Patents

Literature

40results about How to "Excellent high temperature corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multipurpose low-conductivity ceramic/noble metal lamellar composite thermal barrier coating

InactiveCN102345122AGood heat insulationNo insulationBlade accessoriesEfficient propulsion technologiesAviationThermal insulation

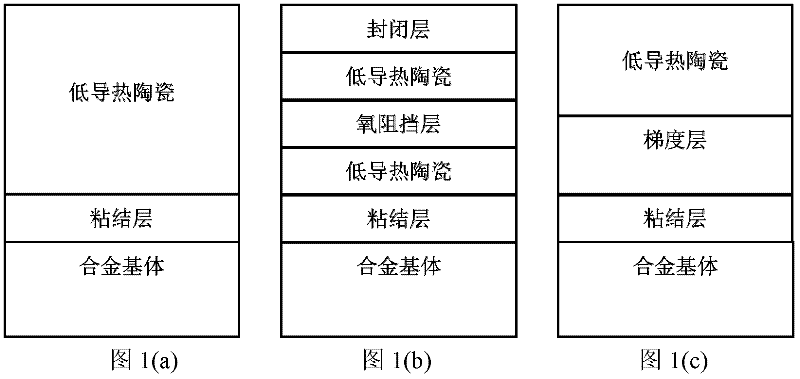

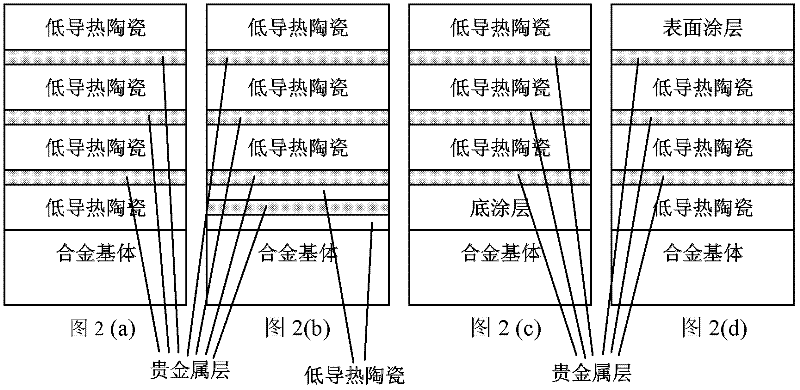

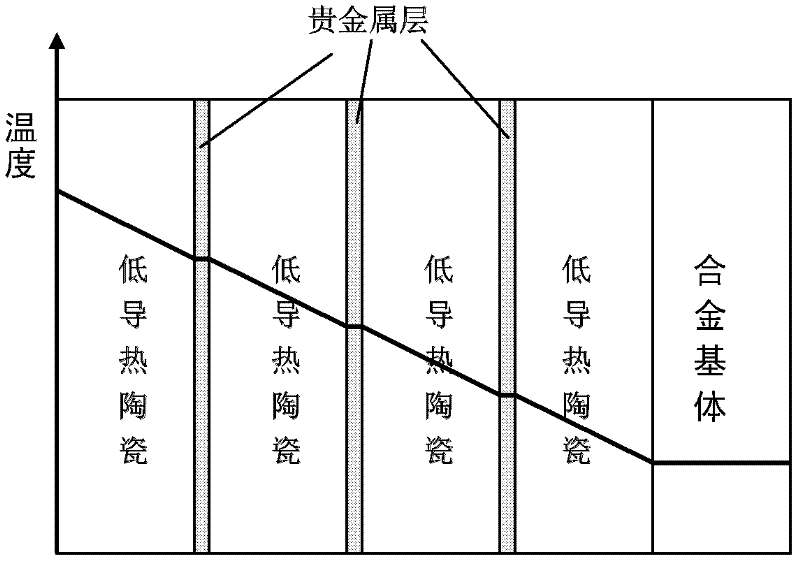

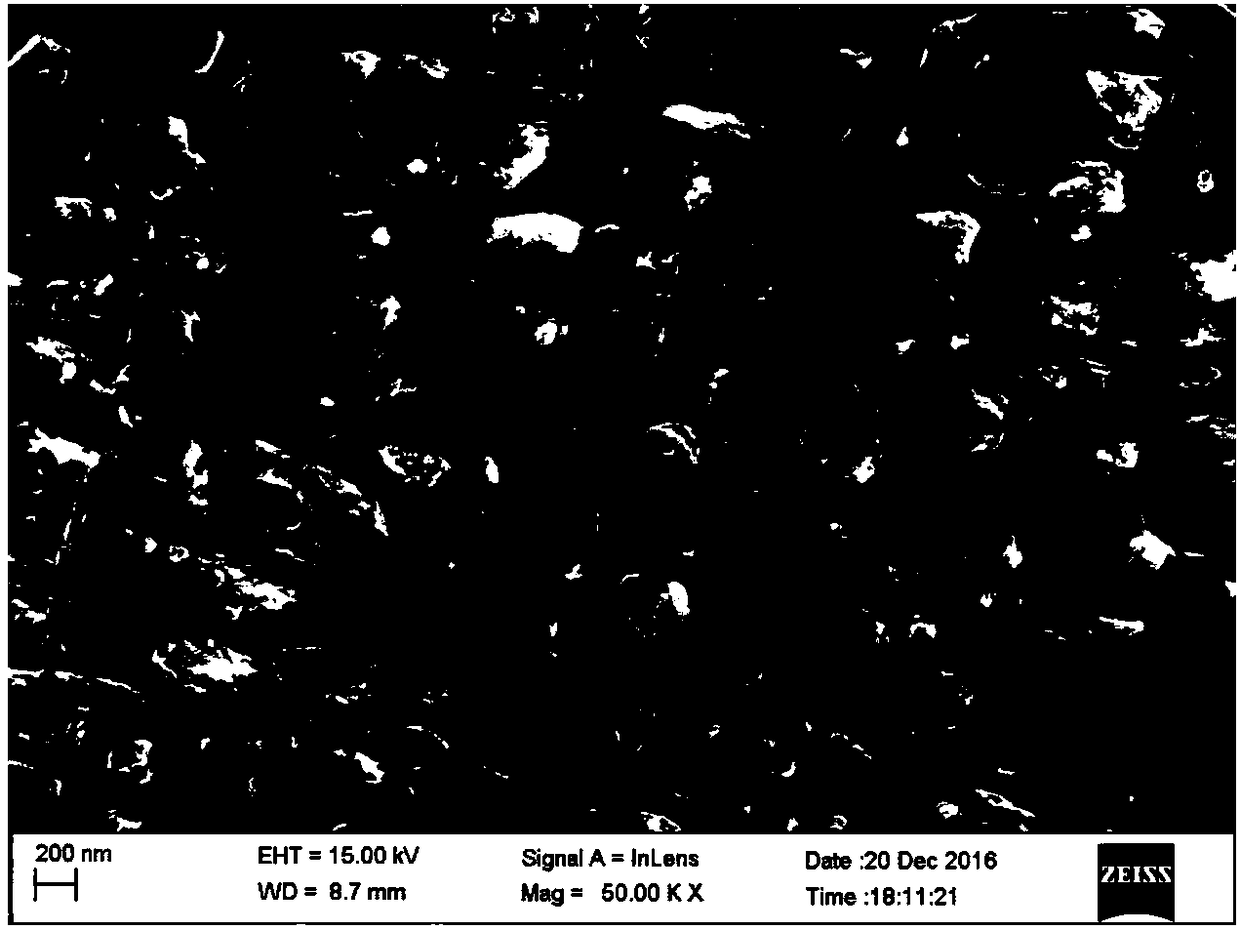

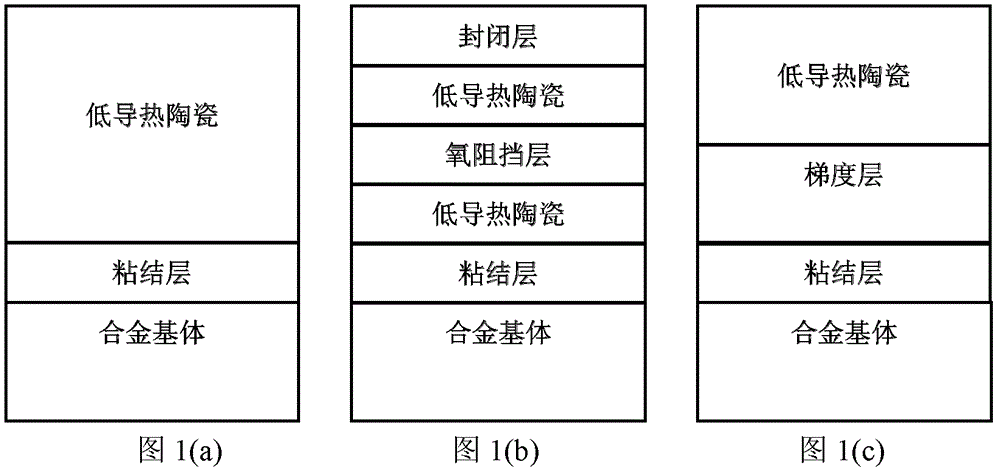

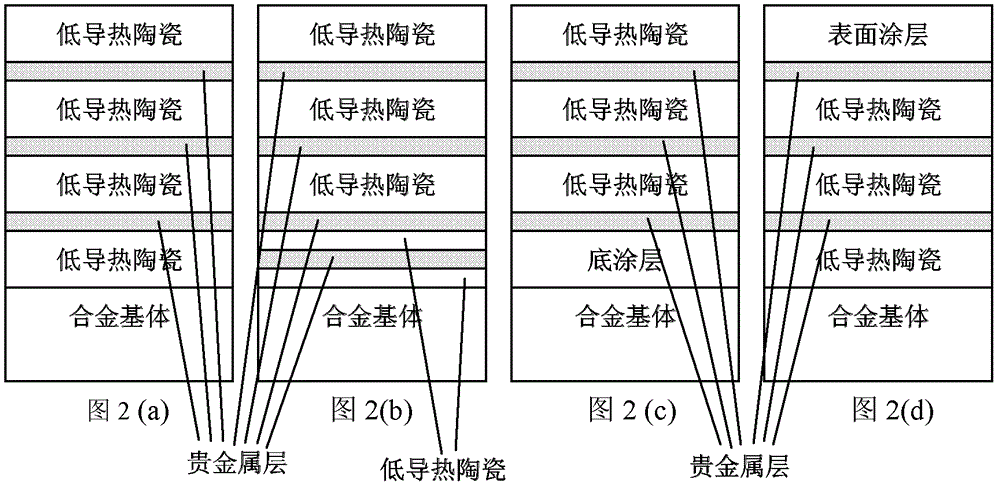

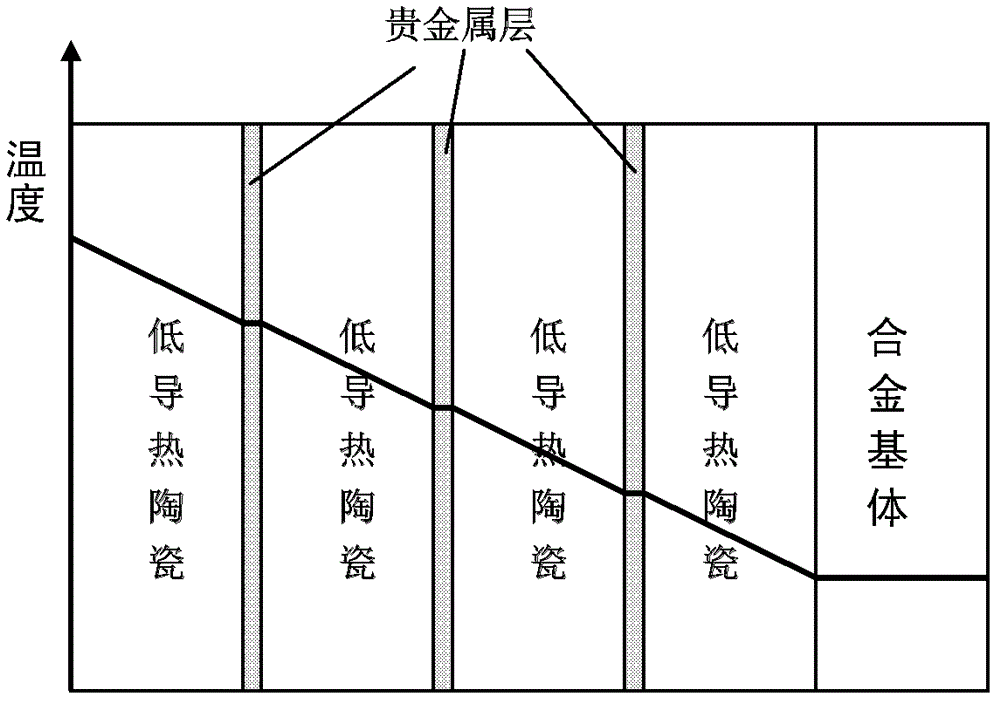

The invention discloses a multipurpose low-conductivity ceramic / noble metal lamellar composite thermal barrier coating, relating a composite material and coating technology. The coating is divided into four types: (1) regularly and alternatively depositing low-conductivity ceramic layers and noble metal layers; (2) irregularly and alternatively depositing low-conductivity ceramic layers and noblemetal layers; (3) exerting low-conductivity ceramic and noble metal lamellar composite thermal barrier coatings on antioxidant protection layers deposited on the surface of a basic alloy; and (4) depositing other functional coatings on the outer surface of the low-conductivity ceramic / noble metal lamellar composite thermal barrier coating. According to the invention, the lamellar composite thermal barrier coating formed by alternatively depositing the low-conductivity ceramic layers and the noble metal layers has the advantages of excellent thermal insulation performance and thermal shock resistance, stable coating structure and long service life and can be applied to the high temperature protection of hot end components of refractory alloys or high temperature alloys such as an aircraft engine, a marine engine, a ground gas turbine, a rocket engine, and the like.

Owner:UNIV OF SCI & TECH BEIJING

High-temperature resistant seamless steel pipe and production method thereof

InactiveCN102690995AHigh strengthImprove creep resistanceFurnace typesRigid pipesEconomic benefitsTemperature difference

The invention relates to a high-temperature resistant seamless steel pipe and a production method thereof. The seamless steel pipe is characterized by consisting of the following chemical components in percentage by mass: 0.08 to 0.12 percent of C, 0.20 to 0.45 percent of Si, 0.40 to 0.60 percent of Mn, 8.50 to 9.50 percent of Cr, 0.85 to 1.10 percent of Mo, less than or equal to 0.40 percent of Ni, 0.06 to 0.10 percent of Nb, 0.18 to 0.25 percent of V, 0.03 to 0.07 percent of N, less than or equal to 0.018 percent of P, less than or equal to 0.008 percent of S, less than or equal to 0.01 percent of total Al, less than or equal to 0.003 percent of O, and the balance of Fe and inevitable impurities. The heating temperature of a pipe blank in an annular furnace is 1,230 to 1,260 DEG C, and the temperature difference of the pipe blank in the cross section and the length direction is + / -15 DEG C. A normalizing and tempering technology is adopted in heat treatment, the normalizing temperature is 1,040 to 1,080 DEG C, and the heat preservation time is not less than 1.5 minutes per 1 milliliter of wall thickness and is not less than 30 minutes; and the tempering temperature is 750 to 780 DEG C, the heat preservation time is not less than 1 hour, and cooling is performed in still air. The microstructure of the seamless pipe is martensite. The method is high in production efficiency, can be used for producing pipes with multiple diameters, is high in economic benefits and suitable for large-scale production, and has high popularization value.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

