Preparation method of waterborne polyurethane material with resistance to yellowing

A water-based polyurethane, anti-yellowing technology, used in textiles, papermaking, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Nano TiO 2 Preparation of dispersion

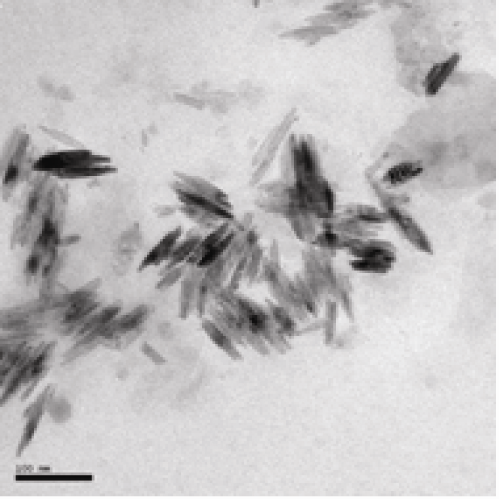

[0036] Add 0.300g sodium hexametaphosphate and 30ml N,N-dimethylformamide to the container, and completely dissolve the dispersant, then add 3.000g nanometer powder TiO 2 , in an ultrasonic cell pulverizer, ultrasonic pulverization at 540w for 30min to obtain nano-TiO 2 The dispersion is ready for use. The nano-powder TiO 2 It is rutile type, the purity is ≥99.9%, and the particle size is 25nm~50nm. From figure 1 It can be seen in the nano-TiO 2 It has good dispersibility in DMF solution.

[0037] The second step: preparing the water-based polyurethane graft emulsion.

[0038] Add 20.000g of polycarbonate diol, 1.095g of isophorone diisocyanate and 9.857g of diphenylmethane diisocyanate into another container, and then place the container in an oil bath at 75°C for 2 hours After the reaction is complete, cool down to 40°C, add 1.557g of dimethylolbutyric acid, react for 1h, raise the temperature to 80°C, add 1.354g...

Embodiment 2

[0047] Step 1: Nano TiO 2 Preparation of dispersion

[0048] Add 0.150g polyethylene glycol-4000 and 30ml N,N-dimethylformamide to the container respectively, and completely dissolve the dispersant, then add 3.000g nanometer powder TiO 2 , in an ultrasonic cell pulverizer, ultrasonic pulverization at 540w for 30min to obtain nano-TiO 2 The dispersion is ready for use; the nano-powder TiO 2 Rutile type, purity ≥ 99.9%, particle size 40nm.

[0049] The second step: the preparation of polycarbonate water-based polyurethane emulsion.

[0050] In another container, add 20.000g of polycarbonate diol, 0.690g of isophorone diisocyanate and 6.210g of diphenylmethane diisocyanate, and place it in an oil bath at 75°C for 2 hours until the reaction is complete. Cool down to 40°C, add 1.883 g dimethylol butyric acid (, react for 1 hour, heat up to 80°C, add 0.154g 1,4-butanediol and keep it warm for 1 hour to obtain a polyurethane prepolymer; cool down the polyurethane prepolymer to 4...

Embodiment 3

[0053] Step 1: Nano TiO 2 Preparation of dispersion

[0054] Add 0.210g sodium dodecylbenzenesulfonate and 30ml N,N-dimethylformamide to the container respectively, and completely dissolve the dispersant, then add 3.000g nanometer powder TiO 2 , in an ultrasonic cell pulverizer, ultrasonic pulverization at 540w for 30min to obtain nano-TiO 2 ; The nano-powder TiO 2 Rutile type, purity ≥ 99.9%, particle size 50nm.

[0055] The second step: the preparation of polycarbonate water-based polyurethane emulsion.

[0056] Add 20.000g of polycarbonate diol, 2.903g of isophorone diisocyanate and 11.612g of diphenylmethane diisocyanate into another container, and then place the container in an oil bath at 75°C for 2 hours After the reaction is complete, cool down to 40°C, add 2.071 g of dimethylolbutyric acid, react for 1 hour, raise the temperature to 80°C, add 1.672g of 1,4-butanediol, and keep warm for 1 hour to obtain a polyurethane prepolymer; Cool the polyurethane prepolymer t...

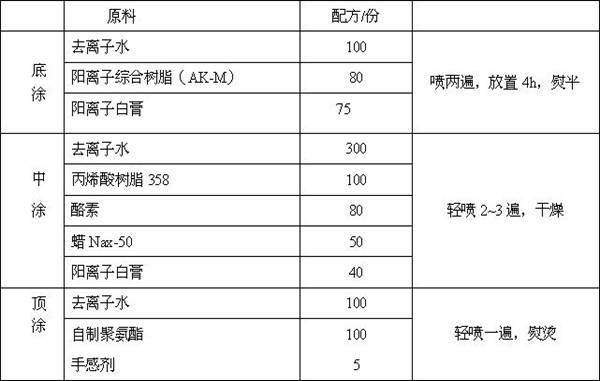

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com