Iron-chromium-aluminum-based porous metal material and preparation method thereof

A technology of iron-chromium-aluminum and porous metal, which is applied in the field of porous metal filter elements and its preparation, can solve the problems of short service life, complex process, high raw material cost, etc., and achieve the effect of long service life and improved heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

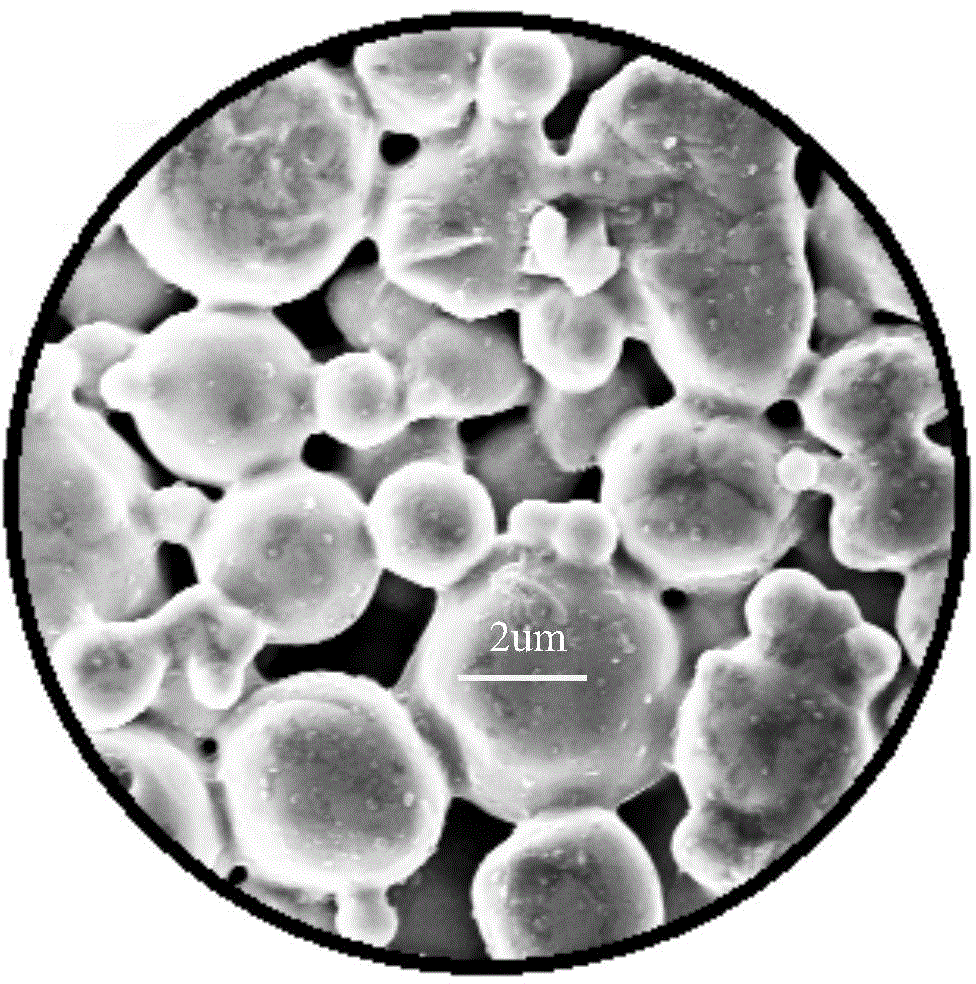

Image

Examples

Embodiment 1

[0036] Prepared iron-chromium-aluminum-based porous metal material components, by mass percentage:

[0037] Aluminum 3, chromium 18, silicon carbide 3, lanthanum cerium mixed rare earth 0.03, and the balance is iron.

[0038] Its preparation method comprises the following steps:

[0039] Step 1: Preparation of rare earth-containing iron-silicon carbide sintered block

[0040] According to the mass ratio of silicon carbide 3 and rare earth 0.03 in the designed iron-chromium-aluminum-based porous metal material, the mass ratio of silicon carbide after 5 times amplification in the same proportion is 15, and the mass ratio of rare earth is 0.15. 15 kg of powder, 0.15 kg of rare earth, mixed with 15.15 kg of iron powder to obtain a mixed powder, the mixed powder is vacuum ball milled and mixed evenly, pressed into shape, vacuum sintered at 1200-1300 ° C for 2 hours, and cooled with the furnace to obtain rare earth-containing iron- SiC sintered block;

[0041] The second step: pr...

Embodiment 2

[0050] Prepared iron-chromium-aluminum-based porous metal material components, by mass percentage:

[0051] Aluminum 5, chromium 20, silicon carbide 6, rare earth yttrium 0.25, and the balance is iron.

[0052] Its preparation method comprises the following steps:

[0053] Step 1: Preparation of rare earth-containing iron-silicon carbide sintered block

[0054] According to the mass ratio of silicon carbide 6 and rare earth 0.25 in the designed iron-chromium-aluminum-based porous metal material, the mass ratio of silicon carbide magnified by 4 times in the same proportion is 24, and the mass ratio of rare earth is 1. Weigh silicon carbide 24 kg of powder, 1 kg of rare earth, and 50 kg of iron powder are mixed to obtain a mixed powder. After the mixed powder is vacuum ball milled and mixed evenly, it is pressed and molded. Silicon sintered block;

[0055] The second step: preparation of iron-chromium-aluminum alloy ingot containing silicon carbide and rare earth

[0056] Ac...

Embodiment 3

[0064] Prepared iron-chromium-aluminum-based porous metal material components, by mass percentage:

[0065] Aluminum 6, chromium 25, silicon carbide 10, rare earth yttrium 0.5, and the balance is iron.

[0066] Its preparation method comprises the following steps:

[0067] Step 1: Preparation of rare earth-containing iron-silicon carbide sintered block

[0068] According to the mass ratio of silicon carbide 10 and rare earth 0.5 in the designed iron-chromium-aluminum-based porous metal material, the mass ratio of silicon carbide after 2 times amplification in the same proportion is 20, and the mass ratio of rare earth is 1. Weigh silicon carbide respectively 20 kg of powder, 1 kg of rare earth, and 21 kg of iron powder are mixed to obtain a mixed powder. After the mixed powder is vacuum ball milled and mixed evenly, it is pressed and molded. Silicon sintered block;

[0069] The second step: preparation of iron-chromium-aluminum alloy ingot containing silicon carbide and rar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com