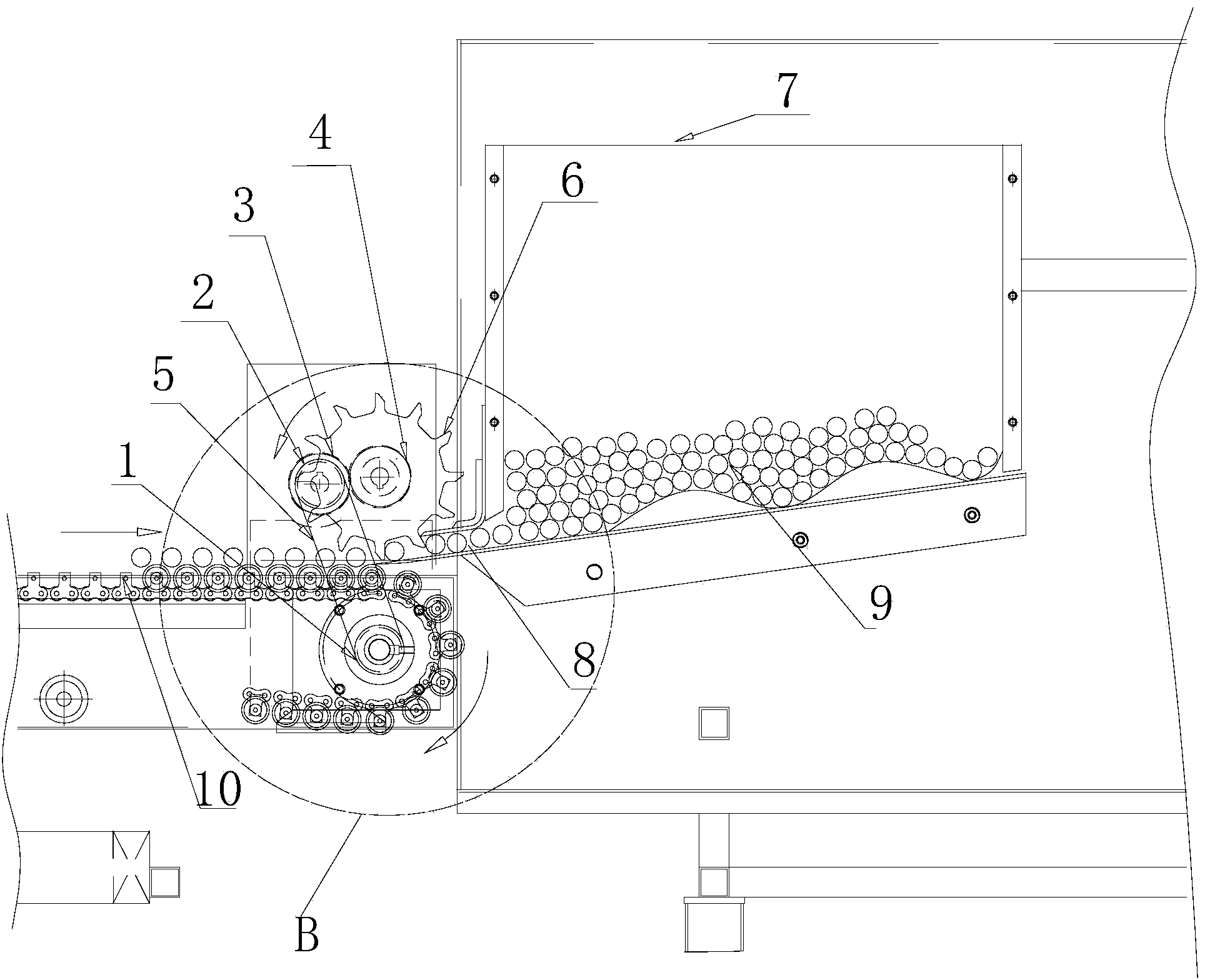

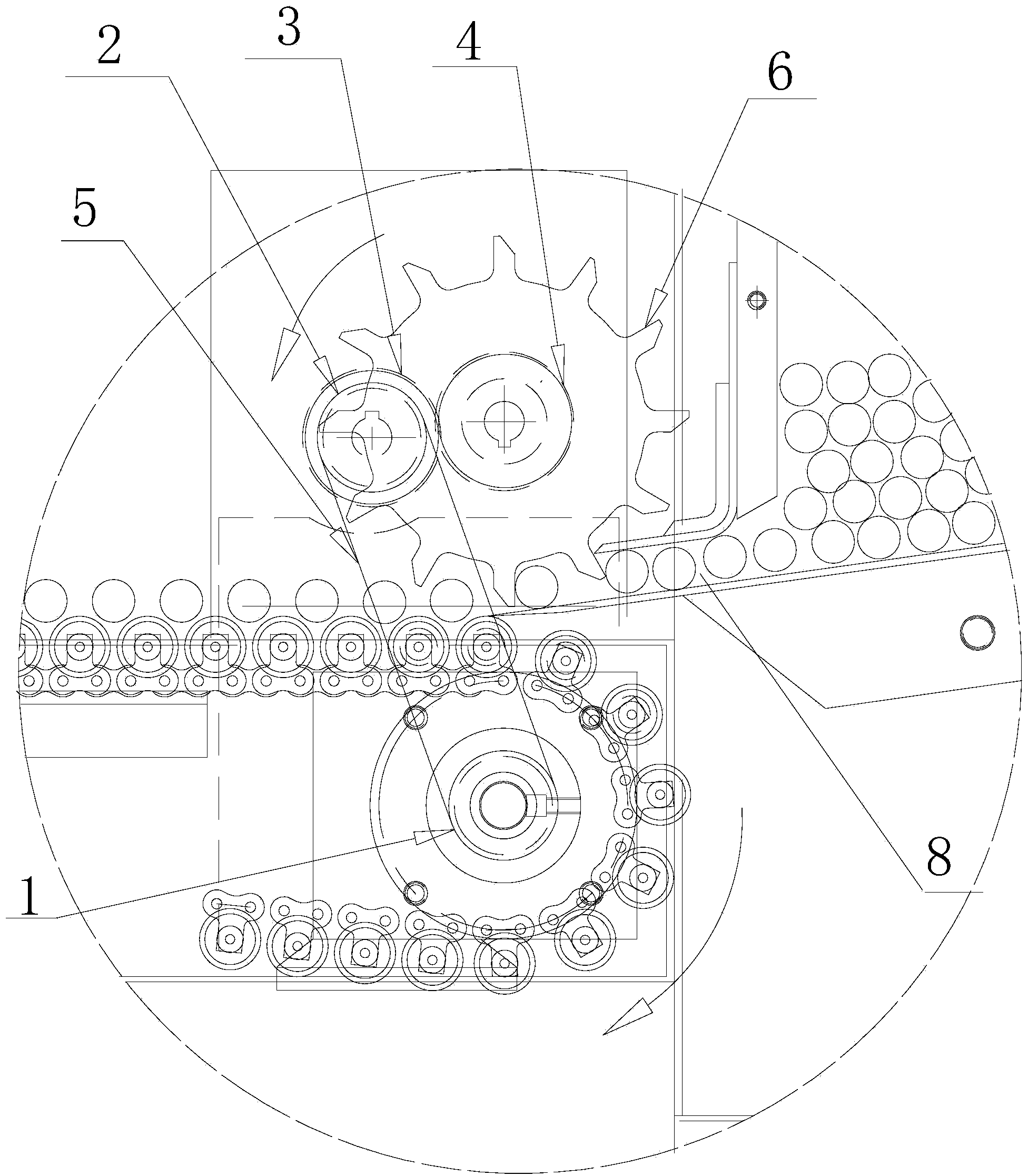

Blood collection tube bottle collection device of blood collection tube labeling machine

