Patents

Literature

148results about How to "Good heat and cold resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

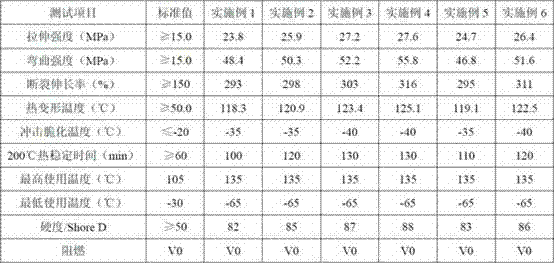

Heat-resisting and cold-resisting environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

ActiveCN103073816AImprove high temperature resistanceImprove low temperature resistancePlasticizerPolyvinyl chloride

The invention relates to the technical field of polyvinyl chloride composite materials, and specifically relates to a heat-resisting and cold-resisting environment-friendly PVC (polyvinyl chloride) modified material and a preparation method thereof. The modified material comprises the raw materials in parts by weight as follows: 80-120 parts of PVC resins, 15-35 parts of a filling agent, 40-80 parts of a plasticizer, 1-10 parts of a fire retardant agent, 1-10 parts of a stabilizing agent, 5-15 parts of impact modifier and 0.2-2 parts of a lubricating agent. The preparation method comprises the steps that the raw materials are weighed in parts by weight to be mixed, after the stirring, extruding granulation is performed through a double screw extrusion machine, and the modified material is obtained. The prepared modified material has the excellent heat-resisting cold-resisting performance, the highest use temperature reaches 135 DEG C, and the lowest use temperature reaches subzero 65 DEG C; and meanwhile the modified material has the advantages of environmental friendliness, high intensity, good fire retardant effect, strong compression performance and toughness, and excellent processing performance and comprehensive performance. The preparation method is simple in processing, convenient to operate and control, stable in quality and high in production efficiency, so that the large-scale industrial production can be realized.

Owner:广东祺龙科技有限公司

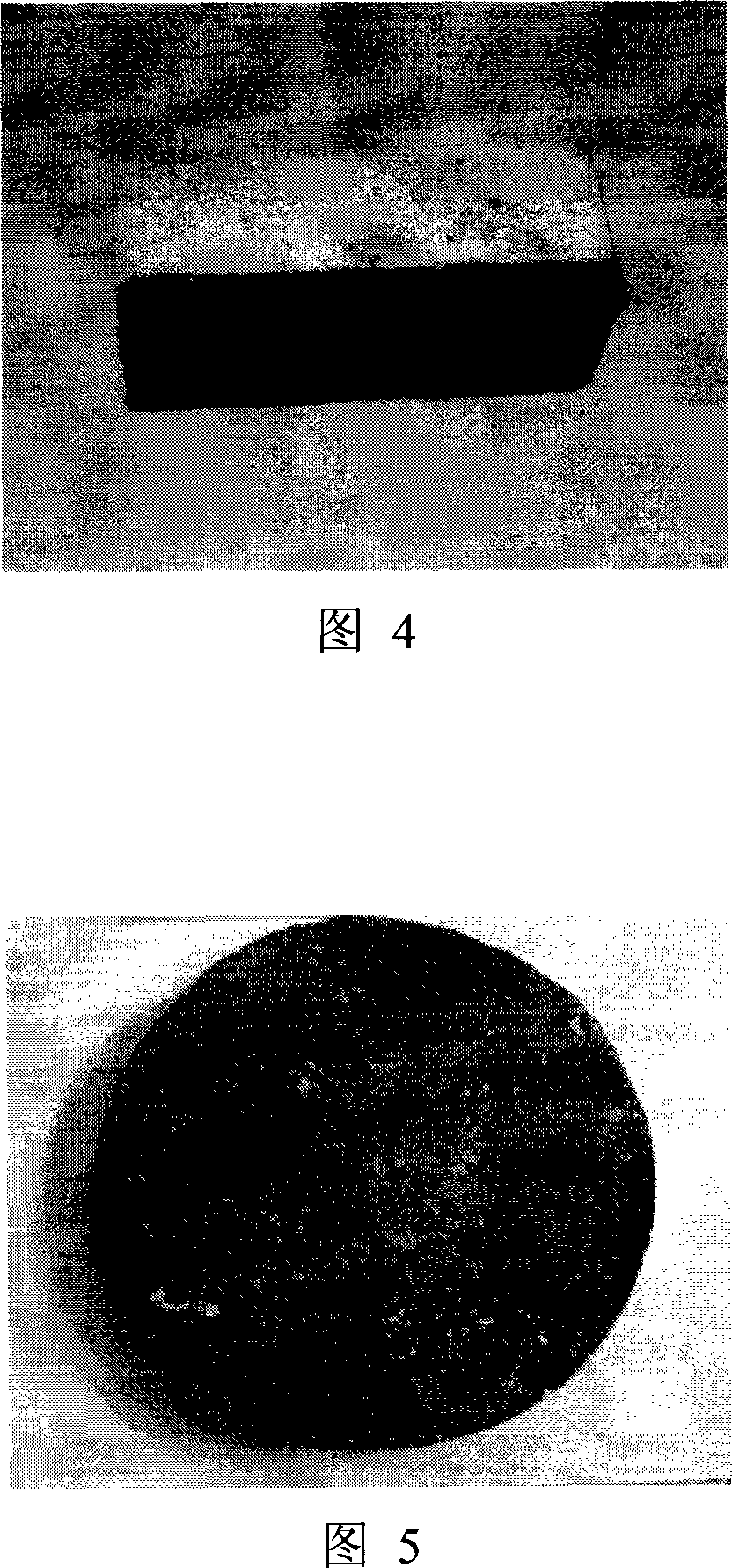

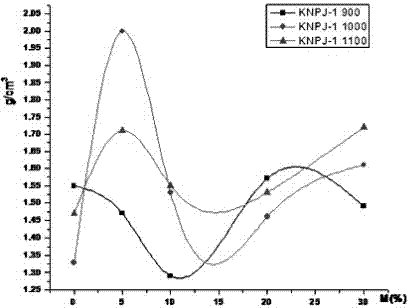

Infrared radiation porous ceramics on furnace lining firebrick and preparation method thereof

The invention relates to an infrared radiation porous ceramic used on the surface of lining firebrick and preparation method thereof. Slurry of the porous ceramic is made of aggregate and binder. The aggregate is made of the following compositions: light floating bead with 20-45 percent, Suzhou earth with 20-40 percent, aluminum oxide micro bead 5-15 with percent, magnesium oxide with 5-12 percent, high emissivity material with 5-15 percent, and coal powder with 1-5 percent. The preparation steps are as follows: 1. separate ball milling of Suzhou earth, magnesium oxide, high emissivity material to prepare for making the light floating bead and prepare for the aggregate processing; 2. the made slurry is sprayed to base, then the base is heated, sintered and cured in furnace. The invention can be sintered under a low temperature of 950-1200 DEG C and has high intensity, small density, low heat conductivity, high normal total emissivity of total infrared band 2.5-20 Mum. The invention can be made under no special equipment, is simple and practical, and can be broadly popularized.

Owner:武钢集团有限公司

Medical coating powder containing nano material

InactiveCN1616105AOvercome the defects that the quality is difficult to guarantee, etc.Simple and fast operationPharmaceutical non-active ingredientsDrageesUltimate tensile strengthMaterials science

The medicinal coating powder containing nanometer material consists of hydromellose 55-65 wt%, copolymer of vinyl pyrrolidone and vinyl acetate 8 wt%, glycerin 15 wt%, Span 8 wt%, coloring agent 2-4 wt%, and nanometer titania 2-10 wt%. The medicinal coating powder containing nanometer material has simple production process, wide application, high performance / cost ratio, no physiological toxicity and many other advantages, and may meet the requirement of coating various solid Chinese medicine preparation.

Owner:GUANGDONG GUOFANG MEDICAL TECH

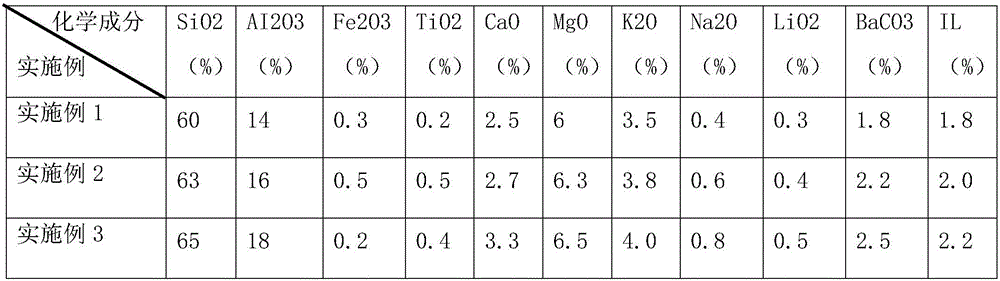

Quick fired fine ceramics made in open flame roller hearth kiln and technical method

The present invention is a new ceramic material and new producing technology. The quick fired fie ceramic is produced with the material including kaolin 20-55 wt%, feldspar 10-20 wt%, and quartz 35-60 wt%, and through quick high temperature biscuit firing in an open flame roller hearth kiln and low temperature glaze firing. The low temperature glaze firing in reducing atmosphere can obtain bright and soft glaze with high transmittance, and product with high impact strength, high heat impact strength and high acid and alkali resistance; and the low temperature glaze firing in oxidizing atmosphere can obtain bright glaze without pinhole. The present invention has simple technological process, low cost, great output and low power consumption, and may be applied widely in ceramic industry.

Owner:张民

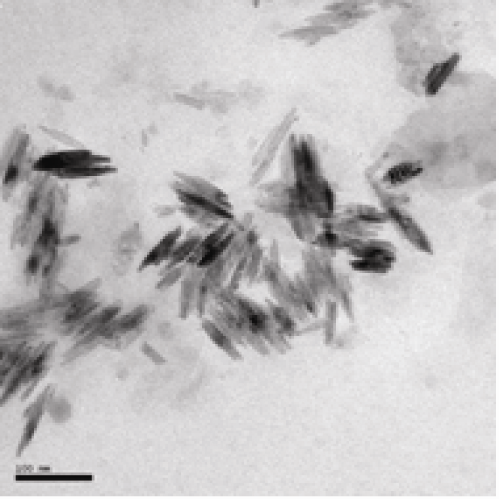

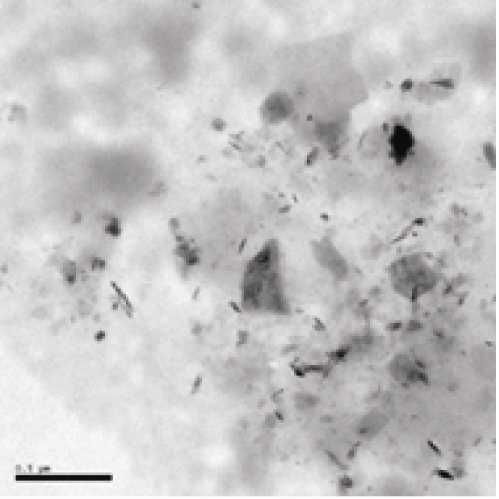

Preparation method of waterborne polyurethane material with resistance to yellowing

InactiveCN102604039AGood yellowing resistanceImprove aging resistanceFibre treatmentPolymer scienceEmulsion

The invention relates to a preparation method of a waterborne polyurethane composite material with high resistance to yellowing. The preparation method comprises the following steps of: well dispersing nano-TiO2 in DMF (dimethylformamide) in a way of adding a dispersant; compounding MDI (diphenyl-methane-diisocyanate) with IPDI (isophorone diisocyanate), and reacting with polycarbonate diol to reduce the reaction degree of the MDI so as to get a waterborne polyurethane emulsion with higher stability; and adding nano-powder TiO2 into the polyurethane emulsion before emulsification, improving the dispersion stability of the nano-powder TiO2 in polyurethane, and adding an antioxidant 1010 and an ultraviolet absorbent UV-327 into the waterborne polyurethane emulsion to achieve better resistance to yellowing, wherein the yellowing grade is improved by 1-1.5 grades.

