Nano talcpowder modified polypropylene composite material and preparation method thereof

A technology of nano talc powder and composite materials, which is applied in the field of high-strength and low-density polypropylene composite materials and high toughness, and can solve the problems of failing to meet the end-use performance requirements of products, limited improvement of material performance, and affecting product performance. Achieve high rigidity and toughness, reduce density and weight, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

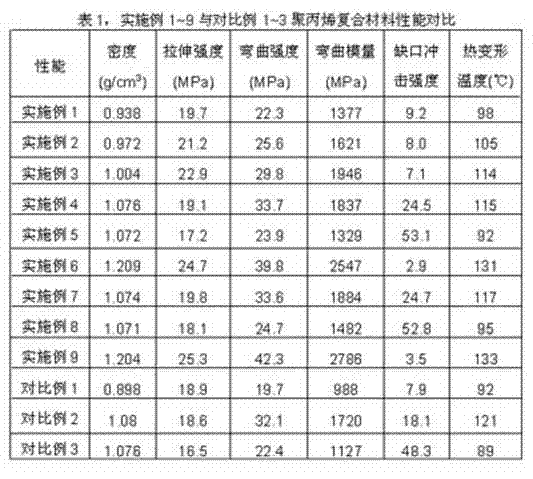

Examples

Embodiment 1

[0059] Main components: polypropylene (melt index 20g / 10min), nano talc powder (average particle size 80nm), maleic anhydride grafted polypropylene (grafting rate 0.5%, melt extruded from block copolymerized polypropylene through maleic anhydride modified) 0.5%, Irganox 1010 (tetrakis[β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionate] pentaerythritol ester, Ciba Company) 0.1%, Igrafos 168 (phosphite tris(2, 4-di-tert-butylbenzene), Ciba) ester 0.1%, Negonox DSTP (stearyl thiodipropionate, British ICE company) 0.3%.

[0060] According to the above weight percentages, the main components are dry mixed in a high-speed mixer for 5 minutes, and then added to a twin-screw extruder for melt extrusion and granulation. The third zone is 210°C, the fourth zone is 210°C, the head is 220°C, and the speed of the twin-screw extruder is 400 rpm. The pellets are dried and injection molded on an injection molding machine.

Embodiment 2

[0062] Main components: polypropylene (melt index 20g / 10min) 91%, nano talc powder (average particle size 80nm) 7%, maleic anhydride grafted polypropylene (grafting rate 0.5%) 1.5%, Irganox 1010 (four [ β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, Ciba) 0.1%, Igrafos 168 (tris(2,4-di-tert-butylphenyl) phosphite, Ciba ) 0.1%, Negonox DSTP (stearyl thiodipropionate, British ICE company) 0.3%.

[0063] Weigh the main components according to the above weight percentage, dry mix them in a high-speed mixer for 5 minutes, and then add them to a twin-screw extruder for melt extrusion and granulation. , 210°C in the third zone, 210°C in the fourth zone, 220°C in the head, and the speed of the twin-screw extruder is 400 rpm. The pellets are dried and injection molded on an injection molding machine.

Embodiment 3

[0065] Main components: polypropylene (melt index 20g / 10min) 81.5%, nano talc powder (average particle size 80nm) 15%, maleic anhydride grafted polypropylene (grafting rate 0.5%) 3%, Irganox 1010 (four [ β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, Ciba) 0.1%, Igrafos 168 (tris(2,4-di-tert-butylphenyl) phosphite, Ciba ) 0.1%, Negonox DSTP (stearyl thiodipropionate, British ICE company) 0.3%.

[0066] Weigh the main components according to the above weight percentage, dry mix them in a high-speed mixer for 5 minutes, and then add them to a twin-screw extruder for melt extrusion and granulation. ℃, 210 ℃ in the third zone, 210 ℃ in the fourth zone, 220 ℃ in the head, and the speed of the twin-screw extruder is 400 rpm. The pellets are dried and injection molded on an injection molding machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com