The invention discloses a blood collection tube bottle collection device of a blood collection tube labeling machine. The blood collection tube bottle collection device of the blood collection tube labeling machine comprises a transmission system, a material shifting mechanism and a material collection hopper, wherein the transmission system is used for receiving labeled blood collection tube bottles and conveying the labeled blood collection tube bottles to the material shifting mechanism, and the material shifting mechanism shifts the labeled blood collection tube bottles into the material collection hopper. The blood collection tube bottle collection device of the blood collection tube labeling machine is simple in structure, conveneint to operate, and capable of automatically finishing collection of the blood collection tube bottles by means of the motive power of the blood collection tube labeling machine, relieves the labor intensity for operators, lowers labor cost, avoids the risk of mechanical injury to the human body in the manual operation process, and improves operation efficiency.

Owner:GUANGZHOU IMPROVE MEDICAL TECH CO LTD

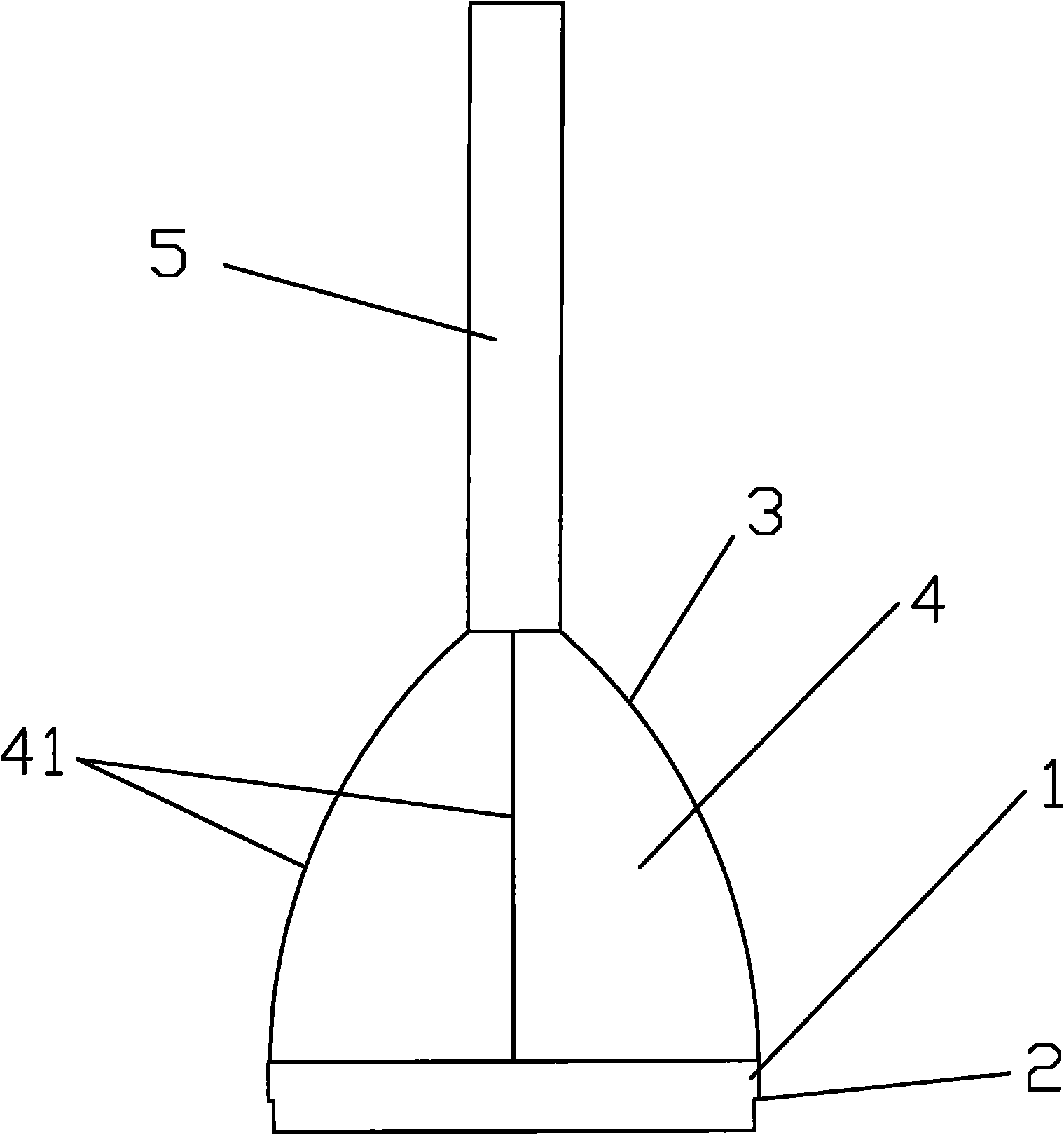

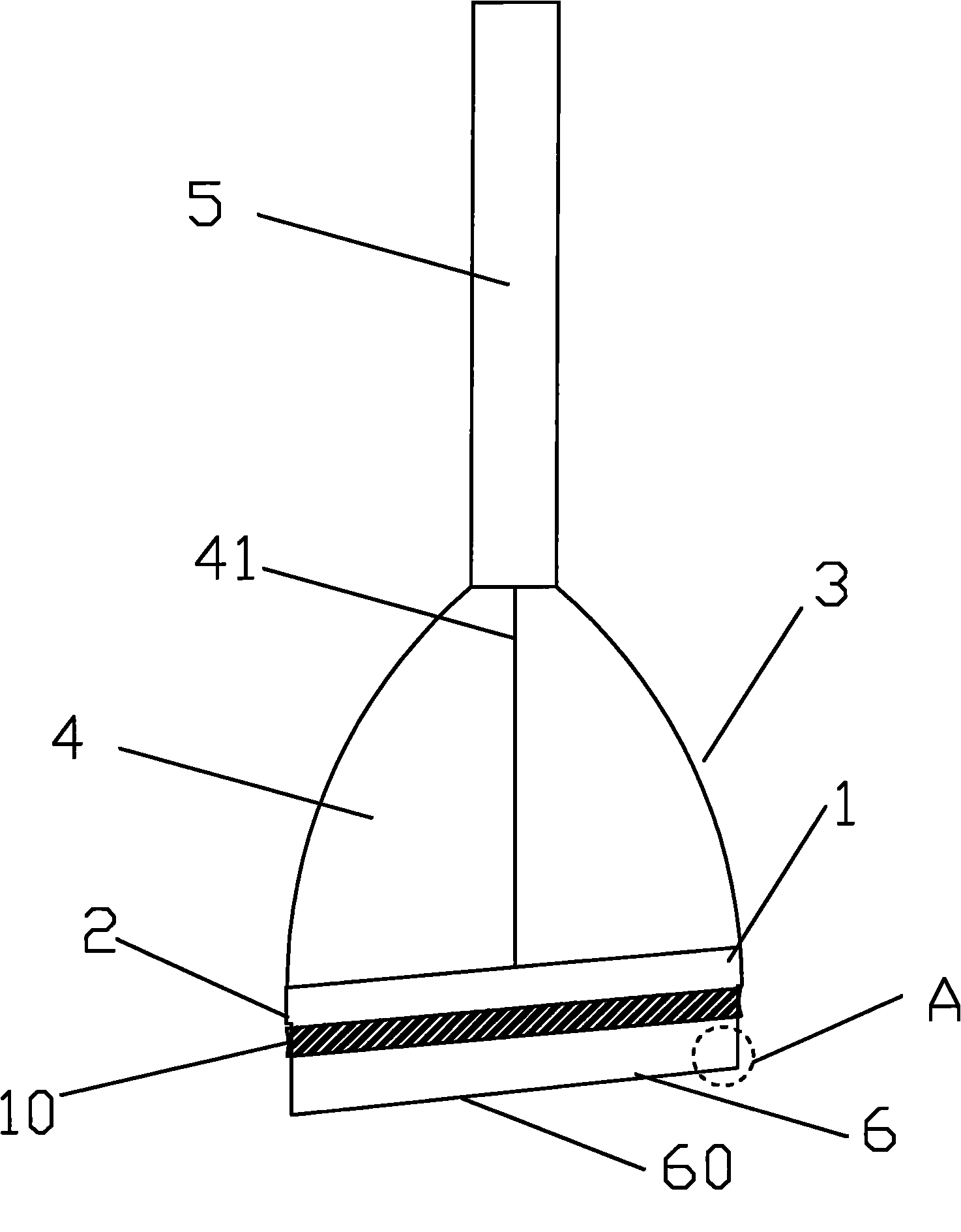

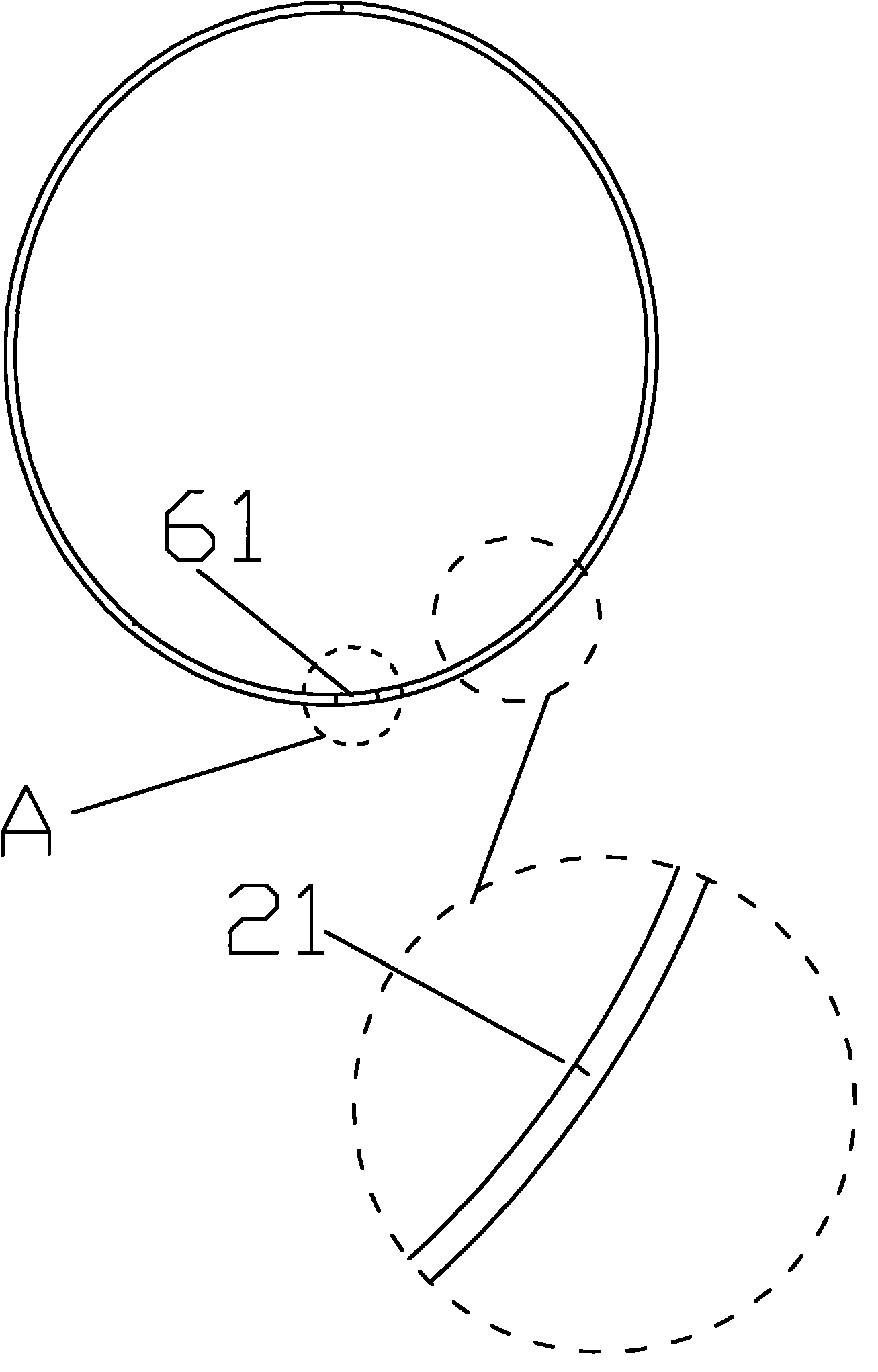

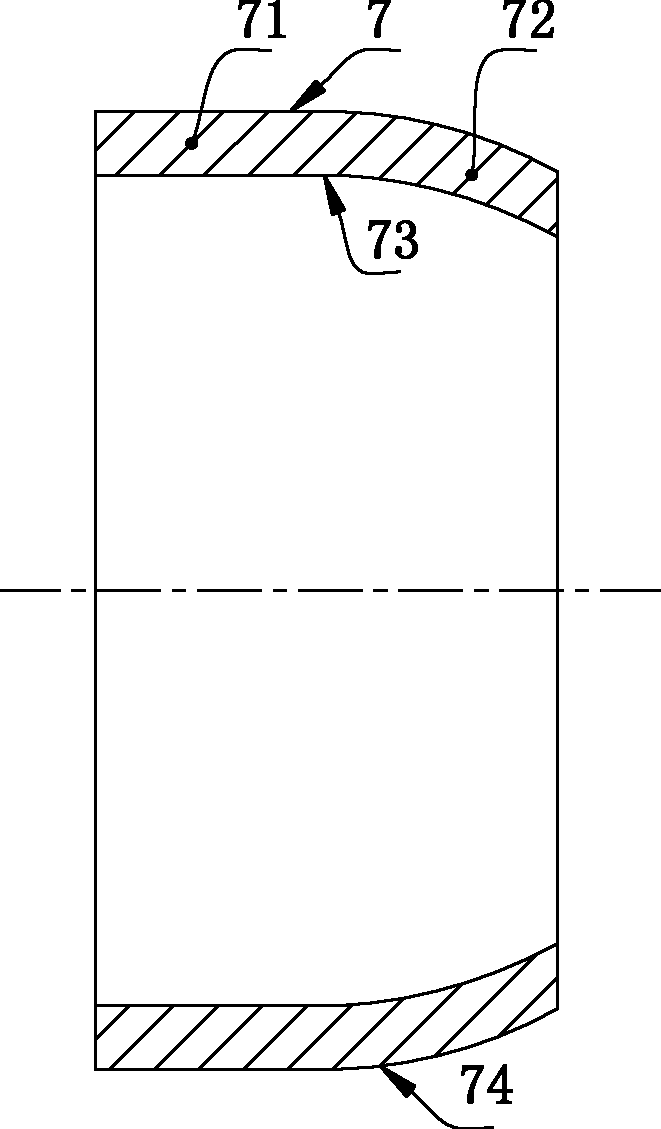

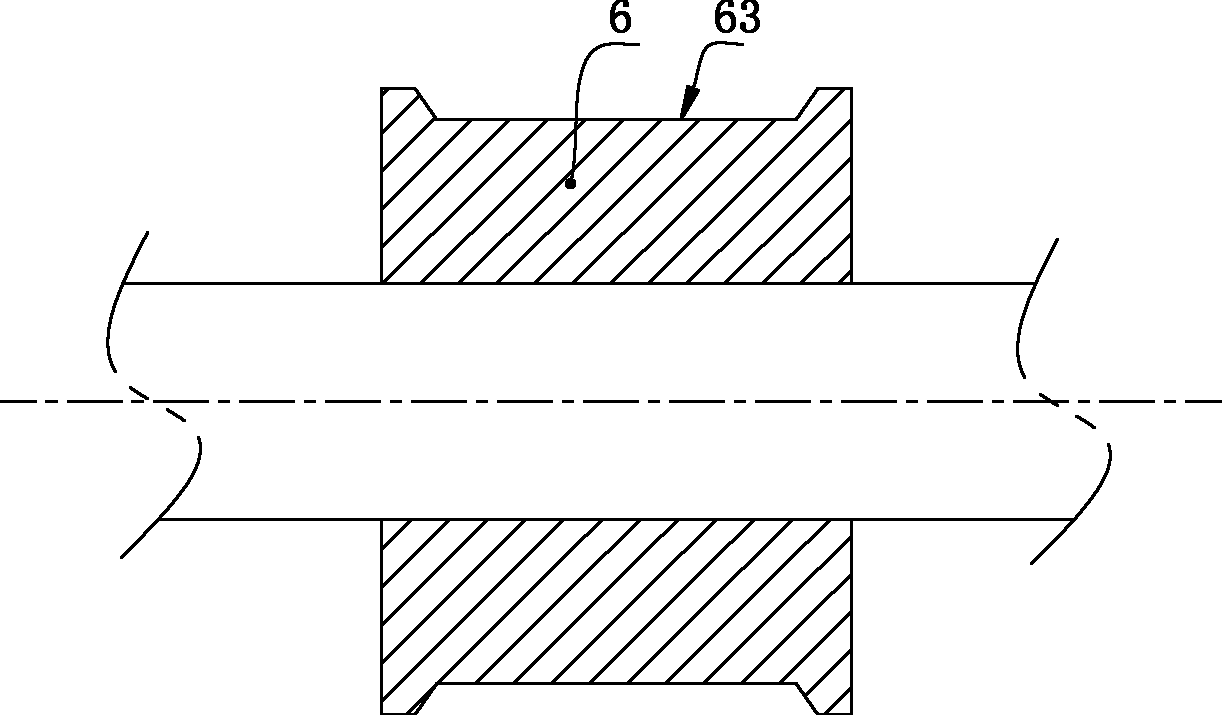

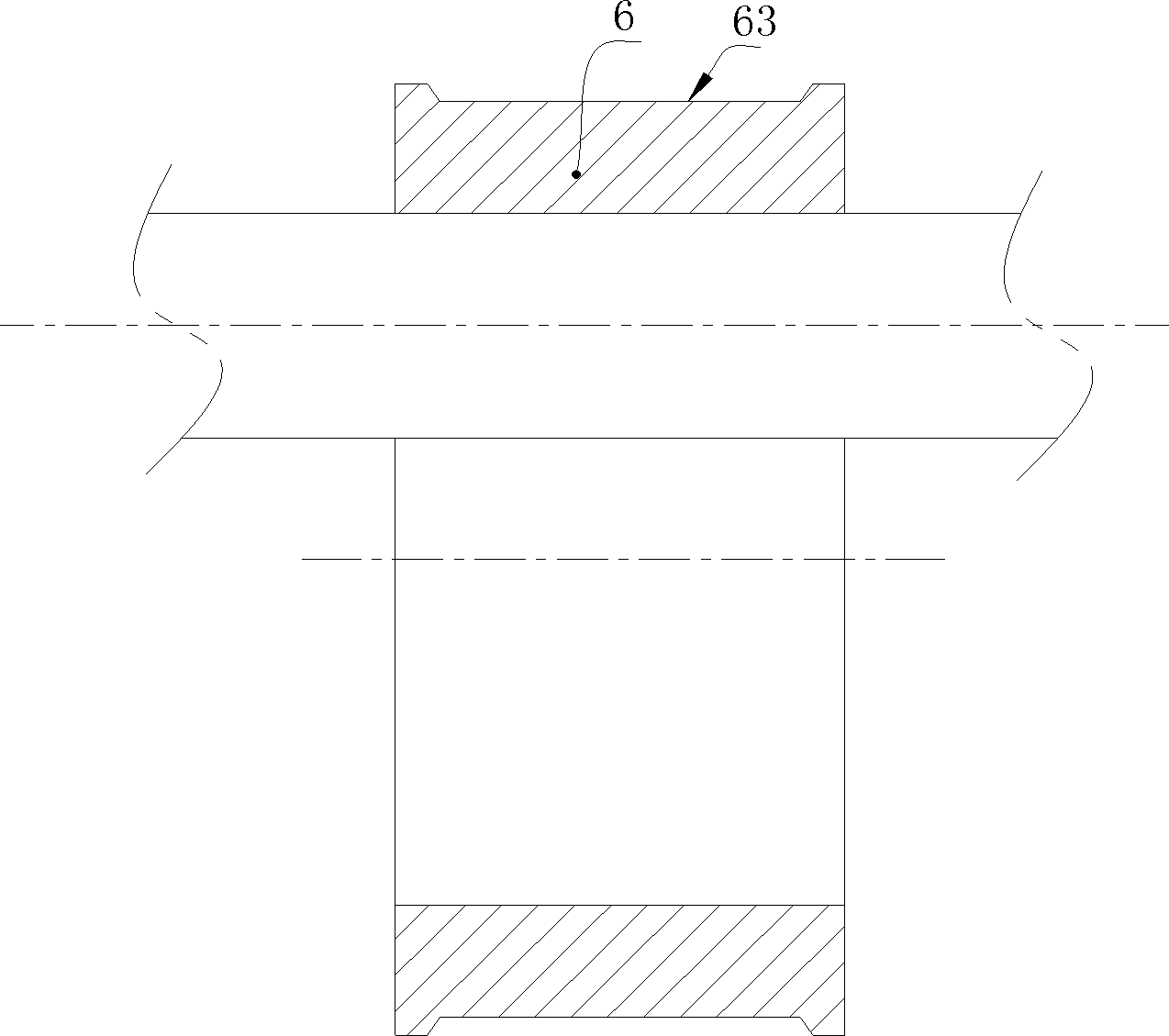

Circumcision locator and disposable circumcision stapler

The invention discloses a circumcision locator and a disposable circumcision stapler. The circumcision locator comprises a fixed sleeve with circular structure. The size of the outer edge of the bottom end of the fixed sleeve is matched with the size of the inner ring of the disposable circumcision stapler, the fixed sleeve is connected with a handle by a connecting part, the connecting part is provided with an accommodation space for accommodating glans penis, the bottom end of the fixed sleeve is extended to arrange a locating part, and the outer end surface of the locating part is in inclined structure. The side surface of the inner ring and the outer ring of the disposable circumcision stapler matched to use is in inclined structure. By adopting the structure, the circumcision locator and the disposable circumcision stapler which is matched with the circumcision locater can be specially used to push the inner ring in order to sheath the glans penis and accurately locate when the disposable circumcision stapler is used to carry out the circumcision.