Owner:王全杰

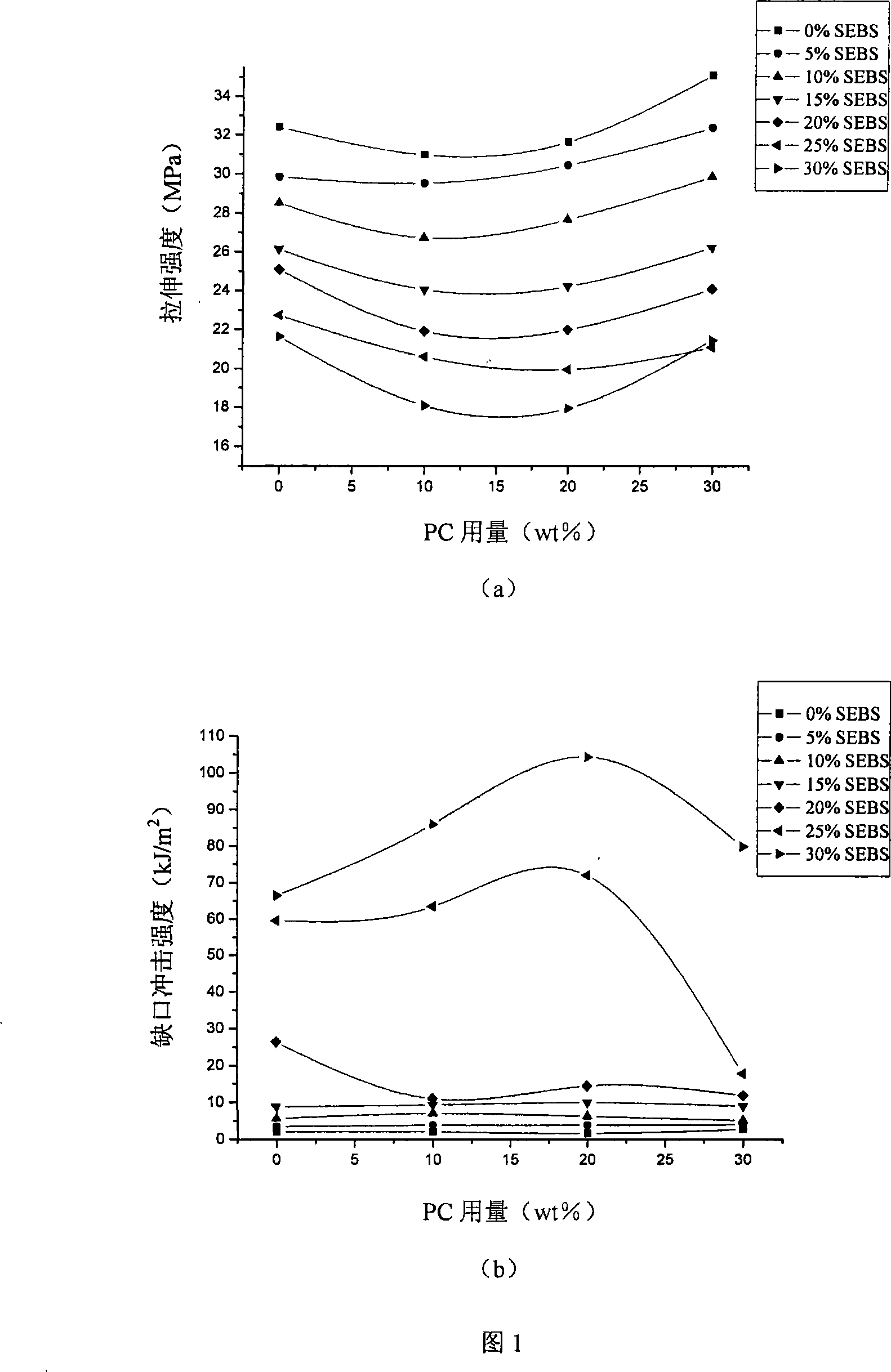

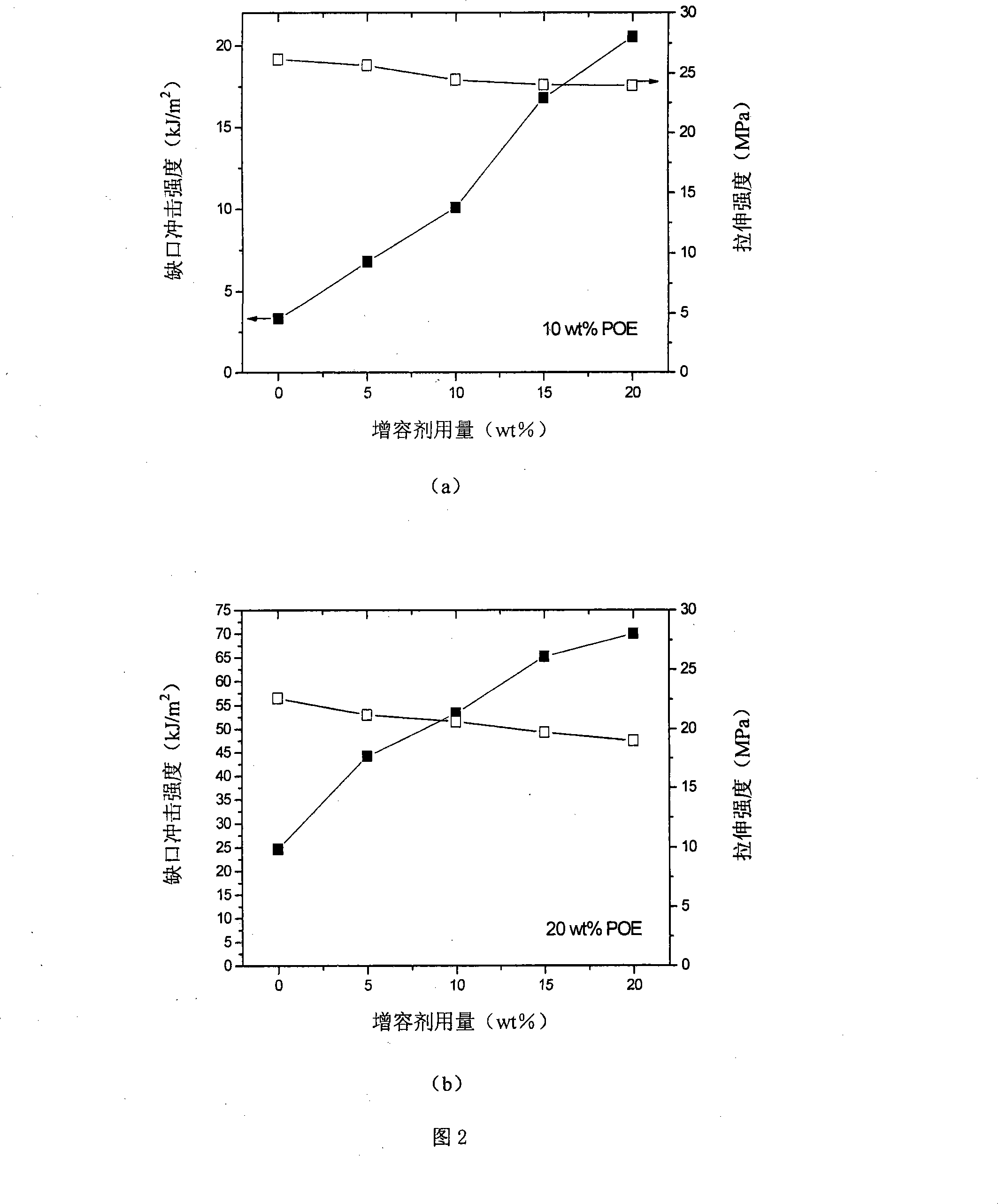

High-strength high-toughness polypropylene blending composite material and preparation method thereof

The invention discloses a blending compound material with high strength and toughness and the preparation method thereof and is characterized in that: (1) the preparation of PP graft: 100 parts of PP are added into an internal mixer to be melted. After that, 0.1 to 1 part of dicumyl peroxide (DCP) as initiator, 3 to 8 parts of grafting monomer (BPA) or (2A) are in sequence added to conduct grafting modification. The PP graft can be obtained under the temperature of 170-200 DEG C, 30-60 rmp of rotational speed and 5 minutes of reaction. (2) The preparation of PP blending compound material: 100 parts of PP, 5 to 30 parts of PC, 5 to 50 parts of toughening elastomer, 1 to 30 parts of bulking agents and 0.1 to 0.5 part of antioxidant are added into a high blending machine to conduct primary blending. Then the primary blending materials are put into a twin screw extruder to be blended and to realize extrusion pelletization under 230 DEG C to 270 DEG C temperature of extruder charging barrel and 50 to 150 rmp of rotational speed. Thereafter, the material obtained after the extrusion pelletization is dried under the temperature of 80 DEG C to 100 DEG C for 2 hours to 4 hours; finally, the blending compound material with high strength and toughness is made.

Owner:SICHUAN UNIV

Method for building high-age medium-frequency induction furnace through quartz sand and use method

The invention discloses a method for building a high-age medium-frequency induction furnace through quartz sand and a use method. The method for building the high-age medium-frequency induction furnace comprises the steps that firstly, sand used for ramming a furnace bottom and furnace walls and furnace mouth mixed materials used for ramming a furnace mouth are prepared; secondly, the furnace bottom, the furnace walls and the furnace mouth are rammed in sequence; finally, the furnace bottom, the furnace walls and the furnace mouth are baked and sintered into a whole so that the furnace can be built. The medium-frequency induction furnace manufactured through the method has the advantages of being resistant to high temperature, good in chemical stability, good in rapid-cooling resistance and rapid-heating resistance, small in thermal expansion coefficient, resistant to corrosion by slag and molten liquid and the like. The medium-frequency induction furnace manufactured through the method can be used over 200 times through a trial. Meanwhile, the method comprises the steps that when the medium-frequency induction furnace is used for melting iron each time, the rated power of the medium-frequency induction furnace is controlled within the range between 35% and 40% half hour before the iron is melted; in addition, each time the medium-frequency induction furnace is cooled, nuts in the positions of an induction coil are fastened, and therefore the induction coil is prevented from falling off when the iron is melted. According to the use method, the service life of the medium-frequency induction furnace is further prolonged.

Owner:齐齐哈尔重型铸造有限责任公司

High temperature resistant far infrared nano paint and preparation method thereof

InactiveCN101602613AImprove adhesion strengthImprove thermal shock resistanceCeramicwareMetallurgyFar infrared

The invention relates to a high temperature resistant far infrared nano paint, which is made into porous ceramic with low heat conductivity and high infrared emission rate after sintering, and belongs to the technical field of high temperature resistant far-infrared paint. The component of the paint mainly comprises ZrO2, Cr2O3, Al2O3, Fe2O3, MnO2, Co2O3, MgO, Suzhou earth, bentonite, active carbon, and coal powder, and the high temperature resistant far infrared nano paint is prepared by grinding the raw materials into fine powder in nanometer stage (500nm or less), mixing them in proportion in the silicochromium aluminum composite sol and mixed solution of carboxy methyl cellulose, and forming a viscous suspension liquid. The paint can be sprayed or brushed onto the inner wall surface of the hearth after ash cleaning, and sintered in the temperature range of 900-1200 DEG C., so as to form a porous ceramic with certain strength, which is low in ceramic density, low in heat conductivity, high in 2.5-20 mu m full infrared wave band normal direction full emissivity (0.91-0.95).