High-strength gamma'-phase-strengthened cobalt-based high-temperature alloy

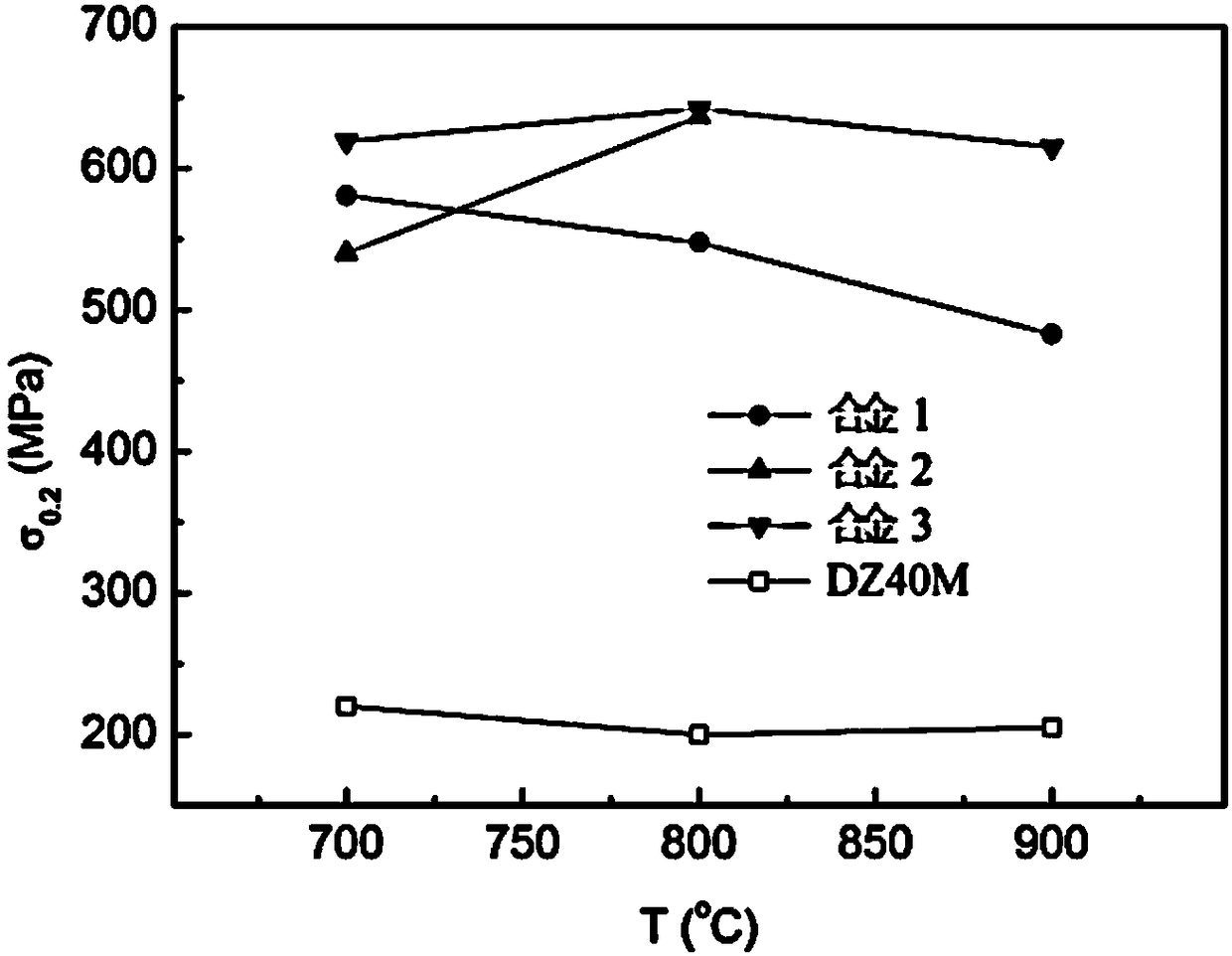

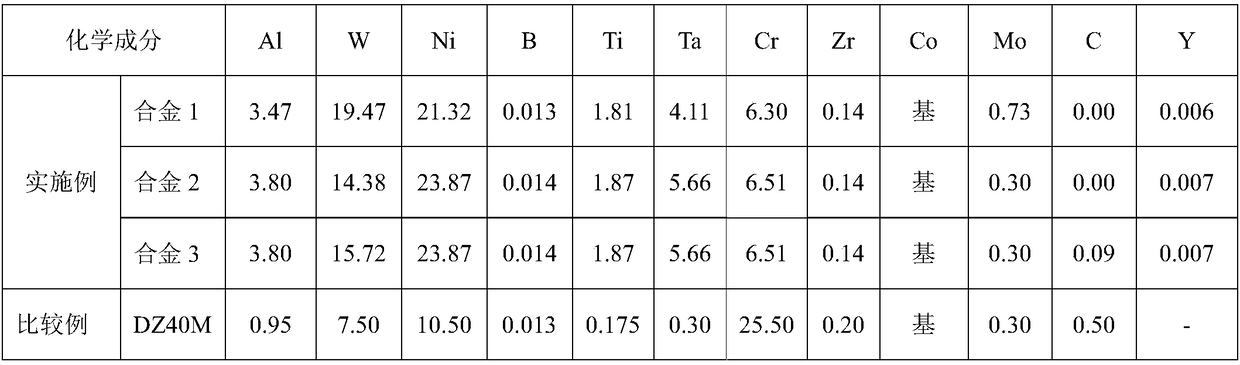

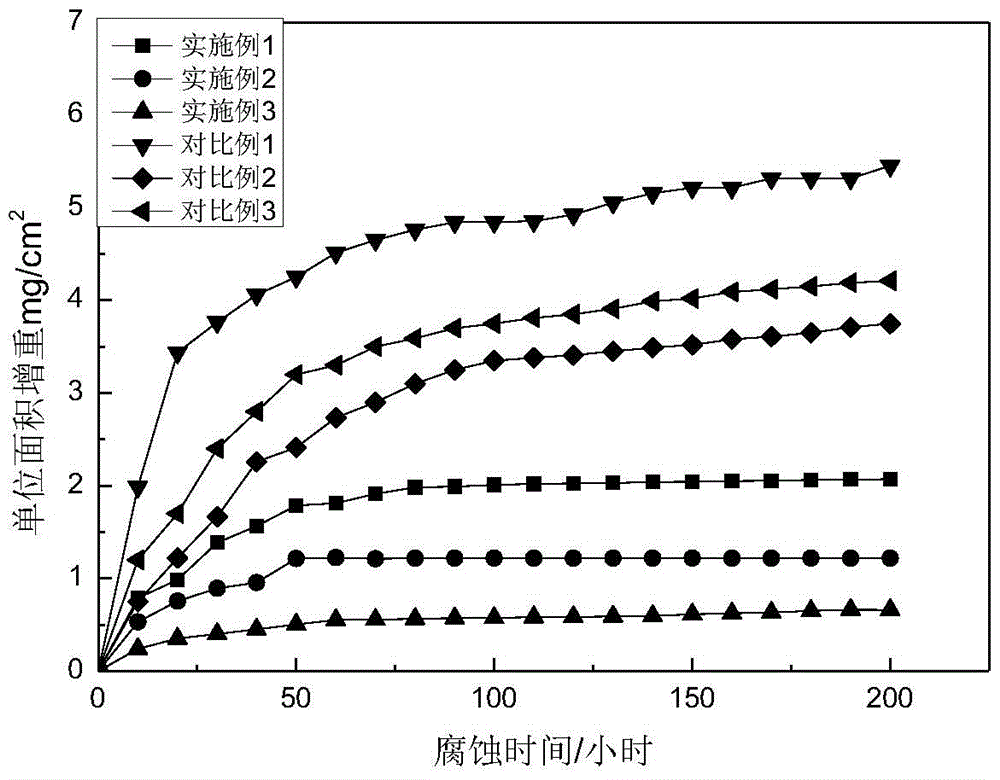

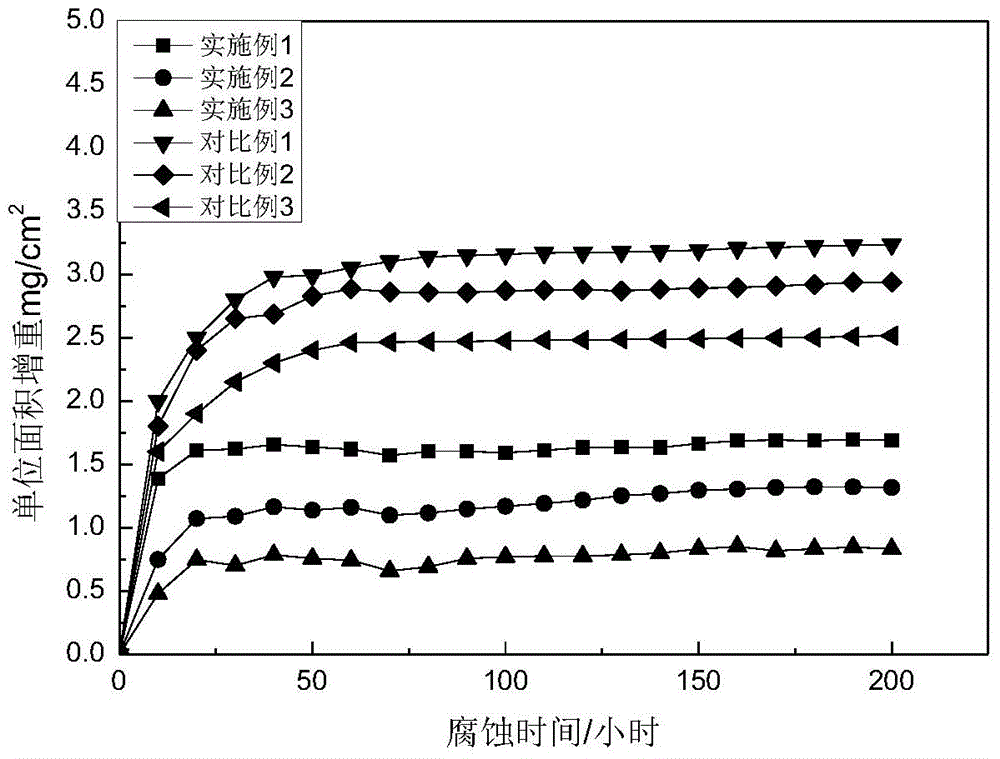

InactiveCN108411163AGood high temperature oxidation resistanceExcellent high temperature corrosion resistanceStatorsMachines/enginesElemental compositionWorking temperature

The invention discloses a high-strength gamma'-phase-strengthened cobalt-based high-temperature alloy which is mainly prepared from the elements: Co, Ni, Al, W, Cr, Ta, Ti and the like. The high-strength gamma'-phase-strengthened cobalt-based high-temperature alloy is prepared from the elements in percentage by mass: 20.0 to 24.5 percent of Ni, 14.5 to 19.5 percent of W, 3.4 to 6.0 percent of Al,3.0 to 6.8 percent of Cr, 4.0 to 5.8 percent of Ta, 1.5 to 2.0 percent of Ti, 0.3 to 1.0 percent of Mo, 0 to 0.14 percent of Zr, 0.01 to 0.015 percent of B, 0 to 0.1 percent of C, 0 To 0.007 percent of Y, and the balance Co. A main composition phase of the alloy is (a) cobalt-based solid solution gamma+intermetallic compound gamma', or (b) cobalt-based solid solution gamma+intermetallic compound gamma'+MC type carbide+crystal boundary disperse precipitation intermetallic compound mu. The alloy can be applied to turbo machine hot end components in the industrial fields such as metallurgy, petroleum, energy and electric power, and the working temperature of the alloy can reach to 900 DEG C. The alloy is higher in high-temperature strength; the yield strength of the alloy under the high temperature condition (700 to 900 DEG C) is about 2 to 3 times of DZ40M; and the endurance property, the high temperature oxidation resistance and the hot corrosion performance of the alloy are excellent and superior to a traditional cobalt-based high-temperature alloy.

Owner:NORTHEASTERN UNIV

Cored wire for preparing nickel-based high-aluminum coating and coating preparation method of cored wire

ActiveCN105671471AHigh hardnessGood high temperature corrosion resistanceMolten spray coatingMaterials processingAluminum coating

The invention provides a cored wire for preparing a nickel-based high-aluminum coating and a coating preparation method of the cored wire, and belongs to the field of thermal spraying in material processing engineering. The cored wire comprises the following components in percentages by mass: 13-25% of Cr, 4-10% of Al, 3-6% of B, 3-6% of Si, and the balance Ni and inevitable impurities. A strip for the skin of the cored wire is a Ni80-Cr20 strip. When the nickel-based high-aluminum coating with good high-temperature corrosion resistance is prepared by electric arc spraying, conditions of a spraying process are as follows: current is 160-200 A, voltage is 28-34 V, pressure of compressed air is 0.4-0.6 MPa, and spraying distance is 190-210 mm. By the cored wire and the coating preparation method, the nickel-based high-aluminum coating with high hardness and good high-temperature corrosion resistance can be obtained.