Owner:WUHU SNNDA MEDICAL TREATMENT APPLIANCE TECH

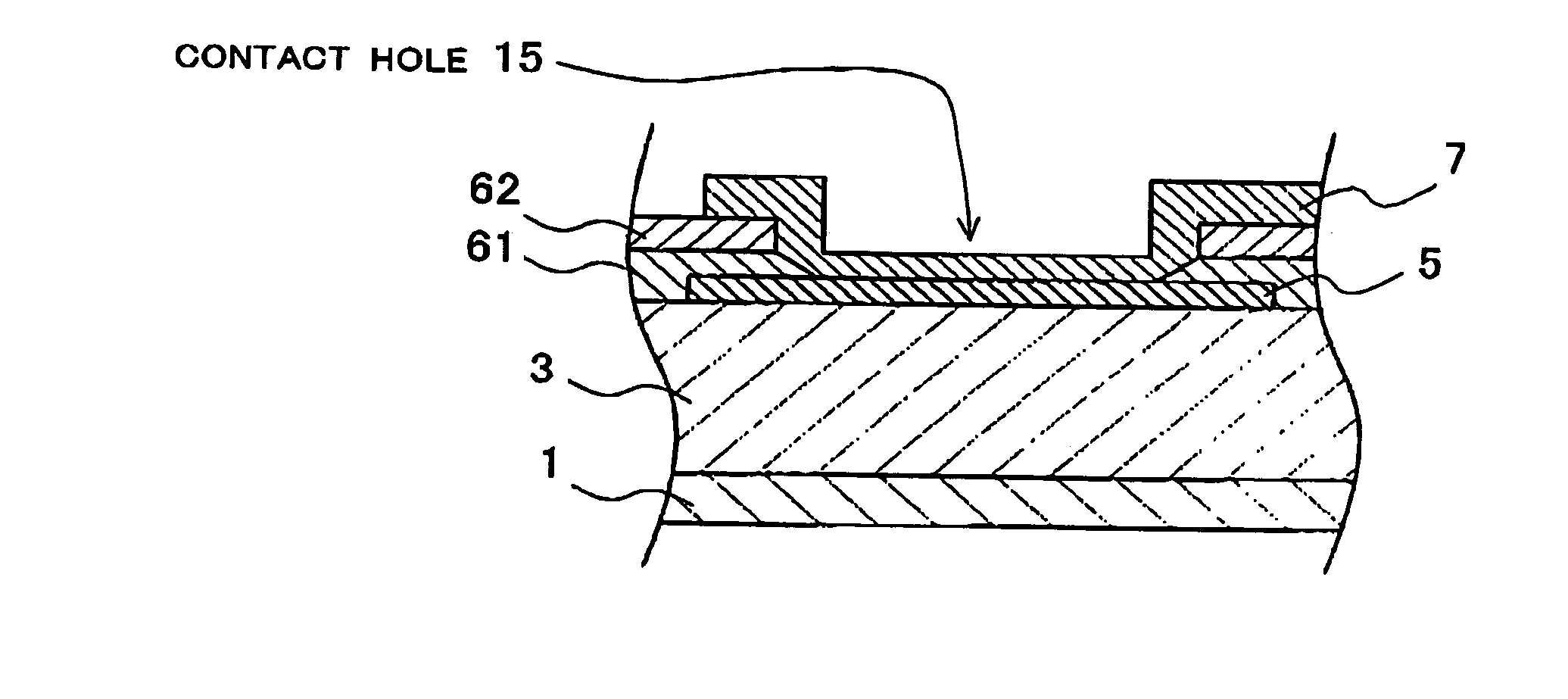

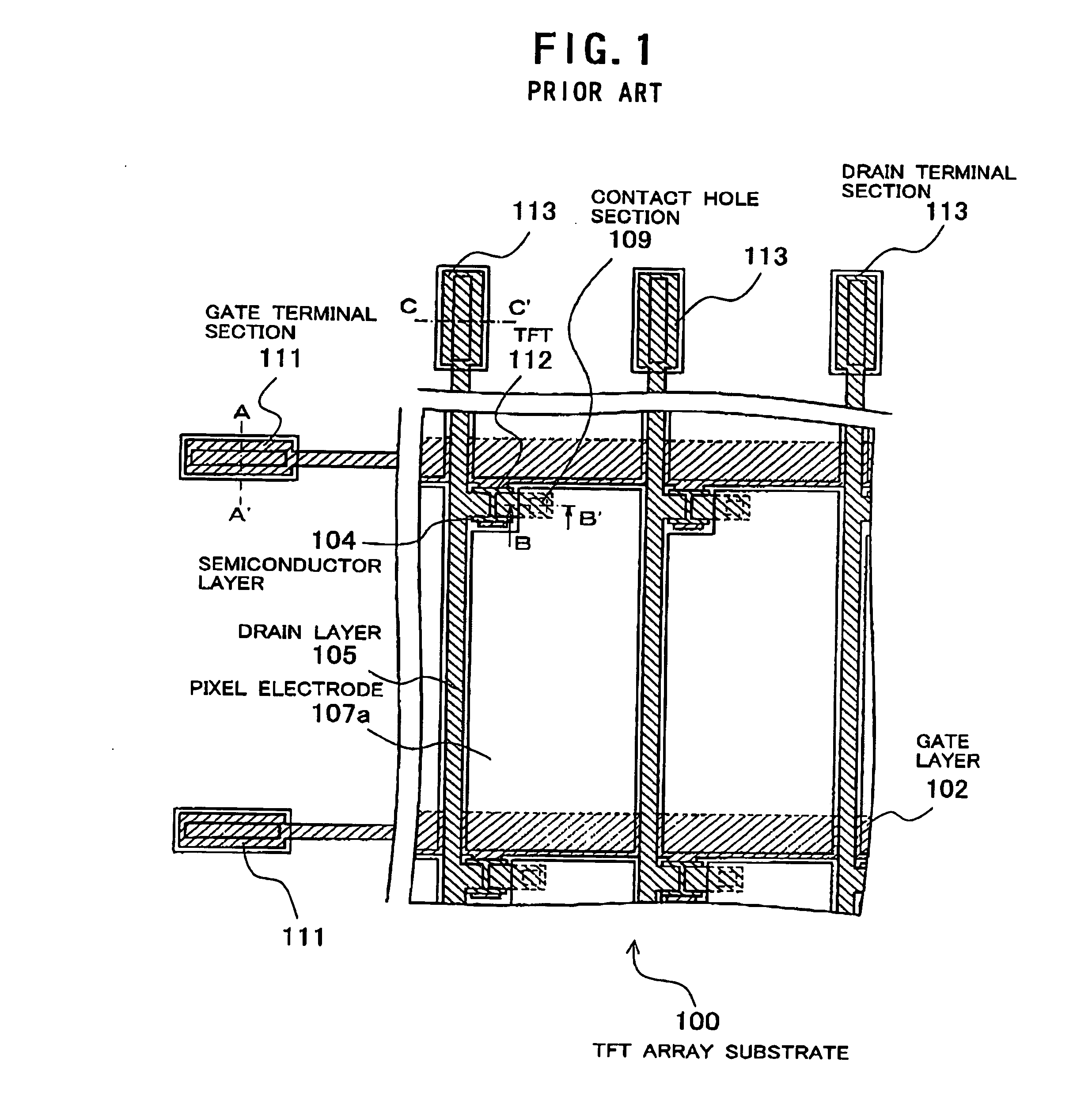

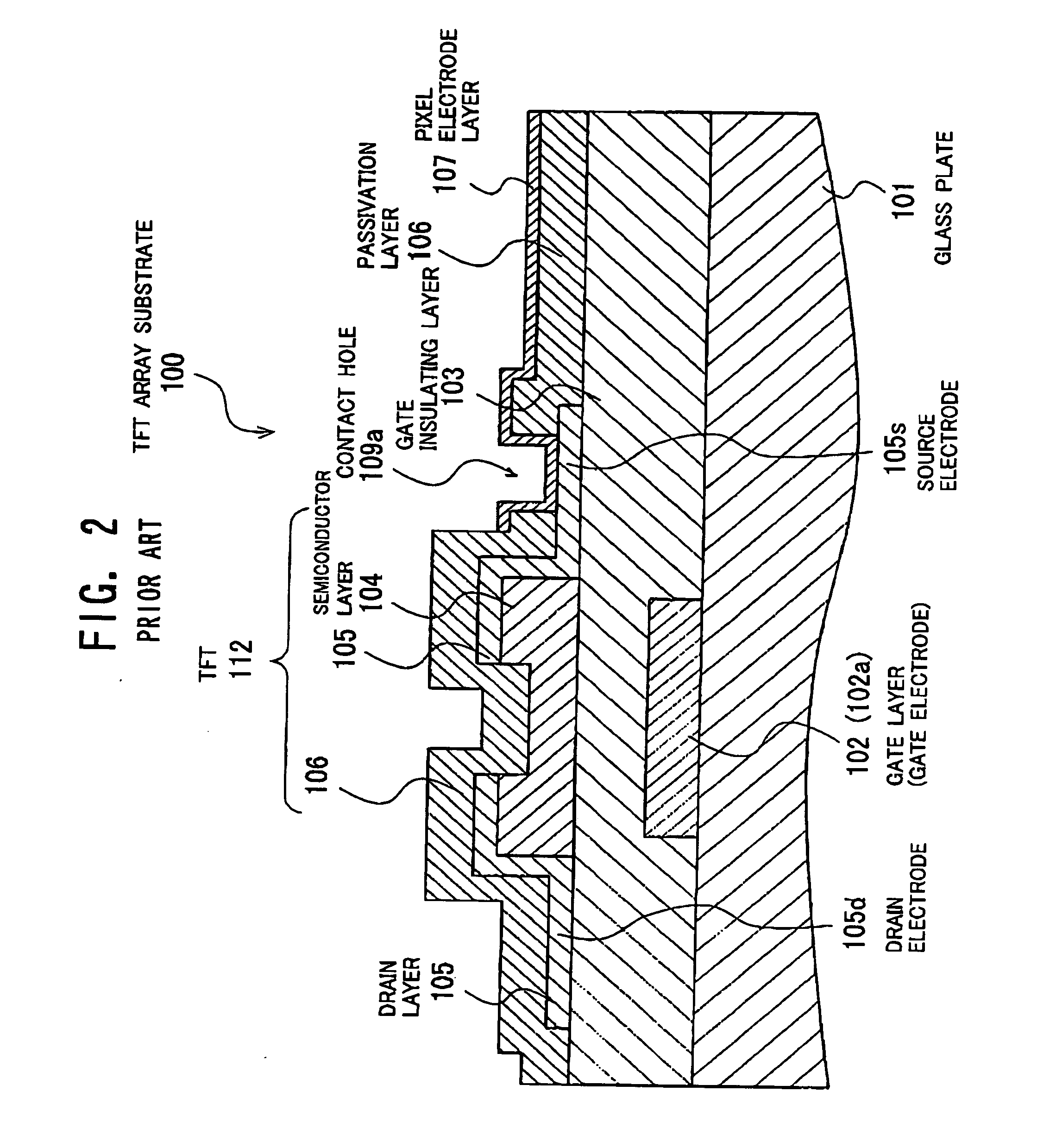

Thin-film transistor, TFT-array substrate, liquid-crystal display device and method of fabricating the same

ActiveUS20070087486A1Avoid cutsSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displaySemiconductor

A thin-film transistor includes a gate layer, a gate insulting layer, a semiconductor layer, a drain layer, a passivation layer (each of which being formed on or over an insulating substrate), and a conductive layer formed on the passivation layer. The conductive layer is connected to the gate layer or the drain layer by way of a contact hole penetrating at least the passivation layer. The passivation layer has a multiple-layer structure comprising at least a first sublayer and a second sublayer stacked, the first sublayer having a lower etch rate than that of the second sublayer. The first sublayer is disposed closer to the substrate than the second sublayer. The second sublayer has a thickness equal to or less than that of the conductive layer. The shape or configuration of the passivation layer and the underlying gate insulating layer can be well controlled in the etching process, and the conductive layer formed on the passivation layer is prevented from being divided.