Owner:张彦文

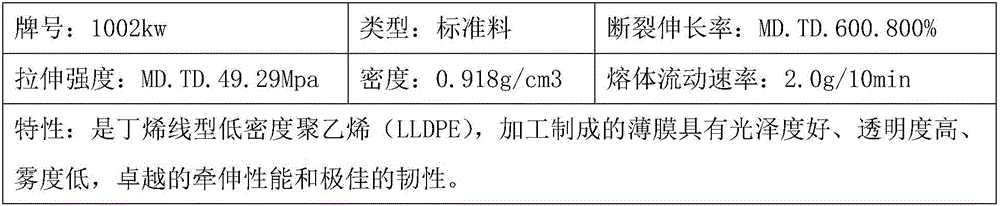

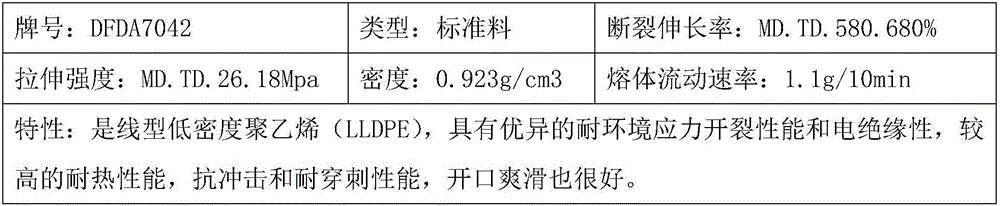

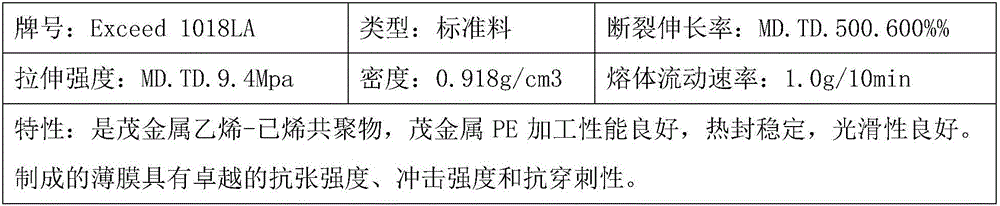

PO film serving as emulsion explosive filling film and preparation method thereof

ActiveCN106739331AGood heat and cold resistanceGood chemical stabilitySynthetic resin layered productsHigh-density polyethyleneEngineering

The invention discloses a PO film serving as an emulsion explosive filling film and a preparation method thereof, and belongs to the technical field of industrial explosive filling films. The PO film consists of an outer layer, a middle layer and an inner layer which are sequentially laminated, wherein the outer layer is prepared from 60-80wt% of reinforced polyethylene and 20-40wt% of butylene linear low-density polyethylene; the middle layer is mainly prepared from 20-40wt% of reinforced polyethylene and 60-80wt% of high-density polyethylene; the inner layer is mainly prepared from 20-40wt% of butylene linear low-density polyethylene, 10-30wt% of a metallocene ethylene-hexene copolymer or metallocene MLLDPE and 40-60wt% of high-density polyethylene. The invention aims to provide the PO film serving as the emulsion explosive filling film, which integrates superior performance of a PP film and a PE film, and the preparation method thereof. The PO film is used for filling an emulsion explosive.

Owner:广东振声智能装备有限公司 +2

Oil-resistant corrosion-resistant cable sheath material

InactiveCN104194175AExcellent ozone resistanceGood physical and mechanical propertiesInsulated cablesInsulatorsWaxCorrosion resistant

The invention discloses an oil-resistant corrosion-resistant cable sheath material which is prepared from the following raw materials in parts by weight: 20-30 parts of chlorosulfonated polyethylene, 20-25 parts of ethylene-vinyl acetate resin, 25-32 parts of semi-reinforcing carbon black, 4-8 parts of light calcium carbonate, 5-7 parts of titanium white, 1-1.5 parts of antimony trioxide, 20-25 parts of nano magnesium hydroxide, 10-15 parts of nano clay, 1-1.5 parts of polyethylene wax, 2-4 parts of Aflux 25, 1-2 parts of anti-aging agent RD, 1-3 parts of oleate, 0.5-1.5 parts of tritolyl phosphate and 1-1.5 parts of dicumyl peroxide. The oil-resistant corrosion-resistant cable sheath material has the advantages of excellent oil resistance, excellent heat resistance, excellent flame retardancy, favorable corrosion resistance and favorable aging resistance.

Owner:ANHUI MENTOR CABLE GROUP

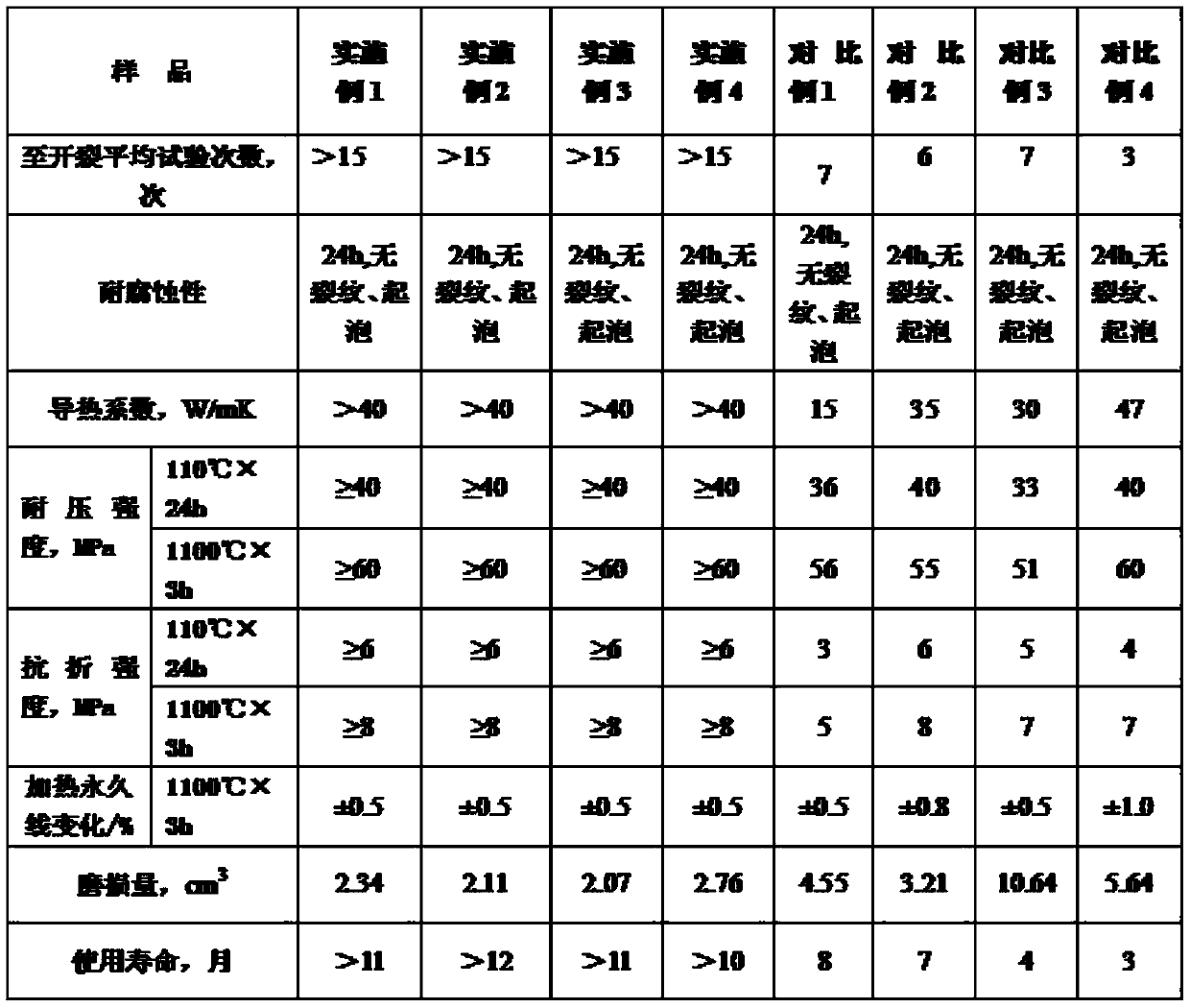

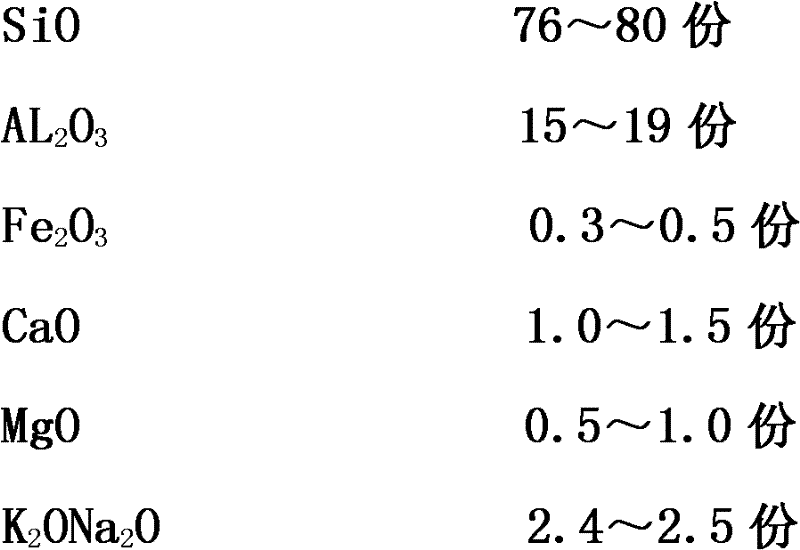

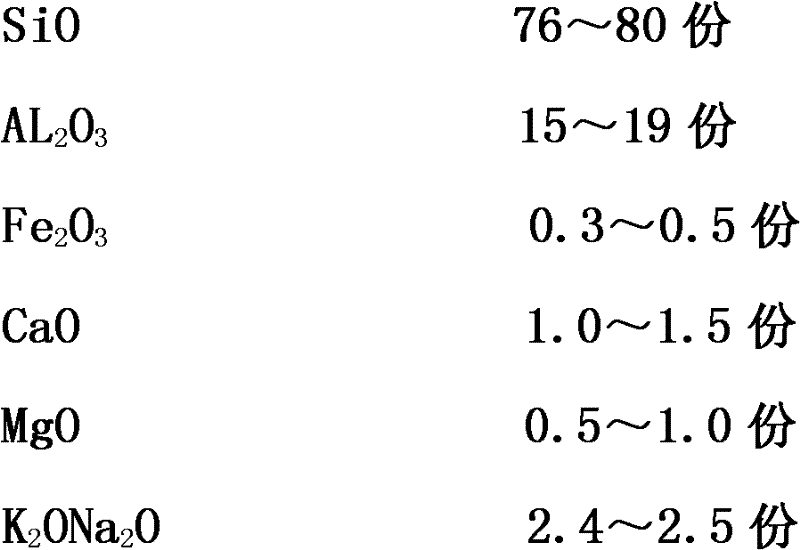

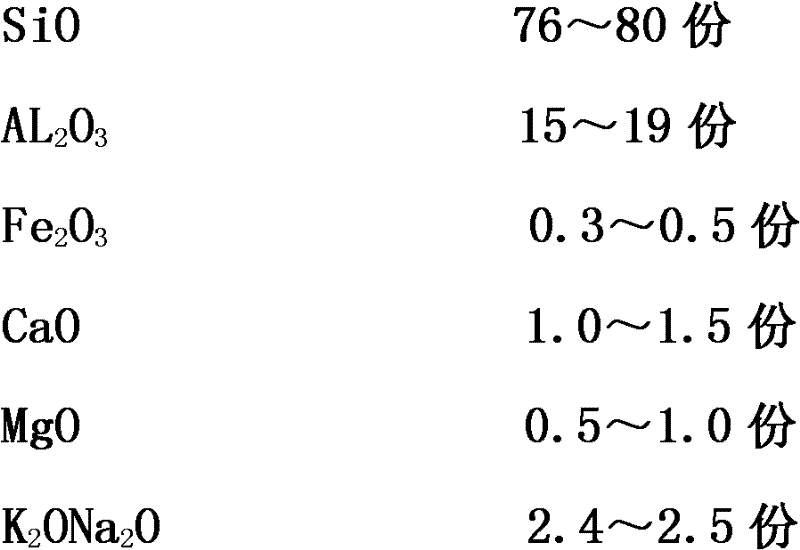

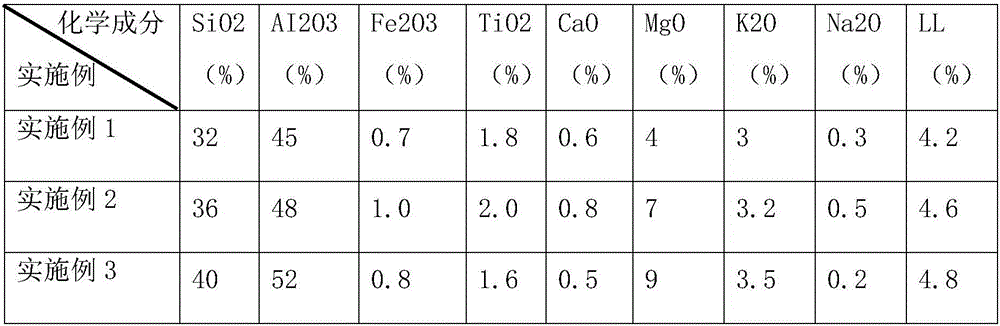

Abrasion-resistant prefabricated part with high heat shock-resistant property for dry quenching coke tank and preparation method thereof