Owner:BEIJING UNIV OF TECH

High-temperature alloy protecting coating and method of preparing the same

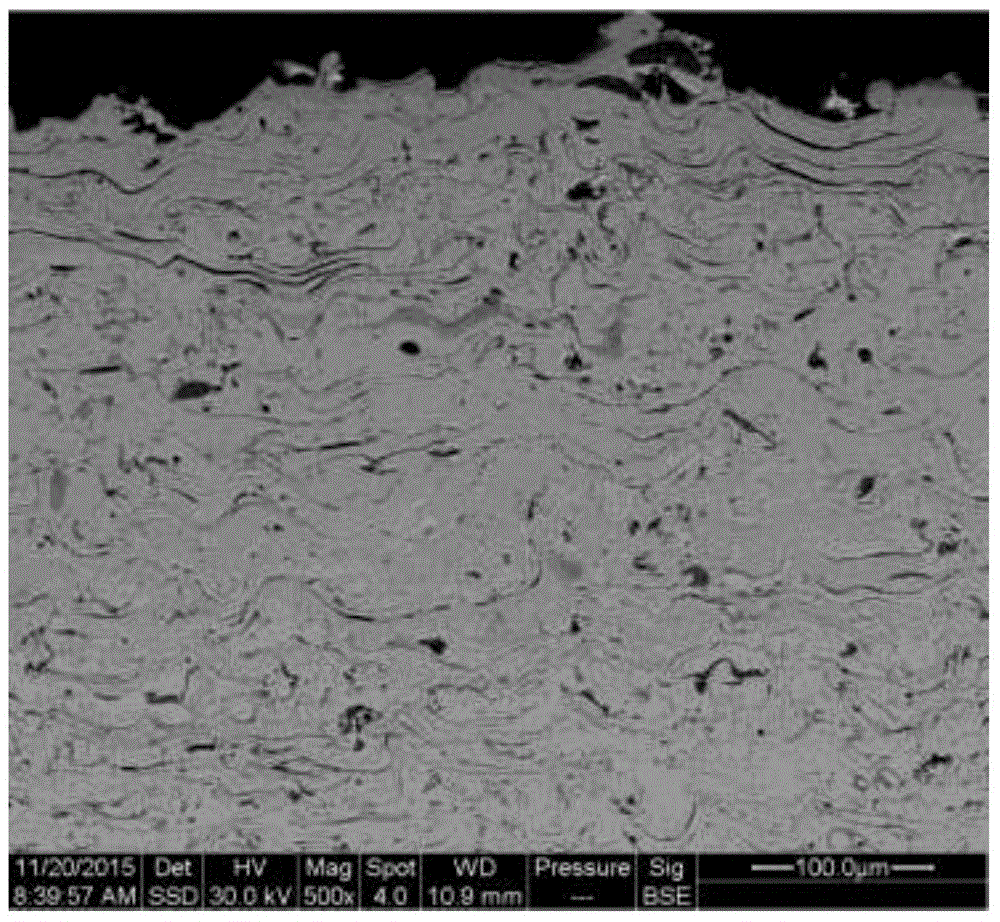

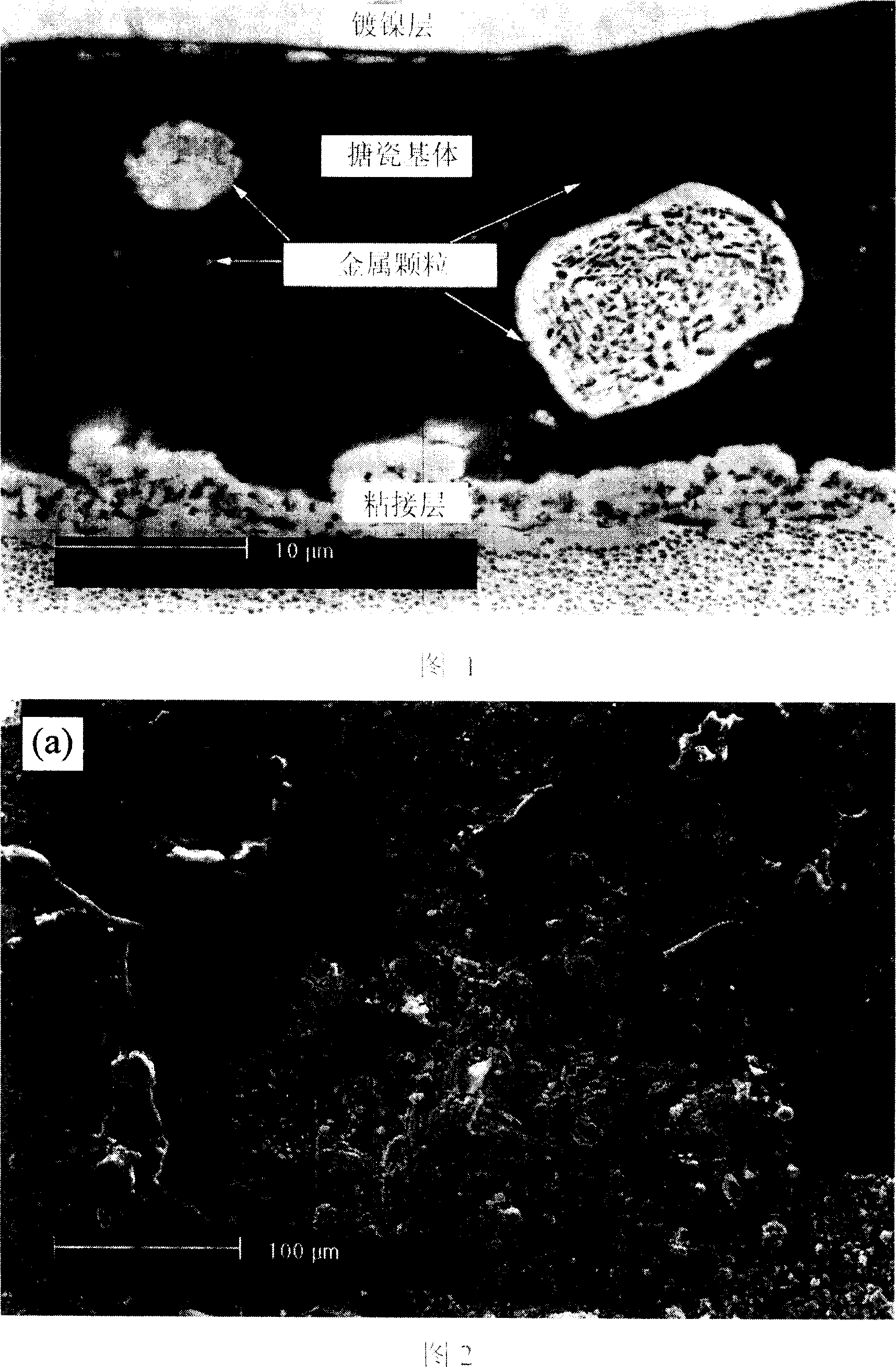

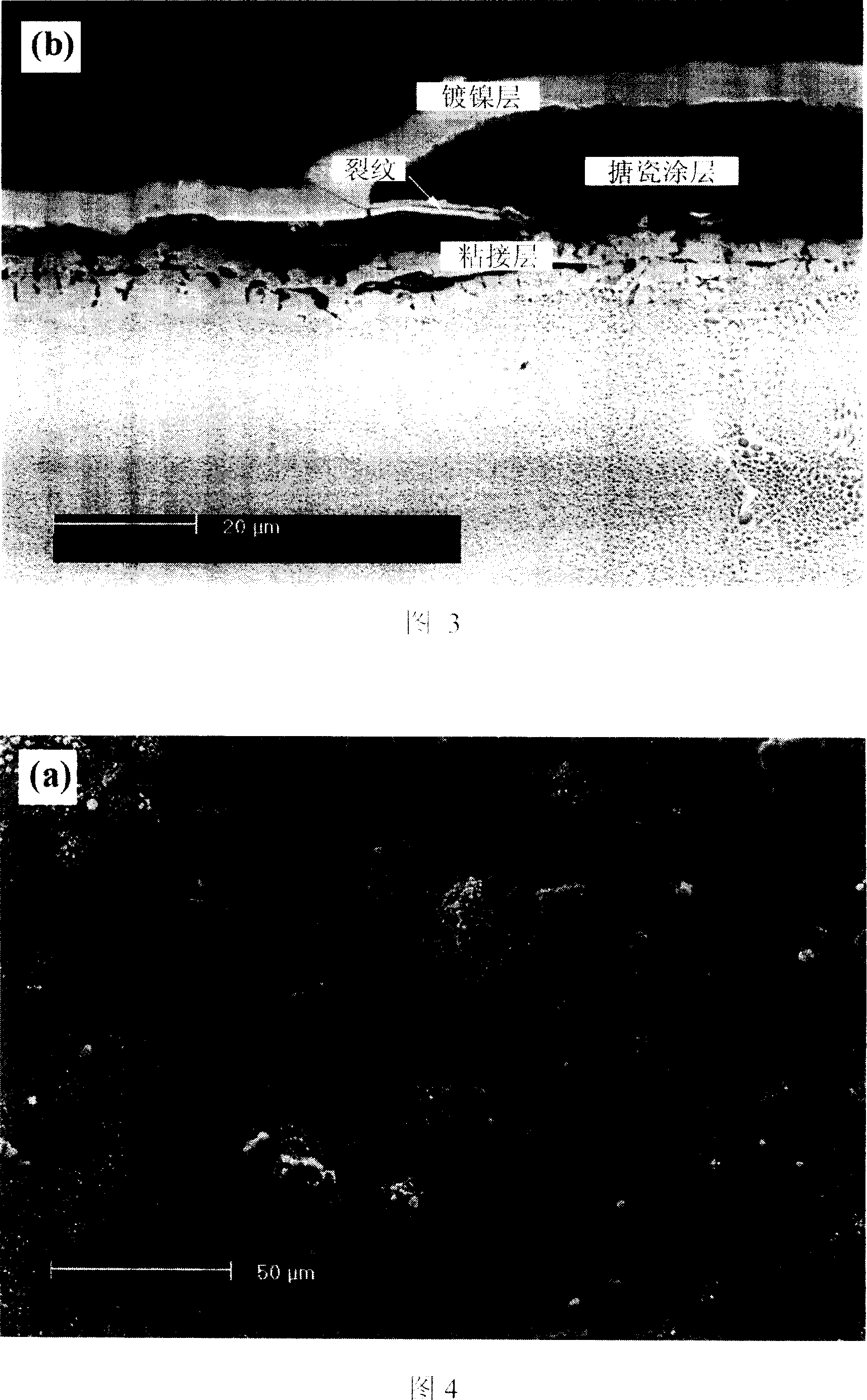

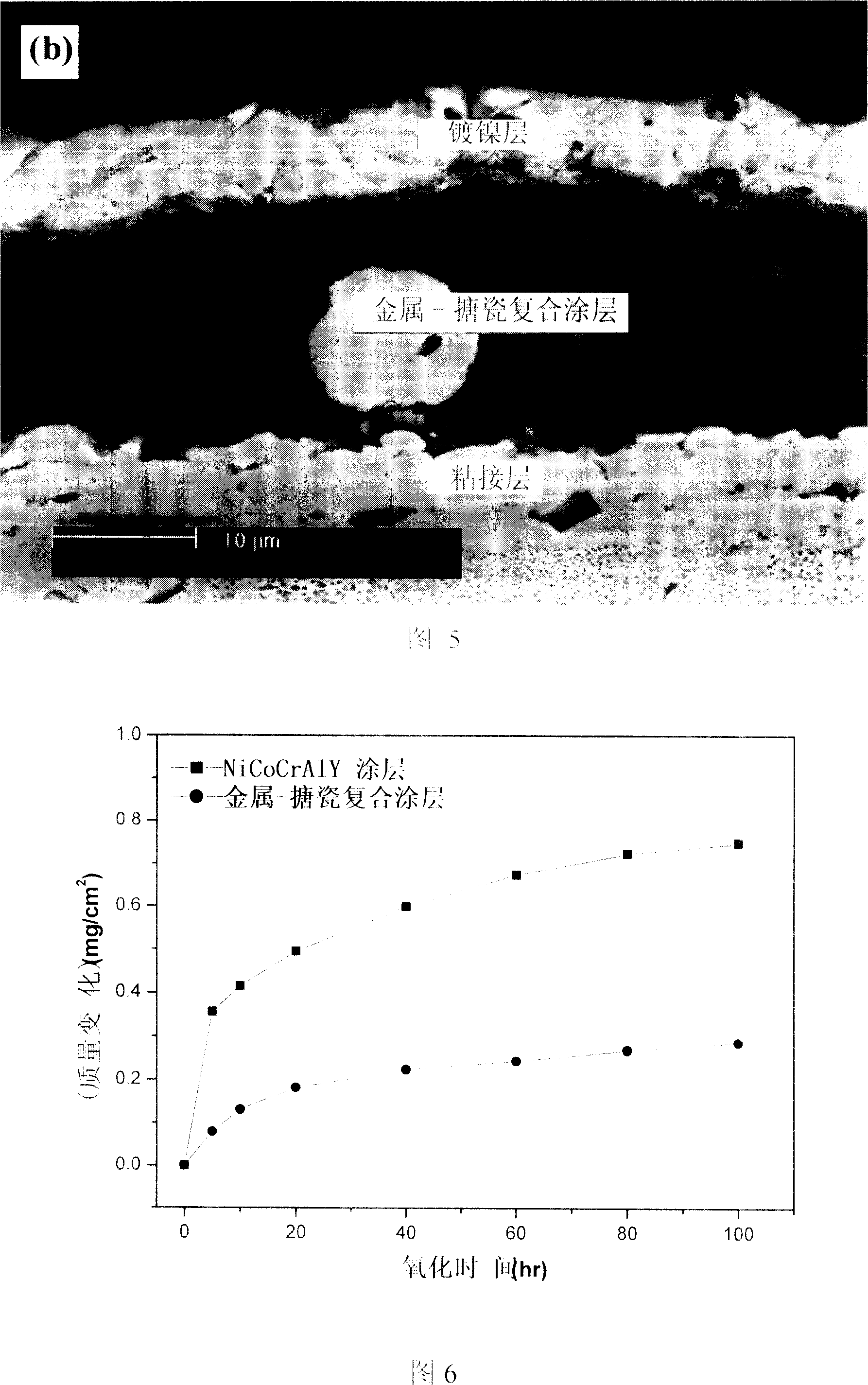

InactiveCN101109086AImprove thermal shock resistanceImprove thermal shock performanceThermal expansionSuperalloy

A protection coating for a hi-temp alloy is characterized in that, the coating is a compound coating of metal and enamel formed by spreading some metallic powder on an enamel substrate. Wherein, the metallic powder is MCrAlY powder of high thermal expansion rate coefficient and good resistance to hi-temp corrosion, M is one from Ni, Co, NiCo or any combination of them. Way for preparing the protection coating for hi-temp alloy is: first of all the metallic powder is fully mixed with the enamel powder, then the mixed powder is sprayed on the surface of a specimen, still then a metal-enamel compound coating spread on the enamel substrate is formed by high temperature sintering. The metal-enamel compound coating prepared by the invention is not only furnished with excellent resistance to hi-temp corrosion, but also highly improved thermal expansion rate coefficient because of the addition of plastic metallic powder, and greatly improved thermal vibration property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-temp alloy of resisting high-temp oxygenation and resisting high-temp corrosion

InactiveCN1775984AExcellent oxidation and corrosion speed in static engineeringImprove high temperature strengthChemical compositionSuperalloy

The invention discloses high temperature alloy that is anti high temperature oxidation and high temperature corrosion. It contains the chemical constituents of C less than 0.08%, Si less than 0.8%, Mn less than 0.8%, Ni 40-50%, Cr 14-20%, Al 13.8-7.5%, Y less than 0.3% and the rest is Fe. The highest usable temperature of the alloy is 1350 degree centigrade, and it has wonderful anti high temperature oxidation capability and high temperature corrosion capability. Moreover, it could take cool or heat modification process.

Owner:CHONGQING MATERIALS RES INST

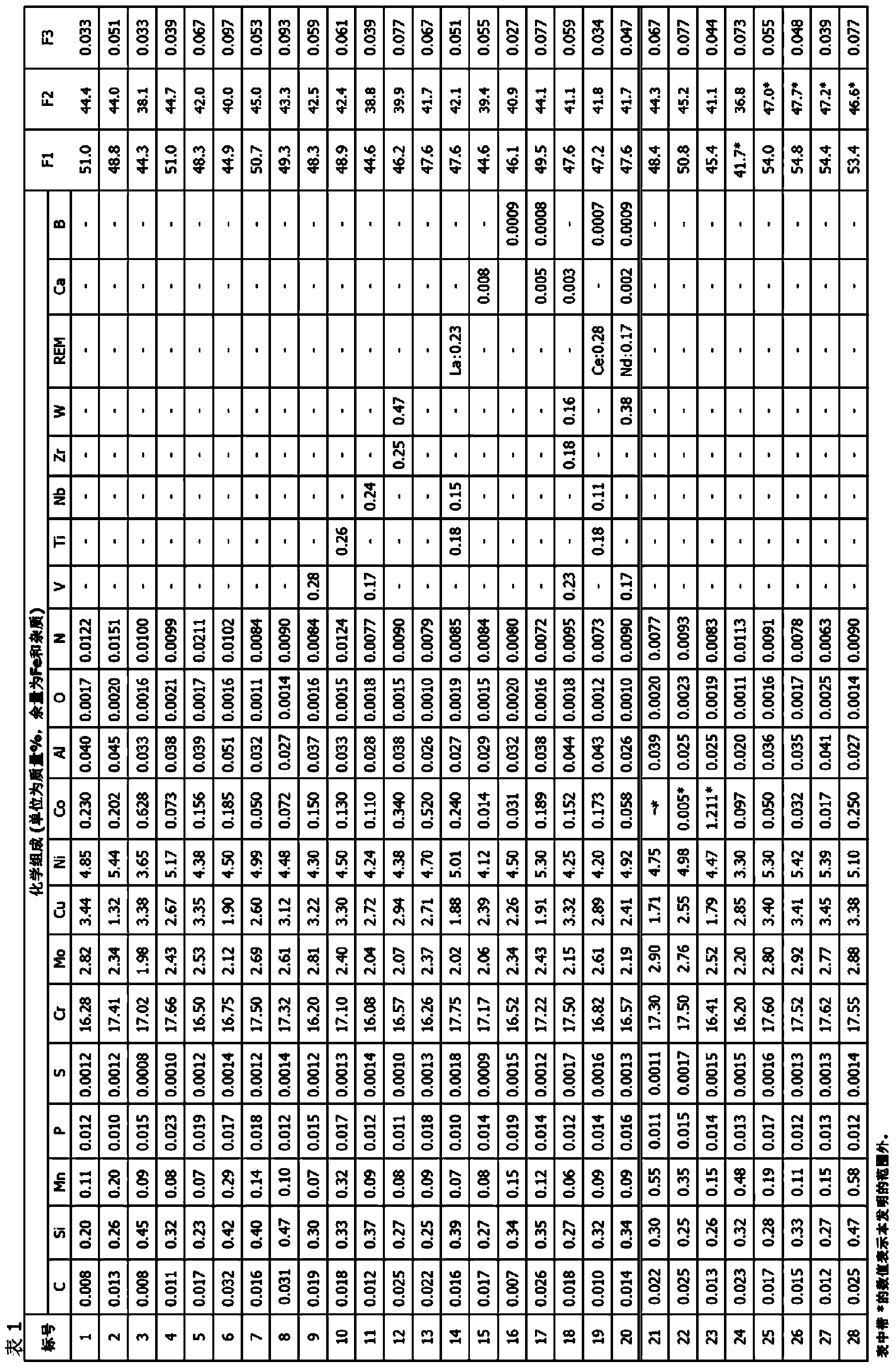

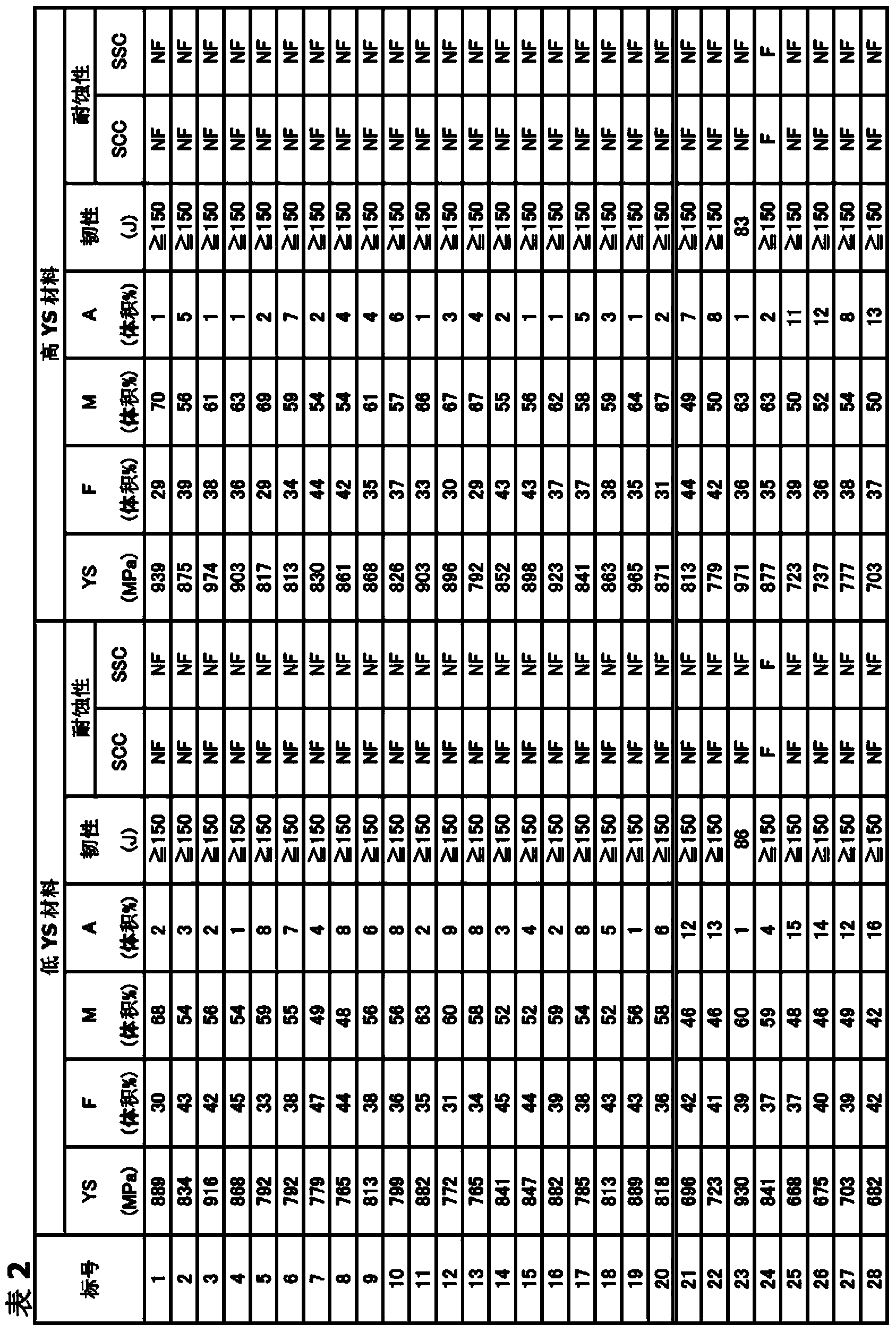

Stainless steel for oil wells and stainless steel pipe for oil wells

InactiveCN104204253AHigh strengthExcellent high temperature corrosion resistanceDrilling rodsFurnace typesOil wellCorrosion

Provided is stainless steel for oil wells, which has excellent corrosion resistance at high temperatures and is capable of stably achieving a strength of 758 MPa or more. This stainless steel for oil wells contains, in mass%, 0.05% or less of C, less than 1.0% of Si, 0.01-1.0% of Mn, 0.05% or less of P, 0.002% or less of S, 16-18% of Cr, 1.8-3% of Mo, 1.0-3.5% of Cu, 3.0-5.5% of Ni, 0.01-1.0% of Co, 0.001-0.1% of Al, 0.05% or less of O and 0.05% or less of N, with the balance made up of Fe and impurities. This stainless steel for oil wells satisfies the following formula (1) and formula (2). Cr + 4Ni + 3Mo + 2Cu >= 44 (1) Cr + 3Ni + 4Mo + 2Cu / 3 <= 46 (2) In this connection, the contents (mass%) of corresponding elements are assigned to respective symbols of elements in formula (1) and formula (2).