Owner:NEC LCD TECH CORP

Liquid die forging and rolling compound formation method for GH4033 high-temperature alloy irregular-section large ring piece

The invention relates to a liquid die forging and rolling compound formation method for a GH4033 high-temperature alloy irregular-section large ring piece. The method comprises the following steps of: 1) smelting; 2) performing liquid die forging, namely fixing a liquid die forging mold on an indirect extrusion casting machine, pouring a quantitative amount of alloy solution into the liquid die forging mold at the pouring temperature of between 1350 and 1450 DEG C, pressurizing at the speed of 40 to 50 mm / s, filling for 1 to 6 seconds at the specific pressure of 300 to 400 MPa, keeping the pressure for 50 to 90 seconds, and thus obtaining a similarly final section ring blank; 3) homogenizing; 4) performing afterheat isothermal rolling, namely cooling the homogenized similarly final section ring blank to the temperature of between 1100 and 1140 DEG C, and performing afterheat isothermal rolling on a radial shaft compound ring rolling machine; 5) performing thermal treatment, namely performing solid solution instant thermal treatment, keeping the ring blank at the temperature of between 900 and 1000 DEG C for 1 to 2 hours, performing air cooling, then heating to the temperature of 1080 DEG C, keeping the temperature for 8 hours, performing air cooling to the temperature of 750 DEG C, keeping the temperature for 16 hours, and performing air cooling; and 6) finishing.