PendingCN110294623AExcellent heat and cold resistanceGood wear resistanceCoke quenchingCorrosion resistantAluminium oxide

The invention relates to an abrasion-resistant prefabricated part with high heat shock-resistant property for a dry quenching coke tank, and belongs to the field of high temperature-resistant materials. The abrasion-resistant prefabricated part with high heat shock-resistant property for the dry quenching coke tank is characterized in that silicon carbide whiskers, bauxite-based homogenized material and silicon dioxide micropowder are used as base materials, and the surface is sprayed with alpha-Al2O3 (aluminum oxide) and MoSi2 (molybdenum disilicide) powders, so that the prepared abrasion-resistant prefabricated part has the high temperature-resistant property, corrosion-resistant property, abrasion-resistant property and heat shock-resistant property, and also has excellent cold shock and heat shock-resistant property. The abrasion-resistant prefabricated part with high heat shock-resistant property for the dry quenching coke tank has the advantages that by using the silicon carbidewhiskers, the abrasion-resistant property is good, the toughness is high, and the heat conduction coefficient is higher; by compounding with the alpha-Al2O3 and MoSi2 powders, the coating tissue is dense, the tendency of phase change is little, the high-temperature mechanical property is excellent, the corrosion-resistant property is good, and the heat shock-resistant property is excellent; the preparation technology is simple and convenient, the installation and updating are convenient, and the abrasion-resistant prefabricated part is suitable for scale production.

Owner:SHANDONG LUMING HIGH TEMPERATURE MATERIAL TECH

Neutral lining refractory material for electric induction furnace and manufacturing method thereof

The invention discloses a neutral lining refractory material for an electric induction furnace and a manufacturing method thereof, which belongs to the technical field of linings of electric induction furnaces. The neutral lining refractory material for the electric induction furnace comprises the following raw materials by weight: 50 to 75% of high bauxite clinker, 20 to 30% of high purity quartz sand, 1 to 3% of alumina and 5 to 15% of an adhesive. The weight percentages of high bauxite clinker with different particle sizes are as follows: high bauxite clinker with a particle size of 0 to 3 mm, 15 to 25%; high bauxite clinker with a particle size of more than 3 mm and no more than 5 mm, 40 to 70%; and high bauxite clinker with a particle size of 6 to 8 mm, 15 to 25%. According to then invention, through usage of the high bauxite clinker as aggregate, reasonable proportion of the high bauxite clinker with different particle sizes and cooperative usage of high purity quartz sand and a small amount of alumina, the neutral lining refractory material has good compactness and a prepared lining has small porosity, great volume density, high uniformity, good sinterability and good resistance to chilling and intense heating.

Owner:安徽中建材开源新材料科技有限公司

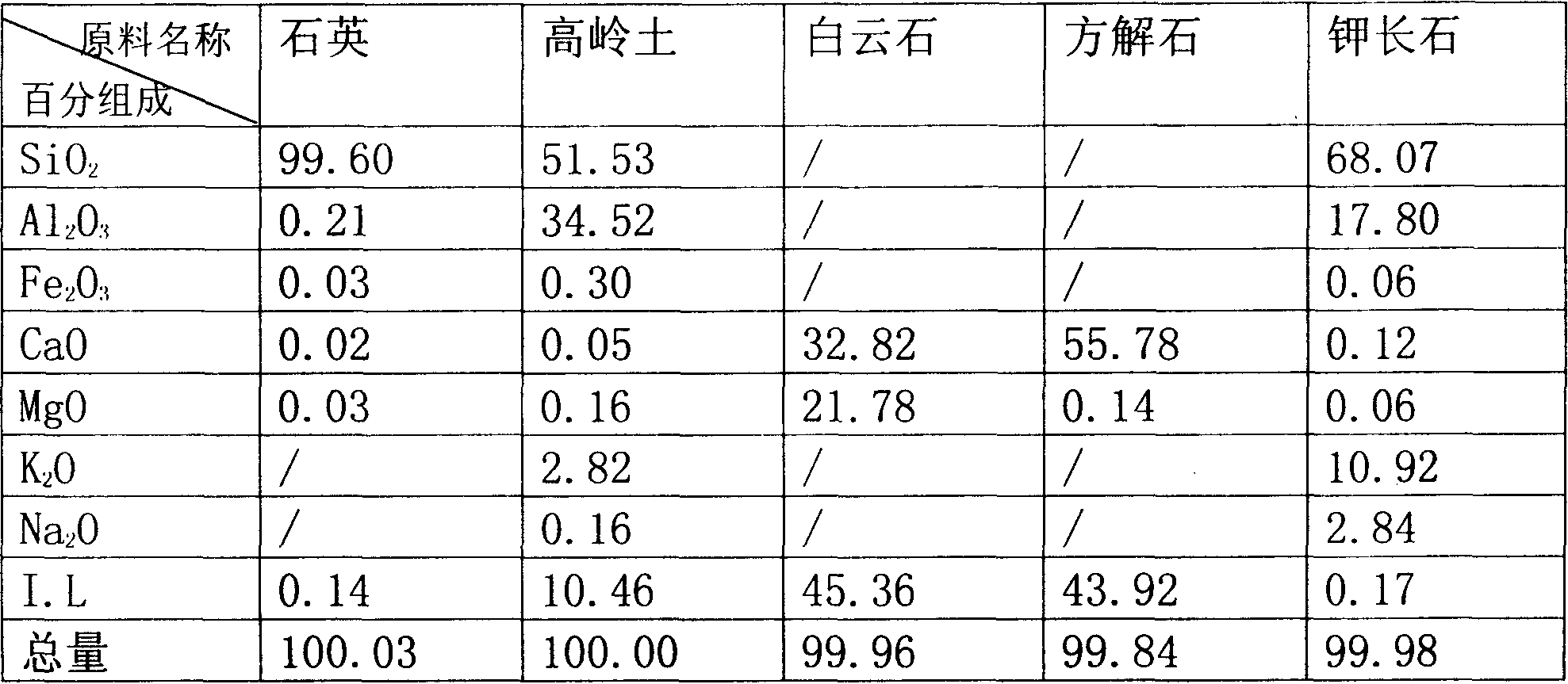

Environment-friendly rice husk ash porcelain blank and preparation method

InactiveCN102503358ASolve the shortageSolve the white and blueCeramic materials productionClaywaresHuskFeldspar

The invention discloses environment-friendly rice husk ash porcelain blank and a preparation method. The environment-friendly rice husk ash porcelain blank is made of, by weight, 30-45 parts of kaolin, 10-15 parts of feldspar, 25-35 parts of quartz and 25-50 parts of rice husk ash. The rice husk ash is used as a production material in a high proportion via repeated compounding tests, and accordingly the problem of shortage of porcelain clay is solved, wastes of crops can be fully used, production cost is reduced, environment is protected, and resources are saved. Further, the problems of blank molding and combination of blank and glaze can be solved, the environment-friendly rice husk ash porcelain can be greenly white, bright and glossy, and characteristics of Chingtechen celadon are truly embodied. Ecological balance is maintained and environment protection is achieved by using wastes of crops.

Owner:JINGDEZHEN MEICHENG CERAMIC

Photo/thermal initiation fast curing adhesive

ActiveCN104927732AMeet the shear strengthMeet the fatigue strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceAdhesive

The invention provides a photo / thermal initiation fast curing adhesive which comprises the following components by mass: 40-70 parts of one or more epoxy resin matrixes, 20-40 parts of a latent thermal initiation curing agent, 0.5-5 parts of one or more photo initiation curing agents, 0.1-2.5 parts of one or more photosensitizers, 15-35 parts of one or more flexibilizers, and 20-40 parts of one or more fillers. A preparation method of the photo / thermal initiation fast curing adhesive comprises the following steps: at first, under the action of ultraviolet light, the photo initiation curing agents are used for initiating part of epoxy resin to perform a curing reaction, under the action of heat released during the curing reaction and an external heat source, the temperature of the cured part reaches the latent imidazole initiation reaction temperature of 70-90 DEG C, a latent imidazole complex is activated, epoxy resin is initiated to be quickly cured within 3 min, the automatic, high-quality and fast-cementing connection requirements of a car composite material are met, and the technical problems such as mismatch between the traditional adhesive curing initiation condition and the connection working condition of the car composite material are solved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

High-quality rubber material for bushes of stabilizer bars

The invention provides a high-quality rubber material for bushes of stabilizer bars. The high-quality rubber material comprises, by weight, 80-90 parts of natural rubber, 10-20 parts of tetrapropyl fluoro elastomer, 5-10 parts of chlorosulfonated polyethylene rubber, 35-50 parts of polyacrylate rubber, 3-5 parts of butadiene styrene rubber, 3-5 parts of fluorinated silicone rubber, 40-45 parts of hydrogenated nitrile butadiene rubber, 15-20 parts of N-cyclohexylthiophthalimide, 10-20 parts of epoxy propane rubber, 5-10 parts of copolymerization chlorohydrine rubber, 5-10 parts of ethylene-vinyl acetate rubber, 3-5 parts of aromatic hydrocarbon oil, 3-5 parts of polyether-ether-ketone, 5-10 parts of carbon black, 5-6 parts of nanometer tin dioxide, 3-5 parts of calcined pottery clay, 3-5 parts of dicumyl peroxide, 4-5 parts of zinc oxide, 3-4 parts of magnesium oxide, 1-5 parts of polyamide wax micro-powder, 3-8 parts of magnesium stearate, 5-10 parts of polyisobutylene rubber, 4-5 parts of titanium dioxide powder and 3-5 parts of naphthenic oil. The high-quality rubber material has the advantages that the high-quality rubber material is excellent in resilience, heat resistance and cold resistance, rubber is good in abrasion resistance, heat aging resistance and dynamic fatigue resistance, and accordingly service requirements of the bushes of the stabilizer bars can be met.