Owner:NIPPON STEEL CORP

Heat-resistant steel used for ethylene cracking furnace tube material, and preparation method for ethylene cracking furnace tube

InactiveCN103469096AExcellent high temperature mechanical propertiesImprove mechanical propertiesThermal non-catalytic crackingChemical compositionRare earth

The invention discloses heat-resistant steel used for an ethylene cracking furnace tube material, and a preparation method for an ethylene cracking furnace tube. The heat-resistant steel comprises the following components by weight: 0.5-1.5% of C, 0.5-1.5% of, 0.5-1.5% of Mn, 30-35% of Cr, 15-20% of Ni, 0.1-0.5% of Nb, 0.05-0.1% of rare earth Ce, smaller than or equal to 0.03% of S, smaller than or equal to 0.03% of P, and the balance being Fe. By changing chemical components, the ethylene cracking furnace tube with the outer layer being austenite and a small amount of Cr7C3 type carbide and the inner layer being Cr7C3 type carbide and a trace of the austenite can be prepared by using a centrifugal casting method accompanied by a certain heat treatment process.

Owner:XI AN JIAOTONG UNIV

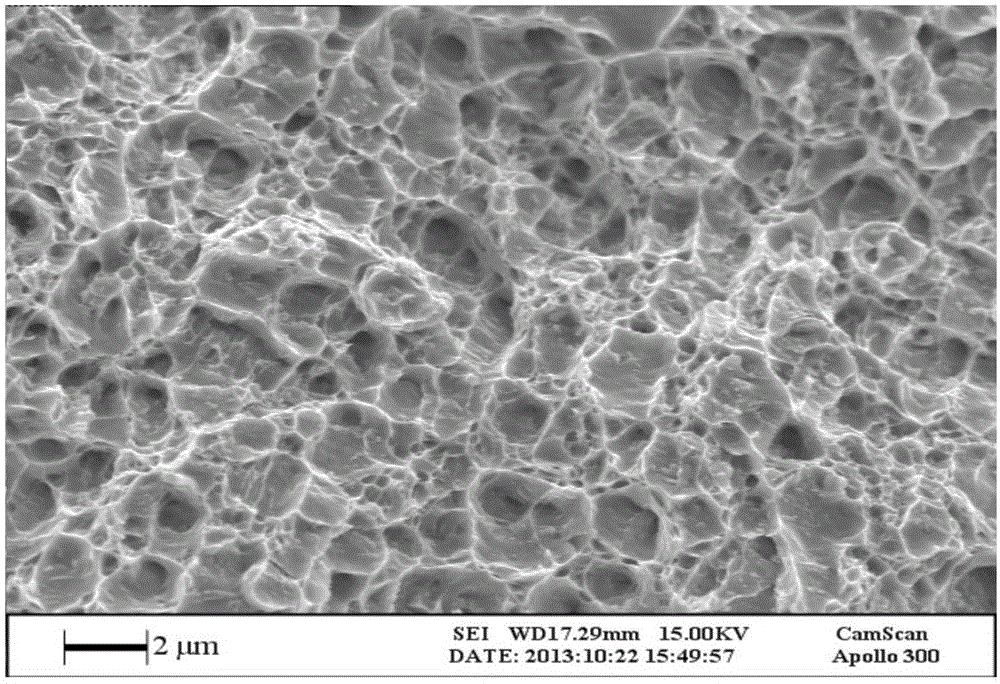

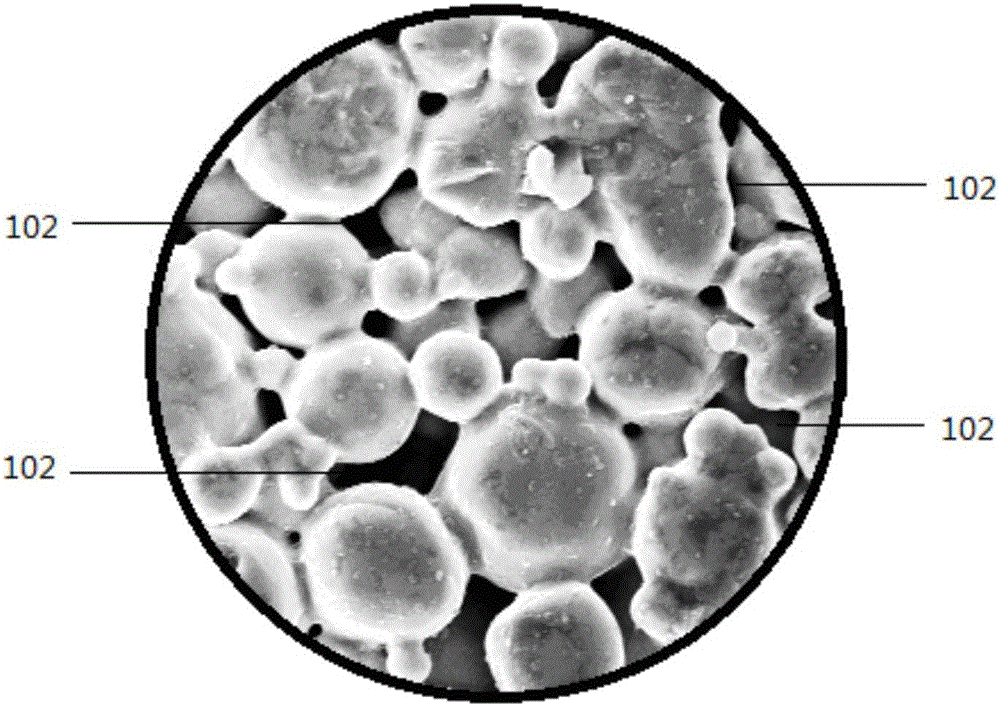

Iron-chromium-aluminum-based porous metal material and preparation method thereof

InactiveCN104630635AExtended service lifeImprove heat transfer performanceCompression moldingIron powder

The invention relates to an iron-chromium-aluminum-based porous metal material and a preparation method thereof. The material comprises through-holes having a pore size of 500nm-40um. The iron-chromium-aluminum-based porous metal material is prepared from the following raw materials: aluminum powder, chromium powder, iron powder, silicon carbide and rare earths. The preparation method of the iron-chromium-aluminum-based porous metal material comprises the following steps: firstly, carrying out vacuum sintering silicon carbide powder, rare earth and iron powder to obtain iron-silicon carbide sintering blocks containing rare earth, smelting the iron-silicon carbide sintering blocks, aluminum ingots, chromium powder and balance iron powder together under the protection of argon to obtain iron-chromium-aluminum-based alloy ingots, crushing the alloy ingots, carrying out vacuum ball milling to obtain alloy powder and finally uniformly mixing alloy powder, a pore-forming agent and a binder, carrying out compression molding and sintering to obtain the iron-chromium-aluminum-based porous metal material. The material has the advantages of long service life at high temperature and the like and furthermore, the large-scale industrialization can be achieved by the preparation method.

Owner:北京绿洁美科技有限公司

High-use-temperature, high strength, anti high temperature oxidation and high-temperature corrosion-deformation resistance high-temperature alloy

InactiveCN1851028AGood high temperature oxidation resistanceHigh temperature strengthChemical compositionOxidation resistant

The invention discloses the high temperature alloy resisting high temperature oxidation and resisting high temperature corrupt, the weight percent of the chemical element: C<=0.08%, Si<=0.8%, Mn<=0.8%, Ni 40-50%, Cr 14-20%, Al 3.8-7.5%, Y<=0.3%, the remaining is Fe. The highest using temperature of the alloy can reached to the 1350 degree, the alloy has many merits such as the excellent high temperature resisting the oxidation ability, the high temperature resisting the causticity, the higher temperature intension, the realization of producing the high temperature of the alloy material by the cool, hot distortional process. So it can be applied in the producing of the high temperature model, the high temperature clamp, the thermocouple protecting pipe resisting the high temperature oxidation and resisting the high temperature corrupt, the shortcoming of the coating on the corundum, the double silicon molybdenum pipe and the surface of the high temperature alloy can be conquered, it solves the problem of using the thermocouple protecting pipe under the temperature 1200-1350 degree.