Owner:SOUTHWEST UNIVERSITY

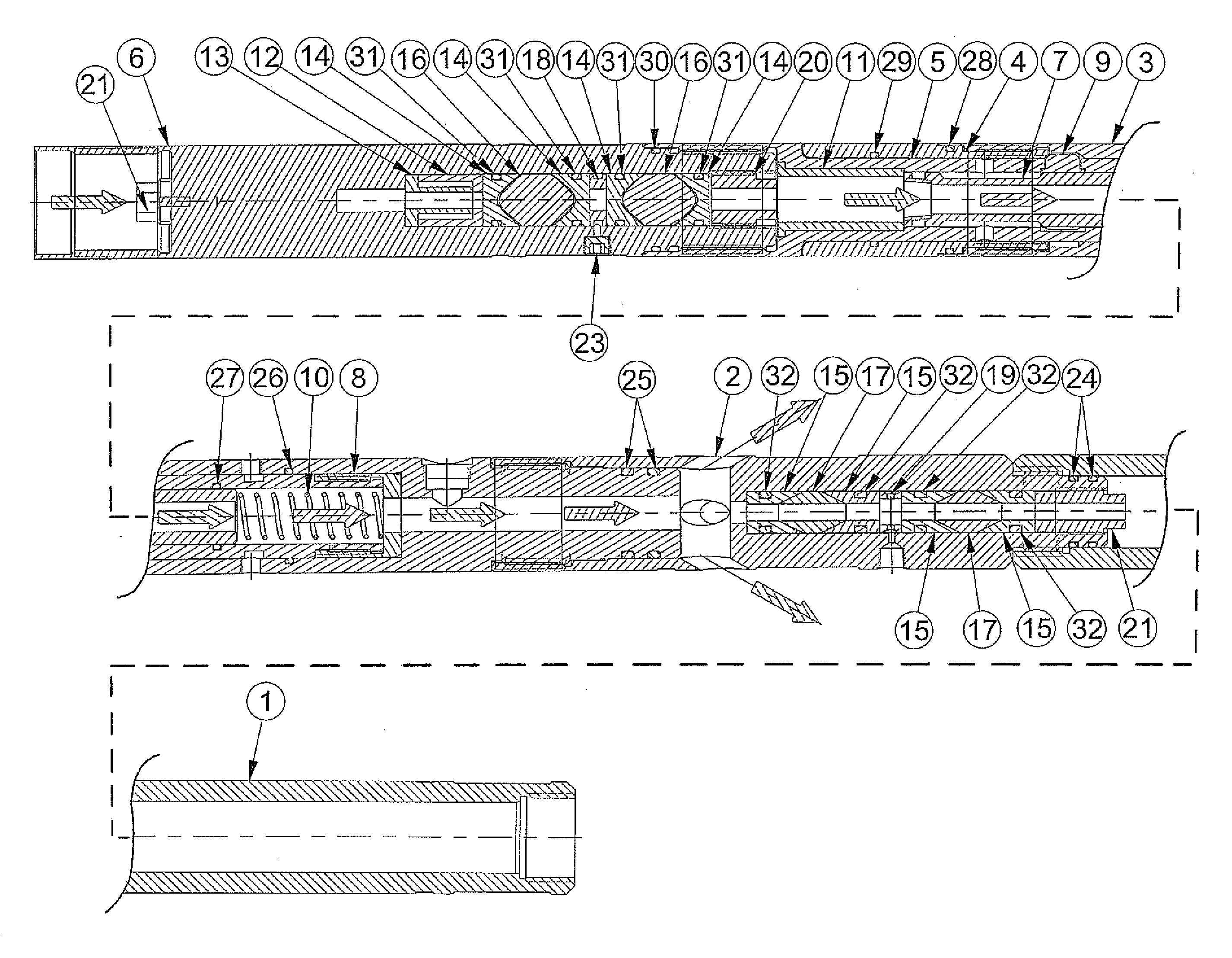

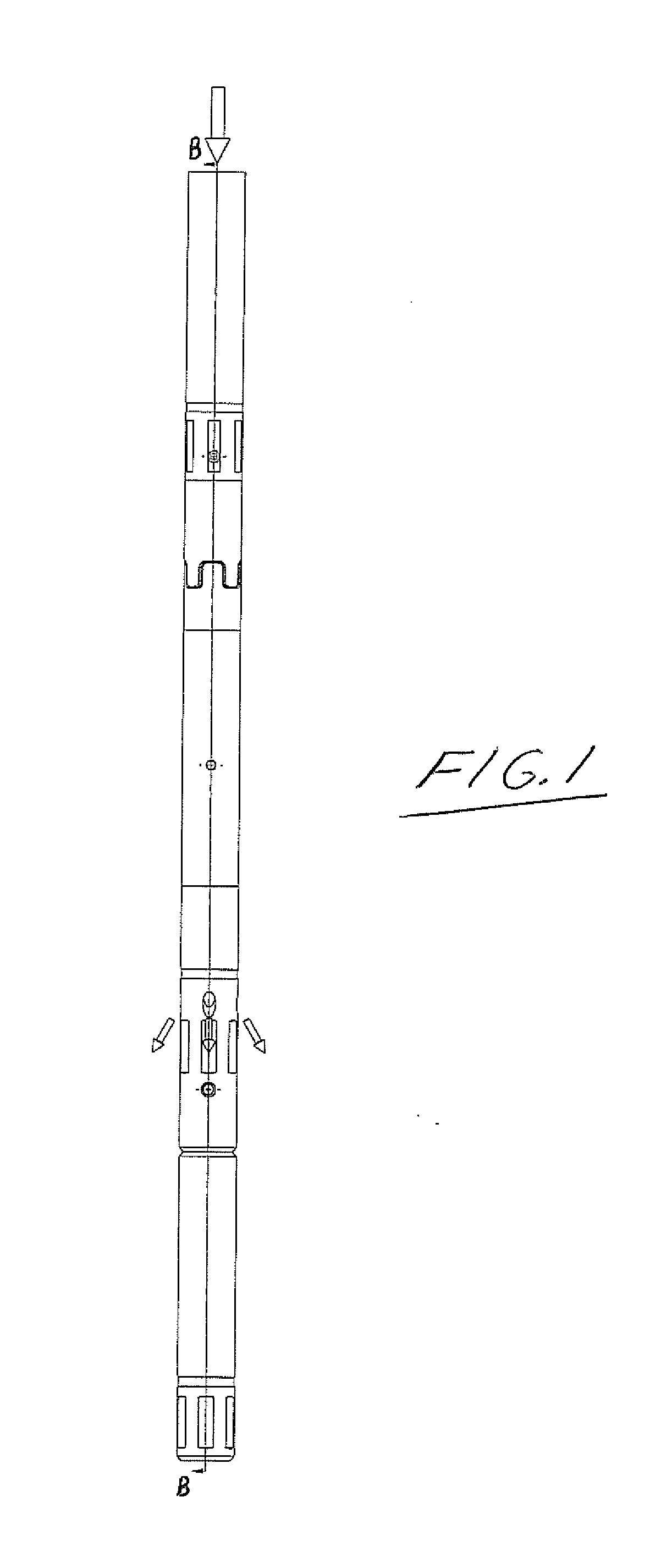

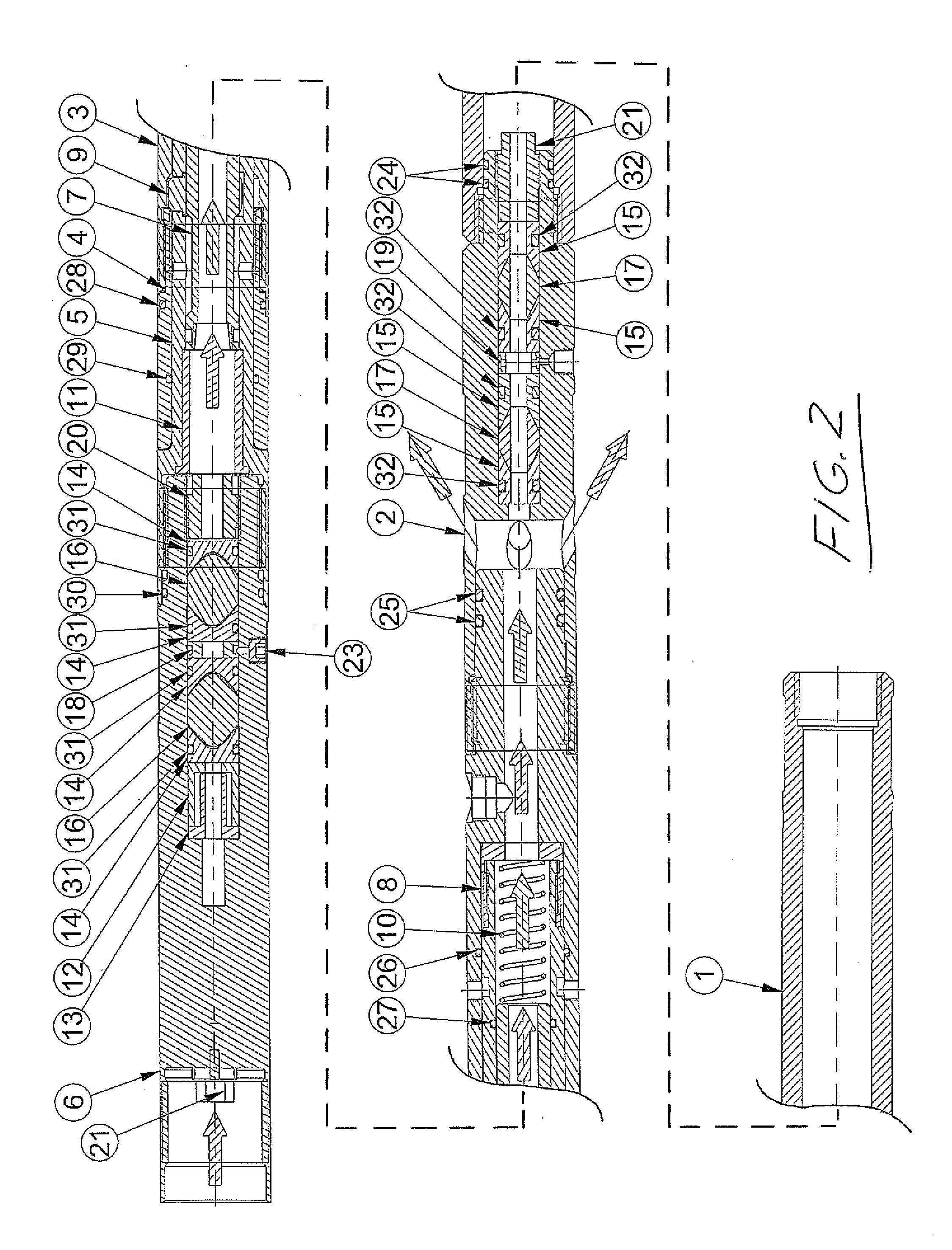

Coil Tubing Cable Head with Tool Release, Fluid Circulation and Cable Protection Features

A cable head for use with coiled tubing electric line in well operations has upper and lower housings attached by a shearable connection to allow release of the lower housing and any downhole equipment carried thereon. A piston is slidable within the housing by fluid pumped through the coil tooling to release a locking mechanism that otherwise prevents the shearing disconnect of the housings. Flow ports in the housing to allow pumping or circulation of fluid through the cable head are positioned to remain continuously open, regardless of the piston position, to maximize the range of flow rates over which fluid can be circulated. The electric line of coiled tubing is only stripped of its armor past sealed receipt thereof in a cable passage below the flow path of the fluid, thereby avoiding exposure of the conductor to the fluid to minimize the potential for damage or failure.

Owner:SPENCE DEAN

Forging forming process of heteromorphic transition section of super large pressure vessel

The invention relates to a forging process of super large workpieces and provides a forging forming process of a heteromorphic transition section of a super large pressure vessel. The process comprises the following steps of: 1) punching; 2) drawing out; and 3) reaming with a special lower reaming anvil by adopting free forging, wherein the forming surface of the special lower reaming anvil is raised along the low and middle parts of the two axial ends of a forging stock; aiming at forming of each indexing region of the forging stock, firstly the two axial ends of the indexing region are deformed through forging and pressing and are matched with the middle raise of the special lower reaming anvil to form bidirectional axial limits; and after reaming, the inner circumferential surface of the forging stock comprises an inner concave surface formed through the middle raise of the special lower reaming anvil. The process has the following beneficial effects that: through the final inner concave surface of the inner circumferential surface of the forging stock, the dressing metals are saved, the raw material consumption can be reduced, the machining allowance is reduced, the metal flow lines are prevented from being cut off and the forging block quality is improved; and the process is suitable for manufacturing the heteromorphic transition section forging of the super large pressure vessel.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com