Owner:安徽纯启动力科技有限公司

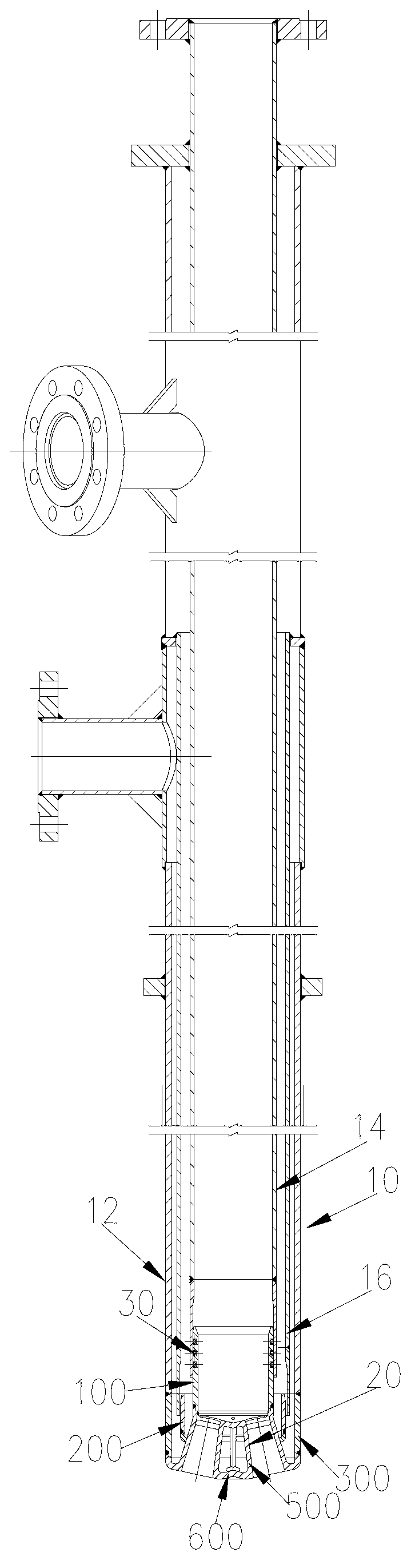

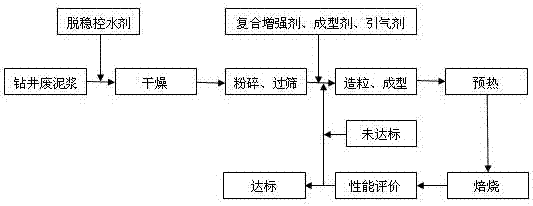

Non-sticky steel converter oxygen lance and manufacturing method thereof

InactiveCN102839254AExtended service lifeReduce the number of replacementsManufacturing convertersQuenchingWetting

The invention discloses a non-sticky steel converter oxygen lance and a manufacturing method thereof. The non-sticky steel converter oxygen lance comprises an oxygen lance connecting pipe and an oxygen lance spraying nozzle located at the bottom of the oxygen lance connecting pipe, wherein a compound coating is arranged at the outer side of the oxygen lance connecting pipe or the oxygen lance spraying nozzle. The non-sticky steel converter oxygen lance disclosed by the invention has the advantages of good quenching and quick heating resistant performance, good combining strength, poor wetting performance with steel liquid and obvious steel dreg-sticking prevention effect, the exchanging frequency of the oxygen lance connecting pipe and the oxygen lance spraying nozzle is reduced, the converter production efficiency is improved, and the potential safety hazard of equipment and persons is reduced; and the non-sticky steel converter oxygen lance has great economic benefits and use values.

Owner:SUZHOU BAOLIAN HEAVY IND

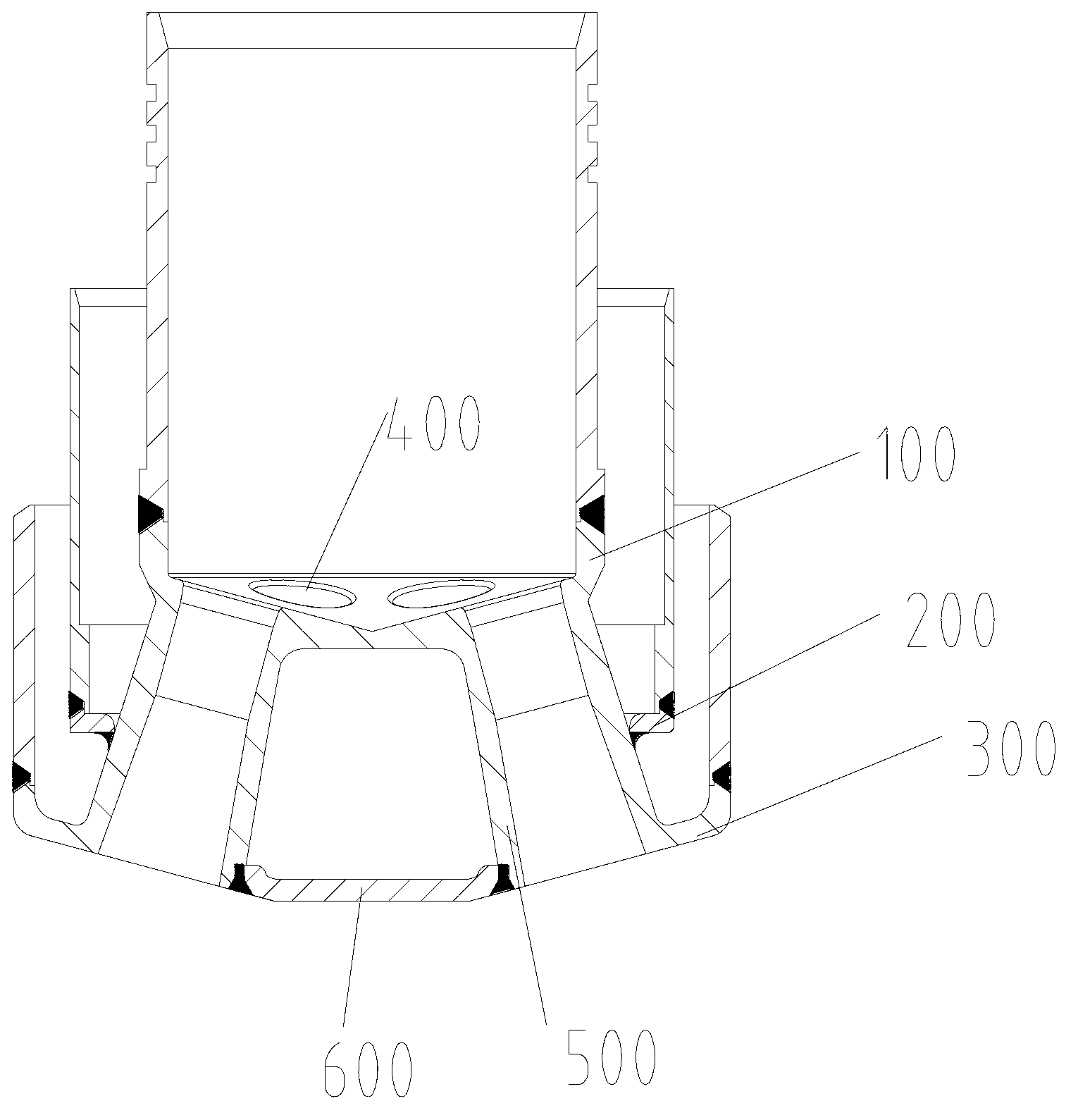

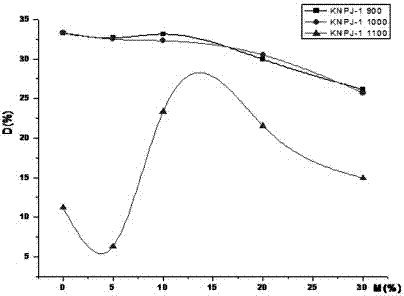

Preparation method and application method of water-based drilling cutting adsorptive filter material

ActiveCN107244887APromote sound and rapid developmentUniform pore sizeCeramic materials productionCeramicwareFilter materialPolymer

The invention discloses a preparation method and application method of a water-based drilling cutting adsorptive filter material. The adsorptive filter material comprises the following components in parts by weight: 100 parts of water-based drilling cuttings, 0 to 30 parts of composite reinforcing agents, 2 to 30 parts of forming agents, 0 to 20 parts of air entraining agents and 2 to 20 parts of water; the composite reinforcing agent is one or a combination of more of a silicon-oxygen compound, diatomaceous earth and fly ash; the forming agent is a hydrophilic polymer compound and / or clay; the air entraining agent is sodium carbonate and / or sodium bicarbonate; the preparation method comprises the following steps: (1) uniformly mixing the water-based drilling cuttings, the composite reinforcing agents, the forming agents, the air entraining agent, other auxiliaries and water, then performing granulation and forming; (2) roasting after preheating, thus obtaining ceramsite adsorptive filter material. The adsorptive filter material prepared by the method is well-developed in pore structure, larger in specific surface area, higher in compressive strength and better in adsorption effects, and the physical property indexes of the adsorptive filter material are obviously superior to the industry standards of China.

Owner:CHINA PETROLEUM & CHEM CORP +1

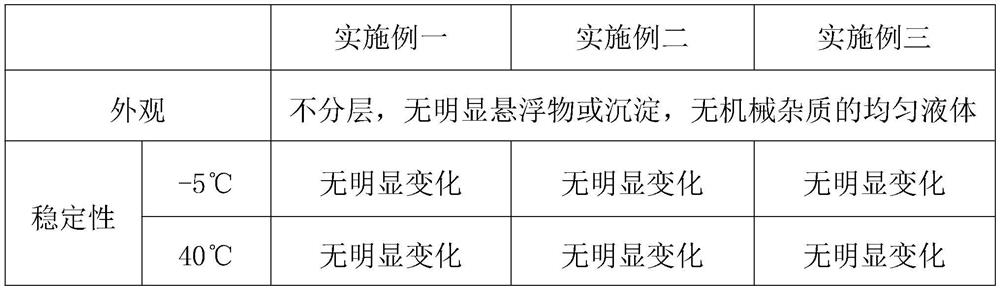

Laundry condensate bead with 8 times of cleaning power and preparation method thereof

ActiveCN111704965AHigh cloud pointDissolve fastOrganic detergent compounding agentsNon-ionic surface-active compoundsSolventLaundry

The invention relates to the technical field of daily chemical detergents, and provides laundry condensate bead with 8 times of cleaning power and a preparation method thereof. The laundry condensatebead comprises the following components in percentage by mass: 8-20% of dodecylbenzene sulfonic acid, 10-20% of sodium alcohol ether sulphate, 7-24% of fatty acid methyl ester ethoxylate, 5-12% of isomeric alcohol ether, 6-18% of AEO-9, 10-20% of a solubilizing agent, 5-15% of triethanolamine, 5-15% of trisodium N,N-dicarboxymethyl alaninate, 0.5-3% of anti-redeposition agent, 0.5-2.5% of protease, 0.3-2% of Kathon, 0.2-2% of DMDM hydantoin and 0.5-3% of daily essence. The laundry condensate bead prepared by the invention has 8 times of cleaning power on carbon black, protein and sebum stains,and solves the problem that a laundry condensate bead formula in the prior art only has 8 times of cleaning effect on a certain stain selected from the carbon black, protein and sebum stains.

Owner:FUJIAN HENGAN HLDG CO LTD +1

Iron-chromium-aluminum-based porous metal material and preparation method thereof

InactiveCN104630635AExtended service lifeImprove heat transfer performanceCompression moldingIron powder

The invention relates to an iron-chromium-aluminum-based porous metal material and a preparation method thereof. The material comprises through-holes having a pore size of 500nm-40um. The iron-chromium-aluminum-based porous metal material is prepared from the following raw materials: aluminum powder, chromium powder, iron powder, silicon carbide and rare earths. The preparation method of the iron-chromium-aluminum-based porous metal material comprises the following steps: firstly, carrying out vacuum sintering silicon carbide powder, rare earth and iron powder to obtain iron-silicon carbide sintering blocks containing rare earth, smelting the iron-silicon carbide sintering blocks, aluminum ingots, chromium powder and balance iron powder together under the protection of argon to obtain iron-chromium-aluminum-based alloy ingots, crushing the alloy ingots, carrying out vacuum ball milling to obtain alloy powder and finally uniformly mixing alloy powder, a pore-forming agent and a binder, carrying out compression molding and sintering to obtain the iron-chromium-aluminum-based porous metal material. The material has the advantages of long service life at high temperature and the like and furthermore, the large-scale industrialization can be achieved by the preparation method.