Owner:CHONGQING MATERIALS RES INST

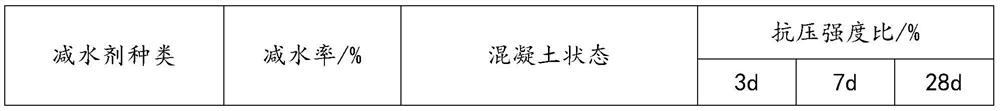

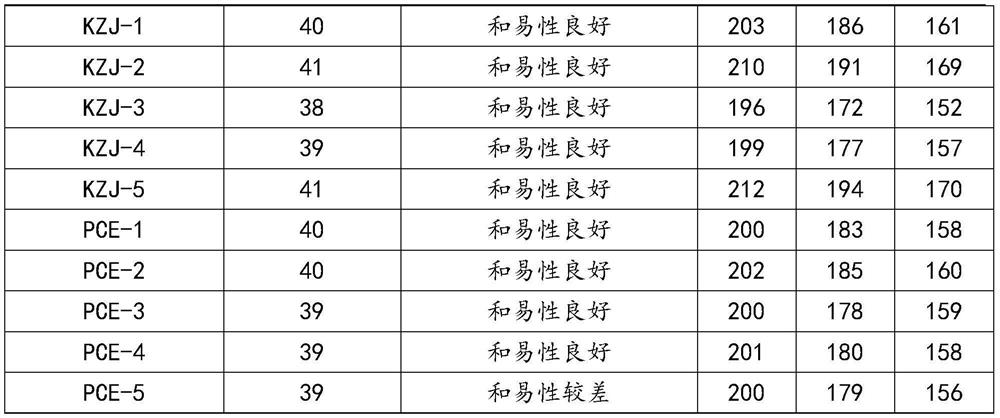

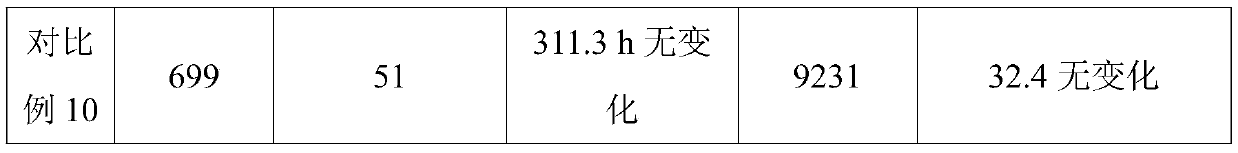

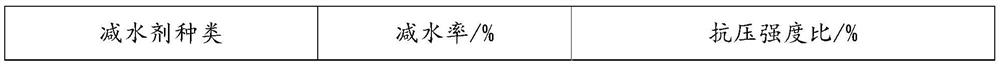

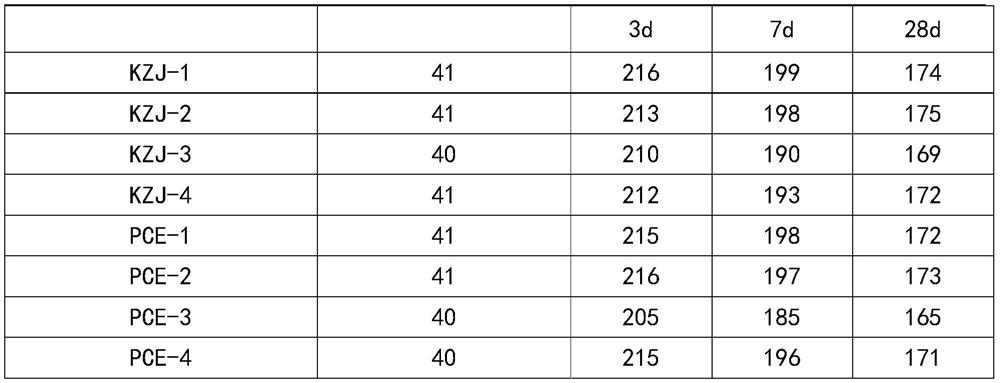

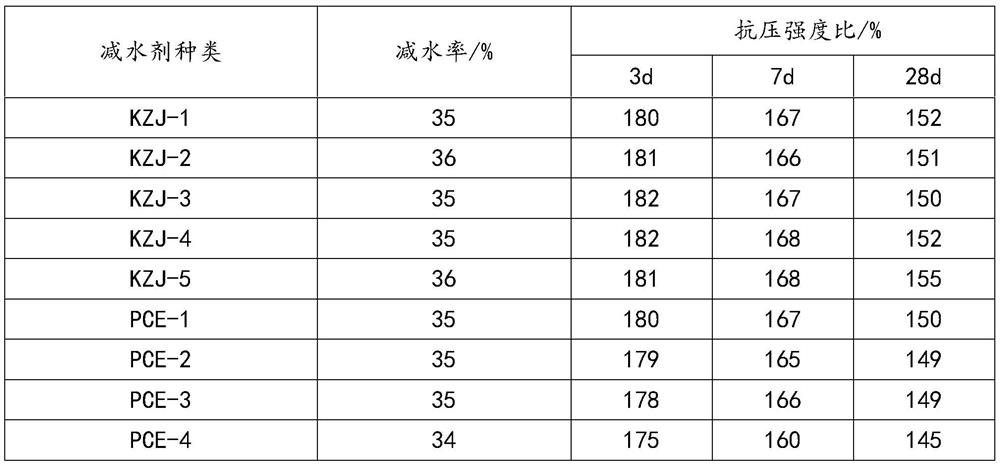

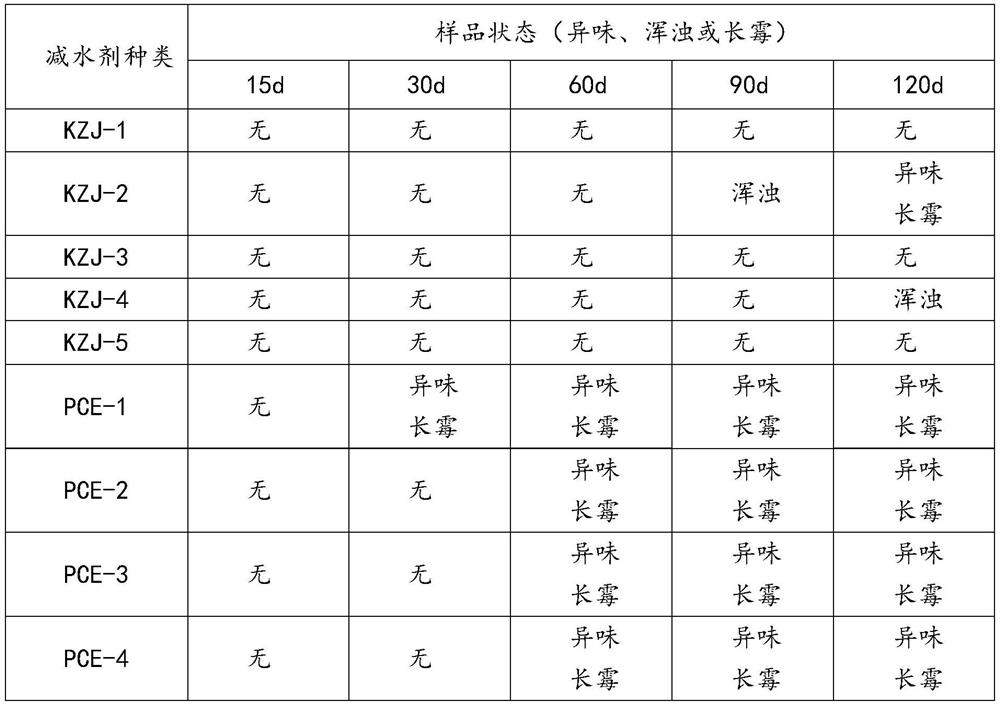

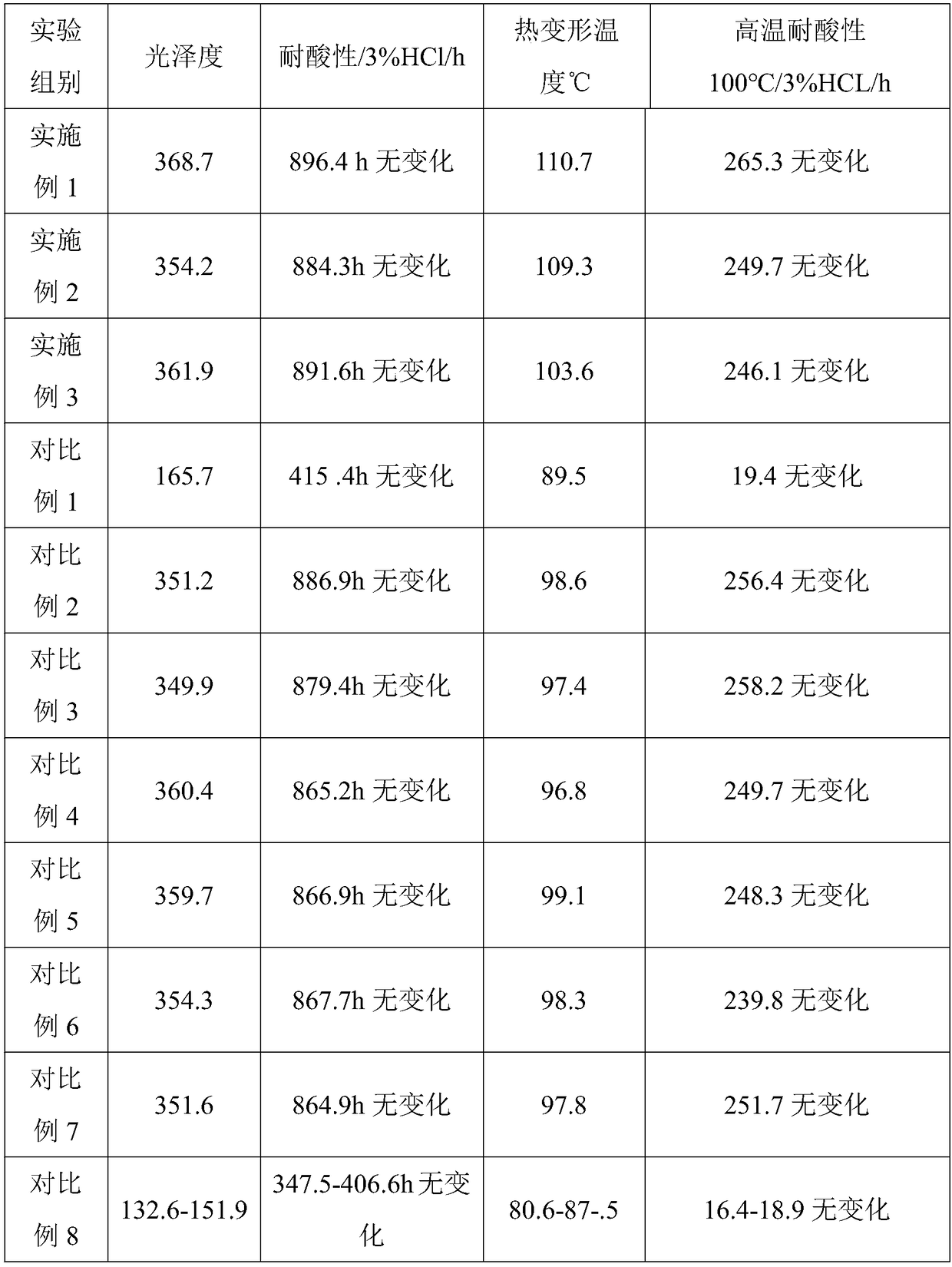

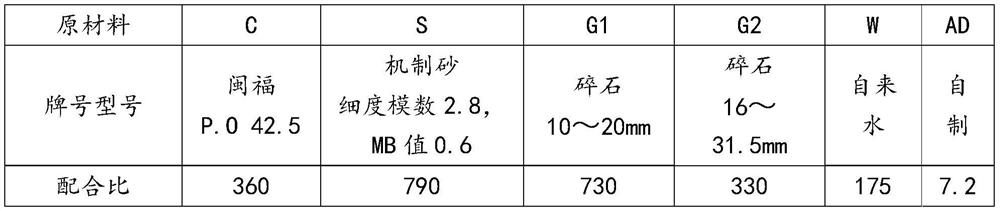

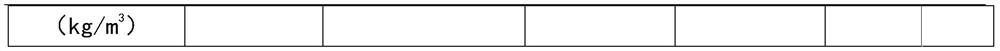

Ether anticorrosive polycarboxylate superplasticizer and preparation method thereof

ActiveCN112708058AExcellent high temperature corrosion resistanceMeet application requirementsPolymer scienceSuperplasticizer

The invention relates to the technical field of building materials, in particular to an ether anticorrosive polycarboxylate superplasticizer and a preparation method thereof. The ether anticorrosive polycarboxylate superplasticizer is prepared by carrying out polymerization reaction on an anticorrosive functional small monomer, an unsaturated ether macromonomer, unsaturated carboxylic acid and / or unsaturated carboxylic acid anhydride and a workability modified small monomer under the action of an initiator and a molecular weight regulator to generate the ether anticorrosive polycarboxylate superplasticizer of which the molecular main chain is linked with the anticorrosive functional small monomer. According to the ether anticorrosive polycarboxylate superplasticizer provided by the invention, the product is an ether superplasticizer with an anticorrosive effect, the anticorrosive and water-reducing effects are excellent, and the obtained ether anticorrosive polycarboxylate superplasticizer product is of a stable macromolecular structure, can tolerate a high temperature of 50 DEG C or more, is more excellent in high-temperature corrosion resistance, and is wide in raw material source. The price is low, the preparation process is simple, and the important practical application value is realized.

Owner:KZJ NEW MATERIALS GROUP CO LTD +2

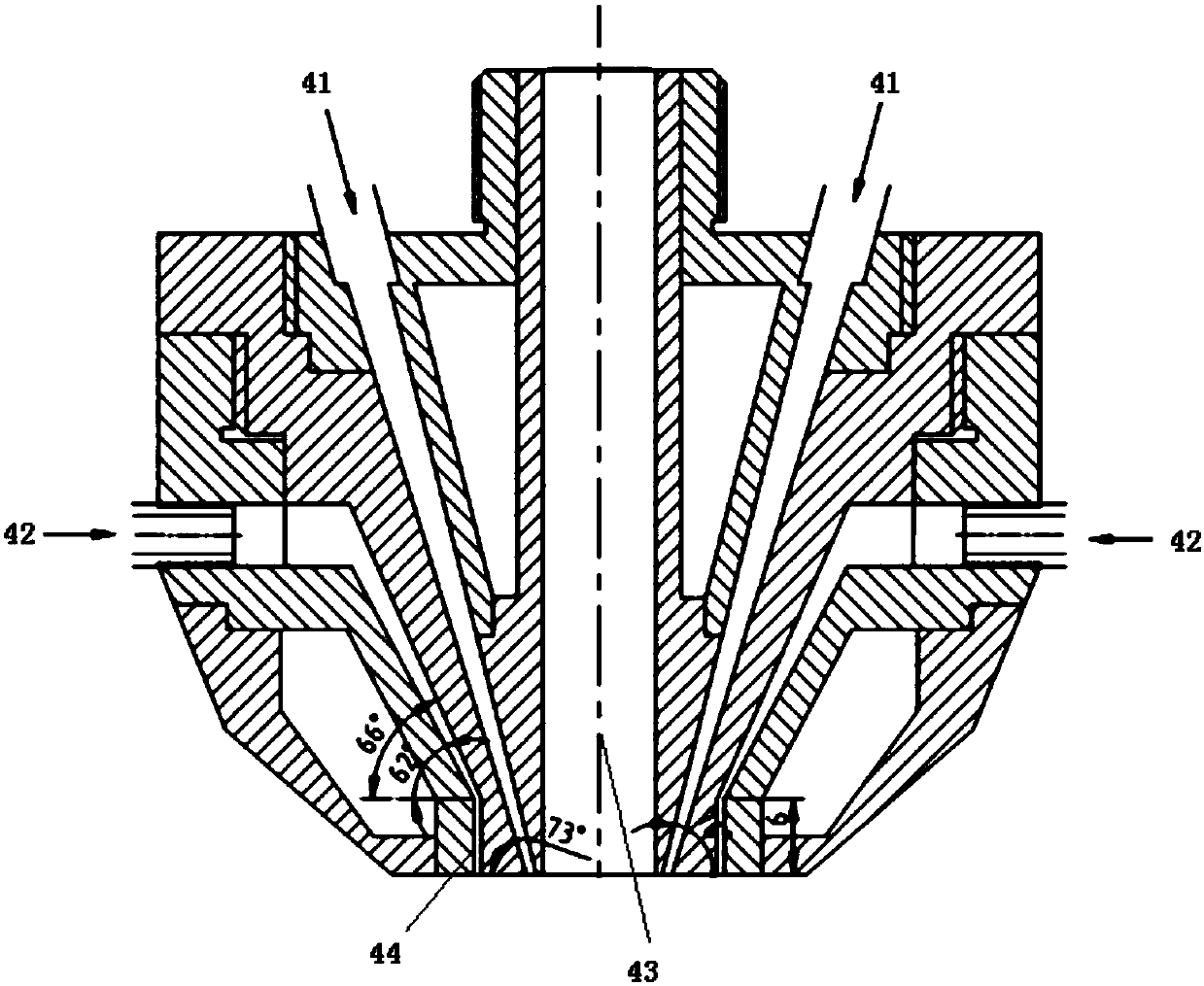

Centrifugation device high-temperature alloy used for glass wool production

The invention discloses centrifugation device high-temperature alloy used for glass wool production. The alloy comprises the following chemical components according to the weight percent: 0.65% to 0.75% of C, 28.5% to 30.5% of Cr, 4.0% to 6.5% of Co, 4.5% to 6.0% of W, 3.0% to 5.0% of Mo, 4.8% to 5.9% of Al, 2.0% to 3.0% of Ti, 0.01% to 0.05% of Ce, 0.01% to 0.05% of B and the balance of Ni. Because of unique formulation, the alloy obtains excellent high-temperature mechanical property, high-temperature corrosion-resisting property and high-temperature oxidation resistance property under the composite action of technical means of solid solution strengthening, precipitation strengthening, crystal boundary strengthening, and the like, and the service life is obviously enhanced.

Owner:WUXI YITONG MECHANICAL TECH

Composite protection process for fire grate segment based on plasma surfacing and laser cladding technologies

ActiveCN112518092AExtend working lifeReduce consumptionMolten spray coatingIncreasing energy efficiencyChromium nickelAlloy

The invention discloses a composite protection process for a fire grate segment based on plasma surfacing and laser cladding technologies. The fire grate segment is divided into a drying section, a combustion section and a burnout section, the drying section and the burnout section are sprayed with high-chromium nickel-based self-fluxing alloy to form a protection layer, and the combustion sectionadopts nickel-based alloy and metal ceramic NiCr-Cr2C3 to be sprayed to form double protective layers. According to the composite protection process, for different working intervals of the fire gratesegment, a comprehensive protection technology, corresponding to the actual working conditions of all the segments, for the surface of the fire grate segment is formulated instead of only adopting the same method for protection, and on the premise that the protection effect and the service life are guaranteed, the energy and materials are saved, and the production cost of enterprises is reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

High-temperature-resistant low-carbon steel material and preparation method thereof

InactiveCN103667917AExcellent high temperature corrosion resistanceGood toughness and plasticityScrapAluminium

The invention relates to a high-temperature-resistant low-carbon steel material which contains the following chemical components in percentage by mass: 0.1-0.25% of carbon, 4.0-4.5% of zinc, 1.3-1.5% of aluminum, 2.6-2.9% of copper, 3.0-3.2% of magnesium, 0.6-0.8% of Si, 6.3-6.5% of Mn, 0.005-0.008% of B, 0.03-0.05% of Ti, at most 0.030% of P, at most 0.030% of S and the balance of iron. By using the raw material combination of the aluminum, magnesium and the like, the proportion, production technique and feed sequence are reasonably arranged, so that the formed alloy material has the characteristics of excellent high-temperature corrosion resistance, no scale at high temperature, high ductility, high plasticity, high strength, high hardness, favorable abrasion resistance and the like. Part of scrap iron is used as the raw material, thereby enhancing the quality stability and uniformity of the alloy. The material is used in cast parts exposed in a high-temperature environment for a long time. The refining agent is added to lower the porosity by 1-2 degrees.

Owner:TONGLING ANDONG CAST STEEL

3D printing material used for pipes in hot casting process

InactiveCN107042302AImprove stabilityImprove high temperature strengthAdditive manufacturing apparatusFiberGlass fiber

The invention provides a 3D printing material for pipe fittings in a hot casting process. Zirconium dioxide: 12-21%, nickel-based alloy powder: 7-15%, auxiliary agent: 5-12%. The invention has excellent high-temperature strength, fatigue resistance, high-temperature corrosion resistance, high-temperature alloy structure stability and excellent temperature-bearing capacity, and has excellent mechanical strength and durability after being formed by 3D printing. Production of special pipe fittings.

Owner:张丹丹

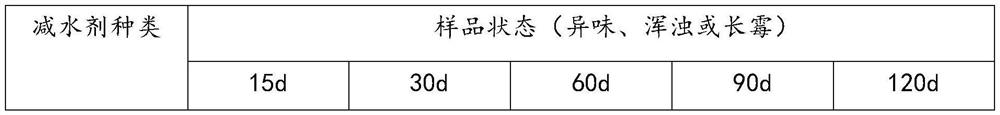

Stamping die surface phosphating processing method

InactiveCN110042376AExcellent high temperature corrosion resistanceGood adhesionMetallic material coating processesHigh-temperature corrosionHot Temperature

The invention discloses a stamping die surface phosphating processing method, and relates to the technical field of mold processing. The stamping die surface phosphating processing method includes thefollowing steps of polishing, heating, phosphating, twice soaking and twice drying processing and pressurizing processing. By means of the stamping die surface phosphating processing method, a uniform and compact phosphating film can be formed on the surface of a stamping die, the surface of the stamping die can be better protected, and the processed stamping die has excellent high-temperature corrosion-resistant performance.

Owner:长沙而道新能源科技有限公司

Novel anti-corrosion polycarboxylate superplasticizer and preparation method thereof

ActiveCN112708060AExcellent high temperature corrosion resistanceWide variety of sourcesGlycol synthesisSuperplasticizer

The invention relates to the technical field of building materials, in particular to a novel anti-corrosion polycarboxylate superplasticizer and a preparation method thereof. The novel anti-corrosion polycarboxylate superplasticizer is prepared by carrying out polymerization reaction on an anti-corrosion functional small monomer, an unsaturated macromonomer, unsaturated carboxylic acid and / or unsaturated carboxylic acid anhydride under the action of an initiator and a molecular weight regulator. The generated novel anti-corrosion polycarboxylate superplasticizer has a molecular main chain linked with an anti-corrosion functional small monomer. The unsaturated macromonomer is at least one of ethylene glycol monovinyl polyethylene glycol ether and 4-hydroxybutyl vinyl polyoxyethylene ether. The novel anti-corrosion polycarboxylate superplasticizer provided by the invention is an ether superplasticizer with an anti-corrosion effect, the anti-corrosion and water-reducing effects are excellent, the finally obtained novel anti-corrosion polycarboxylate superplasticizer product is of a stable macromolecular structure and can tolerate high temperature of 50 DEG C or more, the high-temperature anti-corrosion performance is more excellent, the preparation process is simple, and the cost is low. Important practical application values are realized.

Owner:KZJ NEW MATERIALS GROUP CO LTD +2

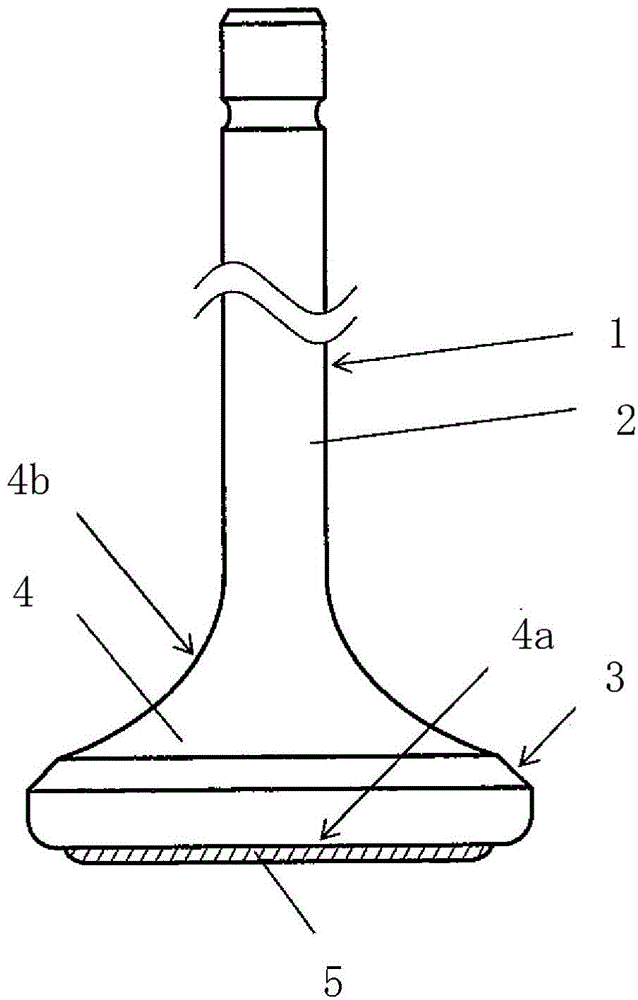

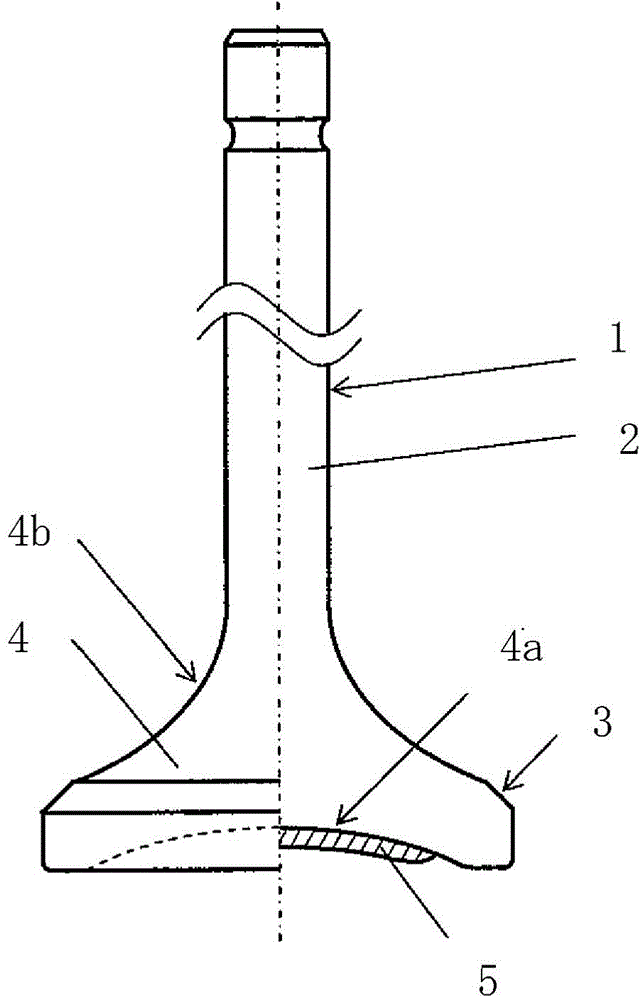

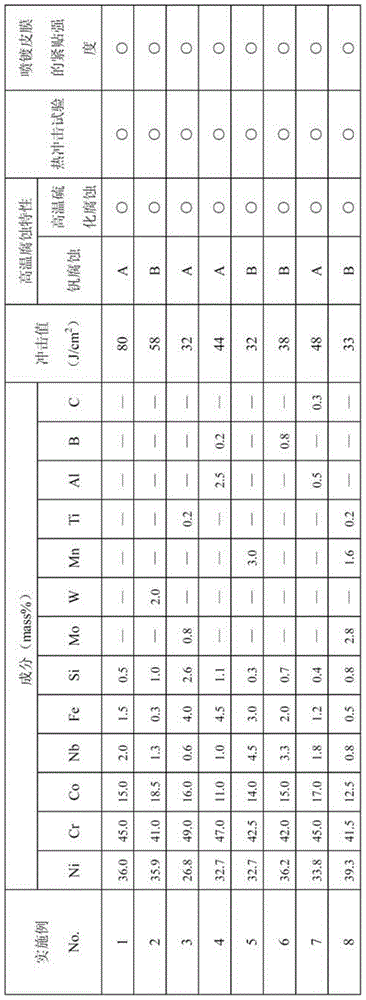

Ni-cr-co-based alloy having high-temperature corrosion resistance properties, and poppet valve having surface modified with same

