Polyolefine toughening modifier and its production

A technology of toughening modifiers and modifiers, which is applied in the field of modifiers and their preparation, can solve problems such as the difficulty of adding inorganic fillers, and achieve remarkable toughening effects, strong compatibility, and good tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of modifier provided by the invention comprises the steps:

[0020] (1) Pre-mixing: add ethylene-vinyl acetate copolymer and low-density polyethylene into a low-speed mixer with a rotation speed of 50-100 rpm in turn, pre-mix at 20-40°C, and then slowly add a cross-linking agent to mix, mix The time is preferably 5 to 8 minutes;

[0021] (2) Cross-linking: Add the material mixed in step (1) into the co-rotating parallel twin-screw extruder, control the extrusion temperature of each section to 150-250°C, and the screw speed to 150-250 rpm. The speed of the machine is 20-50 rpm to obtain cross-linked particles;

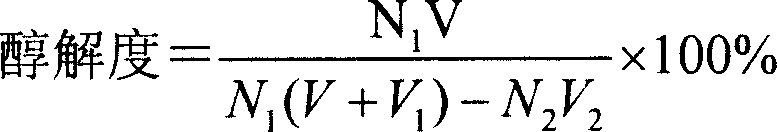

[0022] (3) Partial alcoholysis: adding the cross-linked particles into an aqueous solution containing 1.0-3.0% by mass of potassium hydroxide, reacting at 50-70° C. for partial alcoholysis, and controlling the degree of alcoholysis to be 80-90%.

[0023] The (1) premixed feed can further contain inorganic substances. When feeding, ethylen...

example 1

[0038] Preparation of the partially alcoholyzed cross-linked product of the present invention.

[0039] (1) premixing: get 2100 grams of vinyl acetate (VA) content is 28.0%, melt index is the ethylene-vinyl acetate (EVA) copolymer of 6.2 grams / 10 minutes (produced by Beijing Organic Chemical Factory, trade mark EVA28-6 ), the density of 900 grams is 0.923 g / cm 3 , a melt index of 3.1 grams / 10 minutes of low-density polyethylene (Qilu Petrochemical Company plastic factory production, trade mark TN26), 9 grams of cross-linking agent DTBP (di-tert-butyl peroxide). First mix EVA28-6 and TN26 in a low-speed mixer with a rotation speed of 60 rpm at 25°C for 3 minutes, then add DTBP and mix for 8 minutes to form a mixture.

[0040](2) Cross-linking: Add the mixture in step (1) into a co-rotating parallel twin-screw extruder for granulation. The temperature distribution of the extruder is 160°C in the first zone, 180°C in the second zone, 190°C in the third zone, 190°C in the fourth...

example 2

[0043] Modifier B is prepared according to the method of example 1, except that the crosslinking agent added in (1) step is 9 grams of two "2,5" vulcanizing agents [(2,5-dimethyl-2,5-di (tert-butyl peroxy) hexane].The composition and degree of alcoholysis of modifier B are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com