Owner:北京绿洁美科技有限公司

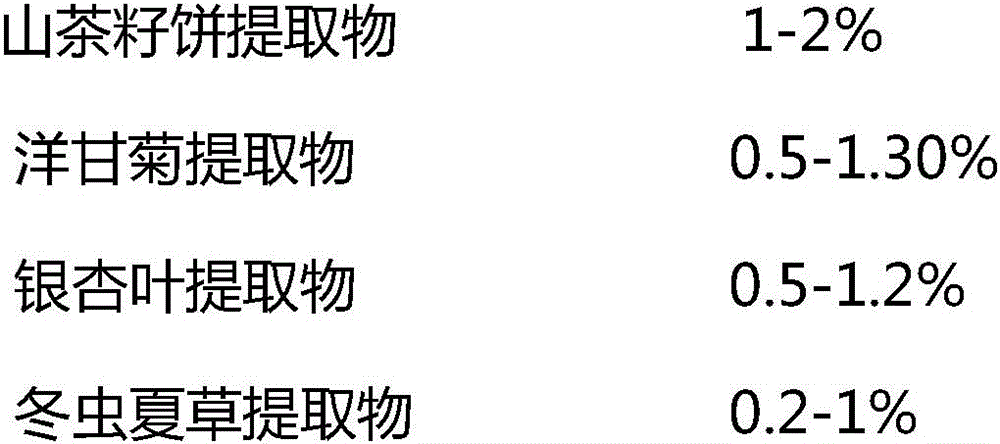

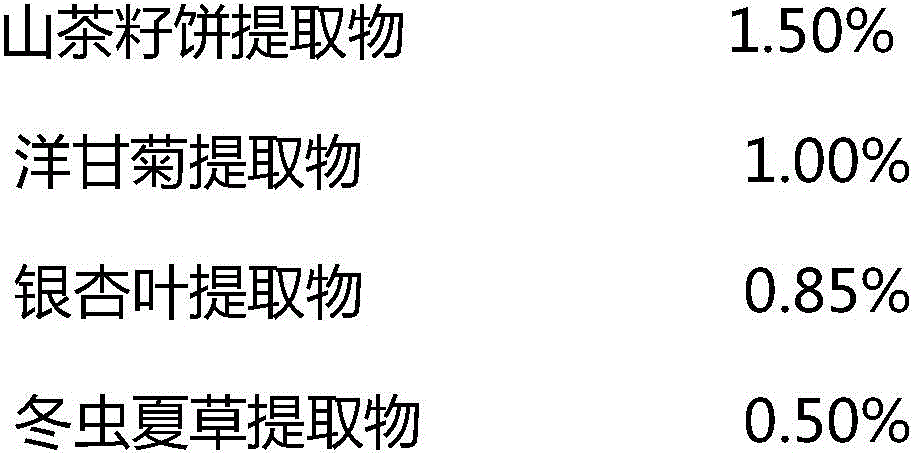

Natural and non-irritant shampoo and preparation method thereof

InactiveCN106726869ALess irritatingHigh viscosityCosmetic preparationsHair cosmeticsGuar hydroxypropyltrimonium chlorideEthylene diamine

The invention discloses natural and non-irritant shampoo, prepared from the following components by mass percent: 10.00-18.00% of sodium laureth sulfate, 1.00-8.00% of sodium lauroamphoacetate, 1.00-6.00% of cocamidopropyl betaine, 2.00-5.00% of natural extracts, 0.50-2.00% of sorbitan octanoate, 0.50-1.00% of cocamidopropyl MEA, 0.10-0.50% of p-anisic acid, 0.10-0.50% of guar hydroxypropyltrimonium chloride and 0.10-0.20% of disodium ethylene diamine tetraacetate (EDTA). The invention also discloses a preparation method of the natural and non-irritant shampoo. The natural and non-irritant shampoo has the beneficial effects that the effects of being natural and mild and nourishing scalp are achieved by synergistic interaction which is realized by means of collocation of a mild surface active agent and the natural extracts under the condition of not adding an irritant preservative; the natural and non-irritant shampoo contains the natural extracts, thus effectively reducing the irritation of the traditional chemical shampoo and getting consumers back to a green and healthy state.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

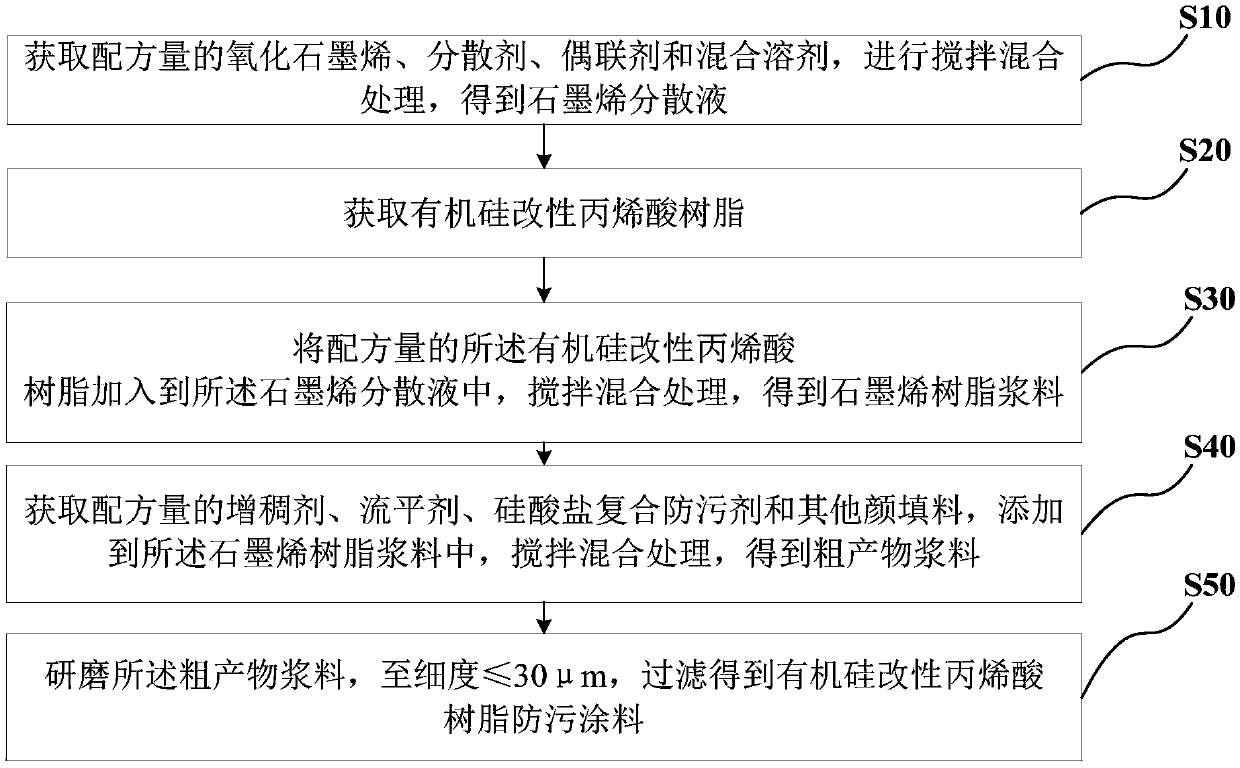

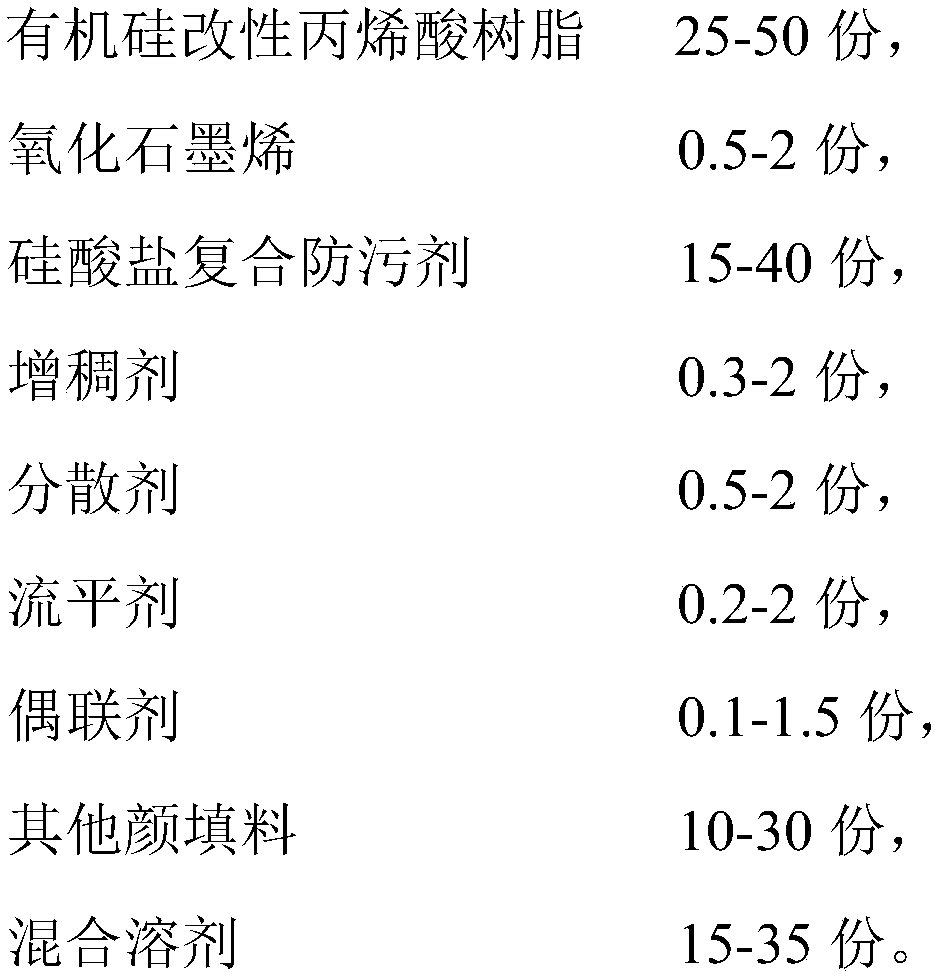

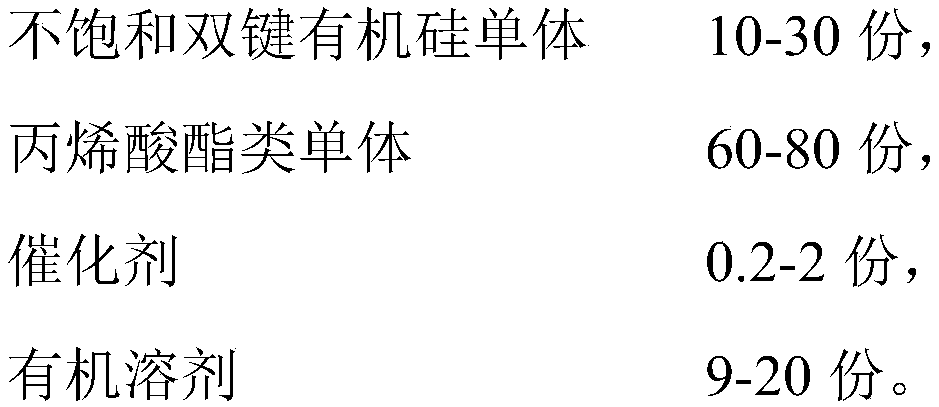

Organic silicon modified acrylic resin antifouling paint and preparation method thereof

InactiveCN109593420AGood heat and cold resistanceImprove stain resistanceAntifouling/underwater paintsPaints with biocidesWeather resistanceAcrylic resin

The invention belongs to the technical field of antifouling paint and in particular relates to organic silicon modified acrylic resin antifouling paint. The organic silicon modified acrylic resin antifouling paint comprises the following raw material components: organic silicon modified acrylic resin, graphene oxide, a silicate compound antifouling agent, a thickening agent, a dispersant, a flatting agent, a coupling agent, a mixed solvent and other pigment and filler, wherein the content of each raw material component is as follows in parts by mass: 25 to 50 parts of the organic silicon modified acrylic resin, 0.5 to 2 parts of the graphene oxide, 15 to 40 parts of the silicate compound antifouling agent, 0.3 to 2 parts of the thickening agent, 0.5 to 2 parts of the dispersant, 0.2 to 2 parts of the flatting agent, 0.1 to 1.5 parts of the coupling agent, 10 to 30 parts of the other pigment and filler and 15 to 35 parts of the mixed solvent. The antifouling paint provided by the invention has excellent staining resistance, weather resistance, adhesive force and the like, and a paint film has good density and mechanical performance. The organic silicon modified acrylic resin antifouling paint can be widely applied to various ocean facility fields including ocean ships, ocean detectors and the like.