ActiveCN104797728ASufficient thermal shock propertiesExcellent high temperature corrosion resistanceMachines/enginesLift valveCrack resistanceMetallurgy

Provided are: a surface-coating material having excellent cracking resistance and peeling resistance and also having excellent high-temperature corrosion resistance properties; and a poppet valve coated with the surface-coating material. A Ni-Cr-Co-based alloy according to the present invention comprises 40.0 to 50.0 mass% of Cr, 10.0 to 20.0 mass% of Co, 0.5 to 5.0 mass% of Nb, 0.01 to 5.0 mass% of Fe and 0.1 to 3.0 mass% of Si, with the remainder being 26.0 to 40.0 mass% of Ni and unavoidable impurities. The Ni-Cr-Co-based alloy may additionally comprise an element or elements respectively selected from Mo, W, Mn, Ti, Al, B and C in the total amount of 5.0 mass% or less, wherein the content of each of Ti and Al is 3.0 mass% or less and the content of each of B and C is 1.0 mass% or less. In the poppet valve according to the present invention, at least the front surface of a head part is coated with the Ni-Cr-Co-based alloy.

Owner:FUKUKA METAL FOIL & POWDER CO LTD +1

Ester anticorrosive polycarboxylate superplasticizer and preparation method thereof

ActiveCN112708061AThere is no problem of uneven distributionExcellent high temperature corrosion resistancePolymer scienceSuperplasticizer

Owner:KZJ NEW MATERIALS GROUP CO LTD +2

Modification method for aluminum proximate matter for building

The invention discloses a modification method for aluminum proximate matter for a building. The modification method comprises the steps that zinc powder, magnesium powder, ganister powder, iron blocks, rhenium ingots, titanium ingots, boron powder, copper blocks, indium ingots, chromium powder and cerium ingots are smelted to obtain alloy liquid, aluminum zirconium wrapped titanium dioxide and zirconium wrapped silicon dioxide mixed powder is added, then pouring into a die is carried out, and a casting is subject to heat treatment to obtain the aluminum proximate matter; a modifying agent is prepared and comprises the following raw materials including sodium fluoride, ammonium bifluoride, potassium permanganate, sodium dimethylnaphthalene sulfonate, polychlorinated polyethylene, potassiumchromate, zinc phosphate, sodium nitrate, praseodymium chloride, edetic acid, malic acid, sodium dodecyl benzene sulfonate, nickel sulfate, triethanolamine, zinc phosphate, magnesium oxide, nanometertitania, a silane coupling agent KH-570, chlorinated polypropylene and water; and then the modifying agent is used for enabling the aluminum proximate matter to be subject to two times of soaking andtwo times of drying to obtain the modified aluminum proximate matter. The aluminum proximate matter prepared through the method has the excellent high temperature corrosion resisting property.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

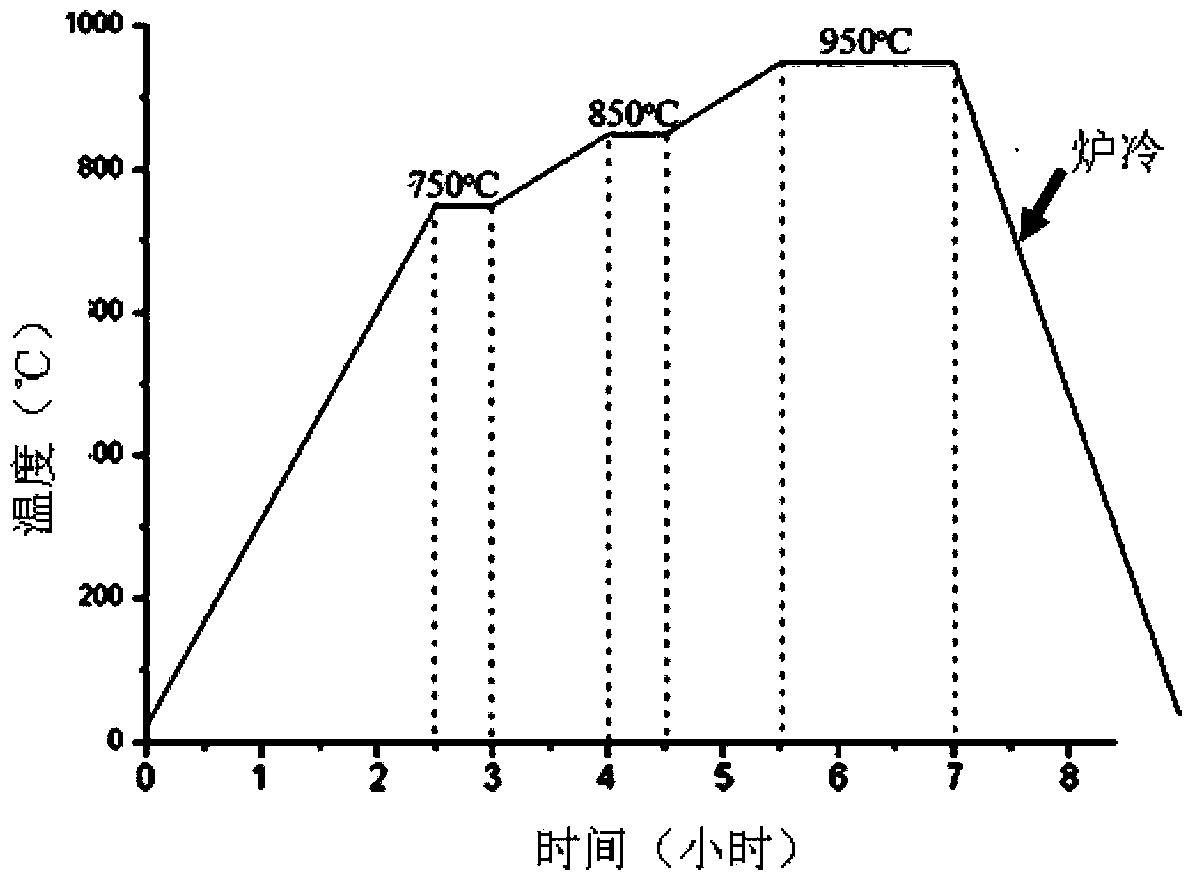

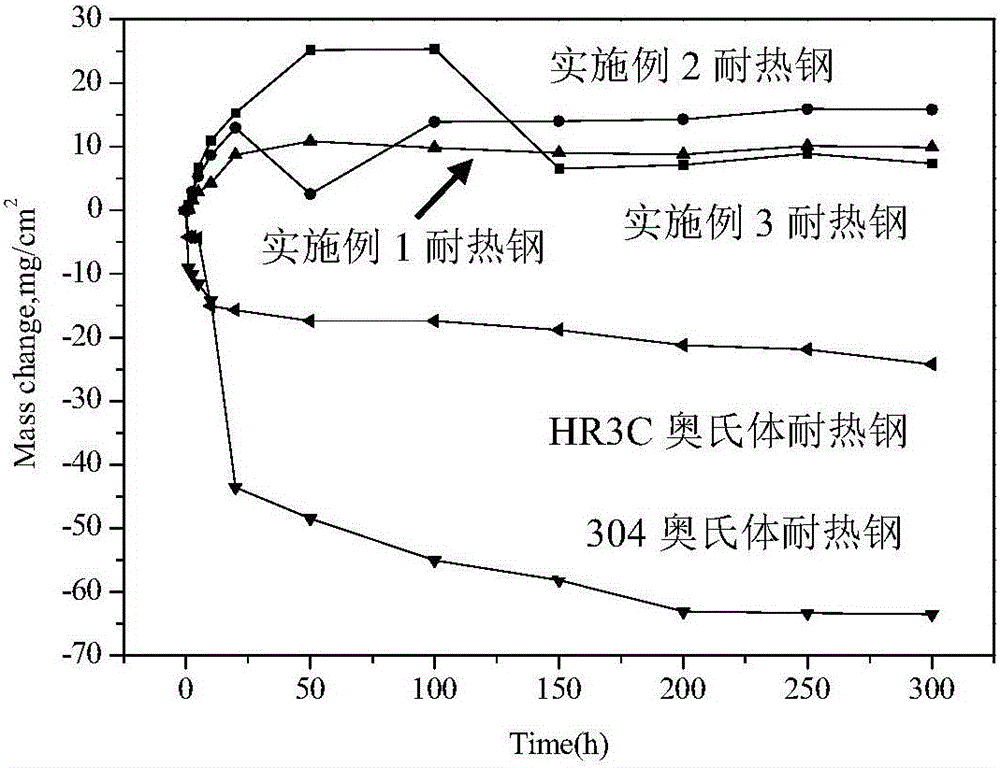

Ferritic heat-resistant steel used for coal-fired thermal power generation boiler piping and valve castings and preparation method thereof

ActiveCN105256247BImprove corrosion resistanceExcellent hot corrosion resistanceHeat resistanceRoom temperature

Owner:JIANGSU SHENGTAI VALVE CO LTD

Anticorrosive polycarboxylic acid slump retaining agent and preparation method thereof

ActiveCN112708059AExcellent high temperature corrosion resistanceWide variety of sourcesBuilding materialCorrosion prevention

The invention relates to the technical field of building materials, in particular to an anticorrosive polycarboxylic acid slump retaining agent and a preparation method thereof. The anticorrosive polycarboxylic acid slump retaining agent is prepared by carrying out polymerization reaction on an anti-corrosion functional small monomer, an unsaturated macromonomer, unsaturated carboxylic acid and / or unsaturated carboxylic acid anhydride and a slow-release slump retaining small monomer under the action of an initiator and a molecular weight regulator. The anticorrosive polycarboxylic acid slump retaining agent has a molecular main chain linked with a small monomer with an anticorrosion function. The anticorrosive polycarboxylic acid slump retaining agent product provided by the invention is a slump retaining agent with an anti-corrosion effect, has excellent anti-corrosion and slump retaining effects, has a stable macromolecular structure, can tolerate a high temperature of 50 DEG C or more. The high-temperature corrosion resistance is more excellent, the used raw materials are wide in source and low in price, the preparation process is simple, and important practical application value is achieved.

Owner:KZJ NEW MATERIALS GROUP CO LTD +2

Multipurpose low-conductivity ceramic/noble metal lamellar composite thermal barrier coating

InactiveCN102345122BImprove mechanical propertiesReduce thermal stressBlade accessoriesEfficient propulsion technologiesAviationThermal insulation

The invention discloses a multipurpose low-conductivity ceramic / noble metal lamellar composite thermal barrier coating, relating a composite material and coating technology. The coating is divided into four types: (1) regularly and alternatively depositing low-conductivity ceramic layers and noble metal layers; (2) irregularly and alternatively depositing low-conductivity ceramic layers and noble metal layers; (3) exerting low-conductivity ceramic and noble metal lamellar composite thermal barrier coatings on antioxidant protection layers deposited on the surface of a basic alloy; and (4) depositing other functional coatings on the outer surface of the low-conductivity ceramic / noble metal lamellar composite thermal barrier coating. According to the invention, the lamellar composite thermal barrier coating formed by alternatively depositing the low-conductivity ceramic layers and the noble metal layers has the advantages of excellent thermal insulation performance and thermal shock resistance, stable coating structure and long service life and can be applied to the high temperature protection of hot end components of refractory alloys or high temperature alloys such as an aircraft engine, a marine engine, a ground gas turbine, a rocket engine, and the like.

Owner:UNIV OF SCI & TECH BEIJING

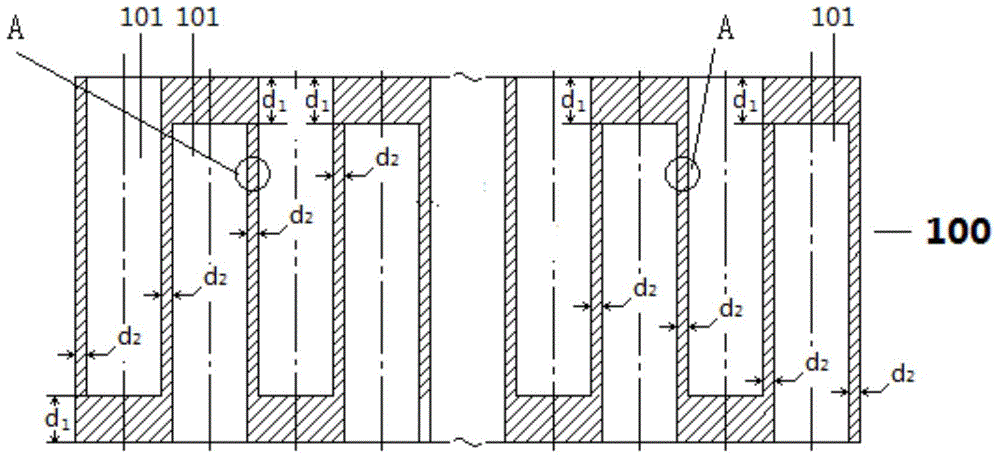

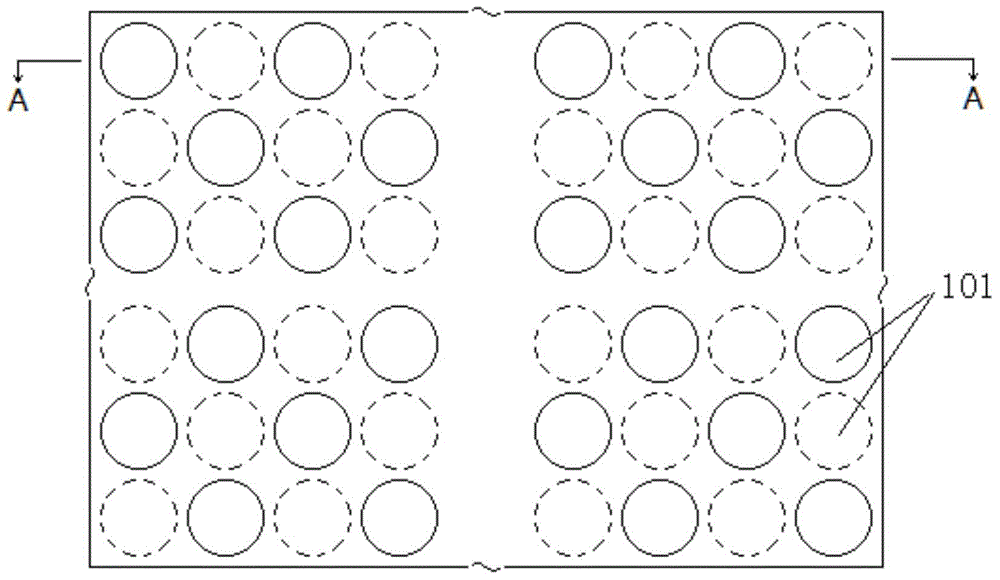

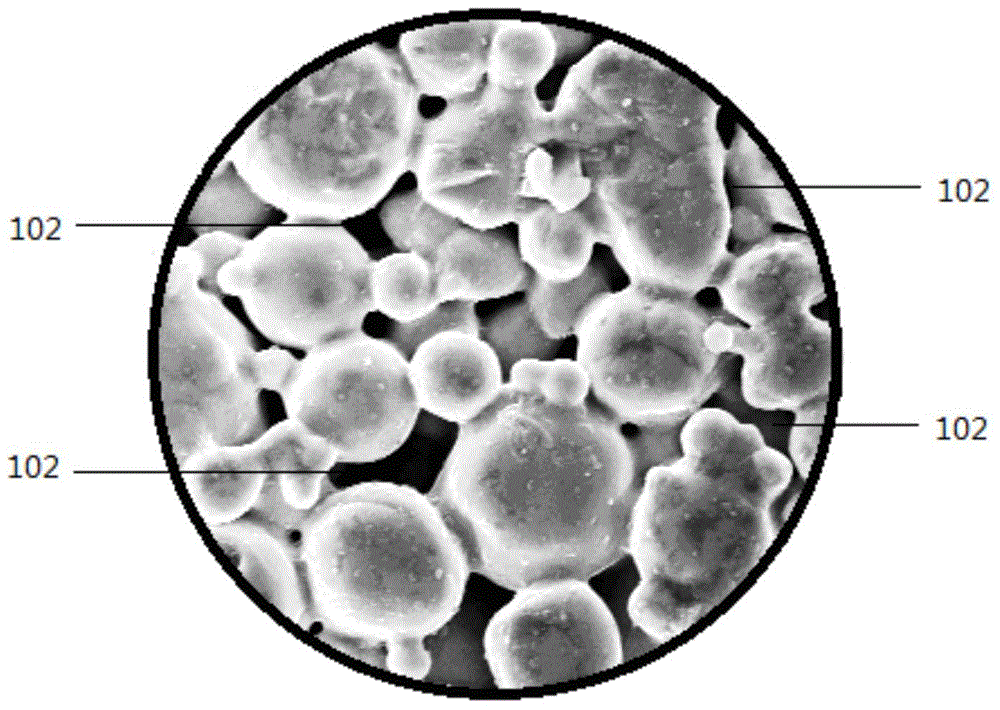

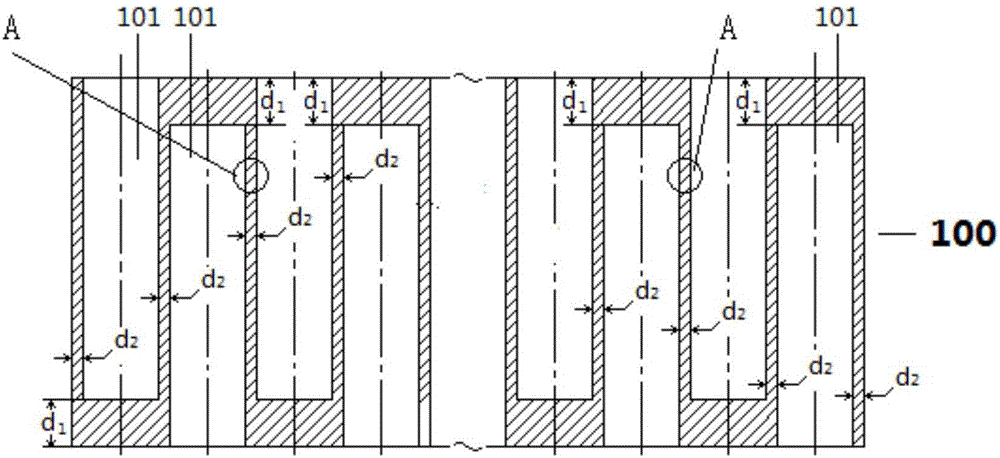

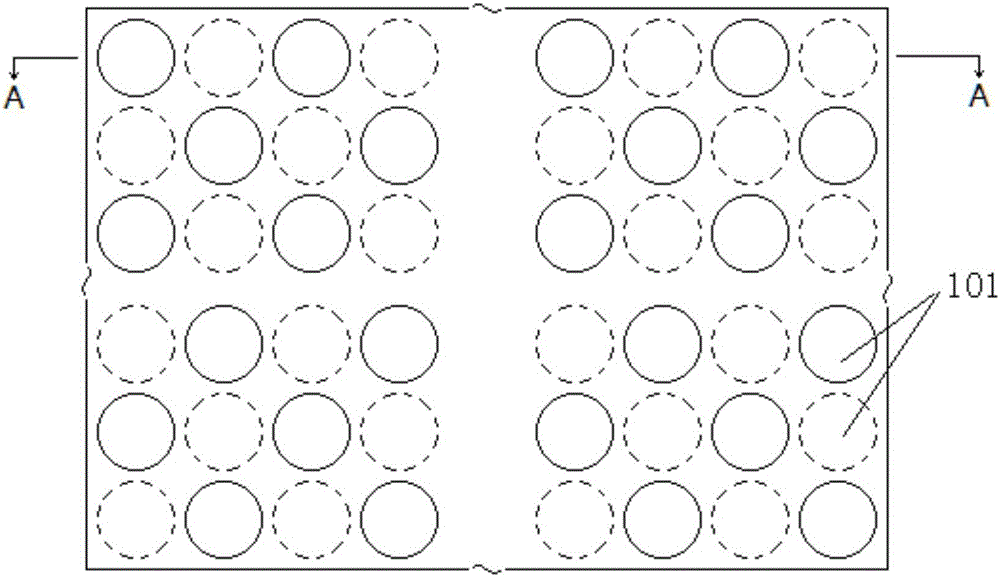

Porous alloy filter element used in high-temperature environment and preparation method of porous alloy filter element

The invention relates to a porous alloy filter element used in a high-temperature environment and a preparation method of the porous alloy filter element. The filter element comprises a plurality of parallel filter channels, wherein one end of each filter channel is closed, the other end of each filter channel is open, closed ends of two adjacent filter channels are opposite, and the filter element is made of an iron chromium aluminum based compound porous alloy material; the diameter of each filter channel ranges from phi 10 mm to phi 100 mm, micropores extending to the surface of the alloy material are distributed in the iron chromium aluminum based compound porous alloy material, and the diameter of each micropore ranges from 500 nm to 40 mu m. The preparation method comprises procedures of preparation of iron chromium aluminum based powder slurry, casting forming, thermal debinding, sintering and the like. The prepared filter element has a good filtering function on high-temperature dusty gas or high-temperature particle-contained fluids, has the advantages of excellent high-temperature strength, large filtering area, long service life in the high-temperature environment, reusability and the like and is suitable for industrial application.

Owner:荣仕国际投资(北京)有限公司

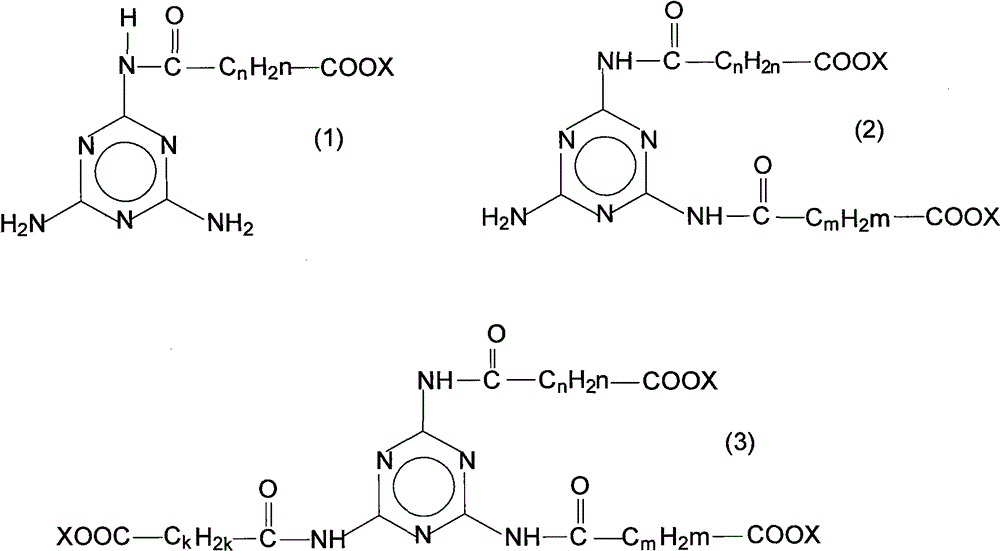

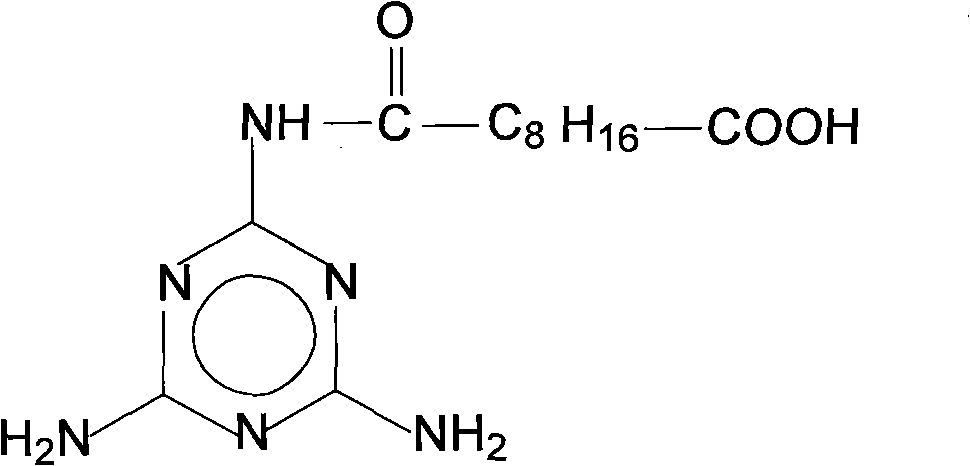

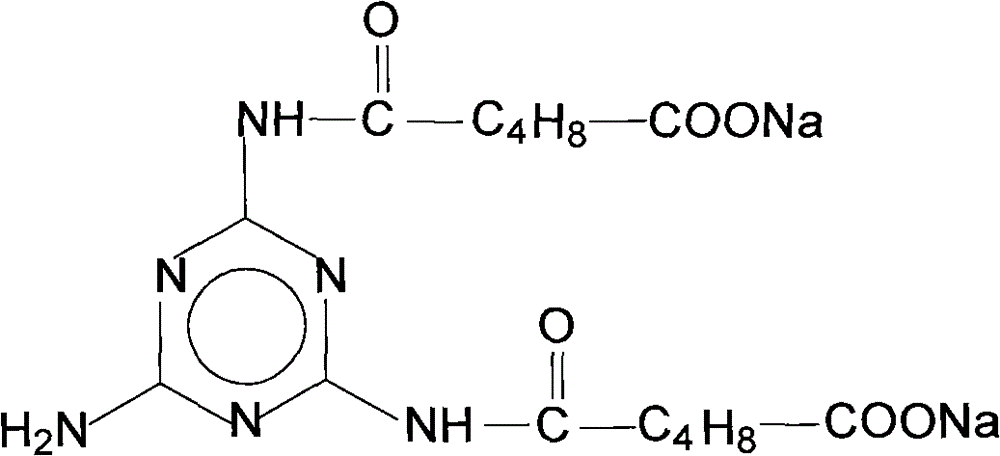

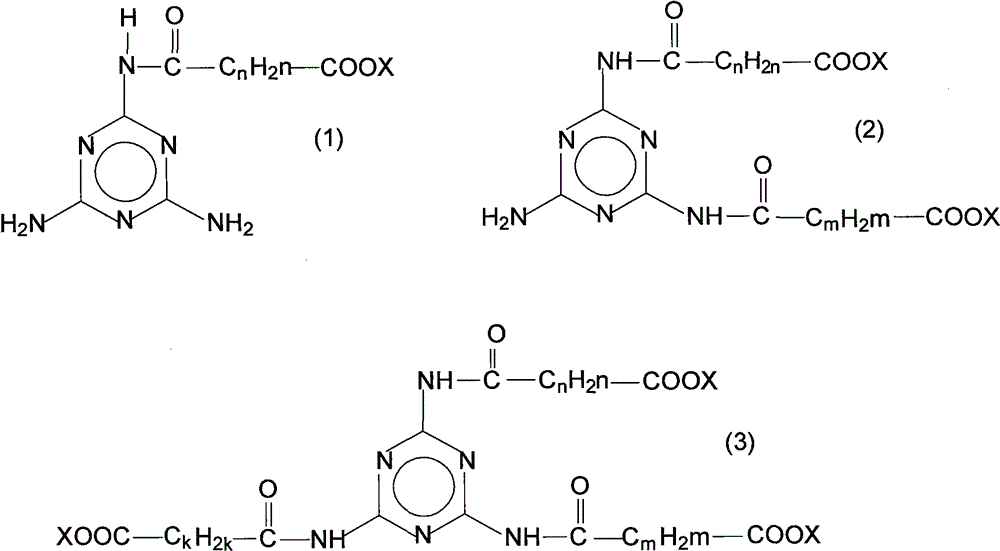

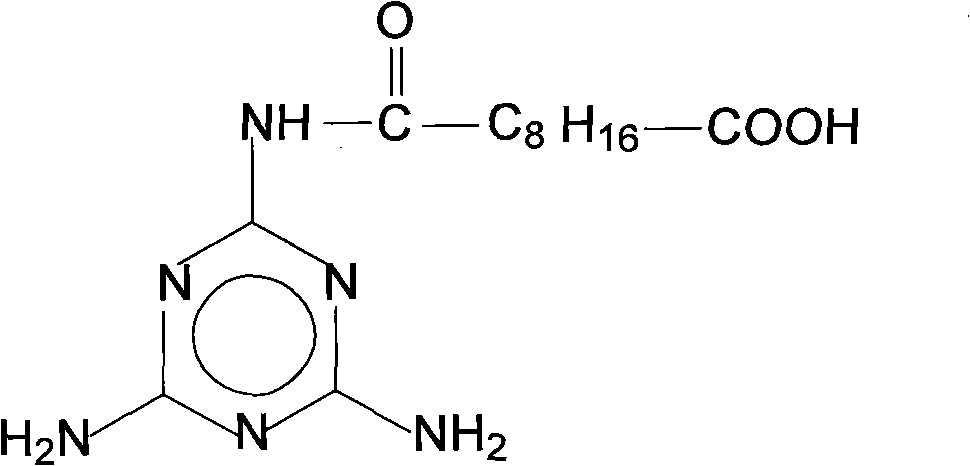

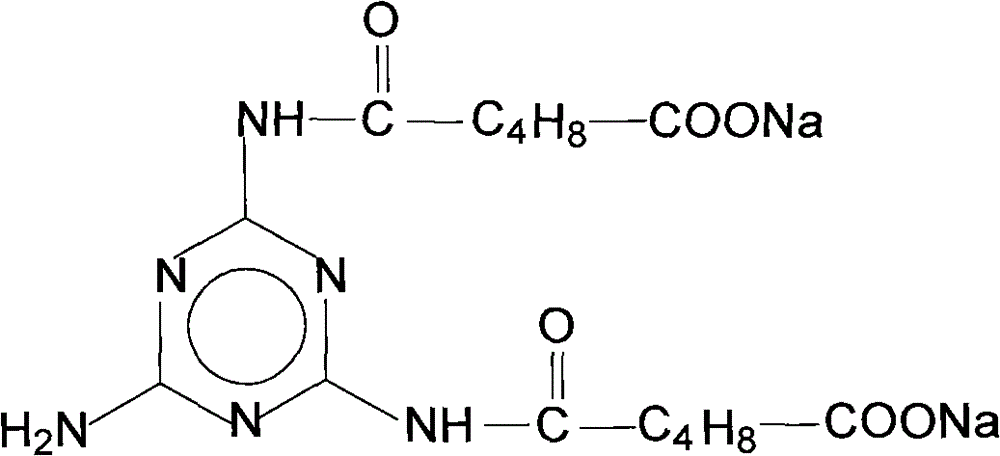

Non-aqueous coolant composition for engine

ActiveCN103059820AExcellent high temperature corrosion resistanceGood corrosion inhibition effectHeat-exchange elementsPhosphateFatty acid

The invention relates to a non-aqueous coolant composition for an engine, which comprises a propylene glycol basic solution and a composite corrosion inhibitor, the composite corrosion inhibitor comprises acylates of tripolycyanamide and poly fatty acid and water soluble salt, hydroxy aromatic acid and its water soluble salt, and also comprises other types of corrosion inhibitors, such as fatty acid and its water soluble salt, molybdate, silicate and a silicate stabilizer. The composition takes propylene glycol as the basic solution, the toxicity is low, the toxic and harmful addictives on human body and environment such as nitrite, nitrate, alcohol amine, phosphate and borate are not contained, the non-aqueous coolant composition is an environment-friendly product, the high temperature corrosion resistance performance is excellent, the low temperature cooling performance and high temperature boiling resistance performance are excellent, and the non-aqueous coolant composition is suitable for the engines with large power, heavy loading and high temperature working environment.