Owner:SHENZHEN GRAPHENE LAND LEGEND TECH CO LTD

Crazing-resistance and high-toughness organic glass and preparation method thereof

The invention discloses crazing-resistance and high-toughness organic glass and a preparation method thereof. The organic glass is prepared from the following raw materials in parts by weight: methyl methacrylate, isobornyl methacrylate, ethylene glycol dimethacrylate, epoxidized soybean oil acrylate, an impact-resistant modifier, ethanol, polyacrylamide, rubber particles, polybutyl acrylate, ternary copolymerized nylon, modified nano-silicon dioxide, diisopropyl peroxydicarbonate, dicumyl peroxide, dioctyl phthalate, ethyl p-hydroxybenzoate, zinc stearate and emulsified silicone oil. The invention provides the crazing-resistance and high-toughness organic glass and the preparation method thereof; the organic glass disclosed by the invention has good toughness, heat resistance and crazing resistance, is not easy to damage and has long service life and good economic benefits.

Owner:蚌埠承永玻璃制品有限公司

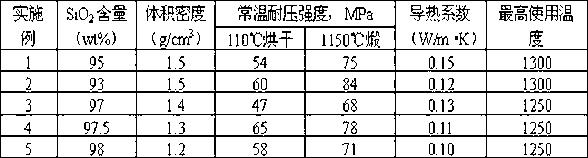

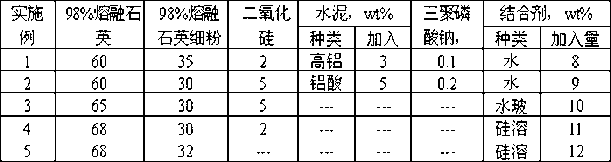

Formula of light castables made of fused silica hollow spheres

The invention discloses a formula of light castables made of fused silica hollow spheres. The formula uses the fused silica hollow spheres as aggregates and comprises, by mass, 60-68% of the fused silica hollow spheres, 30-35% of fused silica fine powder, 2-5% of silica micro powder, 0-5% of cement, sodium tripolyphosphate and binding agents, wherein the sodium tripolyphosphate and the binding agents occupy 0-0.2% and 8-12% of the total weight of the fused silica hollow spheres, the fused silica fine powder, the silica micro powder and the cement respectively. The light castables made of the fused silica hollow spheres has the advantages of low volume density, high resistance to thermal shock, high heat insulation performance and chemical stability.

Owner:洛阳北苑新材料技术有限公司

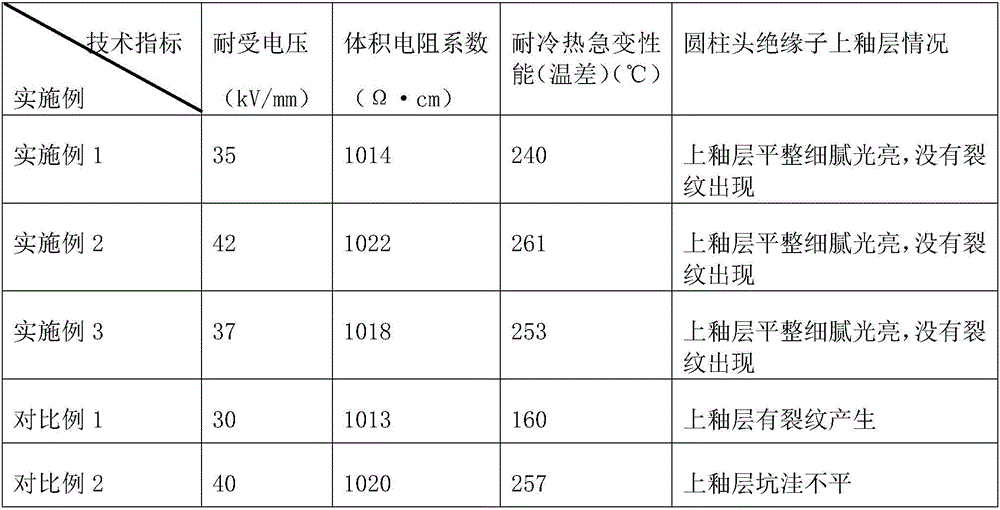

Cylindrical head suspension type insulator-head sanding process

ActiveCN106810213AEnhance binding strengthPlay the role of compressive stress transitionEngineeringArtificial stone

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

Gel air freshener and preparation method thereof

ActiveCN106421852AImprove compatibilityFragrance diffuses slowly and continuouslyDeodrantsMass ratioAntioxidant

The invention relates to a gel air freshener and a preparation method thereof. The gel air freshener contains the following components in parts by weight: 25-80 parts of essential oil, 5-40 parts of fusion agent, 3-30 parts of polyamide resin, 2-6 parts of isocyanurate and 0.2-0.5 part of antioxidant. The preparation method for the gel air freshener comprises the following steps: mixing the polyamide resin with the fusion agent at mass ratio of 80%-90%, uniformly stirring and forming a primarily mixed material; adding the essential oil and the antioxidant into the primarily mixed material, quickly stirring and uniformly mixing, thereby obtaining a semi-finished product; mixing the curing agent with the remaining fusion agent, and then adding into the semi-finished product, uniformly stirring and standing by at room temperature till solidifying. The gel air freshener provided by the invention can load as high as 80% of essence and flavor; the fragrance scattering is slow, continuous and uniform; the gel air freshener has high temperature resistance; under high temperature or low temperature environment, the gel air freshener is difficult to discharge oil or soften structure; and a long-lasting flavor-diffusion effect can be maintained.

Owner:DONGGUAN RIYOU AUTOMOBILE ACCESSORIES

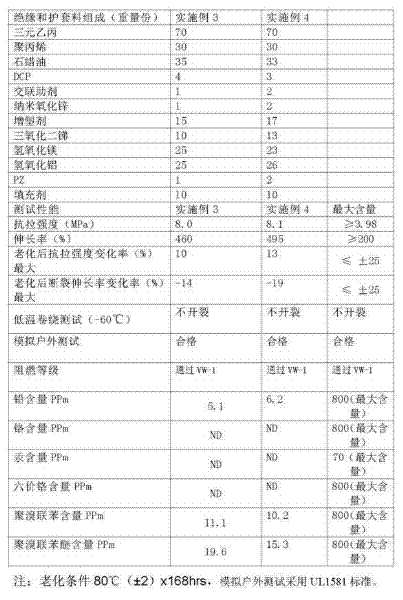

High flame retardant super low temperature resistant environmental flexible cable

ActiveCN102262936AImprove anti-agingGood heat and cold resistancePlastic/resin/waxes insulatorsInsulated cablesElectrical conductorPlasticizer

The invention relates to the technical field of novel material application, in particular to an environment-friendly flexible cable with high flame retardance and super low temperature resistance. The environment-friendly flexible cable with the high flame retardance and the super low temperature resistance comprises a flexible twisted conductor, an insulating layer and an outer protective layer, wherein the insulating layer is wrapped outside the flexible twisted conductor to form single insulated wires; the outer protective layer wraps at least two single insulated wires; the insulating layer and the outer protective layer are made from the same materials, take an ethylene-propylene-diene monomer as a disperse phase and take polypropylene as a continuous phase; the insulating layer contains a plasticizer which is cold-resistant, and also contains 30 to 40 parts of paraffin oil, 2 to 6 parts of cross linking agent and 50 to 70 parts of flame retardant; and the outer protective layer contains the plasticizer which is cold-resistant, and also contains 30 to 40 parts of paraffin oil, 2 to 6 parts of cross linking agent and 50 to 70 parts of flame retardant. Due to the adoption of the technical scheme, the environment-friendly flexible cable with the high flame retardance and the super low temperature resistance has high torsion resistance, the super low temperature resistance and flame retardance, is difficult to age and crack and environment-friendly, and can work stably in low temperature environments of below -60 DEG C.

Owner:GUANGDONG ZHONGDE CABLE

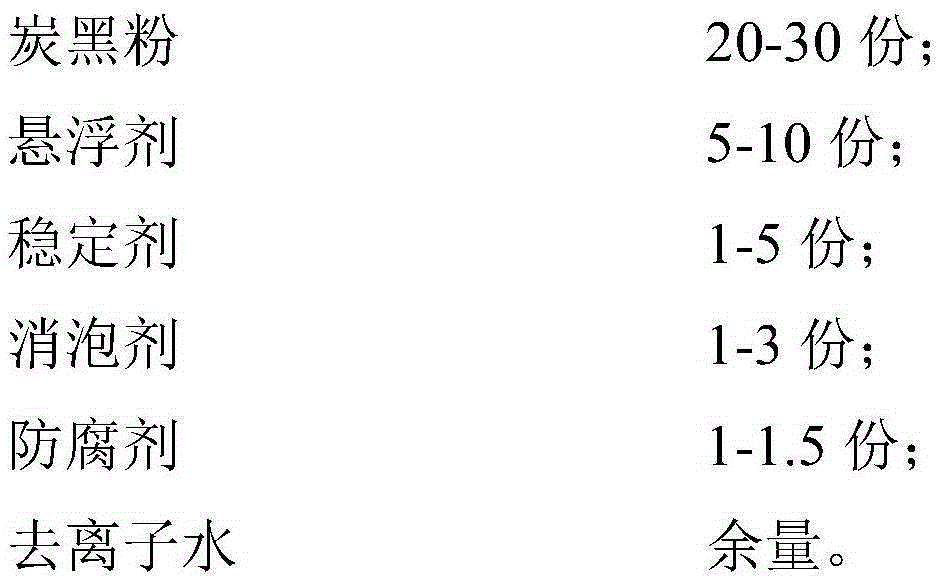

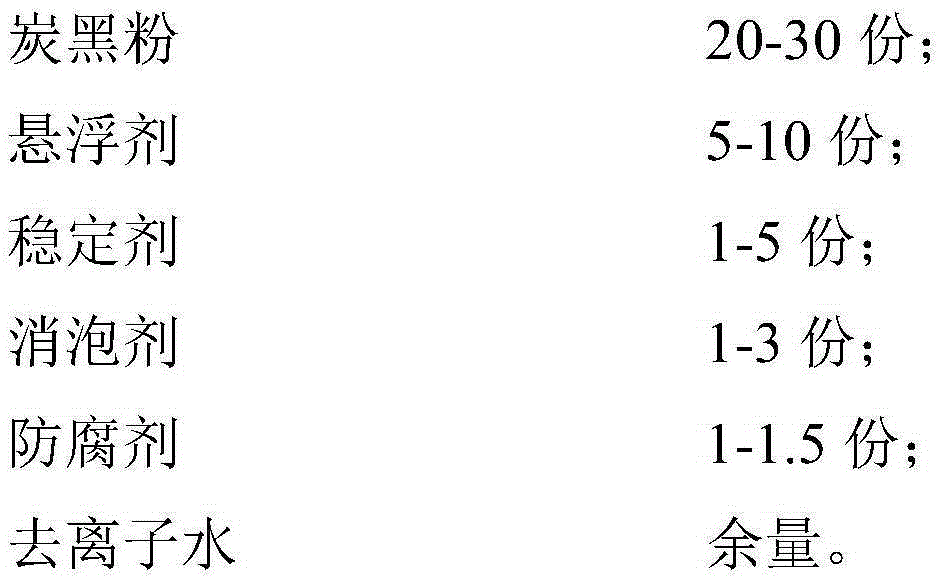

Carbon black water-based color paste with high carbon black content and preparation method thereof

ActiveCN105250146ASimple production processEasy to implementCosmetic preparationsToilet preparationsWater basedHigh carbon

The invention discloses carbon black water-based color paste with high carbon black content and a preparation method thereof. The preparation method comprises the steps that deionized water is heated to the temperature above 85 DEG C, suspending agents are added to water, and stirring is conducted to make the suspending agents fully dissolved; then carbon black powder is added, defoaming agents and stabilizers are added, even stirring is conducted, the stirring speed is adjusted, after stirring is conducted for a period of time, preservative is added, even stirring is conducted, and the carbon black water-based color paste is obtained. The method is simple in operation technology, the prepared carbon black water-based color paste is high in color powder content, low in settleability, low in viscosity and capable of being stably stored for a long time, and the carbon black water-based color paste can be directly used in a formula without being affected by additional mechanical force.