Owner:CHINA PETROLEUM & CHEM CORP +1

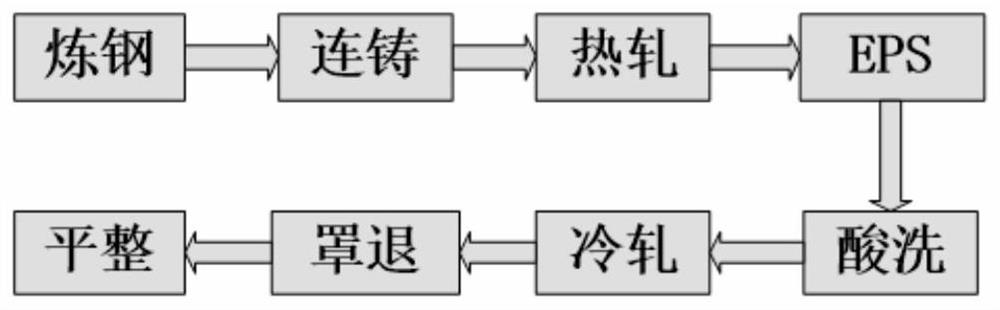

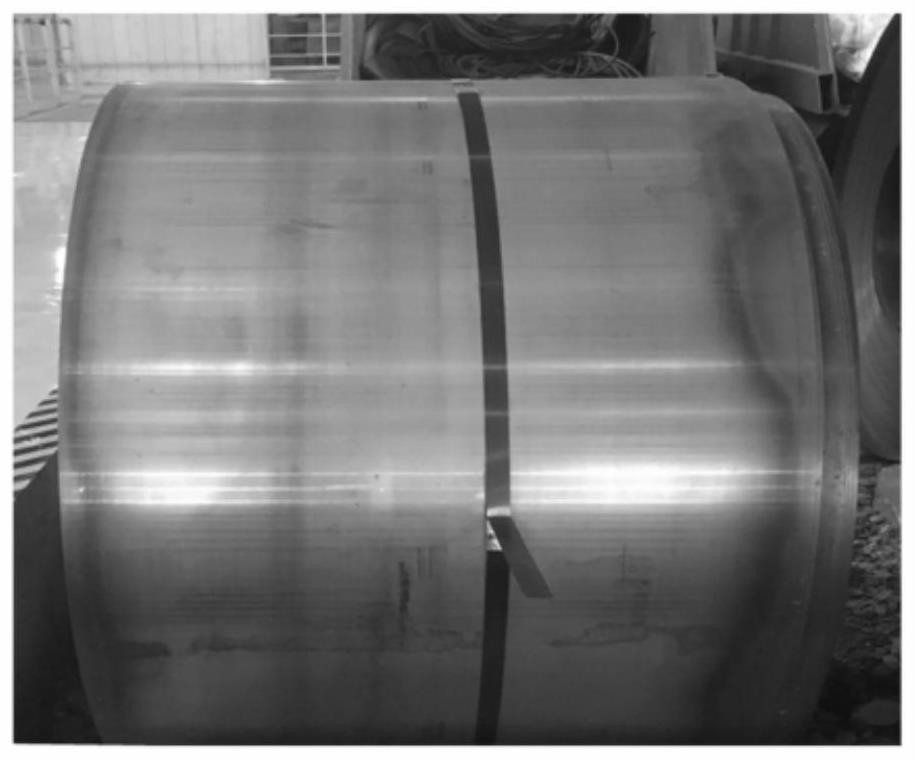

High-temperature-oxidation-resistant cold-rolled steel sheet for hot forming and production and manufacturing method thereof

PendingCN113913671AEasy to paintGood welding performanceTemperature control deviceMetal rolling arrangementsHeating furnaceHigh heat

The invention provides a high-temperature-oxidation-resistant cold-rolled steel sheet for hot forming and a production and manufacturing method thereof. The high-temperature-oxidation-resistant cold-rolled steel sheet comprises the following components: 0.18-0.25% of C, 0.6-1.8% of Si, 1.5-2.5% of Cr, 0.5-1.5% of Mn, 0.04-0.10% of Nb + V + Ti, less than or equal to 0.04% of Ti, 0.04-0.06% of Al, less than or equal to 0.02% of P, less than or equal to 0.01% of S and the balance of Fe. Compared with the prior art, a thin and compact oxide layer with the thickness not exceeding 2 microns is rapidly formed on the surface of the steel plate after the steel plate is taken out of a heating furnace in the hot forming process, the oxide layer is compact in structure and good in adhesion, shot blasting treatment can be omitted after the steel plate is stamped into a part, the size precision of the part is improved, environment friendliness is achieved, and the cost advantage is obvious.

Owner:MAANSHAN IRON & STEEL CO LTD

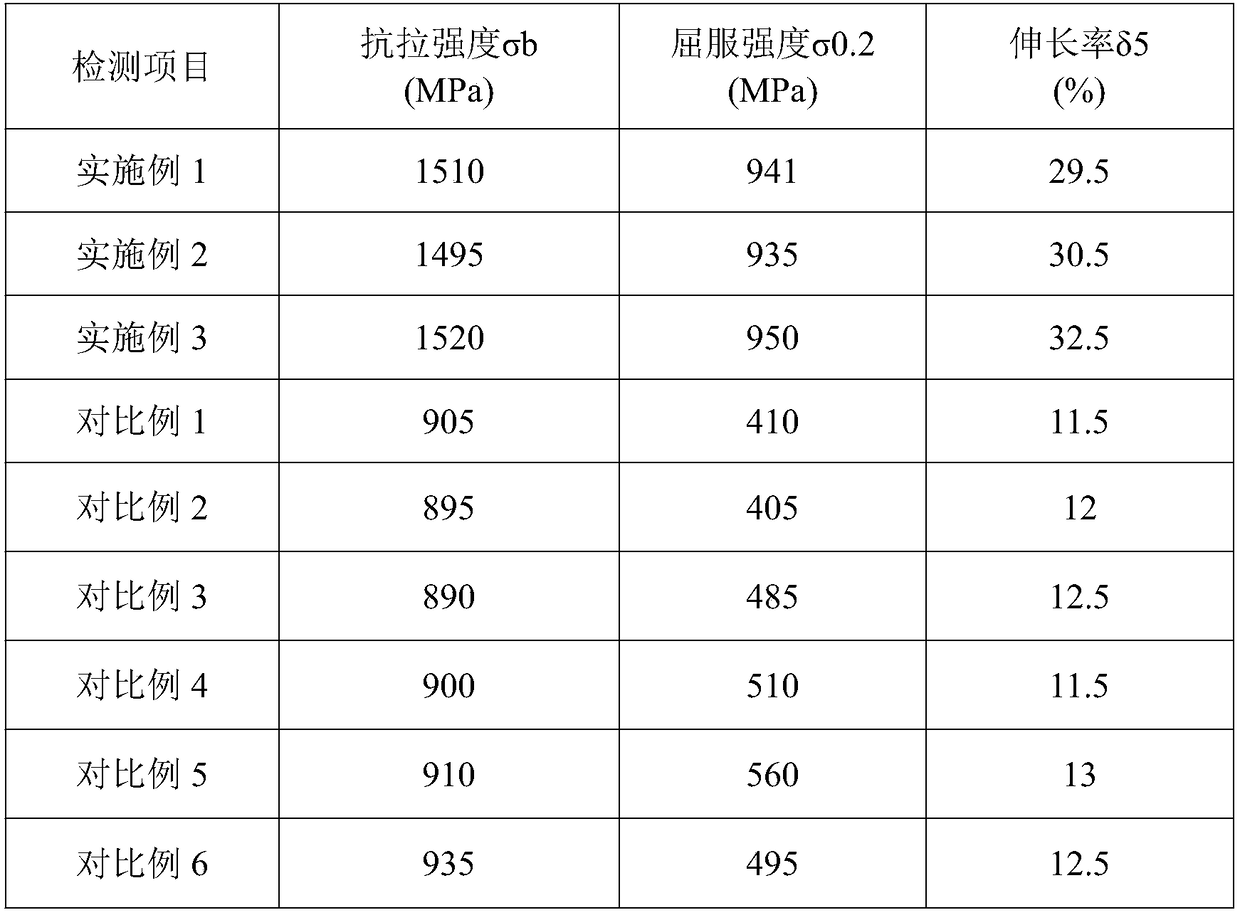

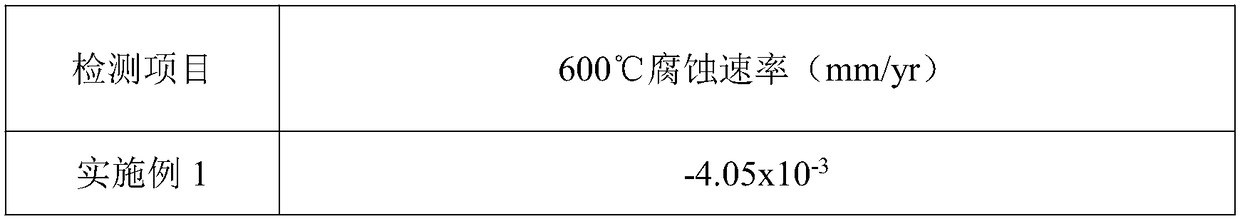

High-strength high-corrosion resistance thallium-based nickel base superalloy and preparation method thereof

The invention relates to the field of nickel base superalloy, and particularly relates to a high-strength high-corrosion resistance thallium-based nickel base superalloy and a preparation method thereof. The nickel base superalloy prepared by the invention contains the following components by weight percent: 8-11% of Cr, 4.5-6% of Tl, 16-18% of Fe, 11-17% of Mo, 0.01-0.025% C, 1.5-2% of Al, 4-6% of Cu, 0.01-0.25% of Nb, and the balance of Ni and inevitable impurities. The method greatly improves the strength of the nickel base superalloy, the tensile strength of which is promoted to 1520MPa, the yield strength of which is promoted to 950MPa, and the elongation of which is promoted to 32.5%, and the corrosion resistance of the nickel base superalloy is greatly promoted, with the annual average corrosion rate of the nickel base superalloy being reduced to -3.91*10<-3>mm / yr at 600 DEG C, and the remarkable effect is obvious.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

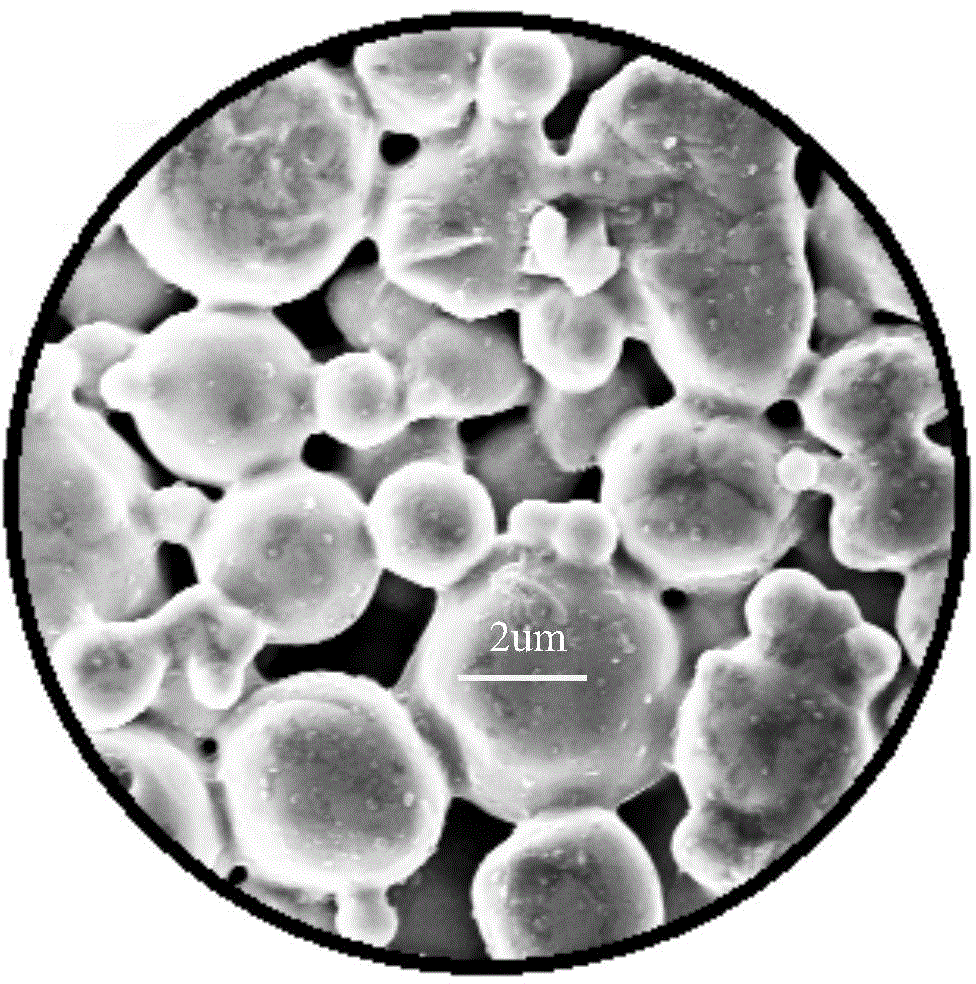

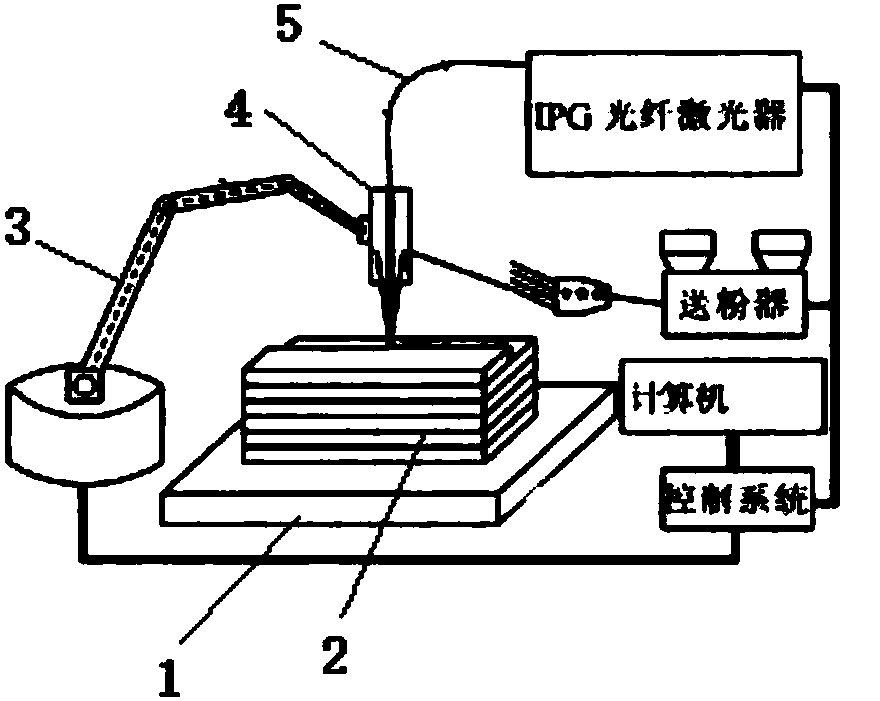

Nickel-based alloy powder material and 3D printing forming method thereof

InactiveCN109680184AImprove high temperature strengthImprove fatigue resistanceAdditive manufacturing apparatusIncreasing energy efficiencyUltimate tensile strengthHigh-temperature corrosion

The invention relates to nickel-based alloy powder material and a 3D printing forming method thereof. The nickel-based alloy powder material comprises the following components in percentage by weight:not greater than 0.01% of C, 0.2-0.8% of Si, 0.3-0.5% of Mn, 18.5-25.5% of Cr, 8.5-11.5% of Mo, 2.5-4.5% of Nb, and the balance nickel; and the particle size of powder is 53-150 microns. The nickel-based alloy powder is outstanding in high-temperature strength, fatigue resistance, high-temperature corrosion resistance and high-temperature stability of an alloy structure, and outstanding in temperature bearing capacity.

Owner:DANYANG HONGTU LASER TECH

Porous alloy filter element used in high temperature environment and preparation method thereof

The invention relates to a porous alloy filter element used in a high-temperature environment and a preparation method of the porous alloy filter element. The filter element comprises a plurality of parallel filter channels, wherein one end of each filter channel is closed, the other end of each filter channel is open, closed ends of two adjacent filter channels are opposite, and the filter element is made of an iron chromium aluminum based compound porous alloy material; the diameter of each filter channel ranges from phi 10 mm to phi 100 mm, micropores extending to the surface of the alloy material are distributed in the iron chromium aluminum based compound porous alloy material, and the diameter of each micropore ranges from 500 nm to 40 mu m. The preparation method comprises procedures of preparation of iron chromium aluminum based powder slurry, casting forming, thermal debinding, sintering and the like. The prepared filter element has a good filtering function on high-temperature dusty gas or high-temperature particle-contained fluids, has the advantages of excellent high-temperature strength, large filtering area, long service life in the high-temperature environment, reusability and the like and is suitable for industrial application.

Owner:荣仕国际投资(北京)有限公司

A kind of engine water-free coolant composition

ActiveCN103059820BExcellent high temperature corrosion resistanceImprove corrosion inhibitionHeat-exchange elementsPhosphateFatty acid

The invention relates to a non-aqueous coolant composition for an engine, which comprises a propylene glycol basic solution and a composite corrosion inhibitor, the composite corrosion inhibitor comprises acylates of tripolycyanamide and poly fatty acid and water soluble salt, hydroxy aromatic acid and its water soluble salt, and also comprises other types of corrosion inhibitors, such as fatty acid and its water soluble salt, molybdate, silicate and a silicate stabilizer. The composition takes propylene glycol as the basic solution, the toxicity is low, the toxic and harmful addictives on human body and environment such as nitrite, nitrate, alcohol amine, phosphate and borate are not contained, the non-aqueous coolant composition is an environment-friendly product, the high temperature corrosion resistance performance is excellent, the low temperature cooling performance and high temperature boiling resistance performance are excellent, and the non-aqueous coolant composition is suitable for the engines with large power, heavy loading and high temperature working environment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com