Owner:SHANGHAI KINGLAND FINE CHEM LTD +1

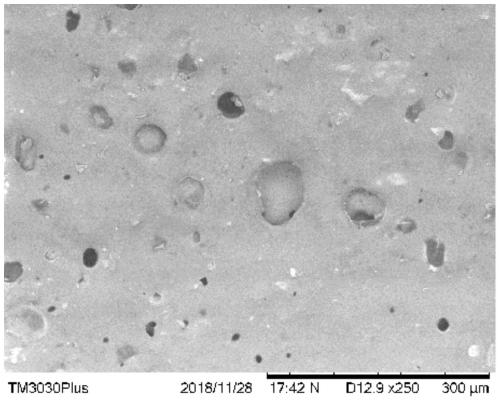

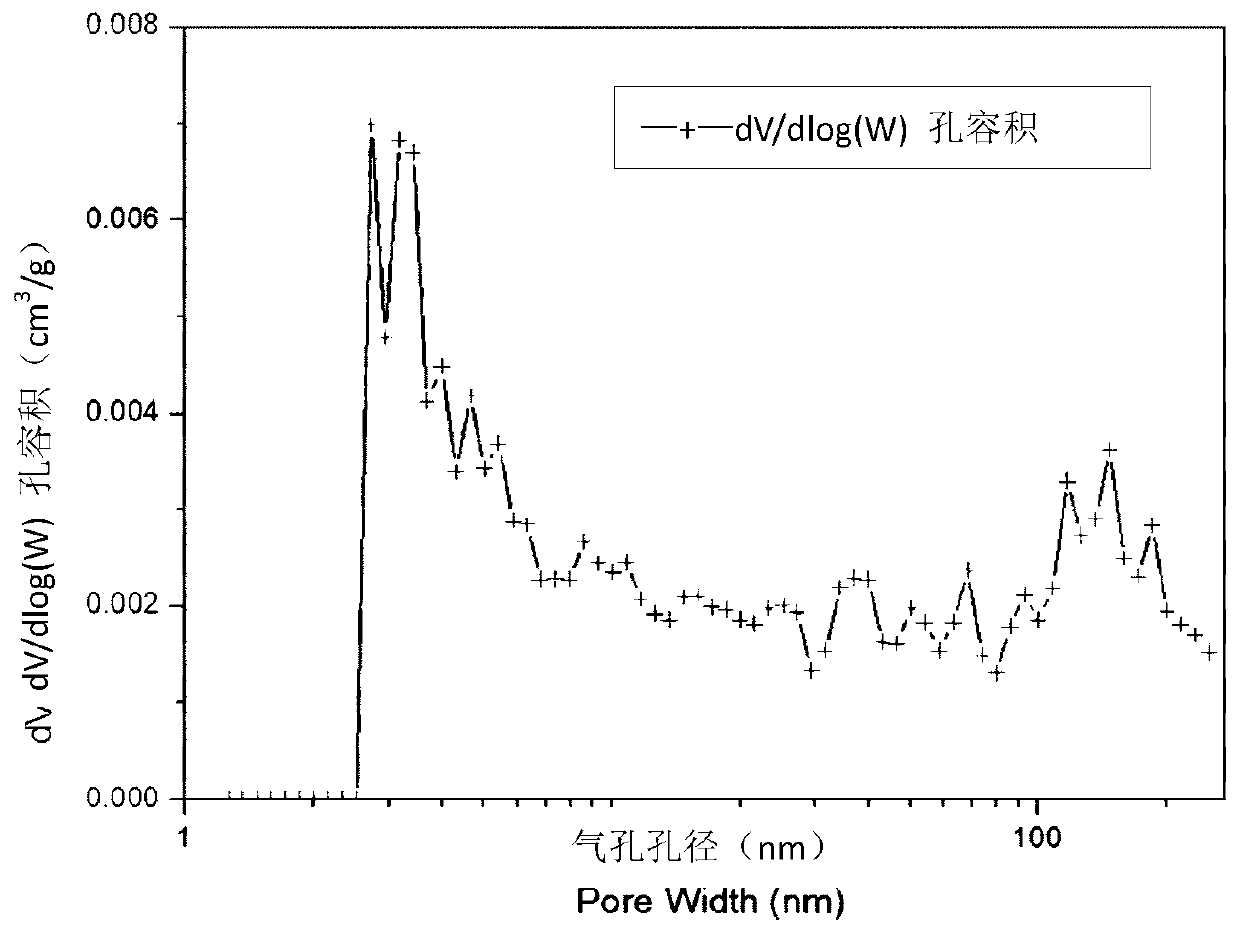

Temperature-sensing ceramic with heat-resistant and cold-proof functions and manufacturing method and application thereof

ActiveCN109836119AHas the function of heat resistance and cold preventionAvoid discomfortClaywaresCeramic glazeTemperature sense

The invention discloses a temperature-sensing ceramic with heat-resistant and cold-proof functions and a manufacturing method and application thereof. The temperature-sensing ceramic comprises a conventional ceramic body layer, and a functional layer which is compounded on the surface of the conventional ceramic body layer and has heat-resistant and cold-proof functions or a decorative layer whichis compounded on the surface of the functional layer. The functional layer is a ceramic glaze layer with a porous structure, pores of which are micro-sized closed pores. The temperature-sensing ceramic has consistent physical properties and chemical properties with existing ceramic products without the application of the functional layer. The manufacturing method comprises steps as follows: preparation of the ceramic body layer and preparation of the functional layer. A formula system adopted by the ceramic functional layer of the invention is adapted to a body formula system of existing ceramic products such that the expansion coefficient of the functional layer is consistent with expansion coefficient of the body layer. On this basis, a pore-forming agent is added to obtain the temperature-sensing ceramic with heat-resistant and cold-proof functions. The discomfort caused by cold or blanching when the body touches the ceramic can be effectively solved, and physical properties and chemical properties of the existing ceramic products will not be changed.

Owner:亚细亚新材料科技股份公司

Method for modifying natural emulsion through pulullan-alcohol soluble protein

The invention relates to a method for modifying natural emulsion through pulullan-alcohol soluble protein. The method comprises four steps of preparing organic silicon emulsion, preparing alcohol soluble protein-organic silicon compound emulsion, modifying natural emulsion by the alcohol soluble protein-organic silicon compound emulsion, and modifying the natural emulsion through pulullan-alcohol soluble protein and organic silicon compound. The natural emulsion prepared by the method has ageing resistance and antianaphylaxis.

Owner:ZHEJIANG XIANGBAN LATEX PROD

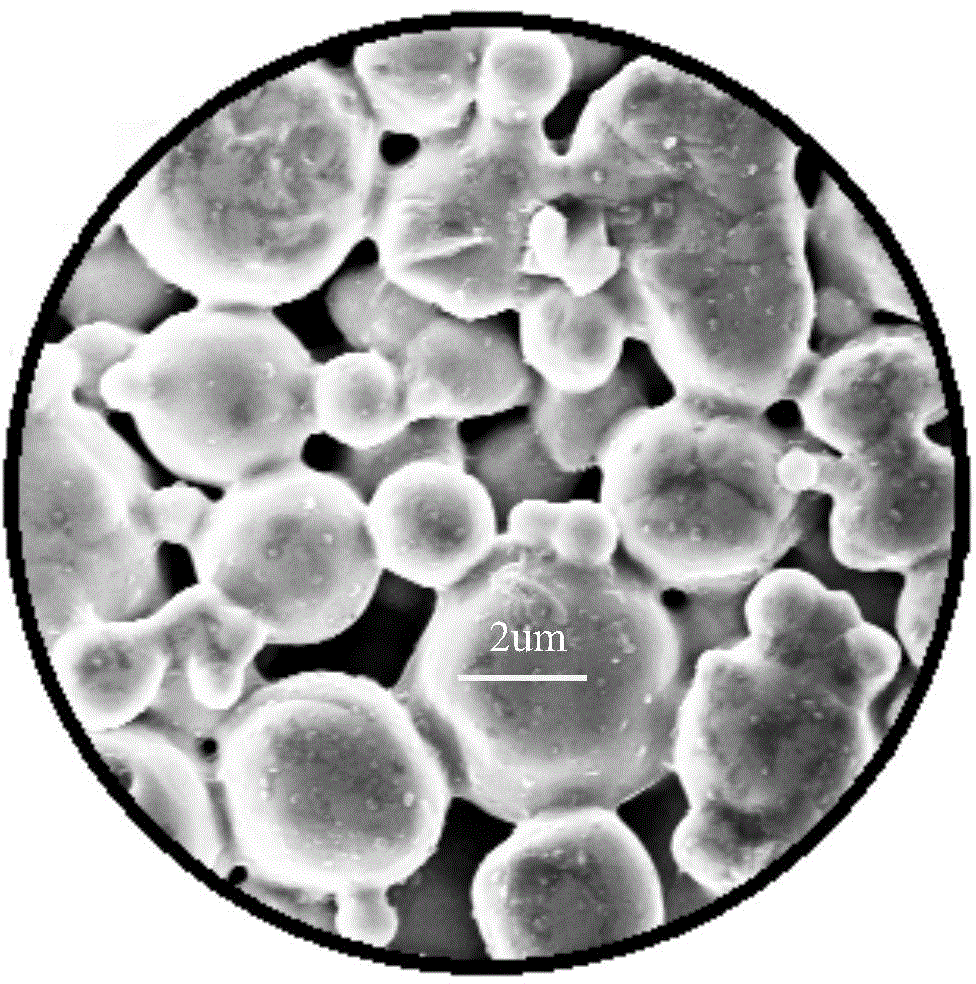

Modified pyridine styrene butadiene rubber latex and synthesis method and application thereof

The invention provides modified pyridine styrene butadiene rubber latex and a synthesis method and application thereof. The modified pyridine styrene butadiene rubber latex is prepared from the following raw materials in percentage by weight: an initiator, an emulsifying agent, a dispersing agent, water and mixed monomers, wherein the dosage of the initiator is 0.2 to 0.6 percent of the weight ofthe mixed monomers; the dosage of the emulsifying agent is 1 to 2 percent of the weight of the mixed monomers; the dosage of the dispersing agent is 2 to 4 percent of the weight of the mixed monomers;the dosage of the water is 95 to 105 percent of the weight of the mixed monomer; and the mixed monomers comprise the following components in percentage by weight: 10 to 85 percent of isoprene, 0 to 50 percent of butadiene, 3 to 15 percent of acrylic ester, 2 to 5 percent of acrylic acid and 10 to 20 percent of monoolefine. The modified pyridine styrene butadiene rubber latex has high solid content, uniform latex particles and low content of residual dialkene, is nontoxic and odorless, and has simple, convenient and safe operations in production and use, good film forming property and good adhesiveness to porous materials and polymer calcic-plastic composite materials; in addition, the chemical stability, the heat resistance and the cold resistance of the modified pyridine styrene butadiene rubber latex are all superior to the conventional pyridine styrene butadiene rubber latex.

Owner:SHANDONG HEYI GAS CO LTD DONGYING CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com